Patents

Literature

1258results about How to "Antistatic" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Preparation method of graphene-polyester nano-composite fiber

ActiveCN105200547AHigh breaking strengthEasy to prepareElectroconductive/antistatic filament manufactureFilament/thread formingNanometreSurface modification

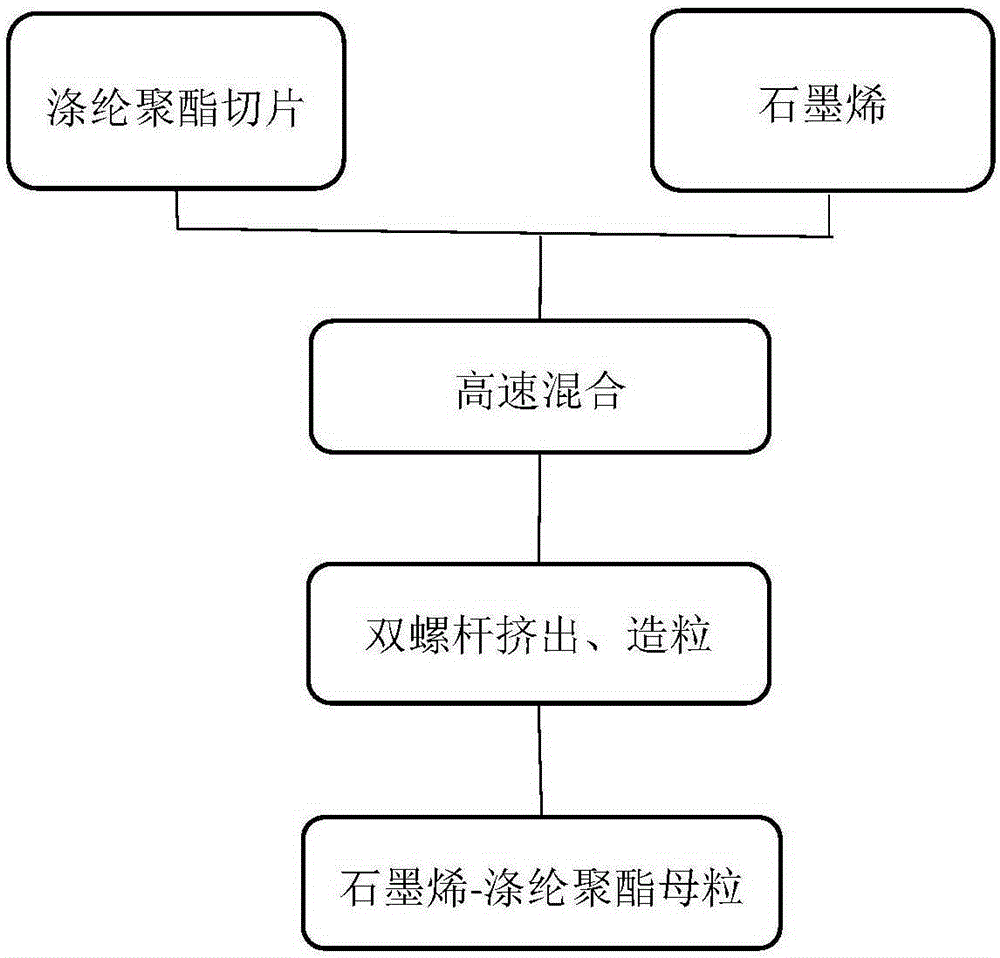

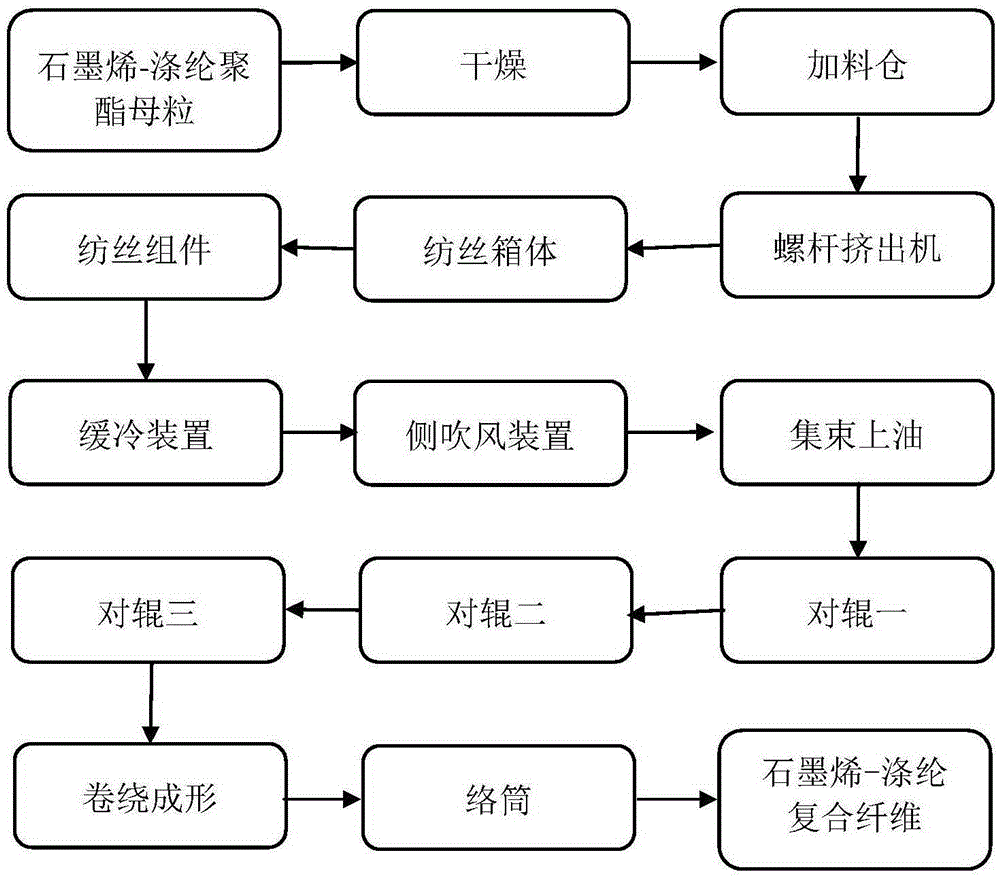

The invention discloses a preparation method of graphene-polyester nano-composite fiber. The preparation method comprises the step of preparing graphene-terylene polyester composite master batch and the step of preparing the graphene-polyester nano-composite fiber from the composite master batch. Compared with other conventional methods, the preparation method has the advantages that the technology is extremely simple, the reinforcing material is excellent in performance and low in cost; besides, excellent mechanical property and functional characteristics of graphene self endow the nano-composite fiber with functionalities like high strength and antistatic property, surface-modified and modified graphene has good dispersity and perfect interfacial compatibility in terylene polyester polymer matrix, which enables graphene to be effectively and uniformly compounded with a terylene polyester chip base material.

Owner:NANTONG QIANGSHENG GRAPHENE TECH CO LTD

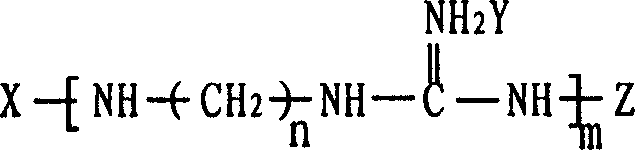

Polyamine guanidine salt copolymer and its uses in antibiotic polyester and polyamide materials

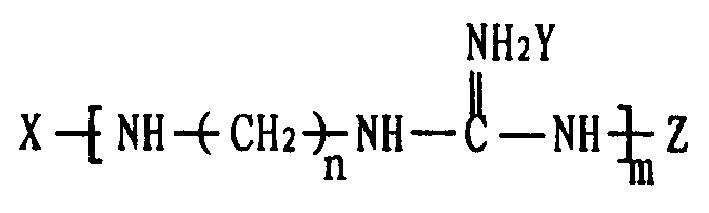

The invention discloses a polyamine guanidine salt polymer, its making method and uses wherein the polyamine guanidine salt polymer is the functionalized mother particles obtained through reaction between polyesters and polyundecaneamide, after mixing this mother particles with the common polyesters and polyundecaneamide by a finite proportion, various multifilament and plastic products can be obtained.

Owner:SHANGHAI FUYUAN PLASTICS SCI CO LTD

Nano wave-absorption fibre and method for making same

InactiveCN101135071AImprove absorbing performanceInfluence of absorbing performanceMonocomponent protein artificial filamentMonocomponent cellulose artificial filamentFiberMaterials science

The present invention belongs to the field of radiation resisting technology, and is especially one kind of nanometer wave absorbing fiber. The nanometer wave absorbing fiber consists of nanometer wave absorbing particle of 1-100 nm diameter of fine fiber of 30-2000 nm diameter in the weight ratio of 3-35 to 65-97. The nanometer wave absorbing fiber has wide wave absorbing range, powerful wave absorbing capacity, lasting wave absorbing effect and high flexibility. It has wave absorbing function, as well as antistatic, bacteriostasis, biochemical protection and other functions.

Owner:上海兰度科技有限公司

PVC (polyvinyl chloride) micro-foam floor and preparation method thereof

Owner:安徽济峰节能材料有限公司

Multifunctional knitting sportswear face fabric and manufacture method thereof

InactiveCN1920144ASatisfy moisture absorption and quick dryingMeet antistaticWeft knittingLiquid/gas/vapor textile treatmentEngineeringPolypropylene

The invention relates to a multifunctional knitting exercise clothes and relative production, wherein it uses four machines to prepare the face fabric with inner layer, middle connecting layer and outer layer; the outer layer is the polyester filament yarn of 75D / 100F and C-O shaped section and porous structure; the middle connecting layer is polypropylene or polyester filament yarn; the inner layer is the polyester filament yarn with ultraviolet resistance, at 75D / 72F + type or Y-shaped, H-shaped, and five-pointed star shape, which is treated with semi delustring. Said material is treated with alkali reduction before doping, and to be softened after doping. The invention and quickly adsorb the sweaty and release the sweaty outside the fabric, to avoid skin cancer, etc.

Owner:河南纺织高等专科学校

Graphene conductive coating material, preparation method therefor and application of graphene conductive coating material

ActiveCN105778740AUniform and stable dispersionEasy to prepareAnti-corrosive paintsPolyurea/polyurethane coatingsChemical reactionMetallic materials

The invention discloses a graphene conductive composite coating material. The graphene conductive composite coating material contains macromolecular film-forming resin, graphene and a graphene dispersant; and the graphene dispersant contains an aniline oligomer or a derivative thereof or soluble polyaniline which can be combined with the graphene through PI-PI interaction so as to enable the graphene to be uniformly and stably dispersed in the macromolecular film-forming resin or a mixture of the macromolecular film-forming resin and water and / or an organic solvent. The invention also discloses a preparation method for the coating material. According to the coating material disclosed by the invention, the graphene can be uniformly and stably dispersed in a coating material matrix, so that the application of the coating material in the aspects of conductive macromolecular coatings and the like can be greatly promoted; the preparation process is simple, does not need complex chemical reactions and is easy to control, and the coatings made from the coating material have good bonding capability on surfaces of macromolecular materials, metallic materials, textile materials and ceramic materials; and meanwhile, the coating material also has the characteristics of radiation resistance, electrostatic resistance, corrosion prevention, wave absorbing, wear resistance and the like, thereby being broad in application prospect.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

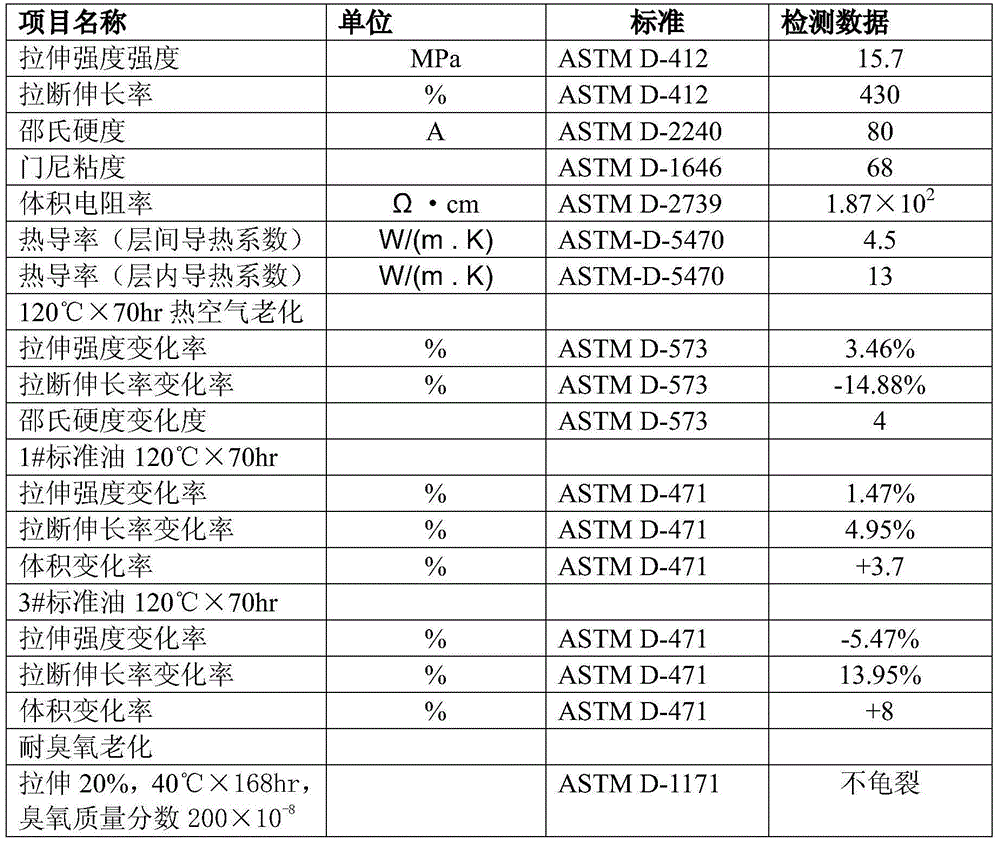

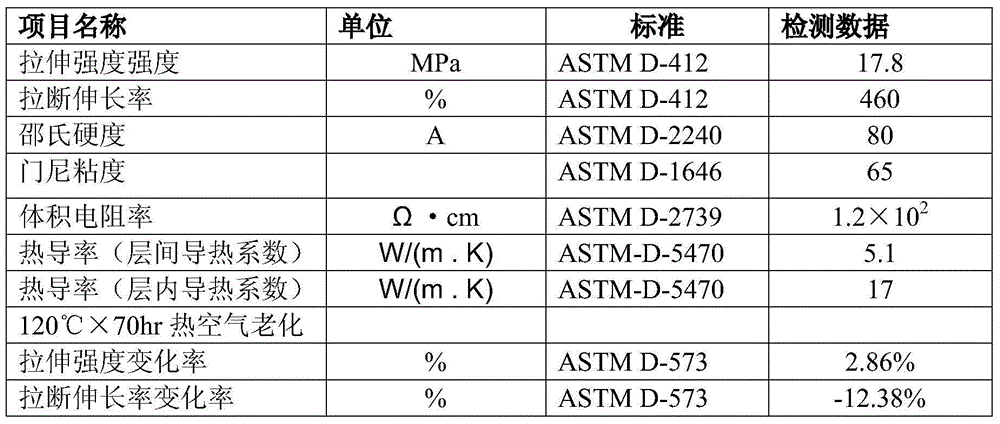

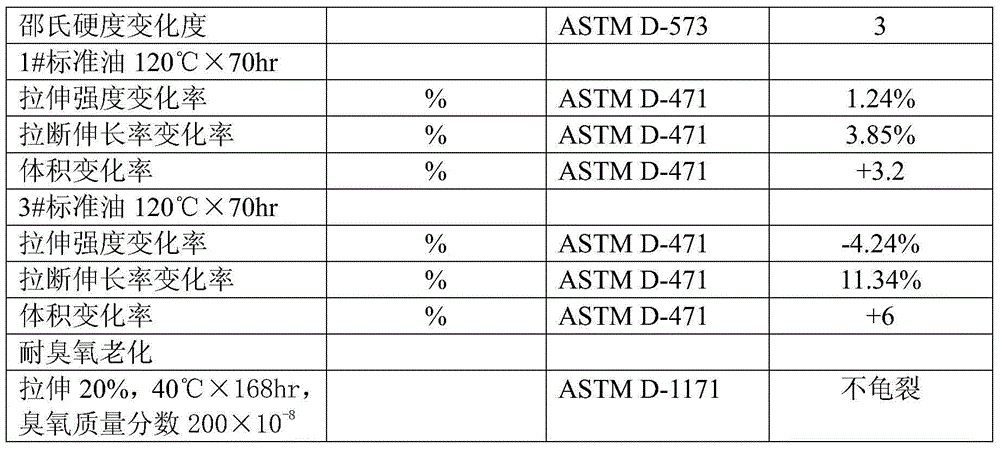

High-electrical conductivity high-thermal conductivity oil-resistant aging-resistant rubber material, and preparation method and applications thereof

ActiveCN104961983AExcellent electrical and thermal conductivityExcellent mechanical properties and oil resistancePetroleumConductive rubber

The invention relates to a high-electrical conductivity high-thermal conductivity oil-resistant aging-resistant rubber material. The high-electrical conductivity high-thermal conductivity oil-resistant aging-resistant rubber material is prepared from following ingredients, by weight, 50 to 100 parts of an electroconductive thermal conductive rubber master batch, 40 to 60 parts of an auxiliary rubber material, 30 to 50 parts of a reinforced material, 30 to 50 parts of a flexibilizer, 30 to 50 parts of a filling material, 8 to 10 parts of a stabilizing agent, 10 to 15 parts of a tackifier, 3 to 5 parts of a vulcanizing agent, and 2 to 3 parts of a vulcanizing assistant agent. The high-electrical conductivity high-thermal conductivity oil-resistant aging-resistant rubber material possesses excellent electrical conductivity and thermal conductivity; volume resistivity is as high as 102 omega.cm; heat conductivity coefficient is higher than 4W / (m.K); the high-electrical conductivity high-thermal conductivity oil-resistant aging-resistant rubber material can be applied to special fields such as petroleum, coal mine, and spaceflight; the high-electrical conductivity high-thermal conductivity oil-resistant aging-resistant rubber material possesses excellent mechanical properties, oil resistance, and air aging resistance, and can be used in oil medium or in outdoor environment.

Owner:青岛科凯达橡塑有限公司

Self-cleaning, antibacterial and anti-fog film

InactiveCN103396634AAntistaticWith anti-electromagnetic radiation performanceUltraviolet lightsHeat sensitive

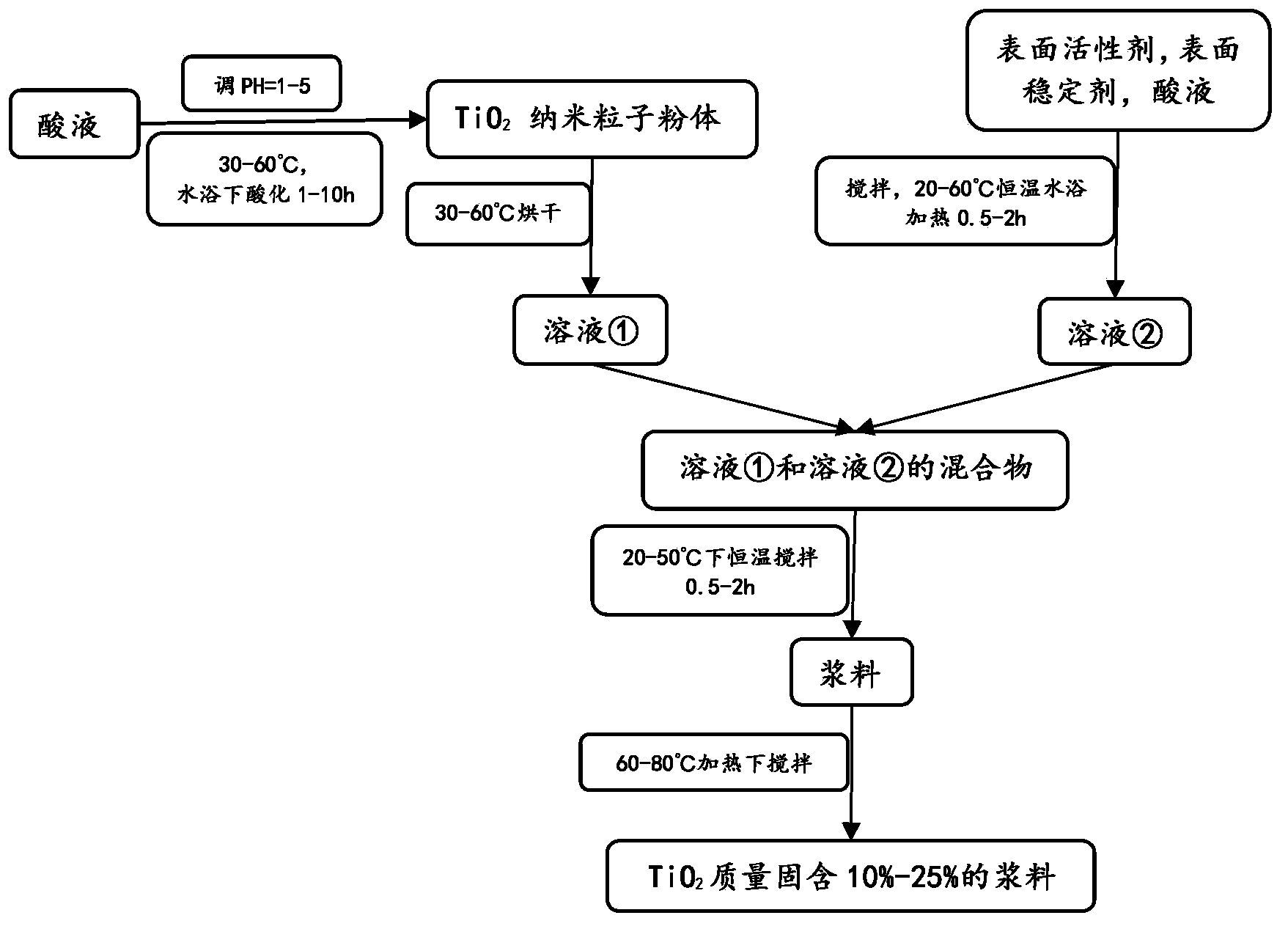

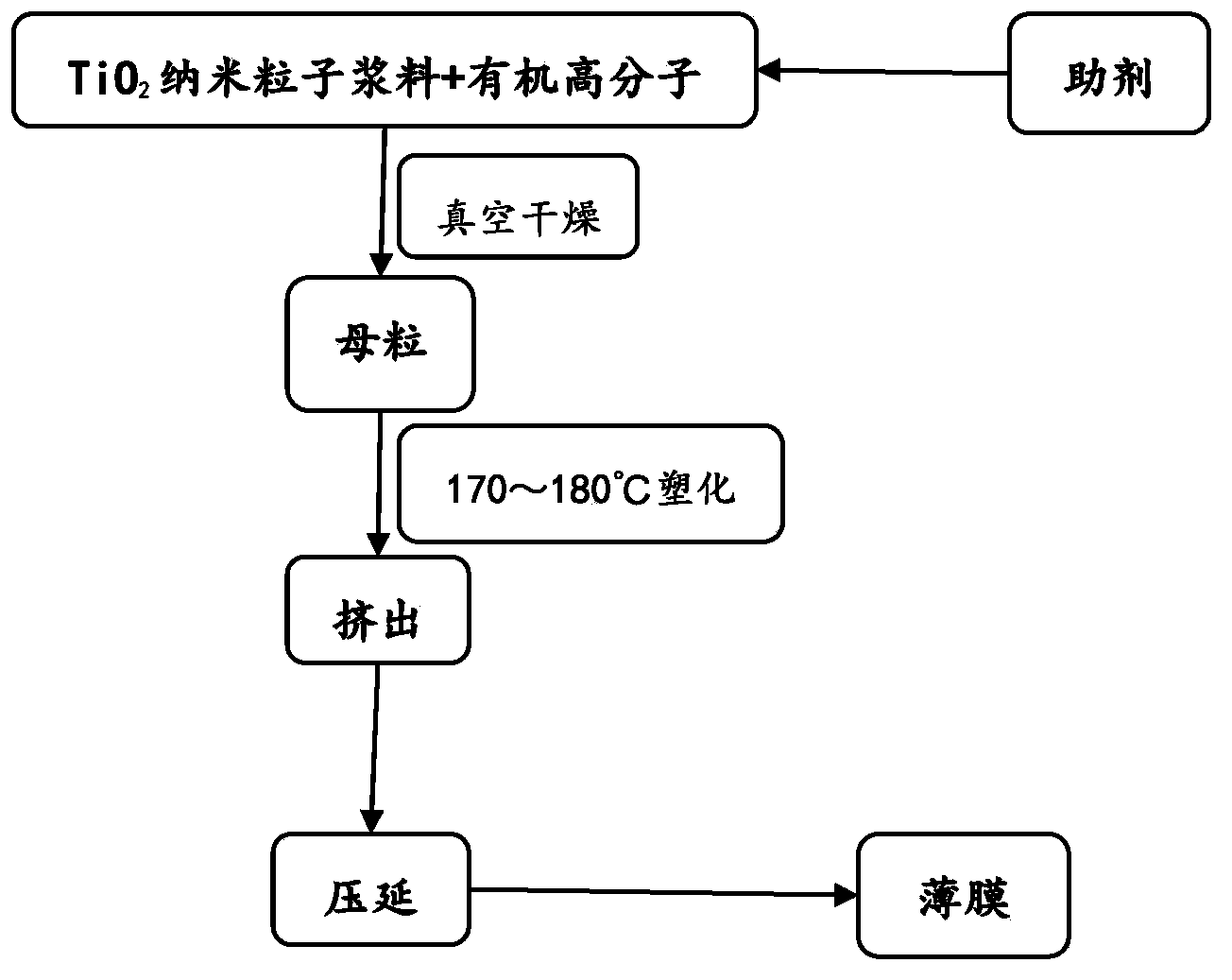

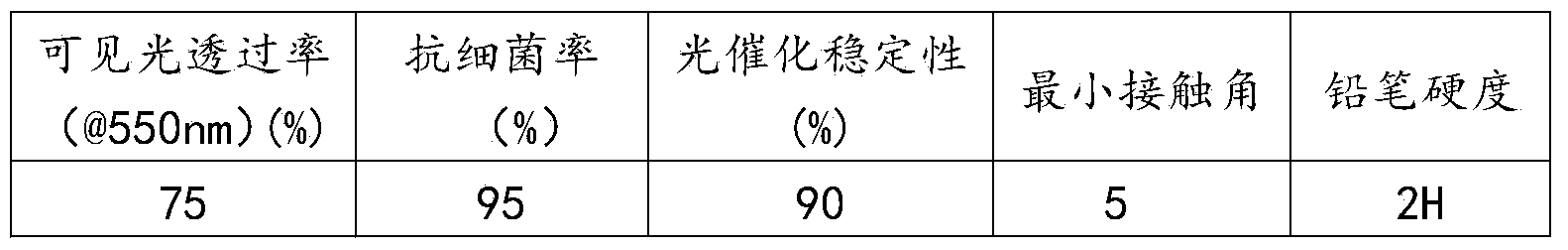

The invention relates to a self-cleaning, antibacterial and anti-fog film. The self-cleaning, antibacterial and anti-fog film is prepared by acidizing TiO2 nano-particle powder, adding a surfactant, a stabilizer, an acid and the like, preparing, and concentrating to obtain TiO2 nano-particle slurry, adequately mixing the slurry with an organic high-molecular polymer and auxiliaries, and drying to obtain master batches; and commonly plasticizing, extruding and calendaring the master batches to prepare the self-cleaning, antibacterial and anti-fog film, wherein the constituents of the film comprise 72.89-92.34 wt% of the organic high-molecular polymer, 0.5-22.63 wt% of TiO2 nano particles and 3.36-23.45 wt% of auxiliaries. The film has a high visible light transmittance, self-cleaning, antibacterial and anti-fog functions, reflection and control effects on ultraviolet light rays and far-infrared light rays, antistatic property and anti-electromagnetic radiation property; the film is prepared with no need of high vacuum and high-temperature heating, simple and practicable equipment, and low cost; the film can be compounded with pressure-sensitive adhesive and heat-sensitive adhesive, used as the films of building glass, and the windows of vehicles and ships for improving the self-cleaning, antibacterial and anti-fog functions of the building glass and the windows, and used for performing transformation and large-area field construction on the installed glass and windows.

Owner:武汉羿阳科技有限公司

Preparation method for graphene reinforced polymer porous sponge fiber

InactiveCN103603081AExtensive sources of raw materialsEasy to getArtificial filaments from viscoseAlginate artificial filamentsSolventCvd graphene

The invention provides a preparation method for graphene reinforced polymer porous sponge fiber. The preparation method is characterized in that: the graphene reinforced polymer porous sponge fiber is prepared by subjecting an oxidized graphene solution having a certain concentration to ultrasonic processing to obtain a uniformly dispersed oxidized graphene solution; dissolving a polymer in a solvent to obtain a polymer solution with a certain concentration; adding the dispersed graphene solution into the polymer solution under stirring to obtain a graphene-polymer blend spinning solution; spraying the graphene-polymer blend spinning solution through a spinning nozzle into a coagulating bath to form fiber by utilization of a wet-method spinning device; washing with water, reducing, and washing with water again; and quickly subjecting the wet fiber to freeze drying or supercritical drying to obtain the graphene reinforced polymer porous sponge fiber. The preparation method is simple in technology and low in cost, and is suitable for large-scale production. The fiber has advantages of high strength, good antistatic performance, good elasticity, small density, large specific surface area, and the like. The fiber can be used for preparing heat insulating fabrics in the weaving field, and can be used for water treatment in the environment protection field, and the like.

Owner:QINGDAO UNIV

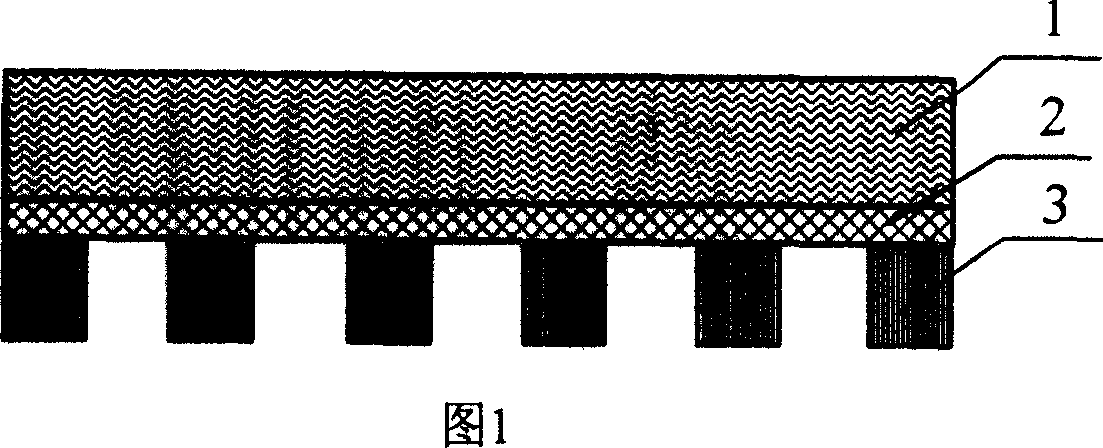

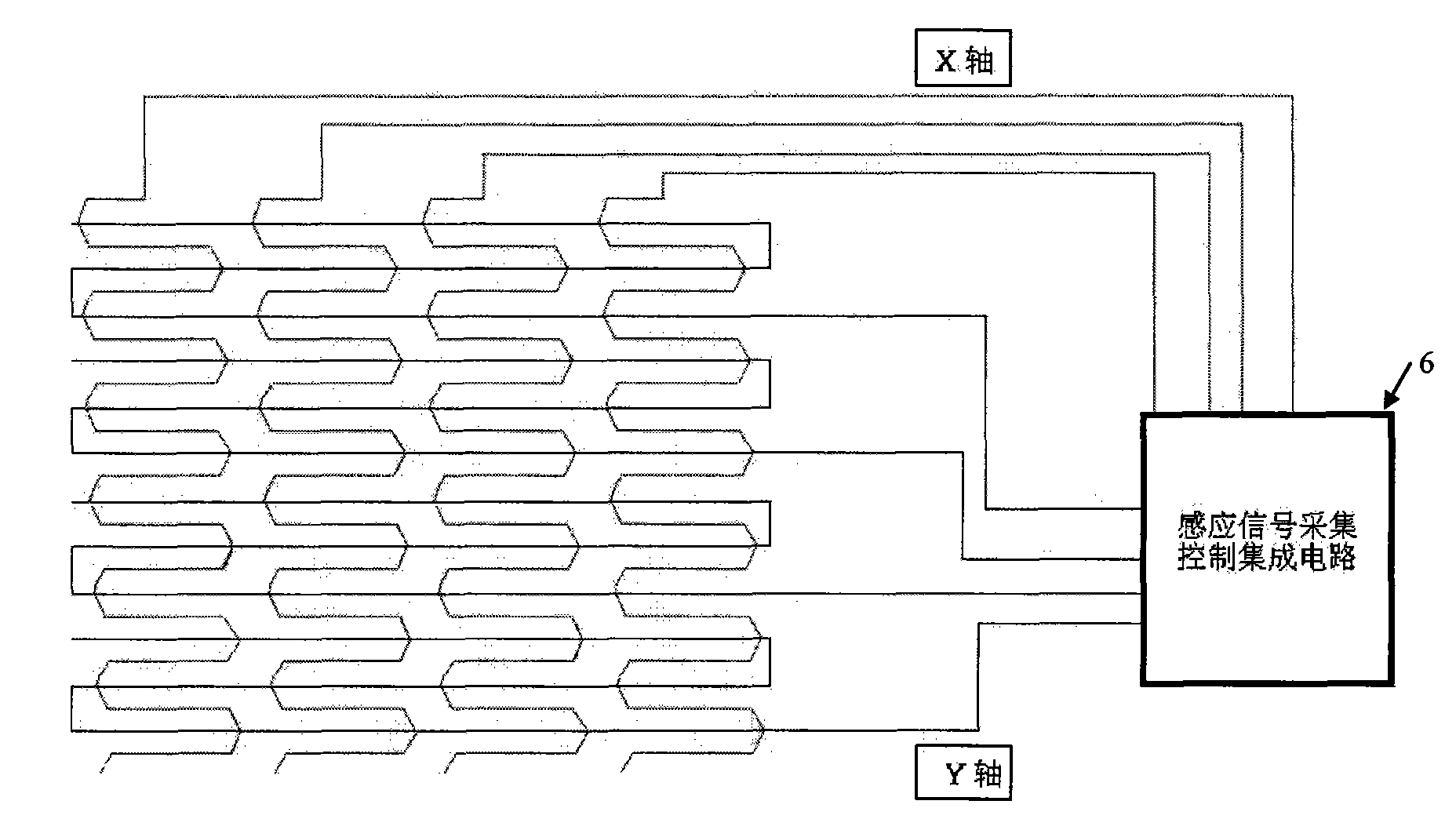

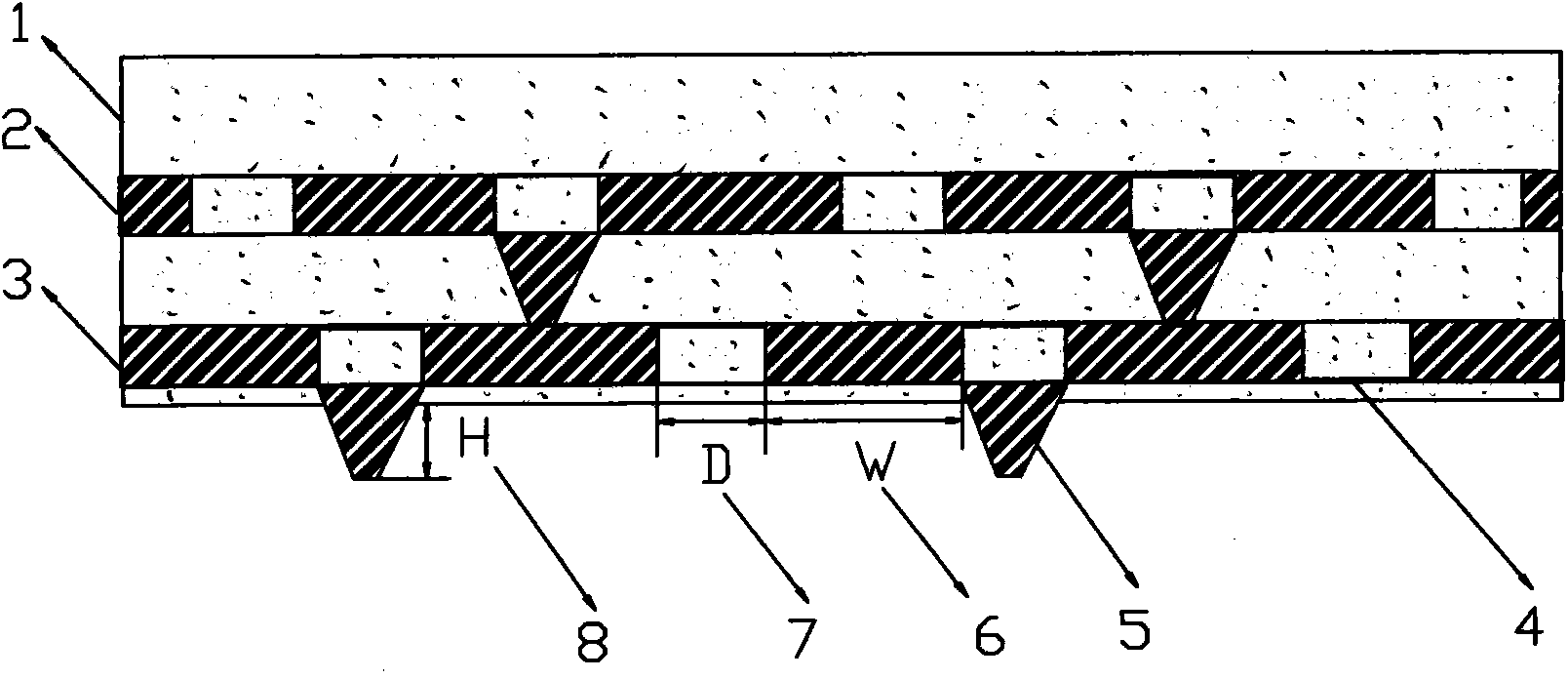

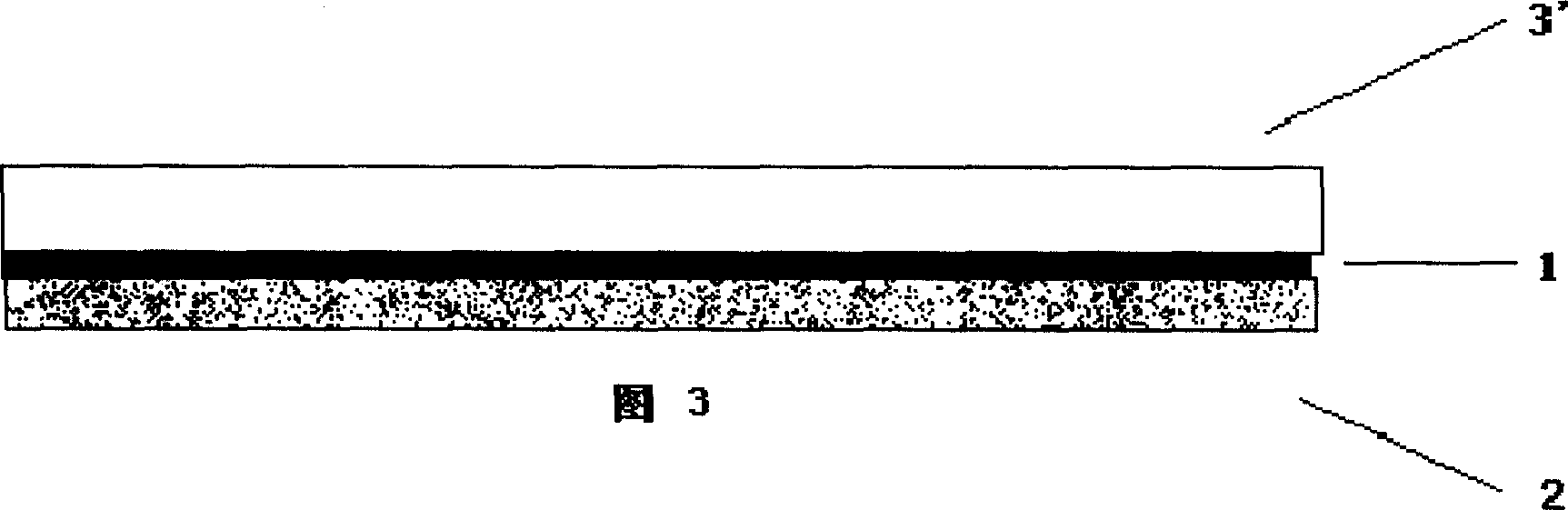

Imaging touch control film and large-screen interactive media system applying imaging touch control film

ActiveCN101615096ATouch precisionImprove recognition accuracyInput/output processes for data processingTectorial membraneLarge screen

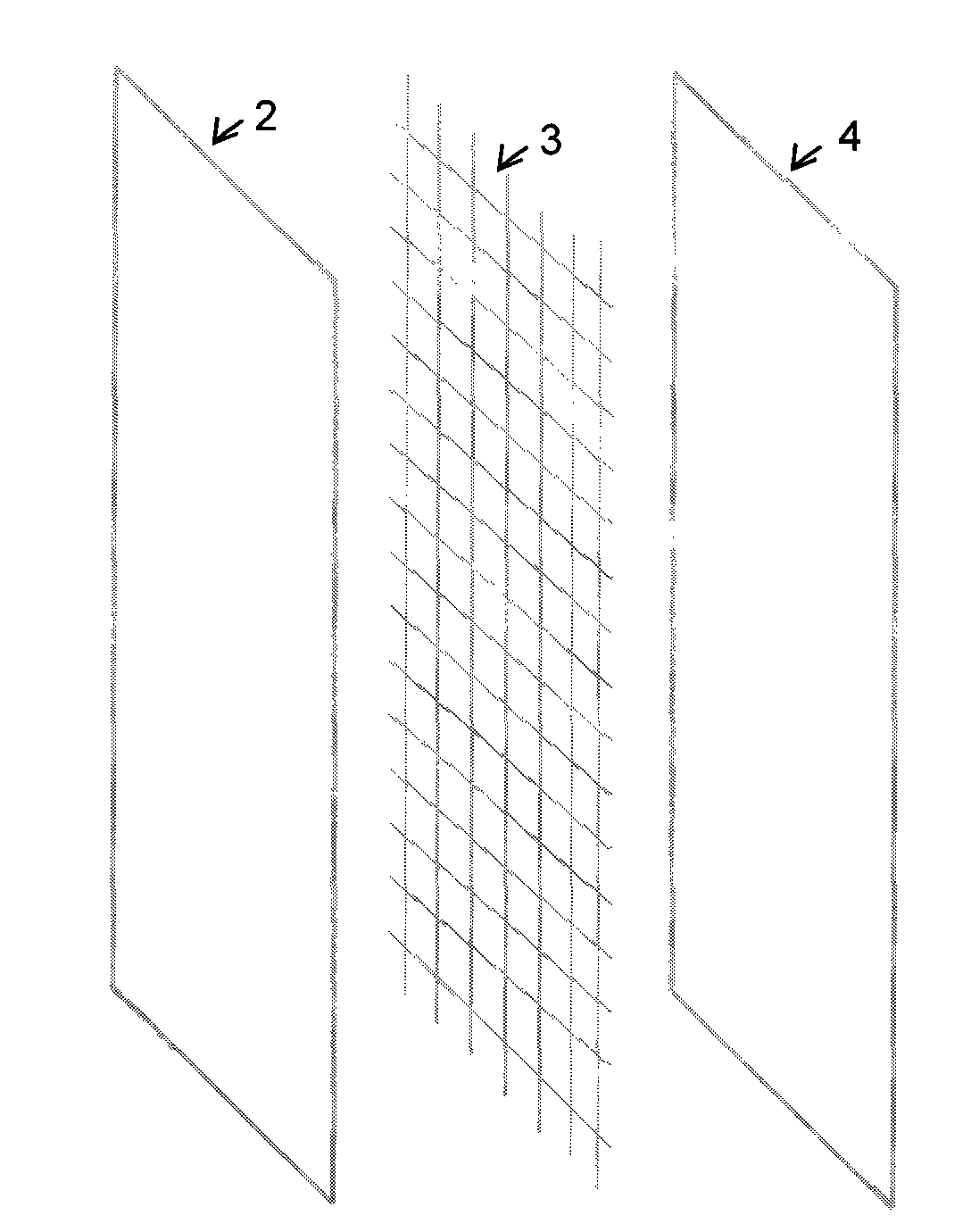

The invention discloses an imaging touch control film. The imaging touch control film comprises a back projection imaging film with back projection imaging function, an electromagnetic induction layer consisting of ultrafine conducting wire grids and a transparent protective film which are orderly attached. The imaging touch control film has lower cost, high recognition precision and long service life, is convenient for assembly and disassembly, and is convenient for mass application. The invention also discloses a large-screen interactive media system applying the imaging touch control film, the large-screen interactive media system comprises the imaging touch control film which is adhered to the rear side of thick sheet glass as well as a controller and a data processor which are connected with the large-screen interactive media system, an output end of the data processor is connected to a liquid crystal display screen or a projector through a VGA, and another output end is connected to an audio through an audio output port. The large-screen interactive media system has the advantages that the large-screen interactive media system saves energy sources, reduces light pollution, has safe use, and is suitable for various occasions, thereby achieving active interactive media effect.

Owner:山东泛普信息科技有限责任公司

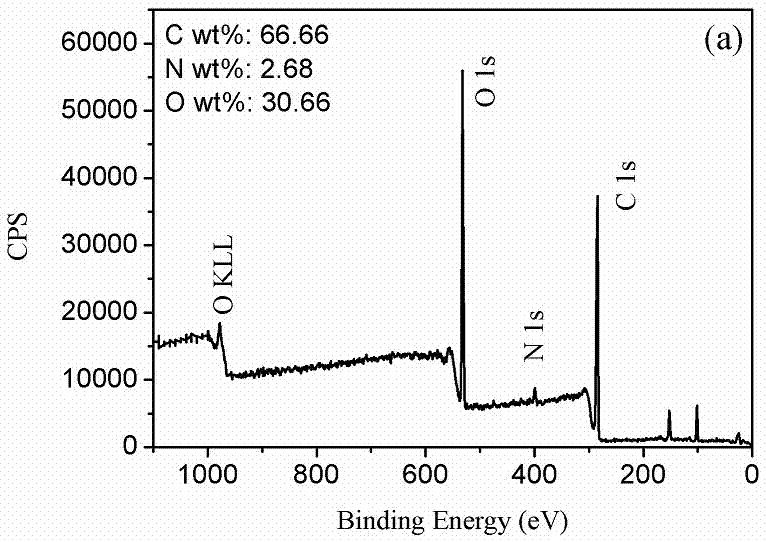

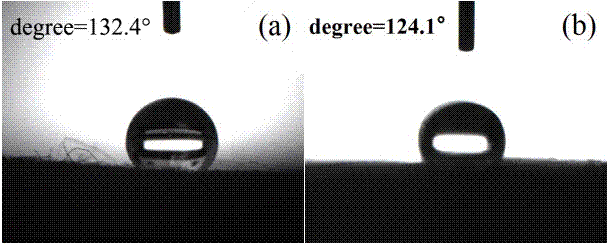

Method of coating polyester piece goods by silk fibroin combination liquid

The invention relates to a method for coating polyester fabric with fibroin composite liquid, wherein it comprises: adding the polyester fabric into the mixture of NaOH solution, ethanediamine solution and surface activator 1227 solution, to chemically etch the surface of said fabric; then washing it with clean water to neutral; or neutralizing with acetic acid, then washing it with clean water to neutral; adding the fabric into fibroin composite liquid to be immerged; then using absolute ethyl alcohol or steam at 120Deg. C to crystallize it; washing it with hot water; dewatering and drying, to obtain the product. The invention uses fibroin solutoin to modify the fucntion of fabric to improve the wet adsoprtion; and it uses chemcial etch method to improve three times of wet adsorption, with static resistance.

Owner:ZHEJIANG UNIV

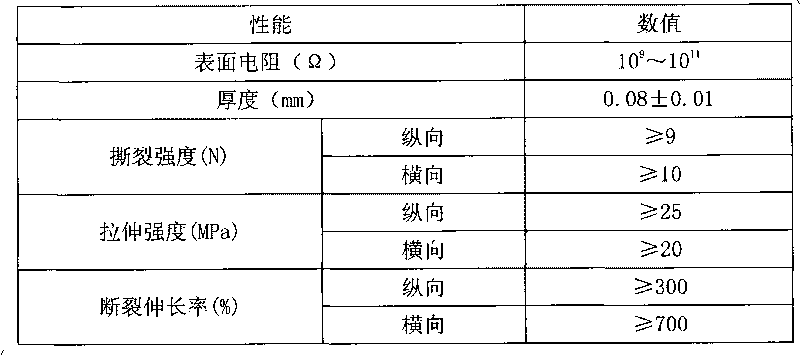

Anti-electrostatic degradable film material and preparation method thereof

The invention discloses an anti-electrostatic degradable film material and a preparation method thereof. The film material is prepared from the following raw materials: LDPE, LLDPE, starch-based degradable plastic materials and anti-electrostatic master batch. The preparation method comprises the following steps: uniformly mixing the raw materials at a high speed; and obtaining a product by extruding, swelling and stretching. The anti-electrostatic degradable film material has good anti-electrostatic effect, is degradable and does not pollute the environment; and the preparation method of the anti-electrostatic degradable film material has simple process and low cost and can prepare finished products with good quality.

Owner:SHENZHEN SELEN SCI & TECH CO LTD +1

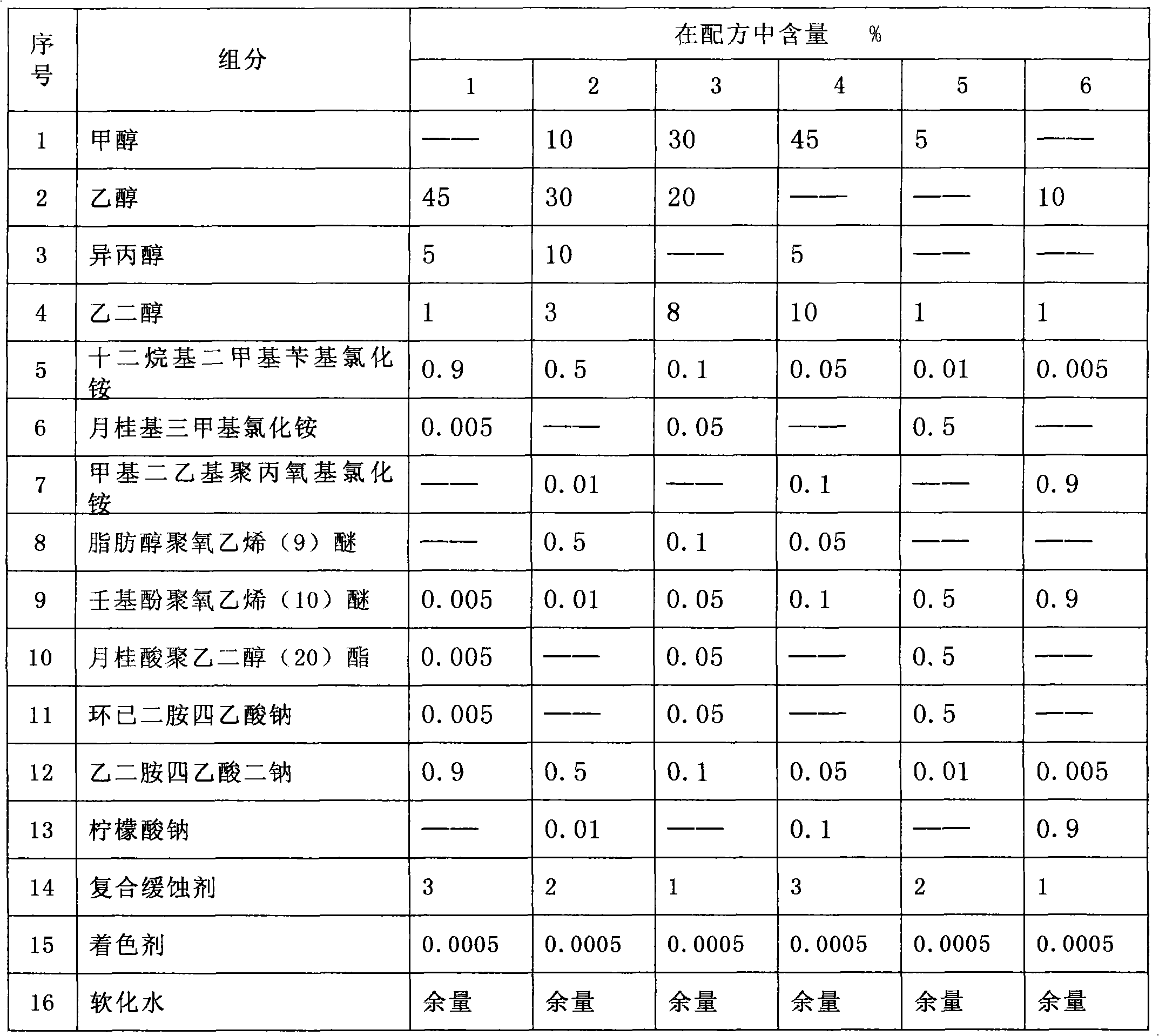

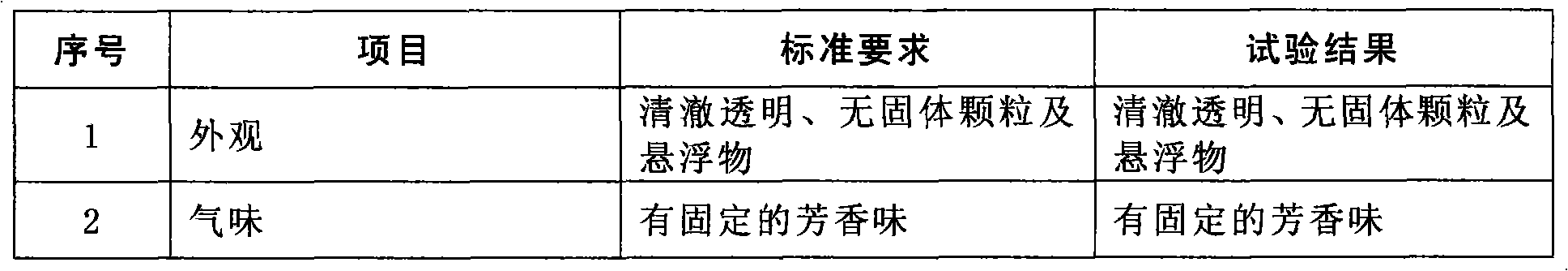

Cleaning agent for automobile windshield

ActiveCN101831360ALow volatilityImprove washing effectInorganic/elemental detergent compounding agentsOrganic detergent compounding agentsChemistryNonionic surfactant

The invention relates to a cleaning agent for an automobile windshield, which consists of the following components in percentage by weight: 1 to 50 percent of monobasic alcohol, 1 to 10 percent of ethylene glycol, 0.005 to 0.1 percent of complexing agent, 0.005 to 0.1 percent of cationic surfactant, 0.005 to 0.1 percent of nonionic surfactant, 0.1 to 3 percent of composite corrosion inhibitor, 0.005 to 0.1 percent of colorant and the balance of water. The cleaning agent has cleaning, anti-freezing, anti-fog, anti-corrosion, anti-static, lubricating properties, can effectively remove dust, dirt, spray mark, gum, lac and the like on the windshield, and has high stability of high and low temperature and no damage to the automobile windshield.

Owner:北京蓝星清洗有限公司

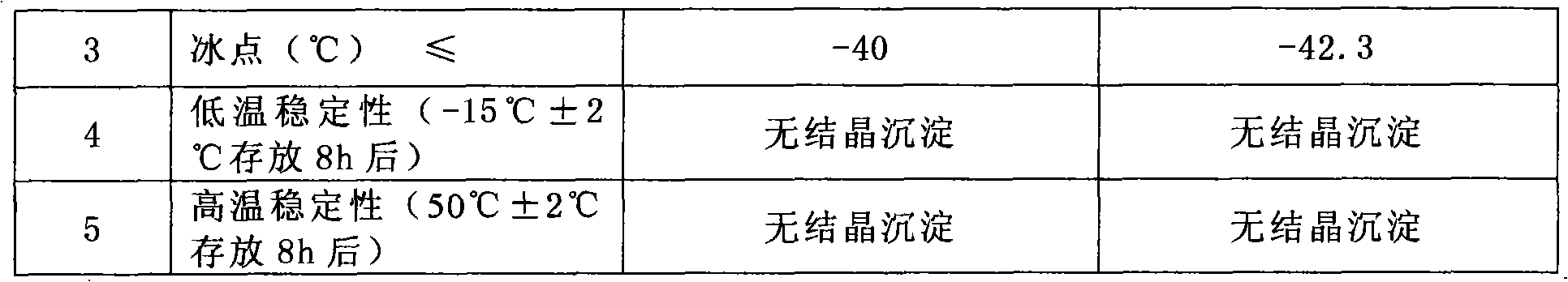

Radar stealth and infrared stealth integrated stealth tarpaulin and making method thereof

ActiveCN104990459AThe overall structure is simpleImprove mechanical strengthCarbon fibresSynthetic resin layered productsCamouflageEnvironmental geology

The invention discloses radar stealth and infrared stealth integrated stealth tarpaulin and a making method thereof. The radar stealth and infrared stealth integrated stealth tarpaulin and the making method thereof are mainly used for achieving stealth of modern weapons such as vehicle-mounted guided missiles, tanks and aircrafts and improving the survival capacity, the defense penetration capacity and the deep strike capacity of the weapons. The integrated stealth tarpaulin comprises a camouflage layer, a radar and infrared integrated stealth layer and a base layer in sequence from outside to inside. The radar and infrared integrated stealth layer is formed by polymerizing silicon carbide fiber cloth and aniline in situ and has not only the wave absorption stealth performance but also antistatic property, high temperature resistance and flame retardant property. The surface of a radar absorption layer is coated with an infrared wave absorbing coating in a coating finishing mode. The tarpaulin is cut and sewn in a three-dimensional mode according to different application types. The integrated stealth tarpaulin can achieve the functions of radar stealth and infrared stealth at the same time, and has the advantages of being antistatic, flame-retardant, high in mechanical strength, flexible, wash-resistant and breathable, and convenient to produce.

Owner:SUZHOU IND PARK HIGH PERFORMANCE CERAMIC FIBER ENG CENT CO LTD

Composite conducting strip

InactiveCN102169760AGood conduction current performanceAntistaticContact materialsMetal layered productsMetal foilCopper foil

The invention provides a composite conducting strip which comprises a high-polymer matrix and one or two or more than two layers of communicated metal foils composited therein; and the total thickness of the composite conducting strip is 0.3-3mm. The surfaces of the metal foils are uneven and have protruding contacts which are exposed to one surface of the high-polymer matrix. The high-polymer matrix includes silicon rubber, nitrile rubber, ethylene propylene rubber, natural rubber, rubber and plastic materials, thermoplastic plastics, thermosetting plastics, fiber reinforced plastics and thelike and can contain 0.1-5% of coupling agent and other auxiliaries. The metal foils are nickel foils, copper foils, aluminum foils, stainless steel foils, gold foils, silver foils with holes or meshgrids. The composite conducting strip has the advantages of being high in composite strength, good in corrosion resistance and good in current conduction performance, can be divided into random shapes and specifications and can be widely used for manufacturing the conductive base materials of various buttons in an electronic industry.

Owner:NANTONG MEMTECH ELECTRONIC INDUSTRY CO LTD +1

Spray coating type fire-retardant antistatic polyurethane elastomer and preparation method thereof

ActiveCN103709362ALow viscosityImprove liquidityFireproof paintsPolyurea/polyurethane coatingsCarbon nanotubeSpray coating

The invention discloses a spray coating type fire-retardant antistatic polyurethane elastomer and a preparation method thereof. The spray coating type fire-retardant antistatic polyurethane elastomer comprises an A component and a B component, wherein the A component is composed of 40-60 parts of isocyanate and 40-60 parts of phosphorus-containing flame-retardant polyol, and the B component is composed of 0-30 parts of chain extender, 0-30 parts of polyether polyol, 10-75 parts of amine-terminated polyether, 0-30 parts of carbon nanotube slurry, 0-3 parts of pigment and 0-3 parts of assistant. The preparation method comprises the following steps: adding the phosphorus-containing flame-retardant polyol into a reaction kettle, heating up to 110 DEG C, vacuumizing for 3 hours, cooling to 30 DEG C, adding the isocyanate, heating up to 105 DEG C, and reacting for 3 hours to obtain a semi-prepolymer A component; sequentially adding the ingredients of the B component into a stirring tank, stirring uniformly, and grinding the mixture in a sand mill for 2.5 hours to prepare the B component; spray-coating the A component and the B component onto a surface through a high pressure spray coating machine, and quickly curing to form. According to the spray coating type fire-retardant antistatic polyurethane elastomer disclosed by the invention, film forming matters are stable, no fire retardant is separated out and the durability is good; a spray coating type fire-retardant antistatic material prepared by the preparation method disclosed by the invention has both fire resistance and anti-static function, so that the material is suitable for application on flame-retardant and explosion-proof occasions.

Owner:QINGDAO ADVANCED MARINE MATERIAL TECH

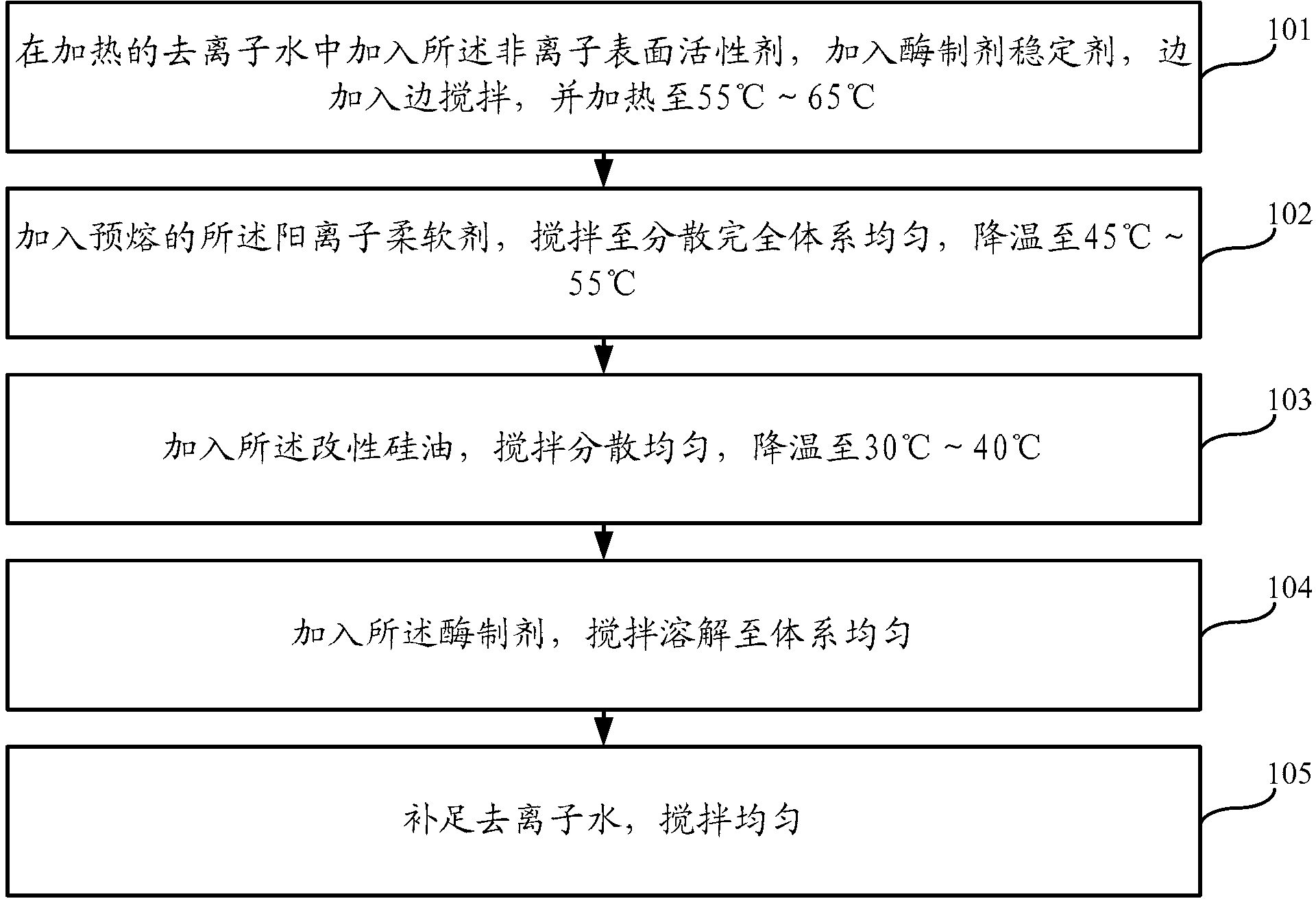

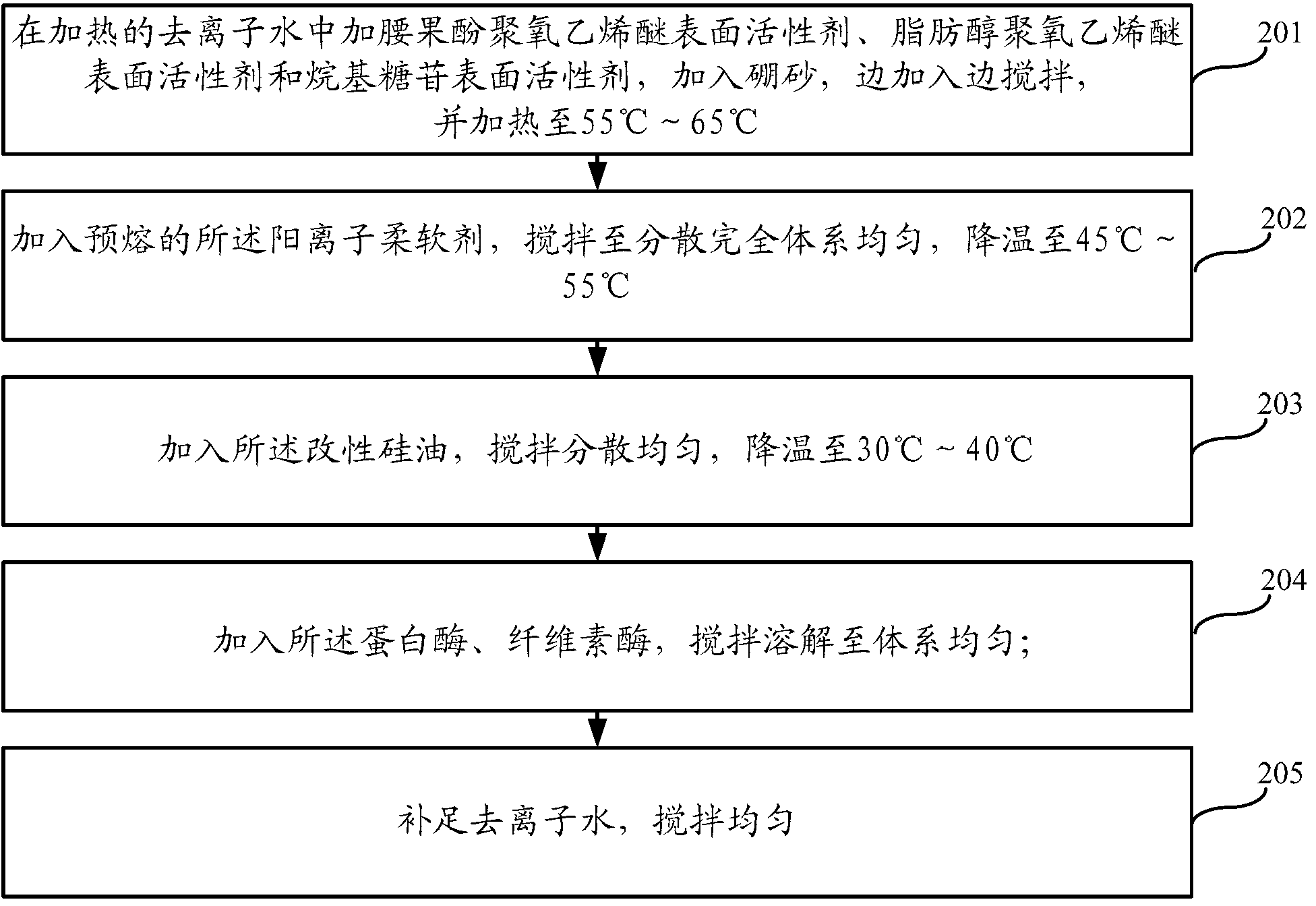

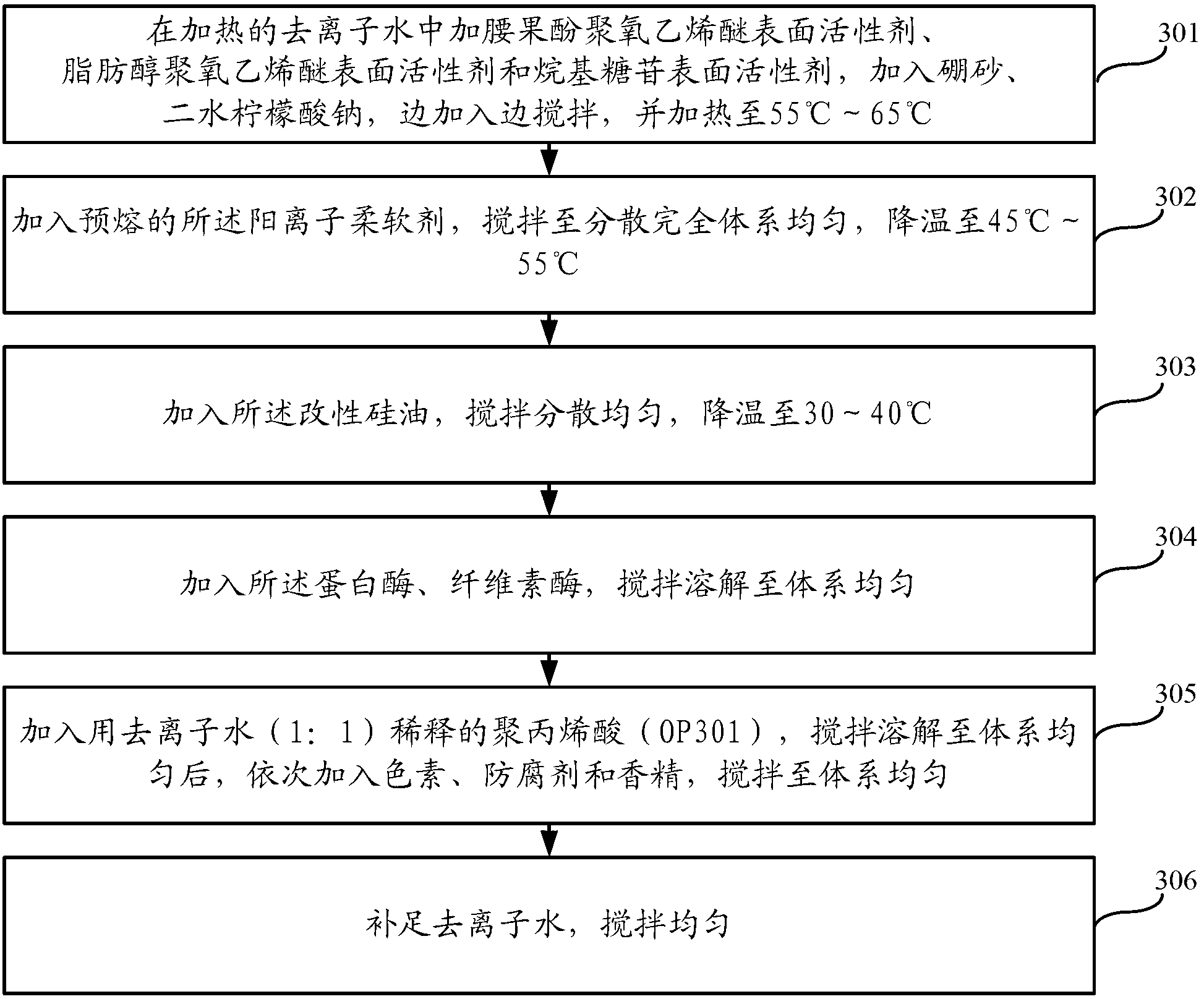

Three-effect liquid laundry detergent composition and preparation method thereof

ActiveCN103242973AIncrease polarityImprove adsorption capacityAmpholytes/electroneutral surface-active compoundsDetergent compounding agentsLiquid laundry detergentSilicone oil

The invention relates to the field of detergents and particularly relates to a three-effect liquid laundry detergent composition and a preparation method thereof. The three-effect liquid laundry detergent composition has the three effects of washing, softness and puffiness and comprises the following components: 0.02-15% of cationic softener, 0.01-10% of modified silicon oil, 2-50% of nonionic surfactant, 0.02-6% of enzymic preparation and 0.01-12% of enzymic preparation stabilizer. The preparation method comprises the following steps of: adding the nonionic surfactant into the heated deionized water, adding the enzymic preparation stabilizer, stirring while adding, and heating the mixture to 55-65 DEG C; adding the pre-molten cationic softener, stirring until the pre-molten cationic softener is completely dispersed and the system is uniform, and cooling to 45-55 DEG C; adding the modified silicon oil, stirring and uniformly dispersing, and cooling to 30-40 DEG C; adding the enzymic preparation, stirring to dissolve the enzymic preparation until the system is uniform; and complementing the deionized water, and uniformly stirring the mixture.

Owner:纳爱斯成都有限责任公司

Method for making conductive fabric through polyaniline-triggered chemical slivering

InactiveCN104452309ABig pollutionReduce pollutionVegetal fibresAnimal fibresElectromagnetic shieldingBiological activation

The invention relates to a method for making conductive fabric through polyaniline-triggered chemical slivering. Fabric is soaked in a mixed solution of aniline and protonic acid, ammonium persulfate is added to the mixed solution, a reaction is carried out for 2-10 hours, and then the processed fabric is obtained after washing; the processed fabric is soaked in a silver nitrate solution, washed, dried, and then soaked in a silvering solution for being silvered for 30-60 min at the temperature of 30-40 DEG C, then the processed fabric is washed and dried, and finally the conductive fabric is obtained. According to the method, the process conditions of sensitization and activation are omitted, polyaniline and silver nitrate replace stannous chloride and palladium chloride high in price, cost is lowered, and environment pollution is reduced. The conductive fabric obtained through the method is good in conductivity, the binding strength of metal and fabric is high, the electromagnetic shielding performance is excellent, and the conductive fabric has an antistatic function, an antibacterial function and the like.

Owner:DONGHUA UNIV

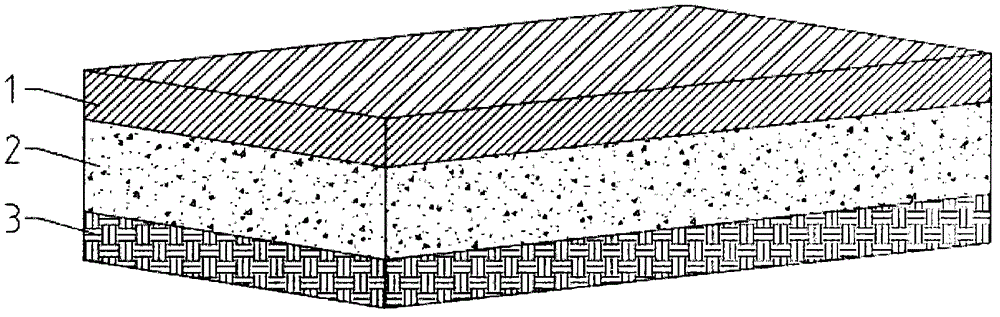

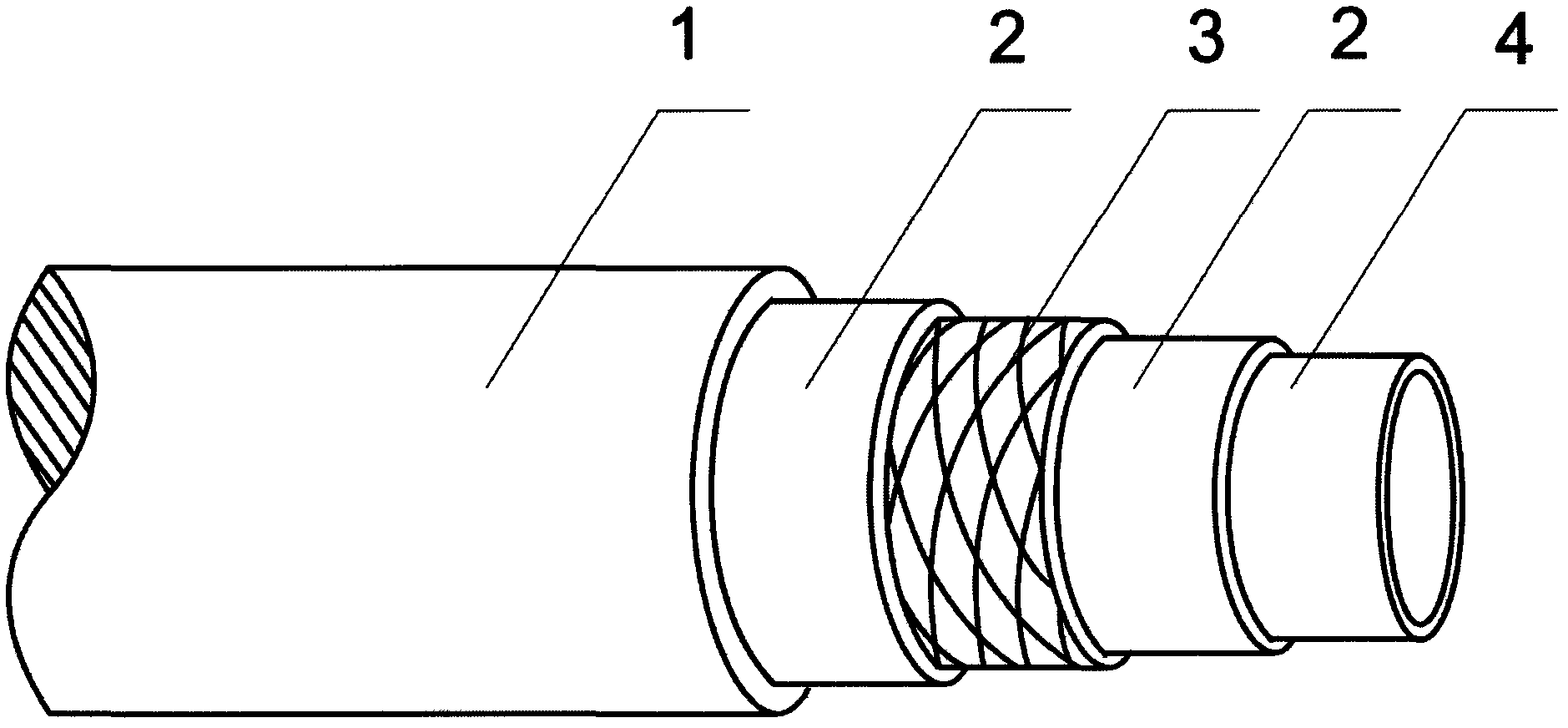

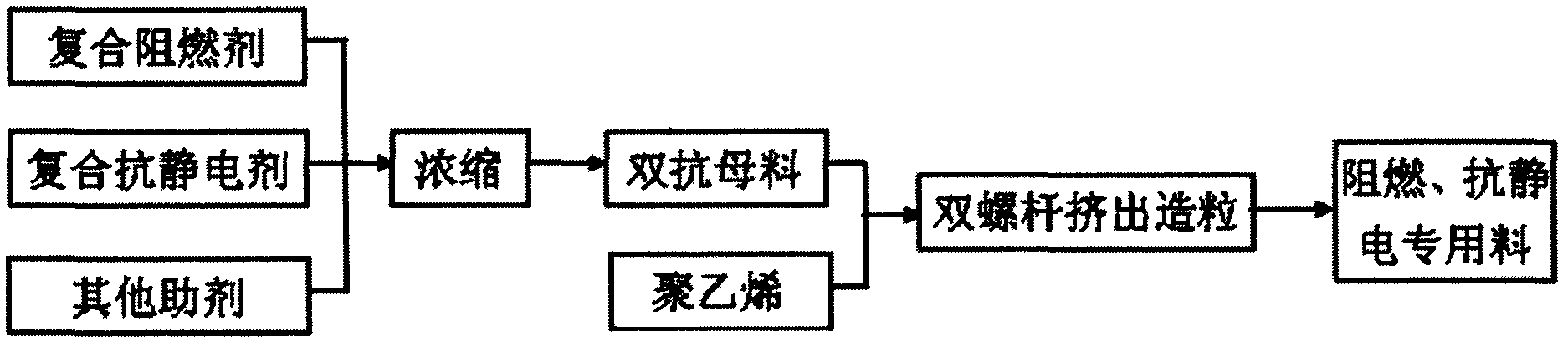

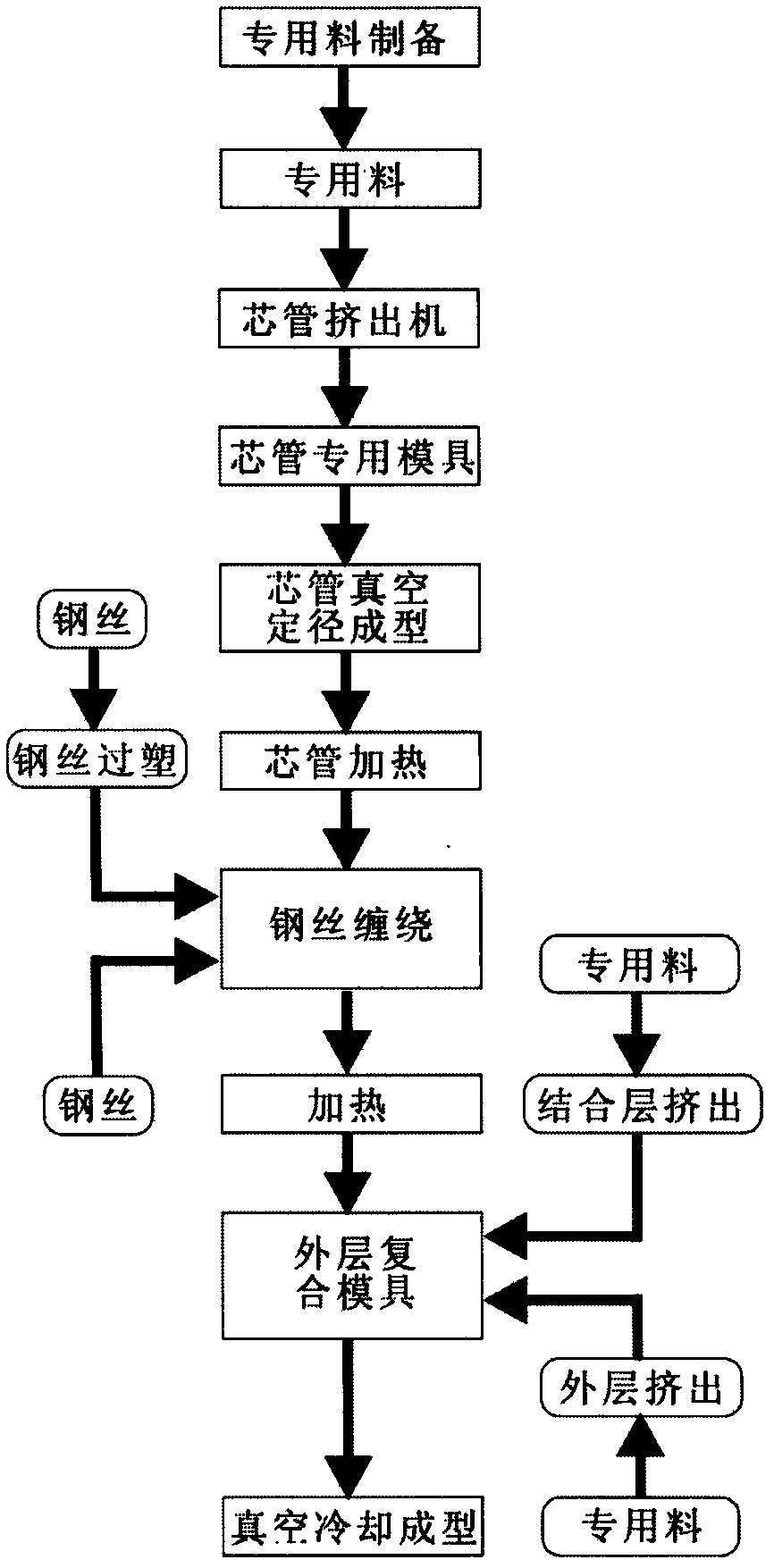

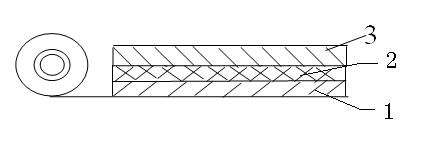

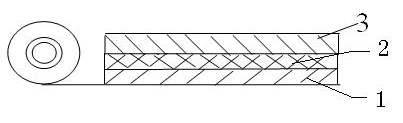

Flame retardant and antistatic steel mesh skeleton polyethylene composite pipe for mining and manufacturing method thereof

InactiveCN102359668AGuaranteed reliabilityGuaranteed uniformityRigid pipesPipe protection against damage/wearFire retardantCoal

The invention relates to a flame retardant and antistatic steel mesh skeleton polyethylene composite pipe for mining and a manufacturing method thereof. The method is characterized in that the polyethylene composite pipe is obtained by the manufacturing processes of subjecting dedicated composite modified polyethylene plastics to flame retarding and antistatic treatment in two steps, compositing the treated plastics with a high-strength steel mesh skeleton and a hot melt adhesive bond for several times, and heating and vacuuming the composite for several times. At least two layers of high-strength steel wires are wound to be reticulate in an oblique crossing manner, arranged between the outer wall of the inner layer and the inner wall of the outer layer as a skeleton, and tightly combined with the pipe body of the inner and outer layers into an integral whole by means of a hot melt adhesive, thus forming a composite pipe for underground coal mines, which is flame-retardant and antistatic and has relatively high mechanical strength and pressure resistance, long service life and other excellent properties. As the pipes are connected through welding by electric melting pipe fittings, the flame retardant and antistatic steel mesh skeleton polyethylene composite pipe for mining has high overall properties and convenience in laying, is applicable to the coal mine industry with strict property requirements in all aspects, and is also applicable to water supply and drainage, fire protection and gas delivery in the municipality and construction.

Owner:GUANGDONG EAST PIPES

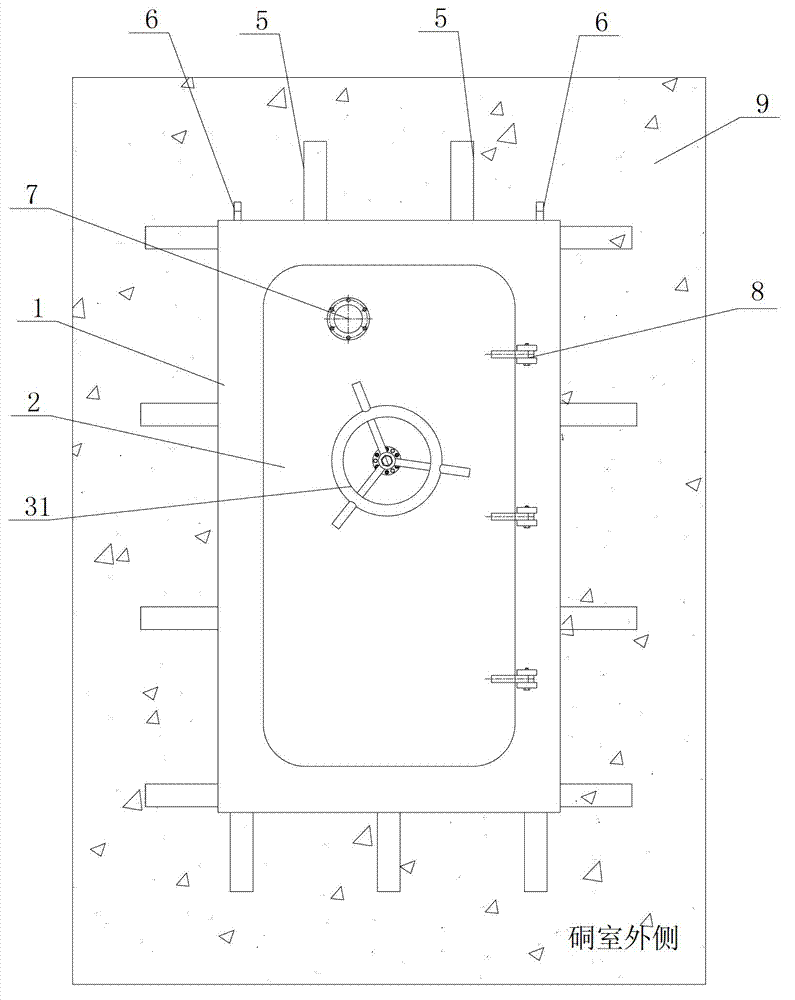

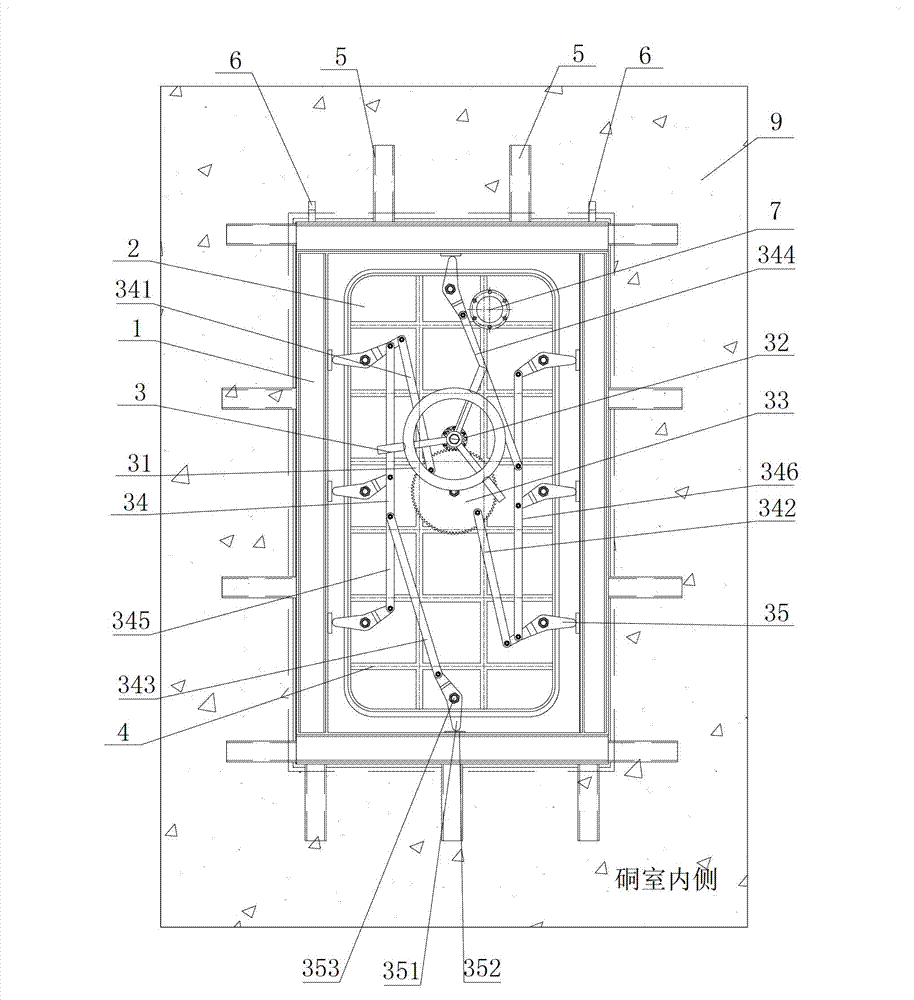

Protective sealing door for underground refuge chamber

ActiveCN102900335AImprove toughnessImprove bindingFireproof doorsConstruction fastening devicesLocking mechanismEngineering

The invention discloses a protective sealing door for an underground refuge chamber. The protective sealing door comprises a door frame and a door plate, wherein the door plate is arranged on the door frame through a rotation shaft; a locking mechanism for locking the door plate on the door frame is arranged on the door plate, a plurality of first reinforcing ribs for reinforcing the strength of the door plate are arranged in the door plate; heat-insulating materials, namely aerogel heat-insulating felts are filled among the reinforcing ribs; at least two annular sealing rings, namely flame-resisting sealing rings are arranged at the joint of the door plate and the door frame; and the periphery of the door plate is locked by the locking mechanism. According to the protective sealing door, the aerogel heat-insulating felts which can bear the temperature of 1,400 DEG C to the maximum are filled in the door plate, so that the door plate can resist high temperature generated during explosion, and the high temperature is insulated out of the refuge chamber; at least two sealing rings which are made of flame-resisting, anti-static, high temperature-resisting and oil-resisting materials are arranged on the contact surface of the door plate and the door frame, so that the protective sealing door has a good sealing effect.

Owner:CCTEG CHINA COAL RES INST

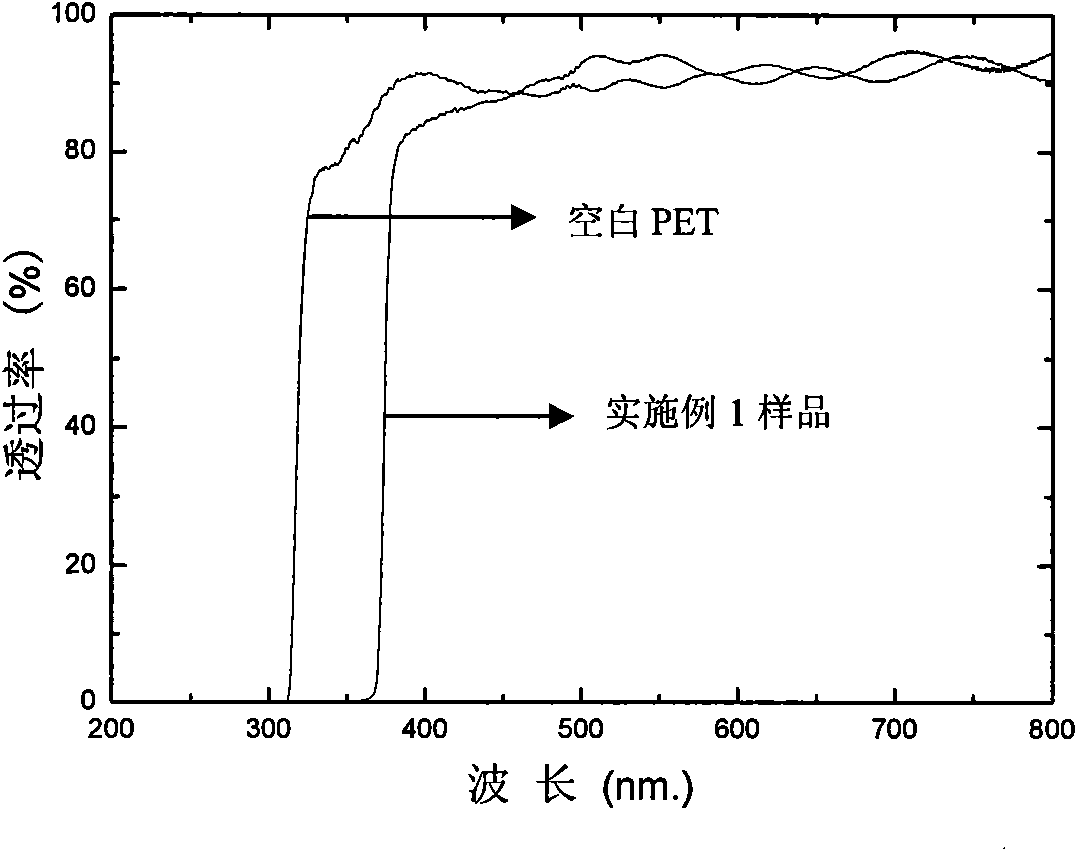

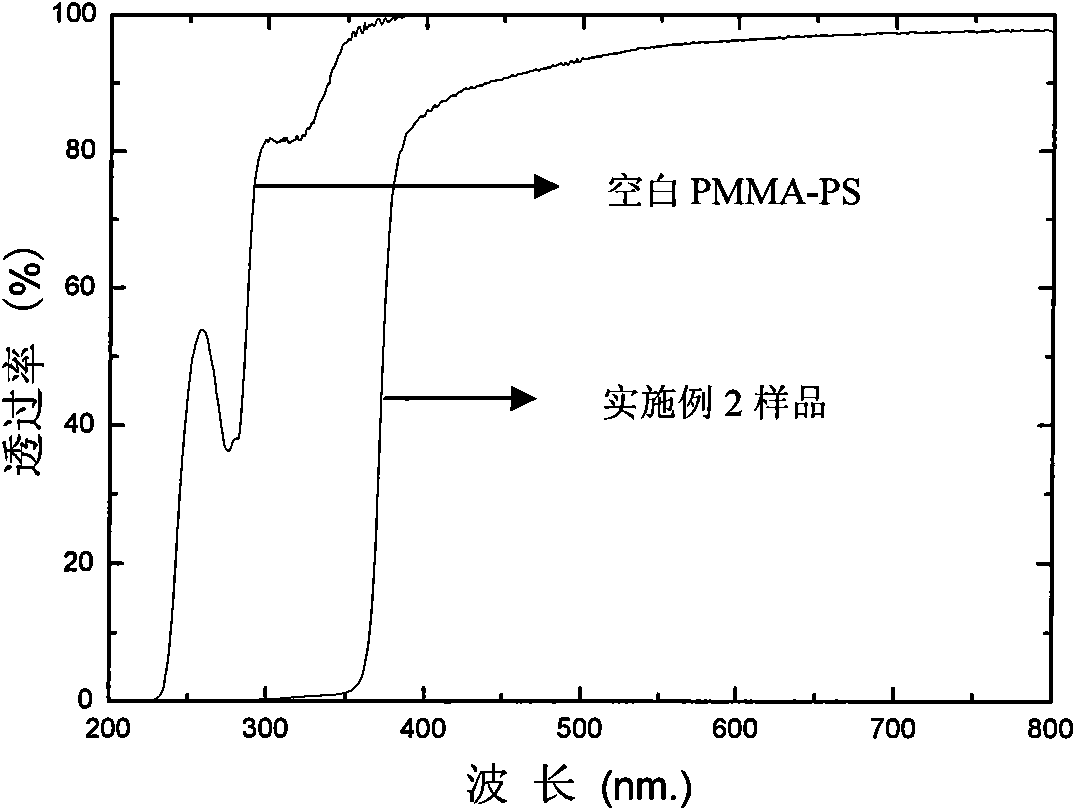

High-transparent ultraviolet-blocking energy-saving membrane and preparation method thereof by way of phase transfer in solution

ActiveCN101974245AImprove transmittanceImprove shielding effectComposite filmMetal oxide nanoparticles

The invention discloses a high-transparent ultraviolet-blocking energy-saving membrane and a preparation method thereof by way of phase transfer in solution, which belong to the field of composite thin films. The high-transparent ultraviolet-blocking energy-saving membrane comprises the following compositions in percentage by weight: 50 to 99.8 percent of high polymer, and 0.2 to 50 percent of metallic-oxide nano particles (at least compring a composite metal oxide nanoparticle with a core-shell structure); and the method for preparing the high-transparent ultraviolet-blocking energy-saving membrane by way of phase transfer in solution comprises the following steps: transferring the metal oxide nanoparticles from an initial disperse system to a solvent system in which the high polymer canbe dissolved through the steps of centrifugal separation and washing and the like, then preparing the metal oxide nanoparticles into metal oxide nanoparticles / thermoplastic polymer / solvent dispersion, namely, stock membrane-making solution; and preparing the stock membrane-making solution into the energy-saving membrane on a substrate. The high-transparent ultraviolet-blocking energy-saving membrane of the invention has the advantages of high transparency, good ultraviolet shielding performance, good energy-saving effect, simple preparation process and low cost, therefore, the membrane is suitable for industrial production.

Owner:BEIJING UNIV OF CHEM TECH

Functional composite face fabric and producing method thereof

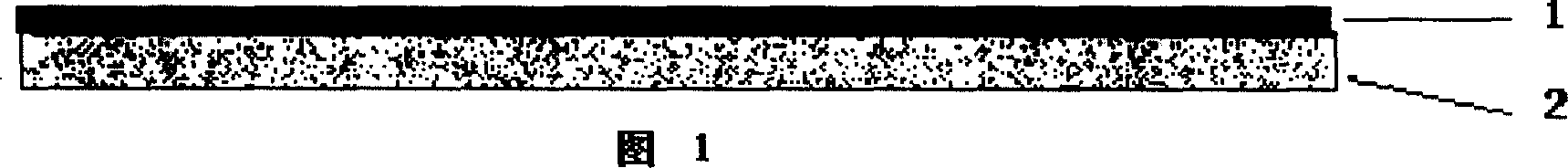

The present invention relates to a new-type functional composite face fabric with several functions of resisting static electricity, resisting radiation, resisting bacteria, killing bacteria, filtering toxic material and protecting health, etc. Said composite face fabric includes functional fibre layer, adhered base layer or surface layer face fabric, the above-mentioned all the layers and combined together by means of physical, chemical or mechanical method so as to obtain the invented product.

Owner:上海兰度科技有限公司

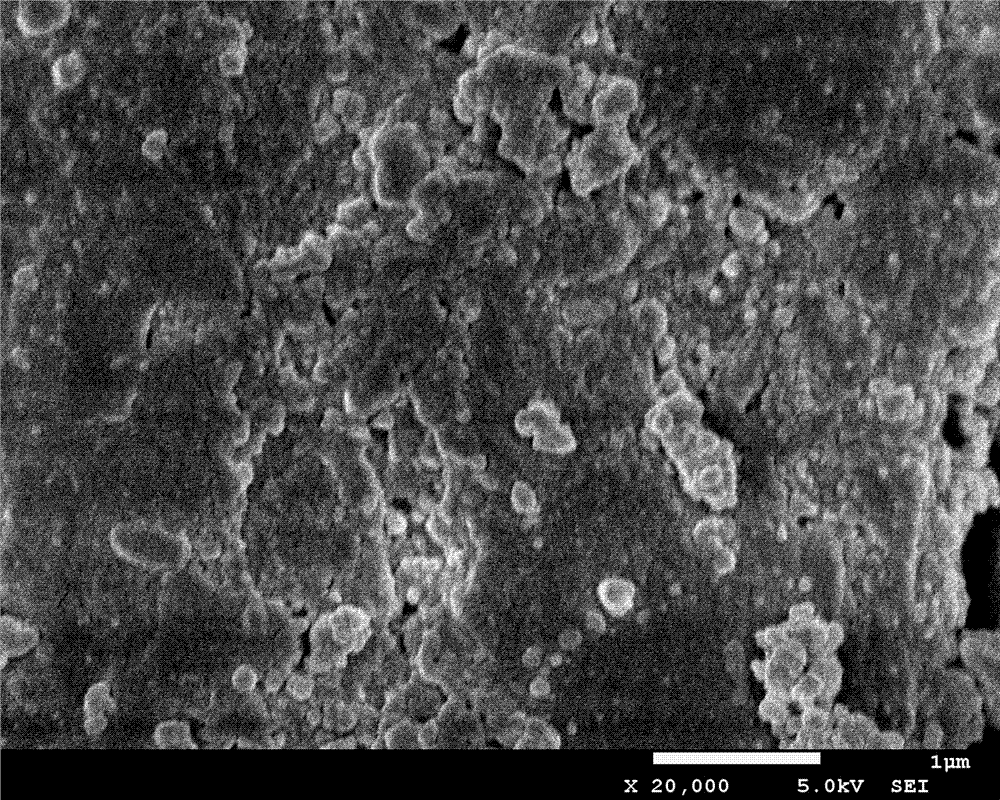

Preparation method of dopamine modified nano-silver textile fabric

InactiveCN105442306AIncrease productivityHigh binding force of nano silverLiquid repellent fibresVegetal fibresAnti bacterialWoven fabric

The invention belongs to the field of multifunctional textile fabrics and particularly relates to preparation of a multifunctional nano-silver textile fabric with antibacterial and water-repellent properties. The nano-silver textile fabric provided by the invention is prepared from raw materials including silver nitrate, a modifying agent and a textile fabric, wherein the mass ratio of the modifying agent to the silver nitrate is 1-50 and the mass of the silver nitrate used in each square meter of the textile fabric is 1g-50g. According to the multifunctional nano-silver textile fabric, dopamine is used as the modifying agent and used for carrying out pre-treatment on the textile fabric; a microwave method is used for preparing and reducing nano silver on the surface of a textile in situ; the multifunctional nano-silver textile fabric has the characteristics of environmental friendliness, high production efficiency, strong nano silver binding force, good repeatability and the like; and the obtained multifunctional nano-silver textile fabric has functional properties of bacterium resistance, water repellency, ultraviolet resistance and the like.

Owner:SICHUAN UNIV

Preparation method of block silicone oil softener

The invention relates to a preparation method of a block silicone oil softener. There are no preparation methods of block silicone oil softeners having the advantages of reliable performances, environmental protection and simple process at present. Raw materials used in the preparation method comprise, by weight, 25-35 parts of block silicone oil, 2.5-4.0 parts of isomeric fatty alcohol polyoxyethylene ether, 0.2-0.3 parts of acetate acid gracial and 60.7-72.3 parts of water. The preparation method comprises the following steps: adding the isomeric fatty alcohol polyoxyethylene ether and the block silicone oil to a reaction bottle, uniformly stirring, emulsifying for 5-10min, adding 15-20 parts of water to obtain a block silicone oil softener precursor, stirring for 10-20min, adding acetate acid gracial and residual water to the block silicone oil softener precursor, uniformly stirring, and filtering to obtain the block silicone oil softener having a pH value of 5-6. The preparation method has the advantages of simple process and easy preparation, and the prepared block silicone oil softener has the advantages of reliable performances and environmental protection.

Owner:浙江亿普新材料科技有限公司

PET (polyethylene terephthalate) protective film for preparing flat-panel display

InactiveCN102134458AReduce polarityImprove cohesionFilm/foil adhesivesSynthetic resin layered productsTectorial membranePolyethylene terephthalate glycol

The invention discloses a PET (polyethylene terephthalate) protective film for preparing a flat-panel display, which is characterized by comprising an optical-level PET protective film base material and low-polarity pressure-sensitive adhesive, wherein the low-polarity pressure-sensitive adhesive is coated on the upper surface of the optical-level PET protective film base material. Since the pressure-sensitive adhesive has the characteristics of low polarity and high cohesive force, is inert, and can be instantaneously attached to the surface of the glass material of the flat-panel display, the protective film prepared from the pressure-sensitive adhesive, optical-level PET protective film and the like has the characteristics of no shedding, easy stripping after coating by vaporization, no adhesive residue, no pollution, high temperature resistance and static resistance, and can effectively avoid damaging the glass lens in the stripping process.

Owner:KUNSHAN BYE MACROMOLECULE MATERIAL CO LTD

Fabric detergent with colour-preserving function and preparation method thereof

InactiveCN101798552AReduced or diminished appearanceReduce or reduce lossesOrganic detergent compounding agentsAmpholytes/electroneutral surface-active compoundsBetaineN-Butanol

The invention provides a fabric detergent with colour-preserving function and preparation method thereof. The detergent contains sodium fatty alcohol ether sulphate, laurylamide propyl betaine, alkyl glucoside, fatty alcohol polyoxyethylene (9) ether, sodium alpha-olefin sulphonate, 3-methooxyl-3-methyl-1-butyl alcohol, 1-vinyl pyrrolidone, 1-vinyl copolymer, sodium chloride, 1, 2-benzisothiazolin-3-one, essence, citric acid monohydrate and deionized water. The invention obtain favourable detergency in clothing washing process while realizing colour-preserving effect; the detergent is environmentally friendly, cleaning and colour-preserving are completed in one step, the detergent is non-toxic and non-irritant, and resource is saved.

Owner:北京绿伞科技股份有限公司

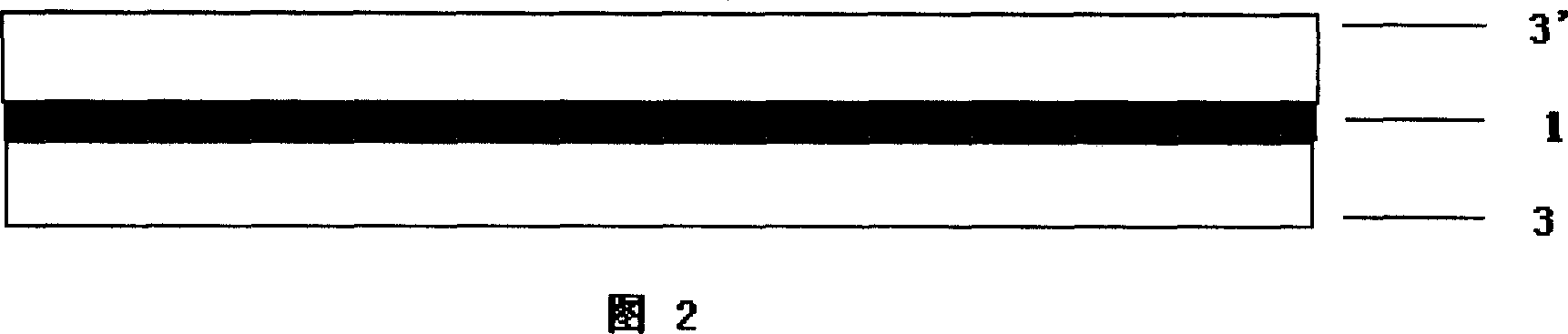

Biaxial stretching polypropylene contraction single film and its preparation method

InactiveCN1476969AEasy to stretchWith transparencySynthetic resin layered productsInter layerEngineering

The present invention discloses a bidirectional stretched polypropylene single film and its preparation method. The single film is divided into upper, intermediate and lowr three-layer structure. Itsexternal layer is film anti-sticking smooth face layer. Intermediate layer is film core layer and lower layer is film anti-sticking smooth face layer. The upper layer is formed from homopolypolypropylene and anti-sticking slipping agent whose weight content is 0.2-6%, its intermediate layer contains homopolypolypropylene and its lower layer contains homopolypolypropylene and anti-sticking slipping agent whose weight content is 0.2-6%. Its production method includes the steps of preparing material, extruding, casting sheet, longitudinal stretching, transverse stretching and rolling up.

Owner:HAINAN SHINER IND

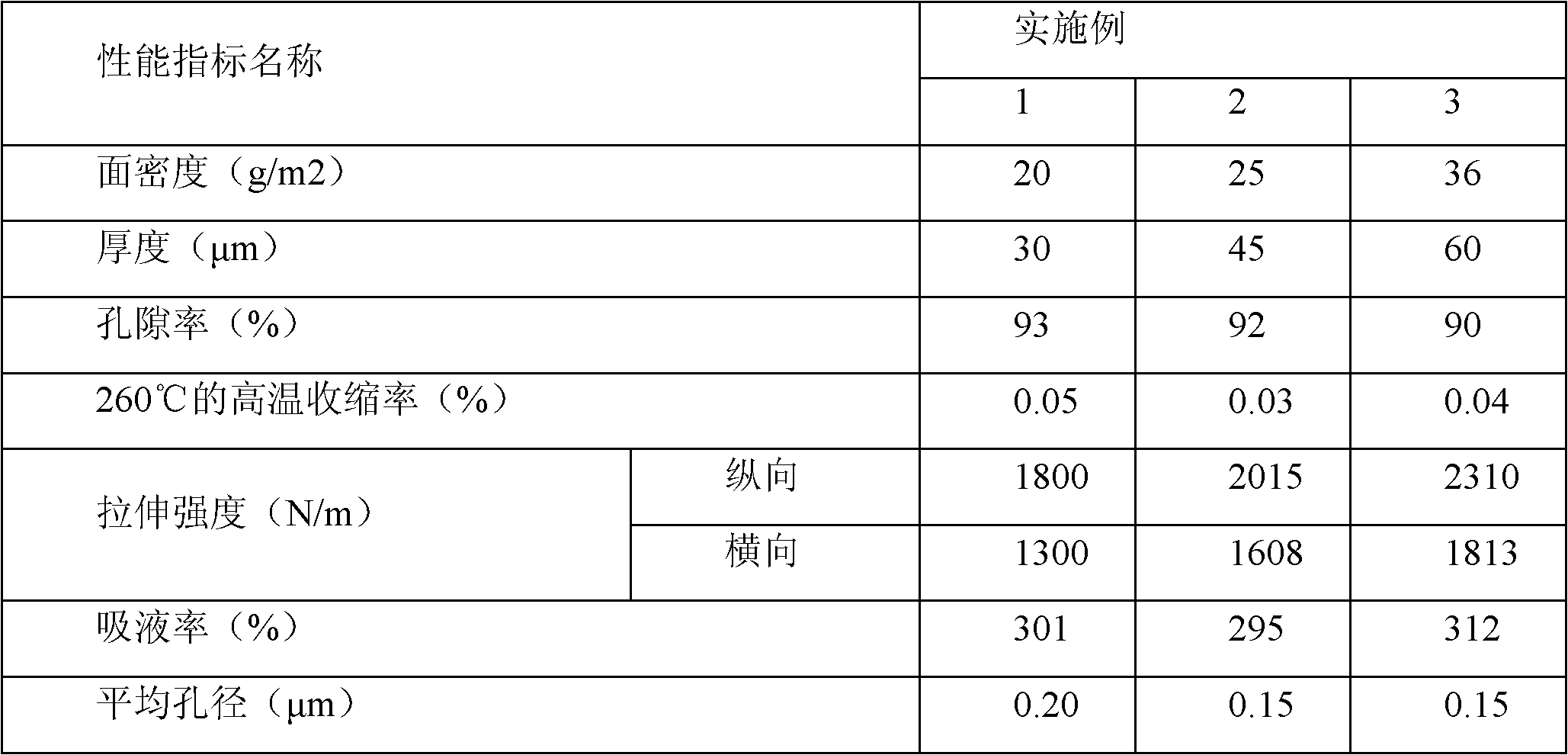

High-temperature resistant micropore thin film material and application thereof

ActiveCN102522514AImprove liquid absorption performanceExcellent liquid retentionCell component detailsPorosityAdhesive

The invention relates to a high-temperature resistant micropore thin film material prepared from inorganic fiber, synthetic fiber, natural organic fiber, nano-grade inorganic powder and an adhesive. The thin film material is a non-woven fabric material prepared through one-step molding with a wet papermaking technology combined with a coating technology. The material has a 3-dimensional network structure and porosity higher than 90%. The high-temperature resistant micropore thin film material has an outstanding high-temperature resistance. Under a temperature of 260 DEG C, excellent dimension and structure stabilities of the material are maintained for a long time. The material has excellent liquid absorbency, excellent liquid retaining capacity, and 3-dimensional stereo pores with good uniformity. An average pore size is 0.02-2.5mum. The high-temperature resistant micropore thin film material can be used as lithium ion power battery separation films, super-capacitor separation films, or filtrating materials.

Owner:莱州联友金浩新型材料有限公司

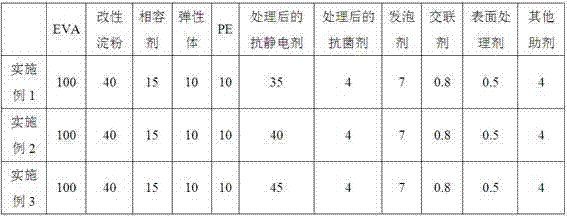

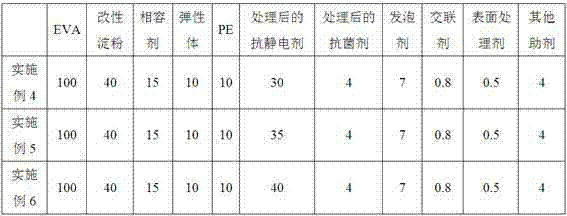

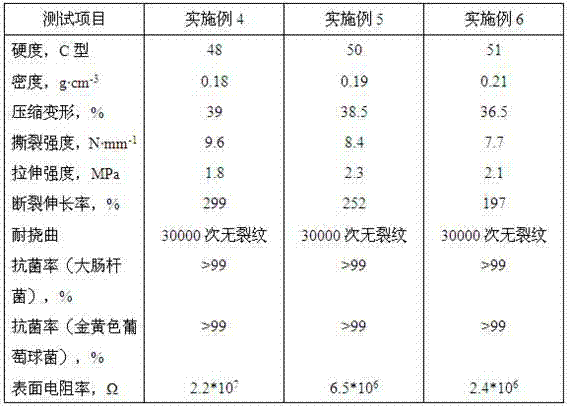

Antibacterial and antistatic EVA/starch/PE composite foaming material and preparation method thereof

The invention discloses an antibacterial and antistatic EVA (ethylene-vinyl acetate) / starch / PE (polyethylene) composite foaming material and a preparation method thereof. The antibacterial and antistatic EVA / starch / PE composite foaming material is prepared by: subjecting completely degradable starch and EVA, PE, a compatibilizer, as well as an elastomer to blending in a Banbury mixer, and adding functional additives, i.e. an antibacterial agent and an antistatic agent, and an inorganic filler, a cross-linking agent, a foaming agent and other aids. According to the invention, the antibacterial agent and the antistatic agent are blended into the foaming material, and the formula is scientific and reasonable, so that the product has both antibacterial and antistatic properties, and can satisfy life and some special environments.

Owner:福州市福通高新材料有限公司

Water-borne polyurethane synthetic leather size and preparation method and application thereof

InactiveCN102863605AHigh peel strengthModerate resilienceTextiles and paperCross-linkPolymer science

The invention discloses a water-borne polyurethane synthetic leather size and a preparation method and an application thereof. The water-borne polyurethane synthetic leather size comprises diisocyanate, poly dibasic alcohol, phosphoric acids, catalysts, hydrophilic chain extenders, neutralizers, small molecule chain extenders or cross-linking agents, surface active agents and the like. The preparation method of the water-borne polyurethane synthetic leather size includes (1) polymerizing the diisocyanate, the poly dibasic alcohol and the phosphoric acids under the action of the catalysts; (2) adding the hydrophilic chain extenders for chain extension; (3) cooling and neutralizing a reaction solution, and continuing the reaction by adding the small molecule chain extenders or cross-linking agents and the surface active agents; and (4) emulsifying and adding auxiliaries to uniformly stir. According to the water-borne polyurethane synthetic leather size and the preparation method and the application thereof, the phosphoric acids are added in the formula, the wettability of the ultimately prepared synthetic leather size and non-woven fabrics is improved, further the process for preparing the synthetic leather can be simplified, properties of the prepared synthetic leather are improved, simultaneously the feed ratio of the diisocyanate and the poly dibasic alcohol is strictly controlled, and the ultimately prepared synthetic leather has the advantages that the peel strength and the hand feeling are good, and the rebound resilience is moderate.

Owner:ZHANGZHOU INST OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com