Patents

Literature

149results about How to "Increase the number of holes" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Supported noble metal catalyst and preparation and application thereof

ActiveCN104923225AGood dispersionEnhanced strong interactionHydrocarbon from carbon oxidesDispersed particle separationMethanationHigh activity

The invention relates to a preparation method and a catalytic application of a supported noble metal catalyst. Active components are noble metals Ru, Rh and Pd, and a carrier is MxOy or perovskite MAlO3 or spinel MAl2O4. The composite oxide carrier is prepared by an impregnation method or a coprecipitation method and is roasted under a medium-high temperature condition of 650-1200 DEG C ultimately, so that while the formed MxOy, MAlO3 or MAl2O4 or even a mixture thereof has a closer effect with an Al2O3 carrier, the number of defects and holes on the surface of Al2O3 is greatly increased, and thus prepared noble metal nanoparticles have high dispersion degree and strong stability. The catalyst preparation method has the advantages of simple operation, convenience for production and application, good product repeatability, high activity in a carbon dioxide methanation reaction and a carbon monoxide oxidation reaction, strong stability in a storage state and reaction, and quite good application prospects.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Glass ceramic coating produced on metal carrier and its producing method

InactiveCN1899997AImprove ductilityNot easy to fall offCatalyst carriersCatalyst protectionCopper oxideAluminium oxide

The present invention belongs to the field of automobile tail gas purifying technology, and is especially glass ceramic coating on metal or alloy carrier of automobile tail gas purifying treater and its preparation process. The oxides of the glass coating include silica in 25-65 wt% and boron oxide in 5.0-27 wt%, except the mixture of other 3-9 oxides selected from 17 kinds of oxides, including sodium oxide, potassium oxide, lithium oxide, aluminum oxide, calcium oxide, etc. The glass coating on the metal carrier can raise the mechanical strength and reaction activity of the catalyst effectively, and this results in saving in active component and lowered cost.

Owner:JILIN UNIV

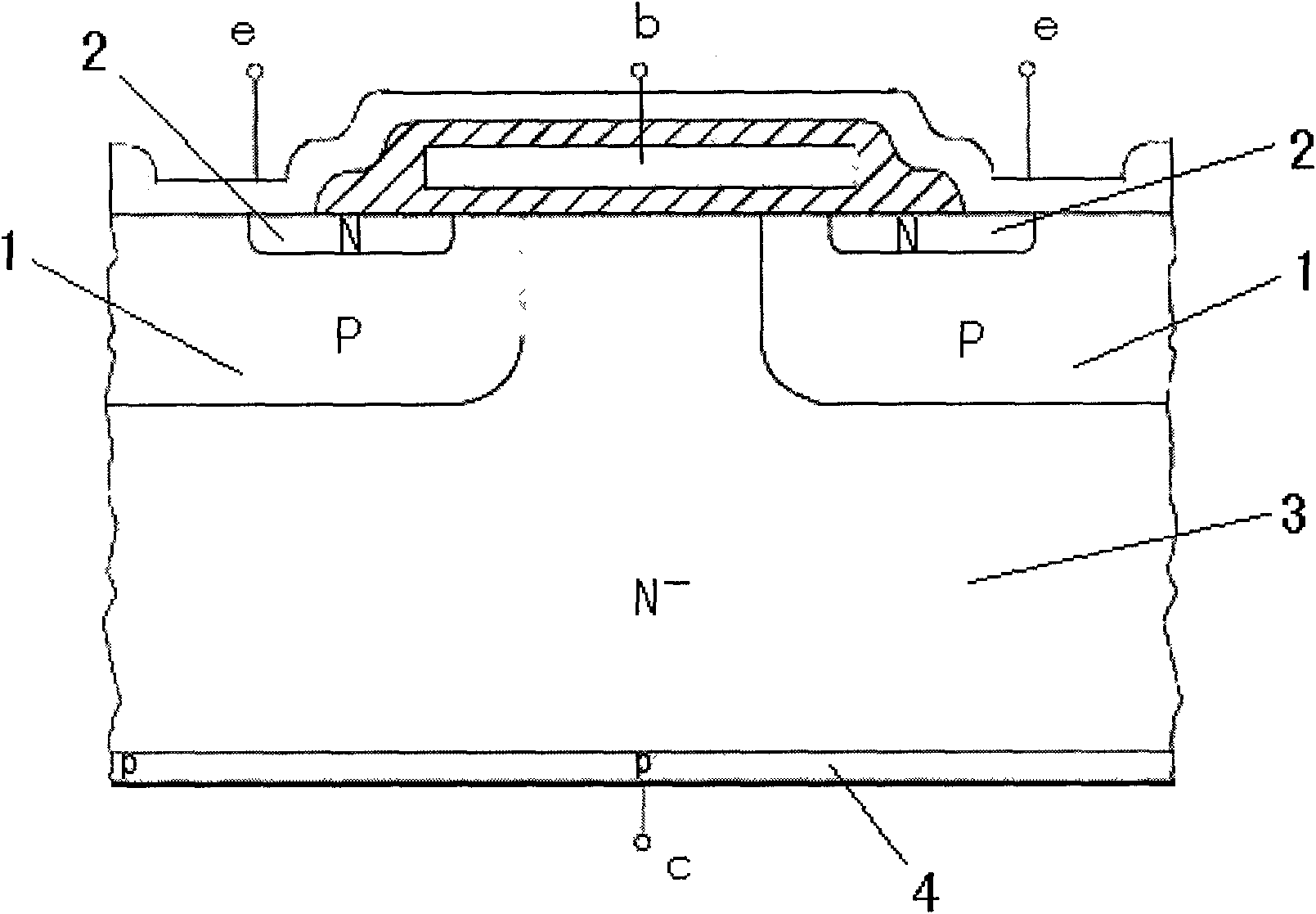

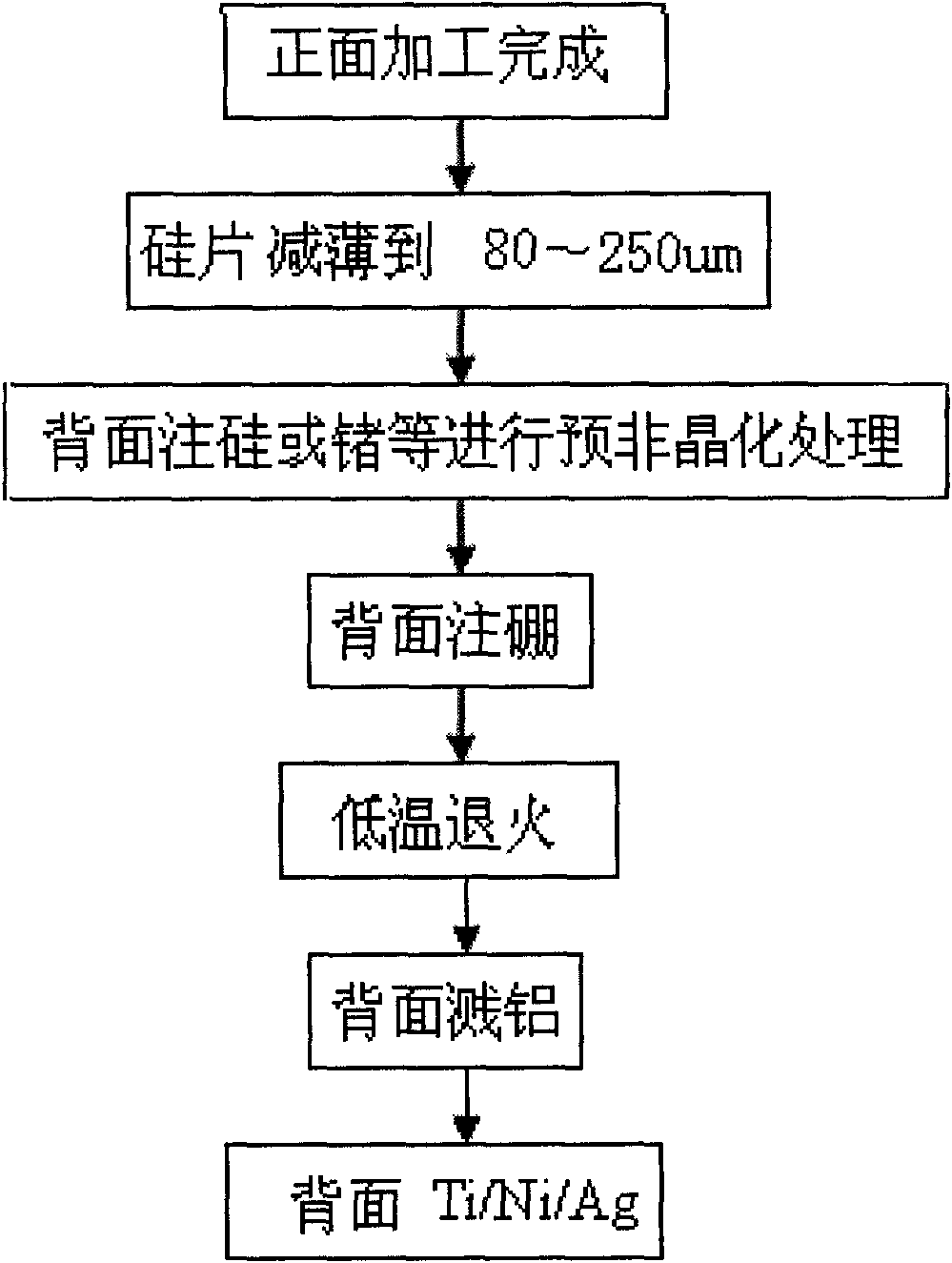

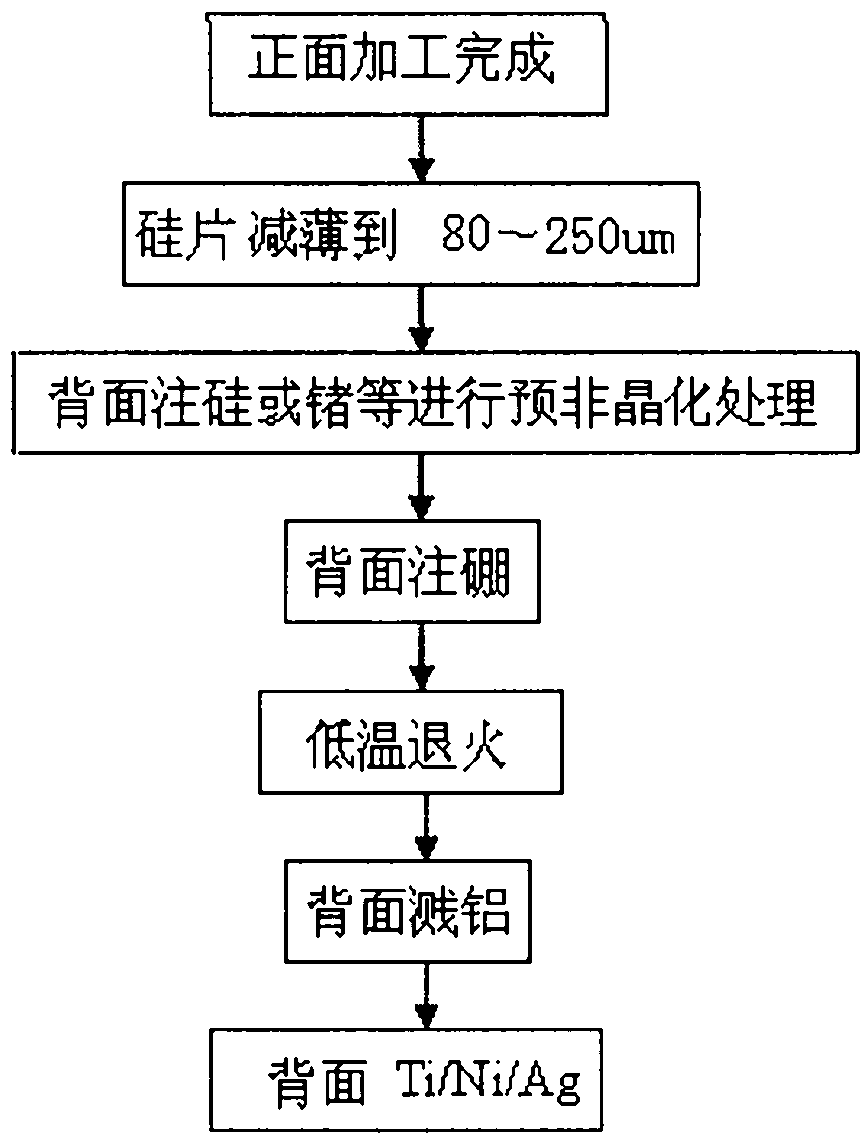

Technique for manufacturing back of non-through insulated-gate bipolar transistor chip

ActiveCN101789375AIncrease activation rateIncrease the number of holesSemiconductor/solid-state device manufacturingIonAluminium

The invention relates to a technique for manufacturing the back of a non-through insulated-gate bipolar transistor chip, comprising the following steps of: (1) finishing a technique for processing the front of the non-through insulated-gate bipolar transistor chip; (2) grinding and thinning the back of a silicon chip, and removing stress; (3) injecting silicon ion, germanium ion or boron difluoride ion at the back of the silicon chip for amorphous pretreatment; (4) injecting boron ion at the back of the silicon chip; (5) carrying out furnace tube low temperature annealing; (6) adopting a sputtering or an evaporating method, generating an aluminium film at the back of the silicon chip, and carrying out alloy treatment; and (7) adopting the sputtering or the evaporating method, respectively preparing a titanium, a nickel and a silver metal layers at the back of the silicon chip. The back of the silicon chip is firstly injected with the silicon ion, the germanium ion or the boron difluoride ion for amorphous pretreatment and then injected with the boron ion for low-temperature annealing, so that the activation rate of injecting the boron impurity is improved, the conductive modulation effect for a drifting area can be enhanced, and the conducting resistance and conducting voltage are effectively reduced. The technique can be widely applied to a manufacturing technique of a semiconductor.

Owner:TSINGHUA UNIV

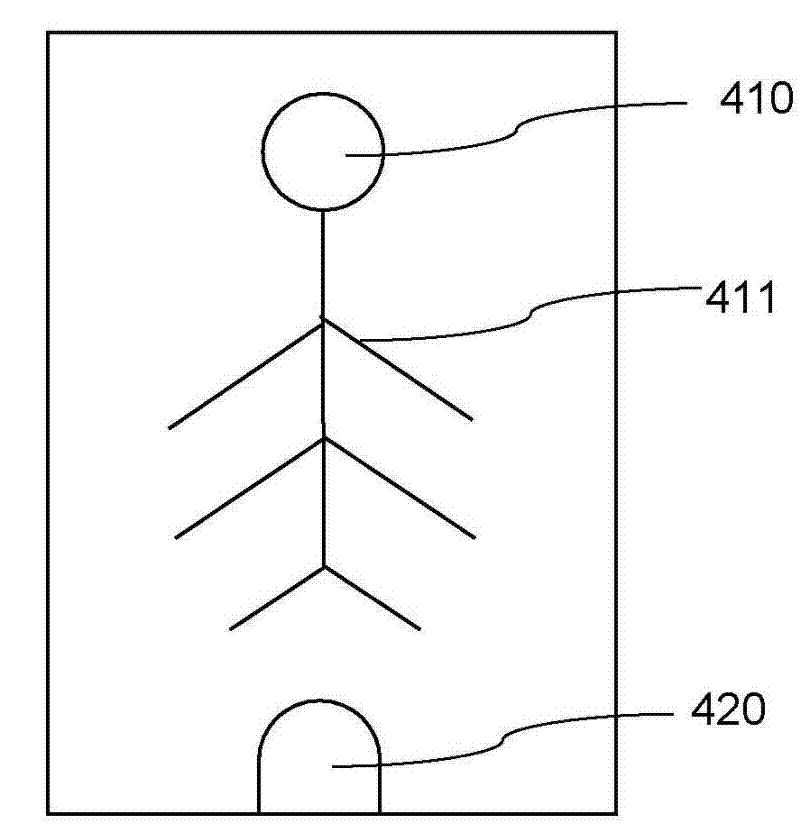

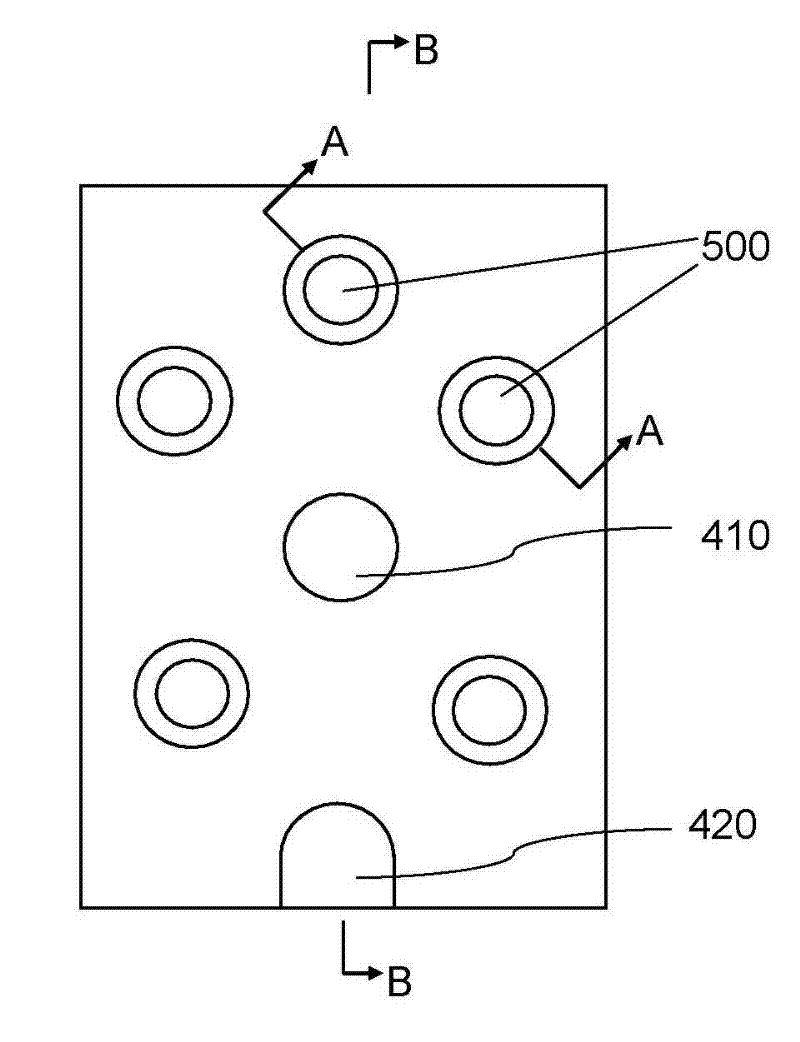

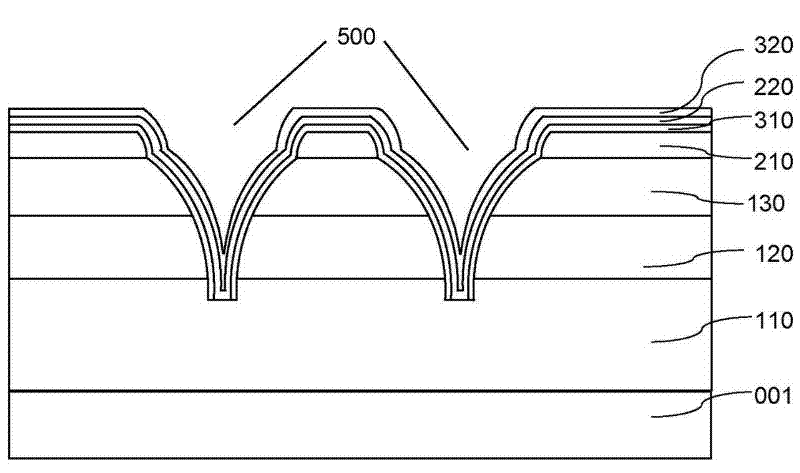

Gallium nitride based light emitting diode and manufacturing method thereof

InactiveCN102420279AImprove luminous efficiencyIncrease the number of holesSemiconductor devicesGallium nitrideElectrically conductive

The invention discloses a gallium nitride based light emitting diode and a manufacturing method thereof. In the invention, a double-layer transparent conducting layer structure is designed, a first transparent extension layer is formed on a p type semiconductor layer, a p electrode is provided at a center area of an epitaxial structure layer, peripheral of the p electrode is provided with a hole structure, and a second transparent extension layer is formed in the hole structure and is connected with an n electrode to form an equipotential surface. After current is injected from the p electrode, the current diffuses to a whole light emitting surface through the first transparent extension layer and flows to an n type layer through the p type semiconductor layer, and since the second transparent extension layer and the n electrode are in a same electric potential, the current diffuses to the second transparent extension layer to reach the n electrode finally. According to the gallium nitride based light emitting diode and the manufacturing method, in a process that the current flows to the n electrode from the p electrode, the current is uniformly distributed on an epitaxial luminescent layer, a current flow through path of a P layer is shorter, simultaneously, structure of partial light emitting surface is changed, and luminescence efficiency is effectively raised.

Owner:XIAMEN SANAN OPTOELECTRONICS TECH CO LTD

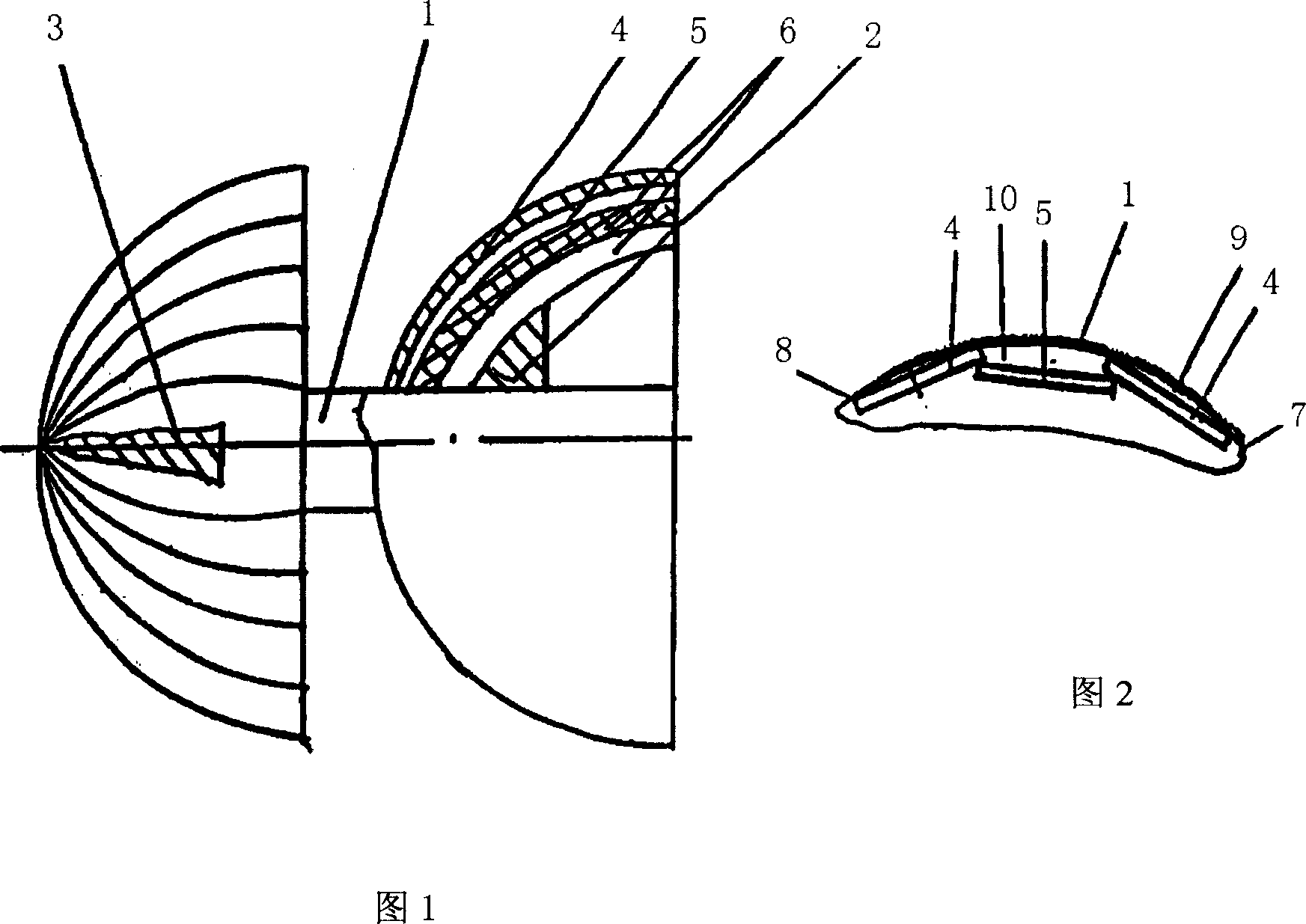

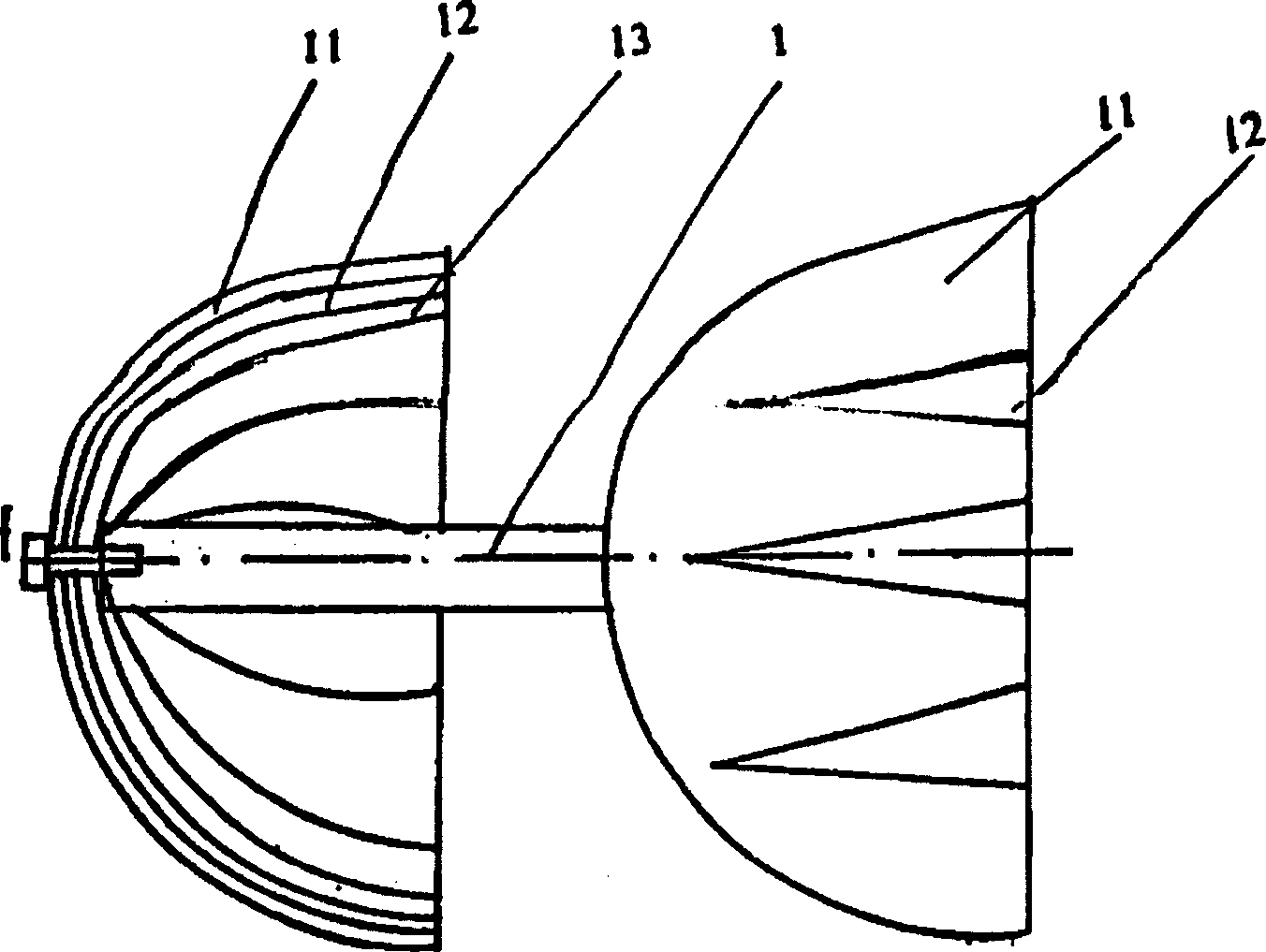

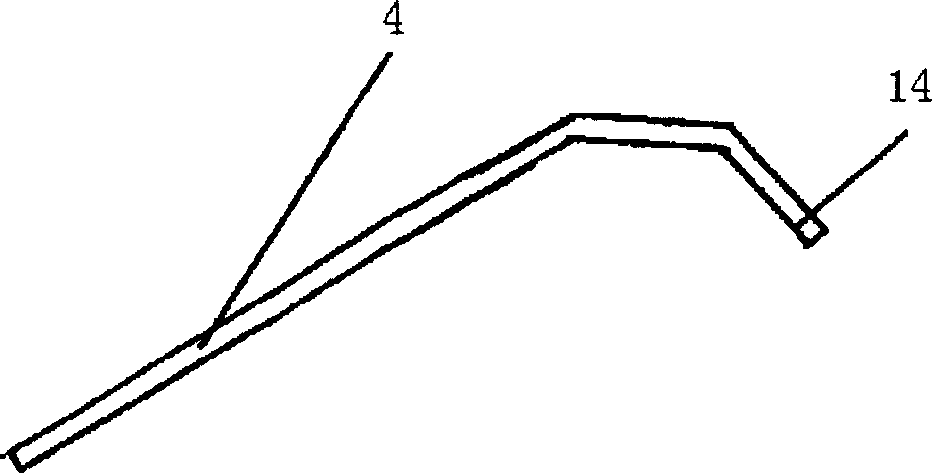

Pipeline cleaning method and device

A method for cleaning pipeline features that a bowl-shaped cleaning part is driven by liquid stream to move in a pipeline, its edge can generate the liquid jet, and its vibration can squeeze the dirt and generate holes in fluid, so removing the dirt from the inner surface of pipeline. Its apparatus is composed of an axle with axle sleeve and the elastic sheets and elastic soft sheets, which are installed to said axle.

Owner:大连玛斯特科技发展有限公司

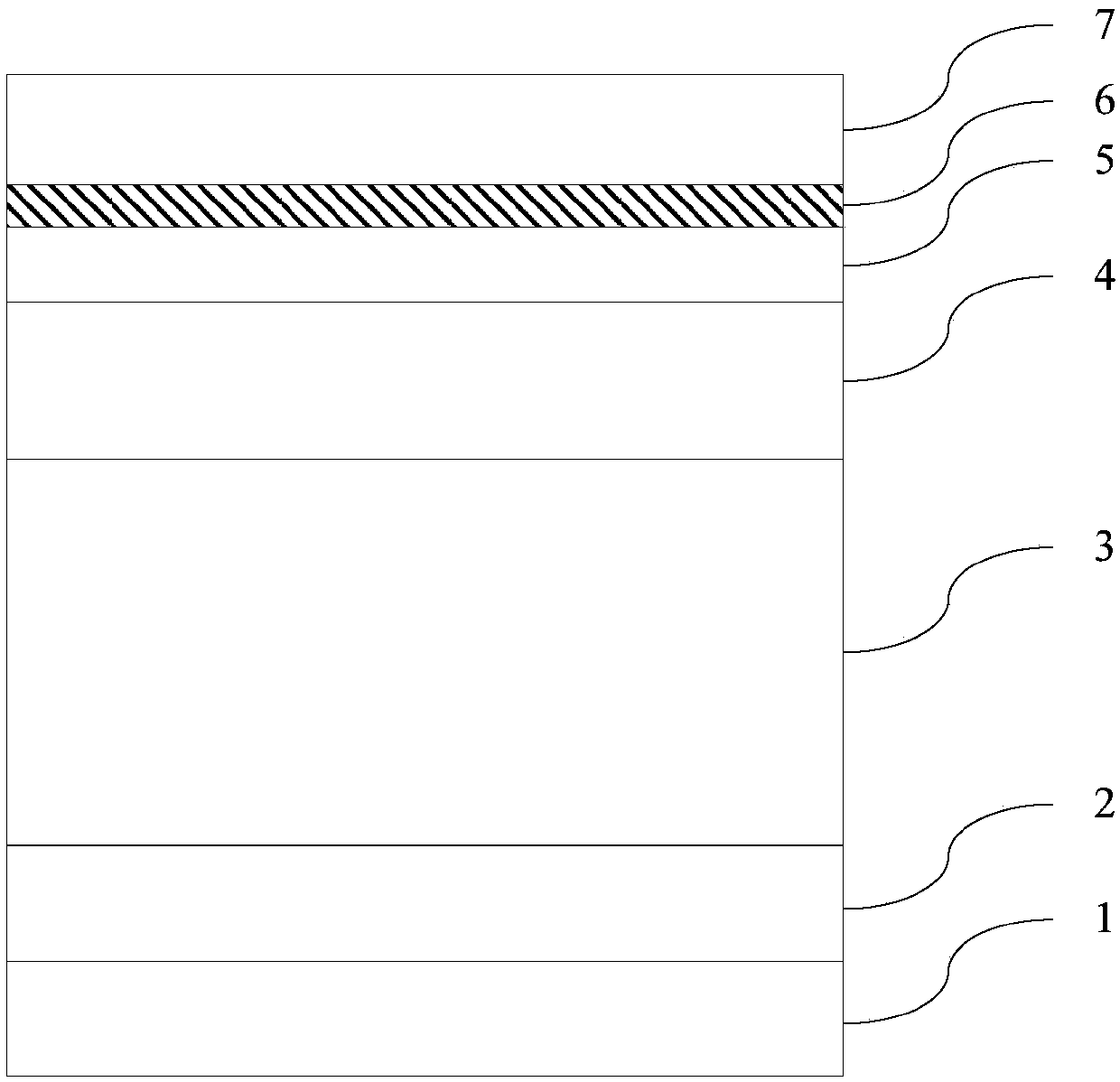

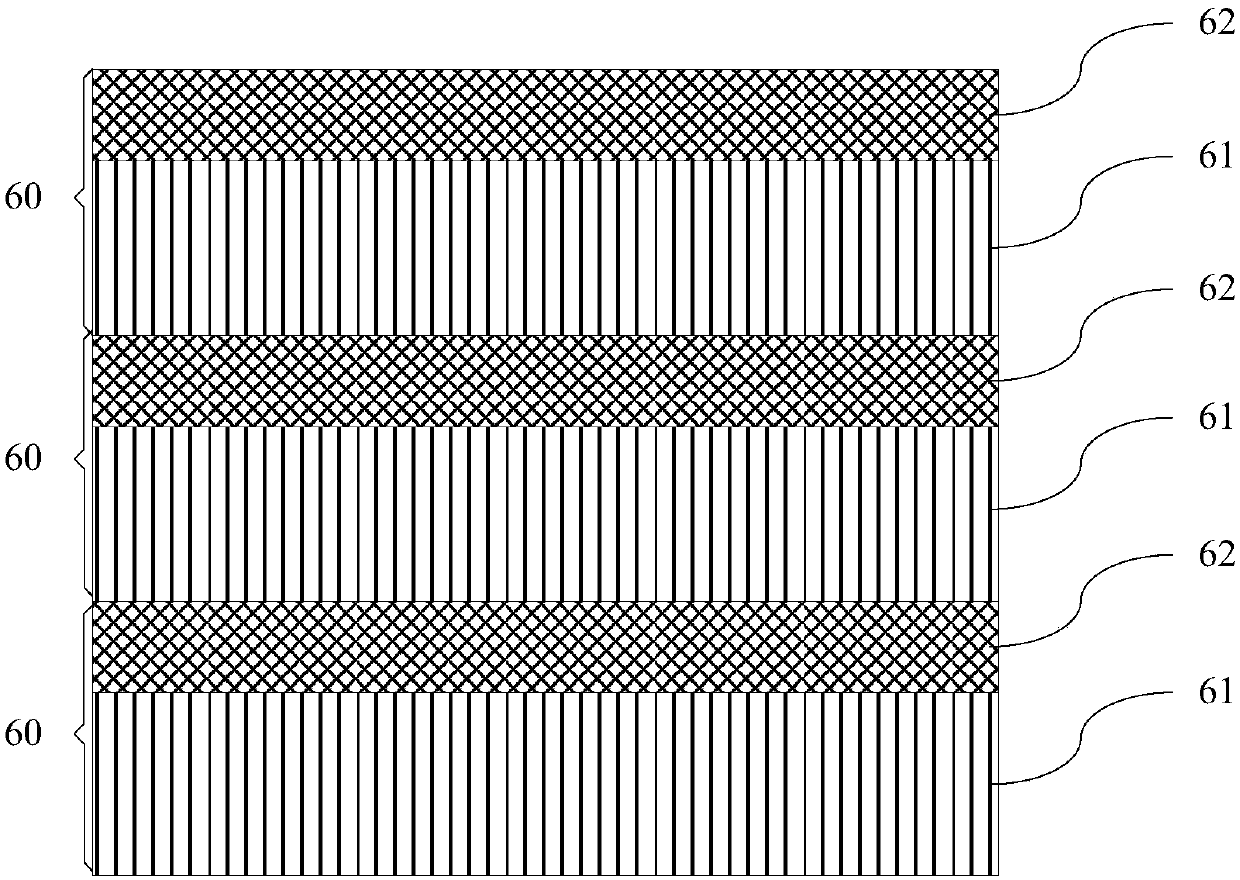

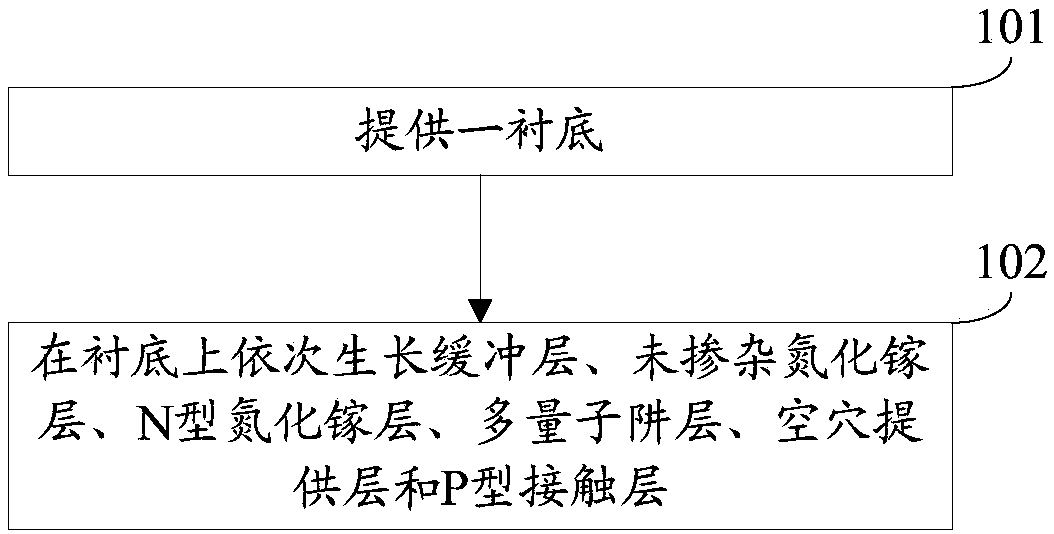

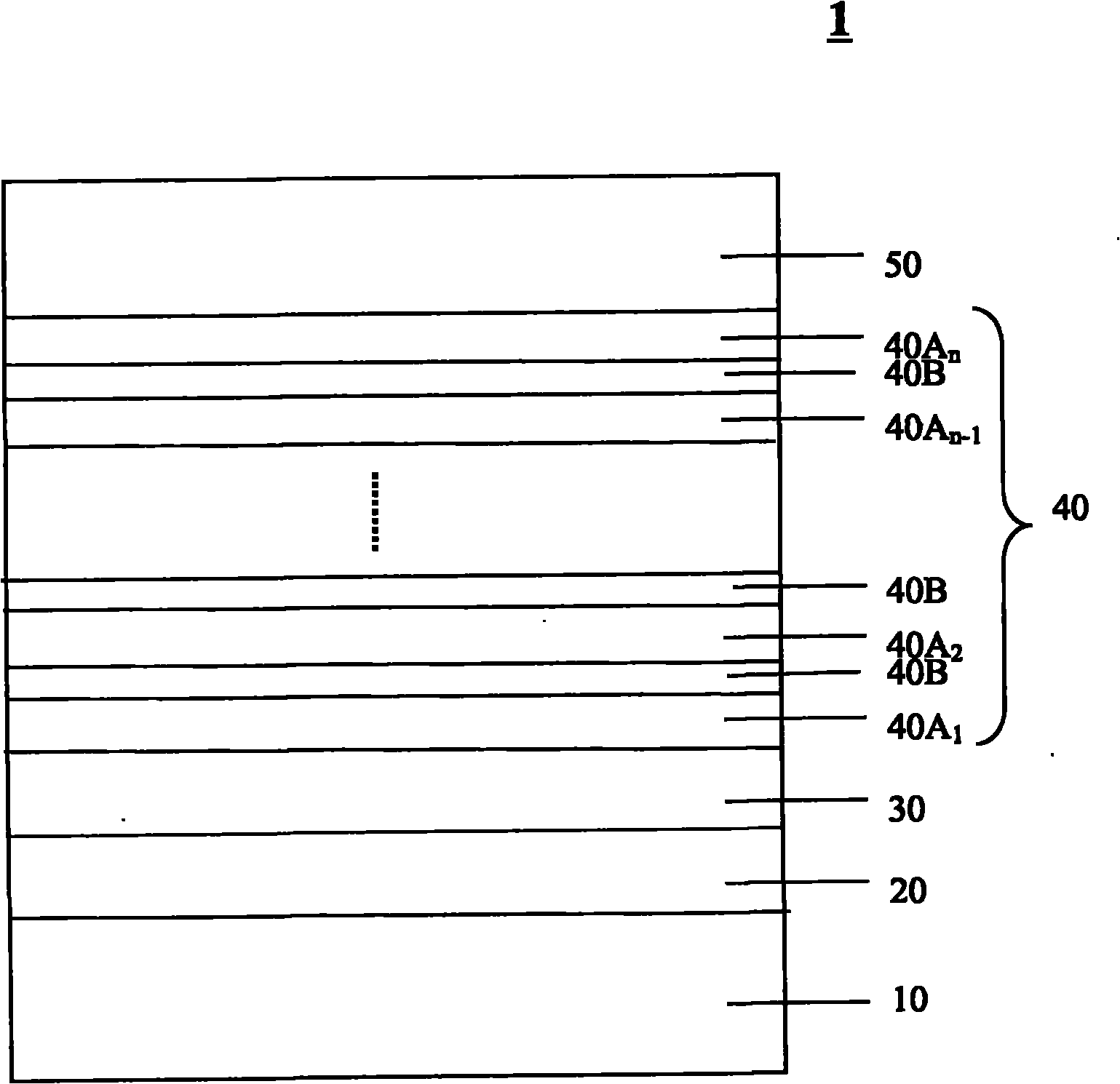

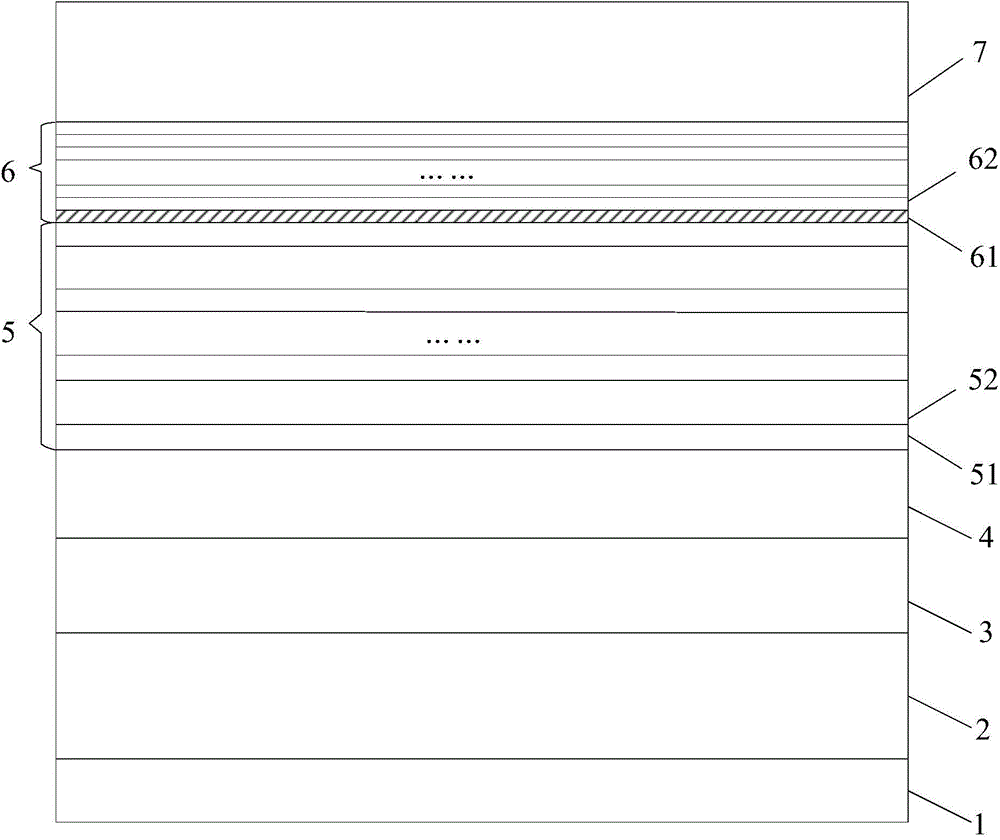

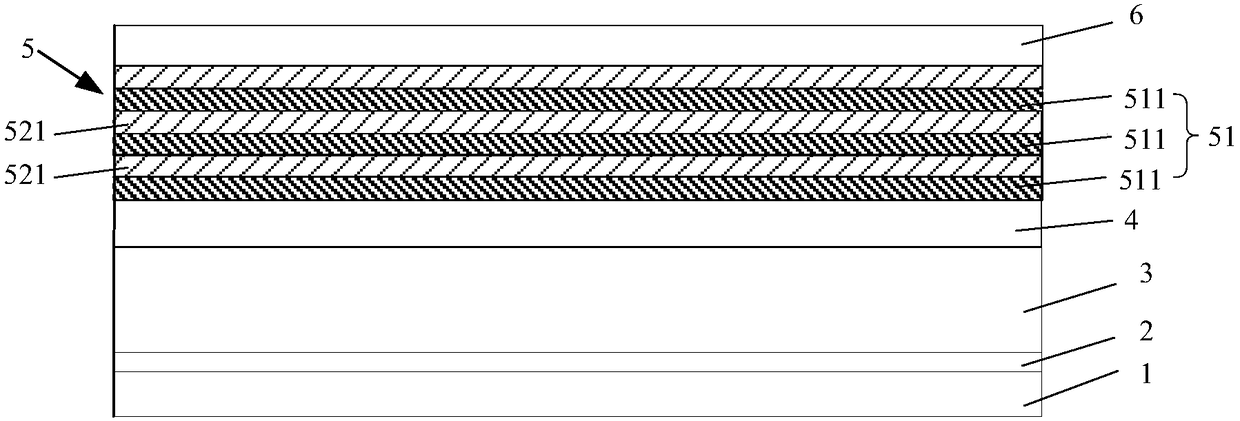

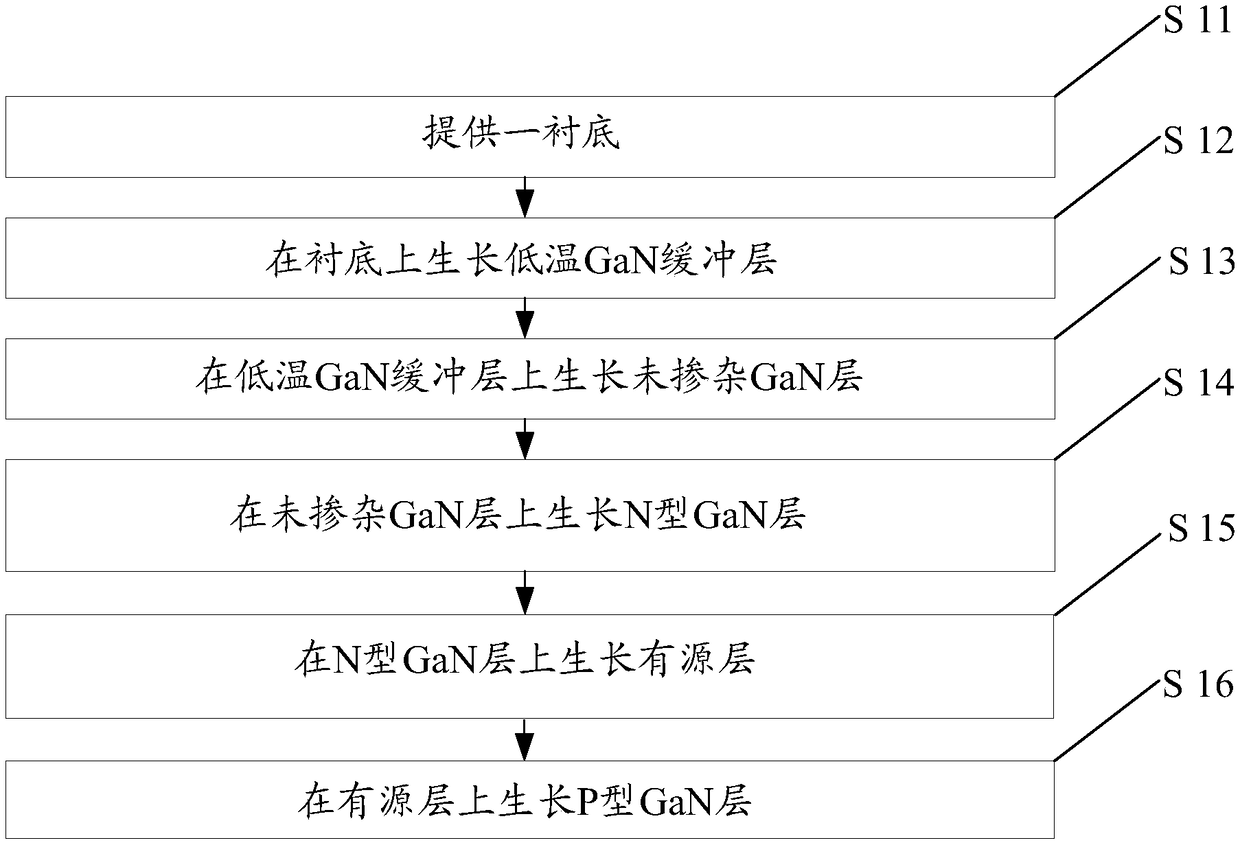

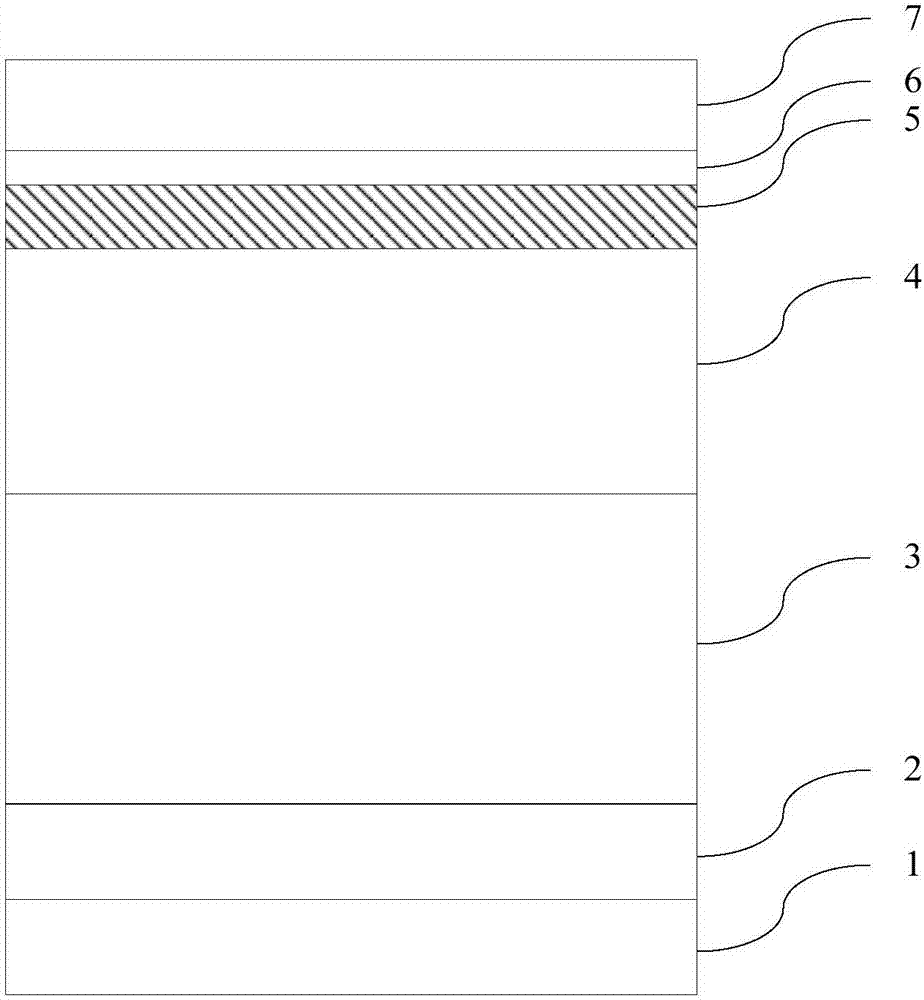

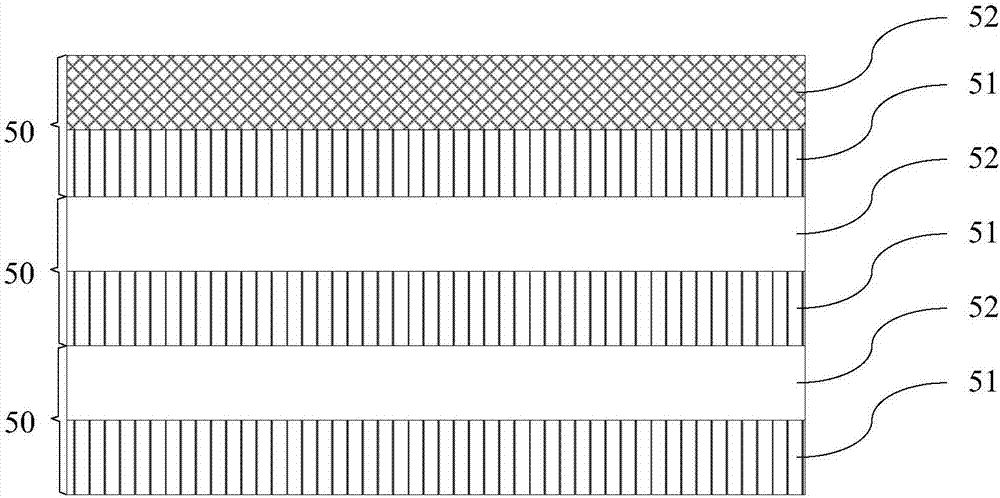

Epitaxial wafer of light-emitting diode and preparation method thereof

InactiveCN107591466AFacilitates planar spreadingImprove uniformitySemiconductor devicesContact layerGallium nitride

The invention, which belongs to the technical field of the semiconductors, discloses an epitaxial wafer of a light-emitting diode and a preparation method thereof. The epitaxial wafer comprises a substrate, a buffer layer, an un-doped gallium nitride layer, an N type gallium nitride layer, a multi-quantum-well layer, a hole supply layer and a P type contact layer, wherein the buffer layer, the un-doped gallium nitride layer, the N type gallium nitride layer, the multi-quantum-well layer, the hole supply layer and the P type contact layer are laminated on the substrate successively. The hole supply layer includes at least one sub layer including a P type doped indium gallium nitride layer and an aluminum nitride layer stacked on the P type doped indium gallium nitride layer. According to the invention, because the P type doped indium gallium nitride layer is used for providing a hole and the aluminum nitride layer is used for replacing an electron barrier layer to suppress over flowingof electrons in at the hole supply layer, the distance between the hole supply layer and the multi-quantum-well layer is reduced, the electrons provided by the hole supply layer are injected into themulti-quantum-well layer, the number of holes of the multi-quantum-well layer is increased, so that the light emitting efficiency of the light-emitting diode is improved.

Owner:HC SEMITEK ZHEJIANG CO LTD

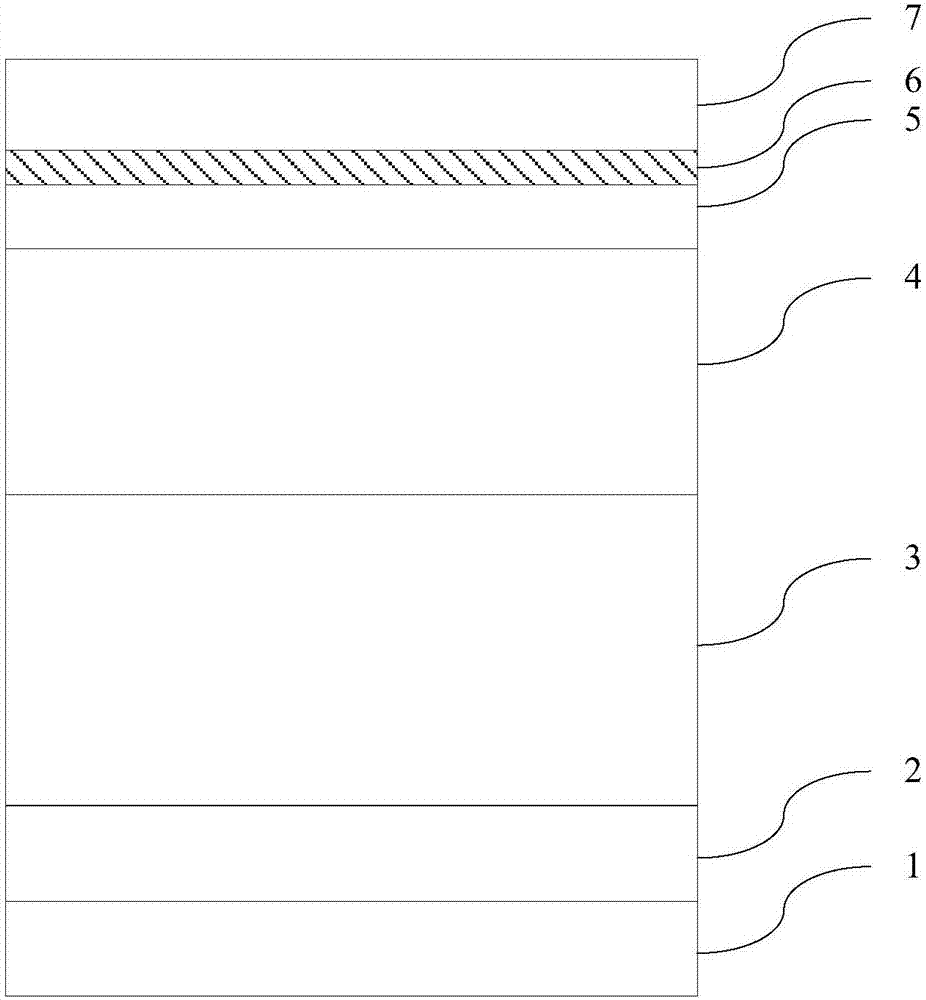

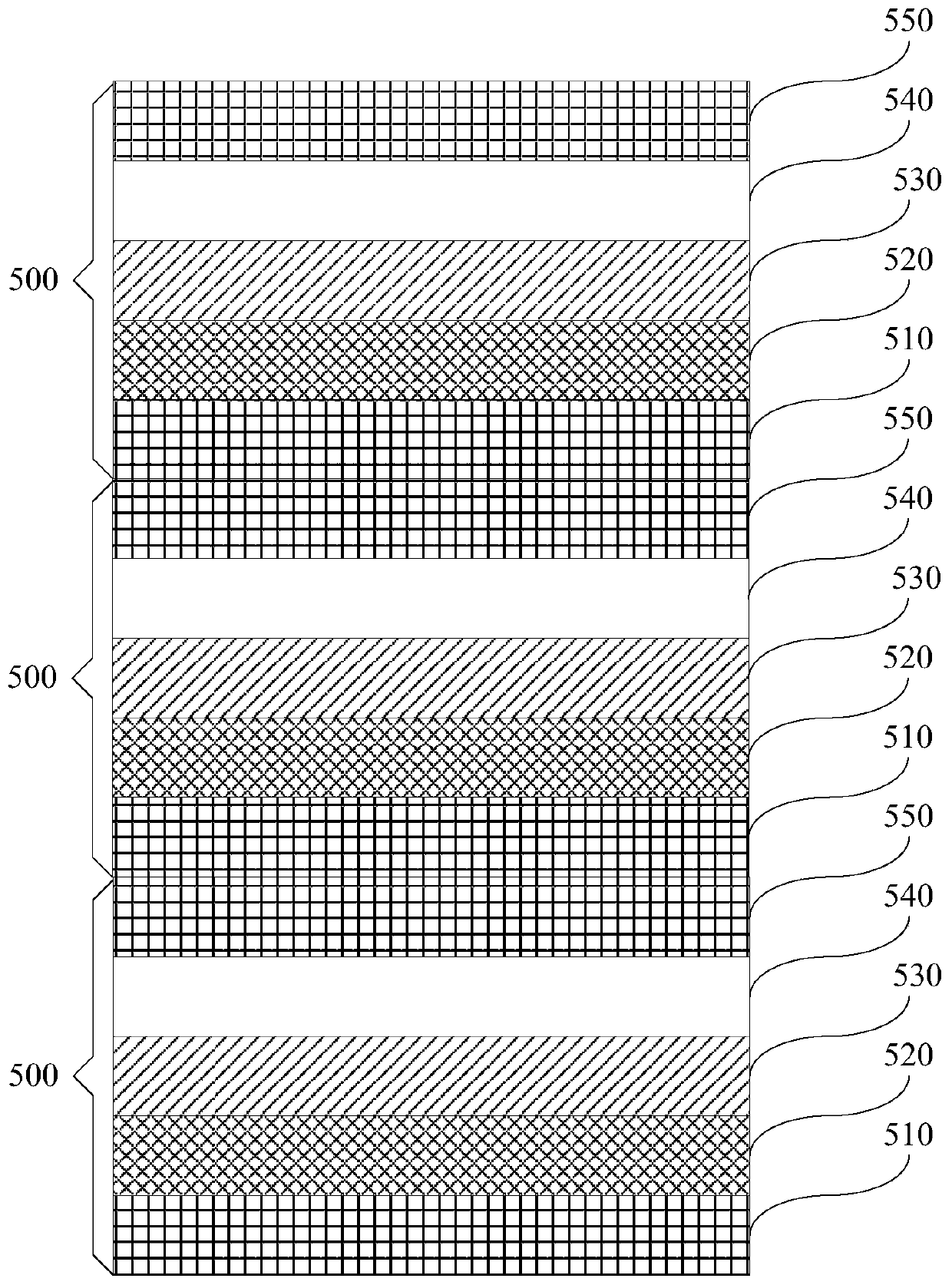

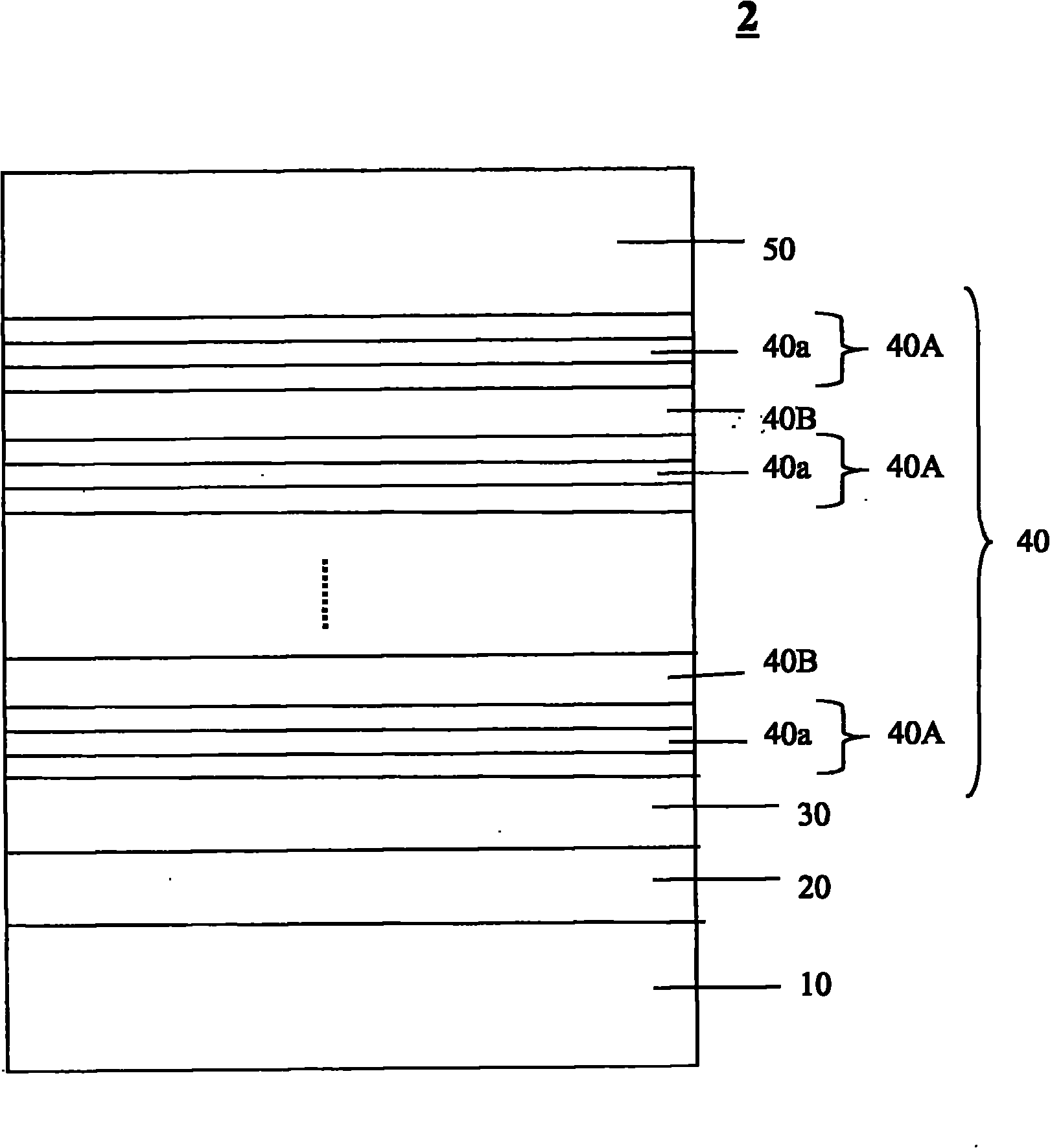

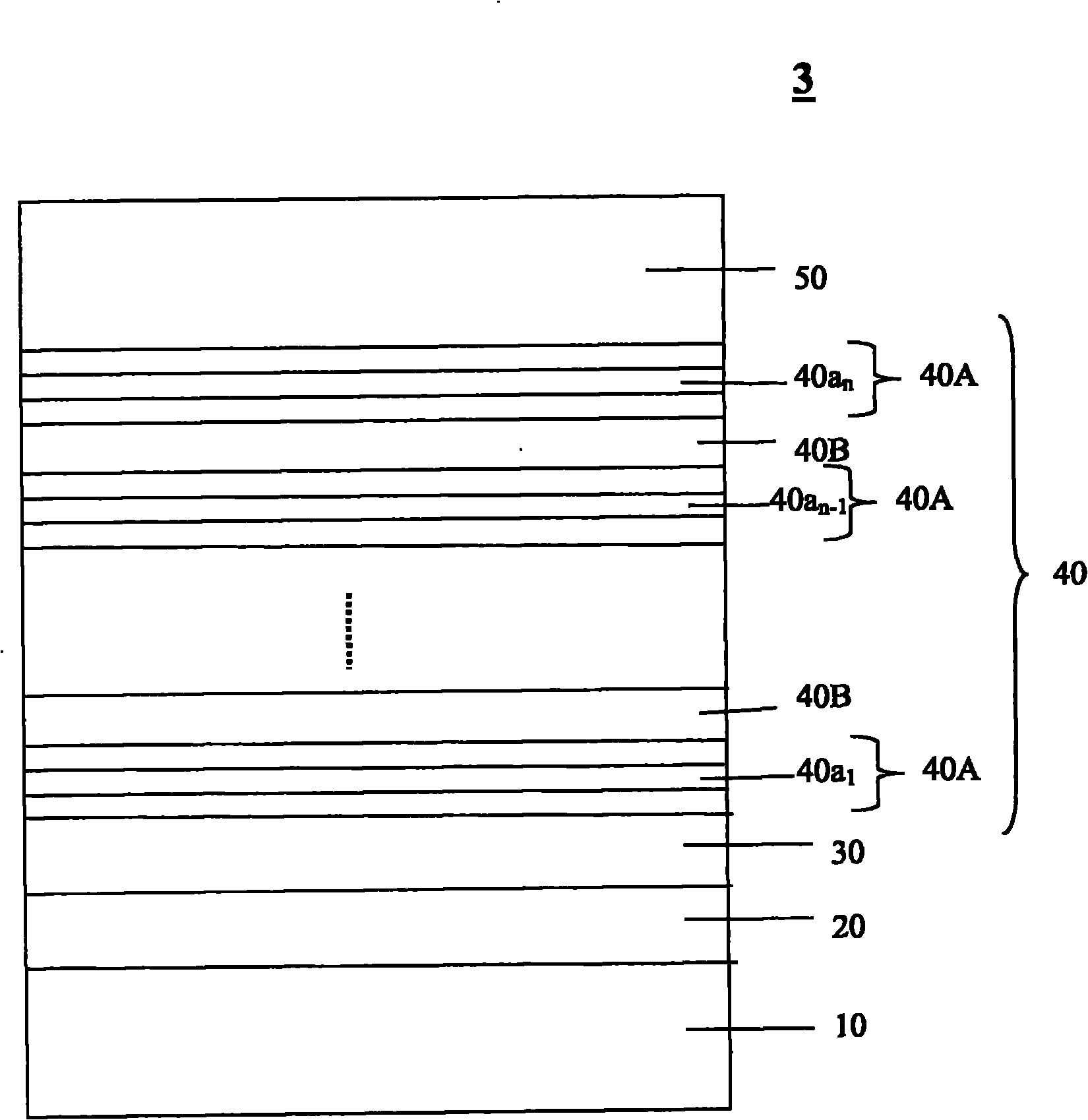

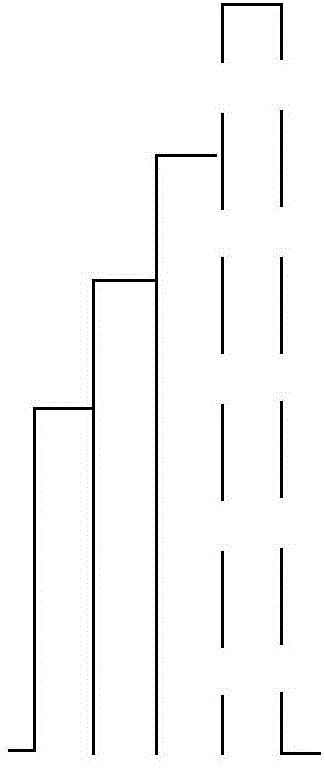

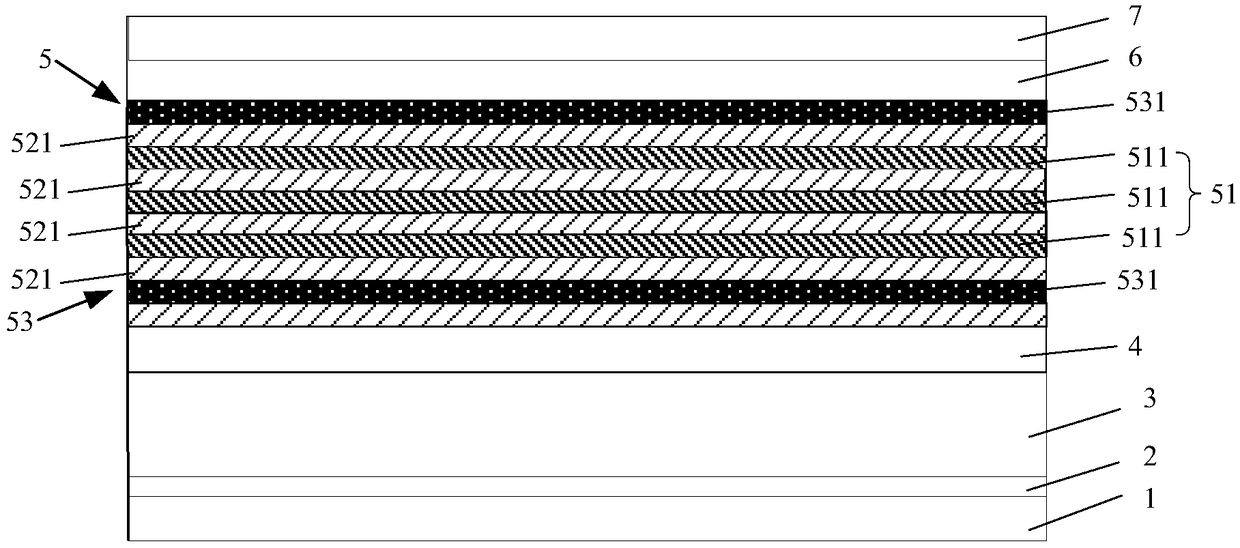

Light emitting diode epitaxial wafer and manufacturing method therefor

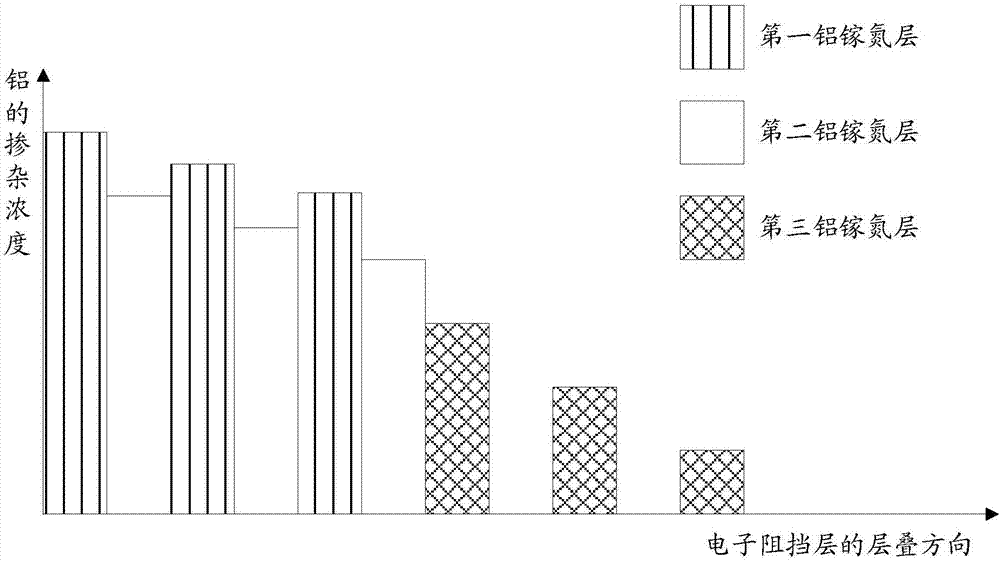

ActiveCN107195738APrevent proliferationImprove luminous efficiencySemiconductor devicesMagnesium dopingNon doped

The invention discloses a light emitting diode epitaxial wafer and a manufacturing method therefor, and belongs to the technical field of a semiconductor. The epitaxial wafer comprises a substrate, a buffer layer, a non-doped gallium nitride layer, an N type gallium nitride layer, a multi-quantum-well layer, an electron barrier layer and a P type gallium nitride layer; the electron barrier layer comprises a first sub layer, a second sub layer and a third sub layer; the first sub layer comprises multiple first aluminum gallium nitride layers and multiple second aluminum gallium nitride layers which are stacked alternately; the second sub layer comprises multiple third aluminum gallium nitride layers and multiple first indium gallium nitride layers which are stacked alternately; the third sub layer comprises gallium nitride layer and second indium gallium nitride layers which are stacked alternately; the aluminum doping concentration in the first aluminum gallium nitride layers and the second aluminum gallium nitride layers is greater than that in the third aluminum gallium nitride layers; the first indium gallium nitride layers, the gallium nitride layers and the second indium gallium nitride layers are all doped with magnesium; the magnesium doping concentration in the first indium gallium nitride layers is lower than that in the gallium nitride layers and the second indium gallium nitride layers. By virtue of the light emitting diode epitaxial wafer and the manufacturing method therefor, hole injection can be improved and LED light emitting efficiency can be improved.

Owner:HC SEMITEK ZHEJIANG CO LTD

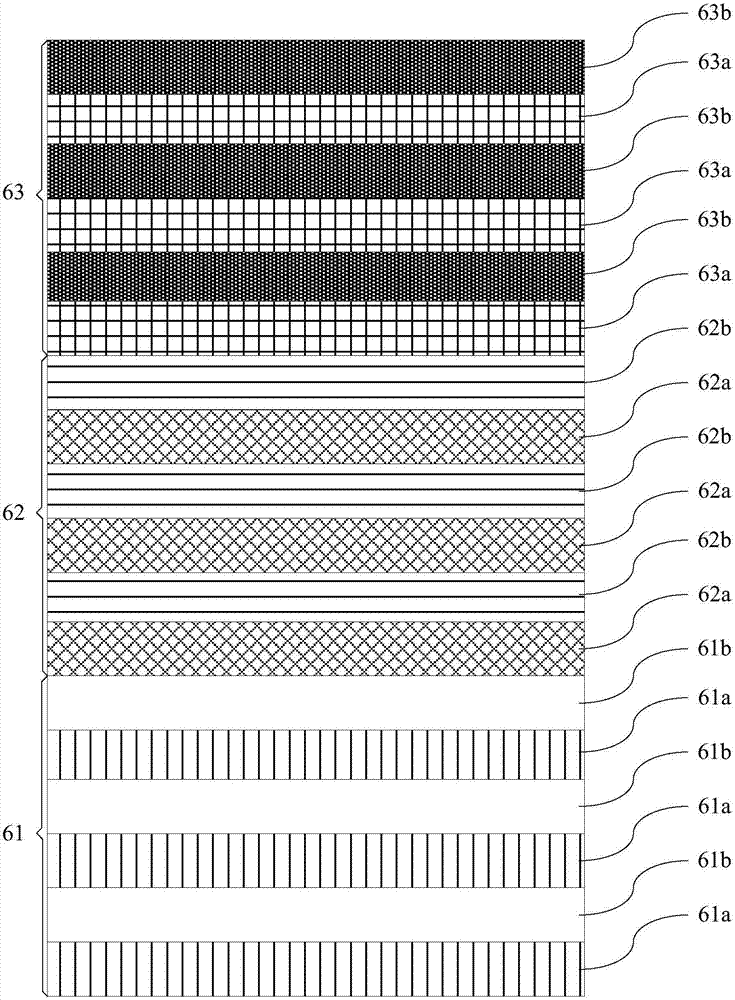

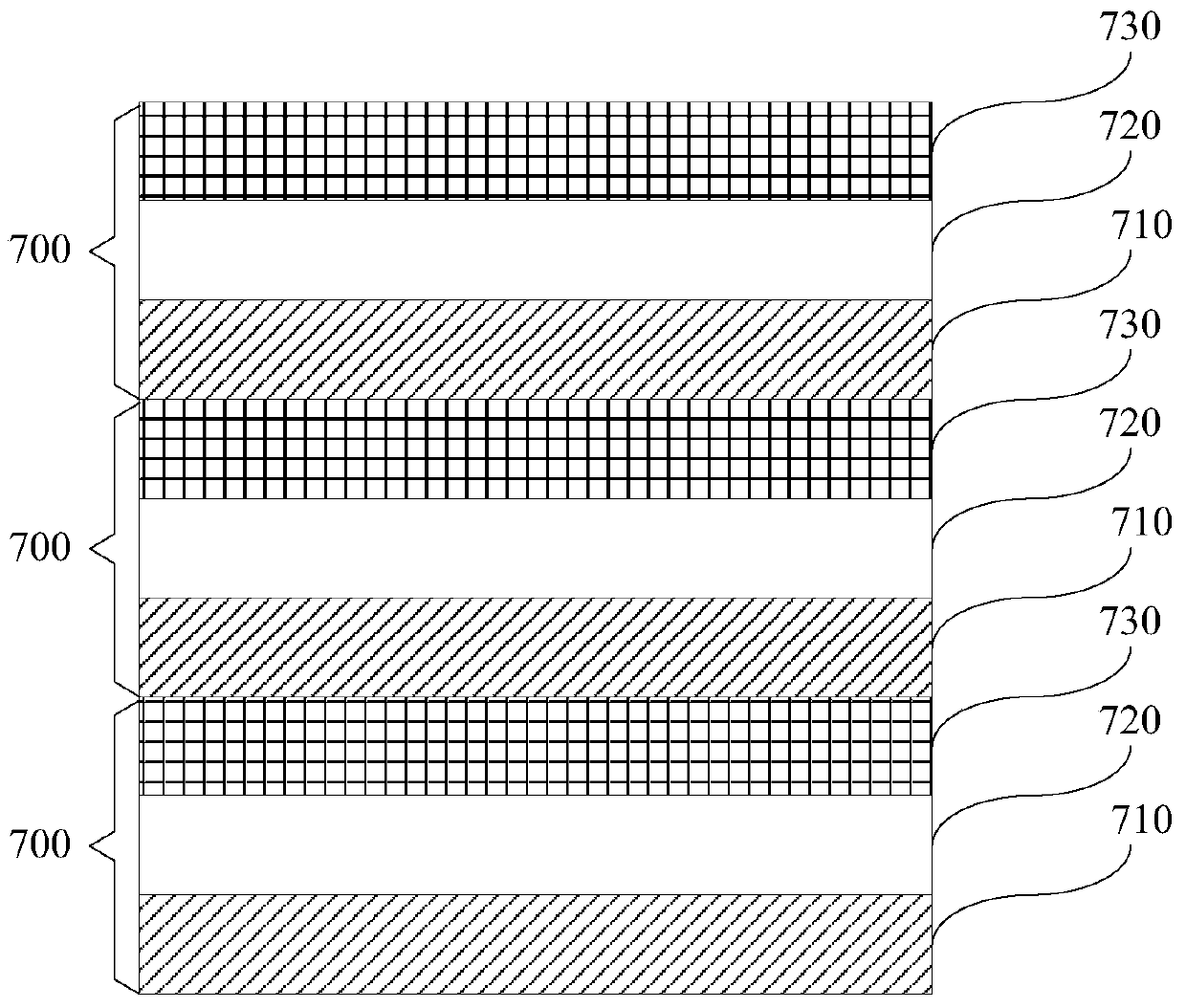

GaN-based light-emitting diode epitaxial wafer and manufacturing method thereof

ActiveCN110311022AImprove luminous efficiencyEasy injectionSemiconductor devicesQuantum wellElectron blocking layer

The invention discloses a GaN-based light-emitting diode epitaxial wafer and a manufacturing method thereof, which belong to the technical field of semiconductors. The GaN-based light-emitting diode epitaxial wafer includes a substrate, a buffer layer, an N-type layer, a multi-quantum well layer, an electron blocking layer, and a P-type layer which are sequentially stacked, wherein the electron blocking layer is composed of a plurality of first composite structures stacked sequentially; each first composite structure is composed of a first sub-layer, a second sub-layer, a third sub-layer, a fourth sub-layer and a fifth sub-layer which are sequentially stacked; both the first sub-layer and the fifth sub-layer are undoped AlGaN layers; the content of the Al component in the first sub-layer is smaller than the content of the Al component in the fifth sub-layer; the second sub-layer is an undoped InGaN layer; the third sub-layer is an undoped MgN layer; the fourth sub-layer is an undoped GaN layer; and Mg in the third sub-layer is diffused to the fourth sub-layer. The light-emitting efficiency of the LED can be improved.

Owner:HC SEMITEK ZHEJIANG CO LTD

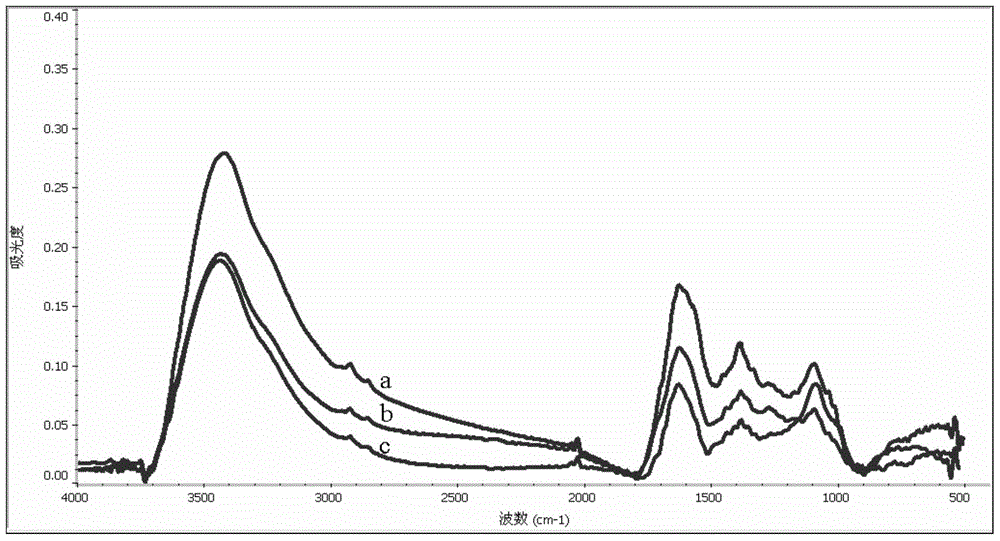

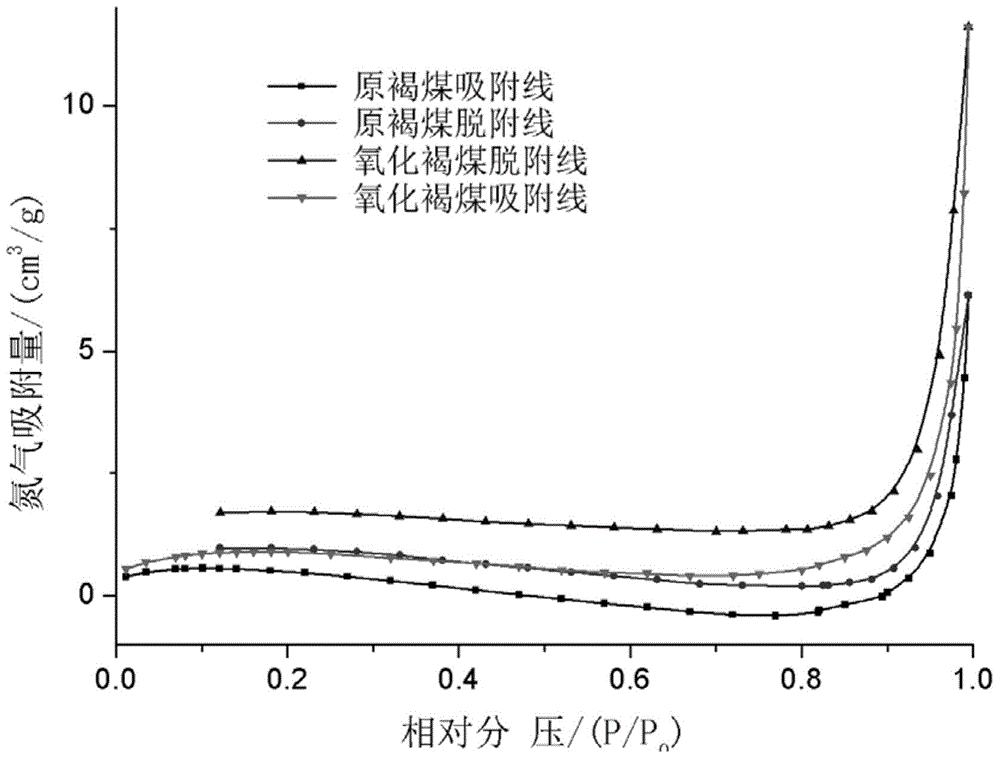

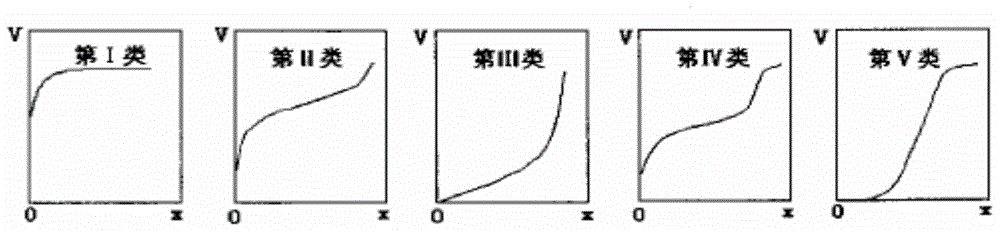

Method for preparing brown coal adsorption material

InactiveCN103816867AImprove wettabilityHigh electronegativityOther chemical processesWater/sewage treatment by sorptionZeta potentialElectronegativity

The invention discloses a method for preparing a brown coal adsorption material, and belongs to the field of preparation of adsorption materials. The method comprises the following steps: using brown coal powder as a raw material, and performing oxidation modification treatment on the raw material to obtain the brown coal adsorption material. The method modifies coal powder through oxidation, the peak intensity and the peak width of characteristic oxygen-containing functional groups of phenolic hydroxyl, carboxyl, carbonyl and the like of the modified brown coal are significantly increased, the contact angle of brown coal is changed, the wettability of brown coal gets better, the Zeta potential absolute value of the brown coal is increased, larger electronegativity is shown, and the electronegativity is increased along with the increase of a pH value. The pore diameter distribution in coal is not significantly changed, and the main reason of the increase of total specific area and the total pore volume is the increase of the mesopore number. The modified brown coal can effectively remove methylene blue mainly contained in azo organic wastewater, is suitable for being used as the adsorption material of the azo organic wastewater, and can facilitate the recycle and reuse of brown coal powder used as the adsorption material in a solid-liquid separation mode.

Owner:CHINA UNIV OF MINING & TECH (BEIJING)

Preparation method of porous honeycomb ceramic catalyst with high specific surface area

ActiveCN104258856APlay a role in enhancingAvoid easy cloggingDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsCerium nitrateCerium nitrate hexahydrate

The invention discloses a preparation method of a porous honeycomb ceramic catalyst with a high specific surface area. The porous honeycomb ceramic catalyst is prepared by taking titanium dioxide, montmorillonite and alpha aluminum oxide as carriers and ammonium metatungstate, ammonium metavanadate, cerium nitrate and palladium acetate as active components through mixing, aging, kneading, molding, drying and roasting under the accompanying of auxiliary materials, wherein the auxiliary materials comprise monoethanolamine, ammonia water, lactic acid, stearic acid, glass fibers, macromolecular polymer fibers, hydroxypropyl methyl cellulose, polyoxyethylene, citric acid and water. According to the preparation method of the porous honeycomb ceramic catalyst with the high specific surface area, the catalyst carriers are optimized in order to be adapted to application conditions of frequent temperature variation, high concentration of nitrogen oxides, high heat stability and high specific surface; the montmorillonite and the alpha aluminum oxide are used for replacing one part of the titanium dioxide, the montmorillonite has the enhancing effect and the aluminum oxide has the effect of high heat stability; and meanwhile, the macromolecular polymer fibers are used for replacing wood pulp so that a grinding tool is difficult to block in a production process and the production efficiency is improved.

Owner:山东信义汽车配件制造有限公司

Light-emitting component and manufacturing method thereof

The invention relates to a light-emitting component and a manufacturing method thereof. The light-emitting component contains an n-shaped bound layer, a p-shaped bound layer and an active layer, wherein the active layer is positioned between the n-shaped bound layer and the p-shaped bound layer and in a multiple-quantum well structure formed by piling multiple barrier layers and multiple well layers in a stagger way; the barrier layers are doped with p-shaped impurities to increase the number of cavities, the barrier layers which are closer to the n-shaped bound layer have lower doping concentration, and the barrier layers which are closer to the p-shaped bound layer have higher doping concentration so as to form a barrier layer structure with gradual change type doping concentration. Thelight-emitting component can enhance the combination probability of the cavities and electrons, thereby enhancing the light-emitting efficiency.

Owner:EPISTAR CORP

Active carbon absorbent for removing mercury in flue gas

InactiveCN105056885AImprove adsorption capacityIncrease the number ofOther chemical processesDispersed particle separationActivated carbonFlue gas

The invention aims to provide an active carbon absorbent for removing heavy metals especially mercury in flue gas and a preparation method thereof. By improving the preparation method of active carbon, the ratio of mesoporous pore canals in active carbon is increased, thus the oxidant load capacity and dispersion degree of active carbon are both improved; the performance of active carbon on absorbing mercury is enhanced, thus the mercury can be removed more easily, and moreover, the provided method has little pollution and can be applied to the industry.

Owner:QINGDAO JINZHI HIGH NEW TECH

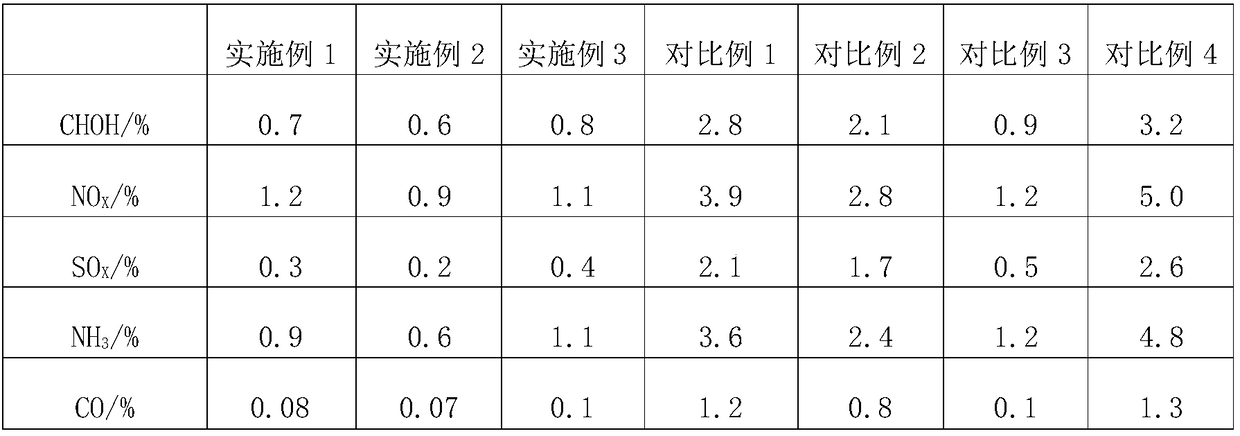

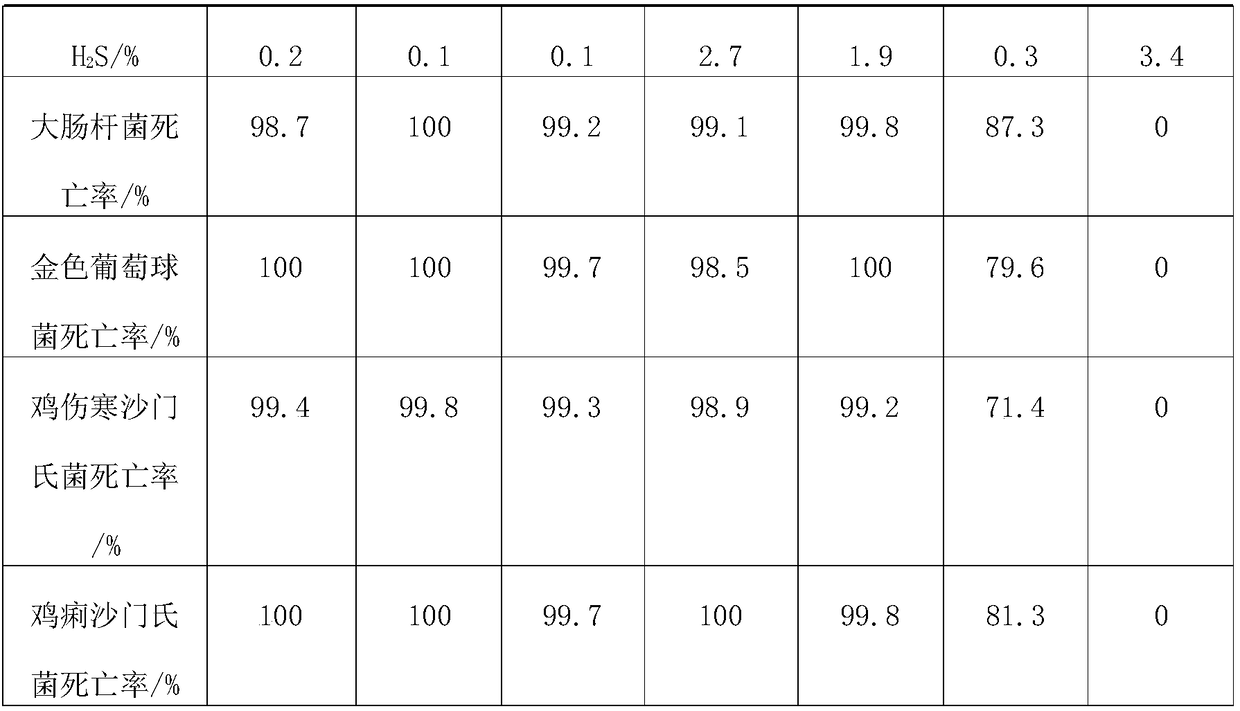

Preparation method of bacteriostatic air purifier

InactiveCN108452673AIncrease the number of holesImprove absorption rateBiocideGas treatmentHydrazine compoundLanthanum

The invention discloses a preparation method of a bacteriostatic air purifier. The preparation method comprises the following steps: step I: acid leaching, calcining, and producing modified maya blue;step II: fermenting various plants by virtue of probiotics, filtering a fermented solution, and preparing plant enzymes; step III: under a condition of argon charged, dissolving zirconium dioxide andtitanium dioxide in tartaric acid, and then preparing a lanthanum-doped composite photocatalyst by virtue of the coupling bonding of lanthanum oxide; step IV: mixing tea polyphenols, quercetin and hydrazine carbonate according to a weight ratio of 1: (1.2 to 1.6): (0.3 to 0.5), condensing by using a coating agent, and preparing a coated synergist; and step V: mixing 20 to 30 parts of modified maya blue, 40 to 60 parts of plant enzymes, 12 to 16 parts of lanthanum-doped composite photocatalyst, and 15 to 20 parts of coated synergist, thus obtaining the air purifier. By adopting the preparationmethod, the pathogenic bacteria can be effectively eliminated, the air spreading route of the pathogenic microorganism can be blocked, the air pollutants can be effectively degraded, and the air quality can be improved.

Owner:HUAIBEI ZHIHUAI TECH CO LTD

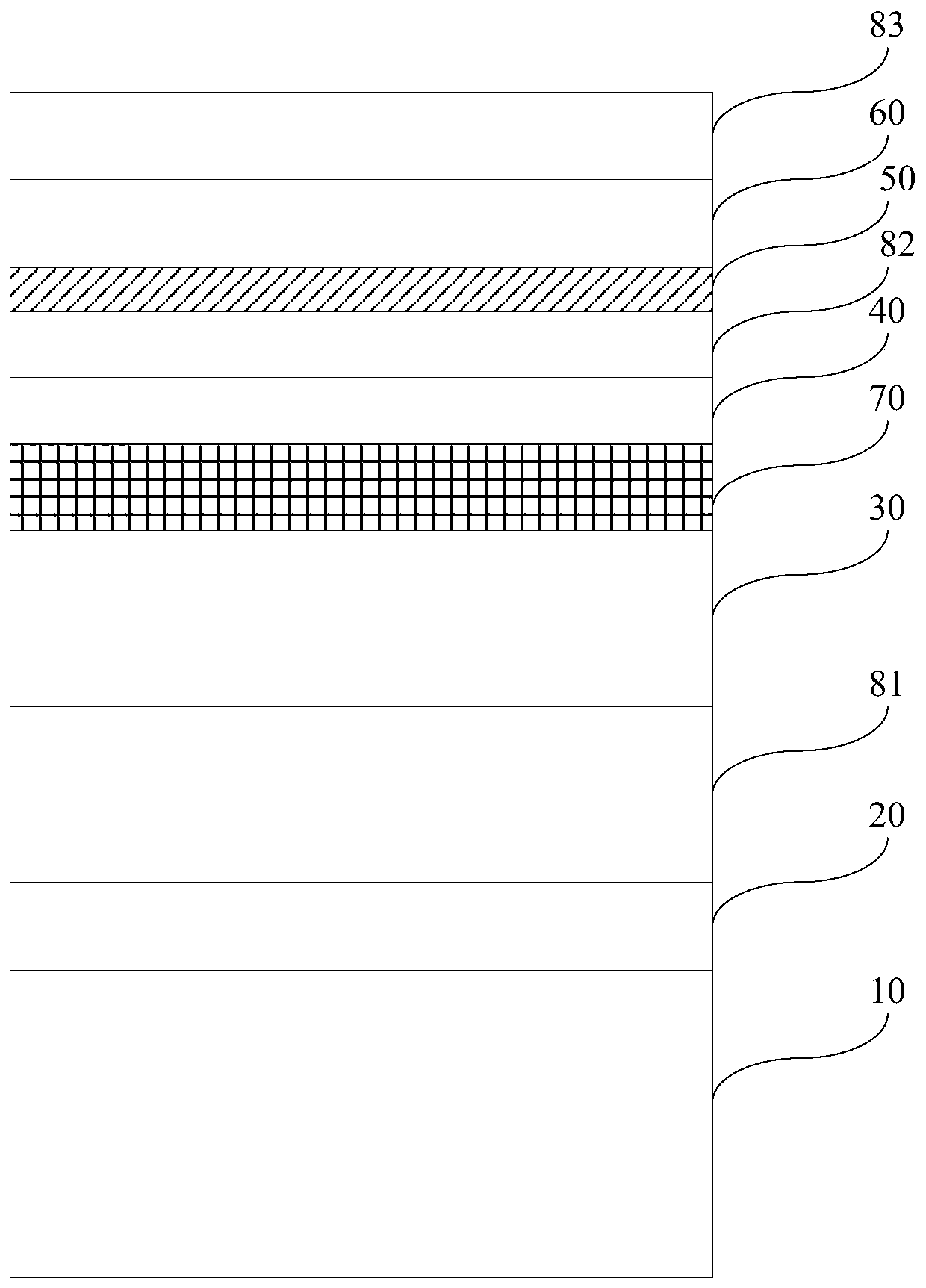

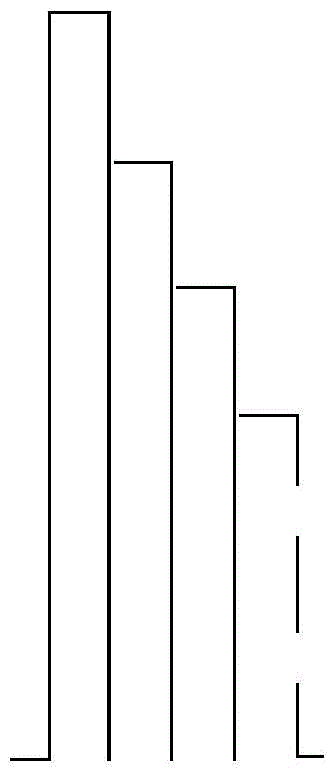

Epitaxial wafer of light emitting diode and manufacturing method thereof

ActiveCN104157763AReduce blocking effectImprove the blocking effectSemiconductor devicesQuantum wellElectron blocking layer

The invention discloses an epitaxial wafer of a light emitting diode and a manufacturing method thereof and belongs to the technical field of semiconductors. The epitaxial wafer comprises an underlayer and a low temperature buffer layer, a high temperature buffer layer, an N type layer, an active layer, an electronic resisting layer and a P type layer which are stacked on the underlayer in sequence, wherein the electronic resisting layer comprises a GaN layer and at least two AlGaN layers stacked on the GaN layer; the Al component content of the AlGaN layers increases or reduces layer-by-layer in the growing direction of the epitaxial wafer. According to the invention, the electronic resisting layer is arranged, so that the energy level height of the electronic resisting layer increases or reduces layer-by-layer, the resisting function of injecting the active layer to a hole is weakened, electrons can be prevented from leaking from a quantum well, and the luminous efficiency is improved.

Owner:HC SEMITEK SUZHOU

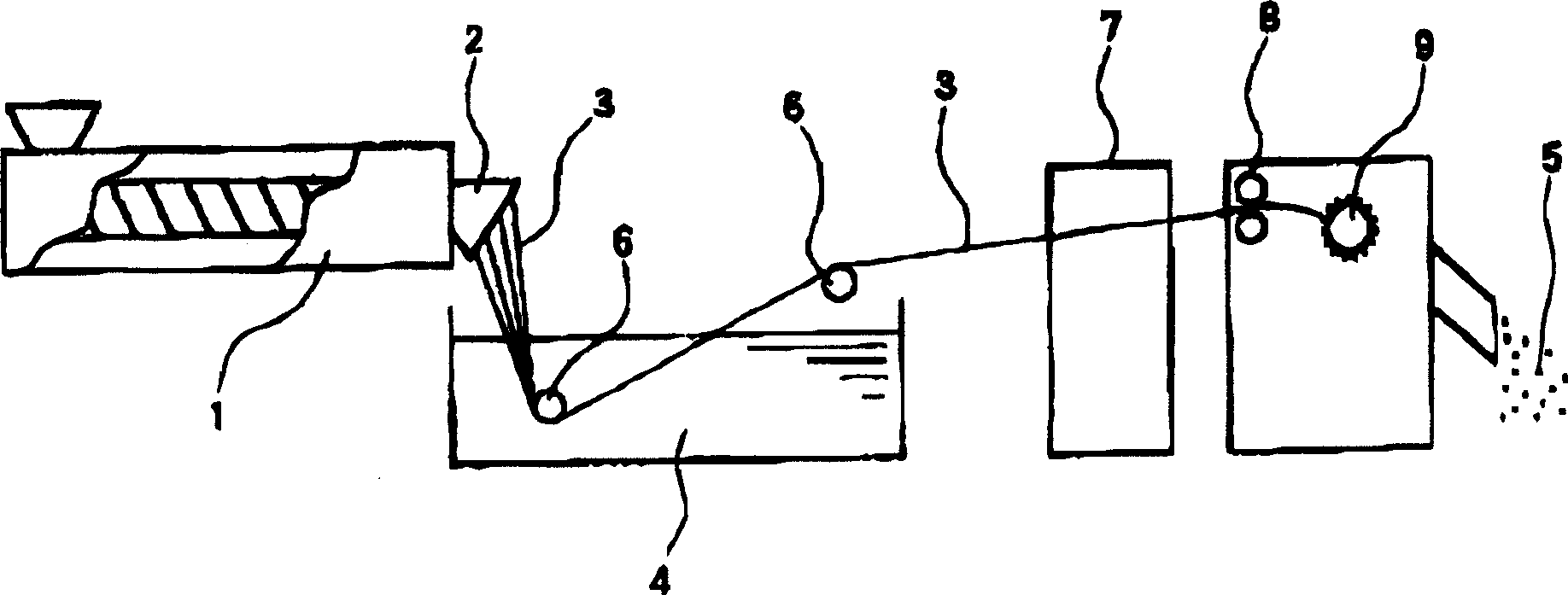

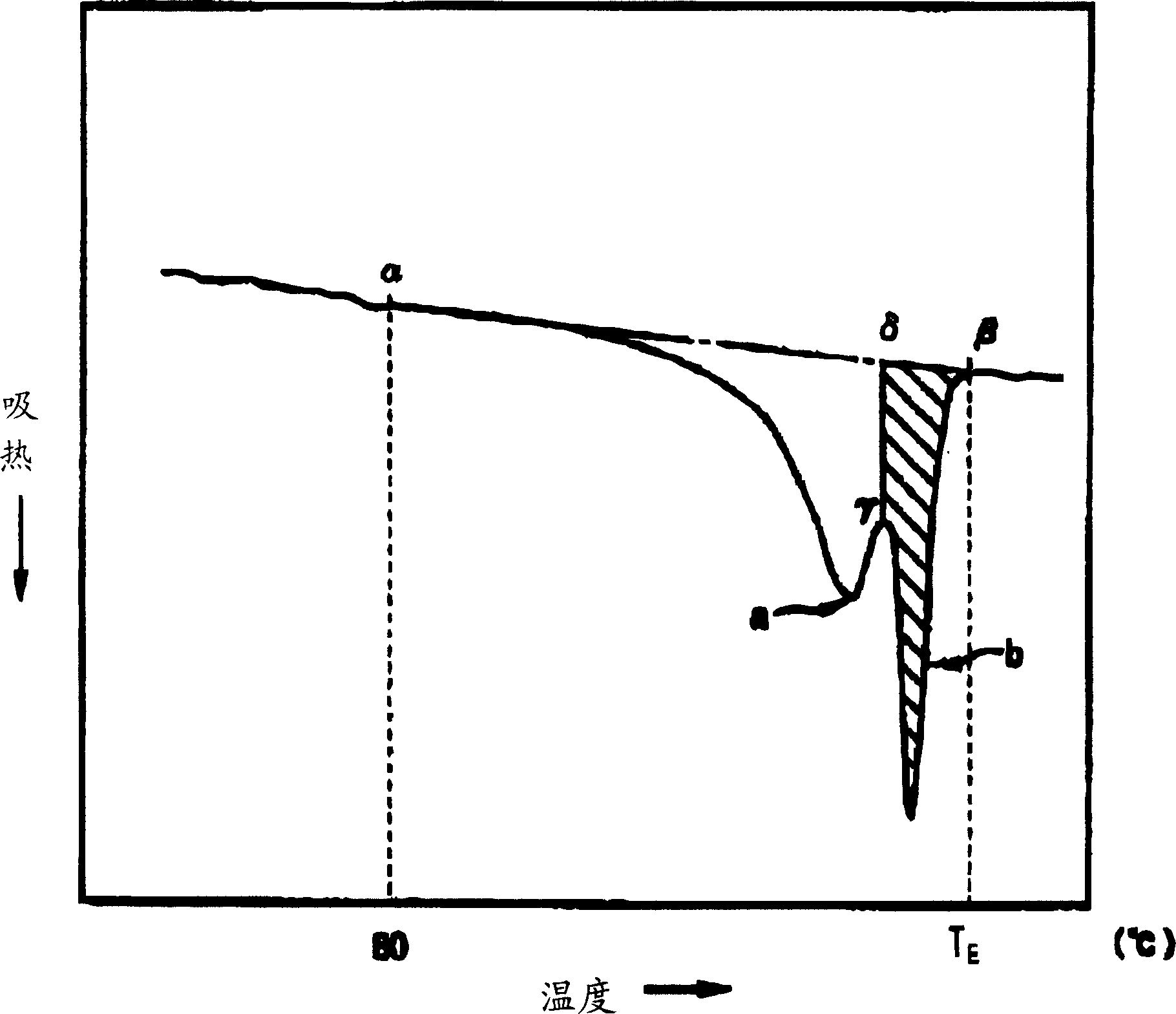

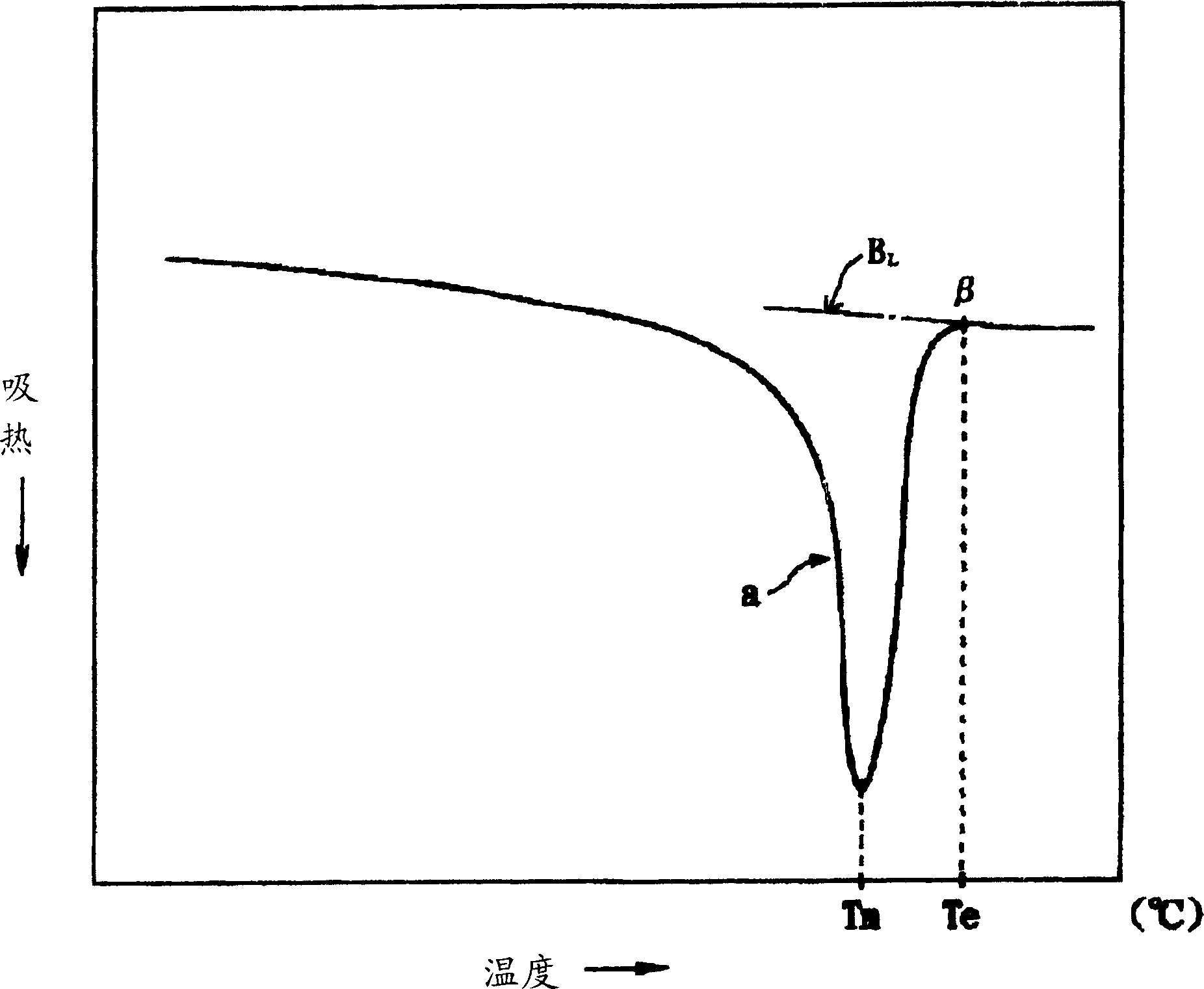

Thermoplastic resin pellet, process for preparing thermoplastic resin pellets and expanded thermoplastic resin bead

A process for preparing thermoplastic resin pellets, including extruding a melt of a thermoplastic resin into a gas phase through a die in the form of strands, immersing the strands in a bath containing water and a surfactant to cool the strands, taking the cooled strands out of the bath, and cutting the taken-out strands into pellets. A thermoplastic resin pellet is a cylindrical pellet obtainable by a process and having a diameter of D and a length of L, wherein the ratio L / D is greater than 1 but not greater than 5. An expanded thermoplastic resin bead is obtainable by foaming and expanding the thermoplastic resin pellet and has an apparent density of 10 to 600 g / L.

Owner:JSP CORP

Light-emitting diode epitaxial wafer and preparation method thereof

ActiveCN108807620AAvoid accessImprove luminous efficiencySemiconductor devicesElectron blocking layerActive layer

The invention discloses a light-emitting diode epitaxial wafer and a preparation method thereof and belongs to the field of light-emitting diode manufacturing. An active layer is arranged to include afirst barrier layer and a plurality of InGaN well layers, wherein a plurality of first sub-barrier layers with a GaN / In<x>Ga<1-x>N / Al<z>Ga<1-z>N / In<y>Ga<1-y>N / GaN superlattice structure in the firstbarrier layer and the InGaN well layers are alternately stacked. The GaN / In<x>Ga<1-x>N / Al<z>Ga<1-z>N / In<y>Ga<1-y>N / GaN superlattice structure is relatively high in energy band and can play a role in preventing electrons from entering a P-type GaN layer, so that an electron blocking layer does not need to be arranged to prevent the electrons from flowing out of an active layer. Through the arrangement, the number of holes entering the active layer can be improved while the electrons are restricted from leaving the active layer, so that the number of the holes which are compounded with the electrons to emit light in the active layer is improved; and furthermore, the polarization condition, caused by the arrangement of the electron blocking layer, between the electron blocking layer and the active layer and the P-type layer in an epitaxial layer can also be reduced, so that reduction of a light-emitting band gap in the epitaxial layer is avoided and the recombination efficiency of the electrons and the holes is improved, thereby improving the light-emitting efficiency of a light-emitting diode.

Owner:HC SEMITEK ZHEJIANG CO LTD

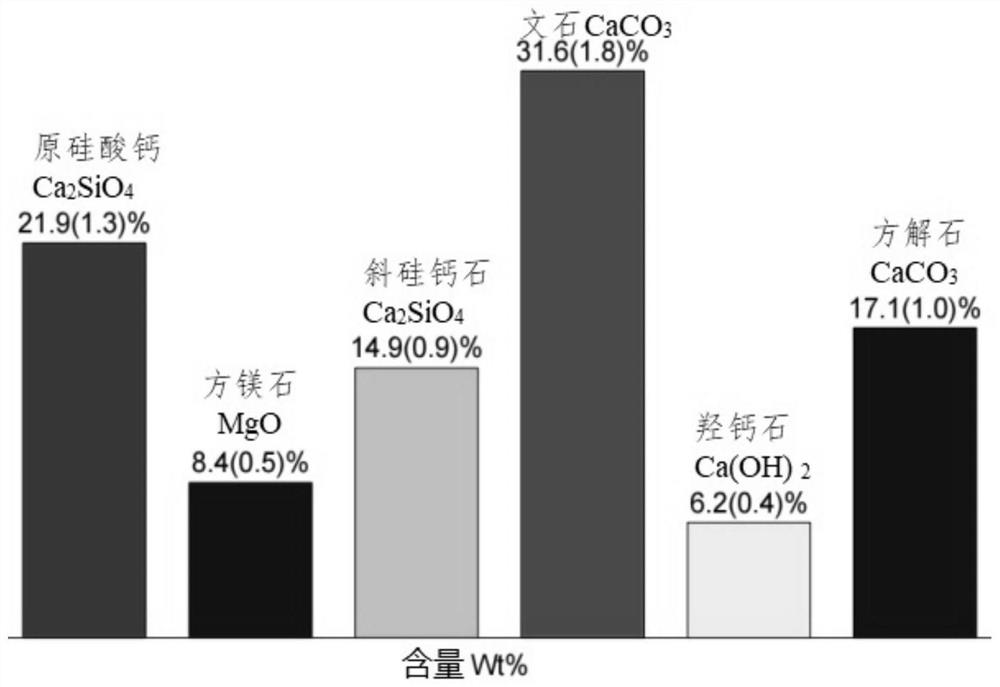

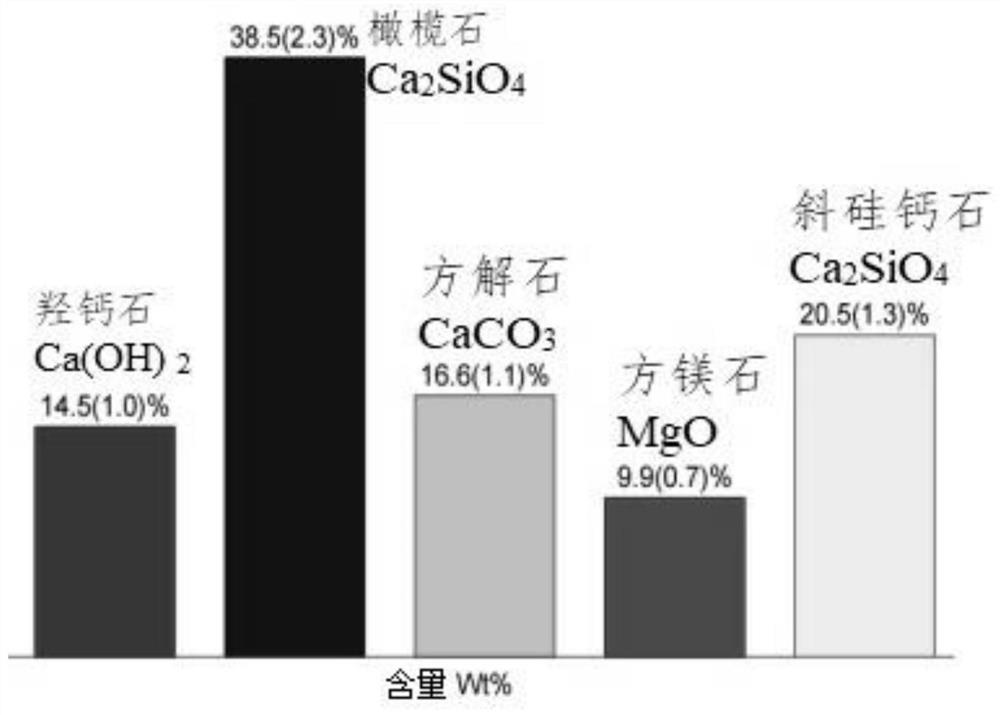

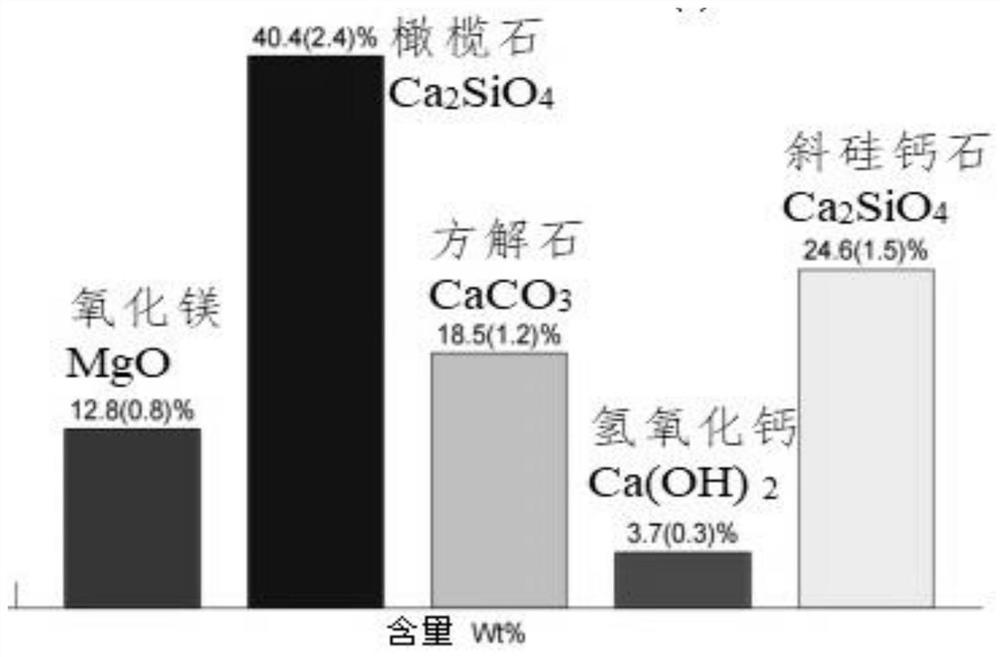

Homogeneous carbonization preparation method of magnesium slag cementing material for smelting magnesium by silicothermic method

The invention discloses a homogeneous carbonization preparation method of a magnesium slag cementing material for smelting magnesium by a silicothermic method. The method comprises the following steps: 1, discharging magnesium slag generated by smelting magnesium by the silicothermic method, and quickly cooling by air cooling to obtain cooled magnesium slag; 2, ball-milling the cooled magnesium slag, sieving, and collecting to obtain a screen underflow magnesium slag; 3, uniformly stirring the undersize magnesium slag with water until the magnesium slag is gathered into a cluster, and forming to obtain a magnesium slag cementing blank; 4, curing the magnesium slag cementing blank for 3-28 d at the humidity of 50%-90% and the normal temperature; and 5, introducing hot flue gas into the cured magnesium slag cementing blank for carbonization, and obtaining the magnesium slag cementing material. According to the method, the magnesium slag generated by smelting magnesium through the silicothermic method is discharged out of the furnace, and the hydration activity is improved through rapid air cooling, so that the pore number and pore distribution uniformity in the magnesium slag cementing blank after maintenance and hydration are improved, the uniformity of the subsequent carbonization process is improved, and the problems that the magnesium slag cementing material is too long in reaction time, non-uniform in reaction and insufficient in internal reaction are solved, and the quality of the magnesium slag cementing material is improved.

Owner:SHAANXI ACAD OF ARCHITECTONICS

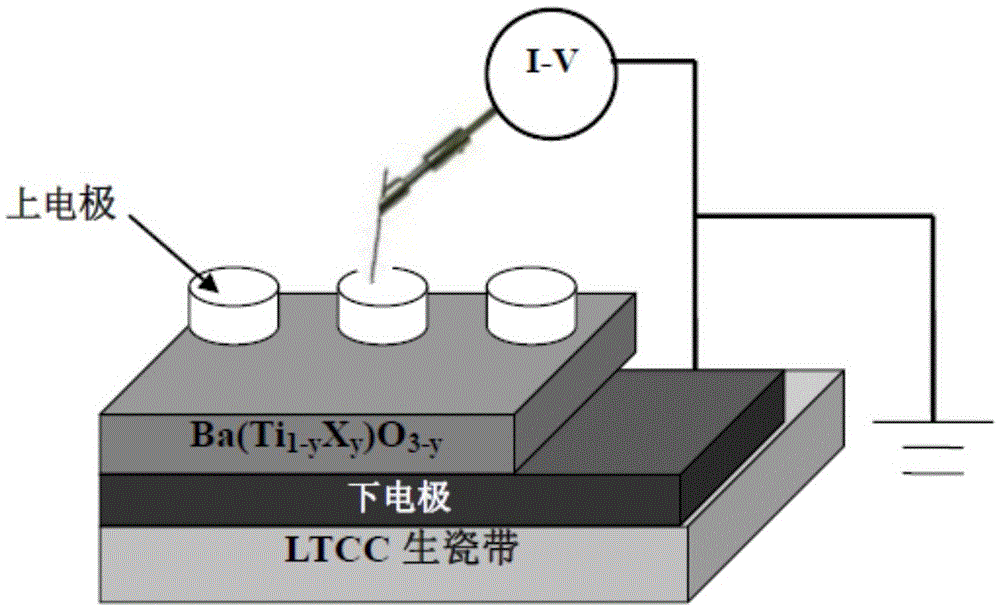

Preparation method of flexible single-layer nano-film memristor

ActiveCN105576121AHold resistanceOmit the pre-firing stepMaterial nanotechnologyElectrical apparatusGreen tapeCeramic sintering

The invention discloses a preparation method of a flexible single-layer nano-film memristor. Holes and ionized oxygen ions generated by the single-layer nano-film memristor under a bias voltage are utilized as charge carriers; and the change principle of the resistance of a device is achieved by change of output of the holes and the ionized oxygen ions, so that a relatively low calcination temperature is combined by omitting a pre-sintering step of a ceramic material of a resistance film and selecting a raw material with a lower nano ceramic sintering temperature from two aspects of simplification of the preapration technology and chemical formulation of the nano ceramic material of the resistance film; B-site substitution is carried out by partially replacing Ti<4+> with X<2+>; the asymmetry of the molecular structure and the hole quantity in the resistance film are increased; by a series of technical means of coating a green tape to form a 'flexible' lower electrode and the like, the preparation technology is simplified; the technological process is shortened; the production efficiency is improved; the production energy consumption and the manufacturing cost are reduced; and the memristive property of the memristor is greatly improved.

Owner:SHANDONG UNIV OF SCI & TECH

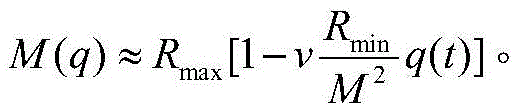

Ultra-fine denier polyurethane filament

InactiveCN1667167AEasy to stretchHigh strengthConjugated synthetic polymer artificial filamentsStretch-spinning methodsLow-density polyethyleneBreakdown strength

The invention relates to a superfine denier polyurethane filament and the method to manufacture. The filament is an island type superfine denier polyurethane filament that the low density polyethylene as see const and the polyurethane as the island const. And the weight ratio of polyethylene is from 0.4 to 1.5:1. The filament number after the island separated is from 0.08 to 0.3dtex. And the density of finished silk fiber product is 150-200dtex; breakdown strength of fiber is 1.9-2.1CN / dtex; the elongation at break is 100-150%. The invention is easy to be industrialization manufactured.

Owner:DONGHUA UNIV +1

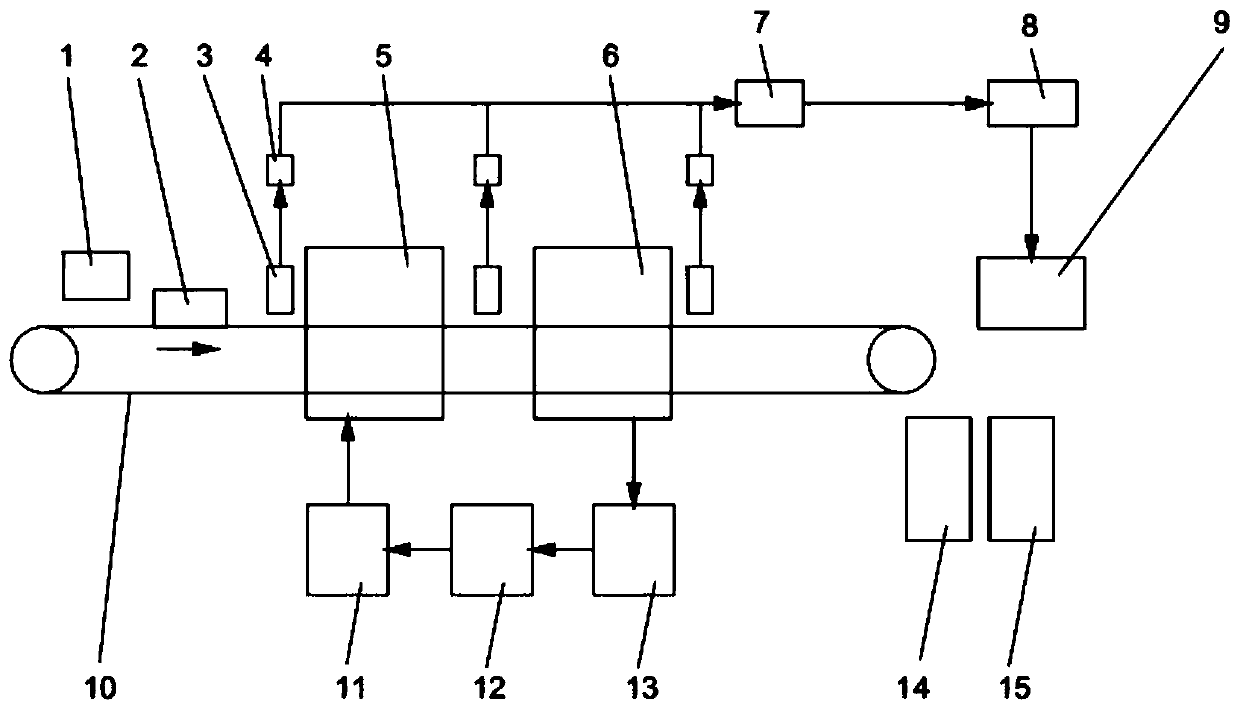

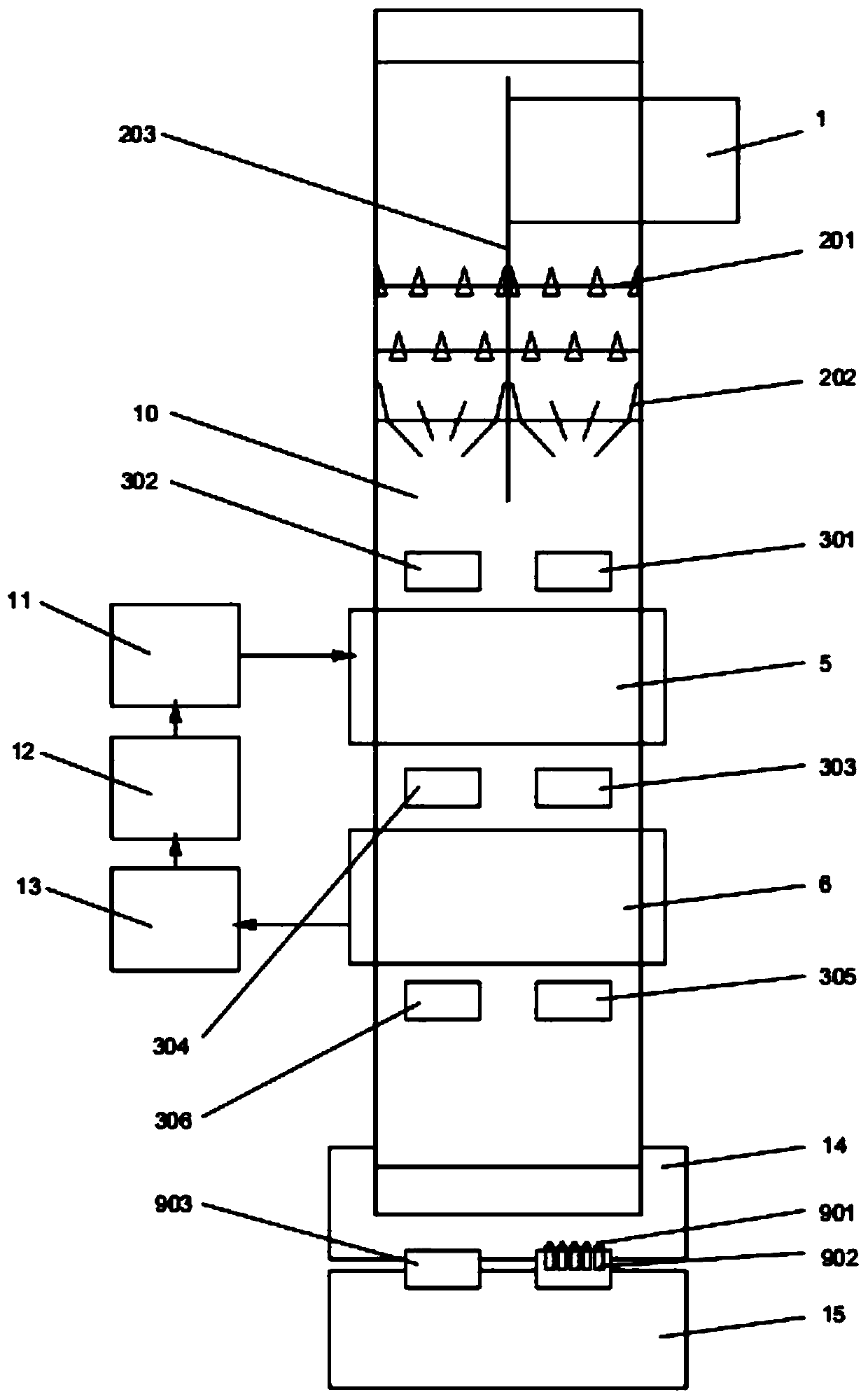

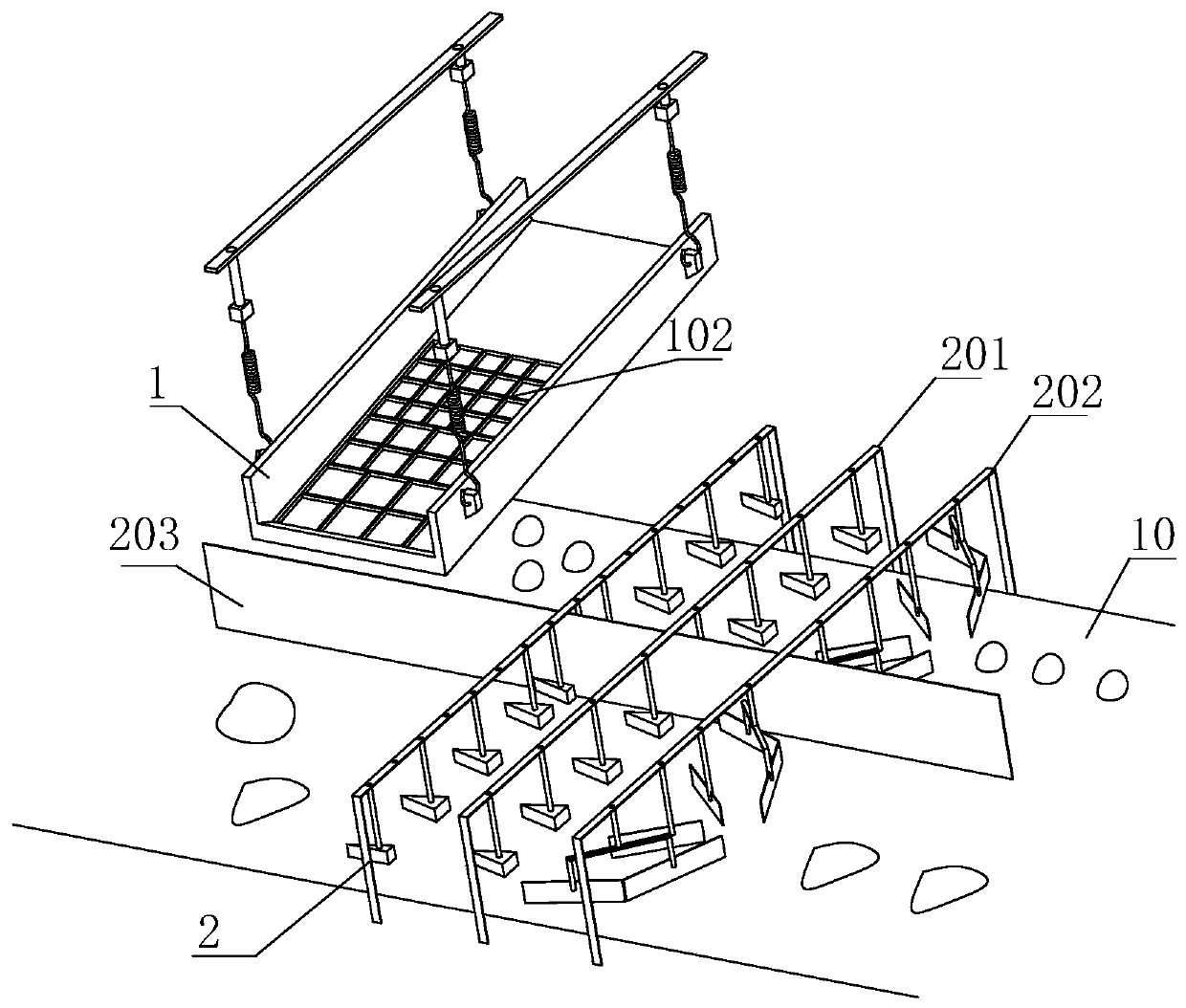

Automatic coal and gangue separation system and method based on temperature changes

The invention relates to the field of automatic separation of coal and gangue, in particular to an automatic coal and gangue separation system and method based on temperature changes. The automatic coal and gangue separation system based on temperature changes comprises a conveying belt, a collection hoper, a feeding device, a queuing device, a detection device, a gas treatment device and a motionexecution device. The feeding device comprises a small suspension-type vibrating screen. The queuing device comprises a lining device, a gathering support and an isolation plate. The detection devicecomprises a thermal infrared temperature sensor, a data acquisition card and a computer. The gas treatment device comprises a gas inflation box, a gas desorption device, a gas collection box, a gas filtering and purification box and a gas pressurizer. According to the automatic coal and gangue separation system and method based on temperature changes, on the basis of the principle that the temperature of coal is increased after the coal absorbs gas and is decreased after the coal desorbs the gas and the temperature of gangue is not changed due to the fact that the gangue does not react with gas, the coal is separated from the gangue, the gangue with the temperature unchanged is separated out and is removed through the motion execution device; and the automatic coal and gangue separation system and method based on temperature changes are high in separation efficiency, capable of separating various types of coal and high in adaptability, and water is not needed.

Owner:ANHUI UNIV OF SCI & TECH

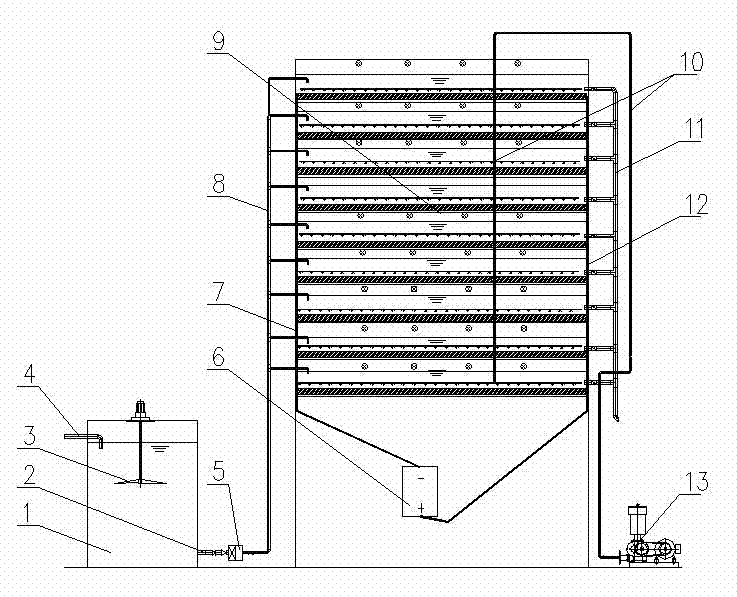

Magnetic nanometer titanium dioxide wastewater treatment and recovery device

InactiveCN102786177ALarge specific surface areaEfficient separation and recoveryWater/sewage treatment by irradiationMultistage water/sewage treatmentPhotocatalytic reactionResource saving

The invention relates to a magnetic nanometer titanium dioxide wastewater treatment and recovery device. The device comprises a mixed water tank and a photocatalytic reaction chamber, wherein the top of the mixed water tank is provided with a stirring machine, the upper part of the mixed water tank is provided with a water inlet tube, the lower part of the mixed water tank is provided with a water outlet tube, the water outlet tube is connected with the water inlet tube of the photocatalytic reaction chamber, the photocatalytic reaction chamber has a multi-layer structure, the upper part in each layer of the photocatalytic reaction chamber is provided with an ultraviolet lamp light source, the middle of the each layer of the photocatalytic reaction chamber is a reaction space, the lower part of each layer of the photocatalytic reaction chamber is provided with a blast aeration tube and an electromagnetic sucker, the blast aeration tube is connected with a blower, and each layer of the photocatalytic reaction chamber is also provided with an overflow tube; and two ends of the photocatalytic reaction chamber are provided with an applied electric field, and the applied electric field is formed by an anode, a cathode and a direct-current power supply. The device which adopts a novel structure of magnetic nanometer titanium dioxide and the rectangular electromagnetic sucker enables the loss rate of the nanometer titanium dioxide to be greatly reduced, a difficult solid-liquid separation problem to be solved, the repeated utilization of a resource to be realized, the treatment cost to be reduced, and resource saving and environmental protection purposes to be reached.

Owner:杰瑞环境工程技术有限公司

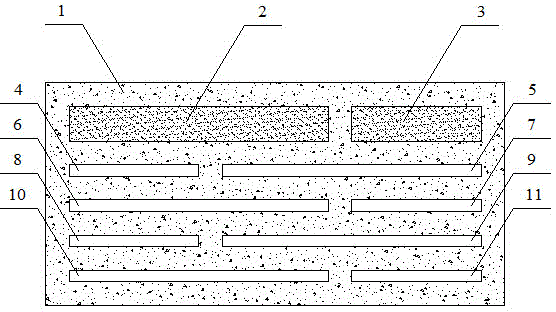

Phase change heat insulation composite hollow building block

InactiveCN104453077AIncreasing the thicknessReduce thicknessConstruction materialThermal insulationThermal comfort

The invention belongs to the technical field of building materials and provides a phase change heat insulation composite hollow building block. Three rows of mutually staggered holes are formed in a building block body in total, and the holes in the row near the indoor side are blind holes and are used for filling a gypsum-based phase change material; and the holes in the other two rows are through holes, thereby forming air spaces inserted with heat insulation material plates at middle parts. According to the phase change heat insulation composite hollow building block provided by the invention, by reasonably selecting a hole structure, the mechanical properties of the composite hollow building block can be ensured, and heat insulation, heat isolation and heat accumulation performances of the building block can be also improved to a greatest extent; the prepared gypsum-based phase change material is less prone to causing leakage of the filled phase change material, has good compatibility with the material of the building block main body, and is used for solving the problem that the heat capacity of a wall body built by traditional hollow building blocks is reduced due to improved heat insulation performance; and furthermore, by reasonably selecting the phase change material with great phase change latent heat and appropriate heat conduction coefficient against climatic conditions in different regions, the best performance of the phase change material is realized, so that indoor heat comfort is improved and the energy consumption of a building is reduced.

Owner:JIANGSU UNIV

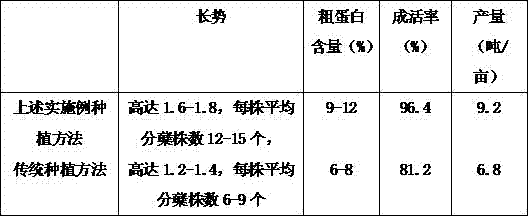

Artificial planting method of Chinese pennisetum, water-retaining and slow-released fertilizer used for planting and preparation method of fertilizer

InactiveCN107032878AImprove adsorption capacityIncrease the number of holesSuperphosphatesCalcareous fertilisersSoil sciencePotassium sulfate

The invention discloses an artificial planting method of Chinese pennisetum. The method includes the steps of soil preparation, Chinese pennisetum seed treatment, cuttage, fertilizer and water management, field management, harvesting, overwintering and the like. The planting method is scientific, reasonable and simple in management, can improve the survival rate and growth vigor of Chinese pennisetum, and makes the yield per mu of Chinese pennisetum reach a high level. The invention further discloses a water-retaining and slow-released fertilizer used for planting and a preparation method of the fertilizer. The fertilizer is prepared from urea, ammonium chloride, calcium superphosphate, potassium sulfate, borax, medicinal diamond, attapulgite and other materials. The fertilizer is high in water retention and good in slow release performance, water and nutrients can be slowly released according to the need of the Chinese pennisetum, leaching and volatilization loss is little, the long-term demand of Chinese pennisetum for nutrients and water is easily met, the utilization rate of the fertilizer can be improved, the planting cost is reduced, and the quality and yield of Chinese pennisetum can also be improved.

Owner:贵州农浩农业科技开发有限公司

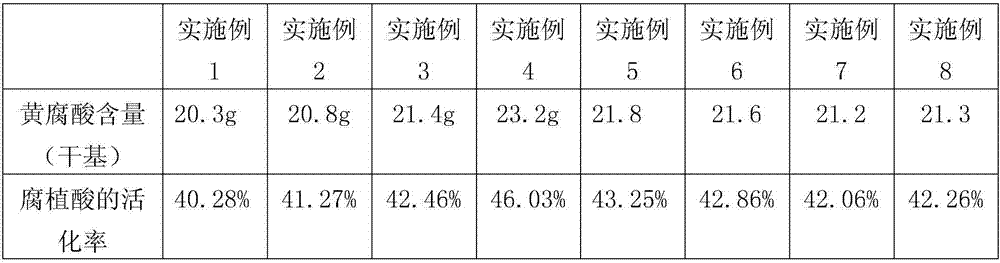

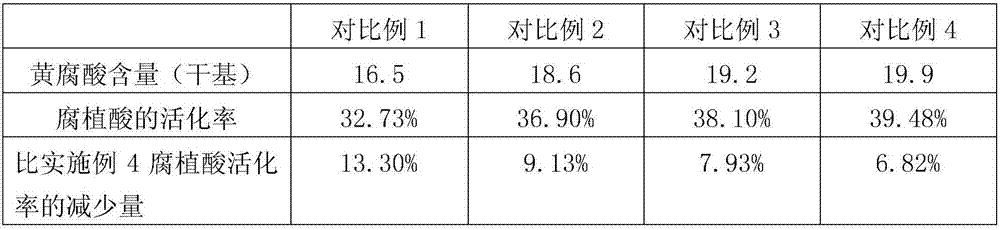

Method for extracting fulvic acid salt from photocatalyst activated lignite

ActiveCN107987283AImprove defect densityIncrease concentrationBiological activationUltraviolet irradiation

The invention provides a method for extracting fulvic acid salt from photocatalyst activated lignite. The method comprises the following steps: uniformly mixing lignite powder and water, adding alkalito regulate the pH value to be 10-11, stirring for 2-3 hours at a temperature of 50-80 DEG C, and performing solid-liquid separation to obtain a humate solution; and adding an oxidizing agent and a photocatalyst, and stirring under ultraviolet irradiation for 3-5 hours, thereby obtaining the fulvic acid salt product. The method disclosed by the invention is simple in production process, low in cost, high in humic acid activation rate in lignite, high in fulvic acid salt extraction rate and suitable for popularization and application in agricultural production.

Owner:QUJING NORMAL UNIV +3

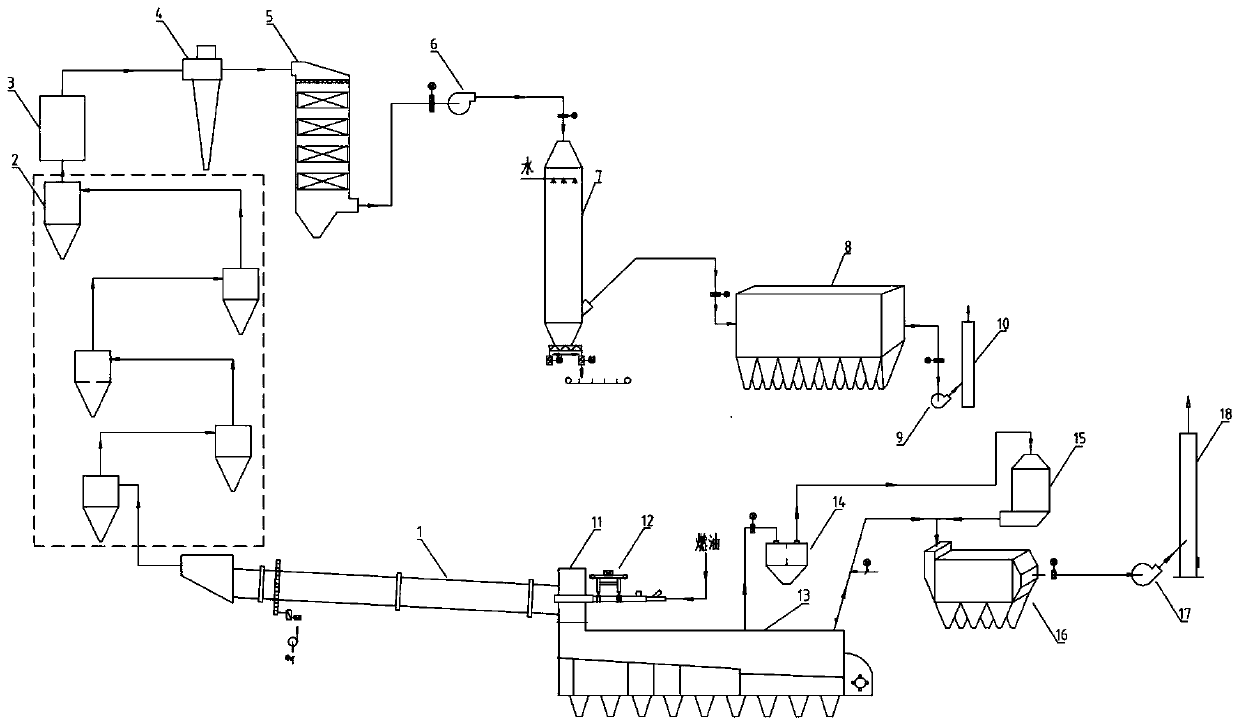

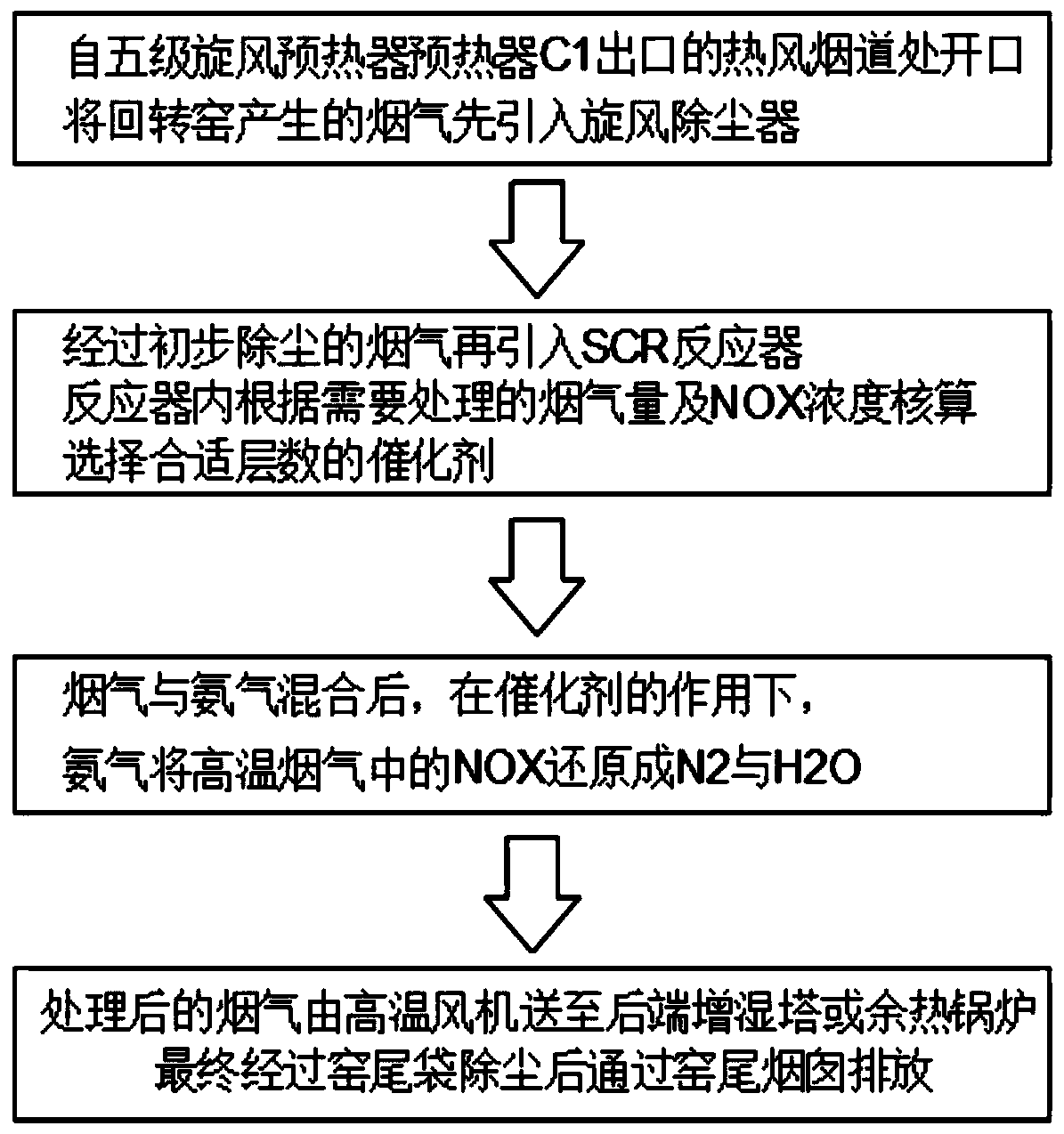

Dust SCR denitration device and technology for cement kiln

PendingCN110314543AReduce soot contentLower the altitudeGas treatmentDispersed particle separationCycloneEngineering

The invention belongs to the technical field of flue gas treatment and environmental protection for cement kilns, and particularly relates to a dust SCR denitration device and technology for a cementkiln. The dust SCR denitration device comprises a rotary kiln, a kiln tail residual gas treatment system and a kiln head residual gas treatment system; the kiln tail residual gas treatment system comprises a five-stage cyclone preheater, an SP furnace, a dust remover, an SCR reactor, a high-temperature blower, a humidifying tower / waste heat boiler, a kiln tail bag dust removing unit, a kiln tail exhaust blower and a kiln tail chimney; the five-stage cyclone preheater is connected to the kiln tail of the rotary kiln; the cyclone dust remover is arranged in front of the SCR reactor for flue gasdust removal, the content of flue gas dust at the SCR reaction is lowered, the number of pores of a honeycomb catalyst can be increased, and the overall height of the catalyst and the reactor can be effectively lowered on the condition that the cubic number and the number of layers of the catalyst are not changed; the pressure loss of the whole reactor is lowered, power of the blower at the rear end can be reduced, and energy consumption is lowered.

Owner:陕西大秦环境科技有限公司

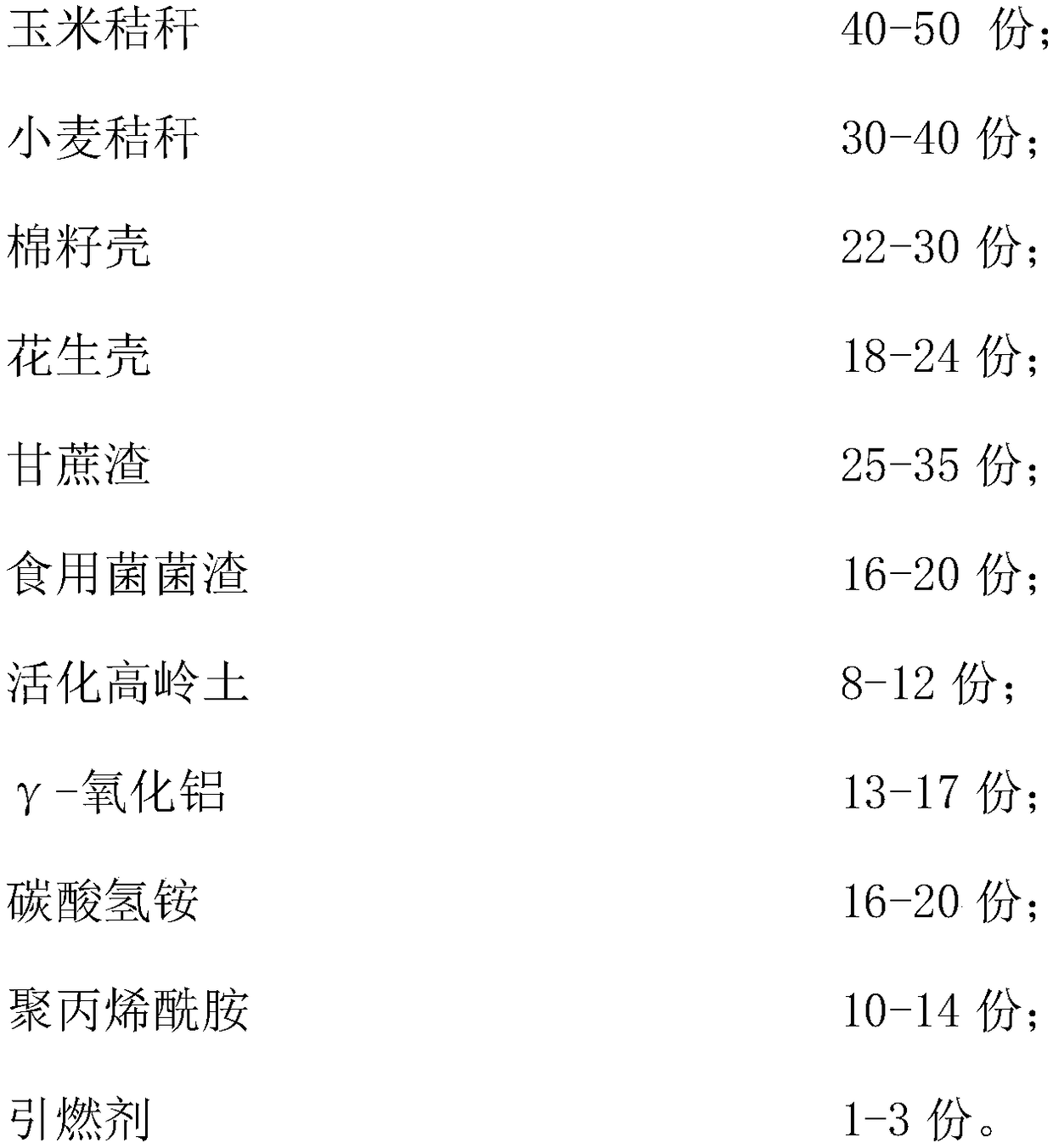

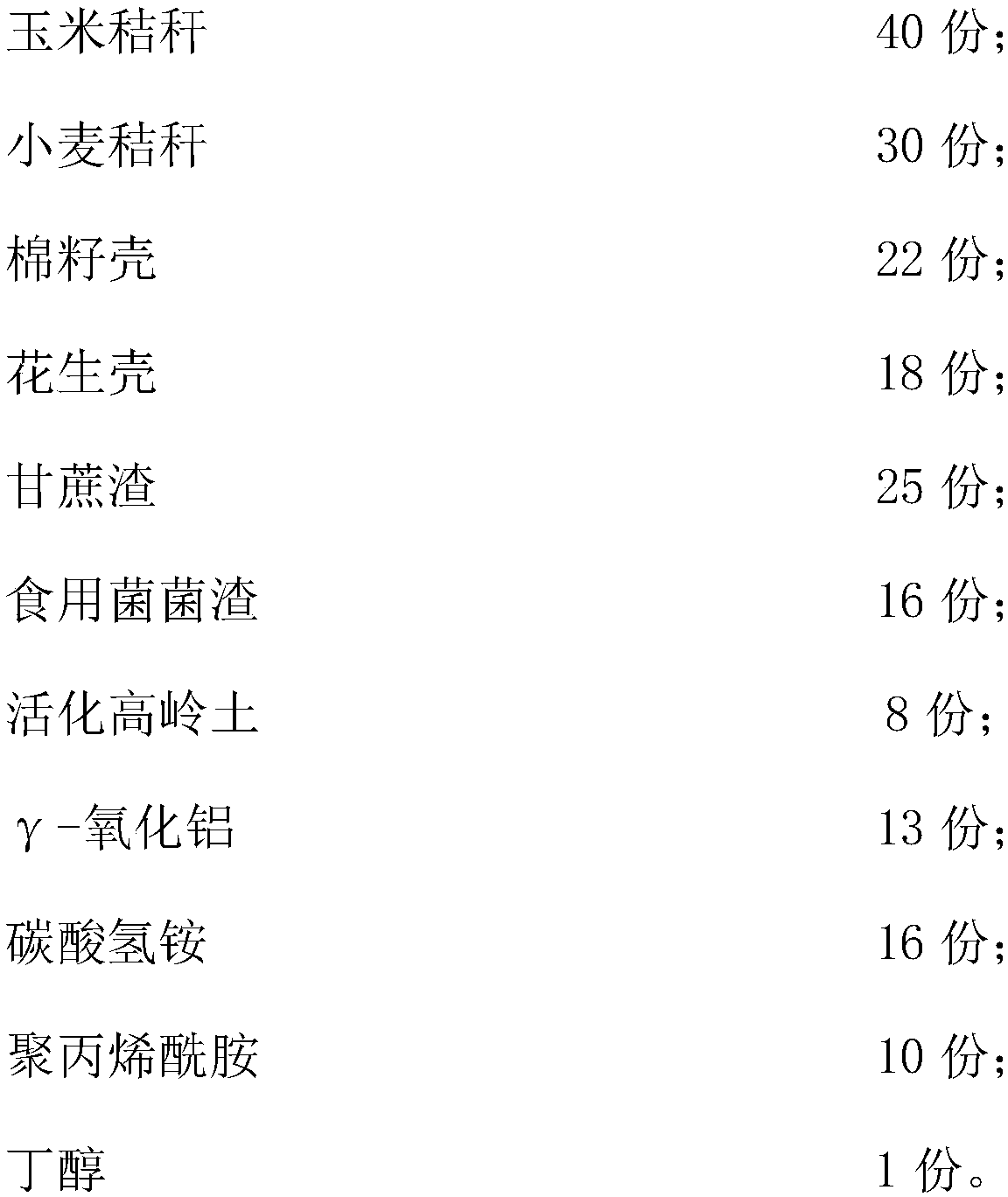

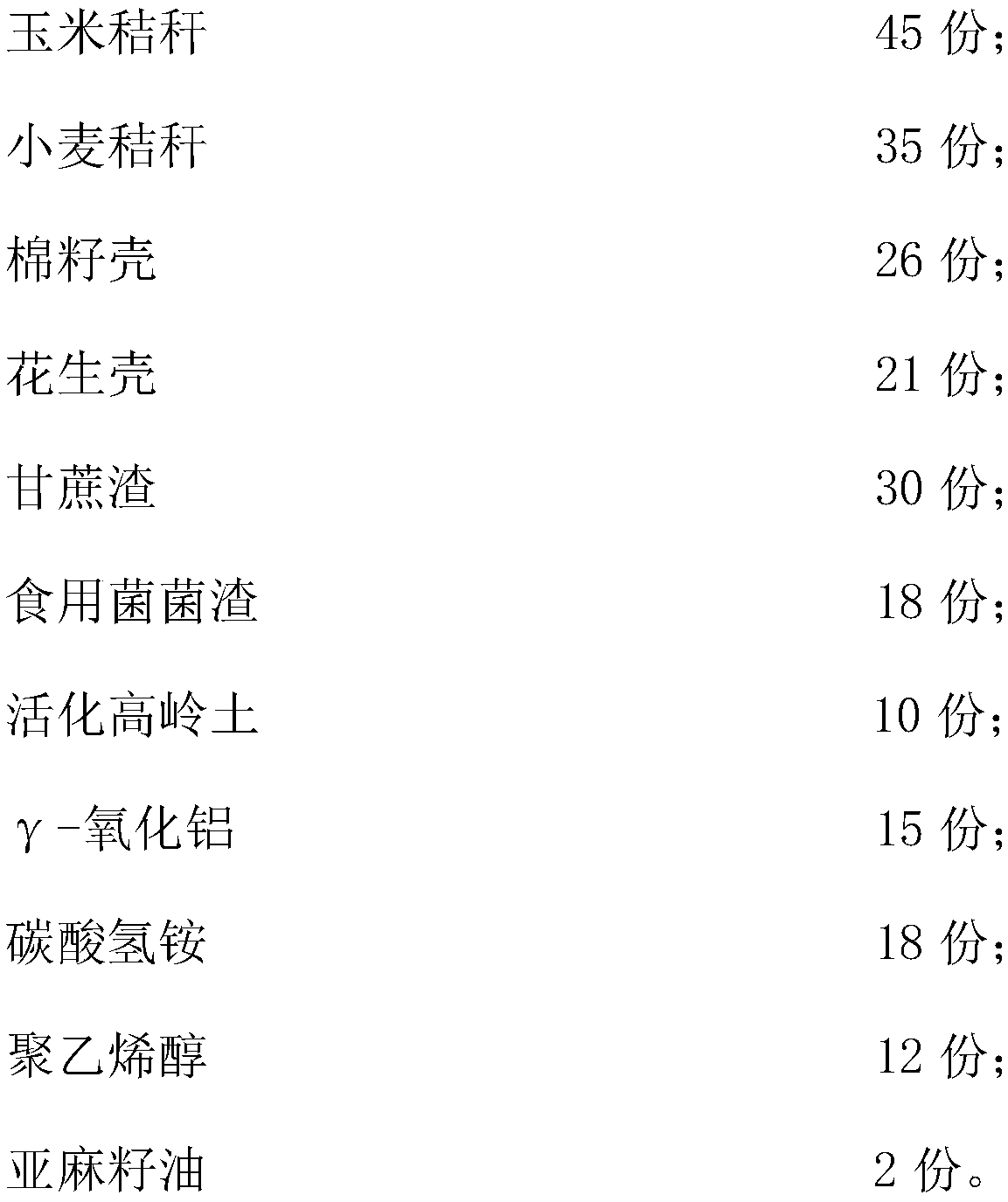

Porous rapid combustion bio-combustible substance particle and preparation process thereof

The invention discloses a porous rapid combustion bio-combustible substance particle and a preparation process thereof. The particle comprises, by weight, 40-50 parts of corn straws, 30-40 parts of wheat straws, 22-30 parts of cotton seed hulls, 18-24 parts of peanut hulls, 25-35 parts of bagasse, 16-20 parts of edible fungi residue, 8-12 parts of activated kaolin, 13-17 parts of gamma-aluminum oxide, 16-20 parts of ammonium bicarbonate, 10-14 parts of polyacrylamide and 1-3 parts of kindling agents. The preparation process of the particle includes the steps: S1 crushing biomass materials, soaking the crushed biomass materials by ammonium hydroxide, and exploding soaked biomass materials by steam; S2 mixing and expanding the biomass materials, the activated kaolin, the gamma-aluminum oxide, the ammonium bicarbonate and the polyacrylamide, performing press forming on the mixed and expanded materials, roasting the formed materials at the temperature of 150 DEG C until the porosity of a green body reaches 20-25%, and spraying the kindling agents. According to the particle, the biomass materials are treated by combining an ammonium hydroxide soaking technology and a steam explosion technology, inner gaps of the biomass materials are enlarged, an irregular porous structure is formed by the aid of thermal decomposition reaction between the ammonium bicarbonate and the polyacrylamide,and complete combustion of fuels is facilitated.

Owner:安徽冠建新能源科技有限公司

Light emitting diode epitaxial wafer and preparation method thereof

ActiveCN107887485AConsolidation and effectPromote radiative recombination luminescenceSemiconductor devicesIndiumElectron blocking layer

The invention discloses a light emitting diode epitaxial wafer and a preparation method thereof, which belong to the technical field of semiconductors. The epitaxial wafer comprises a substrate, a buffer layer, an un-doped GaN layer, an N-type GaN layer, multiple quantum well layers, an electron barrier layer and a P-type GaN layer, wherein the multiple quantum well layers comprise multiple firstsub layers; each first sub layer comprises a quantum well layer and a quantum barrier layer; the quantum barrier layer which is the closest to the electron barrier layer comprises multiple second sublayers and a third sub layer; each second sub layer comprises a fourth sub layer, a fifth sub layer and a sixth sub layer; each fourth sub layer is an AlGaN layer; each fifth sub layer is a GaN layerwith Mg and In doped at the same time; the In doping position in each fifth sub layer is close to the sixth sub layer; each sixth sub layer is a GaN layer; the third sub layer is a GaN layer with Mg and In doped at the same time; and the Mg and In doping concentrations in the third sub layer are higher than those in each fifth sub layer. Hole injection can be increased, and the light emitting efficiency of the LED is improved.

Owner:HC SEMITEK ZHEJIANG CO LTD

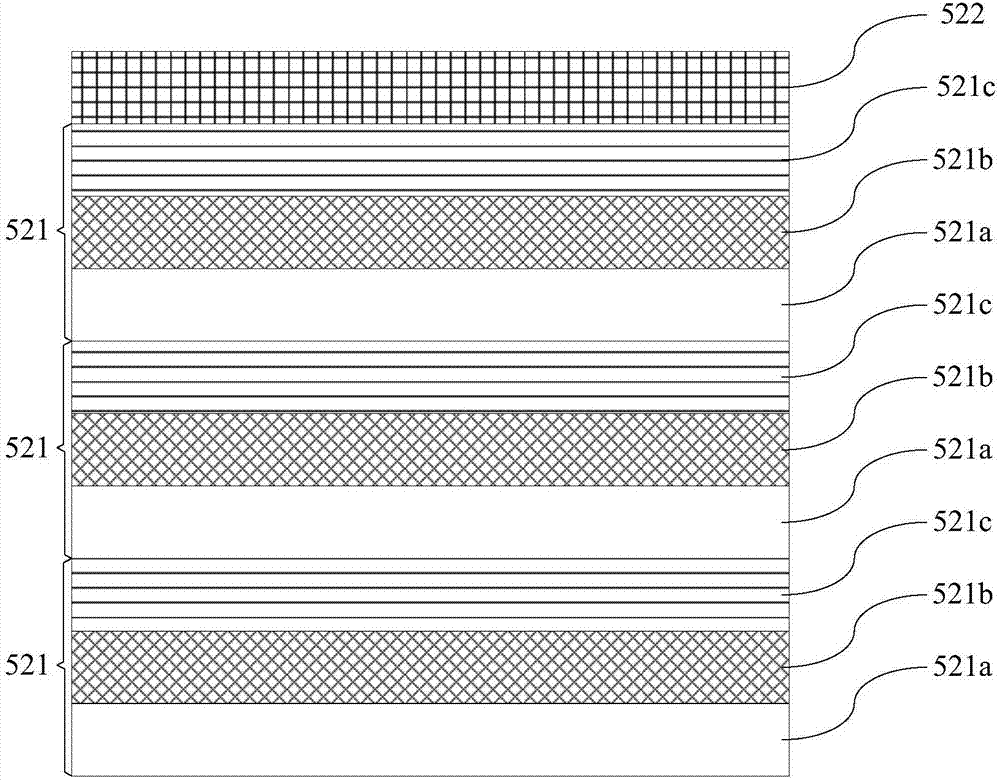

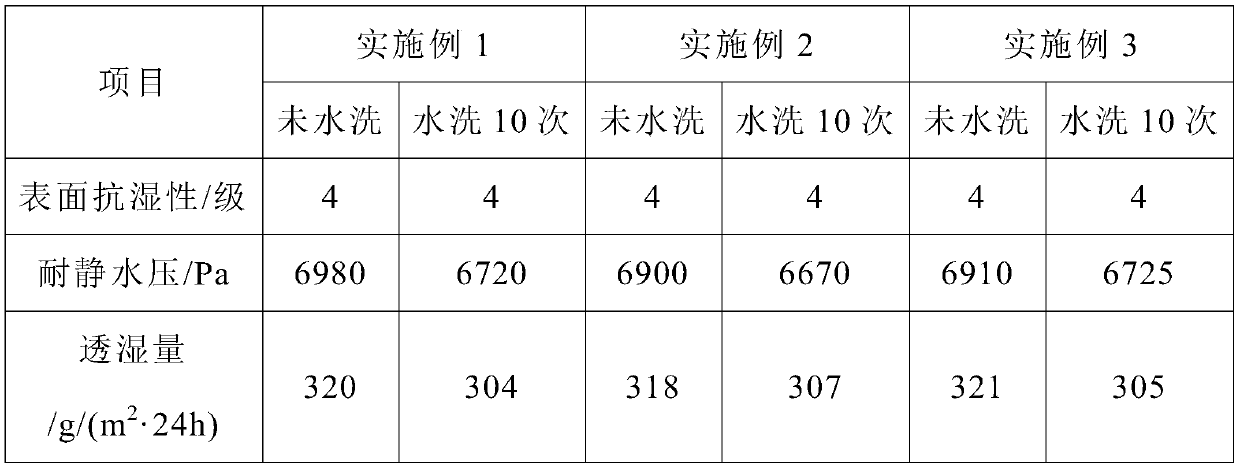

Washable waterproof moisture-permeable foam adhesive laminated fabric and preparation method thereof

ActiveCN111516311AImprove wrinkle resistanceGood quality and stabilityLamination ancillary operationsNon-macromolecular adhesive additivesFoaming agentAdhesive

The invention discloses a washable waterproof moisture-permeable foam adhesive laminated fabric and a preparation method thereof. The laminated fabric comprises a modified fabric, a foam adhesive anda waterproof film from bottom to top, the modified fabric is prepared from a cotton fabric, sodium hydroxide, oxalic acid, a first modifier and a second modifier; wherein the foam glue is obtained byfoaming a foaming agent; the waterproof membrane is prepared from a pretreatment membrane, polydimethylsiloxane and cyclohexane; the pretreatment film comprises a first waterproof layer and a second waterproof layer from bottom to top. The invention discloses a washable waterproof moisture-permeable foam adhesive laminated fabric and a preparation method thereof. The preparation method is simple in process operation and reasonable in component proportion, the waterproof film with hydrophobic, waterproof and moisture-permeable performance is attached to the surface of the modified fabric through a foam glue attaching method, and the prepared attached fabric has excellent waterproof and moisture-permeable performance, high hydrophobic performance, excellent washing resistance and high practicability.

Owner:东莞市听雨轩服装有限公司

Phase-change-material composite hollow building block

InactiveCN104453076AImprove thermal performanceExtended propagation pathConstruction materialClimate change adaptationThermal comfortPhase change

The invention belongs to the technical field of building materials and discloses a phase-change-material composite hollow building block. A building block body is made from light aggregate concrete; five rows of mutually-staggered holes are formed inside the building block, and each row of holes consists of a relatively long hole and a relatively short hole; the holes of one row close to the indoor side are blind holes and are used for being filled with gypsum-based phase-change materials, and the holes of the other four rows are through holes and are air interlayers. According to the phase-change-material composite hollow building block, through reasonably selecting a hole type structure, the mechanical properties of the composite hollow building block are guaranteed, and the heat preservation, heat insulation and heat accumulation properties of the building block can be improved; due to the prepared gypsum-based phase-change materials, the filled phase-change materials are not prone to leaking and have good compatibility with a building block main body material, so that the problem of the traditional hollow building blocks that the heat capacity of a wall body is lowered while the heat preservation property is improved is solved; aiming at climatic conditions of different regions, the phase-change materials with large phase-change latent heat and appropriate coefficient of heat conductivity are reasonably selected, so as to exert the optimal performance of the phase-change materials, so that the indoor heat comfort is improved, and the energy consumption of buildings is lowered.

Owner:JIANGSU UNIV

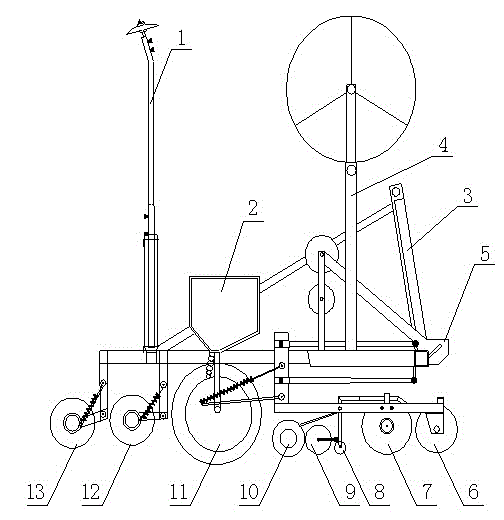

Film-applying drop irrigation sowing earthing device

InactiveCN103141190ARealize reasonable configurationIncrease usagePlantingPressurised distribution of liquid fertiliserDrip irrigationAgricultural engineering

The invention discloses a film-applying drop irrigation sowing earthing device which comprises a rack assembly, and a drip irrigation belt coiled stock, a film coiled stock, a seed box, a row marker assembly, a compacting roller, a film spreading roll, a film pressing edge wheel assembly and a film edge earthing disk which are arranged on the rack assembly. The film-applying drop irrigation sowing earthing device is characterized by also comprising a first earthing device assembly and a second earthing device assembly which are arranged at the rear side of a hole sowing device assembly. Through arrangement of the two earthing devices, the film-applying drop irrigation sowing earthing device meets the earthing requirement of a one-film three-pipe twelve-line mode; and due to the implementation of the one-film three-pipe twelve-line mode, the utilization rate of soil is remarkably increased, and the number of holes in unit area is also greatly increased.

Owner:XINJIANG TIANYE GRP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com