Preparing method for silicon-carbon composite negative electrode material for lithium ion battery

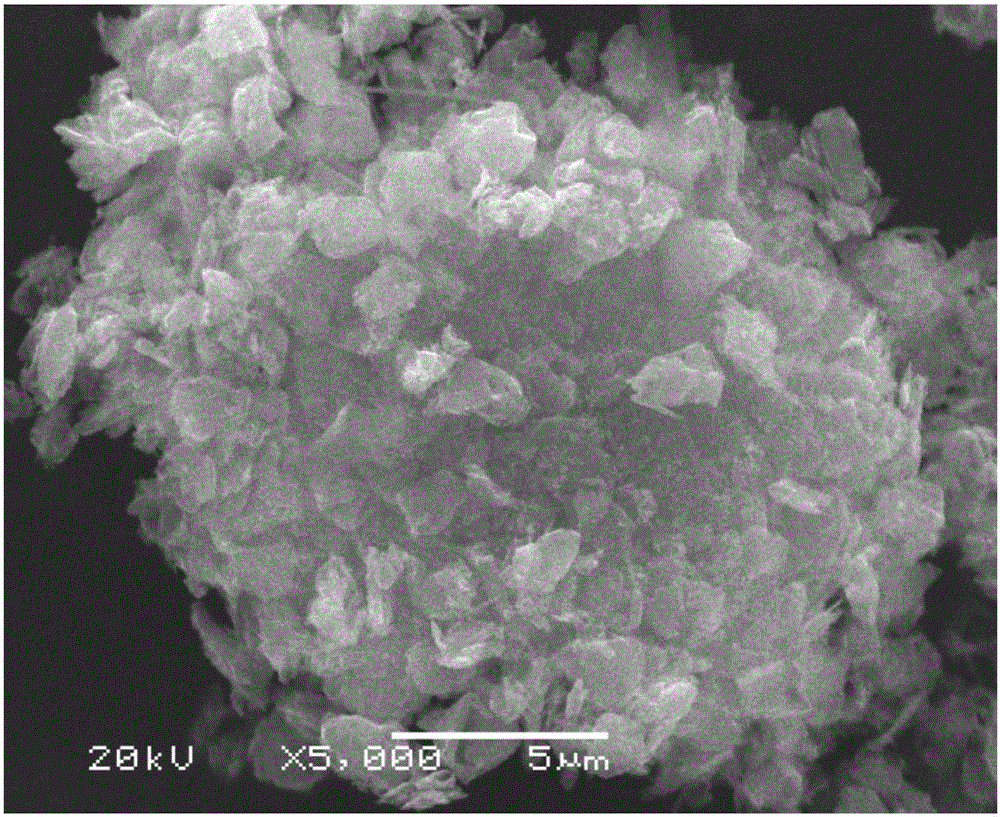

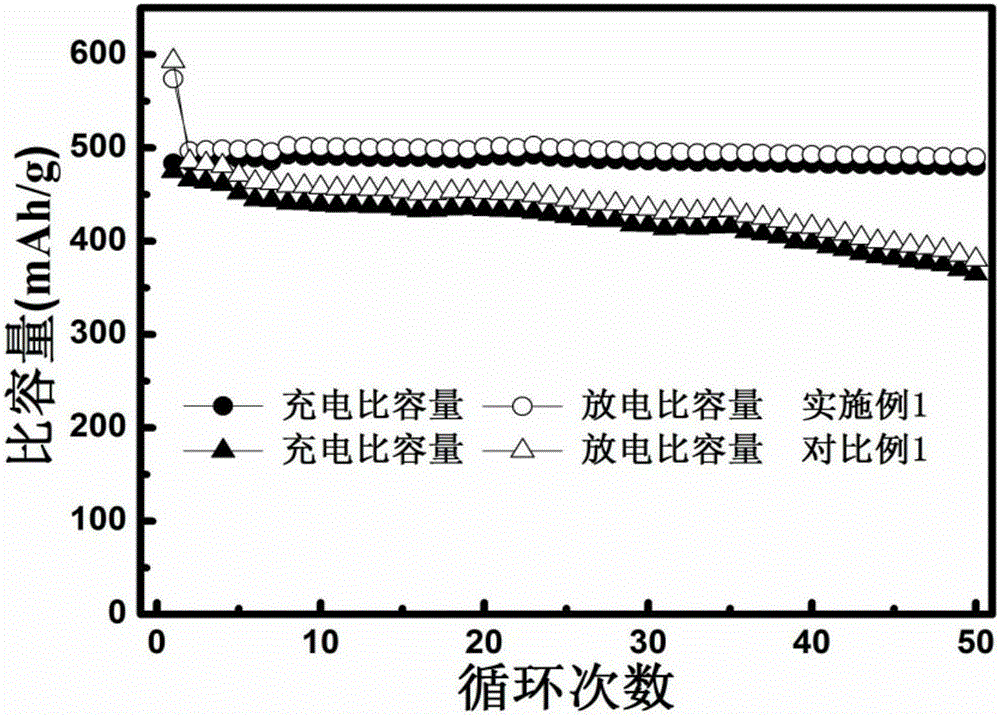

A lithium-ion battery and silicon-carbon composite technology, applied in battery electrodes, nanotechnology for materials and surface science, secondary batteries, etc., can solve problems such as structural damage, uneven distribution of silicon materials, and easy agglomeration. Achieve the effects of reducing the possibility of agglomeration, improving the volume effect and increasing the tap density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] A method for preparing a silicon-carbon composite negative electrode material for a lithium-ion battery, comprising the following steps:

[0039] 1) Take 0.6g of nano-silicon and add it into 80mL of alcohol solution with a volume fraction of 50%, and ultrasonically disperse for 30 minutes to obtain a nano-silicon dispersion. Then add 5g of graphite flakes and 4g of sodium polyacrylate solution with a solid content of 5% into the nano-silicon dispersion, stir and mix evenly with magnetic force, and then disperse evenly by ultrasonication for 30 minutes. Then place the uniformly dispersed mixed solution in a water bath at a constant temperature of 70°C for water bath drying, then place the dried mixture in a tube furnace for carbonization under the protection of an inert gas, and heat it from room temperature to 700°C 3h, the silicon / flake graphite / organic carbon composite material was obtained.

[0040]2) Mix 1g of spherical graphite with 0.08g of coal tar pitch powder,...

Embodiment 2

[0051] A method for preparing a silicon-carbon composite negative electrode material for a lithium-ion battery, comprising the following steps:

[0052] 1) Take 0.6g of nano-silicon and add it into 50mL of deionized water, and ultrasonically disperse for 30min to obtain a nano-silicon dispersion. Then add 2.25g flake graphite to 150mL graphene oxide solution with a concentration of 1mg / mL and mix evenly, and then add 3g solid-containing 5% sodium polyacrylate solution into the nano-silicon dispersion, magnetically stir and mix evenly, and then Ultrasonic for 30min to disperse evenly. Then freeze-dry the uniformly dispersed mixed solution, and then place the dried mixture in a tube furnace under the protection of an inert gas from room temperature at a rate of 8 °C / min to 700 °C for 3 hours to obtain silicon / flaky graphite / Organic carbon composites.

[0053] 2) Mix 1g of spherical graphite with 0.1g of coal tar pitch powder and grind for 30min, then place it in a tube furnac...

Embodiment 3

[0063] A method for preparing a silicon-carbon composite negative electrode material for a lithium-ion battery, comprising the following steps:

[0064] 1) Take 0.6g of nano-silicon and add it into 100mL of alcohol solution with a volume fraction of 50%, and ultrasonically disperse for 30 minutes to obtain a nano-silicon dispersion. Then add 0.8g flake graphite and 8g polyacrylate emulsion with a solid content of 5% to the nano-silicon dispersion, stir and mix evenly by magnetic force, and then disperse evenly by ultrasonication for 30min. Then place the uniformly dispersed mixed solution in a water bath at a constant temperature of 70°C for water bath drying, and then place the dried mixture in a tube furnace under the protection of an inert gas from room temperature to 700°C for 3 hours to obtain silicon / flake graphite / amorphous carbon composite.

[0065] 2) Mix 2g of spherical graphite with 0.03g of coal tar pitch powder and grind for 30 minutes, then place it in a tub...

PUM

| Property | Measurement | Unit |

|---|---|---|

| current efficiency | aaaaa | aaaaa |

| current efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com