Patents

Literature

68results about How to "Reduce the likelihood of reunions" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

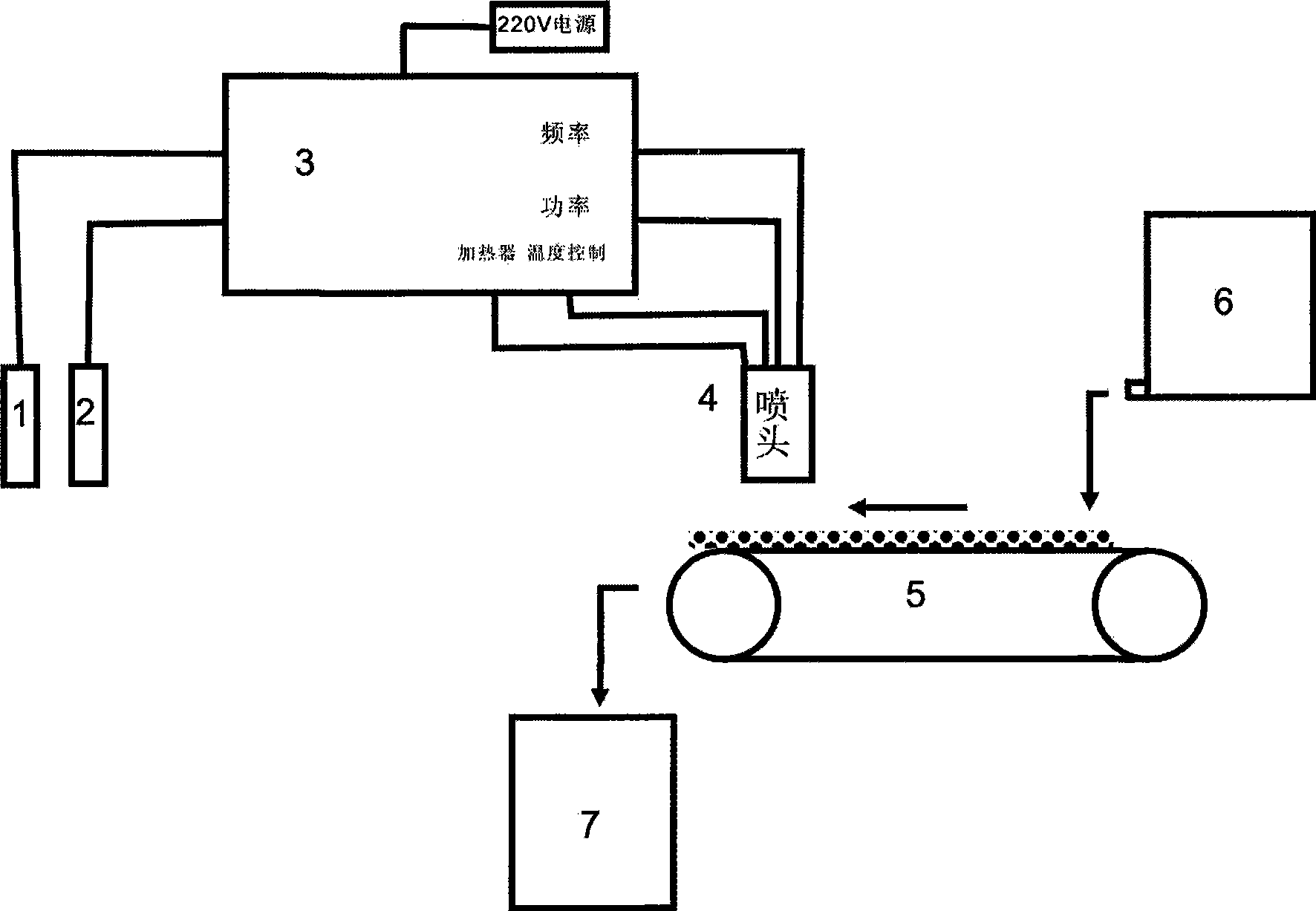

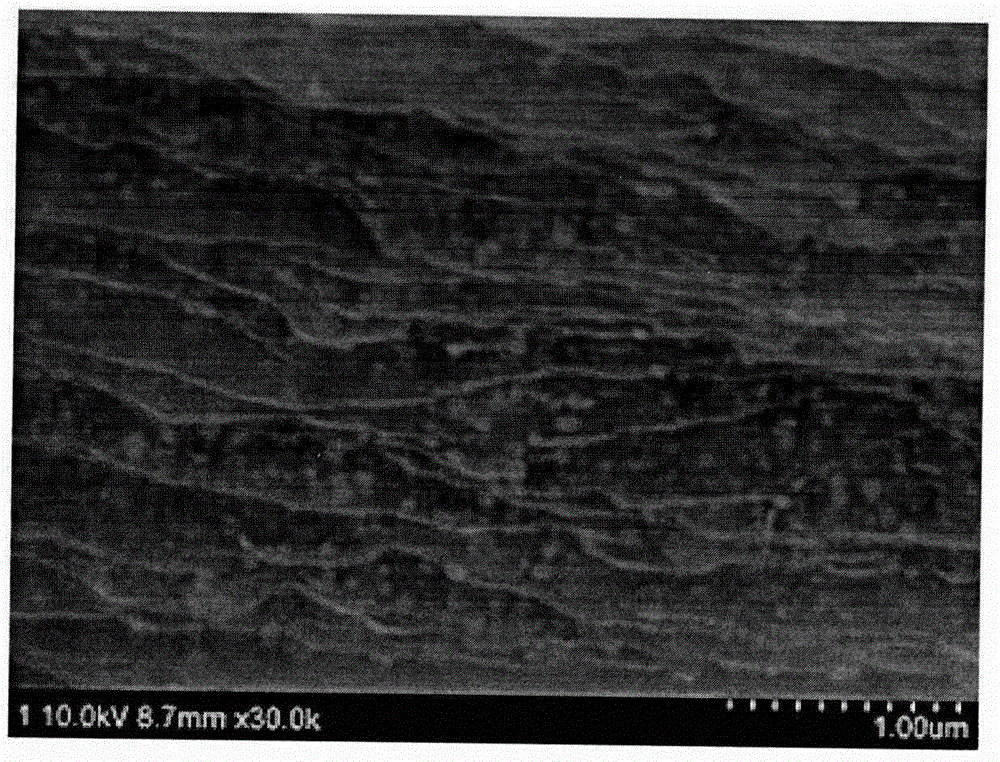

Method for preparing graphene powder

The invention relates to a method for preparing graphene powder in large scale, which is characterized by comprising the following steps of: firstly, uniformly peeling graphene oxide into a graphene oxide suspension solution; then, atomizing the graphene oxide solution by using the spray drying technology comprising spray pyrolysis drying and spray freeze drying, and removing a solvent to obtain graphene oxide powder; and finally, oxidizing grapheme by using the non-expansion heat treatment process to obtain non-agglomerative graphene powder. The continuous preparation process of the spray technology and the non-expansion heat treatment process ensure the large-scale preparation of the graphene powder. The prepared graphene powder comprising intermediate product graphene oxide powder does not have agglomeration and has good dispersivity in the solvent. The graphene powder is used as a filling material to prepare high strength composite materials, conductive composite materials, novel air-tight flame-retardant composite materials, novel nanodevices and the like.

Owner:SHANGHAI INST OF MICROSYSTEM & INFORMATION TECH CHINESE ACAD OF SCI

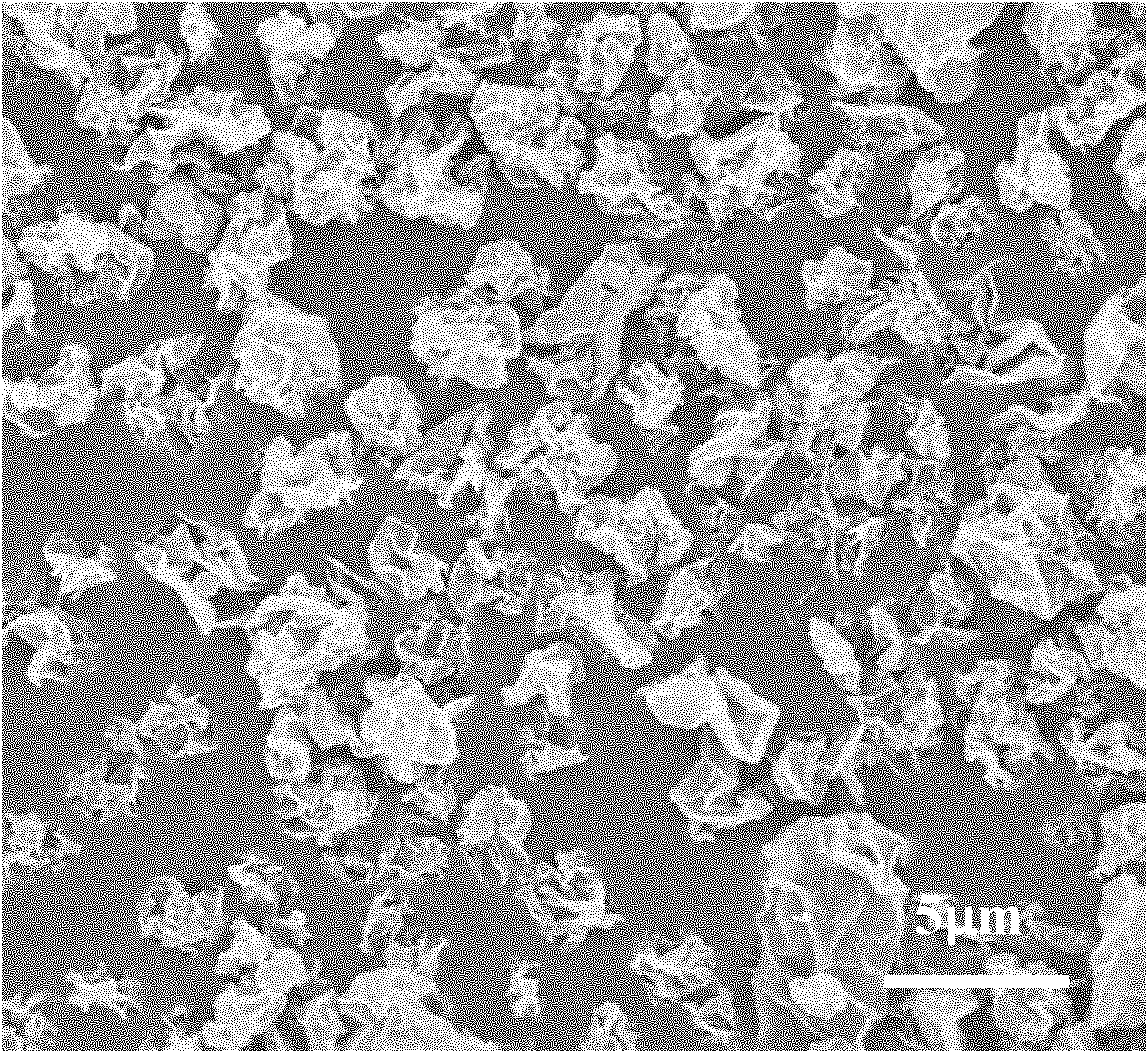

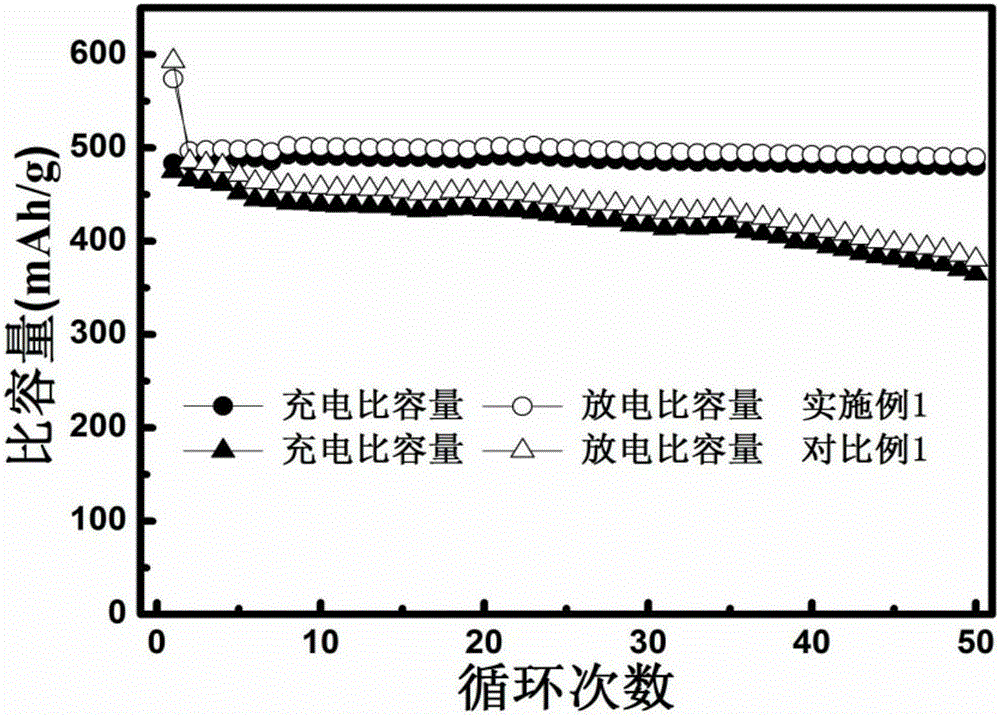

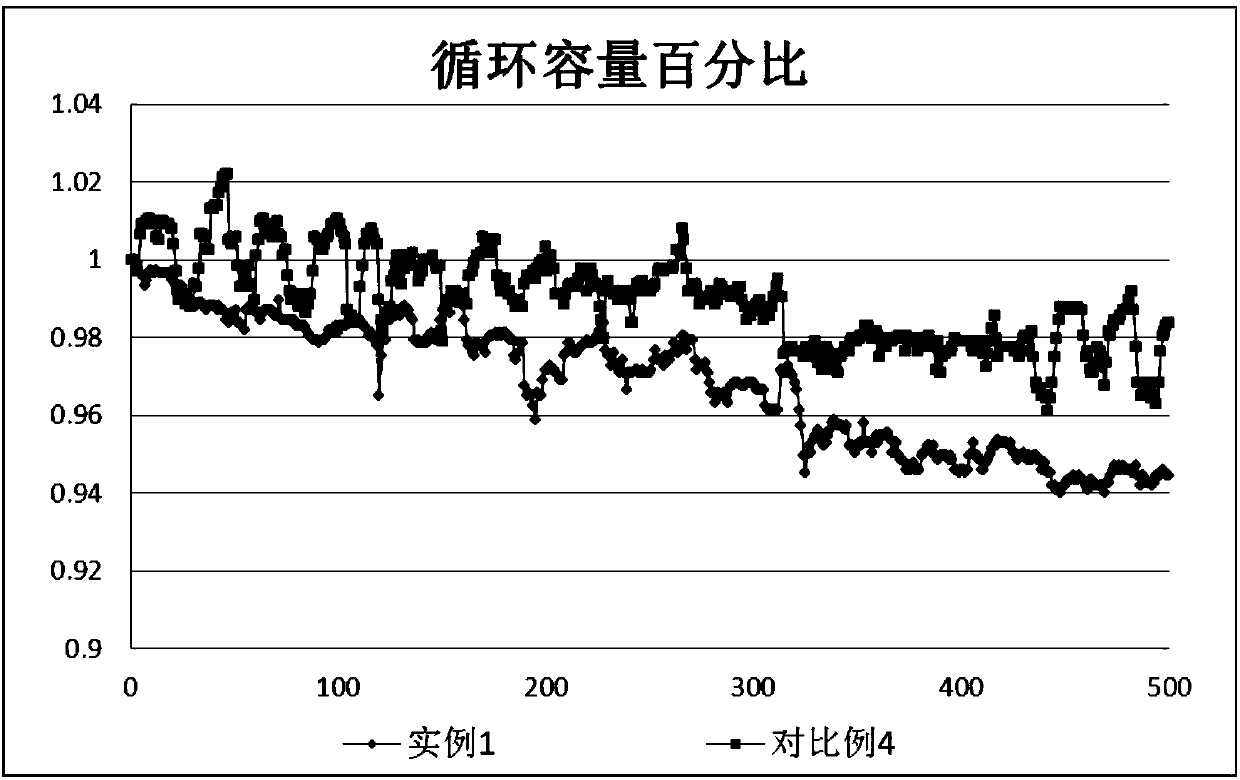

Method of producing silicon carbon negative pole material of lithium ion battery

InactiveCN101153358ABuffer volume effectReduce the likelihood of reunionsElectrode manufacturing processesAdhesiveCarbonization

A preparation method of carbon / silicon cathode for ion lithium battery includes the procedures as follows: firstly a high-molecular polymer is used to treat the silicon powder with the nanometer fineness to form an electroconductive film over the surface of the silicon powder, secondly asphaltum as the adhesive is dissolved into an organic solvent, which is added into the silicon powder prepared in the step 1, mixed adequately and evenly, then added with spheric graphite, mixed evenly and then steamed to eliminate the solvent, to form a covering layer containing silicon on the surface of the spheric graphite, thirdly the material obtained in step 2 undergoes carbonization under the protection with the inert gas and, fourthly the asphaltum as the impregnant is dissolved into an organic solvent, and slowly added into the material obtained in step 3, which is mixed evenly and then steamed to eliminate the solvent, and the asphaltum as the impregnant is used to cover outside the silicon coverage layer, then the material obtained in step 4 undergoes carbonization under the protection with the inert gas to produce the final product. The present invention provides a preparation method of carbon / silicon cathode for ion lithium battery, which helps the active silicon carry out high capacity and is capable of good recycling efficacy at the same time.

Owner:SHENZHEN BAK BATTERY CO LTD

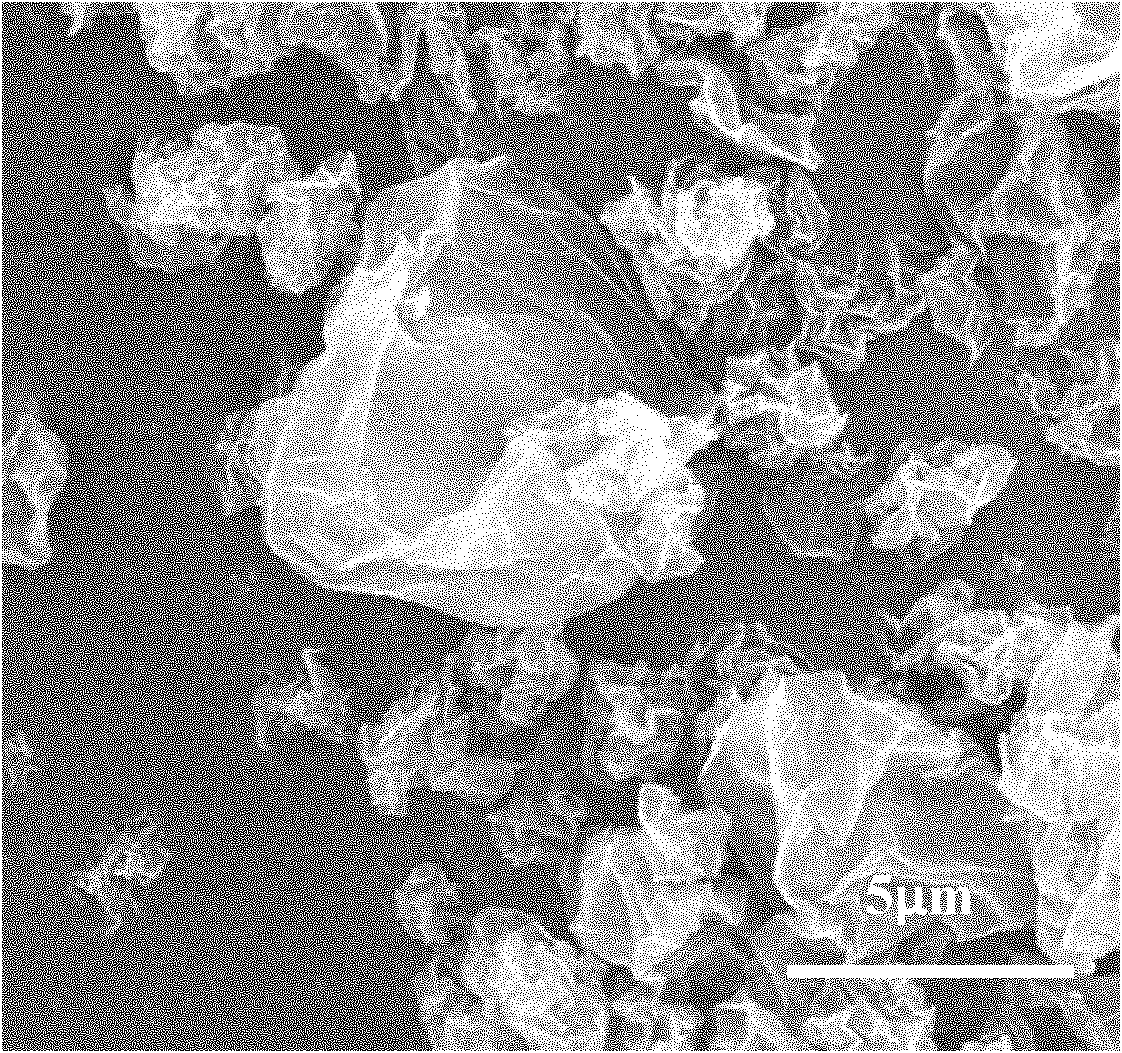

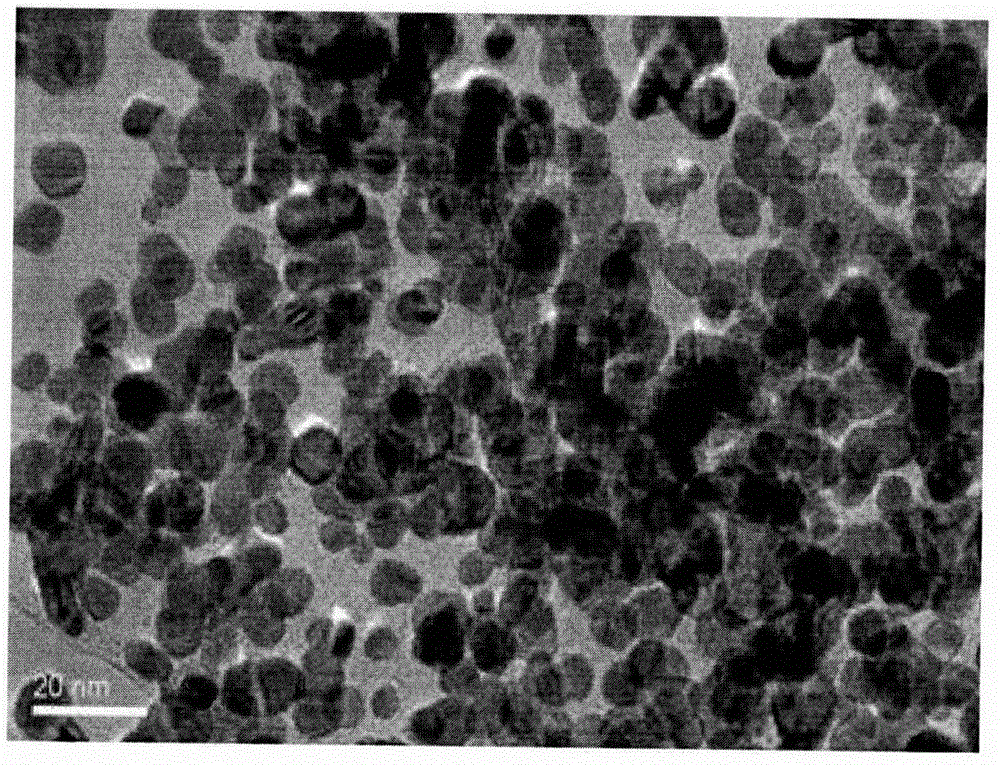

Preparing method for silicon-carbon composite negative electrode material for lithium ion battery

ActiveCN105206801AMaintain stabilityEvenly dispersedMaterial nanotechnologyCell electrodesCarbon compositesCarbonization

The invention discloses a preparing method for a silicon-carbon composite negative electrode material for a lithium ion battery. The preparing method includes the following steps that 1, flake graphite, a polymer solution and nanometer silicon dispersion liquid are evenly mixed, dried and carbonized in a protective atmosphere; 2, pitch and spherical graphite are mixed, ground, placed in an inert protective atmosphere, and subjected to heat treatment to obtain modified spherical graphite; 3, a binder, the modified spherical graphite and the mixed material obtained after carbonization in the step 1 are added into solvent, dispersed evenly and dried to obtain a precursor material; 4, the precursor material is carbonized to obtain the silicon-carbon composite negative electrode material. In the process of the preparing method, it is unnecessary to add special dispersant, nanometer silicon is evenly dispersed in the graphite by means of some ionic groups existing in the polymer solution and high viscosity, the polymer solution has certain stability, and the possibility of nanometer silicon aggregation in the drying process is reduced.

Owner:CENT SOUTH UNIV +1

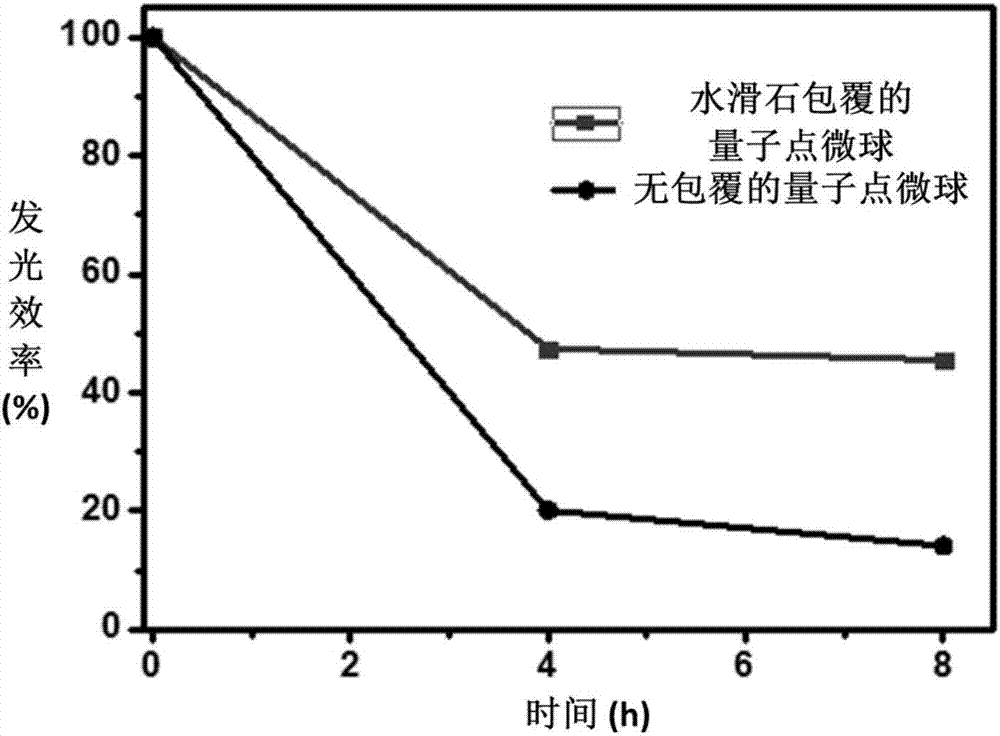

Quantum dot sealing method, quantum dot compound particle and applications

ActiveCN105778887AReduce interactionReduce the likelihood of reunionsLuminescent compositionsNon-linear opticsLiquid-crystal displayQuantum dot

The invention discloses a quantum dot sealing method, a quantum dot compound particle and applications. According to the method, quantum dots are made into quantum dot compound particles, then a blocking layer is arranged on the surface of each quantum dot compound particle so as to seal the quantum dots; after sealing, the interaction among quantum dots is reduced, thus the possibility of agglomeration is reduced; moreover, the air and water are obstructed; at the same time, the possibility that quantum dots are disturbed and destroyed by contacting the external environment, when the quantum dots are further dispersed into other materials or cured or during the device preparation process is reduced; the luminous efficiency of quantum dot is improved effectively, the service life of quantum dot is prolonged; and the provided quantum dot compound particle can be applied to optical devices such as light conversion material of liquid crystal display and has the advantages of high luminous efficiency of quantum dots and long service life.

Owner:TCL CORPORATION

Method for processing barometric pressure, normal-temperature plasma modification on carbon nano-tube surface

InactiveCN101428789AStrong process controllabilitySimple replacement processPigment physical treatmentNanometreSurface modification

The invention relates to a processing method for modifying atmospheric pressure on the surface of a carbon nanometer tube and a normal temperature plasma, which comprises the following steps: placing the carbon nanometer tube on a special transmission device of a plasma processing device; spraying the e plasma to the surface of the carbon nanometer tube under the atmospheric pressure and the openenvironment, so that the carbon nanometer tube moves in the atmosphere of the plasma, wherein the processing power is 10W to 5000W and the time is 0.01s to 6000s; and then generating the surface modification of the carbon nanometer tube. The invention can directly improve the surface property, the structure and the shape of the carbon nanometer tube for one step under the atmospheric pressure andthe normal temperature, and has the advantages of strong process controllability, simple replacement process and less environmental pollution by adopting the dry process. The effect of isosexual repulsion is generated on the particle surface of the carbon nanometer tube, so that the possibility on the reunion of nanometer particles is reduced.

Owner:DONGHUA UNIV +1

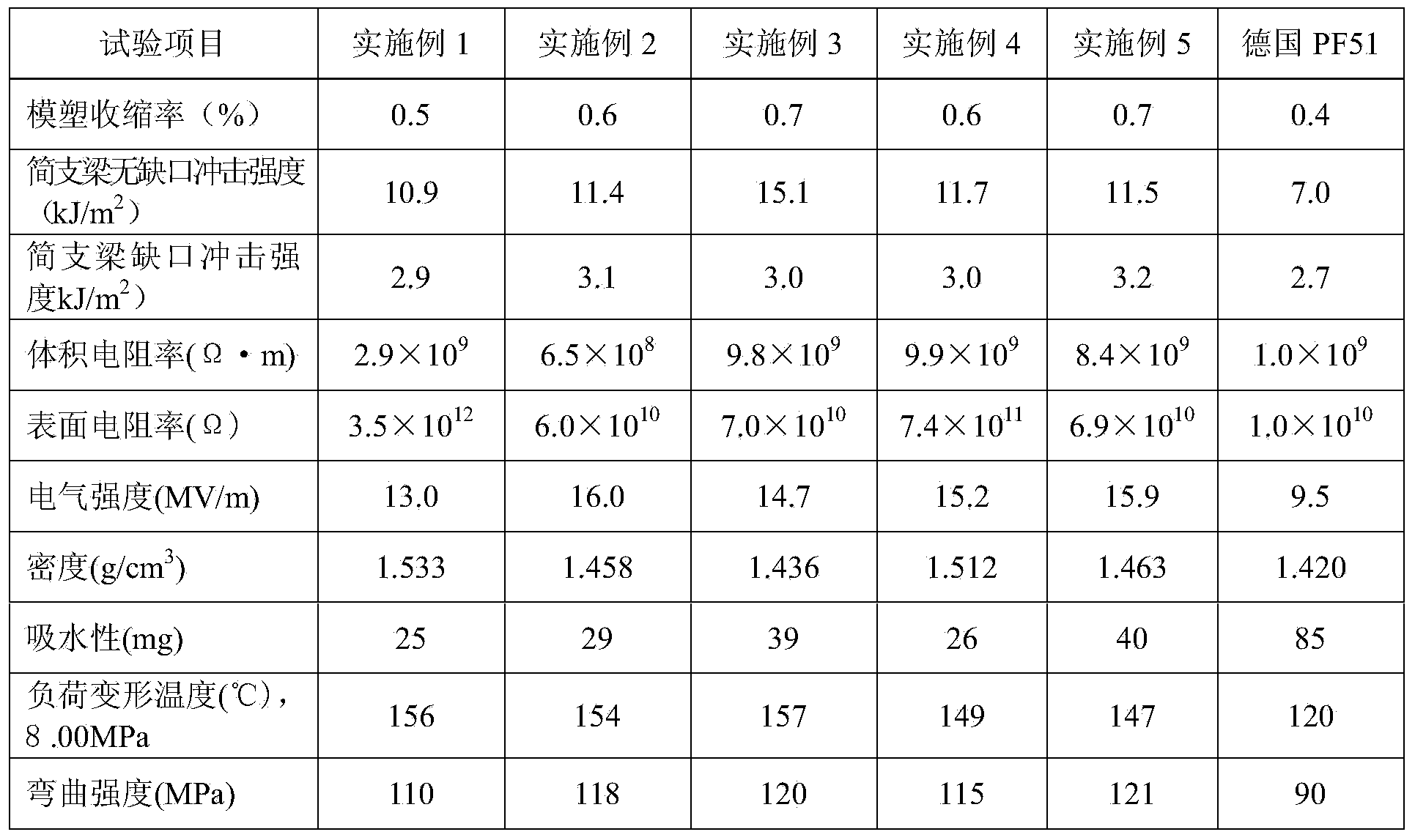

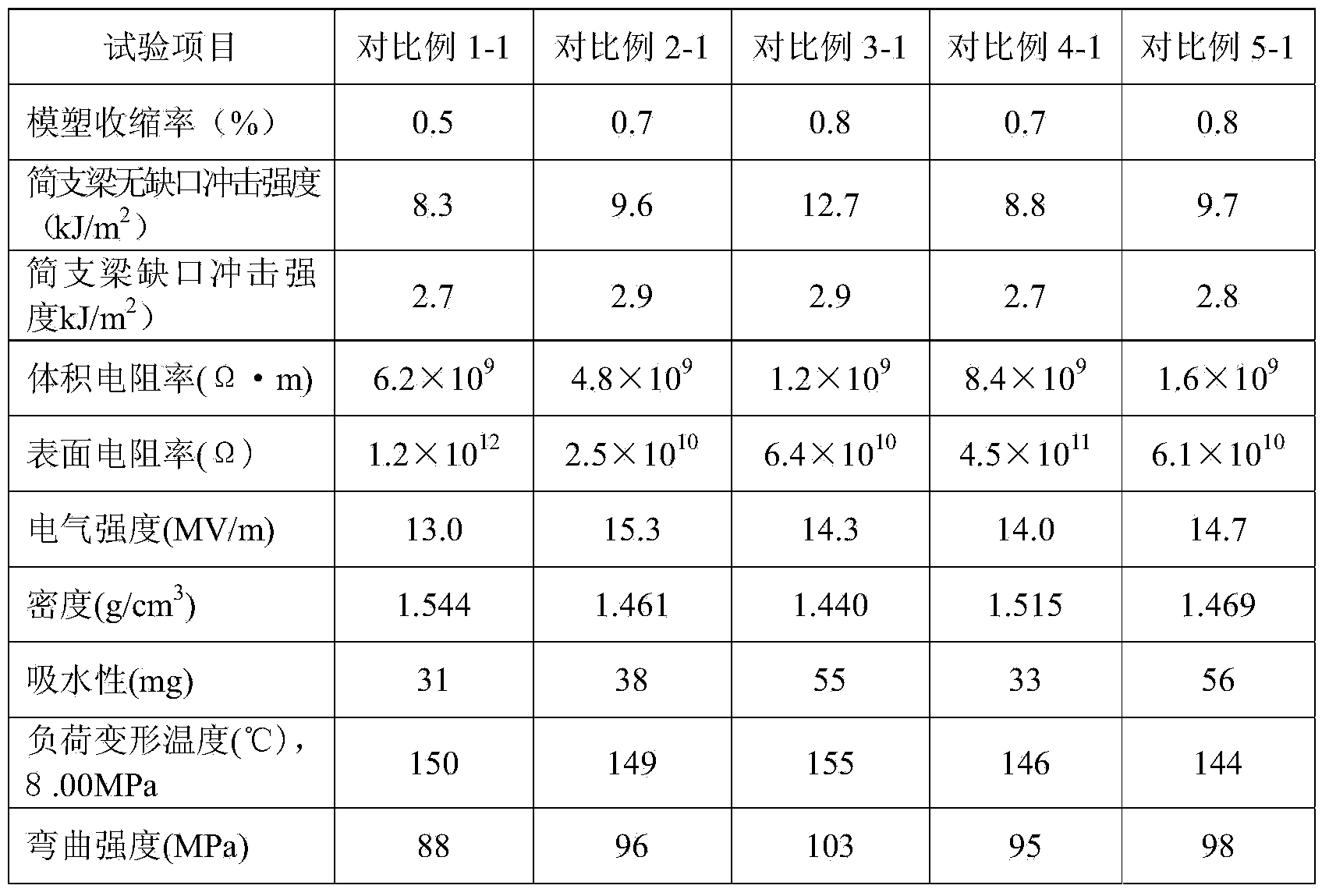

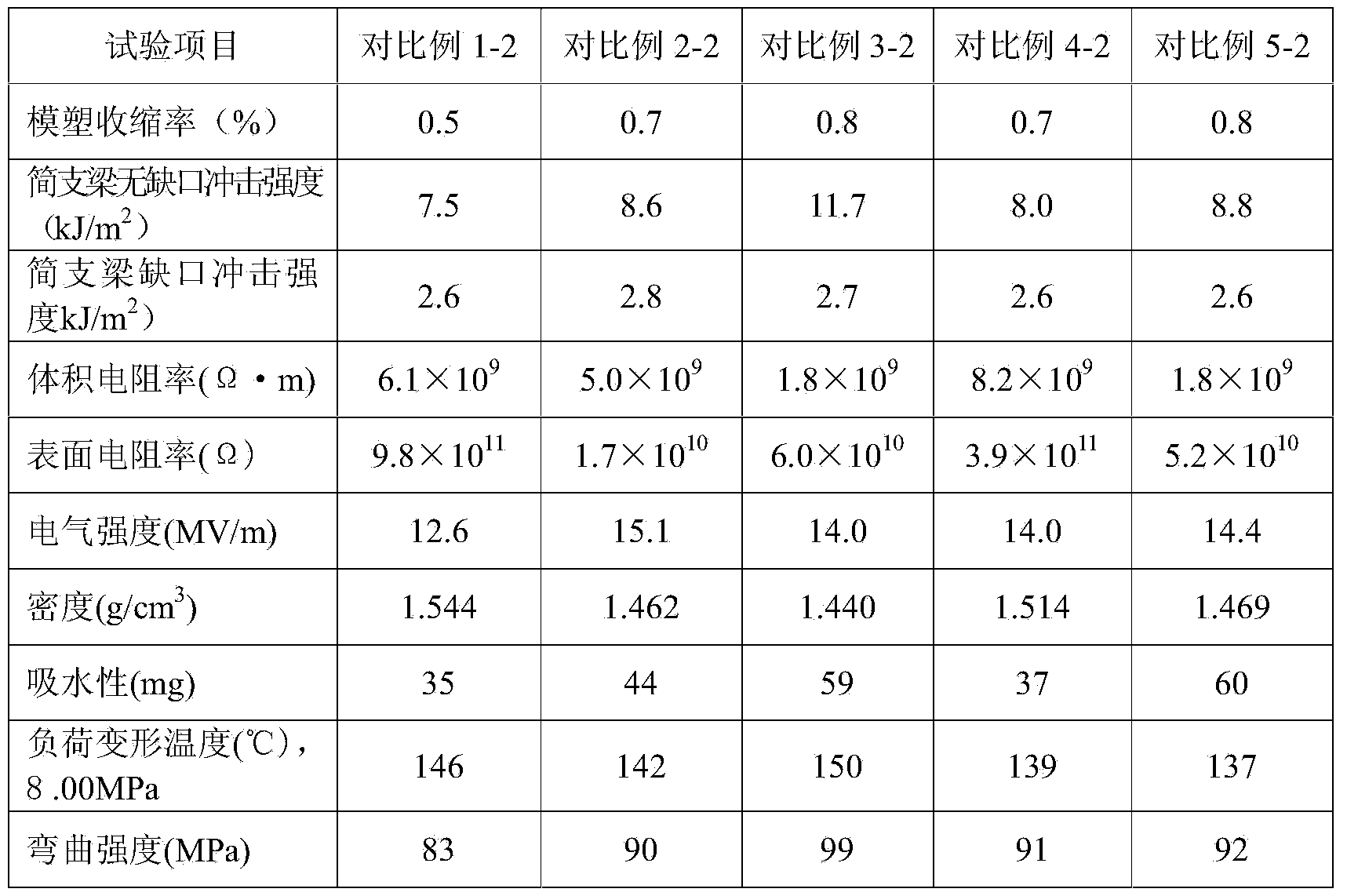

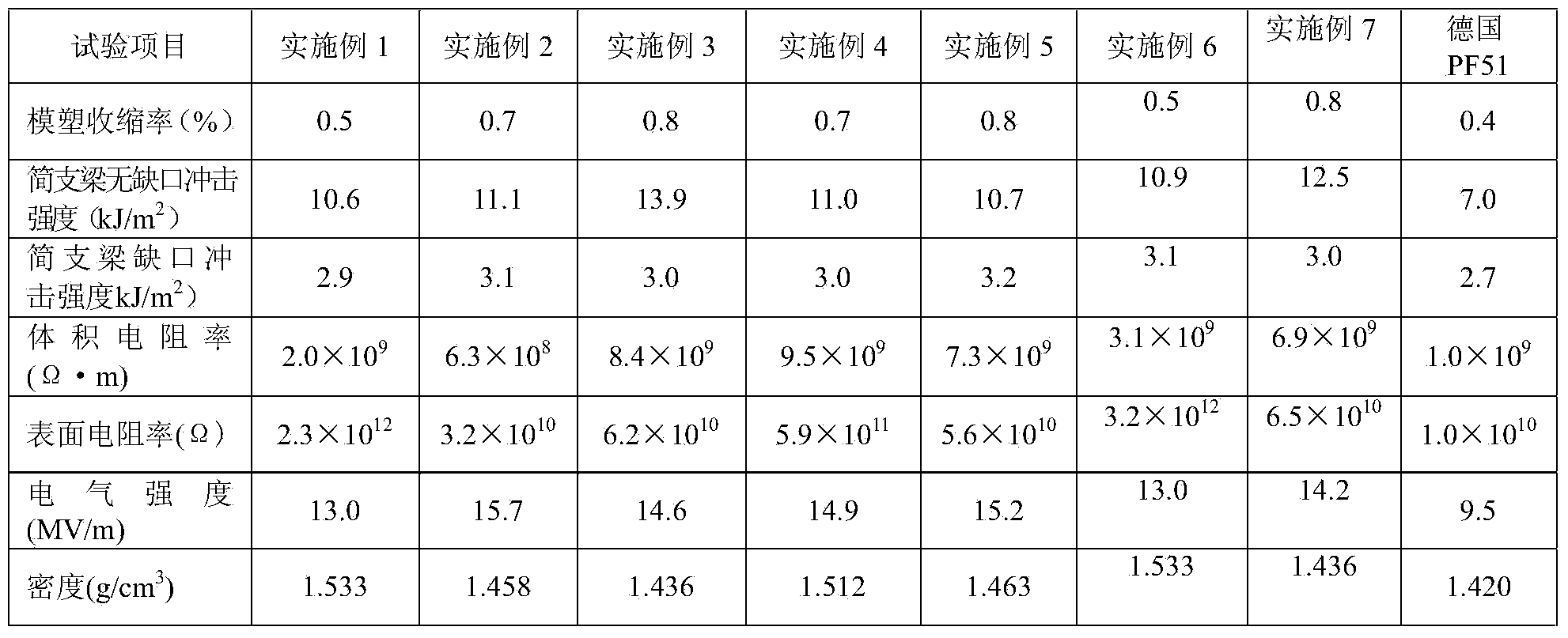

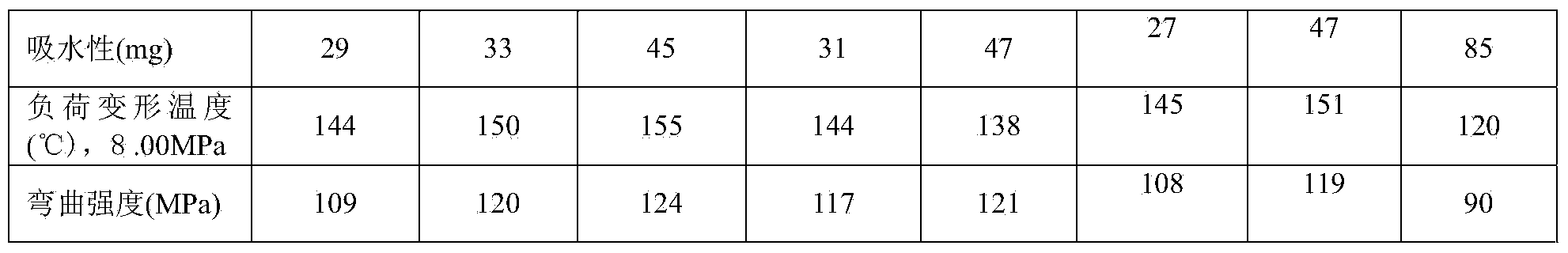

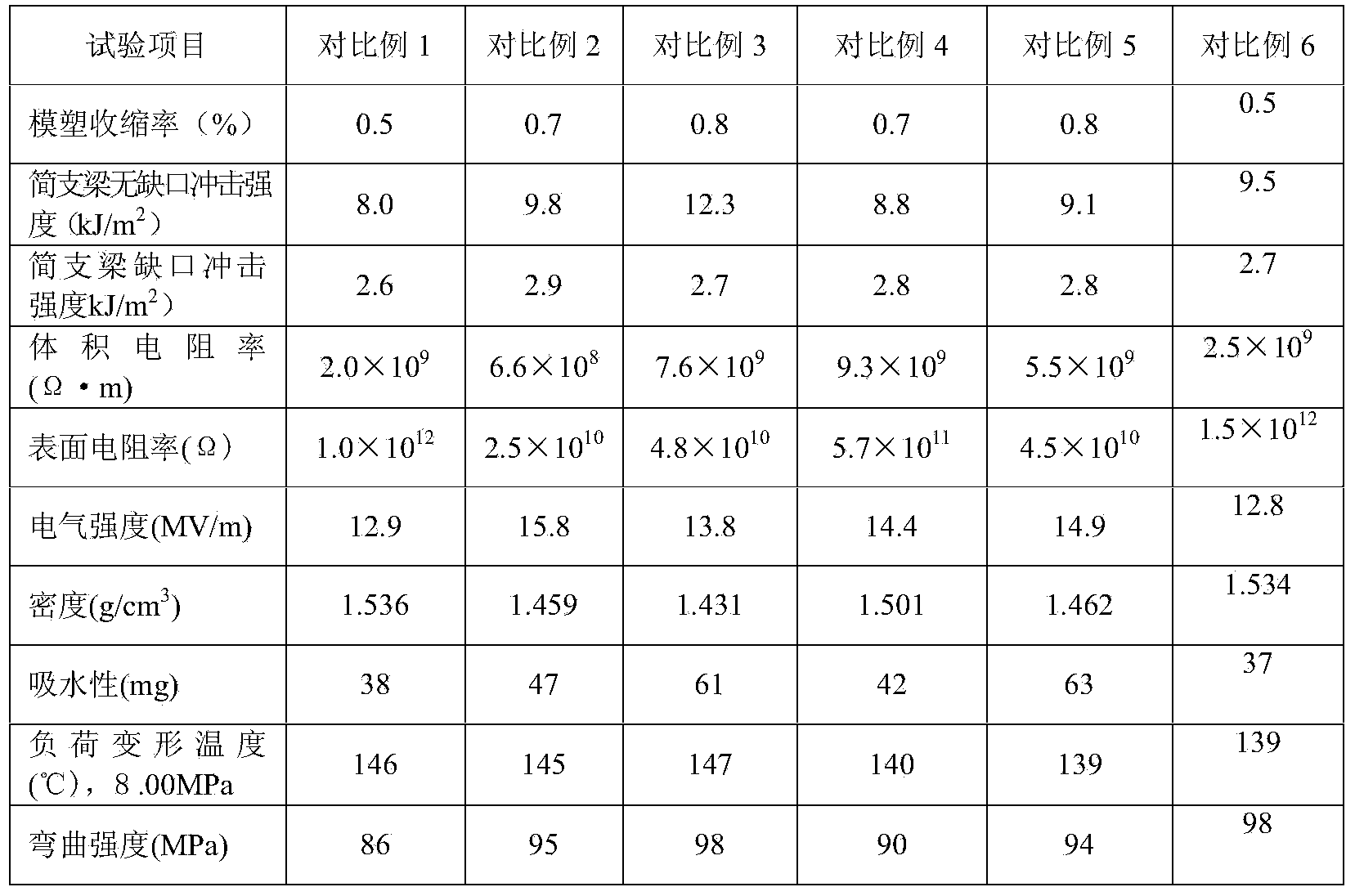

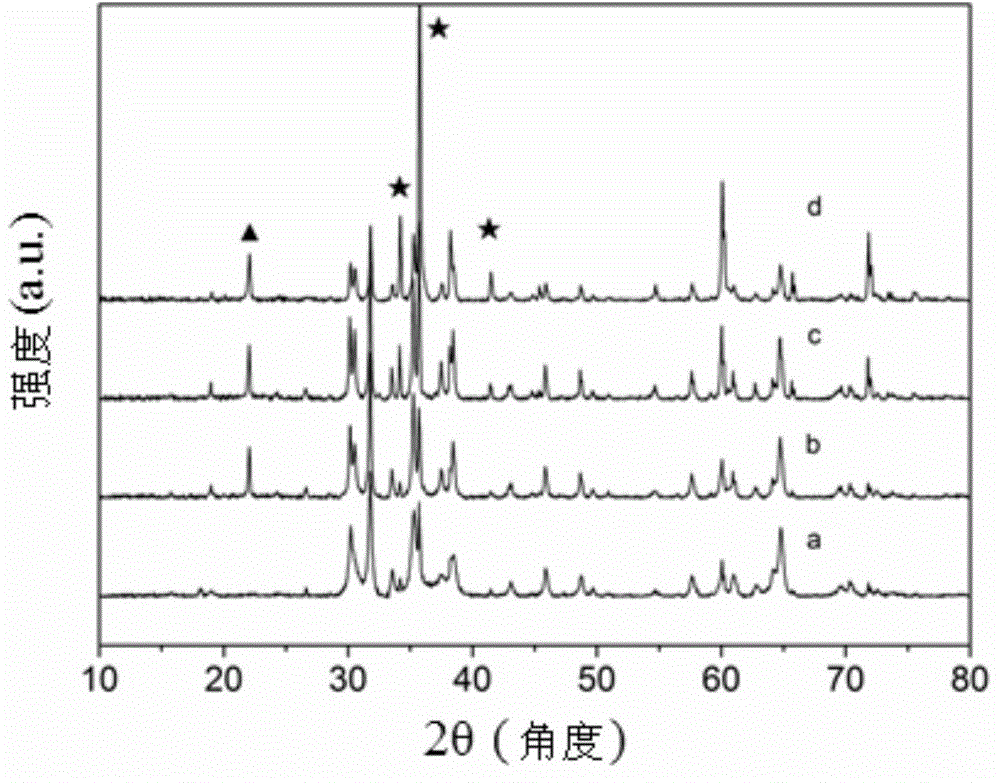

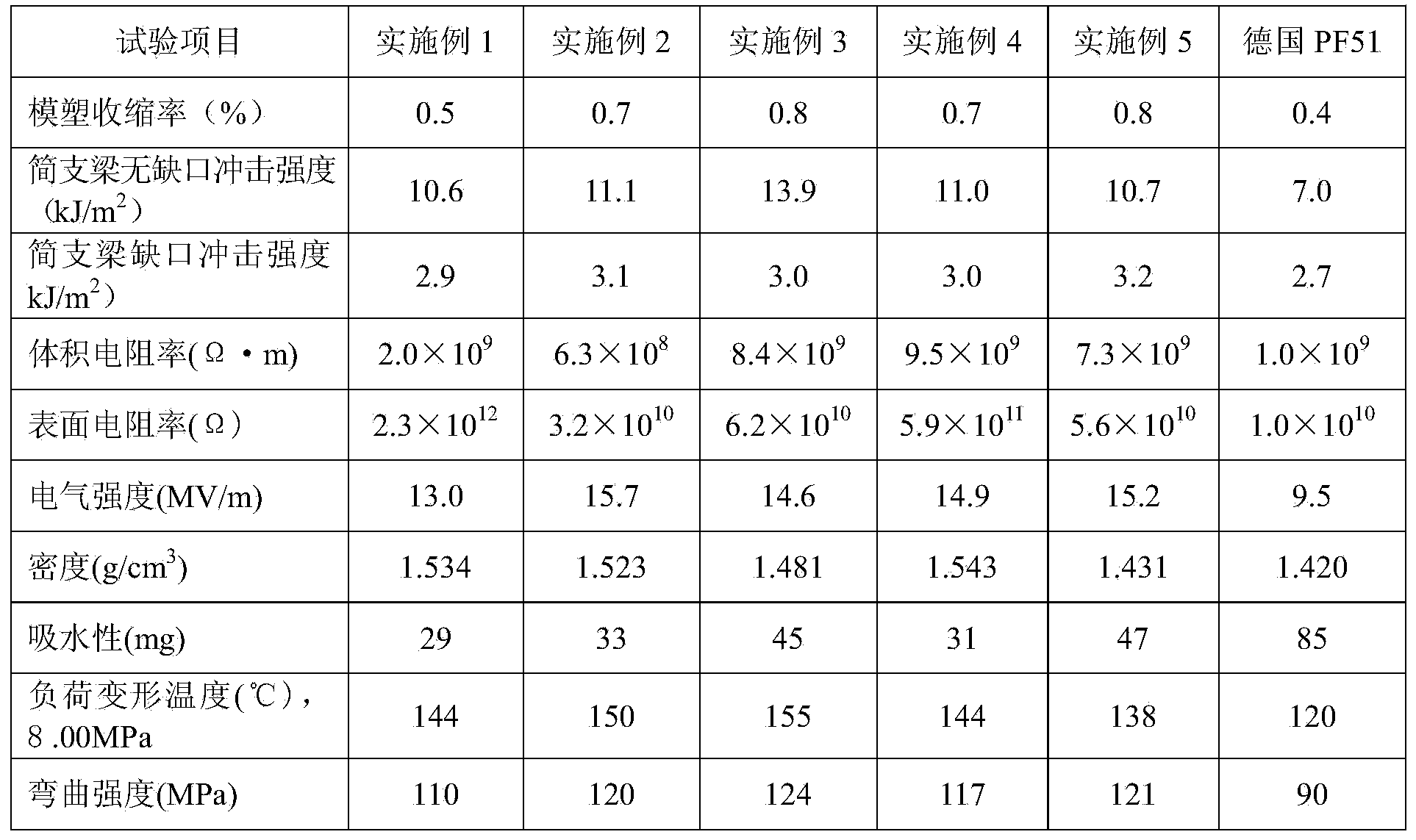

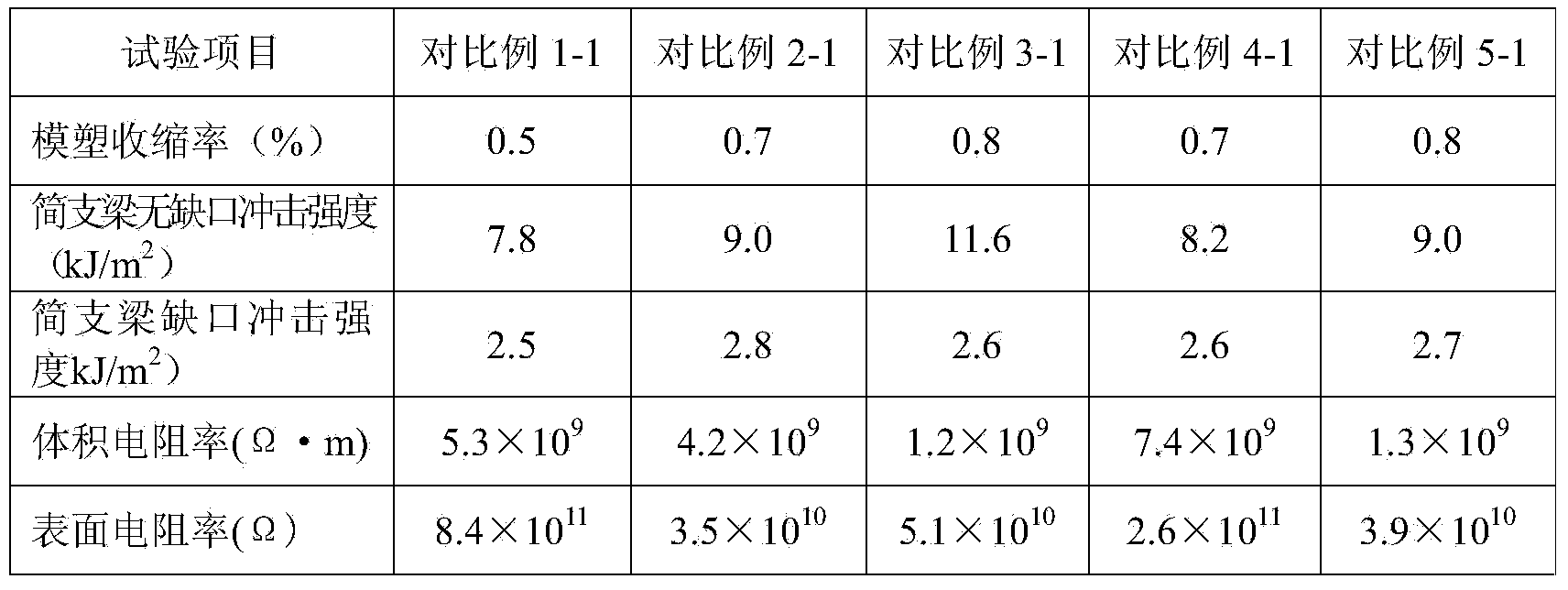

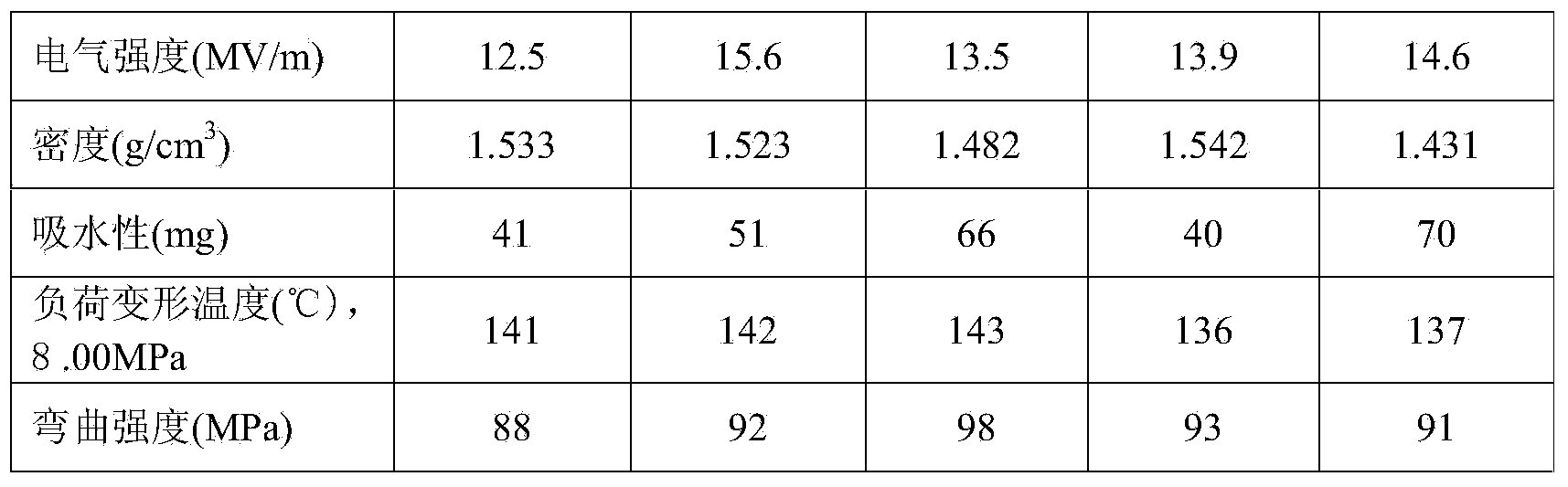

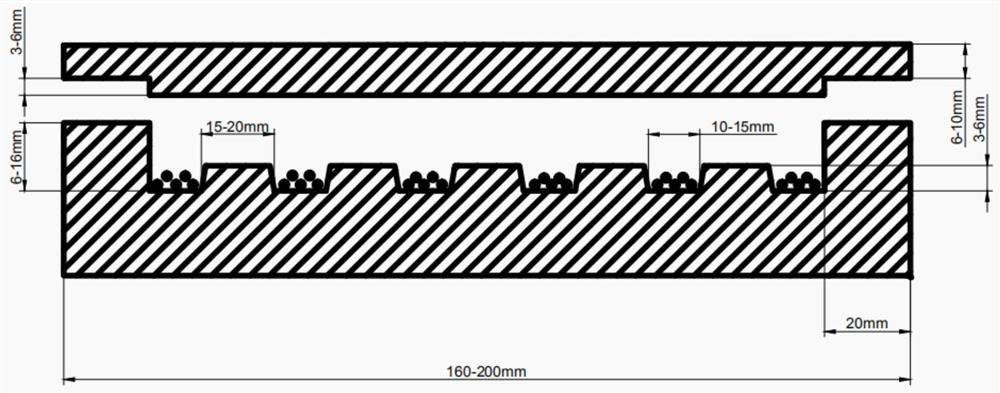

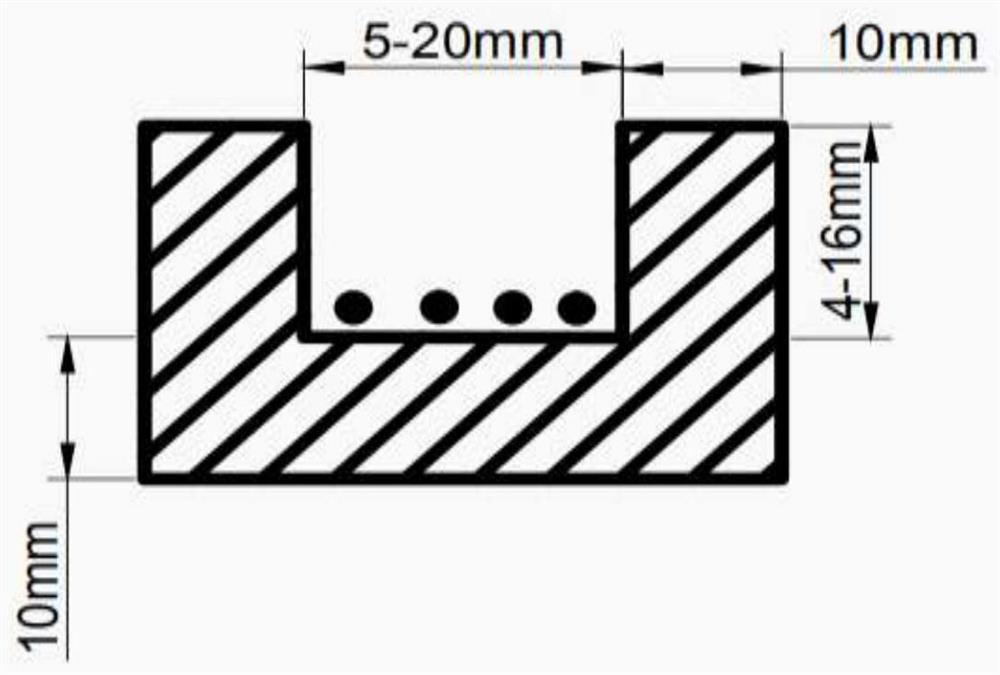

Carbon fiber reinforced injected phenolic moulding plastic and preparation method thereof

The invention discloses a carbon fiber reinforced injected phenolic moulding plastic and a preparation method thereof. The phenolic moulding plastic is mainly prepared from novolac resin, hexamethylenetetramine, inorganic fillers and carbon fibers. The preparation method comprises the following steps: (1) weighing the raw materials for later use; (2) performing uniform ball-milling on the inorganic fillers and a coupling agent in a ball mill or a ball-milling tank, wherein the usage amount of the coupling agent accounts for 0.5wt%-10wt% that of the inorganic fillers, and the inorganic fillers are selected from one or combination of two or more of aluminum hydroxide, silica powder, calcite, talcum, calcium carbonate, glass beads, kaolin and argil powder; (3) grinding hexamethylenetetramine and uniformly mixing with the inorganic fillers and other raw materials subjected to surface treatment to obtain a mixture; (4) extruding the mixture in a double-screw extruder to obtain an extruded material; and (5) cooling and grinding the extruded material to obtain the phenolic moulding plastic. The phenolic moulding plastic prepared by adopting the method is relatively high in mechanical property and relatively low in water absorptivity.

Owner:GUILIN ELECTRICAL EQUIP SCI RES INST

Preparation method of cotton-fiber-reinforced injection-type phenol aldehyde molding compound

The invention discloses a preparation method of a cotton-fiber-reinforced injection-type phenol aldehyde molding compound. The phenol aldehyde molding compound is mainly prepared from linear phenol aldehyde resin, hexamethylenetetramine, inorganic filler and cotton fiber. The preparation method comprises the following steps: 1) weighing the raw materials for later use; 2) putting the inorganic filler and coupling agent in a ball mill or ball milling tank, and carrying out uniform ball milling, wherein the coupling agent accounts for 0.5-10 wt% of the inorganic filler, and the inorganic filler is one or combination of more than two of aluminum hydroxide, silicon micropowder, calcite, talcum, calcium carbonate, glass microballoon, kaolin and ceramic powder; 3) pulverizing the hexamethylenetetramine, and uniformly mixing with the surface-treated inorganic filler and the other raw materials; 4) adding the mixture into a double screw extruder, and extruding; and 5) cooling the extruded stock, and pulverizing. The phenol aldehyde molding compound prepared by the method has the advantages of higher mechanical properties and lower water absorptivity.

Owner:桂林金格电工电子材料科技有限公司

Lithium titanate battery cathode paste and preparation method thereof

The invention provides a preparation method of lithium titanate battery cathode paste. The method comprises the following steps: preparing a raw material formula of the lithium titanate battery cathode paste, wherein the raw material formula comprises 100 parts by weight of a cathode material, 3-7 parts by weight of a conducting agent, 4-5 parts by weight of an adhering agent, and 80-160 parts byweight of N-methyl pyrrolidone; mixing the adhering agent and 30-60 parts of N-methyl pyrrolidone; stirring at low speed in order to uniformly mix; increasing the speed to high speed; stirring to obtain a paste type product; vacuumizing; stirring at low speed; preparing a glue solution; stirring the cathode material and the conducting agent at low speed under normal pressure in order to uniformlymix; adding the glue solution and 10-20 parts of N-methyl pyrrolidone; moisturizing; adding the rest N-methyl pyrrolidone; stirring at high speed under negative pressure, thus obtaining the lithium titanate battery cathode paste.

Owner:SHENZHEN BAK POWER BATTERY CO LTD

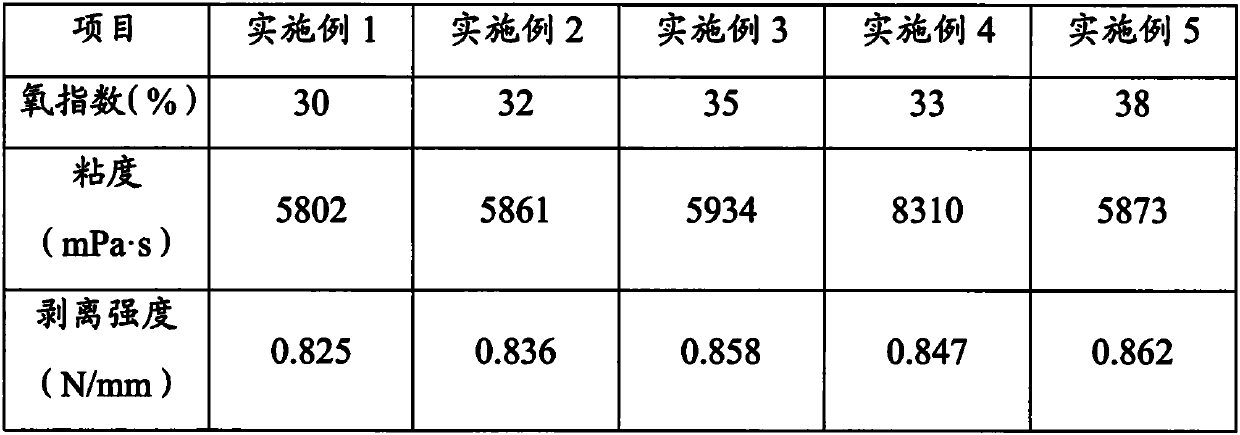

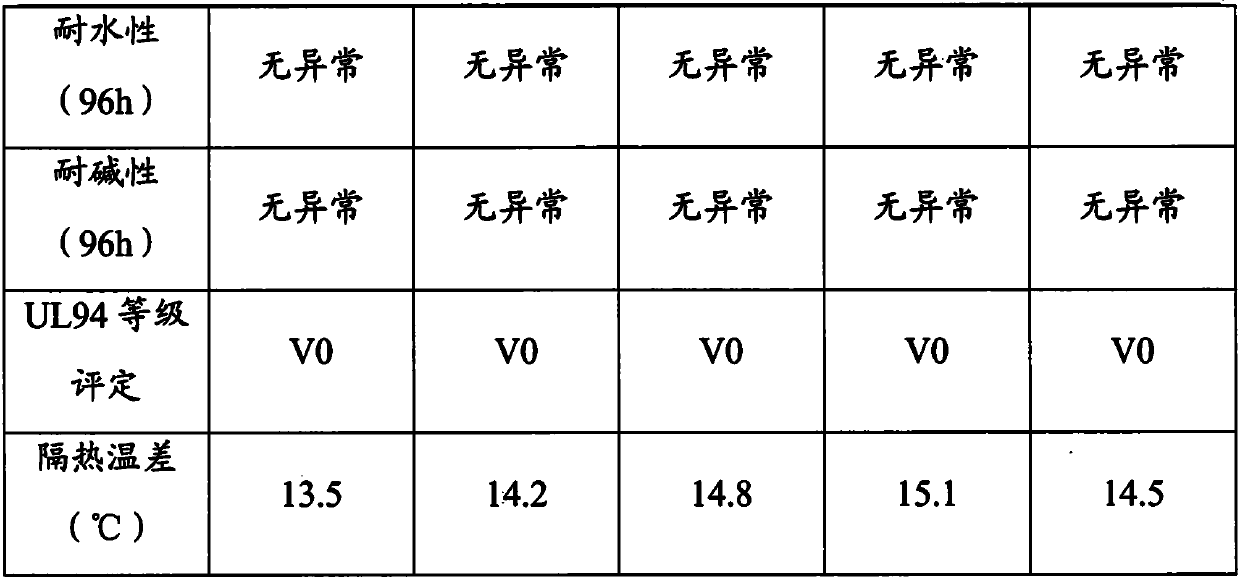

Aqueous heat-insulating flame-retardant coating nanomaterial

InactiveCN109401494AExcellent high temperature resistance and heat insulation performanceGood heat insulationCoatingsSodium BentoniteAcrylic resin

The invention provides an aqueous heat-insulating flame-retardant coating nanomaterial. The aqueous heat-insulating flame-retardant coating nanomaterial comprises the following ingredients in parts byweight: 70-80 parts of silicone acrylic resin, 4-8 parts of modified nano silicon carbide, 1-3 parts of silicon dioxide aerogel, 12-18 parts of hollow glass beads, 3-6 parts of Mg-Al hydrotalcite, 1-3 parts of wetting dispersant, 1-3 parts of diatomite, 3-6 parts of potassium titanate whiskers, 0.2-1 part of antifoamer and 30-40 parts of water, wherein the modified nano silicon carbide is mainlyprepared from nano silicon carbide, bentonite and a silane coupler. The coating material has excellent high-temperature resisting and heat-insulating properties and is good in flame retardance and long in service life.

Owner:合肥晓拂新能源有限公司

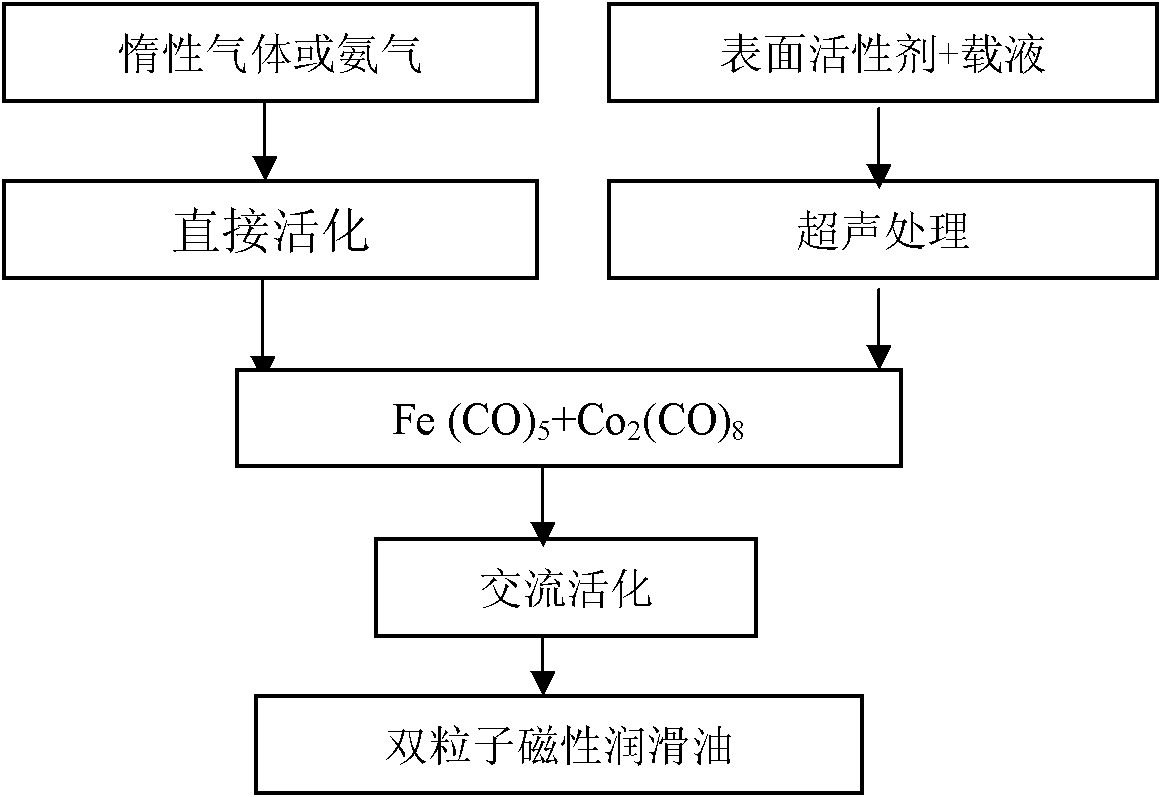

Two-particle nano-magnetic lubricating oil

InactiveCN102002417ALong-term specific surface energyLong-term stability of specific surface energyAdditivesMagnetizationDicobalt octacarbonyl

The invention relates to two-particle nano-magnetic lubricating oil. The lubricating oil is prepared by using a method comprising the following steps of: injecting pentacarbonyl iron and cobalt octacarbonyl into the mixture liquid of a surface active agent and carrier liquid under the protection of inert gases and the addition of ammonia gas; heating a reaction system to 80-90 DEG C, starting a direct current high voltage and starting and adjusting the direct current pulse high voltage to be 7kV while the pulse frequency is approximate 63kHz; carrying out plasma activation on the ammonia gas at approximate 200 DEG C for 130-150min; and then, cooling the reaction system to below 40 DEGC after the reaction is finished and collecting products. The two-particle nano-magnetic lubricating oil prepared by using the plasma activating method of the invention substitutes Co particles with strong magnetic capability for one part of Fe particles aiming at the reasons of low saturation magnetization intensity of original single-particle nano-magnetic lubricating oil, poor stability of nano magnetic particles, and the like, thereby enhancing the saturation magnetization intensity of the magnetic particles and improving the saturation magnetization intensity of the magnetic lubricating oil.

Owner:DALIAN UNIV

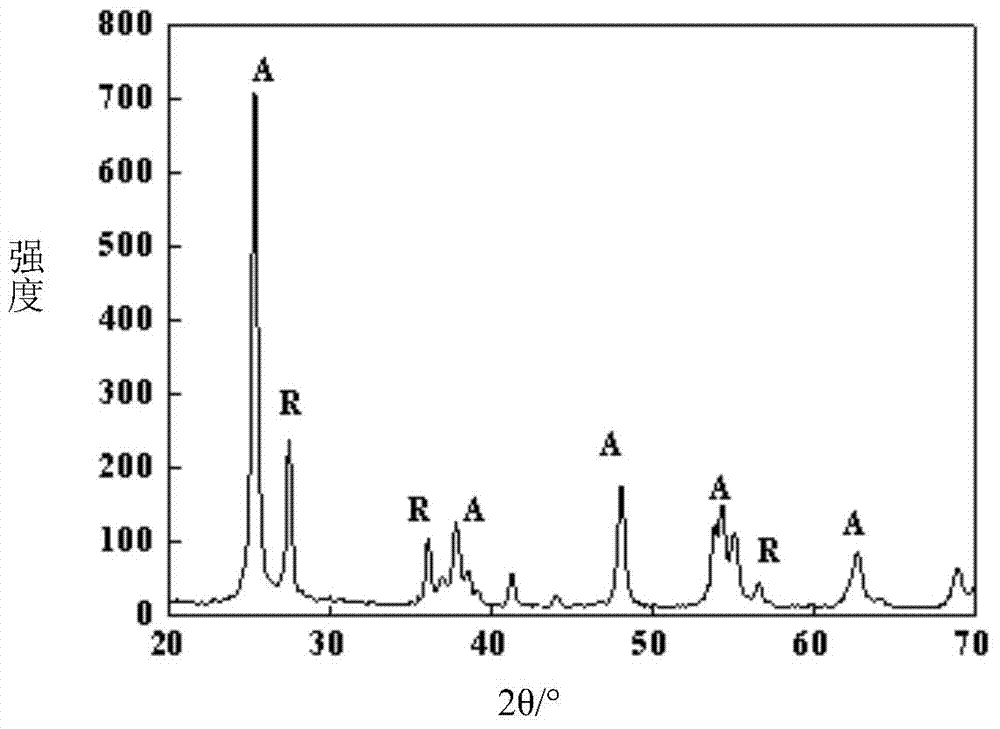

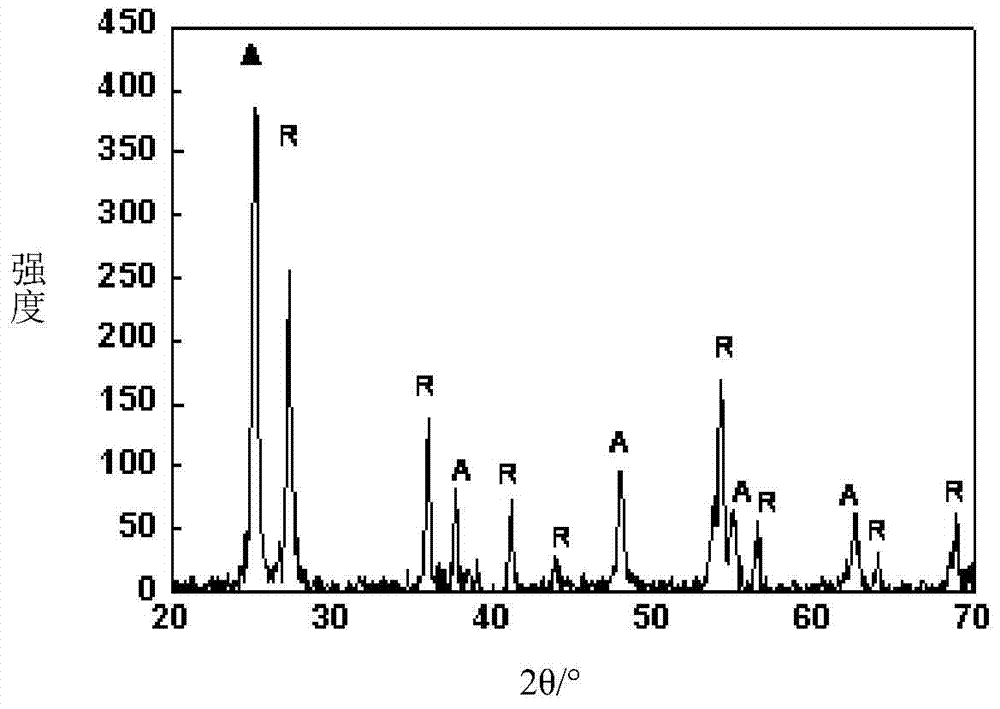

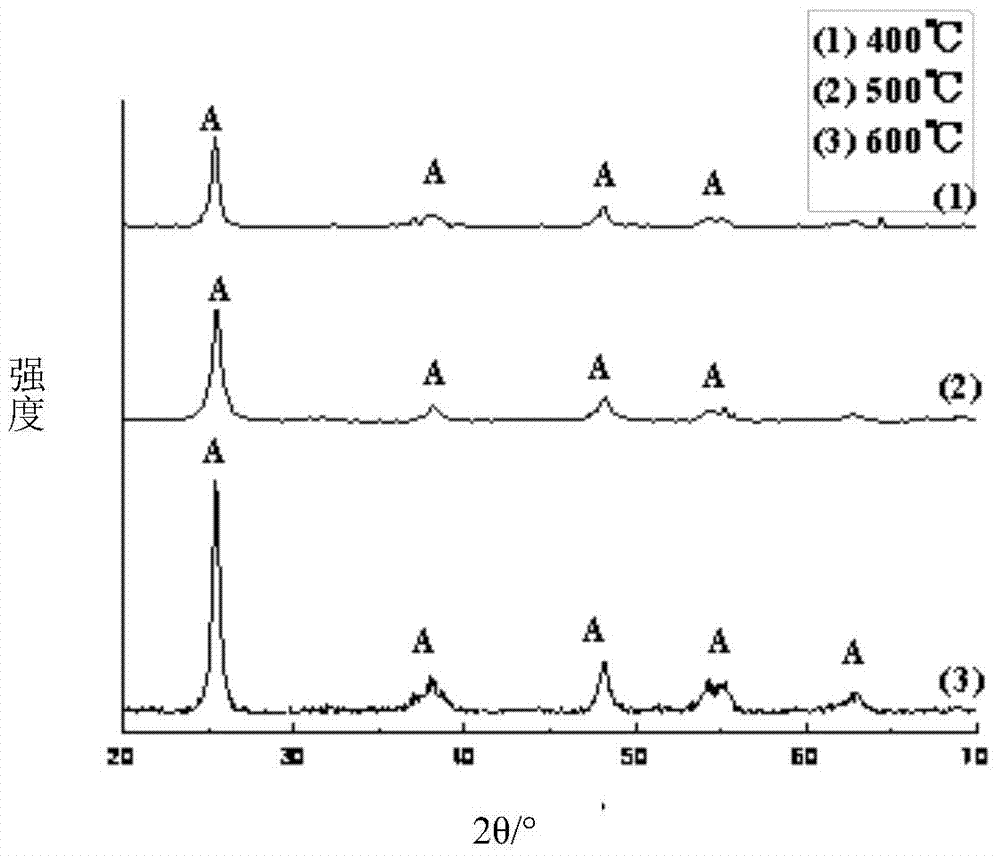

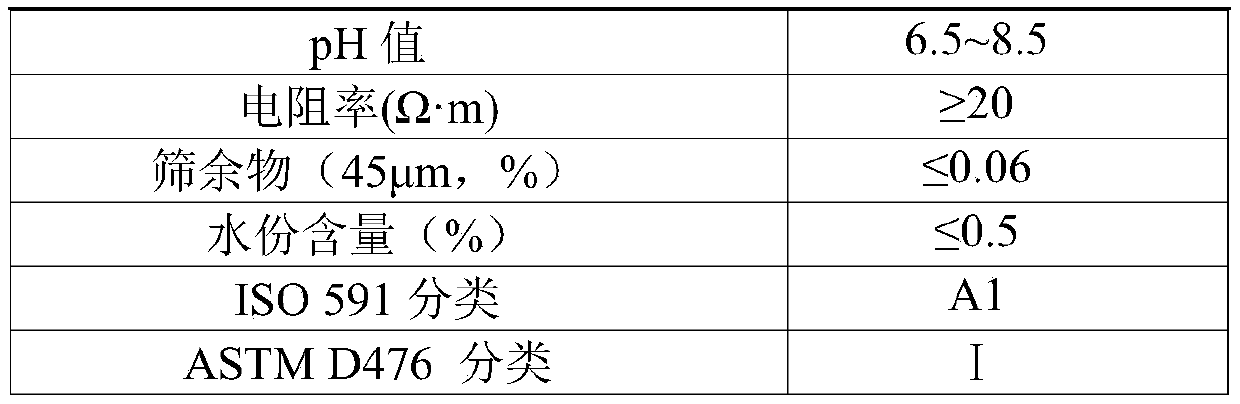

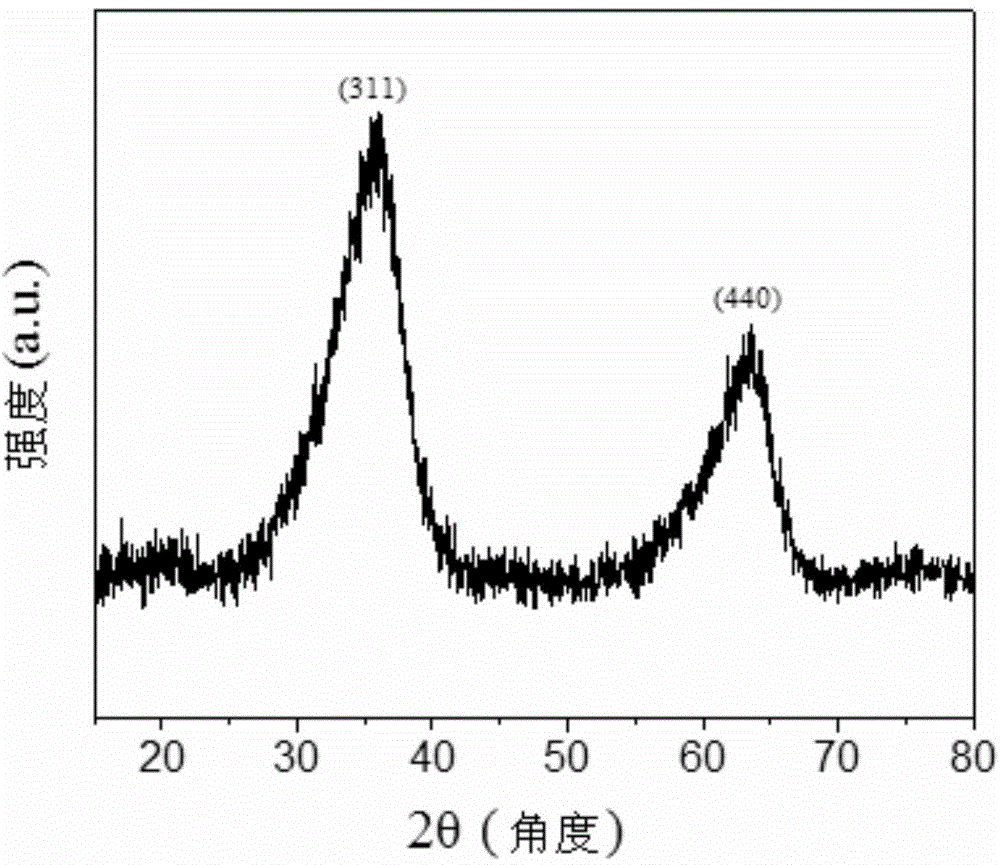

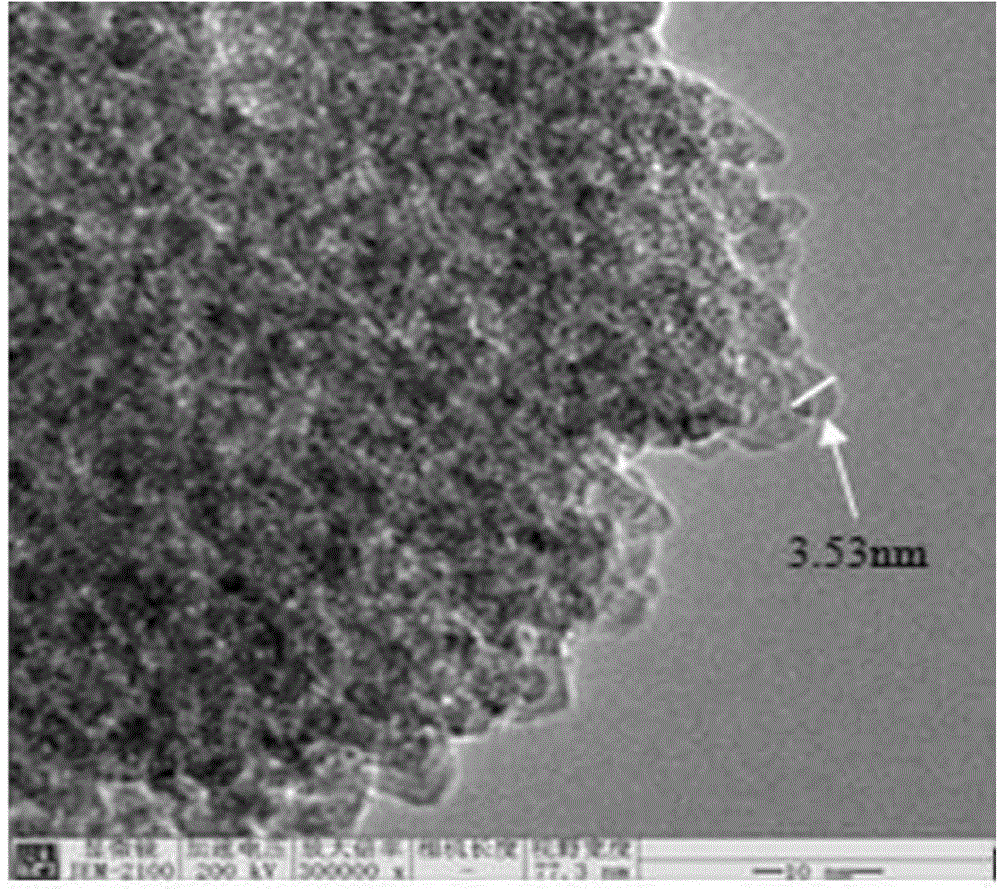

Three-atom-doped titanium dioxide as well as preparation method and application thereof

InactiveCN103769188AImprove abilitiesPromote degradationPhysical/chemical process catalystsDispersed particle separationVanadium dopingSide reaction

The invention discloses three-atom-doped titanium dioxide catalyst as well as a preparation method and application of the three-atom-doped titanium dioxide catalyst, belonging to the technical field of catalysis and indoor air pollution prevention and control. The three-atom-doped titanium dioxide is composed of titanium dioxide crystals comprising nitrogen atoms, vanadium atoms and silicon atoms, having a crystalline form of anatase or a mixed crystalline of anatase and rutile, and having a particle size being 2-20nm, wherein the molar ratio of nitrogen to vanadium to silicon to titanium is (14-56): (0.1-2): (3-16):100, the specific surface area is 70-90m<2> / g, the energy gap is 2.8-3.0ev, and the absorption wavelength is 380-500nm. According to the invention, based on the nitrogen-vanadium-doped titanium dioxide photocatalyst, three-atom-doped titanium dioxide photocatalyst is prepared by using a sol-gel method, the superficial area and pore volume of the product are improved, and the product has catalytic activity under visible light. The preparation method is simple, the reaction process is easy to control, and side reactions hardly occur.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

Preparation method of expanded graphite flake/thermosetting resin composite material

The invention discloses a preparation method of an expanded graphite flake / thermosetting resin composite material, which comprises the following steps: allowing the internal void of expanded graphite to generate negative pressure in conditions that the degree of vacuum is lower than or equal to 10Pa, the temperature is the one keeping thermosetting resin to be in a liquid state, and the viscosityis lower than or equal to 1.5Pa.s, wherein the negative pressure is favorable for the resin to enter the lamellar structure of expanded graphite and sufficiently impregnate the lamellar structure of graphite; and stripping the lamella of expanded graphite through ultrasonic agitation to obtain expanded graphite flakes, at the same time, forming a physical or chemical bond action between the thermosetting resin and the surface groups of the expanded graphite flakes, and curing under a microwave condition to obtain uniformly dispersed expanded graphite flake / thermosetting resin composite material. The preparation method disclosed by the invention overcomes the defects in preparing the expanded graphite composite materials using a solvent method, including that the expanded graphite flakes are likely to agglomerate and the solvent pollutes the environment, and has the characteristics of simpleness, rapidness, environmental friendliness, and energy conservation.

Owner:SUZHOU UNIV +1

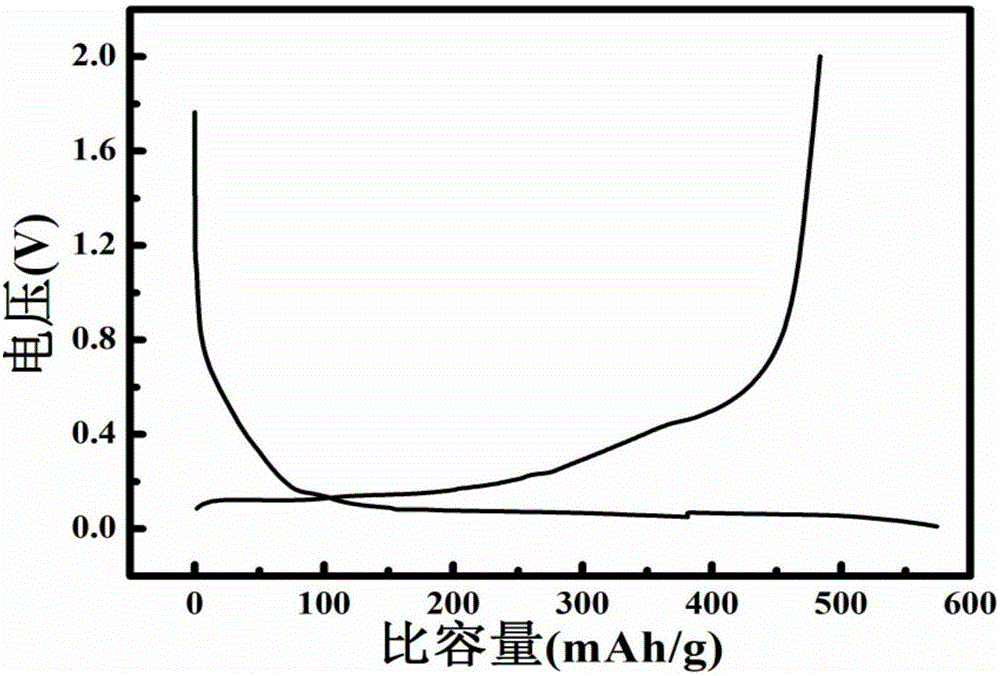

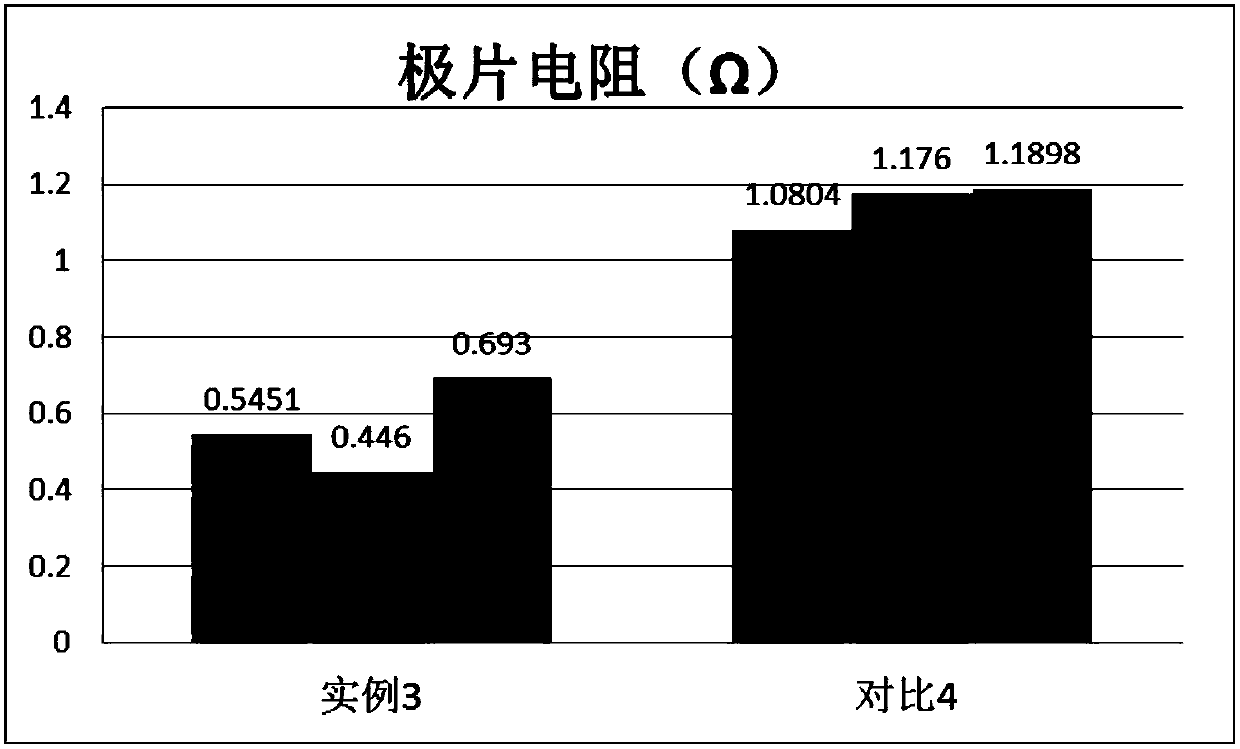

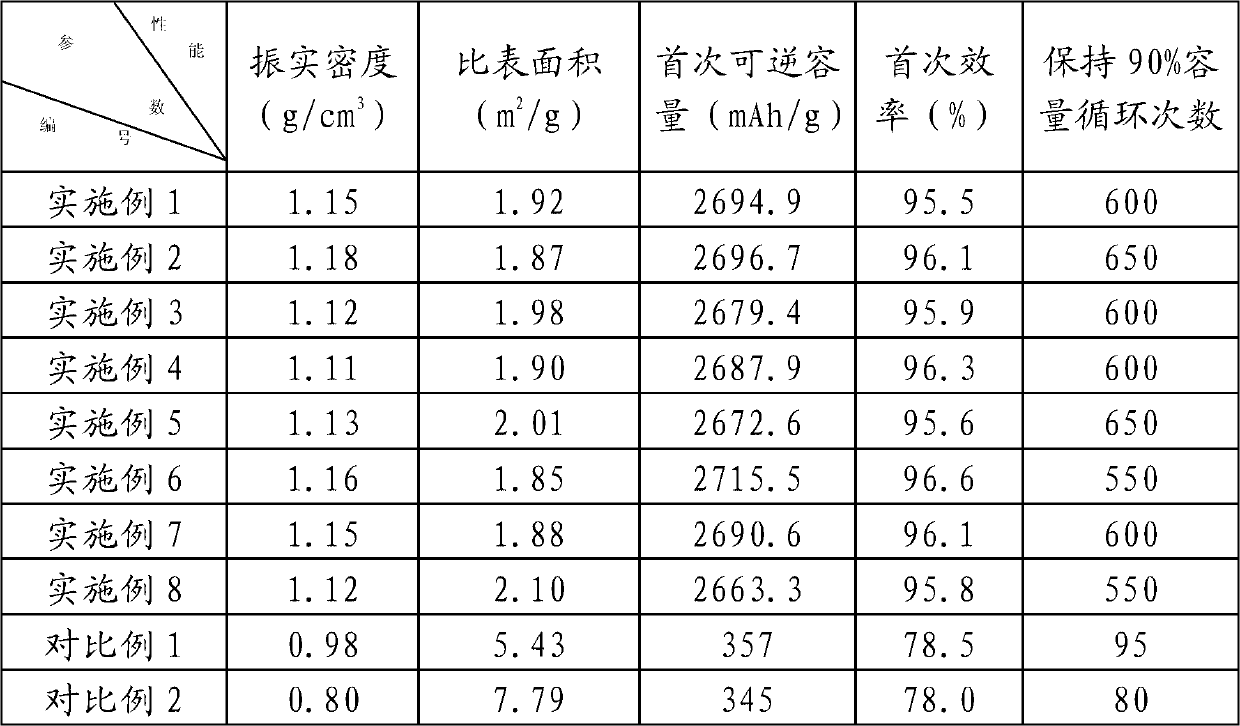

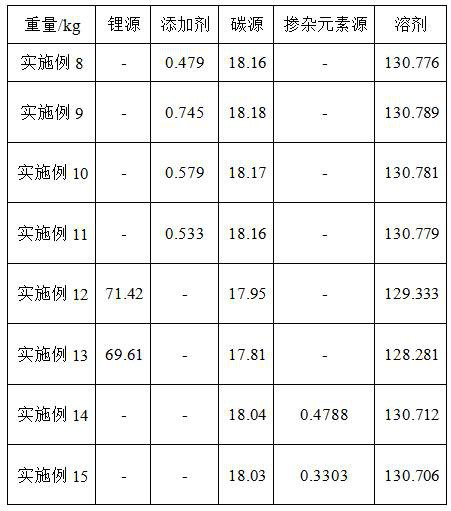

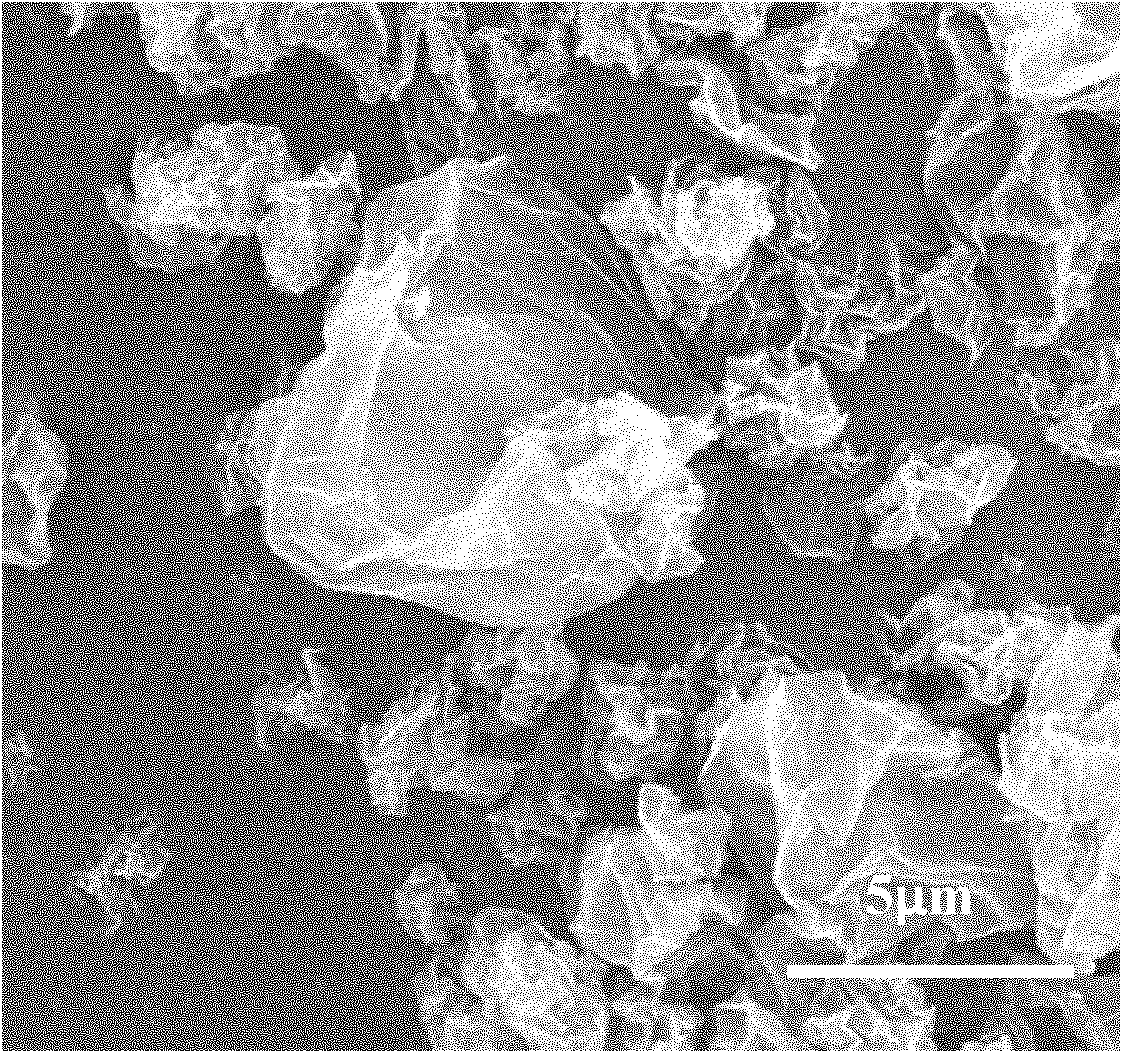

Cathode material of lithium ion battery and preparation method thereof

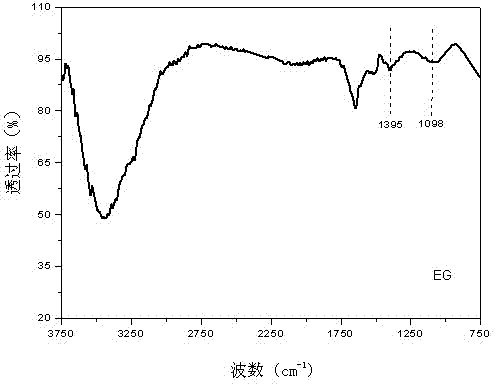

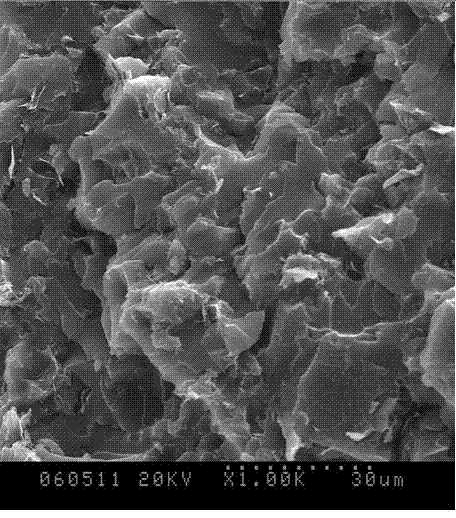

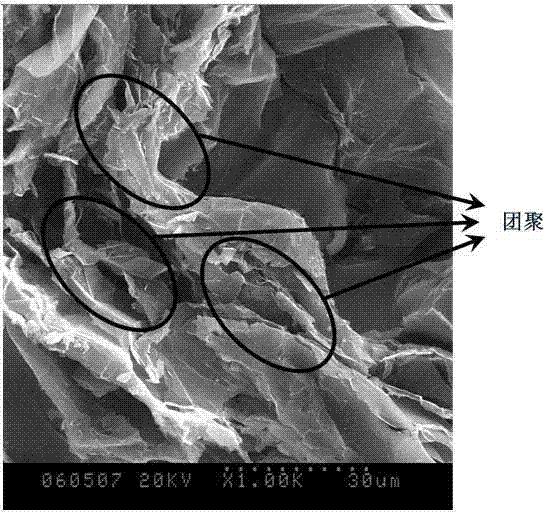

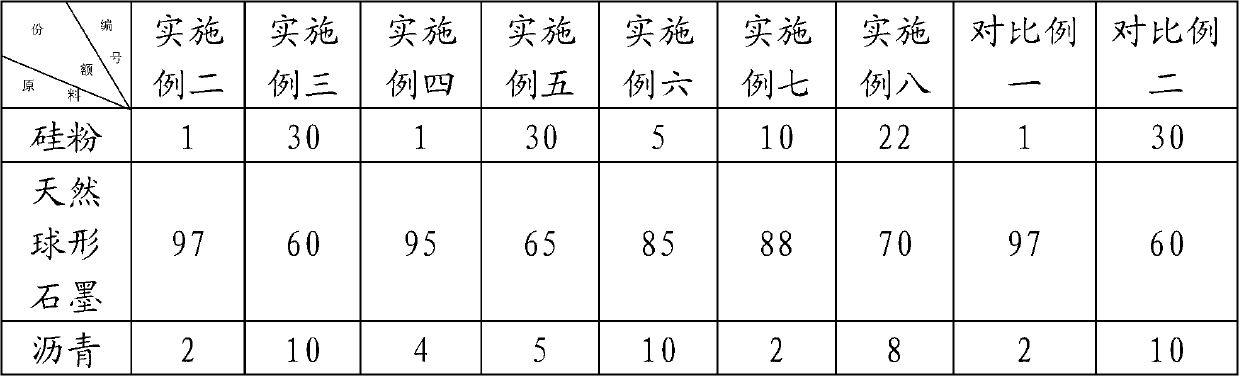

InactiveCN102903894AReduce the likelihood of reunionsImprove the first Coulombic efficiencyCell electrodesSodium-ion batterySolvent

The invention discloses a cathode material of a lithium ion battery and a preparation method thereof. The cathode material comprise the following raw materials by mass parts: 1 to 30 parts of silica fume, 60 to 97 parts of natural spherical graphite and 2 to 10 parts of a coating agent. The method comprises adsorbing a layer of conductive film on the silica fume, mechanically milling and mixing the silica fume and the graphite and then drying under vacuum, putting the mixture into a prepared solution of the coating agent for coating, removing the solvent, drying under vacuum and heating under high temperature, sieving when necessary, and finally getting the cathode material. The preparation method provided by the invention is simple to operate and low in cost; the cathode material prepared by the method has an initial reversible capacity of more than 2663 mAh / g and an initial efficiency of more than 95 %, can maintain a capacity of 90 % after being cycled for 600 times, and is excellent in charging and discharging performances.

Owner:东莞市翔丰华电池材料有限公司

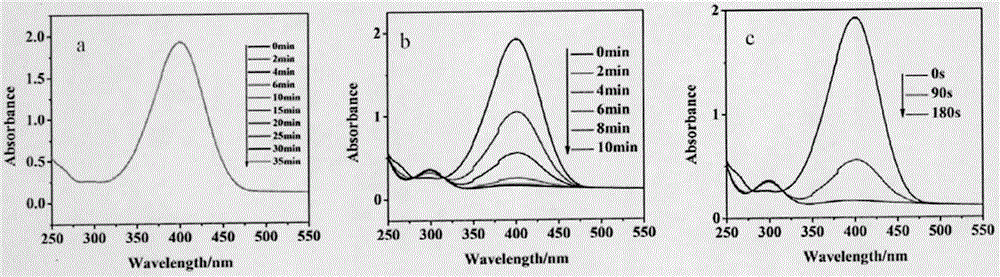

Ag/rGO sandwich-structure nano composite material as well as preparation method and application thereof

InactiveCN107519869AReduce the likelihood of reunionsOrganic compound preparationWater contaminantsReduction ActivityElectrical conductor

The invention discloses an Ag / rGO sandwich-structure nano composite material as well as a preparation method and application thereof. The composite material is characterized in that silver and graphene in AgNO3 / GO are reduced simultaneously through glucose so that silver nanoparticles are doped into a graphene lamellar structure, wherein the glucose is used as an auxiliary reducing agent; the activity of an aldehyde group is great and Ag<+> firstly forms on an Ag crystal seed on graphene oxide modified by the aldehyde group, so that an Ag-C chemical bond is formed; the glucose is added so that the Ag is increased and the graphene oxide is reduced into the graphene; a product sandwich Ag@rGO nano composite structure is obtained through the caking property of noble metal. Meanwhile, the reduced graphene oxide is used as a good conductor and can be used for inhibiting charge recombination. The composite material enters layers in a non-carbon particle form, the layer-to-layer distance of the graphene is increased and the layer-to-layer Van der Waals force is weakened, so that the possibility of agglomeration is reduced. Meanwhile, the reduction activity of the composite material on nitrophenol is greatly improved by a sandwich structure and a high rGO specific surface area of the composite material and the silver is used as a reducing agent.

Owner:董可轶 +2

Pigment blending device for art pattern design

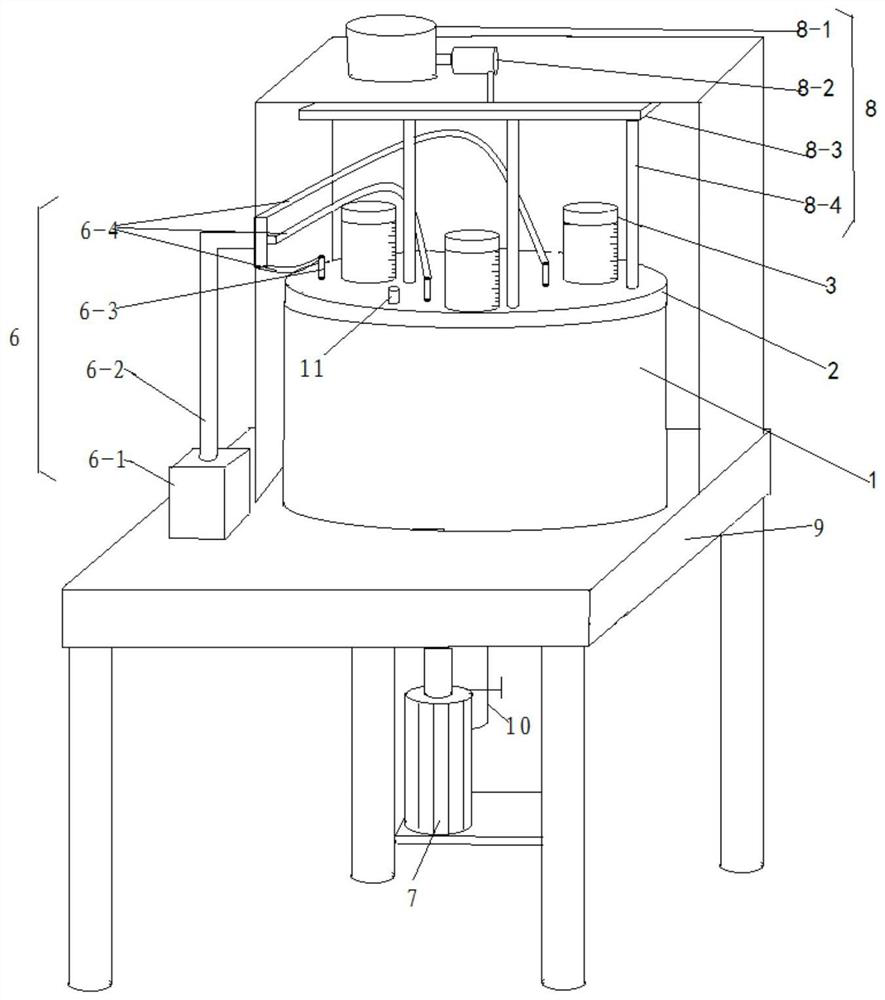

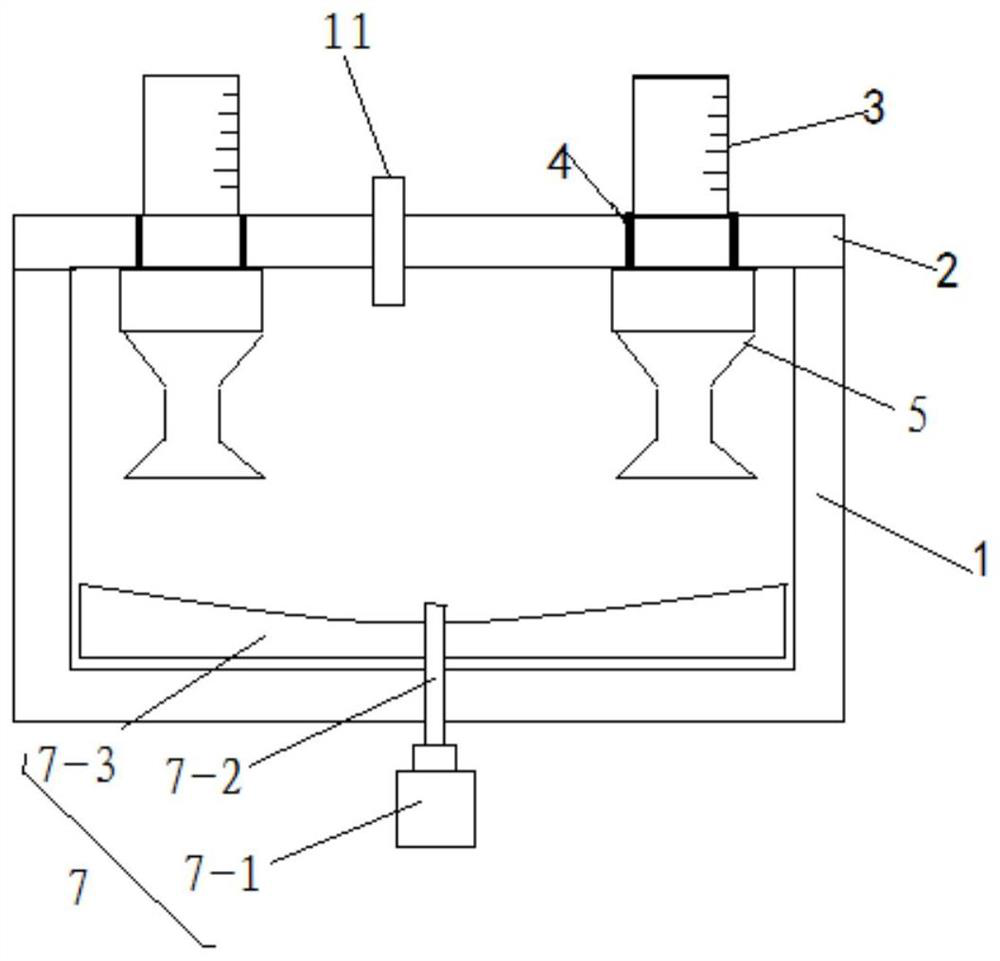

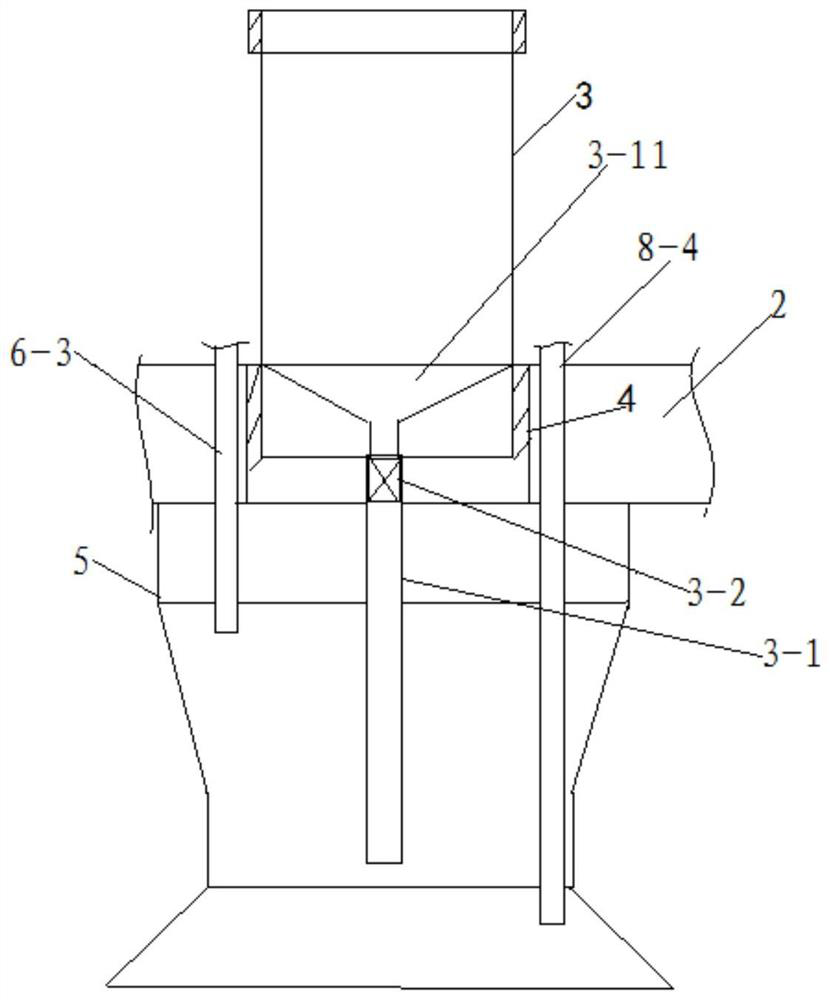

InactiveCN111845183ALow degree of reunionReduce the likelihood of reunionsFlow mixersRotary stirring mixersPolymer scienceGas supply

The invention discloses a pigment blending device for art pattern design. The pigment blending device comprises a pigment blending barrel, a barrel cover, quantitative pigment storage devices, Venturitubes, gas supply devices and conveying pipes; the barrel cover is arranged at the top of the pigment blending barrel, and three first through holes are formed in the barrel cover in the longitudinaldirection; the three quantitative pigment storage devices penetrate into the through holes from the upper end openings of the through holes in the longitudinal direction correspondingly and are connected with the through holes in a sealed mode, and openings for pigment to flow out are formed in the bottom walls of the quantitative pigment storage devices; the three Venturi tubes are correspondingly arranged on the bottom wall of the barrel cover on the peripheral walls of the lower ports of the through holes in the longitudinal direction, and the top ends of the Venturi tubes are connected with the bottom wall of the barrel cover in a sealing mode; the gas supply devices are correspondingly in communication with the Venturi tubes; and the top ends of the three conveying pipes are in communication with the openings correspondingly, the bottom ends of the conveying pipes penetrate through the corresponding through holes and enter the correspondingly Venturi tubes, and electromagnetic valves are further arranged on the conveying pipes. According to the pigment blending device for art pattern design, pigment can be dispersed in the Venturi tubes, agglomeration of the pigment in the pigment blending barrel is reduced, the stirring time can be shortened during blending, and therefore energy consumption is reduced.

Owner:HUAIHUA UNIV

Water-based environment-friendly coating material and preparation method thereof

InactiveCN108102489ALow viscosity increaseStrong anti-mold abilityAntifouling/underwater paintsPaints with biocidesWater basedAcrylic resin

The invention discloses a water-based environment-friendly coating material and a preparation method thereof and belongs to the technical field of coating material preparation. The water-based environment-friendly coating material is prepared from the following raw materials: water-soluble acrylic resin, nano-scale kaolinite, nano-scale montmorillonite, a PBMA-b-PDMAEMA dispersant, diatomite, an acetylene diol antifoamer, tri(hydroxymethyl)propane-tri(3-aziridinyl)propionate, a sodium alginate thickener, a polydimethylsiloxane, a twin siloxane humectant, carboxymethyl chitosan silver, titaniumdioxide and deionized water. The water-based environment-friendly coating material is prepared through the steps of water-soluble acrylic resin preparing, ingredient dispersing, mixing preparation and the like. The water-based environment-friendly coating material disclosed by the invention is good in ingredient compatibility and high in weather resistance and has certain antibacterial capability, and the surface of the coating material can be prevented from generating bacteria and molds; organic pollutants of surrounding environments can be effectively absorbed, so that the water-based environment-friendly coating material is novel.

Owner:CHANGSHA WUDAO IND DESIGN CO LTD

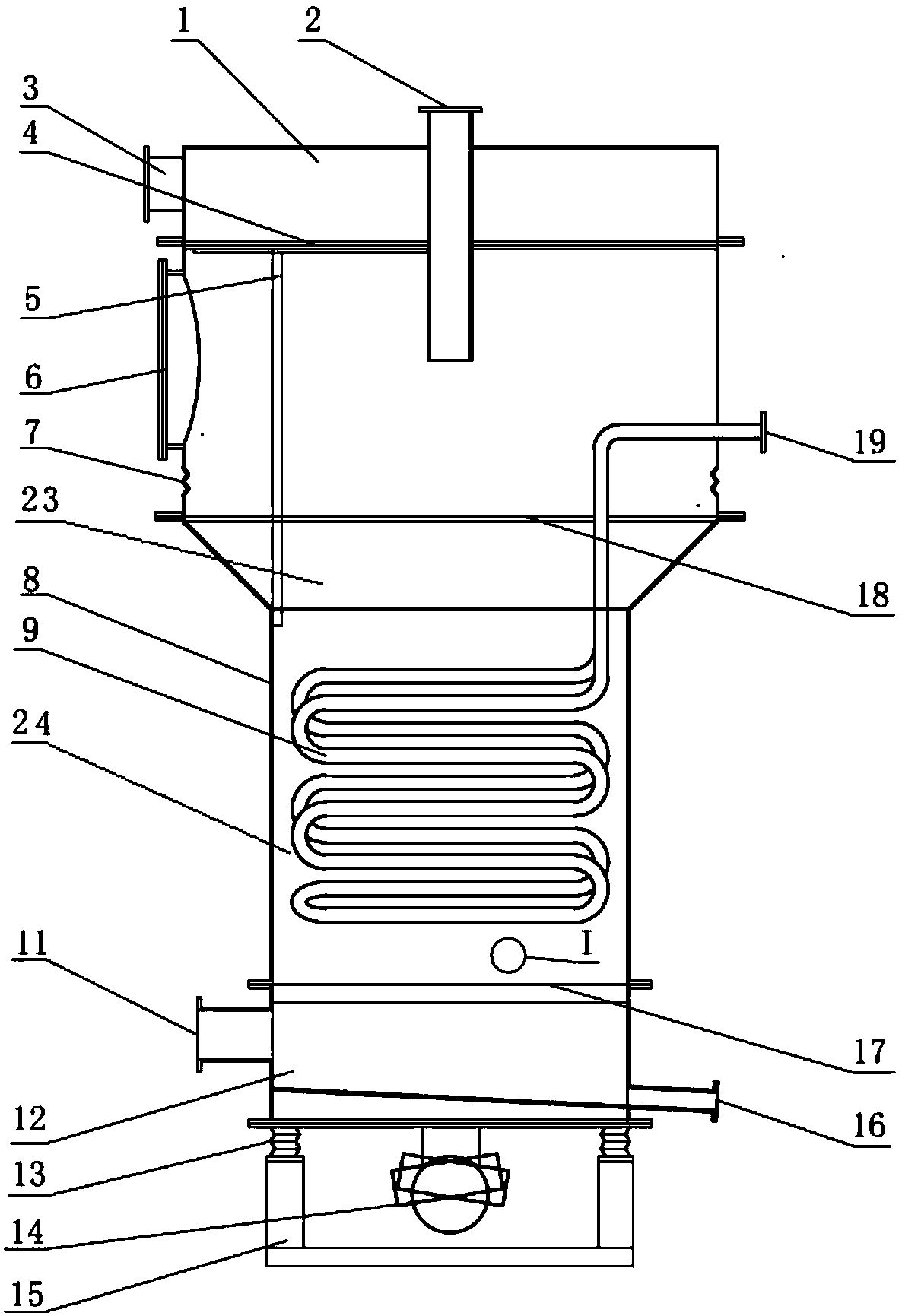

Vibration fluidized bed drying device and drying method

ActiveCN109140905AFast dryingReduce heat lossDrying solid materials with heatDrying gas arrangementsVibratory fluidized bedProcess engineering

The invention relates to a vibration fluidized bed drying device and drying method. The device comprises a particle settling chamber, a vibration fluidized bed body and a material collection box. Theparticle settling chamber is provided with a material inlet and a gas outlet. The material collection box is provided with a discharging opening and a gas air supply opening. A settling area is arranged on the upper portion of the vibration fluidized bed body, and a pre-drying vibration distribution plate is arranged on the settling area. A fluidized bed layer is arranged on the lower portion of the vibration fluidized bed body, and an air distribution plate is arranged between the fluidized bed layer and the material collection box. Material holes and air holes are formed in the pre-drying vibration distribution plate and the air distribution plate. The fluidized bed layer is a dense-phase fluidized bed layer formed by inert particles located in the fluidized bed layer and to-be-dried powder entering from the material inlet. A heat exchanger is arranged in the fluidized bed layer. The material collection box, the vibration fluidized bed body and the pre-drying vibration distribution plate vibrate. By means of the device and method, materials hard to fluidize is fluidized well and dried fast, the heat utilization rate is high, the equipment size is small, and the cost is low.

Owner:北京新佰奥科技有限公司

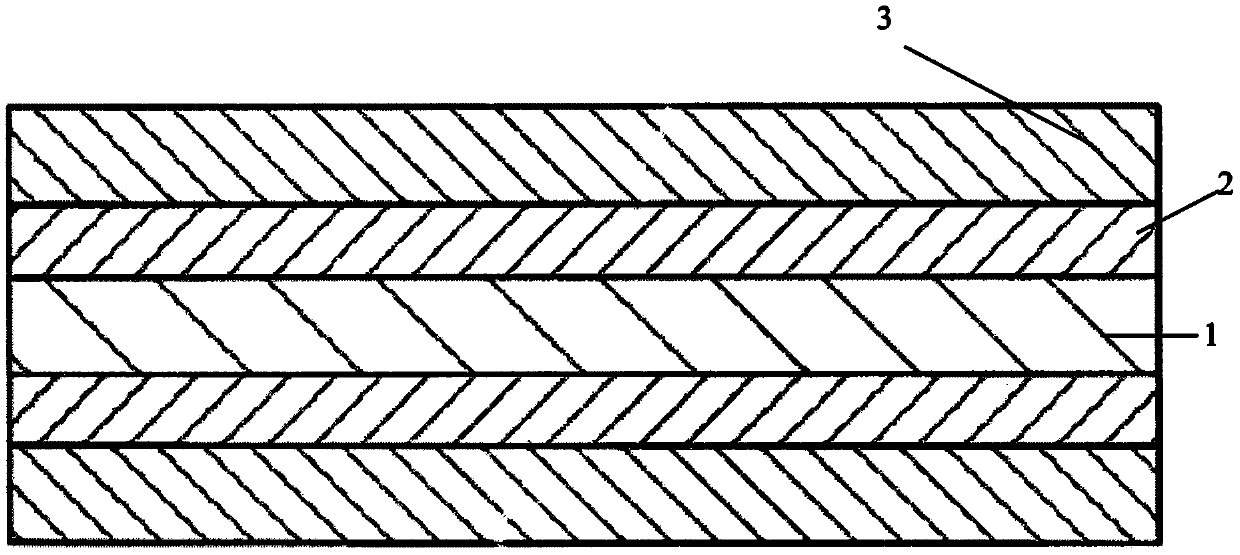

Non-metal heat-insulation flame-retardant multifunctional plate

InactiveCN111349353AImprove flame retardant performanceStrong heat storage capacityFireproof paintsSynthetic resin layered productsInsulation layerSilicon dioxide

The invention discloses a non-metal heat-insulation flame-retardant multifunctional plate which comprises a base material plate, heat preservation layers and heat-insulation flame-retardant layers. The heat preservation layers are arranged on the upper face and the lower face of the base material plate. The heat insulation flame-retardant layer is arranged on the outer side of each heat preservation layer; the base material plate is a wood base material; the heat preservation layers are made of polyurethane foam or rock wool or expanded perlite, and meanwhile, the outer side of each heat-insulation flame-retardant layer is further coated with a heat-insulation flame-retardant coating. The heat-insulation flame-retardant coating is composed of modified nano silicon carbide, diatomite, silicon dioxide aerogel, lauryl sodium sulfate, diisocyanate, a coalescing agent and a flame retardant. In the coating, the polarity of the nano silicon carbide is improved, the possibility of agglomeration of the modified silicon carbide is obviously reduced, and meanwhile, the dielectric property of a coating layer is improved.

Owner:深圳市深炜科技有限公司

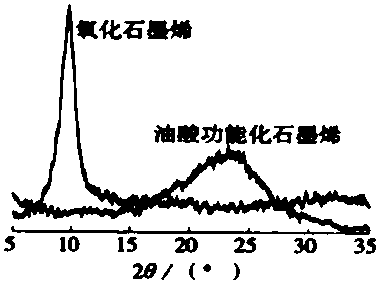

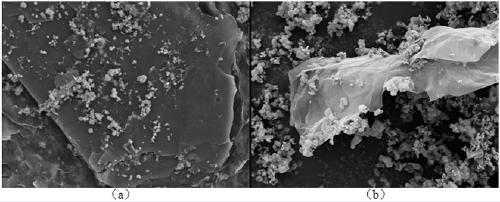

Graphene oxide/zinc oxide antistatic polypropylene cast film

The invention discloses a graphene oxide / zinc oxide antistatic polypropylene cast film and a preparation method thereof, and belongs to the technical field of materials. The graphene oxide / zinc oxideantistatic polypropylene cast film is prepared from, by weight, 100 parts of polypropylene resin and 5-15 parts of antistatic master batch, wherein the antistatic master batch is prepared from polypropylene resin, a composite antistatic agent OA / GO-g-ZnO and EVA resin. The composite antistatic agent OA / GO-g-ZnO used in the antistatic master batch combines the antistatic properties of graphene oxide and oleic acid, and zinc oxide uniformly grows on oleic acid functionalized modified graphene oxide to avoid agglomeration, so that the obtained polypropylene cast film has a good antistatic effect.

Owner:FUZHOU UNIV

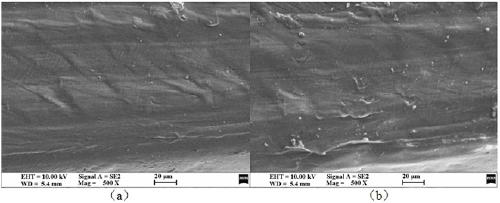

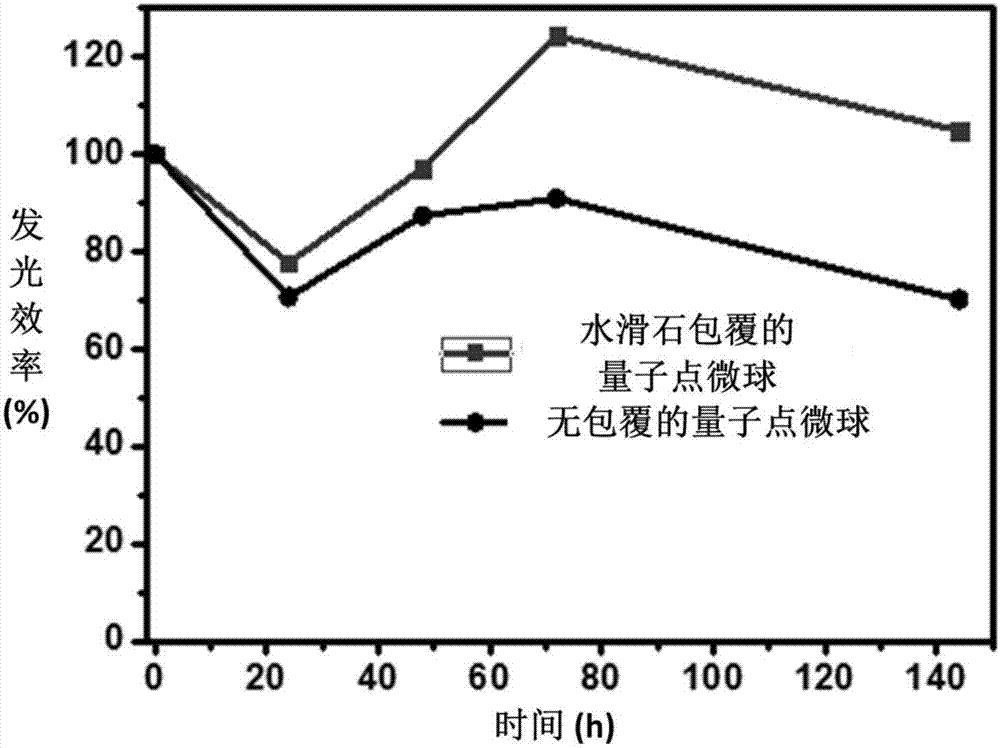

Hydrotalcite coated quantum dot microsphere and preparation method thereof

InactiveCN106905954AImprove stabilityImprove luminous efficiencyLuminescent compositionsCompound aWater vapor

The invention provides a hydrotalcite coated quantum dot microsphere which comprises a quantum dot microsphere and a hydrotalcite coating layer arranged on the surface of the quantum dot microsphere, wherein the quantum dot microsphere is formed by compounding a quantum dot and a primary matrix material. The invention further provides a preparation method of the hydrotalcite coated quantum dot microsphere, which comprises the steps of coating the surface of the quantum dot microsphere with a hydrotalcite material to form the quantum dot microsphere with good luminous efficiency and stability. The inorganic material hydrotalcite is used as a barrier material; due to excellent water resistance and oxygen resistance of the hydrotalcite, the quantum dot microsphere is effectively protected; oxygen and water vapor are isolated to a certain extent; at the same time, an alkaline property of the hydrotalcite is further utilized to improve the stability of the quantum dot microsphere in a dielectric material.

Owner:SUZHOU XINGSHUO NANOTECH CO LTD

A method for sealing quantum dots, quantum dot composite particles and applications

ActiveCN105778887BReduce interactionReduce the likelihood of reunionsLuminescent compositionsNon-linear opticsLiquid-crystal displayQuantum dot

The invention discloses a quantum dot sealing method, a quantum dot compound particle and applications. According to the method, quantum dots are made into quantum dot compound particles, then a blocking layer is arranged on the surface of each quantum dot compound particle so as to seal the quantum dots; after sealing, the interaction among quantum dots is reduced, thus the possibility of agglomeration is reduced; moreover, the air and water are obstructed; at the same time, the possibility that quantum dots are disturbed and destroyed by contacting the external environment, when the quantum dots are further dispersed into other materials or cured or during the device preparation process is reduced; the luminous efficiency of quantum dot is improved effectively, the service life of quantum dot is prolonged; and the provided quantum dot compound particle can be applied to optical devices such as light conversion material of liquid crystal display and has the advantages of high luminous efficiency of quantum dots and long service life.

Owner:TCL CORPORATION

Preparation method for polymer/inorganic nano composite material

The invention discloses a preparation method for a polymer / inorganic nano composite material. The inorganic component of the composite material is nano doped tin oxide sol, the surface of the inorganic component is modified by using gamma-methacryloxypropyltriethoxysilane, and unsaturated double bonds are introduced to the surfaces of inorganic particles and are used as active points of surface polymerization grafting. The modified inorganic component is dissolved in methyl methacrylate monomers through solvent replacement, initiator is added under a certain condition to induce monomers to bepolymerized, and then the polymer / inorganic nano composite material is obtained after thermosetting. According to the method, inorganic sol with high stability is used, and the defect that the inorganic component is easy to agglomerate, and the defect of low dispersibility in a polymer in the conventional preparation process of the polymer / inorganic nano composite material are overcome. The composite material can be used as an energy-saving window material for automobiles, airplanes, buildings and the like.

Owner:上海上惠纳米科技有限公司

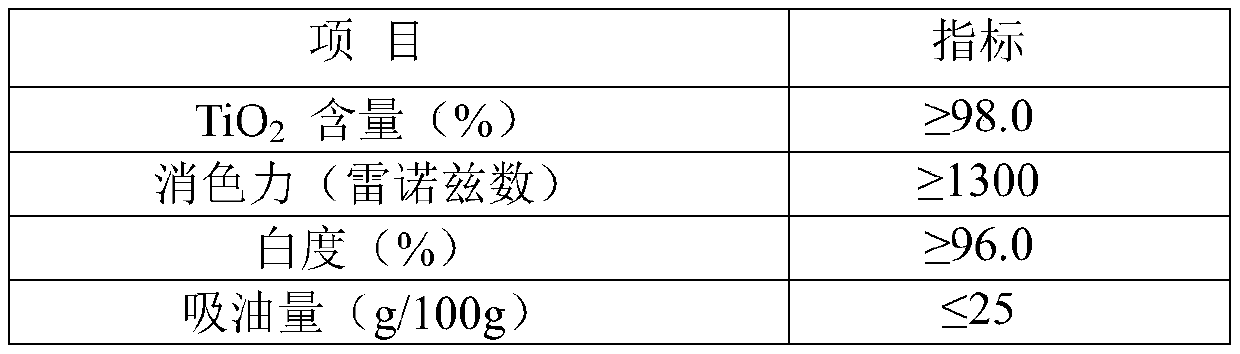

Method for preparing tin-doped nano-amorphous titanium dioxide by using intermediate of chlorination process

InactiveCN110142038AImprove visible light absorptionHigh purityCatalyst activation/preparationMetal/metal-oxides/metal-hydroxide catalystsPeristaltic pumpTitanium tetrachloride

The invention relates to a method for preparing a tin-doped nano-amorphous titanium dioxide by using an intermediate of a chlorination process, belonging to the technical field of preparation of photocatalytic nanometer new materials. The method comprises the following steps: A, simultaneously adding tin tetrachloride and a refined intermediate product, which is produced during the preparation ofrutile titanium dioxide through the chlorination process, into a NaOH mixed aqueous solution containing a surfactant in a parallel flow manner by using a peristaltic pump at room temperature, then adding an aqueous solution of ammonium carbonate, raising temperature to 70-80 DEG C, continuing stirring, performing curing, and then carrying out cooling to room temperature so as to prepare a tin-doped TiO2 hydrate; B, subjecting the tin-doped TiO2 hydrate to pressure filtration, performing washing until the conductivity of a filtrate is less than 10 [mu]s / cm so as to obtain a filter cake; C, drying the filter cake by using microwave drying equipment so as to prepare tin-doped amorphous titanium dioxide; and D, doping the amorphous titanium dioxide with tin, and performing jet milling to prepare tin-doped nano-amorphous titanium dioxide. The tin-doped nano-amorphous titanium dioxide prepared in the invention has the function of efficiently degrading organic pollutants under visible light.

Owner:HEBEI MILSON TITANIUM DIOXIDE

Preparation method of beta-Ga2O3/SiC nanometer composite material

InactiveCN104549397ASimple structureEasy to operateMaterial nanotechnologyPhysical/chemical process catalystsEvaporationFree cooling

The invention relates to a preparation method of a beta-Ga2O3 / SiC nanometer composite material, and solves the problems of large particle diameter, complex preparation process and long reaction time of the traditional method. The preparation method comprises the following steps: 1, adding urea to deionized water, heating and stirring till the urea is completely dissolved, then adding a Ga(NO3)3 solution, and stirring till a colorless transparent solution is obtained; 2, transferring into a container with a polytetrafluoroethylene lining, then placing the container into a microwave digestion furnace for heating, and after reaction is finished, naturally cooling to room temperature to obtain a gamma-Ga2O3 precursor; 3, dropwise adding the gamma-Ga2O3 precursor to SiC, and then firstly drying moisture through microwave evaporation and then carrying out microwave heat treatment to obtain an SiC-containing solid mixture; 4, adding the SiC-containing solid mixture to the deionized water for centrifugalization, and then carrying out vacuum drying to obtain the beta-Ga2O3 / SiC nanometer composite material.

Owner:HEILONGJIANG UNIV

Nylon fiber reinforced injectable phenolic moulding plastic and preparation method thereof

The invention discloses nylon fiber reinforced injectable phenolic moulding plastic and a preparation method of the nylon fiber reinforced injectable phenolic moulding plastic. Raw materials for preparing the phenolic moulding plastic mainly include novolac resin, hexamethylenetetramine, an inorganic filler and nylon fiber. The preparation method of the phenolic moulding plastic comprises the following steps: (1) weighing all the raw materials for later use; (2) placing the inorganic filler and a coupling agent into a ball mill or a jar mill for uniformly ball milling, wherein the dosage of the coupling agent is 0.5-10wt% of that of the inorganic filler, and the inorganic filler is one or a combination of two or more of aluminum hydroxide, silica powder, calcite, talc, calcium carbonate, glass beads, kaolin and pottery clay powder; (3) grinding hexamethylenetetramine, and then evenly mixing with the inorganic filler after surface treatment and other raw materials; (4) putting the mixed materials into a twin-screw extruder for extrusion; (5) grinding extrudate after cooling to obtain the nylon fiber reinforced injectable phenolic moulding plastic. The phenolic moulding plastic prepared by the method is higher in mechanical properties and lower in water absorption.

Owner:桂林金格电工电子材料科技有限公司

Preparation method of basalt fiber reinforced flame-retardant wood-plastic composite material

PendingCN113234329AImprove mechanical propertiesImprove flexural and tensile propertiesBasalt fiberInterface bonding

The invention discloses a preparation method of a basalt fiber reinforced flame-retardant wood-plastic composite material. The preparation method comprises the following steps: (1) carrying out modification treatment on basalt fibers; (2) paving a basalt fiber reinforced blank; and (3) carrying out hot press molding. The basalt fiber is subjected to special modification treatment, so that the surface activity of the basalt fiber is effectively improved, and the basalt fiber can form good interface bonding with other components of the wood-plastic composite material. Meanwhile, novel lignin-phosphorus series, lignin-nitrogen series and lignin-boron series mixed type environment-friendly flame retardants are added, and the rest components are reasonably added, so that the wood-plastic composite material finally has good flame retardance and the like. The basalt fiber reinforced flame-retardant wood-plastic composite material prepared by the invention has good comprehensive mechanical and flame-retardant properties, and the application field of the wood-plastic composite material is widened.

Owner:NORTHEAST FORESTRY UNIVERSITY

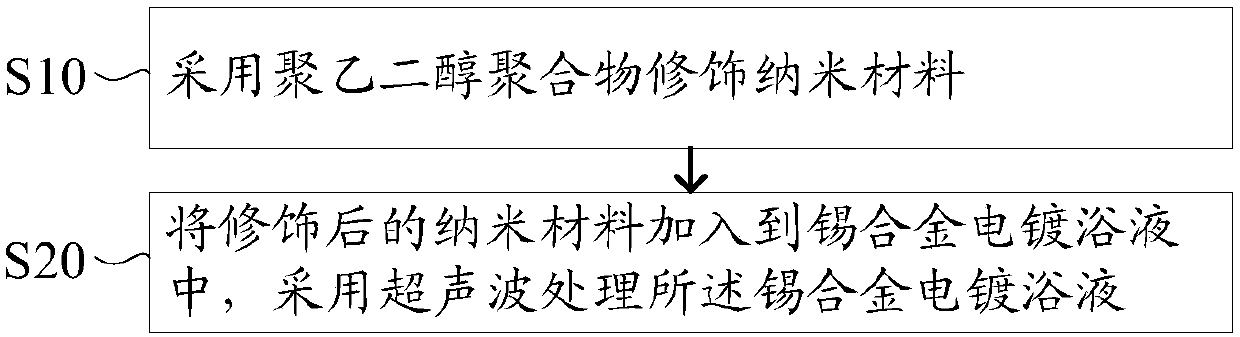

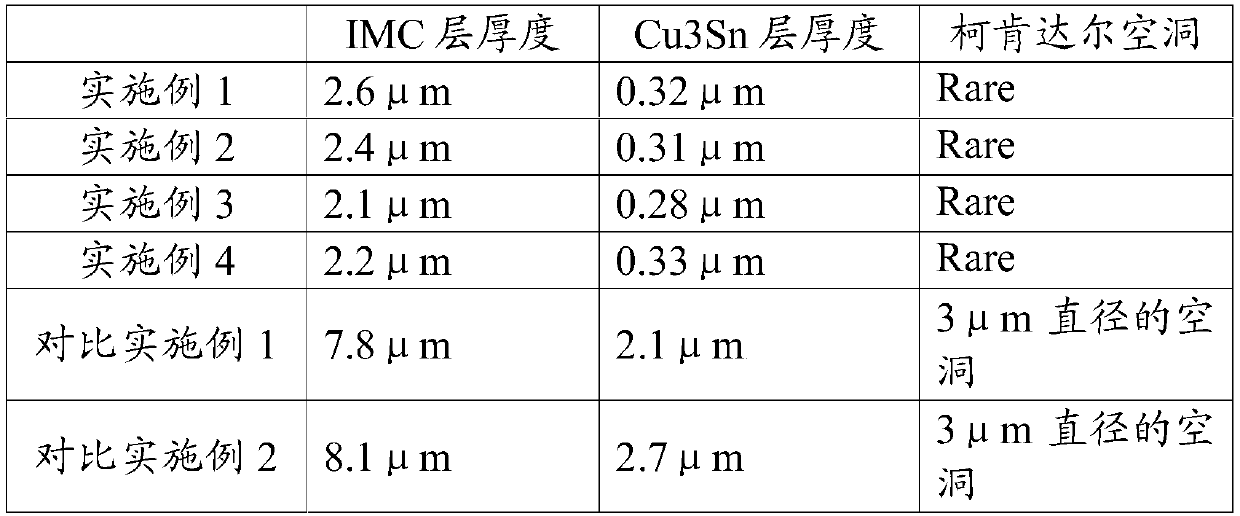

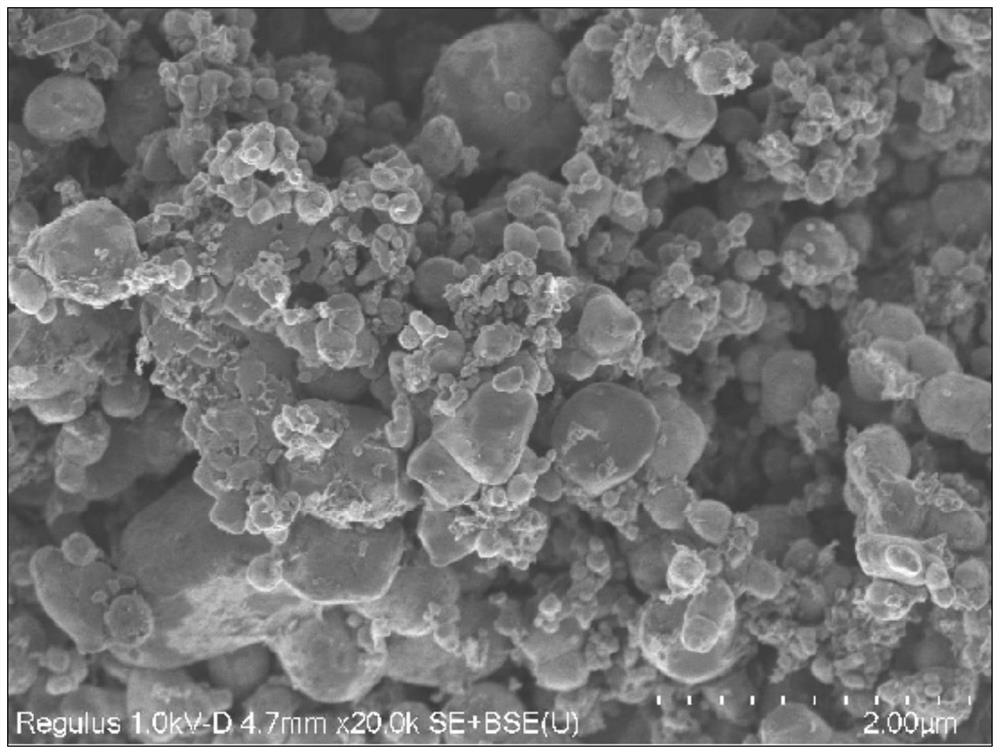

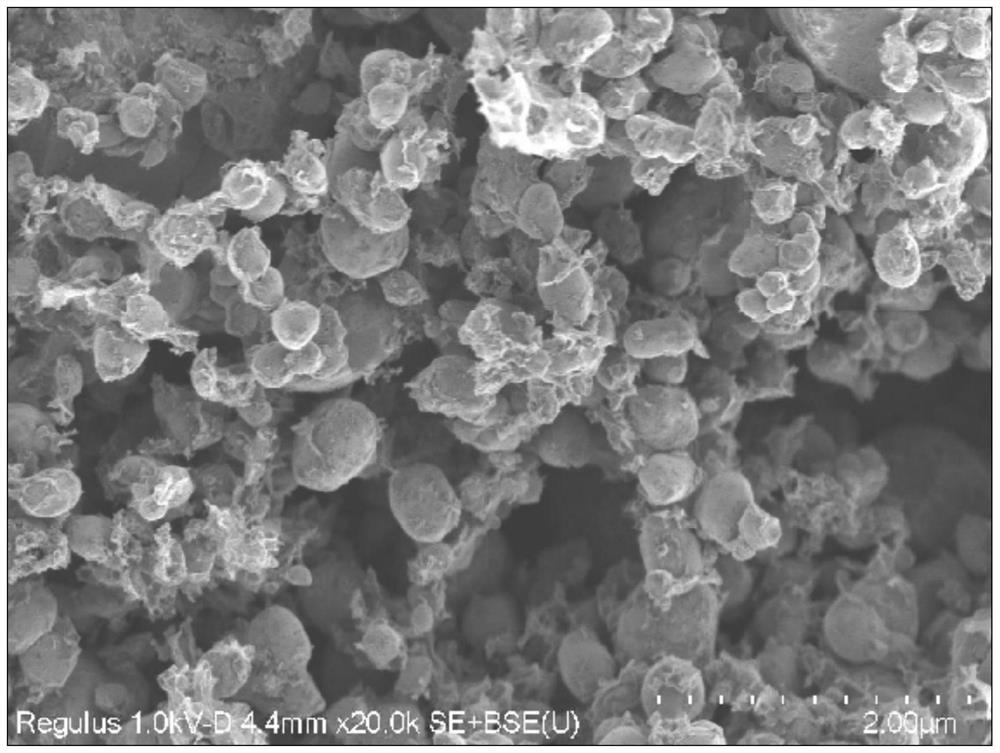

Forming method of tin alloy electroplating bath liquid and preparation method of soldering tin salient point plating

ActiveCN109594108AEvenly dispersedUniform depositionElectrolytic coatingsNanoparticlePolyethylene glycol

The invention provides a forming method of tin alloy electroplating bath liquid, a preparation method of a soldering tin salient point plating and the soldering tin salient point plating. The formingmethod of the tin alloy electroplating bath liquid includes the steps that a nanomaterial is modified with a polyethylene glycol polymer; and the modified nanomaterial is added into the tin alloy electroplating bath liquid, and the tin alloy electroplating bath liquid is treated through ultrasound. According to the forming method of the tin alloy electroplating bath liquid, the preparation methodof the soldering tin salient point plating and the soldering tin salient point plating, the nano-material is surface-modified through the polymer, the modified nanoparticles are evenly dispersed in the tin alloy electroplating bath liquid, the stability of the nanomaterial in the tin alloy electroplating bath liquid is improved, the ultrasound is used for dispersion treatment, the possibility of clustering of the nanoparticles is reduced, uniform deposition during electroplating of the nanoparticles can be effectively guaranteed, the nanoparticles can be effectively embedded into lattices of the formed soldering tin salient point plating, and the effect of inhibiting forming of intermetallic compounds is achieved.

Owner:SHANGHAI INTEGRATED CIRCUIT RES & DEV CENT

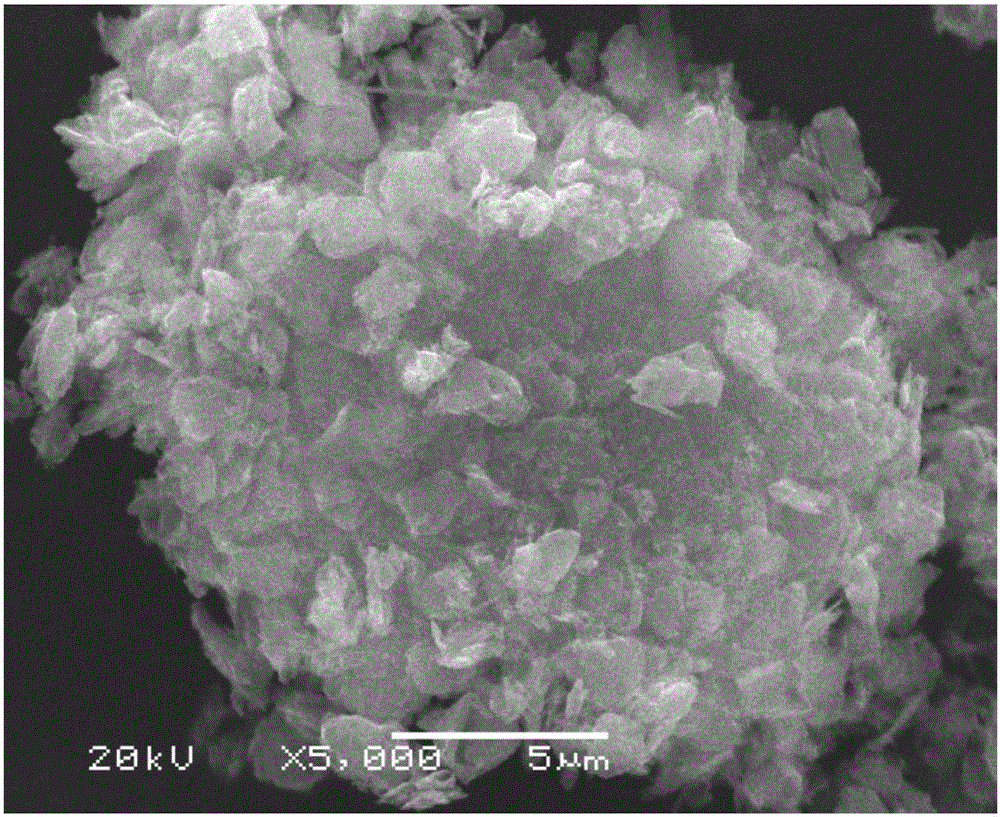

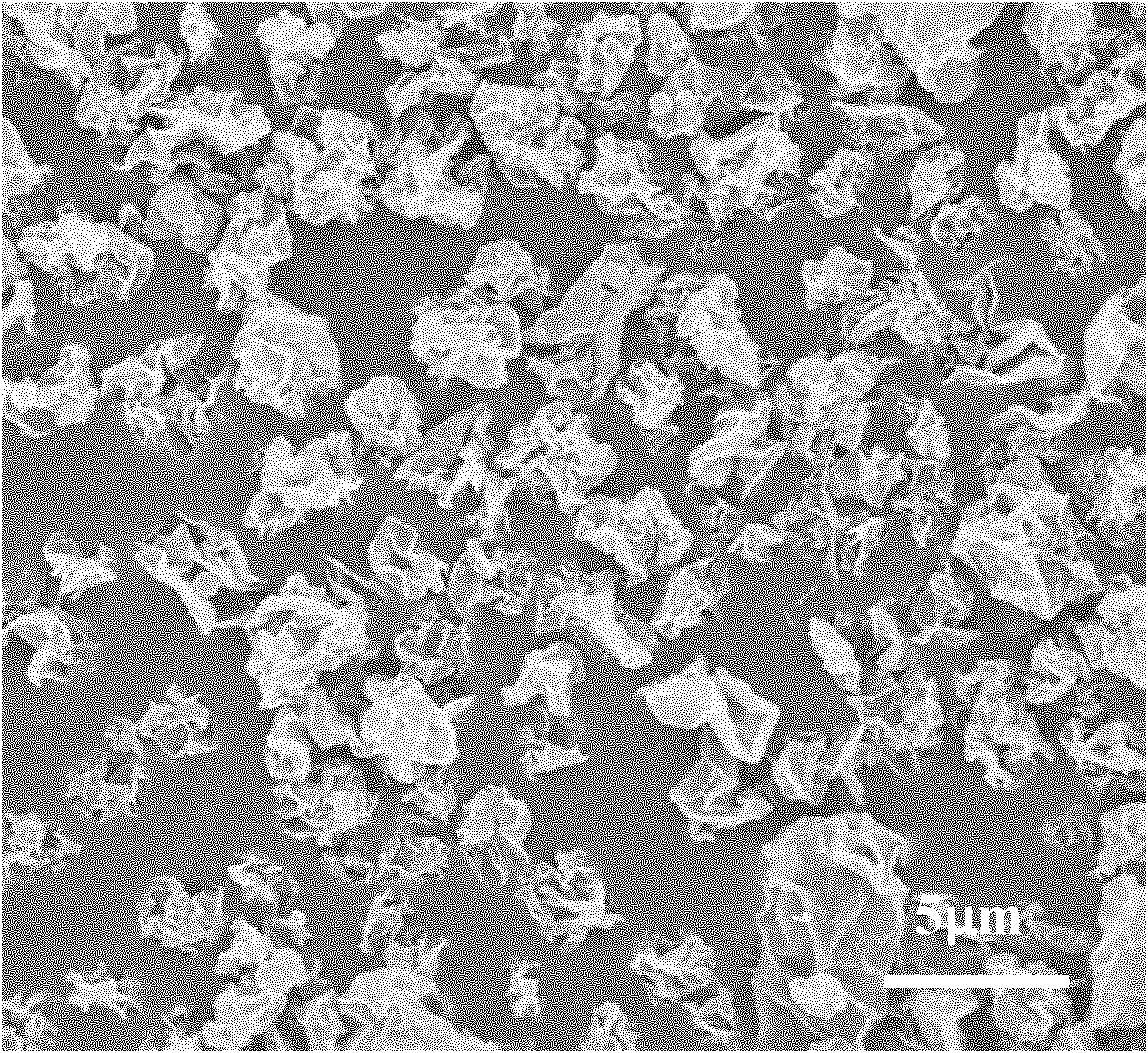

High-compaction lithium iron phosphate and preparation method thereof

PendingCN114291804ASmall sizeReduce the likelihood of reunionsCell electrodesSecondary cellsLithium iron phosphatePhysical chemistry

The invention relates to the field of lithium battery materials, and particularly discloses high-compaction lithium iron phosphate and a preparation method thereof. The high-compaction lithium iron phosphate comprises the following substances in parts by weight: 100-200 parts of a precursor raw material and 30-40 parts of a solvent, the precursor raw material comprises a lithium source, iron phosphate, a doping element source and an additive in a molar ratio of (0.95-1.05): 1: (0-0.01): (0.003-0.008), the precursor raw material further comprises a carbon source, the mass ratio of the carbon source to the precursor raw material is 100: (1-15), and the additive comprises at least one of an iron source and a phosphorus source; the preparation method comprises the following steps: S1, premixing the raw materials; s2, roasting treatment; and S3, crushing treatment. The high-compaction lithium iron phosphate disclosed by the invention can be used for a lithium battery positive electrode material, and has the advantages of high compaction density and excellent electrochemical performance; in addition, the preparation method disclosed by the invention has the advantages of simplicity and convenience in operation and easiness in large-scale operation.

Owner:常州锂源新能源科技有限公司

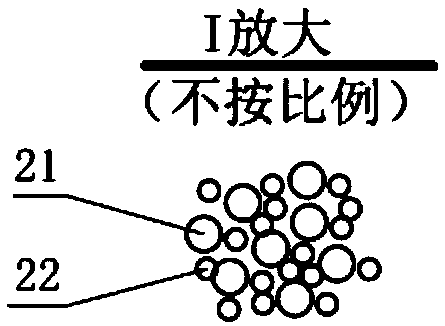

Method for preparing composite material of lithium ion battery cathode, and cathode and battery

ActiveCN101442124BGood lithium intercalation performanceHigh lithium intercalation abilityElectrode manufacturing processesSecondary cellsElectrical batterySlurry

The invention relates to a method for preparing a composite material for a cathode of a lithium ion battery, and the cathode and the battery which comprise the cathode material. The preparation method comprises: uniformly mixing silicon powder, graphite, pyrolytic carbon precursor and a solvent to prepare slurry, wherein the silicon powder comprises micro-silicon powder and nano-silicon powder, and the weight ratio of the micro-silicon powder and the nano-silicon powder is 2-20:1; and removing the solvent in the slurry, performing primary sintering under the protection of inert gas, performing primary ball grinding, performing secondary sintering under the protection of the inert gas, and performing secondary ball grinding, wherein the temperature of the secondary sintering is higher thanthat of the primary sintering. The battery made from the composite material for the cathode of the lithium ion battery obtained by the method has good cycling performance and charge and discharge capacity.

Owner:BYD CO LTD

Method for preparing graphene powder

Owner:SHANGHAI INST OF MICROSYSTEM & INFORMATION TECH CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com