Electric conductive silver paste and manufacturing method thereof

A technology of conductive silver paste and silver paste, which is used in the manufacture of cables/conductors, conductive materials dispersed in non-conductive inorganic materials, circuits, etc. and other problems, to achieve the effects of improved photoelectric conversion efficiency, good thixotropy, and low contact resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

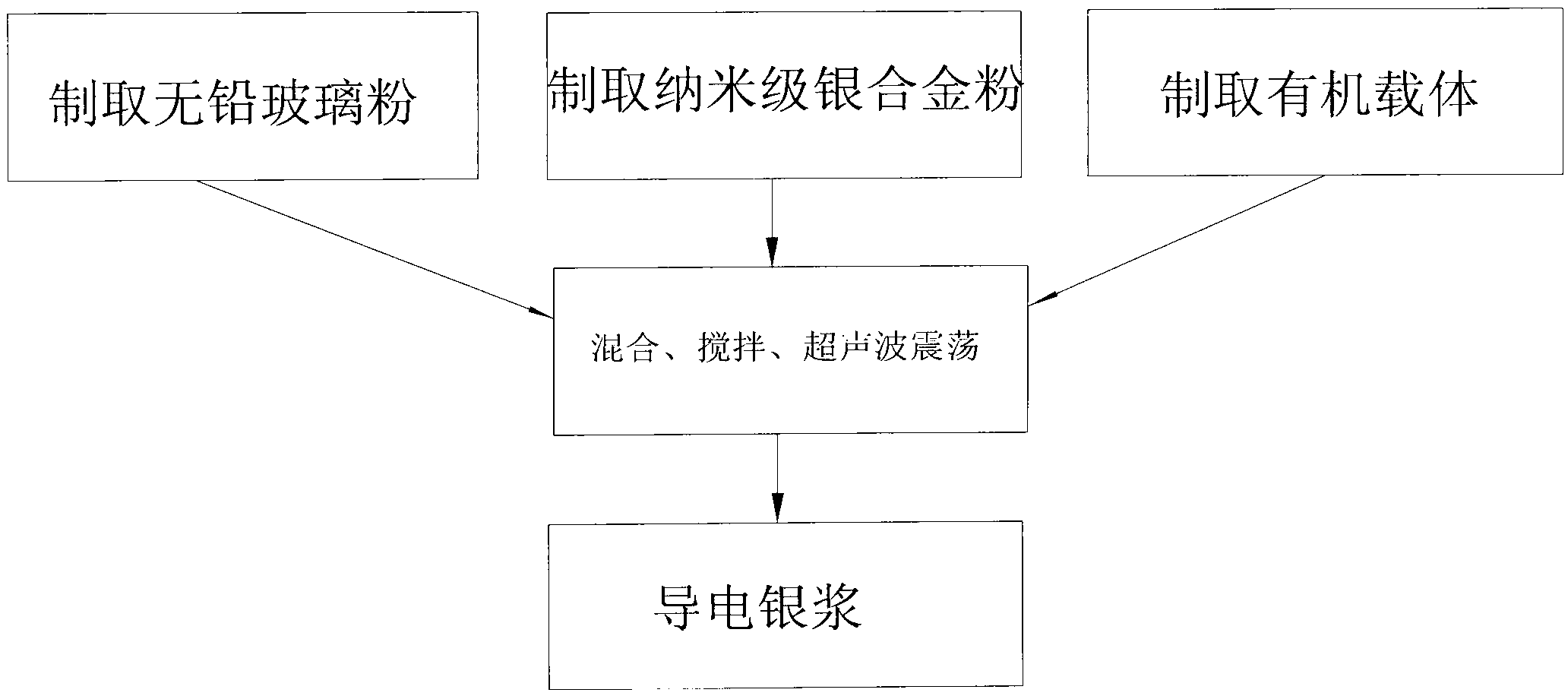

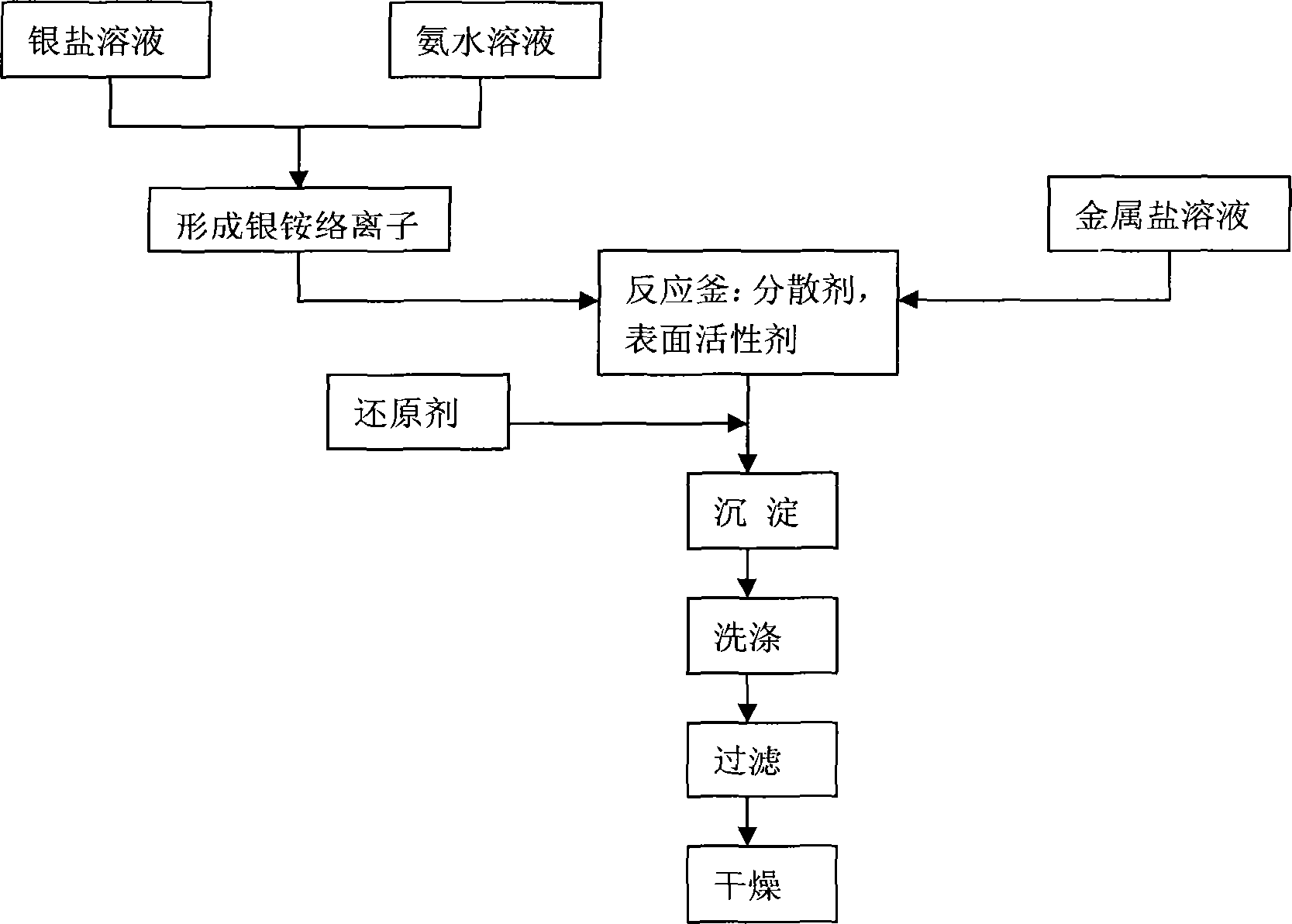

Method used

Image

Examples

Embodiment 1

[0075] For the conductive paste used in ceramics and solar battery cathodes, the composition and weight percentage are as follows:

[0076] Micron silver powder: 55%

[0077] Nanometer silver alloy powder: 12%

[0078] Lead-free glass powder: 8%

[0079] Organic carrier: 25%

[0080] Among them, the organic carrier includes plasticizers, thickeners, solvents, additives, plasticizer dibutyl phthalate, the thickener is ethyl cellulose, the solvent is terpineol, and the additives are hydrogenated castor oil and The foaming agent Holland Tuna DNE12, in which the thickener ethyl cellulose in the organic vehicle is 8%, the plasticizer dibutyl phthalate accounts for 1.5%, the solvent terpineol accounts for 14%, and the additives are selected from hydrogenated castor oil , Antifoaming agent Dutch Tuna DNE12, the ratio of the two is 1:0.5: the two account for 1.5%, the micron-level silver powder refers to the particle diameter in the range of 2-10 nanometers, and the nano-level silver alloy is...

Embodiment 2

[0090] For the conductive paste used in ceramics and solar battery cathodes, the composition and weight percentage are as follows:

[0091] Micron silver powder: 38%

[0092] Nanometer silver alloy powder: 5%

[0093] Lead-free glass powder: 5%

[0094] Organic vehicle: 52%

[0095] Among them, the organic carrier includes thickeners, plasticizers, solvents, additives. The thickener is methyl cellulose, the plasticizer is dibutyl phthalate, the solvent is terpineol, and the additives are hydrogenated castor oil and Antifoaming agent Holland Tuna Chemical DNE12, in which the thickener methyl cellulose in the organic vehicle is 16%, the plasticizer dibutyl phthalate accounts for 3%, the solvent terpineol accounts for 30%, and the additives are selected from hydrogenated Castor oil, antifoaming agent Holland Tuna DNE12, the ratio of the two is 1:0.5: the two account for 3%, the micron-level silver powder refers to the particle diameter in the range of 2-10 microns, and the nano-level sil...

Embodiment 3

[0097] For the conductive paste used in ceramics and solar battery cathodes, the composition and weight percentage are as follows:

[0098] Micron silver powder: 40%

[0099] Nanometer silver alloy powder: 8%

[0100] Lead-free glass powder: 10%

[0101] Organic vehicle: 42%

[0102] Among them, organic vehicles include organic vehicles including thickeners, plasticizers, solvents, additives, thickeners (methyl cellulose), solvents (terpineol), additives (hydrogenated castor oil, defoamer Netherlands Tuna DNE12), where the thickener methyl cellulose in the organic vehicle is 16%, the plasticizer dibutyl phthalate accounts for 3%, the solvent terpineol accounts for 21%, and the additives are selected from hydrogenated castor oil, The foaming agent Dutch Tuna DNE12, the ratio of the two is 1:0.5: the two account for 2%. The micron-level silver powder refers to the particle diameter in the range of 2-10 nanometers. The nano-level silver alloy selects the alloy of silver and cerium, and t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com