Patents

Literature

7330 results about "Photoelectric conversion efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

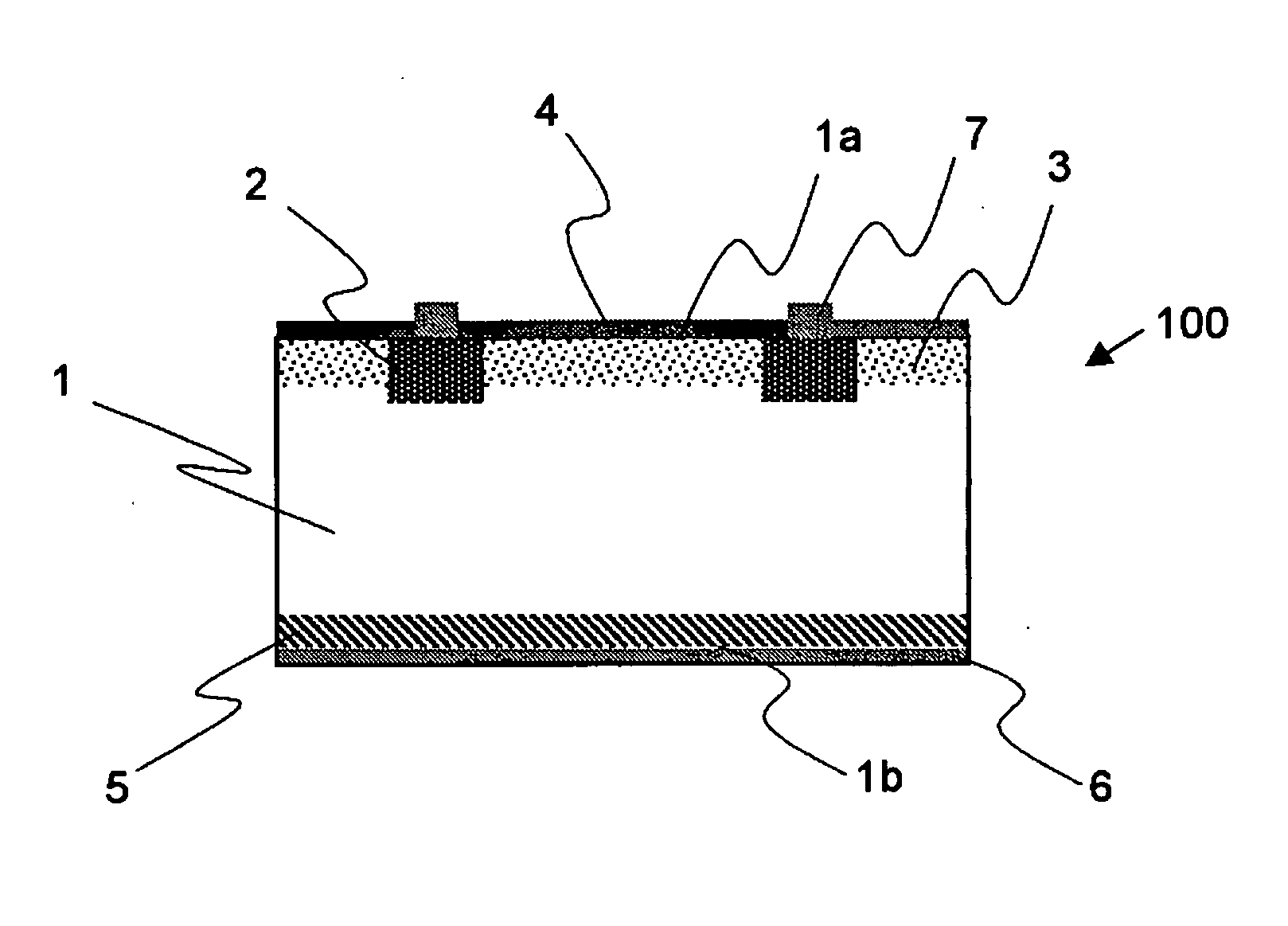

Photoelectric conversion element

InactiveUS6683244B2Improve photoelectric conversion efficiencyPrevent and suppressLight-sensitive devicesDeferred-action cellsPorosityPhotoelectric conversion

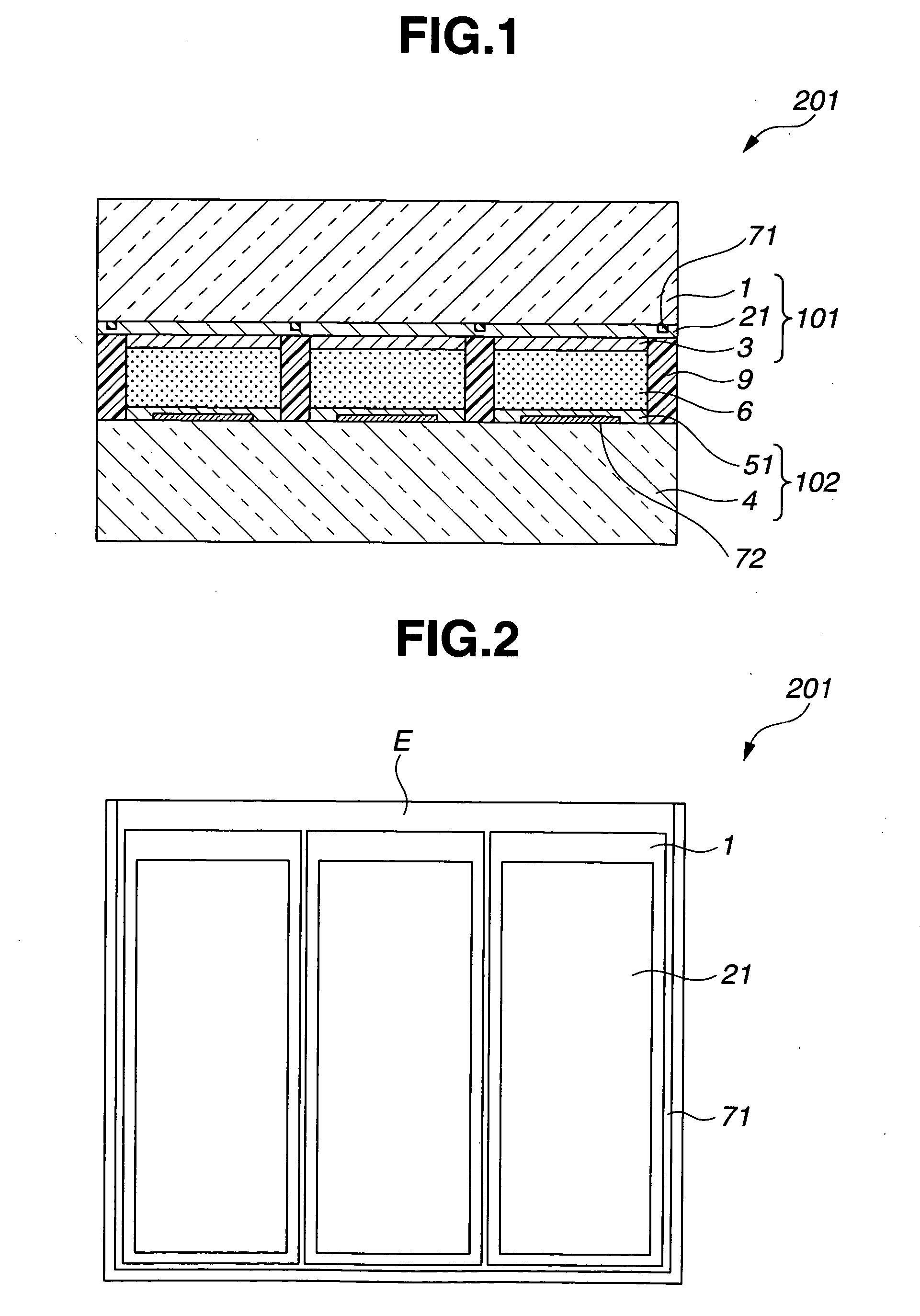

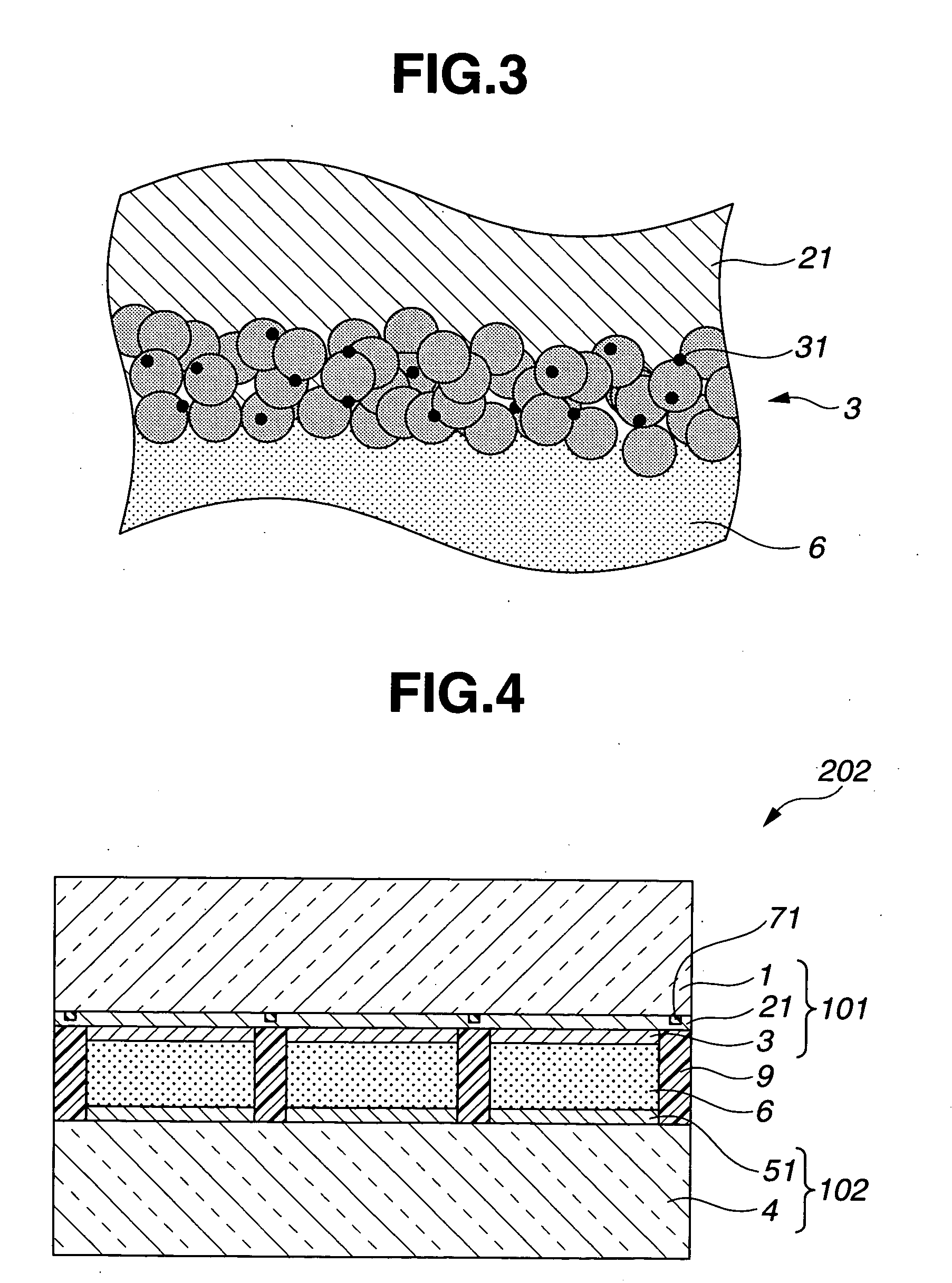

A solar cell including a first electrode, a second electrode arranged opposite to the first electrode, an electron transport layer arranged between the first electrode and the second electrode, a dye layer D which is in contact with the electron transport layer, a hole transport layer arranged between the electron transport layer and the second electrode and being in contact with the dye layer D, and a barrier layer, and these elements are provided on a substrate. The barrier layer prevents or suppresses short-circuit between the first electrode and the hole transport layer. The porosity of the barrier layer is made smaller than that of the electron transport layer. The barrier layer is formed into a film-like shape and arranged between the first electrode and the electron transport layer. The solar cell can accomplish excellent photoelectric conversion efficiency by the provision of such a barrier layer.

Owner:SEIKO EPSON CORP

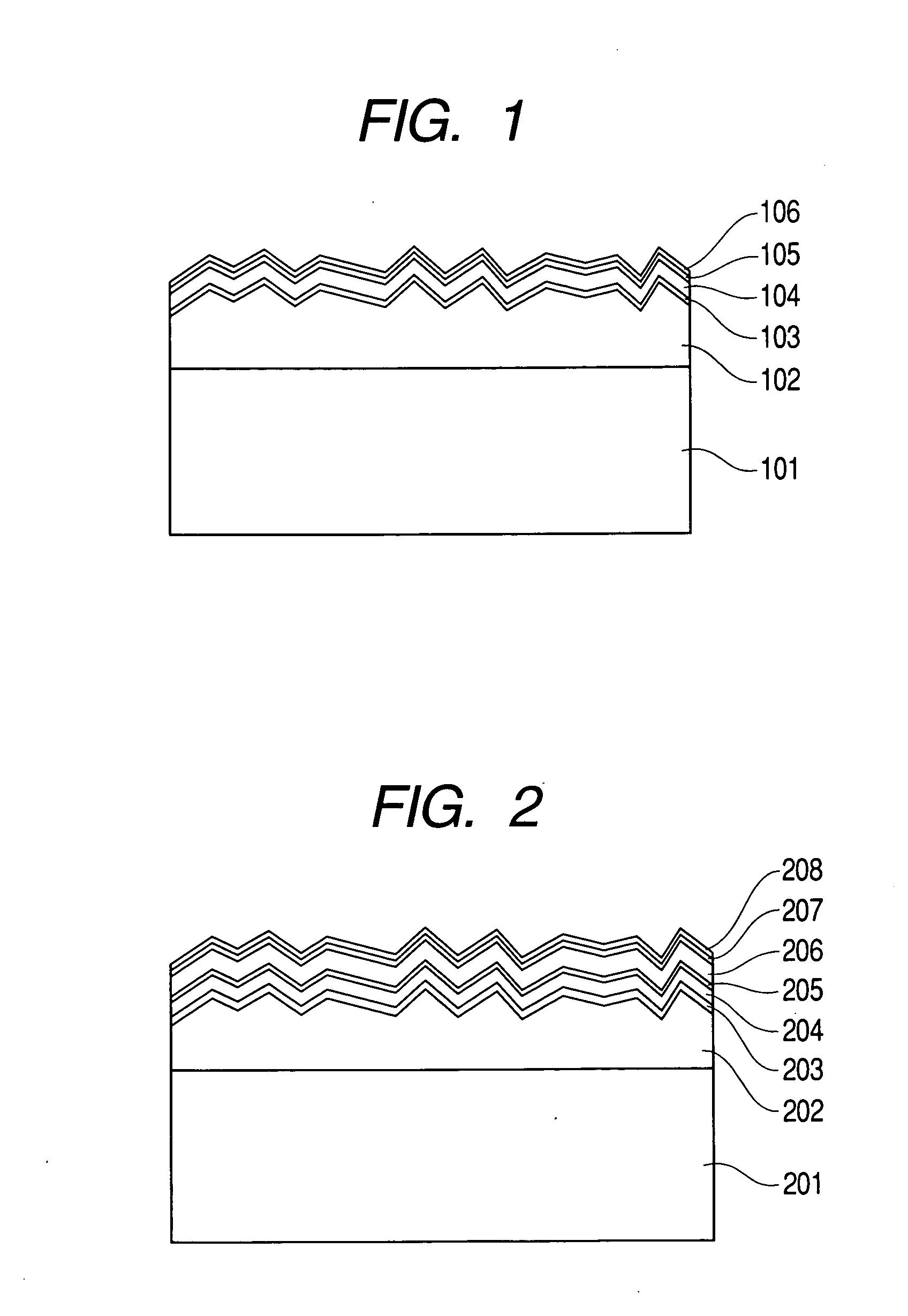

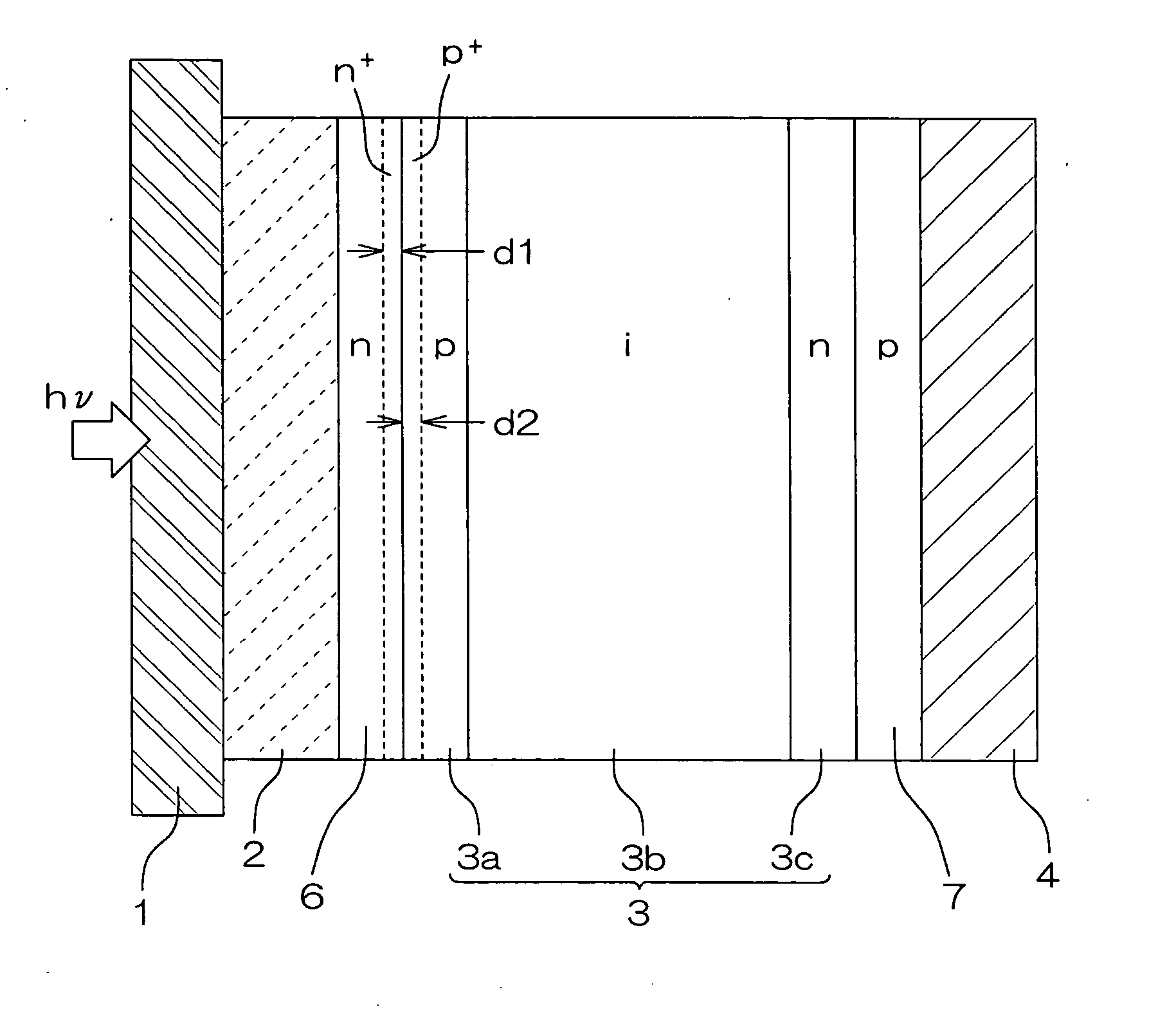

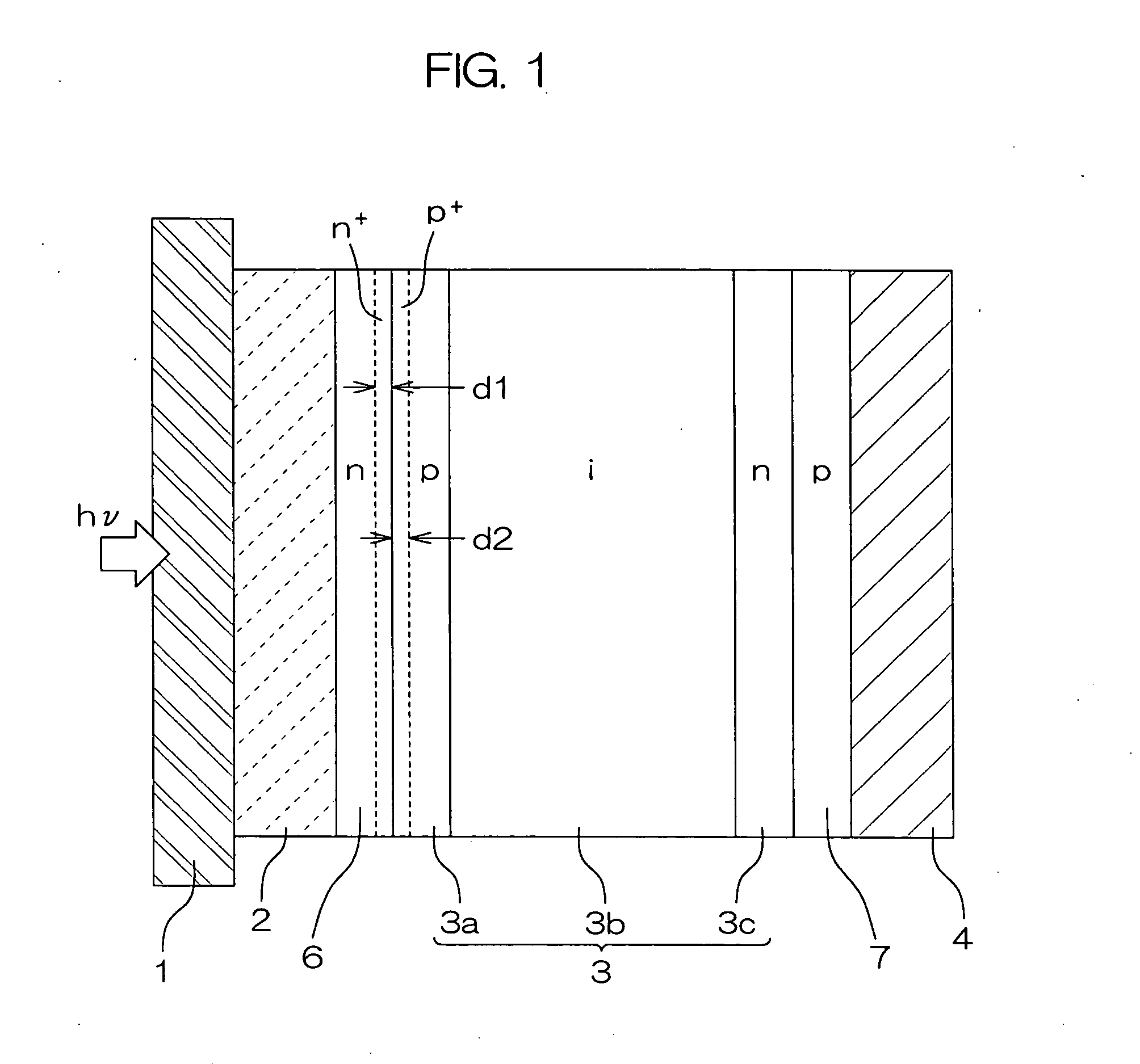

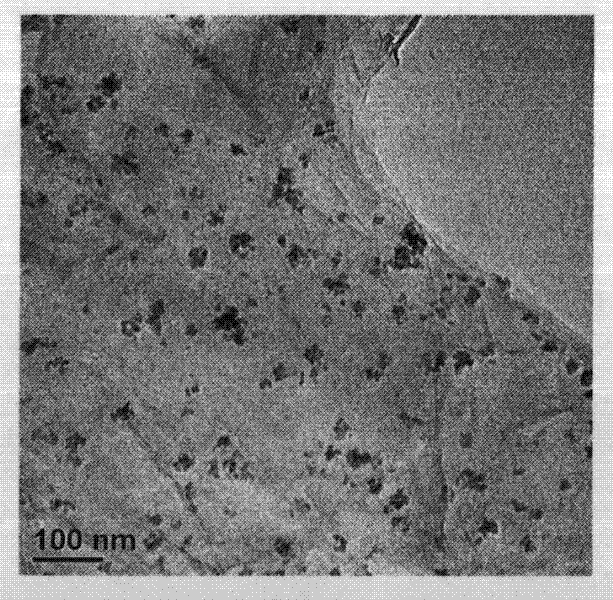

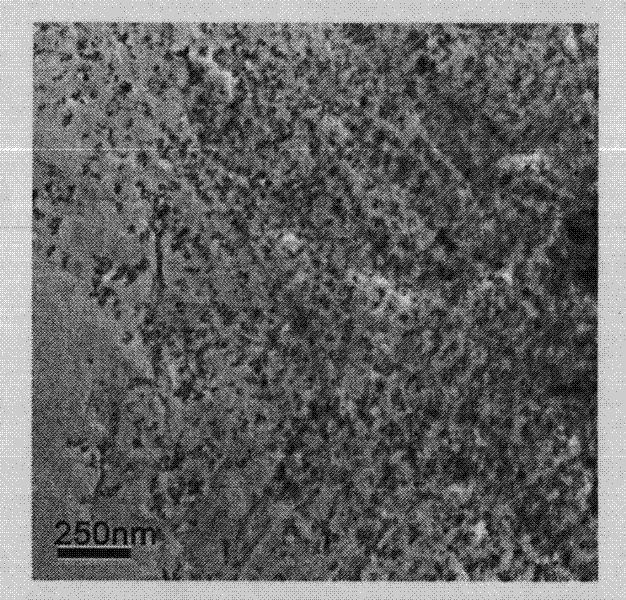

Multi-junction photovoltaic device with microcrystalline I-layer

A photovoltaic element of the present invention is a photovoltaic element having a plurality of pin junctions each formed of a p-type semiconductor layer, an i-type semiconductor layer, and an n-type semiconductor layer each comprising a non-single-crystal material comprising a Group IVA element as a principal component, the photovoltaic element having a first pin junction comprising microcrystal silicon carbide (hereinafter referred to as microcrystal SiC) as a principal component of the i-type semiconductor layer and a second pin junction comprising microcrystal silicon (hereinafter referred to as microcrystal Si) as a principal component of the i-type semiconductor layer, wherein the first pin junction is provided closer to the light incidence side than the second pin junction. Provided thereby are a low cost photovoltaic element which exhibits little photodeterioration and with a high photoelectric conversion efficiency, and production method of the photovoltaic element capable of forming i-type microcrystal silicon and microcrystal SiC at a practical deposition rate.

Owner:CANON KK

Conductive slurry for solar battery front side electrode and production method thereof

ActiveCN101295739AImprove photoelectric conversion efficiencyImprove adhesionFinal product manufactureNon-conductive material with dispersed conductive materialConductive pasteElectrical battery

The invention relates to a conductive paste for the surface electrode of a solar cell, which comprises conductive metal powders, organic carriers, adhesives, solvents and addition agent, wherein, the conductive paste also comprises additives which are selected from phosphorus pentachloride and one or more VIII group metal halide. The additive in the conductive paste of the invention can help improve the adhesive force between the conductive paste and silicon substrate, and lead adhesion between compounds obtained after electrode sintering and silicon substrate to be more firm; the formed compound does not have cracks and bubbles and the electrode surface is flat and smooth, thus providing the solar cell finally prepared with higher photoelectric conversion efficiency.

Owner:BYD CO LTD

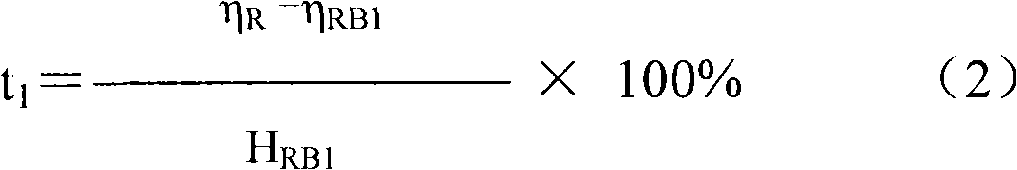

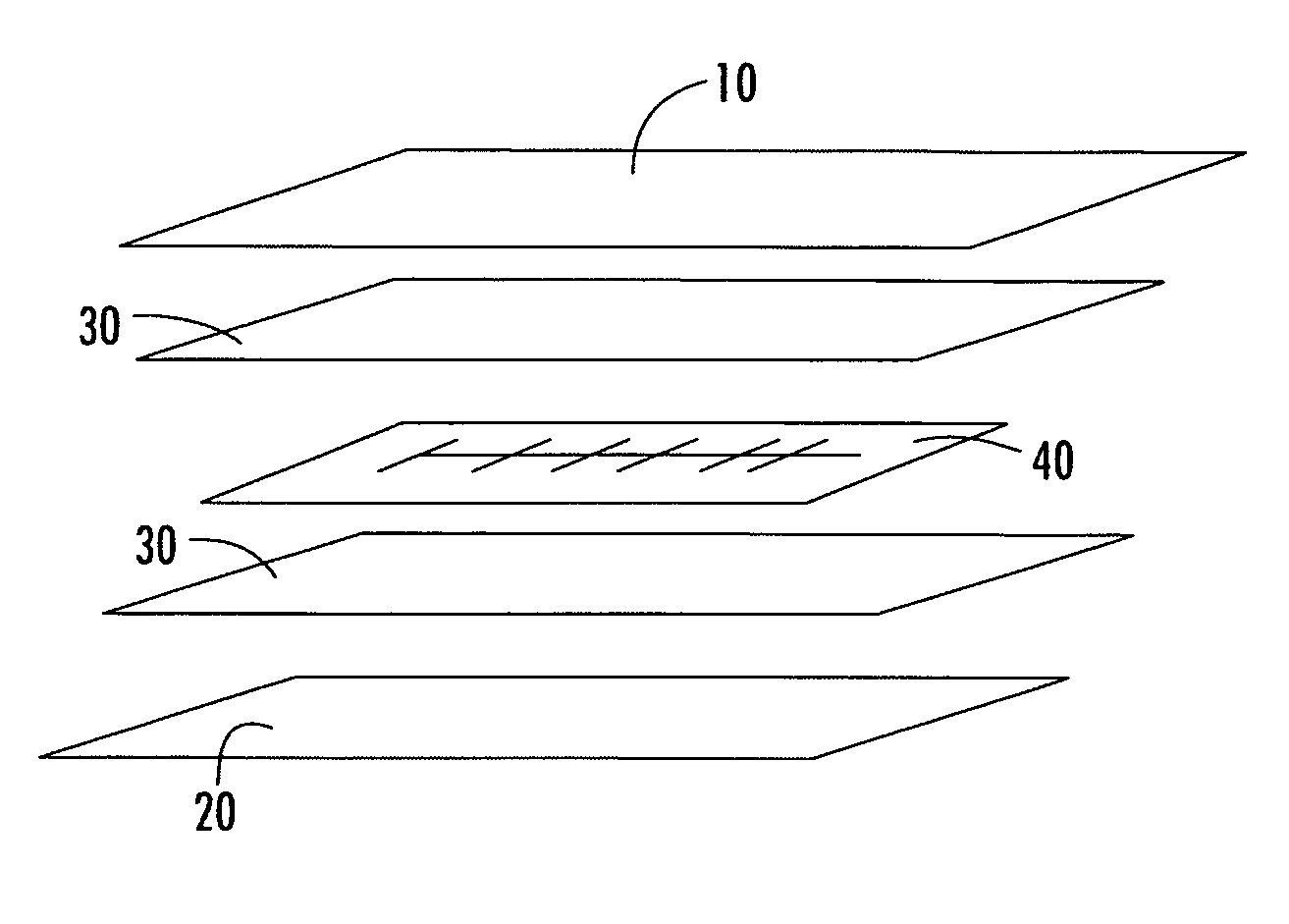

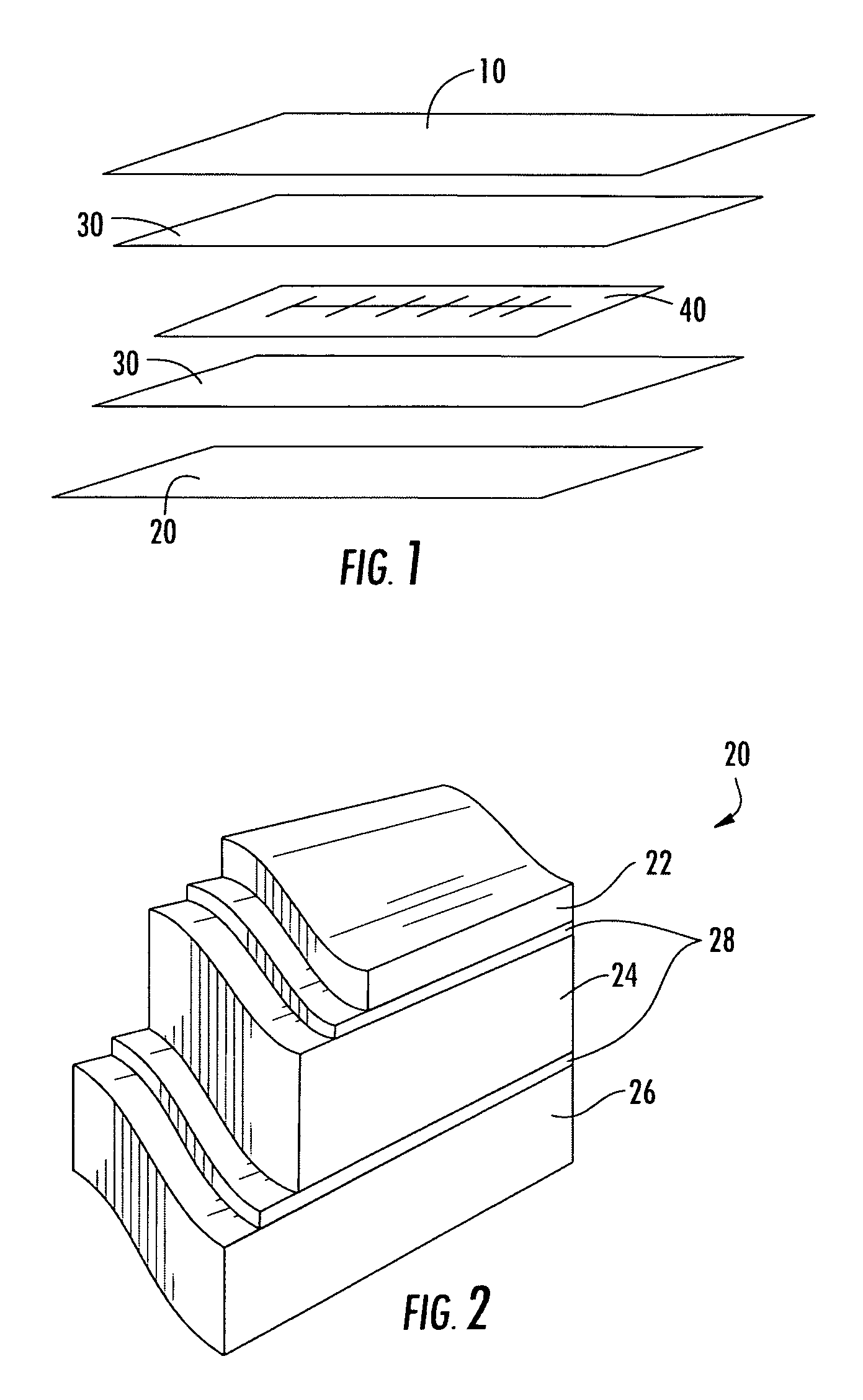

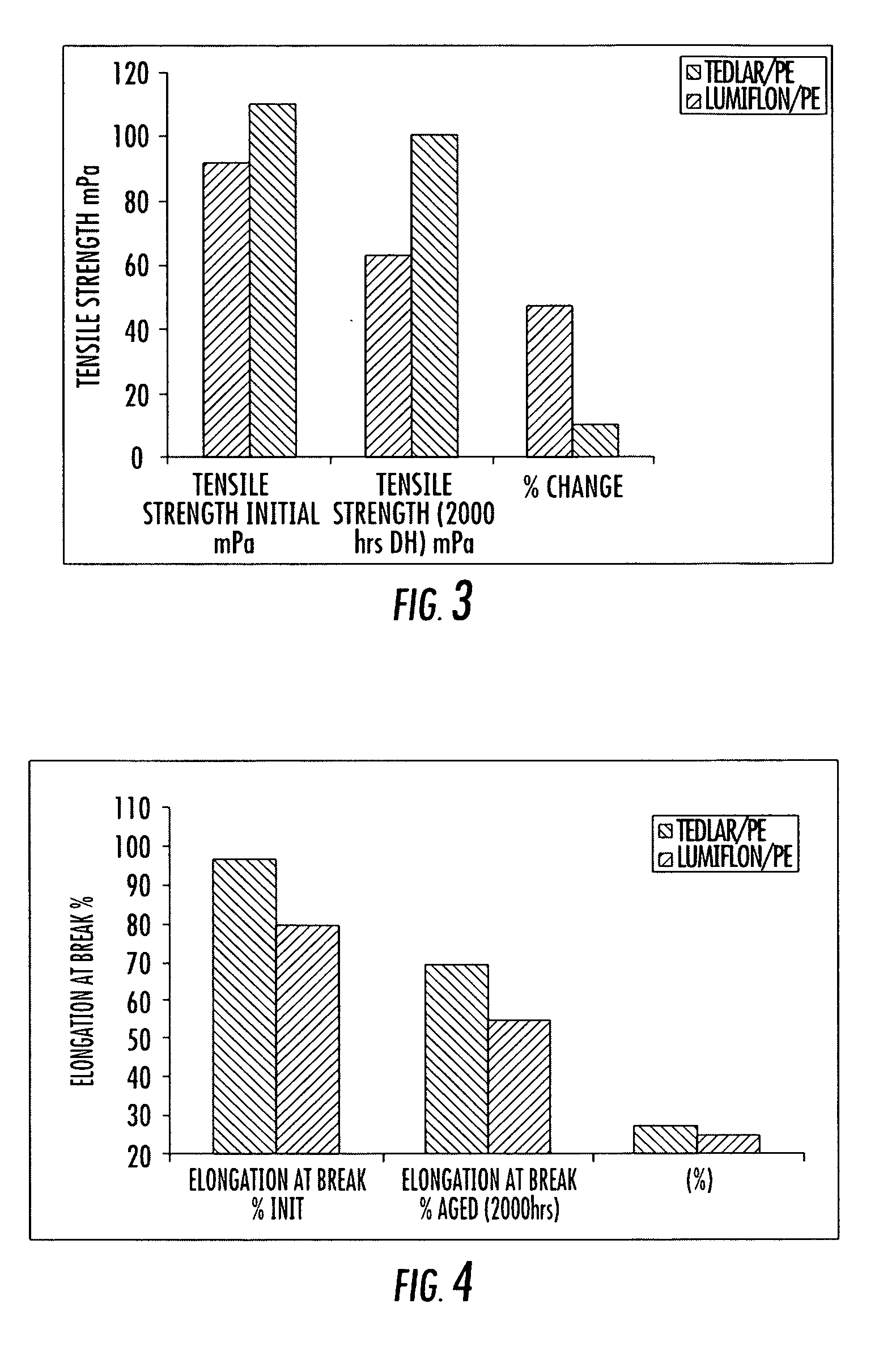

Backing sheet for photovoltaic modules and method for repairing same

InactiveUS20080264484A1Improve adhesionGood color retentionSynthetic resin layered productsCoatingsWeather resistanceHeat resistance

The present invention provides a protective backing sheet for photovoltaic modules. The backing sheets of the current invention possess excellent weather resistance, heat resistance, color retention, adhesion between layers and encapsulant, and scratch resistance. The backing sheet can minimize the deterioration in the performance of the solar module due to moisture permeation. It also can achieve desirable photoelectric conversion efficiency over a long period of time. Additionally the described backing sheet, or alternately referred to backskin, can be made in an aesthetically pleasing form.

Owner:MADICO INC

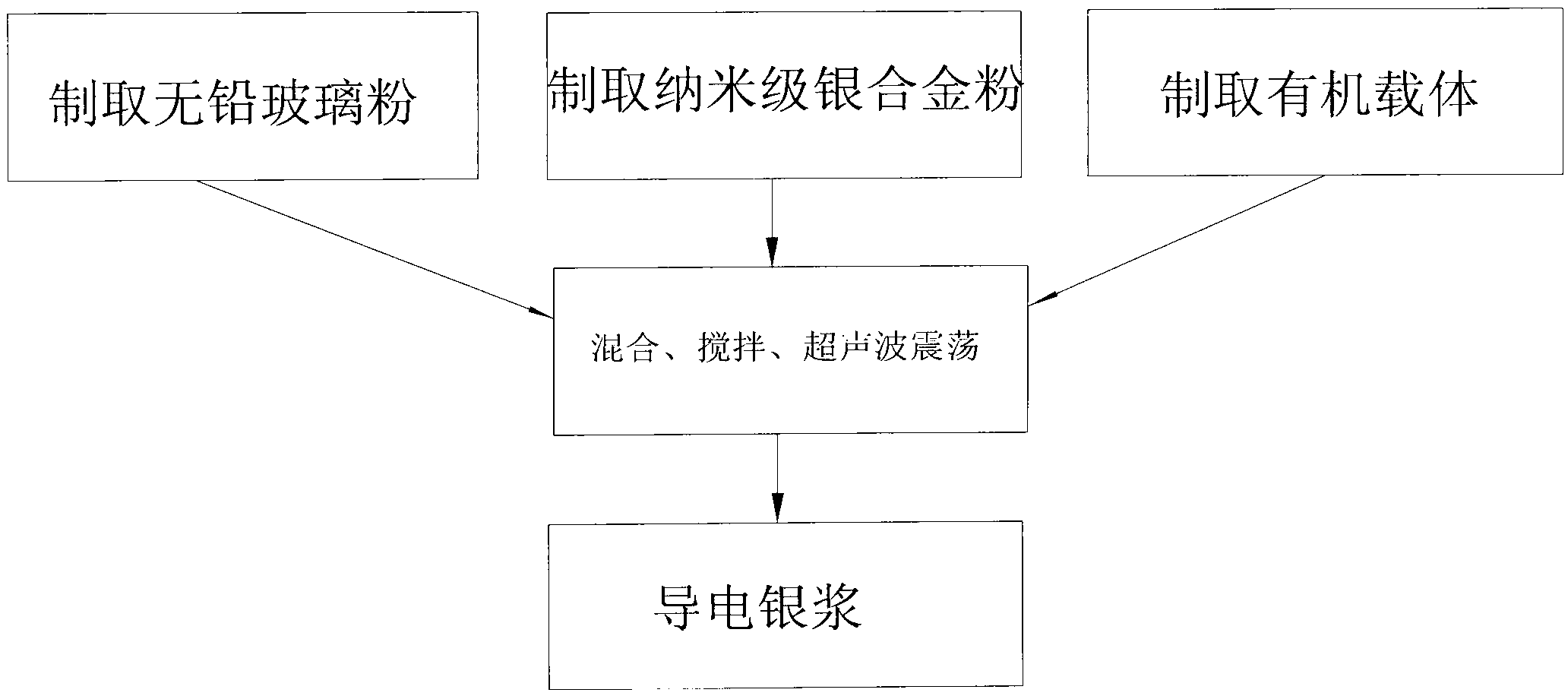

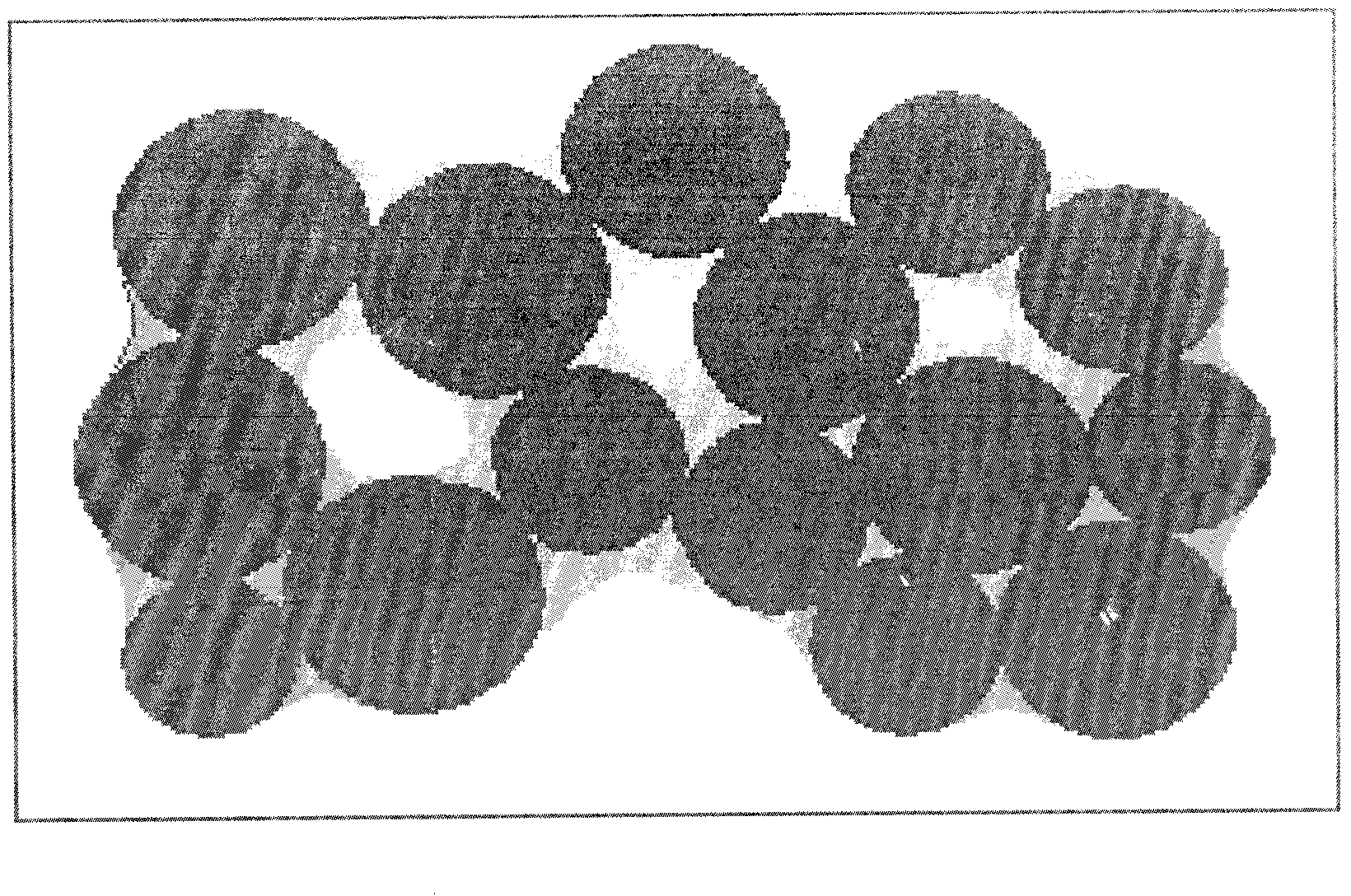

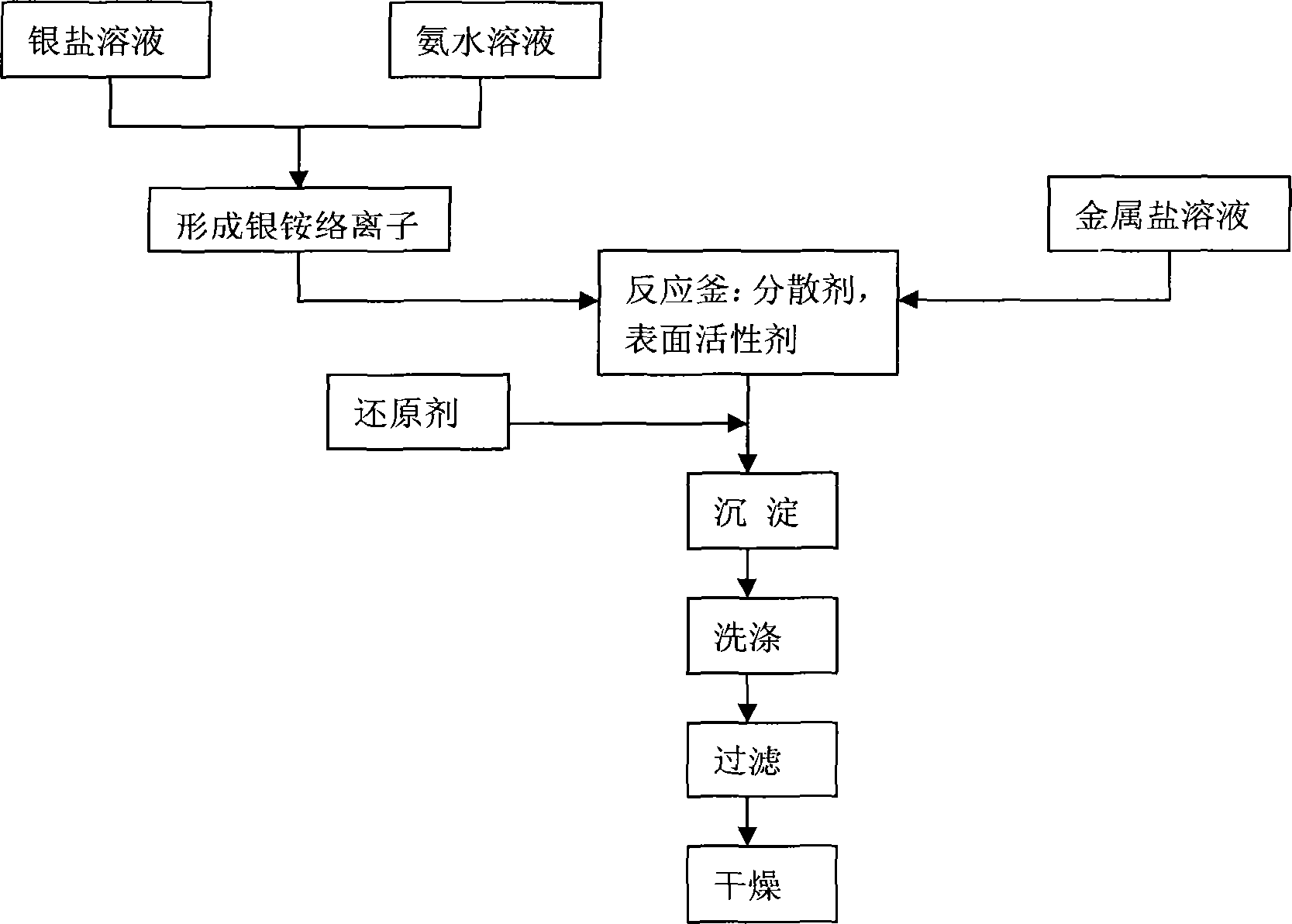

Electric conductive silver paste and manufacturing method thereof

ActiveCN103258584AEnhanced interconnectionIncrease contact areaNon-conductive material with dispersed conductive materialCable/conductor manufactureSilver pasteMetal alloy

The invention discloses electric conductive silver paste and a manufacturing method of the electric conductive silver paste. The electric conductive silver paste comprises, by mass percentage, 35 - 65 % of micron-sized silver powder, 1-10 % of nanometer-sized silver powder of or 1-20 % of nanometer-sized silver and other metal alloy powder, and 1-10 % of an organic carrier; for ceramics, solar cell silver paste comprises 2-15 % of unleaded glass powder, each component is manufactured in parts, weighed, mixed and stirred or mixed and rapidly scattered, and ultrasonic-vibrated or fine adjusted of viscosity of solvent, and therefore the electric conductive silver paste is obtained. Due to the fact that the nanometer-sized silver powder or the nanometer-sized silver alloy powder is mixed with the micron-sized silver powder, intensity of conductivity and a circuit is improved, adhesive force of crushing resistance and a base plate is improved, at the same time unleaded slurry good in thixotropy, low in contacting resistance and low in piece-needed slurry amount replaces lead slurry materials, the electric conductive silver paste is used for manufacturing crystalline silicon solar cells, improves photoelectric conversion efficiency, accords with environmental-protection ideas, and can be produced in large scales continuously.

Owner:SHENZHEN CHENGGONG CHEM

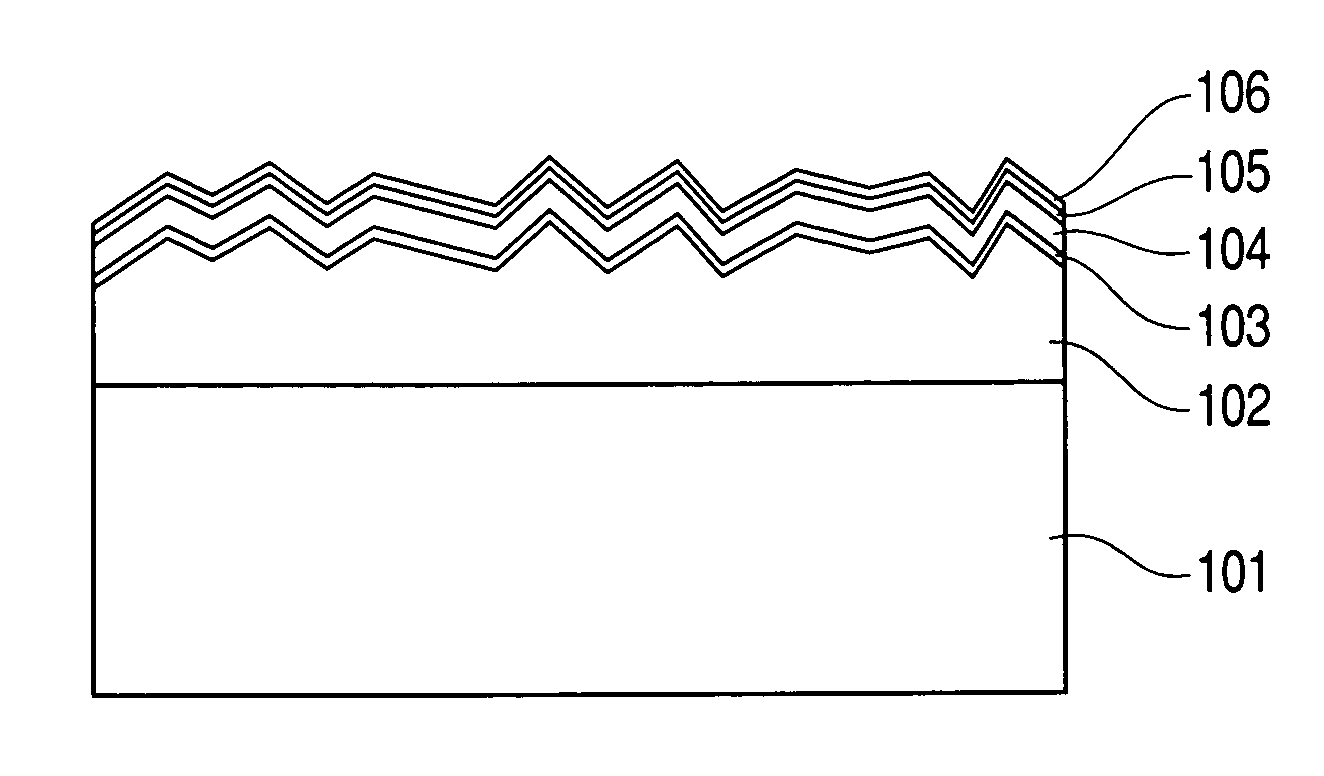

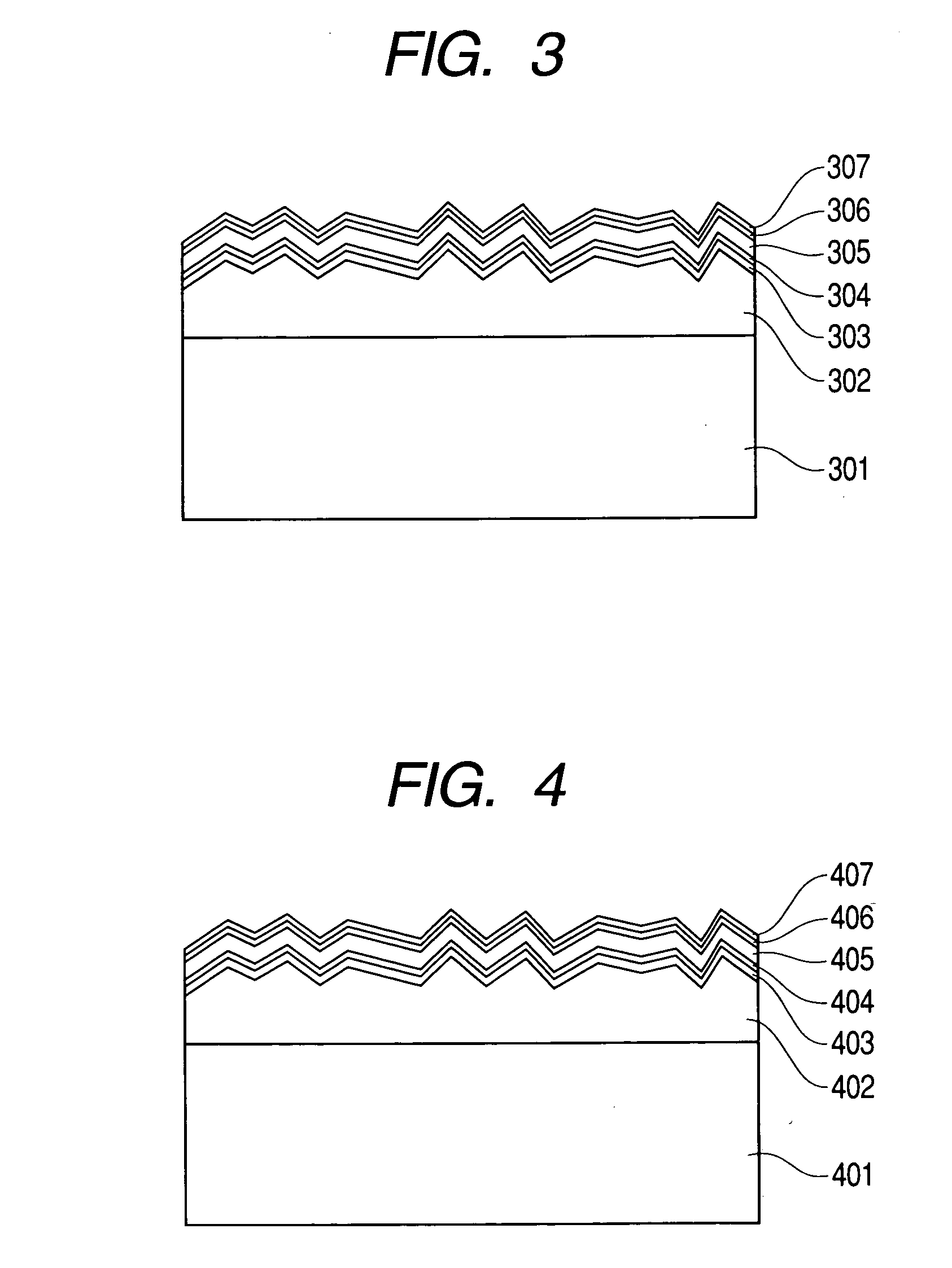

Photovoltaic device and manufacturing method thereof

InactiveUS20050109388A1Increase costLow costFinal product manufacturePhotovoltaic energy generationProduction ratePolycrystalline silicon

There is provided a photovoltaic device in which at least one pin-junction is formed in a thin film semiconductor deposited on a substrate, the substrate including: a base including polycrystalline silicon; and a polycrystalline silicon layer formed on the base by liquid phase growth, in which at least a part of a surface of the polycrystalline silicon layer has unevenness composed of facet surfaces. The photovoltaic device prevents a reduction in photoelectric conversion efficiency due to the absence of preferable unevenness, an increase in cost due to the use of an expensive material, and a reduction in throughput in the photovoltaic device, and has a preferable characteristic and high productivity.

Owner:CANON KK

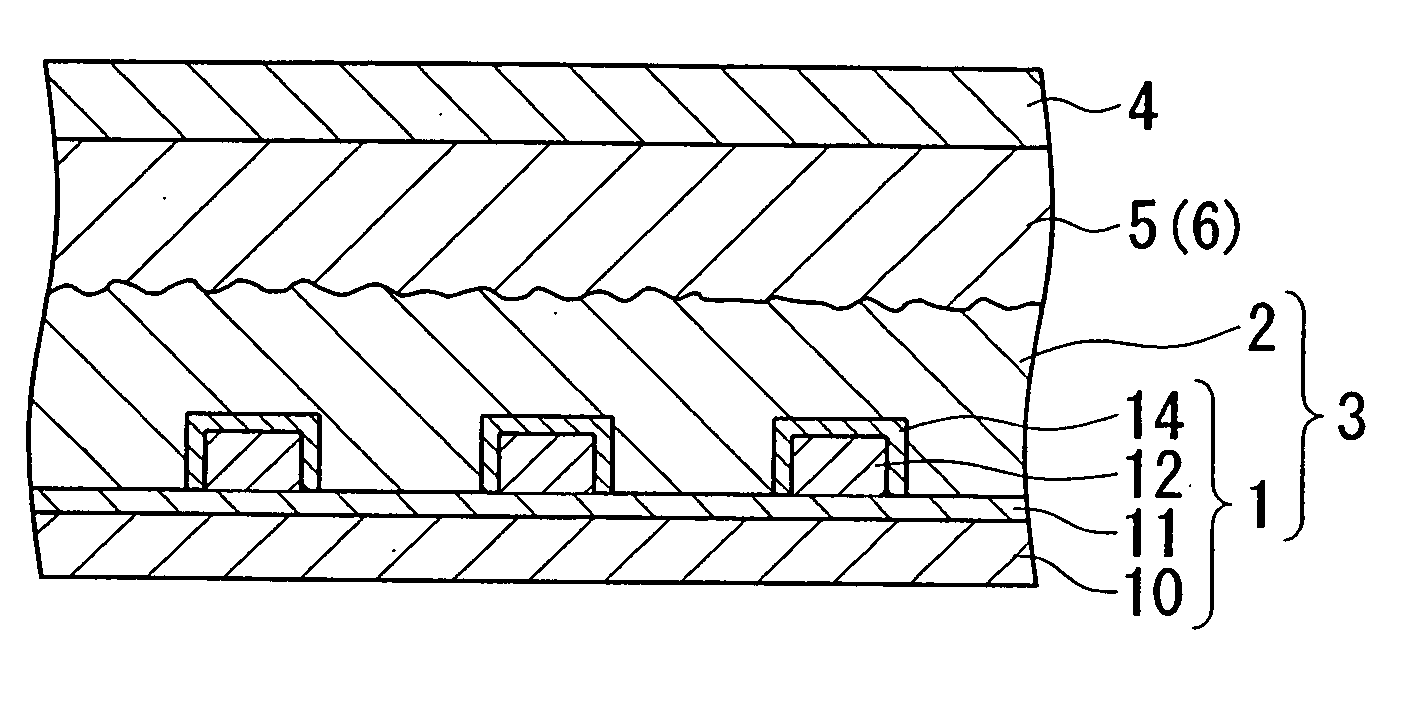

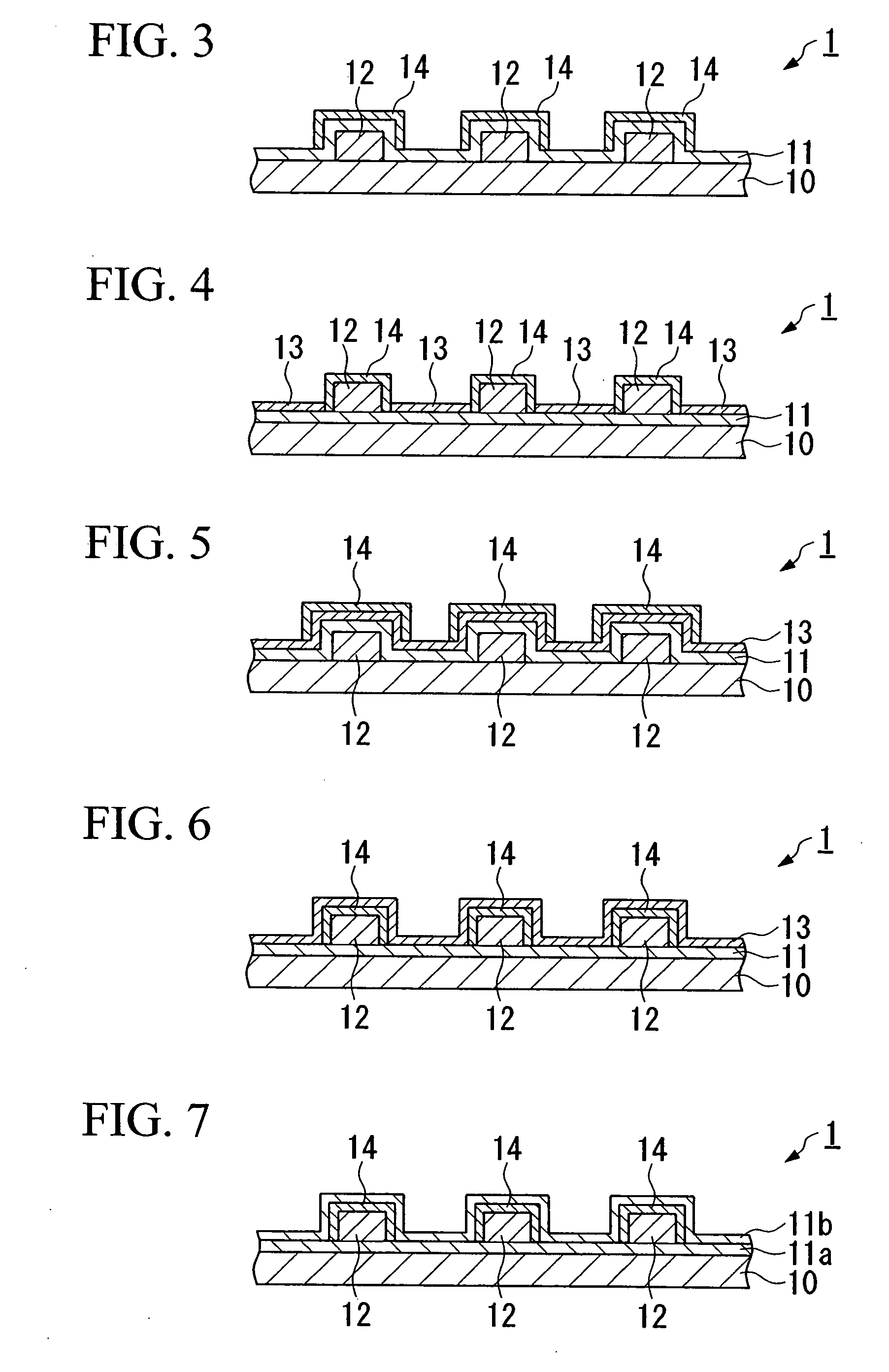

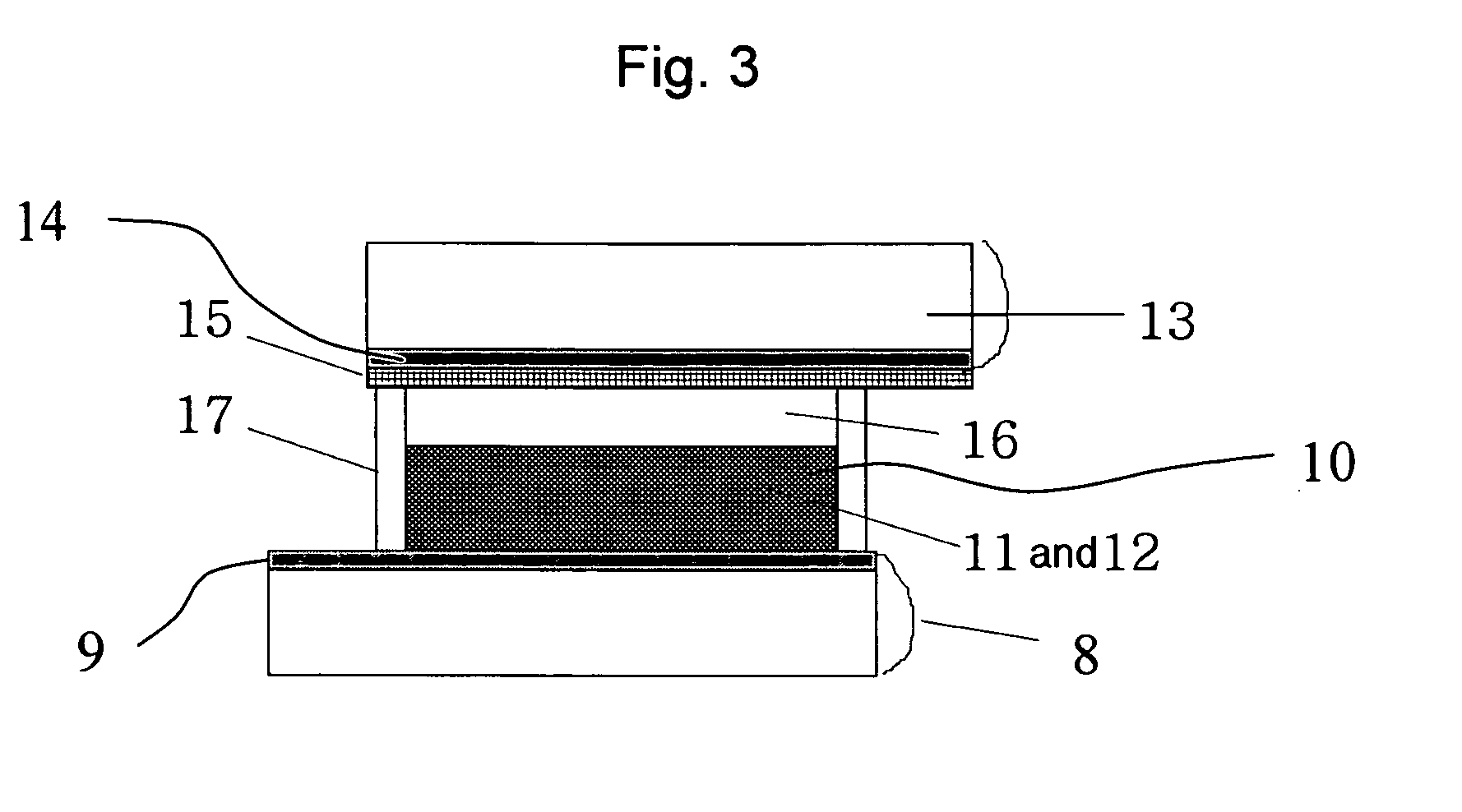

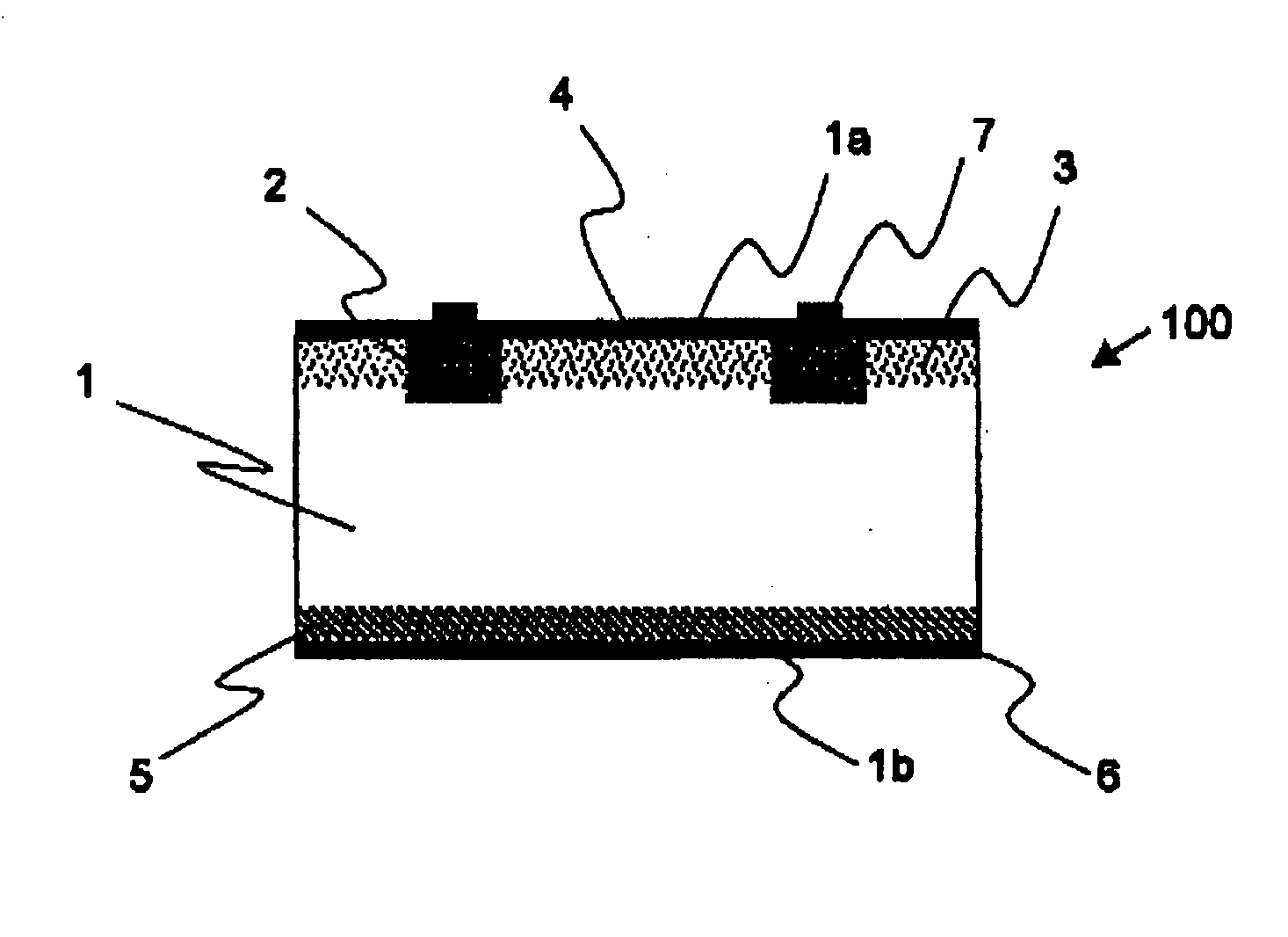

Electrode substrate, photoelectric conversion element, conductive glass substrate and production method therefo, and pigment sensitizing solar cell

ActiveUS20060162770A1Improve conductivityInhibit currentLight-sensitive devicesFinal product manufactureFritPhotoelectric conversion

In an electrode substrate 1, the surface of a metal circuit layer 12 is covered and insulated by an insulating layer 14. In a photoelectric conversion element that uses this electrode substrate 1, the metal circuit layer is reliably shielded from an electrolyte solution or the like so that corrosion and leak current thereof is effectively prevented, and the photoelectric conversion efficiency can be improved. The insulating layer 14 is preferably made of a material that contains a glass component, and is particularly preferably formed by printing a paste that contains glass frit. The metal circuit layer 12 is preferably formed using a printing method.

Owner:THE FUJIKURA CABLE WORKS LTD

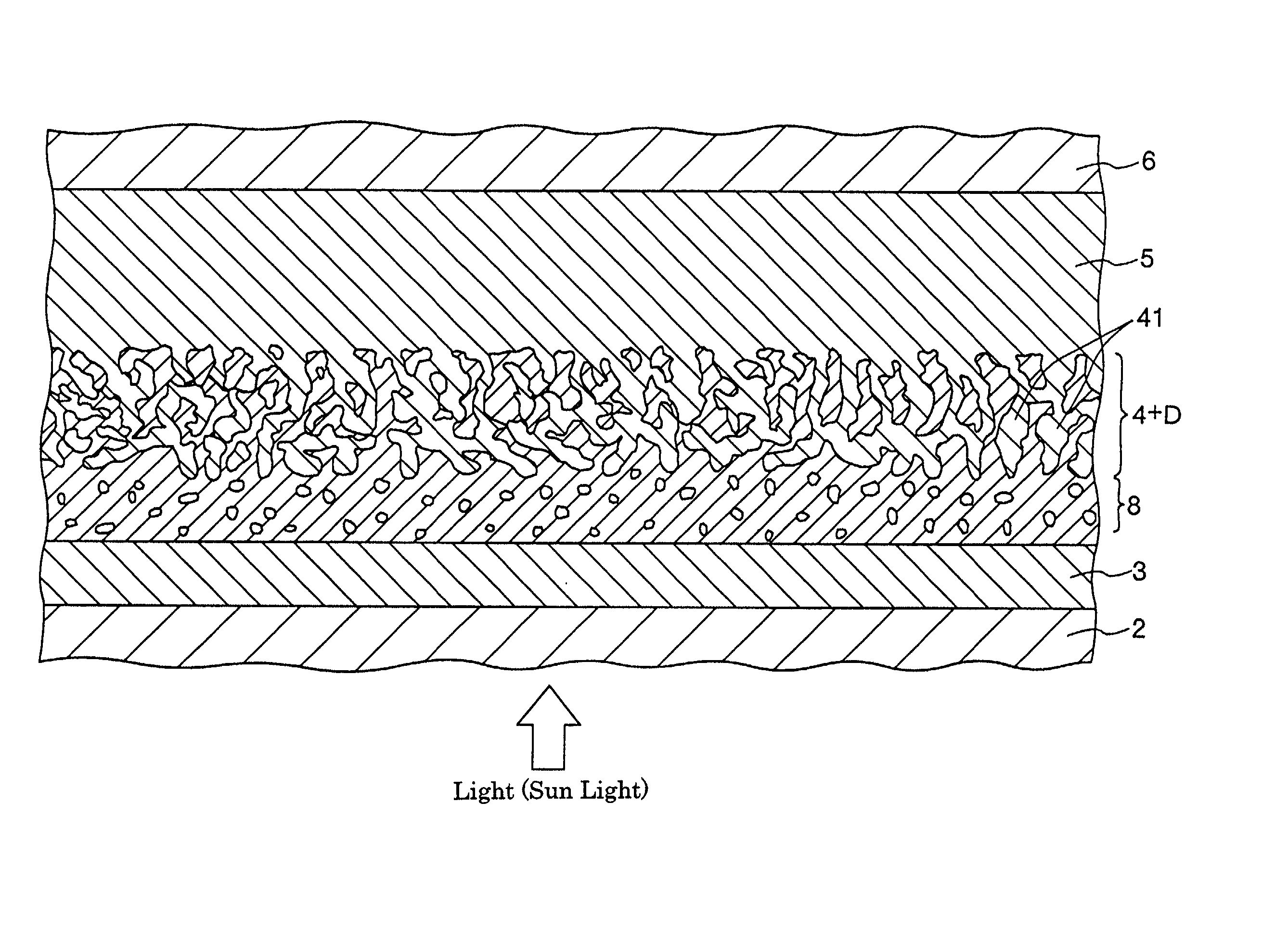

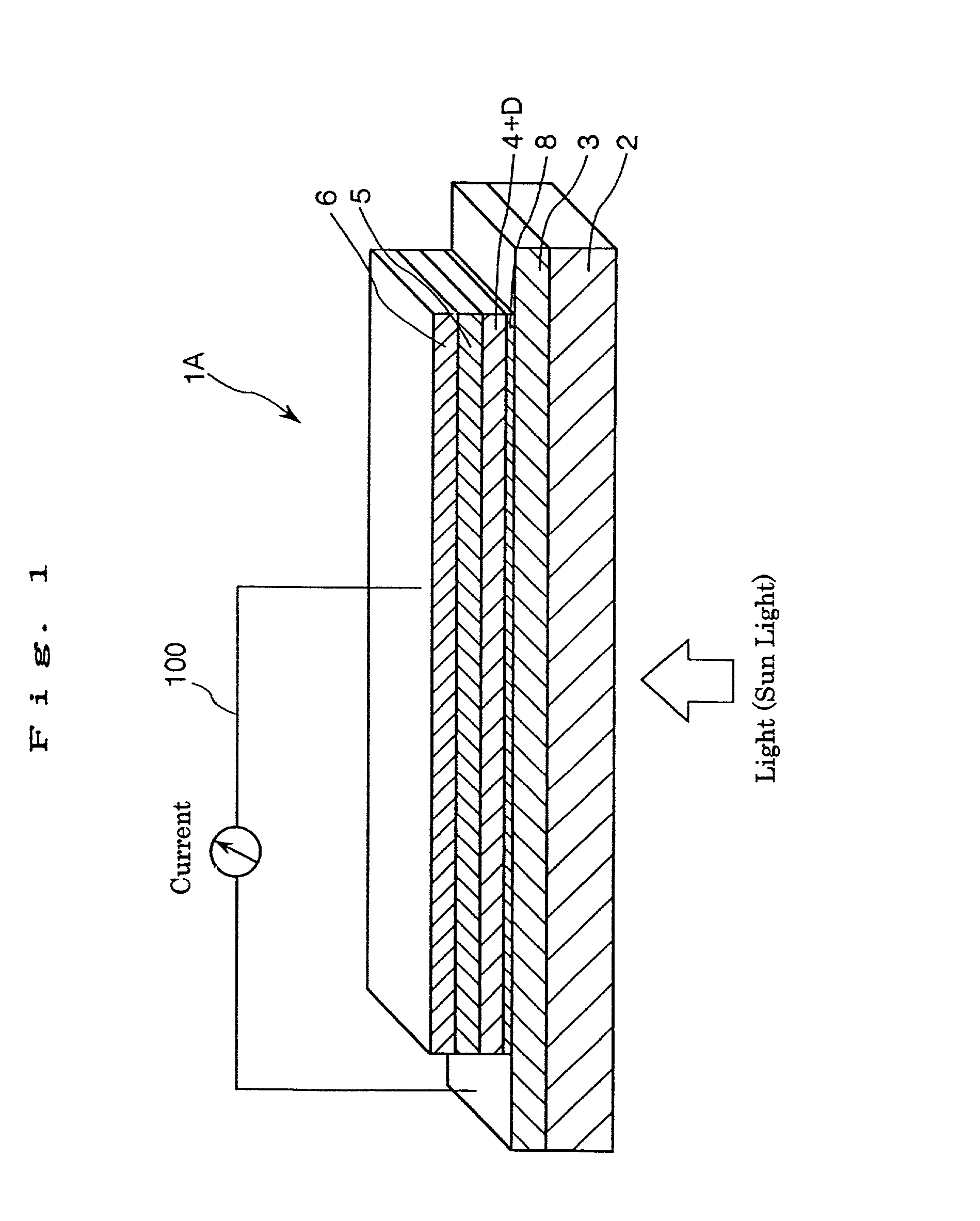

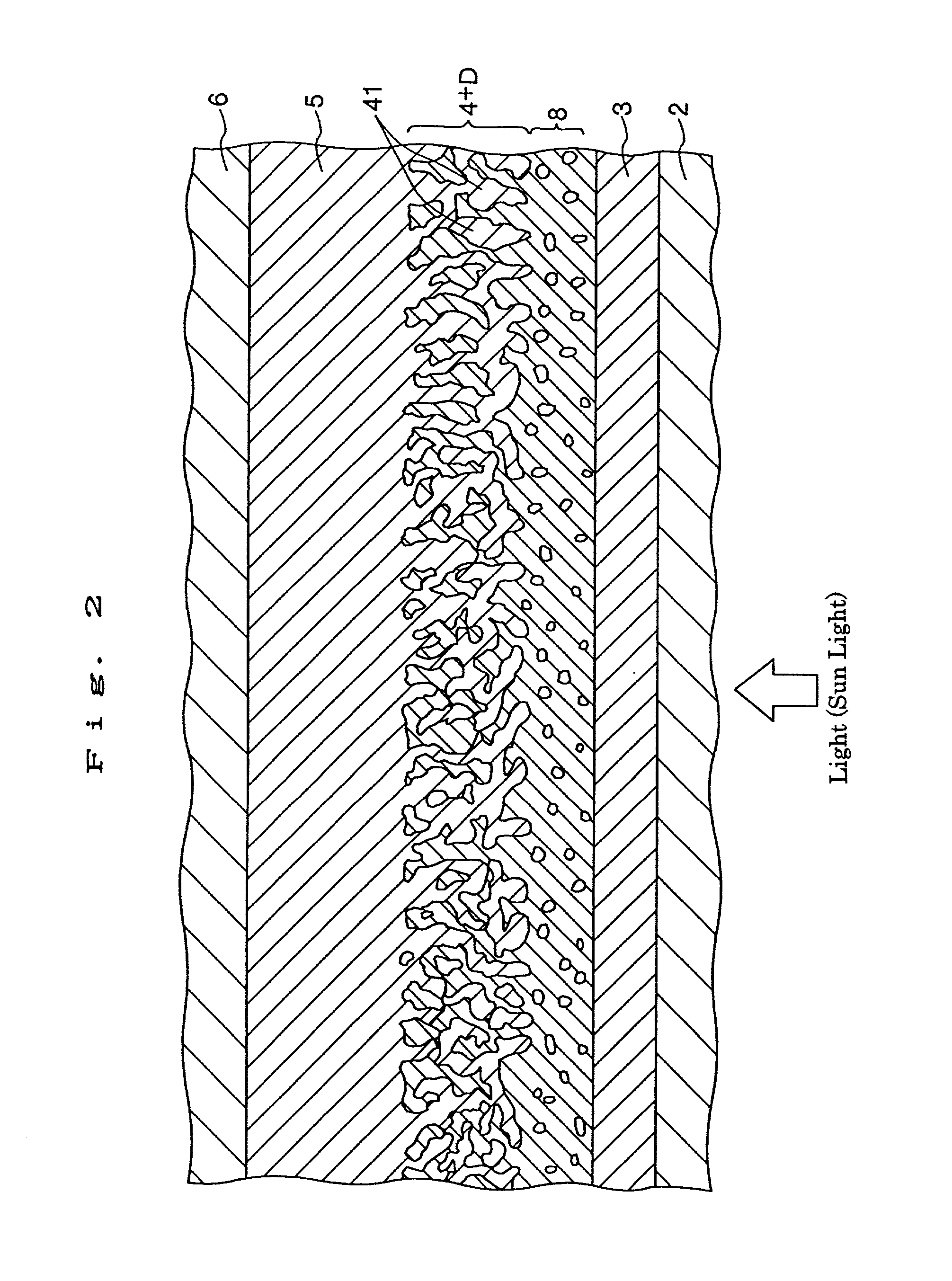

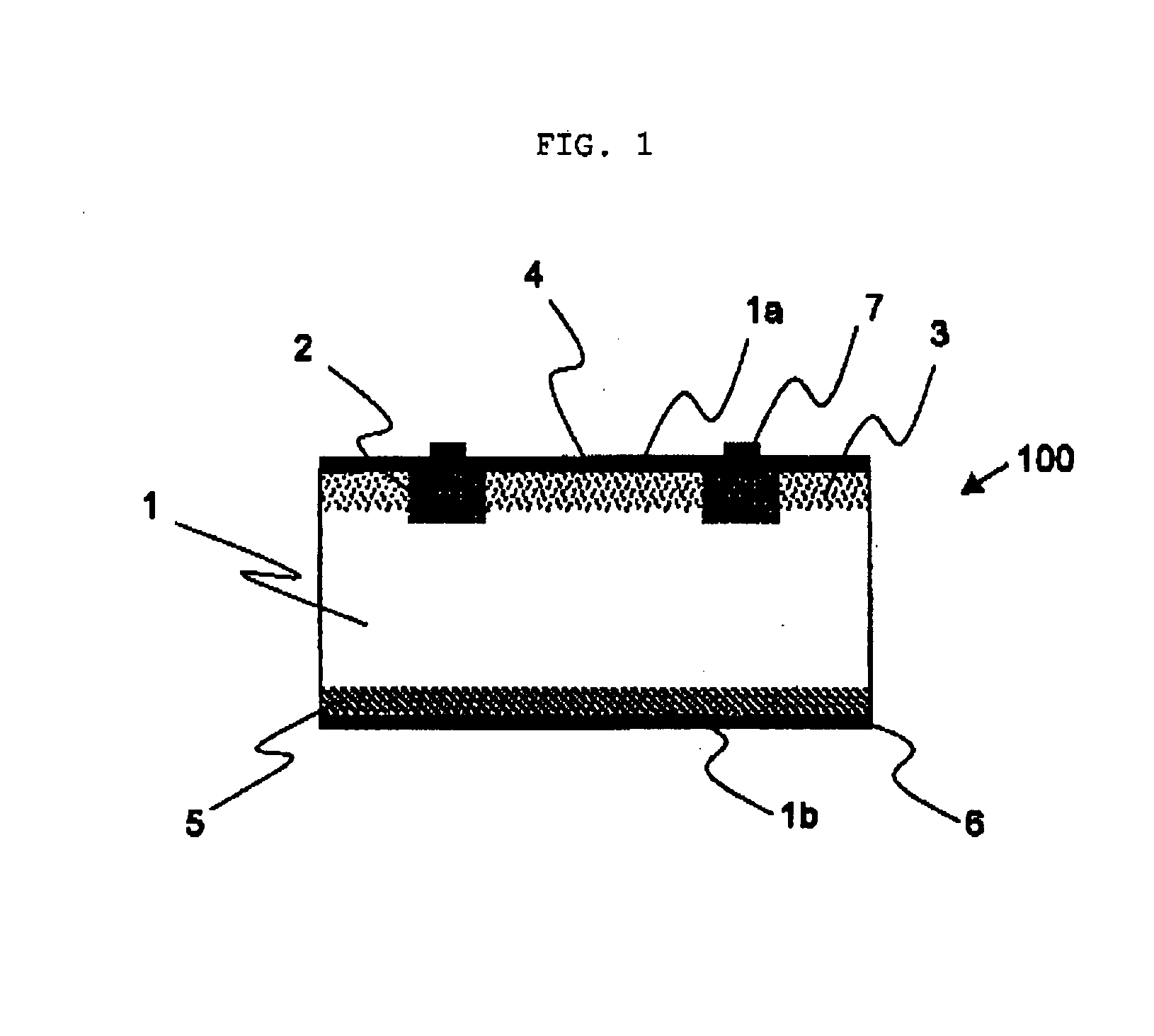

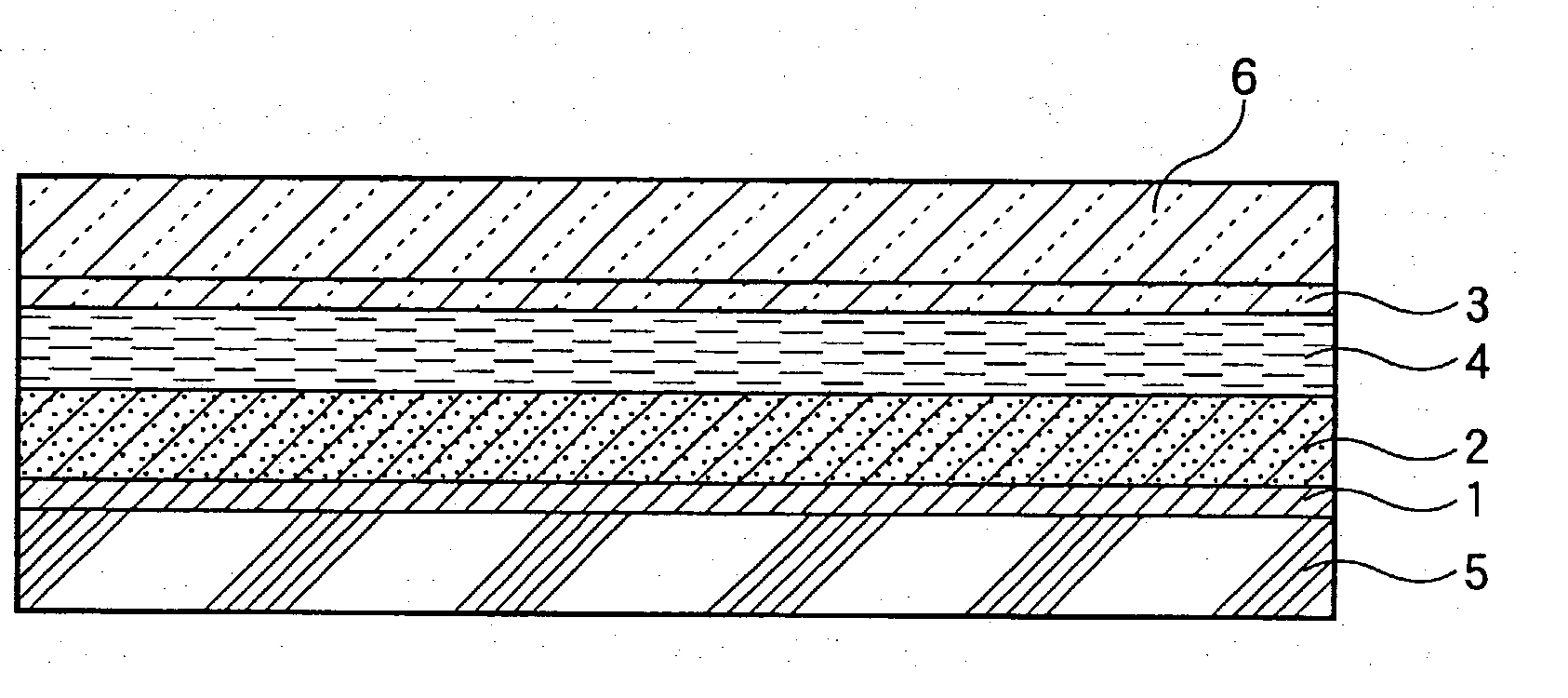

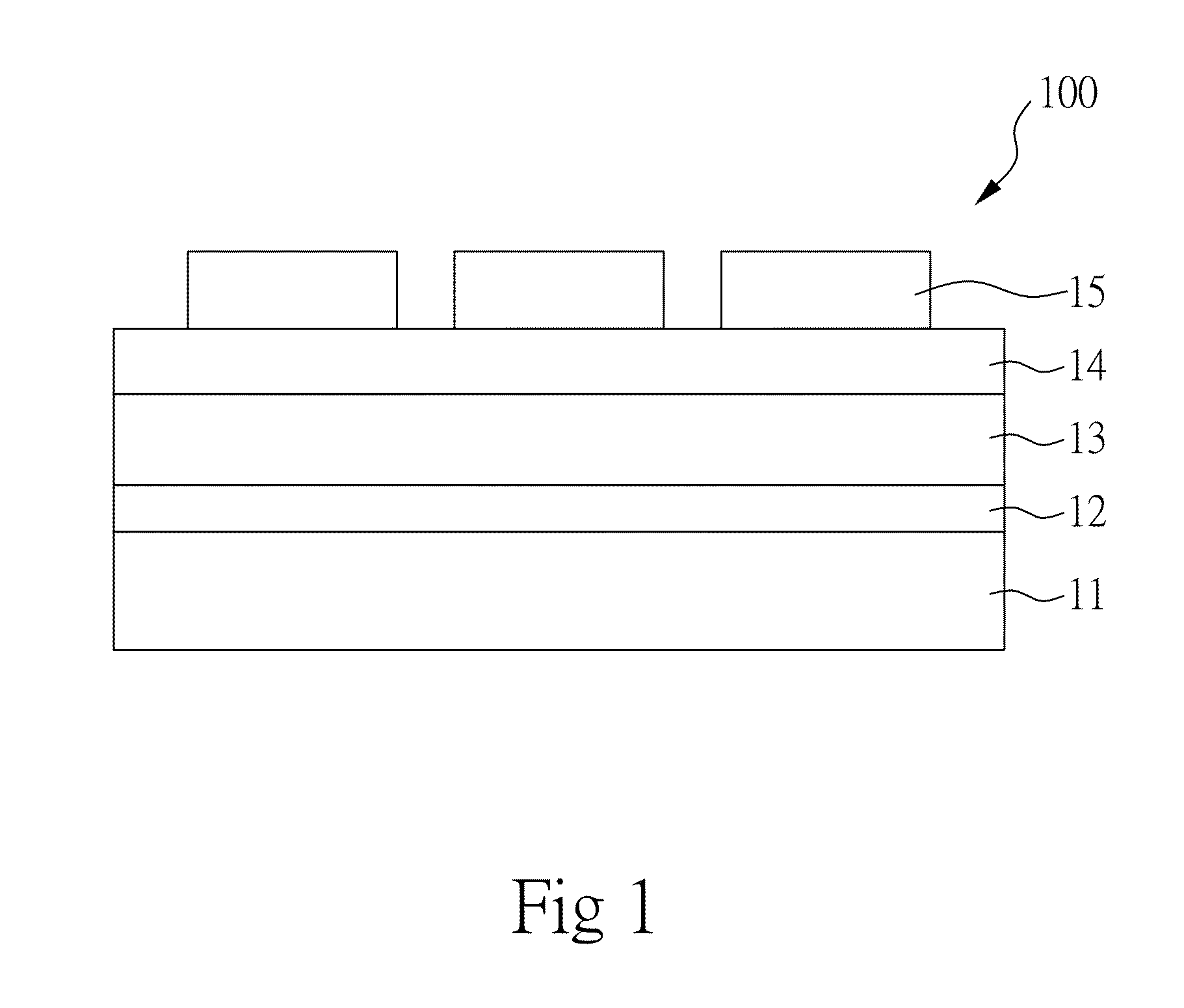

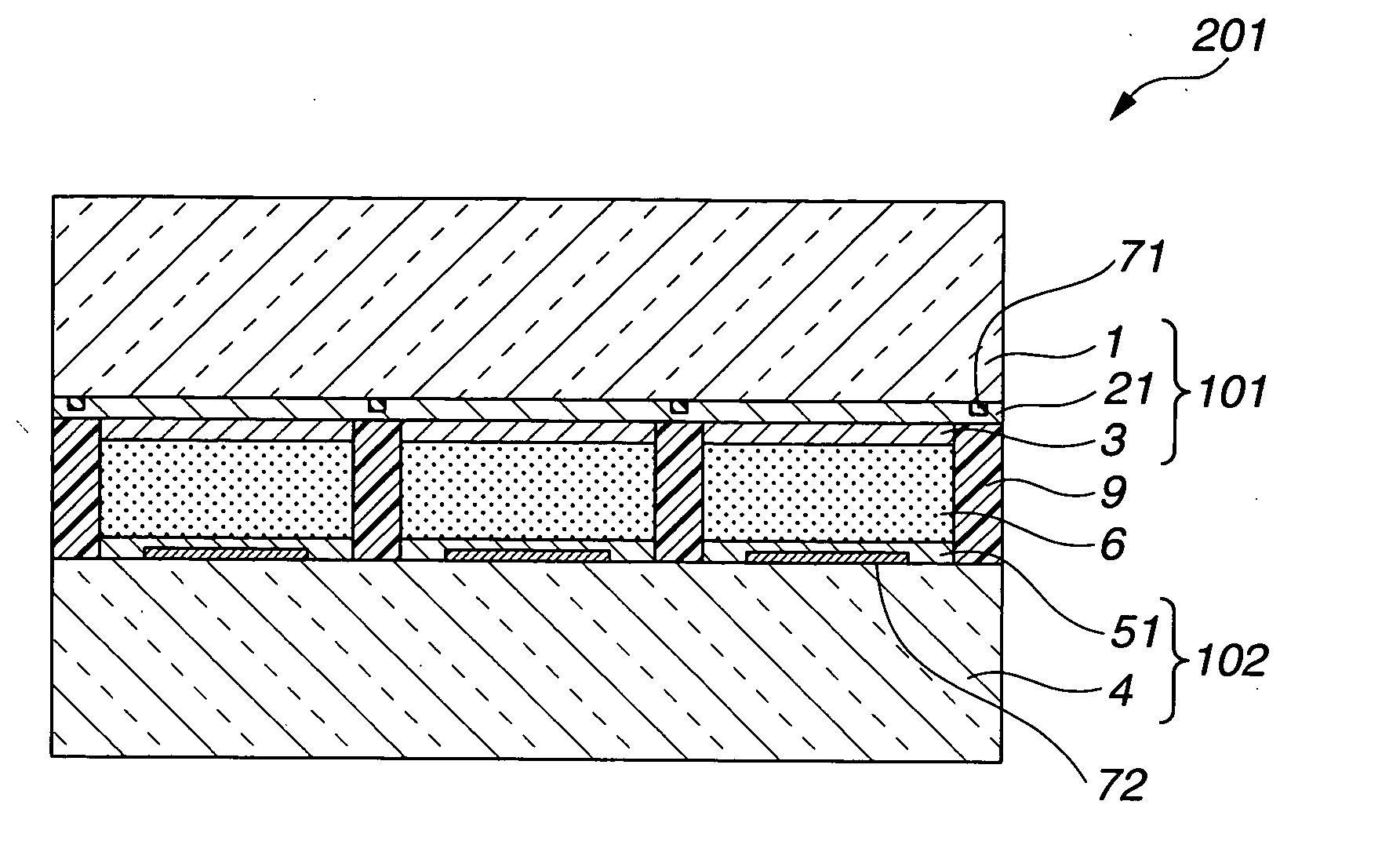

Photoelectric conversion element

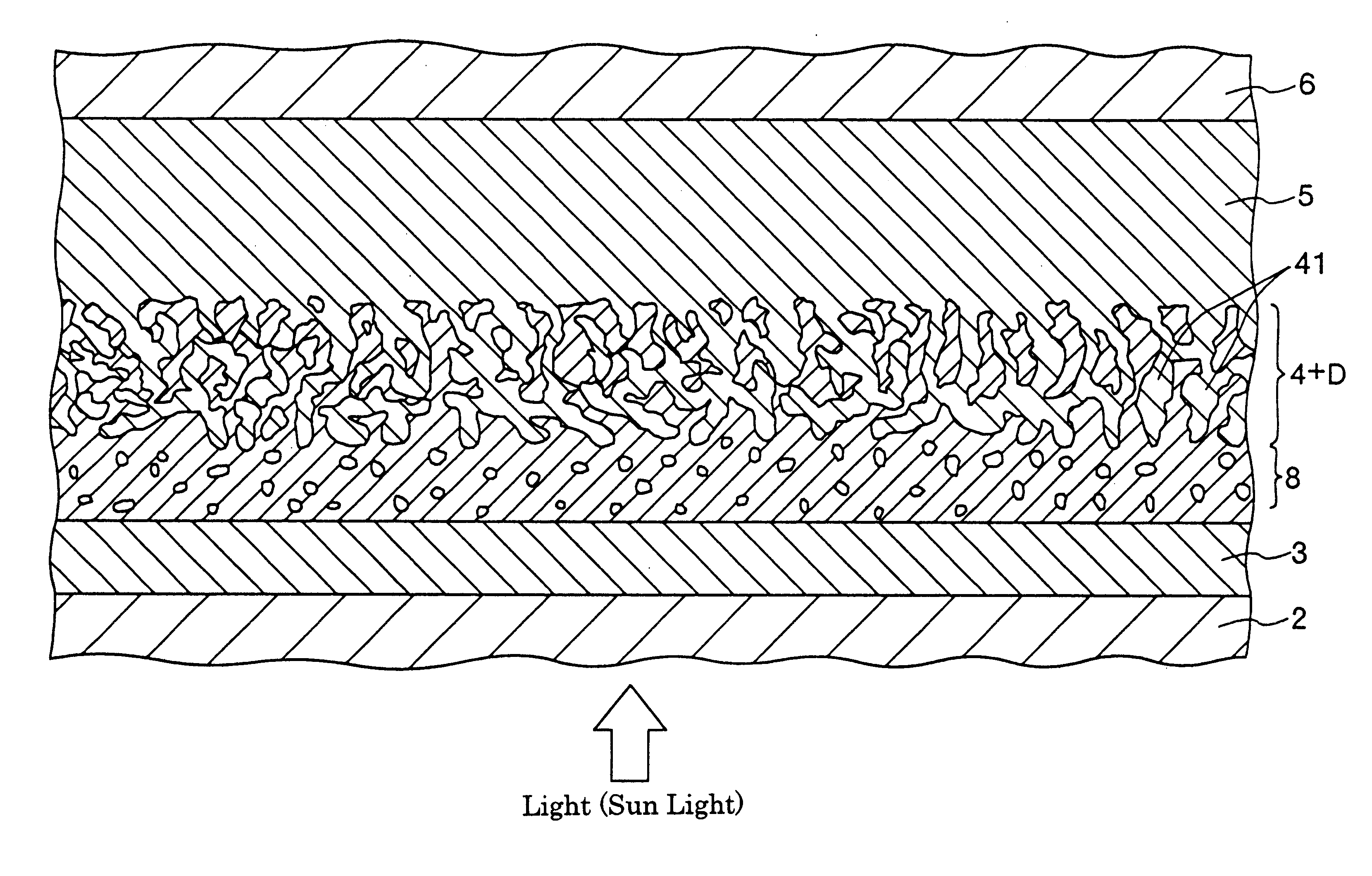

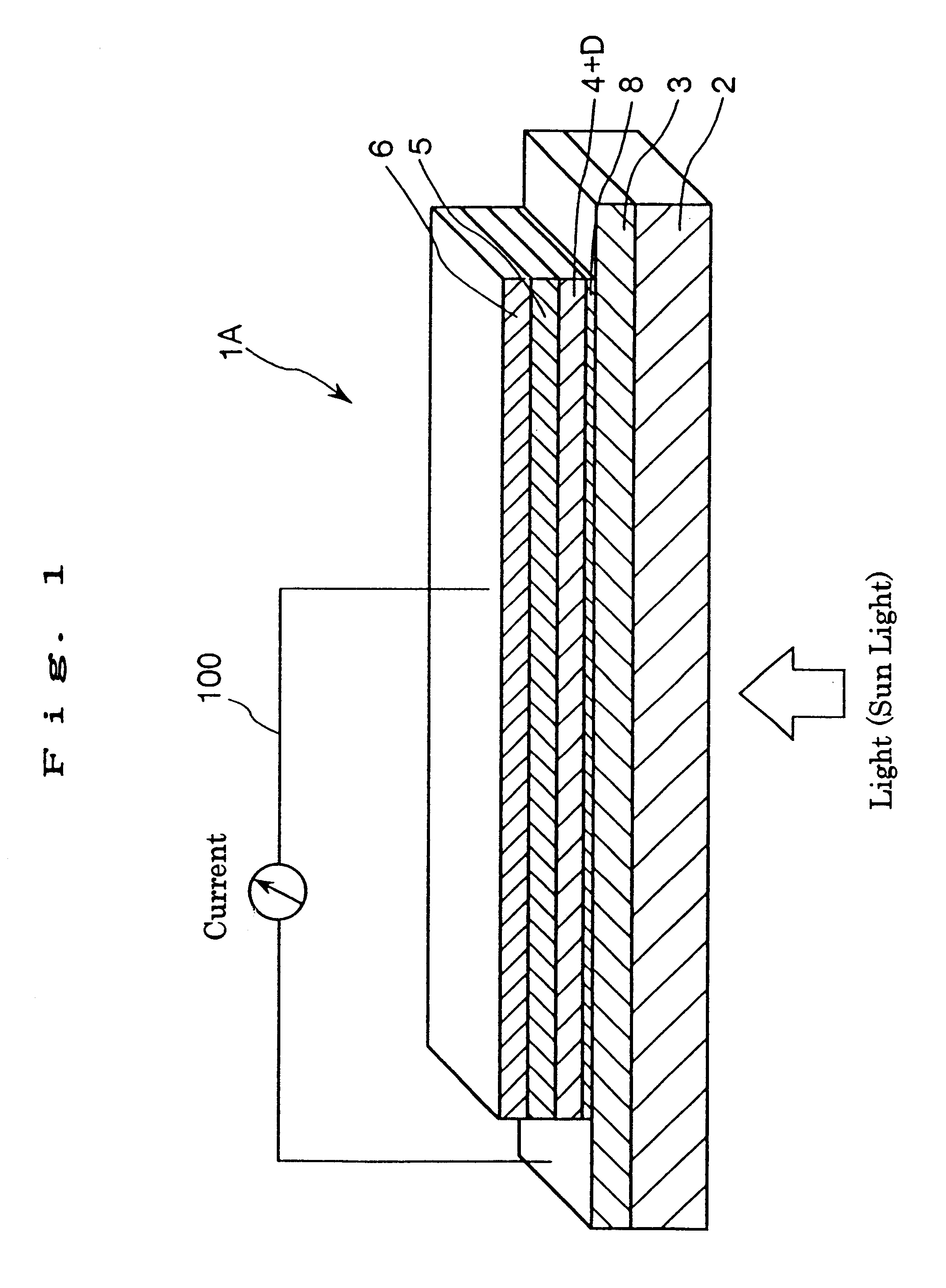

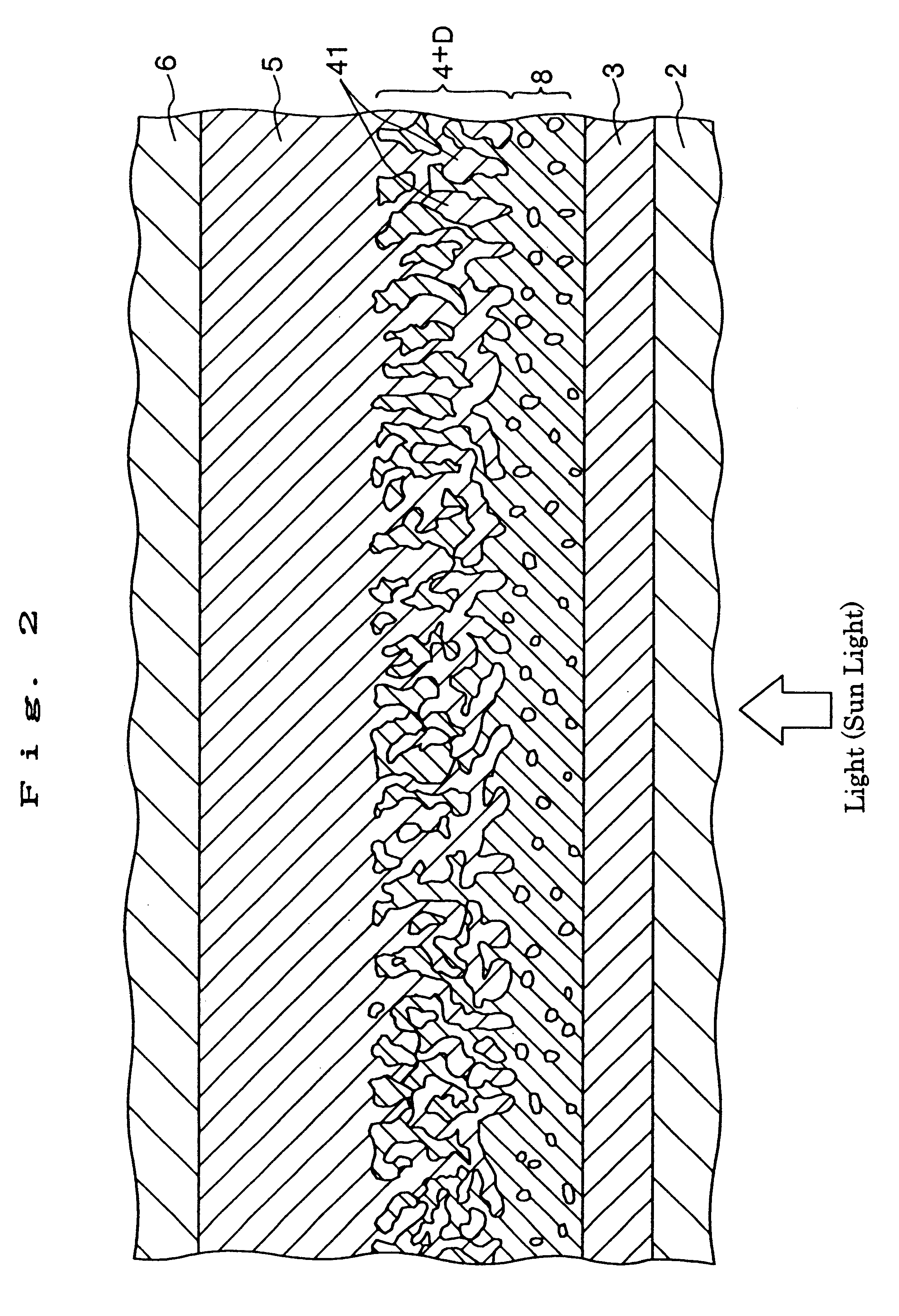

InactiveUS20020108649A1Improve photoelectric conversion efficiencyPrevent and suppressLight-sensitive devicesSolid-state devicesPorosityTransport layer

A solid type dye-sensitized photoelectric conversion element which is excellent in photoelectric conversion efficiency and which can be manufactured at a low cost is disclosed. The photoelectric conversion element can be applied to a so-called wet type solar cell which does not use any electrolyte. The solar cell comprises a first electrode 3, a second electrode 6 arranged opposite to the first electrode 3, an electron transport layer 4 arranged between the first electrode 3 and the second electrode 6, a dye layer D which is in contact with the electron transport layer 4, a hole transport layer 5 arranged between the electron transport layer 4 and the second electrode 6 and being in contact with the dye layer D, and a barrier layer 8, and these elements are provided on a substrate 2. The barrier layer 8 constitutes short-circuit preventing or suppressing means for preventing or suppressing short-circuit between the first electrode 3 and the hole transport layer 5. The porosity of the barrier layer is made smaller than that of the electron transport layer 4. The barrier layer is formed into a film-like shape and arranged between the fist electrode 4 and the electron transport layer 4. The solar cell can accomplish excellent photoelectric conversion efficiency by the provision of such a barrier layer 8.

Owner:SEIKO EPSON CORP

Passivation layer structure of solar cell and fabricating method thereof

InactiveUS20090165855A1Improve passivation effectImprove photoelectric conversion efficiencyFinal product manufactureCoatingsCarrier lifetimePhotoelectric conversion efficiency

A passivation layer structure of a solar cell, disposed on a substrate, is provided. The passivation layer structure has a first passivation layer and a second passivation layer. The first passivation layer is disposed on the substrate. The second passivation layer is disposed between the substrate and the first passivation layer, and the material of the second passivation layer is an oxide of the material of the substrate. Since the second passivation layer is disposed between the substrate and the first passivation layer, the surface passivation effect and carrier lifetime of a photoelectric device are enhanced, and a photoelectric conversion efficiency of the solar cell is increased as well.

Owner:IND TECH RES INST

Aluminum pulp composition of crystal silicon solar cell and preparation method thereof

InactiveCN101728439AEasy to printImprove adhesionFinal product manufactureNon-conductive material with dispersed conductive materialAdhesion forceAdhesive

The invention discloses an aluminum pulp composition of a crystal silicon solar cell and a preparation method thereof, wherein an aluminum pulp is prepared by the following compositions in percentage by weight: 50-85 percent of spherical aluminum powder, 2-15 percent of lead-free glass adhesive, 10-35 percent of organic carrier and 0.5-6 percent of metal / nonmetal power additive. The prepared aluminum pulp is used for a single crystal silicon solar cell, can enable warpage of a silicon wafer to be small, and aluminum films are dense and uniform, have no aluminum pills, do not bulb and have strong adhesion force and high photoelectric conversion efficiency.

Owner:LUOYANG SHENJIA ELECTRONICS CERAMICS

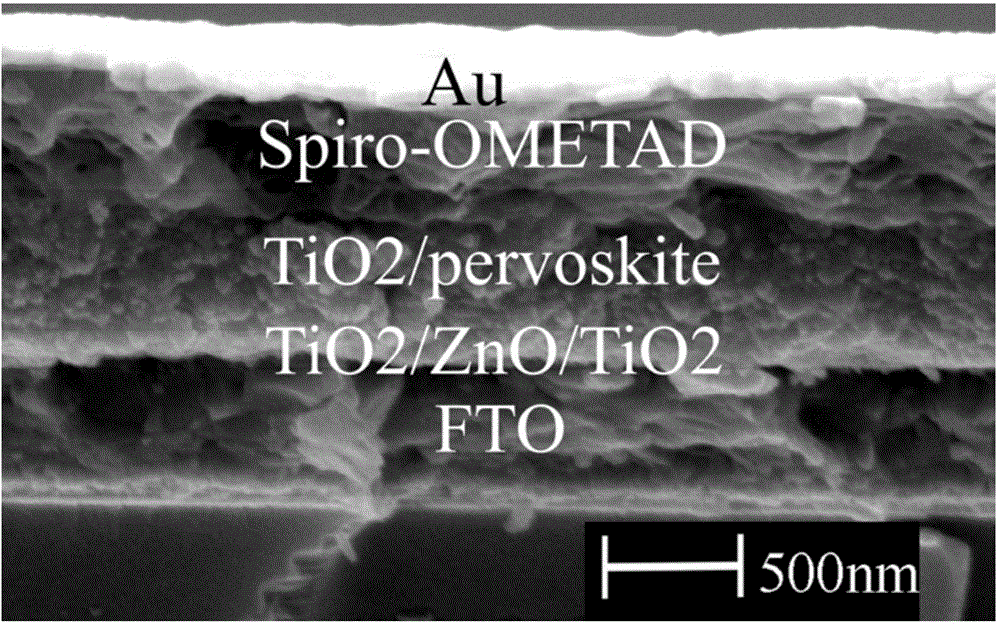

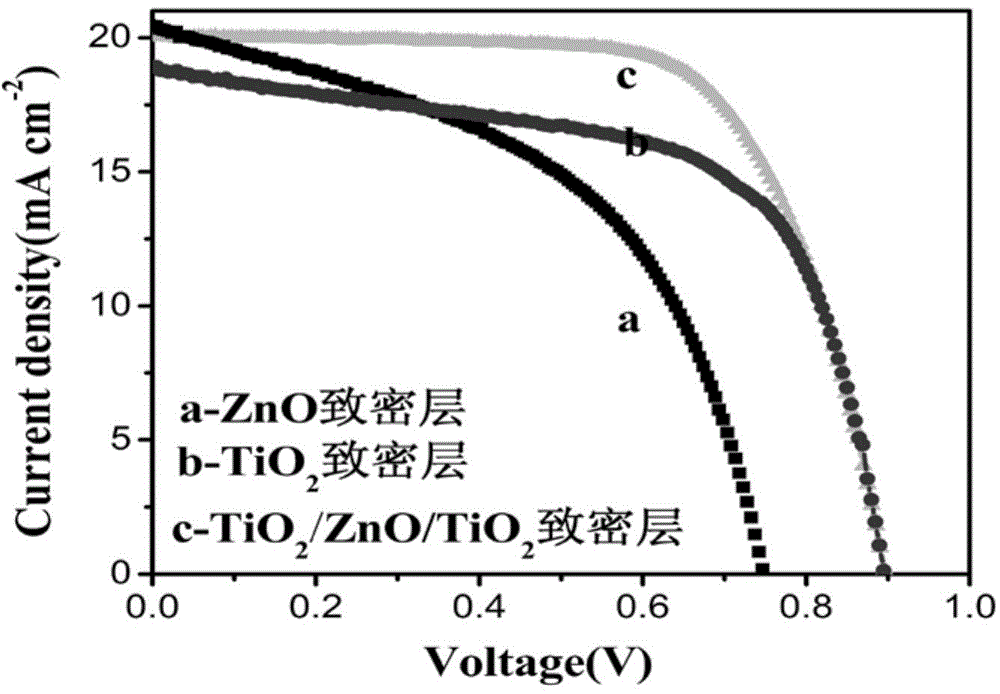

Perovskite solar cell and preparation method thereof

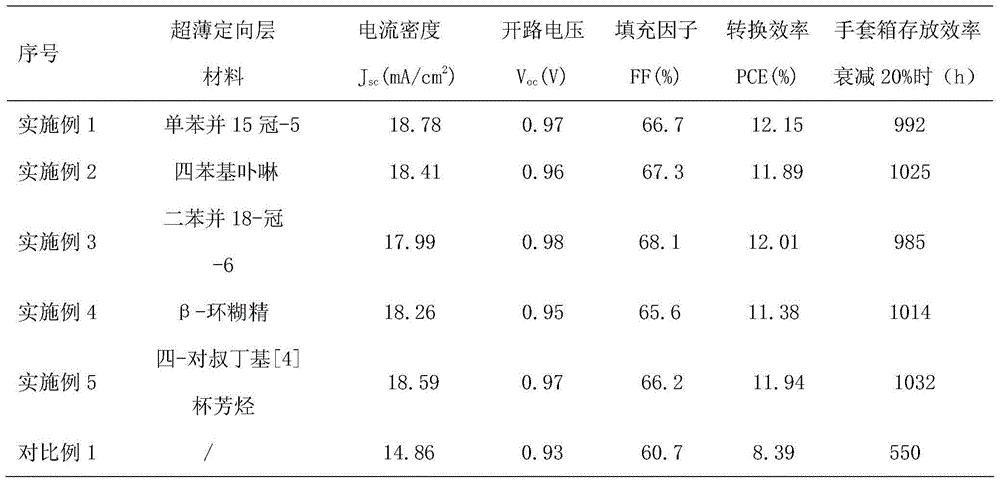

InactiveCN104091888AEasy to prepareControllable parametersSolid-state devicesSemiconductor/solid-state device manufacturingPerovskite solar cellFill factor

The invention relates to a perovskite solar cell and a preparation method thereof. The perovskite solar cell is composed of an FTO glass substrate, a sandwich structure TiO2 / ZnO / TiO2 compact layer, a TiO2 mesoporous / perovskite structure material active light absorption layer, a spiro-OMeTAD hole transferring layer and a gold electrode. Compared with the prior art, the sandwich structure TiO2 / ZnO / TiO2 compact layer combines with the advantages and disadvantages of TiO2 and ZnO, so that fill factors of the perovskite solar cell are improved to 70%, and the photoelectric conversion efficiency reaches 12.6%. Equipment for preparing the perovskite solar cell is simple, the preparing process is simple, control is easy, the cost is low, and the perovskite solar cell has a very good industrial application prospect.

Owner:HUBEI UNIV

Carbon nanotube film based solar cell and fabricating method thereof

InactiveUS20100078067A1Improve conversion efficiencyWide rangeFinal product manufactureNanoinformaticsFilm baseCarbon nanotube

A carbon nanotube-based solar cell and fabricating method thereof are provided. The method is achieved by applying carbon nanotube film (1) photoelectric conversion material and an upper electrode simultaneously. The method improves photoelectric conversion efficiency and life time of the solar cell, the fabricating method of the solar cell is simple, and the fabricating cost is low.

Owner:TSINGHUA UNIV

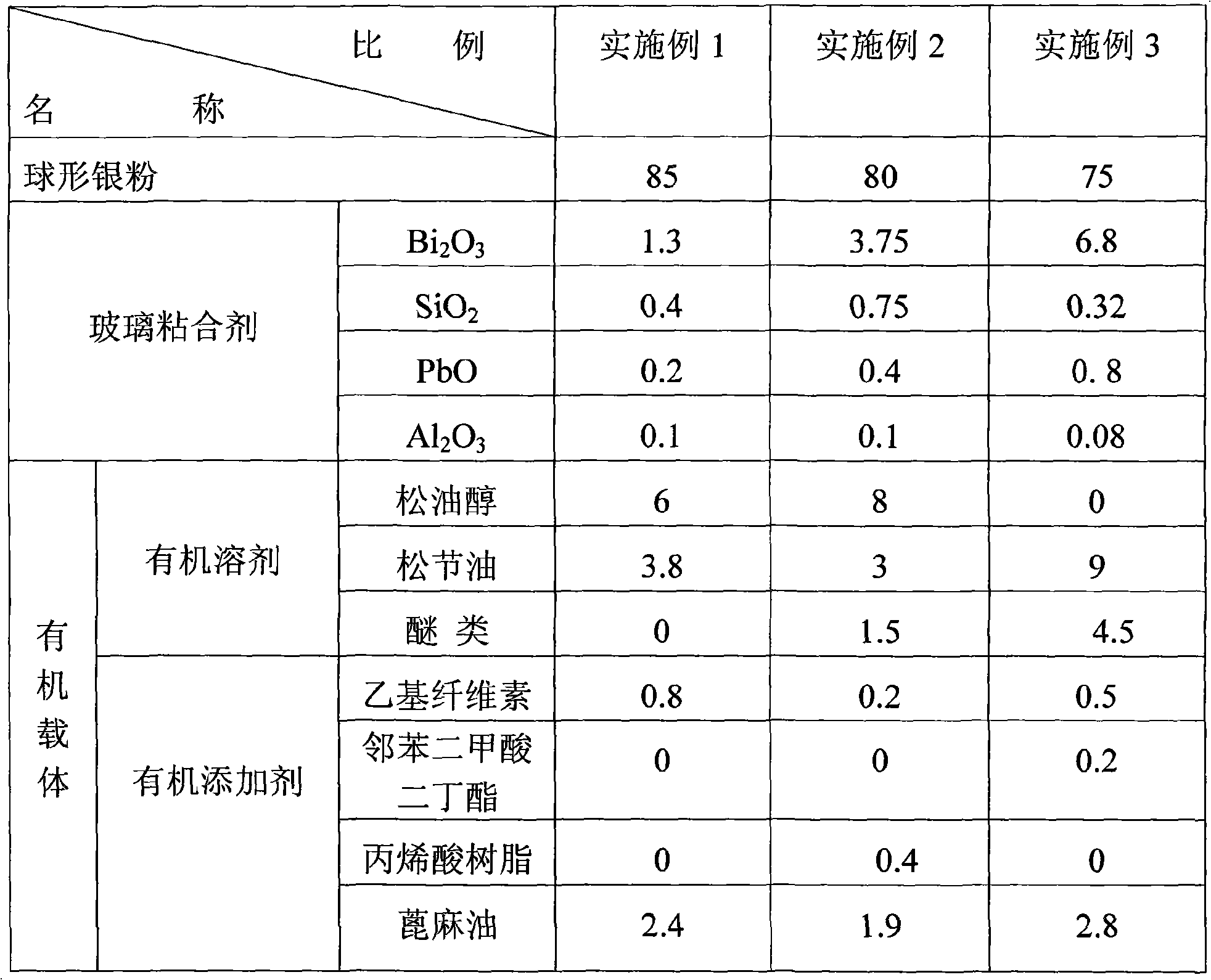

High-viscosity solar cell front side silver paste and method for producing the same

InactiveCN101271928AIncrease aspect ratioImprove photoelectric conversion efficiencyFinal product manufactureNon-conductive material with dispersed conductive materialScreen printingSilver paste

The invention relates to a high viscosity solar cell front silver serum and a preparation method thereof. The composition and the weight ratio of the high viscosity solar cell front silver serum are that conductive silver powder accounts for 75-85 percent, glass glue accounts for 2-10 percent, organic carrier accounts for 5.5-20 percent, the particle size of the conductive silver powder is 0.2-2mum; the composition and the weight ratio of the glass glue are that Bi2O3 accounts for 65-85 percent, SiO2 accounts for 5-20 percent, PbO accounts for 1-15 percent and Al2O3 accounts for 1-5 percent. After such processes are carried out by the serum as screen printing, low temperature drying and high temperature sintering, the aspect ratio of a conducting electrode formed on the surface of solar cell is high, the solar cell produced by using the method has small front shading area and high photoelectric conversion efficiency.

Owner:EGING PHOTOVOLTAIC TECHNOLOGY CO LTD

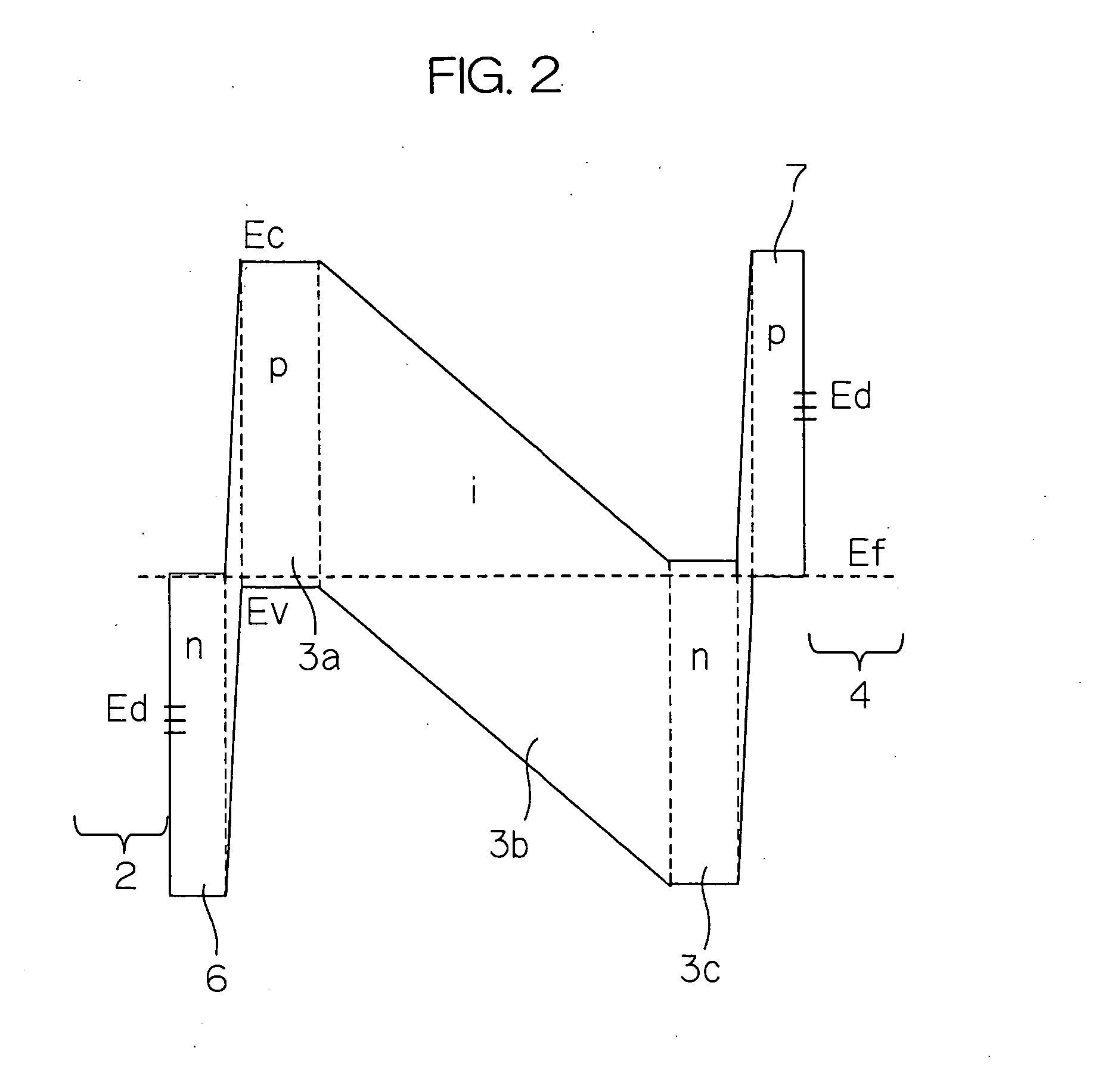

Semiconductor/electrode contact structure and semiconductor device using the same

InactiveUS20050012095A1Reduce recombination rateLow densitySuperconductor devicesPhotovoltaic energy generationSemiconductor electrodeDevice material

In a photoelectric conversion device, in a contact between a p-type semiconductor 3a and an electrode 2, an n-type semiconductor 6 of a conductivity type opposite to that of the p-type semiconductor is provided between the p-type semiconductor 3a and the electrode 2. The existence of the n-type semiconductor 6 allows a recombination rate of photo-generated carriers excited by incident light to be effectively reduced, and allows a dark current component to be effectively prevented from being produced. Therefore, it is possible to improve photoelectric conversion efficiency as well as to stabilize characteristics. Further, a tunnel junction is realized by increasing the concentration of a doping element in at least one or preferably both of the p-type semiconductor 3a and the n-type semiconductor 6 in a region where they are in contact with each other, thereby keeping ohmic characteristics between the semiconductor and the electrode good.

Owner:KYOCERA CORP

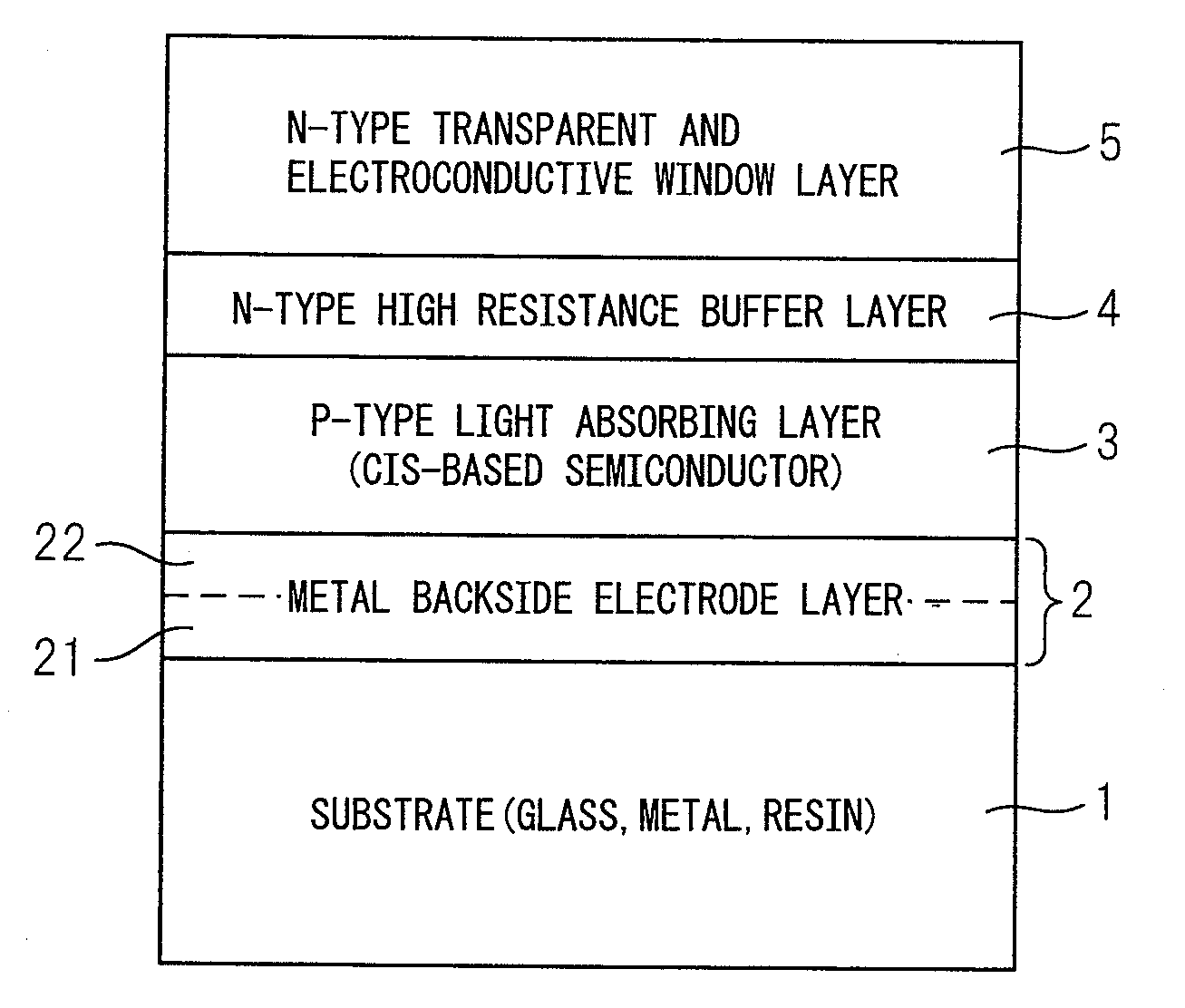

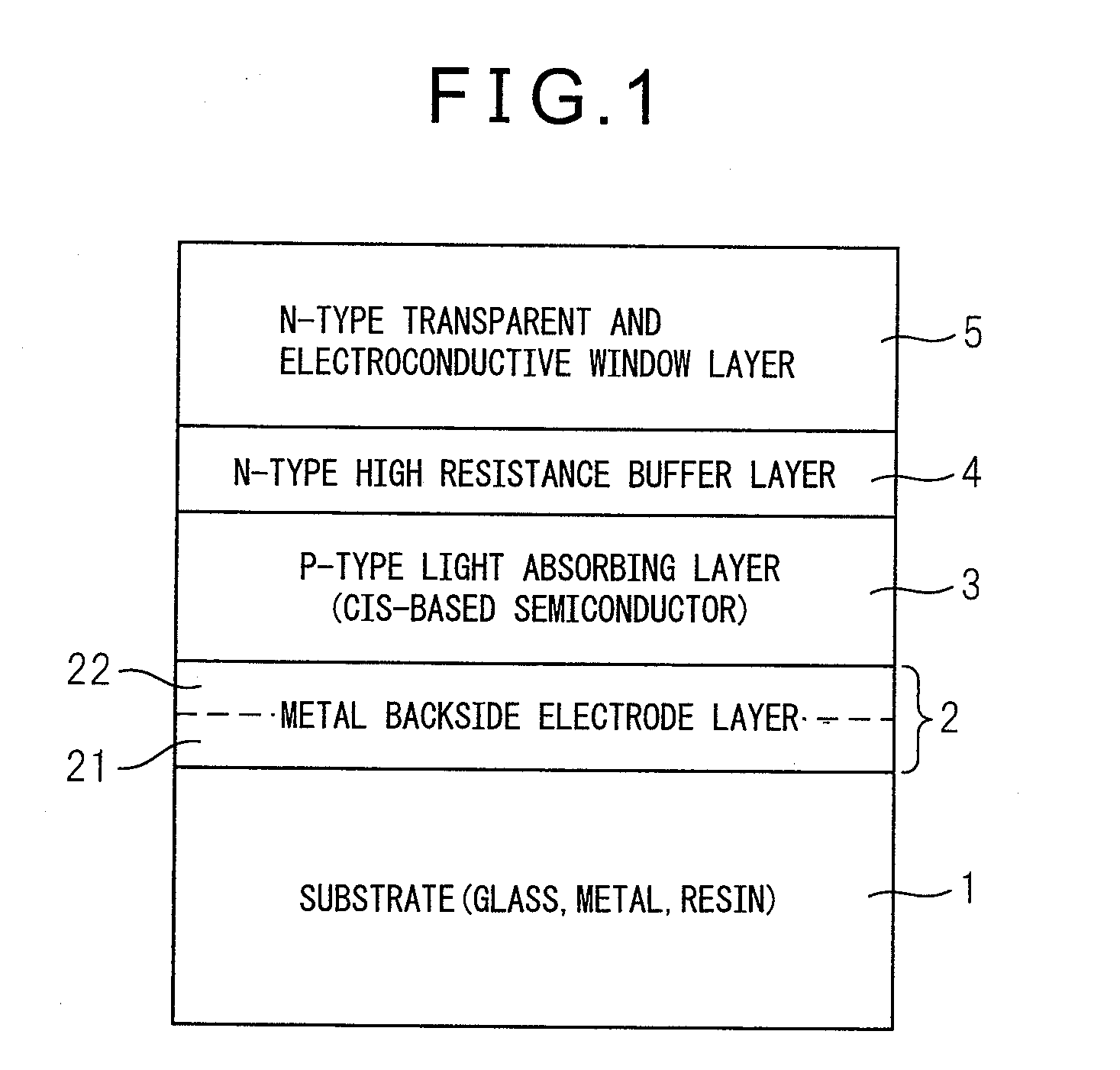

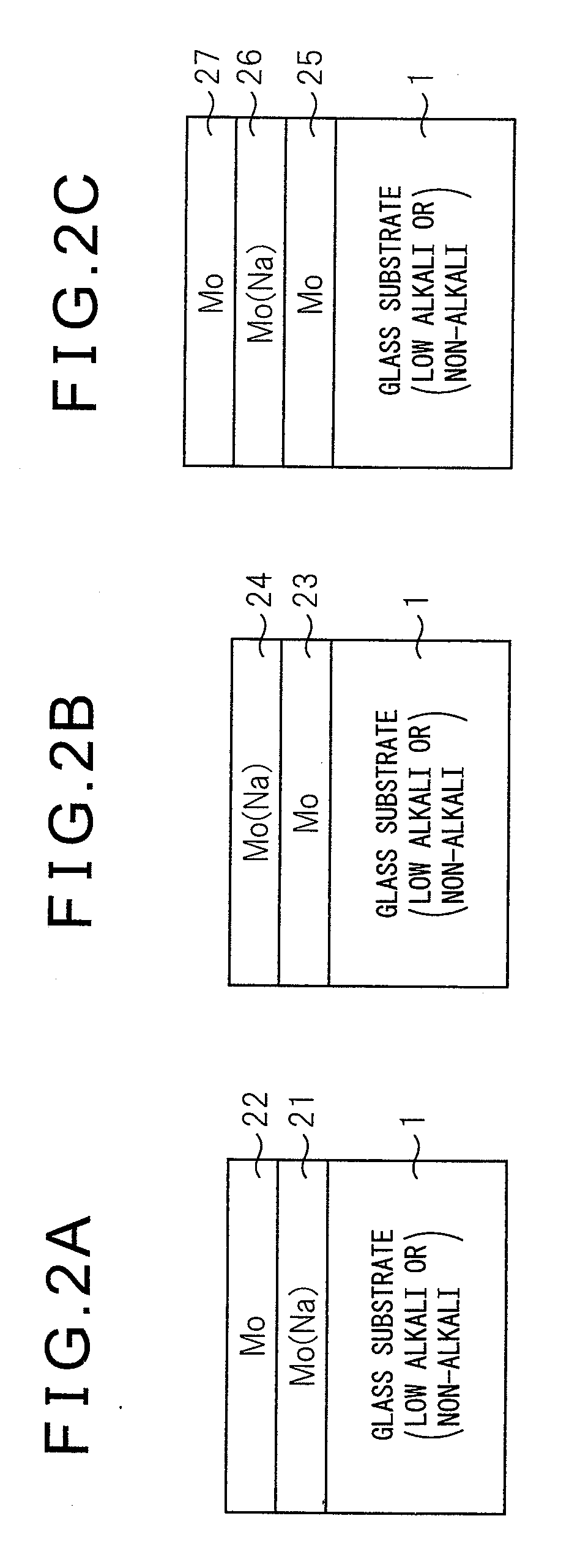

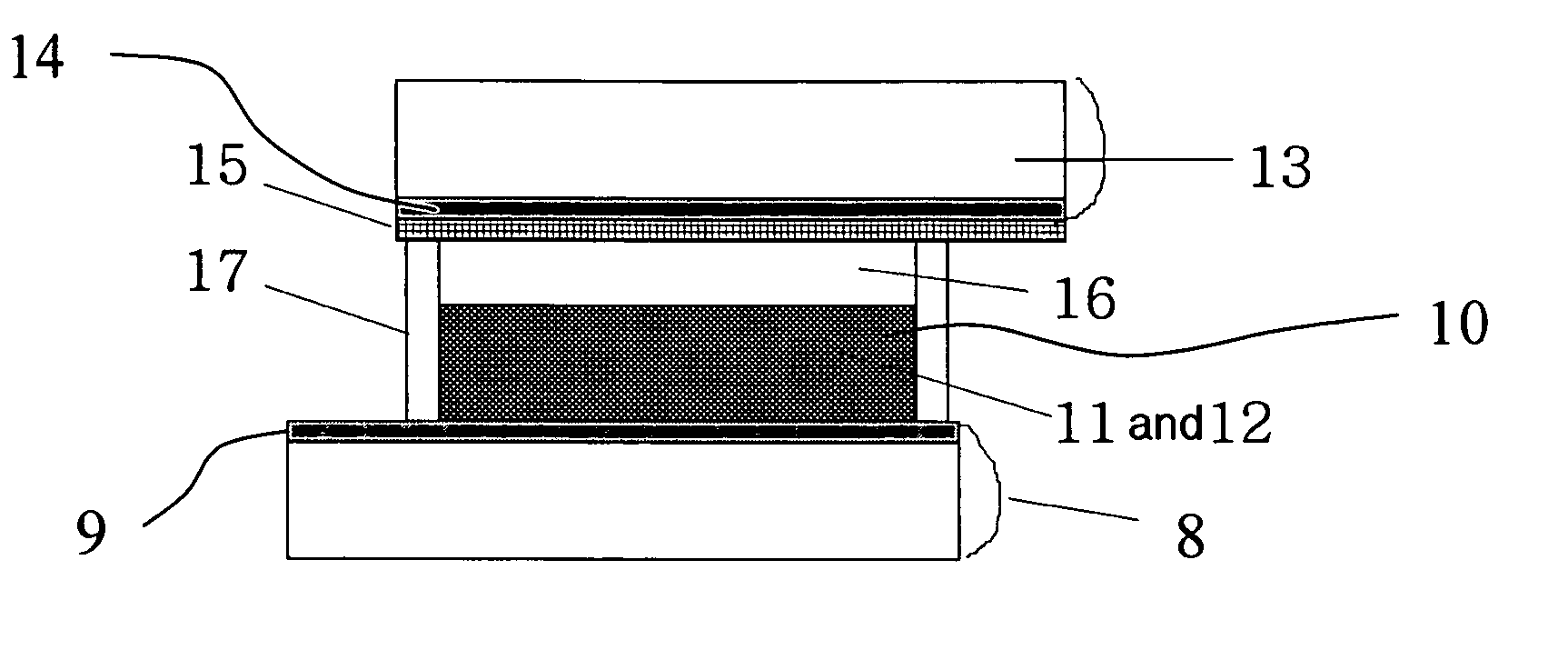

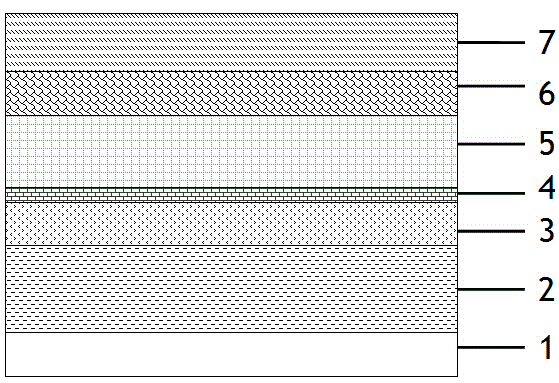

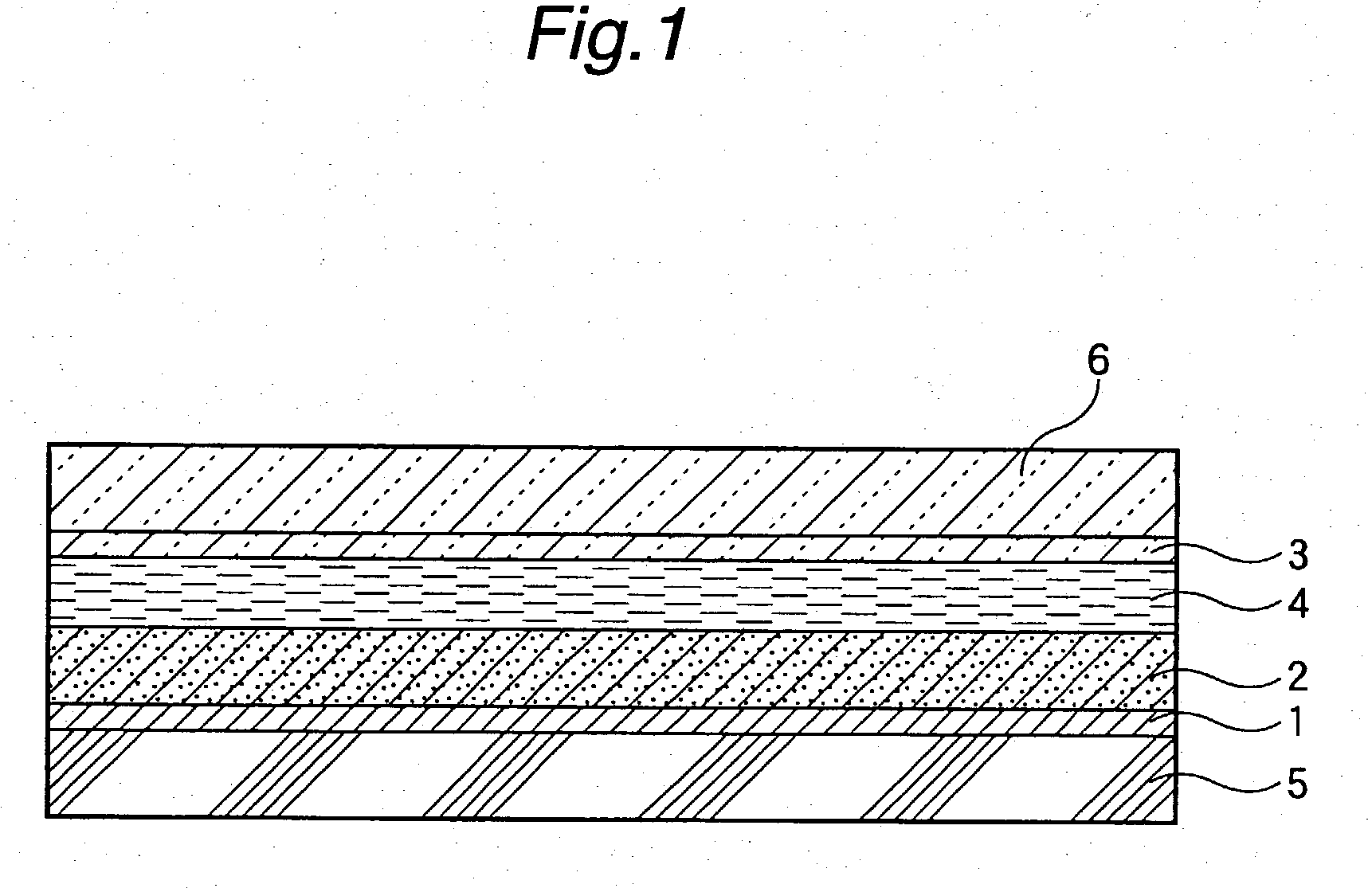

Method for manufacturing cis-based thin film solar cell

ActiveUS20100210064A1Low costIncrease temperatureFinal product manufactureSemiconductor/solid-state device manufacturingTransparent conducting filmControllability

In order to manufacture a CIS-based thin film solar cell that can achieve high photoelectric conversion efficiency by adding an alkali element to a light absorbing layer easily and with good controllability, a backside electrode layer (2) is formed on a substrate (1). Then, a p-type CIS-based light absorbing layer (3) is formed on backside electrode layer (2), and then an n-type transparent and electroconductive film (5) is formed on this p-type CIS-based light absorbing layer (3). At this time, the backside electrode layer (2) is constituted by forming a first electrode layer (21) using a backside electrode material in which an alkali metal is mixed and, then forming a second electrode layer (22) using the backside electrode material that does not substantially contain the alkali metal.

Owner:SOLAR FRONTIER

Electrode for photoelectric conversion device containing metal element and dye-sensitized solar cell using the same

InactiveUS20070028959A1Reduce surface resistanceElectrolytic capacitorsSolid-state devicesEngineeringPhotoelectric conversion

An electrode for a photoelectric conversion device includes a transparent substrate and a transparent conductive film, in which the transparent conductive film contains an added metal element on at least one surface thereof, and the surface resistance of the transparent substrate is reduced in order to improve the photoelectric conversion efficiency. A dye-sensitized solar cell includes the electrode.

Owner:SAMSUNG SDI CO LTD

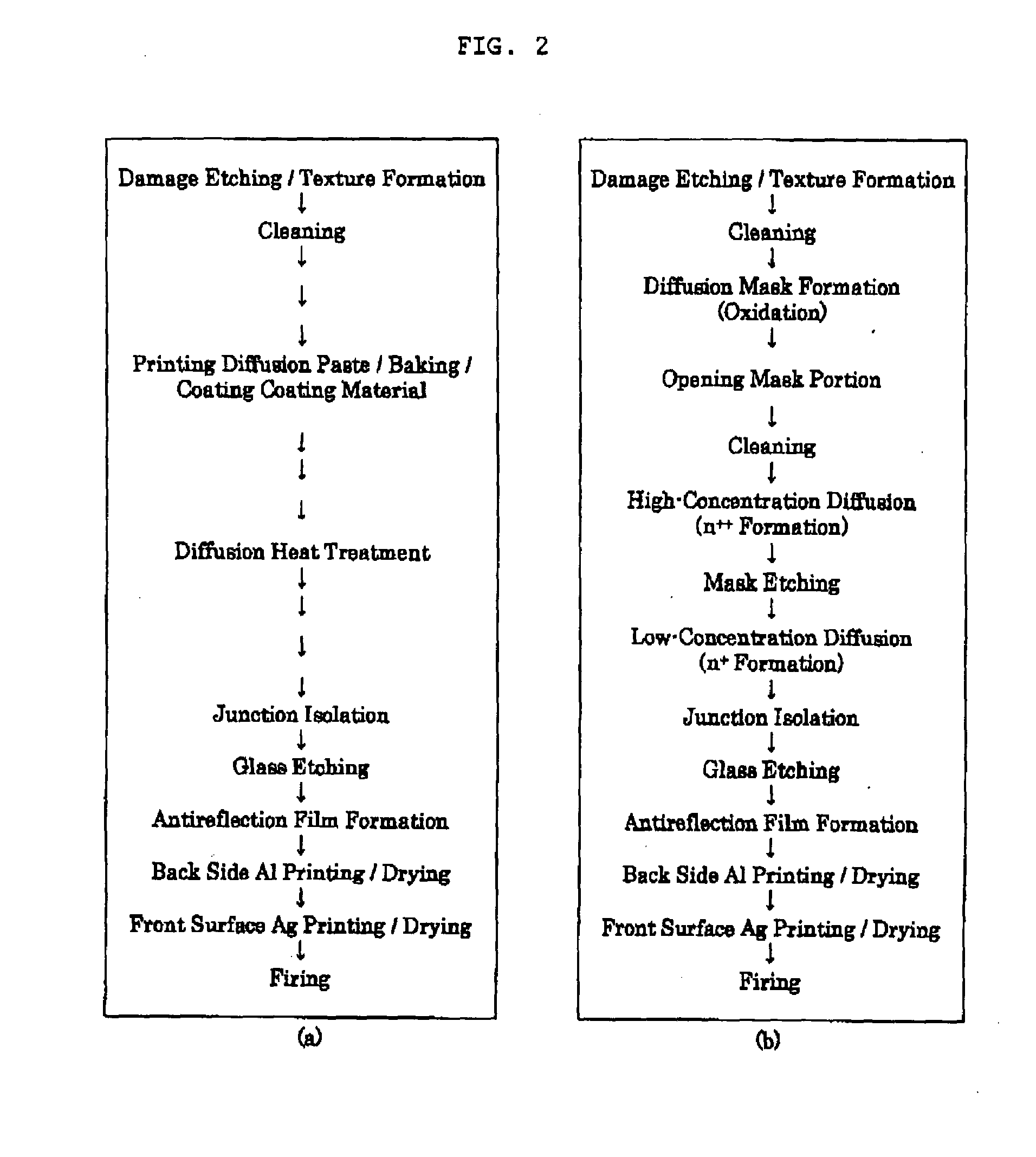

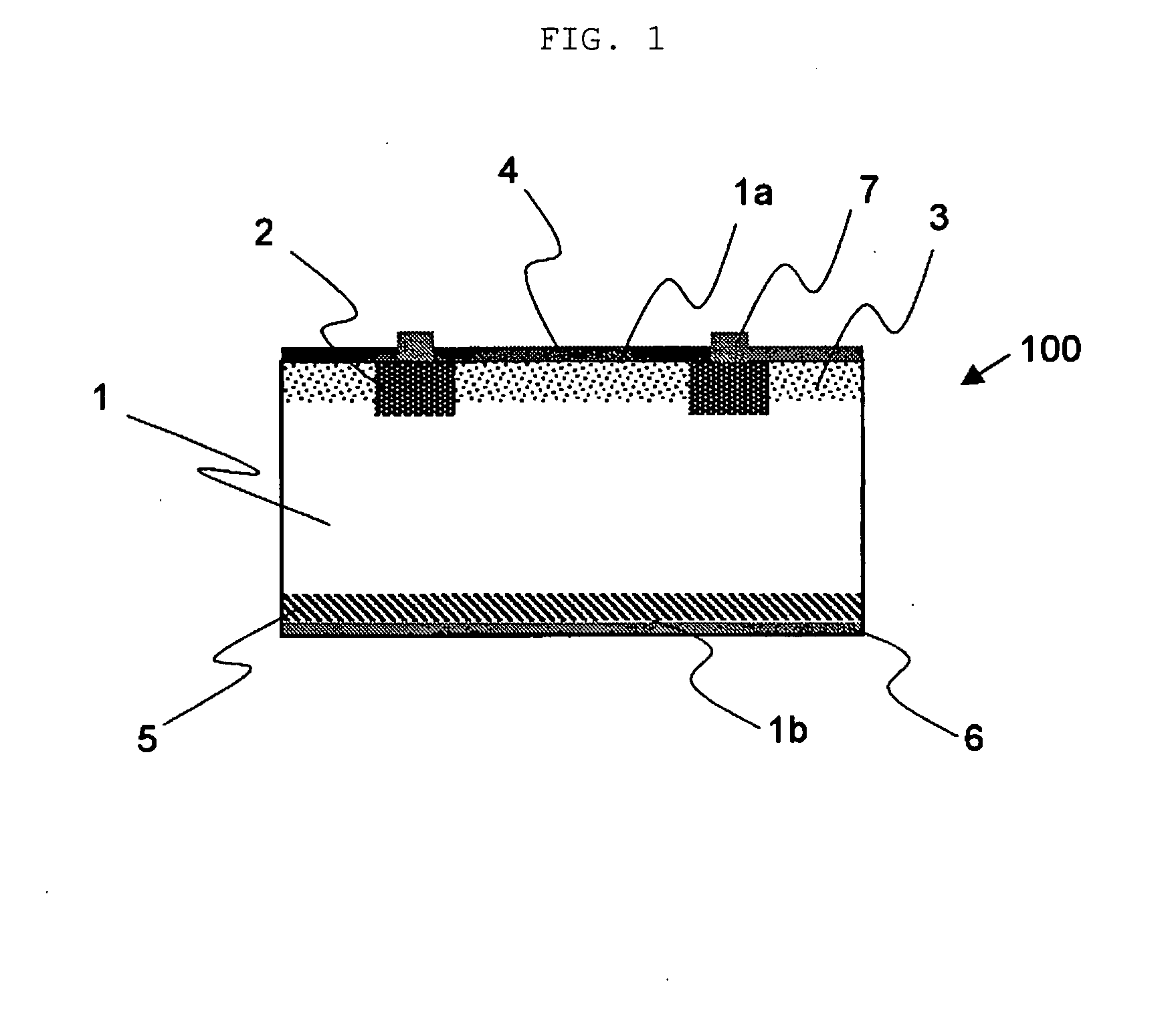

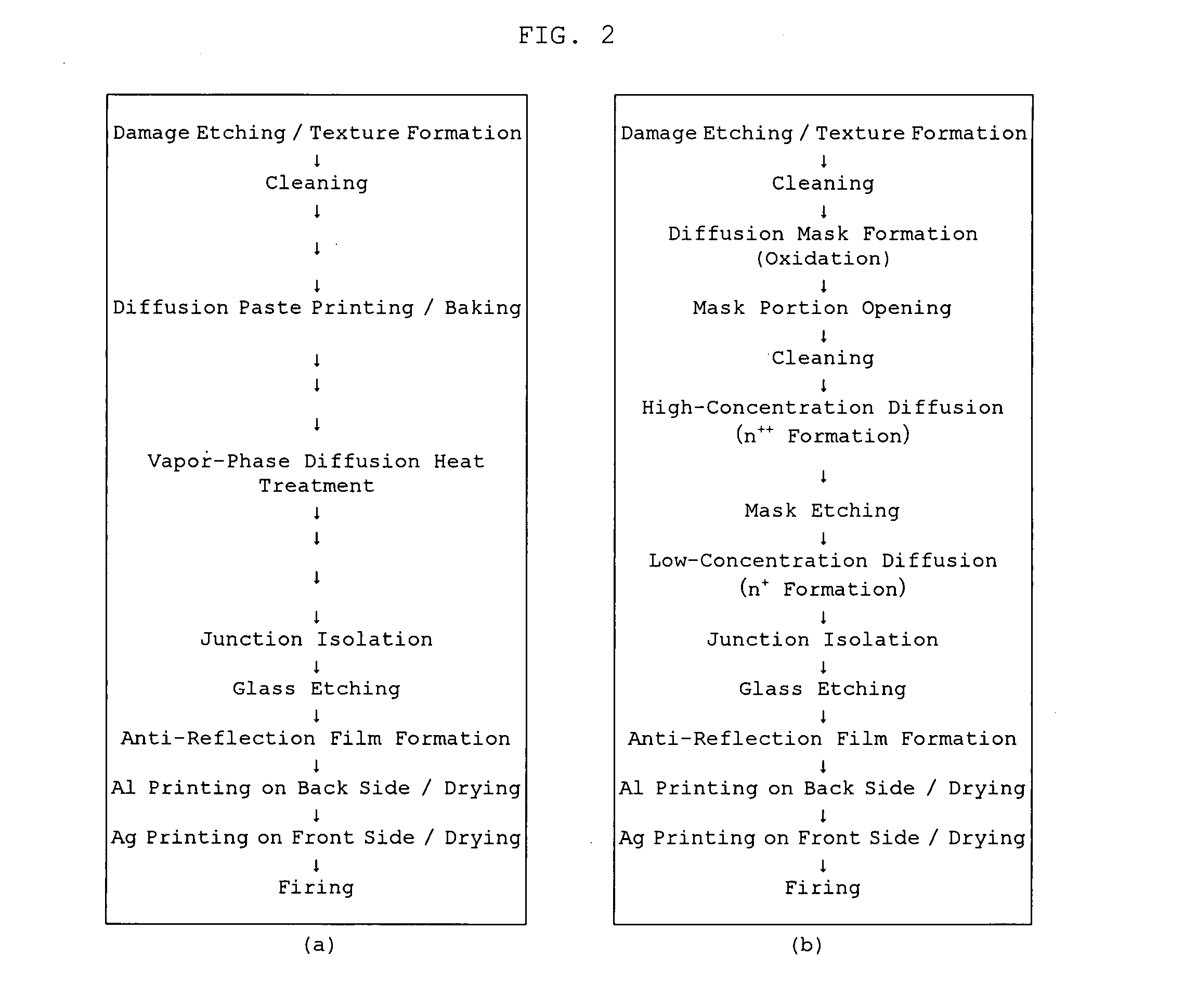

Method for manufacturing solar cell and solar cell, and method for manufacturing semiconductor device

InactiveUS20090020158A1Convenient coatingEasy to implementSemiconductor/solid-state device manufacturingWater-setting substance layered productDiffusionDopant

The present invention is a method for manufacturing a solar cell by forming a p-n junction in a semiconductor substrate having a first conductivity type, wherein, at least: a first coating material containing a dopant and an agent for preventing a dopant from scattering, and a second coating material containing a dopant, are coated on the semiconductor substrate having the first conductivity type so that the second coating material may be brought into contact with at least the first coating material; and, a first diffusion layer formed by coating the first coating material, and a second diffusion layer formed by coating the second coating material the second diffusion layer having a conductivity is lower than that of the first diffusion layer are simultaneously formed by a diffusion heat treatment; a solar cell manufactured by the method; and a method for manufacturing a semiconductor device. It is therefore possible to provide the method for manufacturing the solar cell, which can manufacture the solar cell whose photoelectric conversion efficiency is improved at low cost and with a simple and easy method by suppressing surface recombination in a portion other than an electrode of a light-receiving surface and recombination within an emitter while obtaining ohmic contact; the solar cell manufactured by the method; and the method for manufacturing the semiconductor device.

Owner:SHIN-ETSU HANDOTAI CO LTD +2

Paste for forming solar battery electrode

InactiveCN101609847AConversion efficiency is not affectedConversion efficiency impactFinal product manufactureNon-conductive material with dispersed conductive materialElectrical resistance and conductanceBack surface field

The invention discloses paste for forming solar battery electrode, which comprises the following components by mass percent: 65 to 75 percent of aluminum powder, 20 to 30 percent of organic carrier, 0.2 to 6 percent of inorganic glass powder and 0.5 to 1 percent of functional additive. The aluminum powder comprises at least two types, the average particle diameter of one type of the aluminum powder is smaller than 2 micro meters and the mass of the type of the aluminum powder is 1 to 10 percent of that of the aluminum powder. The paste can form back surface field effect required by a solar battery with a silicon substrate, and has the advantages that the electrical conductivity is good, the contact resistance is low, the adhering to the silicon substrate is firm, the silicon substrate is slightly bent, and the open-circuit voltage of the solar battery and the photoelectric conversion efficiency are high.

Owner:RES INST OF XIAN JIAOTONG UNIV & SUZHOU

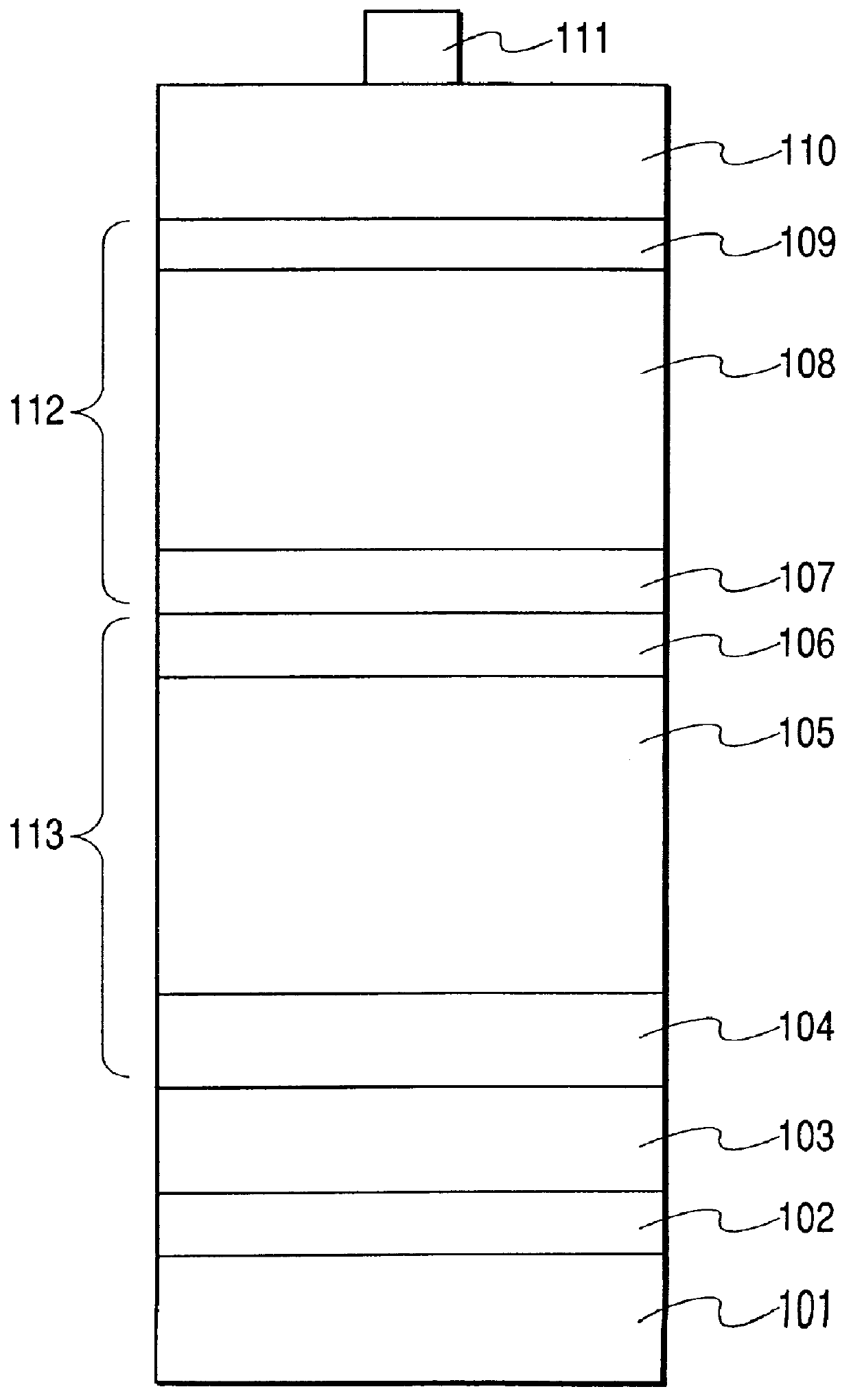

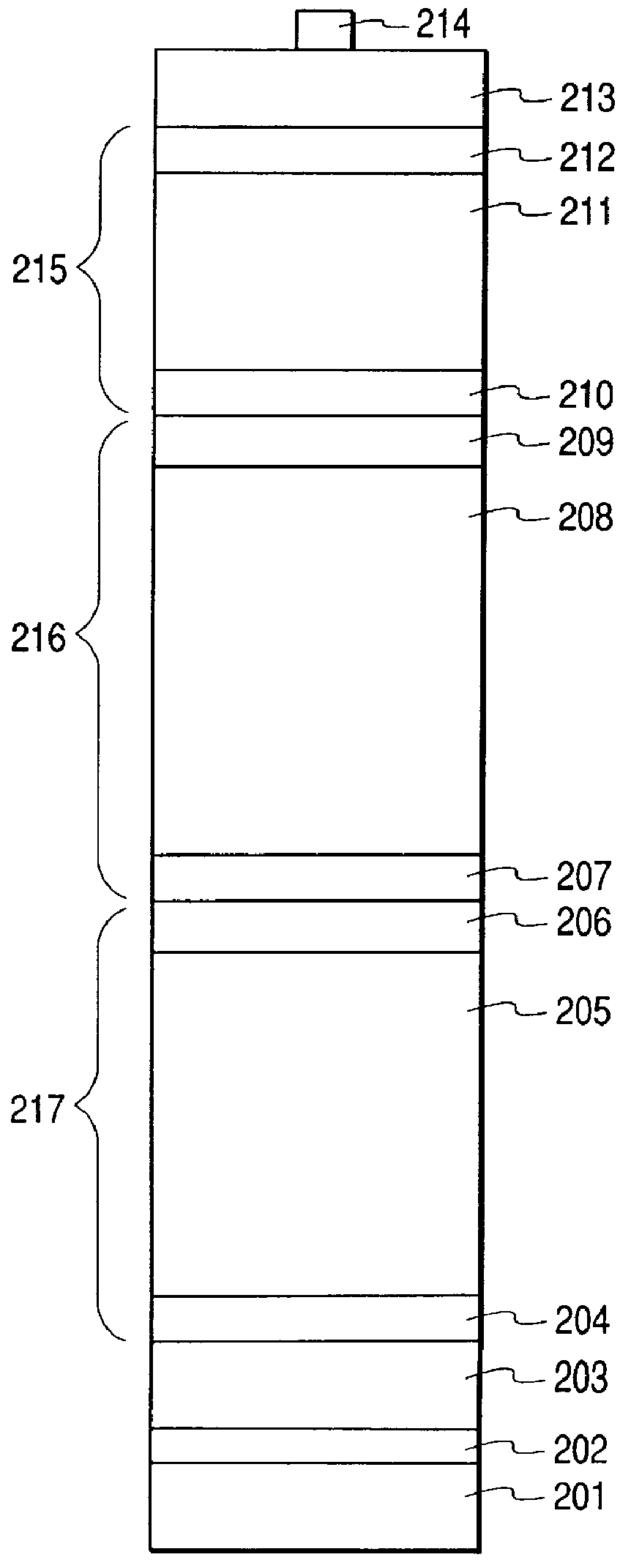

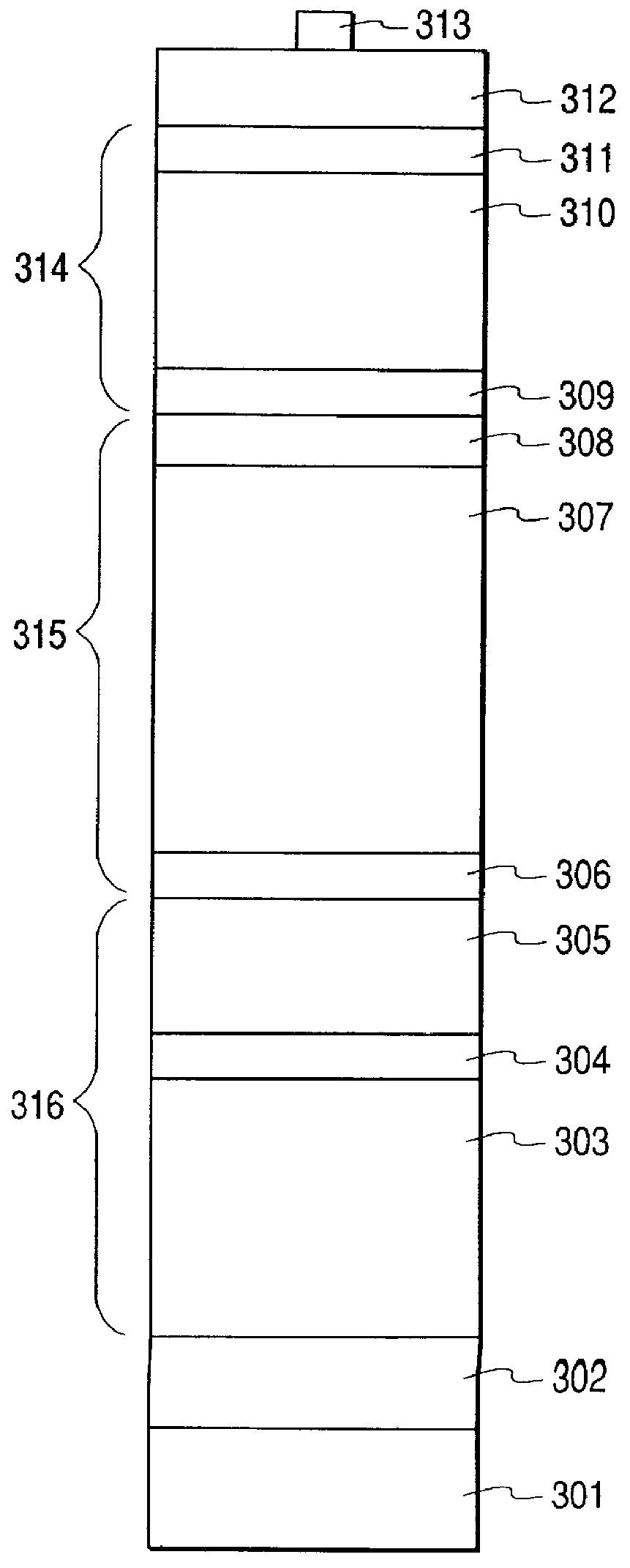

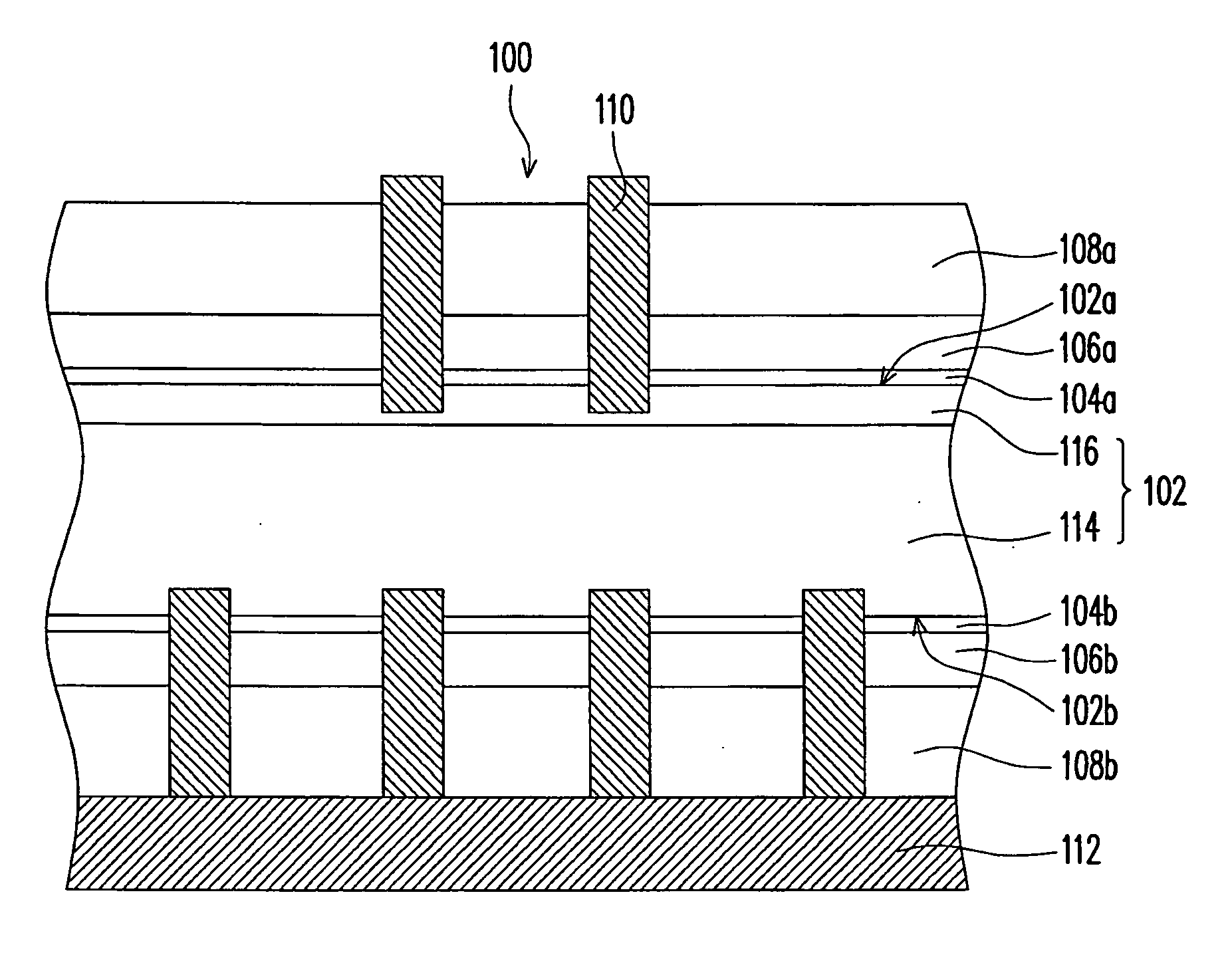

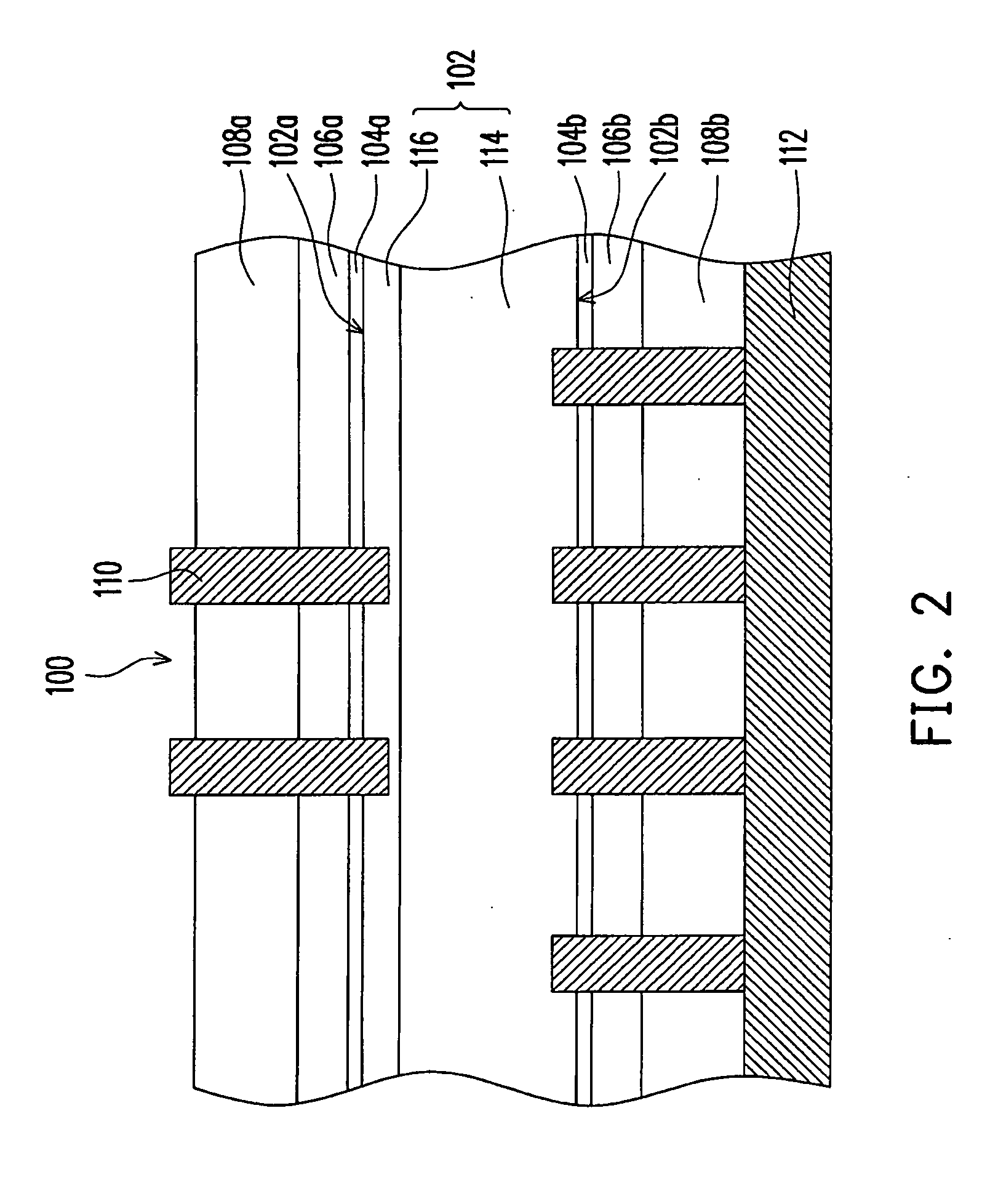

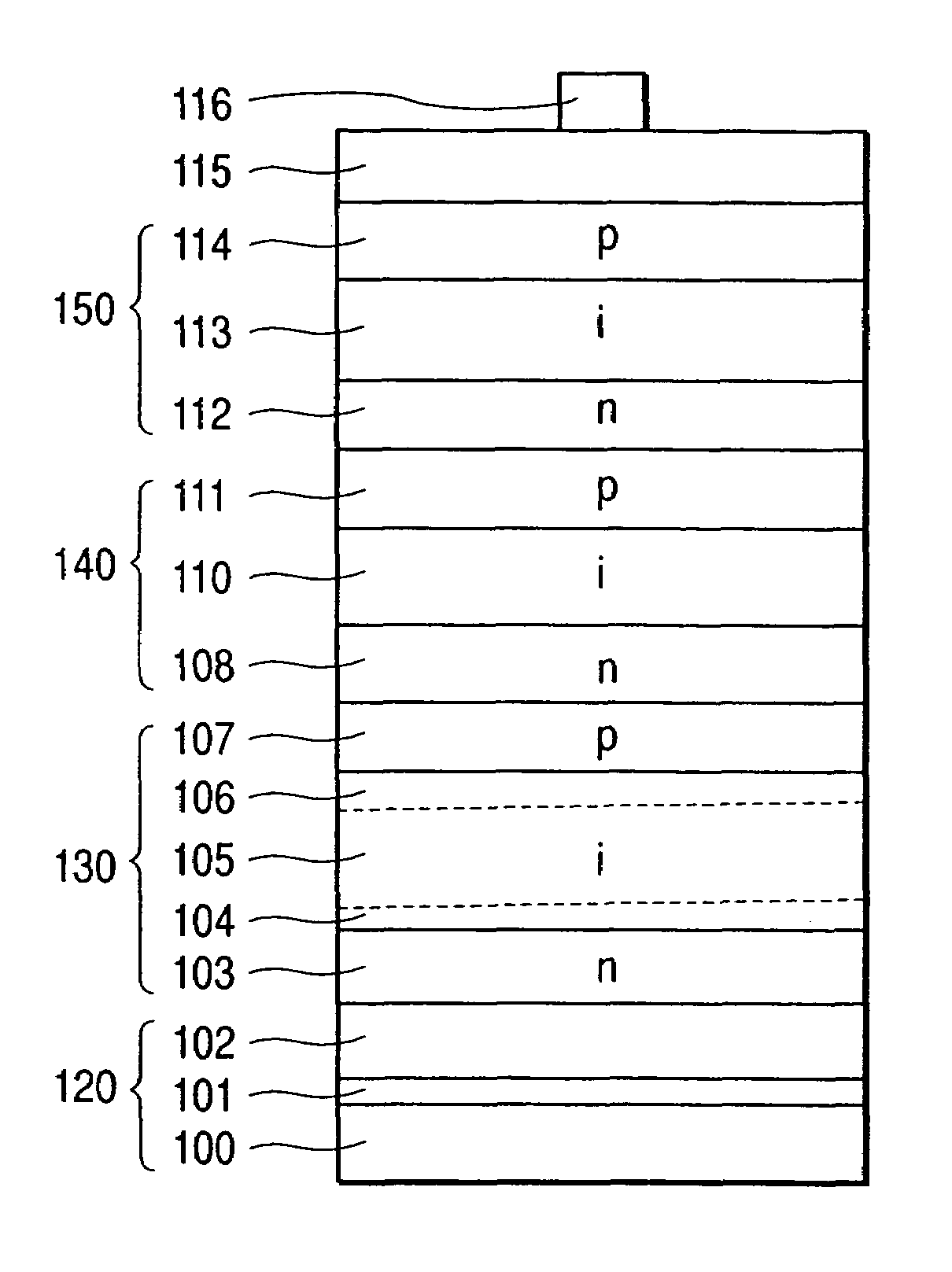

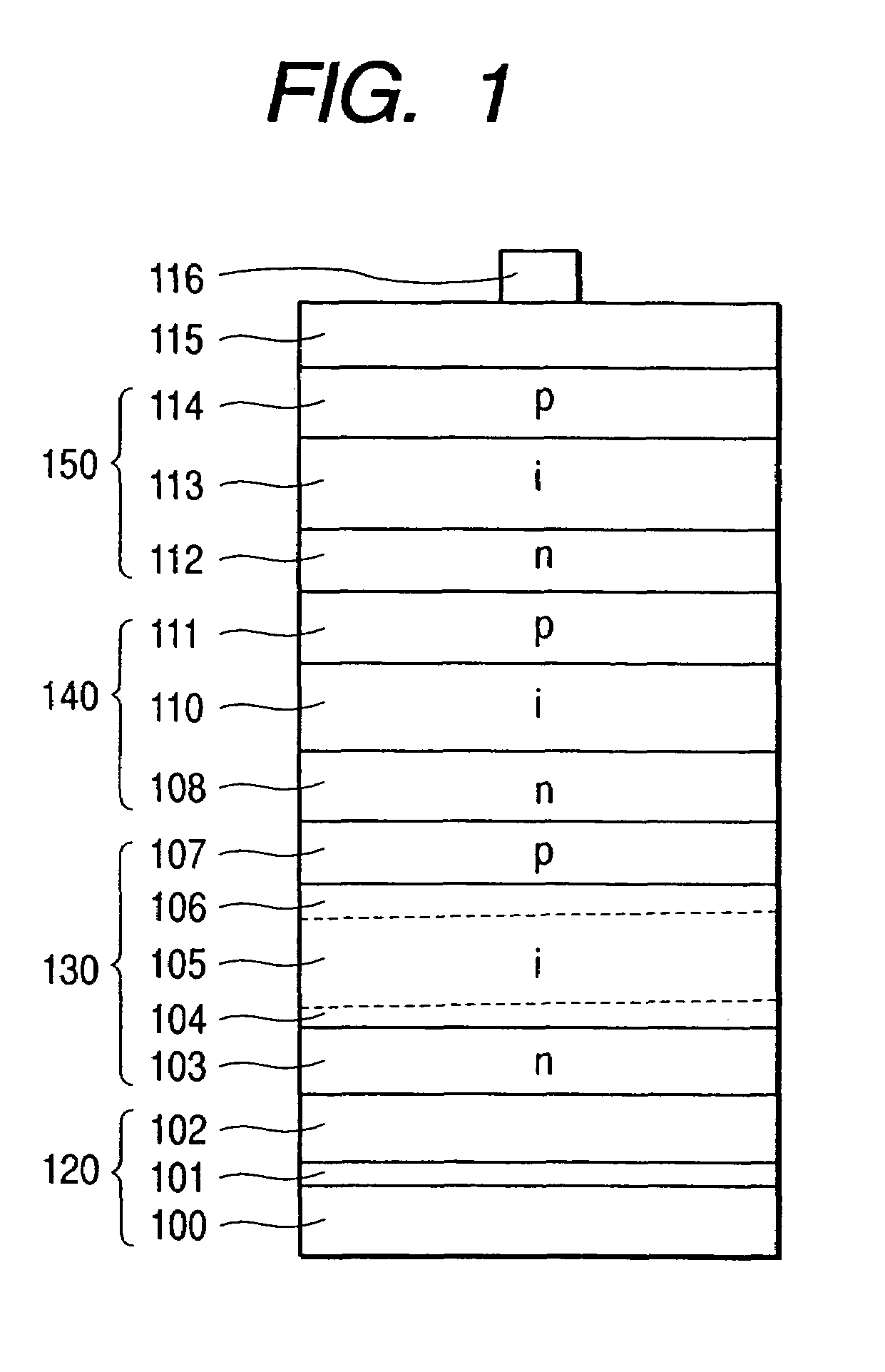

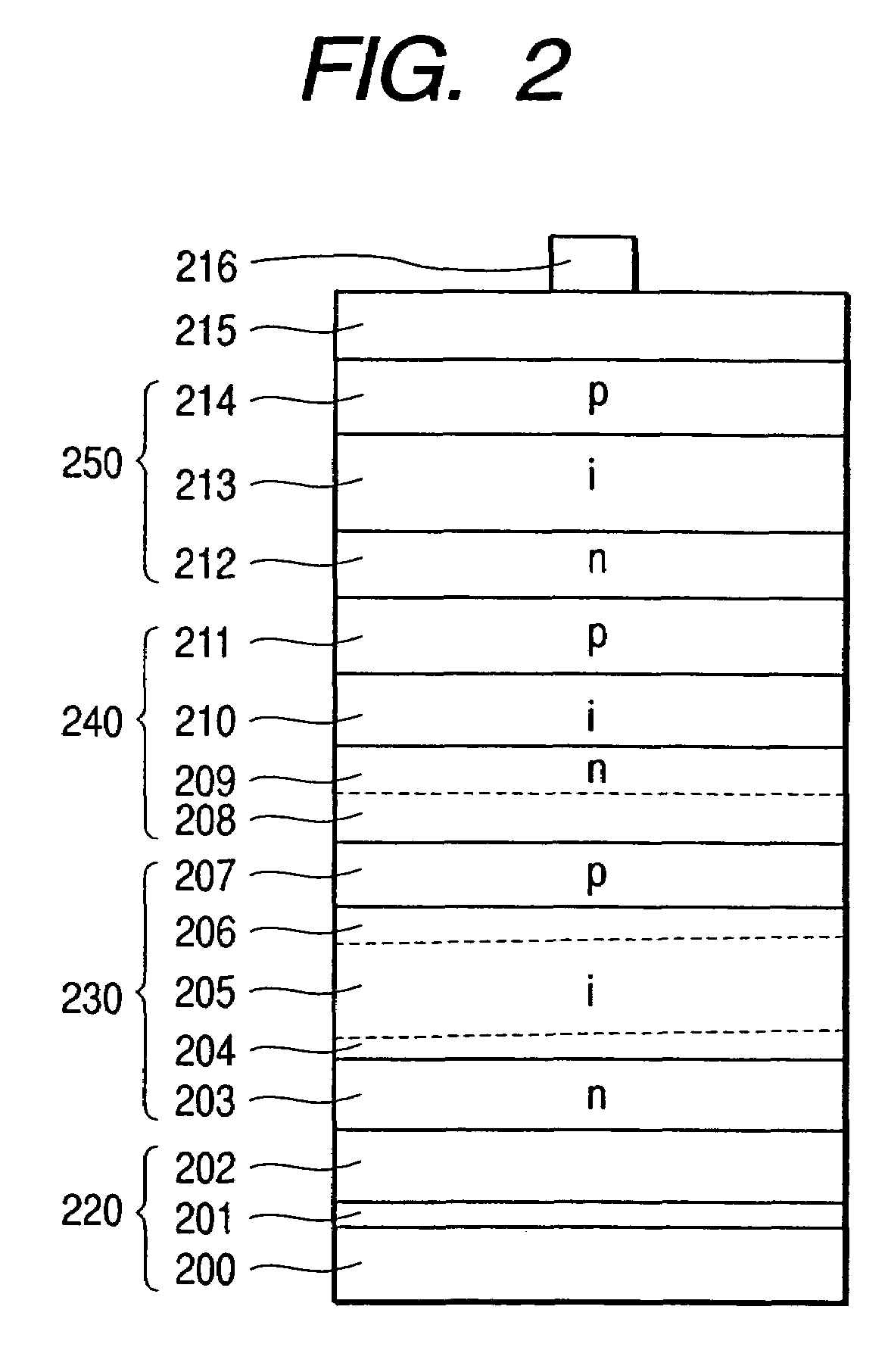

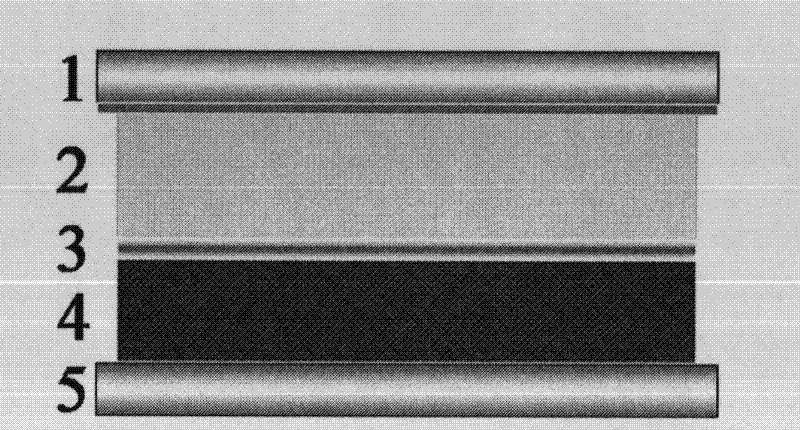

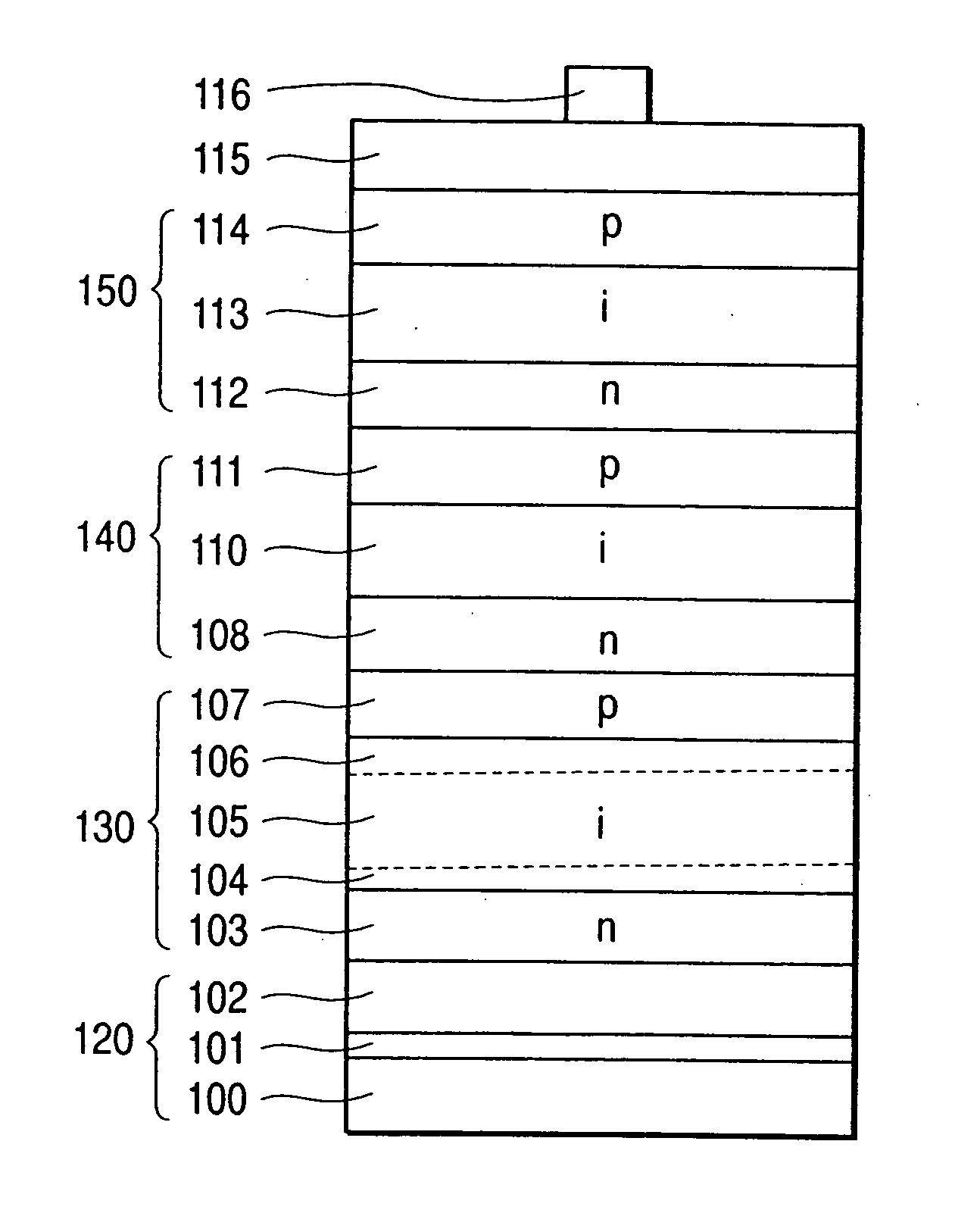

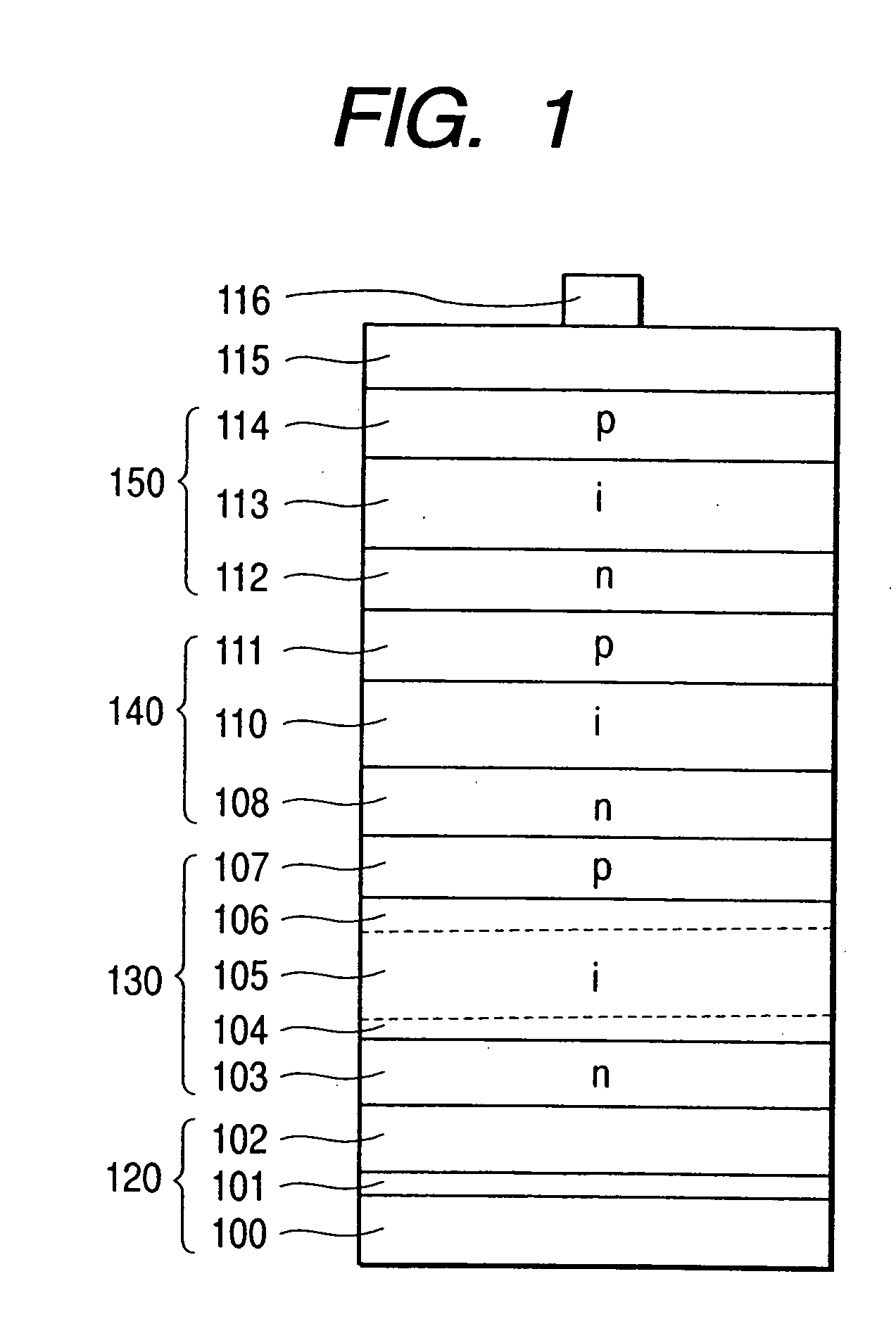

Stacked photovoltaic device

InactiveUS7064263B2Improve reliabilityImprove photoelectric conversion efficiencyFinal product manufacturePV power plantsSingle crystalMicrocrystalline silicon

A stacked photovoltaic device comprises at least three p-i-n junction constituent devices superposed in layers, each having a p-type layer, an i-type layer and an n-type layer which are formed of silicon non-single crystal semiconductors. An amorphous silicon layer is used as the i-type layer of a first p-i-n junction, a microcrystalline silicon layer is used as the i-type layer of a second p-i-n junction and a microcrystalline silicon layer is used as the i-type layer of a third p-i-n junction, the first to third layers being in order from the light incident side. In this way, a stacked photovoltaic device can be provided which is practical and low-cost and yet has high reliability and high photoelectric conversion efficiency.

Owner:CANON KK

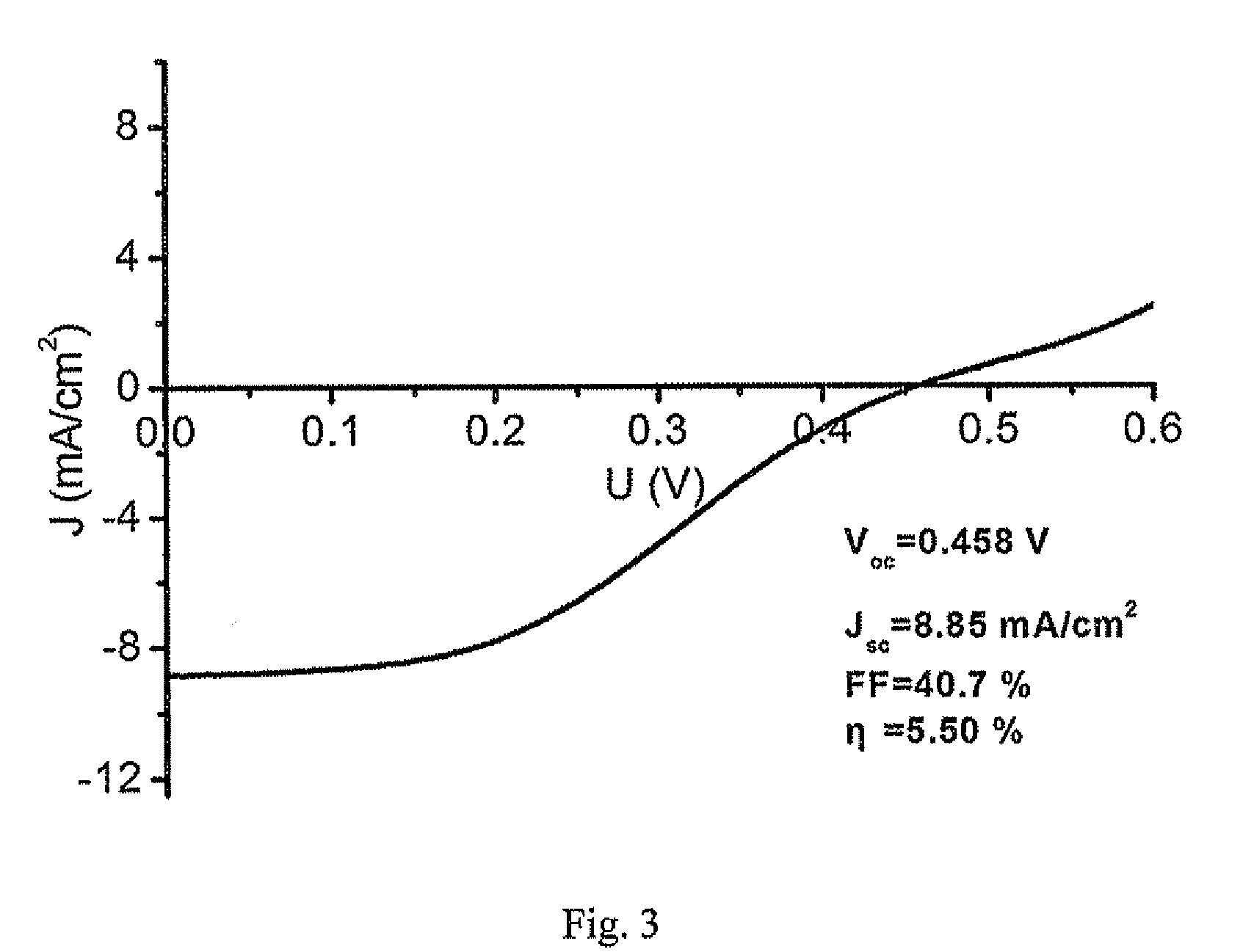

Method for preparing grapheme-quantum dot composite film and solar battery structured by using same

InactiveCN102176382AControl quantityImprove photoelectric conversion efficiencyLight-sensitive devicesFinal product manufactureComposite filmOrganic solvent

The invention relates to a method for preparing a grapheme-quantum dot composite film and a solar battery structured by using the same. The method comprises the following steps of: performing suction filtering on a suspension of grapheme-quantum dot composite powder on a filtering film to obtain a film; and then dissolving the filtering film away with an organic solvent, and transferring the filmto a conductive substrate. The method is characterized in that the ratio of the quantum dot to the grapheme and the thickness of the film can be controlled effectively; in addition, since the film isprepared at normal temperature, the requirement on the conductive substrate is reduced greatly. The prepared film can be used for structuring a novel quantum dot sensitized solar battery. The structured solar battery is of a layer structure, consists of the grapheme-quantum dot film on the conductive substrate, an electrolyte layer and a counter electrode and has the advantages of low cost, simpleness in preparation process, low temperature and stable performance. By the use of the grapheme-quantum dot composite film prepared by the method provided by the invention, the photoelectron transmission performance can be improved, and the photoelectric conversion efficiency of a battery can be enhanced.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

Method for manufacturing solar cell and solar cell

InactiveUS20090020156A1No variation in performanceReduce manufacturing costFinal product manufactureSemiconductor/solid-state device manufacturingDopantGas phase

The present invention is a method for manufacturing a solar cell by forming a pn junction in a semiconductor substrate having a first conductivity type to manufacture a solar cell, including at least: applying a first coating material containing a dopant onto the semiconductor substrate having the first conductivity type; and performing vapor-phase diffusion heat treatment to form a first diffusion layer in a region applied with the first coating material and a second diffusion layer, which is formed next to the first diffusion layer through vapor-phase diffusion, with a conductivity lower than a conductivity of the first diffusion layer at the same time, and provides a solar cell. Hence, it is possible to provide a method for manufacturing a solar cell, which can manufacture a solar cell at a low cost in a simple and easy way while suppressing surface recombination in a light-receiving surface other than an electrode region and recombination in an emitter to increase photoelectric conversion efficiency of the solar cell, and a solar cell.

Owner:SHIN-ETSU HANDOTAI CO LTD +1

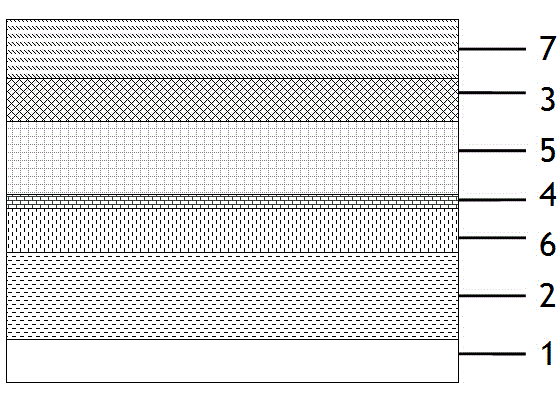

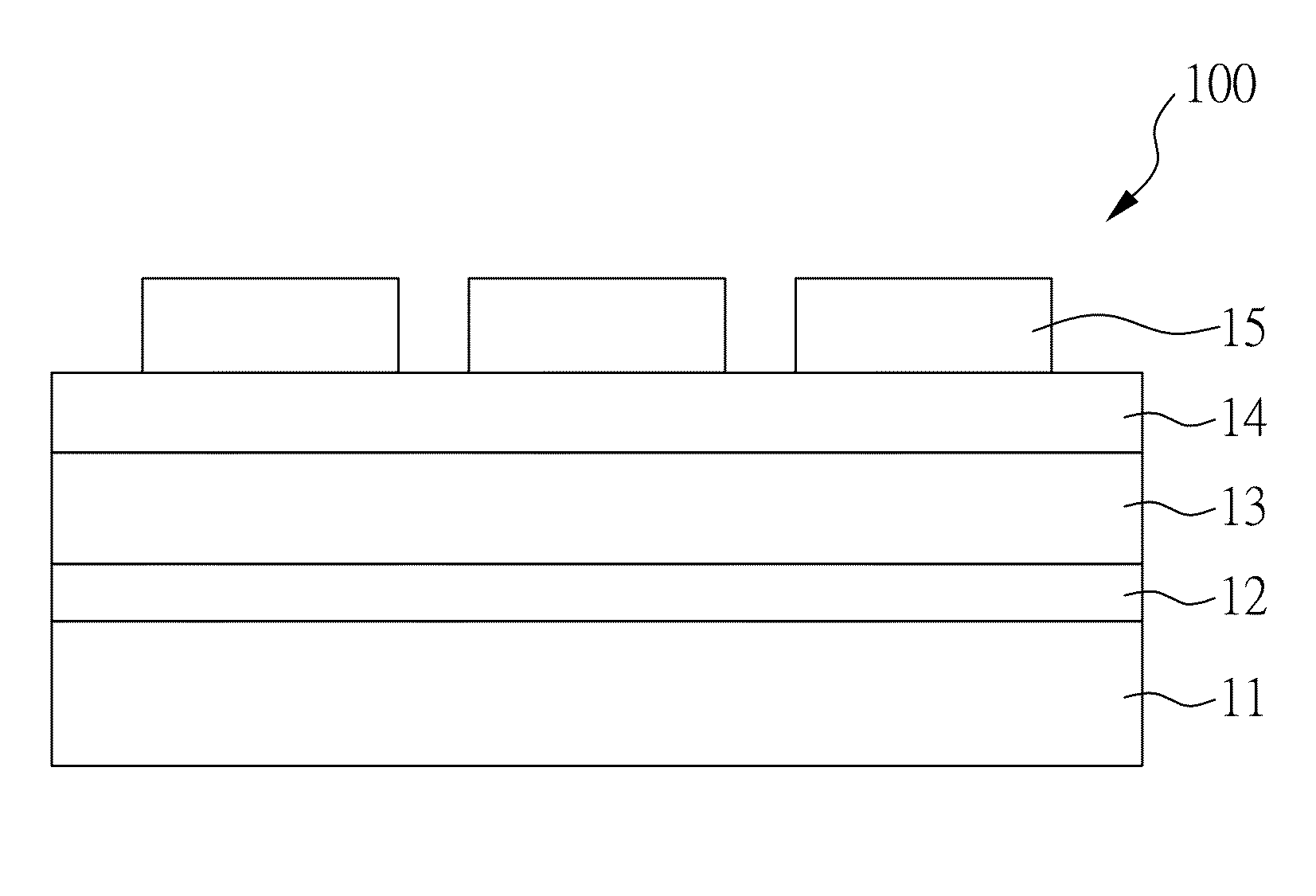

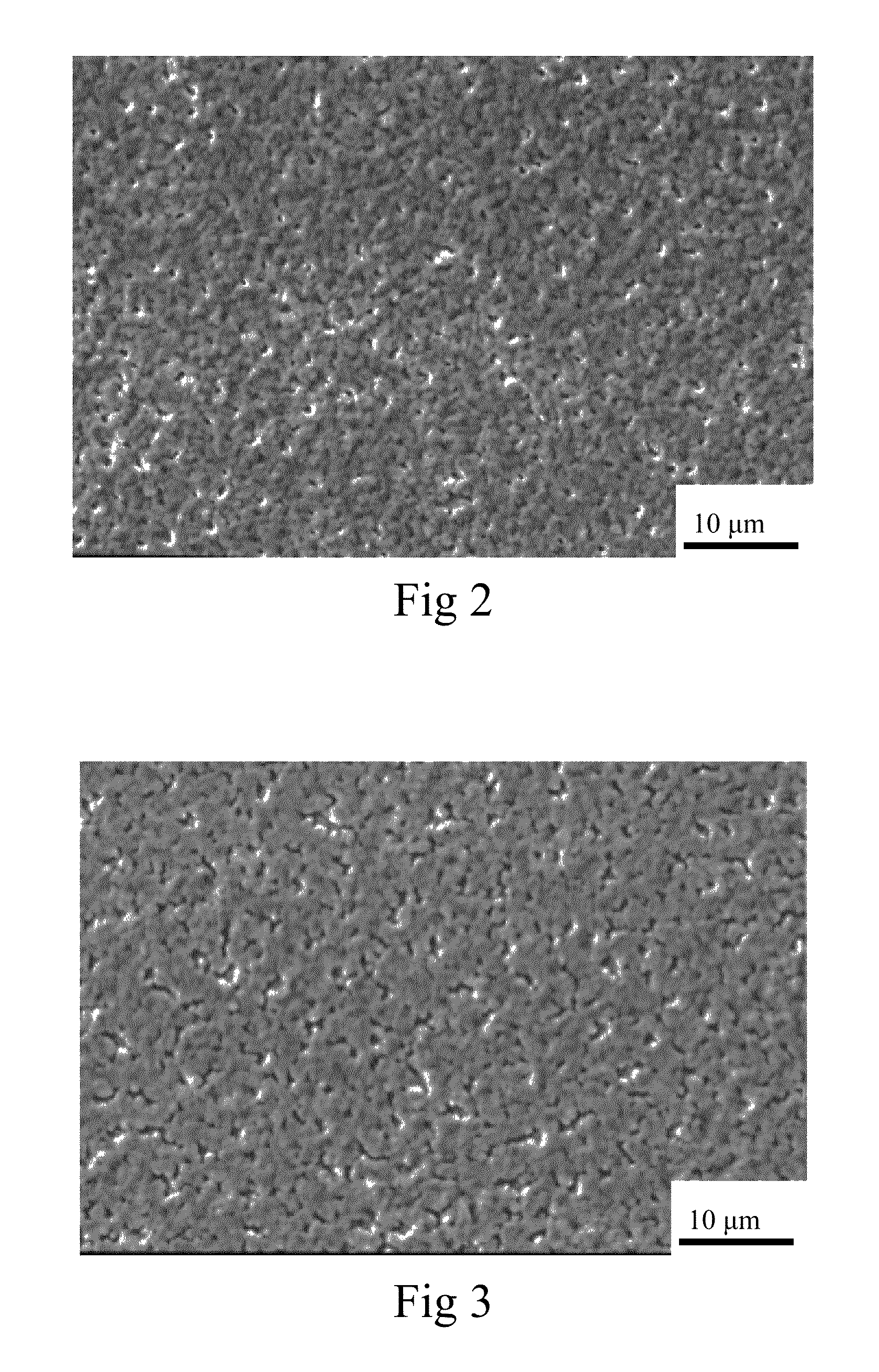

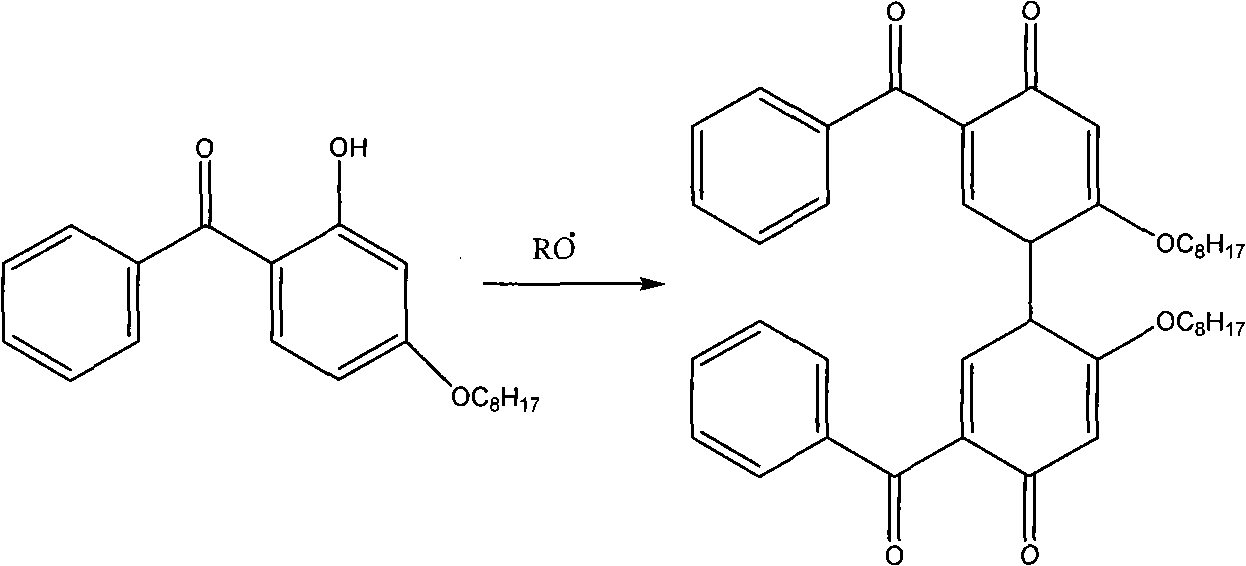

Organic and inorganic hybrid perovskite-based solar cell and method for manufacturing same

ActiveCN104795499AReduce internal defectsIncrease the diffusion lengthSolid-state devicesSemiconductor/solid-state device manufacturingMicro nanoElectron hole

The invention relates to an organic and inorganic hybrid perovskite-based solar cell and a method for manufacturing the same. The organic and inorganic hybrid perovskite-based solar cell comprises a substrate, a transparent electrode, an electron transport layer, an ultrathin orientation layer, a perovskite light absorption layer, a hole transport layer and a counter electrode. The transparent electrode, the electron transport layer, the ultrathin orientation layer, the perovskite light absorption layer, the hole transport layer and the counter electrode are sequentially stacked on the substrate. The method includes modifying micro-nano structures on the surfaces of the electron transport layer or the hole transport layer to form the ultrathin orientation layer before the perovskite light absorption layer is manufactured by the aid of a liquid phase process. The organic and inorganic hybrid perovskite-based solar cell and the method have the advantages that orientated growth of crystals of perovskite is controlled under large-ring structural effects of molecules in the ultrathin orientation layer, accordingly, the crystallization regularity can be improved, and internal defects can be reduced; the diffusion lengths of current carriers inside the perovskite light absorption layer can be effectively increased, accordingly, recombination of electron-hole pairs on the inside and interfaces of the perovskite light absorption layer can be prevented, and the photoelectric conversion efficiency and the stability of the cell can be obviously improved; the crystallization quality of the perovskite light absorption layer cannot be easily affected by film forming conditions under the orientation mold plate effects of the ultrathin orientation layer, accordingly, the device manufacturing repeatability can be improved, and the low-temperature solution method is applicable to industrially producing large-area perovskite solar cells.

Owner:CHINA LUCKY FILM CORP

Stacked photovoltaic device

InactiveUS20050028860A1Inhibit deteriorationHigh currentFinal product manufacturePV power plantsSingle crystalMicrocrystalline silicon

[Problem(s)] A stacked photovoltaic device can be provided which is practicable and low-cost and yet has a high reliability, and also has a high photoelectric conversion efficiency. [Means for Solving the Problem] A stacked photovoltaic device comprises at least three p-i-n junction constituent devices superposed in layers, each having a p-type layer, an i-type layer and an n-type layer which are formed of silicon type non-single-crystal semiconductors. An amorphous silicon is used as the i-type layer of a first p-i-n junction, a microcrystalline silicon is used as the i-type layer of a second p-i-n junction and a microcrystalline silicon is used as the i-type layer of a third p-i-n junction, the first to third layers being in the order from the light-incident side.

Owner:CANON KK

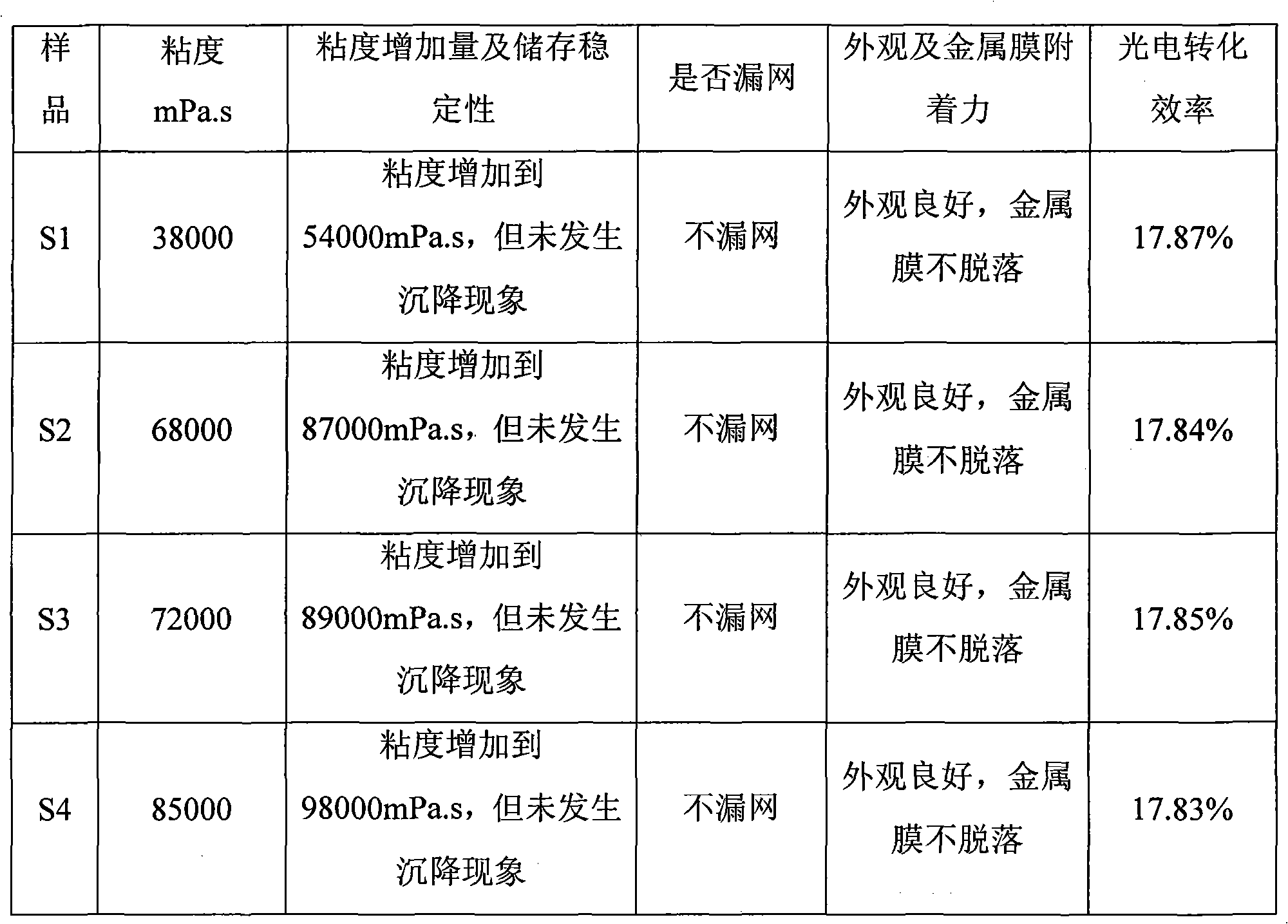

Conductive paste for solar cell and preparation method thereof

InactiveCN102034877AImprove performanceNo sedimentation and caking phenomenonConductive materialInksSilicon matrixSilicon solar cell

The invention provides a conductive paste for a solar cell, comprising the following components based on the total weight: 60-85 percent by weight of conductive metal powder, 0.5-10.0 percent by weight of inorganic binder, 10.0-30.0 percent by weight of water-borne binder and 0.05-5.0 percent by weight of additive, wherein the water-borne binder is a solution formed by dissolving a water-borne polymer into the water. The conductive paste for the solar cell, provided by the invention, has no organic solvent and pollution, is environment-friendly and has low cost of materials; the mesh leakage can be avoided when the conductive paste is stood in a screen mesh; the phenomena of settling and aggregation can be avoided after the conductive paste is stored for a long time; after being subjected to the silk-screen sintering, the conductive paste has firm adhesive force to a silicon matrix and excellent electrical performance; and the average photoelectric conversion efficiency of the produced monocrystal silicon solar cell is more than 17.80 percent.

Owner:BYD CO LTD

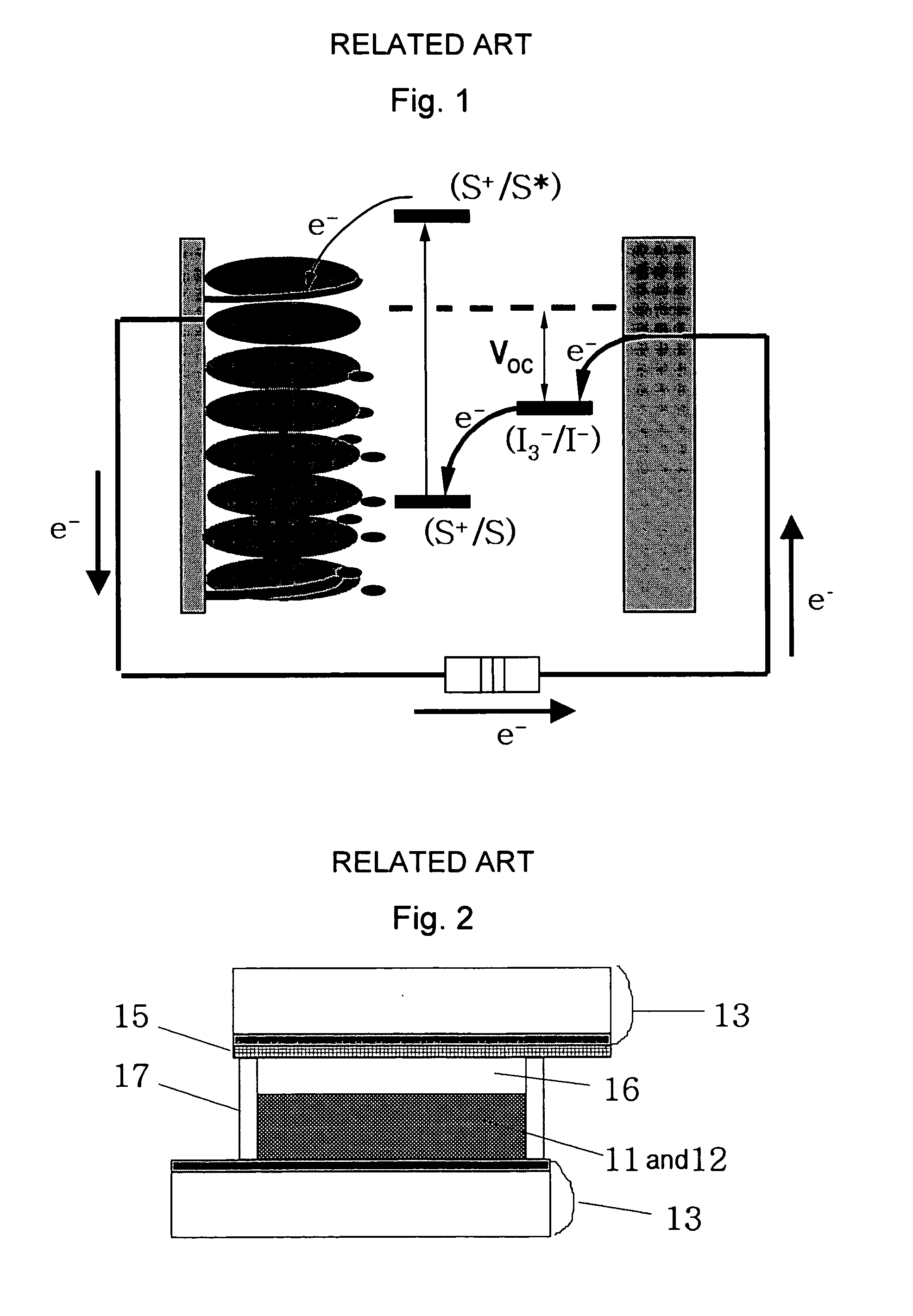

Photovoltaic cell

InactiveUS20030196692A1Smooth movementImprove photoelectric conversion efficiencyLight-sensitive devicesDeferred-action cellsPhotosensitizerDecomposition

Disclosed is a photovoltaic cell comprising a substrate having an electrode layer (1) on the surface and having a porous metal oxide semiconductor film (2) which is formed on the electrode layer (1) and on which a photosensitizer is adsorbed, a substrate having an electrode layer (3) on the surface, both of said substrates being arranged in such a manner that the electrode layer (1) and the electrode layer (3) face each other, and an electrolyte layer provided between the semiconductor film (2) and the electrode layer (3), wherein the semiconductor film (2) contains an inhibitor of back current, and at least one pair of substrate and electrode layer thereon have transparency. The photovoltaic cell is capable of inhibiting back current and decomposition of a spectrosensitizing dye caused by the ultraviolet rays, has high photoelectric conversion efficiency and is capable of generating high electromotive force.

Owner:JGC CATALYSTS & CHEM LTD

Perovskite solar cell

InactiveUS20160079552A1Expand coverageReduce roughnessSolid-state devicesSemiconductor/solid-state device manufacturingPerovskite solar cellElectron transport layer

The present invention relates to a perovskite solar cell, which comprises a first electrode substrate; a perovskite material layer comprising a perovskite organic-inorganic material and a polymer additive, wherein the perovskite material layer is disposed above the first electrode substrate; and a second electrode, which is disposed above the perovskite material layer and corresponds to the first electrode substrate. The coverage of the perovskite material layer on the electrode or an electron-transport layer is significantly improved, and the roughness thereof is also decreased, thereby increasing the photoelectric conversion efficiency of the perovskite solar cell.

Owner:NAT TAIWAN UNIV

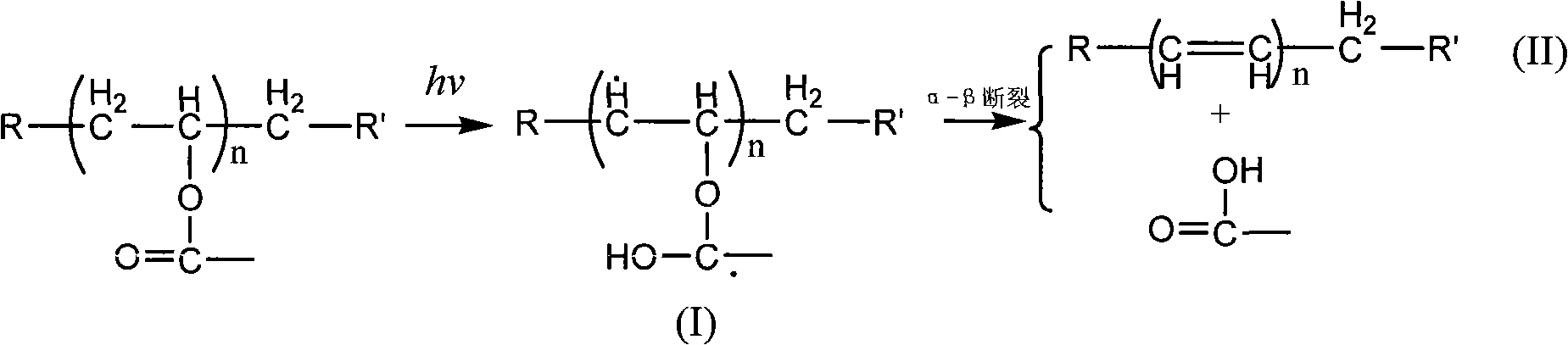

Novel EVA adhesive film

InactiveCN101353558AStrong free radical capture abilityGeneration of blockingFilm/foil adhesivesElectrical equipmentLight energyAdhesive

The invention provides an EVA adhesive film without adding uvioresistant absorbent, which is prepared mainly by the raw materials according to the mass ratio as follows: ethylene-vinyl acetate copolymer, 100 parts; peroxide type crosslinking agent 0.1 to 10 parts, phenolic or phosphite type antioxidant 0.05 to 5 parts; and hindered amine light stabilizer, 0.01 to 5 parts. As the ultraviolet absorbent is not used, the EVA adhesive film obtained does not produce ultra-violet cut-off, leads the solar modules to receive UV district light energy, thereby having higher photoelectric conversion efficiency and excellent uvioresistant anti-aging property, and guaranteeing the service life of PV modules.

Owner:HANGZHOU FIRST APPLIED MATERIAL CO LTD

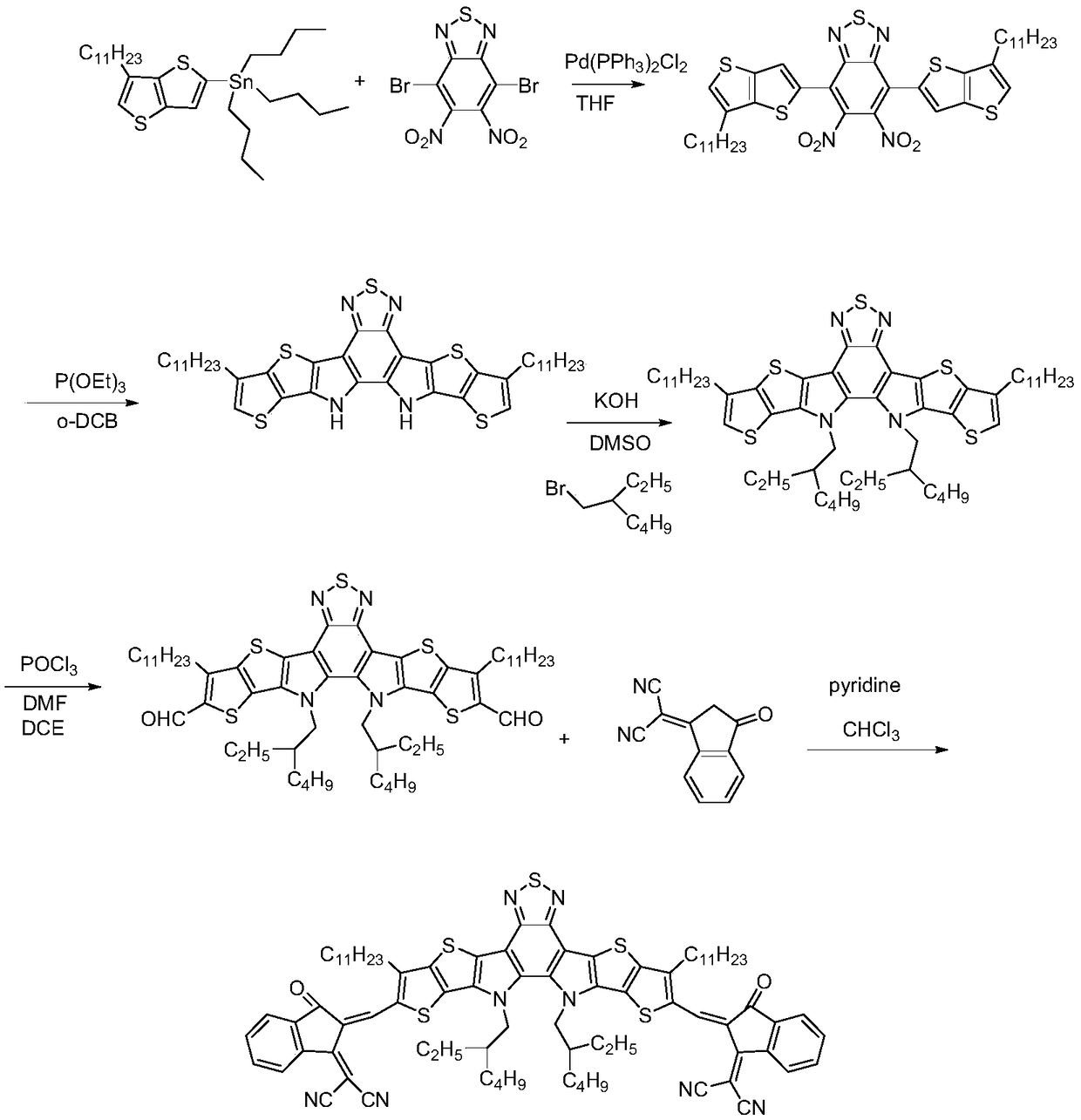

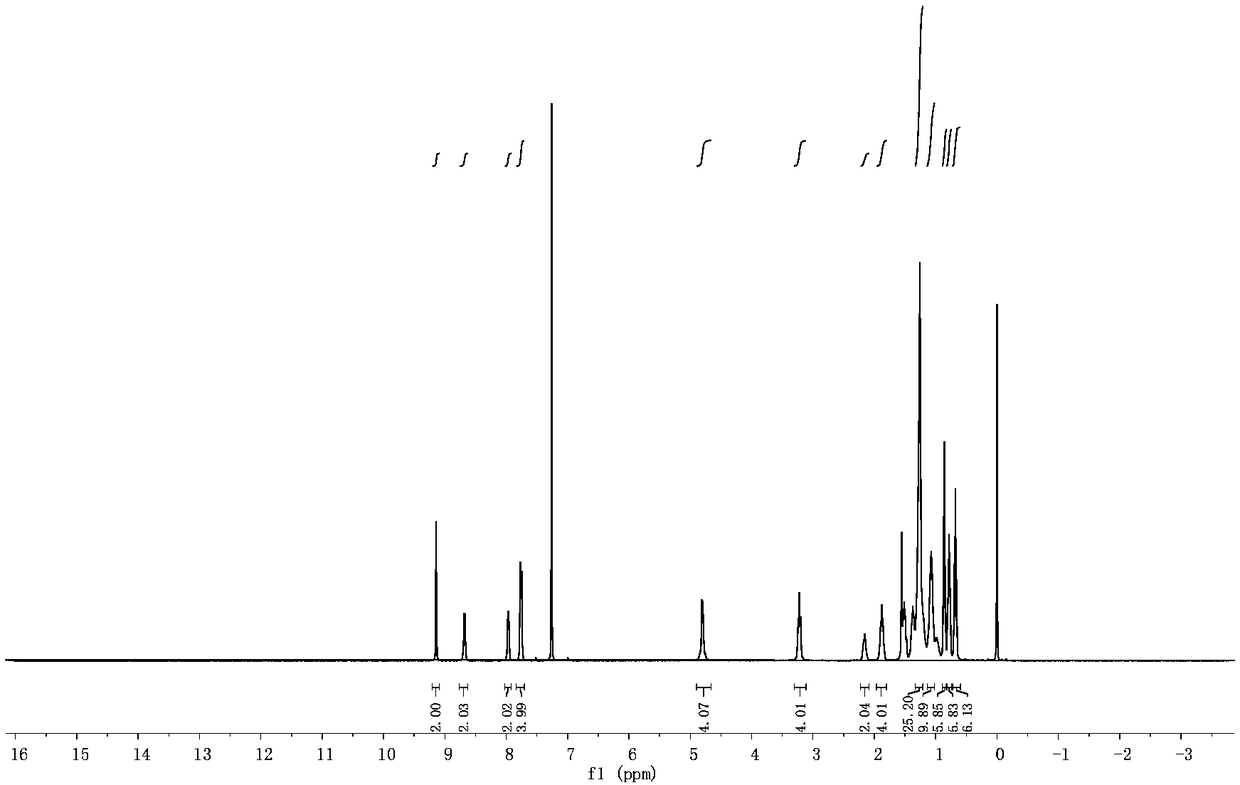

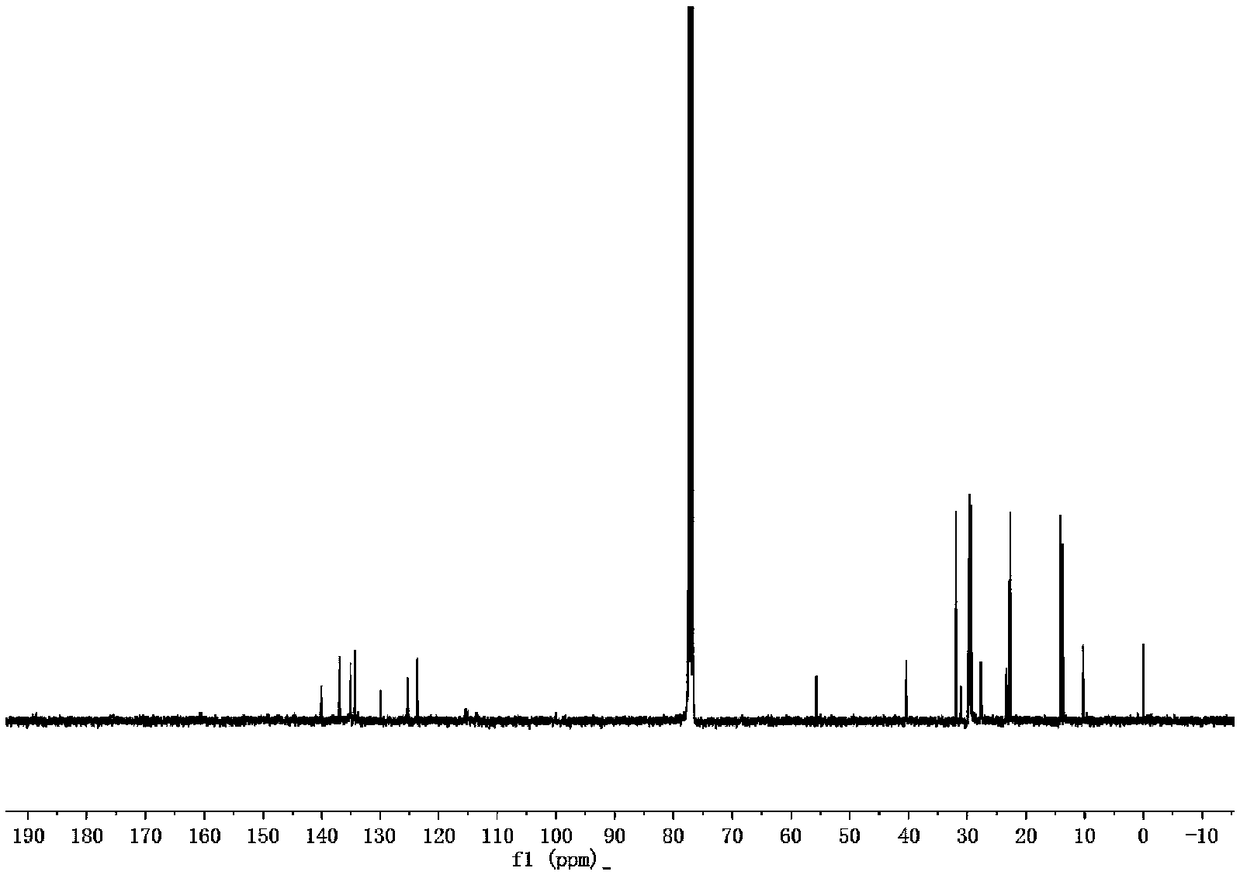

Polycyclic benzothiadiazole non-fullerene acceptor material, preparation method thereof and application of material

ActiveCN109134513AImprove solubilityPromote absorptionOrganic chemistrySolid-state devicesSolubilityOrganic solar cell

The invention discloses a polycyclic benzothiadiazole non-fullerene acceptor material, a preparation method thereof and an application of the material. The polycyclic benzothiadiazole non-fullerene acceptor material comprises a polycyclic benzothiadiazole center core and electrophilic end groups, the polycyclic benzothiadiazole center core is of a nitrogen bridge trapezoidal polycyclic structure,the electrophilic end groups are connected to two ends of the center core, 4, 7-dibromo-5, 6-binitro benzothiadiazole serves as a raw material in the preparation process, Stille coupling and Vilsmeier-Haack reaction are sequentially performed to obtain the polycyclic benzothiadiazole center core, and end-group structures are introduced by Knoevenagel reaction to obtain the polycyclic benzothiadiazole non-fullerene acceptor material. The acceptor material is good in solubility and easily processed into a film, has a good photoelectric conversion function and is used for preparing an organic solar battery device, and photoelectric conversion efficiency reaches nearly 16% of single battery conversion efficiency.

Owner:CENT SOUTH UNIV

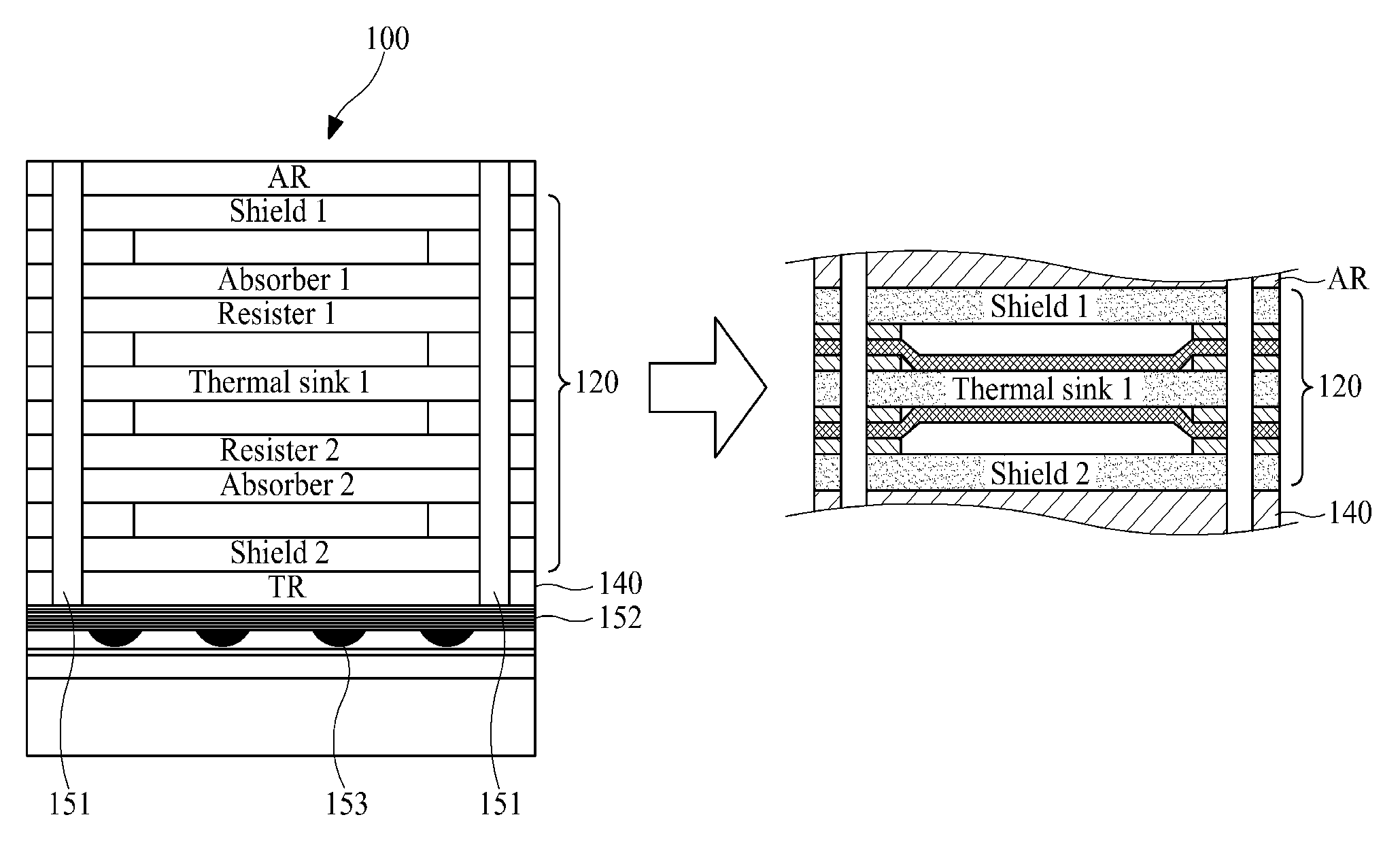

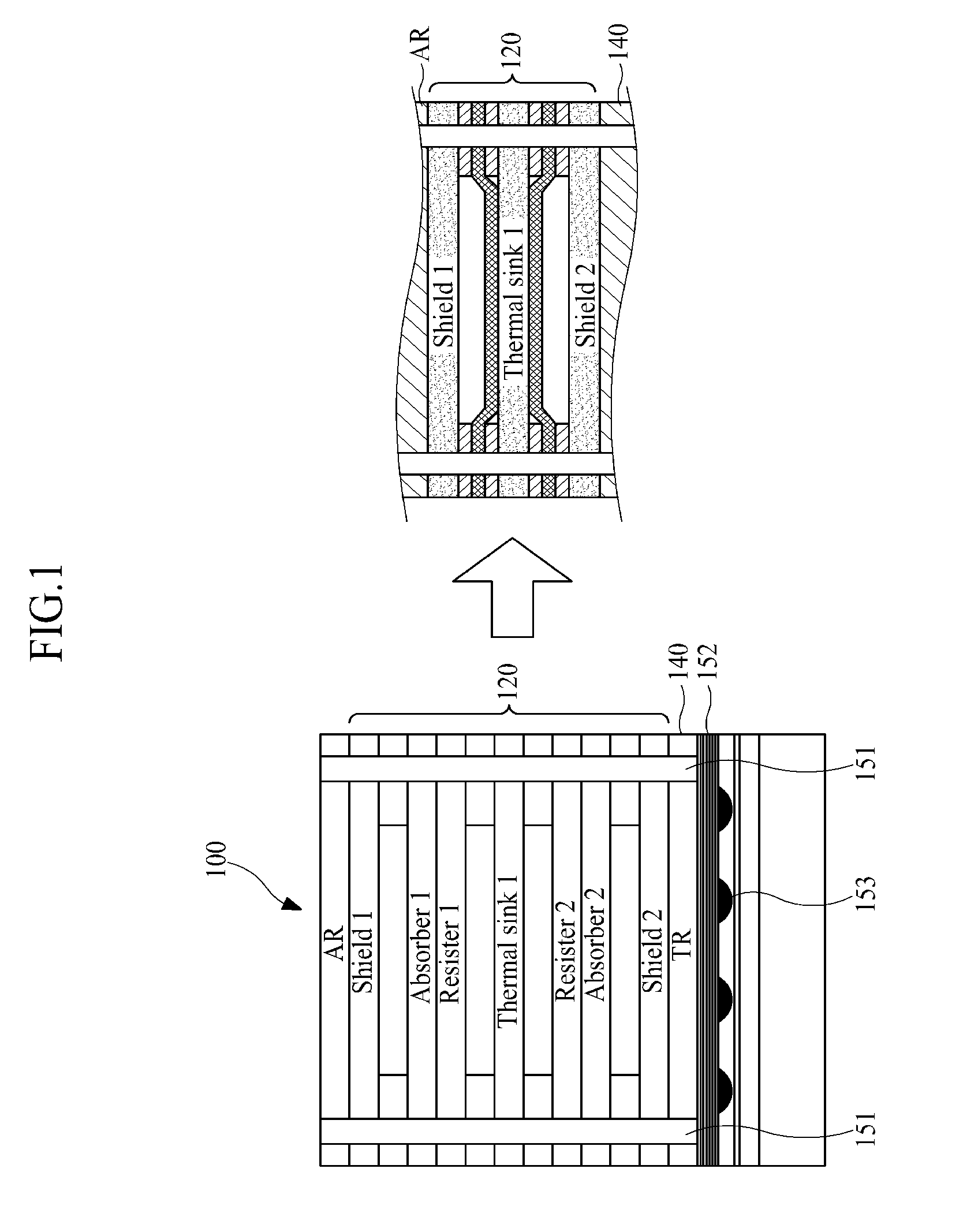

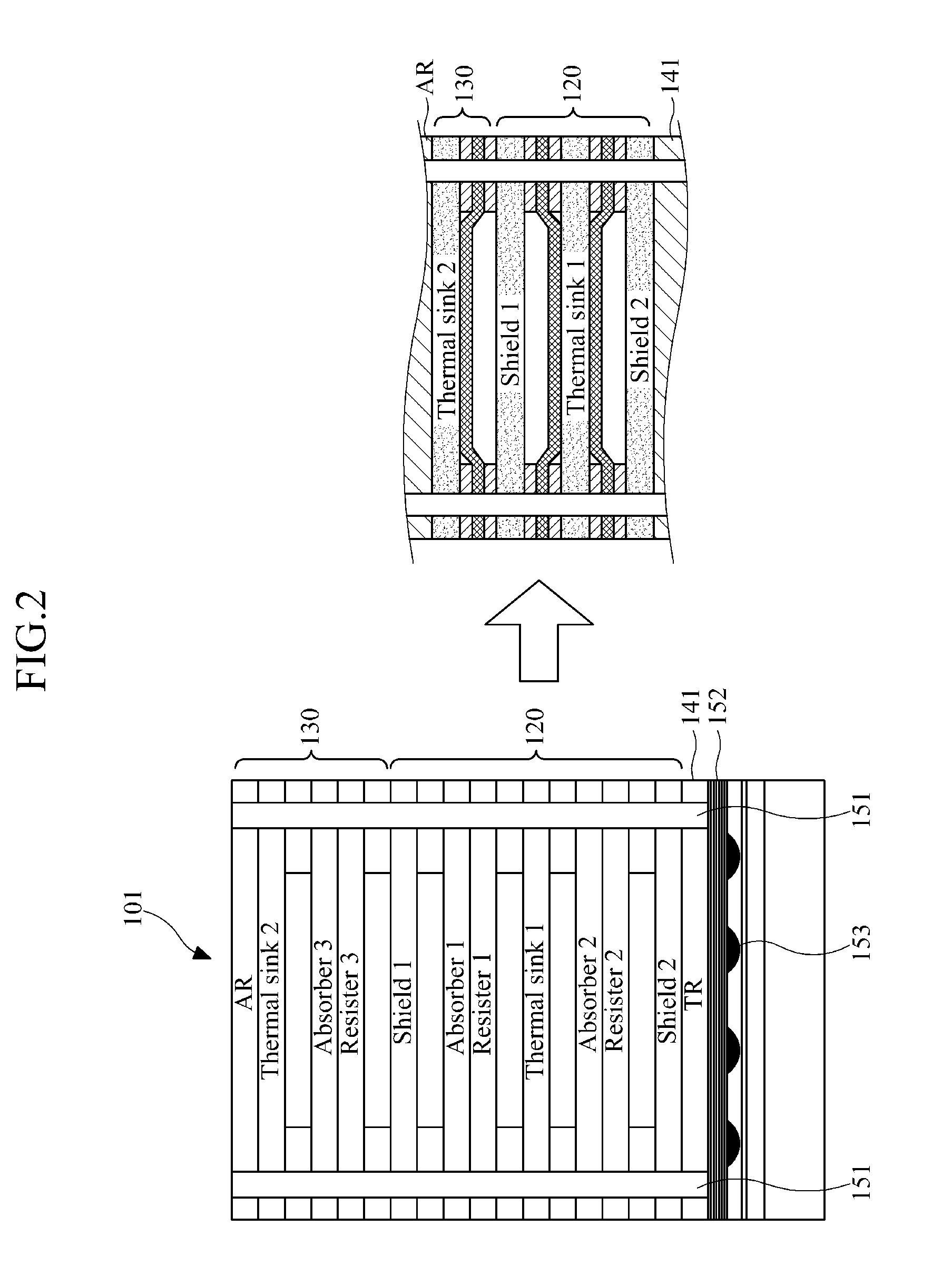

Image sensor for detecting wide spectrum and method of manufacturing the same

ActiveUS7723686B2Reduce light lossImprove photoelectric conversion efficiencyTelevision system detailsSpectrum investigationInfraredOptical distortion

An image sensor for detecting a wide spectrum includes a plurality of infrared ray receiving layers which individually receive infrared rays having different wavelengths for each pixel, the plurality of infrared ray receiving layers stacked to each other. The image sensor, which is an integrated image sensor where at least two micro bolometers are stacked, acquires spectrum information about visible rays and near-infrared rays as well as two or more infrared rays applied on an object, without mechanical / thermal / optical distortion, and provides the spectrum information to a silicon-based semiconductor such as a photodiode, thereby improving photoelectric conversion efficiency.

Owner:HANVISION +1

Dye-sensitized solar cell

InactiveUS20070163645A1Increase resistancePrevent collector electrode corrosionLight-sensitive devicesPhotovoltaic energy generationSemiconductor electrodeEngineering

A dye-sensitized solar cell according to one aspect of the present invention includes: a first base member having a first substrate provided with a light-transmitting property, a light-transmitting conductive layer formed on a surface of the first substrate and a semiconductor electrode formed on a surface of the light-transmitting conductive layer and containing a sensitizing dye; a second base member having a second substrate and a catalyst layer formed on a surface of the second substrate in such a manner that the catalyst layer faces the semiconductor electrode; an electrolyte layer formed between the semiconductor electrode and the catalyst layer; and either a collector electrode containing tungsten or a pair of collector electrodes, at least one of which contains tungsten, to collect charge from the semiconductor electrode. The dye-sensitized solar cell of this aspect of the present invention not only shows a sufficient photoelectric conversion efficiency but attains excellent durability by prevention of corrector electrode corrosion.

Owner:NGK SPARK PLUG CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com