centrifugal pendulum

A technology of centrifugal force pendulum and pendulum quality, which is applied in the field of centrifugal force pendulum, which can solve the problems of limited service life of elastic elements and damage of elastic elements, and achieve the effect of reducing collision noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

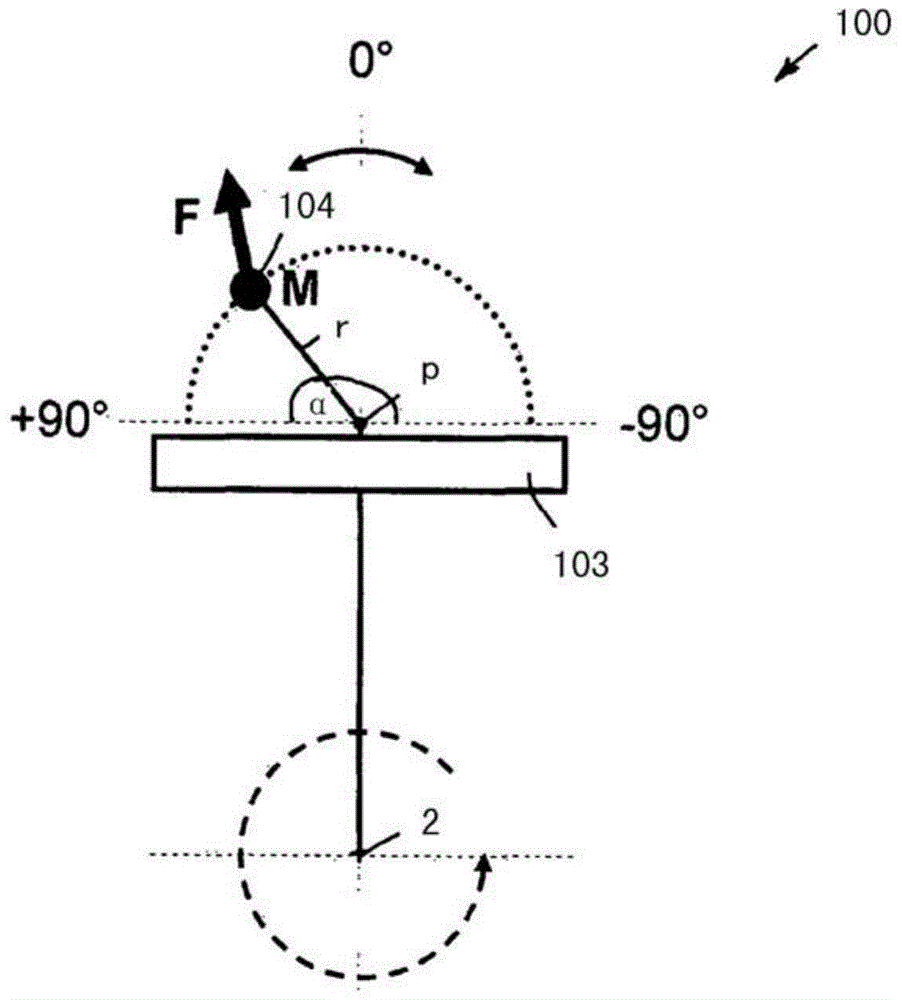

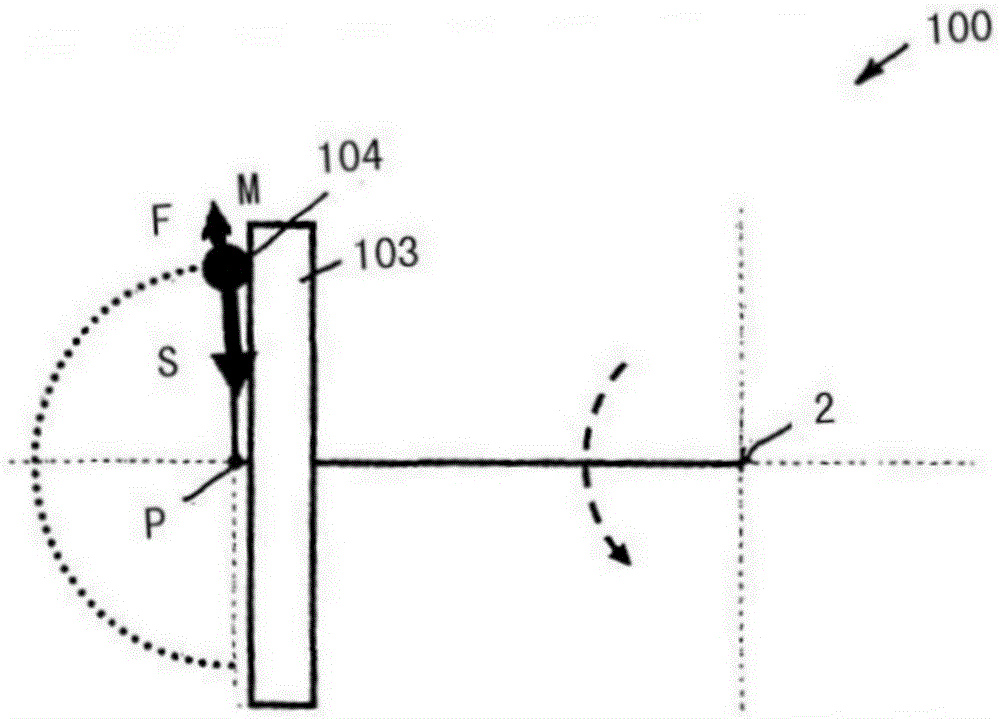

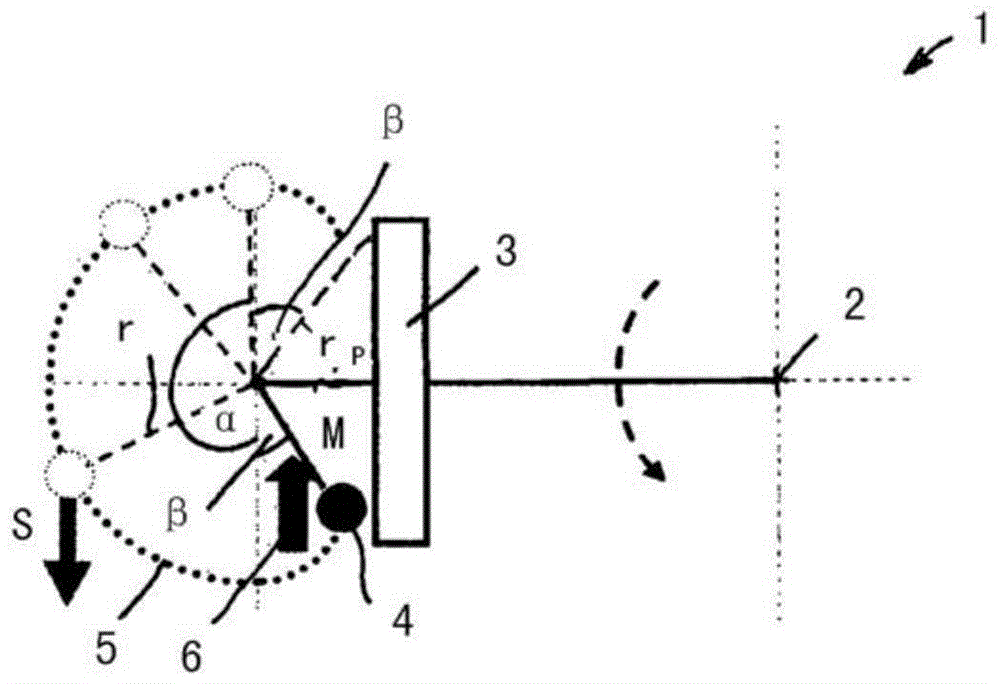

[0025] figure 1 The basic function of a centrifugal pendulum 100 is shown, which has a pendulum flange 103 that rotates about the axis of rotation 2 and a pendulum mass 104 with a center of mass M that is pivotably suspended relative to the pendulum flange on the pivot center point P. . At a constant rotational speed, the center of mass M is accelerated radially outward due to the centrifugal force F and is in an equilibrium position at 0°. If a rotational vibration occurs on the axis of rotation 2, the center of mass M is deflected radially inwards against the centrifugal force F along the vibration angle α, depending on the sign of the moment momentarily transmitted to the pendulum flange 103 and then Again, the excitation frequencies occurring when adjusting the pendulum radius r, the pendulum mass and the oscillation angle α are eliminated in a rotationally adapted manner. Here, the vibration angle α is limited to ±90°. When the maximum oscillation angle is reached, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com