High specific surface area silver powder improving conductivity of solar battery electrode and preparation method

A solar cell, high specific surface area technology, used in metal processing equipment, transportation and packaging to achieve uniform particle size, improved photoelectric conversion efficiency, and high dispersion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

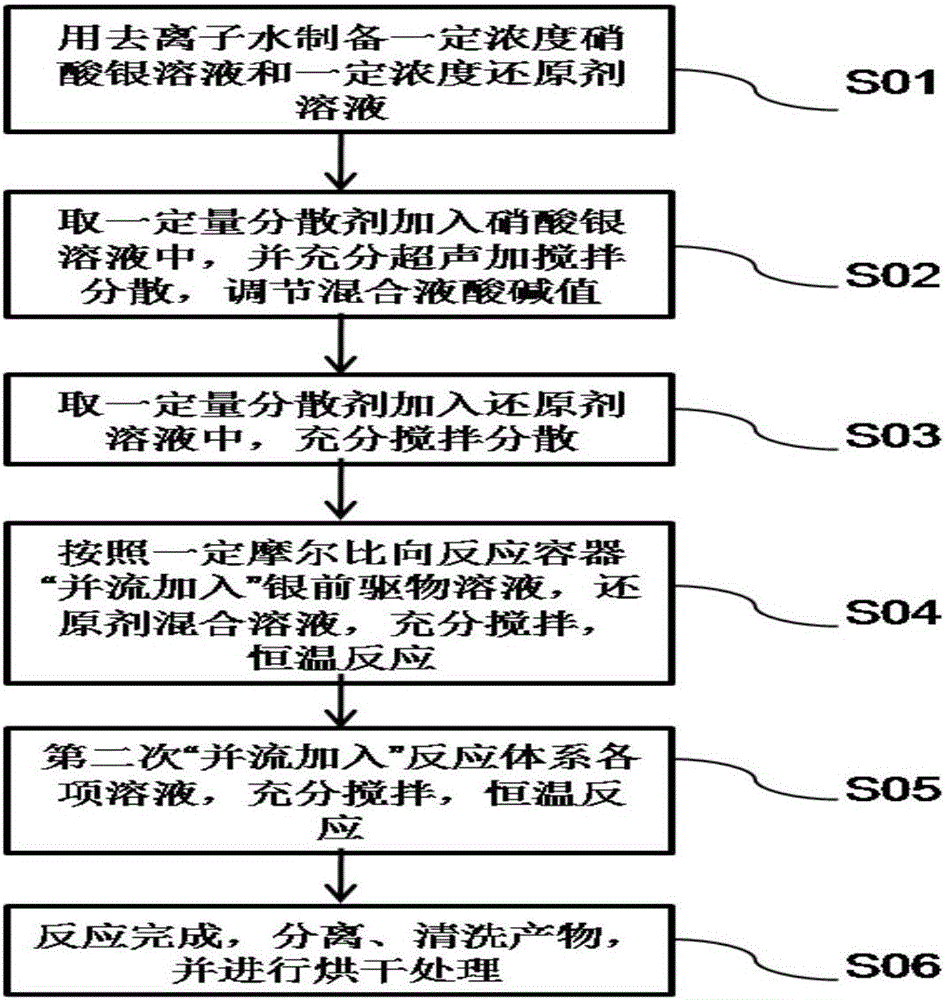

[0028] Such as figure 1 Shown, the preparation method of the described high specific surface area silver powder that improves solar cell electrode conductivity, specifically carries out through following steps:

[0029] S01. the ascorbic acid solution that is the silver nitrate of 1.45mol / L and the ascorbic acid solution that concentration is 1.2mol / L is prepared respectively with deionized water;

[0030] S02. get the 1.5% gelatin of silver nitrate quality, add in the silver nitrate solution of step S01 gained, and in ultrasonic instrument, combine with 400r / min rotating speed stirring to disperse, stirring time 10min, then add the solution that regulates pH value, Make the adjusted pH value 2 to obtain a silver precursor solution;

[0031] S03. Take 1.5% gelatin of the mass of the ascorbic acid solution, add it to the reducing agent solution obtained in step S01, stir at a speed of 400 r / min to disperse, and stir for 10 minutes to obtain a reducing agent mixed solution;

...

Embodiment 2

[0037] The preparation method of the described high specific surface area silver powder that improves solar cell electrode conductivity, specifically carries out through the following steps:

[0038] S01. the ascorbic acid solution that is the silver nitrate of 0.6mol / L and the ascorbic acid solution that concentration is 0.4mol / L is prepared respectively with deionized water;

[0039] S02. Get 6.25% sodium citrate and 6.25% polyvinyl alcohol of the silver nitrate quality, add in the silver nitrate solution gained in step S01, and in the ultrasonic instrument, combine with 400r / min rotating speed to disperse, stirring time 10min, then add adjusting the pH value of the solution so that the adjusted pH value is 2.5 to obtain a silver precursor solution;

[0040] S03. Take 6.25% sodium citrate and 6.25% polyvinyl alcohol of the quality of the ascorbic acid solution, add them to the reducing agent solution obtained in step S01, stir at a speed of 400 r / min for dispersion, and stir...

Embodiment 3

[0045] Embodiment 3: Others are the same as in Embodiment 1, except that the amount added in "secondary parallel flow" is changed to be 0.5 times of the amount added in step S04.

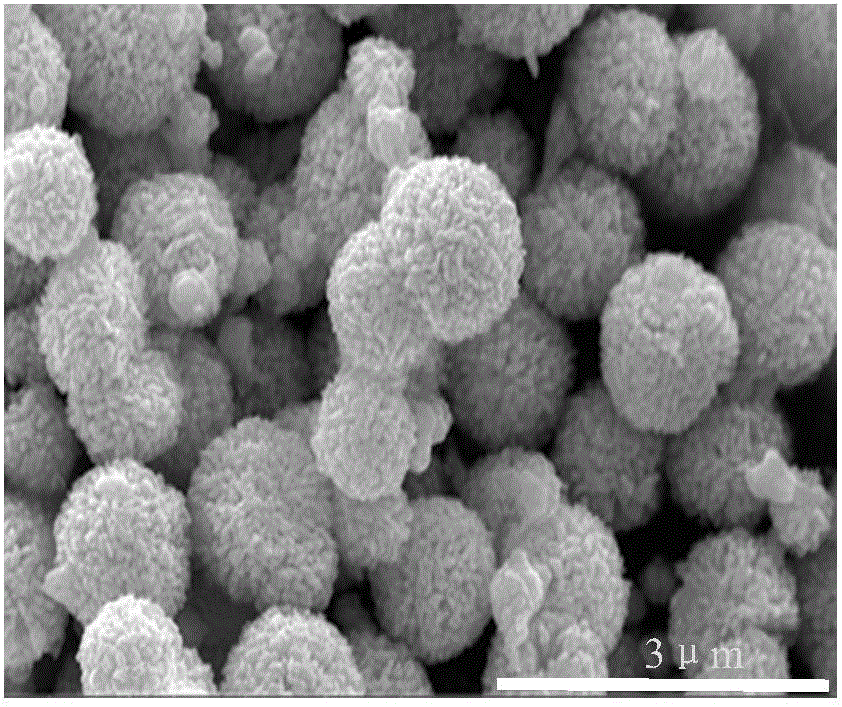

[0046] Such as Figure 4 As shown, the silver powder is spherical particles covered with rod-shaped protrusions on the surface, the average particle size is 2.5-4.0 μm, the bulk density is 3.0 g / mL, the tap density is 6.65 g / mL, and the specific surface area is 0.60 m 2 / g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com