High-compaction lithium iron phosphate and preparation method thereof

A technology of high-pressure lithium iron phosphate, applied in chemical instruments and methods, phosphorus compounds, inorganic chemistry, etc., can solve problems such as poor compaction density of lithium iron phosphate, achieve improved gradation effect, prevent impurities, crystals, etc. The effect of suitable particle size

Pending Publication Date: 2022-04-08

常州锂源新能源科技有限公司

View PDF7 Cites 2 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

preparation example 1

[0048] Take 1kg of ferric hydroxide as iron source 1.

preparation example 2

[0050] Take 1 kg of iron oxide as iron source 2.

[0051] It is worth noting that the iron source includes, but is not limited to, any one of ferric hydroxide, ferrous hydroxide, ferrous oxalate, ferric oxide, and lithium ferrite.

[0052] Phosphorus source preparation example

preparation example 3

[0054] Take 1 kg of ammonium phosphate as phosphorus source 1.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Login to View More

Abstract

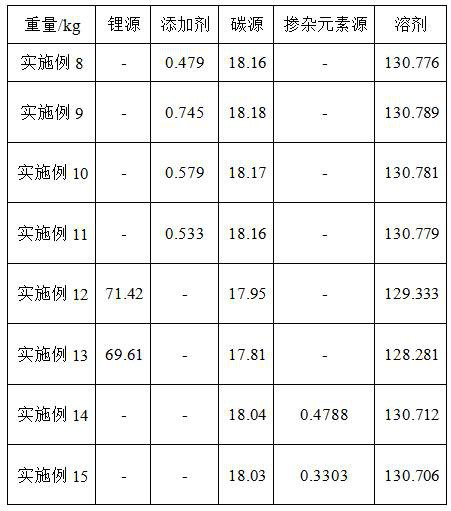

The invention relates to the field of lithium battery materials, and particularly discloses high-compaction lithium iron phosphate and a preparation method thereof. The high-compaction lithium iron phosphate comprises the following substances in parts by weight: 100-200 parts of a precursor raw material and 30-40 parts of a solvent, the precursor raw material comprises a lithium source, iron phosphate, a doping element source and an additive in a molar ratio of (0.95-1.05): 1: (0-0.01): (0.003-0.008), the precursor raw material further comprises a carbon source, the mass ratio of the carbon source to the precursor raw material is 100: (1-15), and the additive comprises at least one of an iron source and a phosphorus source; the preparation method comprises the following steps: S1, premixing the raw materials; s2, roasting treatment; and S3, crushing treatment. The high-compaction lithium iron phosphate disclosed by the invention can be used for a lithium battery positive electrode material, and has the advantages of high compaction density and excellent electrochemical performance; in addition, the preparation method disclosed by the invention has the advantages of simplicity and convenience in operation and easiness in large-scale operation.

Description

technical field [0001] The present application relates to the field of lithium ion secondary battery materials, in particular to a high-pressure compacted lithium iron phosphate and a preparation method thereof. Background technique [0002] The increasingly severe energy crisis is one of the major challenges facing mankind in the 21st century. In order to meet the increasing energy demand of human beings, it is very important to develop new energy sources that are environmentally friendly and sustainable. Lithium-ion batteries have the advantages of high working voltage and high energy density, and are the most potential secondary batteries. At present, power batteries mainly include ternary batteries and lithium iron phosphate batteries in terms of technical routes. The biggest feature of the ternary battery is its high energy density, but it is unstable; the energy density of lithium iron phosphate battery is relatively low, but its stability is very good, and its price...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C01B25/45H01M4/58H01M10/0525

Inventor 孙国林孙丽媛席小兵石俊峰

Owner 常州锂源新能源科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com