Method for integrally forming permeable and sweat absorbing PU clothes

A molding method and clothing technology, which can be applied to household components, applications, household appliances, etc., can solve the problems of discomfort, susceptibility to wear and heat, increased cost and working hours, etc., and achieve the effect of increasing the interconnection relationship.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

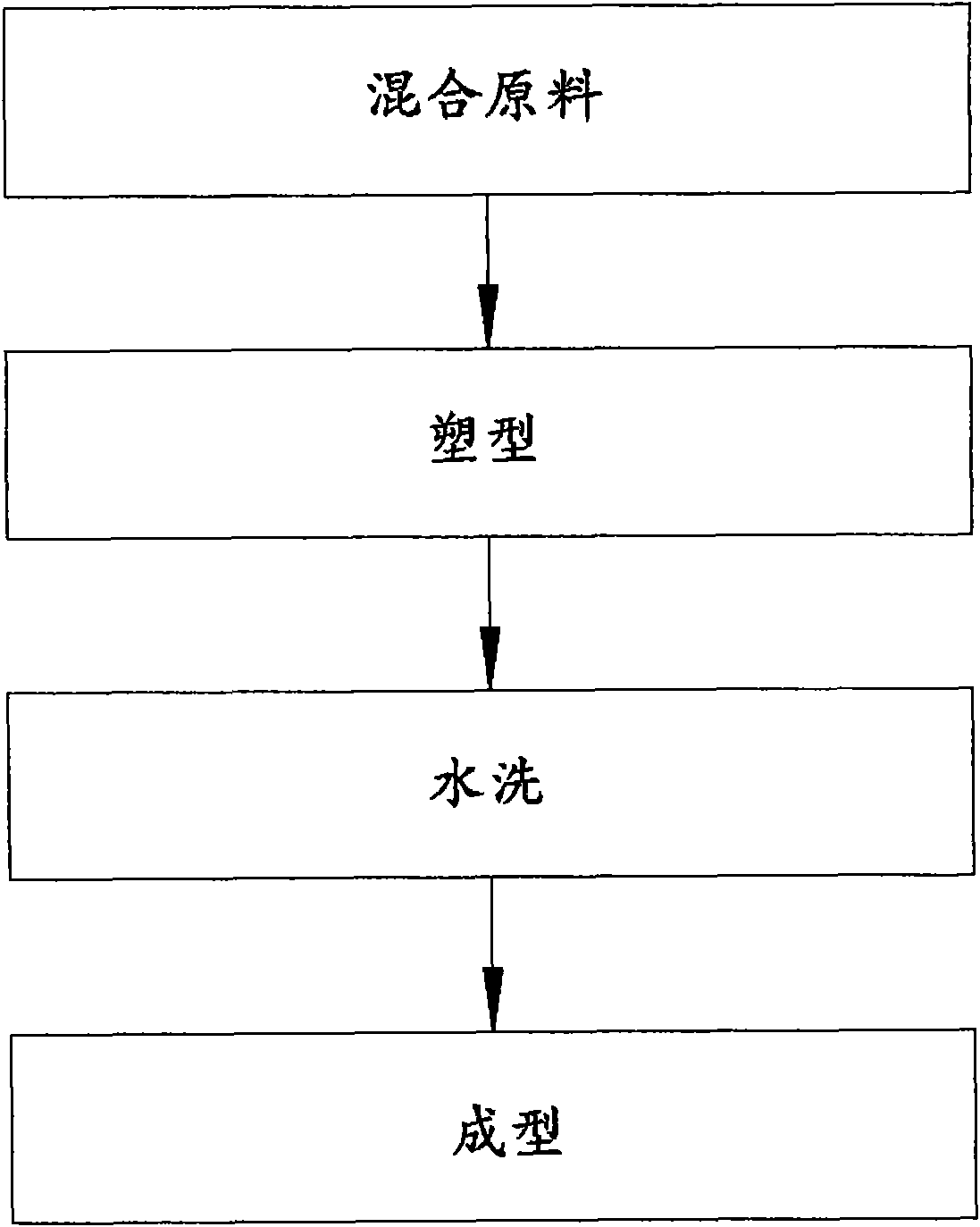

[0018] First, see Figure 1 to Figure 2 Shown, the preferred embodiment of the molding method of breathable, sweat-absorbing clothing of PU integral molding of the present invention, and this method mainly comprises the following steps:

[0019] (1) Mixed raw materials:

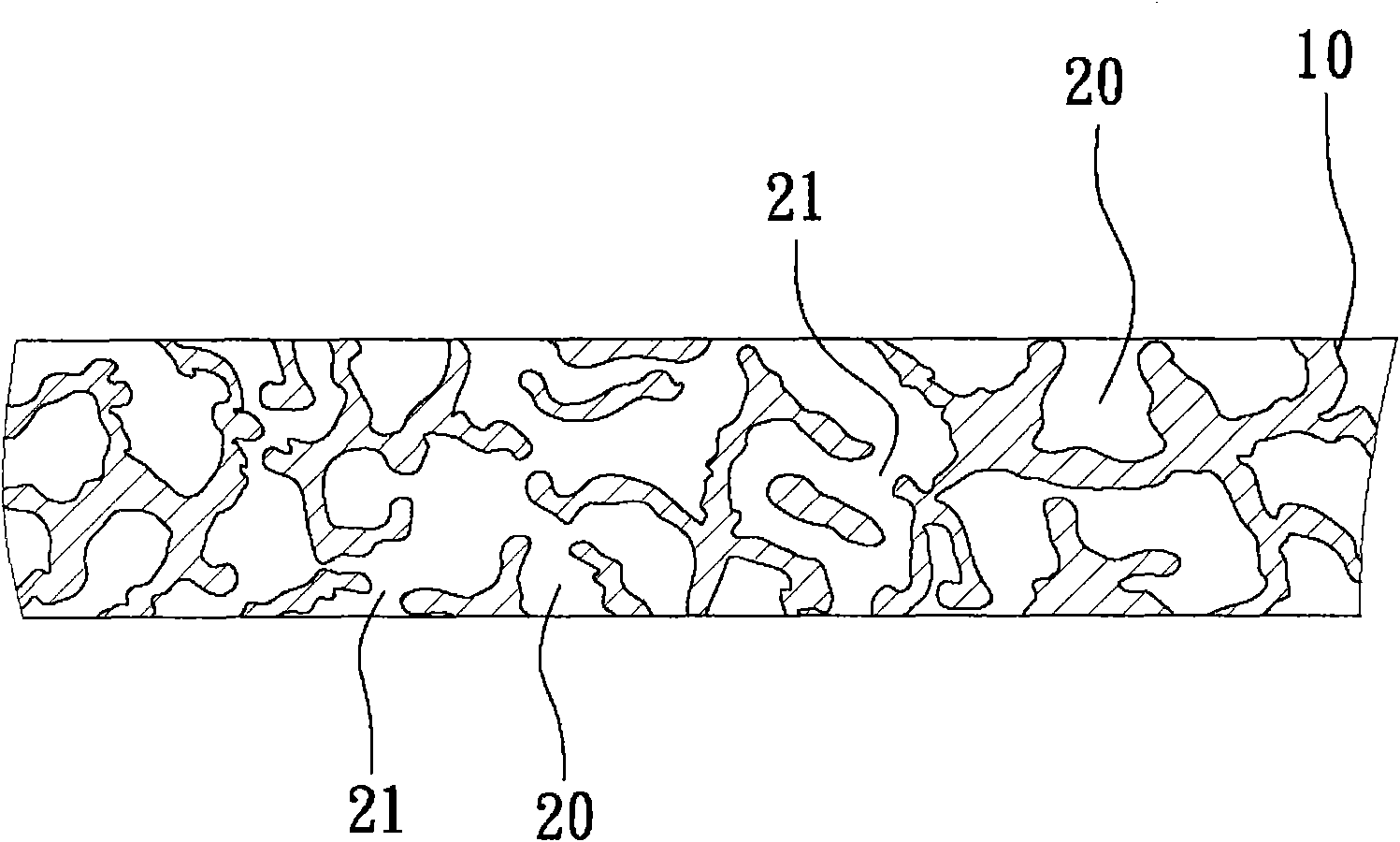

[0020] When a two-component PU raw material 10 is mixed and stirred, a hydrophilic and water-soluble crystal is added at the same time, and the mixing ratio of the PU raw material 10 and the crystal is 100:10~ 100:50 fully stirred to fully mix with each other;

[0021] (2) Shape:

[0022] The mixed raw material that has been fully mixed and contains the PU raw material 10 and the crystals is filled into a molding mold in the shape of the predetermined clothing by extrusion or injection, and molded into the shape of the predetermined clothing;

[0023] (3) Washing:

[0024] The shaped clothes are taken out from the forming mold, washed and cooled in water, so that the crystals in the shaped clothes are dis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com