Patents

Literature

110results about How to "With heat conduction" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

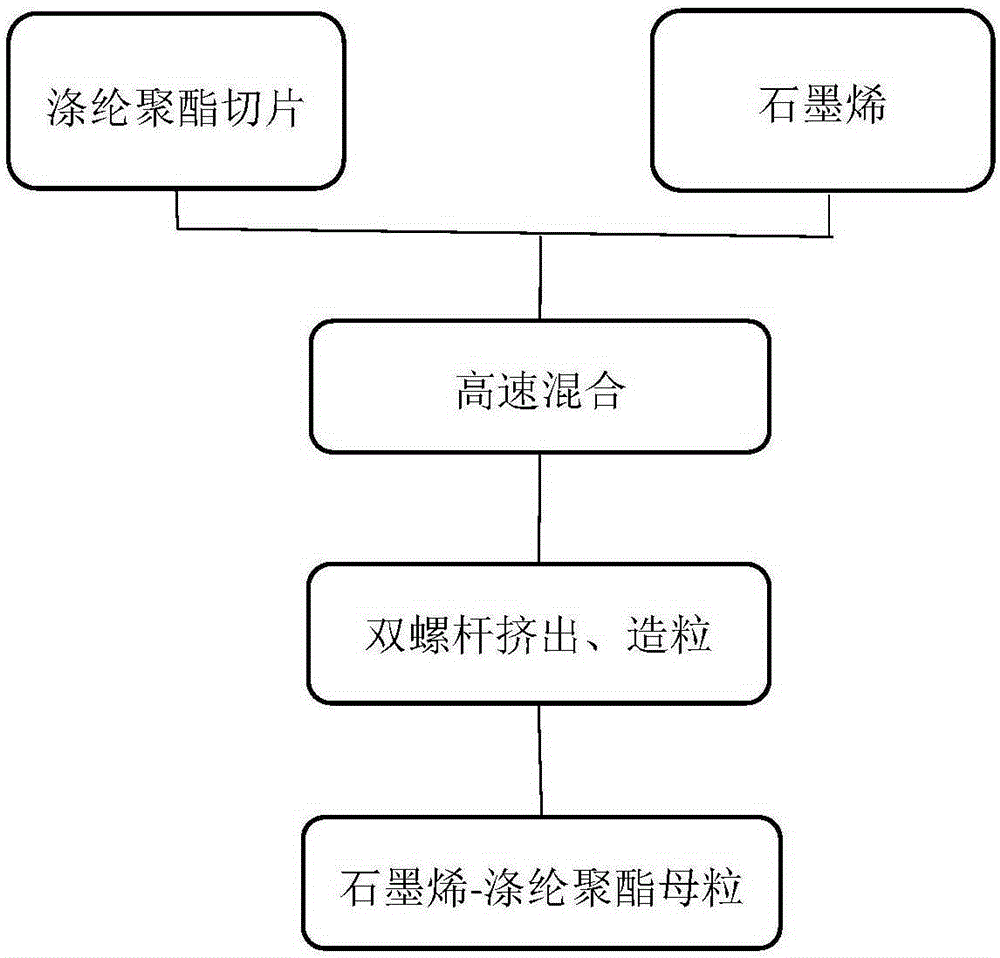

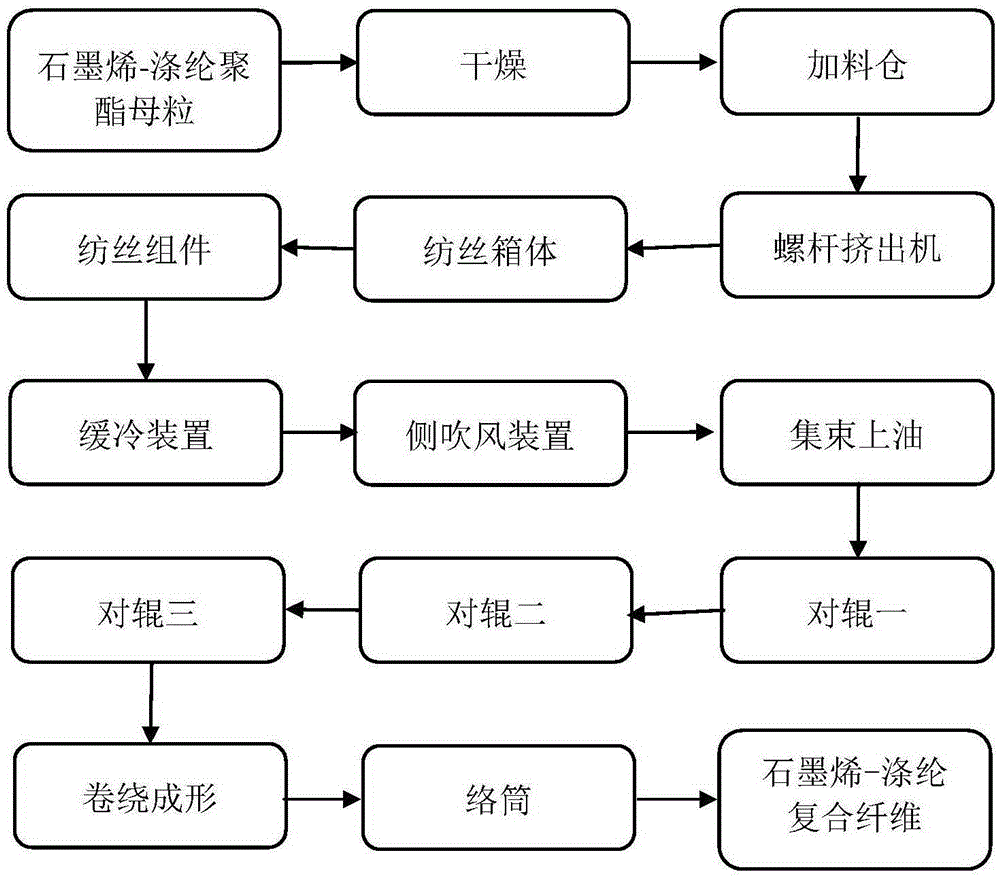

Preparation method of graphene-polyester nano-composite fiber

ActiveCN105200547AHigh breaking strengthEasy to prepareElectroconductive/antistatic filament manufactureFilament/thread formingNanometreSurface modification

The invention discloses a preparation method of graphene-polyester nano-composite fiber. The preparation method comprises the step of preparing graphene-terylene polyester composite master batch and the step of preparing the graphene-polyester nano-composite fiber from the composite master batch. Compared with other conventional methods, the preparation method has the advantages that the technology is extremely simple, the reinforcing material is excellent in performance and low in cost; besides, excellent mechanical property and functional characteristics of graphene self endow the nano-composite fiber with functionalities like high strength and antistatic property, surface-modified and modified graphene has good dispersity and perfect interfacial compatibility in terylene polyester polymer matrix, which enables graphene to be effectively and uniformly compounded with a terylene polyester chip base material.

Owner:NANTONG QIANGSHENG GRAPHENE TECH CO LTD

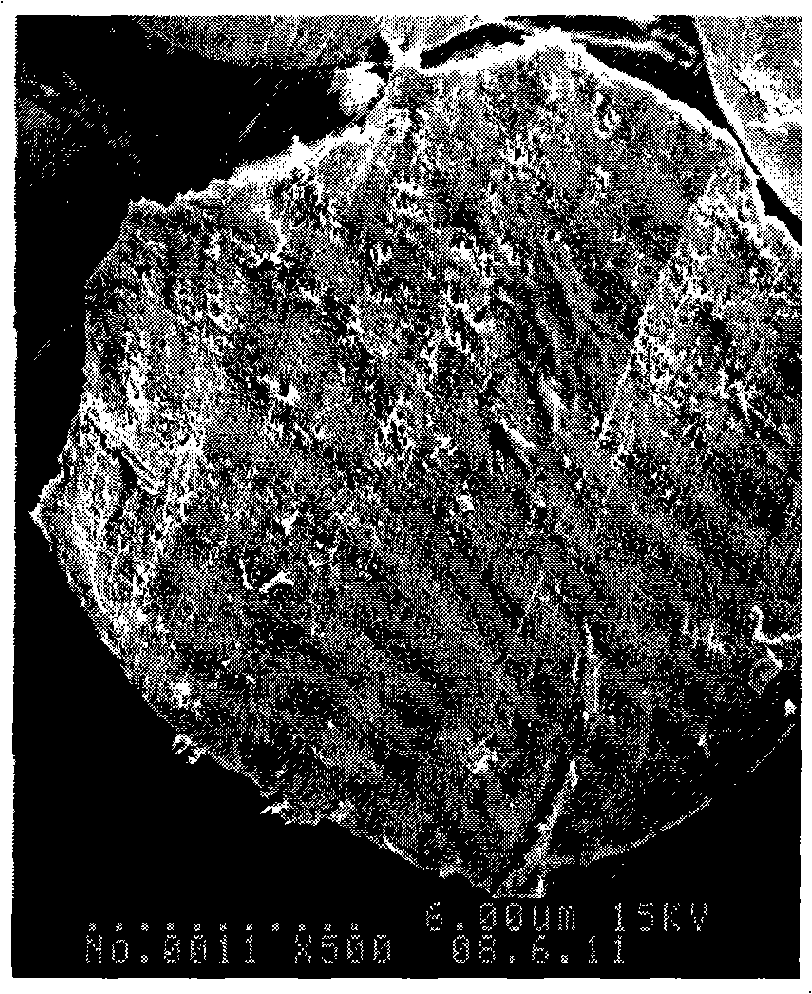

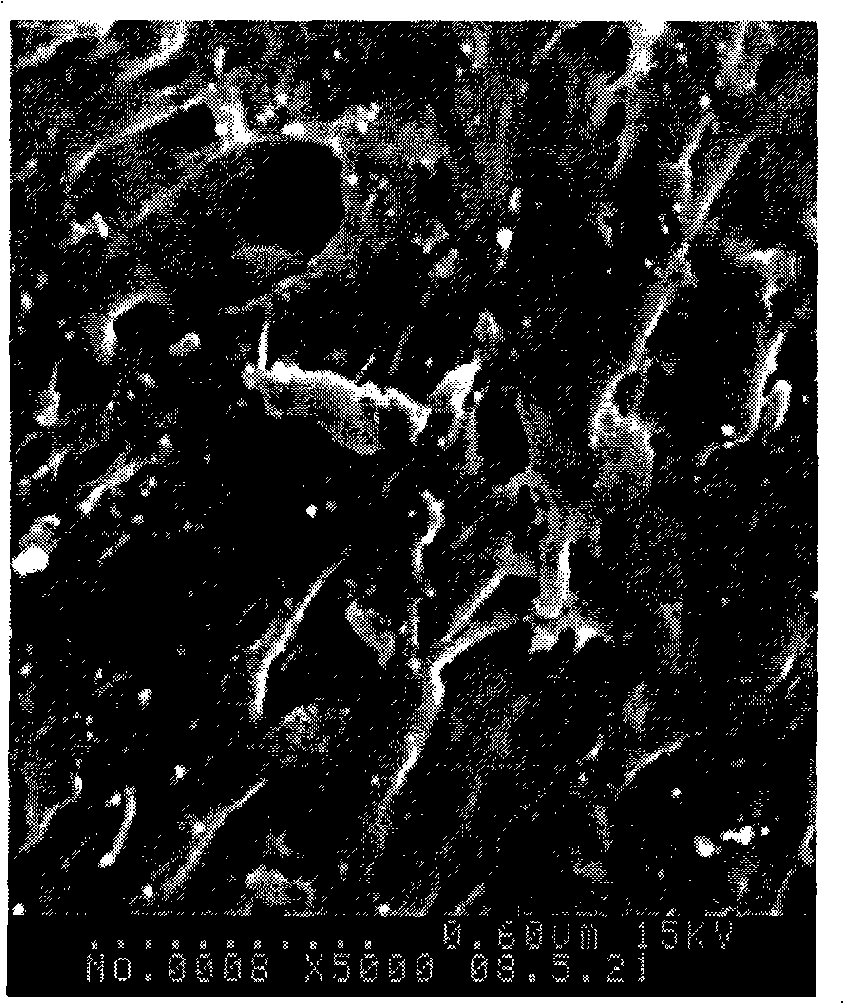

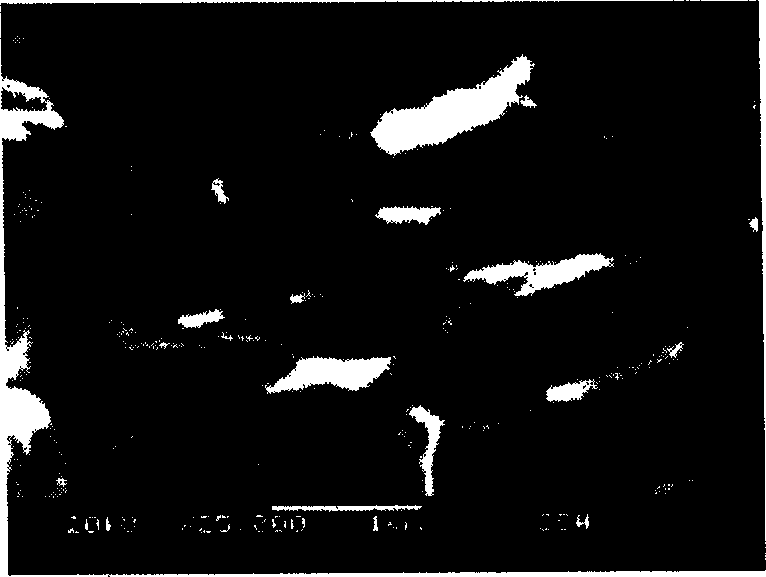

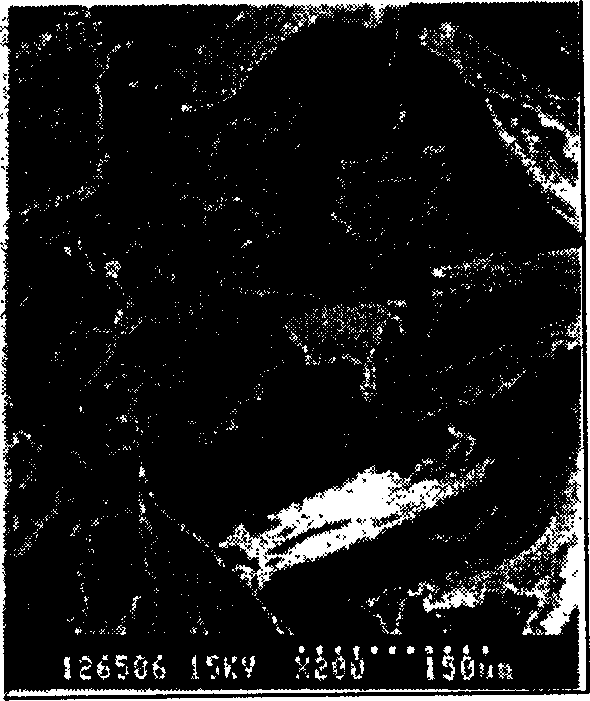

Polyiner/laminate inorganic nano composite material and its milling shearing preparation method

A nanometre-class polymer / laminated inorganic substance composite material features that it is prepared by use of the millstone-shaped force chemical reactor, which has a unique 3-D shear structure to provide strong squeeze-shear force field for grinding inserting, dispersing, and mixing to prepare the polymer / laminated inorganic substance composite powder, and then the said nanometre-class composite material is prepared by the universal processing method.

Owner:SICHUAN UNIV

Method for plating chromium on surface of plastic material

InactiveCN101760721AIncrease metallic lusterHigh hardnessVacuum evaporation coatingSputtering coatingPolymeric surfacePlastic materials

The invention relates to the technical field of plating films on the surface of organic polymers. The invention is realized through the following technical scheme that: the method for plating chromium on the surface of plastic materials sequentially comprises (1) a step for pretreatment; (2) a step for preparing a bottom plating layer; (3) a step for preparing a metallic chromium plating layer; (4) a step for preparing a surface plating layer; (5) inspection; and (6) packaging. The invention is suitable for the mechanical industry, transparent materials and other aspects.

Owner:安徽翰邦科技咨询有限公司

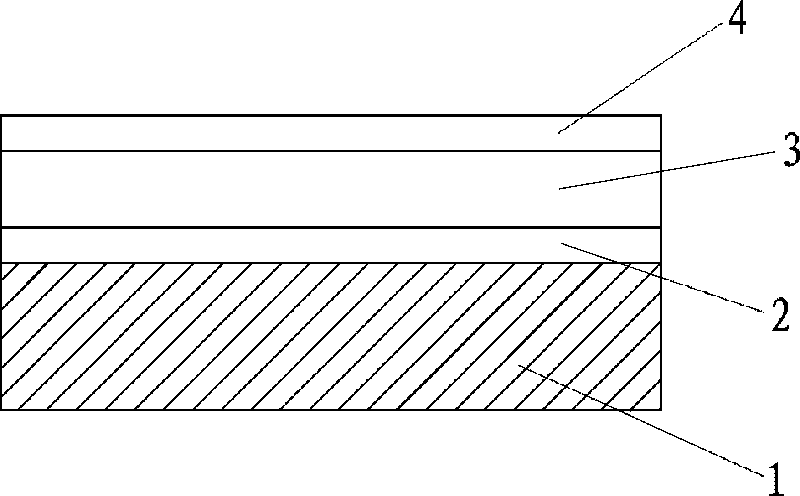

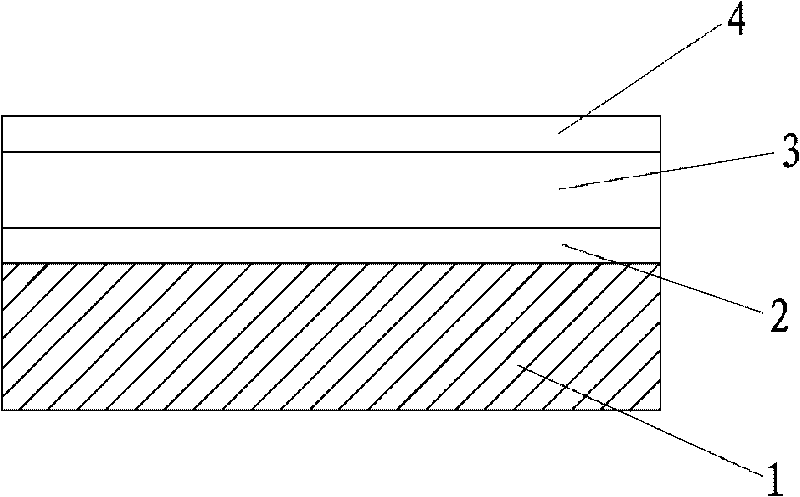

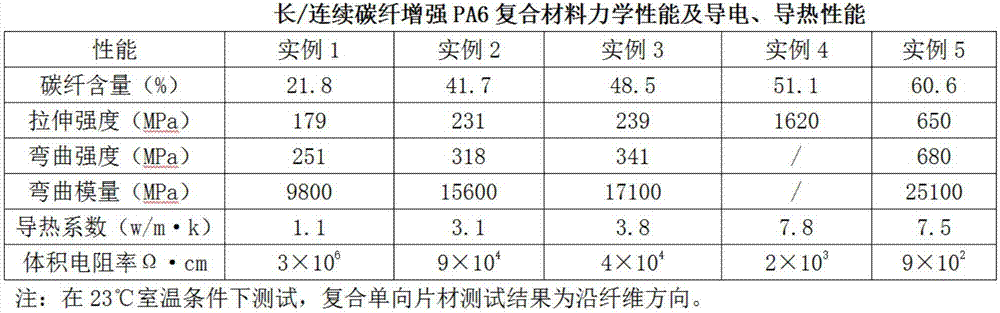

Continuous carbon fiber-reinforced PA6 composite with high strength, high modulus, electrical conductivity and thermal conductivity, and preparation method thereof

InactiveCN106939124AImprove conductivityHigh thermal conductivityHeat-exchange elementsFiberCarbon fibers

The invention relates to a continuous carbon fiber-reinforced PA6 composite with high strength, high modulus, electrical conductivity and thermal conductivity, and a preparation method thereof. The composite comprises, by weight, (1) 100 parts of PA6 resin, (2) 0.2 to 1 part of an anti-oxidant, (3) 0.2 to 1.2 parts of a flow promoter, (4) 2 to 10 parts of a flexibilizer and (5) 1 to 5 parts of a compatilizer. The preparation method comprises the following steps: premixing the above components according to a certain ratio, carrying out melting and mixing via a double / single-screw set and then extruding the obtained mixture into a die head for flow splitting and impregnation so as to prepare the continuous carbon fiber-reinforced PA6 composite with high strength, high modulus, electrical conductivity and thermal conductivity. Compared with conventional staple carbon fiber-reinforced PA6 composites, the continuous carbon fiber-reinforced PA6 composite prepared by using a special impregnation process in the invention has greatly improved mechanical properties since the length retention rate of carbon fibers in a PA6 carrier is high or continuous and has substantially improved electrical conductivity and thermal conductivity due to a continuous network structure, so the application range of the composite is greatly broadened.

Owner:浙江胜钢新材料有限公司

Preparing method of polytetrafluoroethylene / polyaniline electroconductive plastic modified by expanded graphite

InactiveCN103131104ASuperconductingWith heat conductionNon-conductive material with dispersed conductive materialWater/sewage treatment by sorptionPolymer scienceHeat conducting

The invention discloses a preparing method of polytetrafluoroethylene / polyaniline electroconductive plastic modified by expanded graphite. Polytetrafluoroethylene is compound with polyaniline, and at the same time, the expanded graphite and nano-silver are added for modification. The prepared material is good in electric-conducting property and heat-conducting property, good in anti-corrosion property, easy to process and form, low in cost, and easy to obtain, and can be used as cathode material to absorb pollutants in water.

Owner:高润宝

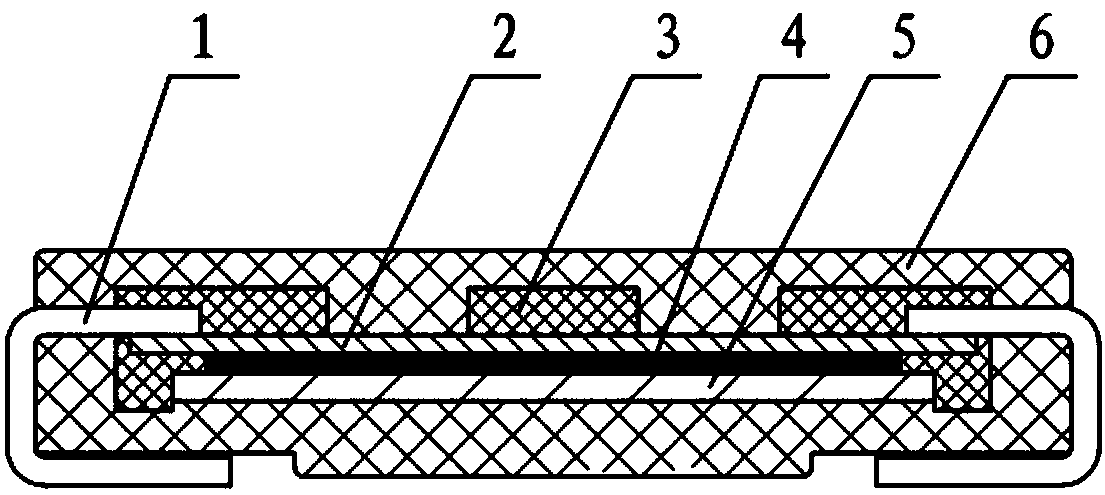

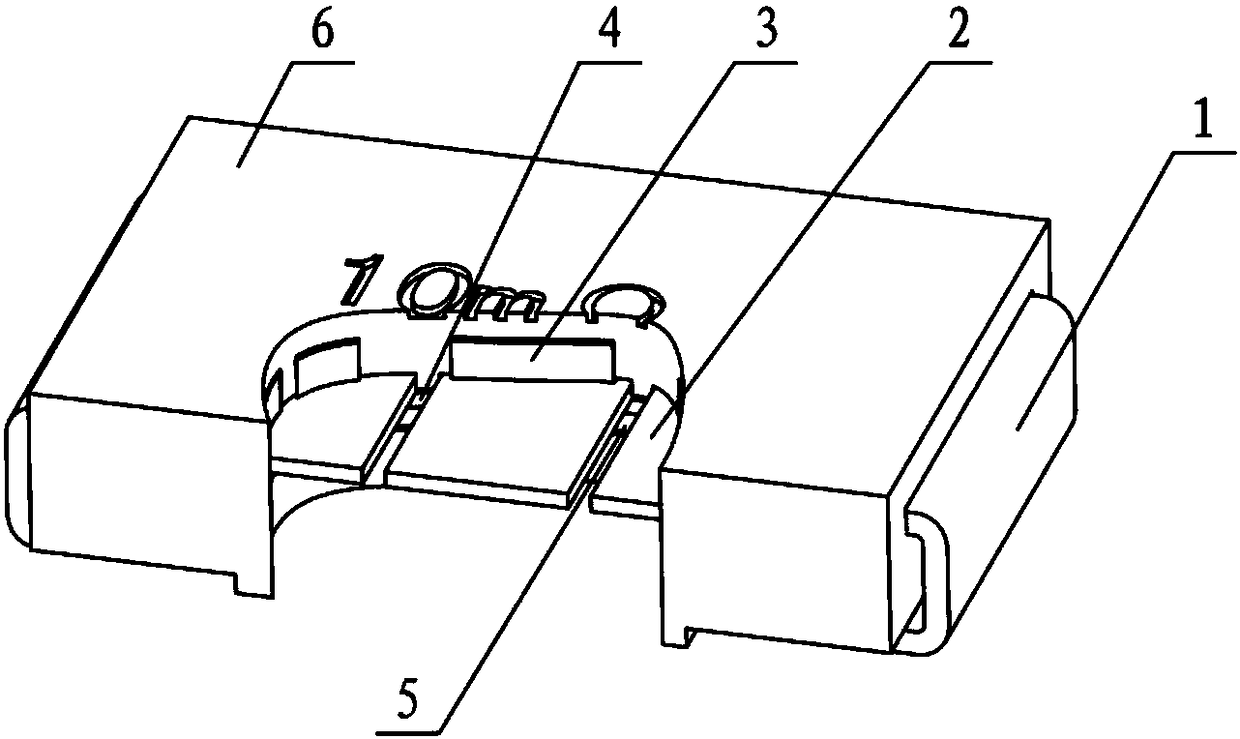

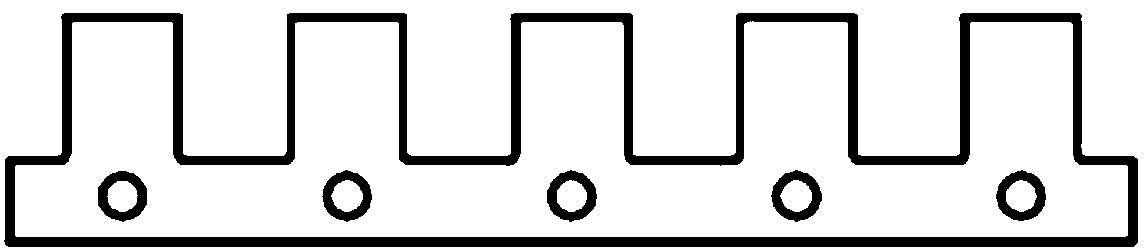

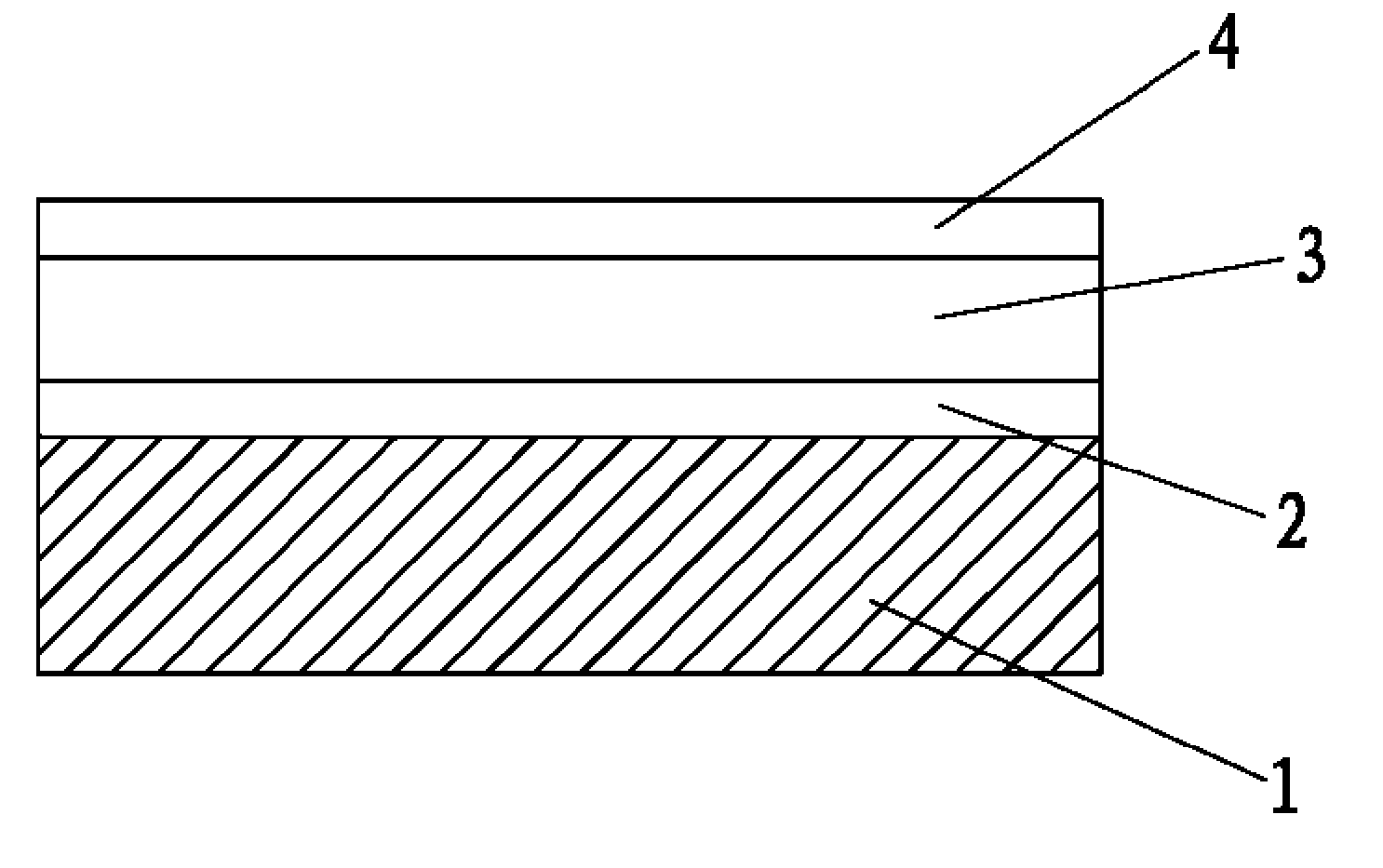

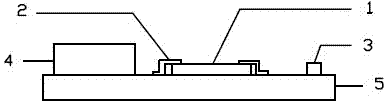

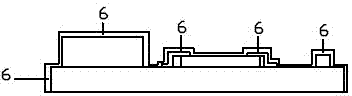

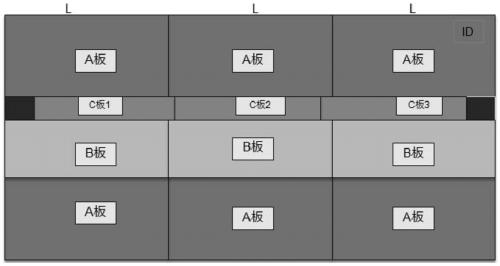

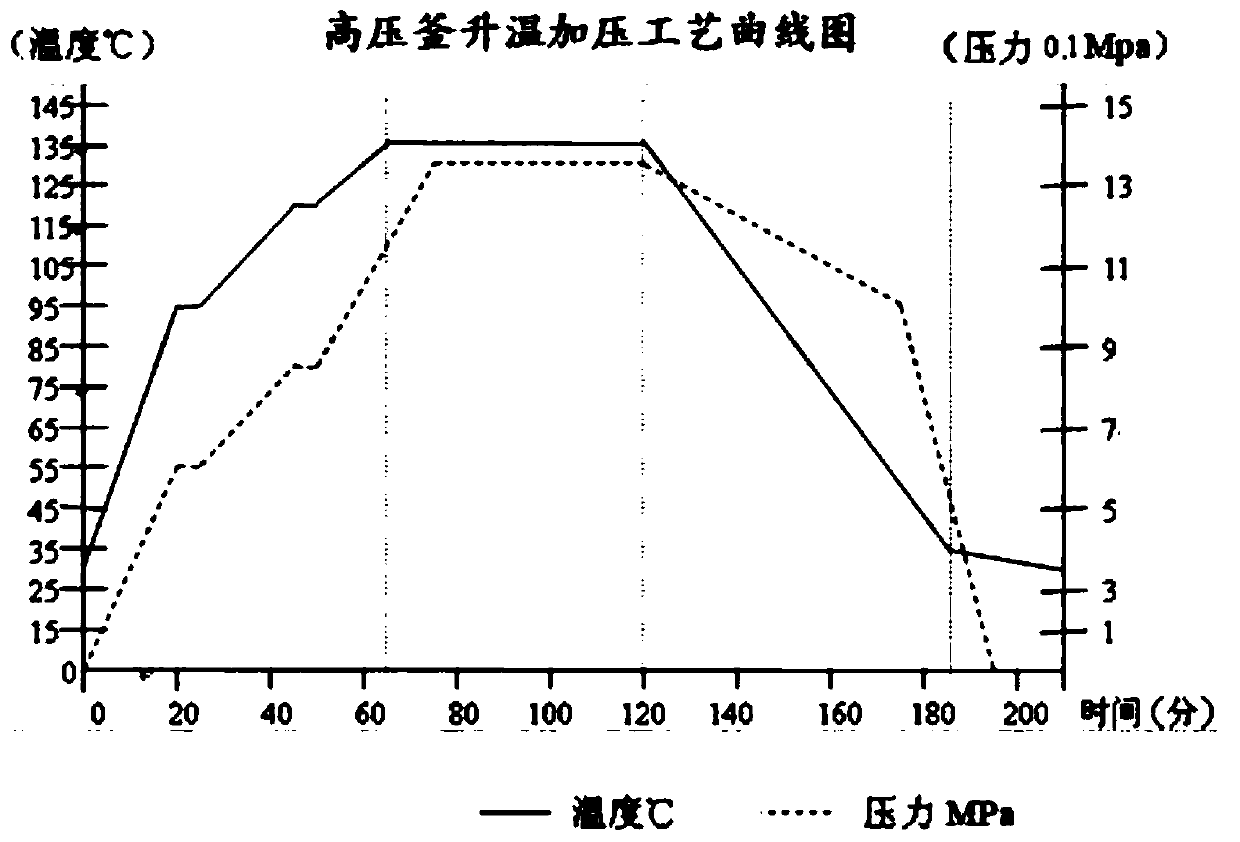

Chip resistor and manufacturing method thereof

PendingCN108538527AImprove insulation performanceHigh temperature and high humidity resistanceEnvelope/housing resistor manufactureResistor cooling/heating/ventillationAdhesiveHeat sink

The invention provides a chip resistor. The chip resistor comprises a resistor sheet, an inner shell which wraps the surface of the resistor sheet, a heat sink bonded to the surface of the resistor sheet through an insulating thermal conductive adhesive, an outer shell at the outermost layer and electrode pins connected with the two ends of the resistor sheet and located outside the outer shell, and the inner shell is provided with a hollowed-out part for coating the insulating thermal conductive adhesive. A manufacturing method of the chip resistor includes the steps of blanking the resistorsheet and the electrode pins, then processing and connecting the resistor sheet and the electrode pins to form a resistor body, conducting rough adjustment and fine adjustment on a resistance value ofthe resistor body, packaging for the first time to form the inner shell, blanking the heat sink, bonding the heat sink to the resistor sheet through the insulating thermal conductive adhesive, packaging for the second time, cutting and bending the electrode pins to form a side U shape, and finally conducting post-processing to obtain the chip resistor. According to the chip resistor, after roughadjustment and fine adjustment are conducted on the resistance value of the resistor body, packaging is conducted for the first time, a layer of inner shell wraps the resistor body to ensure that theheat sink is not contact with the resistor sheet, and the obtained chip resistor has high precision, fast heat dissipation, long service life, safety and reliability, and high product yield.

Owner:常德思高技术有限公司

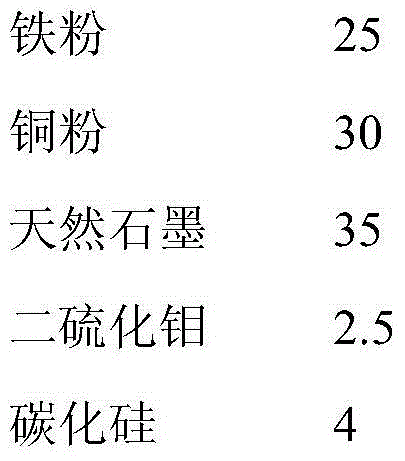

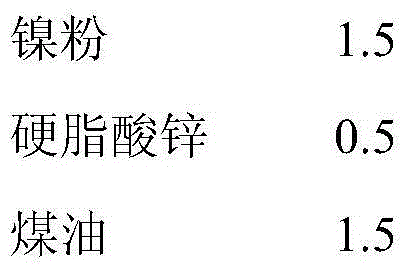

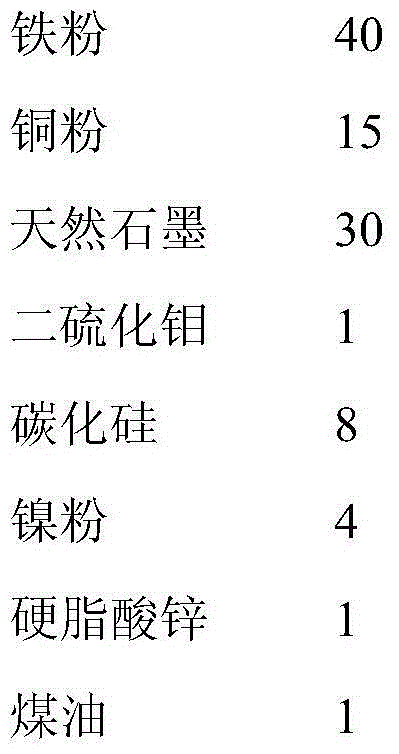

Material for manufacturing powder metallurgy brake block of electric locomotive

ActiveCN105983687ALight in massImprove the lubrication effectTurbinesOther manufacturing equipments/toolsKeroseneBrake shoe

The invention provides a material for manufacturing a powder metallurgy brake block of an electric locomotive. The brake block is a brake pad used for braking of the electric locomotive and comprises iron powder, copper powder, natural graphite, an additive and lubricant. The additive comprises molybdenum disulfide, silicon carbide and nickel powder. The lubricant comprises zinc stearate and kerosene. The electric locomotive brake block which is made of the material provided by the invention is resistant to heat, stable in friction coefficient under the high-load condition, small in attenuation and abrasion, good in heat conduction, capable of quickly conducting out the friction heat of the surface of a friction pair and good in physical, chemical and mechanical properties.

Owner:SUZHOU DONEKA NEW MATERIALS CORP LTD

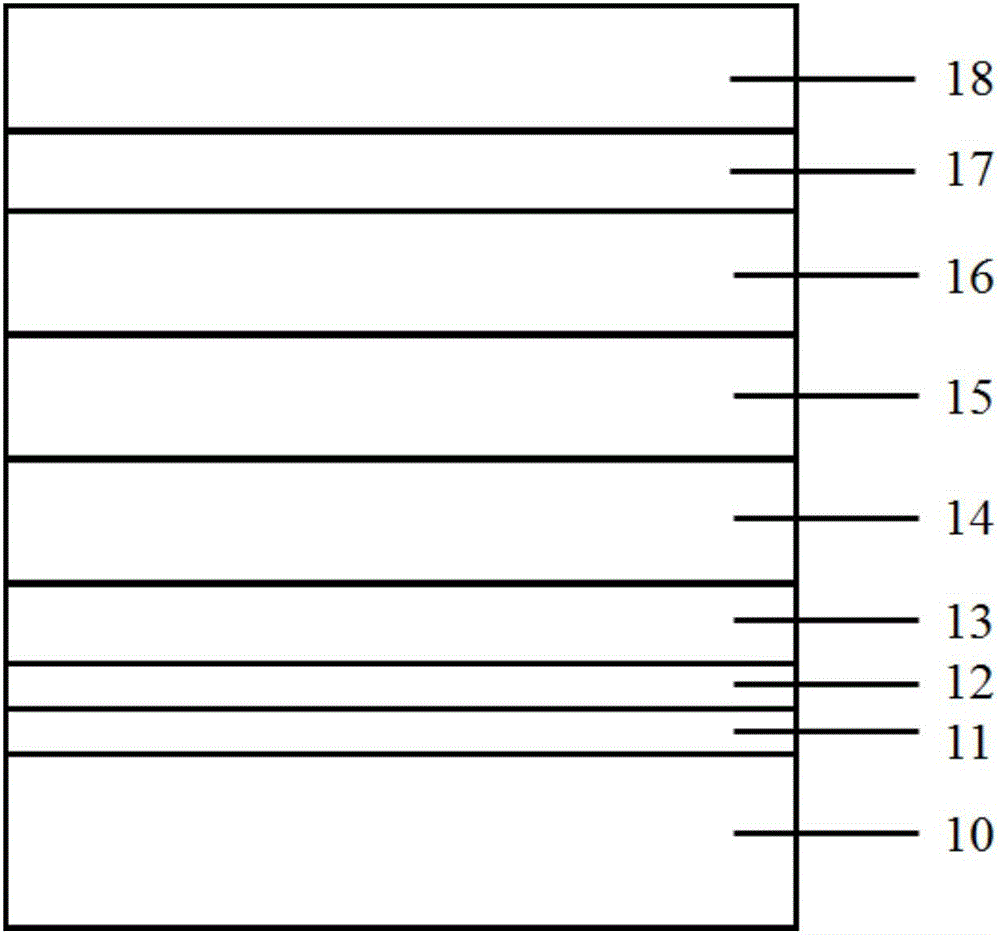

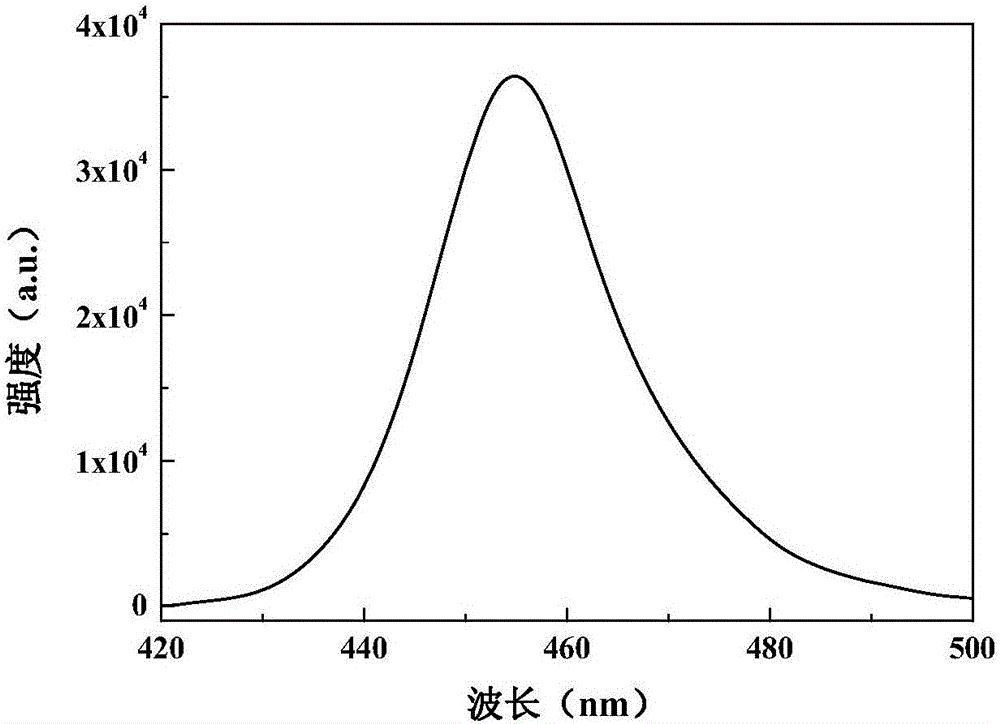

LED epitaxial wafer growing on glass substrate and preparation method of LED epitaxial wafer

ActiveCN106784224AImprove luminous efficiencyQuality improvementSemiconductor devicesOptoelectronicsNon doped

The invention discloses an epitaxial wafer growing on a glass substrate. The epitaxial wafer comprises an aluminum metal layer growing on the glass substrate, a silver metal layer growing on the aluminum metal layer, an AlN buffer layer growing on the silver metal layer, a GaN buffer layer growing on the AlN buffer layer, a non-doped GaN layer growing on the GaN buffer layer, an n-type doped GaN film growing on the non-doped GaN buffer layer, an InGaN / GaN multiple-quantum trap growing on the n-type doped GaN film and a p-type doped GaN film growing on the InGaN / GaN multiple-quantum trap. The invention further discloses a preparation method of the LED epitaxial wafer growing on the glass substrate. The LED epitaxial wafer growing on the glass substrate has the advantages of low defect density, good crystallization quality and excellent light emitting performance.

Owner:SOUTH CHINA UNIV OF TECH

Nano zinc oxide / polypropylene / polylactic acid composite fiber material and preparing method thereof

InactiveCN101407948ASmall particle size distribution rangeGood dispersionConjugated synthetic polymer artificial filamentsArtifical filament manufactureFiberZno nanoparticles

The invention relates to a nano zinc oxide / polypropylene / polylactic acid composite fiber material; the components thereof comprise nano zinc oxide, polypropylene and polylactic acid, with the weight percentage of 0.1 to 20: 80 to 99.9; and the preparation thereof comprises the following steps: (1) nano zinc oxide powder is arranged in a special transmission device of a plasma treatment device for carrying out modification treatment to the nano zinc oxide powder; (2) the nano zinc oxide powder prepared by plasma treatment is mixed with polypropylene / polylactic acid powder or polypropylene / polylactic acid slices according to the proportion of 0.1 to 20 percent, a double screw extruder or a single screw extruder is used for mixing the materials, and melting mixing is carried out at 180 to 260 DEG C to obtain nano zinc oxide / polypropylene / polylactic acid composite slices; and (3) the slices are treated with spinning to obtain the nano zinc oxide / polypropylene / polylactic acid composite fiber material. The composite fibers produced by the method have good spinnability and high fiber-forming strength, and is characterized by controlled conductivity, heat conduction, antistatic and biodegradation.

Owner:DONGHUA UNIV +1

Blended yarn with silver ion and its making process

The present invention relates to spinning engineering, and is especially one kind of blended yarn with silver ion and its producing process. The blended silver ion yarn is produced through three times of merging, four times of mixing and other steps, and has certain silver ion content and high silver ion homogeneity. The blended silver ion yarn is used in weaving fabric containing blended silver ion fiber in 3-9 wt% and chemical fiber in 91-97 wt%, and the fabric has excellent wearability, and antistatic, bacteriostatic, deodorizing, heat conducting and radiation resisting functions.

Owner:SHANGHAI SHENAN TEXTILE

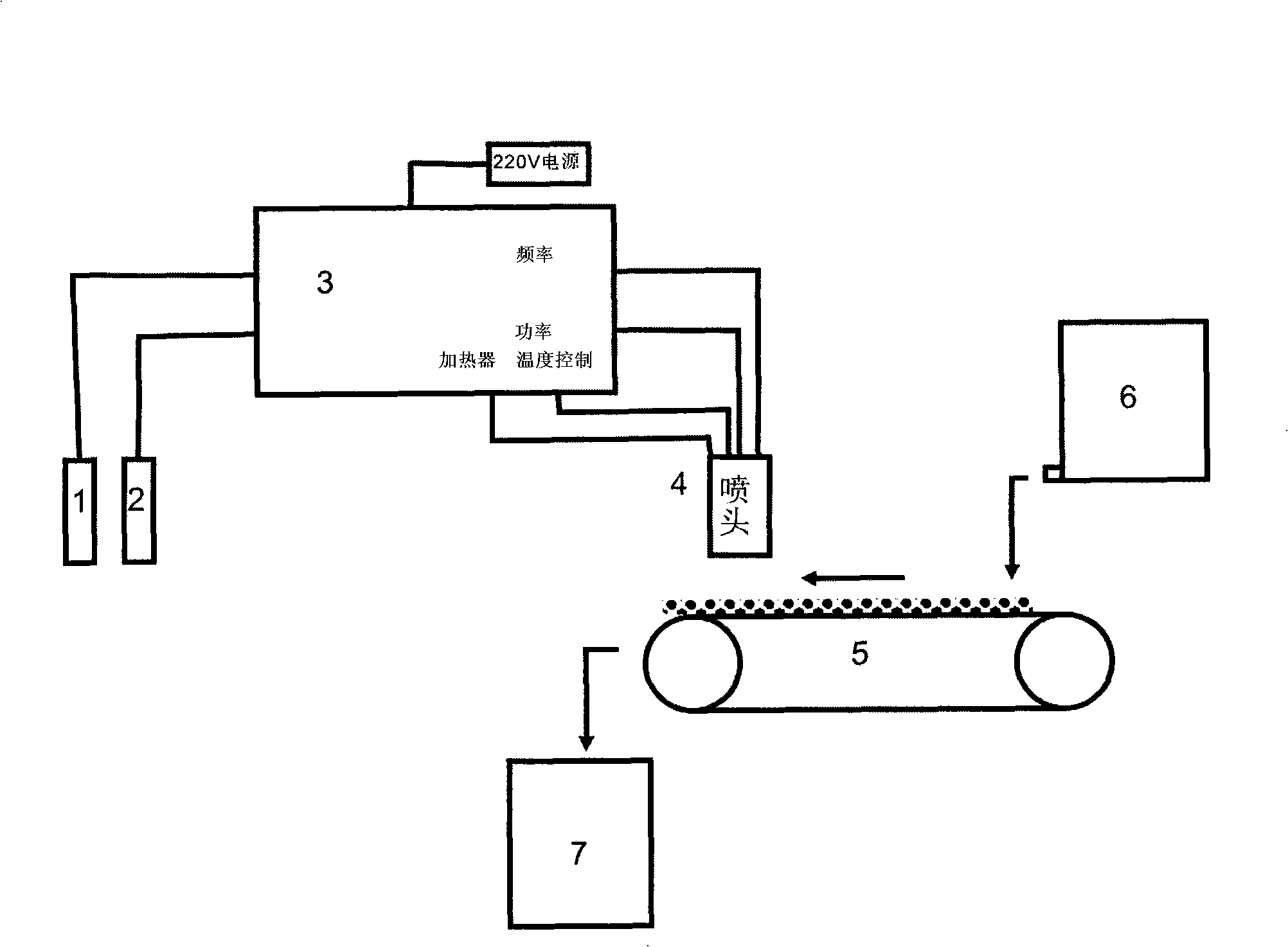

Preparation method of ultrahigh-conductivity 3D printing carbon fiber composite wire

InactiveCN106317767AHigh temperature resistantFriction-resistantAdditive manufacturing apparatusFiberEpoxy

The invention discloses a preparation method of an ultrahigh-conductivity carbon fiber composite wire for 3D printing. The formula comprises the following components: 60-70 parts of HKT800 carbon fiber, 60-64 parts of thermoplastic resin, 5-8 parts of boron trifluoride monoethylamine, 1-4 parts of AG80 epoxy resin, 1-3 parts of antioxidant, 2-5 parts of nanoparticle carrier type catalyst, 2-8 parts of color masterbatch and 4-10 parts of processing aid; and the preparation method comprises the following steps of: preparing the materials according to the formula, and mixing for 2-4min in a high-speed kneading machine; drying for 3-5h in a vacuum drum drying oven at 150 DEG C; and performing extrusion, strip casting, drafting and rolling through a twin-screw extruder to obtain 3D printing carbon fiber composite wires different in wire diameter. The material printed by the 3D printing carbon fiber composite wire has the characteristics of high-temperature resistance, friction resistance, heat conductivity, corrosion resistance and ultrahigh conductivity; the preparation technology is simple and feasible while the cost is low.

Owner:SUZHOU POLYKING COMPOSITE +2

Alloy conductive plastic

InactiveCN102888091AConductive withHigh volume resistivityNon-conductive material with dispersed conductive materialNylon materialSurface conductivity

The invention discloses an alloy conductive plastic, which belongs to the technical field of plastics. The alloy conductive plastic comprises a substrate and a conductive material, wherein the substrate is a nylon material of which the relative viscosity is 1.5-1.7; and the conductive material is alloy powder of Cu, Fe, Ni and Ag of 100-150 meshes, and is blended, pelletized and molded. The volume ratio of the alloy powder of Cu, Fe, Ni and Ag is 1:1:1:1, and the mass ratio of the nylon material to the alloy powder is 10:3-10:6. The conductive plastic produced in the invention has the advantages of high volume resistivity, low specific weight, high tensile strength, current conductivity, heat conductivity, wear resistance, self-lubrication and the like, and can be used for manufacturing various plastic products having the characteristics of current conductivity, heat conductivity, electromagnetic shielding, static resistance and the like.

Owner:DALIAN CHUANGDA TECH TRADE MARKET

Mixed material containing graphite geothermal cushion and production technique thereof

The invention discloses a graphite-containing geothermal cushion layer mixing material and production technology thereof. The mixing material is prepared by the following steps: graphite powder, sepiolite cashmere, lime putty, water-proofing powder, fine sand, water, an auxiliary agent and so on are evenly mixed into slurry according to the mixture ratio, and the needed blank is prepared and is naturally air-dried or dried and maintained; and the graphite powder, the sepiolite cashmere, the water-proofing powder, and the auxiliary agent can also be directly and evenly mixed according to the mixture ratio and are directly used for construction. In the material, the graphite powder has transverse heat conduction function, and the sepiolite cashmere can perform thermal insulation, make the heat radiated in a balanced mode, is more durable, prevents cracks and increases the toughness, so as to ensure that a floor is evenly heated, prolong the average life of the floor, and also improve the effect of geothermal heating. The material has the advantages of good heat conduction and thermal insulation effect, simple production technology, and convenient operation, and can be widely applied to the field of geothermal heating.

Owner:晟茂(青岛)先进材料有限公司

Metallization process for honeycomb epoxy glass fiber reinforced plastic antenna

ActiveCN103741148AWith heat conductionWith magnetic permeabilityRadiating elements structural formsLiquid/solution decomposition chemical coatingEpoxyAntenna design

The invention discloses a metallization process for a honeycomb epoxy glass fiber reinforced plastic antenna. The metallization process comprises a sequential technological process of antenna surface sealed modification treatment and antenna pre-treatment, oil-removing coarsening and modified sealed material coarsening and antenna metallization, and chemical formation of a metal film, electroplating and thickening and three-proofing post-treatment of a metal film layer. After being metalized, the honeycomb interlayer structure epoxy glass fiber reinforced plastic antenna has a metal appearance; surface conduction, heat conduction, magnetism conduction, solvent etching resistance, good conduction resistance and various electrical performance indexes can meet antenna design requirements. Compared with a conventional glass fiber reinforced plastic non-metal material metallization process, the antenna sealed modification treatment is simple in technological process and does not need special technological equipment including plasmas or laser induction and the like; the metallization process has high practicability and reliability and is convenient for use properties of promoting production and machining.

Owner:36TH RES INST OF CETC

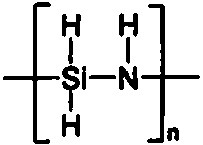

Superhydrophilic anticorrosion coating sol and preparation method and application thereof

InactiveCN108441005AHigh mechanical strengthSimple preparation processFireproof paintsAntifouling/underwater paintsCorrosionHydrophilic coating

The invention discloses superhydrophilic anticorrosion coating sol, made by combining inorganic polysilazane and graphene, and a preparation method and application thereof. Graphene and inorganic polysilazane are combined to obtain coating sol having self-curing property and strong adhesion; and a coating prepared has good corrosion resistance and stable superhydrophilicity, as well as the characteristics, such as heat conductivity, high mechanical strength, and flame retardancy. The preparation method is simple, low in cost and green, the operating conditions are easy to control, the problemsare effectively solved that existing coatings have poor corrosion resistance and the preparation techniques are complex, and the application and development of superhydrophilic anticorrosion technology are benefited.

Owner:泉州三欣新材料科技有限公司

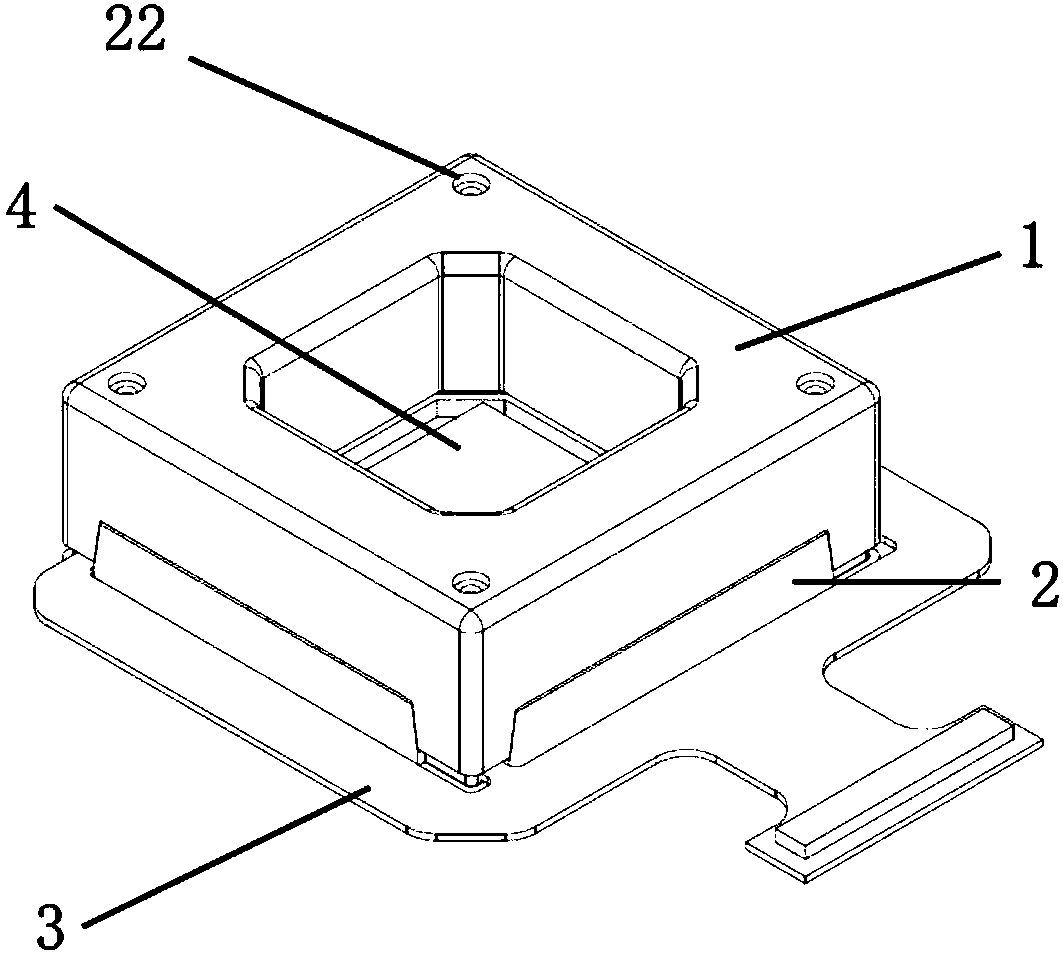

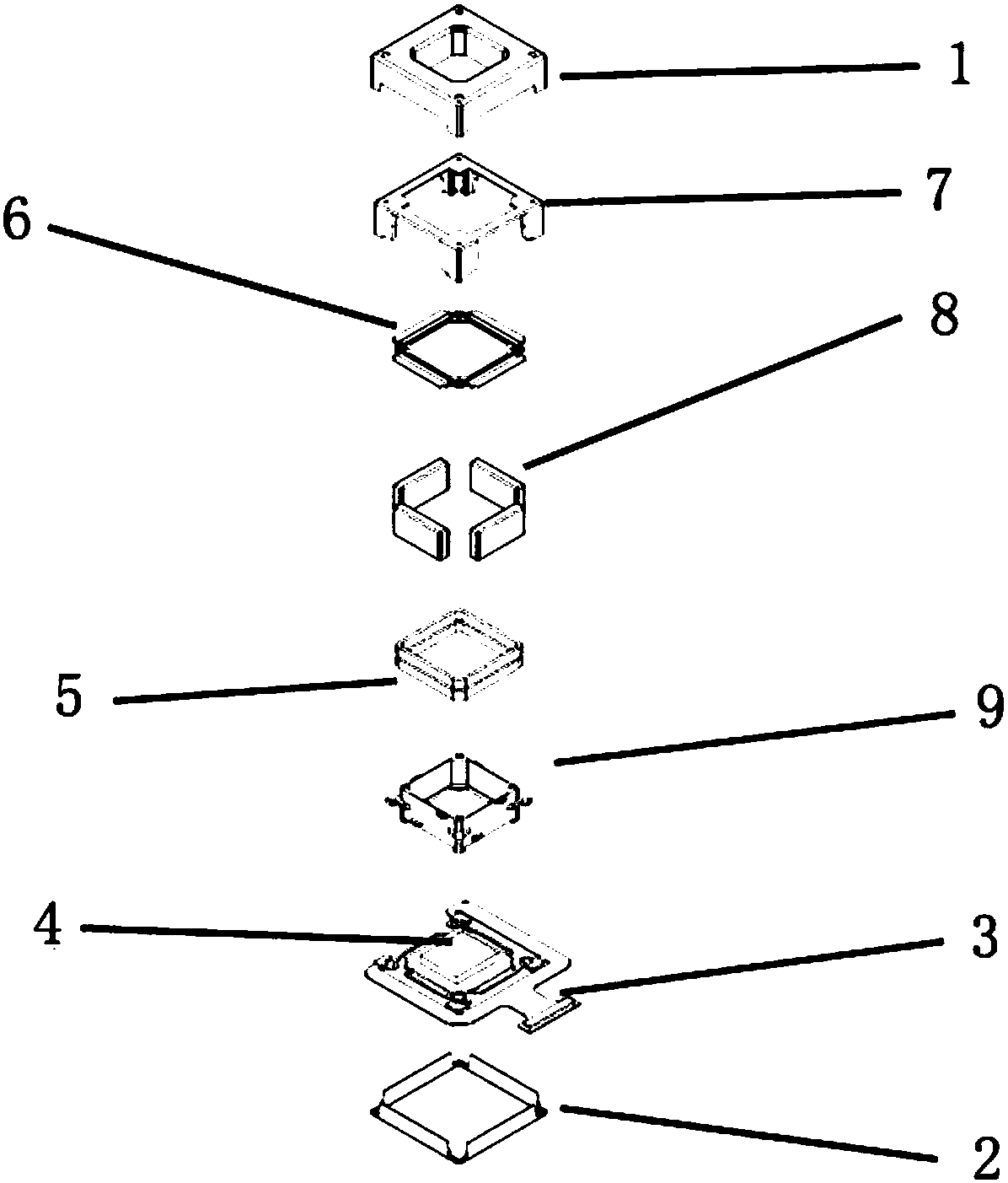

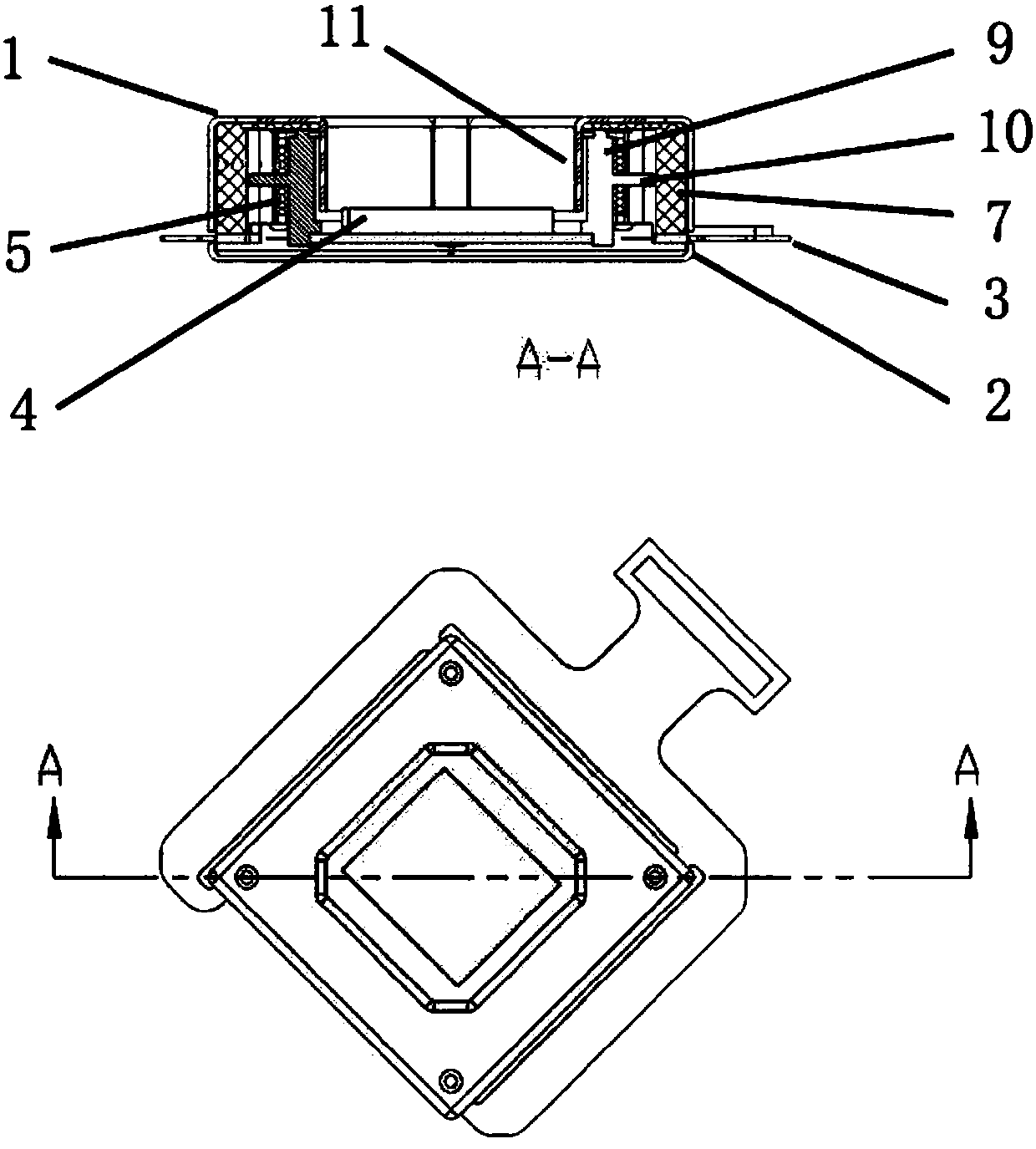

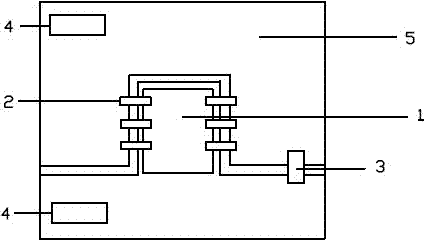

Split-type low-power-consumption small automatic focusing brake device

The invention belongs to the technical field of camera brake devices, in particular to a split-type low-power-consumption small automatic focusing brake device. The split-type low-power-consumption small automatic focusing brake device includes a shell, a spring, a picture sensor carrier, at least one magnet, at least one independent coil and an elastic circuit board; the spring, the picture sensor carrier and the elastic circuit board form a spring vibrator system which has uniaxial displacement freedom degrees, the magnets are arranged on the inner wall of the shell, the independent coils are arranged on the picture sensor carrier and correspond to the magnets, and after being powered on, the independent coils are affected by ampere force in magnetic fields of the magnets. The structureof the split-type low-power-consumption small automatic focusing brake device cannot generate non-linear friction and has the advantages of being good in dust-prevention and heat-dissipation effect.

Owner:VISTA INNOTECH LTD

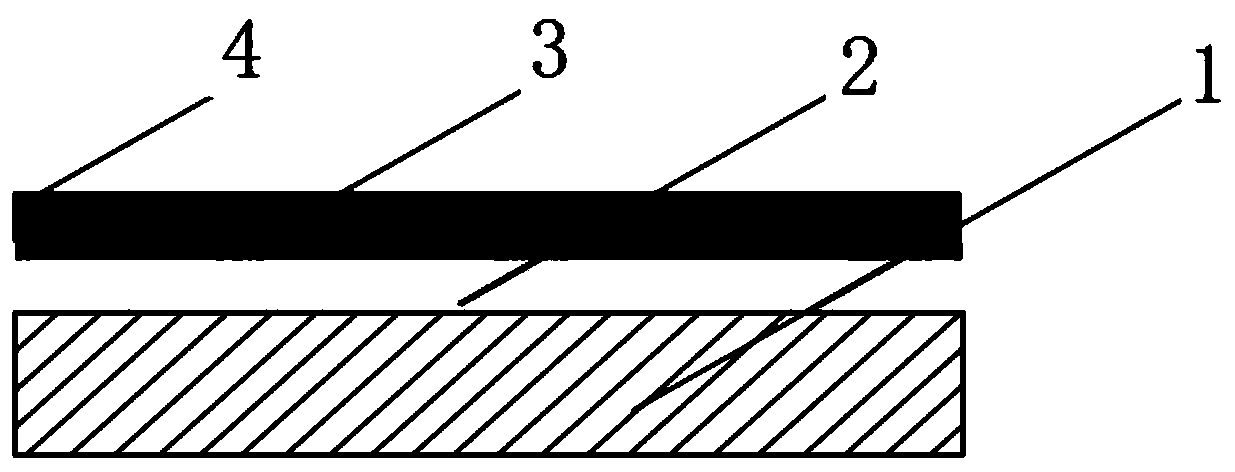

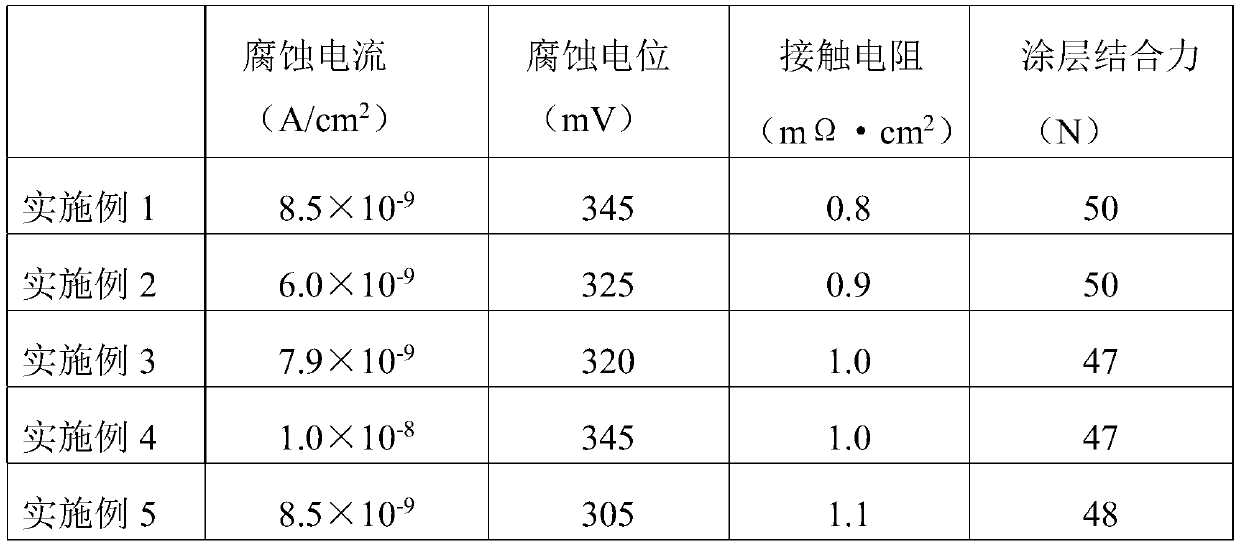

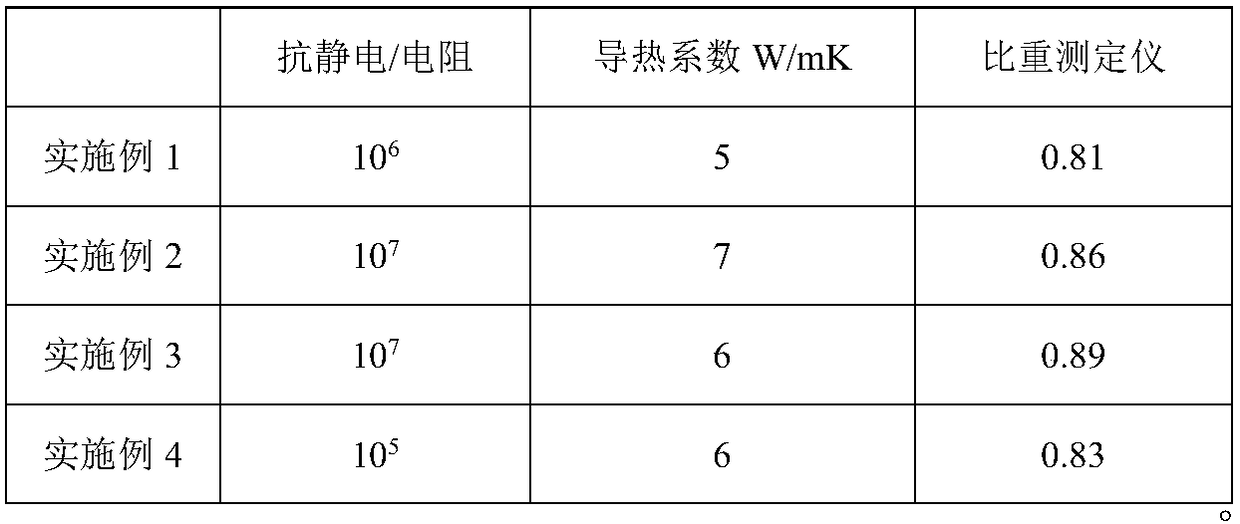

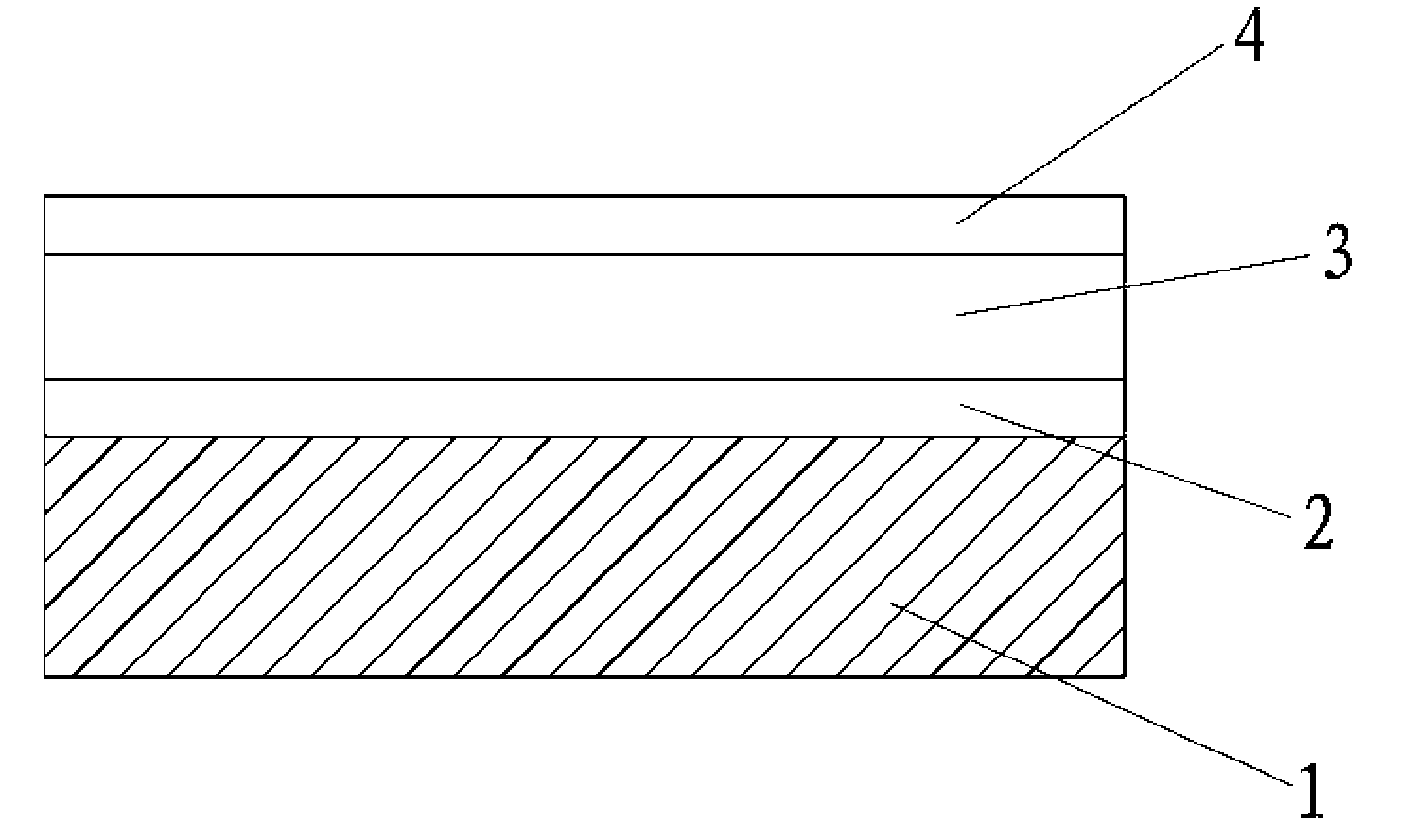

Metal bipolar plate and preparation method thereof and fuel cell

ActiveCN110808384AFast coating speedImprove densification performanceVacuum evaporation coatingSputtering coatingCarbon filmFuel cells

The invention relates to a metal bipolar plate and a preparation method thereof and a fuel cell, and relates to the technical field of fuel cells. The main adopted technical scheme is that the metal bipolar plate comprises a metal substrate, a Cu nano layer, a graphene layer and an amorphous carbon film. The Cu nano layer is deposited on the metal substrate, the graphene layer is prepared on the Cu nano layer and the amorphous carbon film is deposited on the graphene layer. The fuel cell includes the metal bipolar plate. The metal bipolar plate is mainly used for improving the corrosion resistance and the electrical conductivity of the metal bipolar plate and improving the bonding force between the coating and the metal substrate, thus prolonging the service life of the metal bipolar plateand the fuel cell.

Owner:浙江锋源氢能科技有限公司 +1

High-elasticity epoxy resin

The invention relates to a high-elasticity epoxy resin which mainly comprises an epoxy resin and an elastic curing agent. The high-elasticity epoxy resin is characterized by comprising the following components in parts by weight: 420-480 parts of epoxy resin, 20-80 parts of flame retardant agent, 25-40 parts of quadrol, 8-47 parts of accelerant, 3-26parts of binding agent, 11-32 parts of diluent and 0-17 parts of temperature resistant toughening agent. Because the high-elasticity epoxy resin adopted as an electronic potting material has the characteristics of elasticity, vibration prevention, moisture prevention, temperature resistance, heat conduction, flame retardance, electric insulation, and the like, the high-elasticity epoxy resin can ensure the long-term reliability of electronic products. The high-elasticity epoxy resin has the advantages of silicon rubber, can maintain the characteristics of the epoxy resin, has reduced cost and widely expanded application range and adds a novel potting material for the electronic industry.

Owner:舒城金泽信环保材料有限公司

Polylactic acid 3D printing material and preparation method and application thereof

InactiveCN108912629AReduce model weightConductivity specific gravityAdditive manufacturing apparatusHeat-exchange elementsSpecific gravityThermal conductivity

The invention relates to a polylactic acid 3D printing material and a preparation method and an application thereof. The polylactic acid 3D printing material consists of the following components in parts by mass: 30-90 parts of polylactic acid, 10-30 parts of nitrogen-doped graphene, 0.5-3 parts of an antioxidant, 3-7 parts of a dispersant, and 0.1-1 part of a nucleating agent, wherein the molecular weight of the polylactic acid is 40000-100000. The polylactic acid 3D printing material provided by the invention has the advantages of low density, thermal conductivity and electrical conductivity, and can meet the market demand for FDM special consumable materials with high thermal conductivity, electrical conductivity and low specific gravity.

Owner:HUNAN GUOSHENG GRAPHITE TECH CO LTD

Low-density heat-conducting and conductive polylactic acid 3D printed material as well as preparation method and application thereof

ActiveCN107286609AThermal conduction hasLight weightAdditive manufacturing apparatusAntioxidantHeat conducting

The invention relates to a low-density heat-conducting and conductive polylactic acid 3D printed material as well as a preparation method and application thereof. The polylactic acid 3D printed material is prepared from the following components in parts by weight: 30-90 parts of polylactic acid, 20-50 parts of metalized hollow glass microspheres, 0.5-3 parts of an antioxidant, 3-7 parts of a dispersing agent and 0.1-1 part of a nucleating agent, wherein the molecular weight of the polylactic acid is 20,000-150,000; the density of the metalized hollow glass microspheres is 0.05-0.5g / cm<3>, the particle sizes are 5-100 microns and the spherical rate of the metalized hollow glass microspheres is greater than 90%. Various raw materials are mixed and added to a single-screw extruder to be extruded and pelletized to obtain the low-density heat-conducting and conductive polylactic acid 3D printed material. The polylactic acid 3D printed material has low density, heat-conducting property and conductivity, and can meet the requirements of the market on a special FDM material with high heat-conducting property and conductivity and low specific gravity.

Owner:广东波斯科技股份有限公司

Coated polycarbonate

ActiveCN101786351ALow densityLight in massLayered productsVacuum evaporation coatingCoated surfaceTitanium

The invention relates to an organic polymer with a coated surface, in particular relating to coated polycarbonate. The invention is realized by the following technical scheme: the coated polycarbonate comprises a polycarbonate substrate layer and a coating layer, and the coating layer consists of a titanium oxide bottom coating layer, a chrome coating layer and a titanium oxide surface coating layer. The invention is applicable to various aspects like mechanical industry and transparent materials.

Owner:HUZHOU TIAHE AUTOMOBILE PART

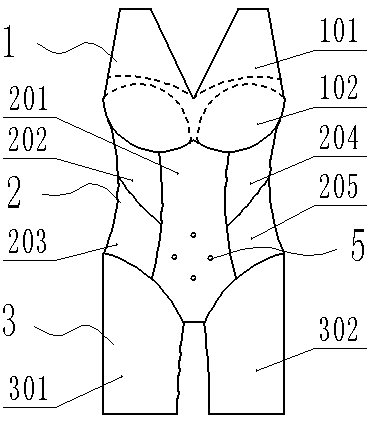

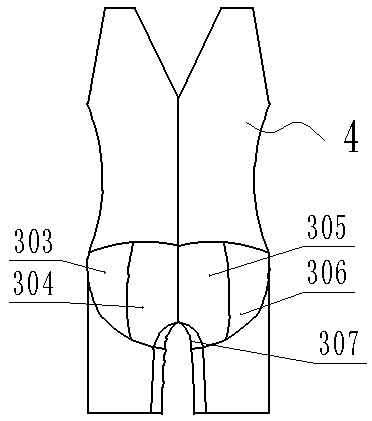

Slimming and breast-shaping suit with bra

The invention relates to a slimming and breast-shaping suit with a bra. The slimming and breast-shaping suit comprises a first area, a second area, a third area and a fourth area, wherein the first area is an area from the shoulders to a position below the breasts, the second area is a waist and abdomen area, the third area is a lower body area, and the fourth area is a back area; the breast partof the first area is made of double-layer fabric, and breathable cups are arranged between the inner fabric and the outer fabric; the abdomen area is provided with energy stones capable of conditioning the abdomen; the crotch position of the third area is provided with a hole to facilitate urination. The slimming and breast-shaping suit has the advantages that the detachable cups are added to theone-piece body-shaping suit to allow the body-shaping suit to also have a bra function, and convenience and comfortableness are achieved; the cups are detachable, so that the breasts of women can be freed from constraint and be natural and healthy while the cups can be replaced according to different functions, use flexibility is also achieved, and the overall shaping effect of the body-shaping suit is outstanding.

Owner:浙江美人计健康科技集团有限公司

Waterproof seal silica gel ring for LED illuminating lamp

InactiveCN107286660AImprove the bactericidal effectWith heat conductionGas-tight/water-tight arrangementsGraphiteBoron nitride

The invention relates to a waterproof seal silica gel ring for an LED illuminating lamp. The waterproof seal silica gel ring is prepared from the following components in percentage by mass: 28-38% of silica gel, 8-15% of nano TiO2, 6-12% of ZnO, 16-24% of epoxy resin, 8-15% of vinyl silicone oil, 5-10% of boron nitride, 4-10% of graphite powder, 0.3-1% of a silane coupling agent, 0.2-1% of a thixotropic agent, 0.3-1% of a flexibilizer and 0.3-1% of a stabilizer. The waterproof seal silica gel ring has high-and low-temperature resistant characteristics, a thermal conduction characteristic and a flame-retarding characteristic, and is safe in use and long in service life.

Owner:ANHUI YANQING TECH GRP CO LTD

Protection film for high-power concentrating photovoltaic system receiver and production method thereof

ActiveCN103545384AAvoid short circuitAvoid failureFinal product manufactureChemical vapor deposition coatingPhysicsThin membrane

The invention discloses a protection film for a high-power concentrating photovoltaic system receiver. The protection film is an Al2O3 film and is arranged on the outer layer of the receiver by the atomic layer deposition technology. The receiver comprises a copper-coated ceramic panel, a solar cell, a Shaw Schottky diode, gold threads and the like. The protection film coats on the outer surface of all components contacting with the air. The Al2O3 film is produced by the ALD (atomic layer deposition) technology is arranged on the upper surface of the receiver and coats on components and circuits on the surface of the receiver. According to the protection film, effects of insulation, water proofing, oxidation resistance and thermal conductivity can be achieved by adjusting parameters of different precursor acting time, air pressure, thickness and the like during Al2O3 film production, and the protection film of the receiver is an ideal one.

Owner:DONGFANG ELECTRIC CORP LTD

Cadmium telluride solar cell assembly with thermal insulation layer and preparation method thereof

ActiveCN111540793ALower heat transfer coefficientImprove insulation effectPhotovoltaic supportsWallsInsulation layerThermal insulation

The invention discloses a cadmium telluride solar cell assembly with a thermal insulation layer and a preparation method of the cadmium telluride solar cell assembly. The assembly sequentially comprises cadmium telluride power generation glass, a silica gel layer and a heat preservation layer from bottom to top, the heat preservation layer comprises a plurality of heat insulation plate layers, each heat insulation plate layer is formed by horizontally splicing a plurality of heat insulation plates, heat preservation materials are arranged in the heat insulation plates, and PET / AL / PE compositefilms are arranged on the outer surfaces of the heat insulation plates. The assembly is low in heat transfer coefficient, good in heat preservation performance and high in photoelectric conversion efficiency.

Owner:CNBM CHENGDU OPTOELECTRONICS MATERIAL

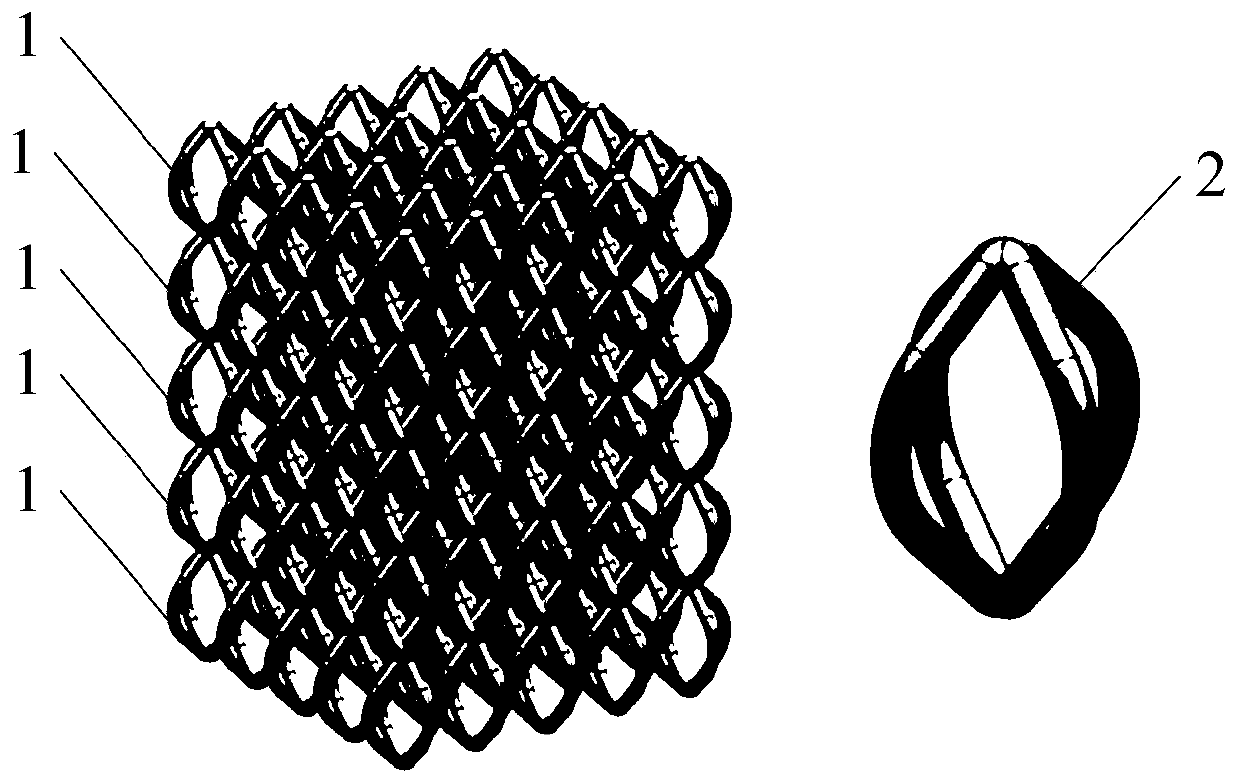

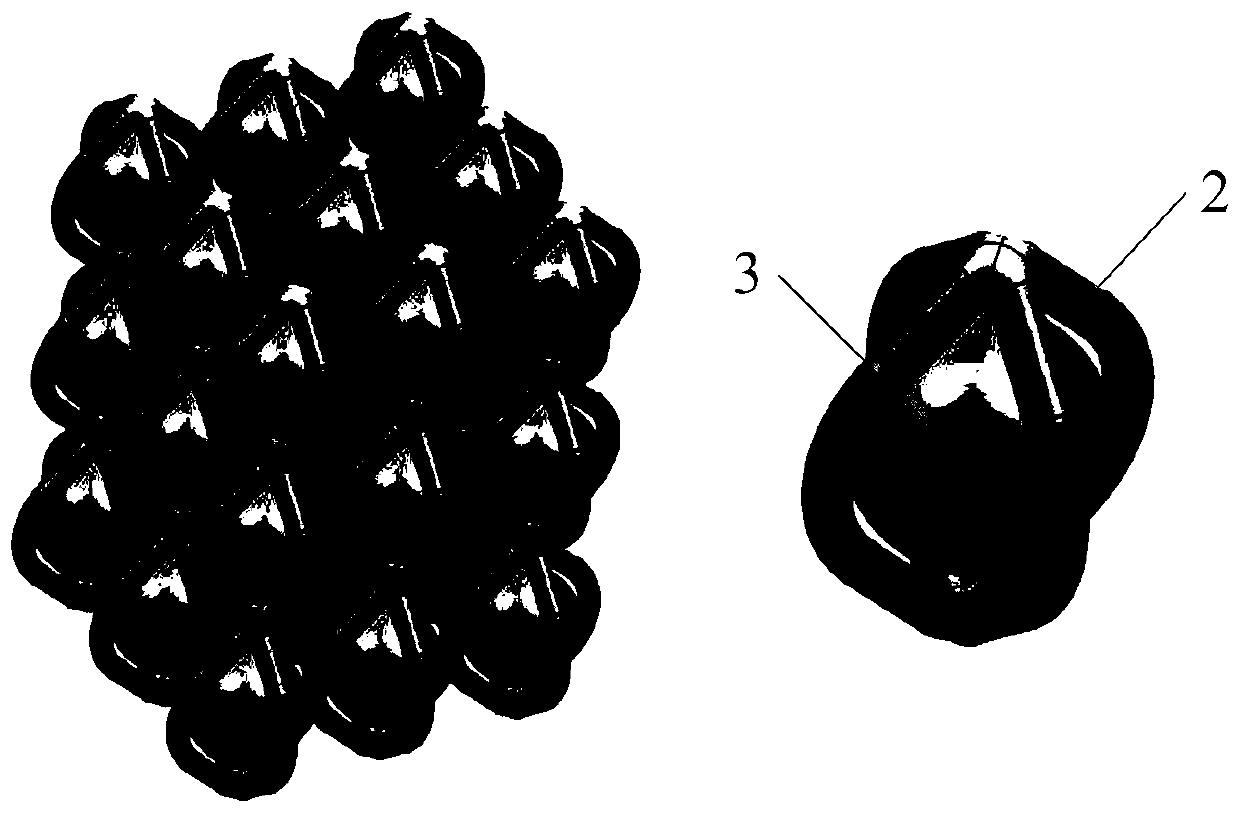

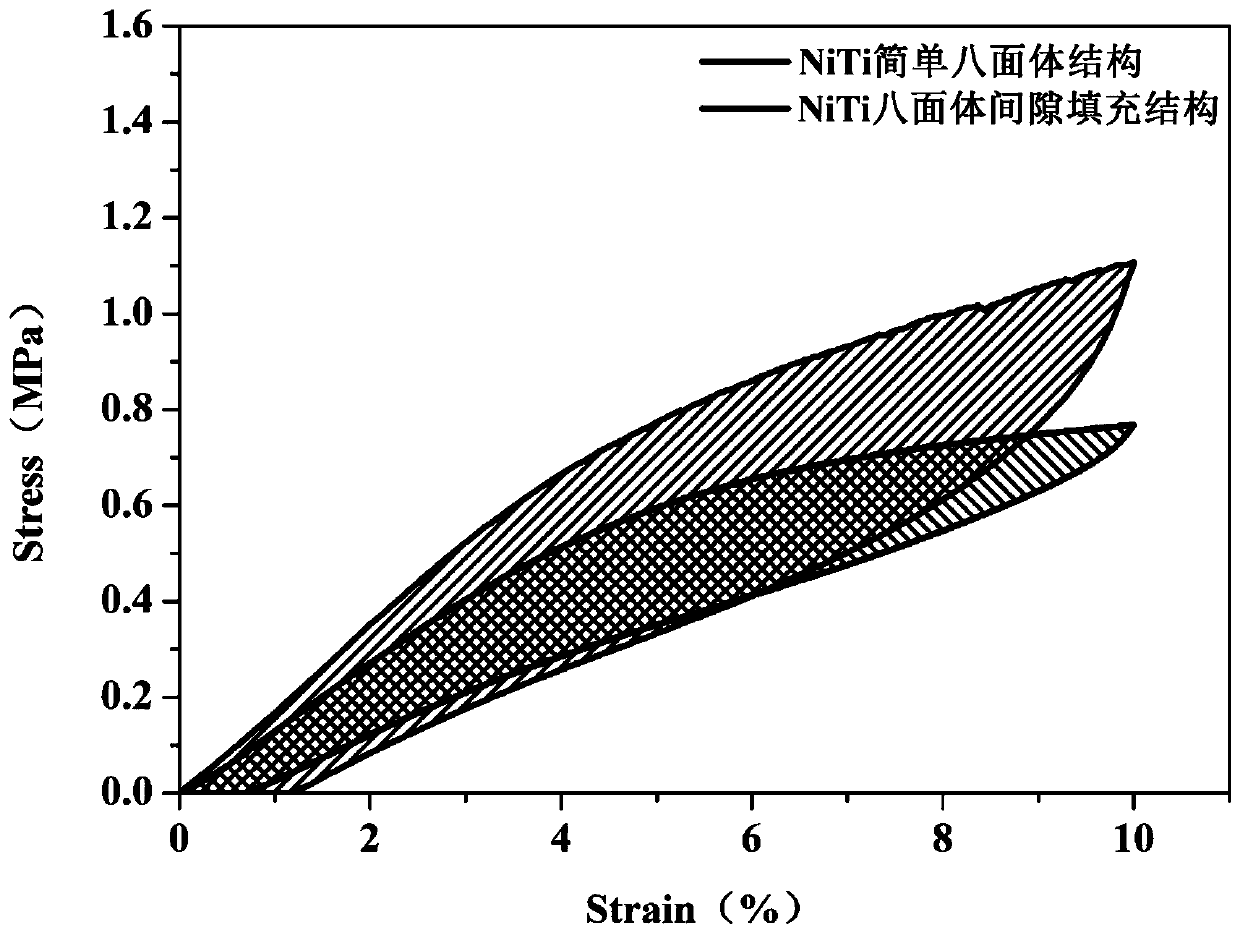

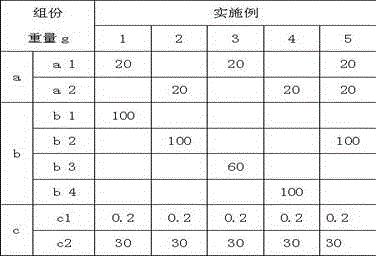

Novel light energy absorption and vibration reduction imitation microstructure and preparation method thereof

ActiveCN110773740ARadiation resistantWith high and low temperature resistanceAdditive manufacturing apparatusCosmonautic vehiclesOctahedronLight energy

The invention discloses a novel light energy absorption and vibration reduction imitation microstructure and a preparation method thereof. The novel light energy absorption and vibration reduction imitation microstructure comprises a plurality of energy absorption layers which are sequentially stacked from top to bottom, each energy absorption layer comprises a plurality of energy absorption frames, and a metal rubber ball is embedded in each energy absorption frame. According to the preparation method, by reference to the mechanism for improving elastic modulus and the strength that a diamondmicro-octahedral structure is filled with an interstitial atom, the micro-new composite structure of filling a NiTi-based octahedral interstice of 3D printing with a NiTi metal rubber ball is proposed, and the elastic modulus, the strength and energy absorption efficiency of a structural part can be improved; compared with a traditional metal rubber, the structure has the advantages of radiationresistance, corrosion resistance, high and low temperature resistance, aging resistance and the like; compared with the traditional metal rubber, the structure has the advantages of high forming precision, being capable of forming a complex structure, high energy absorption efficiency and the like; and compared with a simple NiTi metal-based octahedral lattice structure, the structure has the advantages of high strength, high modulus, high energy absorption efficiency and the like.

Owner:INST OF MACHINERY MFG TECH CHINA ACAD OF ENG PHYSICS

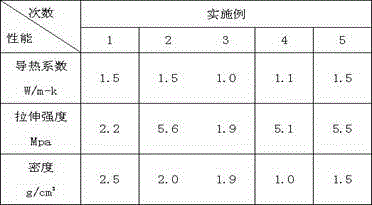

Low-density and high-strength heat-conducting silica gel gasket

InactiveCN106590548AWith heat conductionLow densityHeat-exchange elementsHeat conductingFilling materials

The invention discloses a low-density and high-strength heat-conducting silica gel gasket. The low-density and high-strength heat-conducting silica gel gasket comprises the following components in percent by weight: 5-25% of an organosilicon polymer, 50-85% of heat-conducting powder and 10-25% of an auxiliary agent. The low-density and high-strength heat-conducting silica gel gasket, as a filling material product, has the characteristics of heat conductivity, low density and high tensile strength at the same time, so that the problem that some terminals need these unique compatible characteristics on special occasions is solved; the low-density and high-strength heat-conducting silica gel gasket has all general characteristics of ordinary heat-conducting gaskets, and is simple and easy to prepare, safe and reliable.

Owner:昆山裕凌电子科技有限公司

Polyiner/laminate inorganic nano composite material and its milling shearing preparation method

A nanometre-class polymer / laminated inorganic substance composite material features that it is prepared by use of the millstone-shaped force chemical reactor, which has a unique 3-D shear structure to provide strong squeeze-shear force field for grinding inserting, dispersing, and mixing to prepare the polymer / laminated inorganic substance composite powder, and then the said nanometre-class composite material is prepared by the universal processing method.

Owner:SICHUAN UNIV

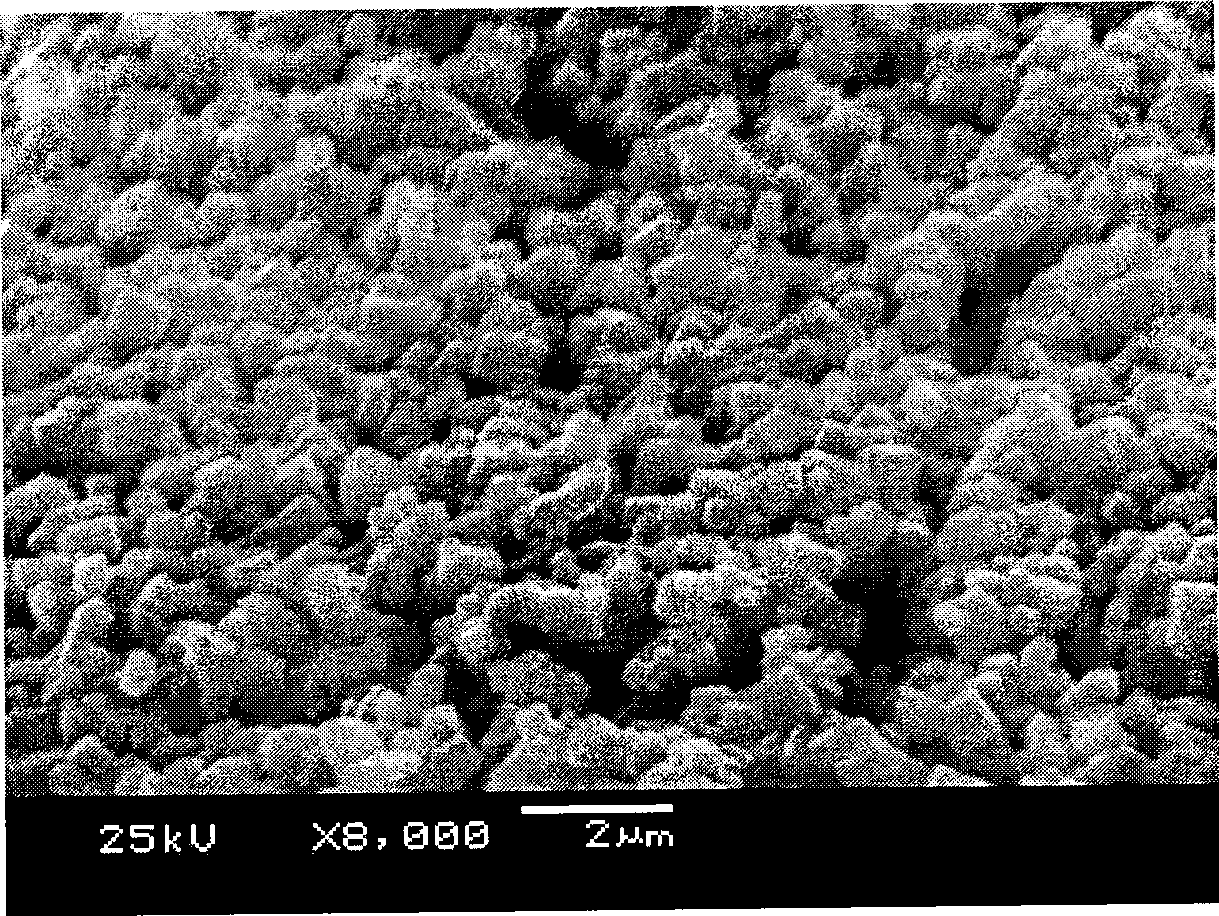

Preparation method for spontaneously-generated copper coating on selectively-oxidized steel surface

InactiveCN103952659AHigh strengthImprove toughnessSolid state diffusion coatingCopper coatingHigh intensity

The invention discloses a preparation method for a spontaneously-generated copper coating on a selectively-oxidized steel surface, which is used for spontaneously generating a copper coating on a matrix surface to effectively solve the problem of bonding of a coating interface. The method comprises the following steps: surface oxidization of copper-containing steel, oxide scale removal and copper coating surface treatment. According to the method disclosed by the invention, a copper-steel composite material with the copper coating can be obtained without using any mode of additionally adding a coating; the prepared copper coating is free from the problem of bonding of any composite interface and stripping because of being spontaneously generated from a matrix; the prepared copper-steel composite material reserves the strength performances, such as high strength and high tenacity of steel, and also has the characteristics of corrosion resistance, electric conduction, heat conduction and the like of copper, and is attractive in appearance.

Owner:UNIV OF SCI & TECH LIAONING

Novel composite conductive ceramic and method for producing the same

InactiveCN101429021ACorrosion resistanceHigh temperature resistantStrontium titanium oxideNumerical range

The invention relates to the field of materials, in particular to a conducting ceramic material, and discloses a novel composite conducting ceramic and a method for preparing the same. The constitution formula of the novel composite conducting ceramic is xLaAlO3:(1-x)SrTiO3, wherein x is a mole number of which the numerical range is between 0.001 and 0.015. The method for preparing the composite conducting ceramic comprises the following steps: grinding and mixing a strontium titanate substrate raw material with lanthanum aluminate evenly; tabletting the mixture at a pressure of between 8 and 12 MPa; and baking the mixture at a temperature of between 1,200 and 1,400 DEG C for 4 to 8 hours. The mol ratio of the strontium element in the strontium titanate matrix raw material to the lanthanum aluminate is (1-x) to x, wherein x is between 0.001 and 0.015. The new novel composite conducting ceramic has the performances of electrical conductivity, corrosion resistance, high temperature resistance, high strength, innocuity, thermal conductivity and the like, and is applicable to sensors, electric heating warming, industrial heating, drying and conductive ceramic for shielding electromagnetic waves for construction.

Owner:SHANGHAI NORMAL UNIVERSITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com