Device for automatically grading pearls on line according to size and shape on basis of monocular multi-view machine vision

A machine vision and automatic grading technology, which is applied in the direction of measuring devices, optical devices, instruments, etc., can solve the problems of high manufacturing cost, difficulty in meeting detection needs, low detection and grading efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0052] The present invention will be further described below in conjunction with the accompanying drawings.

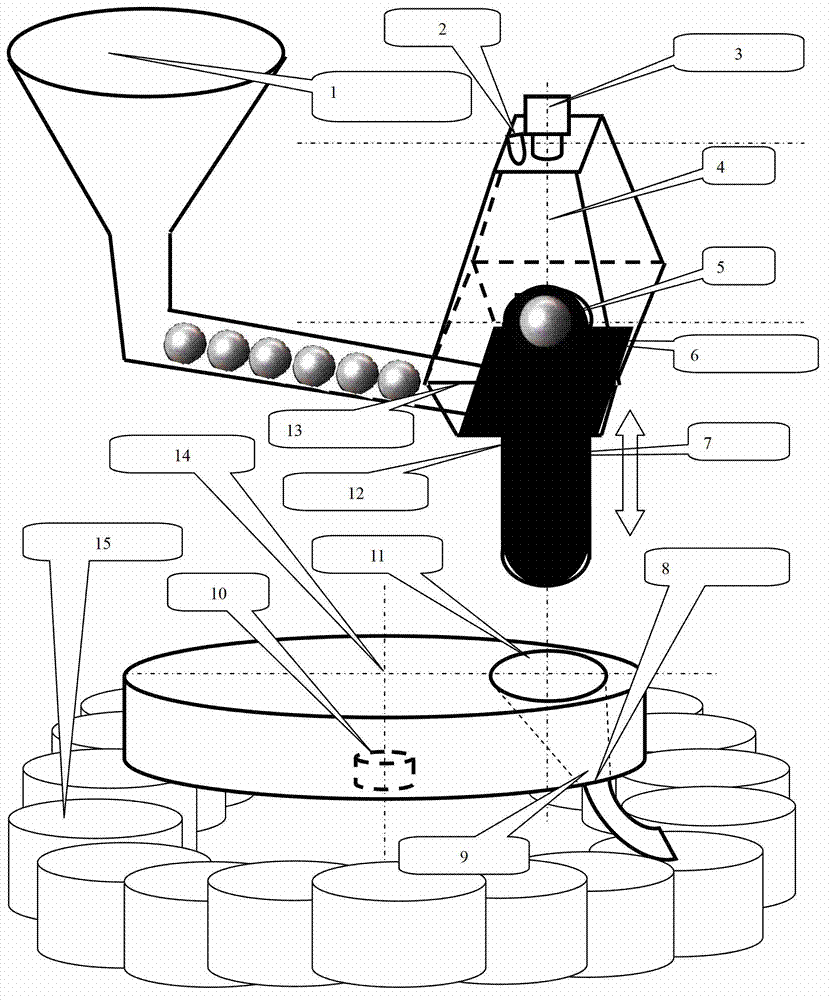

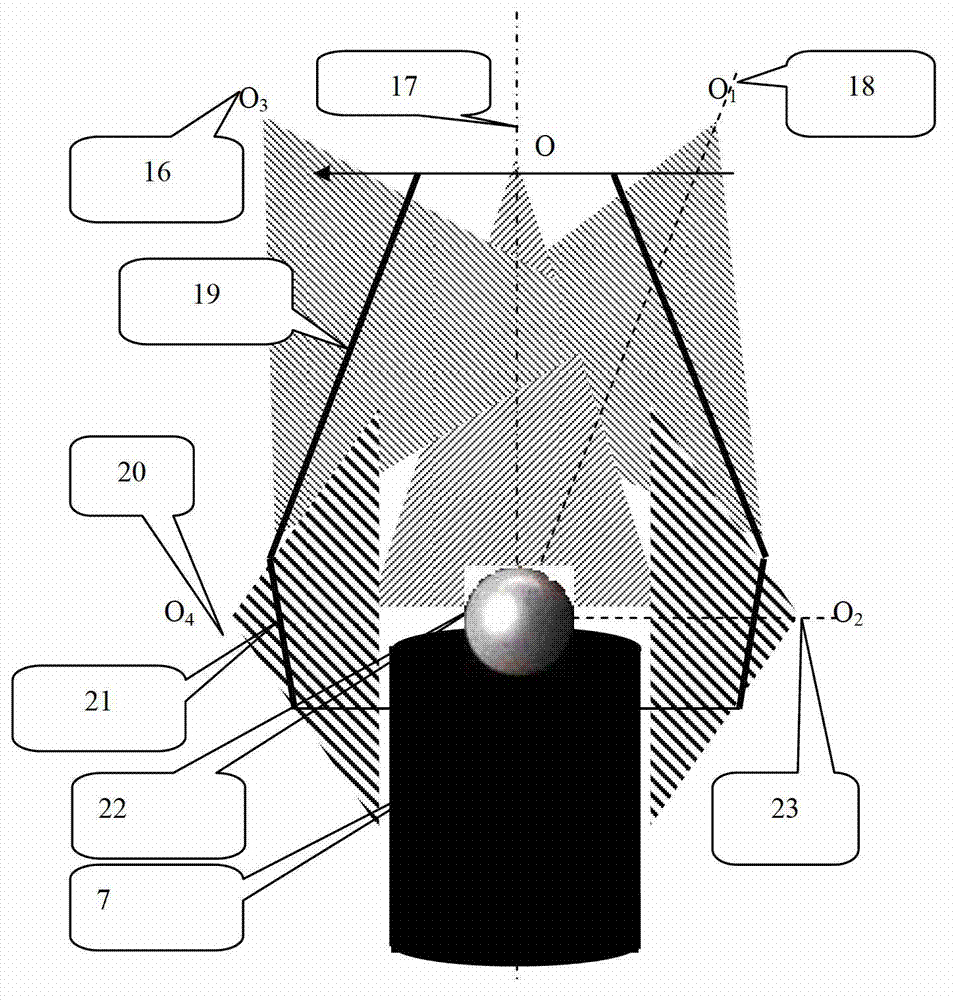

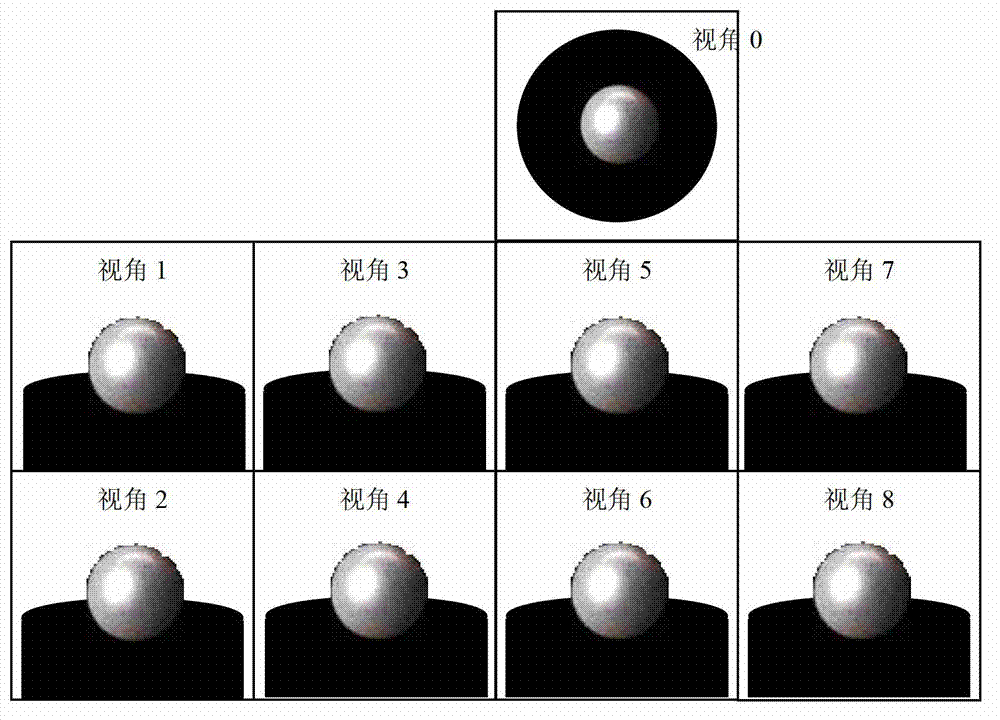

[0053] refer to Figure 1 to Figure 9, an online automatic grading device for pearl size and shape based on monocular multi-viewpoint machine vision, including an assembly line for automatic detection and classification of pearls, a monocular multi-viewpoint machine vision device for shooting images of inspected pearls and a device for A microprocessor that performs image processing, detection, identification, classification, and coordinated actions of various action mechanisms on the assembly line for the image of the inspected pearl, and the assembly line includes a The feeding action mechanism for feeding pearls to the feeding input port, the inspection sending action mechanism for lifting the inspected pearls into the visual inspection box for visual analysis, and the flip plate for the movable ejector rod of the inspection sending action mechanism The unloading a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com