Patents

Literature

360results about How to "Buffer volume expansion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Silicon/graphene laminar composite material for lithium ion battery cathode and preparation method thereof

ActiveCN102064322ALarge active surface areaImprove cycle performanceCell electrodesSurface-active agentsElectrochemistry

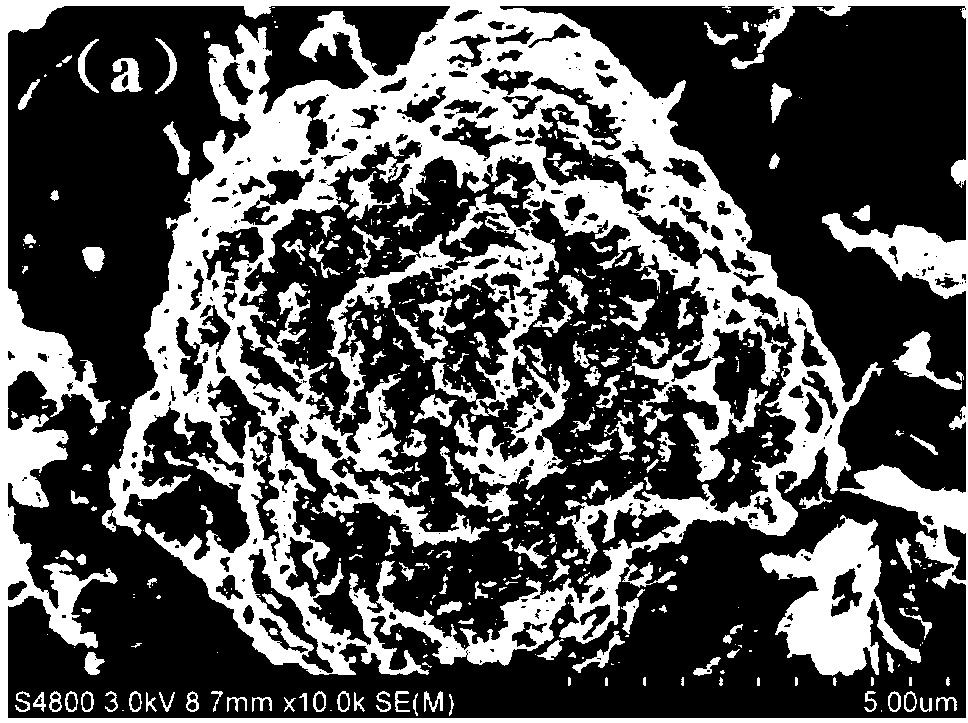

The invention relates to a preparation method of a silicon / graphene laminar composite material for lithium ion battery cathode. The composite material adopts a laminar sandwich structure, silicon nano-particles are dispersed on each lamina of the grapheme, the laminas of the grapheme are separated from one another by the silicon nano-particles and the edges of the laminas are in lapped joint so as to constitute a laminar conductive network structure. The preparation method thereof comprises the steps of: formulating anhydrous silicon tetrachloride, surface active agent, sodium naphthalene and graphite oxide to tetrahydrofuran solution, adding the tetrahydrofuran solution into a reactor for reaction in vacuum at the temperature ranging from 380 to 400 DEG C, filtering the reactant to result in the product, and then washing, drying and heating the product to obtain the silicon / grapheme composite material. The preparation method of the invention has the advantages of simple preparation process and great easiness for industrial production; and the silicon / graphene laminar composite material prepared according to the method includes excellent conductivity, power performance, electrochemical activity and cycle stability, and is particularly suitable for manufacturing lithium ion battery cathode.

Owner:深圳清研紫光科技有限公司

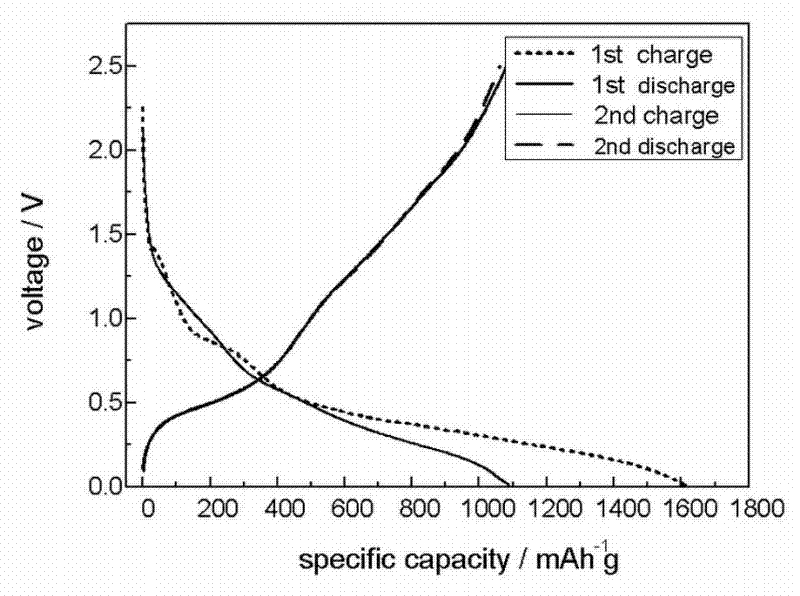

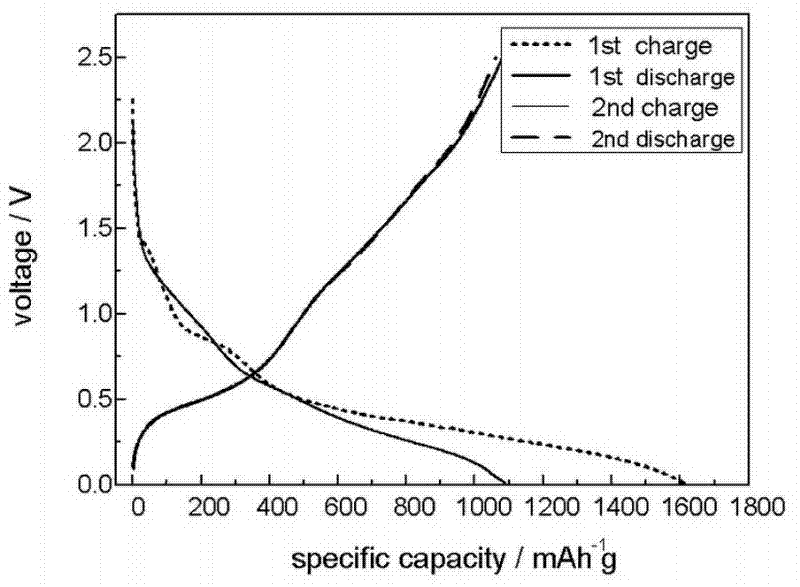

Monox/carbon composite material as well as preparation method and use thereof

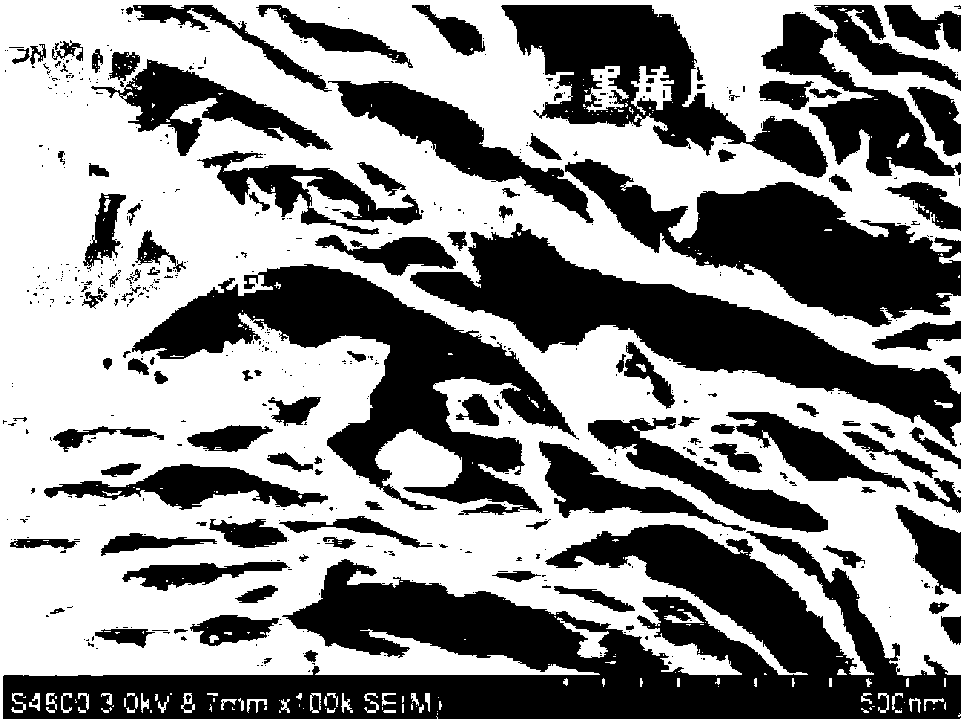

InactiveCN103311526AGood electrical contactShorten the diffusion pathCell electrodesSecondary cellsCarbon compositesGraphite

The invention relates to a monox / carbon composite material, comprising monox / graphene particles, organic matter pyrolysis carbon and graphite powder, wherein monox particles are adhered to the surface of a grapheme sheet; the organic matter pyrolysis carbon coats the monox / graphene particles, and then is compounded with graphite. The preparation method of the monox / carbon composite material comprises the steps of: mixing monox particles with graphene to obtain the monox / graphene particles; coating organic carbon by obtained monox / graphene particles, thereby obtaining the monox / graphene material coated by the organic matter pyrolysis carbon; and mixing the obtained monox / graphene material coated by the organic matter pyrolysis carbon with the graphite powder, so as to obtain the monox / carbon composite material. The monox / carbon composite material is used as a lithium ion battery cathode material. Thus, the monox / carbon composite material has the characteristics of high first charge and discharge efficiency, excellent cycle performance and power charge and discharge properties, and low volume expansion effect.

Owner:BTR NEW MATERIAL GRP CO LTD

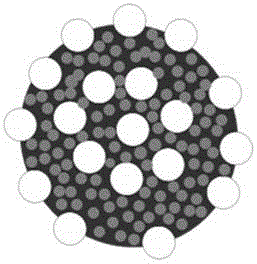

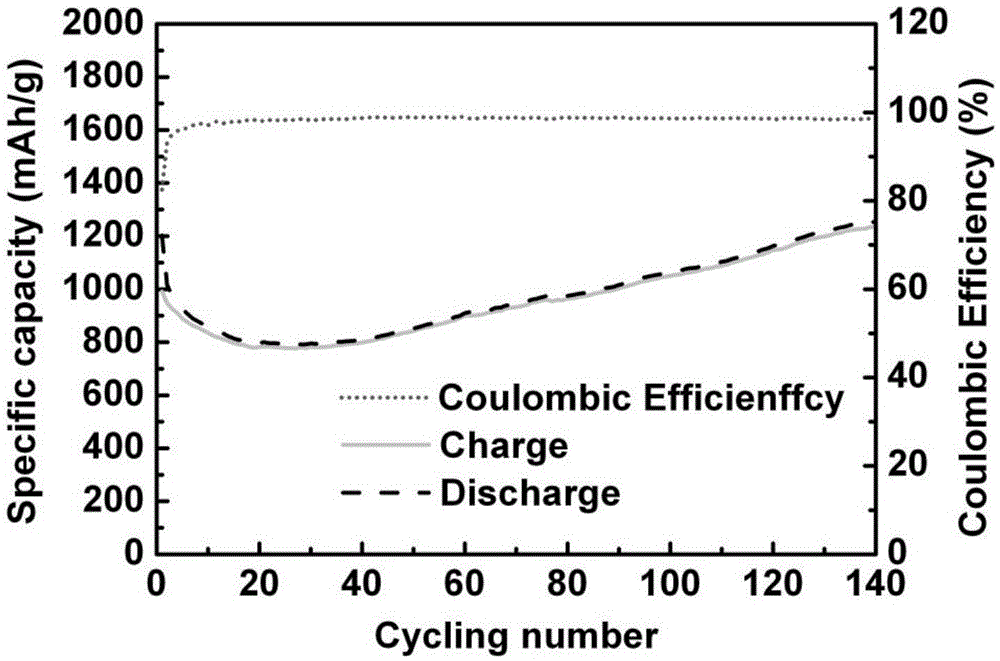

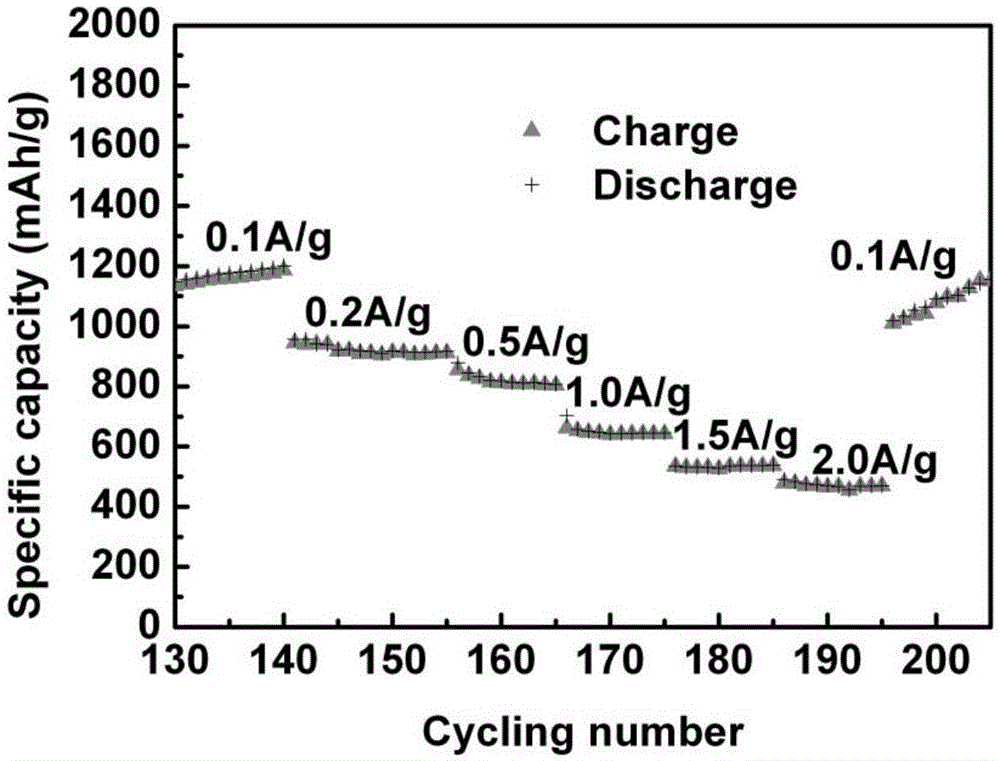

Graphene macroscopic body/tin oxide composite lithium ion battery anode material and process thereof

ActiveCN102244250AImprove conductivityLarge specific surface areaCell electrodesPorous grapheneElectrolytic agent

The invention relates to a graphene macroscopic body / a tin oxide composite lithium ion battery anode material and a process thereof. The anode material consists of a three-dimensional graphene macroscopic body and nano tin dioxide which grows in a pore of the three-dimensional graphene macroscopic body in an orientated way; and a volume is 500 to 2,000 mAh / g; the coulomb efficiency is 80 to 99.5 percent, wherein a mass ratio of the three-dimensional graphene macroscopic body to the tin dioxide is 1:(0.1-20). The characteristic of high electric conductivity of graphene is kept, the transfer and transport of charges are facilitated, and microscopic and macroscopic electric network structures are formed; meanwhile, the three-dimensional graphene macroscopic body has a big specific surface area and abundant pore spaces, so that the transfer of lithium ions is facilitated, and the contact area of the electrode material and electrolyte is enlarged; and the preparation process is environment-friendly, pollution-free and suitable for industrial production.

Owner:SHENZHEN GRADUATE SCHOOL TSINGHUA UNIV

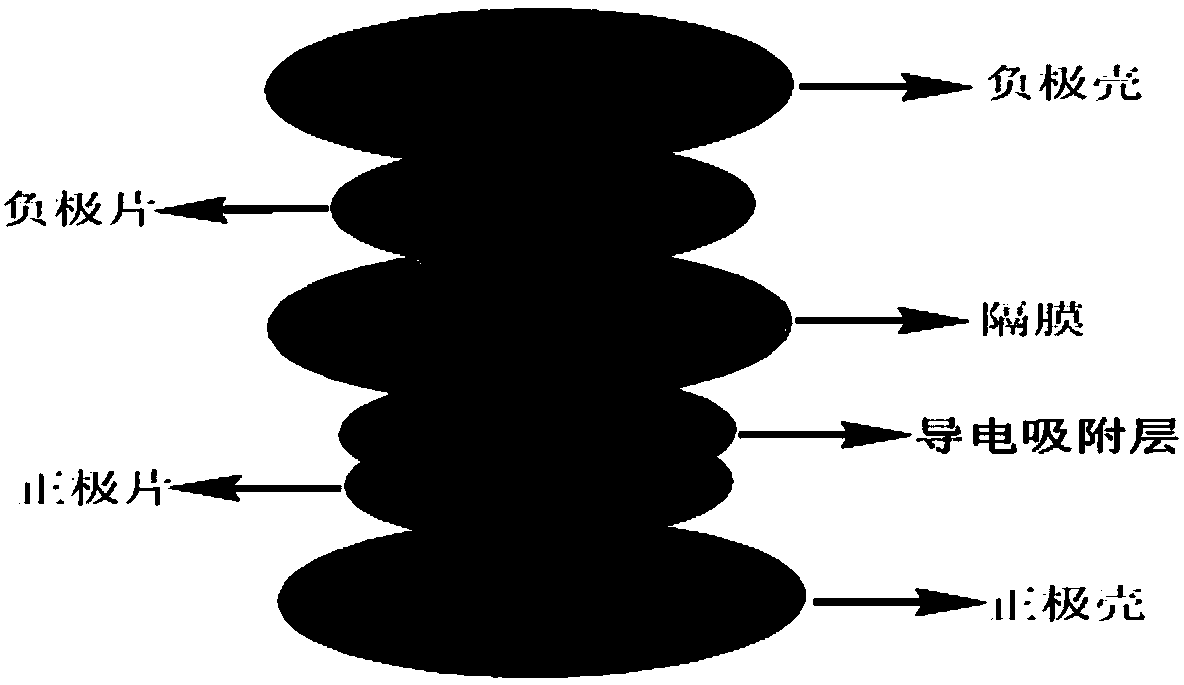

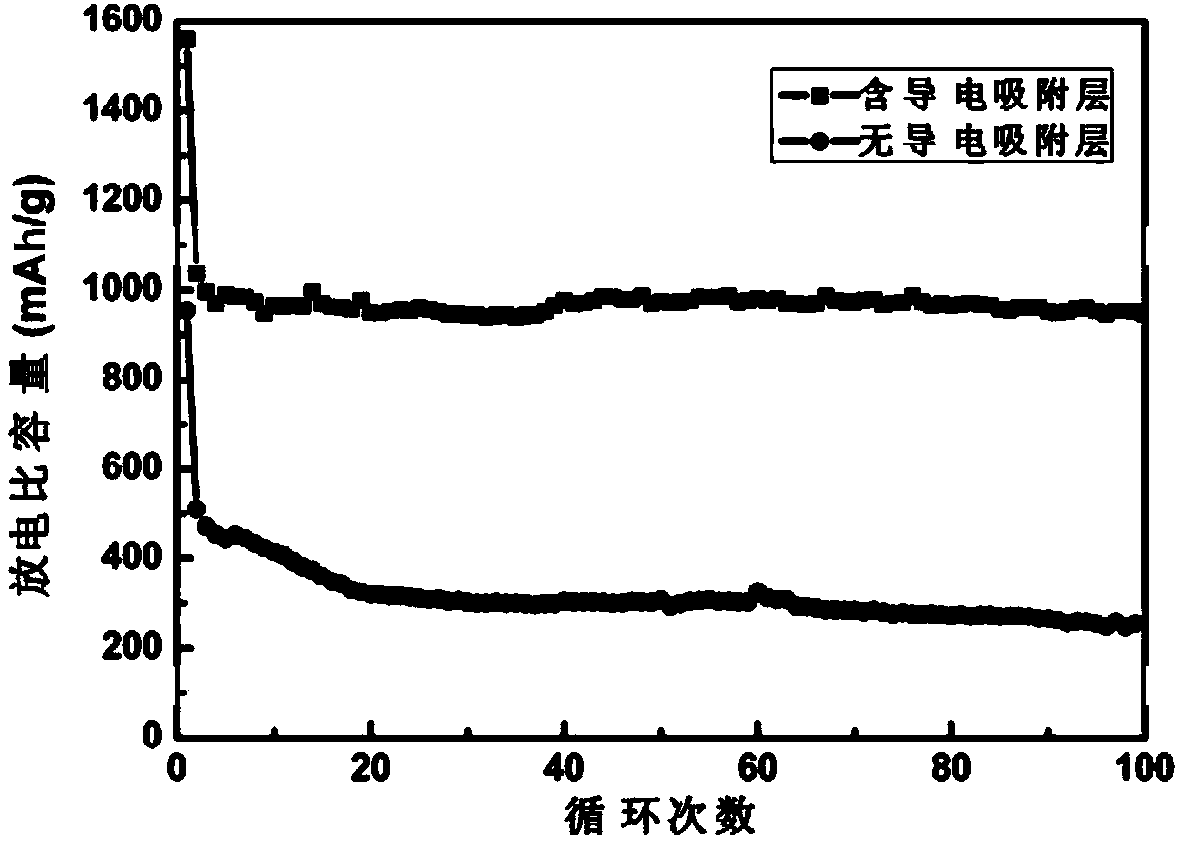

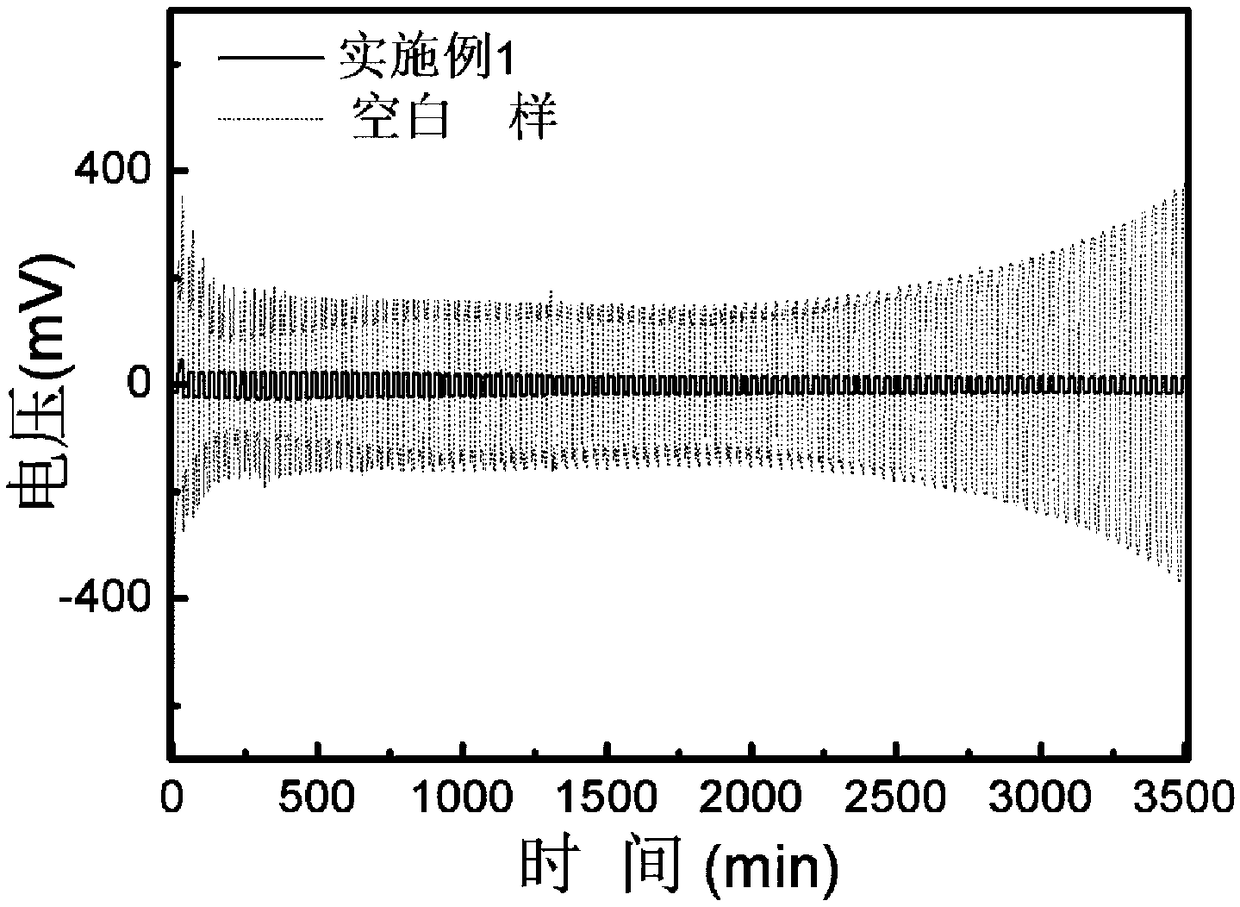

Lithium-sulfur battery with conductive adsorption layer, and application of conductive polymer film

InactiveCN103515646AEnhance electrical conductivityInhibition of the shuttle effectElectrode carriers/collectorsLi-accumulatorsChemistryAdhesive

The invention discloses a lithium-sulfur battery with a conductive adsorption layer, and an application of a conductive polymer film. The lithium-sulfur battery comprises a sulfur-containing positive electrode sheet, a separation film, and a lithium negative-electrode sheet. A conductive absorption layer is arranged between the sulfur-containing positive electrode sheet and the separation film. The application comprises that the conductive polymer film prepared from a conductive polymer, a conductive agent, and an adhesive is arranged as a conductive absorption layer between the sulfur-containing positive electrode sheet and the separation film of the lithium-sulfur battery, such that the lithium-sulfur battery is prepared. The prepared lithium-sulfur battery has the characteristics of high specific capacity, high coulombic efficiency, and long service life. The conductive polymer film has the advantages of low raw material cost, simple preparation method, and suitability for industrialized productions.

Owner:CENT SOUTH UNIV

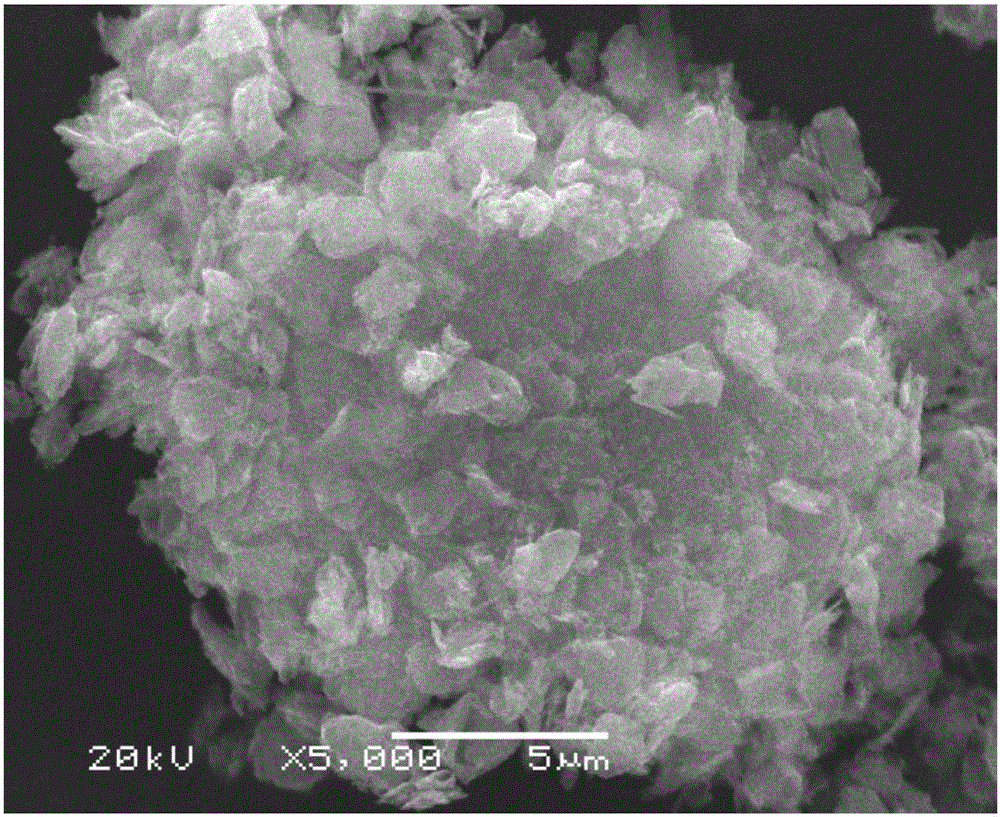

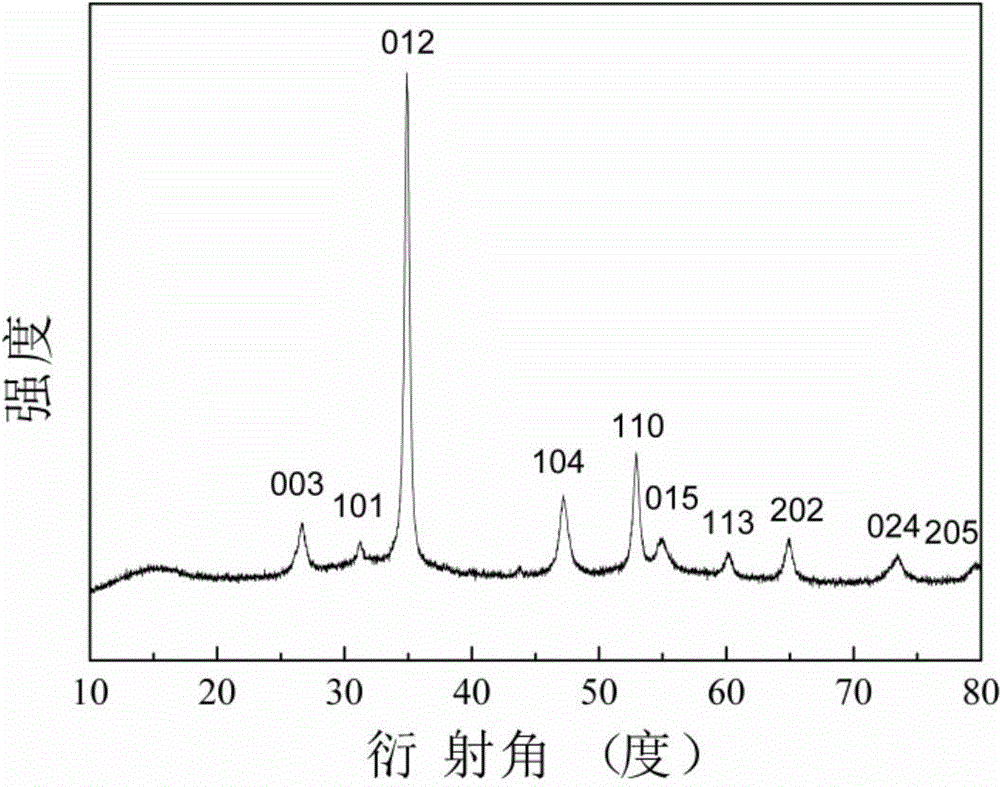

Phosphate-doping silicon carbon negative electrode material for lithium ion battery and preparation method of phosphate-doping silicon carbon negative electrode material

InactiveCN108172775ABuffer volume expansionImprove electronic conductivityMaterial nanotechnologyCell electrodesPhosphatePhosphoric acid

The invention discloses a phosphate-doping silicon carbon negative electrode material for a lithium ion battery. The phosphate-doping silicon carbon negative electrode material is formed by sinteringa phosphate-doping nanosilicon material, graphite and an organic carbon source after spray granulation. The invention also proposes a preparation method of the phosphate-doping silicon carbon negativeelectrode material for the lithium ion battery. The preparation method comprises the steps of uniformly dispersing the nanosilicon material in a phosphoric acid solution, and performing spraying anddrying to obtain the phosphate-doping nanosilicon material; performing primary sintering on the phosphate-doping nanosilicon material; and uniformly dispersing the phosphate-doping nanosilicon material subjected to primary sintering in water, adding the graphite and the organic carbon source, and performing spraying, drying and secondary sintering after complete dispersion. The preparation methodof the phosphate-doping silicon carbon negative electrode material for the lithium ion battery, proposed by the invention, has the advantages of simple process, low cost and convenient subsequent processing mode and is convenient to operate, the raw material is natural and available, mass production is easy, and the obtained negative electrode material is high in electron conductivity and small involume expansion.

Owner:HEFEI GUOXUAN HIGH TECH POWER ENERGY

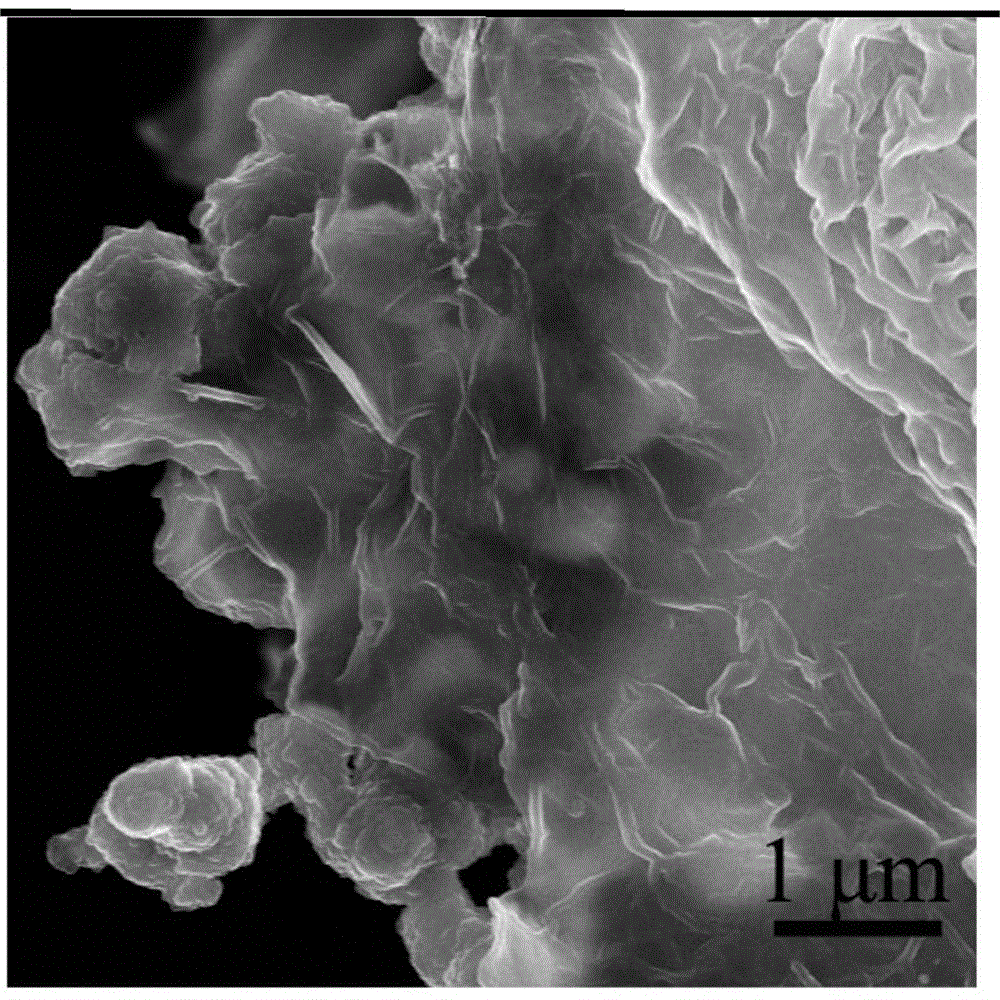

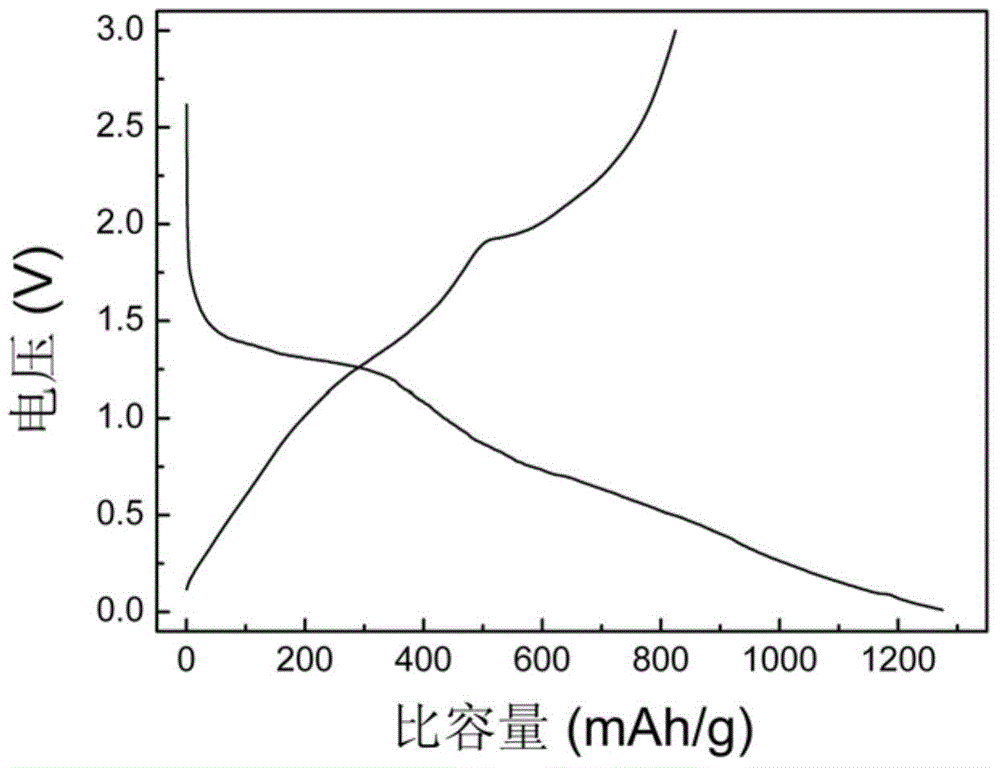

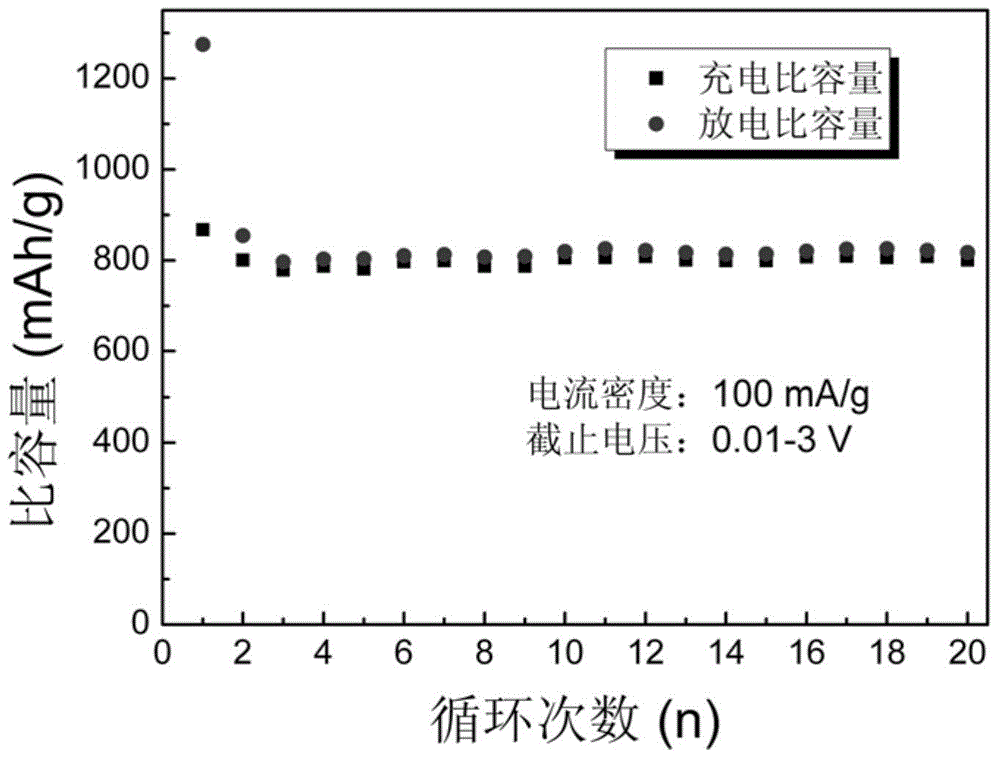

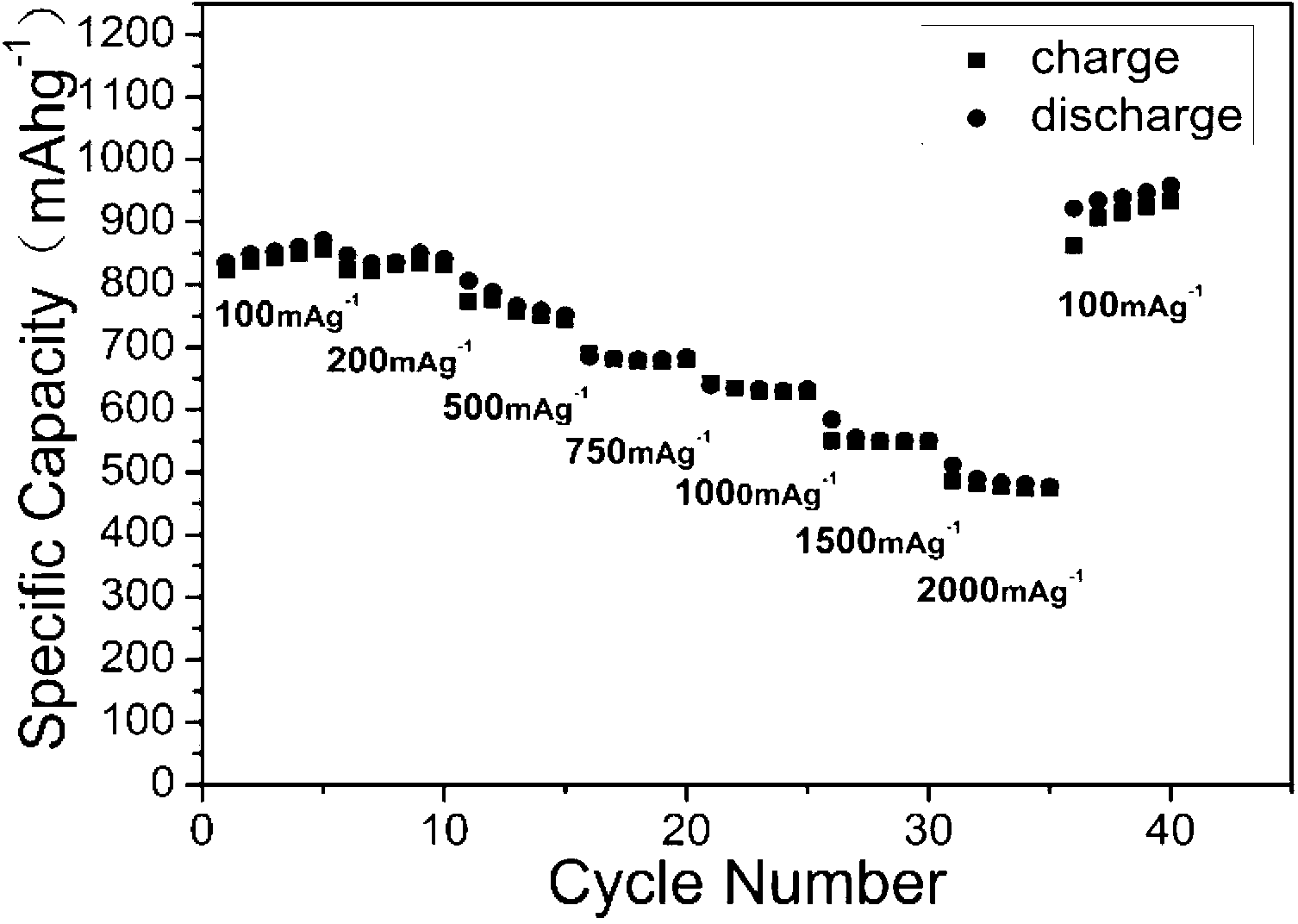

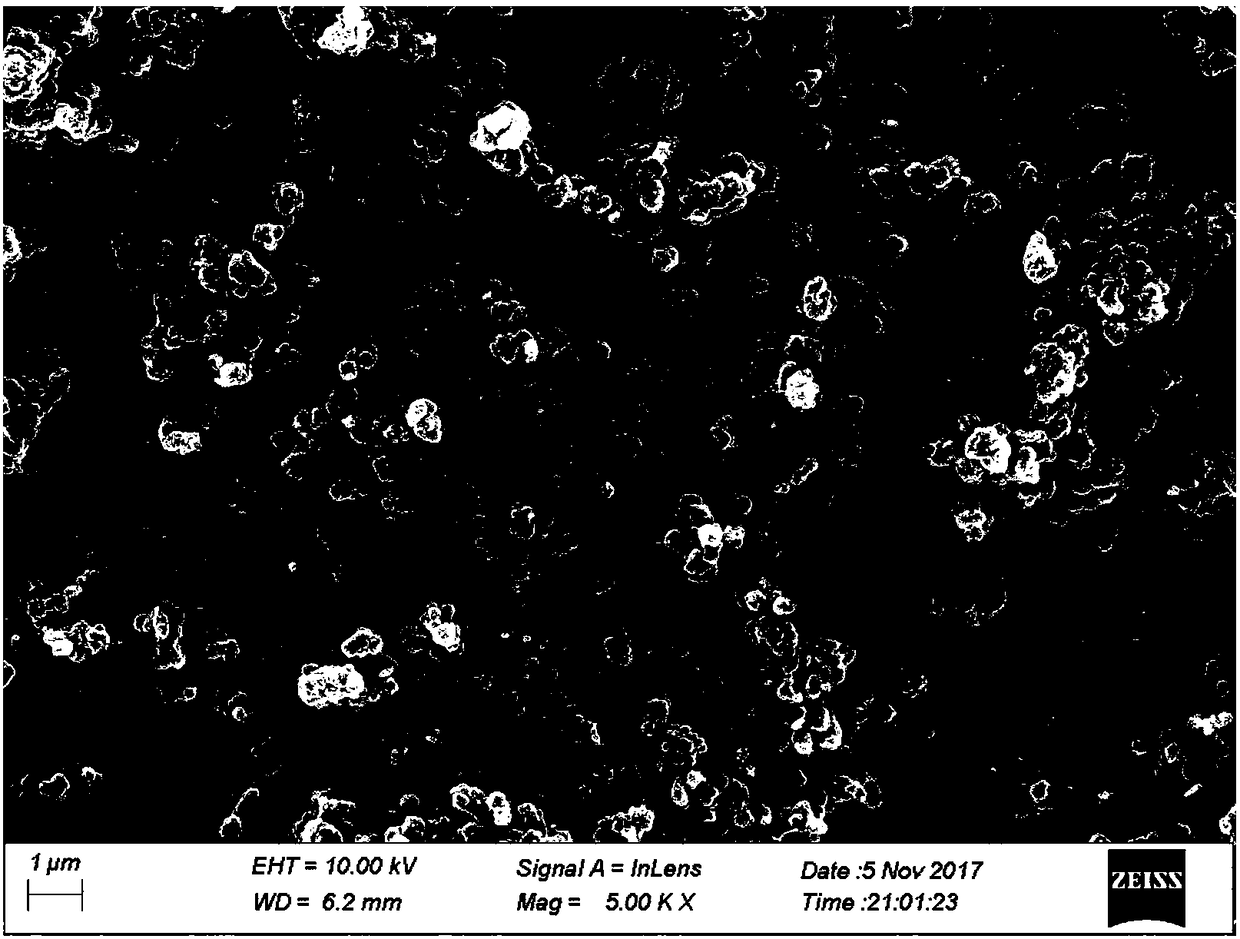

Nano-NiS/graphene composite anode material and preparation method thereof

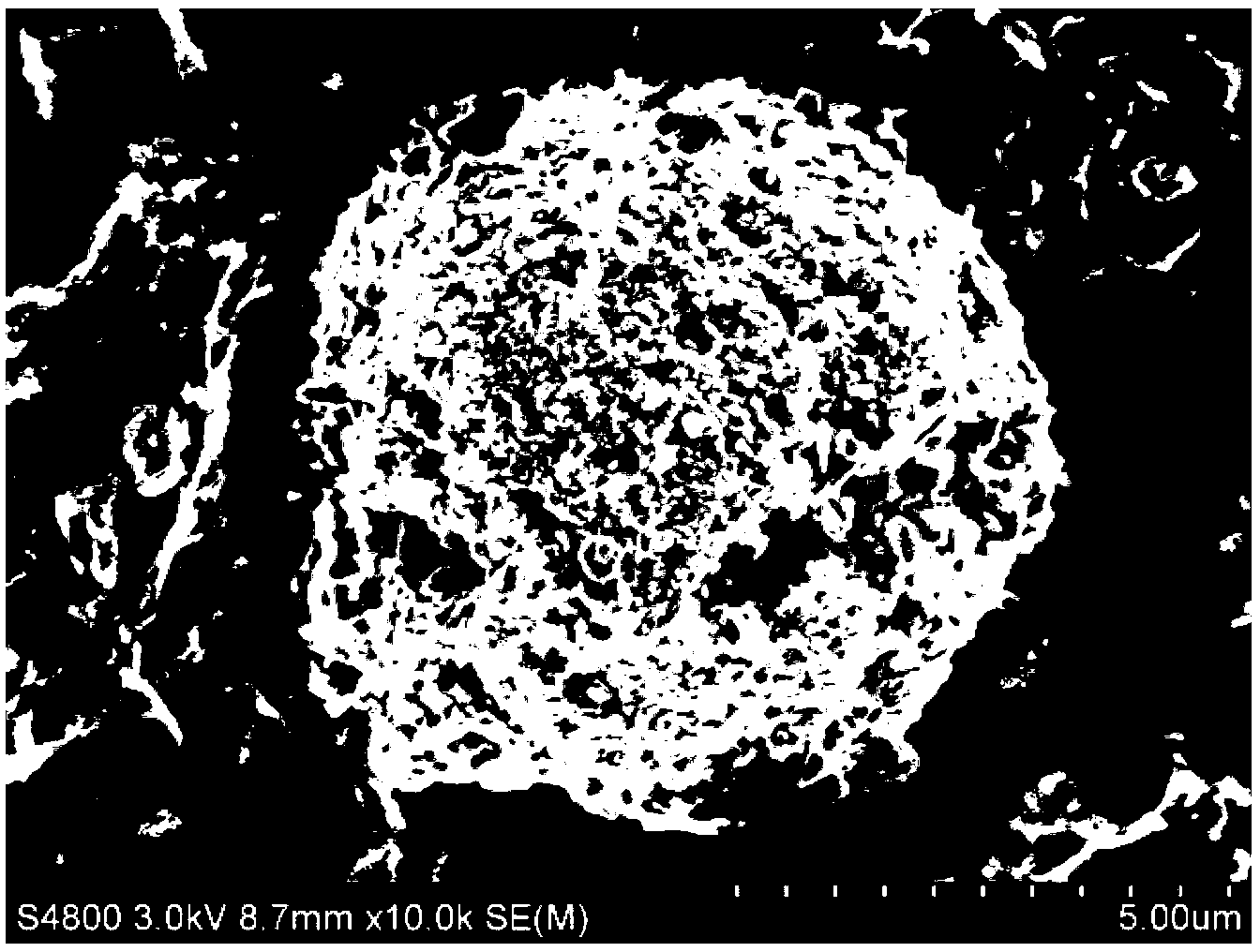

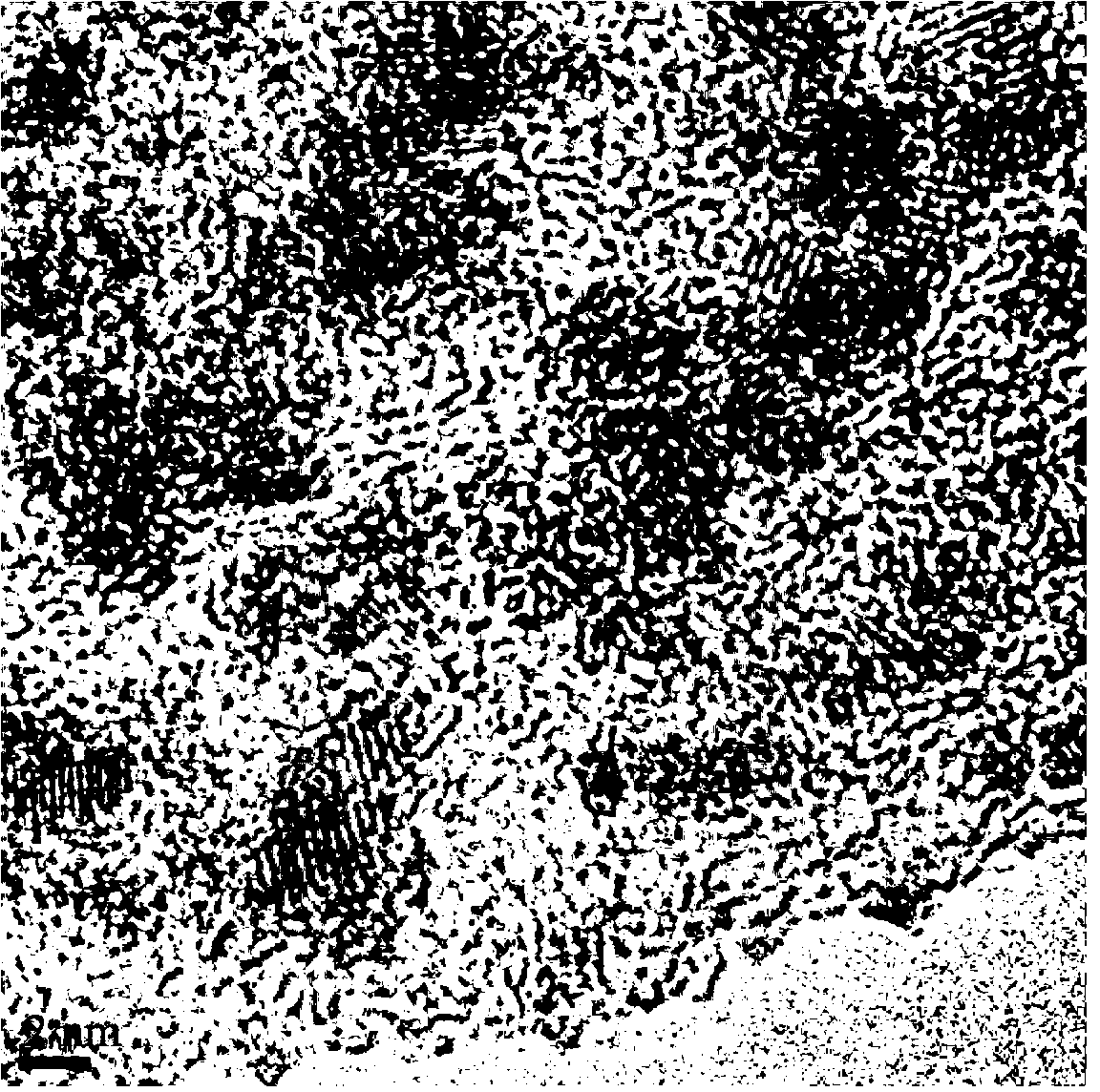

ActiveCN104134783ABuffer volume expansionImprove cycle stabilityCell electrodesSecondary cellsActive agentDissolution

The invention provides a preparation method of a NiS / graphene composite anode material. The method includes: firstly preparing NiS nanoparticles by a solvothermal method, performing surface modification on the NiS particles by a surfactant, then compounding the modified NiS particles with graphene oxide under electrostatic attraction; and reducing graphene oxide by hydrazine hydrate so as to finally form graphene packaged nano-NiS / graphene composite anode material. The dispersion and packaging effects of graphene on NiS can effectively buffer NiS's volume expansion generated during charging and discharging, and inhibit dissolution of the product in an electrolyte solution in an electrode reaction process, thus improving the cyclic stability of the composite material. At the same time, graphene provides a good conductive network, which is conducive to rapid transmission of electrons, thereby reducing electrode polarization and greatly improving the rate performance of the composite material. The NiS / graphene composite material prepared by the method provided by the invention has excellent electrochemical performance, and the preparation process is simple, the conditions are mild, so that the method is suitable for large-scale industrialized production.

Owner:UNIV OF SCI & TECH BEIJING

Zinc oxide-metal lithium composite negative electrode and preparation method thereof, and metal lithium secondary battery

InactiveCN108695488ALarge specific surface areaReduce current densityCell electrodesSecondary cellsLithium metalLiquid lithium

The invention discloses a zinc oxide-metal lithium composite negative electrode and a preparation method thereof, and a metal lithium secondary battery. The zinc oxide-metal lithium composite negativeelectrode has a three-dimensional structure and comprises foamy copper and metal lithium and zinc oxide compounded in the foamy copper. The negative electrode utilizes combination of foamy copper andmetal lithium, utilizes three-dimensional foamy copper as a skeleton, utilizes a hydrothermal method to deposit a layer of a zinc oxide nano-layer on the foamy copper surface, and utilizes the lithium loving performances of the zinc oxide nano-layer to melt the solid lithium metal into liquid lithium spontaneously adsorbed into the three-dimensional foamy copper skeleton. Compared with the lithium sheet negative electrode, the three-dimensional metal lithium negative electrode has a large specific surface area and can effectively reduce the current density during charging and discharging. Theporous structure can well limit lithium in the internal space, reduce the volume expansion of the lithium negative electrode during charging and discharging, and effectively inhibit the growth of dendrites.

Owner:SOUTHEAST UNIV

Silicon-based negative electrode material with multi-buffer structure, and preparation method thereof

InactiveCN107623104AInhibition of polymerizationInhibit flakingCell electrodesElectrolytic agentMaterials processing

The invention relates to a silicon-based negative electrode material with a multi-buffer structure, and a preparation method thereof, and belongs to the technical field of material processing. According to the silicon-based negative electrode material provided by the invention, a nanometer titanium dioxide layer is coated on the surface of nanometer silicon powder, the stable structure of the nanometer titanium dioxide is used as a buffer layer of volume change of silicon particles in a lithium embedding and removing process to successfully inhibit the polymerization and peeling of the siliconparticles, and the electrochemical performance of the electrode material is also improved, then an amorphous carbon layer is coated to prepare a silicon-based electrode material with a double-layer coating structure, the volume expansion of the core of the activated silica is effectively buffered by the double-layer coating structure in a charge and discharge process, the stability of an electrode / electrolyte interface and a surface SEI film is maintained, and thus the composite material exhibits good cycle performance.

Owner:常州市宇科不绣钢有限公司

Preparing method for silicon-carbon composite negative electrode material for lithium ion battery

ActiveCN105206801AMaintain stabilityEvenly dispersedMaterial nanotechnologyCell electrodesCarbon compositesCarbonization

The invention discloses a preparing method for a silicon-carbon composite negative electrode material for a lithium ion battery. The preparing method includes the following steps that 1, flake graphite, a polymer solution and nanometer silicon dispersion liquid are evenly mixed, dried and carbonized in a protective atmosphere; 2, pitch and spherical graphite are mixed, ground, placed in an inert protective atmosphere, and subjected to heat treatment to obtain modified spherical graphite; 3, a binder, the modified spherical graphite and the mixed material obtained after carbonization in the step 1 are added into solvent, dispersed evenly and dried to obtain a precursor material; 4, the precursor material is carbonized to obtain the silicon-carbon composite negative electrode material. In the process of the preparing method, it is unnecessary to add special dispersant, nanometer silicon is evenly dispersed in the graphite by means of some ionic groups existing in the polymer solution and high viscosity, the polymer solution has certain stability, and the possibility of nanometer silicon aggregation in the drying process is reduced.

Owner:CENT SOUTH UNIV +1

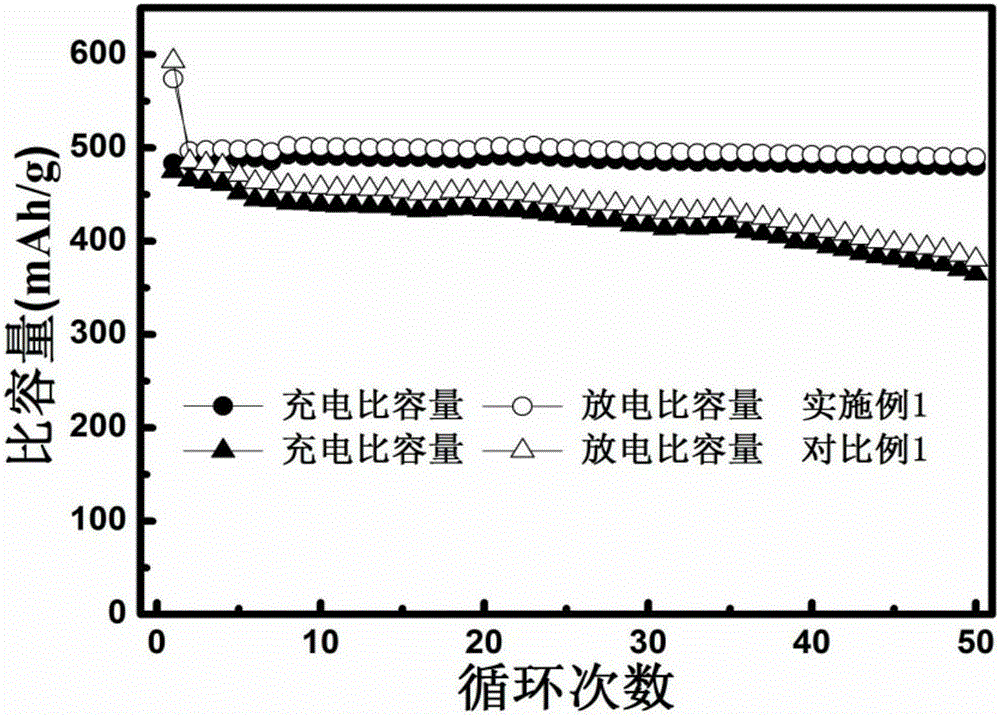

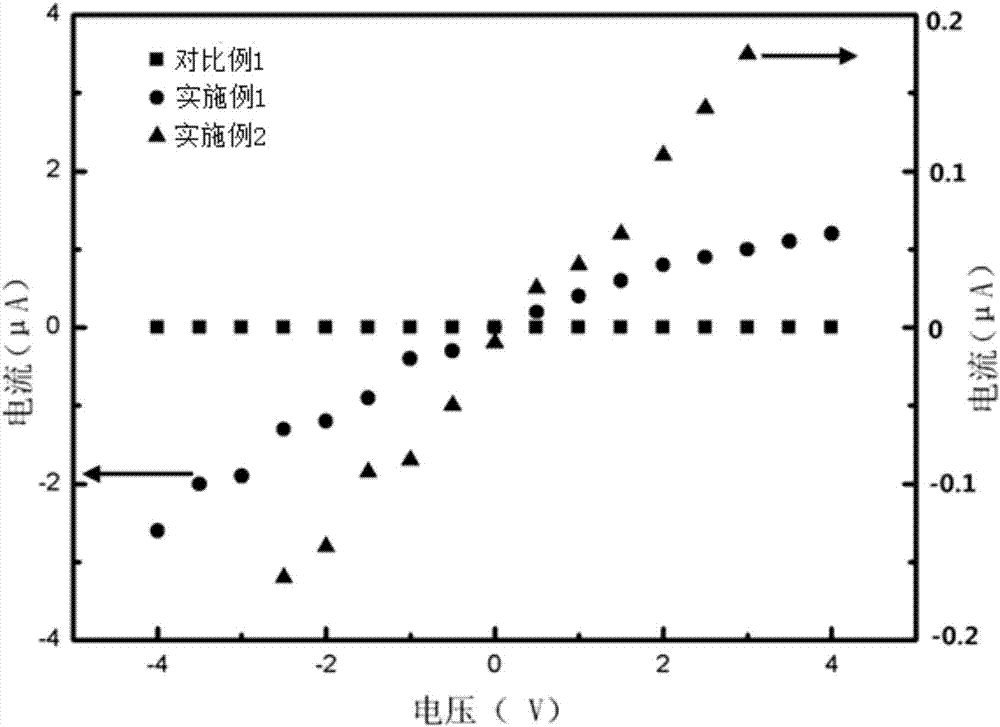

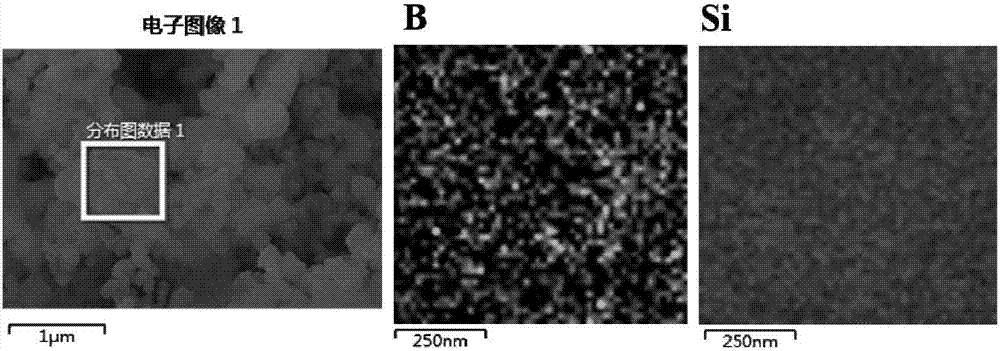

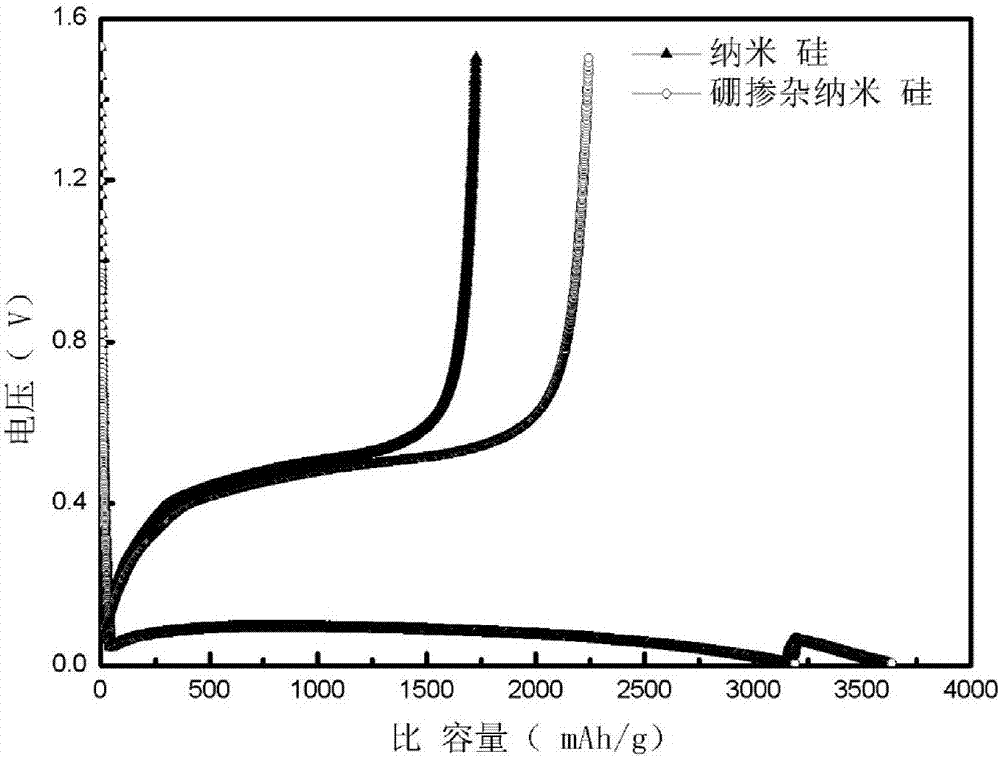

Boron-doped silicon-based negative electrode material used for lithium ion battery

InactiveCN107195893ASimple preparation processEasy to operateMaterial nanotechnologyCell electrodesGraphiteBoron trioxide

The invention discloses a boron-doped silicon-based negative electrode material used for a lithium ion battery. The boron-doped silicon-based negative electrode material is prepared from a boron-doped nanometer silicon material and graphite in a compounding manner, wherein the mass percentage of the boron-doped nanometer silicon material is 3-100%, and the balance is graphite. Diboron trioxide is gradually diffused to the silicon negative electrode material in a high-temperature sintering process to replace a part of silicon atoms to form displacement type doping, so that vacancy carrier concentration in the nanometer silicon material is improved, thereby improving the intrinsic electron conductivity of the silicon material; volume expansion of the silicon material can be buffered by graphite; and the boron-doped silicon-based negative electrode material has simple preparation process, convenience in operation, natural and easily available raw materials, low cost, convenience in subsequent processing mode, and easy realization of large-scale production.

Owner:HEFEI GUOXUAN HIGH TECH POWER ENERGY

Method for preparing tin dioxide/graphene-compounded anode material of lithium ion battery

ActiveCN103078095AExcellent electrochemical performanceRaw ingredients are simpleCell electrodesCvd grapheneLithium electrode

The invention discloses a method for preparing a tin dioxide / graphene-compounded anode material of a lithium ion battery. The method comprises the following steps: uniformly mixing choline chloride, ethylene glycol and graphene oxide to obtain a mixed solution, adding stannous chloride to the mixed solution, performing ultrasonic oscillating reaction, and performing post-processing to obtain the product. According to the method for preparing the tin dioxide / graphene-compounded anode material of the lithium ion battery, a normal-pressure and normal-temperature one-step method is adopted, the adopted raw materials are simple in components and common and easy to obtain, the reaction conditions are mild and controllable, the reaction can be performed at normal temperature and normal pressure, and the preparation process is simple and practicable, has low requirements for equipment so as to be free from geographical restrictions, and is suitable for large-scale industrial production. The prepared tin dioxide / graphene-compounded anode material of the lithium ion battery has excellent electrochemical properties, and can be used as an active electrode substance for preparing an anode of the lithium ion battery so as to have a wide market application prospect.

Owner:SHENZHEN KEXIN COMM TECH

Legume-shaped carbon-coated manganese oxide core-shell structure composite material and preparation method and application thereof

ActiveCN103311529AImprove electronic conductivityImprove cycle stabilityCell electrodesCarbon layerPolyethylene oxide

The invention discloses a legume-shaped carbon-coated manganese oxide core-shell structure composite material and a preparation method and application thereof. The preparation method comprises the following steps: firstly, with a triblock copolymer polyethylene oxide-polypropylene oxide-polyethylene oxide PEO-PPO-PEO (P123) and polyvinyl pyrrolidone (PVP) as surfactants and potassium permanganate as a manganese source, carrying out hydrothermal reaction so as to obtain a precursor nano wire of manganese; then with dopamine as a carbon source, uniformly wrapping a layer of thin polydopamine on the surface of the precursor, and carbonizing for a certain period at a high temperature so as to prepare the legume-shaped carbon-coated manganese oxide core-shell structure composite material. Due to the wrapping of the carbon layer, the electron conductivity of the manganese oxide is improved; due to the large space among the manganese oxide active material, the volume expansion in the repeated charging and discharging process is effectively buffered; and the electrochemical test result shows that the material serving as a lithium ion battery cathode material has excellent multiplying power and circulation property, and the material is expected to be widely applied to the field of lithium ion batteries.

Owner:EAST CHINA UNIV OF SCI & TECH

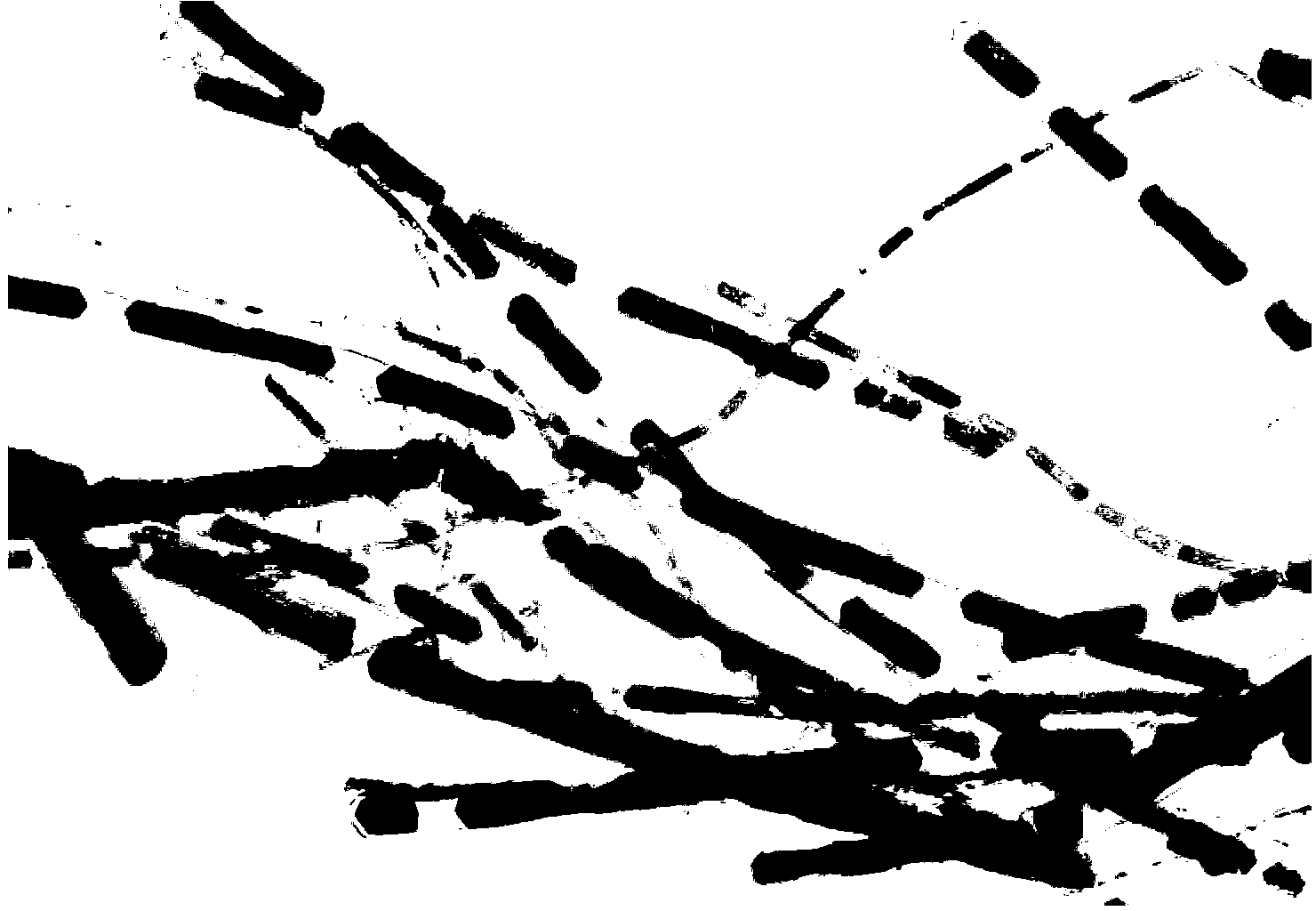

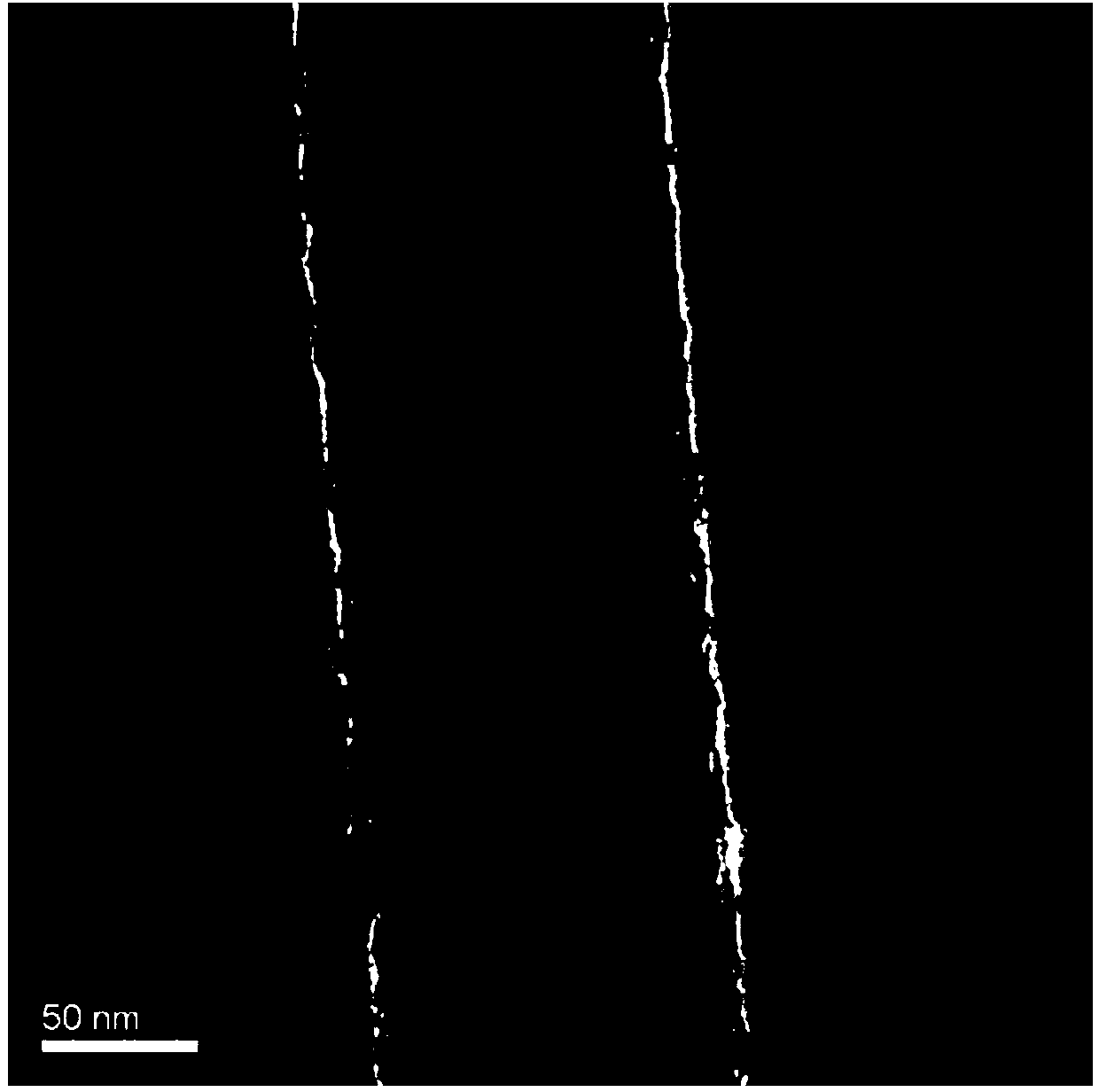

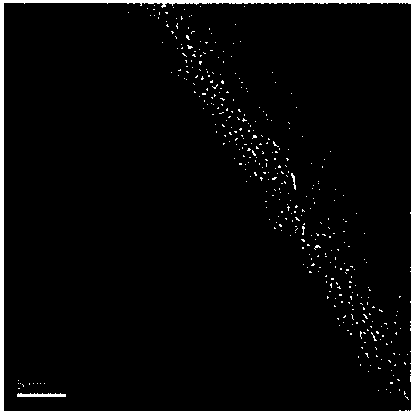

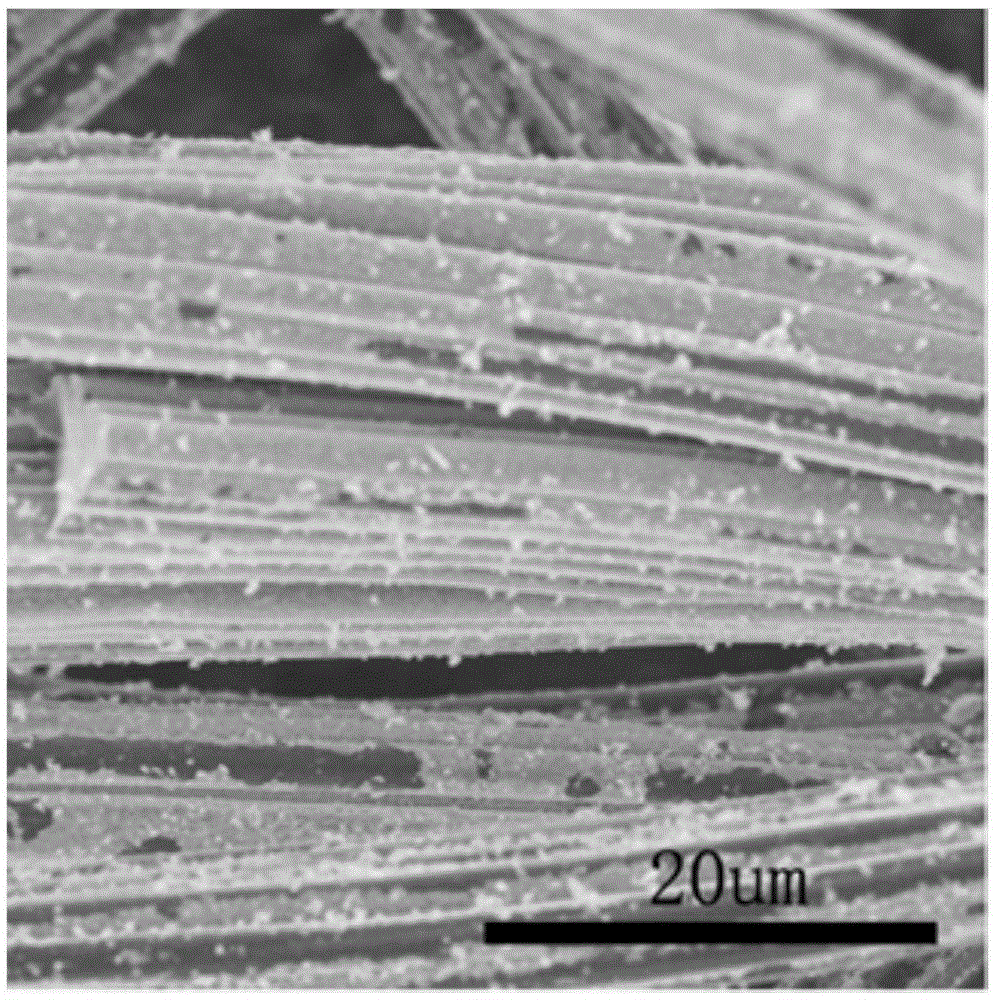

Carbon nanofiber material and preparing method and application of carbon nanofiber material

ActiveCN103803490APrevent contact with electrolyteBuffer volume expansionMaterial nanotechnologyCell electrodesCarbon layerCarbon nanofiber

The invention relates to a carbon nanofiber material and a preparing method and application of the carbon nanofiber material. The technical problems that an exiting material preparing method is complex and high in cost are solved. The inner layer of the carbon nanofiber material is made of titanic oxide, the outer layer is a nitrogen doped carbon wrapping layer, the diameter of the carbon nanofiber ranges from 100 nanometers to 150 nanometers, and the thickness of a carbon layer ranges from 2 nanometers to 8 nanometers. The invention further provides the preparing method and application of the carbon nanofiber material, and the carbon nanofiber material can be widely applied to the field of preparing battery materials.

Owner:BEIJING UNIV OF CHEM TECH

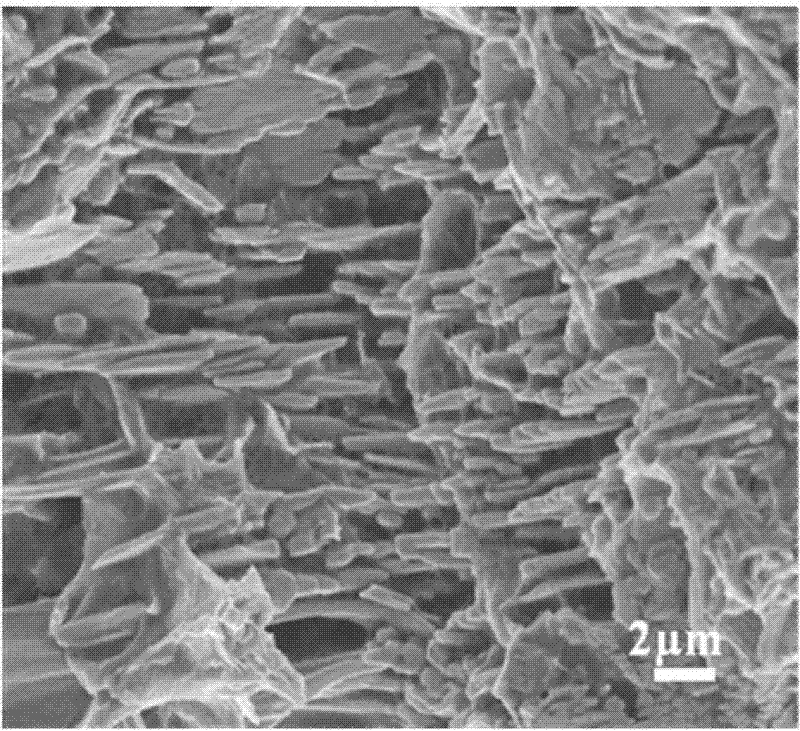

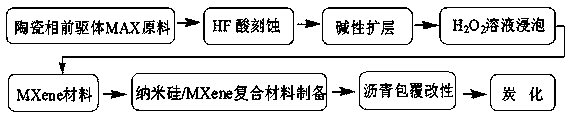

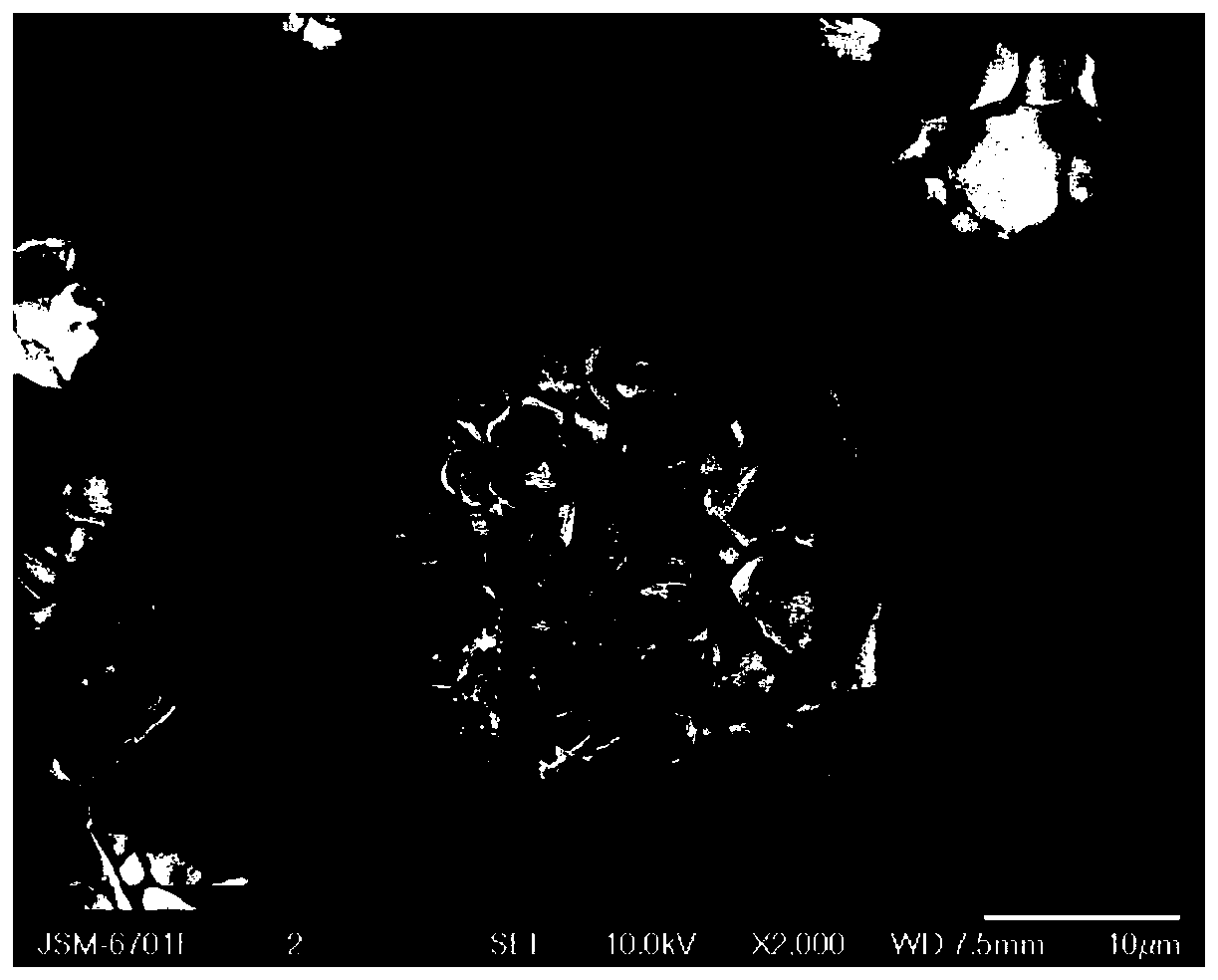

Core-shell structure nanometer silicon-Mxene composite cathode material and preparation method thereof

InactiveCN109346681ABuffer volume expansionAvoid direct contactMaterial nanotechnologyCell electrodesIonSilicon particle

The invention discloses a core-shell structure nanometer silicon-Mxene composite cathode material and a preparation method thereof. During preparation, the core-shell structure nanometer silicon-Mxenecomposite cathode material comprises the following steps: (1) using a ceramic phase precursor MAX as a raw material, etching the ceramic phase precursor MAX by using HCl+LiF and using deionized waterto wash the ceramic phase precursor MAX to obtain an MXene material; (2) adding the MXene material to a nanometer silicon suspension liquid; carrying out high energy ball milling and dispersing on the MXene material so as to obtain a nanometer silicon-Mxene composite turbid liquid; and drying the nanometer silicon-Mxene composite turbid liquid to obtain a nanometer silicon-Mxene composite powder;and (3) coating the nanometer silicon-Mxene composite powder by using asphalt, and carbonizing the nanometer silicon-Mxene composite powder to prepare the core-shell structure nanometer silicon-Mxenecomposite cathode material. The core-shell structure nanometer silicon-Mxene composite cathode material disclosed by the invention has the advantages that the nanometer silicon and the Mxene with a two-dimensional layer structure are combined by using a high energy ball milling method, and a core-shell structure of a porous network is designed; and therefore, volume expansion in the nanometer silicon particle charging and discharging process can be effectively buffered, direct contact between electrolyte and a silicon interface is stopped, the electrical conductivity of an active substance isimproved, so that the specific capacity and cycling stability of a lithium ion battery are improved in a coordinated manner.

Owner:FUJIAN XFH NEW ENERGY MATERIALS CO LTD

Porous silicon-carbon composite material and preparation method thereof

ActiveCN110649236AImprove cycle performanceBuffer volume expansionCell electrodesSecondary cellsComposite materialLithium electrode

Owner:BEIJING IAMETAL NEW ENERGY TECH CO LTD +1

Sodium ion battery negative electrode material containing nitrogen and carbon coated bimetallic sulfide and preparation method thereof

InactiveCN108269987AImprove electrochemical performanceImprove conductivitySecondary cellsNegative electrodesVulcanizationIn situ polymerization

The invention relates to a sodium ion battery negative electrode material containing nitrogen and carbon coated bimetallic sulfide and a preparation method thereof. The preparation method provided bythe invention comprises the steps: firstly, the surface of a bimetallic Prussian blue complex is coated with a nitrogen-containing polymer by an in-situ polymerization method, and then the product isnitrided, carbonized and vulcanized through one-step high temperature annealing. The method has the beneficial effects that the bimetallic Prussian blue complex is coated with nitrogen and carbon, anda bimetallic ion hybrid structure is retained, so that two metal sulfides are formed in the subsequent vulcanization process, and the electrochemical performance of the negative electrode material can be improved by the synergistic action of the two metal sulfides; nitrogen and carbon elements are effectively introduced into the negative electrode material, on one hand, the coated nitrogen and carbon can improve the electrical conductivity of the negative electrode material; on the other end, volume expansion of the negative electrode material in a sodium disembedding process is buffered. Inconclusion, the invention provides the high-performance sodium ion battery negative electrode material.

Owner:HUBEI UNIV +1

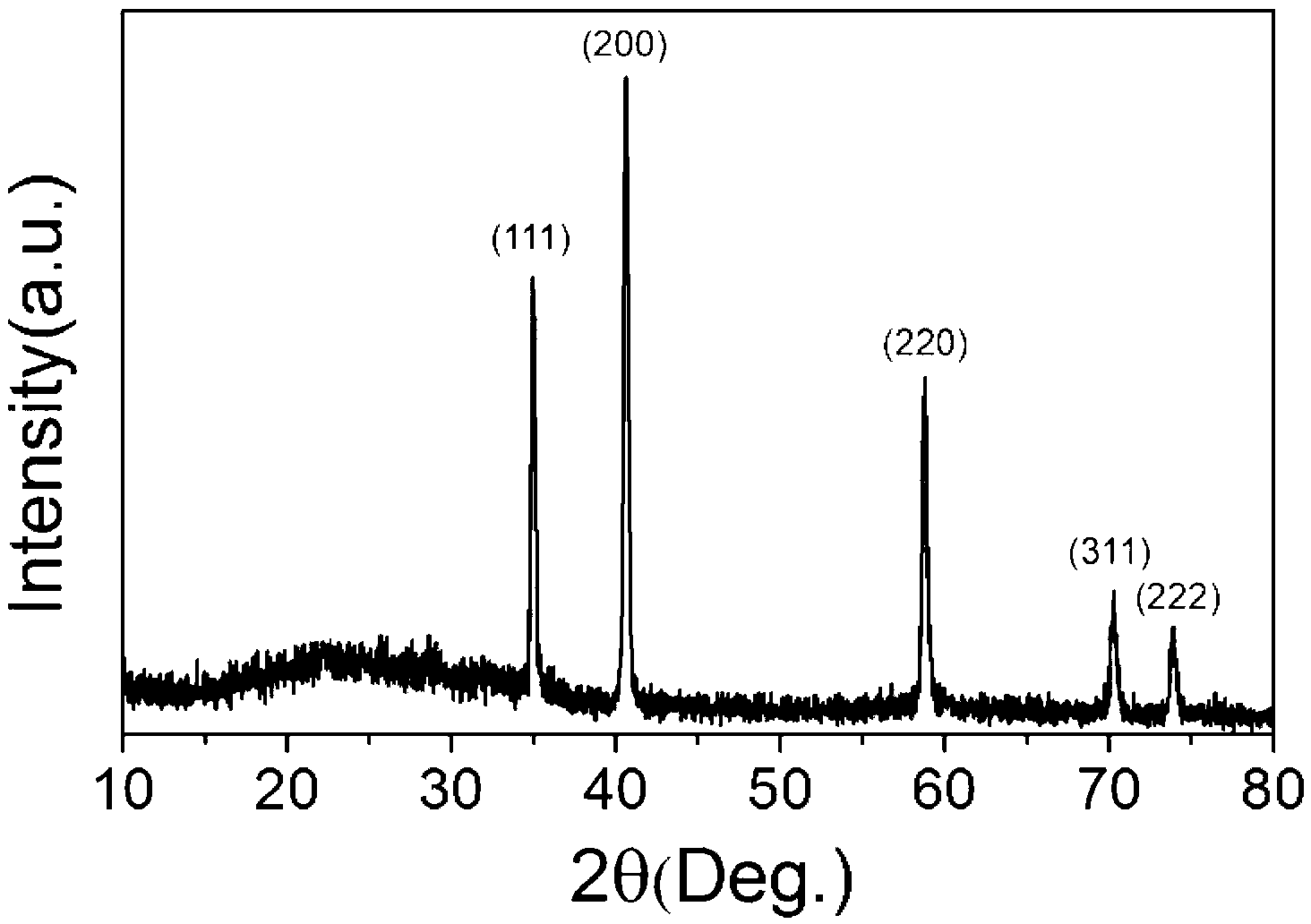

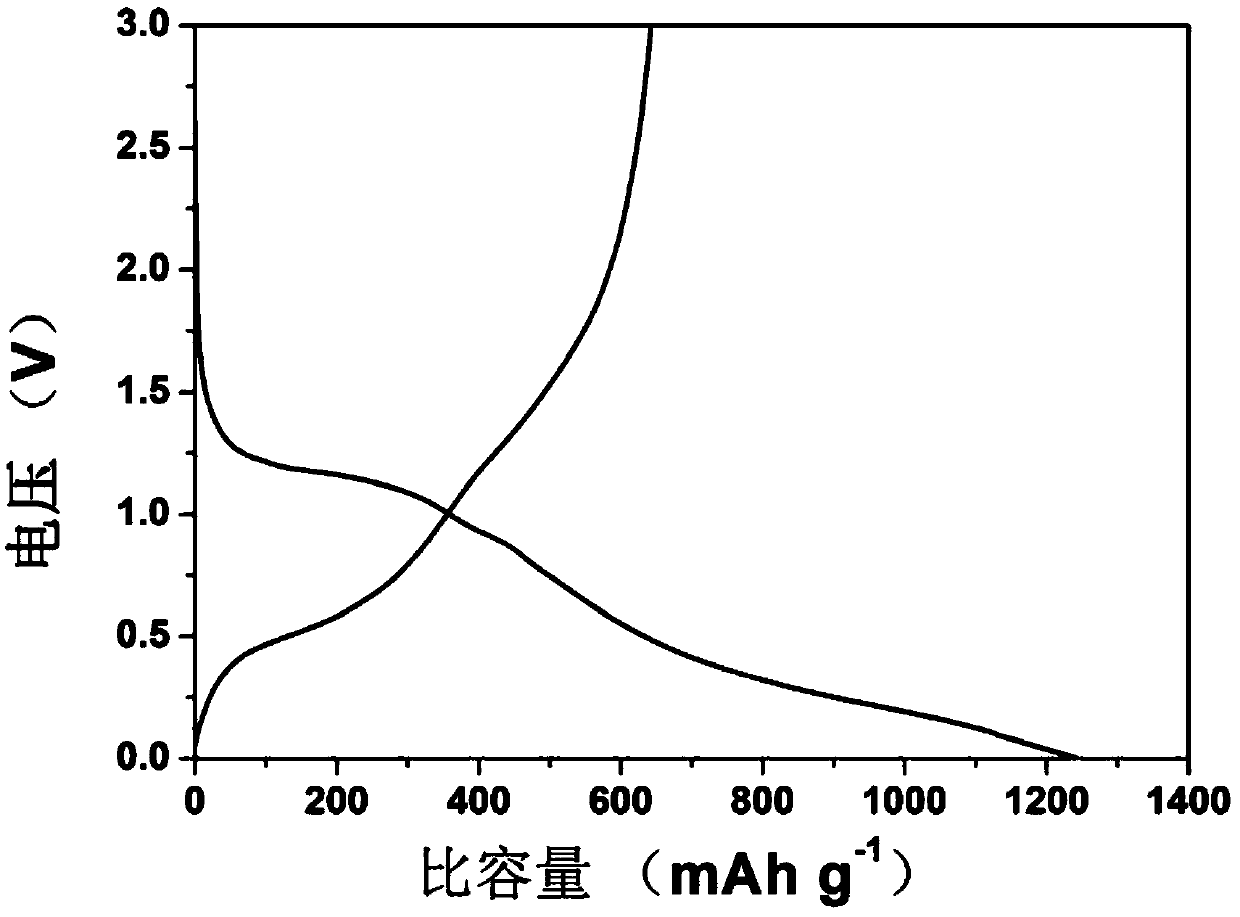

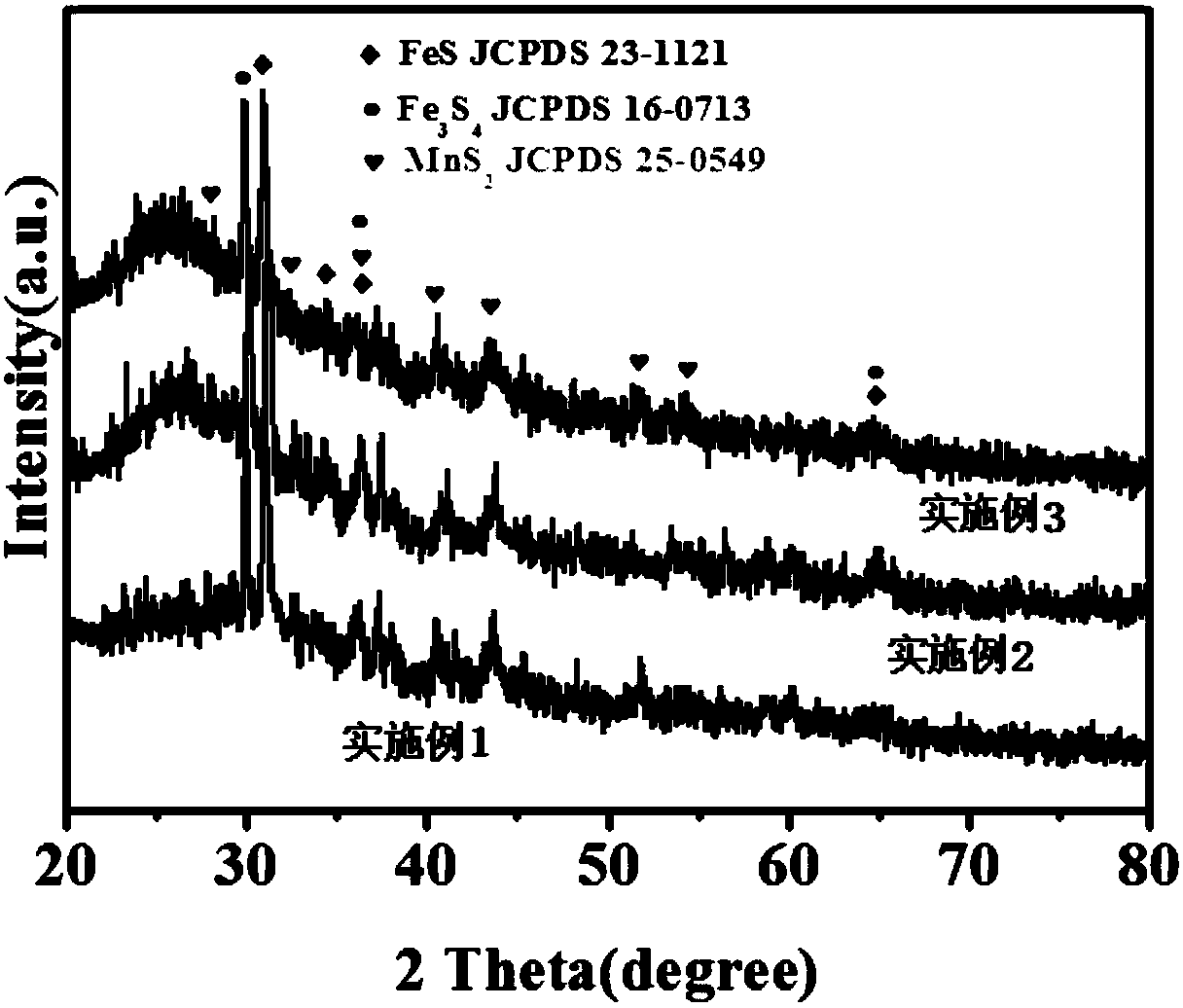

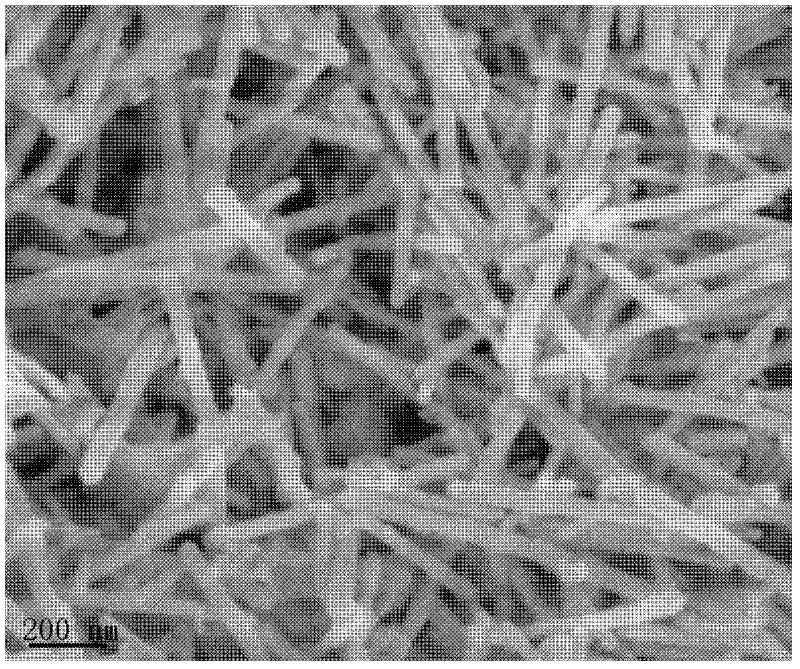

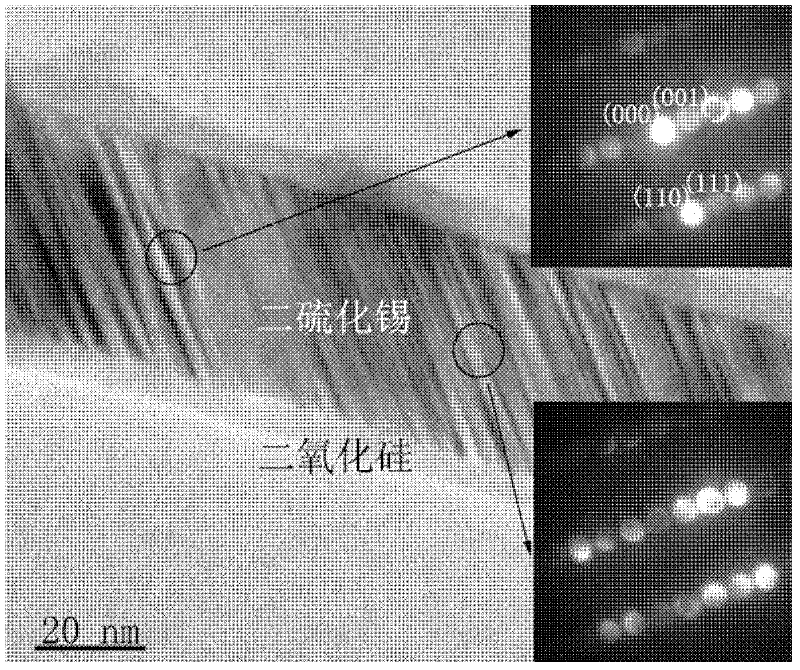

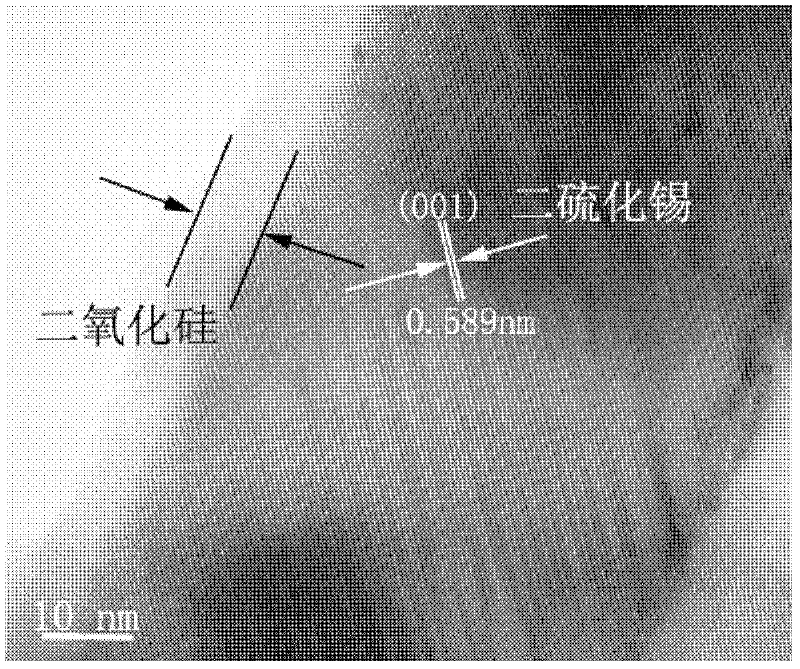

Preparation method of lamellar stannic sulfide/silicon oxide nuclear shell nanorod for lithium battery

ActiveCN102412394AOvercoming Synthetic DifficultiesPromote commercial applicationCell electrodesNanotechnologyVulcanizationSilicon oxide

The invention discloses a preparation method of a lamellar stannic sulfide / silicon oxide nuclear shell nanorod for a lithium battery. The preparation method comprises the following steps of: adding a tin nanorod to ethanol solution and carrying out ultrasonic dispersion; and then sequentially adding a certain amount of water, ammonia water and tetraethoxysilane solution, reacting for 30-720 minutes, carrying out centrifugal separation and drying to obtain a tin / silicon oxide nuclear shell nanorod; carrying out vulcanization reaction on the tin / silicon oxide nuclear shell nanorod in a tube furnace for 30-720 minutes at 400-600 DEG C to finally obtain the lamellar stannic sulfide / silicon oxide nuclear shell nanorod. The preparation method provided by the invention can be used for mass production and is convenient for commercial application to the negative electrode material of a lithium ion battery. After the lamellar stannic sulfide / silicon oxide nuclear shell nanorod which is synthesized by the method disclosed by the invention is applied to the negative electrode material of the lithium ion battery, the cycle performance is remarkably improved.

Owner:ZHEJIANG UNIV

Carbon-coated porous manganese monoxide composite material and preparation method and application thereof

ActiveCN105633373AAvoid growing upImprove conductivityCell electrodesSecondary cellsCarbon layerMicroparticle

The invention discloses a carbon-coated porous manganese monoxide core-shell structure composite material and a preparation method and an application thereof. The preparation method comprises the following steps: firstly, with styrene as a carbon source and potassium peroxodisulfate as an initiator, carrying out soap-free emulsion polymerization to obtain a polystyrene microsphere template, and then carrying out surface modification on microspheres with concentrated sulfuric acid; with common manganese sulfate as a manganese source, preparing manganese carbonate particles embedded with a plurality of polystyrene microspheres by a liquid phase deposition method, and then adding a shell layer material to coat the particle surfaces with a carbon layer; and finally, carrying out high-temperature carbonization to obtain a novel carbon-coated porous manganese monoxide core-shell structure composite material. The composite material is spherical particles with uneven surfaces; and the spherical particles comprise manganese monoxide grains, multi-scale holes and the carbon layer. The special structure with the carbon layer and the multi-scale holes can play a role in buffering volume expansion of manganese monoxide in the repeated charging and discharging processes. The composite material disclosed by the invention has excellent cycling stability and rate capability as an anode material for a lithium-ion battery.

Owner:BEIJING UNIV OF CHEM TECH

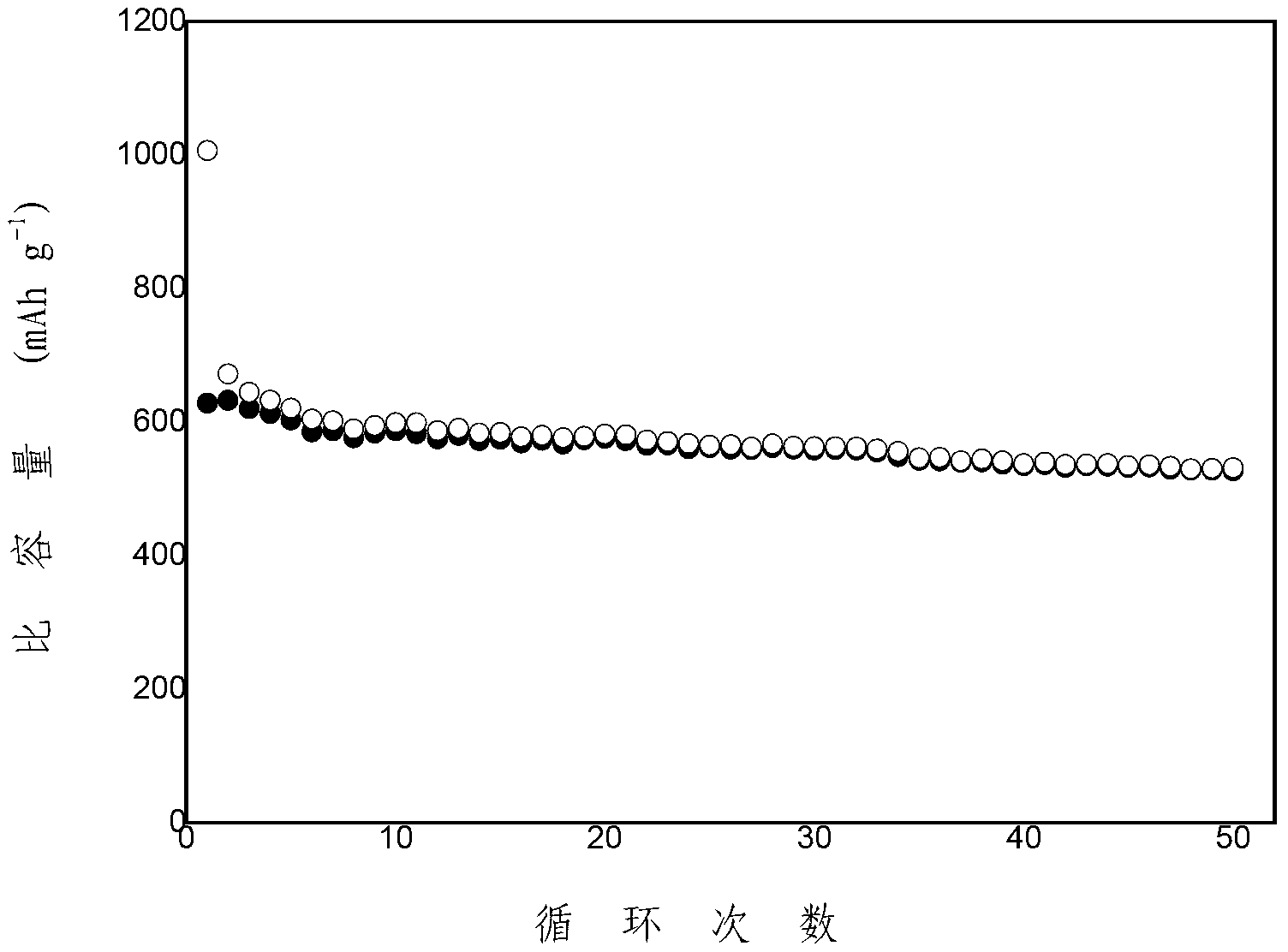

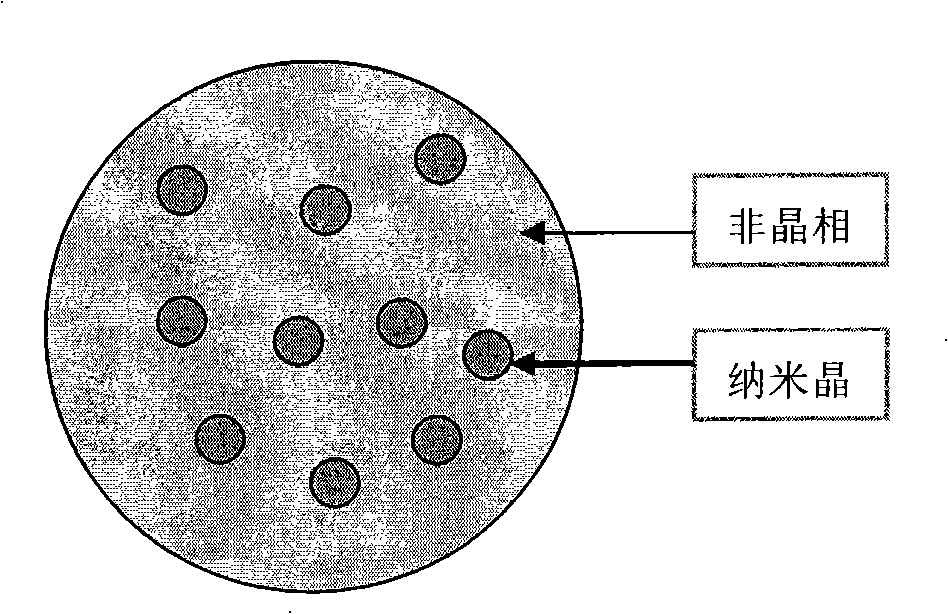

Negative electrode of lithium ionic secondary battery and preparing method thereof

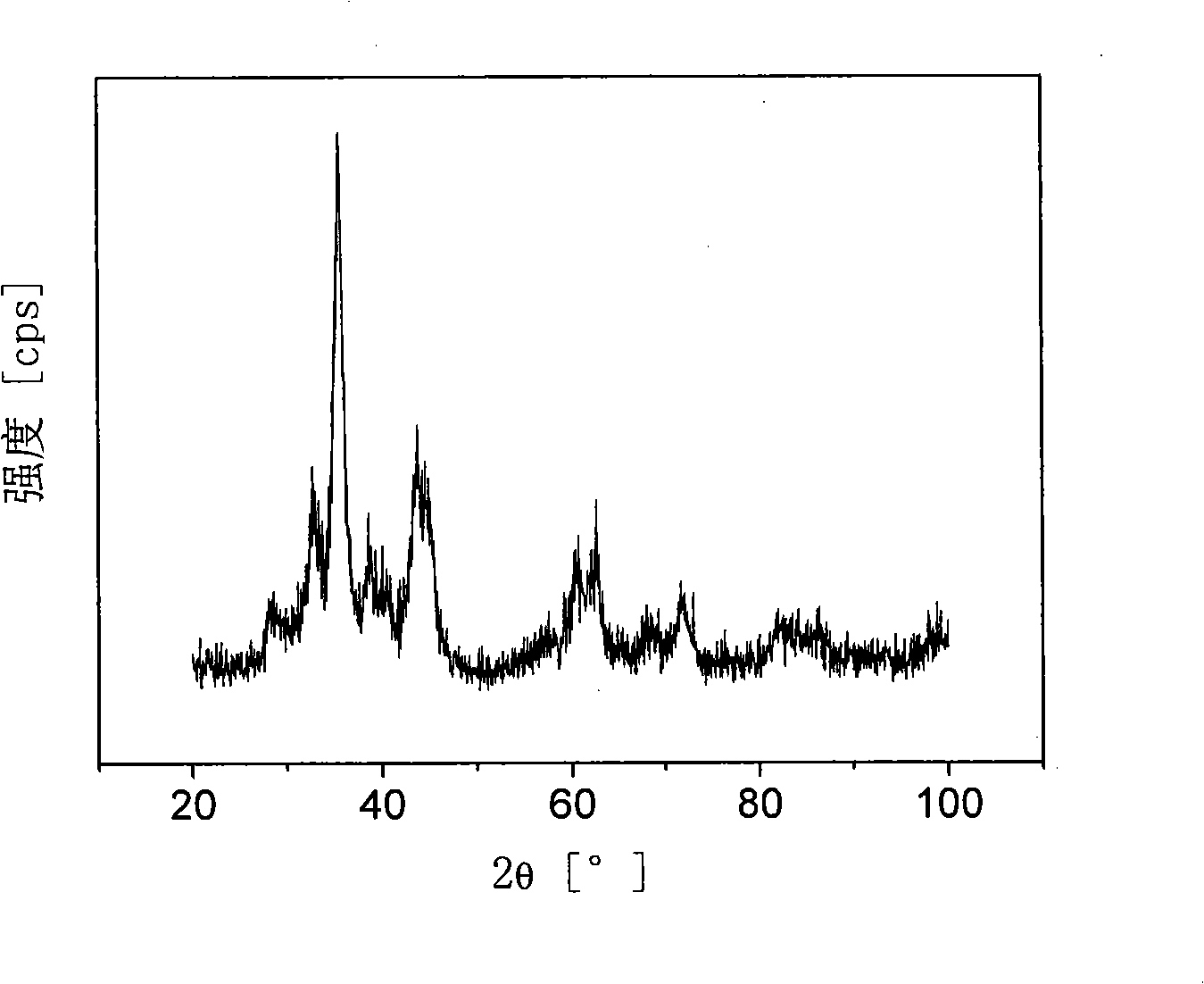

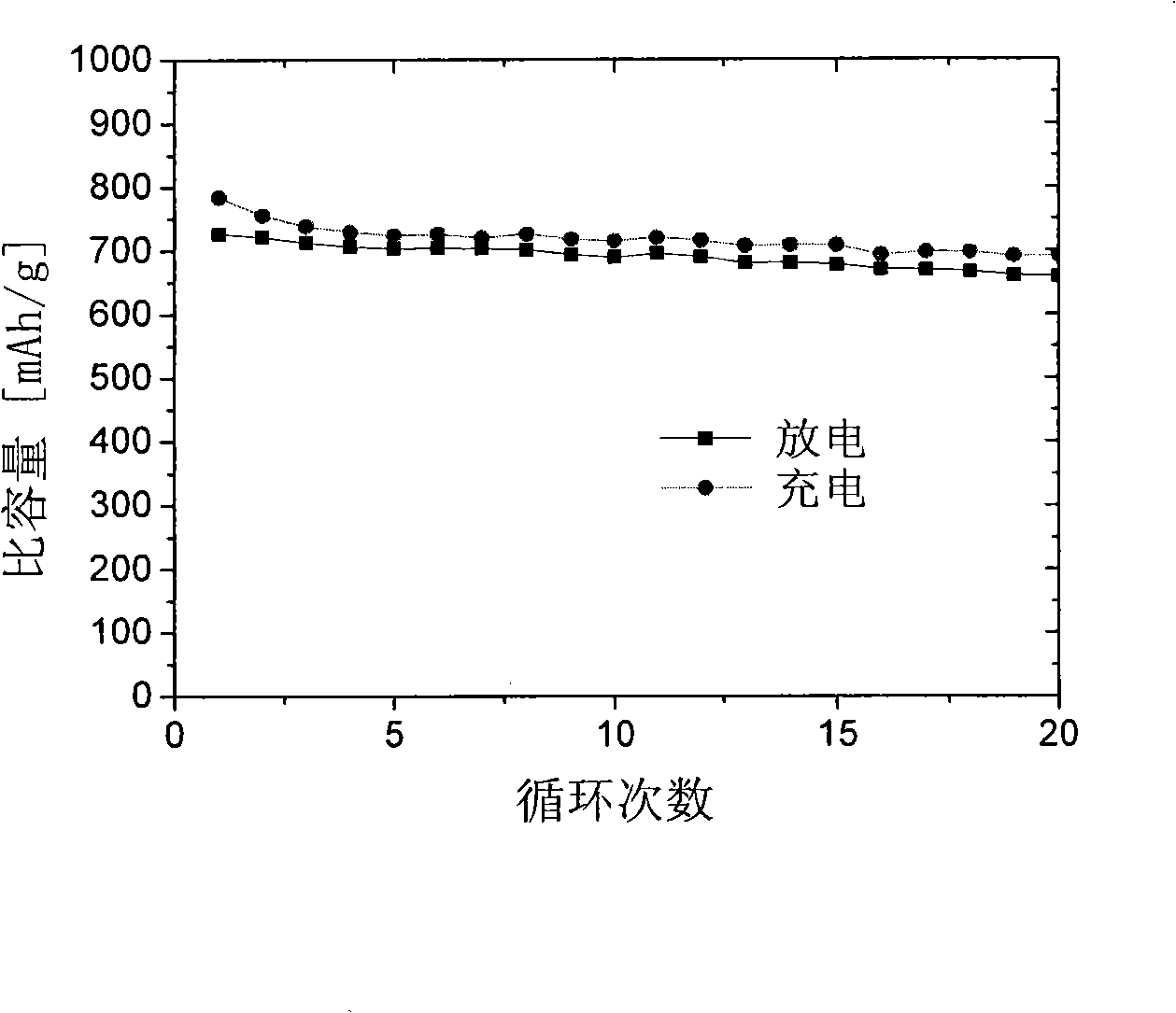

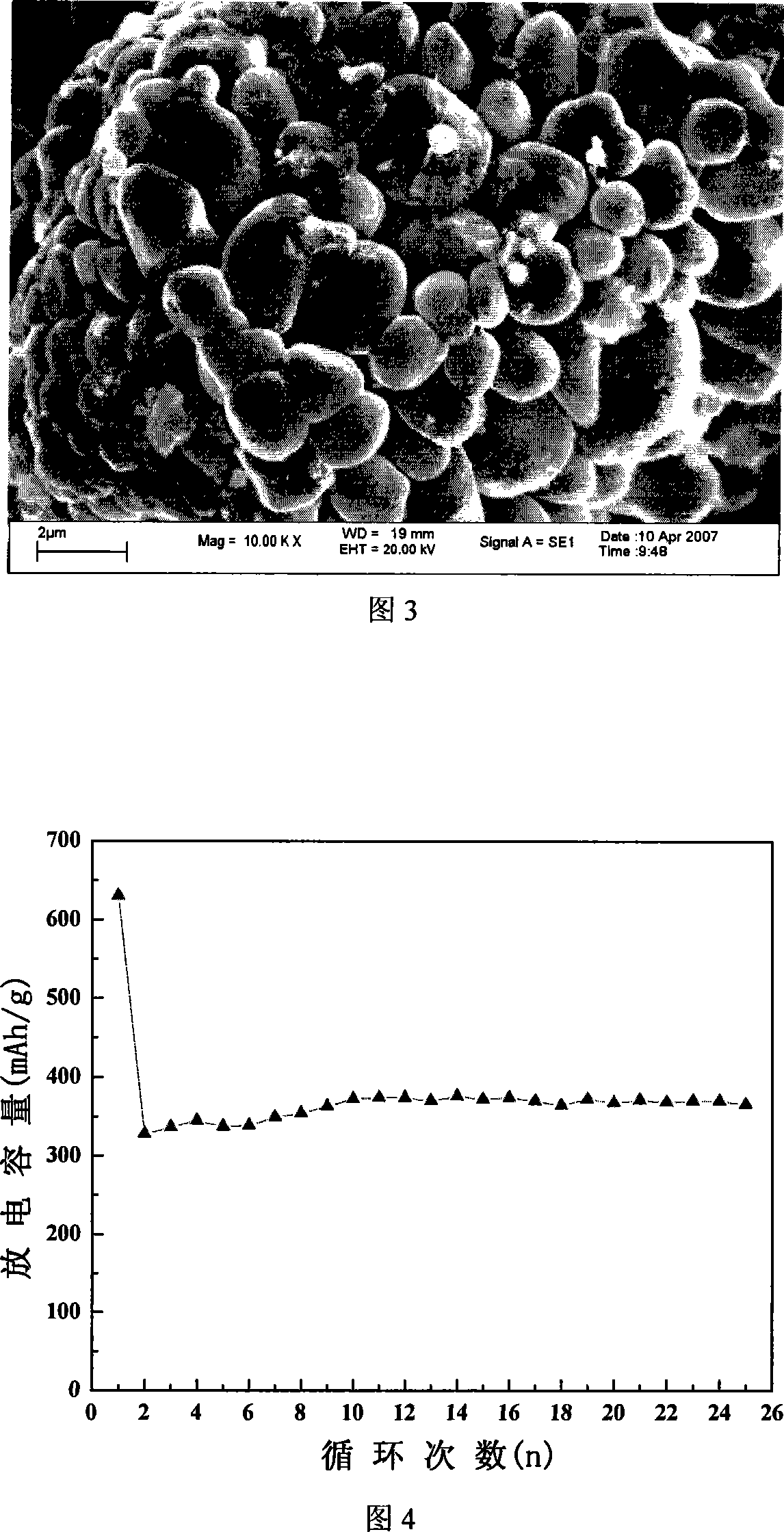

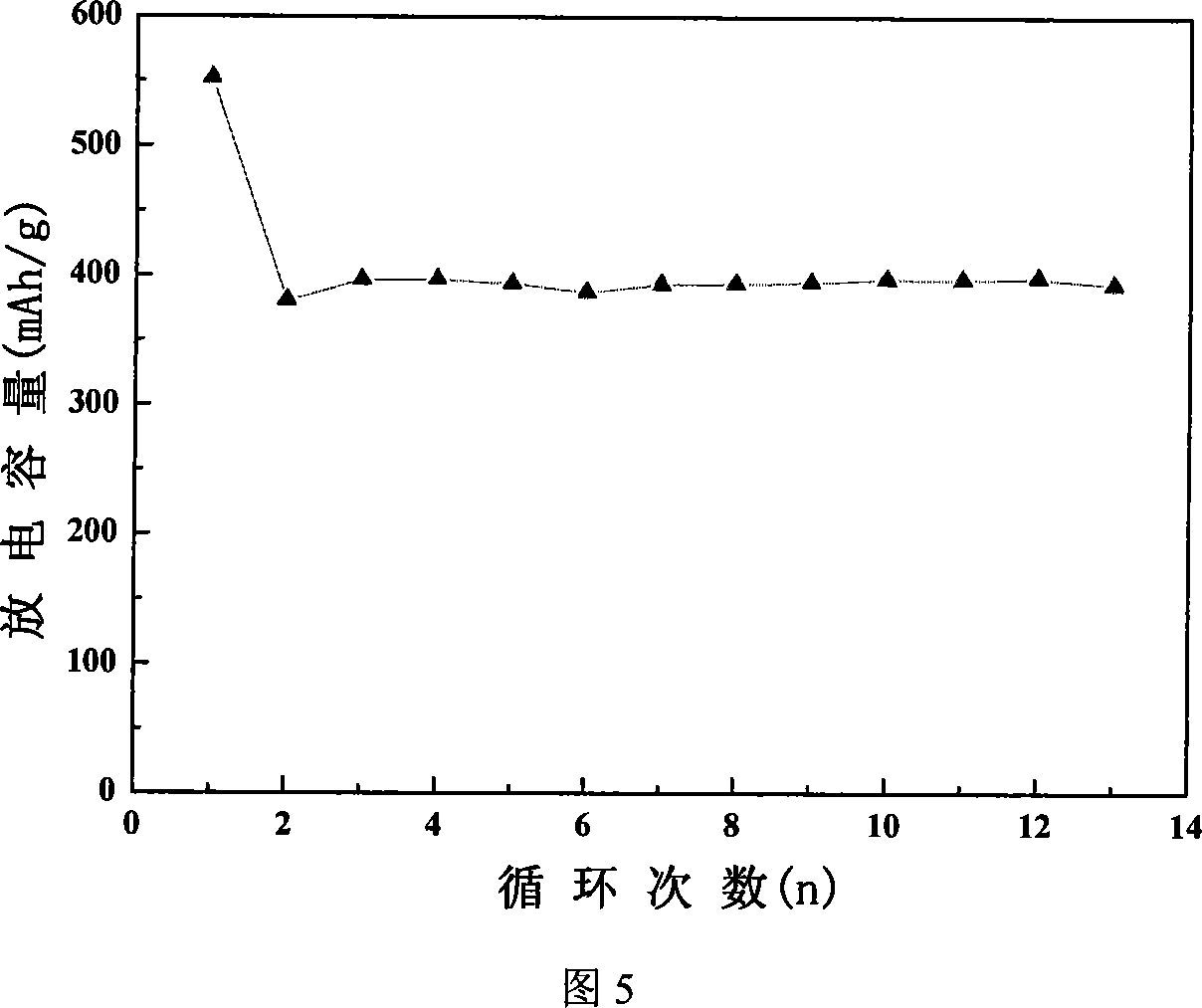

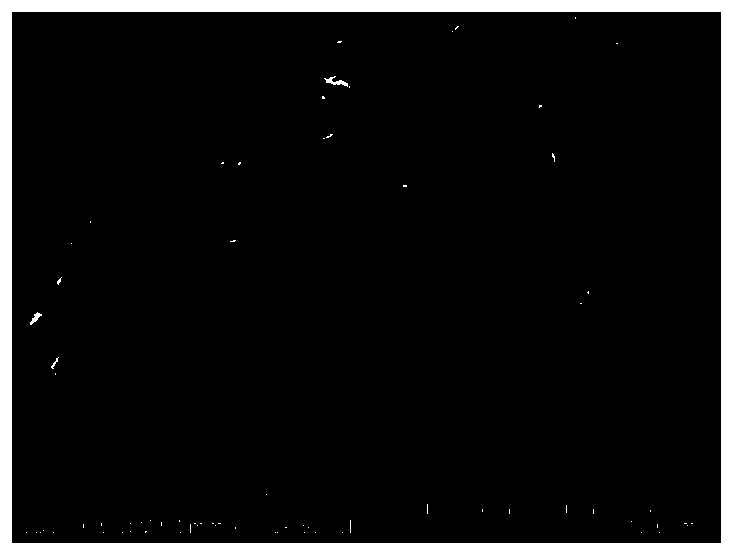

InactiveCN101339990AHigh specific capacityImprove cycle stabilitySecondary cellsActive material electrodesManganeseAlloy

The invention provides a cathode active material of a lithium-ion battery, wherein, the cathode active material comprises a tin base alloy with an amorphous and nanocrystal dual-phase structure. The tin base alloy with the amorphous and nanocrystal dual-phase structure of the invention comprises tin (1); inactive elements (2) which are chosen from one or a plurality of the kinds of iron, cobalt, nickel, copper, titanium, manganese, vanadium and chromium and are not easy to be alloyed with the metal lithium; and carbon (3). The tin base dual-phase alloy of the invention has high specific capacity and good cycling; the maximum reversible capacity can reach 706Ah / g, and the capacity conservation rate keeps more than 96% after 20 cycles. In addition, the invention further provides a method for preparing the cathode active material.

Owner:ADVANCED TECHNOLOGY & MATERIALS CO LTD

Production technology for concrete building block of autoclaving and air entraining of circulating fluid bed fly ash

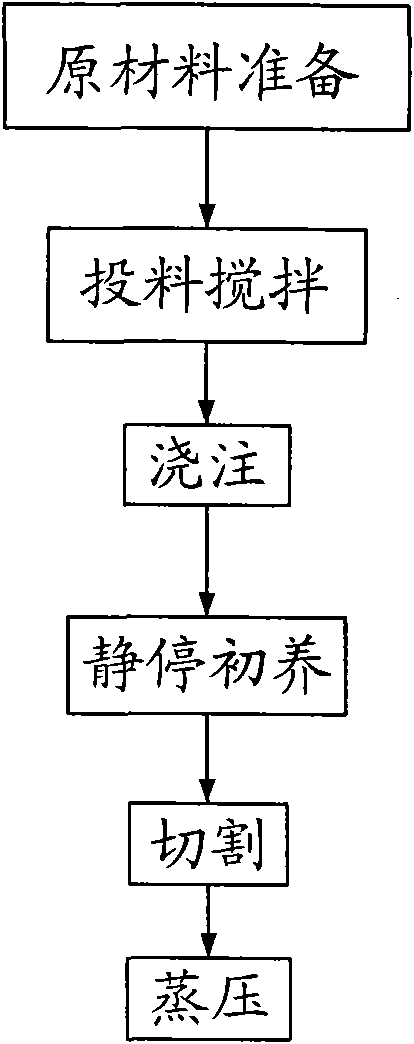

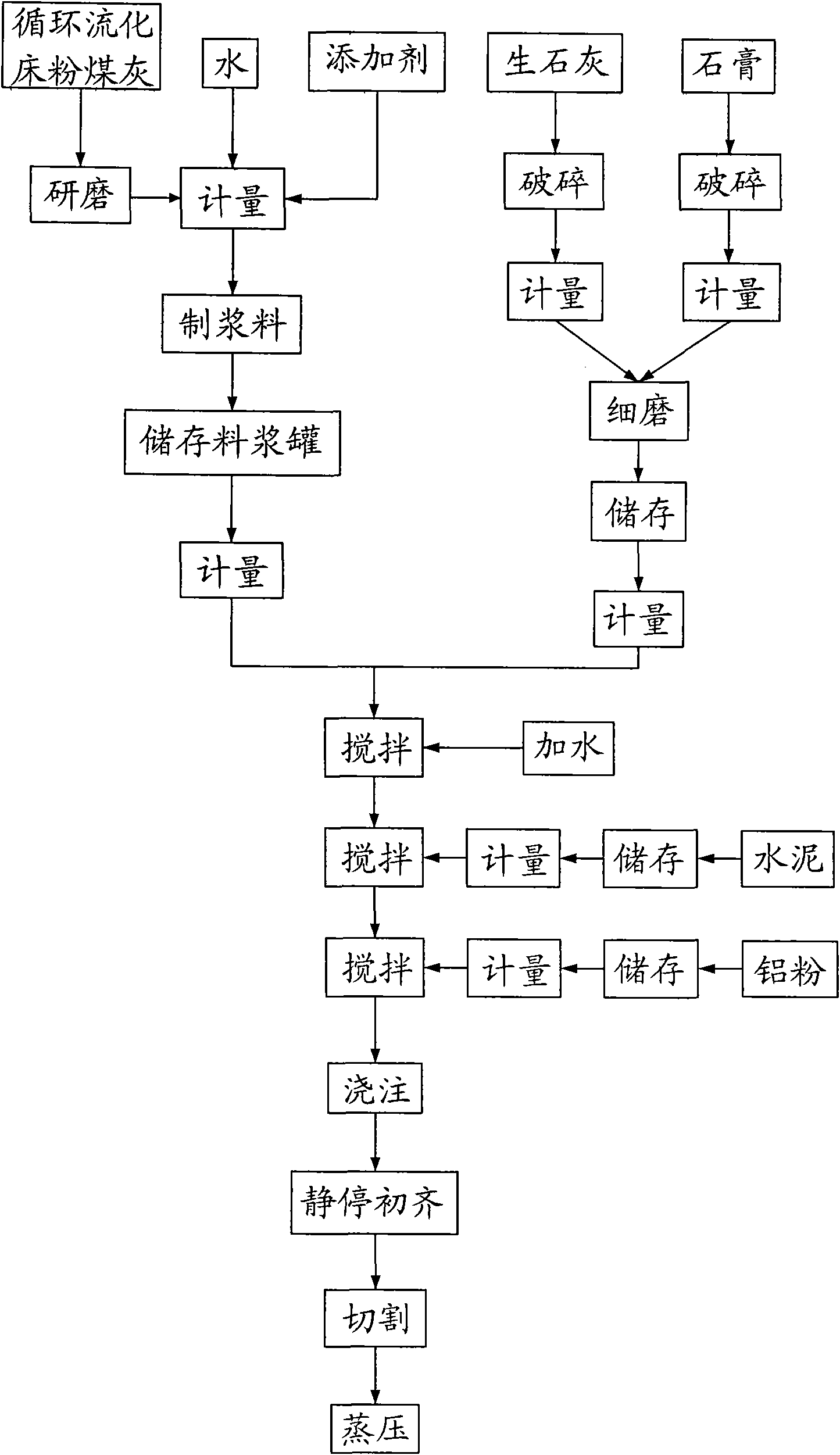

ActiveCN101564866AHigh economic valueReduce formationSolid waste managementMixing operation control apparatusFly ashGypsum

The invention discloses a production technology for a concrete building block of autoclaving and air entraining of circulating fluid bed fly ash, which comprises the steps of raw material preparation, feeding, stirring, pouring, stationary primary maintenance, cutting, autoclaving and finished product obtaining. The raw material proportion in the step of raw material preparation is as follows: 60 to 70 parts of circulating fluid bed fly ash, 16 to 23 parts of quick lime, 3 to 4 parts of plaster, 7 to 10 parts of cement, 0.07 to 0.12 part of aluminum powder, 60 to 70 parts of water, and 1 to 3 parts of additive, wherein the additive is a water reducing agent, Na2SO4 and CaCl2, and the proportion of the water reducing agent, the Na2SO4 and the CaCl2 is 1:1:1. According to the property of the circulating fluid bed fly ash, the invention improves the production technology for the concrete building block of autoclaving and air entraining of common fly ash, uses the additive for inhibiting and reducing the volume expansion caused by the formation of ettringite after the material is hardened, improves the technical flow, and realizes the higher economic value of the circulating fluid bed fly ash.

Owner:FUJIAN UNIV OF TECH

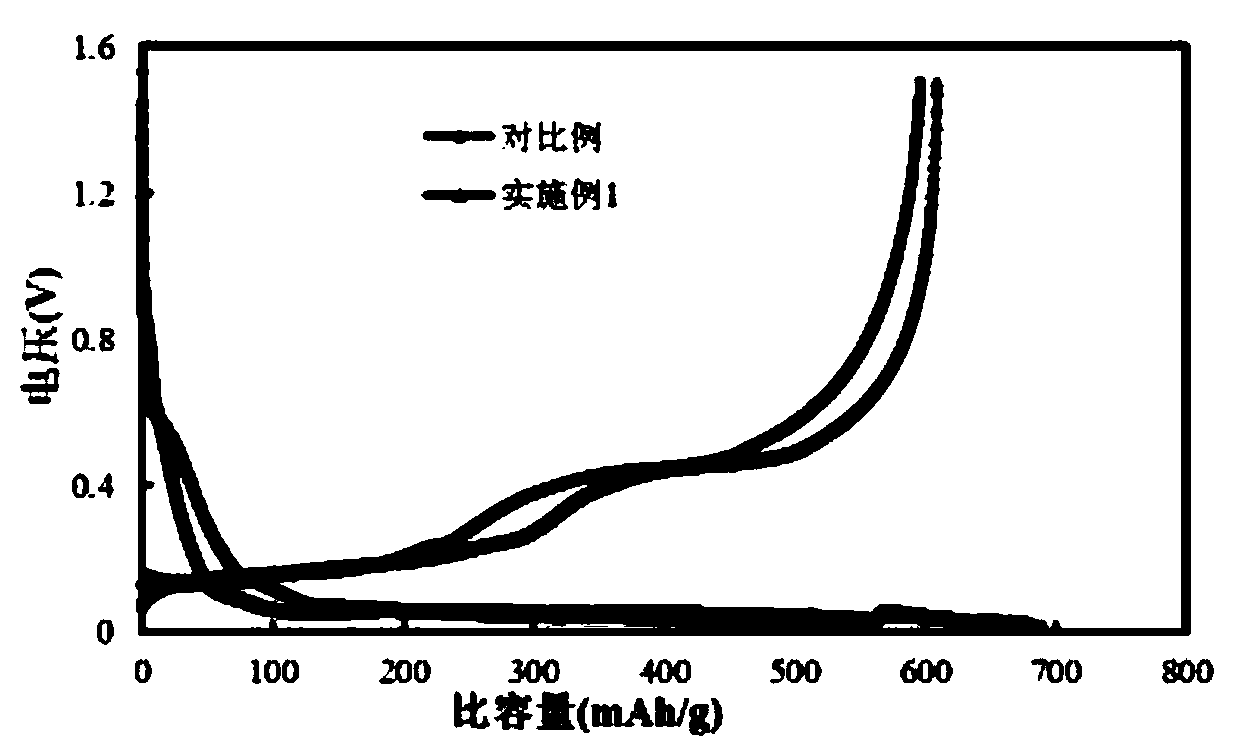

Lithium sulfur battery and preparation method thereof

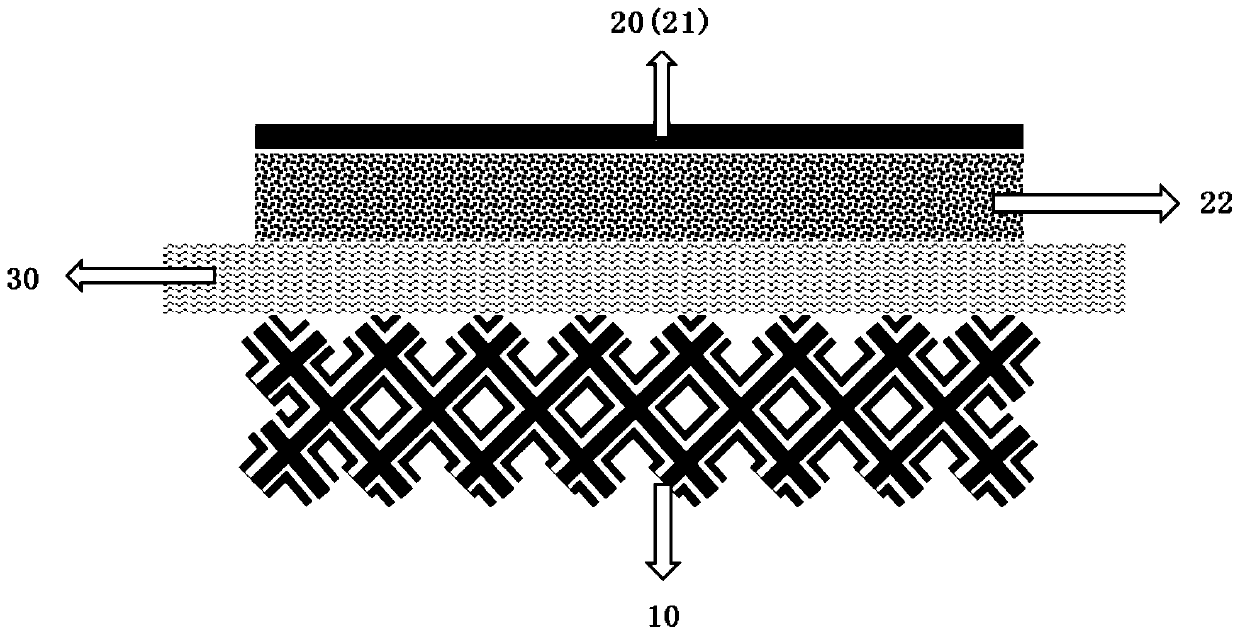

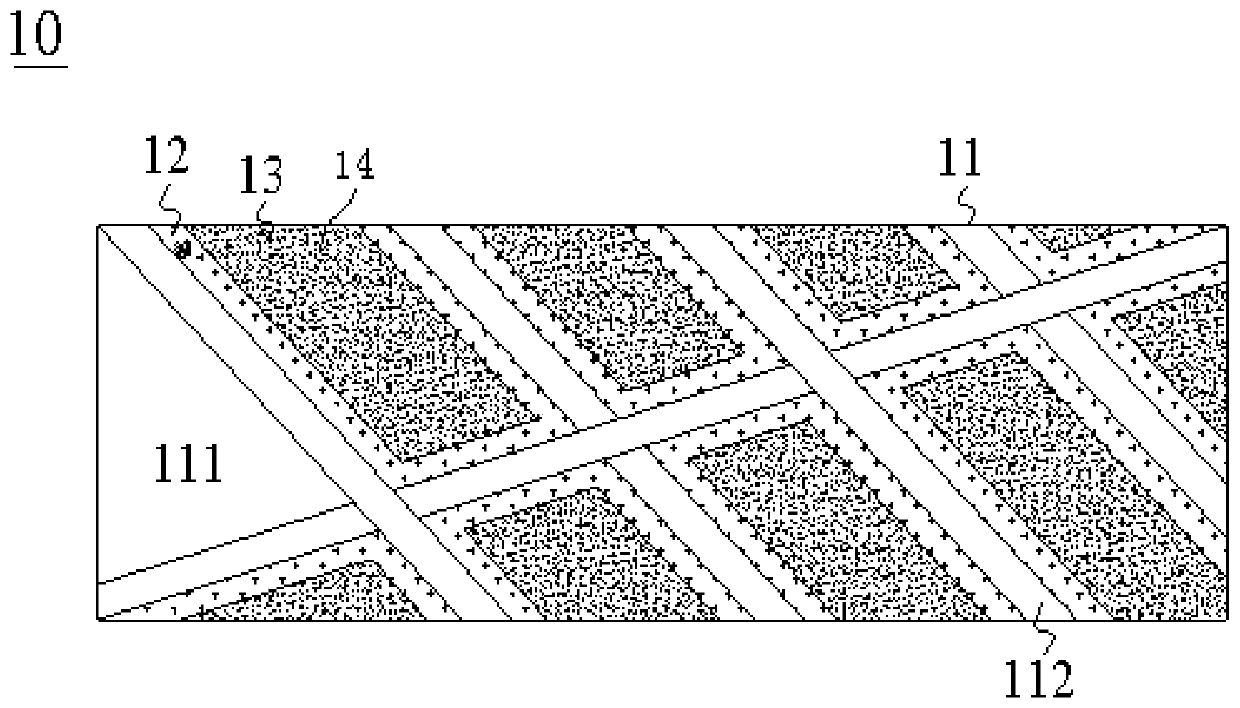

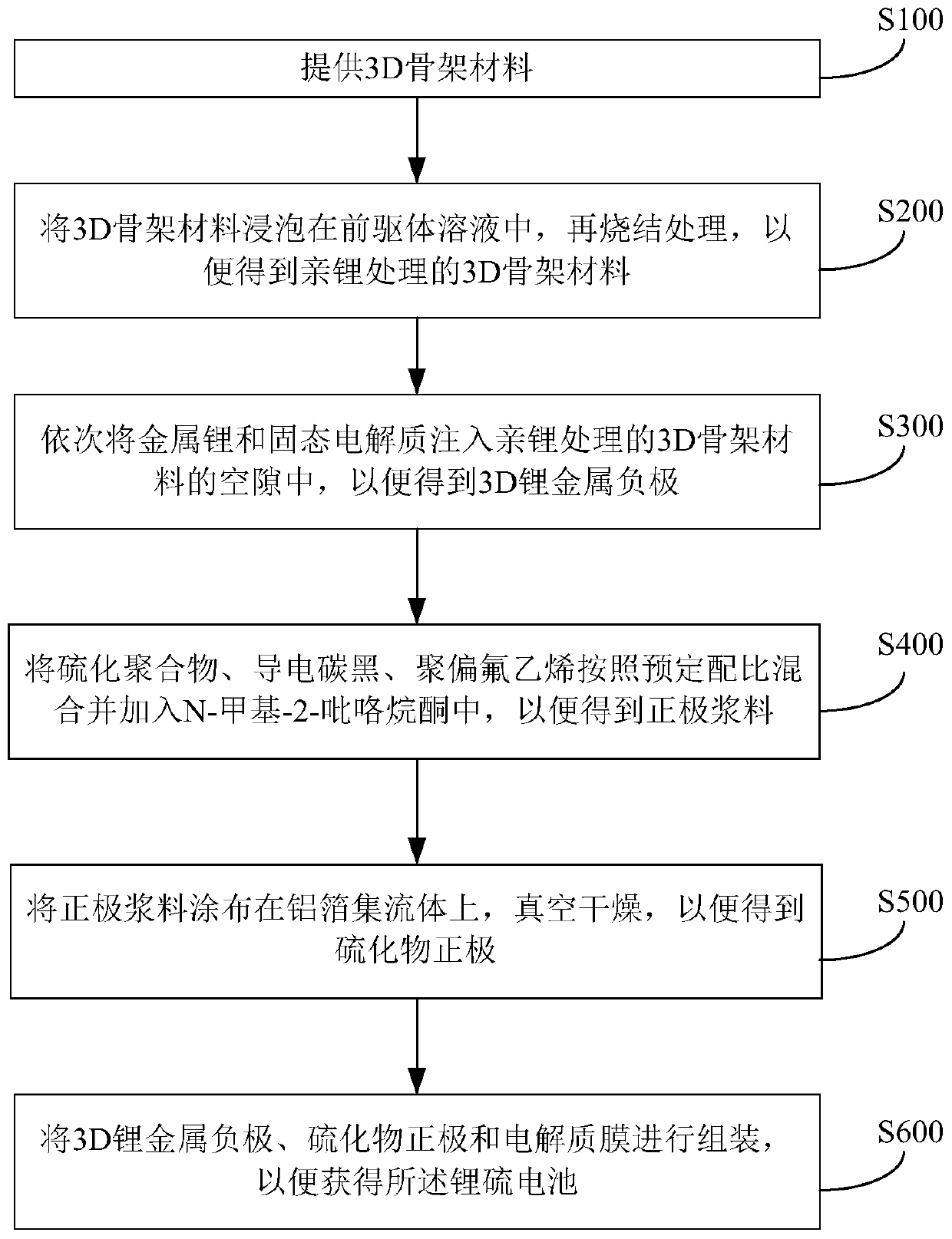

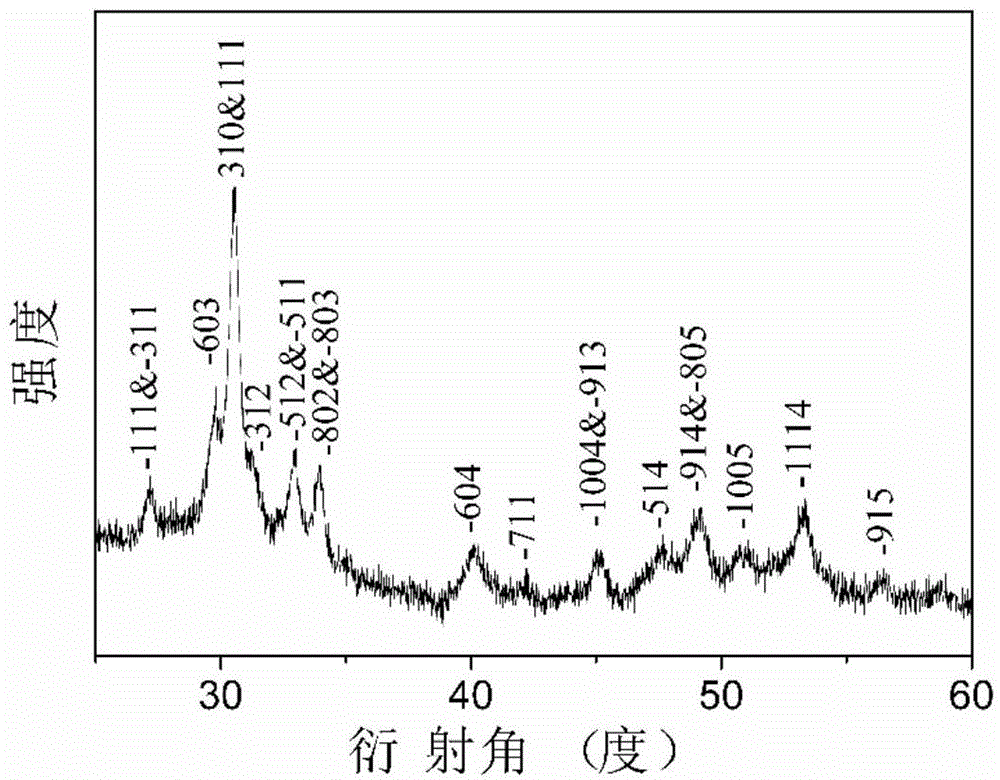

ActiveCN109786669AInhibitionImprove securityElectrode manufacturing processesFinal product manufactureLithium–sulfur batterySulfide

The invention provides a lithium sulfur battery and a preparation method thereof. The lithium sulfur battery comprises a 3D lithium metal negative electrode, a sulfide positive electrode and an electrolyte membrane, wherein the electrolyte membrane is arranged between the 3D lithium metal negative electrode and the sulfide positive electrode, wherein the 3D lithium metal negative electrode comprises a 3D framework material, a lithium-friendly layer, a metal lithium and a solid electrolyte, and the lithium-friendly layer covers the surface of the gap of the 3D framework material; the metal lithium is filled in the gap of the 3D framework material; and the solid electrolyte is filled in the gap of the 3D framework material. The lithium sulfur battery and the preparation method thereof can effectively inhibit the generation of lithium dendrites, reduce the problems of volume expansion and the like, and improve the safety of the lithium sulfur battery system.

Owner:SVOLT ENERGY TECHNOLOGY CO LTD

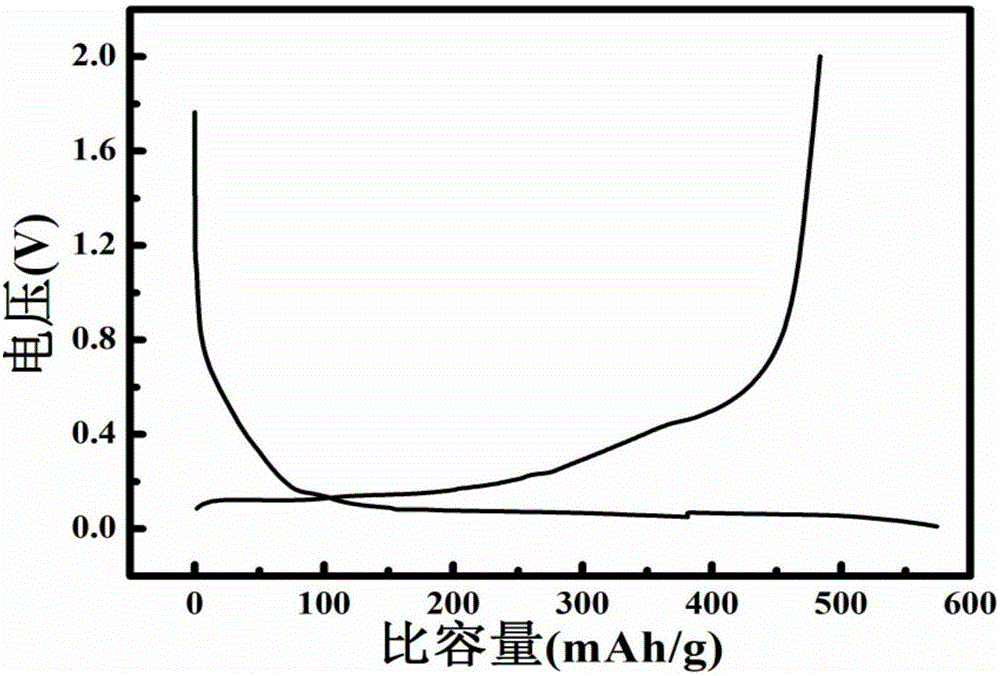

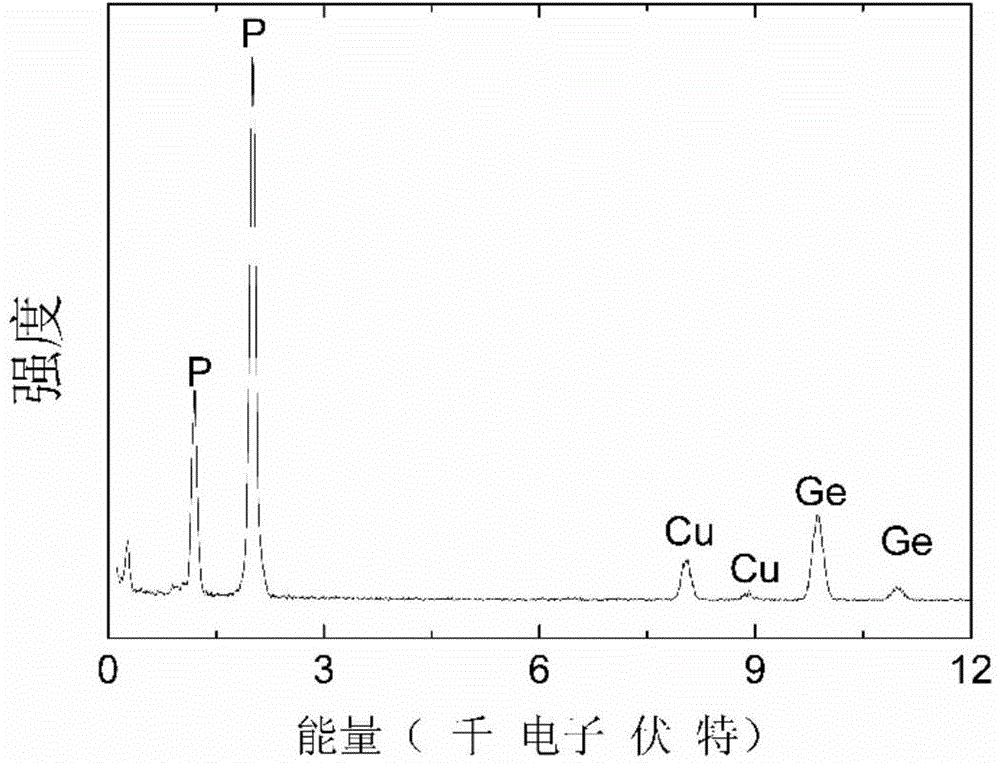

Negative electrode active material for lithium-ion/sodium-ion battery, negative electrode and battery

ActiveCN104600299AHigh lithium/sodium storage capacityHigh lithium/sodium storage activityCell electrodesSecondary cellsLithiumCharge discharge

The invention provides a negative electrode active material for a lithium-ion / sodium-ion secondary battery, a negative electrode and a battery, belonging to the technical field of electrochemistry and batteries. The negative electrode active material comprises a phosphorus-germanium compound, or / and a first complex formed by the phosphorus-germanium compound and elementary P or / and elementary Ge, or / and a second complex formed by the phosphorus-germanium compound and conductive components, or / and a third complex formed by the first complex and conductive components. The negative electrode provided by the invention comprises the negative electrode active material. The negative electrode has the advantages of high specific capacity, high initial Coulomb efficiency, small charge-discharge voltage platform difference and good high-current charge-discharge performance.

Owner:HUAZHONG UNIV OF SCI & TECH

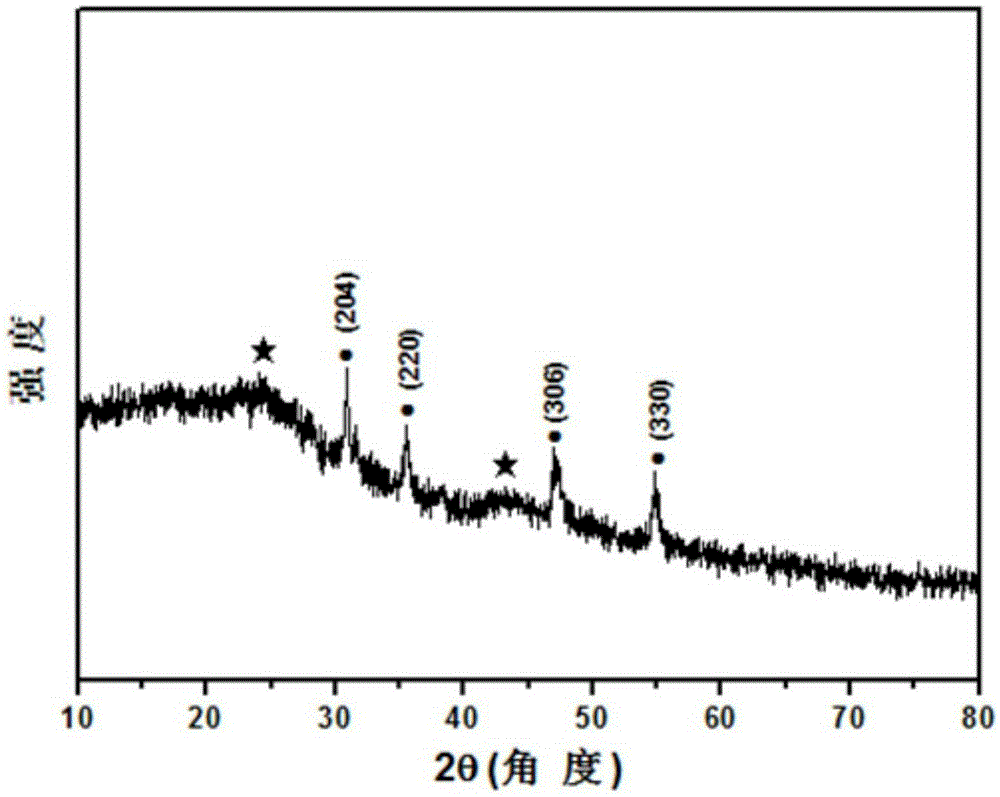

Preparation method of nickel ion doped cobalt sulfide/conductive substrate composite material

ActiveCN105304872AUniform depositionBuffer volume expansionMaterial nanotechnologyCell electrodesLithium-ion batteryBattery cell

The invention relates to a preparation method of a nickel ion doped cobalt sulfide / conductive substrate composite material. The preparation method of the nickel ion doped cobalt sulfide / conductive substrate composite material relates to the technical field of lithium ion batteries, and aims to solve the technical problem that the negative material of an existing lithium ion battery is poor in cycling stability and low in rate capability. The method comprises the following steps of (1) treating a substrate; (2) preparing a solution; (3) preparing a precursor; (4) heat treating. The electrode material prepared by the invention can be used as the negative material to be directly assembled to form the lithium ion battery. The electrode material is directly used as an electrode without adding any conductive agent and binding agent. The electrode preparation process is simplified, the preparation cost is reduced, and the capacity, the power density performance and the cycling stability of the battery are improved.

Owner:HEILONGJIANG UNIV

Lithium ion battery anode material and preparation method thereof

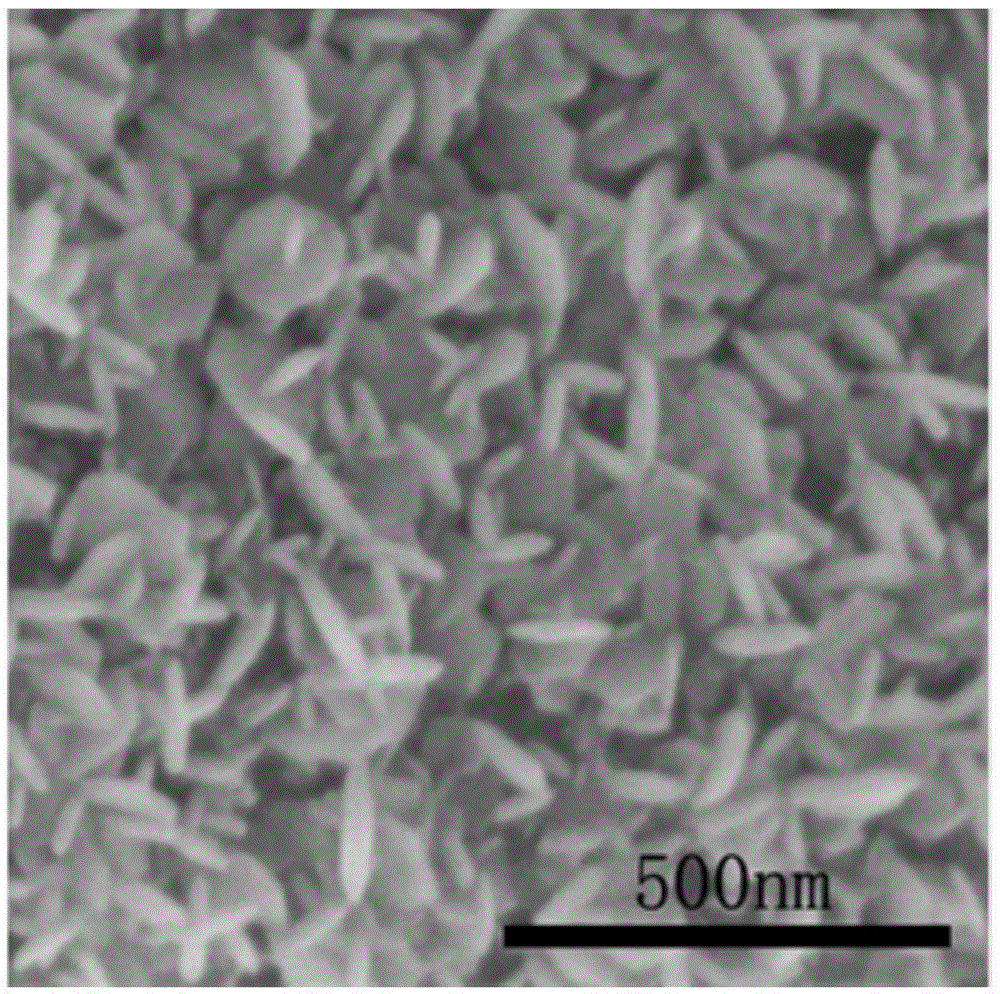

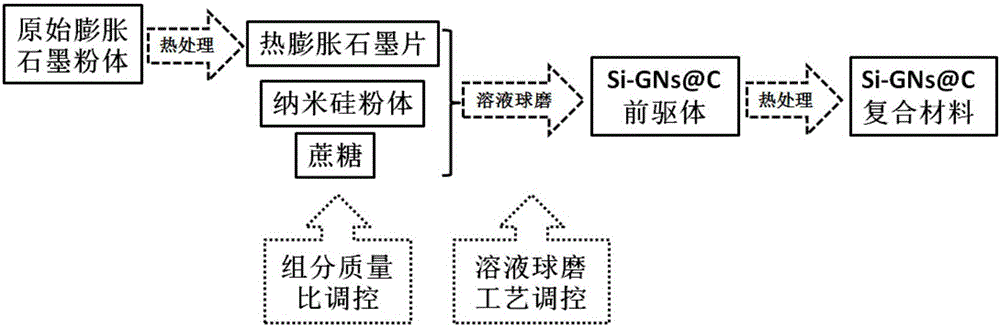

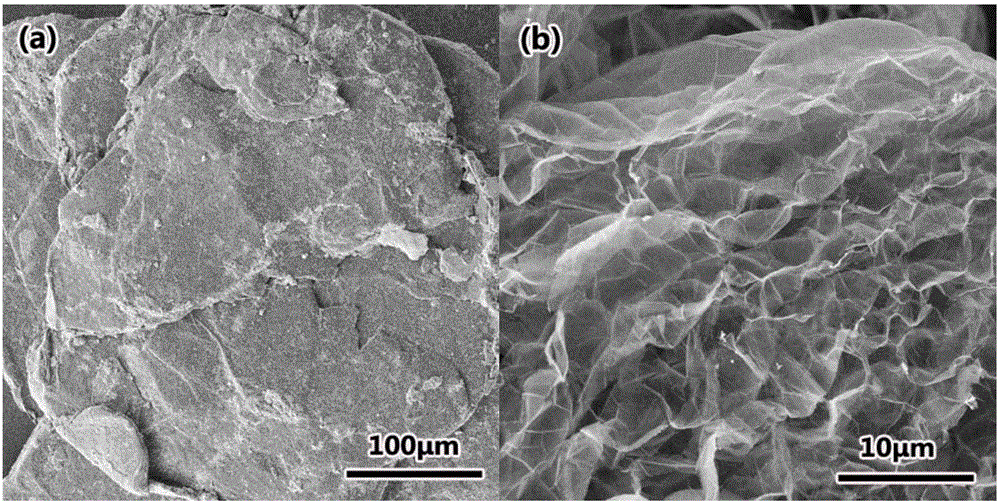

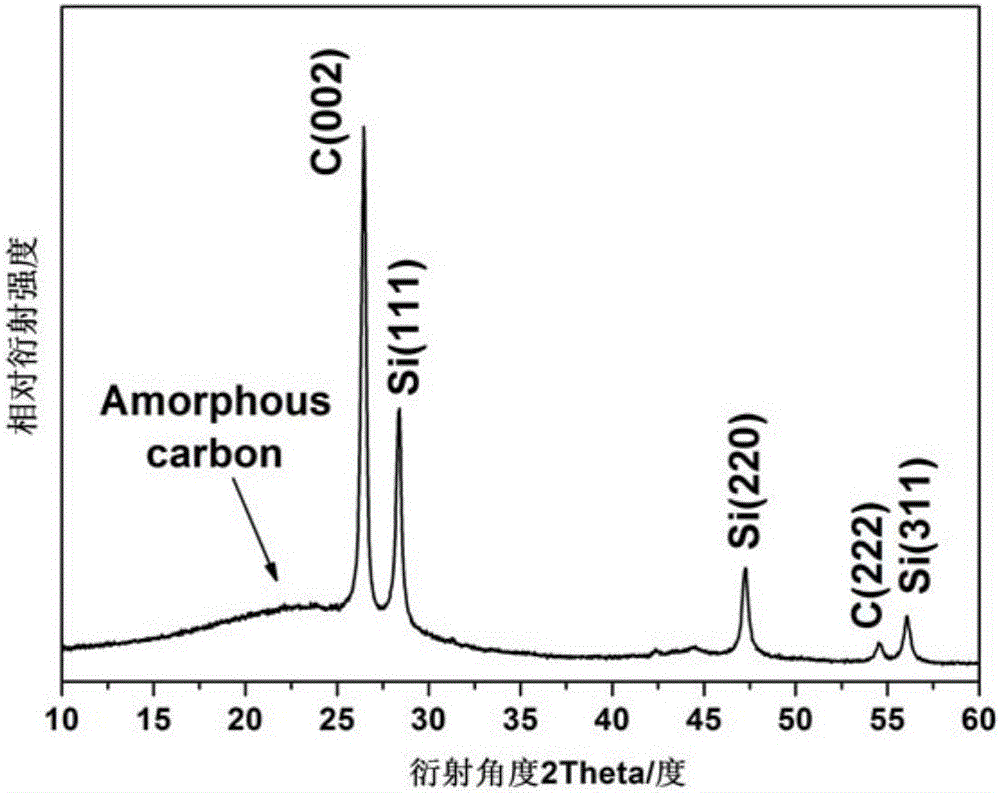

ActiveCN105047888ALow priceSufficient materialCell electrodesSecondary cellsNano siliconCarbonization

The invention discloses a lithium ion battery anode material and a preparation method thereof. The preparation method comprises the following steps: (1), preparing thermal expansion graphite sheets; (2), mixing nano silicon powder, cane sugar and the thermal expansion graphite sheets, adding the obtained mixture to a mixed solution of ethanol and deionized water, stirring and then carrying out solution ball-milling, wherein the ball-milling speed is 800-1600rpm and the ball-milling time is 2-4 hours, so as to obtain an anode material precursor solution; and (3), drying the anode material precursor solution, and carrying out carbonization heat treatment in the atmosphere of a protective gas, so as to obtain the lithium ion battery anode material. The structure characteristics of the lithium ion battery anode material are that nano silicon particles are evenly dispersed on a graphene nanosheet base body and the outermost layer is coated with carbon. The preparation method disclosed by the invention is a method of combining heat treatment with solution ball-milling, and has the characteristics of being simple, efficient and the like; industrialized production is easy to realize; and the lithium ion battery anode material prepared by the method has the advantages of stable structure, good cycle performance and the like.

Owner:SOUTH CHINA UNIV OF TECH

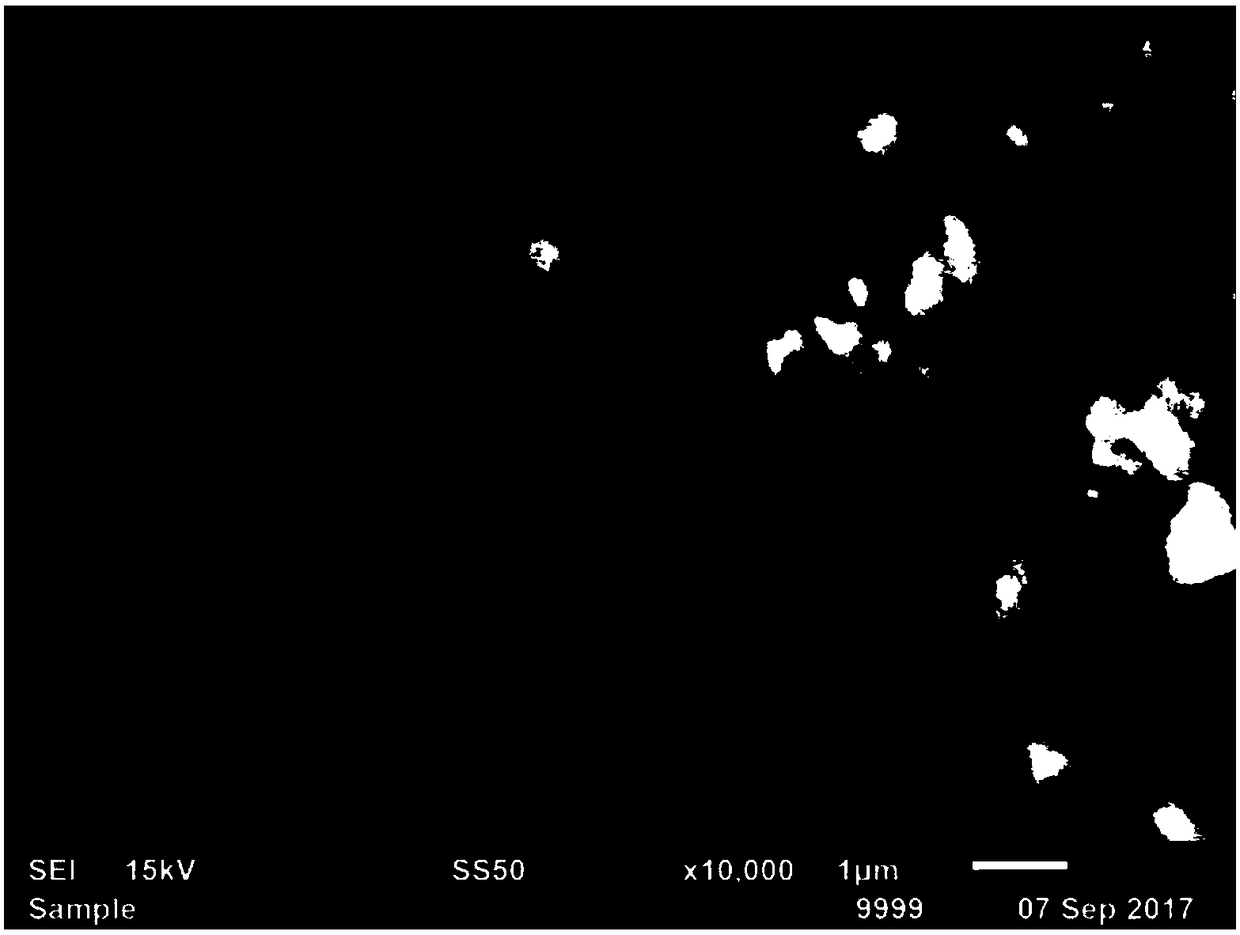

Preparation method for sodium-ion battery antimony/carbon anode composite material with yolk-shell structure

InactiveCN104900858ABuffer volume expansionImprove thermal stabilityCell electrodesSecondary cellsIonYolk

The invention discloses a preparation method for a sodium-ion battery antimony / carbon anode composite material with a yolk-shell structure. The preparation method comprises the following steps: preparing nano antimony particles through a reduction method; sequentially coating the surfaces of the nano antimony particles with a silicon dioxide layer and a poly-dopamine layer; carbonizing, and removing the silicon dioxide layer through an etching method to obtain the antimony / carbon anode composite material with the yolk-shell structure. The antimony / carbon anode composite material is good in mechanical stability and thermal stability, and can be used to prepare a sodium-ion battery with high mass ratio capacity and good rate capability. The preparation method is simple in operation, easy to operate, low in cost and suitable for being applied to industry and mass production.

Owner:CENT SOUTH UNIV

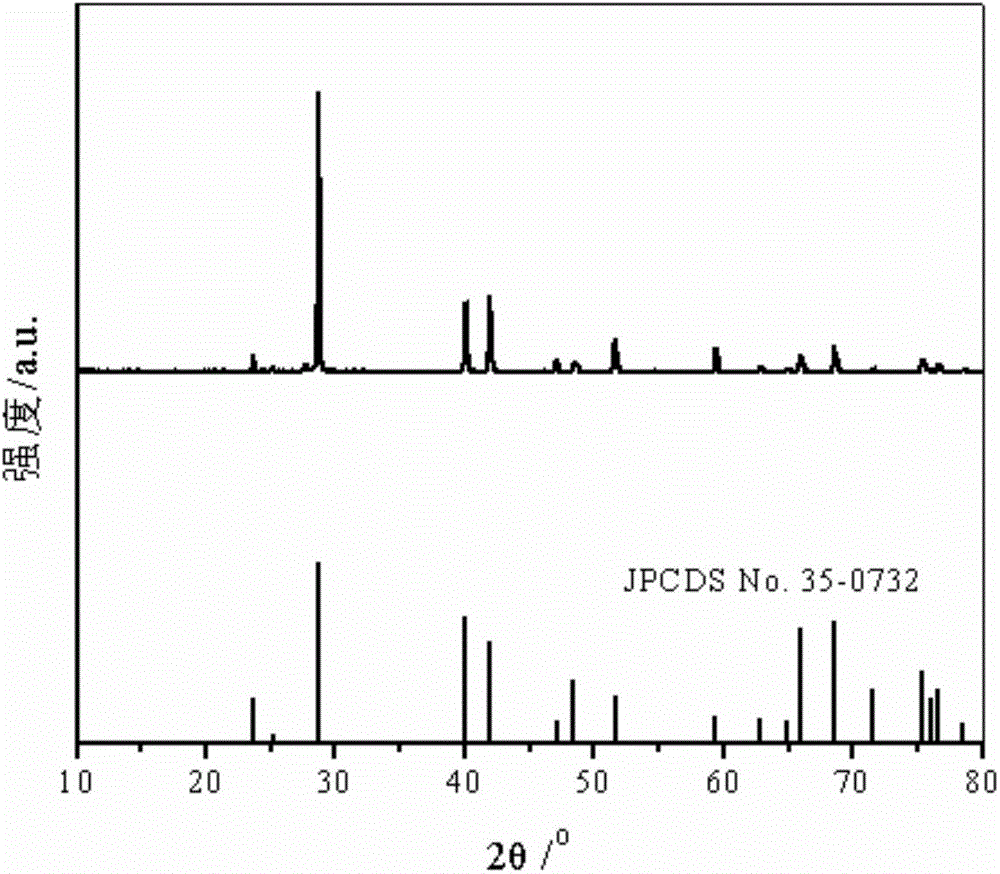

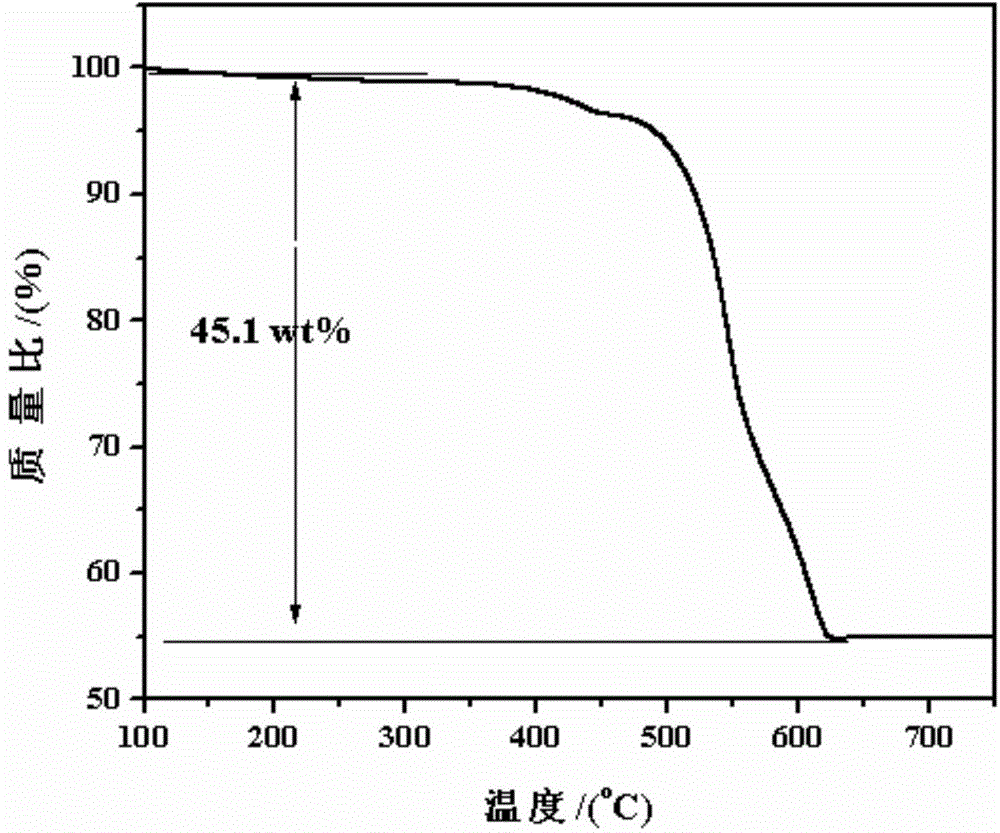

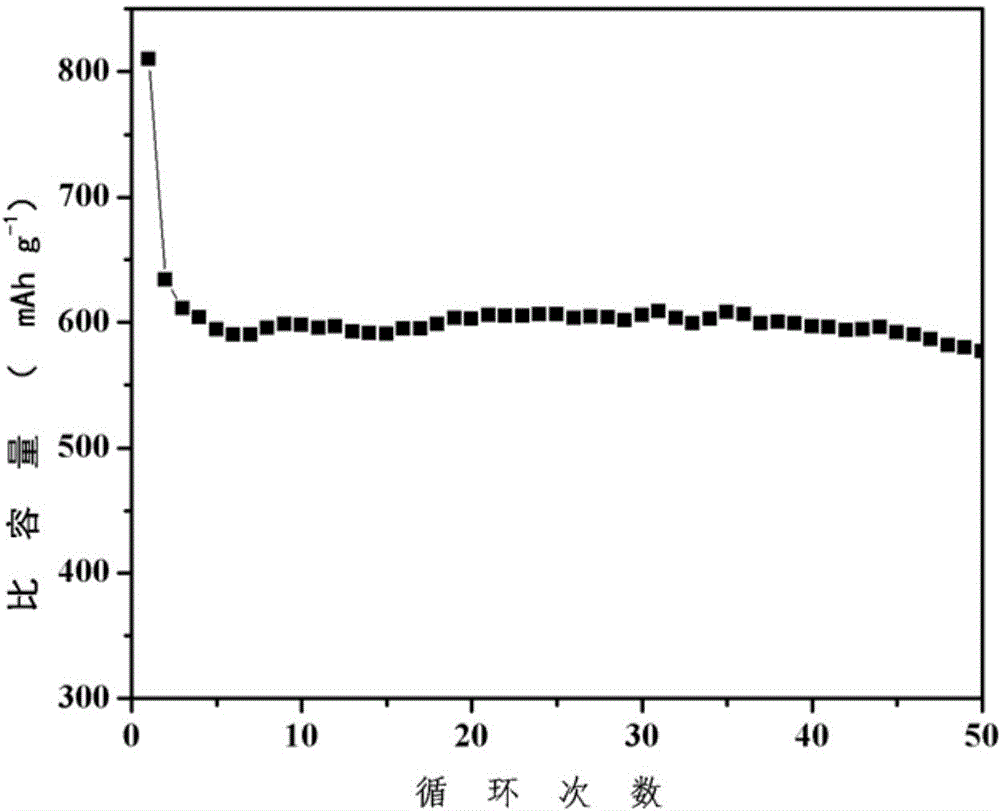

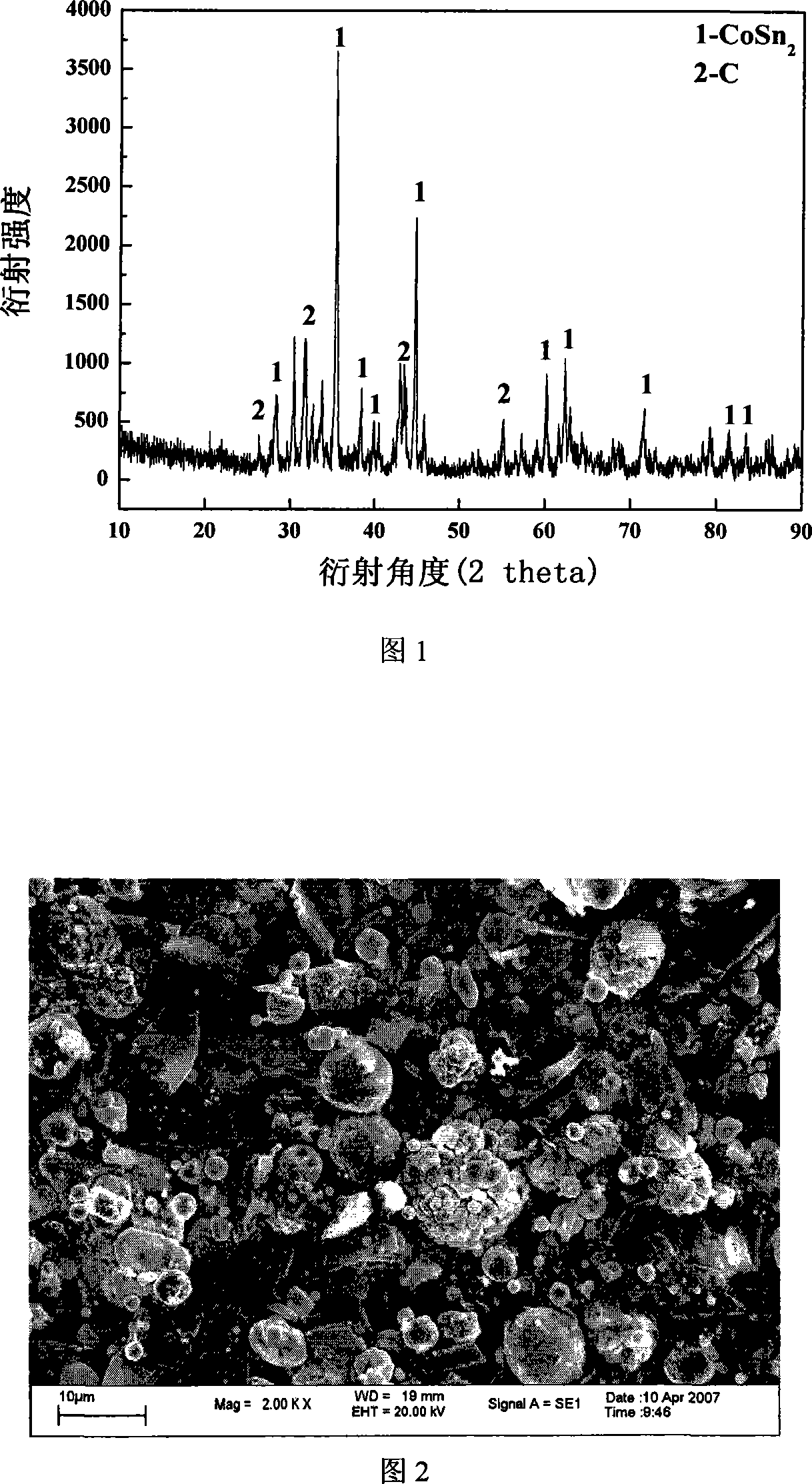

A making method for tin, cobalt and carbon compound cathode materials of lithium ion battery

InactiveCN101188288AHigh crystallinityHigh electrochemical specific capacityElectrode manufacturing processesChemical/physical/physico-chemical processesCarbon compositesAlloy

The invention provides a preparation method of a tin-cobalt-carbon composite cathode material for a lithium ion battery. The method belongs to the field of the lithium ion battery, and adopts carbon thermal reduction. The invention is characterized in that the mixture ratio of a tin oxide and a cobalt compound is 1:1 to 4:1 according to the atomic ratio of Sn / Co, carbon powder is mixed into the mixture as the constituent of a reducer and a composite, and the atomic ratio of C / Co is 1:1 to 20:1. The mixture is arranged in flowing protective air after being ground evenly, the temperature of the protective air is raised to 800 DEG C to 1000 DEG C by the speed of 1 DEG C to 20 DEG C per minute for preserving heat for 0.5 to 6 hours. After preserving heat for 0.5 to 4 hours, the protective air is cut off, and a furnace is sealed for operating. After the heat preservation is over, the mixture is cooled to the room temperature followed the furnace. The invention has the advantages that the cost is low, the preparing technical processing is simple, the particles of Sn-Co-C composite powder is in micron size, carbon which has loose internal structure of particles and encircles alloy particles is all in favor of lowering irreversible capacity of an alloy cathode material for the first time, and enhancing yhr cyclic stability, so that the tin-based alloy cathode material for the lithium ion battery which has high scale prodcution ratio capacity and stable cyclic performance is possible.

Owner:UNIV OF SCI & TECH BEIJING

Silicon-carbon composite lithium ion battery negative electrode material and preparation method thereof

ActiveCN110707314AGood dispersionNot easy to collapseNegative electrodesSecondary cellsCarbon compositesElectrolytic agent

The invention provides a silicon-carbon composite lithium ion battery negative electrode material and a preparation method thereof. The preparation method comprises the following steps of adding micron silicon and a dispersing agent into a solvent, and grinding to obtain nano silicon slurry 1; adding a carbon matrix into the nano silicon slurry 1, and stirring to obtain mixed slurry 2, wherein thecarbon matrix is one or more of flattened artificial graphite, flattened natural graphite and flattened mesocarbon microbeads; and drying the mixed slurry 2, adding into a fusion machine for fusion,mixing with a coating agent, granulating, carrying out heat treatment in a protective atmosphere, carrying out high-temperature carbonization treatment in the protective atmosphere, crushing, gradingand demagnetizing to obtain the silicon-carbon composite negative electrode material. According to the present invention, the structure with better volume expansion can be buffered, the dispersion andcomplete coating of the nano silicon on the carbon matrix are realized, and the direct contact between the nano silicon and the electrolyte is isolated, so that the composite material can form a stable SEI film, and the service life of the battery is greatly prolonged.

Owner:SHAANXI COAL & CHEM TECH INST

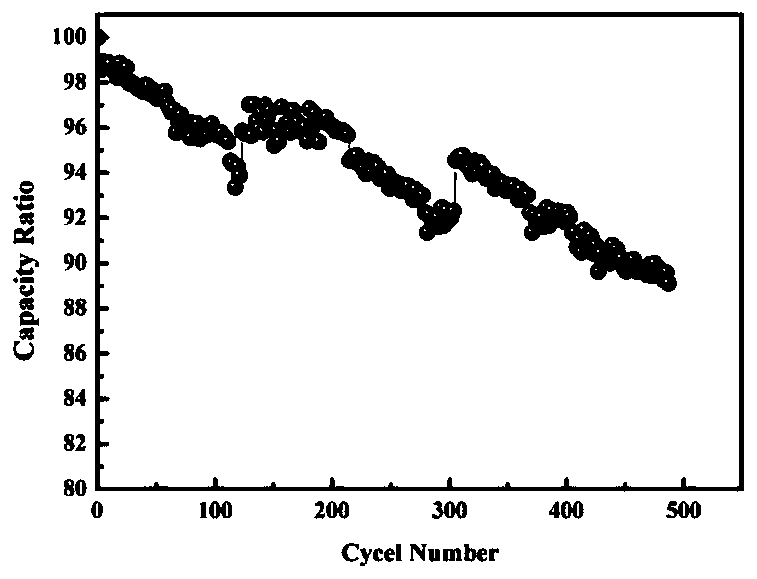

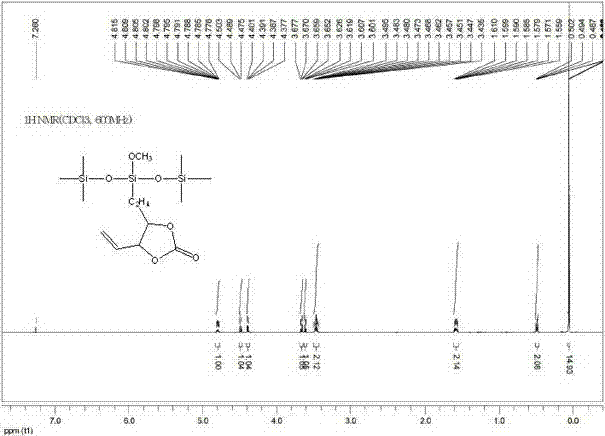

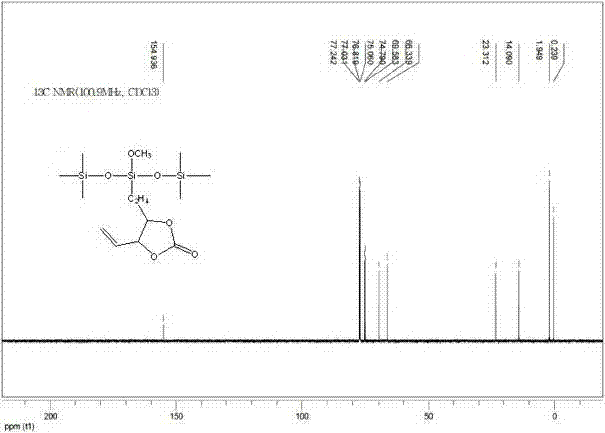

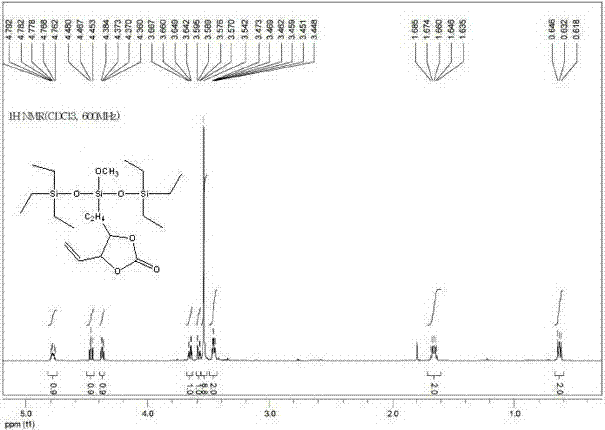

Electrolyte additive, electrolyte containing additive and lithium ion battery using electrolyte

ActiveCN104752766AAvoid damageReduce generationGroup 4/14 element organic compoundsSecondary cellsElectrolysisLithium-ion battery

The invention discloses an electrolyte additive. The additive is carbonic ester containing silicon alkyl and alkylene, wherein the silicon alkyl is connected with methoxy or ethoxy and alkyl. The invention also provides electrolyte containing the additive and a lithium ion battery using the electrolyte on the basis of the electrolyte additive. The electrolyte containing the additive can form a tough envelope on the surface of an electrode, so as to reduce the reaction between the electrode and the electrolyte, and the additive can decompose gases generated in an electrolysis process, so that high capacity and low inflation rate of the battery are maintained, and the service life of the lithium ion battery is prolonged.

Owner:BYD CO LTD

Silicon-carbon composite material as well as preparation method and application thereof

ActiveCN107170965AImprove conductivityImprove cycle stabilityMaterial nanotechnologyCell electrodesCarbon compositesLithium carbonate

The invention discloses a silicon-carbon composite material as well as a preparation method and application thereof. The silicon-carbon composite material comprises nanometer silicon, graphite and lithium carbonate. The nanometer silicon, graphite and lithium carbonate are encapsulated by polymers and carbonized so as to obtain the silicon-carbon composite material. The preparation method comprises the following steps: mixing graphite, lithium carbonate and nanometer silicon so as to obtain a lithium carbonate / silicon / graphite mixture; dispersing the lithium carbonate / silicon / graphite mixture into a polymer solution, and drying to obtain a precursor material; carbonizing the precursor material, thereby obtaining the silicon-carbon composite material. The silicon-carbon composite material disclosed by the invention has high electrical conductivity and excellent cycling stability and can be applied to preparing lithium ion batteries.

Owner:CENT SOUTH UNIV

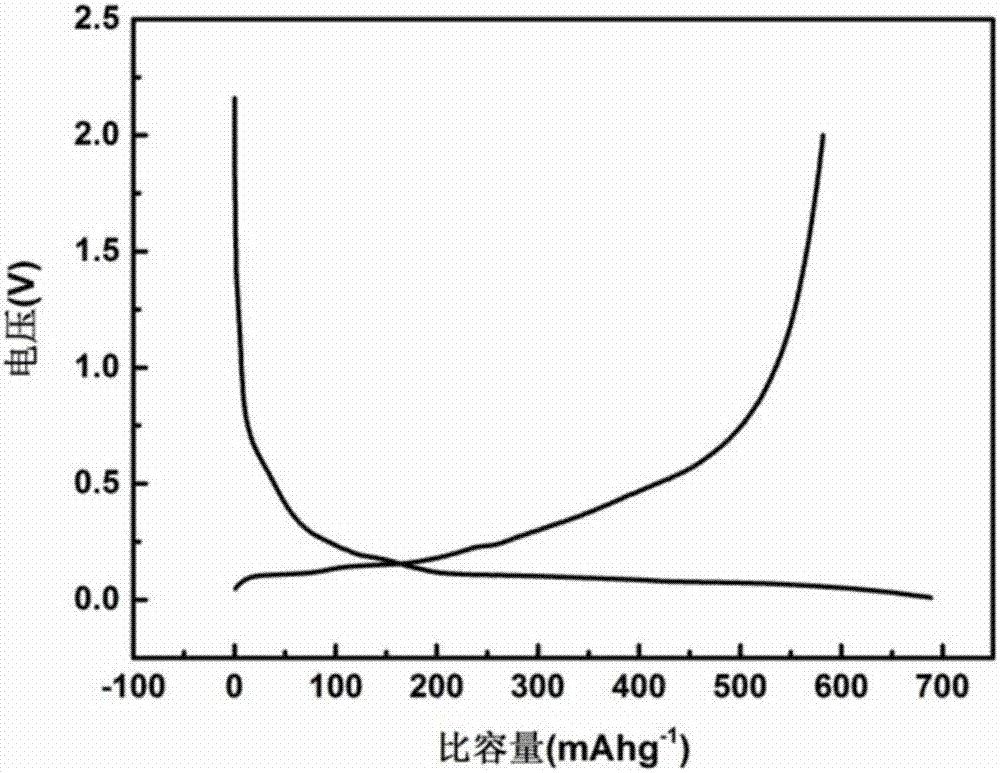

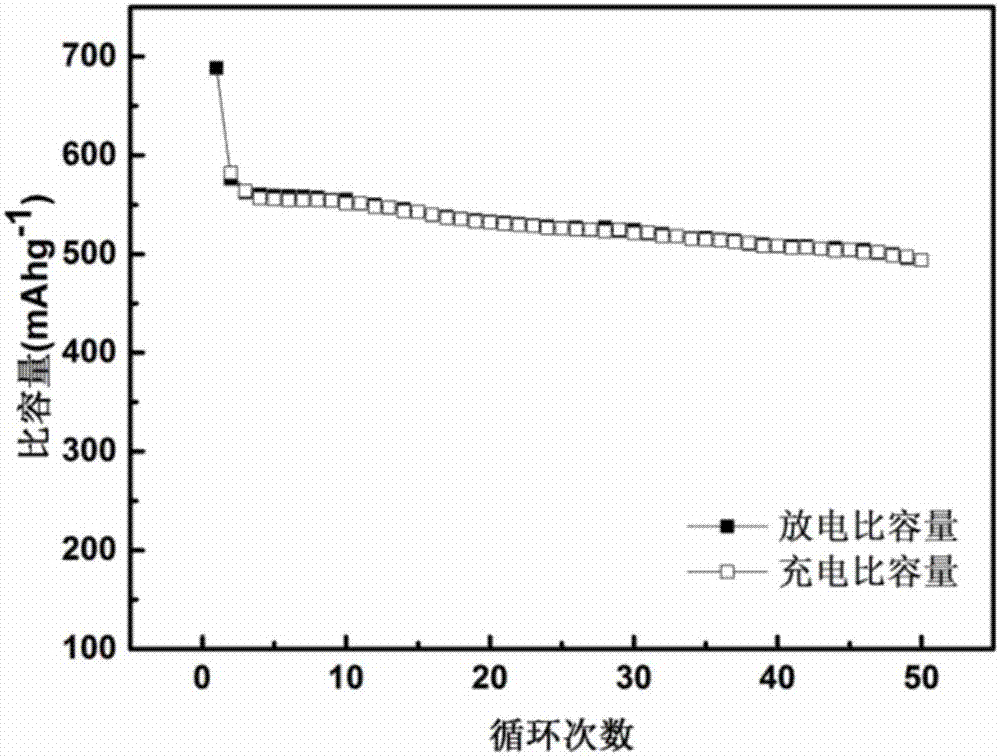

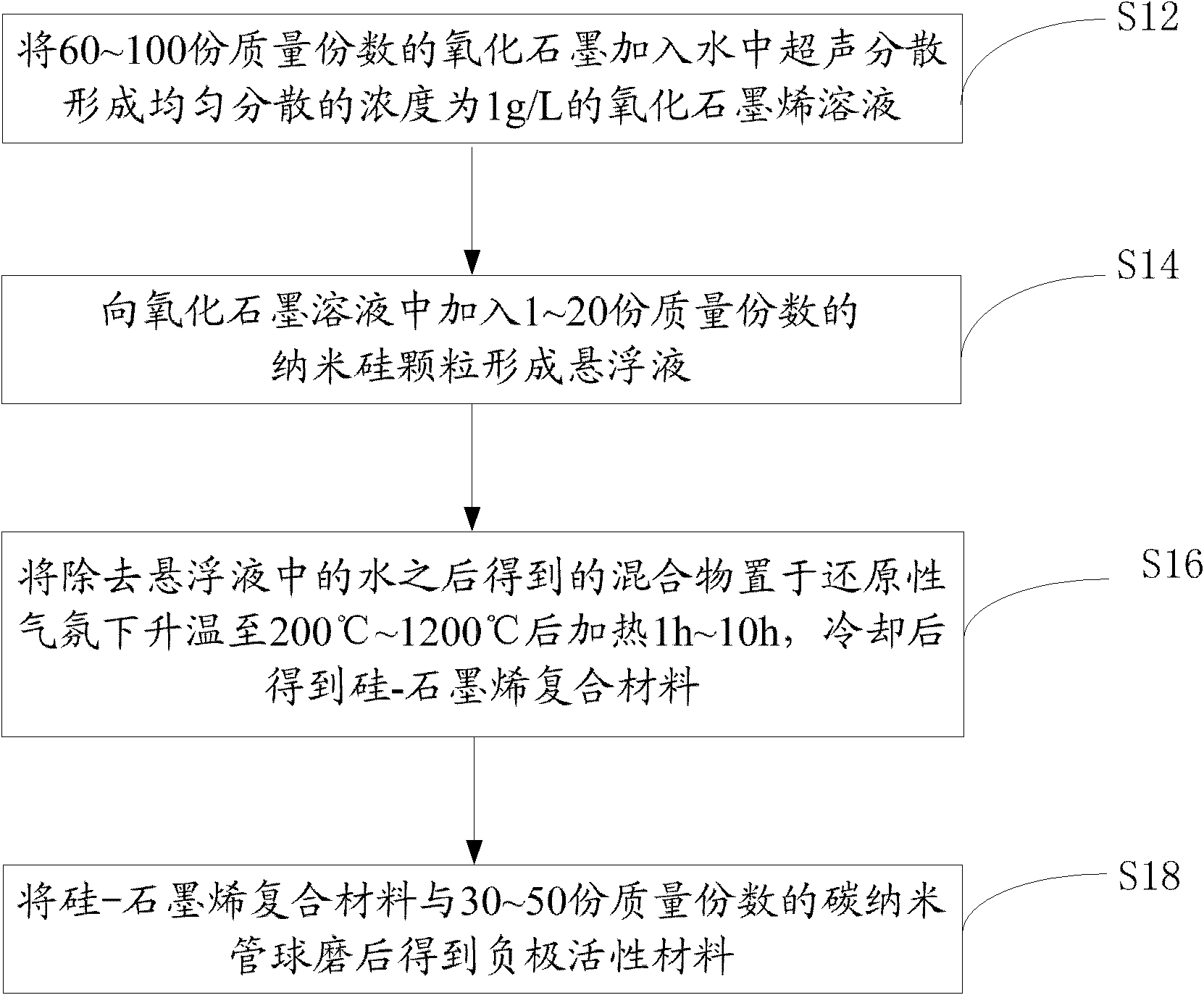

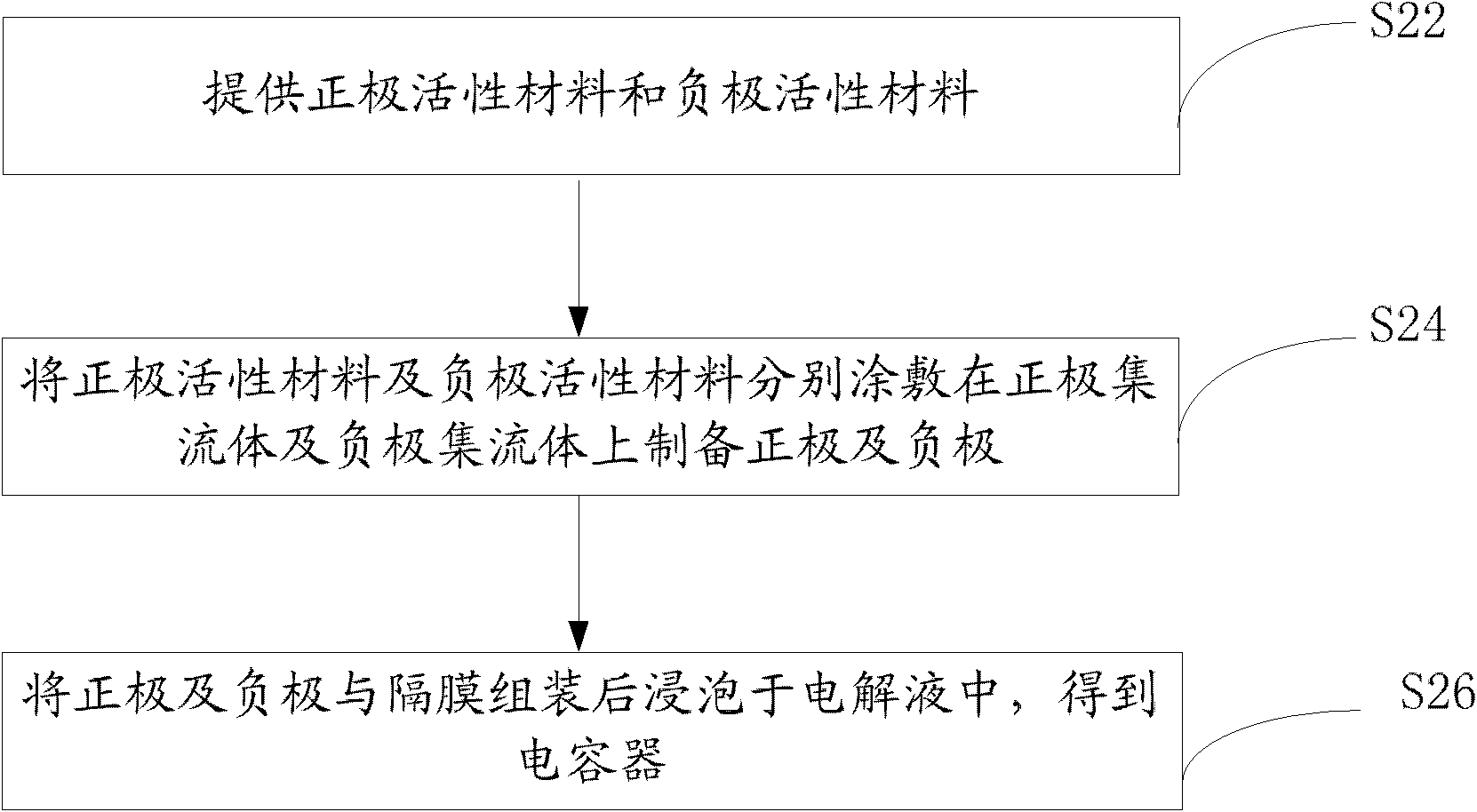

Preparation method of cathode active material and preparation method of capacitor

InactiveCN103000378AImprove conductivityImprove mechanical propertiesElectrolytic capacitorsCarbon nanotubeReducing atmosphere

A preparation method of cathode active material includes the steps of firstly, adding 60-100 parts, by weight, of graphite oxide into water for ultrasonic dispersion so as to obtain evenly dispersed 1g / L graphite oxide solution; secondly, adding 1-20 parts of silicon nanoparticles into the graphite oxide solution to obtain suspension; thirdly, placing mixture obtained by dewatering the suspension in reducing atmosphere, raising the temperature to 200-1200 DEG C, heating for 1-10 hours, and cooling to obtain silicon-graphene composite; and fourthly, subjecting the silicon-graphene composite and 30-50 parts of carbon nanotubes to ball milling to obtain the cathode active material. The cathode active material prepared by the preparation method is high in energy density. In addition, a preparation method of a capacitor using the cathode active material is provided.

Owner:OCEANS KING LIGHTING SCI&TECH CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com