Patents

Literature

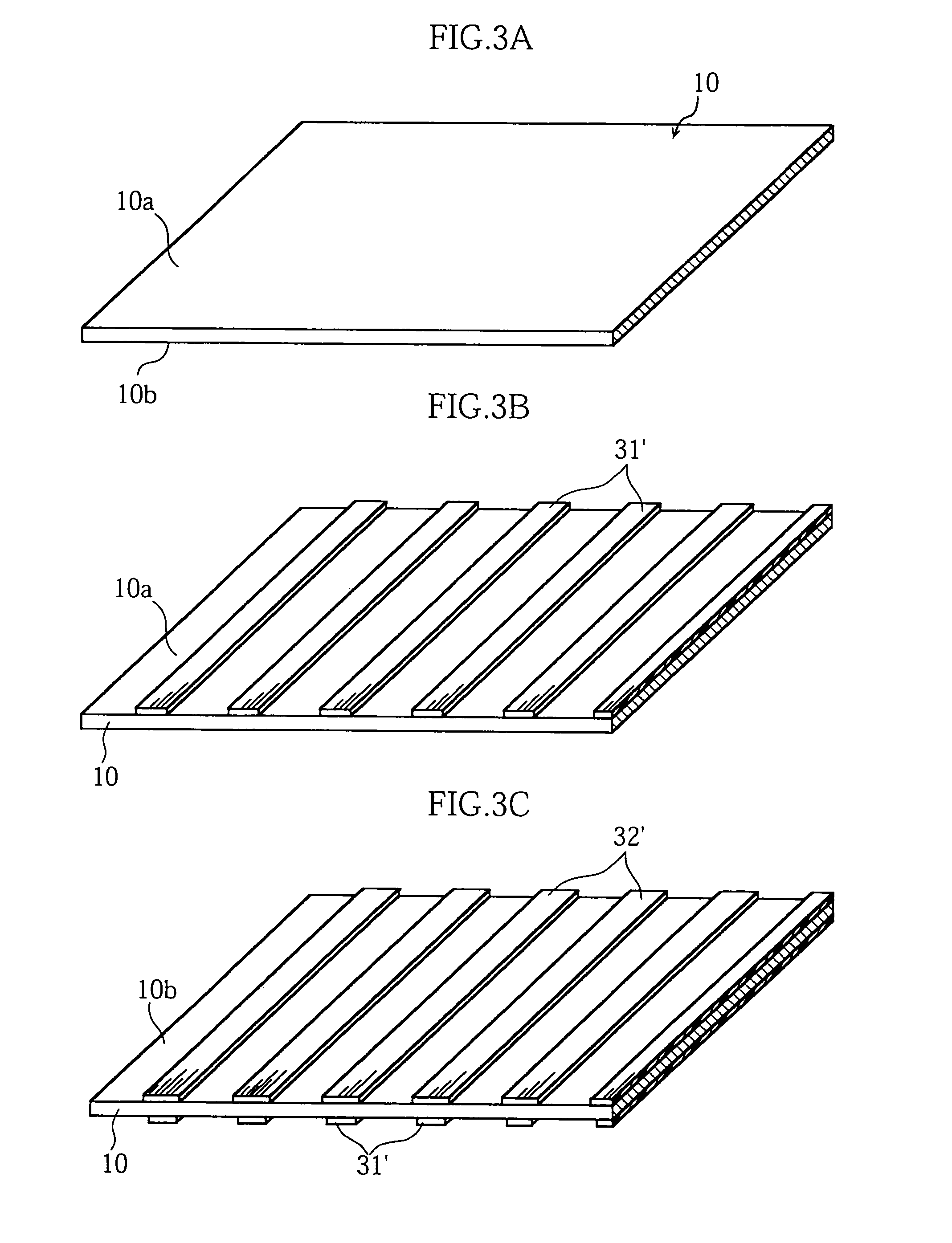

917 results about "Chip resistor" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A chip resistor is a very compact, surface mounted electronic component designed to offer a known resistance to any electrical current flowing through it. A mini resistor of this kind are designed to have the same physical characteristics or form factor as other surface mount devices (SMD) to conform to SMD circuit board geometry.

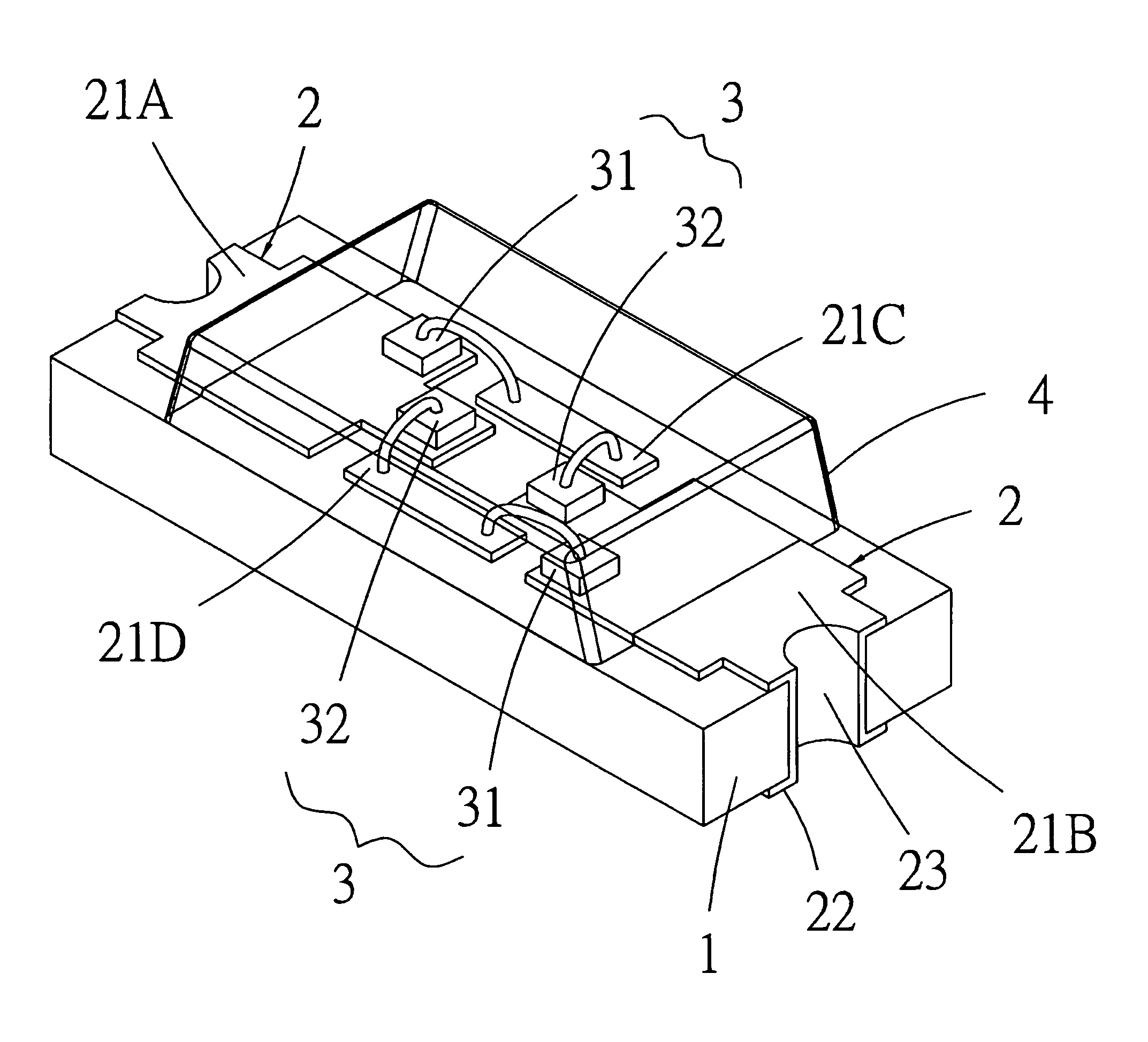

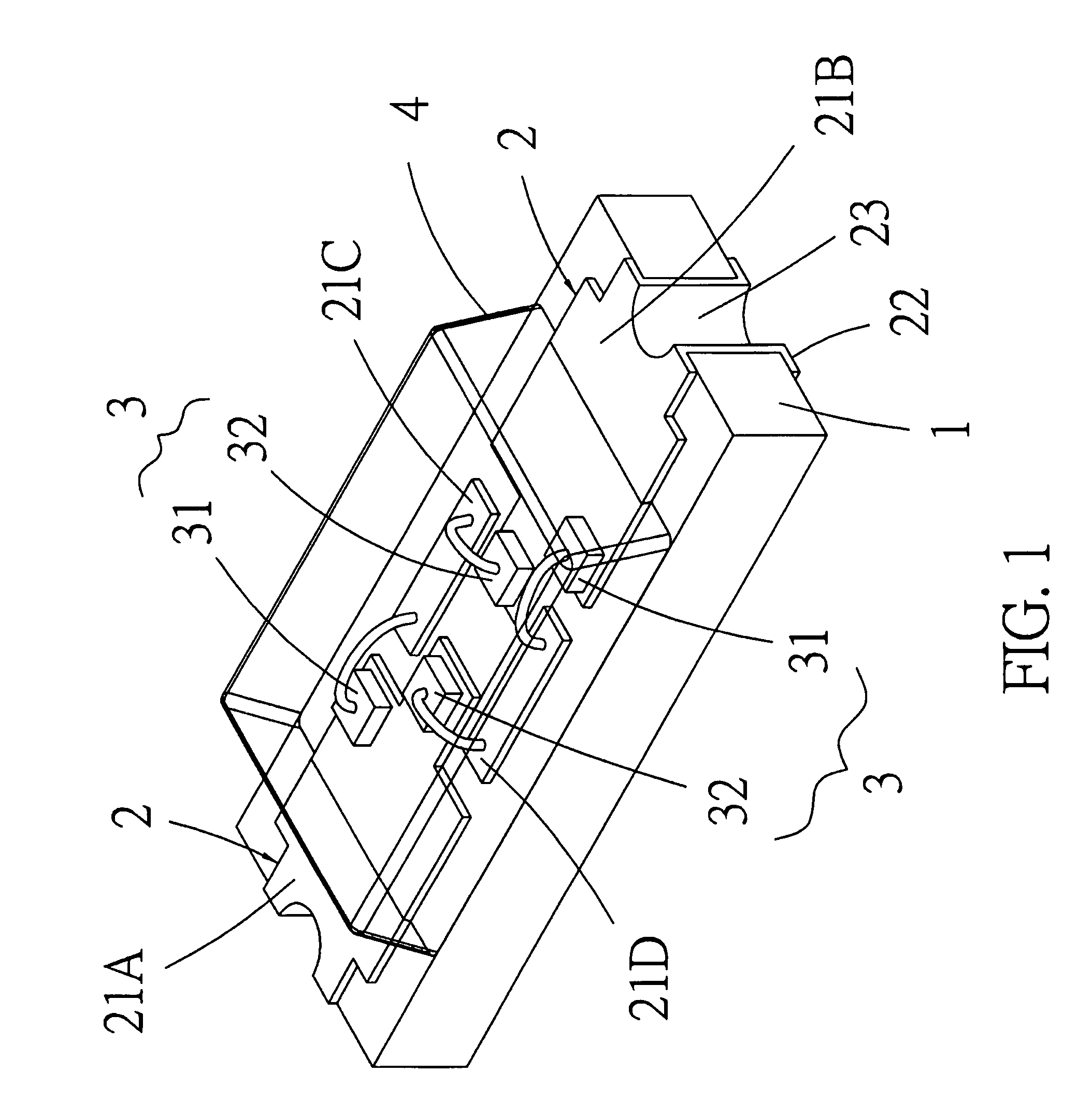

Polarless surface mounting light emitting diode

A polarless surface mounting light emitting diode comprises a substrate; an upper surface of the substrate being etched with four independent metal thin film blocks; a lower surface of the substrate being formed with two independent metal thin film blocks; two ends of the substrate being formed with electroplated through holes; a plurality of metal thin films adhered upon the upper and lower surfaces of the substrate; two light emitting assemblies, each light emitting assembly being formed by a chip resistor and a chip light emitting diode; and a package layer. The connection of the polarless surface mounting light emitting diode of the present invention is not limited by the polarity. Any end of the polarless surface mounting light emitting diode can be connected to positive electrode or negative electrode.

Owner:LIN PETER P W

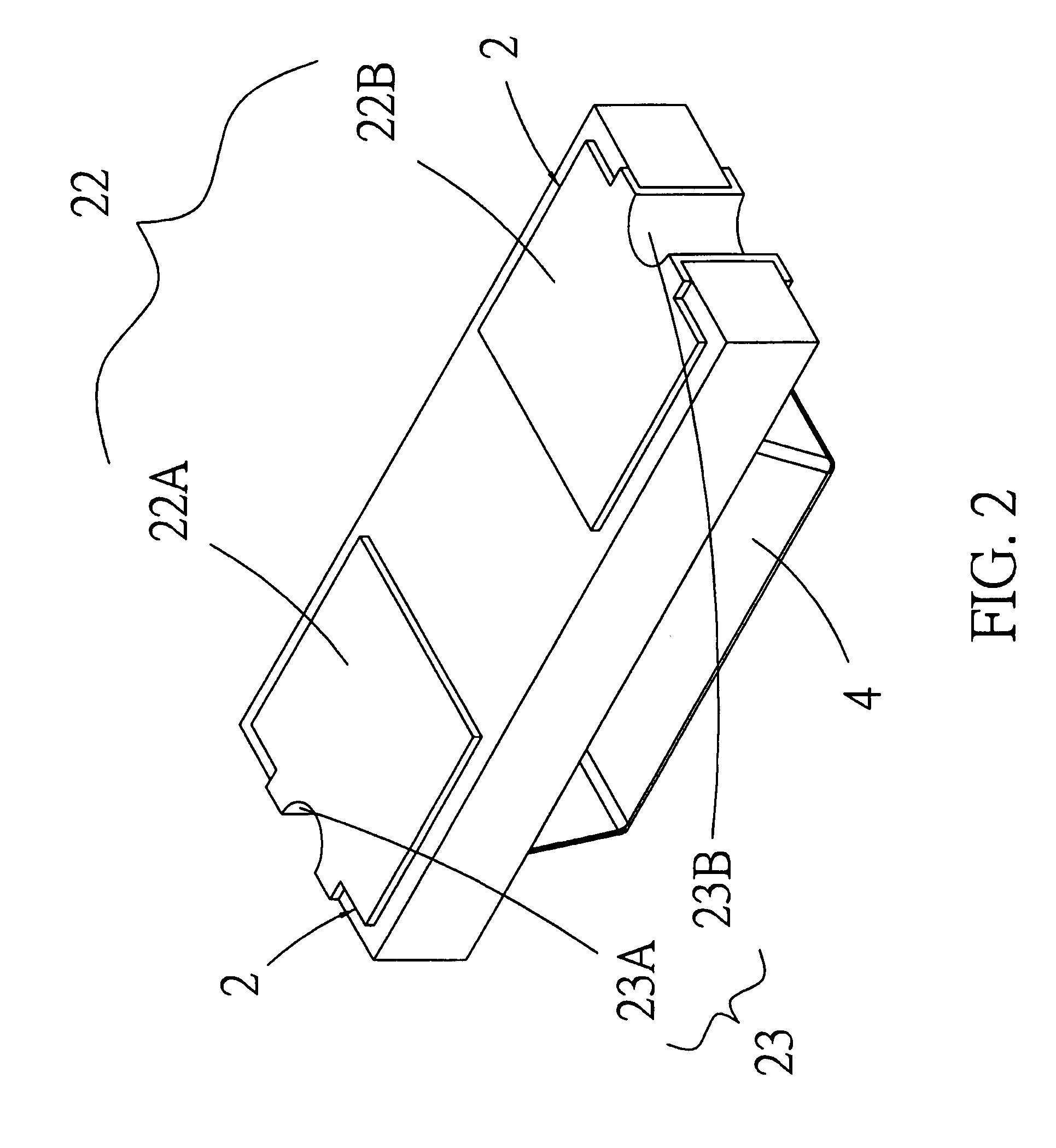

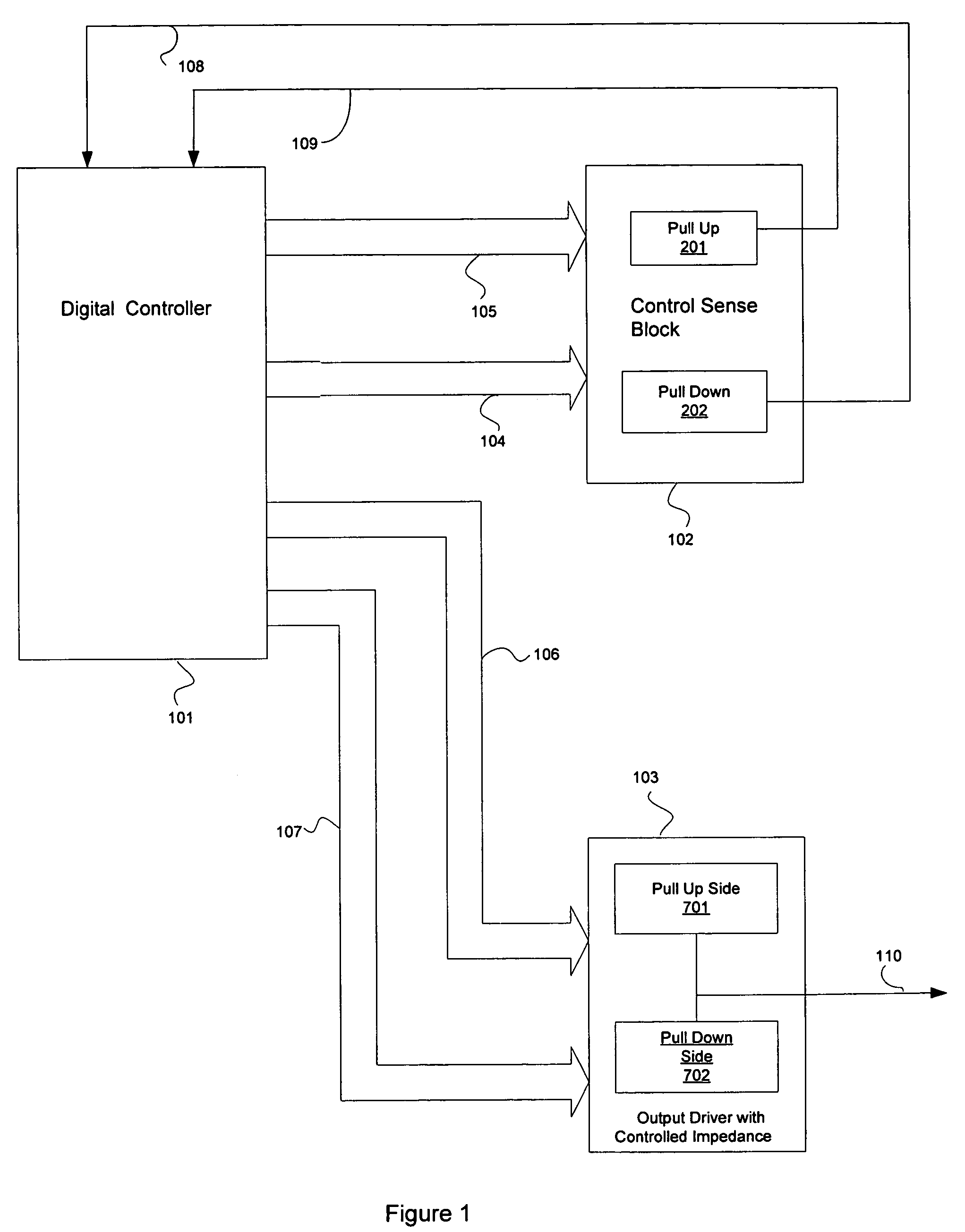

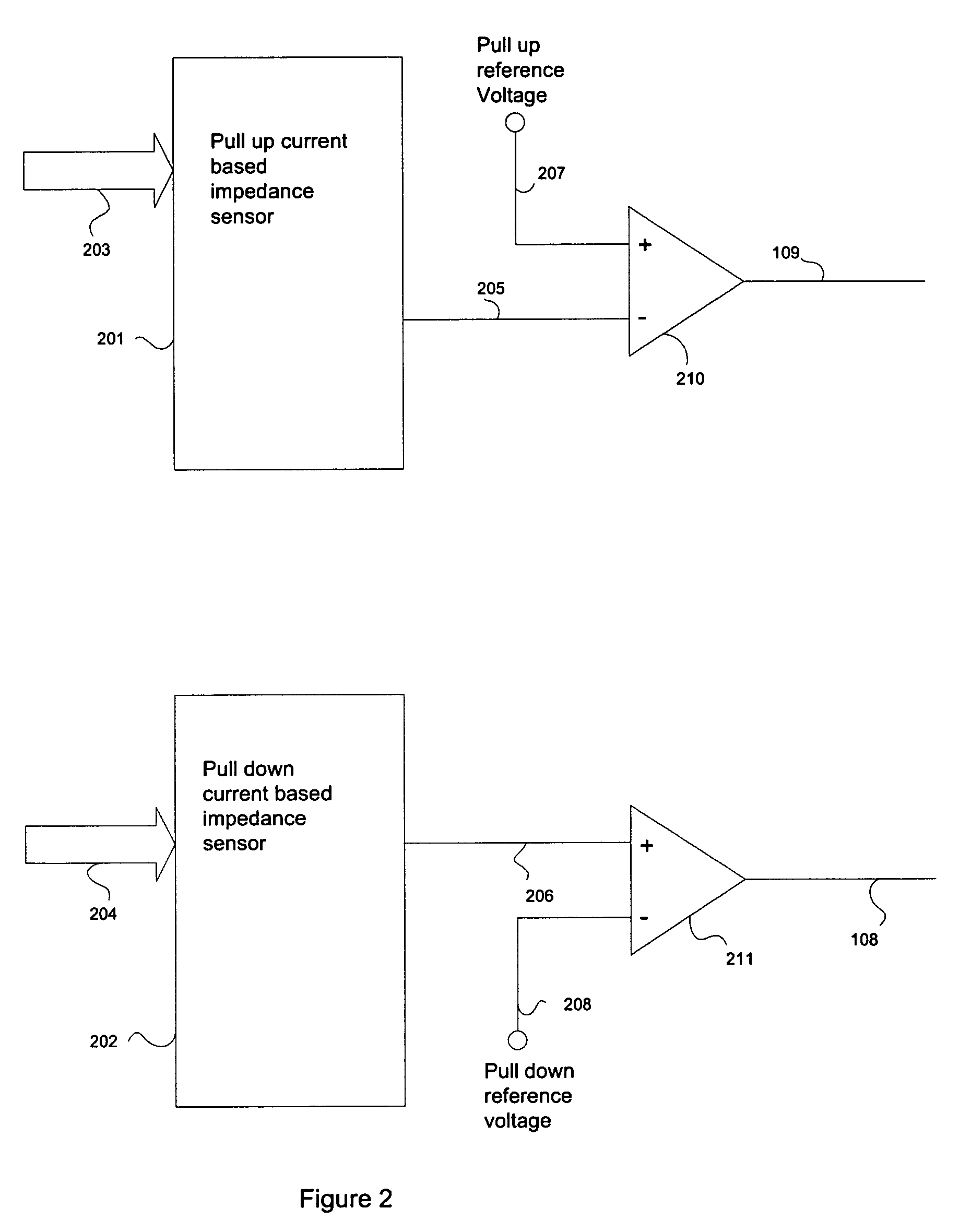

System and method for dynamic impedance matching

InactiveUS7068065B1Improve performanceHigh levelInput/output impedence modificationReliability increasing modificationsEngineeringImpedance matching

An integrated circuit provides dynamic, on chip resistor trimming, including a digital control loop for stabilizing impedance matching among multiple devices communicatively linked over a data transmission line. The digital control loop stabilizes input / output impedance matching of various devices to within a precise ohmic range that is far narrower than standard process variations, such as sheet resistance, within the components themselves. The impedance matching circuit also overcomes EMI problems normally associated with digital control and thus provides dynamic on-chip digital control without non-linearity and with tighter tolerance than is presently possible. Accordingly, the circuit boosts performance of peripheral devices that communicate over a standard USB port, without the need for a computer as a go between or intermediate interface. This makes device to device communication possible as between USB On-the-Go capable devices.

Owner:TAKLA NABIL

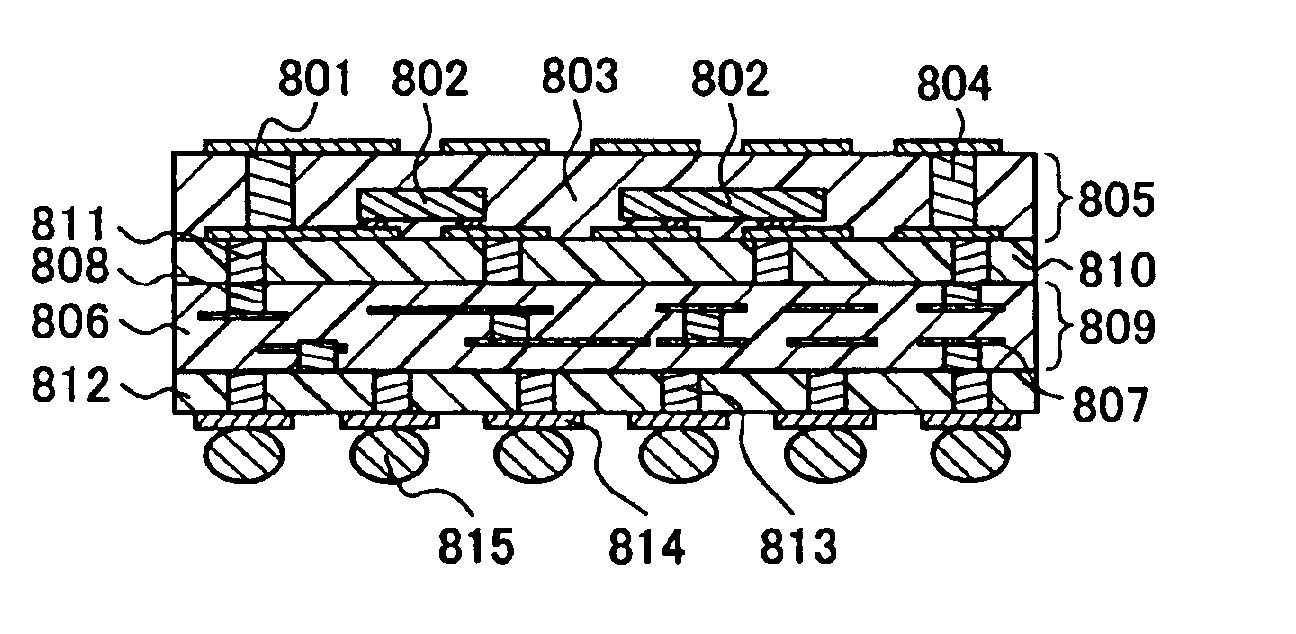

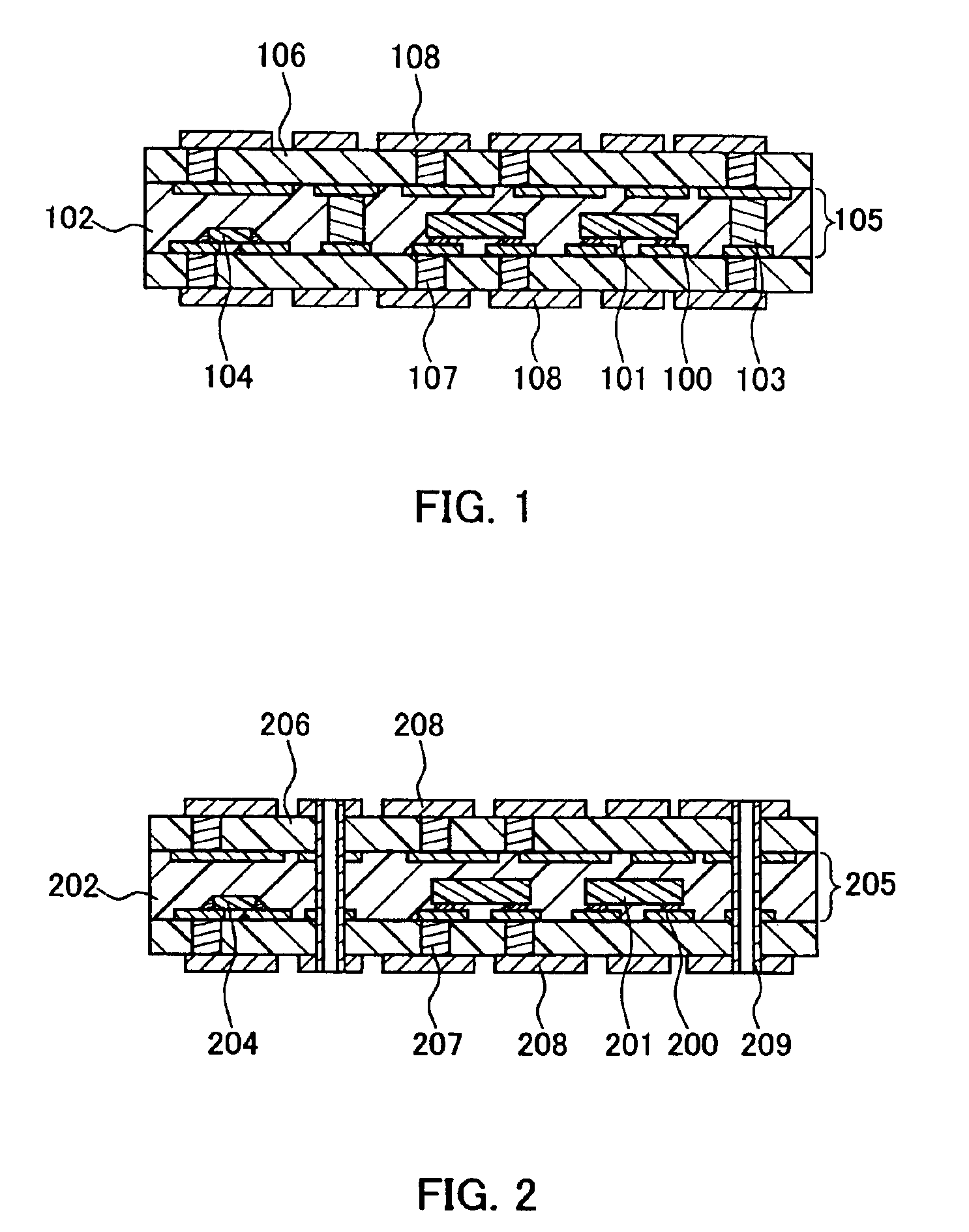

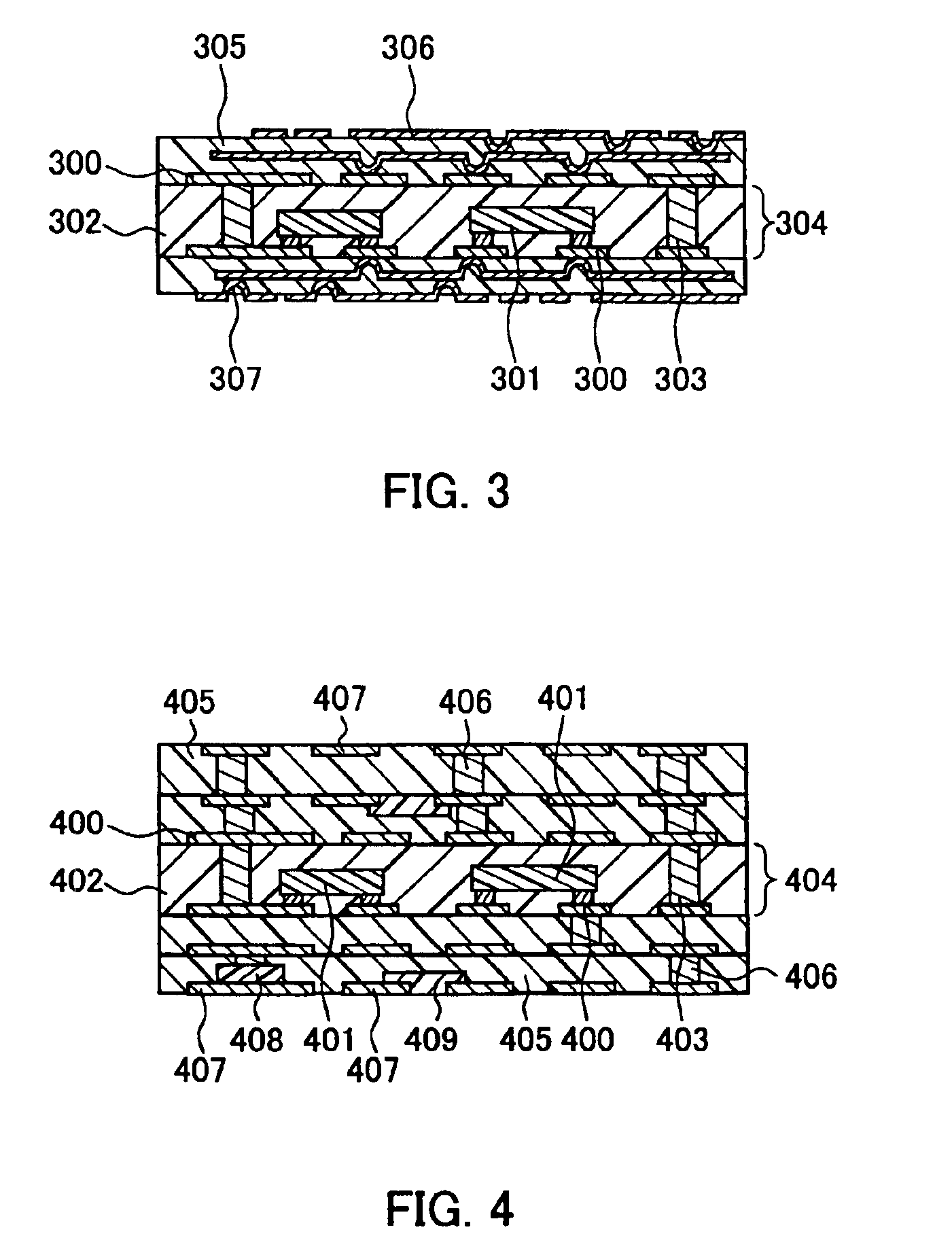

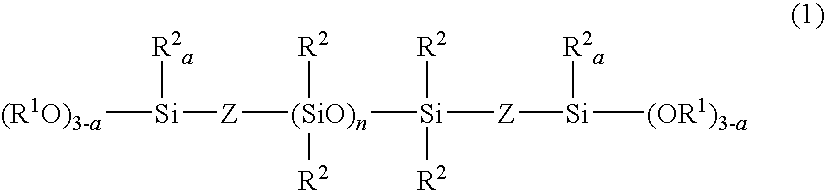

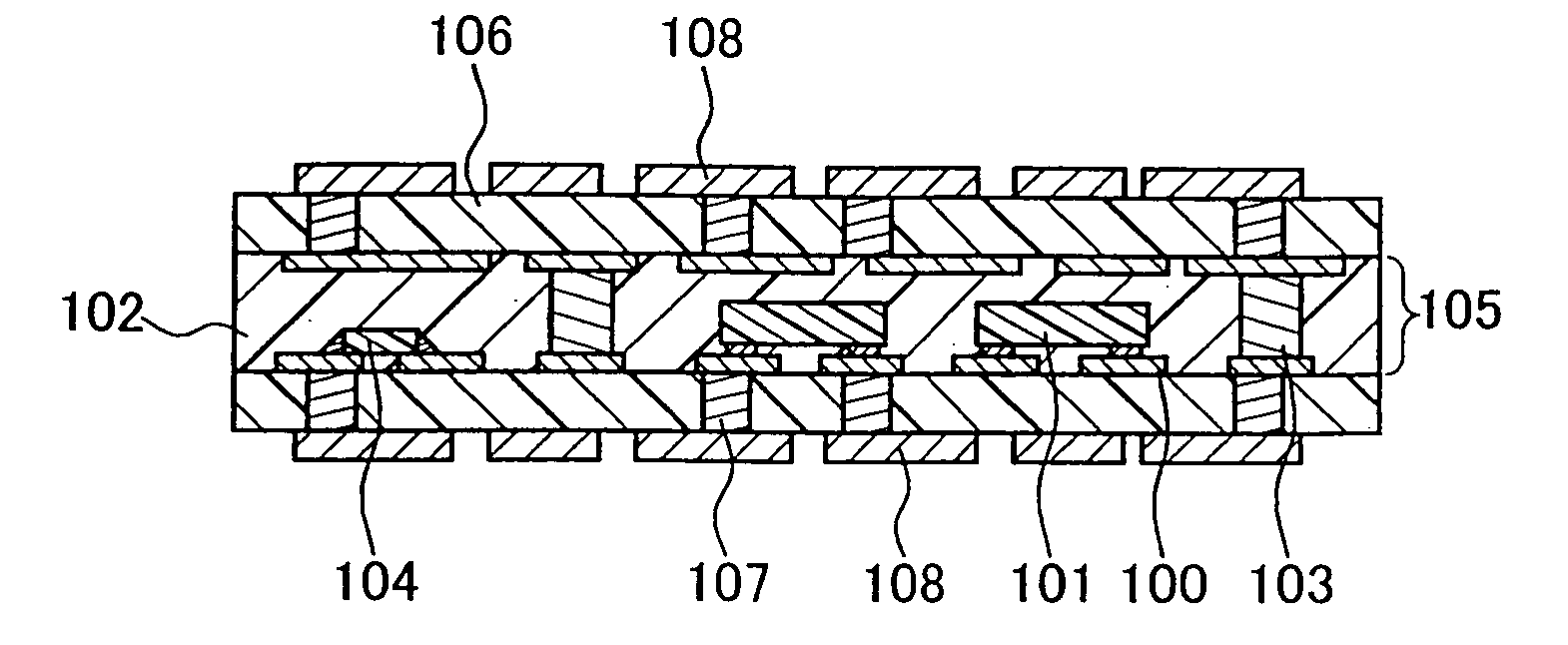

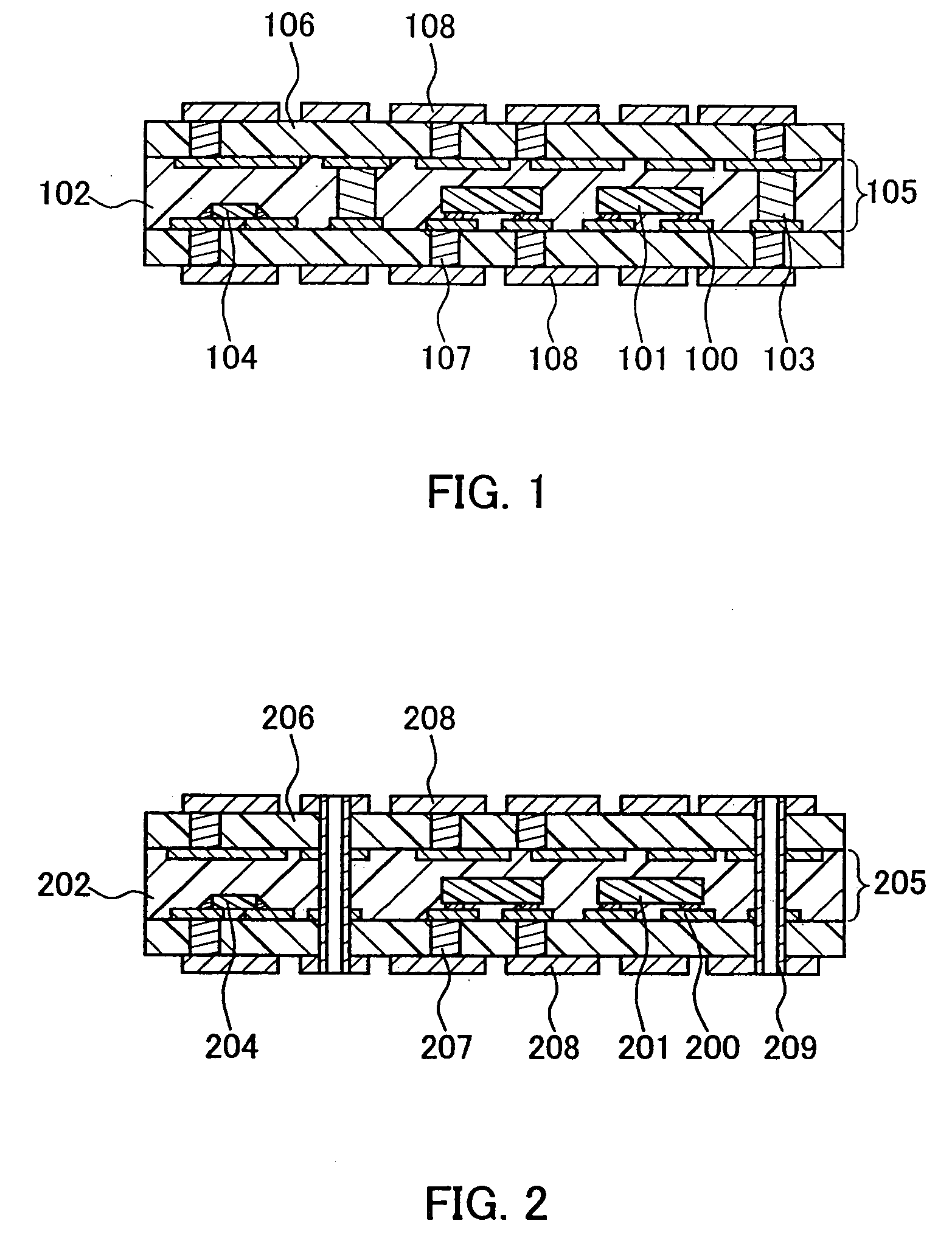

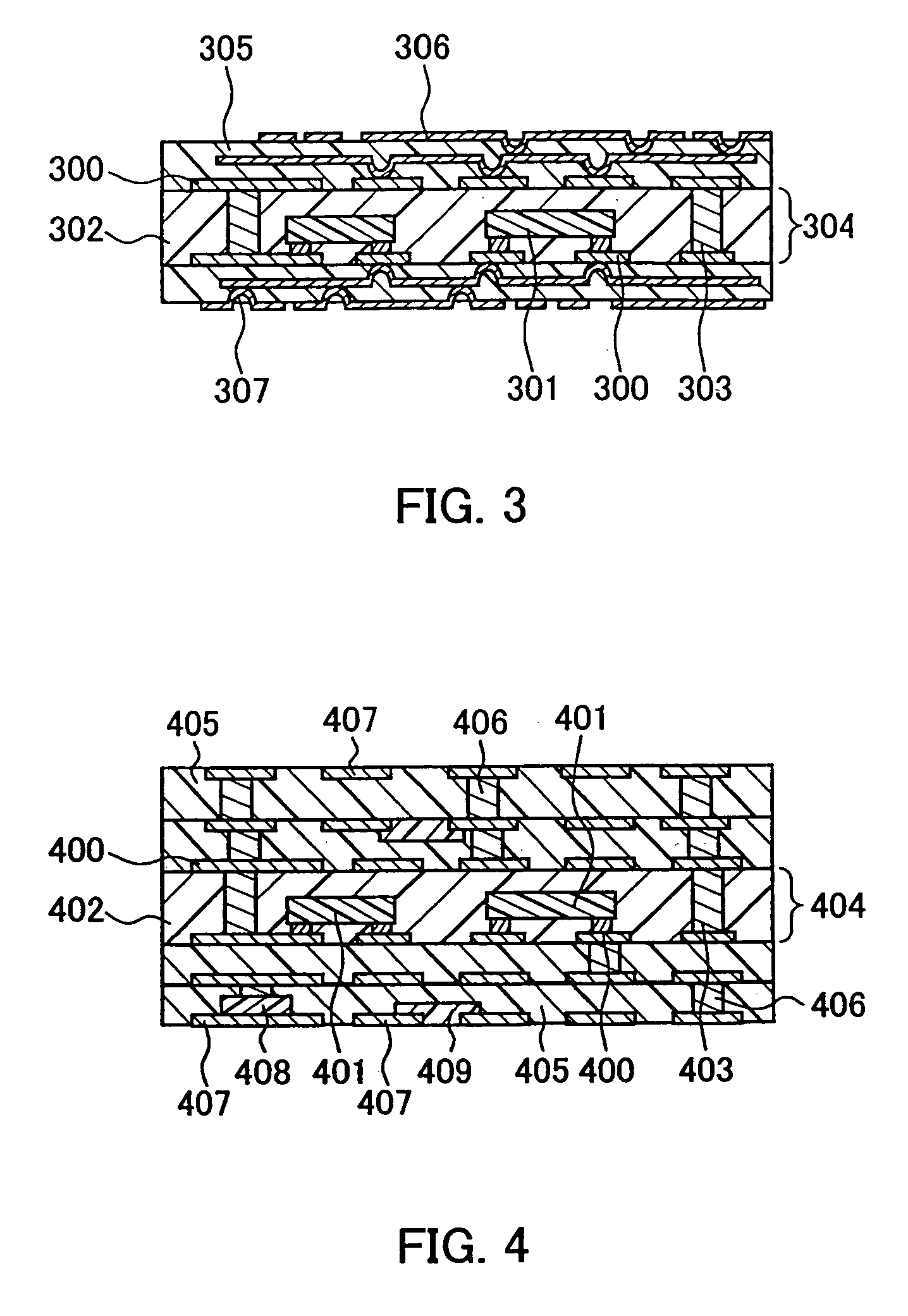

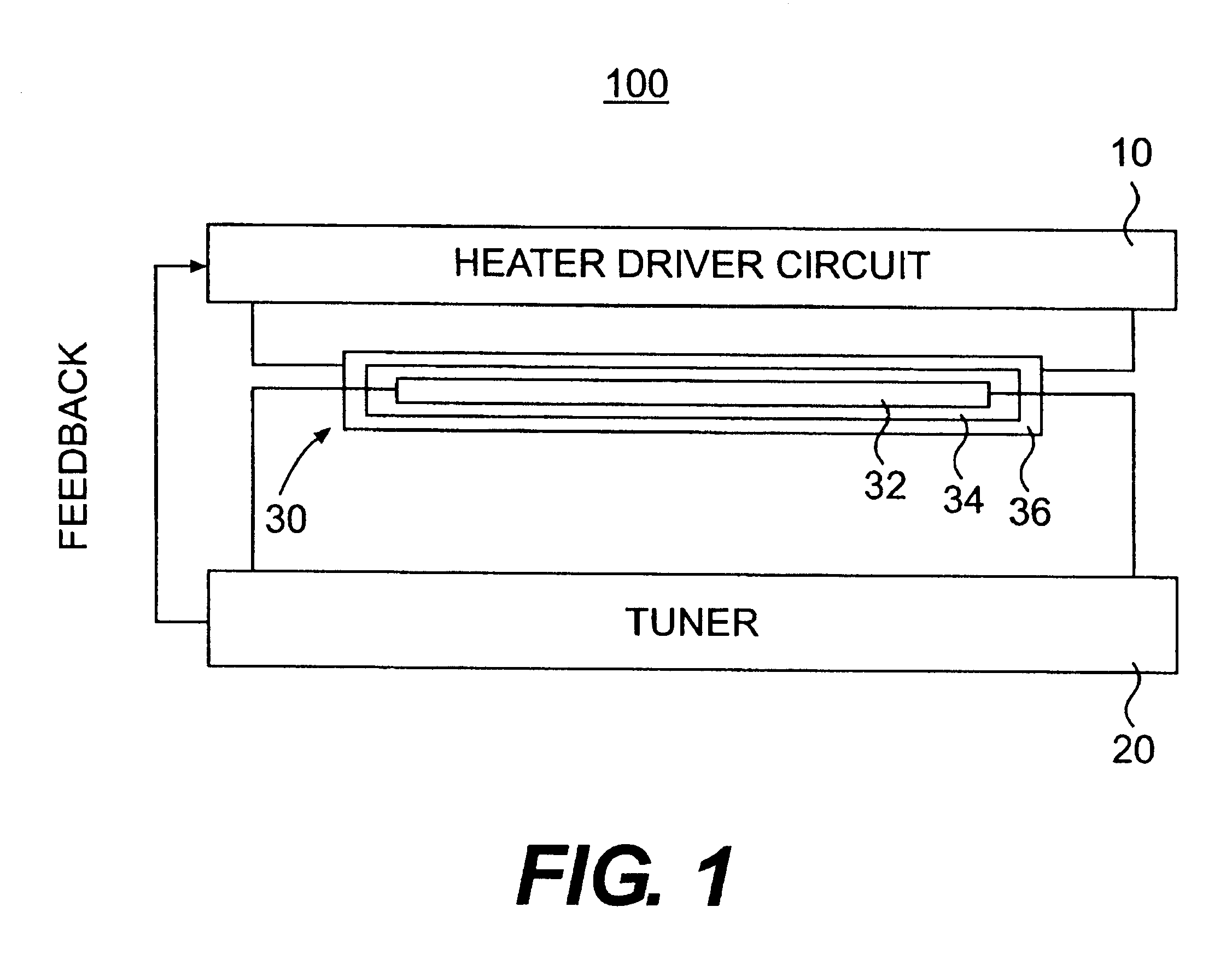

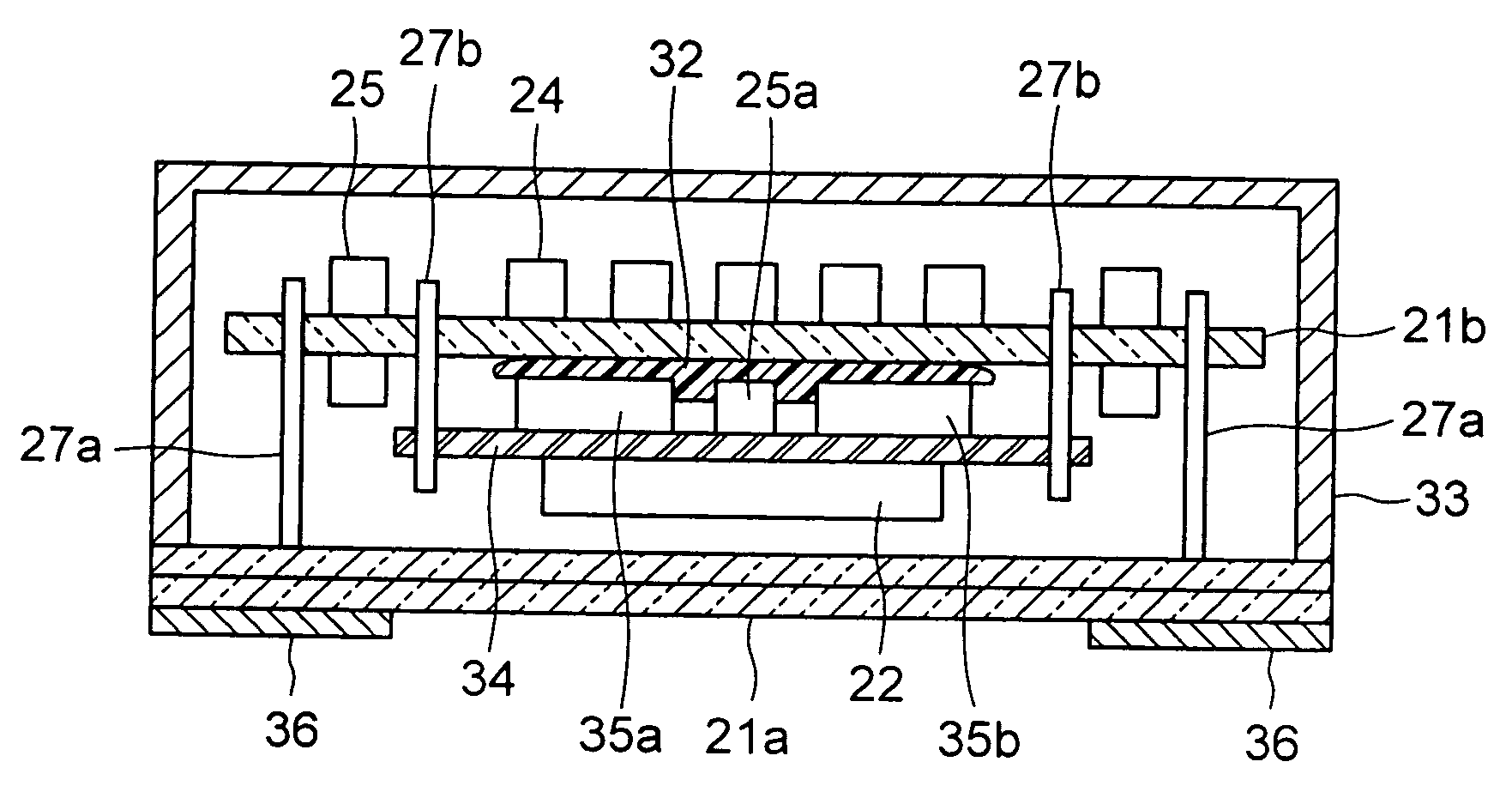

Component built-in module and method for producing the same

InactiveUS6939738B2Excellent in thermal radiation property and dielectric propertySimply formedSemiconductor/solid-state device detailsPrinted circuit aspectsHigh densityActive component

A component built-in module including a core layer formed of an electric insulating material, and an electric insulating layer and a plurality of wiring patterns, which are formed on at least one surface of the core layer. The electric insulating material of the core layer is formed of a mixture including at least an inorganic filler and a thermosetting resin. At least one or more of active components and / or passive components are contained in an internal portion of the core layer. The core layer has a plurality of wiring patterns and a plurality of inner vias formed of a conductive resin. The electric insulating material formed of the mixture including at least an inorganic filler and a thermosetting resin of the core layer has a modulus of elasticity at room temperature in the range from 0.6 GPa to 10 GPa. Thus, it is possible to provide a thermal conductive component built-in module capable of filling the inorganic filler with high density; burying the active component such as a semiconductor etc. and the passive component such as a chip resistor, a chip capacitor, etc. in the internal portion of the substrate; and simply producing a multilayer wiring structure.

Owner:PANASONIC CORP

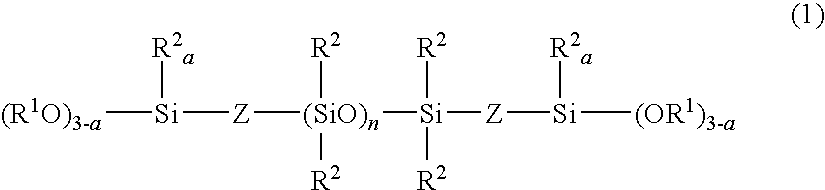

RTV silicone rubber composition for electric and electronic part protection, circuit boards, silver electrodes, and silver chip resistors

InactiveUS7553901B2Prevent and retard partPrevent short-circuitingLayered productsSemiconductor/solid-state device detailsSulfur containingElectron

RTV silicone rubber compositions are provided comprising (A) an organopolysiloxane, (B) an organosilicon compound or partial hydrolytic condensate thereof, and (C) a non-aromatic amino-bearing compound. The compositions, when electric and electronic parts having a copper, silver or other metal portion on their surface are encapsulated or sealed therewith, can prevent or retard the parts from corrosion with sulfur-containing gas.

Owner:SHIN ETSU CHEM IND CO LTD

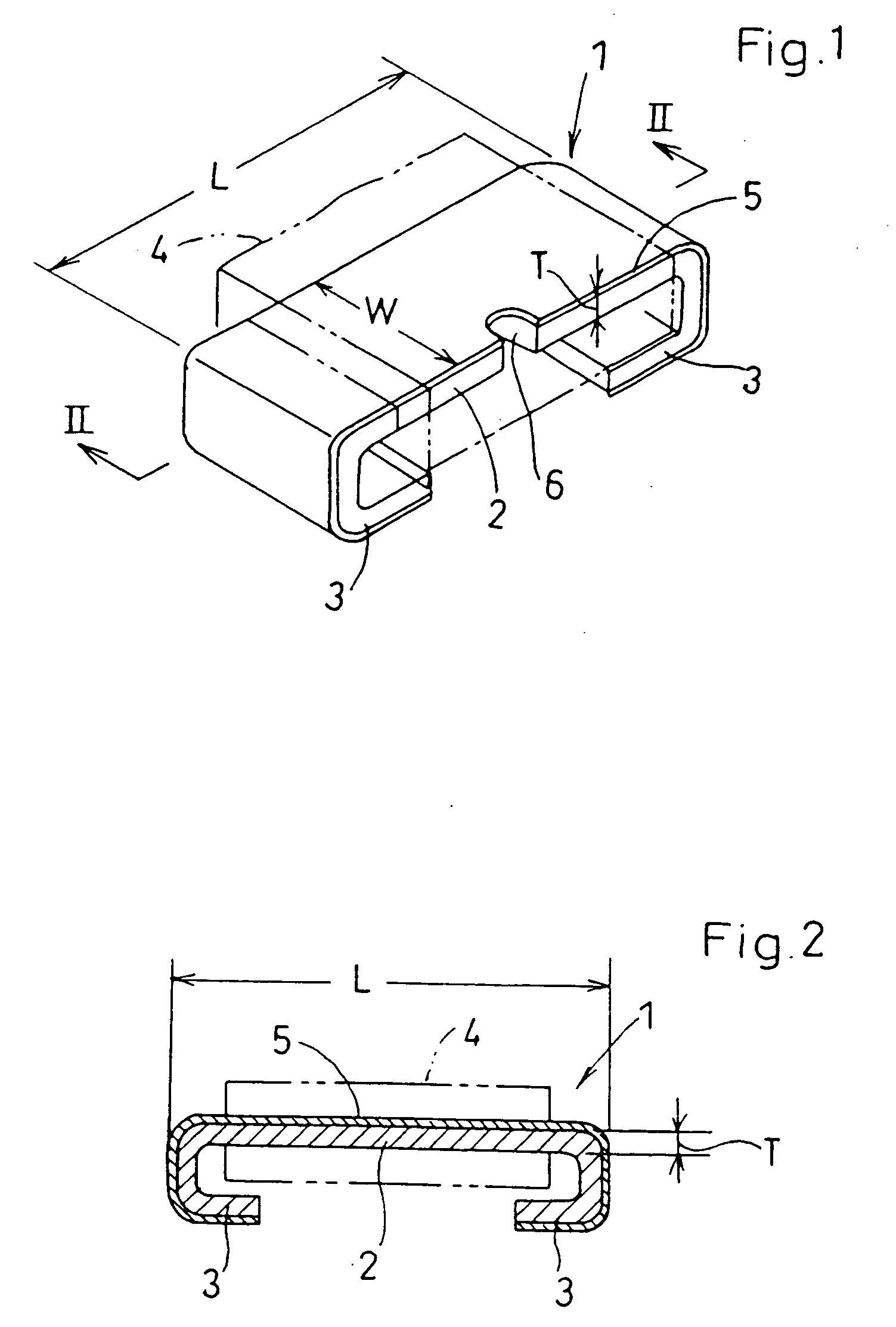

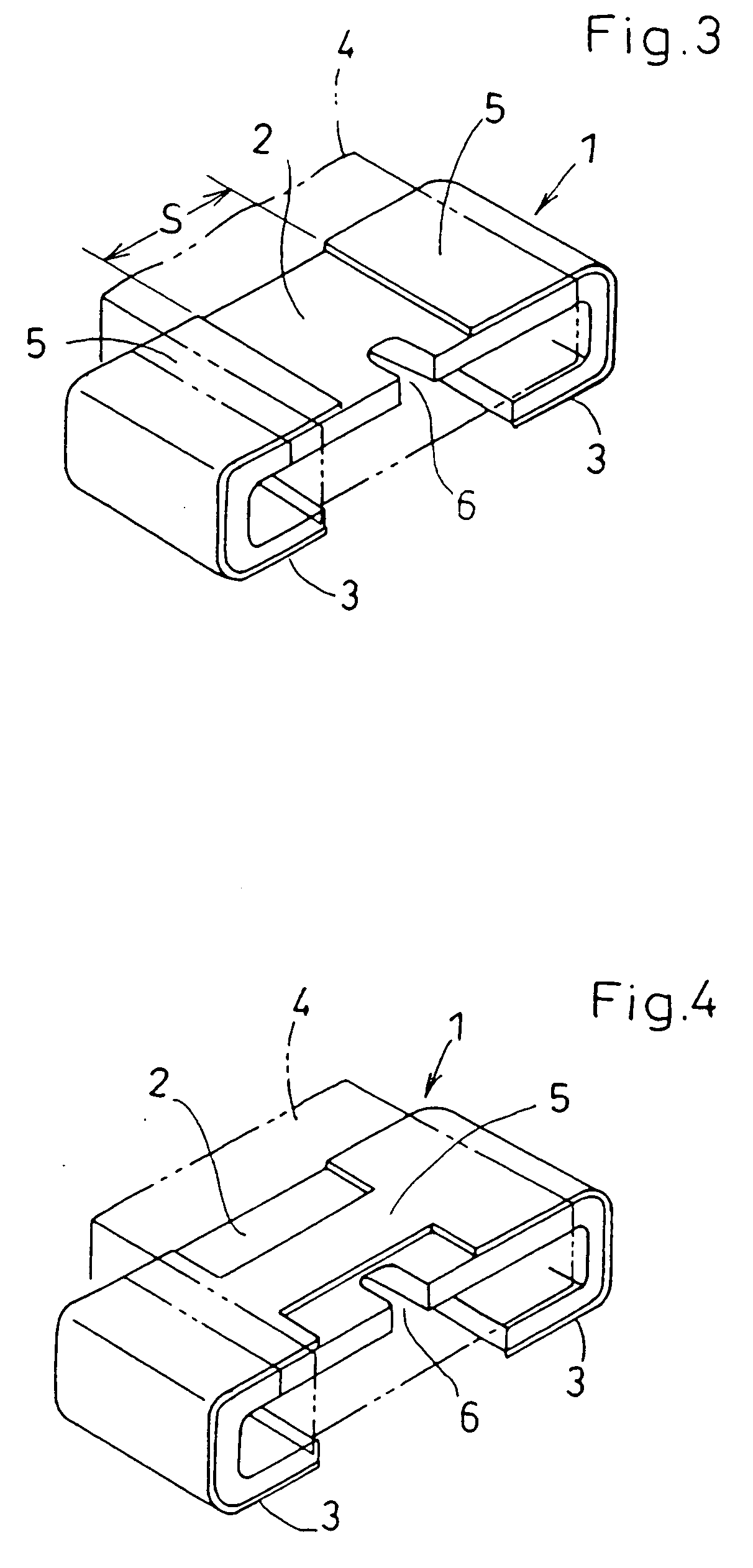

Chip resistor

InactiveUS6943662B2Resistor chip manufactureResistor terminals/electrodesFilm resistanceChemical reaction

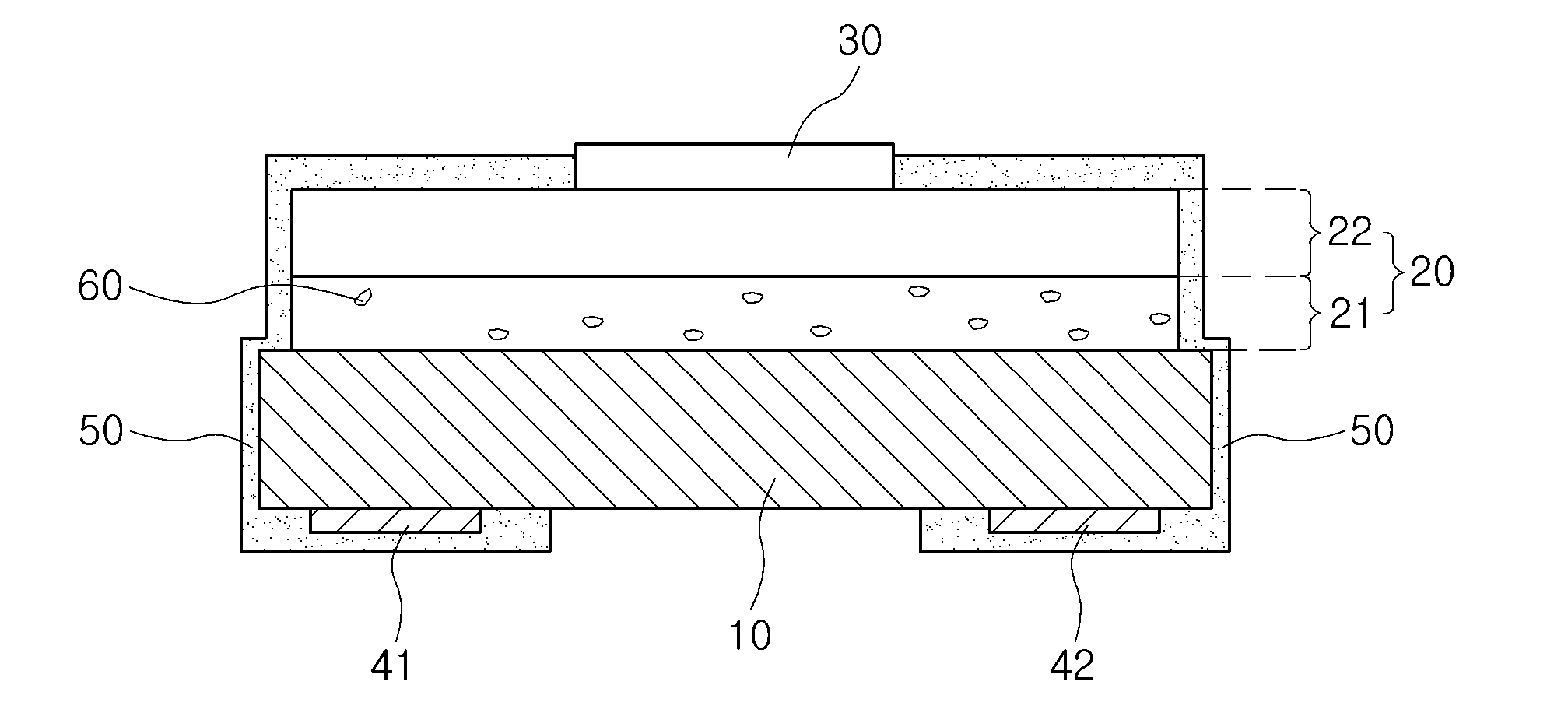

Resistance or side electrodes of a chip resistor is prevented from being lost due to chemical reaction with NaCl contained in human sweat and so on when human sweat, seawater, etc. are adhered thereto. The chip resistor comprises an insulating substrate, thick-film upper surface electrodes formed at opposite ends of the top surface of the insulating substrate, a thin-film resistance made of a constituent material not reacting with NaCl, and formed so as to be extended over the upper surface of the insulating substrate and respective portions of the upper surface of the thick-film upper surface electrodes, thick-film back surface electrodes formed at spots on the back surface of the insulating substrate, corresponding to the thick-film upper surface electrodes, respectively, and thick-film side surface electrodes connecting the thick-film back surface electrodes with respective portions of the thick-film upper surface electrodes, exposed out of the thin-film resistance, respectively.

Owner:ROHM CO LTD

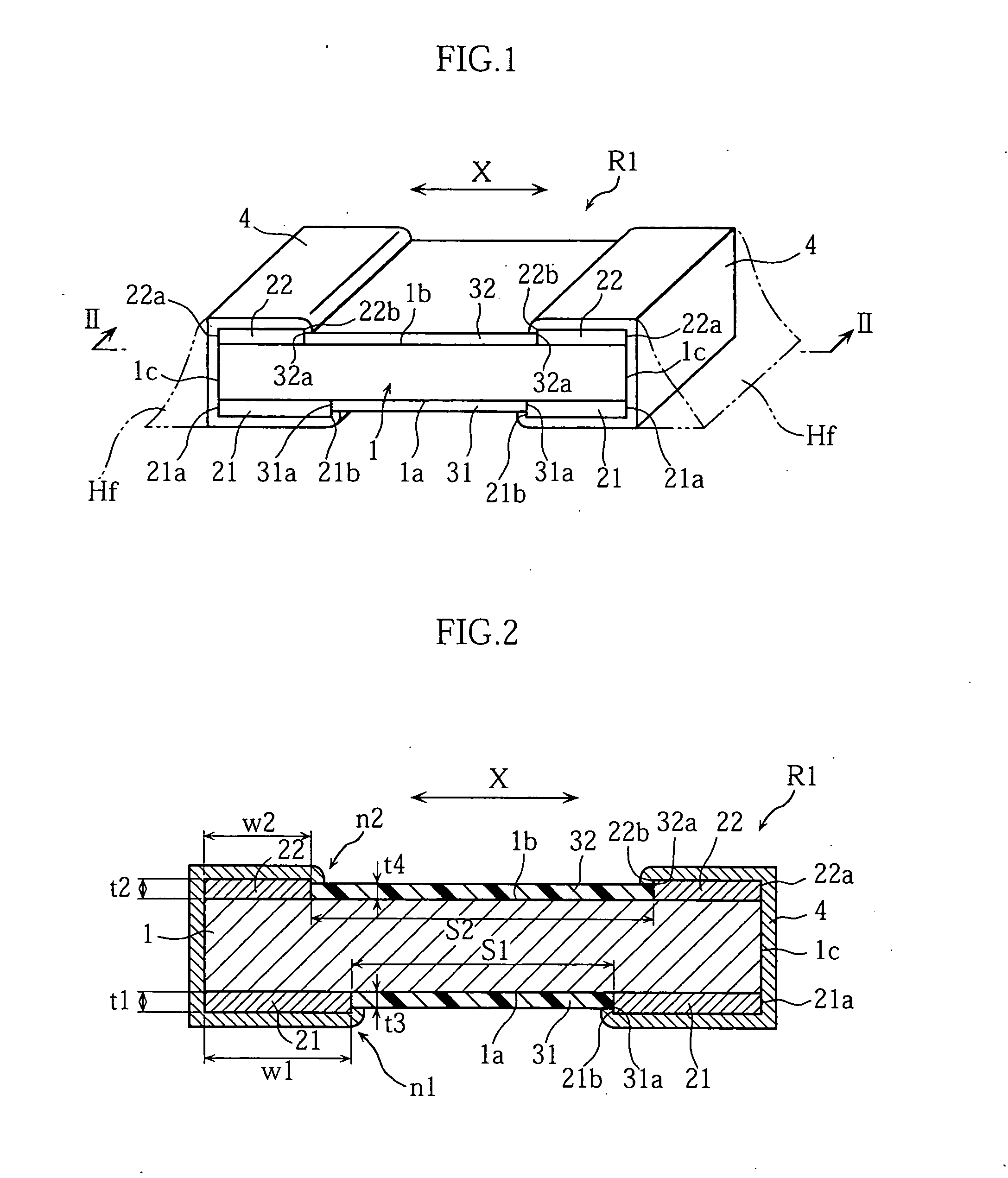

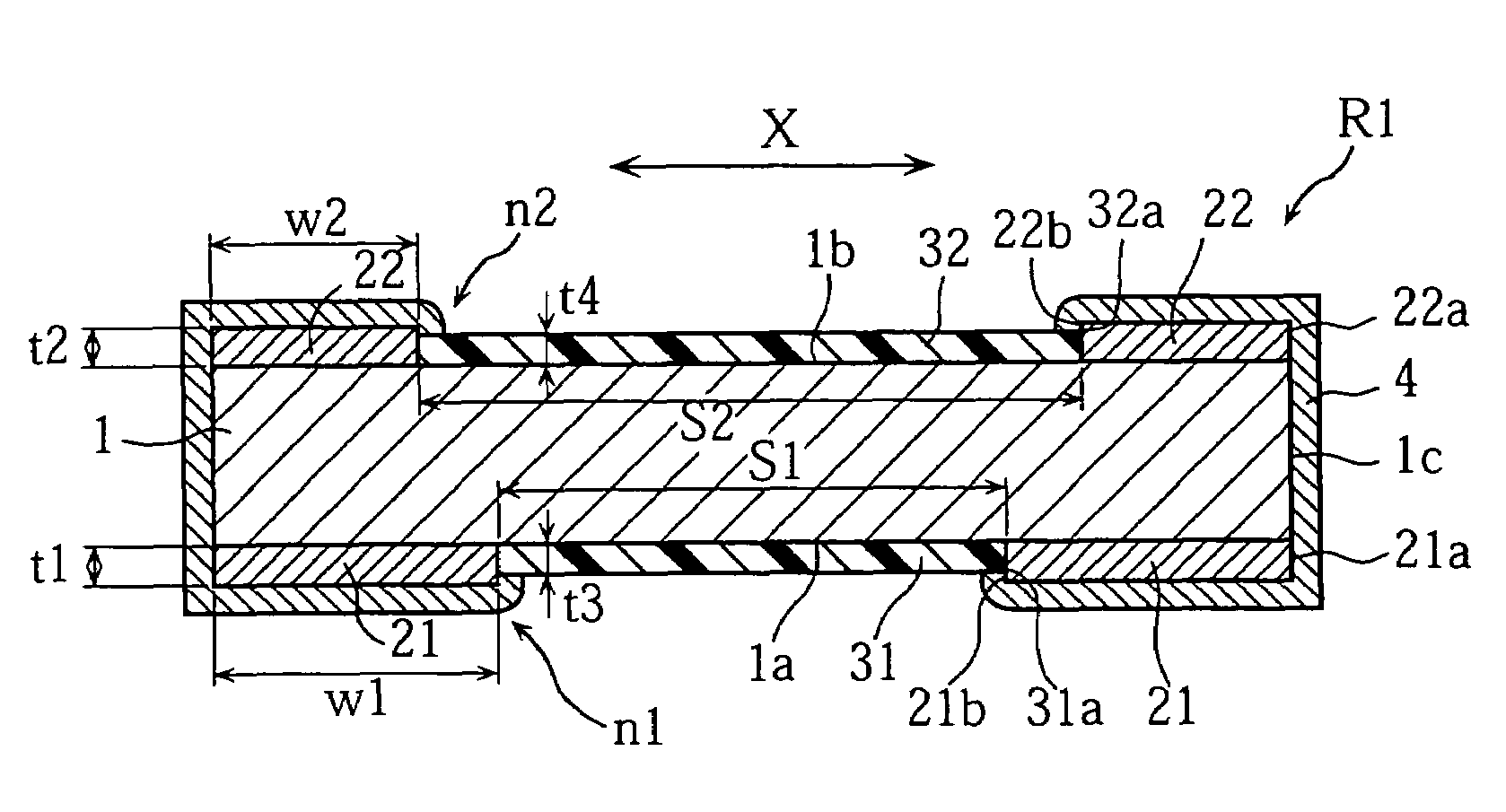

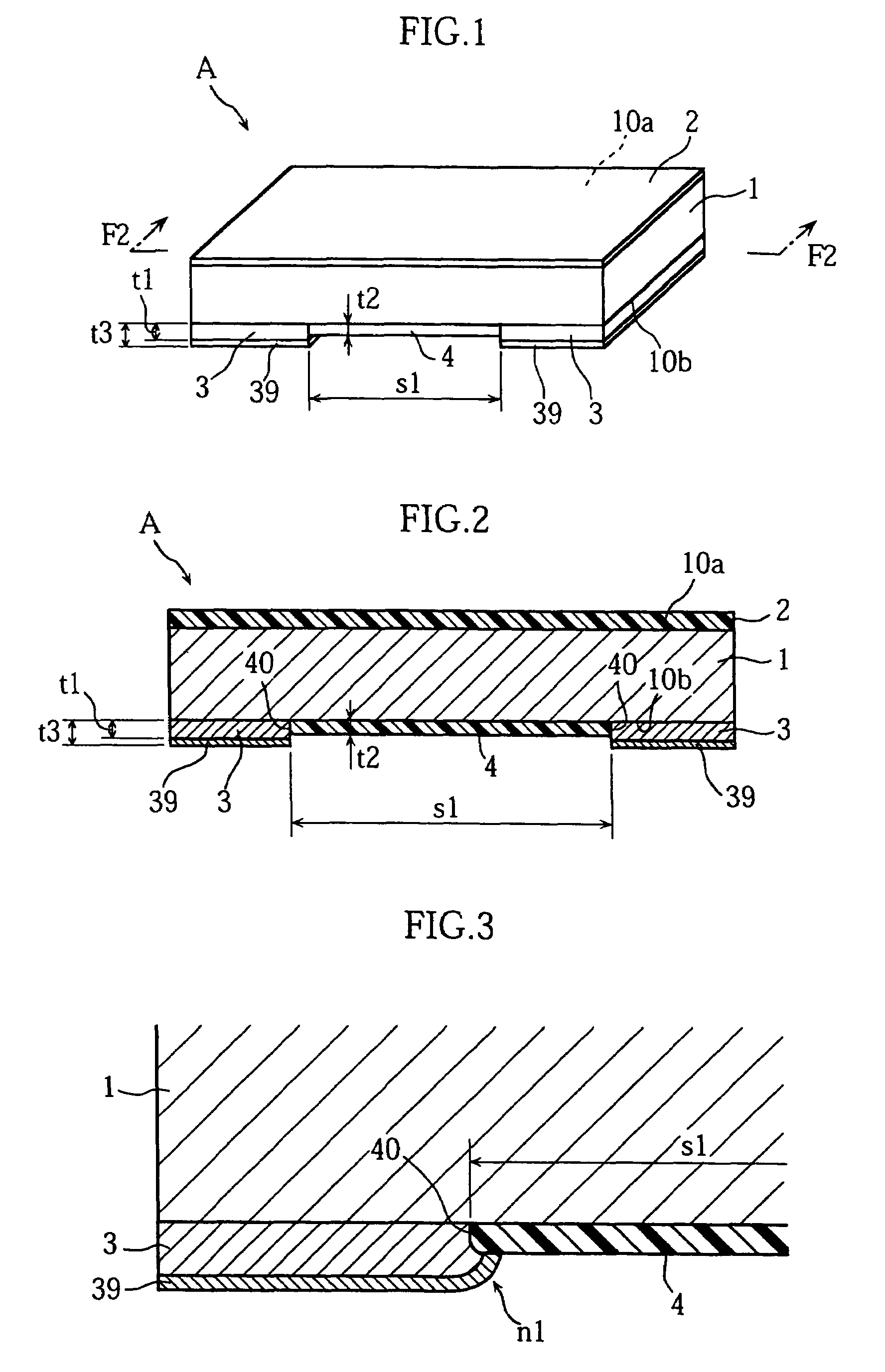

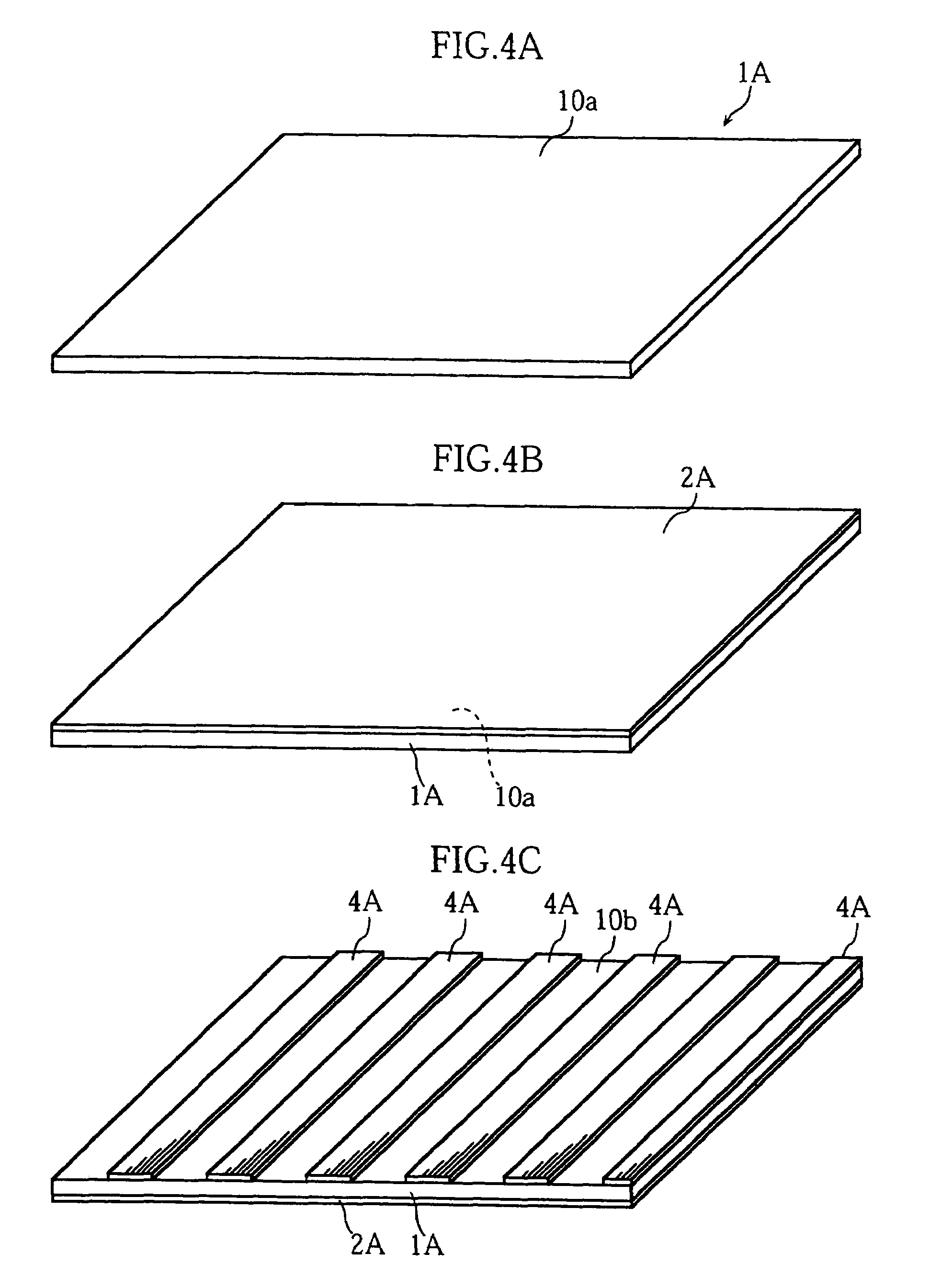

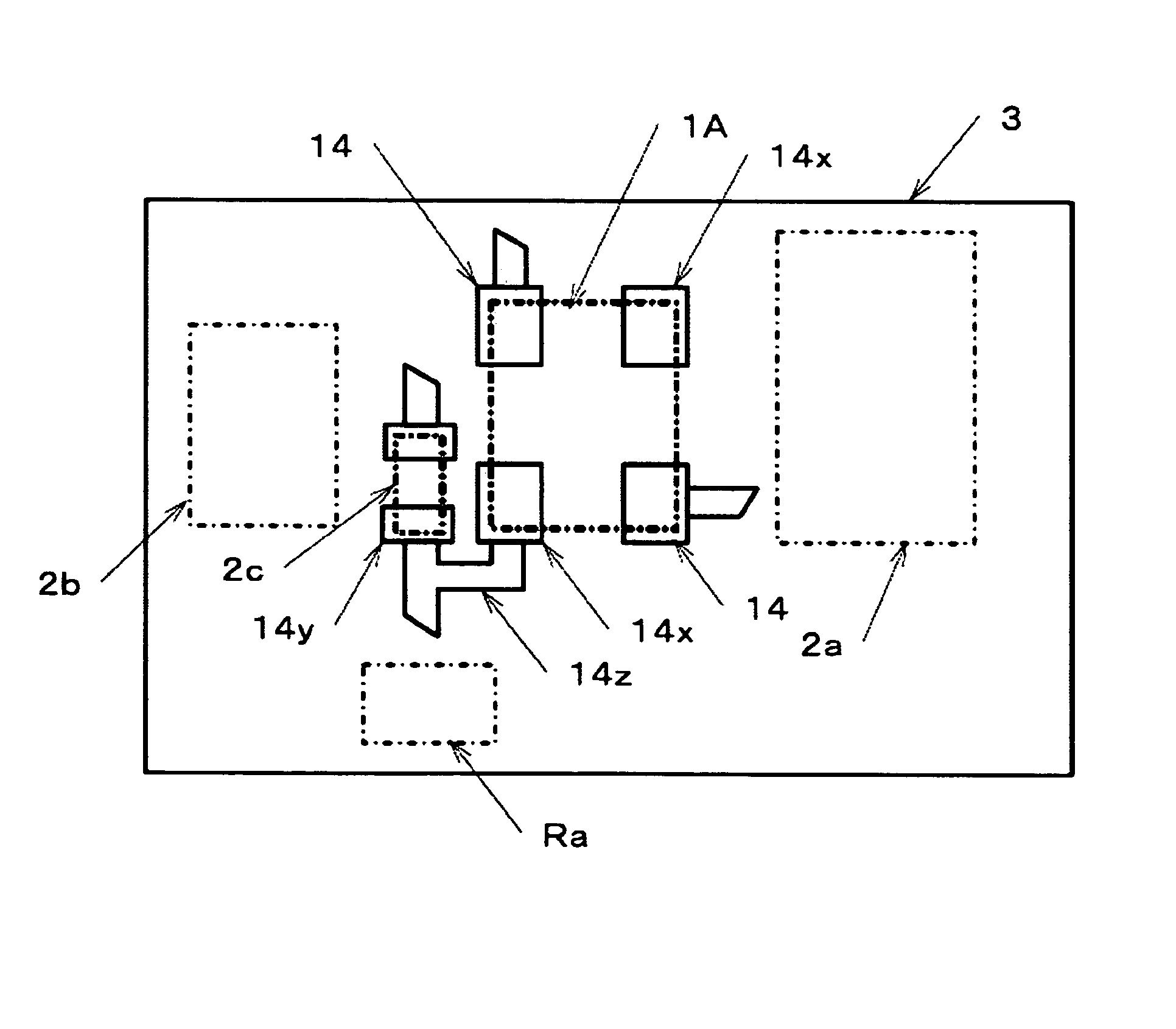

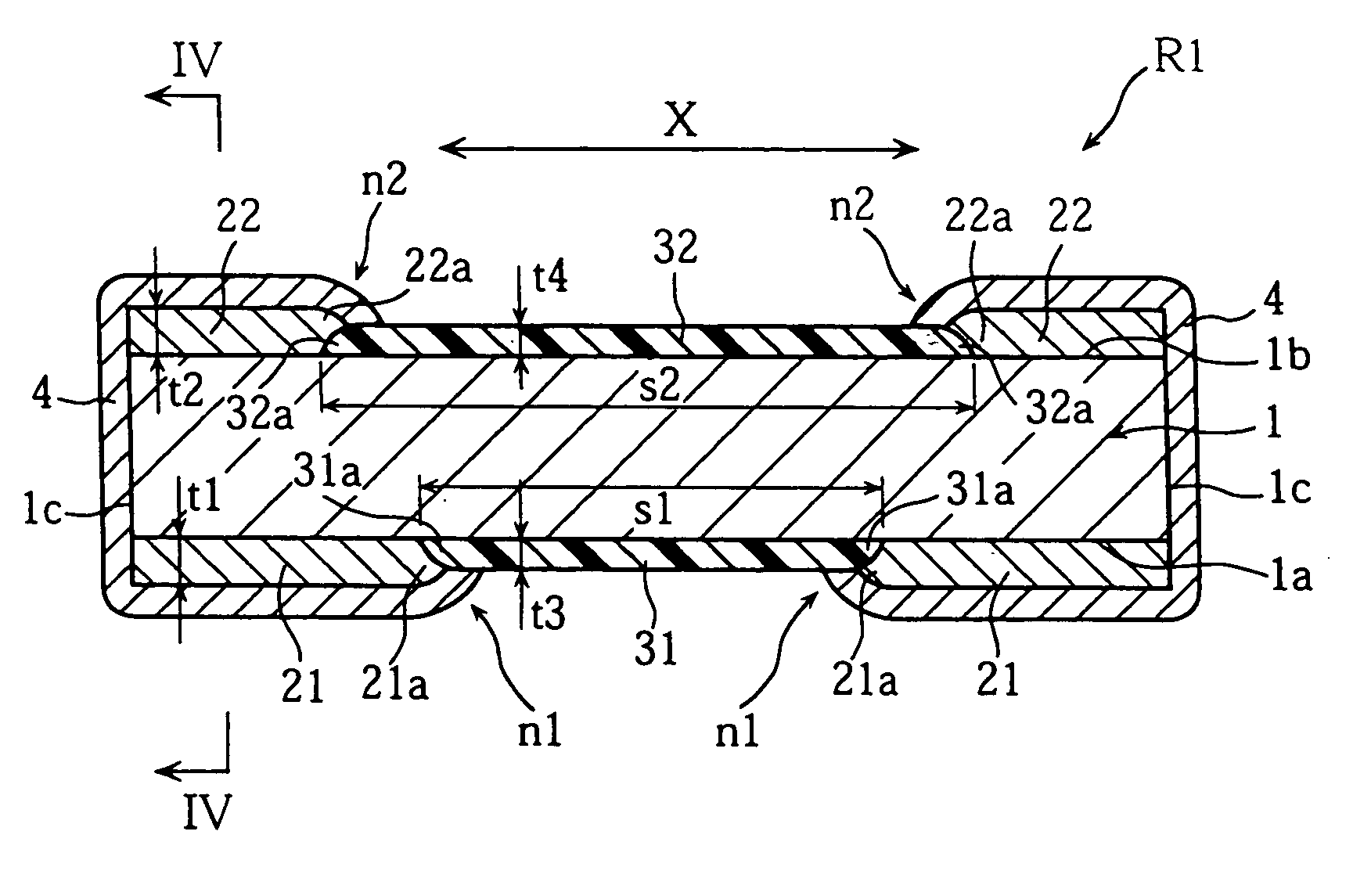

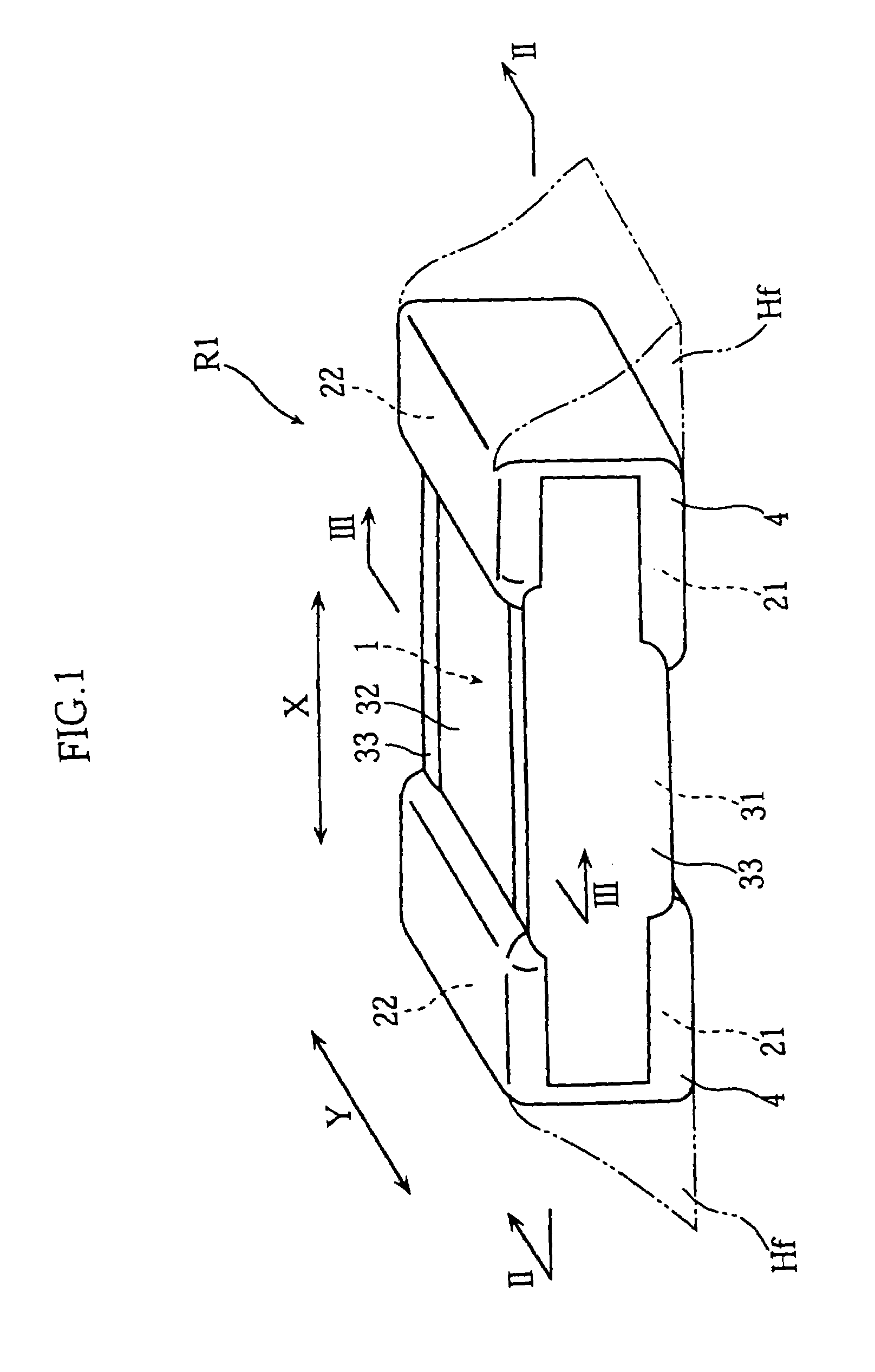

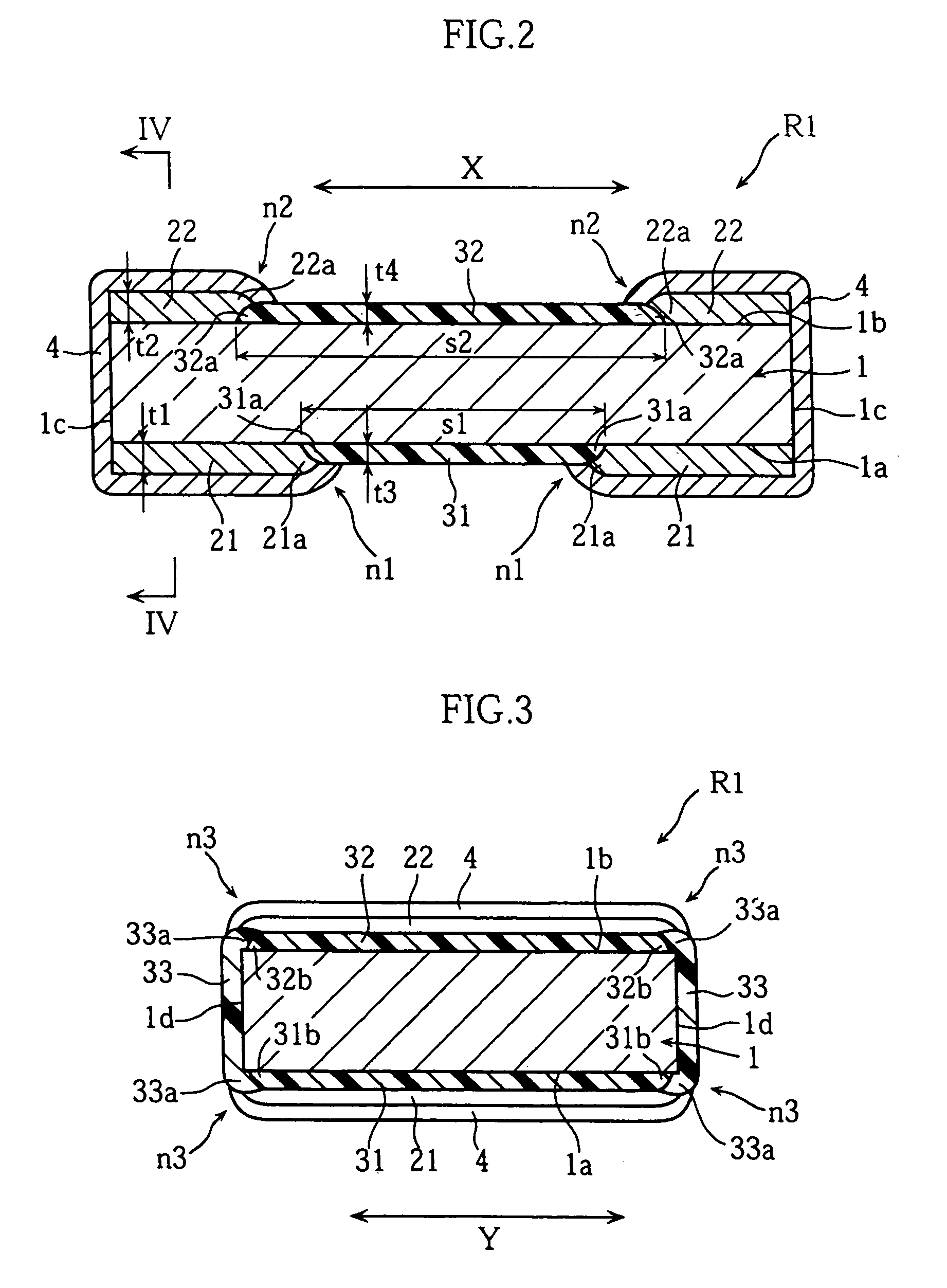

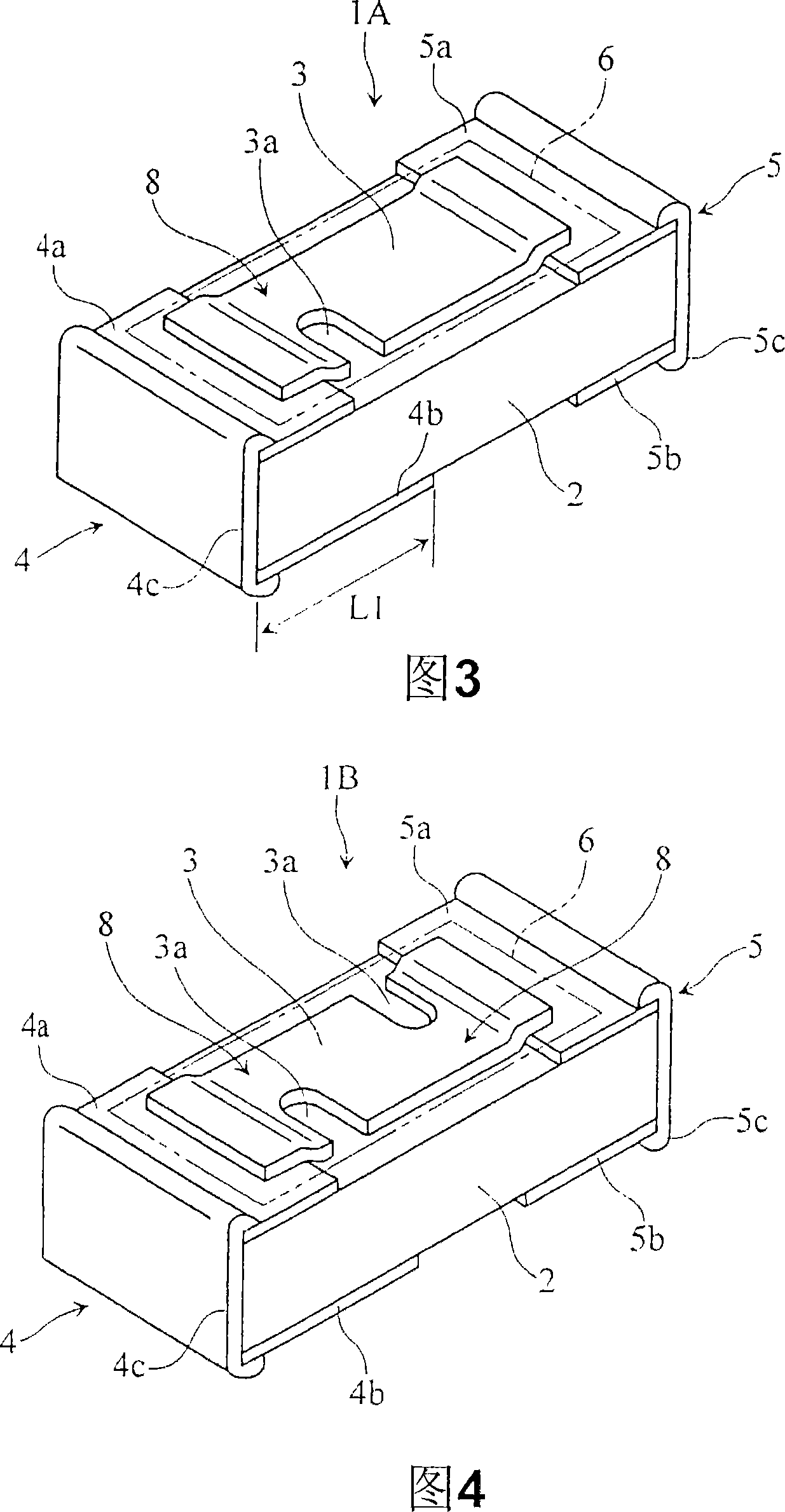

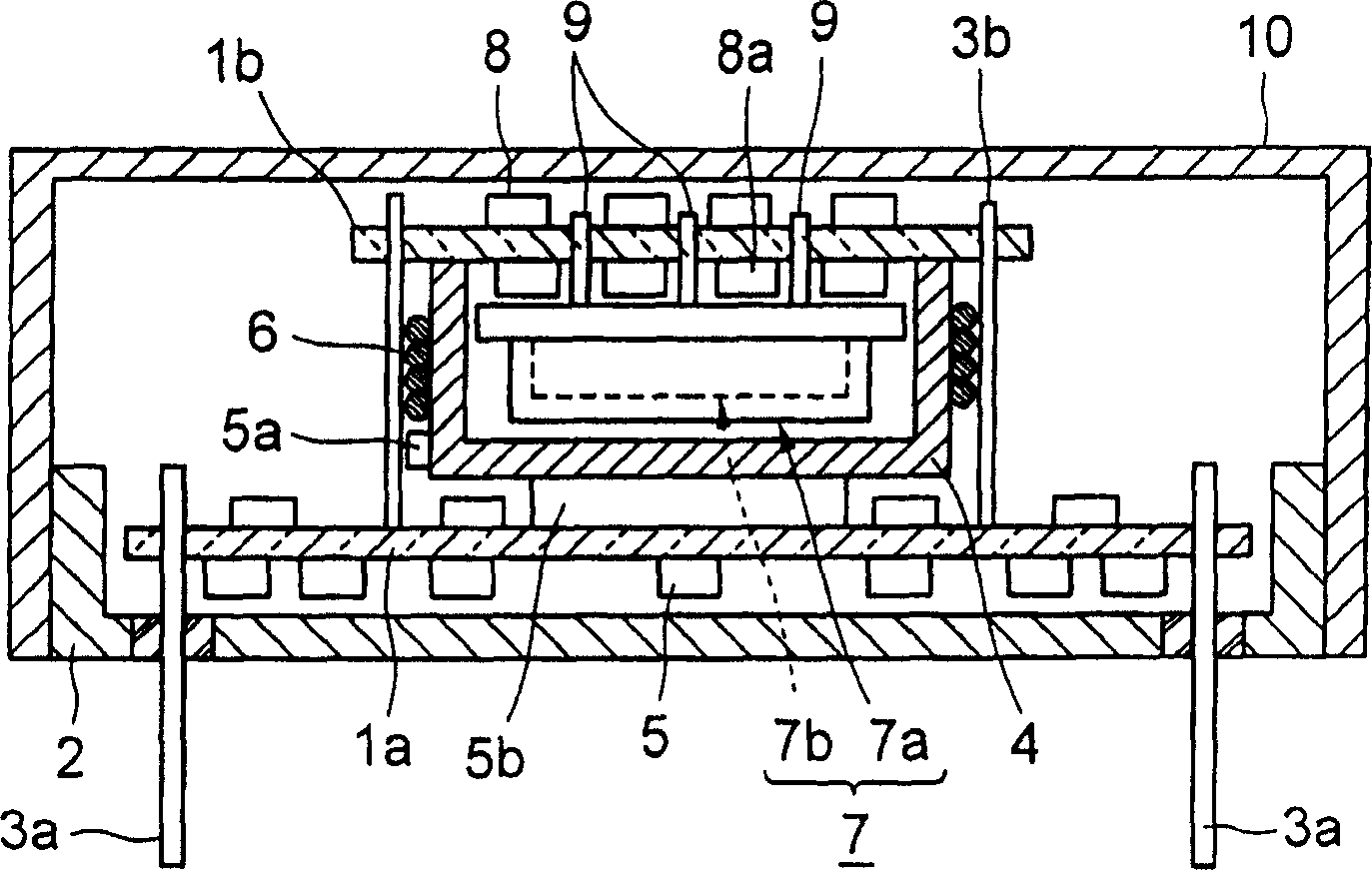

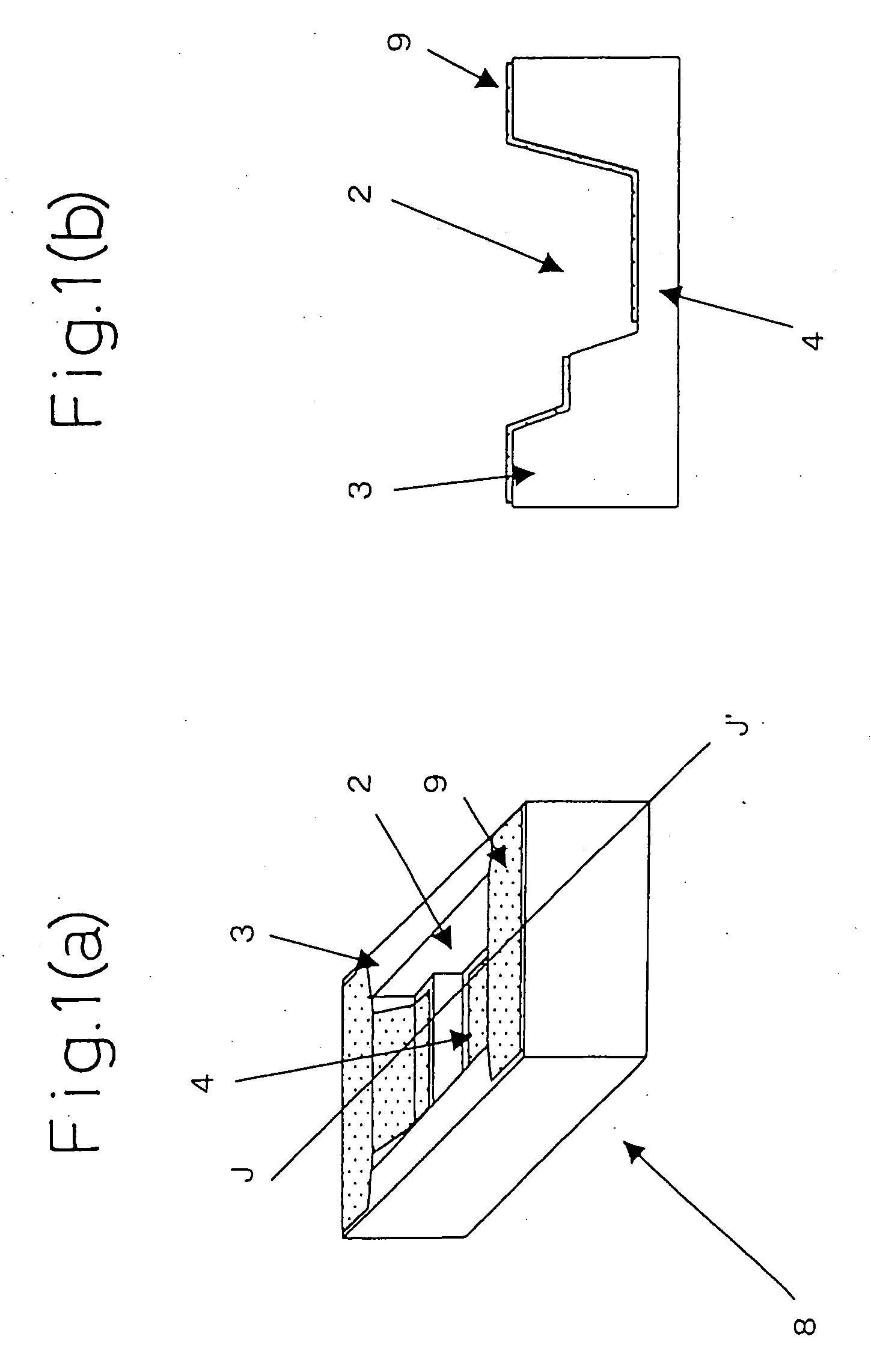

Chip resistor and method for manufacturing same

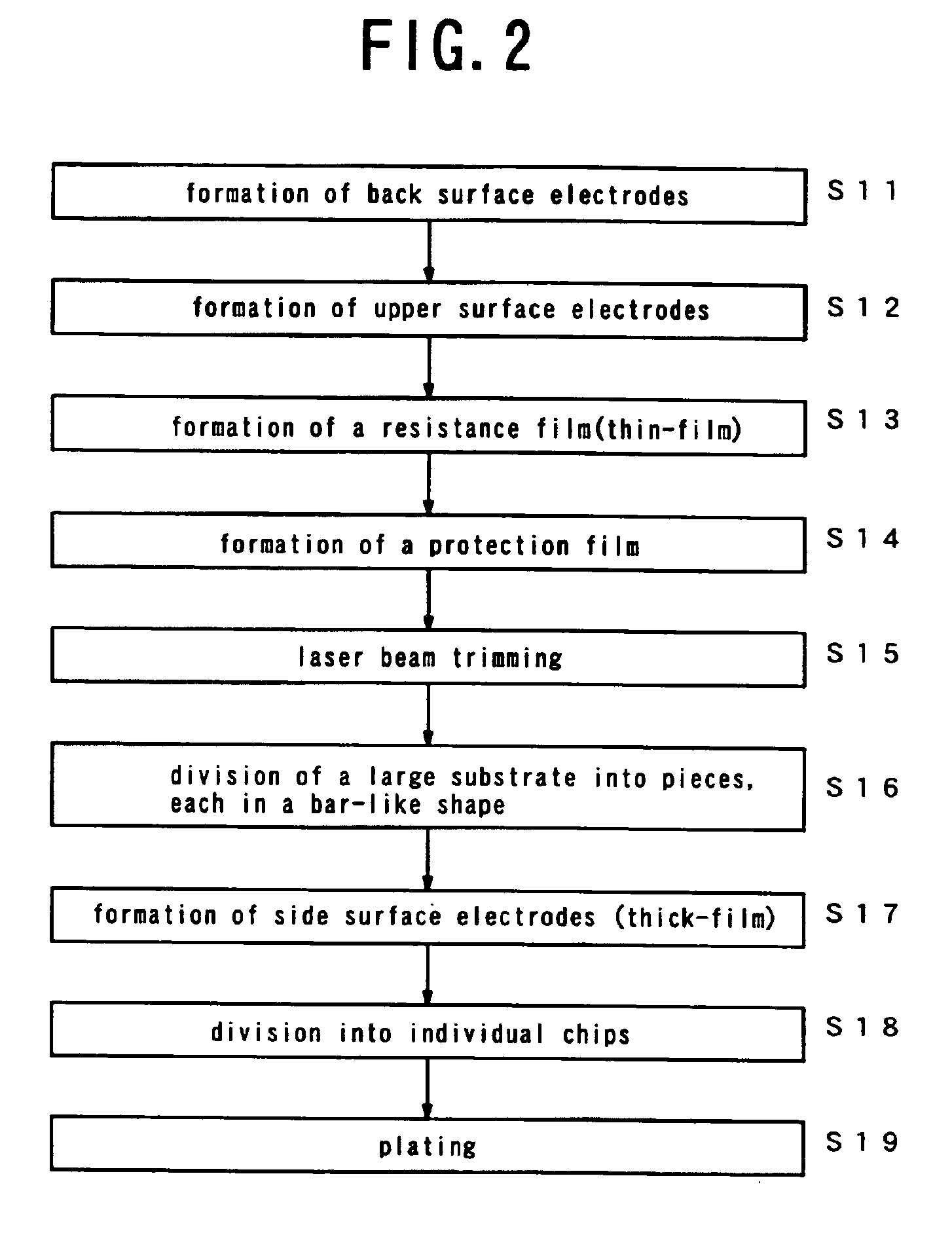

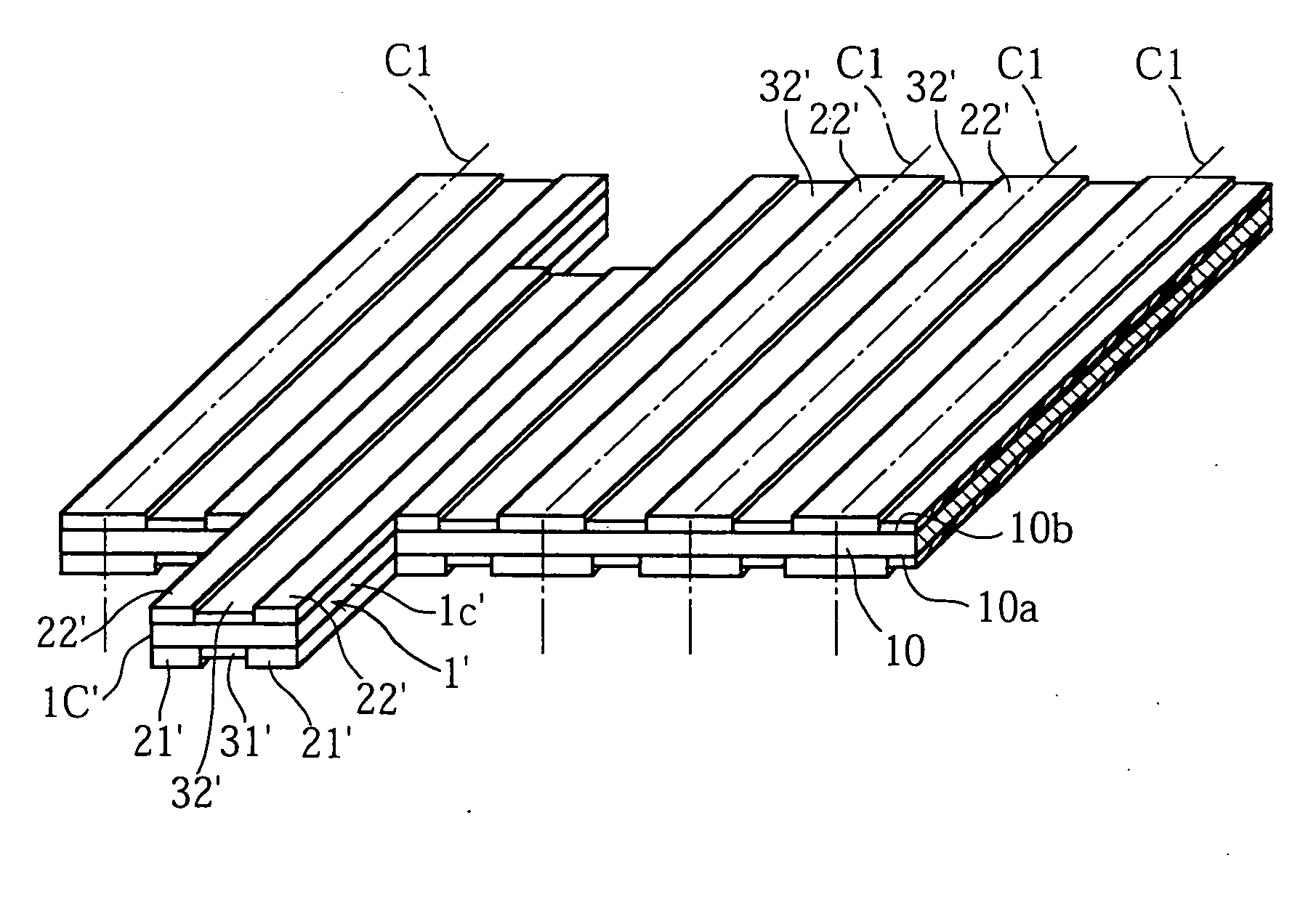

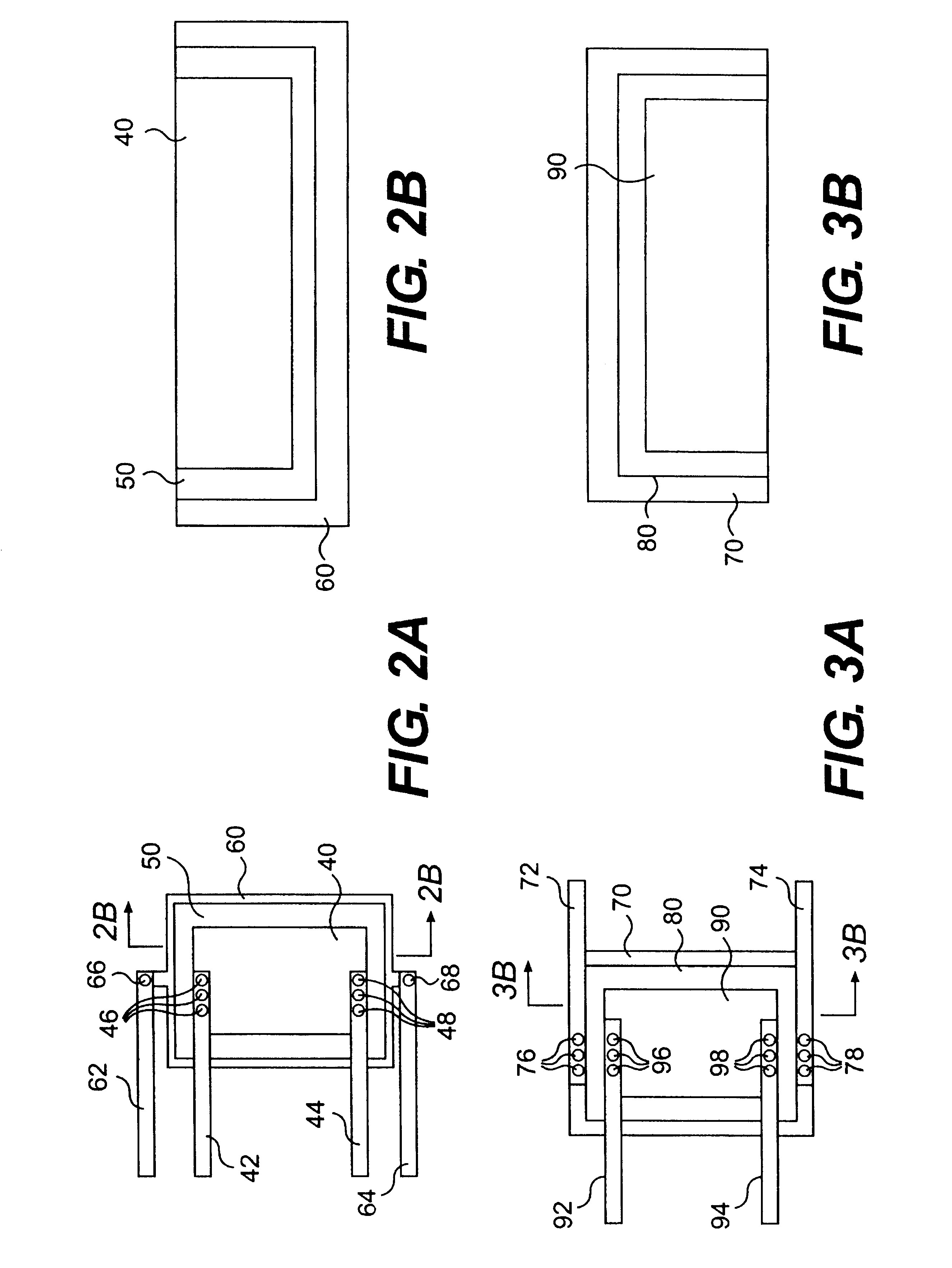

ActiveUS20060205171A1Small resistanceLow production costResistor chip manufactureResistor terminals/electrodesAuxiliary electrodeResistive element

A chip resistor (R1) includes a resistor element (1) having a first surface (1a) and a second surface (1b) opposite to the first surface. Two main electrodes (21), spaced from each other, are provided on the first surface (1a), while two auxiliary electrodes (22), spaced from each other, are provided on the second surface (1b). The auxiliary electrodes face the main electrodes (21) via the resistor element (1). The main electrodes (21) and the auxiliary electrodes (22) are made of the same material.

Owner:ROHM CO LTD

Component built-in module and method for producing the same

InactiveUS20050230848A1Excellent in thermal radiation property and dielectric propertySimply formedSemiconductor/solid-state device detailsPrinted circuit aspectsHigh densityActive component

A component built-in module including a core layer formed of an electric insulating material, and an electric insulating layer and a plurality of wiring patterns, which are formed on at least one surface of the core layer. The electric insulating material of the core layer is formed of a mixture including at least an inorganic filler and a thermosetting resin. At least one or more of active components and / or passive components are contained in an internal portion of the core layer. The core layer has a plurality of wiring patterns and a plurality of inner vias formed of a conductive resin. The electric insulating material formed of the mixture including at least an inorganic filler and a thermosetting resin of the core layer has a modulus of elasticity at room temperature in the range from 0.6 GPa to 10 GPa. Thus, it is possible to provide a thermal conductive component built-in module capable of filling the inorganic filler with high density; burying the active component such as a semiconductor etc. and the passive component such as a chip resistor, a chip capacitor, etc. in the internal portion of the substrate; and simply producing a multilayer wiring structure.

Owner:PANASONIC CORP

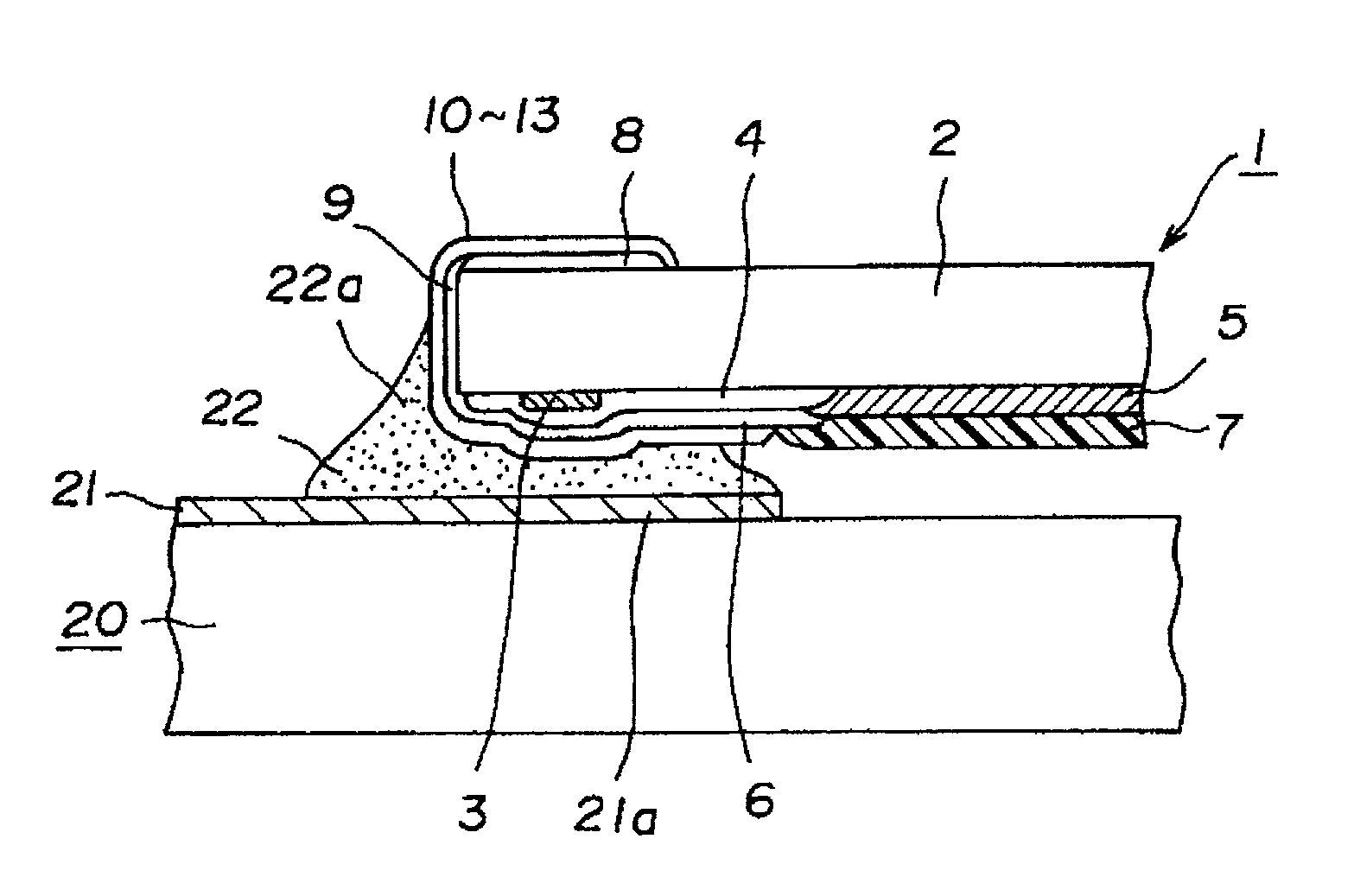

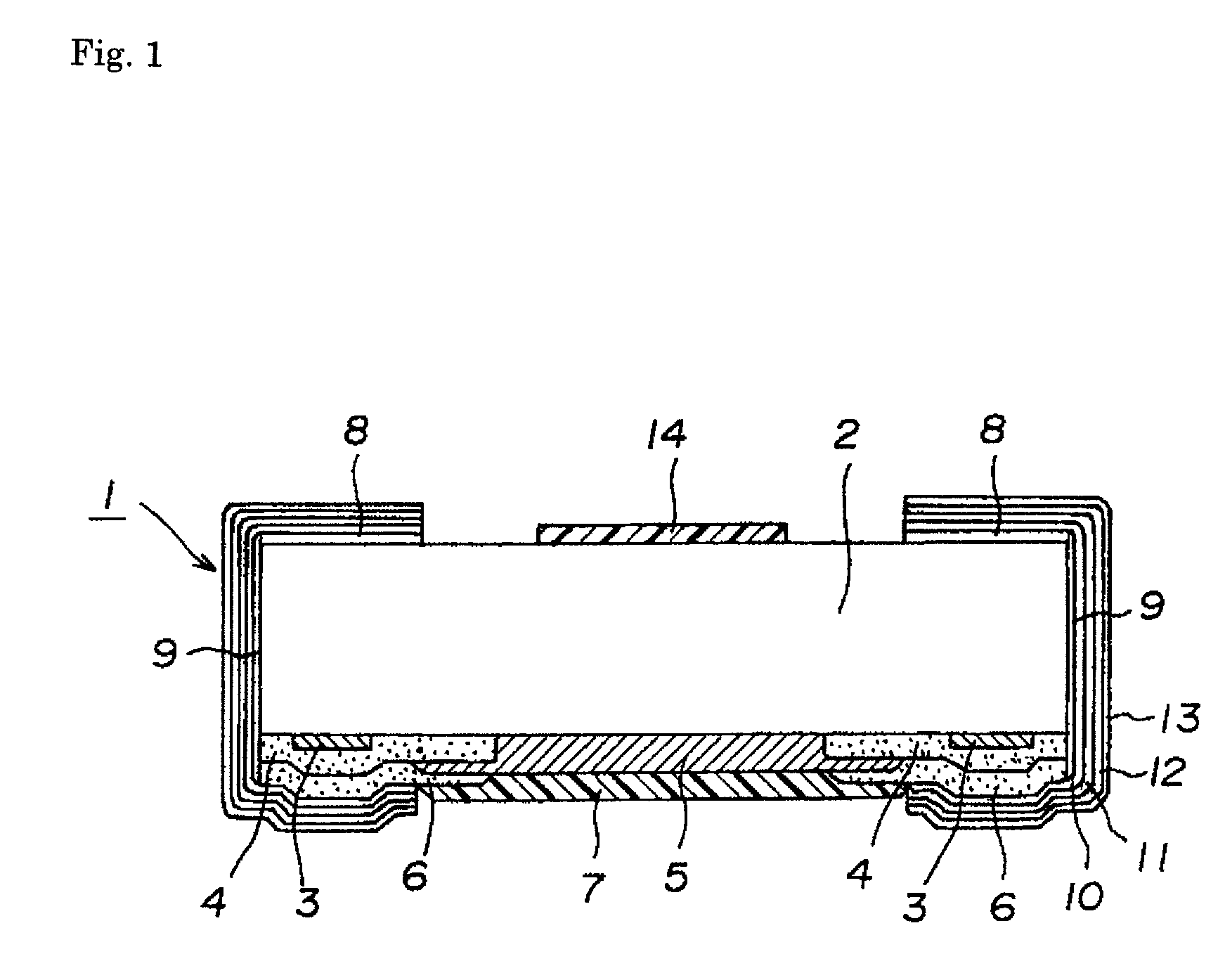

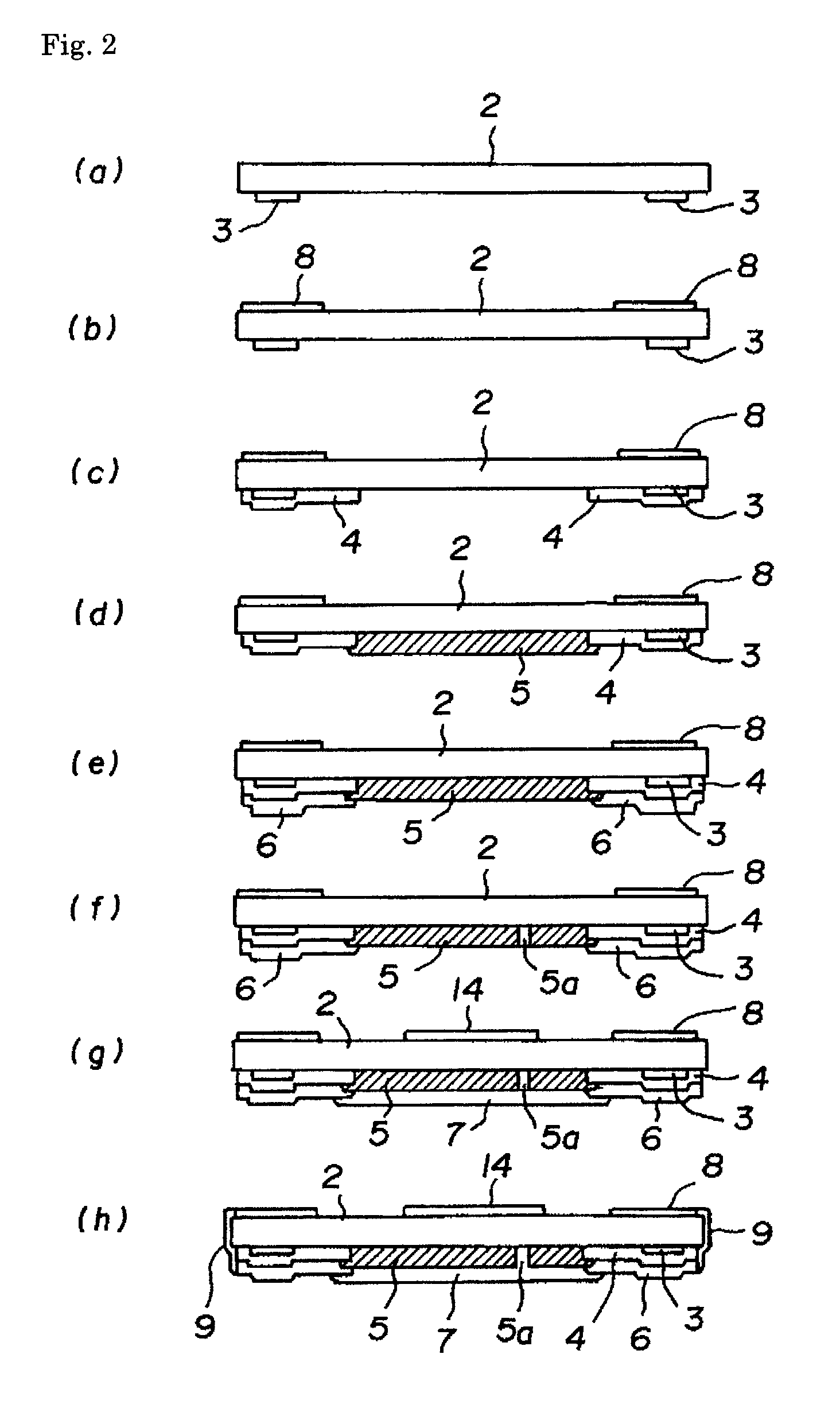

Chip resistor and method for manufacturing same

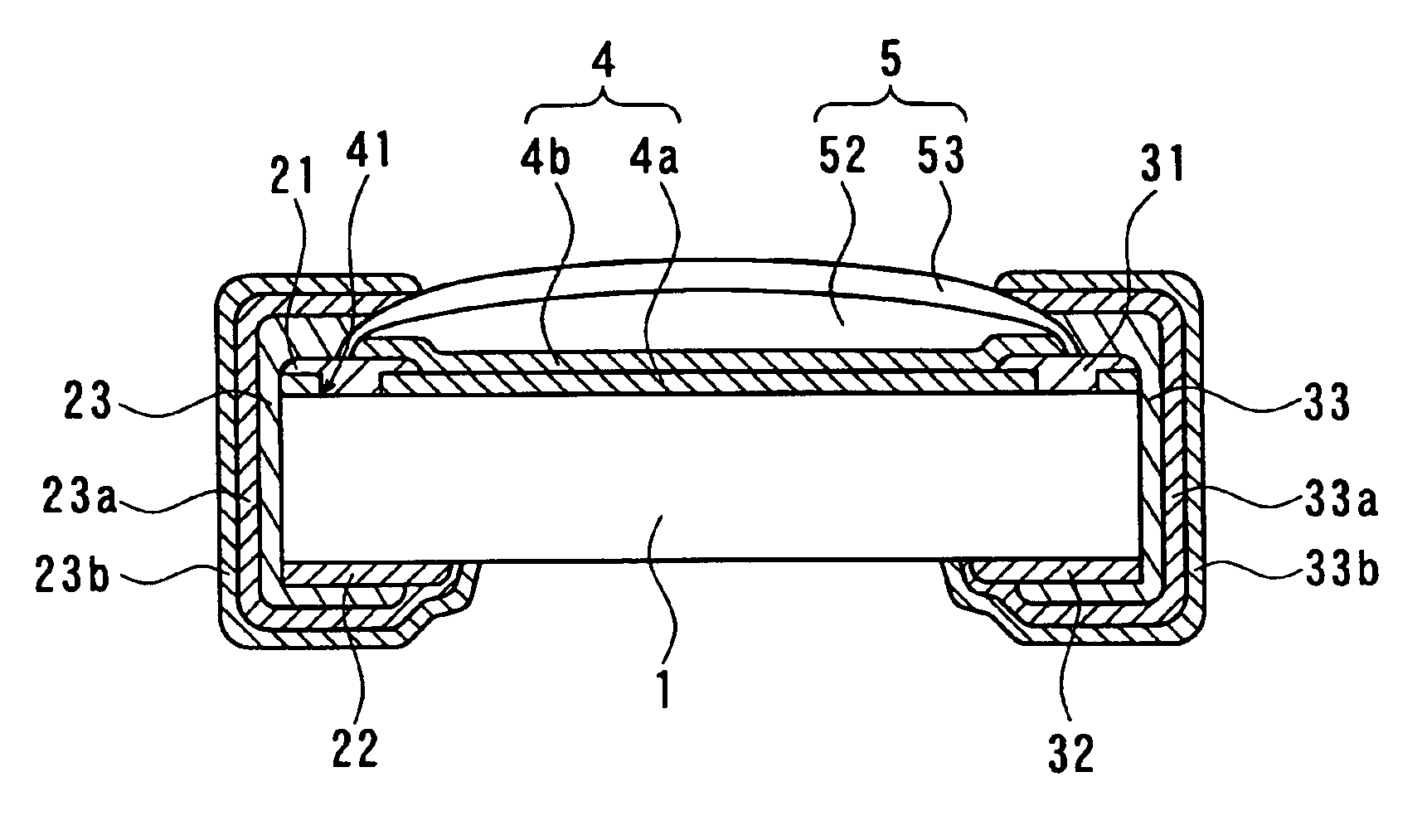

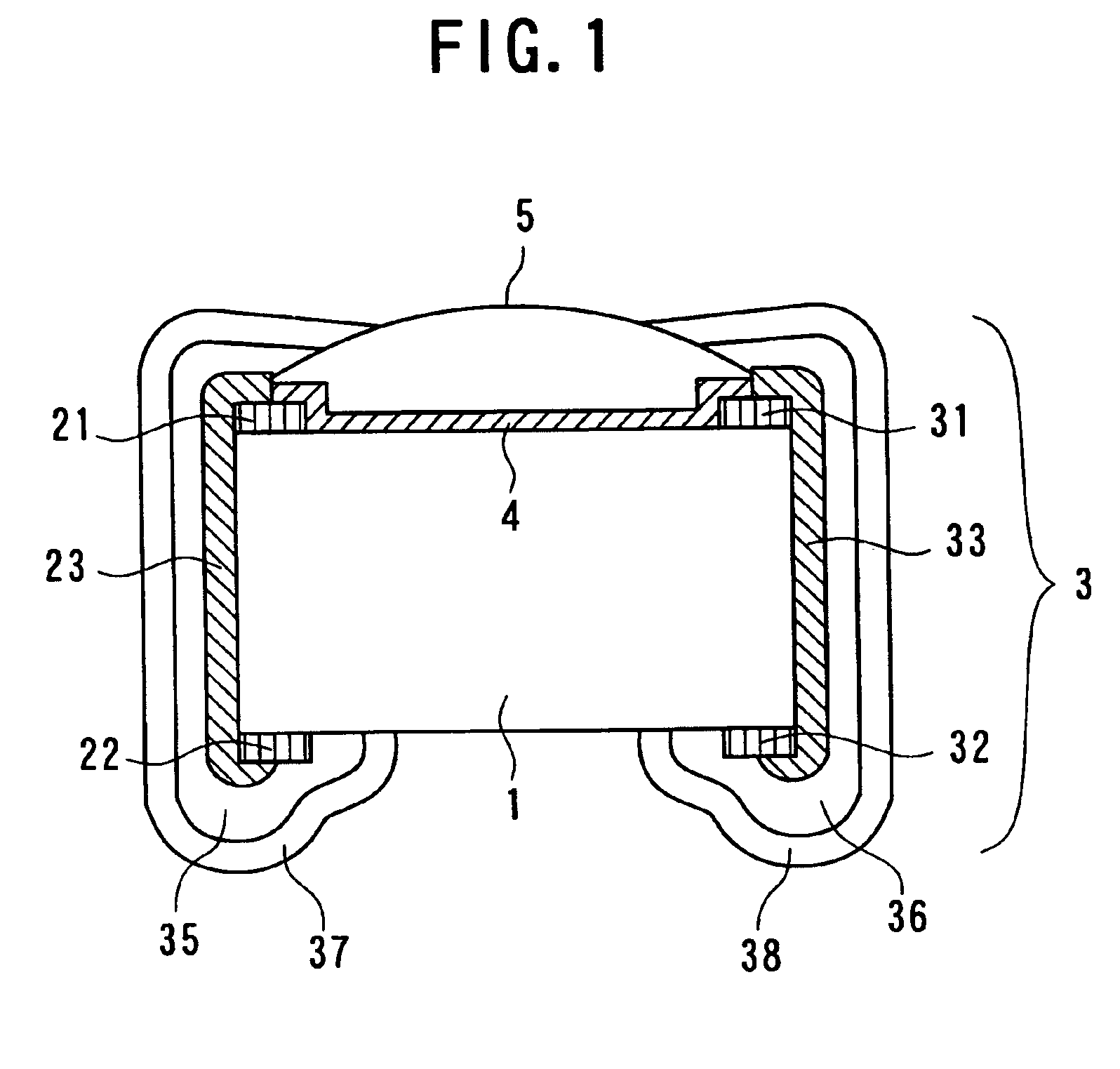

ActiveUS7326999B2Small resistanceLow production costResistor chip manufactureResistor terminals/electrodesAuxiliary electrodeBiomedical engineering

A chip resistor (R1) includes a resistor element (1) having a first surface (1a) and a second surface (1b) opposite to the first surface. Two main electrodes (21), spaced from each other, are provided on the first surface (1a), while two auxiliary electrodes (22), spaced from each other, are provided on the second surface (1b). The auxiliary electrodes face the main electrodes (21) via the resistor element (1). The main electrodes (21) and the auxiliary electrodes (22) are made of the same material.

Owner:ROHM CO LTD

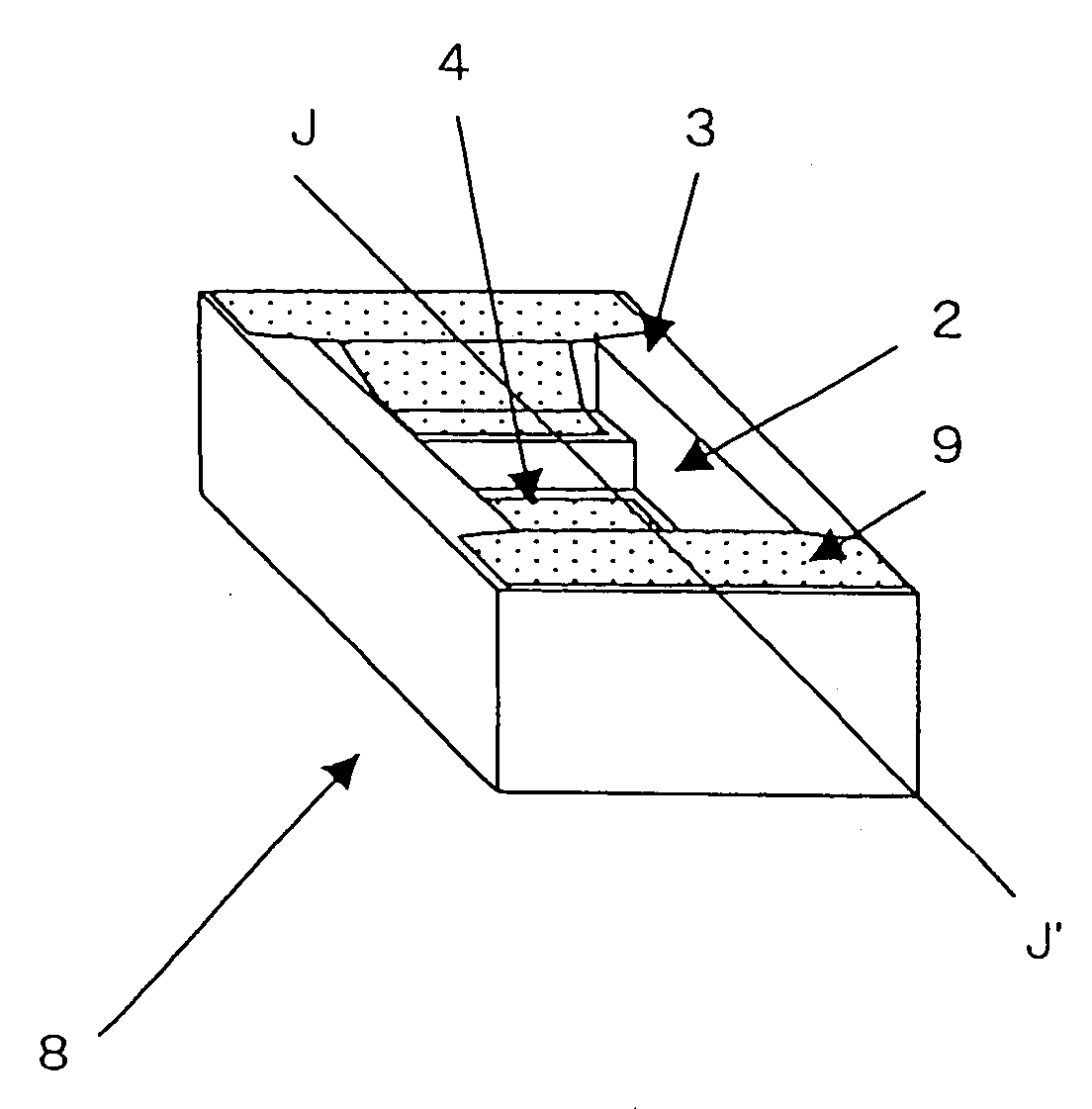

Chip resistor

InactiveUS7782174B2Lower resistanceReduce failure rateResistor detailsThick film resistorsCeramic substrateResistive element

Owner:KOA CORP

Chip resistor and manufacturing method therefor

ActiveUS7330099B2Easy to manufacturePrinted circuit assemblingResistor chip manufactureInsulation layerEngineering

Owner:ROHM CO LTD

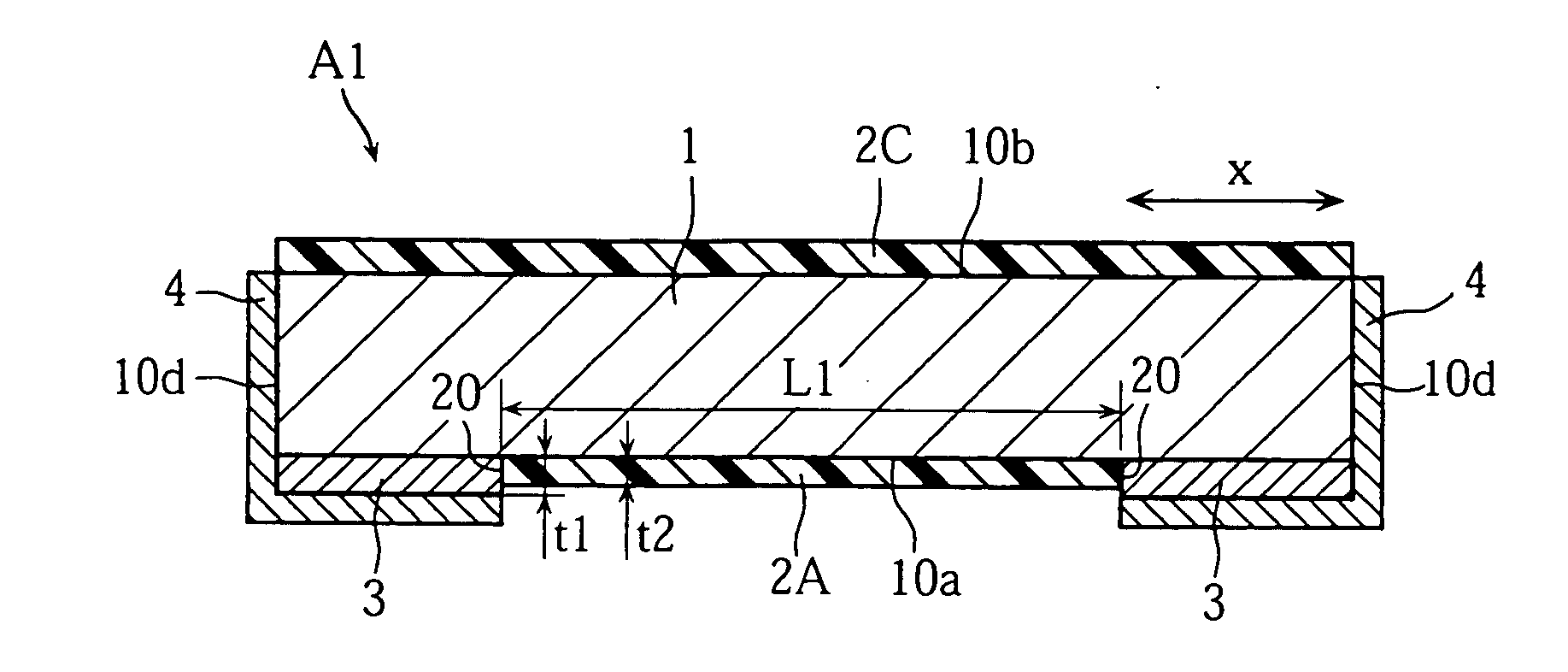

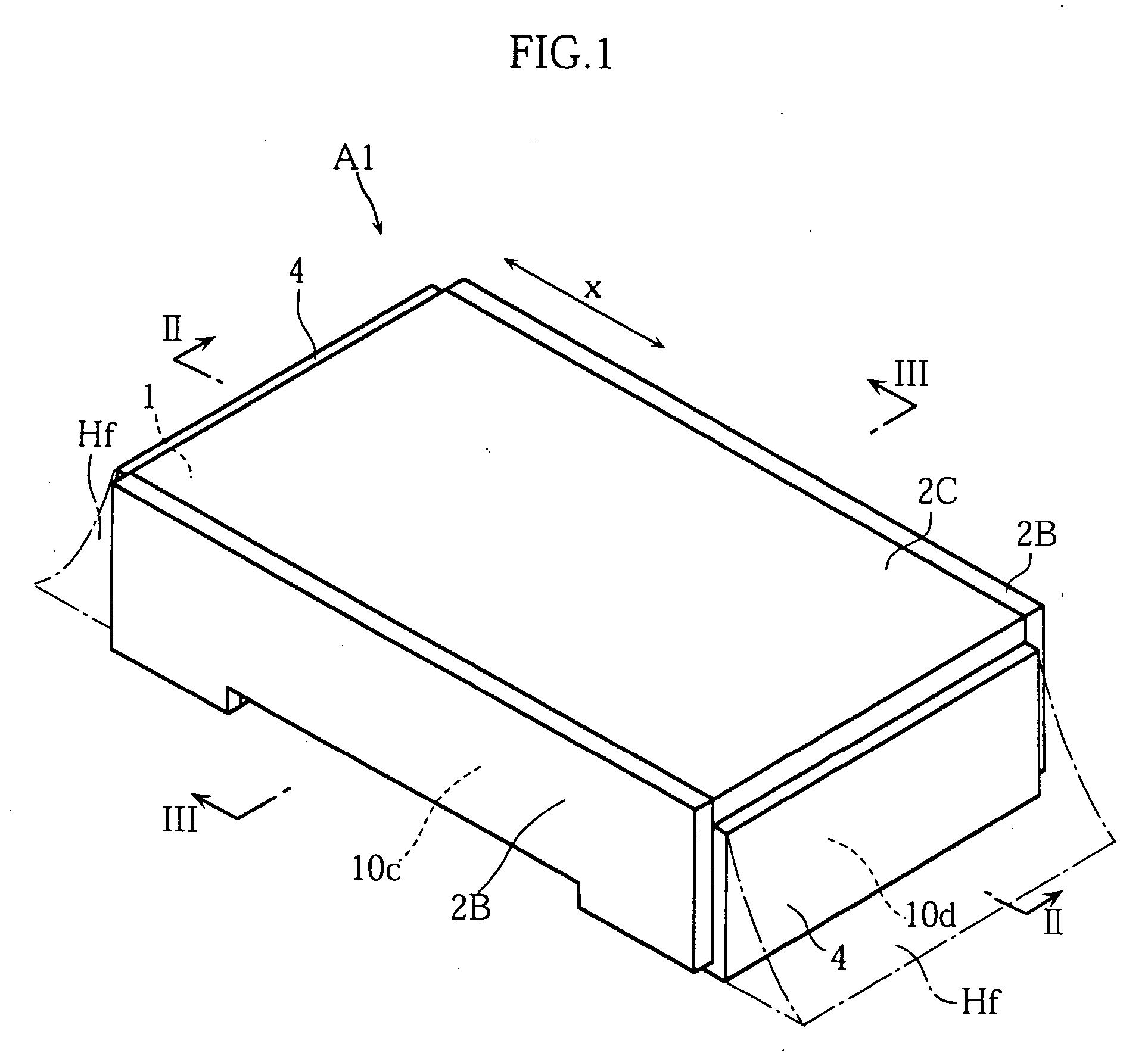

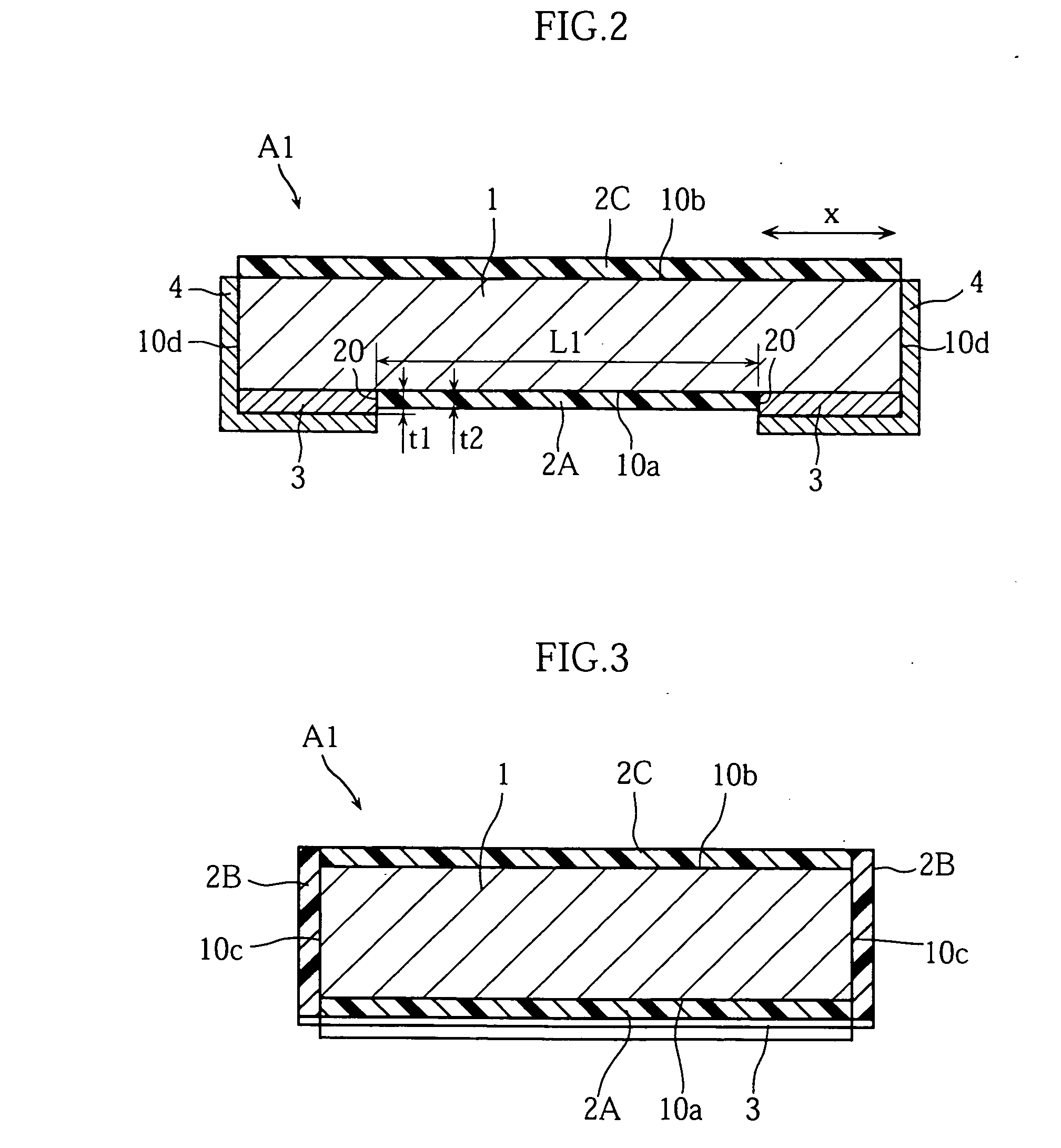

Chip resistor, process for producing the same, and frame for use therein

ActiveUS20060097340A1Manufactured usingPrinted circuit assemblingSemiconductor/solid-state device manufacturingInsulation layerElectrical and Electronics engineering

A chip resistor (A1) comprises a first insulation layer (2A) covering the regions between a plurality of electrodes (3) on a rear surface (10a) of a resistor (1), and a second insulation layer covering a pair of side faces of the resistor (1). Inadvertent adhesion of solder to an improper part of the resistor (1) can thereby be eliminated. A solder layer (4) is preferably formed on a pair of end faces (10d) of the resistor (1). In so doing, a solder fillet can be formed appropriately.

Owner:ROHM CO LTD

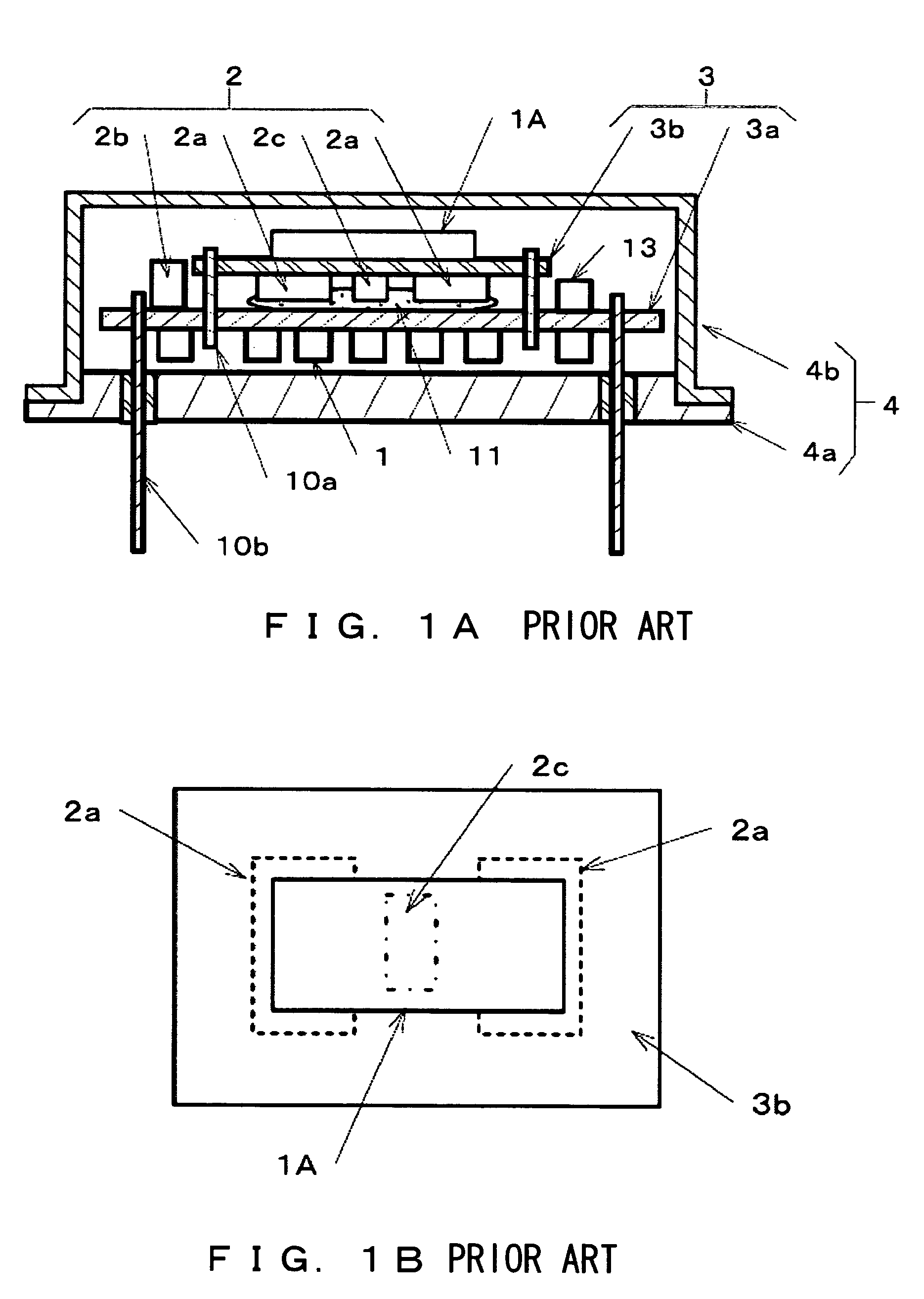

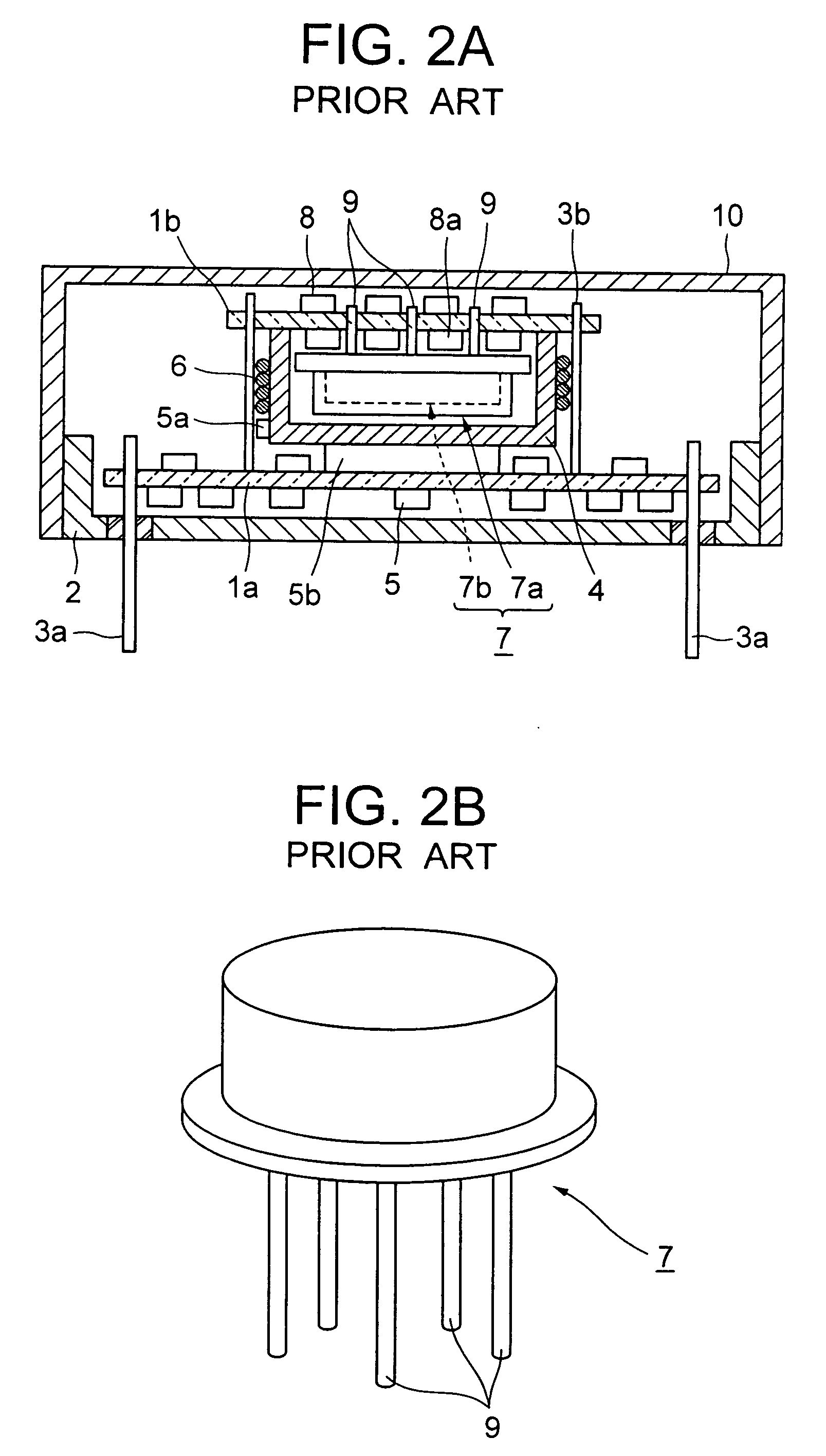

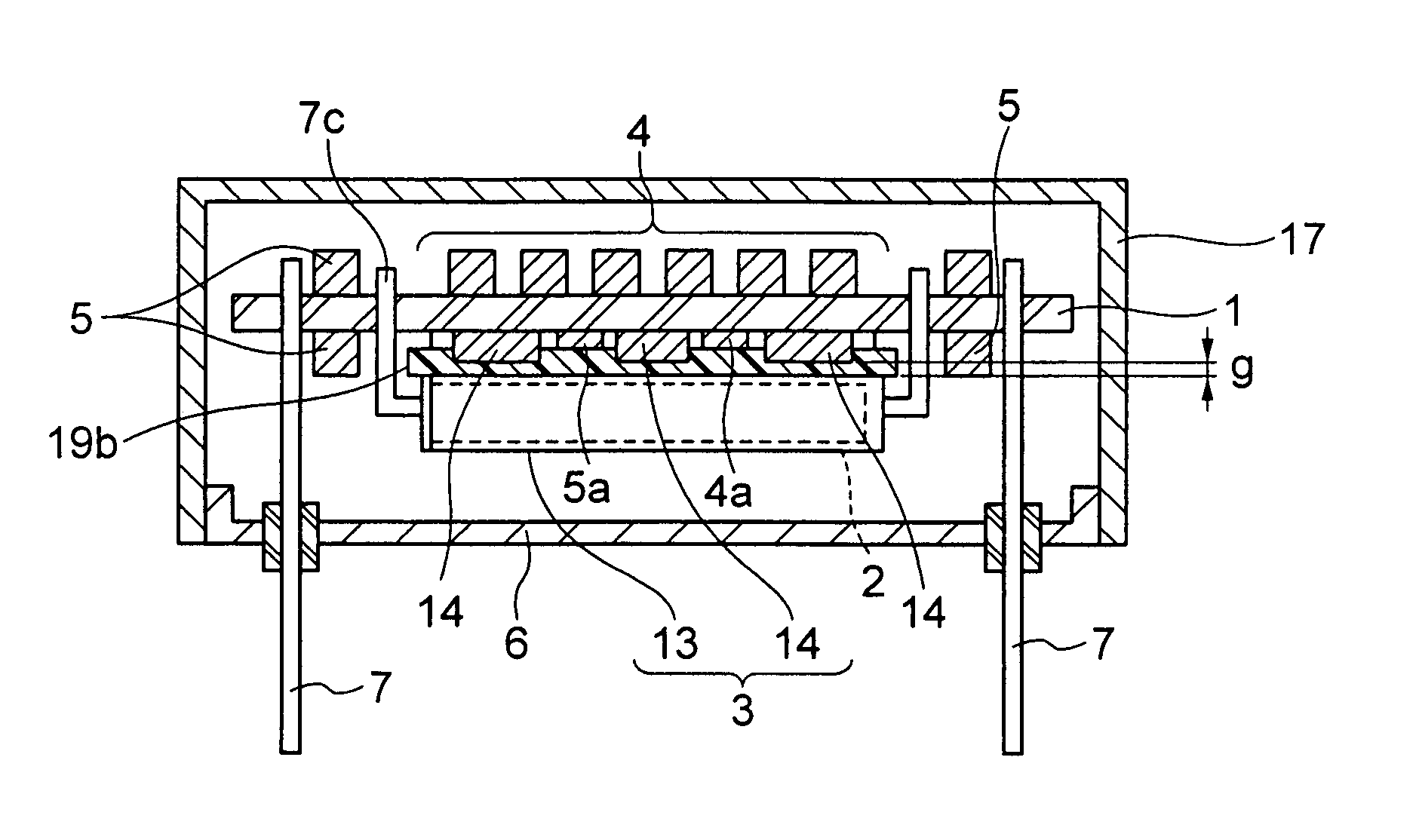

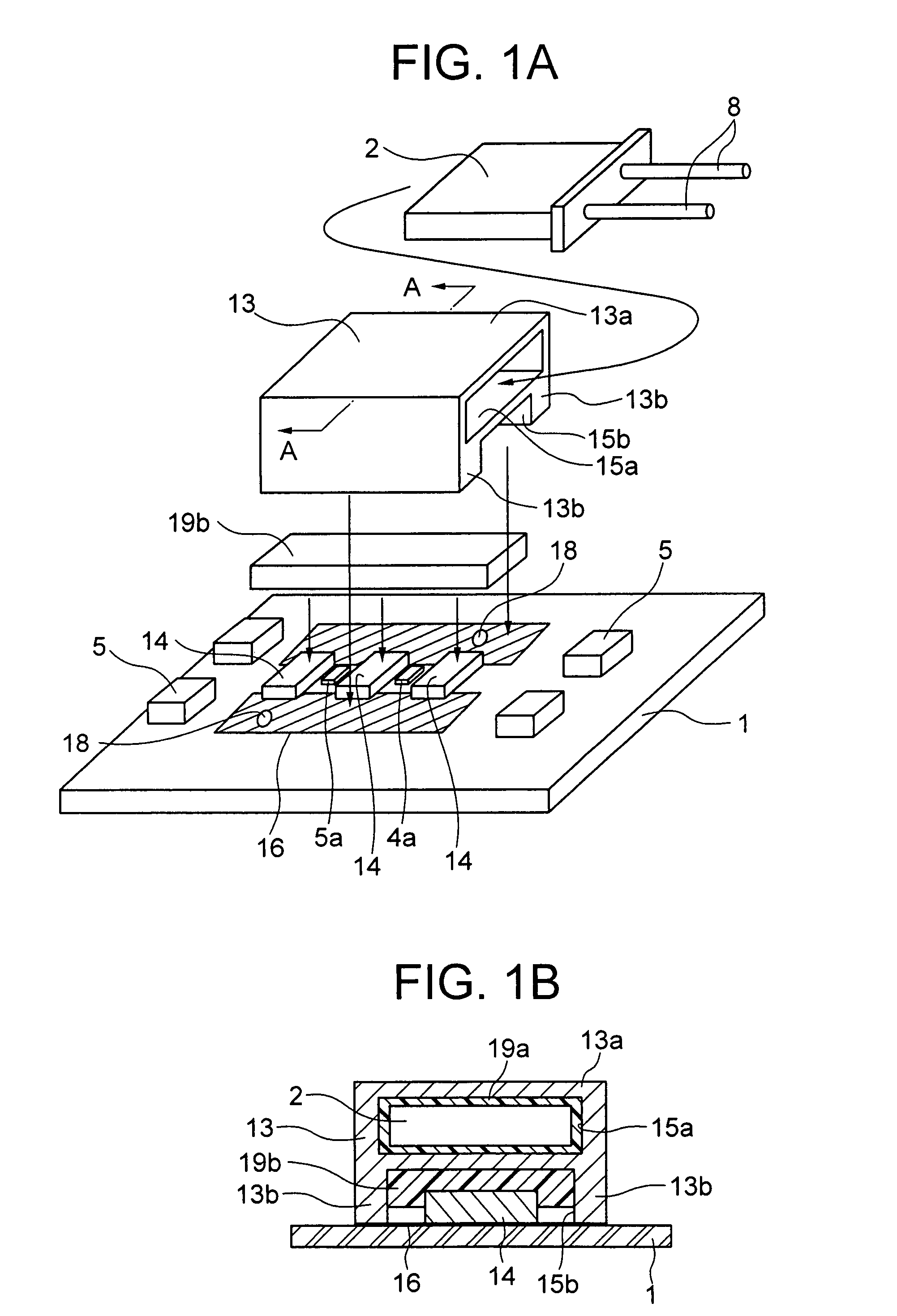

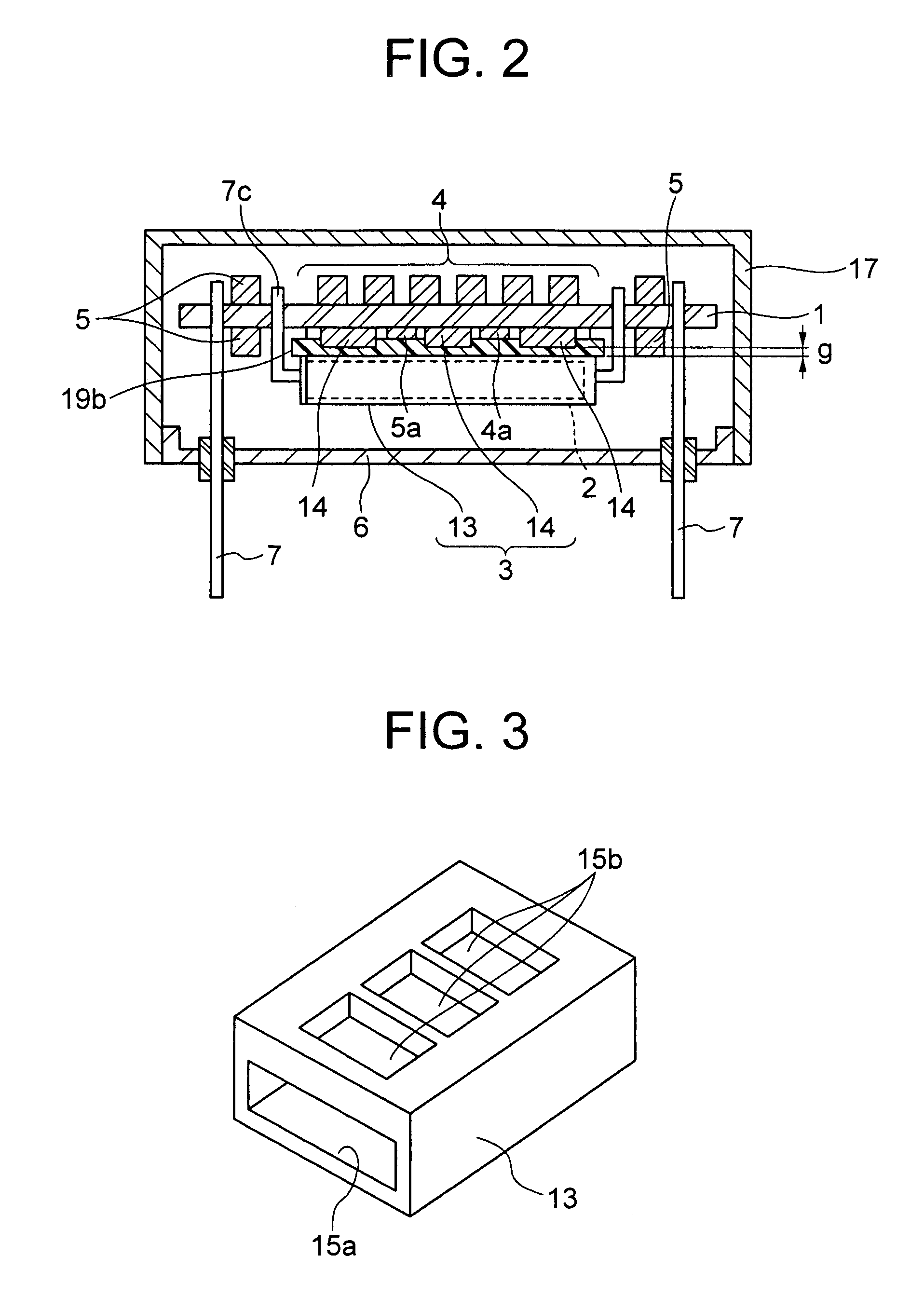

Constant temperature type crystal oscillator

InactiveUS7345552B2Simple structureReduced overall height dimensionPrinted circuit assemblingRadiation pyrometryHeat conductingEngineering

A lead wire led-out type crystal oscillator of constant temperature type for high stability is disclosed, which includes a heat supply body that supplies heat to a crystal resonator from which a plurality of lead wires are led out, to maintain the temperature constant. The heat supply body includes a heat conducting plate which has through-holes for the lead wires and is mounted on the circuit board, and which faces, and is directly thermally joined to, the crystal resonator and a chip resistor for heating which is mounted on the circuit board adjacent to the heat conducting plate, and is thermally joined to the heat conducting plate.

Owner:NIHON DEMPA KOGYO CO LTD

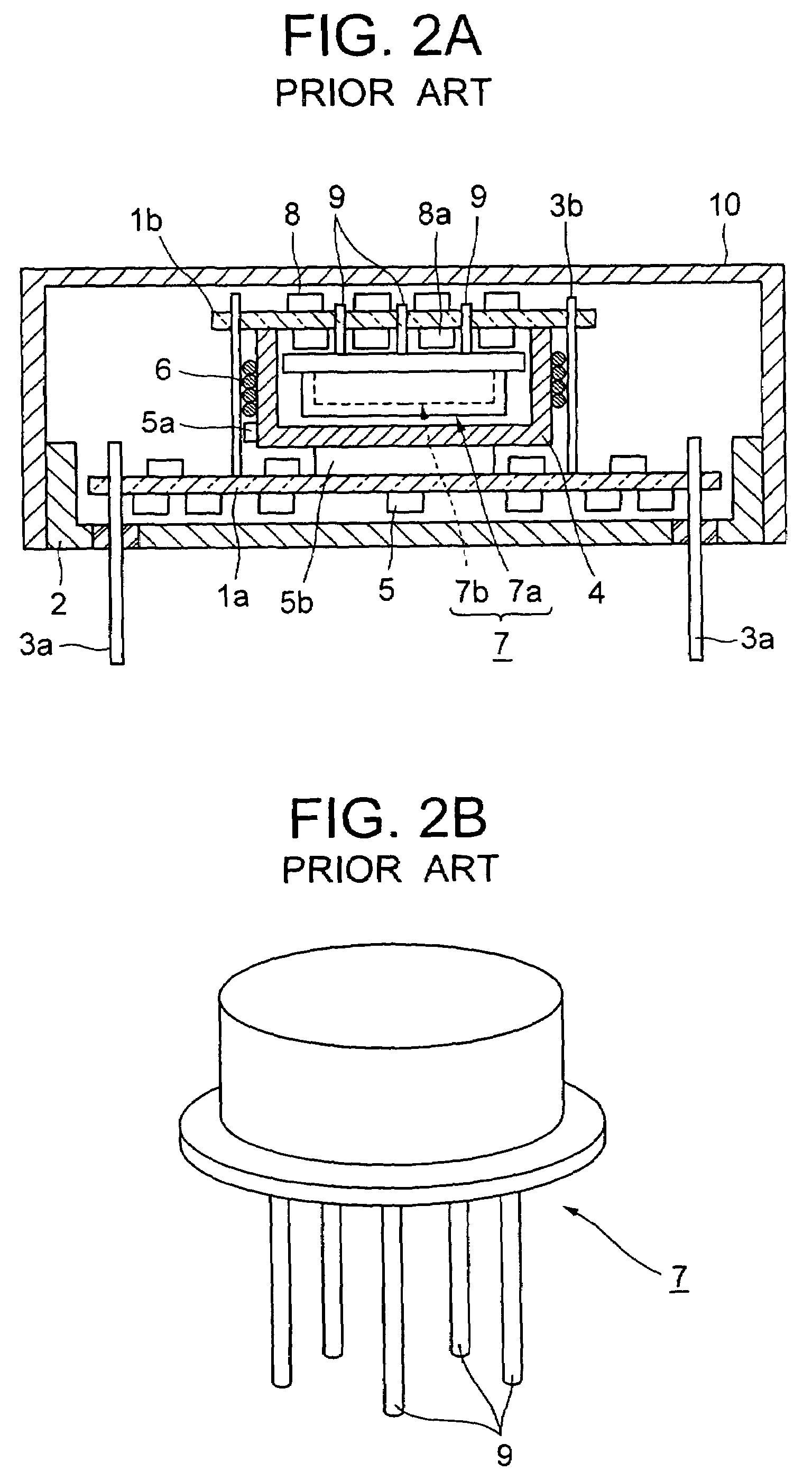

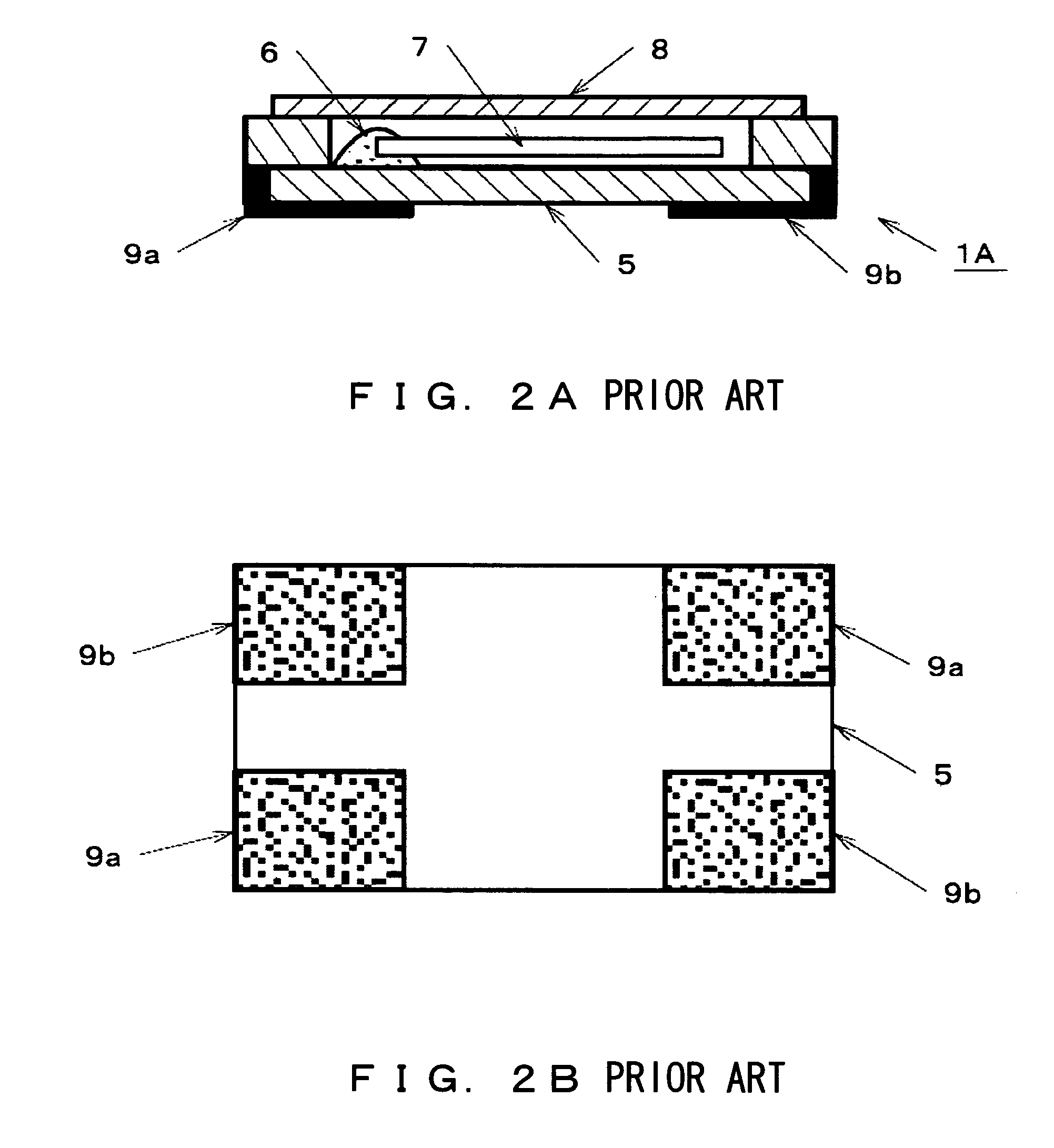

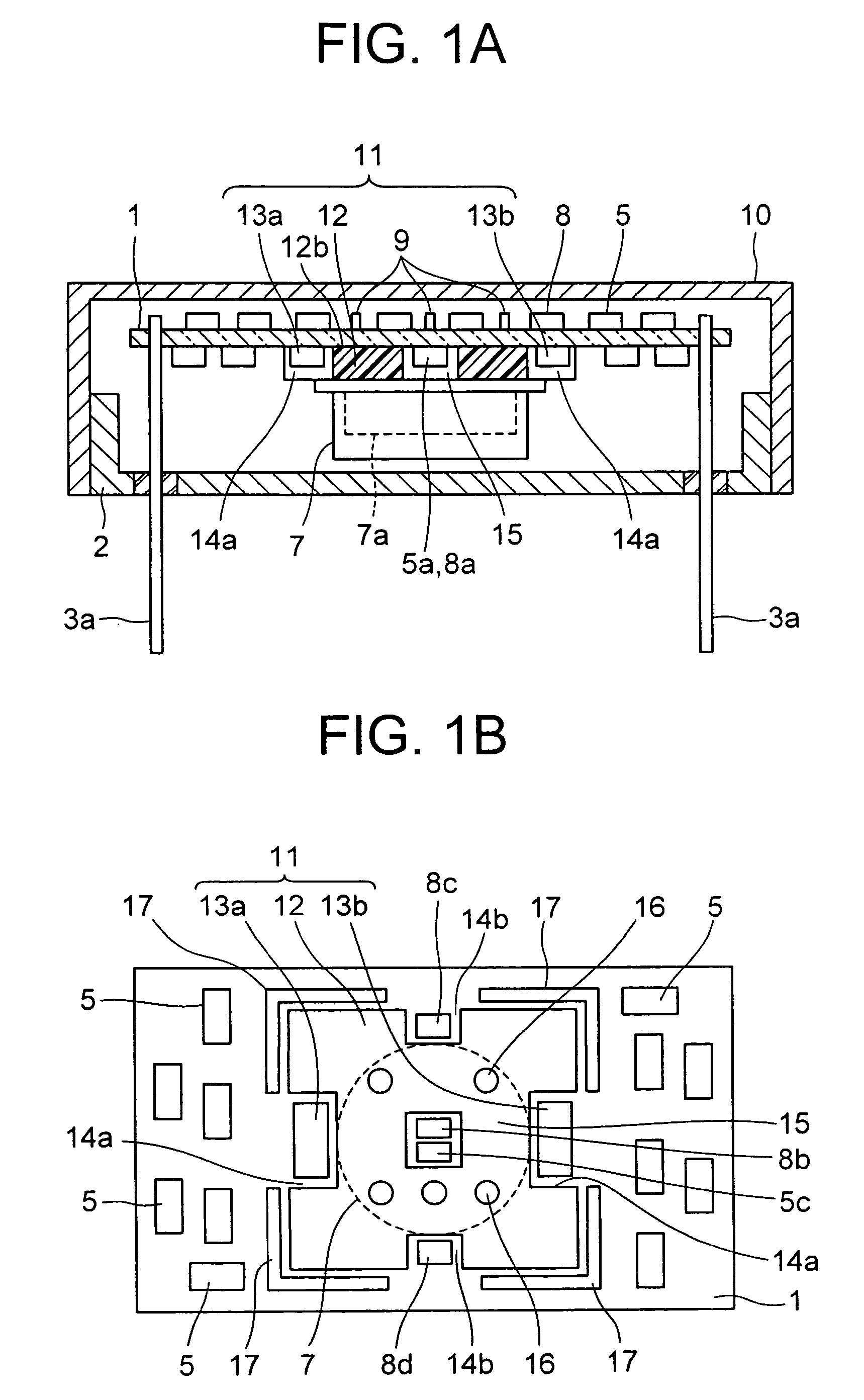

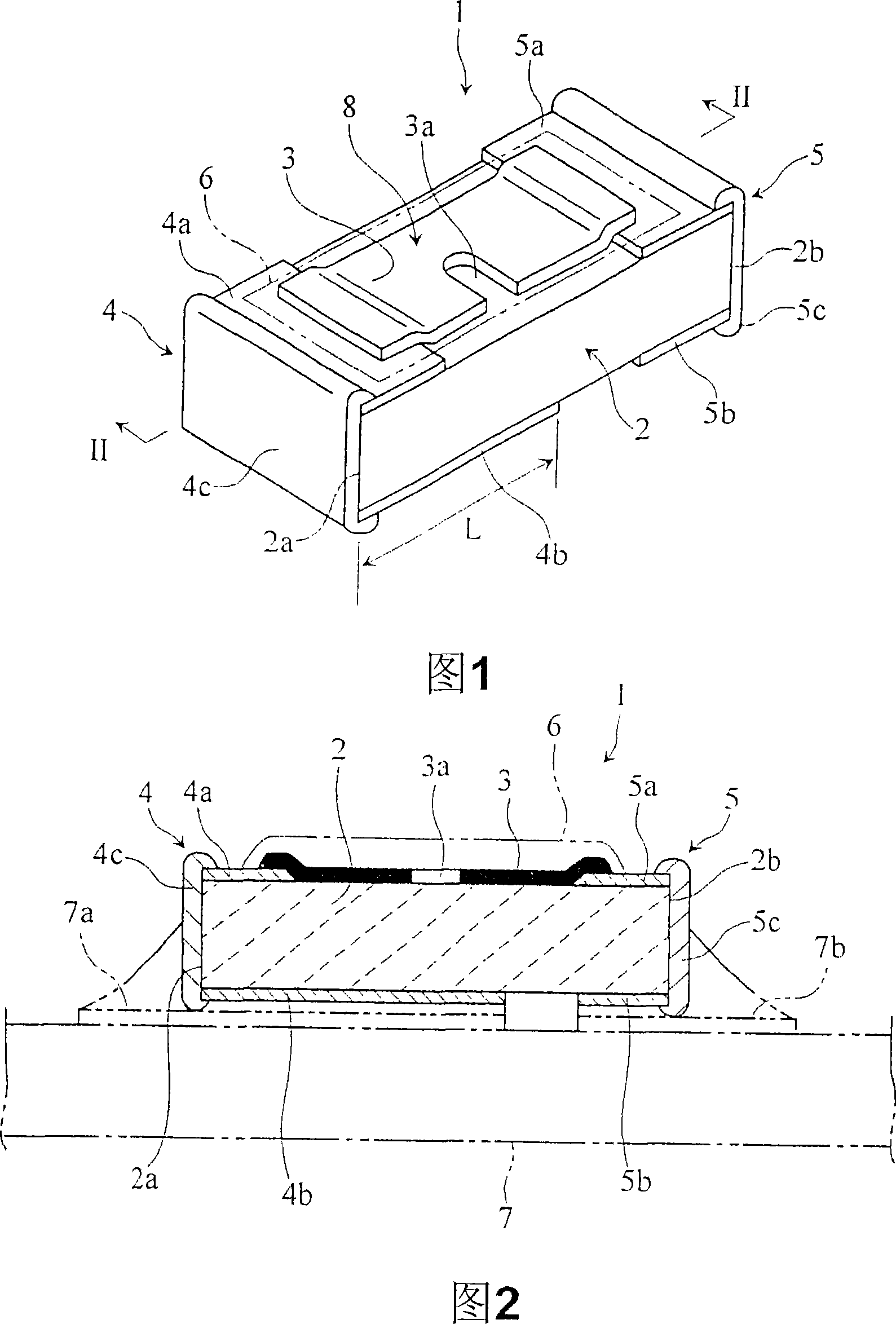

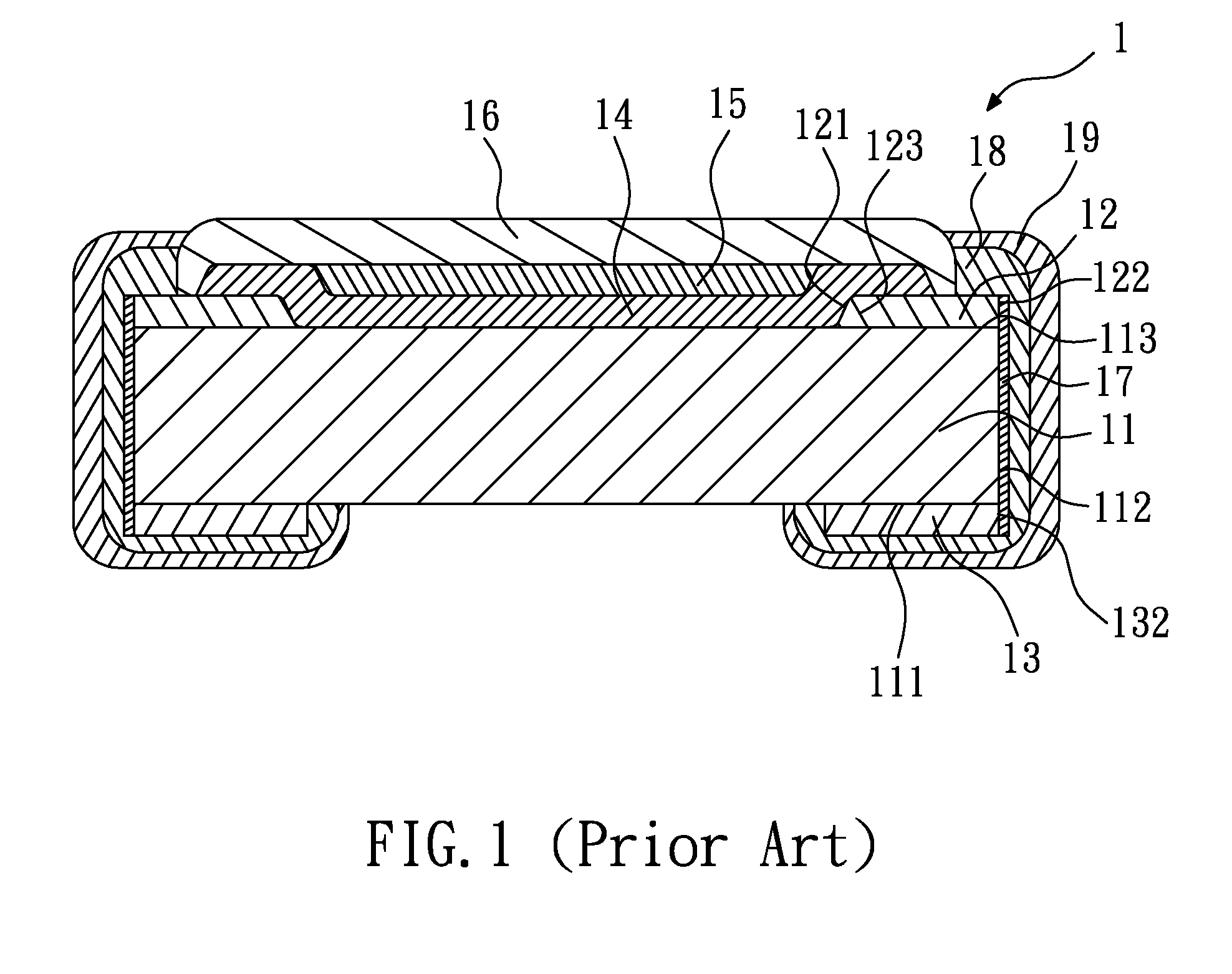

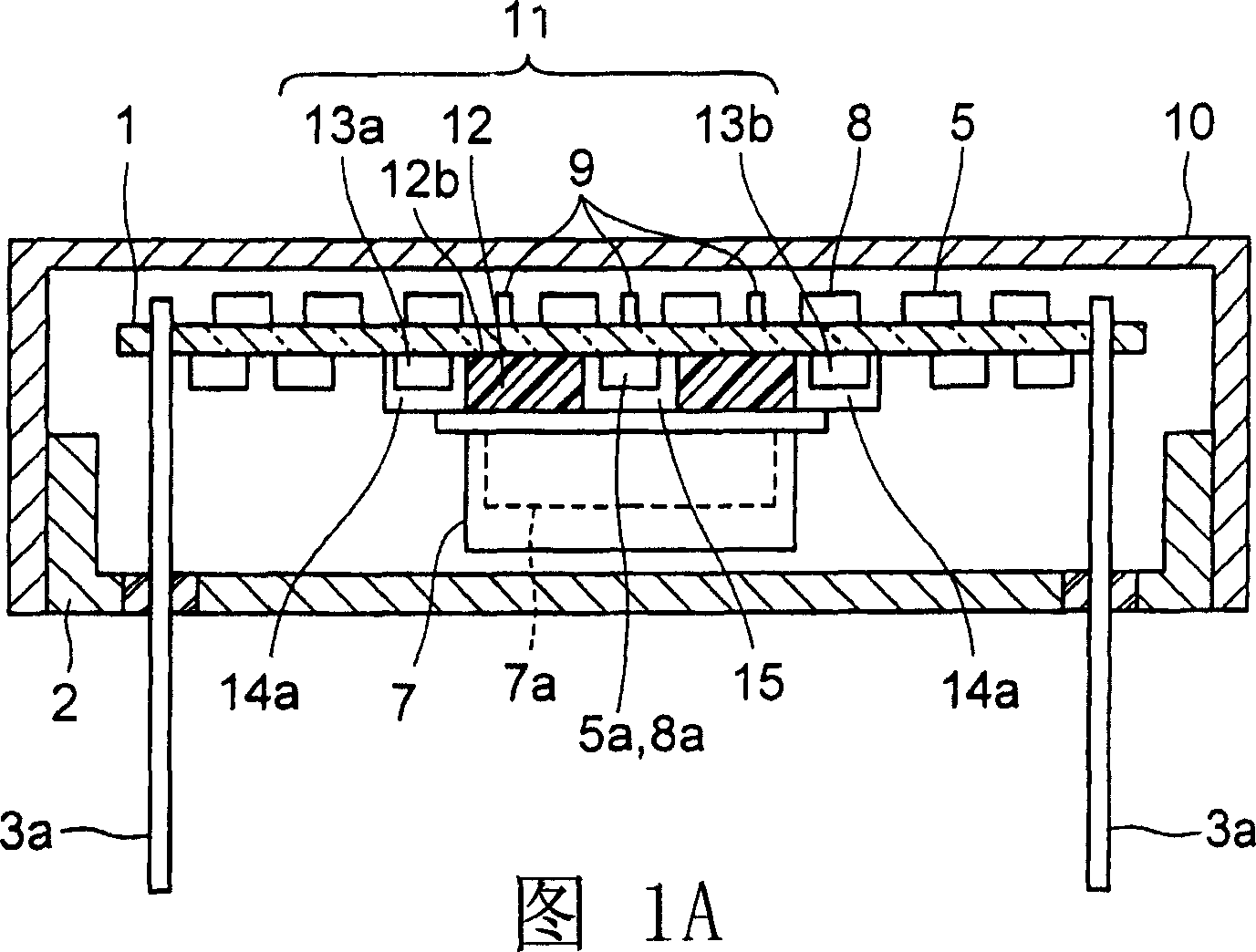

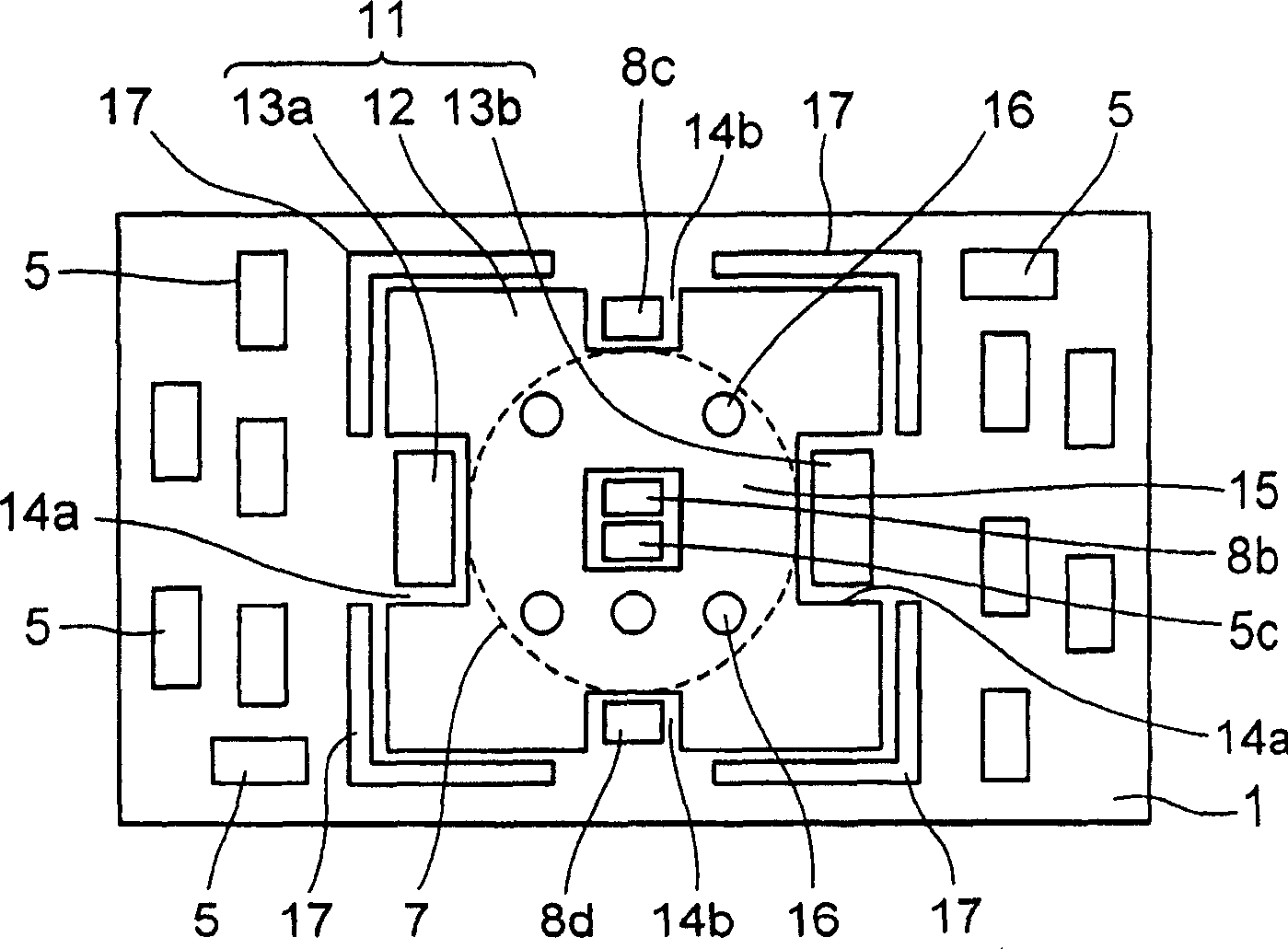

Chip resistor

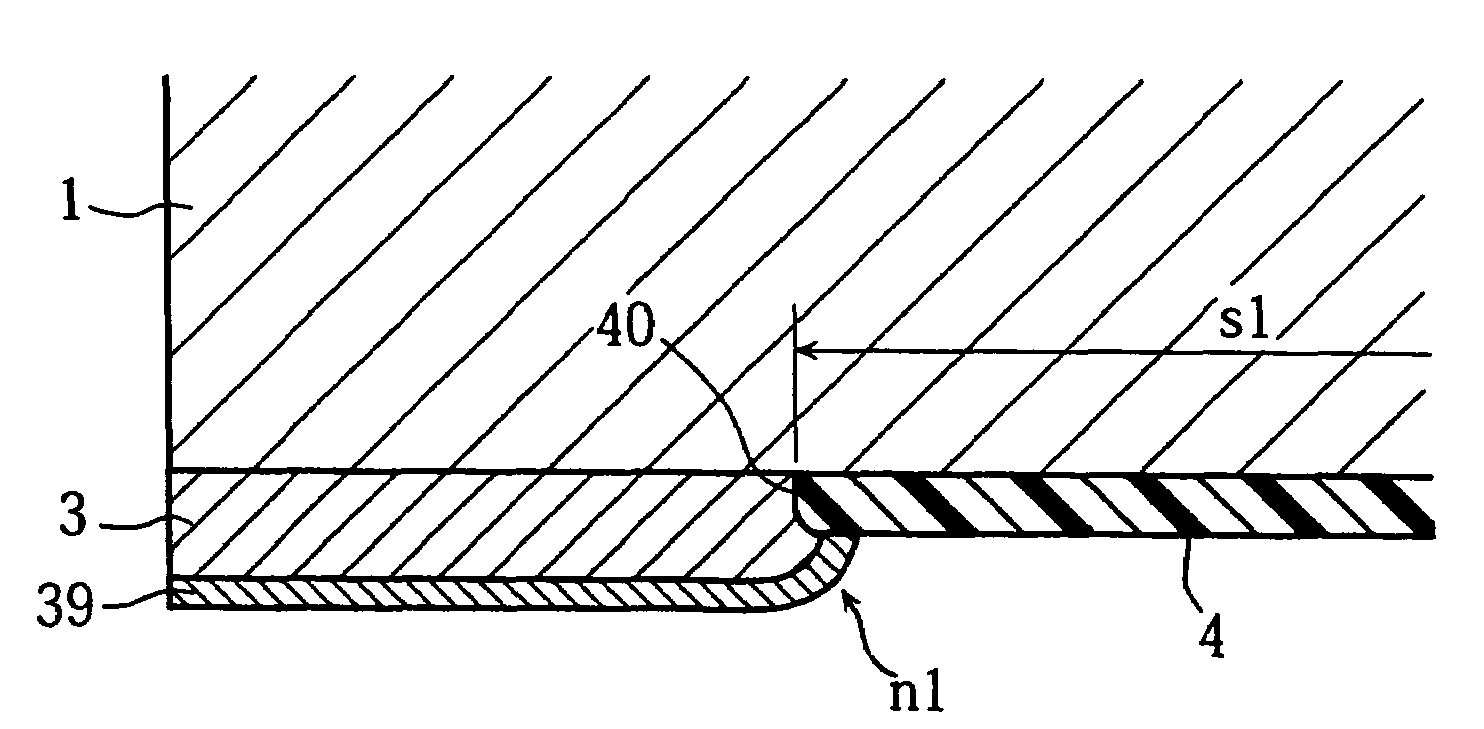

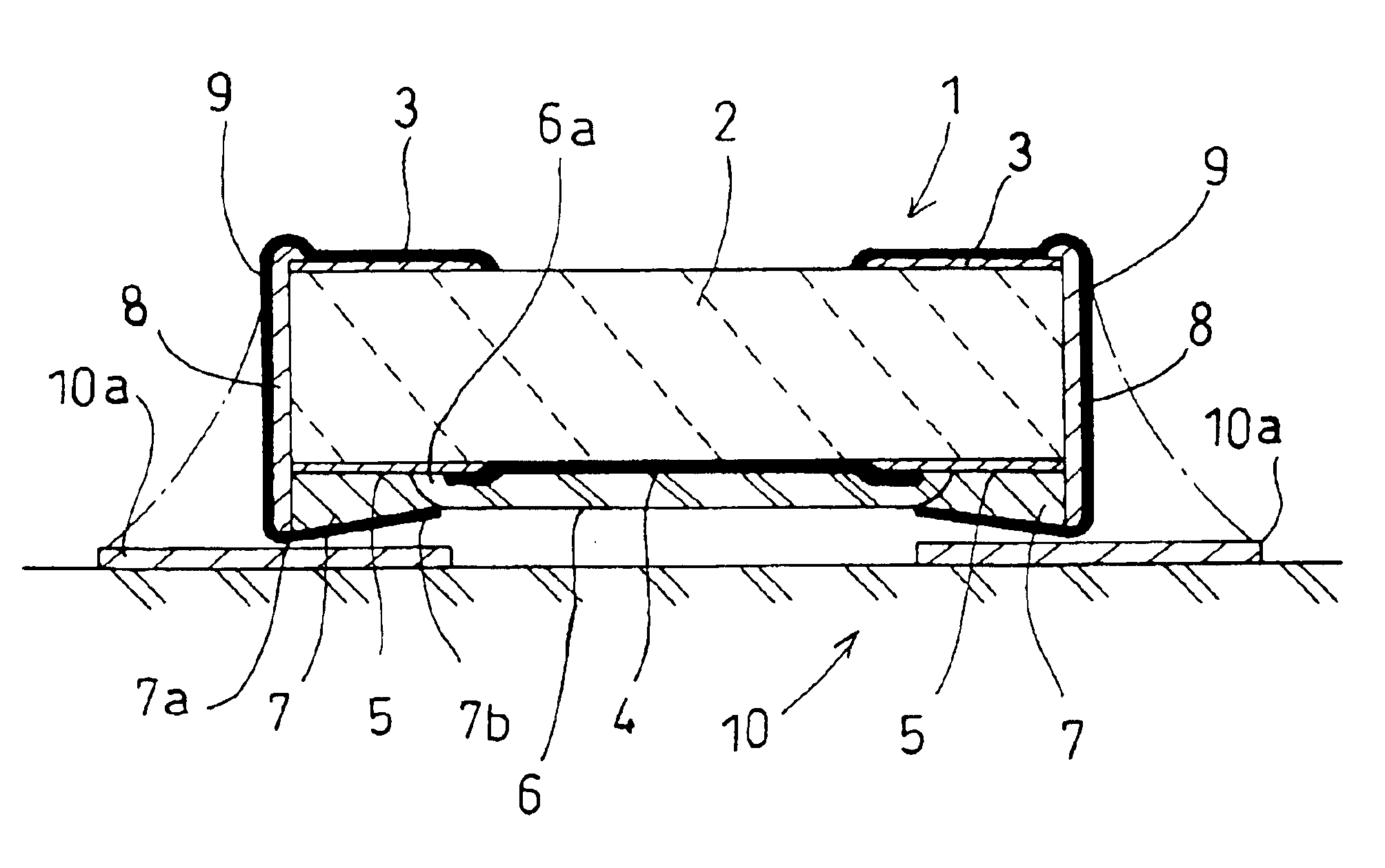

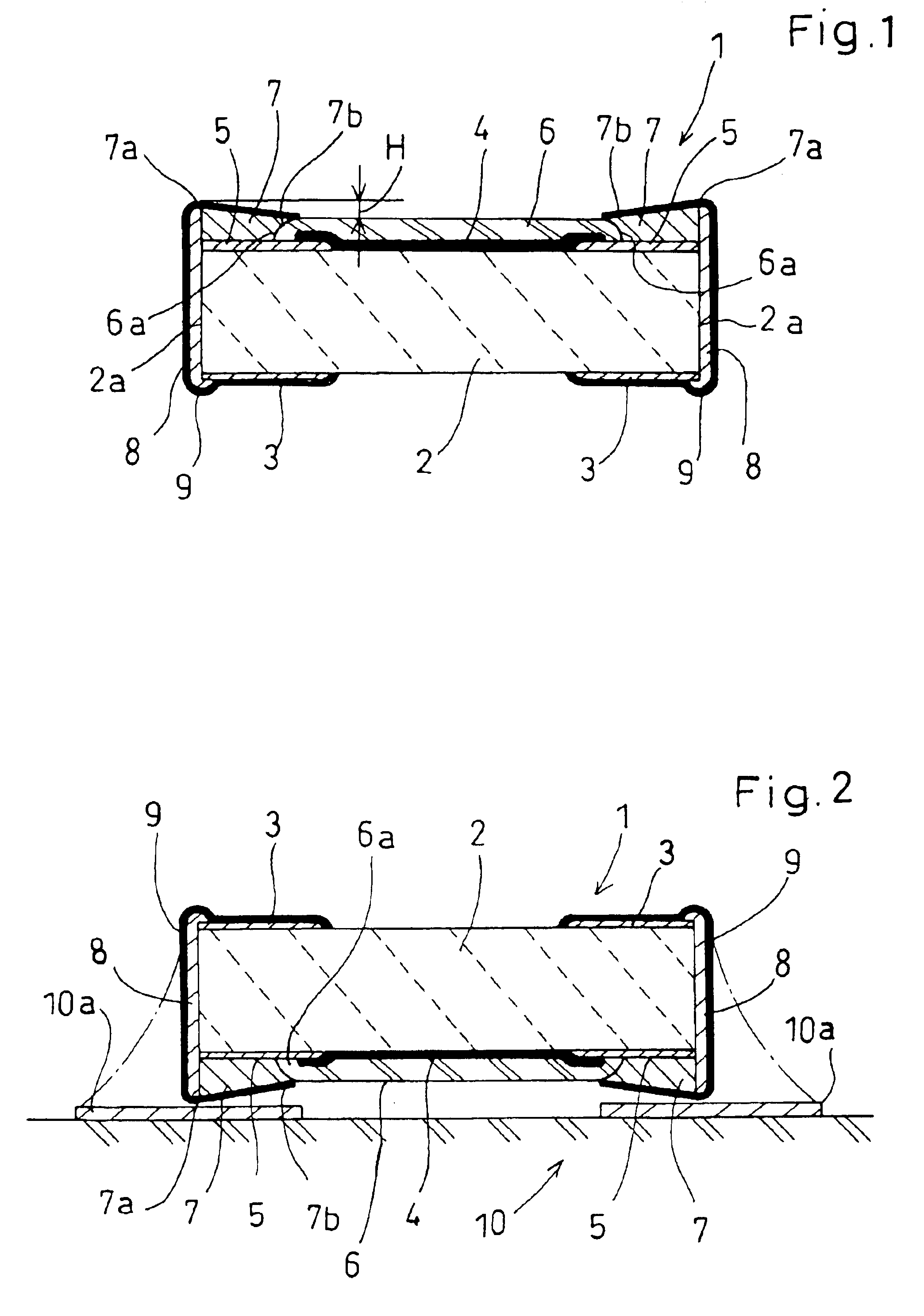

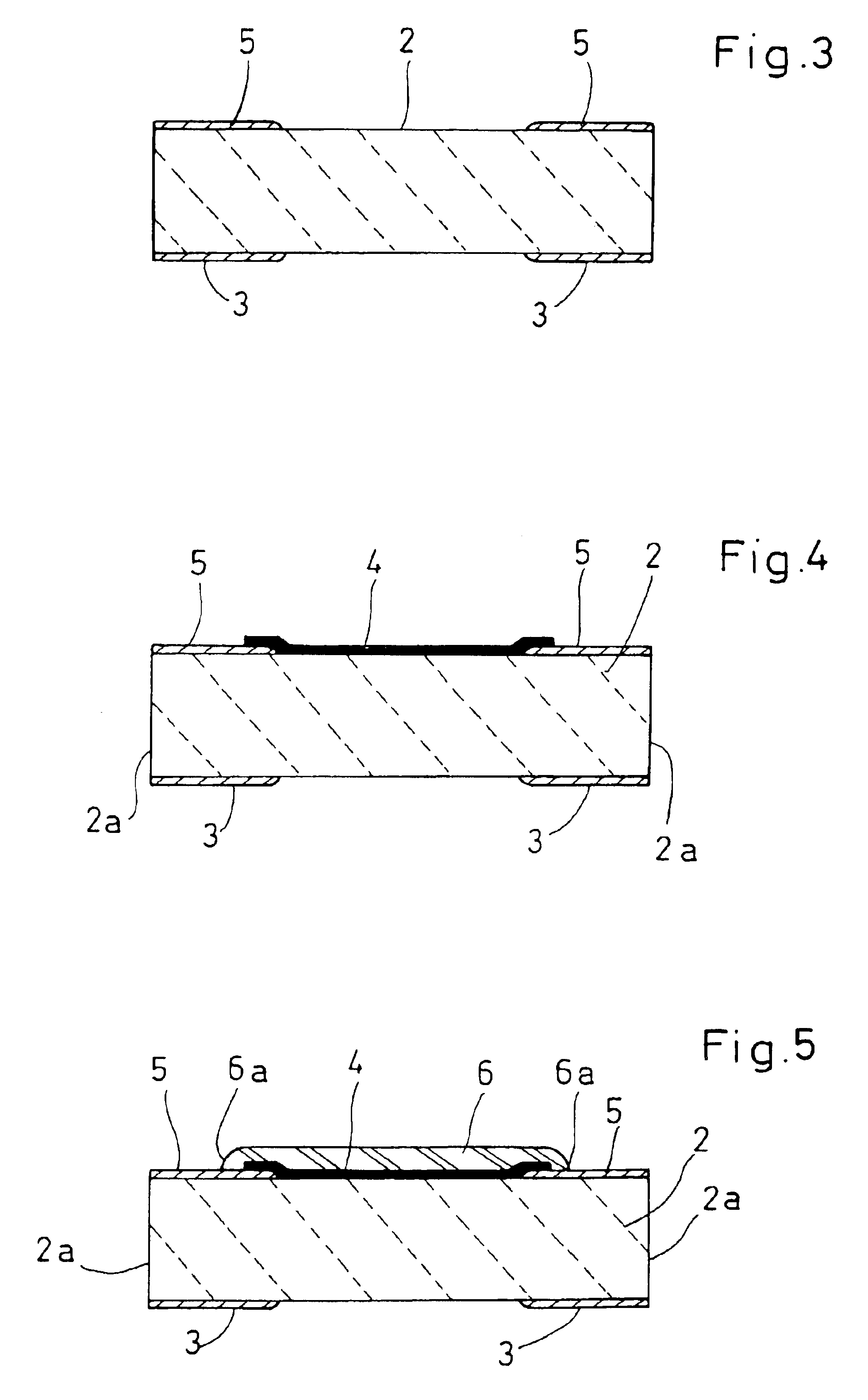

ActiveUS6856234B2Reduce manufacturing costPrevent rising of one endResistor chip manufactureResistor terminals/electrodesElectrical connectionElectrode

A chip resistor includes an insulating substrate 2 in the form of a chip having an upper surface and an opposite pair of side surfaces, a resistor film 4 formed on the upper surface of the insulating substrate 2, a pair of upper electrodes 5 formed on the upper surface of the insulating substrate 2 to flank the resistor film 4 in electrical connection thereto, a cover coat 6 covering the resistor film 4, an auxiliary upper electrode 7 formed on each of the upper electrodes 5 and including a first portion 7a adjoining the relevant side surface of the insulating substrate 2 and a second portion 7b overlapping the cover coat 6, and a side electrode 8 formed on each of the side surfaces of the insulating substrate 2 and electrically connected to at least the upper electrode 5 and the auxiliary upper electrode 7. The first portion 7a of the auxiliary upper electrode 7 has an obverse surface positioned higher than an obverse surface of the second portion 7b for projecting above an obverse surface of the cover coat 6.

Owner:ROHM CO LTD

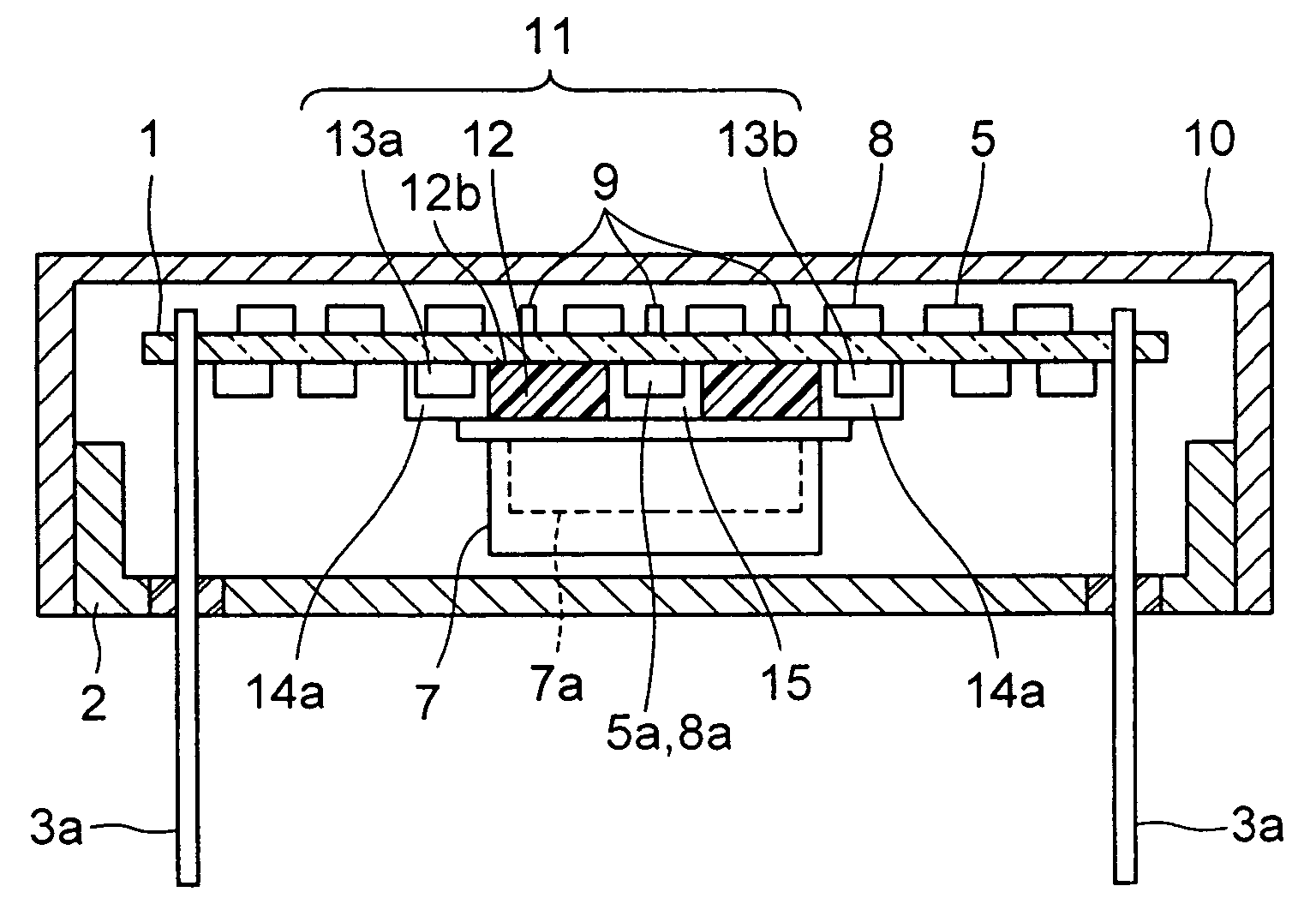

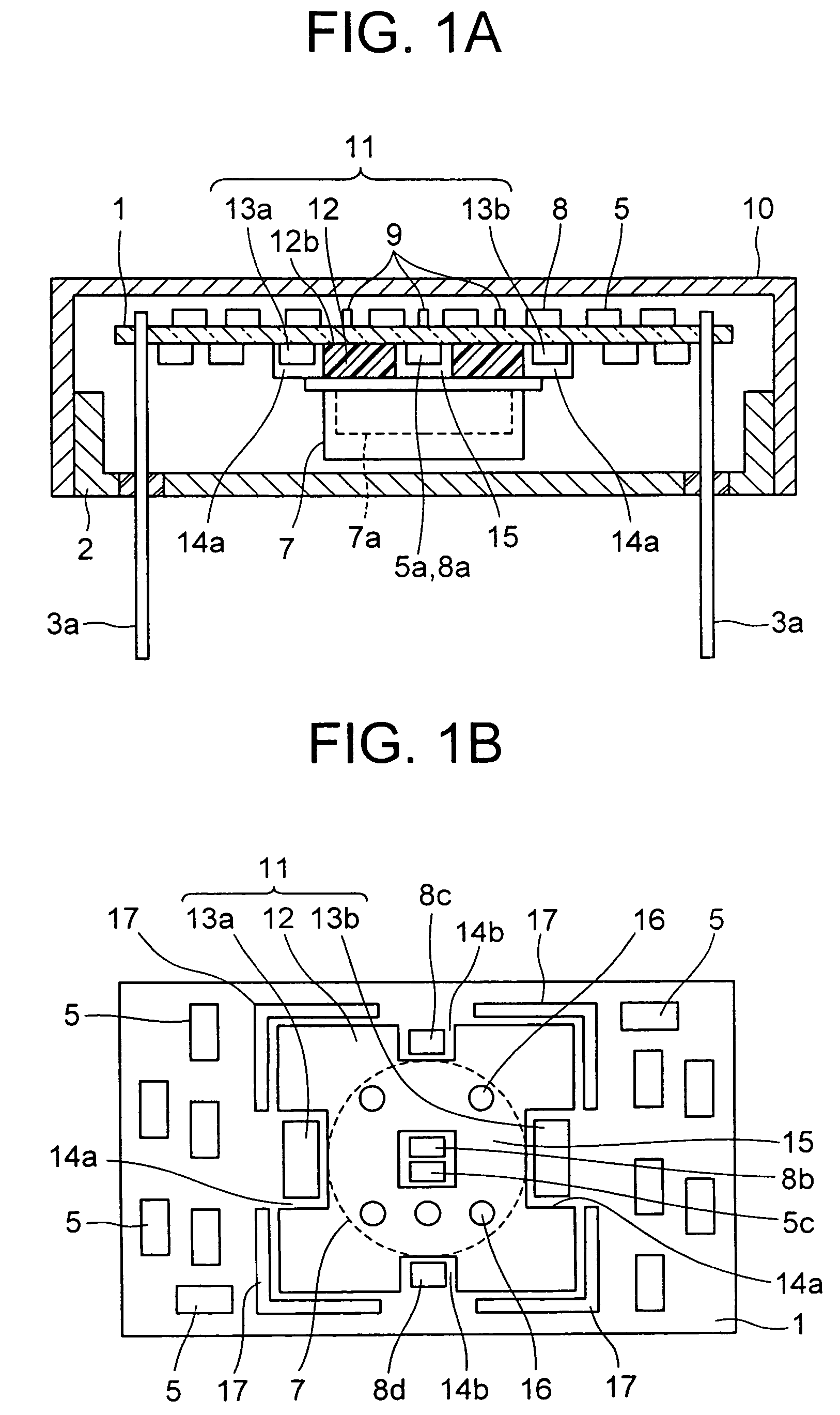

Constant temperature crystal oscillator

InactiveUS7382204B2Easy to useImprove responsivenessGenerator stabilizationOscillations generatorsHemt circuitsEngineering

A constant temperature crystal oscillator includes on a circuit substrate: a surface-mount crystal resonator which is provided with two crystal terminals as mount terminals and a dummy terminal on the bottom surface, and has a metal cover; an oscillation circuit element which forms an oscillation circuit together with the crystal resonator; and a temperature control element which keeps a constant operation temperature of the crystal resonator, in which the temperature control element includes at least a heating chip resistor, a power transistor for supplying electric power to the chip resistor, and a temperature sensitive resistor for detecting the operation temperature of the crystal resonator, wherein a dummy terminal on the substrate side of the circuit substrate for connection to the dummy terminal of the crystal resonator is connected to a resistor terminal on the substrate side to which the temperature sensitive resistor is connected through a conductive path.

Owner:NIHON DEMPA KOGYO CO LTD

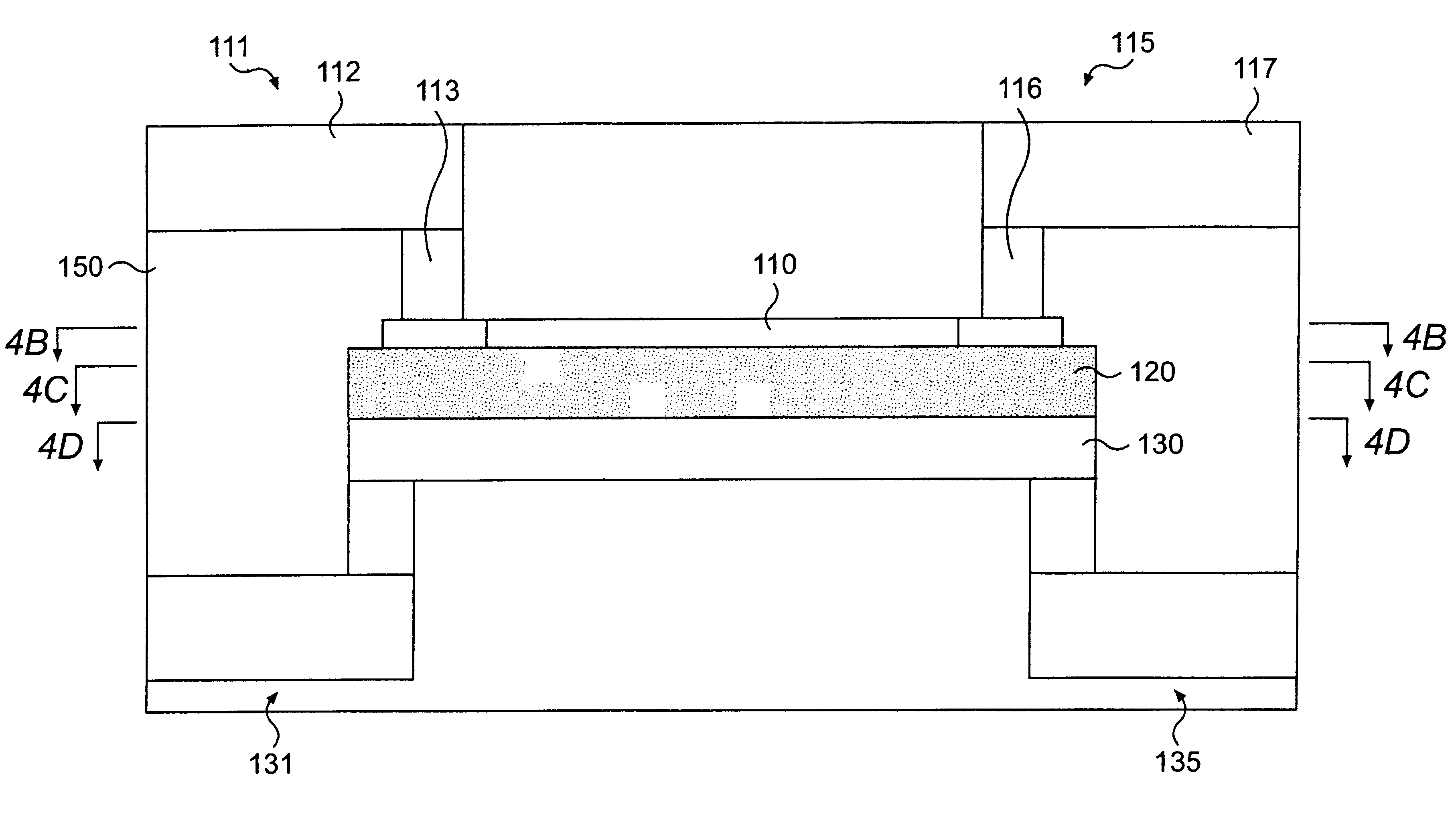

Electrically tunable on-chip resistor

InactiveUS6960744B2Improve circuit performanceResistance of the resistorElectric heatingCurrent responsive resistorsElectrical resistance and conductanceEngineering

A device having a resistor and a heater disposed proximate to the resistor and capable of raising the temperature of the resistor. The device further includes a dieletric disposed between the heater and the resistor and a tuner electrically coupled to the resistor. The heater adjusts the resistance of the resistor in response to the tuner.

Owner:INT BUSINESS MASCH CORP

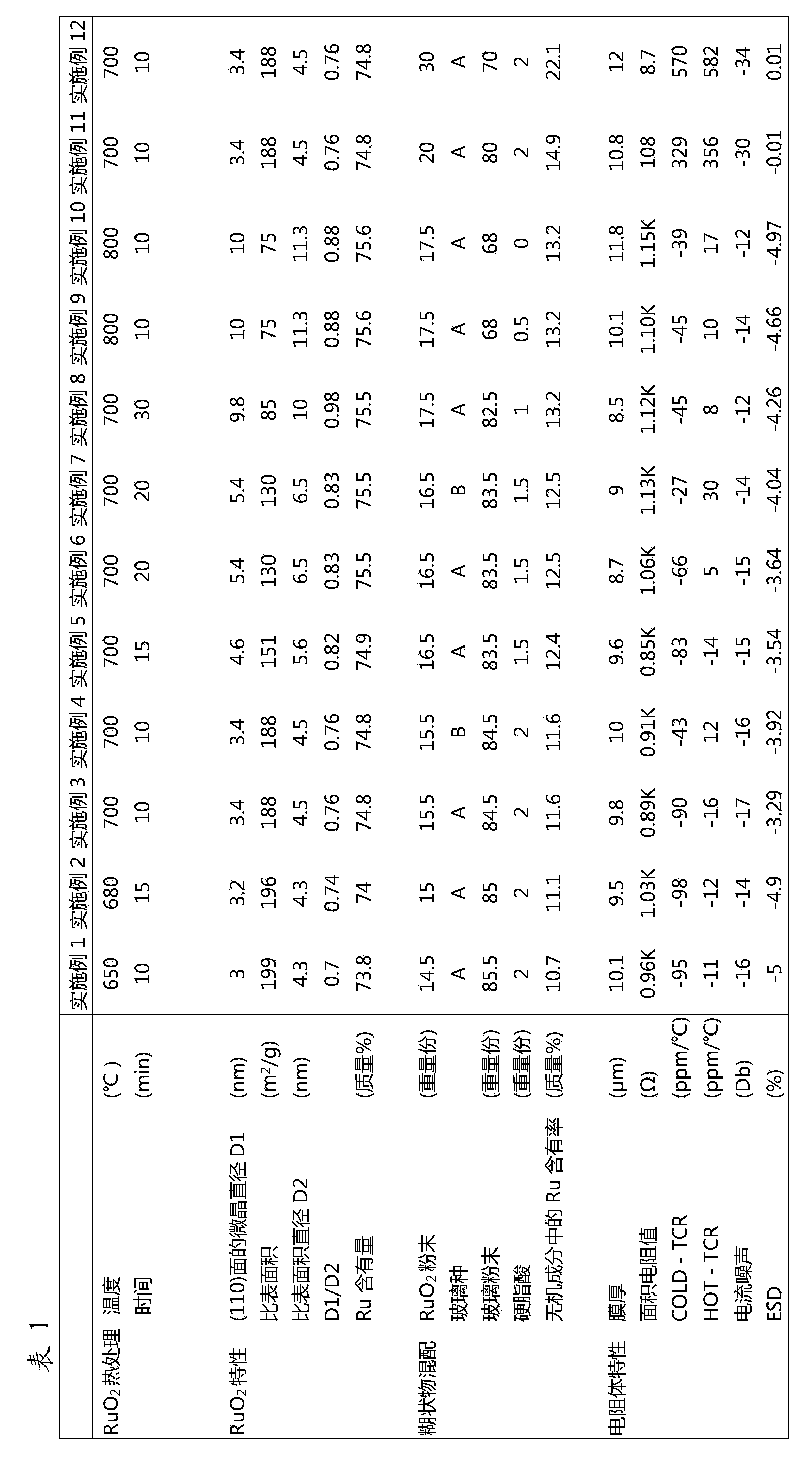

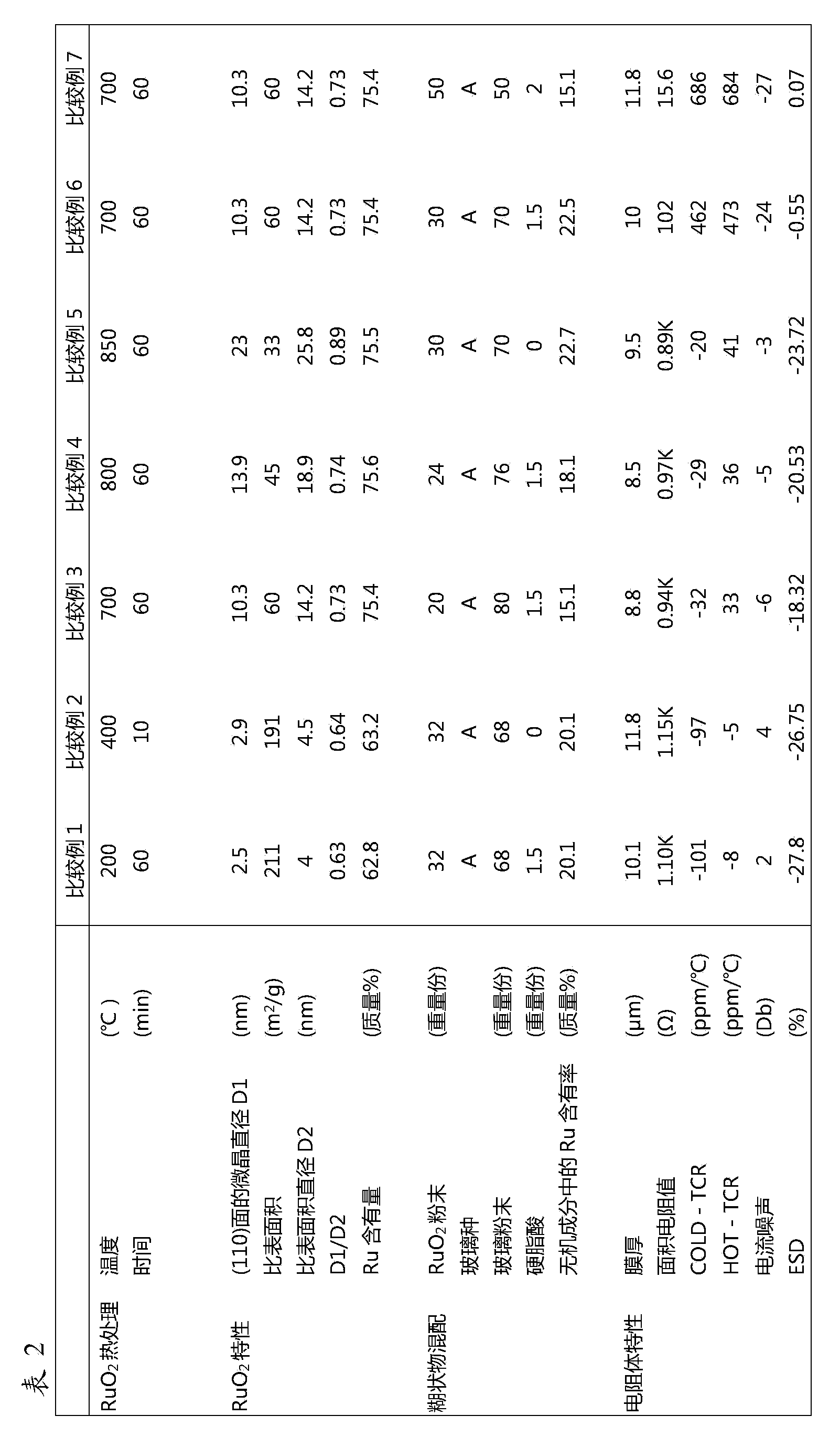

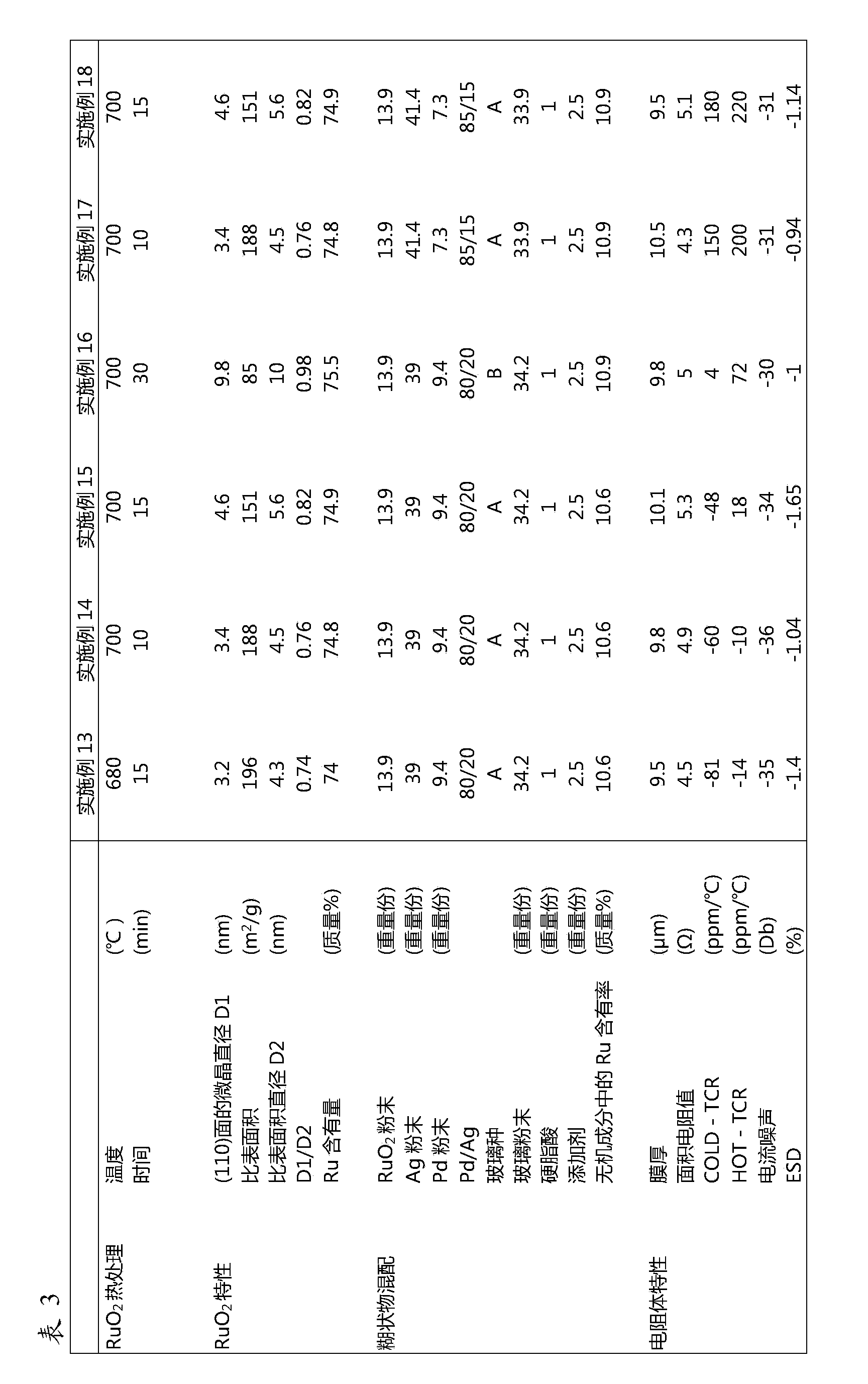

Ruthenium oxide powder, composition for thick film resistor elements using same, and thick film resistor element

ActiveCN103429537AInhibit growthHigh crystallinityRuthenium/rhodium/palladium/osmium/iridium/platinum oxides/hydroxidesThick film resistorsX-rayEngineering

Provided are: a ruthenium oxide powder which is produced, at low cost, as a material for electronic components such as a chip resistor, a hybrid IC and a resistive network each having a sufficient performance, even if the ruthenium content thereof is low; a composition for thick film resistor elements, which uses the ruthenium oxide powder; and a thick film resistor element. Specifically provided are: a ruthenium oxide (RuO2) powder having a rutile crystal structure, which is characterized in that the crystallite diameter of the (110) plane as determined by an X-ray diffraction method is 3-10 nm and the Ru content is 73% by mass or more; a composition for thick film resistor elements, which is obtained by blending a glass powder and conductive particles that are formed of the ruthenium oxide powder as main constituent elements; and a thick resistor element paste, which is obtained by dispersing the composition for thick film resistor elements in an organic vehicle that contains a fatty acid, and which is characterized in that the content of the fatty acid is 0.1-10 parts by weight per 100 parts by weight of the ruthenium oxide.

Owner:SUMITOMO METAL MINING CO LTD

Constant temperature type crystal oscillator

InactiveUS20050258913A1Improve heating efficiencyGuaranteed normal transmissionPrinted circuit assemblingRadiation pyrometryHeat conductingHeat sensitive

The present invention is one where, in a lead wire led-out type crystal oscillator of constant temperature type for high stability, comprising: a heat supply body that supplies heat to a crystal resonator from which a plurality of lead wires are led out, to maintain the temperature constant; an oscillating element that constitutes an oscillating circuit together with the crystal resonator; a temperature control element that constitutes a temperature control circuit for controlling the temperature of the crystal resonator; and a circuit board for mounting the heat supply body, the oscillating element, and the temperature control element, and through which lead wires of the crystal resonator are passed through for mounting, the heat supply body comprises: a heat conducting plate which has through-holes for the lead wires and is mounted on the circuit board, and which faces, and is directly thermally joined to, the crystal resonator; and a chip resistor for heating which is mounted on the circuit board adjacent to the heat conducting plate, and is thermally joined to the heat conducting plate. As a result, a lead wire led-out type crystal oscillator of constant temperature type for high stability wherein the structure is simplified, and in particular the height dimension is reduced can be provided. Moreover, the present invention is a constant temperature type surface mounting type crystal oscillator which uses a crystal resonator for surface mounting which is mounted on the circuit board together with the oscillating elements and temperature control elements, and is constructed such that the crystal resonator is arranged on a ceramic substrate, and at least a chip resistor for heat generation and a highly temperature-dependent highly heat sensitive element are arranged on the ceramic substrate. The structure is such that the crystal resonator is arranged on one principal plane of the ceramic substrate, and the chip resistor and the temperature sensitive element are arranged on the other principal plane of the ceramic substrate, and the other principal plane of the ceramic substrate is positioned facing one principal plane of the circuit board, and heat conductive resin is interposed between the chip resistor and the circuit board. A surface mounted crystal oscillator of constant temperature type in which miniaturization is advanced, and the structure is simplified, is provided.

Owner:NIHON DEMPA KOGYO CO LTD

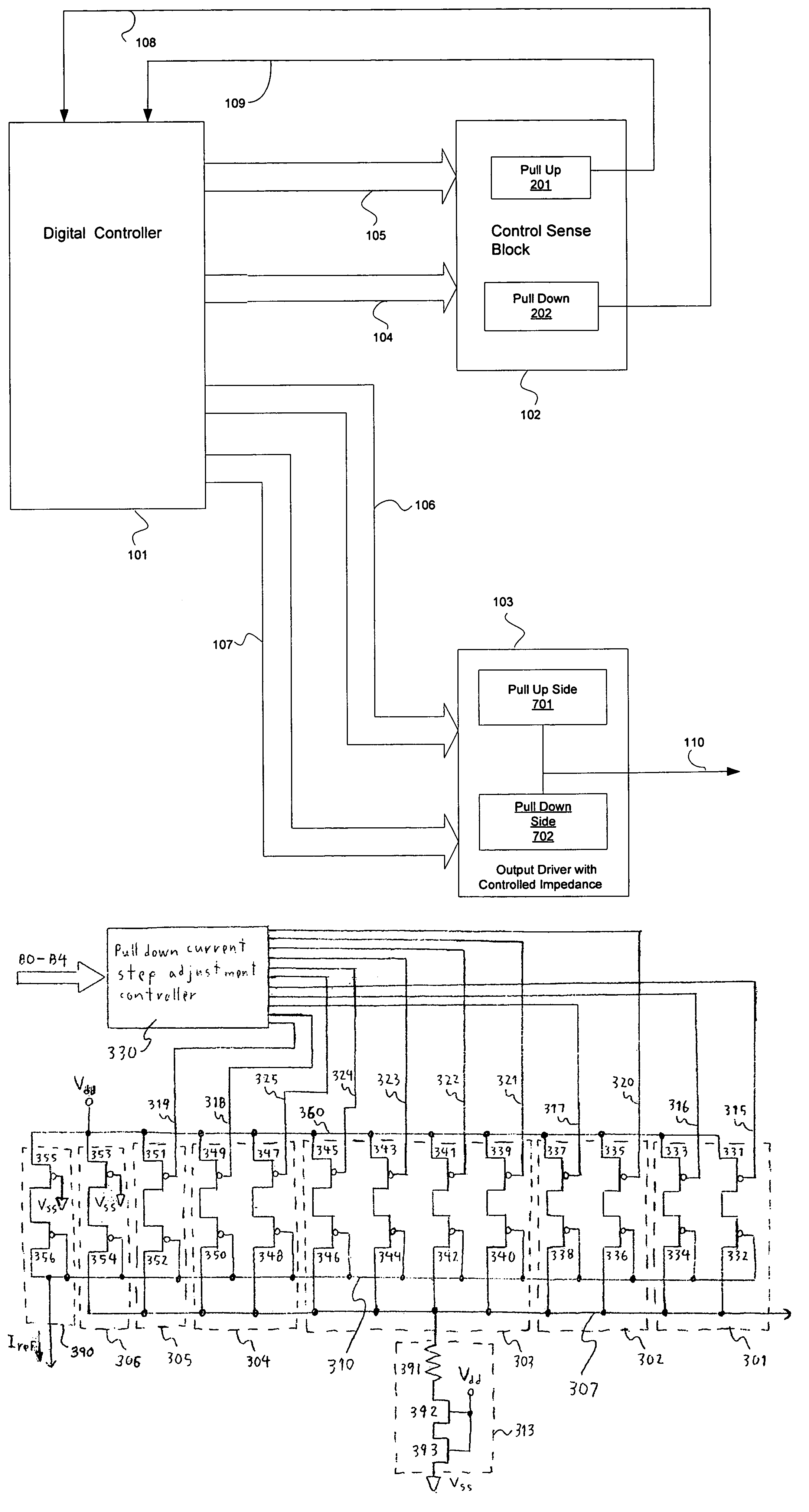

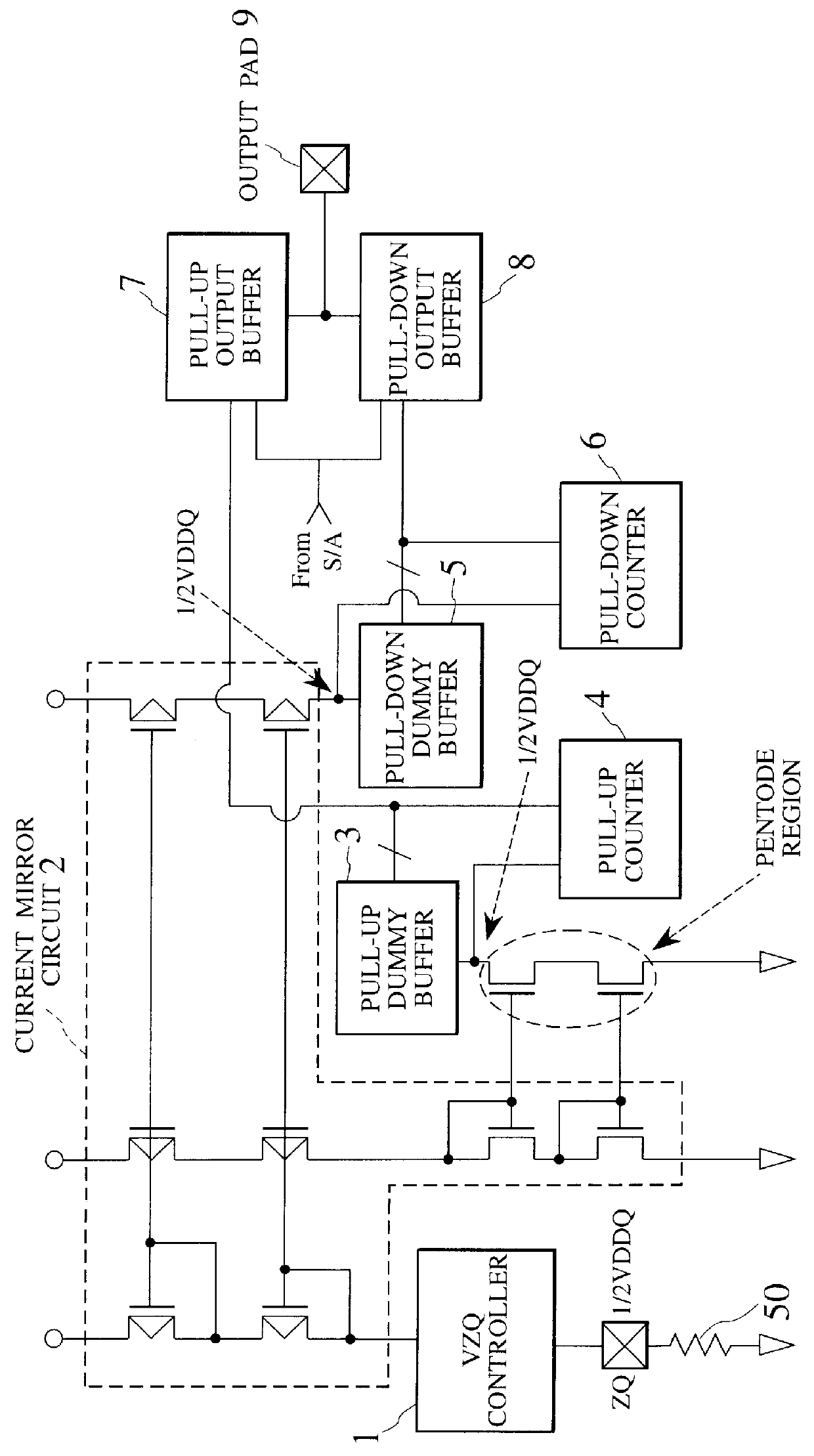

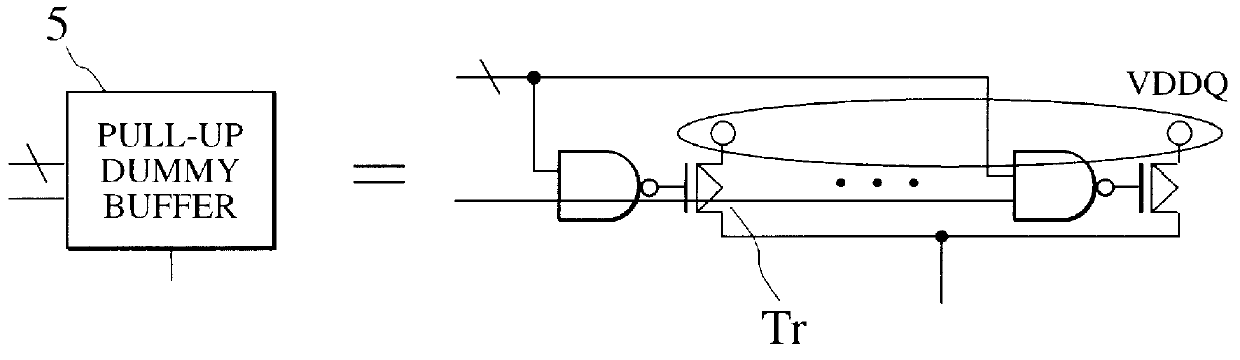

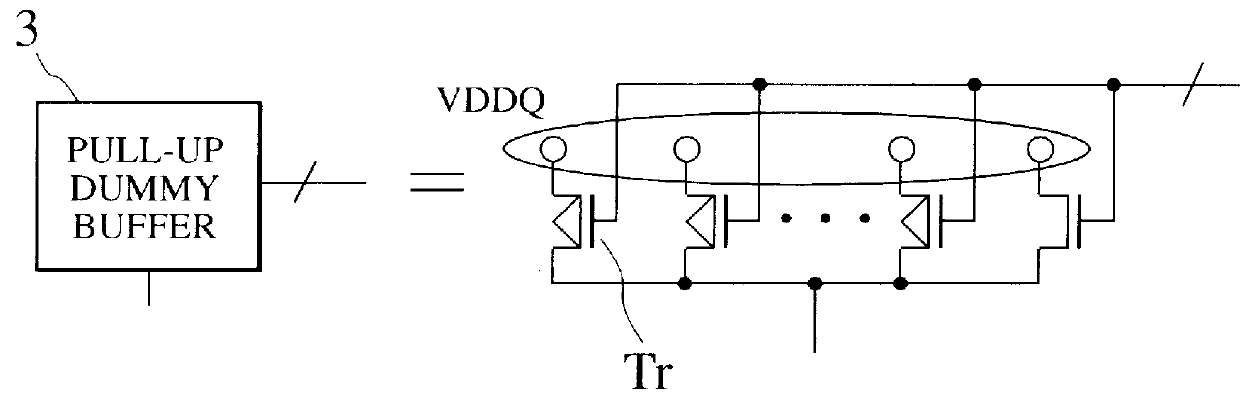

Programmable impedance output buffer drivers, semiconductor devices and static random access memories provided with a progammable impedance output port

The impedance of a pull-down output buffer circuit is adjusted to an integer multiple of the resistance value of an off-chip resistor with reference to the adjustment information obtained by adjusting the impedance of the pull-down dummy buffer circuits 13 and 14 to the resistance value of the off-chip resistor by means of a pull-down counter. The impedance of the pull-up output buffer circuit is adjusted to the pull-down dummy buffer circuit 14, i.e., an integer multiple of the resistance value of an off-chip resistor with reference to the adjustment information obtained by adjusting the impedance of the pull-up dummy buffer circuit to the impedance of the pull-down dummy buffer circuit 14 by means of a pull-up counter.

Owner:KK TOSHIBA

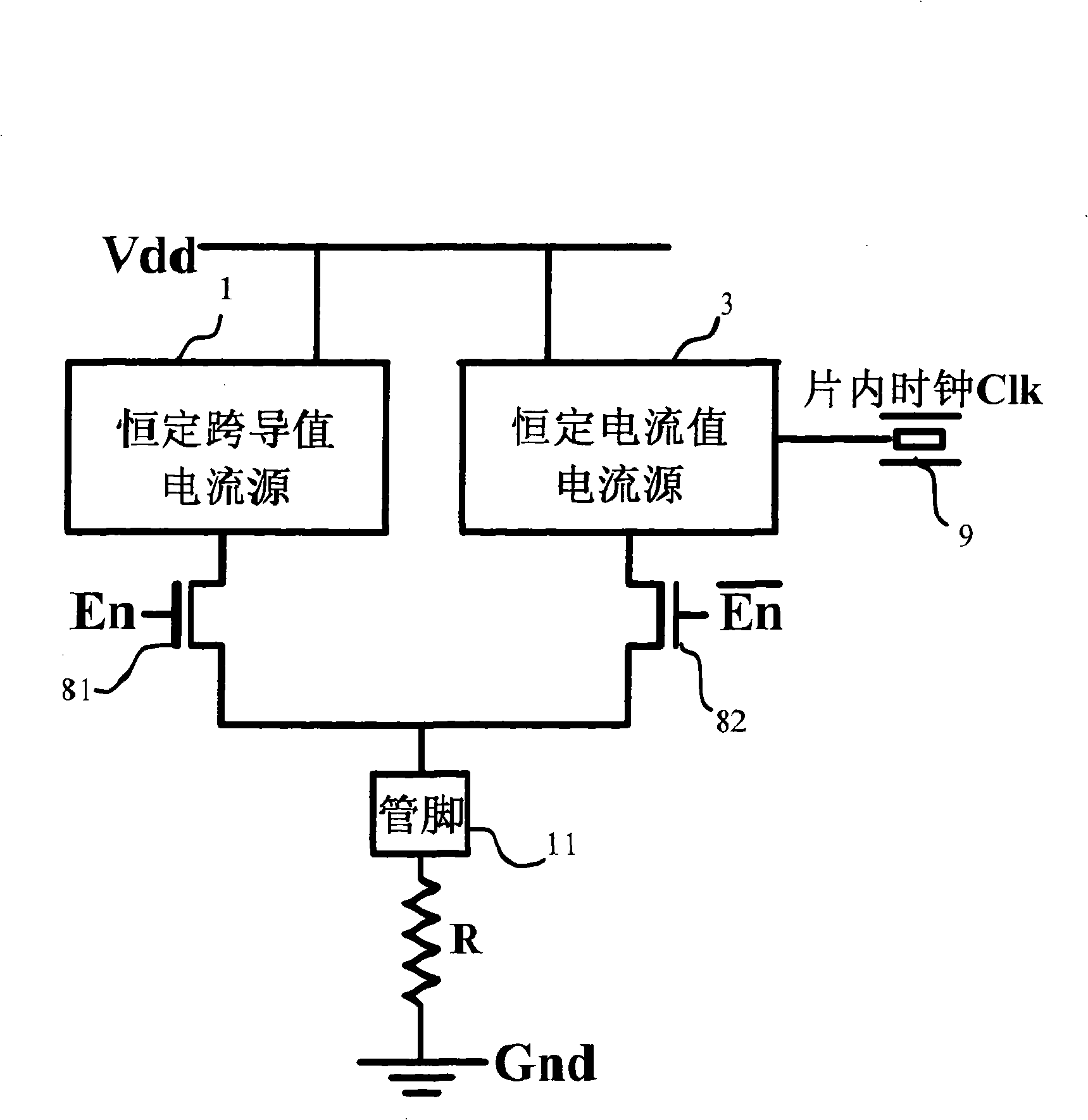

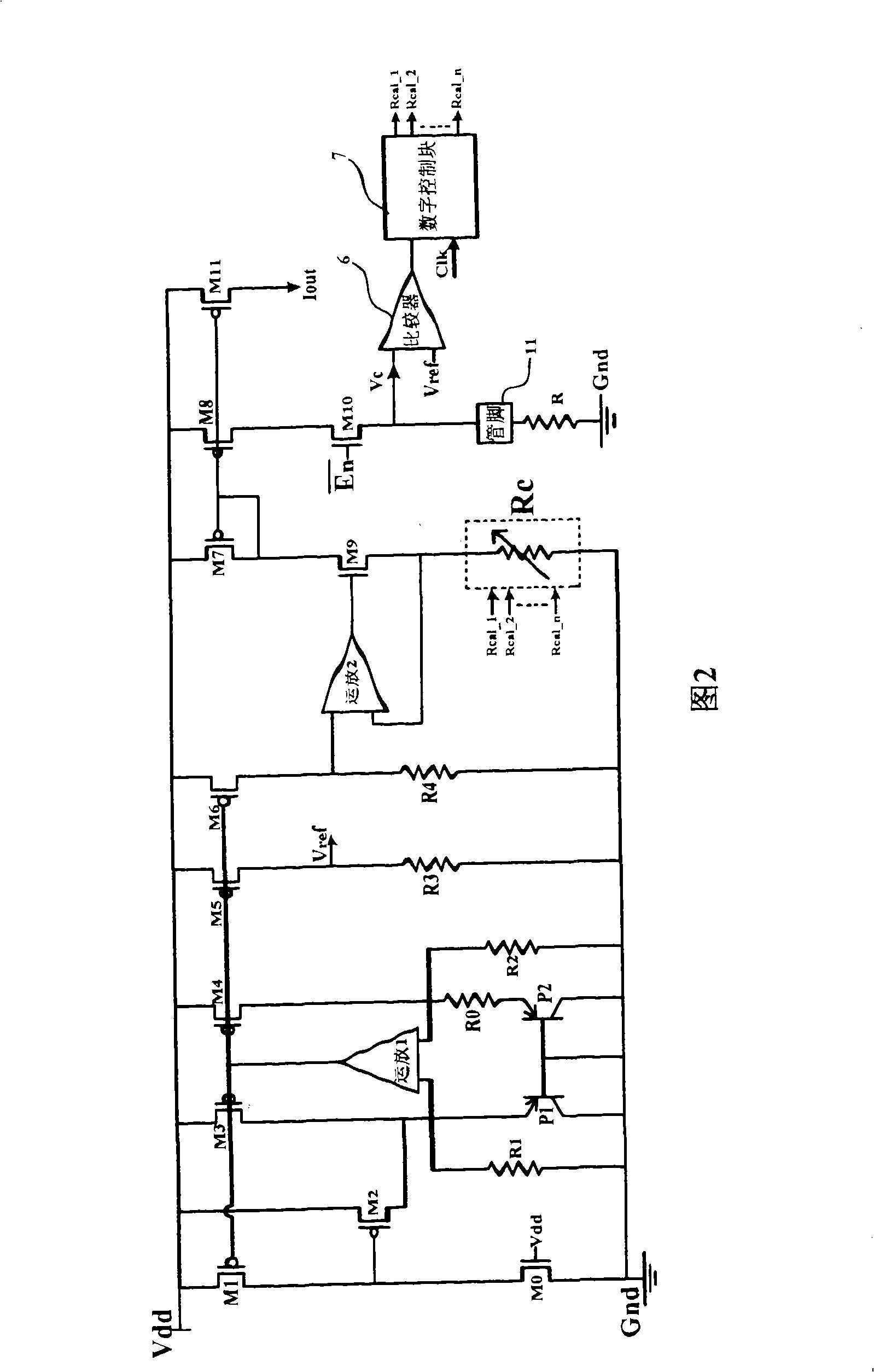

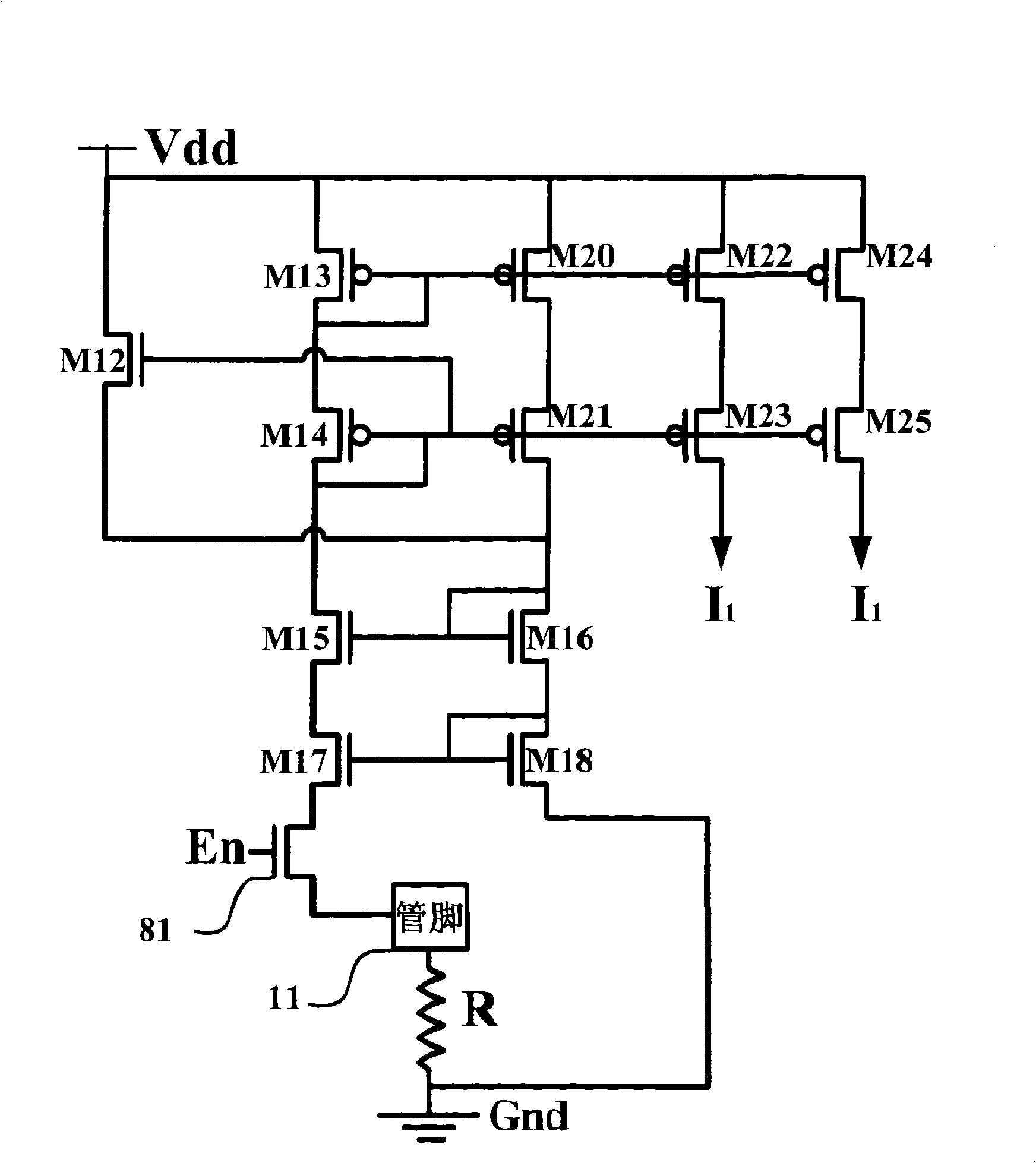

CMOS reference source

InactiveCN101320278AHigh precisionElectric variable regulationCMOSElectrical resistance and conductance

The present invention relates to a CMOS reference source, which comprises a constant transconductance value current source circuit used to output constant transconductance value current, a constant voltage reference-producing circuit used to output a reference voltage and a constant current value current source circuit used to output a constant current value, a comparison voltage is obtained through resistors, and the constant voltage reference-producing circuit applies a voltage to an adjustable resistance array, so that the output current of the constant current value current source circuit can be generated; an off-chip resistor is needed, and the pin of the off-chip resistor is respectively connected with the constant transconductance value current source circuit and the constant current value current source circuit, and therefore a switching parallel circuit is formed; a feedback rectification system, which is composed of the resistor, a comparator and a digital control module, is used to rectify the output current value of the constant current value current source circuit. The present invention provides each core module unit circuit in an integrated CMOS circuit with the stable and high-precision CMOS reference source (a constant transconductance value current source and a constant current value current source) which cannot be affected by temperature change, power supply voltage change and the deviation of a fabrication technique.

Owner:中科威发半导体(苏州)有限公司

Chip resistor and method of making the same

A chip resistor includes a metal resistor element having a flat lower surface. The lower surface is formed with two electrodes spaced from each other, and an insulating resin film is formed between these electrodes. Each of the electrodes partially overlaps the insulating film so that a portion of the insulating film is inserted between each of the electrodes and the lower surface of the resistor element.

Owner:ROHM CO LTD

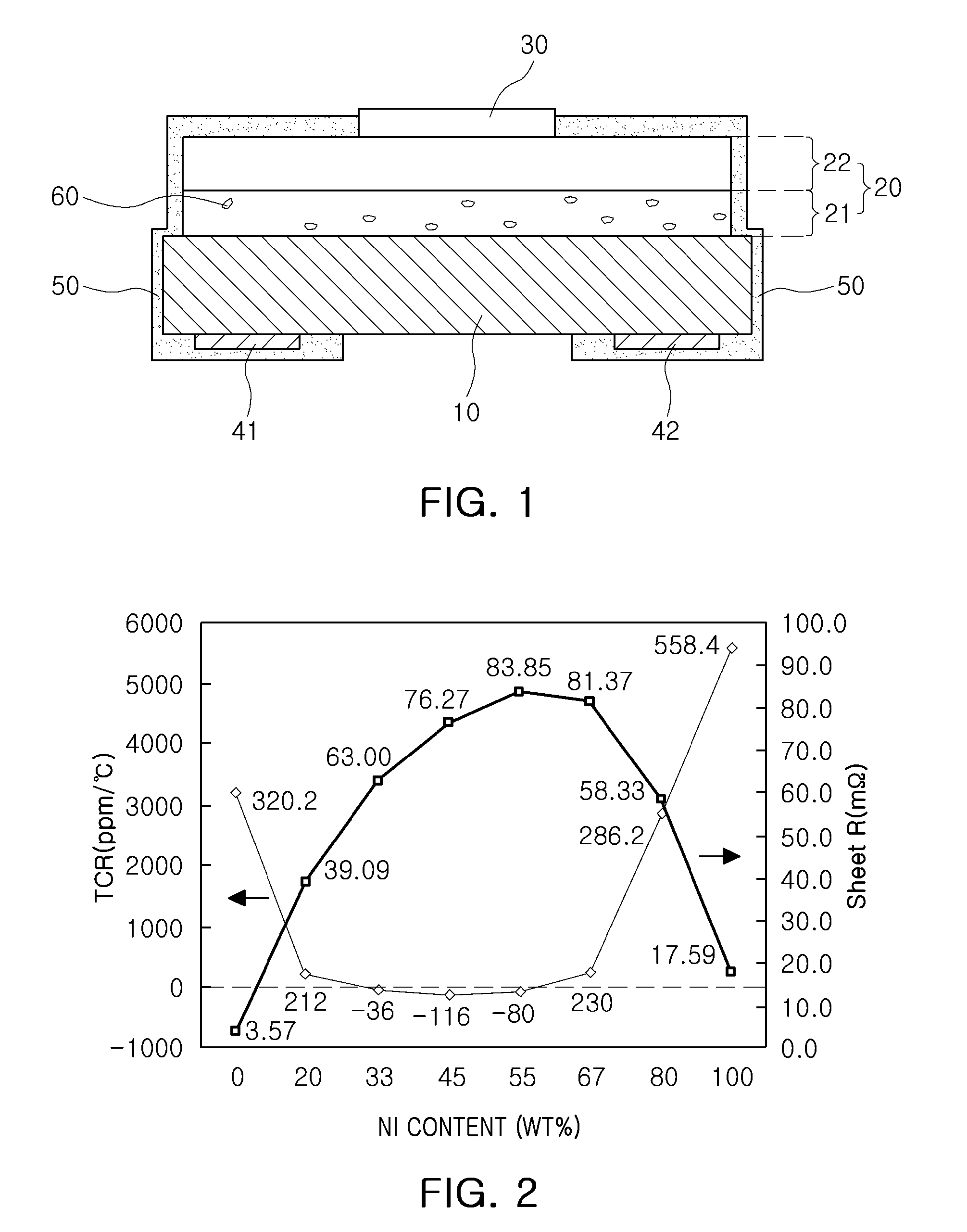

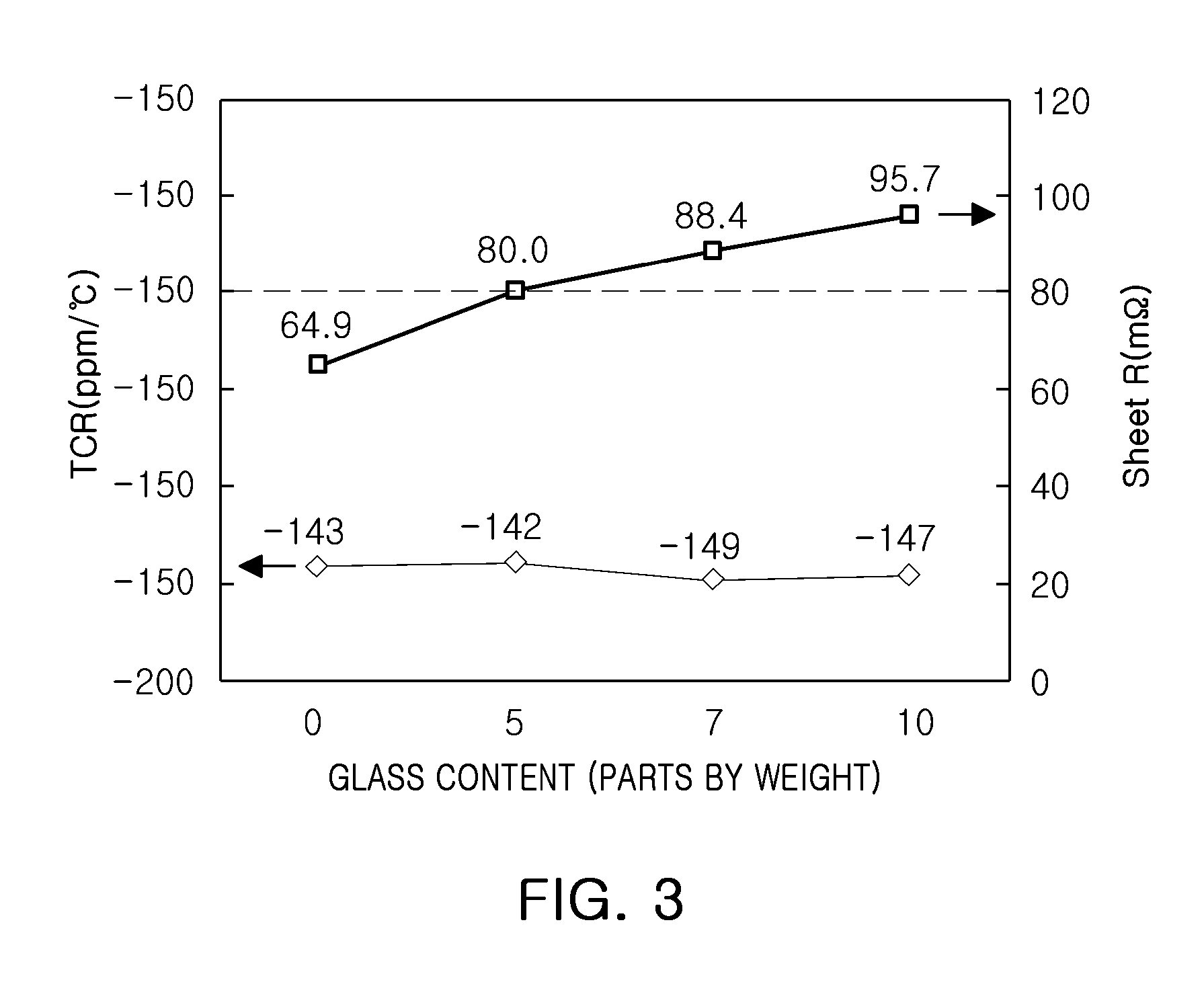

Chip resistor and method of manufacturing the same

ActiveUS20130154790A1Lower resistanceSmall temperature coefficientResistor terminals/electrodesResistor manufactureElectrical resistance and conductanceTemperature coefficient

There is provided a chip resistor including a ceramic substrate; a first resistance layer formed on the ceramic substrate and including a first conductive metal and a first glass; and a second resistance layer formed on the first resistance layer, including a second conductive metal and a second glass, and having a smaller content of glass than the first resistance layer, thereby obtaining relatively low resistance and a relatively small temperature coefficient of resistance (TCR).

Owner:SAMSUNG ELECTRO MECHANICS CO LTD

Chip resistor having low resistance and its producing method

ActiveUS20050200451A1ResistanceIncreasing the thicknessResistor chip manufactureResistor detailsElectrical resistance and conductanceAlloy

A chip resistor includes a resistor element of a rectangular solid made of an alloy composed of high-resistant metal and low-resistant metal, while also including connection terminal electrodes disposed at the ends of the resistor element that are spaced longitudinally of the rectangular solid. The resistance of the chip resistor is expected to be lowered without incurring an increase in the temperature coefficient of resistance and the weight. The above object is attained by forming a plating layer on the resistor element, where the plating layer is made of pure metal having a lower resistance than that of the alloy constituting the resistor element.

Owner:ROHM CO LTD

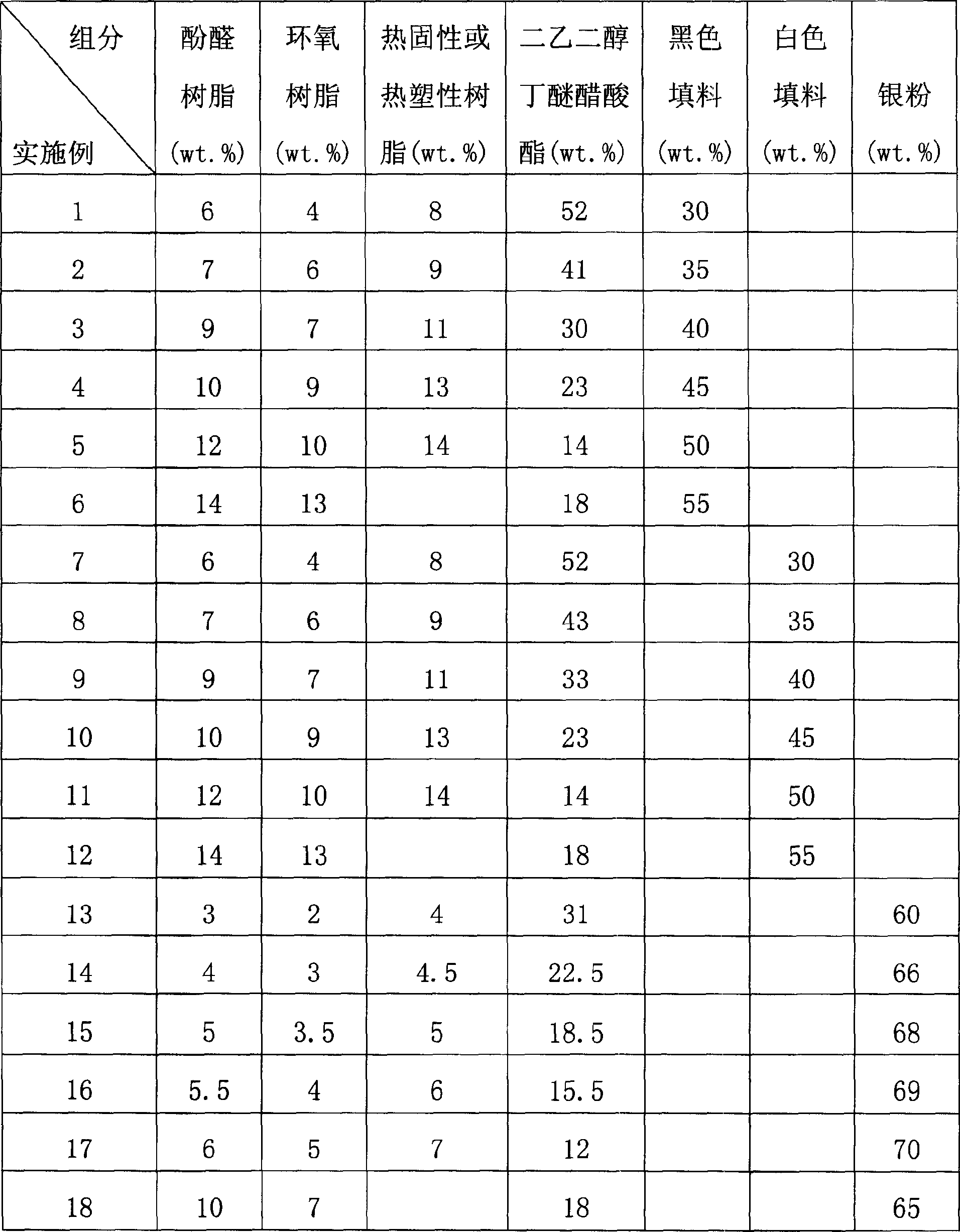

Resin size used for chip resistor

InactiveCN1512522AHigh resistance precisionReduce manufacturing costOther chemical processesResistor housing/enclosing/embeddingEpoxyOrganic solvent

This invention relates to resin sizing material used in sheet resistors including an adhesive and a filler, among which, the adhesive is a mixture of bakelite and epoxy resin formed in an organic solution, the filler is one of white, black fillers or a noble metal powder. The said sizing material is used in a secondary enveloper, markers and end electrodes of the resistor and completely solidified under 160-250deg.C not influencing the sheet resistors.

Owner:GUANGDONG FENGHUA ADVANCED TECH HLDG

Oven controlled crystal oscillator for high stability

InactiveUS7023291B2Improve thermal efficiencyHighly stable oscillatorDomestic cooling apparatusLighting and heating apparatusTemperature controlEngineering

To provide a highly stable crystal oscillator having increased thermal efficiency. The highly stable crystal oscillator comprises; a thermostat mainframe which maintains the temperature of a crystal resonator including a resonator container for sealing a crystal piece constant, an oscillating element which constitutes an oscillation circuit together with said crystal resonator, a temperature control element which controls the temperature inside of said thermostat mainframe, and a circuit board mounted with said thermostat mainframe, said oscillating element, and said temperature control element. The construction is such that a heat generating chip resistor and a highly heat sensitive element having a higher temperature dependency, among said oscillating element and said temperature control element, are arranged on one principal plane of said circuit board, and said heat generating chip resistor, said highly heat sensitive element, and said thermostat mainframe are directly heat bonded by a thermo-conductive material.

Owner:NIHON DEMPA KOGYO CO LTD

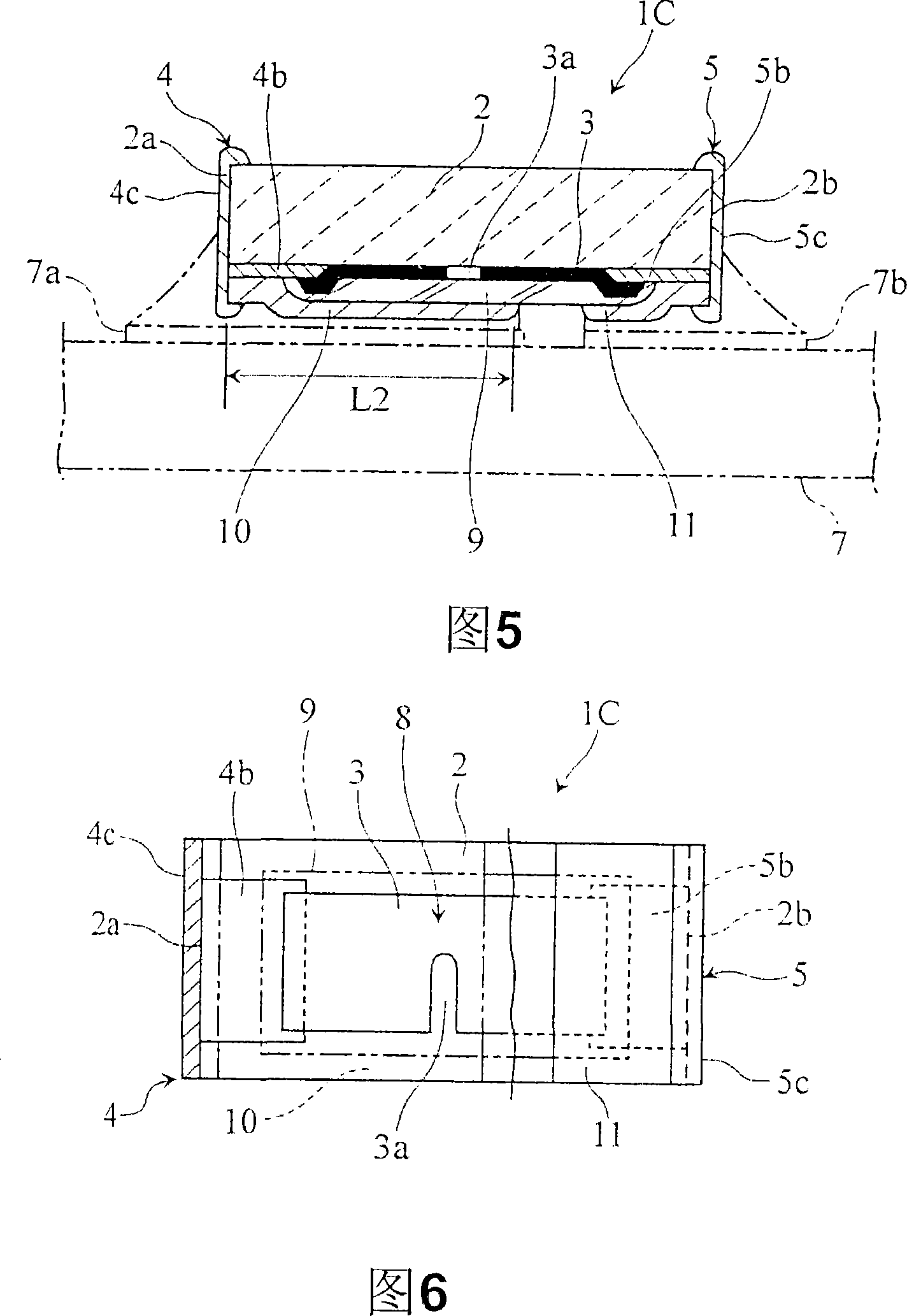

Chip resistor

ActiveCN101243524AImprove heat transfer performanceResistor manufactureResistor detailsElectrical resistance and conductanceEngineering

The present invention provides a chip resistor (1), comprising: a pair of terminal electrodes (4, 5) provided at the ends of an insulating substrate (2) constituting a chip shape; On the upper side, a resistive film (3) is formed in such a manner as to conduct with a pair of terminal electrodes (4, 5), and an adjustment groove (3a) for setting a resistance value is formed on a part thereof. The pair of terminal electrodes (4, 5) includes a lower electrode (4b) formed on the lower surface of the insulating substrate (2), and the lower electrode (4b) extends to the adjustment groove (3a) formed on a part of the resistance film (3). And the position directly below the narrow portion (8) that makes the width dimension of the resistive film (3) narrow.

Owner:ROHM CO LTD

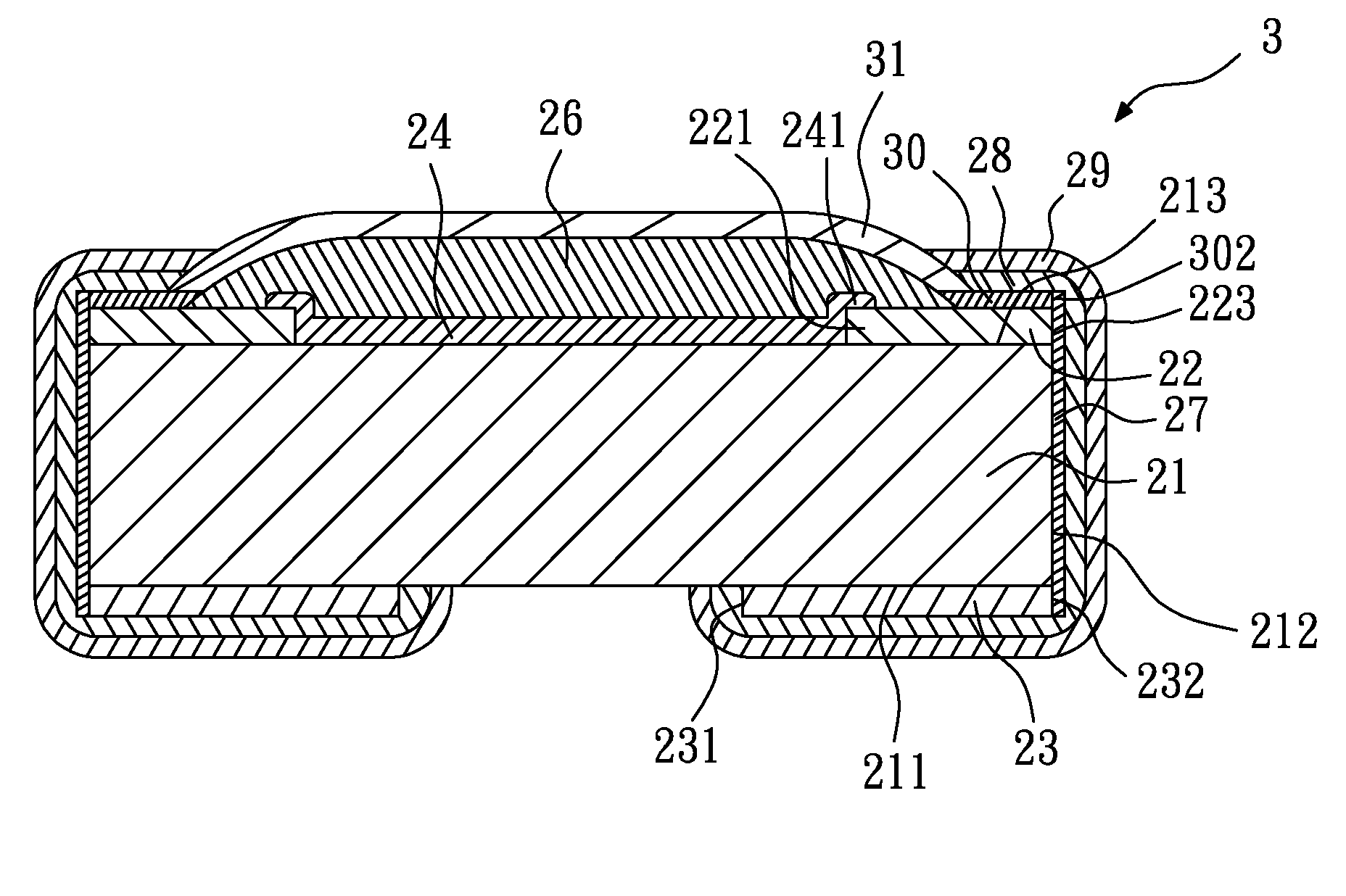

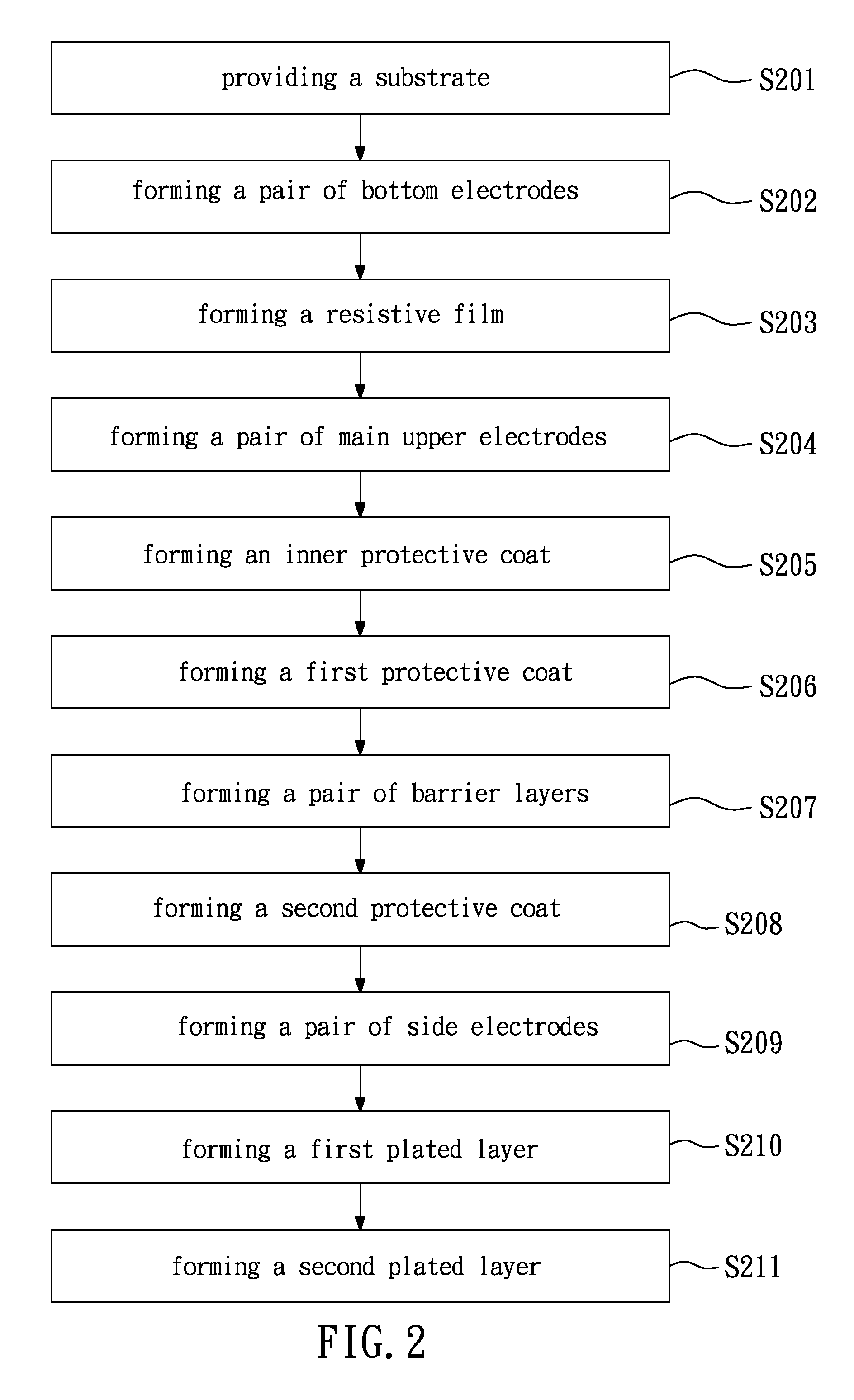

Chip resistor and method for making the same

ActiveUS20100201477A1Effective protectionEasily affectedResistor chip manufactureEnvelope/housing resistor manufactureCorrosionElectrical and Electronics engineering

The present invention relates to a chip resistor and method for making the same. The chip resistor includes a substrate, a pair of bottom electrodes, a resistive film, a pair of main upper electrodes, a first protective coat, a pair of barrier layers, a second protective coat, a pair of side electrodes and at least one plated layer. The first protective coat is disposed over the resistive film, and covers part of the main upper electrodes. The barrier layers are disposed on the main upper electrodes, and cover part of the first protective coat. The second protective coat is disposed on the first protective coat, and covers part of the barrier layers. The plated layers cover the barrier layers, the bottom electrodes and the side electrodes. As a result, the chip resistor features high corrosion resistance.

Owner:YAGEO CORP

Constant temperature type crystal oscillator

InactiveCN1700589ASolve temperature dependenceStable characteristicsTemperatue controlOscillations generatorsTemperature controlHeat conducting

The present invention is one where, in a lead wire led-out type crystal oscillator of constant temperature type for high stability, comprising: a heat supply body that supplies heat to a crystal resonator from which a plurality of lead wires are led out, to maintain the temperature constant; an oscillating element that constitutes an oscillating circuit together with the crystal resonator; a temperature control element that constitutes a temperature control circuit for controlling the temperature of the crystal resonator; and a circuit board for mounting the heat supply body, the oscillating element, and the temperature control element, and through which lead wires of the crystal resonator are passed through for mounting, the heat supply body comprises: a heat conducting plate which has through-holes for the lead wires and is mounted on the circuit board, and which faces, and is directly thermally joined to, the crystal resonator; and a chip resistor for heating which is mounted on the circuit board adjacent to the heat conducting plate, and is thermally joined to the heat conducting plate.

Owner:NIHON DEMPA KOGYO CO LTD

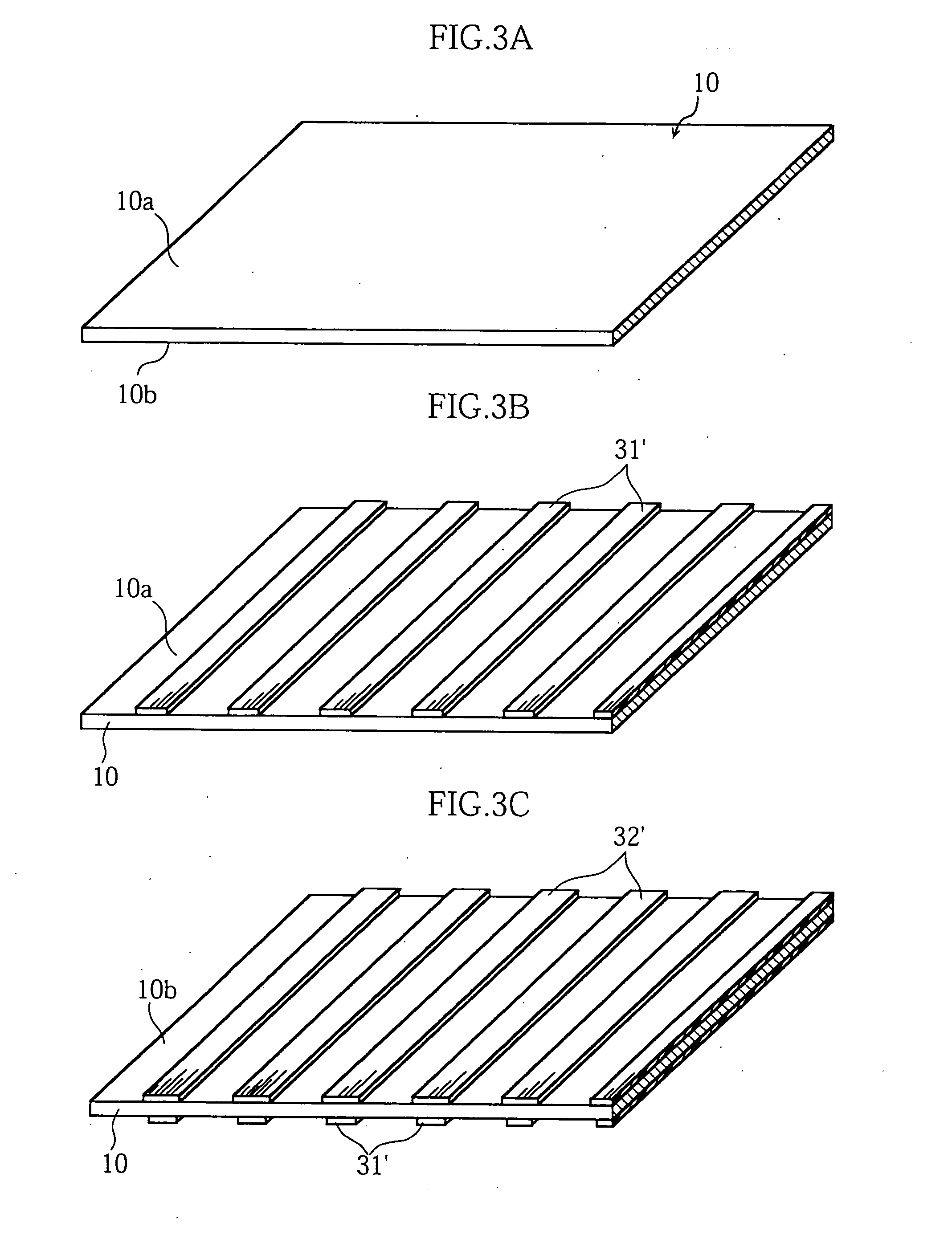

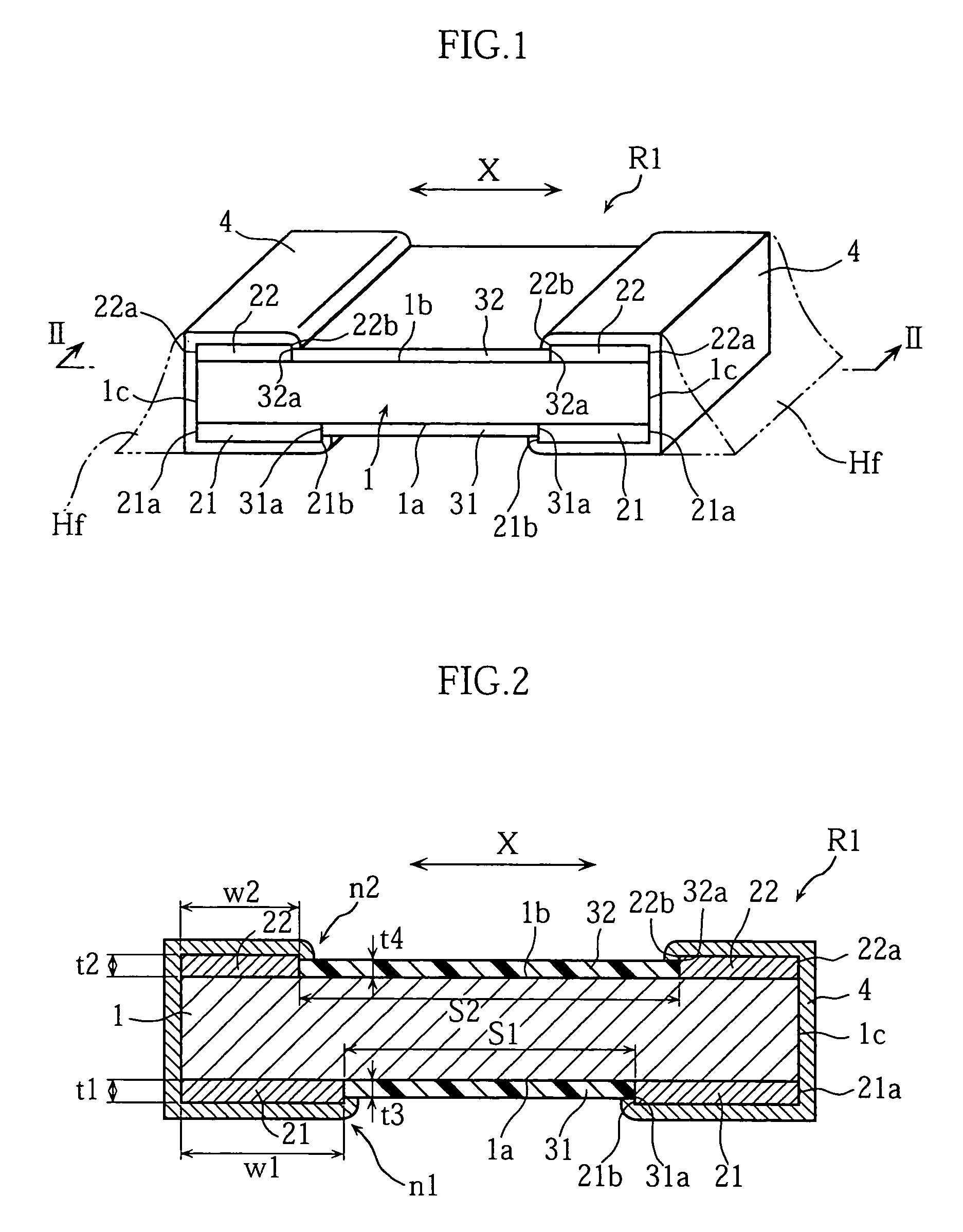

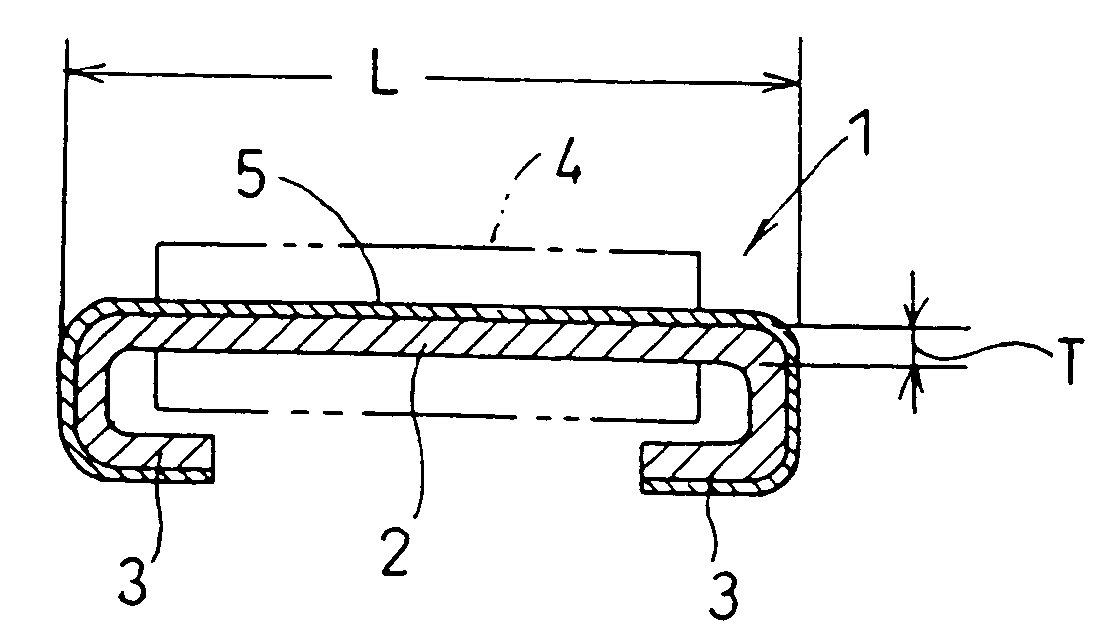

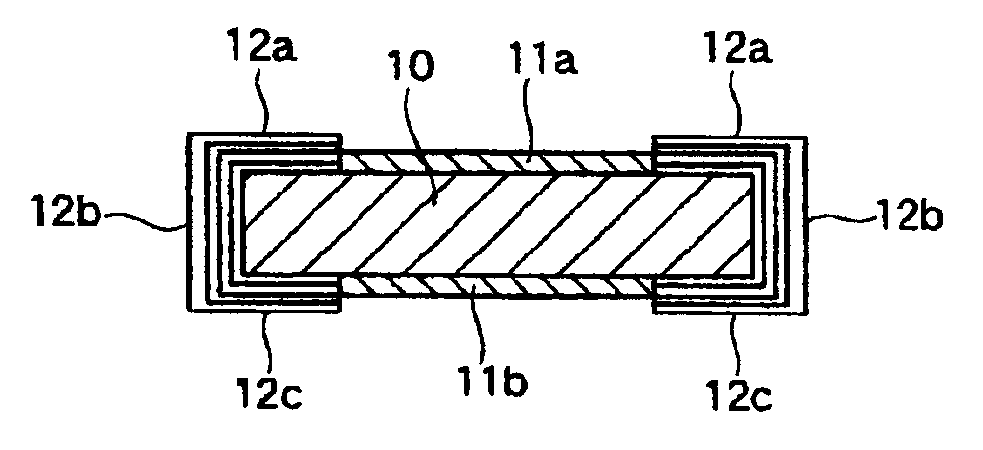

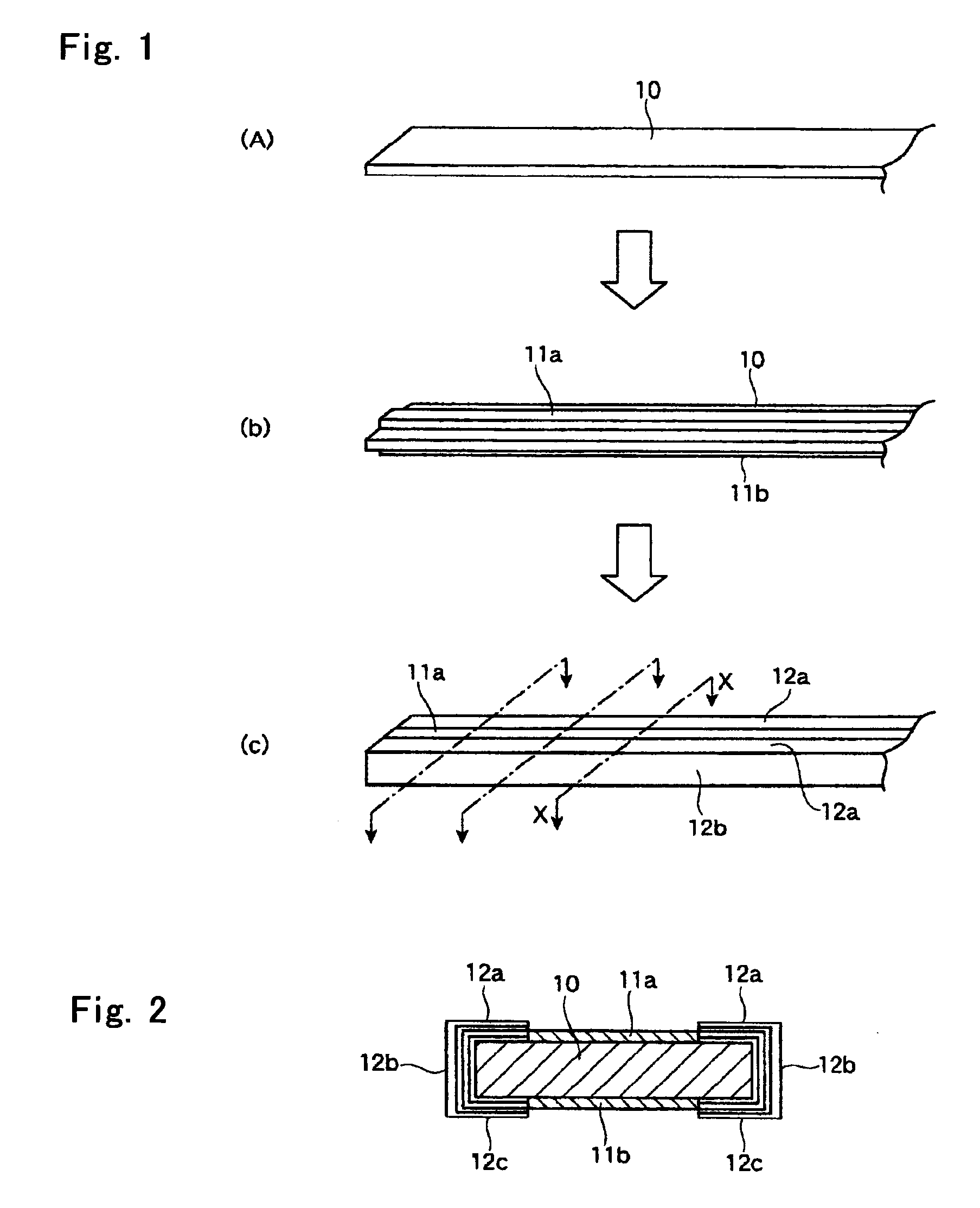

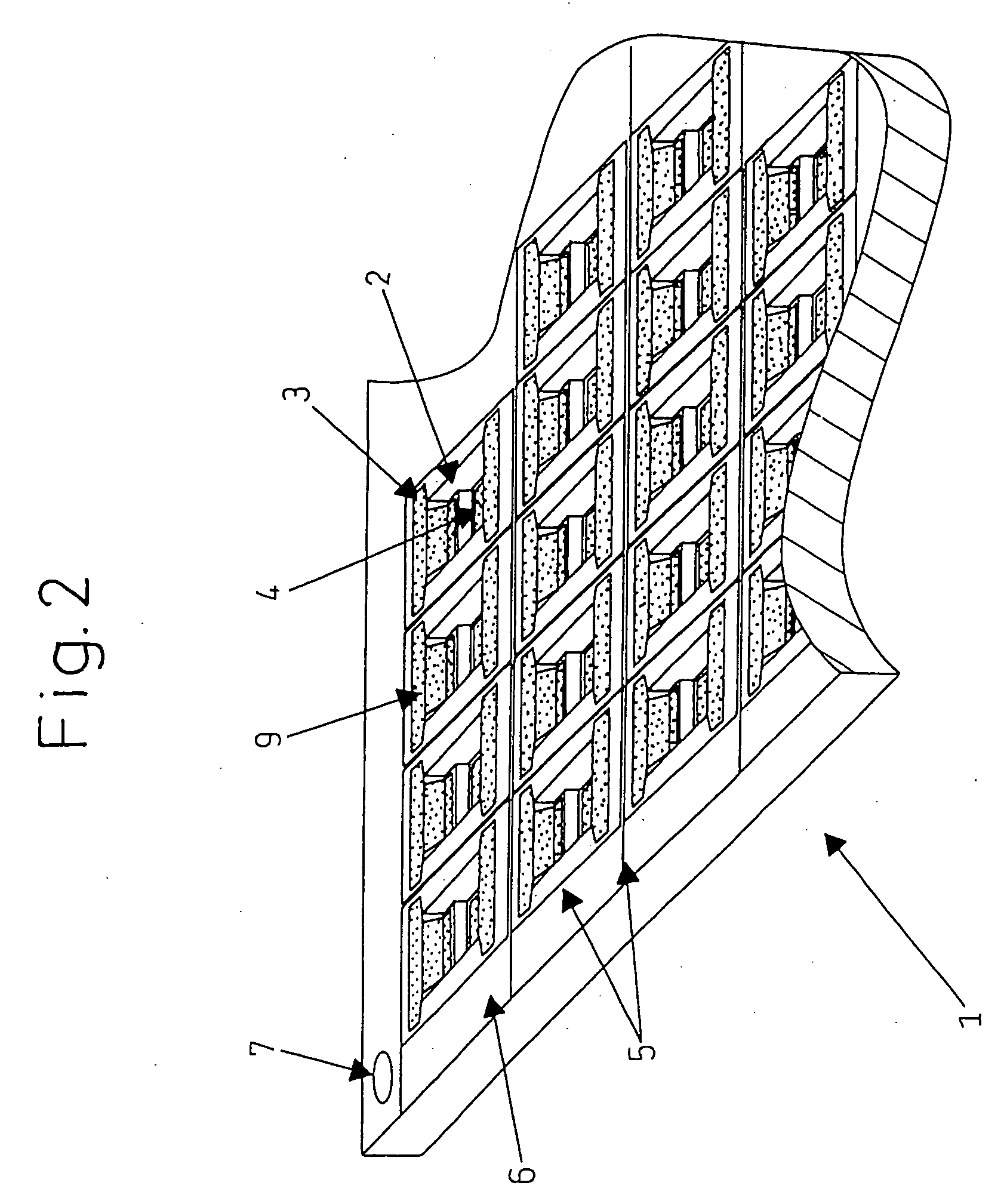

Method for manufacturing rectangular plate type chip resistor and rectangular plate type chip resistor

ActiveUS20100176913A1Low costEfficient preparationResistor chip manufactureResistor terminals/electrodesElectrical resistance and conductanceTectorial membrane

There is provided a method for manufacturing rectangular plate type chip resistors which provides easy and convenient control of resistance, and easy and low cost manufacture of rectangular plate type chip resistors having a reliable electrode structure, as well as a rectangular plate type chip resistor obtained by this method and having excellent properties particularly at low resistance. The method includes the steps of (A) providing a resistive alloy plate strip 10 of predetermined width and thickness, (B) forming an insulating protective film (11a, 11b) of a predetermined width longitudinally along the middle of upper and lower faces of the alloy plate strip, (C) forming an electrode layer 12 composed of integrated surface, back, and end electrodes (12a, 12c, 12b, respectively), along both sides of the protective film by electroplating, and (D) cutting the alloy plate strip coated with the protective films and the electrode layers in step (C) transversely in predetermined lengths, wherein resistance is controlled to be within a predetermined range by adjusting the thickness of the alloy plate strip in step (A), the width of the protective film formed in step (B), and the cutting length in step (D).

Owner:KAMAYA ELECTRIC

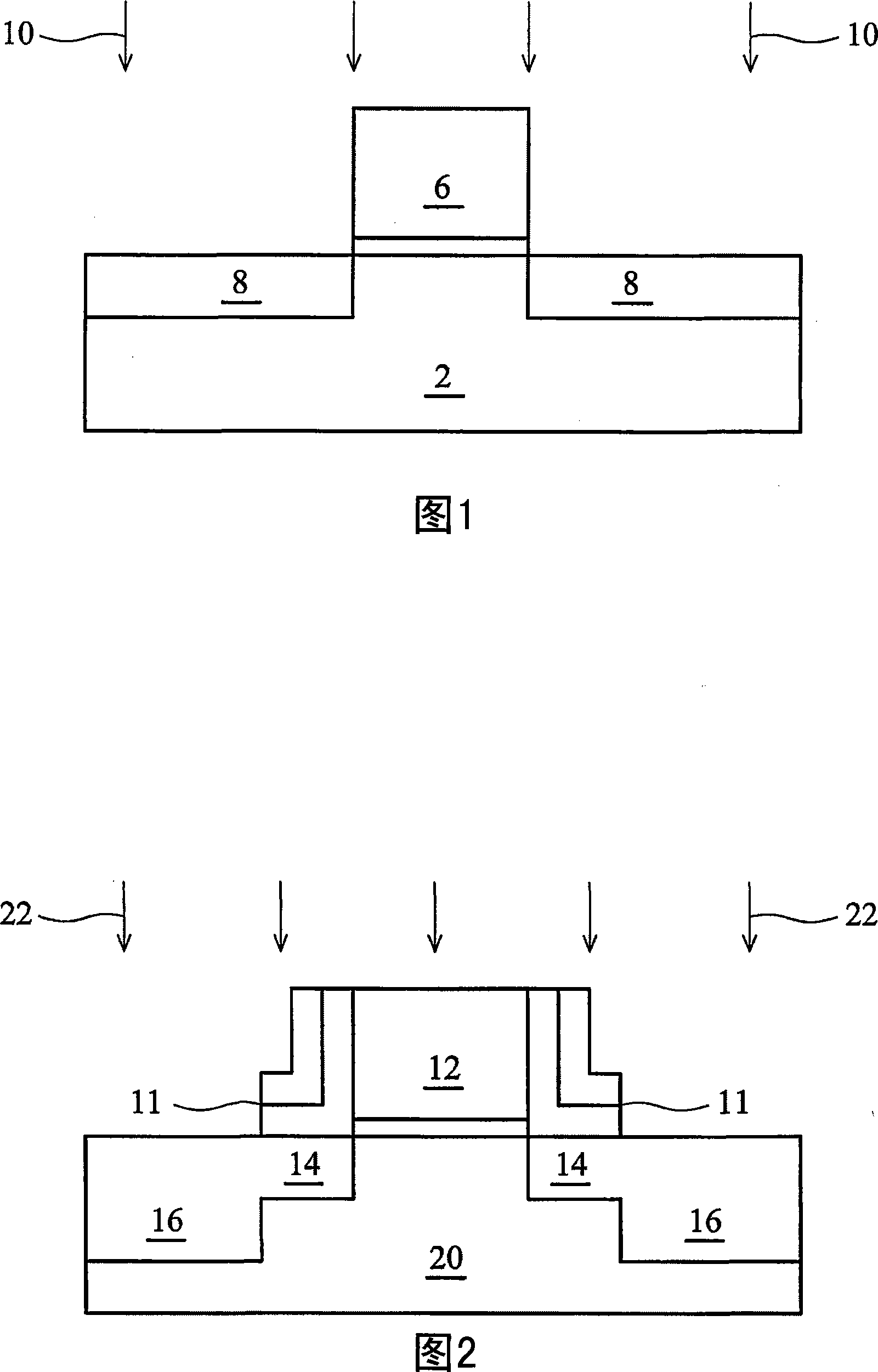

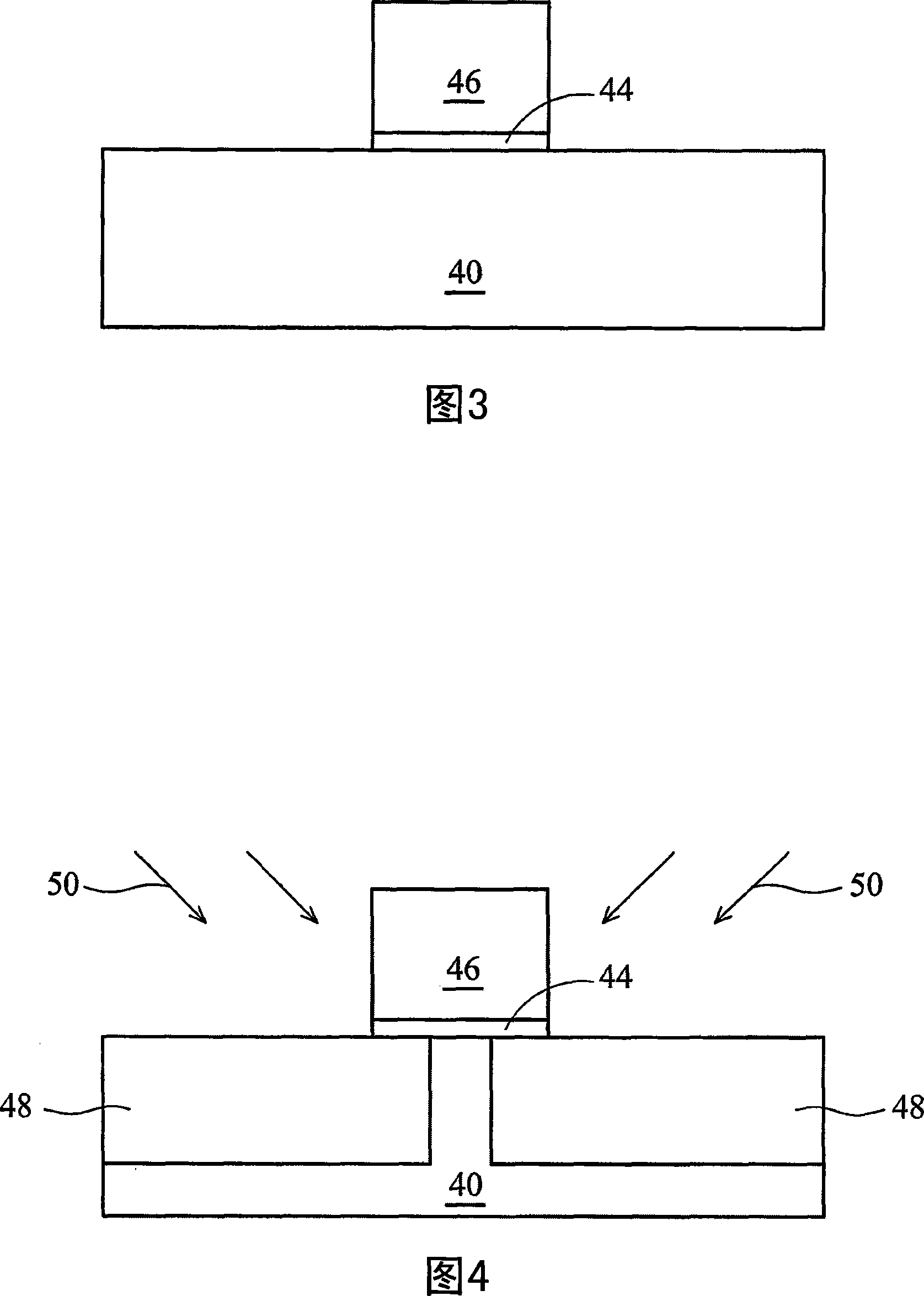

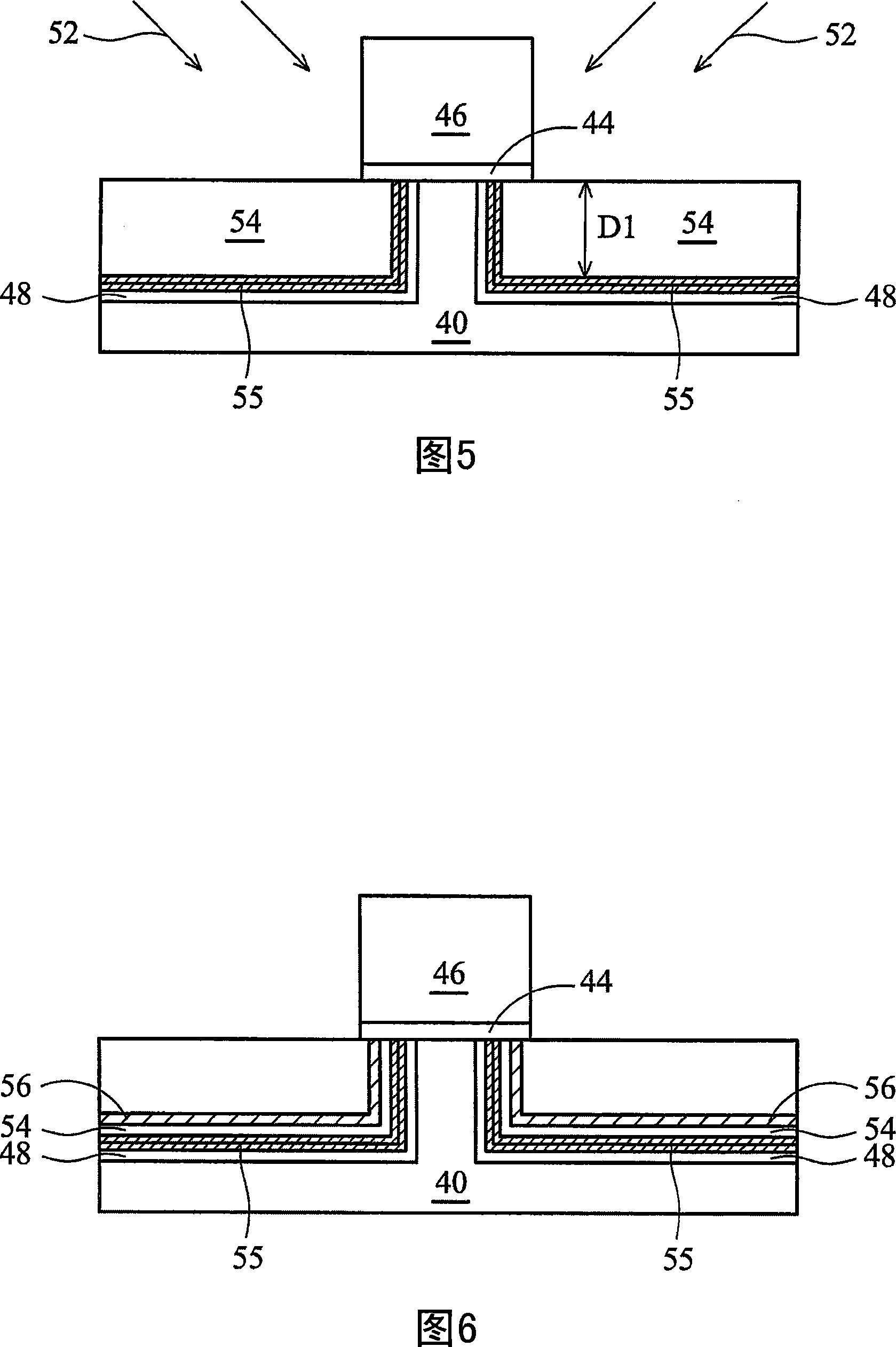

Semiconductor element and its forming method

ActiveCN101087003AReduce spreadHigh activation rateSemiconductor/solid-state device manufacturingSemiconductor devicesHigh activationImpurity

A semiconductor component of the invention comprises a semiconductor substrate; a grid stack which is arranged on the semiconductor substrate; a n-type light doped source / drain area which is arranged in the semiconductor and is stacked adjacent the grid, wherein the n-type light doped source / drain area comprises the n-type impurity; a n-type heavy doped source / drain area, wherein the n-type heavy doped source / drain area comprises the n-type impurity; a pre-amorphized implanting area which is arranged in the semiconductor substrate, wherein the pre-amorphized implanting area comprises a back implanting area; and a clearance blocking area, wherein the depth of the clearance blocking area is larger than the depth of the n-type light doped source / drain area but is less than the depth of the back implanting area. As the clearance blocking area of the invention is arranged between the back implanting area and the light doped source / drain area the problem of phosphorus diffusion in the light doped source / drain area can be reduced. Besides as the phosphorus has high activation rate the MOS element has low chip resistor.

Owner:TAIWAN SEMICON MFG CO LTD

Ceramic package and chip resistor, and method for manufacture thereof

InactiveUS20050082648A1Low costGuaranteed to workResistor chip manufactureEnvelope/housing resistor manufactureMethacrylateConductive paste

A ceramic package and a chip resistor obtained by forming, on a plastic ceramic green sheet comprising 100 parts by weight of a ceramic powder mainly composed of borosilicate glass, into which 10 to 30 parts by weight of an acrylic copolymer obtained by polymerizing 100 parts by weight of a (meth)acrylic acid ester and 1 to 10 parts by weight of a monomer having a functional group of a hydroxyl group, acid amide group, or amino group and having a Tg in the range of −30° C. to +10° C. is compounded, a conductor layer using a plastic conductive paste obtained by compounding, into 100 parts by weight of a conductive powder, 5 to 20 parts a mixture of an acrylic copolymer having a Tg of not more than −30° C. and an ethylcellulose-based binder, press forming the resultant single layer of ceramic green sheet, and calcining the resultant ceramic green sheet having the integrally formed bottom, opening and opening circumferential edge and a method for producing the same.

Owner:NIPPON CARBIDE KOGYO KK

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com