Inductively coupled plasma processing system

A plasma and inductive coupling technology, applied in the direction of circuits, discharge tubes, electrical components, etc., can solve the problems of reducing the production efficiency of plasma processing equipment, uneven window cleaning, and difficult maintenance in the later stage, so as to simplify equipment installation and maintenance, Save a lot of space and make easy effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

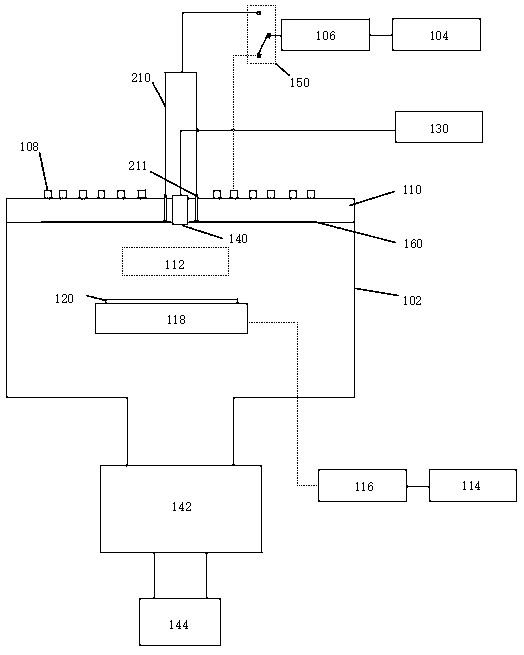

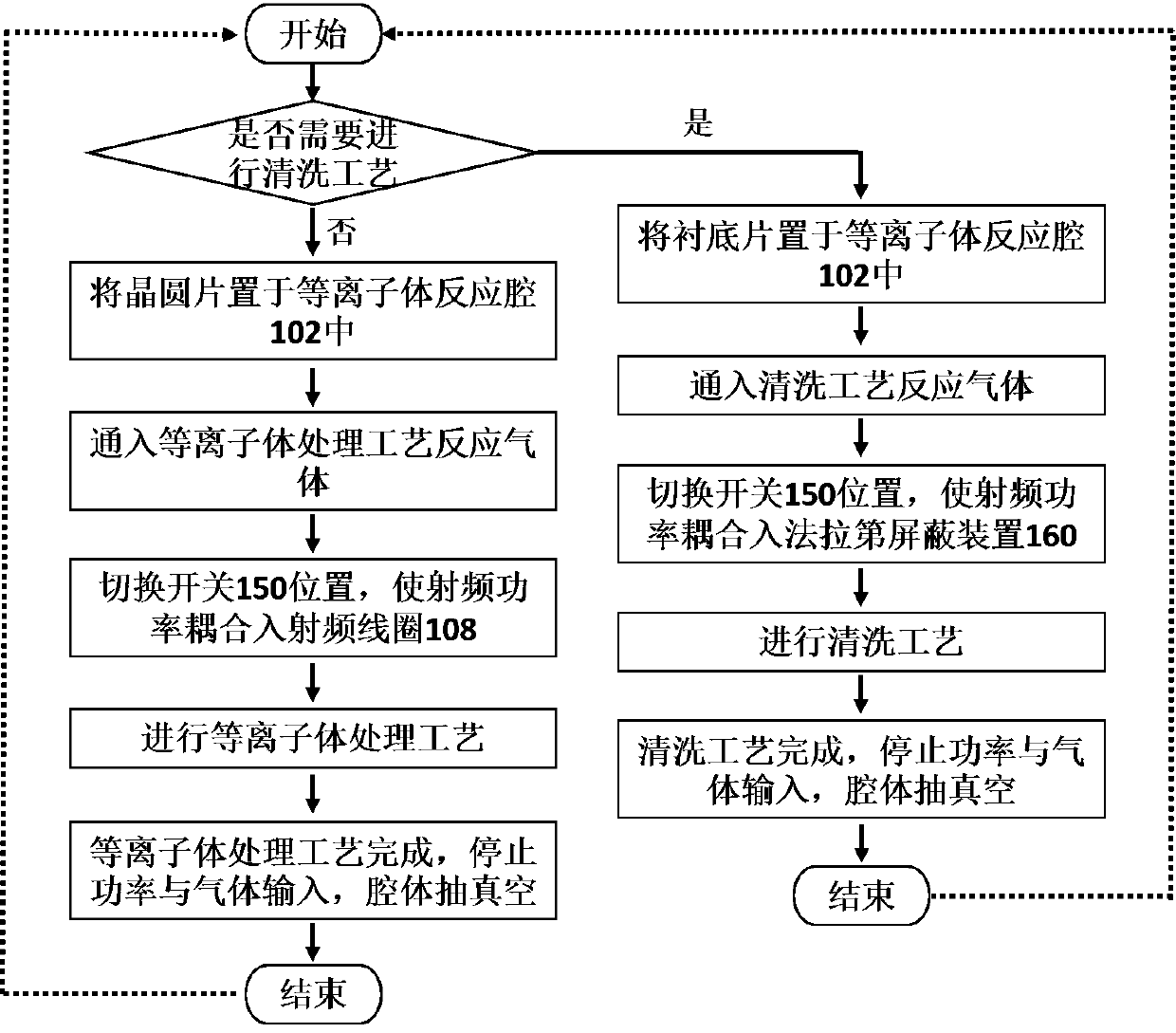

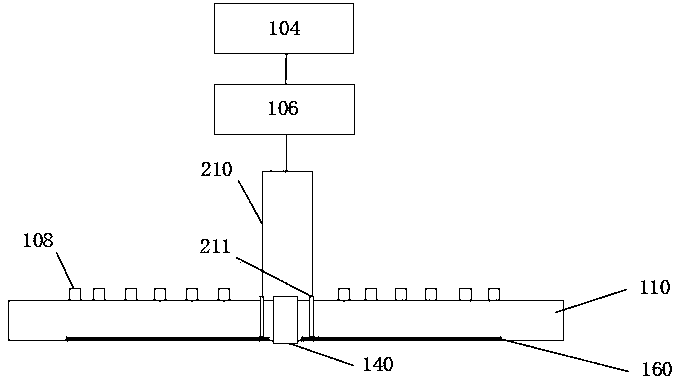

[0034] Such as figure 1 As shown, an inductively coupled plasma processing system, the inductively coupled plasma processing system includes a plasma reaction chamber 102, an excitation RF power supply 104, a matching network A106, a RF coil 108, a dielectric window 110, and a bias RF power supply 114 , matching network B116, electrode 118, substrate sheet 120, gas source 130, gas inlet 140, pressure control valve 142, vacuum pump 144 and three-way switch 150, the excitation RF power supply 104 is tuned through the matching network A106, and then passed through three Power is supplied to the RF coil 108 above the dielectric window 110 through the switch 150, and the plasma 112 is generated in the plasma reaction chamber 102 through inductive coupling. The bias RF power supply 114 provides power for the electrode 118 through the matching network B116, and the substrate sheet 120 is placed Above the electrode 118; the radio frequency coil 108 includes ≥ 2 sub-coils, and the radi...

Embodiment 2

[0040] Such as figure 1 As shown, an inductively coupled plasma processing system, the inductively coupled plasma processing system includes a plasma reaction chamber 102, an excitation RF power supply 104, a matching network A106, a RF coil 108, a dielectric window 110, and a bias RF power supply 114 , matching network B116, electrode 118, substrate sheet 120, gas source 130, gas inlet 140, pressure control valve 142, vacuum pump 144 and three-way switch 150, the excitation RF power supply 104 is tuned through the matching network A106, and then passed through three Power is supplied to the RF coil 108 above the dielectric window 110 through the switch 150, and the plasma 112 is generated in the plasma reaction chamber 102 through inductive coupling. The bias RF power supply 114 provides power for the electrode 118 through the matching network B116, and the substrate sheet 120 is placed Above the electrode 118; the radio frequency coil 108 includes ≥ 2 sub-coils, and the radi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com