Patents

Literature

469results about How to "Not easy to tilt" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

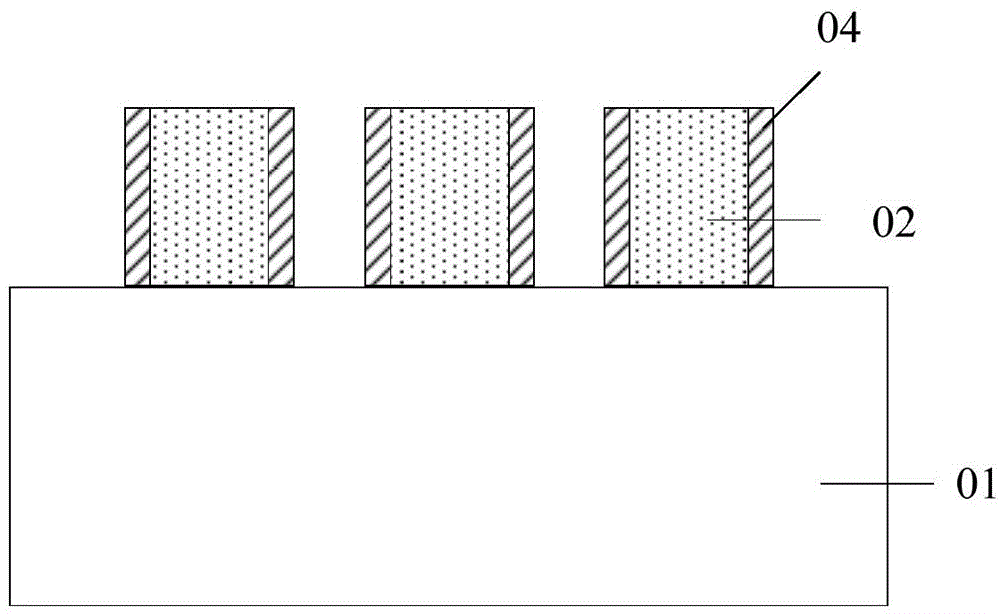

3D NAND storage device and formation method thereof

ActiveCN110176461AImprove support strengthNot easy to deformSolid-state devicesSemiconductor devicesGrid partitionComputer science

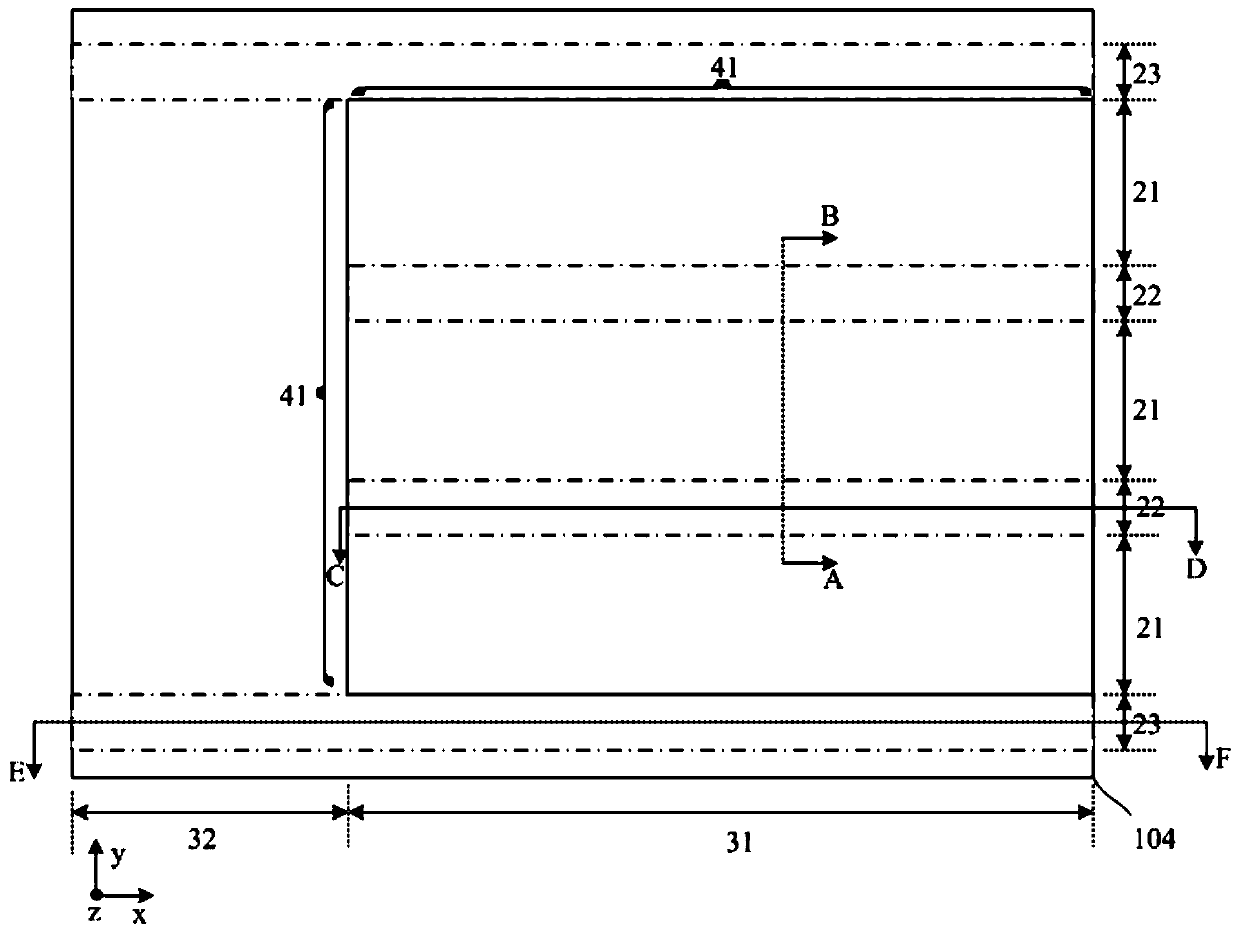

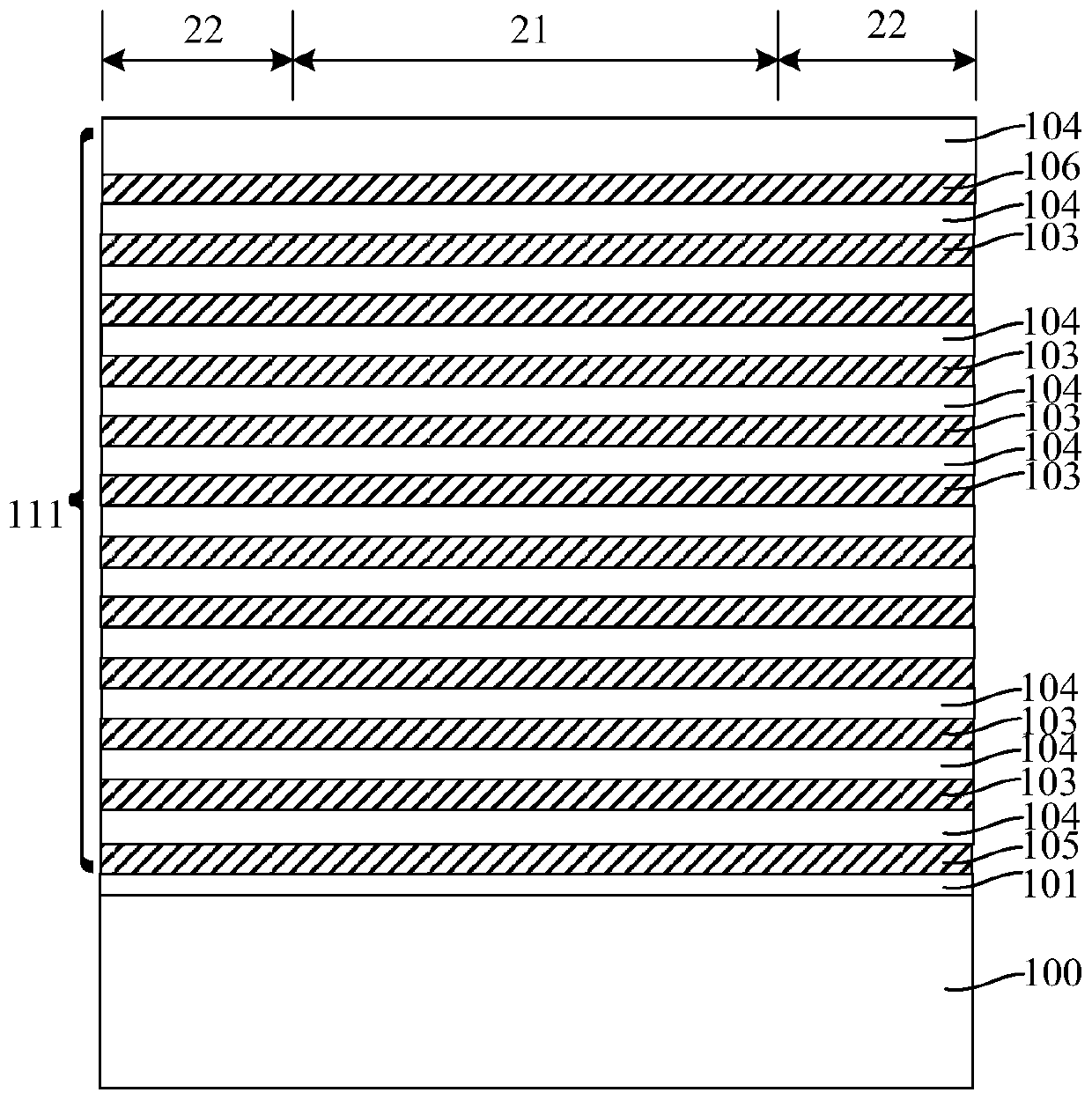

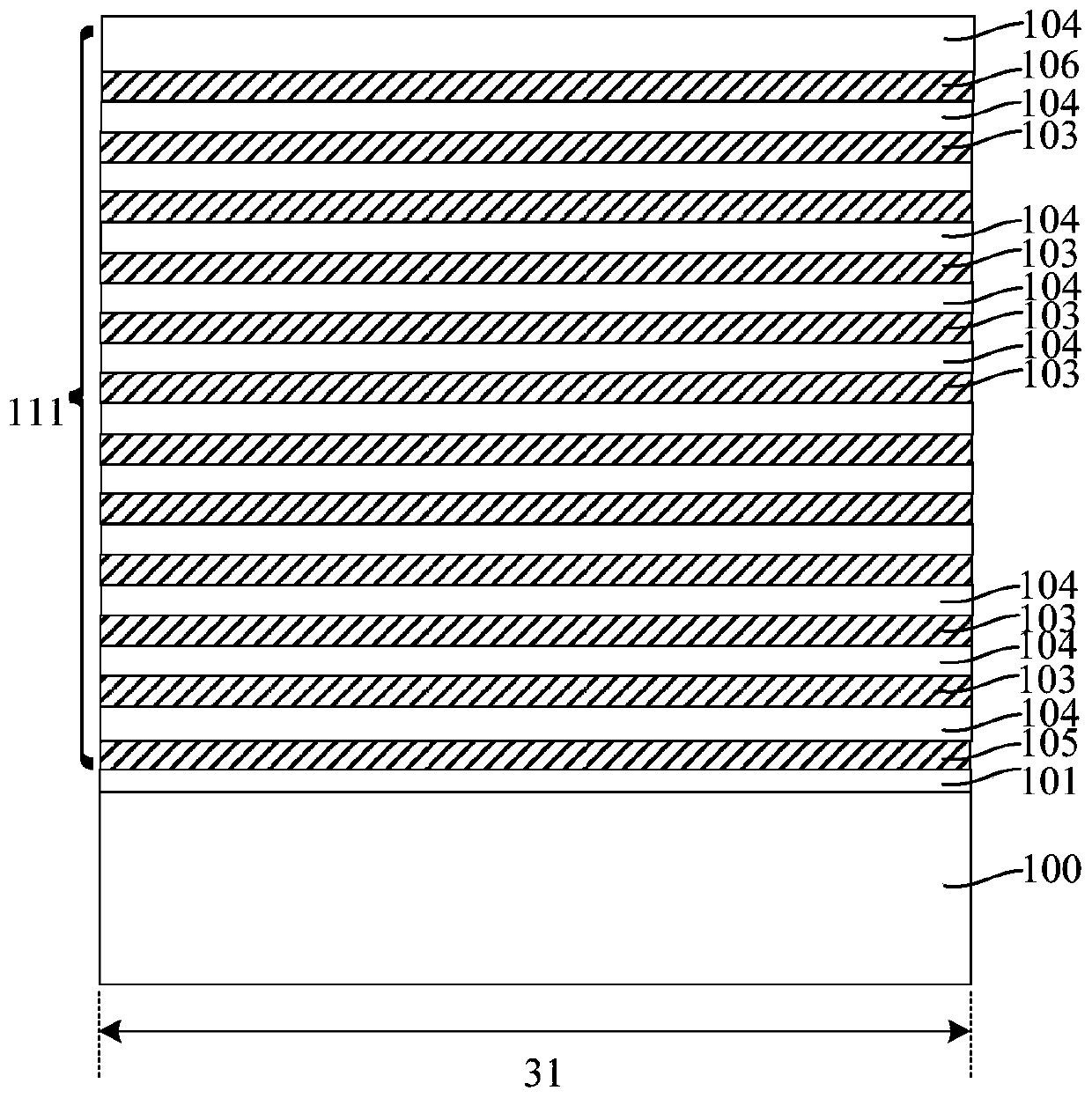

The invention discloses a 3D NAND storage device and a formation method thereof. In the formation method of the 3D NAND storage device, a selective grid sacrificial layer in a first grid partition groove area is disconnected through a first grid partition groove and a plurality of grid partition groove partition areas in the first grid partition groove area, a selective grid sacrificial layer in athrough hole area is disconnected through a selective grid partition area in the through hole area, although the selective grid sacrificial layer on the top of the first grid partition groove area isdisconnected through the first grid partition groove and the grid partition groove partition areas, the sacrificial layer at the bottom of the grid partition groove partition area still remains, namely the sacrificial layers and partition layers in each storage block when the first grid partition groove is formed are still connected together, a stacking structure can be of extremely high supporting strength when the first grid partition groove is formed, and the side wall of the first grid partition groove is unlikely to deform or incline, so that the stability of the feature size of the formed first grid partition groove is guaranteed.

Owner:YANGTZE MEMORY TECH CO LTD

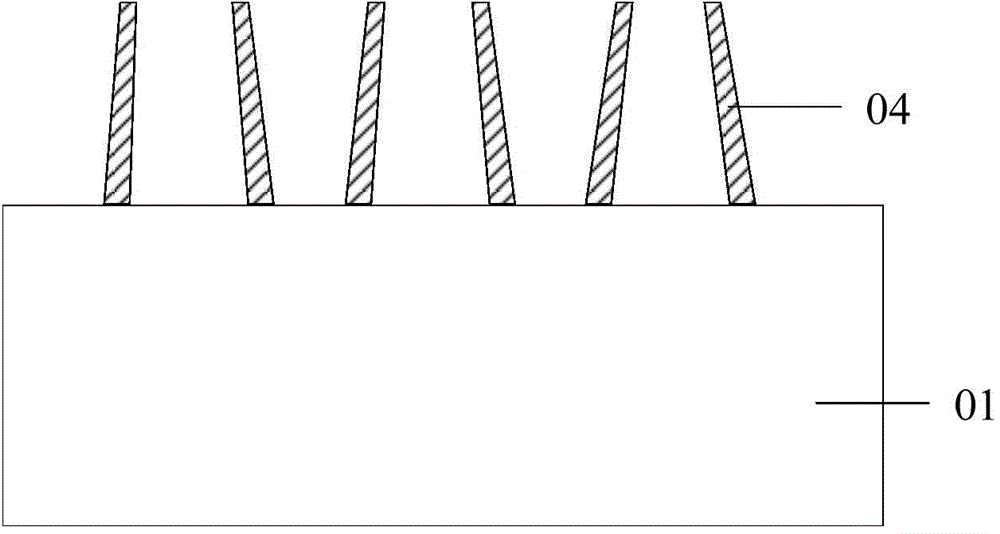

Method for forming semiconductor structure

ActiveCN105719954AImprove shape resolutionProne to tensile stressSemiconductor/solid-state device manufacturingRadio frequencyTension stress

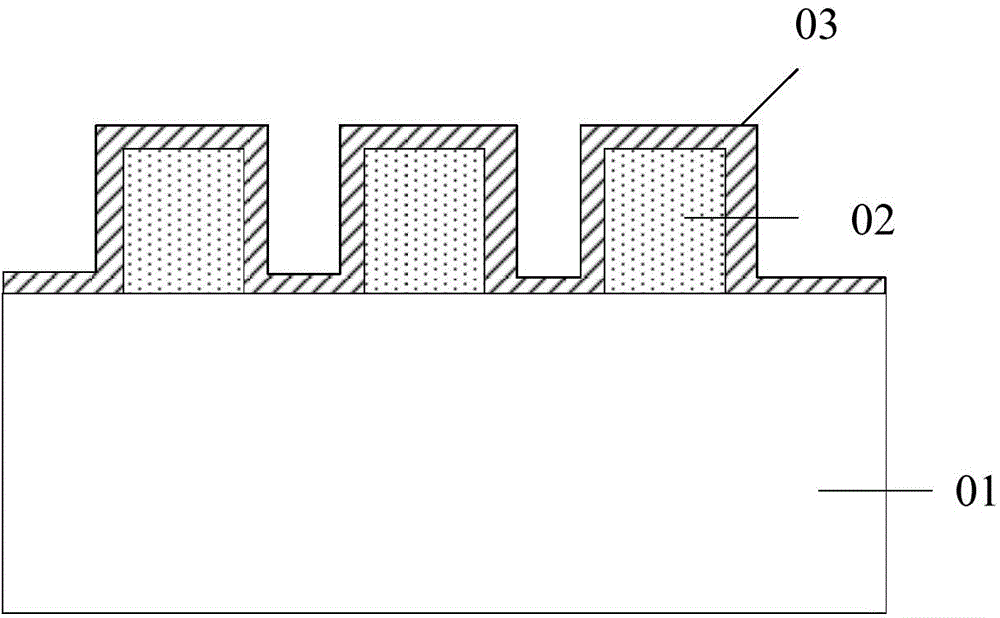

The invention provides a method for forming a semiconductor structure, and the method comprises the steps: providing a substrate; forming a sacrifice pattern on the substrate; depositing side wall material layers on the sacrifice pattern and the substrate through employing deposition equipment, carrying out the etching of the side wall material layers, and forming side walls on side walls of the sacrifice pattern; taking the side walls as hard masks, carrying out the etching of the substrate, and forming a semiconductor figure. The deposition equipment is employed for depositing the side wall material layers on the sacrifice pattern and the substrate, and the output radio frequency power of the deposition equipment is switched between the first power and the second power in the deposition process of the side wall material layers, wherein the first power and the second power have different frequencies. The method can enable tension stress and compression stress generated in the side wall material layers to be counteracted with each other partly, thereby enabling the total stress in the side walls to be smaller after the side walls are formed through the etching of the side wall material layers, and enabling the deformation not to be liable to happen. The feature size of the semiconductor figure is smaller when the side walls are taken as the masks.

Owner:SEMICON MFG INT (SHANGHAI) CORP

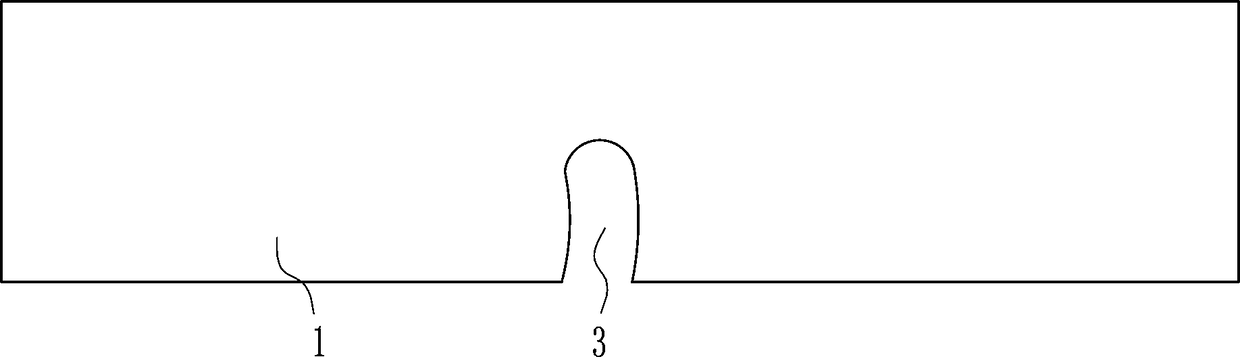

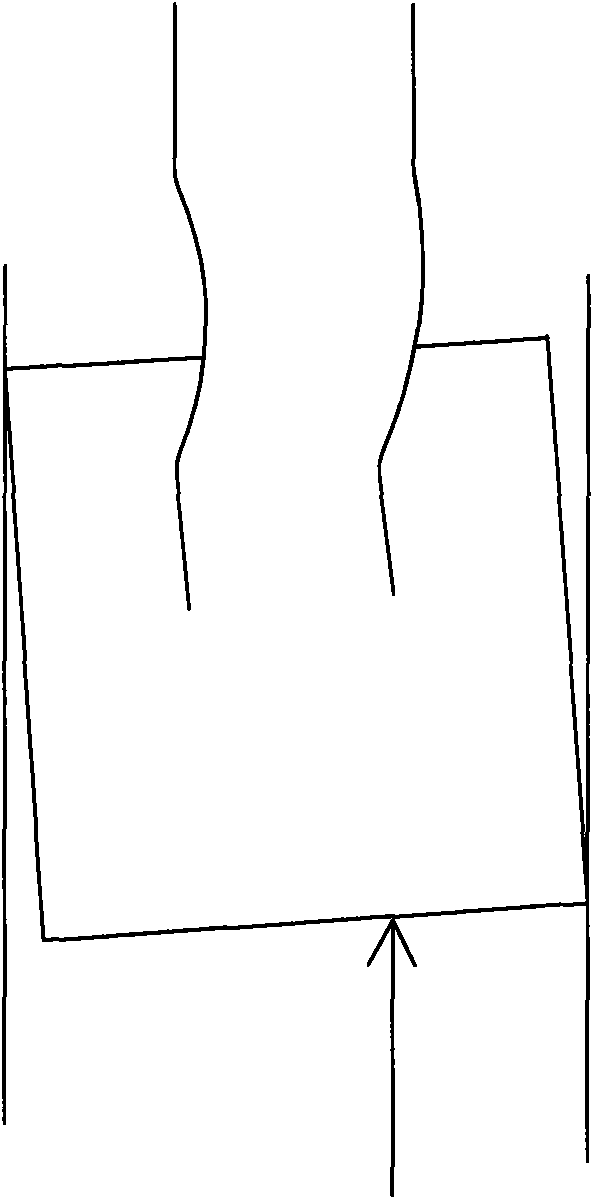

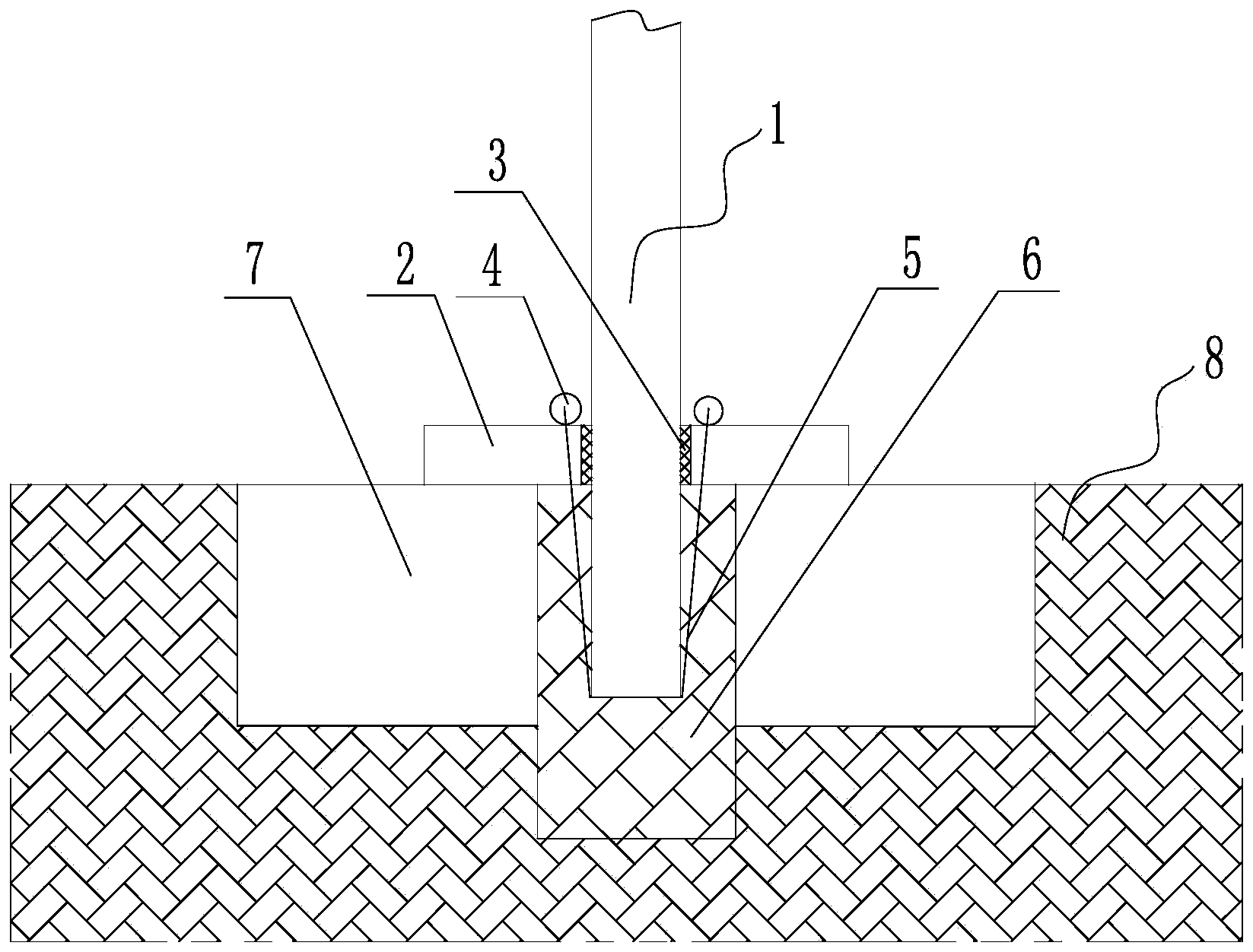

Prestressed concrete precast pile

ActiveCN103572755ANot easy to tiltImprove bending abilityBulkheads/pilesSquare cross sectionPre stress

The invention discloses a prestressed concrete precast pile. The prestressed concrete precast pile comprises a precast pile body with a square cross section, wherein the precast pile body comprises two end plates, a pile body and prestressed reinforcements, the pile body is arranged between the two end plates, and the prestressed reinforcements are arranged in the pipe body and connected with the two end plates; bulge rib which longitudinally extends to an end and a first groove which longitudinally extends and penetrates through the end are arranged on an outer side surface of the precast pile body; and a second groove and a third groove which are corresponding to positions of the bulge rib and the first groove respectively, matched in shape and size and longitudinally extend and penetrate through an end of the precast pile body are formed in one outer side surface which is not adjacent to the outer side surface. According to the prestressed concrete precast pile, the construction is convenient, the engineering cost can be reduced, the water stopping effect is enhanced, and the prestressed concrete precast pile has good bending and shearing resistance.

Owner:宁波中淳高科股份有限公司

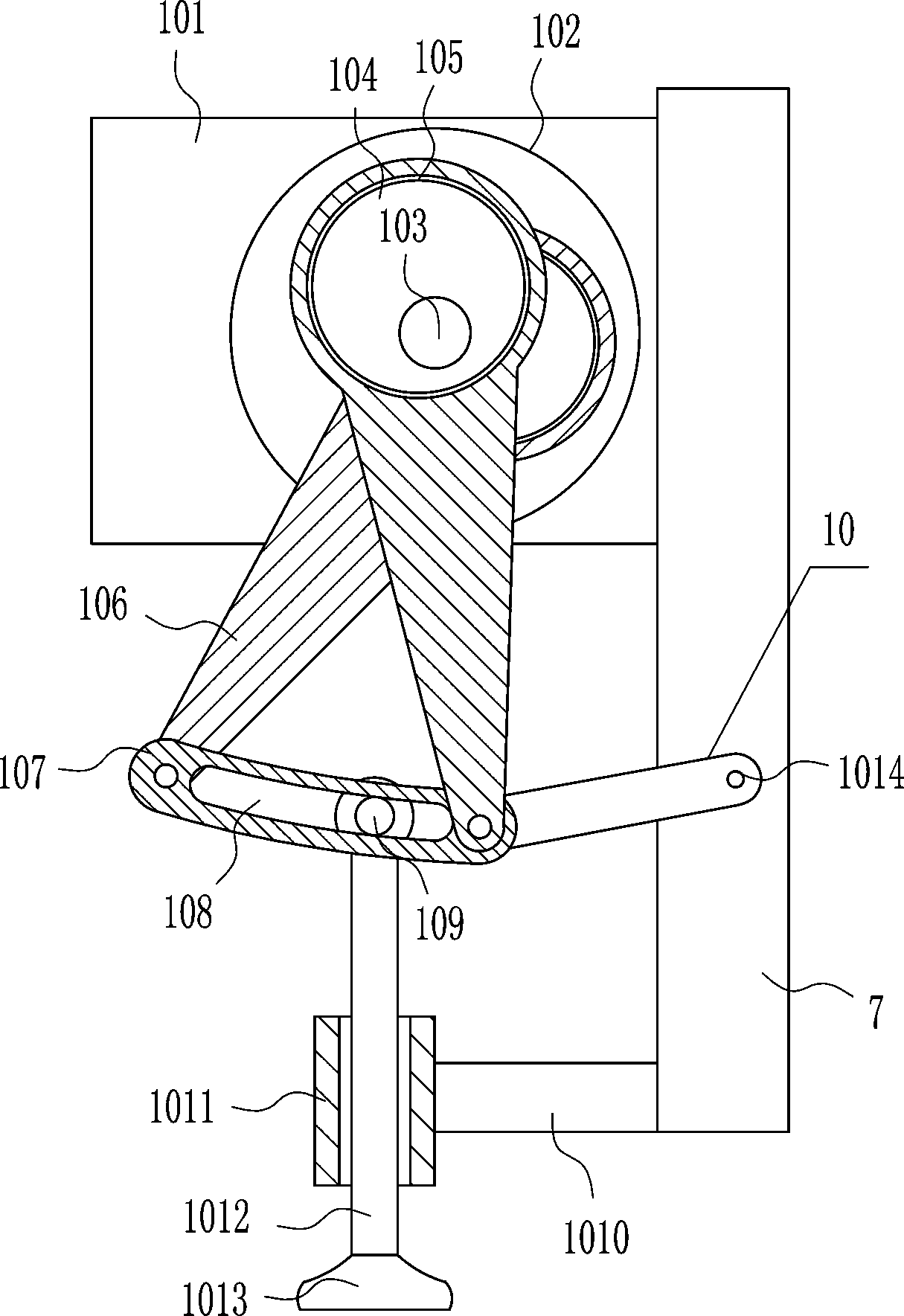

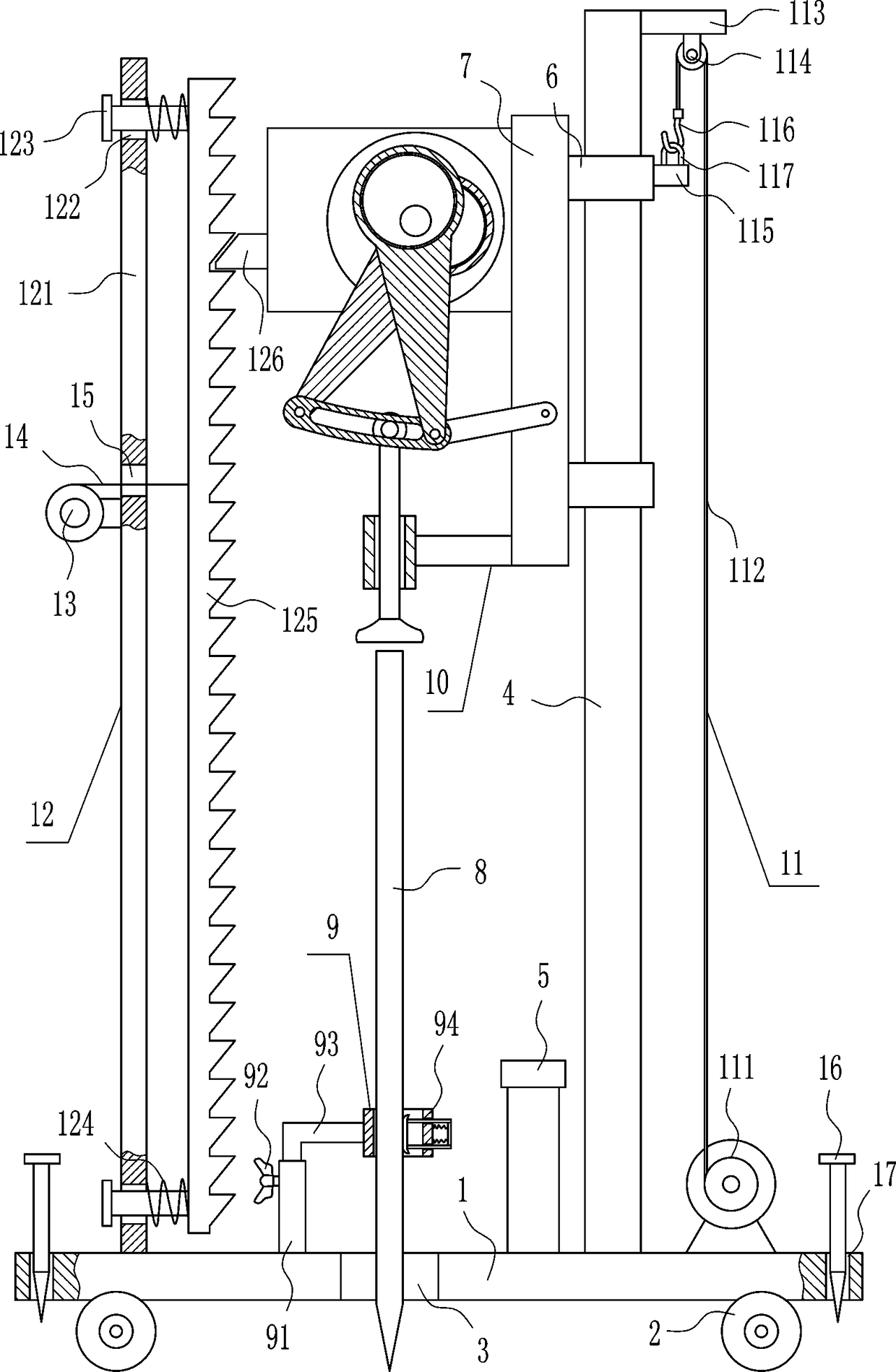

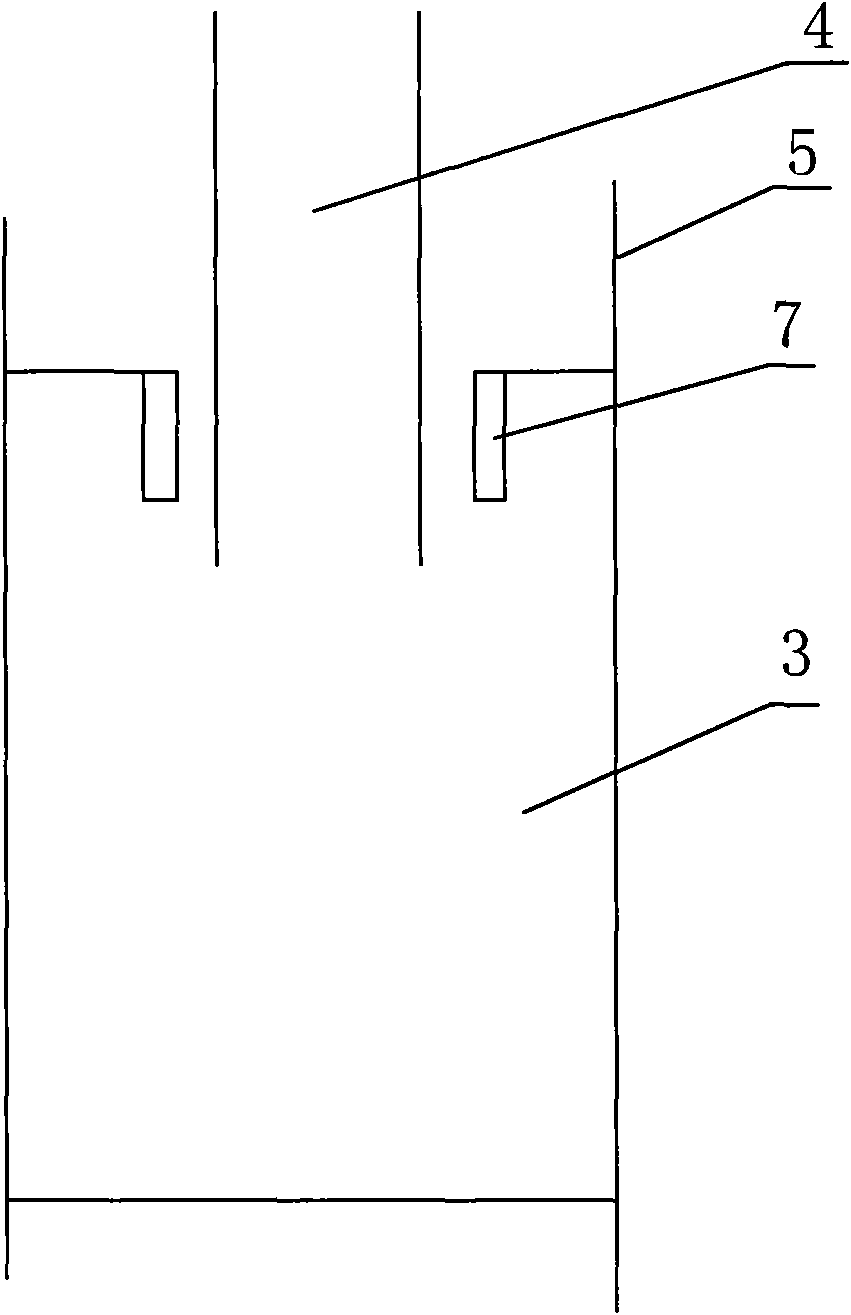

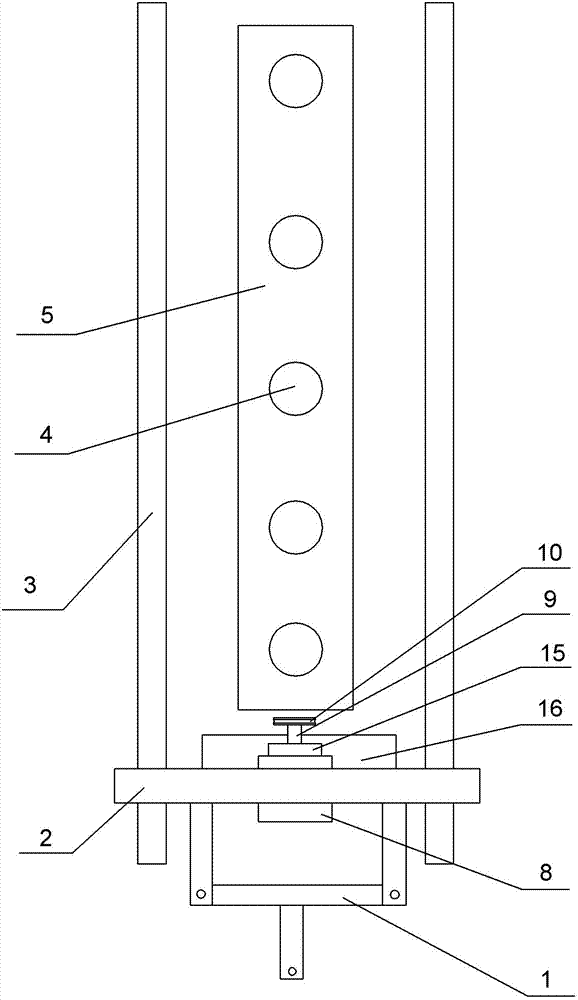

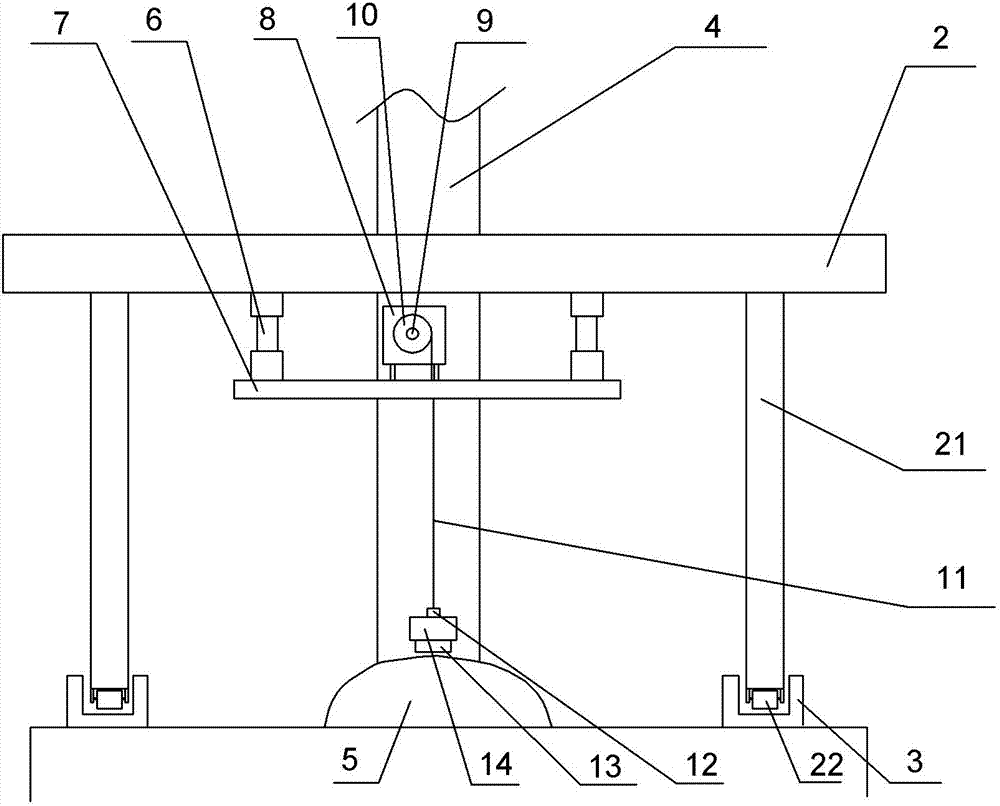

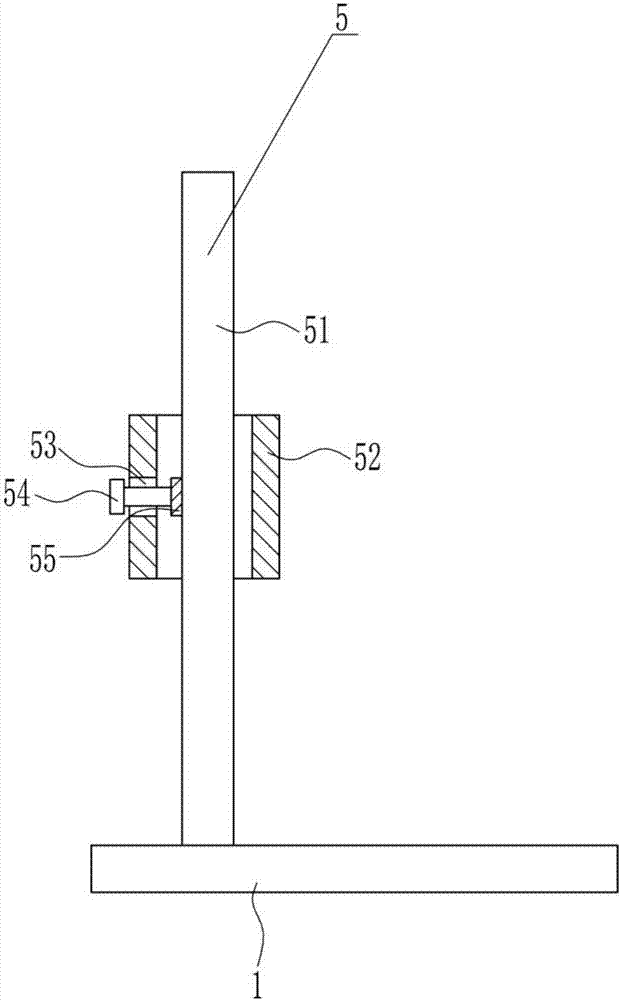

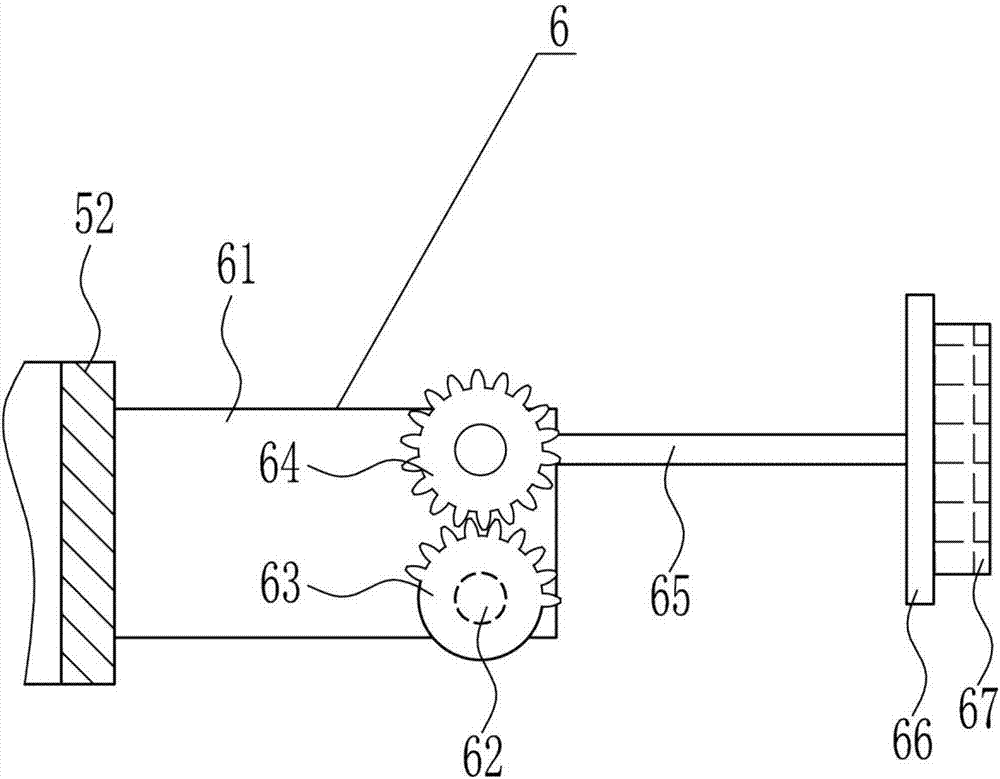

Pile driving equipment of protective fences for agriculture

The invention relates to pile driving equipment, in particular to the pile driving equipment of protective fences for agriculture. According to the pile driving equipment of the protective fences foragriculture, the labor intensity is low, the piling speed is high, and a wood pile is not prone to incline. The pile driving equipment of the protective fences for agriculture comprises a bottom plate, wheels, a first guide rod, a limiting rod and the like, wherein the wheels are symmetrically mounted on the left side and the right side of the bottom of the bottom plate, a first through hole is formed in the front side of the middle part of the bottom plate, and a fixing device is arranged on the left side of the top of the bottom plate; the first guide rod is mounted on the right side of thetop of the bottom plate, two sliding sleeves matched with the first guide rod are arranged on the first guide rod, and a vertical plate is mounted between the left side faces of the two sliding sleeves. According to the equipment, the wood pile can be pressed tightly and fixed by means of the fixing device, so that the wood pile is prevented from inclining when being hit into the land; through a lifting device, an operator does not need to pull the sliding sleeves to enable a hammer head to move upwards, so that time and labor are saved, and the effects that labor intensity is low, the pilingspeed is high and the wood pile is not prone to incline are achieved.

Owner:菏泽市鑫怡新能源有限公司

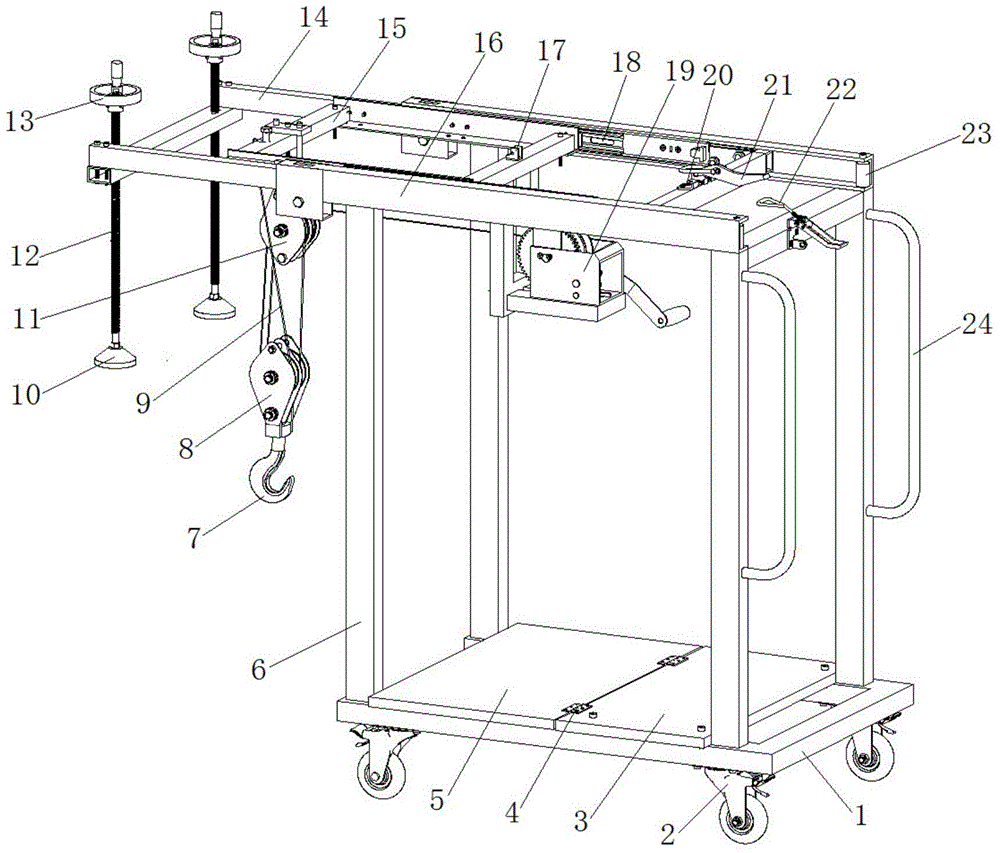

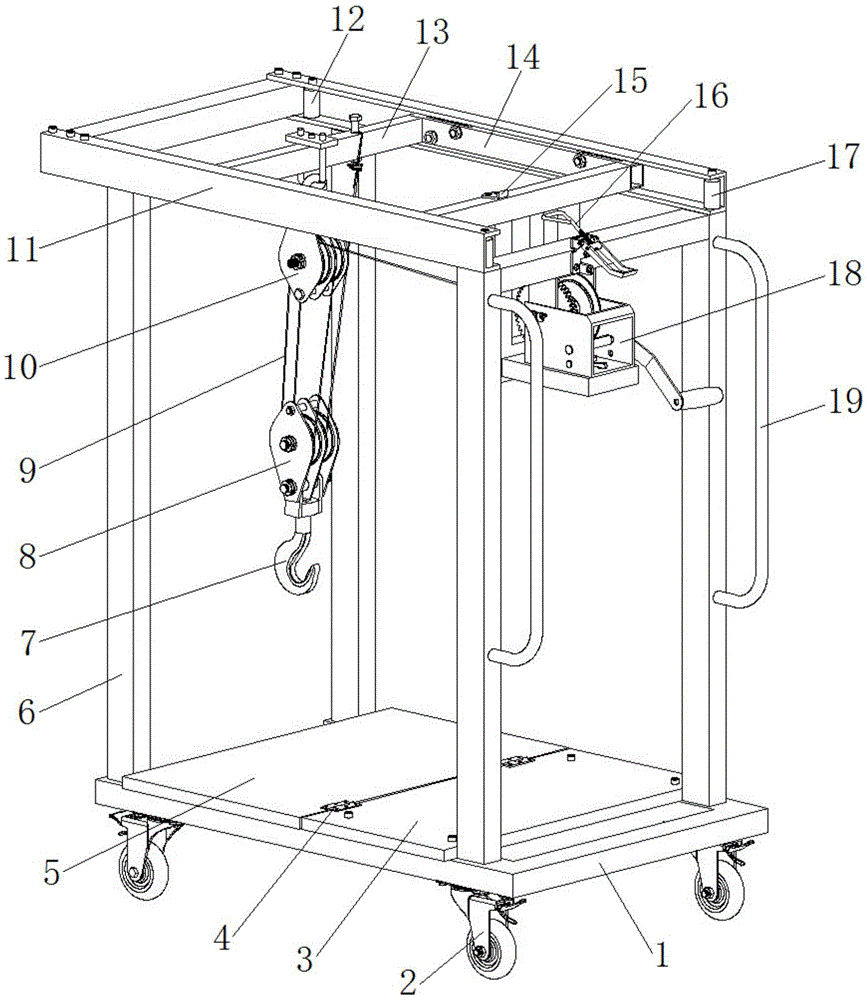

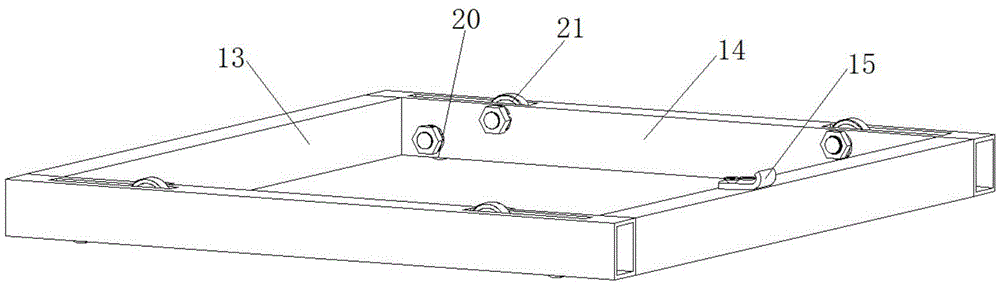

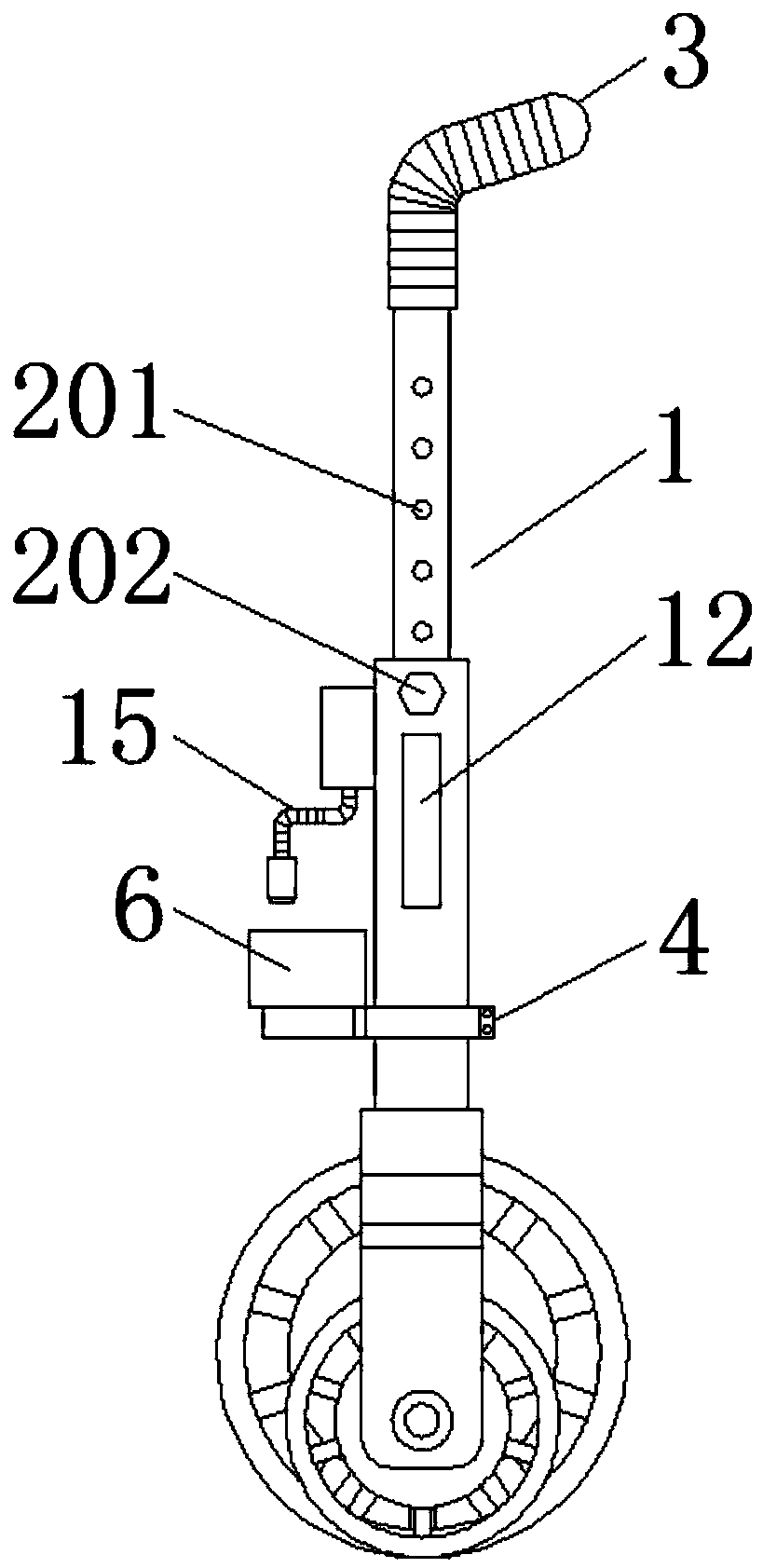

Simple heavy stuff carrying and feeding trolley

ActiveCN104444907AReduced risk of collisionReduce the incidence of work-related injuriesPortable liftingBlock and tackleEngineering

The invention discloses a simple heavy stuff carrying and feeding trolley and belongs to the field of carrying tools. The simple heavy stuff carrying and feeding trolley comprises a base, universal casters, a support, a feeding support, a sliding support, a supporting device, a manual winch, a pulley set and a hoisting hook, wherein the universal casters are arranged on the base, the support and the base are fixed into a whole, the feeding support is arranged on the top of the support, the sliding support is arranged inside the feeding support, the supporting device is arranged in the front of the feeding support, the manual winch is fixed to the back portion of the sliding support, and the pulley set and the hoisting hook are installed in the front of the sliding support. The pulley set comprises a fixed pulley and a movable pulley, a steel wire rope is led from the manual winch, sequentially winds around the fixed pulley and the movable pulley and then is fixed to the sliding support or a fixed pulley support; a fixed supporting plate is installed at the back of the base, and a movable supporting plate is installed in the front of the base. According to the simple heavy stuff carrying and feeding trolley, the functions of heavy stuff hoisting, transferring and machine tool feeding are achieved through a simple structure, and the labor intensity of workers is alleviated; meanwhile, the simple heavy stuff carrying and feeding trolley is simple in structure, convenient to operate, low in cost and high in safety and meets the use requirements of small and medium size enterprises.

Owner:常州东吉路国际贸易有限公司

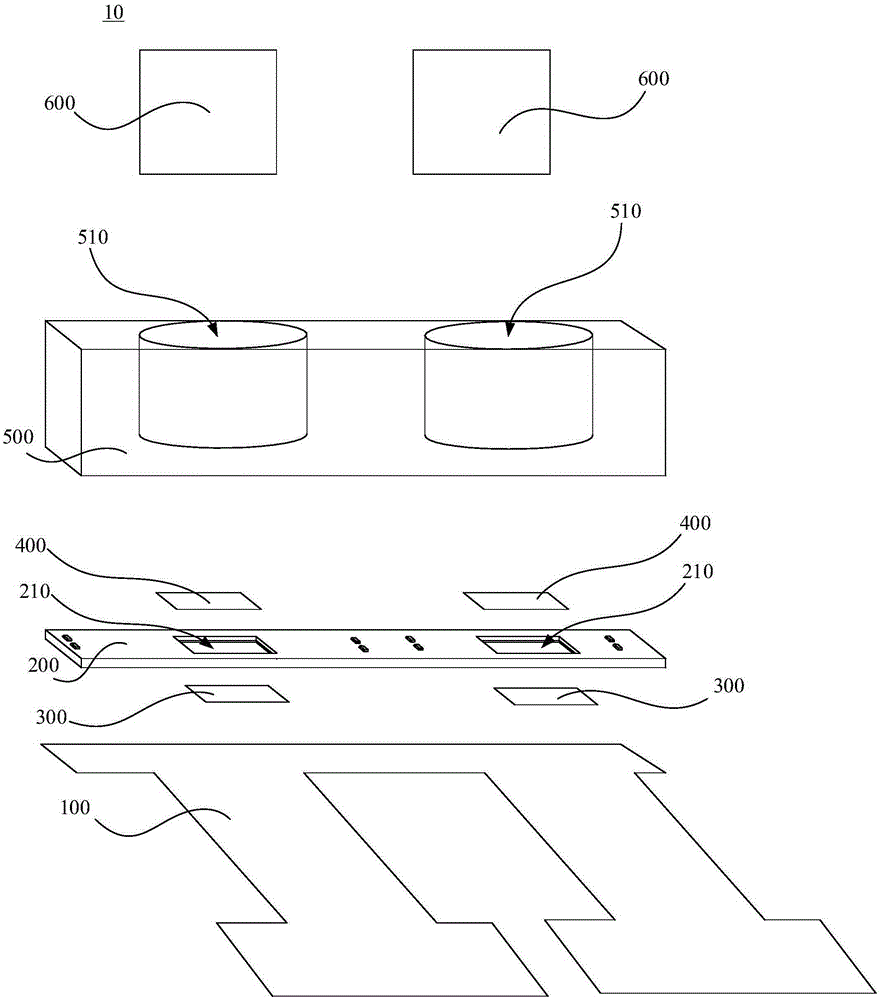

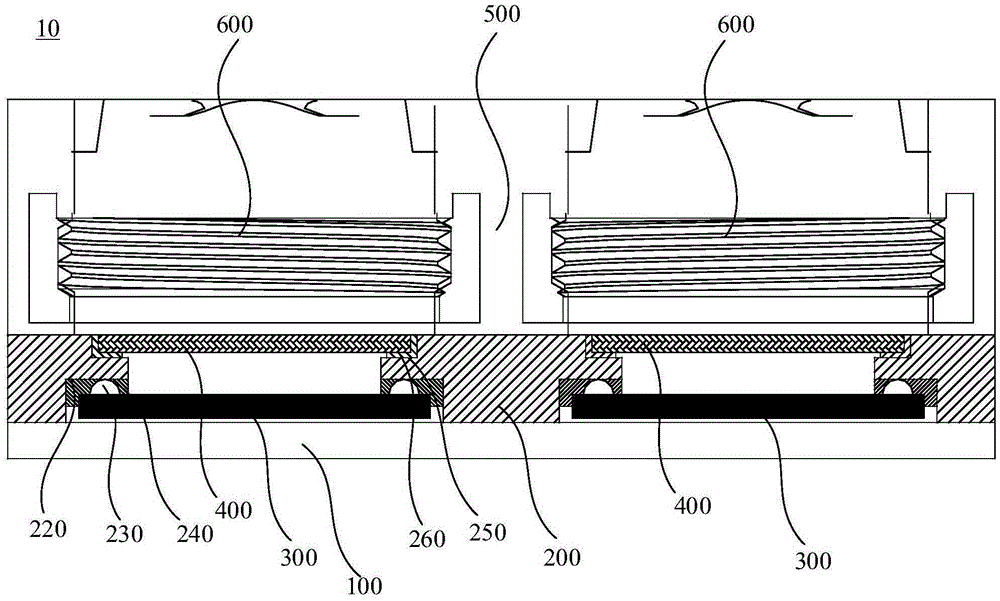

Dual-camera module set

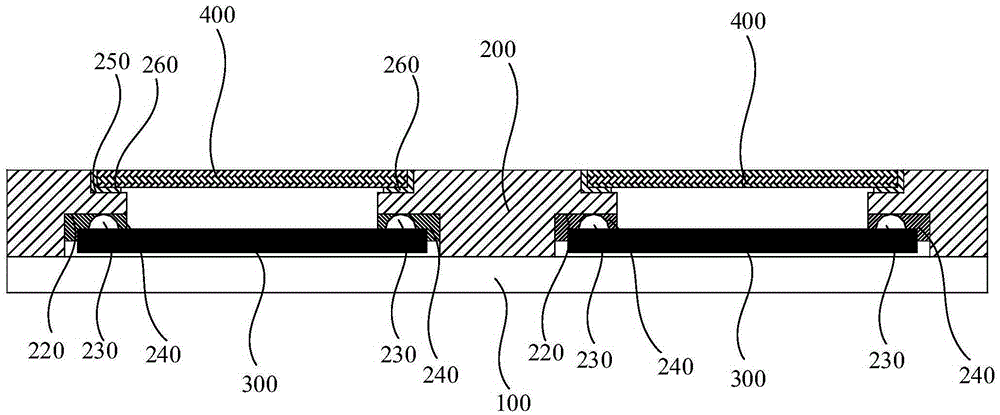

PendingCN106817518ANot easy to tiltImprove image qualityTelevision system detailsColor television detailsImaging qualityEngineering

The present invention relates to a dual-camera module set. The dual-camera module set comprises a circuit board, a substrate and two flip chips; the substrate is arranged on the circuit board and is electrically connected with the circuit board; first through holes are formed in the substrate; the side wall of one end of each first through hole is recessed towards a direction far away from the circuit board so as to form a first recessed groove, wherein the one end of the first through hole is close to the circuit board; the flatness of the first recessed grooves is greater than the flatness of the circuit board; and the two flip chips are encapsulated in the bottoms of the two first recessed grooves. Since the two flip chips are encapsulated in the bottoms of the two first recessed grooves, the chips have less possibility of tilting compared with chips encapsulated by a traditional mode according to which the image sensing chips are directly arranged on a circuit board, and therefore, the parallelism of the central axes of the two flip chips is higher, and imaging quality can be improved.

Owner:NANCHANG OFILM HUAGUANG TECH CO LTD

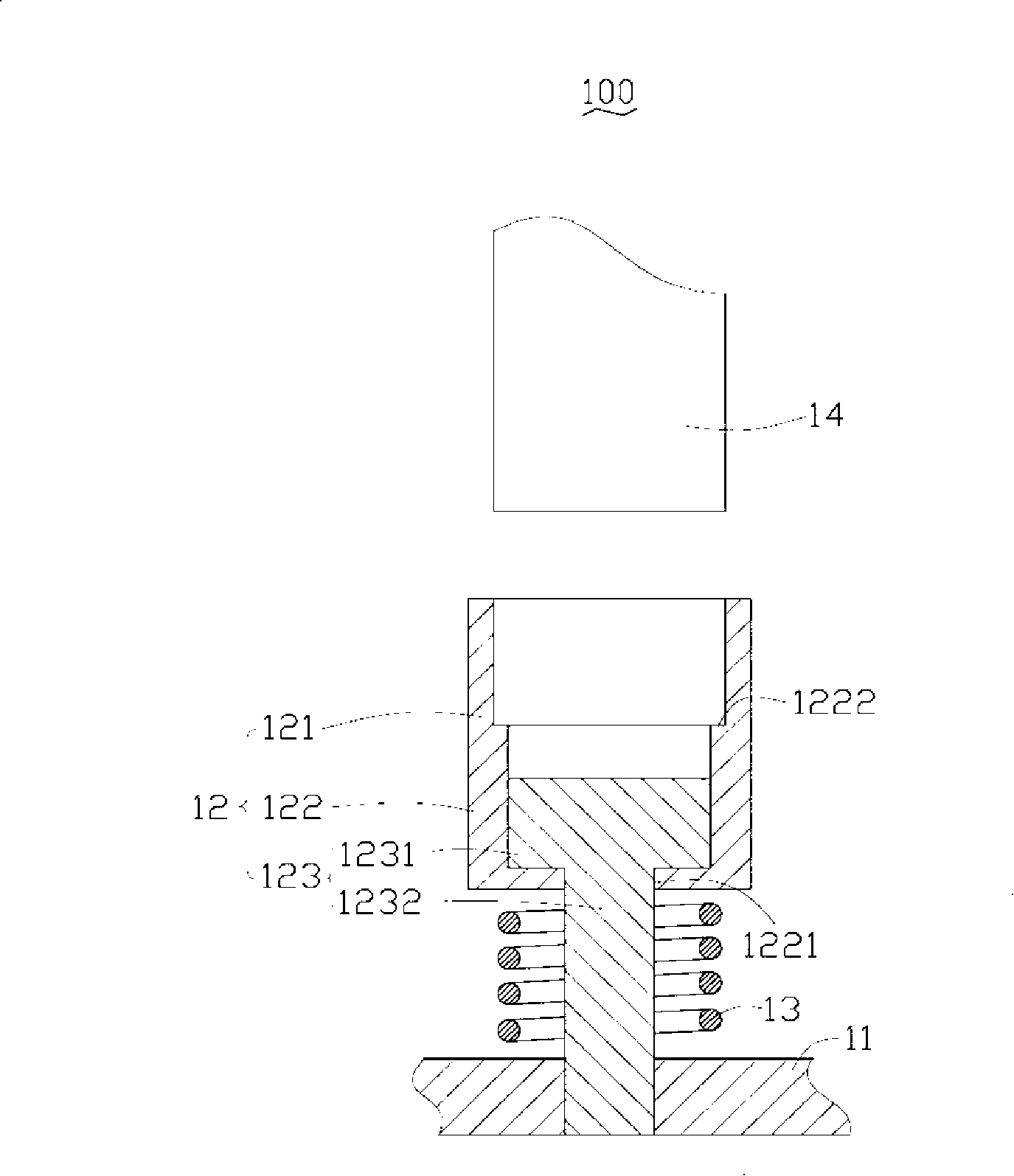

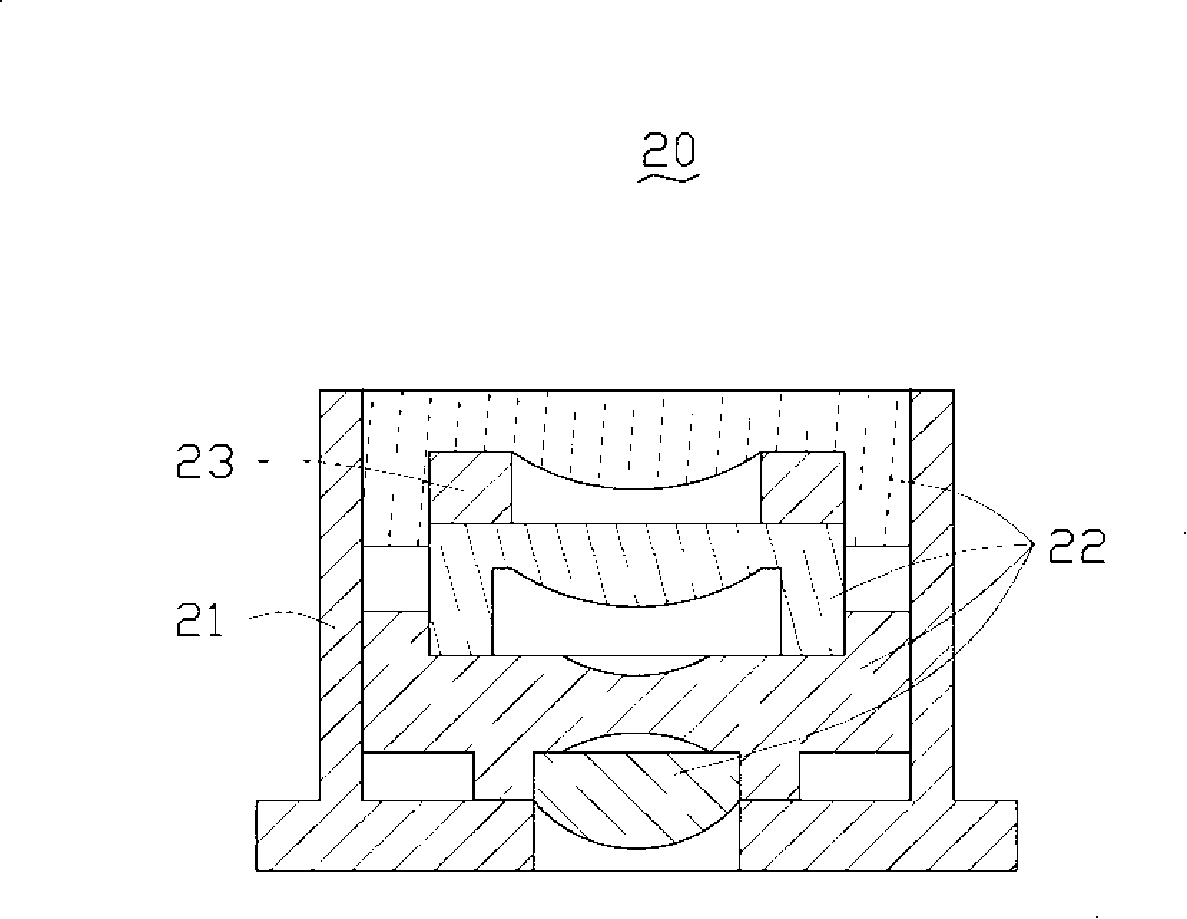

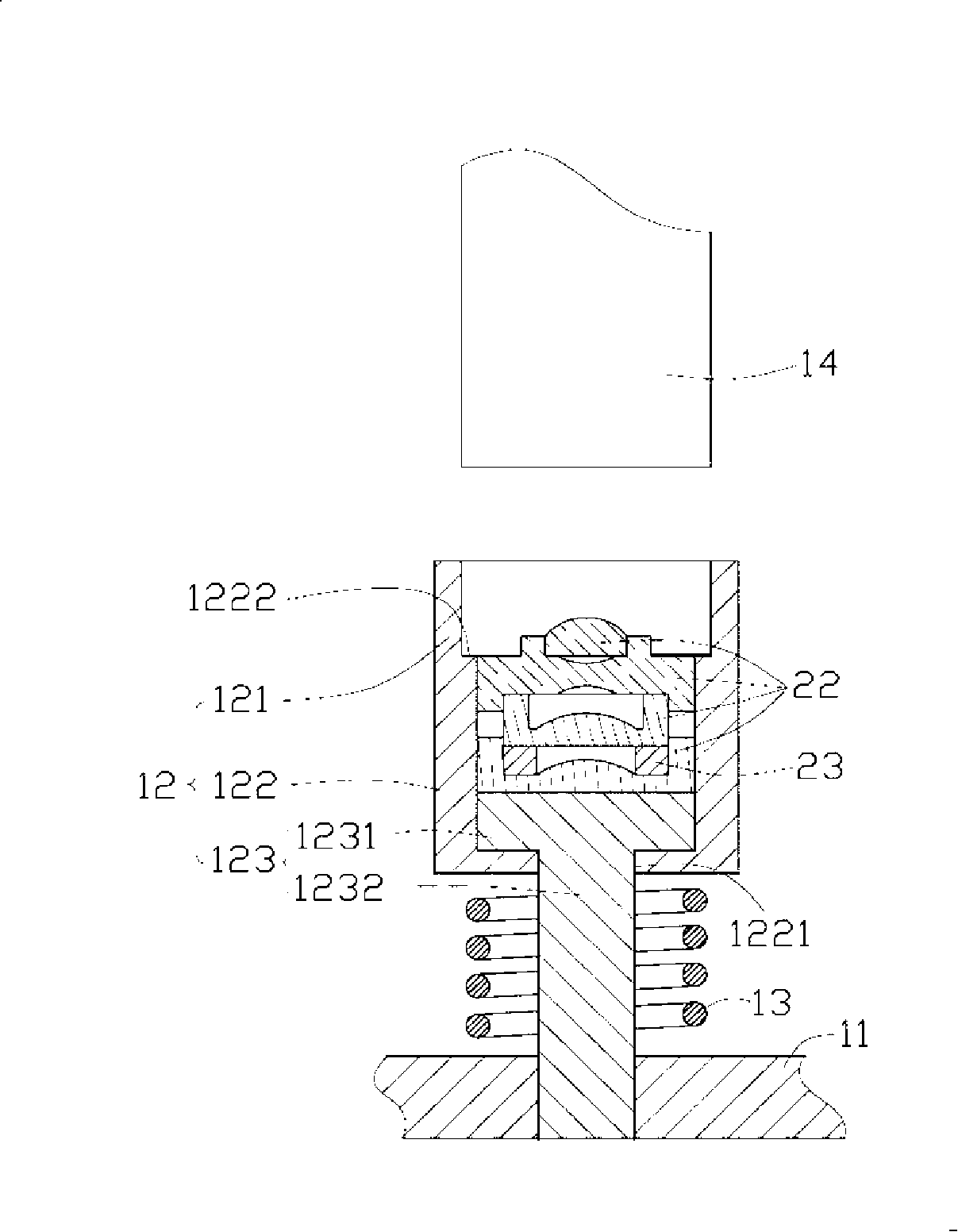

Lens assembled fixture and assembling system possessing same and assembling method

A lens assembly system comprises a holder, a lens assembly fixture on the holder, an elastic element and a push rod. The lens assembly fixture comprises a first shell, a second shell connected with the first shell and a post rod sleeved on the second shell. The first shell is used to contain the drawtube of the lens module. A through hole is provided at one end of the second shell. The post rod is contained with the through hole to push an optical element contained in the second shell out of the second shell and connected with the holder. The push rod is coaxially arranged towards one end of the first shell in interval. The lens assembly system and the assembly fixture make the lens not been sloped so as to improve the nondefective assembly rate. The invention also relates to a assembly method of the lens assembly system.

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

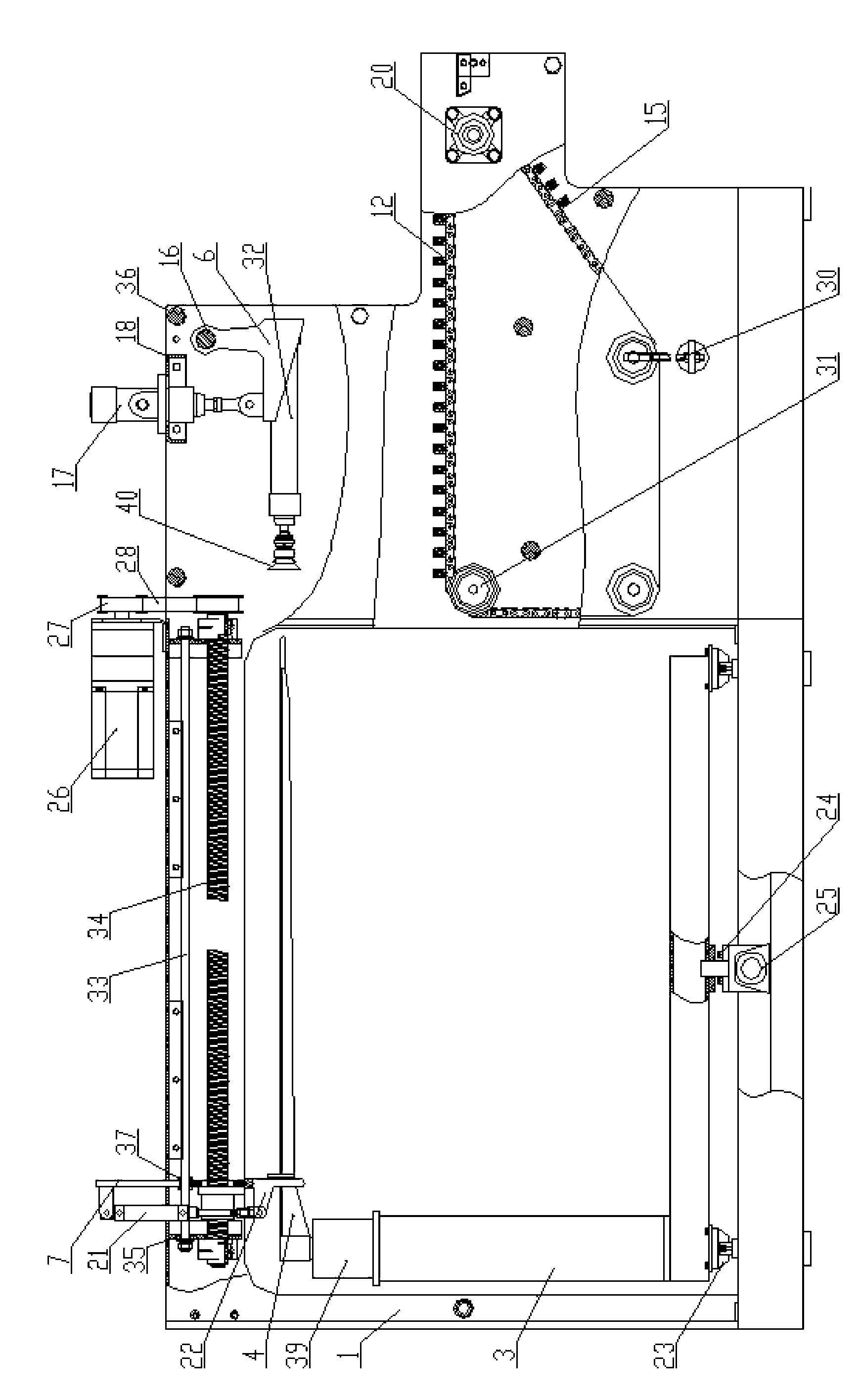

Automatic hand bag feeding machine

ActiveCN103010522ANot easy to tiltReasonable structural designPackaging automatic controlEngineeringInductor

The invention discloses an automatic hand bag feeding machine. The feeding machine comprises an underframe, wherein a left support frame and a right support frame are erected on the underframe, a shifting frame which can shift to left and right is erected on the underframe between the left support frame and the right support frame, one or a plurality of bag frames are erected on the shifting frame, a bag pushing shift fork assembly which can push hand bags to operate is arranged above each bag frame, a bag feeding sucking disc assembly is arranged on the frame on a bag outlet end of each bag frame and installed on a rack, an air cylinder which drives a bag taking sucking disc to horizontally shift to take the bags and rotationally operate to discharge is arranged in each bag feeding sucking disc assembly, a circulation conveying mechanism is arranged on an upper frame of the rack below the bag feeding sucking disc assemblies, and a discharge end of the circulation conveying mechanism is provided with a supporting plate which is matched with the circulation conveying mechanism and an inductor which senses the position of the hand bag and controls the circulation conveying mechanism to operate. The automatic hand bag feeding of an automatic packaging unit is realized, the stacked bags are difficult to incline, the automatic hand bag feeding machine is convenient and quick to operate, the manual labor intensity is reduced, and the working efficiency is increased.

Owner:ANHUI YONGCHENG ELECTRONICS & MECHANICAL TECH

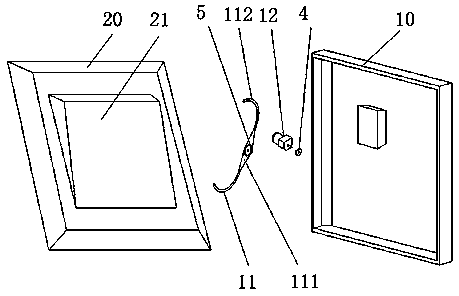

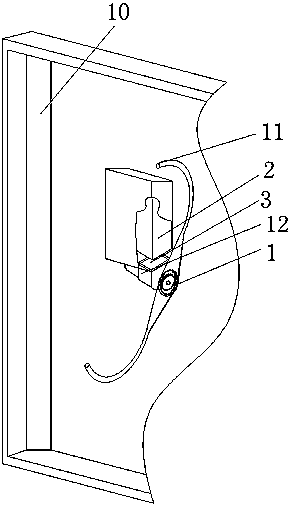

Remote control switch

ActiveCN104077908ARealize switch controlRealize remote controlTransmission systemsTransmissionWireless controlSwitch box

The invention relates to the technical field of switch control, particularly to a remote control switch which is applicable to a household switch box. The remote control switch comprises a casing, wherein the casing is matched with the switch box in shape and is arranged on the switch box; a storage battery, an overturning mechanism and a wireless control circuit are arranged in the casing; the storage battery provides a working power supply for the wireless control circuit and the overturning mechanism; the wireless control circuit receives wireless control signals and controls overturning of the overturning mechanism; the overturning mechanism overturns to touch a seesaw button or a thumb button on the switch box to swing the seesaw button or the thumb button from a first direction to a second direction opposite to the first direction, so as to realize on / off control over a lamp. The remote control switch performs overturning control over the position of the seesaw button or the thumb button on the conventional 86 switch box so as to realize remote on / off control; the remote control switch adopts the storage battery to realize passive remote on / off control, is safe and reliable, is convenient to mount and doesn't need to change the conventional circuit layout.

Owner:ZHEJIANG HOOEASY SMART TECH

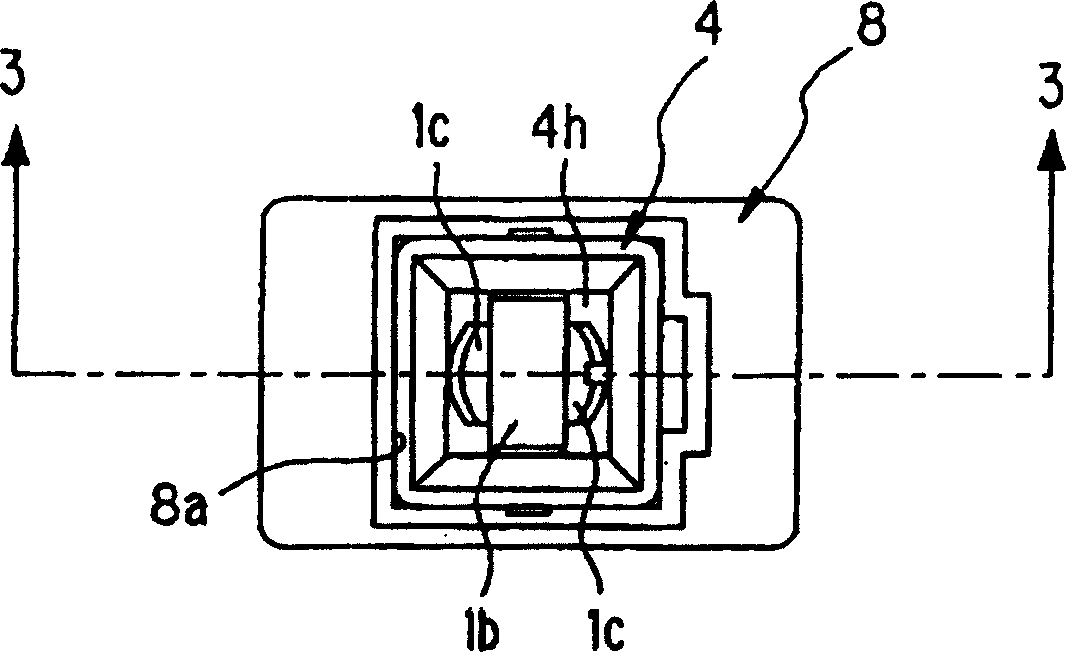

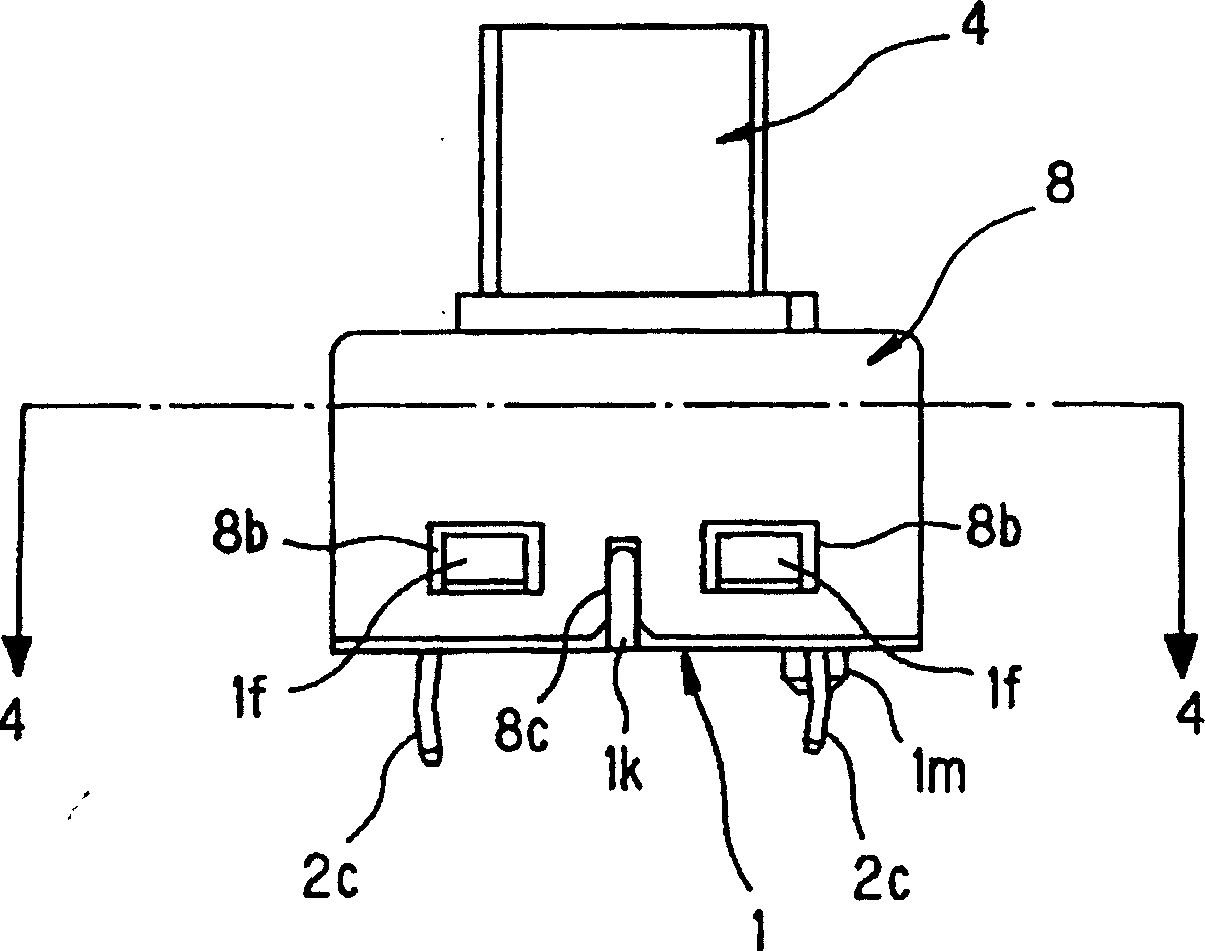

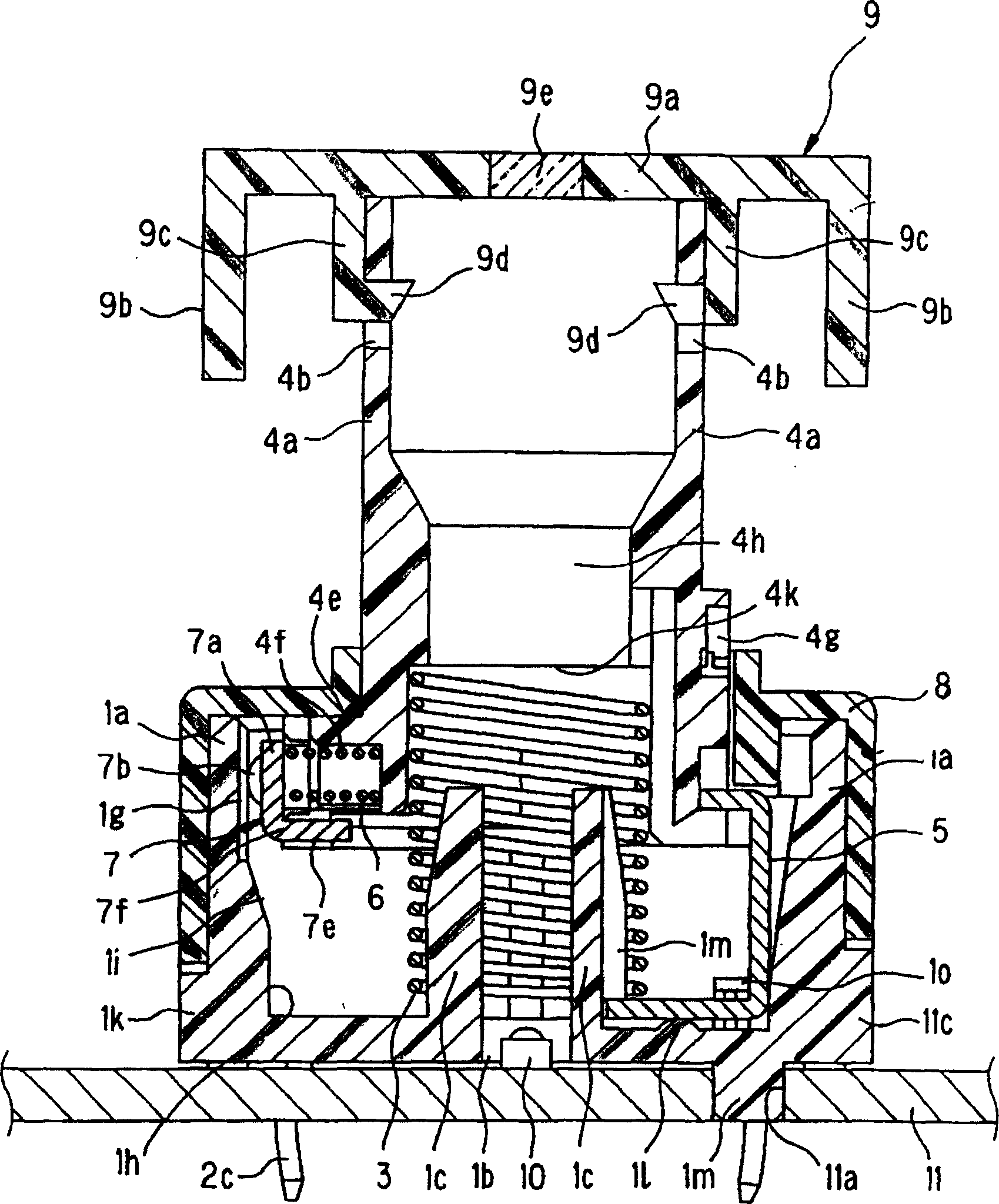

Push switch

In order to provide a miniature button switch which can arrange a display part near a light source by a simple structure and can illuminate the display part efficiently, the miniature button switch is provided with a casing which is pressed and operated and is provided with a through hole at the central part of the casing, the display part is formed at the top of the through hole, and the bottom surface of the casing is provided with an inserting hole which is opposite to the through hole; the miniature button switch is also provided with the light source which is contained inside the inserting hole and the through hole, and the through hole is linear along the pressing direction. Or in order to provide a button switch realizing miniaturization, the button switch is provided with the casing which is provided with a pair of fixed contacts which are parallel extended along the pressing operation direction, a movable contact component which is kept at an operating shaft, is elastically forced by an elastic component and is provided with movable contacts which are formed by a pair of protrudent parts which are elastically contacted with the fixed contacts respectively, and a contact separation guide part which is arranged at the casing and is contacted with a part between a pair of protrudent parts at a closing position along with the pressing operation to separate the movable contacts from the fixed contacts.

Owner:ALPS ALPINE CO LTD

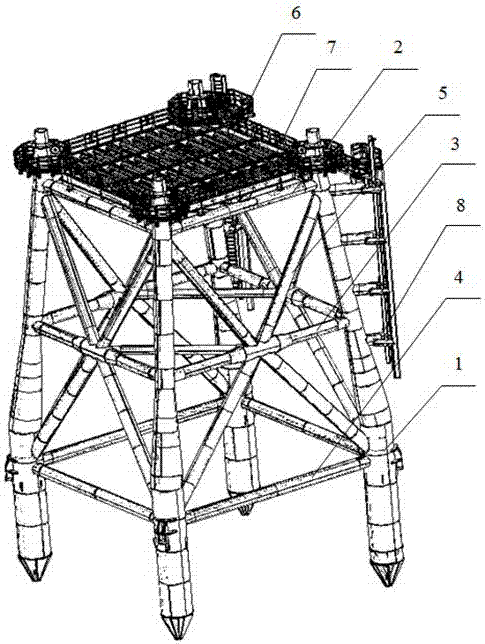

Construction process for lower component of seaborne booster station

ActiveCN107470860ANot easy to tiltGuaranteed long-term operation and maintenanceWind motor supports/mountsSteel platesSteel tube

The invention discloses a construction process for a lower component of a seaborne booster station. The construction process comprises the following steps: (1) blanking of a steel plate according to a copy map; (2) scribing and groove cutting; (3) manufacture of a steel tube pile, a horizontal stay bar and an oblique stay bar; and (4) gathered welding of the steel tube pile, the horizontal stay bar and the oblique stay bar. All the sections are horizontally built at first and then vertically welded in a gathered manner, the construction process is clear in order, the construction efficiency is greatly improved, the supporting stability of the lower component is guaranteed, and long-term maintenance of the seaborne booster station is guaranteed. The steel tube pile comprises a vertical part and an inclined part inclined inwards, so that the supporting performance of the lower component is greatly improved, the probability of inclination is low, and the demands on edge rolling and cutting are high. As submerged-arc welding is adopted, the welding quality is stable, the welding productivity is high, arc light is less, and soot is less. The welding margin is reasonably reserved to guarantee the welding quality and the welding accuracy, the supporting performance of the lower component is greatly improved, and the whole seaborne booster station has a certain stability.

Owner:NANTONG BLUE ISLAND OFFSHORE CO LTD

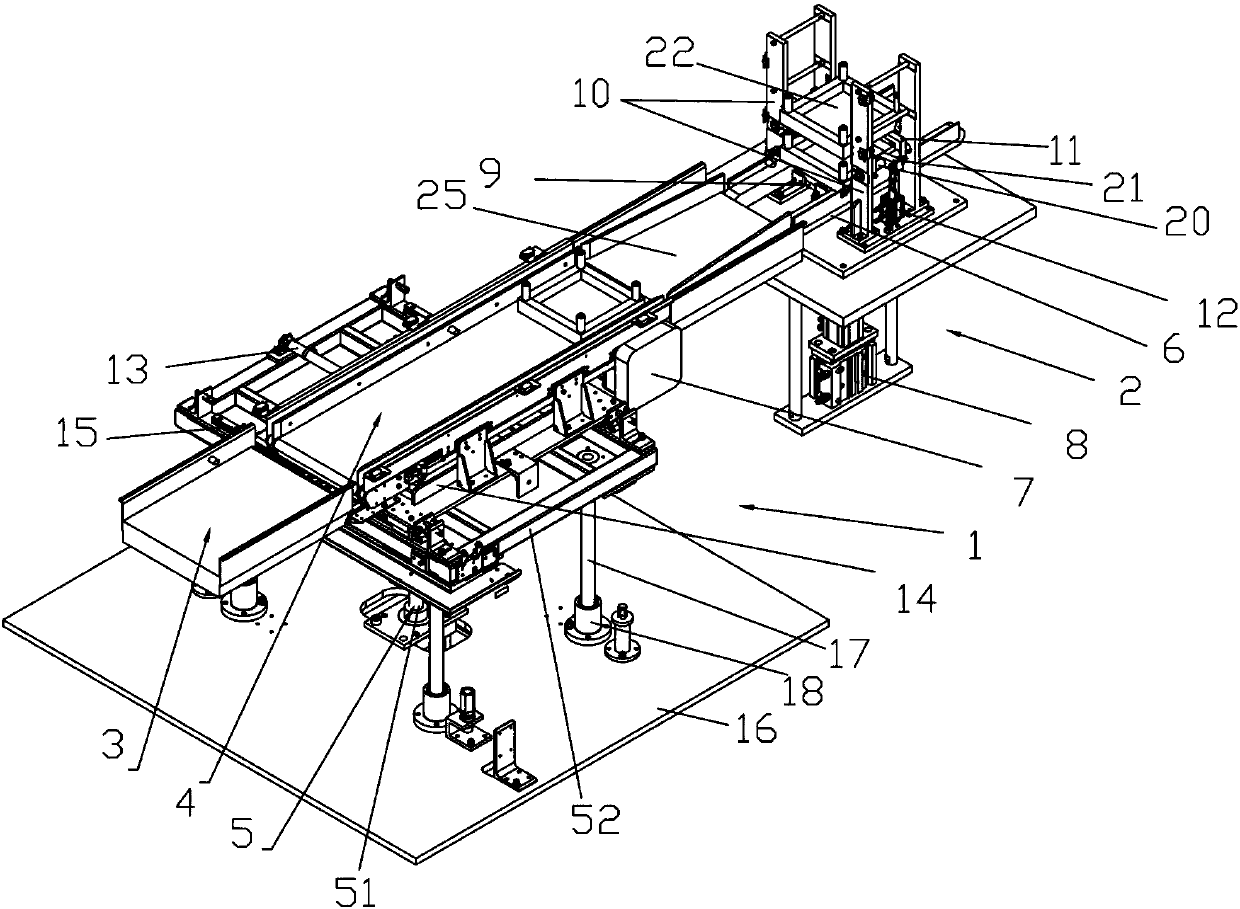

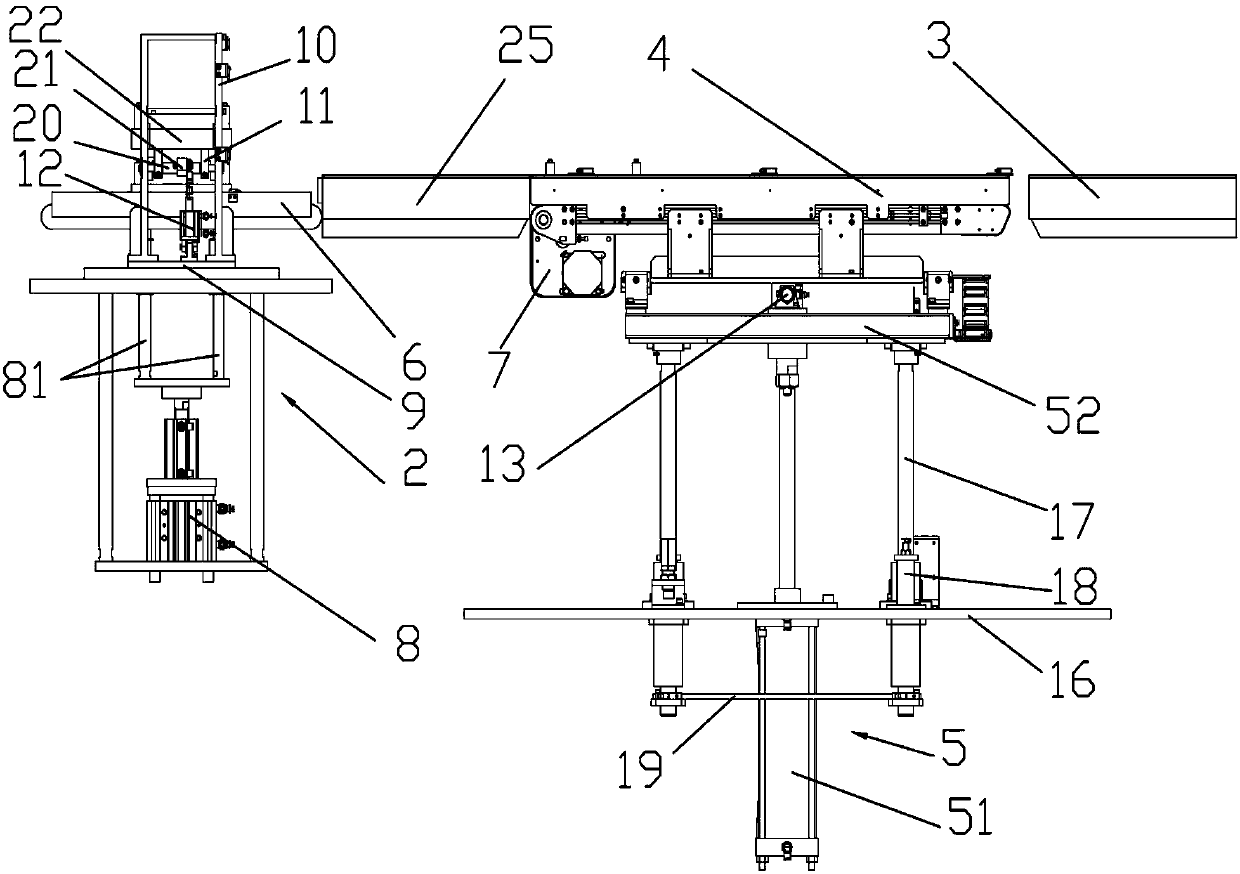

Pallet stacking and conveying device

InactiveCN107640565AConvenient handoverAvoid position shiftConveyorsStacking articlesEngineeringPallet

The invention discloses a pallet stacking and conveying device which comprises a conveying lifting mechanism and a pallet stacking mechanism. The conveying lifting mechanism comprises a first conveying belt, a second conveying belt, a lifting mechanism driving the second conveying belt to ascend and descend and a third conveying belt which are sequentially distributed in a conveying direction, thelifting mechanism comprises a first linear executor in vertical placement and a load bearing frame connected with an output shaft of the first linear executor, the third conveying belt is arranged inthe middle of the pallet stacking mechanism, and the pallet stacking mechanism comprises a second linear executor in vertical placement, a lifting frame fixedly connected with an output shaft of thesecond linear executor and two supporting frames fixed on two sides of the third conveying belt. Pallets among the conveying belts at different heights can be transferred through the lifting mechanism, the pallet stacking mechanism stacks the pallets together, and finally the pallets are conveyed again. The pallet stacking and conveying device is simple in structure and high in stacking efficiency, and deflection during conveying and stacking of the pallets is avoided.

Owner:黄润豪

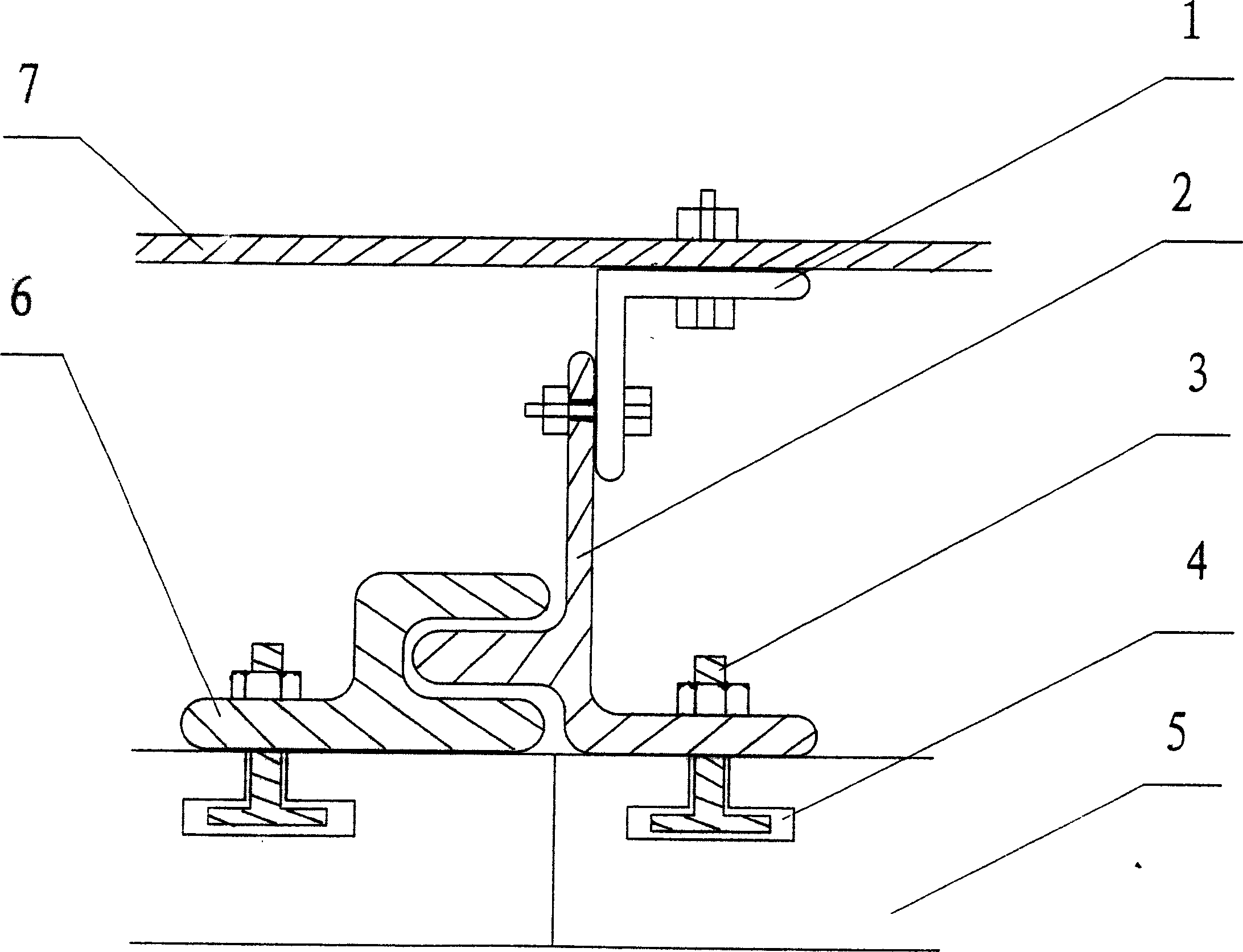

Ceramic stone connector and connecting method

The present invention relates to decoration and installation technology, and especially one ceramic and stone connector and connecting method. The ceramic and stone connector includes fixing steel section with long slot for vertical regulation and T-shaped slot for dual direction regulation, convex steel rack and concave steel rack meshed each other, T-shaped screw with elastic head, and stone material with T-shaped slot, with fixing glue being filled between the convex steel rack and the concave steel rack and between the T-shaped screw and the T-shaped slot in stone material. The connecting method with the ceramic-stone connector includes fixing the steel section with screw to the top, installing the convex steel rack, meshing the convex steel rack and the concave steel rack, and installing the stone material with the T-shaped screw onto the convex steel rack and the concave steel rack.

Owner:刘超

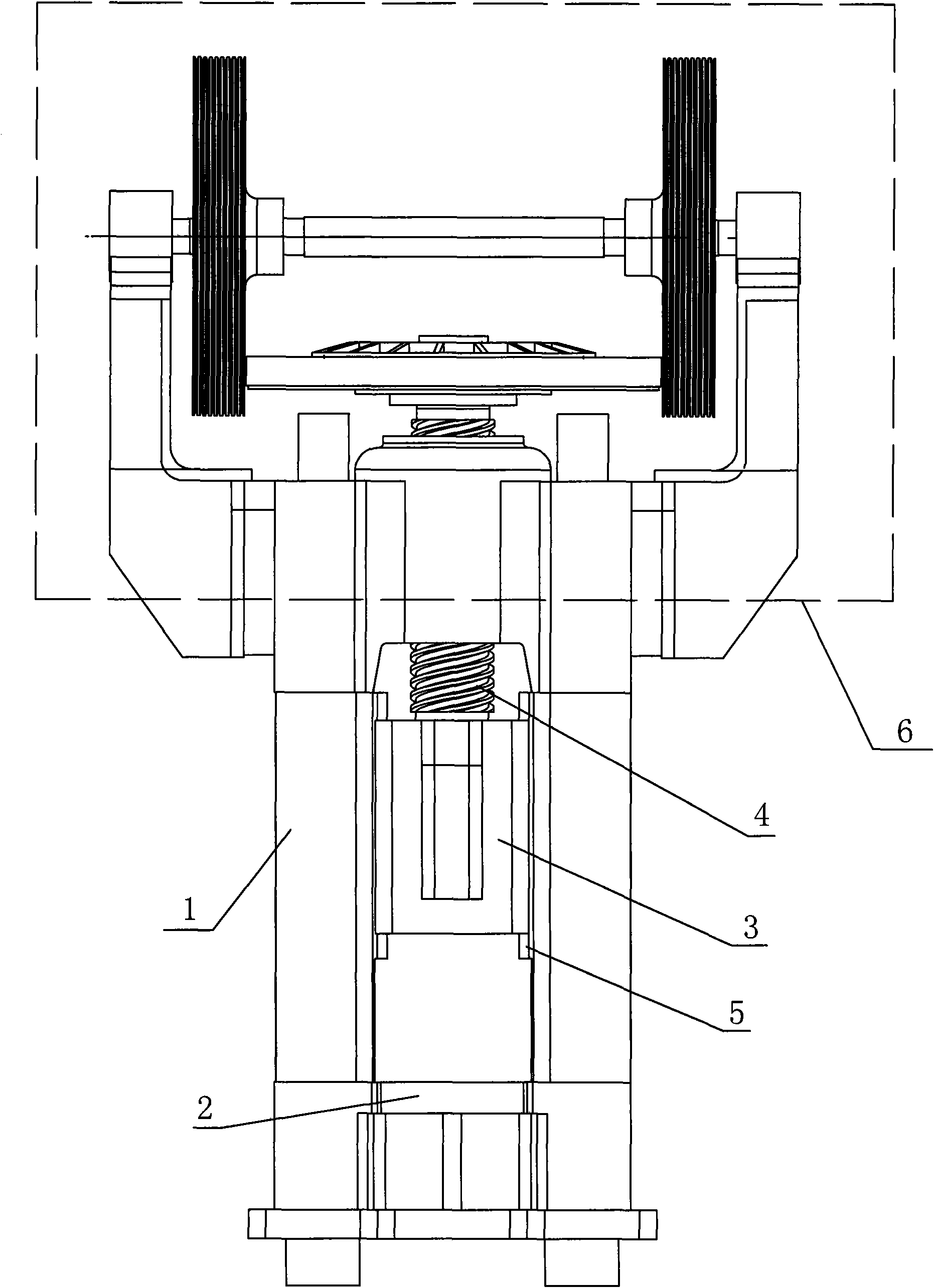

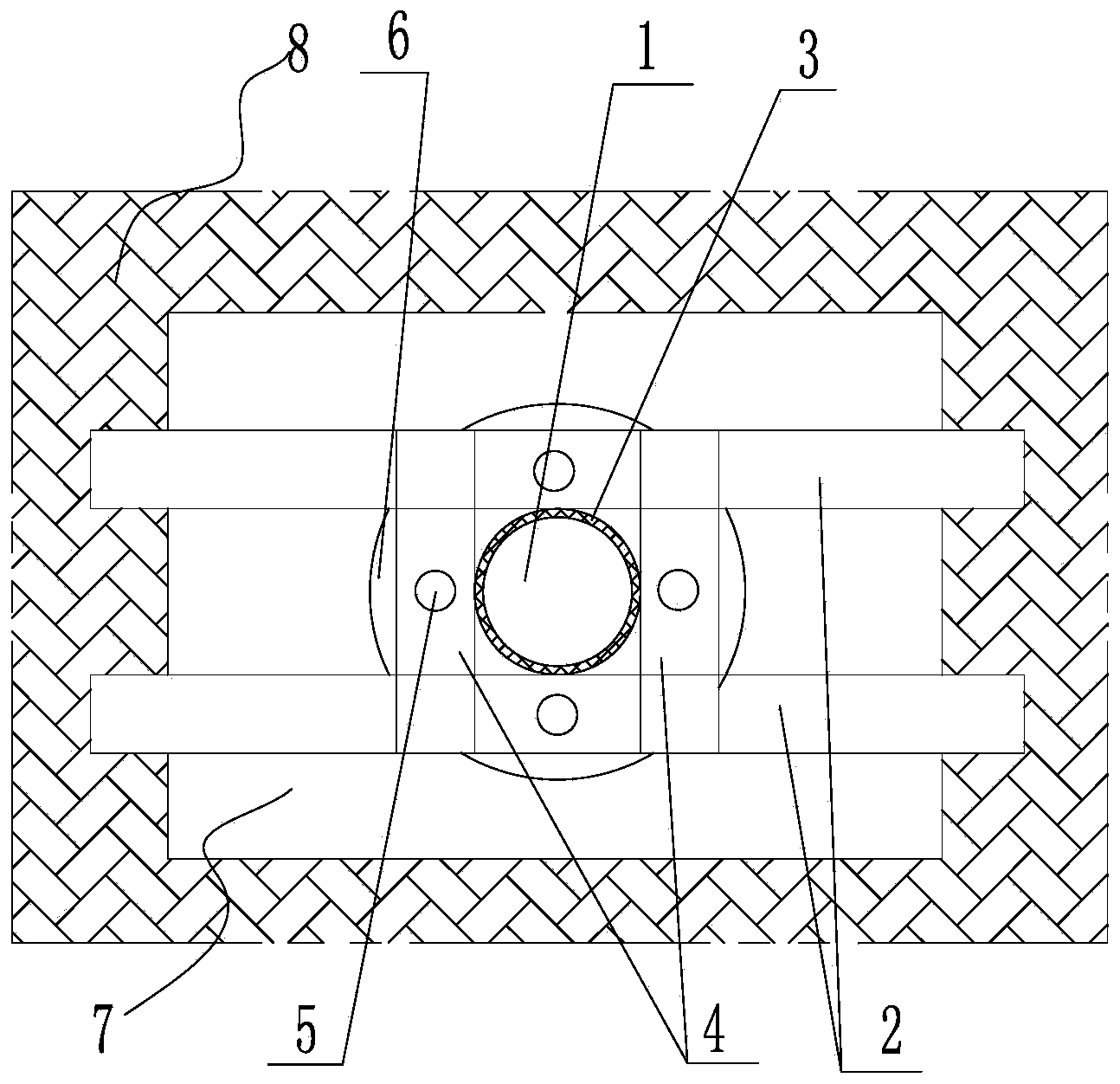

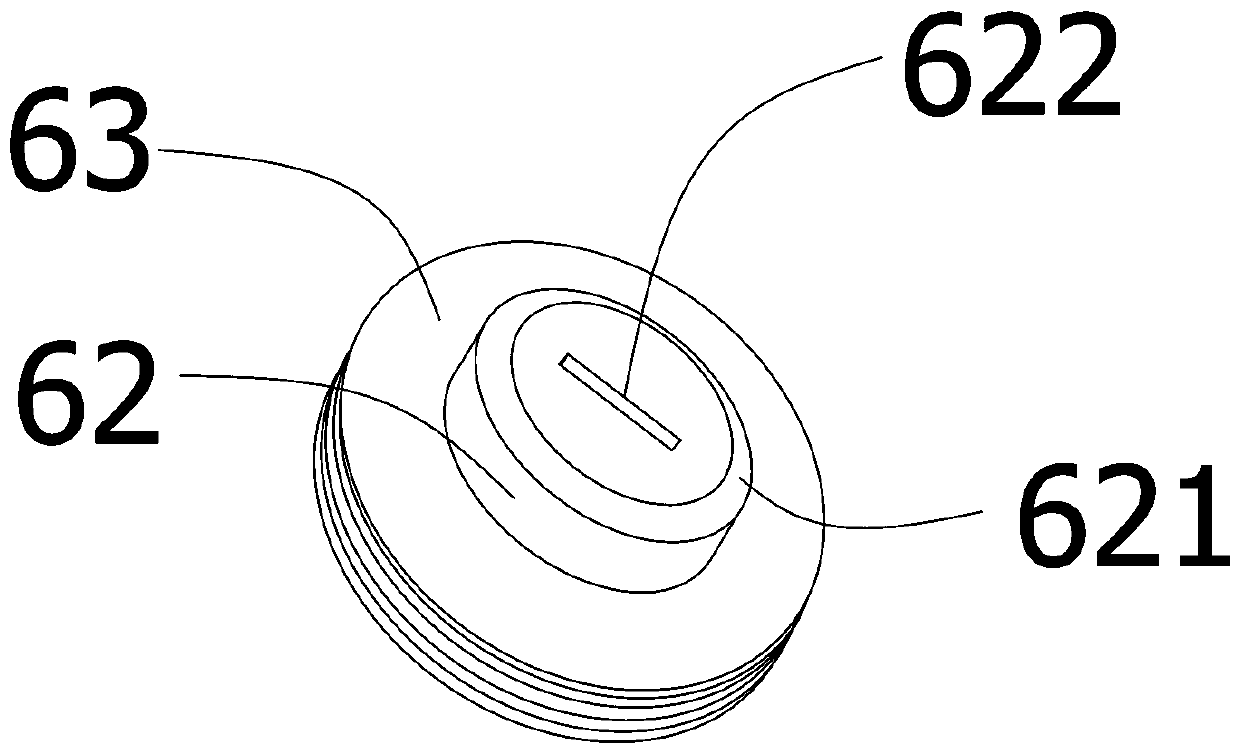

Self-lubricating self-sealing graphite gas-floatation electrostatic pressure spindle structure

ActiveCN105195764ALow costImprove rigidityLarge fixed membersMaintainance and safety accessoriesGraphiteLubricant

The invention relates to a self-lubricating self-sealing graphite gas-floatation electrostatic pressure spindle structure. The spindle structure comprises a spindle, a thrust collar arranged on the end part of the spindle, a sleeve arranged outside the spindle in a sleeving manner, a motor stator and a motor rotor, wherein a front bearing bush and a rear bearing bush which are made of a porous material are arranged between the sleeve and the spindle; the front bearing bush is arranged on the front end of an inner hole of the sleeve; the rear bearing bush is arranged on the rear end of the inner hole of the sleeve; a front end cover and a rear end cover are respectively arranged on both ends of the spindle. Because a porous bearing which has good radial rigidity and thrust rigidity is adopted and a throttler and the bearing are integrated into a whole, the cost of the throttler is saved; the front bearing bush and the rear bearing bush are made of the porous graphite material, and because graphite is a solid lubricant per se and a gas membrane is a gas lubricant per se while floating, the spindle does not easily undergo bearing shoe grinding and has good self-lubricating property when the rotating stability is relatively poor; the spindle structure disclosed by the invention also has the advantages of simple structure, relatively stable sealing property, difficulty in inclination of the spindle, stable swinging operation and the like.

Owner:SUZHOU CHENNA AUTOMATION TECH CO LTD

Formwork removal-free reinforced concrete column construction device

PendingCN107313554AReduce dosageAvoid damageStrutsForms/shuttering/falseworksReinforced concrete columnFiber

The invention relates to the field of construction engineering structural technologies and construction, in particular to a removal-free reinforced concrete column construction device. The formwork removal-free reinforced concrete column construction device comprises a column steel reinforcement cage. The formwork removal-free reinforced concrete column construction device is characterized in that the outer side of the steel reinforcement cage is provided with cement fiber plates which are connected with the sealing steel reinforcement cage surface, the inner surface of each cement fiber plate is provided with rectangular bulge blocks which are distributed in a quincuncial mode, outer side connecting angels of every two connected cement fiber plates are provided with angle part angle iron in the vertical direction at intervals, and connecting parts are arranged between the every two adjacent angle part angle iron in the same horizontal plane. The formwork removal-free reinforced concrete column construction device is simple in structure and flexible in application, the using amount of steel formworks or wooden formworks is reduced, steel materials and wooden materials are reduced, and the environment is protected.

Owner:BINZHOU UNIV

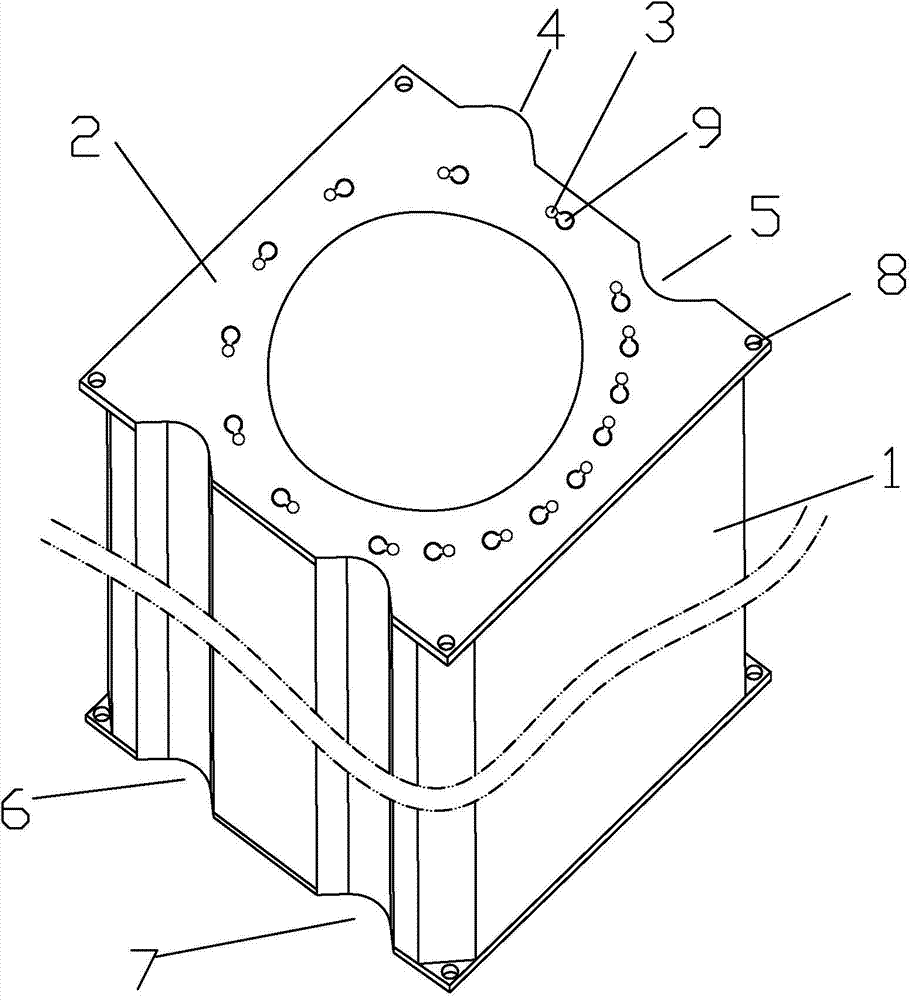

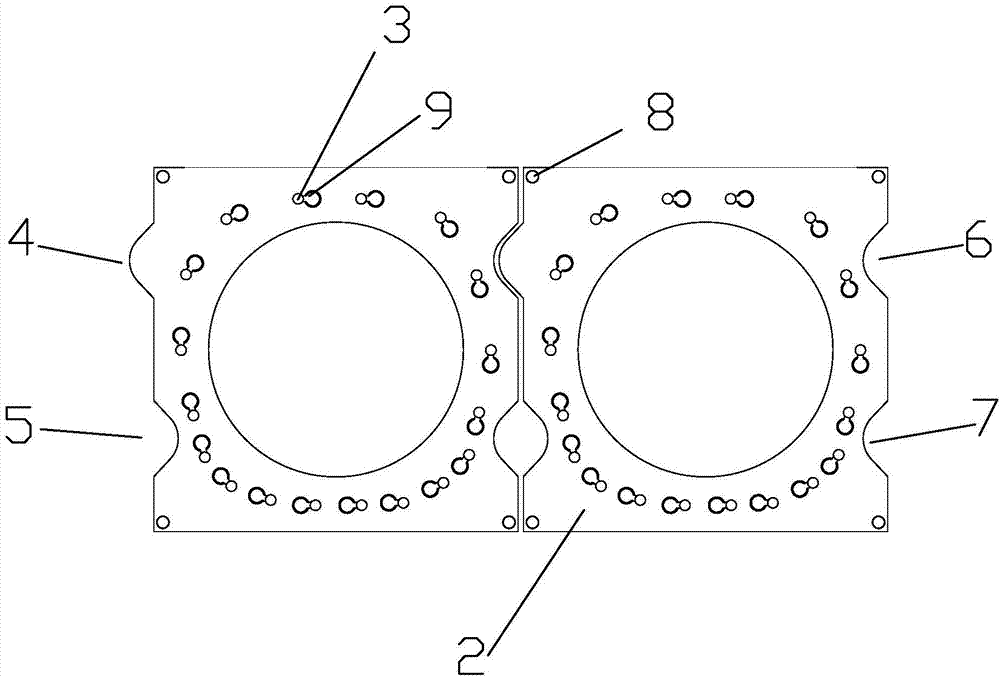

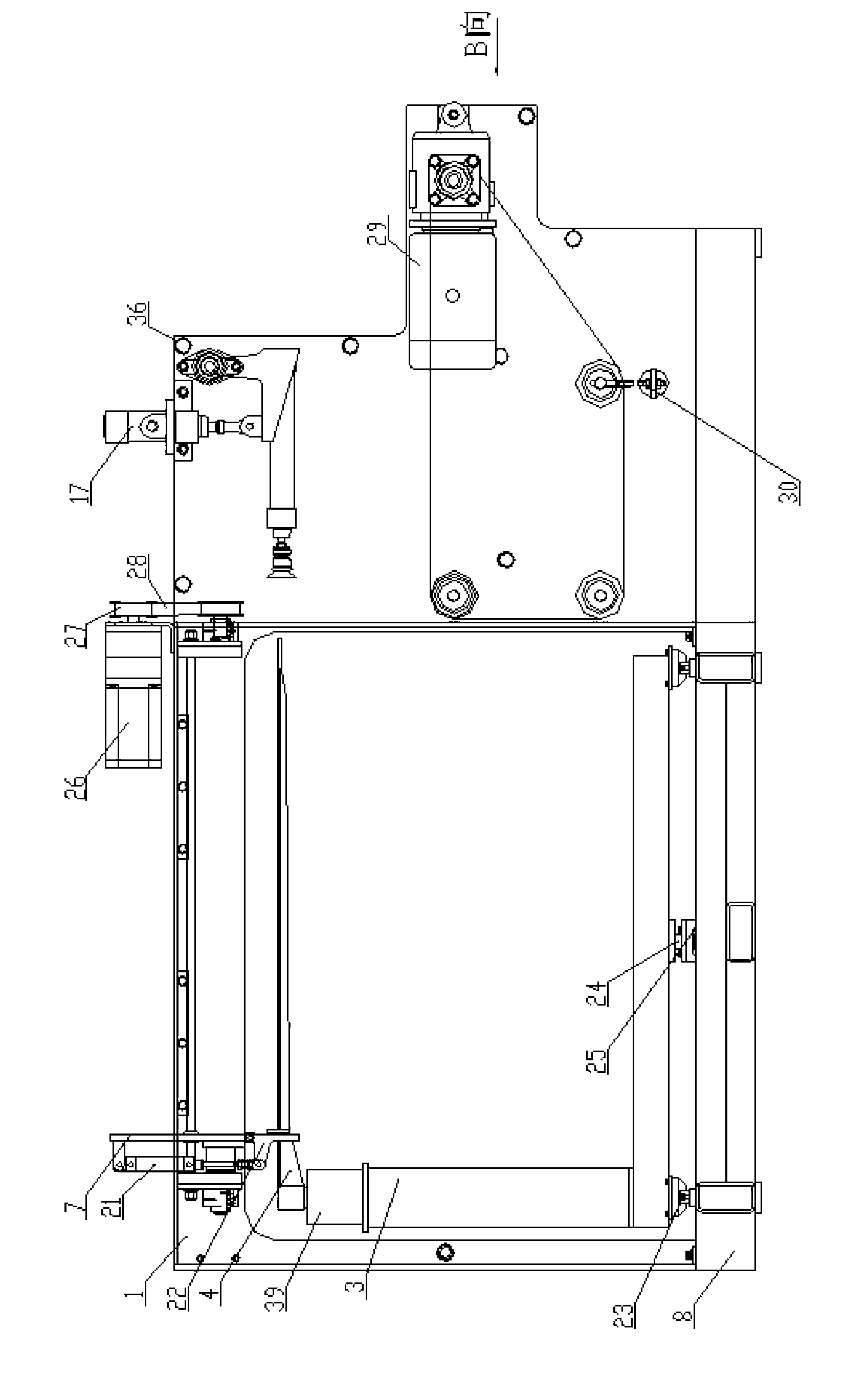

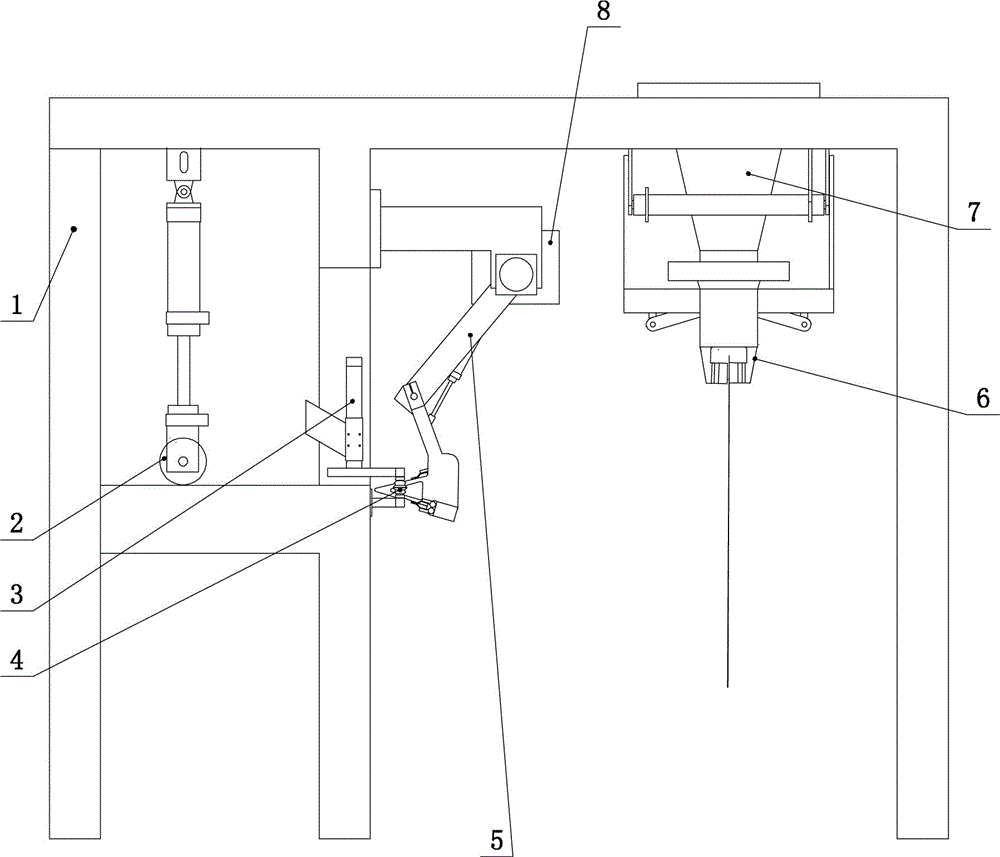

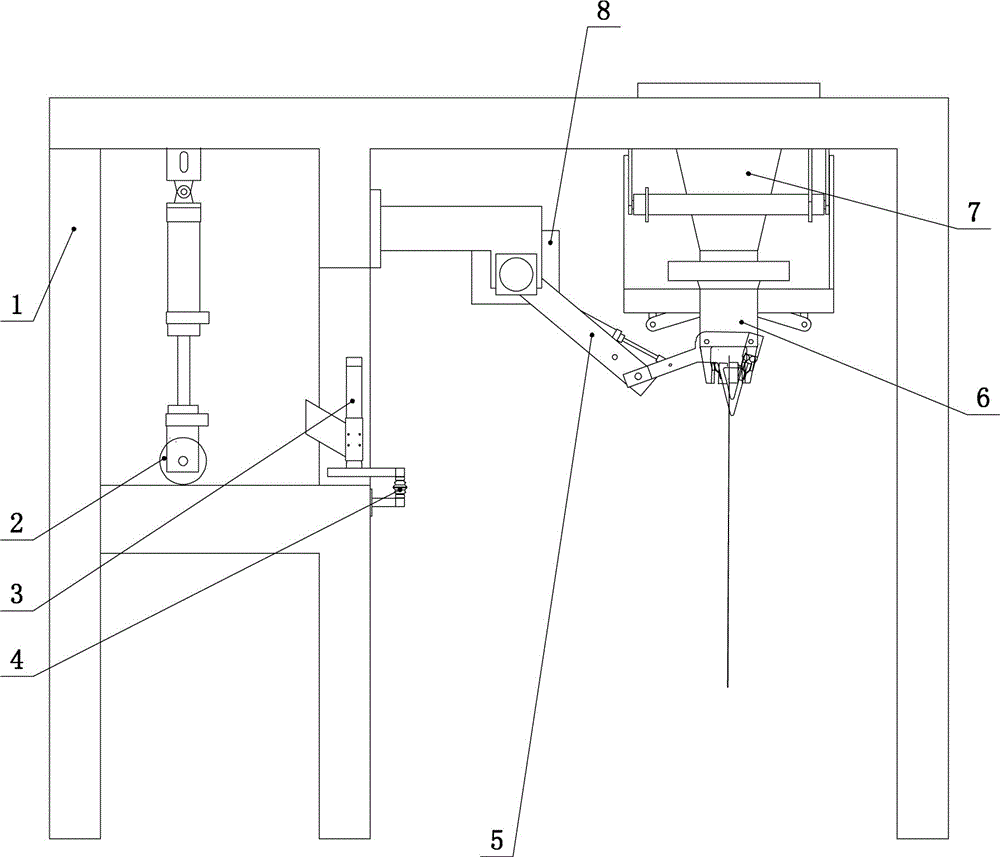

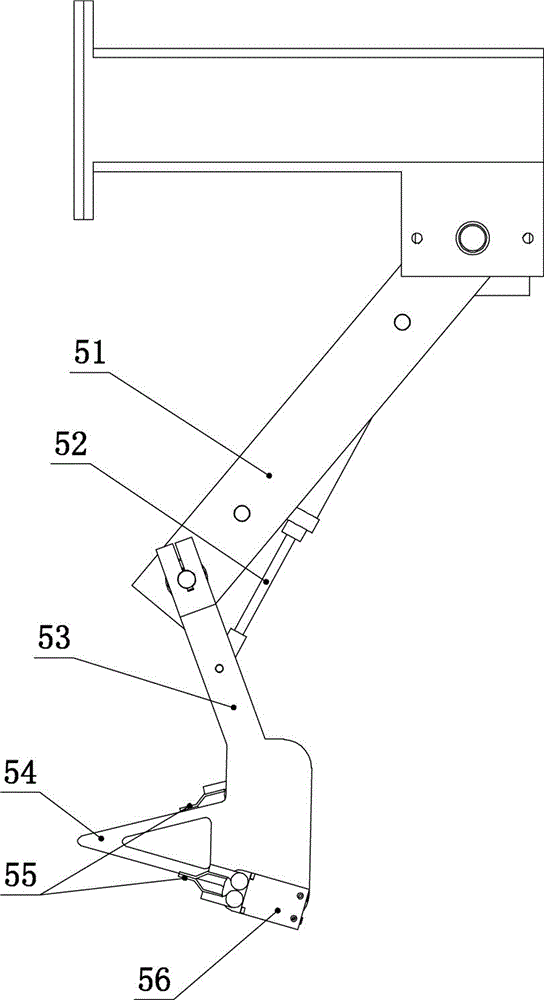

Multi-station friction screw press

The invention relates to a multi-station friction screw press which comprises a body, a multi-station mold, a slide block, a screw, a plurality of guide rails and a screw driving device, wherein the multi-station mold is arranged on the workbench of the body; the slide block is arranged above the multi-station mold; one end of the screw is inserted into the slide block and is rotatablely connected with the slide block, and the screw drives the slide block to move up and down; the plurality of guide rails are arranged on the body and are used for guiding the slide block, and the distance amongthe guide rails is suitable for the slide block to slide among the guide rails; the screw driving device is connected with the other end of the screw and can drive the screw to rotate forward or backward and simultaneously rise or fall; the ratio of the longitudinal height of the slide block along the length direction of the guide rails to the minimum transverse width of the size of the slide block is greater than 1.5; and the gap between the outer diameter of the screw and the minimum inner diameter of the opening at the inserting end of the slide block is 0.3-0.5mm. The invention provides an economical multi-station friction screw press which can be used for multi-station forging.

Owner:BEIJING RES INST OF MECHANICAL&ELECTRICAL TECH +2

Automatic bagging machine

The invention discloses an automatic bagging machine, which comprises a rack, wherein the rack is provided with a roller, an opening stretching cylinder and an opening stretching suction cup, wherein the opening stretching suction cup is in transmission connection with the opening stretching cylinder; the roller is horizontally arranged and corresponds to the opening stretching suction cup; the rack is also fixedly provided with a servo motor; the servo motor is in transmission connection with a manipulator; the manipulator comprises an upper arm which is in transmission connection with the servo motor; the other end of the upper arm is hinged to a lower arm; a sharp nozzle cylinder is fixedly connected between the upper arm and the lower arm; the other end of the lower arm is fixedly connected with a bag opening retaining sharp nozzle; the bag openingretaining sharp nozzle corresponds to the opening stretching suction cup and comprises two opening stretching clamping arms; one ends of the two opening stretching clamping arms are contacted together; the other ends of the opening stretching clamping arms are hinged to the lower arm respectively; an opening stretching clamping cylinder is fixedly connected between the other ends of the two opening stretching clamping arms; and the outer side of the bag openingretaining sharp nozzle is connected with a clamping pneumatic claw. The outer sides of both edges of the bag openingretaining sharp nozzle are both hinged to the clamping pneumatic claw.

Owner:三维汉界机器(山东)股份有限公司

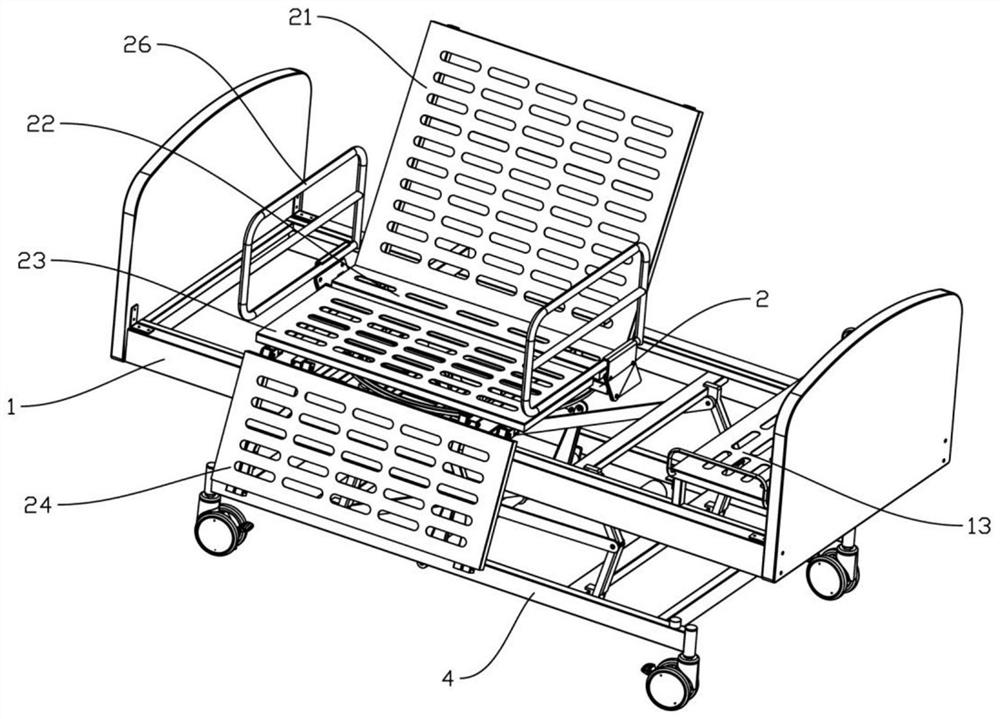

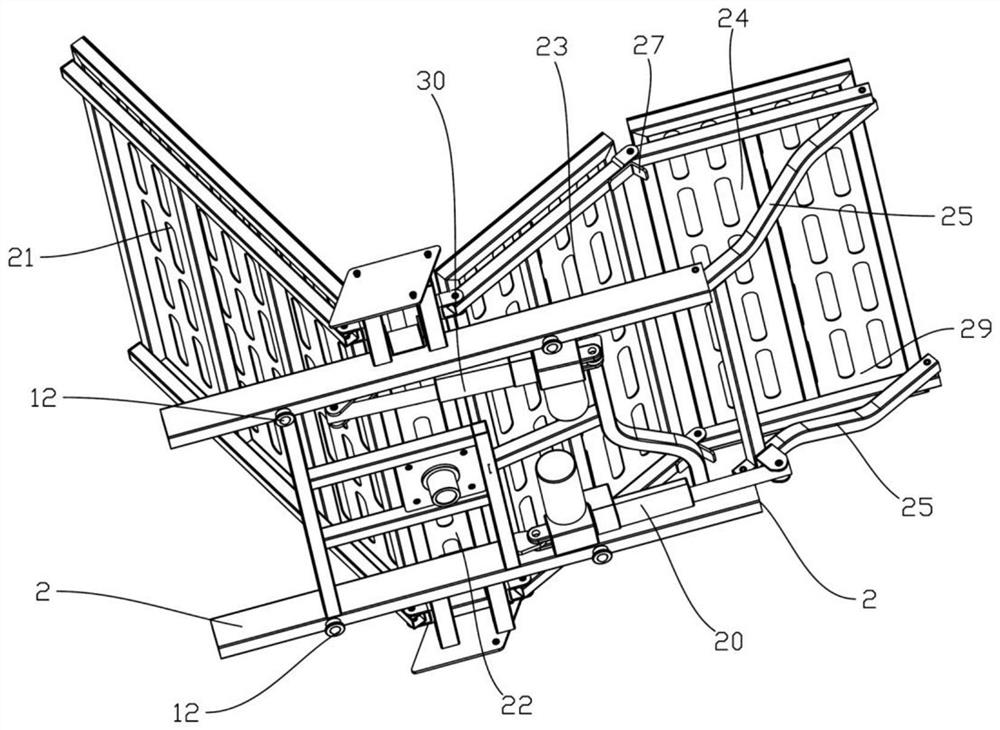

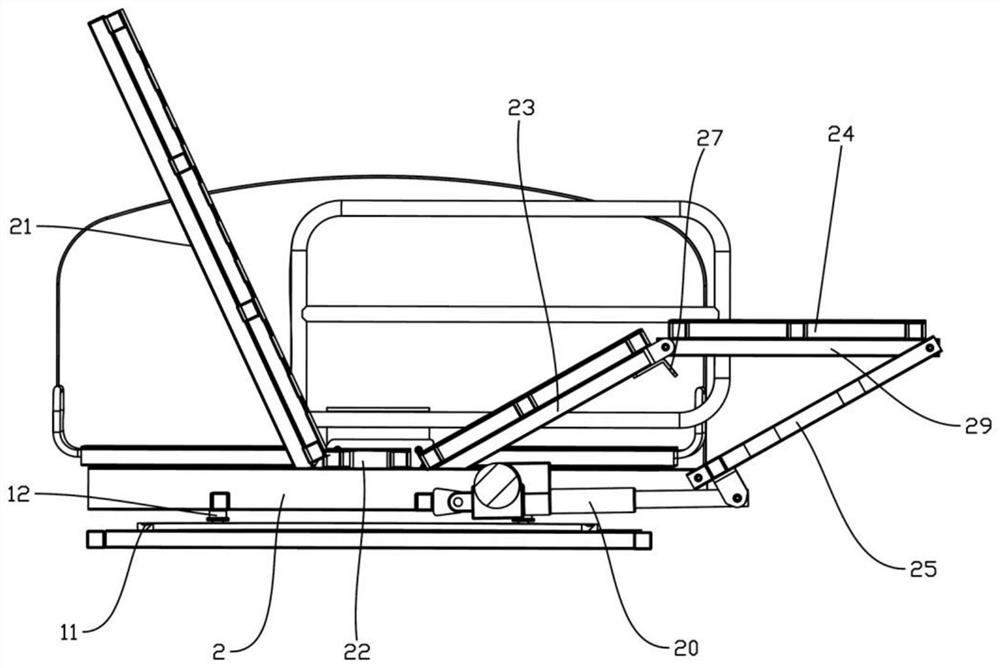

Nursing bed

PendingCN112076035AEasy to moveImprove comfortNursing bedsPhysical medicine and rehabilitationNursing care

The invention relates to a nursing bed. The nursing bed comprises a bed frame, wherein a mattress is arranged on the upper side of the bed frame and comprises a backrest cushion, a fixed cushion, a thigh supporting cushion and a shank supporting cushion, one end of the backrest cushion is rotationally fixed with the fixed cushion, one end of the thigh supporting cushion is rotationally fixed withthe fixed cushion, the shank supporting cushion is rotationally fixed with the other end of the thigh supporting cushion, the fixed cushion is fixed with a mattress frame, the mattress frame is supported and connected onto the bed frame in a manner of horizontally rotating around the vertical axis, and the shank supporting cushion is connected with a leg support driving mechanism for overturning the shank supporting cushion. The nursing bed has the advantages that the use and operation steps are fewer, the use comfort is higher, and the mattress is more stable and not prone to inclination during use.

Owner:ZHEJIANG INNUOVO REHABILITATION DEVICES CO LTD

Vertical rod reinforcement device used for earth excavation and vertical rod reinforcement method

Owner:新疆兵团水利水电工程集团有限公司

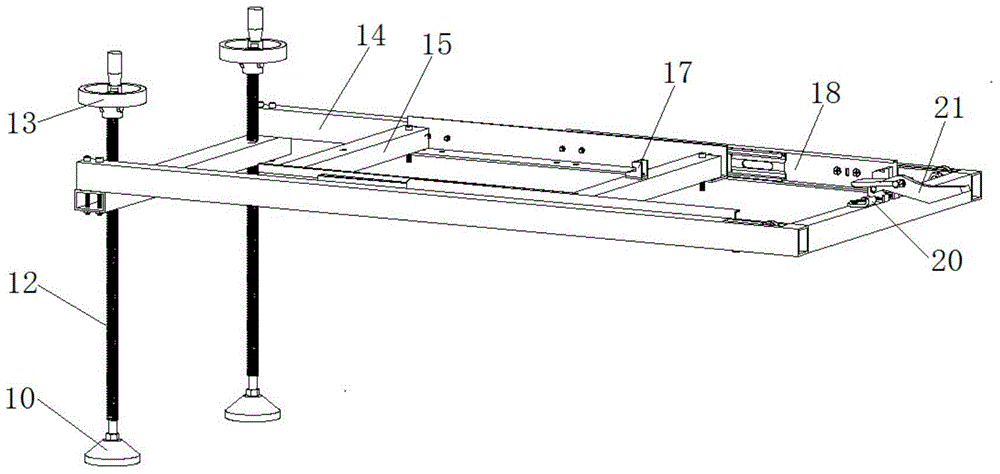

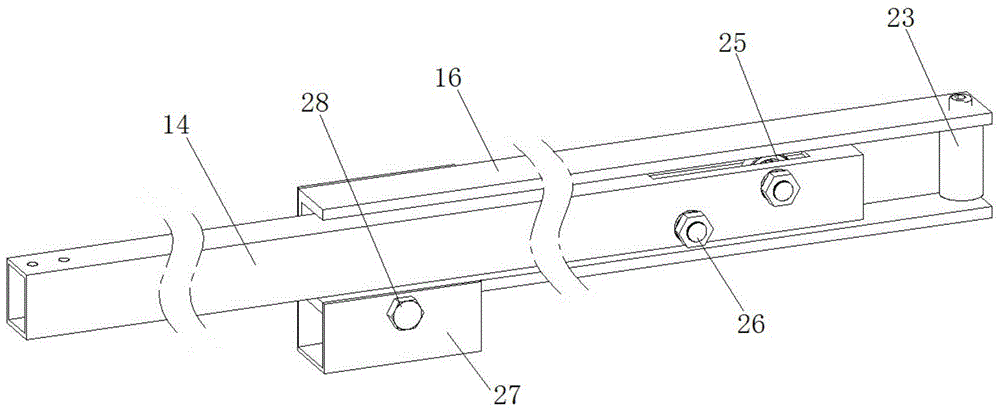

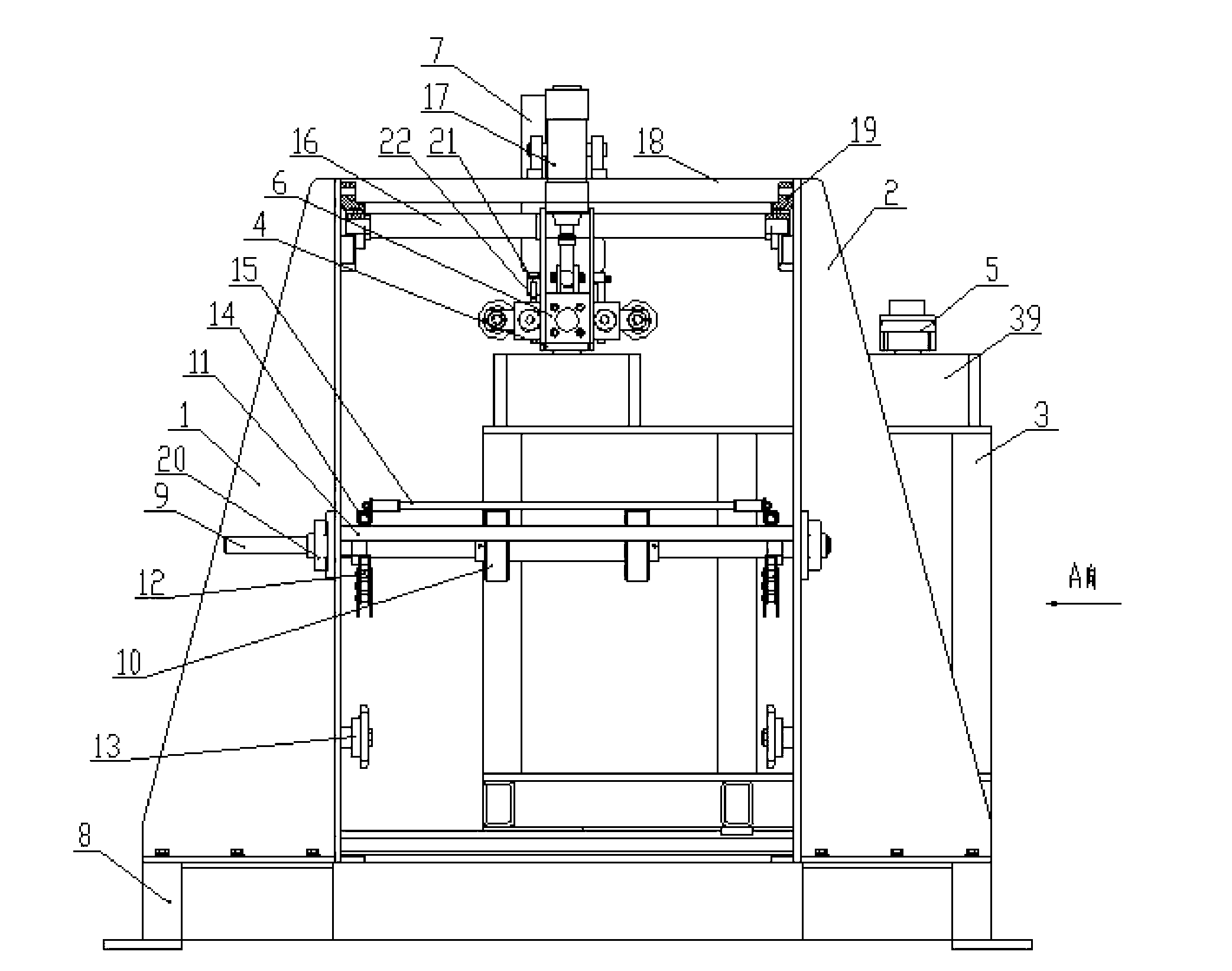

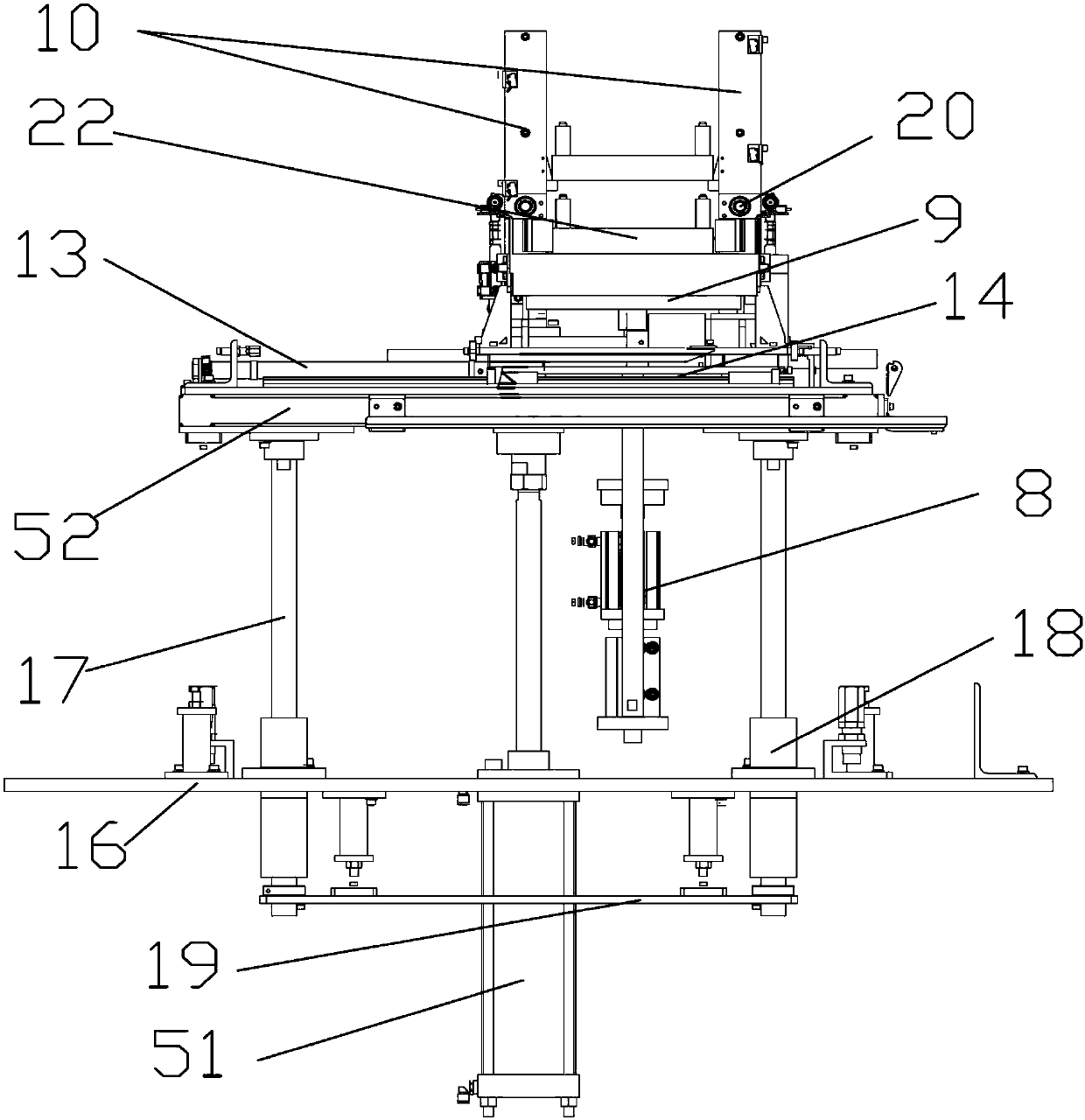

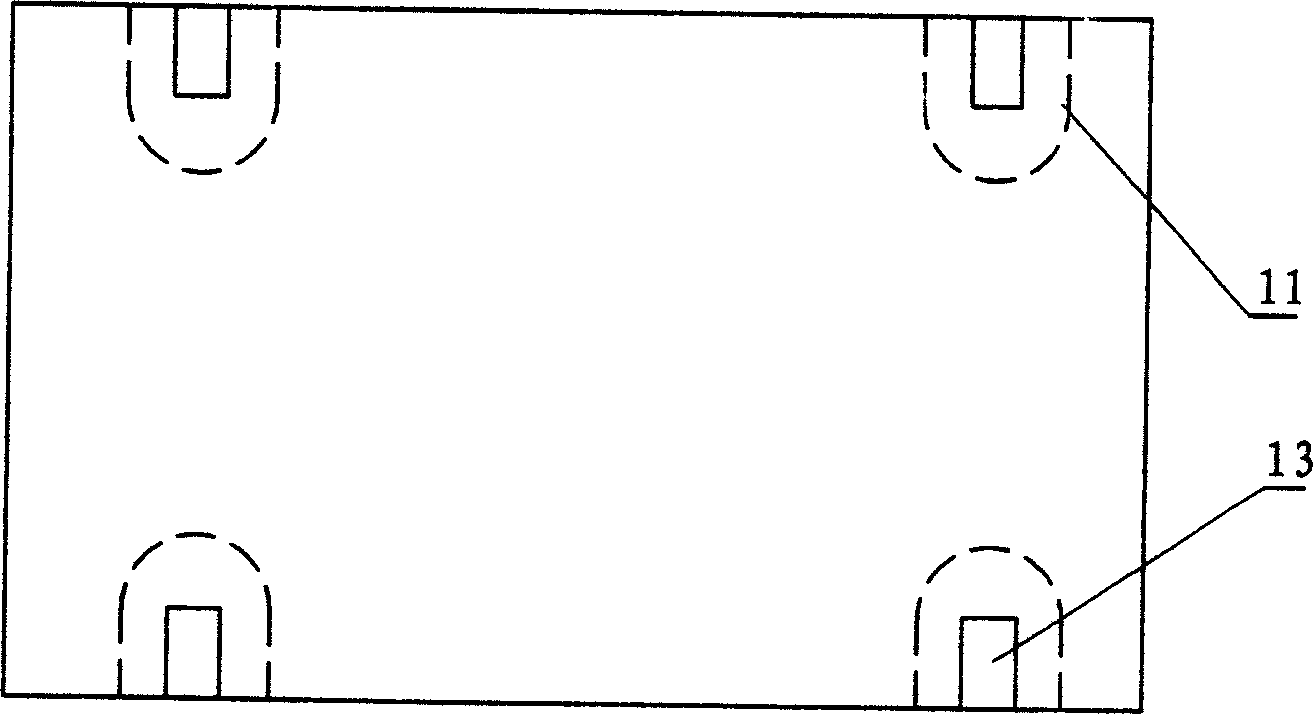

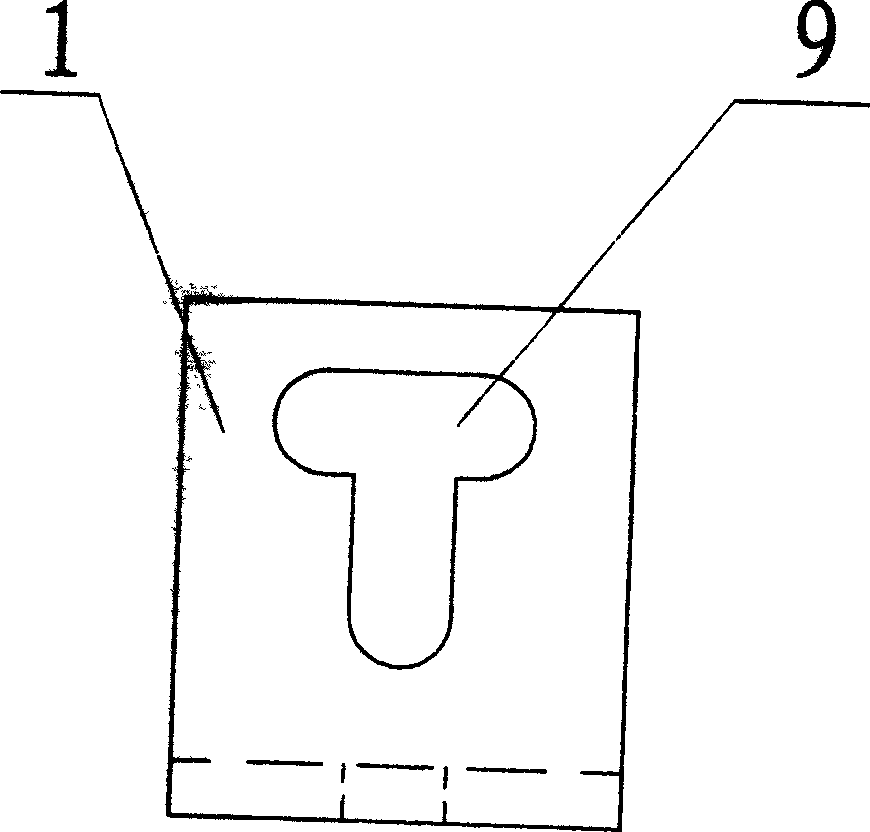

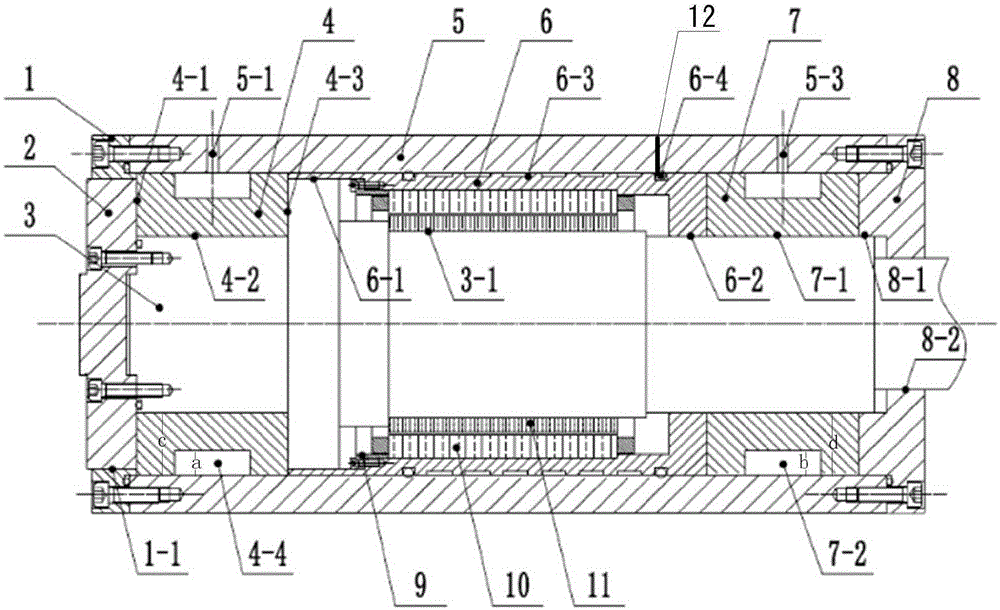

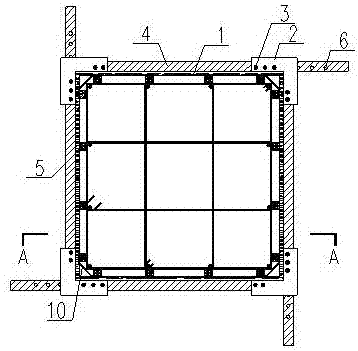

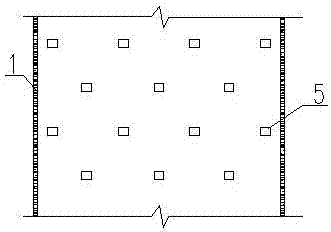

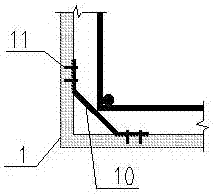

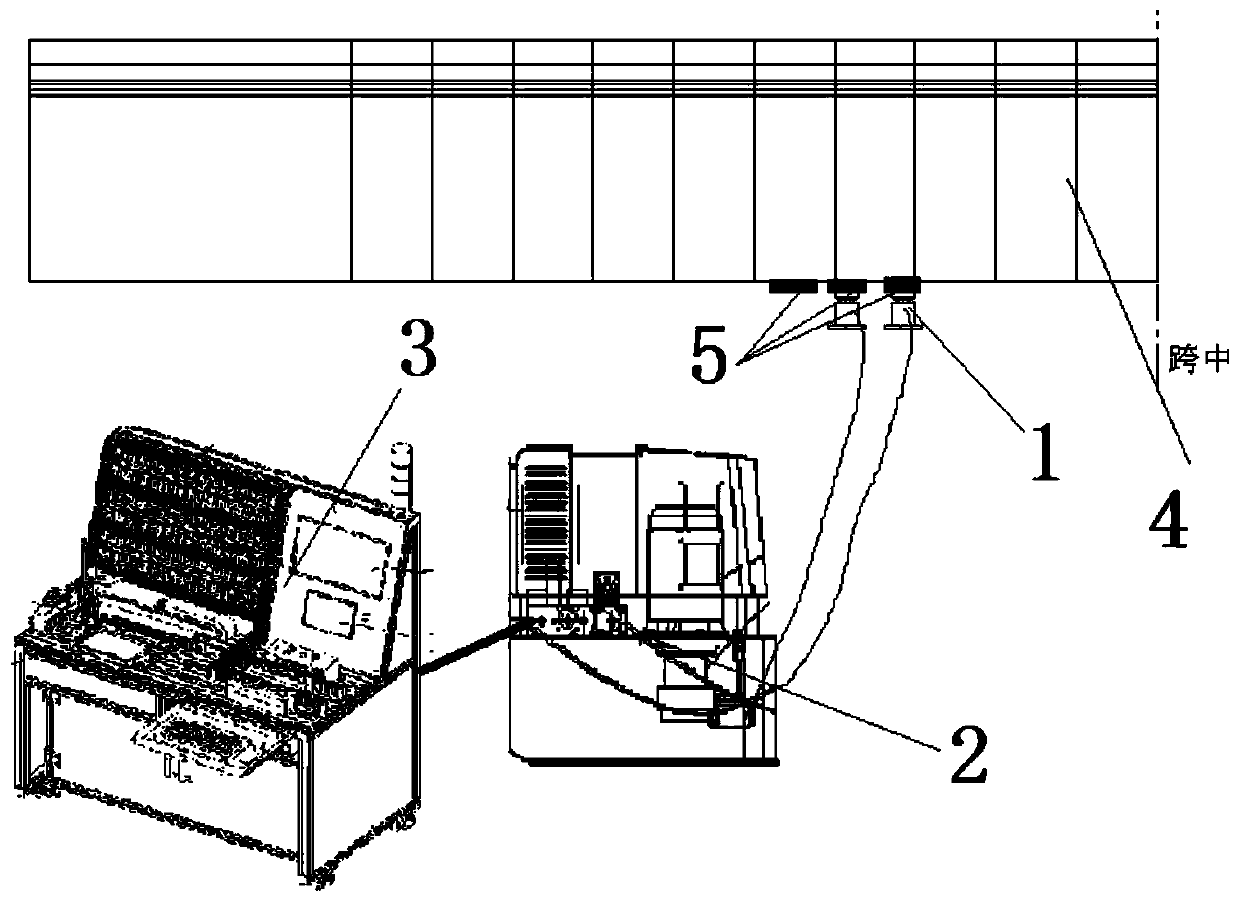

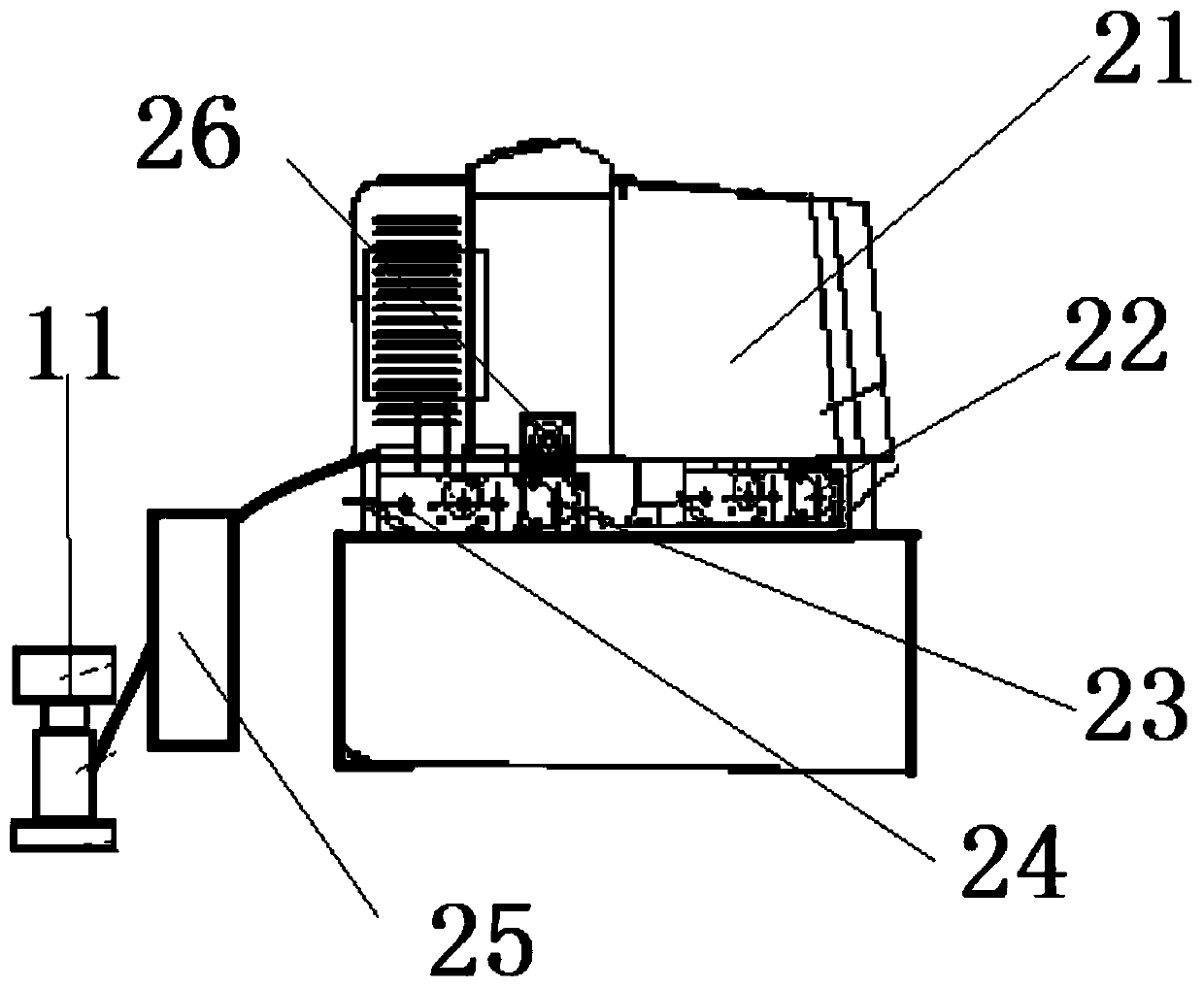

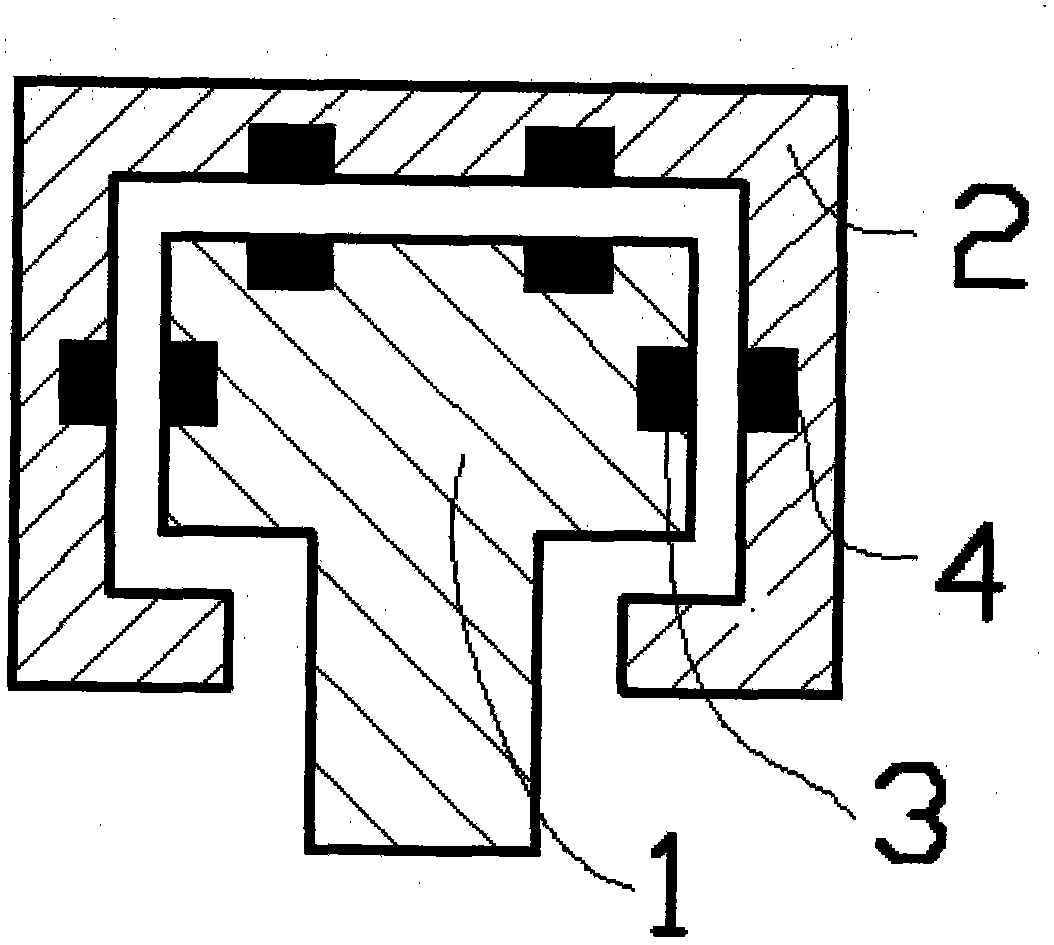

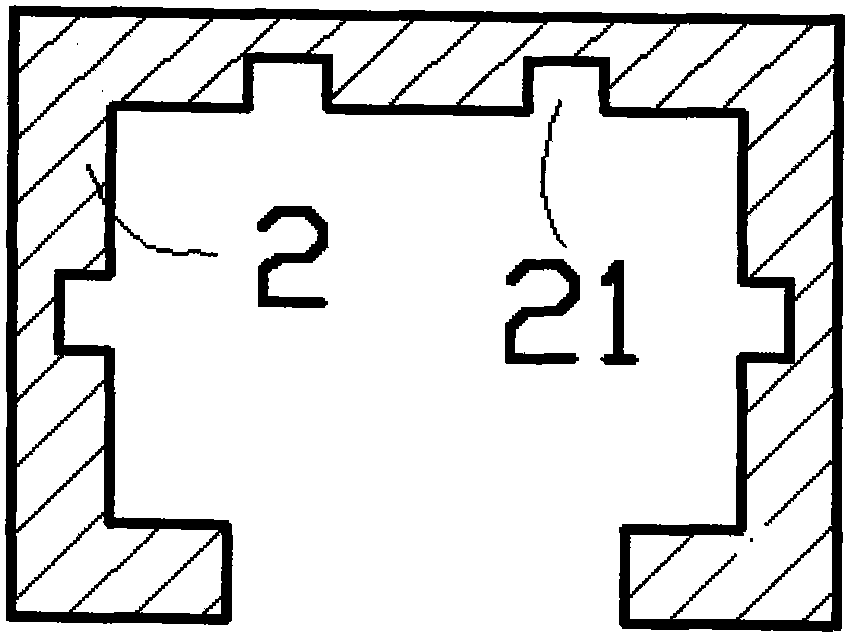

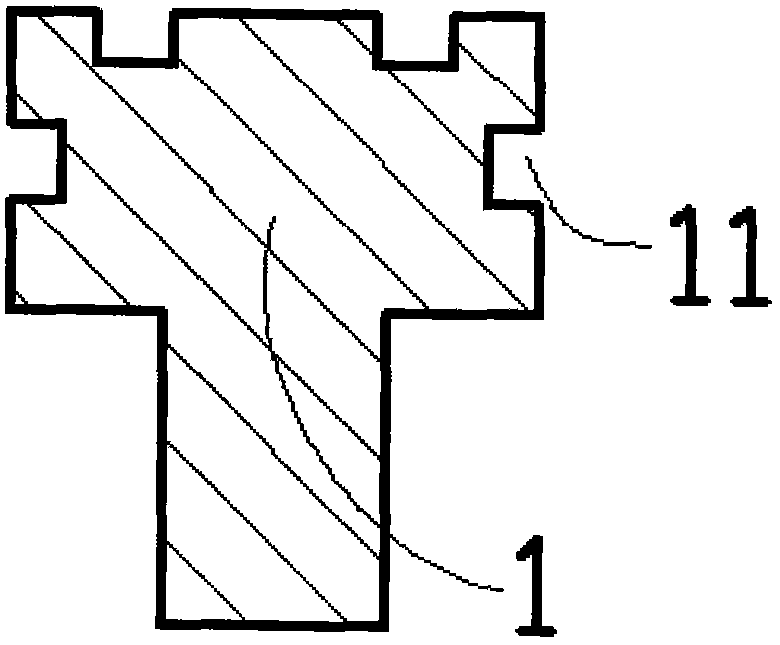

Synchronous jacking system for prefabricated box girder template

PendingCN110181650AAvoid high pressure leaksSolve high load startCeramic shaping plantsLifting devicesControl systemBox girder

The invention discloses a synchronous jacking system for a prefabricated box girder template. The synchronous jacking system comprises jacking system bodies (1), a power system (2), a control system (3), a prefabricated box girder template body (4) and a sensor (5), wherein the jacking system bodies (1) are vertically and uniformly arranged at the lower end of the prefabricated box girder templatebody (4); the power system (2) is connected with the jacking system bodies (1) and used for providing power for the jacking system bodies (1); the control system (3) is connected with the power system (2) and used for controlling the power system (2) to provide power for the jacking system bodies (1); the jacking system bodies (1) comprise at least one pair of jacks (11); and the jacks (11) located in the same longitudinal row are connected in parallel through the power system (2). According to the synchronous jacking system for the prefabricated box girder template, millimeter-level intelligent pre-camber adjustment of the prefabricated box girder template is achieved.

Owner:RAILWAY ENG RES INST CHINA ACADEMY OF RAILWAY SCI +2

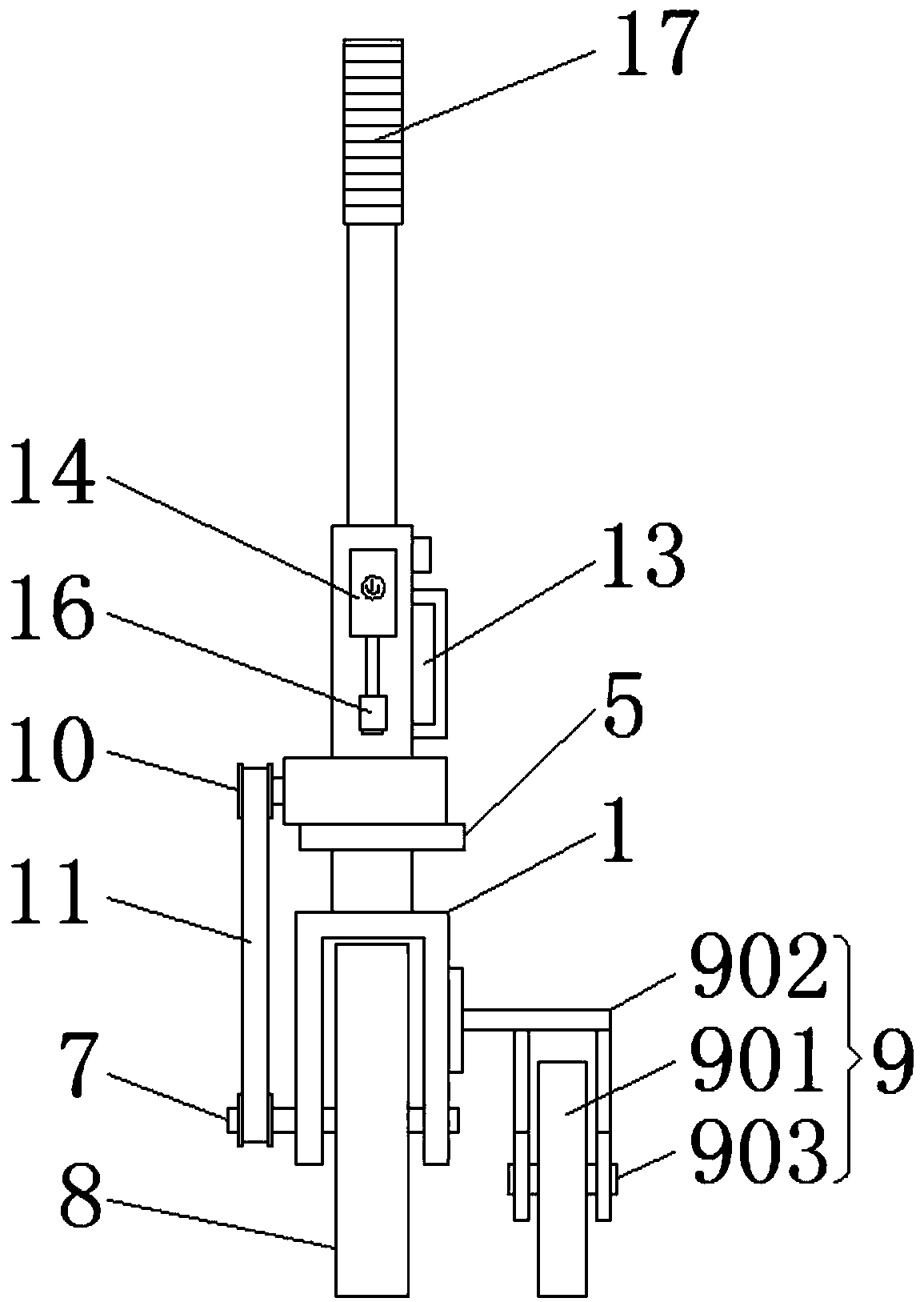

Simple heavy object carrier

The invention discloses a simple heavy object carrier belonging to the field of carrying tools. The simple heavy object carrier comprises a base, universal trundles arranged on four bottom legs of the base, a bracket fixed together with the base to form a whole body, a sliding bracket which is arranged at the top of the bracket and is capable of sliding forwards and backwards on the bracket, a manual winch fixed to the rear part of the sliding bracket, a pulley block mounted on the front part of the sliding bracket and a lifting hook, wherein the pulley block comprises a fixed pulley and a movable pulley; a steel wire rope is led out of the manual winch, sequentially bypasses the fixed pulley and the movable pulley and then is fixed on the sliding bracket or a fixed pulley bracket; the lifting hook is connected with the movable pulley; a fixed support plate is mounted on the rear part of the base; a movable support plate is mounted on the front part of the base; and the movable support plate is articulated with the fixed support plate. By utilizing a simple structure, the double functions of lifting and transporting the heavy objects are realized; the labor intensity of workers is alleviated; meanwhile, the simple heavy object carrier is simple in structure, convenient to operate and low in cost; the use requirements of small and medium-sized enterprises can be met.

Owner:常州东吉路国际贸易有限公司

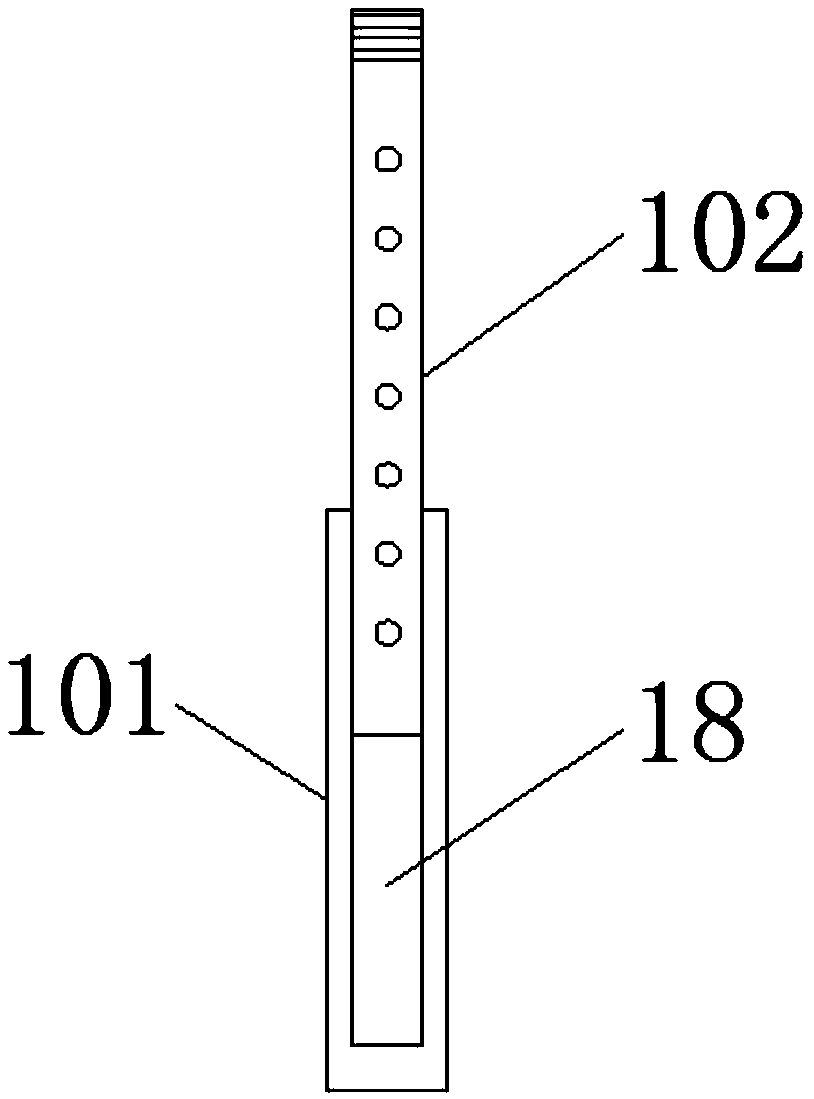

Idler wheel measurement device

InactiveCN108662965AAccurate countEasy to useMechanical measuring arrangementsMeasurement deviceLocking mechanism

The invention discloses an idler wheel measurement device. The idler wheel measurement device comprises a telescopic support, wherein the telescopic support comprises a sleeve rod, an insertion rod and a U-shaped installation rack; an empty groove is formed in the sleeve rod, one end of the insertion rod is inserted in the empty groove, and the sleeve rod and the insertion rod are tightly locked through a locking mechanism; a grip is threadedly connected with the other end of the insertion rod, the bottom of the insertion rod is fixedly welded to the U-shaped installation rack, an installationplate is fixedly mounted on the insertion rod through a hoop, and the hoop is hinged to the installation plate; a counter is fixedly mounted on the installation plate, an idler wheel is mounted on the U-shaped installation rack through a wheel shaft and a damper bearing, an auxiliary rolling mechanism is further arranged on the U-shaped installation rack, and two sets of synchronous wheels are fixedly mounted on the wheel shafts and the counter, and are in transmission connection through a synchronous belt. The idler wheel measurement device can better adapt to users with different heights, is accurate in counting, convenient to use and place, and moves stably.

Owner:XIAOGAN QISIMIAOXIANG CULTURAL MEDIA

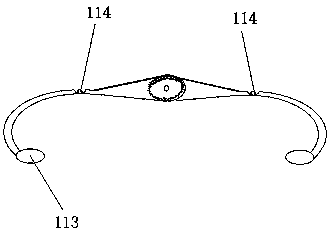

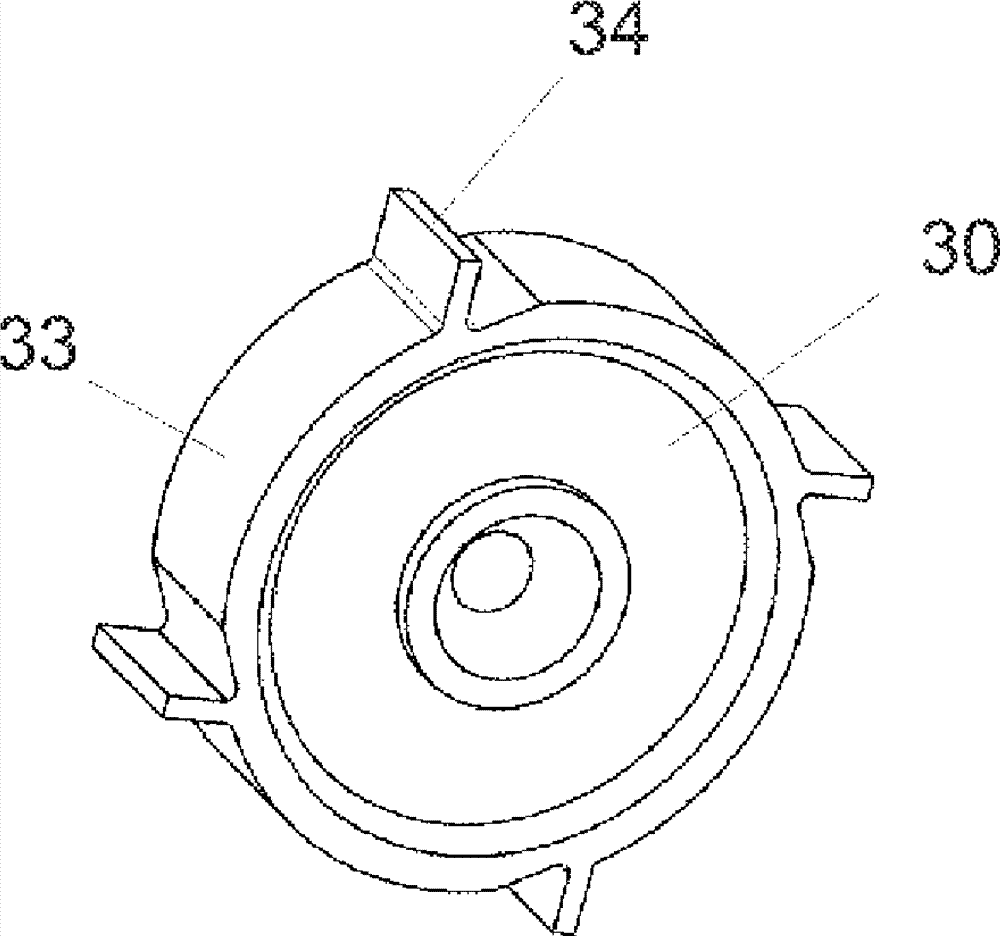

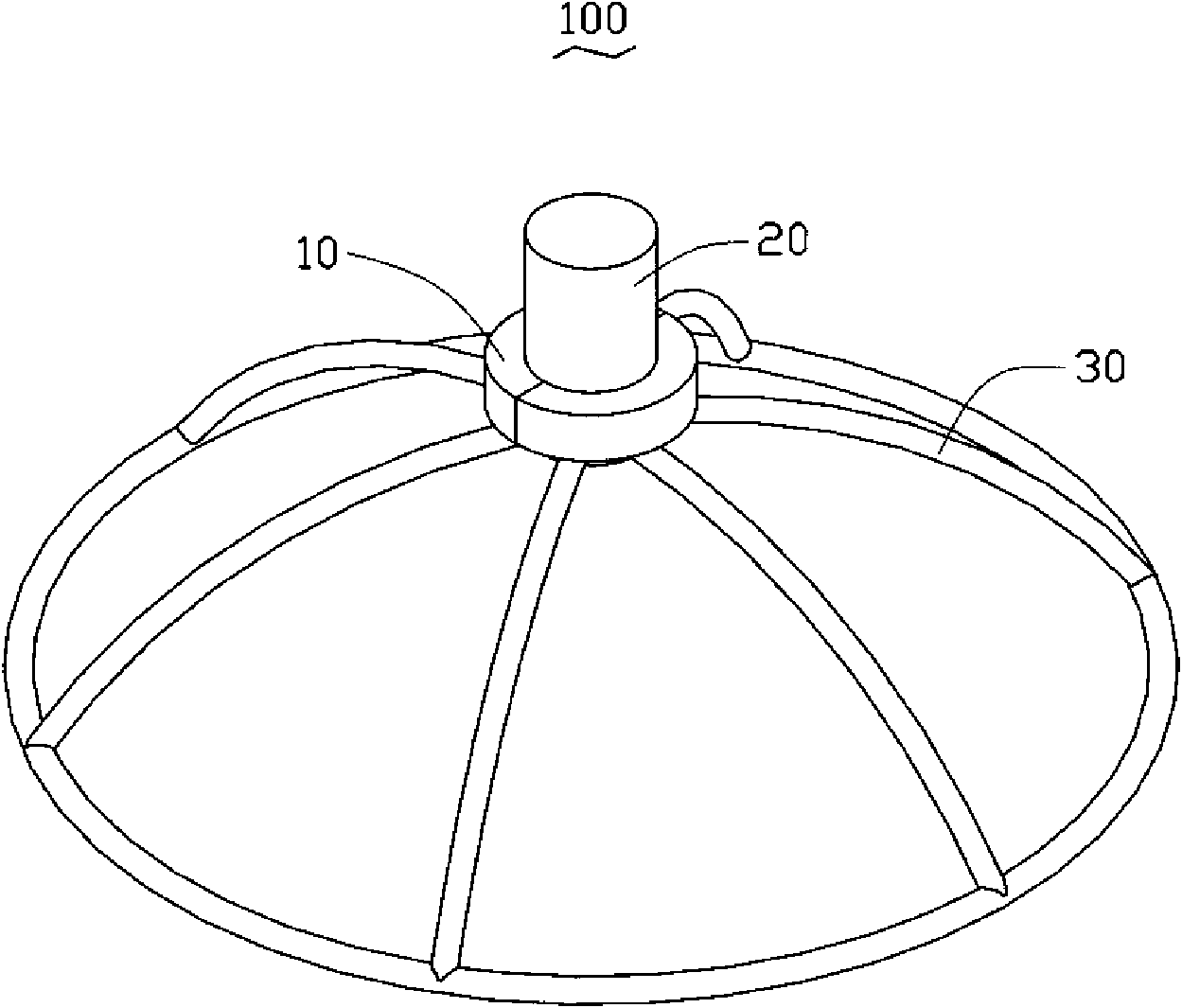

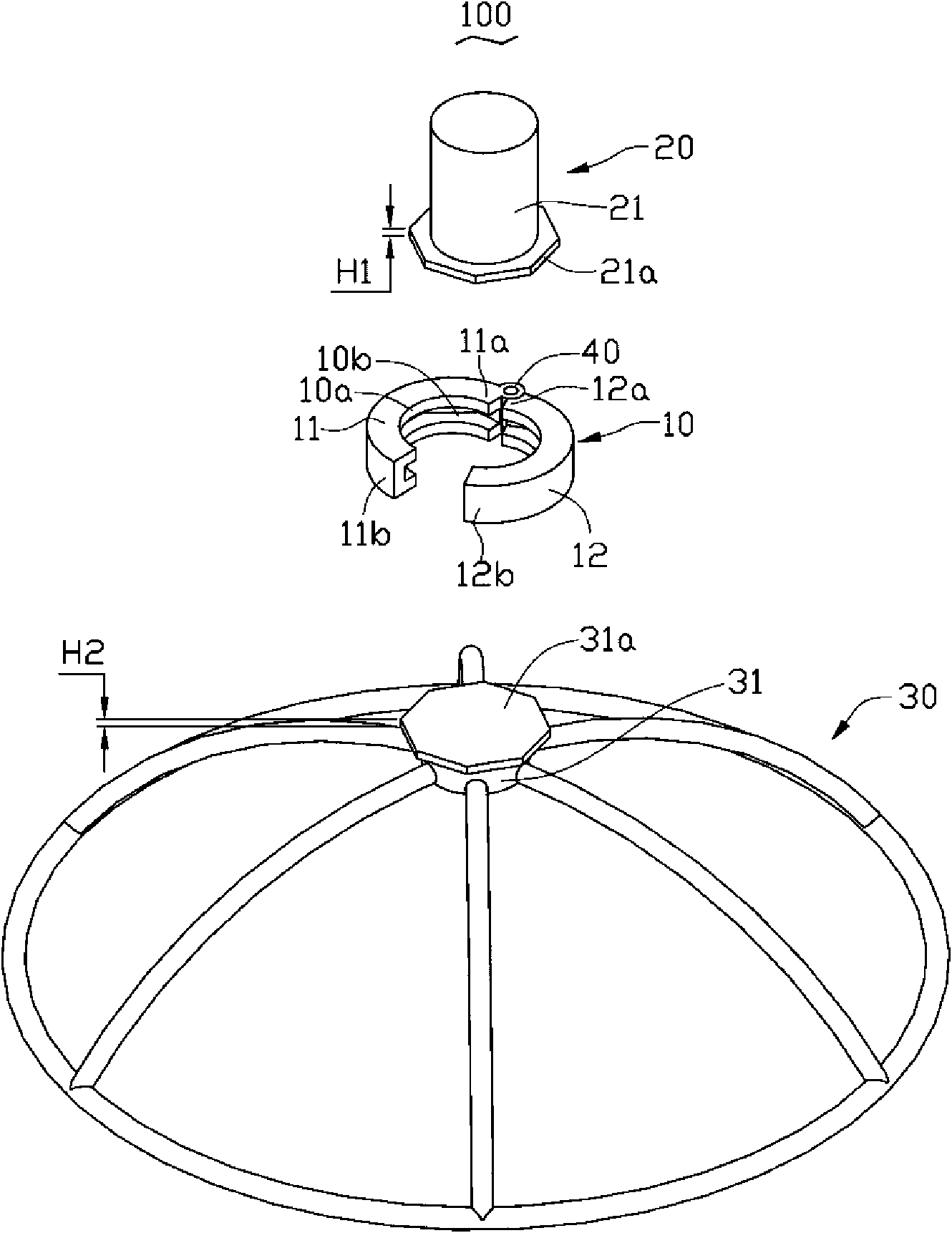

A piston rod foot

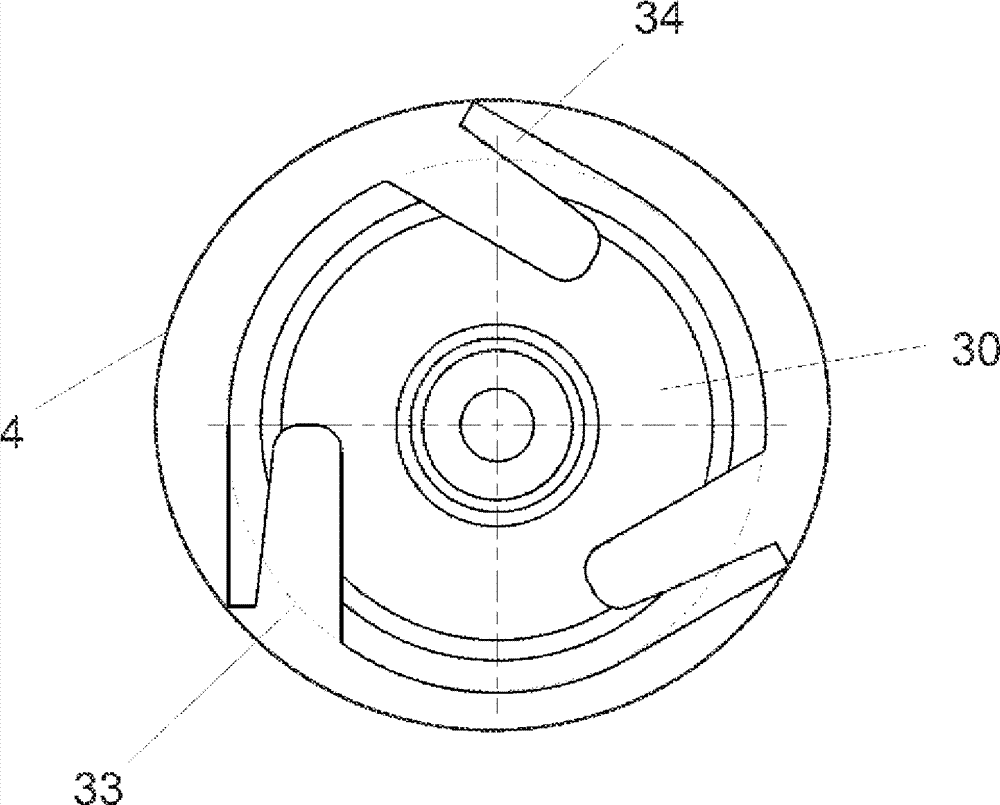

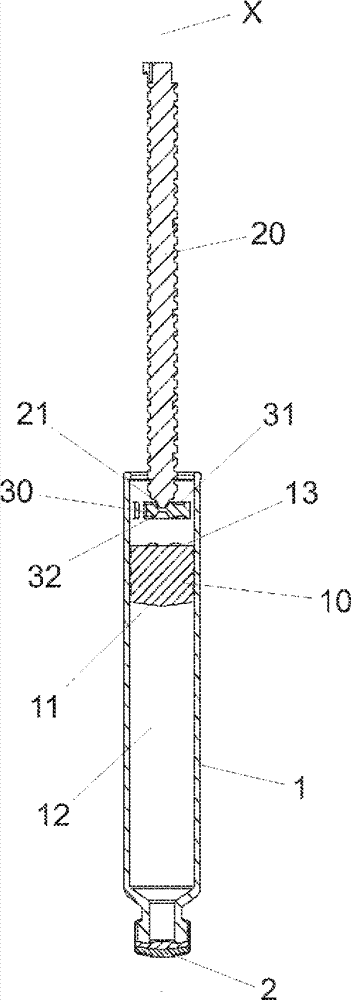

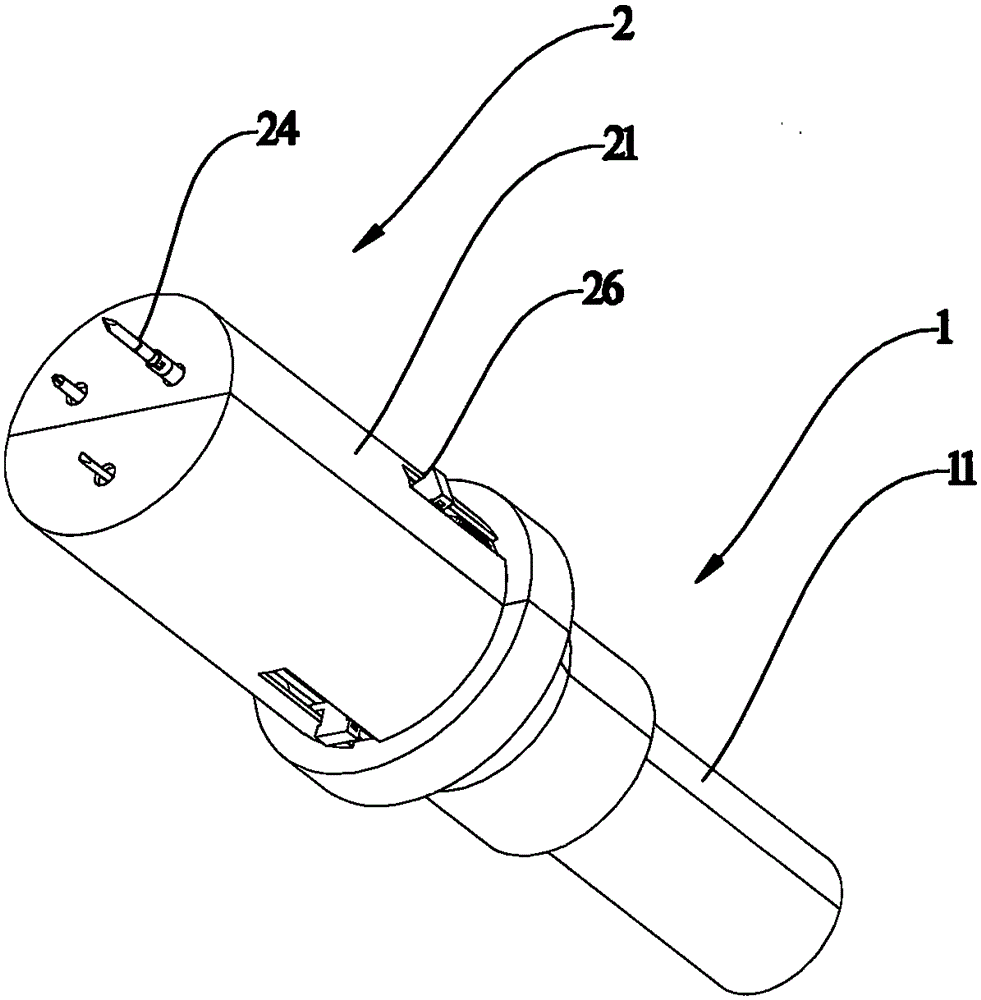

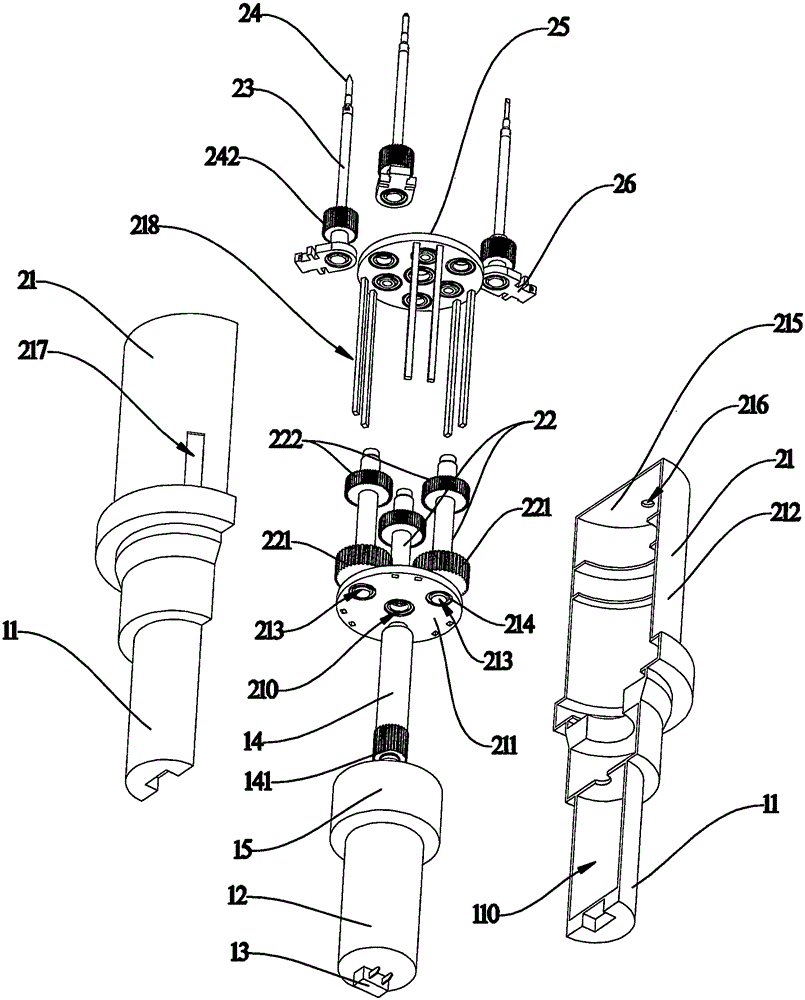

InactiveCN102971032AImprove security levelNot easy to tiltAmpoule syringesIntravenous devicesMechanical engineeringPiston rod

The invention relates to a medical drug delivery apparatus which comprises a cartridge (1) being closed at one end by a flexible membrane (2) and at the opposite end by a movable piston (10). The movable piston rod (19) is moved forward by a piston rod (20). In order to distribute the force from the piston rod (20) to the movable piston (10) a piston rod foot (30) is provided sandwiched between the piston rod (29) and the movable piston (10) The piston rod foot (30) provided between the piston rod (20) and the movable piston (10) has a plurality of arms (34) extending in a direction perpendicular to a longitudinal axis (X) of the cartridge (1) and which arms (34) engages the inner wall (4) of the cartridge (1) thereby obtaining geometric guidance or generating a force of friction between the piston rod foot (30) and the inner wall (4) of the cartridge (1).

Owner:NOVO NORDISK AS

Electric screwdriver with tool bits capable of being replaced rapidly

The invention provides an electric screwdriver with tool bits capable of being replaced rapidly. The electric screwdriver with the tool bits capable of being replaced rapidly comprises a screwdriver body and a tool bit part arranged at the front end of the screwdriver body. The tool bit part comprises a plurality of secondary output shafts which are matched with a primary output shaft of the screwdriver body through a transmission gear set so that the primary output shaft can drive the secondary output shafts to rotate. The tool bit part further comprises a plurality of tool bit connecting rods which can move between a work position and a non-work position. When the tool bit connecting rods move to the work position, the tool bit connecting rods are matched with the secondary output shafts, and meanwhile the tool bits at the front ends of the tool bit connecting rods extend out of a shell. At the time, the tool bits can be used for screwing screws. When the tool bit connecting rods move to the non-work position, the tool bit connecting rods are separated from the secondary output shafts, and meanwhile the tool bits draw back into the shell.

Owner:宁波中旺工具有限公司

Cultivating method for kiwifruit through rootstock grafting

The invention belongs to the technical field of plant grafting, and specifically discloses a cultivating method for kiwifruit through rootstock grafting. The method comprises the steps of rootstock treating, scion treating and grafting, wherein an automatic rootstock cutting device is adopted during rootstock treating, and comprises a rack and a walking mechanism, and the rack is connected with a mounting plate capable of moving up and down; a cutter is fixedly arranged on the mounting plate, and a pulley is rotatably connected with the mounting plate; a cable is wound round the pulley, and a weight block is fixedly connected with the other end of the cable; a tension sensor is arranged between the weight block and the cable, and a pressure sensor is arranged at the bottom of the weight block; a distance sensor is also arranged on the rack. According to the cultivating method for kiwifruit through rootstock grafting, rootstock can be automatically cut, the cutting efficiency of the rootstock is improved, and the height can be automatically adjusted without manual measurement of the height cutting value of each rootstock.

Owner:贵州省湄潭县蓬勃农业发展有限公司

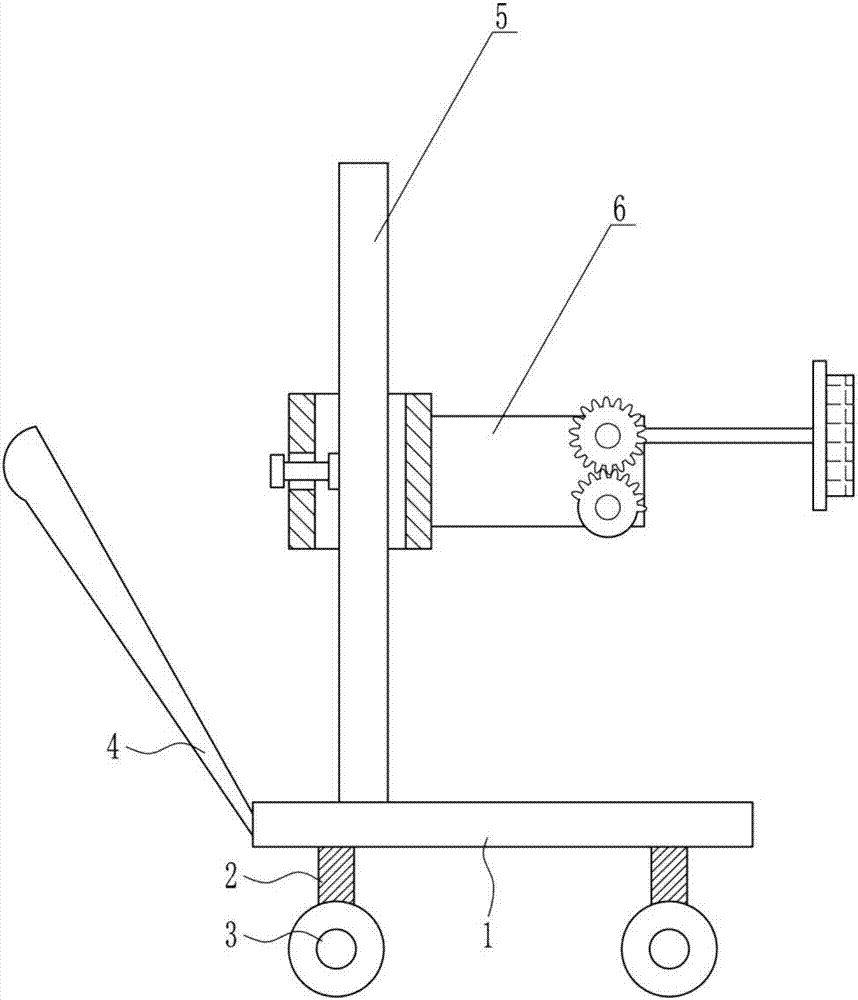

Medical equipment surface cleaning equipment for neurology department

ActiveCN107511342AWipe all overImprove work efficiencyCleaning using toolsCleaning using gasesMedical equipmentNeurology department

The invention relates to medical equipment surface cleaning equipment, in particular to medical equipment surface cleaning equipment for the neurology department. The medical equipment surface cleaning equipment for the neurology department is time-saving, labor-saving, low in labor intensity and high in working efficiency. The medical equipment surface cleaning equipment for the neurology department comprises a bottom plate and the like. The bottom of the bottom plate is provided with vertical rods in a left-right symmetrical mode. The tops of the vertical rods are connected with the bottom plate through a bolt connecting mode. The bottom ends of the vertical rods are provided with wheels. The left side surface of the bottom plate is obliquely connected with a pushing hand in the bolt connecting mode. The left side of the top of the bottom plate is provided with a lifting device. By means of the medical equipment surface cleaning equipment for the neurology department, medical equipment is cleaned, the operation is simple, and the effects of being time-saving, labor-saving, low in labor intensity and high in working efficiency are achieved.

Owner:威海高新园区运营管理有限公司

Optical film coating device

InactiveCN101608298AFirmly connectedNot easy to tiltVacuum evaporation coatingSputtering coatingBiochemical engineeringFlange

The invention relates to an optical film coating device which comprises a rotating shaft, a substrate supporting frame and a clamping ring, wherein one end of the rotating shaft is provided with a first flange; the substrate supporting frame is provided with a second flange; a groove is arranged around the inner ring surface of the clamping ring; the first flange and the second flange are contained in the groove; and the clamping ring comprises a first semi ring and a second semi ring which can be connected mutually. By clamping the two flanges of the rotating shaft and the substrate supporting frame into the groove of the clamping ring, the optical film coating device provided by the invention ensures that the substrate supporting frame is connected stably relative to the rotating shaft and does not incline easily.

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

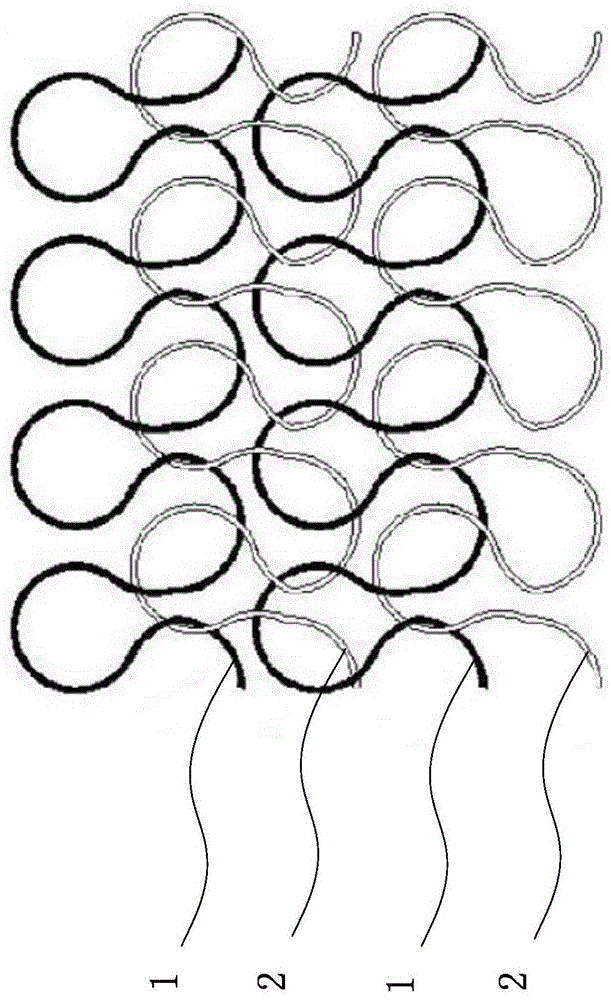

Blending high-grade knitting fabric

The invention provides a blending high-grade knitting fabric, and belongs to the technical field of knitting. The blending high-grade knitting fabric is characterized in that according to the percentage by weight in the high-grade knitting fabric, 32% of tencel fibers, 32% of cotton fibers and 10% of copper ammonia fibers are blended and spun, and 10% of rayon is added to be twisted into first yarns and second yarns, each first yarn adopts the S twisting direction, each second yarn adopts the Z twisting direction, and the first yarns and the second yarns are interweaved into the fabric. The blending high-grade knitting fabric has the advantages that the elasticity is good, the strength is high, the hand feel is soft, the luster and brightness are realized, and the trend of environment-friendly clothes is met; the good moisture-absorbing, moisture-discharging, anti-electrostatic, hanging and hydrophily functions are realized.

Owner:ZHEJIANG YANA TEXTILE

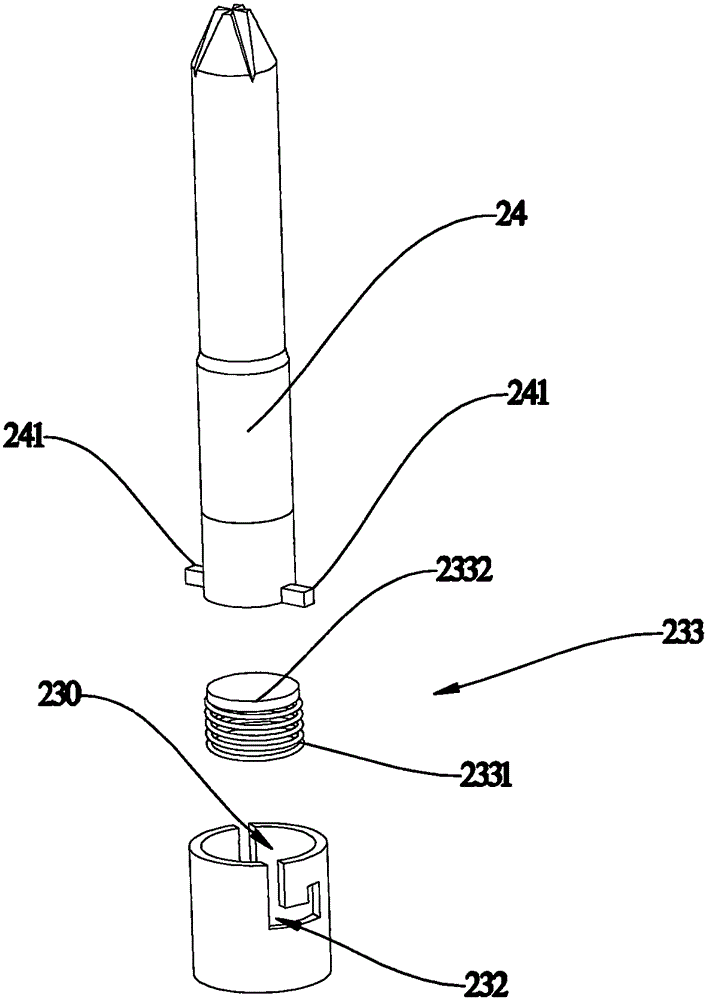

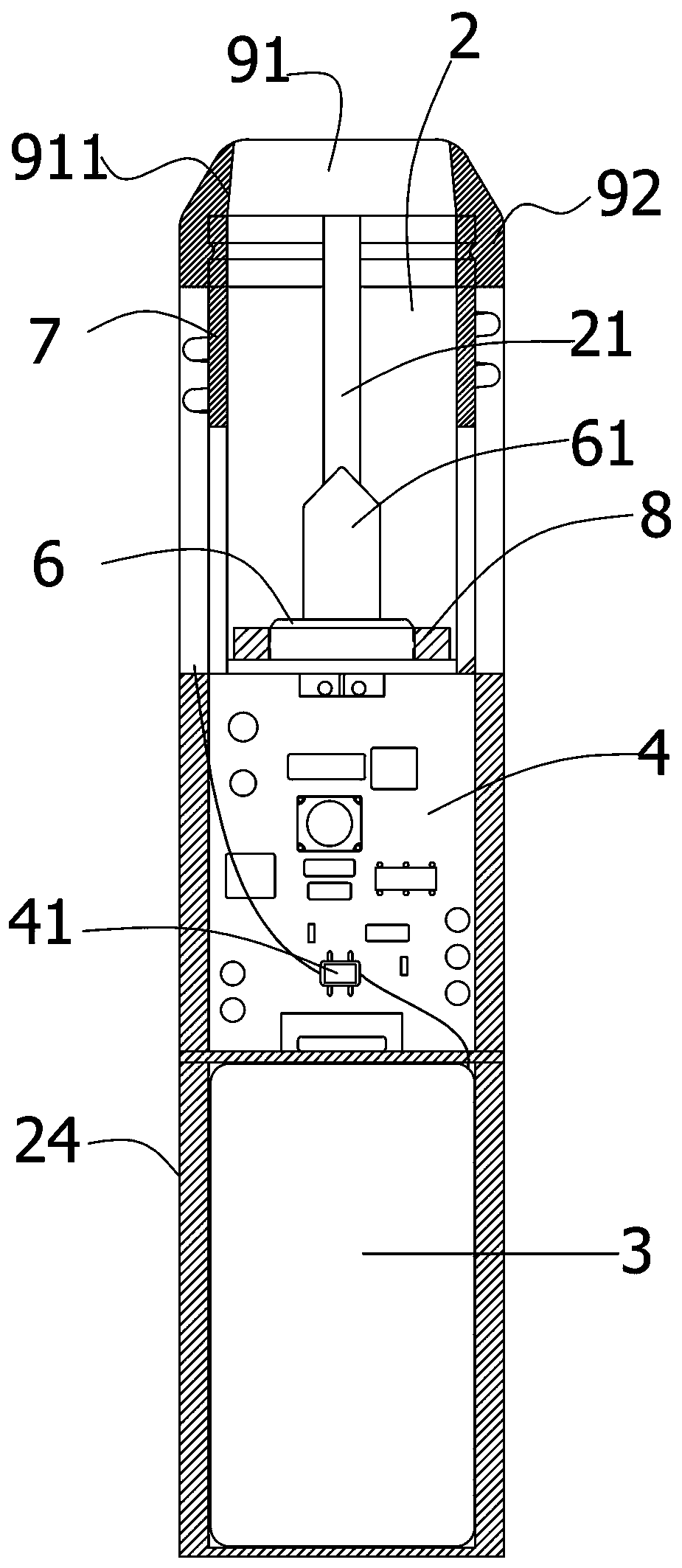

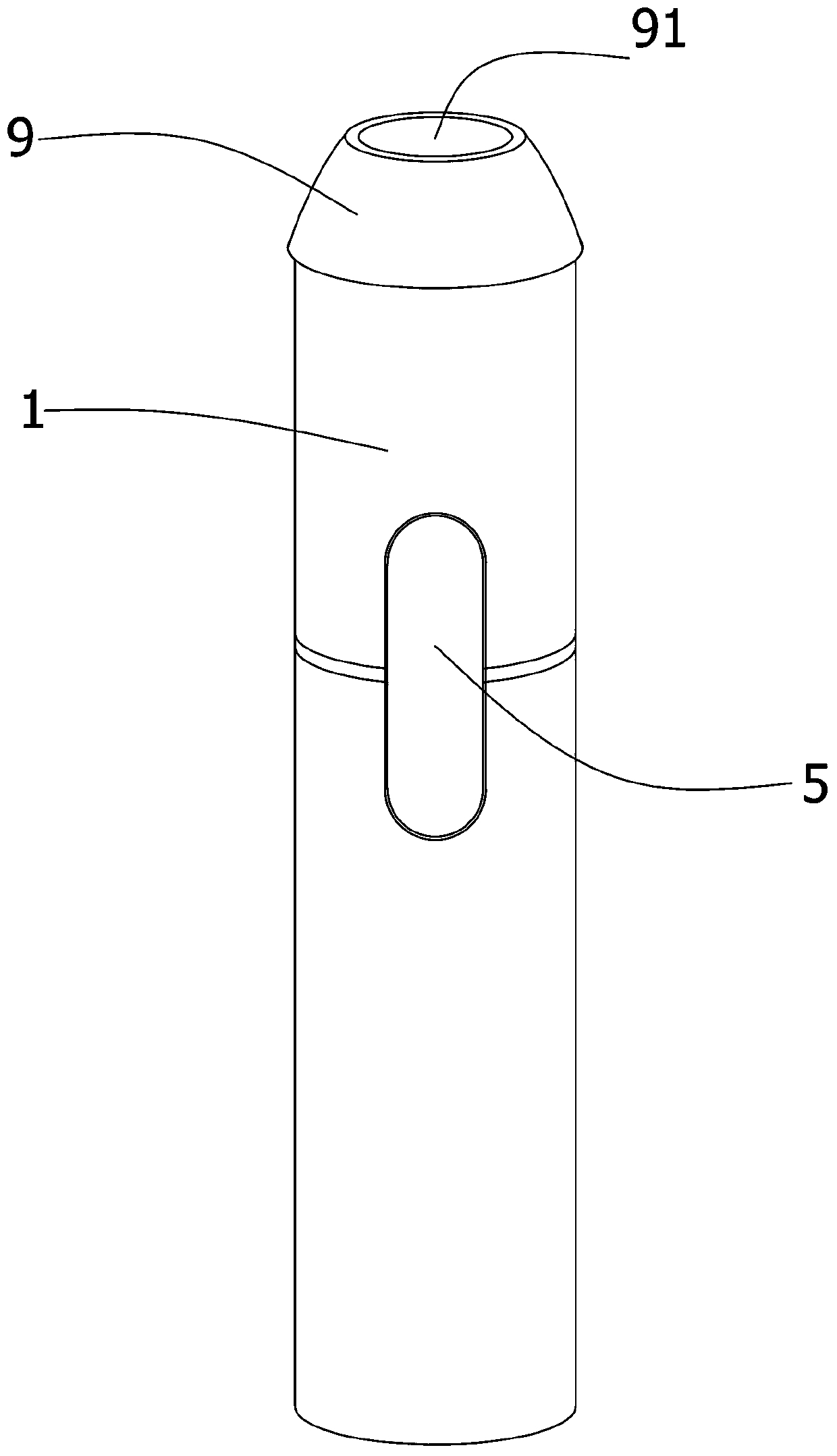

Heating non-combustion electronic cigarette appliance with smoke cartridge capable of automatically popping up

The invention discloses a heat-not-burn electronic cigarette appliance with smoke cartridges capable of automatically popping up. The heat-not-burn electronic cigarette appliance comprises a body, a heating chamber which is arranged in the body and is used for accommodating and heating the smoke cartridge, a battery used for providing heating electric energy for the heating chamber, and an integrated circuit board which is used for integrally controlling a heating circuit. A heating base is fixedly arranged on a bottom side in the heating chamber, a heating part is detachably arranged on the heating base and is used for allowing the smoke cartridge to be inserted and fixed and heating the smoke cartridge, and an attraction part which generates a magnetic field and generates magnetic forcewhen being powered on is arranged at the top of the heating chamber, the heat-not-burn electronic cigarette appliance also comprises a pop-up piece which is arranged on the heating base in a sliding and sleeving mode and used for rapidly moving upwards under the magnetic force of the attraction part and driving the smoke cartridge to pop up, a cover cap which is arranged at an outer end of the heating chamber in a sleeving mode and used for limiting the pop-up piece, and a boosting module which is used for increasing the voltage of the battery to enhance the magnetic force of the attraction piece to the pop-up piece. The smoke cartridge does not need to be manually pulled and inserted or moved out through the control of a supporting cap, and the problems of abrasion, abnormal sound and thelike of smoking set accessories are effectively avoided.

Owner:HUBEI CHINA TOBACCO IND +1

Linear magnetic suspension bearing

The invention provides a linear magnetic suspension bearing comprising a T-shaped rail, a suspension block, inner magnetic strips, and outer magnetic strips. The T-shaped rail is in a strip shape with a T-shaped cross-section. Two or more inner strip-shaped rails are arranged on the upper surface of the T-shaped tail. A inner strip-shaped rail is arranged on each of the two sides of the T-shape. The inner magnetic strips are arranged in the inner strip-shaped rails. The cross section of the suspension block is an inverted recess. The outer magnetic strips are arranged in the recesses at positiones corresponding to the T-shaped rail. Opposite planes of the outer magnetic strips and the inner magnetic strips are same magnetic poles. The suspension block covers and suspends on the upper part of the T-shaped rail. Paired inner magnetic strips and outer magnetic strips are arranged on sides of the T-shaped rail and the suspension block, such that repulsive force is provided on the sides, and the suspension block suspending on the T-shaped rail is prevented from inclining. With the magnetic suspension of the suspension block, the resistance during running is extremely small, and friction is prevented, such that damage is prevented, and lubrication is not needed. Therefore, application cost is reduced, and pollution is reduced.

Owner:WUHU BAOYI AMUSEMENT EQUIP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

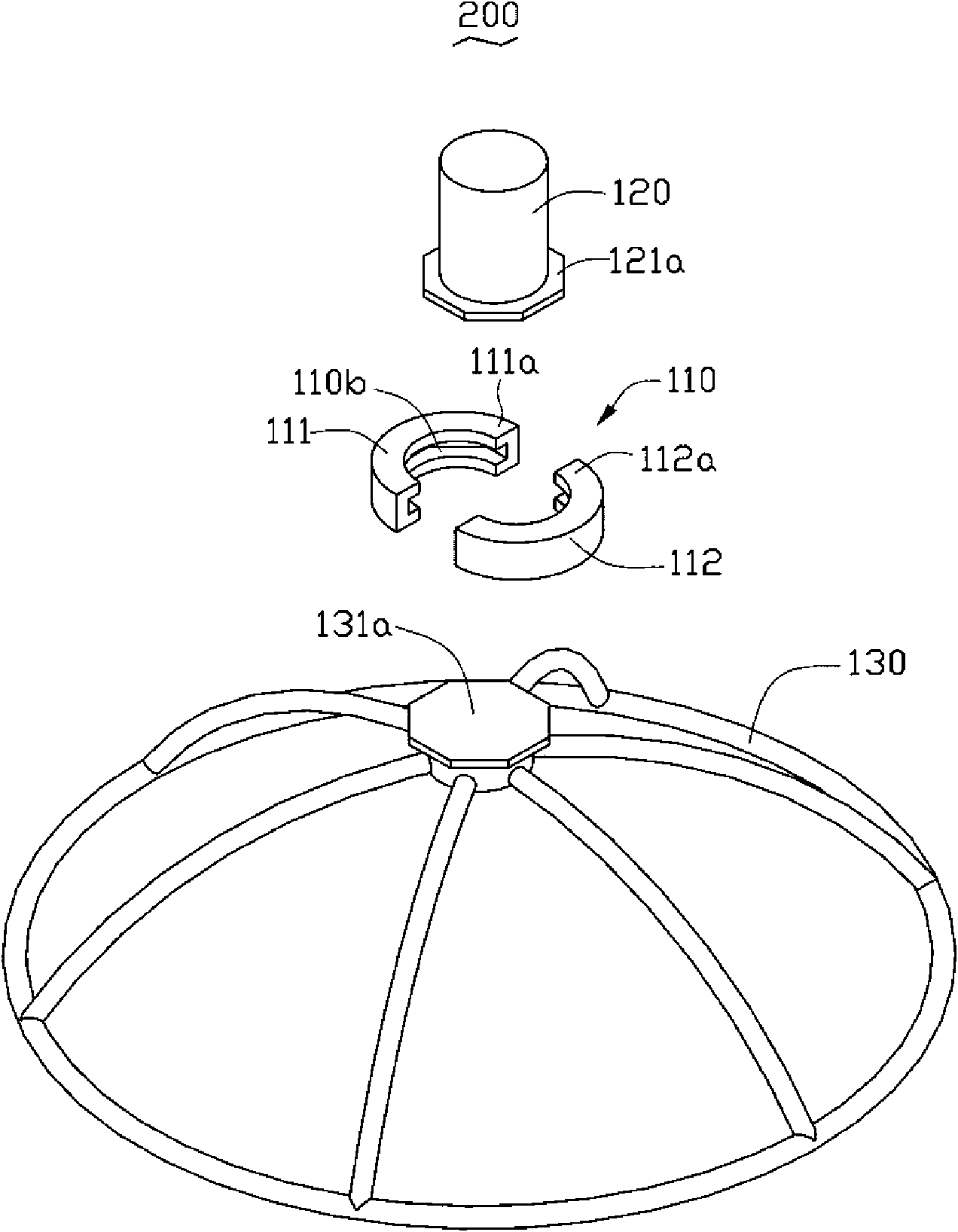

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com