Legume-shaped carbon-coated manganese oxide core-shell structure composite material and preparation method and application thereof

A composite material and core-shell structure technology, applied in structural parts, electrical components, battery electrodes, etc., can solve the problems of low initial charge and discharge efficiency, excessive potential platform difference, etc., achieve excellent electrochemical performance, buffer volume expansion, The effect of improving the magnification performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

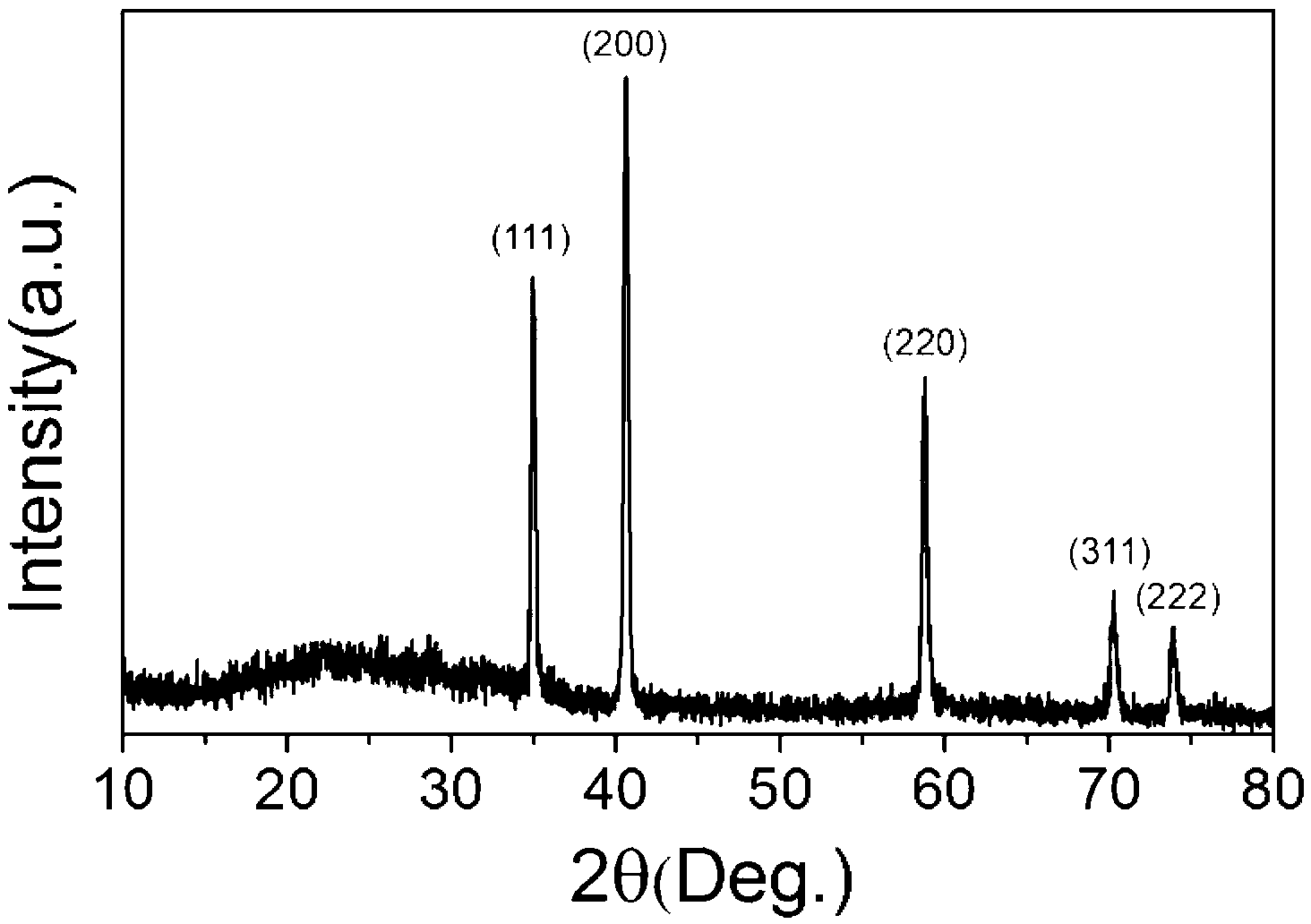

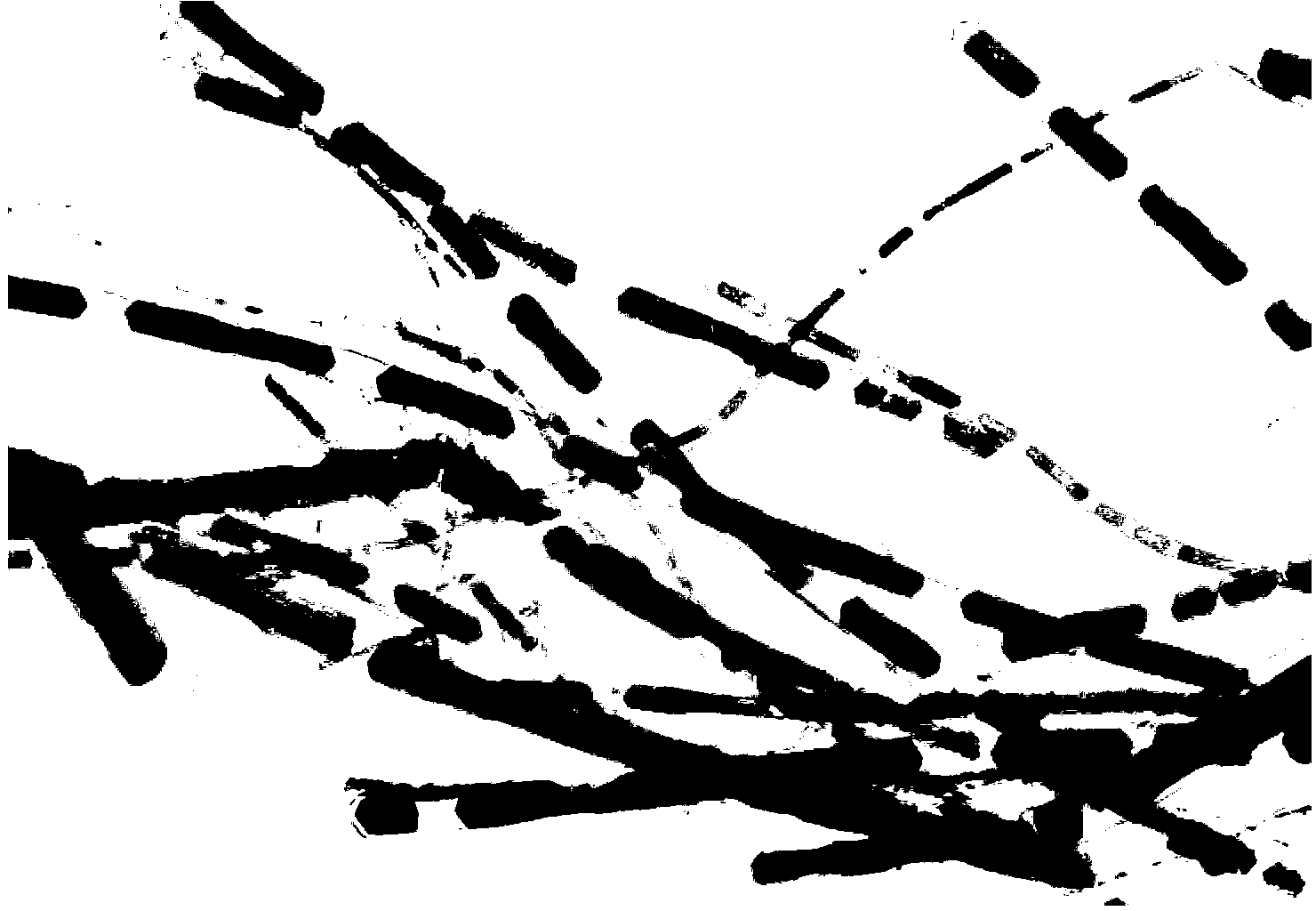

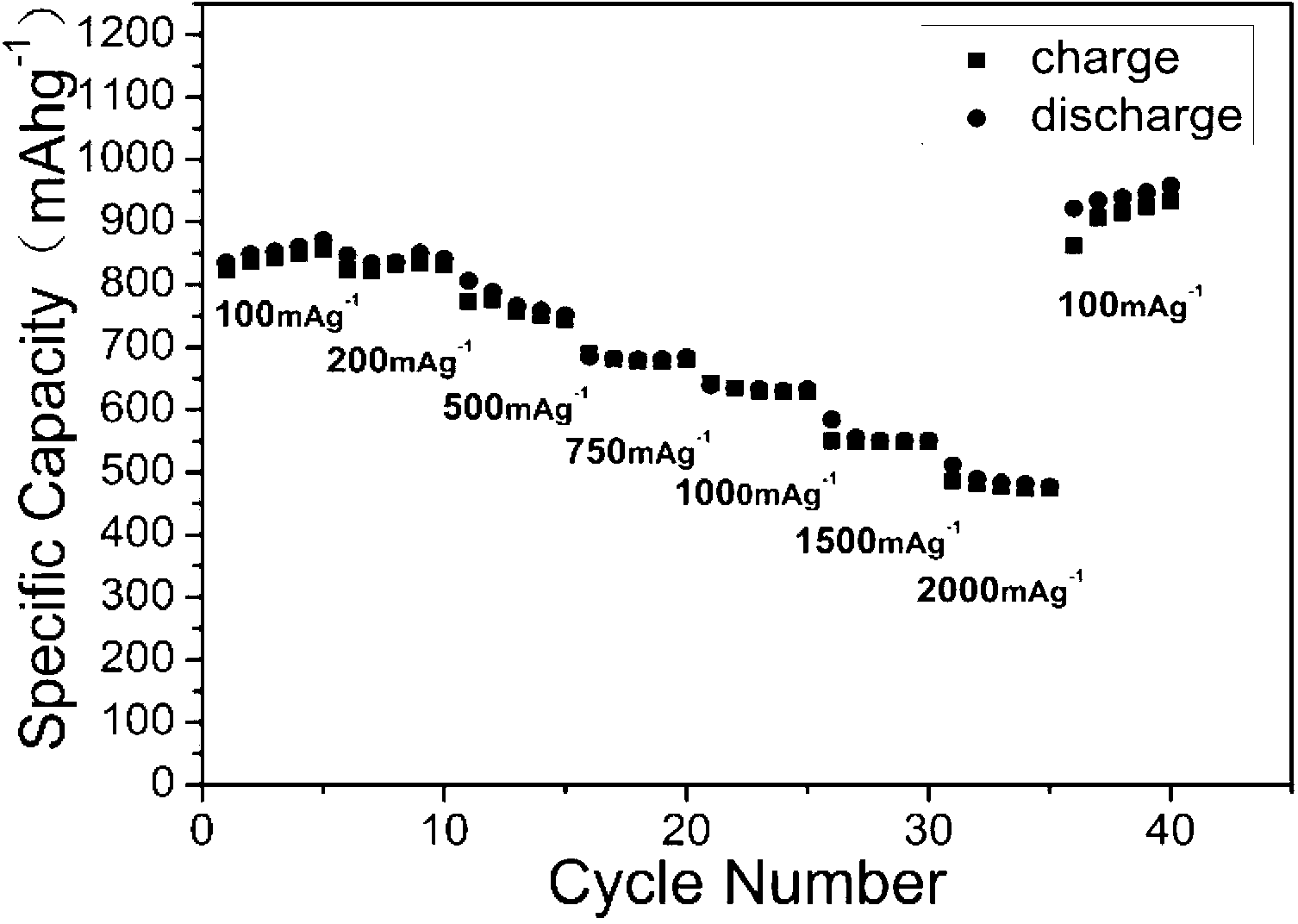

[0022] Dissolve 50mg P123 in water, add 50mg PVP and stir until clear, then add 0.1M KMnO 4 6ml of the solution was stirred evenly, subjected to hydrothermal reaction at 150°C for 8h, cooled to room temperature, washed and collected the reaction product. Dissolve 0.2g of P123 in 200ml of water, then add 0.25g of tromethamine and stir to obtain a buffer solution, then disperse the product obtained above in 100ml of the buffer solution, sonicate for 30min and cool to room temperature. Add 20mg of dopamine to the above solution while stirring, stir and react at room temperature for 5h, filter and wash to collect the reaction product. Then the obtained product was subjected to high-temperature carbonization at 850°C for 2 hours in an argon atmosphere to obtain a pod-shaped carbon-coated manganese oxide core-shell composite material. The XRD curve of the product is as follows: figure 1 Shown, the transmission electron microscope picture of the product is as follows figure 2 show...

Embodiment 2

[0024] Dissolve 50mg P123 in water, add 30mg PVP and stir until clear, then add 0.1M KMnO 4 8ml of the solution was stirred evenly, subjected to hydrothermal reaction at 160°C for 10h, cooled to room temperature, washed and collected the reaction product. Dissolve 0.4g of P123 in 400ml of water, then add 0.5g of tromethamine and stir to obtain a buffer solution, then disperse the product obtained above in 40ml of the buffer solution, sonicate for 60min and cool to room temperature. Add 40 mg of dopamine to the above solution while stirring, stir and react at room temperature for 10 h, filter and wash to collect the reaction product. Then the obtained product was subjected to high-temperature carbonization at 750° C. for 4 hours in an argon atmosphere to obtain a pod-shaped carbon-coated manganese oxide core-shell composite material. The electrochemical test is partly the same as in Example 1, and the prepared material shows almost the same experimental results as in Example 1...

Embodiment 3

[0026] Dissolve 50mg P123 in water, add 80mg PVP and stir until clear, then add 0.1M KMnO 4 20ml of the solution was stirred evenly, subjected to hydrothermal reaction at 180°C for 12h, cooled to room temperature, washed and collected the reaction product. Dissolve 0.6g of P123 in 500ml of water, then add 0.75g of tromethamine and stir to obtain a buffer solution, then disperse the product obtained above in 200ml of the buffer solution, sonicate for 90min and cool to room temperature. Add 80mg of dopamine to the above solution while stirring, stir and react at room temperature for 24h, filter and wash to collect the reaction product. Then, the obtained product was subjected to high-temperature carbonization at 900° C. for 2 h in an argon atmosphere to obtain a pod-shaped carbon-coated manganese oxide core-shell composite material. The electrochemical test is partly the same as in Example 1, and the prepared material shows almost the same experimental results as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com