Patents

Literature

1797results about How to "Improve classification efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method and system for detecting Chinese phishing website

ActiveCN104217160AImprove classification efficiencyReduce false alarm ratePlatform integrity maintainanceSpecial data processing applicationsFeature vectorWeb site

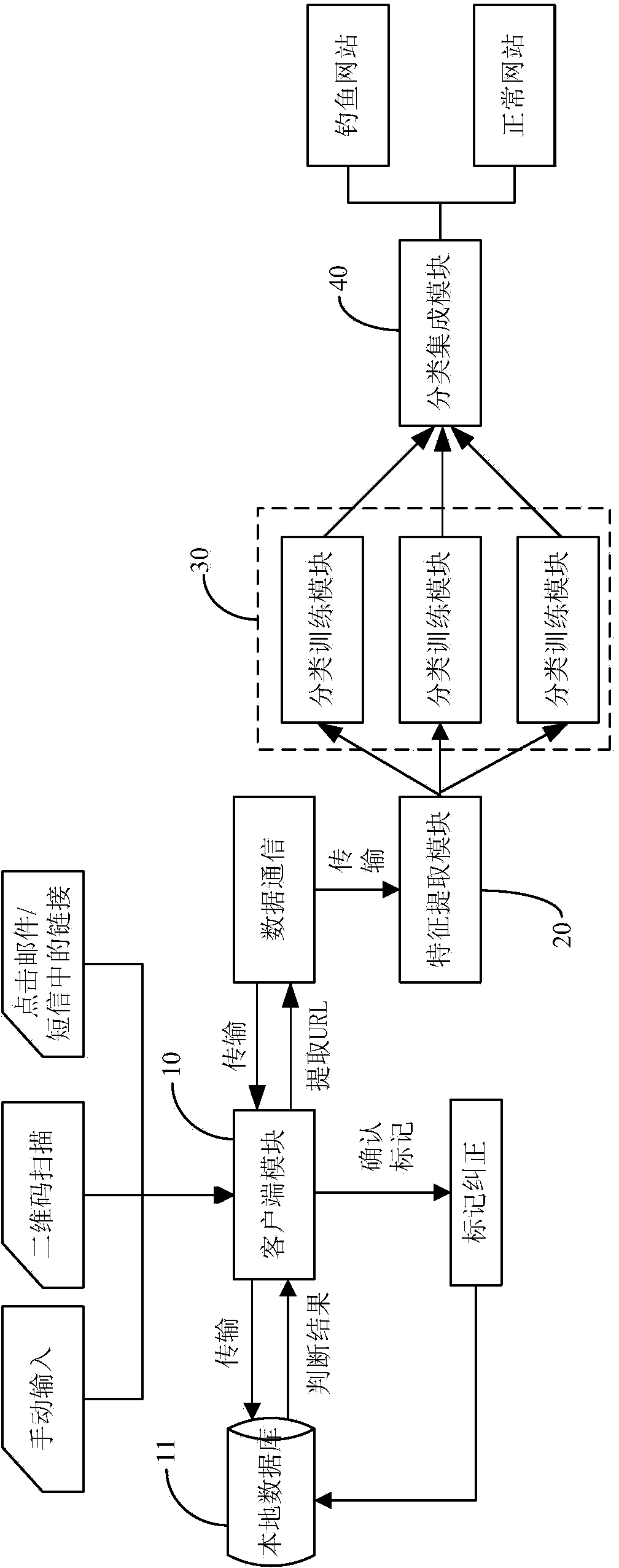

The invention discloses a method and a system for detecting a Chinese phishing website. The method comprises the following steps: S1, acquiring a URL (Uniform Resource Locator) by a client; S2, extracting URL features and website page content features as feature vectors respectively; S3, performing classification trainings on the feature vectors through an SVM (Support Vector Machine), an extended website page content feature NBC (Naive Bayes Classifier), a decision tree algorithm and a link and form processing method; S4, performing classification integration on classification training results, and judging whether a website with the URL is a phishing website. According to the method and the system, the URL features and the website page content features are extracted as the feature vectors, the corresponding classification trainings are performed through the SVM, the NBC, the decision tree algorithm and the corresponding processing of links and forms, prediction results are integrated by virtue of classification integration to obtain a final result, and therefore the classification accuracy is greatly improved.

Owner:SHENZHEN INST OF ADVANCED TECH CHINESE ACAD OF SCI

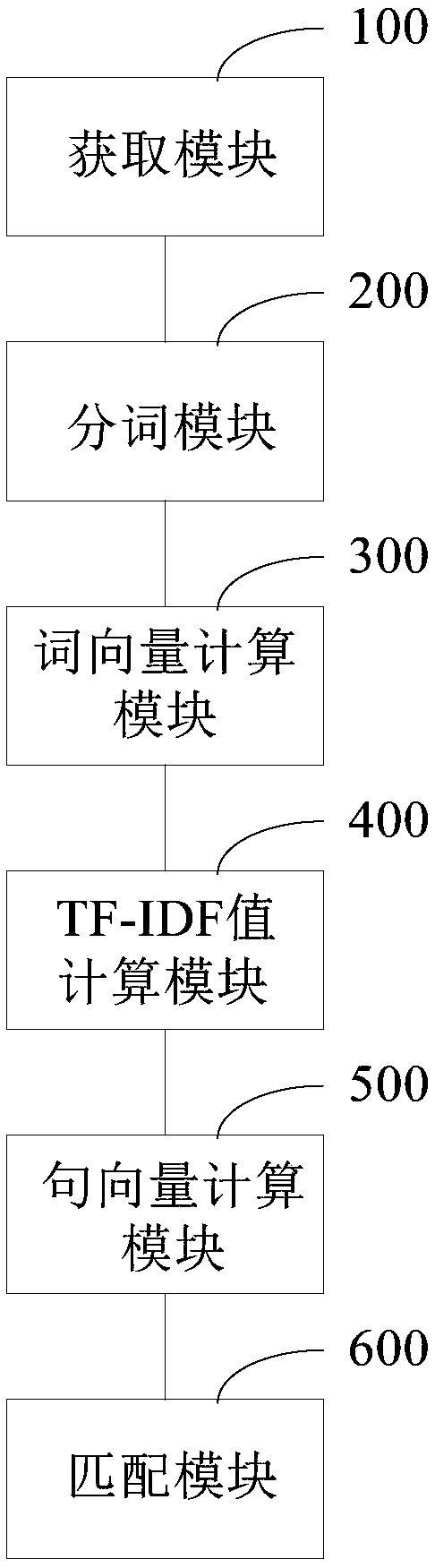

Text information similarity matching method and device, computer device and storage medium

InactiveCN108628825AHigh precisionImprove efficiencyNatural language data processingSpecial data processing applicationsCosine similarityAlgorithm

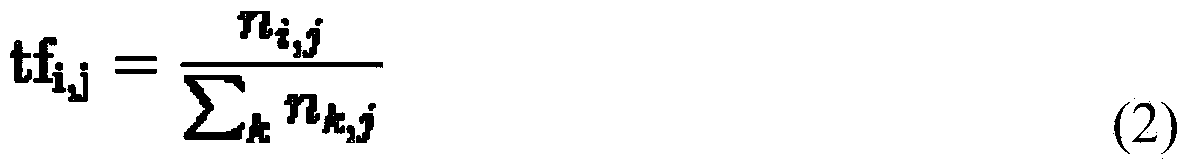

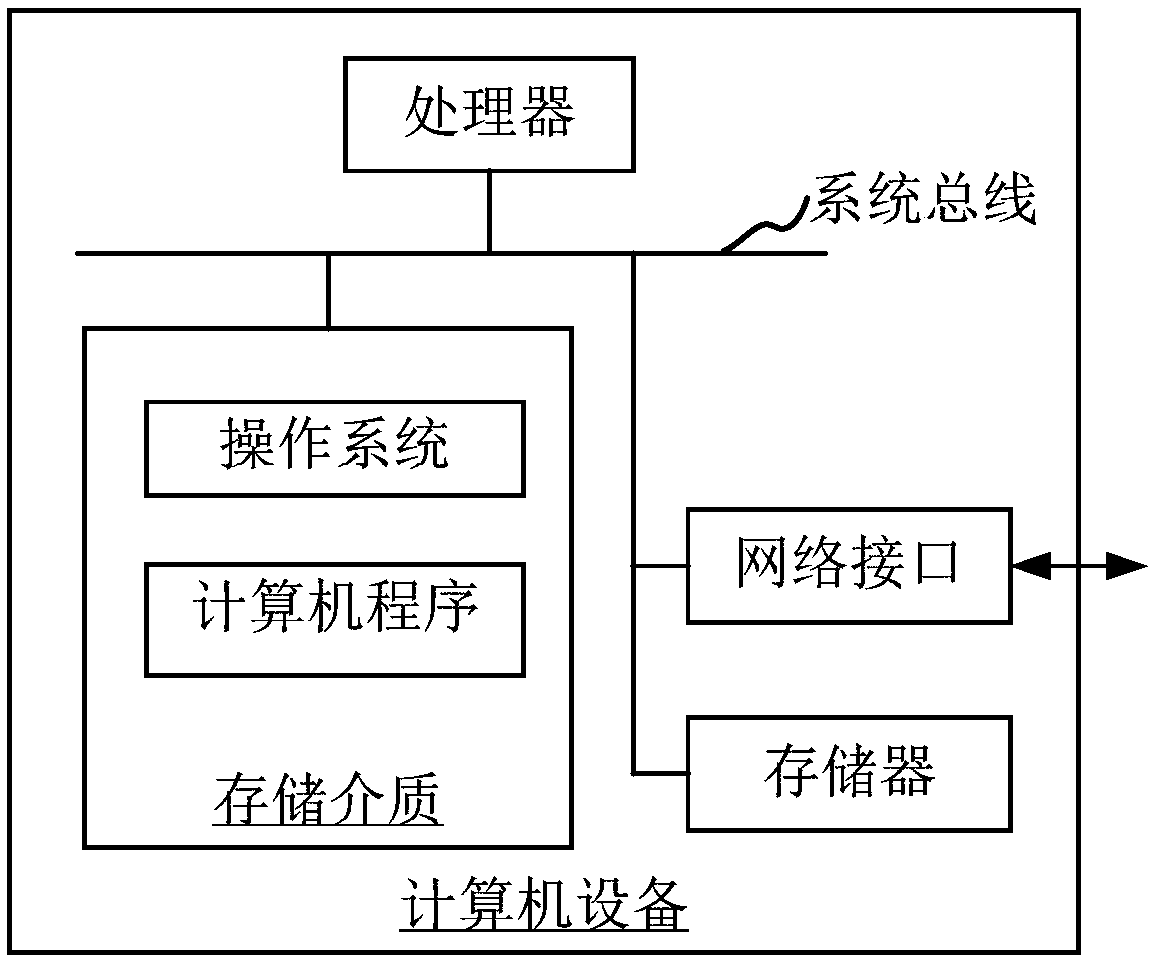

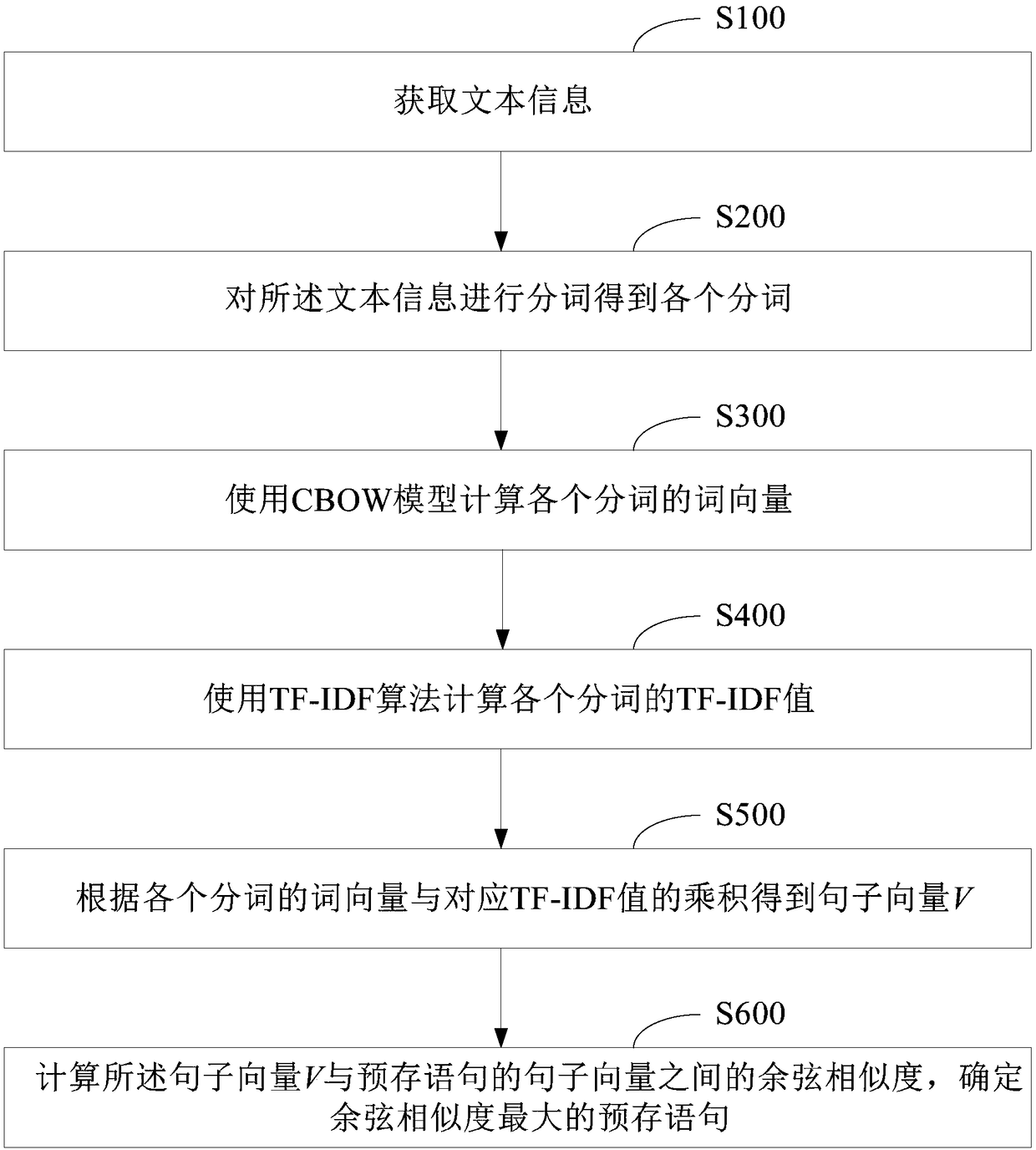

The invention provides a text information similarity matching method and device on the basis of TF-IDF. The method includes the steps of acquiring text information; performing word segmentation on thetext information to obtain word segments w1, w2, ..., wn-1 and wn; using a CBOW model for calculating word vectors V(w1), V(w2), ..., V(wn-1) and V(wn) of the word segments respectively; using the TF-IDF algorithm for calculating TF-IDF values k1, k2, ..., kn-1 and kn of the word segments respectively; according to products of the word vectors of the word segments and the corresponding TF-IDF values, obtaining a sentence vector V; calculating the cosine similarity between the sentence vector V and sentence vectors of pre-stored statements, and determining the pre-stored statement with the maximum cosine similarity. Through the process above, the pre-stored statement which is the most similar to the text information can be found, the accuracy of problem recognition can be improved in the aspects of robot dialogue, information classification and the like, and therefore the dialogue efficiency or the classification efficiency is improved. A computer device and a storage medium are also provided.

Owner:PING AN TECH (SHENZHEN) CO LTD

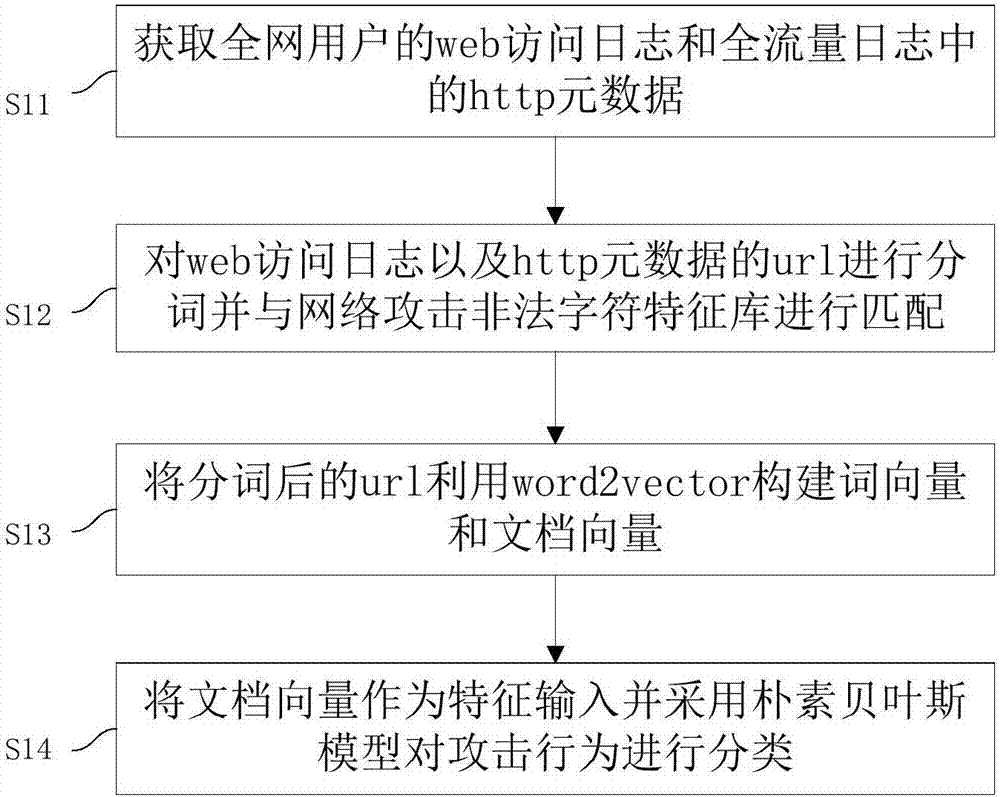

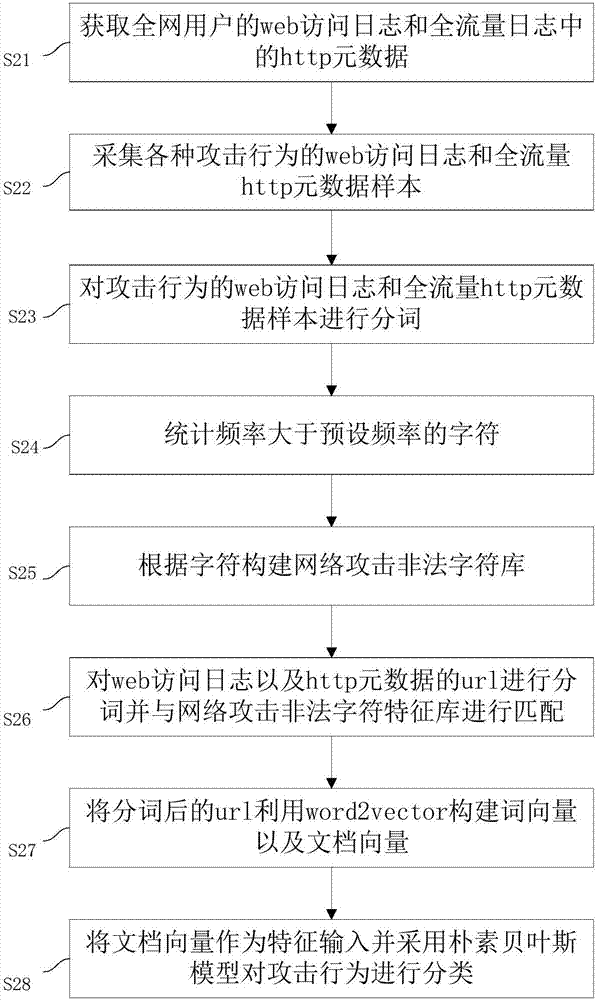

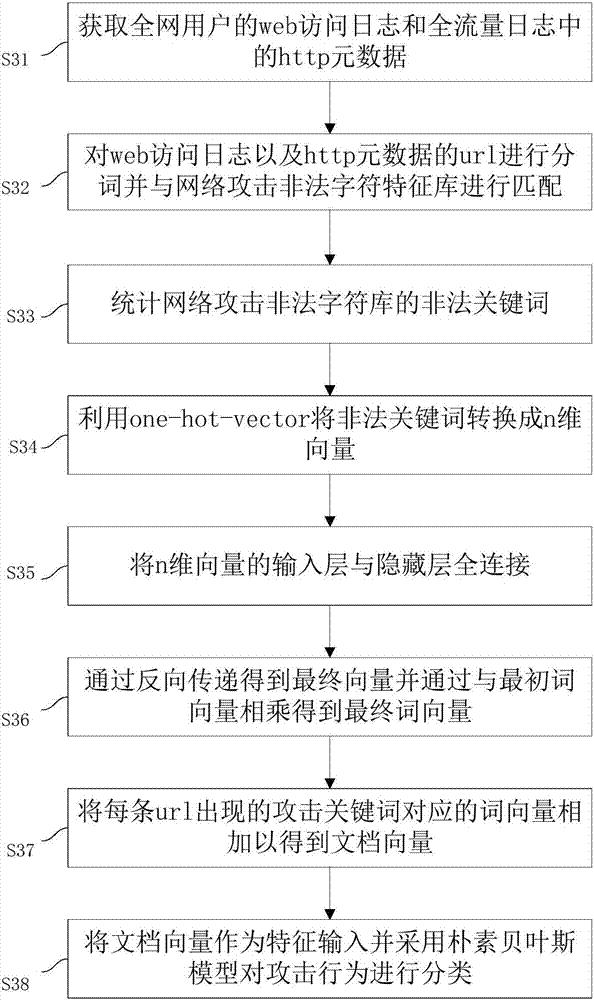

Network security accident classification and predicting method and system

ActiveCN107241352AImprove classification efficiencySave time and costTransmissionNetwork attackTime cost

The invention discloses a network security accident classification and predicting method and a system, which are used for solving the problems of the prior art on lacking the capability of timely finding the characteristics of attack behaviors and accurately classifying the attack behaviors. The method comprises the following steps: S1. acquiring web access log of users in a whole network and http metadata in full-flow log; S2. segmenting the web access log and the url of the http metadata, and matching with a network attach illegal character feature library; S3. constructing a word vector and a document vector of the segmented url by utilizing word2vector; and S4. inputting the document vector as a feature and classifying the attack behavior by adopting a naive bayes model. The real-time monitoring of key points can be realized, the abnormal behavior carrying mainstream attack feature can be found by means of machine learning, the classification efficiency of network attack behaviors can be improved, and the time cost of manual check can be lowered, continuously changed attack behaviors can be adapted, and the classification detection accuracy can be enhanced, thus providing guarantee for network security.

Owner:ZHEJIANG PONSHINE INFORMATION TECH CO LTD

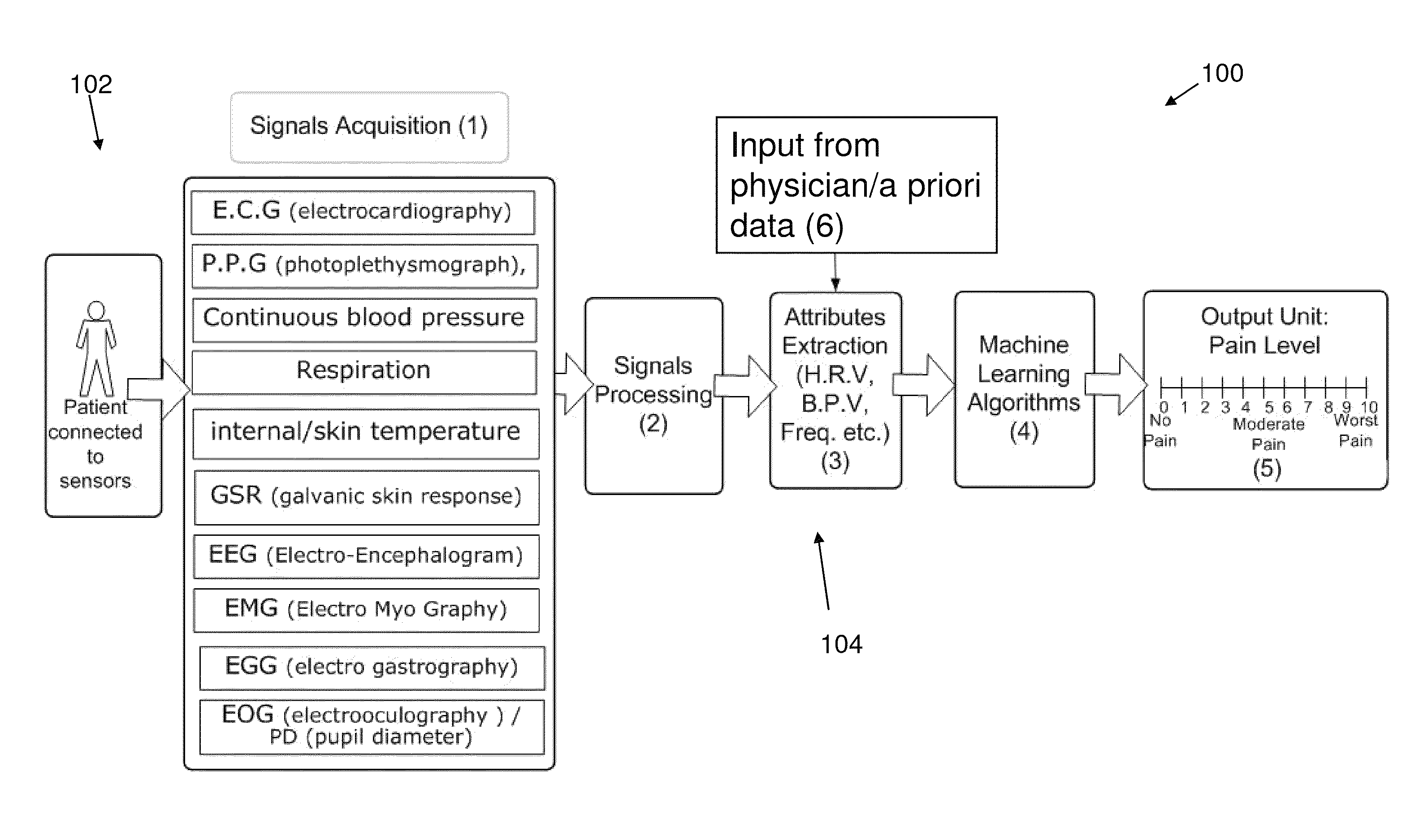

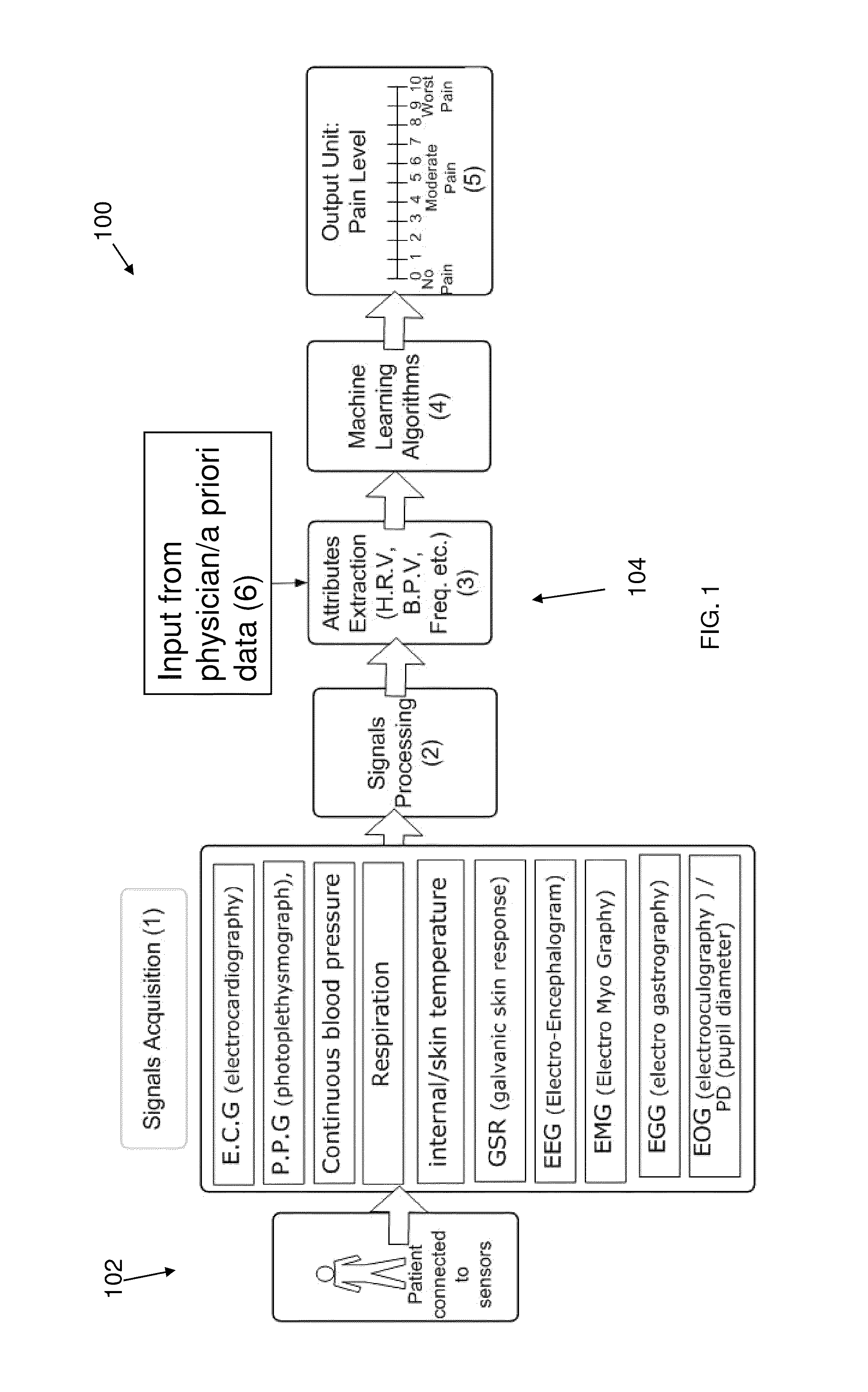

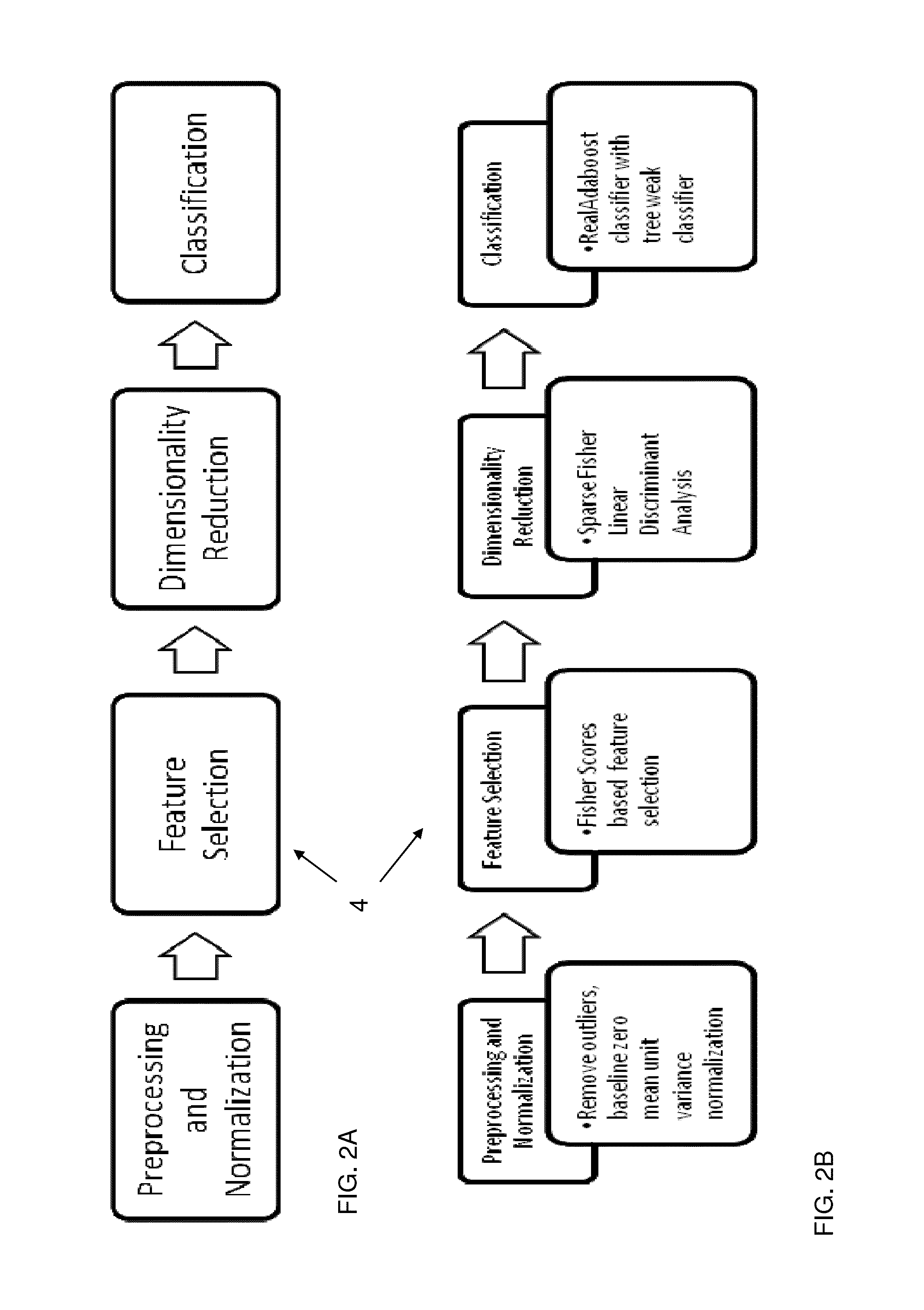

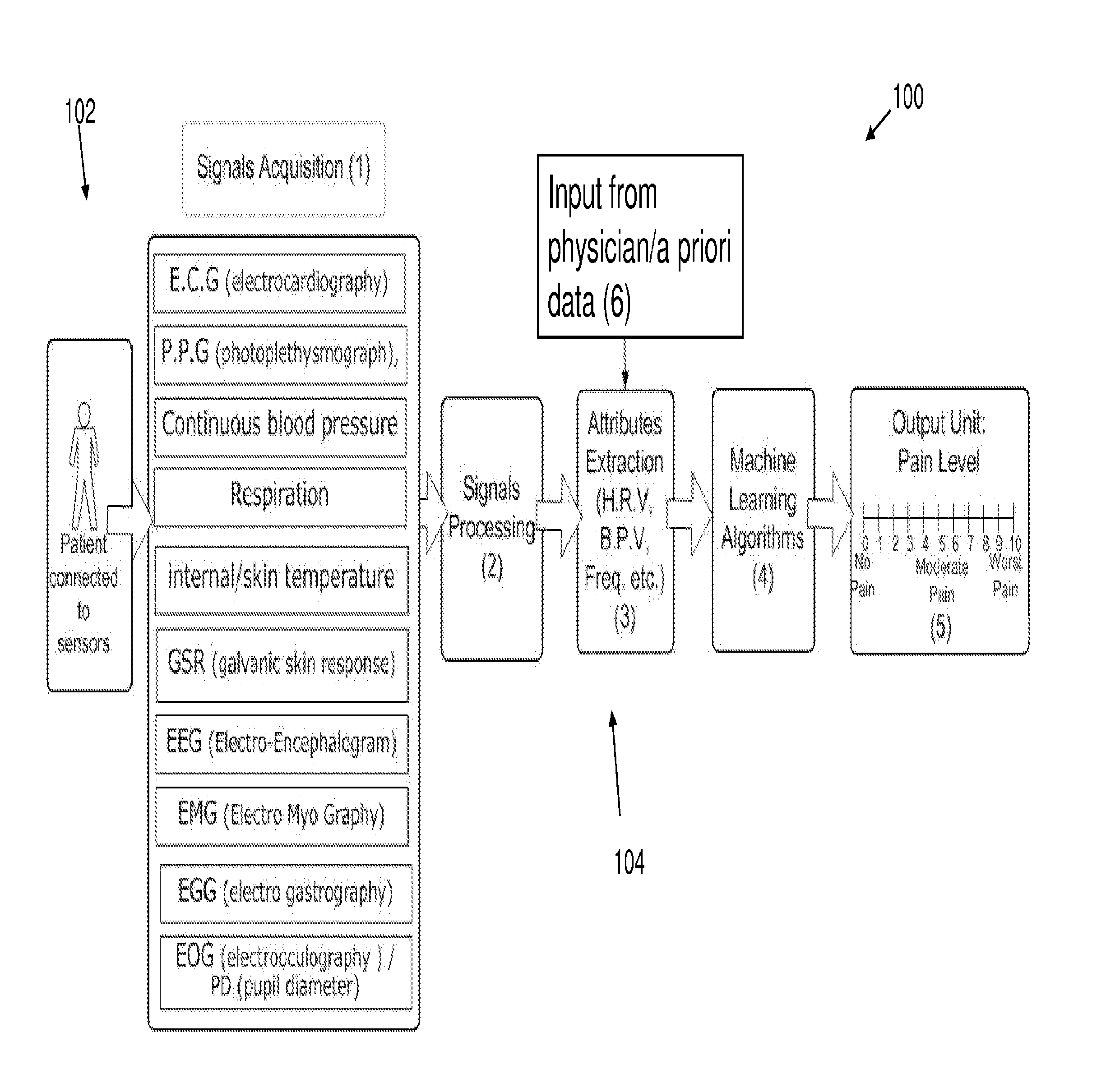

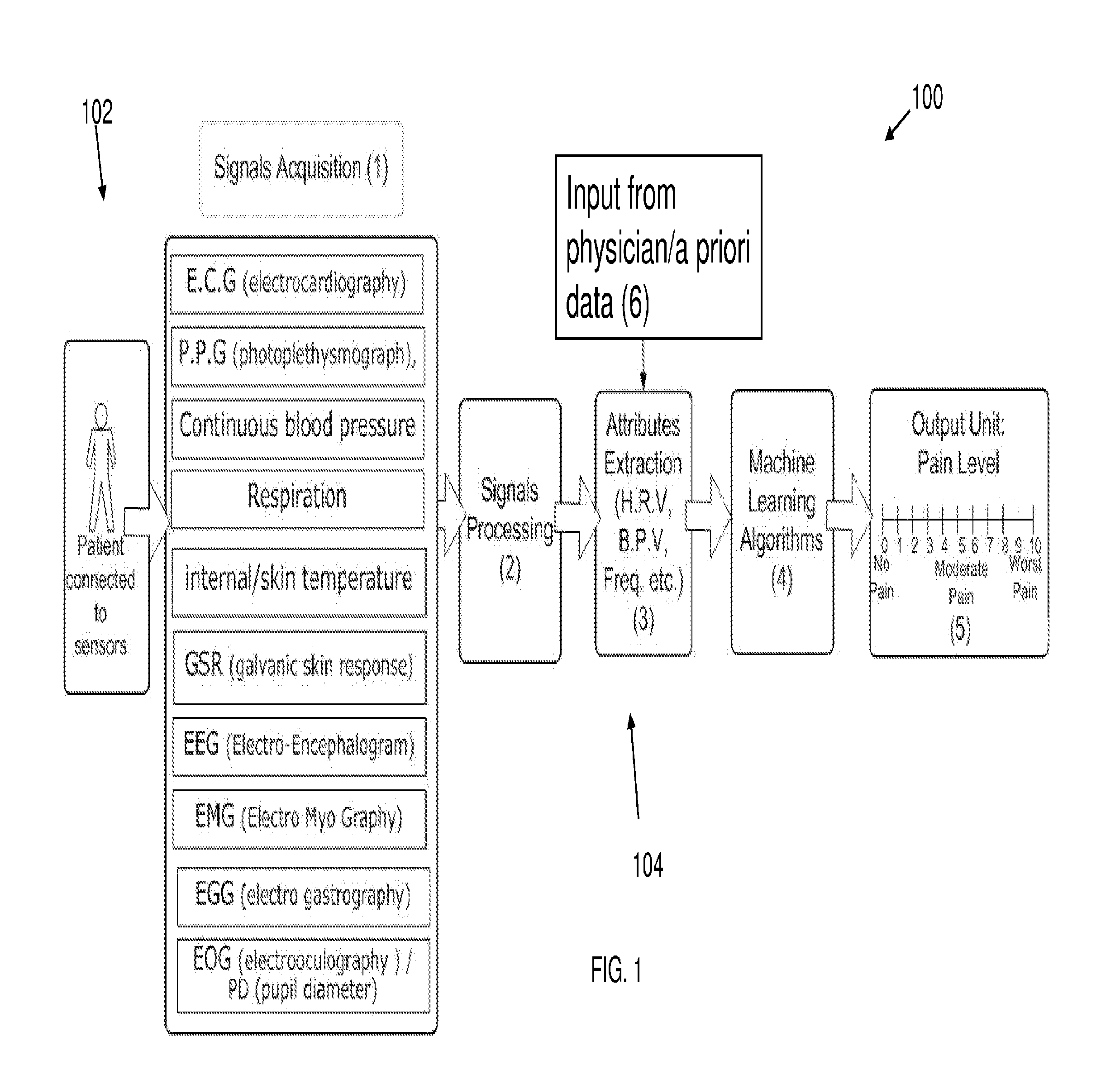

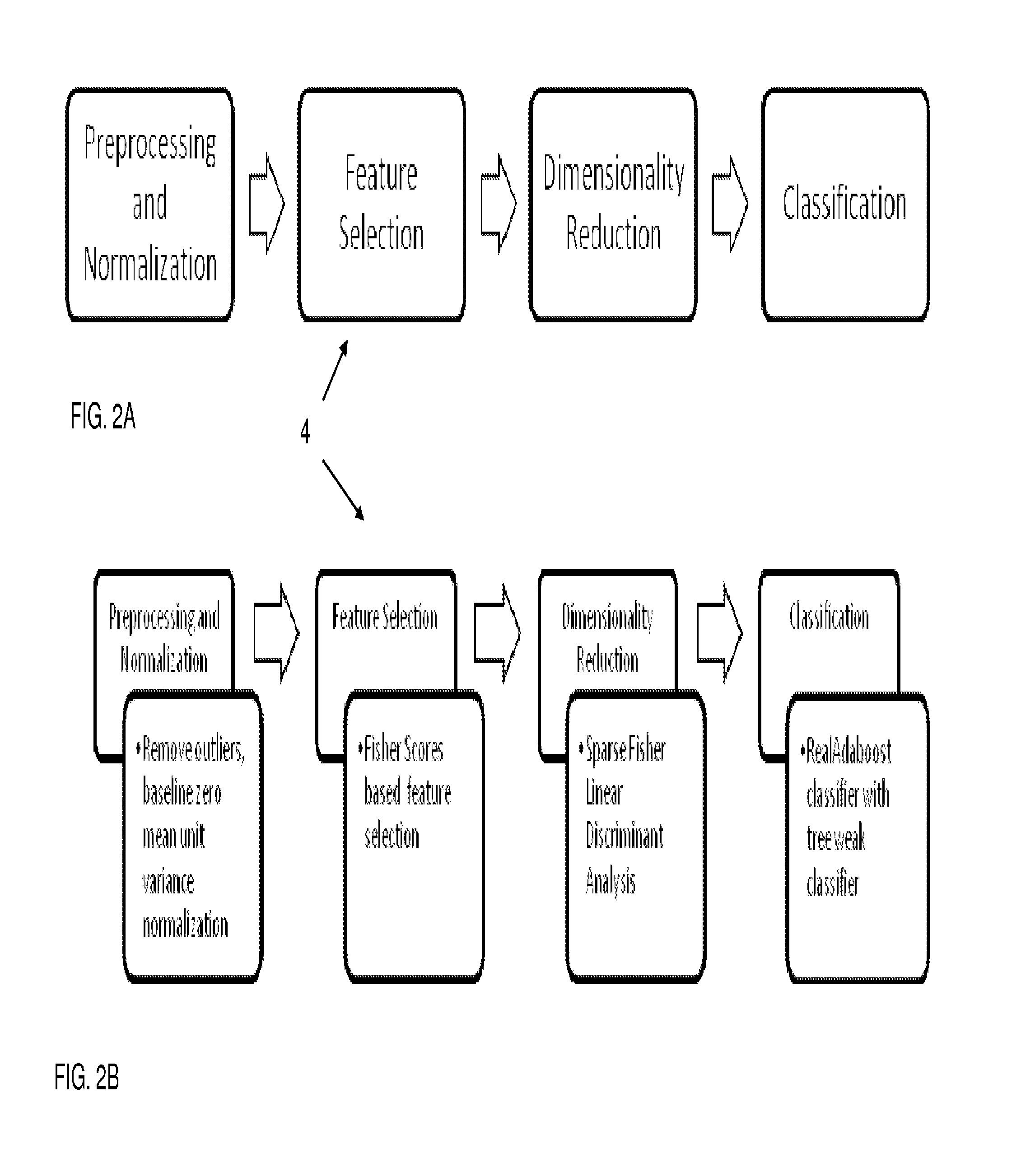

System and method for pain monitoring using a multidimensional analysis of physiological signals

ActiveUS8512240B1Improve classification efficiencyEasy to detectBioelectric signal measurementInertial sensorsMedicine

The present invention is for a method and system for pain classification and monitoring optionally in a subject that is an awake, semi-awake or sedated.

Owner:MEDASENSE BIOMETRICS

System and method for pain monitoring using a multidimensional analysis of physiological signals

ActiveUS20130310660A1Improve classification efficiencyEasy to detectMedical data miningHealth-index calculationMedicinePhysical therapy

The present invention is for a method and system for pain classification and monitoring optionally in a subject that is an awake, semi-awake or sedated.

Owner:MEDASENSE BIOMETRICS

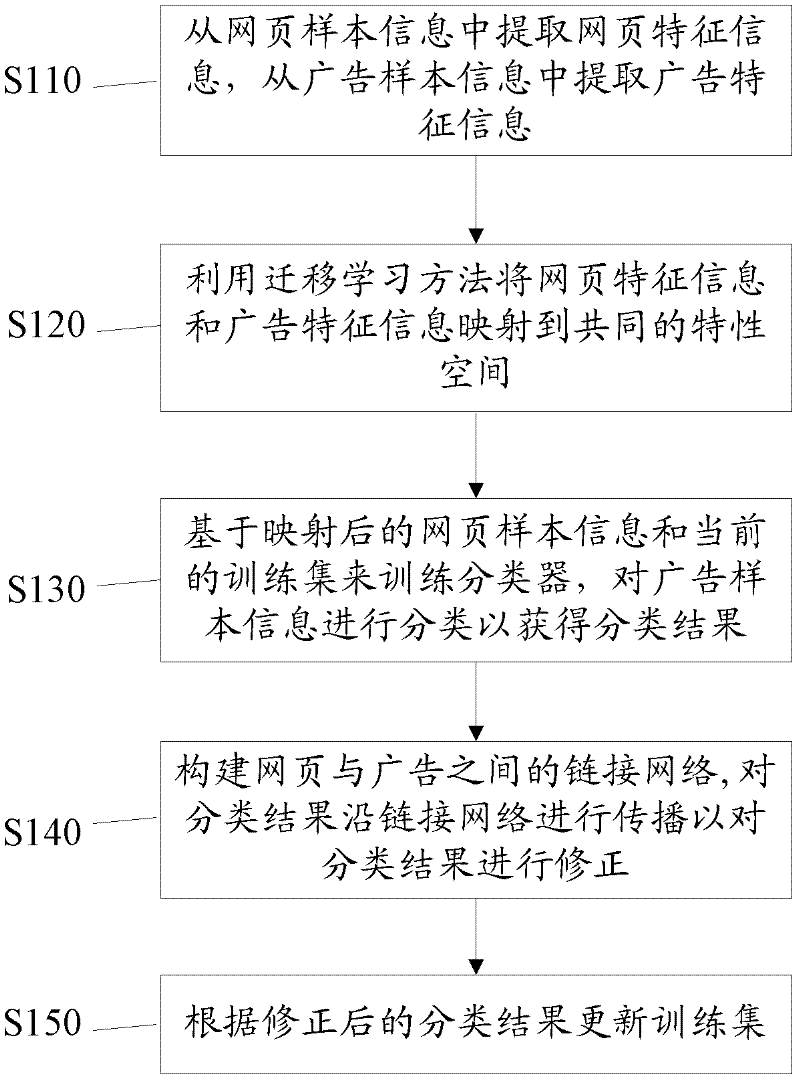

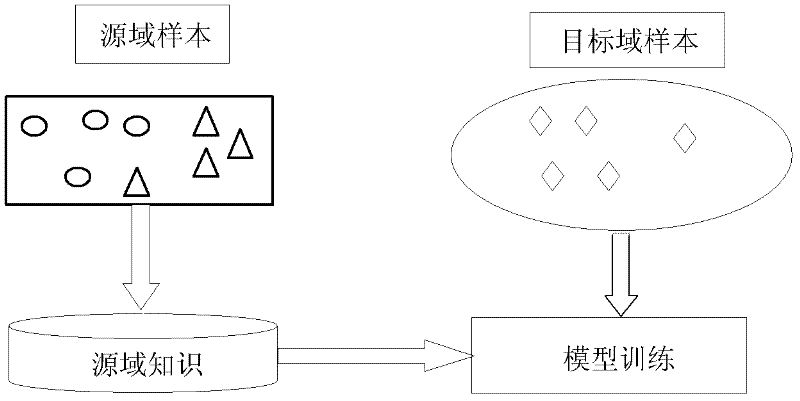

Advertisement classification method and device based on webpage characteristic

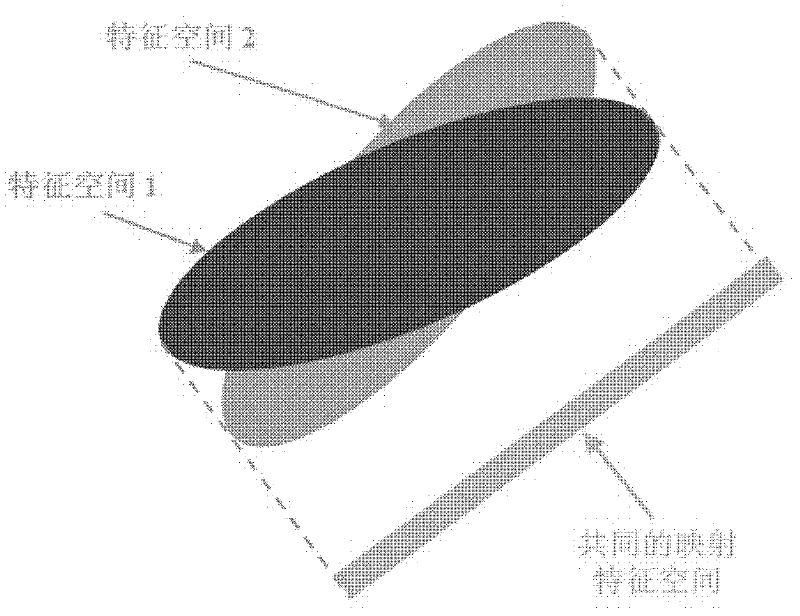

InactiveCN102508859AImprove classification efficiencyImprove classification accuracySpecial data processing applicationsInformation mappingClassification result

The invention discloses an advertisement classification method and system based on a webpage characteristic. The method comprises the following steps of: extracting the webpage characteristic information from the webpage sample information and extracting the advertisement characteristic information from the advertisement sample information; mapping the webpage characteristic information and the advertisement characteristic information to a common characteristic space by use of a transfer learning method to obtain the webpage sample information and advertisement sample information mapped to the common characteristic space; training a classifier based on the webpage sample information mapped to the common characteristic space and a current training set, and classifying the advertisement sample information according to the trained classifier to obtain a classification result; establishing a link network between the webpage and the advertisement according to the historical release and click data of the advertisement sample information so that the classification result is transmitted along the link network and the corrected classification result is obtained; and updating the training set according to the corrected classification result. Through the invention, existing mark data can be sufficiently utilized, and a large amount of repeated work is avoided.

Owner:亿赞普(北京)科技有限公司

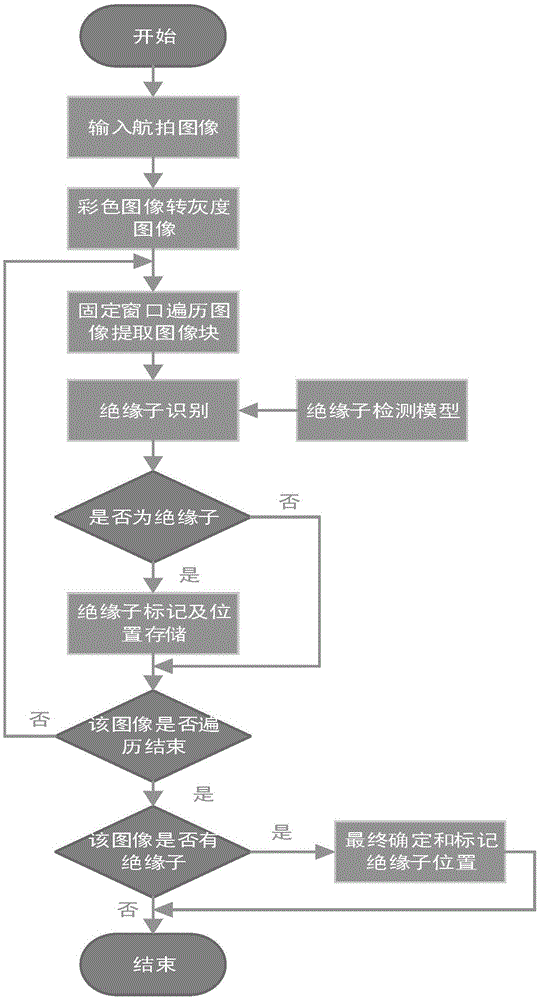

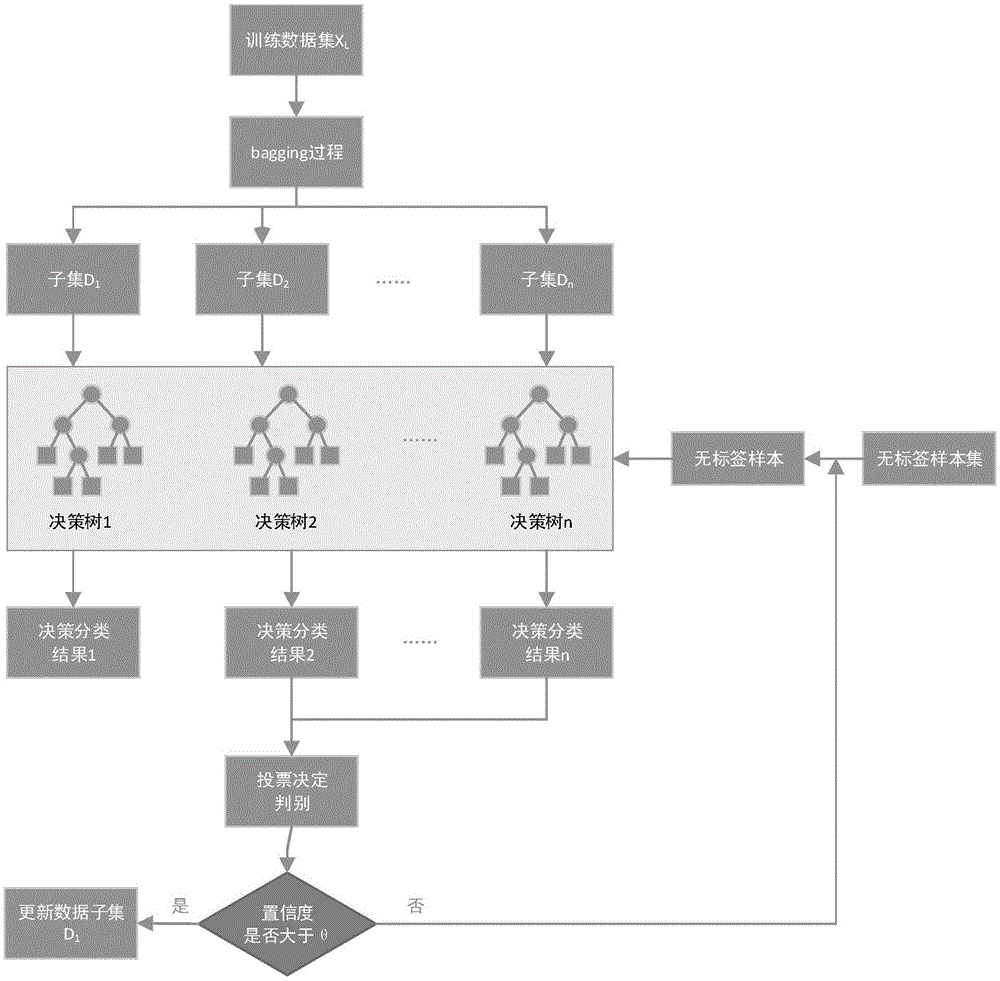

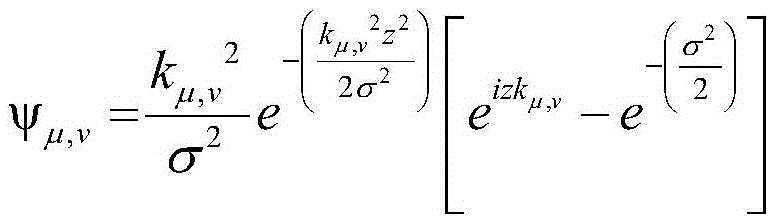

Method for identifying and positioning power transmission line insulators in unmanned aerial vehicle aerial images

InactiveCN105528595AImprove recognition rateTo achieve the purpose of texture analysisScene recognitionRobustificationData set

The invention belongs to the technical field of image processing, discloses a method for identifying and positioning power transmission line insulators in unmanned aerial vehicle aerial images, and solves the problems in the prior art that the detection precision of an identification algorithm of the insulators is not high, the robustness is low, and the identification algorithm is easy to be affected by sample number. A group of Gabor wavelet basis with different sizes and different directions and training sample images are taken as convolutions so as to form a group of characteristic vectors which accurately describe sample image texture characteristics. A random forest machine learning algorithm with a semi-supervised learning mode is used to train sample data sets of the known category and the unknown category so as to obtain an insulator identification model. Through the mode from left to right and from top to bottom, a detection window with the same size as the training sample traverses the input images with different sizes. The detection window combining the identification model detects and positions the positions of the insulators in the input images with different sizes. And finally the accurate positions of the insulators in the input image with the original size are determined by using a non-maximum inhibition method.

Owner:CHENGDU TOPPLUSVISION TECH CO LTD

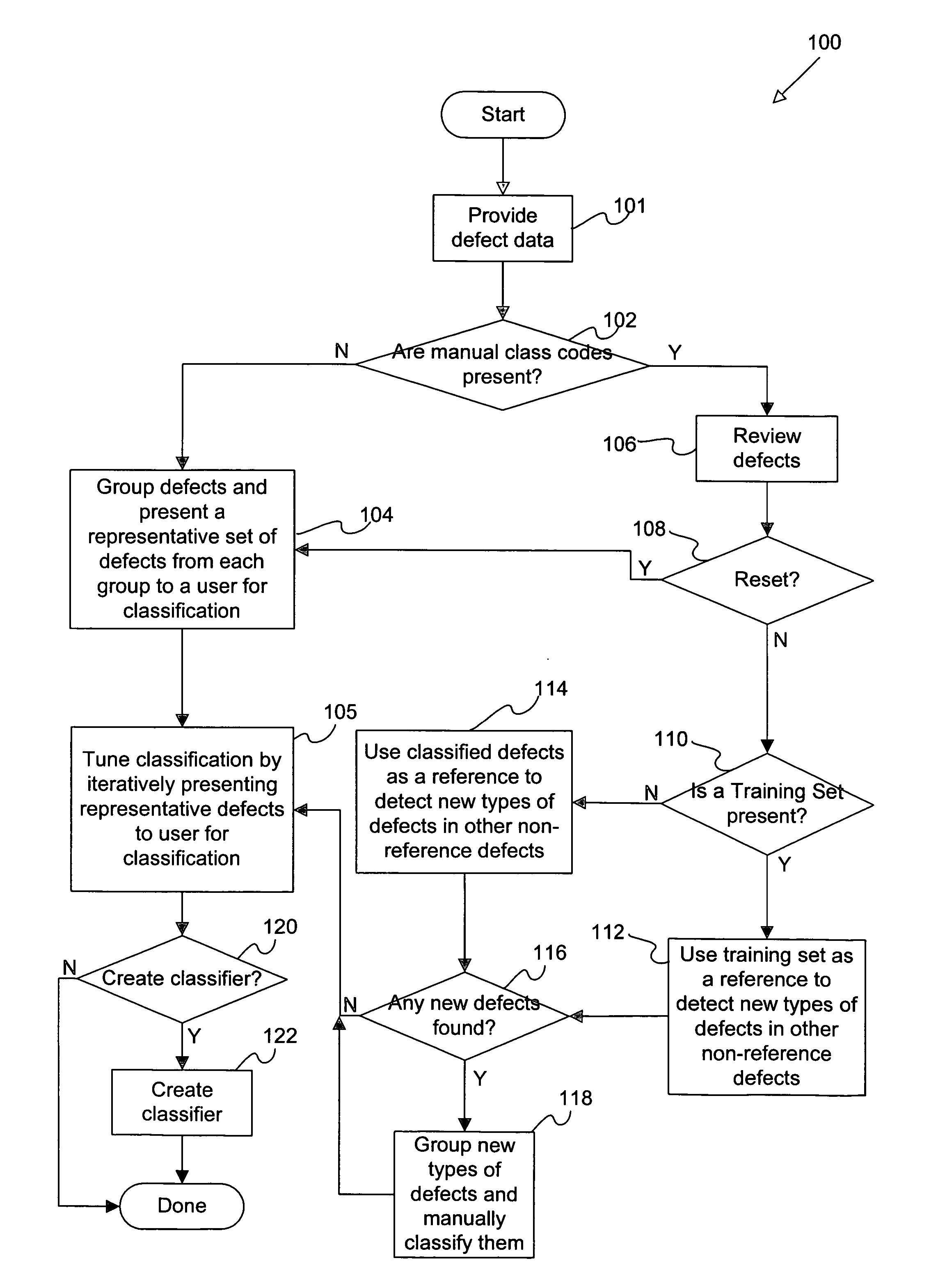

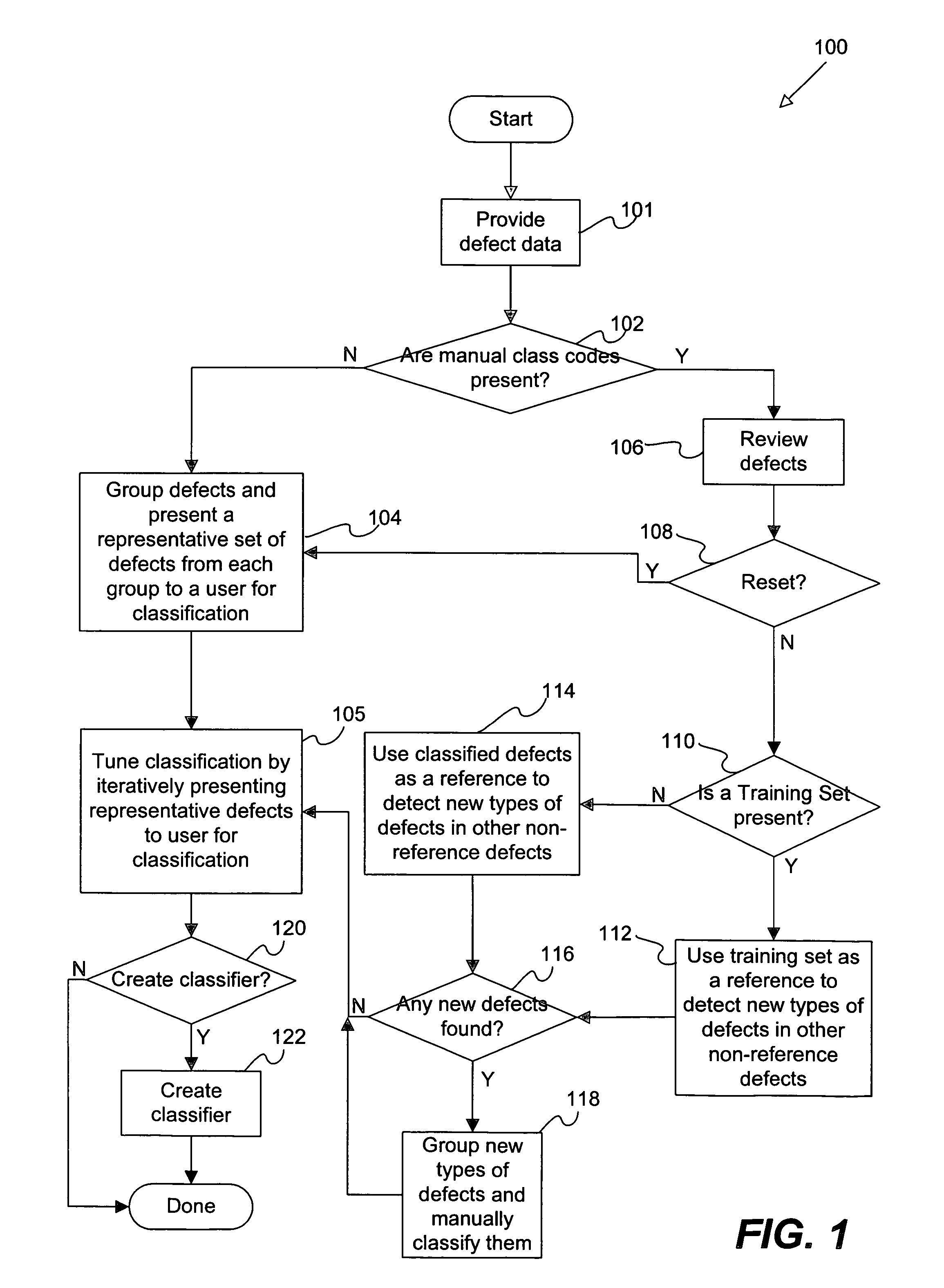

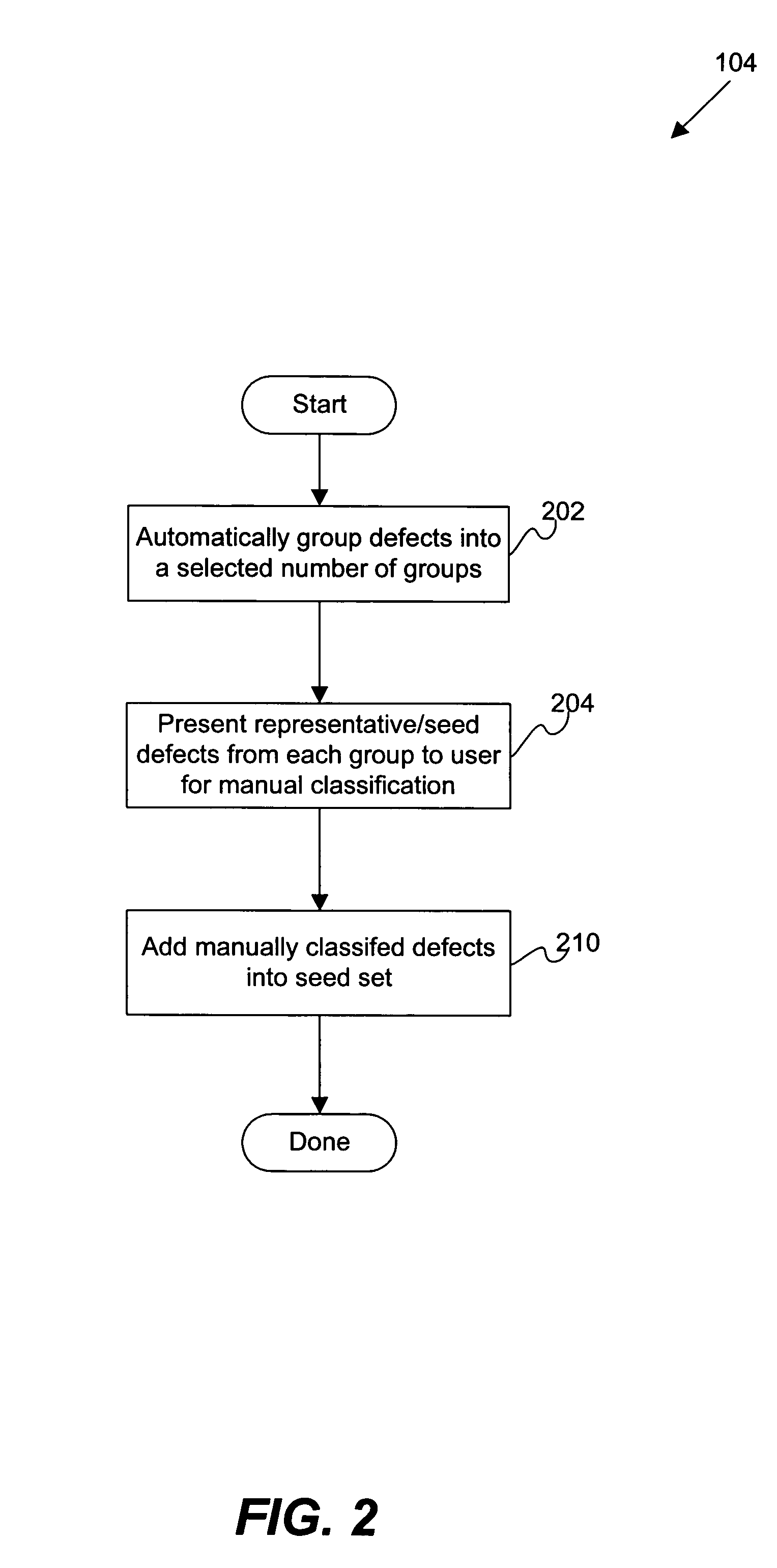

Automatic supervised classifier setup tool for semiconductor defects

ActiveUS7359544B2Effective maintenanceEfficient settingsImage analysisCharacter and pattern recognitionPattern recognitionData mining

Disclosed are methods and apparatus for efficiently setting up and maintaining a defect classification system. In general terms, the setup procedure optionally includes automatically grouping a set of provided defects and presenting a representative set from each defect group to the user for classification. After the initial manual classification of the representative defects, the setup procedure includes an automatic procedure for classifying the non-reviewed or unclassified defects based on the manual class codes from the user-reviewed defects. After the automatic classification operation, the user may also be presented with defects from each class which may require re-classification. In particular embodiments, the user is iteratively presented with defects which have classifications that are suspect, which are near classification boundaries, or have classifications that have a low confidence level until each class is pure or contains a same type of defect classes as assigned by the user.

Owner:KLA TENCOR TECH CORP

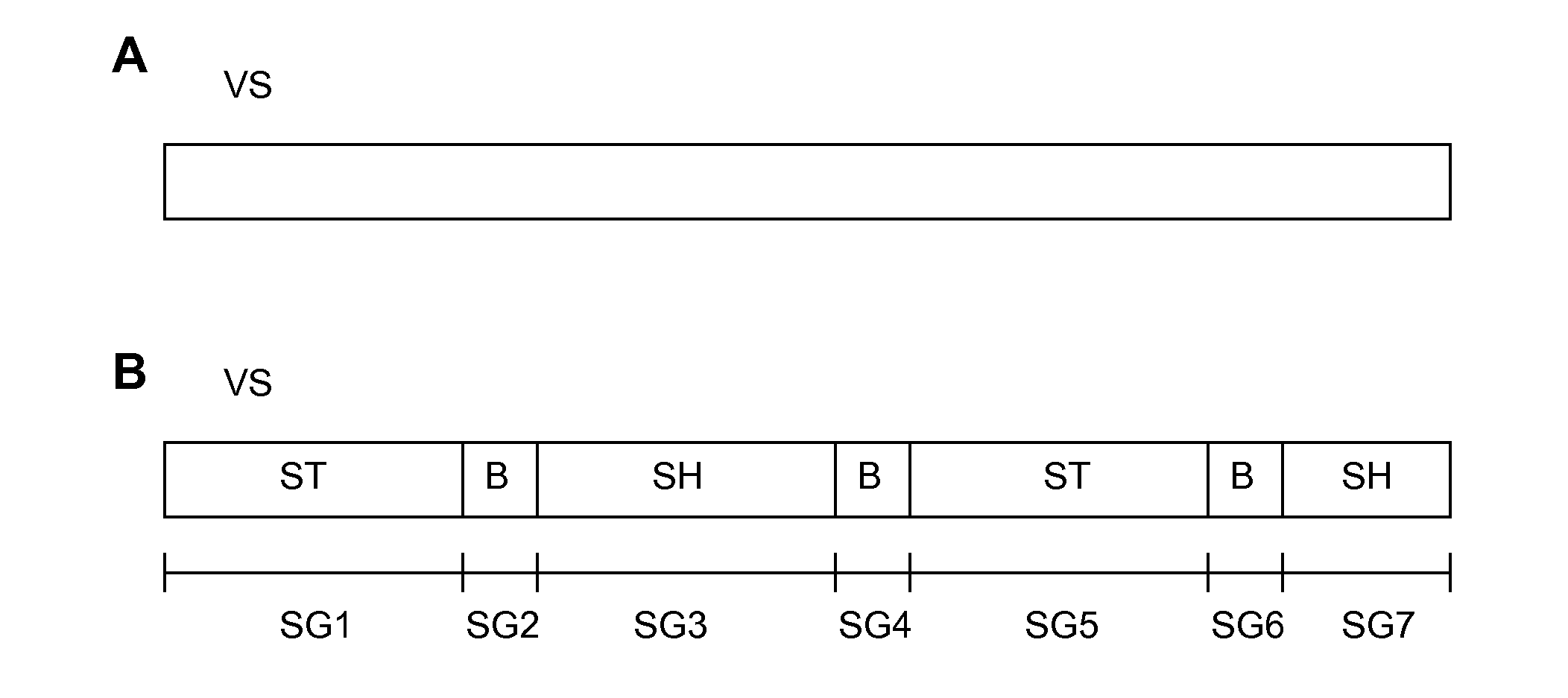

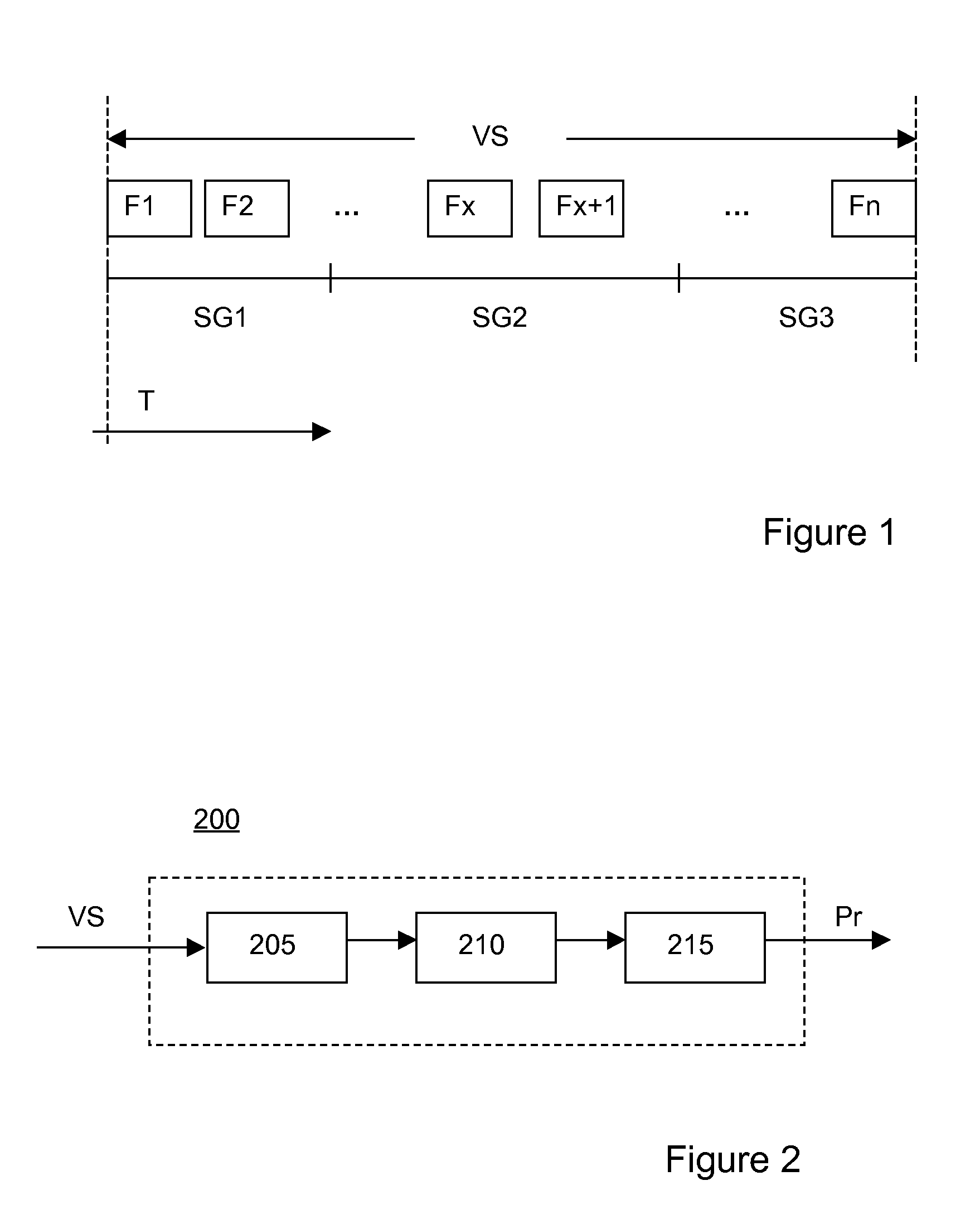

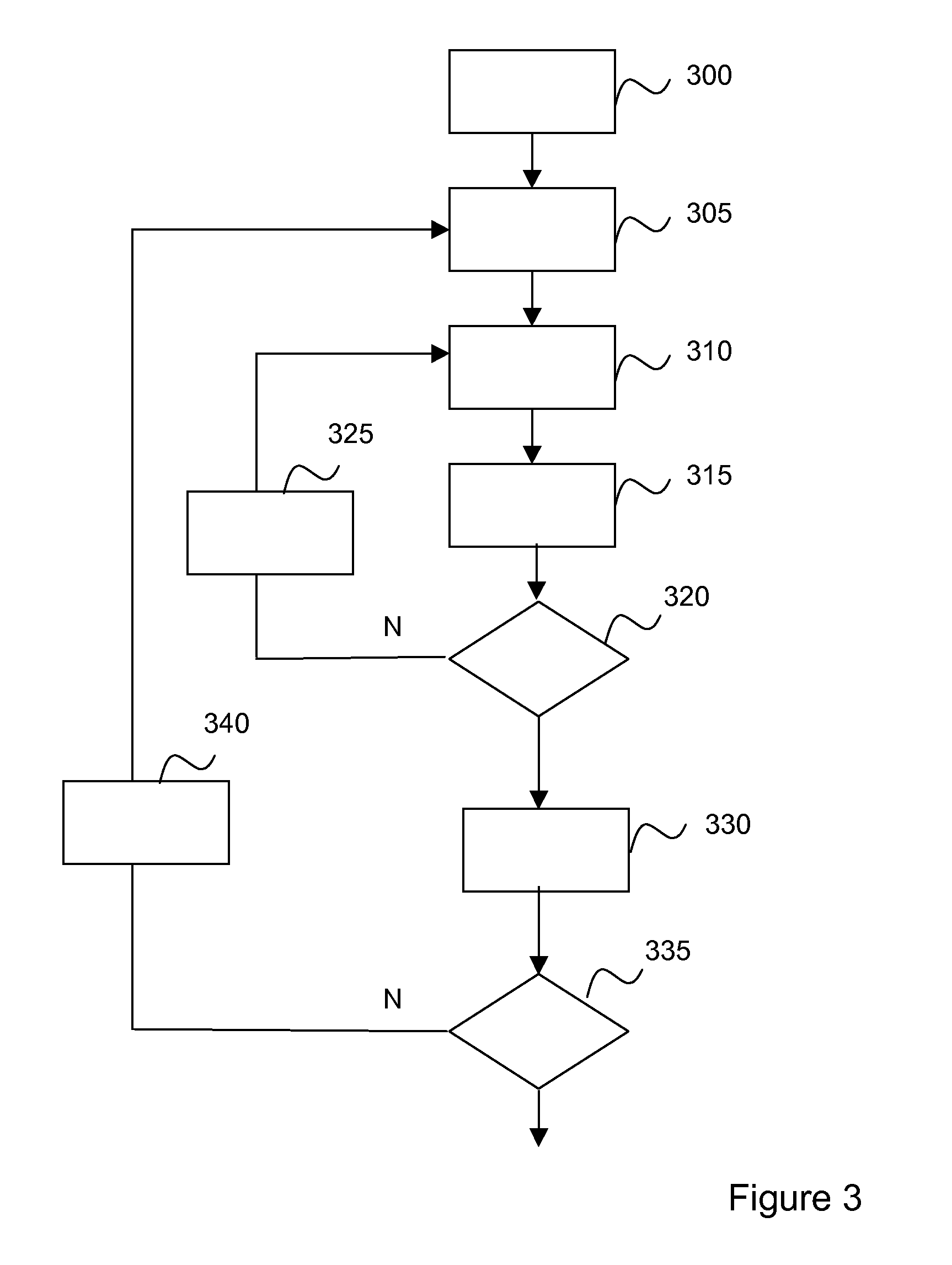

System and method for parsing a video sequence

InactiveUS20110255844A1Easy to classifyDefined more accuratelyTelevision system detailsElectronic editing digitised analogue information signalsDigital videoVideo sequence

A system and method are provided for parsing a digital video sequence, having a series of frames, into at least one segment including frames having a same camera motion quality category, selected from a predetermined list of possible camera motion quality categories. The method includes obtaining, for each of the frames, at least three pieces of information representative of the motion in the frame. The information includes: translational motion information, representative of translational motion in the frame; rotational motion information, representative of rotational motion in the frame; and scale motion information, representative of scale motion in the frame. The method further includes processing the at least three pieces of information representative of the motion in the frame, to attribute one of the camera motion quality categories to each of the frames.

Owner:FRANCE TELECOM SA

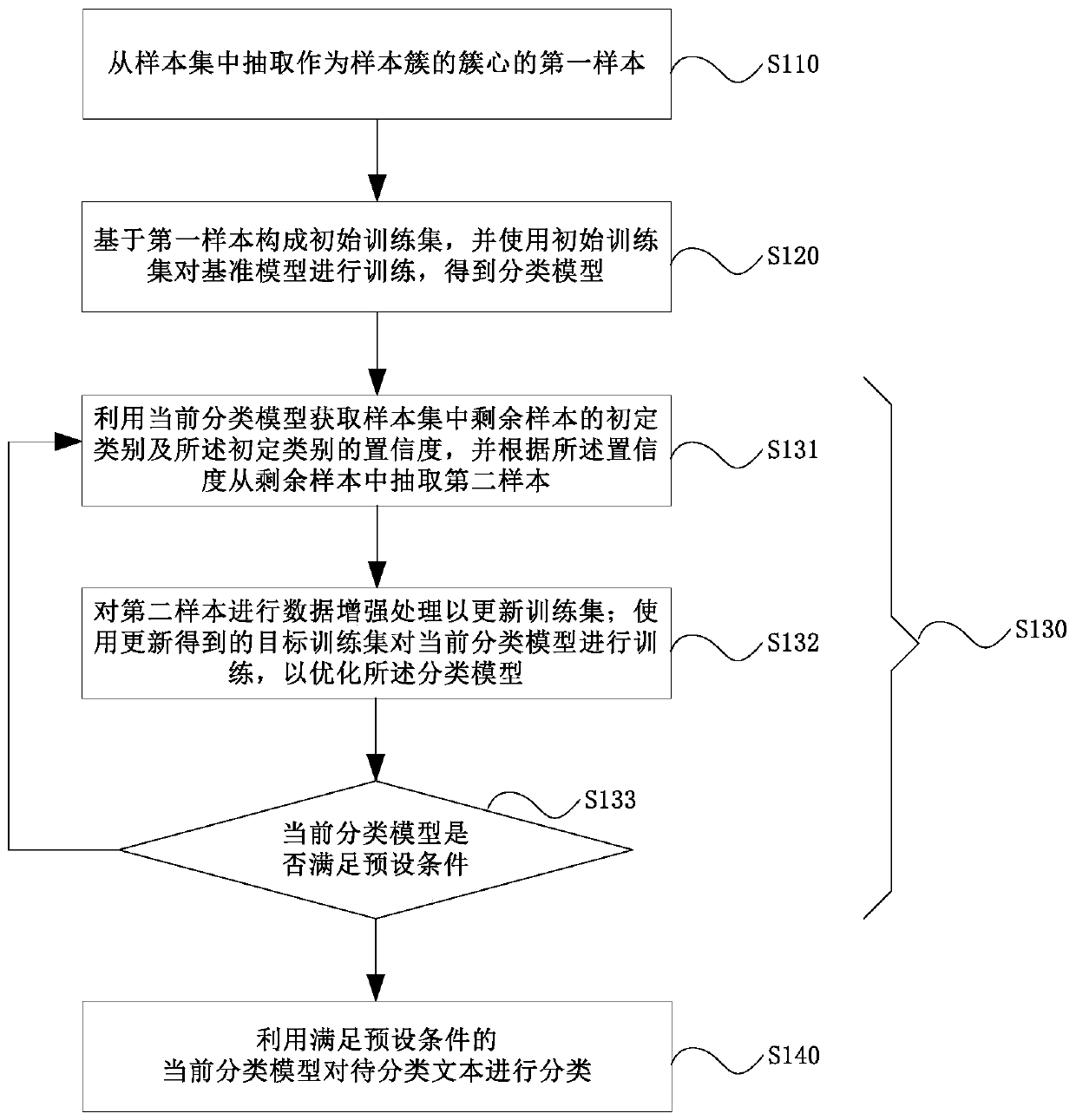

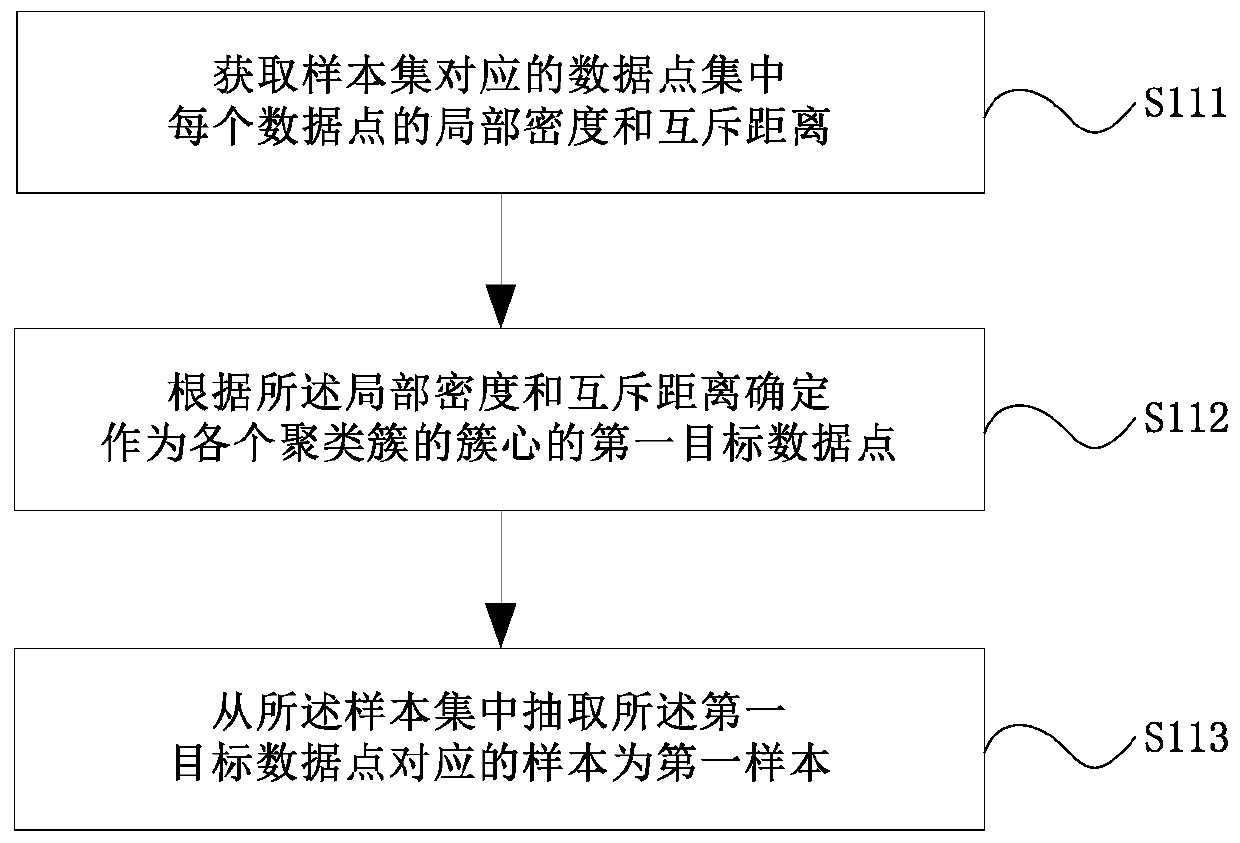

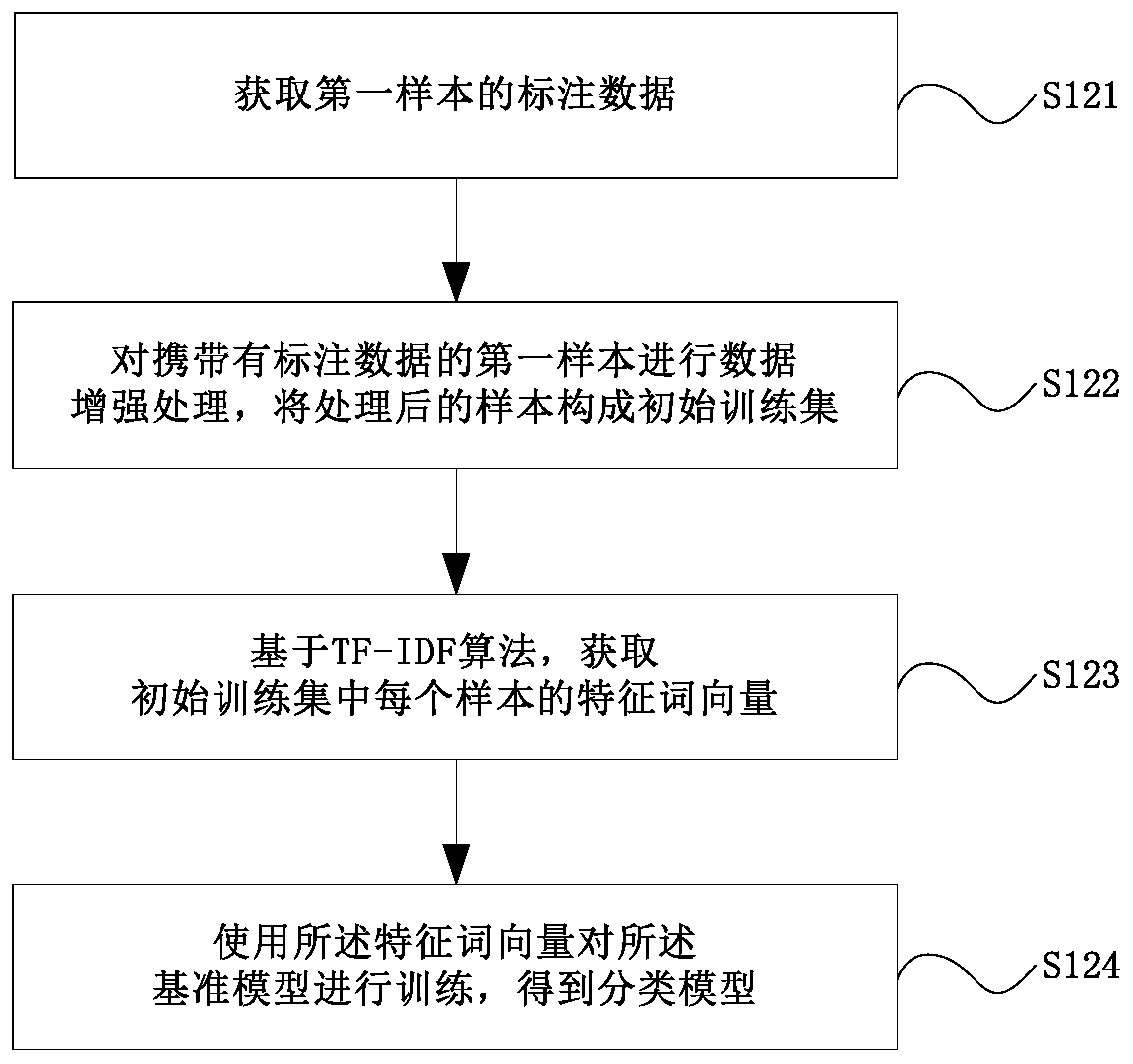

Weak supervised text classification method and device based on active learning

ActiveCN109960800AImprove generalization abilityImprove robustnessSemantic analysisCharacter and pattern recognitionReference modelText categorization

The invention discloses a weak supervised text classification method and device based on active learning. The method comprises steps of firstly, extracting a first sample serving as a cluster center of a sample cluster from an unlabeled sample set; forming an initial training set based on the first samples, training a reference model by using the initial training set to obtain an initial classification model, and forming the initial training set by using the first samples, thereby not only reducing the number of training samples, but also ensuring the accuracy of the classification model at the initial stage; repeatedly utilizing the classification model to obtain the initial classification and confidence coefficient of the remaining samples in the sample set, so that manual labeling is not needed; extracting a second sample from the remaining samples according to the confidence coefficient, and performing data enhancement processing on the second sample to update the training set, thereby improving the generalization capability and robustness of the model; and finally, training the classification model by using the updated target training set until the classification model meets apreset condition, thereby realizing multi-round active training of the classification model.

Owner:安徽省泰岳祥升软件有限公司

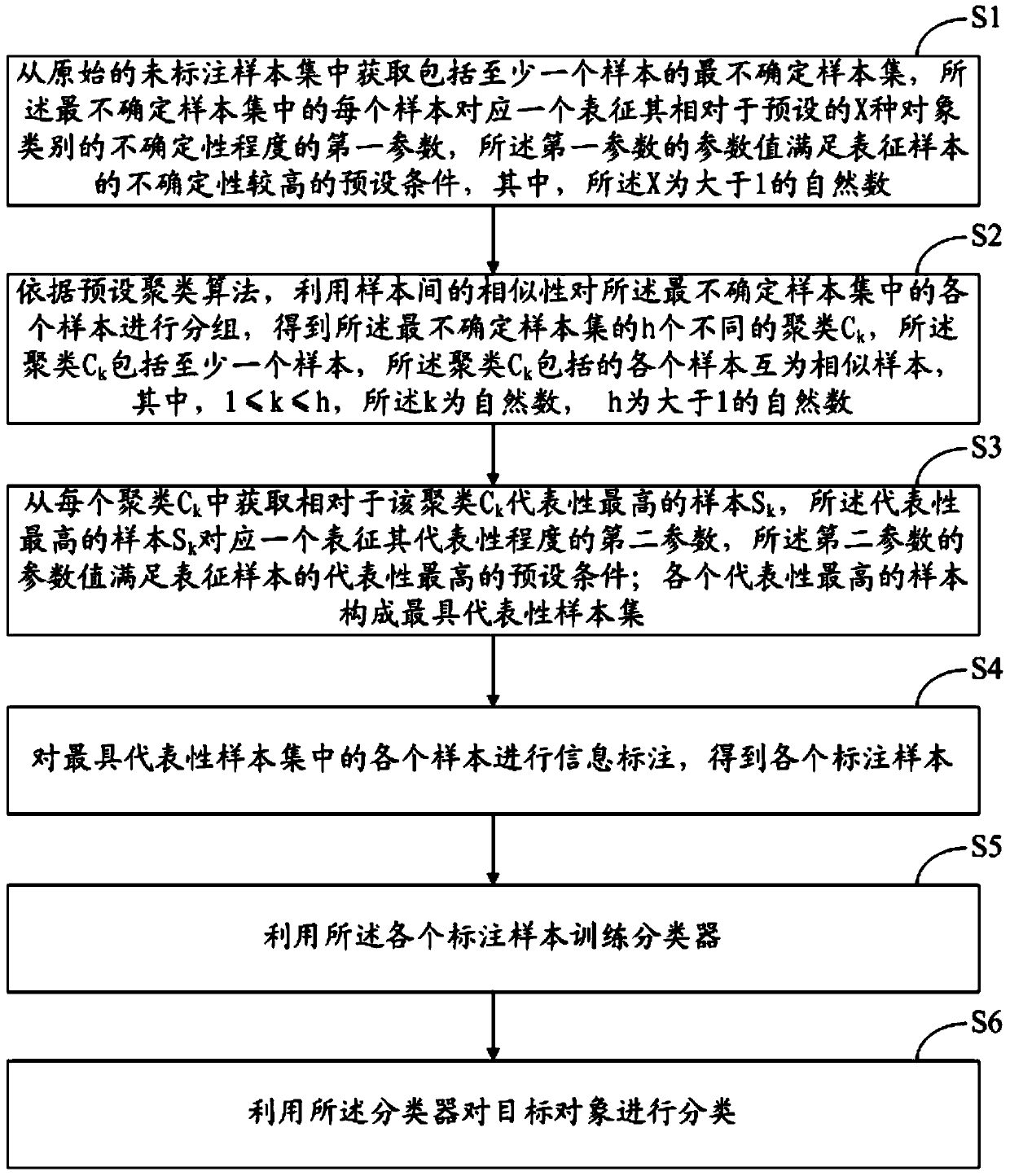

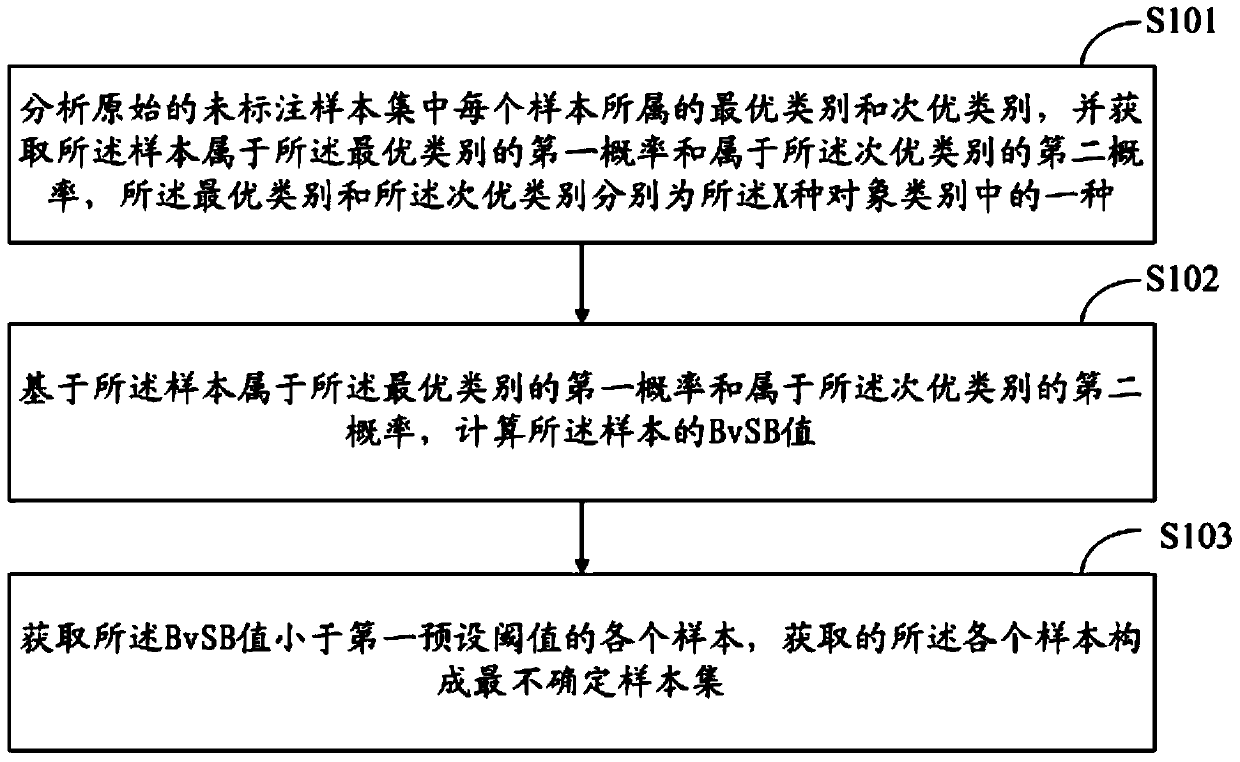

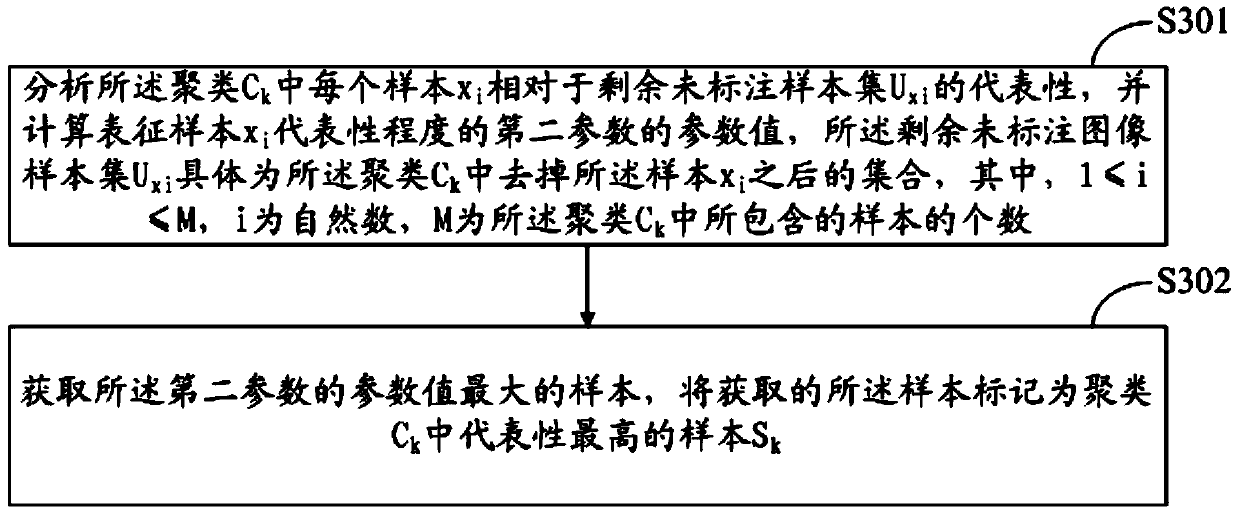

Sorting method and system for active learning

InactiveCN103617429AHigh information contentShorten the timeCharacter and pattern recognitionPattern recognitionWorkload

The invention discloses a sorting method and system for active learning. The sorting method comprises the following steps: firstly sorting all samples with relatively high uncertainty from original unmarked samples in a concentrated manner so as to obtain a most uncertain sample set; then dividing the most uncertain sample set into h different clusters by utilizing the similarity among the samples, dividing the samples with the relatively high similarity into the same cluster, and screening out most representative samples in each cluster to form the most representative sample set; and subsequently, carrying out information marking on the most representative sample set, and finally realizing the sorting of target objects by utilizing a marked sample train sorter and a trained analyzer. Therefore, the sorting method and system disclosed by the invention has the advantages that by clustering, the similar and relatively-high-redundancy samples are divided into the same type, and the screening is carried out on the basis of the clustering, so that the redundancy among the finally-selected samples to be marked is avoided, the marking time and workload are reduced and the sorting efficiency is improved.

Owner:SUZHOU UNIV

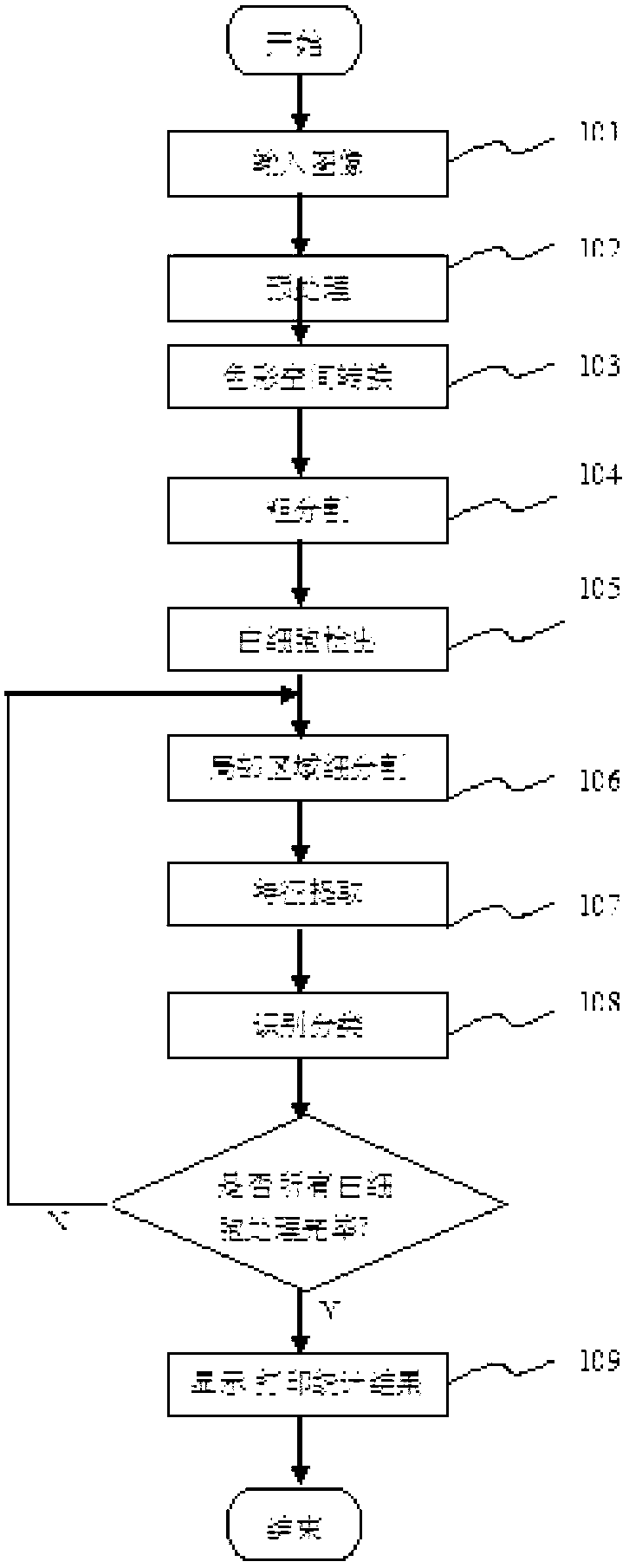

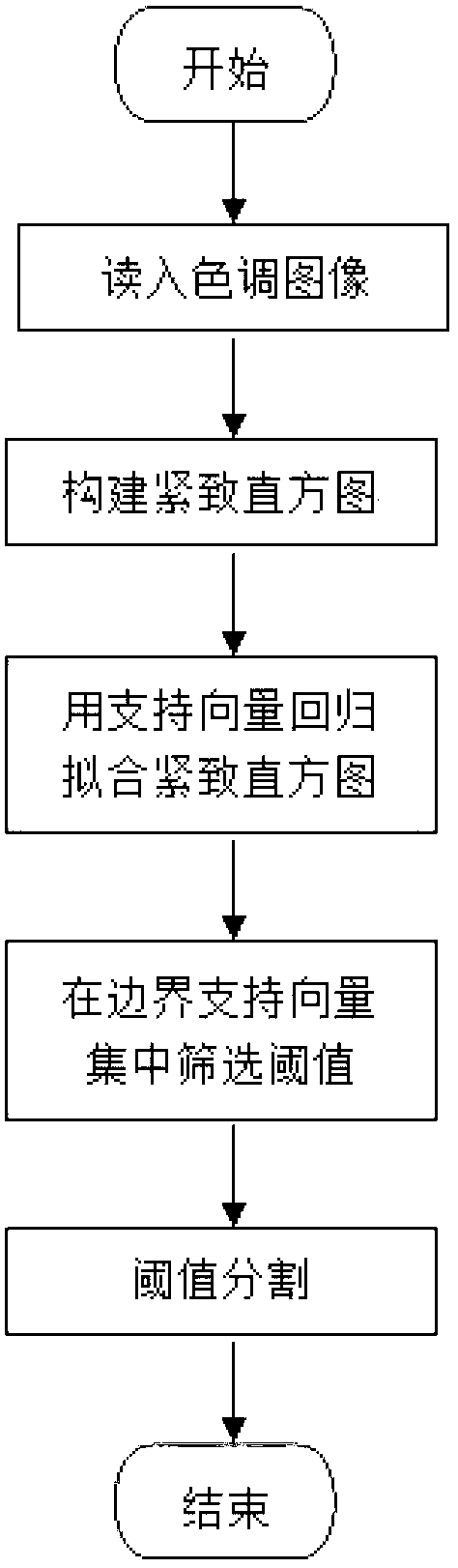

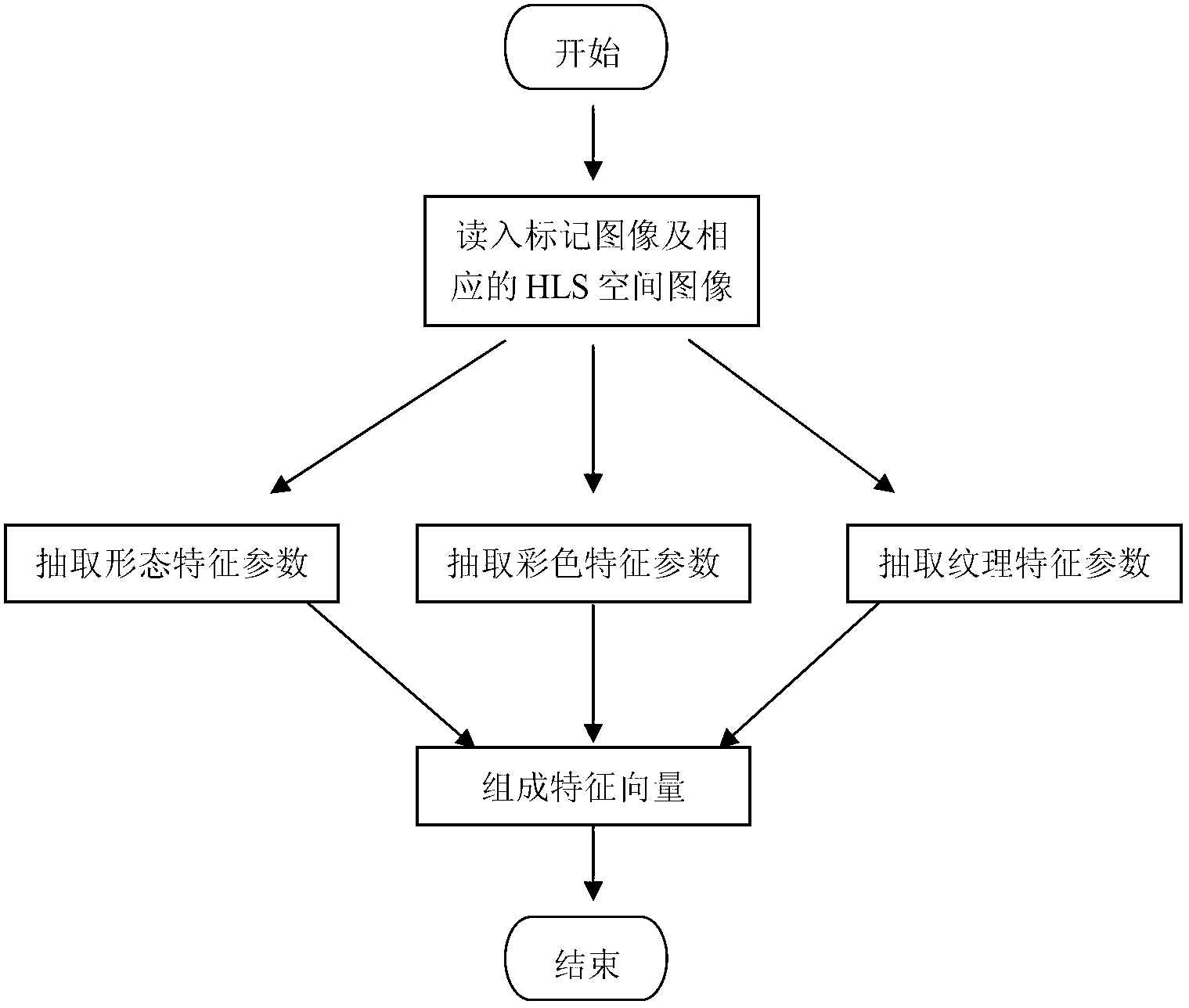

Method for automatically identifying and counting white blood cells

InactiveCN103020639AImplement classificationImprove classification efficiencyCharacter and pattern recognitionColor/spectral properties measurementsSupport vector machineWhite blood cell

The invention provides a method for automatically identifying and counting white blood cells. The method comprises the following steps of: preprocessing, color space conversion, coarse segmentation, checking of white blood cells, fine segmentation, characteristic parameter extraction, identification and classification, result output and the like. The method can be used for automatically identifying and classifying the white blood cells in blood by extracting a group of cell characteristic parameters and utilizing a support vector machine, and has the advantages of high classification efficiency, good effect, high accuracy, high stability and high robustness.

Owner:HOHAI UNIV

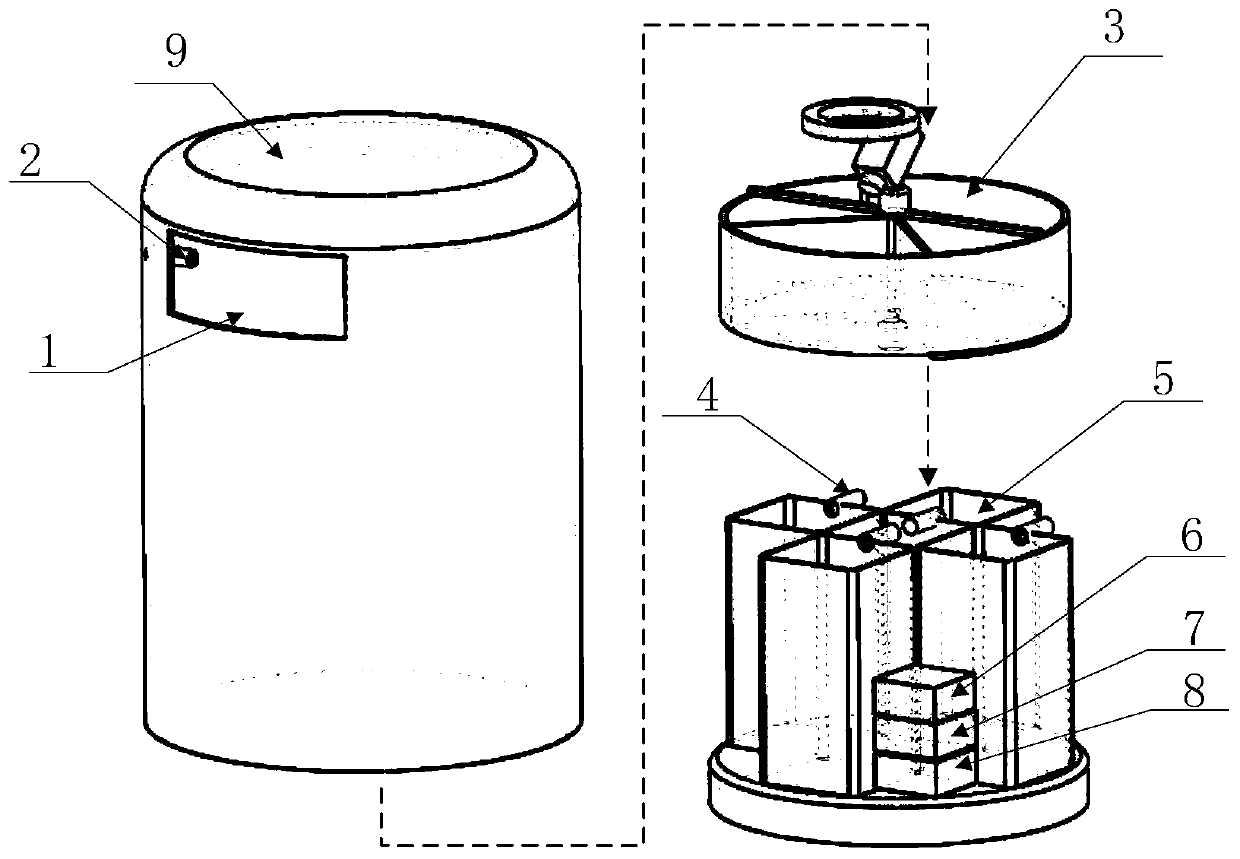

Garbage can capable of automatic classifying based on visual recognition and classifying method

InactiveCN110861852AImprove accuracyRealize handlingWaste collection and transferRefuse receptaclesComputer hardwarePhotoswitch

The invention discloses a garbage can capable of automatic classifying based on visual identification and a classifying method. The garbage can comprises a garbage throwing opening, a first photoelectric switch sensor, an identifying and classifying tray, second photoelectric switch sensors, sub garbage cans, an image identification component, an STM32 controller, a double-path stepping motor driver and a garbage can shell, wherein the garbage throwing opening is formed in the side wall of the garbage can shell; the first photoelectric switch sensor is arranged in the garbage throwing opening;a plurality of sub garbage cans are arranged in the garbage can shell; a second photoelectric switch sensor is mounted in a can opening position of each sub garbage can; the identifying and classifying tray is arranged in the garbage can shell and is located above the sub garbage cans; the identifying and classifying tray comprises a garbage tray, a V-shaped baffle stepping motor, a camera, a V-shaped baffle, a support frame, a rotary baffle stepping motor and a rotary baffle. According to the garbage can, the camera is used for collecting garbage images; a TensorFlow deep learning frameworkis adopted; through transfer training of a model, the accuracy rate of garbage identification is increased.

Owner:石家庄邮电职业技术学院

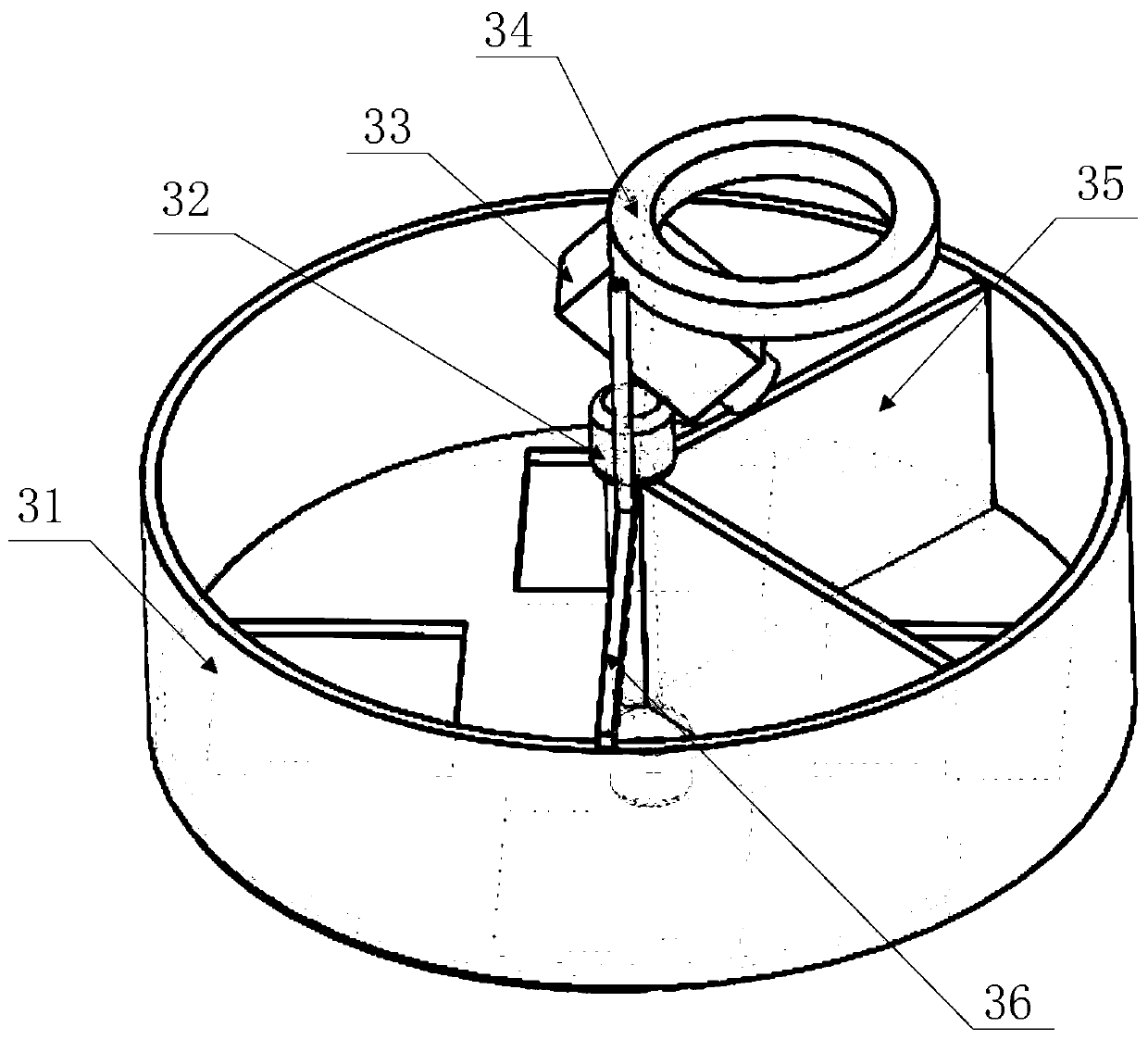

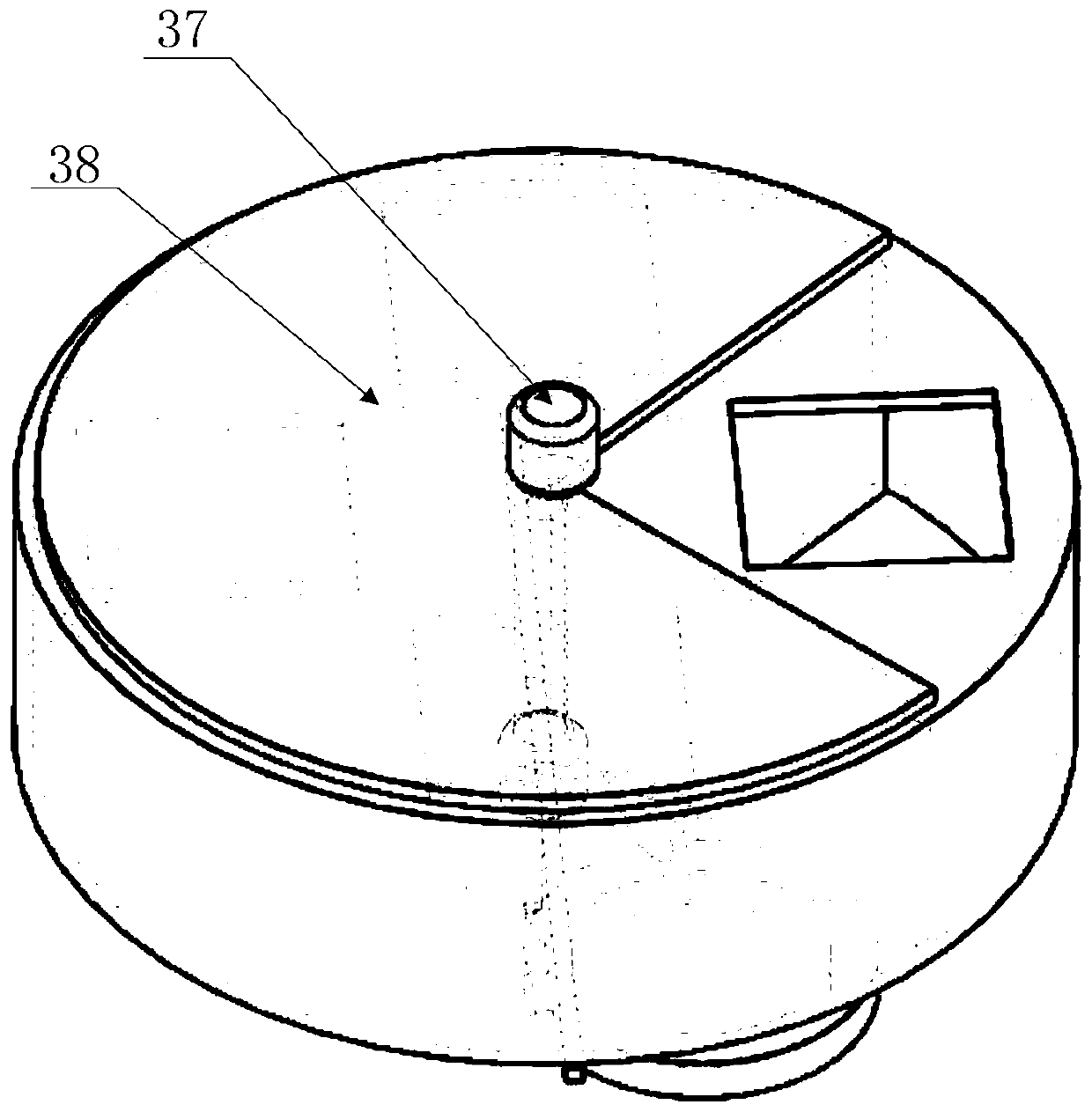

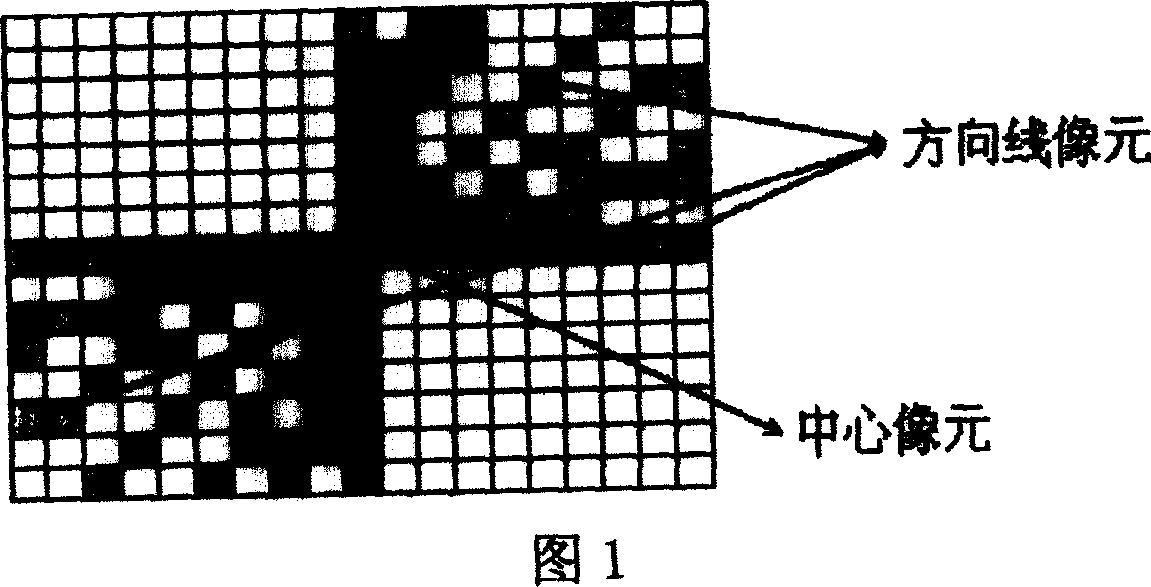

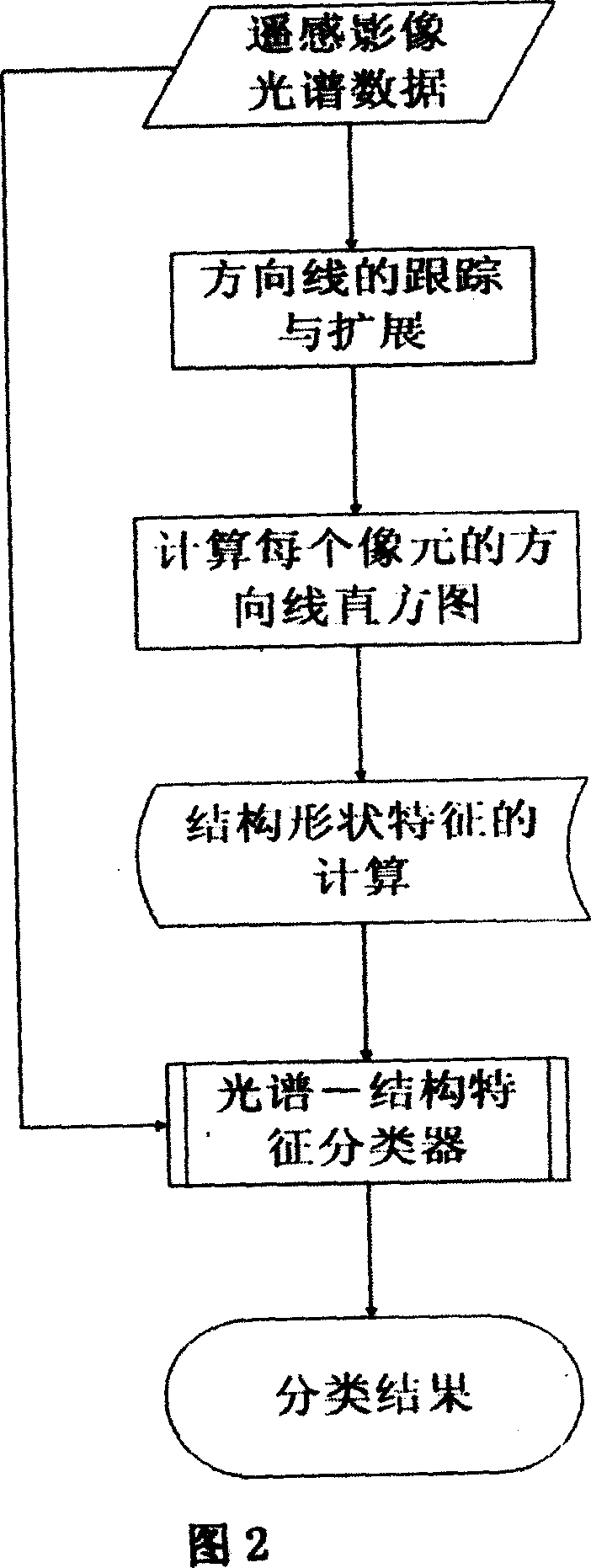

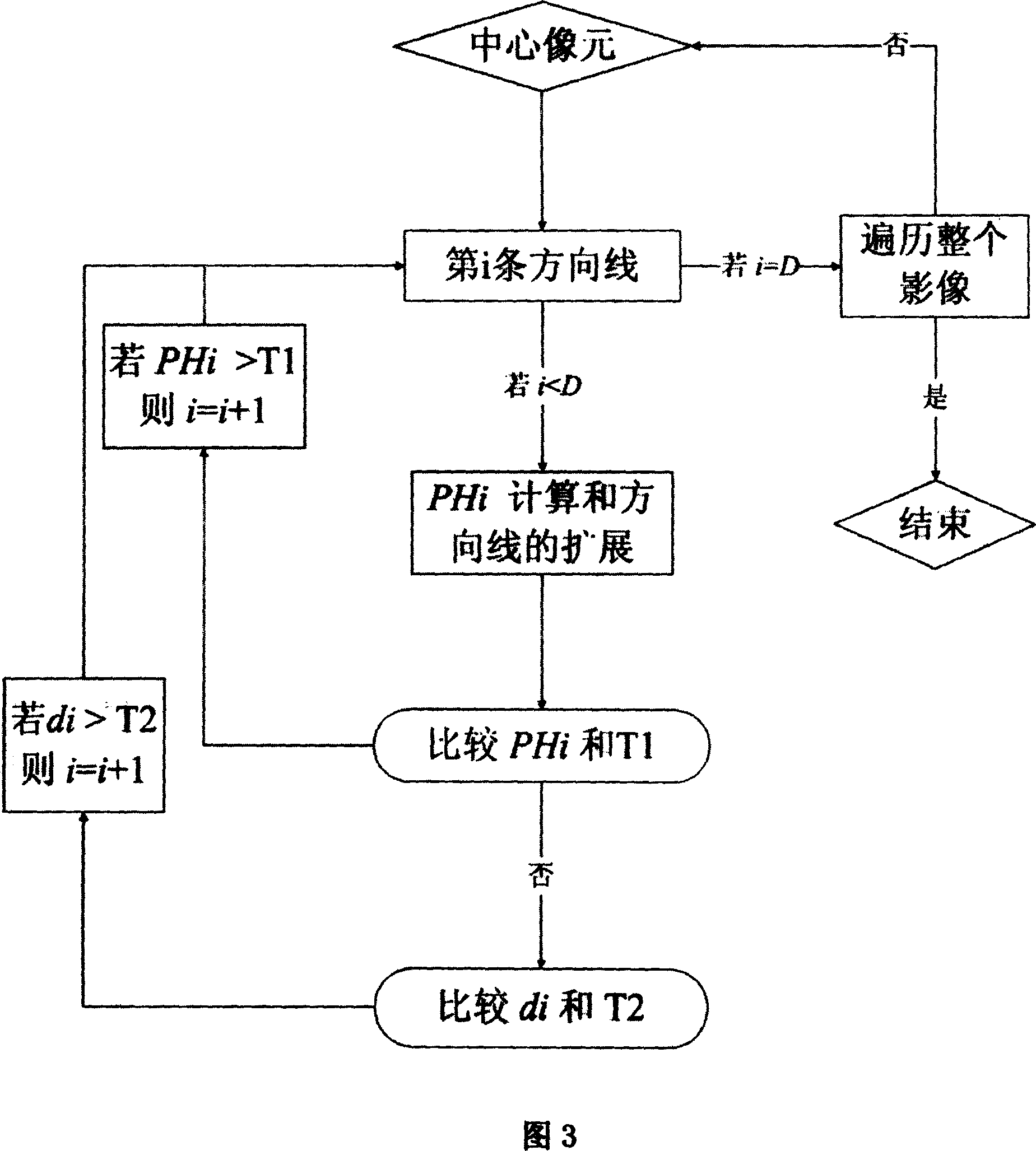

Remoto sensing image space shape characteristics extracting and sorting method

InactiveCN1932850AReflect anisotropyImprove classification accuracyCharacter and pattern recognitionFeature extractionSpatial structure

One picking-up and classify method for remote sensing picture space figure character, tests the space figure structure character of pixel by a series of direction line in equal interval surrounding with center pixel. The amount of direction line is 5 to 48, and its length is controlled by Inter-item consistency referenced threshold and the biggest length referenced threshold and different with each other to embody the anisotropic of video. The square diagram of pixel's direction line reflects its structure character for picking-up space figure structure character more effectively. It reduces the dimensional number of character, and adopts length, width, pixel figure exponent, ratio of length and wide, weighted means and variance to pick-up the square diagram character of direction line to each pixel. It adopts spectrum and space structure character amalgamation classified method to select one method of many kind of neural network and machine study arithmetic to dispose high dimensional structure space.

Owner:WUHAN UNIV

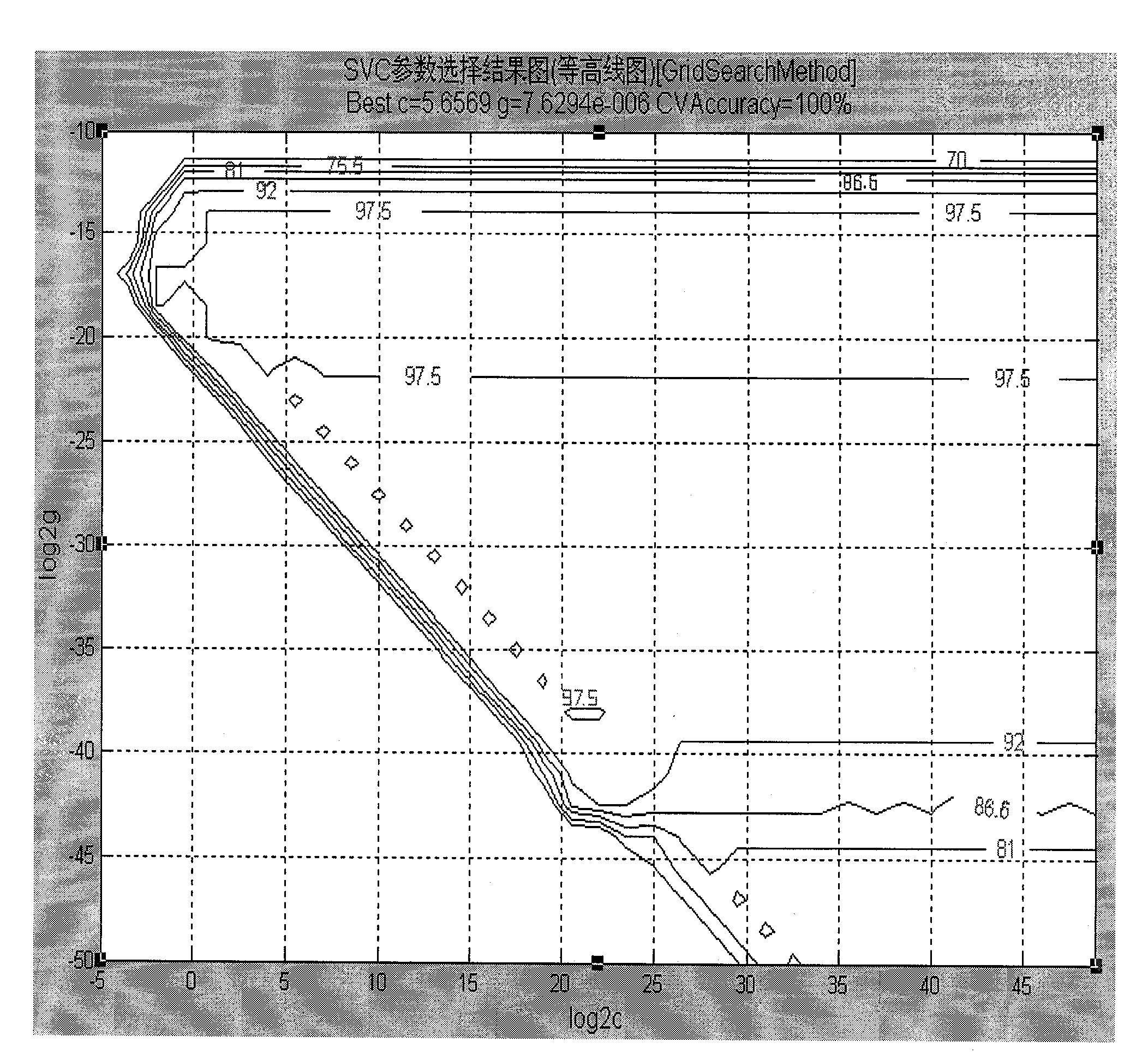

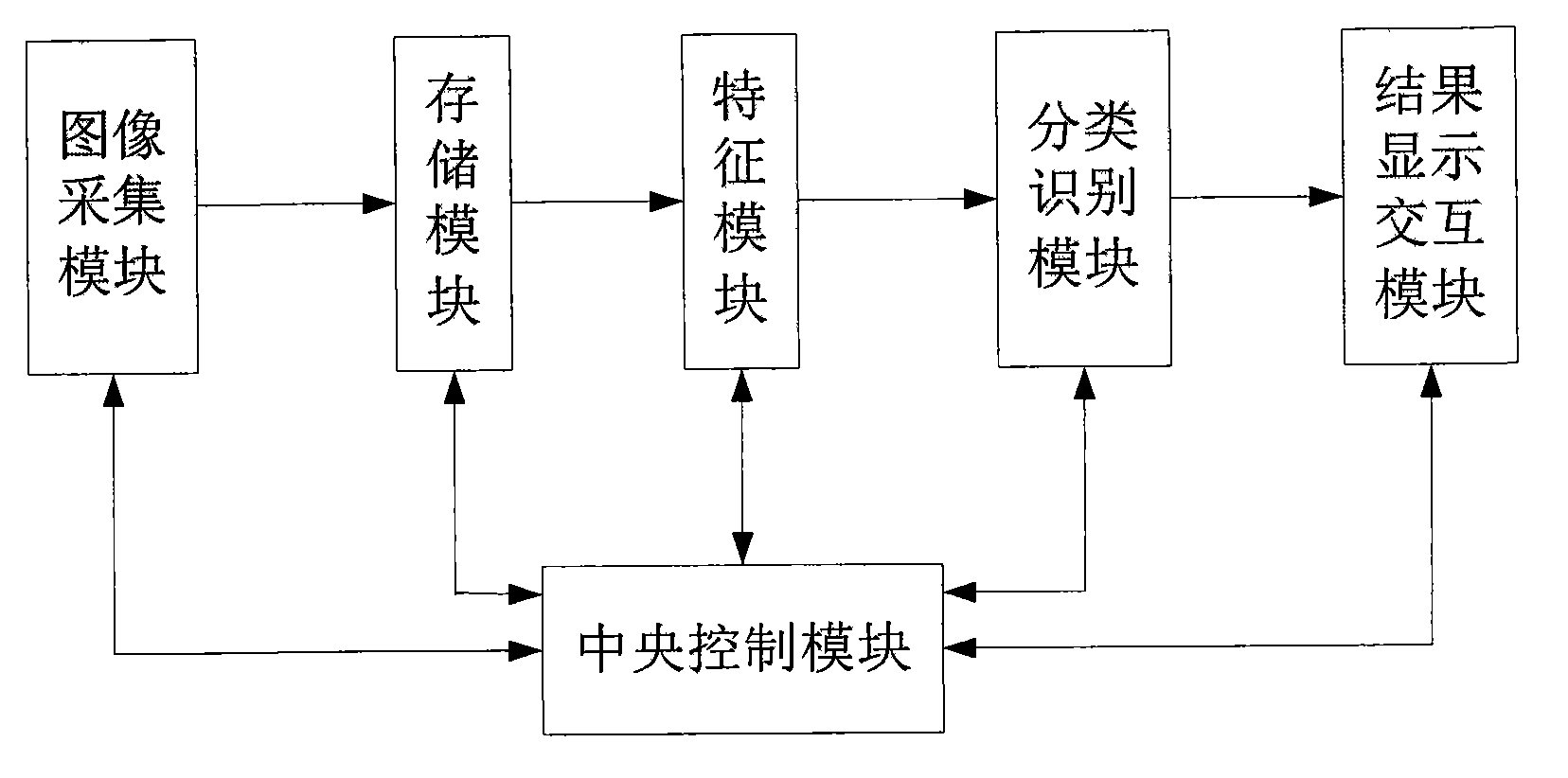

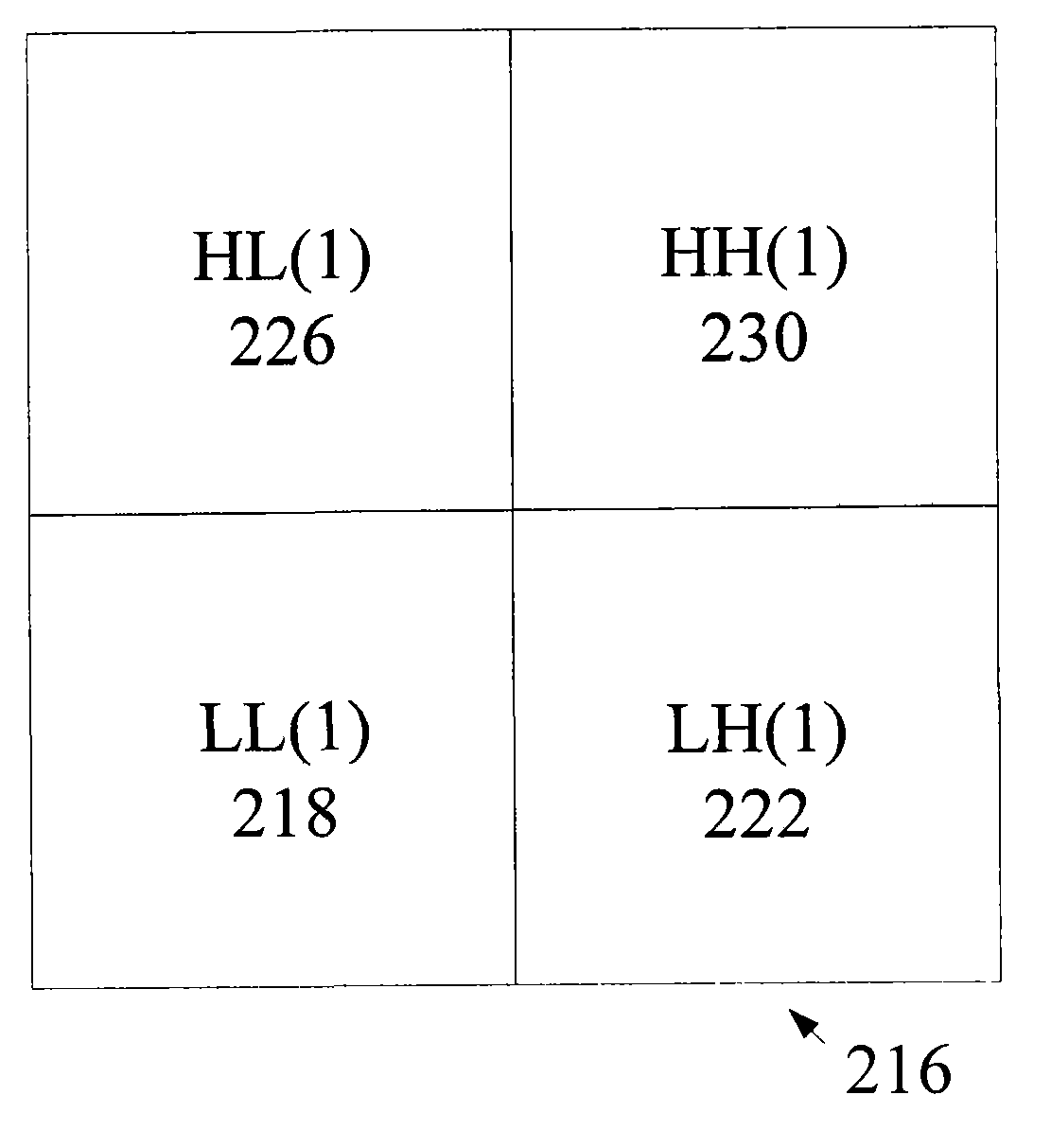

Method and system for coal and rock boundary dividing based on coal and rock image feature extraction and classification and recognition

ActiveCN103207999AImprove classification accuracyImprove classification efficiencyCharacter and pattern recognitionCoal miningDecomposition

Disclosed are a method and a system for coal and rock boundary dividing based on coal and rock image feature extraction and classification and recognition. The method includes firstly, photographing coal and rock images on a coal mining working face, extracting texture feature information of the coal and rock images, and constructing a feature vector, wherein the texture feature information comprises the original images and the angular second moment, the contrast, the correlation, the mean value and the variance of every low-frequency coefficient image with Daubechies wavelet decomposition scale, and the texture feature information also comprises the total mean value and the total variance for calculating high-frequency coefficient images in horizontal, vertical and diagonal directions; and lastly, creating a best classifier to recognize the coal and rock boundary. The system comprises an image acquisition module, a feature module, a classification and recognition module, a result display interactive module, a memory module and a central control module. The method and the system for the coal and rock boundary dividing based on the coal and rock image feature extraction and the classification and recognition have simple calculation, less human intervention and low cost, can improve classification accuracy and efficiency of the coal and rock images in complex environments effectively, and provides accurate and reliable coal and rock boundary information.

Owner:CHINA UNIV OF MINING & TECH (BEIJING)

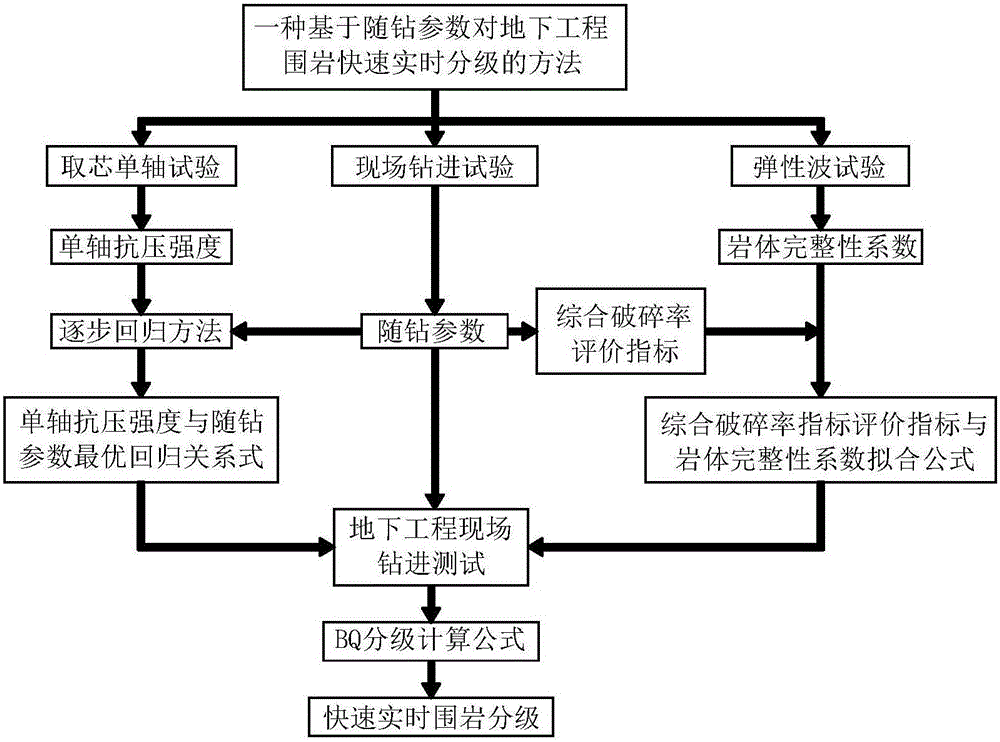

Method for fast grading underground engineering surrounding rock in real time based on parameters while drilling

ActiveCN105938611AQuick gradingImprove classification efficiencyData processing applicationsComplex mathematical operationsLaboratory testingGeophysics

The present invention discloses a method for fast grading underground engineering surrounding rock in real time based on parameters while drilling. According to the method, a on-site drilling test is implemented; uniaxial compressive strength along the drilling depth direction of a tunnel face and a rock mass integrity index are obtained based on parameters while drilling measured in a drilling process; a relational expression of the parameters while drilling, the uniaxial compressive strength and the rock mass integrity index is built; in actual underground engineering, the obtained parameters while drilling are introduced into the above relational expression; and surrounding rock in front of the tunnel face is graded fast in real time according to a surrounding rock basic quality (BQ) index grading calculation formula. With the method for fast grading the underground engineering surrounding rock in real time based on the parameters while drilling provided by the invention, it only need to utilize a drilling machine in an engineering field to carry out a drilling test on the surrounding rock, and coring and an laboratory testing are not required, and the surrounding rock can be graded fast in real time, and grading efficiency is high; and the grade of the surrounding rock can be determined just based on the drilling parameters, and various kinds of testing modes in a traditional grading method are not required. The method of the invention has the advantages of simplicity and operational easiness.

Owner:SHANDONG UNIV

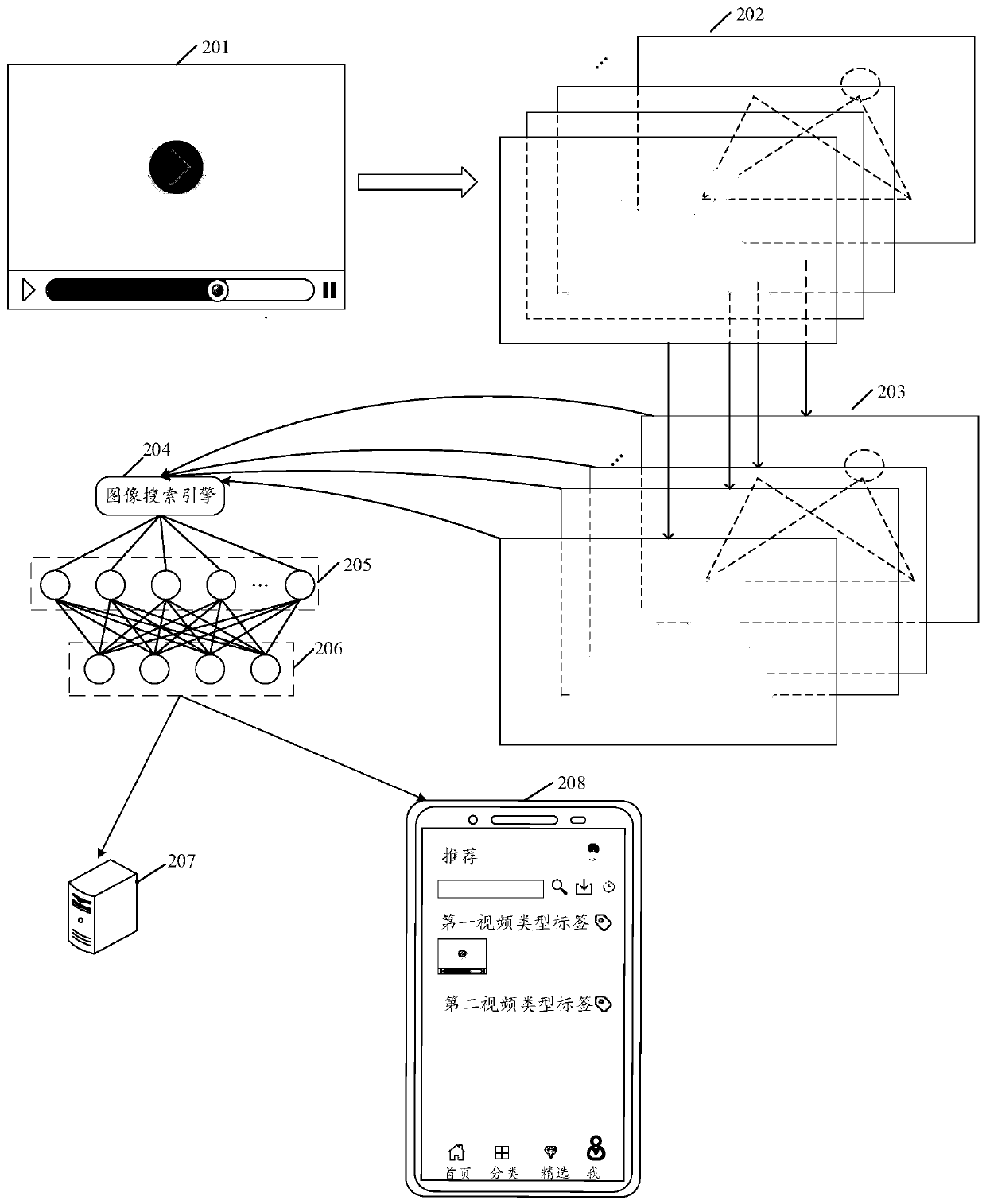

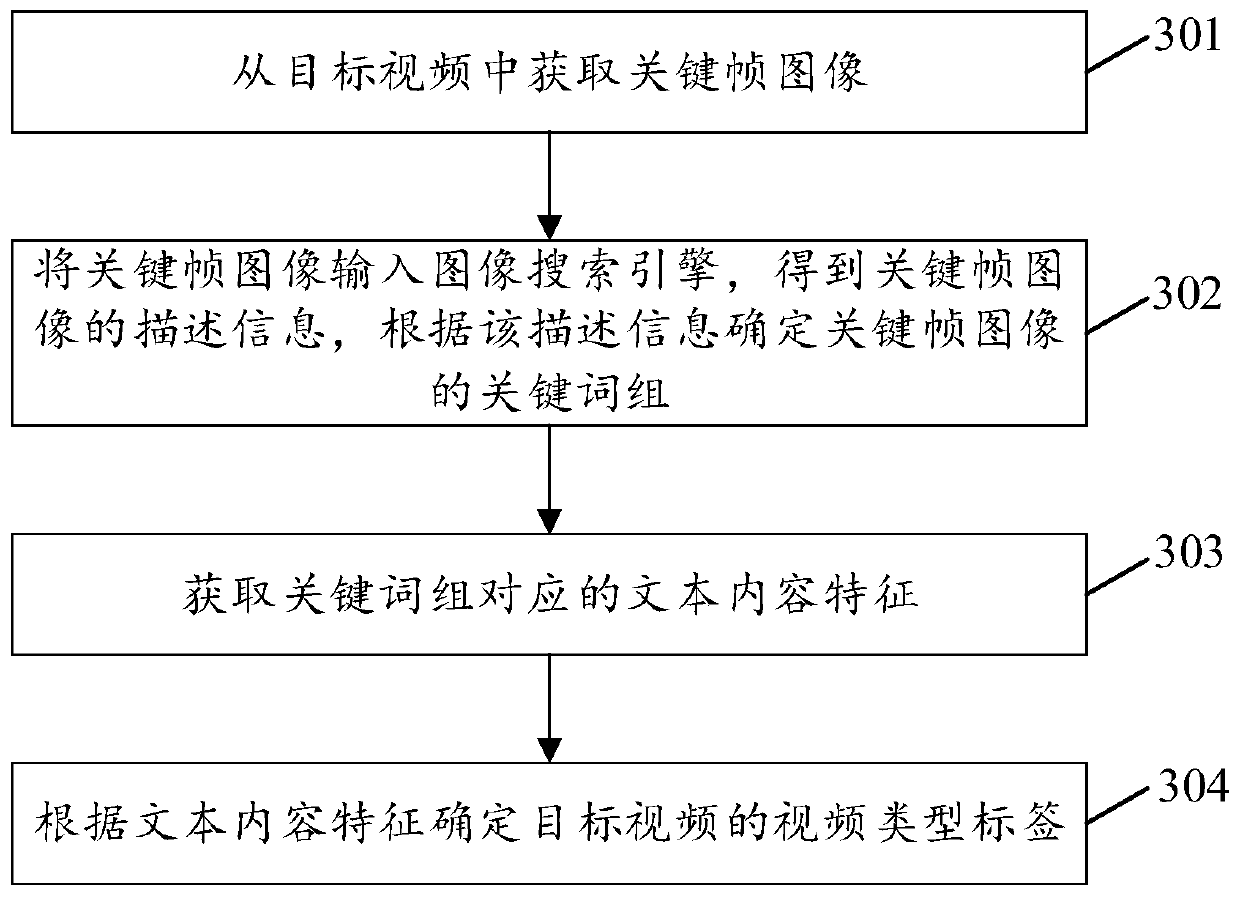

Video classification method and device, computer and readable storage medium

PendingCN110837579AAvoid time consuming situationsImprove classification efficiencyVideo data clustering/classificationSpecial data processing applicationsRadiologyKey frame

The embodiment of the invention discloses a video classification method. The method comprises the steps of obtaining a key frame image from a target video; inputting the key frame image into an imagesearch engine to obtain description information of the key frame image, and determining a keyword group of the key frame image according to the description information; obtaining text content characteristics corresponding to the keyword group; and determining a video type label of the target video according to the text content characteristics. By adopting the method and the device, the text content characteristics of the target video can be determined on the basis of the key frame images in the plurality of frame images forming the target video and the corresponding description information inthe image search engine, so that the video type label of the target video is obtained, and the video classification efficiency is improved.

Owner:TENCENT TECH (SHENZHEN) CO LTD

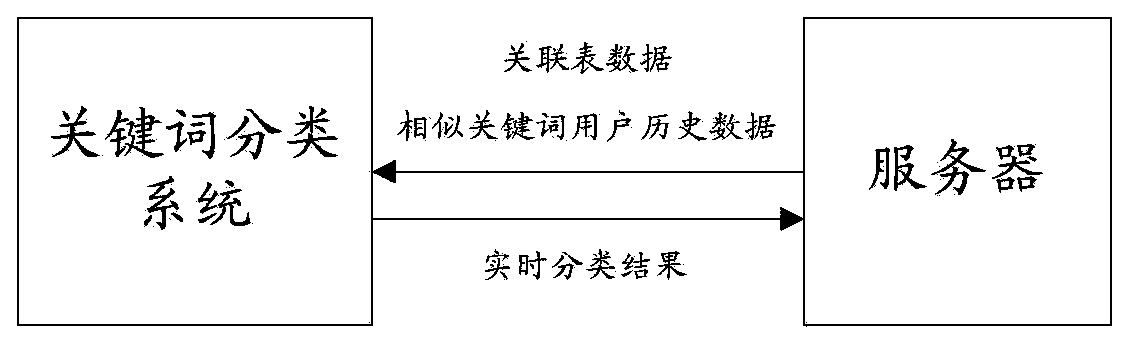

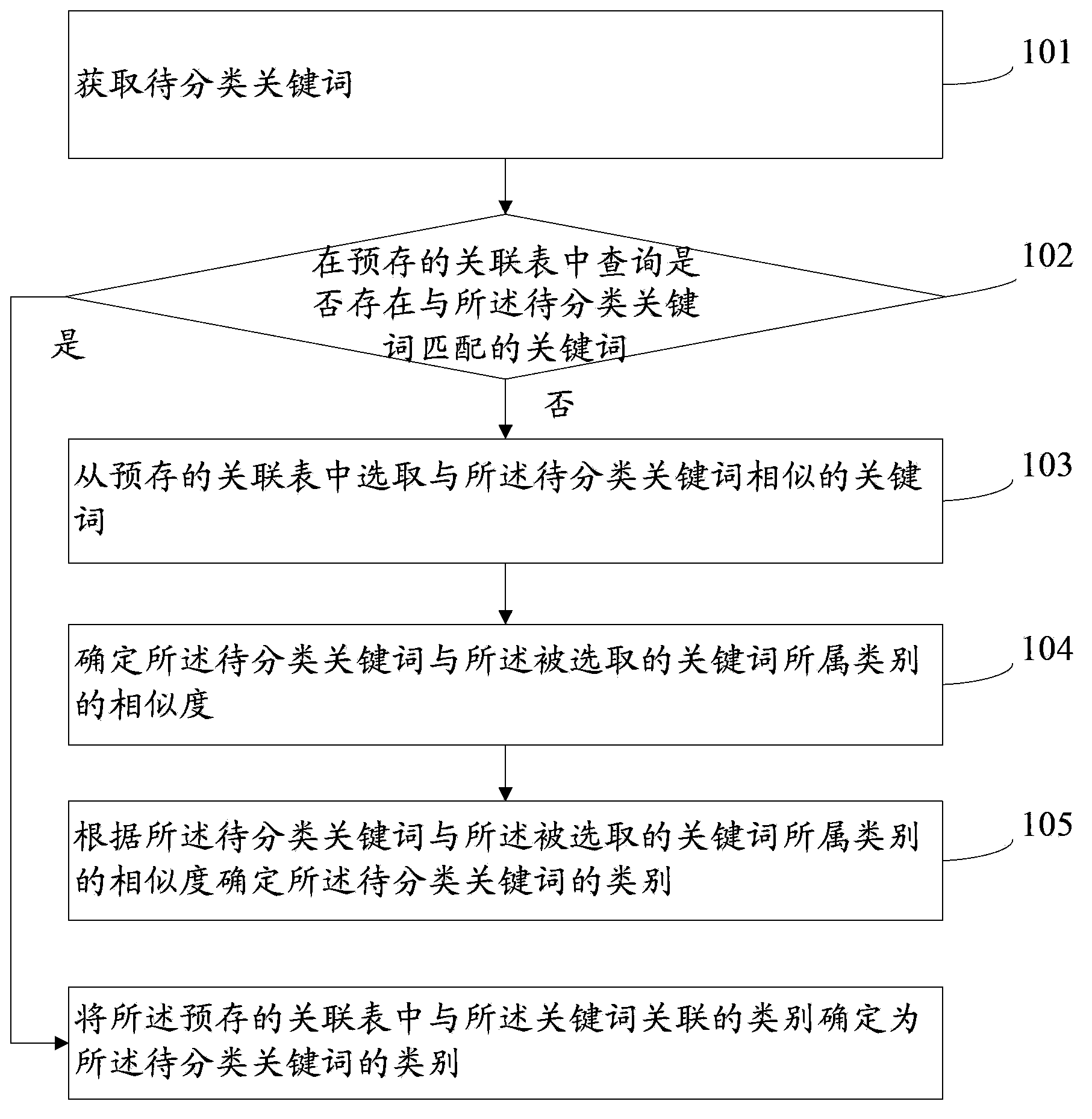

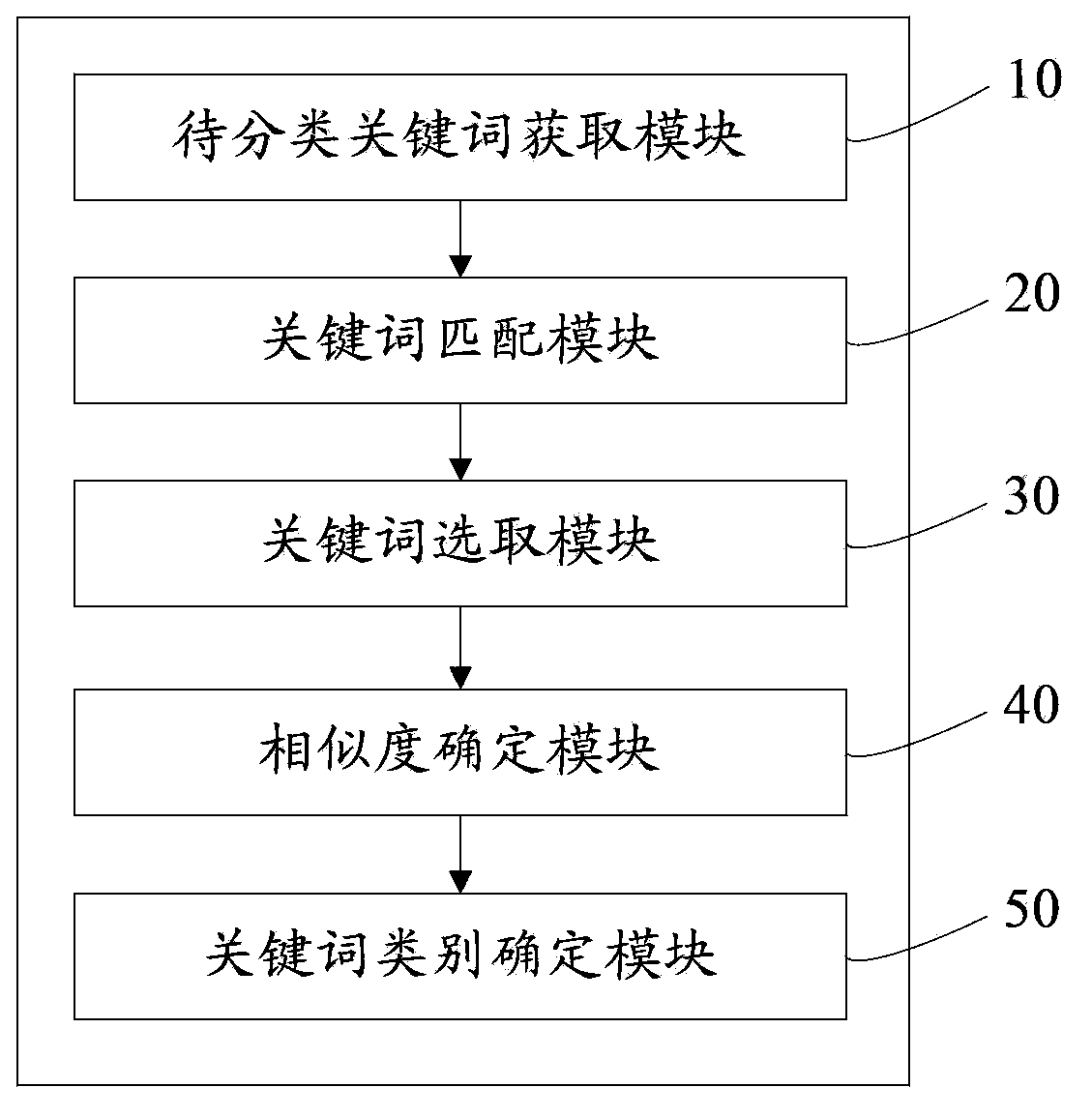

Keyword classification method and system

ActiveCN103577423AAvoid occupyingSmall amount of calculationWeb data indexingSpecial data processing applicationsClassification methodsData mining

The invention provides a keyword classification method. The method includes the following steps: obtaining keywords to be classified; inquiring whether keywords matched with the keywords to be classified exist in a pre-stored association table, on yes judgment, determining classification related to the keywords in the pre-stored association table as the classification of the keywords to be classified, and on no judgment, conducting the next step; selecting keywords similar to the keywords to be classified from the pre-stored association table; determining the similarity of classifications of the keywords to be classified and the selected keywords; according to the similarity of the classifications of the keywords to be classified and the selected keywords, determining the classification of the keywords to be classified. A keyword classification system for achieving the method is further provided. By means of the keyword classification method and system, keyword classification efficiency can be improved, response speed of the system is increased, and system operating amount is reduced.

Owner:ALIBABA GRP HLDG LTD

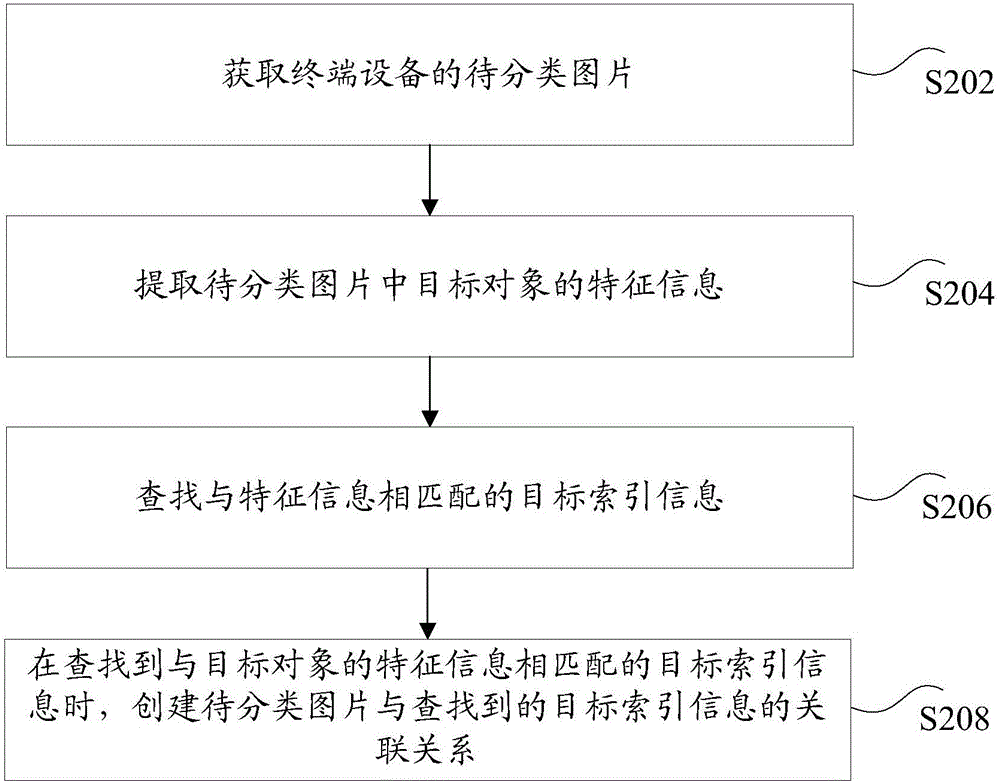

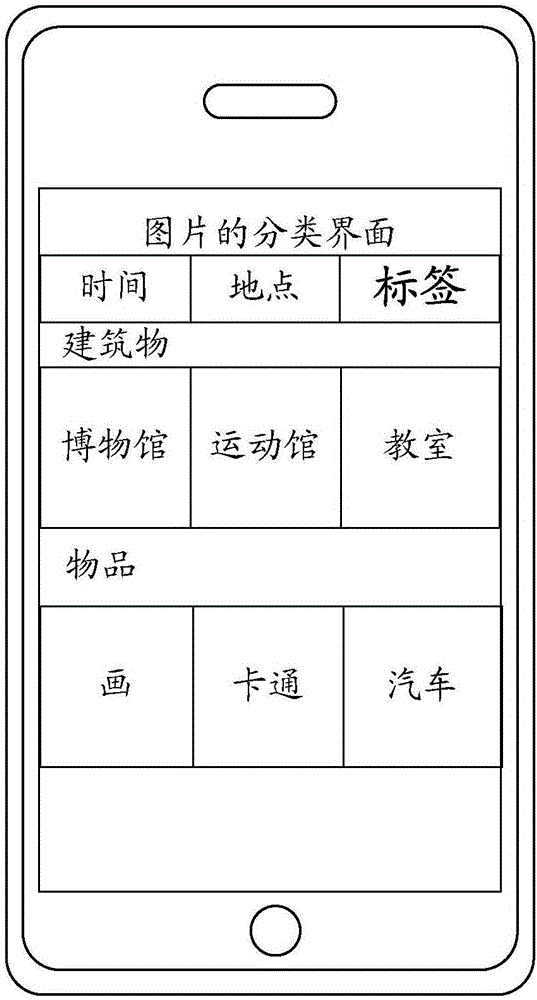

Picture classification method and apparatus

InactiveCN106445995ATo achieve the purpose of classificationImprove classification efficiencySpecial data processing applicationsTerminal equipmentClassification methods

Owner:TENCENT TECH (SHENZHEN) CO LTD

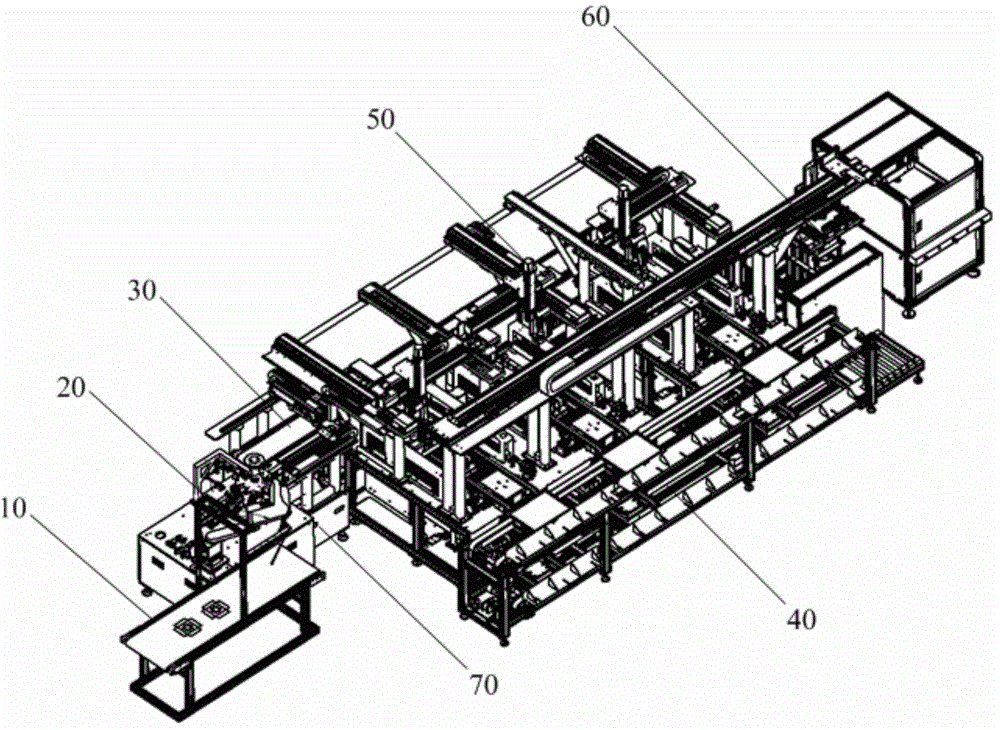

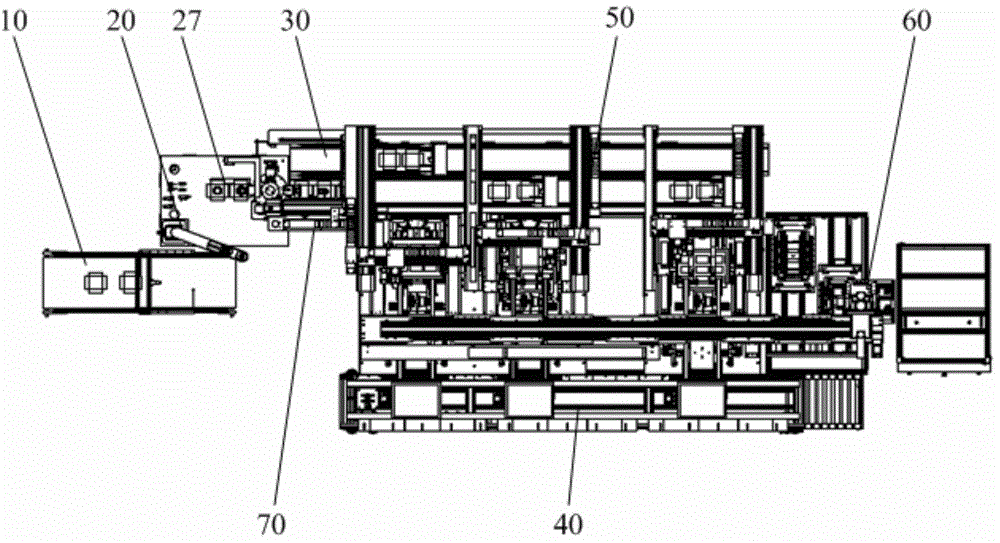

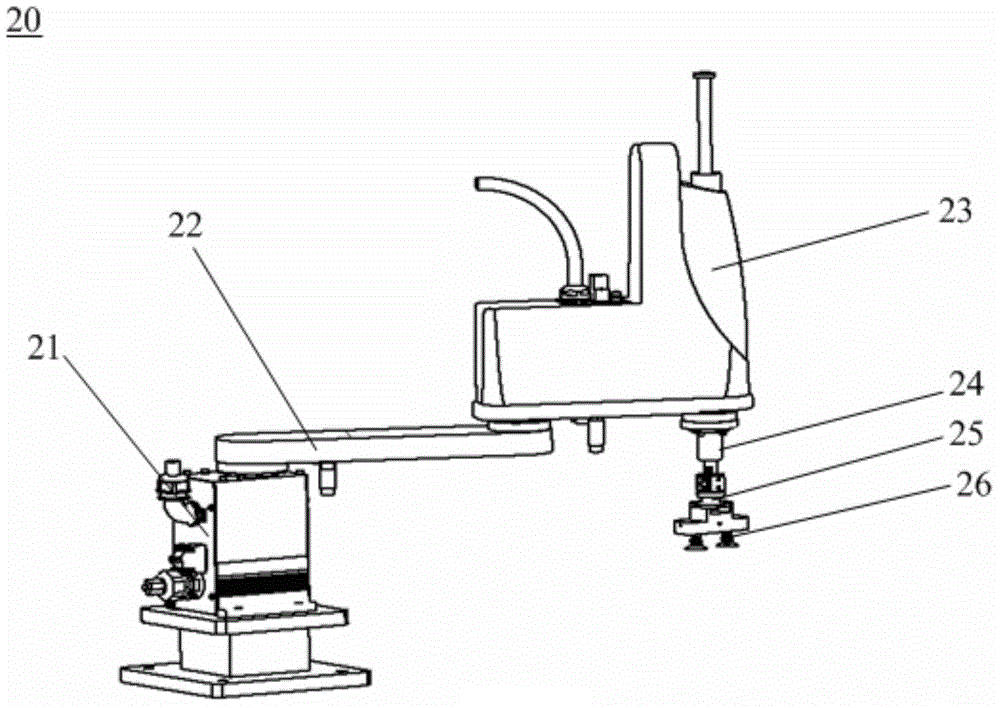

Liquid crystal module classified packaging device

ActiveCN104528038AEasy to operateImprove classification efficiencyConveyorsPackagingButt jointEngineering

The invention discloses a liquid crystal module classified packaging device which comprises a feeding assembly line, a four-axis mechanism arm, a liquid crystal module classification mechanism, a tray conveying mechanism, a liquid crystal module taking and placing mechanism and an interval paper conveying mechanism. The four-axis mechanism arm, the liquid crystal module classification mechanism, the tray conveying mechanism, the liquid crystal module taking and placing mechanism and the interval paper conveying mechanism are all fixed to a rack. The four-axis mechanism arm is located at the left end of the rack, the feeding assembly line is located in a work region of the four-axis mechanism arm, the liquid crystal module classification mechanism is adjacent to the four-axis mechanism arm, the liquid crystal module taking and placing mechanism is adjacent to the liquid crystal module classification mechanism and located at the rear end of the rack, the tray conveying mechanism is in butt joint with the liquid crystal module classification mechanism and located at the front end of the rack, and the interval paper conveying mechanism is adjacent to the tray conveying mechanism and located at the right end of the rack. The liquid crystal module classified packaging device is simple in operation and high in classified packaging efficiency and accuracy.

Owner:KUSN JINGXUN ELECTRONICS TECH

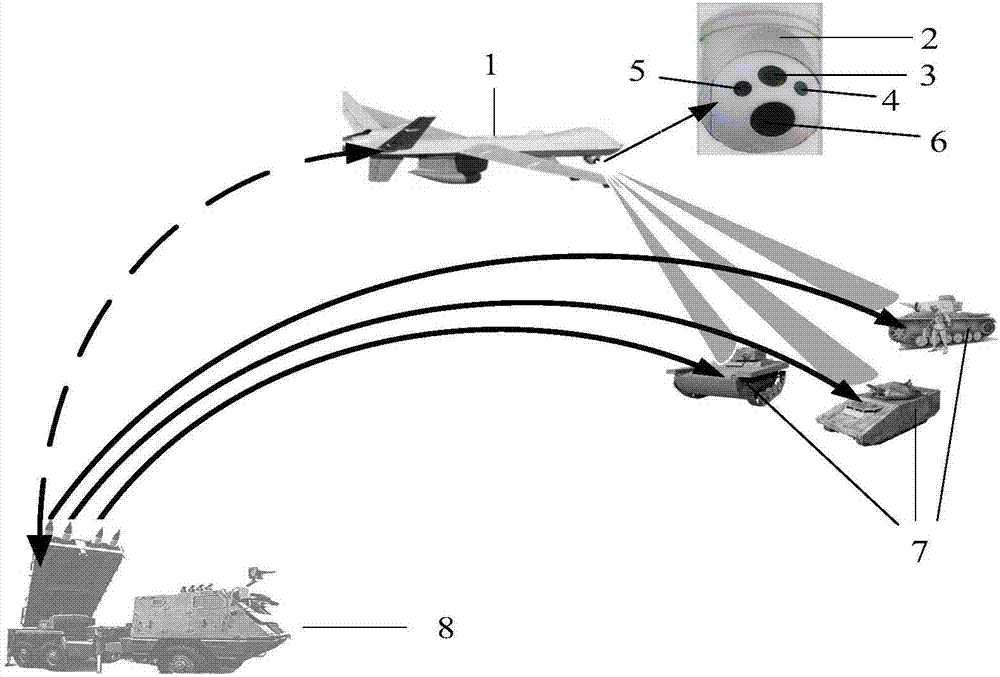

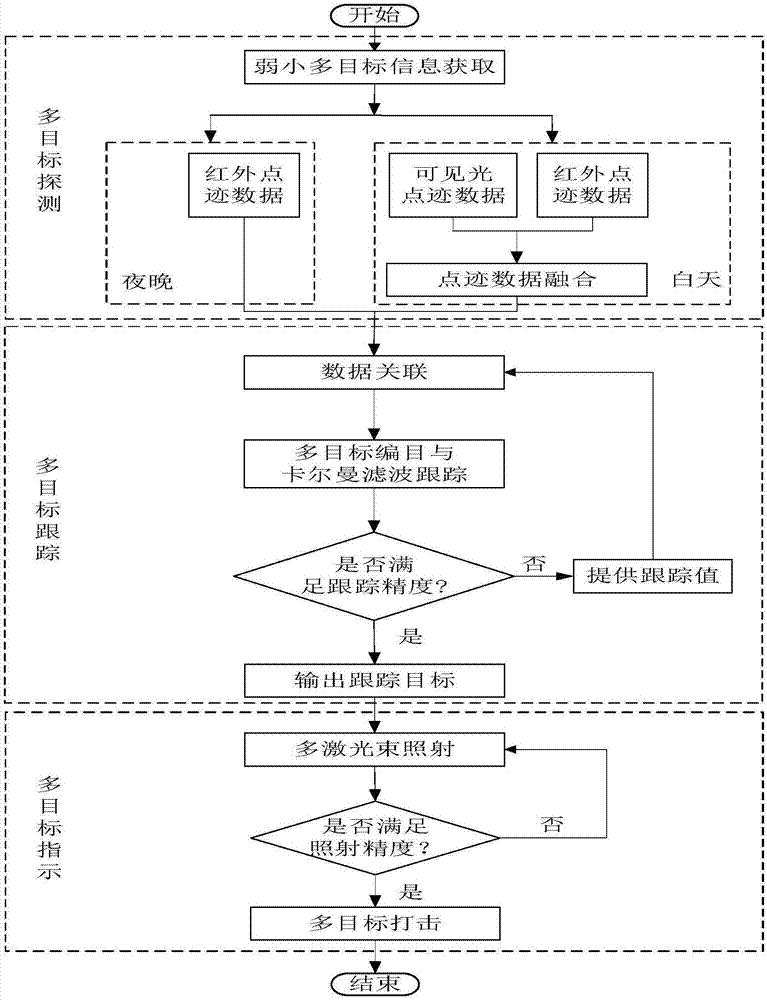

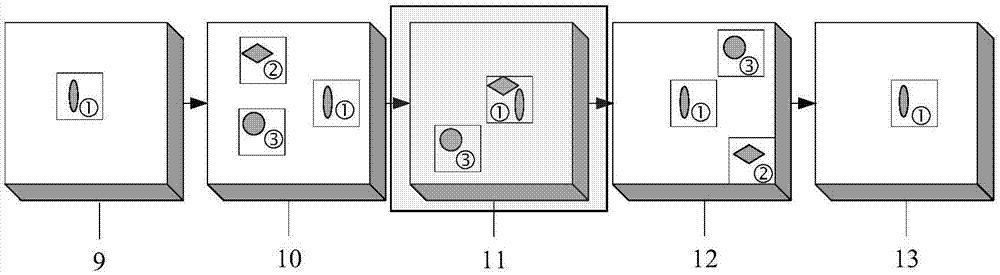

UAV onboard multi-target detection tracking and indication system and method

ActiveCN107977987AHigh precisionImprove robustnessImage enhancementImage analysisControl systemFeedback control

The invention discloses an UAV onboard multi-target detection tracking and indication system and method, and belongs to the technical field of target detection tracking and indication. The invention discloses an UAV onboard multi-target detection tracking and indication system comprising a multi-target detection and tracking system and a multi-target laser indication system. The multi-target detection and tracking system comprises an infrared camera, a visible light image sensor and a high-speed parallel image processing and tracking feedback control circuit. The multi-target indication systemincludes an integrated laser, a fast reflector, a fast reflector control module, and a laser control module. In order to improve laser indication accuracy, the UAV onboard multi-target detection tracking and indication system also includes a laser pointing control system. The invention also discloses an UAV onboard multi-target detection tracking and indication method based on the UAV onboard multi-target detection tracking and indication system. The UAV onboard multi-target detection tracking and indication system and method realize multi-target all-weather detection tracking and high-precision stable laser indication under the condition of a UAV onboard platform.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

Text classification method based on chi square statistics and SMO algorithm

InactiveCN103995876AImprove classification accuracy and efficiencyImprove classification accuracySpecial data processing applicationsText database clustering/classificationMachine learningWeight value

The invention discloses a text classification method based on chi square statistics and an SMO algorithm. The method comprises the steps that first, training texts are subjected to word segmentation, stop word removing and preprocessing, and then a chi square statistics quantity is used as a standard for selecting a set number of words to be used as feature words; then, the feature weight values of the training texts and testing texts are computed respectively; feature vectors of each training text and each testing text are converted into training document vector models and testing document vector models; and a trained classifier carries out classification on the feature vectors of the testing texts, and the classifying result of each testing text is obtained. According the method, the shortcomings that a lot of text classification features and a lot of noise exist due to the fact that all words are used as features can be overcome, and text classification accuracy and efficiency can be improved.

Owner:SHANGHAI UNIV

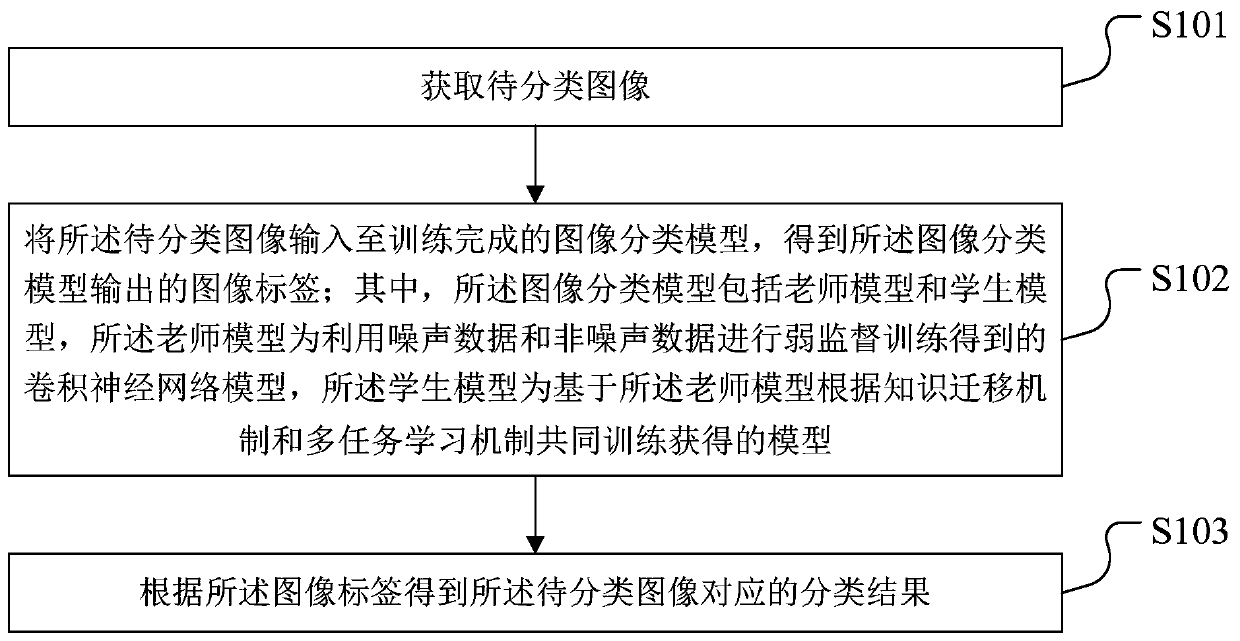

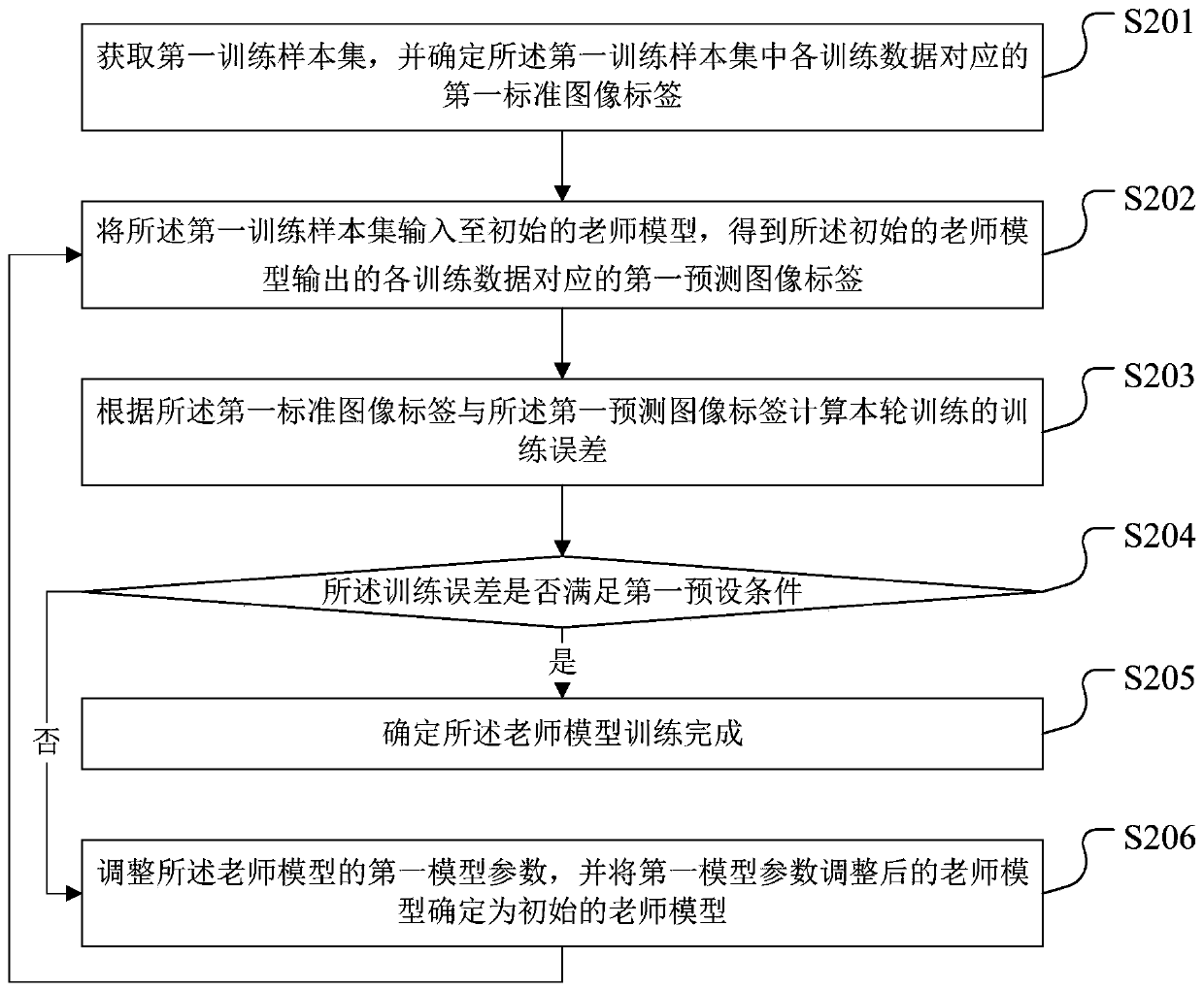

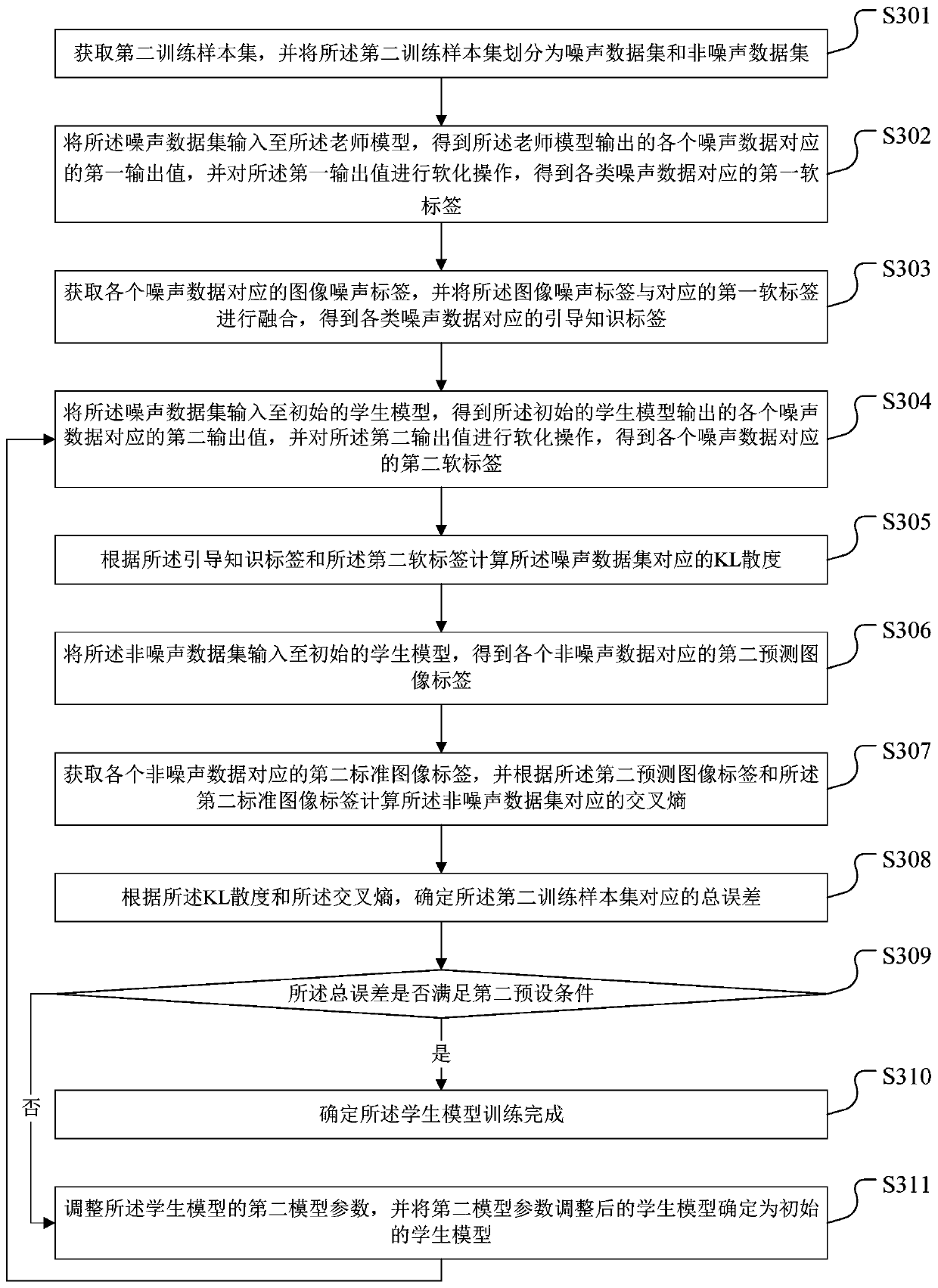

Image classification method and device, readable storage medium and terminal equipment

ActiveCN110147456AImprove classification efficiencyImprove classification accuracyCharacter and pattern recognitionStill image data clustering/classificationImaging processingClassification methods

The invention relates to the technical field of image processing, in particular to an image classification method and device, a storage medium and terminal equipment. The image classification method provided by the invention comprises the following steps: obtaining a to-be-classified image; inputting the to-be-classified image into a trained image classification model to obtain an image label output by the image classification model, wherein the image classification model comprises a teacher model and a student model, and the teacher model is a convolutional neural network model obtained by carrying out weak supervision training by utilizing noise data and non-noise data, and the student model is a model obtained by carrying out joint training according to a knowledge migration mechanism and a multi-task learning mechanism based on the teacher model; obtaining a classification result corresponding to the to-be-classified image according to the image label, using the teacher model to perform knowledge migration, and using the noise data and the non-noise data to perform multi-task learning training, thereby improving the classification efficiency and the classification accuracy of the image classification model.

Owner:SHENZHEN INST OF ADVANCED TECH CHINESE ACAD OF SCI

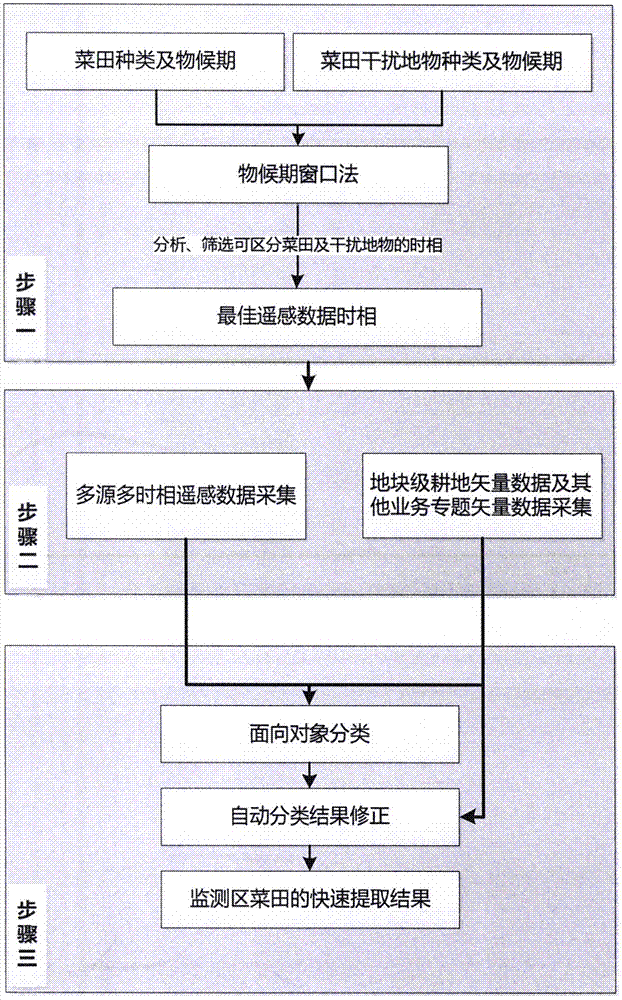

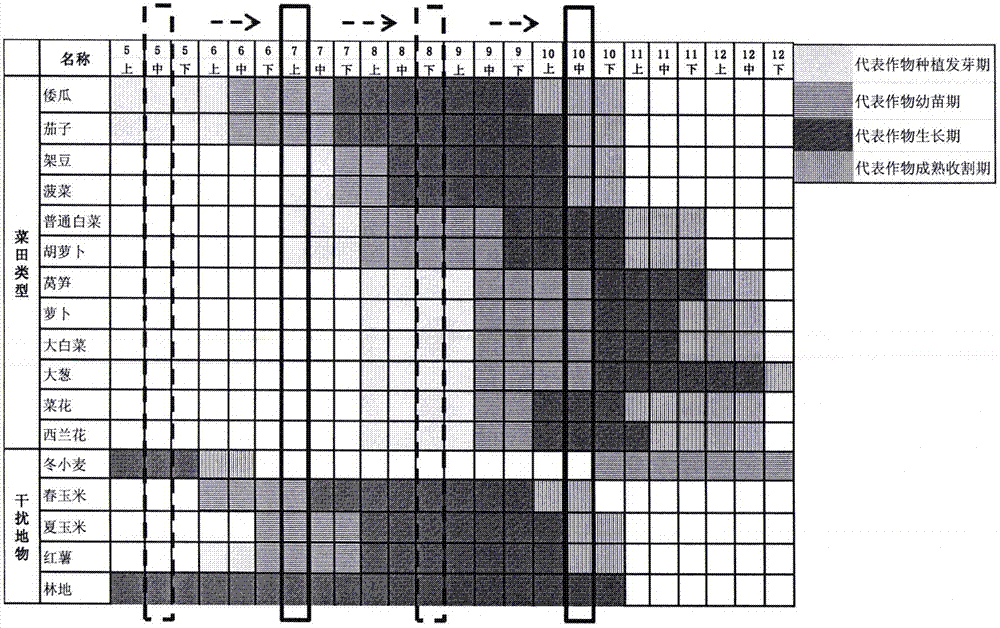

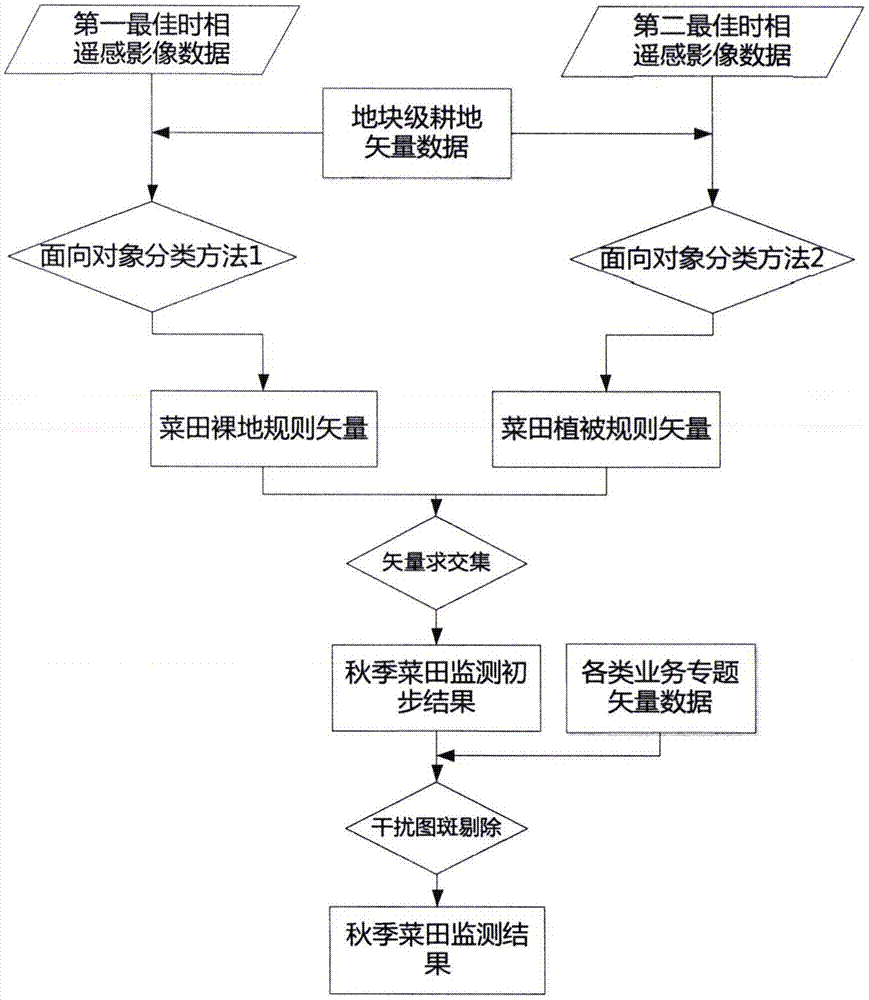

Vegetable field monitoring method based on multi-source multi-temporal remote sensing image data

ActiveCN105447494ATake texture into accountTaking into account the spectral characteristicsCharacter and pattern recognitionClassification methodsRemote sensing application

The present invention belongs to the technical field of remote sensing application, and discloses a vegetable field monitoring method based on multi-source multi-temporal remote sensing image data. The method comprises the steps of: determining a type and a phenological phase of a vegetable field and an interfering ground object, and selecting optimal phases of vegetable field and interfering ground object identification; acquiring multi-source multi-temporal remote sensing image data and service specific vector data; and by using an object-oriented classification method and combining parcel-level cultivated land vector data, performing vegetable field data extraction, and extracting vegetable data according to the two optimal phases and taking an intersection, so as to obtain a vegetable field monitoring result. According to the method, vegetable field monitoring is performed based on multi-source multi-temporal remote sensing image data, so that influence of interfering ground object is effectively reduced, and monitoring precision is improved.

Owner:TWENTY FIRST CENTURY AEROSPACE TECH CO LTD

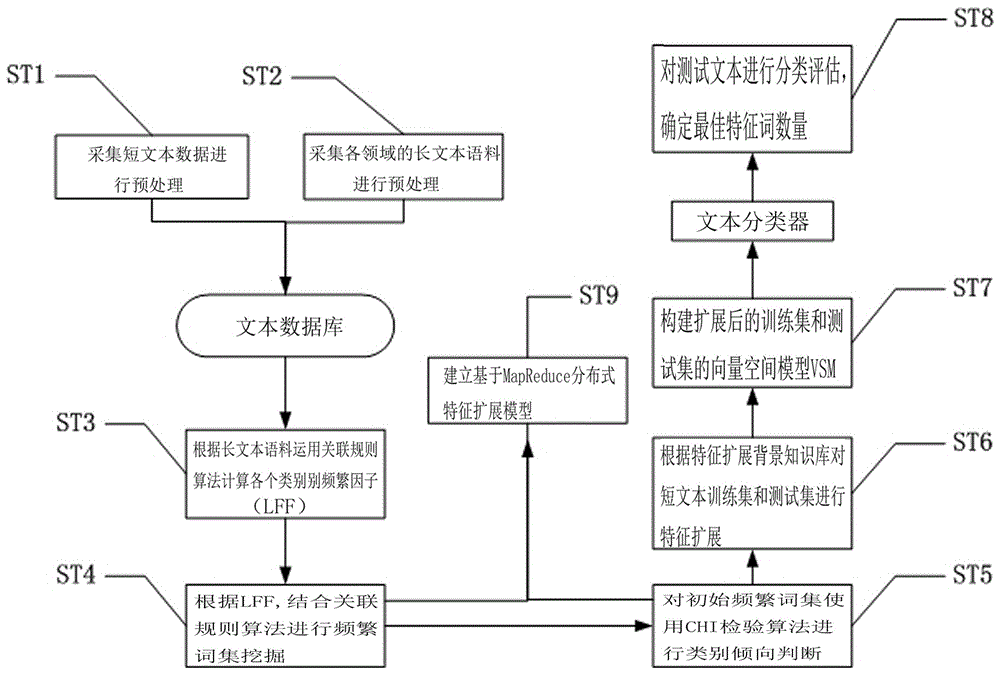

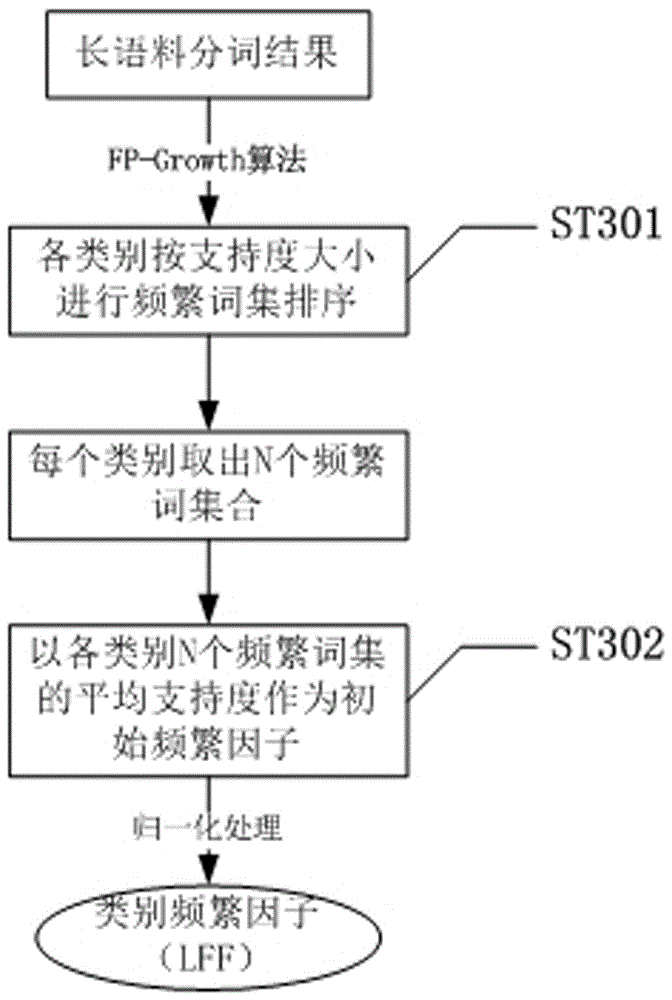

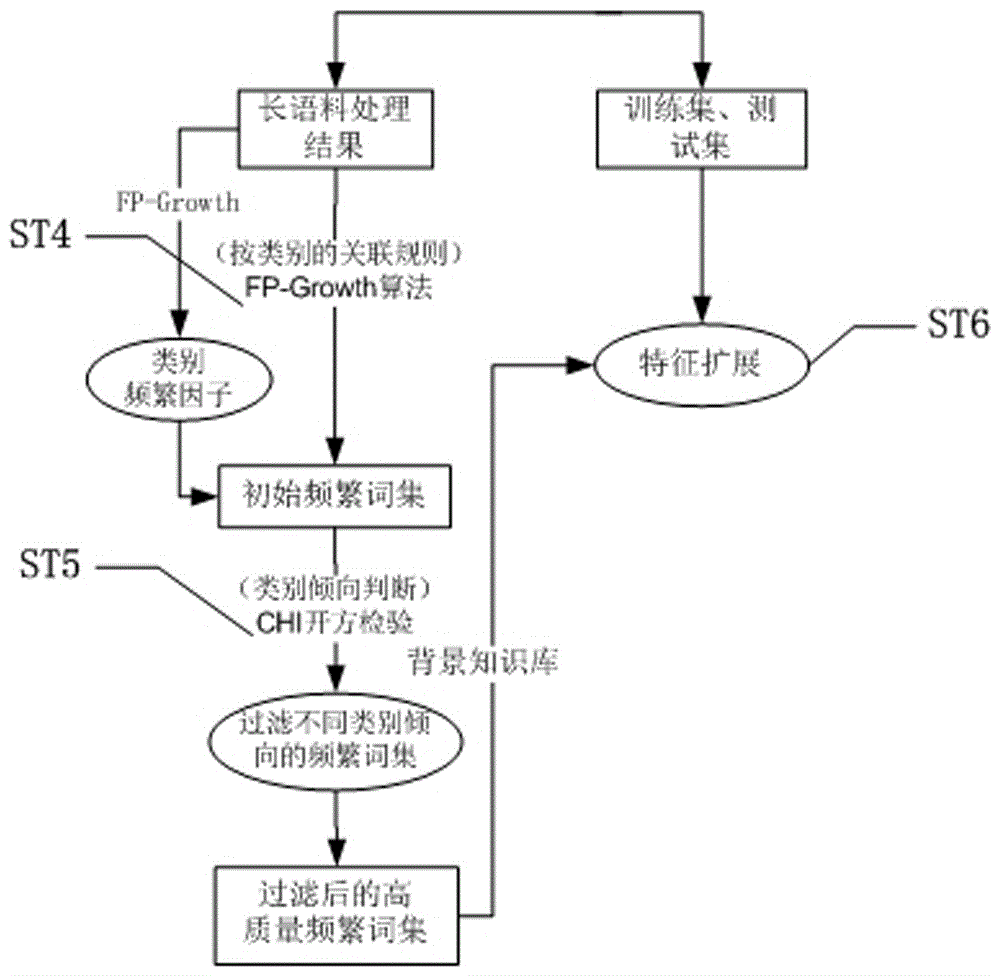

Short text classification method based on CHI and classified association rule algorithm

ActiveCN106202518AOvercoming skewed situationsImprove controllabilitySpecial data processing applicationsText database clustering/classificationAlgorithmText categorization

The invention provides a short text classification method based on CHI and a classified association rule algorithm. The frequencies of frequent word sets of different types of texts are measured, a category frequent factor (LFF) is introduced, the minimum support threshold values of text categories are reasonably allocated through the LFF, the phenomenon that frequent word set categories mined by adopting a traditional FP-Growth algorithm are deflective is avoided, meanwhile category tendency judgment is conducted on the frequent word sets, a CHI checking algorithm is adopted to measure the relevance degree of characteristic words and the categories instead of measurement based on simple word frequency statistics, the step that best parameters are determined through manual parameter setting and experiments is omitted, and the controllability of a classification system is enhanced. In addition, the invention further provides a parallel characteristic extension short text classification algorithm based on a Hadoop / MapReduce big data computing platform. MapReduce parallelization design is conducted on a category frequent factor calculating and characteristic extension method, the short text classification accuracy rate and classification efficiency are improved, and the controllability of the system is improved.

Owner:GUILIN UNIV OF ELECTRONIC TECH

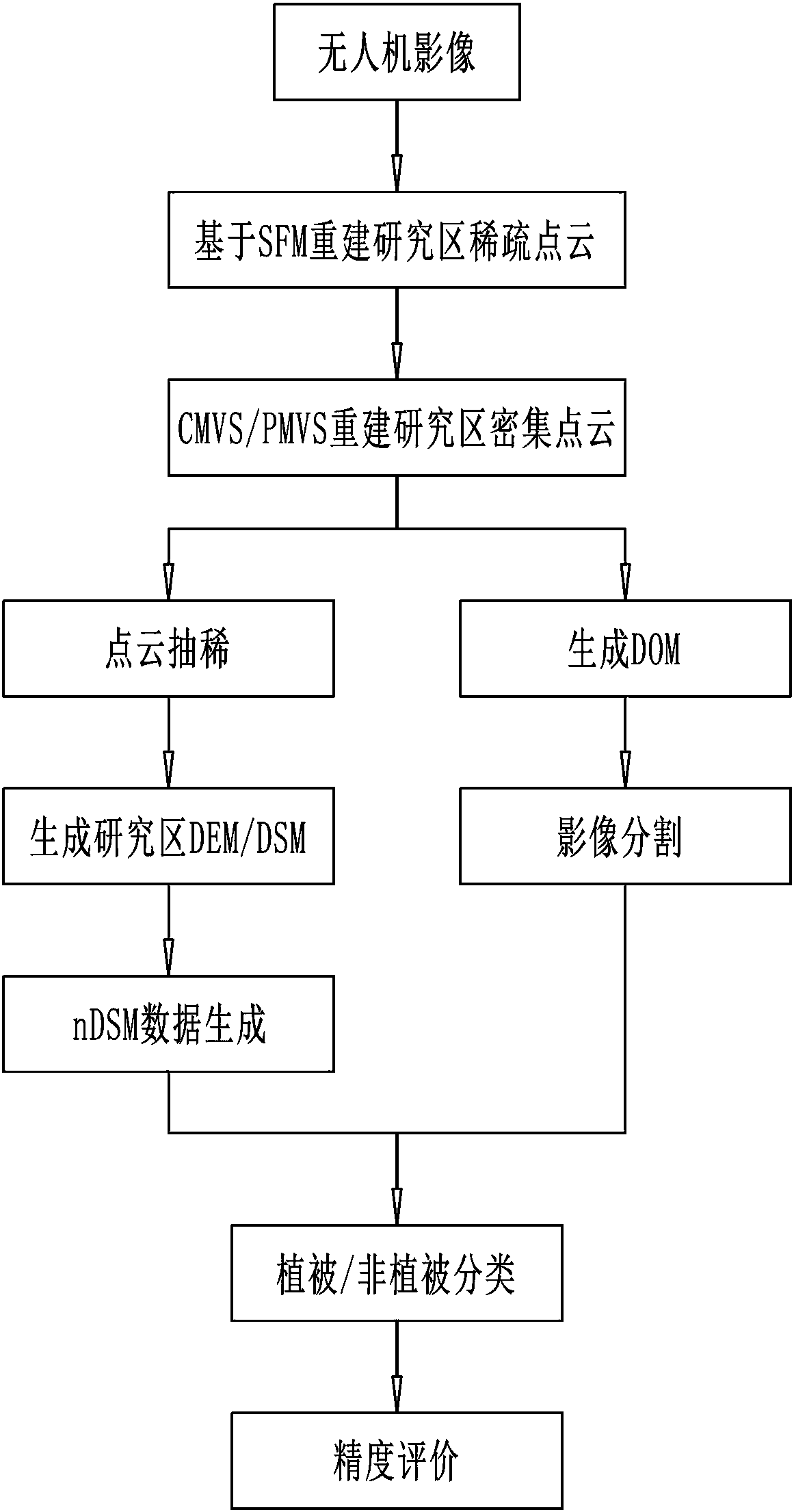

Urban vegetation classification method based on unmanned aerial vehicle images and reconstructed point cloud

ActiveCN108363983AHigh precisionImprove classification efficiencyCharacter and pattern recognitionStructure from motionPoint cloud

The present invention provides an urban vegetation classification method based on unmanned aerial vehicle images and reconstructed point cloud. The method comprises the steps of: performing point cloud reconstruction of original unmanned aerial vehicle images; generating nDSM (normalized digital surface model) information of a research area; performing vegetation index calculation based on visiblelight; and performing classification discrimination of image objects. The method provided by the invention reconstructs point cloud of the research area based on a structure from motion (SFM) and cluster multi-view stereo (CMVS) and based on a patch-based multi-view stereo (PMVS) algorithm, performs filtering and interpolation to generate a digital elevation model (DEM) of the research area and the nDSM, and combines image spectral information to perform classification extraction of urban vegetations with different heights; an image analysis method facing the objects is employed to achieve differentiation of the categories of vegetations with different heights according to spectral information such as the nDSM information, normalized green-red difference indexes (NGRDI) and visible lightwave band difference vegetation indexes (VDVI) so as to greatly improve the differentiation precision.

Owner:HENAN POLYTECHNIC UNIV

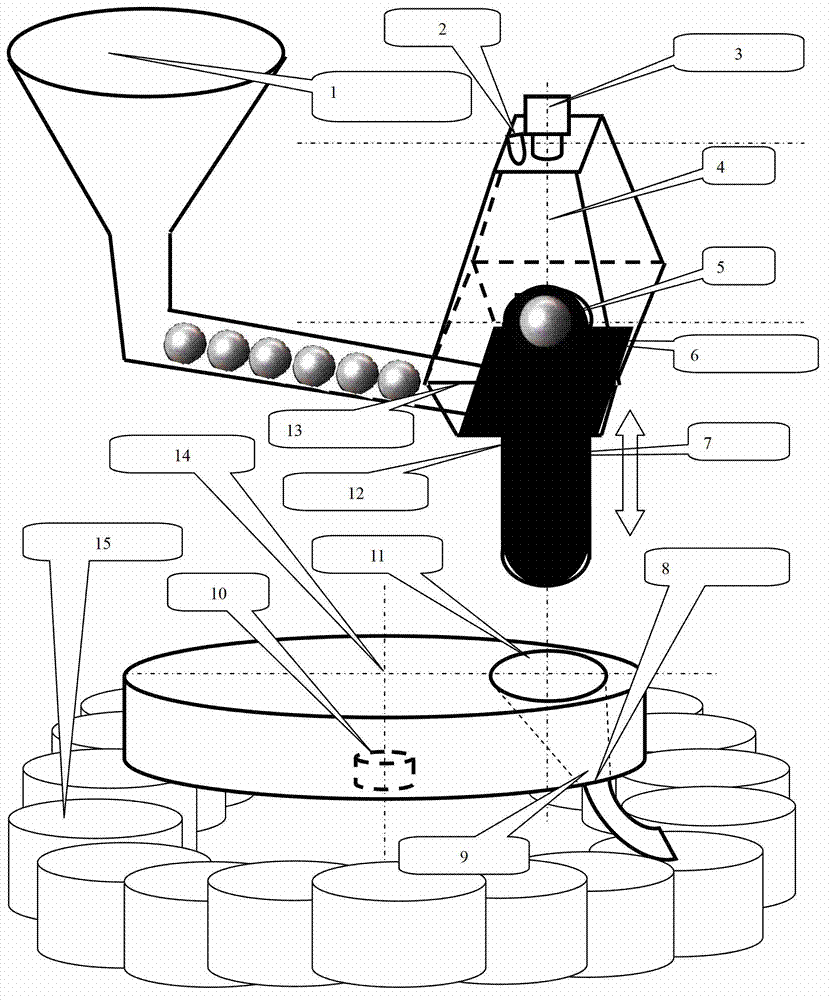

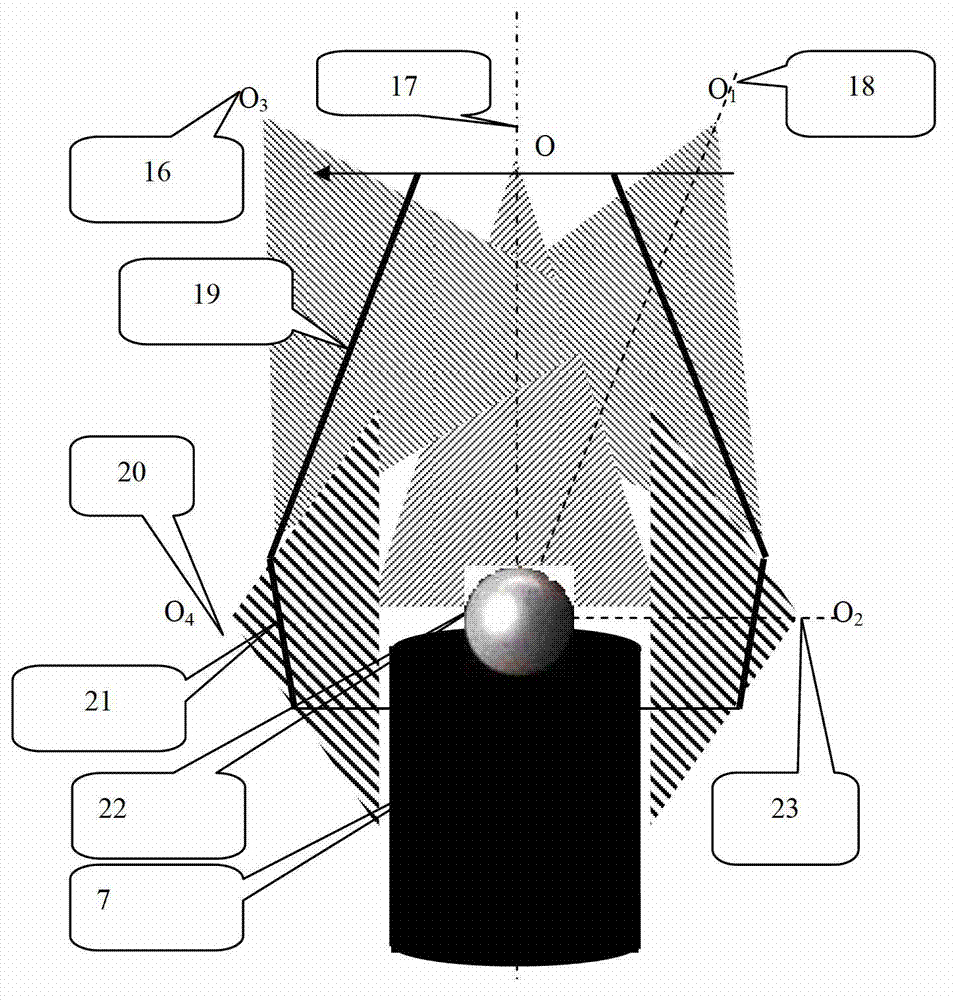

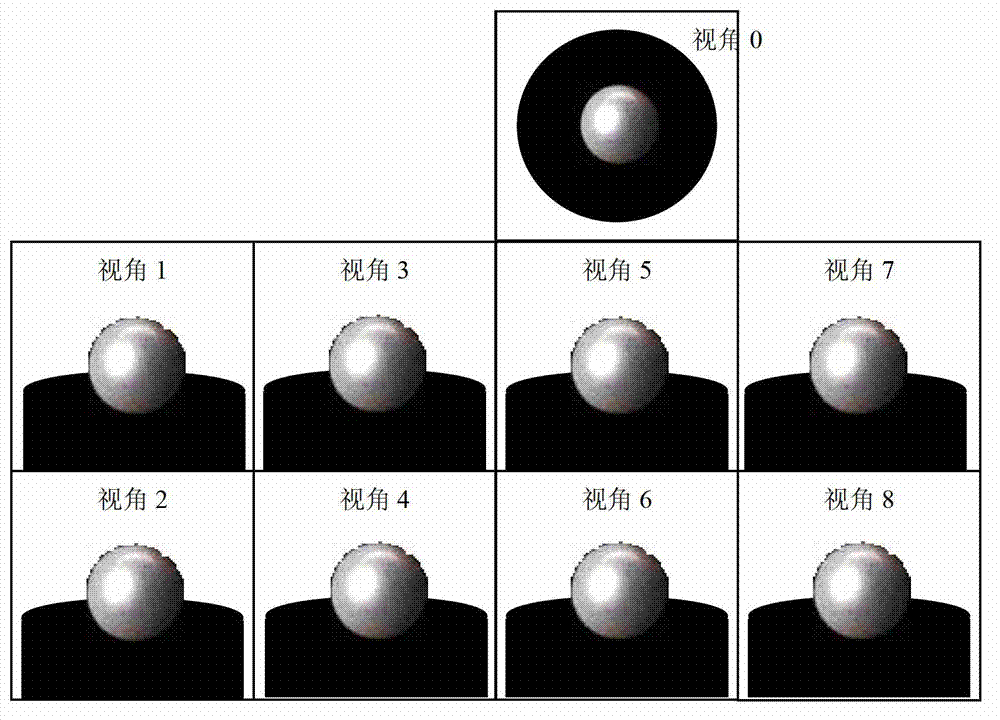

Device for automatically grading pearls on line according to size and shape on basis of monocular multi-view machine vision

ActiveCN102928431ASimplify complexityImprove detection efficiencyInvestigating jewelsUsing optical meansMachine visionImaging processing

The invention relates to a device for automatically grading pearls on line according to the size and the shape on the basis of monocular multi-view machine vision. The device comprises a flow line, a monocular multi-view machine vision device and a microprocessor, wherein the flow line is used for automatically detecting and classifying pearls and comprises a feeding action mechanism, an inspection action mechanism, a discharging action mechanism, a classifying action mechanism and a classifying execution mechanism; the multi-view machine vision device is used for shooting images of pearls to be detected; and the microprocessor is used for carrying out image processing, detecting, identifying and classifying on the pearls to be detected and coordinately controlling coordinated action of the action mechanisms. The device for automatically grading the pearls on line according to the size and the shape on the basis of the monocular multi-view machine vision, disclosed by the invention, has the advantages of simple mechanism, low manufacturing cost, capability of meeting the detection of quality indexes, such as size and shape, high grading efficiency, convenience for use and maintenance and high automation degree.

Owner:ZHEJIANG UNIV OF TECH

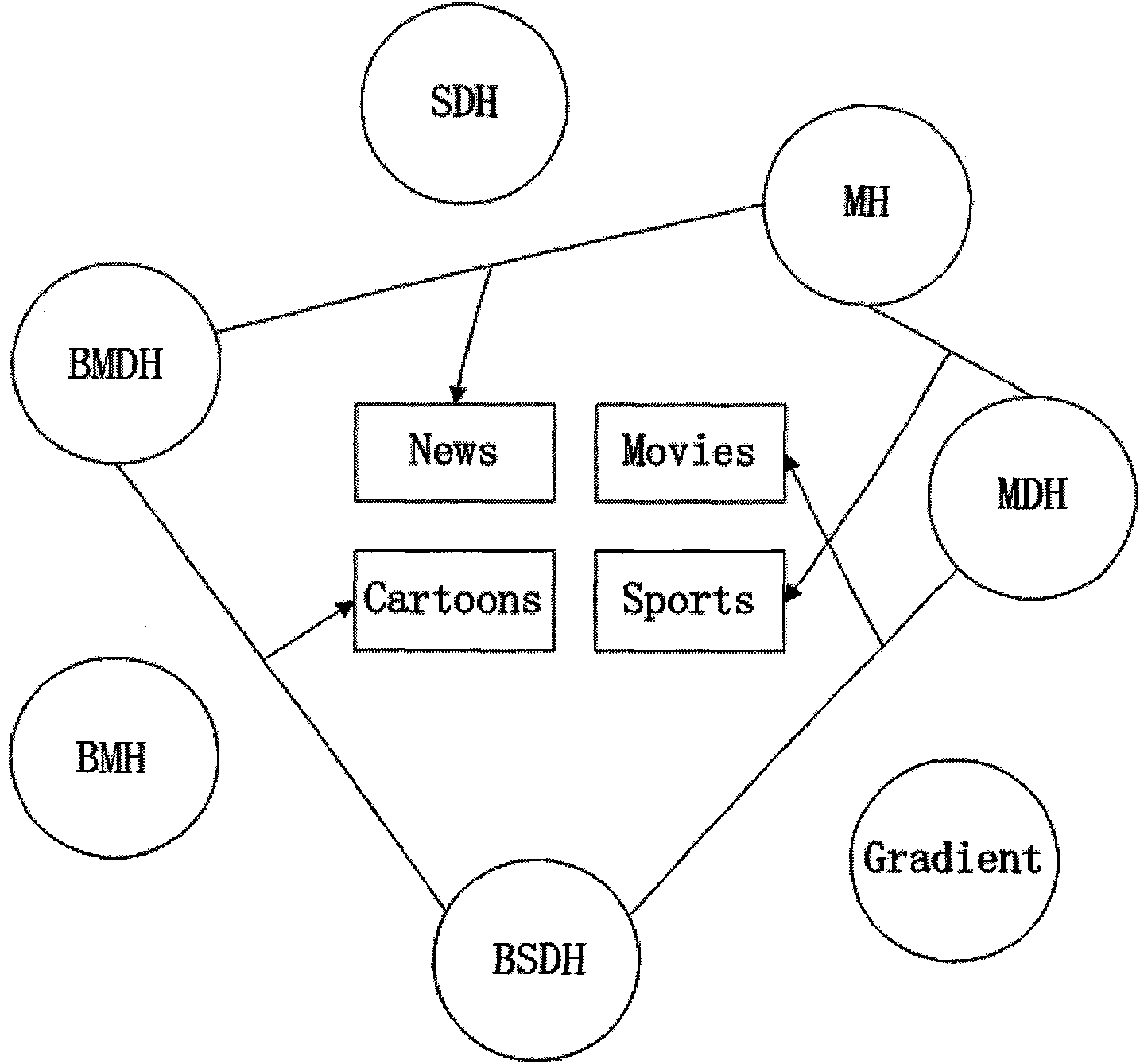

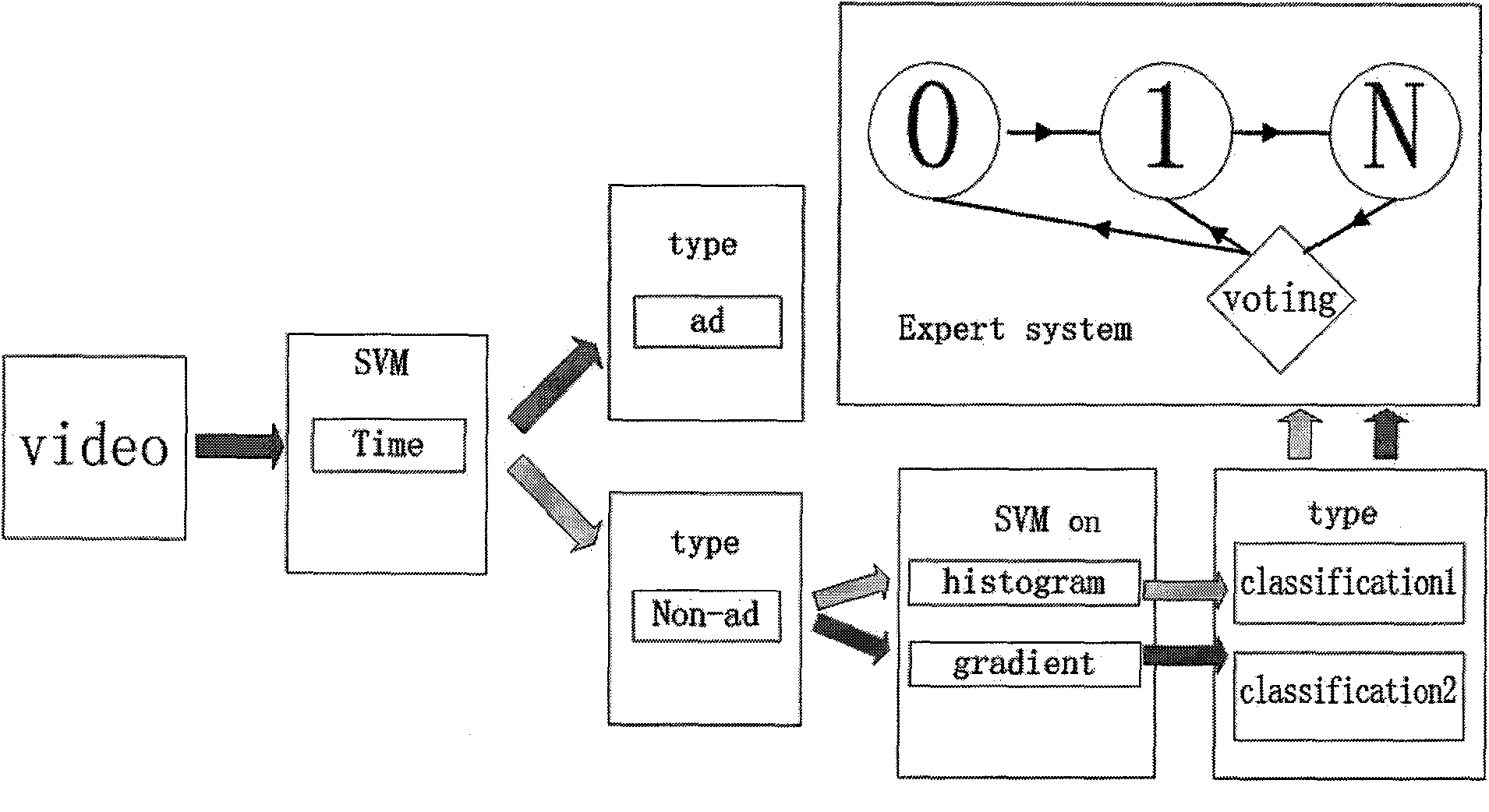

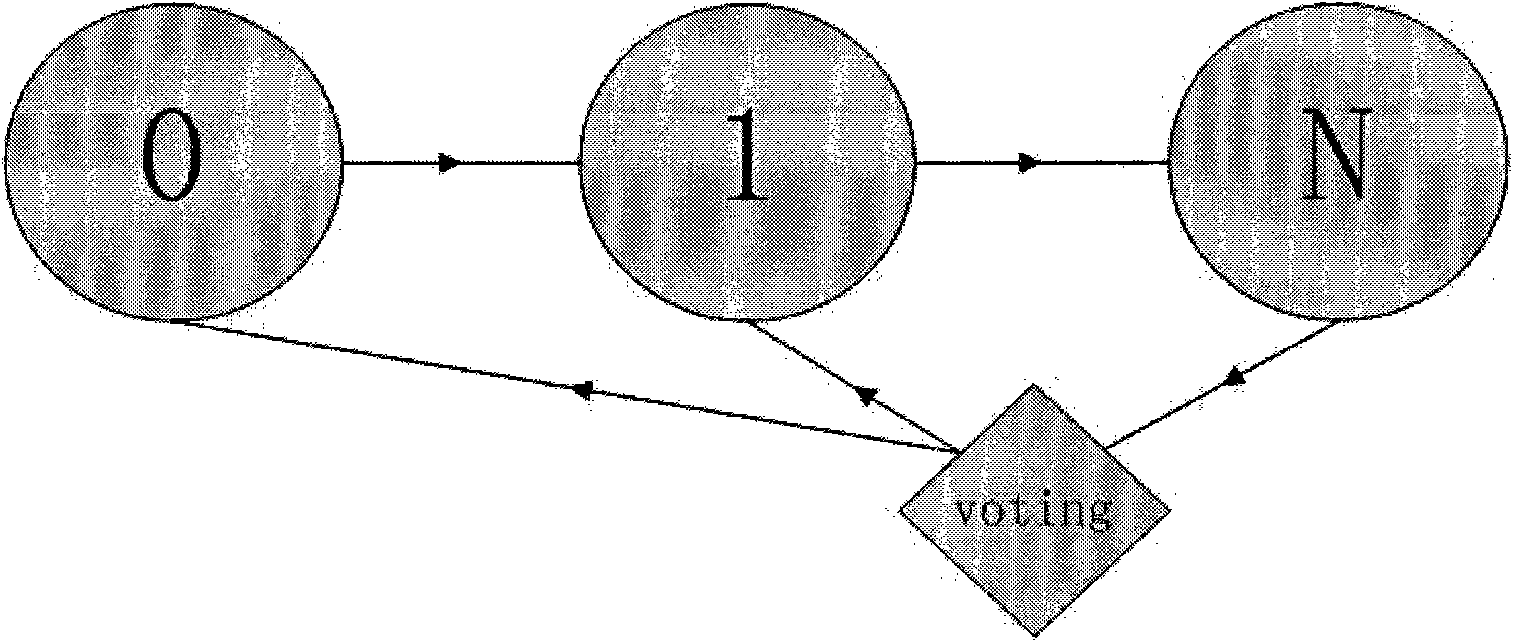

Content-based video classification method

InactiveCN101894125AImprove classification efficiencyImprove classification effectSpecial data processing applicationsClassification methodsVideo processing

The invention belongs to the technical field of computer video treatment and particularly discloses a video classification method. The time and color feature fusion-based classification method is provided by taking cartoons, commercial advertisements, films, news and athletic contests as classification objects, determining to select a color with the best classification effect from bottom-layer features (such as color, texture and shape) of a video as a classification feature on the basis of summarizing and analyzing conventional classification algorithms, and performing comparison, analysis and summarization on various classification algorithms based on the color feature. As each feature has a preference for a certain type of video classification effect and the preference is referred to as an expert feature of the video of the type, an expert system is further used for making the features cooperate to improve the classification accuracy and the efficiency at the same time.

Owner:FUDAN UNIV

Method for carrying out mangrove forest map making on intermediate resolution remote sensing image by utilizing object-oriented classification method

The invention relates to a method for carrying out mangrove forest map making on intermediate resolution remote sensing image by utilizing object-oriented classification method, which relates to a method for mangrove forest map making and solves the problems of time and labor waste, bad timeliness and serious neglected and wrong classification of mangrove forest in positioning and map making of mangrove forest map making through conventional means at present. The method comprises the following steps: firstly, carrying out ortho-rectification and geometric exact correction on Landsat TM data so as to obtain Landsat TM images after registration; secondly, carrying out multi-layered multi-dimensioned division on the Landsat TM images after registration, wherein each division unit is used as an object; thirdly, extracting textural and topological characteristics, and calculating normalized vegetation index and ground surface humidity index; fourthly, removing a non-vegetated object so as to obtain a vegetated object; fifthly, extracting a mangrove forest object from the vegetated object; sixthly, exporting the mangrove forest object so as to generate a mangrove forest vector; and seventhly, manufacturing a mangrove forest thematic map. The method disclosed by the invention is used for mangrove forest map making.

Owner:NORTHEAST INST OF GEOGRAPHY & AGRIECOLOGY C A S

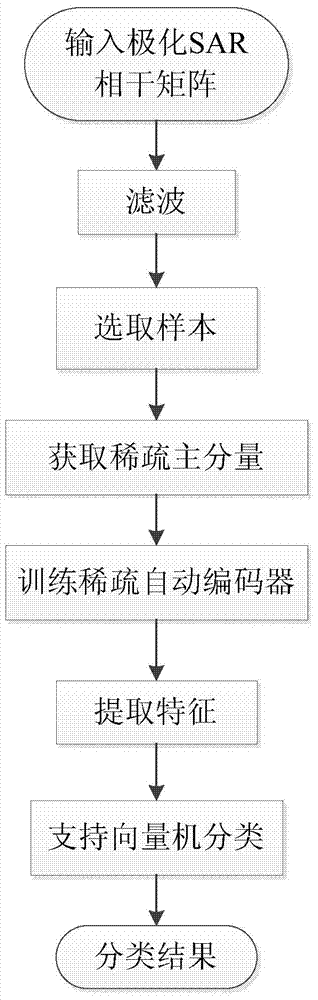

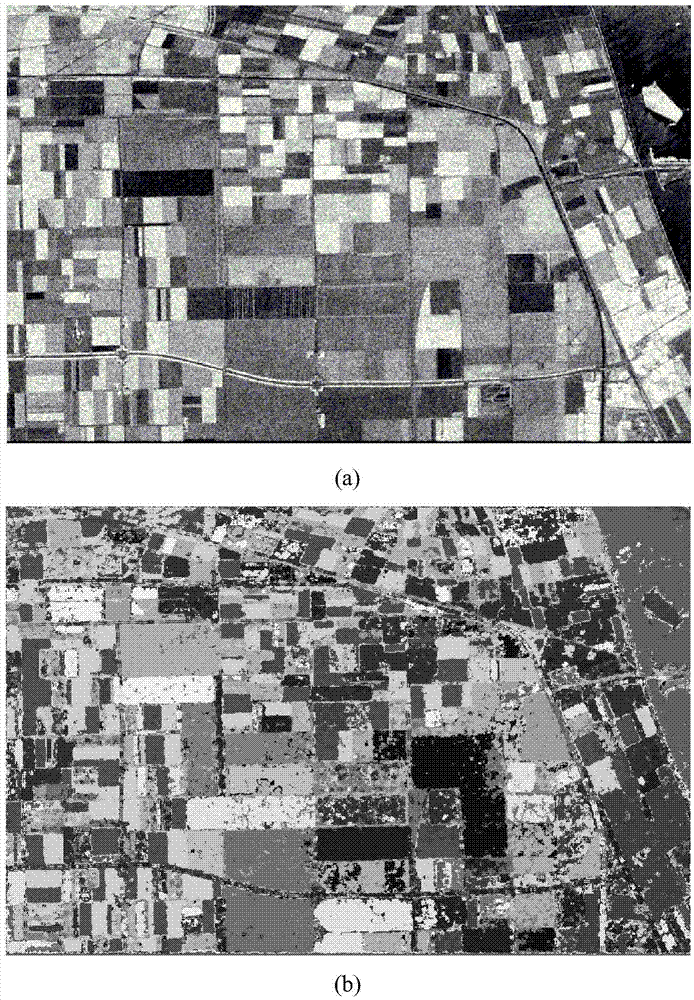

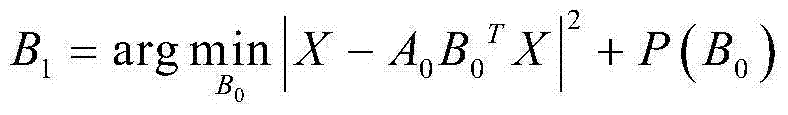

Polarized SAR image classifying method based on sparse automatic encoder

ActiveCN103886336AImprove classification efficiencyOvercoming the drop in classification accuracyCharacter and pattern recognitionClassification methodsImaging Feature

The invention discloses a polarized SAR image classifying method based on a sparse automatic encoder. The problem that extraction of polarized SAR image features is influenced by data irrelevance and redundancy, accordingly the classifying process is complicated and unreasionabl feature selection causes low classifying accuracy is mainly solved. The polarized SAR image classifying method based on the sparse automatic encoder comprises the specific steps of 1 inputting coherence matrixes of polarized SAR images to be classified; 2 perform filtering, 3 selecting samples; 4 obtaining sparse principal components; 5 training the sparse automatic encoder; 6 extracting the features; 7 performing classification through a support vector machine; 8 outputting a classification result. The polarized SAR image classifying method has the advantage of having remarkable polarized SAR image classifying effect and can be further used for target detection and target recognition of the polarized SAR images.

Owner:XIDIAN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com