Patents

Literature

194results about How to "Efficient separation and recovery" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

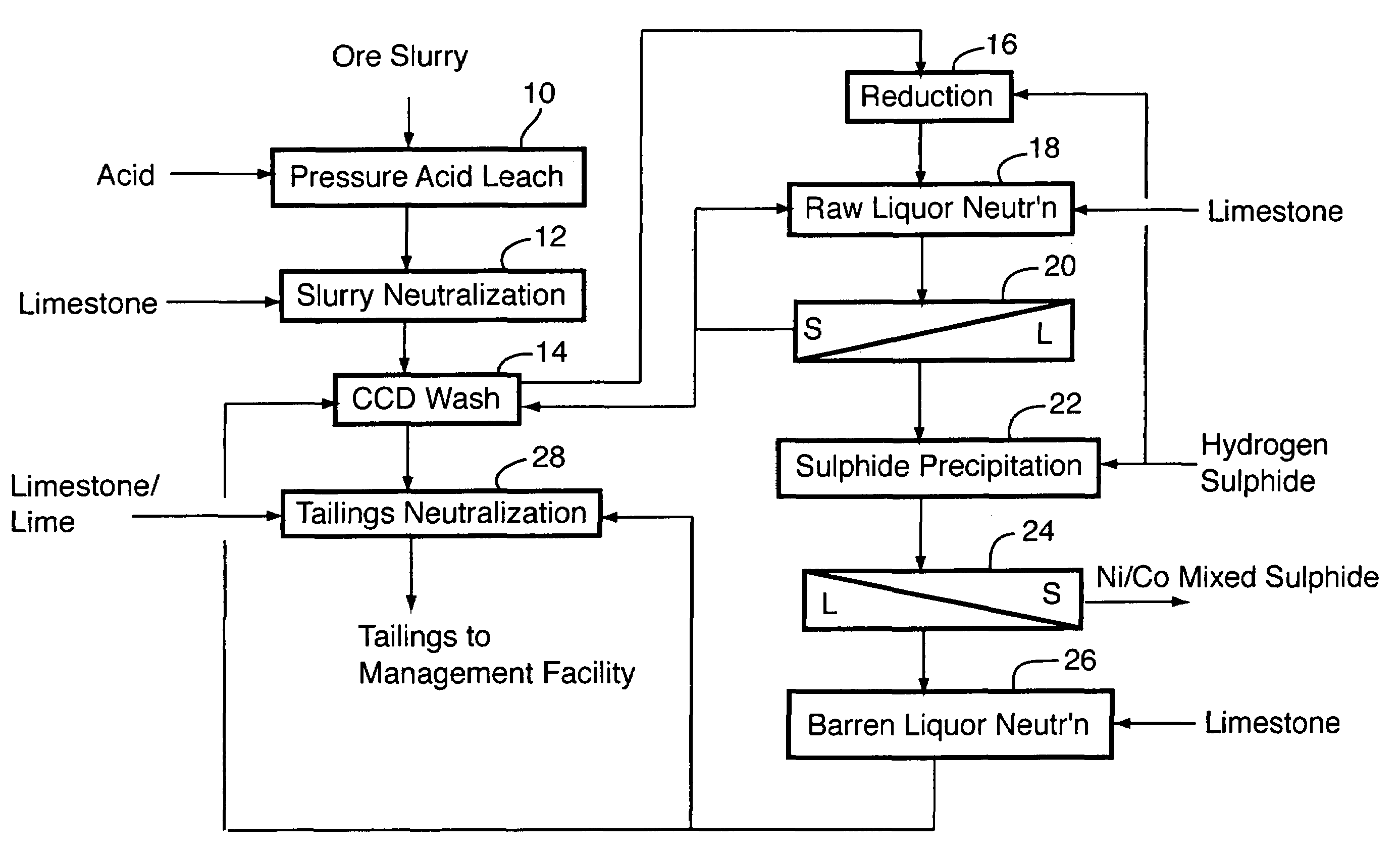

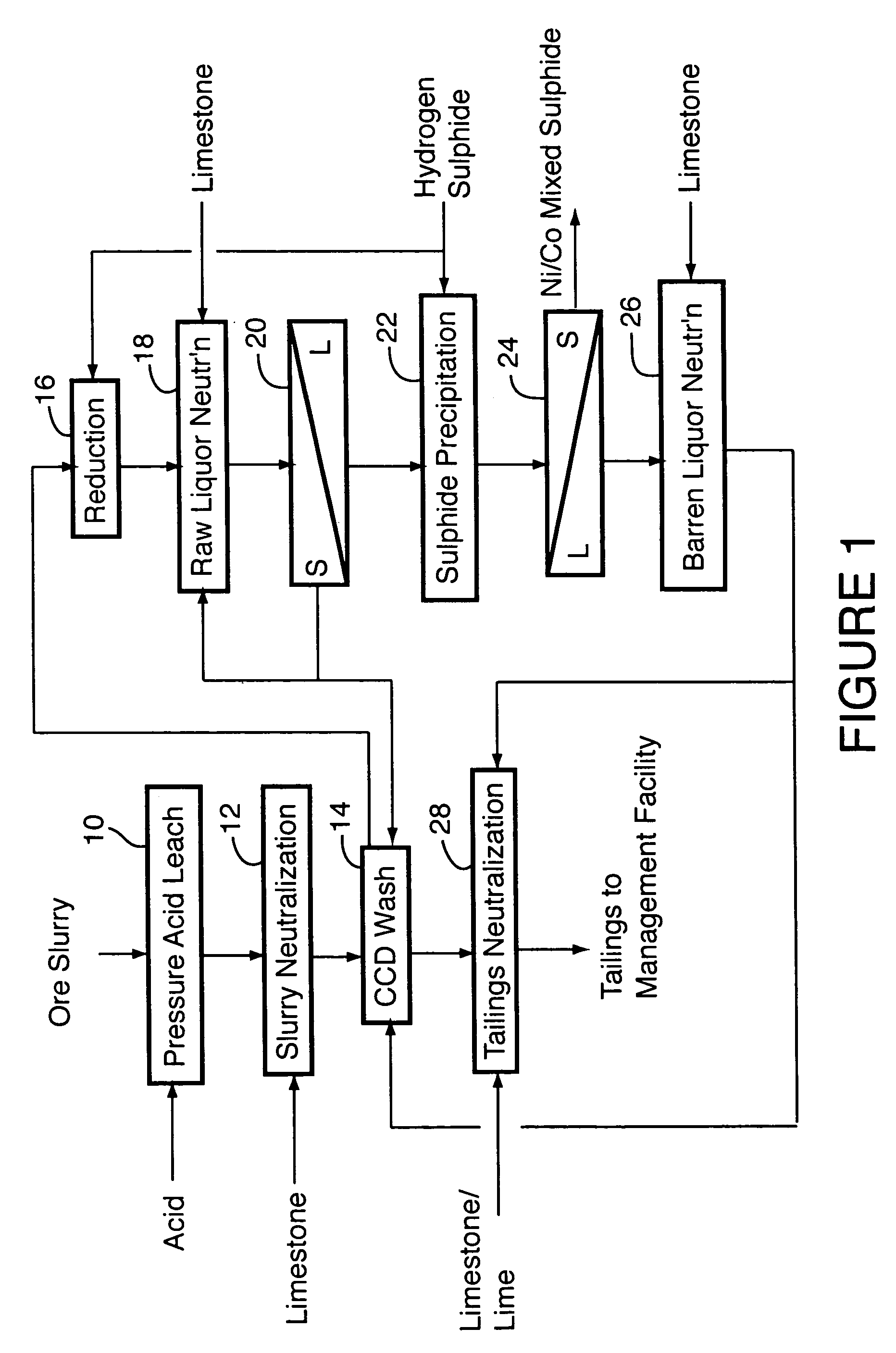

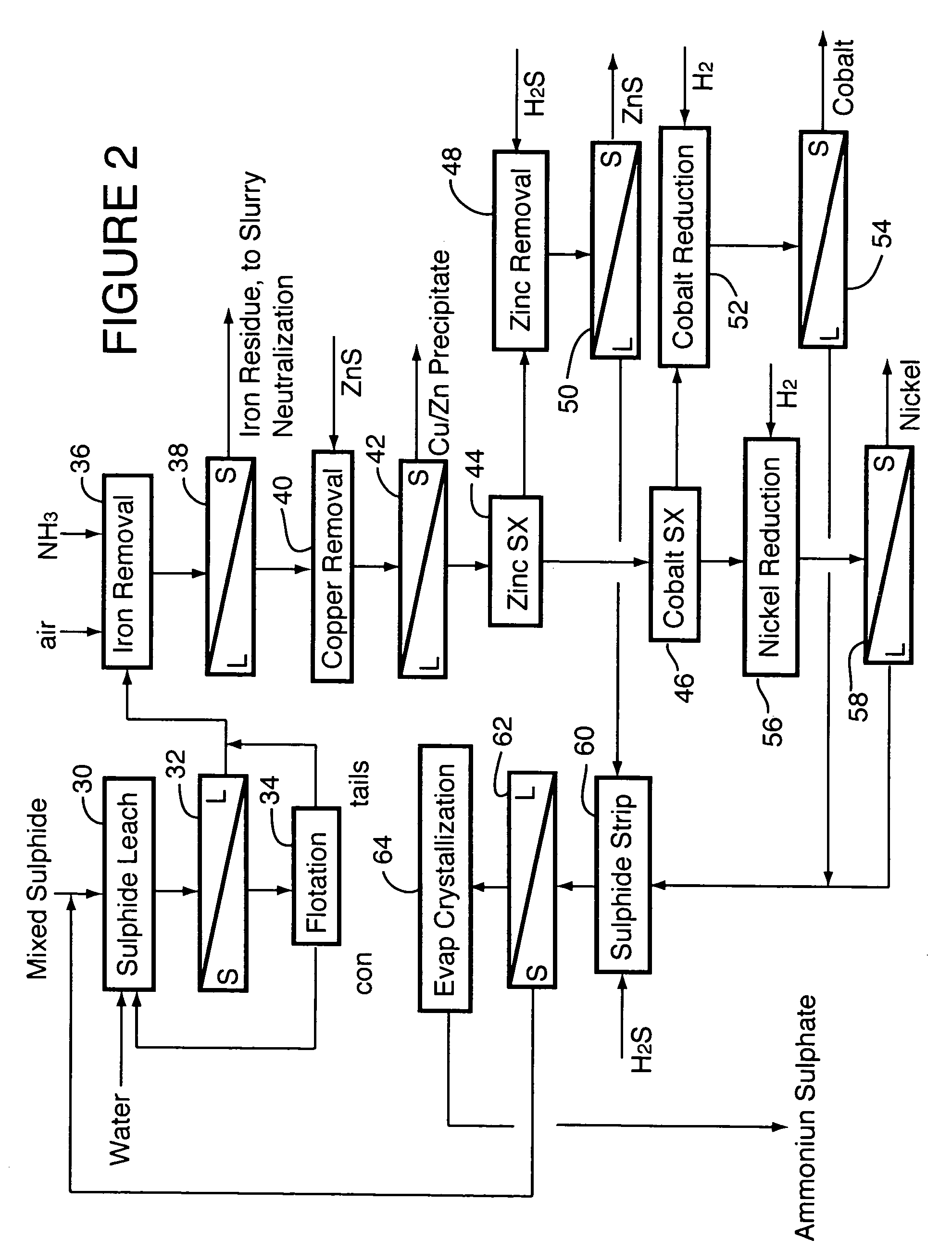

Process for recovery of nickel and cobalt from laterite ore

ActiveUS20060228279A1Efficient separation and recoveryHigh purityCobalt sulfidesSolvent extractionFree solutionSlurry

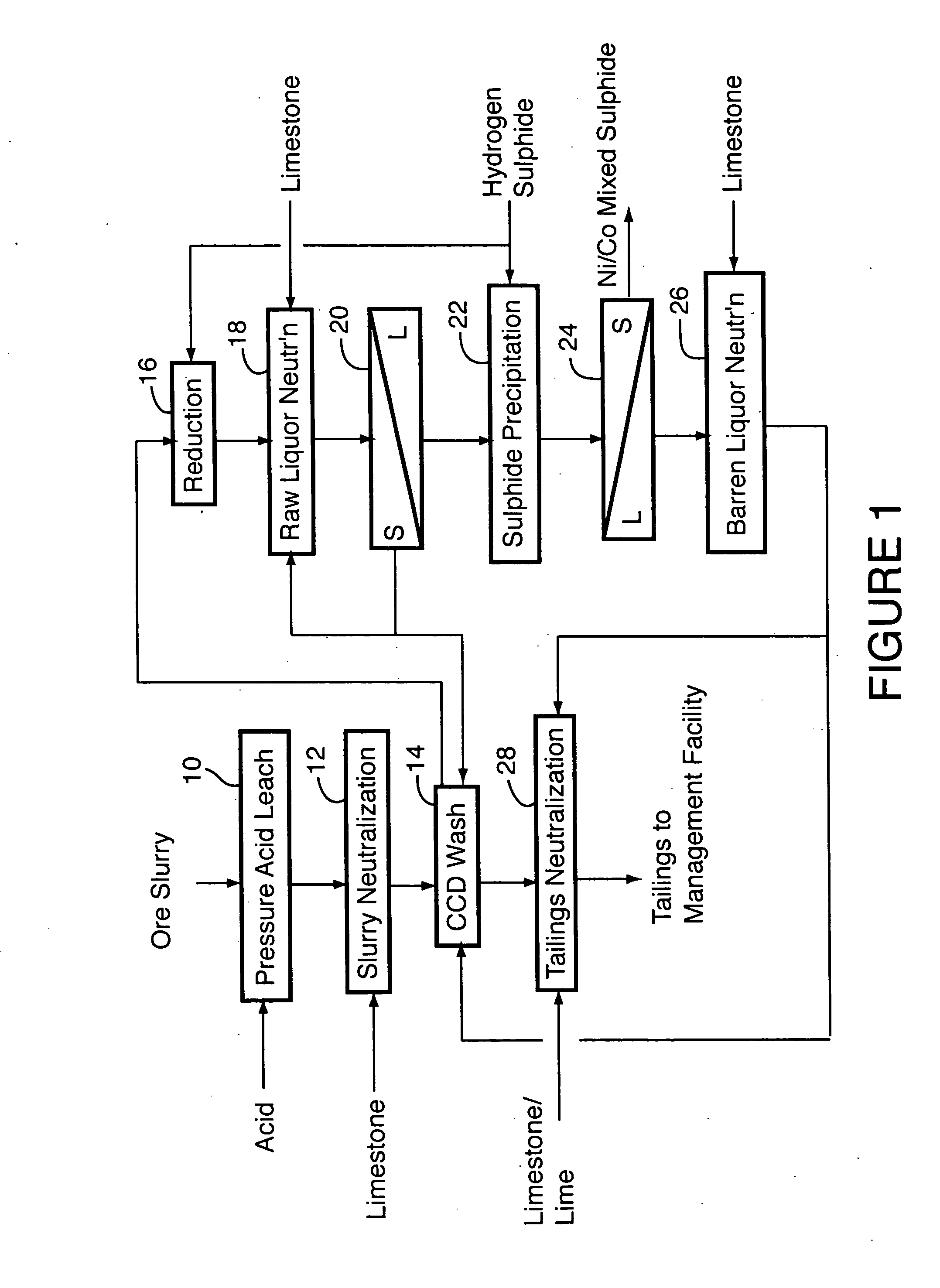

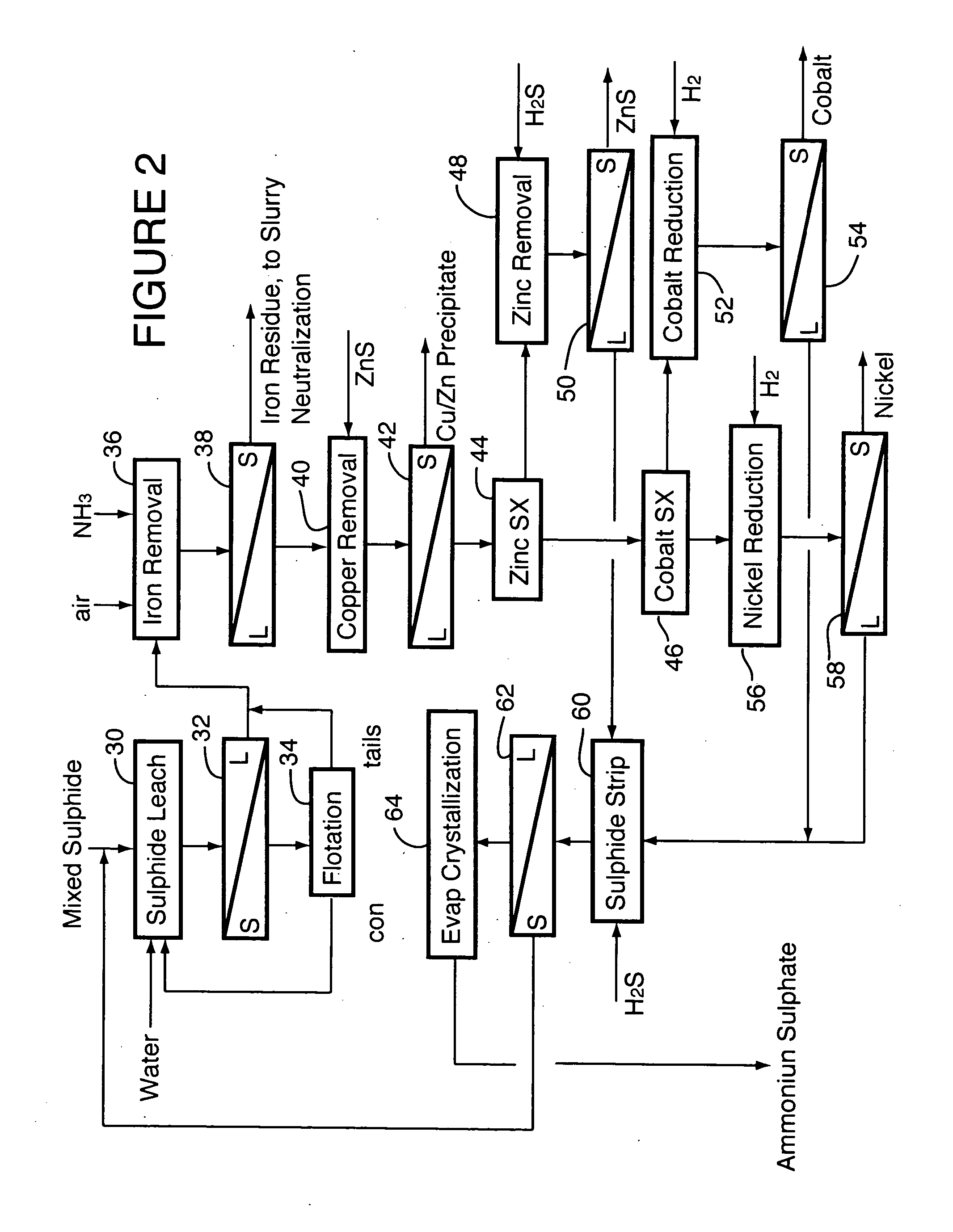

A process for recovering nickel and cobalt values from nickel- and cobalt-containing laterite ores as an enriched mixed nickel and cobalt sulphide intermediate and for producing nickel and cobalt metal from the nickel and cobalt sulphide intermediate. The laterite ore is leached as a slurry in a pressure acid leach containing an excess of aqueous sulphuric acid at high pressure and temperature, excess free acid in the leach slurry is partially neutralized to a range of 5 to 10 g / L residual free H2SO4 and washed to yield a nickel- and cobalt-containing product liquor, the product liquor is subjected to a reductant to reduce any Cr(VI) in solution to Cr(III), the reduced product liquor is neutralized to precipitate ferric iron and silicon at a pH of about 3.5 to 4.0, and the neutralized and reduced product liquor is contacted with hydrogen sulphide gas to precipitate nickel and cobalt sulphides. The precipitated nickel and cobalt sulphides can be leached in a water slurry in a pressure oxidation leach, the leach solution subjected to iron hydrolysis and precipitation, the iron-free solution contacted with zinc sulphide to precipitate copper, the iron- and copper-free solution subjected to zinc and cobalt extraction by solvent extraction to produce a nickel raffinate, the nickel raffinate contacted with hydrogen gas to produce nickel powder and the cobalt strip solution from the solvent extraction step contacted with hydrogen gas to produce cobalt powder.

Owner:SHERRITT INTERNATIONAL

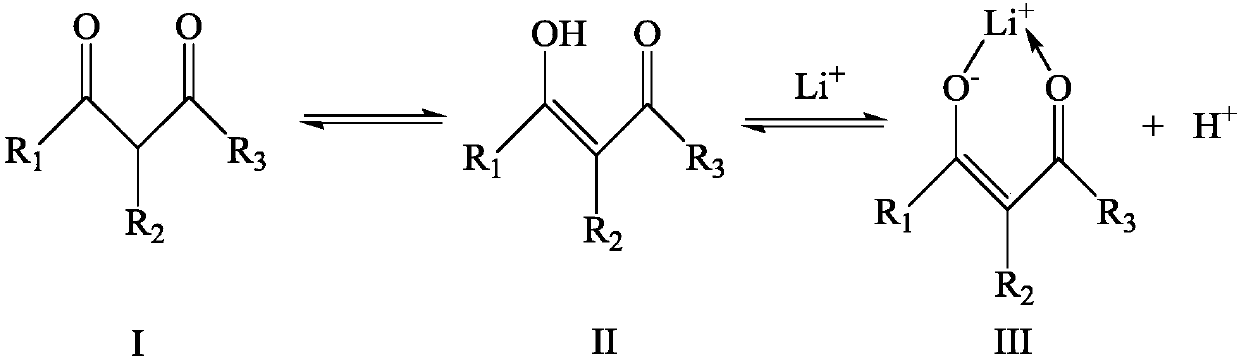

Application and method of neutral phosphamide extraction agent for extracting and separating thorium

ActiveCN104131164AImprove extraction abilityEfficient separation and recoveryProcess efficiency improvementPurification methodsThorium

The invention relates to a thorium separation and purification method and in particular relates to an application of a neutral phosphamide extraction agent shown as a general formula I in the specification for extracting and separating thorium, as well as a method for extracting and separating thorium by using the neutral phosphamide extraction agent.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

Method for extracting vanadium and chromium from materials containing vanadium or/and chromium

InactiveCN105420519AEasy to separateHigh recovery rateProcess efficiency improvementPregnant leach solutionVanadate

A method for extracting vanadium and chromium from materials containing the vanadium or / and the chromium is characterized by comprising the following steps: taking salt and alkali of alkali metal or the alkali of the alkali metal as an oxidation transformation medium of the materials containing the vanadium or / and the chromium; carrying out treating for 0.5-6 hours at the temperature of 160-600 DEG C under the effect of an oxidizing agent and enabling the vanadium and the chromium in the materials to be converted into soluble vanadate and soluble chromate; carrying out water leaching to obtain leaching liquor containing the vanadium or / and the chromium; adding a precipitant A in the leaching liquor containing the vanadium or / and the chromium to selectively precipitate the vanadium at first, and adding a precipitant B to precipitate the chromium to obtain vanadium-rich residues and chromium-rich residues; and then separating and recycling the vanadium and the chromium from the vanadium-rich residues and the chromium-rich residues respectively. The vanadium and the chromium are separated and recycled effectively, and moreover, the effect of removing impurities simultaneously is achieved; liquor obtained after chromium precipitation is subjected to oxidization regeneration, evaporated and concentrated to obtain media, and the media are returned to an oxidation transformation procedure for the materials containing the vanadium or / and the chromium and are recycled. The method has the advantages of the simple technology, easiness and convenience in operation, the good vanadium and chromium separating effect, a high metal recovery rate, low production cost, environmental friendliness and the like, and is suitable for industrial application of extracting the vanadium and the chromium from the materials containing the vanadium or / and the chromium.

Owner:CENT SOUTH UNIV

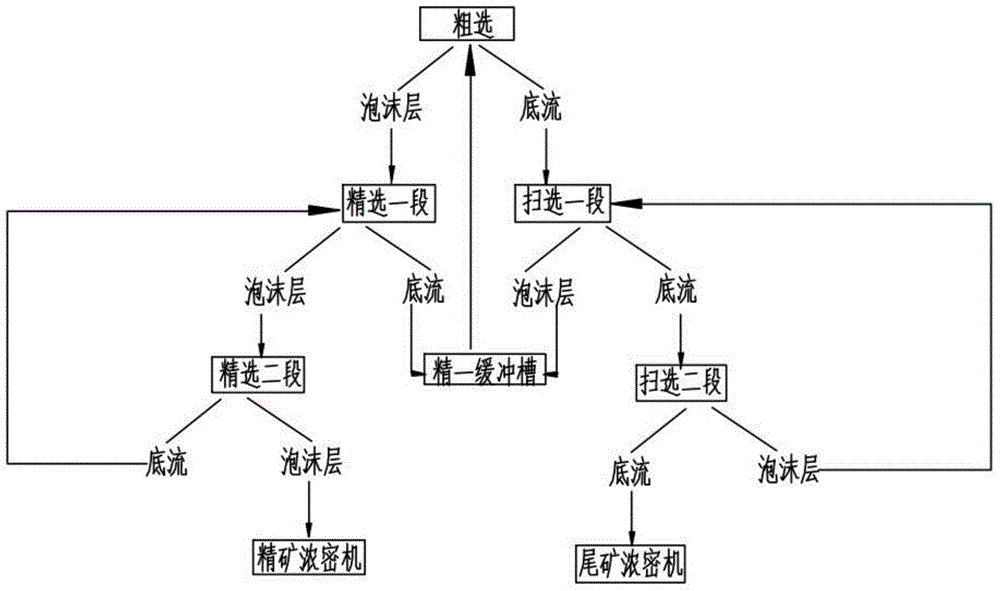

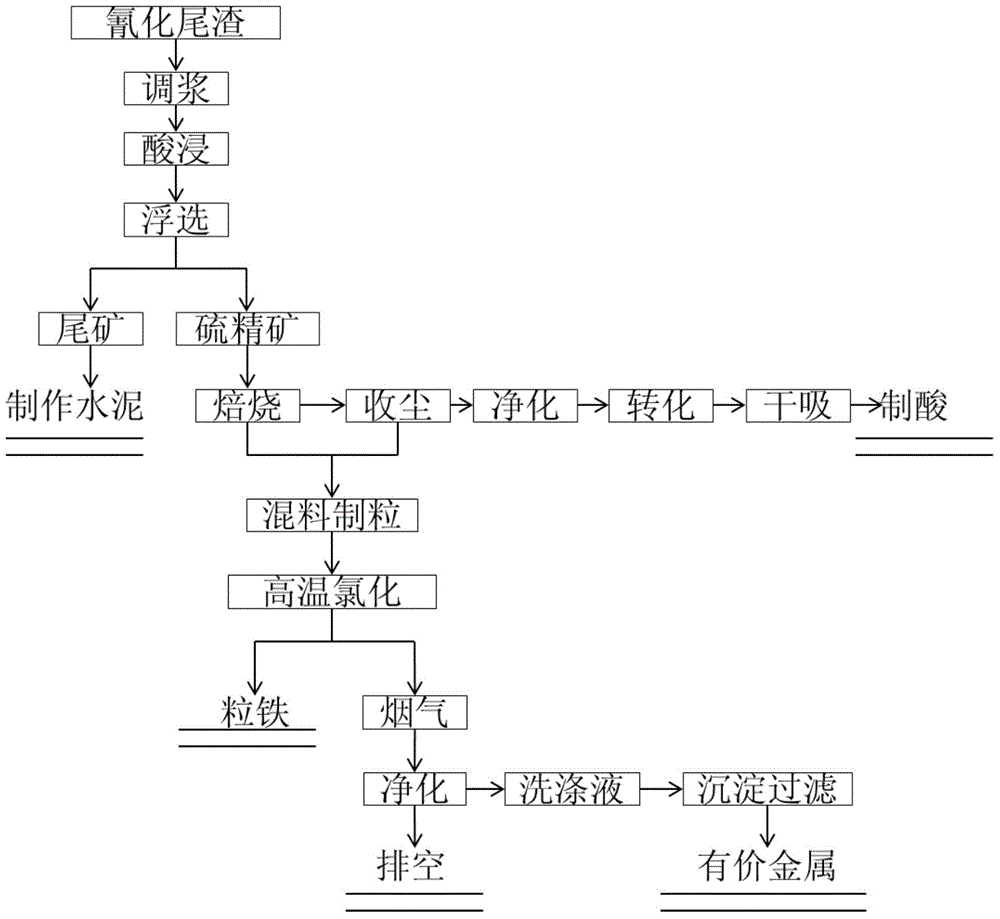

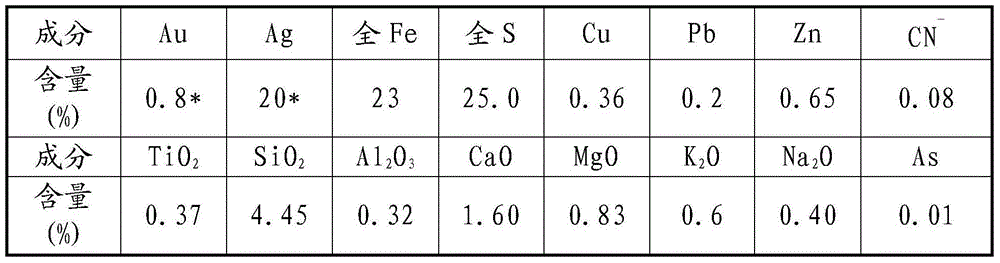

Comprehensive recycling method of cyanide tailing slag

ActiveCN103981370AEfficient separation and recoveryImprove utilization efficiencySolid waste managementSulfur compoundsCyanideSulfur

The invention belongs to the technical field of metallurgical waste slag recovery and in particular relates to a comprehensive recycling method of cyanide tailing slag. Cyanide tailings is floated to obtain sulfur concentrate and tailing, sulfur concentrate is roasted by weak oxygen to obtain sulfuric acid, and pyritic slag is subjected to chlorination roasting to enable valuable elements to be recycled. By virtue of the comprehensive recycling method disclosed by the invention, the valuable elements can be efficiently separated and recovered from cyanide tailing slag, and cyanide tailing slag is utilized to a maximum extent, the comprehensive utilization efficiency of resources is improved and the pollution of cyanide tailing slag to the environment is reduced.

Owner:ZHAOJIN MINING +1

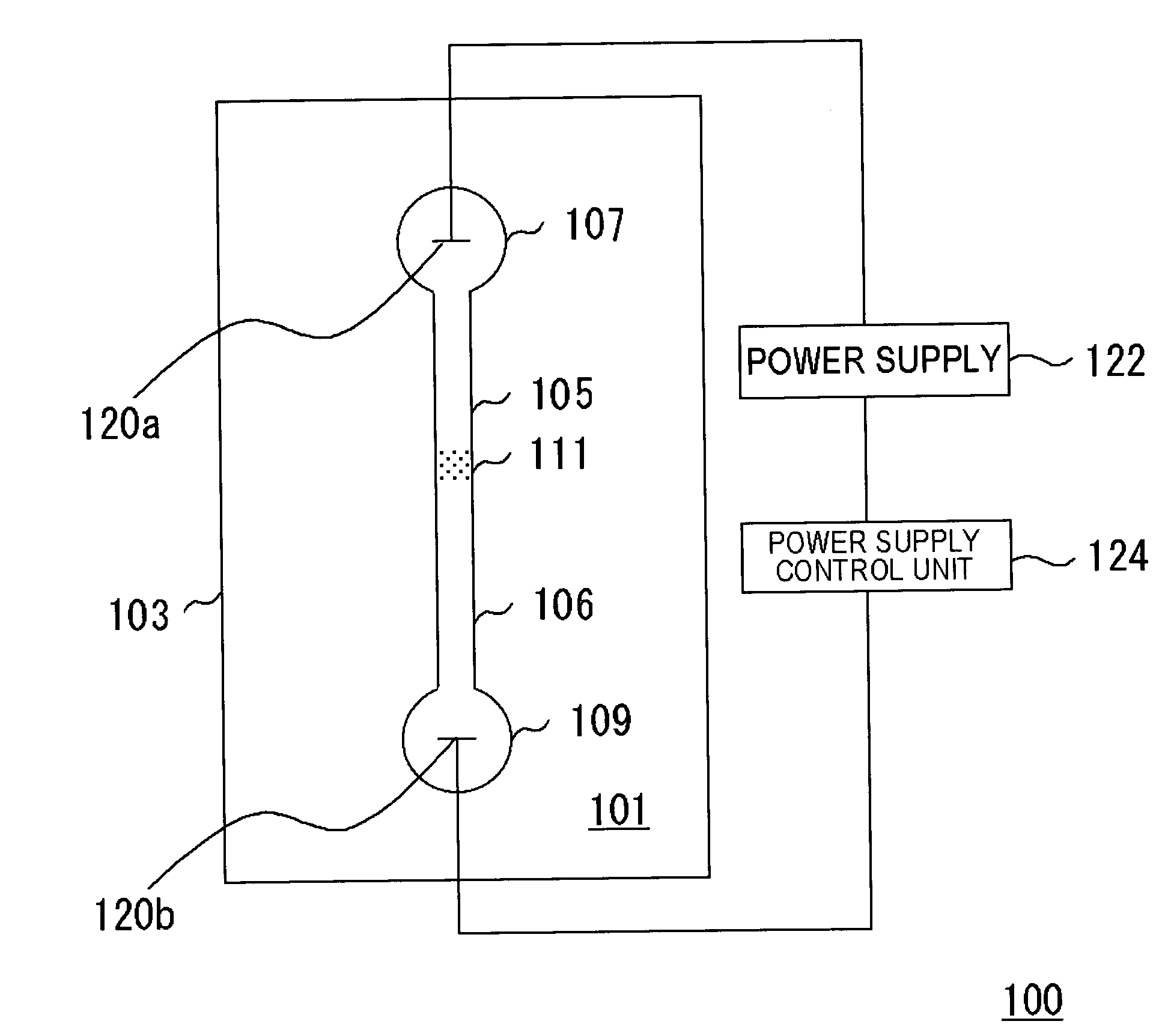

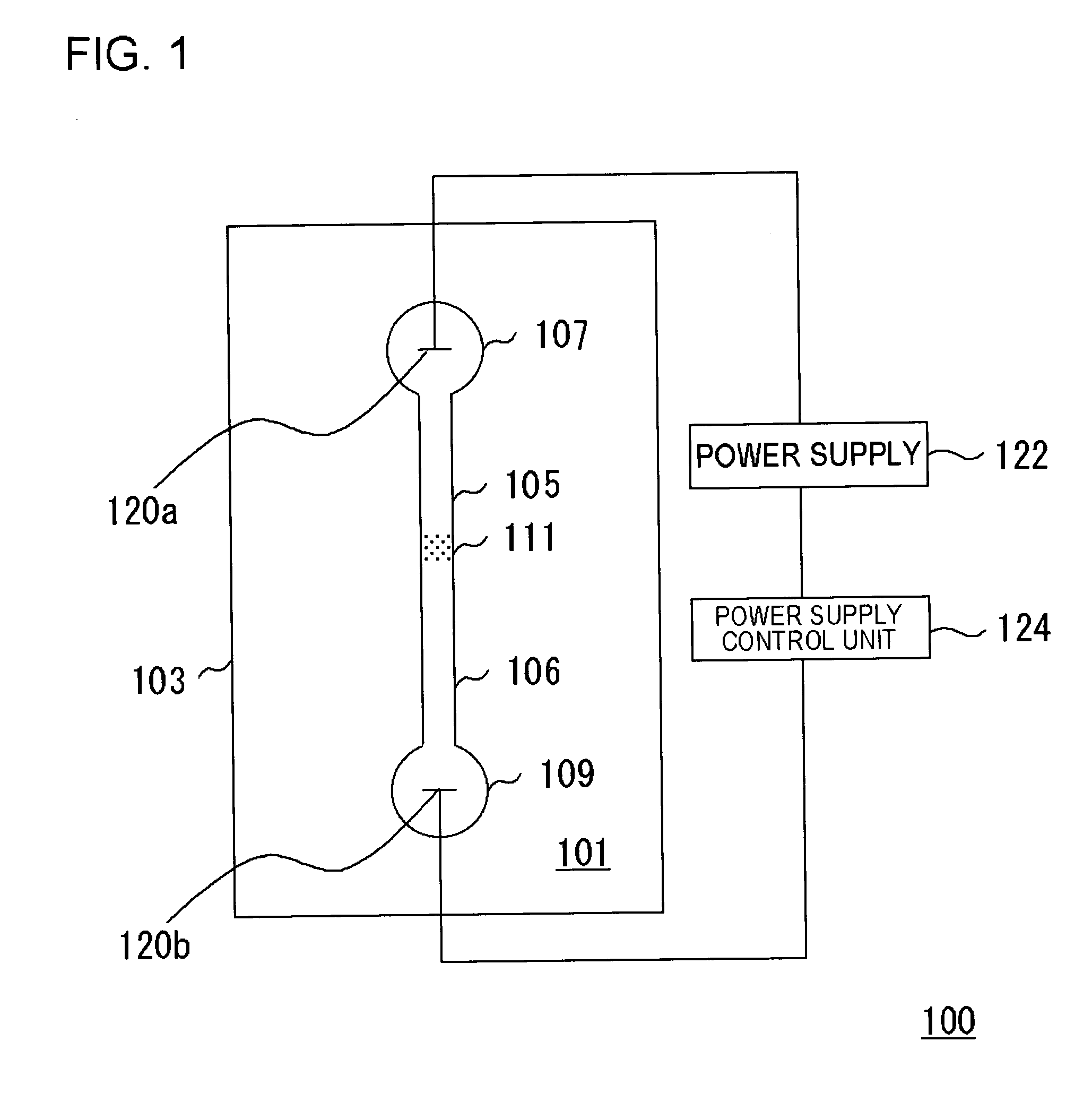

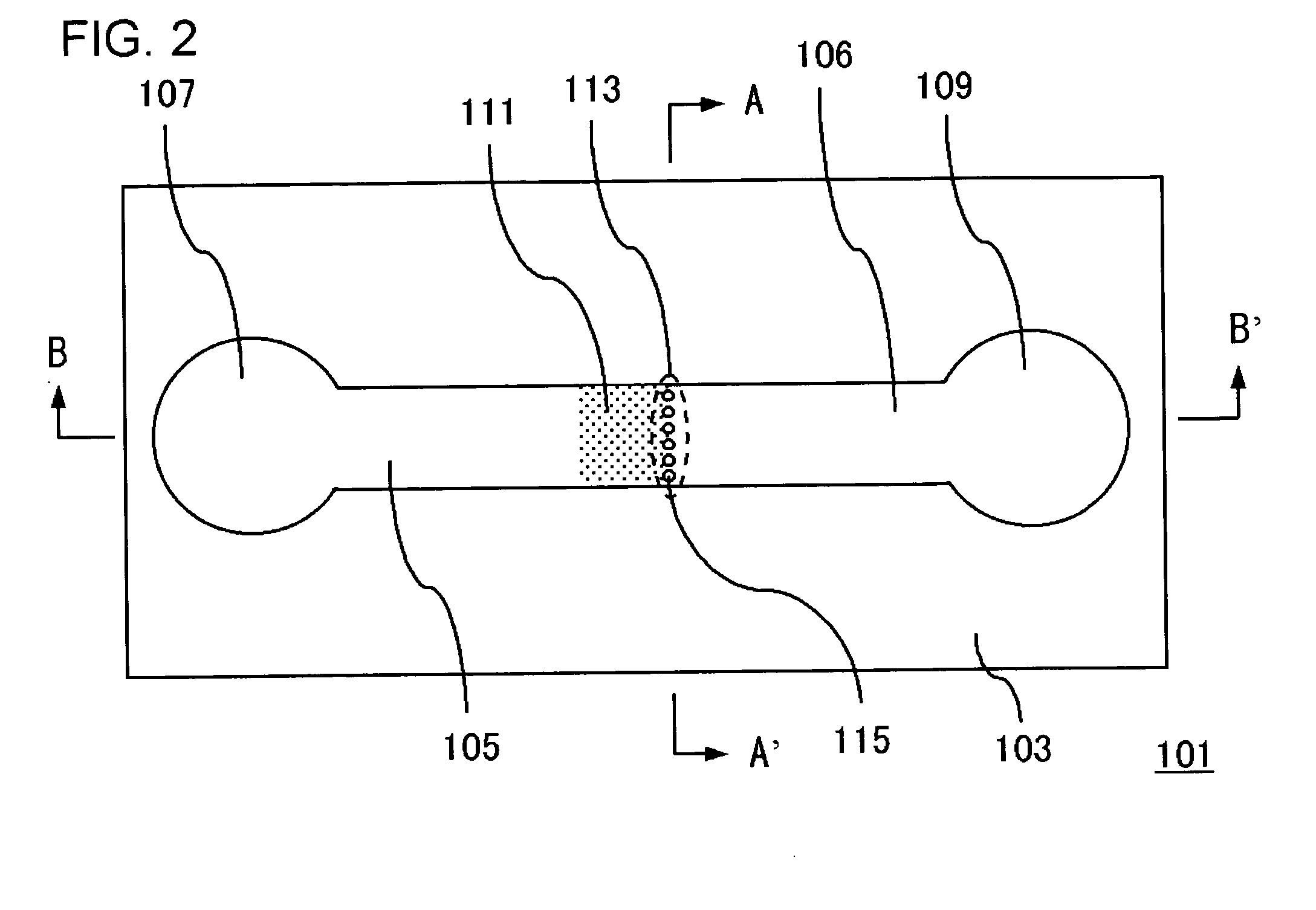

Microchip, sampling method, sample separating method, sample analyzing method, and sample recovering method

InactiveUS20060177350A1Securely holdIncrease freedomAnalysis using chemical indicatorsWithdrawing sample devicesRecovery methodAnalysis method

A sample-carrier complex (119) is introduced into a sample introducing portion (107), and the sample-carrier complex (119) is moved and deposited on a damming portion (111). The damming portion (111) is heated at a stage in which the predetermined amount of sample-carrier complex (119) is deposited on the damming portion (111). A temperature is increased to a predetermined temperature to break down the sample-carrier complex (119) into a sample (121) and a carrier (123). A voltage is applied between the sample introducing portion (107) and a sample recovery portion (109) to cause the sample (121) to pass through a gap between columnar bodies (115) and move into a second channel (106) to perform predetermined separation and analysis or recovery operation.

Owner:NEC CORP

Method for concentration of gold in copper sulfide minerals

ActiveUS20100242681A1Efficient separationEffective recoveryPhotography auxillary processesGold compoundsEnrichment methodsHydrometallurgy

Disclosed herein is a method for concentrating gold contained in a leach residue obtained in a copper hydrometallurgical process for recovering copper from a copper sulfide mineral to efficiently separate and recover gold from the leach residue. According to the method, a gold-bearing copper sulfide mineral is subjected to pressure leaching with sulfuric acid at a temperature higher than 102° C. and 112° C. or lower to obtain a leach residue, and the leach residue is subjected to flotation to separate it into a float fraction and a sink fraction. The float fraction obtained by flotation is desulfurized by heating at a temperature of 250 to 800° C. under an inert atmosphere to obtain a desulfurized product. The desulfurized product is subjected to oxidative roasting by heating at a temperature of 600 to 800° C. under an atmosphere of flowing oxygen or air to obtain an oxidatively-roasted product. The oxidatively-roasted product is dissolved in a sulfuric acid solution to obtain a copper solution, and a gold-bearing residue is separated and recovered from the copper solution.

Owner:SUMITOMO METAL MINING CO LTD

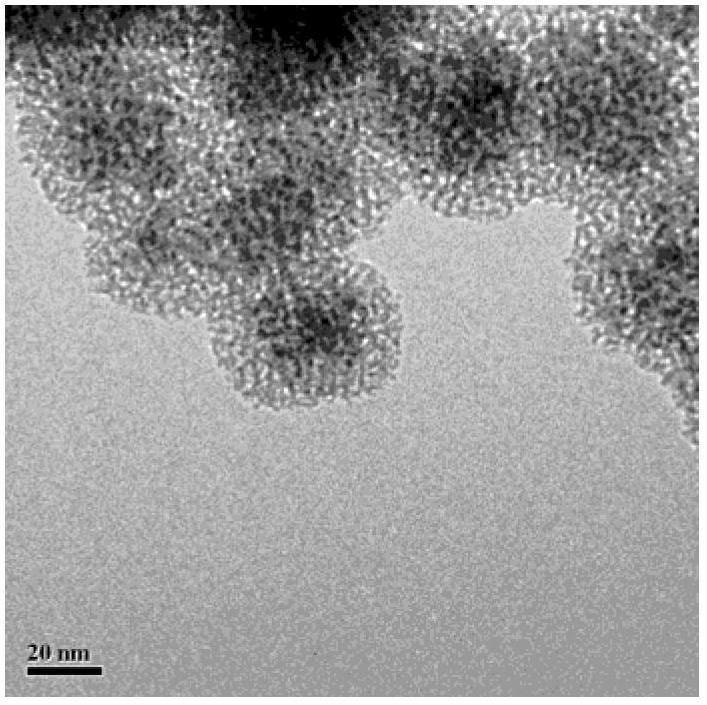

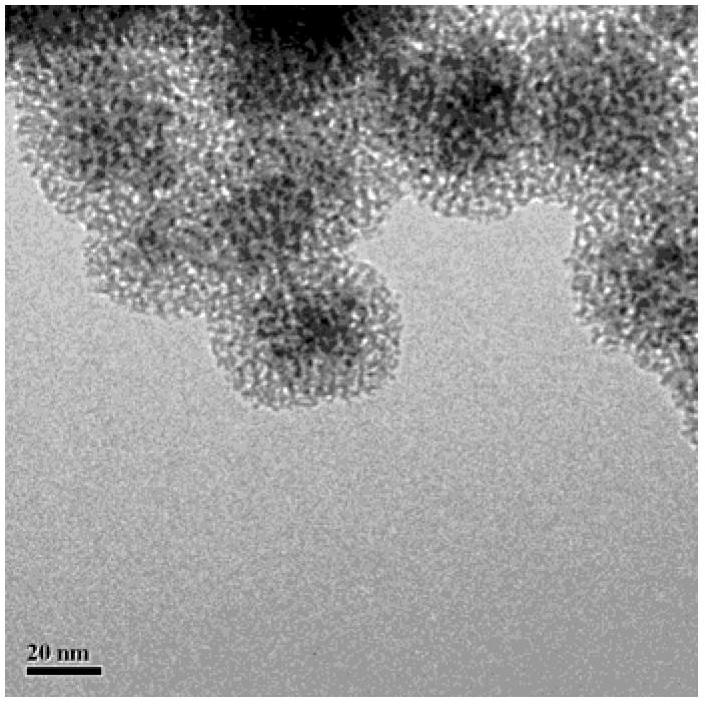

Fe3O4/CuO/pSiO2 catalyst and preparation method thereof

InactiveCN102688760AEfficient separation and recoveryReduce catalyst lossOrganic chemistryMetal/metal-oxides/metal-hydroxide catalystsActive agentSurface-active agents

The invention relates to a Fe3O4 / CuO / pSiO2 (porous silica) catalyst, a preparation method thereof and application thereof in olefin epoxidation reaction. The preparation method comprises the following processes of: obtaining Fe3O4 microspheres serving as magnetic cores by adopting a co-precipitation method, and modifying the surfaces of the Fe3O4 microspheres by using polyvinyl pyrrolidone (PVP) in order to improve the adsorption effect of the surfaces of the Fe3O4 microspheres on metal cations; coating a CuO nano shell layer on the surfaces of the Fe3O4 microspheres by using copper acetate as a copper source through hydrothermal synthesis; and finally, coating the porous silicon dioxide shell layer by using cetyl trimethyl ammonium bromide (CTAB) as a surfactant and using ethyl orthosilicate as a silicon source, and thus obtaining a composite catalytic material with a magnetic Fe3O4 / CuO / pSiO2 core-shell structure. The catalytic performance of the composite material is researched by respectively using epoxidation reaction of styrene and cyclooctene as probe reaction, and the results prove that the catalytic material has high reaction activity and selectivity, and the catalytic material is easy to separate and recover by introducing the magnetic ores; and the catalytic material has a good circulating effect, still can keep excellent catalytic performance by dozens of times of circulation, and has a great application prospect.

Owner:UNIV OF SCI & TECH BEIJING

Recovery of nickel, cobalt, iron, silica, zinc and copper from laterite ore by sulfuric acid leaching

ActiveUS7387767B2Efficient separation and recoveryHigh purityCobalt sulfidesSolvent extractionFree solutionSlurry

A process for recovering nickel and cobalt values from nickel- and cobalt-containing laterite ores as an enriched mixed nickel and cobalt sulphide intermediate and for producing nickel and cobalt metal from the nickel and cobalt sulphide intermediate. The laterite ore is leached as a slurry in a pressure acid leach containing an excess of aqueous sulphuric acid at high pressure and temperature, excess free acid in the leach slurry is partially neutralized to a range of 5 to 10 g / L residual free H2SO4 and washed to yield a nickel- and cobalt-containing product liquor, the product liquor is subjected to a reductant to reduce any Cr(VI) in solution to Cr(III), the reduced product liquor is neutralized to precipitate ferric iron and silicon at a pH of about 3.5 to 4.0, and the neutralized and reduced product liquor is contacted with hydrogen sulphide gas to precipitate nickel and cobalt sulphides. The precipitated nickel and cobalt sulphides can be leached in a water slurry in a pressure oxidation leach, the leach solution subjected to iron hydrolysis and precipitation, the iron-free solution contacted with zinc sulphide to precipitate copper, the iron- and copper-free solution subjected to zinc and cobalt extraction by solvent extraction to produce a nickel raffinate, the nickel raffinate contacted with hydrogen gas to produce nickel powder and the cobalt strip solution from the solvent extraction step contacted with hydrogen gas to produce cobalt powder.

Owner:SHERRITT INC

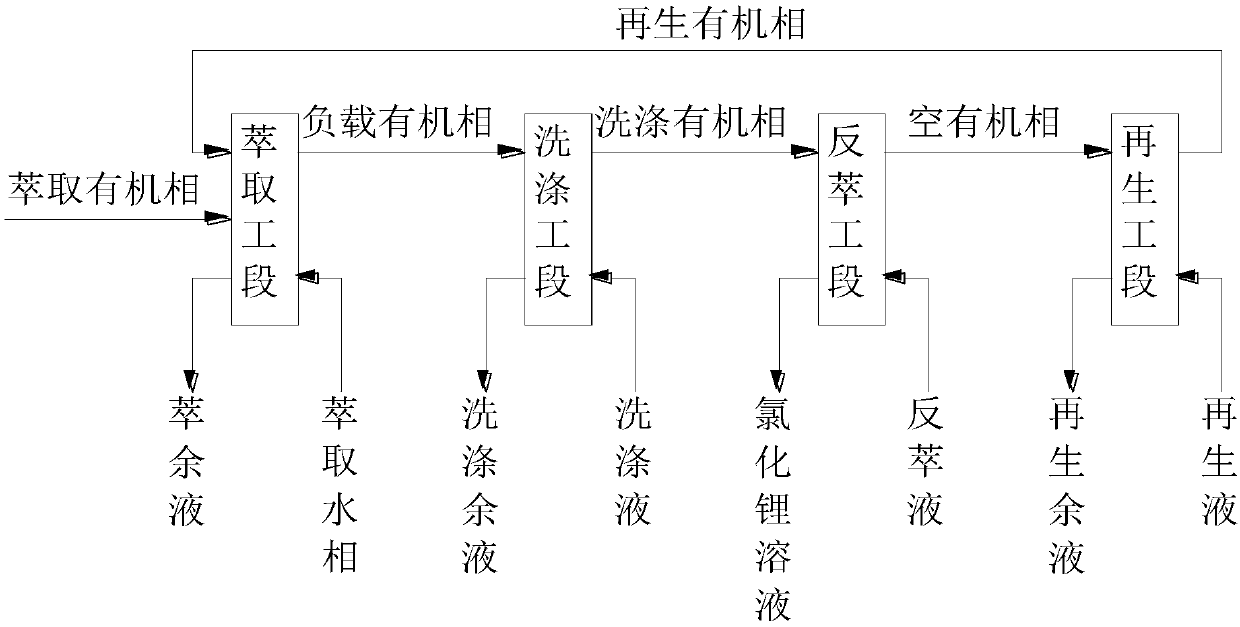

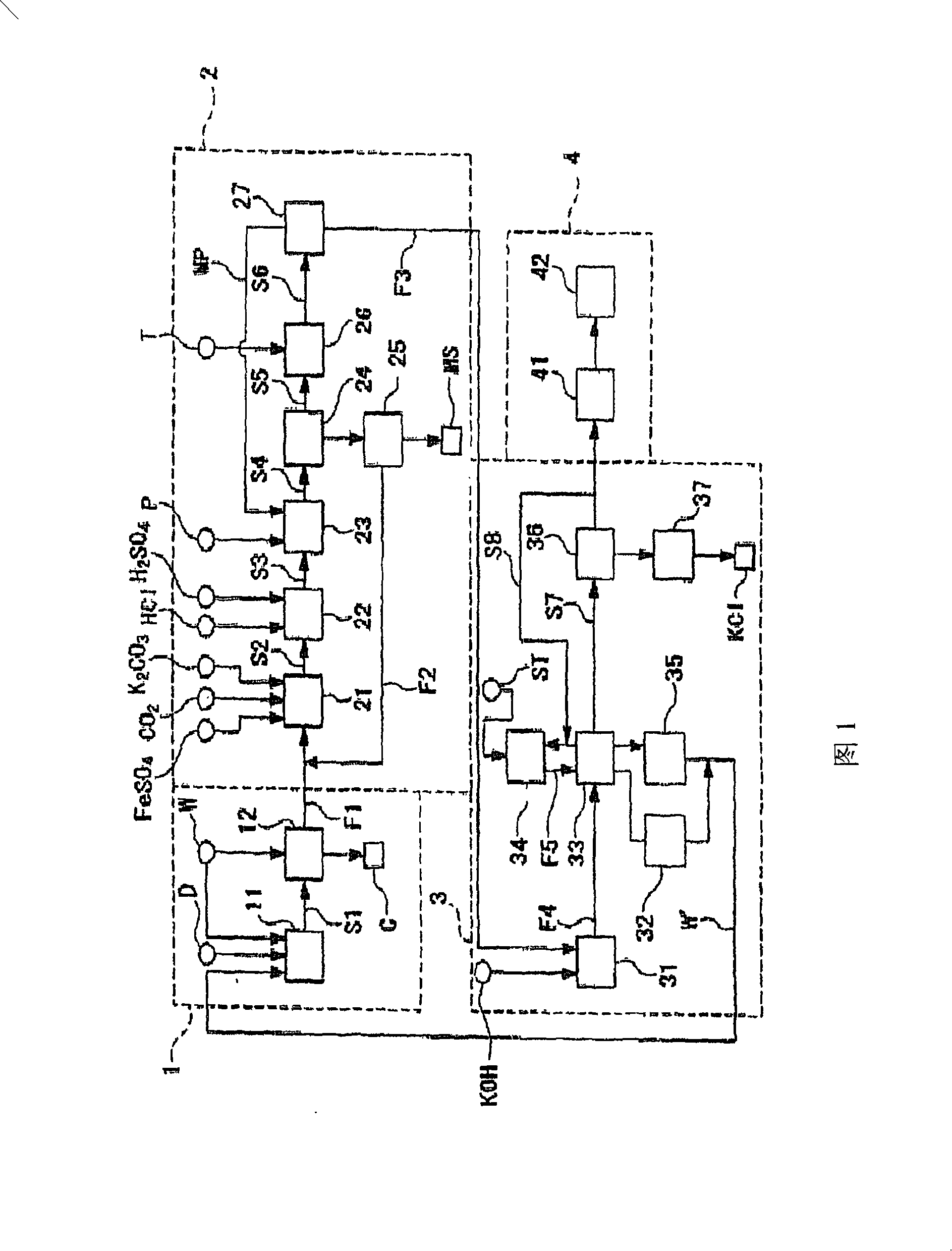

Technology for extracting lithium from alkaline bittern

ActiveCN107779612AReduce usageLow water solubilityProcess efficiency improvementLithium chlorideLithium carbonate

The invention discloses a technology for extracting lithium from alkaline bittern. The technology comprises the following steps of supplying an aqueous phase extraction, supplying an organic phase extraction, extracting, washing, reverse extracting and regeneration. The technology adopts an extraction system different from the tradition, and can extract lithium from an alkaline bittern system, meanwhile a complete process comprising the steps of extraction, washing, reverse extraction and regeneration is determined for the first time while not staying at basic researching of an extraction section, technology parameters such as the series of each section, the phase ratio and the concentration of each agent matched with the extraction system are finally determined, and a basic technology route is provided for industrialized expanded production. The technology for extracting lithium from the alkaline bittern is particularly suitable for a system that filter liquid is generated in the preparation process of a lithium carbonate product by using a lithium chloride solution, so that lithium is further extracted from the alkaline filter liquid bittern system where lithium carbonate is saturated, accordingly rear comprehensive cyclic utilization of salt lake bittern can be achieved, and the technology has practical meaning.

Owner:QINGHAI INST OF SALT LAKES OF CHINESE ACAD OF SCI

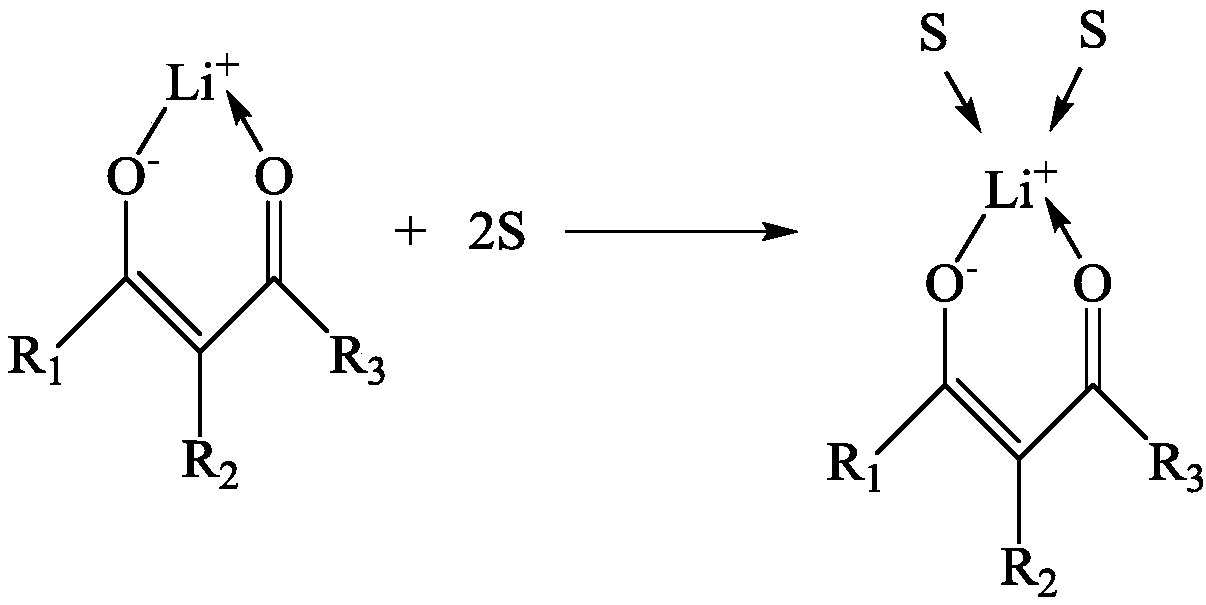

Method for recovering noble metals from metallic carrier catalytic device

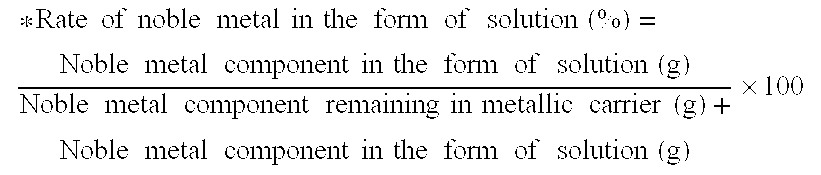

InactiveUS20070183951A1Efficient separationEfficient separation and recoverySolvent extractionGold compoundsExhaust gasAqueous solution

This invention provides a method for efficiently separating and recovering a wash coat which supports noble metal-containing catalytic component from a metallic carrier of a spent metallic carrier catalytic device for such purposes as the purification of exhaust gas from internal combustion engine, without substantially crushing or dissolving said metallic carrier, which method comprises subjecting a metallic carrier catalytic device which is composed of a metallic carrier having a wash coat provided thereon and a noble metal-containing catalytic component which is supported on the wash coat to a treatment with an aqueous solution of mixed acid which contains sulfuric acid and nitric acid.

Owner:ISHIFUKU METAL IND CO LTD

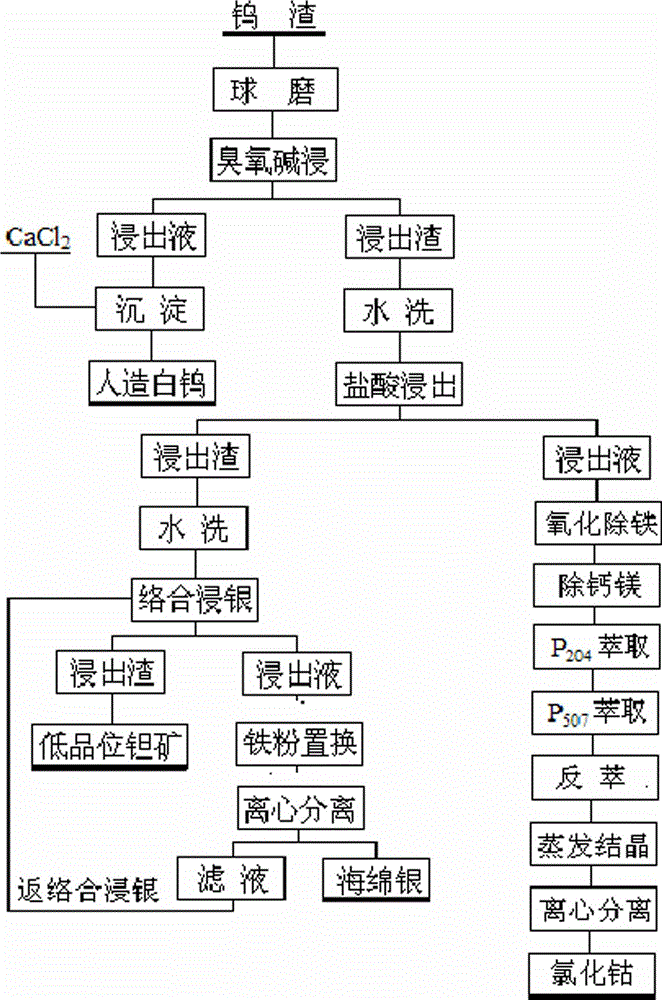

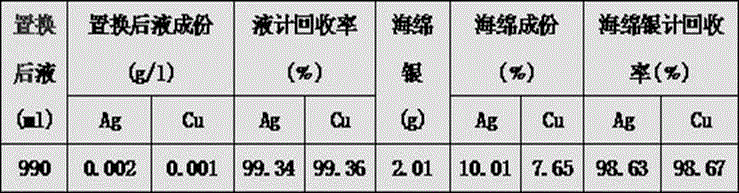

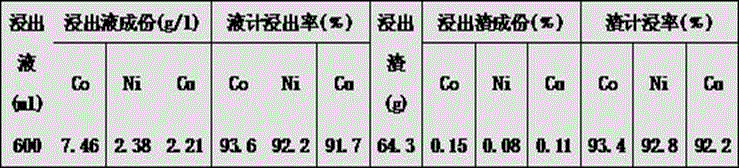

Method for separating and recycling valuable metal in tungsten slag

The invention discloses a method for separating and recycling valuable metal in tungsten slag. The method can be used for recycling artificial scheelite, electronic-grade cobalt chloride, silver sponges, copper sponges, nickel carbonate and low-grade tantalum-niobium ore from the polymetallic tungsten slag. The method comprises the steps that the tungsten slag is subjected to ball milling in a wet mode to obtain fine powder slurry; tungsten is separated and recycled through an ozone alkali leaching method; nickel, cobalt and copper are separated and recycled through a hydrochloric acid leaching method; silver is recycled through a hydrochloric acid complexing leaching method; a leaching agent obtained in the hydrochloric acid leaching procedure is subjected to deironing and calcium-magnesium removal through fluoride in a sodium jarosite method to obtain pre-extraction liquid, the pre-extraction liquid is subjected to P204 extraction, copper, manganese and zinc are separated through deep purification, and the electronic-grade cobalt chloride is obtained by separating nickel and cobalt from sodium ions through P507 extraction. By the adoption of the ozone alkali leaching technology, by-products only produce O2 and H2O, no harmful effect is generated on the environment, tungsten, cobalt, copper, nickel, silver, tantalum and niobium can be separated efficiently, the recovery rate is high, and the comprehensive recycling effect is good; moreover, energy consumption is low, and the method is environmentally friendly, simple, easy to implement and suitable for industrial production.

Owner:湖南金鑫新材料股份有限公司

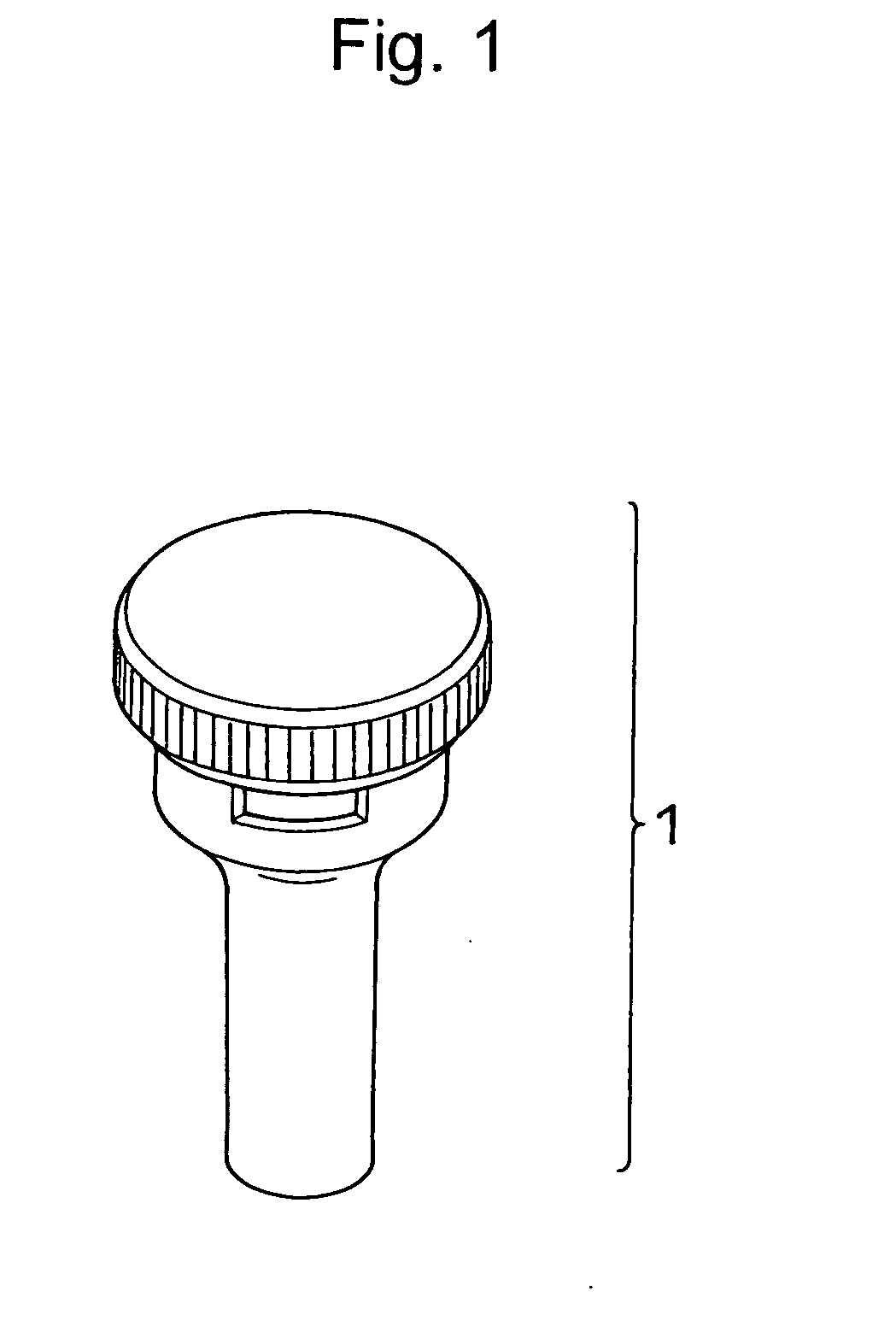

Tool for Recovering Biological Samples and Method for Recovering Biological Samples

InactiveUS20080047908A1Simpler and accurate clinical testingOvercomes drawbackWater/sewage treatment by centrifugal separationAnalysis using chemical indicatorsEngineeringTrace Amounts

This invention provides a tool for recovering biological samples for realizing more simple and accurate clinical testing with the use of a trace amount of the blood sample, a kit comprising the same, and a method for recovering and separating biological samples using the same. Such tool comprises: a recovery container body composed of an upper container portion having a medium-accommodating portion, provided with an upper opening, for accommodating and conserving an absorption medium to be impregnated with the recovered biological samples and a lower container portion for accommodating the biological samples separated from the medium; and a lid for closing the upper opening of the medium-accommodating portion, the bottom of such medium-accommodating portion being provided with an open area in communication with the lower container portion.

Owner:EIKEN KAGAKU

Treatment method for wastewater containing small-molecular organic matter

InactiveCN105906026AOptimizationEasy to handleWater contaminantsWater/sewage treatment bu osmosis/dialysisSalt contentMembrane distillation

The invention discloses a treatment method for wastewater containing small-molecular organic matter. The method includes the steps that firstly, wastewater is subjected to wet oxidation and / or photocatalytic oxidation to obtain a treatment solution; secondly, volatile small molecules in the treatment solution are removed through membrane distillation. The method further includes the preprocessing step. Preprocessing is conducted in at leas one of the following modes. According to the first mode, wastewater is adjusted to be alkaline, stands still and is layered to obtain an aqueous phase and an oil phase, the aqueous phase serves as the wastewater, and the first step or a second mode continues to be conducted. According to the second mode, small molecules are removed from wastewater through membrane distillation, the obtained solution serves as the wastewater, and the first step continues to be conducted. According to a third mode, wastewater is rectified to separate small-molecular organic matter, and the first step continues. By means of the method, organic amine can be completely and effectively recycled or decomposed, the byproduct, namely ammonia salt, is obtained, and harmless treatment is conducted. Meanwhile, wastewater high in COD and salt content can be effectively treated, and the method is environmentally friendly and suitable for wastewater treatment of industrial devices.

Owner:ZHEJIANG QICAI ECO TECH CO LTD

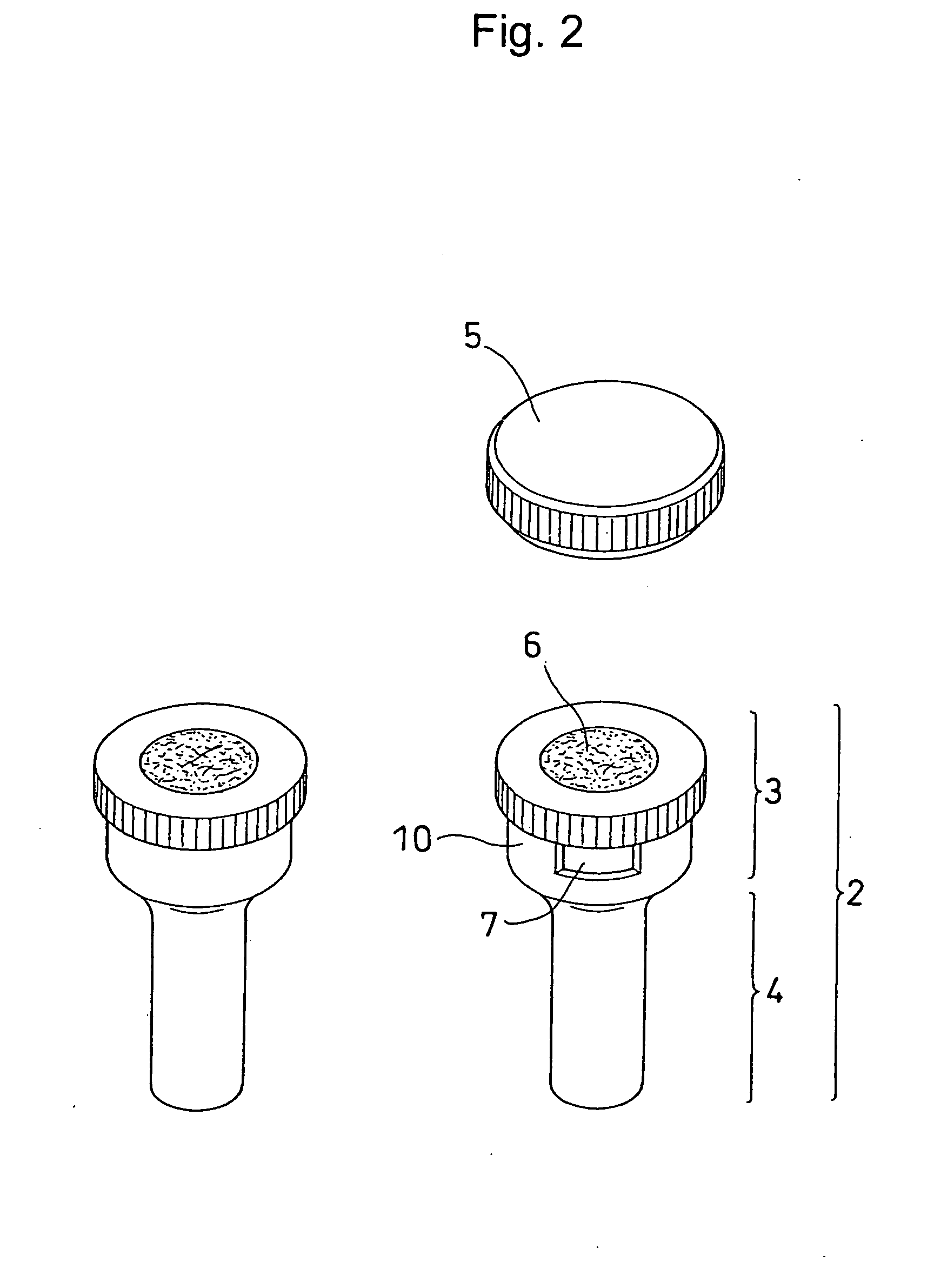

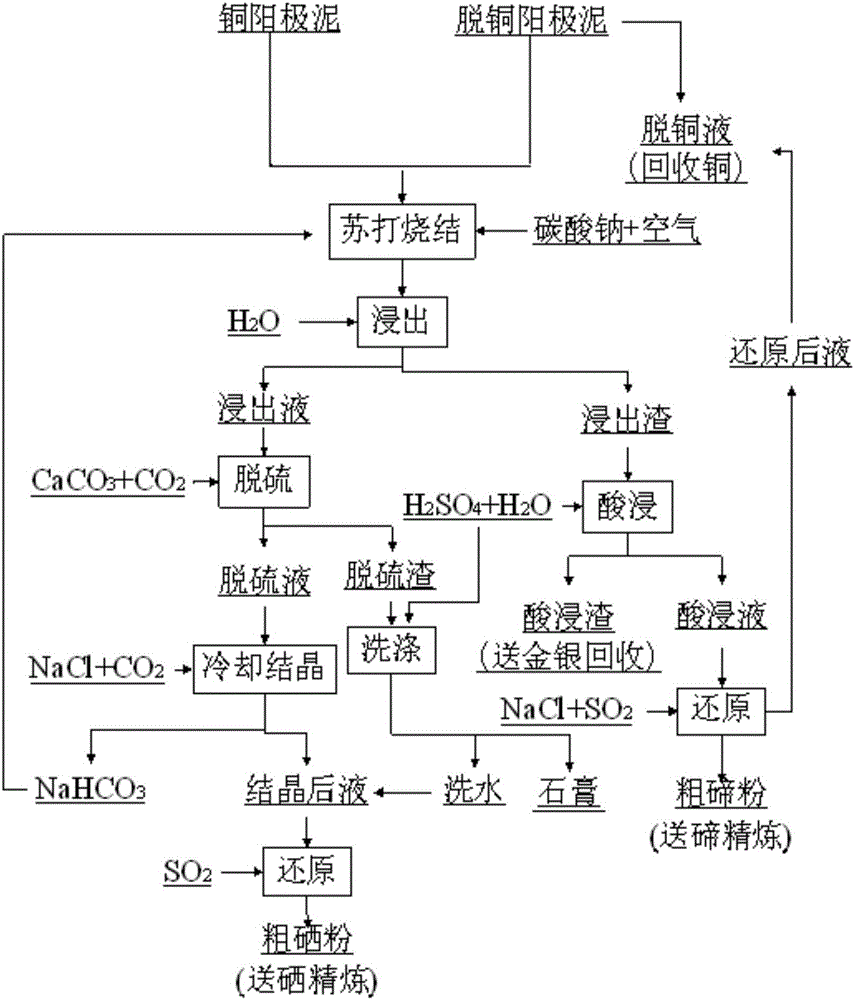

Method for separating and recycling selenium and tellurium from copper anode mud

InactiveCN106477533AReduce pressure on environmental protectionEfficient separation and recoveryElemental selenium/telluriumSulfite saltCopper

Disclosed is a method for separating and recycling selenium and tellurium from copper anode mud. The method includes: performing soda sintering on the copper anode mud or copper-removed anode mud obtained after copper removing is performed on the copper anode mud, adding water into the sintered material for leaching, and filtering to obtain selenium-rich leachate and tellurium-rich leach residues; subjecting the selenium-rich leachate to sodium carbonate separating and recycling, using sodium sulfite or SO2 to revivify and recycle selenium in the selenium-rich leachate or filtrate, filtering to obtain rough selenium powder, and further refining the rough selenium powder to obtain metal selenium; leaching the tellurium-rich leach residues via a sulfuric acid solution, filtering to obtain acid leachate and acid leach residues; subjecting the acid leachate to silver separating through chlorination, using sodium sulfite or SO2 to revivify and precipitate tellurium in the chlorinated acid leachate, filtering to obtain rough tellurium powder, and further refining the rough tellurium powder to obtain metal tellurium. The method has the advantages that by the integral redesign of the process and the mutual cooperation of the steps, the process route for separating and recycling the selenium and the tellurium from the copper anode mud is simplified greatly, environmental protection pressure during a copper anode mud processing process is alleviated greatly, and the method conforms to the development tendency of energy saving and emission reduction technical transformation; the method is simple in process, simple to operate, low in production cost, high in selenium and tellurium recycling rate, good in working environment, suitable for industrialized application, and the like.

Owner:CENT SOUTH UNIV

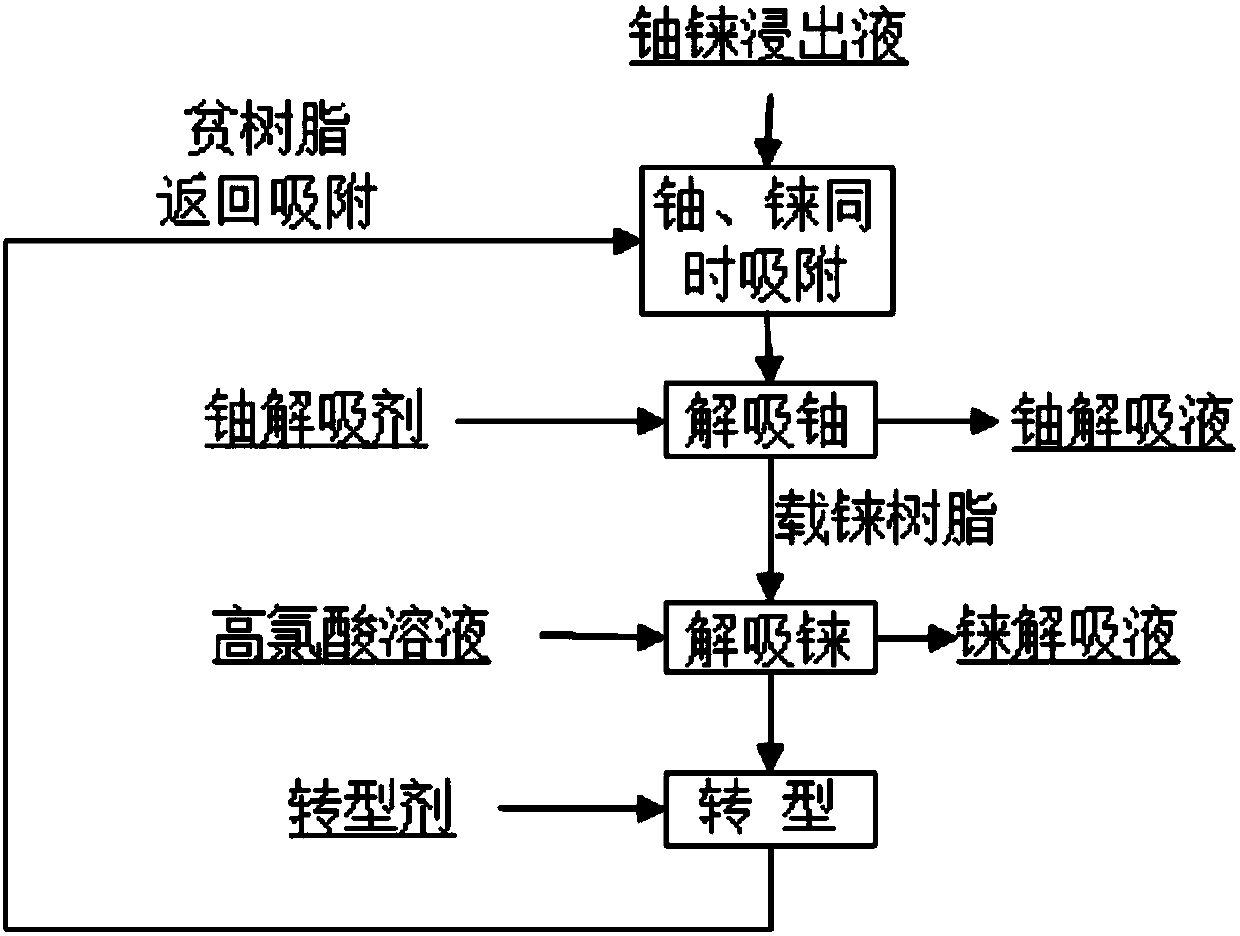

Method for comprehensively recovering uranium and rhenium from leaching solution with ion exchange resin

ActiveCN107686900AEfficient separationEfficient separation and recoveryPregnant leach solutionRhenium

The invention relates to a method for comprehensively recovering uranium and rhenium from a leaching solution with ion exchange resin. Aiming to the problems of large mass concentration ratio of the uranium and the rhenium in a rhenium ore and uranium ore containing leaching solution and difficulty in separation recovery, strongly basic anion-exchange resin with stronger adsorption ability is preferred to adsorb the uranium and the rhenium in the leaching solution firstly at the same time; and then aiming to uranium and rhenium loading resin, by utilizing the characteristic that the resin is stronger in the binding capacity to the rhenium than to the uranium and adopting desorption agents with different desorption capacities to sequentially realize respective desorption and separation of the uranium and the rhenium, comprehensive recovery of the uranium and the rhenium in the leaching solution is finally realized. By adopting the method, 98 percent or above of the uranium and 95 percent or above of the rhenium in the rhenium ore and uranium ore containing leaching solution can be recovered; in an obtained uranium qualified liquid, rho (U) reaches 10g / L or above, and rho (Re) is smaller than 1.0mg / L, and in an obtained rhenium qualified liquid, rho (Re) reaches 0.5g / L, and rho (U) is smaller than 5mg / L. The method is good in separation effect of the uranium and the rhenium, highin recovery rate of the uranium and the rhenium and simple in technological process and is an effective way of comprehensively recovering the uranium and the rhenium from the leaching solution.

Owner:BEIJING RESEARCH INSTITUTE OF CHEMICAL ENGINEERING AND METALLURGY

Method for absorbing and separating ammonia gas from ammonia-containing exhaust gas

ActiveCN106474873AImprove solubilityHigh separation selectivityGas treatmentDispersed particle separationSolubilityDesorption

The invention discloses a method for absorbing and separating ammonia gas from ammonia-containing exhaust gas. The method comprises the following steps: adopting a hybrid eutectic solvent as an absorbent, the solvent contacting with ammonia-containing exhaust gas to obtain an ammonia-absorbing liquid, and then conducting the desorption of the ammonia-absorbing liquid to obtain ammonia gas. The hybrid eutectic solvent consists of three components, weak acid compounds, salt compounds and additives. The invention adopts the method of absorption and desorption by using the hybrid eutectic solvent as the absorbent to recover and separate ammonia gas. The absorbent has high ammonia solubility and separation selectivity, and can achieve the efficient separation and recovery of ammonia gas.

Owner:ZHEJIANG UNIV

A method for separating and recovering ammonia in ultra-high concentration ammonia nitrogen wastewater

InactiveCN102259967AEfficient separationEfficient separation and recoveryEnergy inputWater/sewage treatmentHigh concentrationPotassium ferrate

The invention provides a method for separating and recovering ammonia from ultrahigh concentration of ammonia nitrogen wastewater. The method comprises separation and recovery and is characterized in that the separation process comprises: firstly pumping the ultrahigh concentration of ammonia nitrogen wastewater into an aeration tank of a denitrogenation tower, adding a denitrogenation agent, andcarrying out aeration treatment with a blower or compressed air at the pH not smaller than 9.5 and the temperature of 45-55 DEG C until the content of ammonia nitrogen in the wastewater is decreased to below 10 mg / L, wherein the denitrogenation agent is formed by mixing 60-70wt% of sodium carboxymethyl cellulose, 10-20wt% of butanediol transaminase, 5-10wt% of potassium ferrate and 5-10wt% of sodium persulfate and has a concentration of 10-30 ppm; and introducing the separated ammonia gas into a multi-stage absorbing tower from the tower top. Through once treatment of the method provided by the invention, the content of ammonia nitrogen in the ultrahigh concentration of ammonia nitrogen wastewater is decreased to below 5 mg / L, the separated ammonia is recovered, and the waste heat is simultaneously utilized.

Owner:陈平 +2

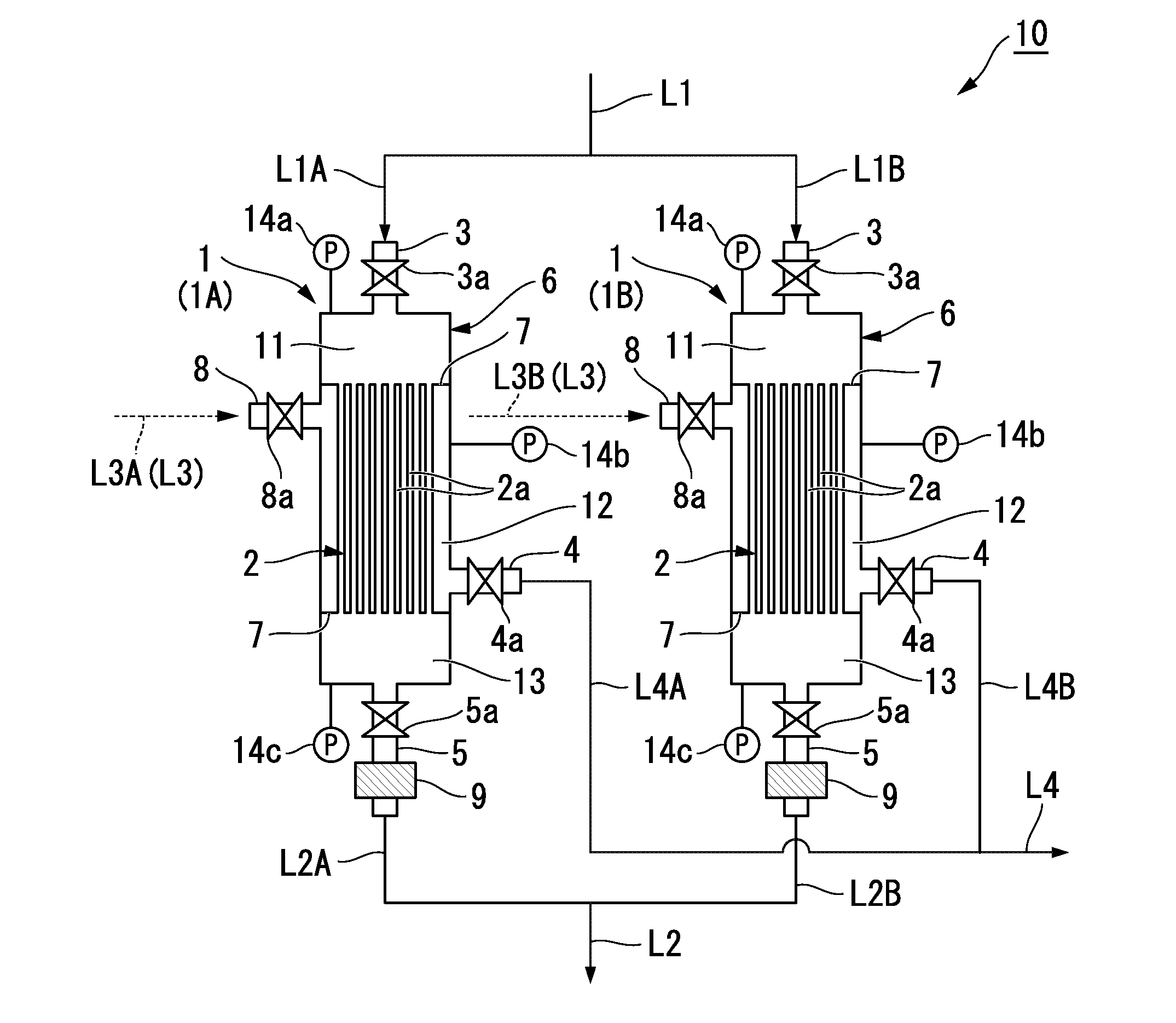

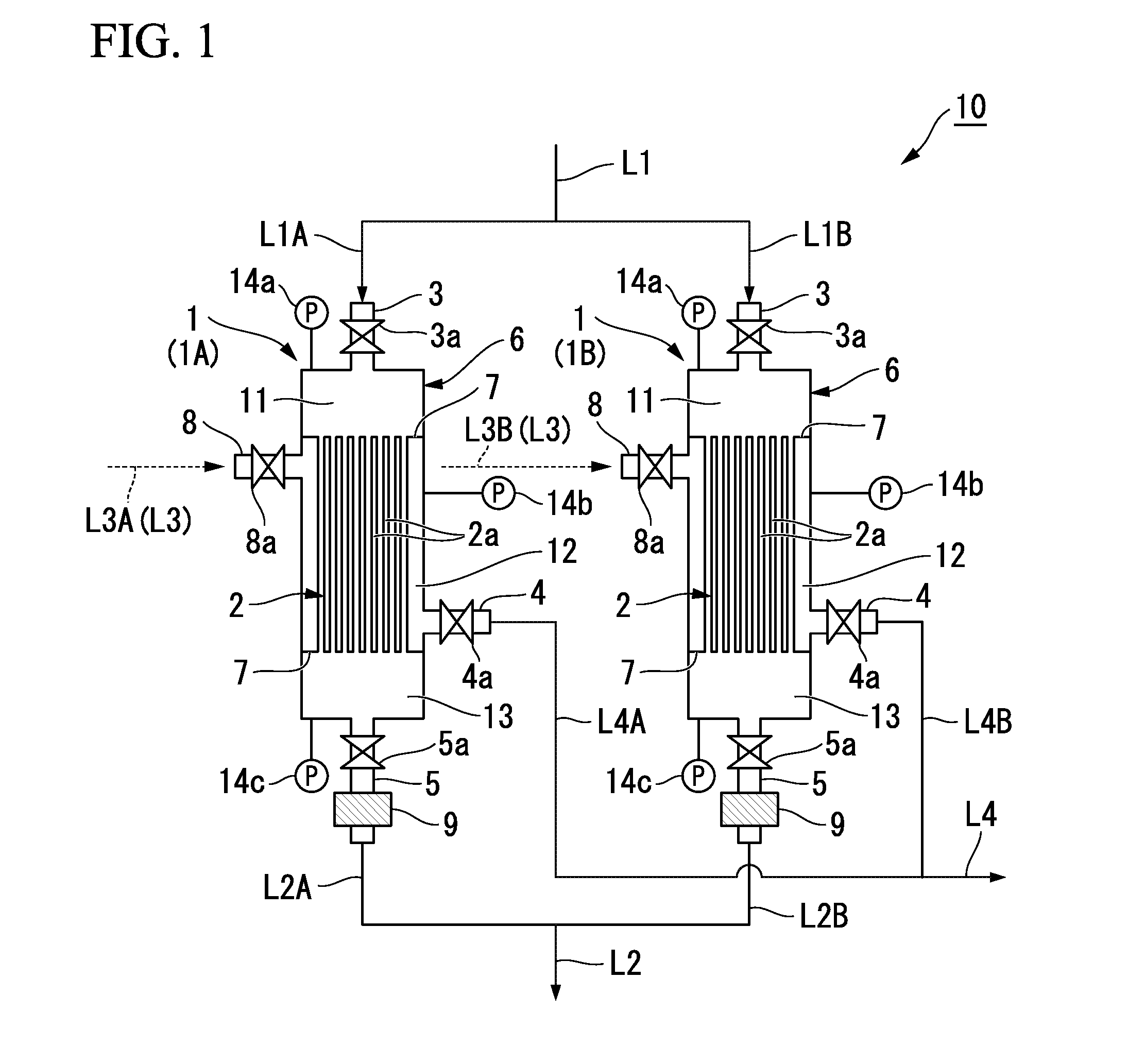

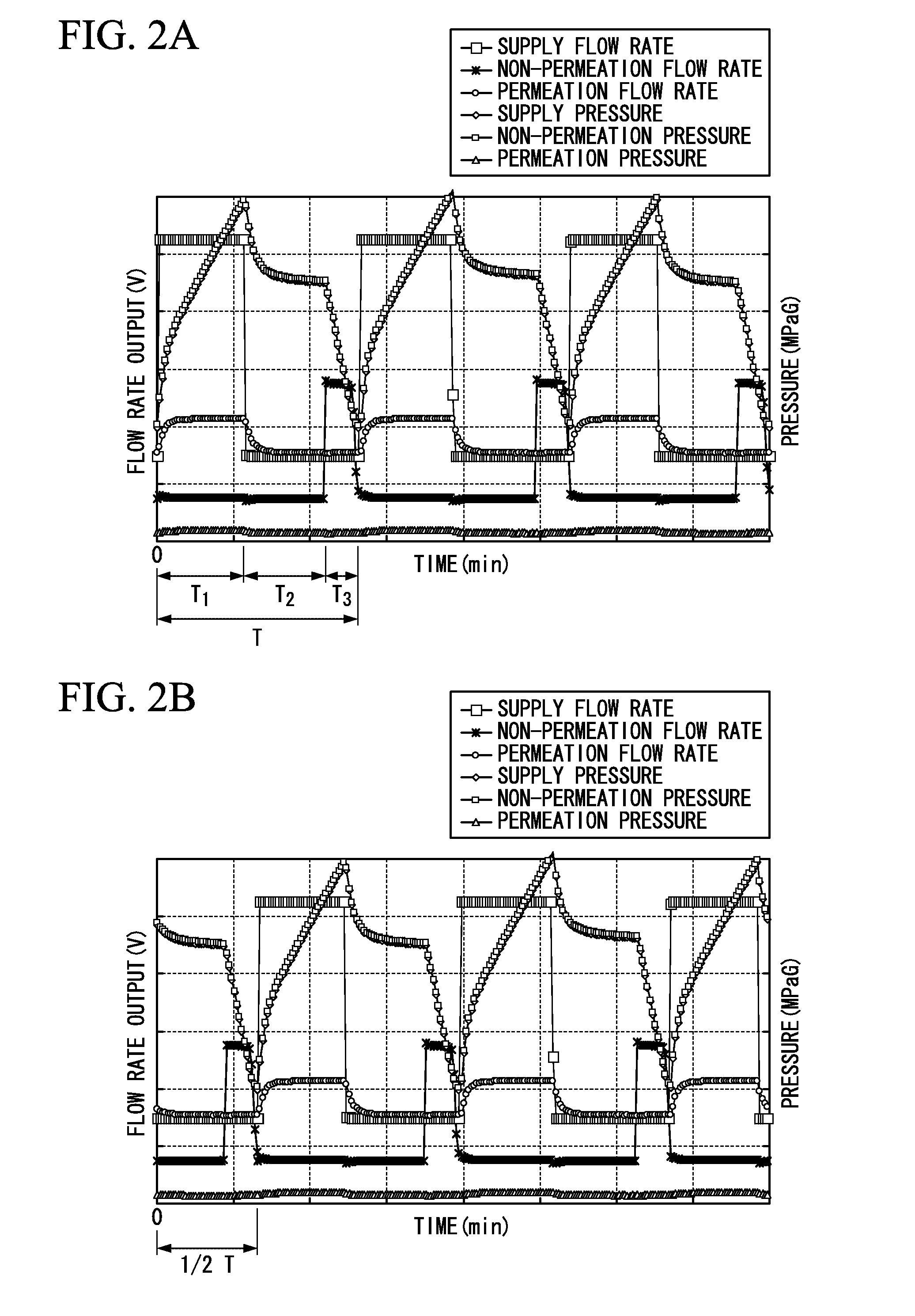

Method for separating/recovering oxygen-rich air from air, its apparatus and gas separation membrane module

InactiveUS7682422B2Efficient separationEffective recoveryDispersed particle filtrationSolid sorbent liquid separationProduct gasEngineering

A method for separating and recovering oxygen-rich air from the air, comprising, using a gas separation membrane module where a laminate consisting of a permeate-side spacer for forming a permeate gas channel communicated with a hollow section in a core tube for collecting and discharging a permeate gas and two flat-film gas separation membranes sandwiching the spacer and a feed-side spacer for forming a feed gas channel are spirally wound around the core tube such that the laminate and the feed-side spacer are alternately superimposed, vacuuming the hollow section of the core tube to 95 kPaA (absolute pressure) or less by vacuuming means while feeding the air into the feed gas channel by air feed means such that a maximum feed-air flow rate and a maximum static pressure divided by an effective membrane area of the gas separation membrane are 100 m3 / min·m2 or less and 4000 Pa / m2 or less, respectively, to separate and recover oxygen-rich air from the hollow section of the core tube. Oxygen-rich air can be separated and recovered from the air by this method with high separation efficiency.

Owner:UBE IND LTD

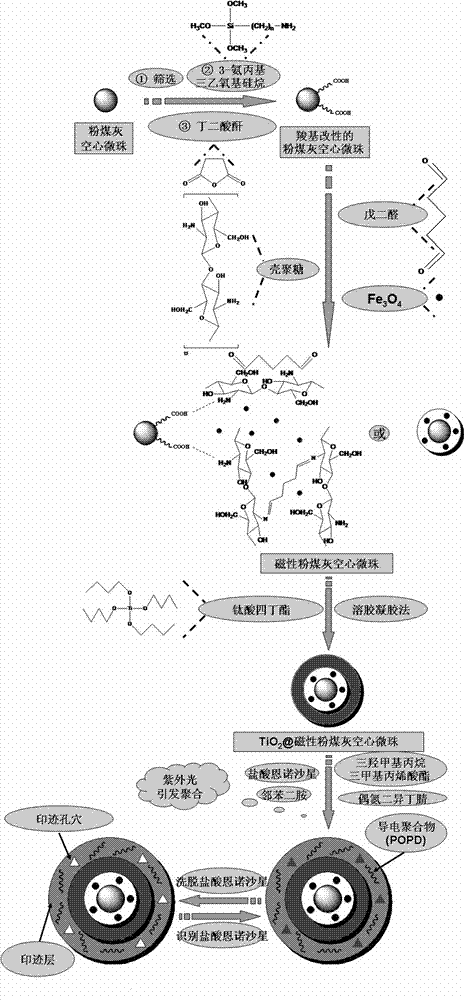

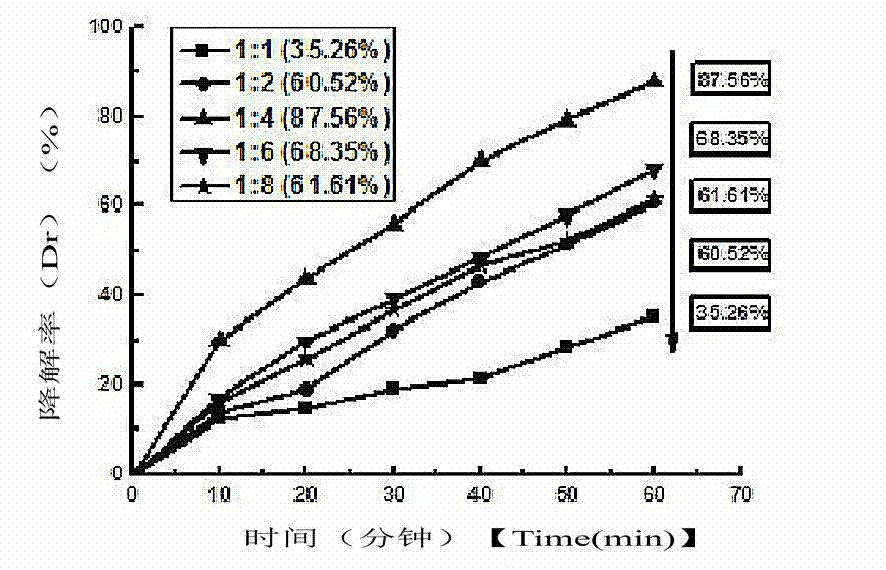

Preparation method of photodegraded enrofloxacin hydrochloride floating type magnetic conductive surface molecular imprinting composite photocatalyst and application

InactiveCN103071537AIncrease profitEasy to separate and recycleOrganic-compounds/hydrides/coordination-complexes catalystsMicrosphereMagnetite Nanoparticles

The invention belongs to the environmental material preparation technical field, and relates to a preparation method of a photodegraded enrofloxacin hydrochloride floating type magnetic conductive surface molecular imprinting composite photocatalyst and an application. According to the invention, fly ash is modified, the floating type carboxyl modified fly ash hollow microspheres can be prepared, chitosan is used to perform a crosslinking preparation on magnetic Fe3O4 nano-particles to prepare the magnetic fly ash hollow microspheres, a sol-gel method is used to prepare the TiO2@magnetic fly ash hollow microspheres photocatalyst through photo-initiation polymerization, and the fly ash hollow microspheres photocatalyst is performed with ultrasonic modification, the template molecule enrofloxacin hydrochloride is added for photo polymerization, and is eluted, and leached by absolute ethyl alcohol and then dried. The prepared floating type magnetic conductive surface molecular imprinting composite photocatalyst can be used for degrading the enrofloxacin hydrochloride; the surface molecular imprinting composite photocatalyst has high selectivity on enrofloxacin hydrochloride after photocatalytic degradation no matter in a single-phase antibiotic solution or in a binary mixed phase antibiotic solution; and the magnetic separation characteristic enables convenience and high efficiency for separating and recovering.

Owner:JIANGSU UNIV

Separating and recovering method of ABS/PS (Acrylonitrile Butadiene Styrene/Poly Styrene) waste plastic

InactiveCN103159979AEasy to separate and recycleEfficient separation and recoveryPlastic recyclingSolventAcrylonitrile butadiene styrene

The invention discloses a separating and recovering method of ABS / PS (Acrylonitrile Butadiene Styrene / Poly Styrene) waste plastic. The method comprises the following steps of: crushing ABS / PS mixed plastic to 4-40mm; adding to a solvent, wherein the ratio of ABS / PS mixed plastic and solvent is 8-20g / ml, and the solvent is dimethylbenzene or carbon disulfide; stirring and dissolving for 150-280 minutes at 10-90 DEG C; filtering the liquid and drying the filter dregs filtered to obtain ABS plastic; evaporating the filtrate at 30-60 DEG C and drying separated solute to obtain PS plastic. ABS / PS waste plastic can be simply and efficiently separated and recovered by the method. The recovery rate of ABS reaches 92.7-95.4% and recovery rate of PS reaches 91.2-95.4%.

Owner:CENT SOUTH UNIV

Method for operating gas separation device

InactiveUS20130032028A1Improve gas separation performanceEfficient separation and recoveryMembranesSemi-permeable membranesProduct gasMixed gas

Owner:NIPPON SANSO CORP +1

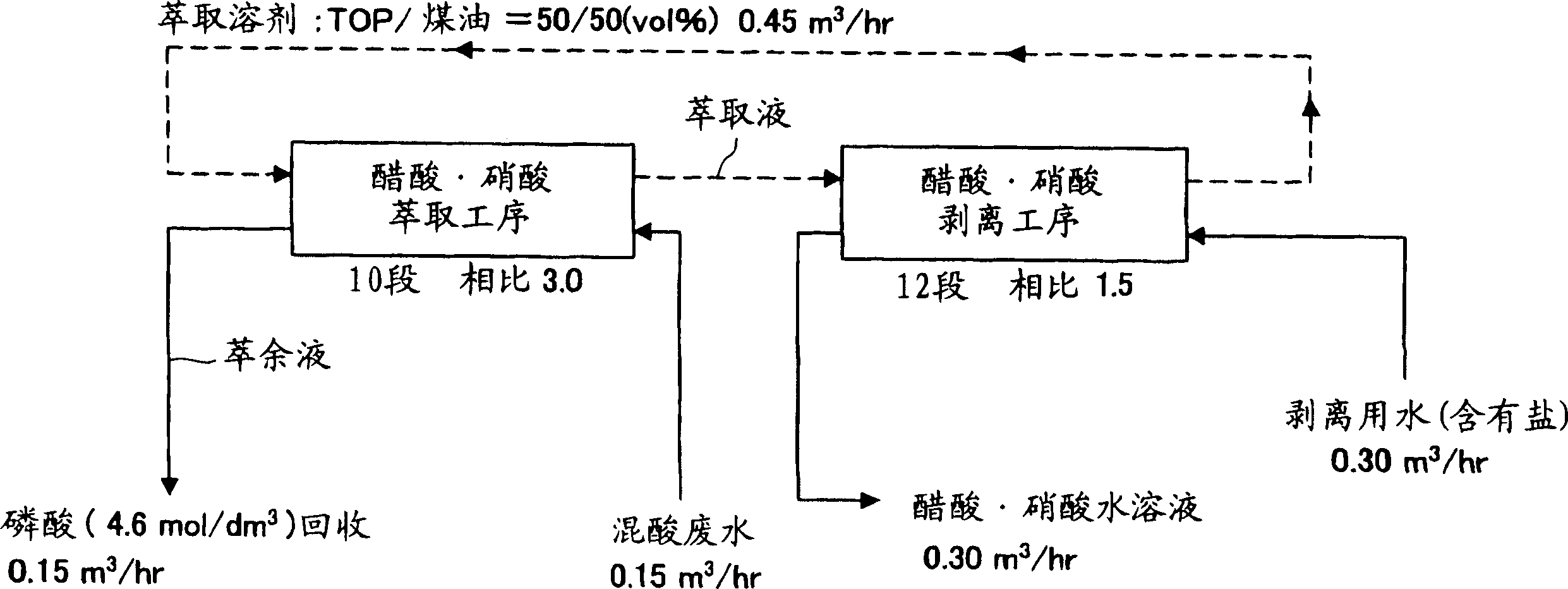

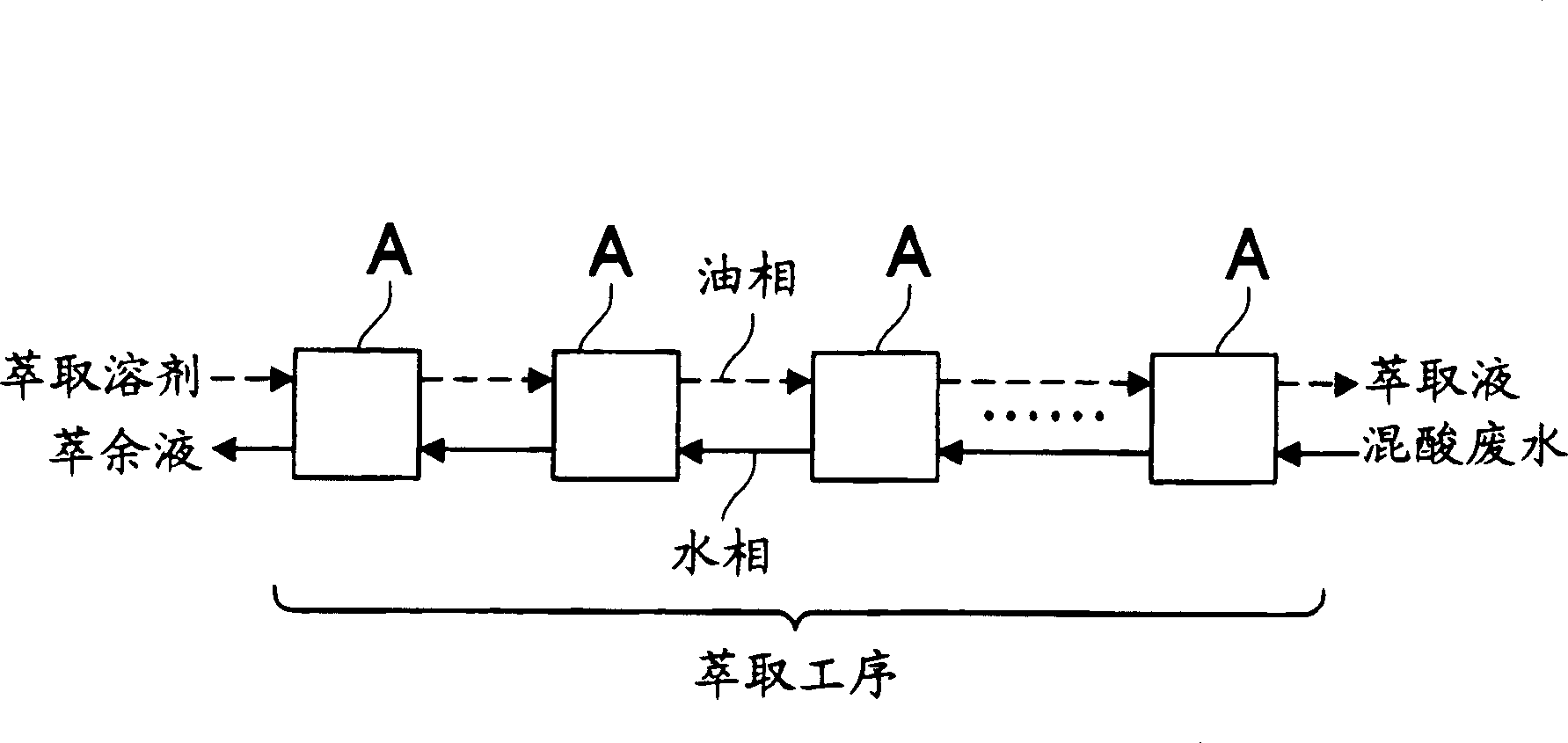

Method for separating and recovering phosphonic acid from acetic acid-nitric acid-phosphonic acid waiste liquid

InactiveCN1781842ACan be used continuouslyRecycling can be continuousAlkali orthophosphate fertiliserAmmonium orthophosphate fertilisersAcetic acidLiquid waste

To provide a method capable of highly efficiently, selectively separating and recovering phosphoric acid from a mixed acid waste liquid containing acetic, nitric and phosphoric acids even in a practical large scale production by suppressing the emulsification of an oil phase with a water phase in a settling state in a separation process to enable the circulating use of an extractant solution sufficiently. The separating / recovering method comprises an extraction process for selectively dissolving acetic and nitric acids in the extractant solution to extract by mixing the waste liquid containing those acids with the extractant solution containing trialkyl phosphate, a recovery process for recovering phosphoric acid from a residual liquid left by the above process, and a separation process for bringing the obtained acetic / nitric acids-containing extractant solution into contact with a salt-containing water for separation to dissolve and transfer their acids into the above water for separation. The extractant solution can circularly be used by feeding back the oil-phase solution obtained from the separation process to the extraction process.

Owner:芝田 隼次 +2

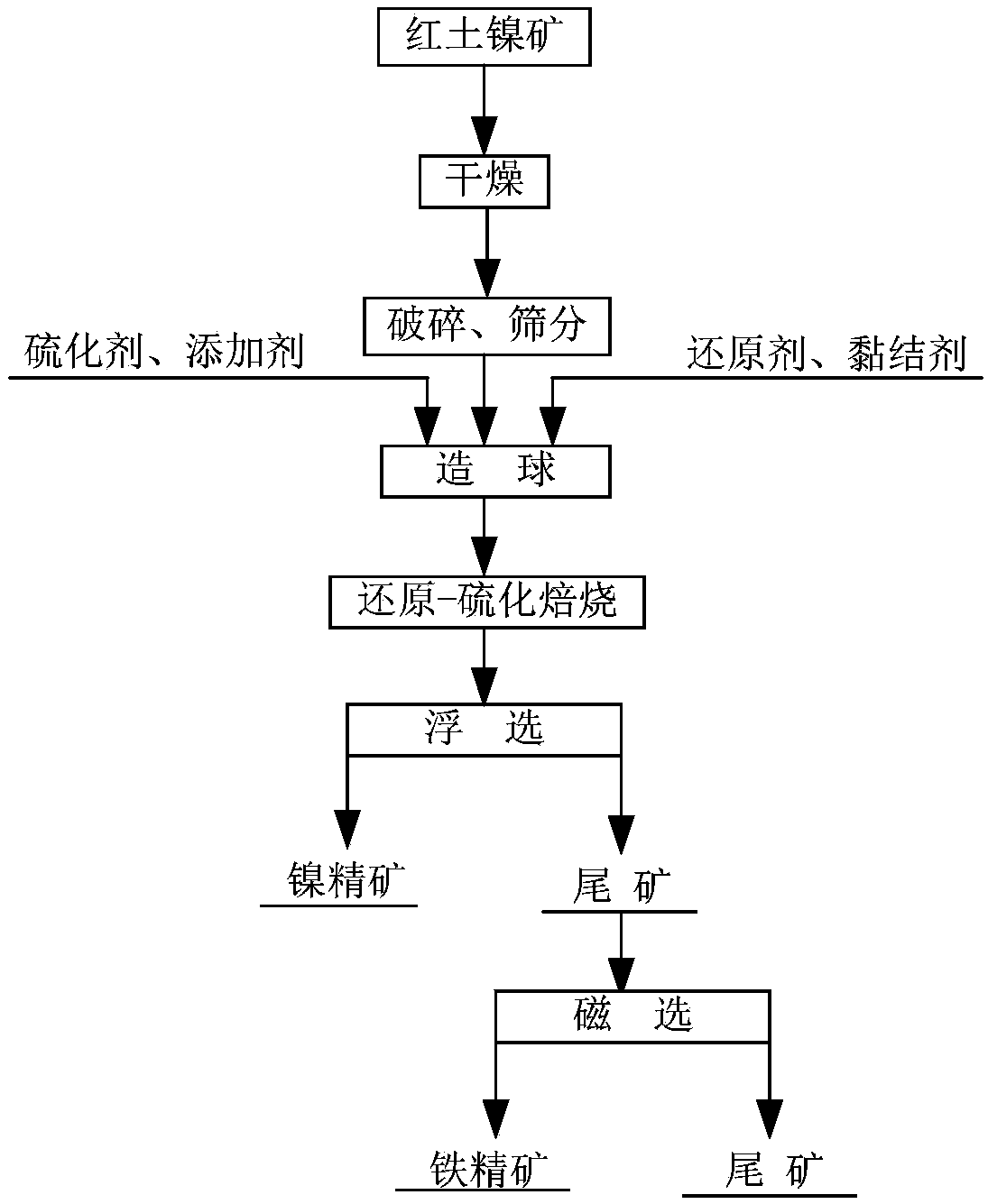

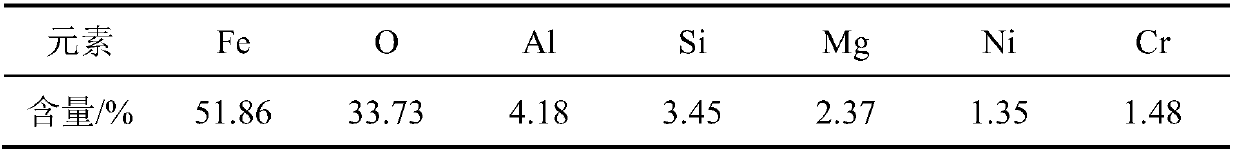

Method of selective sulfidation roasting for laterite nickel ore

ActiveCN109097562AEfficient separation and recoveryLow recovery rateRotary drum furnacesFlotationSulfidationLaterite

The invention discloses a method of selective sulfidation roasting for laterite nickel ore. According to the method of selective sulfidation roasting for the laterite nickel ore, the laterite nickel ore is mixed with raw materials including a carbonaceous reducing agent, a sulfurizing agent, an alkali metal salt additive and a binder for even mixing and pelletizing, the obtained pellets are roasted in the first stage at low temperature and roasted in the second stage at high temperature; and nickel products are recovered from roasted materials by a flotation method, and iron products are recovered from flotation tailings by a magnetic separation method. The method has a good recovery effect on nickel and iron, low energy consumption, low cost and simple process, and is beneficial to industrial large-scale production and application.

Owner:CENT SOUTH UNIV

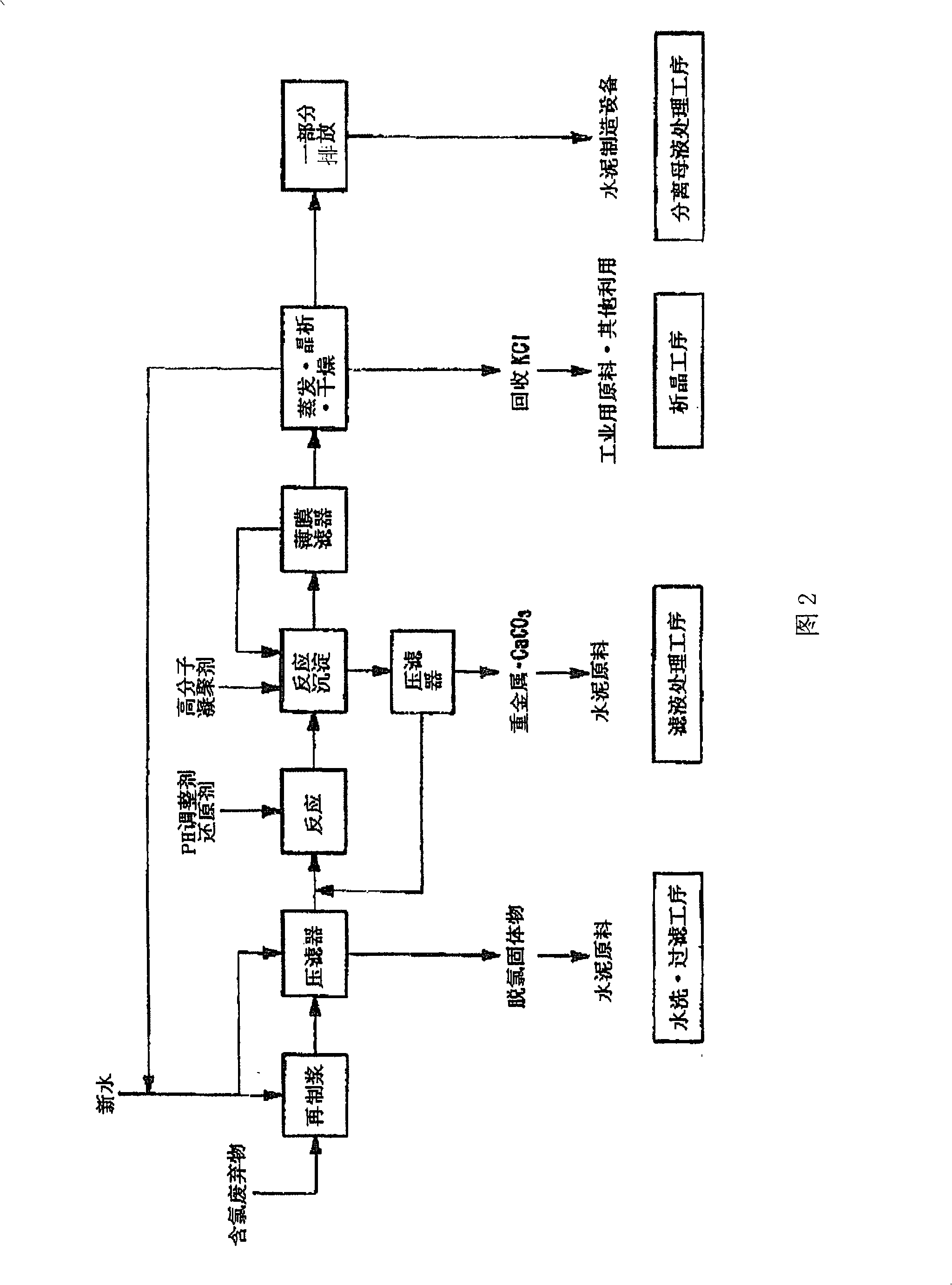

Method of and apparatus for treating chlorine-containing waste

ActiveCN101309761AReduce usageEfficient removalSolid waste disposalSeparation devicesFiltrationEvaporation

Owner:SUMITOMO OSAKA CEMENT CO LTD +1

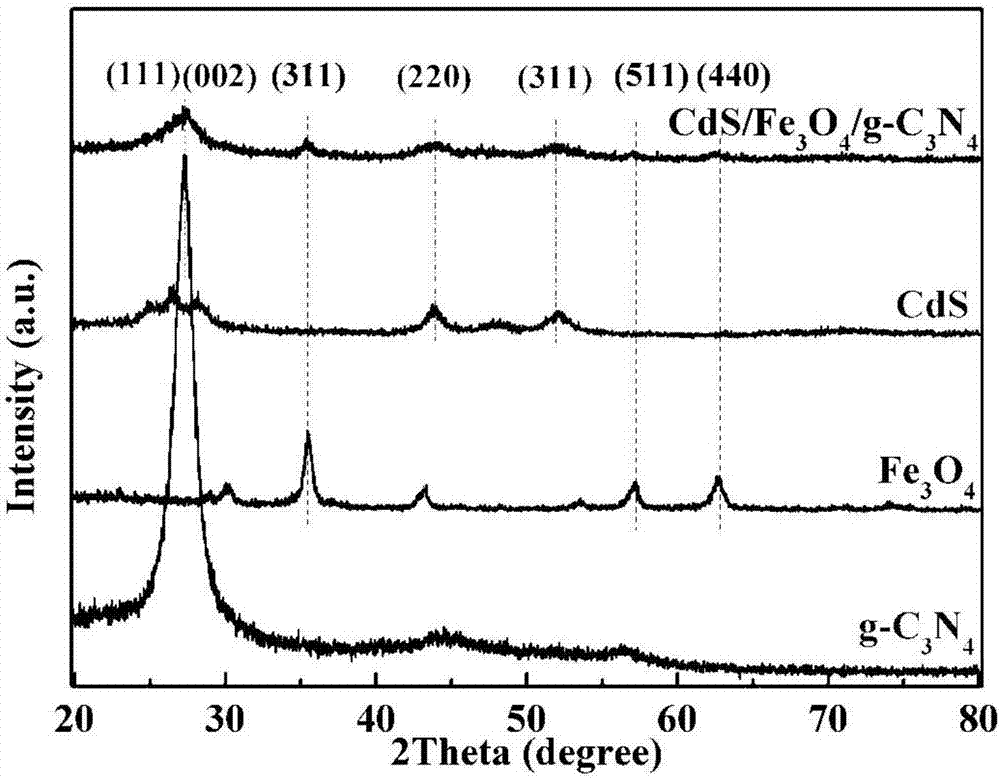

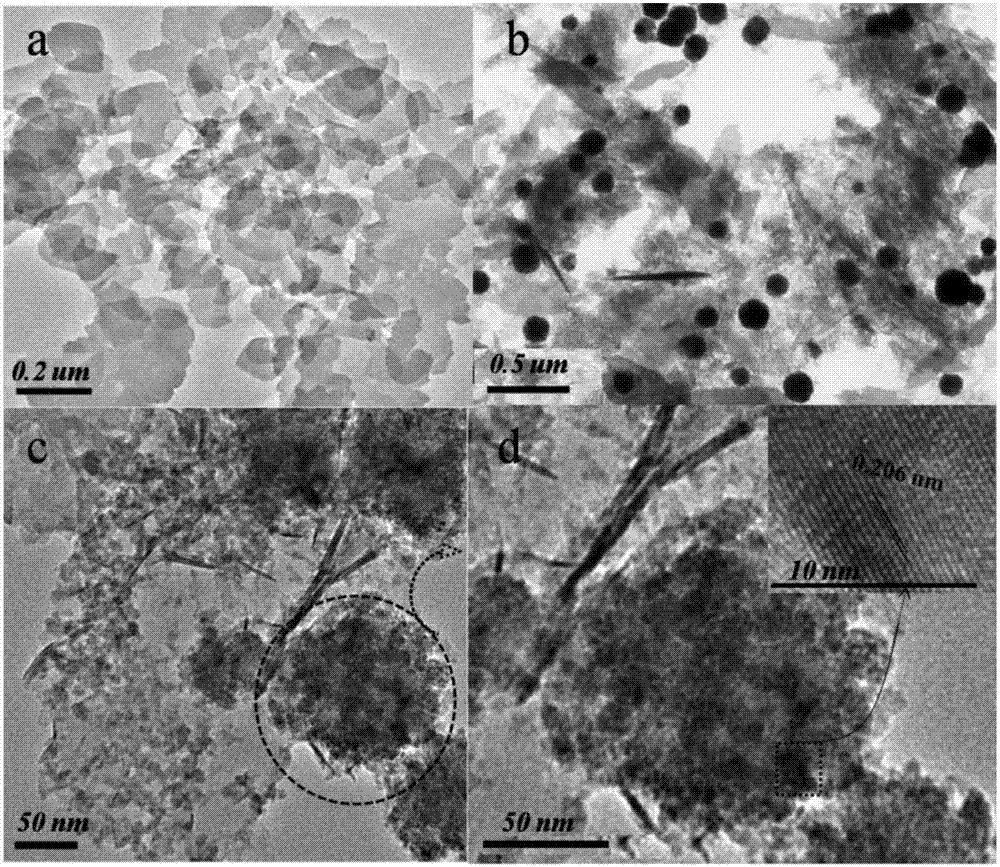

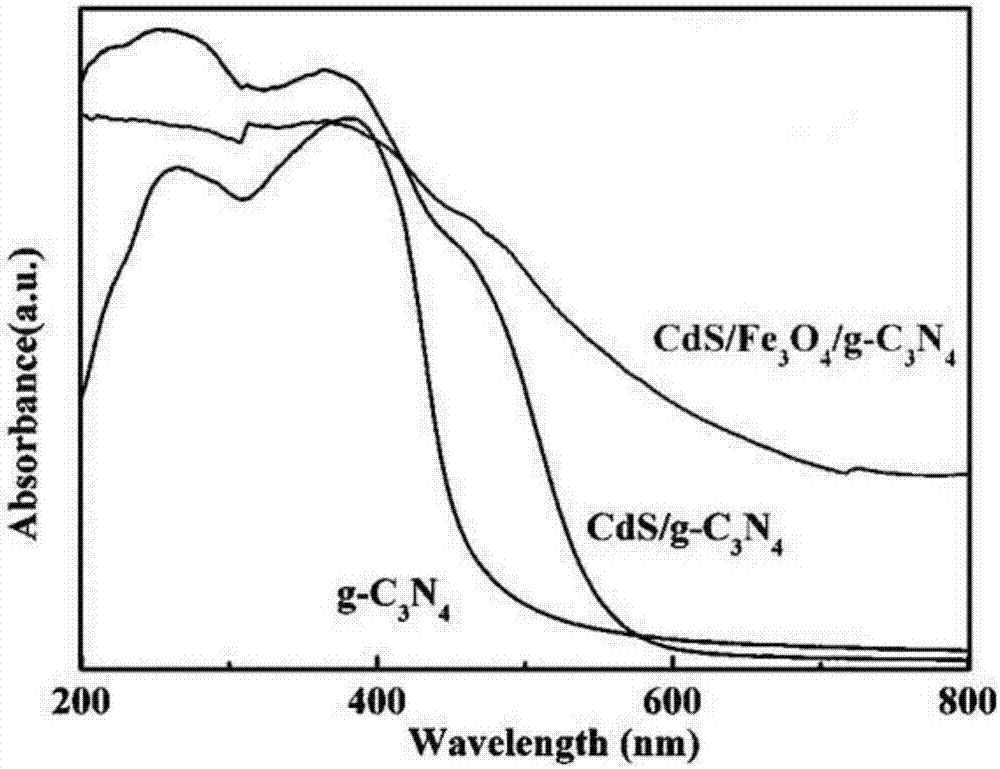

CdS/Fe3O4/C3N4 composite photocatalyst as well as preparation method and use thereof

InactiveCN107042119APromote degradationEasy to synthesizePhysical/chemical process catalystsWater/sewage treatment by irradiationPhysical chemistryPhoto catalysis

The invention provides a CdS / Fe3O4 / C3N4 composite photocatalyst as well as a preparation method and use thereof. The preparation method comprises the following steps: 1, preparing g-C3N4; 2, preparing a Fe3O4 / g-C3N4 magnetic composite material; 3, preparing the CdS / Fe3O4 / g-C3N4 composite photocatalyst. The CdS / Fe3O4 / g-C3N4 composite photocatalyst prepared by the method is more convenient, faster and efficient to separate and recycle; the CdS / Fe3O4 / g-C3N4 composite photocatalyst has better photocatalytic activity and stability.

Owner:JIANGSU UNIV

Method for recycling rhenium and bismuth from acidic waste solution

ActiveCN105714121AEfficient separation and recoveryAvoid hydrolysisProcess efficiency improvementSlagDesorption

The invention provides a method for recycling rhenium and bismuth from an acidic waste solution. The method comprises the following steps that firstly, ion exchange adsorption treatment is conducted on the acidic waste solution through ion exchange resin, and the rhenium and the bismuth in the acidic waste solution are adsorbed to the ion exchange resin; secondly, a mixed solution of sodium hydroxide and tartaric acid is utilized for desorbing the bismuth adsorbed to the ion exchange resin to a liquid phase, bismuth-containing desorption liquid is obtained, the rhenium adsorbed to the ion exchange resin is desorbed to the liquid phase through an ammonium thiocyanate solution, and rhenium-containing desorption liquid is obtained; and thirdly, concentrated hydrochloric acid is dripped into the bismuth-containing desorption liquid to enable the bismuth to be subjected to the precipitation reaction, bismuth enrichment slag is obtained, after heating and concentrating are conducted on the rhenium-containing desorption liquid, crystallization treatment is conducted, and ammonium perrhenate is obtained. According to the method, the rhenium and the bismuth in the acidic waste solution can be efficiently separated and recycled, the separation effect is obvious, the technology is simple and feasible, the equipment investment is small, and industrial application is facilitated.

Owner:NORTHWEST INSTITUTE FOR NON-FERROUS METAL RESEARCH

Method for extracting chromium from chromium-containing waste liquor

ActiveCN104150570AEfficient separation and recoveryReduce processing costsWater contaminantsWater/sewage treatment by magnetic/electric fieldsSlagChromium

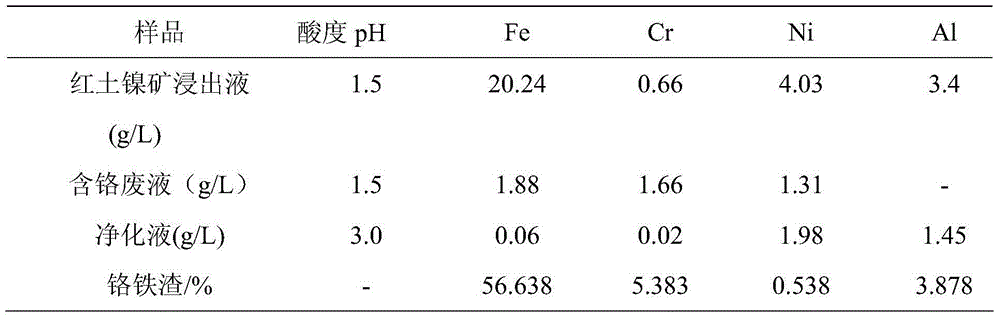

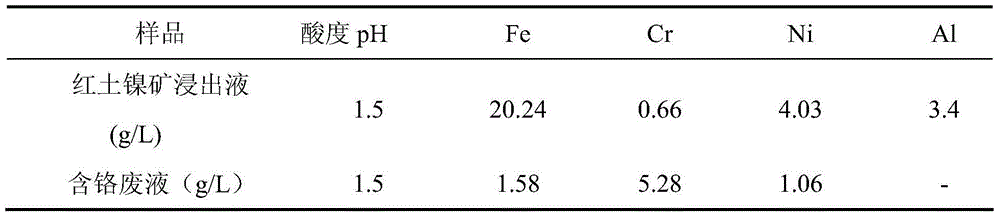

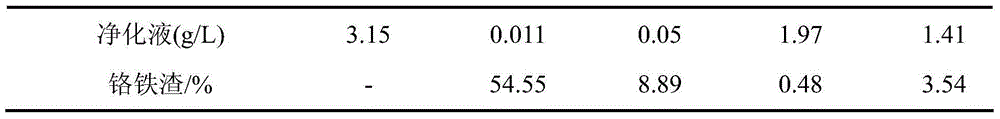

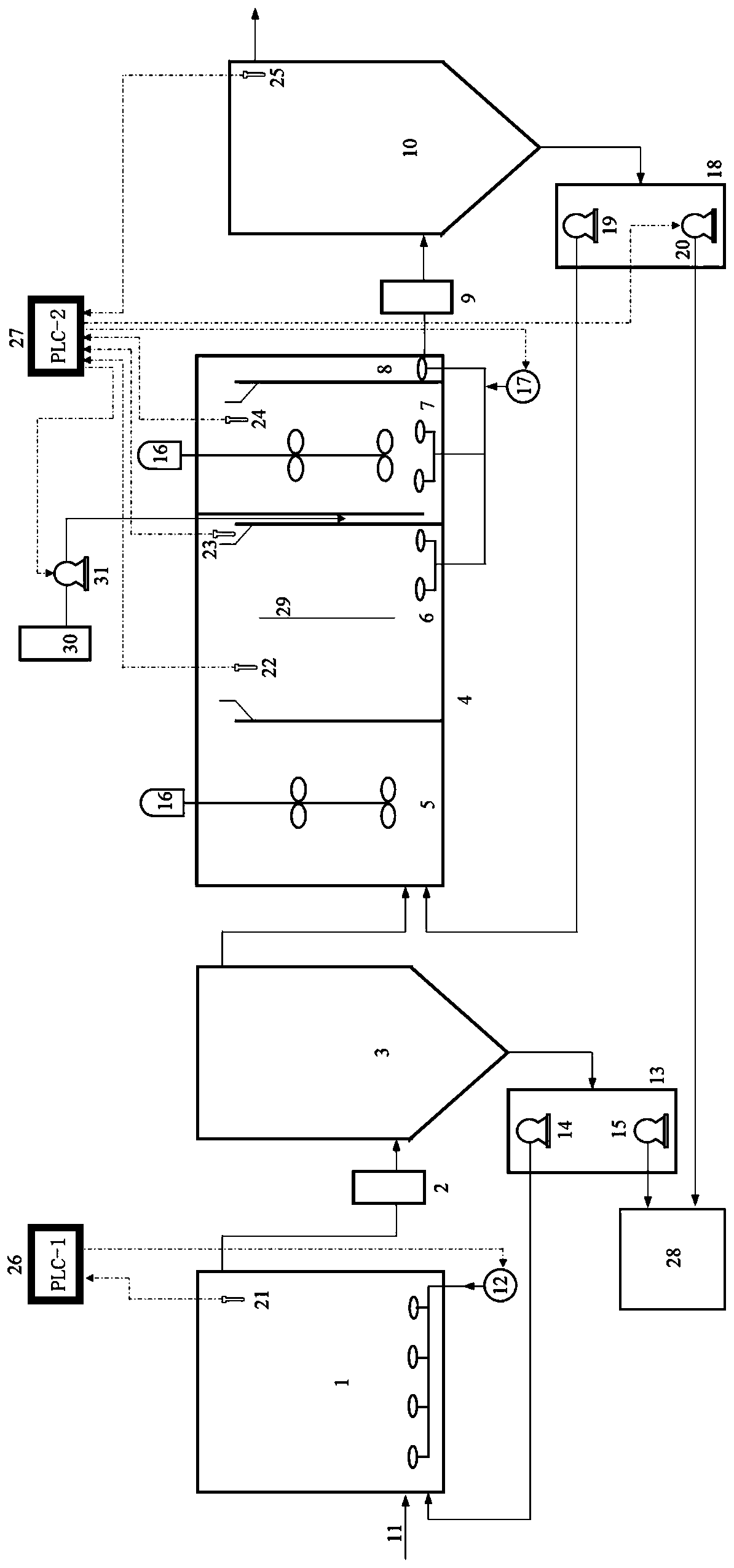

The invention discloses a method for extracting chromium from chromium-containing waste liquor. According to the method, magnetite powder is taken as a magnetic crystal nucleus, a compound which mainly comprises chromium and iron is generated by reacting chromium-containing waste water with laterite-nickel ore acid leach liquor, and the compound is wrapped on the surface of the magnetic crystal nucleus through adsorption and then separated by utilizing the magnetism of the magnetic crystal nucleus. The method disclosed by the invention can be used for preparing chromium-rich iron slag by fast, efficiently and selectively extracting the chromium from the chromium-containing waste liquor by adopting low cost and sufficiently recovering the iron resources contained in the laterite-nickel ore acid leach liquor, is simple in process and convenient to operate and meets the requirement for industrialized production.

Owner:CENT SOUTH UNIV

Device for treating municipal sewage by carbon separation coupled mainstream anaerobic ammonia oxidation biological denitrification and operation method thereof

PendingCN111453944AAvoid excessive oxidative decompositionEfficient separation and recoveryWater treatment parameter controlWater treatment compoundsMunicipal sewageAmmonia

The invention relates to a device for treating municipal sewage by carbon separation coupled mainstream anaerobic ammonia oxidation biological denitrification and an operation method of the device. The device consists of five main parts, namely a high-load carbon separation reaction tank, a first sedimentation tank, a mainstream anaerobic ammonia oxidation reaction tank, a second sedimentation tank and a sludge anaerobic digestion capacity unit, wherein the mainstream anaerobic ammonia oxidation reaction tank is sequentially divided into an anoxic zone, a main PN / A zone, a nitrogen polishing zone and a degassing zone. Most of organic pollutants are separated and recycled in the high-load carbon separation reaction tank for capacity utilization, and nitrogen in sewage is removed through denitrification of the anoxic zone, partial nitrosation / anaerobic ammonia oxidation of the main PNA zone and multi-mode purification of a nitrogen polishing zone. The device and the operation method havethe advantages of sewage potential recycling, stable operation, excellent effluent quality, low energy consumption and material consumption and the like, and are a new device and a new process suitable for urban sewage treatment.

Owner:NORTH CHINA MUNICIPAL ENG DESIGN & RES INST

Method for concentration of gold in copper sulfide minerals

ActiveUS8052774B2Efficient separationEffective recoveryPhotography auxillary processesGold compoundsEnrichment methodsHydrometallurgy

Disclosed herein is a method for concentrating gold contained in a leach residue obtained in a copper hydrometallurgical process for recovering copper from a copper sulfide mineral to efficiently separate and recover gold from the leach residue: a gold-bearing copper sulfide mineral is subjected to pressure leaching with sulfuric acid at a temperature higher than 102° C. and 112° C. or lower to obtain a leach residue, and the leach residue is subjected to flotation to separate it into a float fraction and a sink fraction; the float fraction obtained by flotation is desulfurized to obtain a desulfurized product; the desulfurized product is subjected to oxidative roasting to obtain an oxidatively-roasted product; the oxidatively-roasted product is dissolved in a sulfuric acid solution to obtain a copper solution, and a gold-bearing residue is separated and recovered from the copper solution.

Owner:SUMITOMO METAL MINING CO LTD

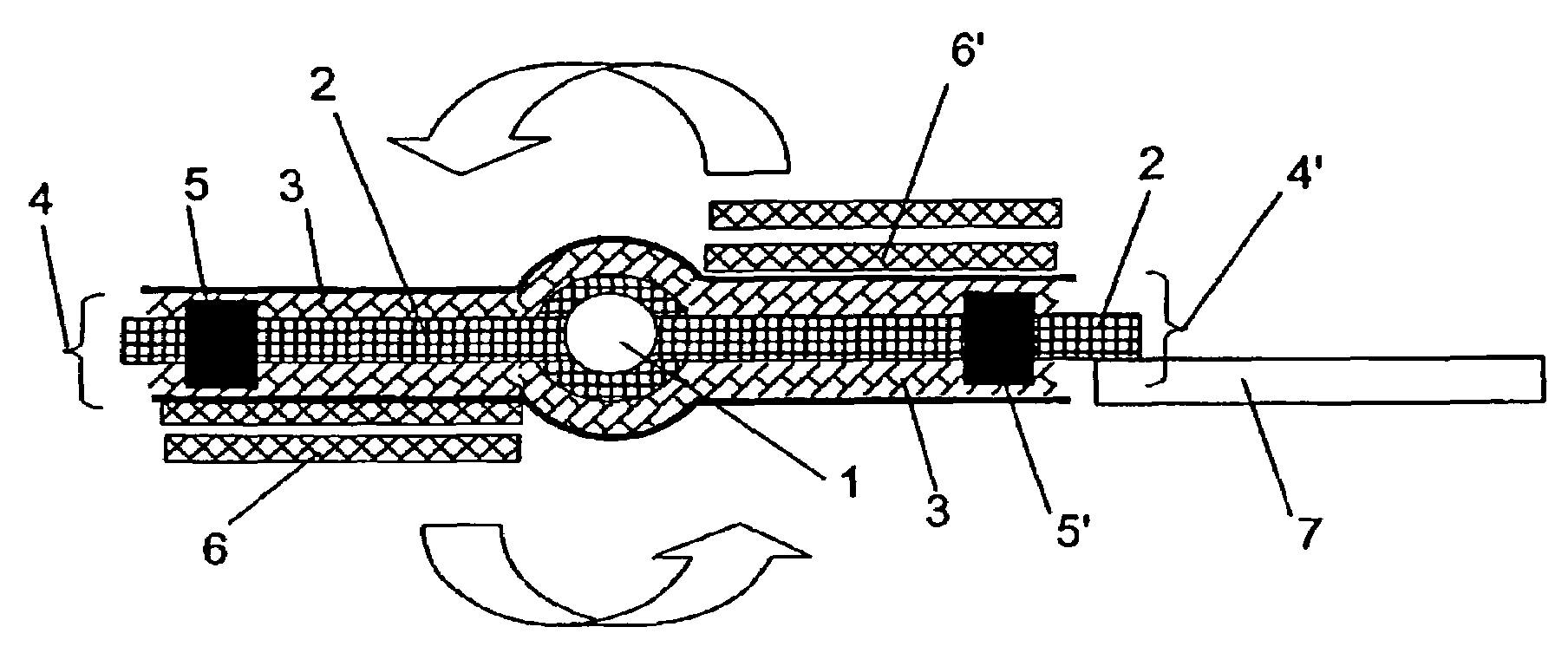

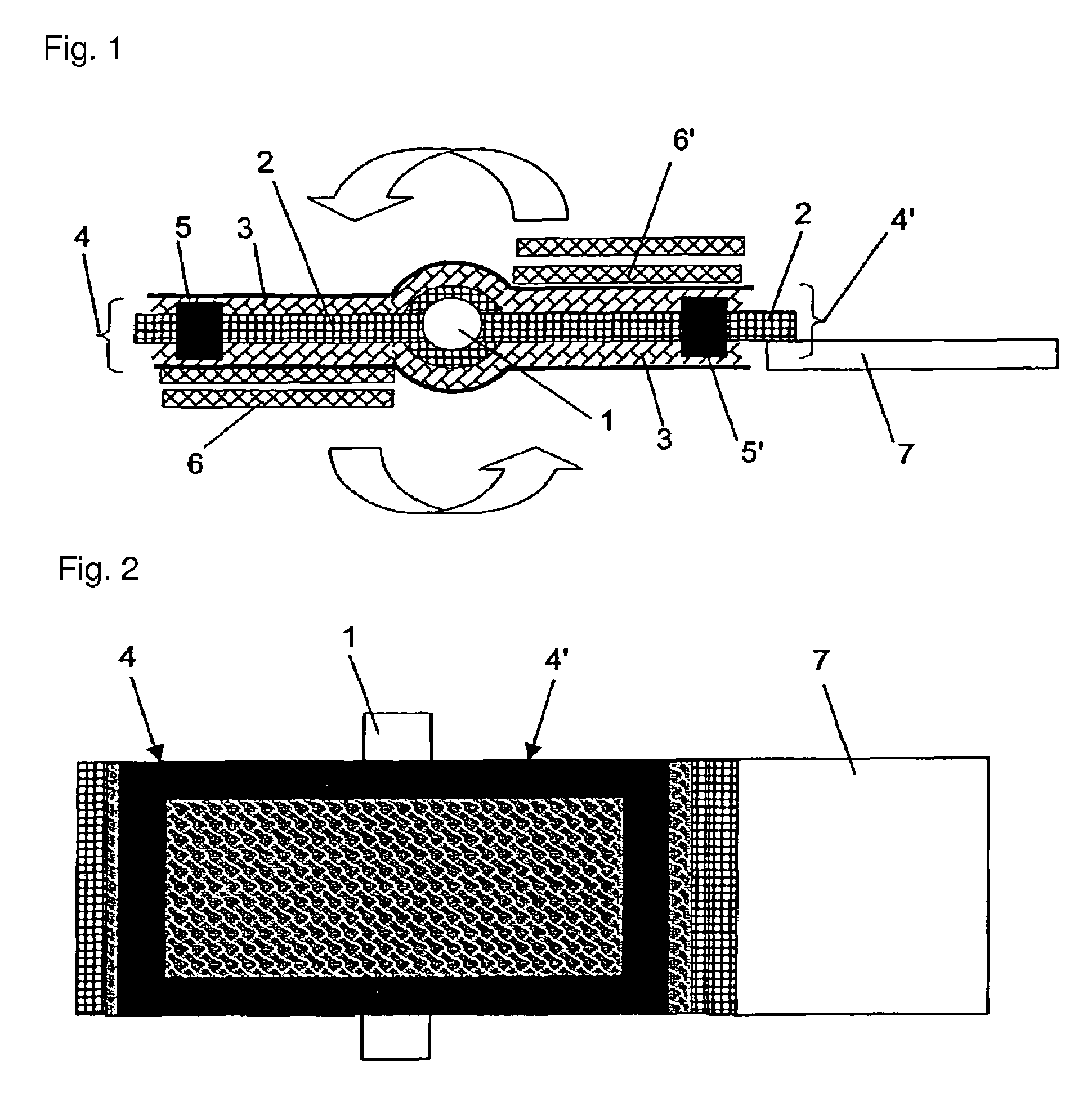

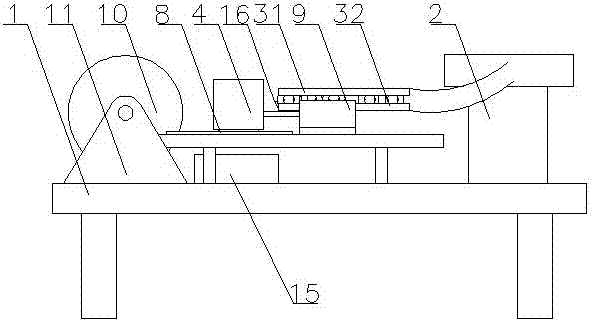

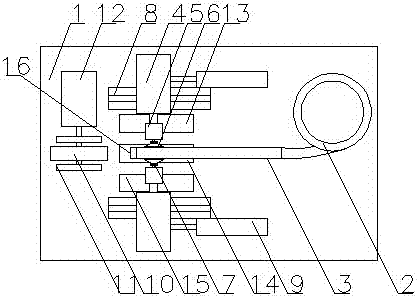

Automatic lithium battery gasket disassembling machine

PendingCN107196009AEfficient separation and recoveryAvoid accidental injuryWaste accumulators reclaimingBattery recyclingElectric machineLithium battery

The invention relates to an automatic lithium battery gasket disassembling machine. The automatic lithium battery gasket disassembling machine comprises a workbench; a vibration disk, a clamping component and a grinding wheel component are sequentially arranged and installed on the workbench; the tail end of the guide rail of the vibrating disk is connected to a guide track; the guide track stretches into the clamping component; the clamping component comprises a set of opposite coaxial clamping cylinders; rotary motors are fixedly installed on the extension ends of the clamping cylinders respectively; the rotating shaft end parts of the rotary motors are respectively connected to vacuum chucks; the vacuum chucks are installed on the rotating shaft end parts of the rotary motors through rotary joints; the rotary joints are connected to a vacuumizing device through a pipeline; the two vacuum chucks are arranged oppositely and coaxially; and the guide track is arranged between the two rotary motors.

Owner:JIANGSU FUBANG ELECTRONICS TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com