Patents

Literature

258 results about "Cobalt sulphide" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Cobalt sulfide is the name for chemical compounds with a formula CoxSy. Well-characterized species include minerals with the formula CoS, CoS2, Co3S4, and Co9S8. In general, the sulfides of cobalt are black, semiconducting, insoluble in water, and nonstoichiometric.

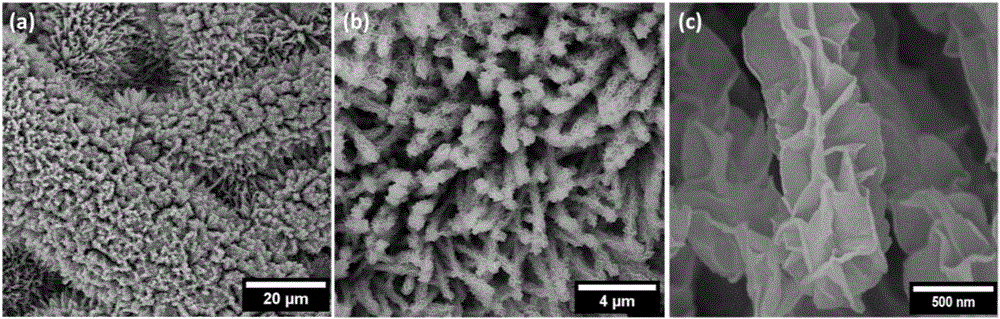

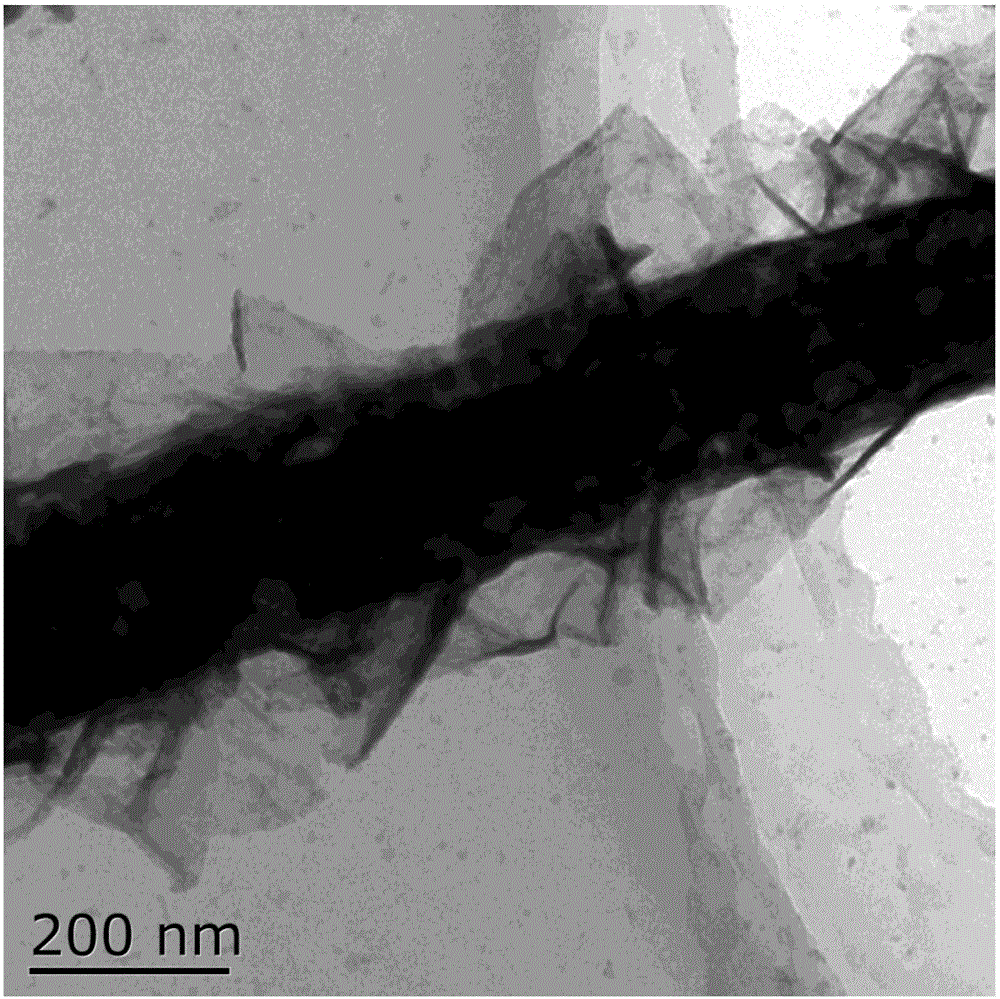

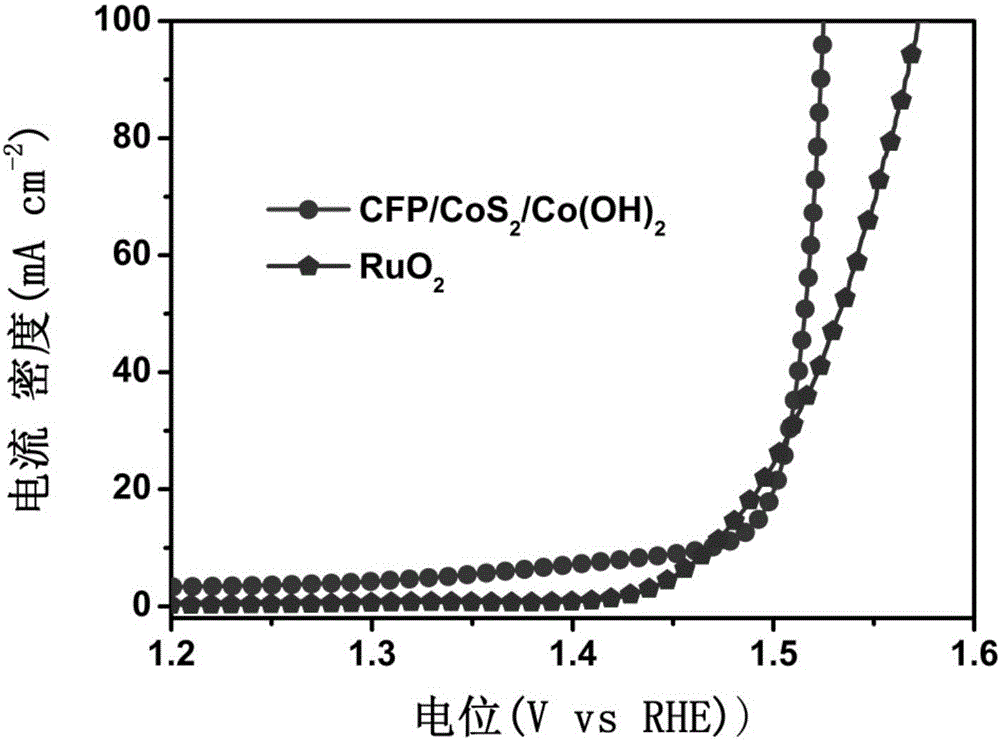

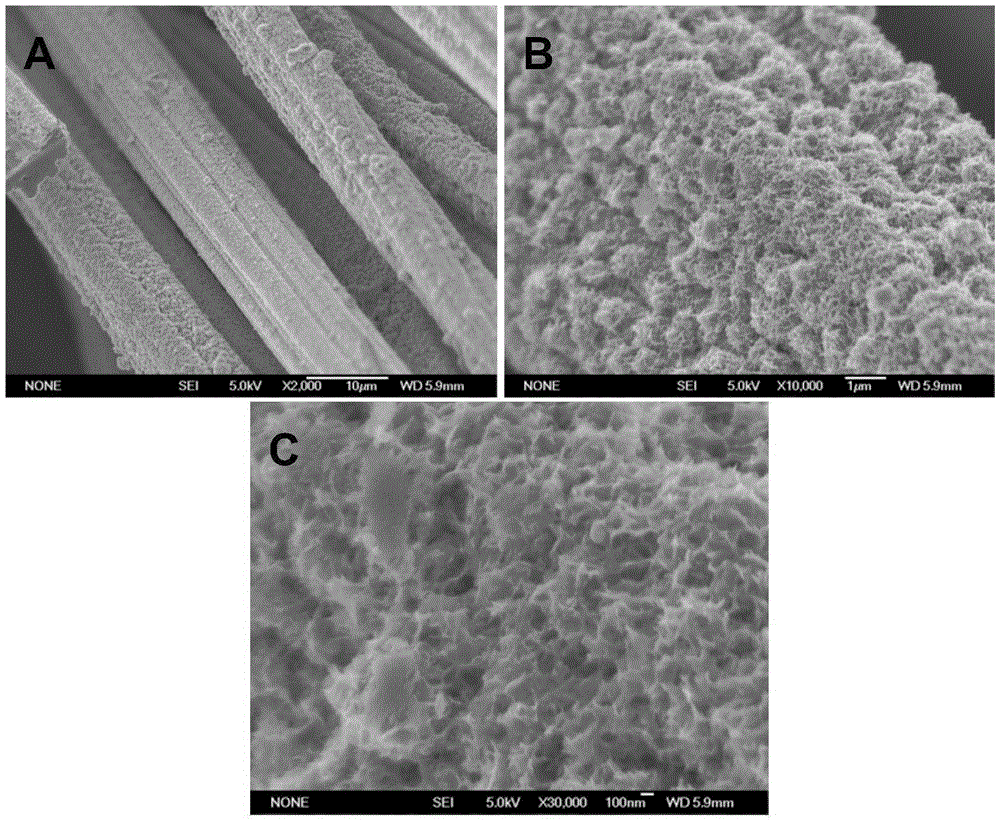

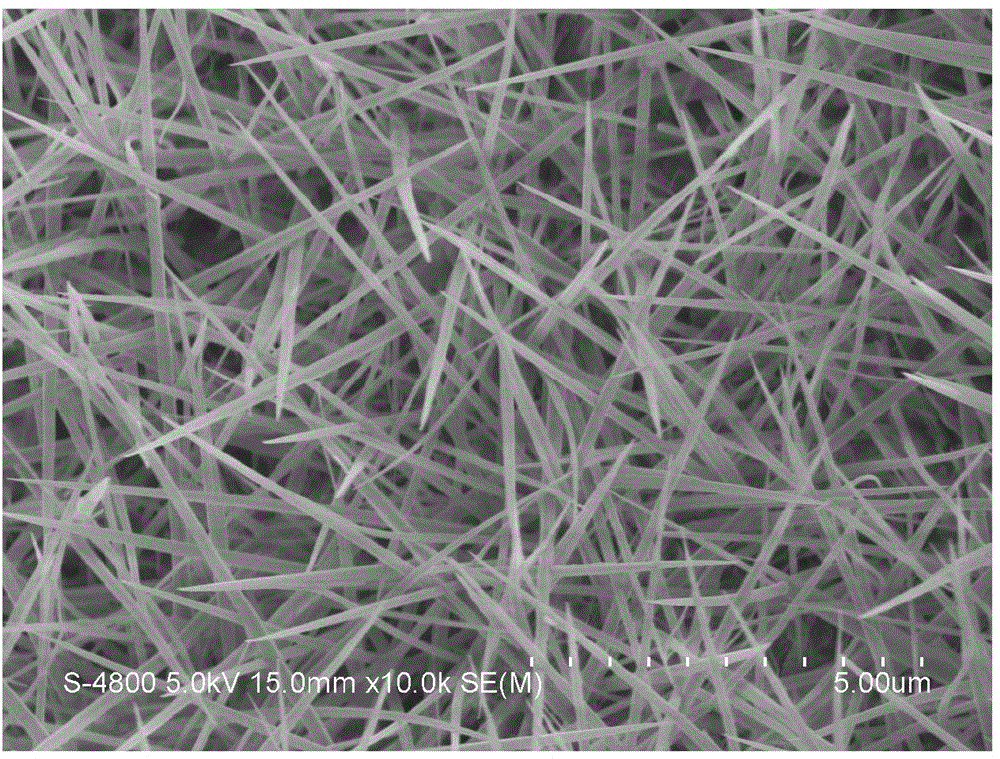

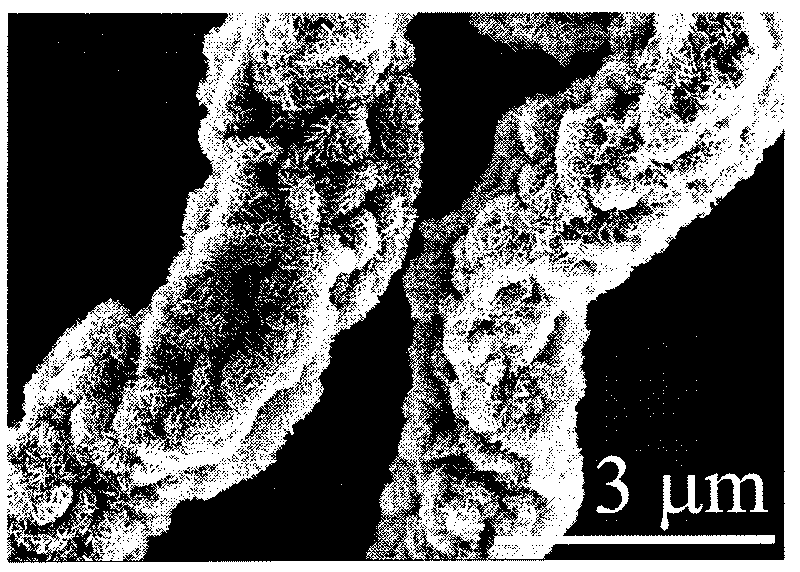

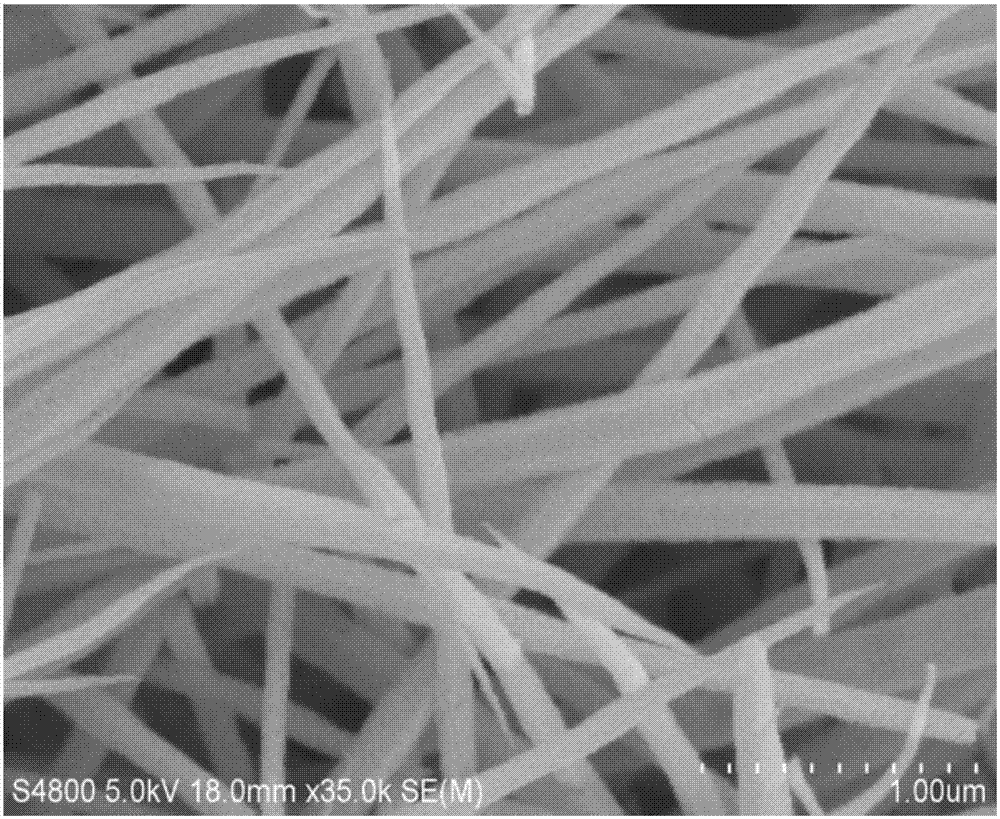

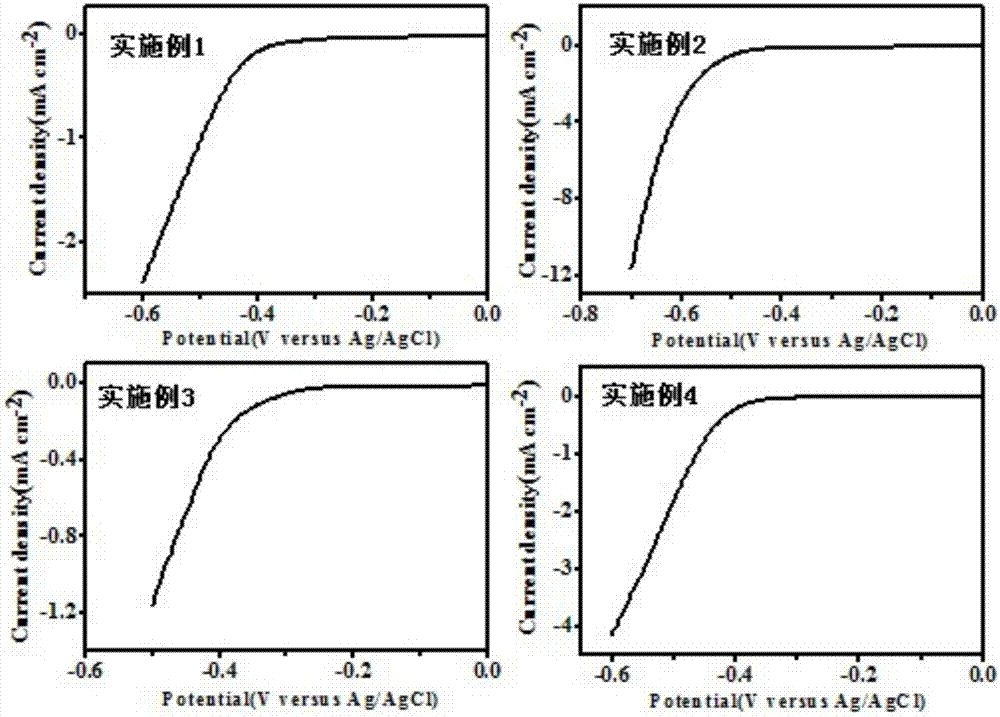

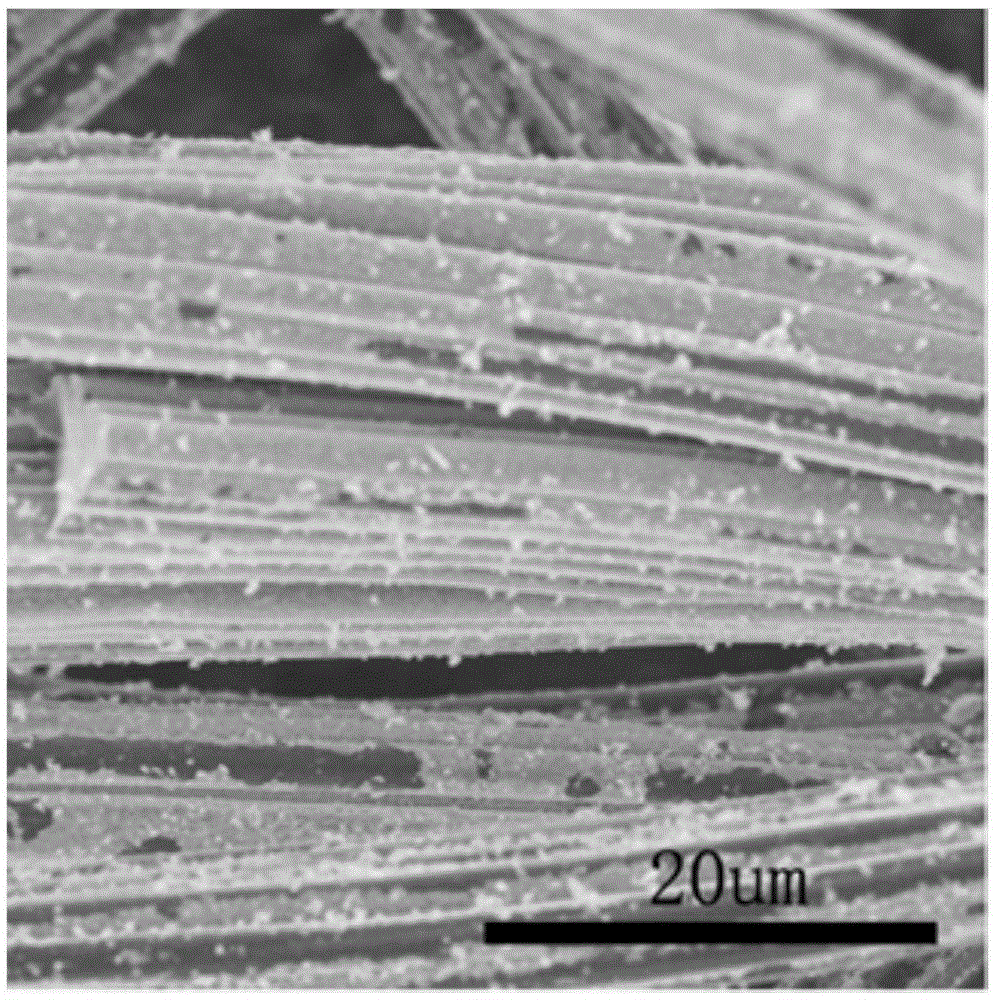

Electrocatalyst with cobalt-based multi-stage nano-composite structure for oxygen production by electrolysis of water and preparation method of electrocatalyst

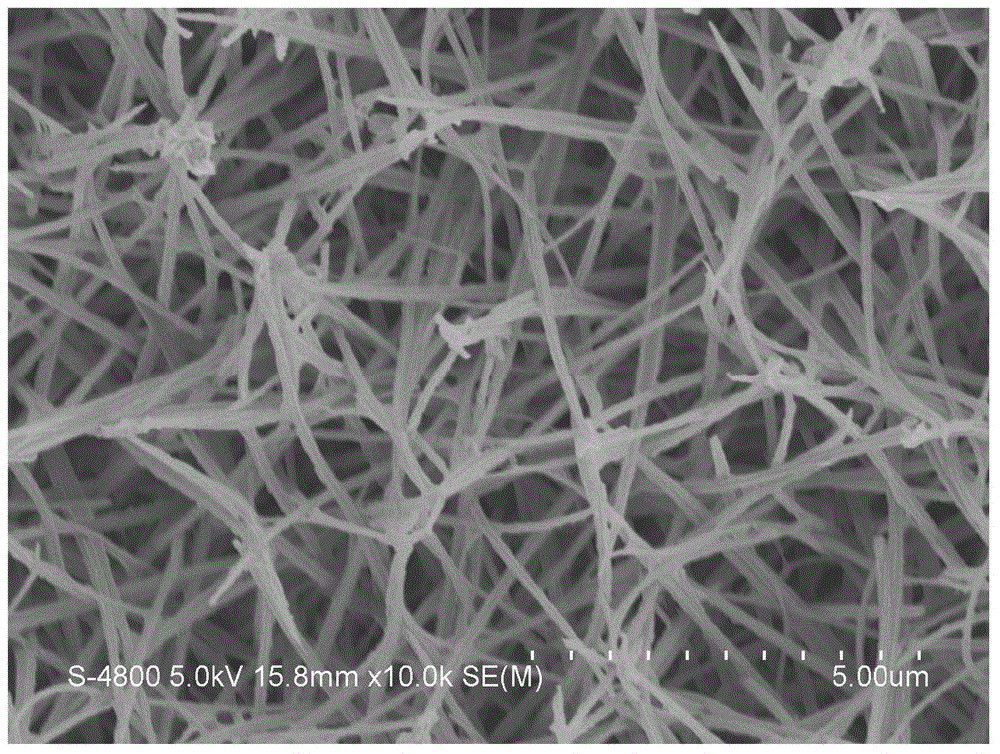

InactiveCN106011926ALow costEasy to operateCobalt sulfidesElectrolytic inorganic material coatingFiberCarbon fibers

The invention provides an electrocatalyst with a cobalt-based multi-stage nano-composite structure for oxygen production by electrolysis of water and a preparation method of the electrocatalyst. The preparation method comprises the following steps: dissolving cobalt nitrate hexahydrate, urea and ammonium fluoride in deionized water to obtain a precursor solution; transferring the precursor solution into a hydrothermal reactor; adding carbon fiber paper; enabling basic cobalt carbonate nanowires to grow on the carbon fiber paper through solvothermal reaction; after finish of reaction, naturally cooling; then taking out a product; washing and drying to obtain a carbon fiver paper loaded basic cobalt carbonate nanowire composite structure; by taking powdered sulfur as the raw material, preparing a carbon fiber paper loaded cobalt sulfide nanowire composite structure through low-temperature sulfuration reaction under the condition of an inert gas; and finally, electroplating the surface of the carbon fiber paper loaded cobalt sulfide nanowire composite structure with a layer of cobalt hydroxide nanosheets by use of the electrochemical deposition method so as to obtain the electrocatalyst with the cobalt-based multi-stage nano-composite structure for oxygen production by electrolysis of water. As the sulfide and the hydroxide of transition metal cobalt are adopted as the catalyst, in comparison with noble metals, the cost of the catalyst is lowered.

Owner:JIANGSU UNIV

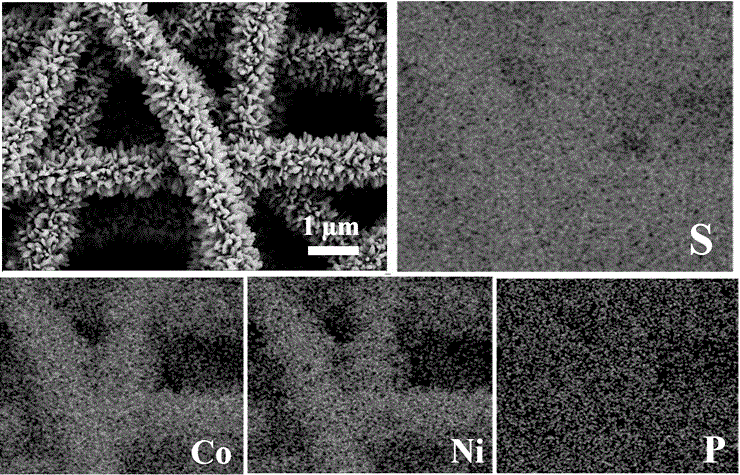

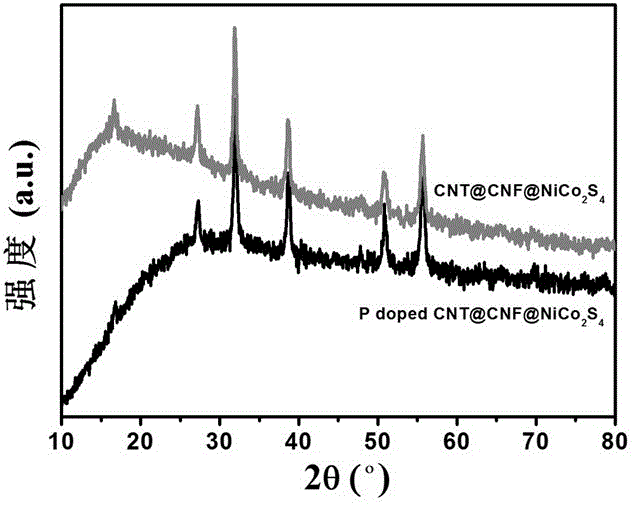

Phosphorus-doped nickel cobalt sulfide/carbon nanotube-carbon nanofiber composite material and preparation method thereof

InactiveCN106076377AEasy to makeEasy to operatePhysical/chemical process catalystsElectrodesFiberNew energy

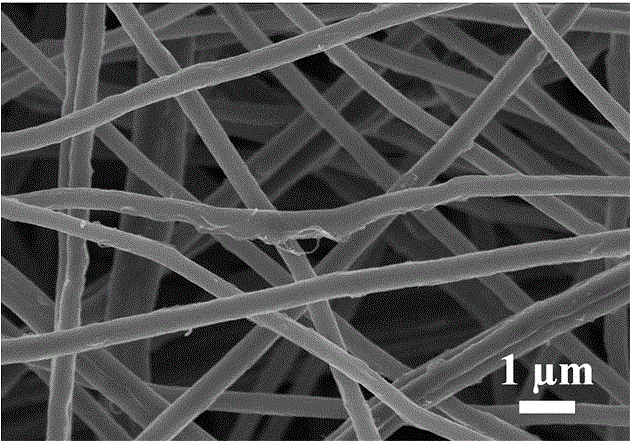

The invention belongs to the technical field of transitional-metal sulfide-carbon materials, and concretely relates to a phosphorus-doped nickel cobalt sulfide / carbon nanotube-carbon nanofiber composite material and a preparation method thereof. The preparation method comprises preparing carbon nanotube-doped carbon nanofiber through electrostatic spinning and high-temperature carbonization, then growing nickel cobalt sulfide nanorod in situ through a hydrothermal process, and finally calcining a phosphorus-containing precursor at a high temperature in an atmosphere of an inert gas, so as to prepare the phosphorus-doped composite material. The prepared carbon nanofiber possesses relatively large specific surface area, and the electric conductivity is effectively enhanced by doping carbon nanotube. By taking the carbon naofiber as a substrate, nickel cobalt sulfide nanorod uniformly densely grows on the surface of the composite fiber, and the synergistic effect of various substances is fully displayed. By doping phosphorus, the electrochemical activity of the composite material is further improved. The prepared phosphorus-doped nickel cobalt sulfide / carbon nanotube-carbon nanofiber composite material is applicable as a high-performance electro-catalytic material and an electrode material of lithium ion battery, solar cells and other new-energy-source devices.

Owner:FUDAN UNIV

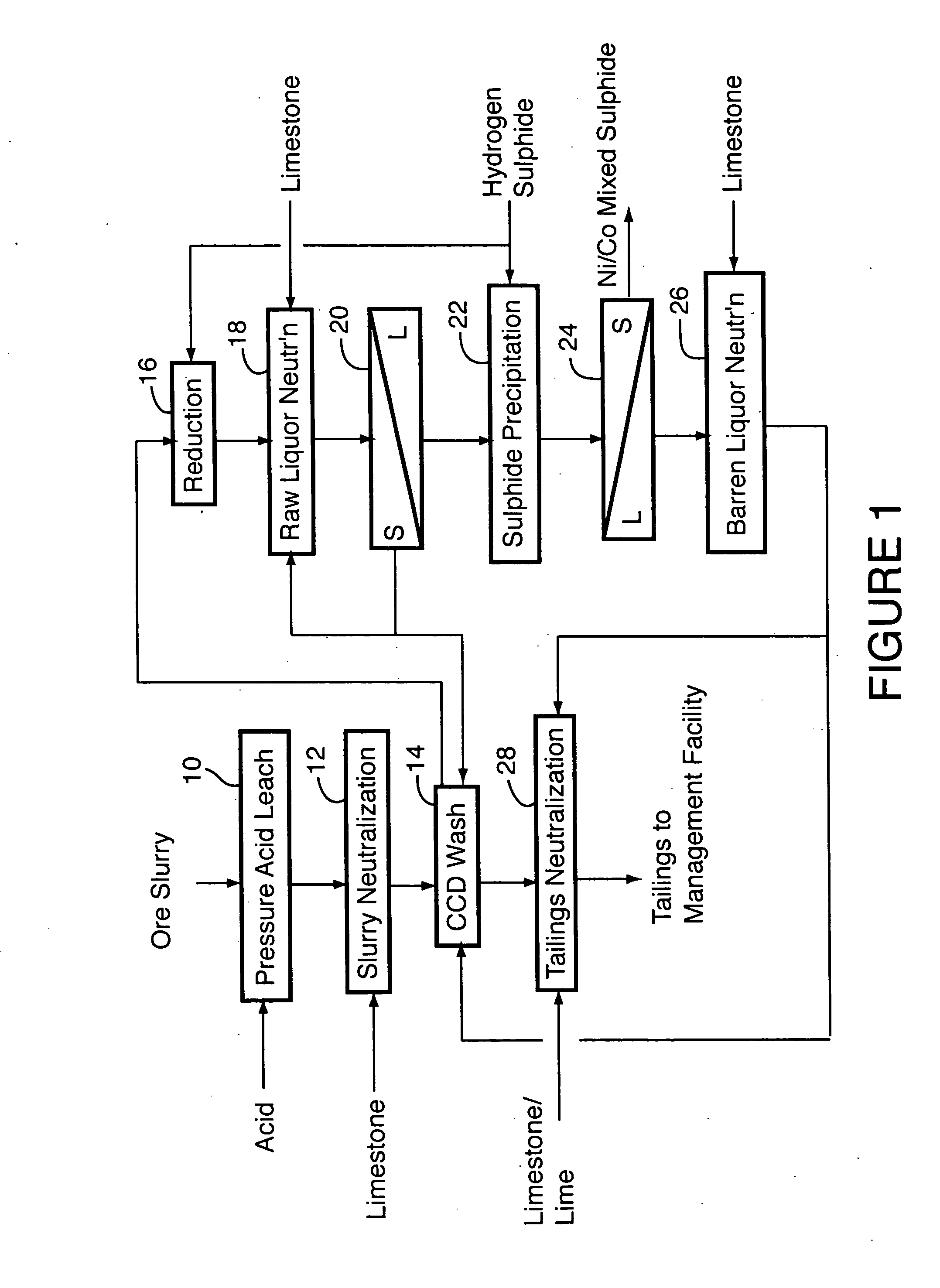

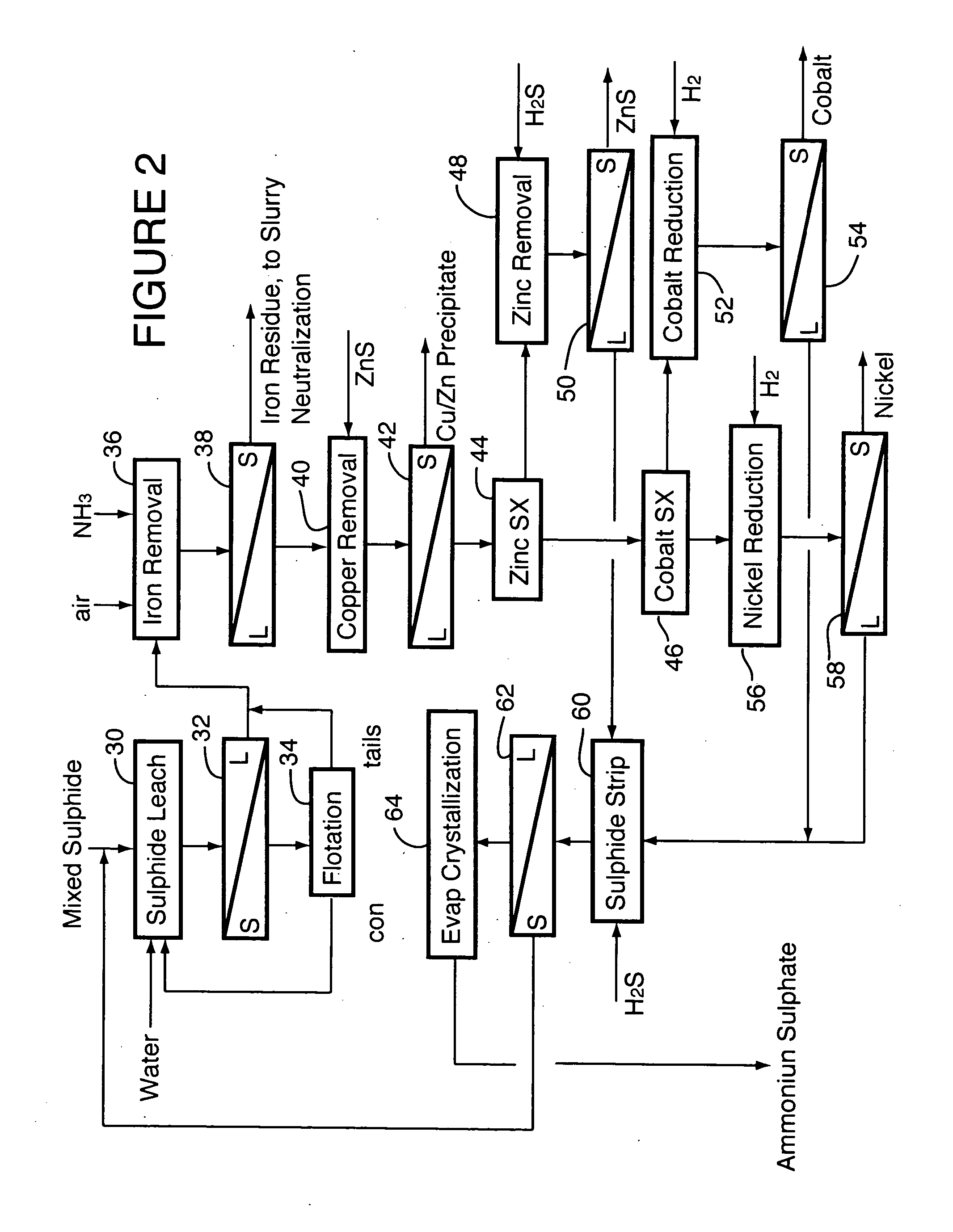

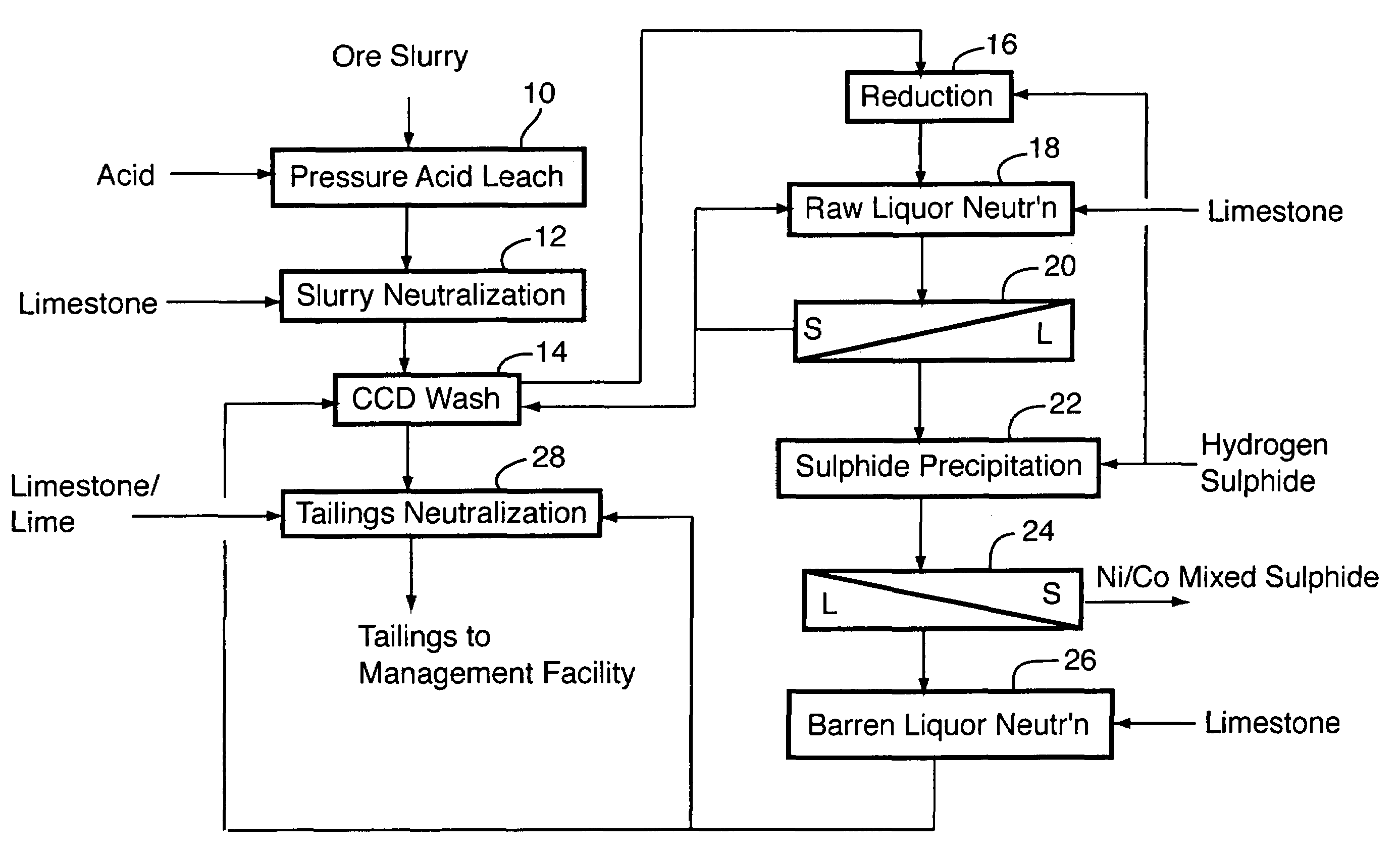

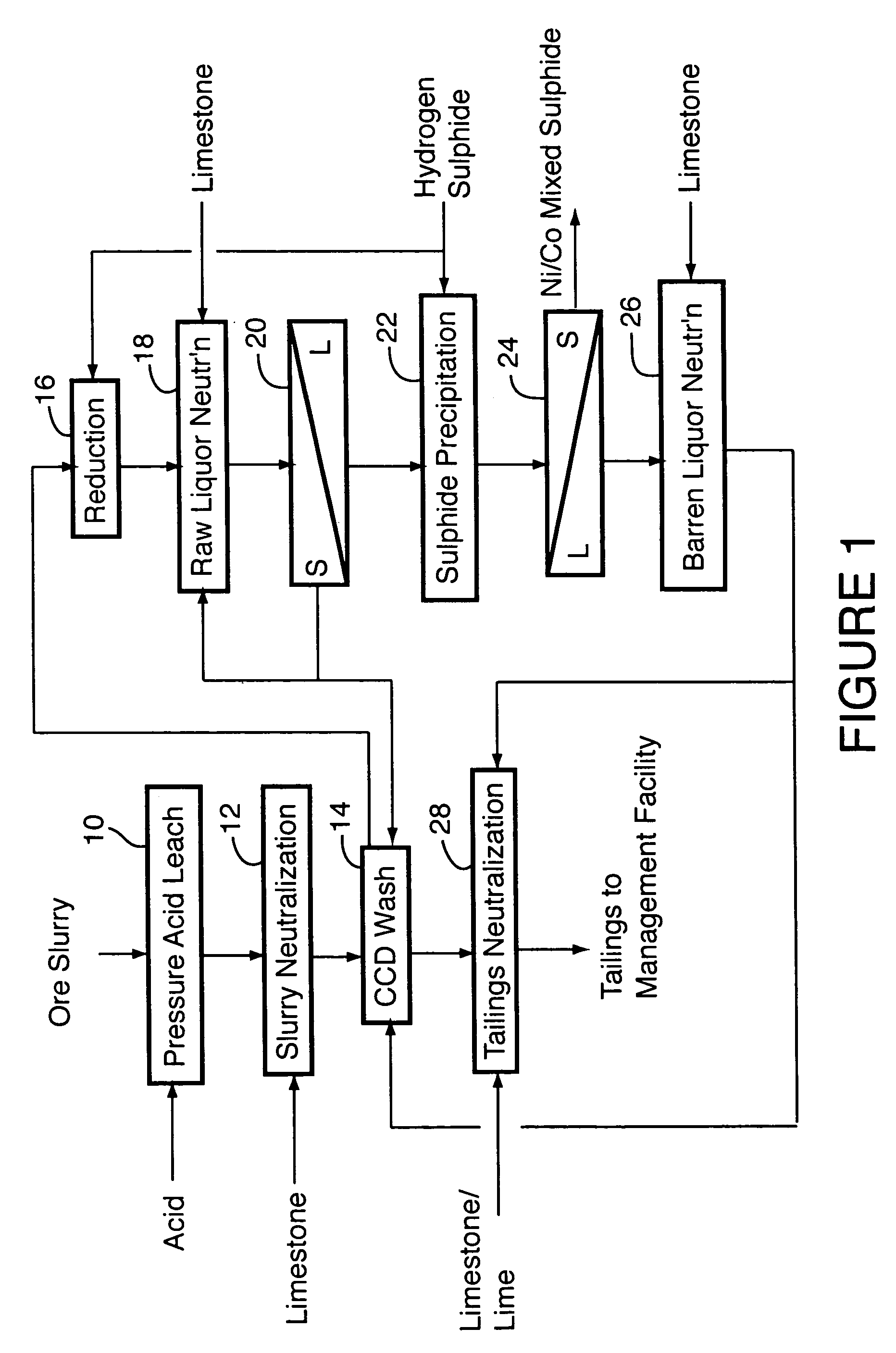

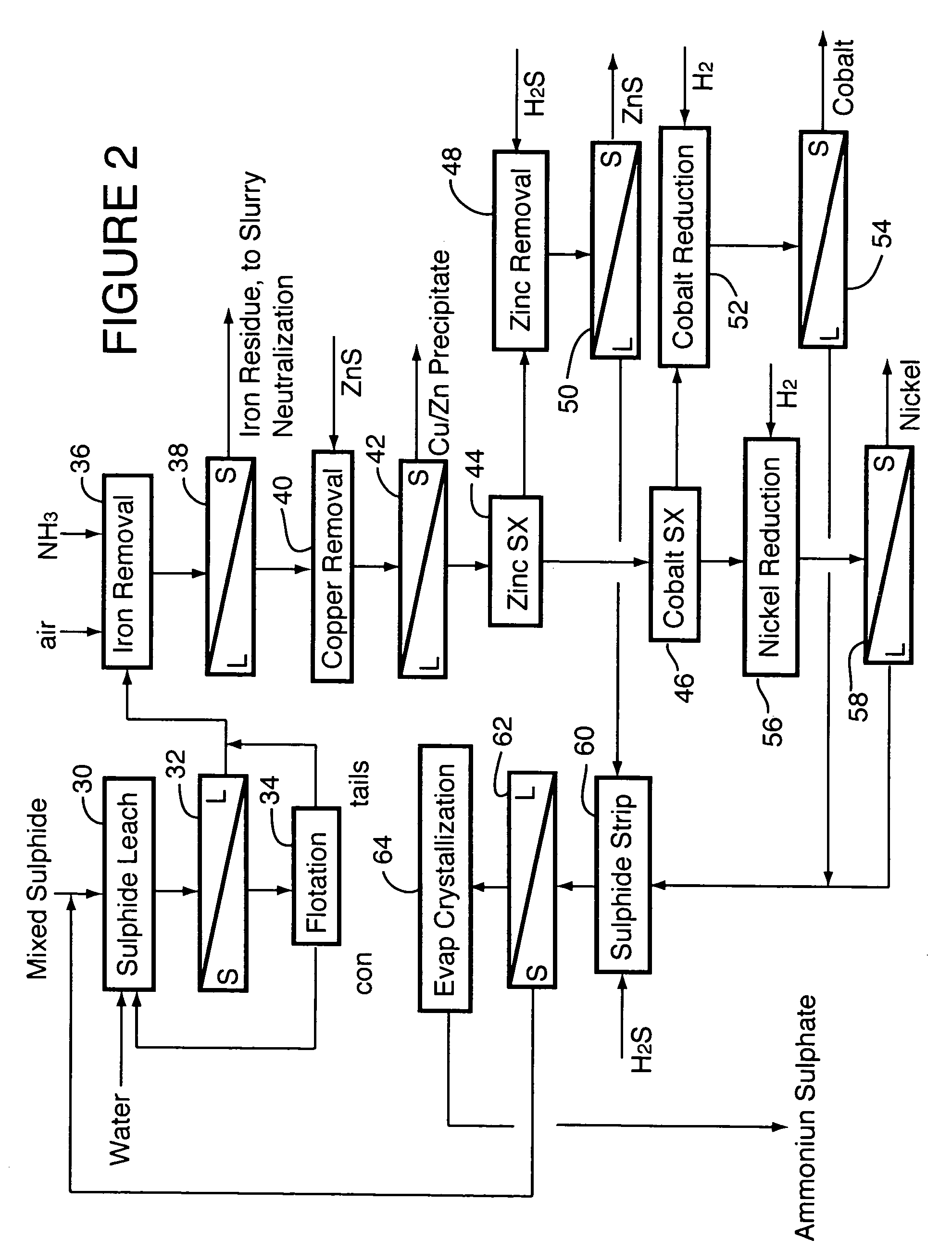

Process for recovery of nickel and cobalt from laterite ore

ActiveUS20060228279A1Efficient separation and recoveryHigh purityCobalt sulfidesSolvent extractionFree solutionSlurry

A process for recovering nickel and cobalt values from nickel- and cobalt-containing laterite ores as an enriched mixed nickel and cobalt sulphide intermediate and for producing nickel and cobalt metal from the nickel and cobalt sulphide intermediate. The laterite ore is leached as a slurry in a pressure acid leach containing an excess of aqueous sulphuric acid at high pressure and temperature, excess free acid in the leach slurry is partially neutralized to a range of 5 to 10 g / L residual free H2SO4 and washed to yield a nickel- and cobalt-containing product liquor, the product liquor is subjected to a reductant to reduce any Cr(VI) in solution to Cr(III), the reduced product liquor is neutralized to precipitate ferric iron and silicon at a pH of about 3.5 to 4.0, and the neutralized and reduced product liquor is contacted with hydrogen sulphide gas to precipitate nickel and cobalt sulphides. The precipitated nickel and cobalt sulphides can be leached in a water slurry in a pressure oxidation leach, the leach solution subjected to iron hydrolysis and precipitation, the iron-free solution contacted with zinc sulphide to precipitate copper, the iron- and copper-free solution subjected to zinc and cobalt extraction by solvent extraction to produce a nickel raffinate, the nickel raffinate contacted with hydrogen gas to produce nickel powder and the cobalt strip solution from the solvent extraction step contacted with hydrogen gas to produce cobalt powder.

Owner:SHERRITT INTERNATIONAL

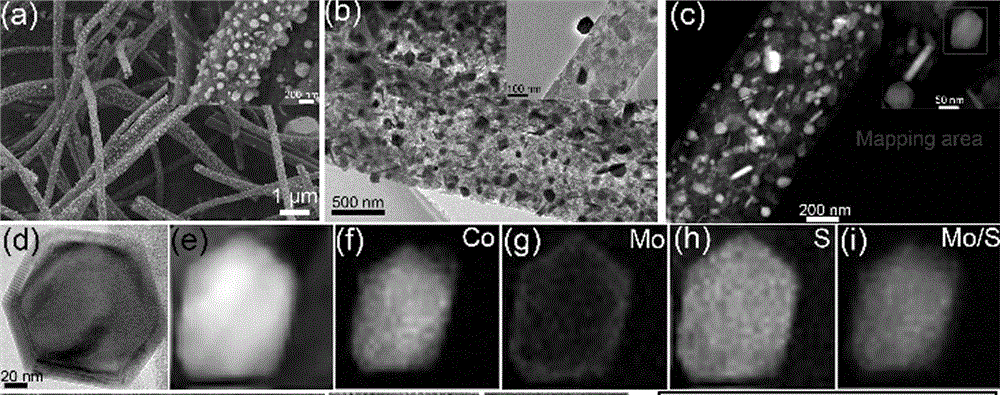

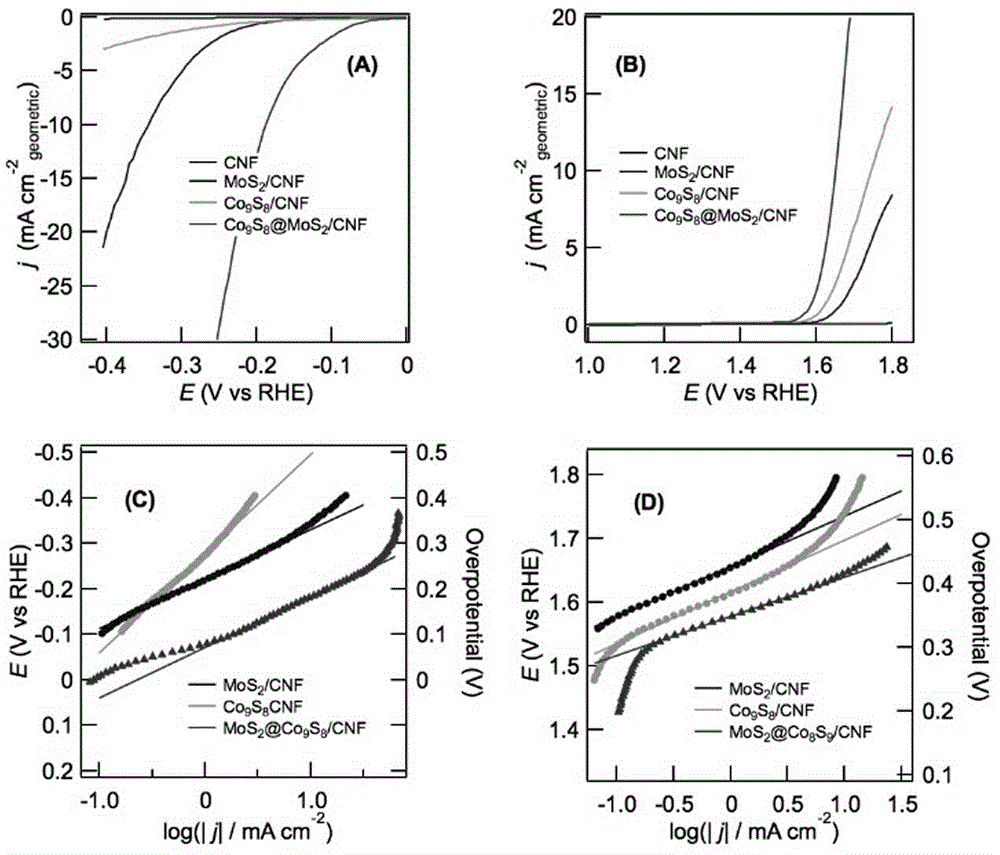

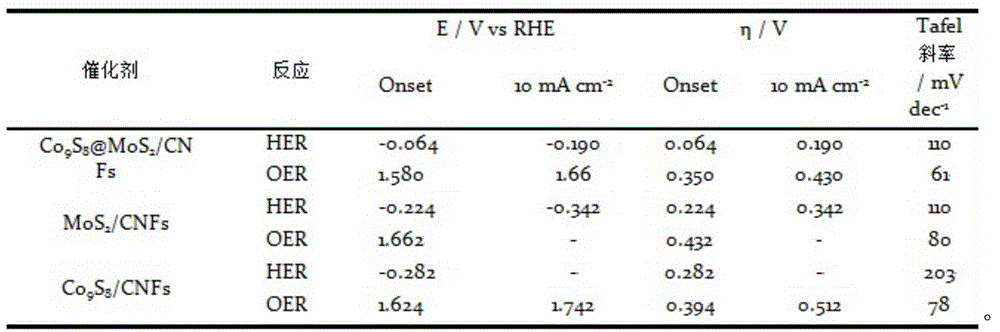

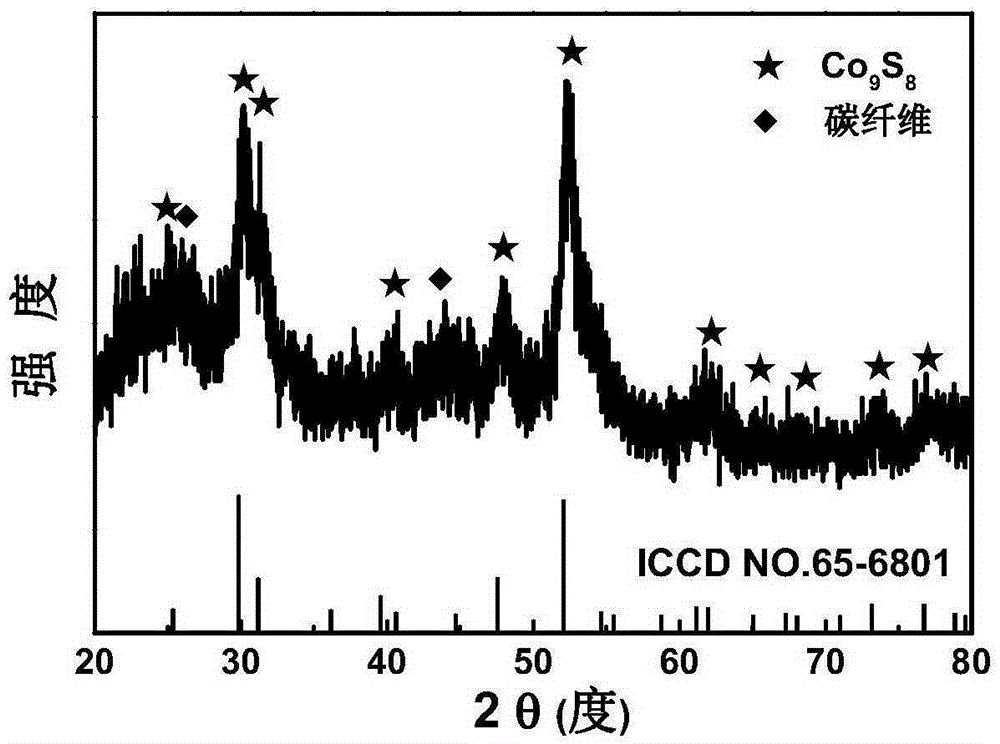

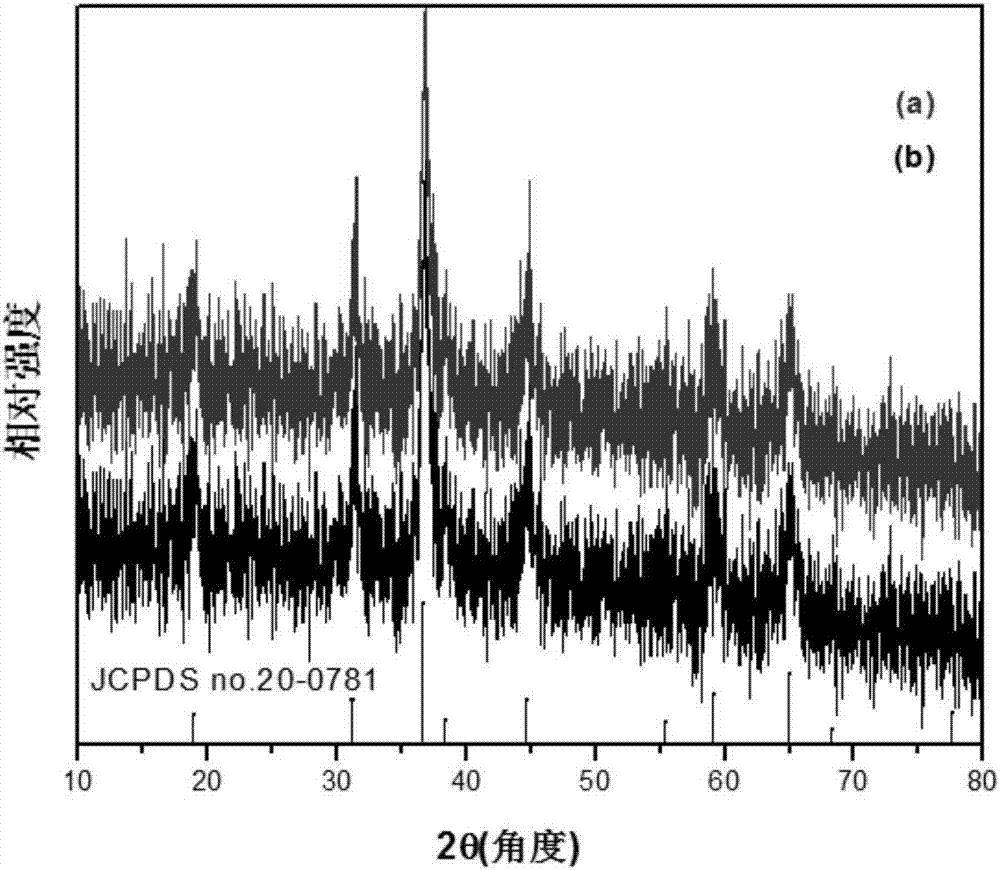

Electrolyzed-water catalytic material with nanometer core-shell structure of cobalt sulfide and molybdenum disulfide

ActiveCN104971744AIncrease the areaHigh porosityPhysical/chemical process catalystsElectrolysis componentsFiberPorosity

The invention discloses an electrolyzed-water catalytic material with a nanometer core-shell structure of cobalt sulfide and molybdenum disulfide. The electrolyzed-water catalytic material is composed of a catalytic active material and a carrier, wherein the catalytic active material is a material with the nanometer core-shell structure of cobalt sulfide and molybdenum disulfide; molybdenum disulfide is a shell; cobalt sulfide is a core; and the carrier is ultrafine carbon fiber. The electrolyzed-water catalytic material provided by the invention has high specific surface area and porosity, is favorable for diffusion and gas desorption of electrolyte, has the characteristics of dual functions of hydrogen evolution and oxygen evolution at the same time, and can be directly used as an electrode for electrocatalytic hydrogen preparation without the need of loading onto the electrode.

Owner:ZHEJIANG SCI-TECH UNIV

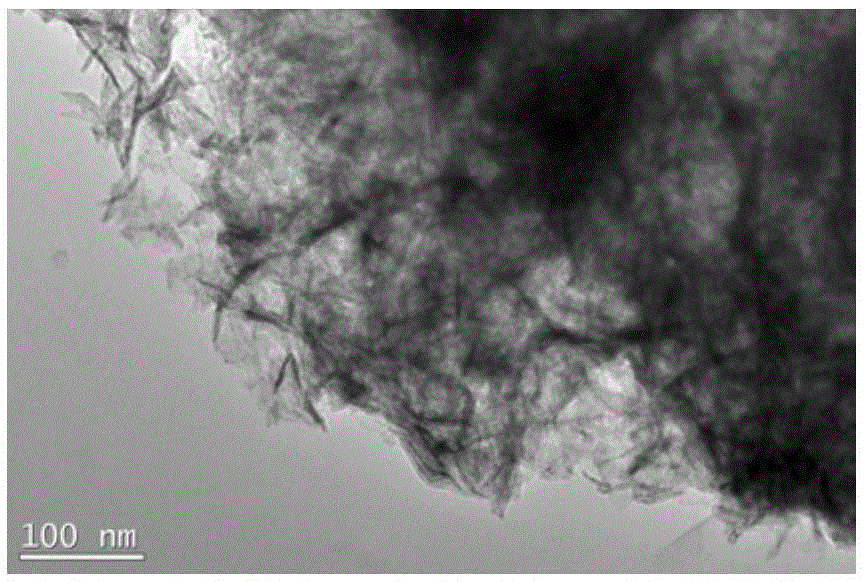

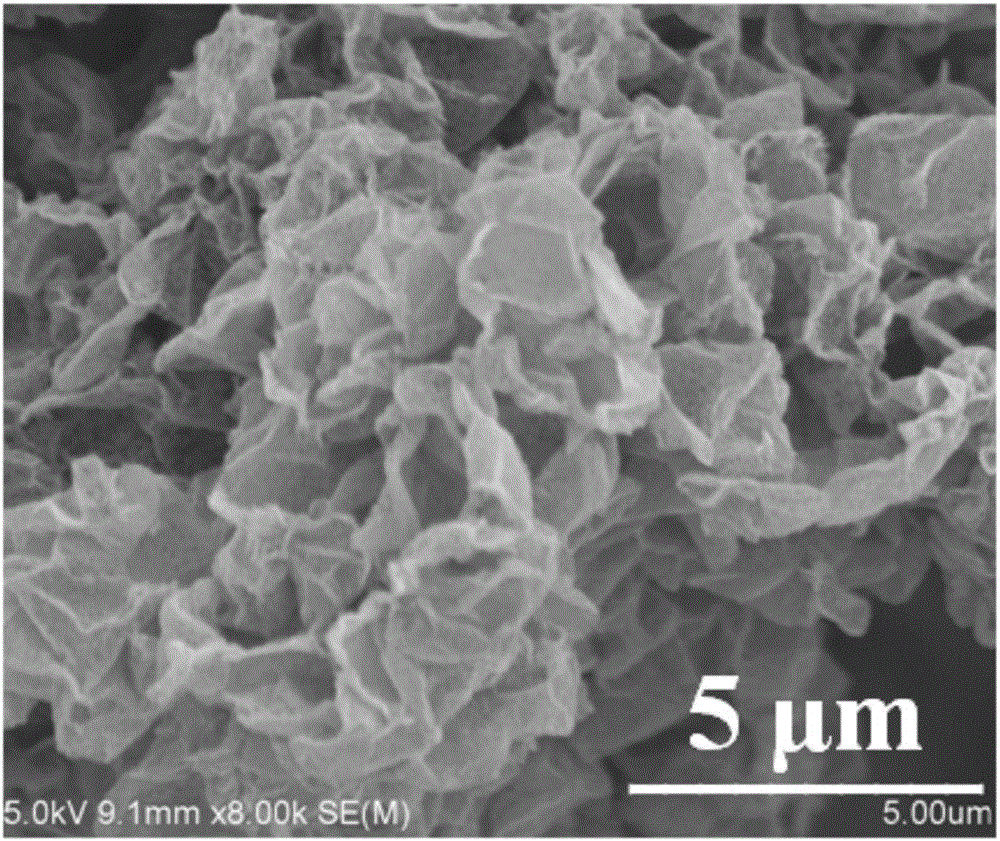

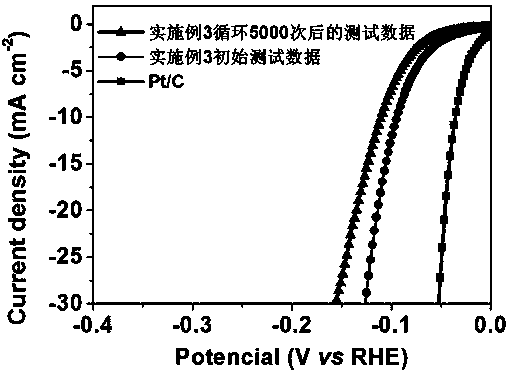

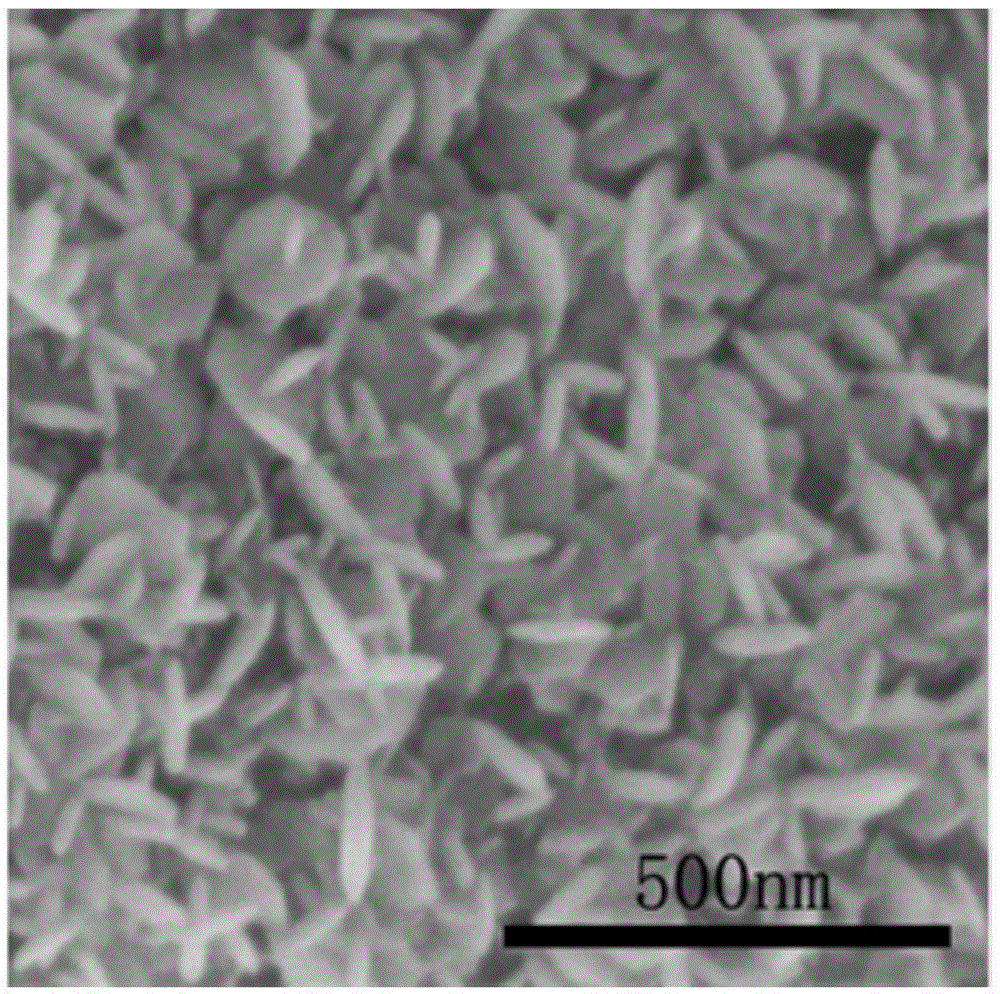

Carbon fiber supported cobalt sulfide nanosheet catalyst and application thereof

InactiveCN105289658AThe synthesis method is mild and simpleSynthetic raw materials are cheapPhysical/chemical process catalystsElectrolysis componentsFiberCarbon fibers

The invention provides a carbon fiber supported cobalt sulfide nanosheet catalyst and application thereof and belongs to the technical field of synthesis and application of catalysts. Firstly, metallic cobalt salt and a sulfur source are dissolved in ethylene glycol, then the solution is fed into a reaction kettle with a polytetrafluoroethylene liner, and a carbon-based conductive material is added and then is processed at a certain temperature to obtain the carbon fiber supported cobalt sulfide nanosheet catalyst. The carbon fiber supported cobalt sulfide nanosheet catalyst is prepared by adopting a solvothermal method through one step, and the synthesis method is moderate and simple, has no high device requirement and is suitable for scale production. In addition, synthesis raw materials are cheap, the controllability is high, and the reproducibility of sample properties is good. What's emphasized is that more catalytic active sites can be exposed and electric catalytic cracking hydrogen production performance of the cobalt sulfide can be greatly improved through combination of cobalt sulfide nanosheets generated in situ and the flexible three-dimensional structure of carbon fiber.

Owner:JILIN UNIV

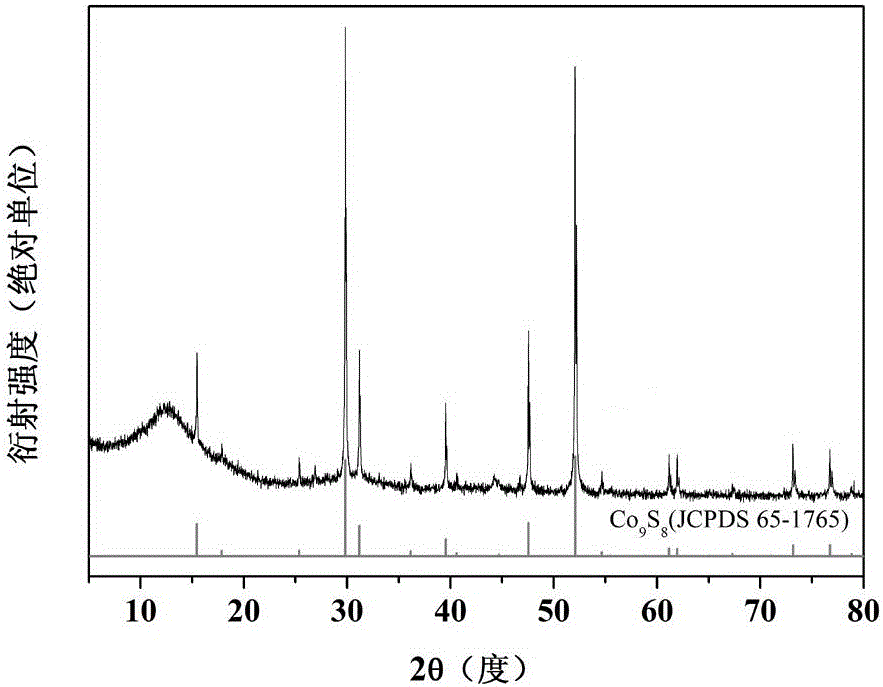

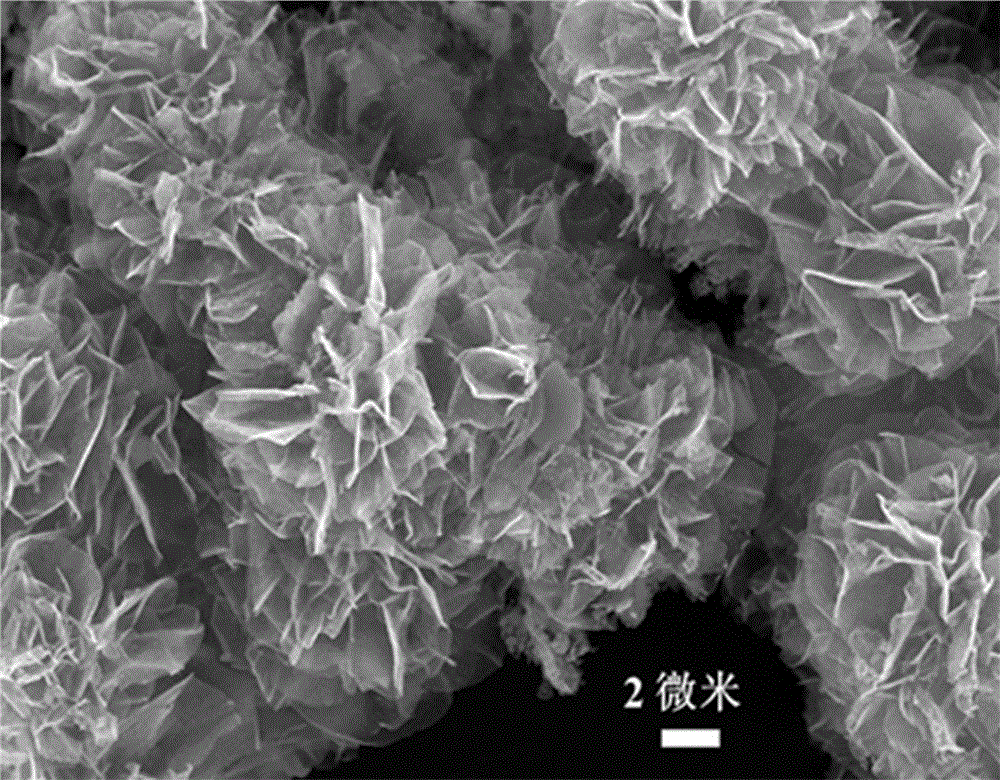

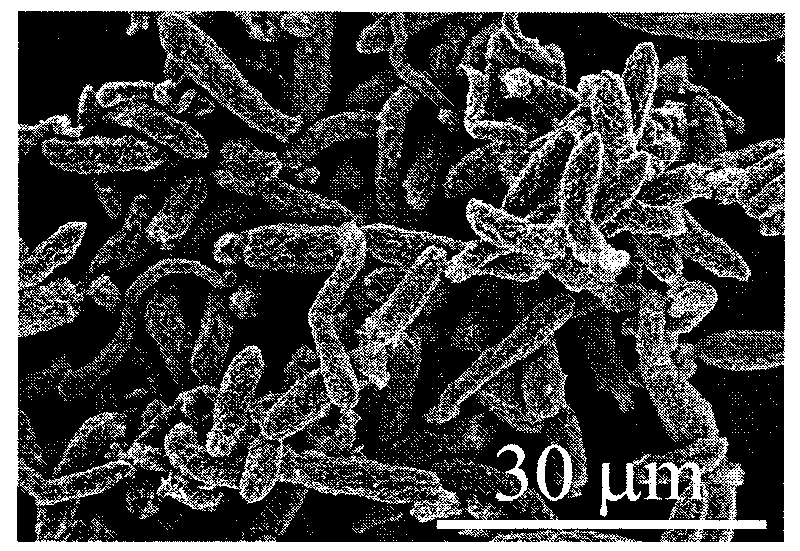

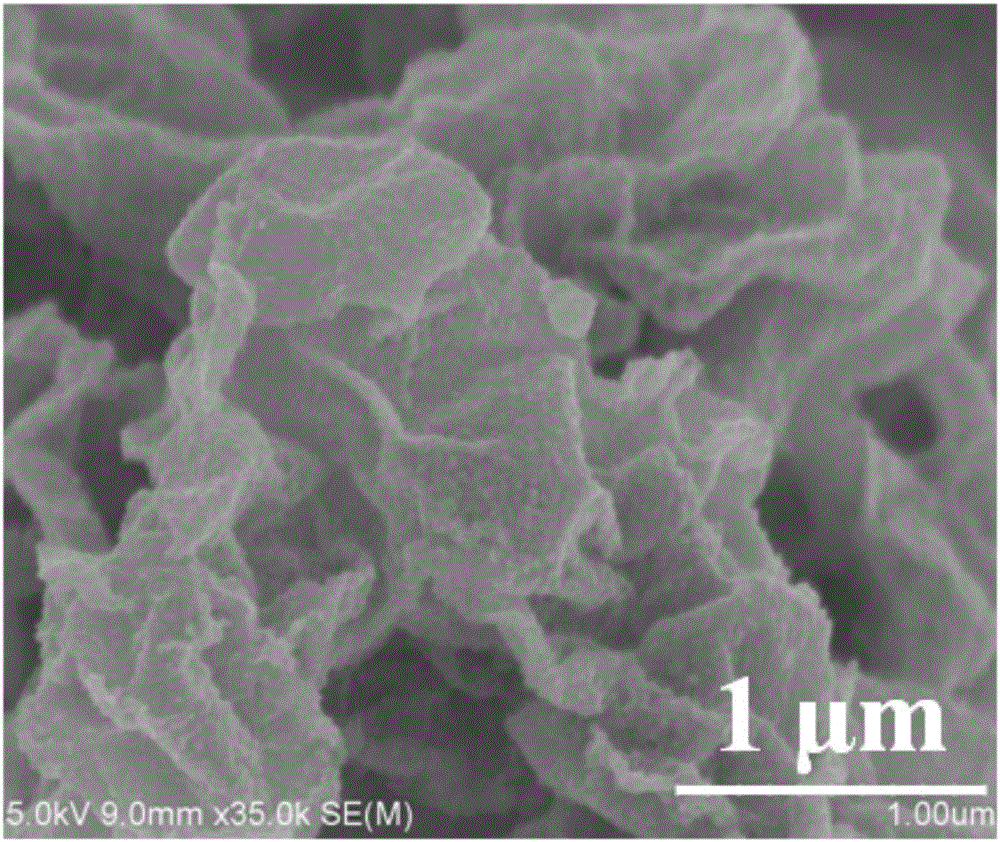

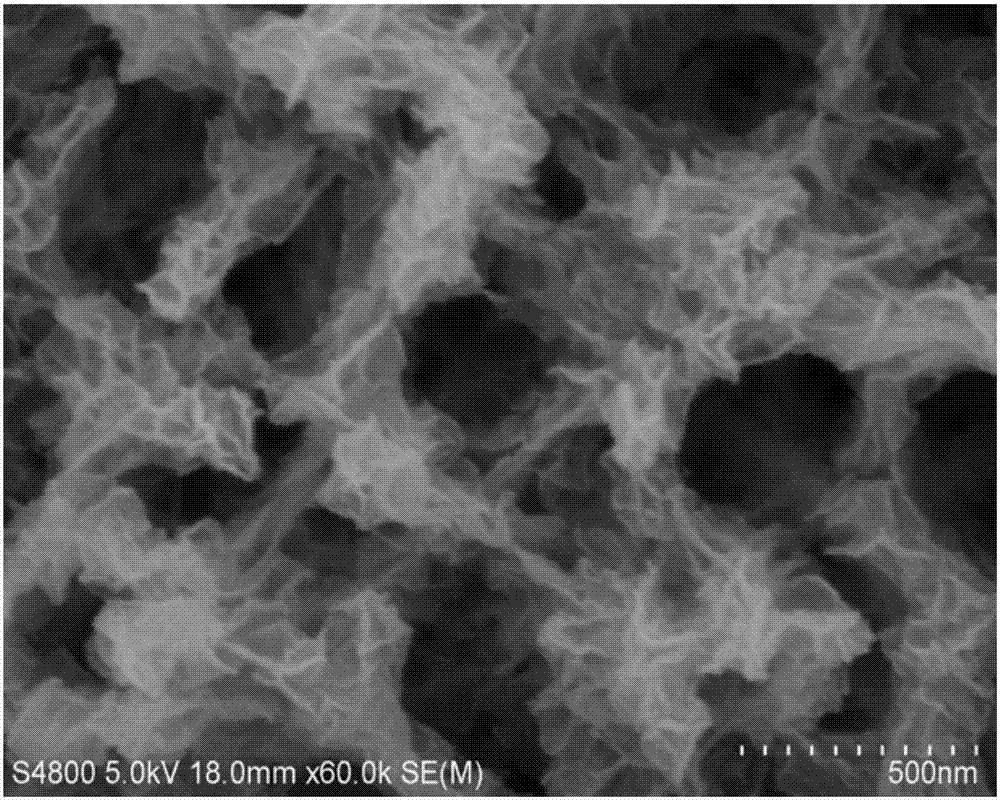

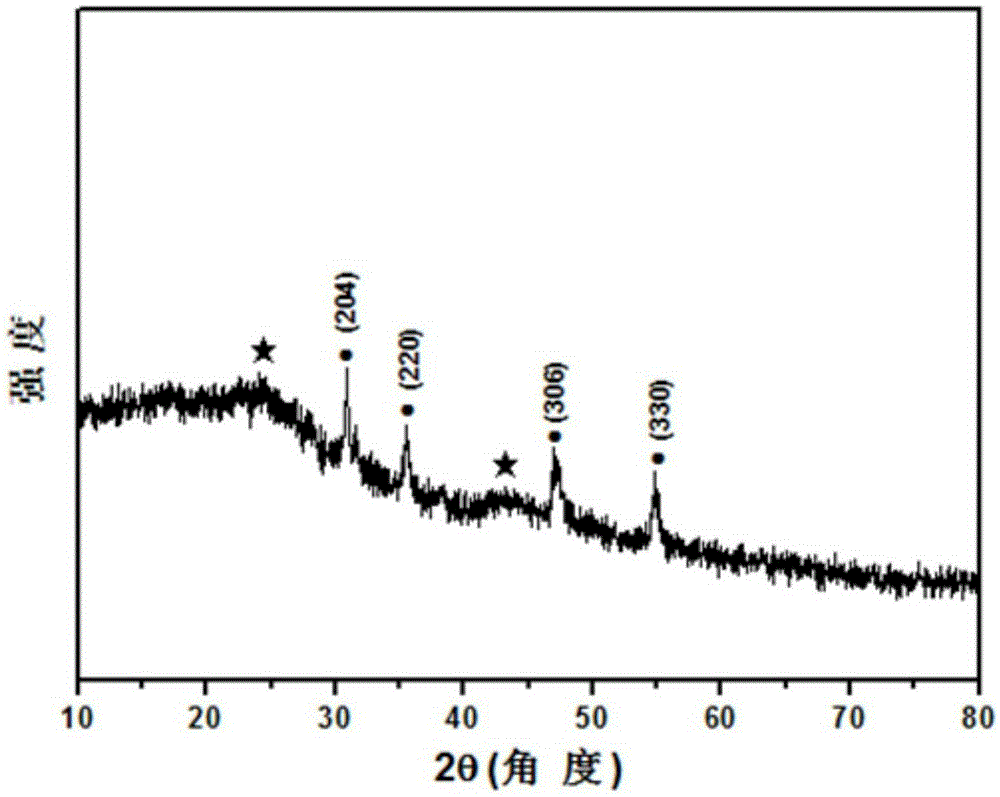

Cobalt sulfide/carbon composite material with flower-like structure and preparation method thereof

InactiveCN106099126ALarge specific surface areaExcellent electrocatalytic activity for oxygen reduction ORRMaterial nanotechnologyCell electrodesCarbon compositesFlower like

The invention provides a cobalt sulfide / carbon composite material with a flower-like structure and a preparation method thereof, and belongs to the technical field of fuel cell electrocatalysts and preparation thereof. The cobalt sulfide / carbon composite material with the flower-like structure is prepared from flower-like carbon with the diameter of 1-5 microns and Co9S8 with the particle sizes of 5-70nm; the mass percent content of the Co9S8 is 30%-80%; the flower-like carbon is prepared from interconnected carbon nanosheets of which the radial sizes are 0.5-3 microns and the thicknesses are 5-20nm; and Co9S8 particles are uniformly loaded on the carbon nanosheets. The preparation method of the cobalt sulfide / carbon composite material with the flower-like structure comprises the steps of intercalating anions of organic small molecules between layered cobalt hydroxide layers through hydrothermal reaction to obtain an intercalated structure precursor, mixing the intercalated structure precursor with powdered sulfur, and then carrying out high-temperature calcination to obtain the cobalt sulfide / carbon composite material with the flower-like structure. The method has the advantages that the method is environment-friendly and nontoxic, the technology is simple and the production cost is low.

Owner:BEIJING UNIV OF CHEM TECH

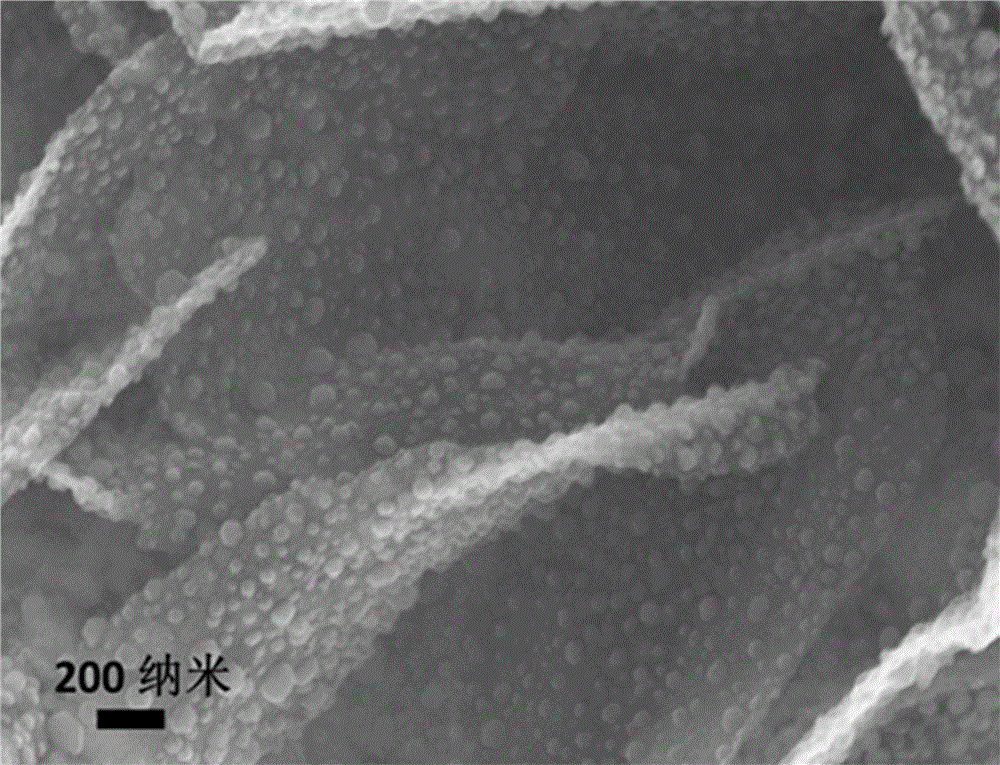

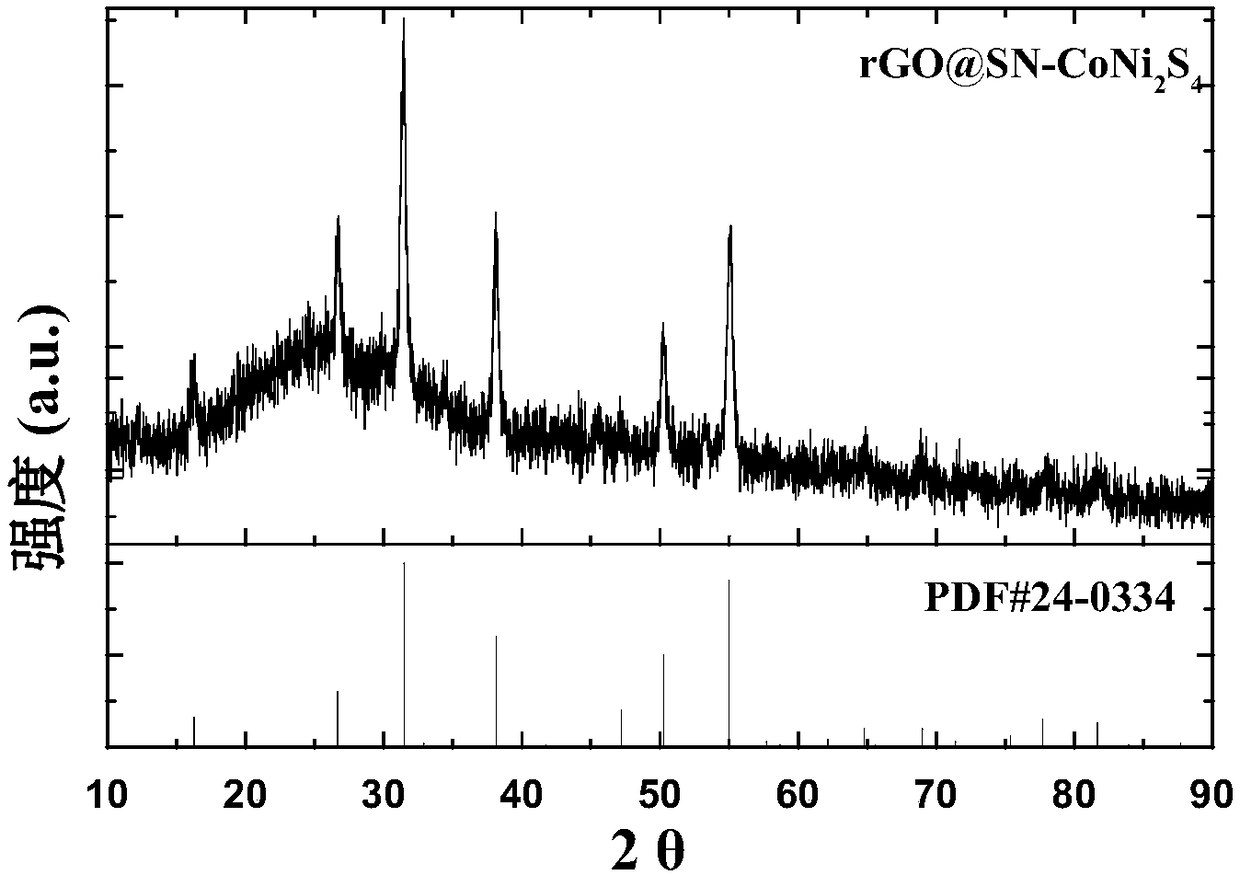

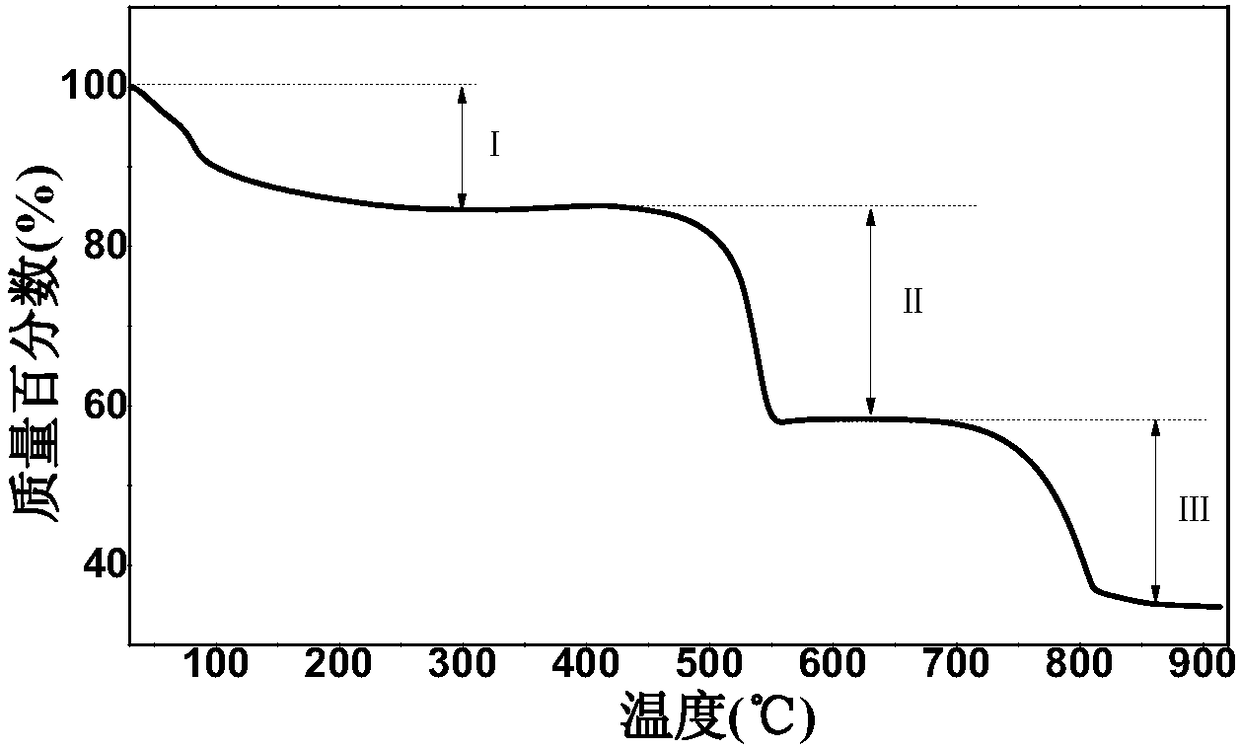

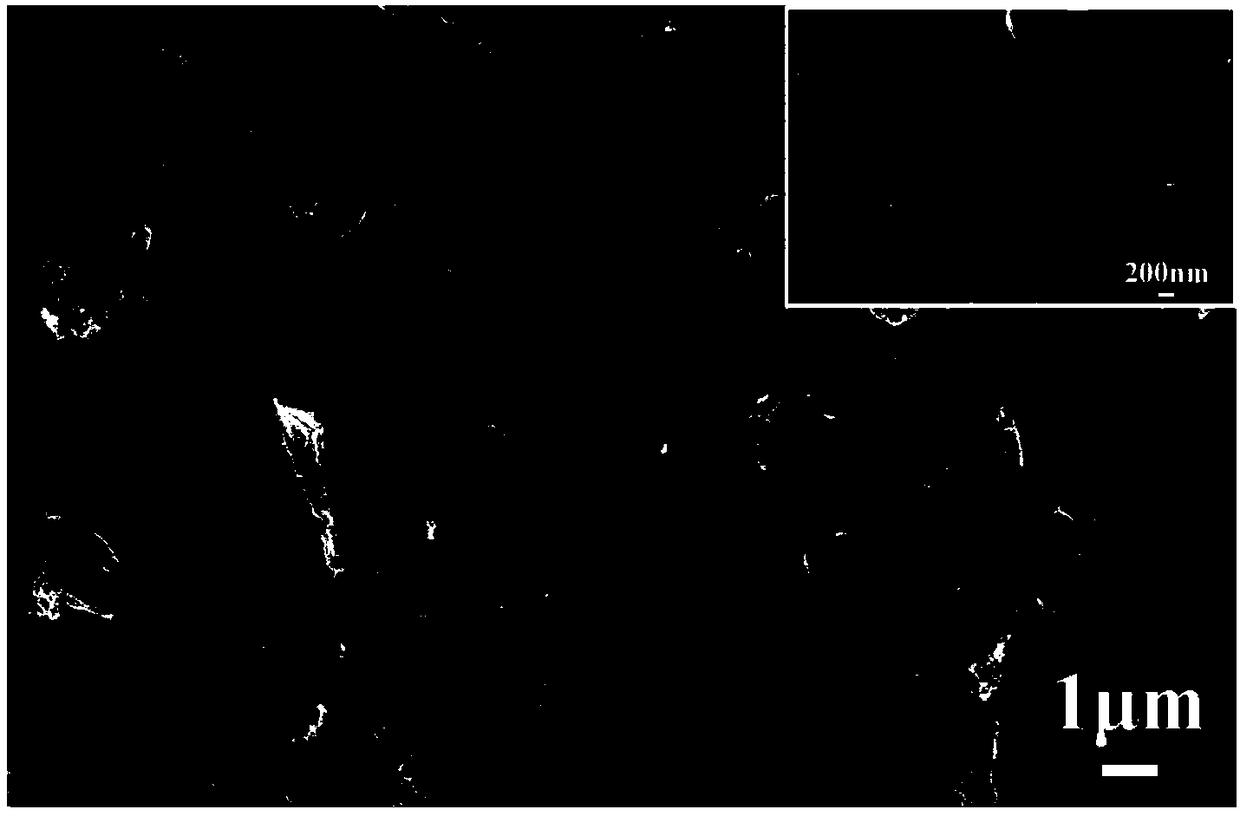

Sulfur and nitrogen codoping graphene loaded vulcanized cobalt and nickel catalytic material and preparation and application

The invention belongs to the field of electrochemical materials, and discloses a sulfur and nitrogen codoping graphene loaded vulcanized cobalt and nickel catalytic material and preparation and application. A metal cobalt source, a nickel source and thiourea are dissolved in a solvent, a mixture is subjected to ultrasonic stirring and mixing, later, ammonium hydroxide is added dropwise, a mixtureis stirred and mixed, then, graphene oxide is added, a mixture is subjected to ultrasonic stirring and mixing and then subjected to hydro-thermal treatment, next, centrifugal washing and freeze dryingare carried out, and a graphene loaded vulcanized cobalt and nickel composite material is obtained; and then, in a nitrogen atmosphere, calcination treatment is carried out, graphene oxide is furtherreduced to obtain the sulfur and nitrogen codoping graphene loaded vulcanized cobalt and nickel catalytic material. The synthetic method is simple, the cost is low, the energy consumption is relatively low, environmental friendliness is achieved, and the obtained product has good electrical conductivity and electrochemical catalysis performance and is suitable for actual application of a water cracked cathode and anode catalytic material.

Owner:SOUTH CHINA UNIV OF TECH

Embedded cobalt sulfide and porous carbon nanorod composite electrode material and preparation method and application thereof

InactiveCN106531999AImproved magnification performanceIncrease profitCell electrodesSecondary cellsPorous carbonHigh pressure

The invention relates to an embedded cobalt sulfide and porous carbon nanorod compound and a preparation method thereof. Cobalt sulfide nanoparticles are embedded in a porous carbon nanorod, the porous carbon nanorod is of a one-dimensional porous rod-like structure, the sizes of the cobalt sulfide nanoparticles are 5 to 10 nm, the length of the porous carbon nanorod is 2 microns, and the diameter of the porous carbon nanorod is 200 nm. The preparation method comprises the following steps: 1) dissolving a cobalt salt soluble in organic solvents into an organic solvent, adding a ligand, and stirring to form a transparent solution; 2) transferring into a high-temperature high-pressure reaction still, heating for reacting, and cooling to obtain a solution containing a cobalt metal organic skeleton compound; 3) carrying out filtering, washing and vacuum drying treatment on the solution in sequence so as to obtain Co-MOF powder; and 4) carrying out grinding and mixing on the powder and sublimed sulfur in a certain proportion, and calcining to obtain a target product. The compound has the advantages that the rate capability of the material is improved, and the compound still can show relatively high specific capacity and good cycle performance under large current density.

Owner:WUHAN UNIV OF TECH

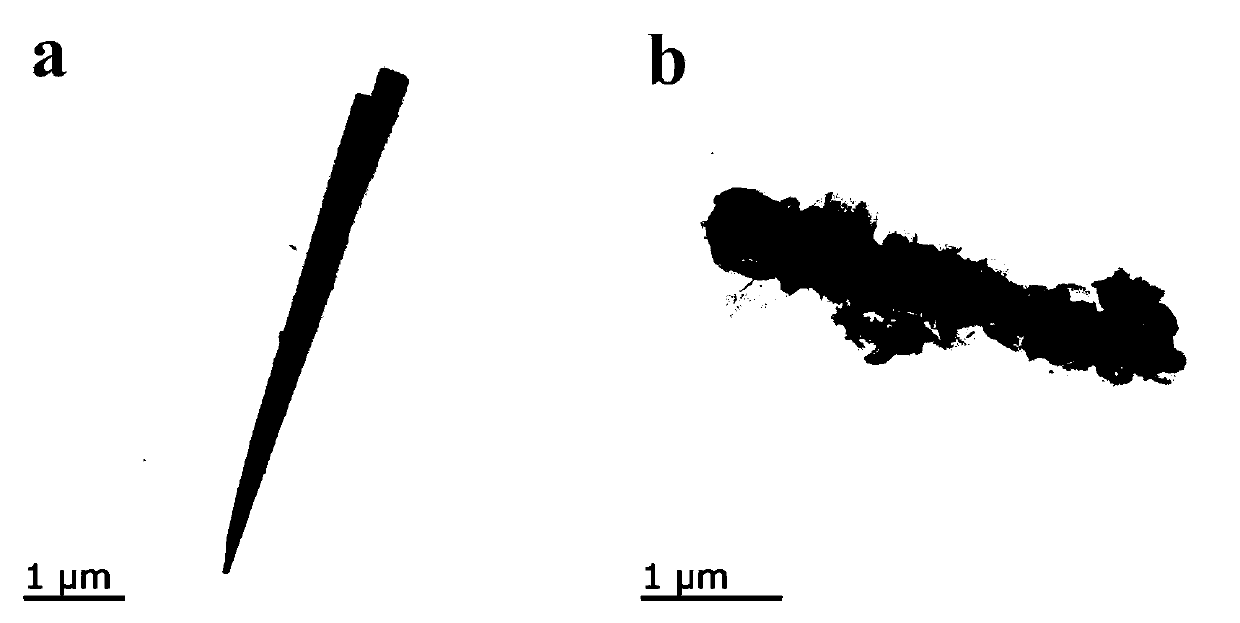

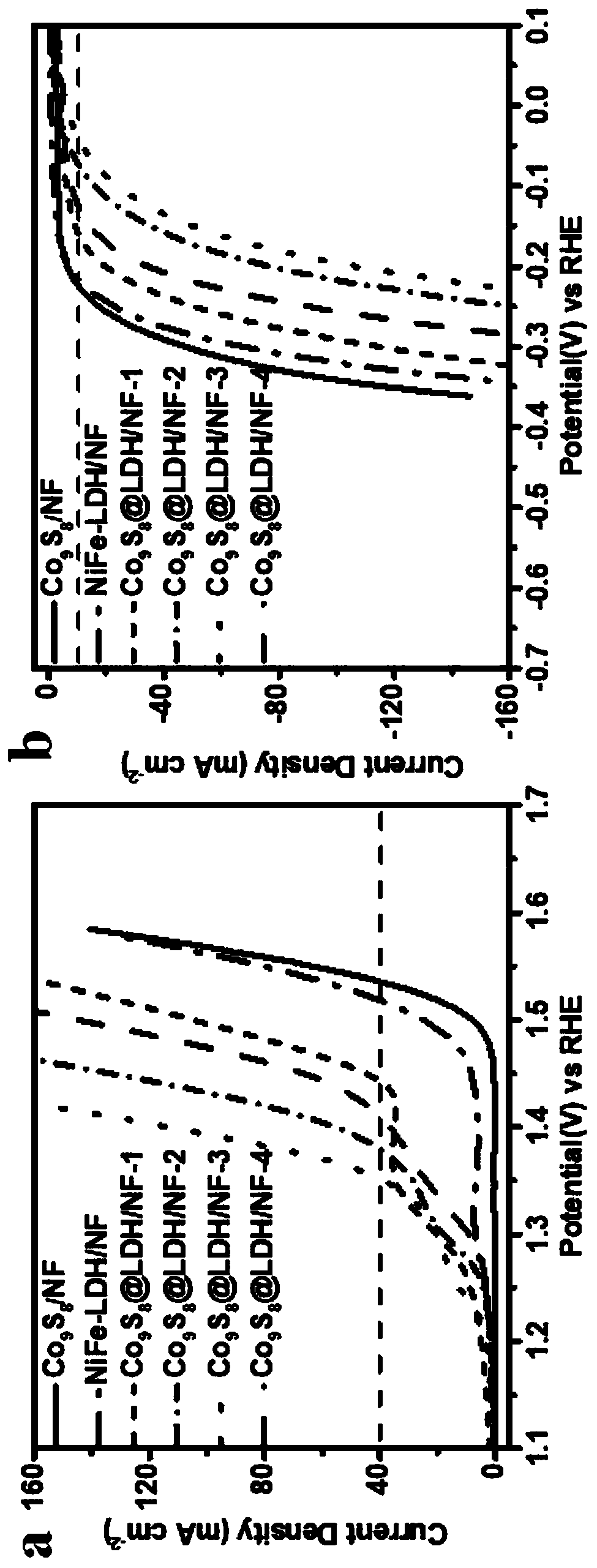

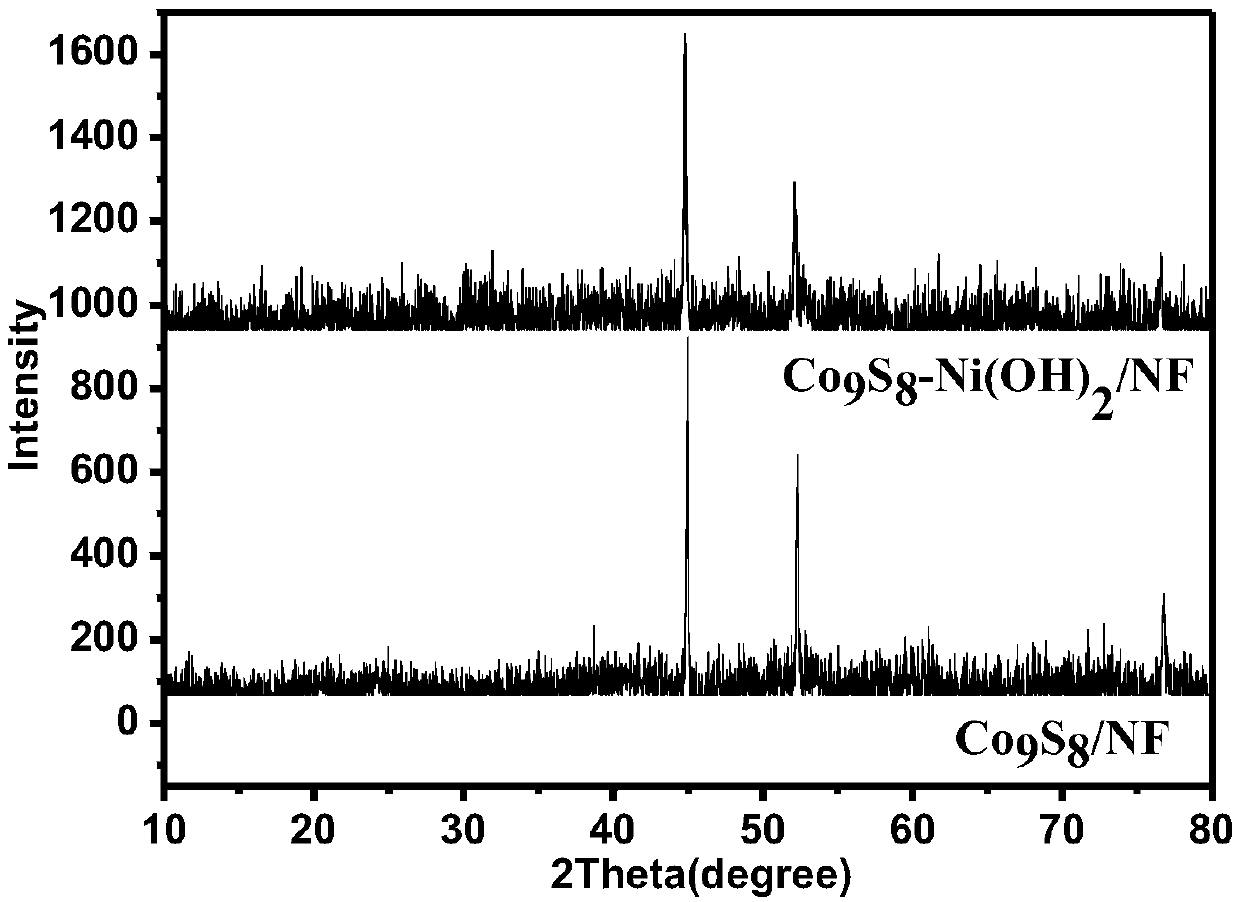

Cobalt sulfide/layered double metal hydroxide composite electrocatalyst and preparation method thereof

InactiveCN110106517AImprove stabilityLarge specific surface areaElectrolytic inorganic material coatingCatalyst activation/preparationOxygen evolutionPrepared Material

The invention relates to a cobalt sulfide / layered double metal hydroxide composite electrocatalyst and a preparation method thereof, and belongs to the technical field of electrocatalysts. Co9S8 / NF with a good stability and a good conductivity is used as a precursor, and nanosheets with a high specific surface area and uniform composition are loaded on the surface of the precursor in a compoundingmanner to prepare the cobalt sulfide / nickel-iron layered double metal hydroxide / foamed nickel composite electrocatalyst. The prepared material can be used for electrocatalytic hydrogen evolution andoxygen evolution, has a good electrocatalytic performance, is of great significance to prepare, develop and apply the cobalt sulfide / layered double metal hydroxide composite electrocatalyst, and hasa broad application prospect in fields of electrocatalytic hydrogen evolution and oxygen evolution.

Owner:JIANGSU UNIV

Preparation method and product of cobalt manganese sulfide electrocatalyst

InactiveCN107855128ARaw materials are cheap and easy to getEasy to preparePhysical/chemical process catalystsElectrodesVulcanizationOxygen

The invention relates to a cobalt manganese sulfide electrocatalyst and a preparation method thereof. The preparation method comprises the following steps that 1, cobalt salt, manganese salt and ureaare weighed, the weighed cobalt salt, manganese salt and urea are dissolved in water, stirring is conducted, and evenly mixed solution is obtained; 2, the solution and carrier are placed into a reactor together to undergo a hydrothermal reaction, and supported cobalt manganese carbonate is obtained; 3, the supported cobalt manganese carbonate is put into aqueous solution containing vulcanizing agent to undergo a vulcanization reaction, and supported cobalt manganese sulfide is obtained. The cobalt manganese sulfide electrocatalyst and the preparation method have the following advantages that the adopted raw materials are cheap and easy to obtain, the preparation method is simple, operation is easy and convenient, and the cost is low; the manganese element is introduced into cobalt, binarycobalt manganese sulfide is prepared, meanwhile carbon paper, carbon cloth, foam nickel, foam copper, titanium mesh or stainless steel mesh are combined and used as substrate, the two-in-one structureof catalyst and electrode is directly formed, testing is convenient, and the catalyst is endowed with excellent electrochemical catalysis hydrogen evolution or oxygen evolution performance by means of the synergistic effect of cobalt manganese sulfide and the substrate.

Owner:JIANGHAN UNIVERSITY

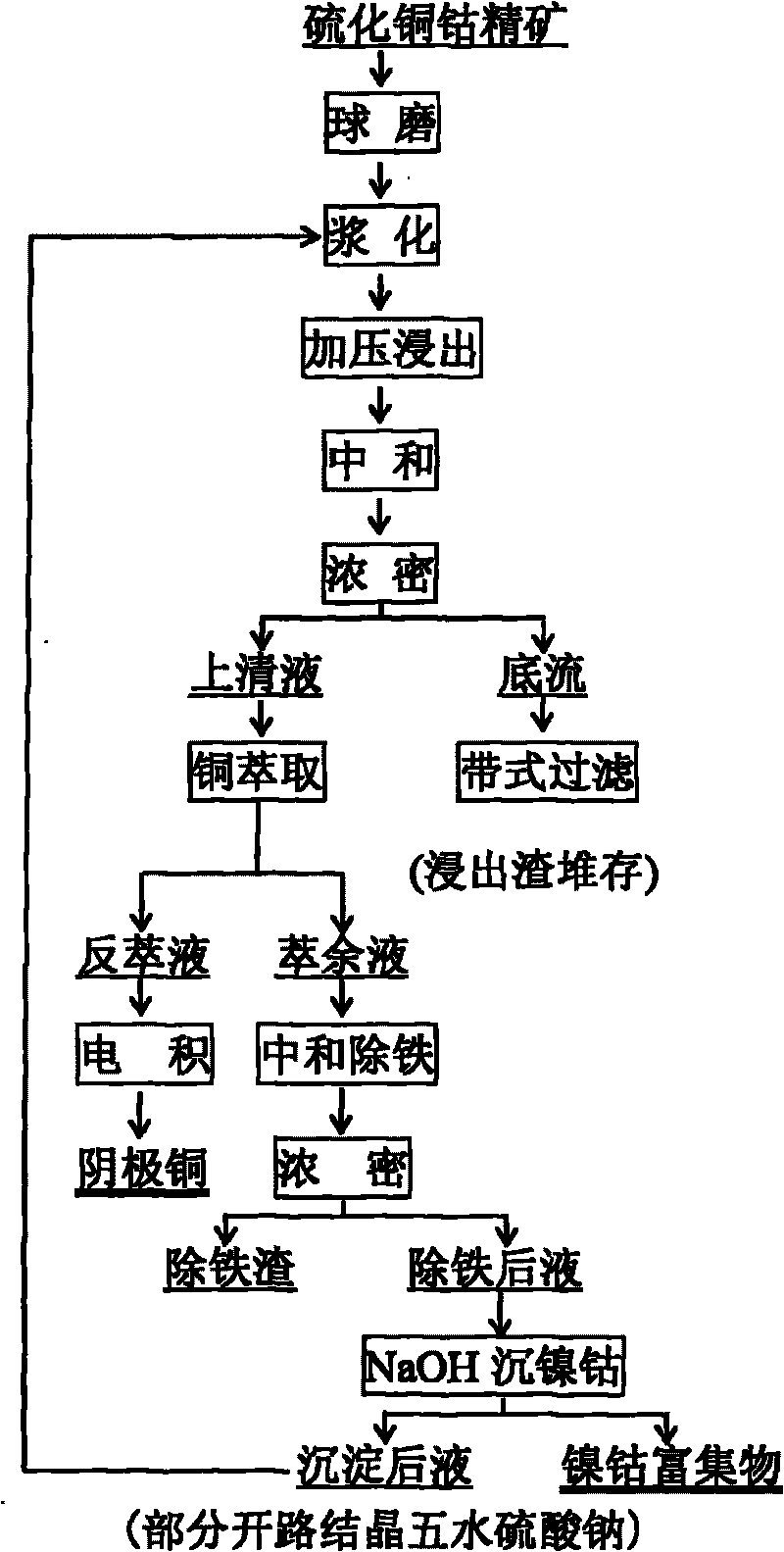

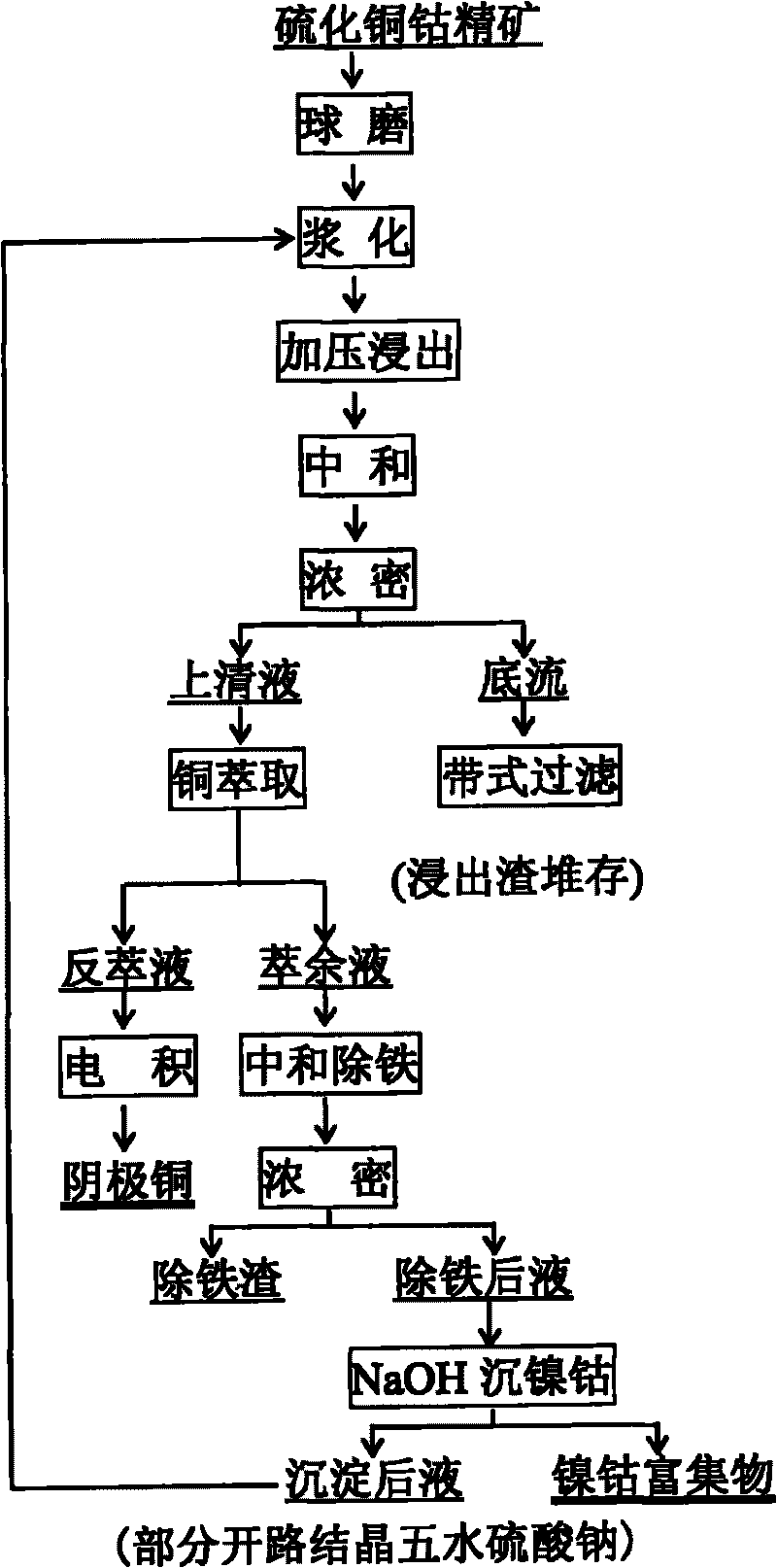

Method for extracting cobalt in copper cobalt sulfide ore

ActiveCN101705371AAchieve recyclingRealize self-heatingPhotography auxillary processesProcess efficiency improvementRaffinateSulfur containing

The invention provides a method for extracting cobalt in a copper cobalt sulfide ore, and relates to a method for extracting the cobalt in a copper cobalt ore which is in low grade and hard to treat and contains cobalt mineral raw materials. The method is characterized by comprising the following steps: (1) crushing and grinding low sulfur containing copper cobalt ore; (2) adding water into the grinded ore material for autoclave leaching; (3) neutralizing and filtering the leached ore pulp, and sending leaching residue into tailing; (4) carrying out copper extraction, extract stripping and strip liquor electrodeposition on the filtered solution to prepare cathode copper; (5) neutralizing copper extracting raffinate to remove iron and aluminum, filter-pressing and separating the neutralized ore pulp, and performing the neutralizing step after the filter-pressed and separated residue is returned to the step (3) for leaching; (6) precipitating cobalt and nickel in filter-pressed and separated solution by adopting sodium hydroxide, wherein the separated precipitate is cobalt nickel hydroxide concentrate; and (7) returning separated after-precipitating solution to the step (2) for the leaching process. The method has simple technical process and less equipment corrosion, and realizes comprehensive reclamation and utilization of valuable metals in the low sulfur containing copper cobalt concentrate.

Owner:BEIJING GENERAL RES INST OF MINING & METALLURGY +1

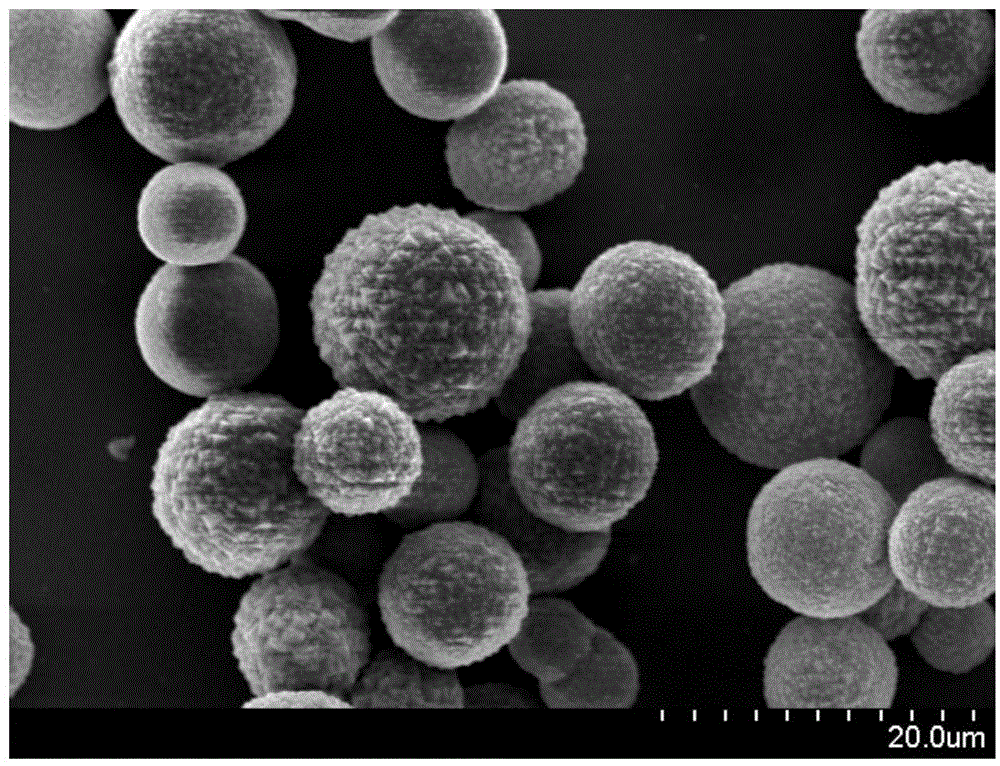

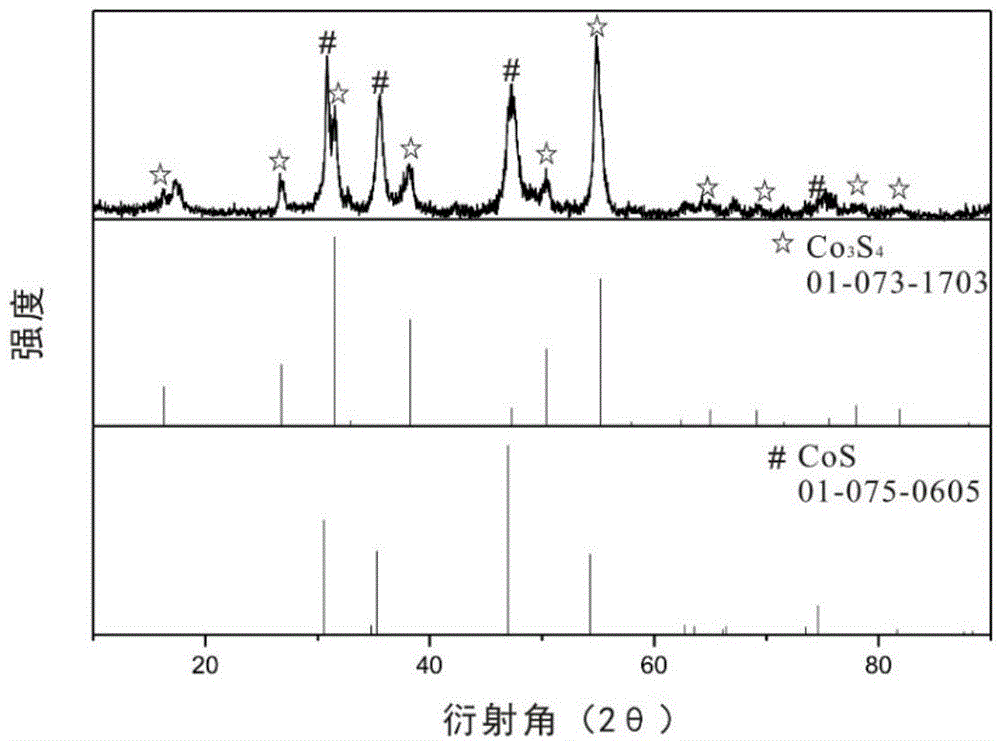

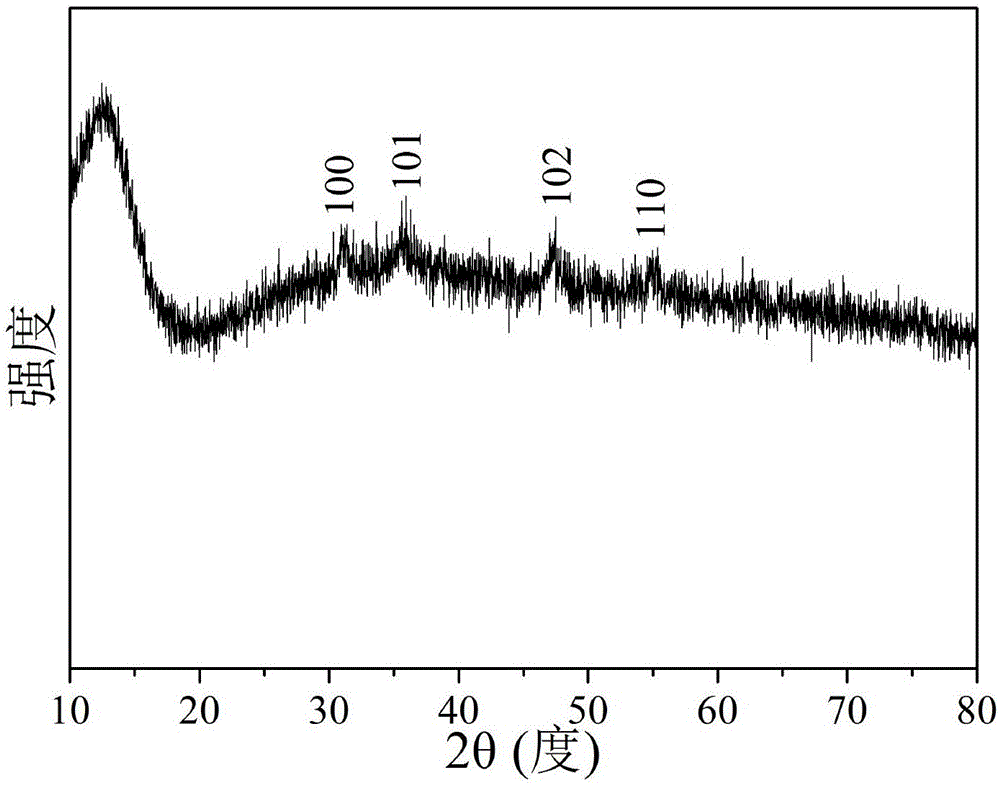

Preparation method and application of cobalt sulfur compound

ActiveCN104993132AWide range of sourcesHigh specific capacityCobalt sulfidesCell electrodesSemiconductor materialsSolar cell

Relating to cobalt sulfur compounds, the invention provides a preparation method and application of a cobalt sulfur compound. The method includes: dissolving a water soluble cobalt source and urea in a mixed solvent to form a solution, carrying out reaction to obtain cobalt carbonate, performing calcinations to obtain a cobalt oxide, and reacting the cobalt oxide with a sulfur source in a reducing atmosphere to obtain a micrometer-scale cobalt sulfur compound. The micrometer-scale cobalt sulfur compound can be spherical cobalt sulfur compound or lamellar square-like cobalt sulfur compound, and the obtained cobalt sulfur compound can be Co9S8, CoS, Co3S4 and CoS2, etc. The cobalt sulfur compound prepared by the preparation method provided by the invention can be applied as an electrode active material in preparation of secondary battery electrodes. According to the invention, specific shape cobalt sulfide can be prepared, is low in synthesis cost and has high tap density, and can be applied to secondary battery electrode materials, optical parametric oscillators, semiconductor materials, solar cells and other aspects.

Owner:XIAMEN UNIV

Nanotube array material with core shell heterostructure of nickel cobalt sulfide@double-metal nickel iron hydroxide and preparation method and application of nanotube array material

ActiveCN108380224AHigh purityGood dispersionPhysical/chemical process catalystsElectrodesElectrolysisCore shell

The invention discloses a nanotube array material with a core shell heterostructure of nickel cobalt sulfide@double-metal nickel iron hydroxide and a preparation method and application of the nanotubearray material. The nanotube array material is formed by coating the exterior of a nickel-cobalt sulfide nanotube skeleton with a double-metal nickel iron hydroxide nano-film material. The nanotube array material with the core shell heterostructure of nickel cobalt sulfide@double-metal nickel iron hydroxide grows on foamed nickel, and can be directly used as an electrode material for water electrolysis, not only long-term stability but also a large specific surface area is achieved, so that a larger active area is provided, and fast and efficient electrolysis of water is achieved.

Owner:ANHUI NORMAL UNIV

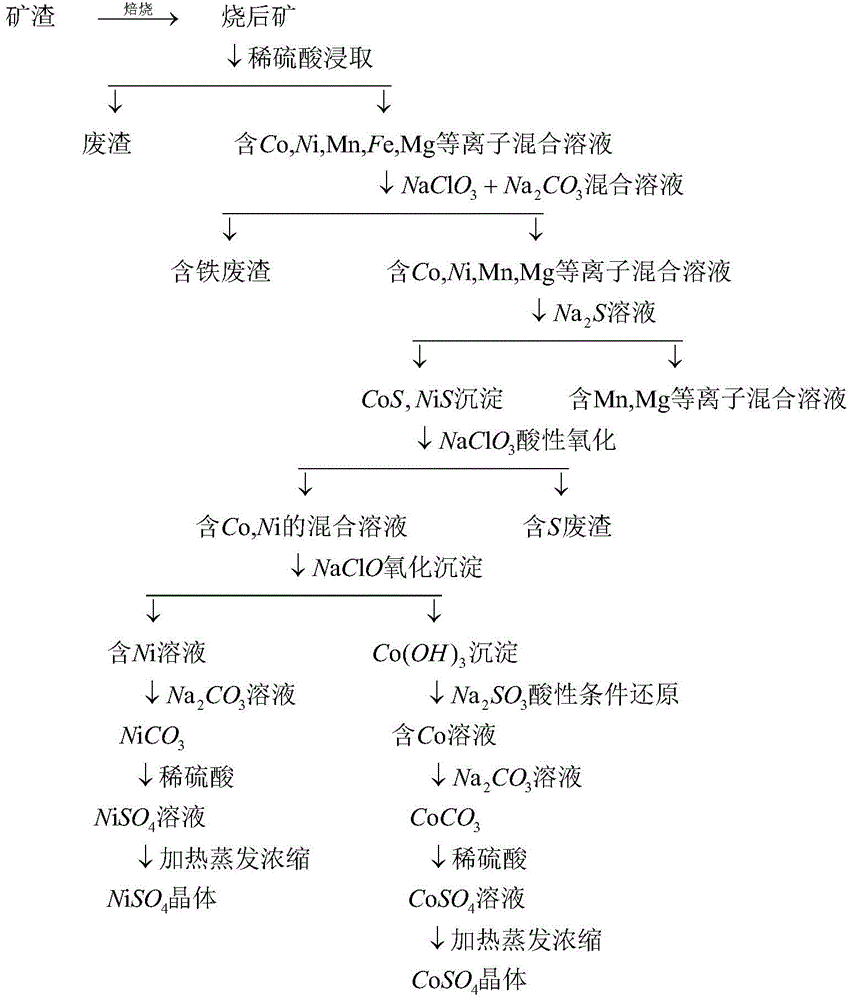

Process method for extracting cobalt and nickel from manganese waste slag

The invention discloses a process method for extracting cobalt and nickel from manganese waste slag, belonging to the field of comprehensive utilization of resources. The process method comprises the steps of carrying out oxidizing roasting and acid leaching, removing iron by virtue of oxidation hydrolysis, separating cobalt, nickel and manganese by virtue of precipitation, carrying out oxidizing and acid dissolving on cobalt sulfide and nickel sulfide, and separating cobalt and nickel by virtue of oxidizing hydrolysis. According to the method, the problem of high energy consumption, high pollution and high cost in traditional complex cobalt and nickel extraction industries are solved; the method is applicable to industries for extracting cobalt and nickel from mineral slag, and metals such as cobalt and nickel can be directly separated from the manganese waste slag by virtue of a simple process having the characteristics of high efficiency, low pollution, low cost and short period. According to the process method iron is removed by virtue of an oxidizing hydrolysis method, so that the iron removal efficiency is high, the loss ratio of valuable components is low, the operability is strong, and the cost is low.

Owner:UNIV OF SCI & TECH BEIJING

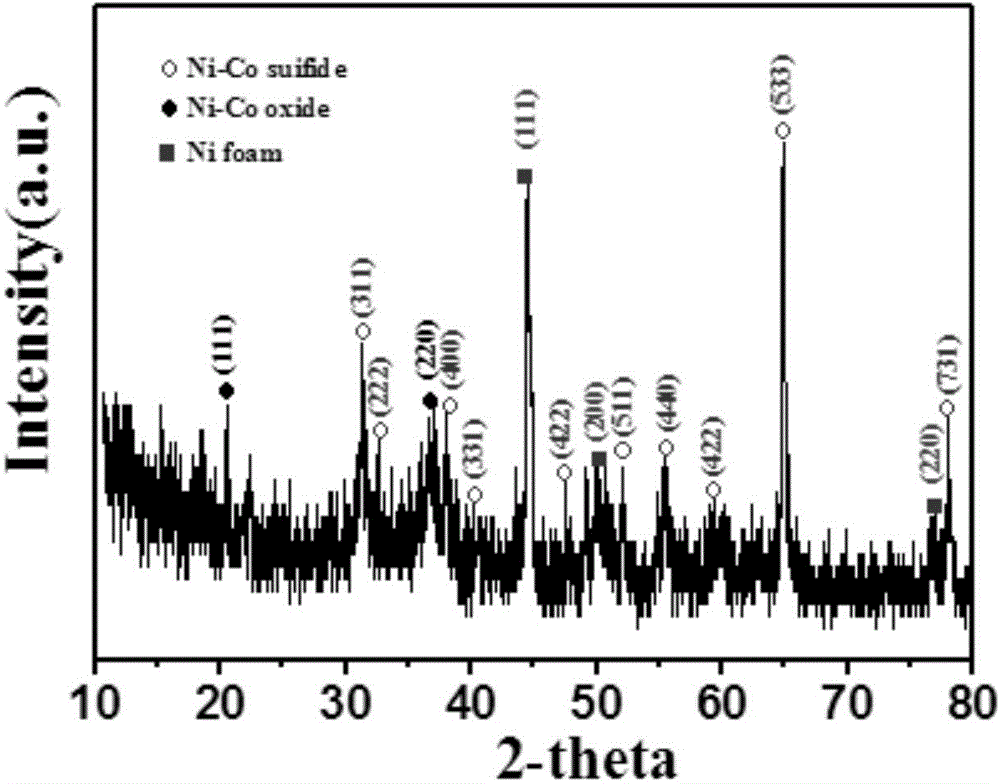

Wire-shaped nickel cobalt oxide@nickel cobalt sulfide hetero-structure composite, and preparation method and purpose thereof

InactiveCN104795245AHigh purityGood dispersionHybrid capacitor electrodesHybrid/EDL manufactureCapacitanceDispersity

The invention relates to a wire-shaped nickel cobalt oxide@nickel cobalt sulfide hetero-structure composite, and a preparation method and purpose thereof. The wire-shaped nickel cobalt oxide@nickel cobalt sulfide hetero-structure composite has the advantages that the composite uses nickel cobalt oxide nanowires as a framework, and an anion exchange method is used to convert the nickel cobalt oxide nanowires into the nickel cobalt oxide@nickel cobalt sulfide nanowires which are large in surface area and good in conductivity and flexibility through sulfur ion etching; the preparation of the nanowires uses a hydrothermal method and an in-situ growth method, the nanowires which structurally vertically grow are neat in arrangement and has a regular three-dimensional hetero-structure; compared with the prior art, the composite prepared by the method is high in purity, good in dispersity, good crystal form, controllable, low in production cost and good in reproducibility; the prepared composite grows on foam nickel and can be directly used as the electrode material of super capacitors, and long circulation stability, large specific capacitance, high energy density and power density and high commercial value are achieved.

Owner:ANHUI NORMAL UNIV

Recovery of nickel, cobalt, iron, silica, zinc and copper from laterite ore by sulfuric acid leaching

ActiveUS7387767B2Efficient separation and recoveryHigh purityCobalt sulfidesSolvent extractionFree solutionSlurry

A process for recovering nickel and cobalt values from nickel- and cobalt-containing laterite ores as an enriched mixed nickel and cobalt sulphide intermediate and for producing nickel and cobalt metal from the nickel and cobalt sulphide intermediate. The laterite ore is leached as a slurry in a pressure acid leach containing an excess of aqueous sulphuric acid at high pressure and temperature, excess free acid in the leach slurry is partially neutralized to a range of 5 to 10 g / L residual free H2SO4 and washed to yield a nickel- and cobalt-containing product liquor, the product liquor is subjected to a reductant to reduce any Cr(VI) in solution to Cr(III), the reduced product liquor is neutralized to precipitate ferric iron and silicon at a pH of about 3.5 to 4.0, and the neutralized and reduced product liquor is contacted with hydrogen sulphide gas to precipitate nickel and cobalt sulphides. The precipitated nickel and cobalt sulphides can be leached in a water slurry in a pressure oxidation leach, the leach solution subjected to iron hydrolysis and precipitation, the iron-free solution contacted with zinc sulphide to precipitate copper, the iron- and copper-free solution subjected to zinc and cobalt extraction by solvent extraction to produce a nickel raffinate, the nickel raffinate contacted with hydrogen gas to produce nickel powder and the cobalt strip solution from the solvent extraction step contacted with hydrogen gas to produce cobalt powder.

Owner:SHERRITT INC

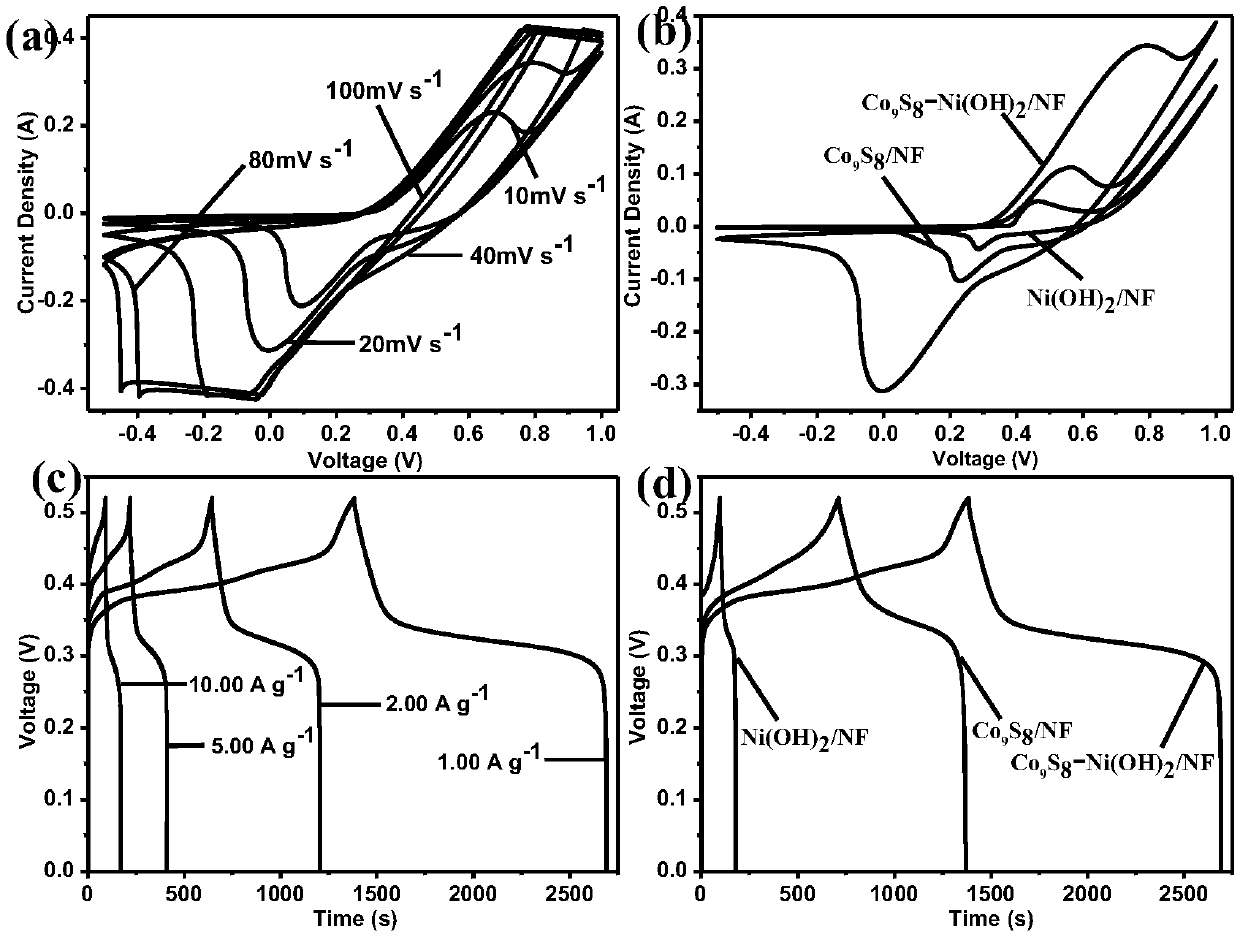

Supercapacitor electrode material and preparation method thereof

InactiveCN108682561AImprove cycle performanceImprove Capacitive PerformanceHybrid capacitor electrodesHybrid/EDL manufactureCapacitanceEconomic shortage

The invention belongs to the technical field of super capacitor material preparation and relates to a cobalt sulfide / nickel hydroxide / foam nickel super capacitor electrode material and a preparation method thereof. Cobalt sulfide is grown on foamed nickel, and nickel hydroxide is electrochemically deposited on the surface of the cobalt sulfide to form a composite material of cobalt sulfide / nickelhydroxide / foam nickel. According to the super capacitor electrode material and the preparation method, a transition metal hydroxide is loaded on a surface of the cobalt sulfide with a high specific surface area and good electrical conductivity through a composite mode, and the cobalt sulfide / nickel hydroxide / foam nickel composite material is prepared. Through the synergistic effect between components of the composite material, the components promote virtues and avoid shortages, and at the same time, combined with a high cycle life, high power density and high stability of a double-electric-layer capacitor and a high specific capacitance of a pseudo capacitor, the overall performance of the super capacitor is improved.

Owner:JIANGSU UNIV

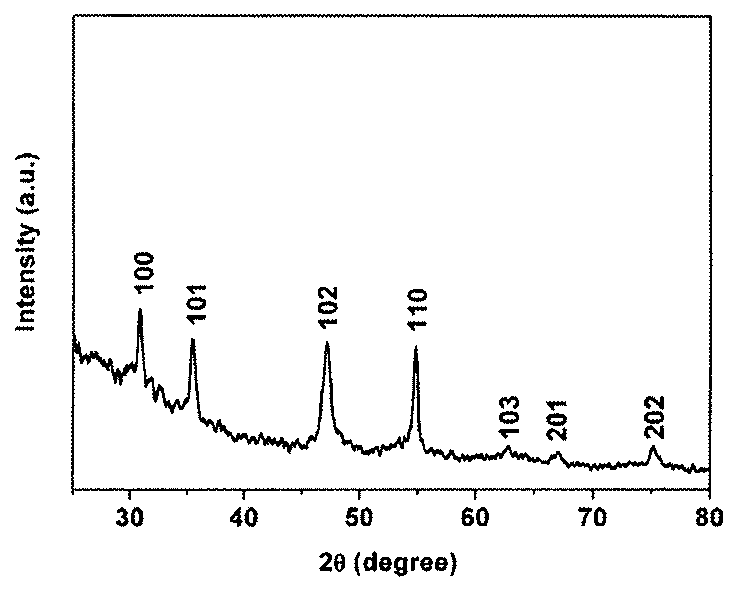

Preparation method of cobalt sulfide micro tube with hiberarchy structure

InactiveCN101746837ALarge specific surface areaHigh specific capacitanceSemi-permeable membranesFixed microstructural devicesEthylenediamineSynthesis methods

The invention belongs to an inorganic chemical synthesis method and in particular relates to a preparation method of a cobalt sulfide micro tube with hiberarchy structure; in the invention, water-soluble cobalt salt is used as a metal source, thioacetamide is used as a sulphur source, ethanediamine is used as metal chelating agent, and cetyl trimethylammonium bromide CTAB is used as a template agent, in a closed reactor, hydro-thermal reaction is carried out under a certain temperature condition, so as to synthesize the micron tube-like cobalt sulfide with the hiberarchy structure, the outer diameter of the tube is about 1.5micron, the thickness of the tube wall is about 400nm, the average length is about 15micron, the tube wall is a nanoscale hexagonal sheet, and the length and the thickness of the sheet are 90nm and 22nm respectively; the synthesis method has the advantages of cheap and easy-obtaining raw material, simple equipment, low reaction temperature and good process repeatability and overcomes the problem of environment pollution caused by organic solvent in the previous synthesis method; the obtained product has wide application prospect in the field of biology, catalysis and material science and the like.

Owner:NORTHEAST NORMAL UNIVERSITY

Preparation method of cobalt sulfide/graphene nanocomposite material, negative electrode of lithium-ion battery and lithium-ion battery

ActiveCN106207172AEvenly distributedImprove performanceMaterial nanotechnologyCell electrodesGraphene nanocompositesNanoparticle

The invention discloses a preparation method of a cobalt sulfide / graphene nanocomposite material, a negative electrode of a lithium-ion battery and the lithium-ion battery. The preparation method comprises a hydrothermal process and a composition process. According to the preparation method, cobalt sulfide carries out composite in-situ growth on the surface of three-dimensional reduced graphene oxide, so that the material is unique in shape and form, and has very large specific surface area; and falling between the cobalt sulfide and graphene is effectively prevented in the lithiation process. Above all, the problem of aggregation of graphene and cobalt sulfide nanoparticles is solved to a great extent; and the disadvantages that a negative electrode material is relatively poor in stability, relatively poor in conductivity and the like are well overcome, so that the target of improving the performance of the lithium battery is achieved.

Owner:ANHUI NORMAL UNIV

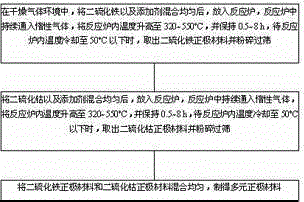

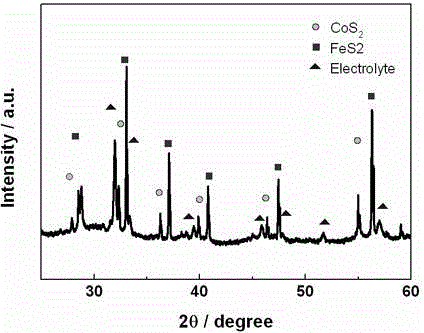

Preparation method of thermal battery positive electrode material, and thermal battery made of thermal battery positive electrode material

InactiveCN106207085ALower internal resistanceIncrease working voltagePrimary cell electrodesThermal BatteryIron disulfide

The invention discloses a preparation method of a thermal battery positive electrode material. The preparation method comprises the following steps: 1, mixing iron disulfide with additives in dry gas environment until the iron disulfide and the additives are uniform, putting the obtained mixture in a reaction furnace, continuously introducing an inert gas to the reaction furnace, rising the temperature in the reaction furnace to 320-550 DEG C, keeping the temperature for 0.5-8 h, taking out the obtained iron disulfide positive electrode material when the temperature in the reaction furnace decreases to 50 DEG C or below, crushing the iron disulfide positive electrode material, and sieving the crushed iron disulfide positive electrode material; 2, mixing cobalt sulfide with the additives until the cobalt sulfide and the additives are uniform, putting the obtained mixture in the reaction furnace, continuously introducing an inert gas to the reaction furnace, rising the temperature in the reaction furnace to 320-550 DEG C, keeping the temperature for 0.5-8 h, taking out the obtained iron disulfide positive electrode material when the temperature in the reaction furnace decreases to 50 DEG C or below, crushing the cobalt disulfide positive electrode material, and sieving the crushed cobalt disulfide positive electrode material; and 3, mixing the iron disulfide positive electrode material with the cobalt disulfide positive electrode material until the iron disulfide positive electrode material and the cobalt disulfide positive electrode material are uniform in order to prepare the polynary positive electrode material. The invention also discloses a thermal battery made of the positive electrode material.

Owner:SHANGHAI INST OF SPACE POWER SOURCES

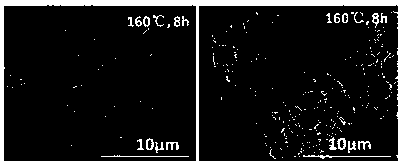

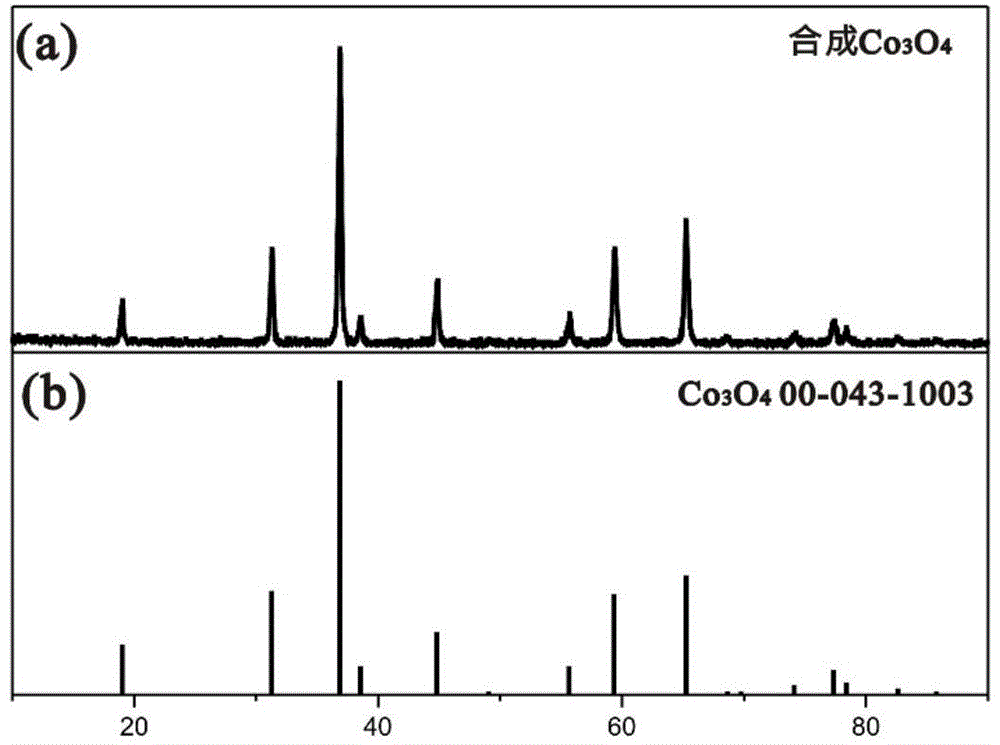

Cobalt sulfide preparation method

InactiveCN103214041ALarge specific surface areaGood capacitance characteristicsCobalt compoundsCapacitanceYarn

The invention discloses a cobalt sulfide preparation method comprising the steps that: 1.72mmol of cobalt nitrate and 1.31mmol of thiourea are dissolved in a solvent; the solution is sealed in a 25mL stainless steel autoclave with a liner of polytetrafluoroethylene; a reaction is carried out for 24h under a temperature of 160 DEG C; a precipitate is fetched, and is washed twice respectively by using deionized water and anhydrous ethanol; and the product is dried for 24h under a temperature of 60 DEG C, such that cobalt sulfide with a hollow structure is obtained. The cobalt sulfide provided by the invention has yarn-ball-shaped, cabbage-shaped, and snowflake-shaped hollow structures, such that the cobalt sulfide has excellent capacitance characteristics and good charge-discharge performance. A maximal capacitor value under a current density of 5mAcm<-2> is 389FG<-1>, and a capacitor value under a current density of 50mAcm<-2> is 277FG<-1>. The cobalt sulfide can be widely applied in super capacitor materials and electrode materials.

Owner:ZHEJIANG SCI-TECH UNIV

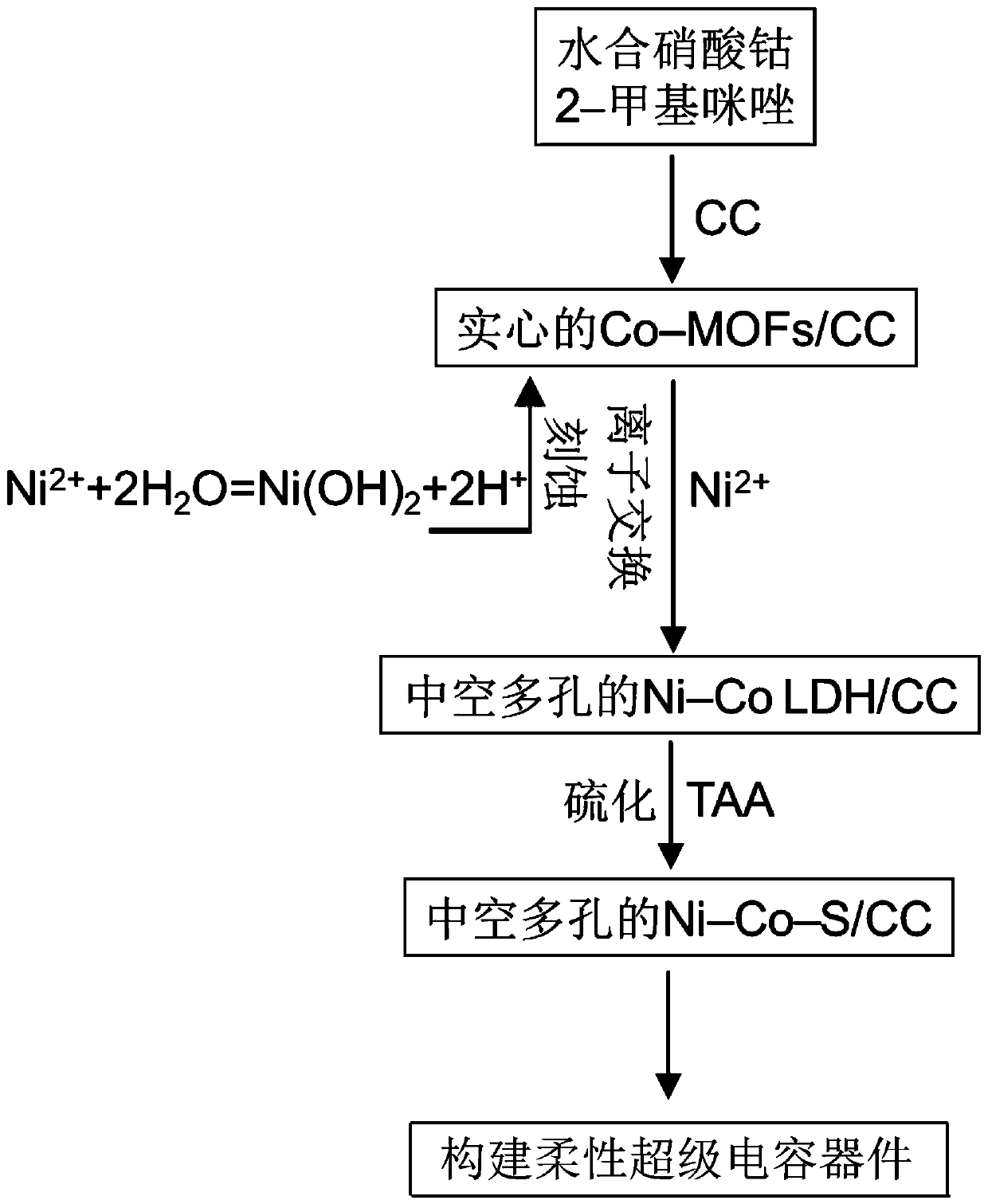

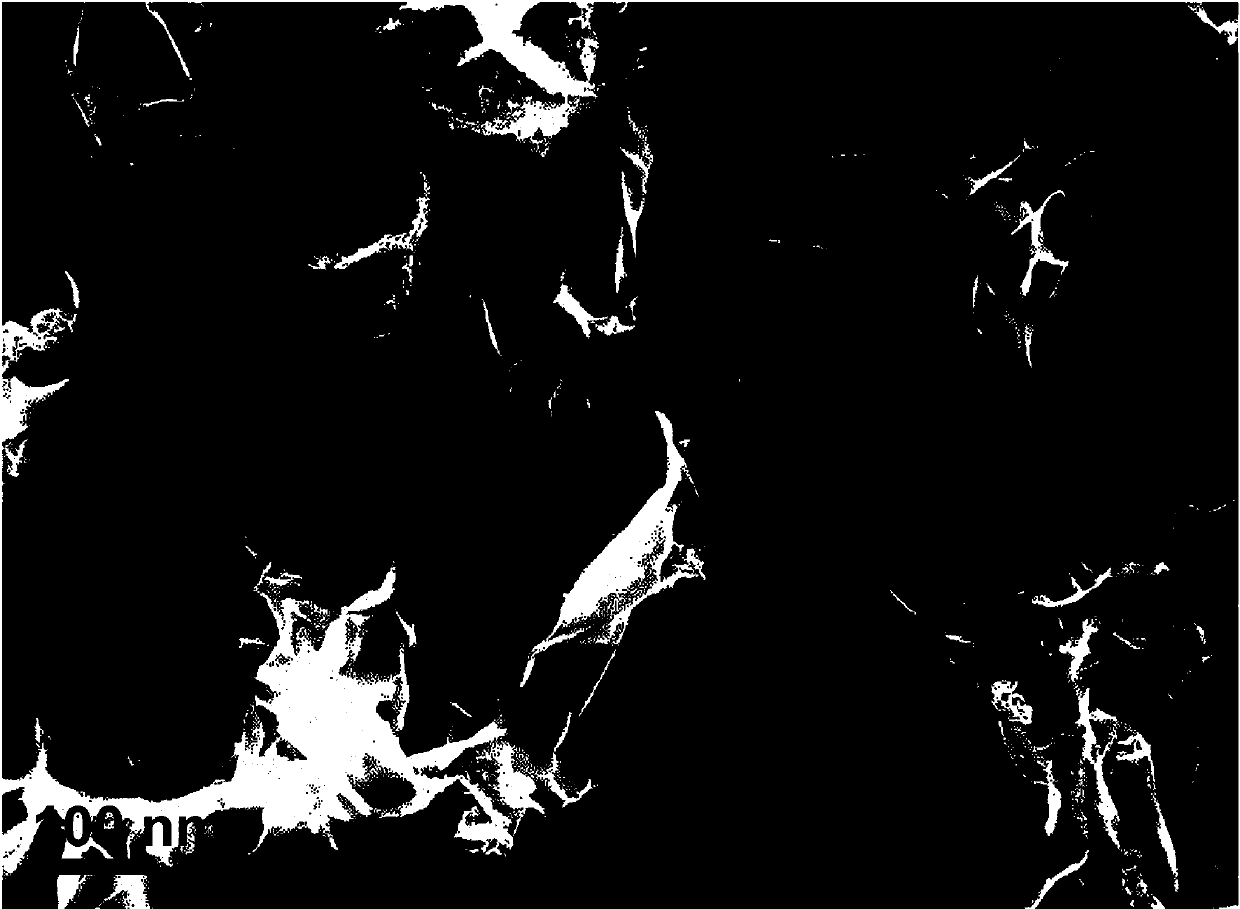

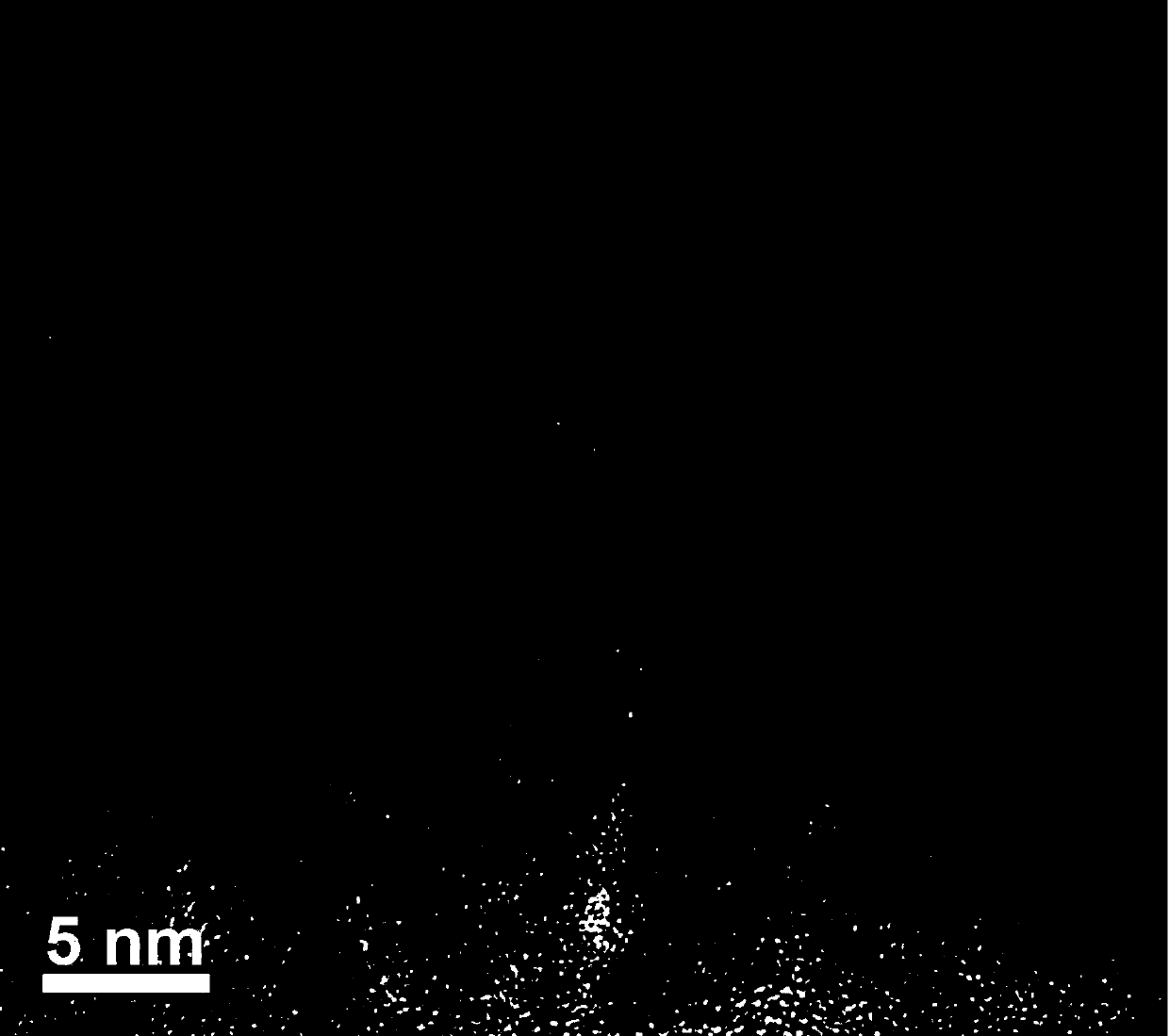

Method for preparing hydrolysis-regulated nickel cobalt sulfide/carbon cloth porous supercapacitor electrode material

InactiveCN110136980AStay porousPrevent collapseHybrid capacitor electrodesHybrid/EDL manufactureCapacitanceEtching

The invention provides a method for preparing a hydrolysis-regulated nickel cobalt sulfide / carbon cloth porous supercapacitor electrode material. The method comprises the preparation of a cobalt-basedmetal organic frame / carbon cloth composite material, the preparation of a porous nickel-cobalt layered double-metal hydroxide / carbon cloth composite material and the preparation of a porous nickel cobalt sulfide / carbon cloth composite material. According to the invention, in the preparation process of the porous nickel-cobalt layered double-metal hydroxide / carbon cloth composite material, holes are generated through the ion exchange of a cobalt-based metal organic frame material Co-MOFs and a nickel nitrate solution and the etching of Co-MOFs by a Ni2+ hydrolysis effect, the nickel-cobalt layered double-metal hydroxide with a hollow porous structure grown on carbon cloth is synthesized, on the basis of maintaining the shape of a MOFs parent body, a hollow porous morphology structure of abinary metal sulfide with multiple valence states, large specific surface area and high electroactivity based on the carbon cloth is prepared, and the capacitance property, rate performance and electrochemical cycle life of the composite material as an electrode are improved.

Owner:NANYANG INST OF TECH

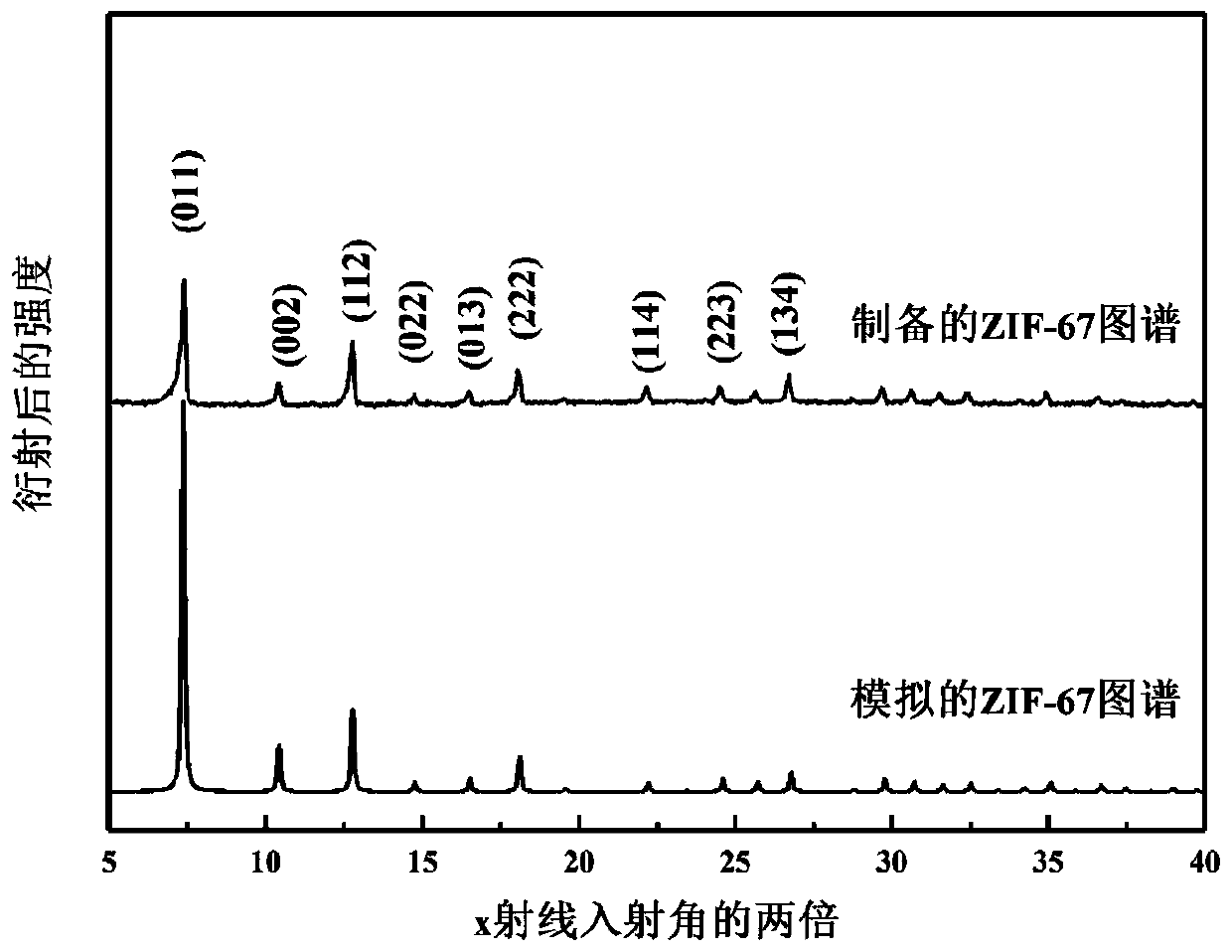

Cobalt sulfide-based composite material as well as preparation method and application thereof

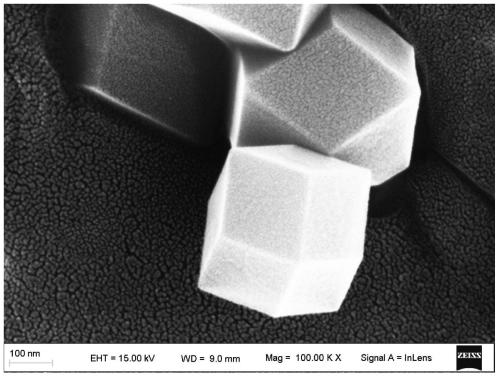

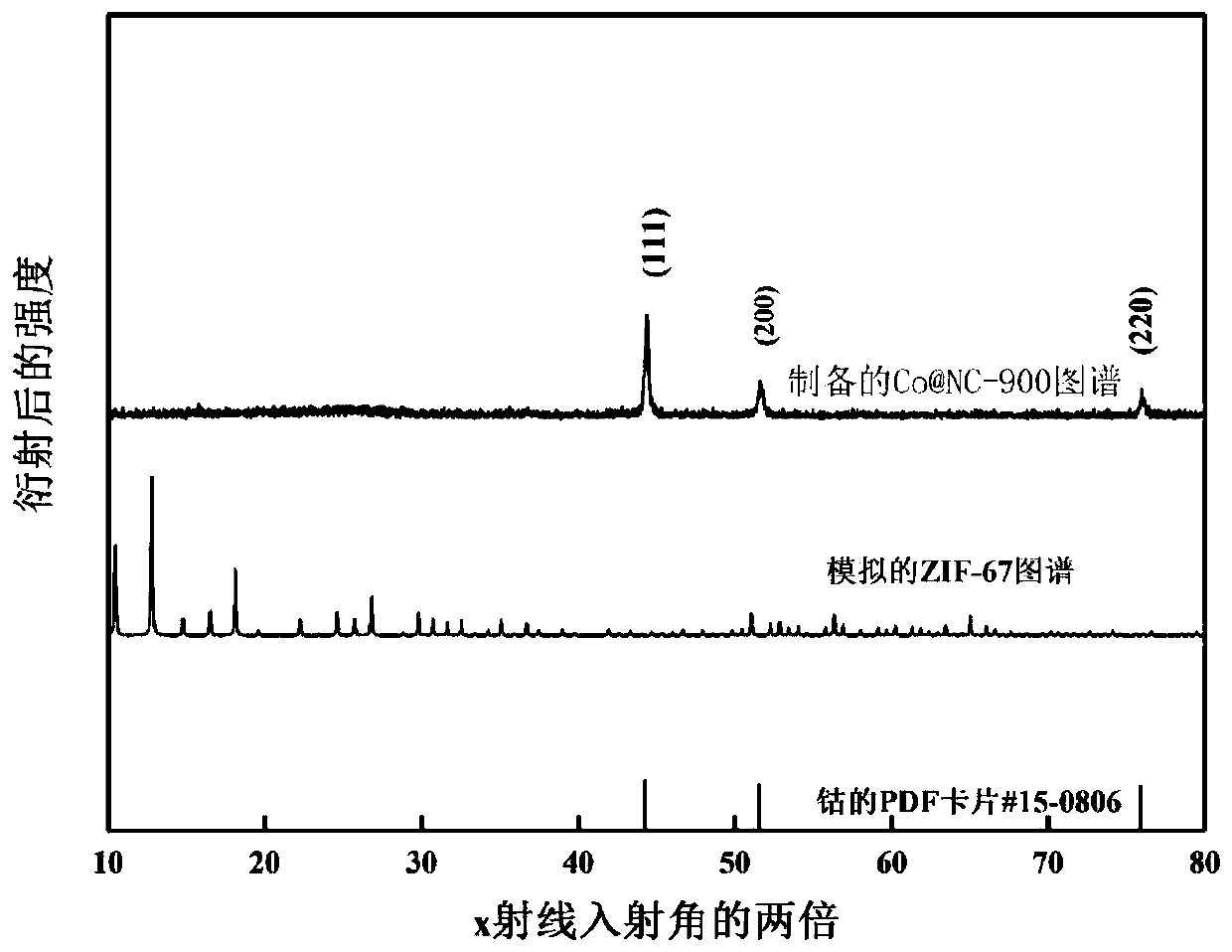

ActiveCN111370707AUniform particle sizeGood lookingMaterial nanotechnologyCobalt sulfidesElectrical batteryLithium–air battery

The invention provides a cobalt sulfide-based composite material as well as a preparation method and application thereof. The cobalt sulfide-based composite material is CoS2NC, the preparation methodof the cobalt sulfide-based composite material comprises the following steps: (1) synthesizing a ZIF-67 precursor by using a precipitation method; (2) transferring the ZIF-67 precursor into a tubularfurnace, and calcining the ZIF-67 precursor in an inert gas environment to obtain a nitrogen-doped carbon-coated cobalt-based nano material CoNC; and (3) taking the nitrogen-doped carbon-coated cobalt-based nano material CoNC as a Co source, taking sulfur powder as a sulfur source, fully mixing the Co source and the sulfur source, and carrying out secondary calcination under the protection of inert gas to obtain the cobalt sulfide-based composite material. The cobalt sulfide-based composite material prepared by the method is good in electrochemical performance, high in specific surface area and good in crystallinity; when applied to the lithium-air battery, the material has high specific capacity and cycle performance, and the preparation method is simple and suitable for large-scale production.

Owner:东北大学秦皇岛分校

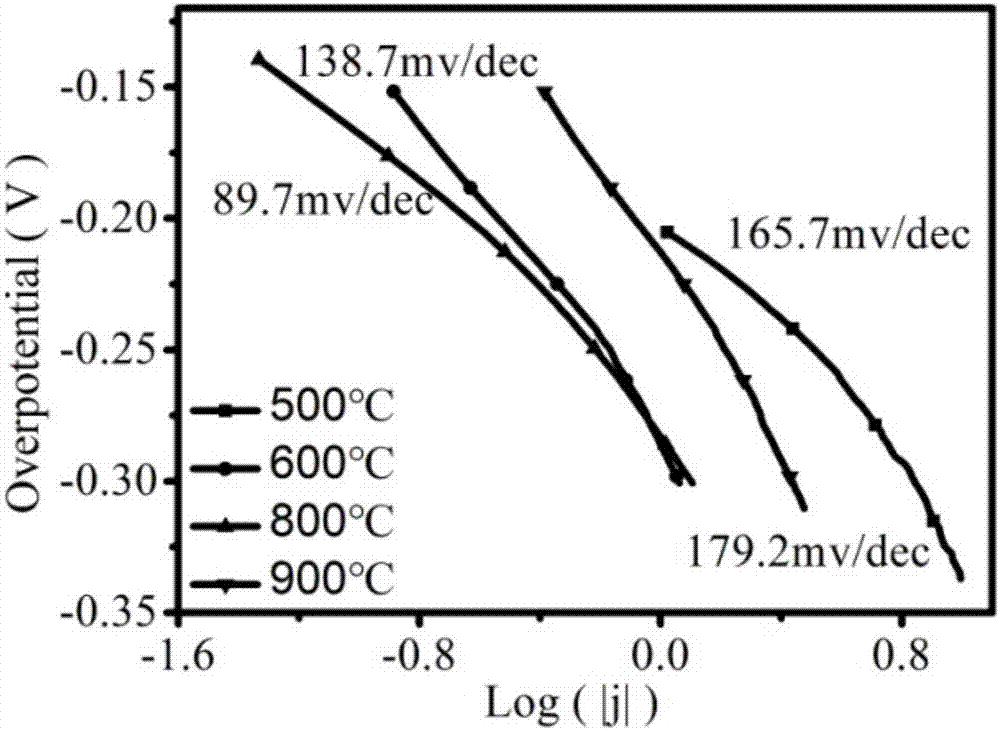

Preparation method of hollow cobalt sulfide microsphere catalyst

The invention discloses a preparation method of a hollow cobalt sulfide microsphere catalyst. The method comprises the following steps: dissolving a cobalt source and a sulfur source into a solvent and adding a certain amount of ethylene diamine; sealing the solution into a stainless steel high-pressure reactor with the volume of 70mL, which has a polytetrafluoroethylene lining; cooling the solution to room temperature after reaction and taking out precipitate; washing and drying to obtain a cobalt sulfide material. The method disclosed by the invention has the advantages of simplicity, controllability, short reaction time, low cost and easiness in mass production. The prepared cobalt sulfide material has a hollow microsphere structure consisting of nanometer acicular crystals, and has theadvantages of higher specific surface area, higher porosity and good electrochemical hydrogen production performance. Under the condition of strong base, the cobalt sulfide material still has lower catalytic starting point potential of 27.9mV (when the electric current density is 1mA cm<-2>); electric potential is only 89.7mV when the current density is 10mA cm<-2>; the preparation method has a good prospect of wide application in producing hydrogen by using brine electrolysis under the alkaline conditions.

Owner:FUZHOU UNIV

Nickel cobaltate/nickel cobalt sulfide nanocomposite of rodlike core-shell structure, preparation method and application

InactiveCN106898503AIncrease surface areaImprove conductivityMaterial nanotechnologyHybrid capacitor electrodesElectrochemistryCore shell

The invention provides a nickel cobaltate / nickel cobalt sulfide nanocomposite of a rodlike core-shell structure, a preparation method and application. Compared with the prior art, a gaseous phase hydrothermal method is utilized, in the prepared core-shell structure nanocomposite, the core is a NiCo2O4 nanorod, and the shell is NiCo2S4 nanosheets; and the NiCo2S4 nanosheets grow outside as the shell, have a relatively large superficial area, has excellent conductivity and an abundant oxidoreduction characteristic, and thus can provide excellent electrochemical performance. The NiCo2O4 nanorod serves as the core, apart from being capable of participating electrochemical energy storage, can also effectively provide support for the NiCo2S4 nanosheets, and prevent nanosheets from being superimposed together and influencing full play of the electrochemical performance. In addition, the preparation method is simple to operate, does not need special equipment, and thus is easy to popularize.

Owner:ANHUI NORMAL UNIV

Process for purifying cobalt by electro-depositing cobalt chloride solution through cyclone electrolysis technology and reclaiming residual chlorine

ActiveCN102808194AHigh purityAvoid emissionsElectrolysis componentsPhotography auxillary processesManganeseWater chlorination

The invention discloses a process for purifying cobalt by electro-depositing a cobalt chloride solution through a cyclone electrolysis technology and reclaiming residual chlorine, and belongs to the technical field of hydrometallurgical electro-deposition of nonferrous metals. The process comprises the following steps of: dissolving a cobalt-containing material into acid to remove iron, extracting and purifying with P204 to remove impurities such as copper, zinc and manganese, performing secondary purification, extracting with P507 to separate cobalt and nickel, performing back extraction to obtain the cobalt chloride solution, performing cyclone electro-deposition to obtain high-purity electro-deposited cobalt, delivering the produced residual chlorine to a reclaiming system, burning to form hydrochloric acid, and recycling a hydrochloric acid concentration product. The process is applied to the furthest recycling of the cobalt in cobalt arsenide, cobalt sulfide and cobalt oxide mines and industrial cobalt-containing wastes, and solves the problems of release and discharge of chlorine serving as a harmful gas in the electro-deposition process at the same time; and the chlorine is prepared into the hydrochloric acid product through the shortest flow, and the cyclone electrolysis technology is adopted, so the process is efficient, low in energy consumption, low in production and operating cost, easy and convenient to operate and environment-friendly, effectively solves the produced harmful chlorine and realizes reutilization of waste gas.

Owner:浙江科菲科技股份有限公司

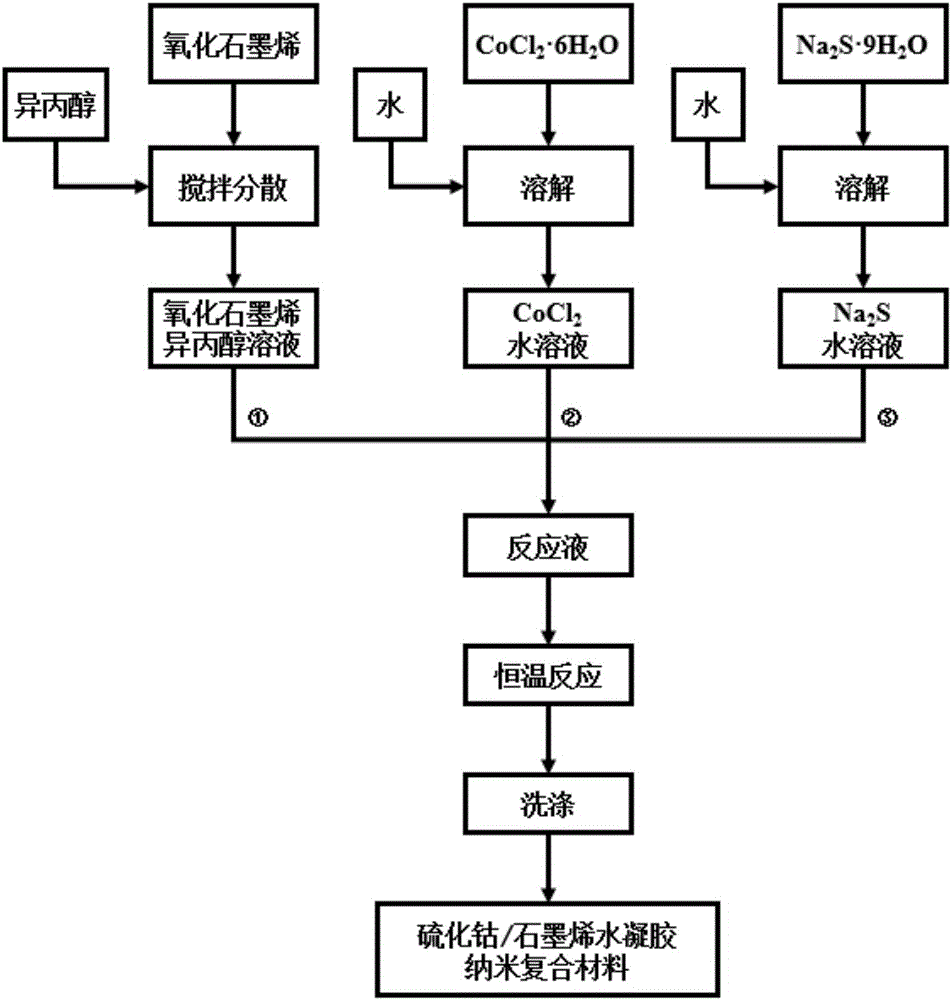

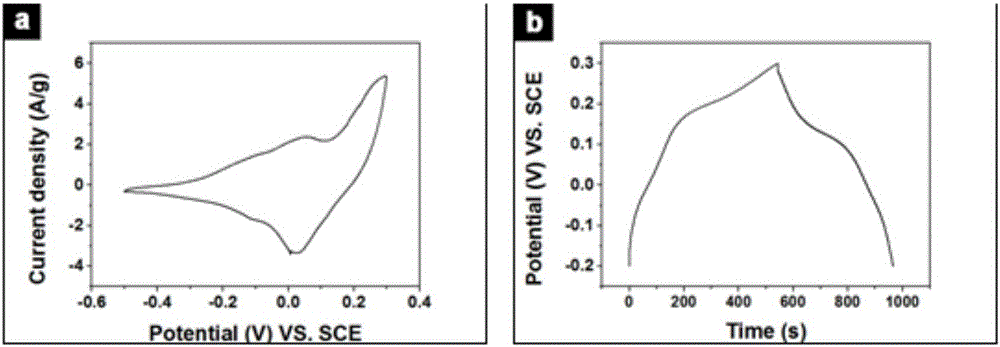

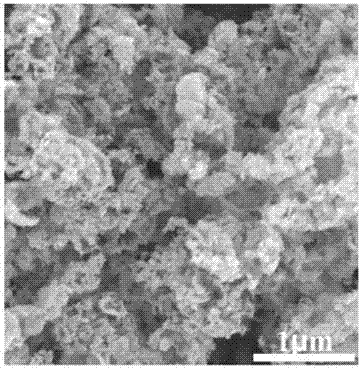

Method for quickly preparing cobalt sulfide/graphene hydrogel nano composite material

InactiveCN105161317AEasy to operateEasy to testMaterial nanotechnologyHybrid capacitor electrodesNano compositesElectrochemistry

The invention discloses a method for quickly preparing a cobalt sulfide / graphene hydrogel nano composite material, which comprises the steps of stirring and dispersing graphene oxide into an isopropyl alcohol solution so as to obtain a dispersion liquid; sequentially placing the dispersion liquid, a CoCl2 aqueous solution and a Na2S aqueous solution into a container to acquire a reaction liquid, placing the reaction liquid into a closed reactor, and carrying out constant temperature reaction at a temperature of 100-220 DEG C; and washing an obtained product so as to acquire the composite material. The preparation method disclosed by the invention is simple and convenient to test, and does not need addition of any binder; and advantages of graphene and cobalt sulfide are well combined, a synergistic effect of the graphene and the cobalt sulfide is utilized, and a large specific surface area of the graphene is inherited, thereby effectively suppressing phenomena of stacking of graphene sheet layers and gathering of cobalt sulfide nano particles, and further improving the electrochemical performance of the material.

Owner:NANJING UNIV OF SCI & TECH

Cobalt sulfide material, preparation method and application of cobalt sulfide material

ActiveCN106865624AImprove electrocatalytic activityEffective generationPhysical/chemical process catalystsCell electrodesSodium carbamateMole ratio

Owner:WENZHOU UNIVERSITY

Preparation method of nickel ion doped cobalt sulfide/conductive substrate composite material

ActiveCN105304872AUniform depositionBuffer volume expansionMaterial nanotechnologyCell electrodesLithium-ion batteryBattery cell

The invention relates to a preparation method of a nickel ion doped cobalt sulfide / conductive substrate composite material. The preparation method of the nickel ion doped cobalt sulfide / conductive substrate composite material relates to the technical field of lithium ion batteries, and aims to solve the technical problem that the negative material of an existing lithium ion battery is poor in cycling stability and low in rate capability. The method comprises the following steps of (1) treating a substrate; (2) preparing a solution; (3) preparing a precursor; (4) heat treating. The electrode material prepared by the invention can be used as the negative material to be directly assembled to form the lithium ion battery. The electrode material is directly used as an electrode without adding any conductive agent and binding agent. The electrode preparation process is simplified, the preparation cost is reduced, and the capacity, the power density performance and the cycling stability of the battery are improved.

Owner:HEILONGJIANG UNIV

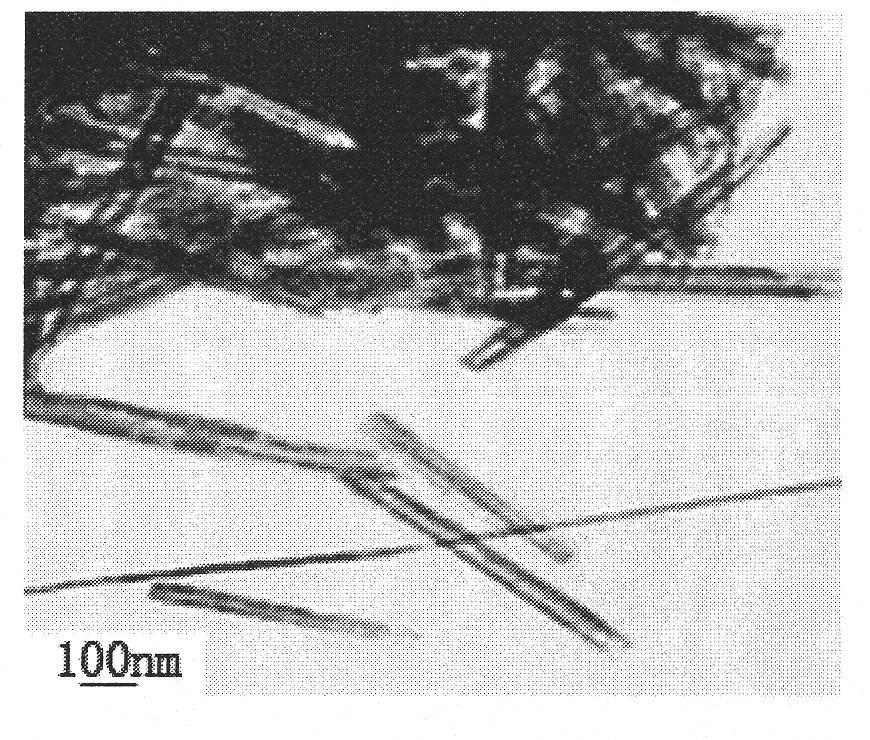

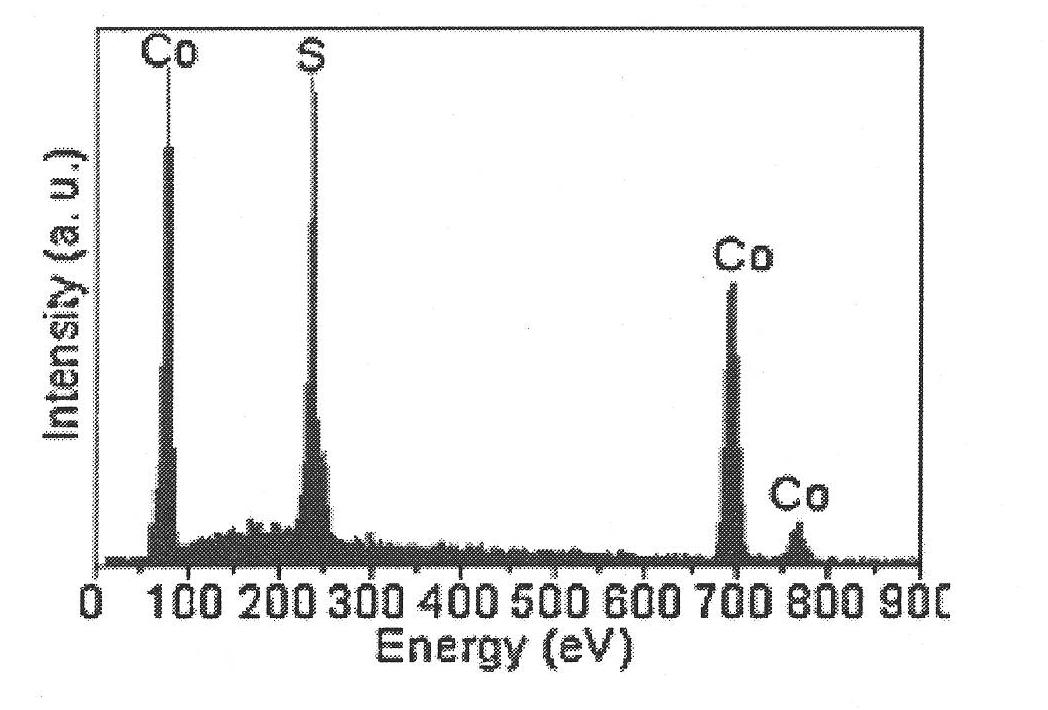

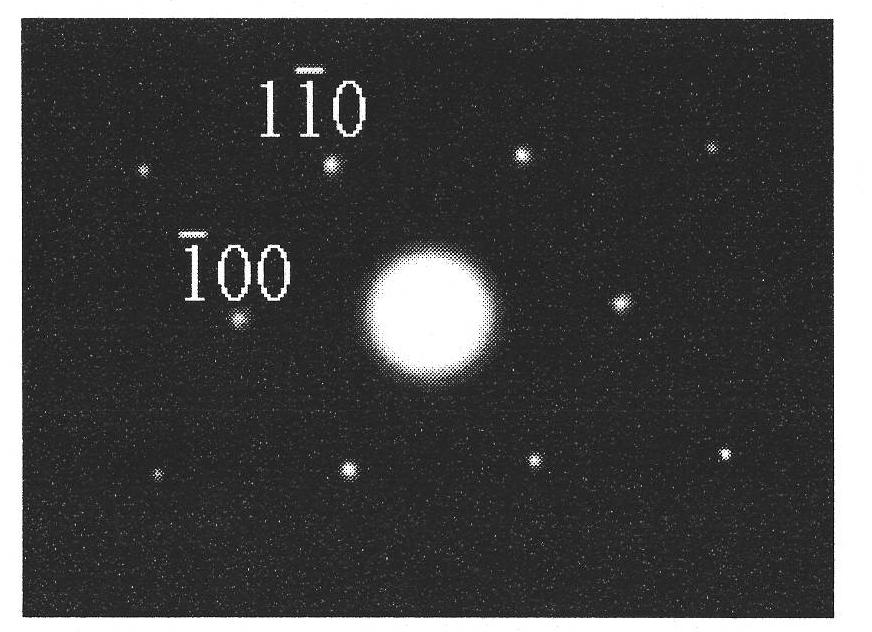

Preparation method of cobalt sulfide nanotubes or nanowires based on porous anodic aluminum oxide template

The invention discloses a preparation method of cobalt sulfide nanotubes or nanowires based on a porous anodic aluminum oxide template, which comprises the following steps: producing the porous aluminum oxide template; filling cobalt chloride and thiourea solution into holes of the aluminum oxide template; adopting the step-by-step heating method to prepare the cobalt sulfide nanotubes or the nanowires; and placing the aluminum oxide template in strong base solution for etching off the aluminum oxide template, and preparing the cobalt sulfide nanotubes or the nanowires with the controllable size, wherein the nanowires or the nanotubes are placed in the holes of the aluminum oxide template. The cobalt sulfide nanotubes or the nanowires have cheap raw materials, simple operation, short synthesis time and low temperature. The size of the cobalt sulfide nanotubes or the nanowires and the size of the holes of the template can be controlled and adjusted. The outer diameter of the holes of the cobalt sulfide nanotubes is 60-150nm, and the inner diameter is 20-80nm. The diameter of the nanowires is about 60-150nm. The invention relates to the method for preparing the cobalt sulfide nanotubes or the nanowires and an array thereof, which is relatively economical.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY AND SCIENCE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com