Negative electrode of lithium ionic secondary battery and preparing method thereof

A negative electrode active material and lithium-ion battery technology, applied in secondary batteries, battery electrodes, active material electrodes, etc., can solve the problems of lack of cycle stability, poor cycle stability, and large volume expansion of alloys, and achieve high reversible intercalation Lithium capacity, high specific capacity, and improved cycle life

- Summary

- Abstract

- Description

- Claims

- Application Information

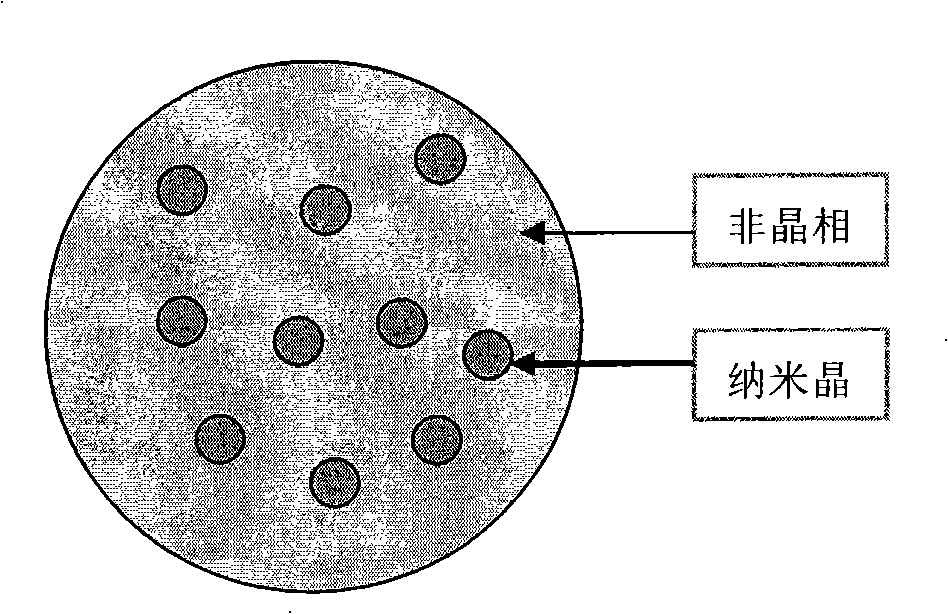

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

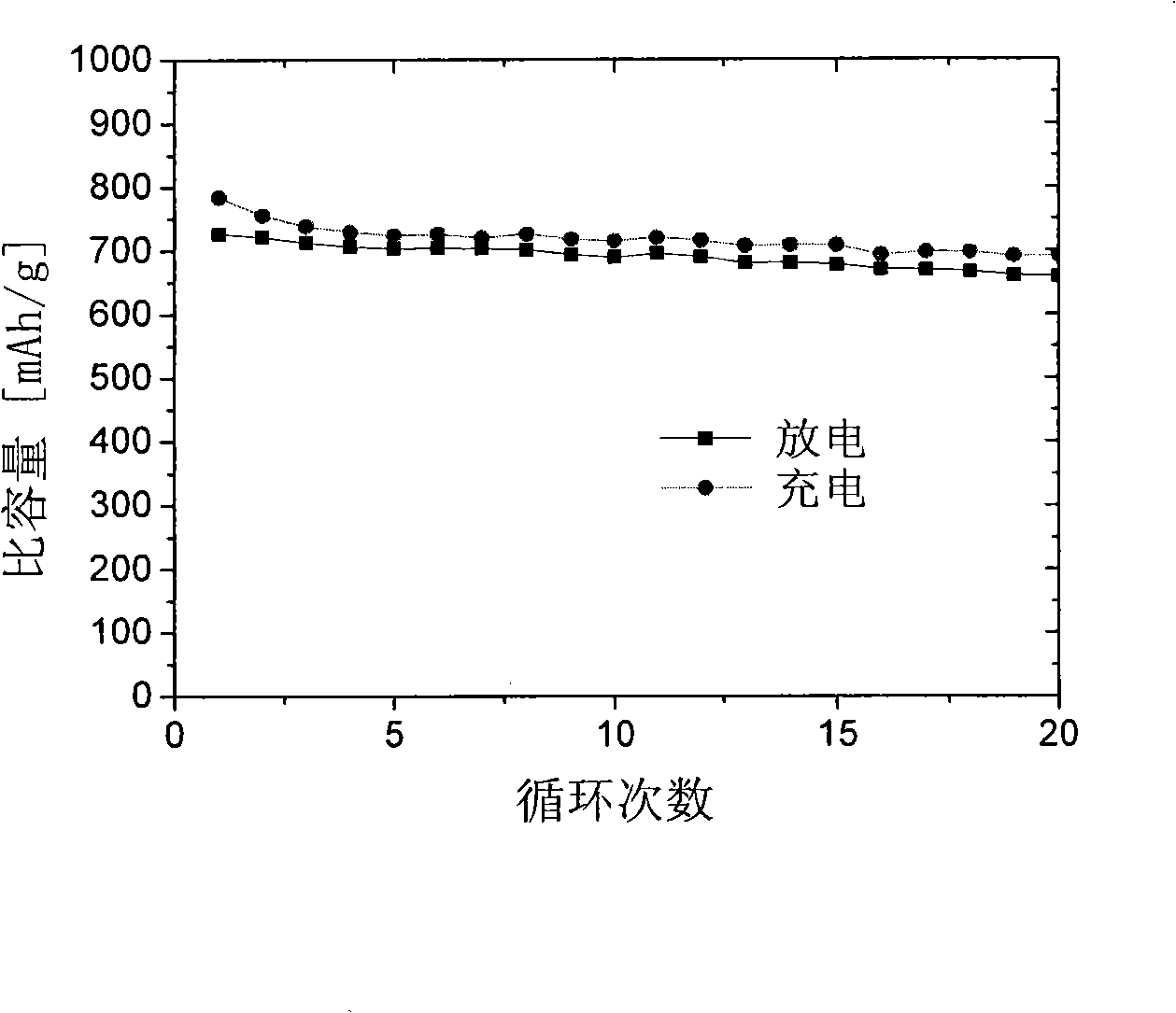

[0046] Metal tin and metal cobalt are melted to form a master alloy according to a mass ratio of 4:1, and put into a vacuum single-roller stripping device for strip making. The cooling roll speed is 27m / s. The prepared alloy strips are crushed to make coarse particles smaller than 1mm, and then the pre-alloyed coarse particles and graphite are mixed in a weight ratio of 4:1, and then put into a high-energy horizontal rotor ball mill with a protective atmosphere for grinding to prepare active Material. The grinding medium is a stainless steel grinding ball with a diameter of Φ5, and the ball-to-material ratio is 15:1; the protective atmosphere in the grinding chamber is argon, and the grinding method is alternating intermittent grinding with variable speed, that is: 600rpm for 24s, 1200rpm for 36s, after 10 cycles, Intermittent 10 minutes; accumulated grinding time 5h. Put the ground alloy powder into a vacuum heat treatment furnace with a protective atmosphere for heat treatm...

Embodiment 2

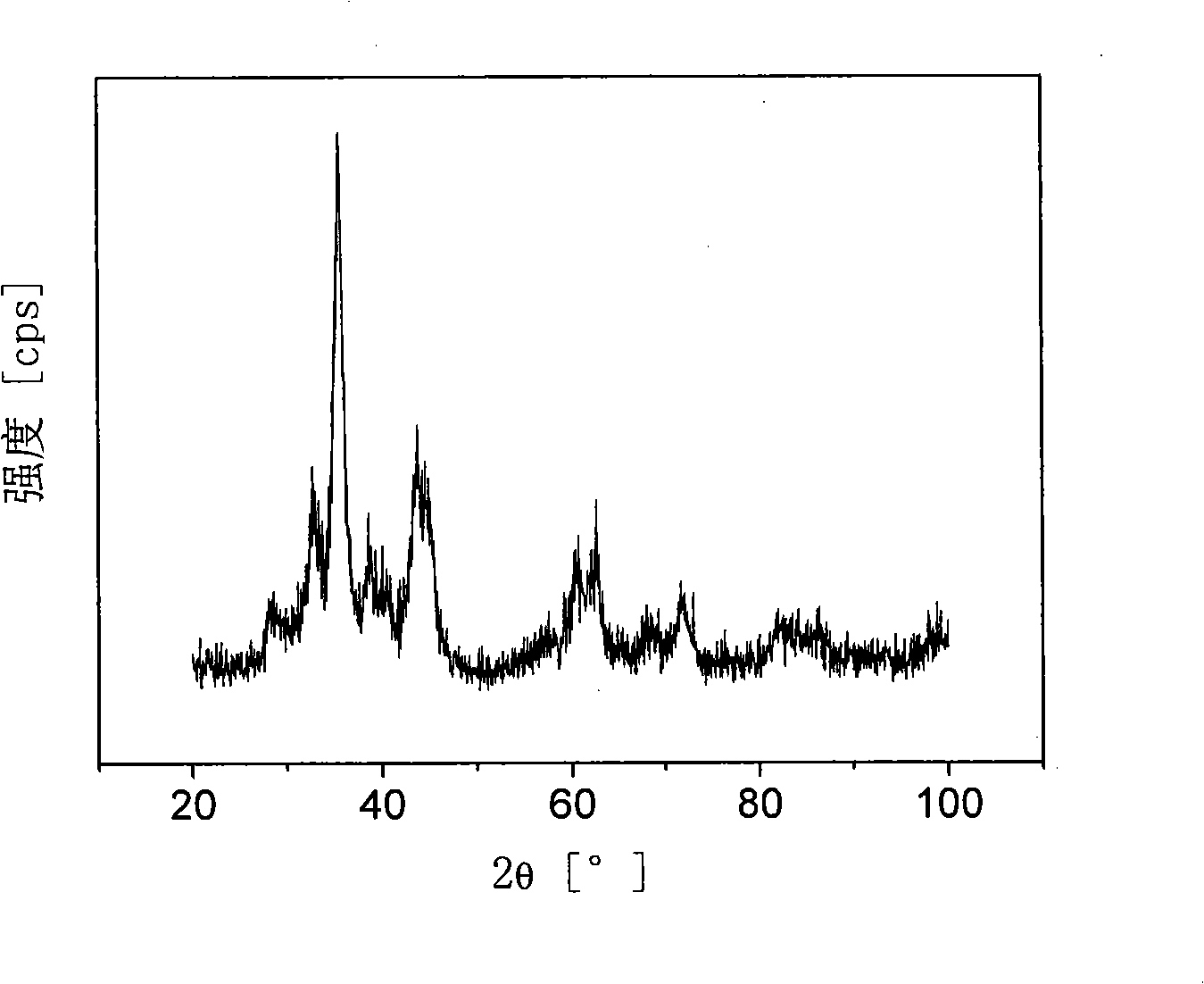

[0051] The negative electrode active material was prepared according to the situation of Example 1, except that the time for grinding the pre-alloy by the high-energy ball mill accumulated for 10 hours, and the negative electrode active material of Example 2 was obtained. The phase structure analysis of these alloy powders was carried out by using X-rays with Cu Kα rays as the radiation source, and the results showed that the alloy powders had an amorphous and nanocrystalline dual-phase structure.

[0052] Using the active material prepared in Example 2, a button-type simulated battery was prepared according to the situation in Example 1, and the performance of the battery was tested. It was found that the reversible capacity of the tin-based dual-phase alloy reached 509mAh / g in the first charge and discharge process, 20 times The capacity retention after cycling was 91%.

Embodiment 3

[0054] The negative electrode active material was prepared according to the situation of Example 1, except that the mass ratio of the SnCo pre-alloy was 3:1, and the negative electrode active material of Example 3 was obtained. The phase structure analysis of these alloy powders was carried out by using X-rays with Cu Kα rays as the radiation source, and the results showed that the alloy powders had an amorphous and nanocrystalline dual-phase structure.

[0055] Using the active material prepared in Example 3, a button-type simulated battery was prepared according to the situation in Example 1, and the performance of the battery was tested. It was found that the reversible capacity of the tin-based dual-phase alloy reached 498mAh / g in the first charge and discharge process, 20 times The capacity retention after cycling was 94%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| retention rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com