Superhydrophobicity coating based on waterborne emulsion and preparing method and application thereof

A super-hydrophobic coating, water-based emulsion technology, applied in antifouling/underwater coatings, anti-corrosion coatings, polyurea/polyurethane coatings, etc., can solve problems such as unfavorable production applications, achieve large-scale industrial production, simple steps, Easy-to-control effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

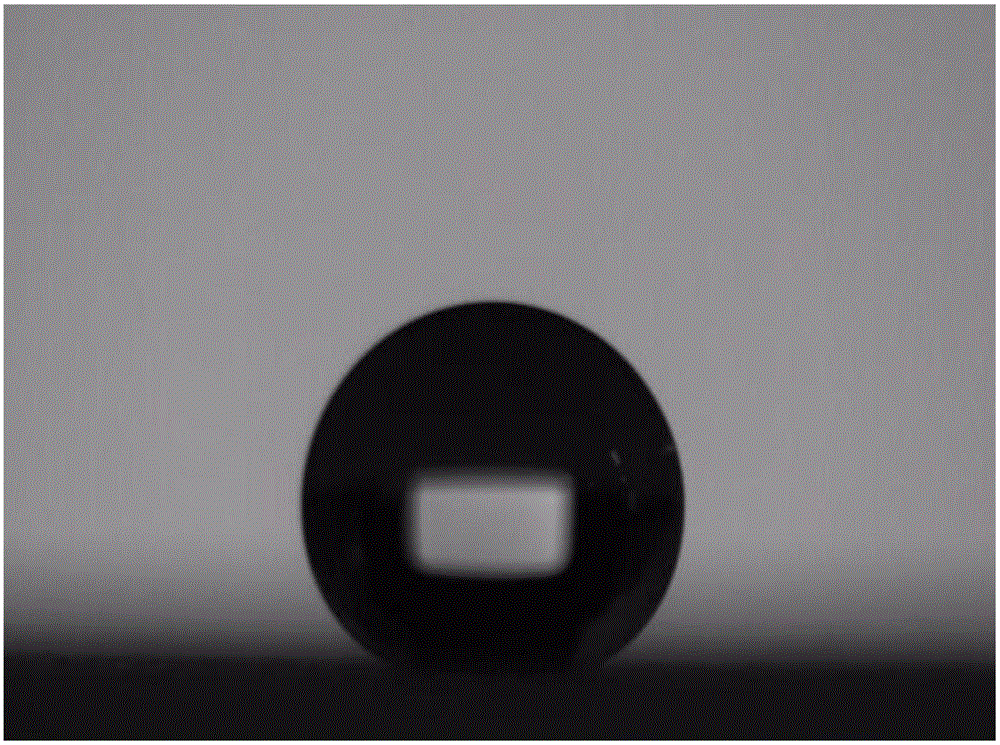

[0024] The aqueous silicon acrylic emulsion with a solid content of 38% was diluted with ethanol to a solid content of 10%. Add 3 g of a mixture of nano-silica particles with diameters of 14 nm and 50 nm (mass ratio: 3:1) into 5 mL of ethanol, and sonicate for 15 min to obtain a uniform dispersion. Add 20 mL of ethanol-diluted silicon-acrylic emulsion and 0.3 g of tridetrifluoroalkyltriethoxysilane under stirring condition, and continue stirring for 2 hours to obtain the super-hydrophobic coating. The superhydrophobic coating was prepared by spraying, and the obtained superhydrophobic coating was sprayed onto a glass sheet, and dried at 50° C. for 24 hours to obtain a superhydrophobic coating. The water contact angle of the coating is 155 degrees, and the rolling angle is 7.5 degrees.

[0025] figure 1 Static water contact angle measurements of the prepared superhydrophobic coatings.

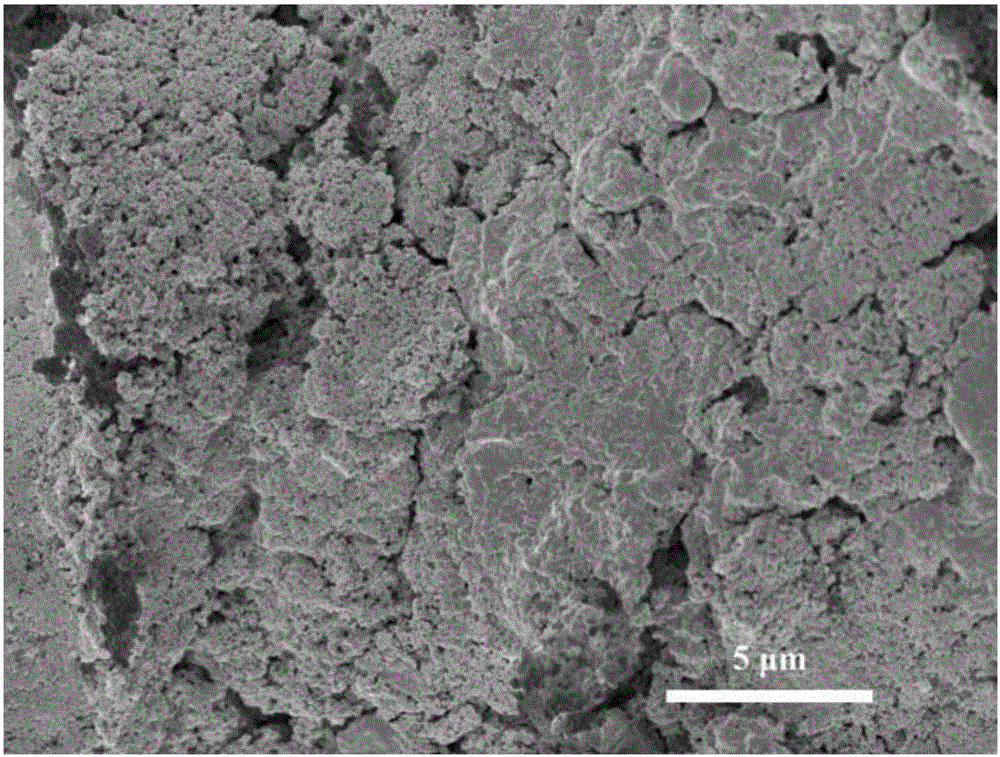

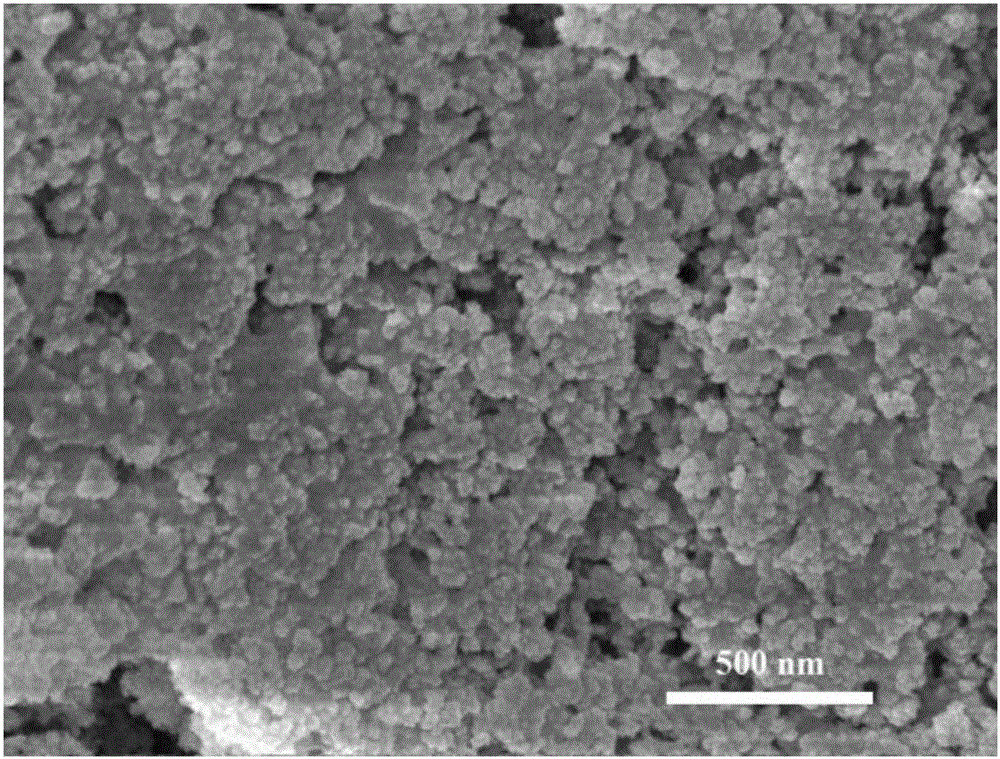

[0026] figure 2 The 5 micron-SEM image of the surface of the prepared superhydrophobic ...

Embodiment 2

[0030] Dilute the water-based styrene-acrylic emulsion with a solid content of 40% to a solid content of 10% with ethanol. Add 3 g of nano-silica particles (particle diameter: 14 nm) into 30 mL of ethanol, and ultrasonicate for 15 min to obtain a uniform dispersion. 20 mL of ethanol-diluted styrene-acrylic emulsion and 0.6 g of trifluoroalkyltrimethoxysilane were added under stirring conditions, and the superhydrophobic coating was obtained after stirring for 2 hours. The superhydrophobic coating was prepared by spraying, and the obtained superhydrophobic coating was sprayed onto a glass sheet, and dried at 50° C. for 24 hours to obtain a superhydrophobic coating. The water contact angle of the coating is 154 degrees, and the rolling angle is 6 degrees.

[0031] The static water contact angle measurement figure, SEM figure and surface atomic force microscope figure of the superhydrophobic coating prepared in this embodiment are similar to those in Example 1.

Embodiment 3

[0033] The aqueous acrylate emulsion with a solid content of 44% was diluted with ethanol to a solid content of 10%. Add 3 g of nano-silica particles (50 nm in particle size) into 10 mL of ethanol, and sonicate for 15 min to obtain a uniform dispersion. Add 20 mL of ethanol-diluted acrylate emulsion and 0.3 g of heptadecafluoroalkyltrimethoxysilane under stirring condition, and continue stirring for 2 hours to obtain the super-hydrophobic coating. The superhydrophobic coating was prepared by spin coating, and the obtained superhydrophobic coating was sprayed onto a glass sheet, and dried at 50° C. for 24 hours to obtain a superhydrophobic coating. The water contact angle of the coating is 152 degrees, and the rolling angle is 9 degrees.

[0034] The static water contact angle measurement figure, SEM figure and surface atomic force microscope figure of the superhydrophobic coating prepared in this embodiment are similar to those in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| contact angle | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com