Patents

Literature

204results about How to "Improve grading effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

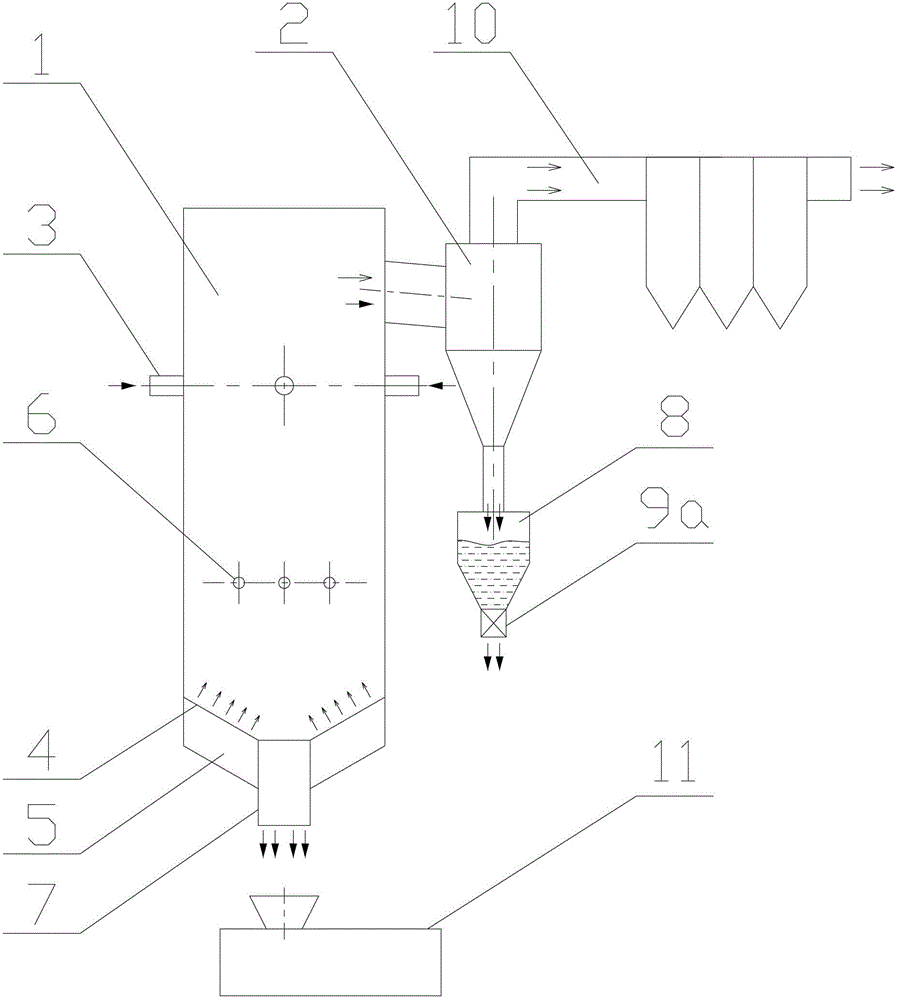

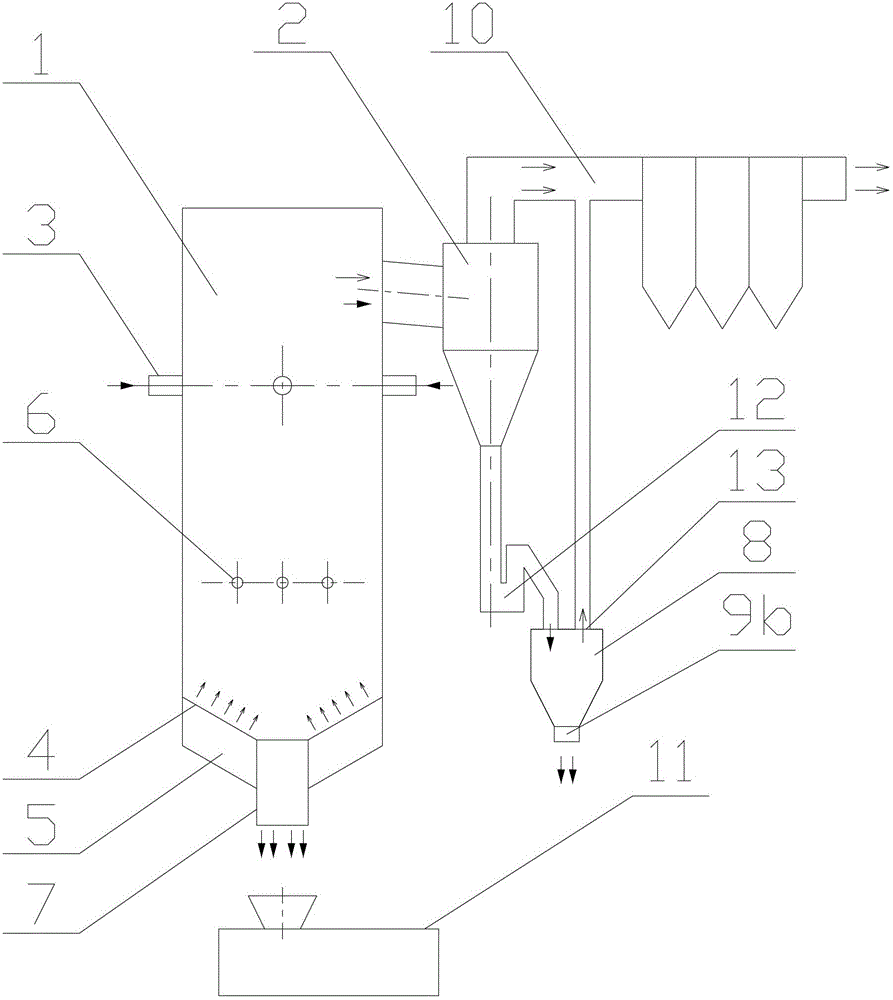

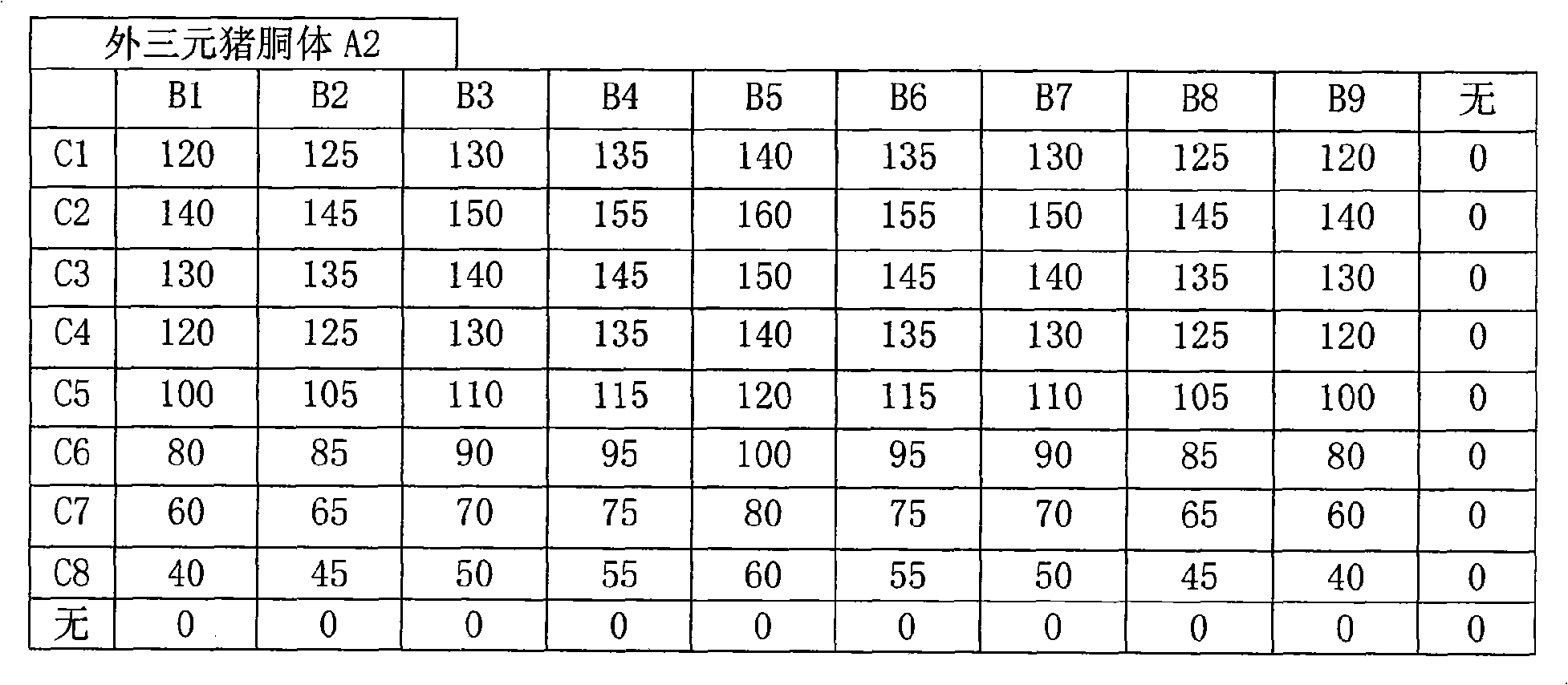

Pneumatic particle size classifying device for solid particles

InactiveCN102716857AAffect balanceAffect normal working conditionsGas current separationSolid particleEngineering

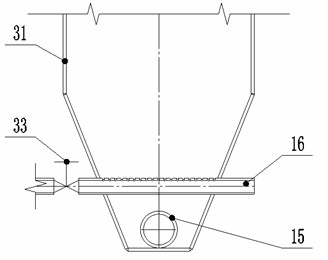

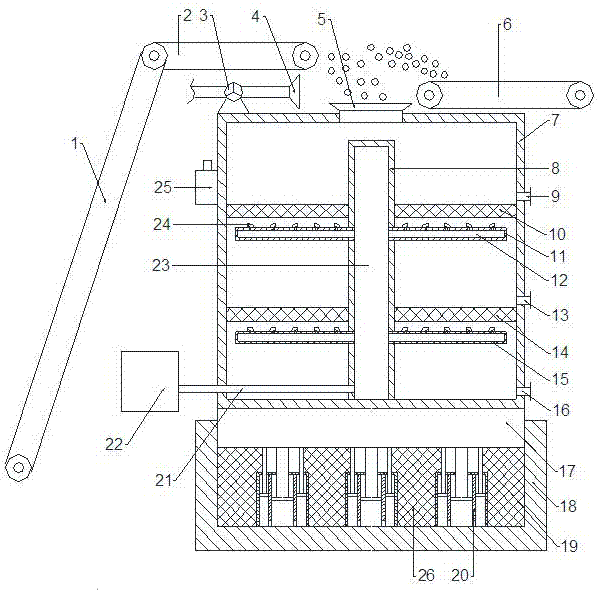

A pneumatic particle size classifying device for solid particles comprises a fluidized bed main body, a cyclone separator, material inlets, an air distributing system, a secondary air port, a coarse material outlet and a fine material collecting and discharging system. The material inlets are positioned on the middle upper portion of the fluidized bed main body and are distributed on four walls in a multi-point manner, the hopper-shaped air distributing system consists of an inclined air distributing plate, the coarse material outlet is arranged in the center of the inclined air distributing plate, the fine material collecting and discharging system consists of a fine material collecting chamber and an intermittent discharging valve and is directly connected with a lower particle outlet of the cyclone separator, or the fine material collecting and discharging system can consist of a fine material collecting chamber and a fine material discharge port and is connected with a particle outlet of a feedback valve. The pneumatic particle size classifying device is simple in structure, effective pneumatic particle size classification for selective coking coal particles is carried out by fluidization technology, retaining time of the particles in the bed body can be effectively prolonged, the pneumatic particle size classifying device is stable in running and fine in separation effect, and energy and coking coal resources are greatly saved.

Owner:TSINGHUA UNIV

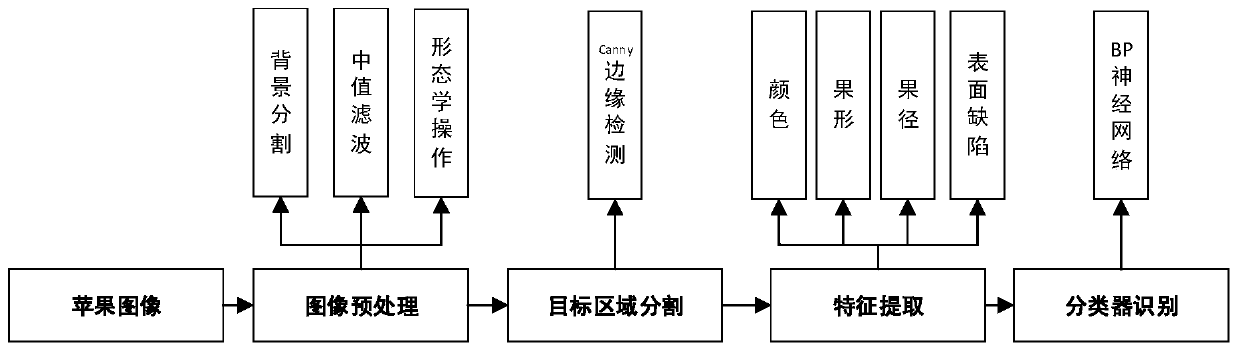

Apple grading method and system based on machine vision

PendingCN110276386AReduce classification errorAccurate classificationImage analysisCharacter and pattern recognitionFeature extractionMachine vision

The invention discloses an apple grading method and system based on machine vision, and the method comprises the steps: collecting a set number of sample images, and building a sample image set; collecting a to-be-detected sample image, and carrying out image preprocessing; performing feature extraction on the sample to be detected; respectively extracting a color feature, a fruit shape feature, a fruit diameter feature and a surface defect feature of the to-be-detected sample image; establishing a classification standard, and establishing a classification model of sample characteristics and grades by utilizing a genetic algorithm and a BP neural network; and inputting the extracted color feature, fruit shape feature, fruit diameter feature and surface defect feature of the to-be-detected sample image into the classification model, and outputting the grade classification of the to-be-detected sample. The method has the advantages that clear apple surface images can be obtained, and classification errors are reduced. The BP neural network model optimized based on the genetic algorithm can accurately classify apples, and the classification efficiency of the apples is greatly improved.

Owner:UNIV OF JINAN

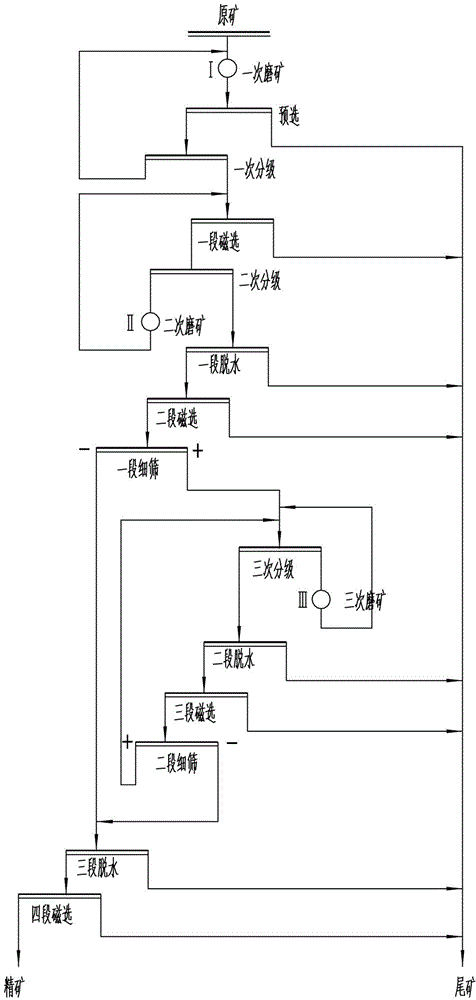

Simple magnetic separation process for Anshan type iron carbonate-containing lean magnetite ore

ActiveCN104128259AEasy to handleImproved particle size compositionMagnetic separationPhysical chemistryMagnetic separator

The invention relates to a simple magnetic separation process for Anshan type iron carbonate-containing lean magnetite ore. The process includes ore grinding, grading and magnetic separation and comprises the following concrete steps: ore grinding three times; presorting with a large-wrap angle medium-intensity magnet separator; grading with a cyclone three times; dehydration in three stages; fine sieving in two stages; and magnetic separation with a magnet separator in four stages. The invention provides the energy-saving, low-carbon, environment-friendly and reliable production process for treatment of iron carbonate-containing lean magnetite ore by using a simple magnetic separation method; the process can further improve treating capability, enhance technical and economic indexes, reduce production cost and greatly increase the utilization efficiency of inferior resources while improving ore grinding, grading and sorting efficiency.

Owner:ANSTEEL GRP MINING CO LTD

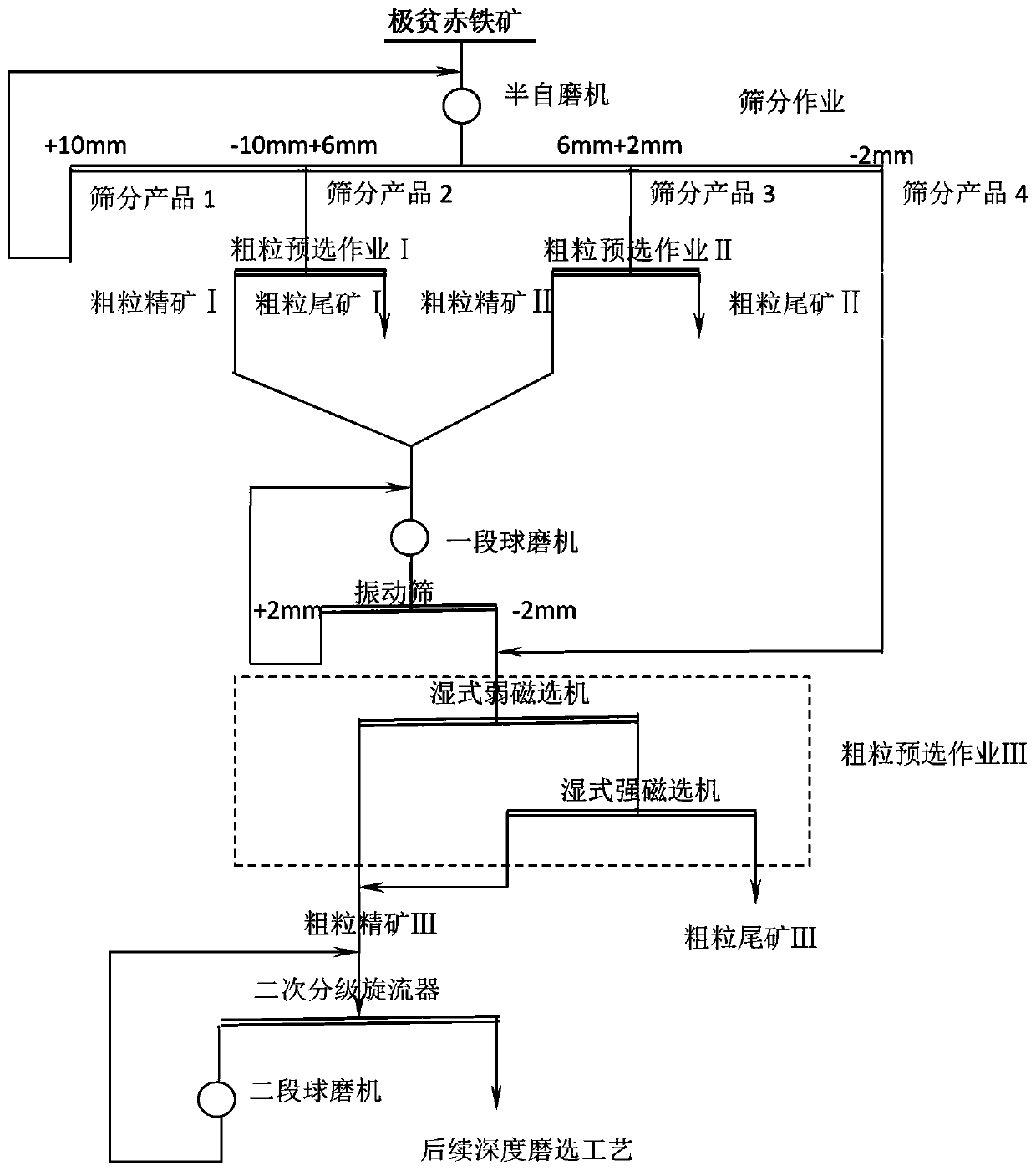

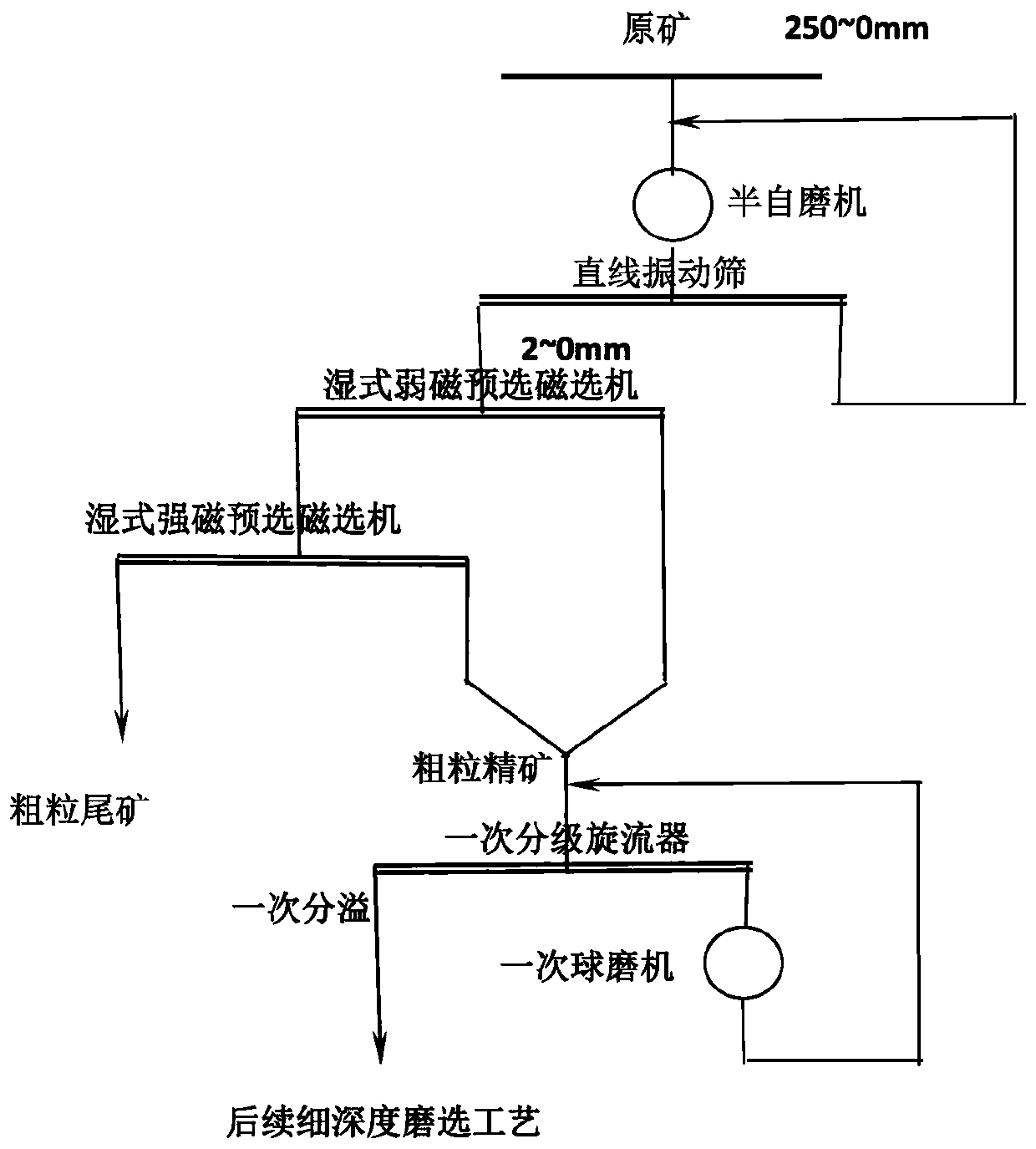

Size-fractionated pre-selection tailing discarding process of extremely-poor hematite

ActiveCN110898957AReduce cycle loadProcessing capacity when releasing the tableSievingScreeningEngineeringTailings

The invention relates to a size-fractionated pre-selection tailing discarding process of extremely-poor hematite. The process comprises a step of carrying out semi-autogenous grinding to obtain semi-autogenous grinding discharge ore with a particle size of 14-0mm. The process is characterized by screening; carrying out coarse grain pre-selection I; carrying out coarse grain pre-selection II; carrying out first-section closed-circuit grinding; carrying out coarse grain pre-selection operation III; and carrying out second-section closed-circuit grinding. A three-layer linear vibrating screen isadopted for screening. In four products, the product with a size fraction of-14 mm to 10 mm is returned to semi-autogenous grinding. The coarse grain pre-selection I and the coarse grain pre-selectionII are used for pre-selecting a -10mm-6mm size fraction and a -6mm-2mm size fraction. Coarse-grain tailings are thrown out, coarse-grain concentrates are combined and fed into first-section closed-circuit ore grinding, a first-section closed-circuit ore grinding product and the screened -2 mm size fraction are fed into coarse-grain pre-selection operation III for pre-selection tailing discarding,coarse-grain pre-selection operation III concentrates are fed into second-section closed-circuit ore grinding, and second-section closed-circuit ore grinding overflow is fed into subsequent sorting operation. The process has advantages that discharge ore is divided into narrow grades for respective pre-selection; qualified coarse grain tailings are thrown out; and a problem of stubborn stone accumulation is solved, and a processing capacity of a semi-autogenous mill is improved.

Owner:ANSTEEL GRP MINING CO LTD

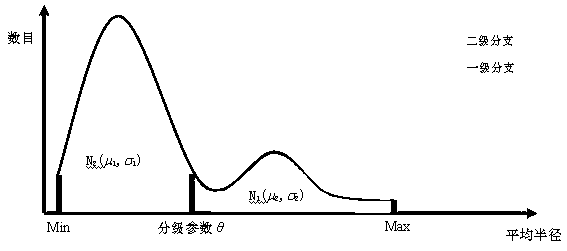

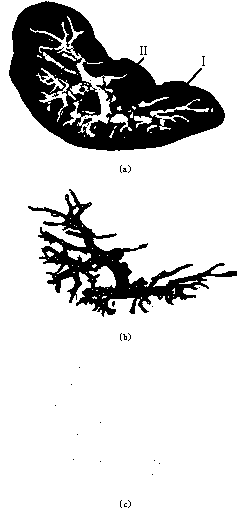

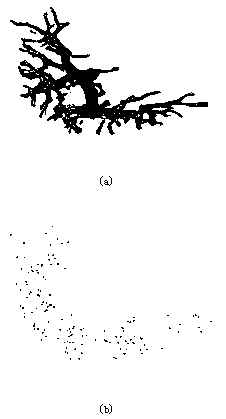

Liver image segregation method based on hierarchy vessel tree division

The invention relates to a liver image segregation method based on hierarchy vessel tree division. The method comprises the steps that firstly, a directed tree is utilized to represent a topological structure of a liver portal vein vessel, then according to space distribution and branch average radius information of the liver portal vein vessel in a specific clinical case image, vessel hierarchical parameters are determined and a hierarchical vessel tree is created, a second-level subtree set providing blood for a liver is marked, marked second-level subtrees are divided into eight kinds according to blood supplying areas, the liver is divided into eight hepatic segments through the adoption of the shortest distance algorithm to be analyzed, and clinical interesting information is extracted. According to the method, for liver vessels with multiple branches and complex structures, good hieratical effects can be obtained, blood supplying effects of most second-level branches are considered, and hepatic segment distribution and attribute information obtained through segregation also accord with the Couinaud hepatic segmentation theory.

Owner:TONGJI UNIV

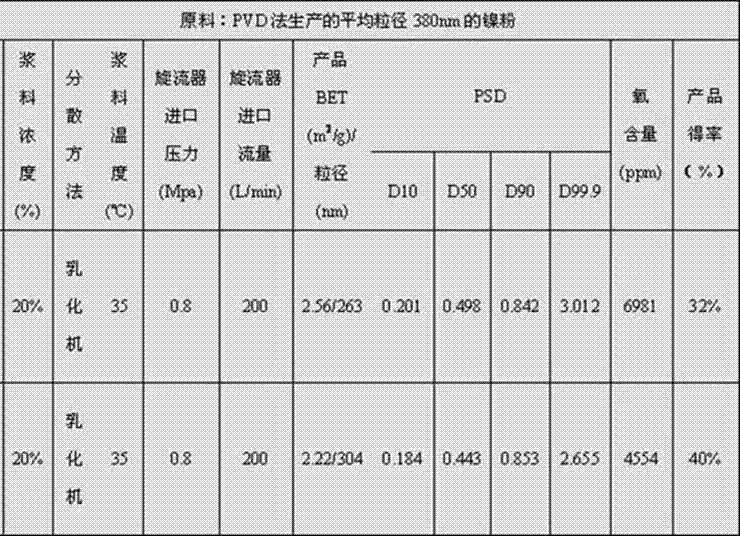

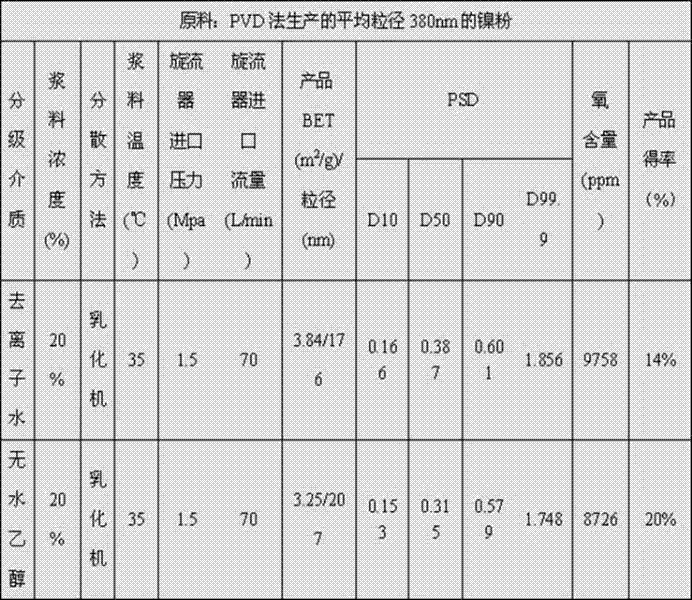

Method taking organic solvent as medium for grading nano-nickel powder for MLCC (multilayer ceramic capacitor)

The invention discloses a method taking an organic solvent as a medium for grading nano-nickel powder for an MLCC (multilayer ceramic capacitor), which comprises the following steps of: taking metal nickel powder in the average particle size of below 1000nm as raw materials, adding into the organic solvent and mixing so as to get a solid-liquid system; then performing mechanical dispersion treatment to get slurry; sending the slurry into a cyclone through a booster pump, controlling the pressure of the slurry at an inlet of the cyclone at 0.1-2.0Mpa, controlling the flow rate at a material inlet of the cyclone at 10-200L / min, and controlling the flow rate at an underflow port of the cyclone at 2-20L / min; and collecting the slurry overflowed from an overflow port of the cyclone to get the nickel powder with the required particle size distribution. The method has the advantages of not only ensuring the grading efficiency of the cyclone, but also preventing affecting the surface morphology of the powder.

Owner:JIANGSU BOQIAN NEW MATERIALS

Rice producing process

InactiveCN103480443AExtended storage timeGuaranteed smoothnessGrain treatmentsBrightness perceptionHorticulture

The invention relates to a rice producing process. The process comprises the following steps of (1) drying, (2) metering, (3) clearing, (4) stone removing, (5) shelling, (6) separating, (7) rice milling, (8) first grading, (9) rice cooling, (10) first polishing, (11) color sorting, (12) secondary polishing, (13) secondary grading, namely repeating the step (8), (14) storing and (15) quantitative packing. The preservation time of rice can be effectively prolonged, and deterioration can be avoided; the brightness of the rice can still be kept by the secondary polishing; crushed rice is prevented from reoccurring in the last procedure by the secondary grading and the grading effect is ideal; meanwhile, the problems such as non-timely packing can be avoided; the product quality of the rice can be improved and the economical risk of relevant production enterprises can be greatly reduced.

Owner:ANHUI YONGAN RICE PROCESSING PURCHASE & SALE

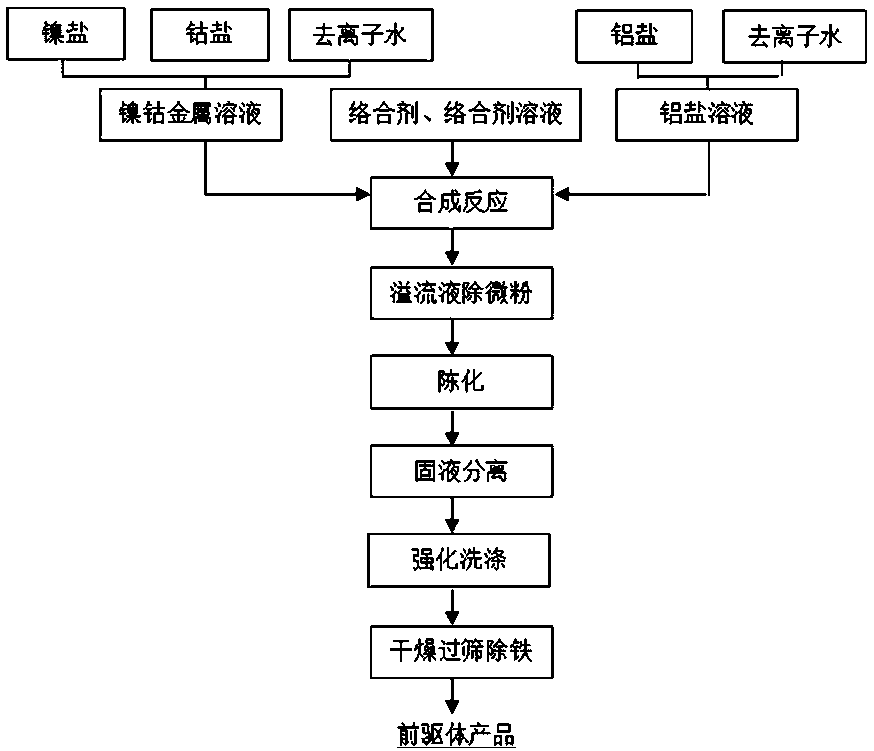

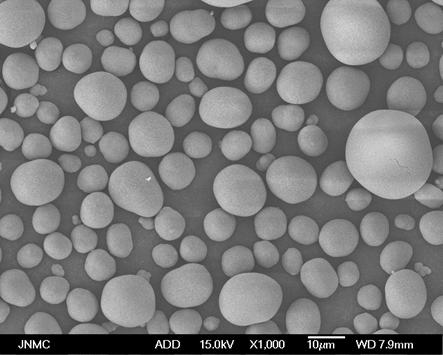

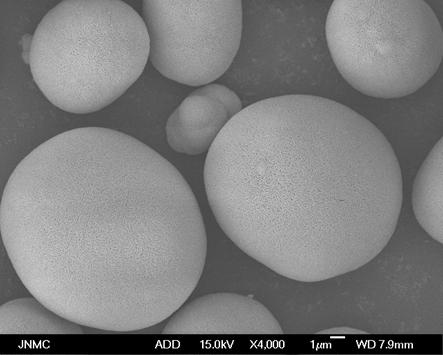

Method for synthesizing wide-particle-size-distribution nickel-cobalt-aluminum positive electrode material precursor through continuous coprecipitation

ActiveCN110028112AImprove grading effectEvenly distributedCell electrodesSecondary cellsDispersityNickel oxide hydroxide

The invention discloses a method for synthesizing a wide-particle-size-distribution nickel-cobalt-aluminum positive electrode material precursor through continuous coprecipitation. Through coprecipitation in a reactor, spherical nickel cobalt aluminum hydroxide powder with wide particle size distribution is synthesized. In the synthesis process, two stages of starting kettle reaction for constructing particle size gradient and maintaining particle size stability are carried out separately, process parameter control is carried out according to different pH value process conditions; overflow liquid is subjected to synthesis treatment for eliminating micro powder, so that the nickel cobalt aluminum hydroxide powder with wide particle size distribution is obtain; and after solid-liquid separation, residues in the powder are removed in a reinforced washing mode, dispersity of the powder is guaranteed, and after full drying, a nickel-cobalt-aluminum positive electrode material precursor withan adjustable average particle size D50 in a range of 10-15 [mu]m and a tap density of 2.0 g / cm<3> or above is prepared. The preparation method is simple in technological process and suitable for industrial large-scale production of the nickel-cobalt-aluminum positive electrode material precursor.

Owner:JINCHUAN GROUP LIMITED +1

Graded purifying method of humic acid subfractions in sludge and straw mixed compost

InactiveCN106220863AImprove adsorption efficiencyFast balance abilityOrganic chemistryActivated carbonPurification methods

The invention discloses a graded purifying method of humic acid subfractions in sludge and straw mixed compost. The method includes the following steps of a, the separation, extraction and purification process of humic acid (HA) in the sludge and straw mixed compost, wherein a humic acid coarse product in the sludge and straw mixed compost is separated and extracted, and a humic acid sample is obtained after dialysis and freeze-drying; b, the graded extraction process of humic acid (HA) in the sludge and straw mixed compost, wherein an adsorption enrichment column is leached through NaNO3 leaching solutions with five different pH values being 3, 5, 7, 9 and 13 through the adsorption performance of an XAD-8 resin and activated carbon mixed adsorption enrichment column to obtain the corresponding humic acid subfractions under different pH values. The new method is provided for obtaining the humic acid subfractions through separation and graded extraction in the sludge and straw mixed compost.

Owner:CHINESE RES ACAD OF ENVIRONMENTAL SCI

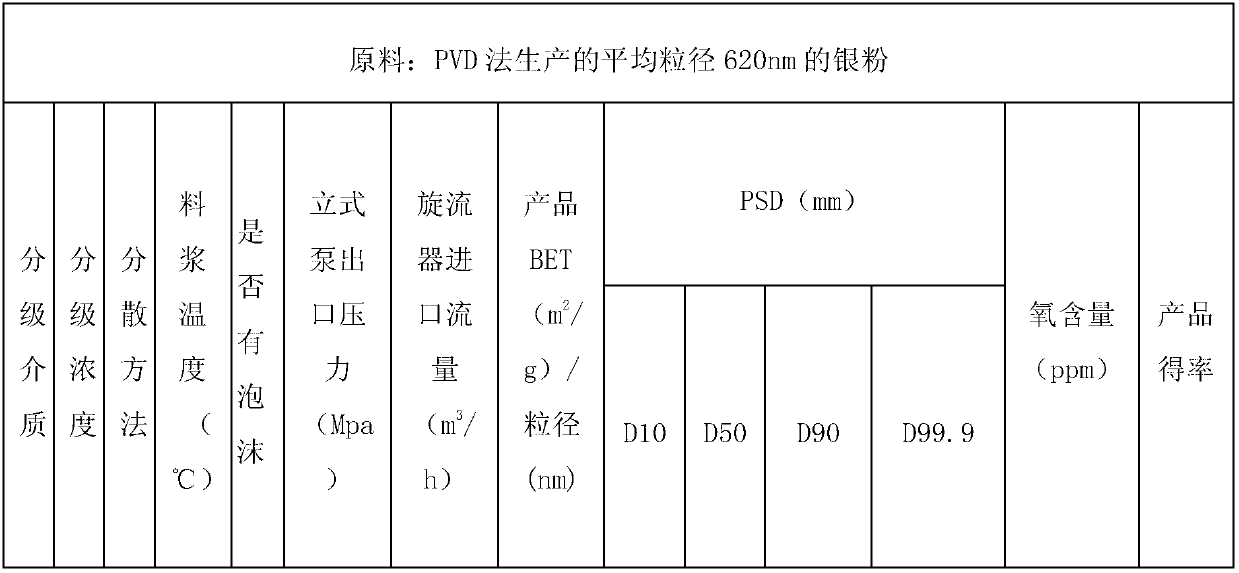

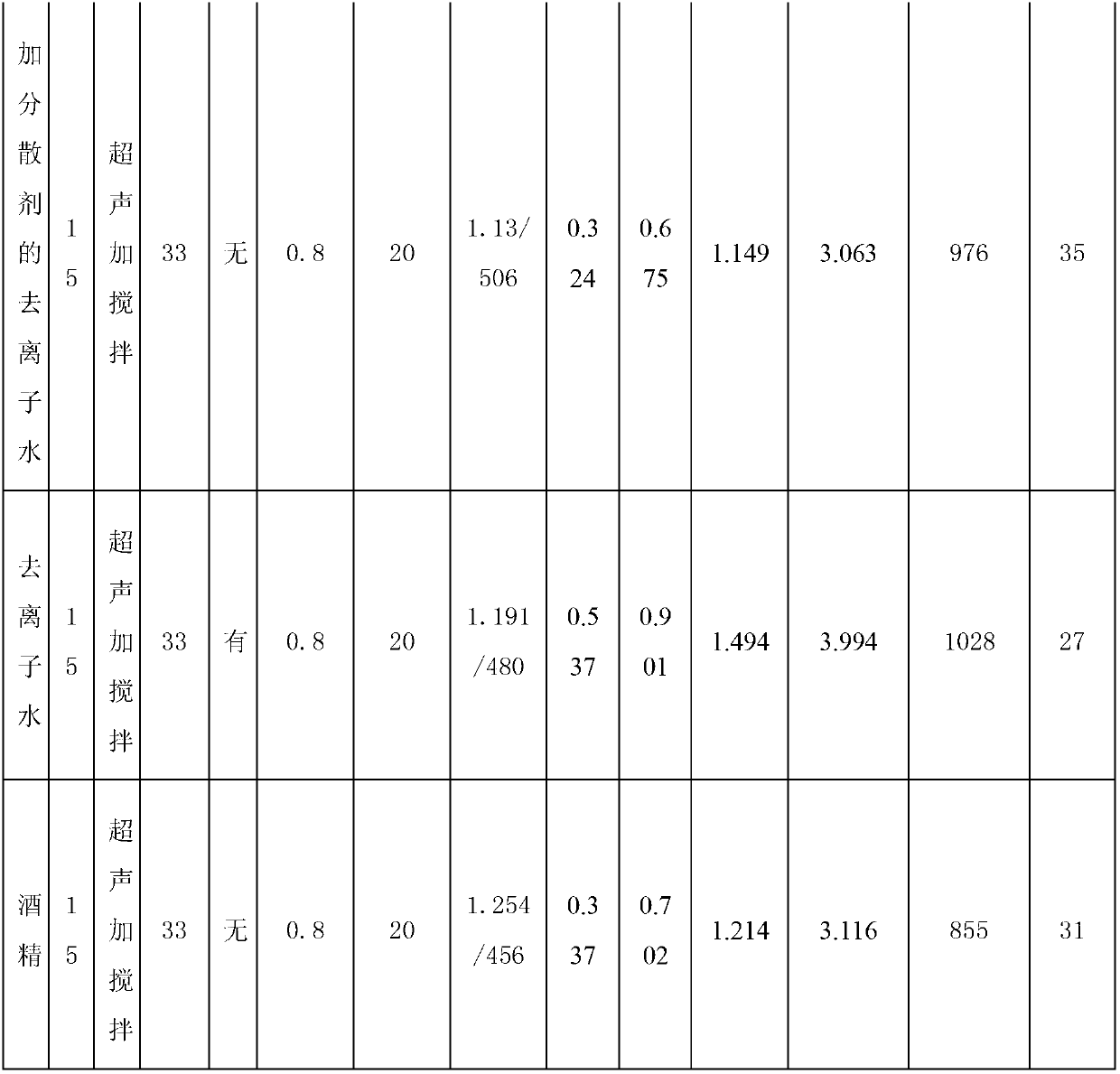

Method for grading silver powder for solar battery

The invention discloses a method for grading silver powder for a solar battery, and the method comprises the following steps of: adding a dispersant agent to deionized water to prepare a 0.1%-2% by weight of dispersant agent water solutions; adding metal silver powder to the dispersant agent water solutions, and mixing into a solid-liquid system with solid content controlled at 1%-30% by weight; then carrying out mechanical dispersion to obtain uniformly dispersed slurry; collecting the slurry through a screen mesh of 40-600 meshes, adding to a stirring kettle, delivering to a hydraulic cyclone by using a booster pump, wherein the outlet pressure of the booster pump is controlled at 0.2-1.6 MPa, the inlet flow rate of the hydraulic cyclone is controlled at 5-30m<3> / h, and the overfall outlet flow rate of the hydraulic cyclone is controlled at 0.3-3m<3> / h; controlling the grading time of the hydraulic cyclone at 1-1.5 h, and collecting the slurry positioned on the overfall outlet of the hydraulic cyclone to obtain the silver powder for the solar battery. The method disclosed by the invention has the advantages of grading efficiency guarantee, simple process, low cost, safety and environmental friendliness and can ensure that the powder dispersibility meets the use requirement of the silver powder for the solar battery.

Owner:JIANGSU BOQIAN NEW MATERIALS

Production method of superfine kaolin

The invention relates to a production method of superfine kaolin, comprising the steps of collecting slurry, removing impurities, preparing kaolin pulp, classifying by adopting a horizontal screw centrifuge, chemical bleaching, washing to remove the iron, filter pressing, dispersing to prepare the slurry, sieving, spray drying and the like. The invention has simple operation, low cost and stable product quality. The kaolin product with mass percentage of 93-99.9 percent and with the grain diameter of -2 microns can be obtained by classifying with the horizontal screw centrifuge without delaminating.

Owner:MAOMING PETROCHEM MINING IND

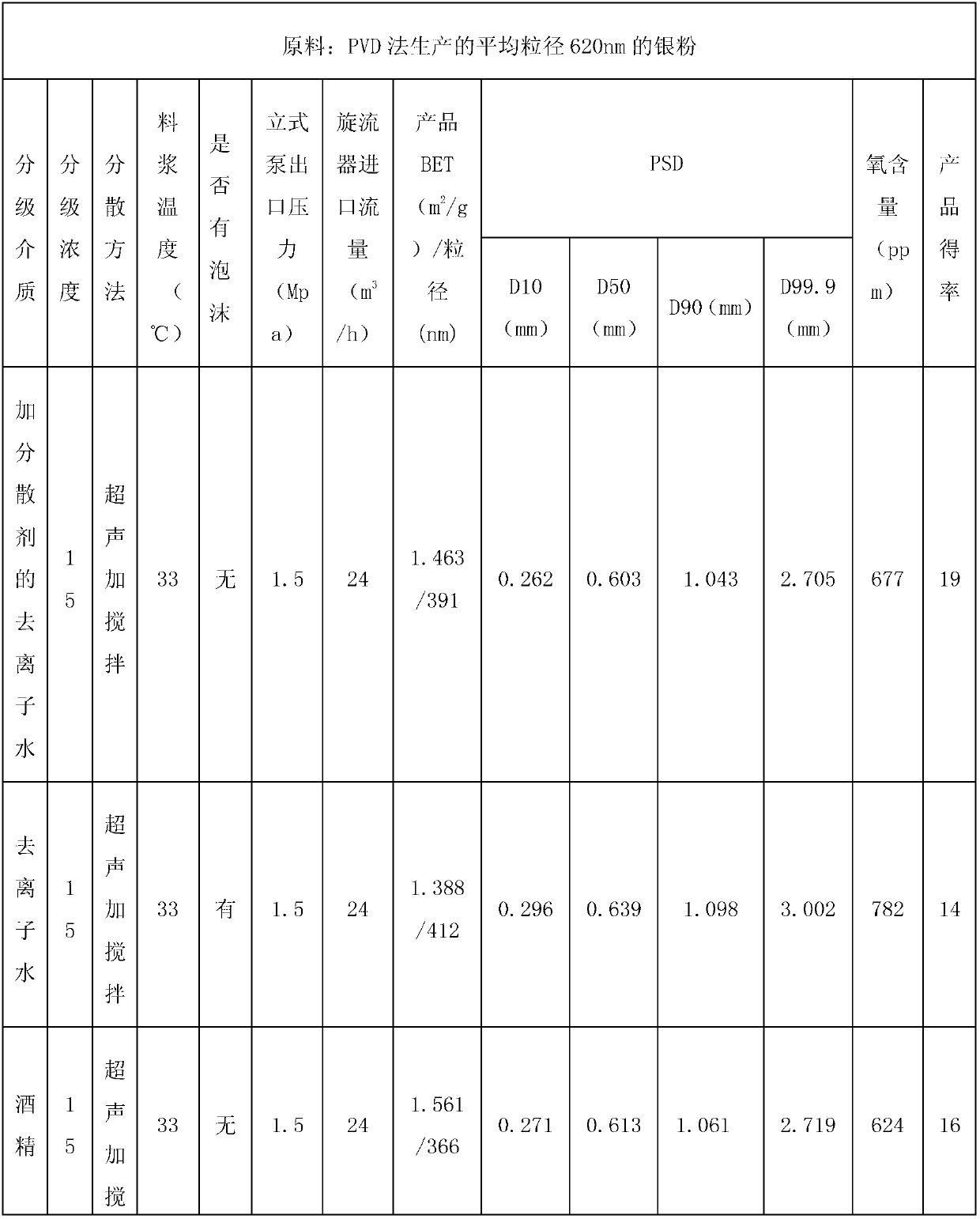

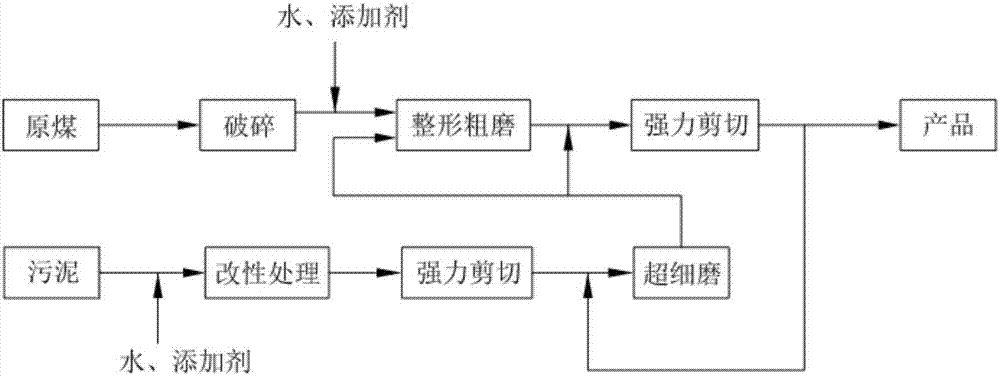

Method for preparing novel coal water slurry product from multiple materials

ActiveCN107267235AQuality improvementEfficient and clean utilizationLiquid carbonaceous fuelsCoal waterMulti material

The invention provides a method for preparing a novel coal water slurry product from multiple materials. The method includes the following steps: (1) after raw coal is crushed, a material A is obtained; (2) after being modified together, sludge, optional coal slime, water and additive then undergo strong shear treatment, so that a material B is obtained; (3) the material B is ultrafinely ground, so that a material C is obtained; (4) the material A, part of the material C, water and additive are shaped and roughly ground, so that a material D is obtained; (5) after being mixed, the material D and the remaining material C undergo strong shear, and thereby the coal water slurry product is obtained. The grain size distribution of the multi-material coal water slurry prepared by the preparation method is reasonable, and the novel coal water slurry product has good stability, flowability and good atomizing effect, and is also applicable to the preparation of fuel and gasified coal water slurry; in addition, the preparation method is easy to implement, energy consumption is low, and the problem on how to utilize sludge and coal slime on a large scale can be reasonably solved.

Owner:CCTEG CLEAN ENERGY CO LTD

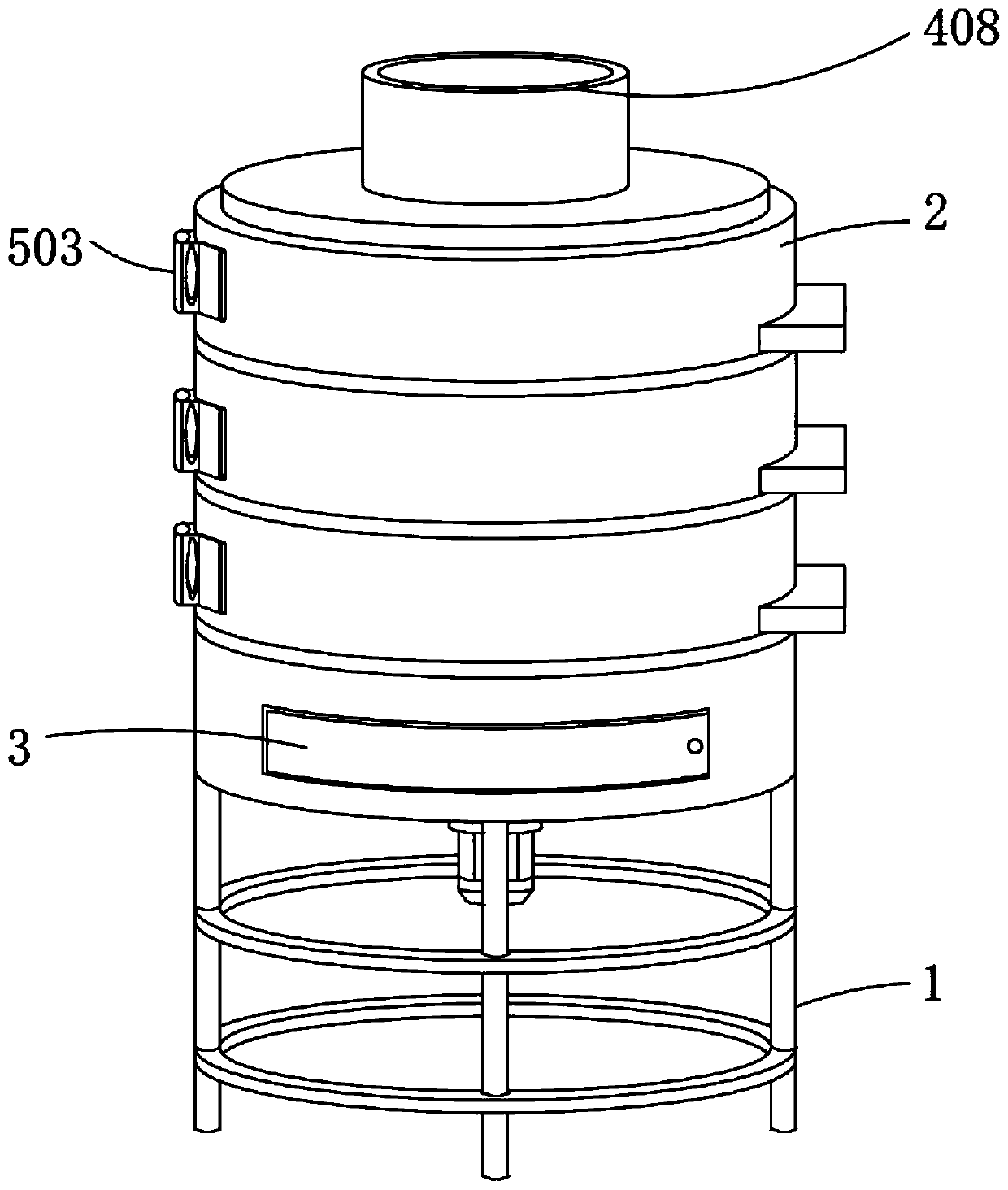

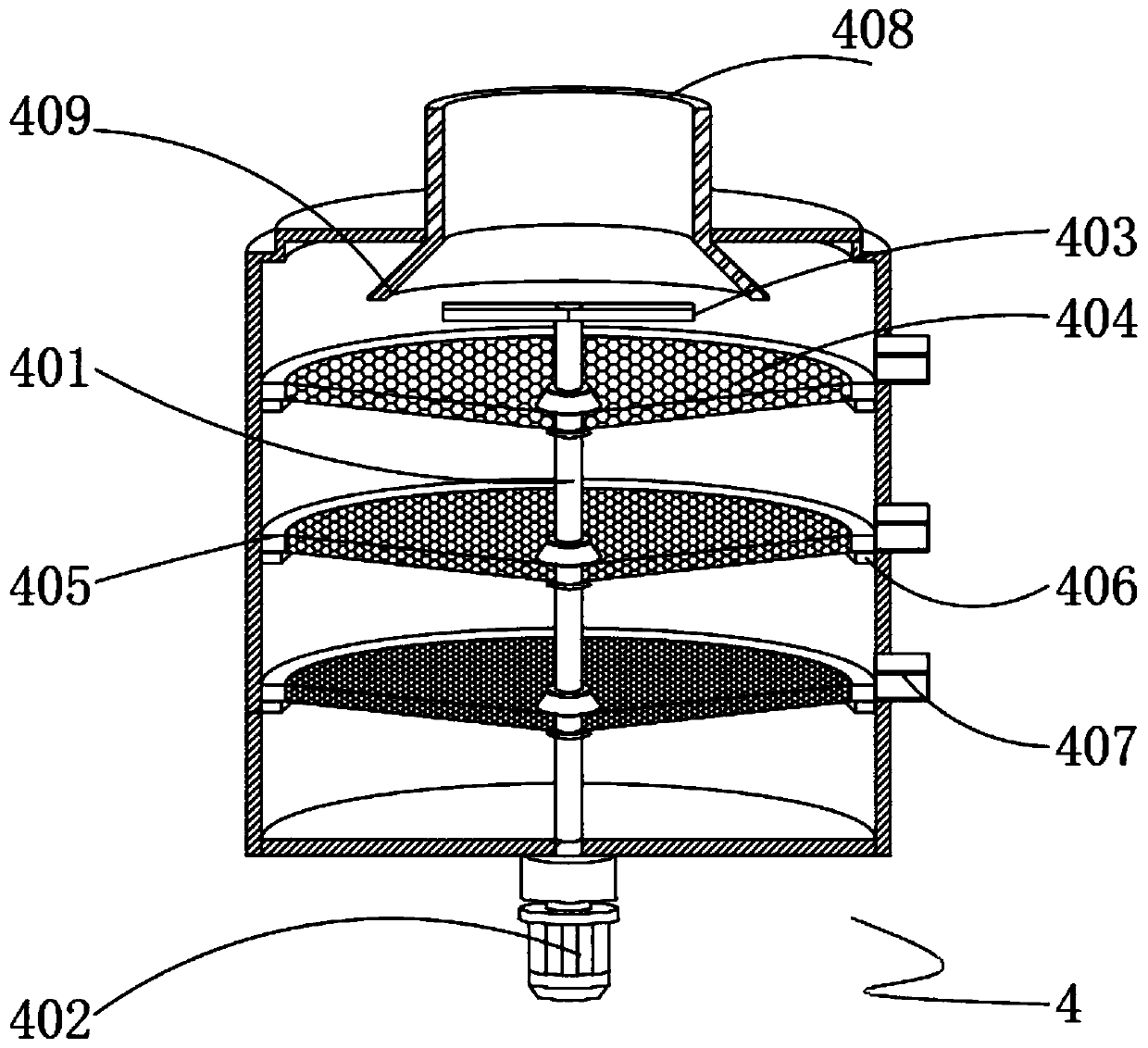

Multistage automatic particle classifying equipment for amorphous refractory

InactiveCN110624812AScientific and reasonable structureEasy to useSievingScreeningBristleMotor drive

The invention discloses multistage automatic particle classifying equipment for an amorphous refractory. A classifying assembly is installed in a shell. A motor is connected to the bottom end of a rotary shaft. A sieve plate is evenly connected to the middle of the rotary shaft in a sleeving mode. A support ring is welded to the position, close to the bottom end of a locating ring, of the inner wall of the shell. A sweeping assembly is installed on one side of the shell. Balls are inlaid in both the top end and bottom end of the interior of a sweeping opening. Bristles are installed at the bottom end of a sweeping plate. During classifying, the motor drives the sieve plate to rotate, along with rotation of the motor, under the action of centrifugal force, raw materials are thrown out alongthe top face of the sieve plate and are then discharged from a discharge pipe, discharge is convenient, and the raw materials are not liable to be accumulated. When the raw materials are fed in, along with rotation of a connection rod, the raw materials are scattered by the connection rod and are dispersed more evenly, and screening and classifying effects are better. After screening is completed, the sweeping plate is conveyed in through the sweeping opening, the sieve plate rotates, the sweeping plate is pulled back and forth, the surface of the sieve plate is swept by the bristles, and sweeping is convenient and fast.

Owner:长兴县中泰耐火材料有限公司

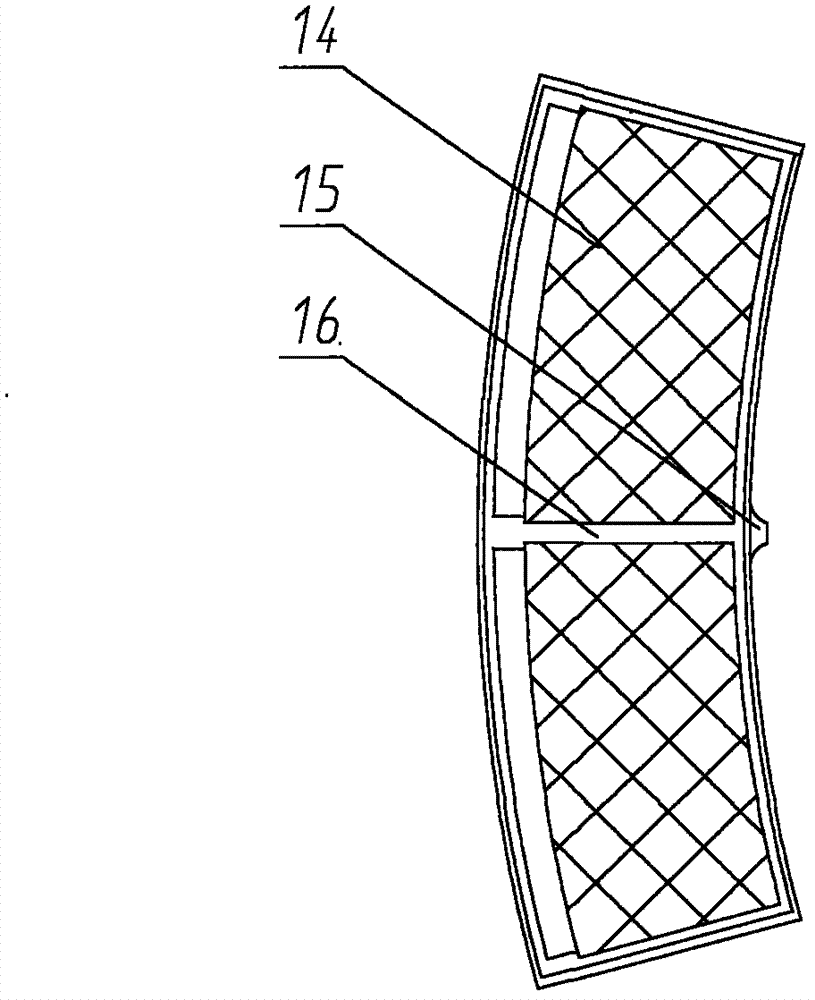

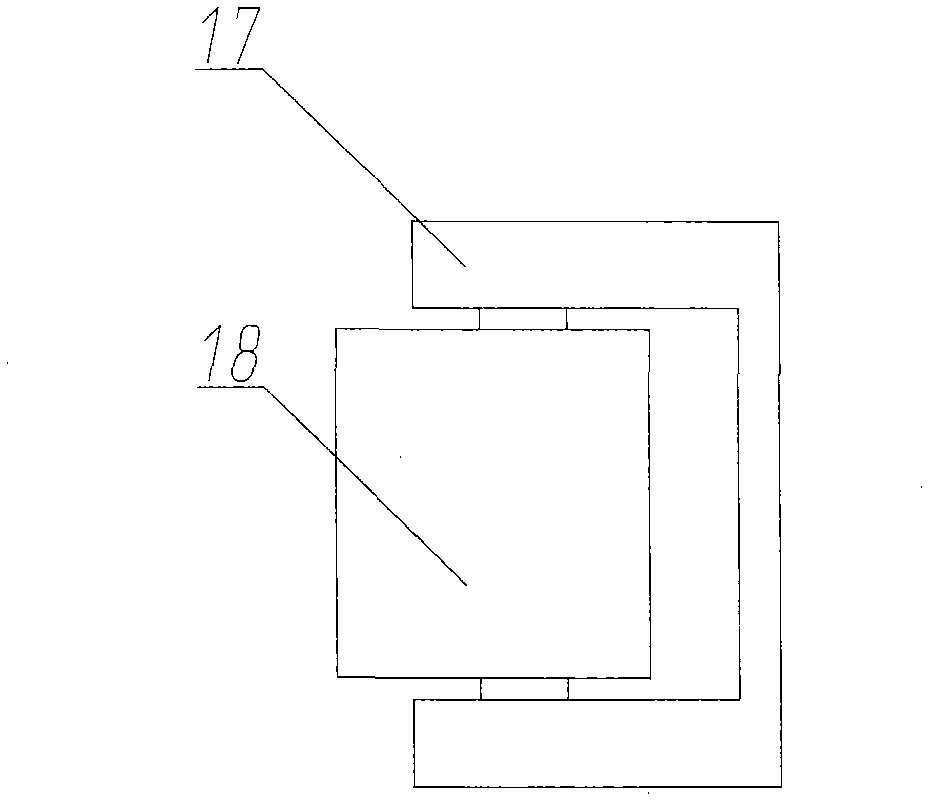

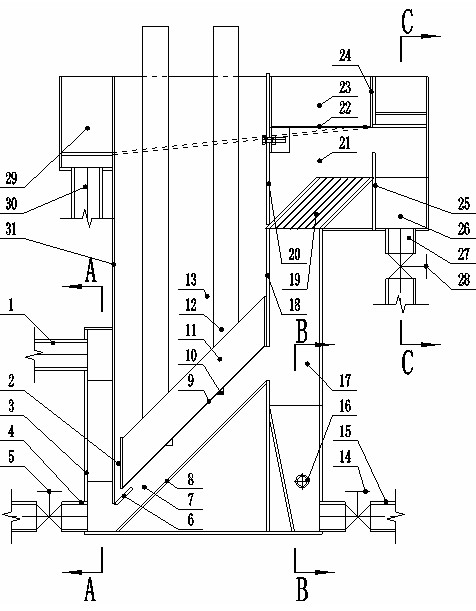

Double-layer internal screening device

InactiveCN102784707ACompact structureThe follow-up process system is simpleGrain treatmentsMechanical engineeringMillstone

The invention relates to a double-layer internal screening device of a vertical pregrinding roller mill, which comprises an upper screening device, a lower screening device, a crude material annular groove, a fine powder annular groove, a material scraping device 1, a material scraping device 2, a crude material discharge port, a fine powder discharge port, and an eccentric sheave knocker. The device is characterized in that the upper screening device comprises a screen rack, a screen mesh, a static ring, and a mobile ring; the screen rack, the screen mesh, and the static ring are fixed on an upper housing, and the mobile ring is fixed on a millstone; the lower screening device comprises a screen rack, a screen mesh, and a boss, and the fine powder annular groove is fixed on a lower housing; the material scraping device 1 is fixed at the waist part of the millstone; the material scraping device 2 is fixed at the bottom part of the millstone; the crude material discharge port is located above the fine powder discharge port, and is staggered with the fine powder discharge port so as to facilitate the respective discharge of the screened crude materials and fine powder into a material collecting device outside the device. When the double-layer internal screening device is disposed in a vertical pregrinding roller mill, multi-grade classification of materials can be realized; the material grading capability is greatly improved; the structure of the vertical pregrinding roller mill is more compact; subsequent technology system is simple; the land occupation, basic construction investment and auxiliary equipment quantity for the vertical pregrinding roller mill are reduced; and thus the grinding capability and grinding efficiency are increased.

Owner:王燕

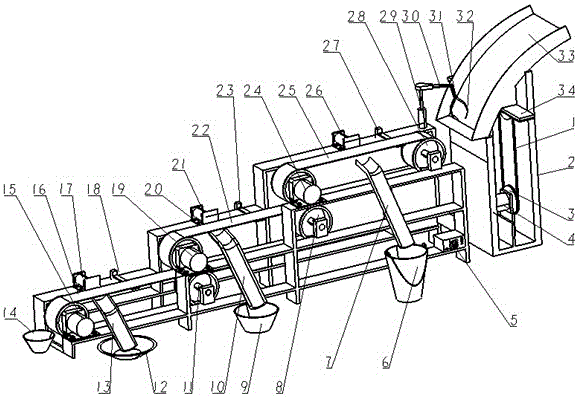

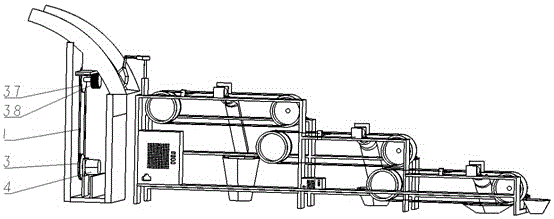

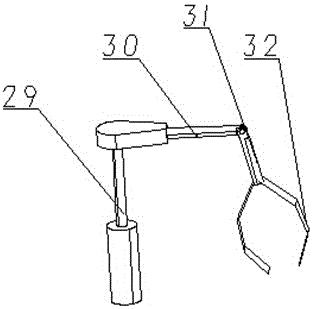

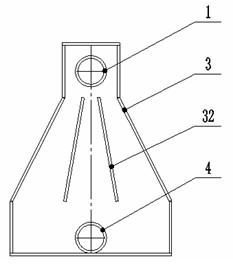

Full-automatic multistage panax notoginseng classifier

ActiveCN106216263AHigh degree of automationAchieve independent operationSortingPANAX NOTOGINSENG ROOTElectronic control system

The invention relates to a full-automatic multistage panax notoginseng classifier, which belongs to the technical field of Chinese herbal medicine mechanical equipment, and comprises an electronic control system, an automatic panax notoginseng clamping device, a conveying and classifying device and a collecting device. The electronic control system is located on a rack; all stepping motors for controlling the classifier, a pressure sensor and the panax notoginseng clamping device are arranged; the automatic panax notoginseng clamping device clamps panax notoginseng onto the conveying and classifying device from the forefront part of the rack; and the conveying and classifying device is used for mainly transferring the panax notoginseng with different head parts, and finally guiding the panax notoginseng with different head parts into the collecting device through hydraulic guide rods. According to the full-automatic multistage panax notoginseng classifier provided by the invention, functions of clamping, transferring, classifying, collecting and the like can be completed at a time; and the multistage transfer is adopted, so that the multistage classifying of the panax notoginseng with different head parts is realized, the problem that the market sales revenue and volume is delayed due to the difficulty in manual classification of the panax notoginseng is solved, and the full-automatic multistage panax notoginseng classifier has a wide market economic prospect, and is suitable for panax notoginseng farming popularization and application in various planting scales.

Owner:KUNMING UNIV OF SCI & TECH

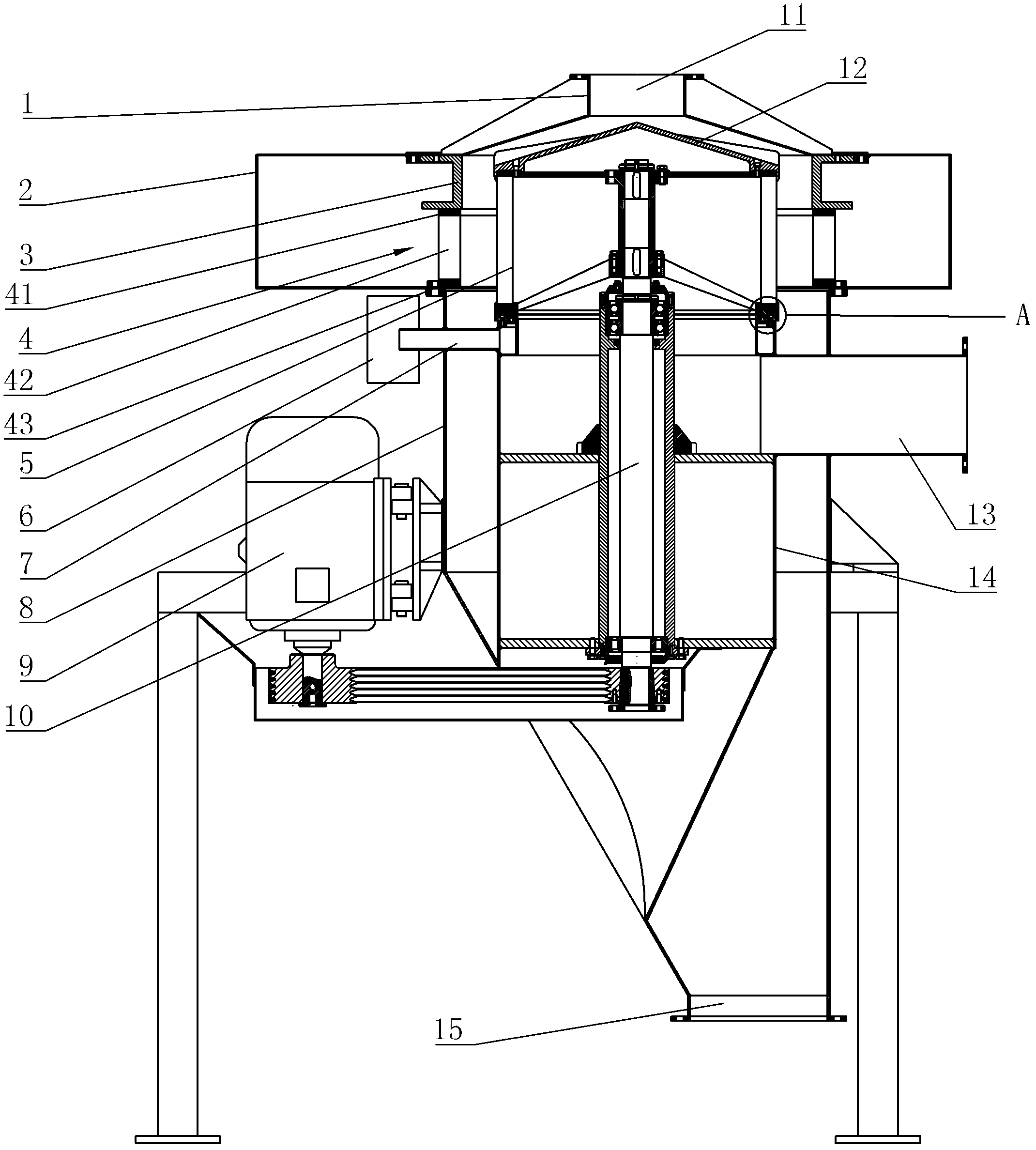

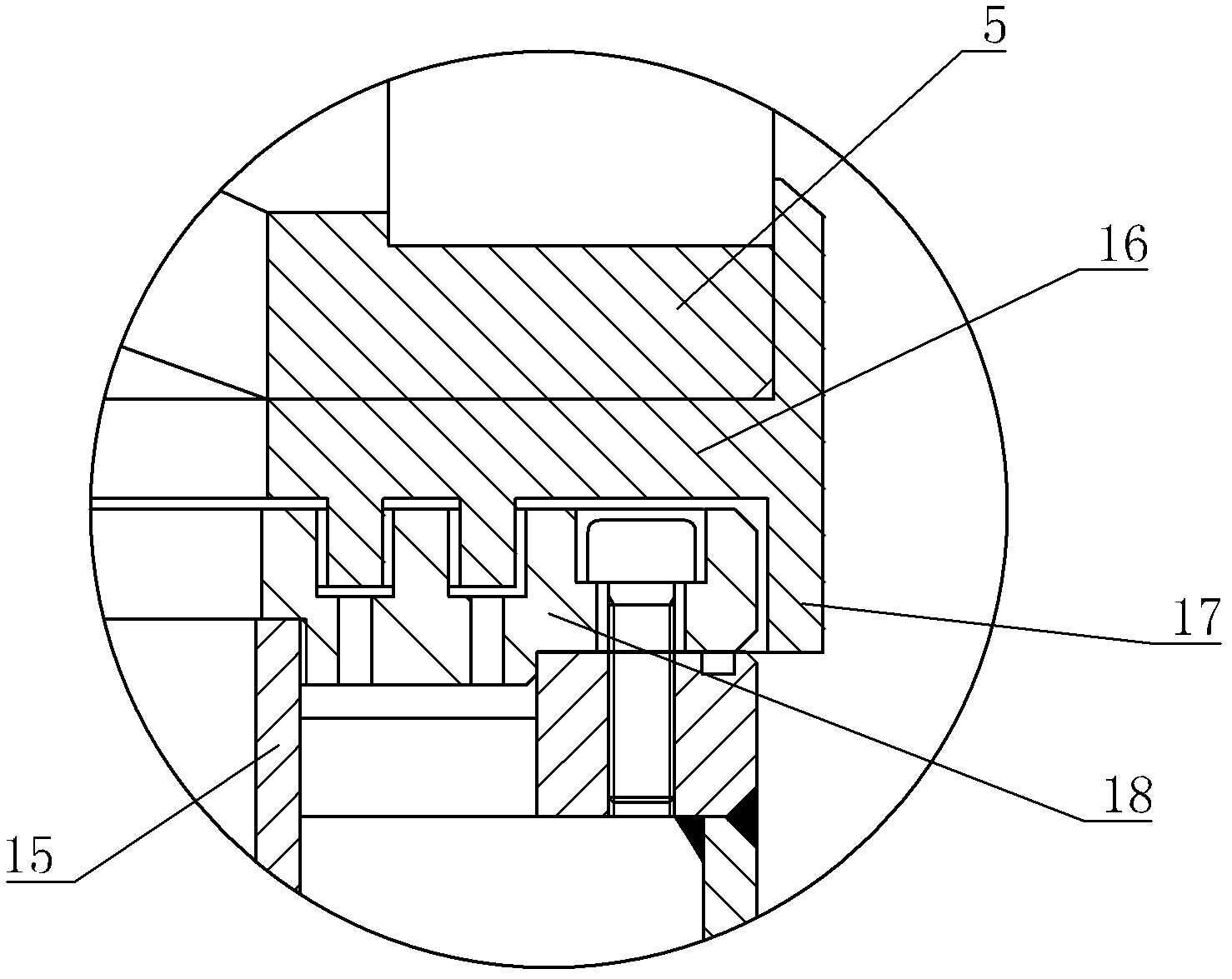

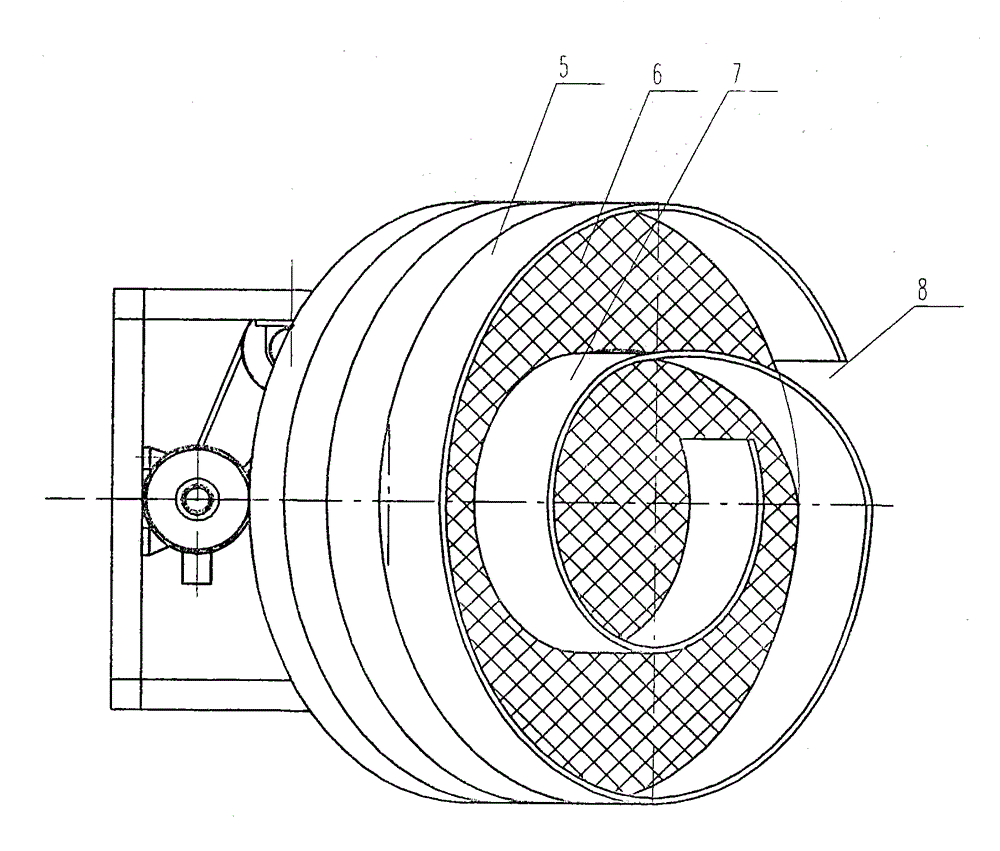

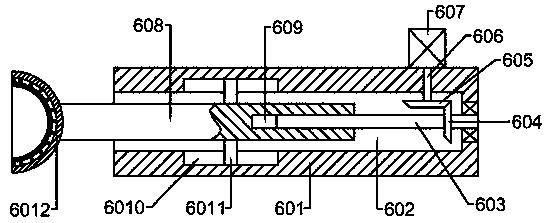

Airflow grader

The invention discloses an airflow grader, which belongs to the technical field of solid powder grading equipment and comprises a grading impeller driven by a power device. A cyclone barrel is sleeved on the periphery of the grading impeller, grading airflow flows through the cyclone barrel, a feeding opening at the position corresponding to that of the grading impeller is arranged at the top of the cyclone barrel, an air inlet is arranged on the cyclone barrel, a material grading cavity is formed between the cyclone barrel and the grading impeller, an inner barrel is disposed below the grading impeller, a sealing device is disposed between the inner barrel and the grading impeller, a fine powder discharge opening is arranged at the bottom of the inner barrel, the lower side of the cyclone barrel is hermetically connected with an outer barrel surrounding the inner barrel, a coarse powder discharge opening is arranged at the bottom of the outer barrel, materials are graded by the structure and drop in the grading cavity from the feeding opening by the aid of gravity, only one cyclone barrel and the grading impeller are used for separating coarse powder from fine powder, and the airflow grader is simple in structure, stable in performance and low in energy consumption.

Owner:山东惟远新材料装备有限公司

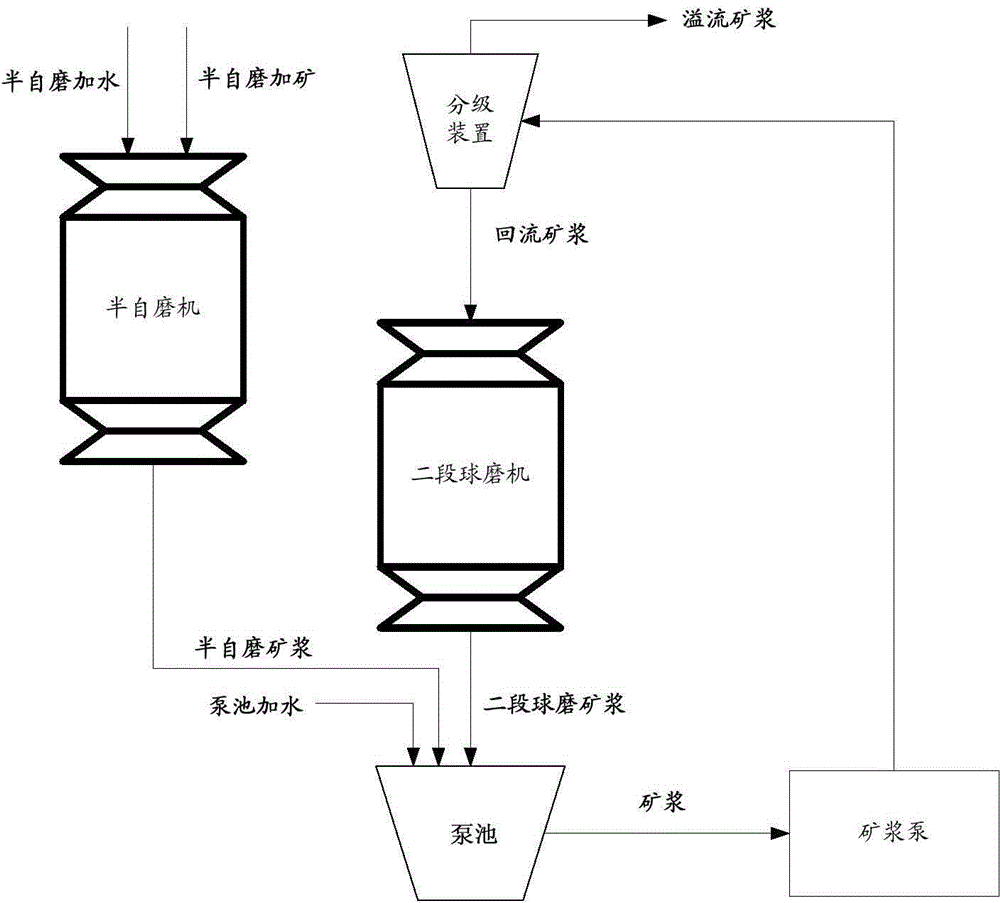

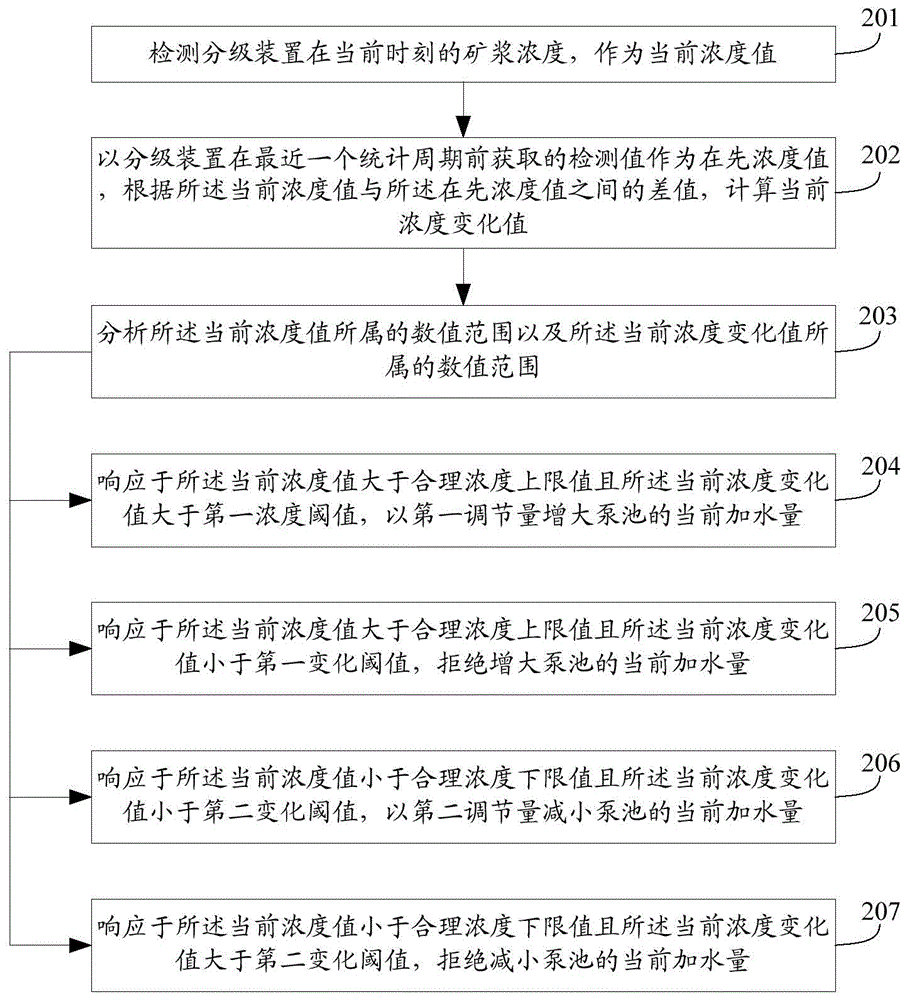

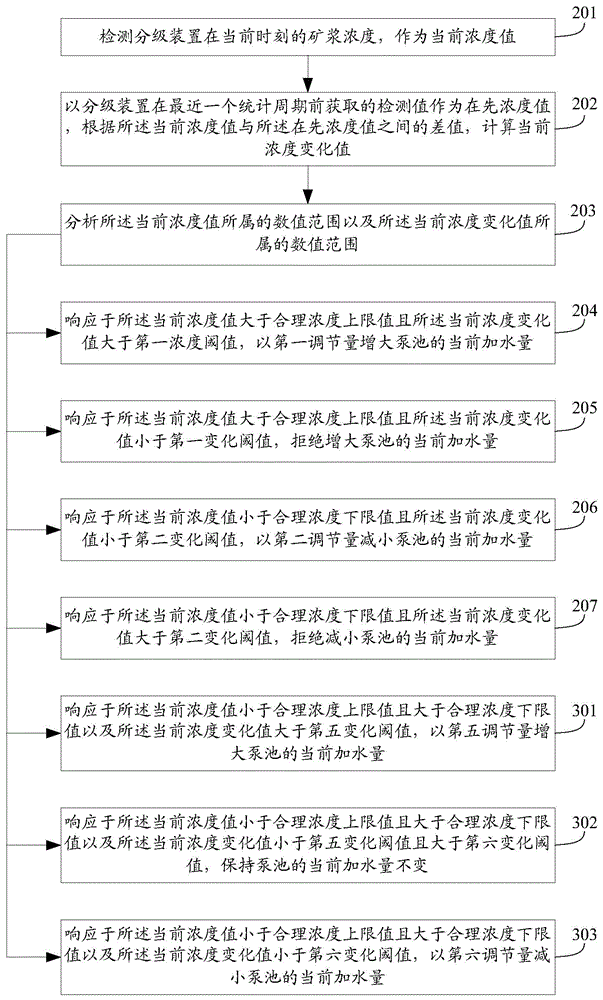

Method and device for controlling pulp concentration in ore grinding classification course

The invention discloses a method for controlling pulp concentration in an ore grinding classification course. The method comprises the steps of detecting a current concentration value of a classification device; calculating a changeable value of the current concentration value according to the difference between the current concentration value and a previous concentration value; analyzing the value range of the current concentration value and the value range of the changeable value of the current concentration value; increasing the water addition amount of a pump sump in response to the condition that the current concentration value is larger than an upper limit value of a reasonable concentration value as well as the changeable value of the current concentration value is larger than a first changeable threshold value; refusing to increase the water addition amount of the pump sump in response to the condition that the current concentration value is larger than the upper limit value of the reasonable concentration value as well as the changeable value of the current concentration value is smaller than the first changeable threshold value; decreasing the water addition amount of the pump sump in response to the condition that the current concentration value is smaller than a lower limit value of the reasonable concentration value as well as the changeable value of the current concentration value is smaller than a second changeable threshold value; refusing to decrease the water addition amount of the pump sump in response to the condition that the current concentration value is smaller than the lower limit value of the reasonable concentration value as well as the changeable value of the current concentration value is larger than the second changeable threshold value. In addition, the invention further provides a device for controlling the pulp concentration in the ore grinding classification course.

Owner:ZHONGYE-CHANGTIAN INT ENG CO LTD

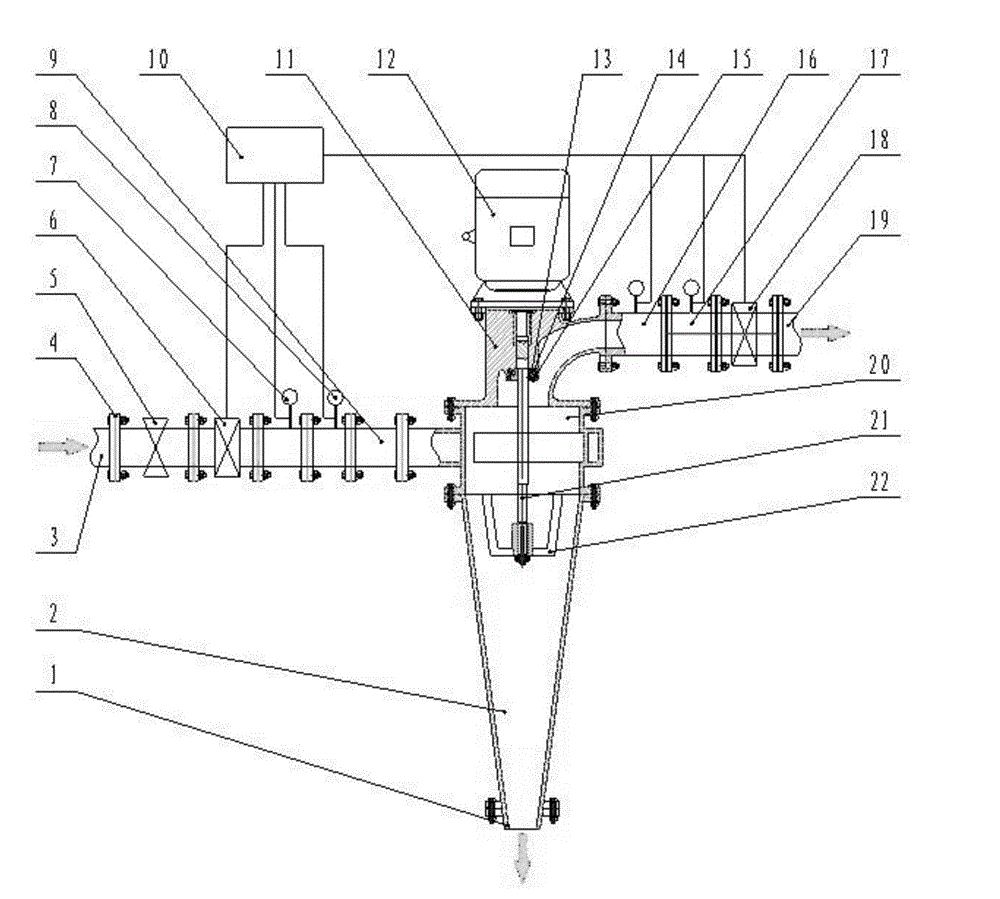

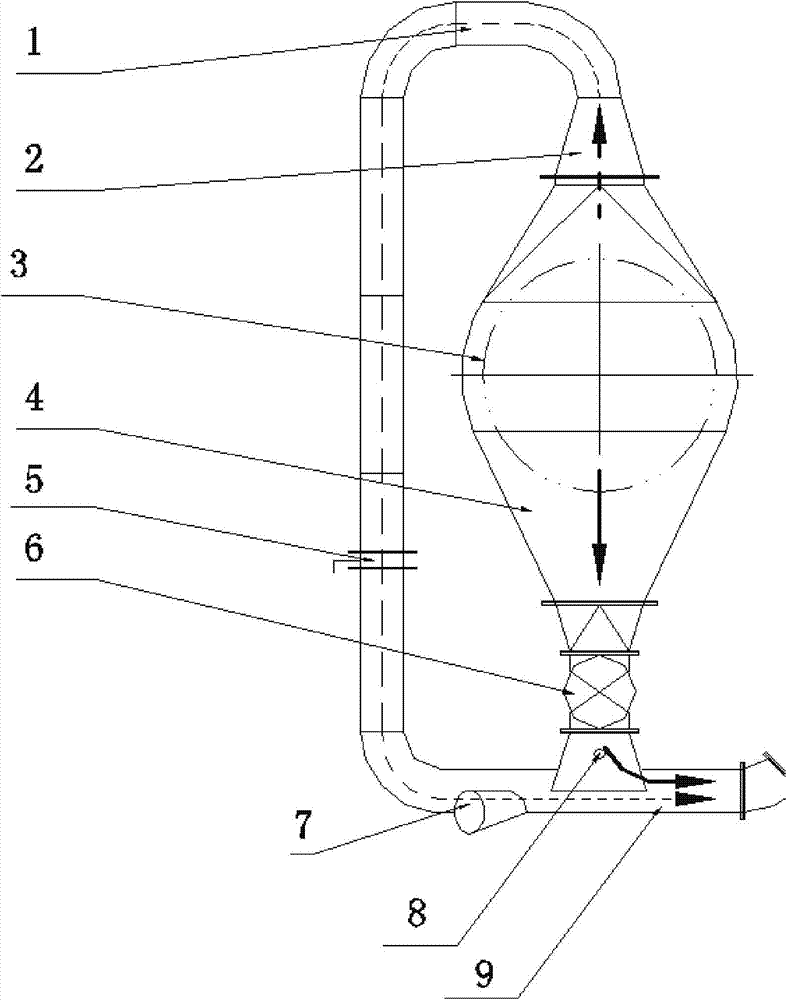

Fuzzy closed circuit self-turning dynamic hydraulic cyclone classifier

InactiveCN103331205AIncrease or decrease separation pressureGrading effect is goodWet separationImpellerCyclone

The invention relates to a fuzzy closed circuit self-turning dynamic hydraulic cyclone classifier which is characterized by comprising a reducing underflow pipe, a tapered cylinder body, a slurry inlet pipe, sealing rings I, a valve, a slurry inlet particle size analyzer, a slurry inlet pressure gauge, a slurry inlet flowmeter, a reducing pipe, a control computer, an overflow cylinder body, a motor, a bearing, a sealing ring II, a bearing cover plate, an overflow pressure gauge, an overflow flowmeter, an overflow particle size analyzer, an overflow pipe, a cylinder body, a center shaft and an impeller. The classifier can achieve an optimal classification effect by replacing the reducing underflow pipes with different diameters according to the particle size composition properties of different minerals, can improve the rotating separation strength of slurry body particles in the cylinder body, and is high in automation degree and control precision, and good in classification effect.

Owner:广西华锡集团股份有限公司

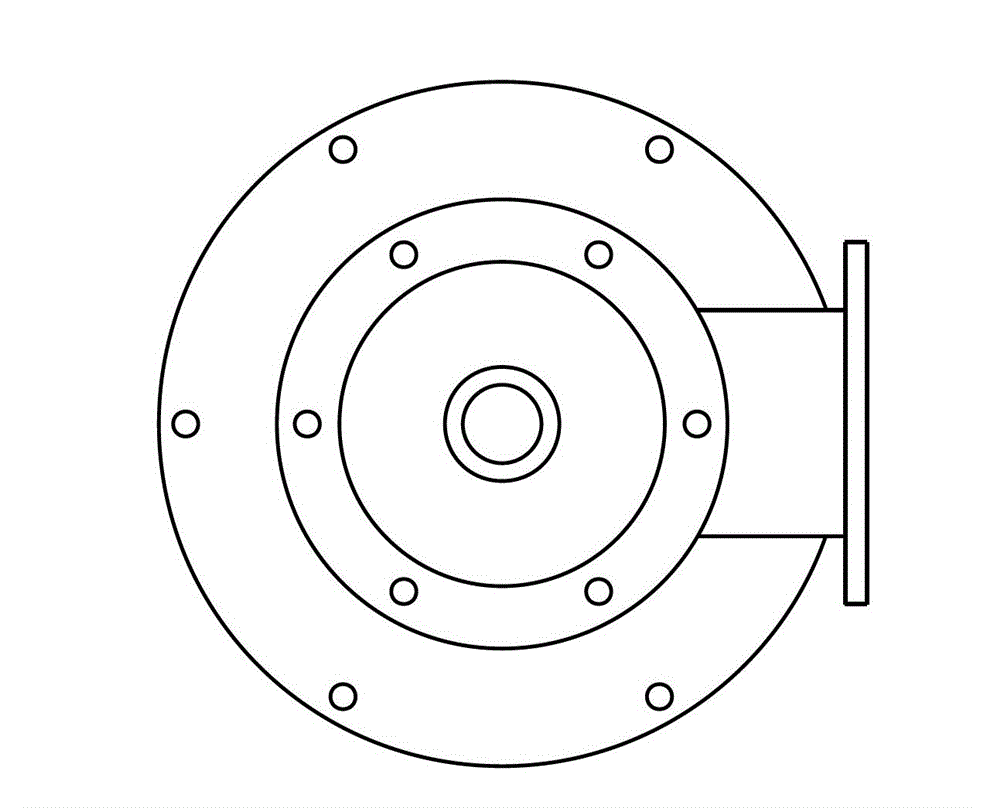

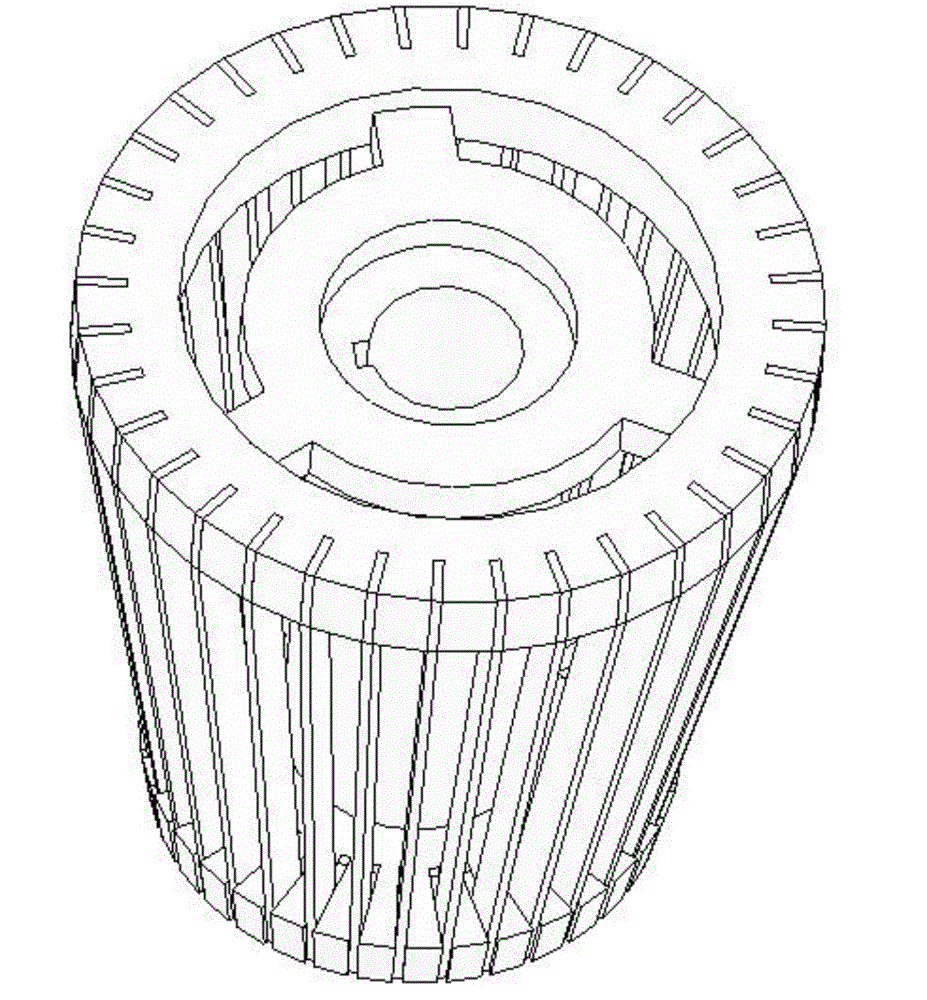

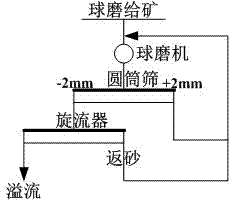

Coarsness grading process for mineral separation and grinding

The invention relates to a coarsness grading process for mineral separation and grinding. The coarsness grading process for the mineral separation and grinding is characterized by comprising the following steps of: 1) preparing a ball grinding machine with a quality classifying screen, namely mounting the quality classifying screen at a mineral discharging outlet of the ball grinding machine, and fixing the quality classifying screen on an end cover at the mineral discharging outlet of the ball grinding machine, wherein the screening aperture of the quality classifying screen is 2mm, and during working, the quality classifying screen rotates together with the ball grinding machine; and 2) feeding and grinding minerals in the ball grinding machine with the quality classifying screen, wherein the minerals flowing out of a grid plate of the ball grinding machine enter a screen body of the quality classifying screen from the mineral discharging outlet of the ball grinding machine, the finely granulated minerals with the granularity of less than or equal to 2 mm are screened out of the screen body of the quality classifying screen under the pushing action of centrifugal force and external spiral, are flushed into an original pump by pressure water and are conveyed by the pump into a hydrocyclone for fine grading; and the roughly granulated minerals with the granularity of more than 2 mm flow into a settling pit and are directly put into a mineral grinding machine through a sand pump to form a closed loop for finishing quality classifying. By the process, a grading effect of the hydrocyclone can be enhanced and power is saved.

Owner:WUHAN UNIV OF TECH

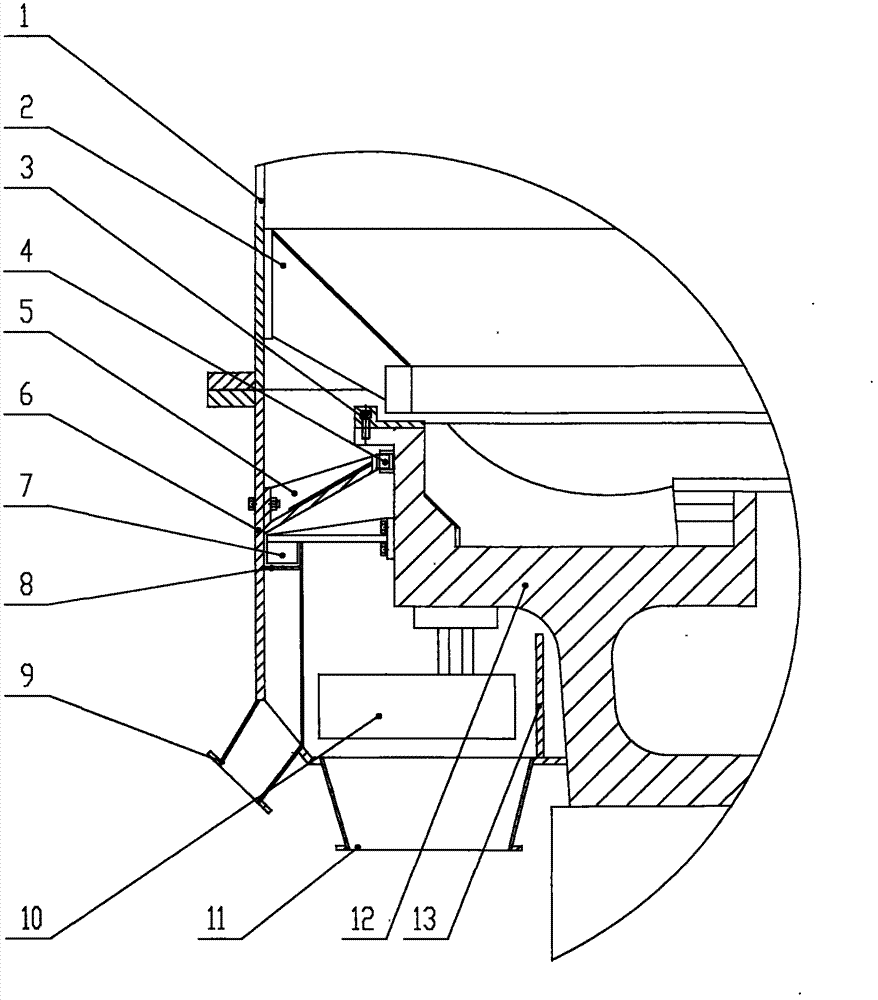

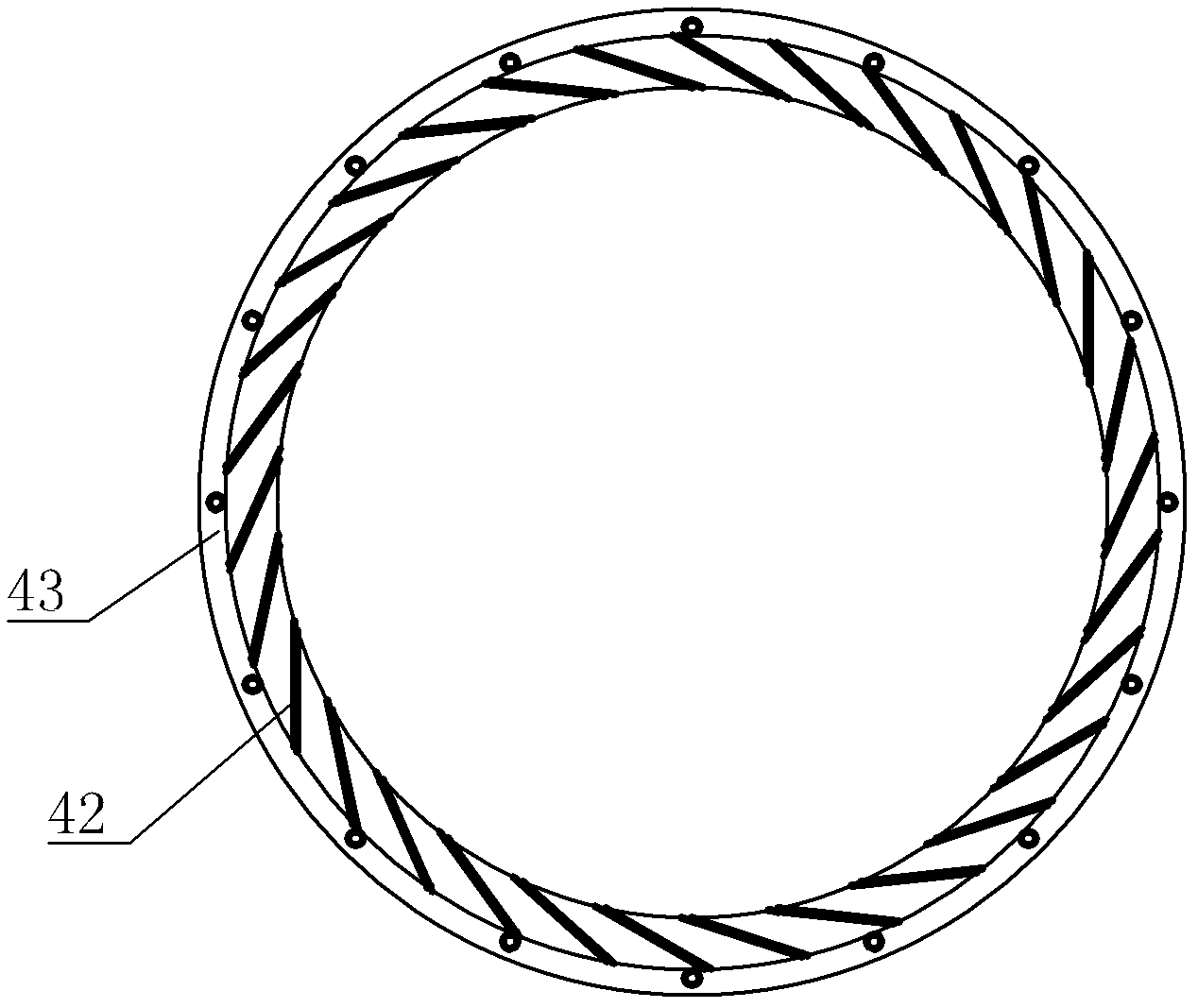

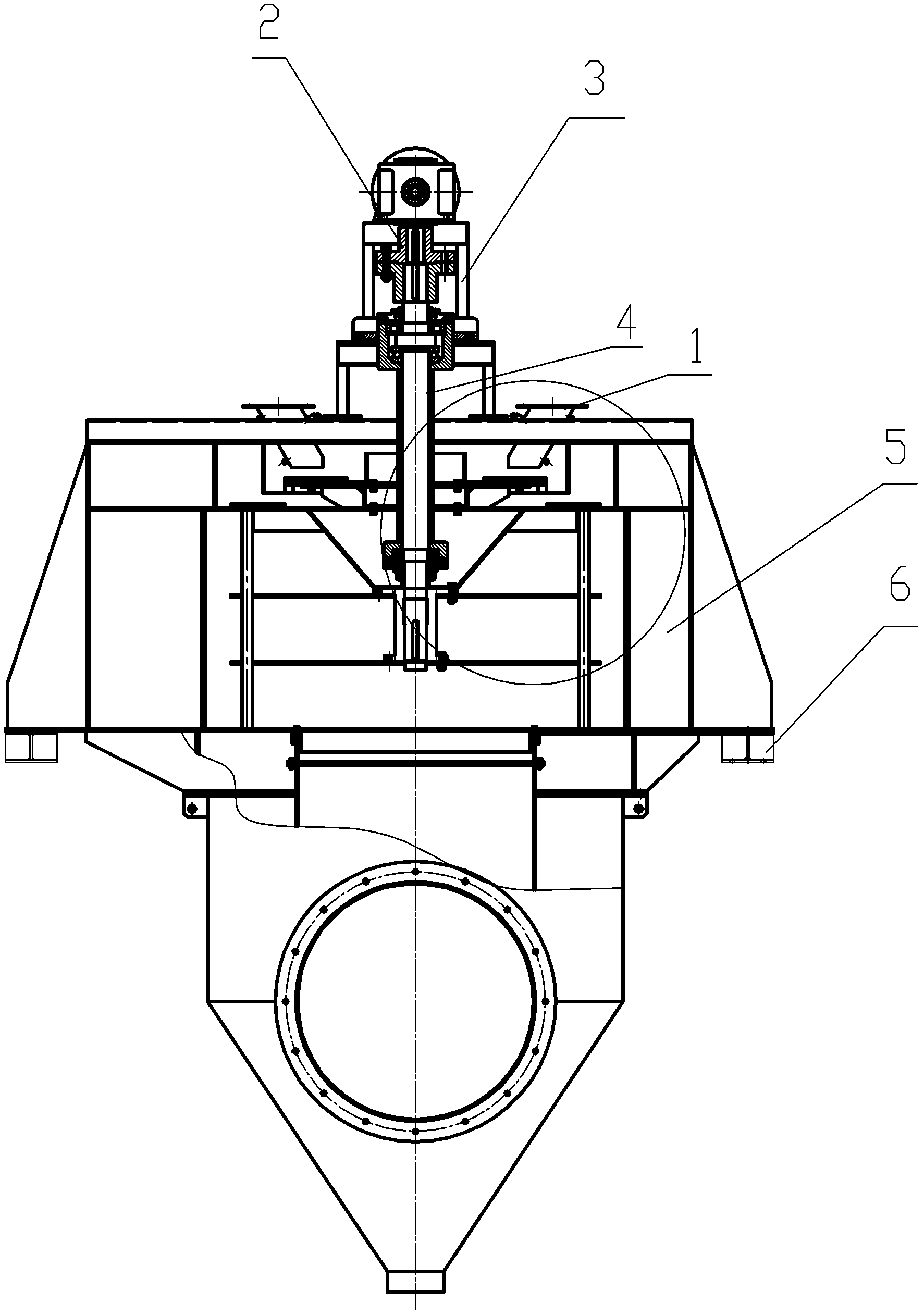

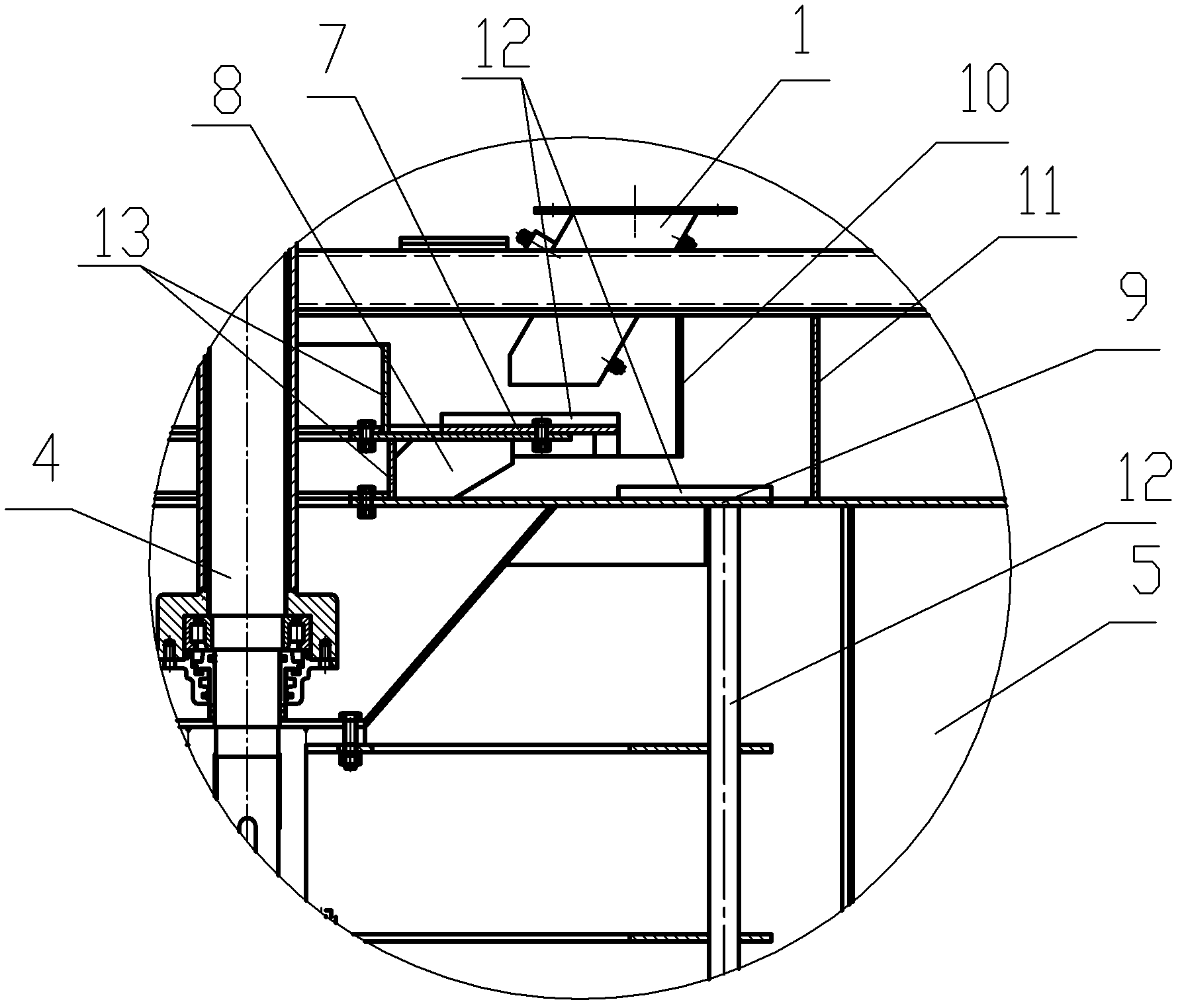

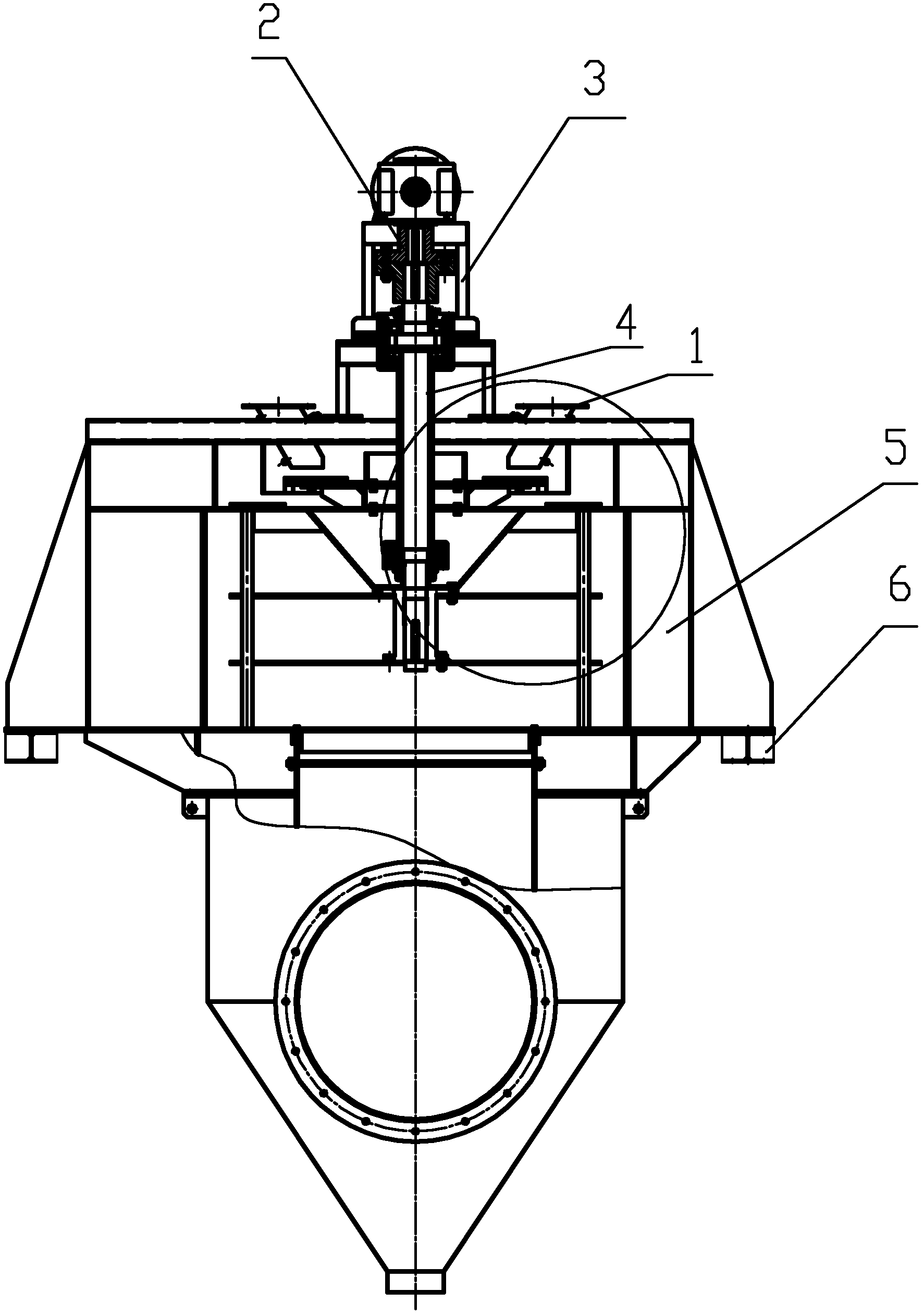

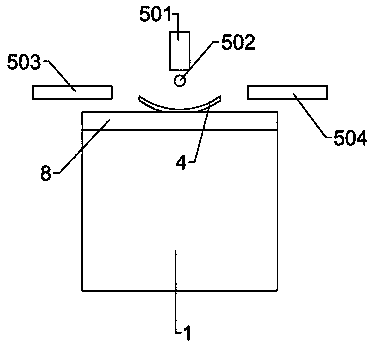

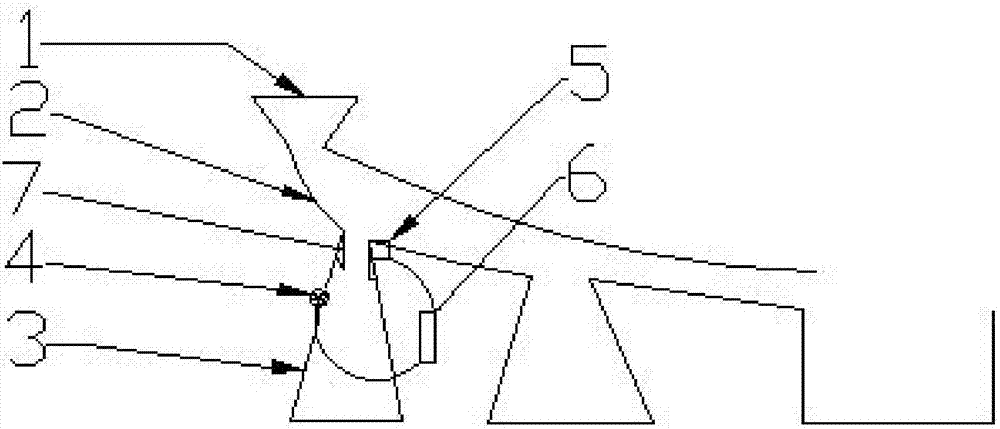

Novel powder selecting machine capable of uniformly scattering material

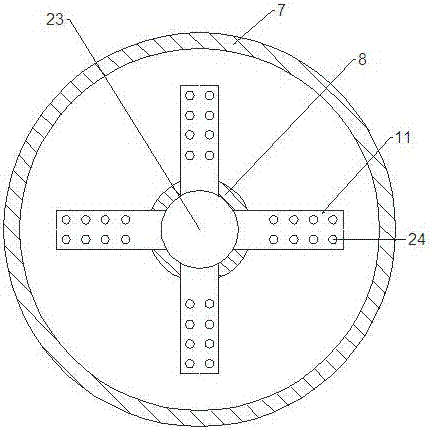

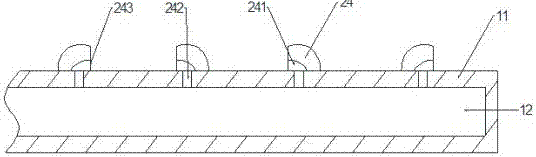

InactiveCN102615046AImprove grading effectAvoid running roughGas current separationEngineeringMaterial scattering

The invention discloses a novel powder selecting machine capable of uniformly scattering a material, which comprises a cylindrical shell, a support base used for supporting the shell, a motor, a speed reducer, a coupling device, a rack and a rotating part arranged in the shell, wherein the rotating part comprises a spindle and a rotor, and an annular material scattering plate is fixedly arranged at the top of the rotor; the material scattering plate is provided with two layers, and comprises a top-layer material scattering plate and a bottom-layer material scattering plate, and the top-layer material scattering plate is arranged under a material inlet of the powder selecting machine; and an annular first-stage baffle plate is arranged correspondingly to the outer edge of the top-layer material scattering plate, the bottom-layer material scattering plate, the diameter of which is larger than the diameter of the top-layer material scattering plate, is arranged under the top-layer material scattering plate, an annular second-stage baffle plate is arranged correspondingly to the outer edge of the bottom-layer material scattering plate, the first-stage baffle plate and the second-stage baffle plate are both fixedly connected with the shell, the lower part of the first-stage baffle plate is corresponding to the plate surface of the bottom-layer material scattering plate, and the lower part of the second-stage baffle plate is corresponding to a material grading zone of the powder selecting machine. The powder selecting machine disclosed by the invention can make the material uniformly and loosely enter into the material grading zone, and enhance the grading precision of the material.

Owner:JIANGSU A BITION ENVIRONMENTAL EQUIP

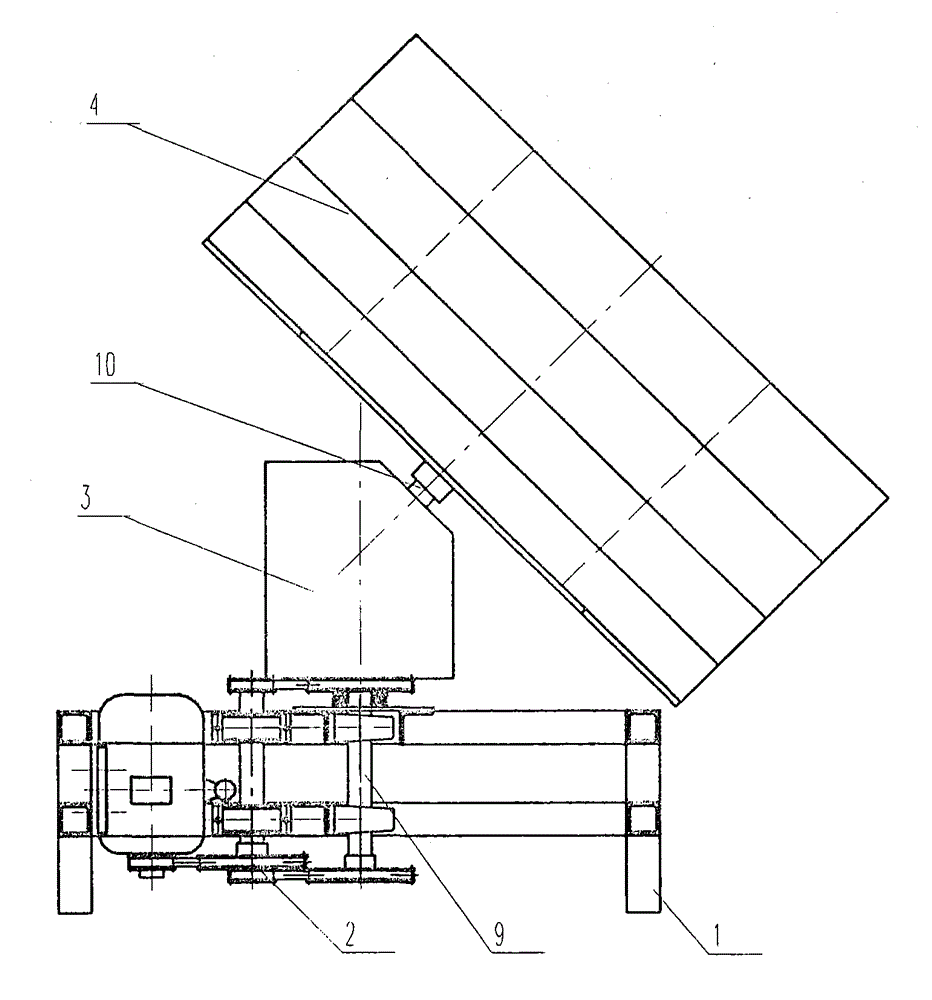

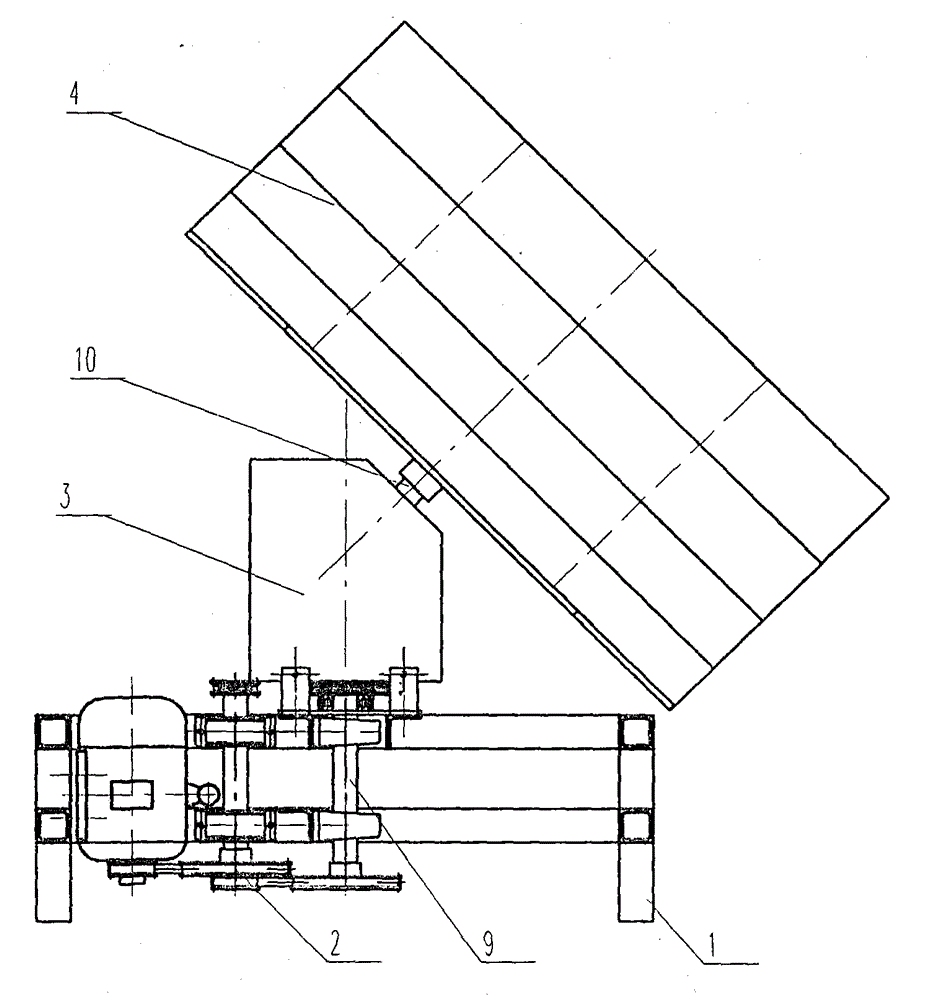

Inclined sieve tray type tea grader

The invention relates to an inclined sieve tray type tea grader. The inclined sieve tray type tea grader comprises a rack, a transmission mechanism, a corner rotating device and a screening device. The screening device is formed by stacking multiple sieve trays. The size of screen holes is reduced layer by layer from top to bottom. The transmission mechanism is mounted on the rack. The corner rotating device is in linkage with a main shaft of the transmission mechanism. The screening device is in linkage with an output shaft of the corner rotating device. In the operation process, the screening device rotates and moves. For the screening device, two rotating modes can be selected; according to the first rotating mode, the main shaft of the transmission mechanism serves as the center to conduct pure rolling and rotating in the axial direction; and according to the second rotating mode, an output shaft of the corner rotating device serves as the center and rotates. Tea is put into the center of the upper sieve trays on the screening device and rolls on the screening face, the tea of which the size is smaller than that of the screen holes falls into the lower-layer sieve trays, and the tea of which the size is larger than that of the screen holes is discharged through tea discharging openings in the sieve tray edge rings. The inclined sieve tray type tea grader has the beneficial effects that the tea grading effect is good, efficiency is high, the tea damage rate is low, the structure is simple, and operation is easy and convenient. Appropriate screen cloth is selected and used, and the inclined sieve tray type tea grader can be used for screening and grading fresh tea leaves and purified tea.

Owner:马文桂

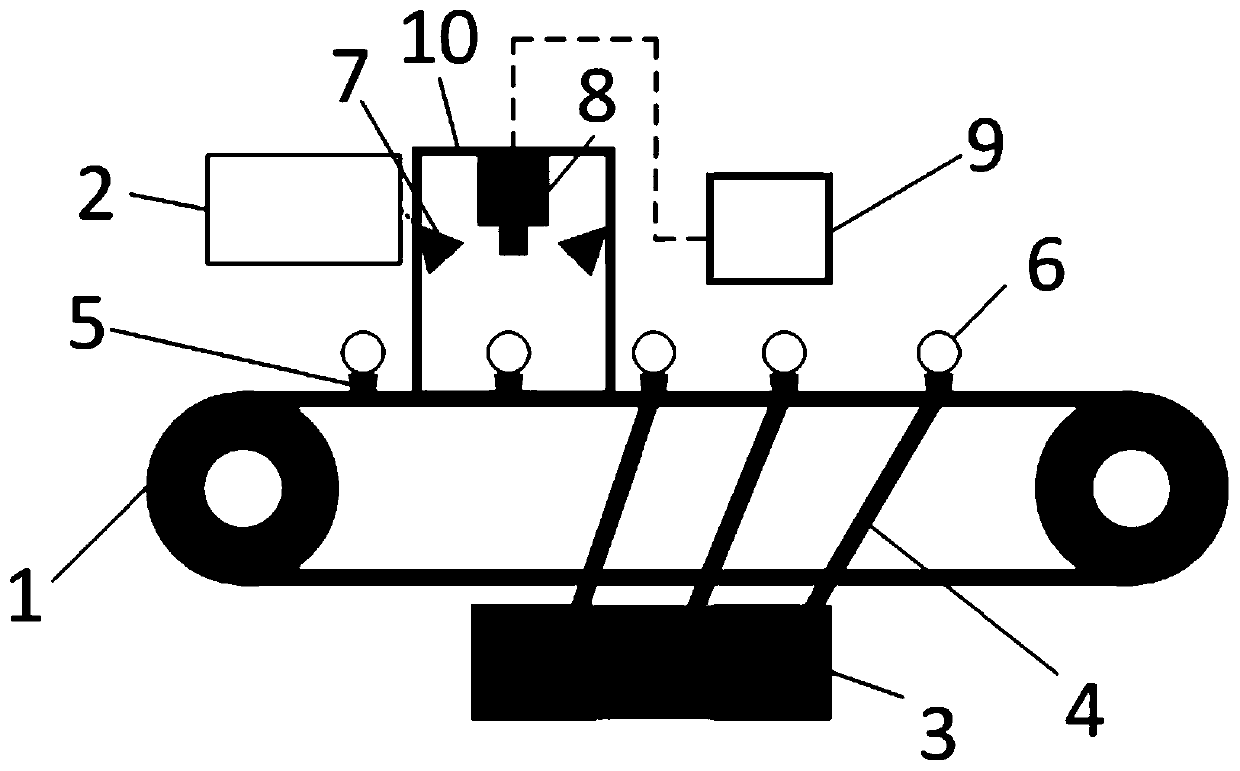

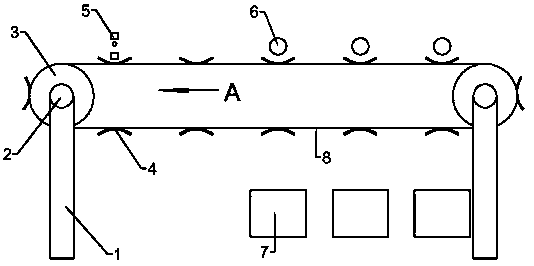

Computer vision-based fruit classifying equipment

InactiveCN108855987ARealize intelligent classification processingImprove grading effectSortingComputer basedClassification treatment

Computer vision-based fruit classifying equipment comprises two supporting frames, wherein the two supporting frames are both rotationally connected with rotating shafts; one end of one rotating shaftis fixedly connected with an output shaft of a driving motor; the rotating shafts are rotationally connected with belt wheels; the two belt wheels are connected through a conveyor belt; a plurality of transportation bodies are uniformly distributed on the conveyor belt; a computer vision identification device is arranged above the supporting frame which is arranged at the left side. The computervision-based fruit classifying equipment disclosed by the invention has the beneficial effects that the computer vision identification device is used for automatically classifying and discriminating fruits, and then a material pushing device is used for pulling the fruits from the transportation bodies to the inner parts of material storage boxes, so that intelligent classification treatment of the fruits is realized, a classification effect of the fruits is effectively increased, the labor is saved, and wide popularization and application value is obtained; rubber gaskets are capable of effectively preventing the loss of the fruits; in addition, springs have an effective buffer function, so that a protection effect on the fruits is further increased.

Owner:金华逻辑回归信息科技有限公司

Automatic walnut sorting device

InactiveCN107282449AReasonable structural designImprove work efficiencyGradingEngineeringForeign body

The invention provides an automatic walnut sorting device. Leaking holes which are enlarged gradually are formed in the bottom face of a grading channel from high to low at intervals. Pressure detection devices are installed on the hole walls of the leaking holes. Blowing pumps are arranged at the lower end of the grading channel, and the blowing directions of the blowing pumps right faces towards the leaking holes. When walnuts roll to the positions of the leaking holes, if the diameter of the walnuts is smaller than that of the leaking holes, the walnuts fall into a collecting frame, the walnuts with the diameter being larger than that of the leaking holes continue to roll and fall into the leaking holes with the diameter being larger than that of the walnuts, when the diameter of the walnuts is slightly larger than that of the leaking holes, the walnuts are stuck in the leaking holes, at the moment, a controller receives the information that the pressure monitors detect compression objects existing over the leaking holes, and a signal is transmitted to the blowing pumps so that the foreign bodies blocking the holes can be blown away. The automatic walnut sorting device has the advantages of being reasonable in structure design, high in working efficiency, good in grading effect, simple in structure, reliable in work and high in stability.

Owner:徐州瑞龙核桃科技开发有限公司

Gravity classification and immersive screen combined classifying method and device utilizing same

InactiveCN102527499AImprove grading effectReduce power consumptionWet separationEngineeringSmall footprint

Disclosed are a gravity classification and immersive screen combined classifying method and a device utilizing the same. Interference settlement, shallow settlement and screening classification are combined by arrangement of immersive screens, a water raise pipe and inclined plates. Materials are classified by a first screening classification chamber, an interference settlement classification chamber, a shallow settlement classification chamber and a second screening classification chamber in a multiple stage manner, so that classification effect of the materials is enhanced. Since fluid pressure provides power for classification of the materials, classification effect is enhanced further while power loss is saved. The adaptability of the device to flow states of fed materials is improvedgreatly. The usage of raise water is reduced, and the unit area treatment capacity and classification efficiency of the device are improved. The overflow grain size is controlled severely. The devicehas the main function of classifying and the auxiliary function of screening, and is simple and compact in structure, small in floor area, simple in operation method and wide in practicability.

Owner:CHINA UNIV OF MINING & TECH

Farm grain preprocessing device integrating drying and screening

ActiveCN107062870AReduce duplicationLow costDrying gas arrangementsDrying chambers/containersScreening effectEngineering

The invention discloses a farm grain preprocessing device integrating drying and screening. The device comprises a feeding device and a shell. The feeding device comprises an inclined conveying belt and a first horizontal conveying belt. The first horizontal conveying belt is connected with the inclined conveying belt. The first horizontal conveying belt is located above the shell. The upper end of the shell is provided with an air blower. An air outlet of the air blower is located under the right end of the first horizontal conveying belt. A second horizontal conveying belt is arranged above the right side of the shell. A first screen net is arranged in the shell. A second screen net is arranged below the first screen net. The mesh diameter of the first screen net is larger than the mesh diameter of the second screen net. The preprocessing device integrated screening and drying, effectively saves equipment investment, reduces the cost and can achieve the effects that classification effect is obvious and drying is uniform, meanwhile has the advantages of being reasonable in structural design, convenient to use, good in screening effect, high in drying efficiency and the like, and has the wide application prospect and the high practical value.

Owner:凤阳昊成粮油贸易有限公司

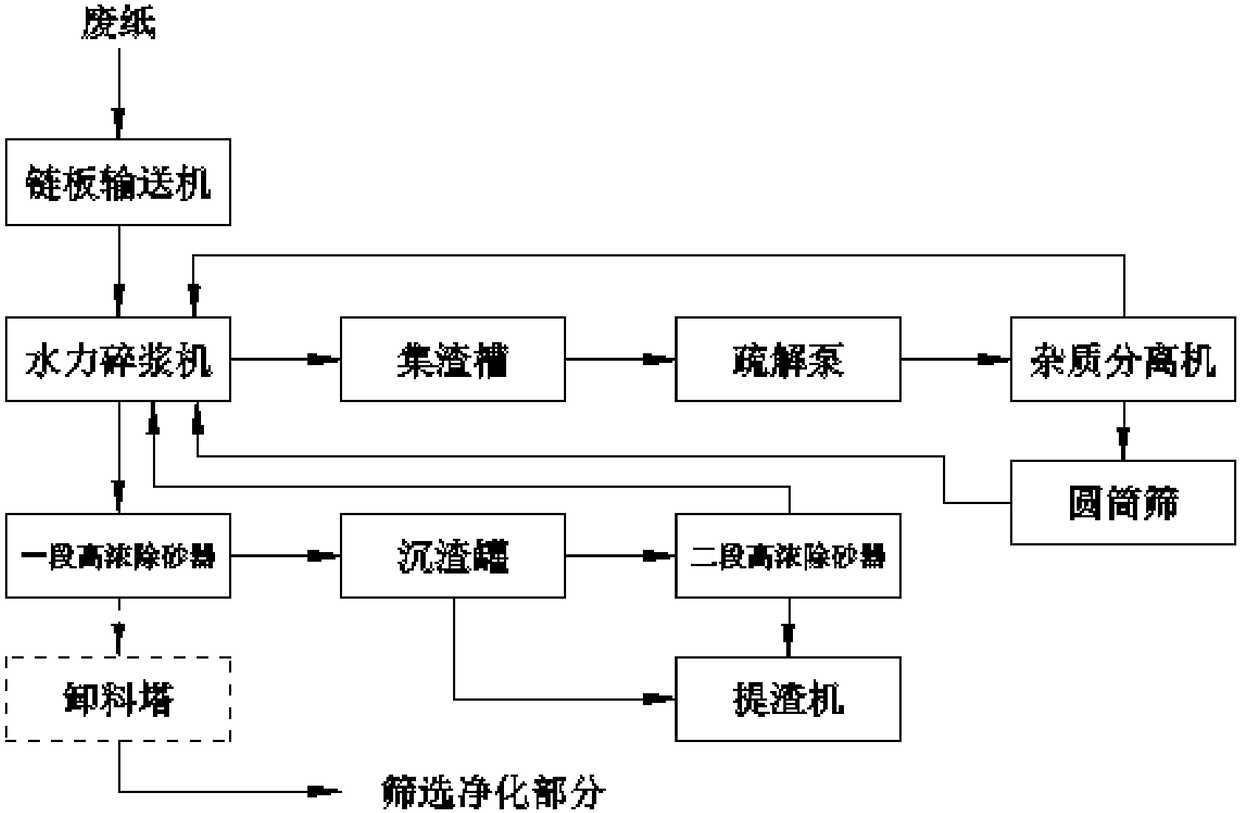

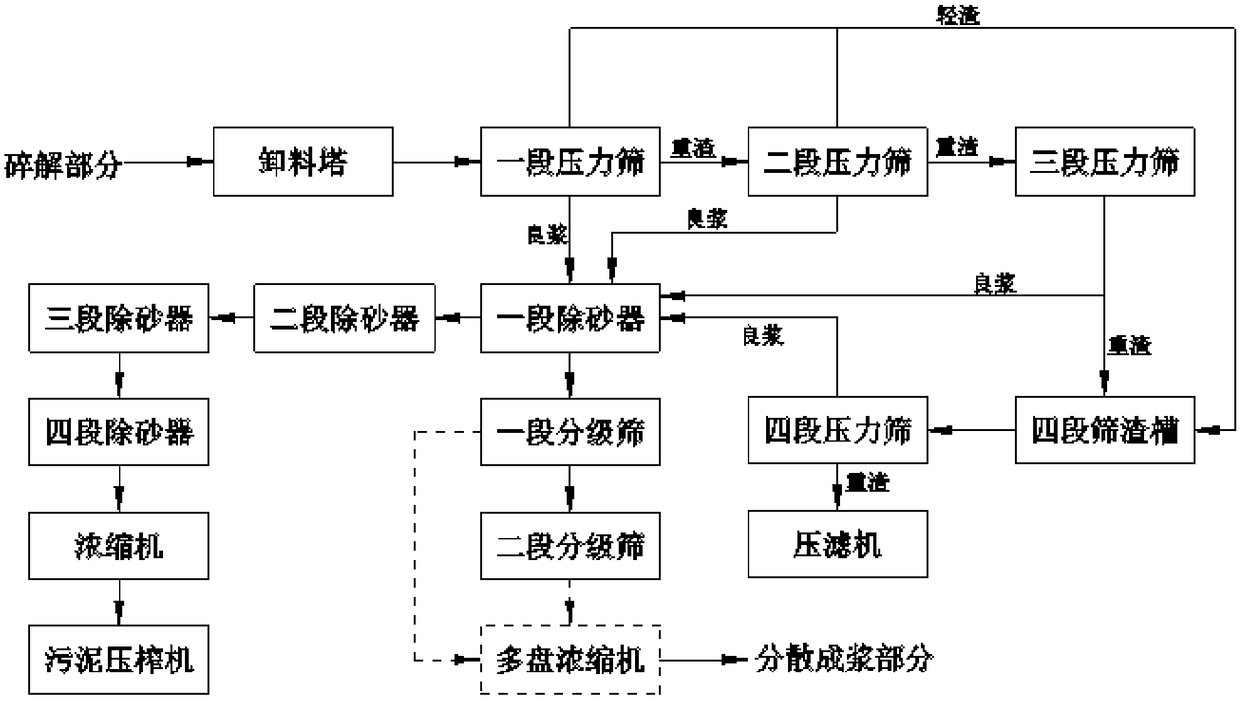

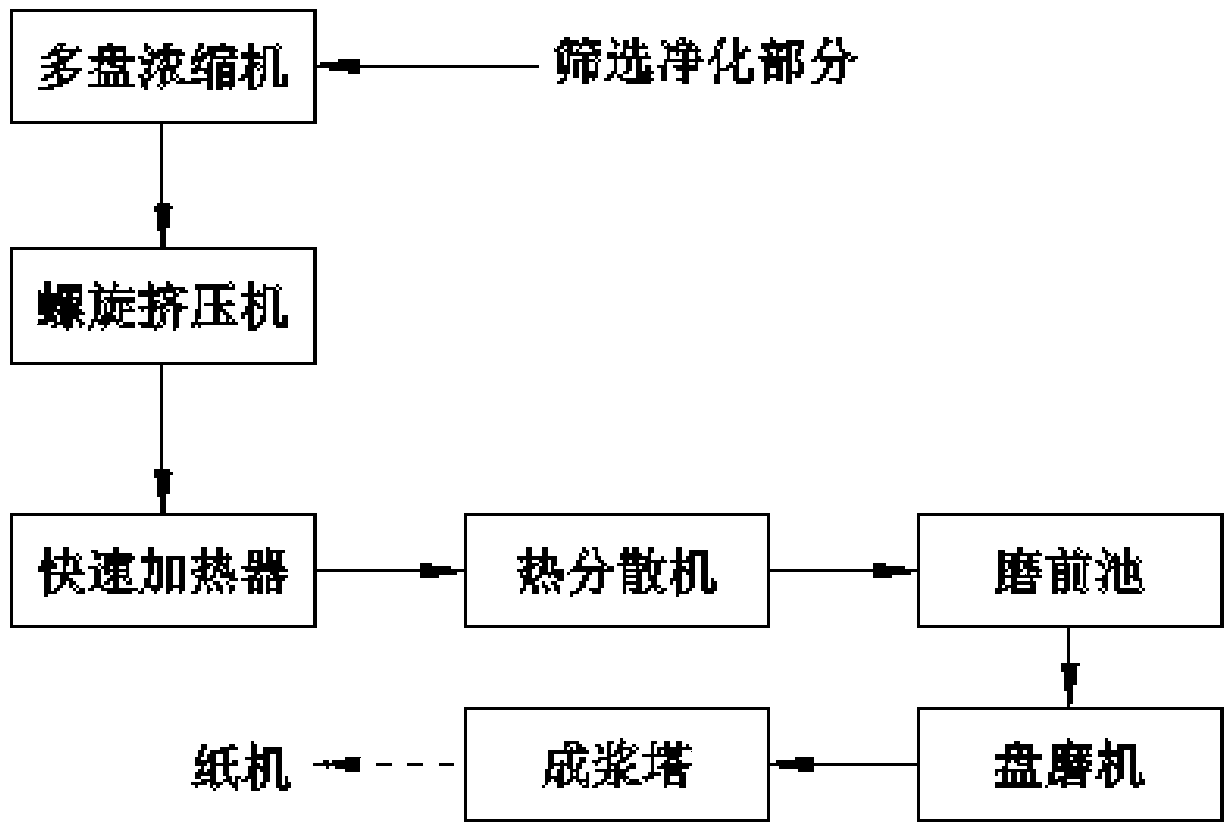

Pulping system of papermaking production line

InactiveCN108660832AReduce refluxIncrease pulp yieldPulp beating/refining methodsCellulose material pulpingHigh concentrationProduction line

The invention discloses a pulping system of a papermaking production line and belongs to the technical field of paper making. The pulping system comprises a crushing part, a screening and purifying part and a dispersing and pulping part, wherein the crushing part comprises a chain scraper conveyor, a hydropulper and a primary-section high-concentration desander which are sequentially connected; the screening and purifying part comprises an unloading tower, a pressurized screen, a desander and a sizing screen which are sequentially connected, and the primary-section high-concentration desanderof the crushing part is connected with the unloading tower; and the dispersing and pulping part comprises a multiple-disc concentrator, a screw extruder, a rapid heater, a thermal dispersion machine,a pre-grinding tank, a disc grinder and a pulping tower which are sequentially connected, and the sizing screen of the screening and purifying part is connected with the multiple-disc concentrator. According to the system disclosed by the invention, a pulping process is refined in three parts, paper pulp is also better purified and sized on the premise that the pulp yield of paper pulp is guaranteed so as to obtain high-quality paper pulp, and production requirements of different papers are met.

Owner:SHANYING INT HLDG CO LTD

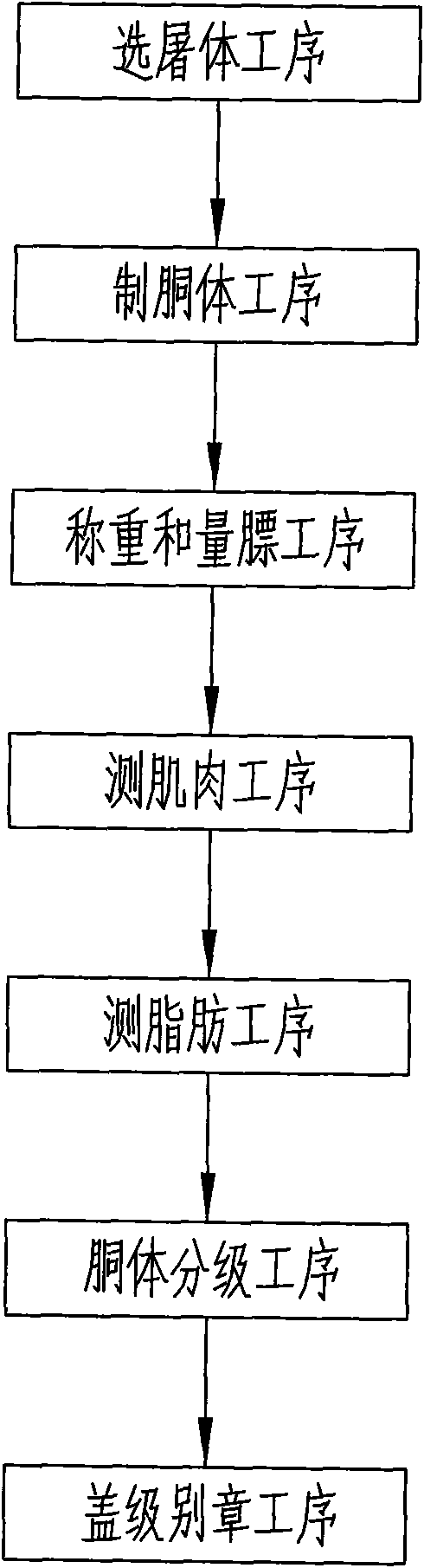

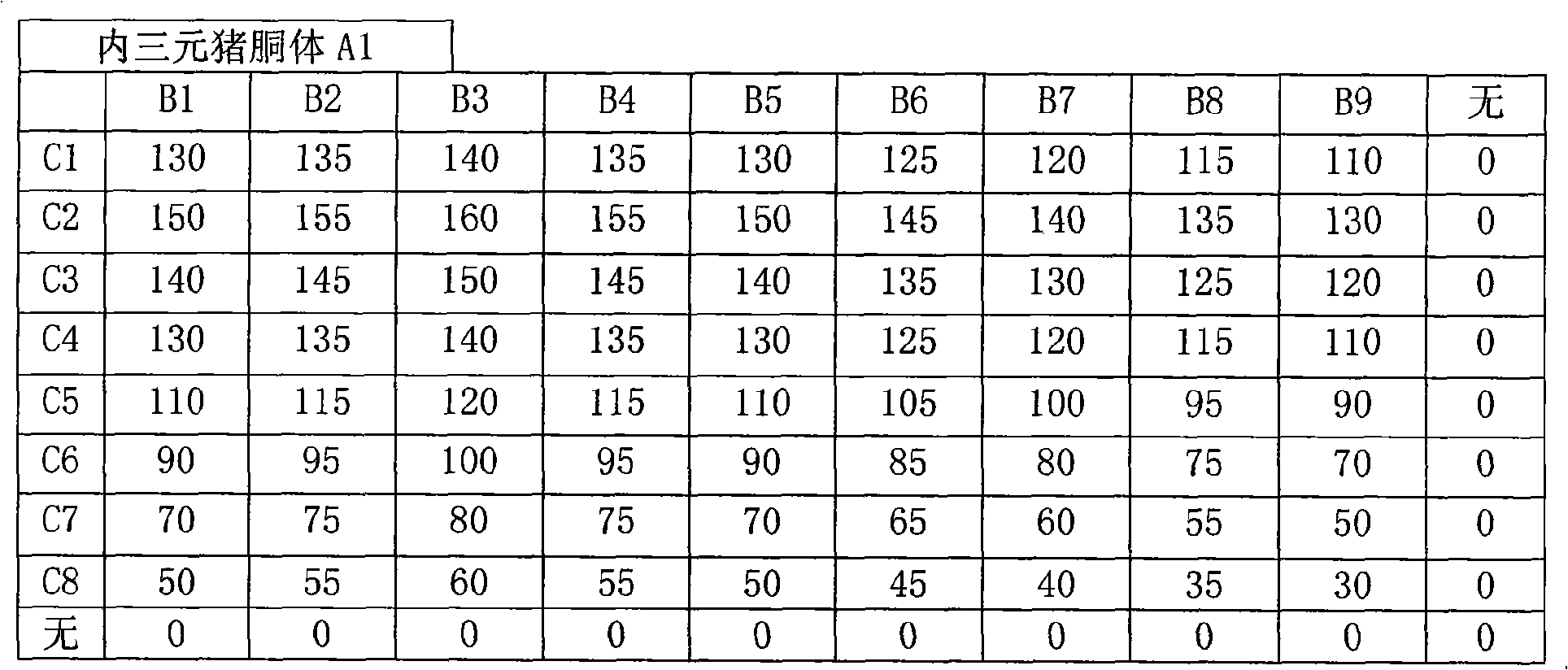

Method for grading skinned pig half carcass

InactiveCN101569325AGuide productionQuality improvementMechanical thickness measurementsTesting foodBack fatFlesh

The invention relates to a method for grading skinned pig half carcass, in particular to a method for grading skinned pig half carcass in three-way cross pigs. The method for grading pig carcass with good grading effect is not available at present. The method comprises the following procedures: selecting and preparing carcass, and the invention is characterized in that the method further comprises the following procedures: weighing carcass and fat, measuring flesh, measuring tail fat and grading carcass, wherein, in the procedure of selecting and preparing carcass, the weight grade index table is inquired by the weight value to acquire the weight grade, the back fat thickness grade index table is inquired by the back fat thickness value to acquire the back fat thickness grade, and the weight and fat thickness matrix table is inquired by the weight grade and the back fat thickness grade to acquire the weight-fat thickness value; in the procedure of measuring flesh, the flesh plumpness index table is inquired by the plumpness to acquire the flesh plumpness value; and in the procedure of measuring tail fat, the tail fat plumpness index table is inquired by the tail fat plumpness to acquire the tail fat plumpness value. The invention has the advantages of convenient gradation, simple procedures, low gradation cost, good effect, high accuracy and broad market outlook.

Owner:ZHEJIANG QINGLIAN FOOD

Device and method for regulating potassium feldspar powder size distribution

ActiveCN103495471AIncreased production flexibilityProduct quality is easy to guaranteeGrain treatmentsAir volumePotassium

The invention discloses a device and a method for regulating potassium feldspar powder size distribution. The device comprises an air regulation system arranged on a discharge hole of a ball mill, wherein the air regulation system comprises a material bin, a main air pipe and a side direction air inlet pipe; the middle in the side direction of the material bin is connected to the discharge hole of the ball mill, one end of the main air pipe is connected to the upper end of the material bin, the other end of the main air pipe downward extends and is bent so as to form a confluence section passing through the lower part of the material bin, and the lower end of the material bin is connected to the confluence section; the side direction air inlet pipe is arranged on the confluence section and is internally provided with an air regulation switch, and a rotating baiting valve is arranged between the lower end of the material bin and the confluence section. The device and the method provided by the invention have the advantages that the air volume of the side direction air inlet pipe is flexibly adjusted in real time in a production process according to the size distribution requirement of the potassium feldspar powder, thus the size distribution of the potassium feldspar powder is adjusted, the production flexibility is greatly improved, and the product quality is easy to guarantee.

Owner:广东奥胜新材料有限公司

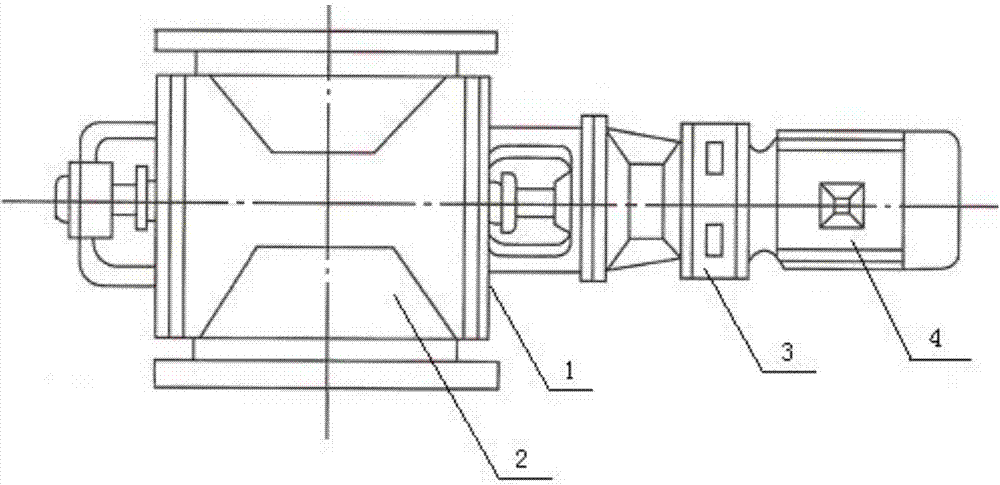

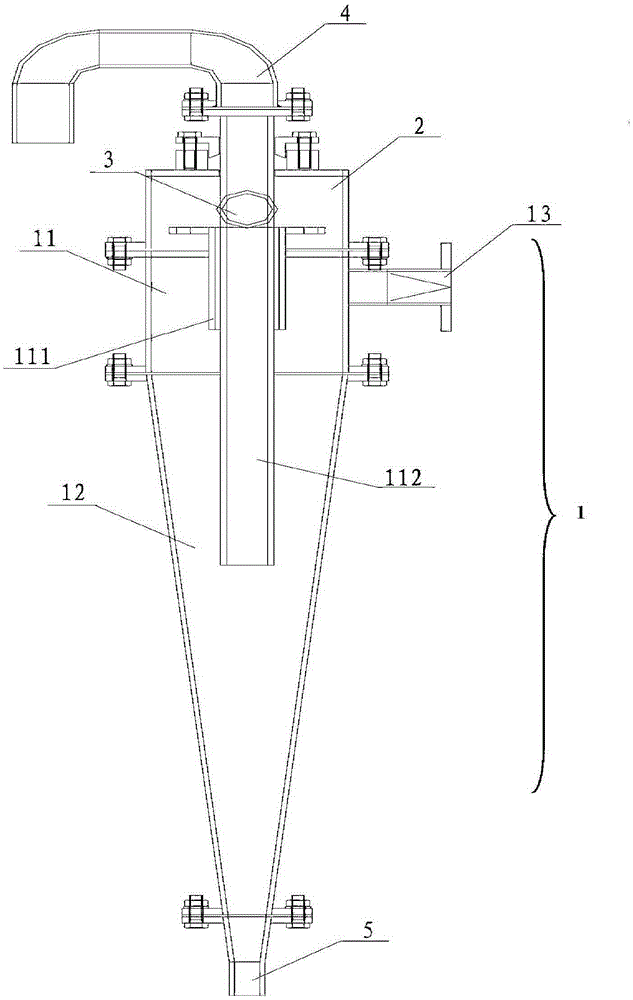

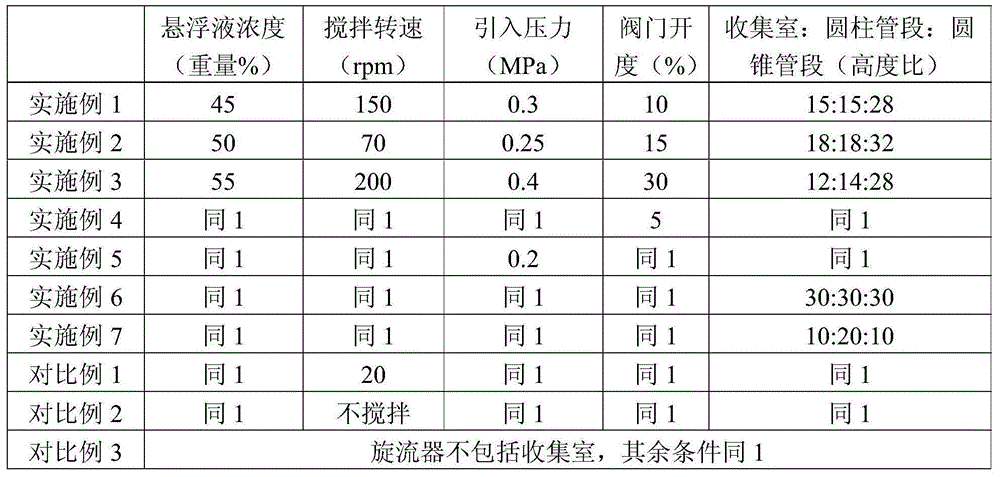

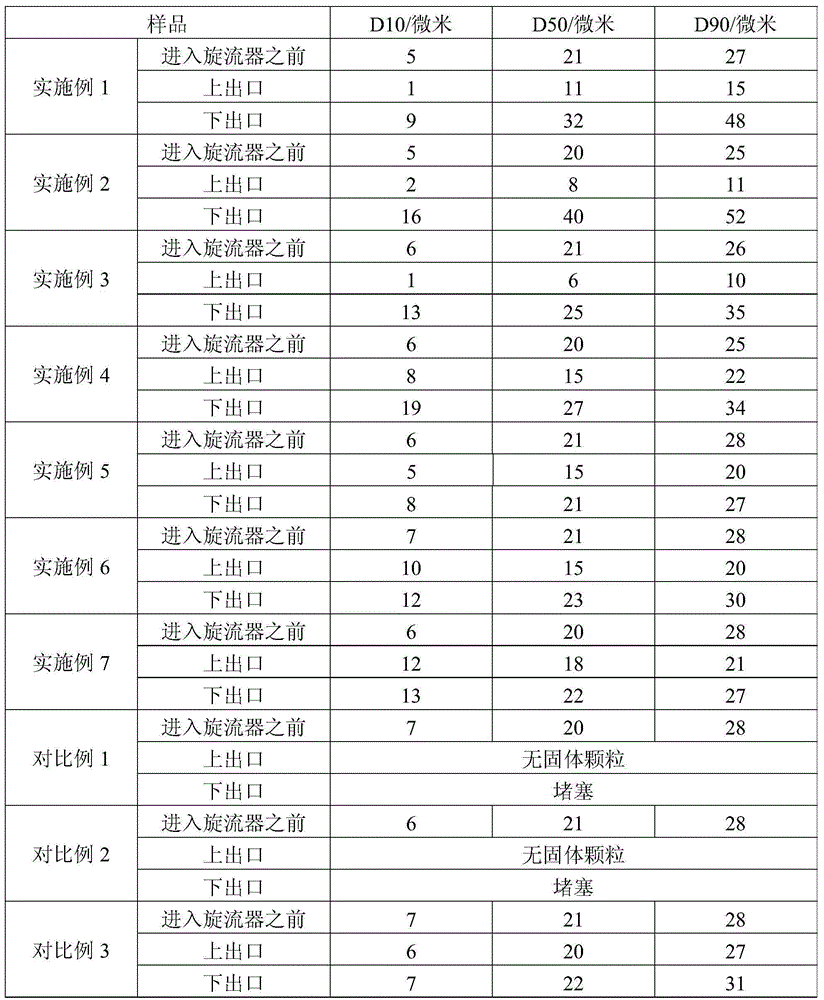

Grading method for olefin polymerization catalyst suspension liquid

The invention relates to the field of olefin polymerization catalysts and discloses a grading method for an olefin polymerization catalyst suspension liquid. Grading is conducted in a cyclone; the cyclone comprises a cyclone body and a collecting chamber; the cyclone body comprises a cylindrical pipe section and a conical pipe section from top to bottom; a first overflow pipe in airtight connection with the collecting chamber is arranged inside the cylindrical pipe section; and the cyclone body communicates with the collecting chamber through the first overflow pipe only. The method comprises steps as follows: the olefin polymerization catalyst suspension liquid is introduced into the cyclone body via a feeding port and rotates in the cyclone body; large particles are discharged via an outlet in the lower part of the conical pipe section; and small particles enter the collecting chamber through the first overflow pipe and are discharged via an outlet in the collecting chamber. The olefin polymerization catalyst suspension liquid is graded with the cyclone, the product particle sizes at the upper outlet and the lower outlet of the cyclone can be effectively controlled, and requirements of different olefin production technologies for the particle sizes of olefin polymerization catalyst particles can be met.

Owner:CHINA PETROLEUM & CHEM CORP +1

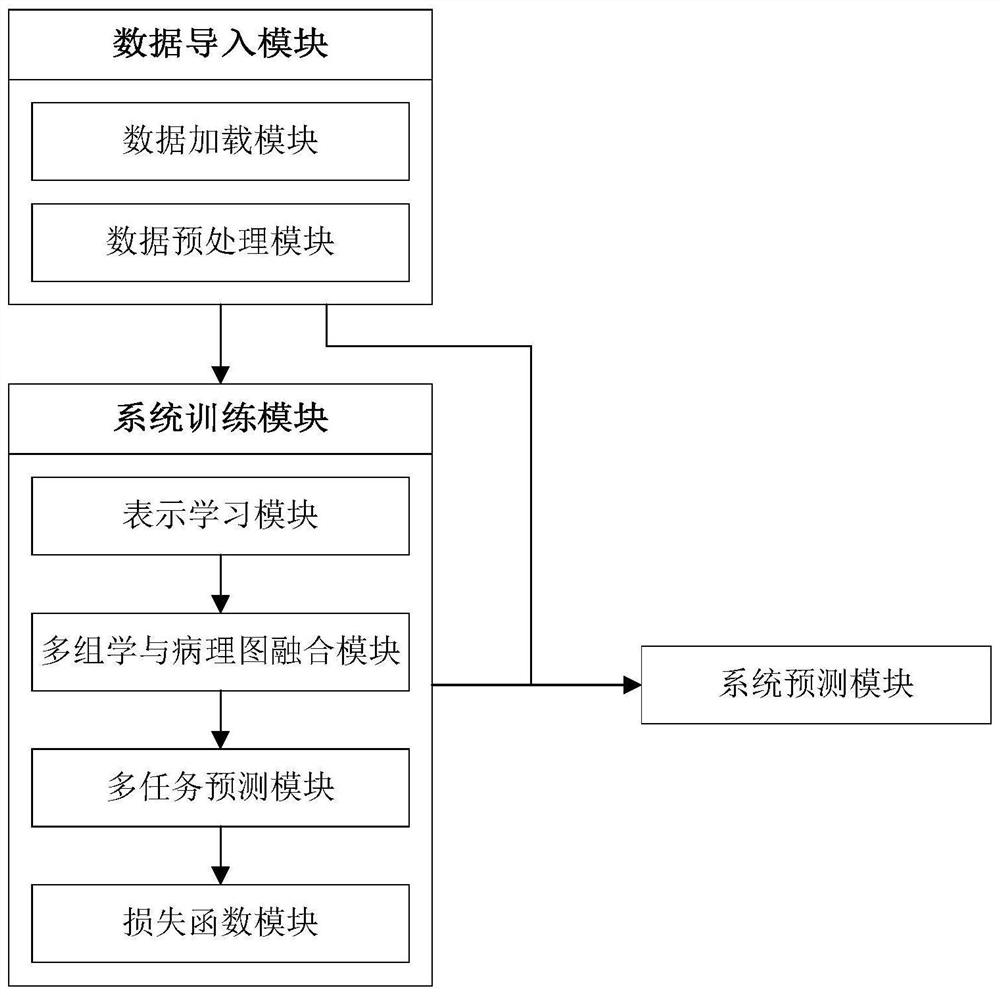

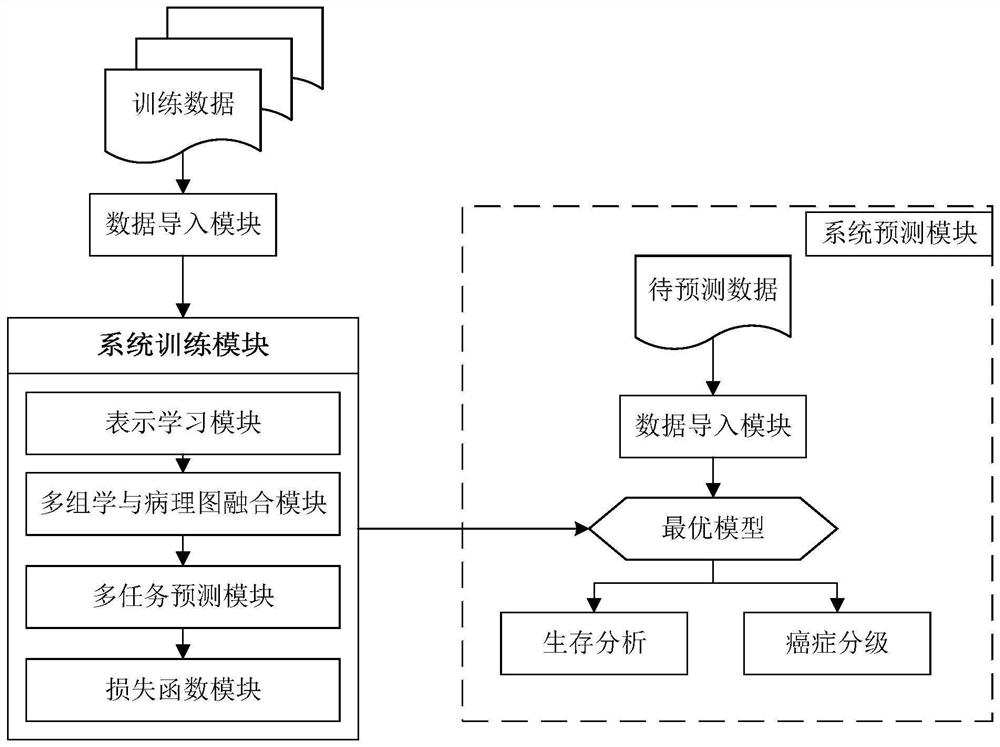

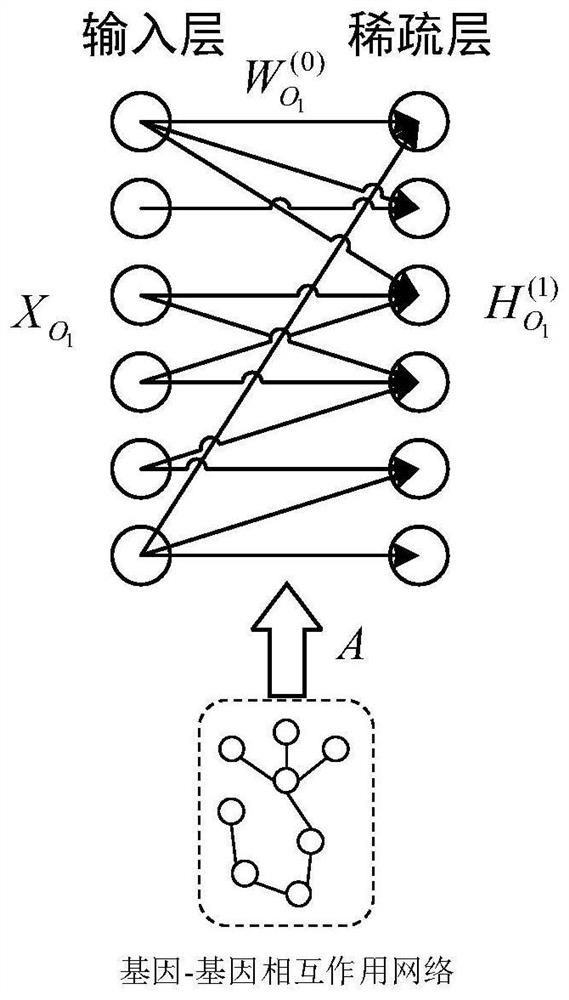

Cancer survival analysis system based on multiple tasks and multiple modes

PendingCN112687327AImprove multimodal fusionImprove the ability of multi-task learningMedical data miningBiostatisticsMulti modal dataData pre-processing

The invention discloses a cancer survival analysis system based on multiple tasks and multiple modes, and the system comprises a data importing module which comprises a data loading module and a data preprocessing module; a system training module, comprising a representation learning module, a multi-omics and pathological map fusion module, a multi-task prediction module and a loss function module; and a system prediction module, used for carrying out survival analysis and grading according to the multi-omics data and the pathological map of the cancer patient. According to the invention, the deep learning technology and the multi-task learning technology are combined with the multi-omics and pathological map data, so that the complementary characteristics among the multi-modal data can be captured, and the sharing relevance among multiple tasks can also be captured, thereby forming a cancer survival analysis system based on multiple tasks and multiple modalities, and providing automatic survival analysis and cancer grading results.

Owner:中山依数科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com