Patents

Literature

149results about How to "Reduce crash noise" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

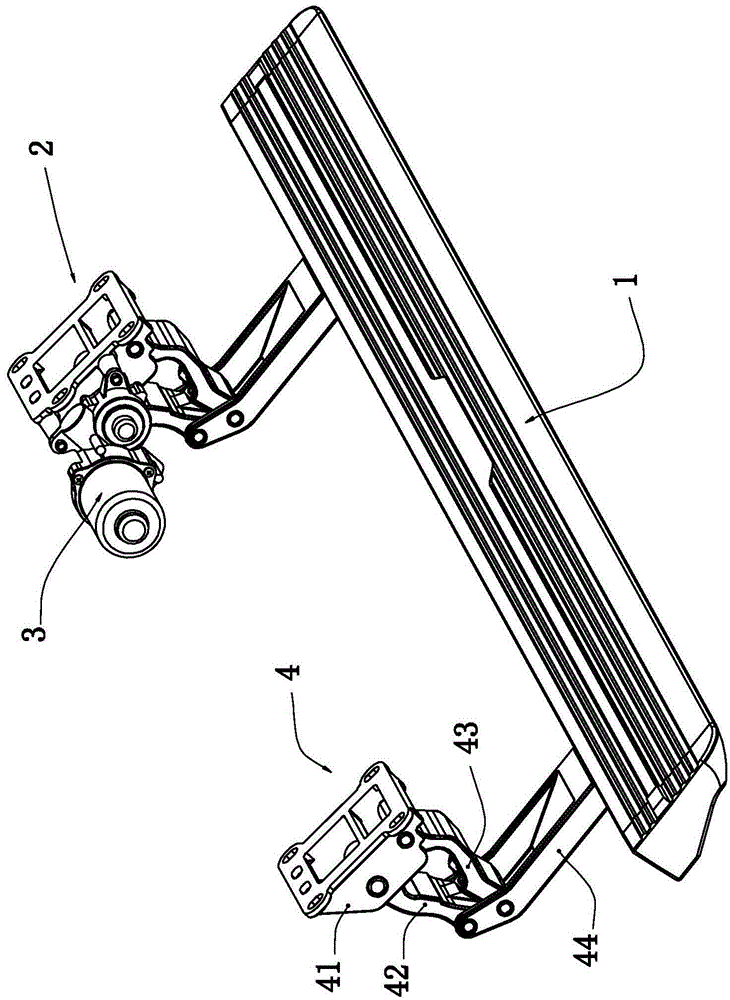

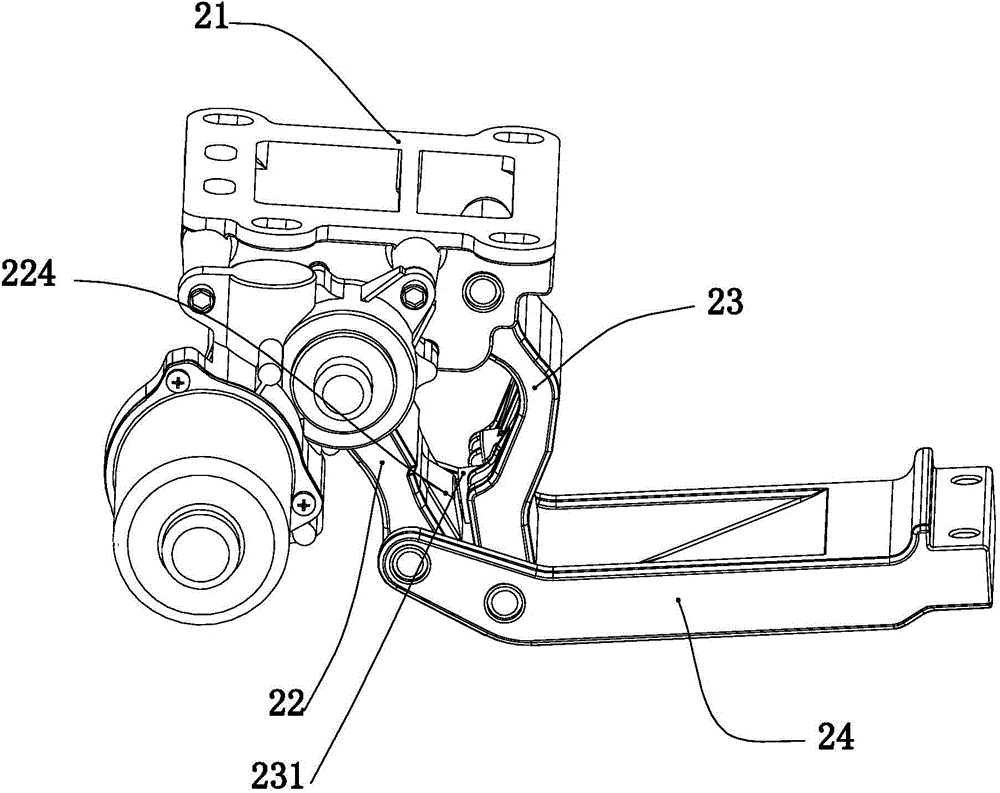

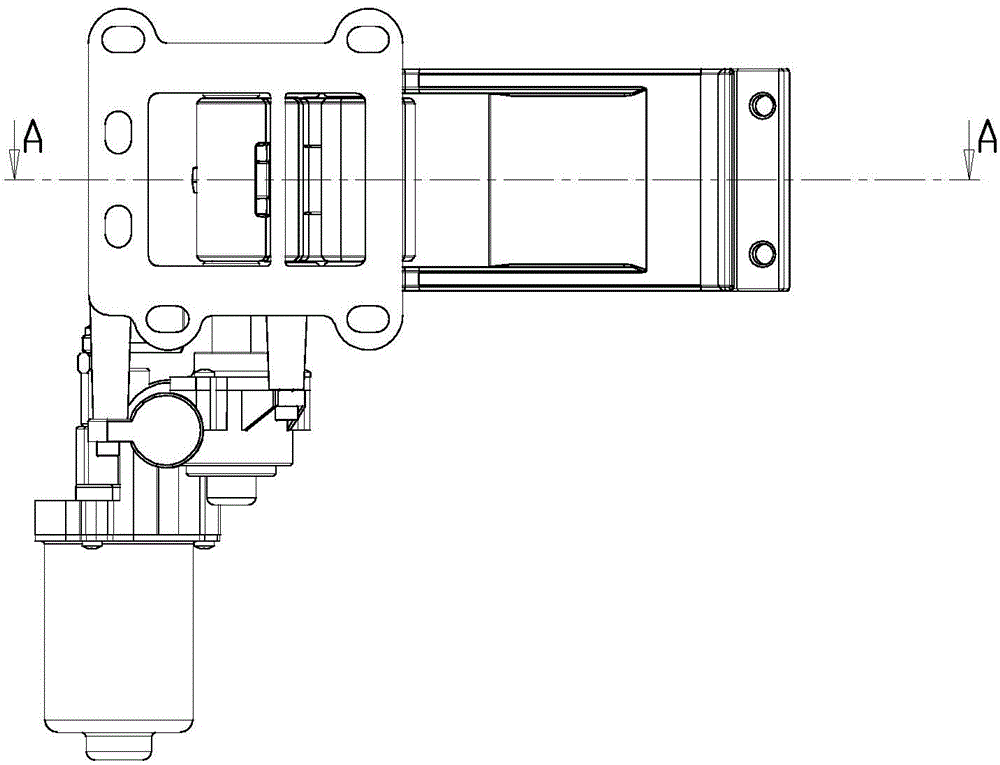

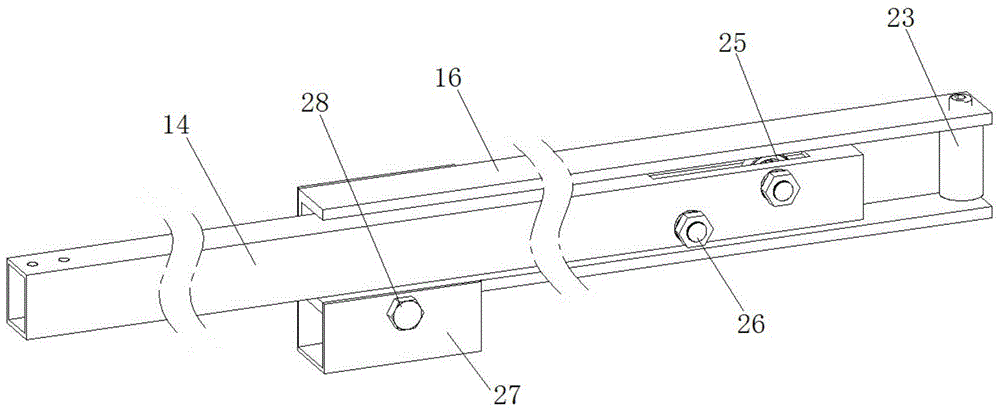

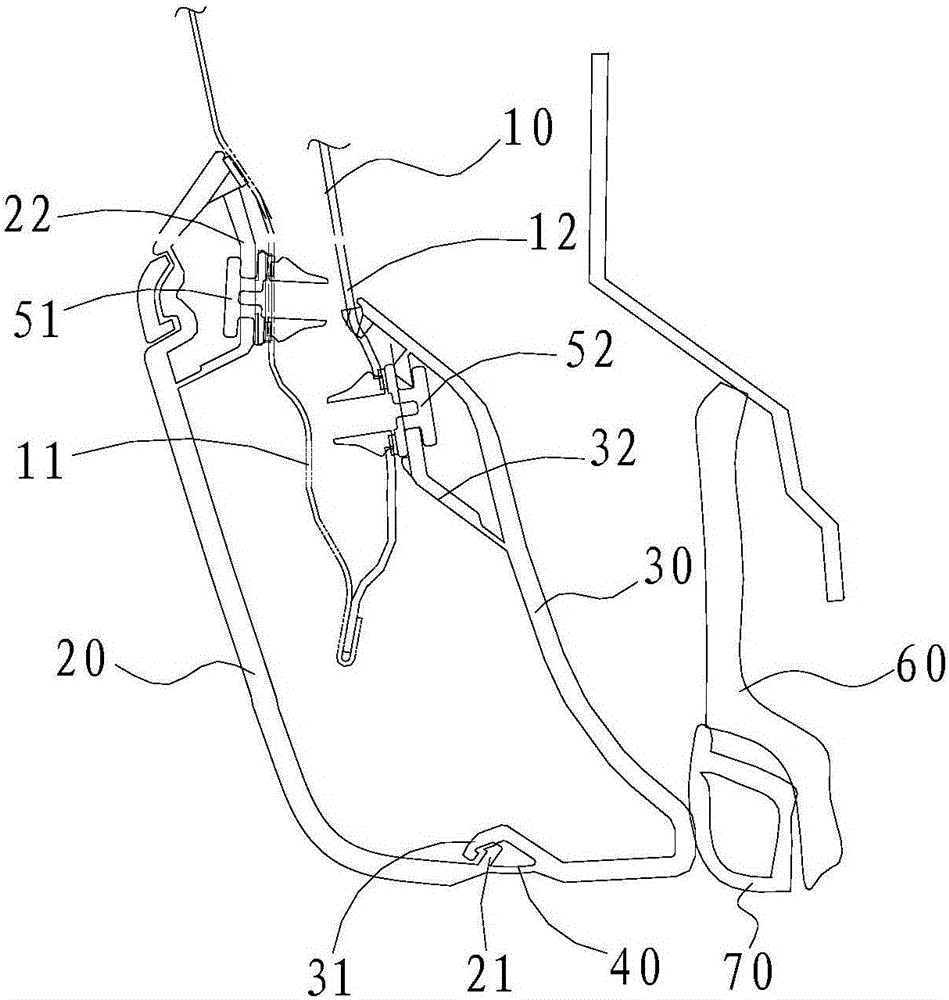

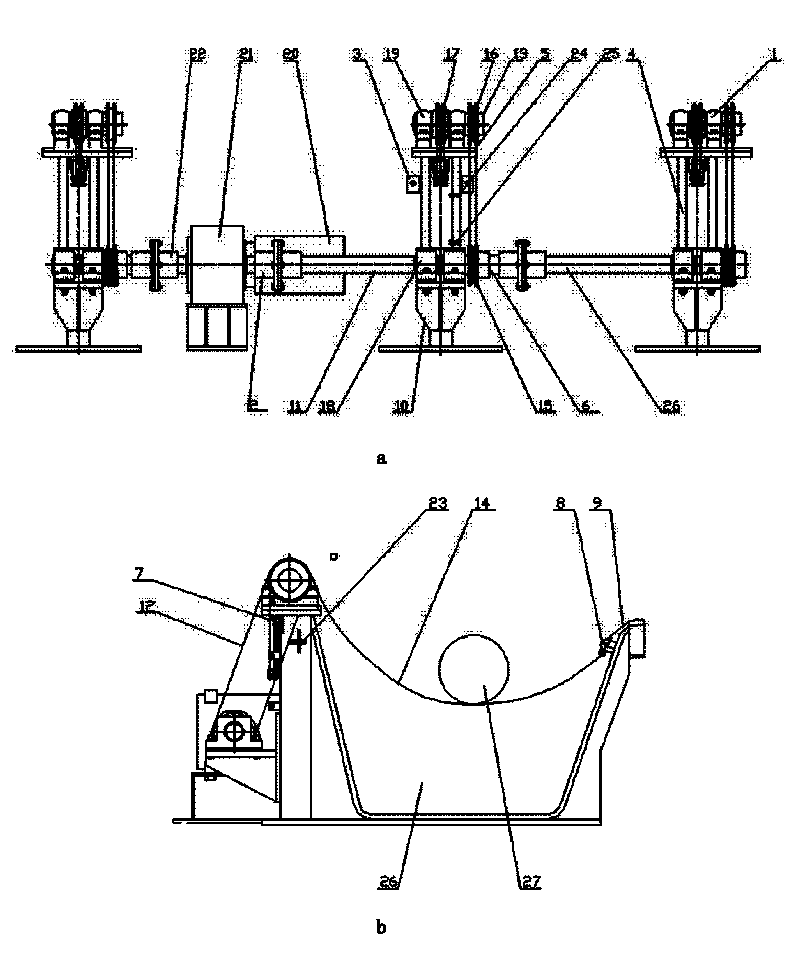

Automobile electric telescopic pedal with double-station support function

ActiveCN104385989AAvoid forceExtended service lifeSteps arrangementMechanical engineeringEngineering

The invention discloses an automobile electric telescopic pedal with a double-station support function. The automobile electric telescopic pedal comprises a pedal body, a first pedal mounting bracket assembly and a positive and reverse rotation motor, wherein the first pedal mounting bracket assembly comprises a first motor mounting frame, a first main driving plate, a first auxiliary connecting plate and a first telescopic bracket, the outer end of the first telescopic bracket is fixedly connected with the pedal body in a support fit way, and the upper ends and the lower ends of the first main driving plate and the first auxiliary connecting plate are respectively hinged and fit with the inner ends of the first motor mounting frame and the first telescopic bracket to form a plane four-connecting rod structure; when the first telescopic bracket is controlled in the extending station state, a limiting convex block of the first main driving plate and a limiting convex block of the first auxiliary connecting plate are mutually abutted, jacked, limited and fit; when the first telescopic bracket is controlled in the retraction station state, the outer contour surface of the first main driving plate is provided with an outer convex part of the first main driving plate, and the outer convex part of the first main driving plate and the upper end surface of the first telescopic bracket are mutually limited and jacked. The automobile electric telescopic pedal has the advantages that the structure design is reasonable, the service life of the motor is prolonged, and the support stability of the pedal is guaranteed.

Owner:RUIAN NOBLE AUTO PARTS

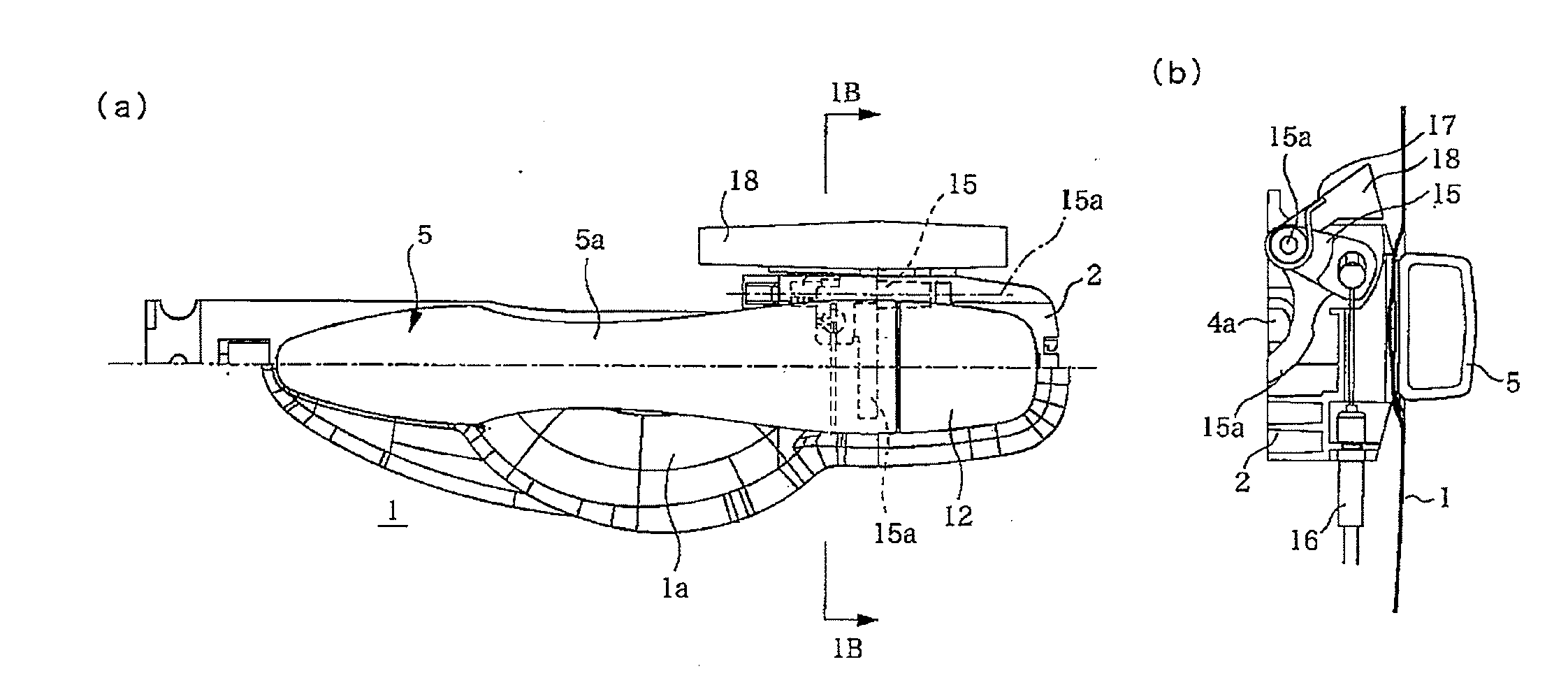

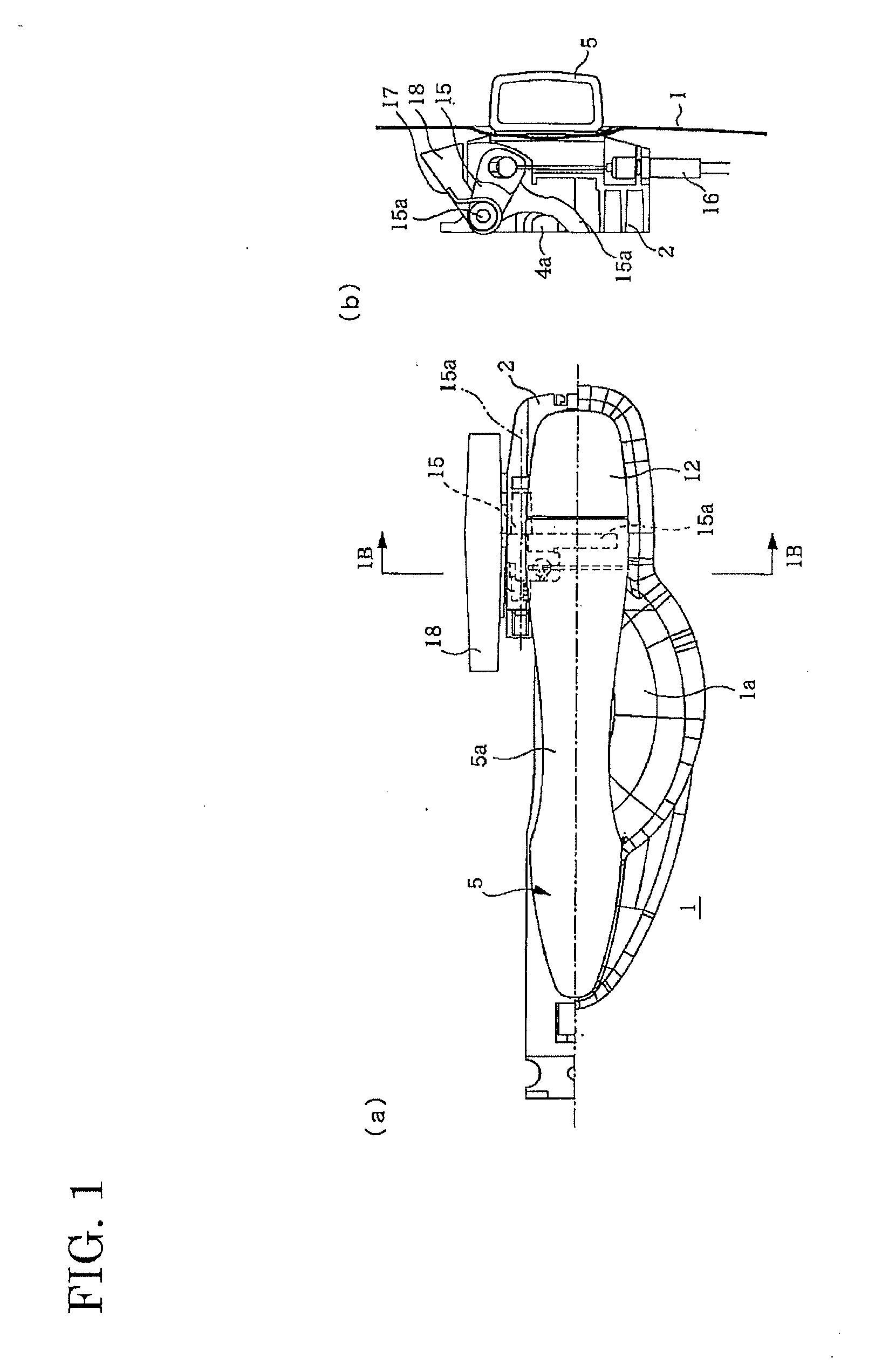

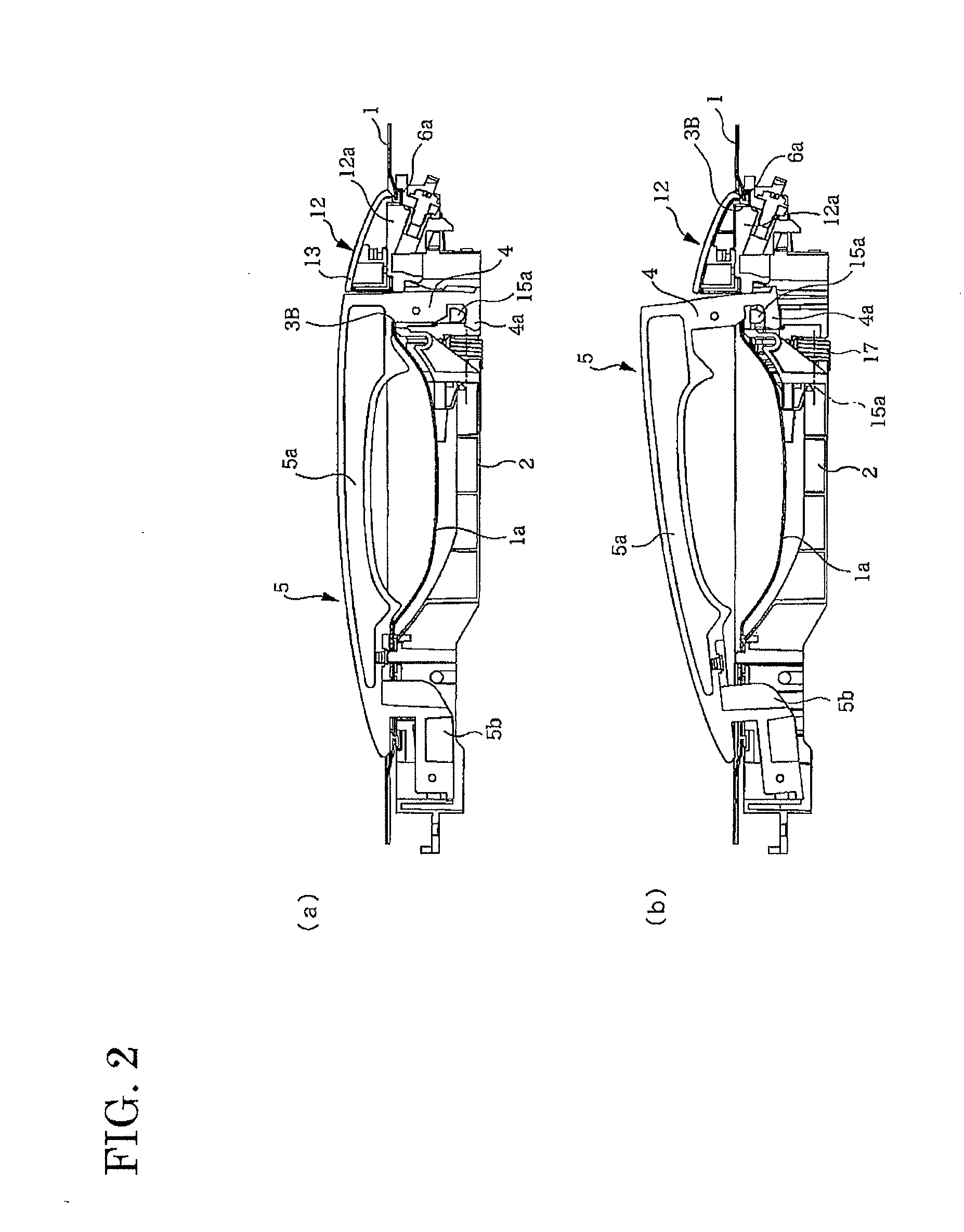

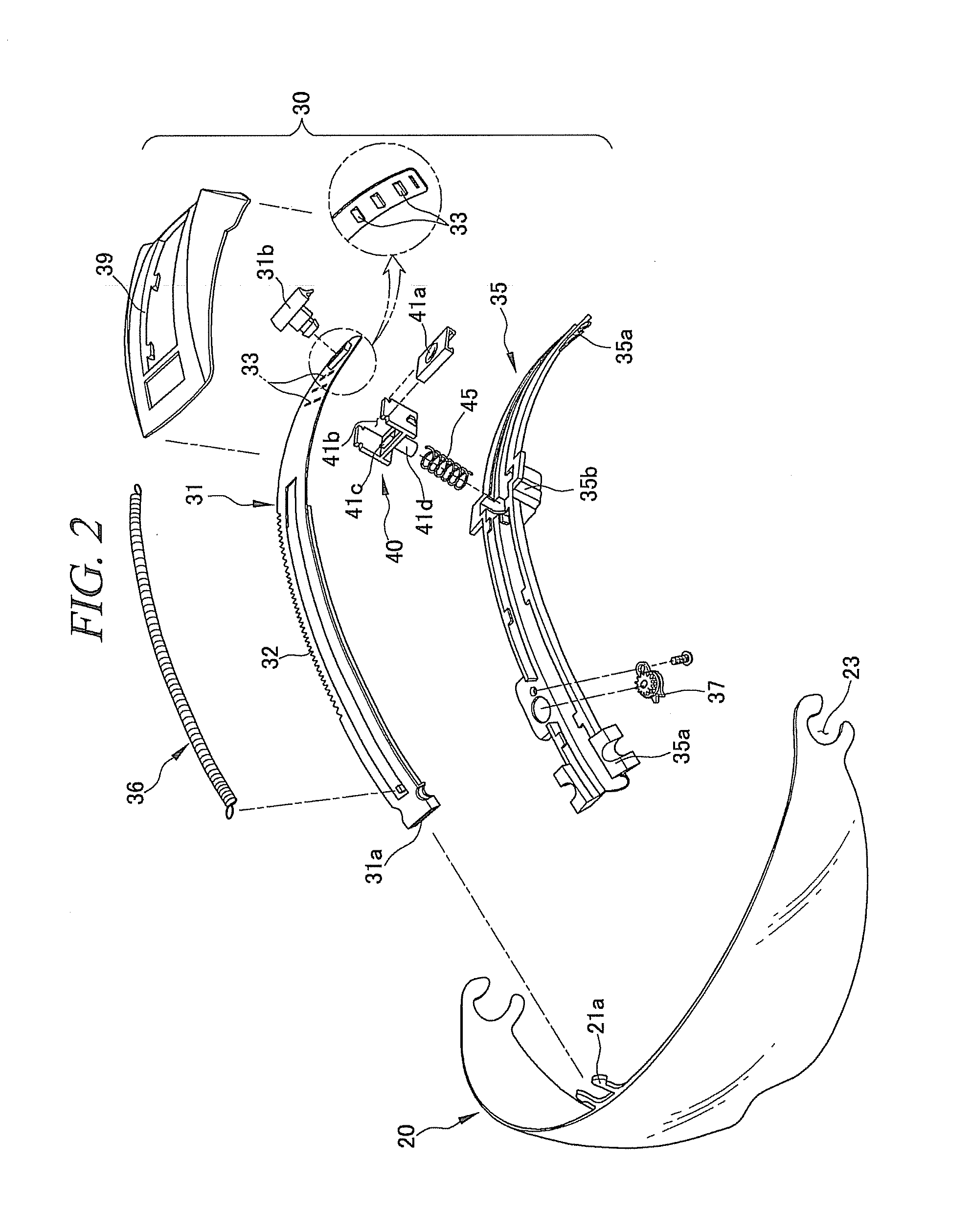

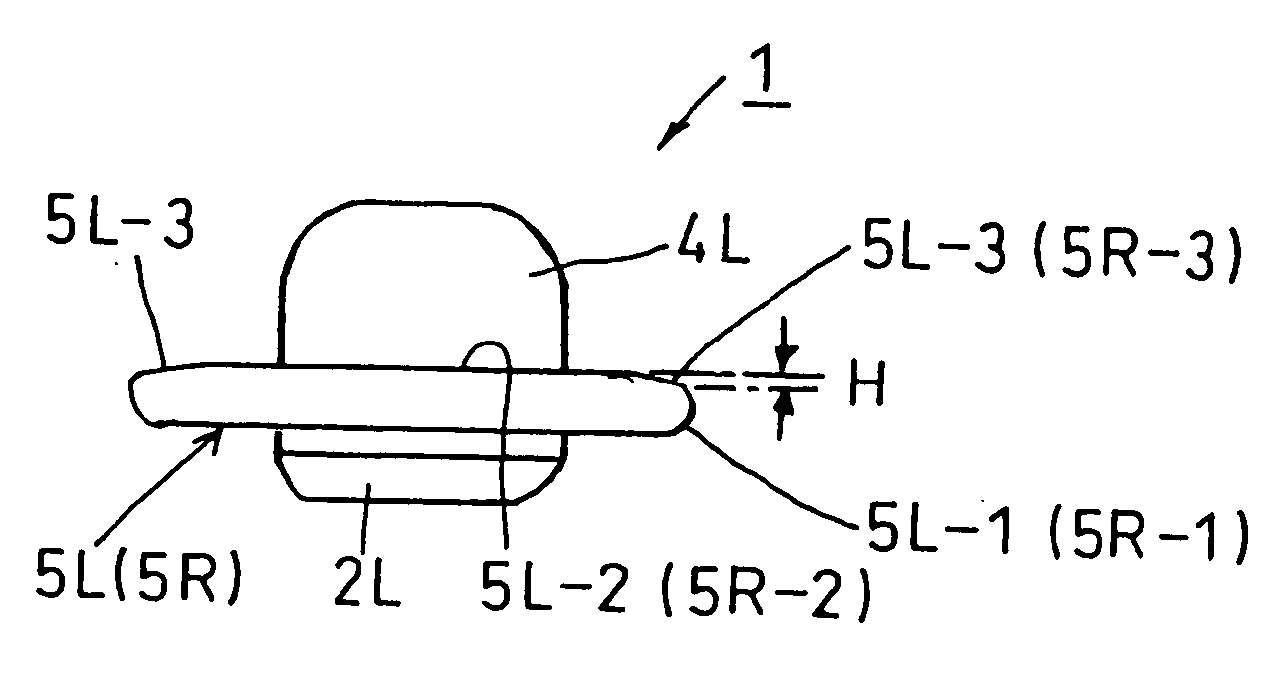

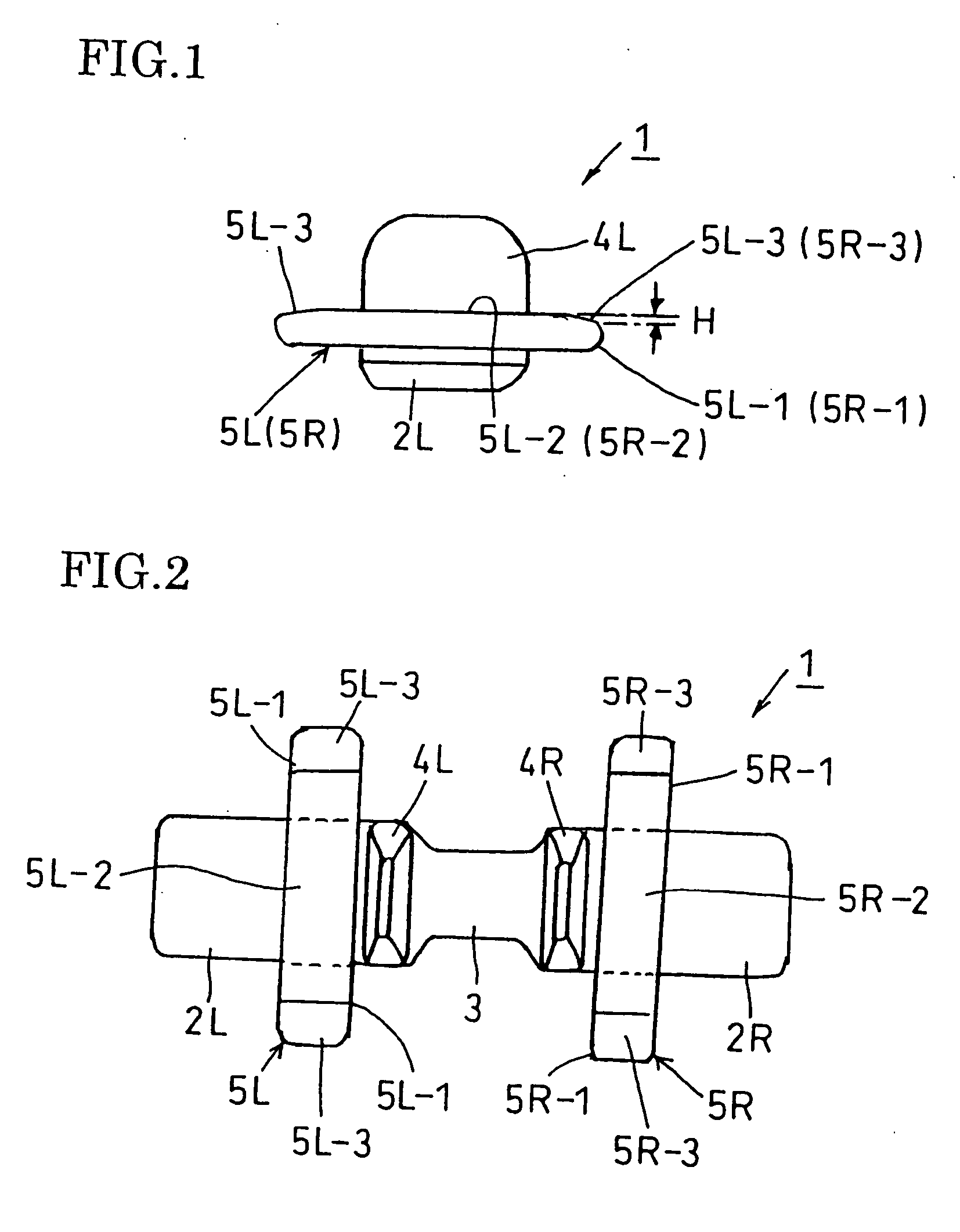

Vehicle door handle device

ActiveUS20140049058A1Reduce crash noiseSimple configurationNoise-prevention/anti-rattling lockingFastening meansEngineeringElectrical and Electronics engineering

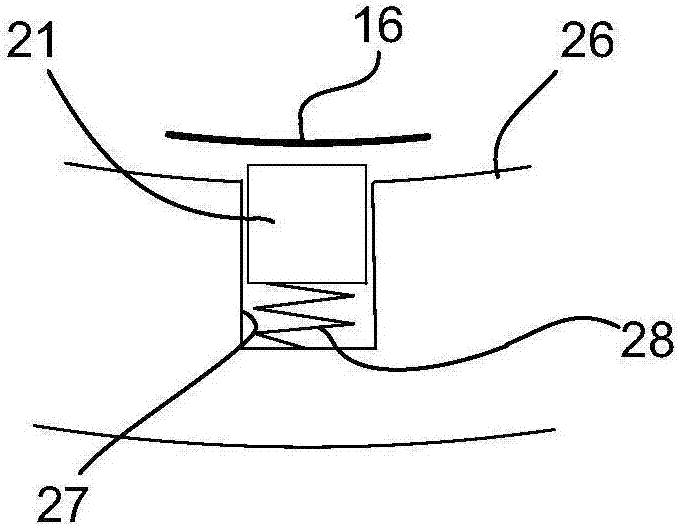

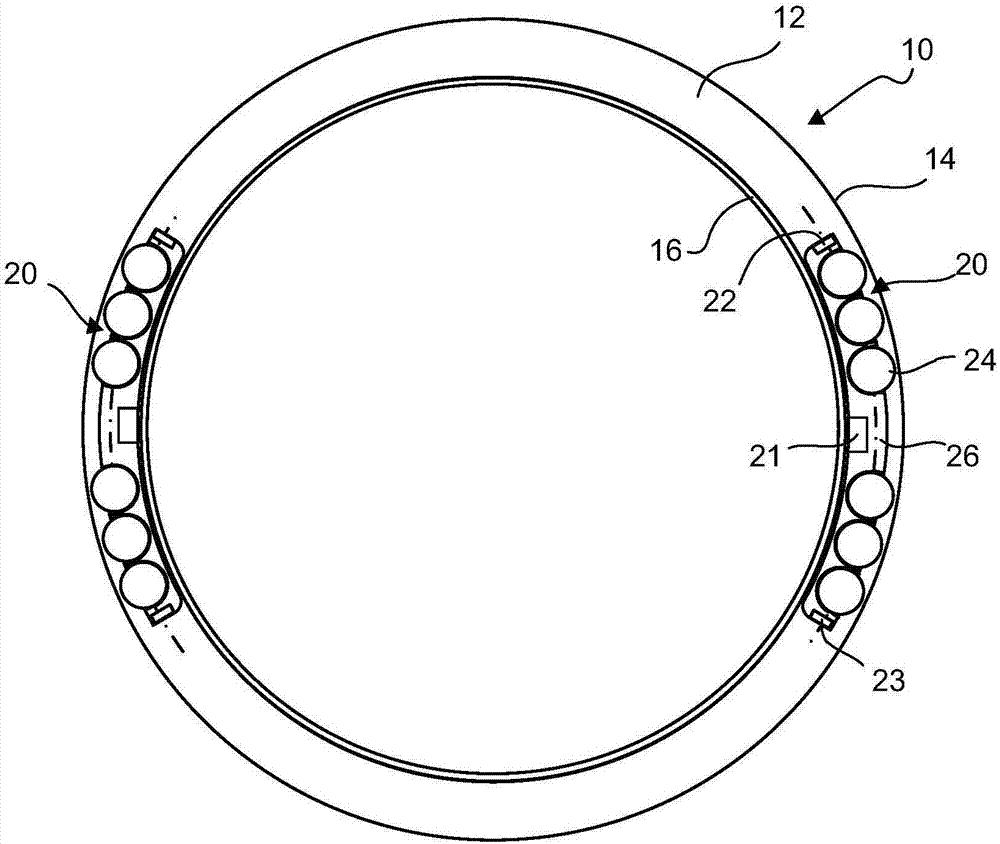

This door handle device is provided with: a handle base; an introduction opening that is opened in a door handle and that supports the handle base; an operation handle that is connected to the handle base; and a gasket that is disposed between the handle base and the operation handle. A handle stopper, of which one end passes through the introduction aperture and is borne by the handle base, and of which the other end contacts the operation handle, is integrally provided to the gasket.

Owner:ALPHA +1

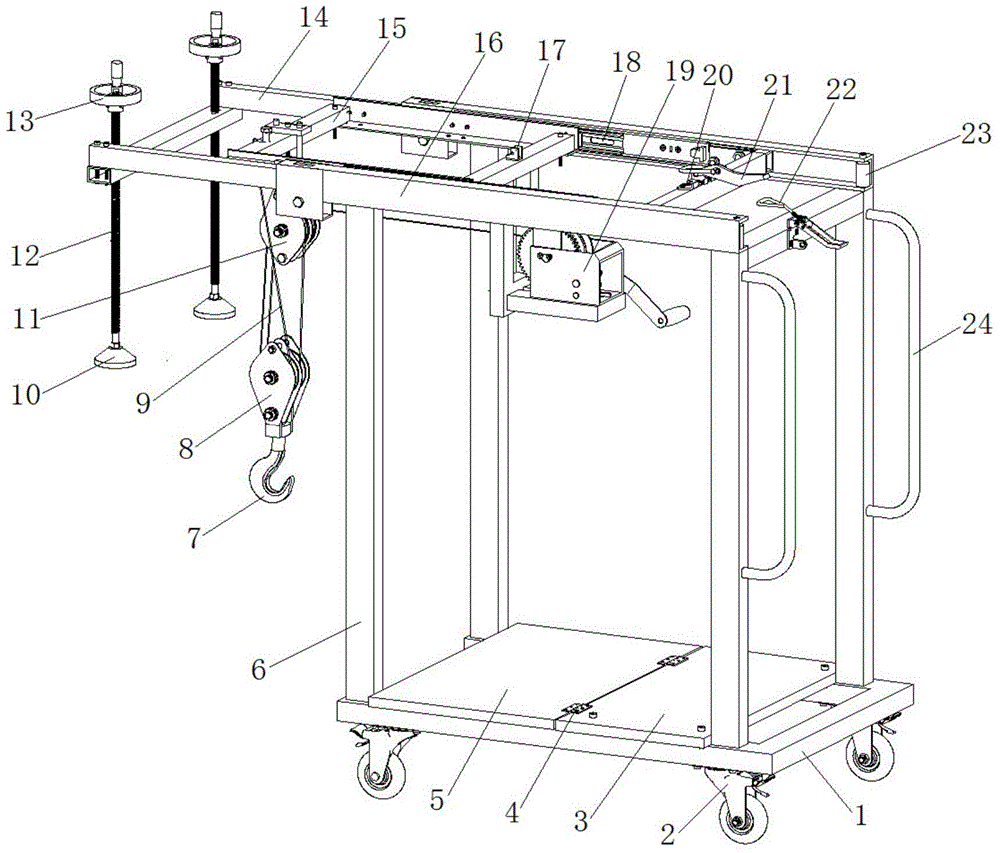

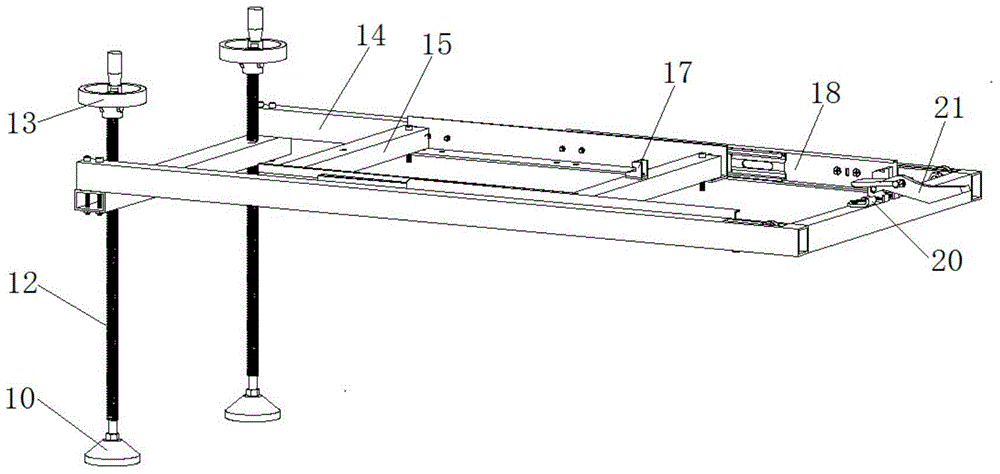

Simple heavy stuff carrying and feeding trolley

ActiveCN104444907AReduced risk of collisionReduce the incidence of work-related injuriesPortable liftingBlock and tackleEngineering

The invention discloses a simple heavy stuff carrying and feeding trolley and belongs to the field of carrying tools. The simple heavy stuff carrying and feeding trolley comprises a base, universal casters, a support, a feeding support, a sliding support, a supporting device, a manual winch, a pulley set and a hoisting hook, wherein the universal casters are arranged on the base, the support and the base are fixed into a whole, the feeding support is arranged on the top of the support, the sliding support is arranged inside the feeding support, the supporting device is arranged in the front of the feeding support, the manual winch is fixed to the back portion of the sliding support, and the pulley set and the hoisting hook are installed in the front of the sliding support. The pulley set comprises a fixed pulley and a movable pulley, a steel wire rope is led from the manual winch, sequentially winds around the fixed pulley and the movable pulley and then is fixed to the sliding support or a fixed pulley support; a fixed supporting plate is installed at the back of the base, and a movable supporting plate is installed in the front of the base. According to the simple heavy stuff carrying and feeding trolley, the functions of heavy stuff hoisting, transferring and machine tool feeding are achieved through a simple structure, and the labor intensity of workers is alleviated; meanwhile, the simple heavy stuff carrying and feeding trolley is simple in structure, convenient to operate, low in cost and high in safety and meets the use requirements of small and medium size enterprises.

Owner:常州东吉路国际贸易有限公司

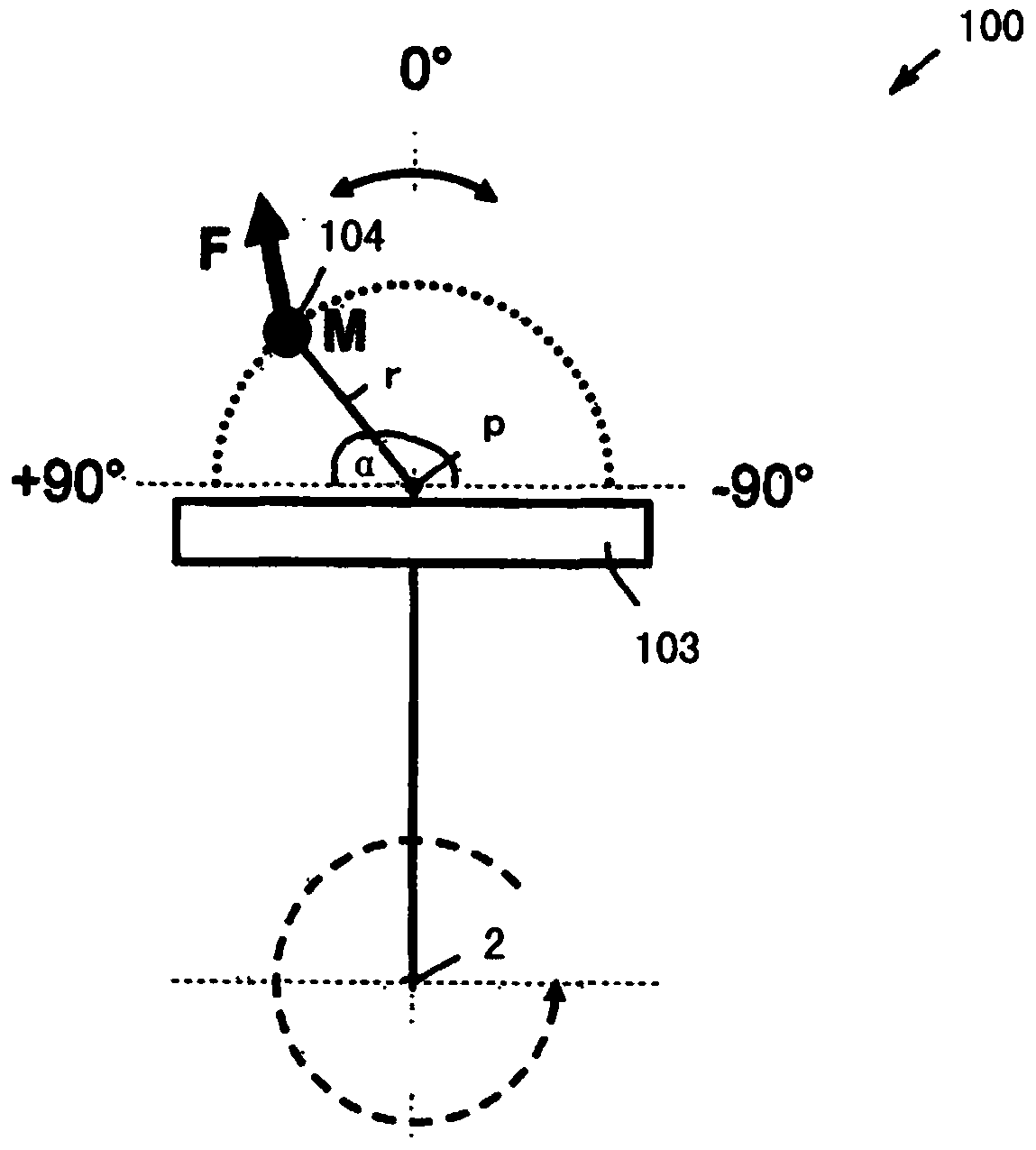

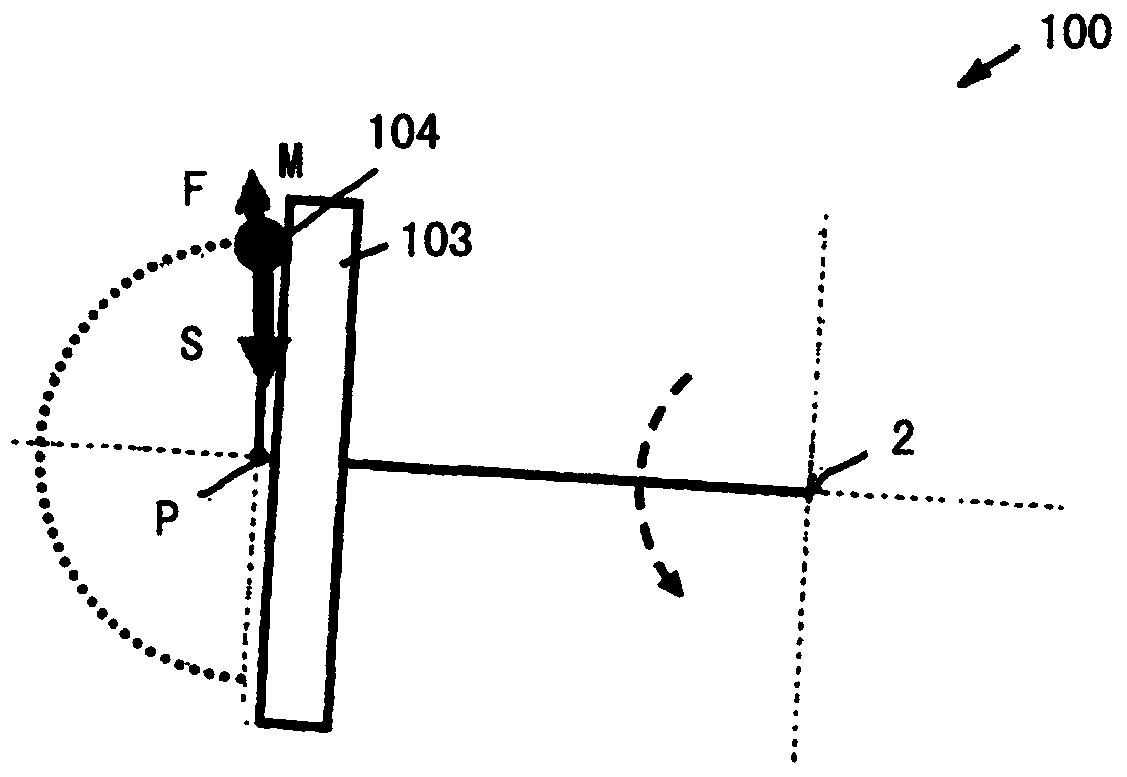

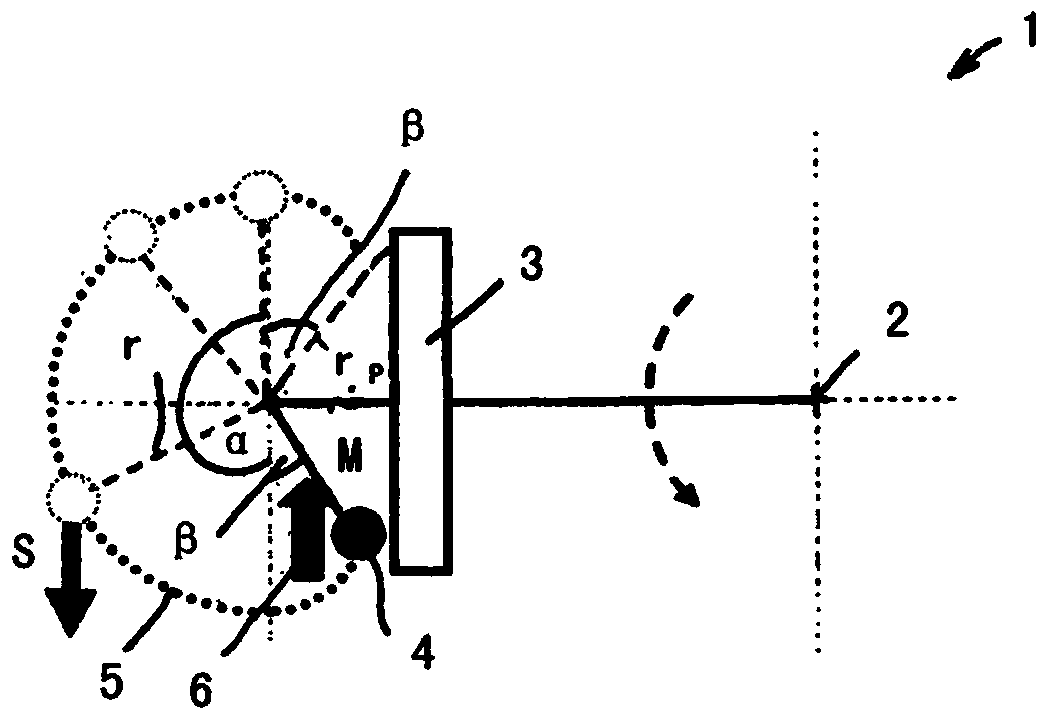

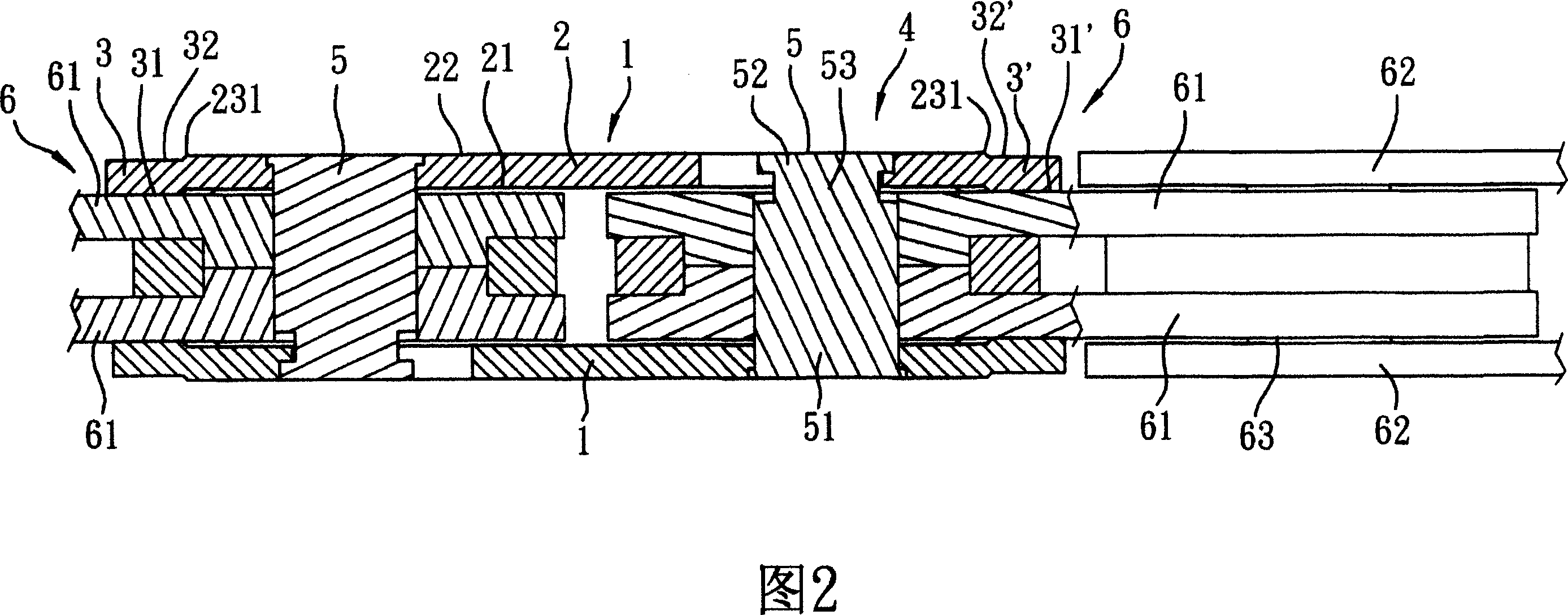

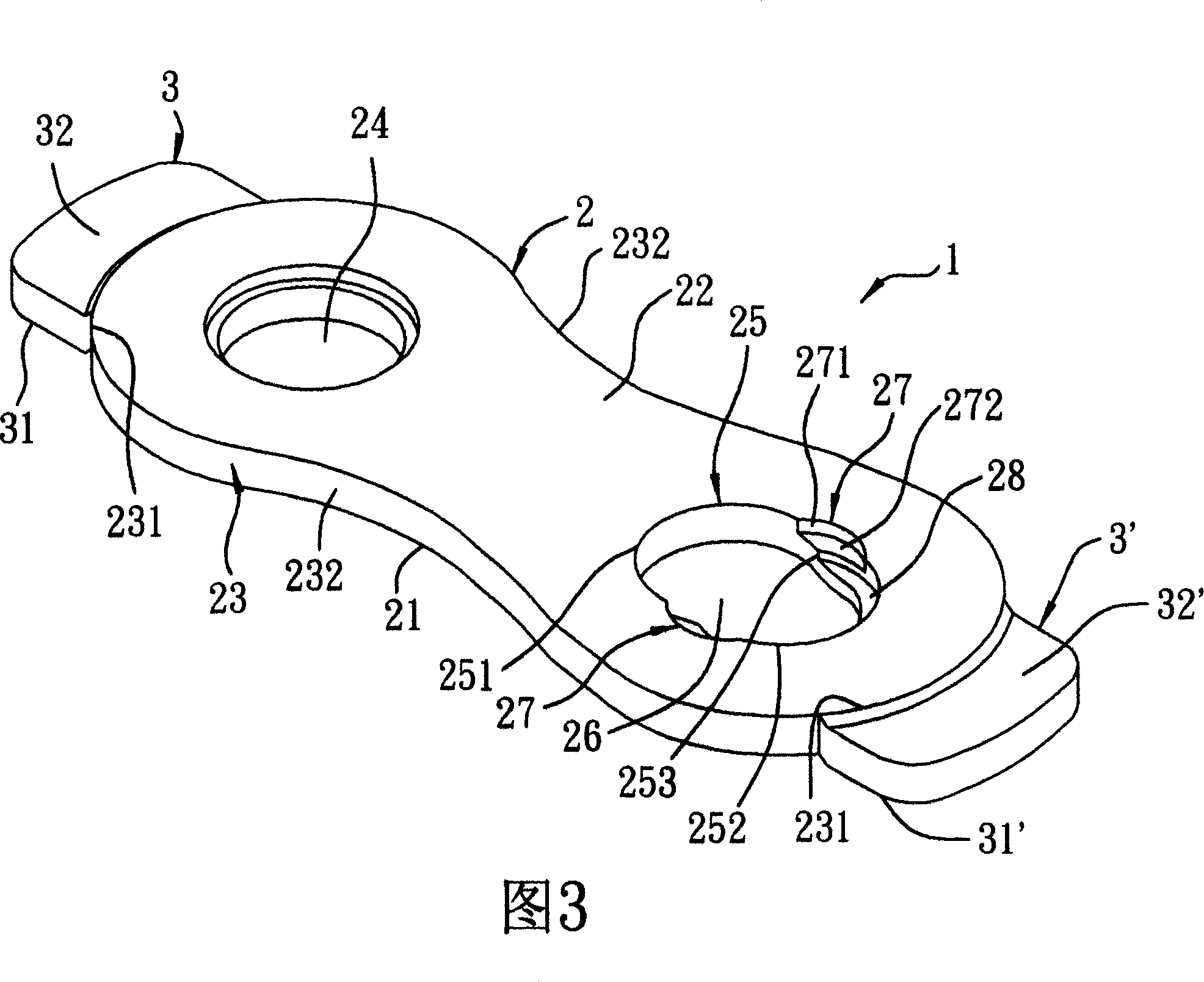

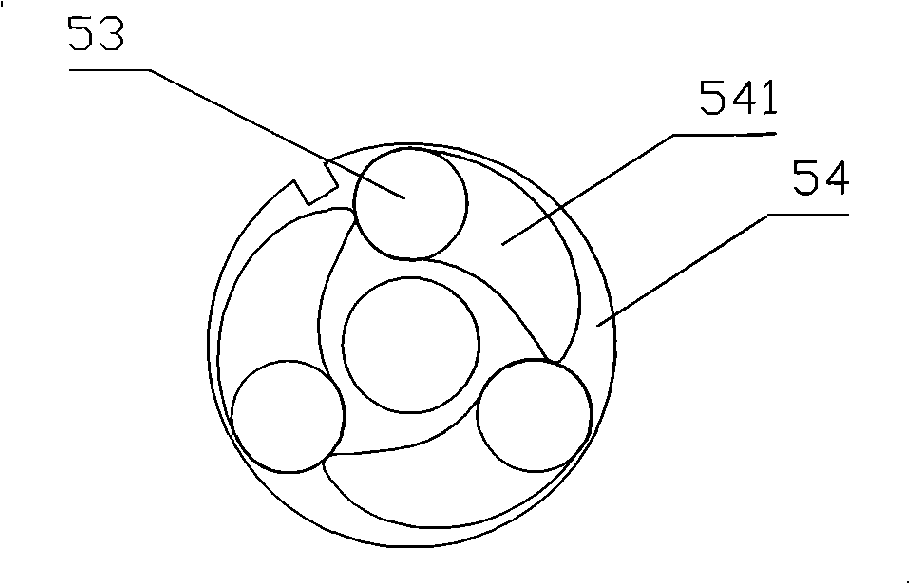

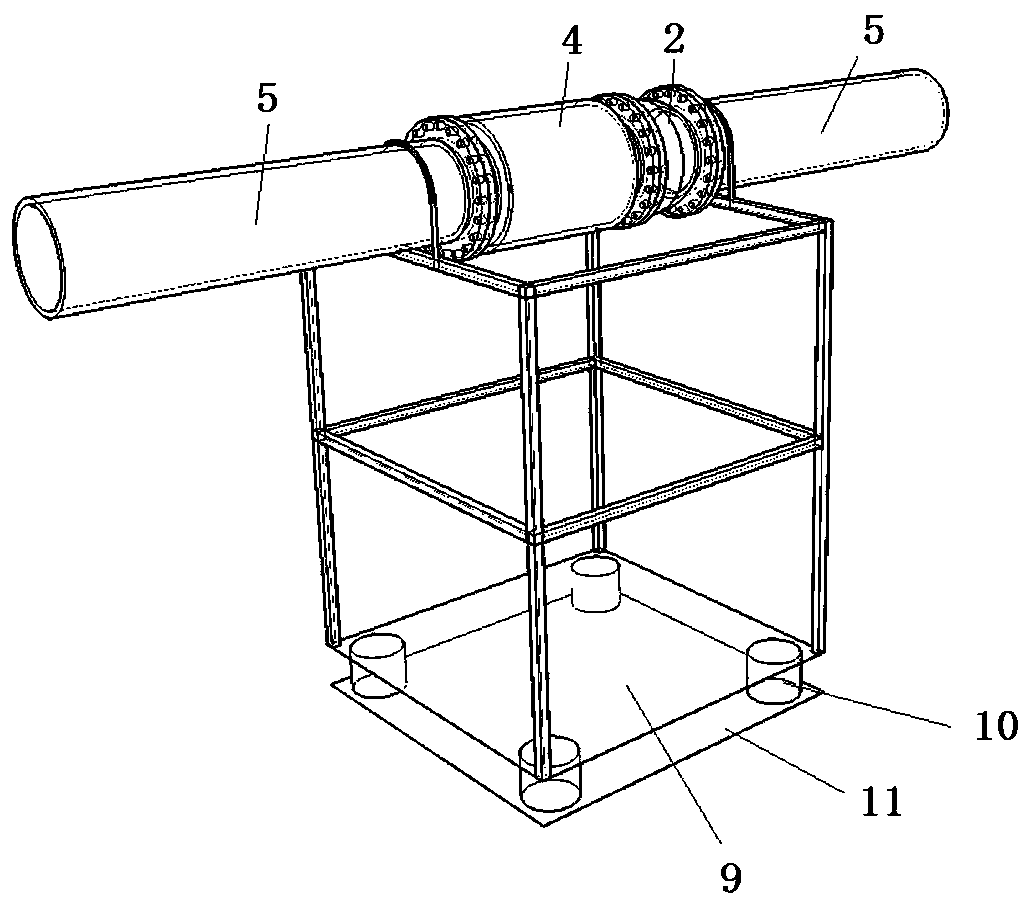

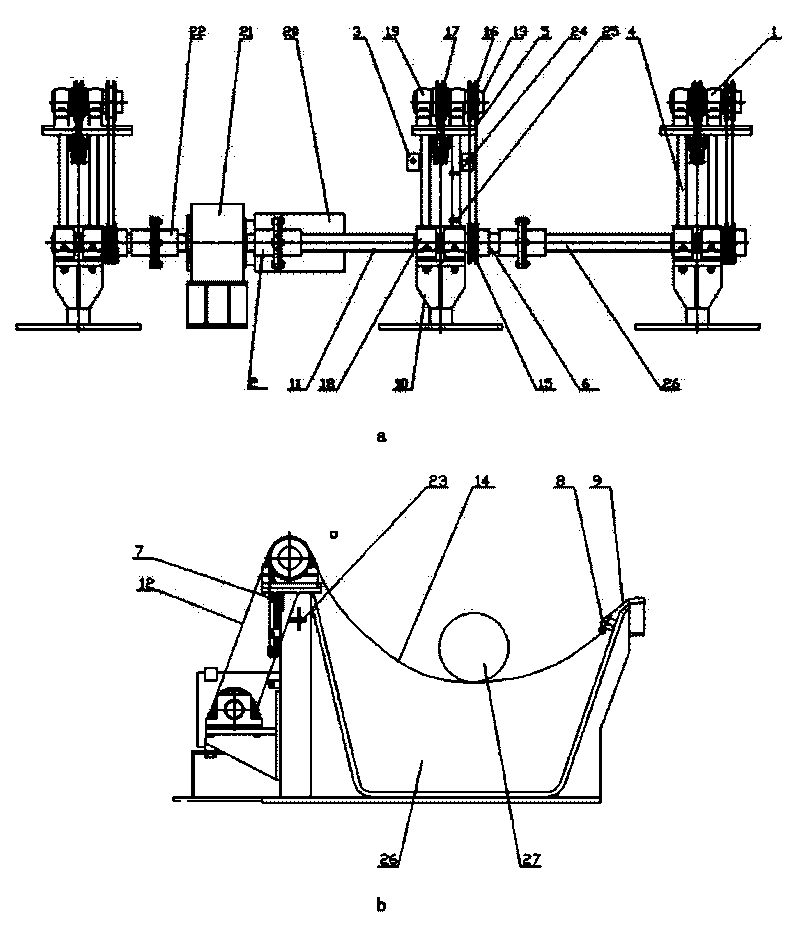

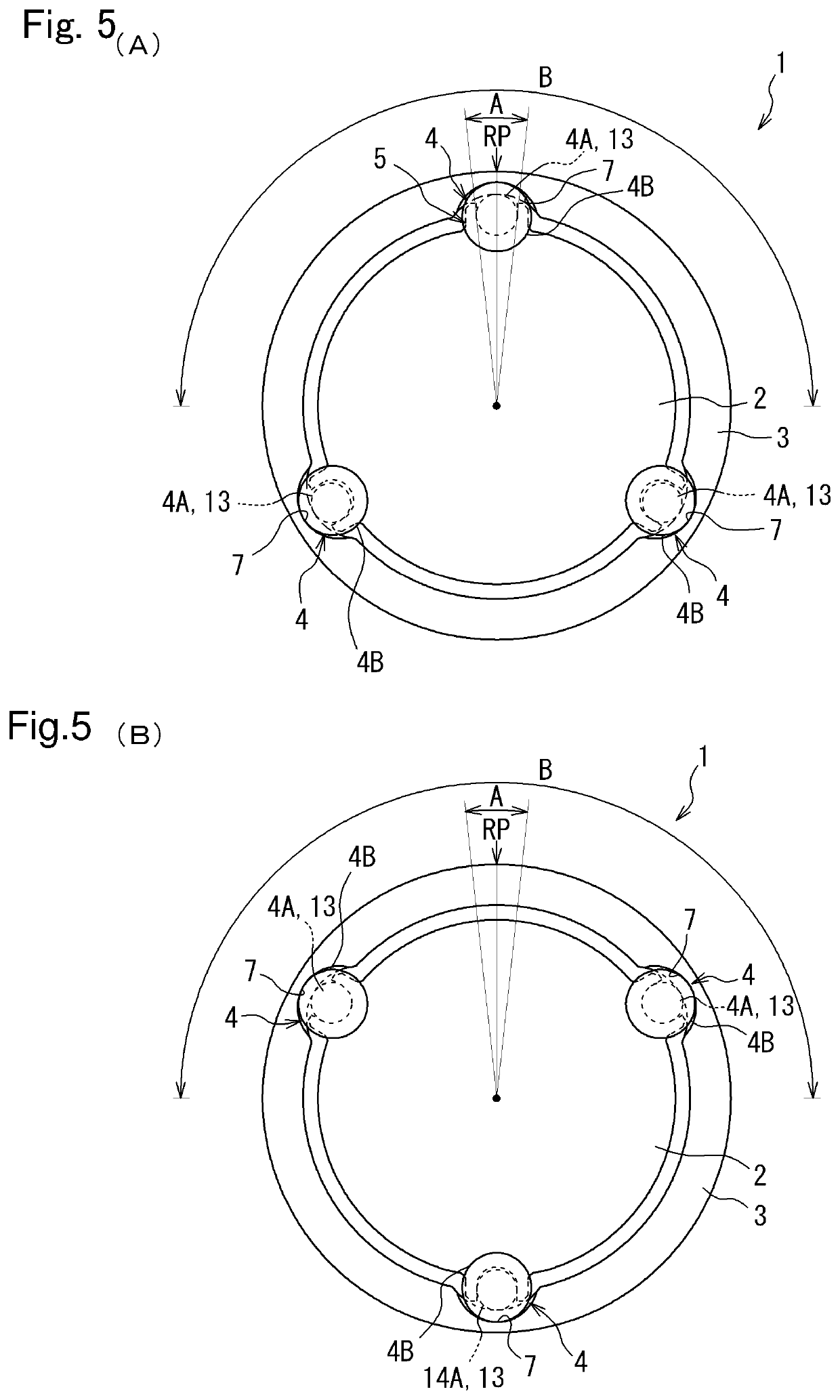

Centrifugal force pendulum

ActiveCN103842686AEffective vibration dampingReduce crash noiseRotating vibration suppressionGravitational forceEngineering

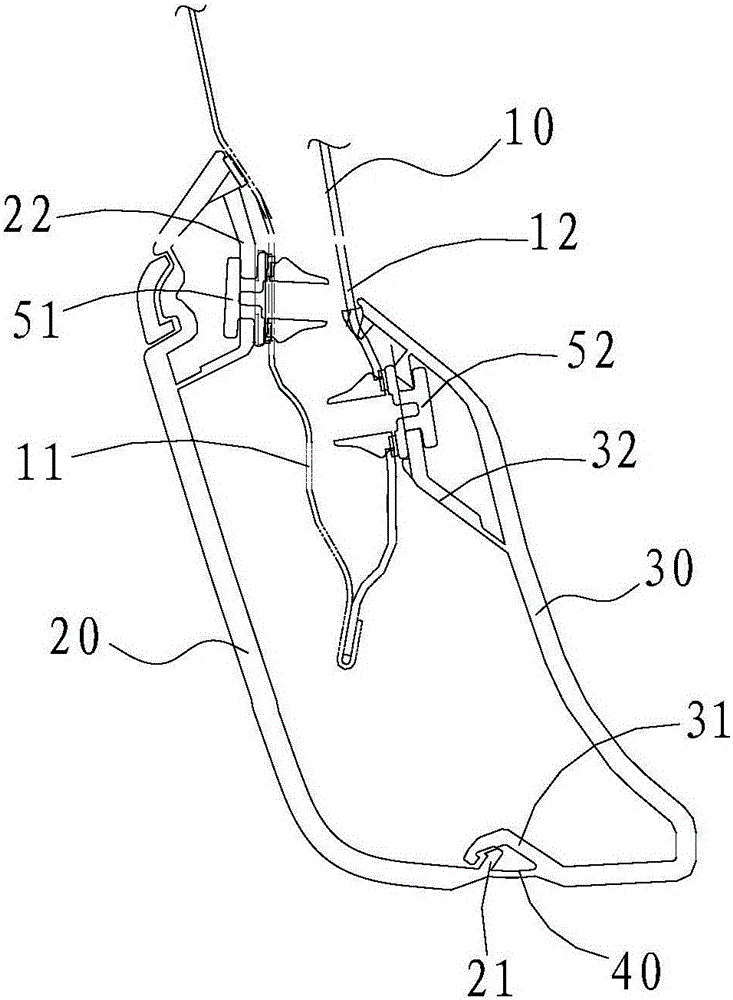

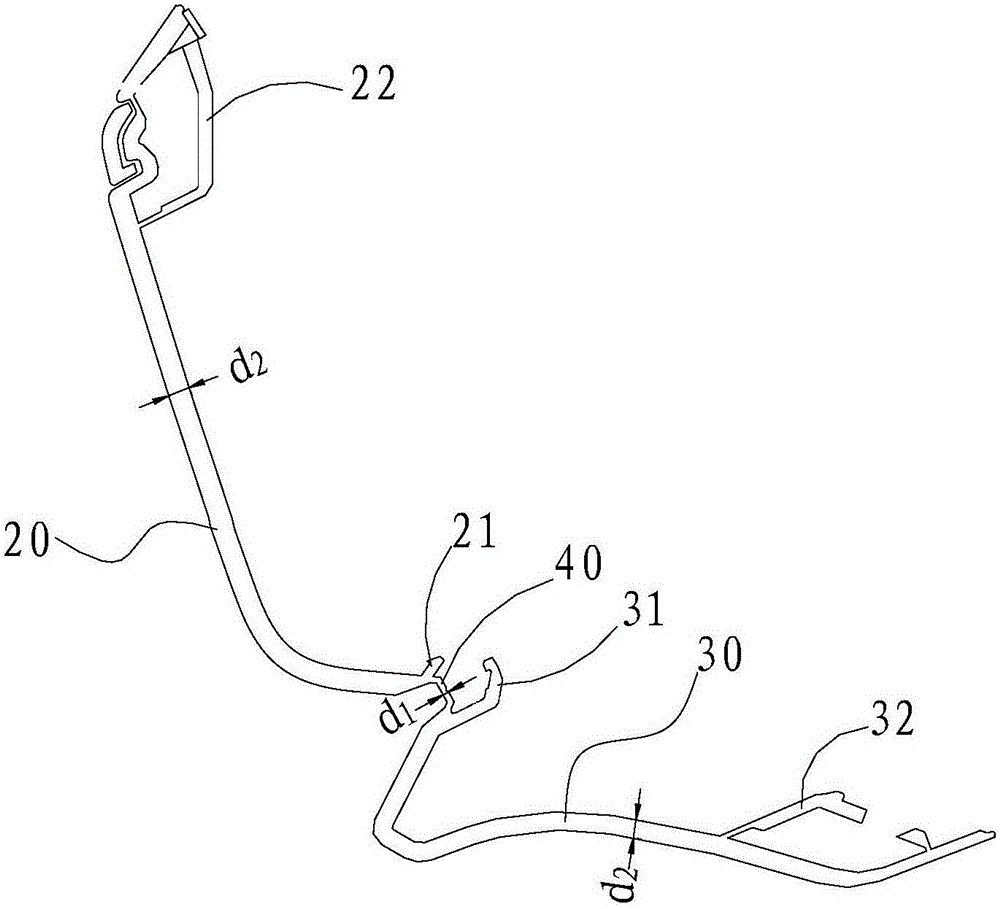

The invention relates to a centrifugal force pendulum (1, 1a) having a pendulum flange (3, 3a) which is arranged so as to be rotatable about an axis of rotation (2) and having a plurality of pendulum masses (4, 4a) which, for rotational-speed-adaptive absorption of rotary oscillations introduced into the pendulum flange (3, 3a), are held so as to be pitovable with a centre of mass (M) about at least one pendulum point (P) with a predefined pendulum radius (r) and a predefined swing angle (a). In order, at low rotational speeds of the pendulum flange (3, 3a), to reduce a generation of noise caused by pendulum masses arranged with the centre of masses thereof above the axis of rotation being accelerated in the direction of the axis of rotation owing to gravitational force, the predefined swing angle (a) is changed by a pendulum angle (ss) with a pendulum radius (rp) which is reduced in relation to the pendulum radius (r).

Owner:SCHAEFFLER TECH AG & CO KG

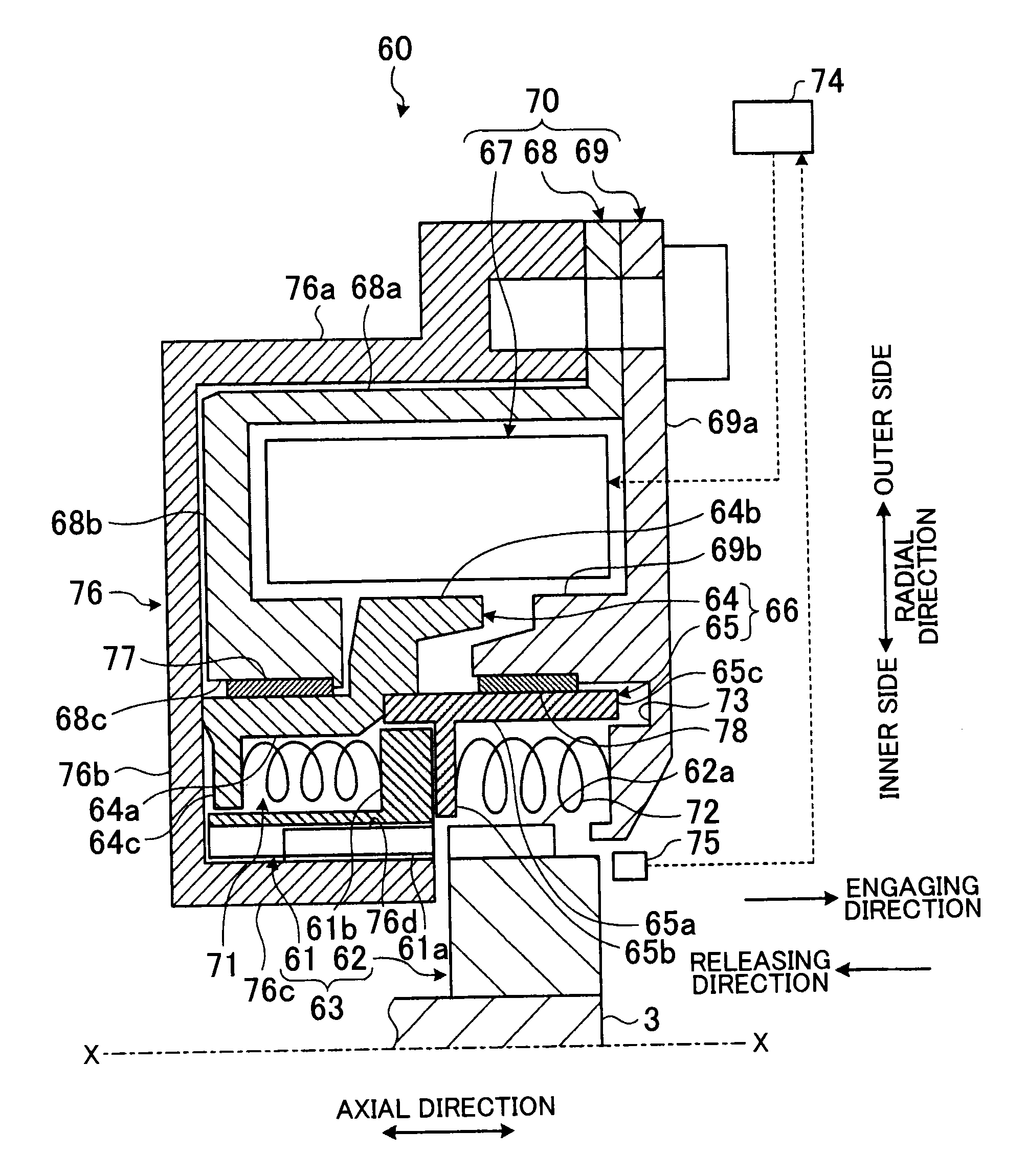

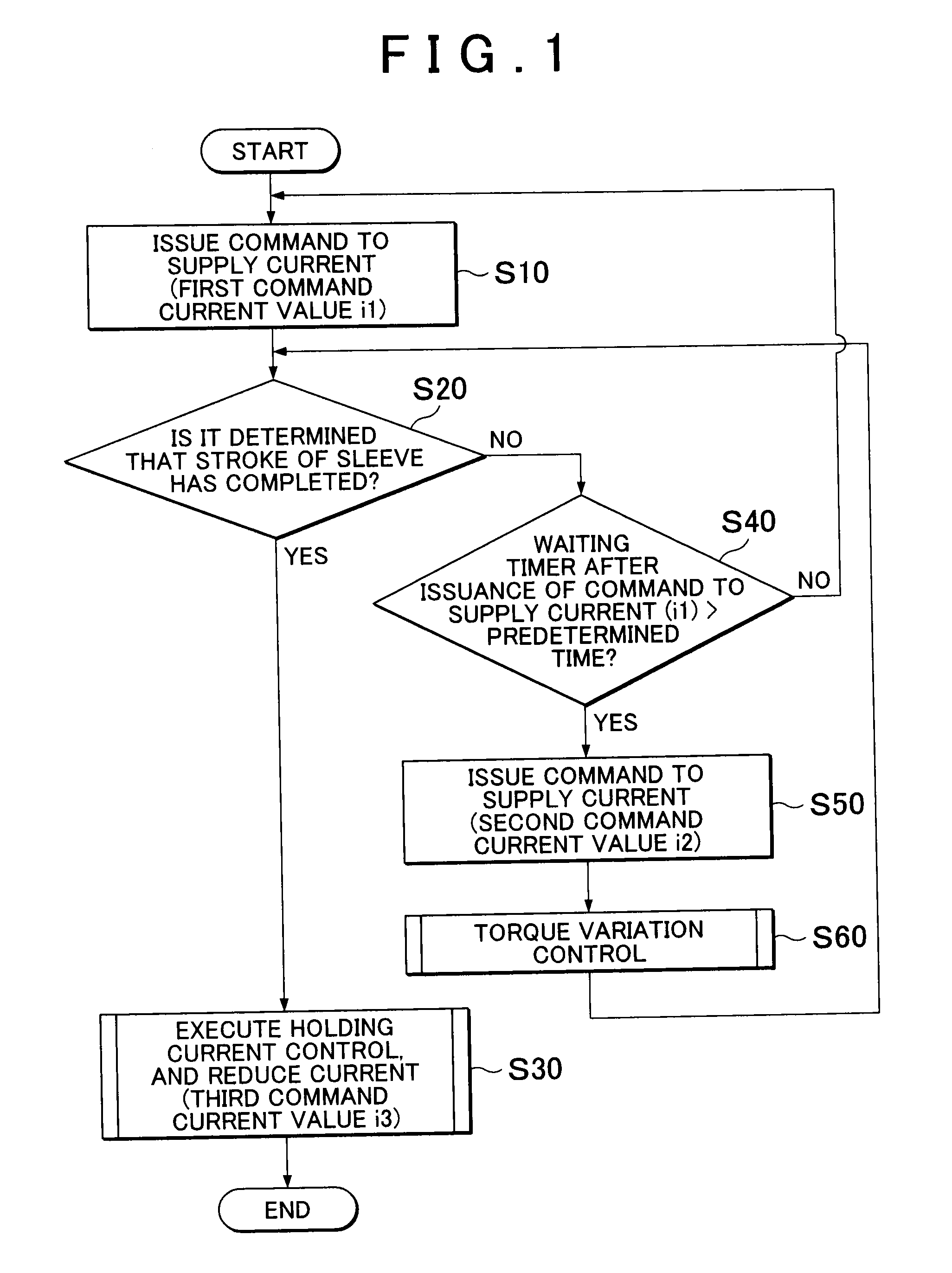

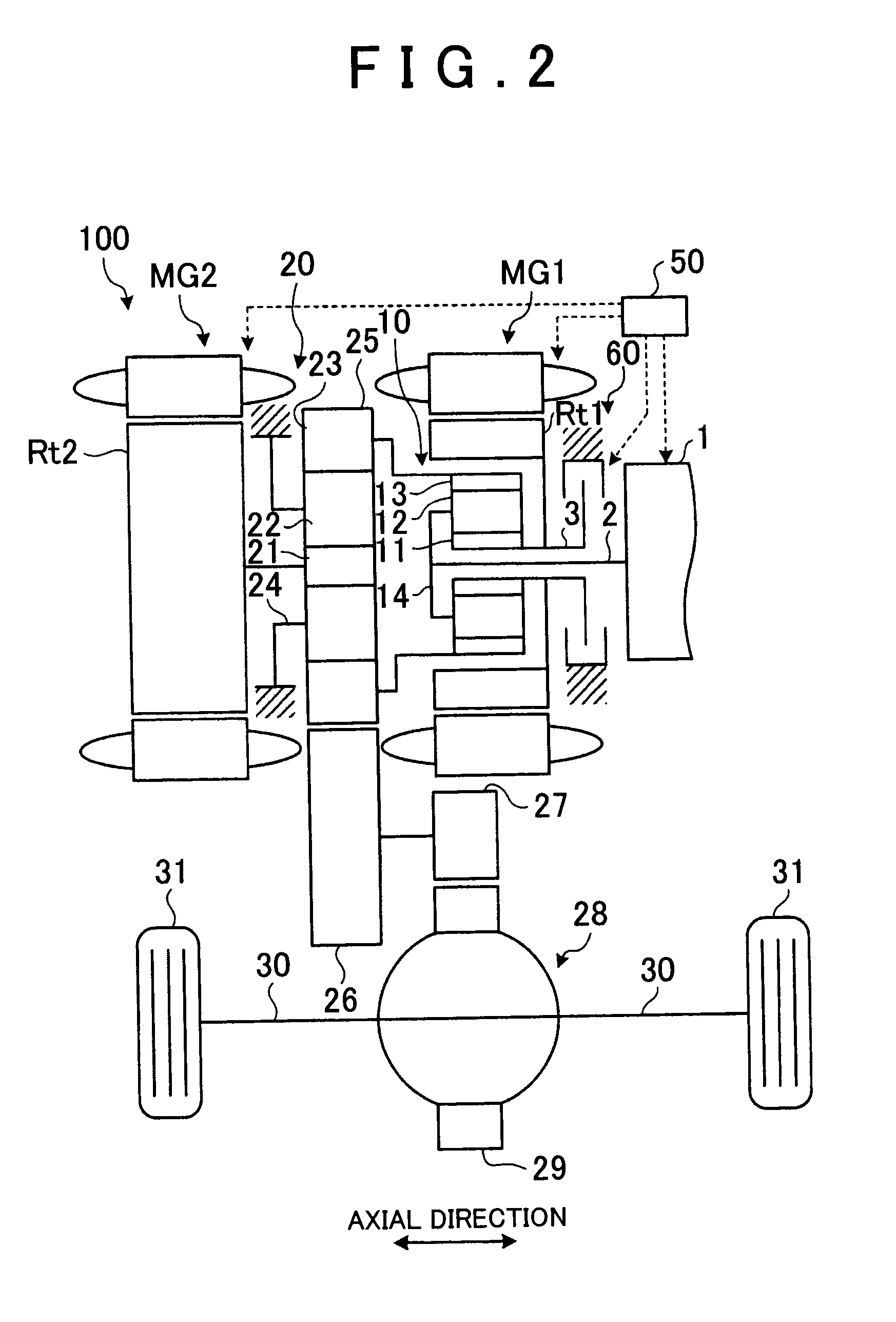

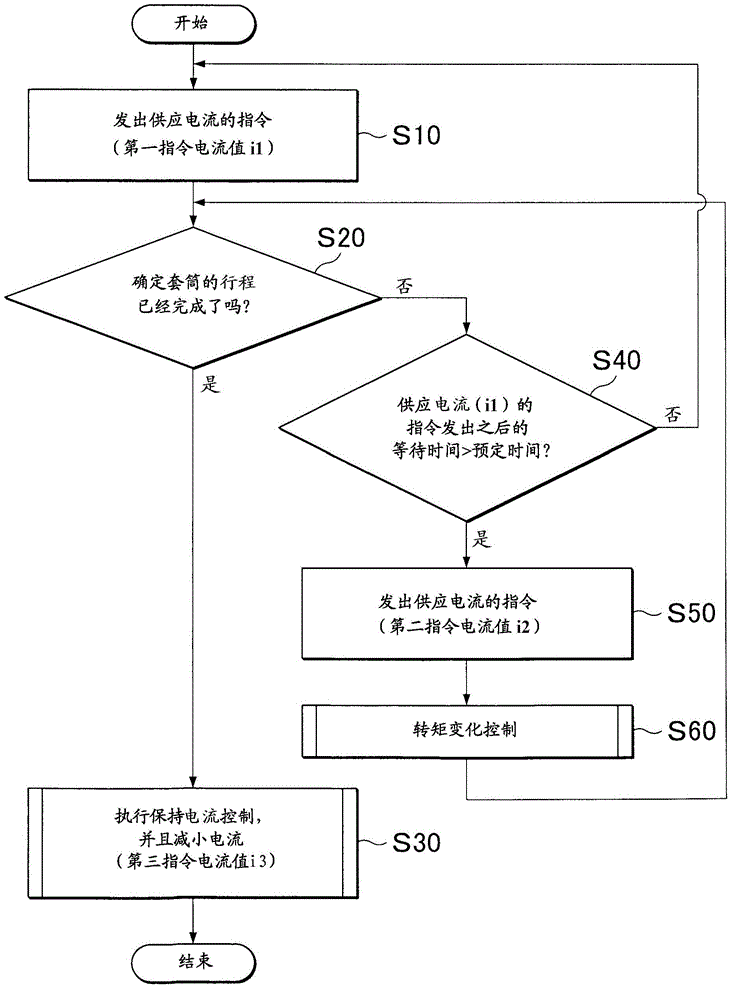

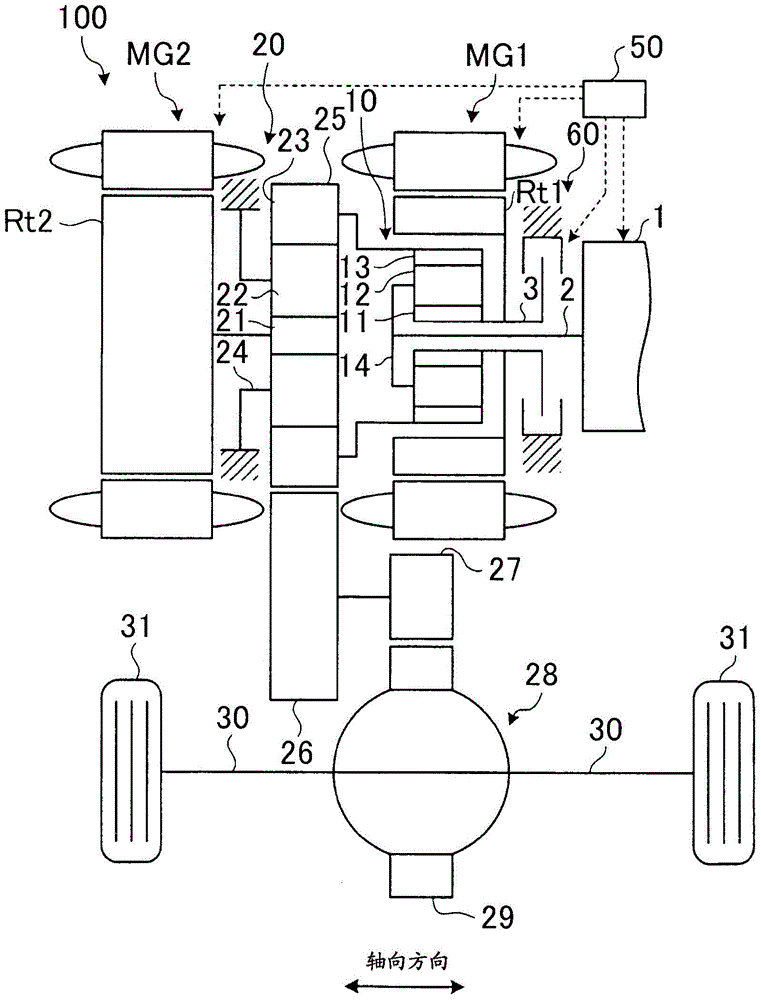

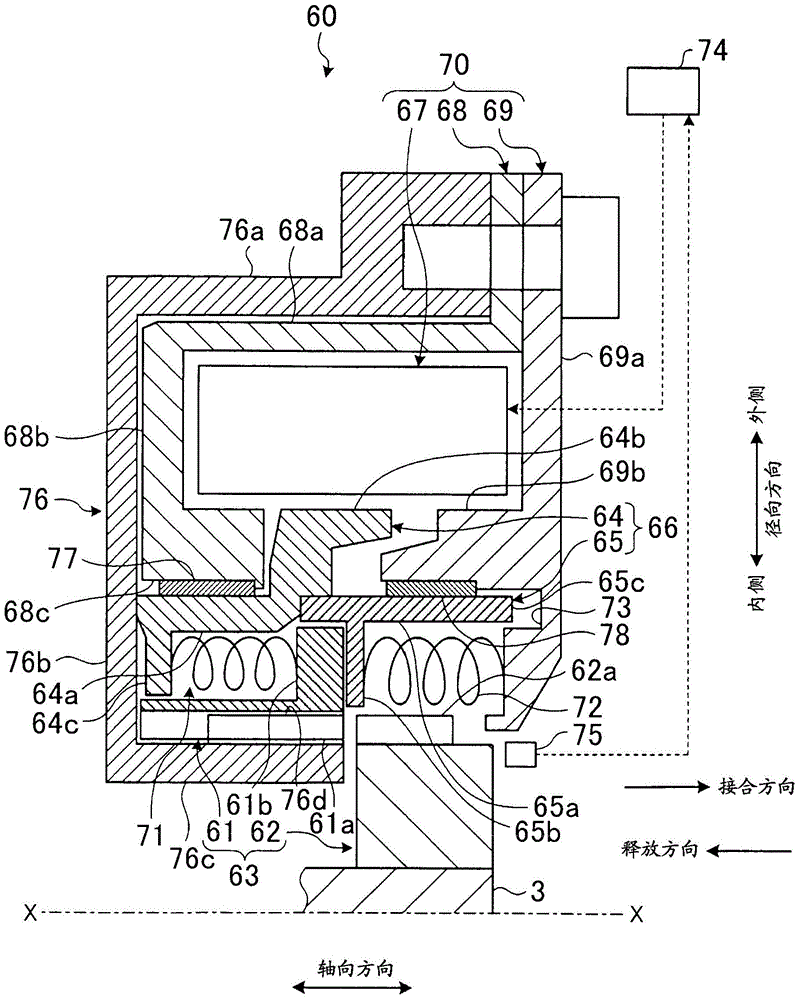

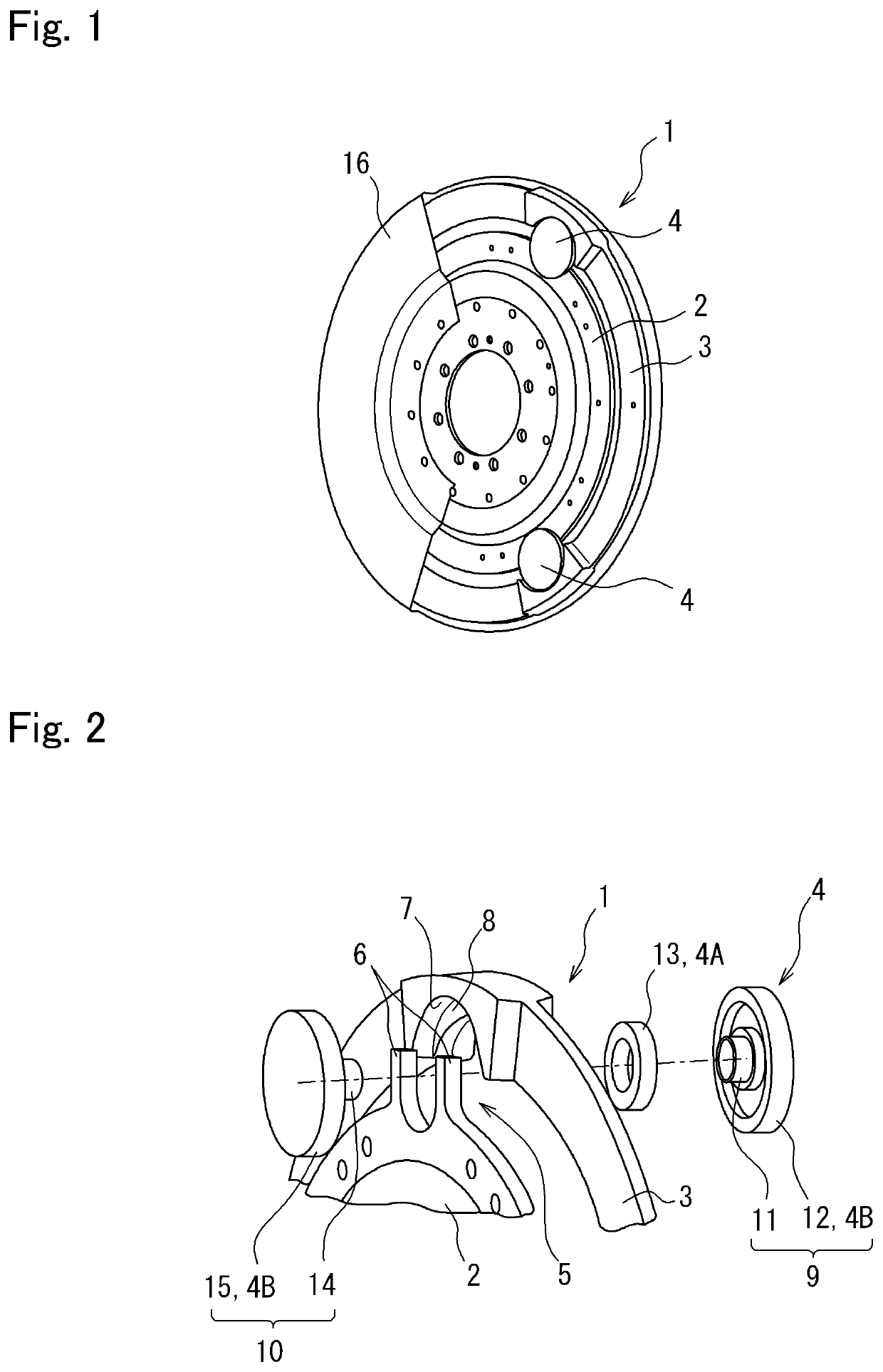

Intermesh engagement device

ActiveUS20150354643A1Reduce crash noiseHybrid vehiclesMagnetically actuated clutchesEngineeringActuator

An intermesh engagement device includes an intermesh engagement mechanism, a moving member, an actuator configured to apply a thrust to a moving member in an engaging direction, a transmission spring configured to transmit the thrust of the actuator from the moving member to a sleeve, a return spring, a stopper, and an electronic control unit configured to control the actuator. The electronic control unit is configured to execute first control for setting the thrust of the actuator to a thrust in a first region, and, when a halfway stopped state has occurred through the first control, execute second control for setting a thrust larger than the thrust in the first control. The first region is a range in which the thrust is larger than an urging force of the return spring and is smaller than the sum of the urging force of the return spring and a maximum urging force of the transmission spring.

Owner:TOYOTA JIDOSHA KK

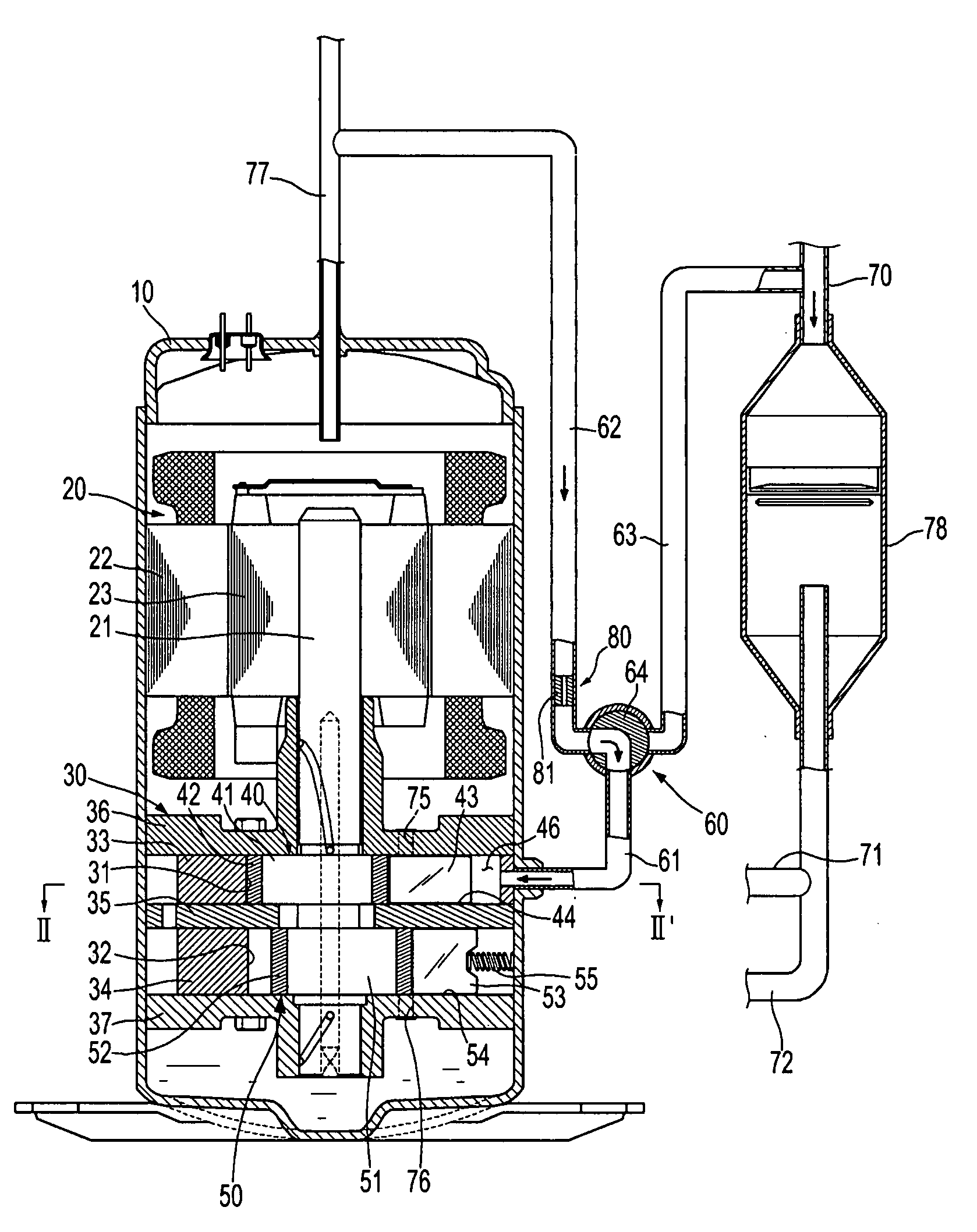

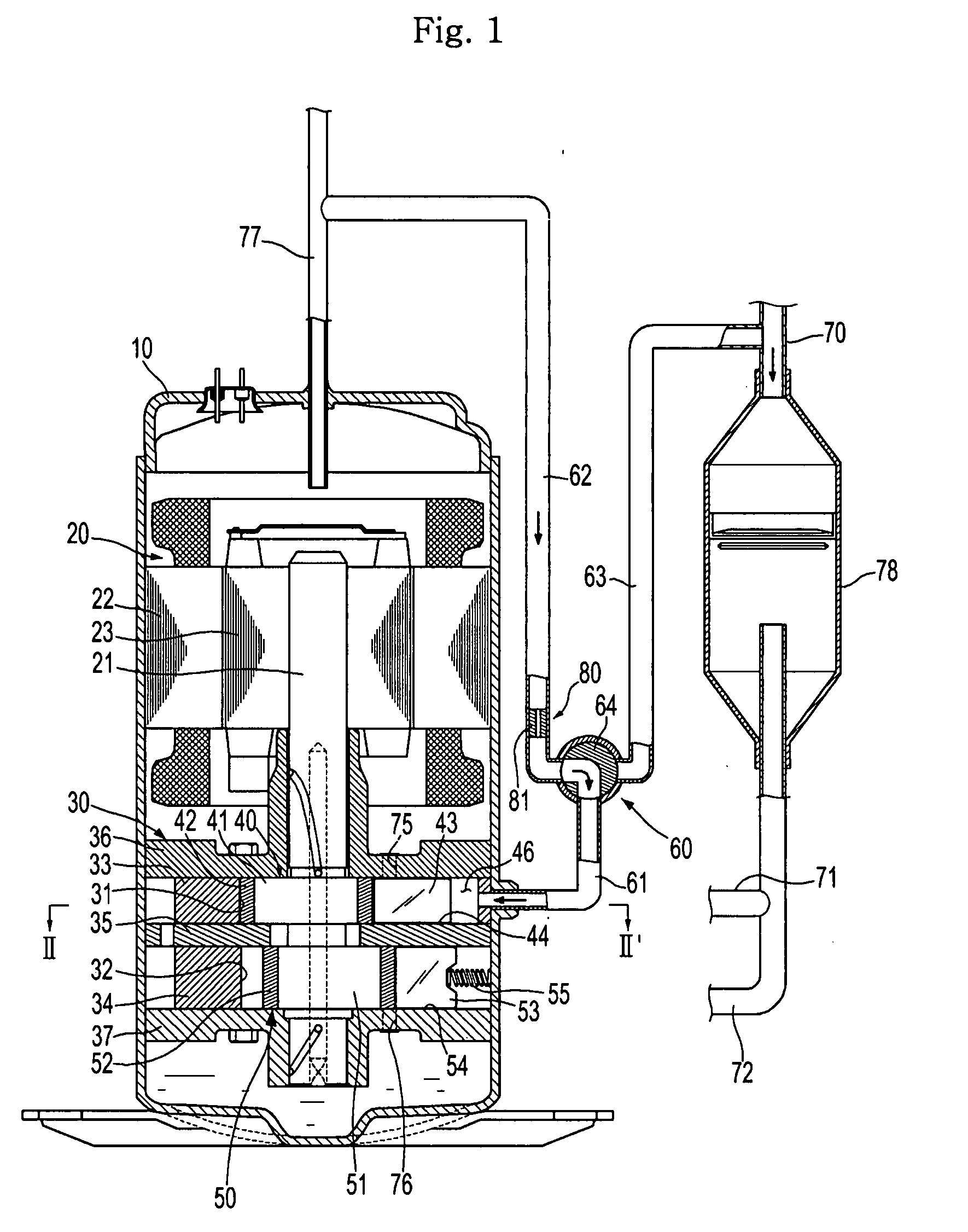

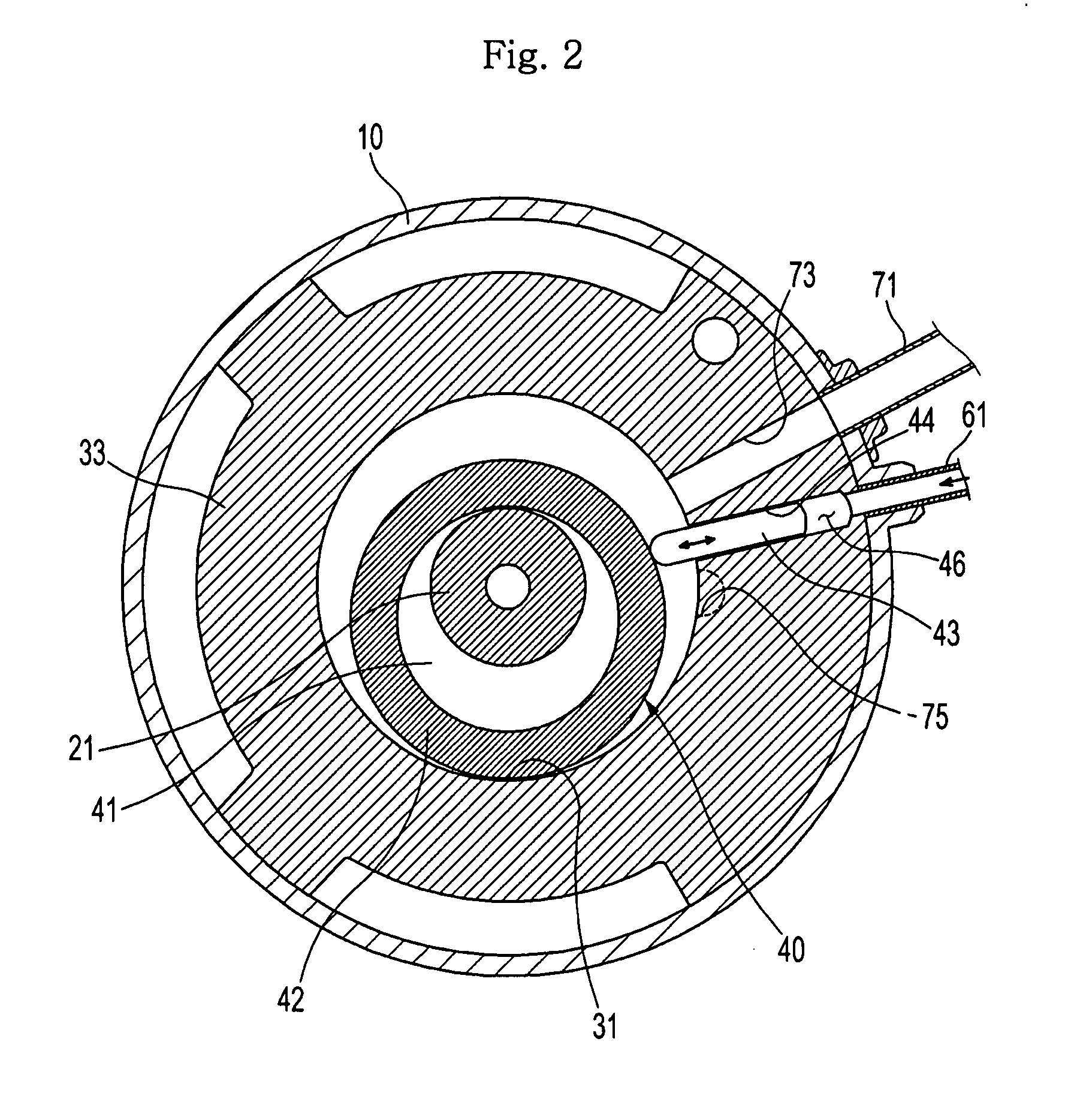

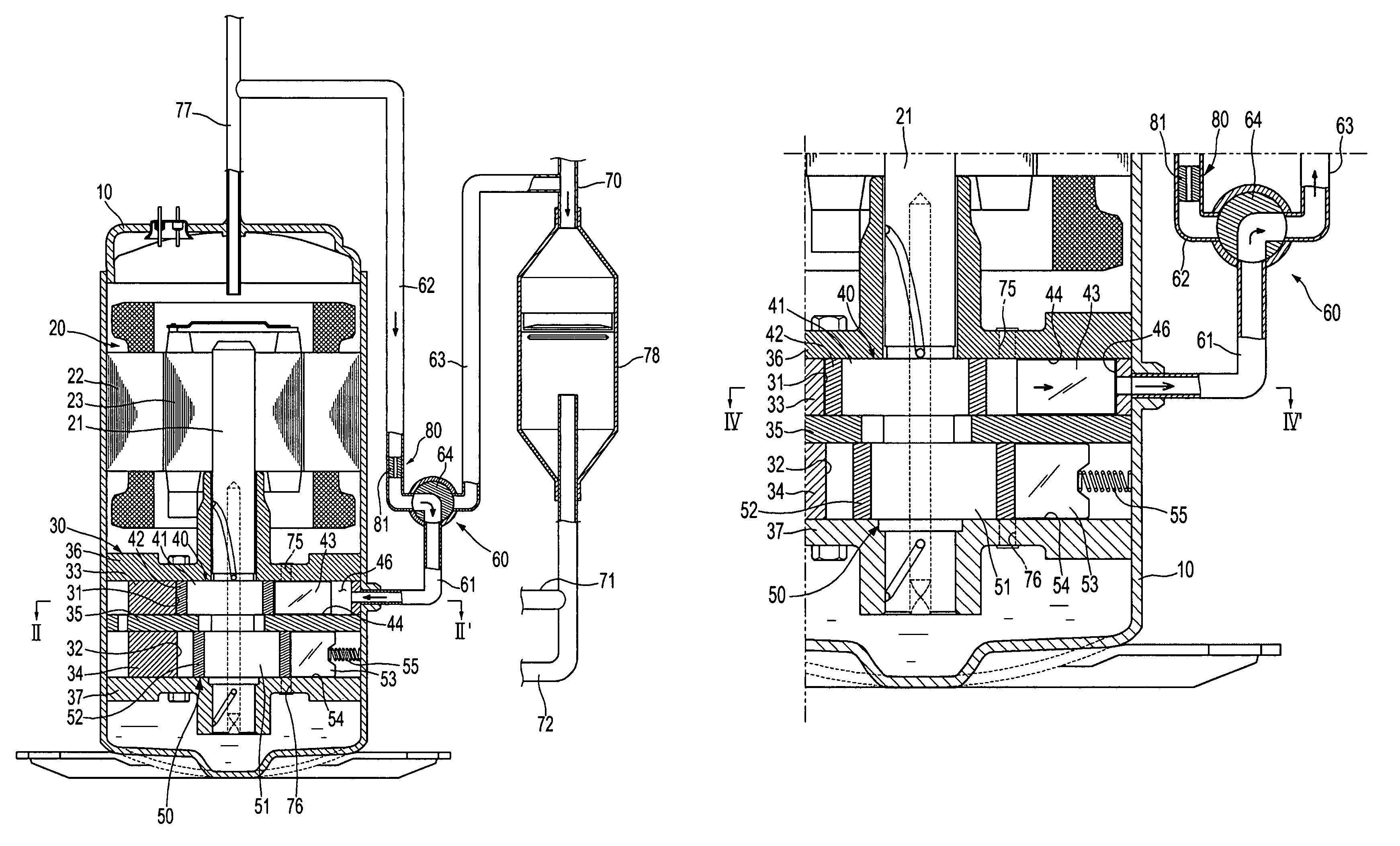

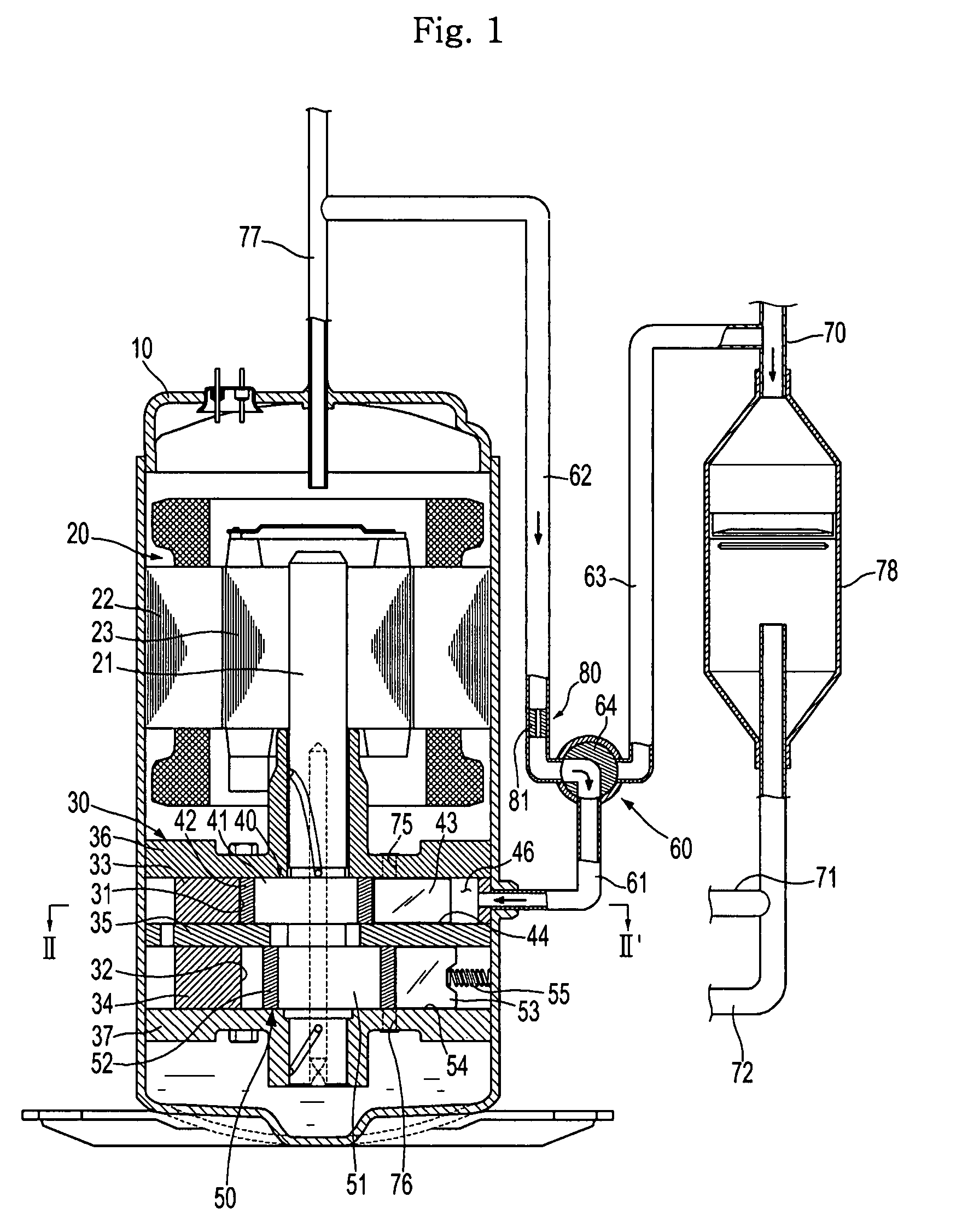

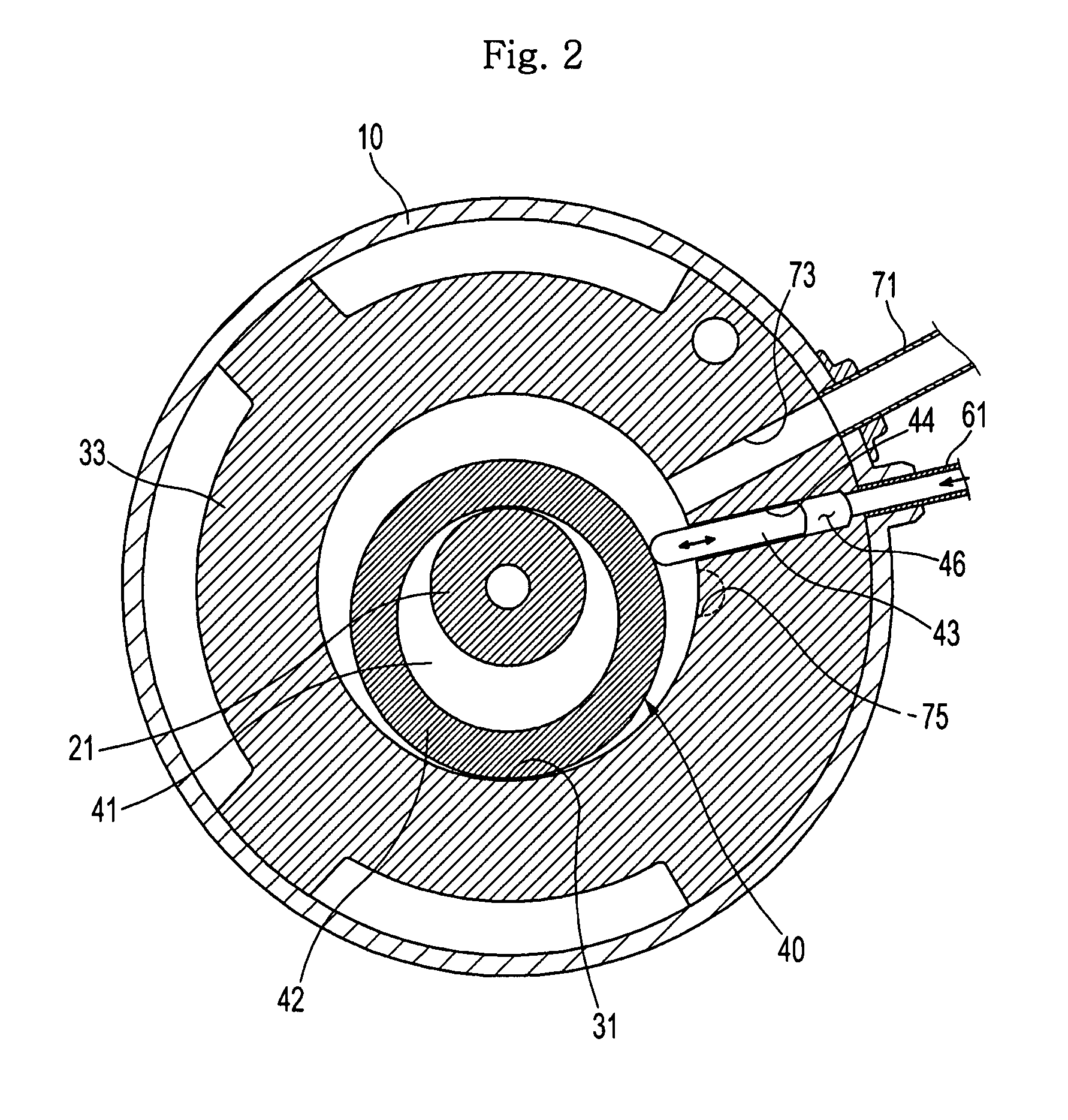

Variable capacity rotary compressor

InactiveUS20080175736A1Reduce crash noiseRotary/oscillating piston combinations for elastic fluidsEngine of arcuate-engagement typeEngineeringHigh pressure

A variable capacity rotary compressor capable of reducing collision noise of a vane with a roller. The variable capacity rotary compressor includes a vane controller controlling the operation of a vane in order to vary compression capacity. The vane controller includes a control valve that switches a fluid channel so as to selectively apply discharge pressure and intake pressure to the vane guide slot, a connection channel that connects the control valve with the vane guide slot, a high-pressure channel that connects the control valve with a discharge side of the compressor, and a low-pressure channel that connects the control valve with an intake side of the compressor, and a throttle section that reduces the fluid channel of at least one of the high-pressure channel and the connection channel in order to reduce an initial discharge pressure applied to the vane guide slot.

Owner:SAMSUNG ELECTRONICS CO LTD

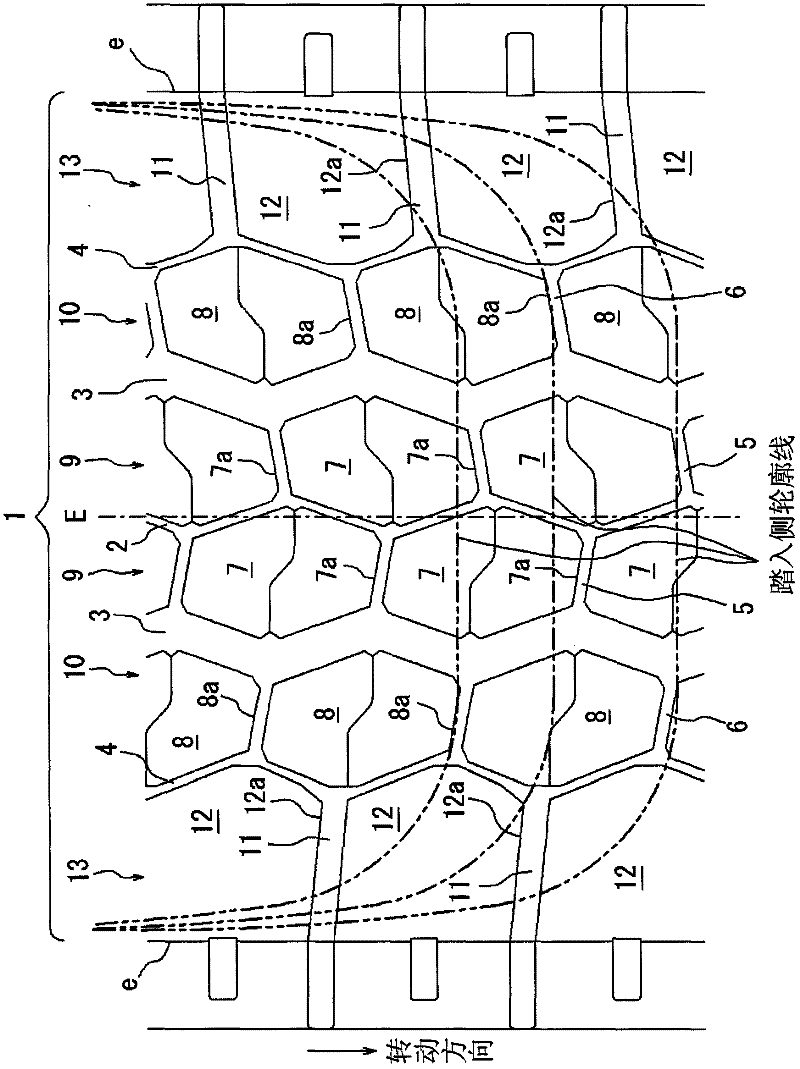

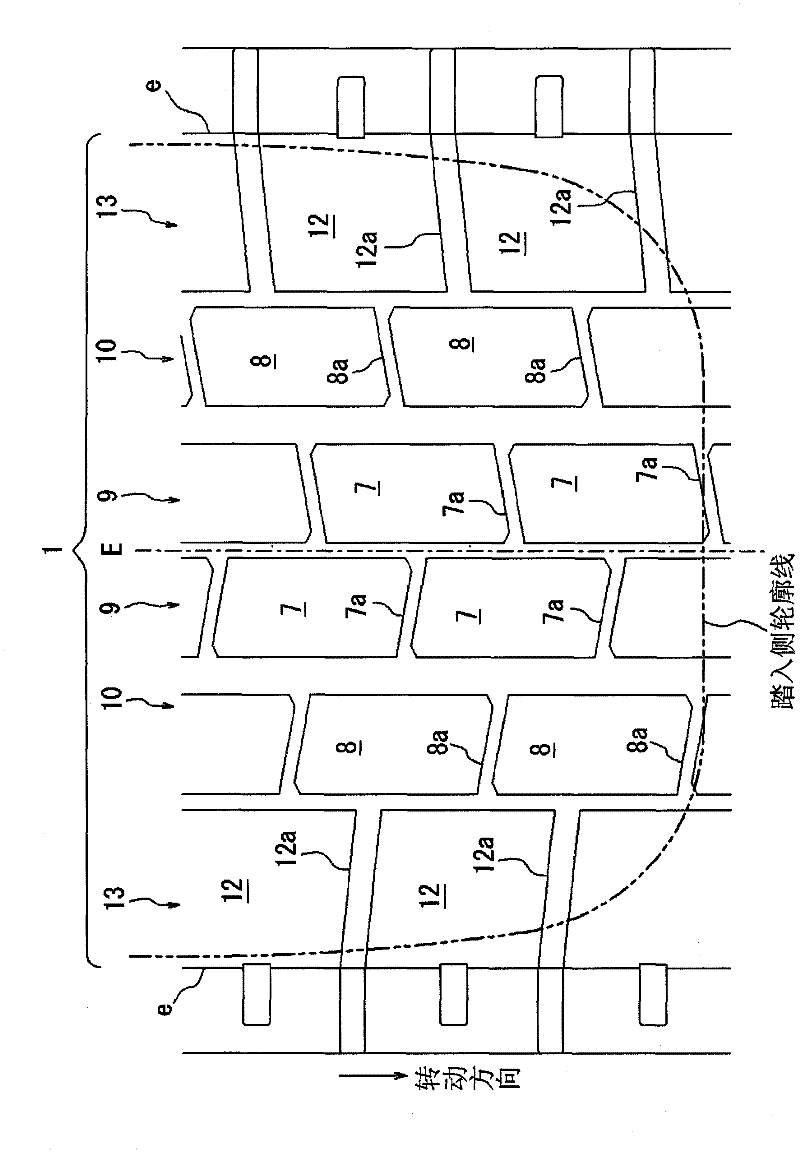

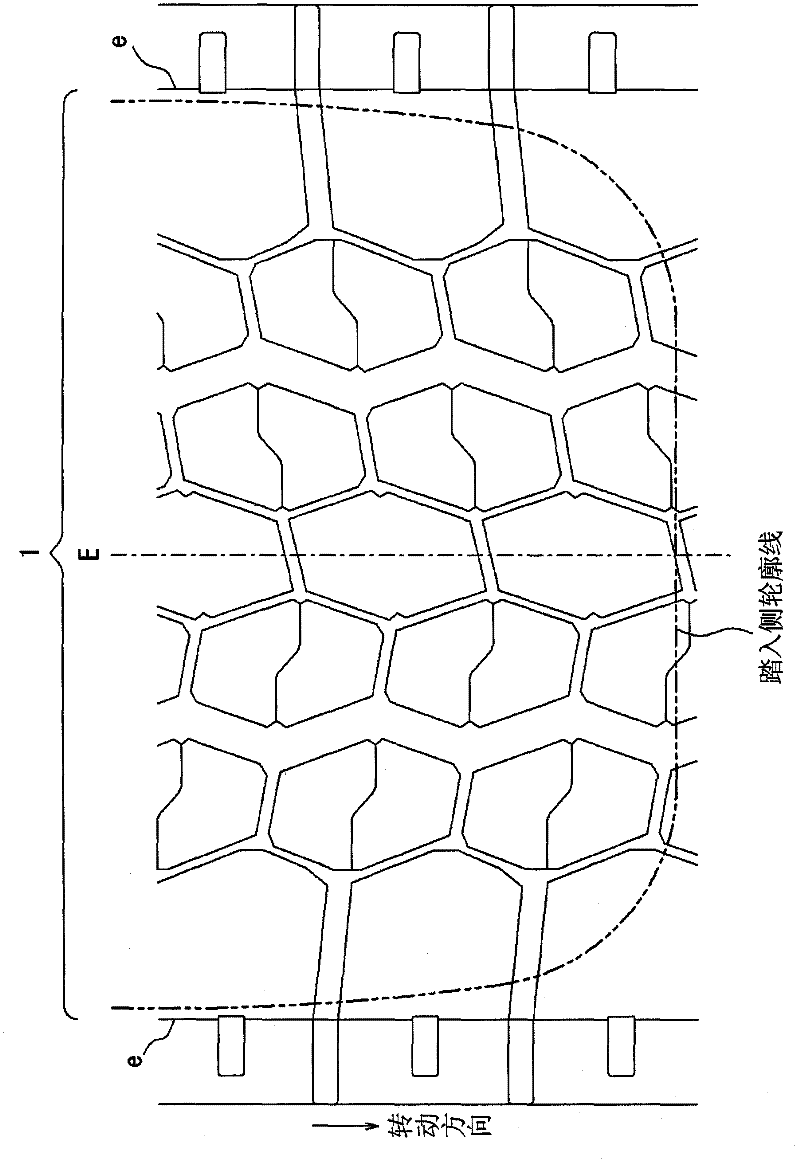

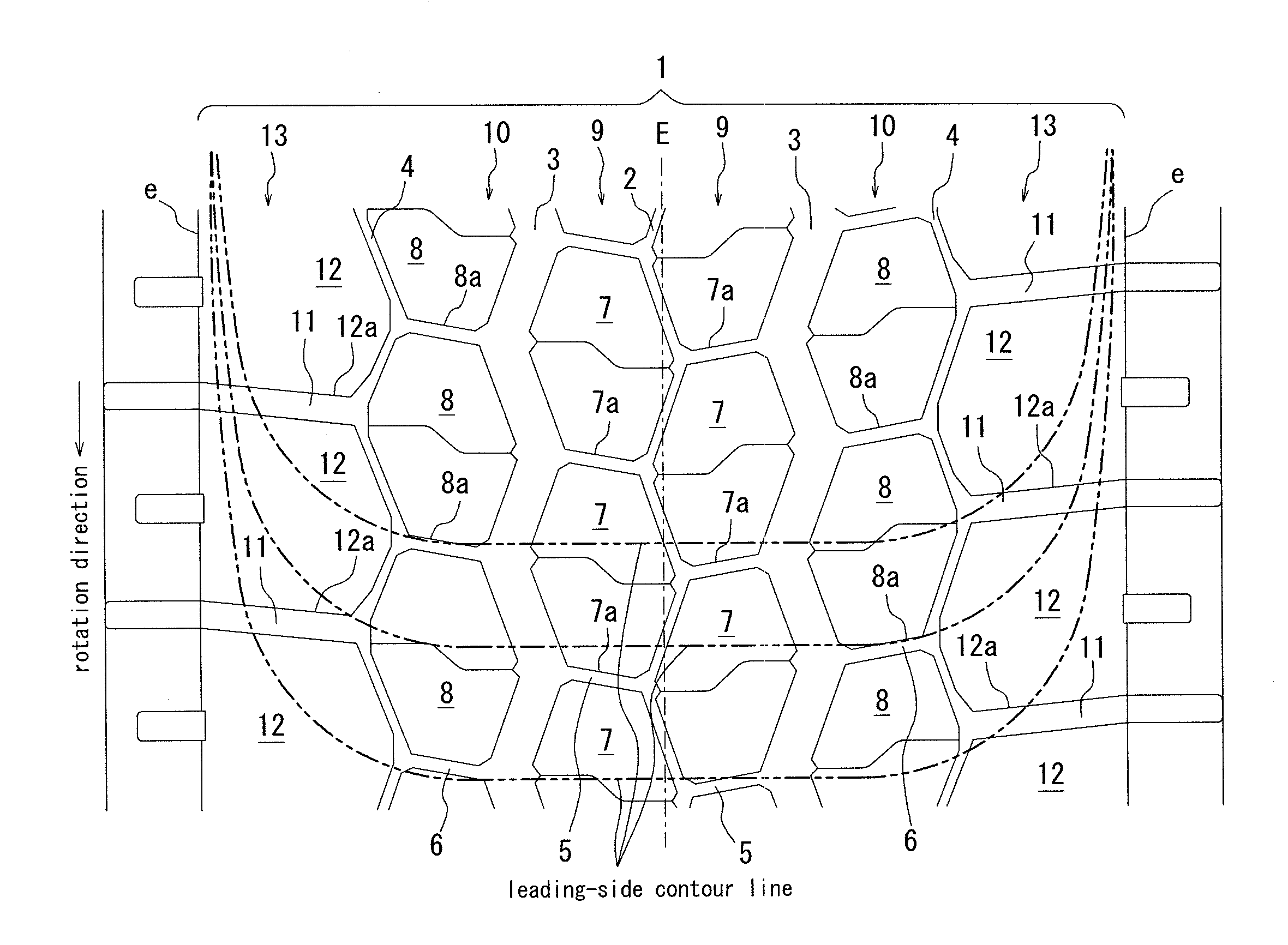

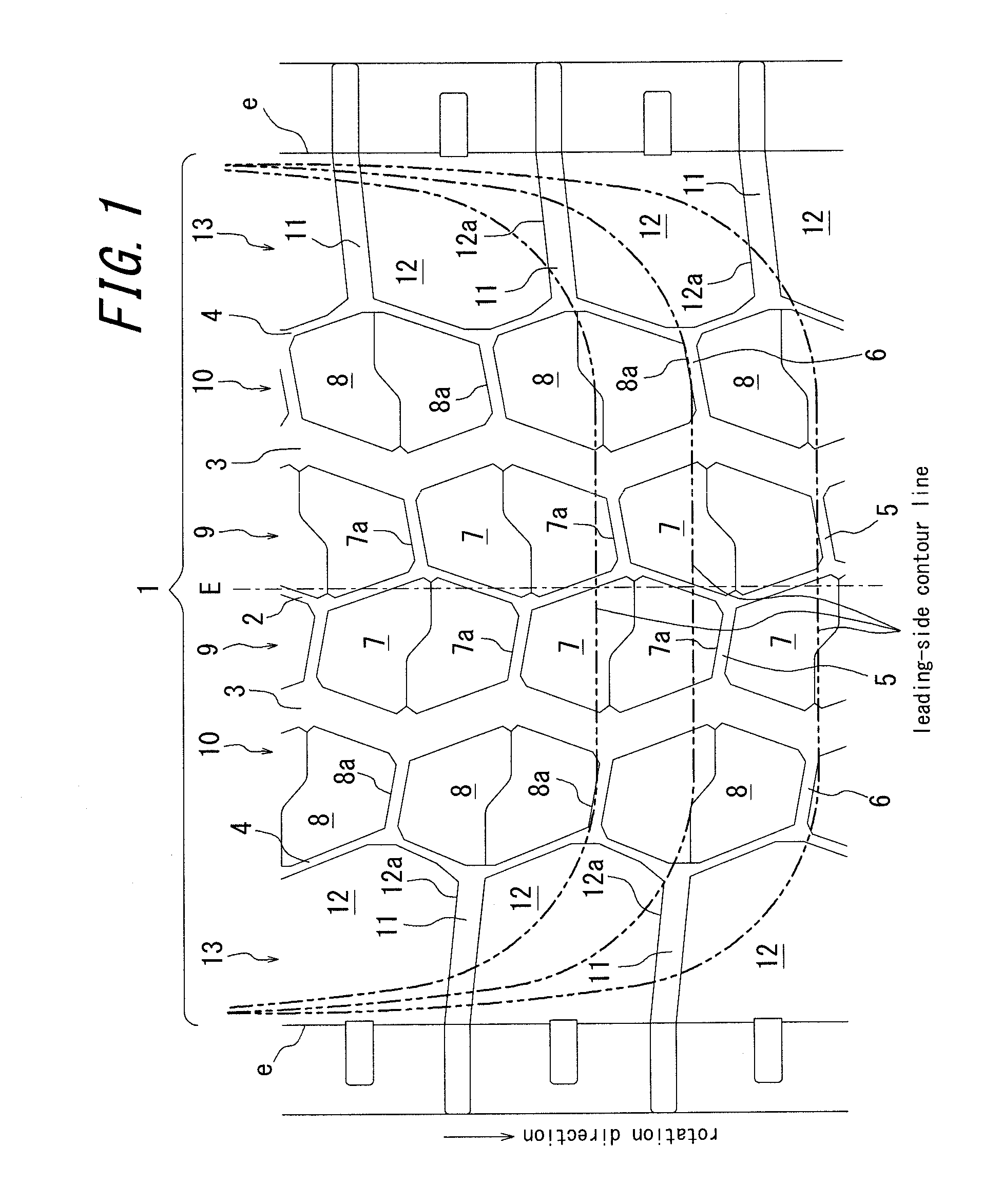

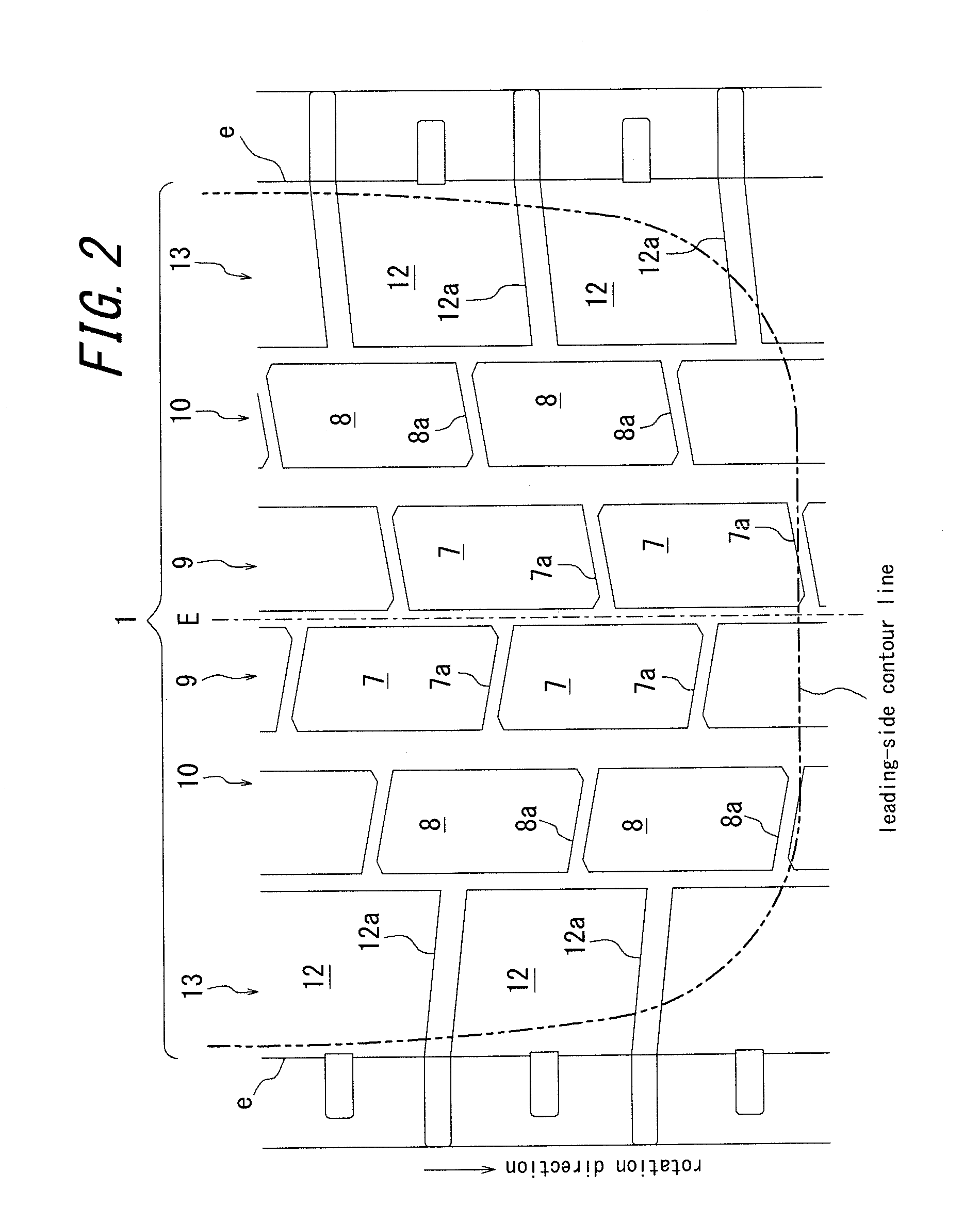

pneumatic tire

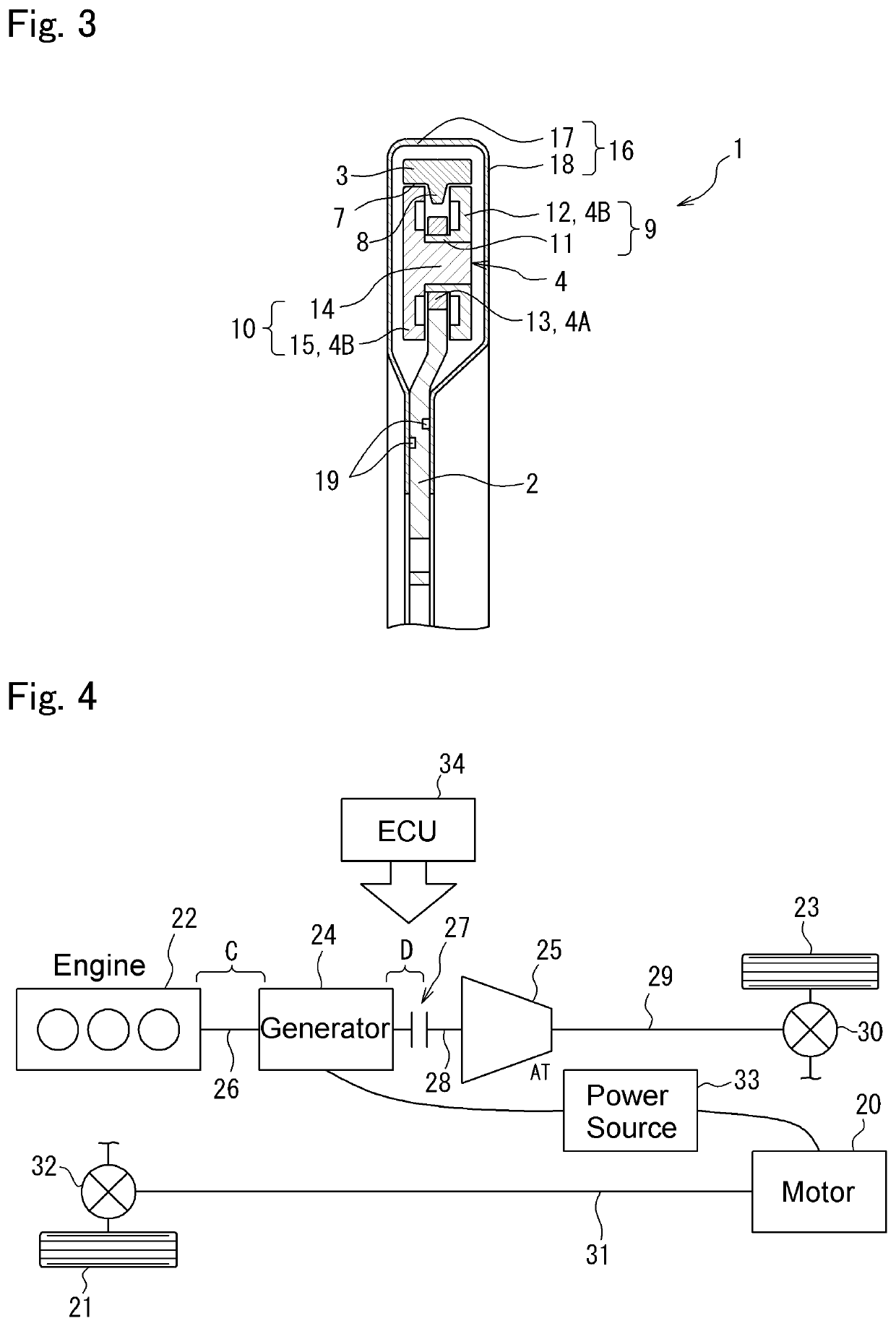

InactiveCN102264561AReduce crash noiseImprove rigidityTyre tread bands/patternsLeading edgeGroove width

The present invention aims to provide a pneumatic tire capable of effectively preventing a large collision noise caused by simultaneous collision of a plurality of blocks of each row with a road surface. The six block rows (9, 10, 13) on the tread contact surface (1) consist of five circumferential grooves (2, 3, 4) extending continuously in a zigzag manner in the circumferential direction of the tread. A plurality of transverse grooves (5, 6, 11) extending in the tread width direction are defined between adjacent circumferential grooves and between the outermost circumferential groove (4) and the corresponding tread side edge (e). The five circumferential grooves (2, 3, 4) include circumferential narrow grooves (2, 4) and a pair of circumferential wide grooves 3, and a pair of circumferential wide grooves (3) are arranged on both sides of the tire equator line and are narrower than the circumferential direction The width of the slots (2, 4) is wide. The transverse grooves (5, 6) are inclined relative to the tread width direction. Each pattern block (7, 8, 12) of the pattern block row (9, 10, 13) has a polygonal plane profile shape with more than six sides, and at the same time, the minimum length of the pattern block in the tread width direction is located at the The length in the tread width direction of the central portion of the block in the tread circumferential direction is longer than the length in the tread width direction of the end portion in the tread circumferential direction. The tread edges (7a, 8a, 12a) of the blocks (7, 8, 12) of each block row (9, 10, 13) are spaced apart from each other in the circumferential direction of the tread when the tire rolls under load.

Owner:BRIDGESTONE CORP

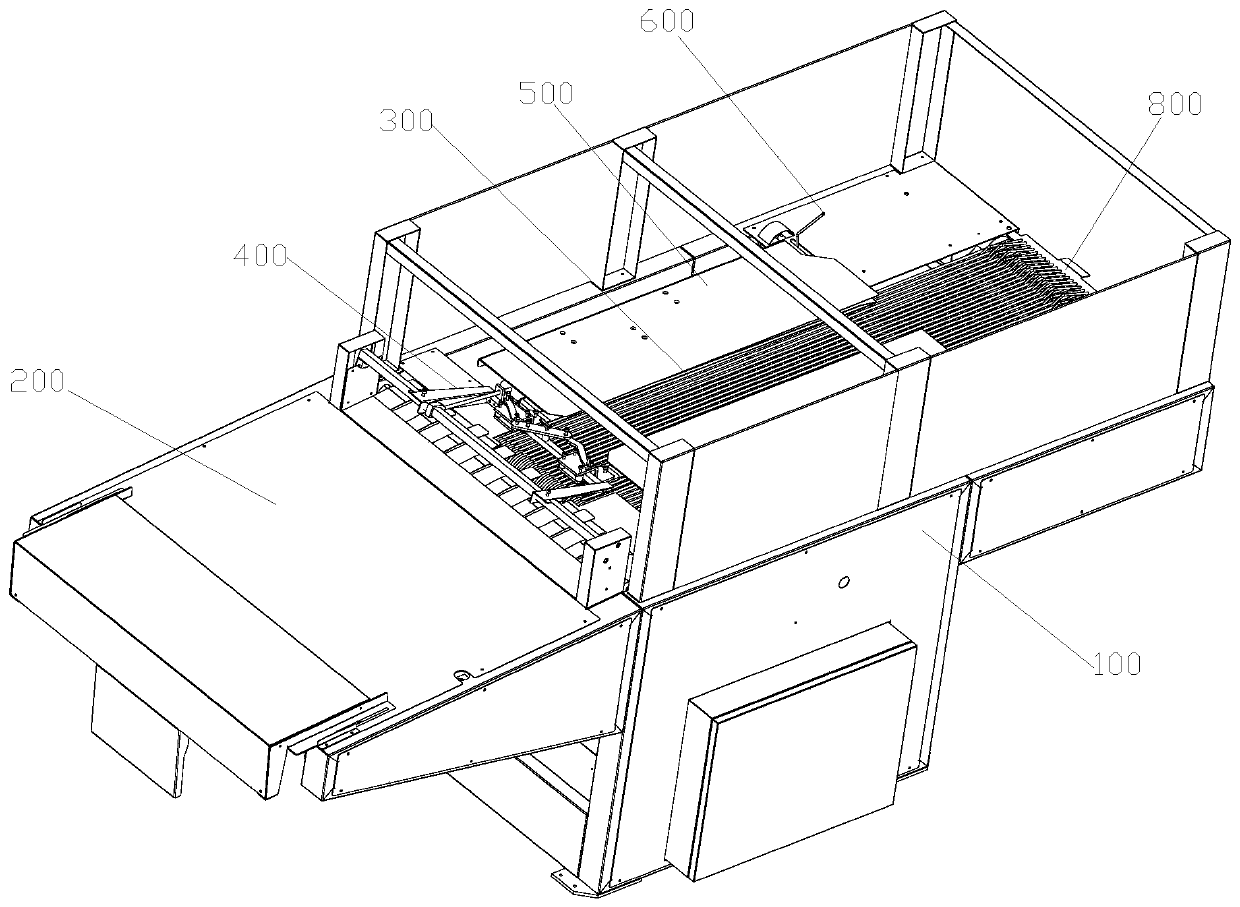

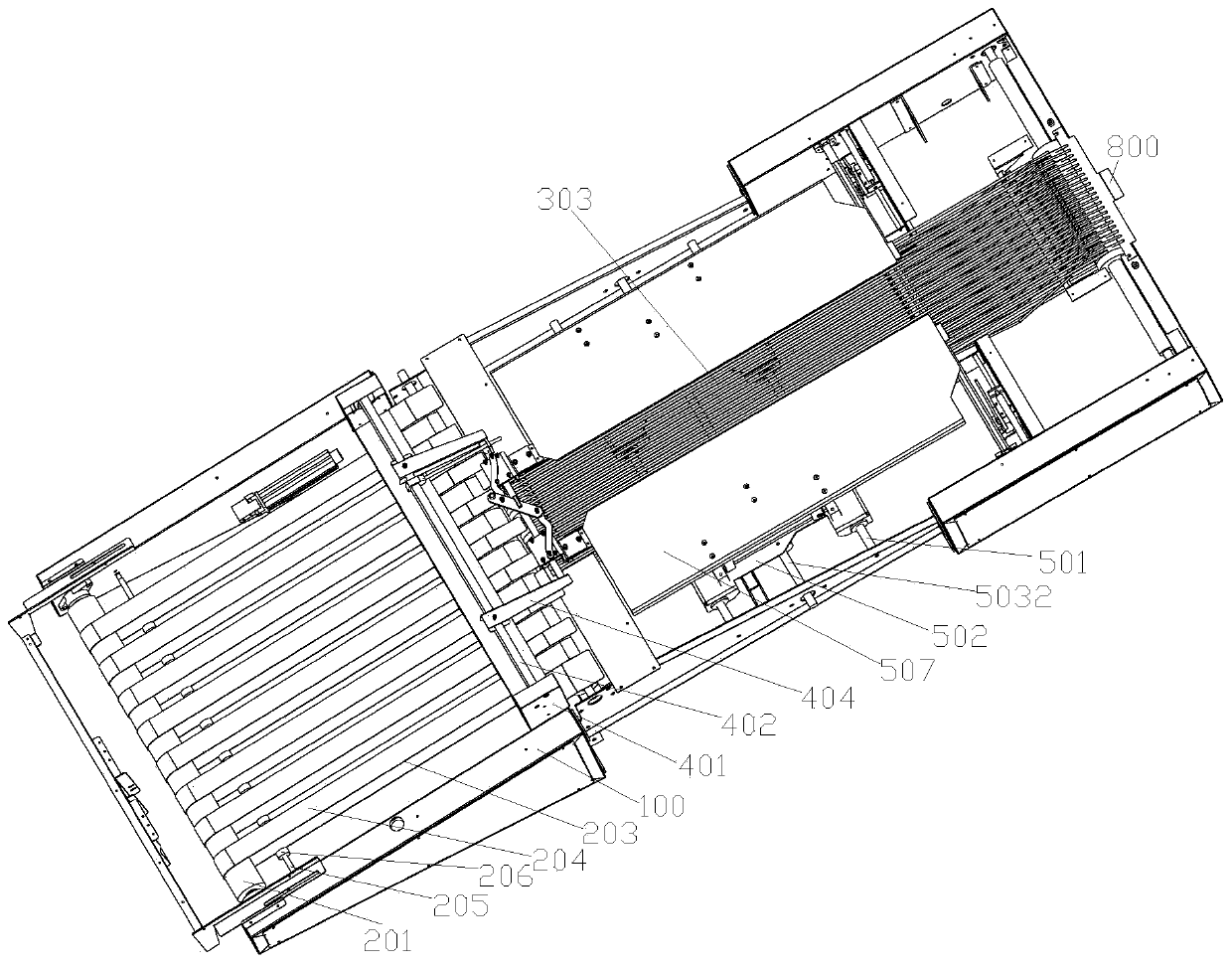

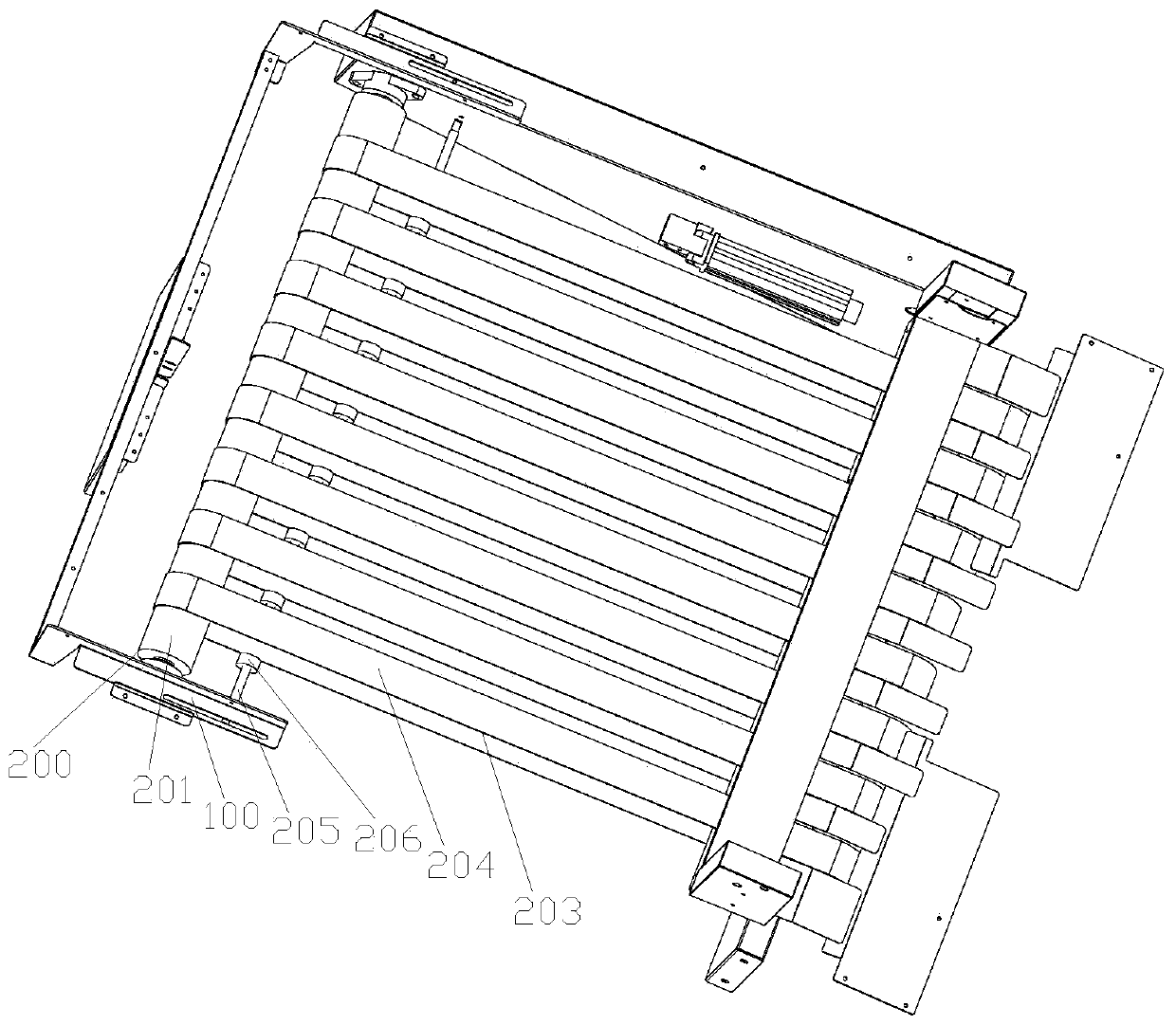

Full-automatic clothes folding machine

InactiveCN110589136AAchieve horizontal foldAchieving Vertical FoldingConveyorsFolding thin materialsEngineeringAutomation

The invention relates to the technical field of clothes packaging, and specifically discloses a full-automatic clothes folding machine. The full-automatic clothes folding machine comprises a machine frame, wherein a first conveying mechanism, a second conveying mechanism, a cloth pressing mechanism, a cloth folding mechanism, a positioning mechanism, a cloth turning mechanism and an output sectionare arranged on the machine frame, the cloth pressing mechanism is positioned above the second conveying mechanism, the position of the cloth folding mechanism on the machine frame corresponds to theposition of the cloth pressing mechanism, the positioning mechanism is located on the machine frame at the position where the clothes are away from the cloth folding mechanism, the cloth turning mechanism is at the position where the machine frame corresponds to the positioning mechanism, and the output section is located at the position where the machine frame is located at the output end of thesecond conveying mechanism. The full-automatic clothes folding machine has the characteristics of no deviation of a conveying strip, good conveying effect, convenient adjustment of the folding width,better adjustment precision, better folding flatness, better folding consistency, better appearance, higher degree of automation, higher production efficiency, low labor intensity and ability of adapting to large-yield demand.

Owner:浙江雅力士自动化设备科技有限公司

Variable capacity rotary compressor having vane controller

InactiveUS7775782B2Reduce crash noiseRotary/oscillating piston combinations for elastic fluidsEngine of arcuate-engagement typeHigh pressureControl valves

A variable capacity rotary compressor capable of reducing collision noise of a vane with a roller. The variable capacity rotary compressor includes a vane controller controlling the operation of a vane in order to vary compression capacity. The vane controller includes a control valve that switches a fluid channel so as to selectively apply discharge pressure and intake pressure to the vane guide slot, a connection channel that connects the control valve with the vane guide slot, a high-pressure channel that connects the control valve with a discharge side of the compressor, and a low-pressure channel that connects the control valve with an intake side of the compressor, and a throttle section that reduces the fluid channel of at least one of the high-pressure channel and the connection channel in order to reduce an initial discharge pressure applied to the vane guide slot.

Owner:SAMSUNG ELECTRONICS CO LTD

Intermesh Engagement Device

ActiveCN105179521AReduce crash noiseHybrid vehiclesMagnetically actuated clutchesEngineeringActuator

Owner:TOYOTA JIDOSHA KK

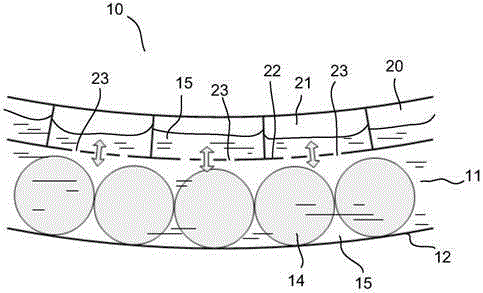

Pneumatic tire

InactiveUS20110220261A1Reduce crash noiseEnhance block stiffnessTyre tread bands/patternsNon-skid devicesRoad surfaceEngineering

The present invention is directed to provide a pneumatic tire capable of effectively preventing large collision noise due to simultaneous collision of plural blocks of respective rows with a road surface. Six rows 9, 10, 13 of blocks on a tread surface 1 are defined by five circumferential grooves 2, 3, 4 continuously extending in a tread circumferential direction in a zigzag manner, a plurality of lateral grooves 5, 6, 11 extending in a tread widthwise direction between the circumferential grooves adjacent to each other and between the outermost circumferential grooves 4 and respective tread side edges e. Five circumferential grooves 2, 3, 4 comprise narrow circumferential grooves 2, 4 and a pair of wide circumferential grooves 3 disposed on each side of the tire equator line and having a width greater than that of the narrow circumferential grooves 2, 4. The lateral grooves 5, 6 are inclined with respect to the tread widthwise direction. Each of the blocks 7, 8, 12 of the block rows 9, 10, 13 has a polygon planar contour shape with six or more sides such that a minimum length of the block in the tread widthwise direction is situated in an end portion of the block in the tread circumferential direction and a middle portion of the block in the tread circumferential direction has a length greater than the length of the end portion in the tread circumferential direction. Leading edges 7a, 8a, 12a of the blocks 7, 8, 12 of each rows 9, 10, 13 when the tire is rolling under load are spaced from each other in the tread circumferential direction.

Owner:BRIDGESTONE CORP

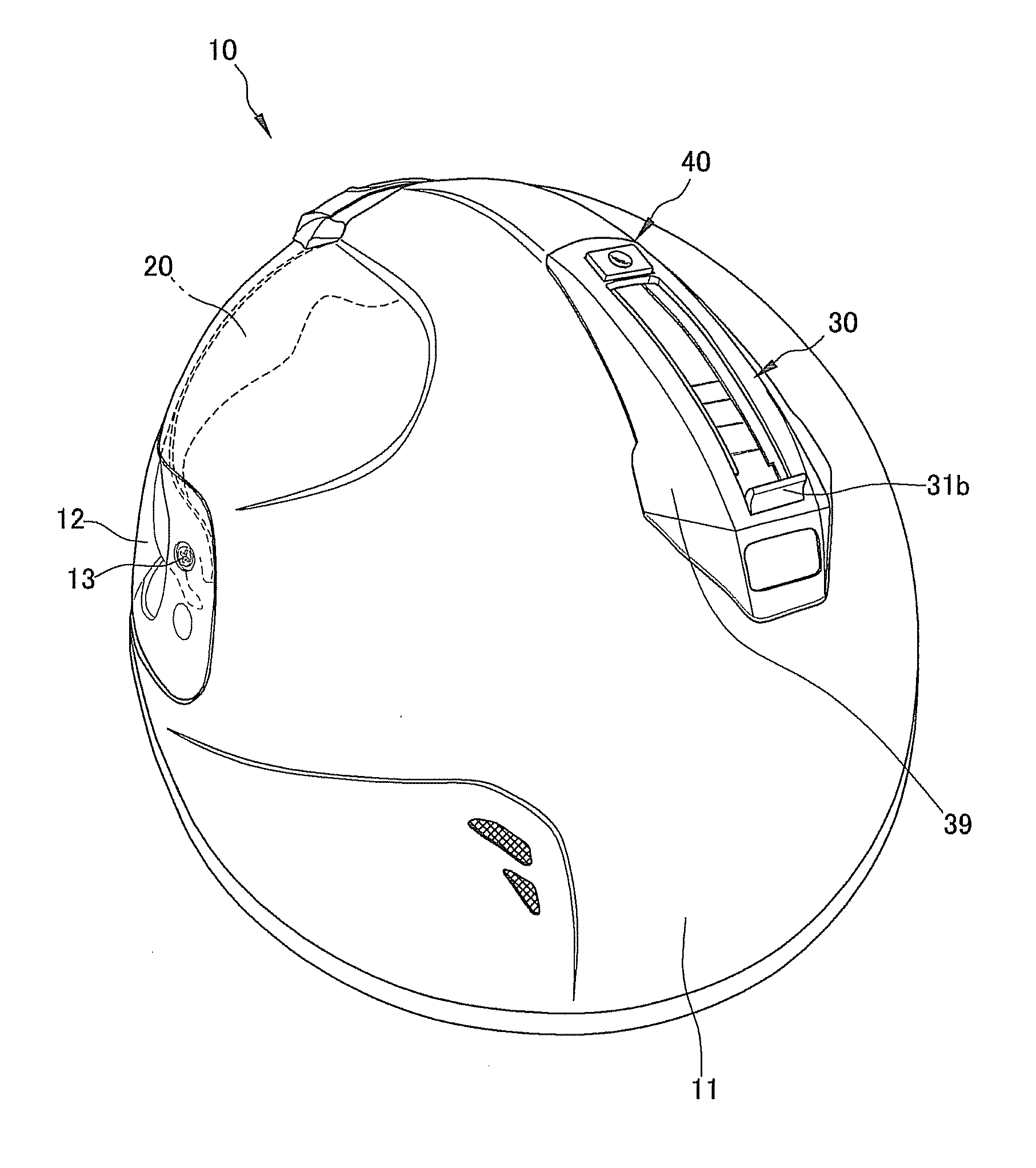

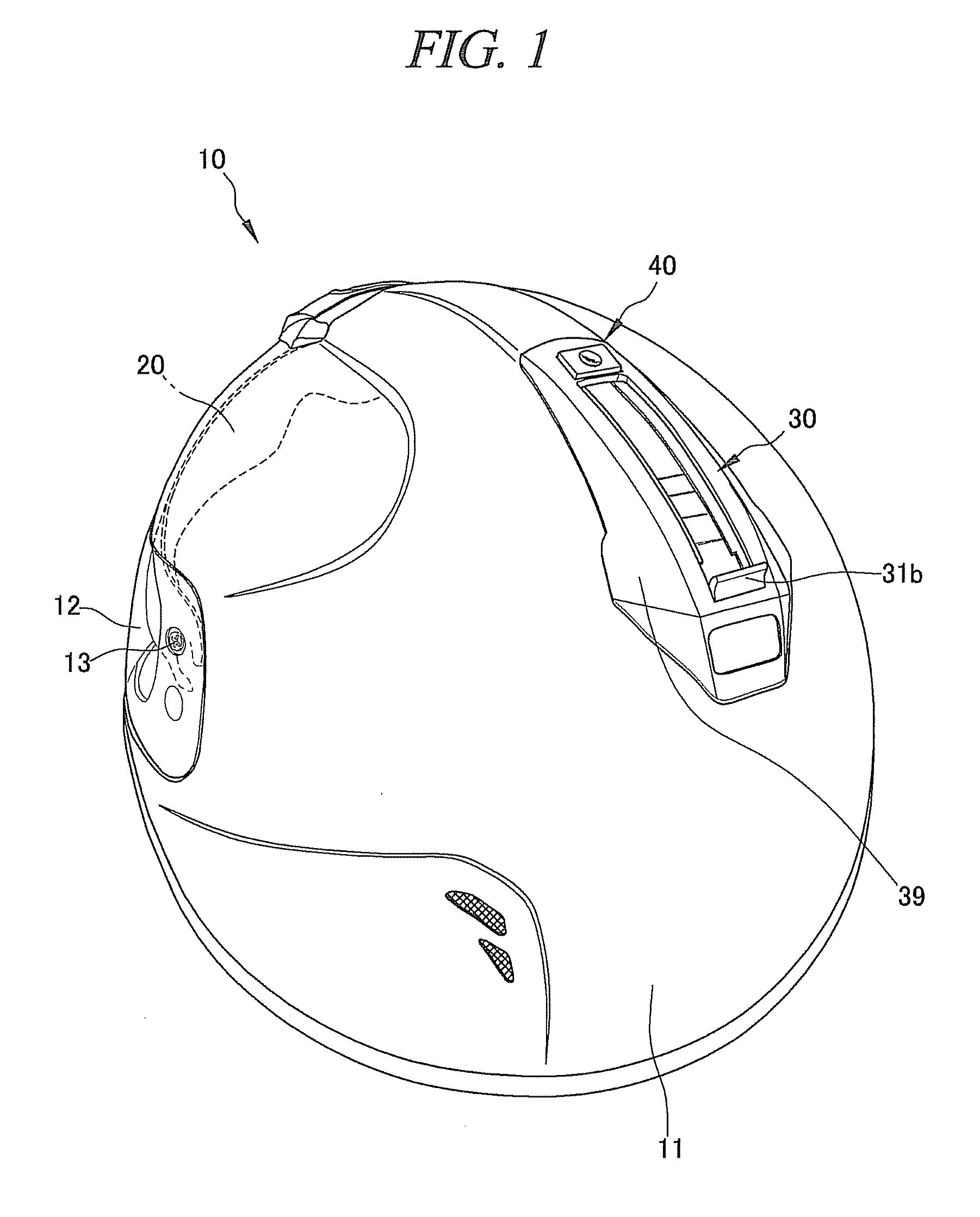

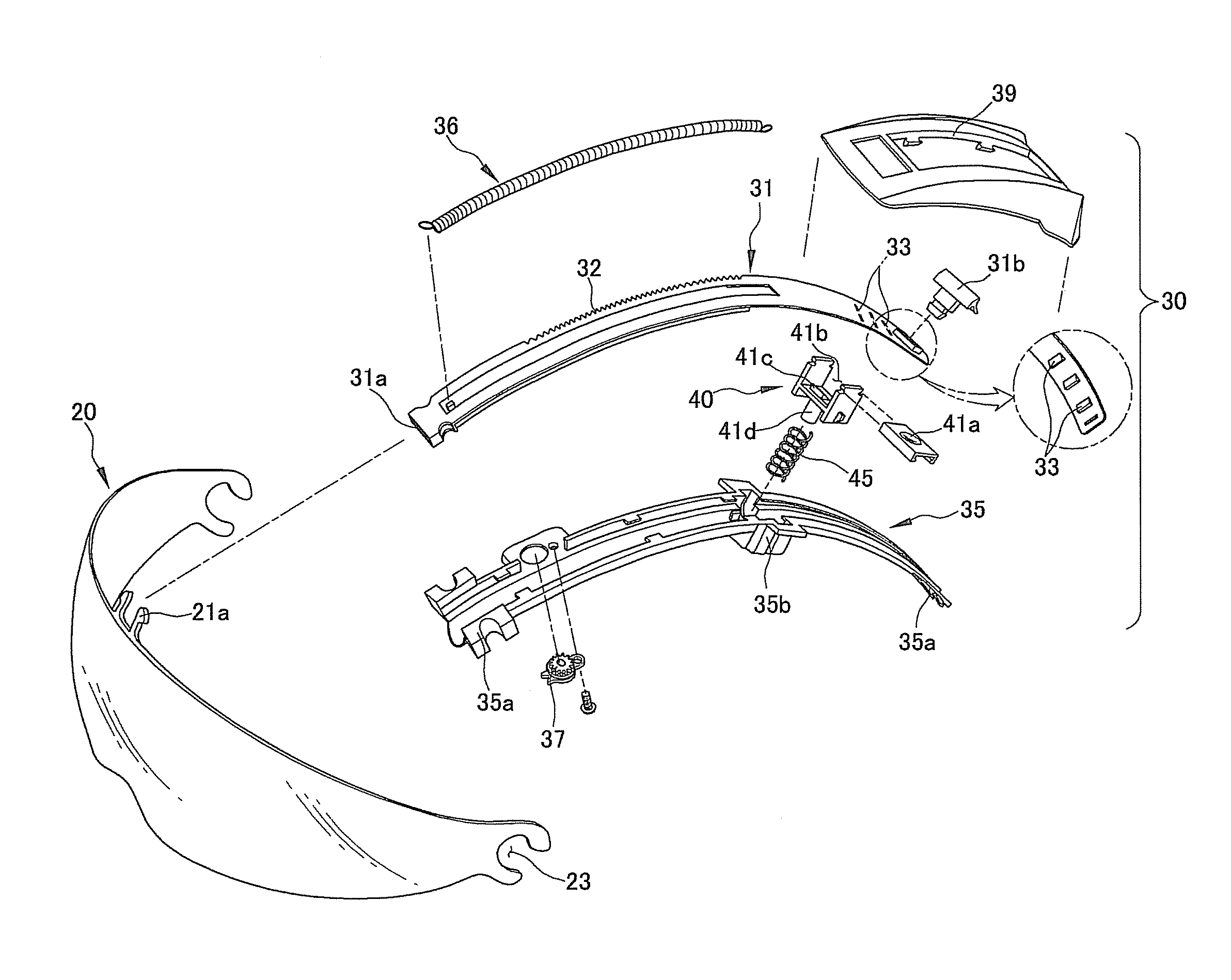

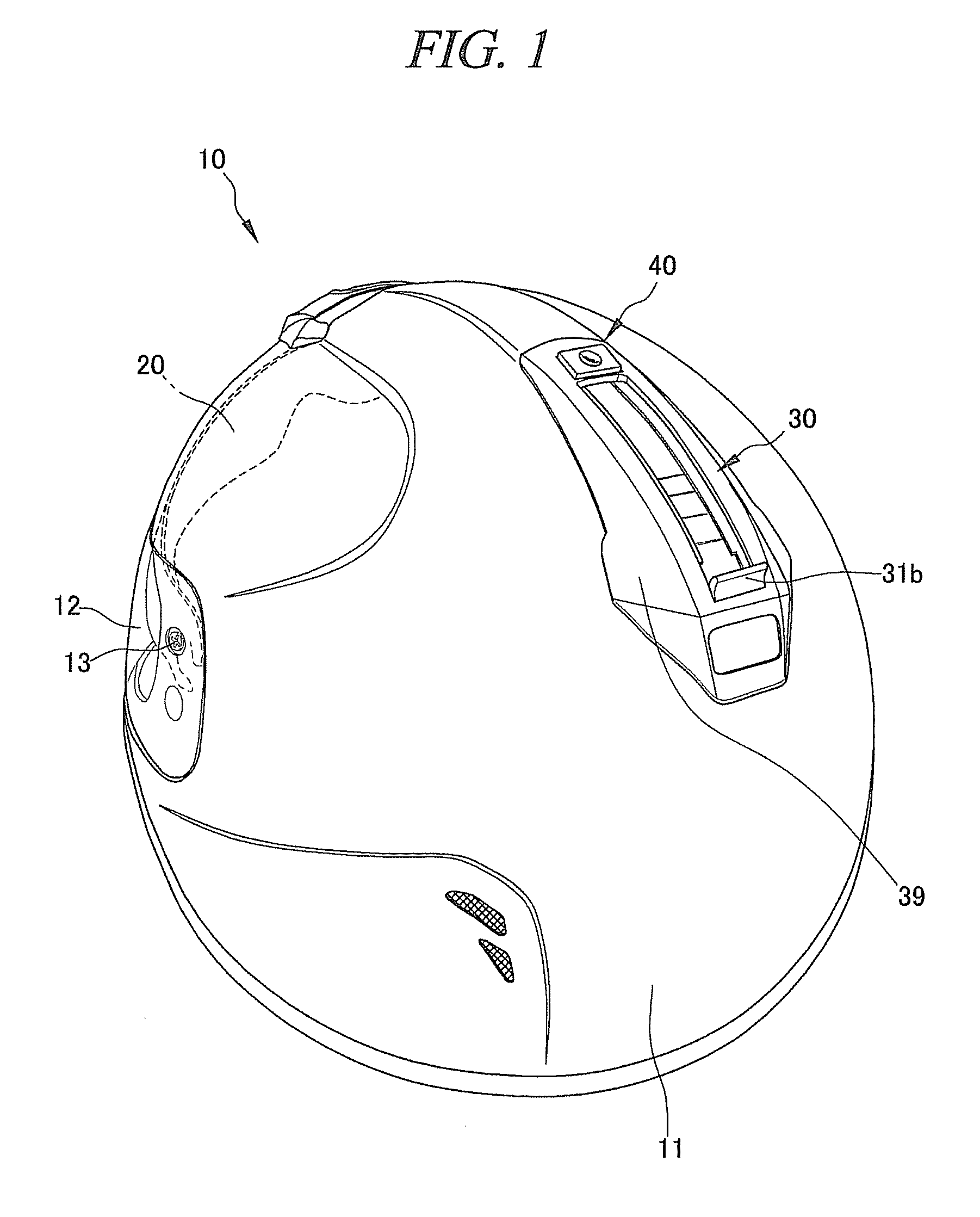

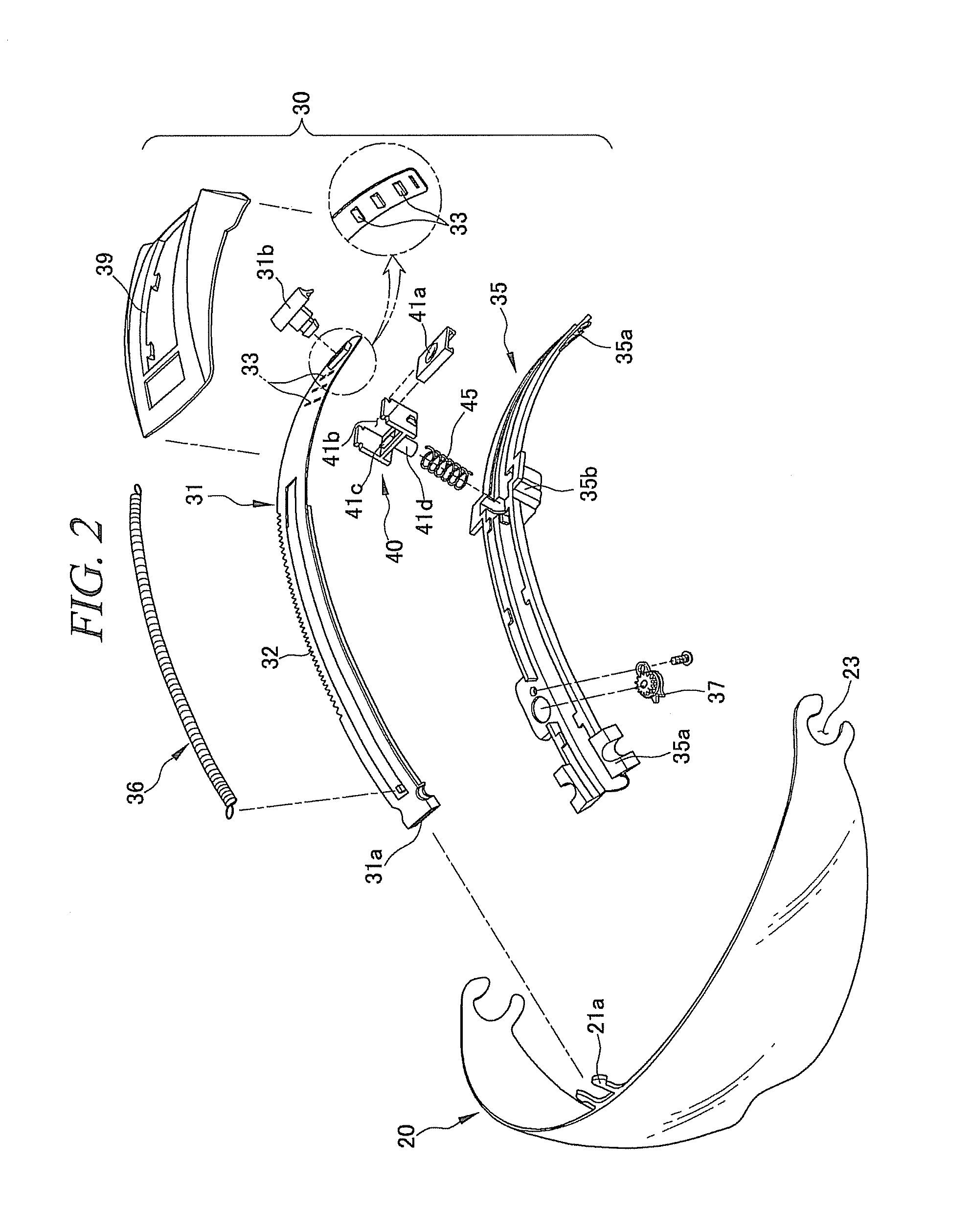

Opening/closing apparatus and helmet including the same

ActiveUS8341771B2Minimum operationExtend your lifeHatsPersonal protection gearEngineeringShock absorber

Owner:HONG JIN CROWN

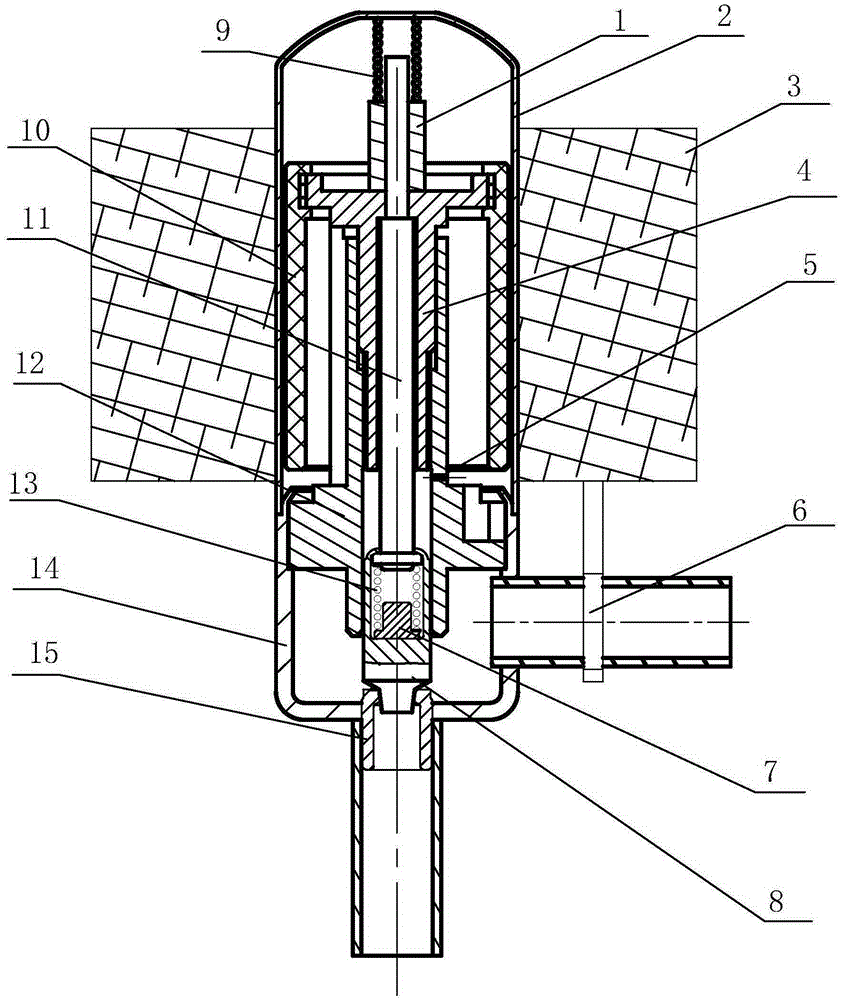

Thread transmission type electronic expansion valve

InactiveCN106766418AIncrease the support surfaceImprove installation firmnessOperating means/releasing devices for valvesEfficient regulation technologiesCavity wallButt joint

The invention relates to a thread transmission type electronic expansion valve, and belongs to valves. An existing electronic expansion valve is large in running noise, and abrasion or clamping of a magnetic steel sleeve is prone to occurrence; the thread transmission type electronic expansion valve is characterized in that a backward step end face leaning shoulder is arranged on the outer circle face of a front base sleeve, the opening end of a back base sleeve is in butt joint with the step end face leaning shoulder in a fixedly welding manner to form a straight-cylinder-shaped shell with two ends closed, a front section of a nut sleeve is inserted into an inner cavity wall of the front base sleeve, and an end face leaning shoulder on the inner cavity wall and an inward turning edge of the opening end of the front base sleeve are used for limiting and fixing; a valve is installed in a hollow inner cavity of a valve rod sleeve fixed to the magnetic steel sleeve in a penetrating manner, the back end of the valve extends out of the back end of the magnetic steel sleeve, and a spacer bush and a spring arranged outside the valve rod in a sleeving manner are used for back stroke limiting; and the valve rod sleeve is matched with inner threads in an axial through hole of the nut sleeve through outer threads to drive the valve rod to move, a buffer connecting piece connected with the front end of the valve rod is arranged on the front section of the axial through hole of the nut sleeve to conduct guide supporting on the valve rod, circumferential limiting protrusions and limiting leaning shoulders which are matched with each other are arranged for front stroke limiting, and the collision noise and friction are reduced.

Owner:新昌县儒岙镇锦云机械厂

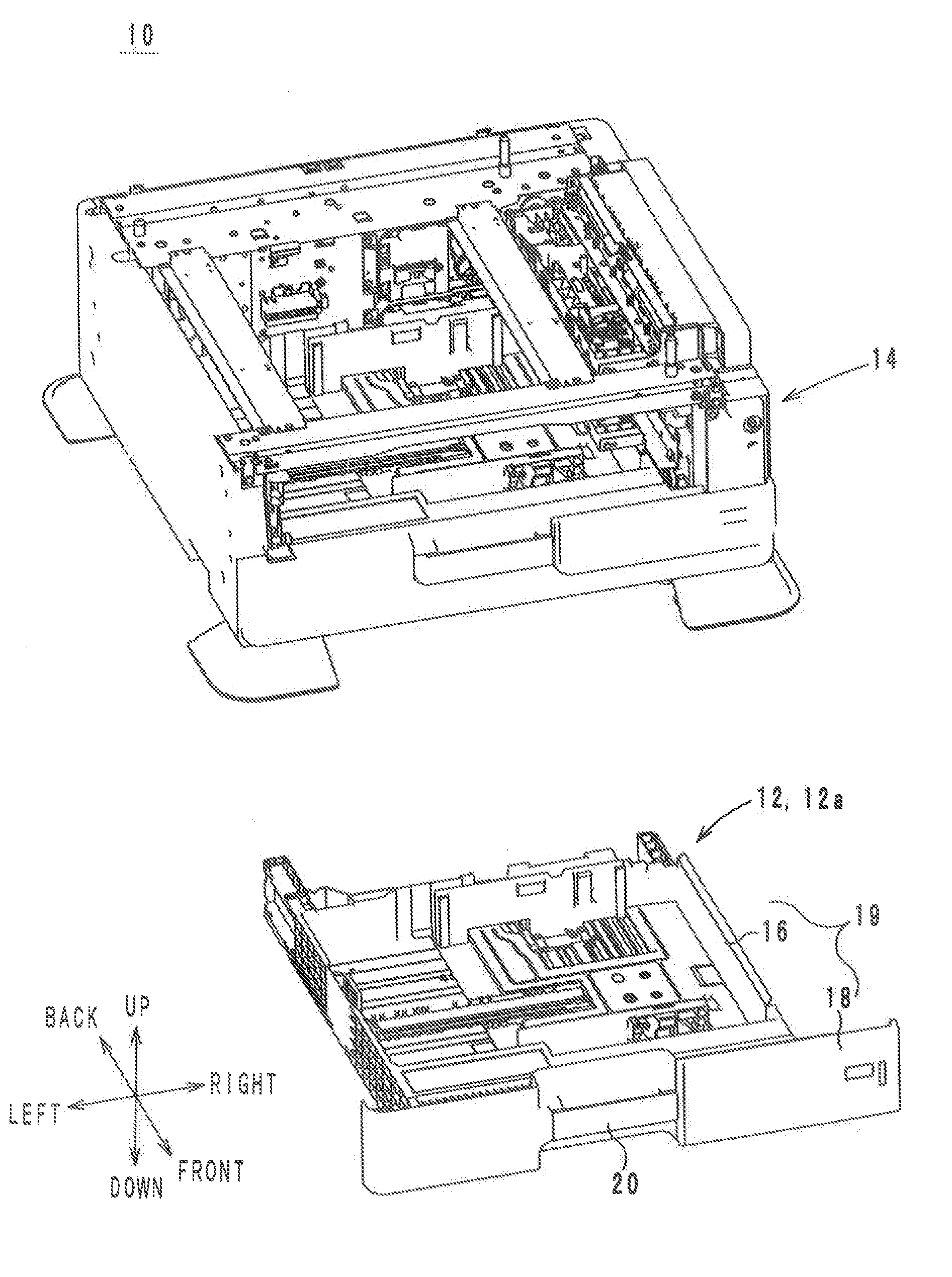

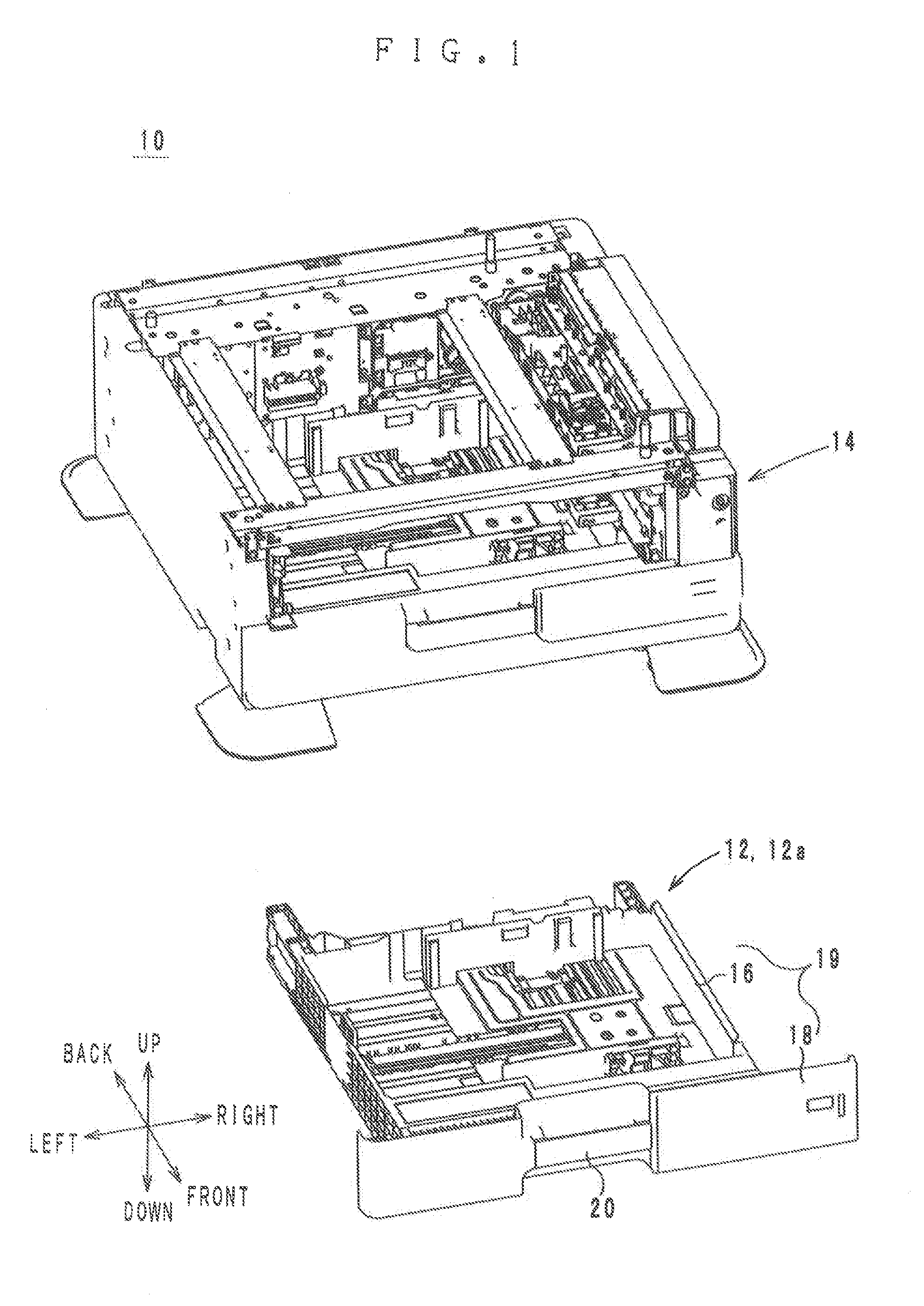

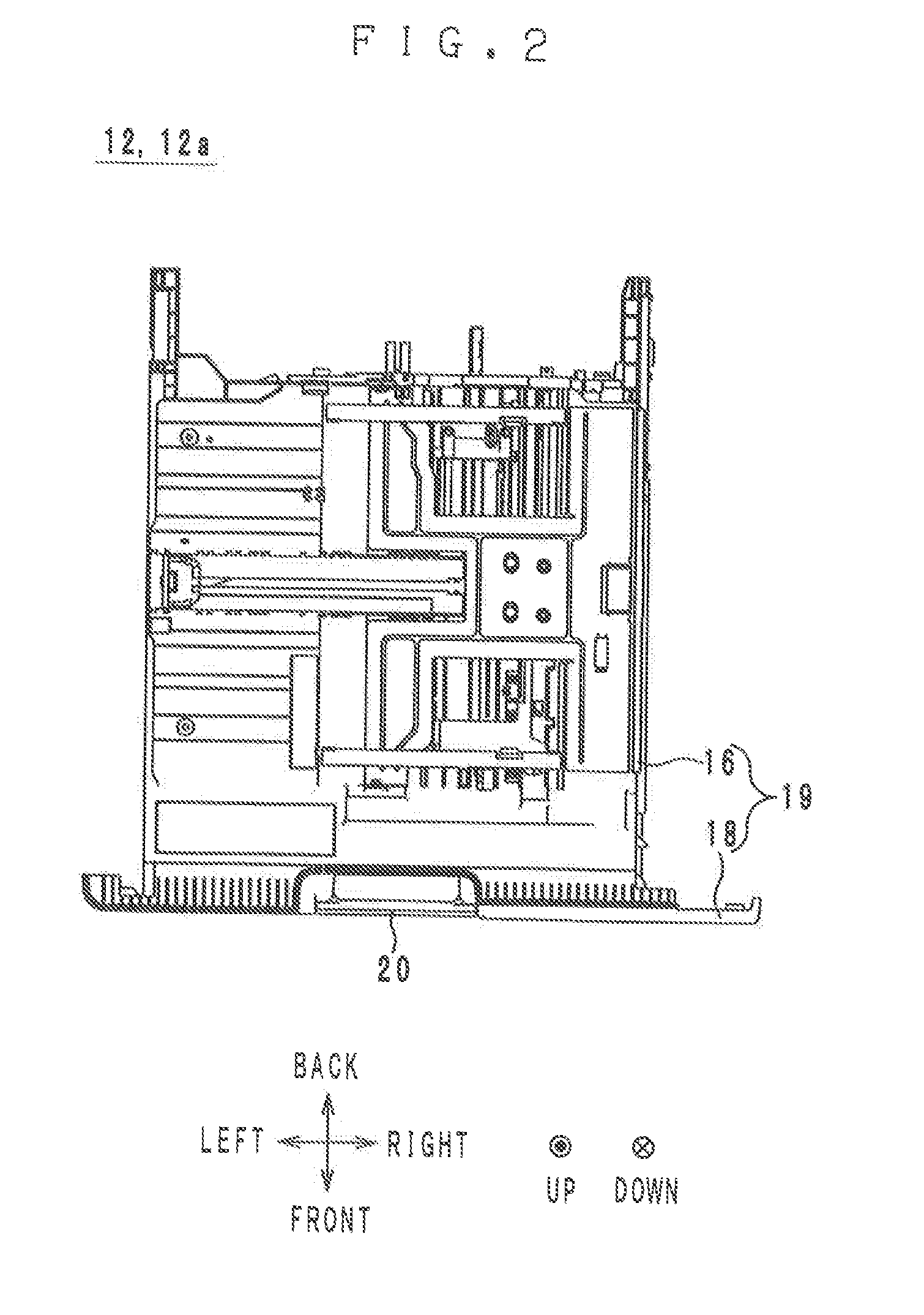

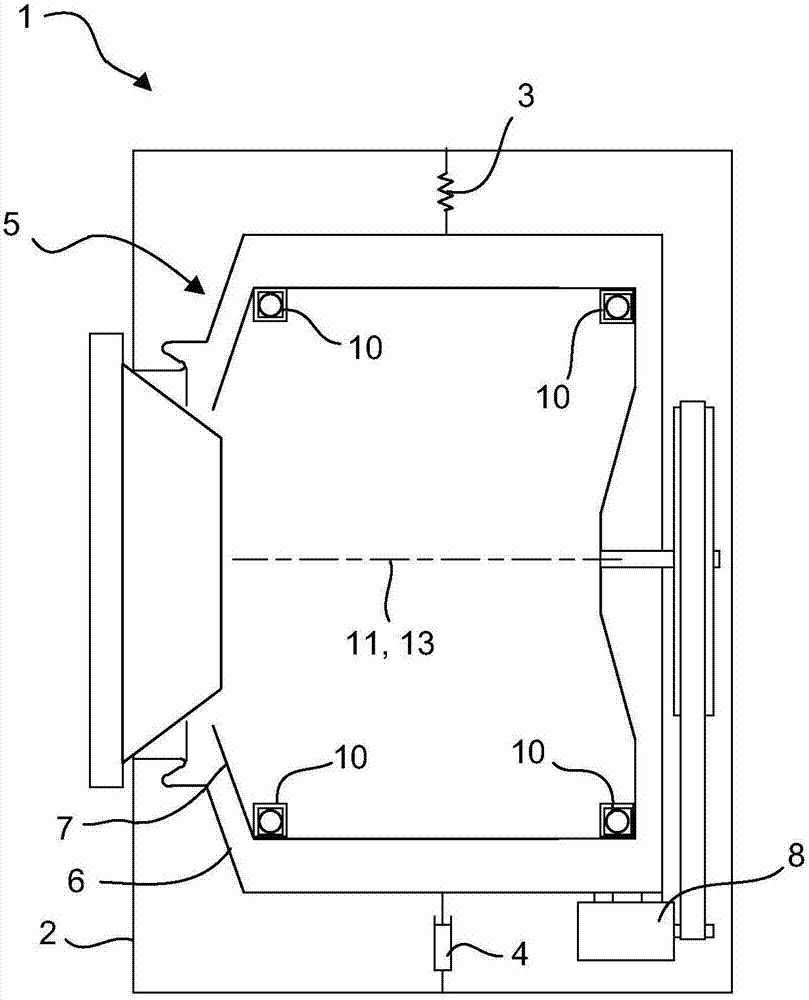

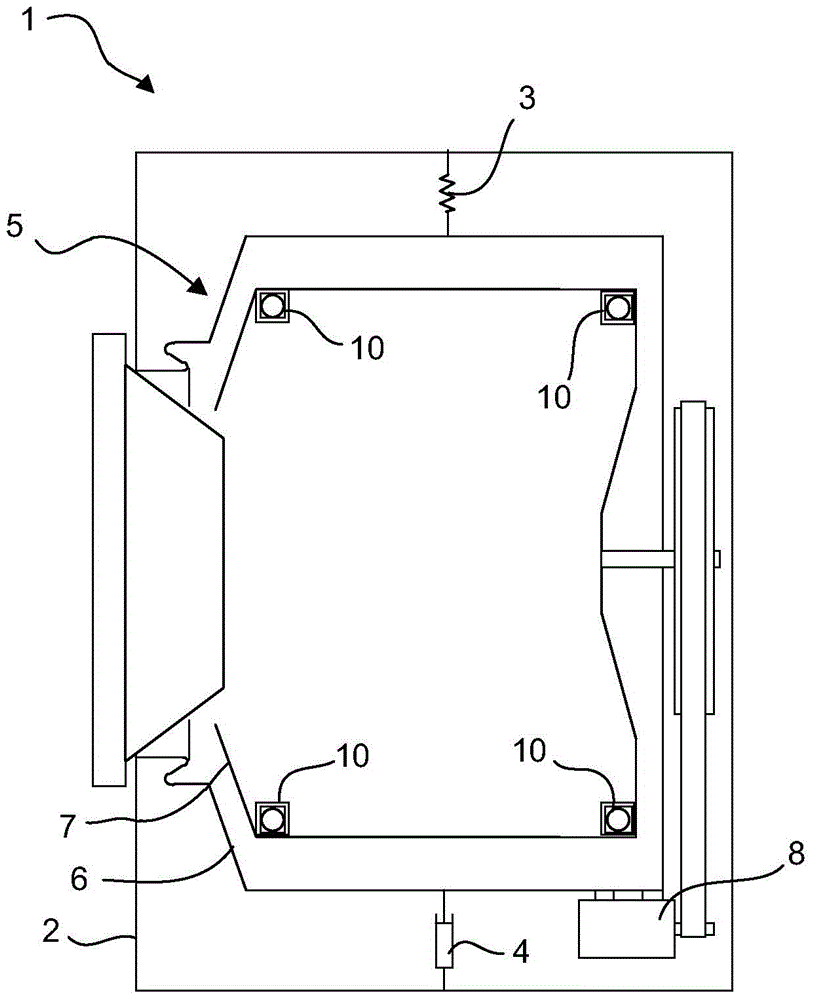

Tray and an image forming apparatus provided with the tray

A tray drawable from an image forming apparatus body in a specified first direction, the tray having: a tray body in which printing media are stored; a handle that is fastened to the tray body so as to be slidable in the first direction by a specified distance, a pull of the handle in the first direction effecting a slide of the handle in the first direction relative to the tray body and applying a pull force in the first direction to the tray body; a lock mechanism for locking the tray body in the image forming apparatus body, the slide of the handle in the first direction relative to the tray body cancelling the lock mechanism; and an elastic member located between the handle and the tray body; wherein at least part of the pull force is transmitted from the handle to the tray body via the elastic member.

Owner:KONICA MINOLTA INC

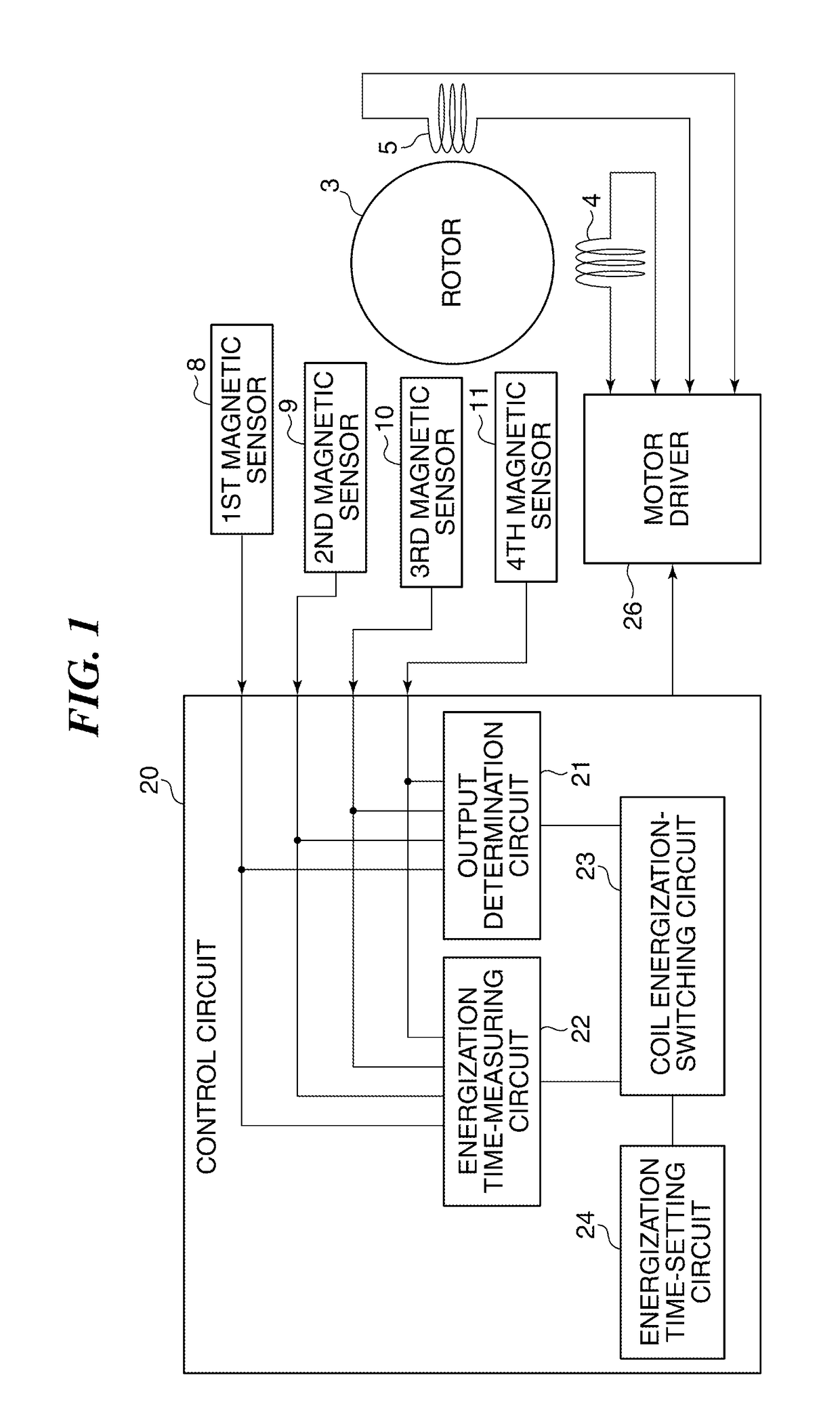

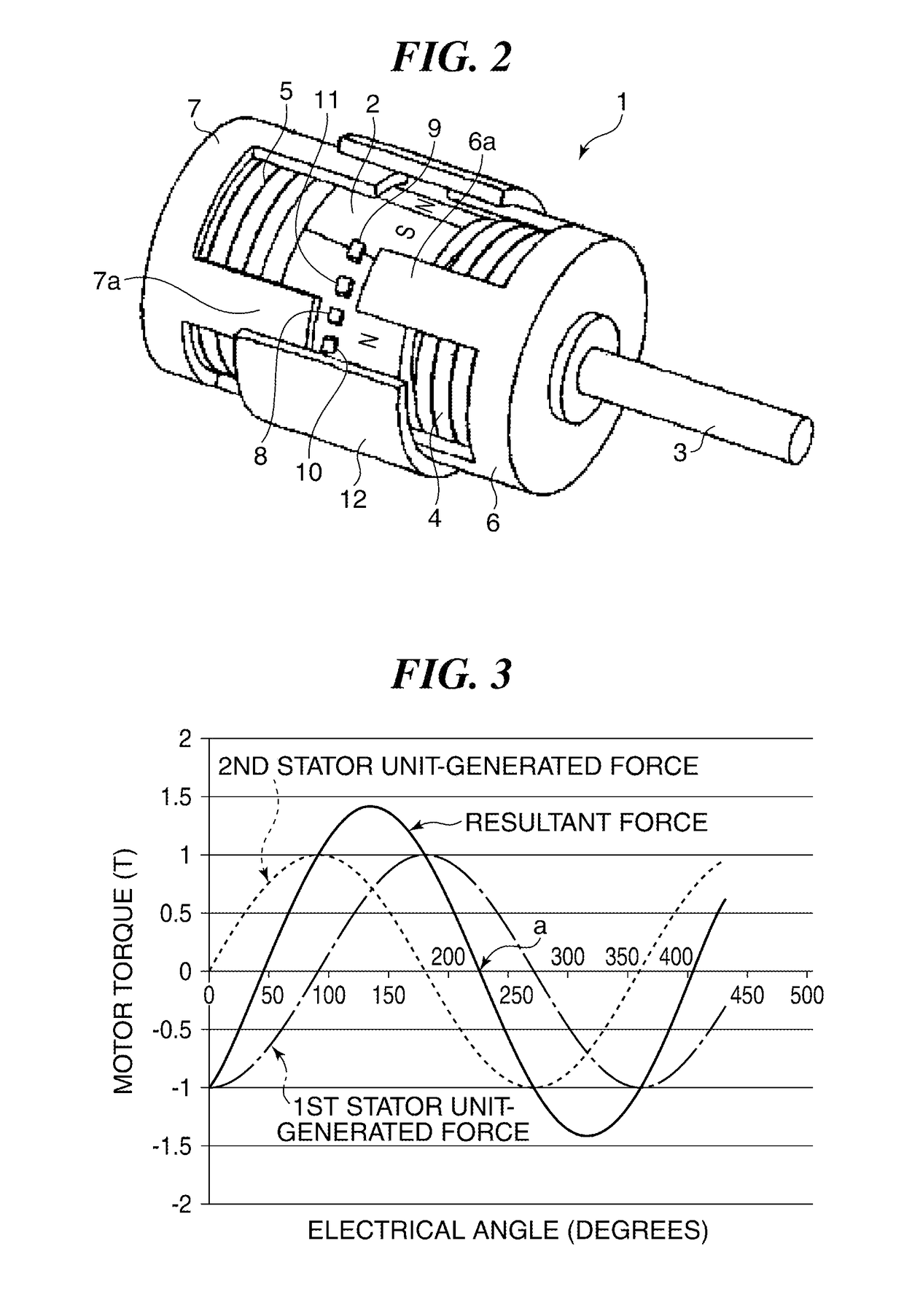

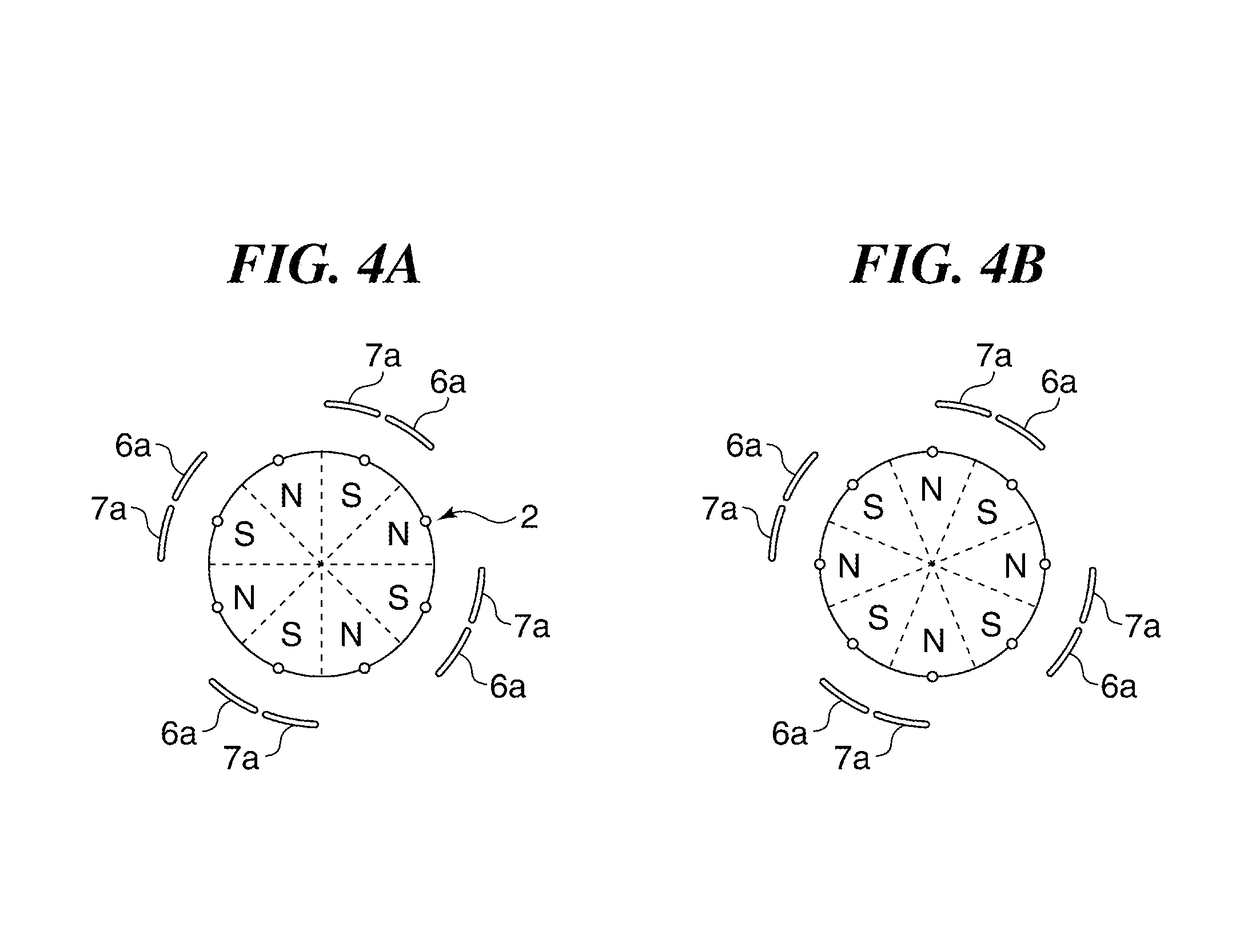

Motor drive device that reduces collision noise of moving member, method of controlling same, and storage medium

InactiveUS20190052786A1Reduce crash noiseTelevision system detailsVector control systemsMotor driveControl theory

A motor drive device that is capable of reducing collision noise generated by a mirror while maintaining a driving speed of the mirror. A control circuit of the motor drive device controls driving of a motor including magnetic sensors for detecting a rotational position of a rotor. An energization time-setting circuit of the control circuit sets an energization time period of the motor, and the control circuit controls driving of the motor depending on a detection result output from each magnetic sensor and the set energization time period.

Owner:CANON KK

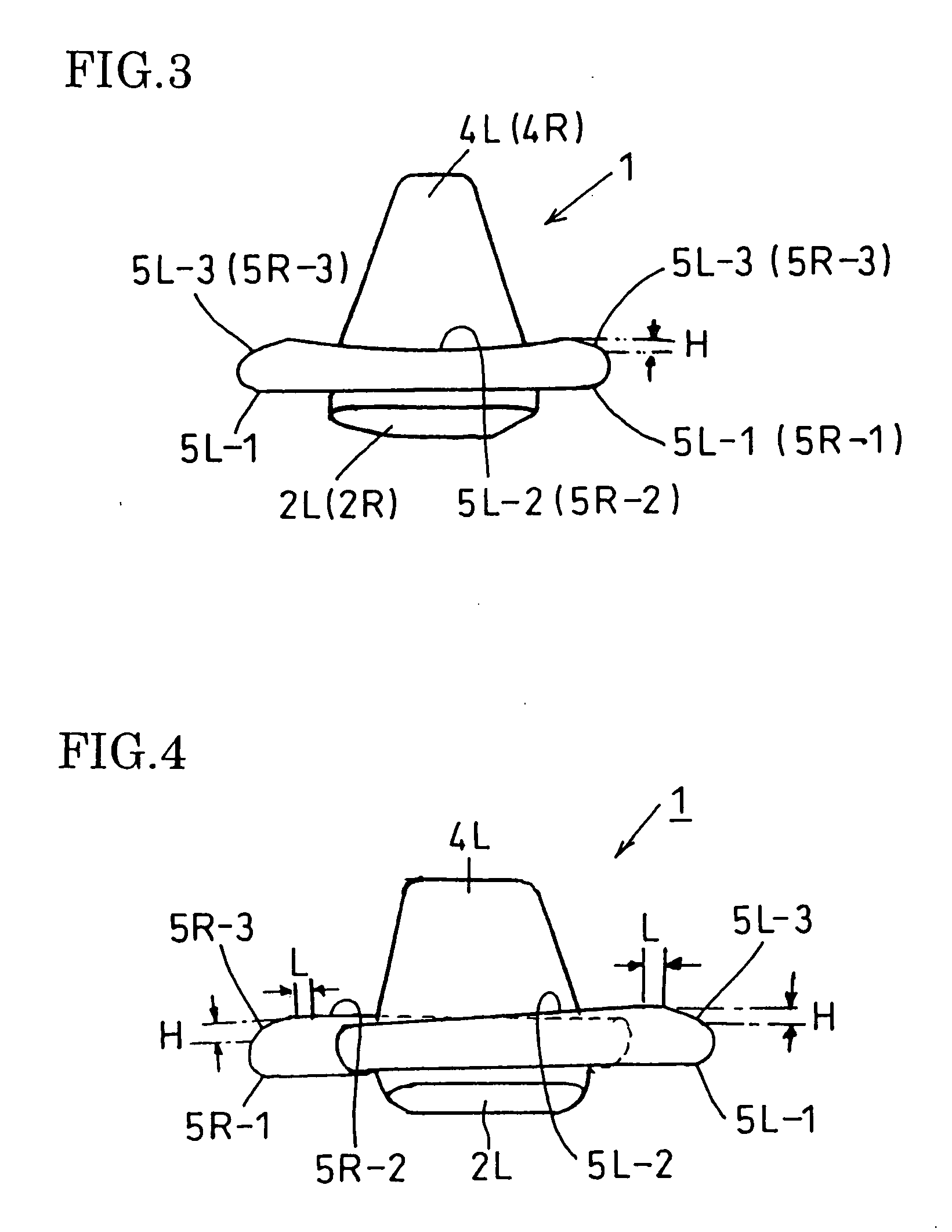

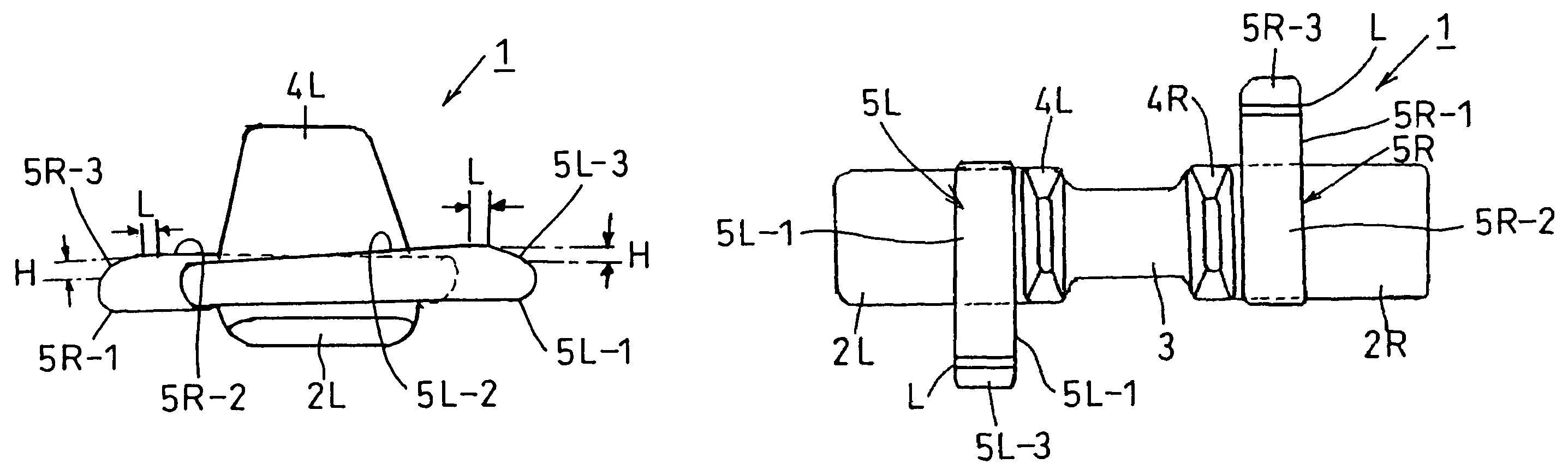

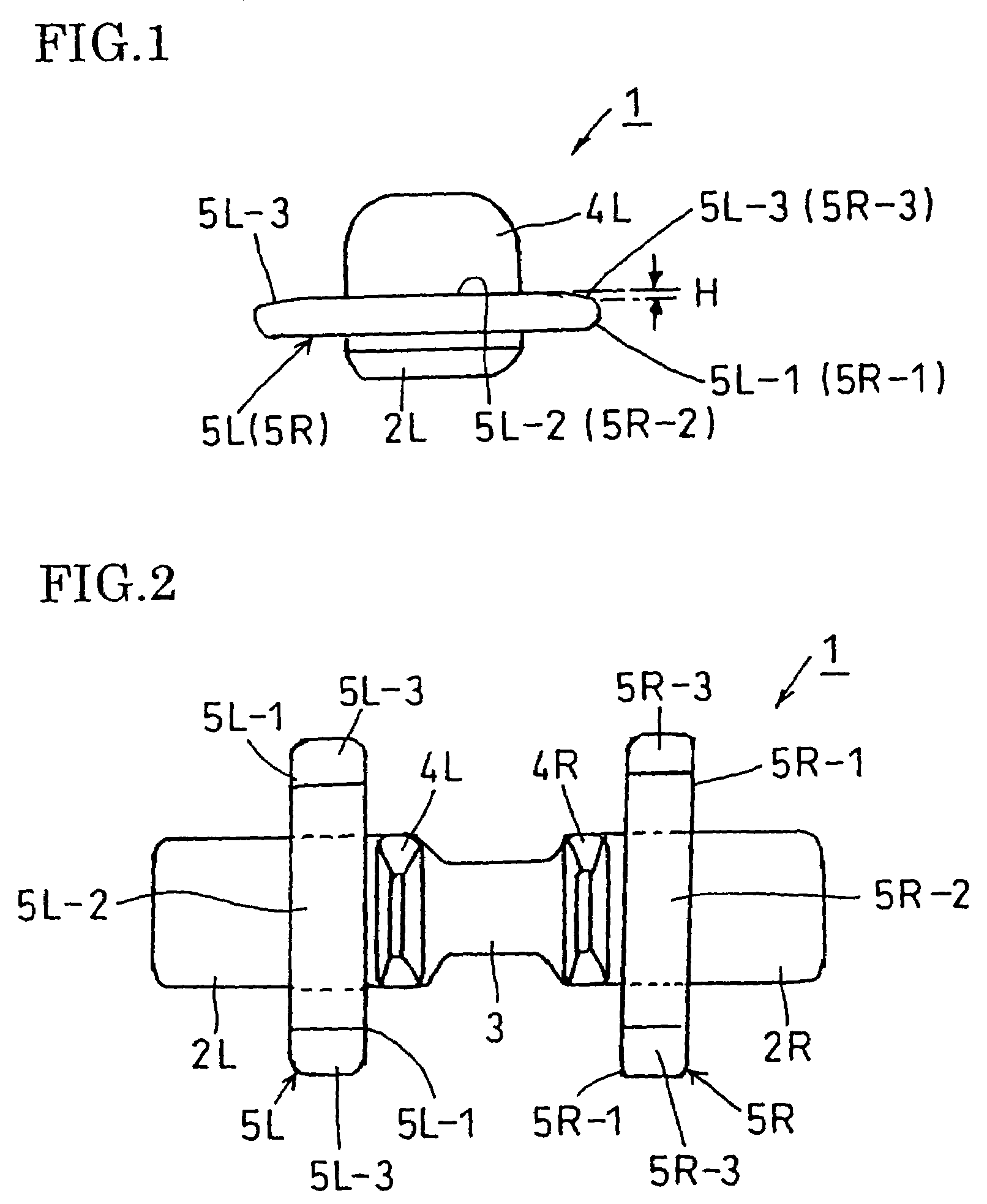

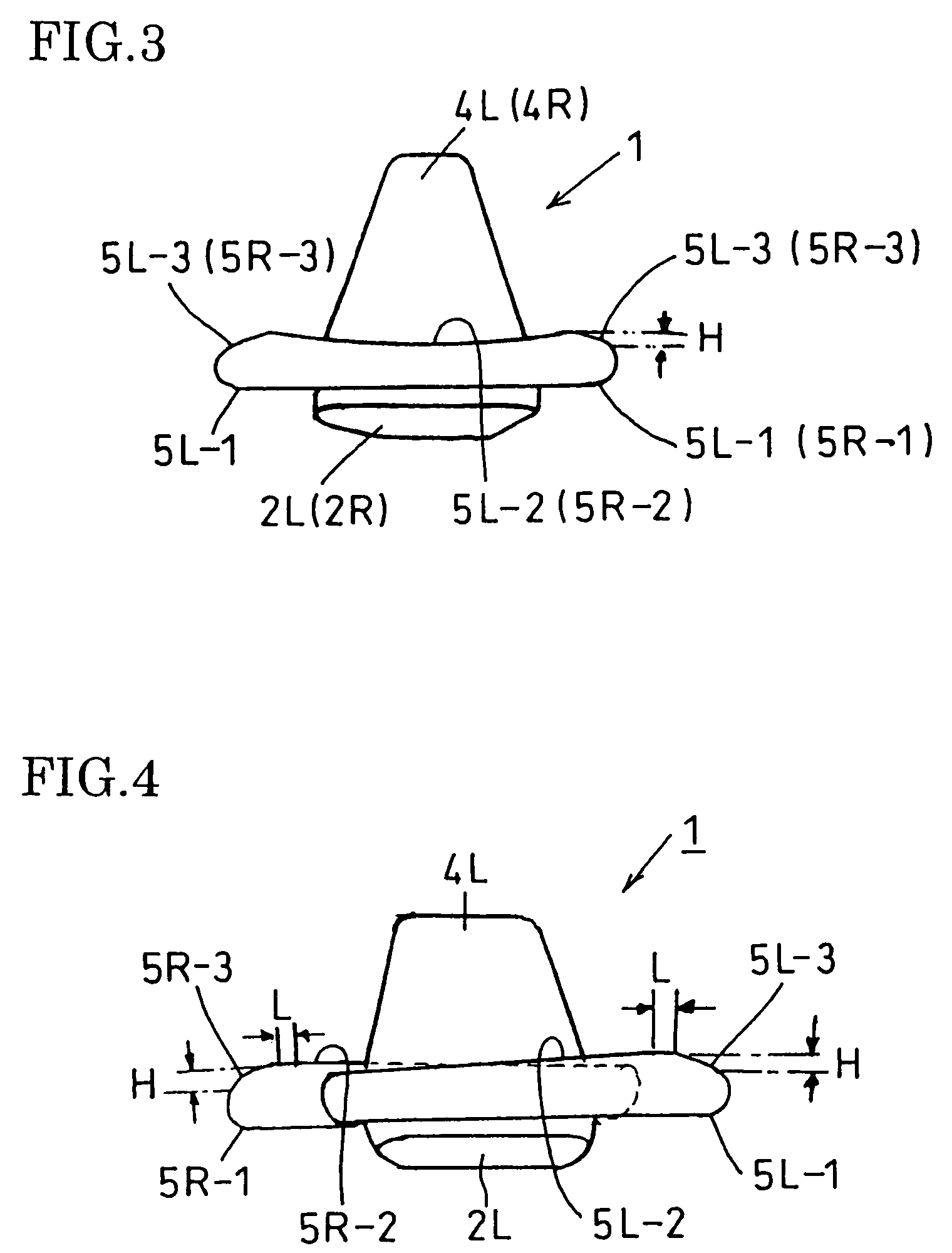

Core bar for rubber crawler and rubber crawler

InactiveUS20050001482A1Reduce height differenceReduce crash noiseEndless track vehiclesEngineeringRight flank

Owner:SUMITOMO RUBBER IND LTD

Core bar for rubber crawler and rubber crawler

InactiveUS7131709B2Reduce height differenceReduce crash noiseEndless track vehiclesRight flankAerospace engineering

Owner:SUMITOMO RUBBER IND LTD

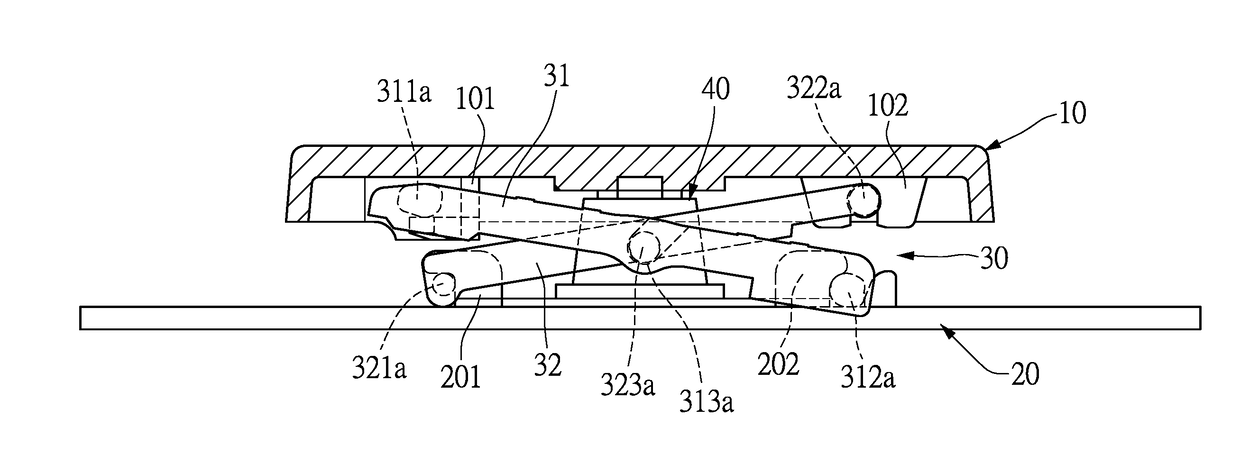

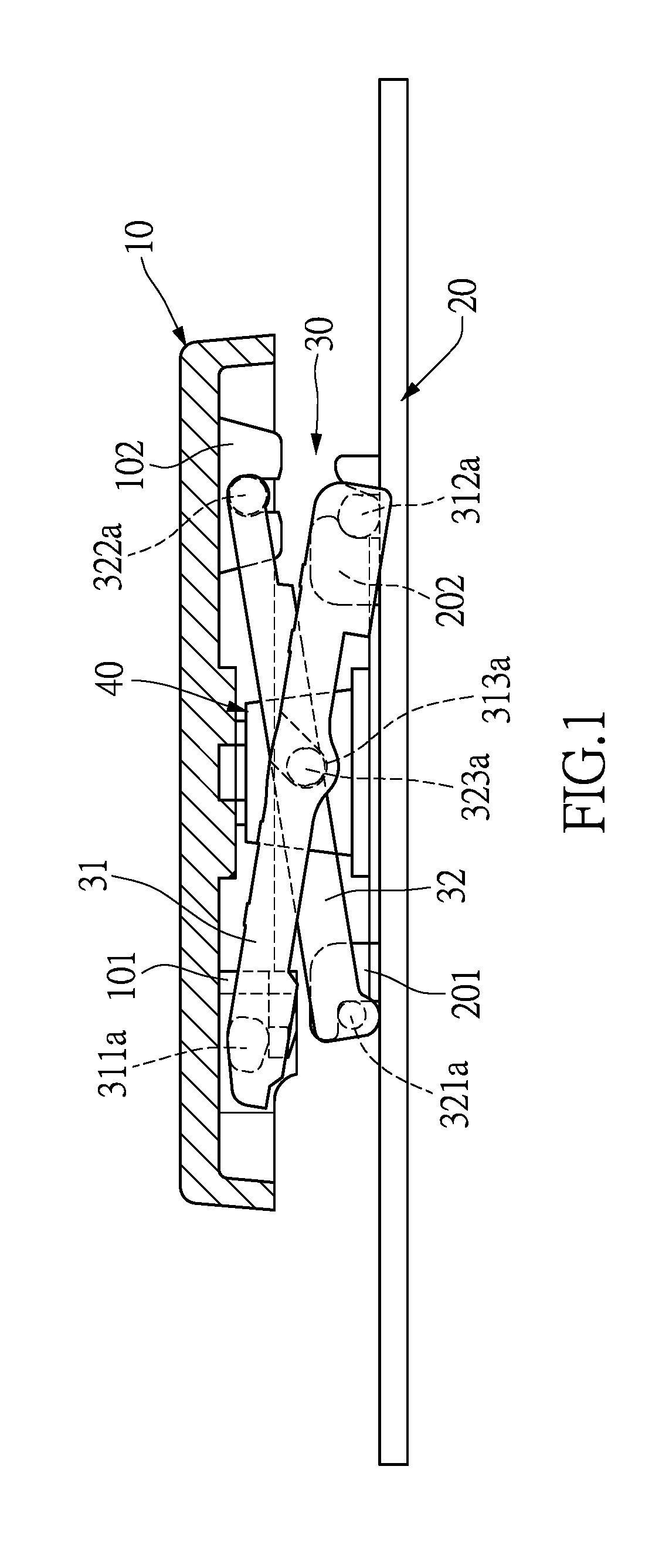

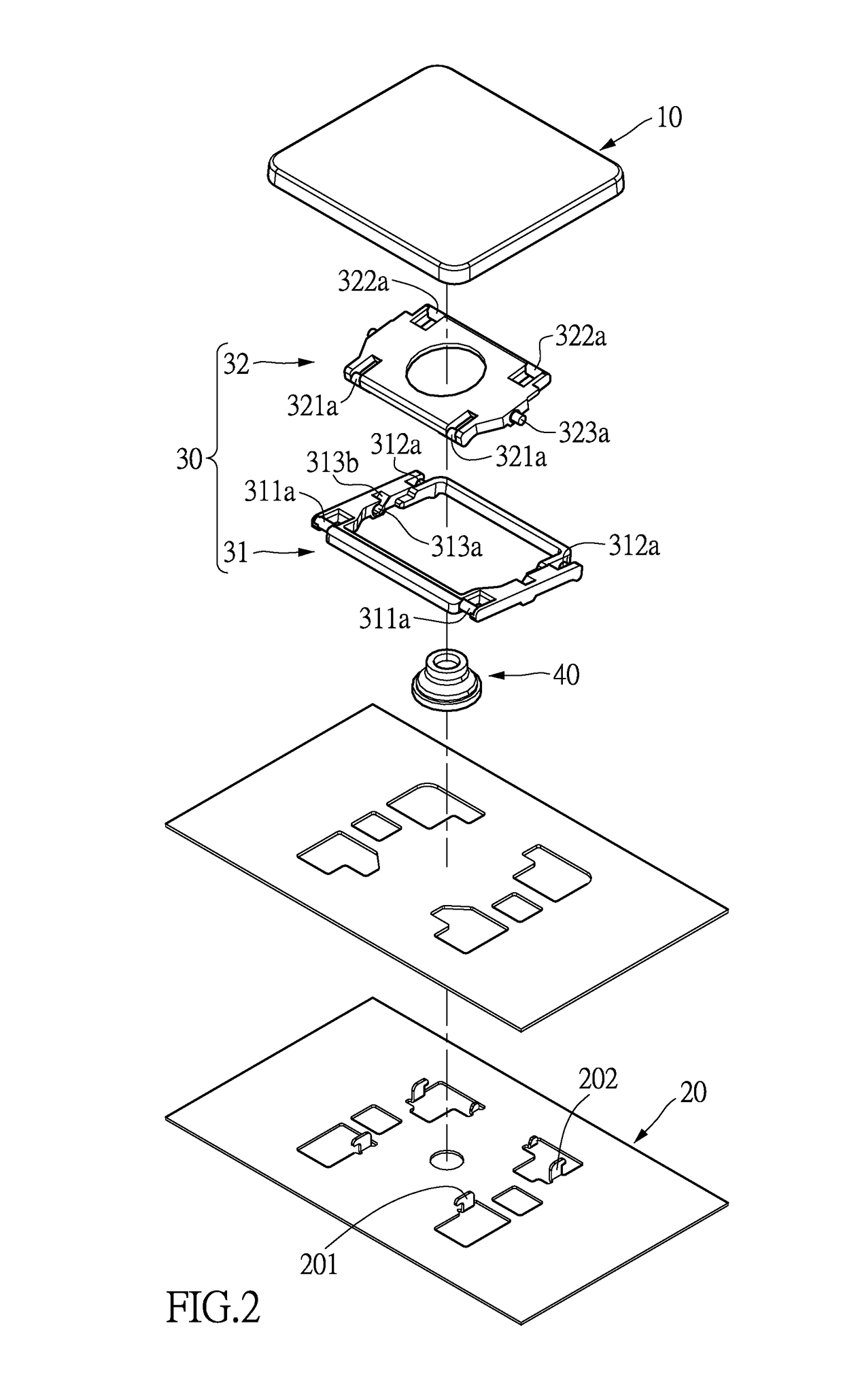

Key supporting structure

ActiveUS20170191612A1Reduced strengthSolve the real problemInput/output for user-computer interactionContact mechanismsPlastic injection moldingEngineering

Disclosed is a key supporting structure. The key supporting structure includes a scissor-type component having a first supporting element and a second supporting element that are pivotally connected to each other. The first supporting element has a first frame, and two end of the first frame have at least one first pivot and at least one second pivot respectively. The second supporting element has a second frame, and two end of the second frame have at least one third pivot and at least one fourth pivot respectively. The first frame and the second frame are made from a powder sintered material. The first pivot, the second pivot, the third pivot, and the fourth pivot are formed on the first frame and the second frame by plastic injection molding method.

Owner:LITE ON ELECTRONICS (GUANGZHOU) LTD +1

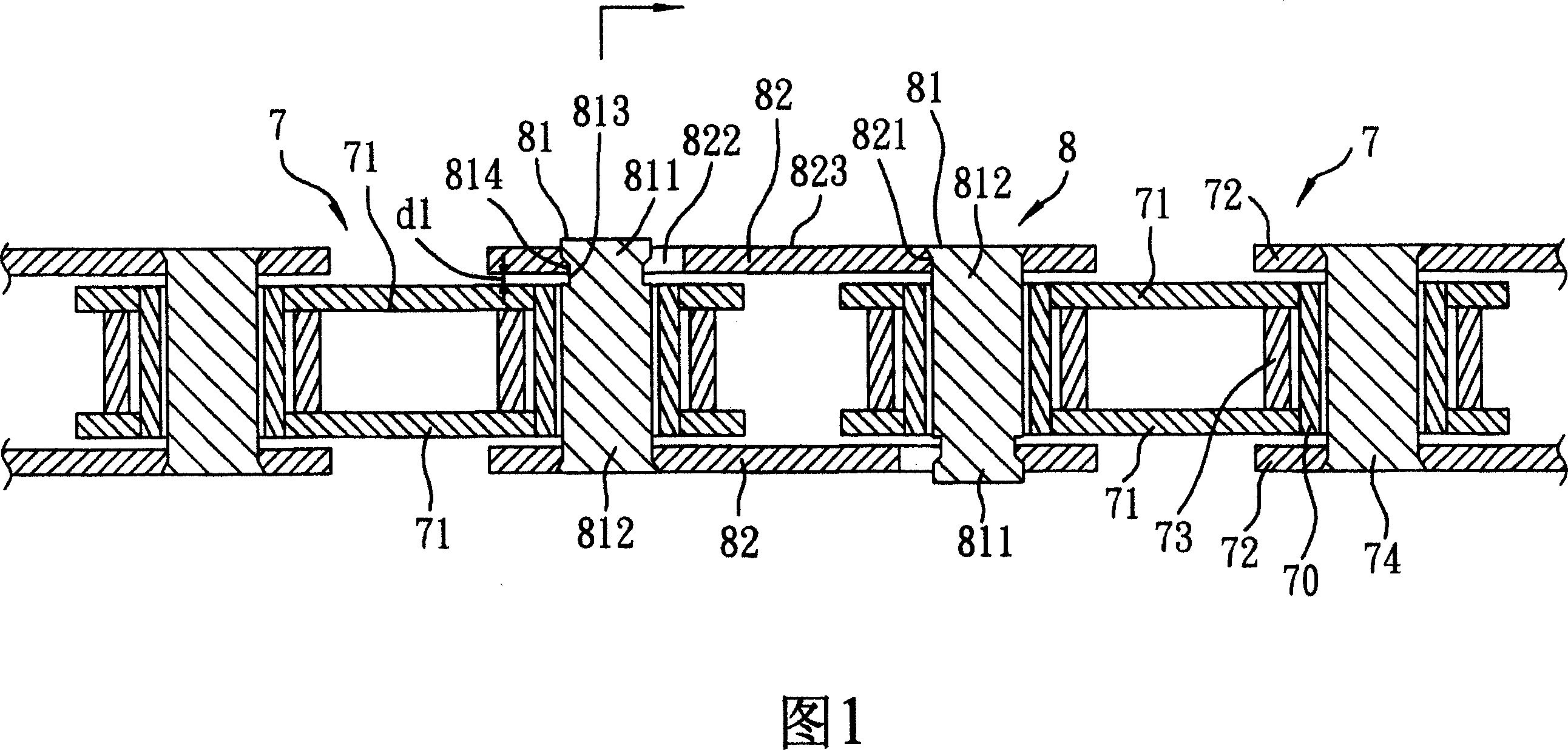

Chain sheet of chain

A chain-sheet of chain can be outer chain-sheet, inner chain-sheet and joint chain-sheet according to the installing position, comprising a body and a first raised wing, wherein the body is at interval provided with a first side and a second side of the body, and two outer ends at interval side to side that connect the outer side edge, the first raised wing projects from one outer end with a first side of the first raised wing. The chain-sheet of the invention and another chain-sheet of the chain are assembled to make the first side of the raised wing is more closed to the other chain-sheet than the first side of the body, to reduce the gap between the chain-sheets and reduce the oscillating space while the chain-sheets are vibrated with advantages that it can increase the using safety and reduce the colliding force between the chain-sheets and the colliding noise or the like.

Owner:超汇桂盟传动(苏州)有限公司

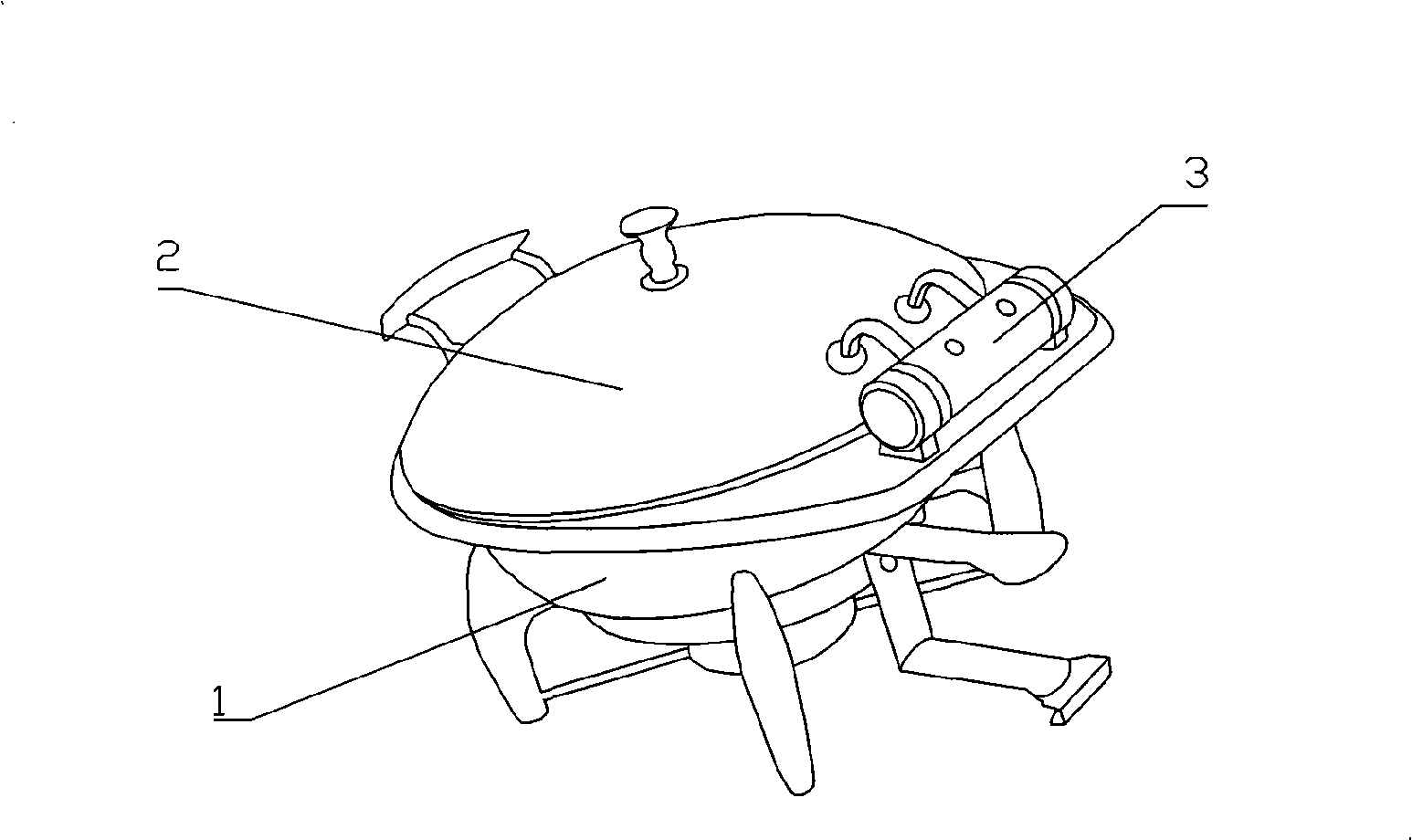

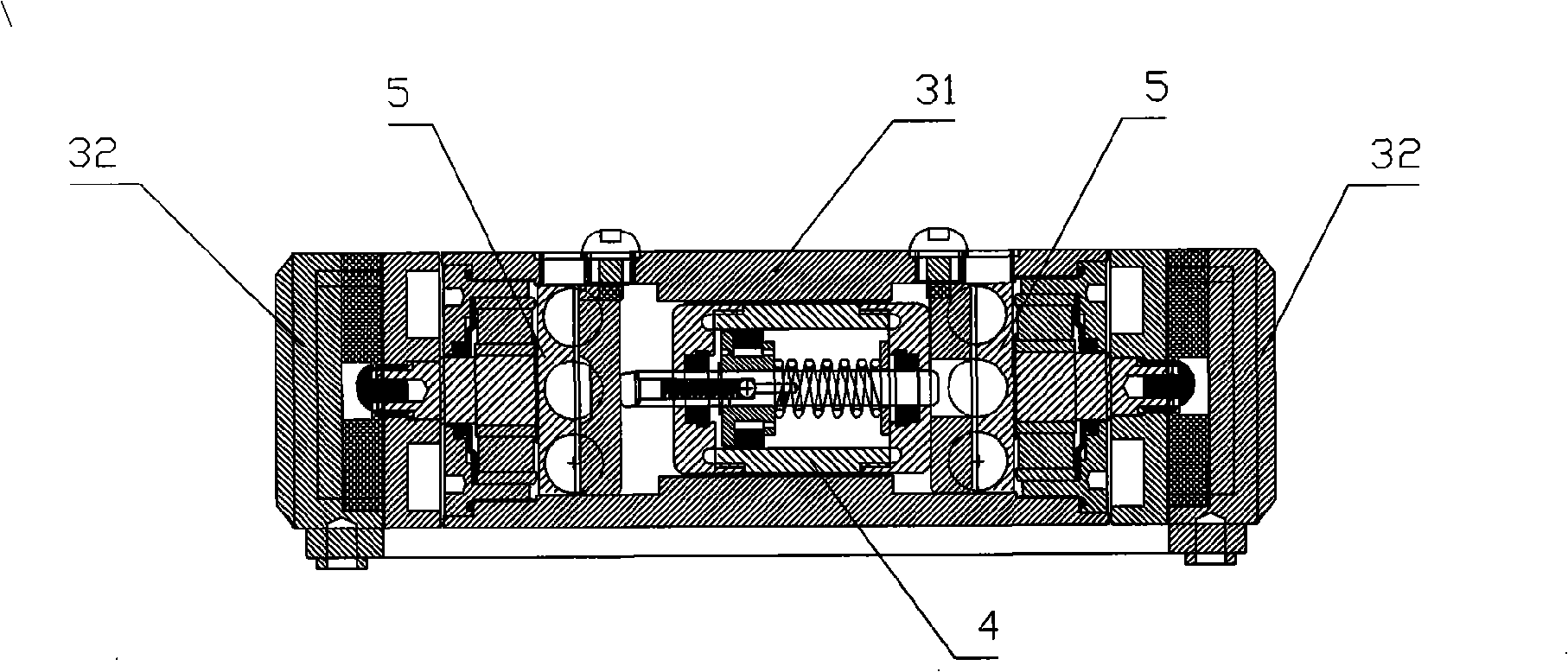

Dining stove

ActiveCN101301164AReduce crash noiseAvoid damageSpringsCooking-vessel lids/coversEngineeringHydraulic cylinder

The invention discloses a stove for dinner comprising a water disk with an overturn cover arranged above, the water disk is provided with a hydraulic buffer which comprises a casing, a hydraulic buffer cylinder is arranged inside the casing, and both sides of the hydraulic buffer cylinder are respectively equipped with a driving mechanism capable of transforming rotation into linear movement and driving the hydraulic buffer cylinder to act, the driving mechanism is driven by a rotation base fixedly connected to the overturn cover, thereby buffering the action of the overturn cover when opening or closing the cover, reducing the noise caused by collision between the overturn cover and the water disk, and preventing the overturn cover from damage due to the collision.

Owner:江门市宇辉西厨设备有限公司

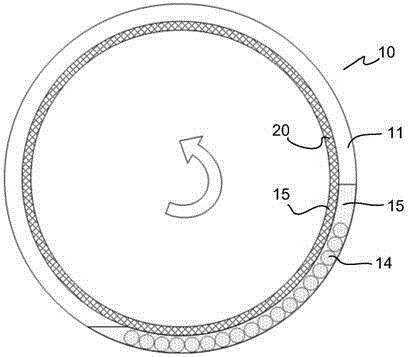

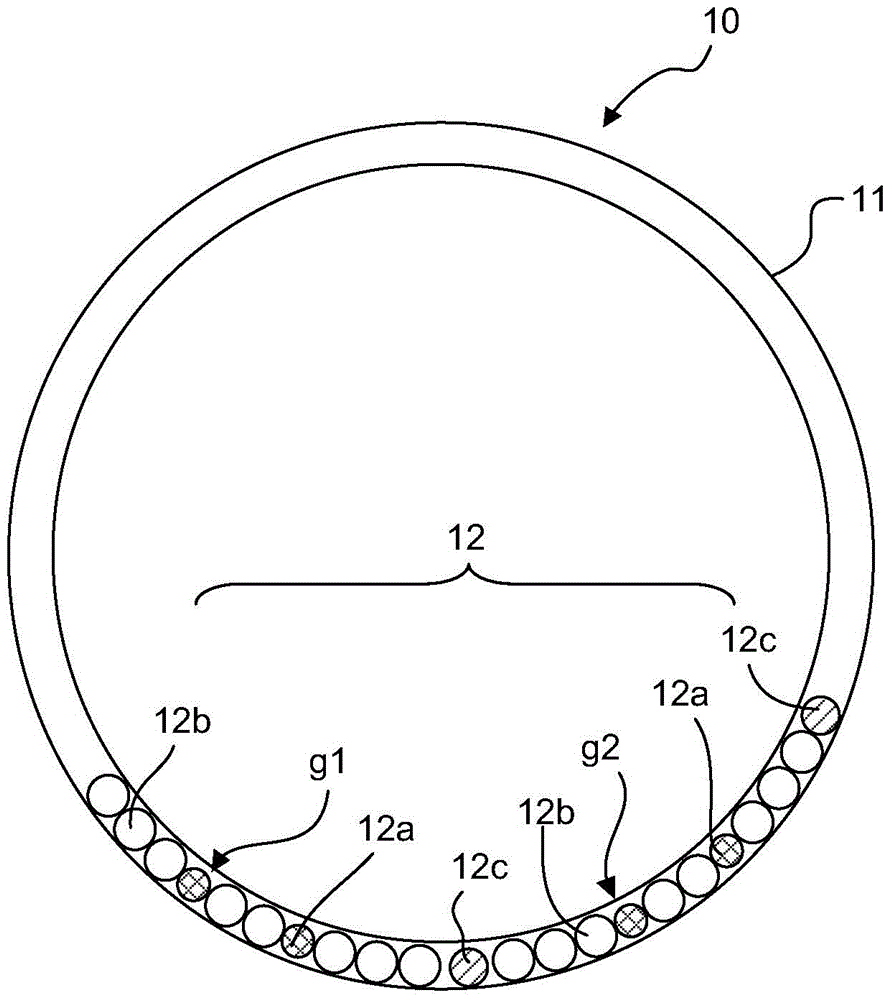

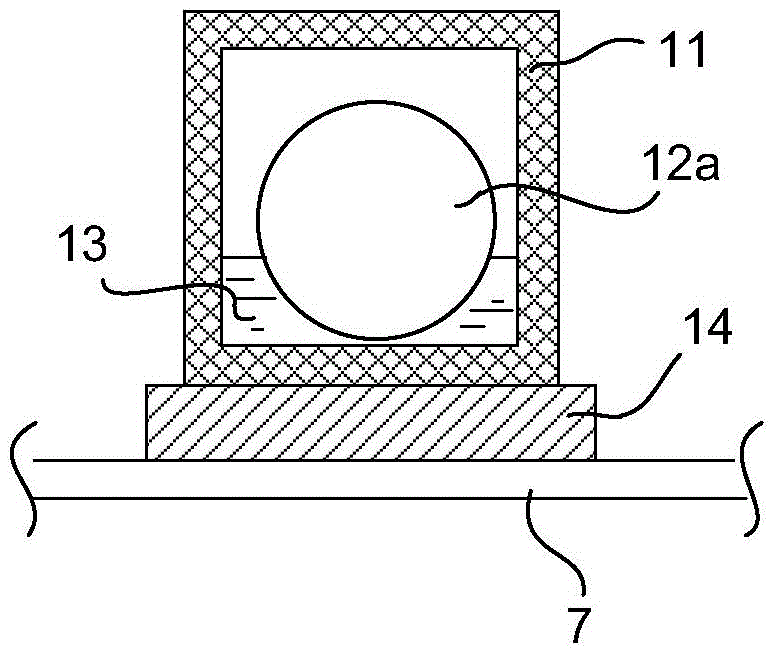

Washing machine and balance ring used for washing machine

ActiveCN106811923AReduce crash noiseOther washing machinesTextiles and paperEngineeringMechanical engineering

Provided is a balance ring used for a washing machine. The balance ring used for a washing machine comprises a housing with an annular inner cavity. The annular inner cavity is provided with a viscous fluid and a plurality of balls which can roll along the annular inner cavity. One side of the annular inner cavity, close to the center shaft of the annular inner cavity, is provided with a liquid retaining device. When the balance ring is static or rotates around the center shaft in velocity lower than first rotating speed, the viscous fluid is absorbed by the liquid retaining device, and is maintained in the liquid retaining device. Thus, the viscous fluid in the annular inner cavity is reduced, and viscosity force of the viscous fluid on the balls is reduced, so the balls are remained in relatively low positions of the annular inner cavity and are not pushed to cross the highest point of the annular inner cavity, so as to prevent the balls from colliding each other and preventing noise. The invention also discloses a washing machine including the balance ring.

Owner:BSH ELECTRICAL APPLIANCES JIANGSU +1

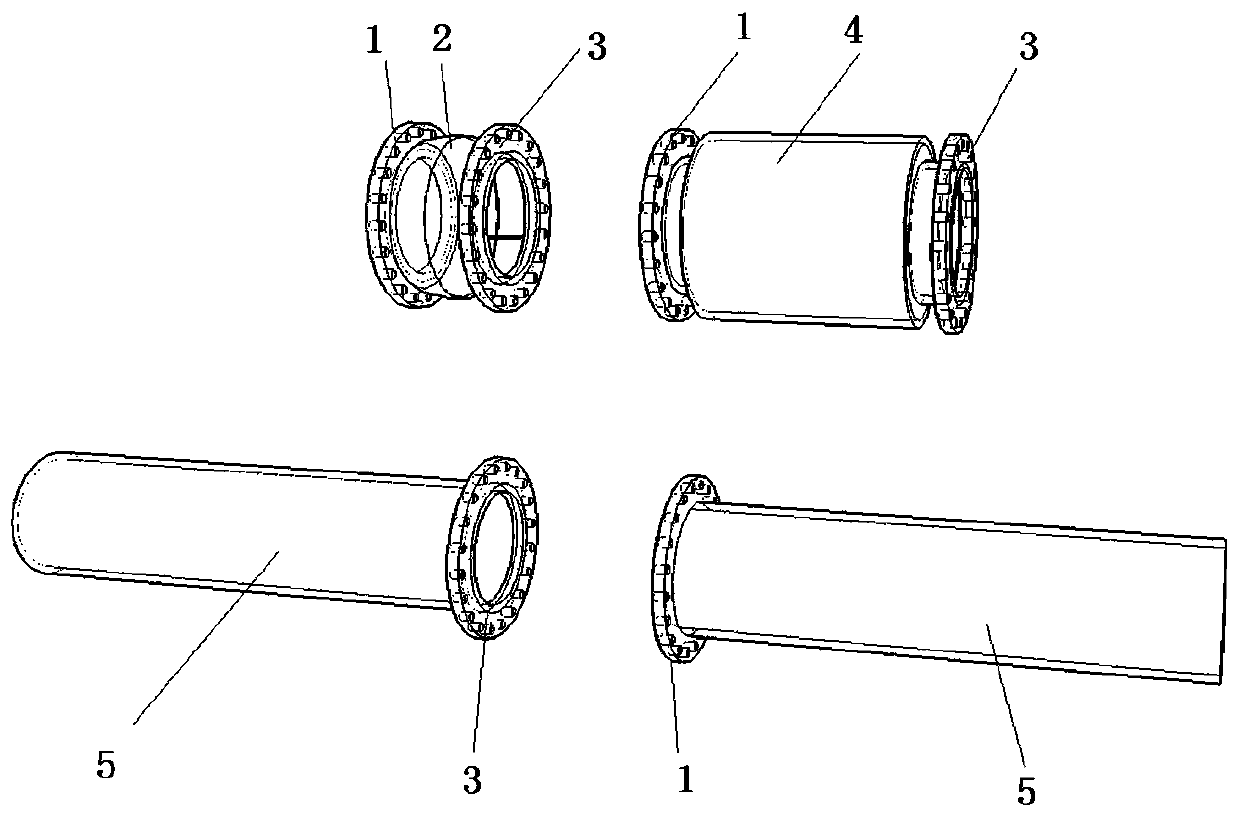

Sound attenuation and noise reduction device applied to air duct

PendingCN110848497AReduce transmissionReduce operating and maintenance costsPipe supportsPipe elementsNoise generationNoise

The invention relates to a sound attenuation and noise reduction device applied to an air duct. The sound attenuation and noise reduction device includes a flexible joint and a muffler. Flange piecesare arranged at both ends of the flexible joint and the muffler. A pipe at the original air duct is cut and removed, and the flange pieces are installed at pipe orifices by welding. The flange piece at one end of the flexible joint is connected with the flange piece on the end part of the pipe on one side, and the flange piece at the other end of the flexible joint is connected with the flange piece at one end of the muffler. The flange piece at the other end of the muffler is connected with the flange piece on the end part of the pipe on the other side. The sound attenuation and noise reduction device can realize arbitrary combination, disassembly and installation. Meanwhile, the sound attenuation and noise reduction device can be quickly connected and installed with the pipes at any desired position in an original pipeline. Through the installation of the sound attenuation and noise reduction device in the middle of the existing pipe, the impact of vibration generated during the operation of the air duct on existing surrounding structures can be efficiently and safely reduced, the decibel value of noise generated during the operation is reduced, and it is ensured that the factoryboundary noise meets the standard.

Owner:SHANGHAI MUNICIPAL ENG DESIGN INST GRP

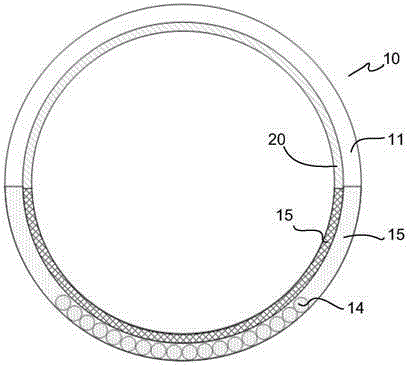

Washing machine and balancing ring used for the washing machine

ActiveCN107366131AReduce crash noiseOther washing machinesTextiles and paperEngineeringCentrifugal force

Provided is a balancing ring used for a washing machine. The balancing ring comprises a housing with an annular inner cavity. The annular inner cavity is internally provided with at least mass bodies capable of moving along the annular inner cavity. Centripetal sides of the mass bodies are provided with first magnets. The centripetal side of the housing is provided with an attraction part which can be attracted by magnetic force. Each balancing ring remains static or rotates around a central shaft at the speed lower than the pre-set rotation speed. The mass bodies are fixed by magnetic attraction of the first magnets and the attraction part. The mass bodies and the housing of the balancing ring rotate as a whole. When the balancing ring rotates around the central shaft at the speed higher than or equal to the pre-set rotation speed, centrifugal force enables magnetic attraction to be overcome. The mass bodies can move in the annular inner cavity at the proper position to achieve balance. The invention further discloses the washing machine having the balancing ring.

Owner:BSH ELECTRICAL APPLIANCES JIANGSU +1

Car door side skirt mounting structure

The invention discloses a car door side skirt mounting structure. The mounting structure comprises a car door sheet, a first side skirt and a second side skirt, wherein the first side skirt is connected to the outer side of the car door sheet, and the second side skirt is connected to the inner side of the car door sheet; the first side skirt and the second side skirt are both made of a resin material. According to the car door side skirt mounting structure, the second side skirt is added on the inner side of the car door sheet, the first side skirt and the second side skirt are made of the resin material as a whole, so that direct contact between human bodies and the car door sheet can be avoided, harm caused by collisions to users can be substantially reduced, and the user experience effect can be enhanced. Besides, after the side skirts are damaged, compared with traditional sheet metal parts, the resin material is low in cost, easy to replace and low in maintenance cost.

Owner:SWELL MARUI GUANGZHOU AUTOMOBILE PARTS

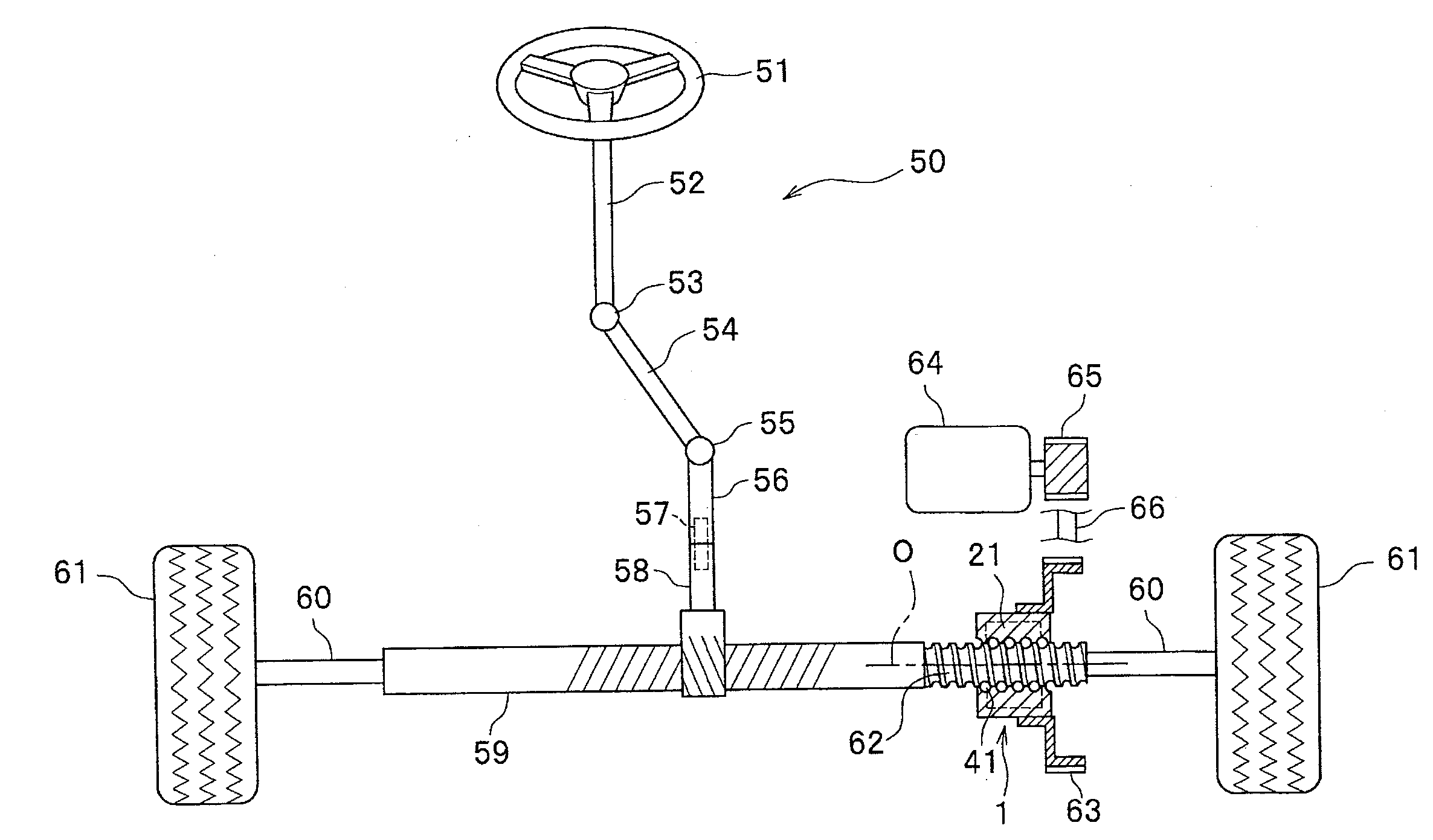

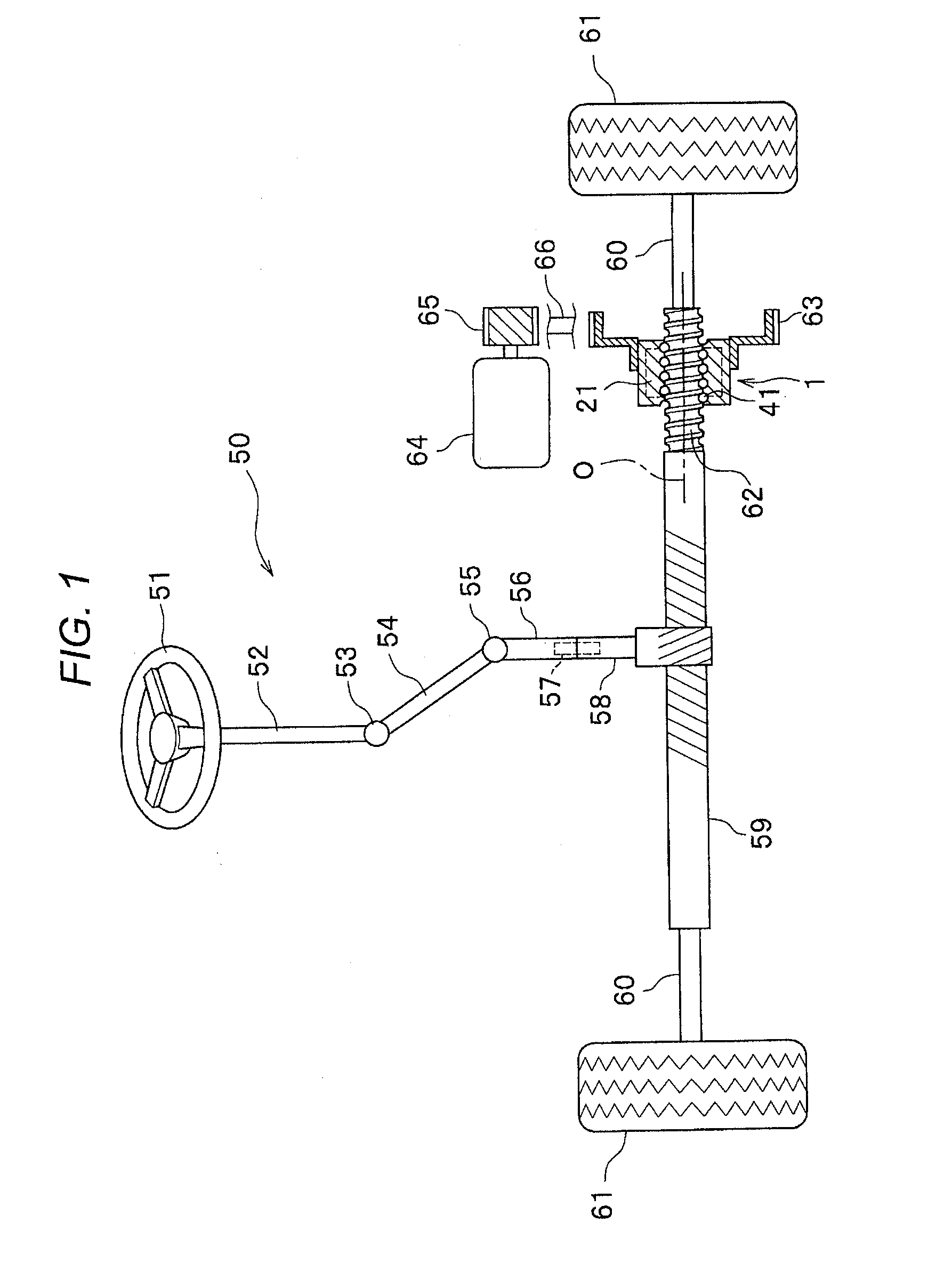

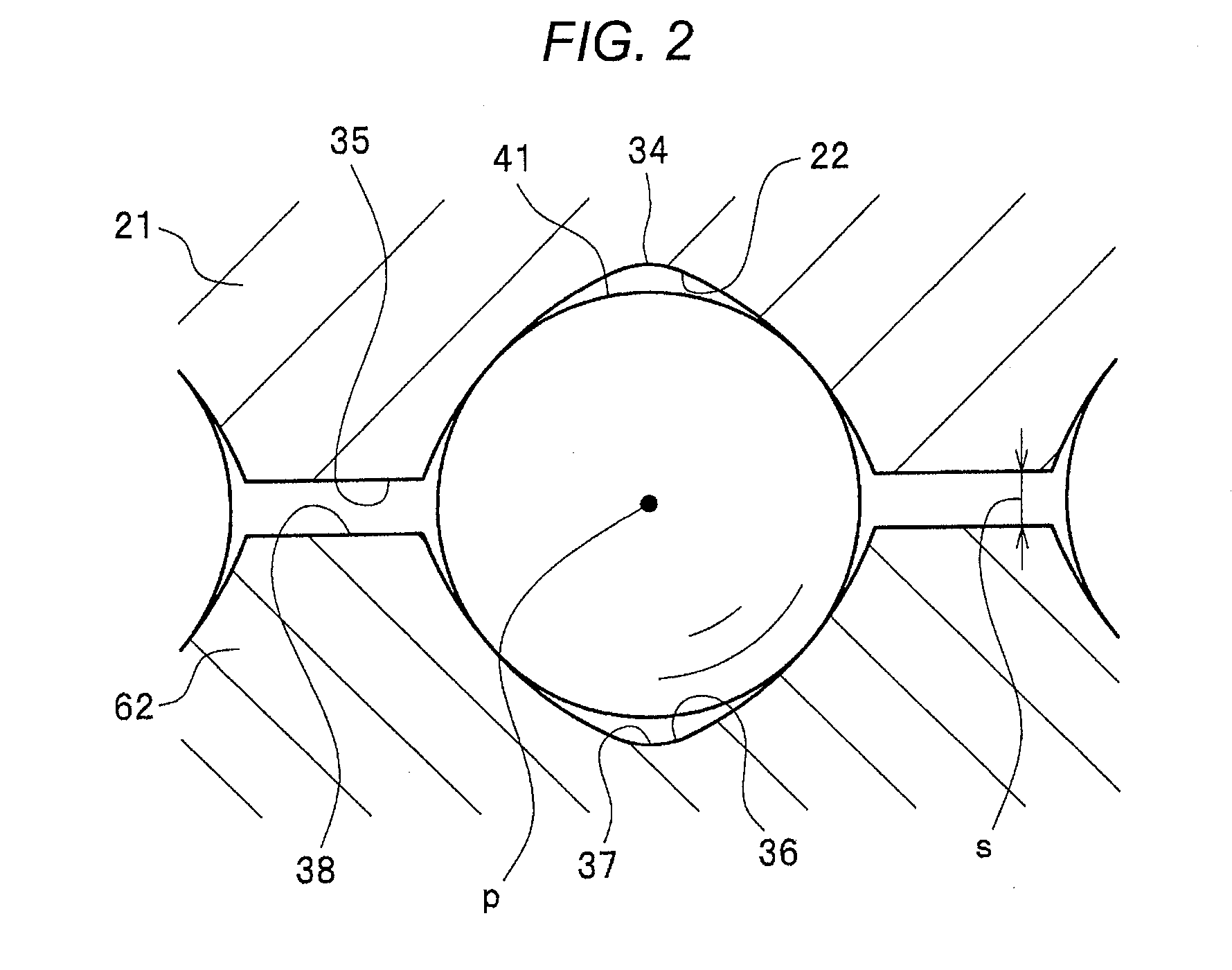

Ball screw and steering apparatus

InactiveUS20150239493A1Avoid crash noiseAvoid collisionToothed gearingsMechanical steering gearsBall screwEngineering

A ball screw includes: a nut; a screw shaft; and an end deflector that is attached to the nut, and has a guiding protrusion portion which protrudes toward a helical groove of the screw shaft, in which a guiding tip edge of the guiding protrusion portion picks up a ball and guides the ball into the end deflector, the end deflector includes a ball lifting portion that lifts the ball along one groove side surface of the helical groove, and the guiding tip edge picks up the ball lifted by the ball lifting portion.

Owner:SHOWA CORP

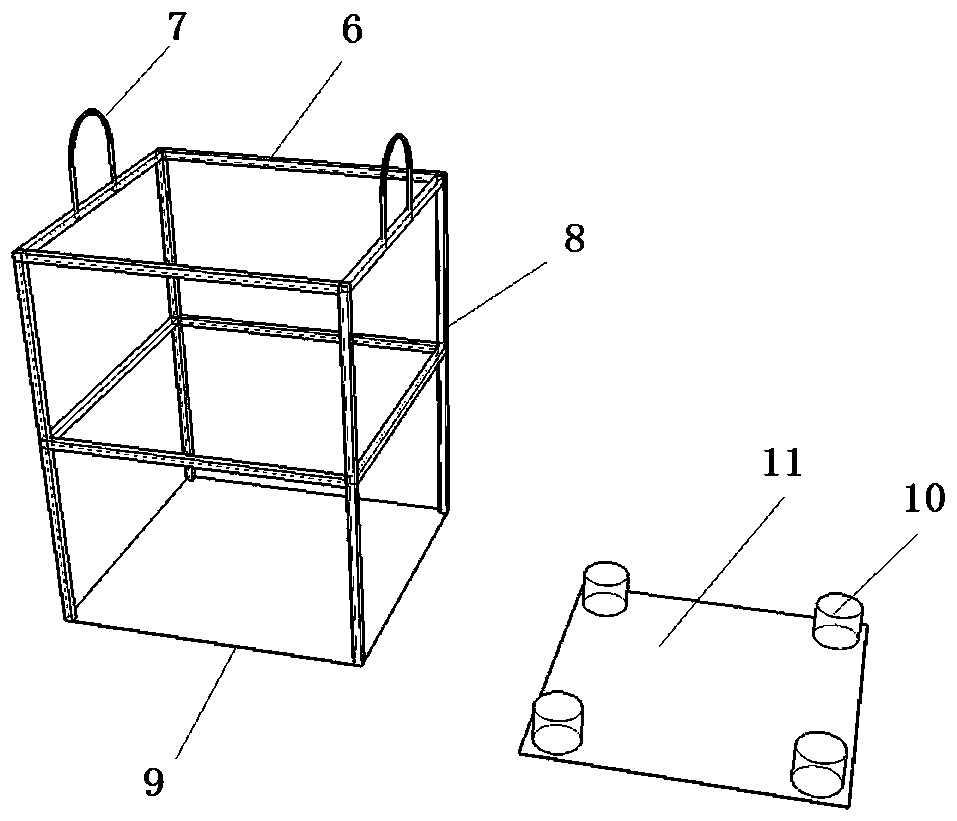

Steel pipe blanking frame capable of automatically reducing noise

InactiveCN101758417AReduce crash noiseReduce dropMetal working apparatusConveyor partsSteel tubeArchitectural engineering

The invention relates to a steel pipe blanking frame capable of automatically reducing noise, belonging to the technical field of the steel pipe. The steel pipe blanking frame comprises a plurality of chain lifting mechanisms, driving mechanisms and sensing mechanisms. The chain lifting mechanisms are sequentially connected with the driving mechanisms in series, the sensing mechanisms and chain lifting mechanisms are arranged oppositely, and the driving mechanisms are connected with the sensing mechanisms to receive control commands. The steel pipe blanking frame reduces the noise from the collision of steel pipes by reducing the steel pipe blanking disparity and the strength of the collision of the steel pipes.

Owner:SHANGHAI JIAO TONG UNIV

Torsional vibration damper and control device for torsional vibration damper

ActiveUS20210156453A1Control damageReduce noiseRotating vibration suppressionInertia force compensationClassical mechanicsDamper

A torsional vibration damper that can reduce collision noise of an inertia body when a rotary member is stopped, and a control device therefore. In the torsional vibration damper, a rotary member is mounted on an output shaft of an engine such that none of rolling masses is situated within a predetermined angle range above a rotational center axis of the rotary member when the engine is stopped. Therefore, when the engine is stopped, the inertia body will not be supported by only one of the rolling masses situated within the predetermined angle range.

Owner:TOYOTA JIDOSHA KK

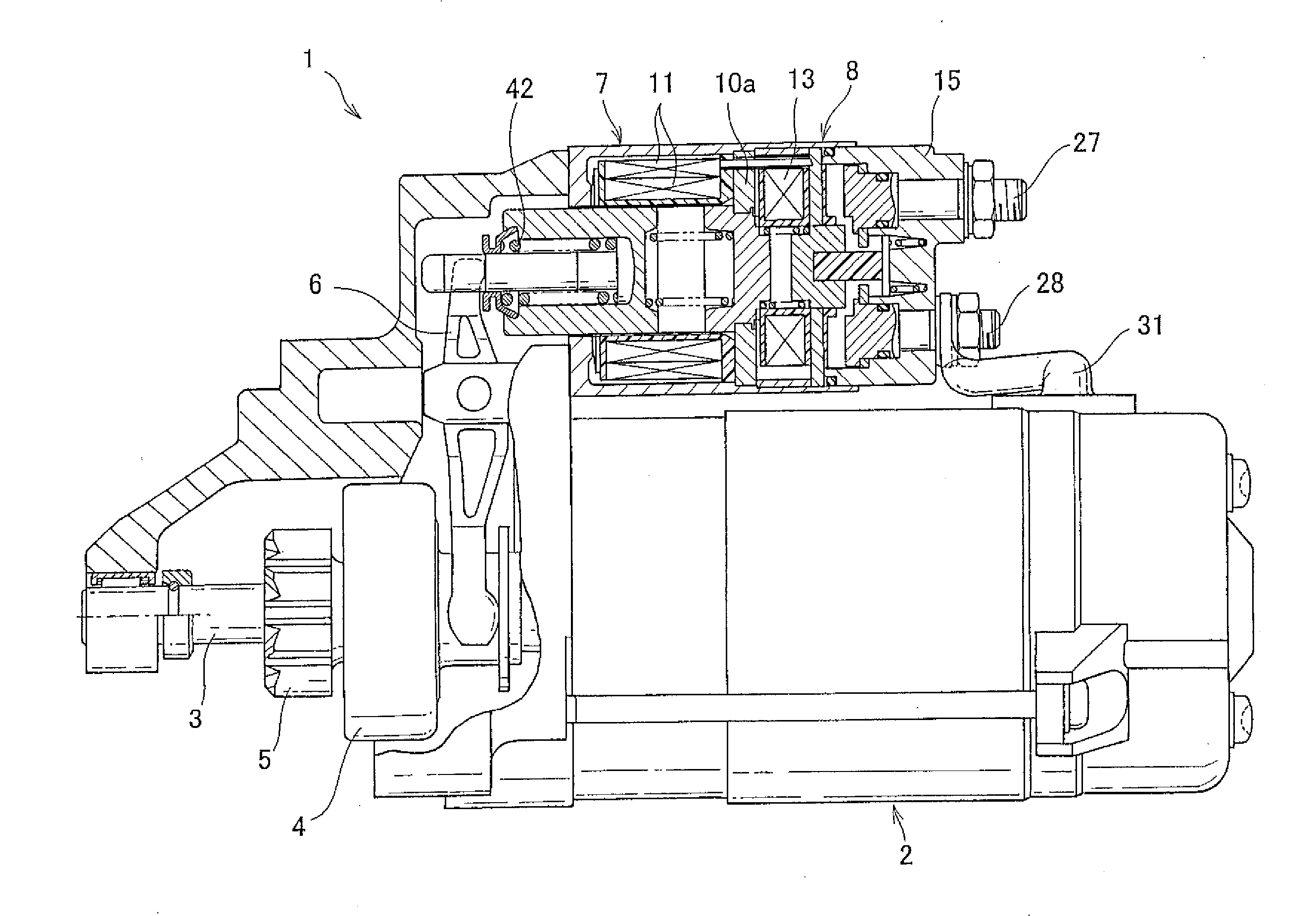

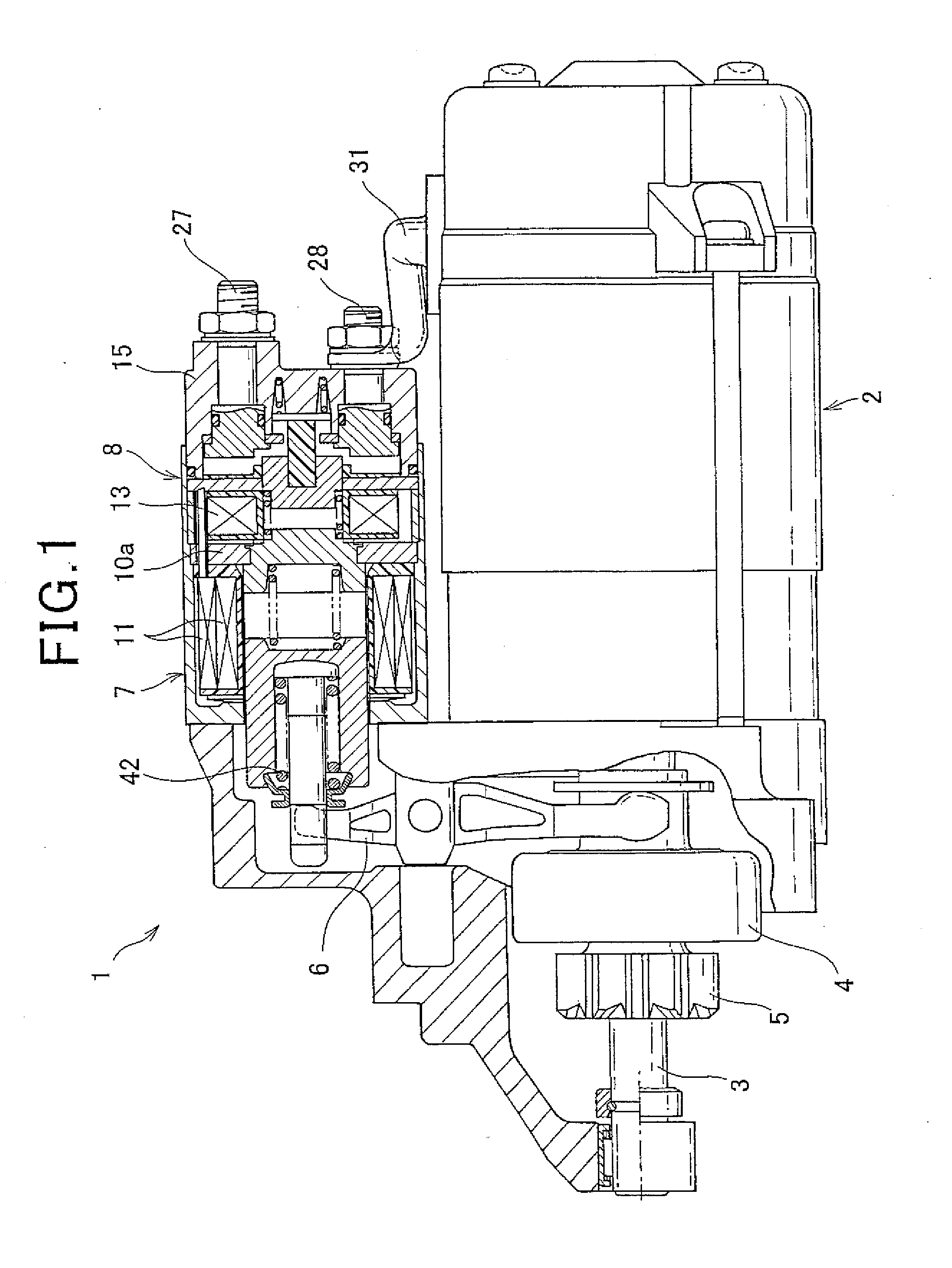

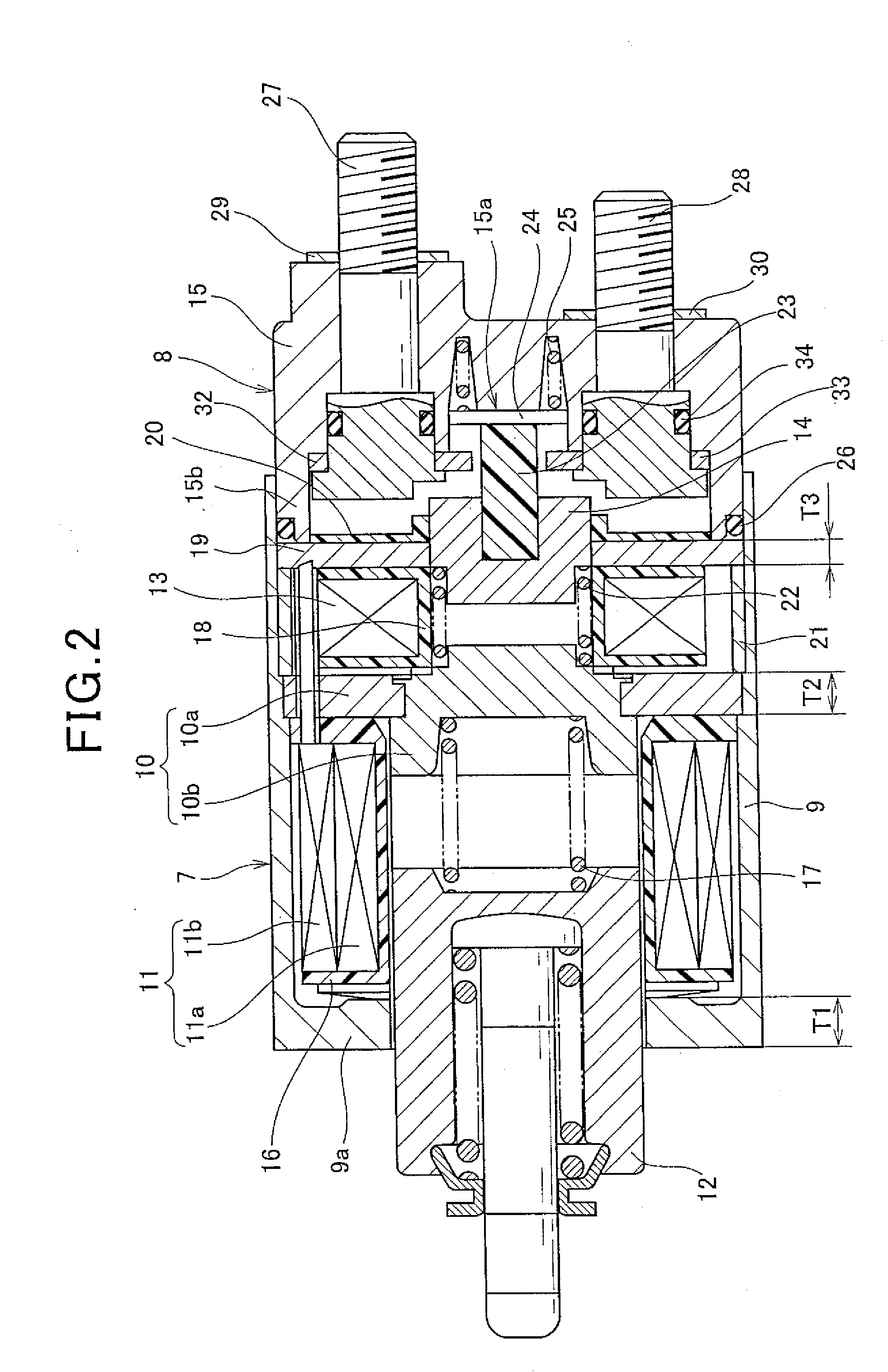

Starting Device for Engines

ActiveUS20120119497A1Reduce crash noiseImprove wear resistancePower operated startersElectrical controlEngineeringMotor circuit

Owner:DENSO CORP

Washing machine and balance ring used in washing machine

ActiveCN105734899AReduce noiseMove freelyOther washing machinesTextiles and paperMagnetic tension forceElectric machinery

The invention discloses a washing machine which comprises a bucket which can be rotated under driven of a motor, wherein an annular channel is disposed along circumferences of the bucket; multiple spheres which can roll along the channel are installed in the channel; and the multiple spheres comprise magnetic balls and non-magnetic balls which can be attracted by magnetic force. Because of attracting force of the magnetic balls, the multiple spheres can be attracted together to form a mass body, the spheres in the mass body do not collide, or a few of spheres on edges collide when rotational motion of the bucket is unstable, so that noise generated from sphere collision can be reduced effectively. The invention also discloses a balance ring used in the washing machine.

Owner:BSH ELECTRICAL APPLIANCES JIANGSU +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com