Patents

Literature

400 results about "Spheroid" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A spheroid, or ellipsoid of revolution, is a quadric surface obtained by rotating an ellipse about one of its principal axes; in other words, an ellipsoid with two equal semi-diameters. A spheroid has circular symmetry.

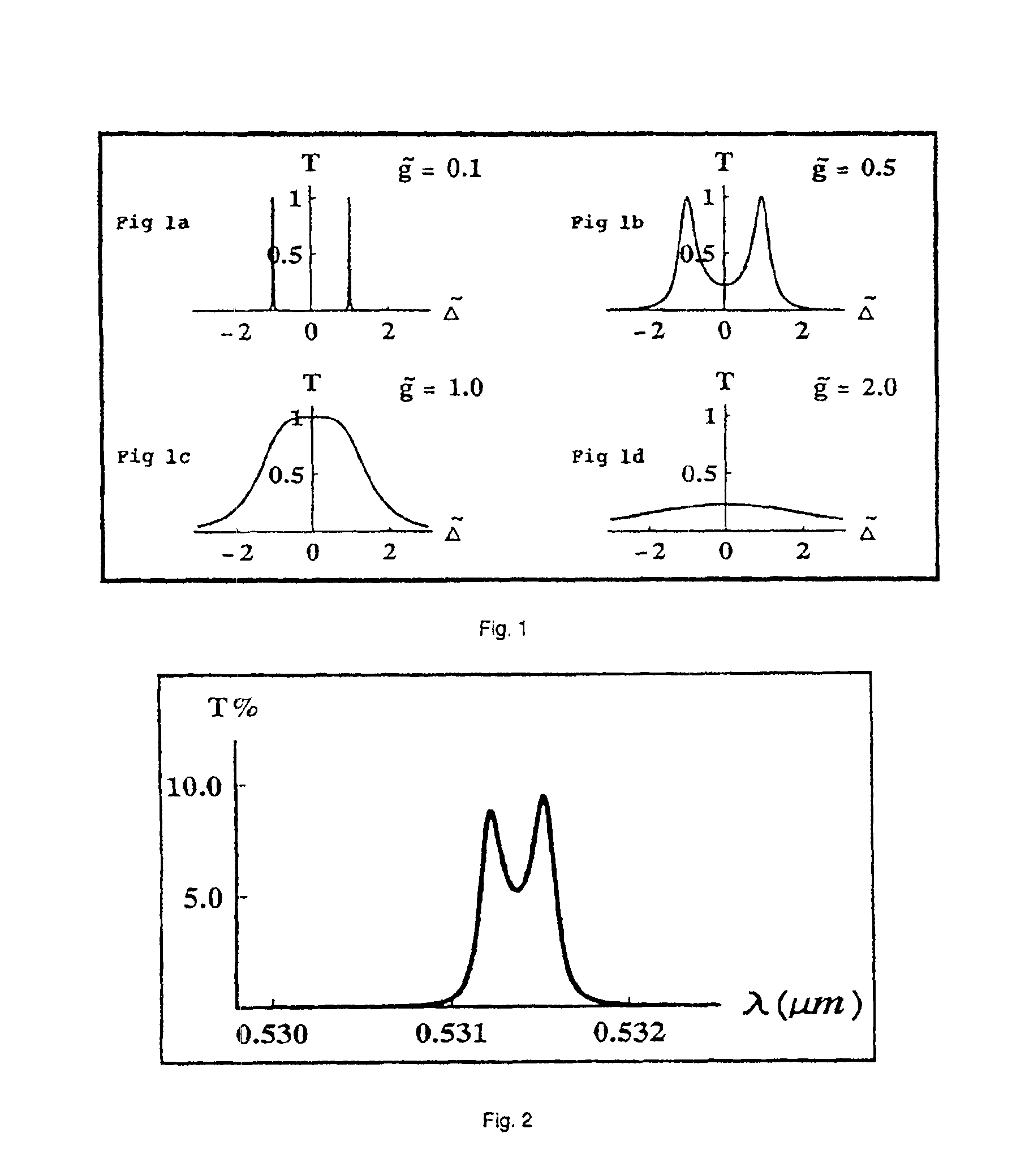

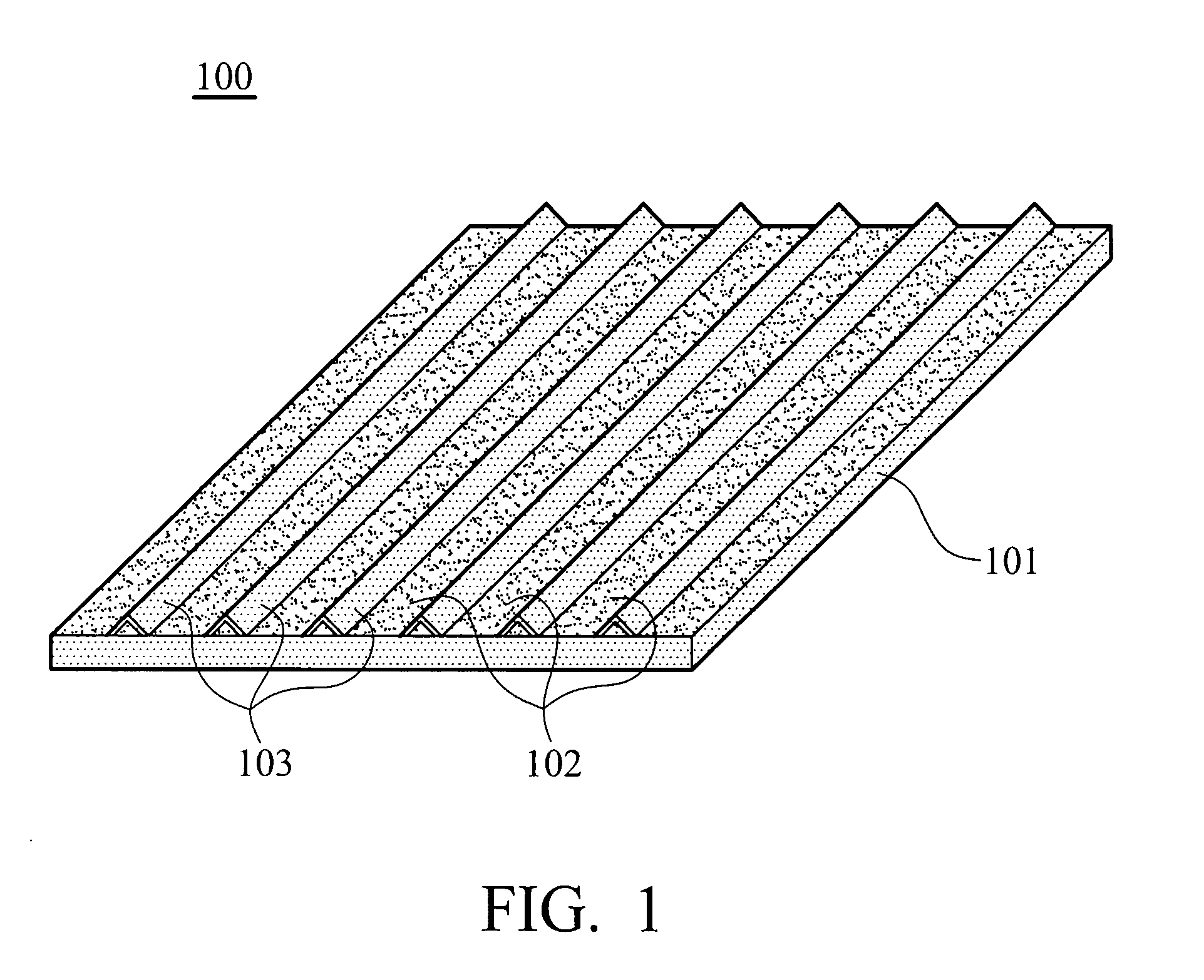

Method for producing UV polarizers

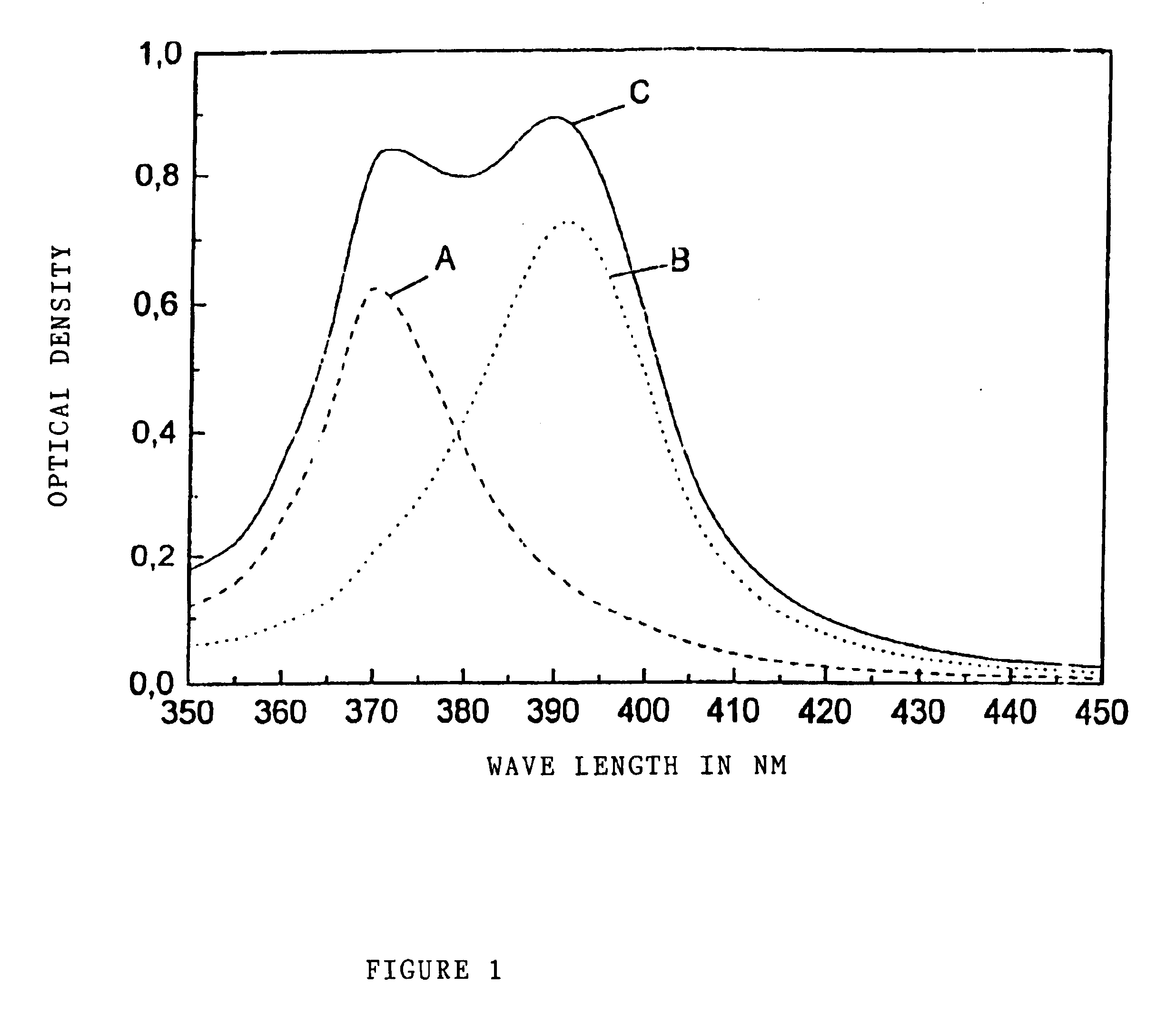

The invention relates to a method for producing UV polarizers, according to which spheroid particles situated near the surface of the glass are incorporated into the support material (primarily standard float glass) in a novel arrangement. According to the method for producing UV polarizers, after the introduction of metal ions (e.g., silver ions) into the glass surface, a large size distribution of particles is achieved by multiple alternation of a heat treatment for separating out spherical metal particles, followed by the renewed introduction of metal ions and a subsequent heat treatment. A deformation of the glass produces spheroid particles of various sizes and different semi-axis relationships. The particles are characterized by their large size distribution and are deformed differently in relation to their spheroid shape. In this way UV polarizers are produced which have a wide absorption range since the absorption bands having different maximum positions overlap.

Owner:F O B GES ZUR FERTIGUNG FARBIGER OPTOELEKTRONISCHER BAUELEMENTE

Plasmonic nanophotonics methods, materials, and apparatuses

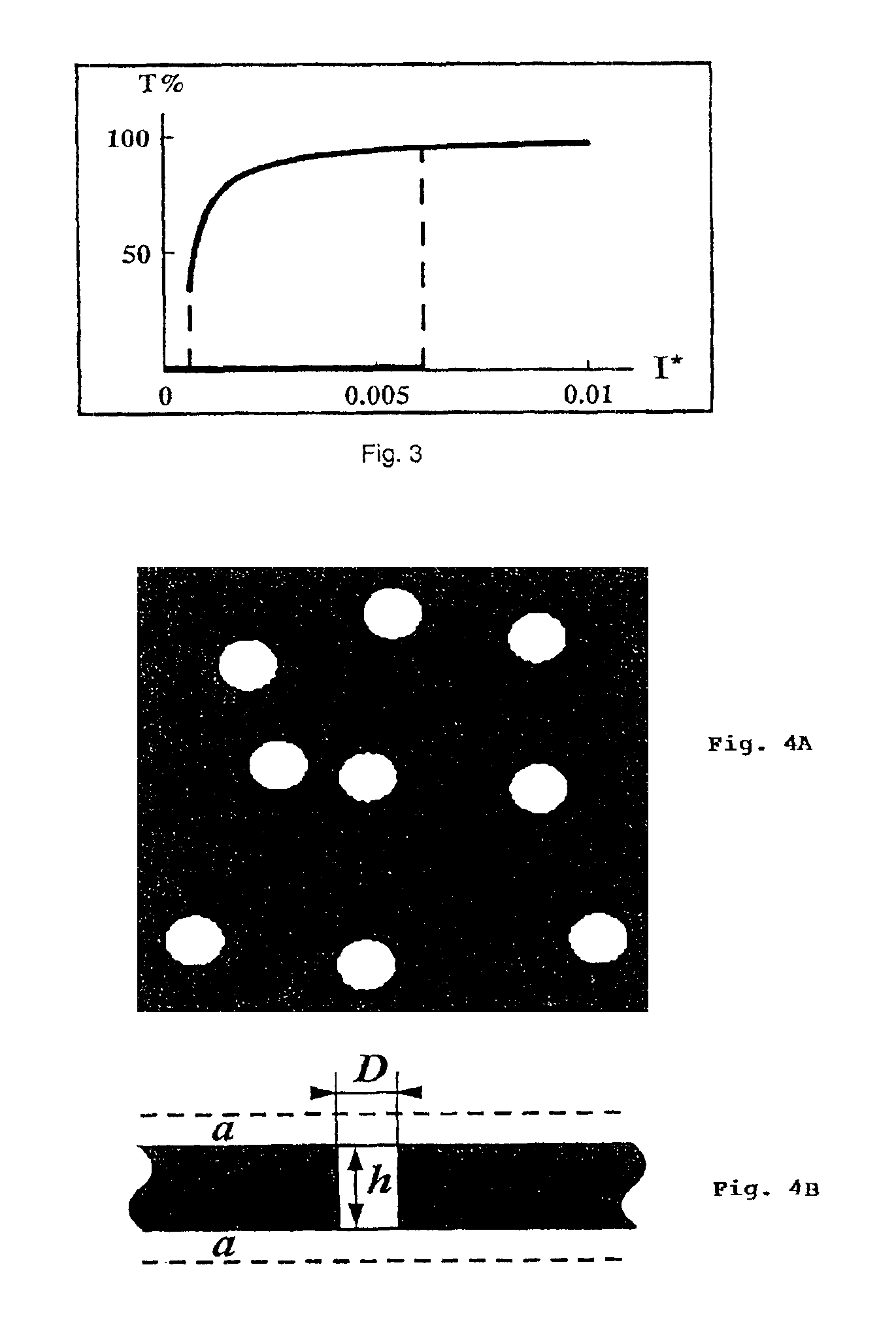

Controlling, guiding, manipulating, and circuiting light and performing surface-enhanced spectroscopy in a medium comprising plasmonic nanomaterials via the excitation of plasmon modes in the materials. The plasmonic nanomaterials are based on metal films with or without arrays of nanoholes and / or on metal nanowires and / or spheroids. Also devices and methods employing such plasmonic nanomaterials.

Owner:NEW MEXICO STATE UNIV TECH TRANSFER

Bioprocess for the generation of cells from spheroid-forming cells

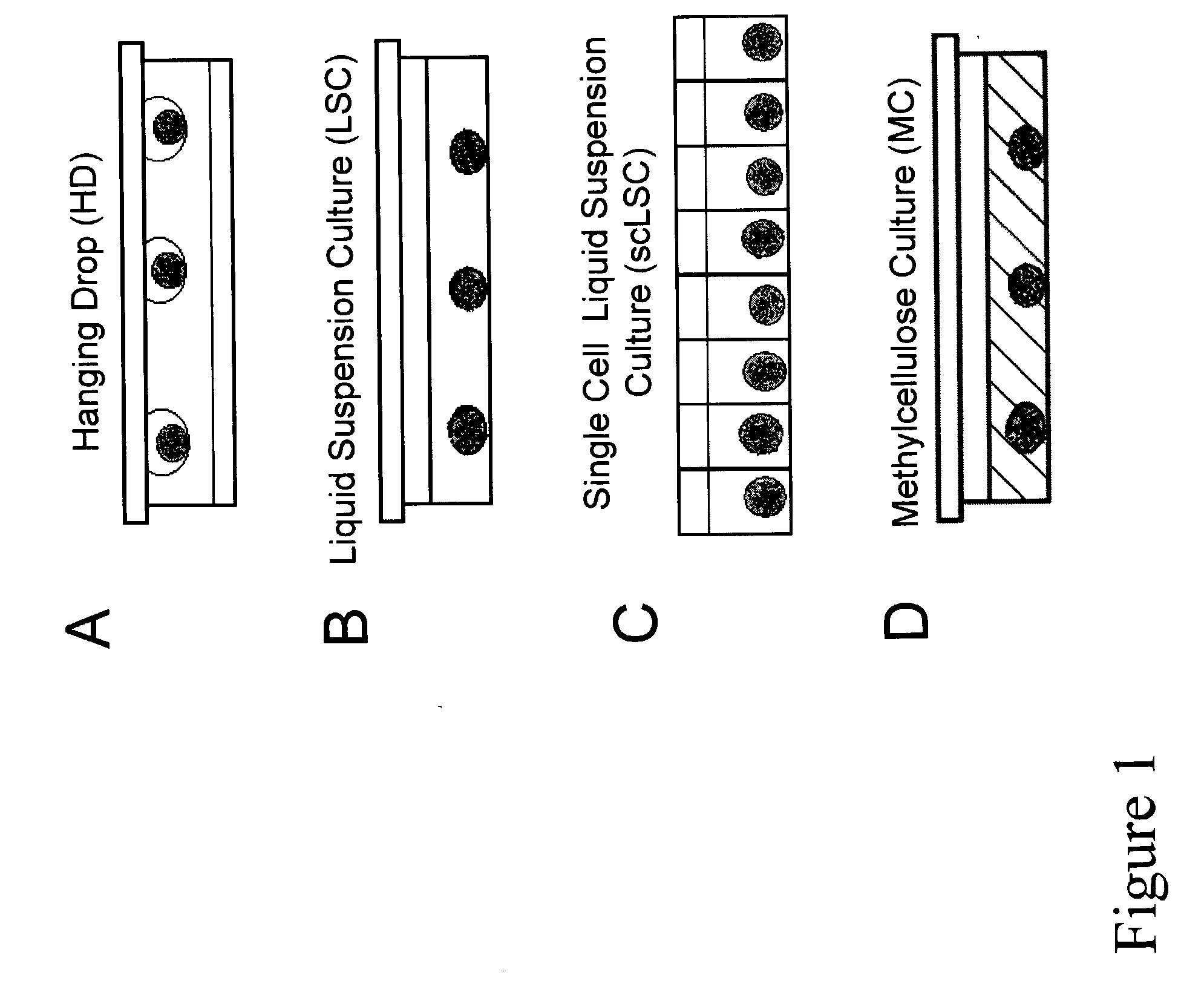

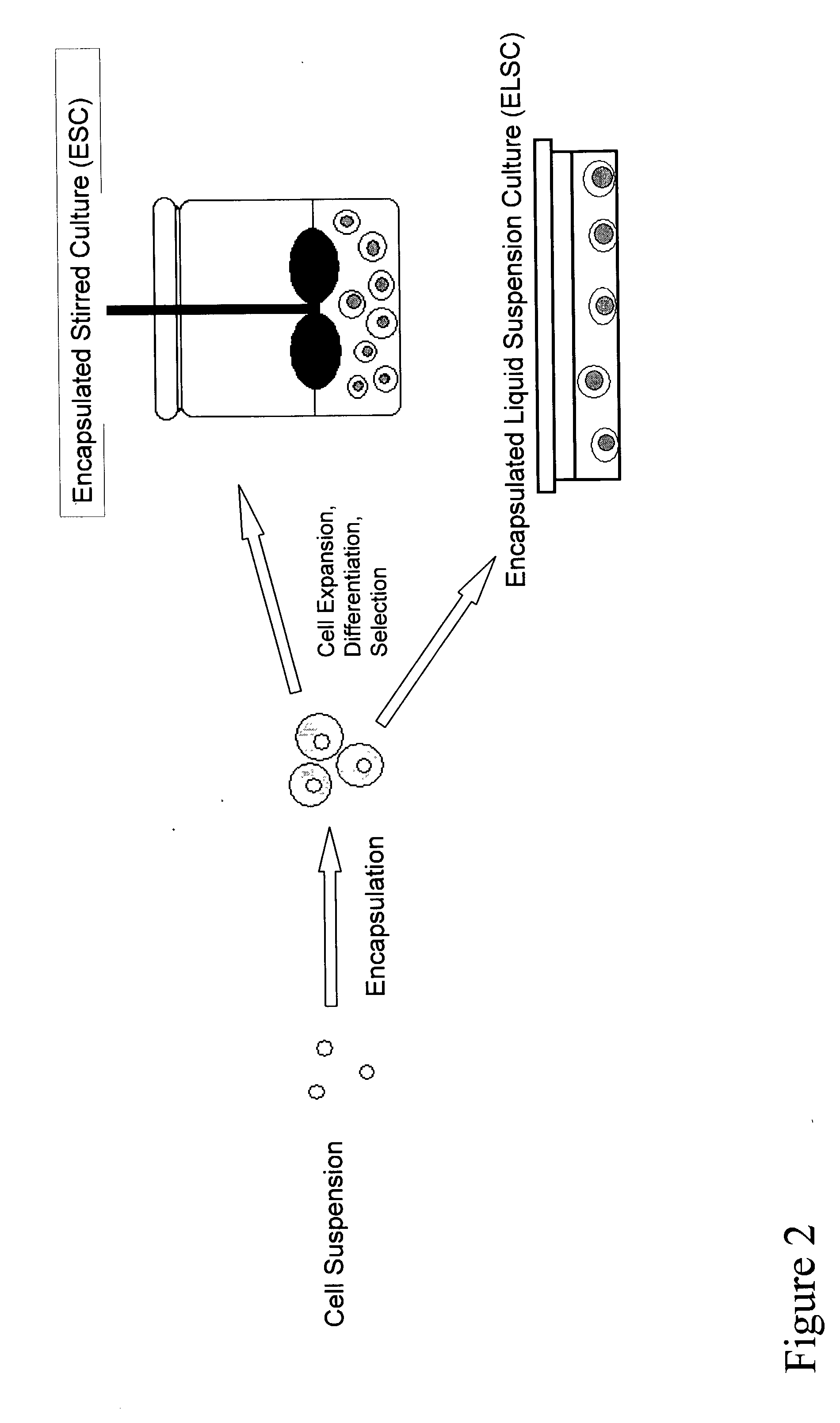

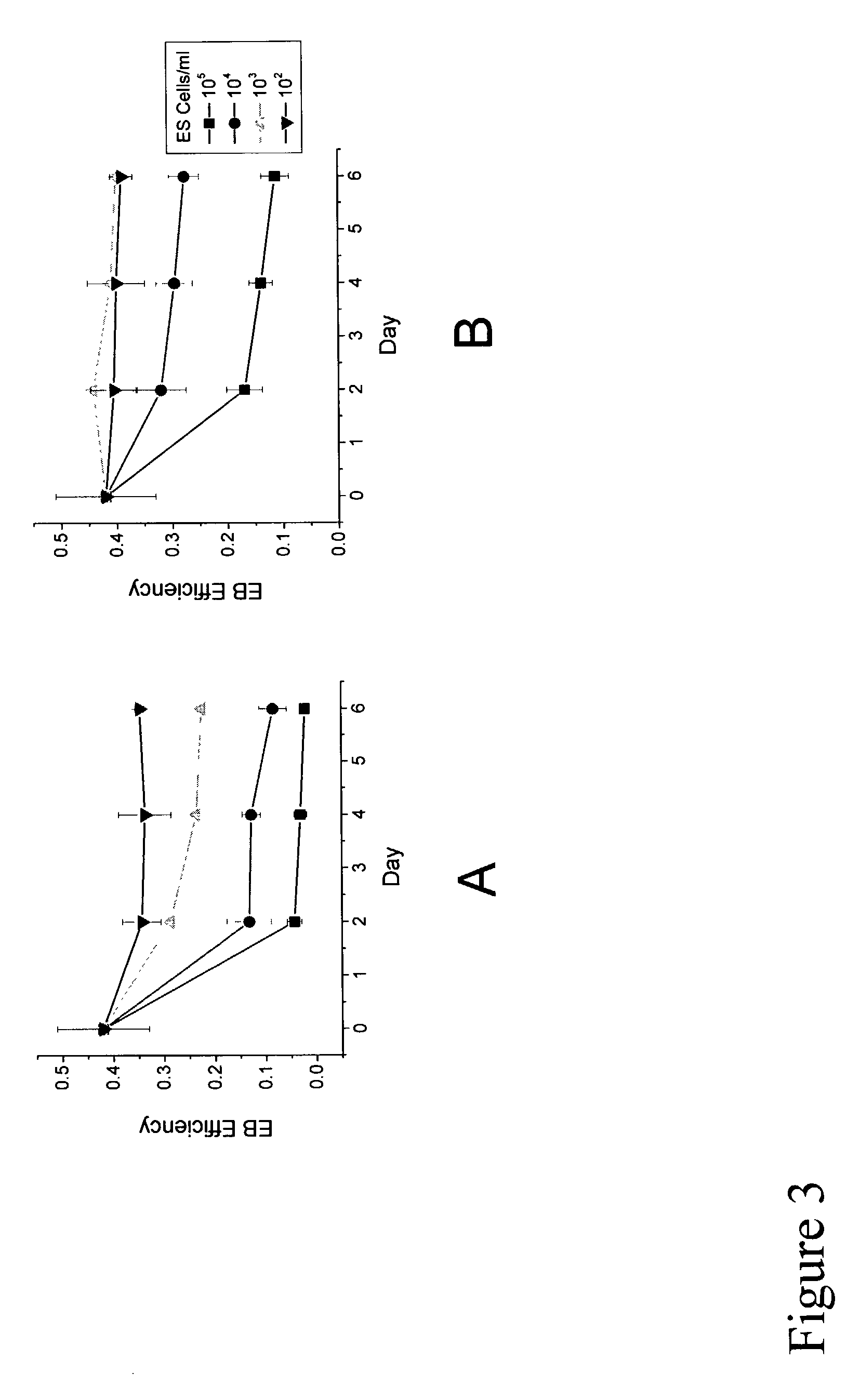

InactiveUS20030119107A1Inhibit aggregationCell culture supports/coatingTissue/virus culture apparatusHigh cellVolumetric Mass Density

The present inventors identified aggregation of embryonic stem cells and embryoid bodies (EBs) as the cause of the difficulty in generating large numbers of the embryonic stem cells (ES) cell-derived tissues. To counter this, the invention provides a novel bioprocess where aggregation of spheroid forming cells, such as embryonic stem cells and spheroids, such as EBs is controlled, such as by encapsulation of within a matrix. As a result, EBs can be generated with high efficiency and cultured in high cell density, well-mixed systems. Well-mixed conditions facilitate measurement and control of the bulk media conditions and allow for the use of scalable bioreactor systems for clinical production of tissue. Therefore, the invention enables generation of ES cell-derived tissue on a clinical scale. The invention is also applicable to any spheroid-forming cells and other types of pluripotent cells.

Owner:CARDION AG

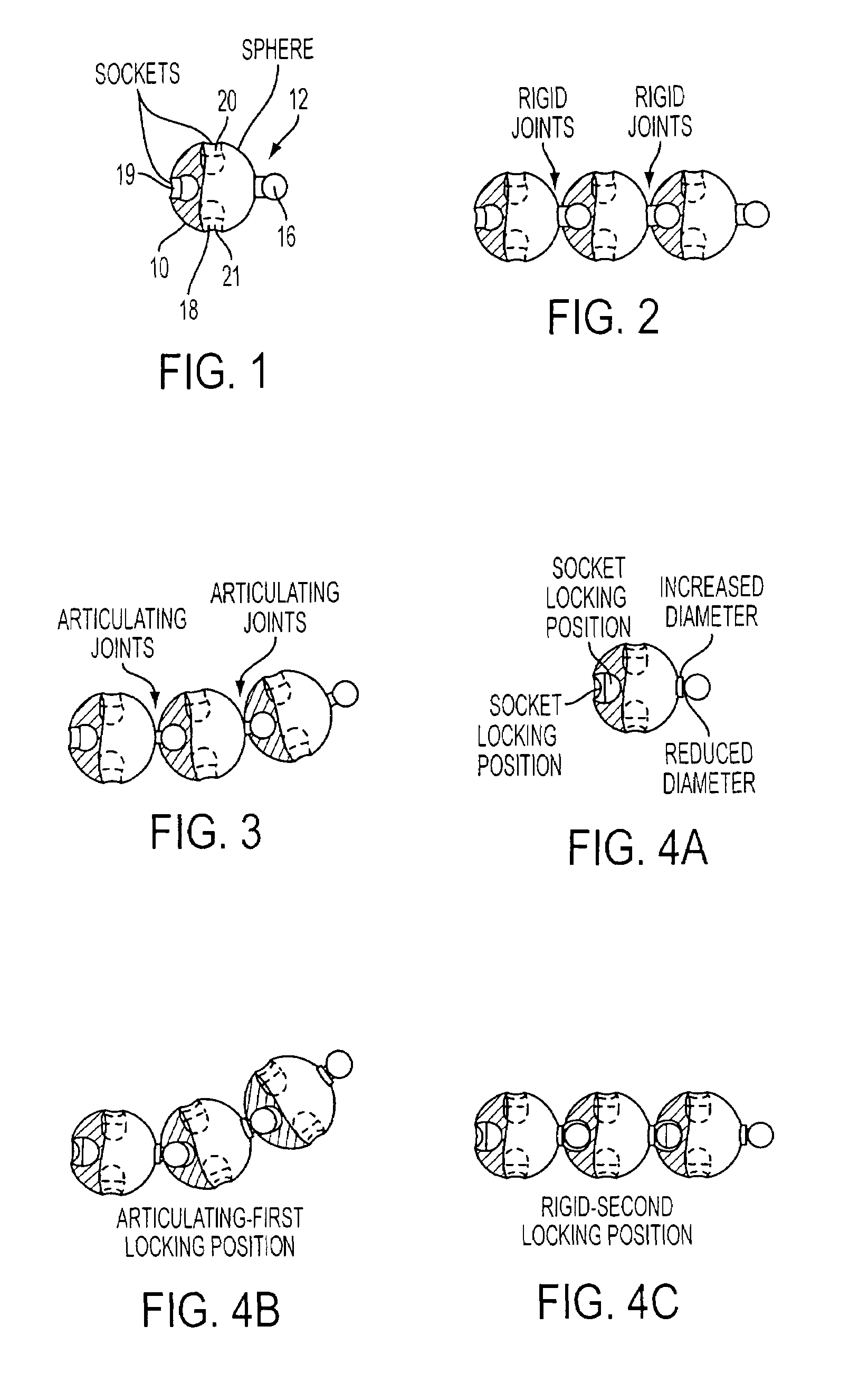

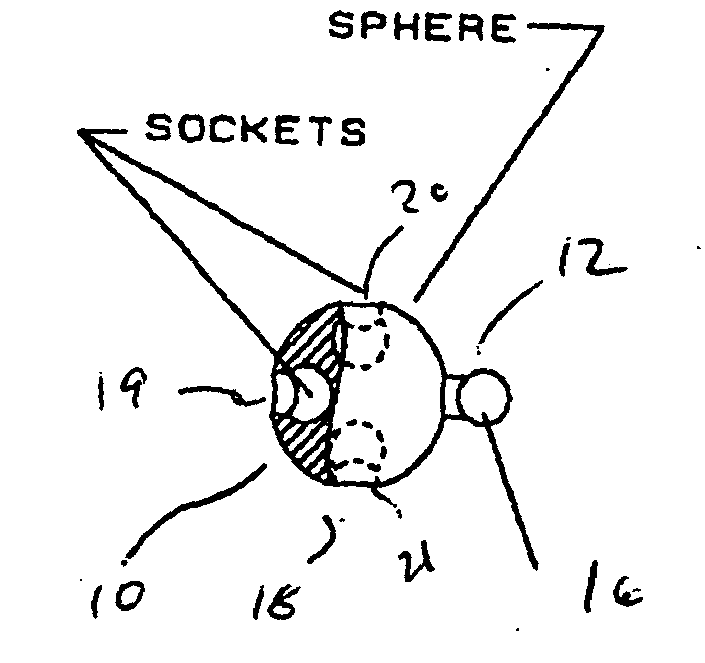

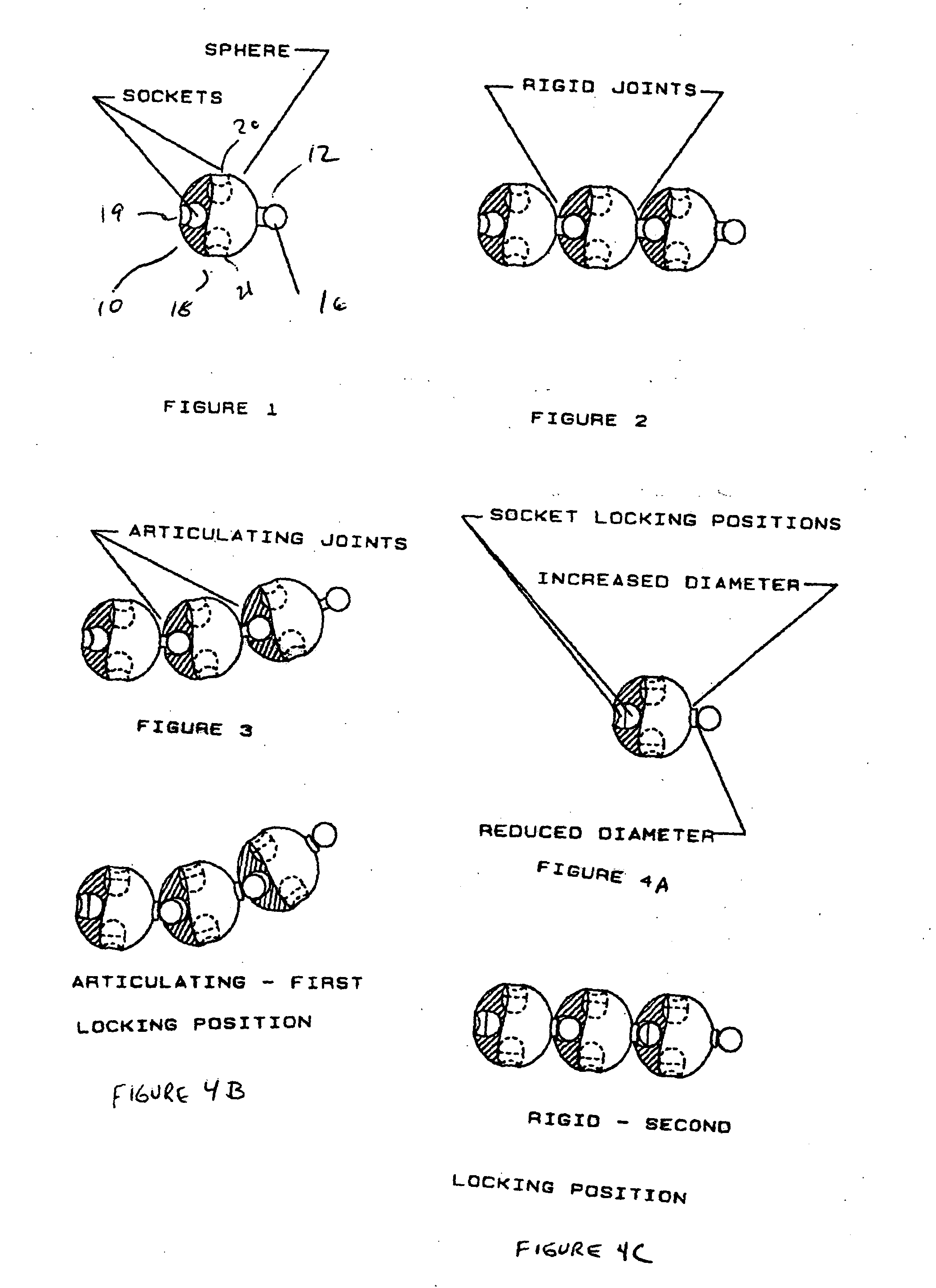

Connection for beads with locked and articulating engagement

An assembly of two elements including a first element that has a cavity with an external opening connected to a first region defined by a sidewall that is a spherical segment and the diameter of the external opening is smaller than the diameter of the sidewall in the first region. Adjacent to the first region is a second region also defined by a second spheroid segment that is separated from the first region by an annular ring extending from the sidewalls towards a central axis of the cavity. The annular ring forms a passage having a diameter approximately the same as the external opening. An extension member on the second element is inserted into the cavity which has a first rod section terminating in a second spherically-shaped section. The spherically shaped section has a diameter larger slightly larger than the external opening on the first element and accordingly, the spherical section may be snap-fitted through the external opening to a first position in a first region, and be retainer there and, it may be further snap-fitted through the passage to the second region and be retained there. Also disclosed is flange structure that engages an annular seat when the spherically shaped member is in the second position.

Owner:LYNX SA

Plasmonic nanophotonics methods, materials, and apparatuses

Controlling, guiding, manipulating, and circuiting light and performing surface-enhanced spectroscopy in a medium comprising plasmonic nanomaterials via the excitation of plasmon modes in the materials. The plasmonic nanomaterials are based on metal films with or without arrays of nanoholes and / or on metal nanowires and / or spheroids. Also devices and methods employing such plasmonic nanomaterials.

Owner:NEW MEXICO STATE UNIV TECH TRANSFER

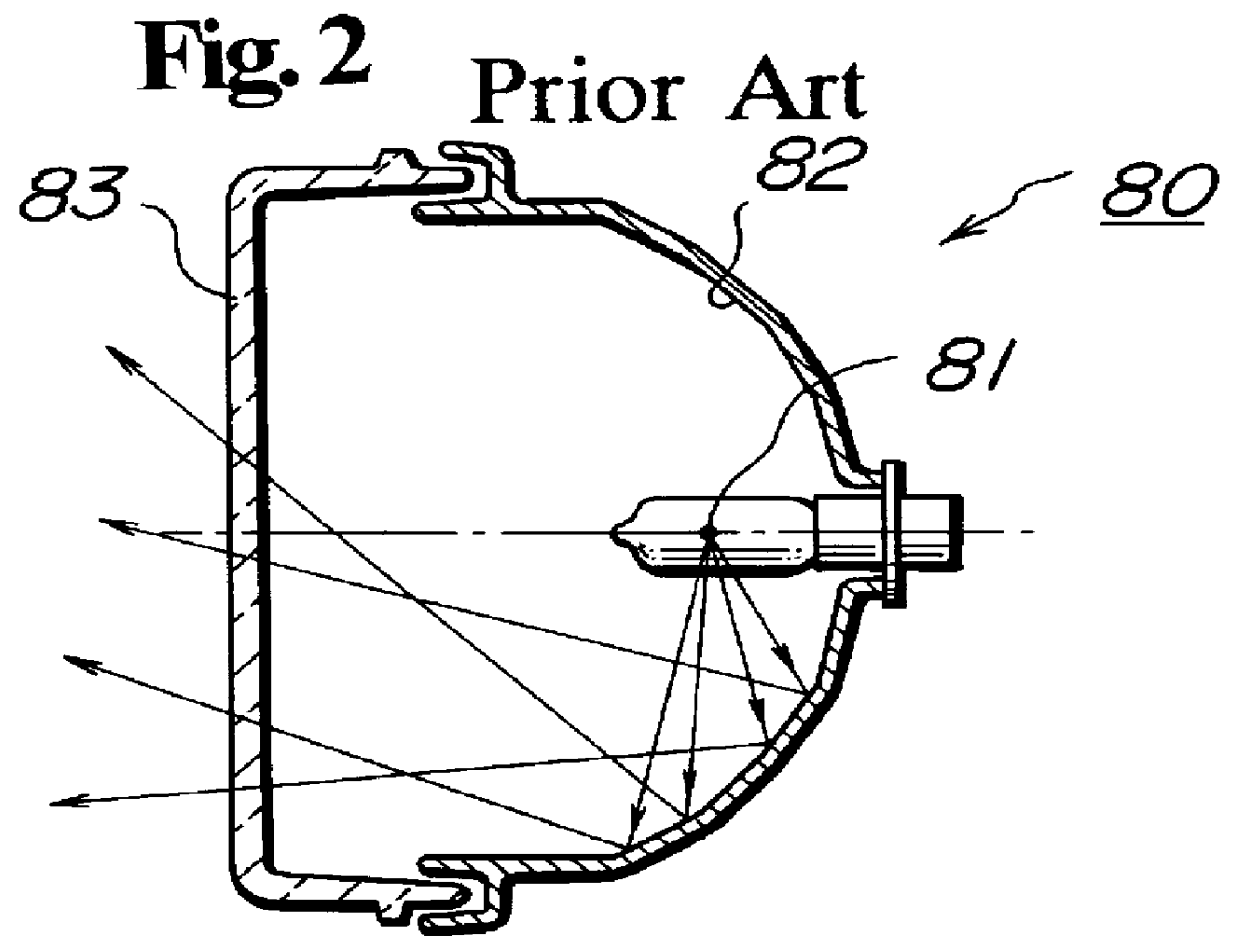

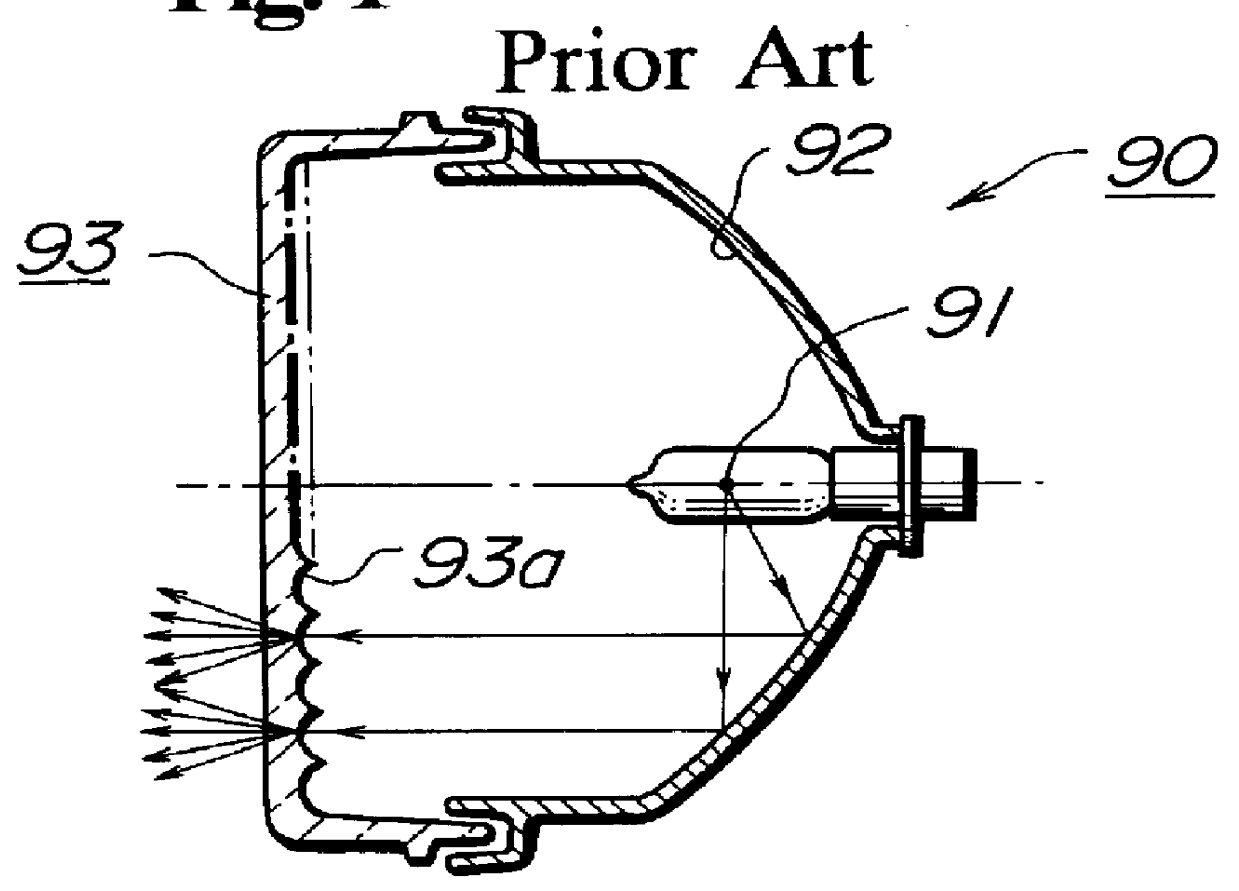

Lamp with petaline reflector and aspheric lenses

InactiveUS6109772AIncrease flexibilityImprove marketabilityLighting applicationsVehicle headlampsDistribution patternLight beam

A lamp including a light source, a petaline reflector, and aspheric lenses. The petaline reflector is formed of a plurality of reflecting surface units combined radially around the center axis of the light source. Each of the reflecting surface units is obtained by cutting, radially around the center axis, a portion from a spheroid having a first focal point located on the center axis and adjacent the light source and a second focal point located on a line passing through the first focal point and tilted appropriately from the center axis such that the cut portion spans a range of 15.degree. to 60.degree. around the center axis. The aspheric lenses are disposed to correspond to the respective second focal points of the reflecting surface units of the petaline reflector and converge reflected light beams from the respective reflecting surface units. Shades for forming a light distribution pattern are disposed at the respective near-focal points of the aspheric lenses.

Owner:STANLEY ELECTRIC CO LTD

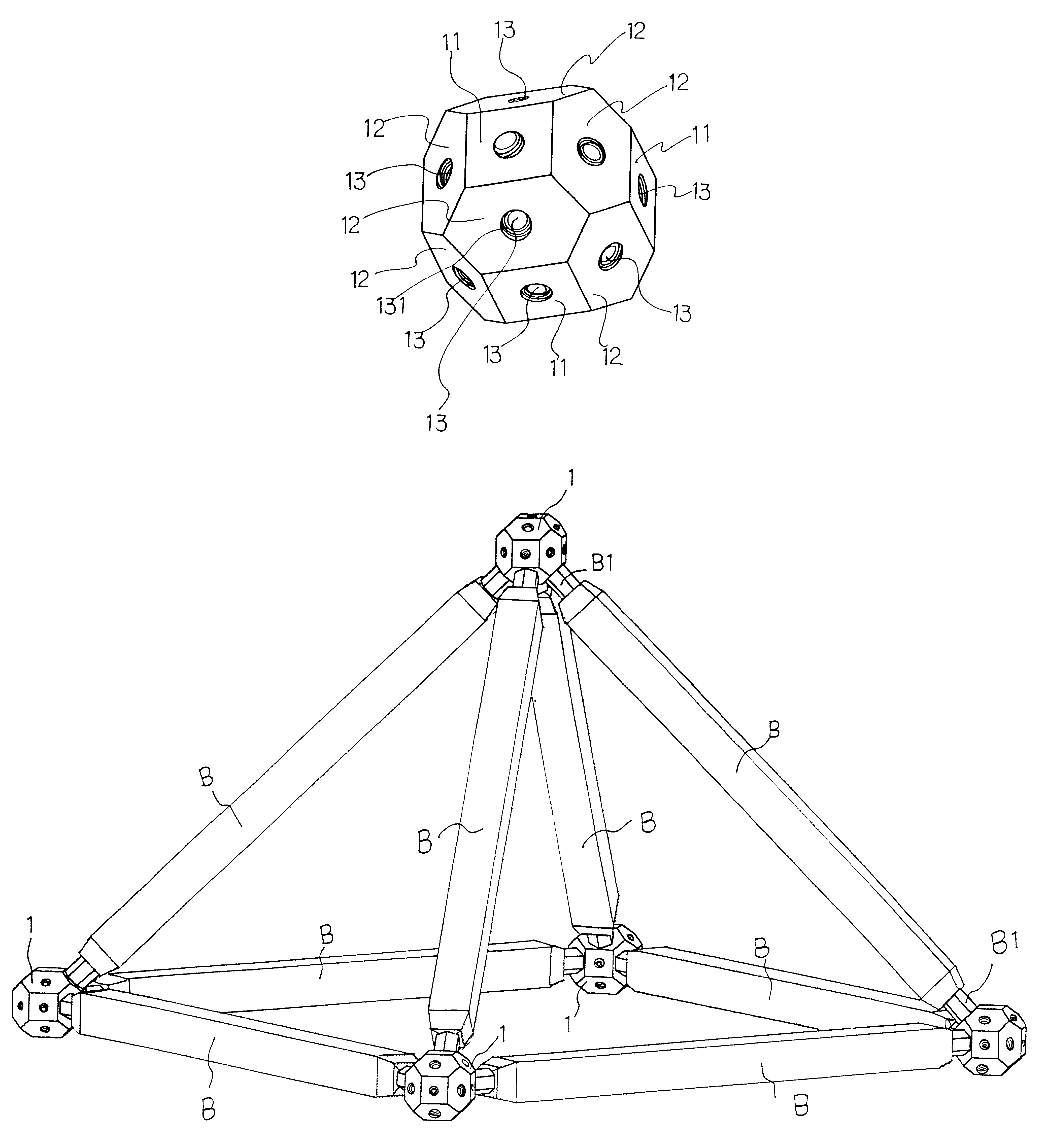

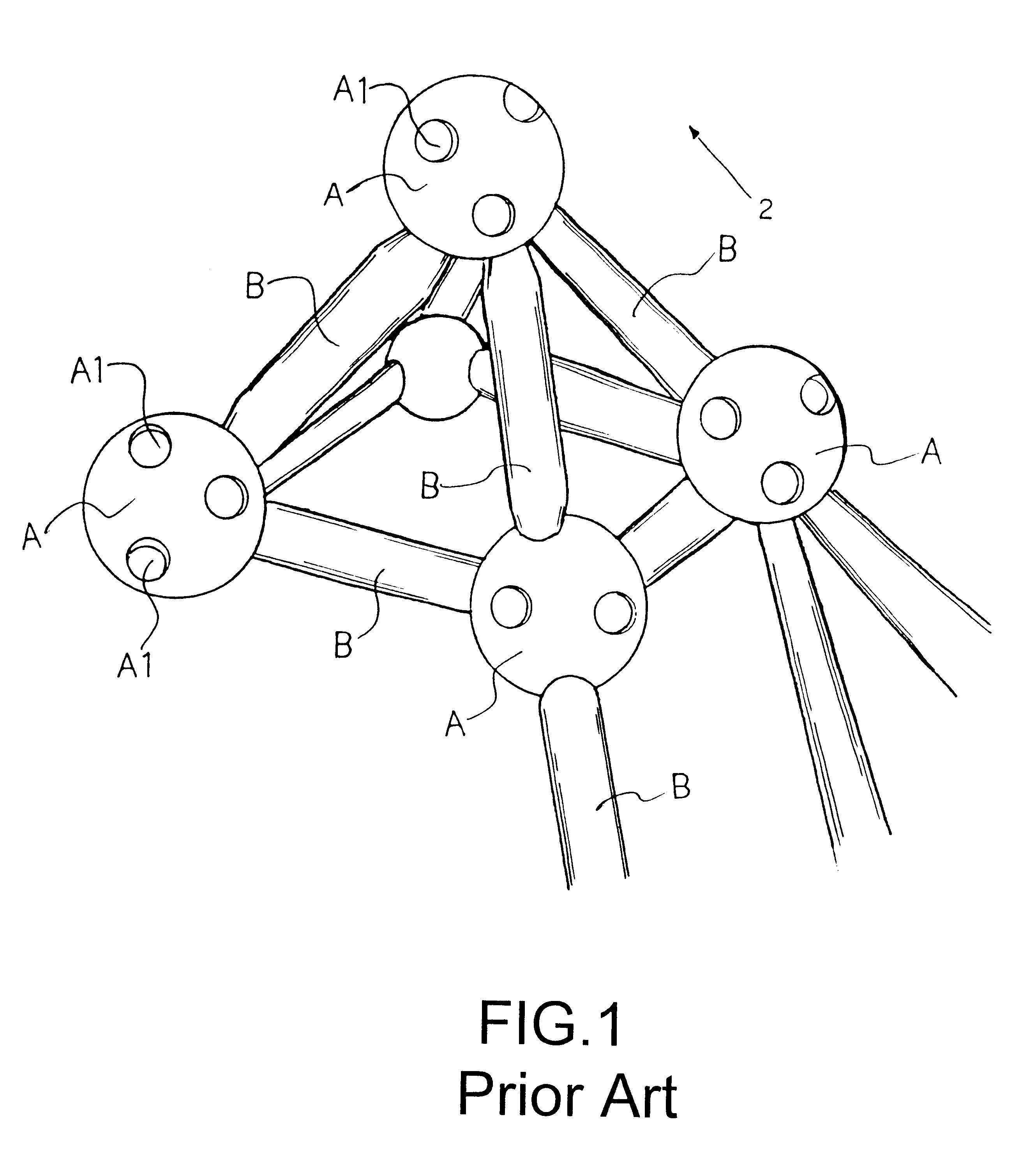

Spherical connector and supporting rod assembly

InactiveUS6672789B2Broaden applicationMeet the requirementsYielding couplingRopes and cables for vehicles/pulleyEngineeringMechanical engineering

The invention herein of a spherical connector and supporting rod assembly is mainly designed as a structure of a multi-angular spheroid with multiple tangent planes of six cubical quadrilaterals and twelve beveled hexagons, and with mounting holes disposed respectively at the centers of the quadrilateral and the beveled hexagonal tangent planes to make each spherical connector having eighteen mounting holes with included angles pointing at different directions so as to increase the application of a single spherical connector and to make all the spherical connectors have the identical structure for exchangeable connection to not only fully comply with the needs of specific application, but also to be able to make various applications by using the supporting rods pointing at different mounting angles to directly fulfill the specific need of the assembly.

Owner:CHEN CHUNG TENG

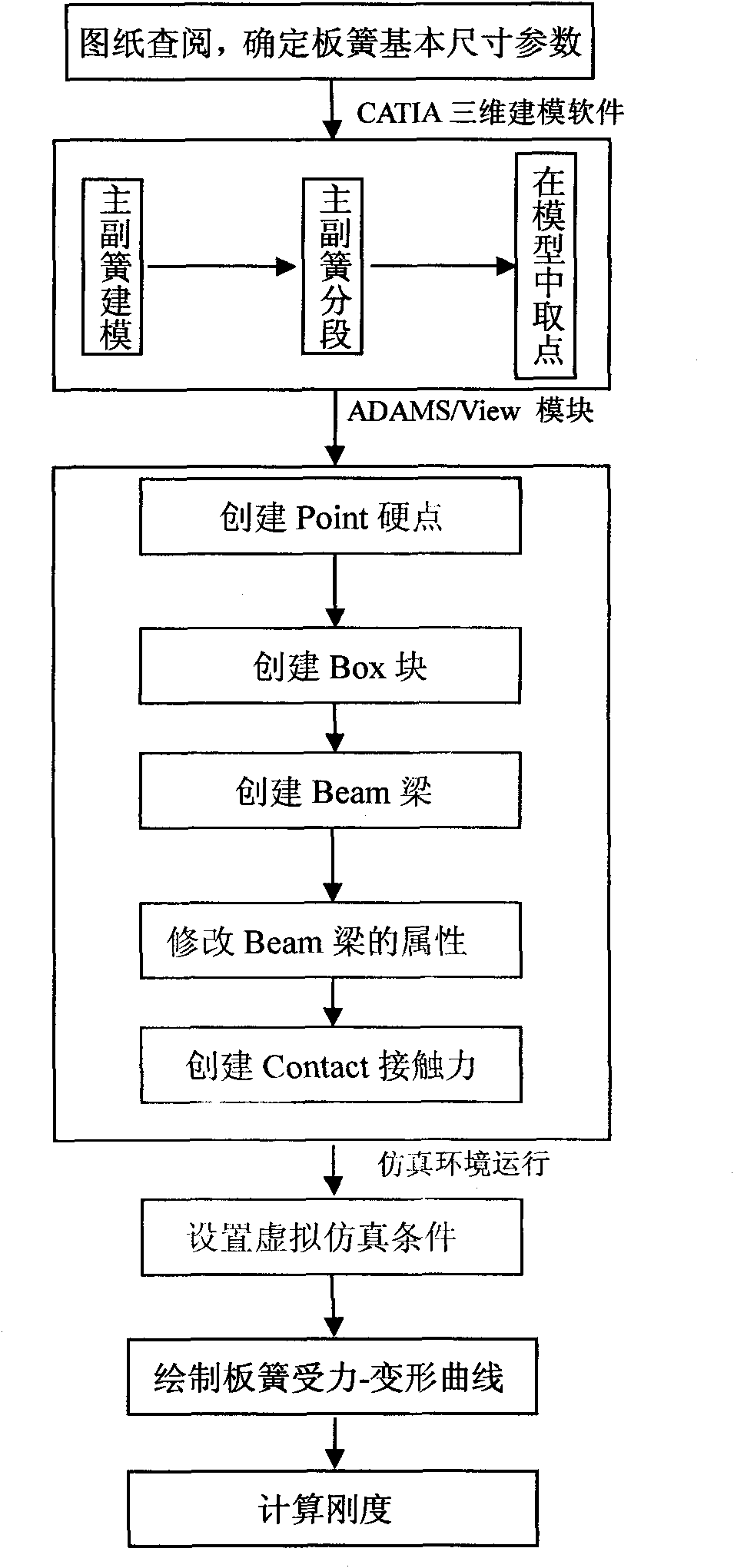

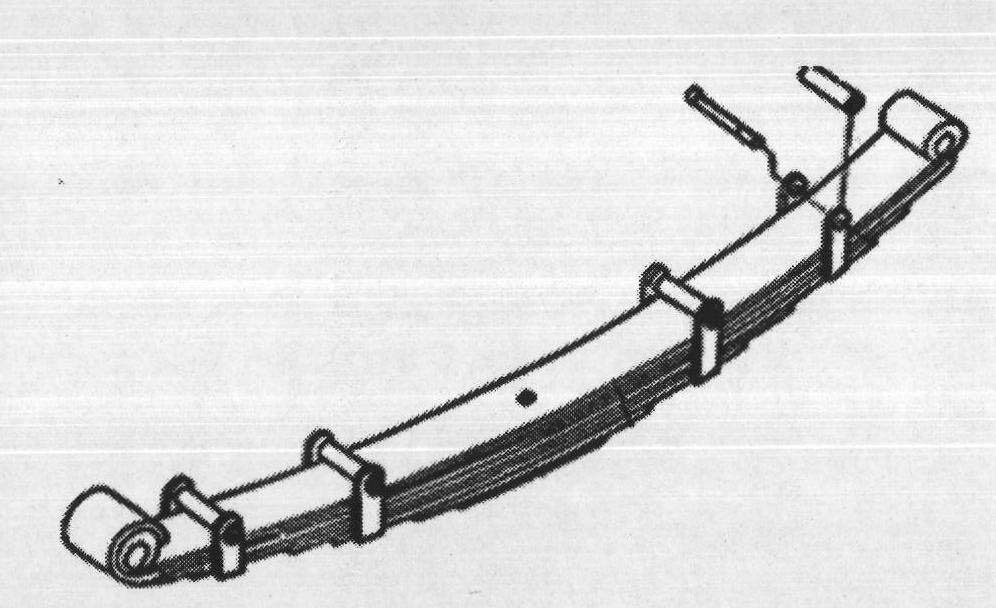

Method for solving rigidity of plate spring by using automatic dynamic analysis of mechanical system (ADAMS)

InactiveCN101866378AIncrease stiffnessCalculation speedSpecial data processing applicationsBasic dimensionSimulation

The invention discloses a method for solving rigidity of a plate spring by using an automatic dynamic analysis of mechanical system (ADAMS). The method comprises the following steps of: step one, determining basic dimension parameters of the plate spring according to a design paper of the plate spring; step two, establishing a three-dimensional model by employing CATIA software to perform reasonable segmentation, and selecting necessary coordinate points; step three, establishing a Point hard-point, a Box block and a Beam beam in an ADAMS / View, putting forward an equivalent middle surface method in attribute setting of the Beam beam, and establishing contact force Contact; and step four, setting a simulation analysis environment of a stress-deformation curve of the plate spring, and employing a method for loading loads through contact of a flat plate and a spheroid to obtain a simulation curve. The method solves the problems in establishing a plate spring flexible body model through the ADAMS software, and the problems in performing simulation setting on the stress-deformation curve of the plate spring flexible body model, and has important meanings for improving the modeling, analyzing and solving accuracies and the calculation speed of mechanical simulation software.

Owner:HUAIYIN INSTITUTE OF TECHNOLOGY

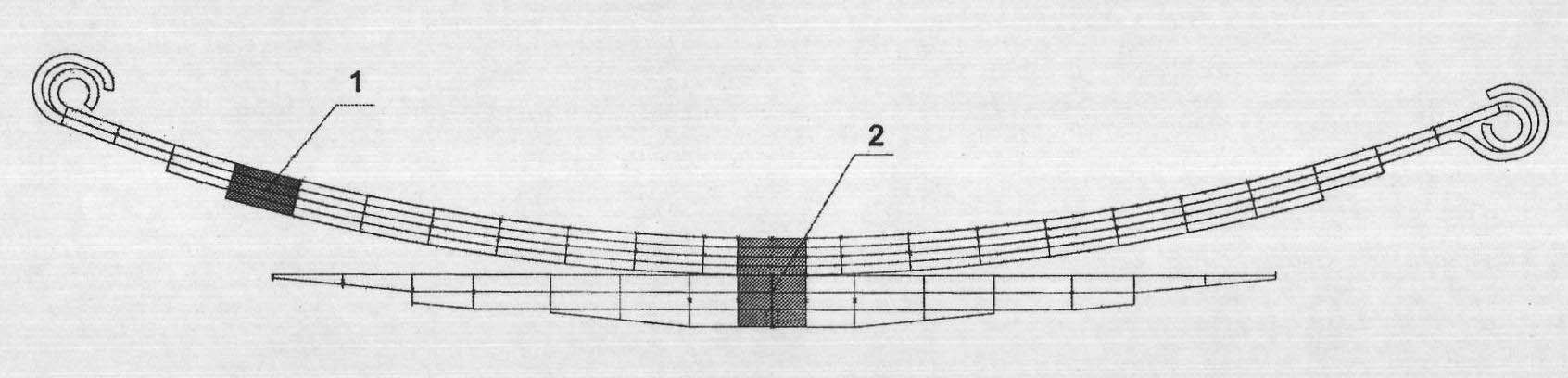

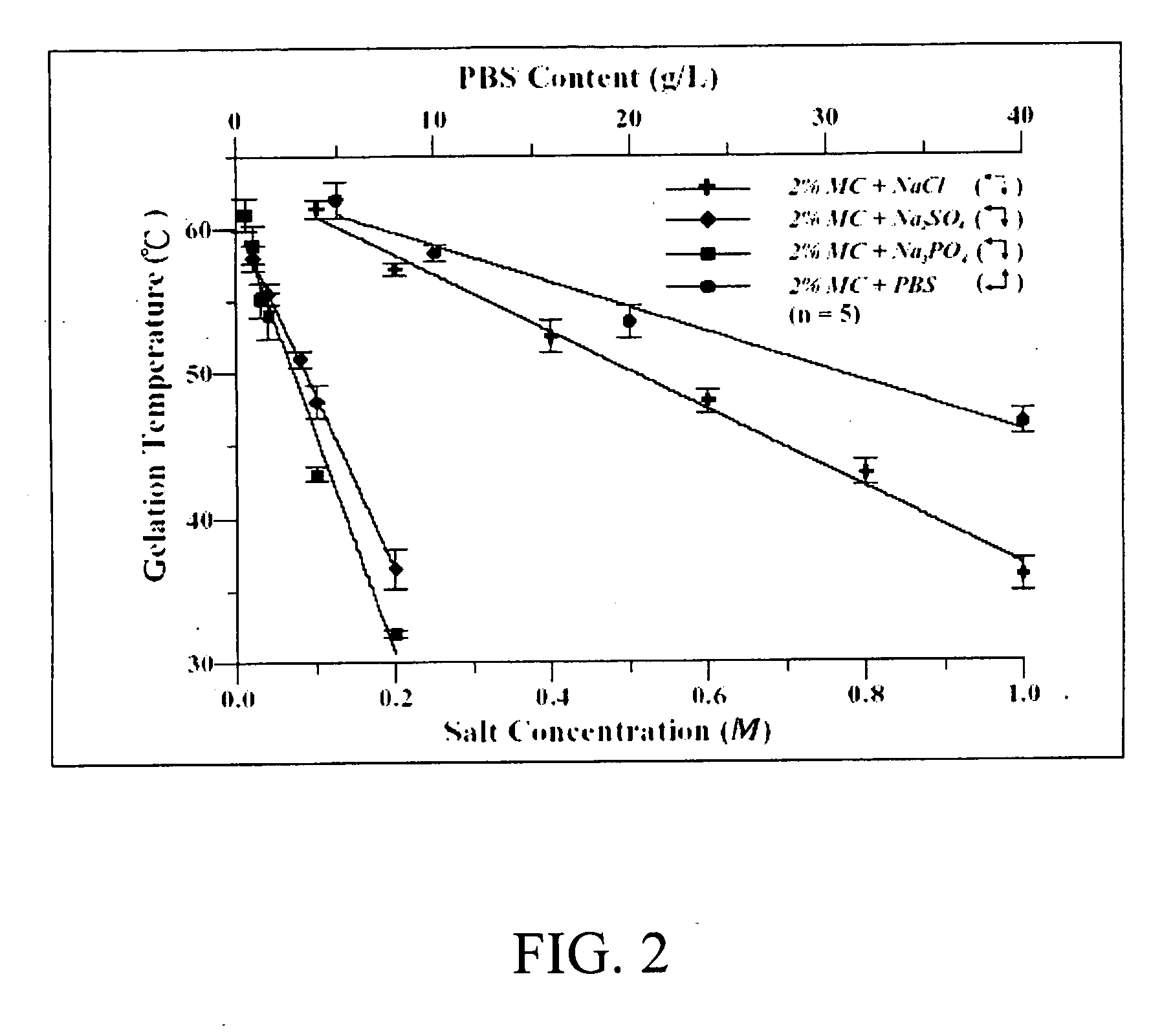

Medical device and methods for living cell injection

A novel method, using a thermoreversible MC / PBS / Collagen hydrogel coated on the TCPS dish, for harvesting a living cell sheet or spheroid with ECM. In one application, the obtained living cell sheet / spheroid is administered to a joint adapted for implantation and for cartilage regeneration. In another application, the living cell sheet / spheroid is administered, preferably via percutaneous injection, to an infarcted cardiac tissue as a novel therapy for treating myocardial infarction.

Owner:GP MEDICAL

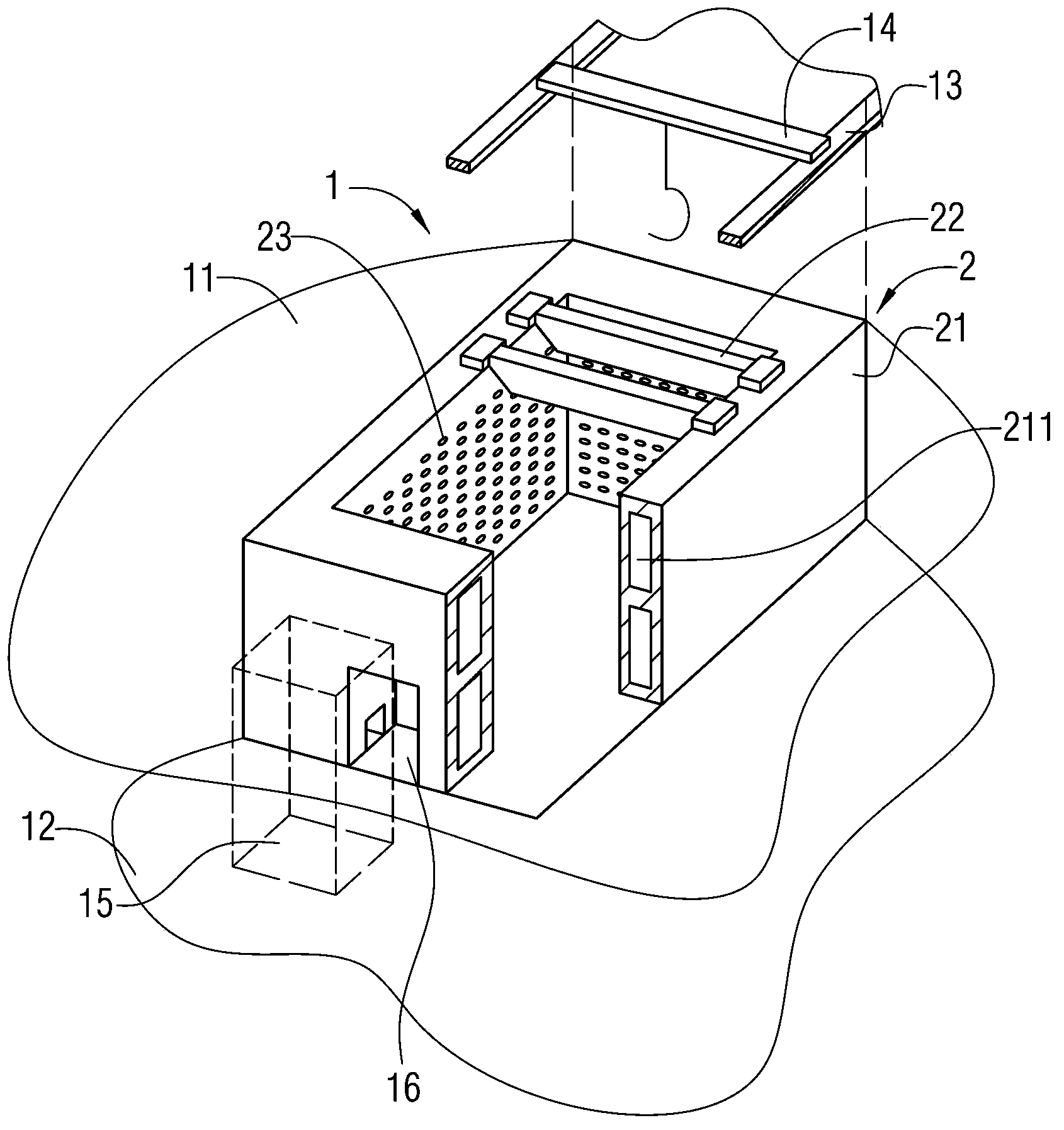

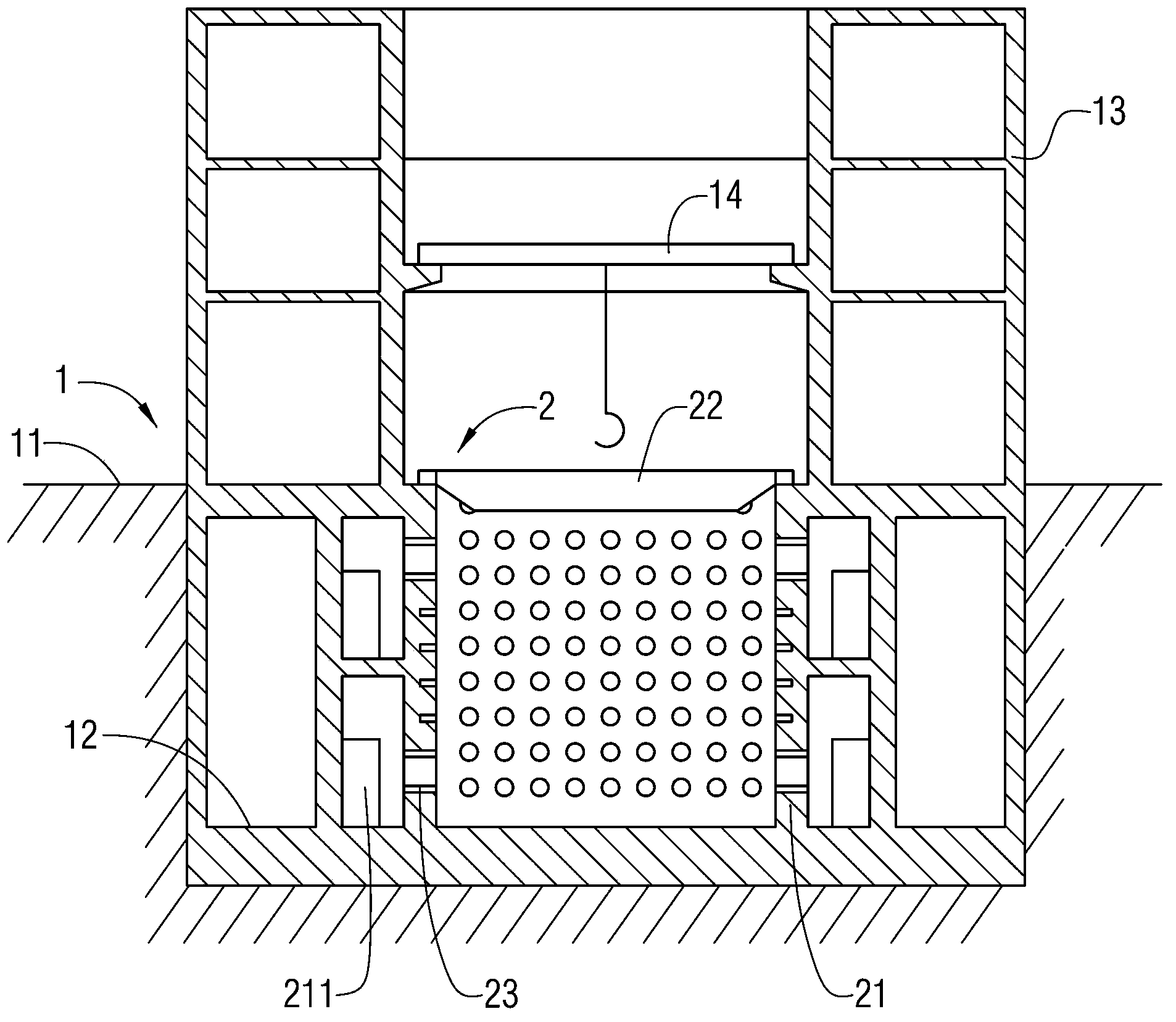

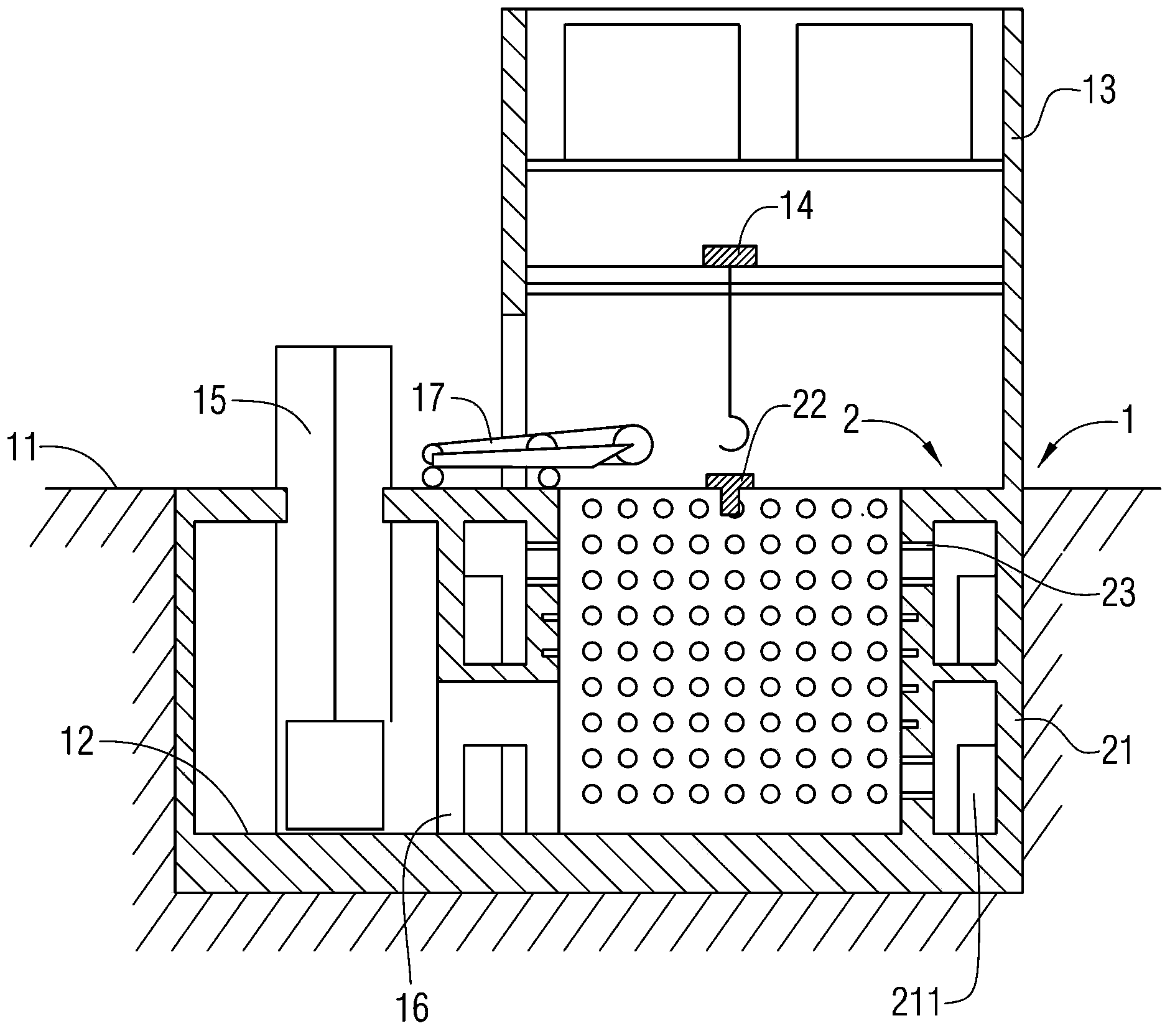

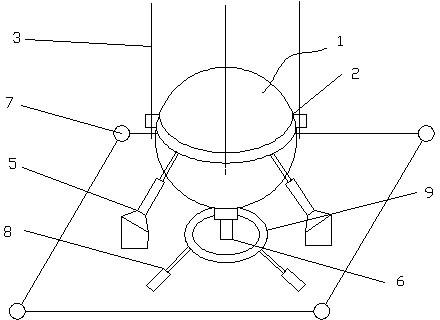

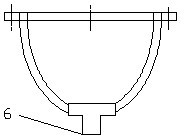

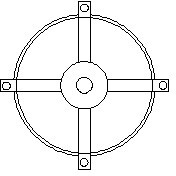

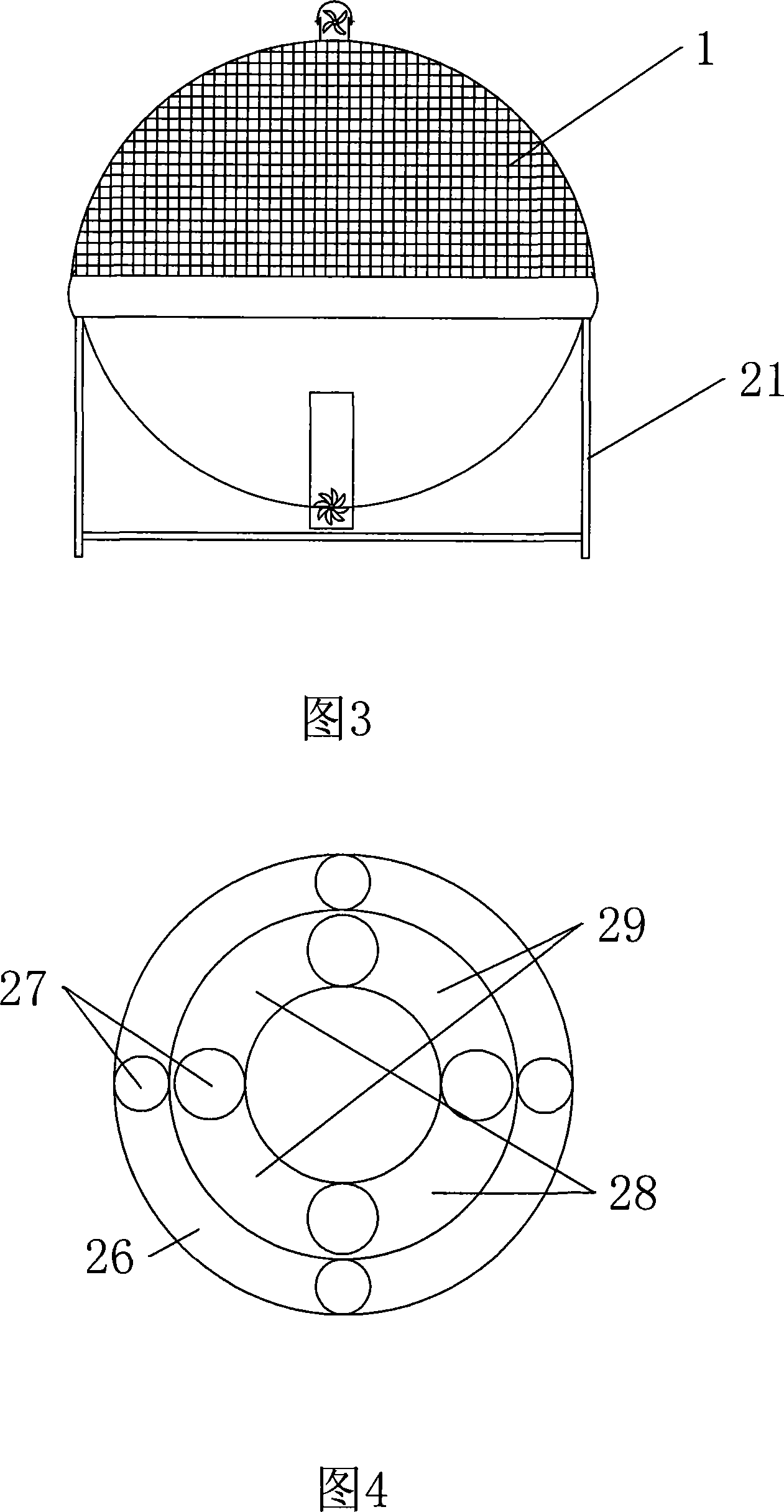

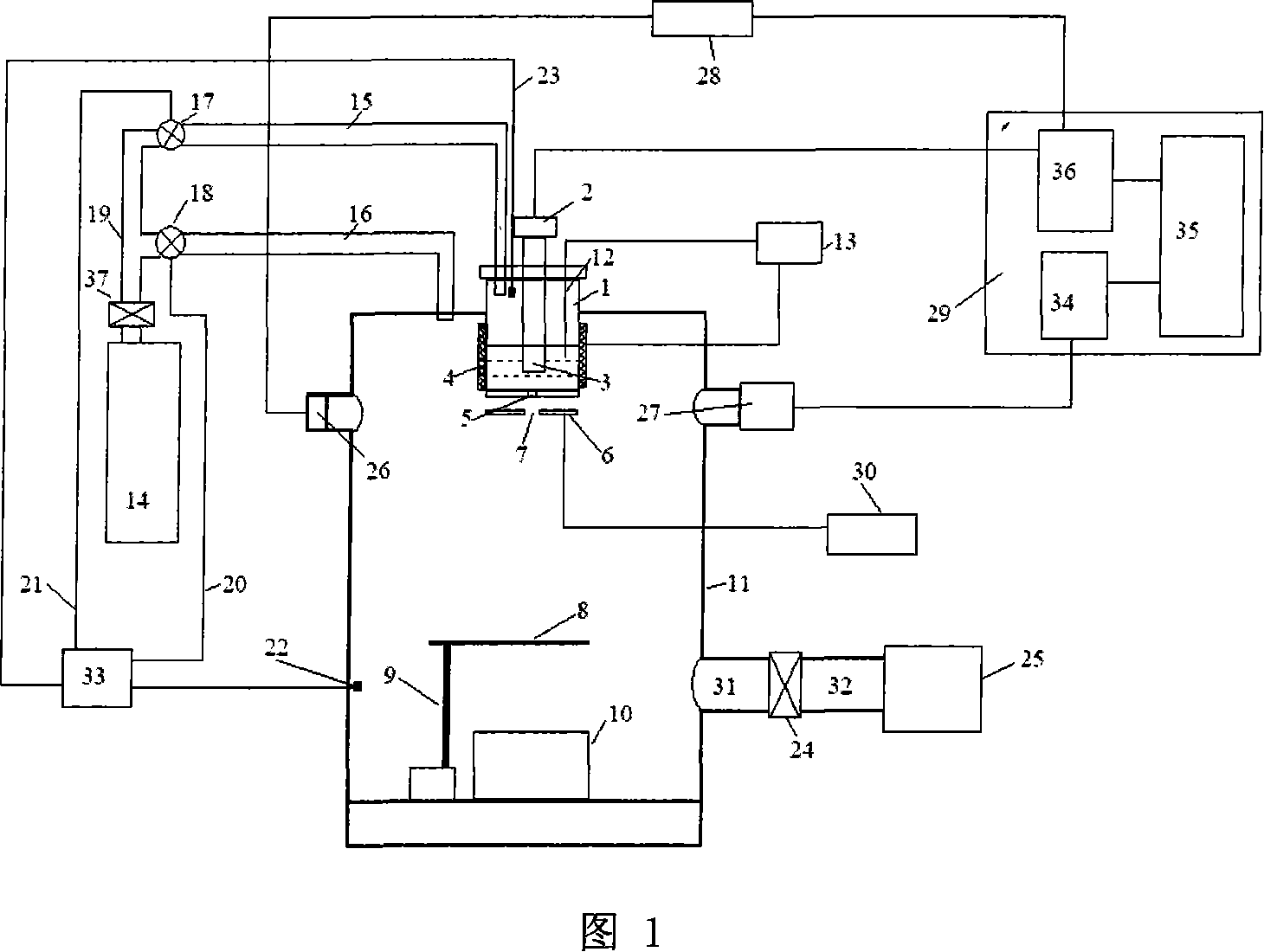

Model box applied to large stereoscopic synthesis simulation test bench in geotechnical engineering

ActiveCN103454400ARealize true 3D loadingEarth material testingStructural/machines measurementPhysical modelActuator

The invention discloses a model box applied to a large stereoscopic synthesis simulation test bench in geotechnical engineering, wherein four sides of the model box are spliced by a plurality of horizontal loading plates; the top of the model box is formed by splicing a plurality of vertical loading plates; each horizontal loading plate is connected with a horizontal loading actuator through a spheroid joint; each horizontal loading actuator is fixedly connected with a reaction wall through connection bolts; each vertical loading plate is connected with a vertical loading actuator through a spheroid joint; each vertical loading actuator is fixedly connected with a reaction beam; sealing joint strips are embedded between the side surfaces of the adjacent horizontal loading plates. The model box disclosed by the invention can be applied to a simulation test of soil engineering with different functions, such as underground space and excavation simulation tests, foundation and slope engineering simulation tests under the condition of rain and underground water level variation, dynamic response tests of pile foundations and soil around the pile foundations, segment simulation tests, and structure part performance tests; simultaneously, due to the adoption of the model box, the true three-dimensional loading of a large-sized physical model is realized.

Owner:北京宝和源装备科技发展有限公司

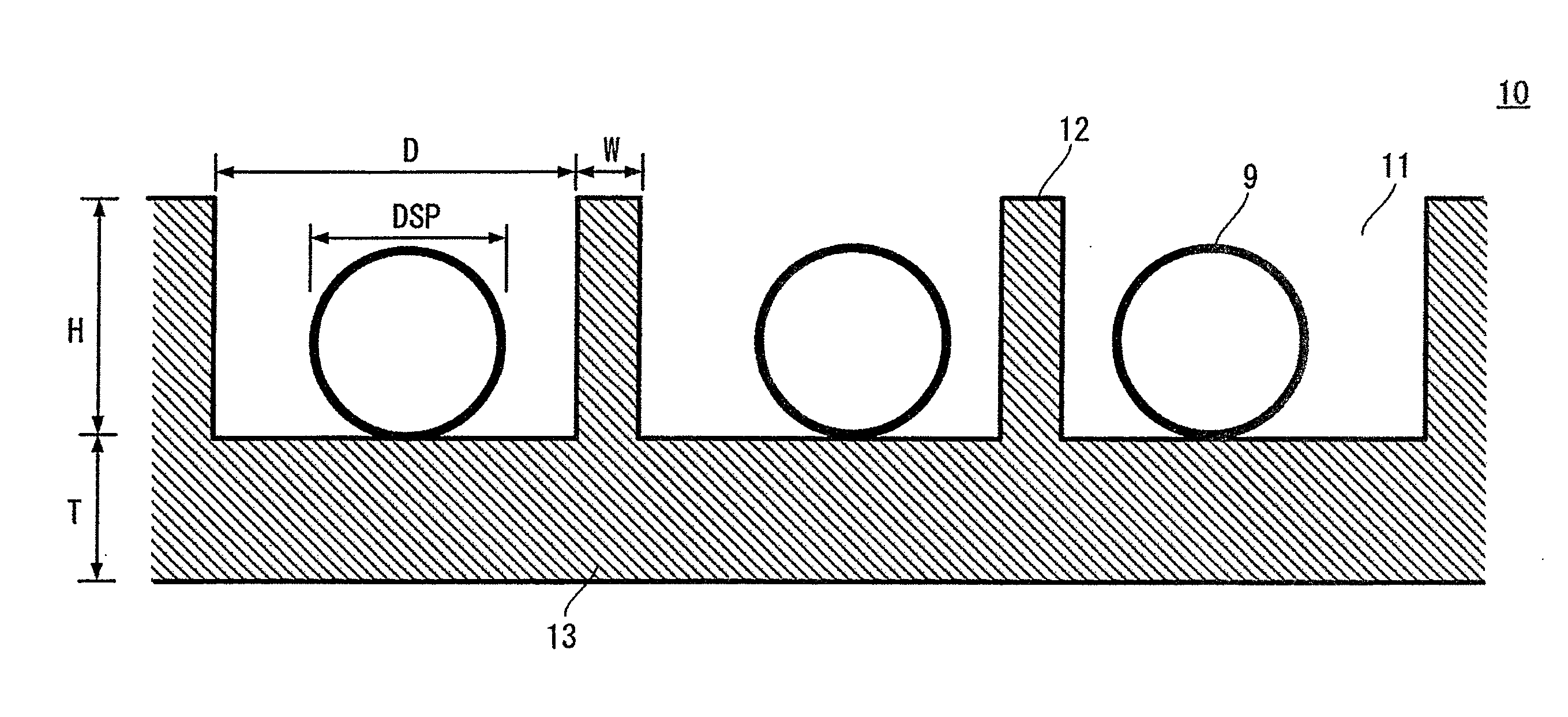

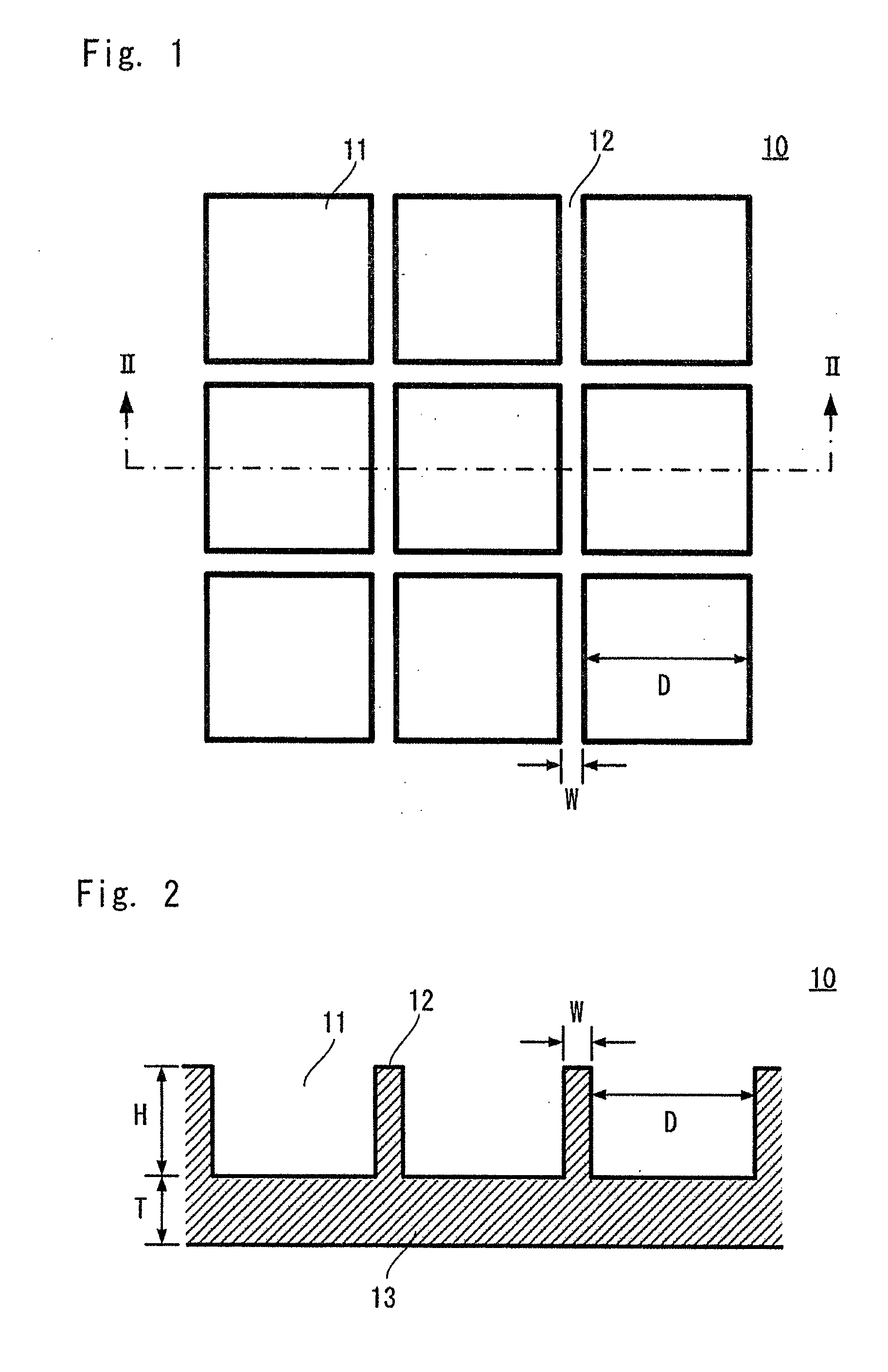

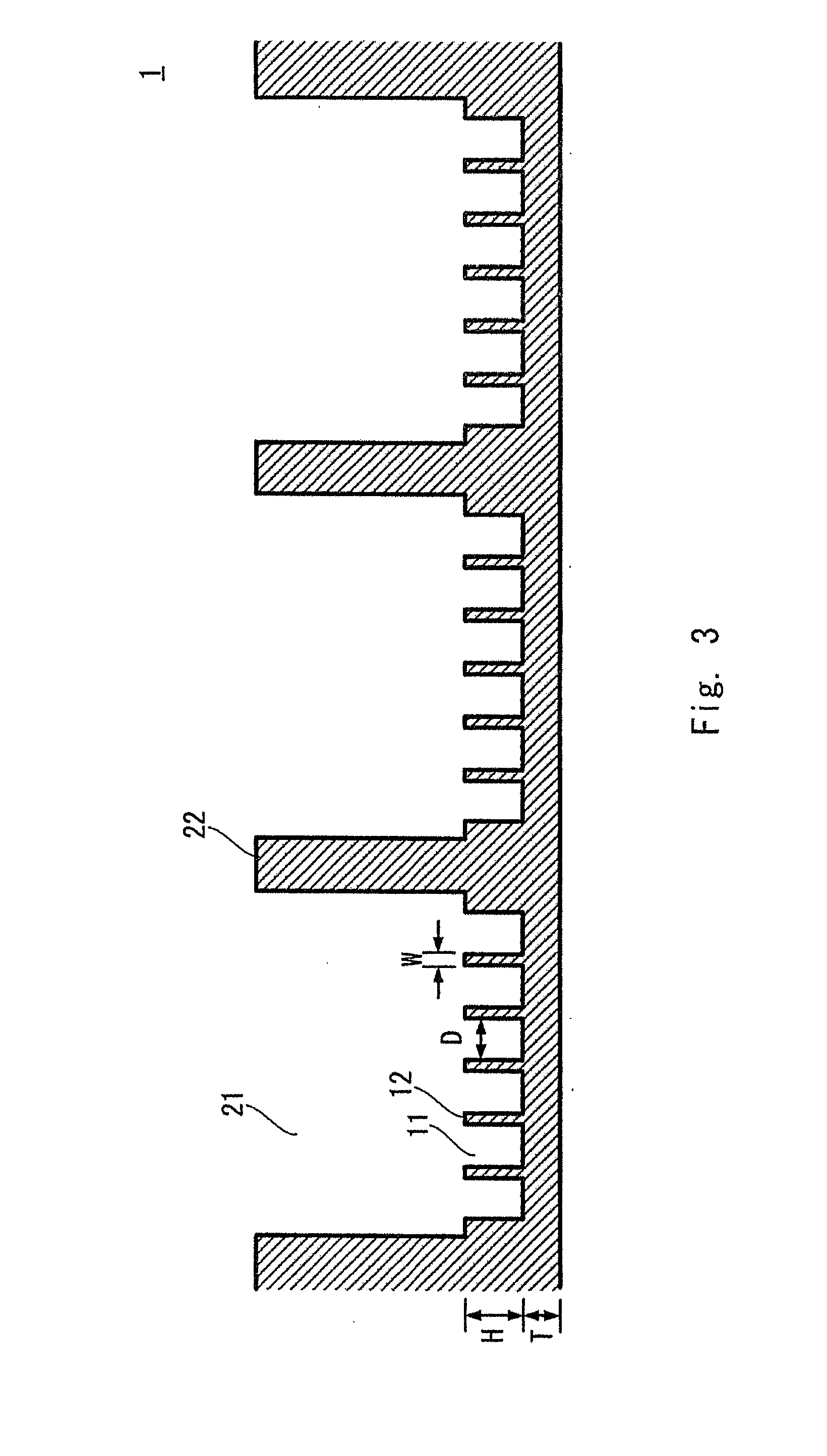

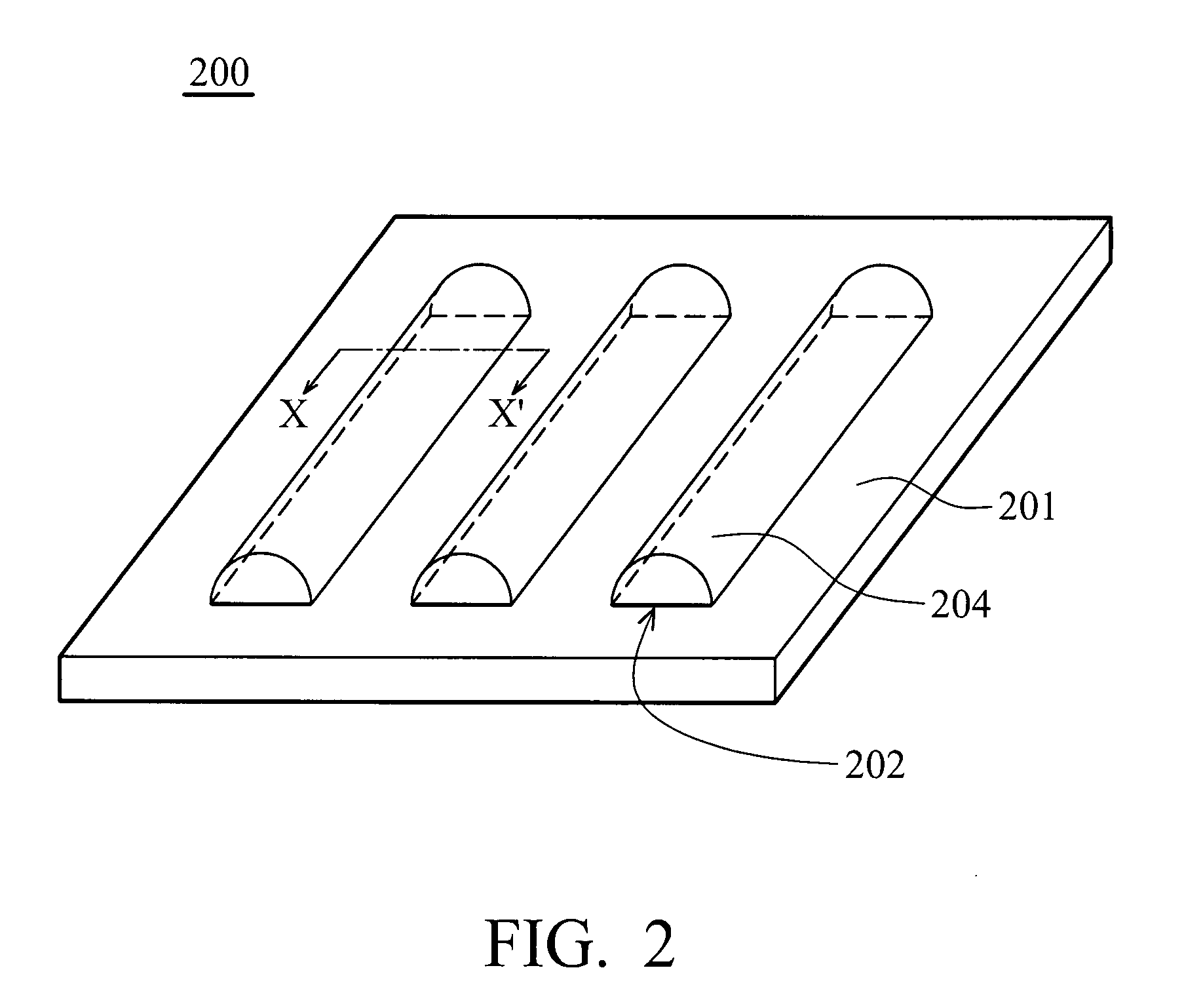

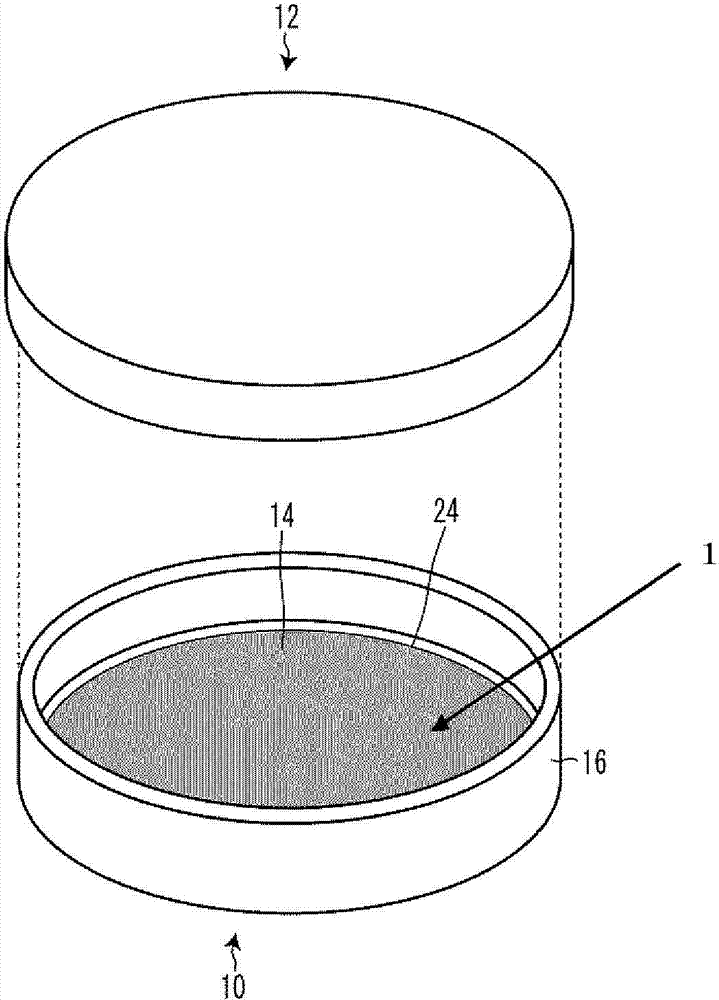

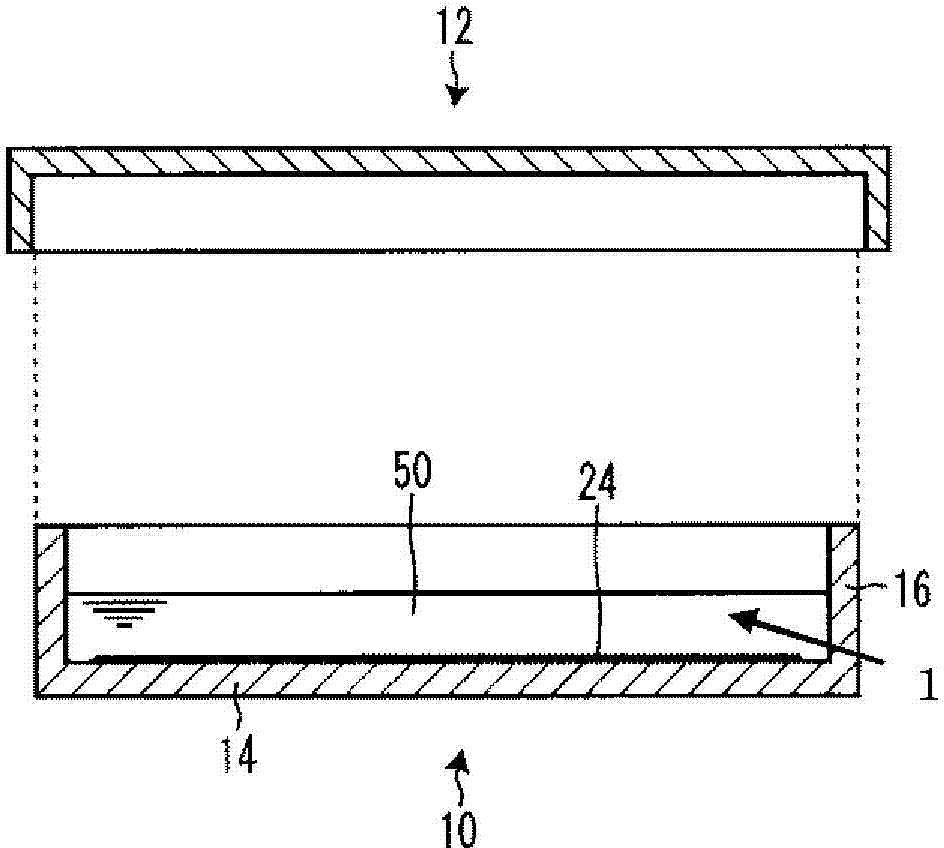

Adherent cell culture method

ActiveUS20140227784A1High densityBiochemistry apparatusCell culture supports/coatingWater contactMicrobiology

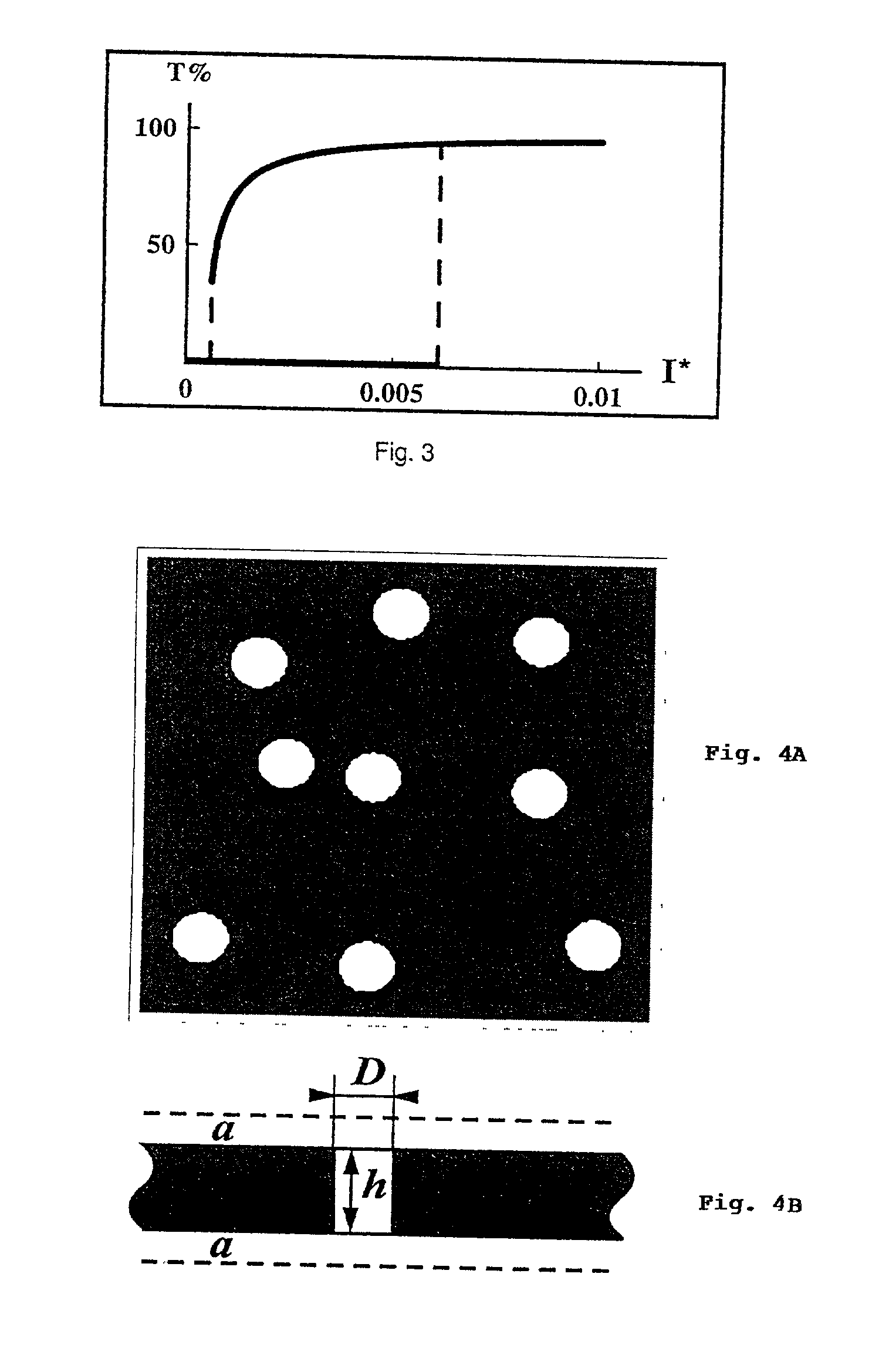

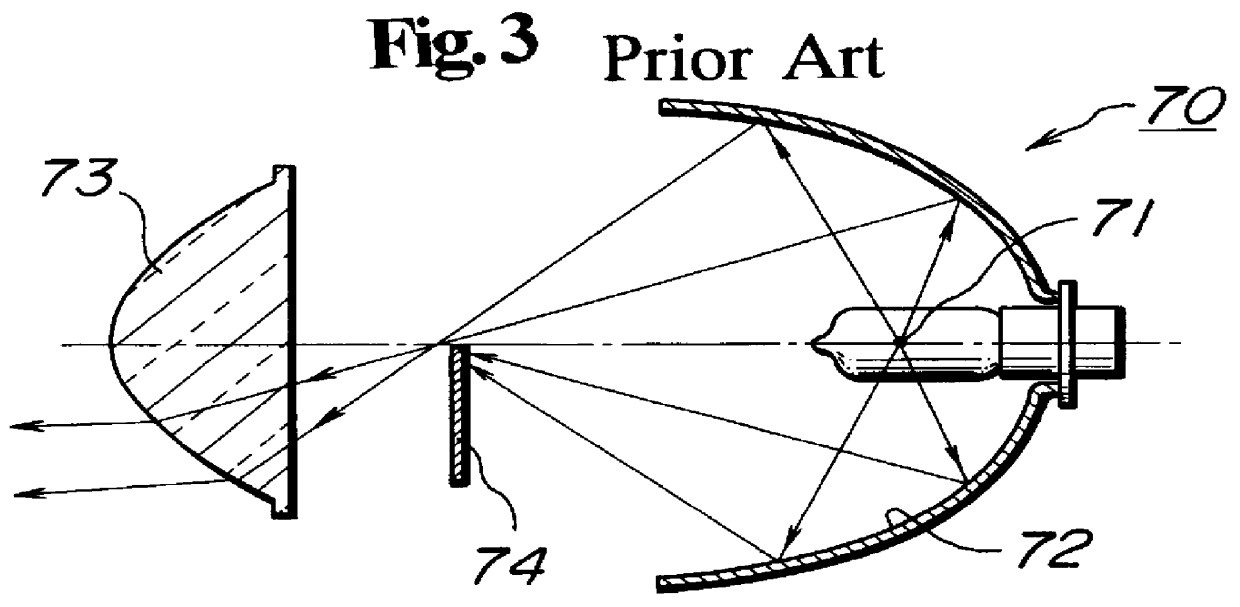

Provided are a method capable of evaluating adherent cells under an environment similar to an in vivo environment by a culture method similar to a two-dimensional culture, and applications thereof. An adherent cell culture method uses, as a culture chamber (10), a chamber in which two or more culture spaces each having an equivalent diameter (D) that is 1 to 5 times the diameter of a desired spheroid and each having a height (H) that is 0.3 to 5 times the equivalent diameter are arranged and a surface of each of the culture spaces has a water contact angle of 45 degrees or less. Spheroids of adherent cells are cultured in the respective culture spaces (11) arranged in the culture chamber (10).

Owner:CORNING INC

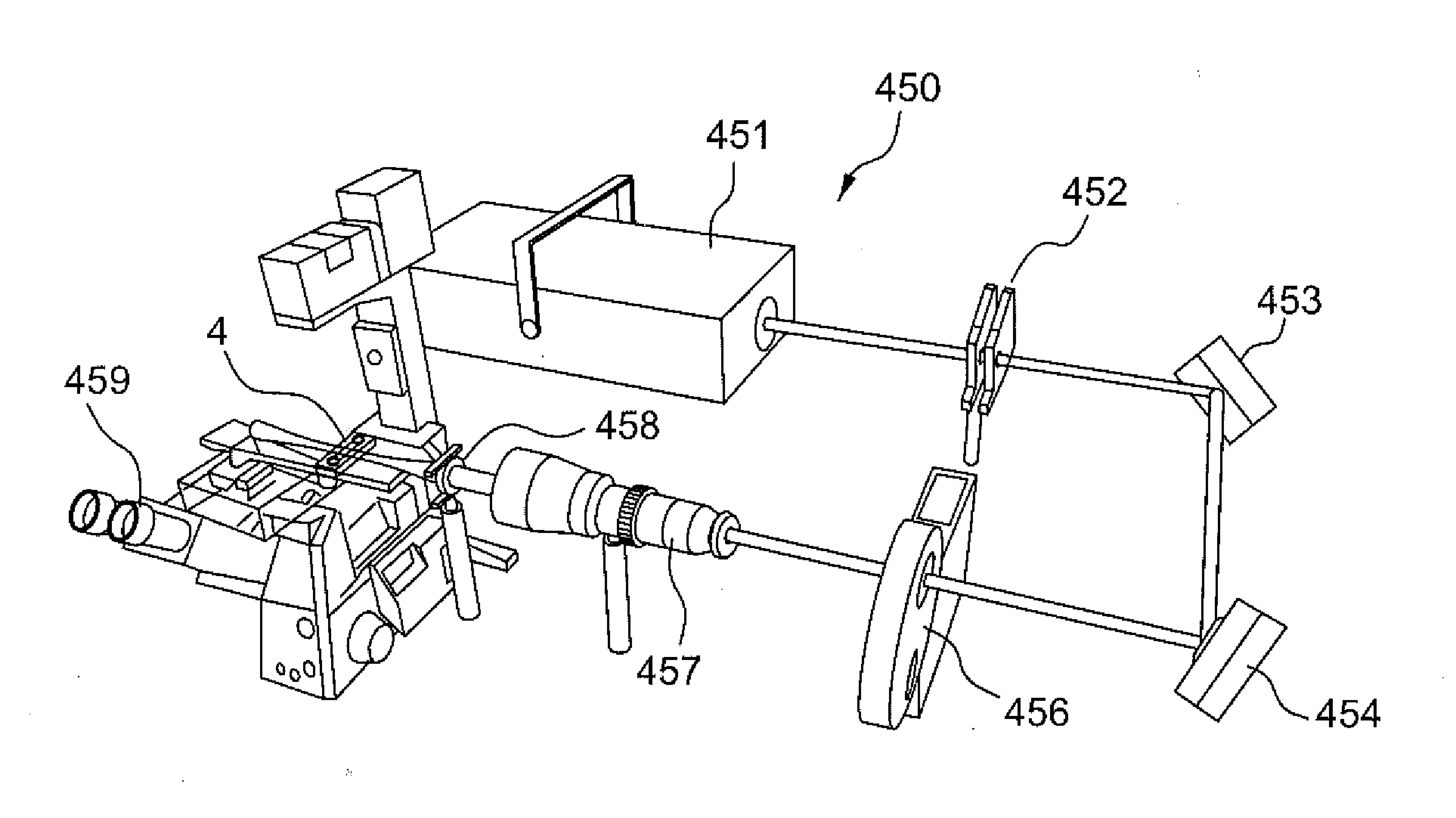

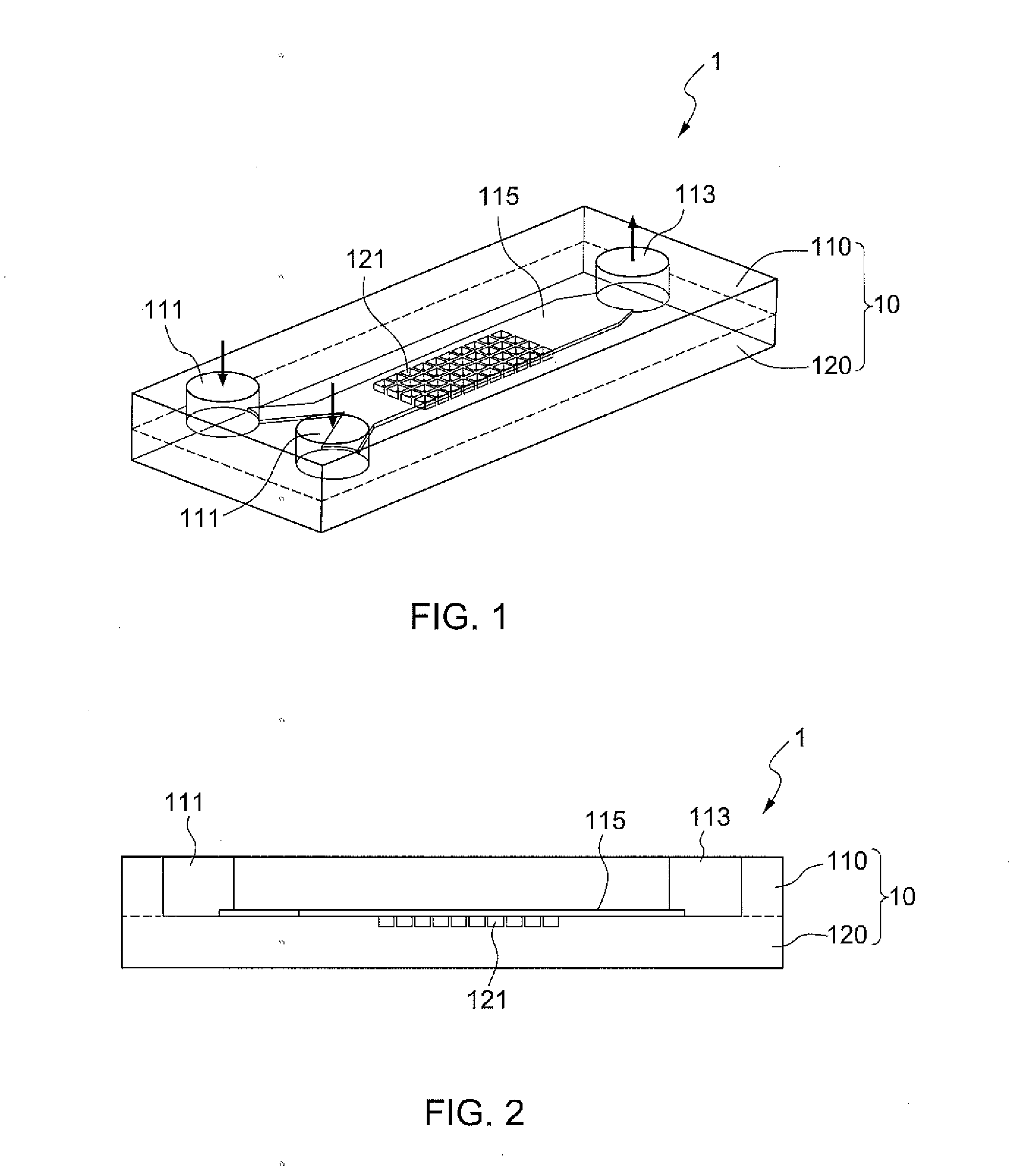

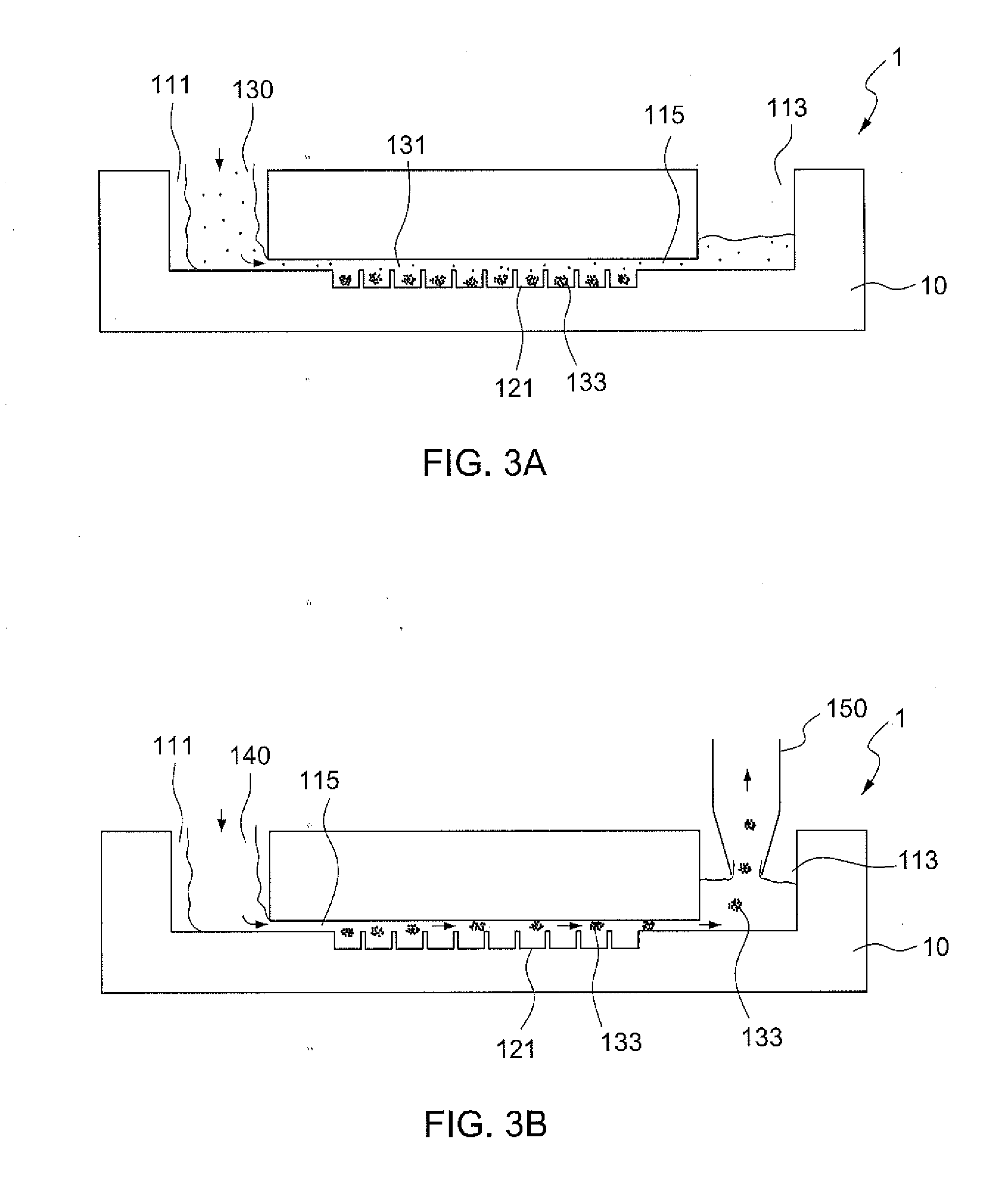

Microfluidic device for cell spheroid culture and analysis

InactiveUS20160097028A1Bioreactor/fermenter combinationsBiological substance pretreatmentsCulture cellAnimal body

The invention relates to a microfluidic device for culturing spheroids of human or animal body cells. The device can generate ample numbers (e.g., 5000) of uniform-sized spheroids, and the spheroids can be harvested for conventional biochemistry analysis (e.g. flow cytometry). In addition, the device can be used for observing the cultured samples using selective plane illumination microscopy (SPIM). In at least one embodiment, the microfluidic device incorporates a main body; a fluid channel extending inside the main body and having two inlets and an outlet open to the outside; and a plurality of chambers for culturing cell spheroids which are formed at the underneath of the fluid channel.

Owner:ACAD SINIC

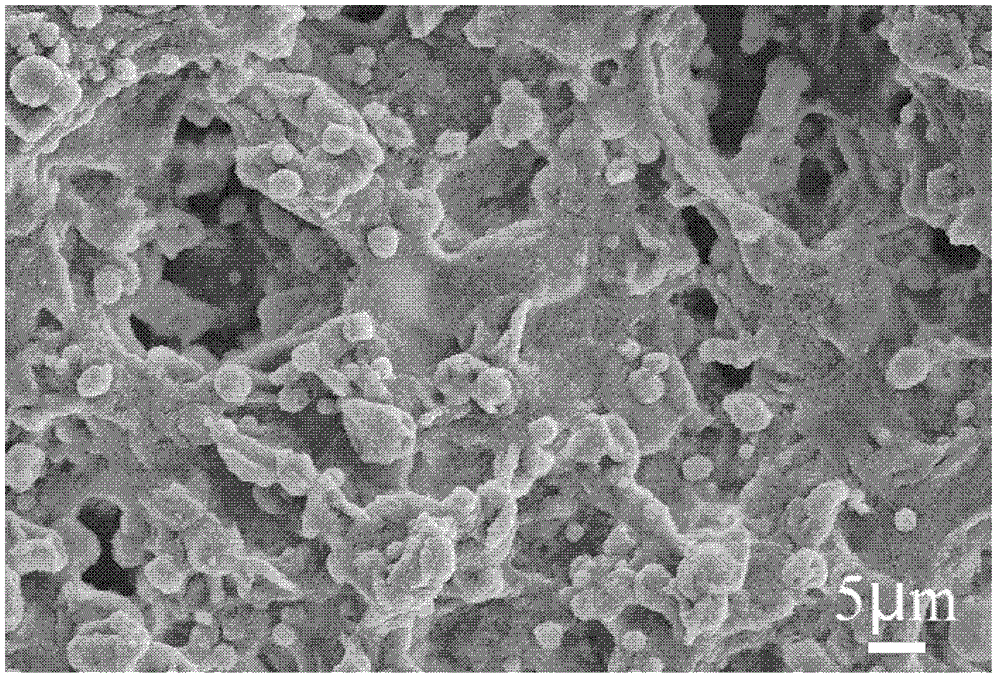

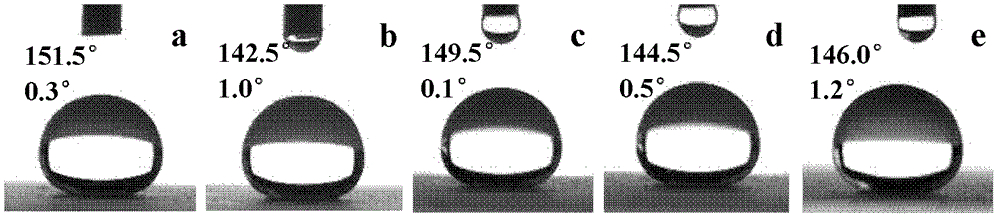

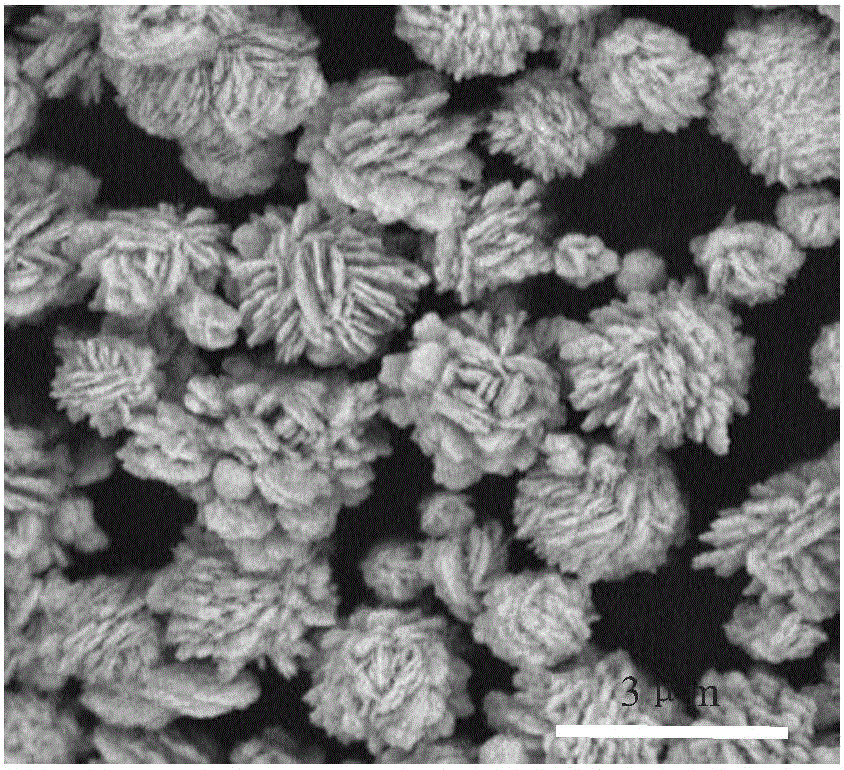

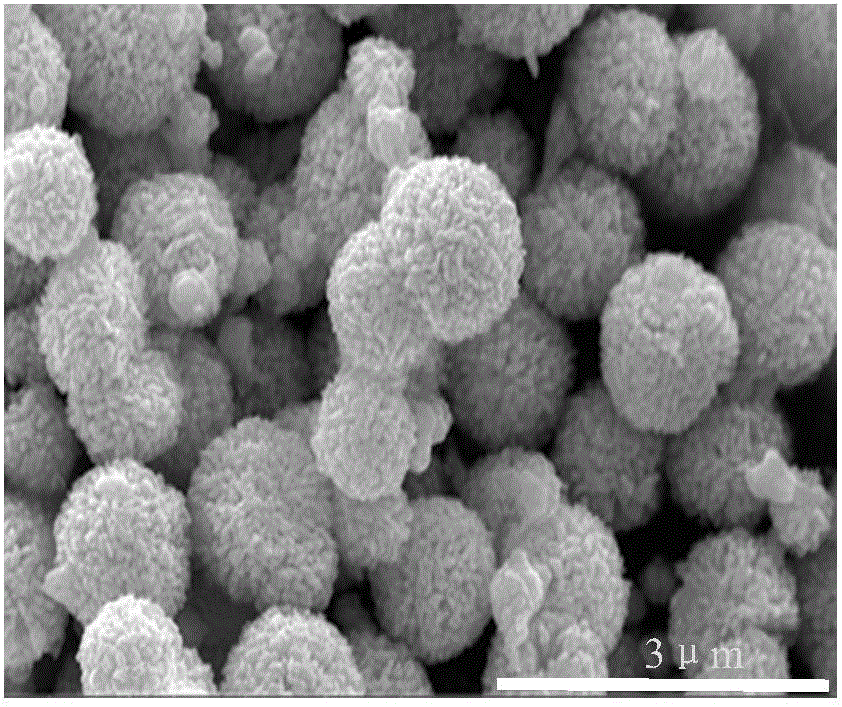

Super hydrophobic self-cleaning coating and preparation method thereof

The invention belongs to the technical field of preparation of nano materials, and in particular relates to a super hydrophobic self-cleaning coating and a preparation method thereof. The method comprises the following steps of: dispersing hydrophobic silicon resin and hydrophilic nano SiO2 particles into an organic solvent to obtain dispersion; and spraying the dispersion on a clean and dry glass sheet substrate, drying, and thus obtaining the super hydrophobic self-cleaning coating. The coating has a hierarchical structure compounded by using organic and inorganic components, namely the hydrophobic silicon resin and the hydrophilic nano SiO2 particles, and the structure has compound micro-nano surface topography; and the compound micro-nano hierarchical structure is constructed by spheroid-like protrusions with the diameters of 1 to 10 microns and agglomerate spheres with the diameters of 20 to 100 nanometers on the surface of the coating, wherein the spheroid-like protrusions are constructed by agglomerate spheres with the diameters of 20 to 100 nanometers. The contact angle between the coating and water is 140 to 155 degrees, and the rolling angles of water drops on the surface of the coating are less than 2 degrees.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

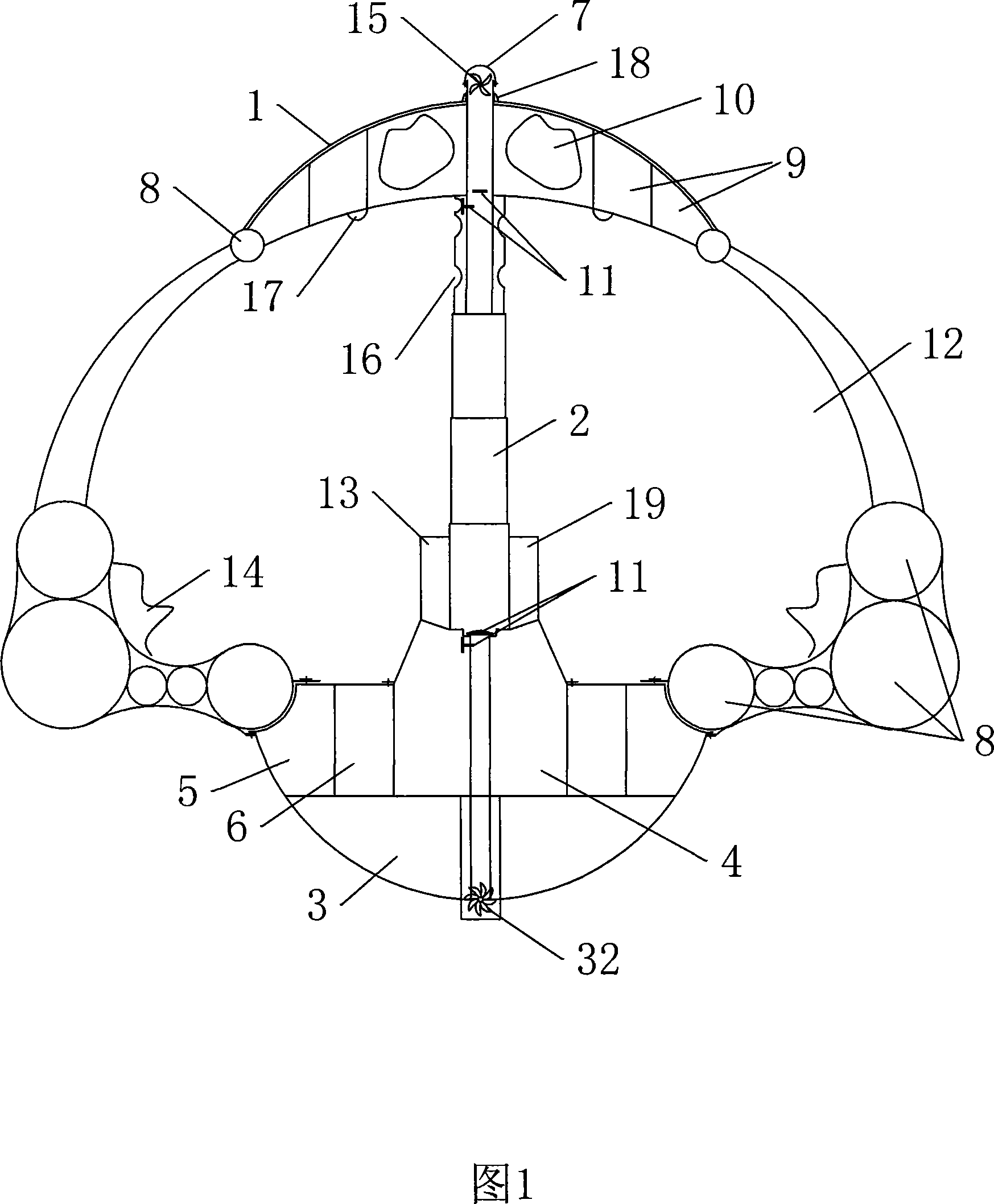

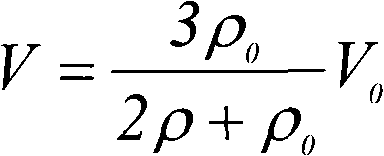

Tempering damper system used for improving wind resistance stability of transmission tower based on single pendulum model

ActiveCN102535674AGood stability against windEasy maintenanceShock proofingTransmission towerEngineering

The invention relates to a tempering damper system used for improving wind resistance stability of a transmission tower based on a single pendulum model. The damper system is composed of a spheroid mass block, a bracket, oil pressure type dissipation energy dampers, an oil pressure type anticollision damper, steel ropes and a buffering steel ring and the like, wherein the spheroid mass block is composed of a roundness steel disc; four groups of steel ropes support the lower half part of the spheroid mass block through the bracket and four groups of oil pressure type dissipation energy dampers are arranged around the bracket to achieve the purpose of energy consumption and vibration attenuation; in addition, when the swing amplitude of the spheroid mass block is oversize, and a tubular steel bar arranged below the bracket can collide the buffering steel ring so as to slow down the motion of the buffering steel ring; and the performance of the tempering damper system mainly depends on the size of rotational inertia, if the rotational inertia ratio of the tempering damper system to a controlled system is larger, the control effect is better. The tempering damper system is suitable for transmission towers of different tower types, is easy to install, and can obviously improve the wind resistance stability property of the transmission tower.

Owner:ELECTRIC POWER RES INST OF GUANGDONG POWER GRID +1

Process for ex vivo formation of mammalian bone and uses thereof

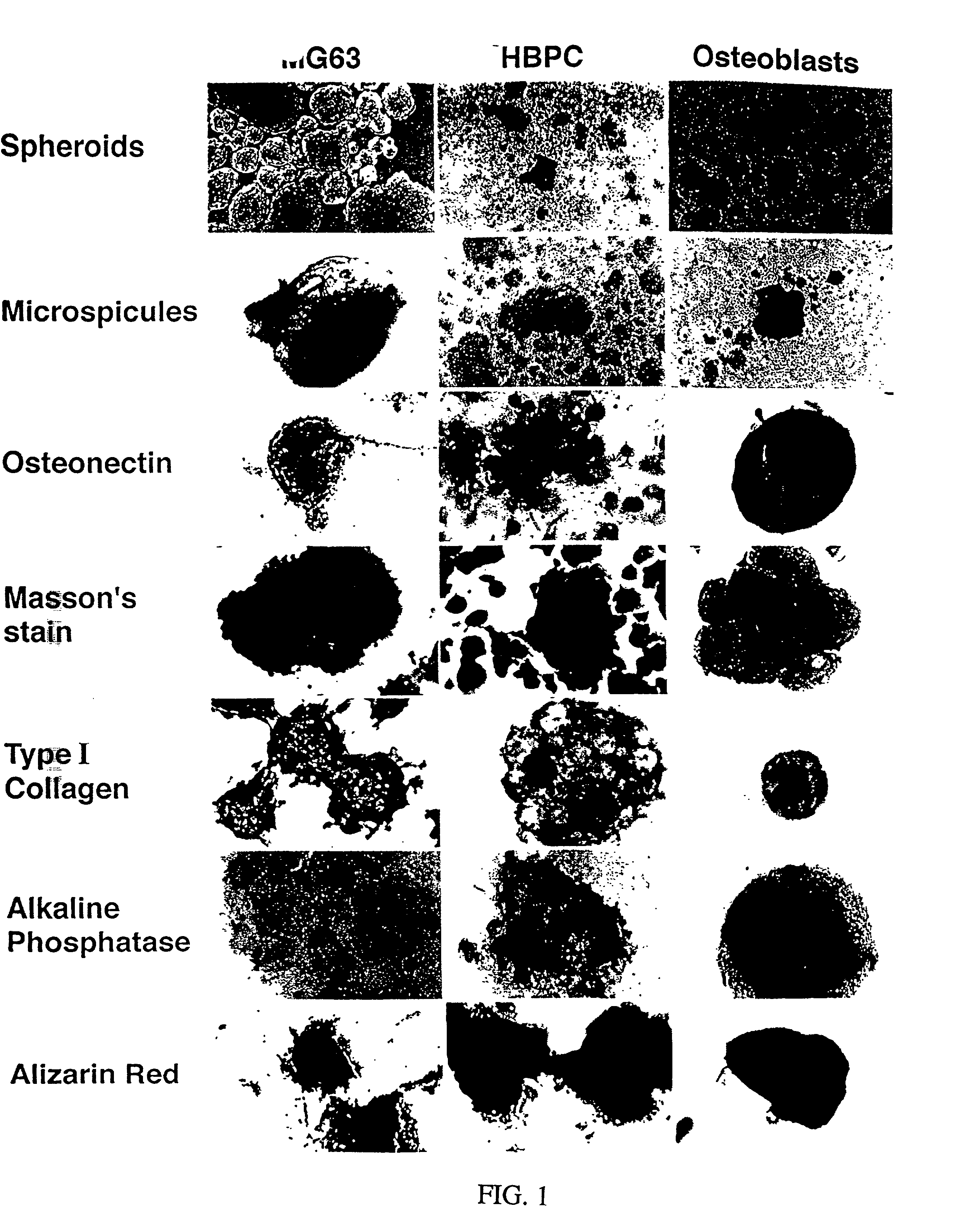

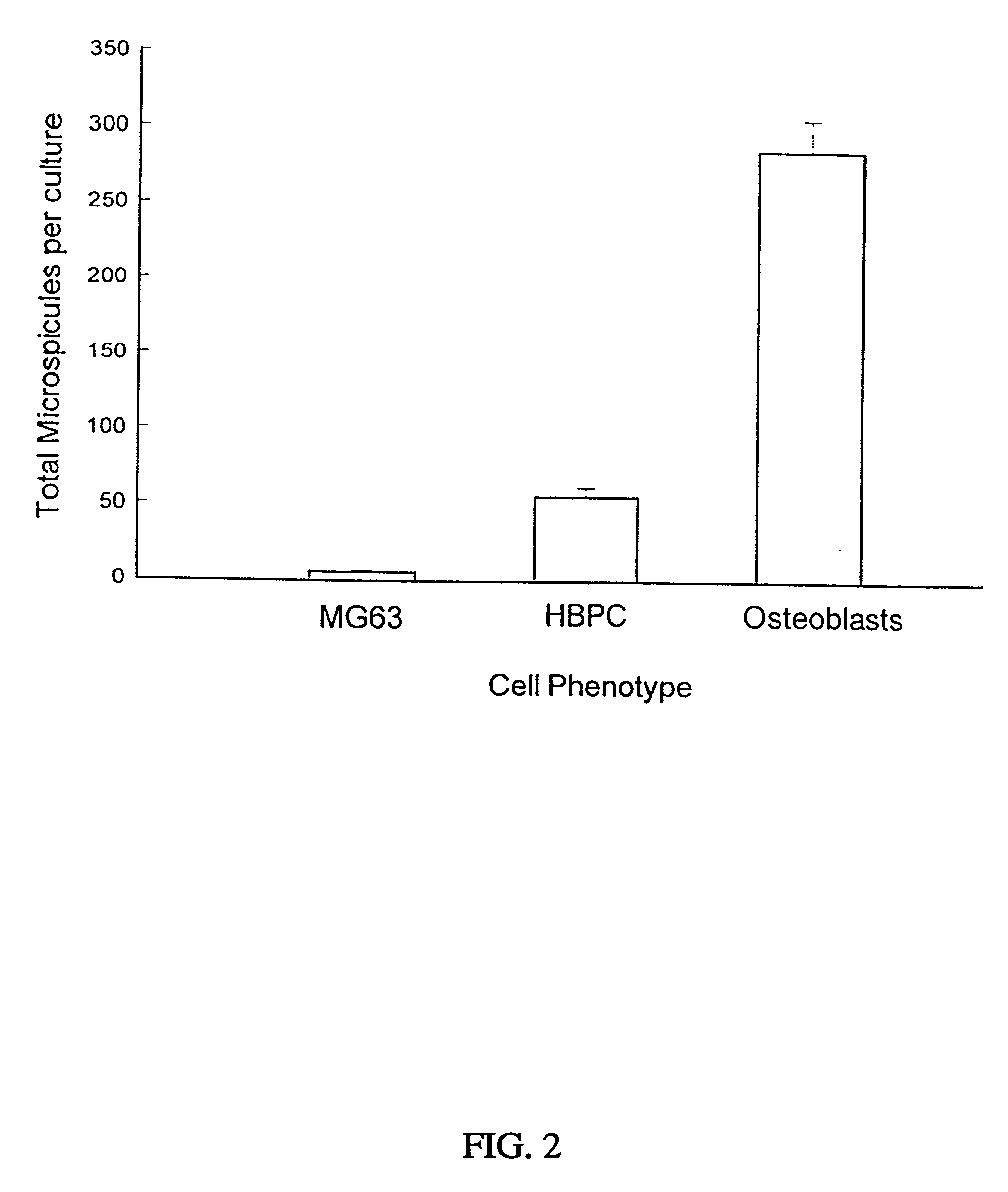

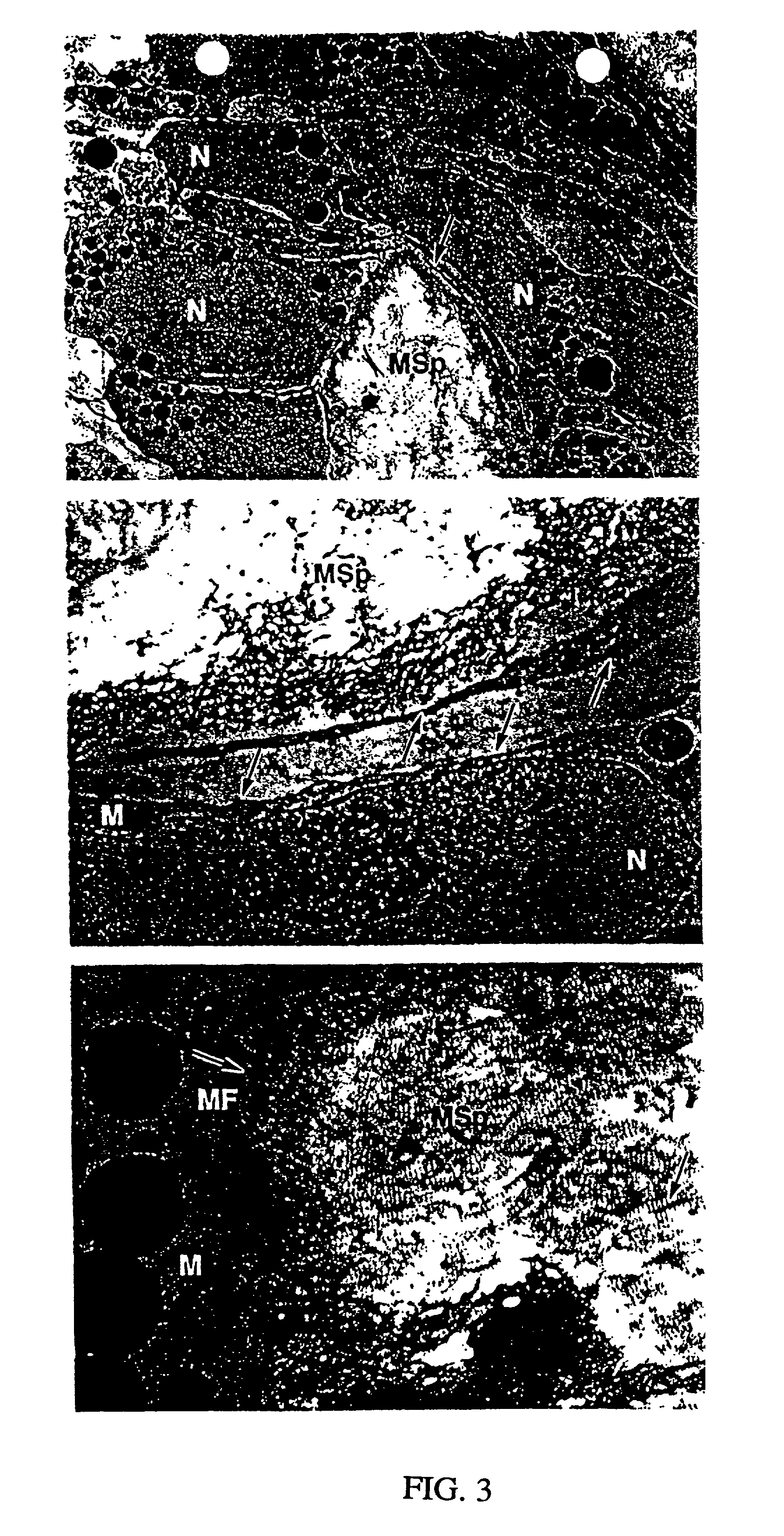

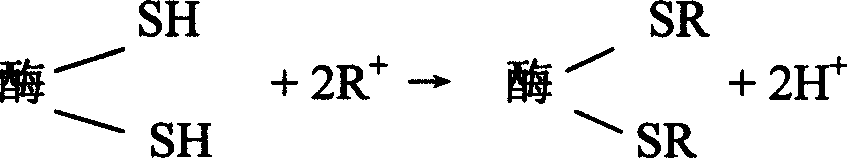

The present invention concerns methods for the ex vivo formation of mammalian bone and subsequent uses of the bone. A critical and distinguishing feature of the present invention are defined tissue culture conditions and factors resulting in the formation of bone cell spheroids. The invention also provides for methods of implanting into subjects the ex vivo formed bone. Also described are methods for genetically altering the bone cell spheroids to affect bone formation, identification of candidate modulators of bone formation, and identification of genes involved in bone formation.

Owner:RGT UNIV OF MICHIGAN

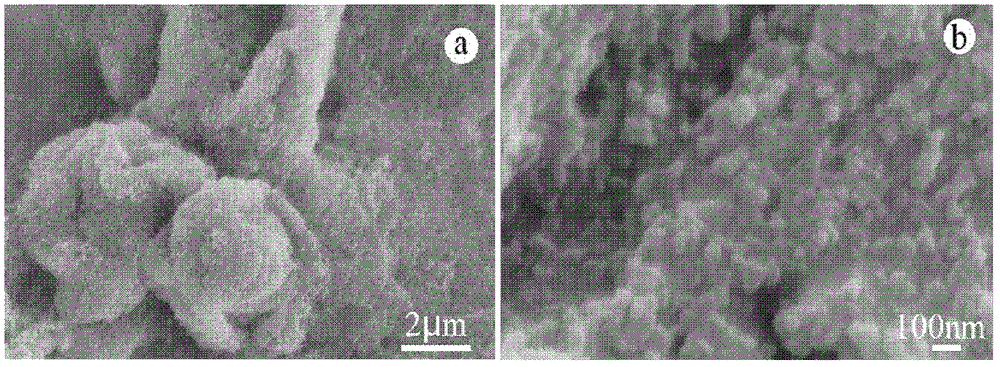

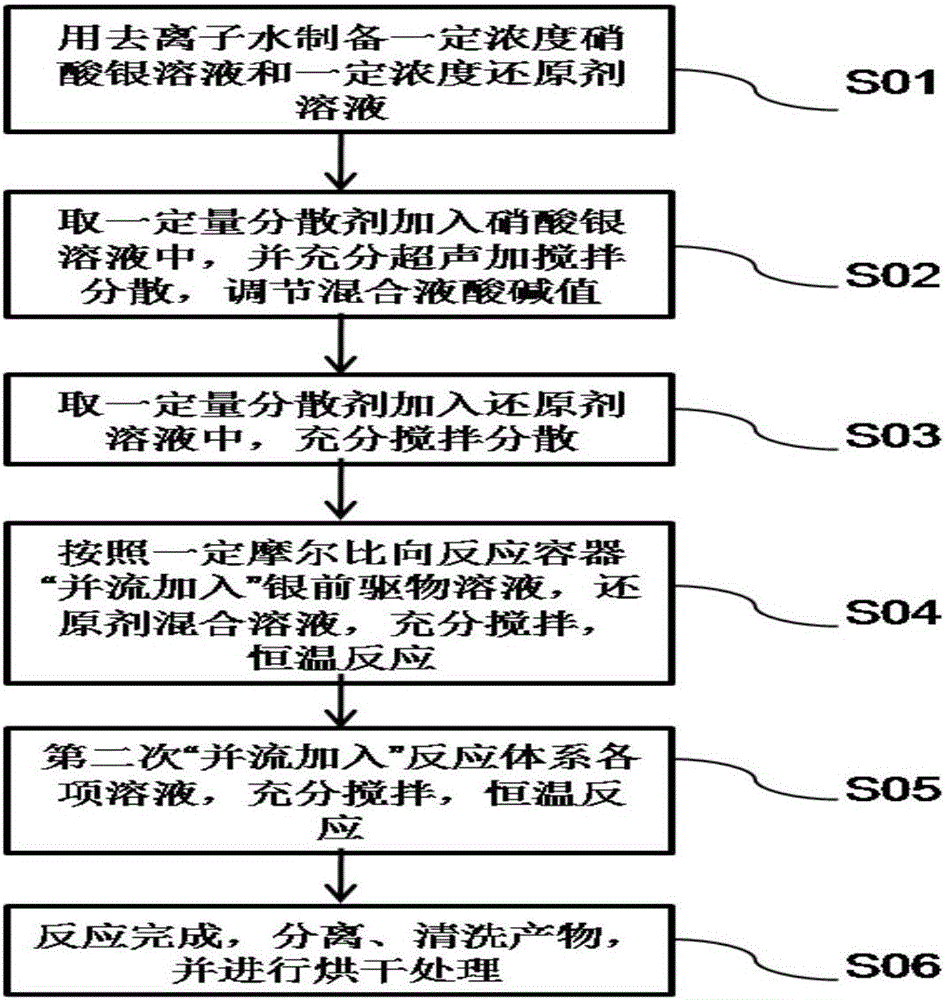

High specific surface area silver powder improving conductivity of solar battery electrode and preparation method

InactiveCN106825544AImprove photoelectric conversion efficiencyGood dispersionTransportation and packagingMetal-working apparatusDispersitySlurry

The invention discloses high specific surface area silver powder improving conductivity of a solar battery electrode and a preparation method. The silver powder has an average particle size of 0.6-0.75 micrometers, an apparent density of 2.5-5.0g / mL, a tap density of 4.15-6.95g / mL and specific surface area of 0.45-0.75m<2> / g. The method comprises the steps of preparing a silver nitrate solution and a reducer solution, adding a dispersing agent, performing parallel flow addition of various reaction system solutions into a reaction vessel by twice in a twice addition manner, uniformly mixing the reaction system solutions for the first time, keeping a PH value and temperature of reaction liquid as 2-5 and 25-60 DEG C, continuing stirring for 10-30min after feeding, and adding a mixed reaction solution in a parallel flow addition manner with the addition volume of 0.25-0.75 time of the total addition volume of the first time. The silver powder is a spheroid covered with bulges on the surface, is uniform in particle size and has a good crystal surface and high dispersity; the photoelectric conversion efficiency can be improved when the silver powder is used as front silver electrode slurry of crystalline silicon solar battery; the silver powder particularly has excellent characteristics in aspects of short-circuit current, contact resistance, fill factor and the like.

Owner:ENVIRONMENTAL NATURAL CHEM JIANGSU

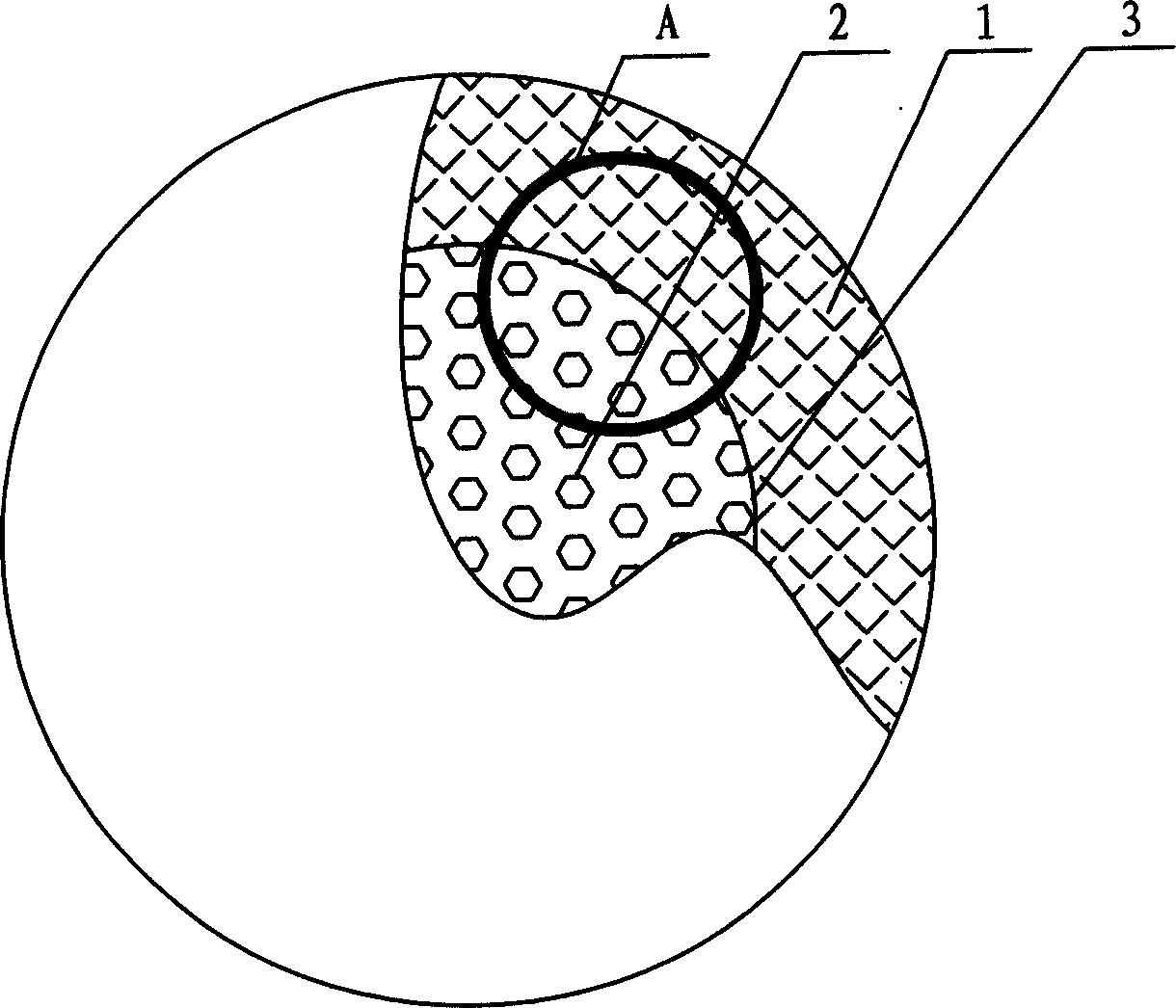

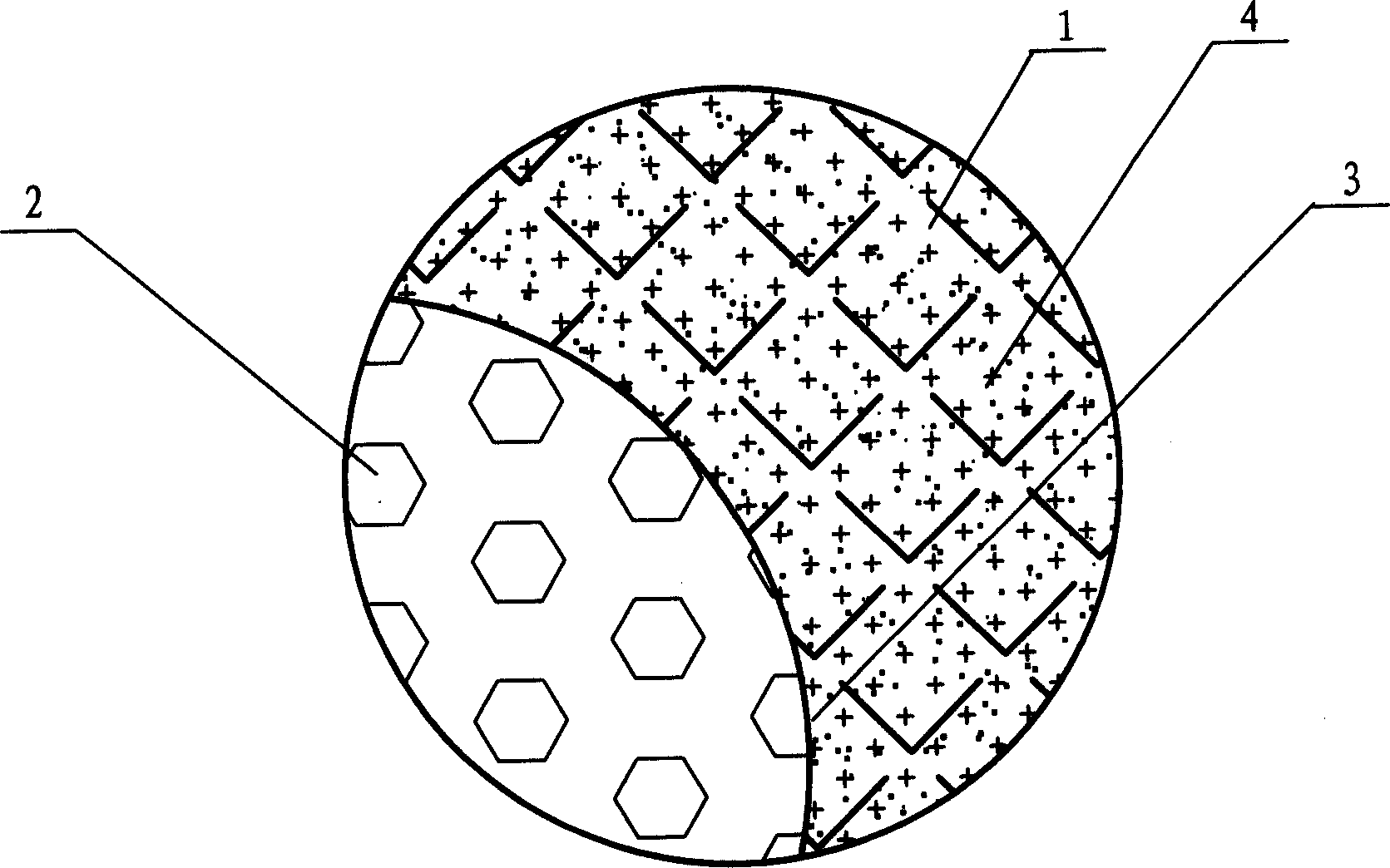

Microporous ceramic ball for comprehensive control of plant growth and its prepn process

ActiveCN1636942AEfficient antibacterial and sterilizationPromote growthFertiliser formsCeramicwareGrowth plantTrace element

The microporous ceramic ball for comprehensive control of plant growth belongs to the field of microporous ceramic. It is irregular spheroid comprising core of complex structure and tightly connected sintered shell, the core is one complex microporous structure of randomly combined compact structure and loose structure, and the sintered shell is microporous structure with fertilizer particle adsorbed inside the pores. The present invention also discloses the composition and preparation process. The present invention has antibiotic function of killing various kinds of bacteria, function of regulating soil humidity of soil, and function of releasing infrared ray and releasing plant nourishing matters and trace elements to promote plant growth, and may be used in the plantation of high grade flower and other plant.

Owner:淄博博纳科技发展有限公司

Cultured cell construct containing spheroids of cultured animal cells and utilization thereof

InactiveUS7470424B2Improve abilitiesShow resistance (stability) to peelingBiocideHepatocytesHydrophilic polymersMicrobiology

Parenchymal cells are cultivated on cultivated endothelial cells or cultivated fibroblasts which have been separated by a surface of a specific hydrophilic polymer, and which have been patterned. A culture which contains thus formed patterned spheroids of cultivated parenchymal cells is thereby provided by this invention. This culture maintains a function which is specific to the parenchymal cells over a long period of time.

Owner:KAZUNORI KATAOKA +1

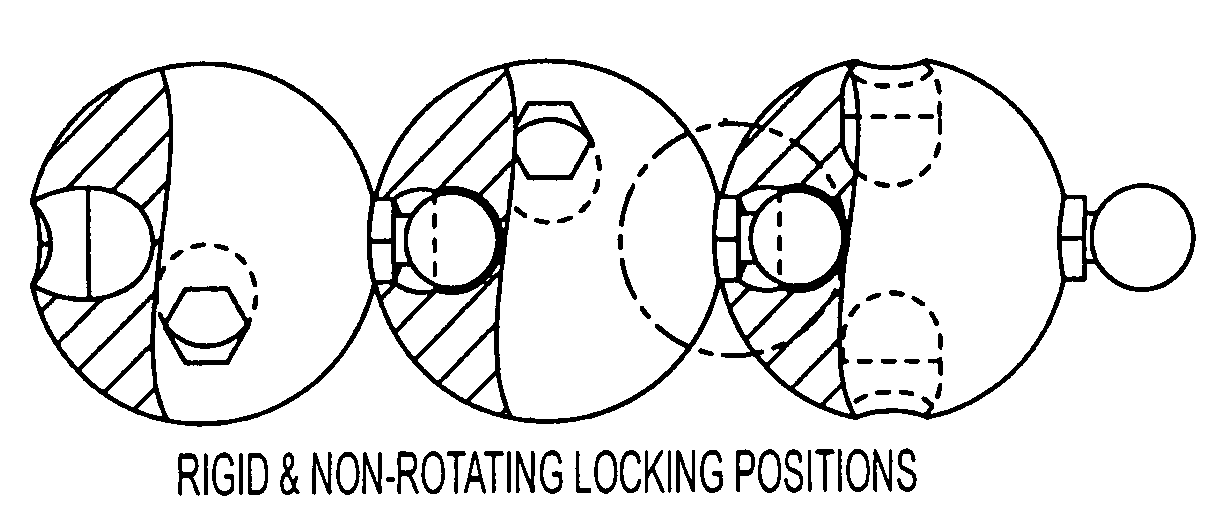

Connection for beads with locked and atriculating engagement

An assembly of two elements including a first element that has a cavity with an external opening connected to a first region defined by a sidewall that is a spherical segment and the diameter of the external opening is smaller than the diameter of the sidewall in the first region. Adjacent to the first region is a second region also defined by a second spheroid segment that is separated from the first region by an annular ring extending from the sidewalls towards a central axis of the cavity. The annular ring forms a passage having a diameter approximately the same as the external opening. An extension member on the second element is inserted into the cavity which has a first rod section terminating in a second spherically-shaped section. The spherically shaped section has a diameter larger slightly larger than the external opening on the first element and accordingly, the spherical section may be snap-fitted through the external opening to a first position in a first region, and be retainer there and, it may be further snap-fitted through the passage to the second region and be retained there. Also disclosed is flange structure that engages an annular seat when the spherically shaped member is in the second position.

Owner:LYNX SA

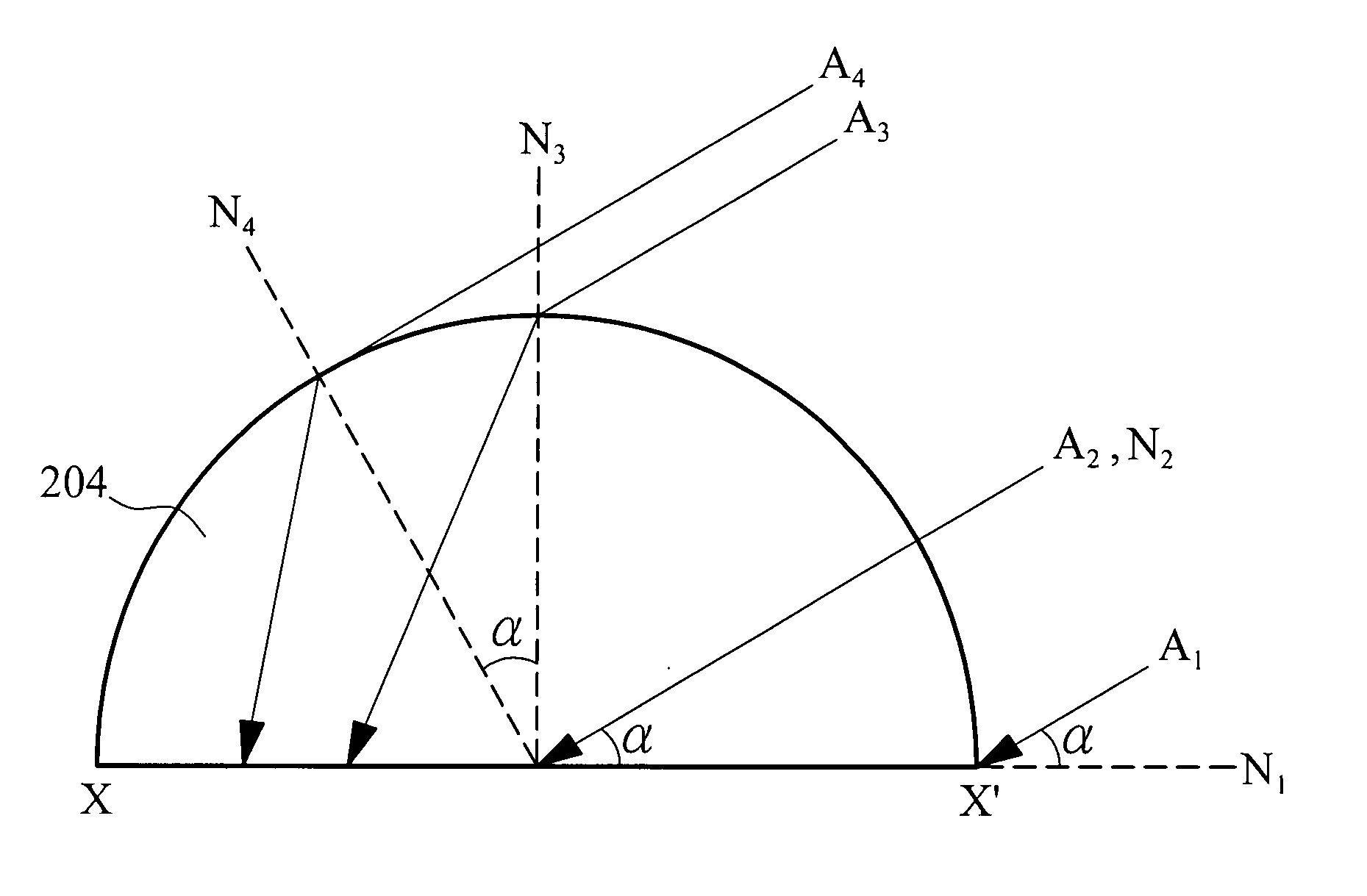

Energy collecting system

InactiveUS20080060696A1Easy to collectPV power plantsPhotovoltaic energy generationEngineeringEnergy analysis

The invention discloses an energy collecting system comprising a substrate; a photosensitive layer selectively disposed on the substrate; and at least one convex lens disposed on the photosensitive layer. The shape of the convex lens is a semi-spheroid, thinner semi-spheroid, semi-columned, or thinner semi-columned shape. The convex lenses are arranged in an array order and are coated with an anti-reflection layer.

Owner:DELTA ELECTRONICS INC

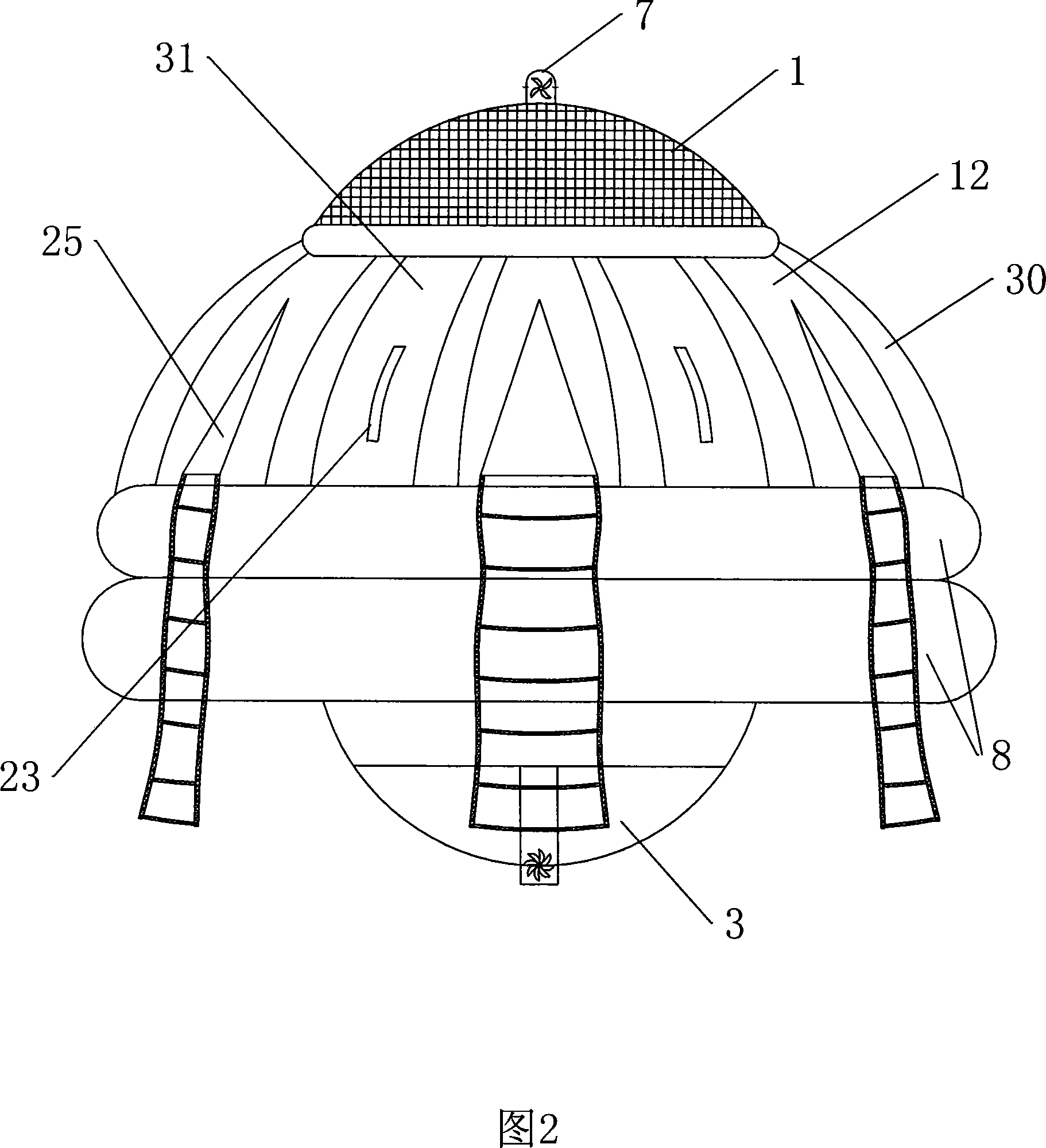

Solar multifunctional full-automatic expansion overthrow preventing life float

Provided is a full-automatic multifunctional solar life-raft which can not be overturned when being unfolded, and comprises a survival capsule, an automatic extension arm, a divided storage chamber and counterweight. The survival capsule is composed of pluralities of annular air sacs, arc air sacs and double-layered outer covers. The roof of the survival capsule is provided with a solar cell panel cover, the bottom of the survival capsule is provided with a power bay and the divided storage chamber, the middle of the survival capsule is provided with the automatic extension arm for supporting. A dismountable counterweight chamber is arranged under the storage chamber, sail lift-off balloons which can be folded for storage are installed in the solar cell panel cover, cabin doors and sail balloon bags are in interval arrangement by pluralities of double-layered outer covers, folded sail balloons are arranged inside the sail balloon bags, and an engine, an electric air pump, a sea water purifier, a divided storage box and pluralities of lifesaving articles are arranged inside the sail balloon bags. The life-raft is a multifunctional lifesaving appliance which can automatically advance, travel by wind force and even lift off, being powered by solar energy, the sea water purifier and the pluralities of lifesaving articles can prolong the survival time of casualties as long as possible, and the life-raft which is just a spheroid after being deflated and recovered is easy to be placed on boats.

Owner:赵鹿

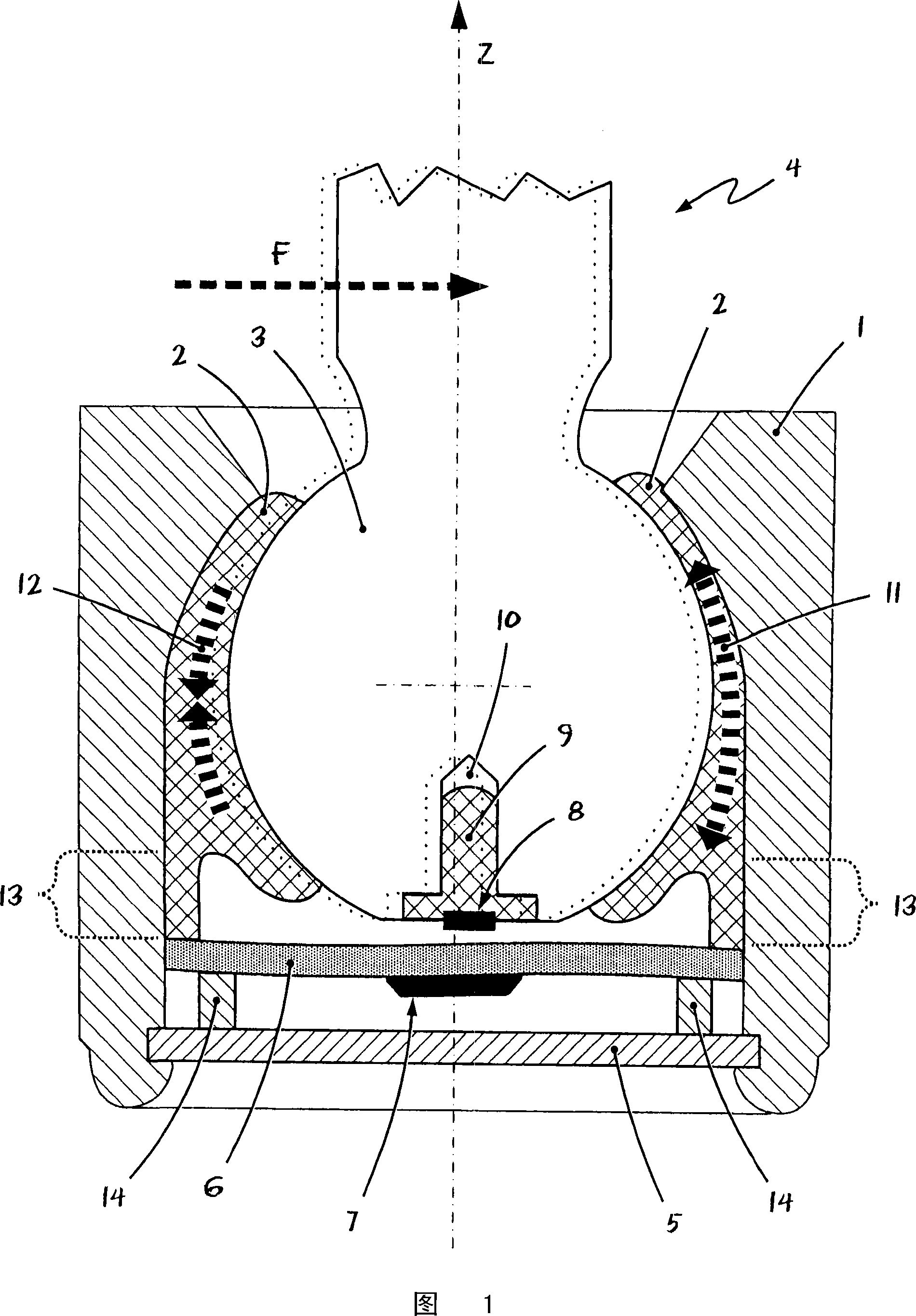

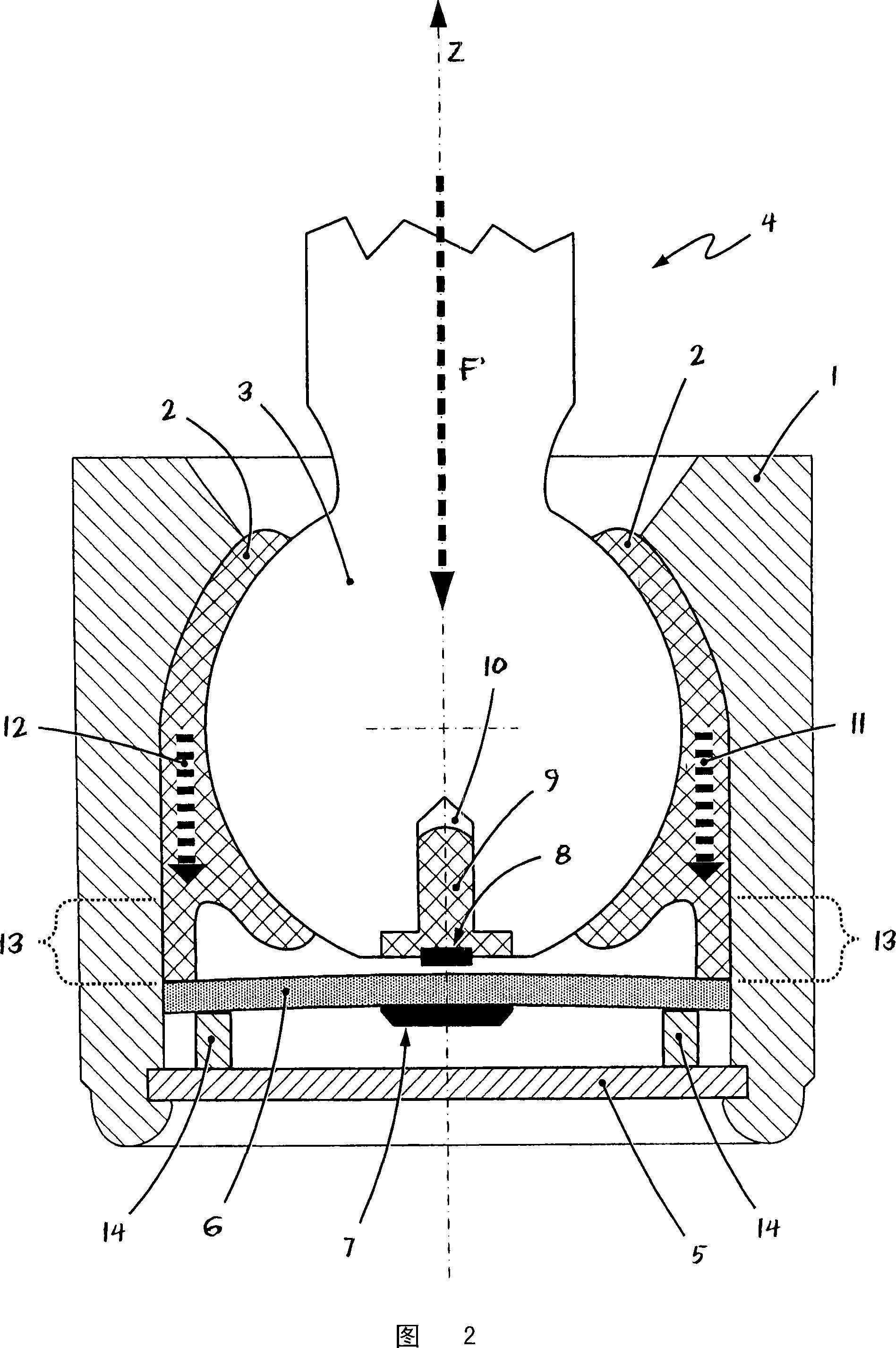

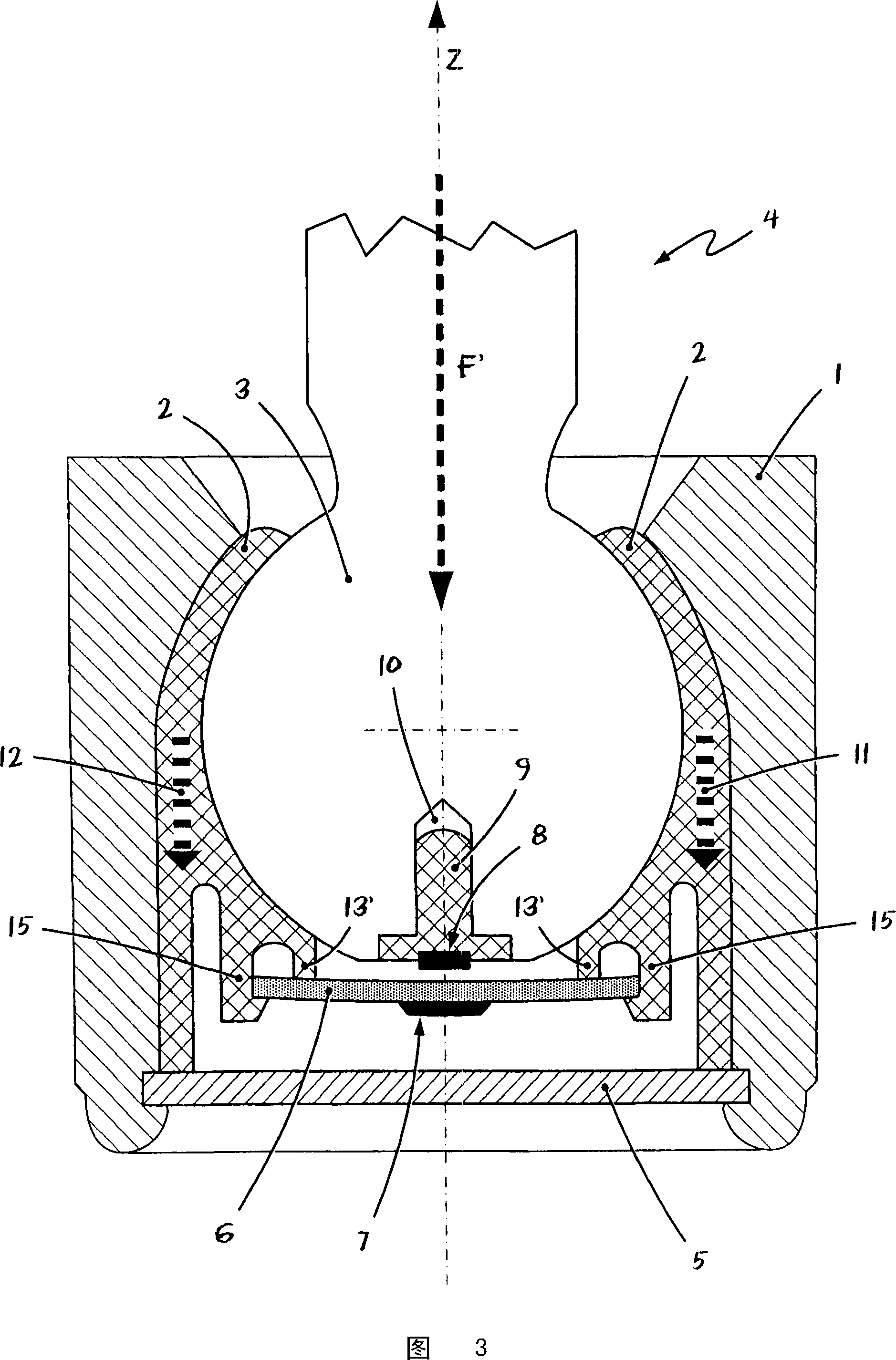

Ball-and-socket joint with sensor system and wear measurement method

The invention relates to a ball joint, eg for an axle system of a motor vehicle, and to a method for measuring wear on a ball joint. The ball and socket joint has an essentially annular or pot-shaped joint housing (1), in the essentially cylindrical interior of which a spherical bushing (2) is arranged. The ball (3) of the spherical journal (4) is slidably accommodated in the spherical bushing (2). Furthermore, the ball and socket joint has a sensor device ( 7 ) for force or load measurement. According to the invention, the ball and socket joint is distinguished in that the sensor device ( 7 ) is arranged on a flexurally elastic printed circuit board ( 6 ). The printed circuit board (6) is flexibly and movably fixed in the joint housing (1), wherein the sensor device (7) is configured to adjust the curvature or Mechanical stress is measured. In this case, the ball and socket joint includes a transmission element by means of which a force or a bending moment is introduced into the sensor printed circuit board (6) when the spherical bushing (2) deforms. The ball joint according to the invention can be produced very robustly and inexpensively and allows the measurement of forces or loads acting on the ball joint. The method according to the invention permits permanent determination of the state of wear of the ball joint by means of the measurement of the prestressing force of the spherical bushing.

Owner:ZF FRIEDRICHSHAFEN AG

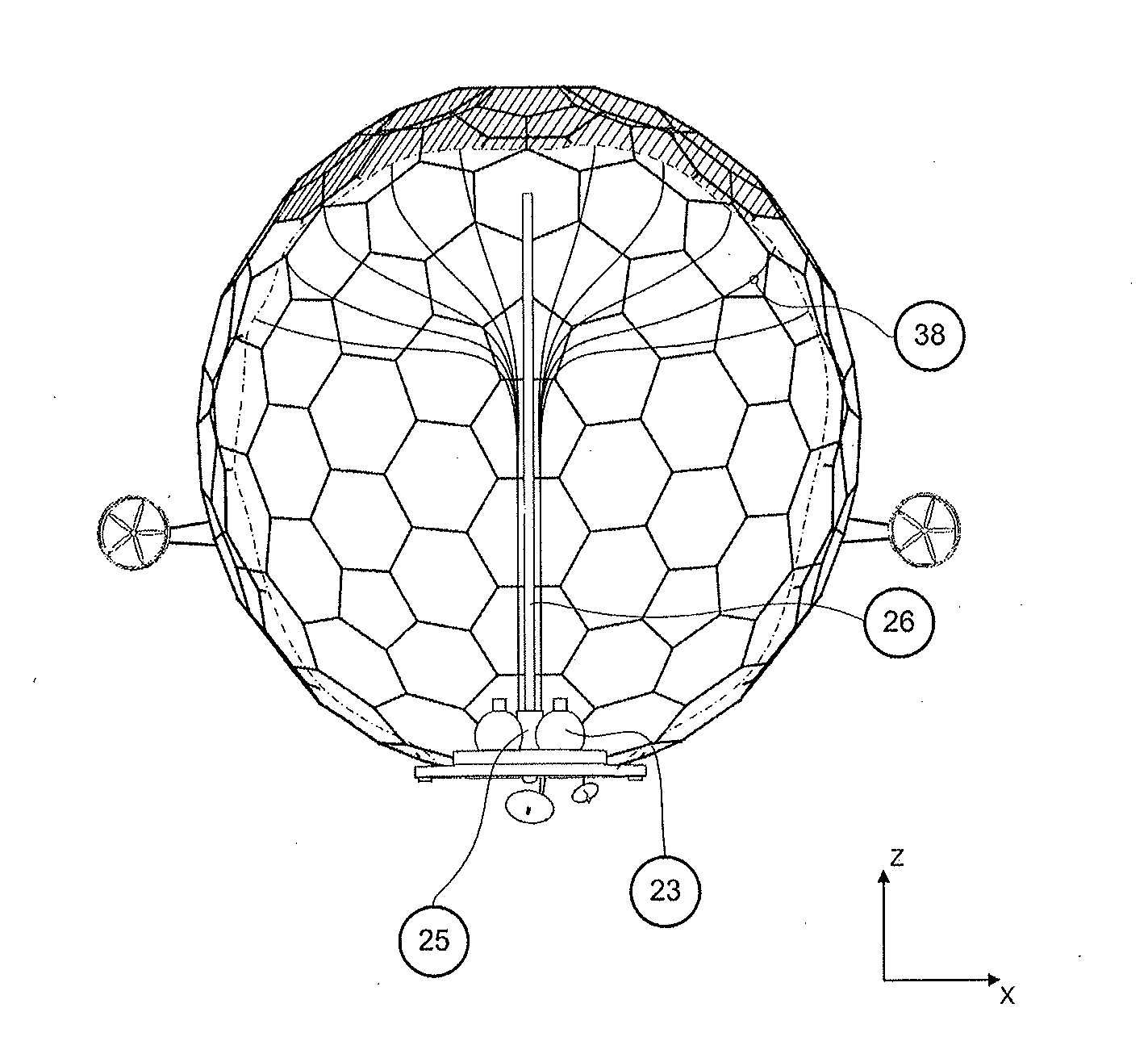

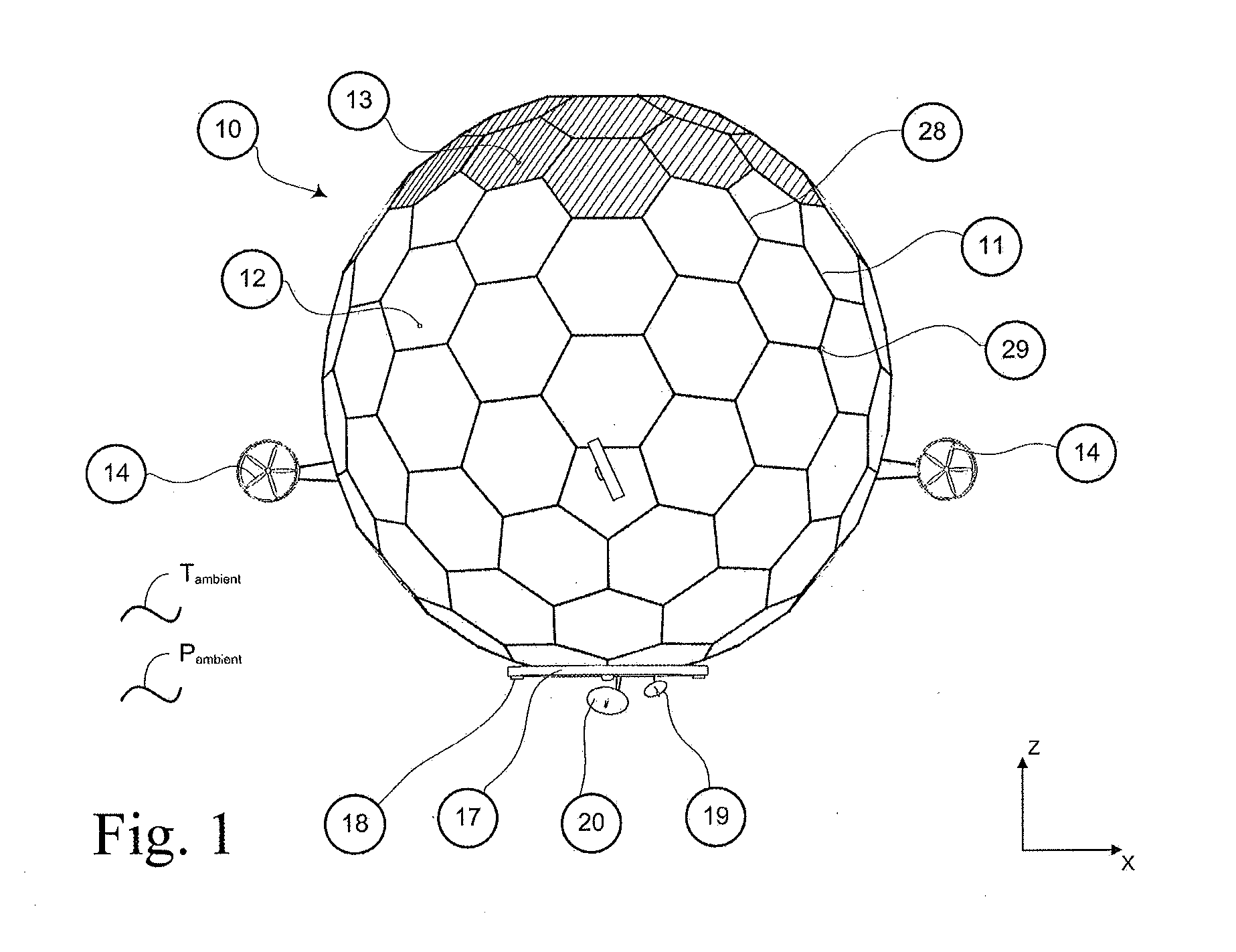

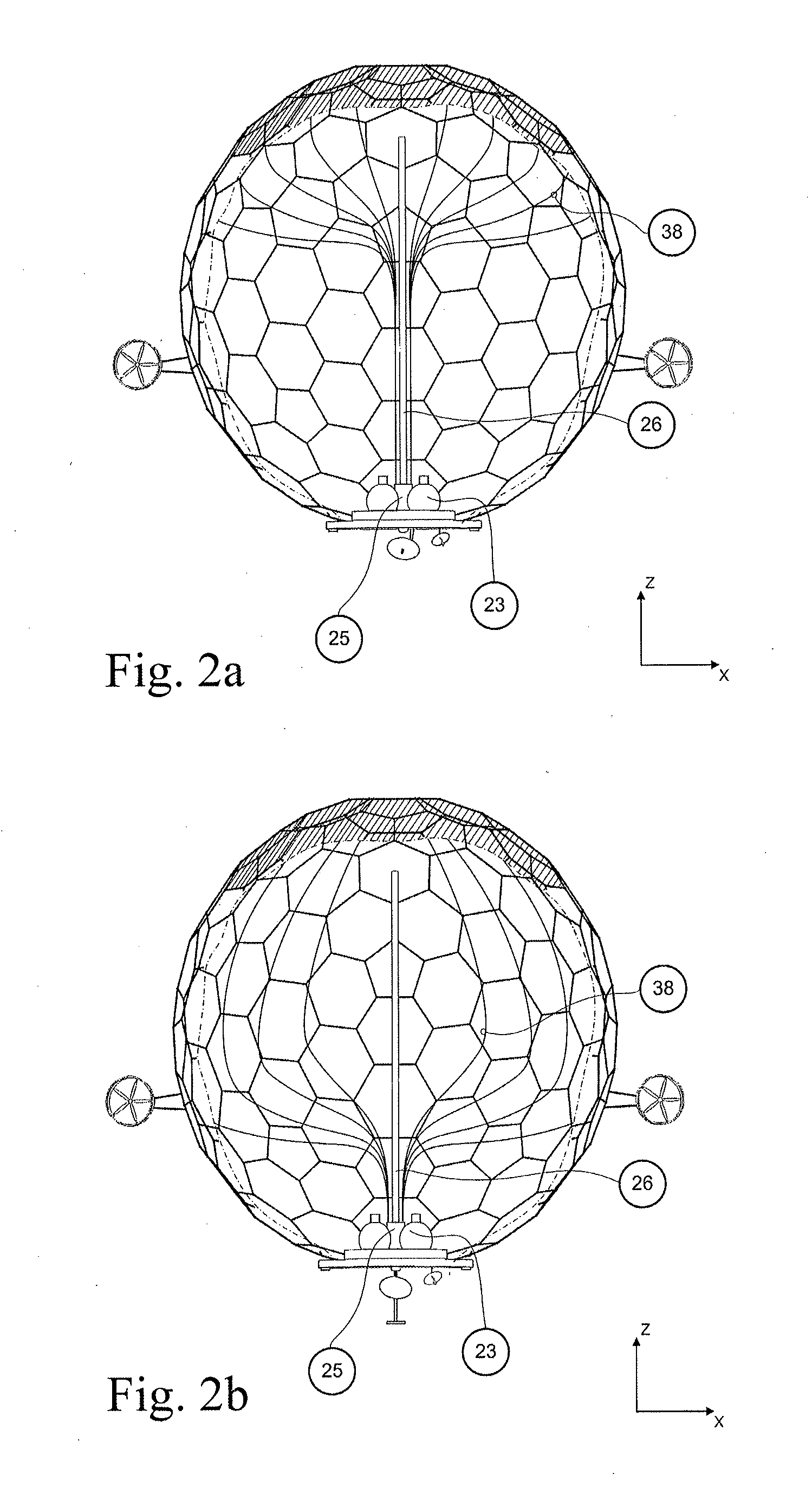

Autonomous stratospheric unmanned airship

ActiveUS20130146703A1Improve stabilityReduce frequencyUnmanned aerial vehiclesNon-rigid airshipsClassical mechanicsInfilled frames

An autonomous stratospheric unmanned airship with an operating altitude from 5-22 km and with a mutli-month operational cycle. Spheroid rigid geodesic frame of constant volume formed by a multitude of struts, with an outer envelope enclosing the frame defining the eigenfrequency spectrum of the airship above 20 Hz, with vibrational amplitudes between 0.1 and 1 cm. Independently controllable electrical propulsion units, attached to the frame in the horizontal plane passing through the center of mass, can change the direction and value of the thrust vector. Buoyancy is controlled with a system integrated inside the geodesic frame including buoyant fluid pressurized tanks, valves for the release of the buoyant fluid through the buoyant fluid conduit into the buoyant gas cell which fills the geodesic frame. Valves at the subsystem support platform enable ambient atmosphere to fill the internal volume of the frame not occupied by the buoyant gas cell.

Owner:PECNIK BOJAN

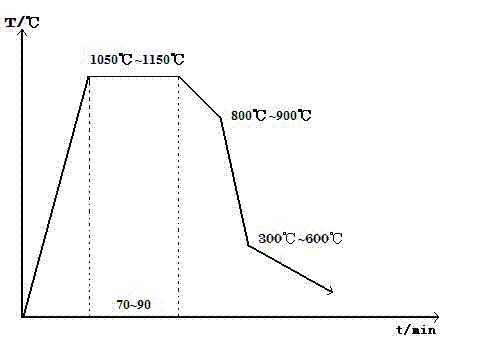

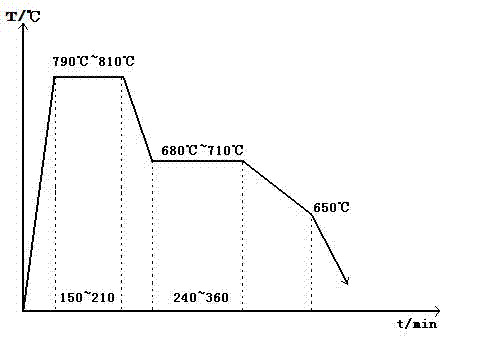

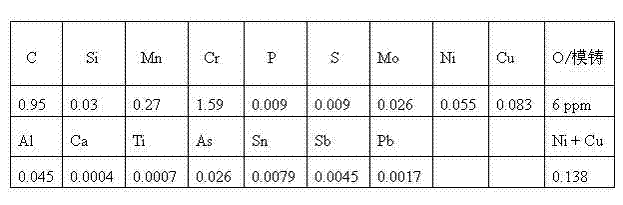

Heat treatment method of bearing

ActiveCN102758073AExtended service lifeControl of retained austenite contentFurnace typesHeat treatment furnacesAusteniteQuenching

The invention relates to a heat treatment method of a bearing. The heat treatment method comprises the following six steps of: heating, insulating, quenching, cleaning, cold treatment and tempering. The heat treatment method is characterized in that before the heating step, a fining treatment step of carbide is arranged; the fining treatment step comprises two steps of forging and spheroids annealing; the temperature of initial forging in the forging steps is 1050-1150 DEG C; the insulating time is 70-90 minutes; the temperature of the final forging and forming is 800-900 DEG C; then the stirring and cooling are carried out in boiling water till the temperature is 300-600 DEG C; the bearing is taken out of water and air-cooled till room temperature; and the spheroids annealing step comprises specific steps of: heating to 790-810 DEG C, insulating for 150-210 minutes under the temperature, air cooling to 680-710 DEG C, insulating for 4-6 hours, cooling till 650 DEG C along with a furnace, taking out of the furnace and carrying out air cooling. The cold-treatment step is carried out in 2 hours after the cleaning steps is finished after quenching, liquid nitrogen is adopted as cooling medium, cooling is carried out till the temperature is minus 70-minus 80 DEG C, insulation is carried out for 1.5-2 hours under the temperature, and returning the temperature naturally till the room temperature. The heat treatment method has the advantage that the service life of the bearing is prolonged by fining carbide particles, improving the hardness and controlling the content of the retained austenite in the metallographic structure.

Owner:汇洲智能技术集团股份有限公司 +1

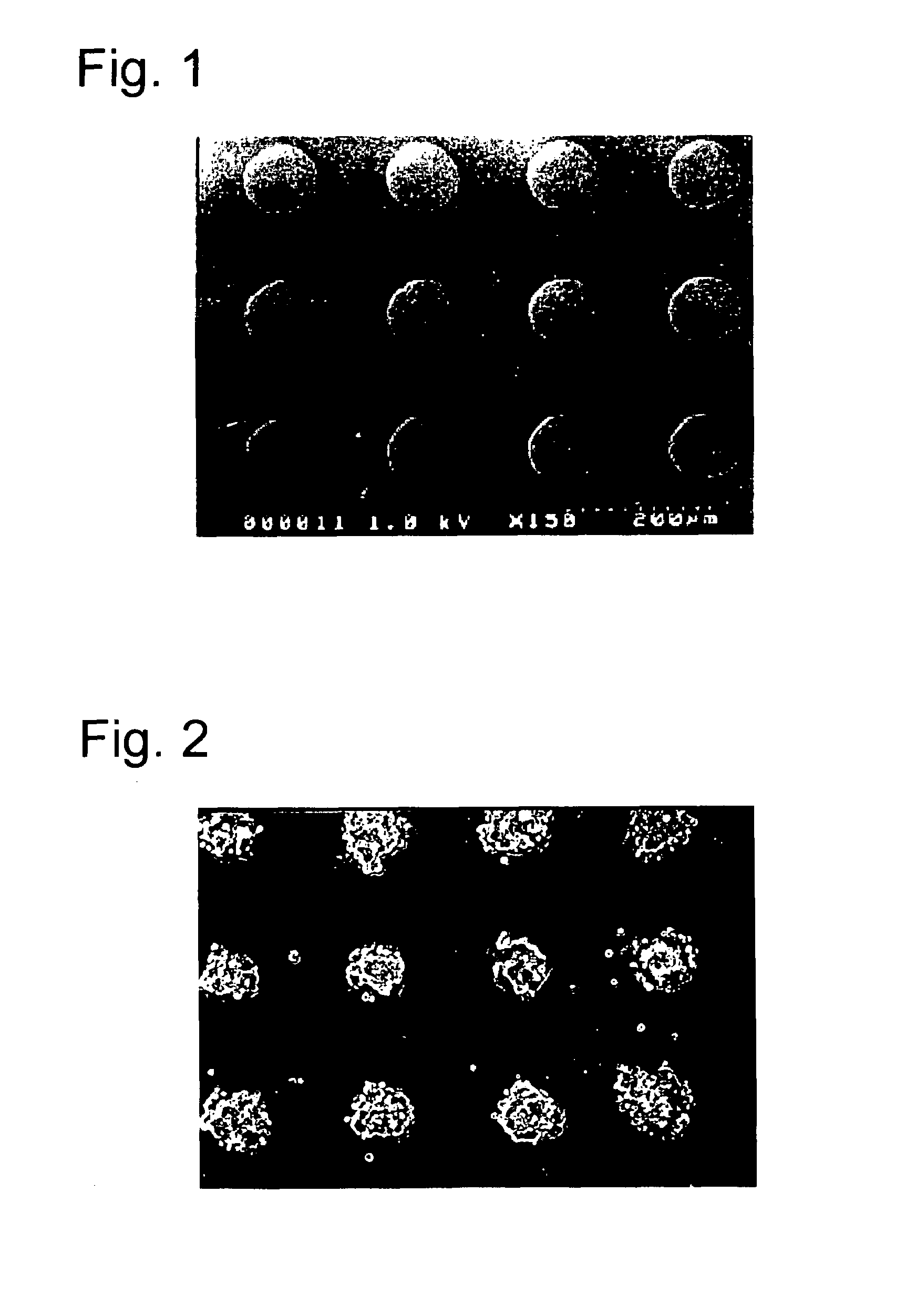

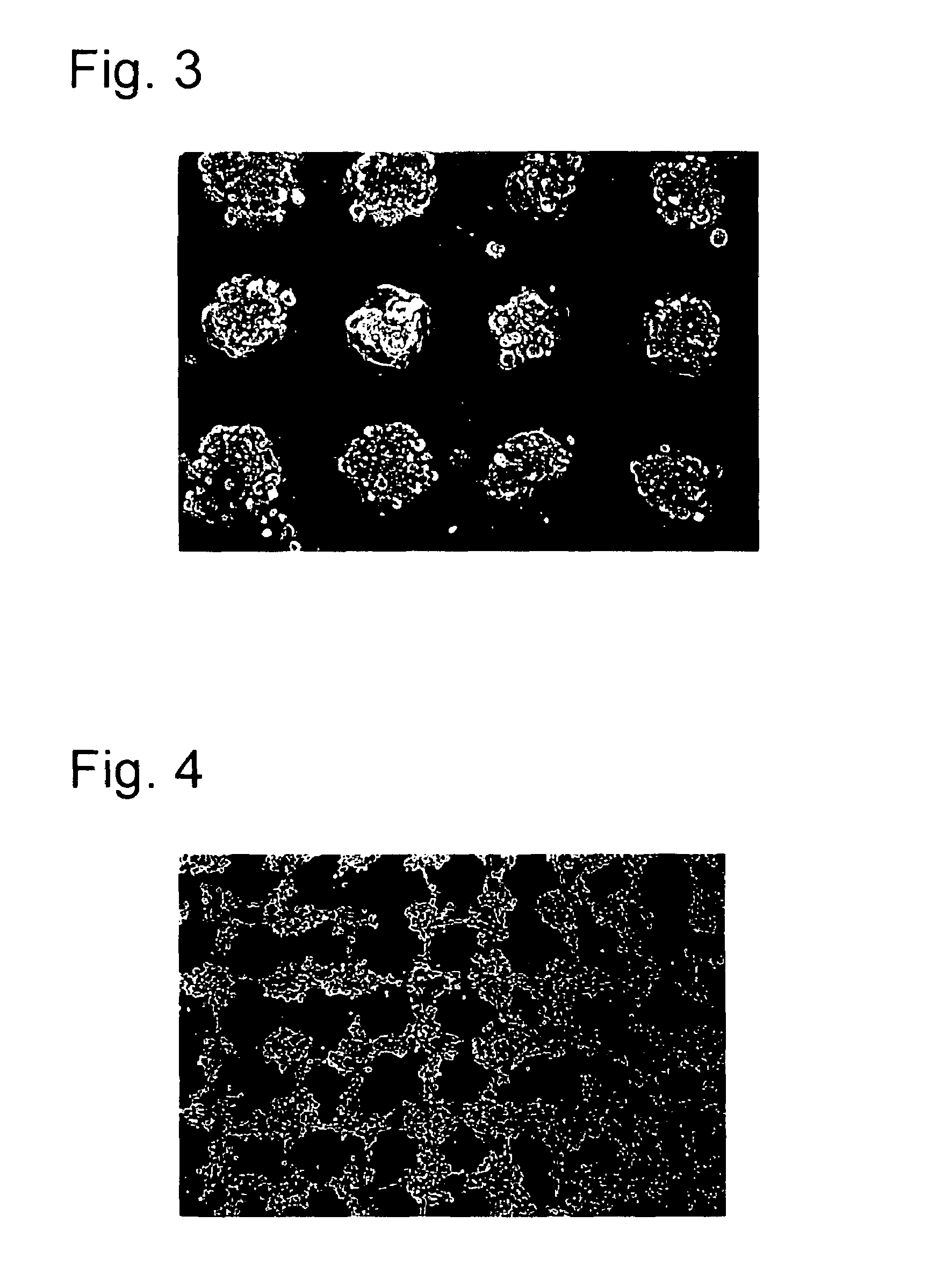

Culture substrate

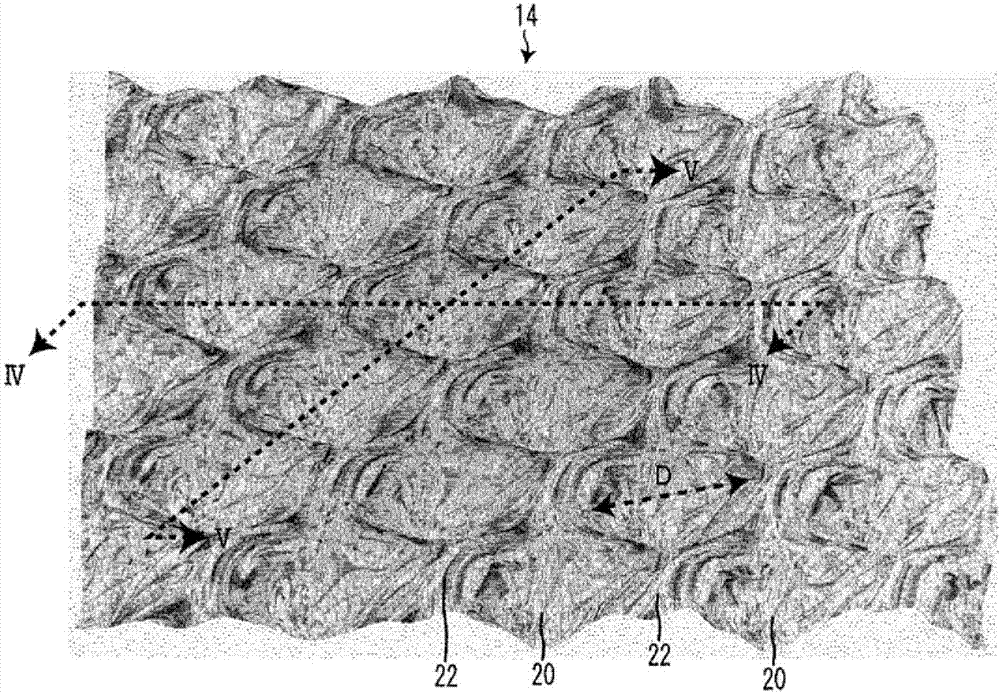

To efficiently carry out spheroid culturing. A culture substrate is a culture container to culture cells and three-dimensionally aggregate them to prepare spheroids. The culture substrate is made of a synthetic resin material. On a surface of the culture substrate, a plurality of dents 20 to be compartments in which cells are cultured are formed. The plurality of dents 20 are formed by laser irradiation on the culture substrate surface. At the peripheries of openings of the dents 20, the synthetic resin material is melted and piled up to form banks 22. The culture substrate surface between two adjacent dents 20 is a non-flat surface.

Owner:AGC TECHNO GLASS

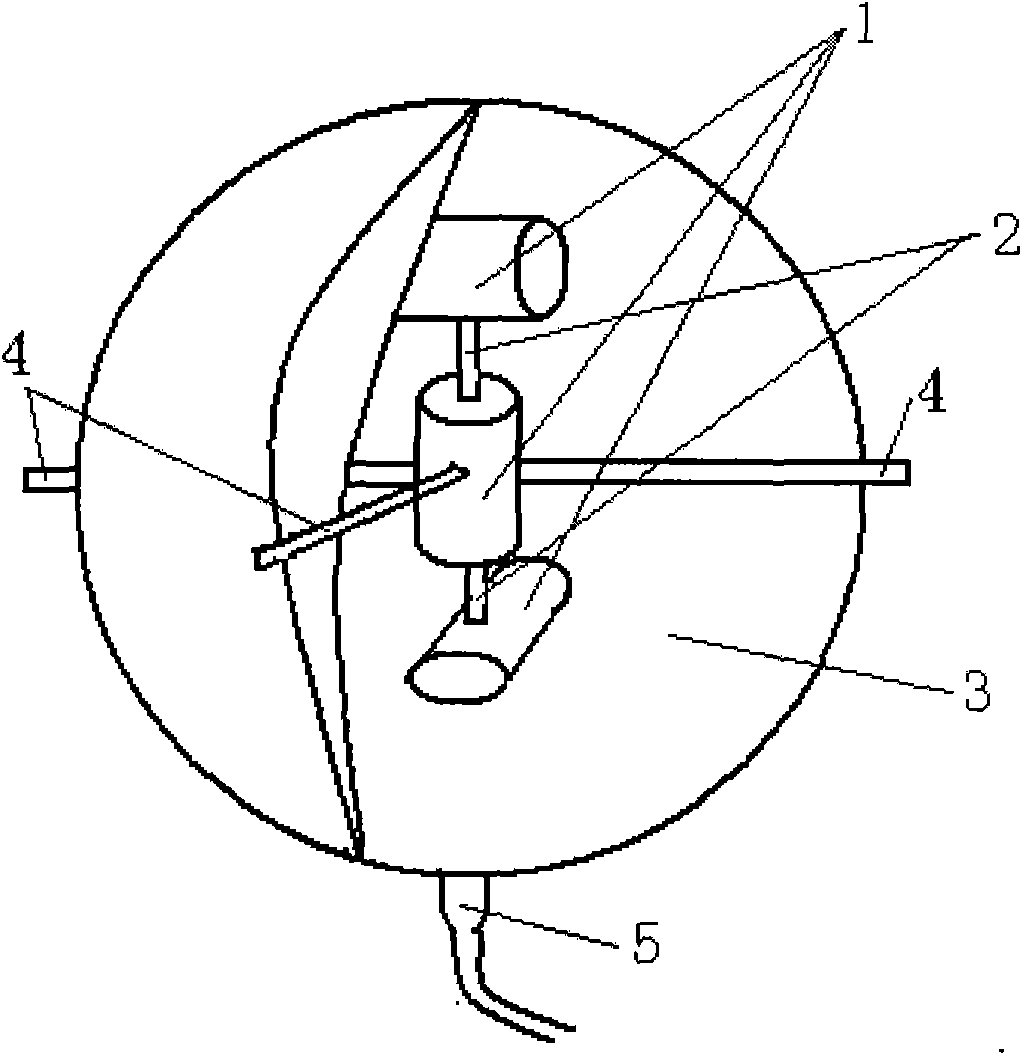

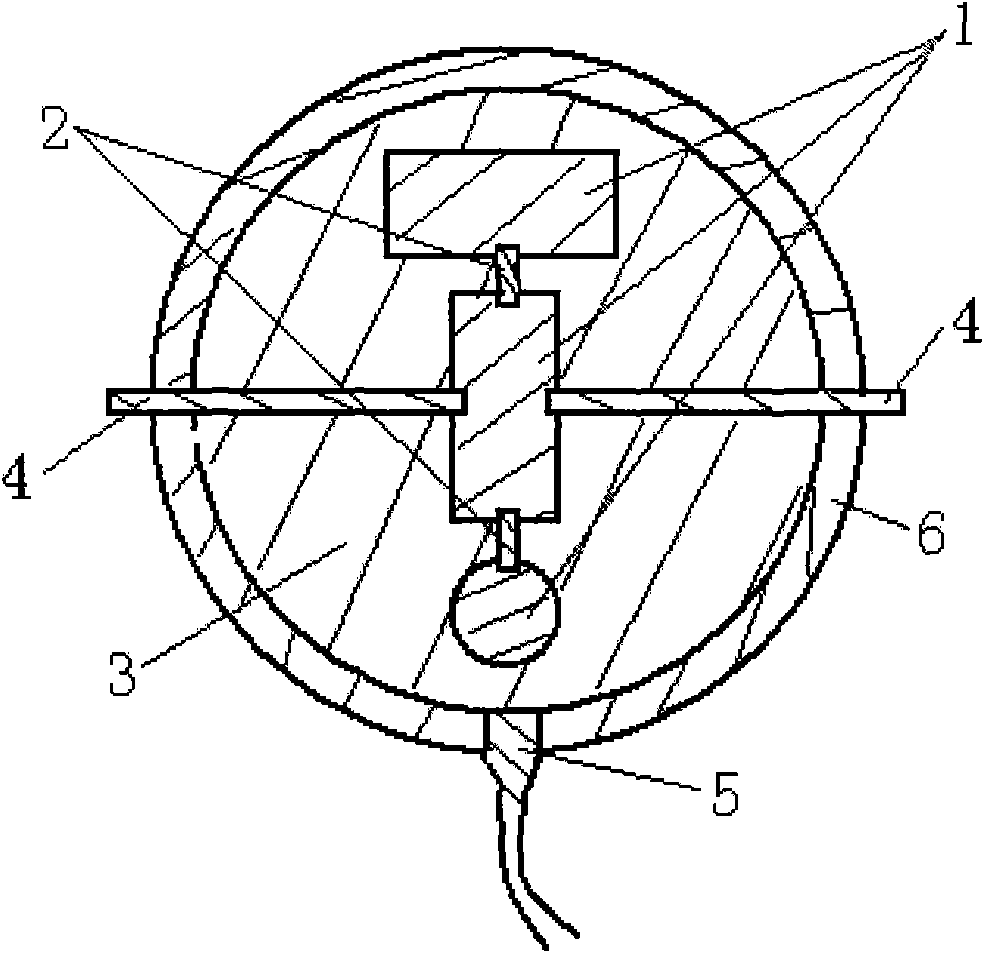

Trivector hydrophone based on piezoelectric velocity sensor

InactiveCN101561313AMeet the design requirementsSimple structureWave based measurement systemsSubsonic/sonic/ultrasonic wave measurementLow noiseHydrophone

The invention provides a trivector hydrophone based on a piezoelectric velocity sensor, which comprises a spheroid, and hanging elements, a velocity sensor and a multi-core output tape cable all arranged in the spheroid, wherein the velocity sensor comprises three piezoelectric velocity sensors which are connected in sequence through connecting rods; one end of the four hanging elements is fixed on the middle piezoelectric velocity sensor, while the other end extends out of the spheroid; and the spheroid is a solid sphere. The average density of the vector hydrophone approximates to the water medium density; the channel sensitivity is high in a working frequency band below 2,000 hz and is irrelevant to the frequency; the vector hydrophone has good cosine directivity; and the vector hydrophone is not limited by an obliquity during working. The vector hydrophone can be widely used in various fields of hydroacoustics, such as sonobuoys, low noise motion target measurement, target orientation and the like.

Owner:HARBIN ENG UNIV

Even-sized particles producing device and method for preparing the same

The present invention belongs to technology field of manufacturing metal powder, which specifically relates to a method and a device of manufacturing spheroid metal and alloy granular by making use of uniform liquid drop spray application techniques. Inert gas used by the present invention is bled into a crucible and a vacuum tight chamber that can obtain steady differential pressure by means of pressure control system, which makes mental fusant ejected in the form of laminar jet from a micro-nozzle positioned on a bottom of the crucible. Vibration disturbance mental shooting flow produced by a piezoelectric oscillator turns metal shooting flow into uniform droplets. And real-time size parameters of the droplets mentioned-above can be obtained by camera system and computer analysis software. Subject to the optimum parameters, frequency of control oscillator is fed back, thereby reducing size error of the metal droplets and predetermined droplets. The present invention is able to directly manufacture granular that is homogenized in size, shape and thermodynamic condition. The present invention has short technological process and products have good quality, which greatly reduces equipment investments.

Owner:TIANJIN UNIV

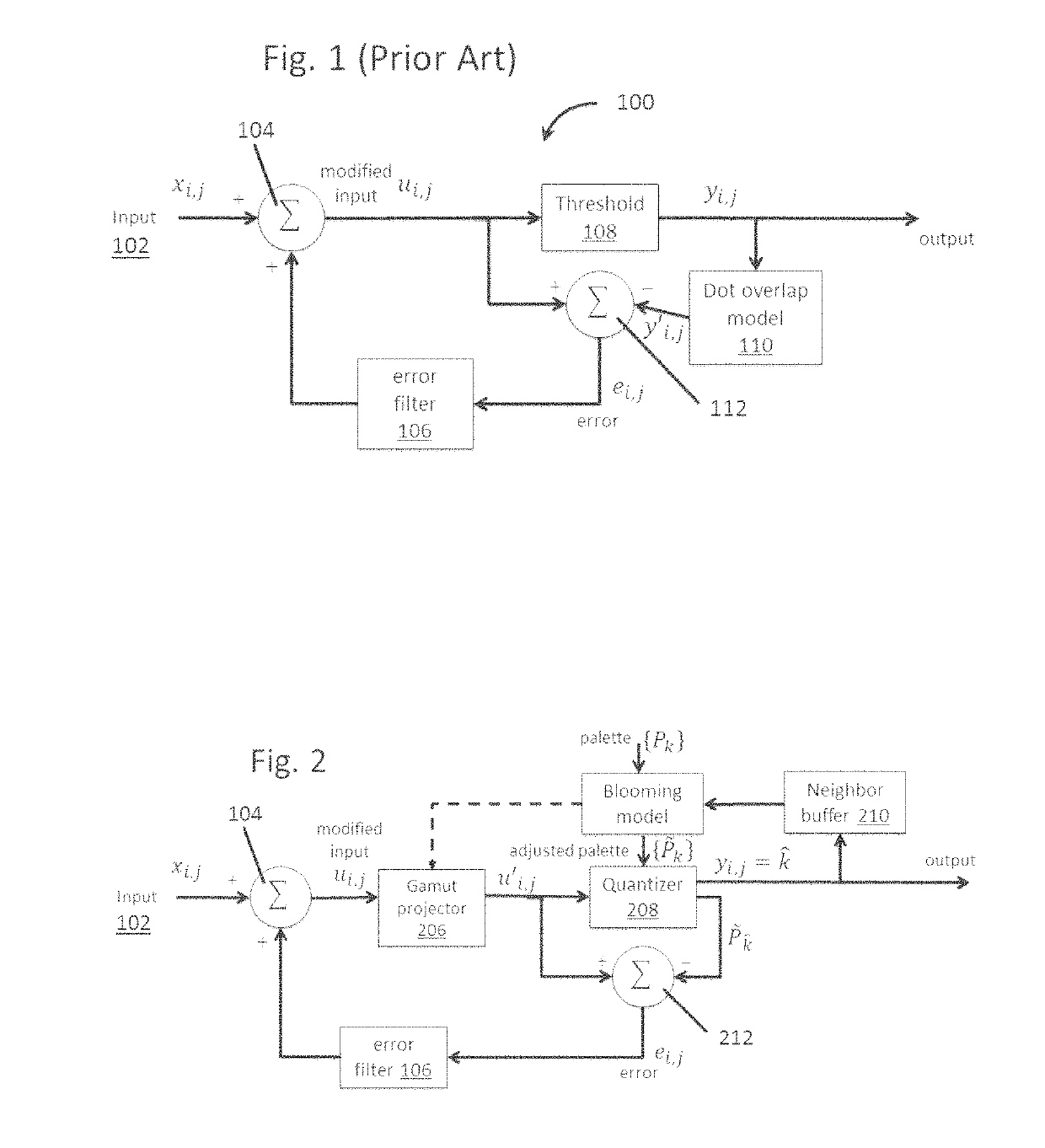

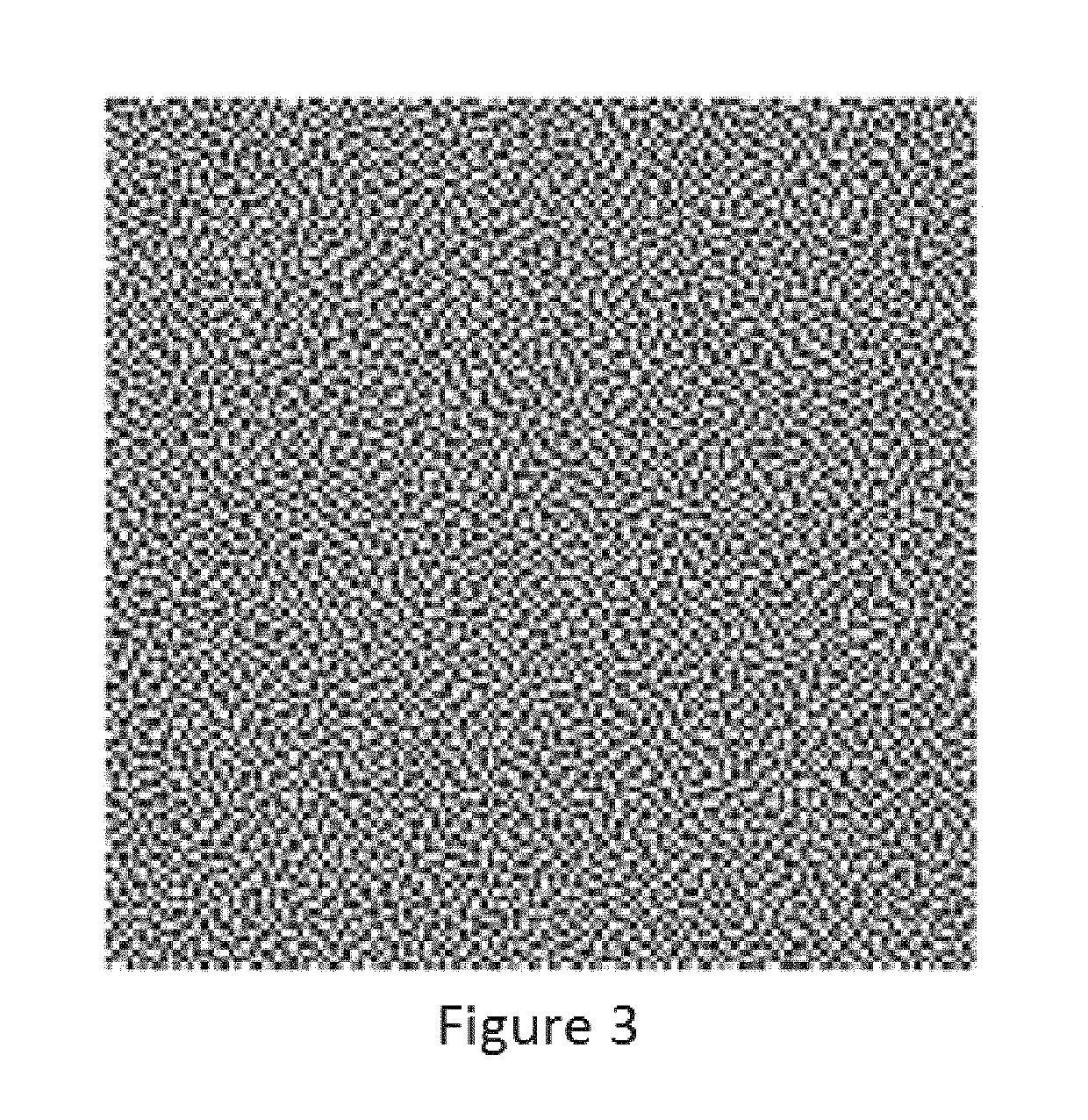

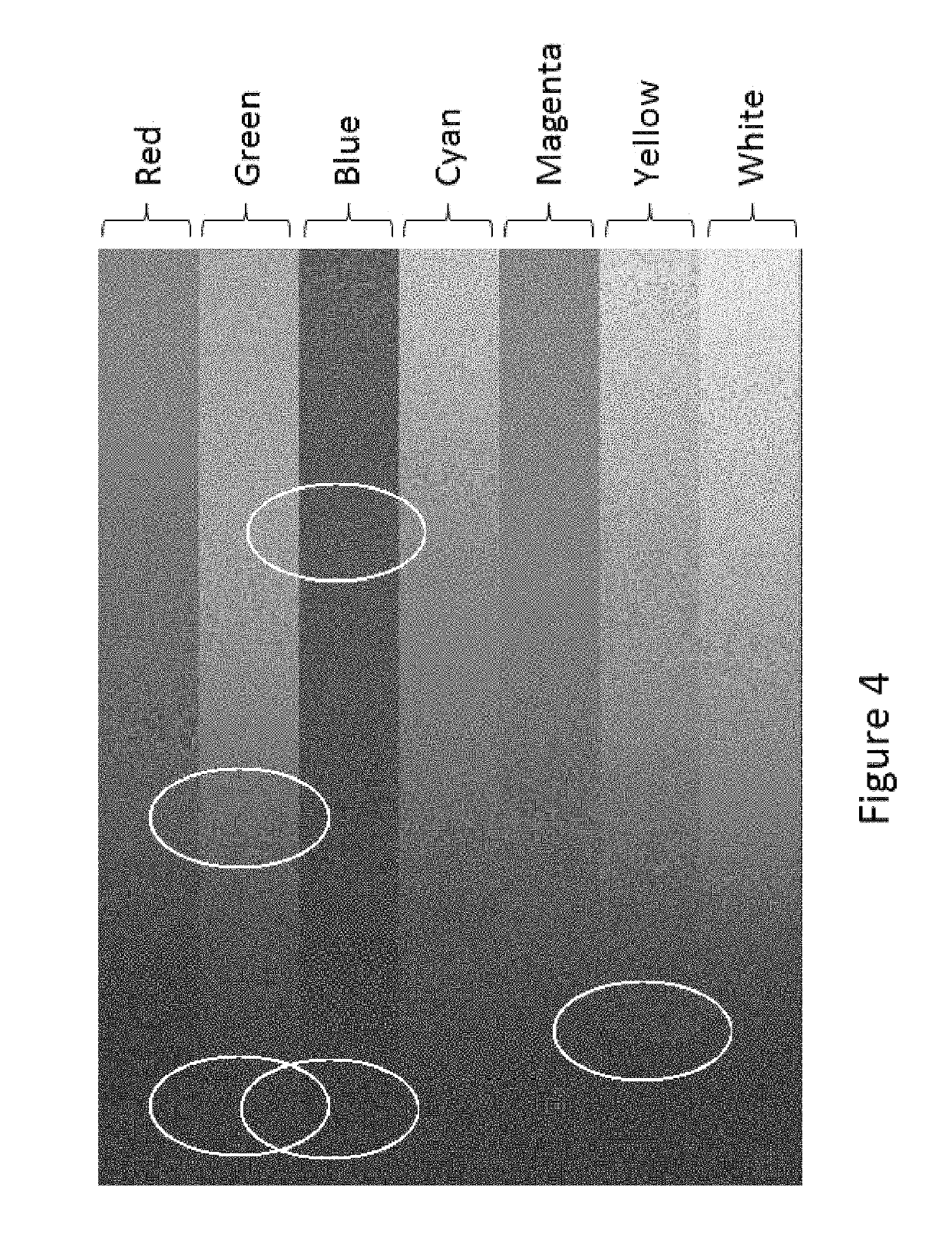

Method for rendering color images

ActiveUS10467984B2Reduces cost and bulkHigh quality imagingTelevision system detailsColor signal processing circuitsColor imageGamut

A system for rendering color images on an electro-optic display when the electro-optic display has a color gamut with a limited palette of primary colors, and / or the gamut is poorly structured (i.e., not a spheroid or obloid). The system uses an iterative process to identify the best color for a given pixel from a palette that is modified to diffuse the color error over the entire electro-optic display. The system additionally accounts for variations in color that are caused by cross-talk between nearby pixels.

Owner:E INK CORPORATION

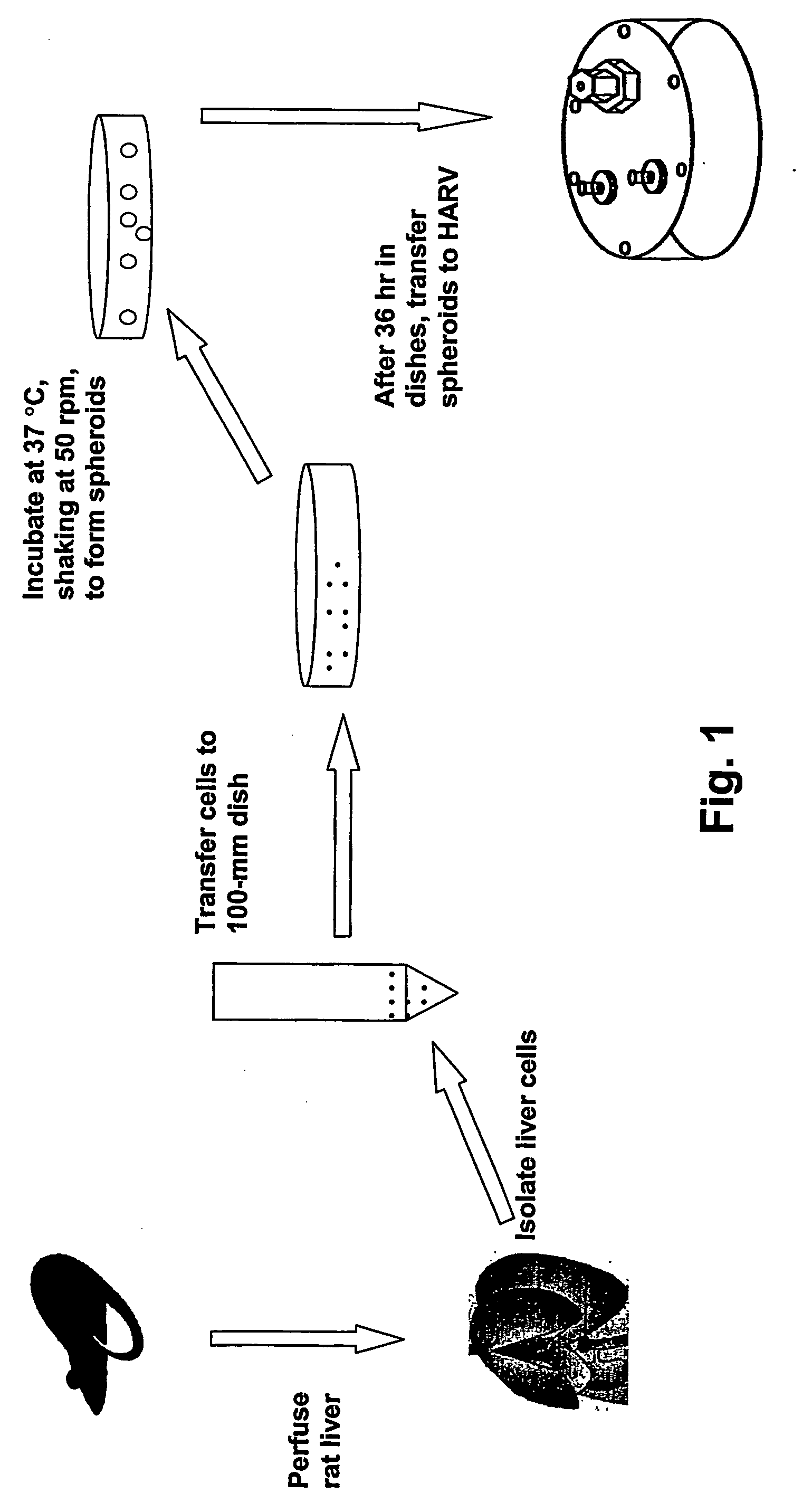

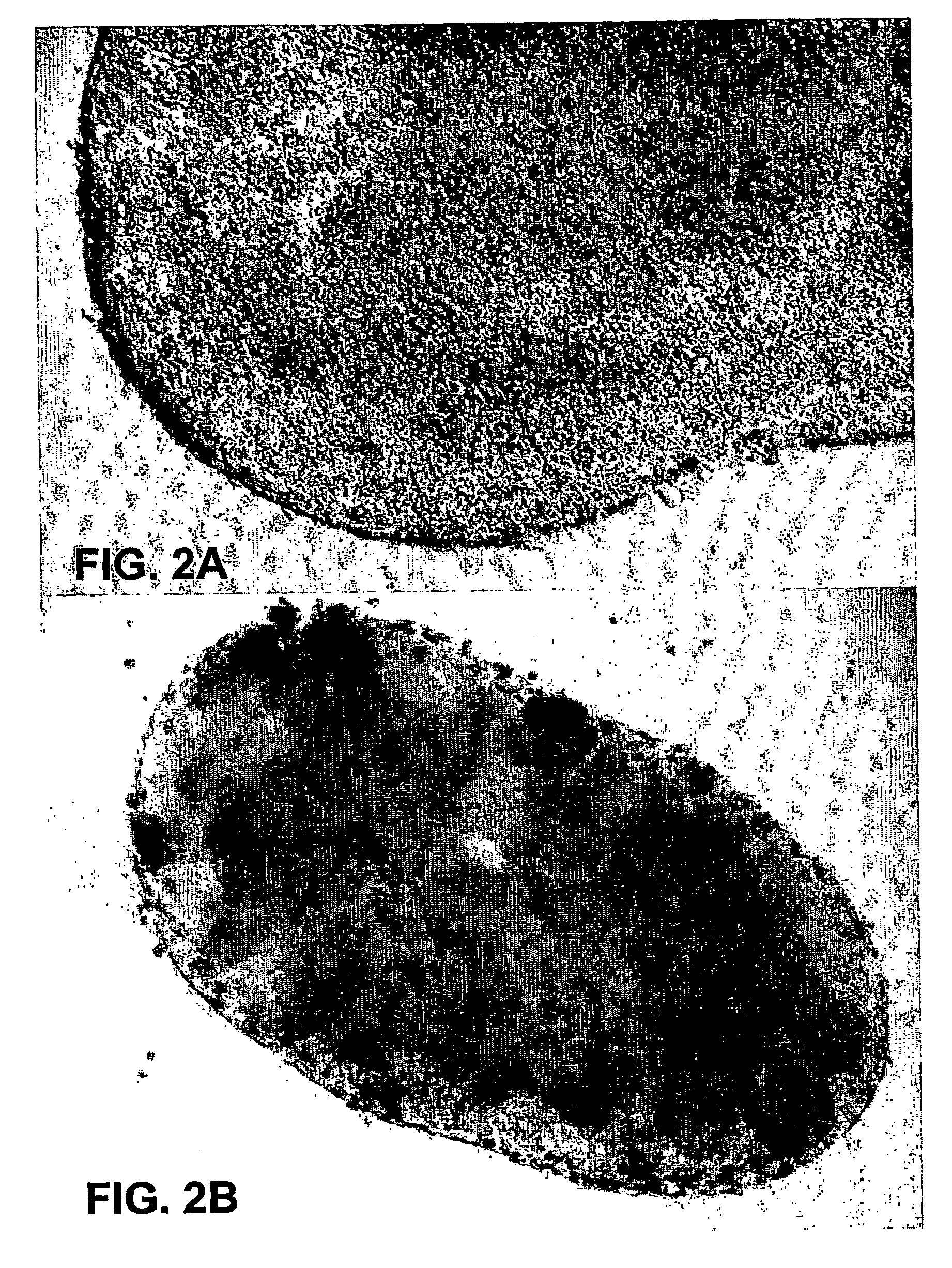

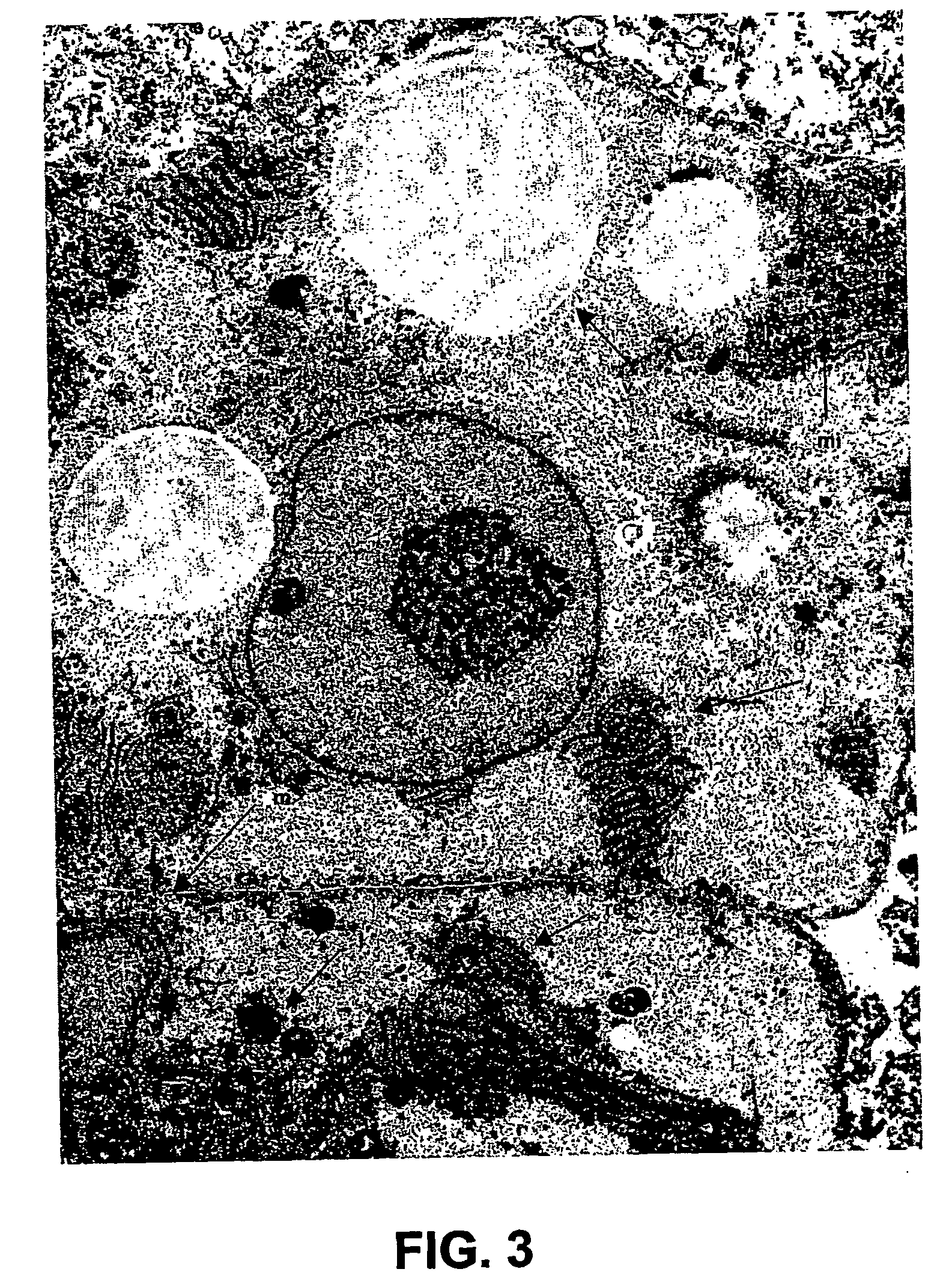

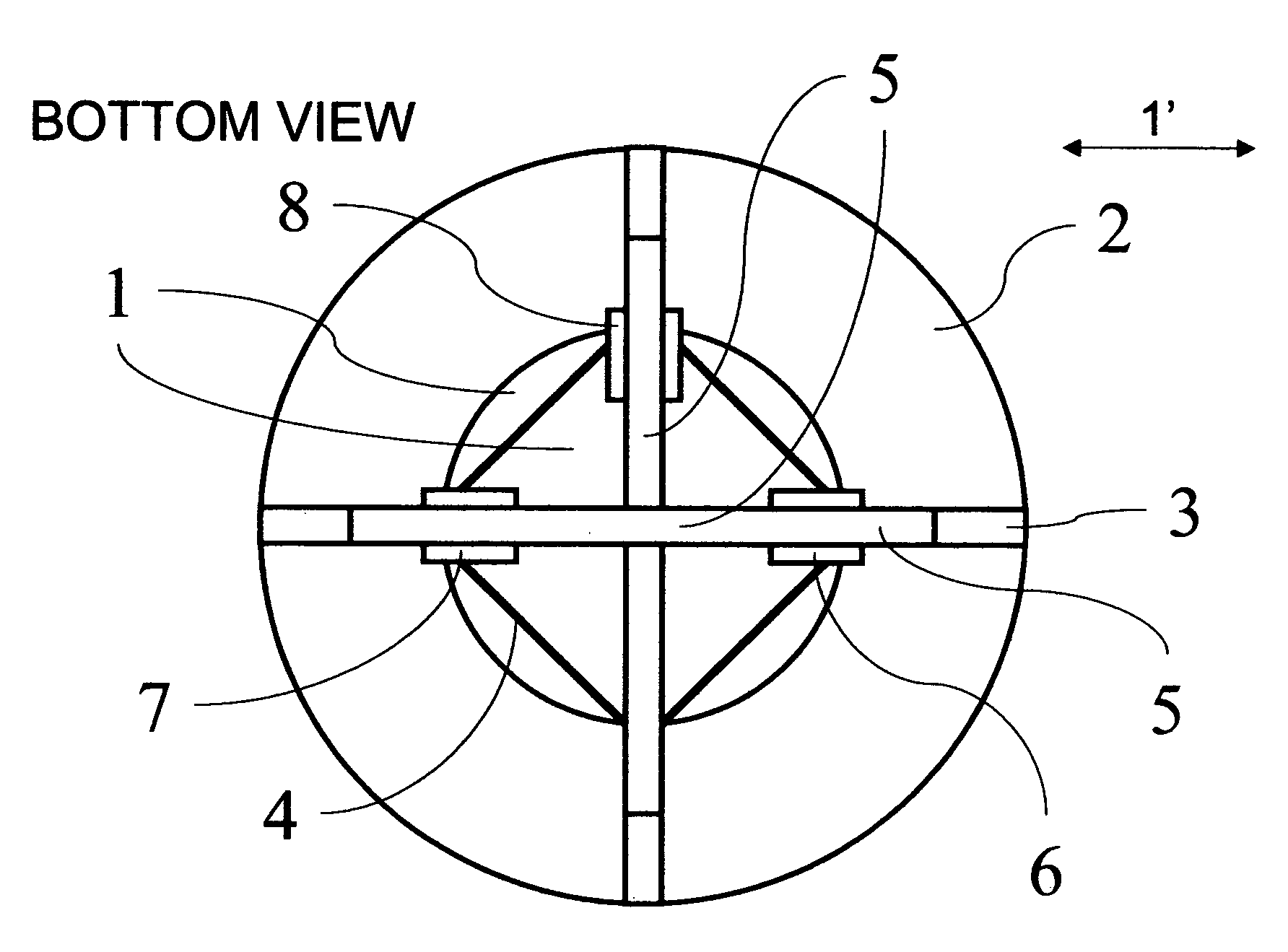

Hepatocyte bioreactor system for long term culture of functional hepatocyte spheroids

A rotating wall vessel is used as a culture vessel and bioreactor for the cultivation of hepatocytes in the form of spheroids to generate a culture with many properties of the intact liver. These properties include enzyme activity comparable to fresh cells and long-term maintenance of viability and cellular function for periods on the order of months. The cultures may be used to produce hepatocyte products, evaluate metabolism of an agent, propagate Hepatitis C virus and test agents as inhibitors of this virus. Thus, the culture system disclosed herein makes long term functional cultivation of human hepatocytes feasible.

Owner:IN VITRO TECH

Human-bearing inflatable device

InactiveUS20060252601A1Low costHighly robustSwimming aidsHollow inflatable ballsRecreationTherapeutic Devices

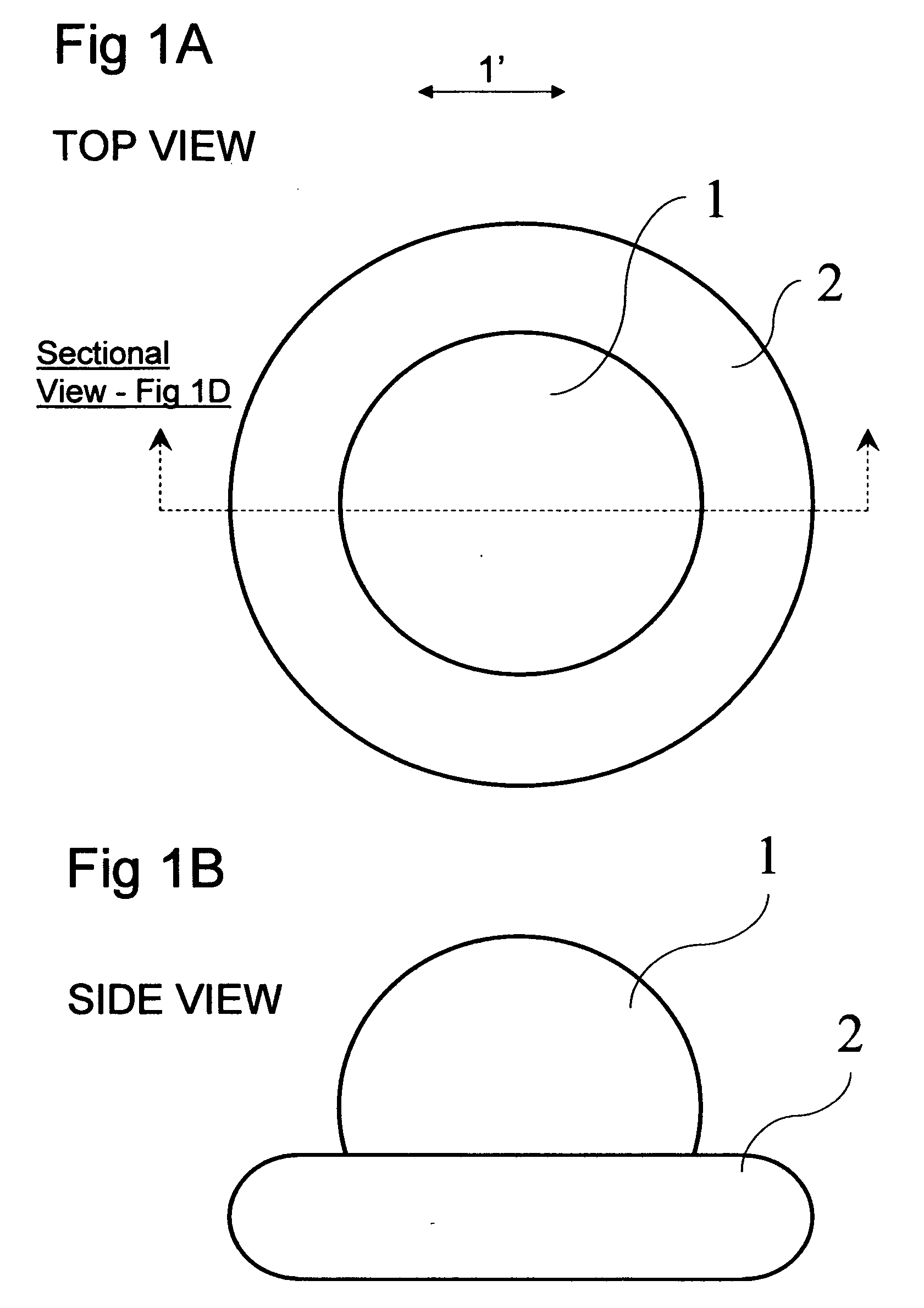

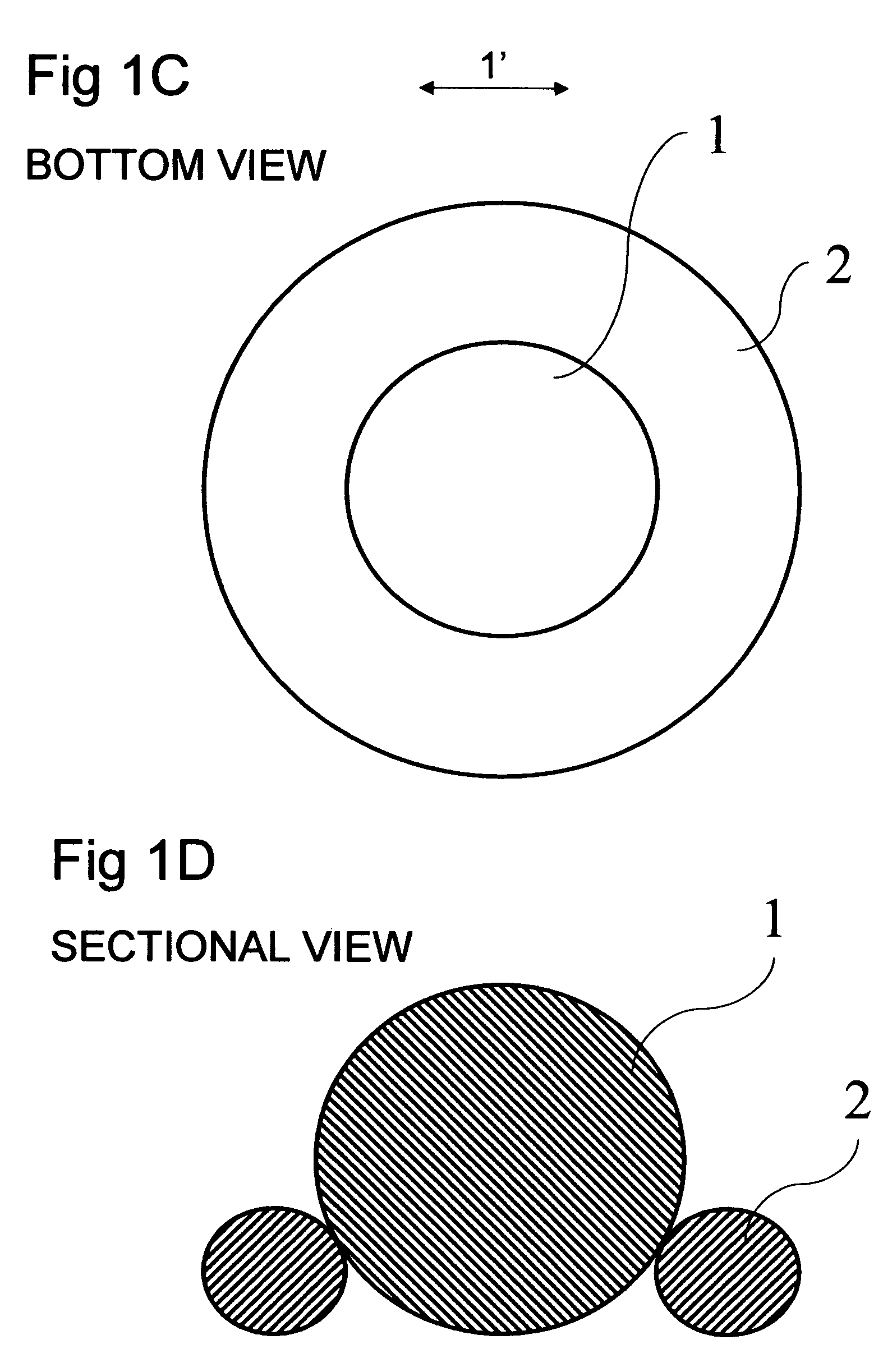

An inflatable device serving in one or more roles as furniture and / or equipment for exercise, recreation, and / or therapeutic equipment, or in some combination of these functions is disclosed. The device consists of an inflatable base (2) with one or more cavities or holes, with rounded inflatable spheroid(s) (1) in said cavities or holes. The device may optionally include a system of straps (3 and 4) or a form-fitting covering around the base, which may serve to correct an asymmetry in said base. The device may include a weighted base (11). The device may also include means for generating lights, sound, and / or video (6, 7, 8, 9, 10, 12, and / or 13) responsive to the actions of users on or around the device.

Owner:BAUM AARON WOLF

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com