Patents

Literature

285results about How to "High activation rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

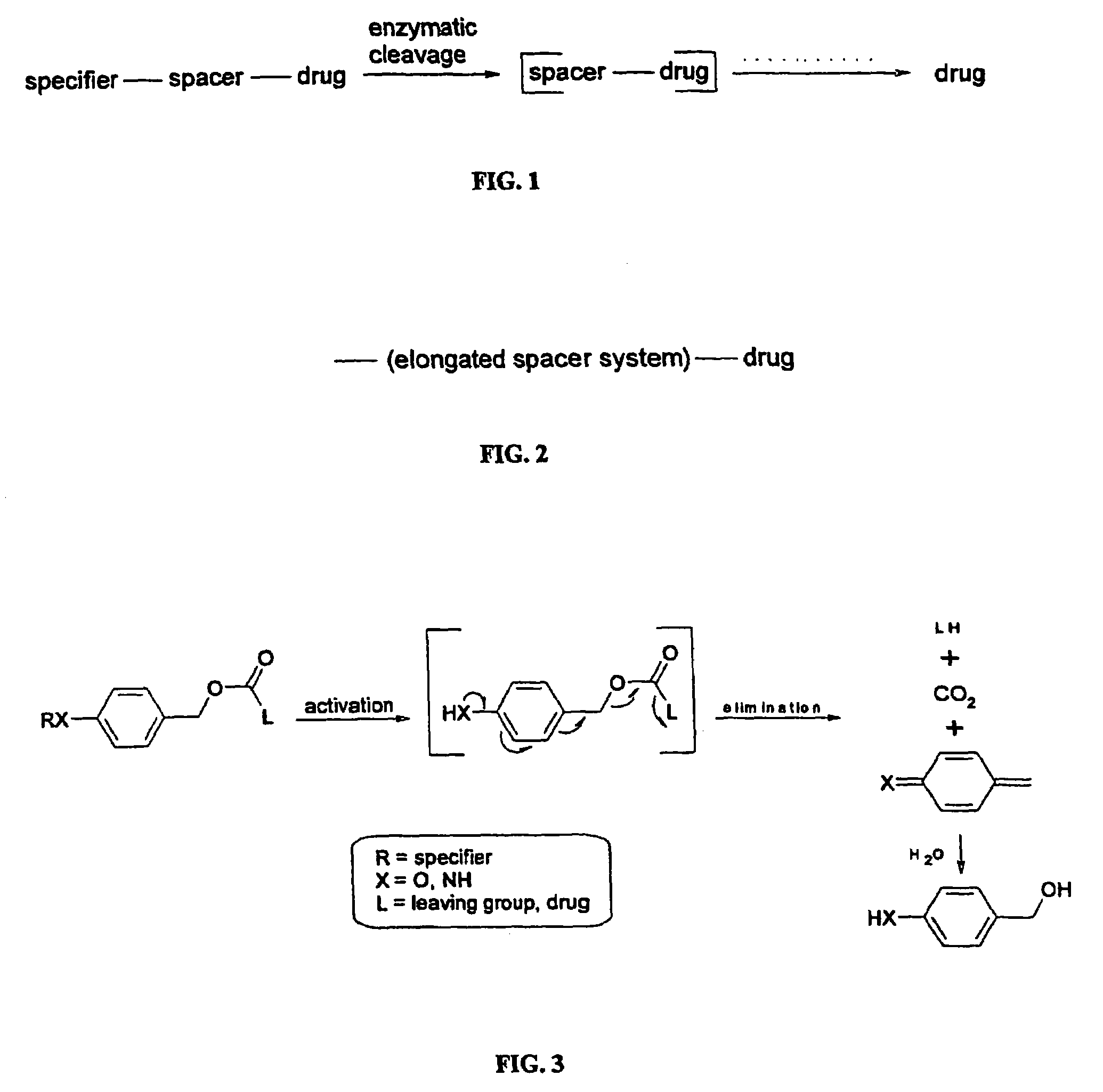

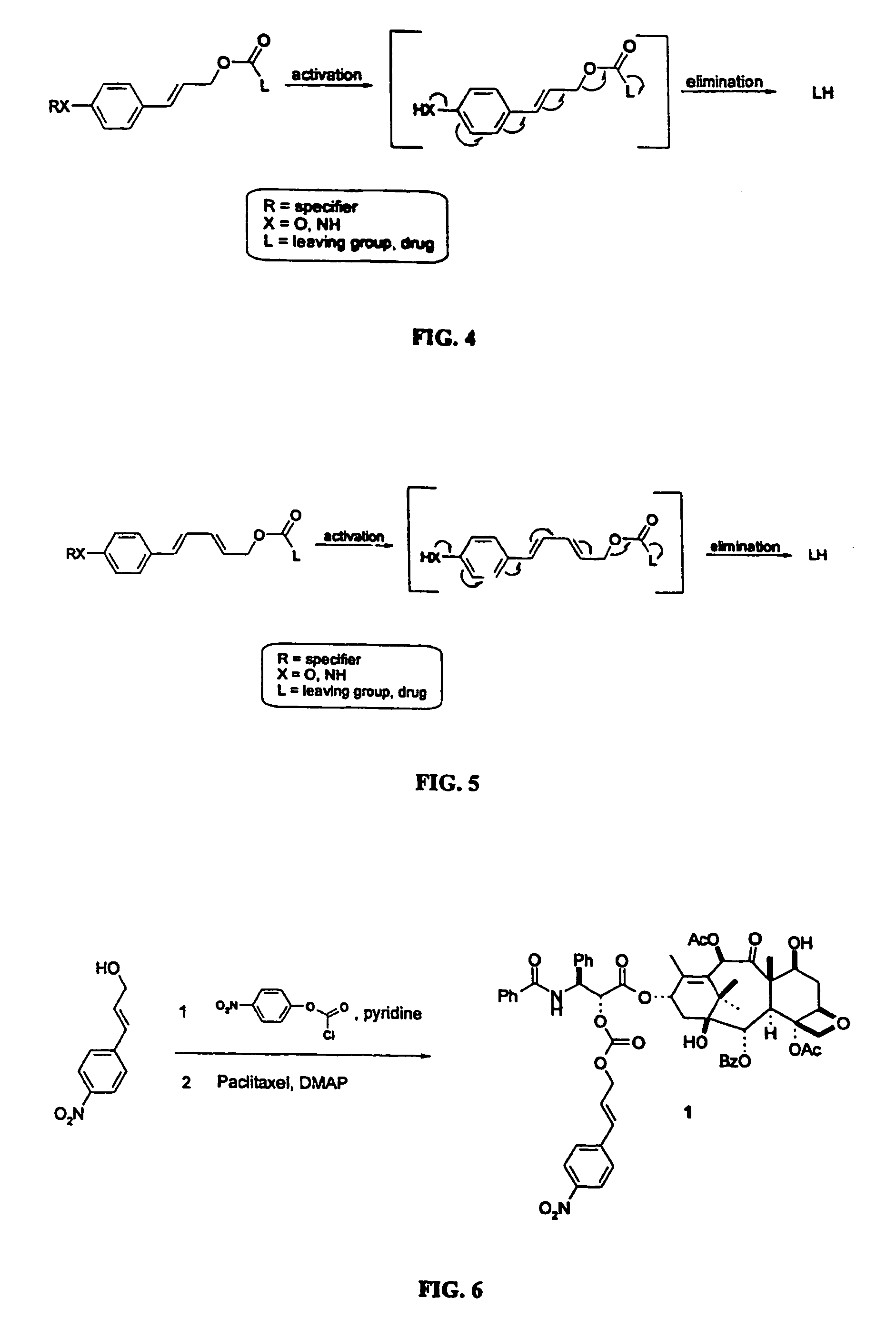

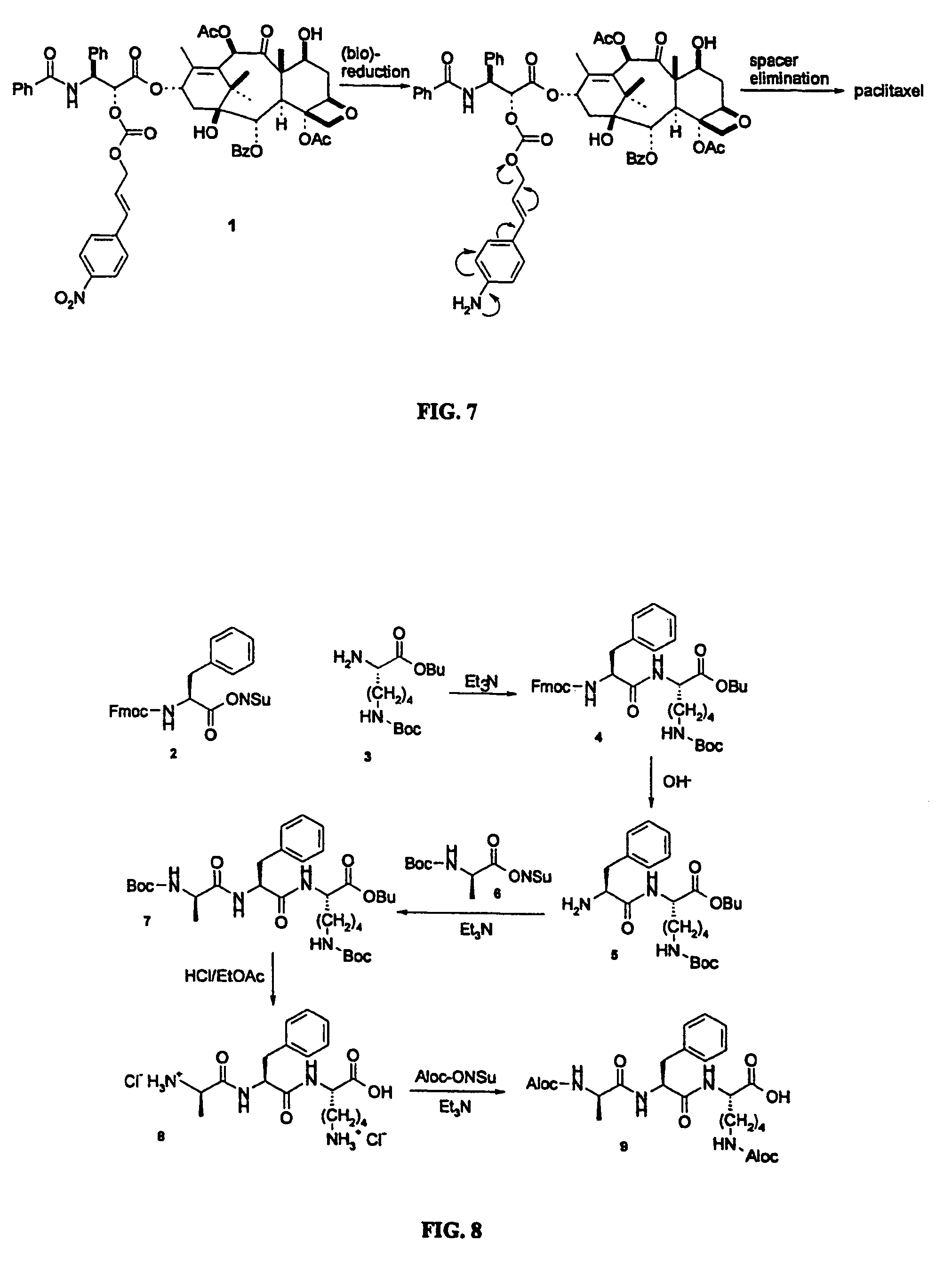

Elongated and multiple spacers in activatible prodrugs

InactiveUS7223837B2Improved kineticsFacilitate enzymatic cleavageAntibacterial agentsOrganic active ingredientsTumor cellsChemistry

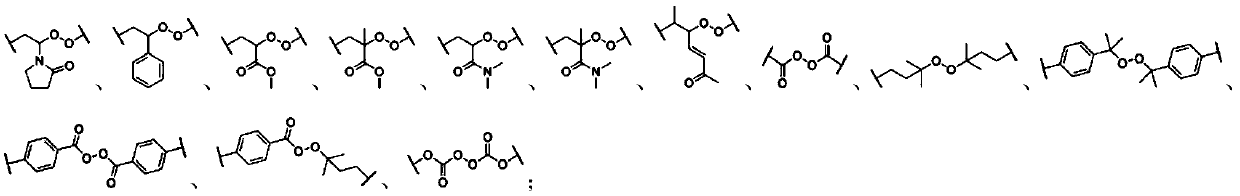

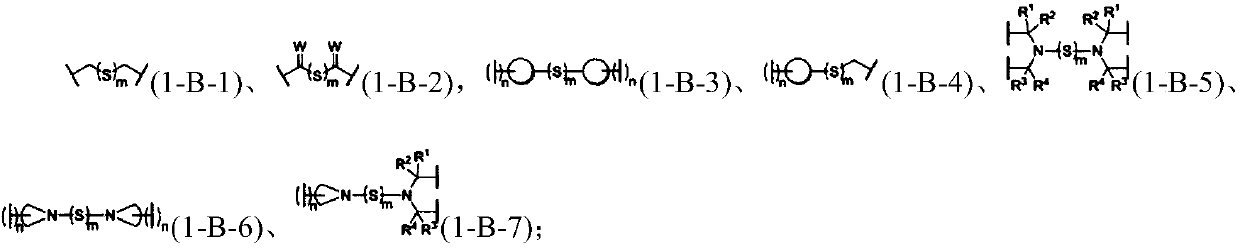

This invention is directed to prodrugs that can be activated at the preferred site of action in order to selectively deliver the corresponding therapeutic parent drugs to target cells or to the target site. This invention will therefore primarily but not exclusively relate to tumor cells as target cells. More specifically the prodrugs are compounds of the formula V—(W)k—(X)l—A—Z, wherein: V is a specifier; (W)k—(X)l—A is an elongated self-elimination spacer system; W and X are each a 1,(4+2n) electronic cascade spacer, being the same or different; A is either a spacer group of formula (Y)m wherein: Y is a 1,(4+2n) electronic cascade spacer, or a group of formula U being a cyclization elimination spacer; Z is a therapeutic drug; k, l and m are integers from 0 (included) to 5 (included); n is an integer of 0 (included) to 10 (included), with the provisos that: —when A is (Y)m: k+l+m≧1, and if k+l+m=1; —when A is U: k+l≧1.

Owner:BYONDIS BV

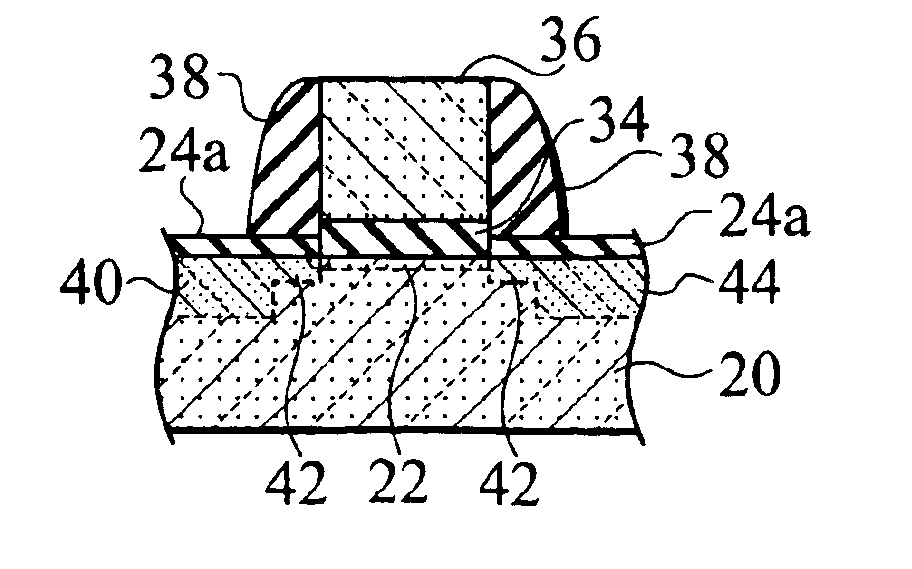

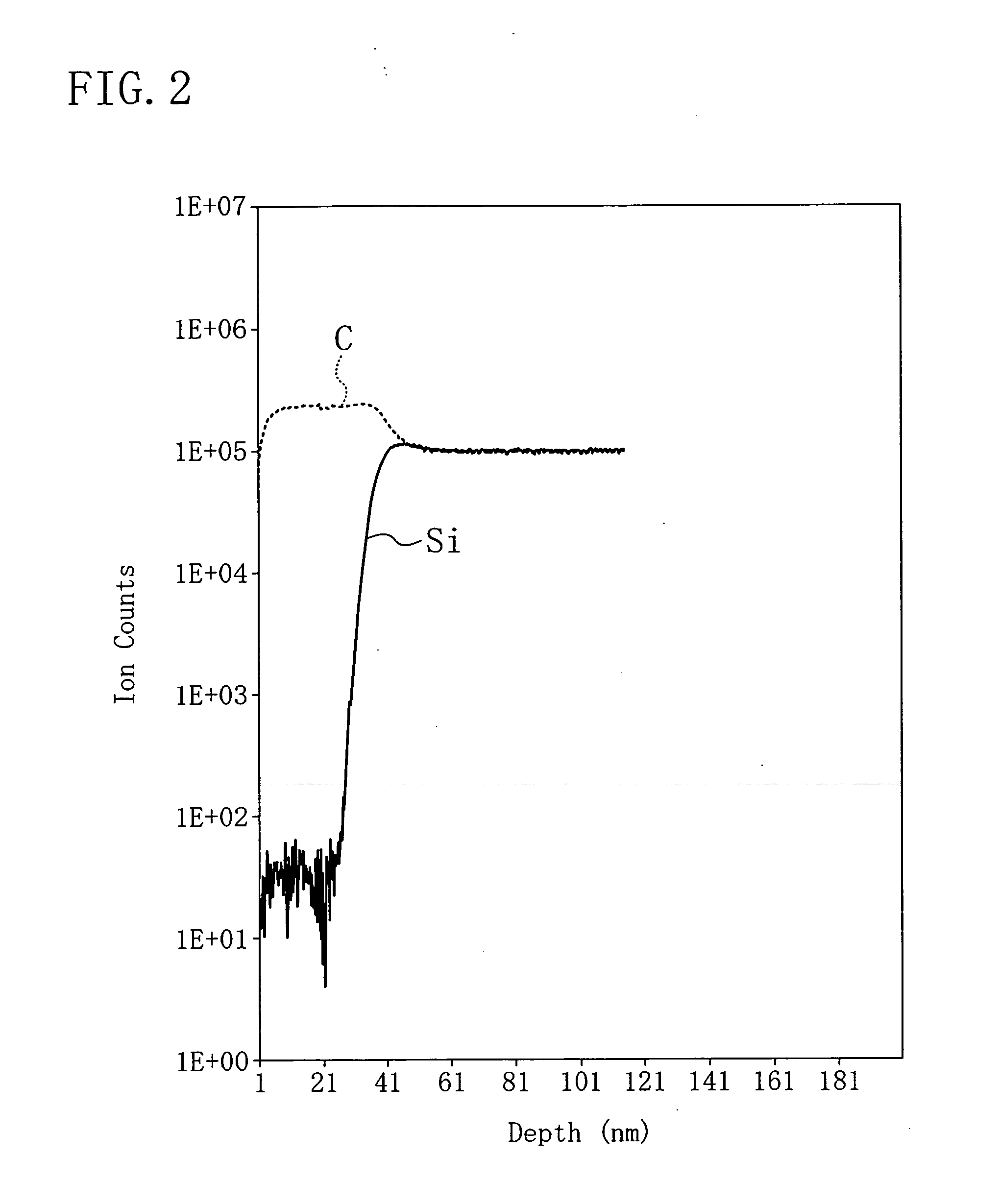

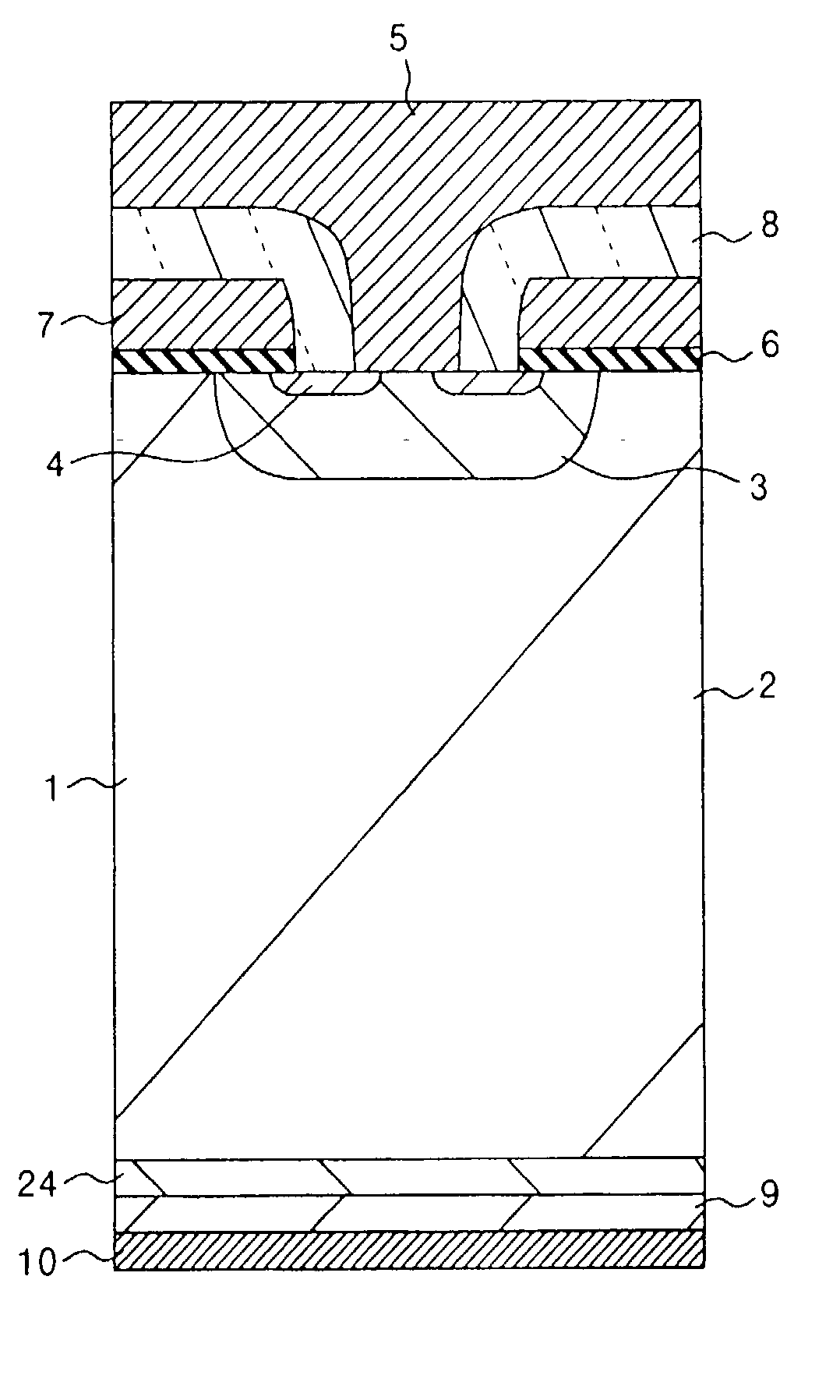

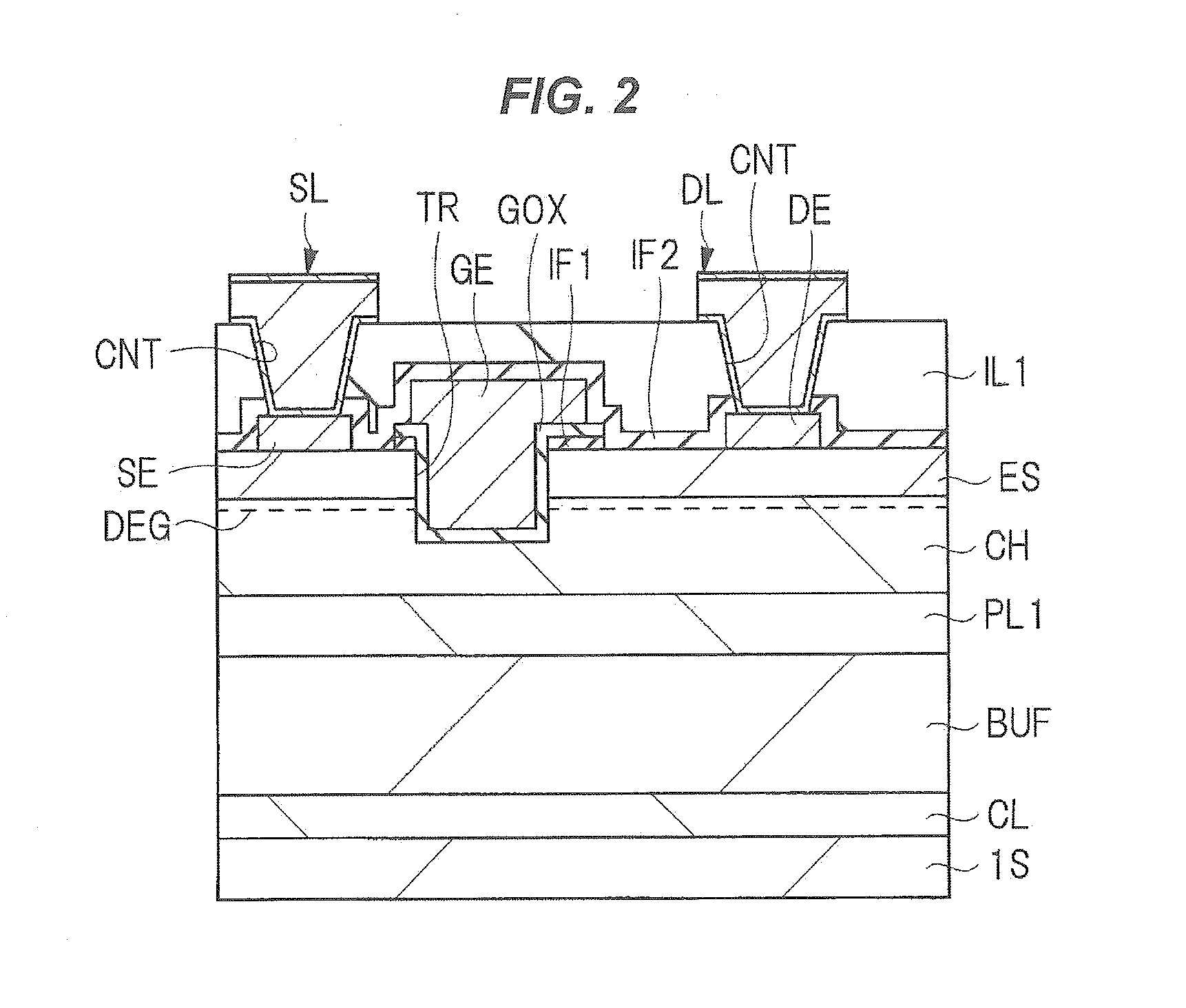

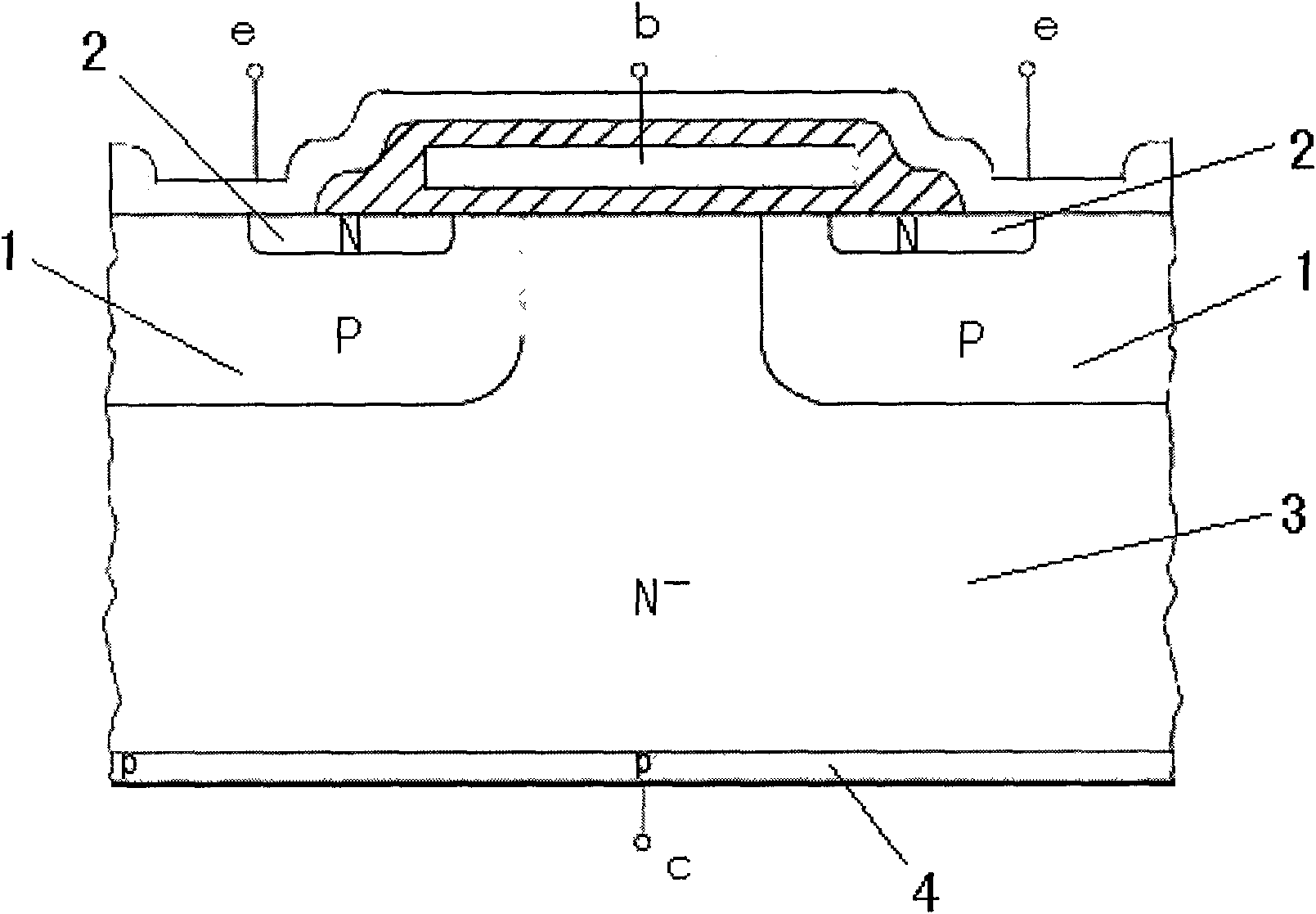

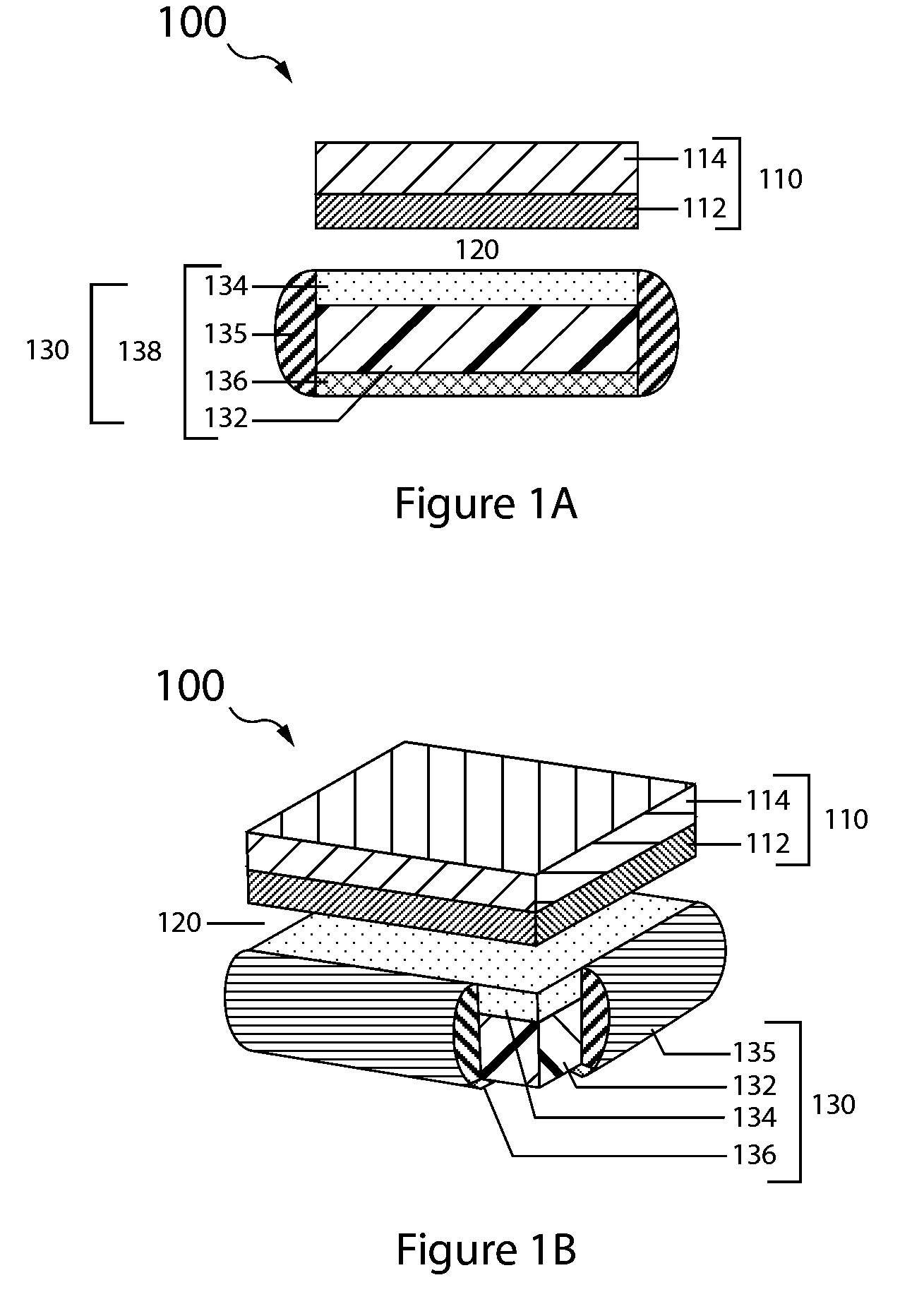

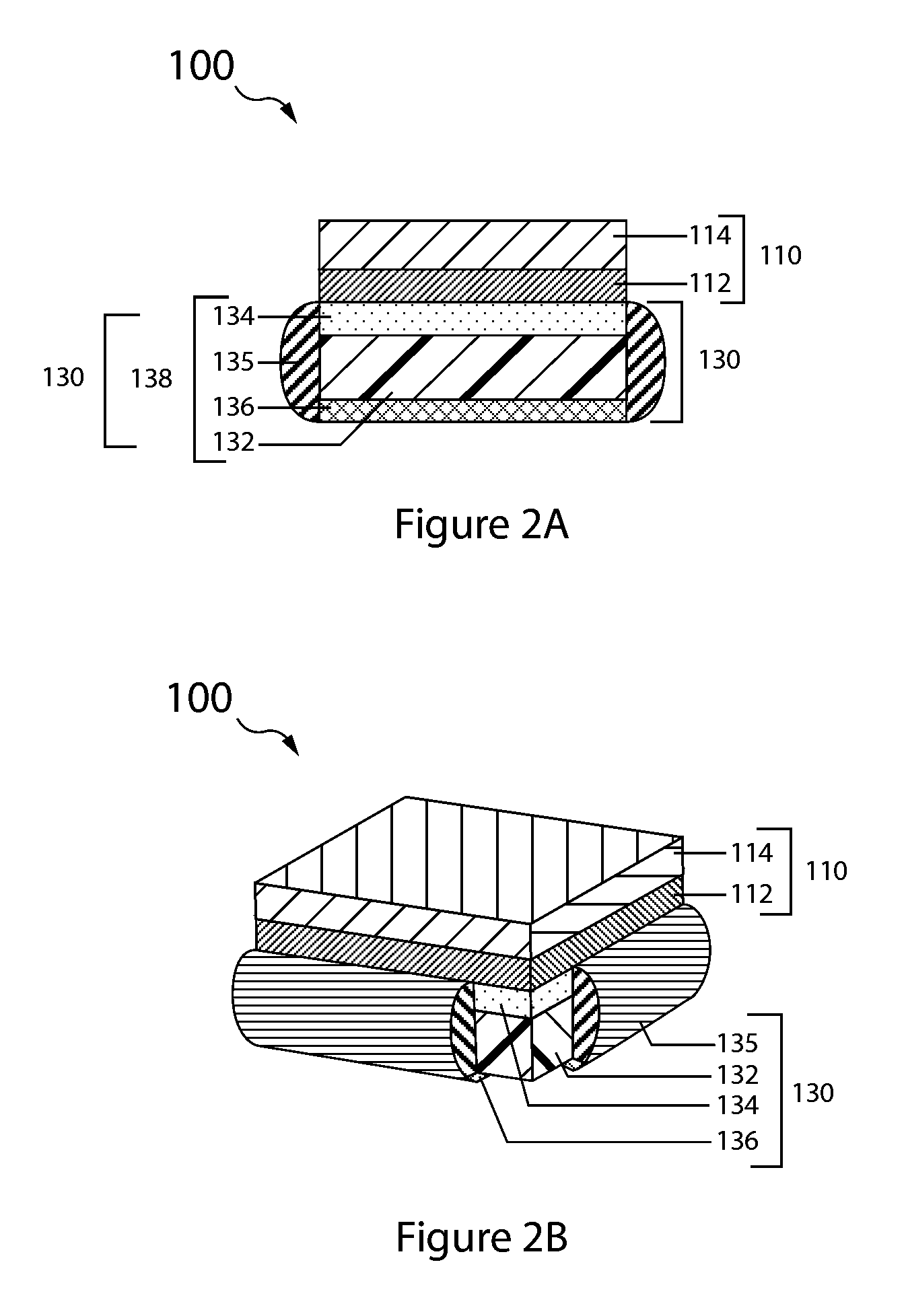

Semiconductor device and manufacturing method of the same

InactiveUS6930360B2High activation rateSuppress DiffuseTransistorSolid-state devicesNear neighborSite location

A semiconductor device having a semiconductor layer, includes: a first impurity atom having a covalent bond radius larger than a minimum radius of a covalent bond of a semiconductor constituent atom of a semiconductor layer; and a second impurity atom having a covalent bond radius smaller than a maximum radius of the covalent bond of the semiconductor constituent atom; wherein the first and second impurity atoms are arranged in a nearest neighbor lattice site location and at least one of the first and second impurity atoms is electrically active.

Owner:KK TOSHIBA

Silicon carbide semiconductor device and process for producing the same

InactiveUS20060220027A1High activation ratioHigh activation rateSemiconductor/solid-state device manufacturingSemiconductor devicesSemiconductorDevice material

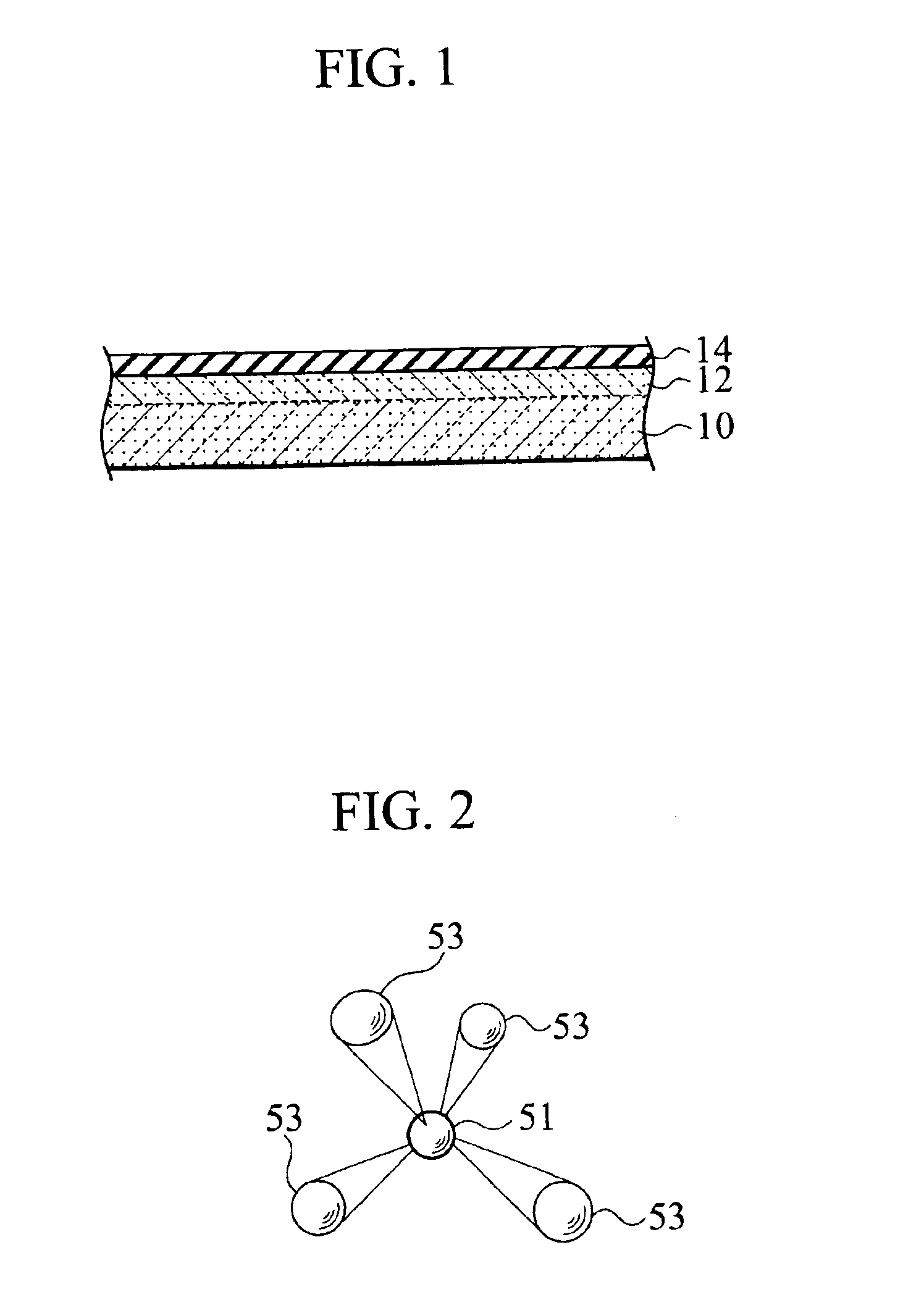

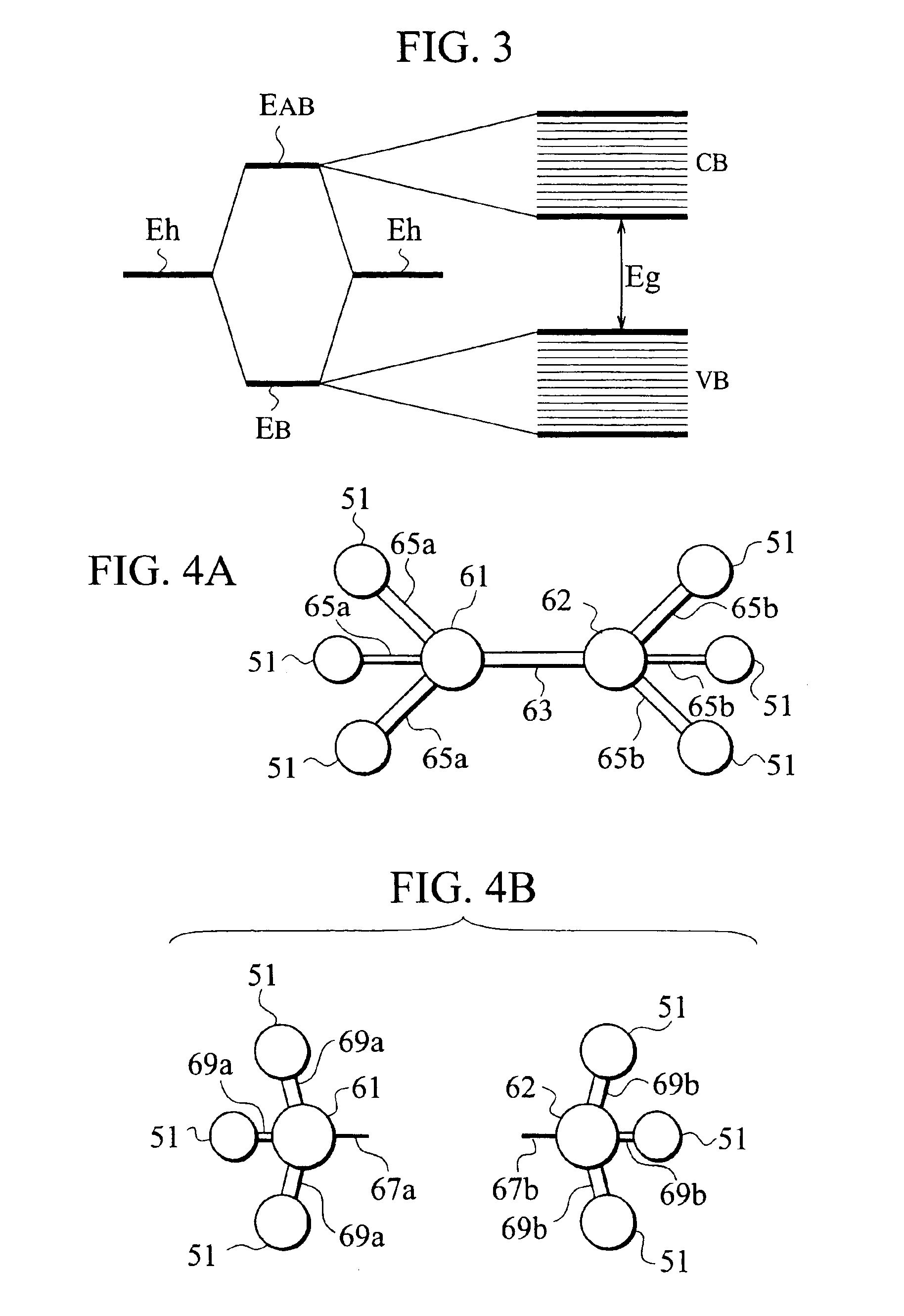

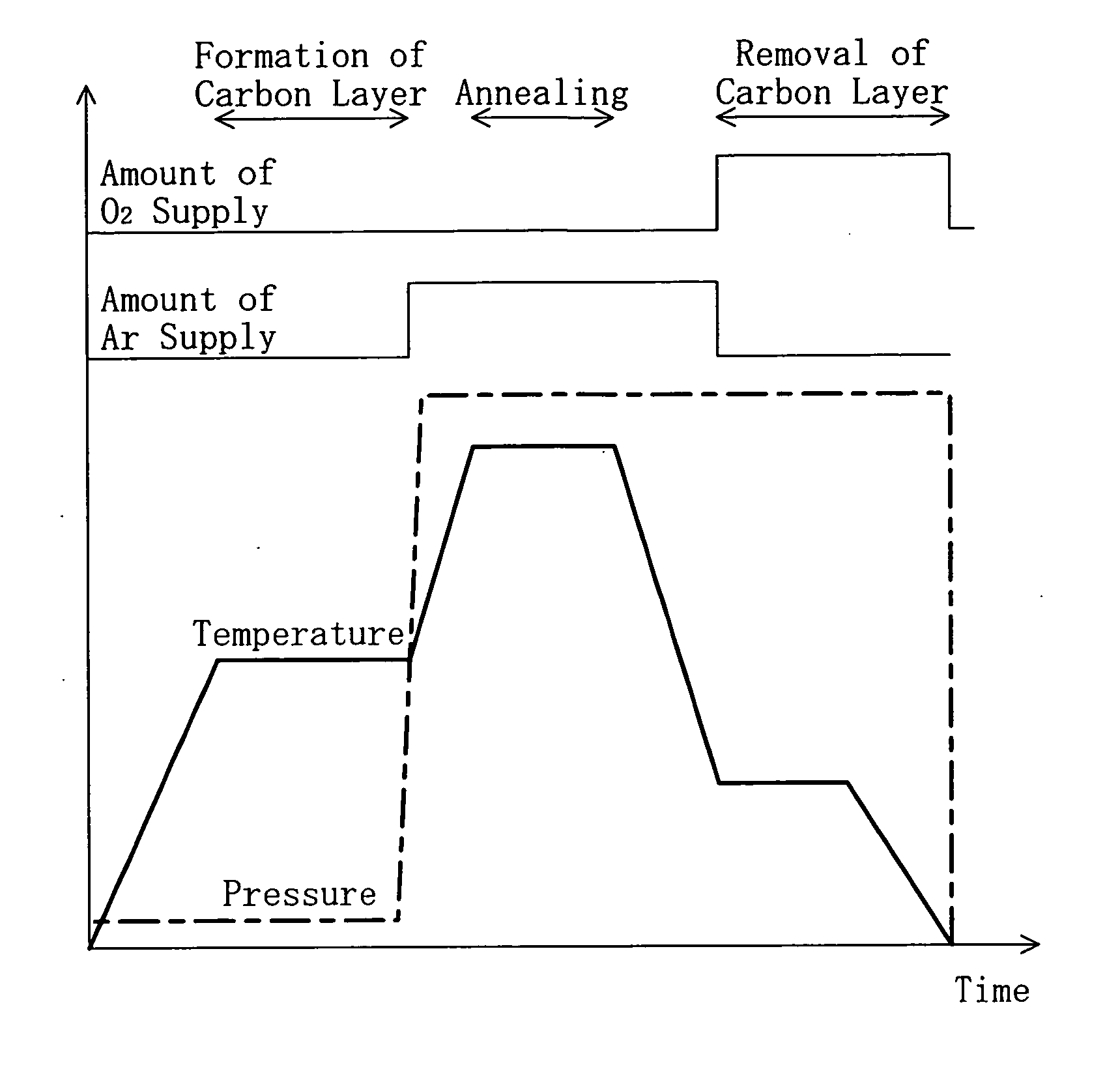

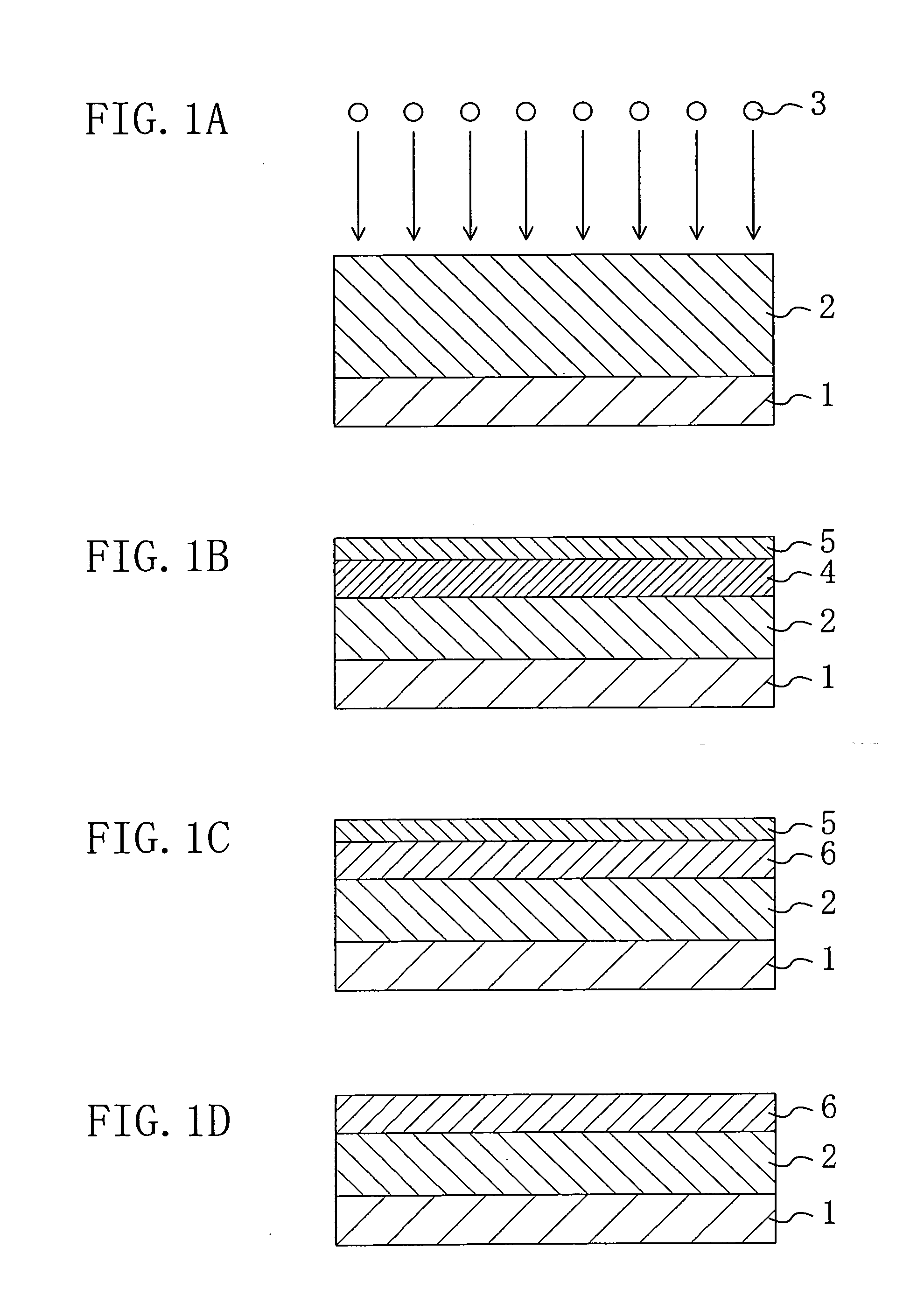

A method for fabricating a semiconductor device includes the steps of implanting ions into a silicon carbide thin film (2) formed on a silicon carbide substrate (1), heating the silicon carbide substrate in a reduced pressure atmosphere to form a carbon layer (5) on the surface of the silicon carbide substrate, and performing activation annealing with respect to the silicon carbide substrate in an atmosphere under a pressure higher than in the step of forming the carbon layer (5) and at a temperature higher than in the step of forming the carbon layer (5).

Owner:PANASONIC CORP

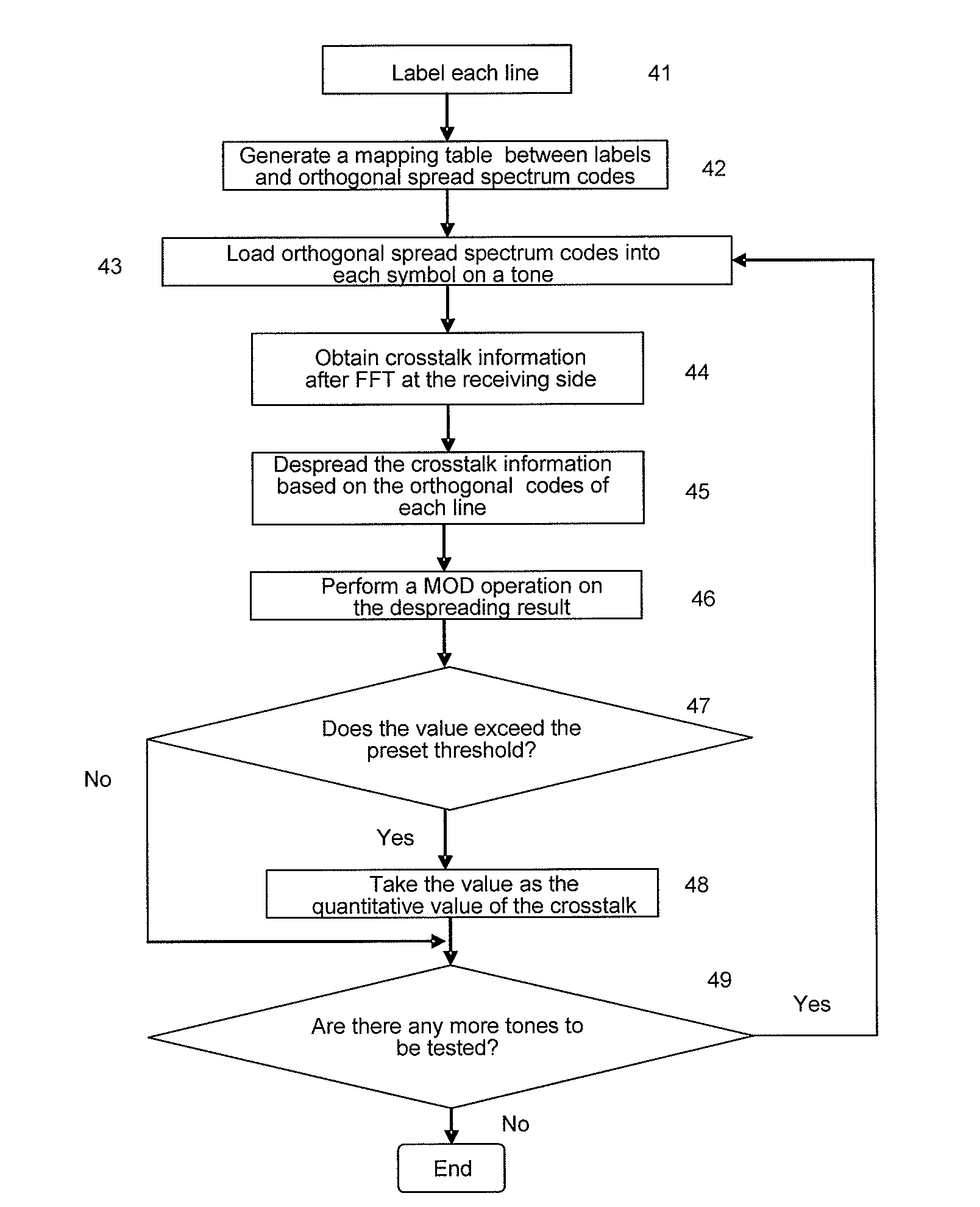

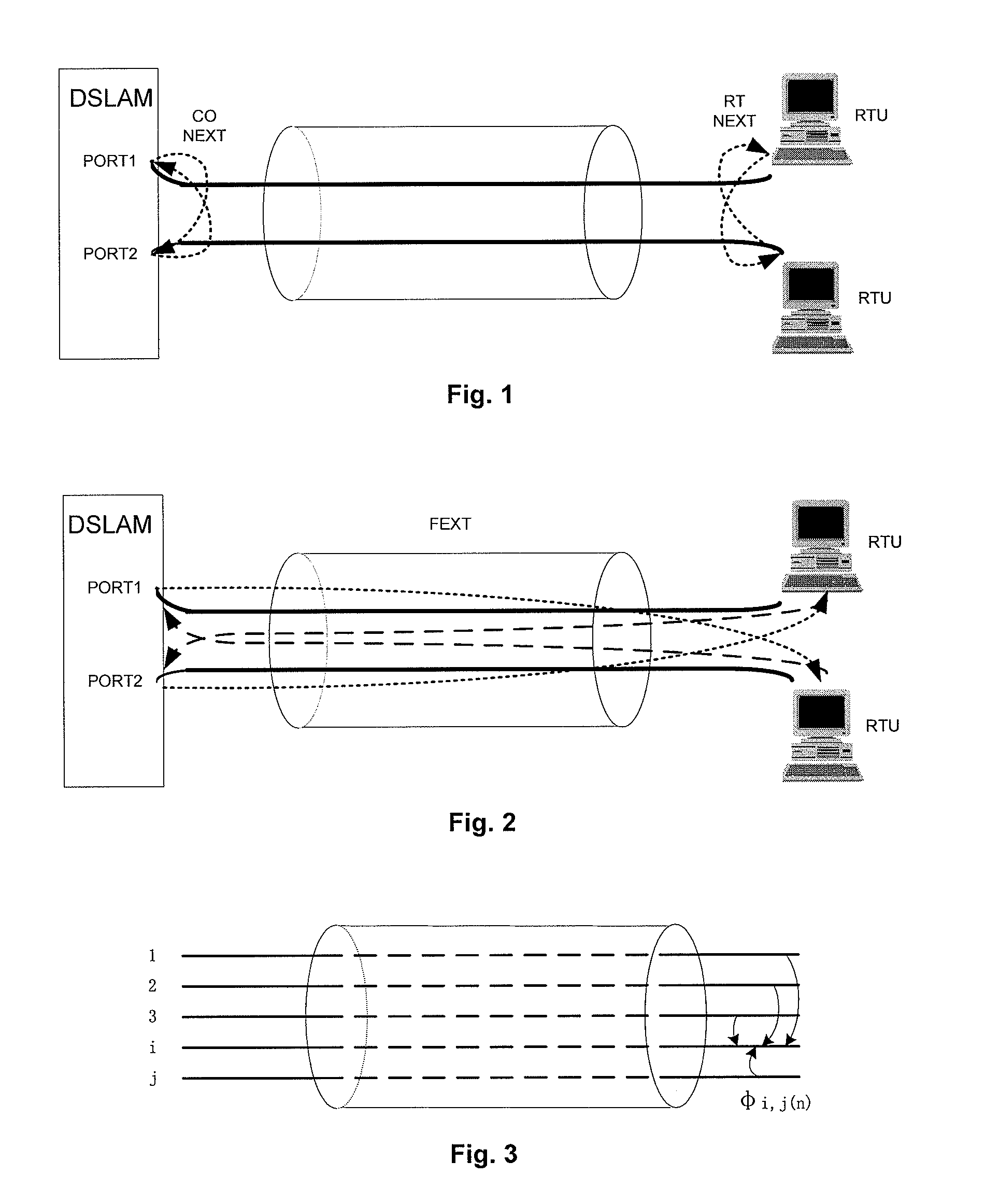

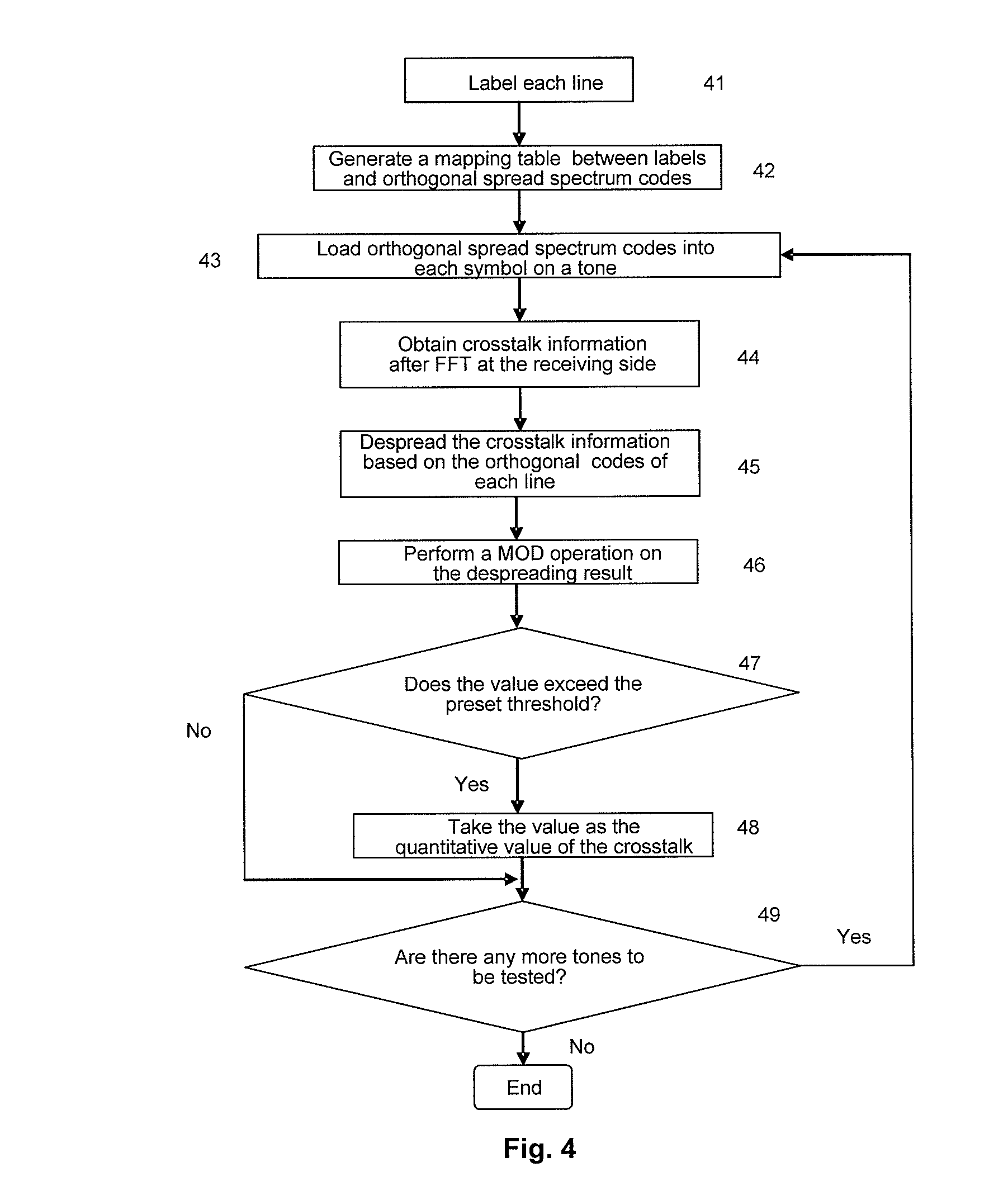

Method, apparatus and system for crosstalk test on multi-subscriber communication lines

ActiveUS20080188185A1High and stable transmission ratePerformanceError preventionModulated-carrier systemsFrequency spectrumDynamic spectrum management

A method, apparatus, and system for crosstalk test on multi-subscriber communication lines. The core of the invention is: loading a group of orthogonal spread spectrum codes to the transmitting side of each line, and testing the crosstalk of xSDL lines based on the received signal vector at the receiving side so that the source, amplitude, and phase of the crosstalk can be identified. With the invention, crosstalk test can be implemented in real time on xSDL lines without impacting the transmission performance of other lines. In addition, the test result shows how many lines have a significant impact on the line under test and reflects the severity of the impact, providing a powerful basis for dynamic spectrum management, and optimization of DSLAM system performance.

Owner:HUAWEI TECH CO LTD

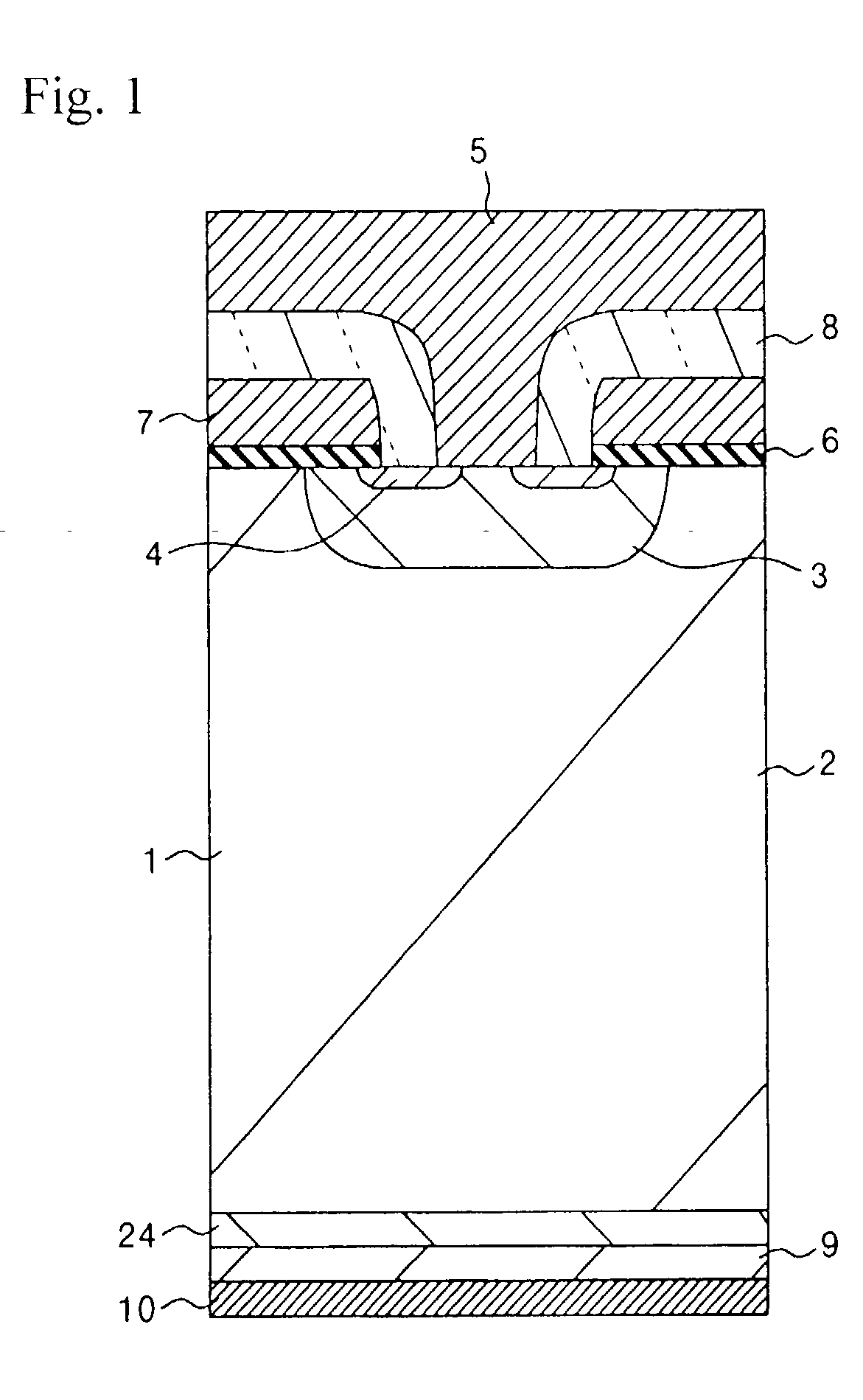

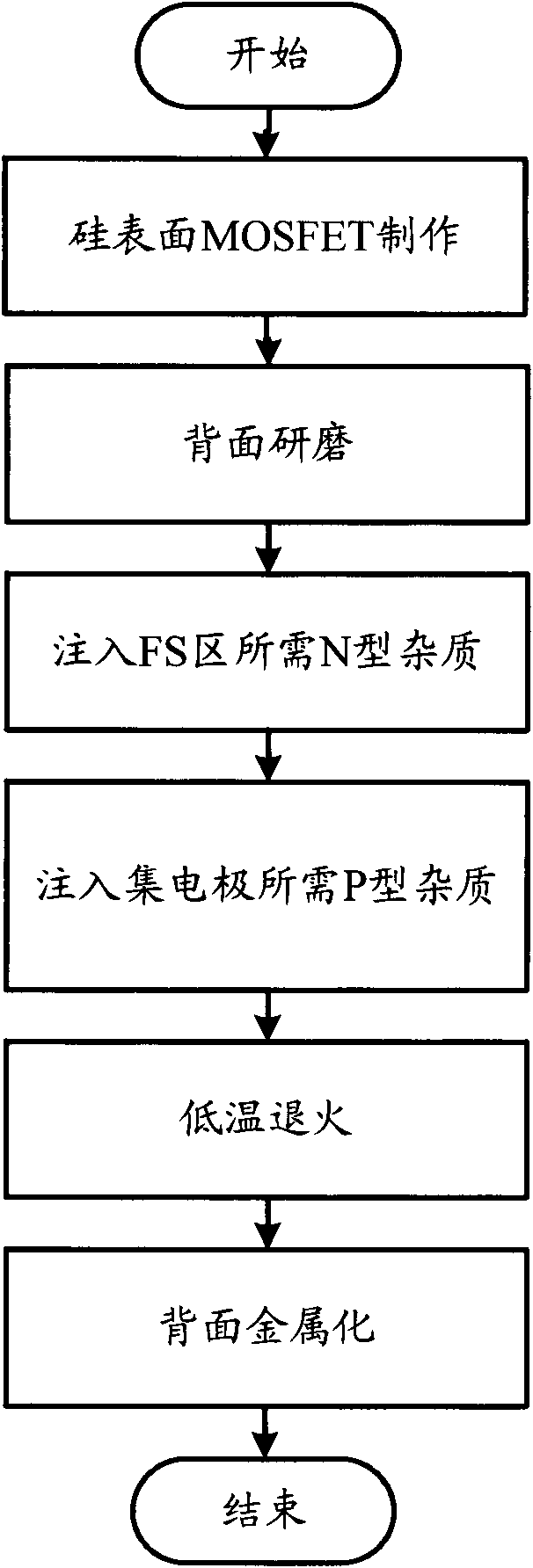

Method for manufacturing a semiconductor device

InactiveUS20020127783A1Lower resistanceIncrease concentrationTransistorSemiconductor/solid-state device manufacturingCompound (substance)Engineering

A method for manufacturing a semiconductor device constituting an IGBT is provided that allows to manufacture the device using an inexpensive wafer and with high yields, and achieves low losses. Specifically, after an emitter electrode is formed, a reverse principal surface is polished to a specified thickness. The center line average height Ra of the polished surface is controlled to be not more than 1 .mu.m, and the filtered center line waviness Wca is kept within 10 .mu.m. The polished surface is selectively cleaned with chemicals-dissolved water to remove particles. To the cleaned surface, phosphorus ions are implanted for forming a field-stop layer and boron ions are implanted for forming a collector layer. The wafer is then put into a diffusion furnace and annealed at a temperature from 300.degree. C. to 550.degree. C. to form a field-stop layer and a collector layer. Finally, a collector electrode is formed.

Owner:FUJI ELECTRIC CO LTD

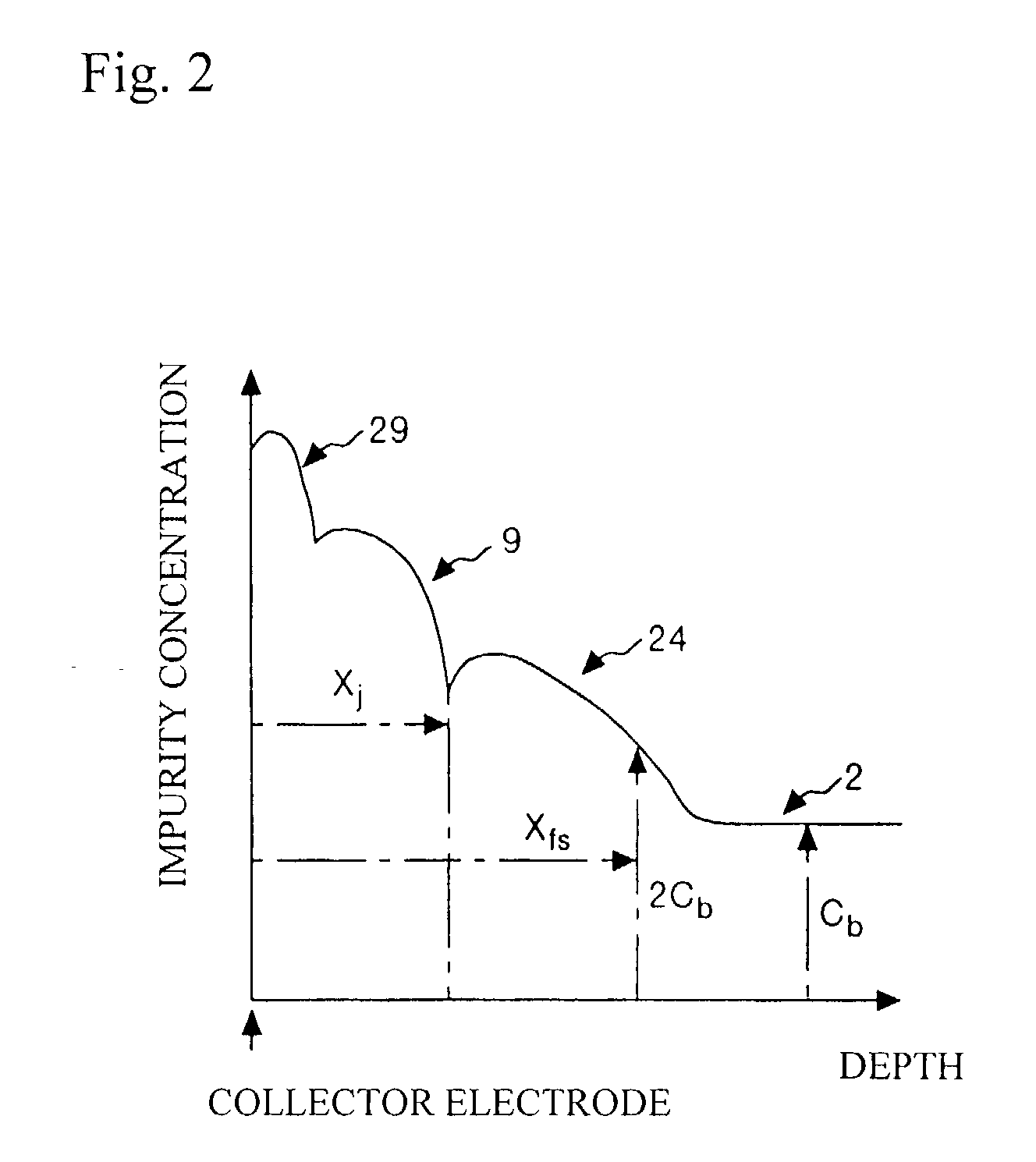

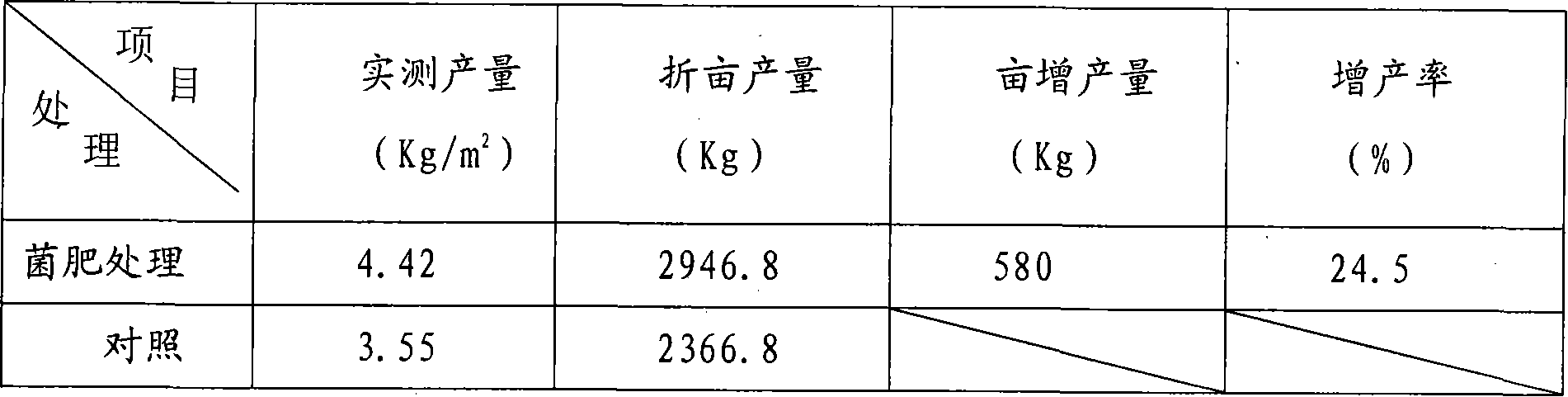

Grain type humic acid compound biological fertilizer and manufacturing method therefor

InactiveCN101130465AHigh activation rateImprove absorption efficiencyFertiliser formsOrganic fertilisersChemistryHumic acid

The invention discloses a particle-typed biological composite fertilizer and preparing method of humic acid, which is characterized by the following: adopting low-temperature graining and drying without breaking germ; dispensing solid particle typed fertilizer of humic acid, biological bacterial fertilizer and middle and trace element with weight rate at 2: (0. 1-0. 2): (0. 05-0. 1) through effective compatibility of microbe composite germ and humic acid and relative element; solving the coordinate action of each bacteria in the composite microbe fertilizer without mutual antagonism; making the bacteria display heat-proof property; blending the microbe and fitful quantity of azophoska fertilizer to act; fitting for increasing production and effectiveness in the agricultural domain.

Owner:新疆惠森生物技术有限公司

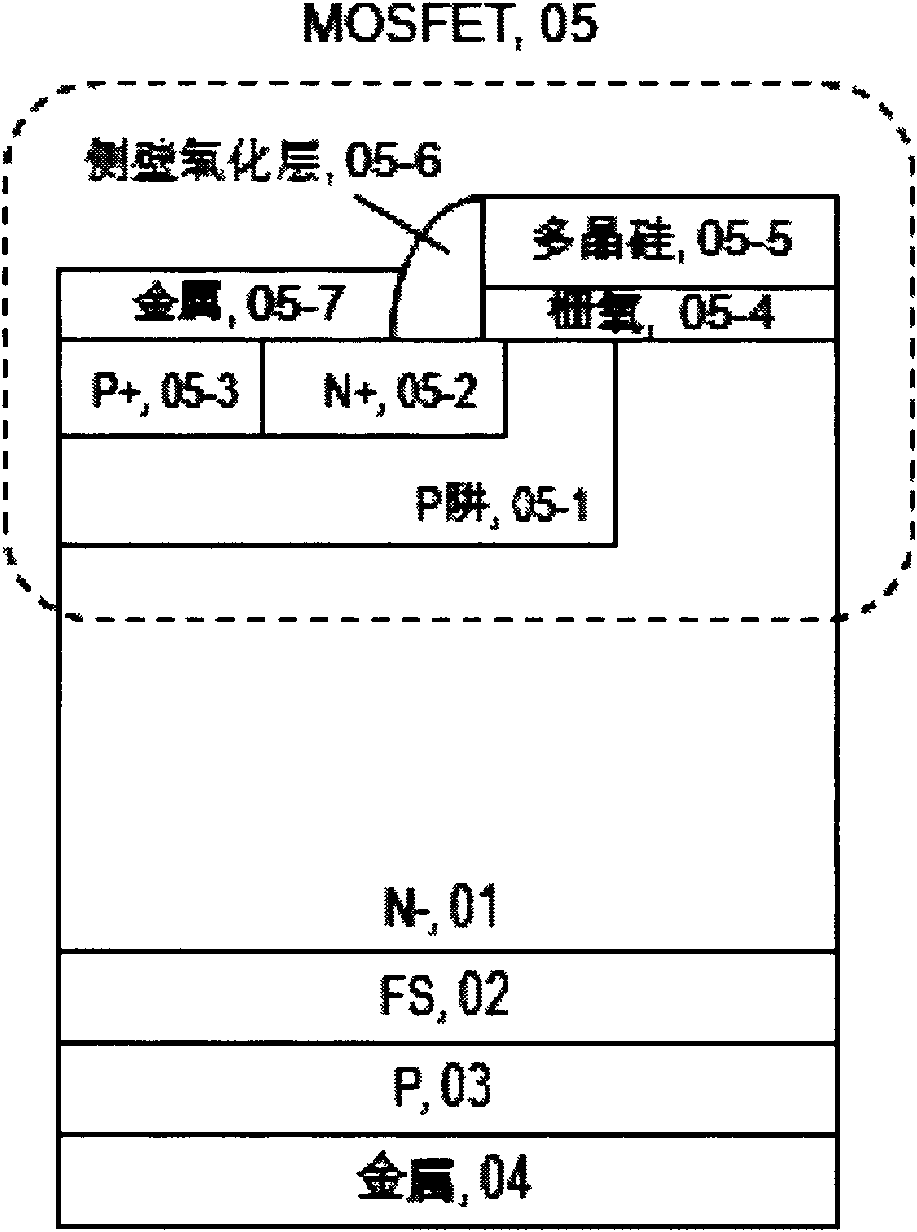

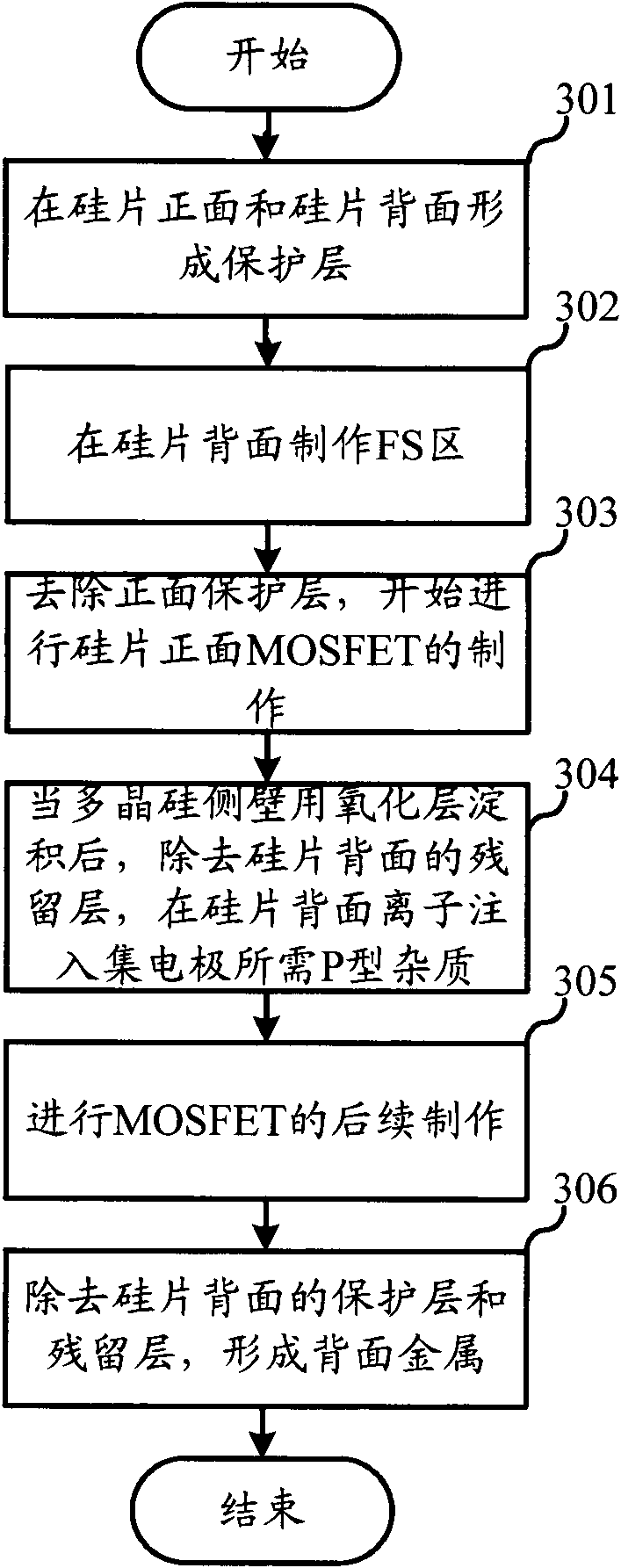

Method and apparatus for manufacturing IGBT device

InactiveCN102693912AImplementation is flexibleEliminate damageTransistorSemiconductor/solid-state device manufacturingMOSFETEngineering

The invention, which relates to the electronic device field, discloses a method and apparatus for manufacturing an insulated gate bipolar transistor (IGBT) device. According to the invention, forming of a field stop (FS) region and a collector at a back side of an IGBT device is not carried out after completion of a metal-oxide-semiconductor field effect transistor (MOSFET) manufacturing of the IGBT and back-side grinding but is carried out before, after and during the MOSFET manufacturing process in an interspersed mode. A thick FS is formed; after the forming of the FS with the needed thickness, devices like a front-side MOSFET are manufactured without influencing characteristics of devices that are manufactured afterwards and includes a MOSFET at a front side of a silicon ship. And the high temperature process of the manufacturing of the devices at the front-side of the silicon chip has little impact on the FS with the thickness of 20 to 30 micrometers. Ion implantation of P type impurities of the back-side collector is carried out after deposition of an oxide layer at the side wall of the front-side MOSFET and the activation of the P type impurities is carried out by the thermal process of the manufacturing of the front side MOSFET; and the activation rate is high and the damage caused by the ion implantation can be eliminated. Therefore, an IGBT with high breakdown voltage, low electricity leakage, conduction voltage drop positive temperature coefficient and low switching loss is manufactured.

Owner:上海永电电子科技有限公司

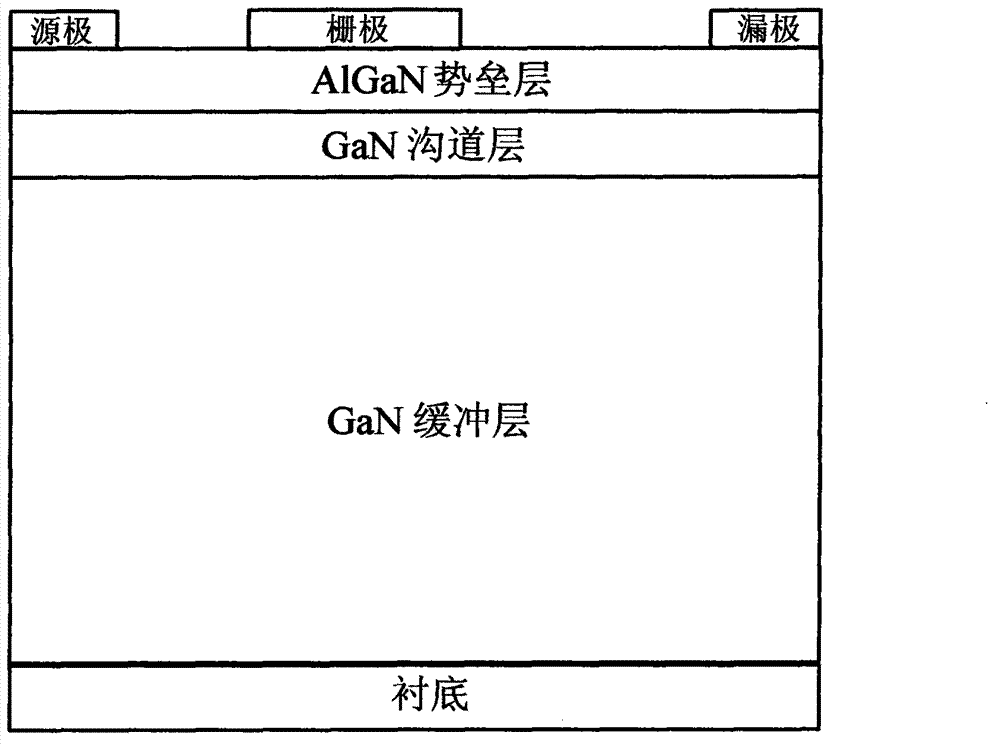

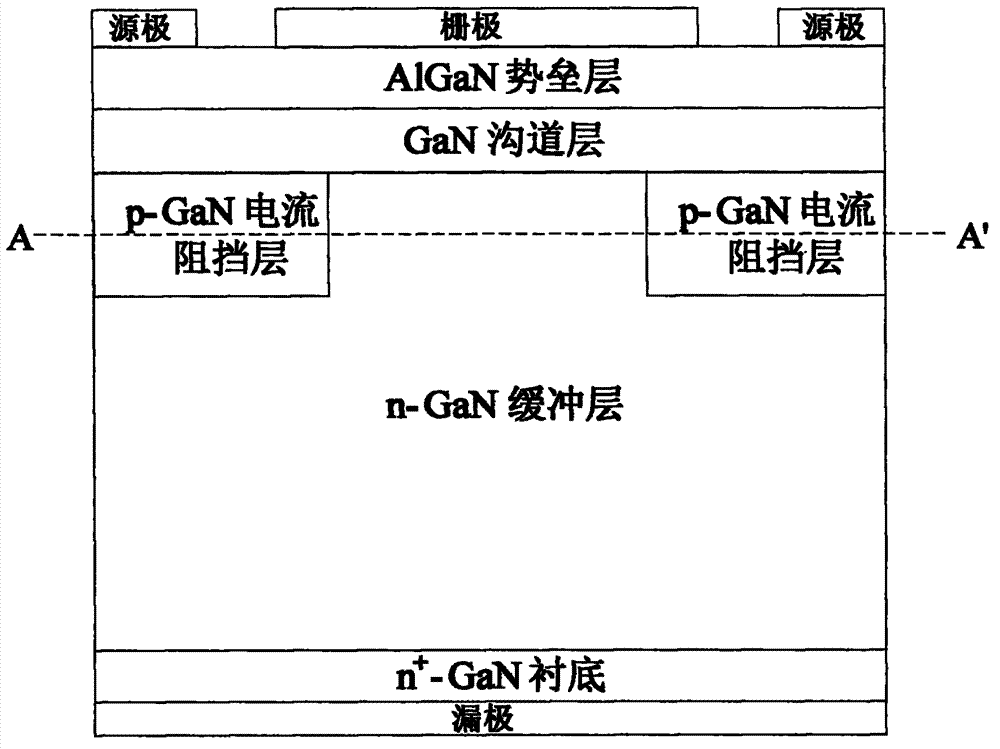

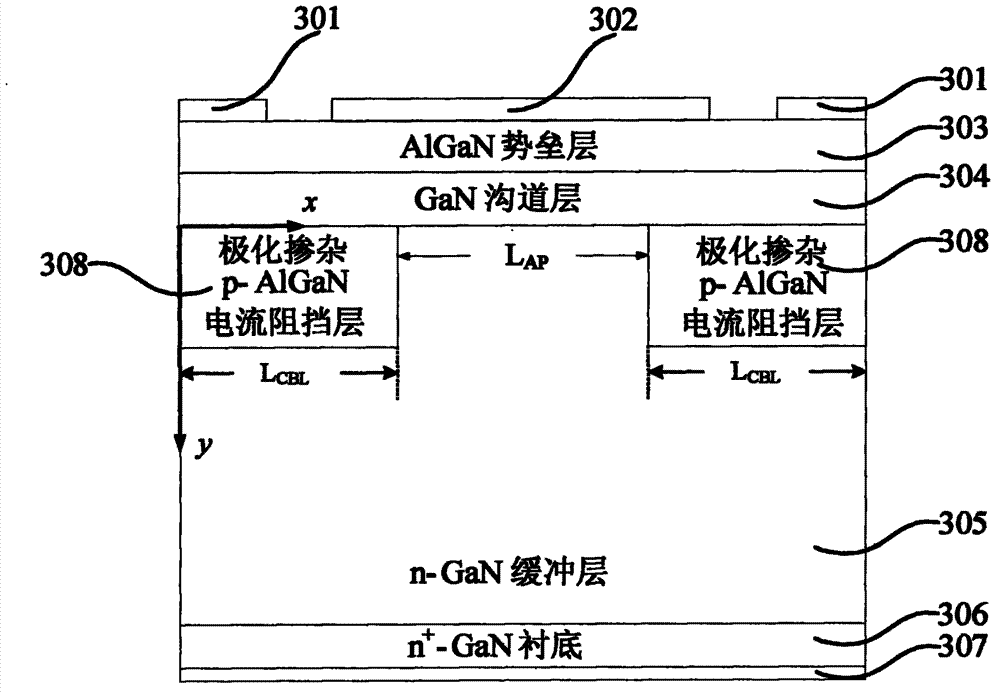

Vertical gallium nitride based nitride heterojunction field effect transistor with polarized doped current barrier layer

InactiveCN103035706AImprove thermal stabilityHigh activation rateSemiconductor devicesOhmic contactGallium nitride

The invention provides a vertical gallium nitride based nitride heterojunction field effect transistor with a polarized doped current barrier layer, which sequentially and mainly comprises a drain electrode, an n<+>-GaN substrate, an n-GaN buffer layer, a GaN channel layer, an AlGaN barrier layer, a source electrode on the AlGaN barrier layer and a grid electrode on the AlGaN barrier layer from bottom to top, wherein the source electrode and the drain electrode are both in ohmic contact, the grid electrode is in Schottky contact, the vertical gallium nitride based nitride heterojunction field effect transistor further comprises the polarized doped p-AlGaN current barrier layer between the n-GaN buffer layer and the GaN channel layer, and an Al component in the current barrier layer increases gradually in the y direction. According to the vertical gallium nitride based nitride heterojunction field effect transistor with the polarized doped current barrier layer, a polarized electric field, produced by the gradual change of the Al component in the current barrier layer, increases the activation rate of p-type impurities and the hole concentration of the current barrier layer, so that the breakdown voltage of an element is increased.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

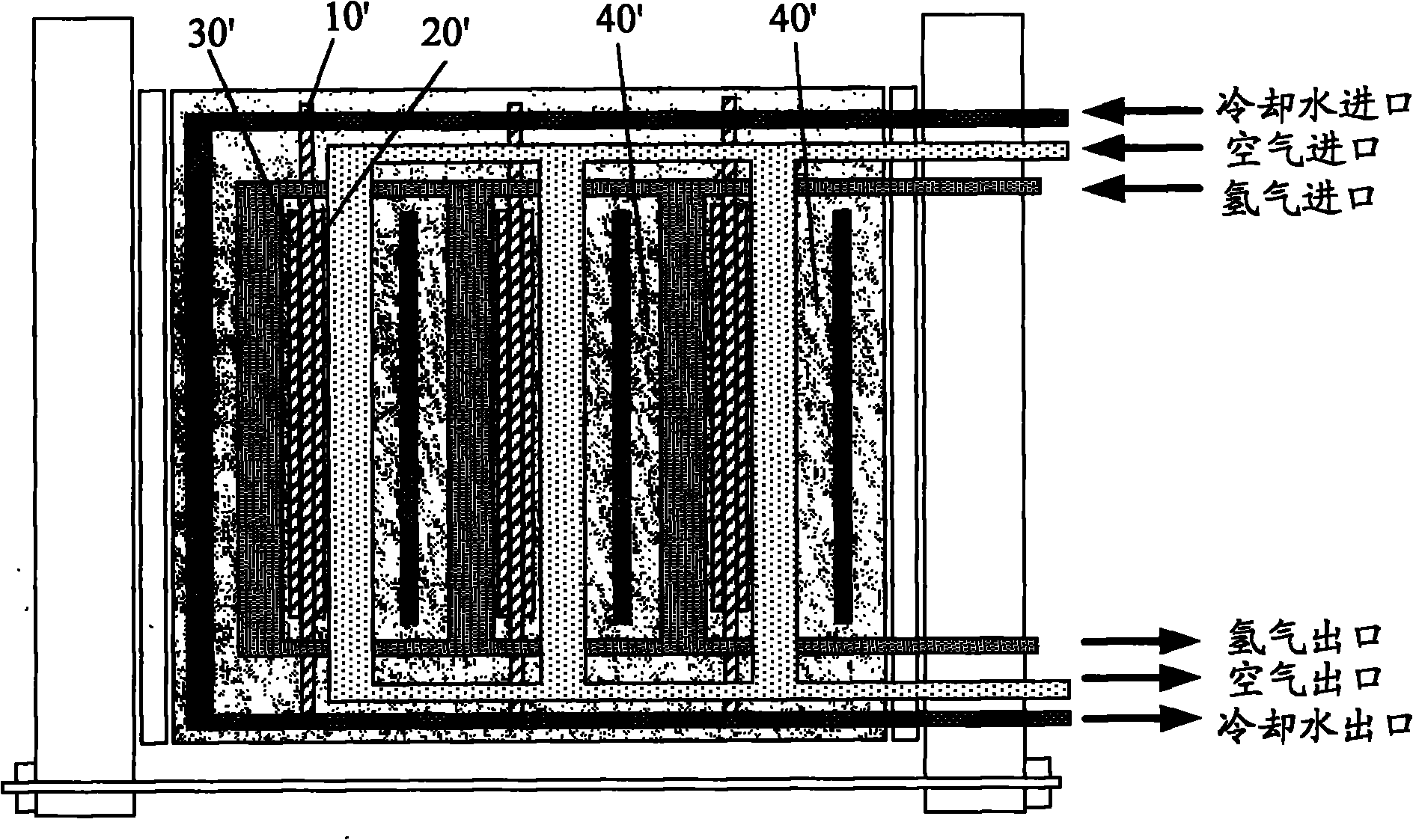

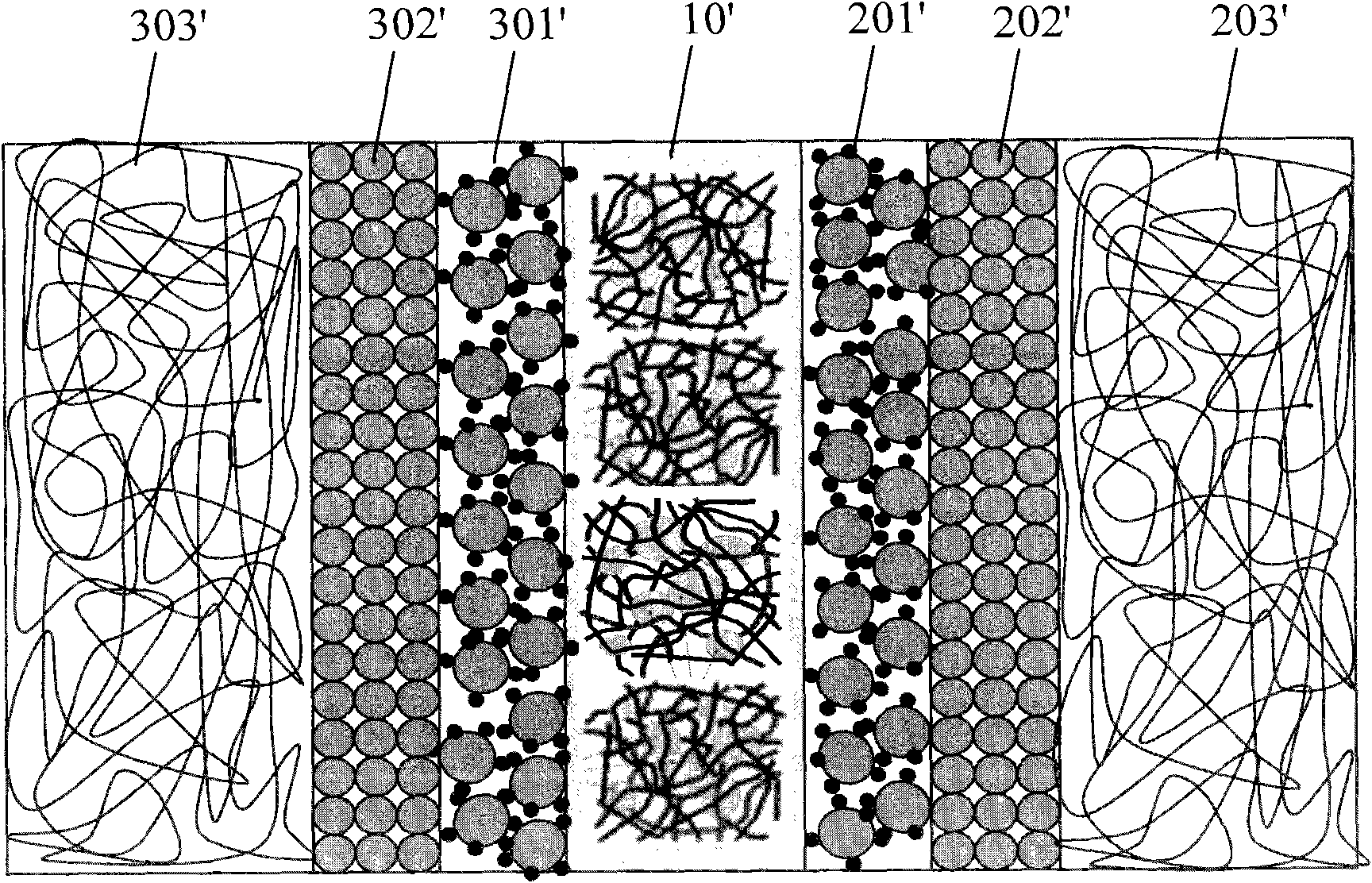

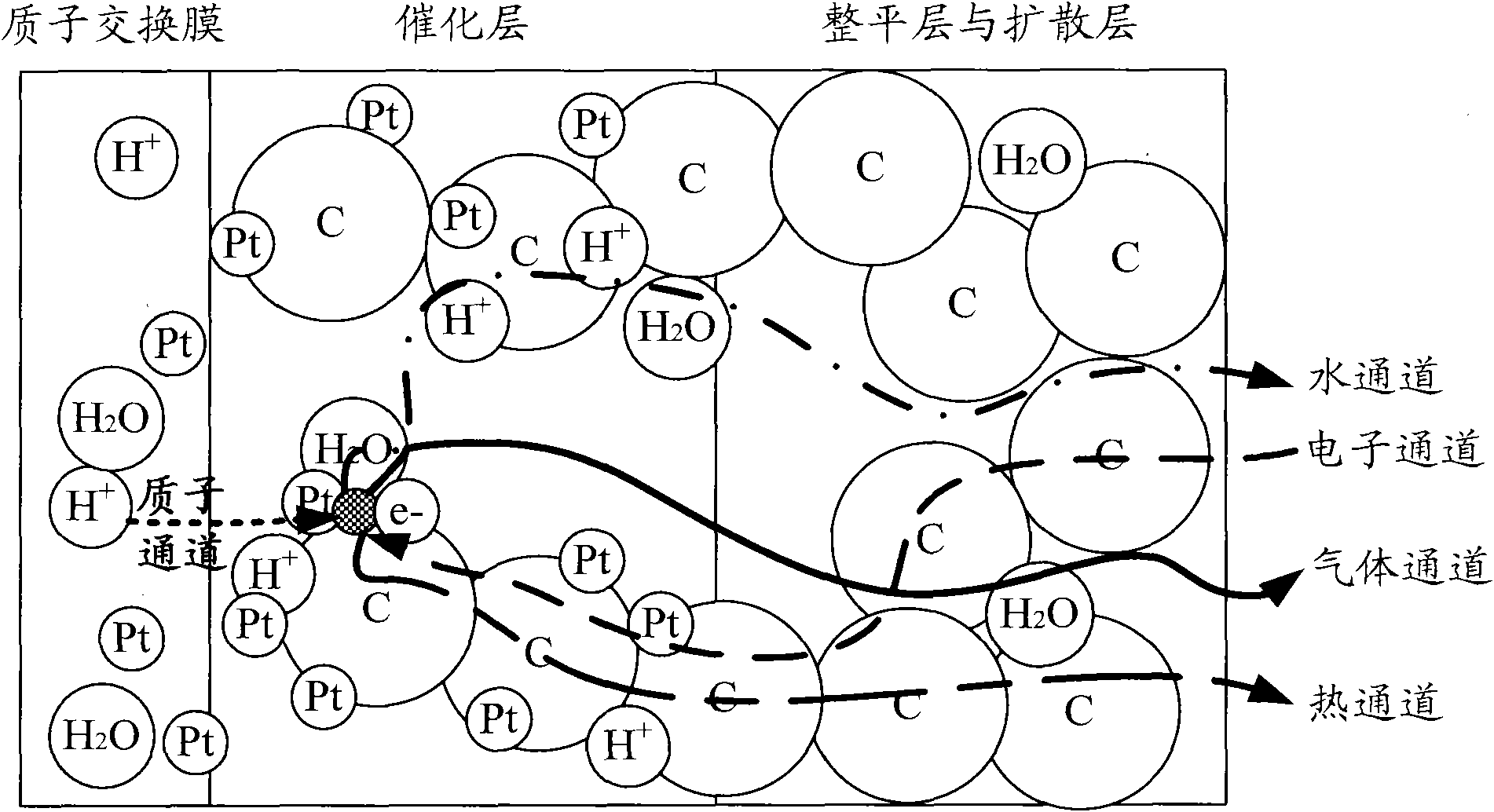

Method and device for activating proton exchange membrane fuel cell

ActiveCN102097631ABest activation rateHigh activation rateFuel cell auxillariesConcentration polarizationPower flow

The embodiment of the invention discloses a method and device for activating a proton exchange membrane fuel cell. The method comprises the following steps of: continuously adding deionized water to a gas channel of the proton exchange membrane fuel cell; adjusting a galvanic pile clamp of the cell according to a preset rule after stopping adding deionized water and removing the deionized water; continuously pumping corresponding reaction gases to the gas channel and adjusting a load so that a current is output according to a preset step gradient until the output voltage of the cell reaches apreset voltage; fully moisturizing a membrane electrode by continuously adding deionized water to the gas channel; decreasing ohmic polarization and concentration polarization to acquire an optimal range between the ohmic polarization and the concentration polarization by adjusting the galvanic pile clamp; and outputting the current by the cell according to the preset step gradient by adjusting the load after pumping the reaction gases so that the transmission channels of water, heat, electrons, protons and gases are internally adjusted, more catalysts become effective reaction points, and the activation effect is better.

Owner:内蒙古快为科技有限公司

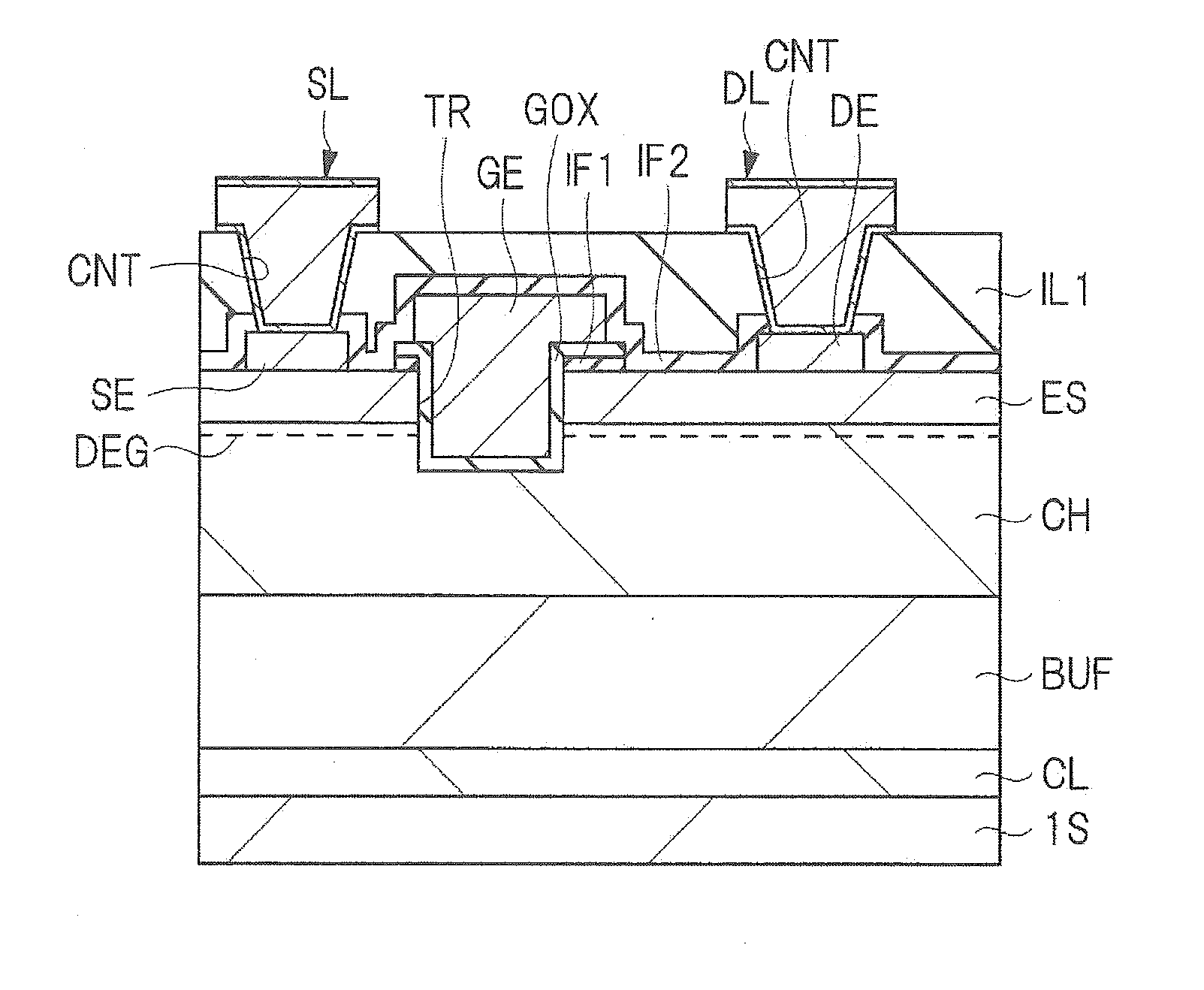

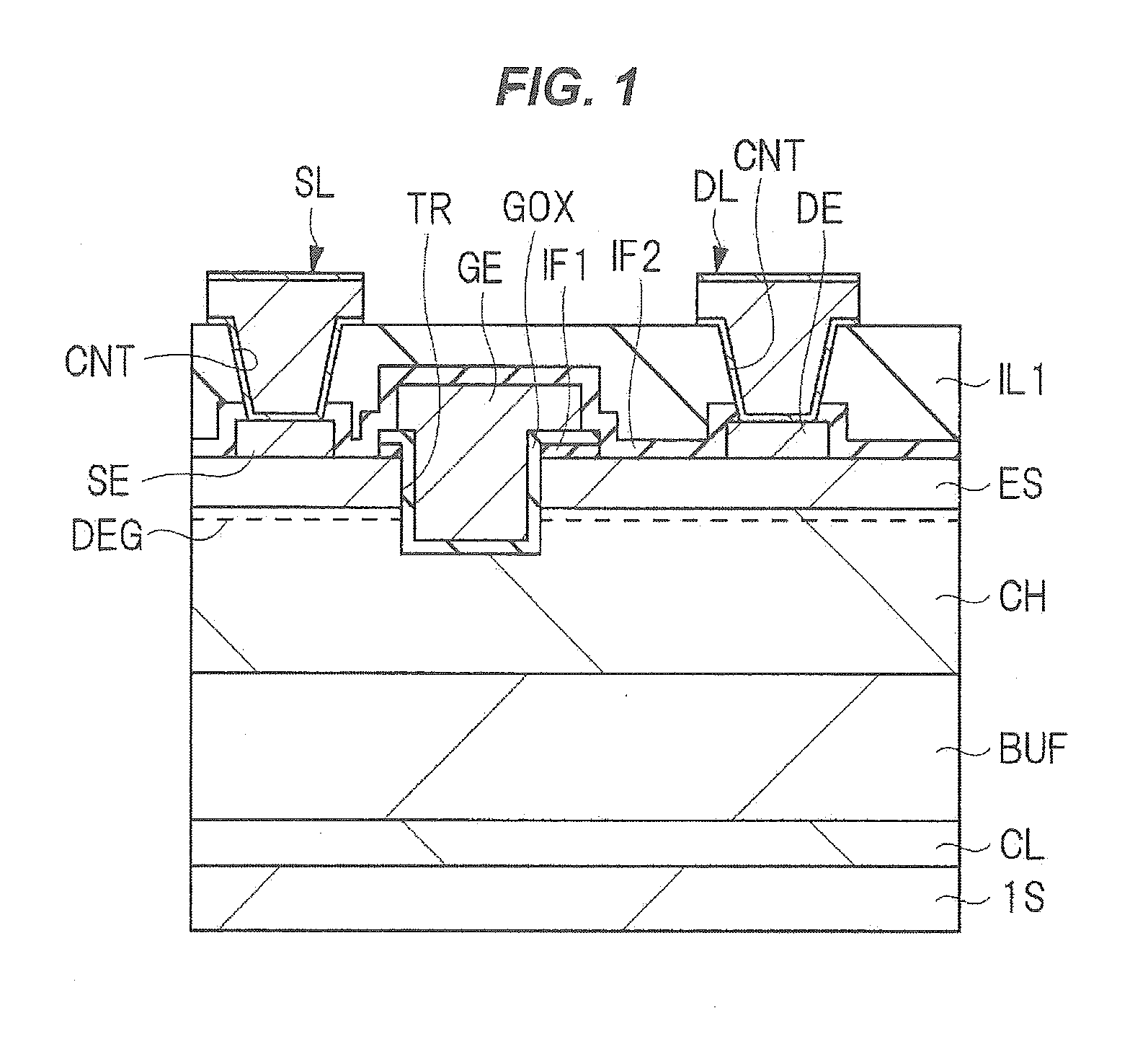

Semiconductor device

ActiveUS20140264274A1Improve semiconductor device performanceHigh activation rateSemiconductor devicesDevice materialNitride semiconductors

To improve performance of a semiconductor device. For example, on the assumption that a superlattice layer is inserted between a buffer layer and a channel layer, a concentration of acceptors introduced into nitride semiconductor layers forming a part of the superlattice layer is higher than a concentration of acceptors introduced into nitride semiconductor layers forming the other part of the superlattice layer. That is, the concentration of acceptors introduced into the nitride semiconductor layers having a small band gap is higher than the concentration of acceptors introduced into the nitride semiconductor layers having a large band gap.

Owner:RENESAS ELECTRONICS CORP

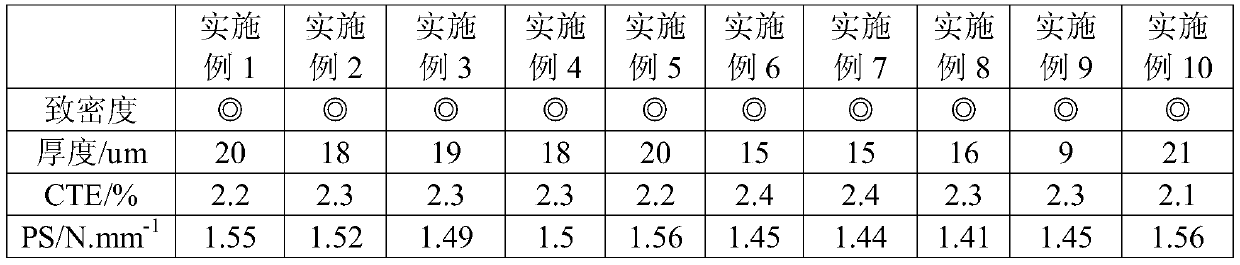

Microbial preparation for gangue reclaimed soil and method for reclaiming gangue soil by using microbial preparation

ActiveCN104630109ASolve the real problemSolving the gangue problemBacteriaMicroorganism based processesBacillus licheniformisAzotobacter chroococcum

The invention discloses a microbial preparation for gangue reclaimed soil. The microbial preparation comprises three microbial preparations which are respectively used independently, wherein the I type microbial preparation contains bacillus subtilis and bacillus licheniformis; the II type microbial preparation contains bacillus mucilaginosus and the bacillus licheniformis; the III type microbial preparation contains azotobacter chroococcum, bacillus megaterium, the bacillus mucilaginosus and lysine bacillus; the total viable count of every gram of the microbial preparation is (2-200)*10<8> CFU. The gangue reclaimed soil is covered in layers by using the microbial preparation disclosed by the invention, a first gangue layer, a sticky loess and fly ash mixing covering layer, a second gangue layer, a fly ash covering layer, a fine granular gangue layer and a loess covering layer are sequentially arranged from bottom to top, the I type microbial preparation is applied to the sticky loess and fly ash mixing covering layer, the II type microbial preparation is applied to the fly ash covering layer, the III type microbial preparation is applied to the loess covering layer, and crops are planted on the loess covering layer.

Owner:INST OF AGRI ENVIRONMENT & RESOURCE SHANXI ACAD OF AGRI SCI

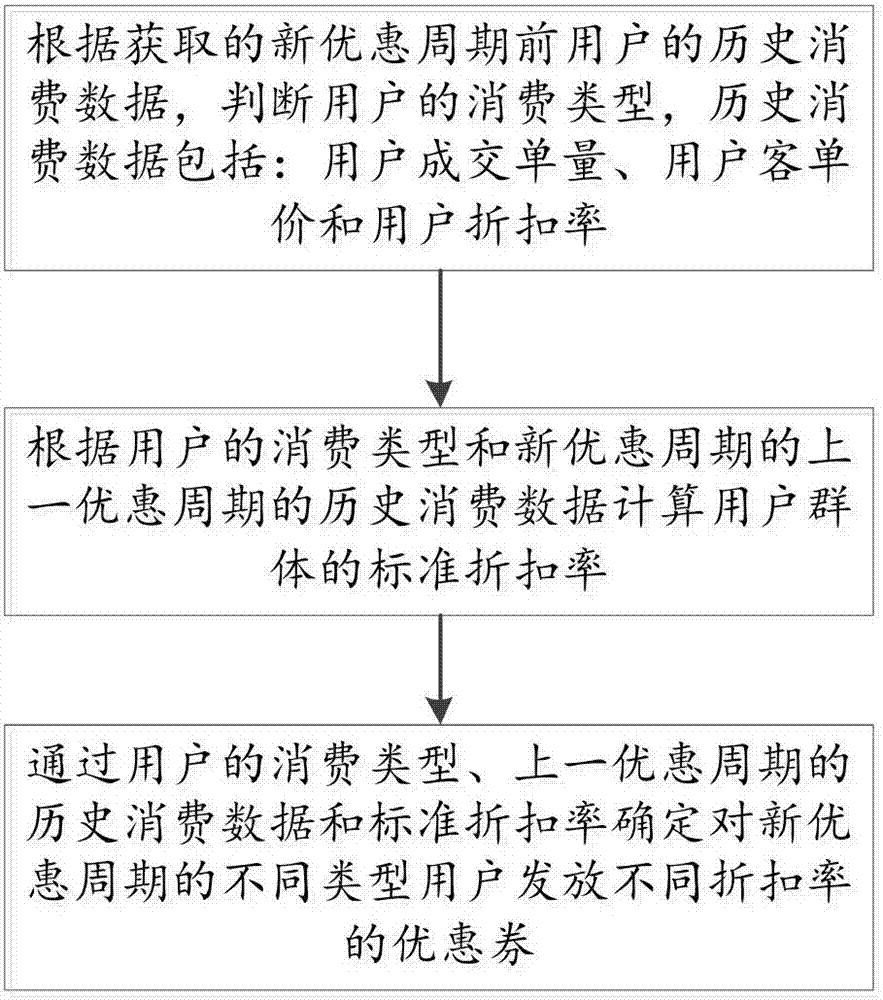

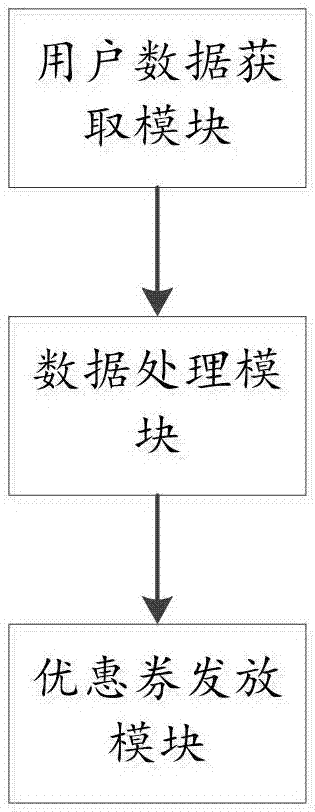

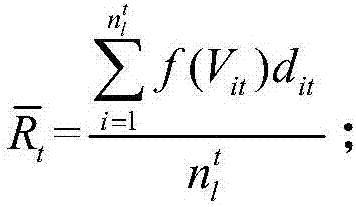

Coupon management method and system

The invention relates to a coupon management method and system. The management system includes a user data acquisition module, a data processing module and a coupon distribution module. Historical consumption data of users is acquired and sent to the data processing module, standard discount rates of user groups are calculated according to consumption types of the users and the historical consumption data of the users in a previous preference cycle, and coupons with different discount rates are distributed to different types of the users in a new preference cycle. The historical consumption data of the users is analyzed to determine group types, to which the users belong, through acquiring the historical consumption data of the users, the standard discount rate of each type of the user groups is calculated, the coupons with the different discount rates in the new preference cycle are distributed to the users, who belong to the different consumption types of the user groups, through comparing the discount rates of the users in the previous preference cycle and the standard discount rates in the new preference cycle, preference is provided to the users under the circumstance of achieving cost reducing, a maintenance ratio of the users is guaranteed, and a user activation rate is increased.

Owner:卓集送信息科技(武汉)有限公司

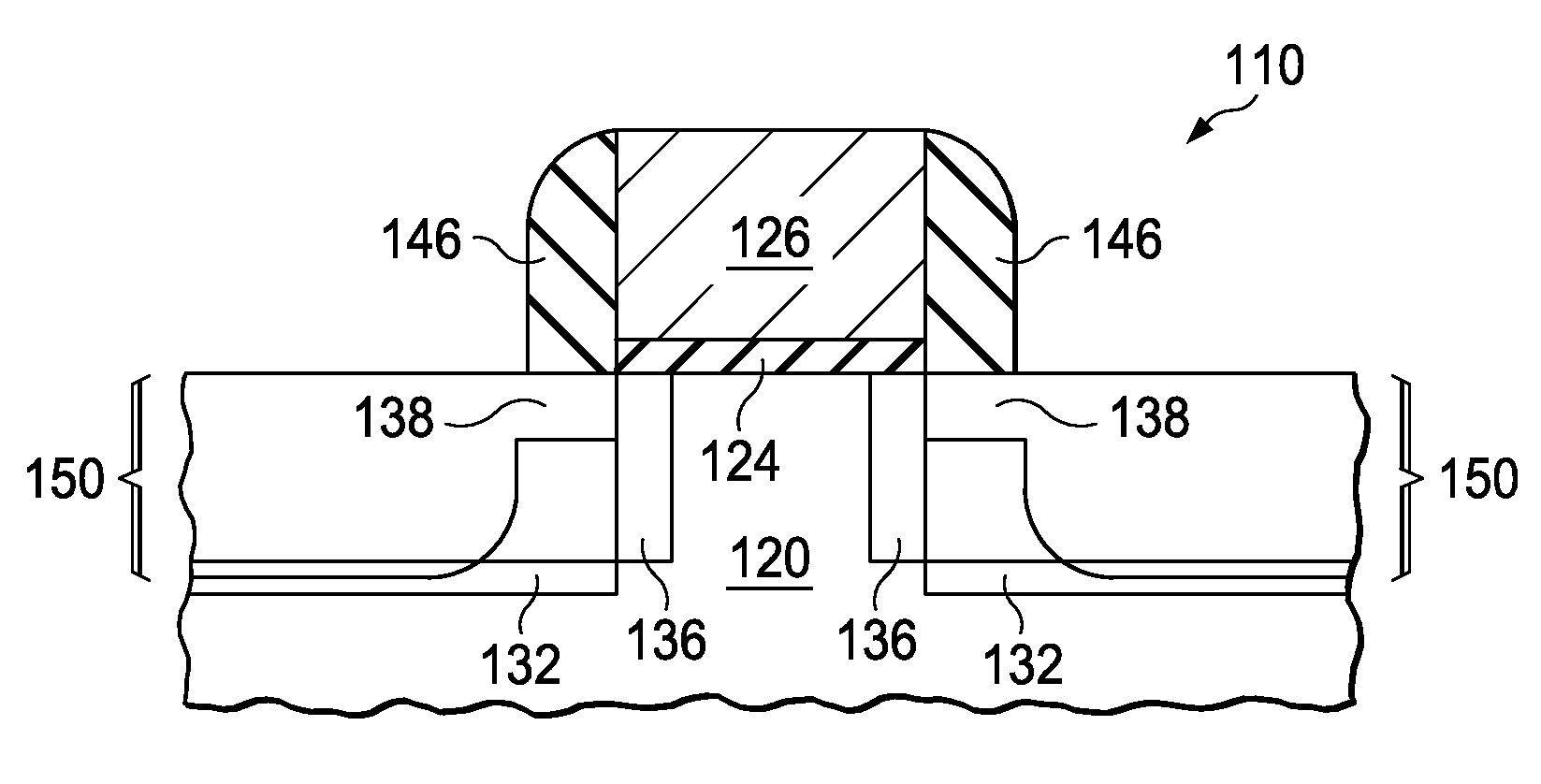

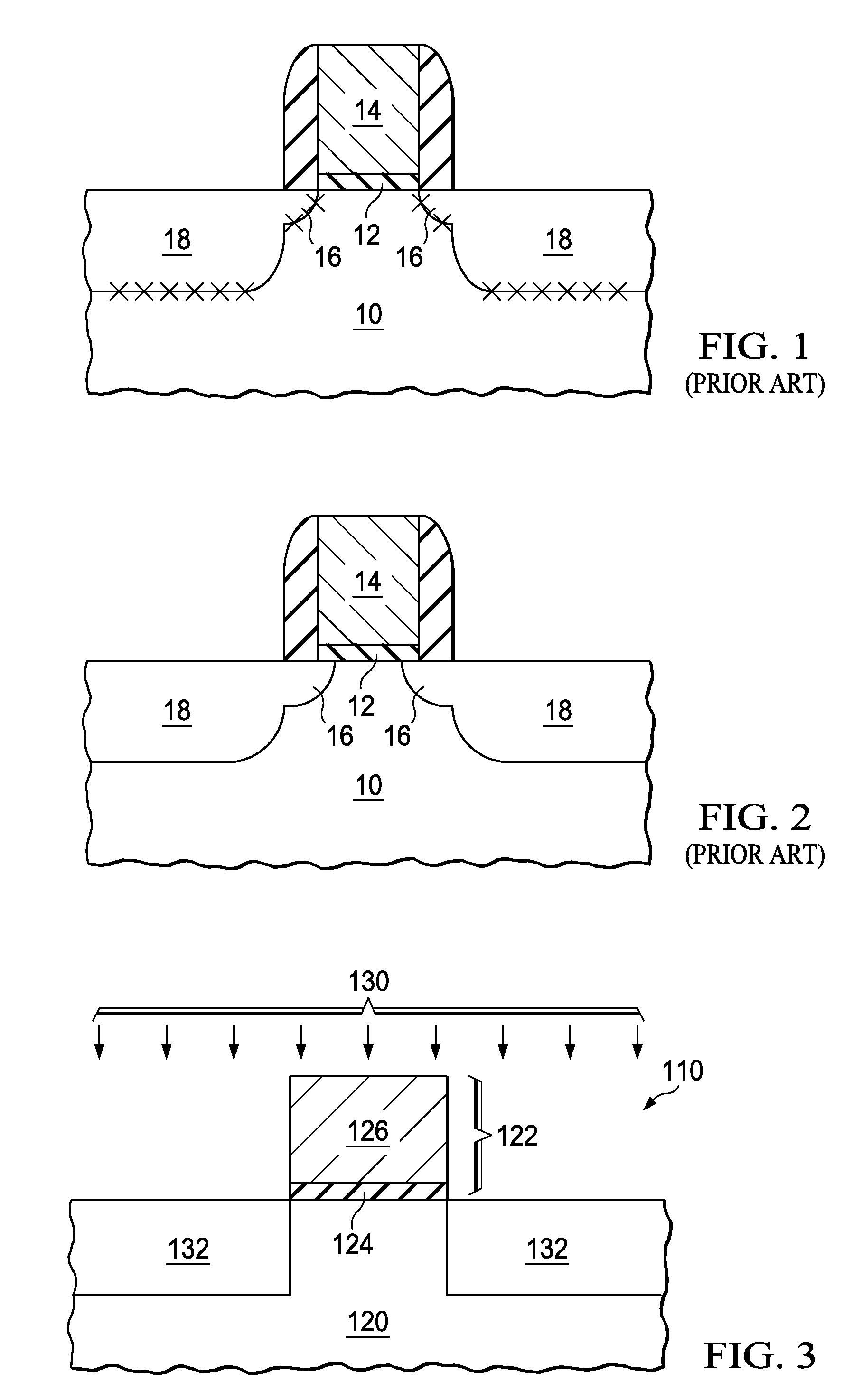

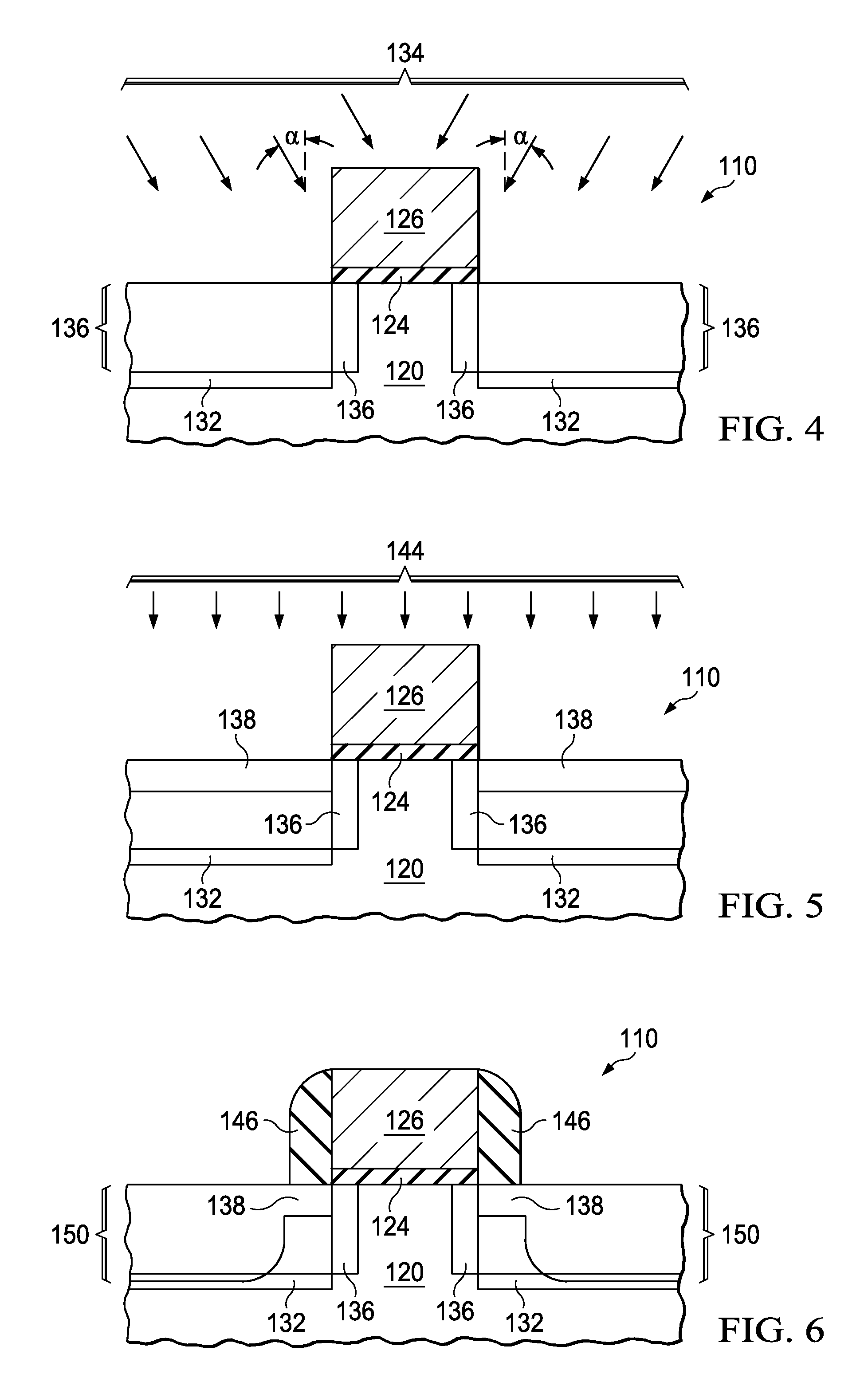

Junction Profile Engineering Using Staged Thermal Annealing

InactiveUS20100210086A1High activation rateReduce diffuseTransistorSemiconductor/solid-state device manufacturingRoom temperaturePeak value

An annealing method includes performing an activation annealing on a wafer with a peak temperature of greater than about 1200° C., wherein the activation annealing has a first duration; and performing a defect-recovery annealing on the wafer at a defect-recovery temperature lower than the peak temperature for a second duration. The second duration is longer than the first duration. The annealing method includes no additional annealing steps at temperatures greater than about 1200° C., and no room-temperature cooling step exists between the activation annealing and the defect-recovery annealing.

Owner:TAIWAN SEMICON MFG CO LTD

Force-induced response dynamic polymer and application thereof

The invention discloses a force-induced response dynamic polymer. The polymer chain skeleton contains at least one force-sensitive group and at least one boron-free dynamic covalent bond, optionally contains at least one boron-containing dynamic covalent bond, and also optionally contains at least one supramolecular interaction; and under the action of mechanical force, the force-sensitive group in the dynamic polymer is subjected to chemical and / or physical change to realize force-induced response. According to the dynamic polymer, the force-sensitive group with a force-induced response characteristic, the boron-free dynamic covalent bonds with different dynamic properties, the optional boron-containing dynamic covalent bond and the supramolecular interaction are introduced, so that the force-induced response dynamic polymer material with a wide controllable range, a rich structure and various properties can be prepared. The force-induced response dynamic polymer can be widely appliedas a functional coating with a force-induced response function, a self-repairing material, an energy storage device material, an energy absorbing material, a photoelectric device material, a mechanical probe and the like.

Owner:厦门天策材料科技有限公司

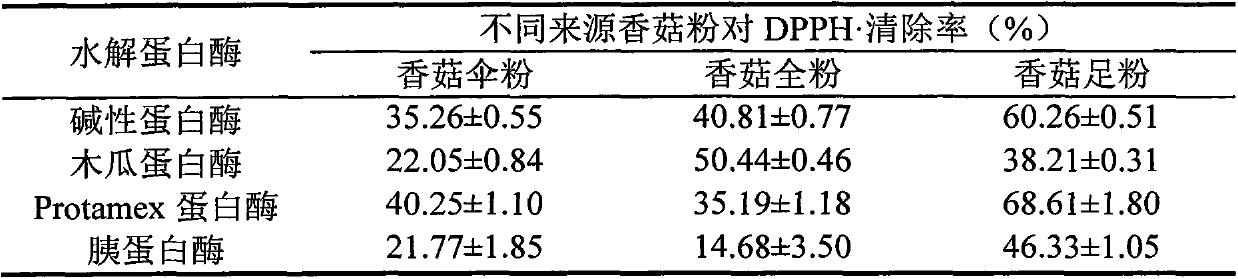

Method for preparing shiitake bioactive peptide

ActiveCN104004813AFast bioabsorptionPromote absorptionNervous disorderAntinoxious agentsShiitake mushroomsSodium hydroxide

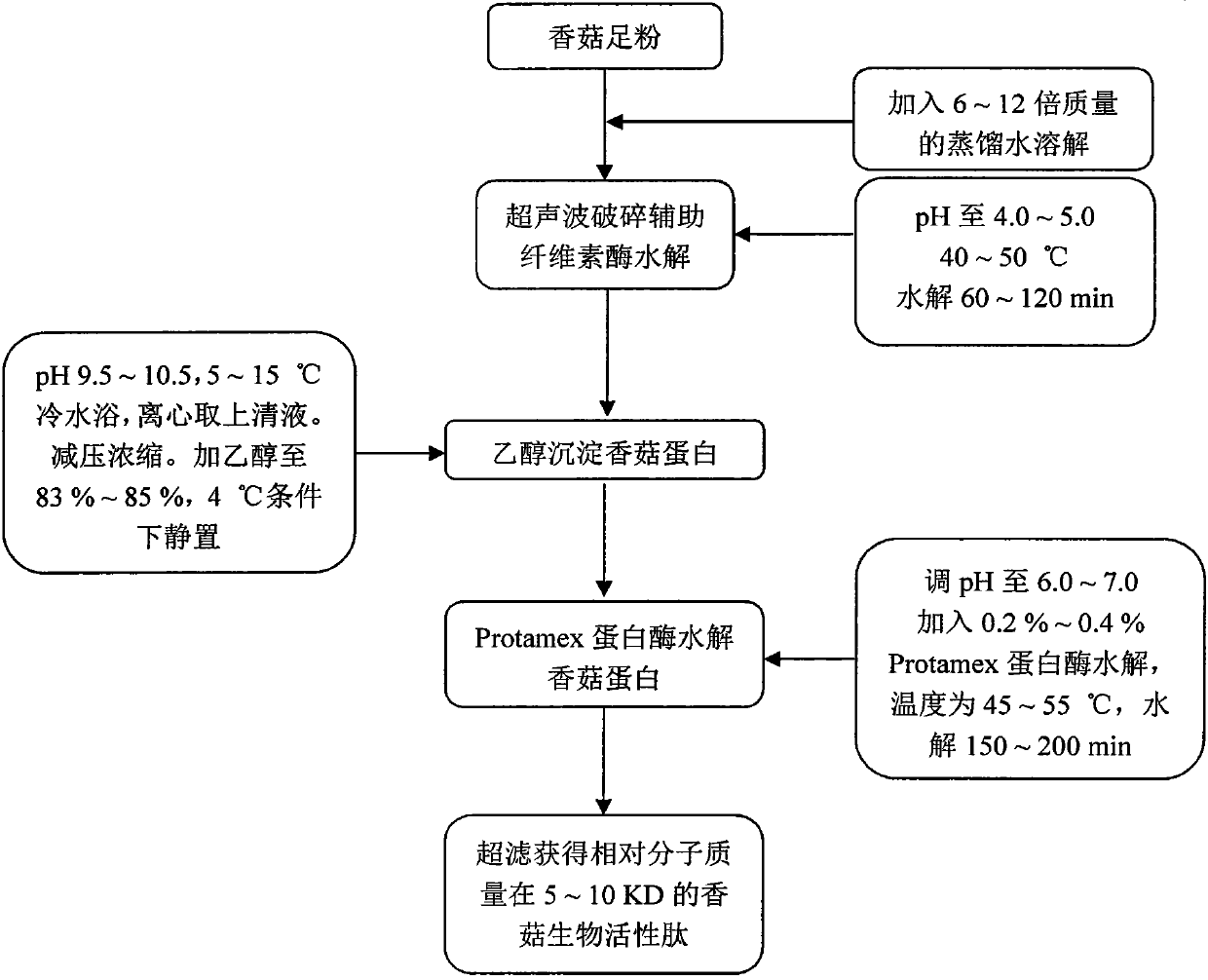

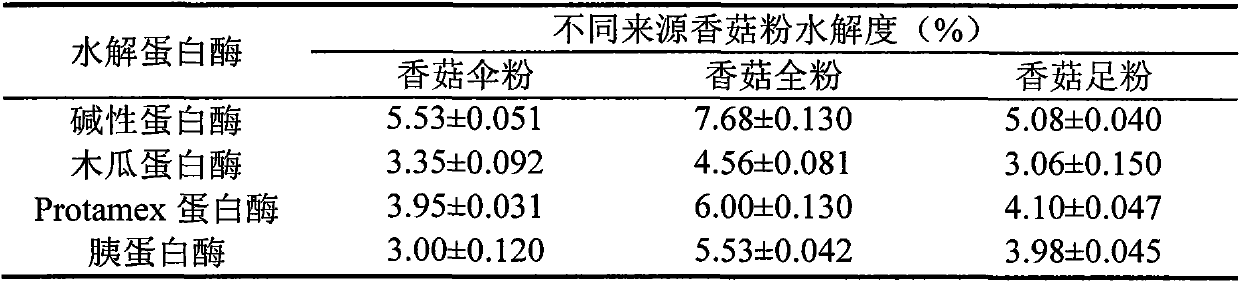

The invention discloses a method for preparing shiitake bioactive peptide. The method specifically comprises the following steps that (1) distilled water with the weight 6-12 times that of shiitake foot powder is added to the shiitake foot powder and the shiitake foot powder is dissolved; (2) ultrasonic disruption is conducted, 100 thousand to 200 thousand international units of cellulase are added to per kilogram of the shiitake foot powder, the pH value is adjusted to be 4.0 to 5.0, the temperature is adjusted to be 40 DEG C to 50 DEG C, and hydrolyzing lasts for 60 min to 120 min; (3) the shiitake foot powder solution is cooled to the indoor temperature, the pH value of the shiitake foot powder solution is adjusted to be 9.5 to 10.5 by sodium hydroxide, cold bath extraction is conducted for 20 min to 40 min at the temperature of 5 DEG C to 15 DEG C, supernate is extracted in a centrifugal mode, pressure reduction concentration is conducted, absolute ethyl alcohol is added until the concentration reaches 83% to 85%, standing is conducted for 60 min to 90 min at the temperature of 4 DEG C, centrifugation is conducted, precipitate is collected, and shiitake protein is obtained after drying; (4) the shiitake protein is dissolved in distilled water with the weight 40-60 times that of the shiitake protein, the pH value is adjusted to be 6.0 to 7.0, 0.2%-0.4% compound protease is added for hydrolysis, the temperature ranges from 45 DEG C to 55 DEG C, hydrolysis is conducted for 150 min to 200 min, enzyme deactivation is conducted, centrifugation is conducted, and filtrate is collected; (5) microfiltration is conducted through a filtering film of 0.22 micron, ultrafiltration is also conducted, peptide fragments with relative molecular mass ranging from 5 KD to 10 KD are collected, vacuum freeze drying is conducted, and therefore brown freeze-dried powder of the shiitake bioactive peptide is obtained. The prepared shiitake bioactive peptide has the good antioxidant activity in vitro and sobering activity.

Owner:BEIJING FORESTRY UNIVERSITY

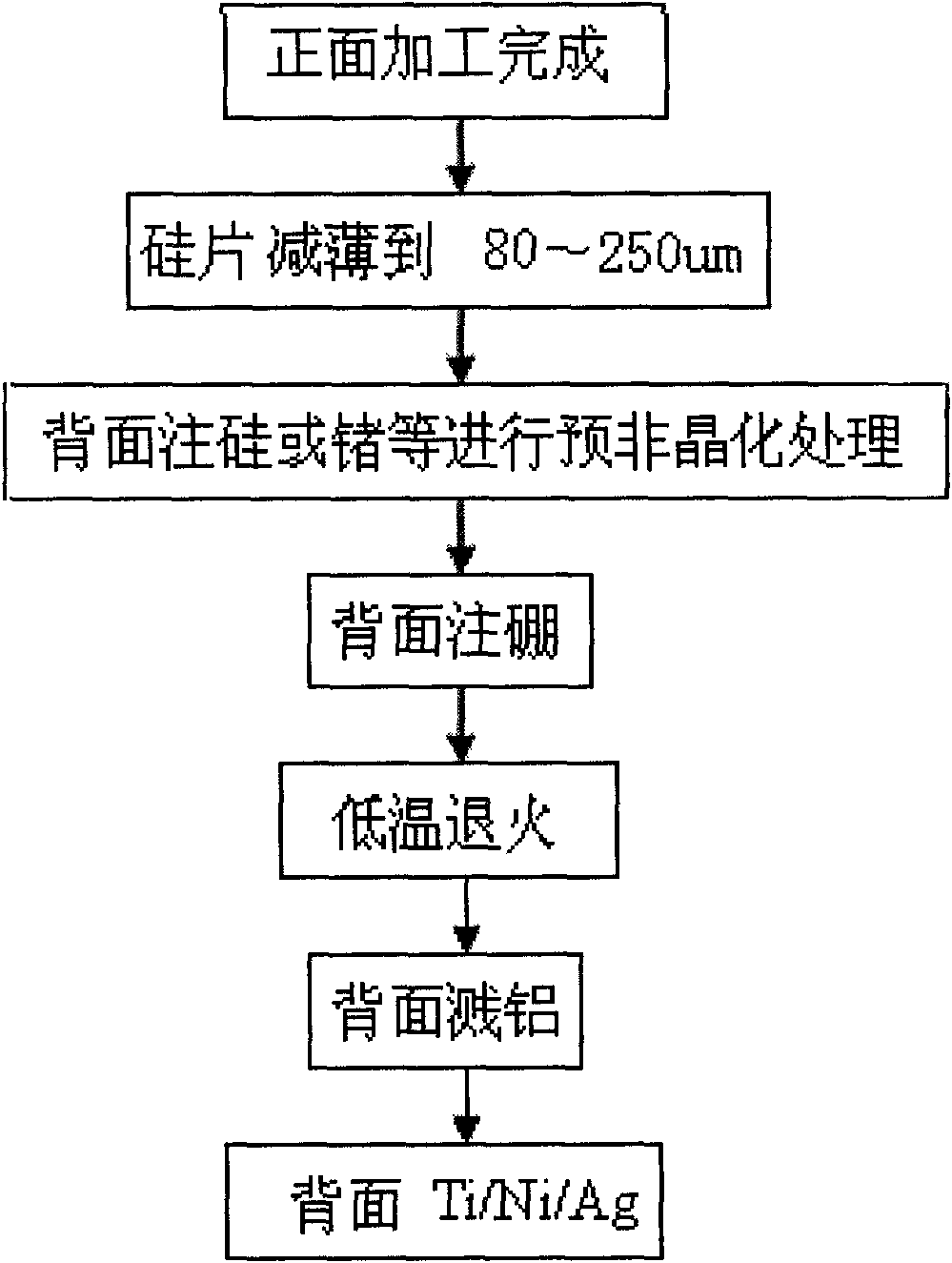

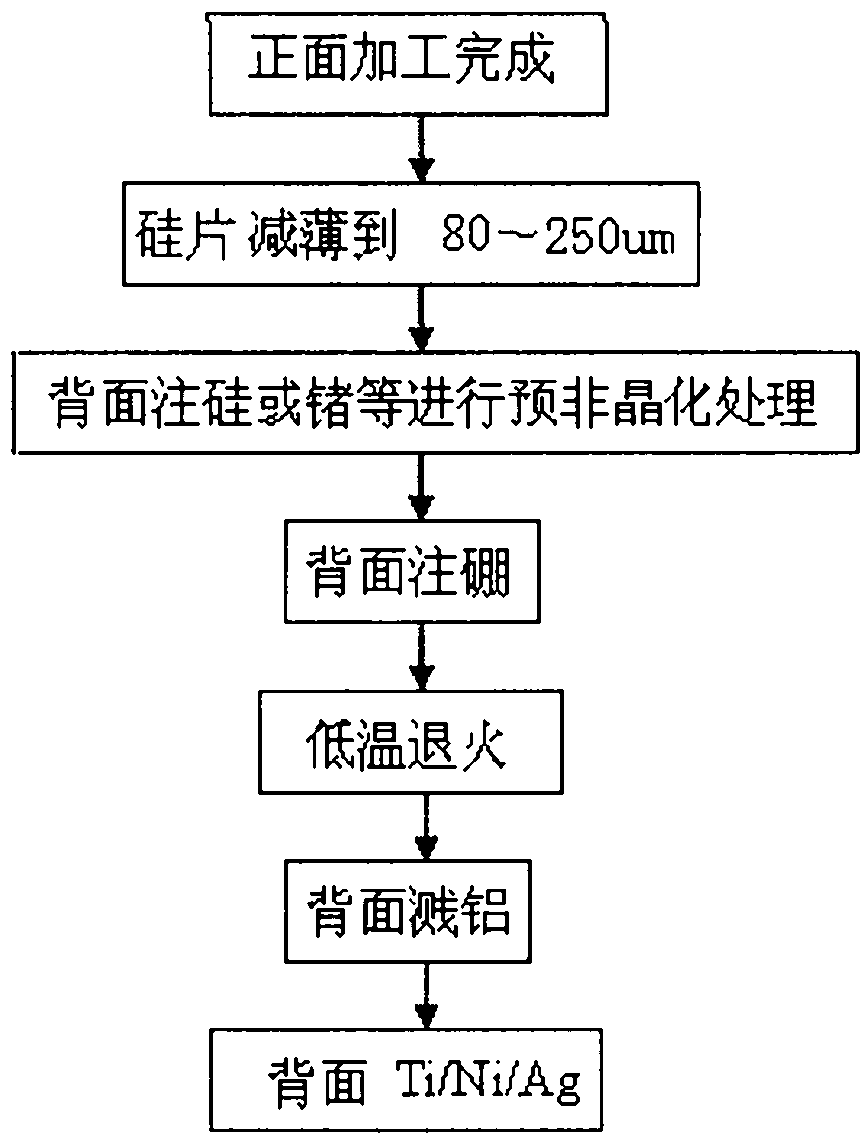

Technique for manufacturing back of non-through insulated-gate bipolar transistor chip

ActiveCN101789375AIncrease activation rateIncrease the number of holesSemiconductor/solid-state device manufacturingIonAluminium

The invention relates to a technique for manufacturing the back of a non-through insulated-gate bipolar transistor chip, comprising the following steps of: (1) finishing a technique for processing the front of the non-through insulated-gate bipolar transistor chip; (2) grinding and thinning the back of a silicon chip, and removing stress; (3) injecting silicon ion, germanium ion or boron difluoride ion at the back of the silicon chip for amorphous pretreatment; (4) injecting boron ion at the back of the silicon chip; (5) carrying out furnace tube low temperature annealing; (6) adopting a sputtering or an evaporating method, generating an aluminium film at the back of the silicon chip, and carrying out alloy treatment; and (7) adopting the sputtering or the evaporating method, respectively preparing a titanium, a nickel and a silver metal layers at the back of the silicon chip. The back of the silicon chip is firstly injected with the silicon ion, the germanium ion or the boron difluoride ion for amorphous pretreatment and then injected with the boron ion for low-temperature annealing, so that the activation rate of injecting the boron impurity is improved, the conductive modulation effect for a drifting area can be enhanced, and the conducting resistance and conducting voltage are effectively reduced. The technique can be widely applied to a manufacturing technique of a semiconductor.

Owner:TSINGHUA UNIV

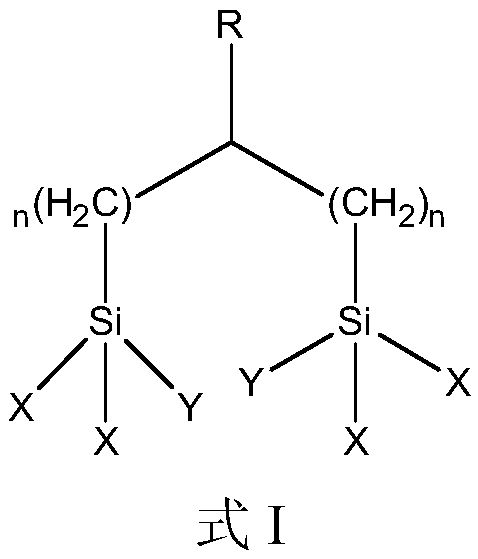

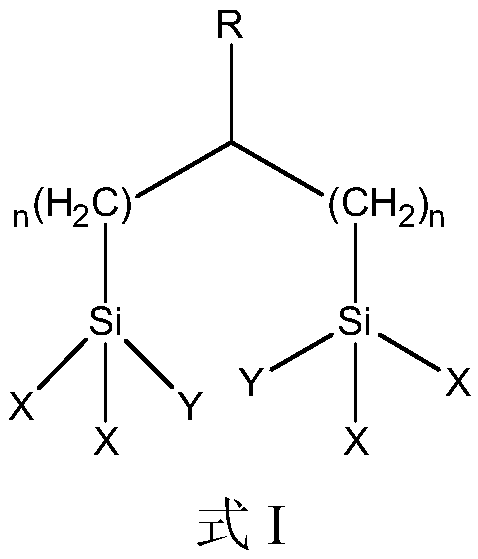

Thermosetting resin composition as well as prepreg, laminated board and circuit carrier containing same

ActiveCN105504686ASmall expansion coefficientPromote absorptionSynthetic resin layered productsGlass/slag layered productsThermal expansionCopper

The invention provides a thermosetting resin composition as well as a prepreg, a laminated board and a circuit carrier containing the same. The thermosetting resin composition comprises thermosetting resin, a laser direct forming additive, an inorganic filler, and a silane coupling agent with 2-3 groups capable of being hydrolyzed at each of two ends of a molecular chain. The laser direct forming additive is added in the thermosetting resin composition provided by the present invention to ensure that a circuit can be formed on thermosetting resin after laser irradiation and metallization, the CTE of the composition can be reduced and the absorption of laser energy by a matrix can be enhanced by adding the inorganic filler and the silane coupling agent with 2-3 groups capable of being hydrolyzed at each of the two ends of the molecular chain, the activation rate of an LDS auxiliary agent is effectively improved, the attachment and the sedimentary thickness of the matrix to copper are obviously enhanced at the same time, and three types of components mutually cooperate with the thermosetting resin to ensure that the thermosetting resin composition has a low coefficient of thermal expansion, thereby making the prepared circuit carrier have relatively good quality of signal transmission.

Owner:江苏生益特种材料有限公司

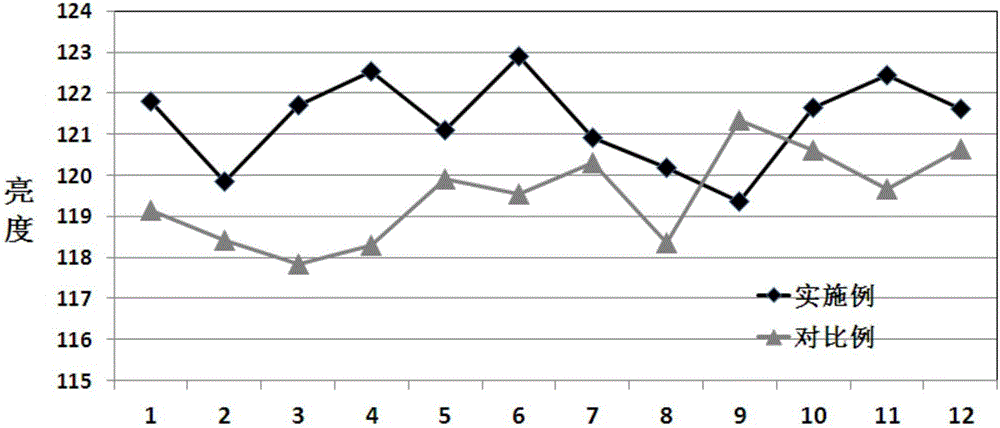

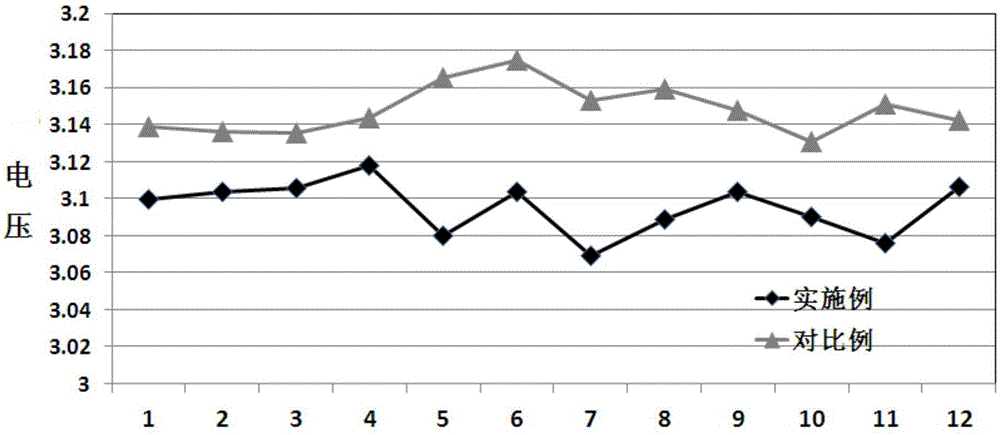

LED epitaxial structure of composite P-type GaN layer and fabrication method of LED epitaxial structure

InactiveCN106784184AImprove solubilityImprove luminous efficiencySemiconductor devicesDopantSolubility

The invention provides an LED epitaxial structure of a composite P-type GaN layer and a fabrication method of the LED epitaxial structure. The P-type GaN layer of the LED epitaxial structure sequentially comprises a first P-type GaN layer, a second P-type GaN layer and a third P-type GaN layer, wherein the thickness of the first P-type GaN layer is 40-80 nanometers, the thickness of the second P-type GaN layer is 30-70 nanometers, and the thickness of the third P-type GaN layer is 4-10 nanometers. In the P-type GaN layer structure, two effects are achieved by simultaneously doping an n-type dopant and a P-type dopant: the solubility of the dopants (the formation energy of the dopants is reduced) is increased to prevent a self-compensation effect, and the activation ratio is improved by reducing an acceptor level, so that the self-compensation effect of the P-type GaN layer is prevented better, the hole concentration is improved, and the purpose of improving the luminous efficiency and the electricity of a GaN device is achieved.

Owner:XIANGNENG HUALEI OPTOELECTRONICS

Treating method for city life garbage burning flyash

InactiveCN1586743AHigh activation rateLow leaching solubilitySolid waste disposalBLENDER/MIXERWater baths

The present invention belongs to the field of environment protecting and powder surface modifying technology. The treating method of the city life garbage burning flyash adopts anionic surfactant with chelating function and over 8 carbon chain structure. The wet flyash modifying process includes the following steps: weighing certain amount of flyash, adding into water solution, stirring in stirrer and heating in water bath at 25-80 deg.c for 10 min; adding specific chelating anionic surfactant with C12H25OPO3K2 as main component in 2-5 %; further stirring at certain amount of temperature and rotation speed for 15-25 min; sieving and sealed maintenance.

Owner:SHANGHAI UNIV

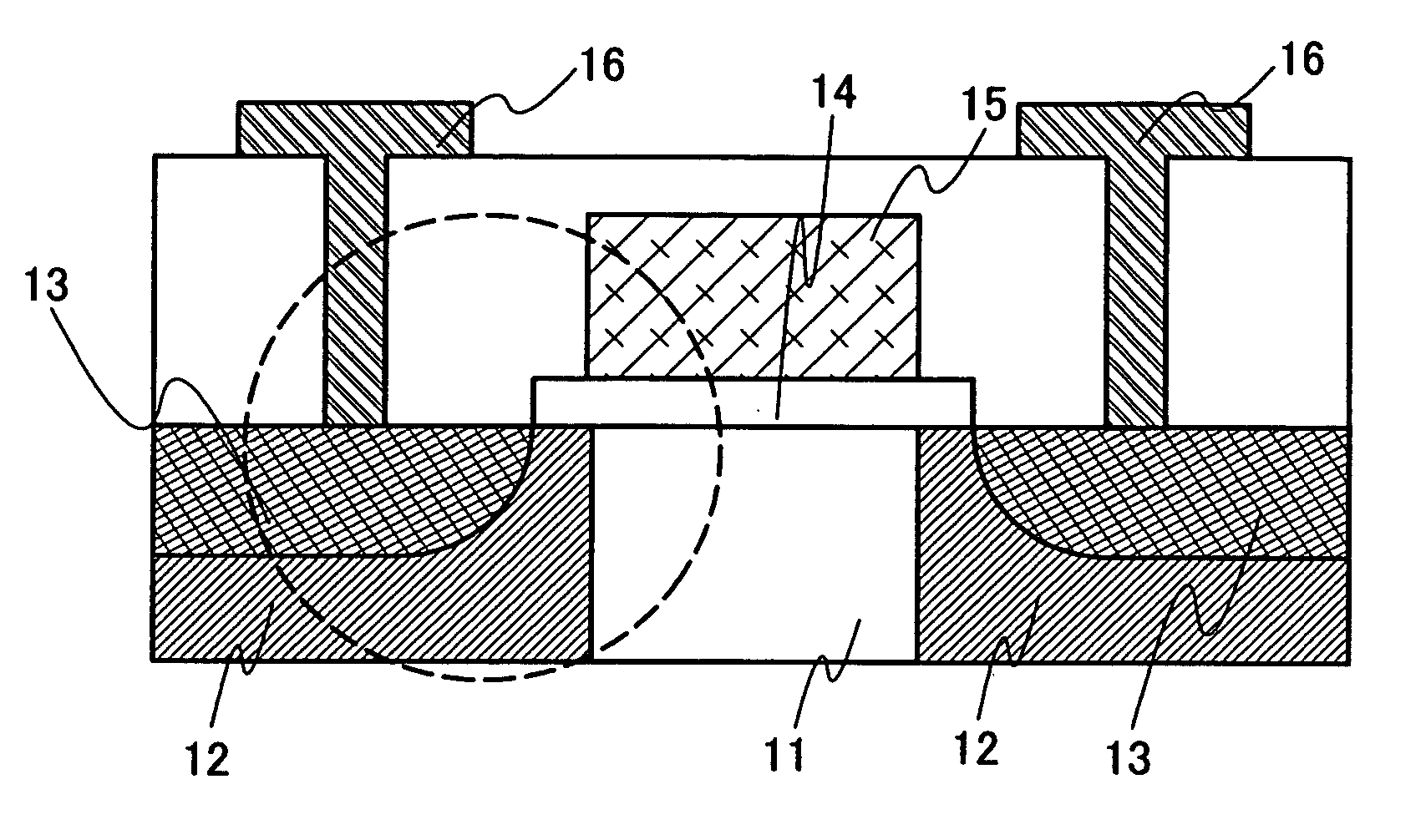

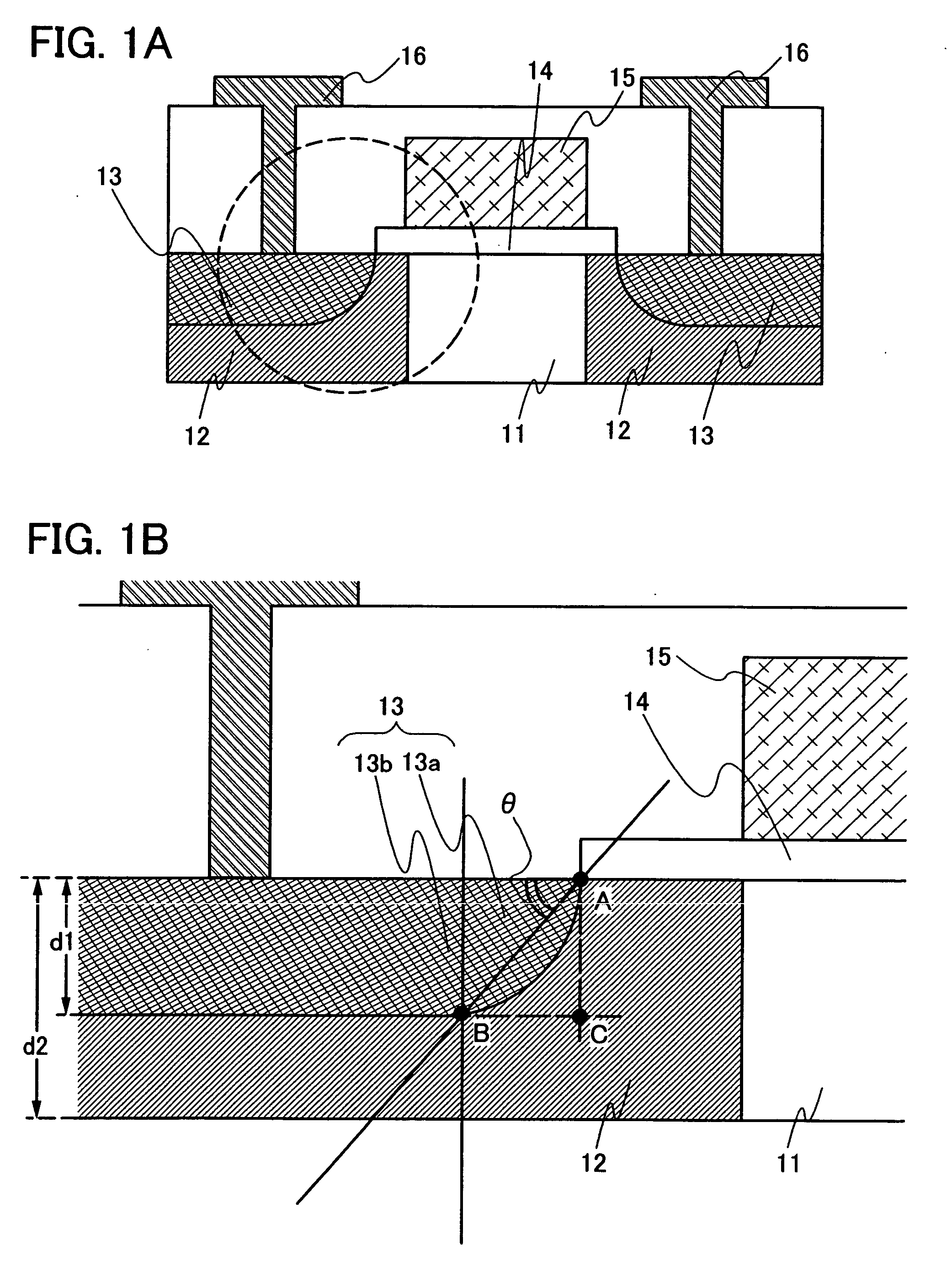

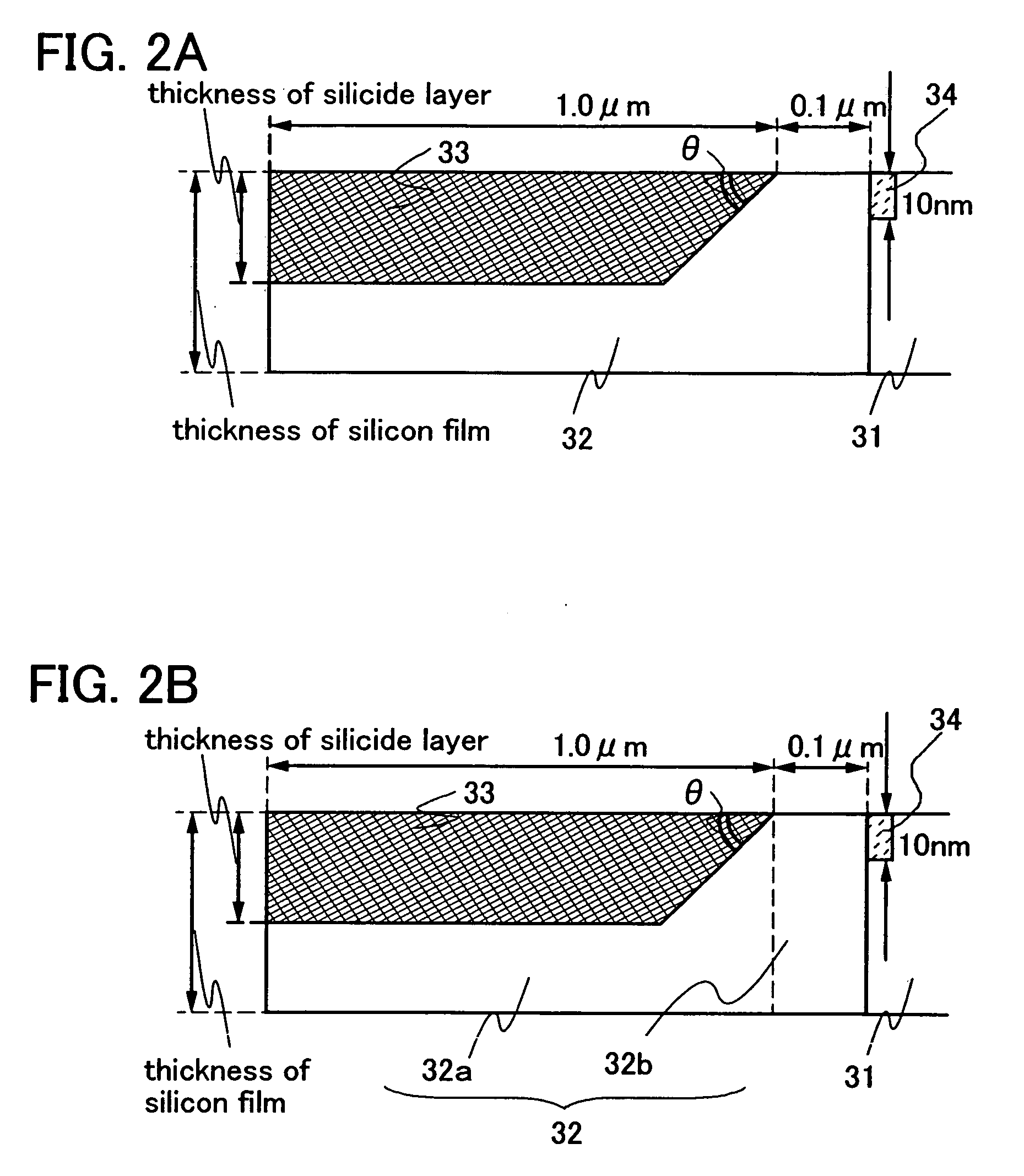

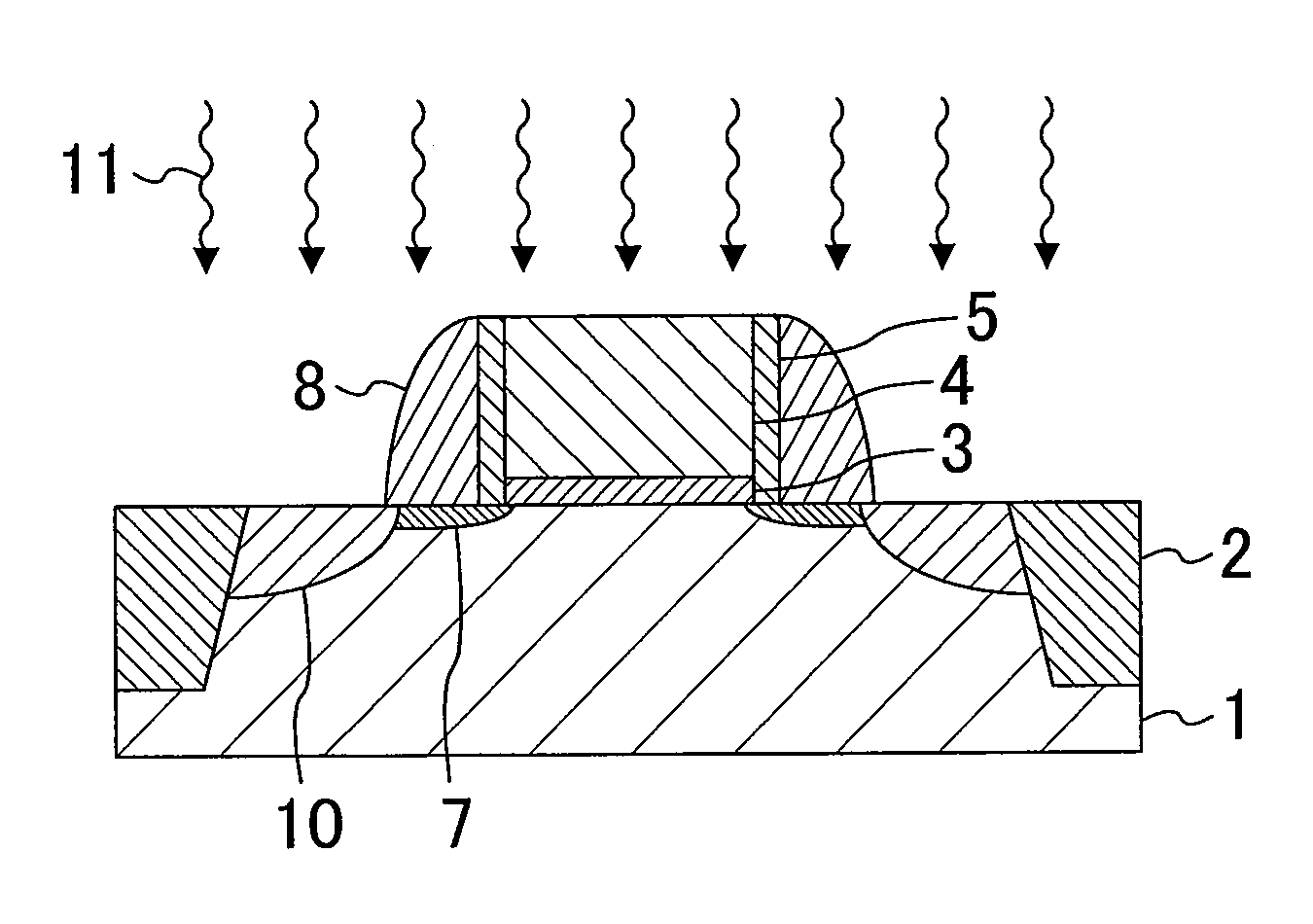

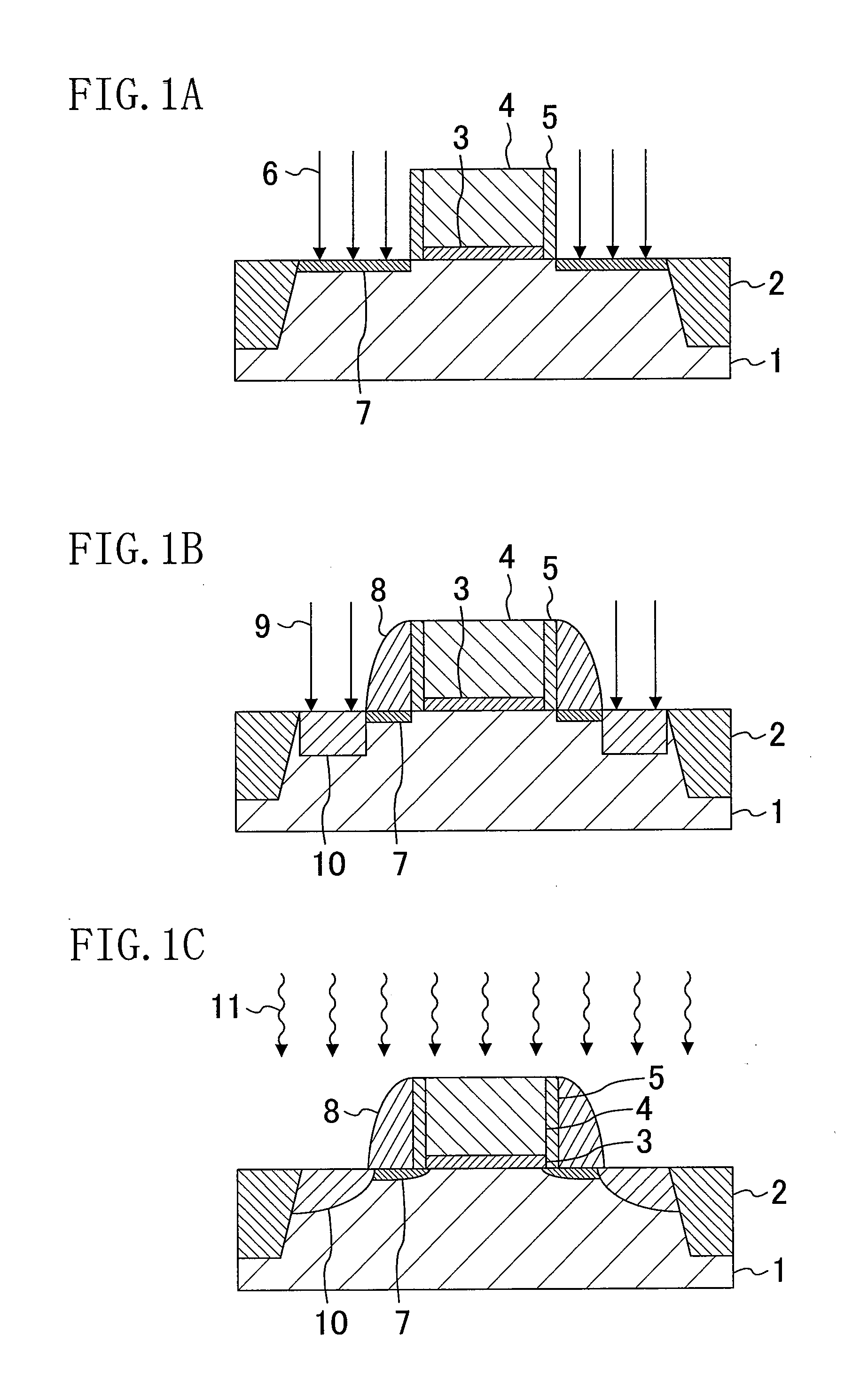

Semiconductor device and manufacturing method thereof

InactiveUS20070126058A1High currentReduce sheet resistanceTransistorSolid-state devicesSiliconCondensed matter physics

It is an object of the present invention to obtain a transistor with a high ON current including a silicide layer without increasing the number of steps. A semiconductor device comprising the transistor includes a first region in which a thickness is increased from an edge on a channel formation region side and a second region in which a thickness is more uniform than that of the first region. The first and second region are separated by a line which is perpendicular to a horizontal line and passes through a point where a line, which passes through the edge of the silicide layer and forms an angle θ (0° <θ<45°) with the horizontal line, intersects with an interface between the silicide layer and an impurity region, and the thickness of the second region to a thickness of a silicon film is 0.6 or more.

Owner:SEMICON ENERGY LAB CO LTD

Method for producing ZnTe system compound semiconductor single crystal, ZnTe system compound semiconductor single crystal, and semiconductor device

InactiveUS20080090327A1High crystallinityEasy to controlPolycrystalline material growthSemiconductor/solid-state device manufacturingDopantDevice material

The present invention relates to a method for producing an n-type ZnTe system compound semiconductor single crystal having high carrier concentration and low resistivity, the ZnTe system compound semiconductor single crystal, and a semiconductor device produced by using the ZnTe system compound semiconductor as a base member. Concretely, a first dopant and a second dopant are co-doped into the ZnTe system compound semiconductor single crystal so that the number of atoms of the second dopant becomes smaller than the number of atoms of the first dopant, the first dopant being for controlling a conductivity type of the ZnTe system compound semiconductor to a first conductivity type, and the second dopant being for controlling the conductivity type to a second conductivity type different from the first conductivity type. By the present invention, a desired carrier concentration can be achieved with a doping amount smaller than in earlier technology, and crystallinity of the obtained crystal can be improved.

Owner:JX NIPPON MINING & METALS CORP

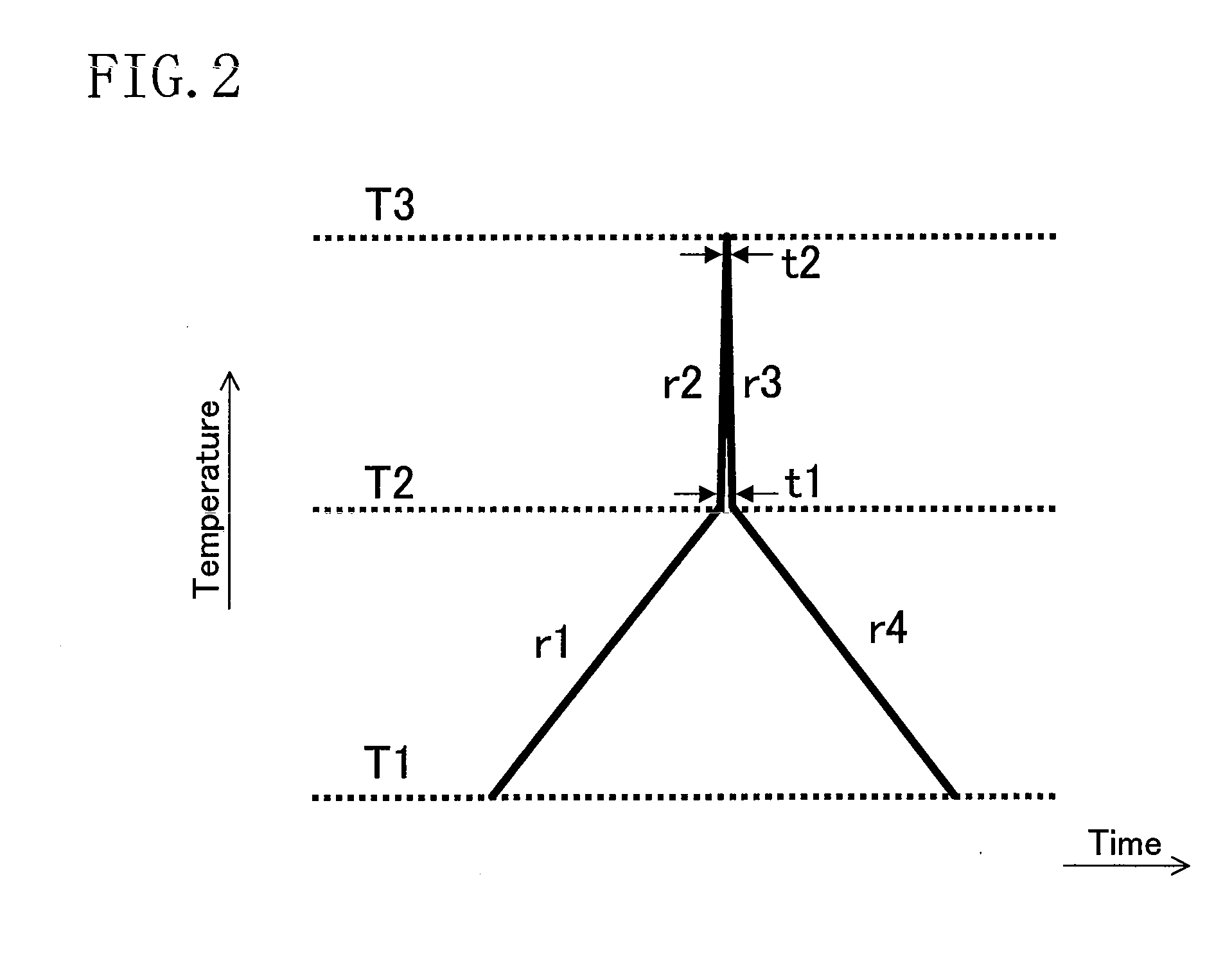

Impurity-activating thermal process method and thermal process apparatus

InactiveUS20090197428A1Improve impurity activation rateReduce resistanceTransistorDrying solid materials with heatThermal treatmentImpurity

An impurity-activating thermal process is performed after a target is subjected to an impurity introduction step. In this thermal process, while a spike RTA process including a holding period for holding a temperature at a predetermined temperature is performed, at least one iteration of millisecond annealing at a temperature higher than the predetermined temperature is performed during the holding period of the spike RTA process.

Owner:PANASONIC CORP

Method for modifying surface of nano calcium carbonate

ActiveCN108047766AGood dispersionEasy to processPigment treatment with non-polymer organic compoundsDispersityBiological activation

The invention discloses a method for modifying the surface of nano calcium carbonate. The method comprises the steps that 1, lime milk is added to a bubbling carbonatation reaction kettle, mixed gas containing carbon dioxide is introduced to the reaction kettle for a carbonatation reaction, carbonatation is conducted till the pH is equal to 7.0, carbonatation is completed, and a nano calcium carbonate suspension solution is obtained; 2, a stabilizer is added to the nano calcium carbonate suspension solution, the temperature is controlled within 50-60 DEG C, and heat preservation is conducted for 20-30 min; 3, a fatty acid modifier is heated and melted in water, an emulsifier is added to the fatty acid modifier, stirring is conducted for 10-30 min, and a modifier emulsion is obtained; 4, the nano calcium carbonate suspension solution obtained in the second step is added to the modifier emulsion, stirring is conducted for 30-60 min, and then through filter-pressing dehydration, drying and smashing, a nano calcium carbonate product is obtained. The prepared nano calcium carbonate has the advantages of good dispersity and processability, low oil absorption value, high thixotropy and activation rate, good stability, pH value close to neutral and the like. The method is low in production cost and simple in technology, facilitates industrial production and has good economic, social and ecological benefits.

Owner:ANHUI PROVINCE XUNCHENG CITY HUANA NEW MATERIAL TECH CO LTD

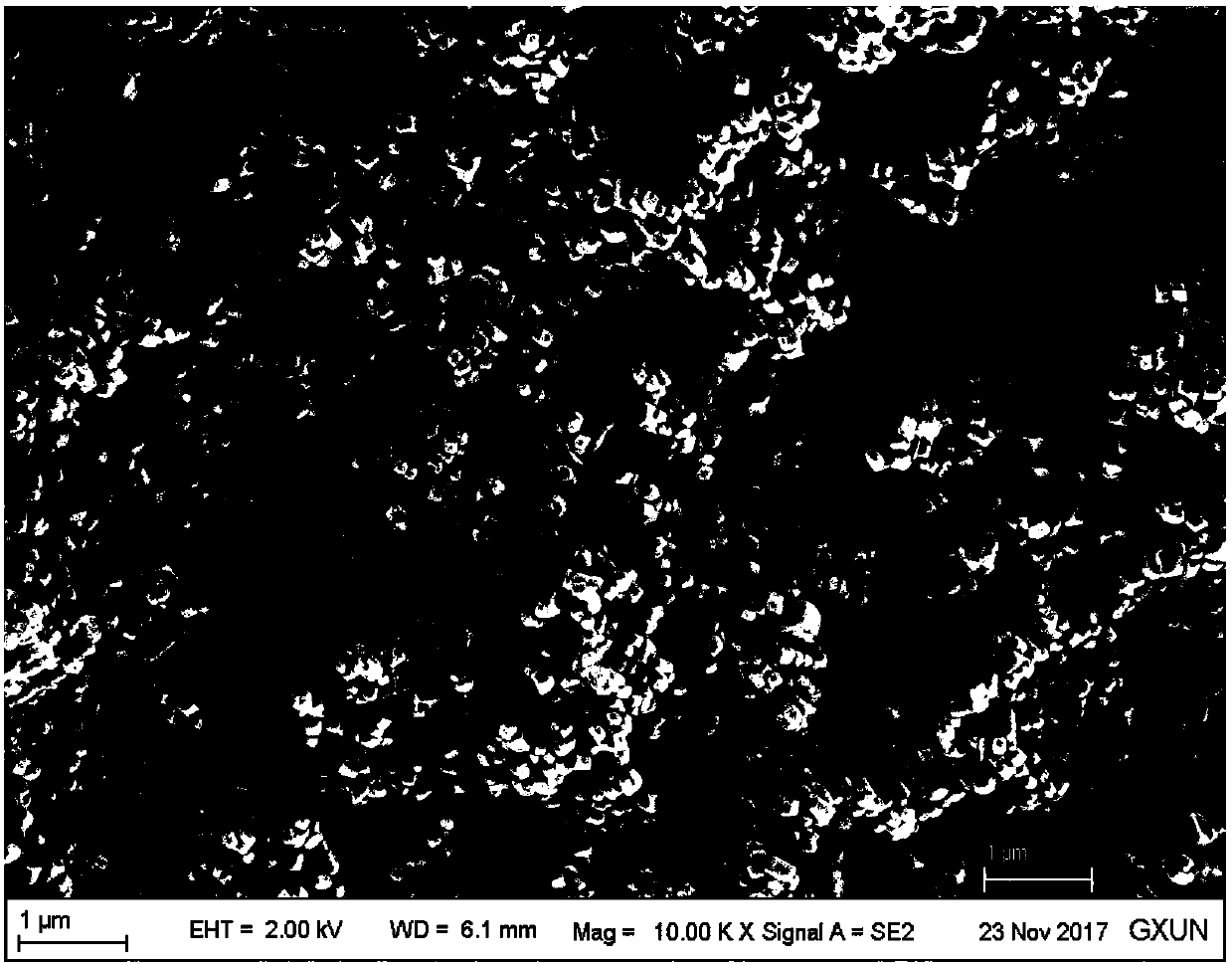

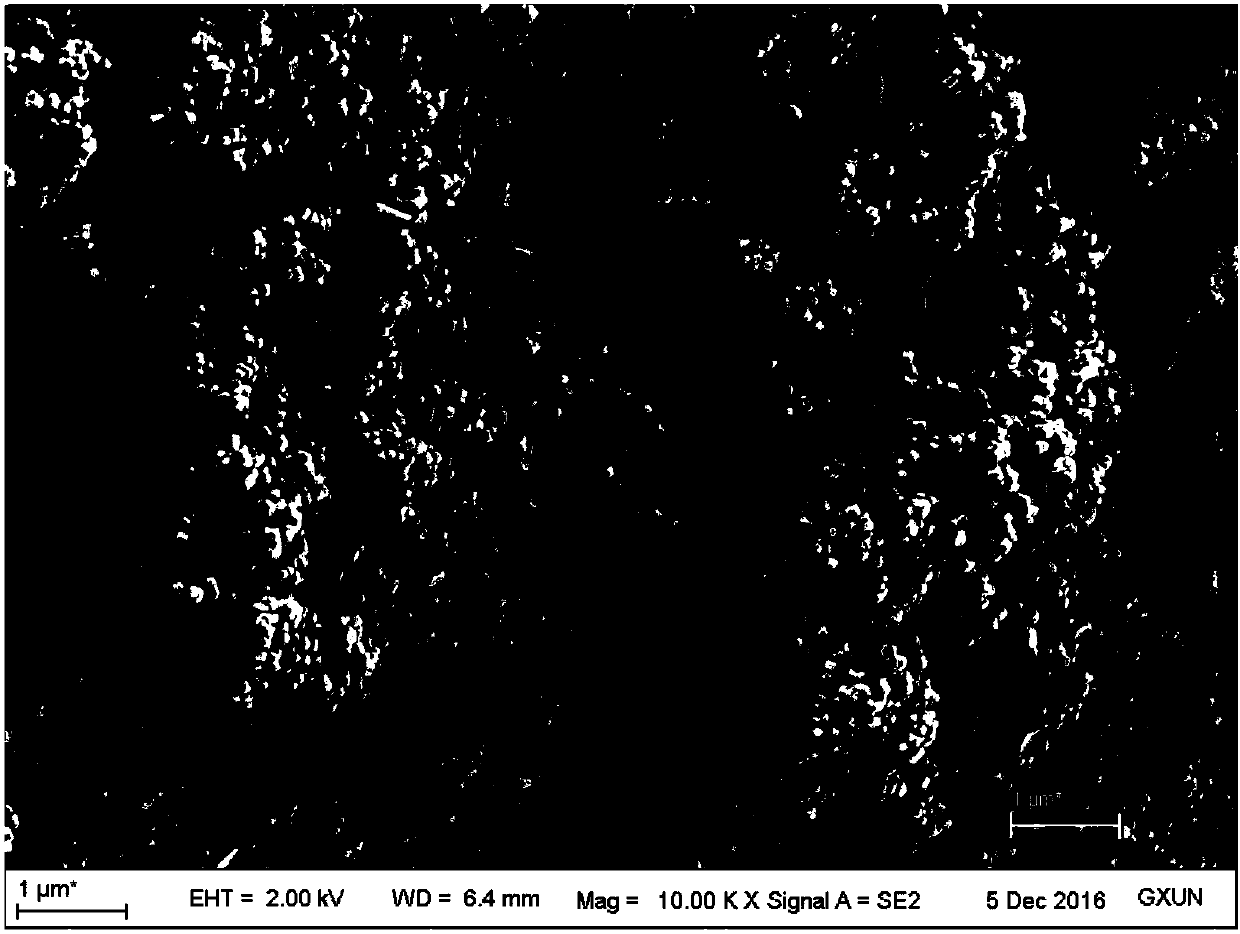

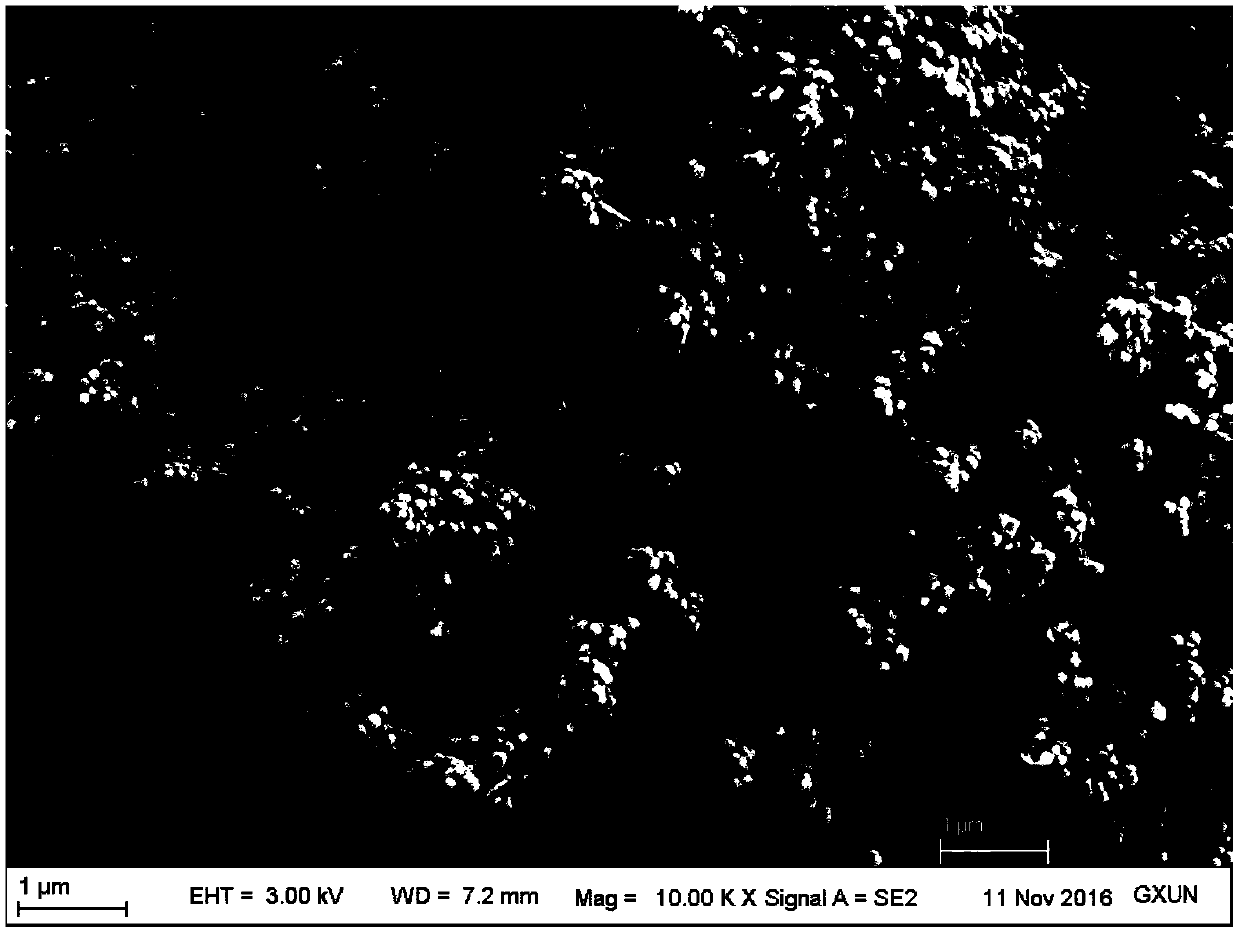

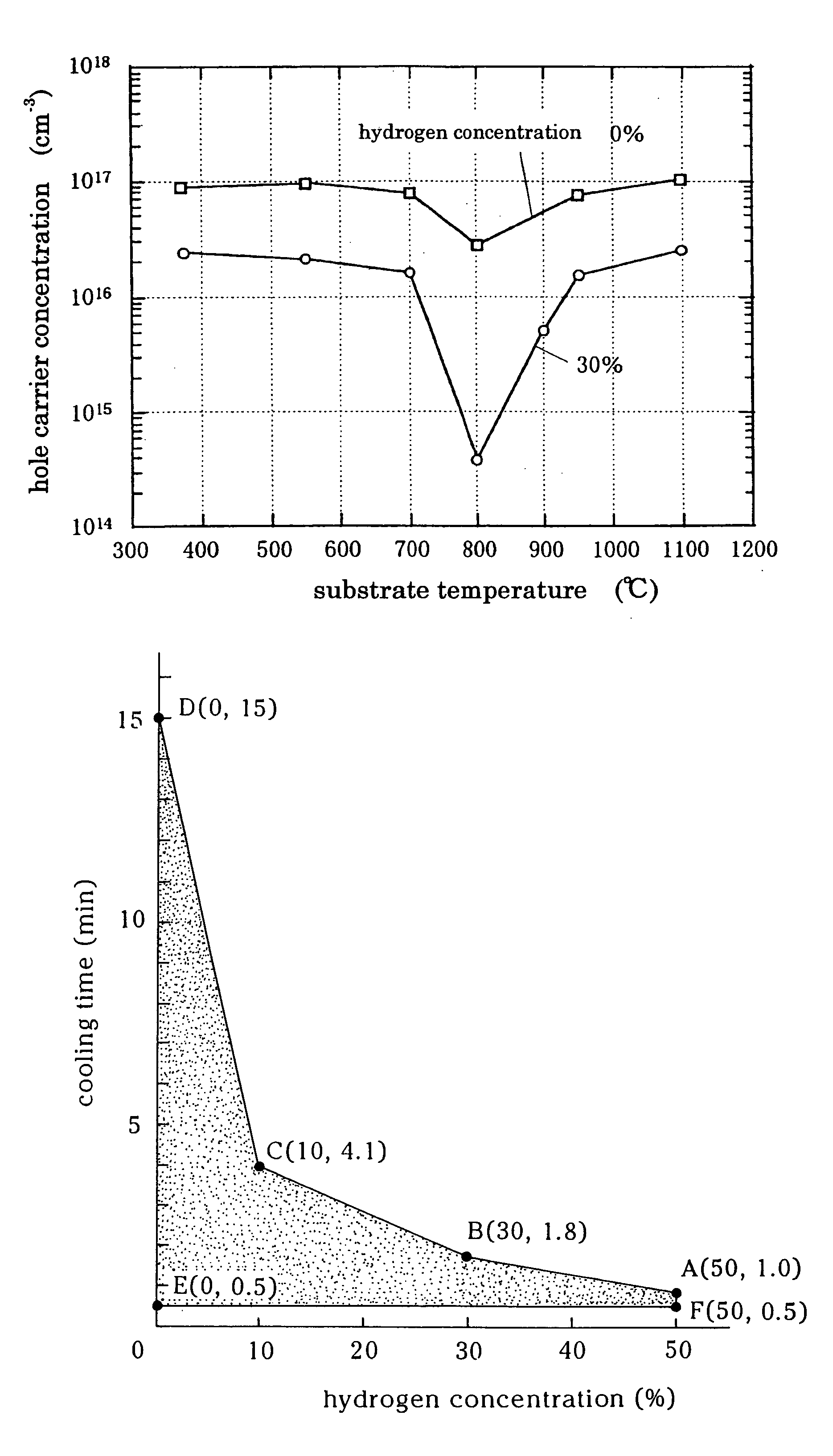

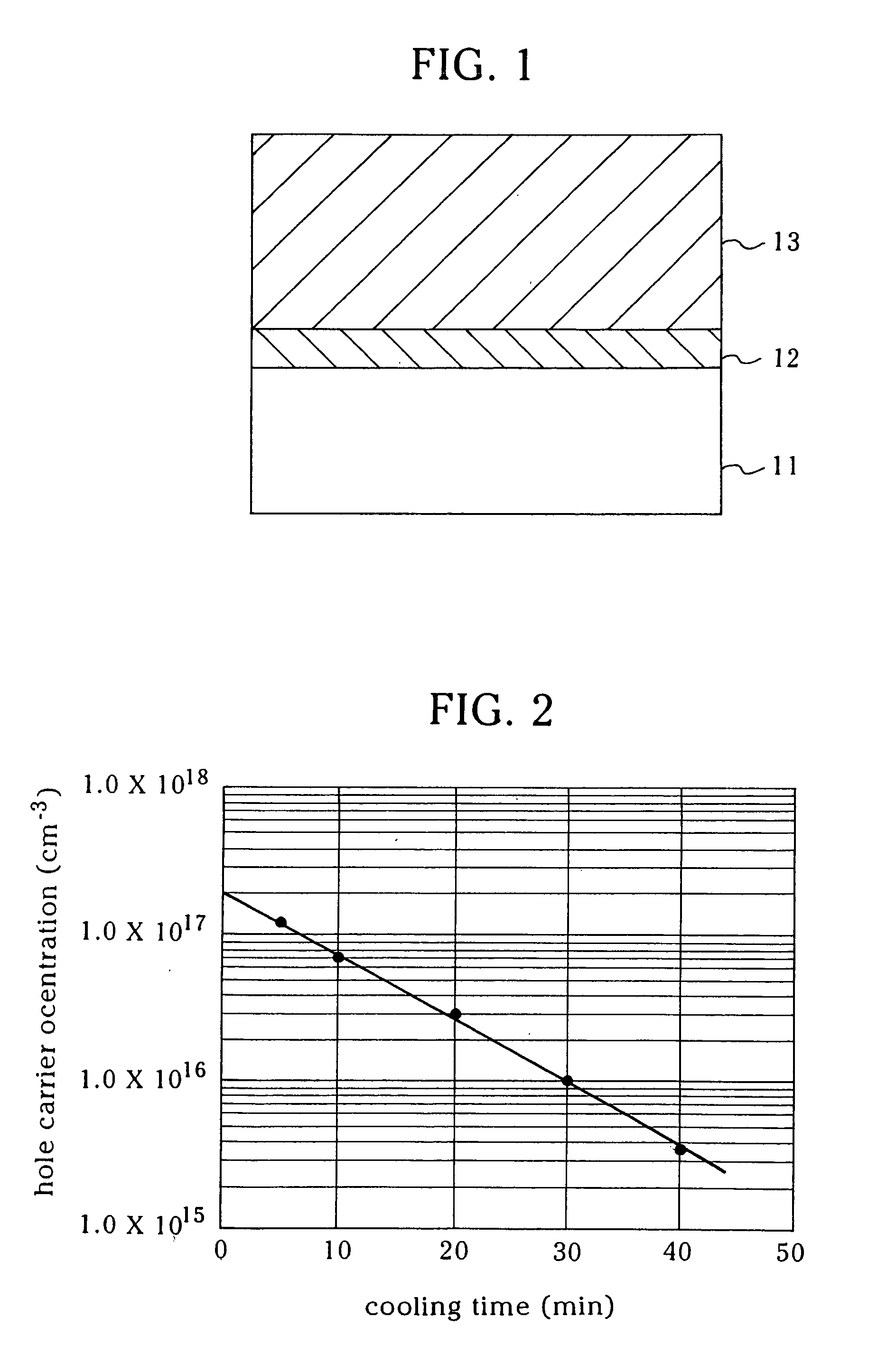

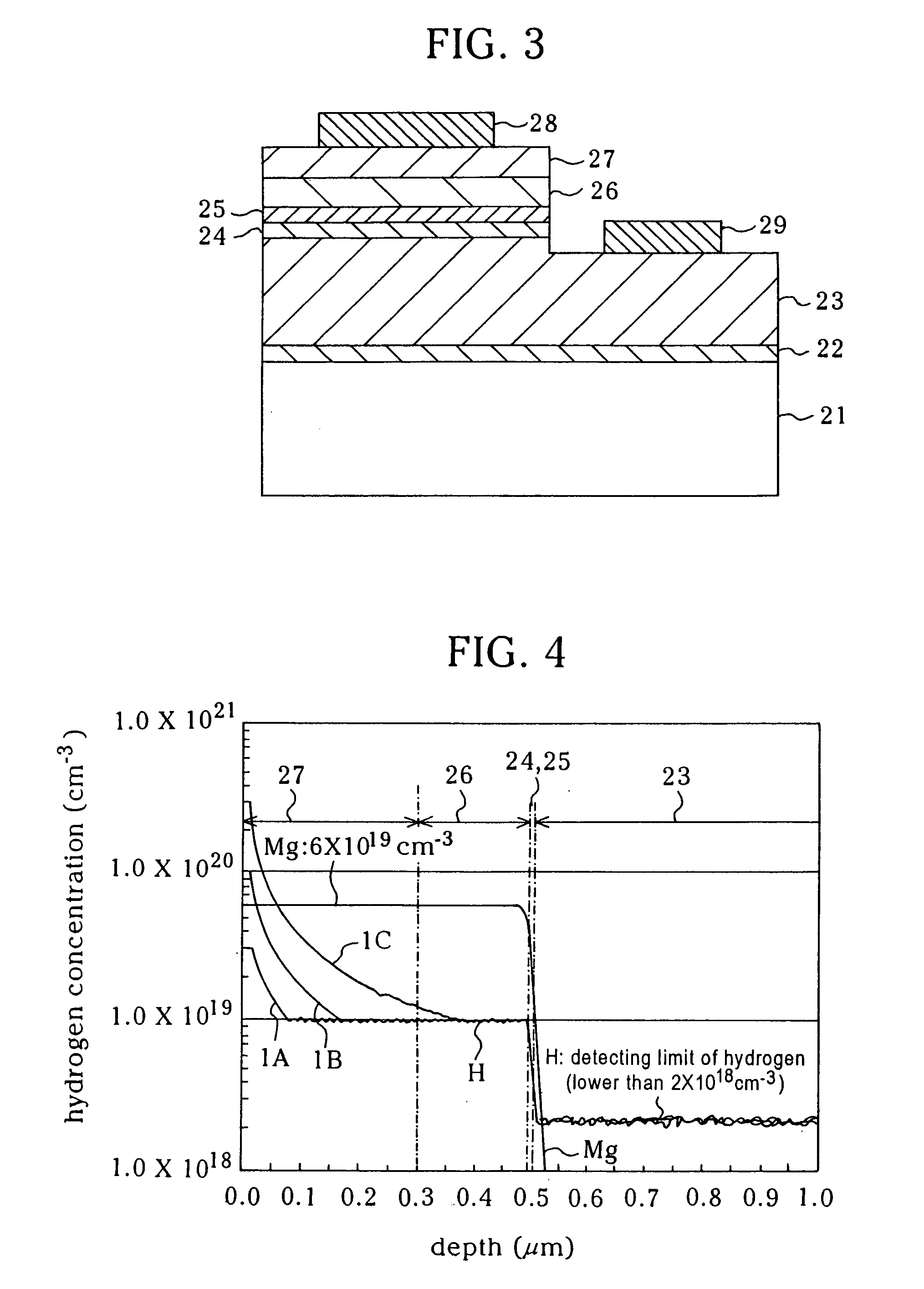

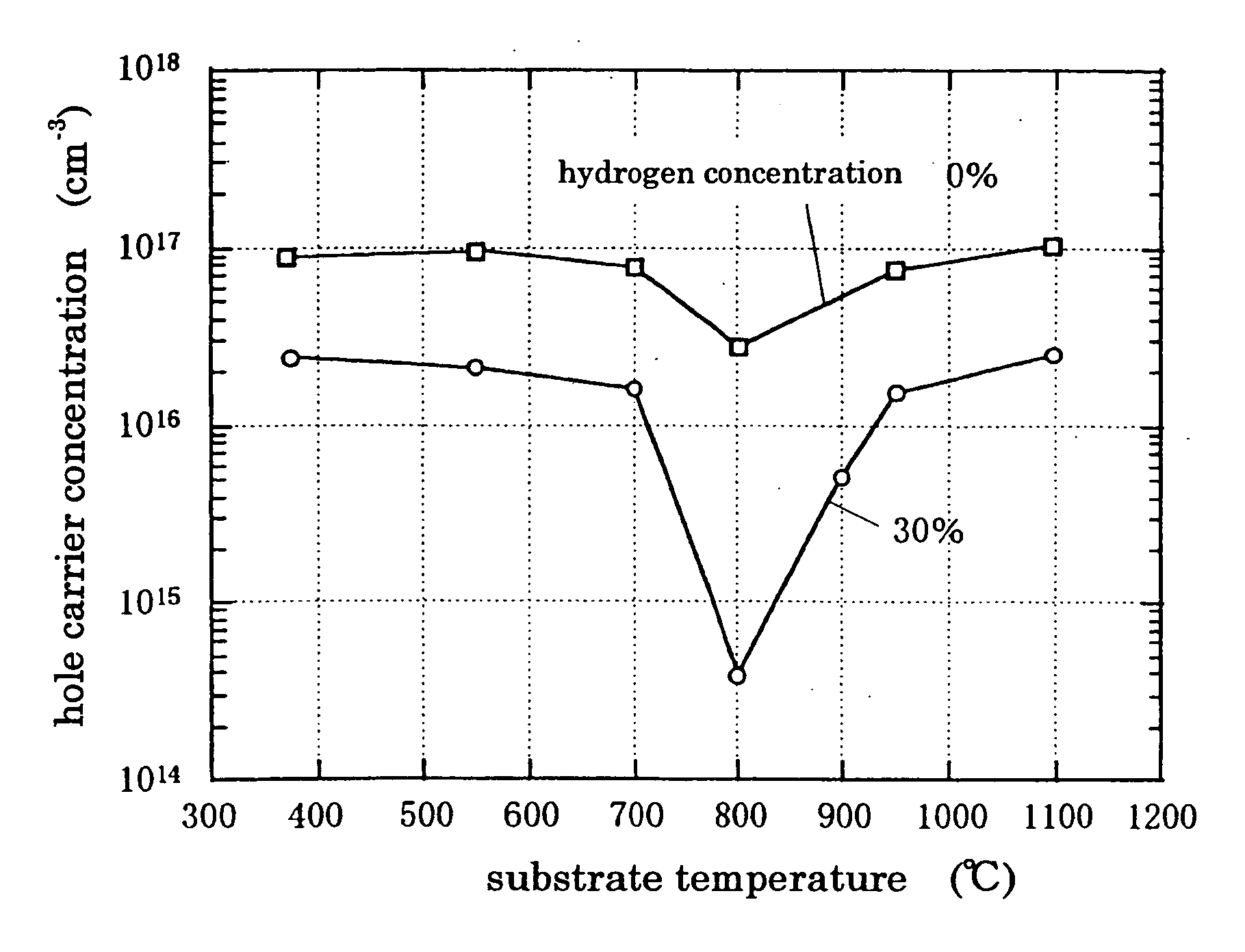

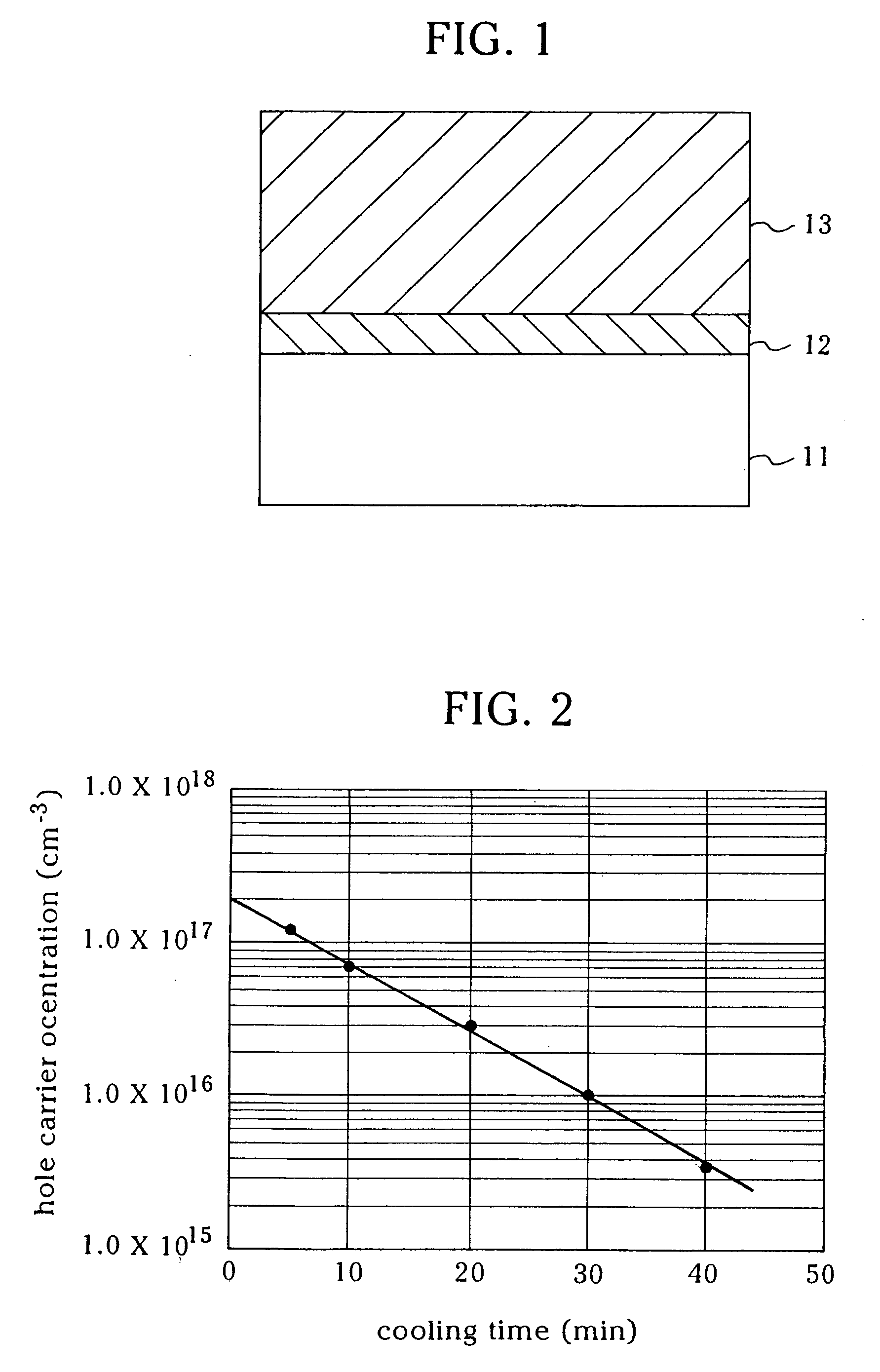

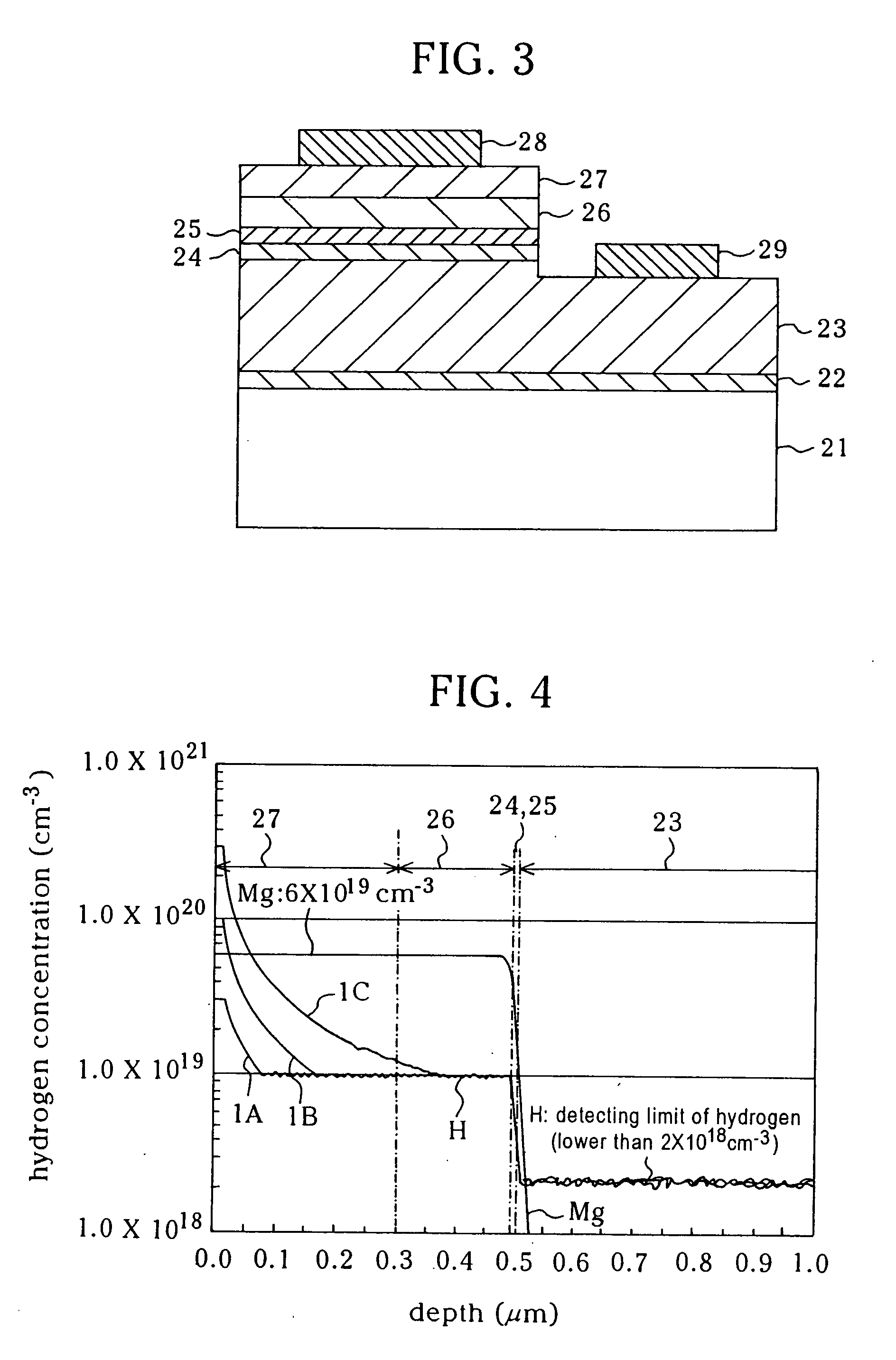

P-type nitride semiconductor and method of manufacturing the same

InactiveUS7056755B1Improve crystal qualityLower resistanceSemiconductor/solid-state device manufacturingSemiconductor devicesDopantNitrogen

A method for manufacturing p-type nitride semiconductor comprising a semiconductor layer forming process where a low resistivity p-type nitride semiconductor layer is formed on a substrate by introducing the sources of p-type dopant, nitrogen and Group III sources on a substrate held at a temperature of 600° C. or higher and a cooling process for cooling the substrate which is bearing the p-type nitride semiconductor layer. The manufacturing method features in that the hole carrier concentration of the p-type nitride semiconductor layer decreases during the cooling process. A superior quality p-type nitride semiconductor is made available, without needing any annealing treatment after growth, by properly specifying the concentration of atmosphere gas and the cooling time.

Owner:PANASONIC SEMICON SOLUTIONS CO LTD

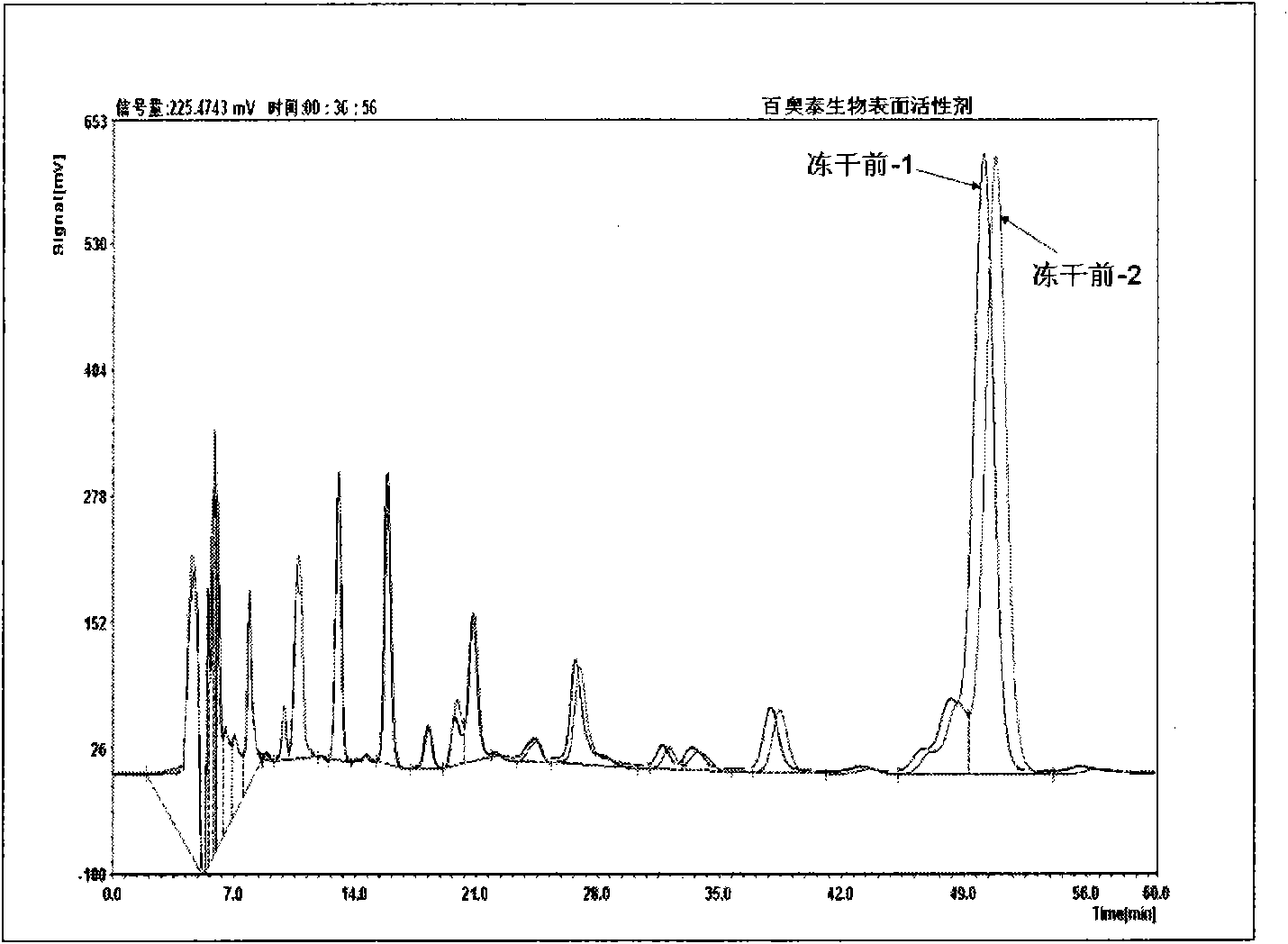

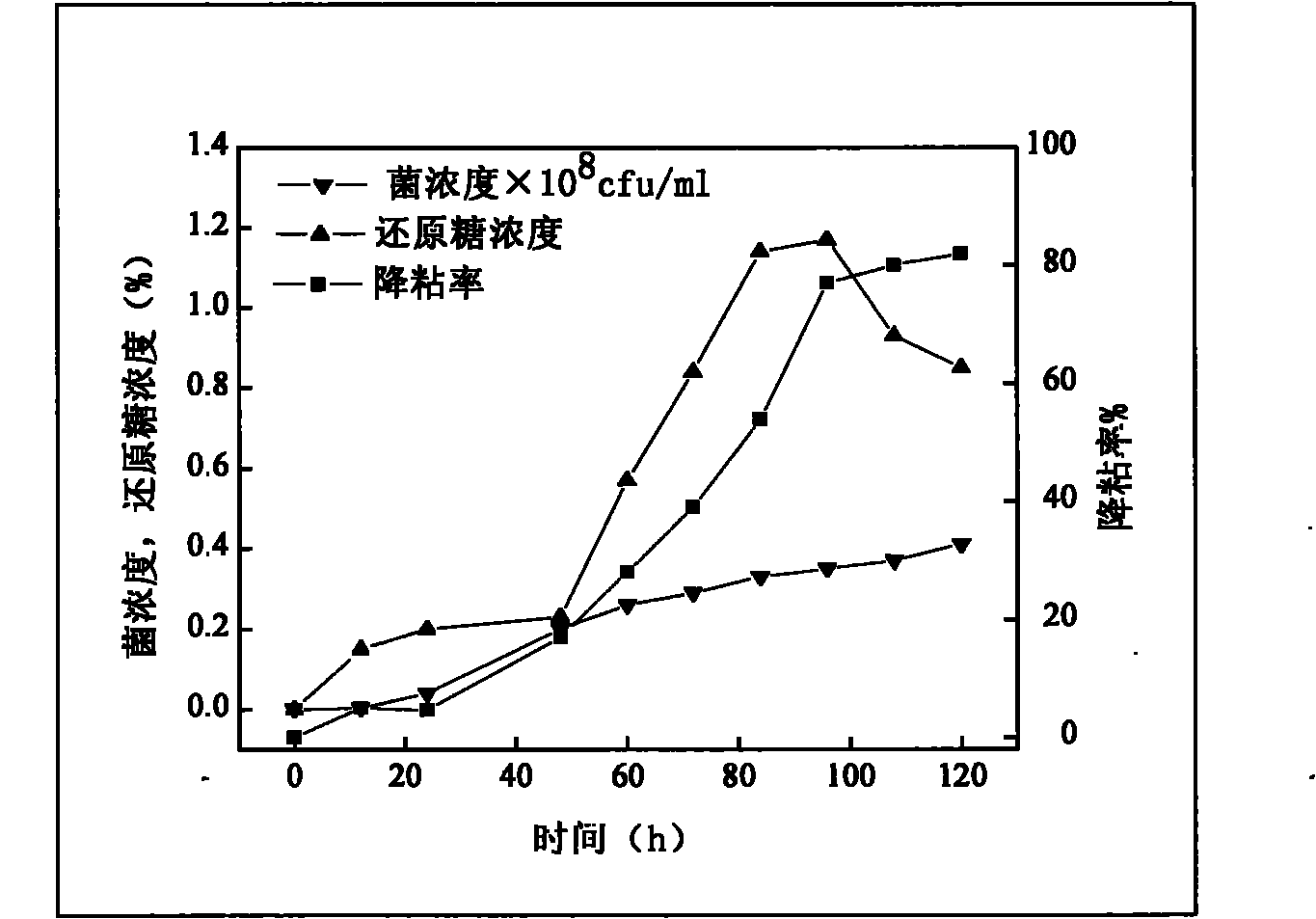

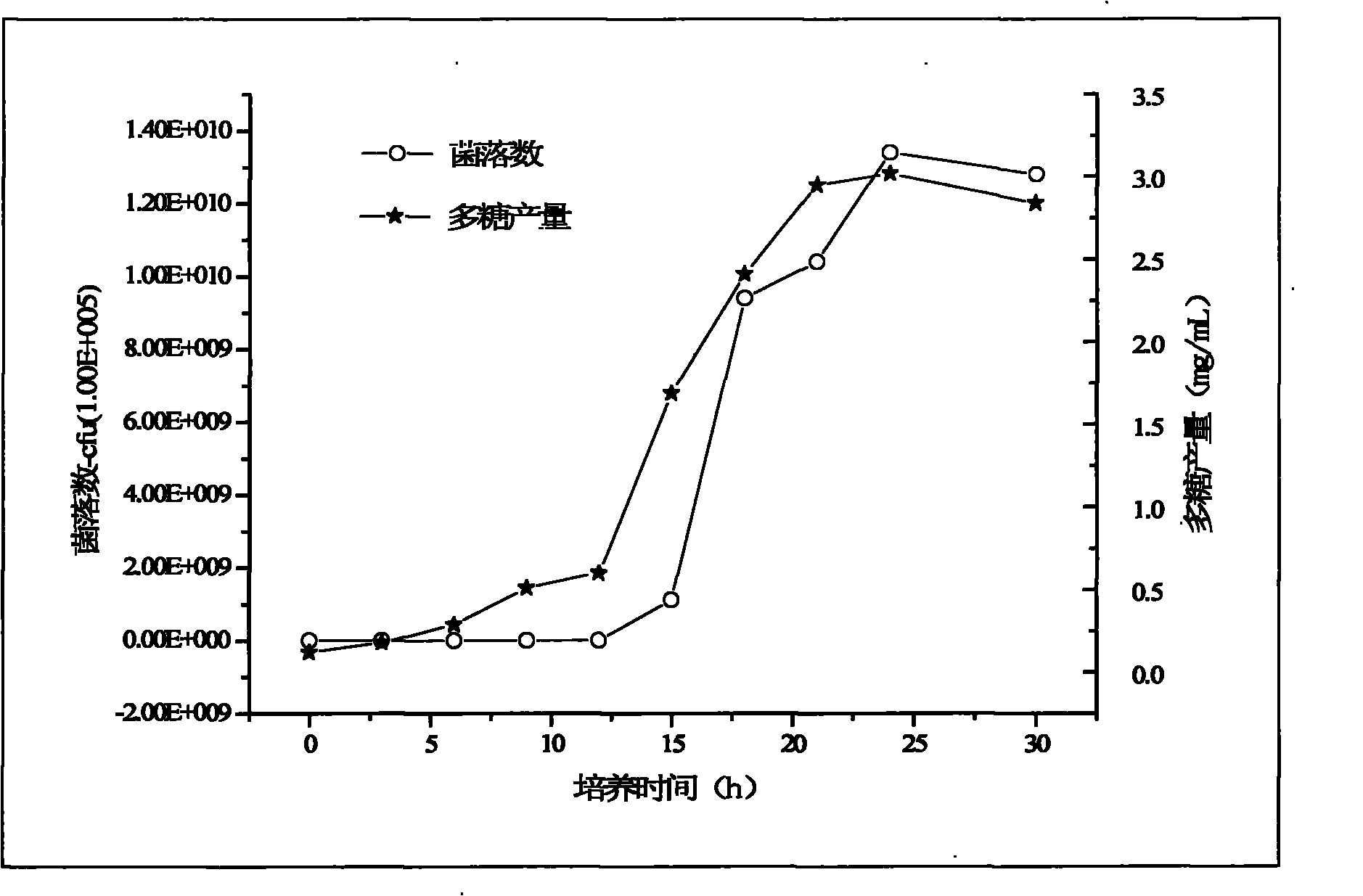

Method for preparing microorganism agent for increasing production of oilfield microorganisms or protecting environment

InactiveCN101914439AHigh activation rateLong storage timeBacteriaMicroorganism based processesMicroorganismHigh activation

The invention discloses a method for preparing a microorganism agent for increasing production of oilfield microorganisms or protecting the environment. A composite microorganism agent is prepared by compounding microorganism sludge obtained by centrifugal sedimentation of microorganism fermentation liquor and a protecting agent and drying the compound; and every one gram of microorganism agent totally comprises 1*109 to 1*1,011 living microorganisms. In the method, powder with high activation rate is prepared from single microorganism or complex microorganism, so the aims of prolonging the product storage time, saving the transportation cost and simplifying the using method are fulfilled. The method for preparing the agent has the characteristics of simple operation, convenient use, wide application range for microorganisms, low cost and suitability for laboratories and batch production.

Owner:DALIAN BITEOMICS INC

P-type nitride semiconductor and method of manufacturing the same

InactiveUS20060183260A1Improve crystal qualityLower resistanceSemiconductor/solid-state device manufacturingSemiconductor devicesDopantNitrogen

A method for manufacturing p-type nitride semiconductor comprising a semiconductor layer forming process where a low resistivity p-type nitride semiconductor layer is formed on a substrate by introducing the sources of p-type dopant, nitrogen and Group III sources on a substrate held at a temperature of 600° C. or higher and a cooling process for cooling the substrate which is bearing the p-type nitride semiconductor layer. The manufacturing method features in that the hole carrier concentration of the p-type nitride semiconductor layer decreases during the cooling process. A superior quality p-type nitride semiconductor is made available, without needing any annealing treatment after growth, by properly specifying the concentration of atmosphere gas and the cooling time.

Owner:PANASONIC CORP

Use of fly ash from burning city domestic garbage

InactiveCN1810894AImprove securityReduce leaching concentrationPigment treatment with non-polymer organic compoundsActive agentEnvironmental engineering

The present invention relates to new use of fly ash from burning city domestic garbage, and the fly ash is used as stuffing for polymer material after being activated with surfactant in a dry process. Fly ash is first crushed to 500-1200 mesh and stoved, and then mixed with surfactant in the ratio of 100 to 1-5 inside a ball mill through grinding for 5-30 min, with the modified fly ash being preserved hermetically. The modified fly ash in 10-15 wt% is added into polypropylene base material to produce product reaching relevant standard. The present invention has wide material source, low cost, no secondary pollution caused by the activation treatment and excellent market foreground.

Owner:TONGJI UNIV

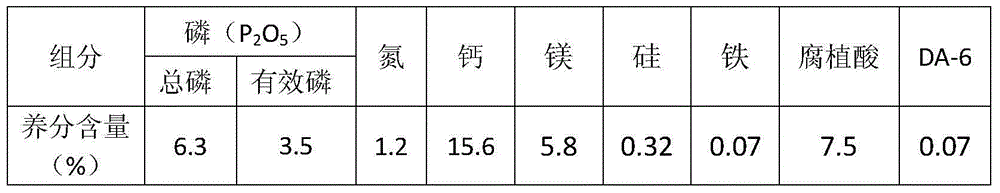

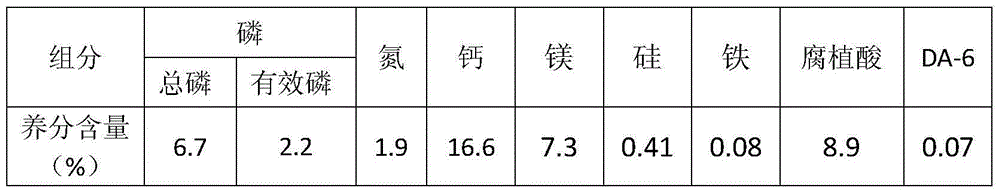

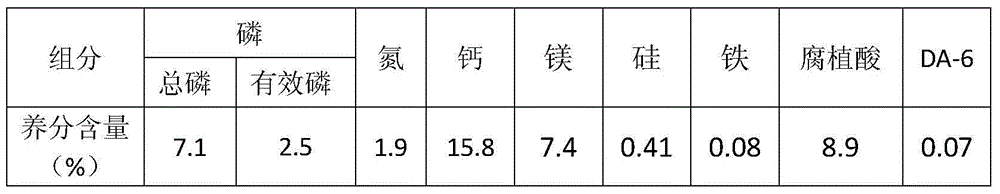

Soil conditioner prepared by activating phosphate rock tailings by using organic/inorganic activators and preparation method thereof

The invention relates to a soil conditioner prepared by activating phosphate rock tailings by using organic / inorganic activators and a preparation method thereof. The soil conditioner is prepared by taking phosphate rock tailings as raw materials through carrying out mixed grinding on the phosphate rock tailings so as to activate the phosphate rock tailings in an organic-inorganic combined activation mode, in such a way, the influence of impurities in the phosphate rock tailings is overcome, so that low-content calcium, magnesium, phosphorus, silicon and iron in the phosphate rock tailings are fully activated, and then released into elements which can be effectively utilized by plants, therefore, the product has rich silicon, calcium, magnesium, nitrogen and phosphorus elements and the like, and has a good effect on the improvement and conditioning of acidic soil. The method has the advantages of simple operation, easily available raw materials, good product quality, simple reaction process, environmental friendliness, and the like.

Owner:KINGENTA NORSTERRA CHEM CO LTD

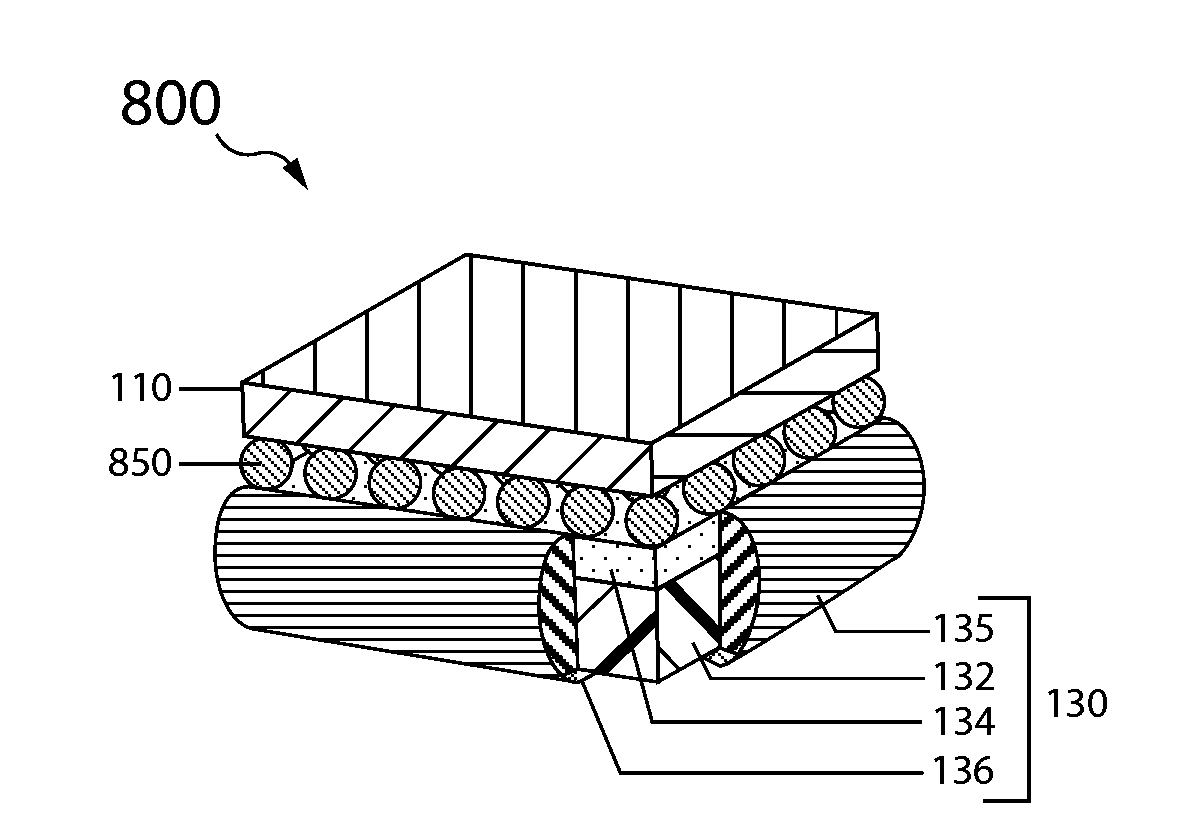

Bi-polar protected electrodes and multi-cell stacks

InactiveUS20140335392A1Improve stabilityReduced ion exchangeFinal product manufactureNegative electrodesHigh energyActive component

Water activated alkali metal battery cells, protected anode bi-polar electrodes and multi-cell stacks are configurable to achieve very high energy density. The cells, bi-polar electrode and multi-cell stacks include a protected anode and a cathode having a solid phase electro-active component material that is reduced during cell discharge.

Owner:POLYPLUS BATTERY CO INC

Method for producing ZnTe system compound semiconductor single crystal, ZnTe system compound semiconductor single crystal, and semiconductor device

InactiveUS20080090390A1High crystallinityEasy to controlPolycrystalline material growthSemiconductor/solid-state device manufacturingDopantDevice material

The present invention relates to a method for producing an n-type ZnTe system compound semiconductor single crystal having high carrier concentration and low resistivity, the ZnTe system compound semiconductor single crystal, and a semiconductor device produced by using the ZnTe system compound semiconductor as a base member. Concretely, a first dopant and a second dopant are co-doped into the ZnTe system compound semiconductor single crystal so that the number of atoms of the second dopant becomes smaller than the number of atoms of the first dopant, the first dopant being for controlling a conductivity type of the ZnTe system compound semiconductor to a first conductivity type, and the second dopant being for controlling the conductivity type to a second conductivity type different from the first conductivity type. By the present invention, a desired carrier concentration can be achieved with a doping amount smaller than in earlier technology, and crystallinity of the obtained crystal can be improved.

Owner:JX NIPPON MINING & METALS CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com