Magnetic nanometer titanium dioxide wastewater treatment and recovery device

A nano-titanium dioxide and wastewater treatment technology, which is applied in the directions of water/sewage multi-stage treatment, light water/sewage treatment, water/sludge/sewage treatment, etc., can solve the problem of inability to recycle and recycle waste water, and high loss rate of particle photocatalysts , low catalytic efficiency and other problems, to achieve the effect of solving the difficulty of solid-liquid separation, reducing the probability of recombination, and high catalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

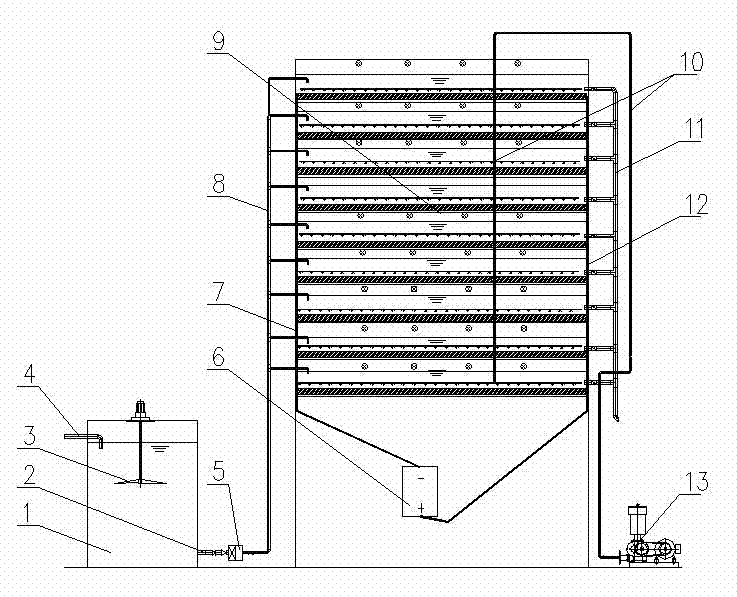

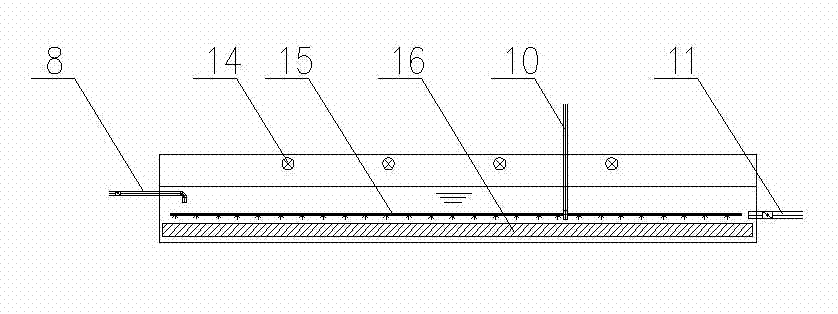

[0020] Such as figure 1 As shown, a magnetically loaded nano-titanium dioxide wastewater treatment and recovery device includes a mixing water tank 1 and a photocatalytic reaction chamber 9 .

[0021] The top of the mixing water tank is equipped with a mixer 3 , the upper part is provided with a water inlet pipe 4 , and the lower part is provided with a water outlet pipe 2 , and the water outlet pipe 2 is connected with the water inlet pipe 8 of the photocatalytic reaction chamber 9 through a water pump 5 . Printing and dyeing wastewater enters the mixing tank 1 after conventional physical, chemical and biochemical treatment, and the mixer 3 on the top of the mixing tank 1 rotates continuously for stirring and mixing, so that the wastewater and the magnetic nano-titanium dioxide photocatalyst are fully mixed, and then transported to the photocatalytic r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com