Blending high-grade knitting fabric

A knitted fabric, high-grade technology, applied in the field of textile fabrics, can solve the problems of high strength and elasticity without cotton fiber, easy to break, non-mechanical friction, etc., and achieve the effects of excellent moisture absorption, soft hand feeling and good hydrophilicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

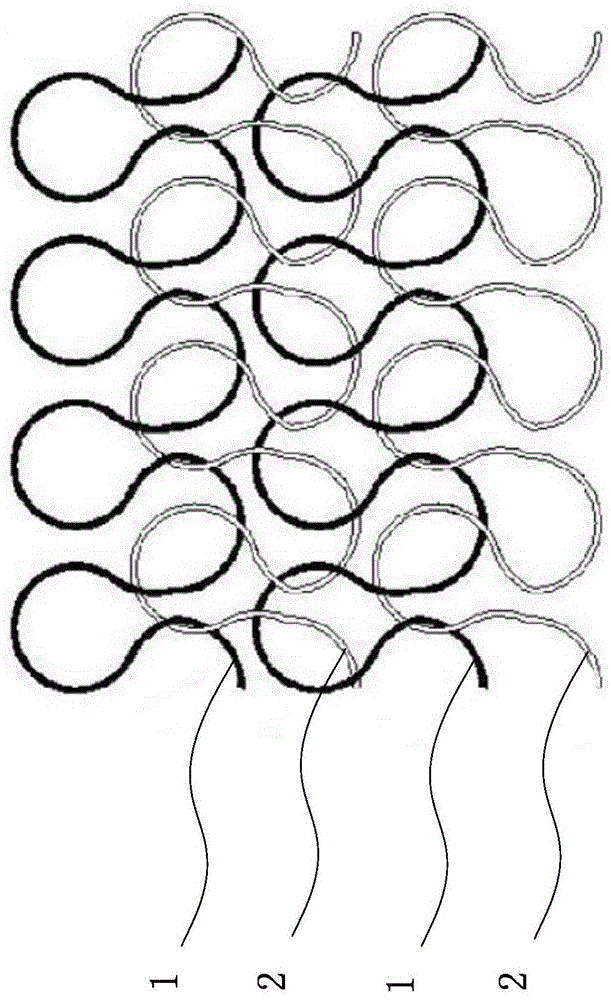

[0026] Such as figure 1 As shown, the blended high-grade knitted fabric is made of tencel fiber, cotton fiber and cupro ammonia fiber, and then twisted with rayon to form the first yarn 1 and the second yarn 2. The first yarn 1 is the S twist direction, the second yarn 2 is the Z twist direction, and the first yarn 1 and the second yarn 2 are interwoven into fabrics at intervals, in which rayon, tencel fiber, cotton fiber, and cupro fiber account for high-grade knitting fabrics. The percentages of the total fabric weight are 36%; 32%; 32%; 10%.

[0027] The first coils formed by interweaving the first yarns are inclined towards the first direction, the second coils formed by the second yarns are inclined towards the second direction, and the first direction is opposite to the second direction.

[0028] Tencel fiber adopts Lenzing A100 Tencel.

[0029] The cotton fiber is made of high-quality long-staple cotton, the length of which is more than 35mm, the linear density is 1.5...

Embodiment 2

[0033] Blended high-grade knitted fabric, the high-grade knitted fabric is made of tencel fiber, cotton fiber, cupro ammonia fiber mixed yarn, and then twisted with rayon to make the first yarn 1 and the second yarn 2, the first yarn Thread 1 is in the S twist direction, and the second yarn 2 is in the Z twist direction. The first yarn 1 and the second yarn 2 are interwoven at intervals to form a fabric, in which rayon, tencel fiber, cotton fiber, and cupro fiber occupy high grades. The percentages of the total weight of the knitted fabric are 36%; 32%; 32%; 10%.

[0034] Tencel fiber adopts Lenzing A100 Tencel.

[0035] The cotton fiber is made of high-quality long-staple cotton, the length of which is more than 35mm, the linear density is 1.18dtex, and the strength is more than 4.9cN.

[0036] The linear density of cupro ammonia fiber is 1.33dtex.

[0037] The fabric is made by interweaving the yarns composed of the above-mentioned tencel fibers, cotton fibers, cupro ammon...

Embodiment 3

[0039]Blended high-grade knitted fabric, the high-grade knitted fabric is made of tencel fiber, cotton fiber, cupro ammonia fiber mixed yarn, and then twisted with rayon to make the first yarn 1 and the second yarn 2, the first yarn Thread 1 is in the S twist direction, and the second yarn 2 is in the Z twist direction. The first yarn 1 and the second yarn 2 are interwoven at intervals to form a fabric, in which rayon, tencel fiber, cotton fiber, and cupro fiber occupy high grades. The percentages of the total weight of the knitted fabric are 36%; 32%; 32%; 10%.

[0040] Tencel fiber adopts Lenzing A100 Tencel.

[0041] The cotton fiber is made of high-quality long-staple cotton, the length of which is more than 35mm, the linear density is 1.36dtex, and the strength is more than 4.9cN.

[0042] The linear density of cupro ammonia fiber is 0.89dtex.

[0043] The fabric is made by interweaving the yarns composed of the above-mentioned tencel fiber, cotton fiber, cupro ammonia ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com