Simple heavy stuff carrying and feeding trolley

A heavy and simple technology, applied in the direction of portable lifting devices, hoisting devices, etc., can solve the problems of reducing the use of special hoisting equipment, low safety, troublesome handling of heavy objects, etc., to reduce the risk of bumping, reduce labor intensity, The effect of not easy to tilt

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

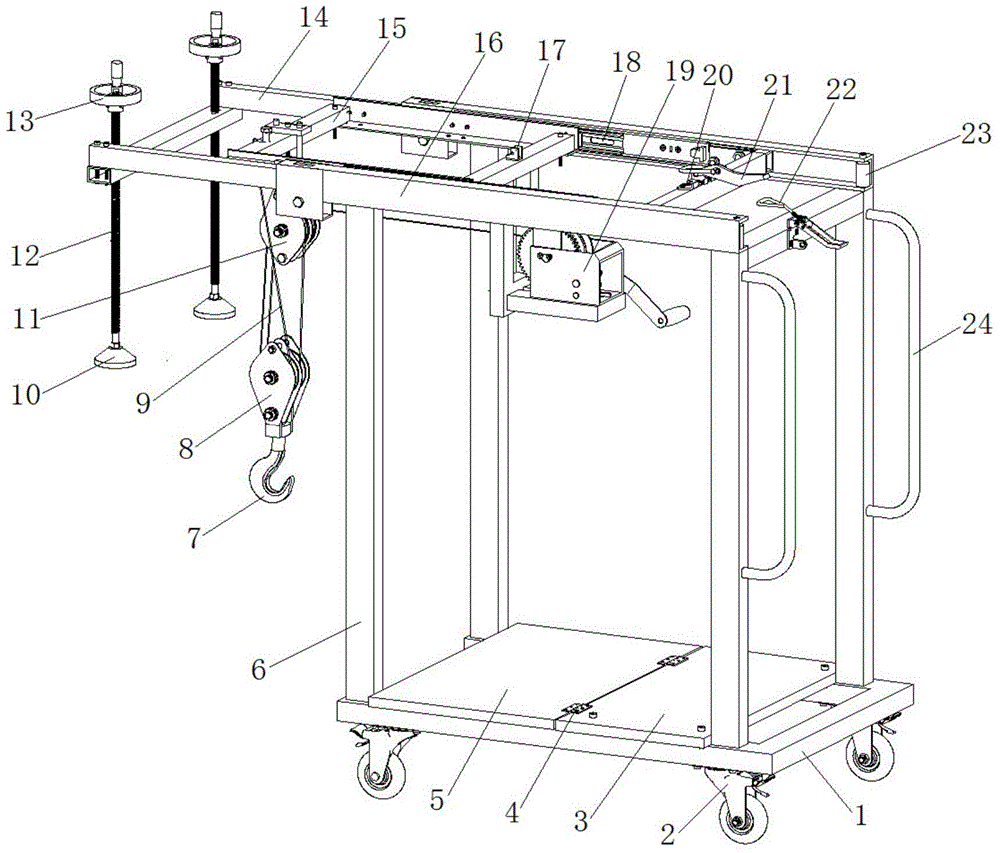

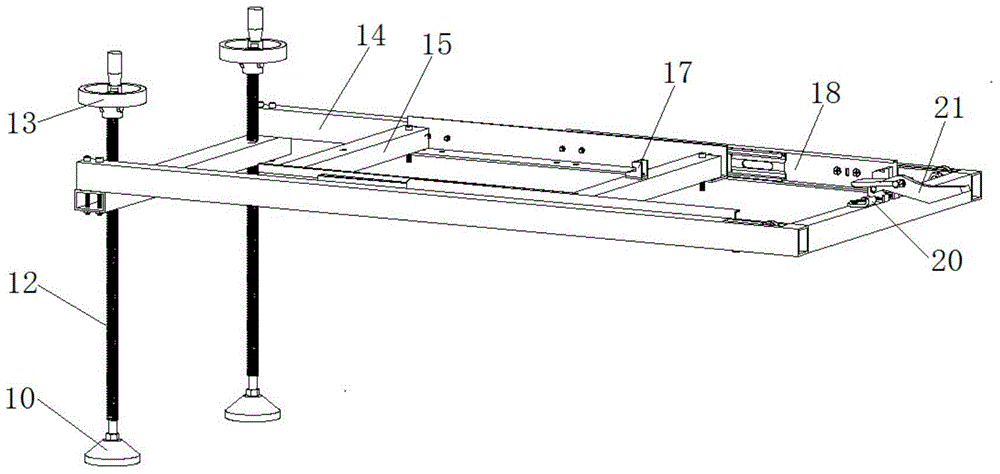

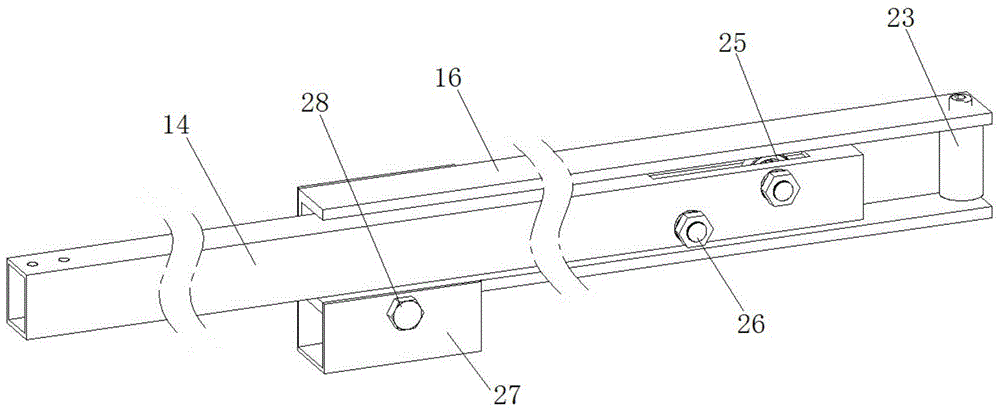

[0035] combine figure 1 , a kind of simple heavy object handling loading vehicle of this embodiment is mainly used in the frequent hoisting, handling and machine tool loading of workpieces, molds, equipment, etc. in machinery industry workshops. The universal caster 2 on the first foot, the support 6 fixed as one with the base 1, the loading bracket 14 that is located on the top of the bracket 6 and can slide back and forth on the bracket 6, is located in the loading bracket 14 and can be placed on the upper bracket 14. The sliding bracket 15 that slides back and forth on the material bracket 14, the supporting device that is arranged on the front of the feeding bracket 14, the manual winch 19 fixed on the rear of the sliding bracket 15, the pulley block and the lifting hook 7 installed on the front of the sliding bracket 15 . The frame structure in which the base 1 and the bracket 6 are fixedly connected together has a firm structure and a light weight. The universal caster...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com