Method taking organic solvent as medium for grading nano-nickel powder for MLCC (multilayer ceramic capacitor)

An organic solvent, nano-nickel powder technology, applied in chemical instruments and methods, solid separation, wet separation, etc., can solve the problems affecting the classification efficiency of hydrocyclones, the increase of powder surface roughness, and the large specific surface area and surface energy. and other problems, to achieve the effect of good dispersion, narrow particle size distribution and good number of large particles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

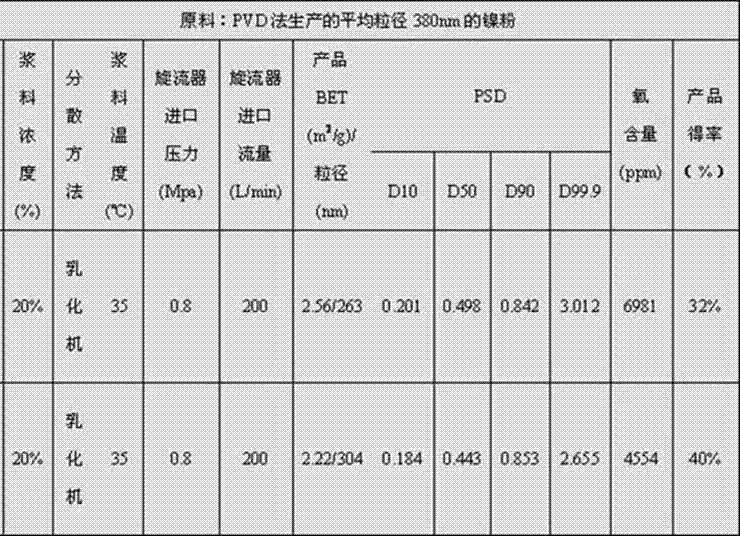

Embodiment 1

[0025] (1) Nano-nickel powder with an average particle size of 380nm prepared by PVD method is used as a raw material, and it is added to 99.9% absolute ethanol, and the solid content is controlled at 20%;

[0026] (2) Use an emulsifier to emulsify and disperse the above solid-liquid system, maintain the dispersion time for 30 minutes, and control the slurry temperature at 30°C~35°C;

[0027] (3) Use a centrifugal pump to send the dispersed slurry into the hydrocyclone. The inlet pressure of the cyclone is controlled at 0.8Mpa, the flow rate of the slurry at the inlet of the cyclone is controlled at 200L / min, and the flow rate of the slurry at the bottom outlet of the cyclone is controlled at 20L / min;

[0028] (4) Use SEM / BET / PSD (scanning electron microscope / specific surface area detection / laser particle size analysis) to detect the overflow slurry, and control the classification time of the hydrocyclone to 60 minutes according to the detection results. Qualified nickel powd...

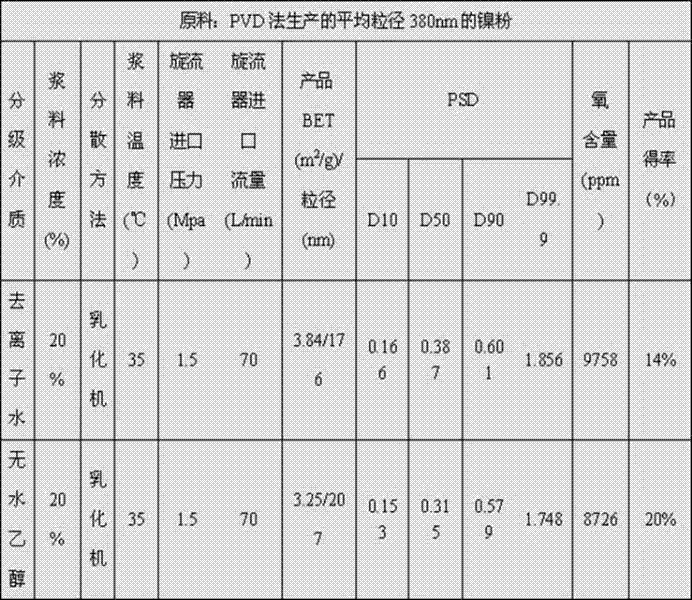

Embodiment 2

[0032] (1) Nano-nickel powder with an average particle diameter of 300nm prepared by PVD method is used as a raw material, and it is added to 99.9% isopropanol, and the solid content is controlled at 20%;

[0033] (2) Use an emulsifier to emulsify and disperse the above solid-liquid system, maintain the dispersion time for 30 minutes, and control the slurry temperature at 30°C~35°C;

[0034] (3) Use a centrifugal pump to send the dispersed slurry into the hydrocyclone. The inlet pressure of the cyclone is controlled at 1.5Mpa, the flow rate of the slurry at the inlet of the cyclone is controlled at 70L / min, and the flow rate of the slurry at the bottom outlet of the cyclone is controlled at 17L / min.

[0035] (4) Use SEM / BET / PSD to detect the overflow slurry, and control the classification time to 15 minutes according to the detection results, and classify to obtain qualified nickel with uniform particle size, few large particles (≥0.6um), and an average particle size of about ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com