Patents

Literature

1295 results about "Form processing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Forms processing is a term used for describing the conversion of hard data into electronic form. Forms processing typically denotes an imaging method that converts printed forms to an electronic format, and then hand-written information is extracted from them using highly sensitive algorithms.

Computerized verification form processing system and method

InactiveUS6272506B1Data processing applicationsNatural language data processingForm processingDatabase

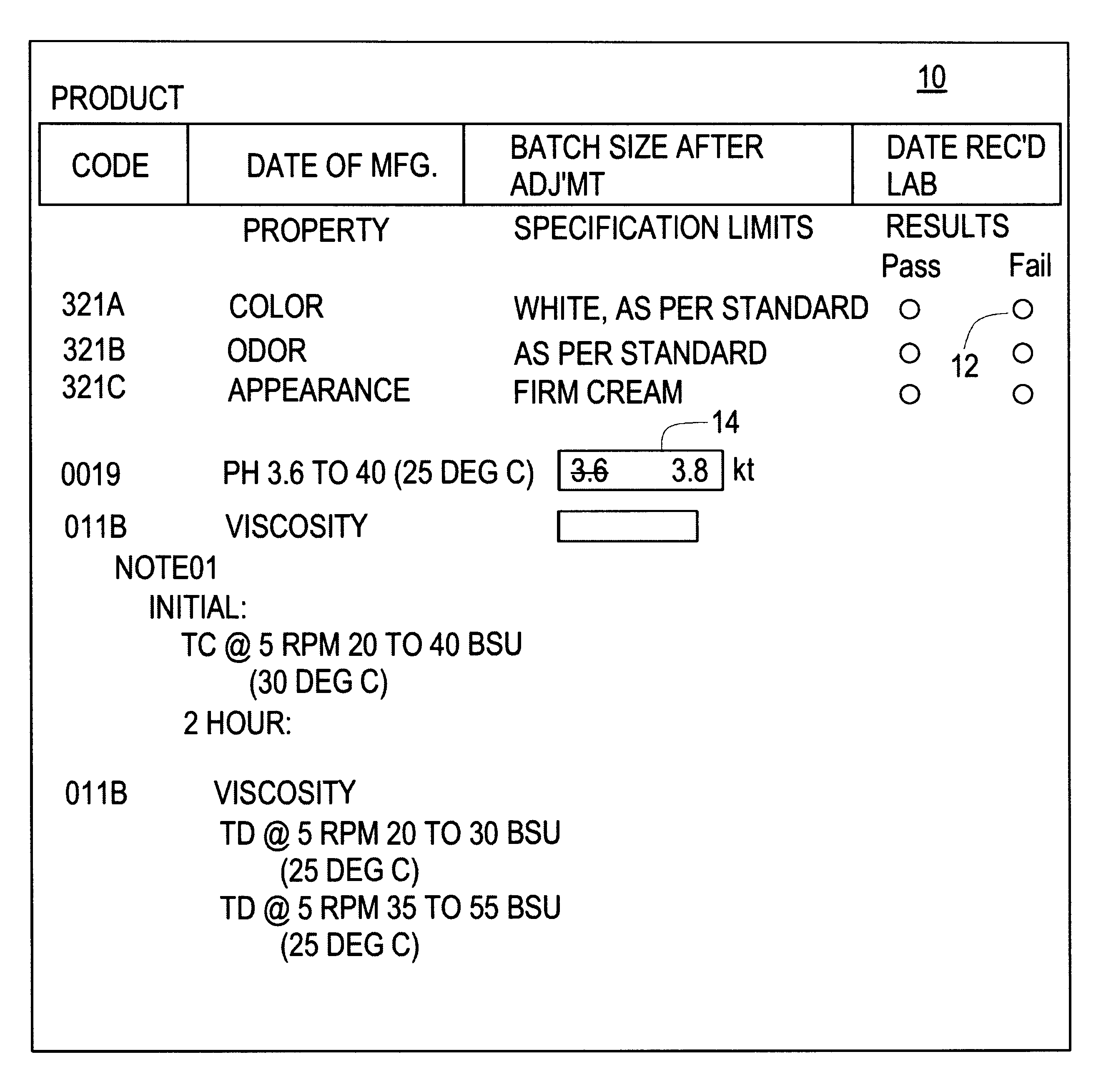

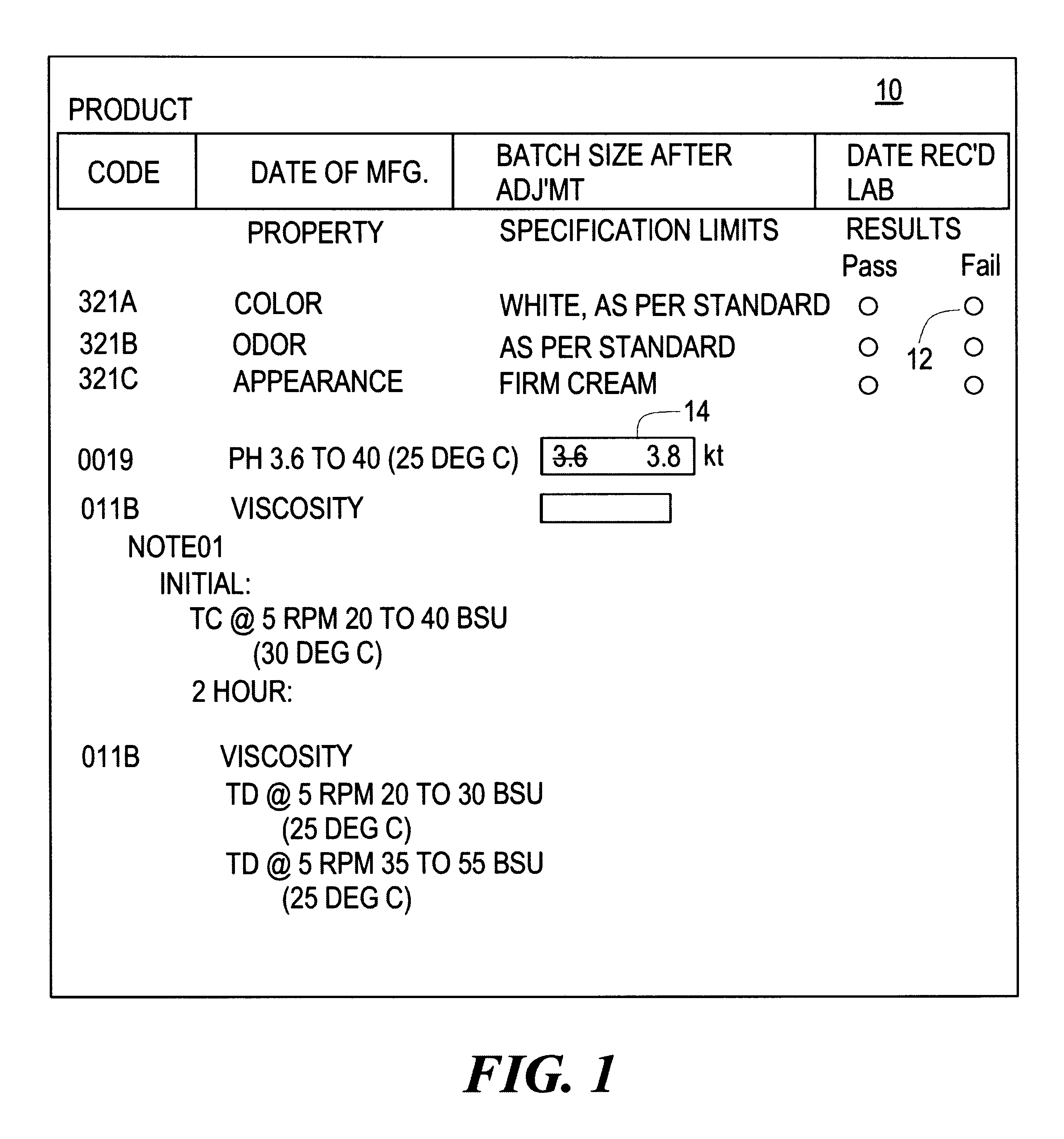

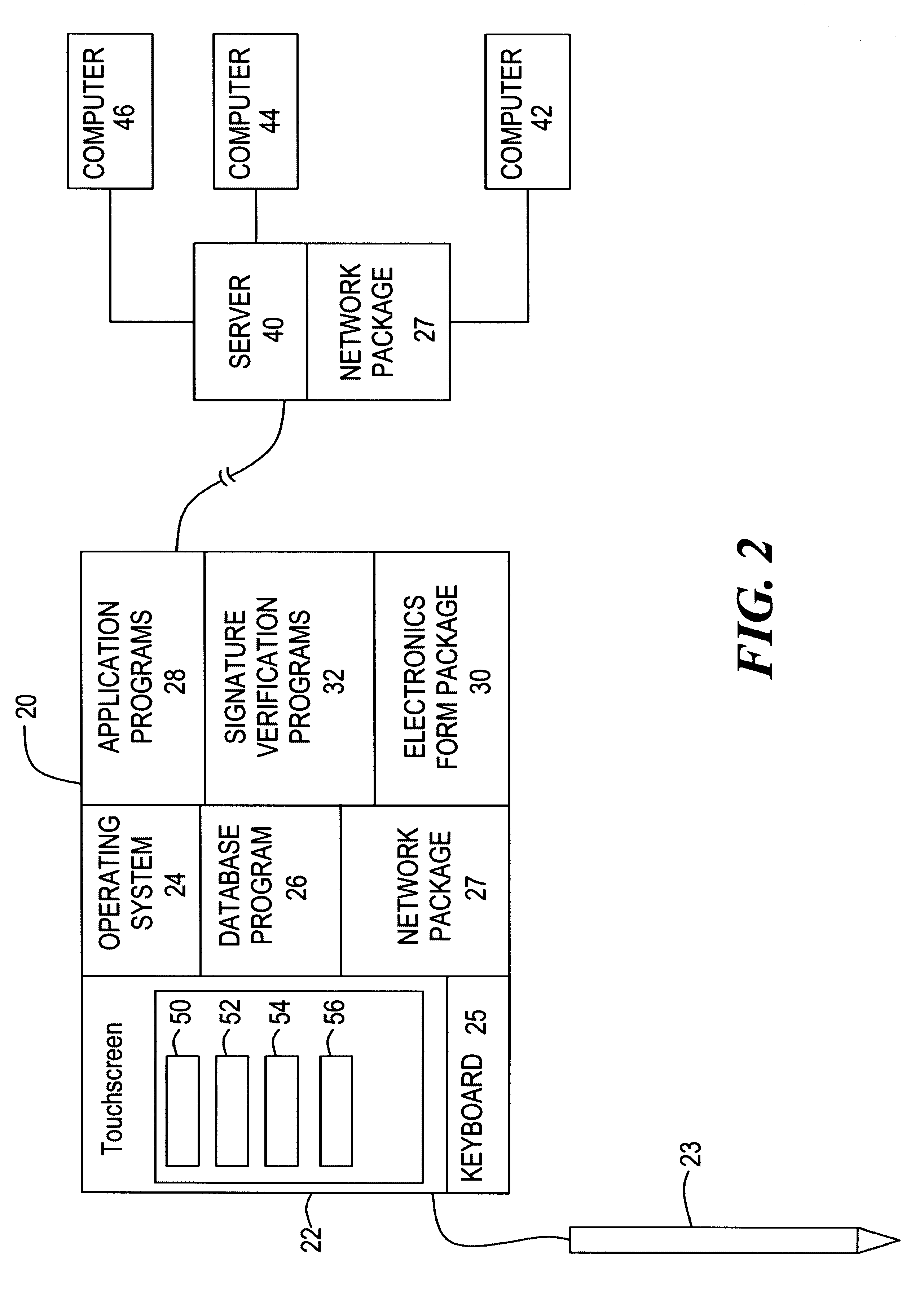

A computerized form processing system including a database for storing at least one form having one or more fields; a viewer for viewing a stored form; a data entry device for entering information into the fields of a form; programming for monitoring whether the information in a field has changed and for automatically flagging any changes to the information entered into a field.

Owner:FLECTERE LLC

Printer control and document management system

InactiveUS20040105122A1Digital data processing detailsVisual presentation using printersComputer printingElectronic form

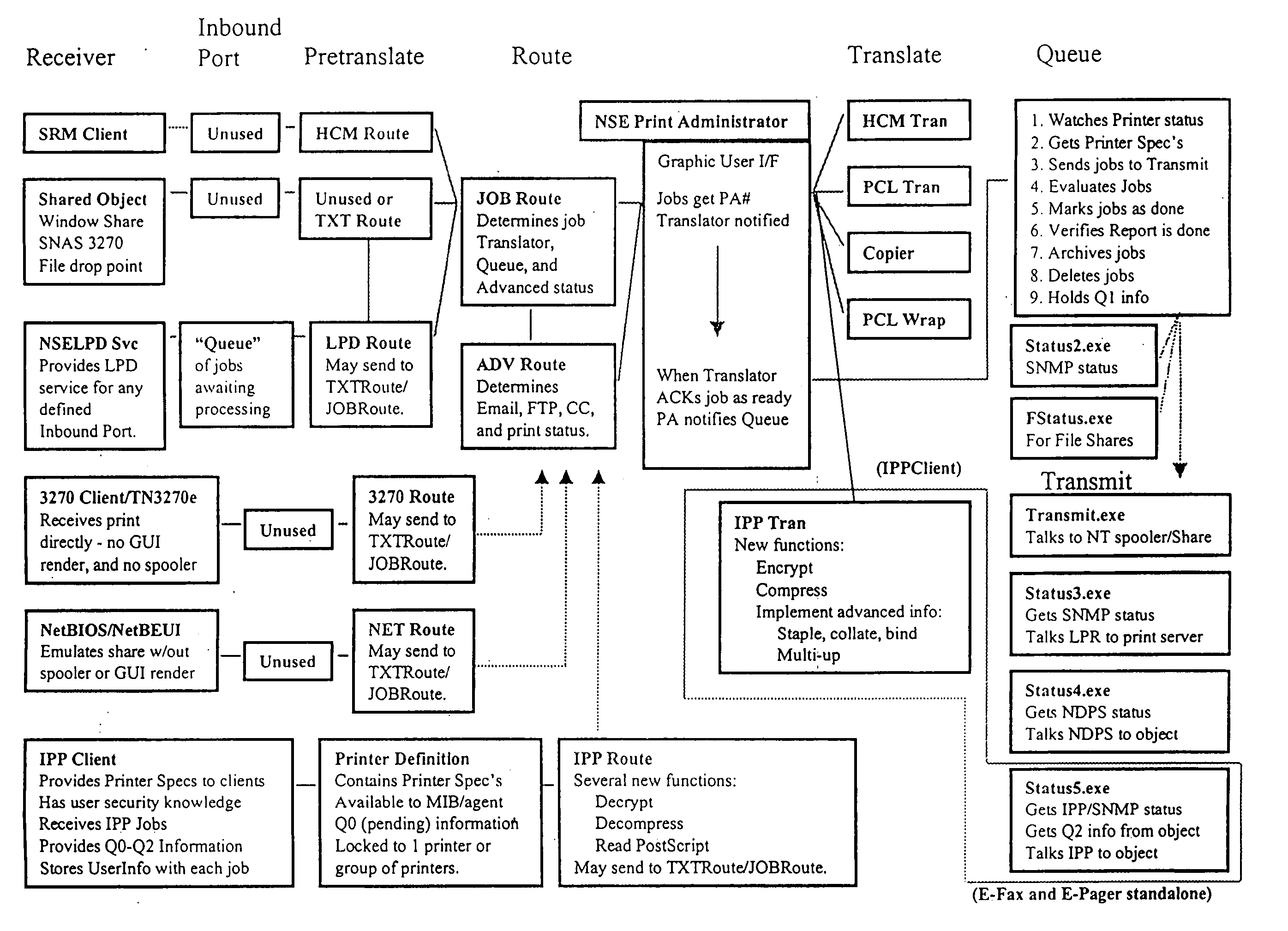

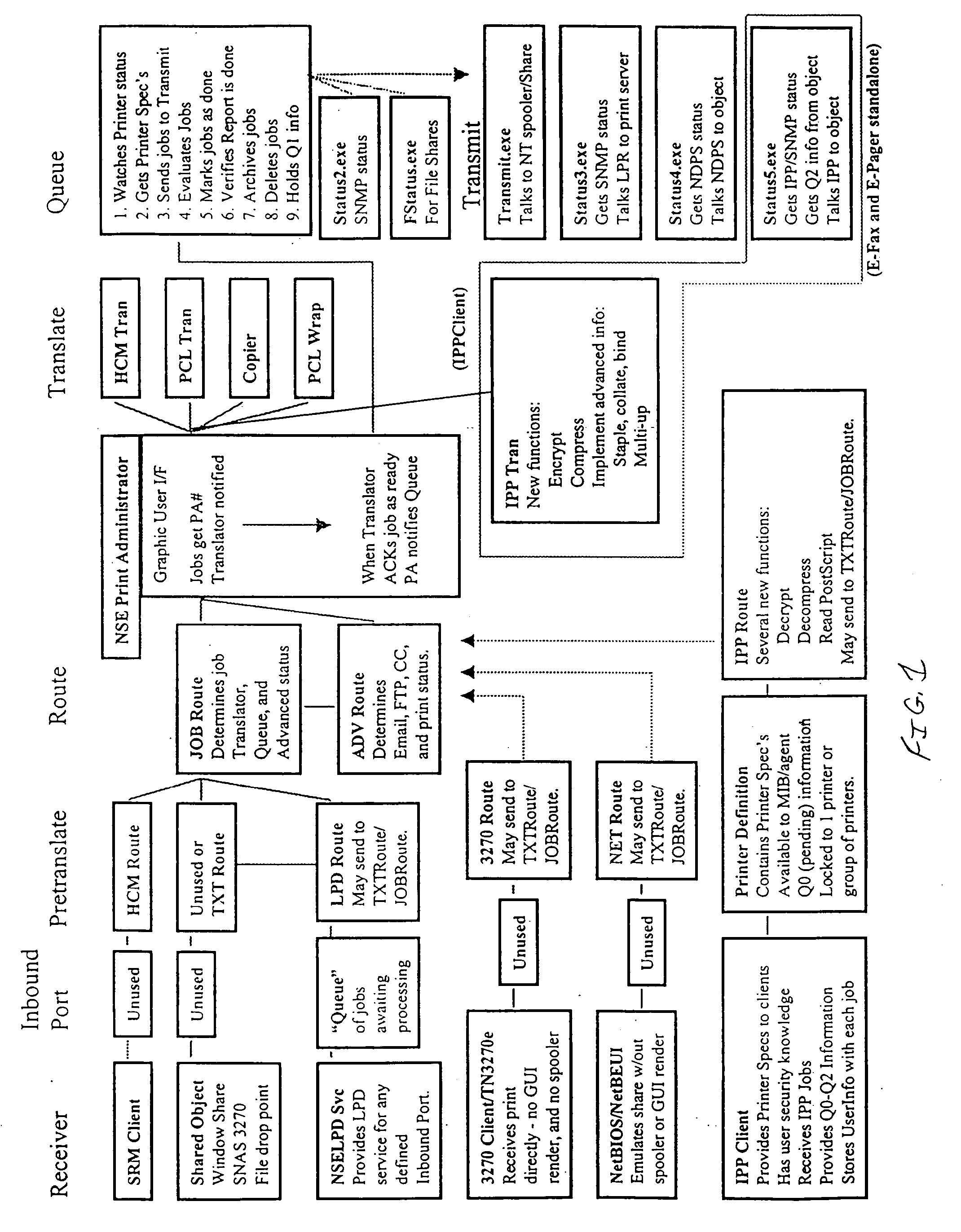

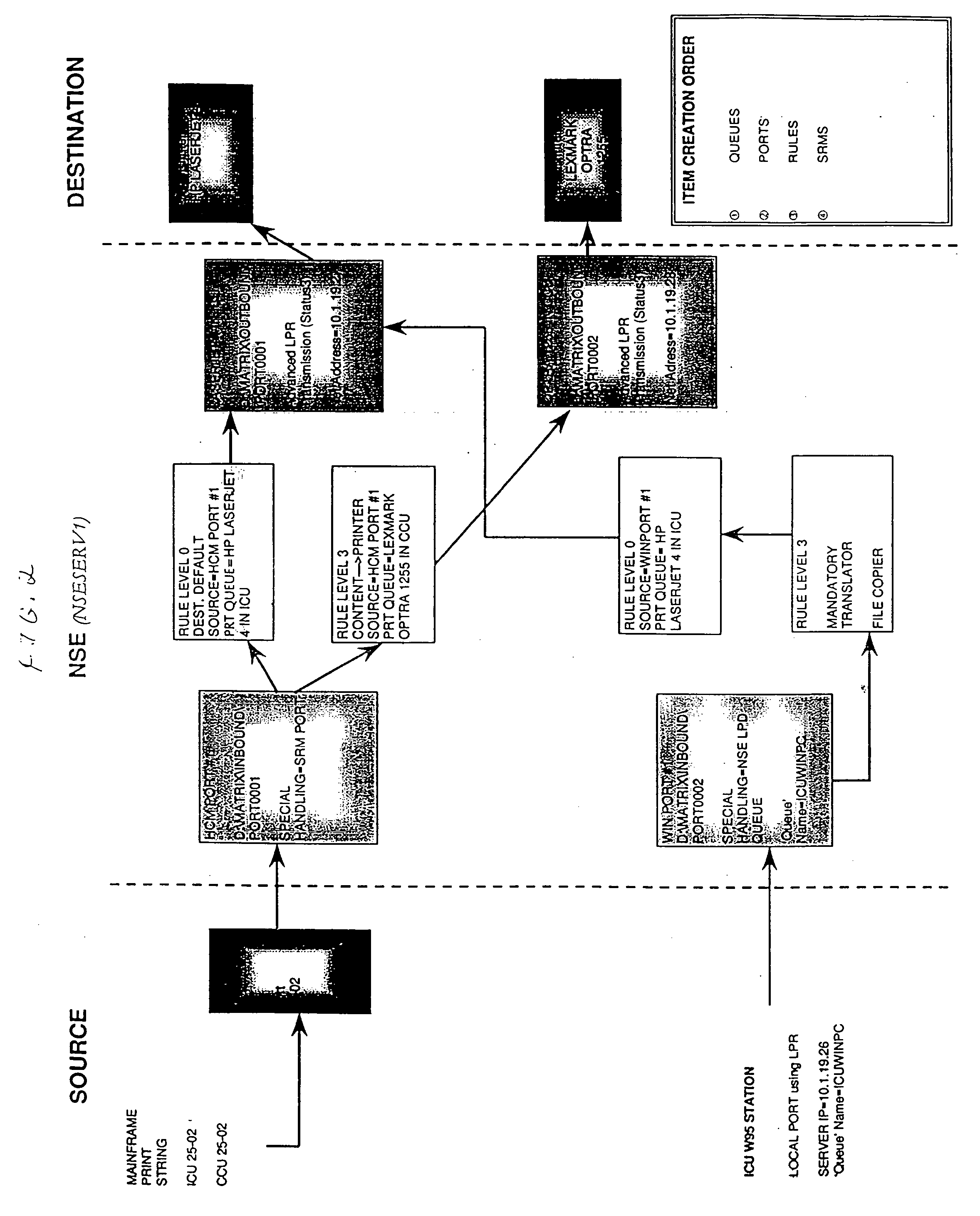

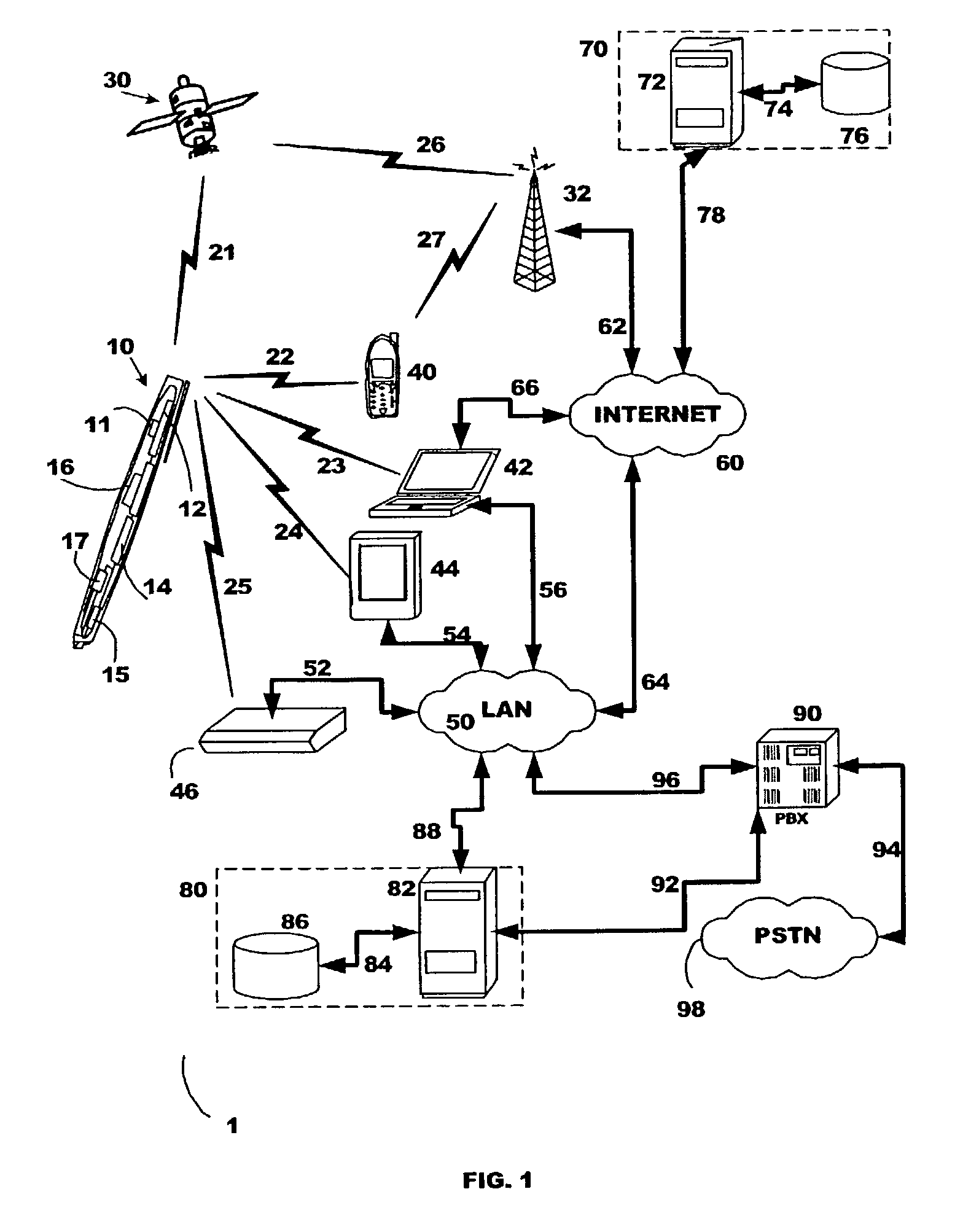

A printer control and information management system is provided employing numerous individual satellite modules, and providing an enterprise-wide output system capable of receiving all types of input and redirecting of all types of output. Data can be inputted from any location in an enterprise system and coordinated into a coherent format for reporting and forms processing. Forms can be automatically generated based on the data inputted, which forms can be directed to the appropriate personnel. The system provides for notifications to the appropriate personnel in order to resolve problems which may arise from the operation of the various equipment utilized in the enterprise network system. Information can be redirected to anyone within the system, the user identifying the manner and format of the information to be presented. Thus, inbound reports can be received from different systems and outputs delivered in the format that is preferred by the user. Report recognition is provided for any application, with the ability to merge textual information with electronic forms. Additionally, the forms can be completed with bar code information to prevent inadvertent disclosure of sensitive information. Large and contiguous host generated reports can be electronically distributed to users, as well as the ability to automatically fax any type of report directly to any recipient. The system can be accessed via the Internet for ease of inputting and reviewing information at any location.

Owner:ST CLAIR MANAGEMENT RESOURCES

Heat conductive insulation material and preparation method thereof

InactiveCN101899209AExcellent formabilityImprove insulation performanceLiquid crystal compositionsPlastic/resin/waxes insulatorsFiberMetallurgy

The invention discloses a heat conductive insulation material and a preparation method thereof. The heat conductive insulation material comprises the following components in percentage by weight: 15 to 50 percent of plastic substrate, 15 to 45 percent of heat conductive insulation filler A, 5 to 15 percent of heat conductive filler B, 10 to 30 percent of mineral fiber C, 0 to 2 percent of coupling agent and 0 to 2 percent of lubricant. The heat conductive insulation material has the advantages of perfect forming processing performance, high heat conductivity, higher uniformity and a small amount of gas content during processing; heat conductive fillers with different length-diameter ratios are combined, fillers with a large length-diameter ratio are arranged in melt flowing direction, and fillers with a small length-diameter ratio fill gaps left when the fillers with the large length-diameter ratio are arranged, so that the number of interfaces among filler components is greatly reduced, a conduction network is formed more easily, and heat conductivity is remarkably increased; moreover, the mineral fiber is added during the second machining process, so that the loss of material performance can be compensated due to the addition of high-powder fillers, and performance is better.

Owner:KINGFA SCI & TECH CO LTD +1

Form processing device, and form processing method and program

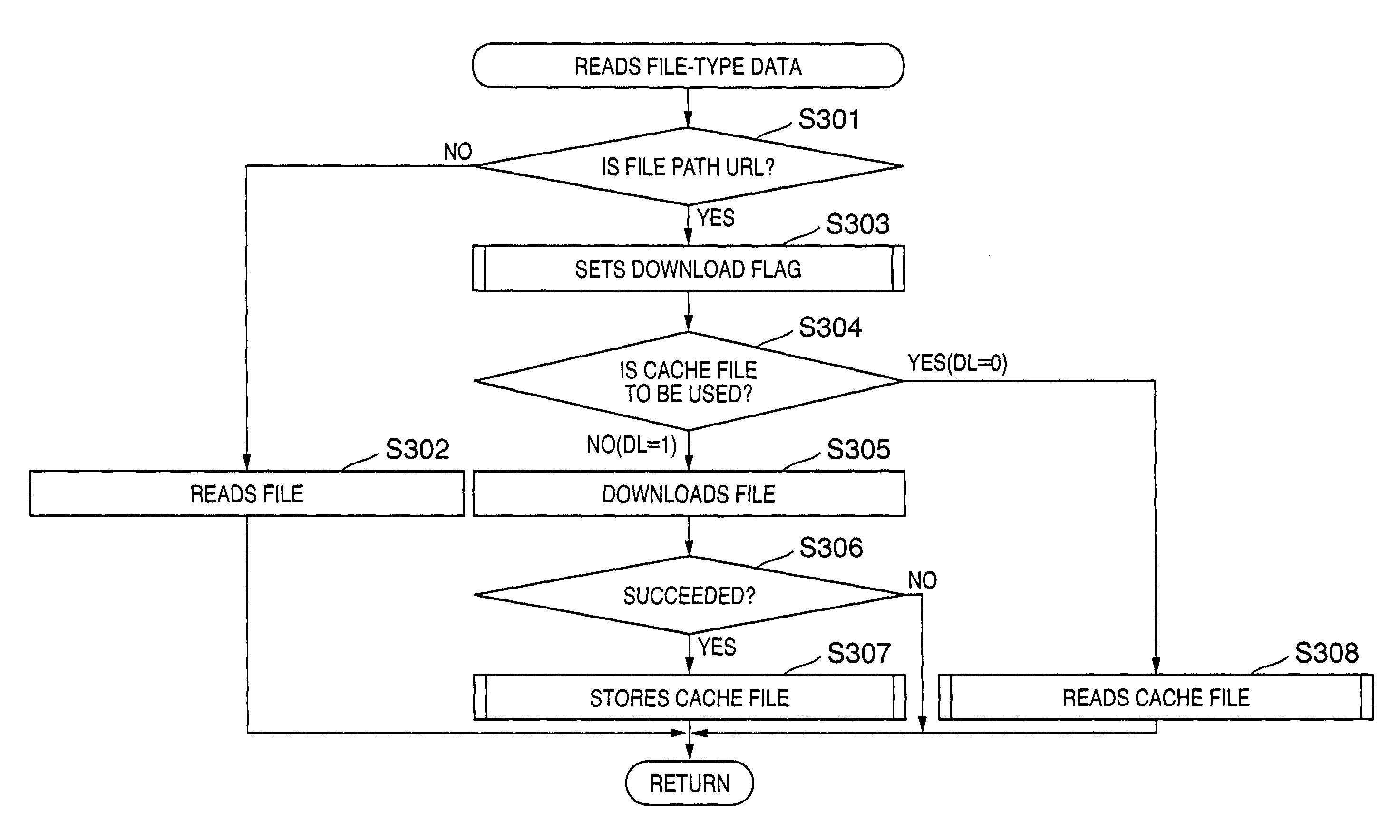

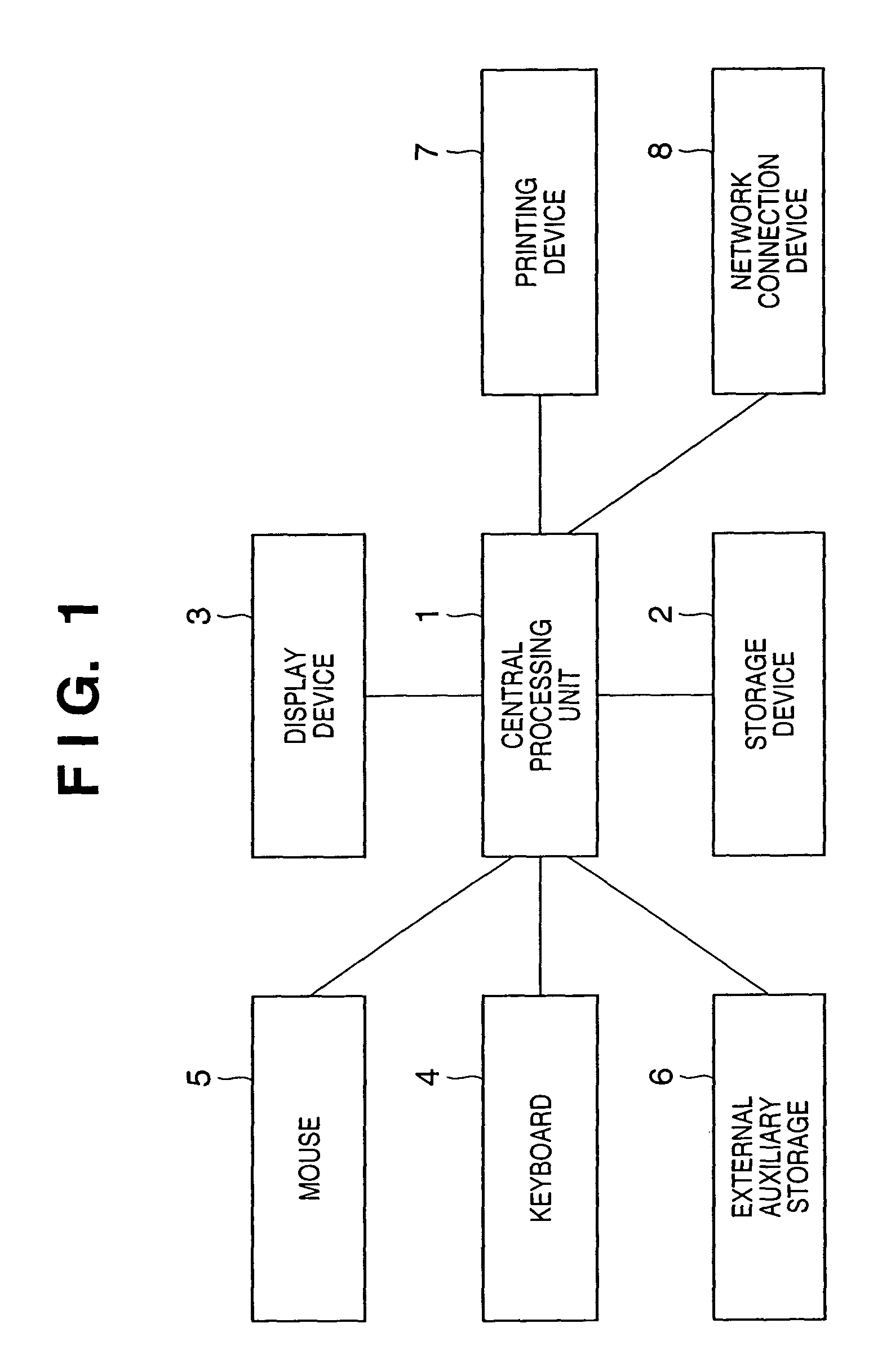

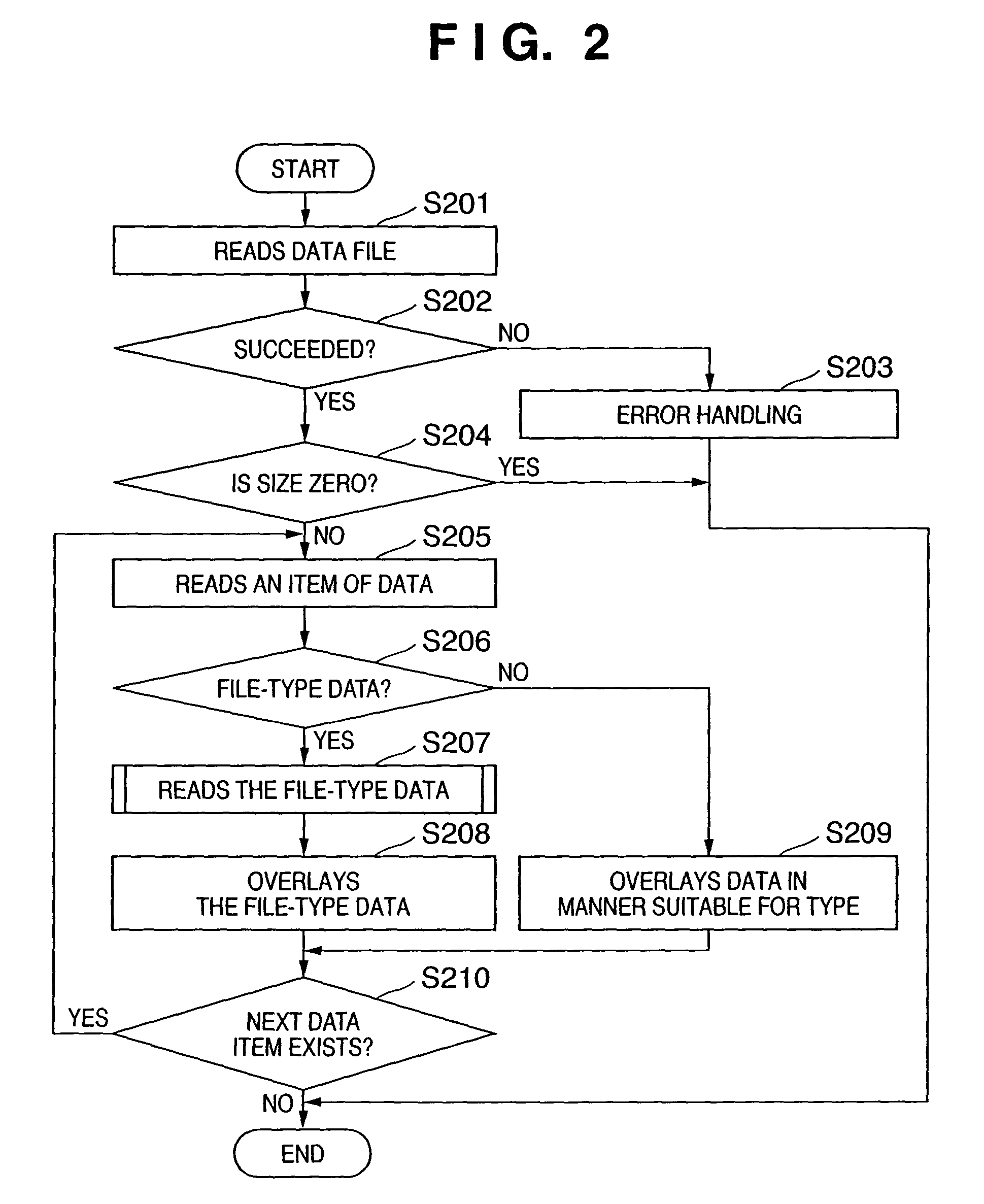

There is provided a format processing method for overlaying data of a file located on an Internet server onto a predetermined field in a form. In particular, there is provided a form processing method for reading a field data file storing data to be overlaid onto a defined field in a form, and overlaying data of the field data file onto a field in the form, the form processing method including: a determination step of determining, if data of the field data file is description specifying an external file, whether the description of the data is in a URL format (step S301); an overlaying step of downloading the external file in a network server in compliance with Internet protocols (step S305) and overlaying the data of the downloaded external file onto the field in the form if the description is determined to be in a URL format at the determination step (step S301).

Owner:CANON KK

System and method for remote, automatic reporting and verification of forms

InactiveUS7296221B1Avoid the needFinanceDigital computer detailsUnique identifierApplication software

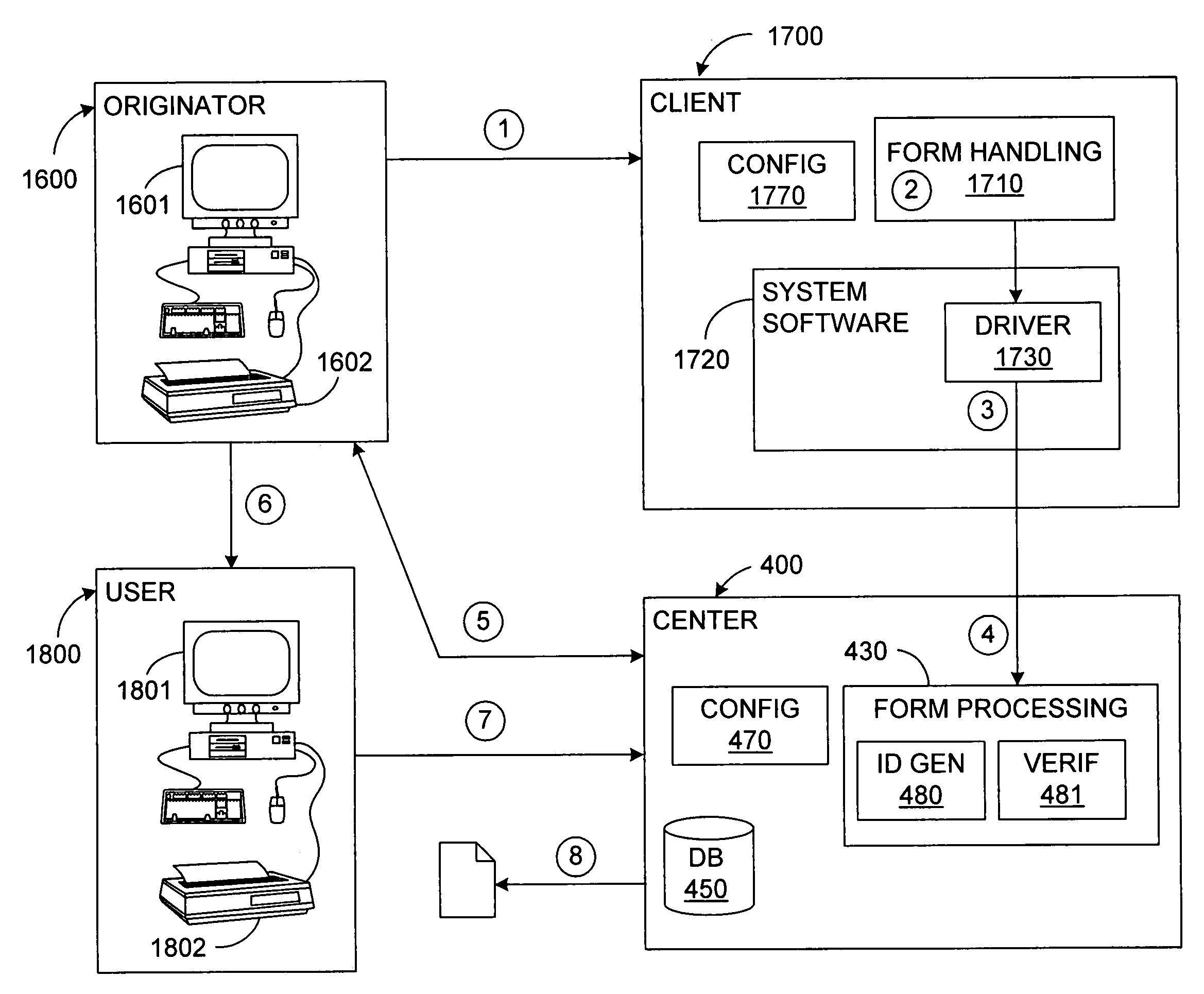

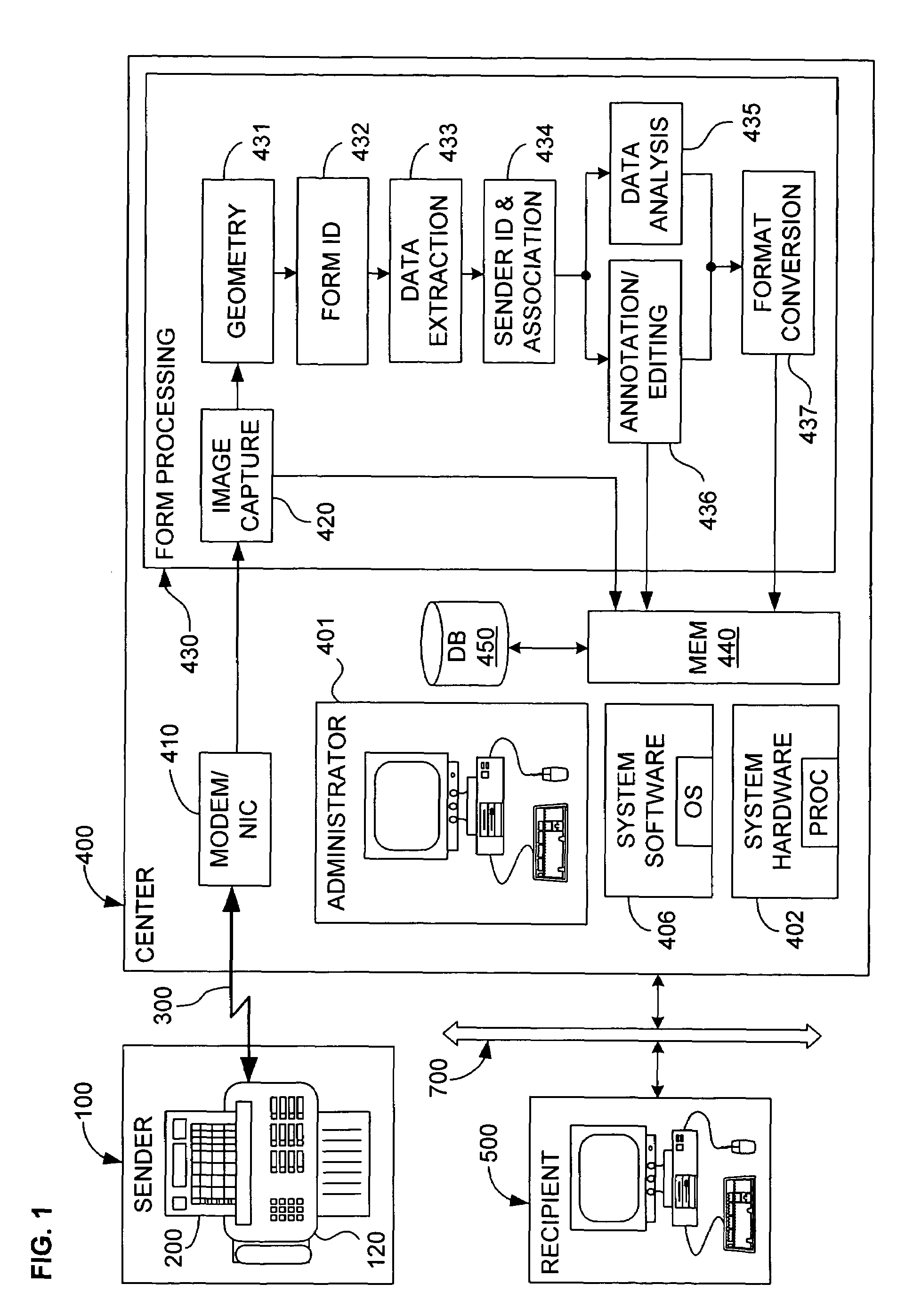

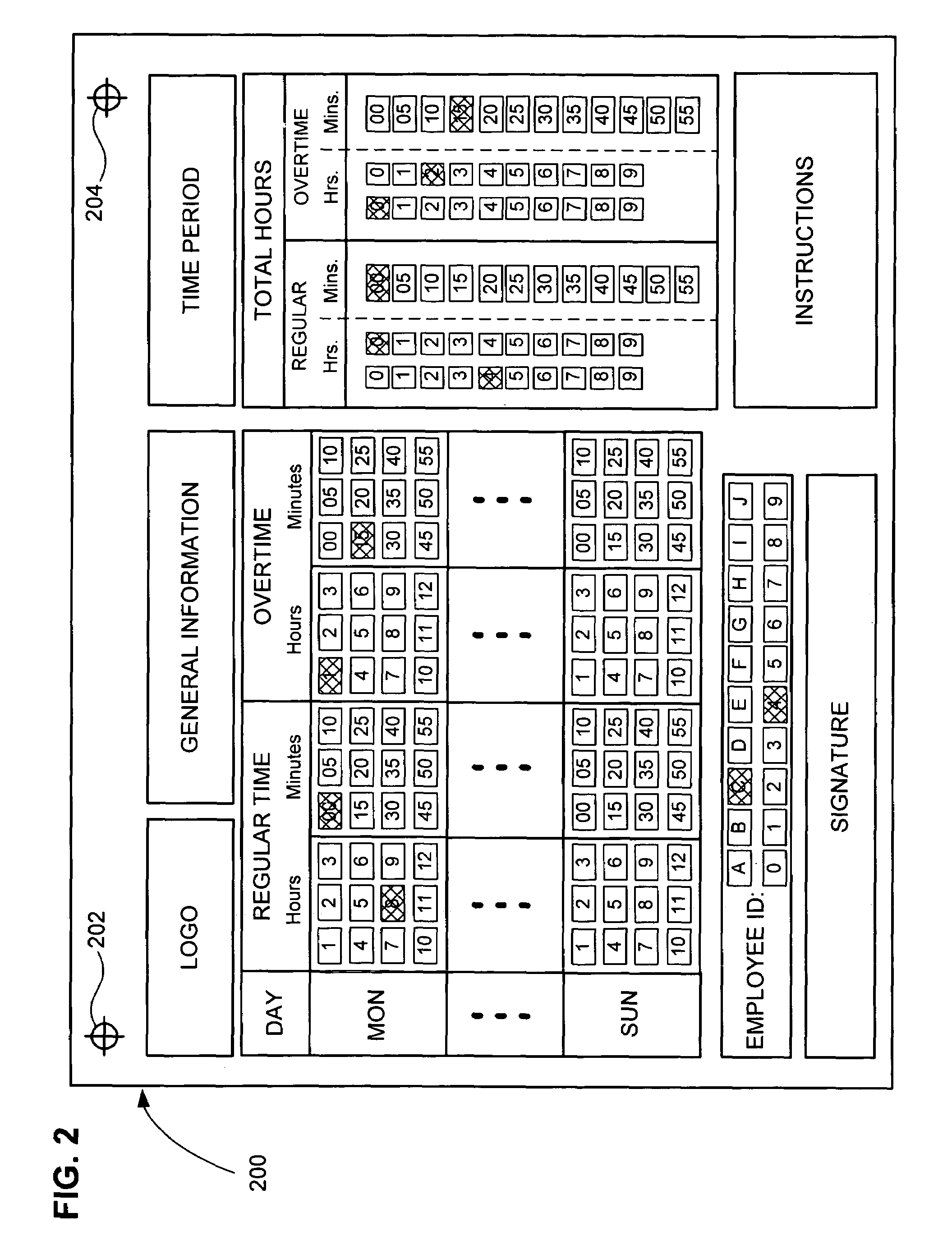

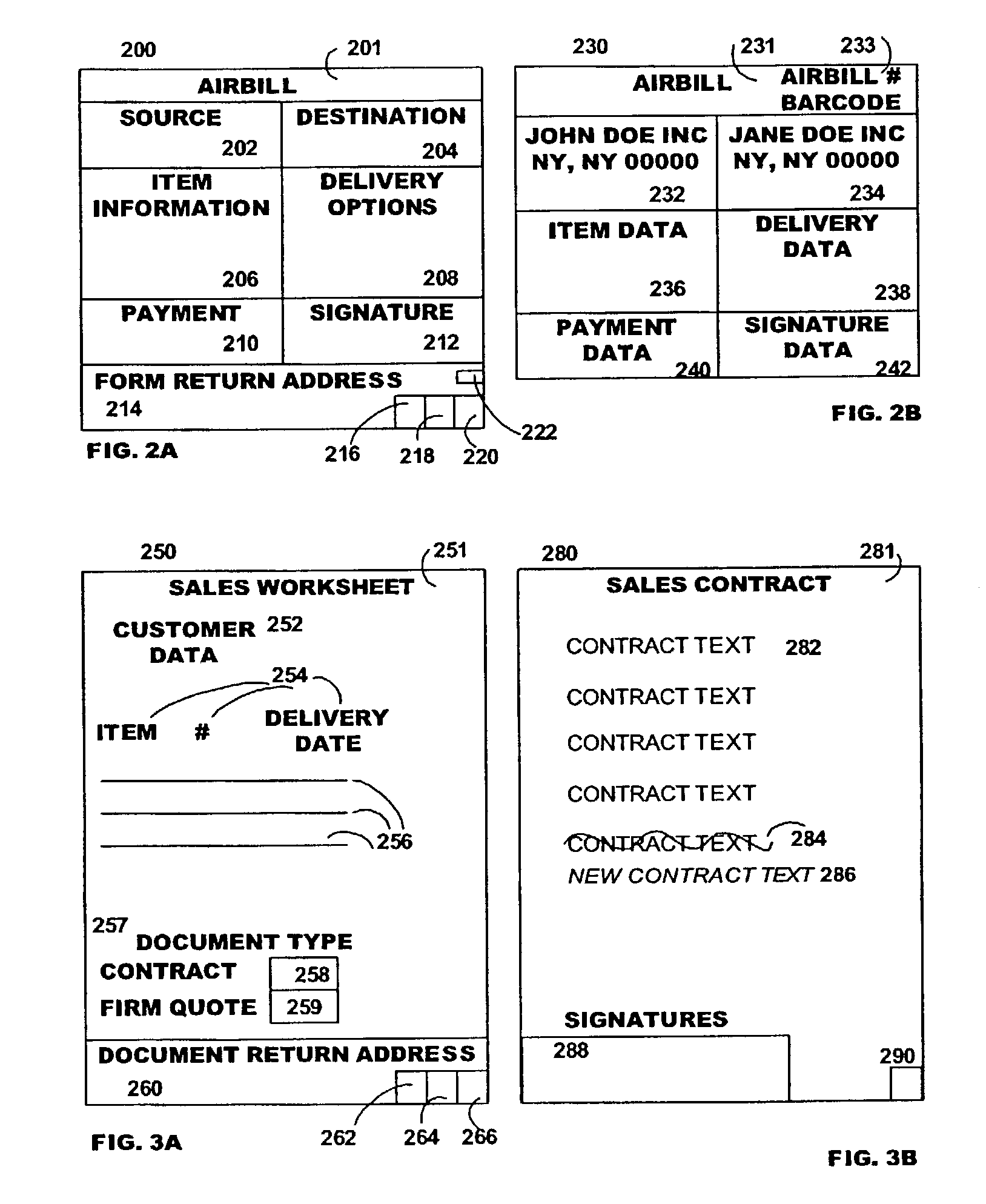

An originator accesses a client system to select a form, then enters data to be associated with a particular instance of the form. When the originator requests printing of the partially completed form, the print command is intercepted by a driver in the client system, which communicates with a form-processing application in the center, which assigns a unique identifier to the form and associates the identifier with the form in a data base. The form is then printed for the originator, who sends the form to a user. The user completes the form, including markings such as a signature or handwritten information and returns it to the center. After extracting the identifier from the returned form and verifying the form, the center automatically routes and / or indexes and / or forwards the image of the form to the proper location(s), and may also automatically enter the extracted data, properly indexed, into a data base.

Owner:CALL TELL

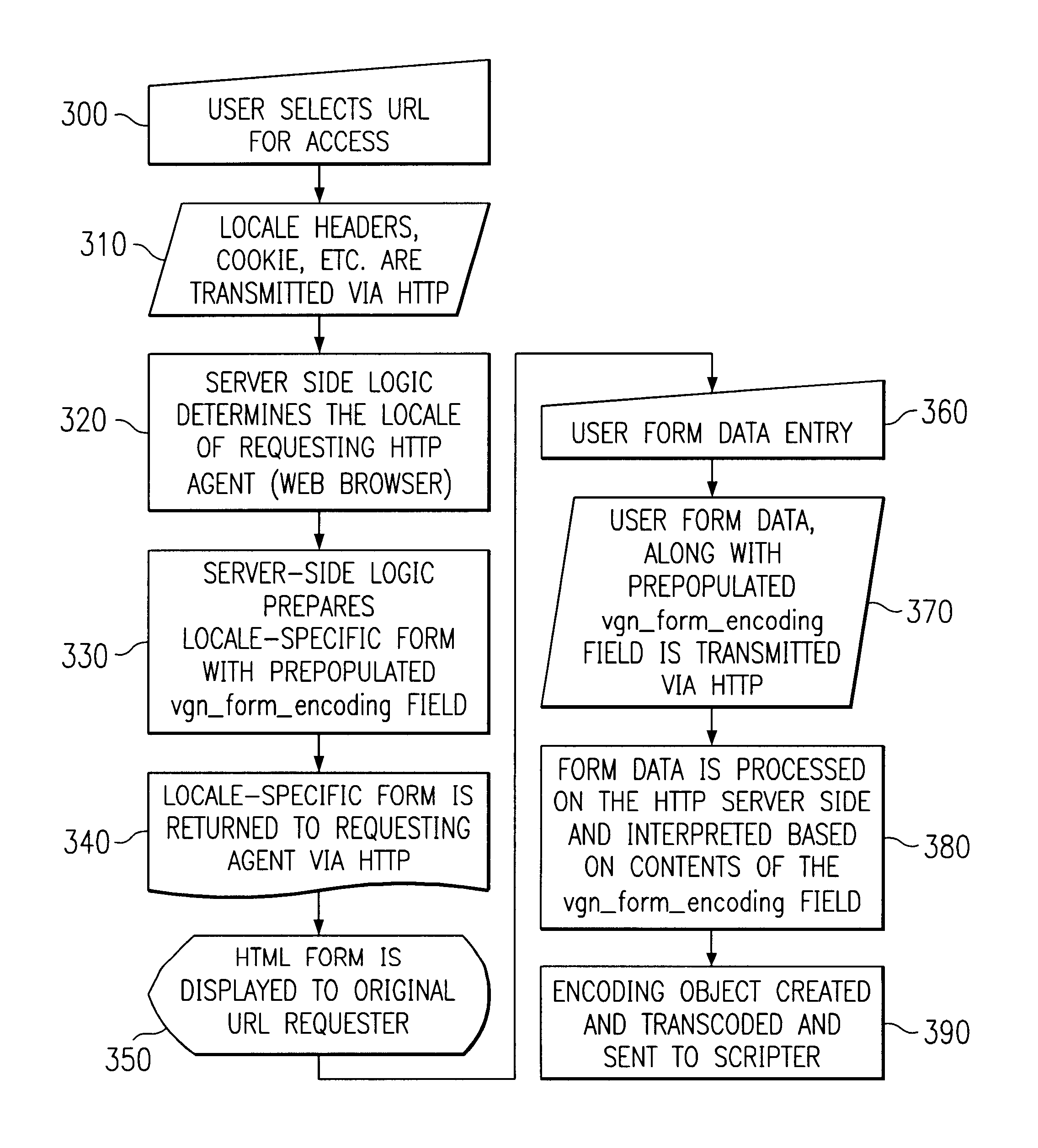

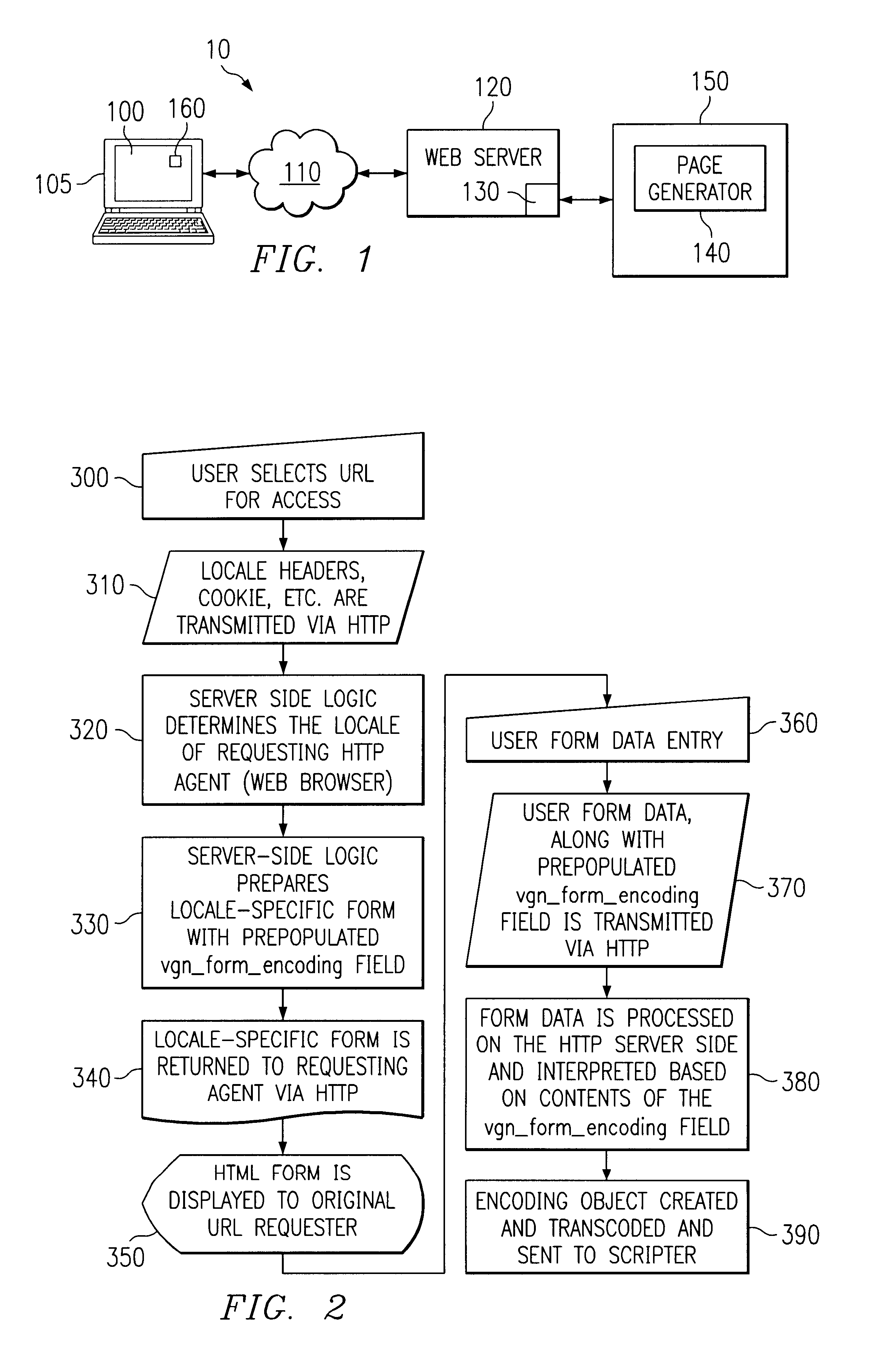

Method and system for native-byte form handling

InactiveUS6850941B1Data processing applicationsMultiple digital computer combinationsWeb siteWeb browser

A method and system are provided for native-byte form handling, one embodiment comprising a method for encoding user-submitted native-byte form data in a client-server computer network. A user, at a client computer, can select a Uniform Resource Locator (“URL”) with his or her web browser for access to a content provider's website. When accessing the content provider's web server, the client computer can transmit client computer specific information to the web server that can be used by the web server to determine the user's locale. The web server can determine the user's (client computer's) locale using, for example, an automatic locale detection algorithm, and forward the user's locale information to a back-end server. The content provider's back-end server can generate a locale-specific form having a pre-populated, uniquely-named field, using, for example, a dynamic page generation program. The locale-specific form can be served to the user's web browser for display to the user. The user can enter, on the locale-specific form, information that he or she wishes to submit to the content provider (e.g., a request for content). The user can transmit the form-entered data, including the pre-populated, uniquely-named field, to the content provider's web server. The web server can process the user form data, and an encoding object can be created, based on the value of the pre-populated field. The user form data can then be transcoded from its original encoding to a new encoding (e.g., the content provider's scripting environment encoding) and forwarded to the content provider's scripting environment.

Owner:OPEN TEXT SA ULC

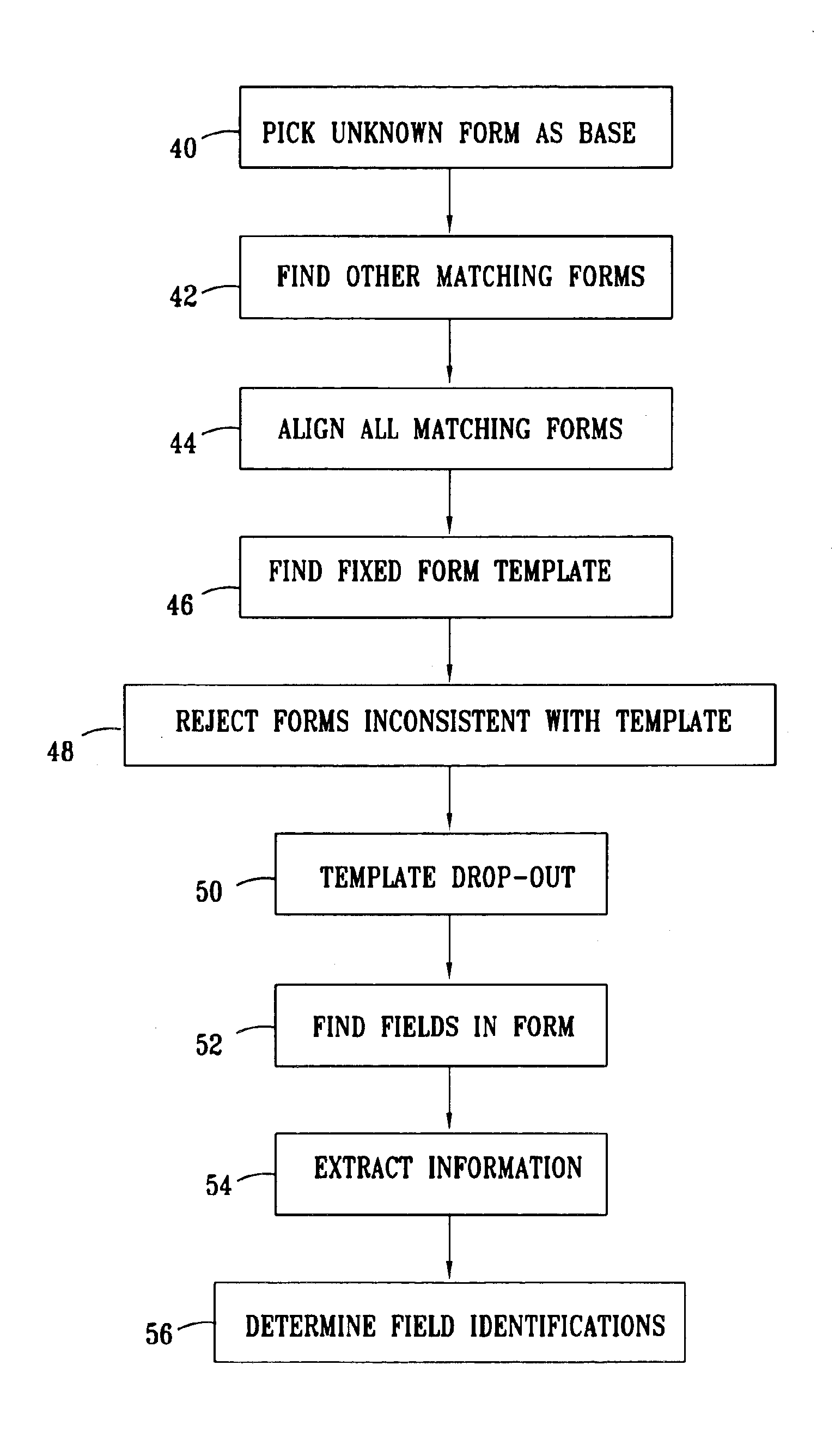

Automatic template and field definition in form processing

InactiveUS6886136B1Improve trustDigital data processing detailsCharacter and pattern recognitionPattern recognitionComputer graphics (images)

A method for processing a plurality of input images containing variable content that is filled into respective, fixed templates. The method includes comparing the images to collect a group of the images having a high degree of similarity therebetween, and combining the images in the group so as to distinguish the variable content from a fixed portion common to a preponderant number of the images in the group. The fixed portion is processed to reconstruct the fixed template that is common to at least some of the images among the preponderant number, and information is extracted from the images using the reconstructed template.

Owner:IBM CORP

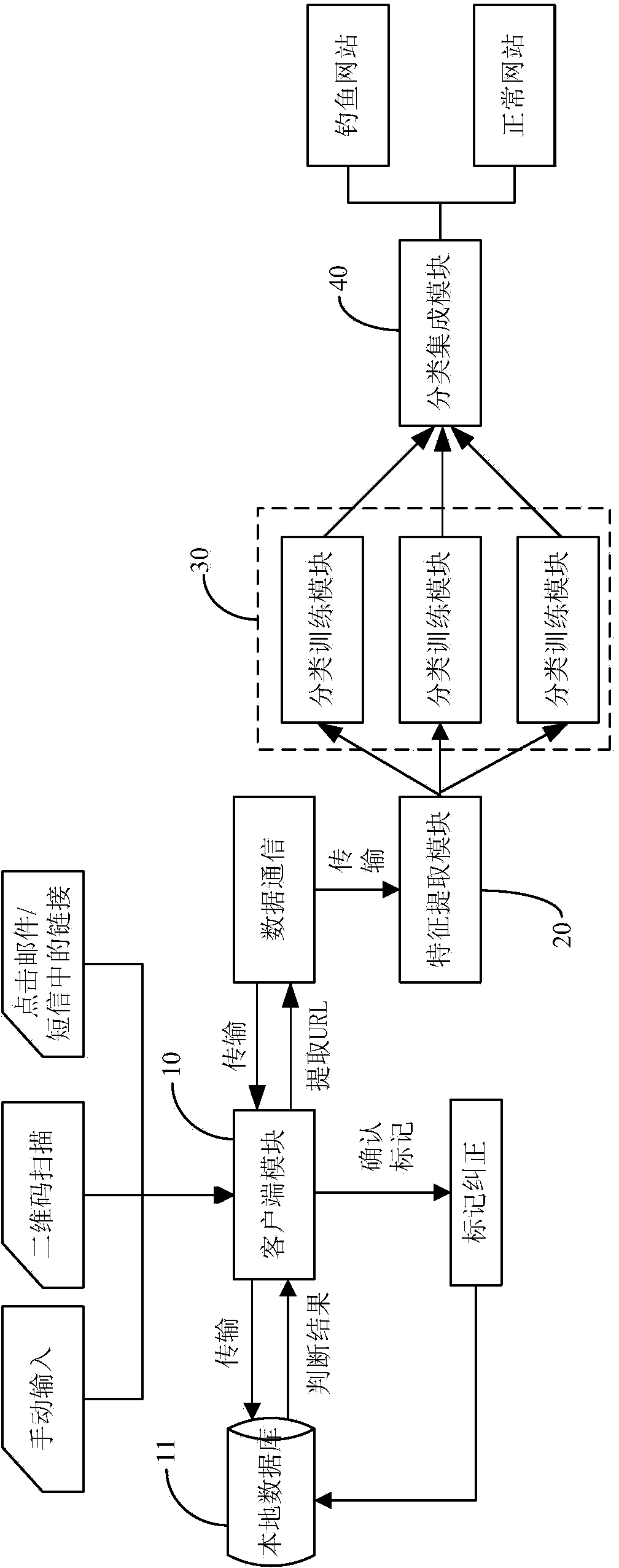

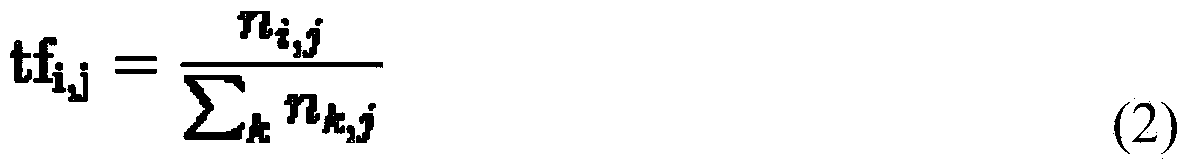

Method and system for detecting Chinese phishing website

ActiveCN104217160AImprove classification efficiencyReduce false alarm ratePlatform integrity maintainanceSpecial data processing applicationsFeature vectorWeb site

The invention discloses a method and a system for detecting a Chinese phishing website. The method comprises the following steps: S1, acquiring a URL (Uniform Resource Locator) by a client; S2, extracting URL features and website page content features as feature vectors respectively; S3, performing classification trainings on the feature vectors through an SVM (Support Vector Machine), an extended website page content feature NBC (Naive Bayes Classifier), a decision tree algorithm and a link and form processing method; S4, performing classification integration on classification training results, and judging whether a website with the URL is a phishing website. According to the method and the system, the URL features and the website page content features are extracted as the feature vectors, the corresponding classification trainings are performed through the SVM, the NBC, the decision tree algorithm and the corresponding processing of links and forms, prediction results are integrated by virtue of classification integration to obtain a final result, and therefore the classification accuracy is greatly improved.

Owner:SHENZHEN INST OF ADVANCED TECH CHINESE ACAD OF SCI

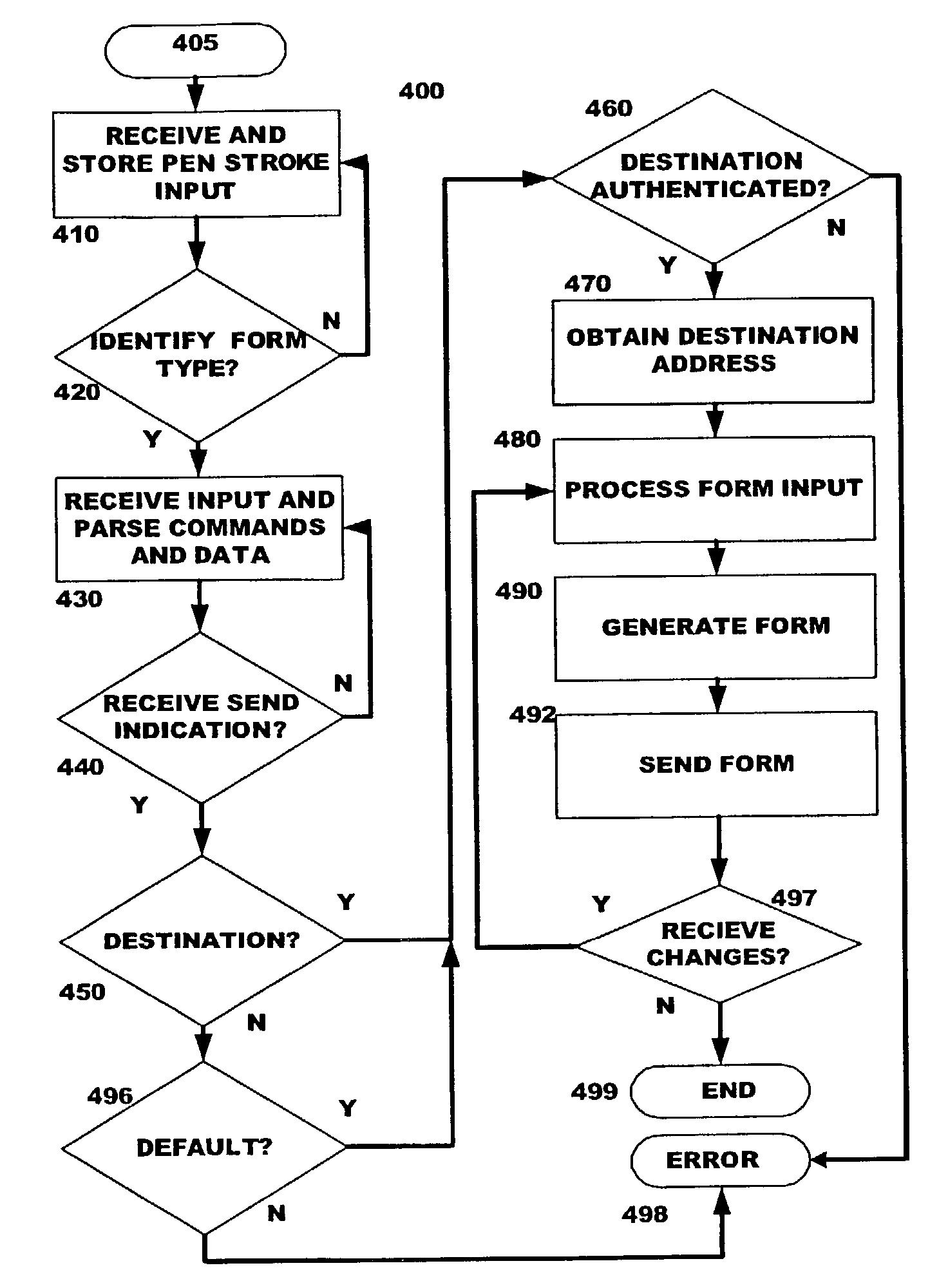

Method and system for remote form completion

InactiveUS7167586B2Input/output for user-computer interactionCharacter and pattern recognitionForm processingDocumentation

Owner:PITNEY BOWES INC

Interactive forms processing system and method

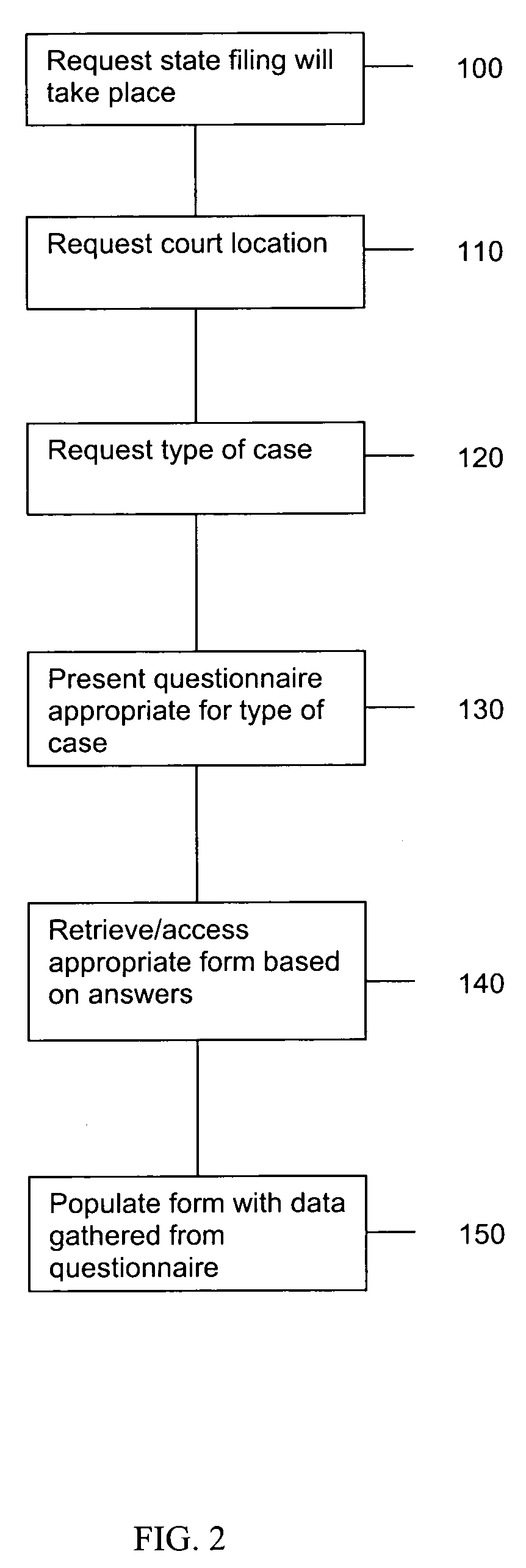

InactiveUS20050198212A1Avoid enteringMore handleFinanceNatural language data processingThe InternetQuestions and answers

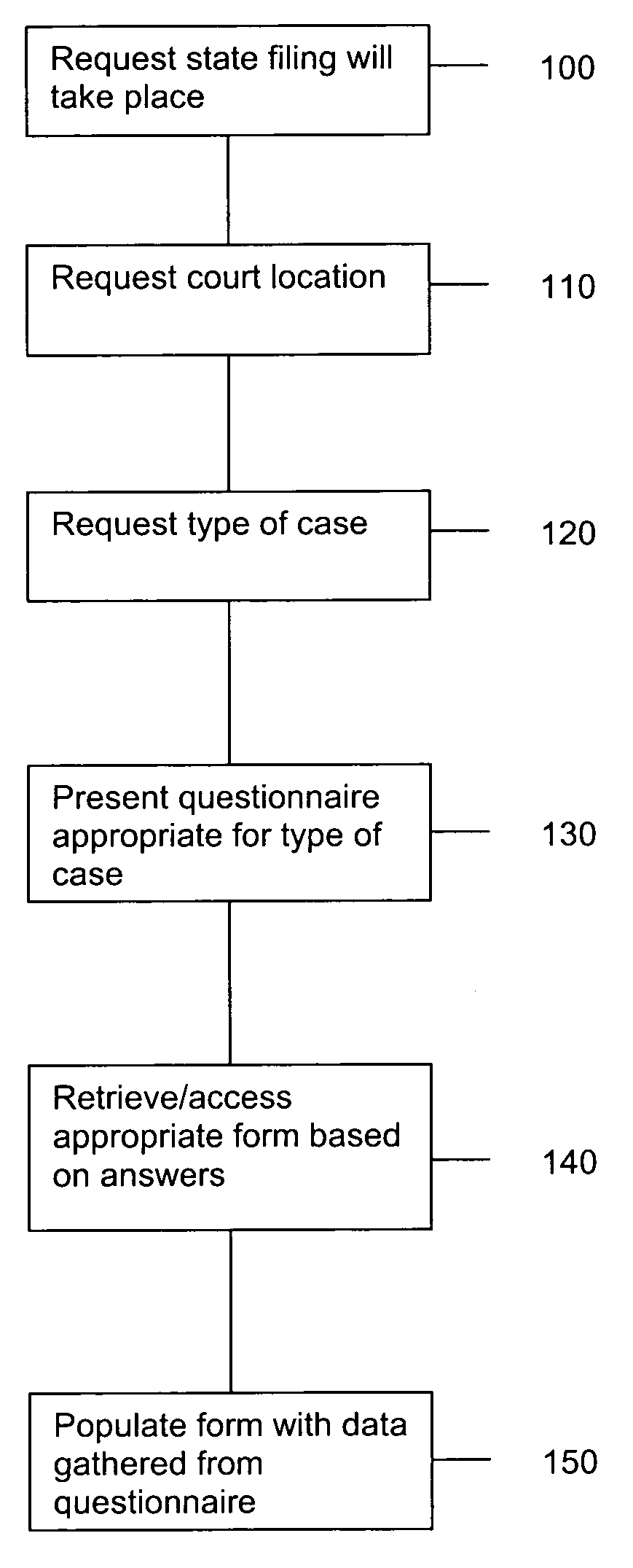

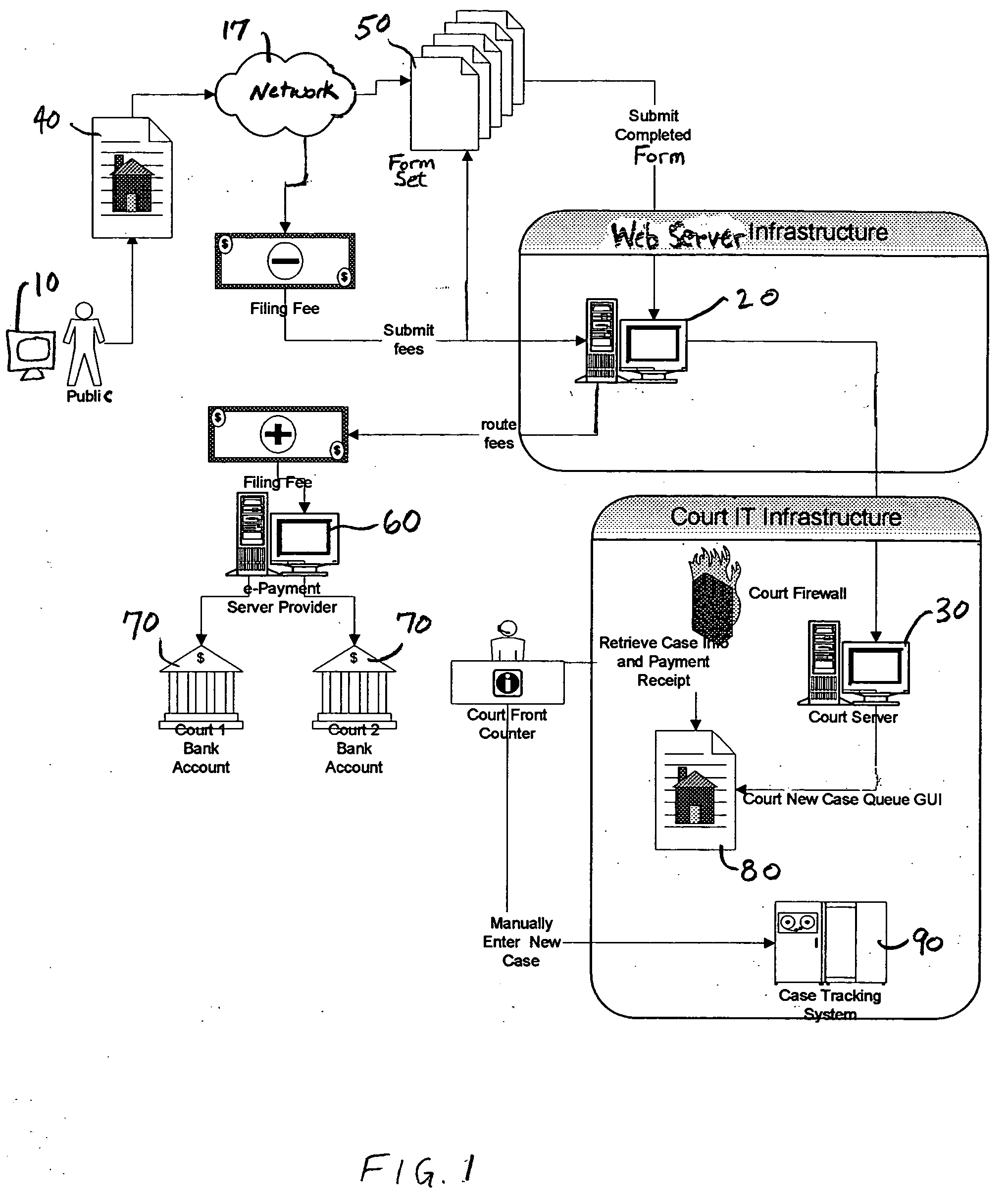

A system and method for assisting self-represented litigants, their agents, or attorneys in completing legal forms for a variety of issues, namely, an interactive forms processing system and method comprising a rules-based, on-line question and answer session that determines the form or forms needed for a particular application, completes those forms consistently and accurately, and allows them to be printed and / or optionally filed in the appropriate court, over a wide area network such as the Internet or other TCP / IP transport.

Owner:INTRESYS

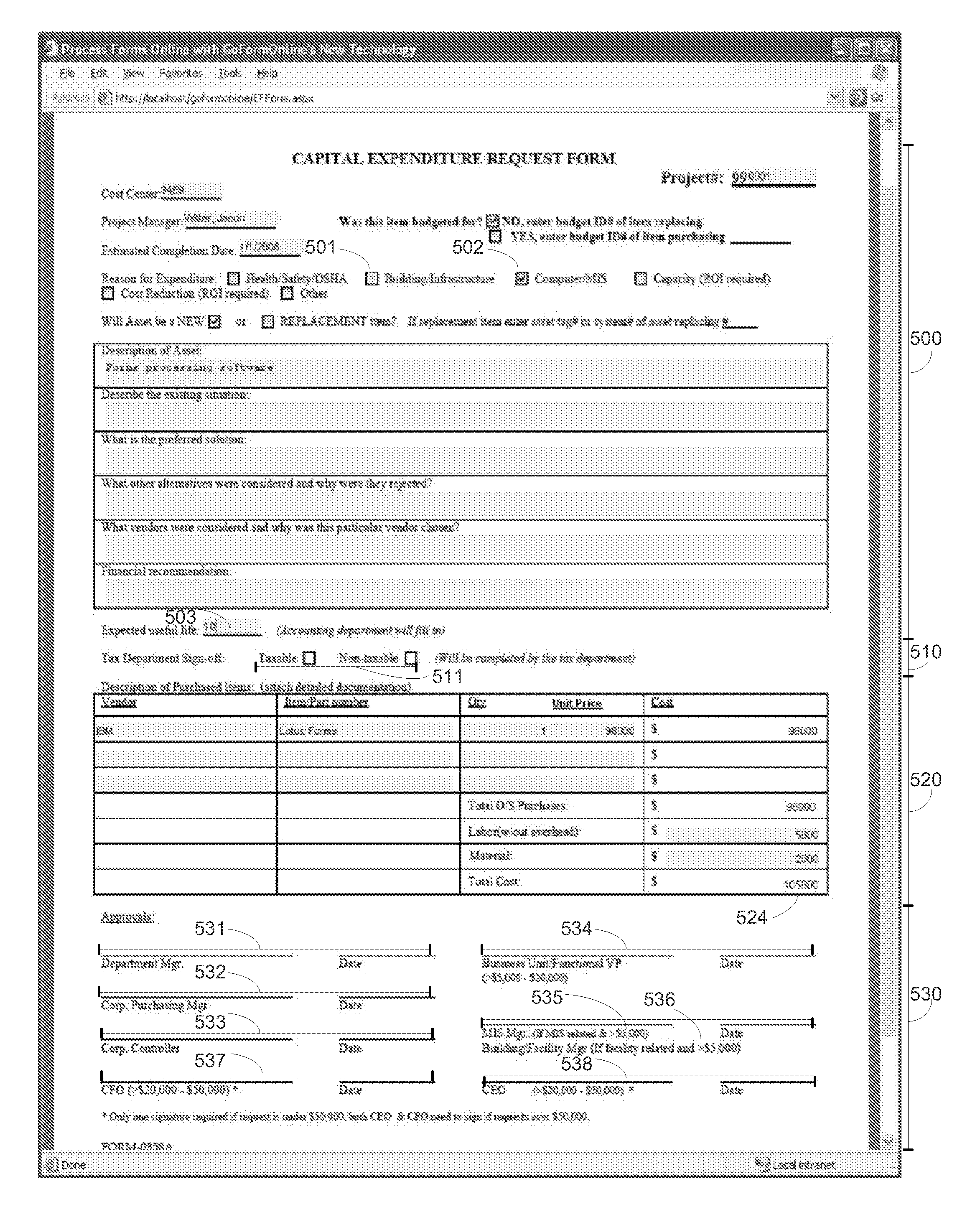

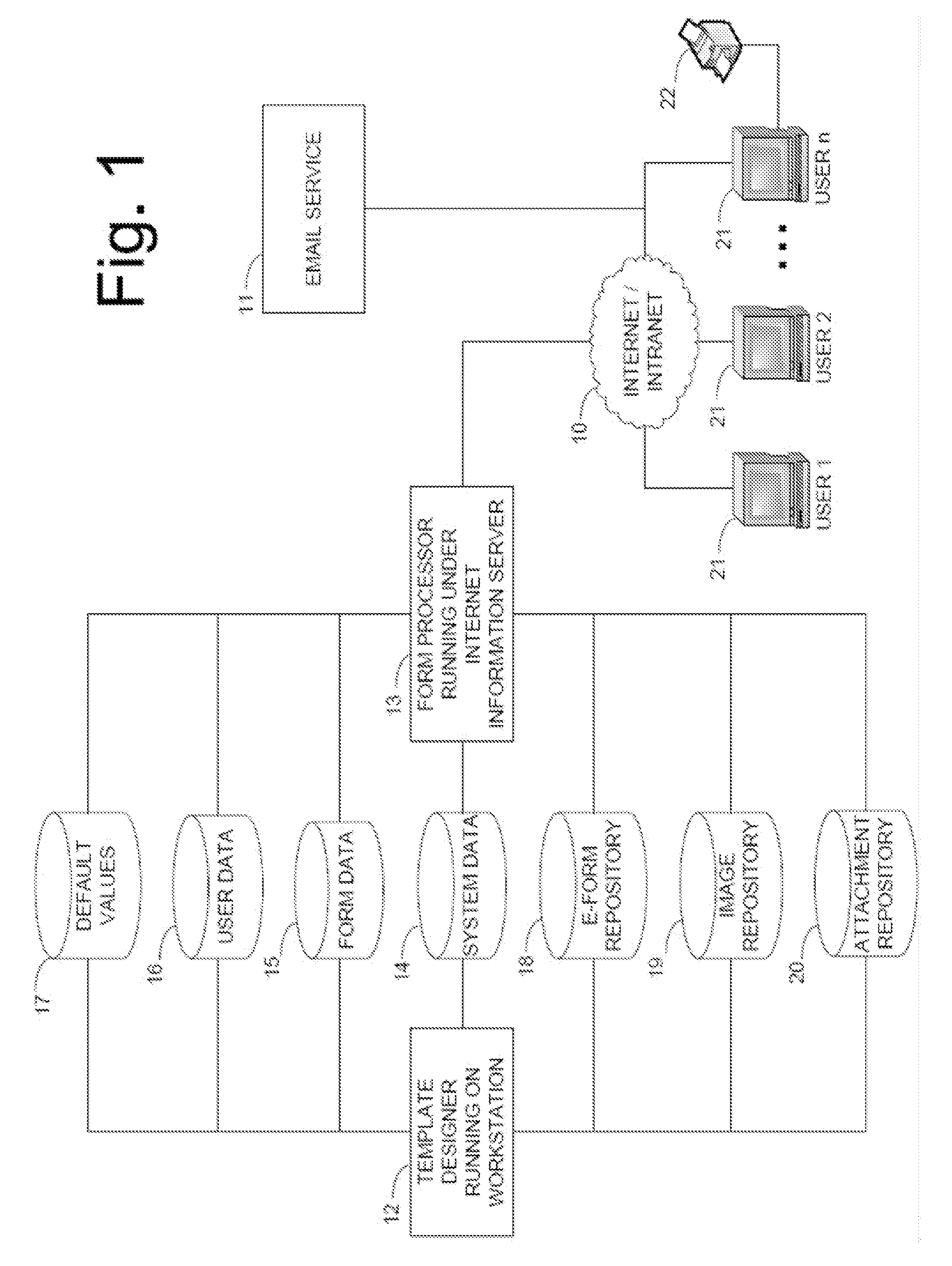

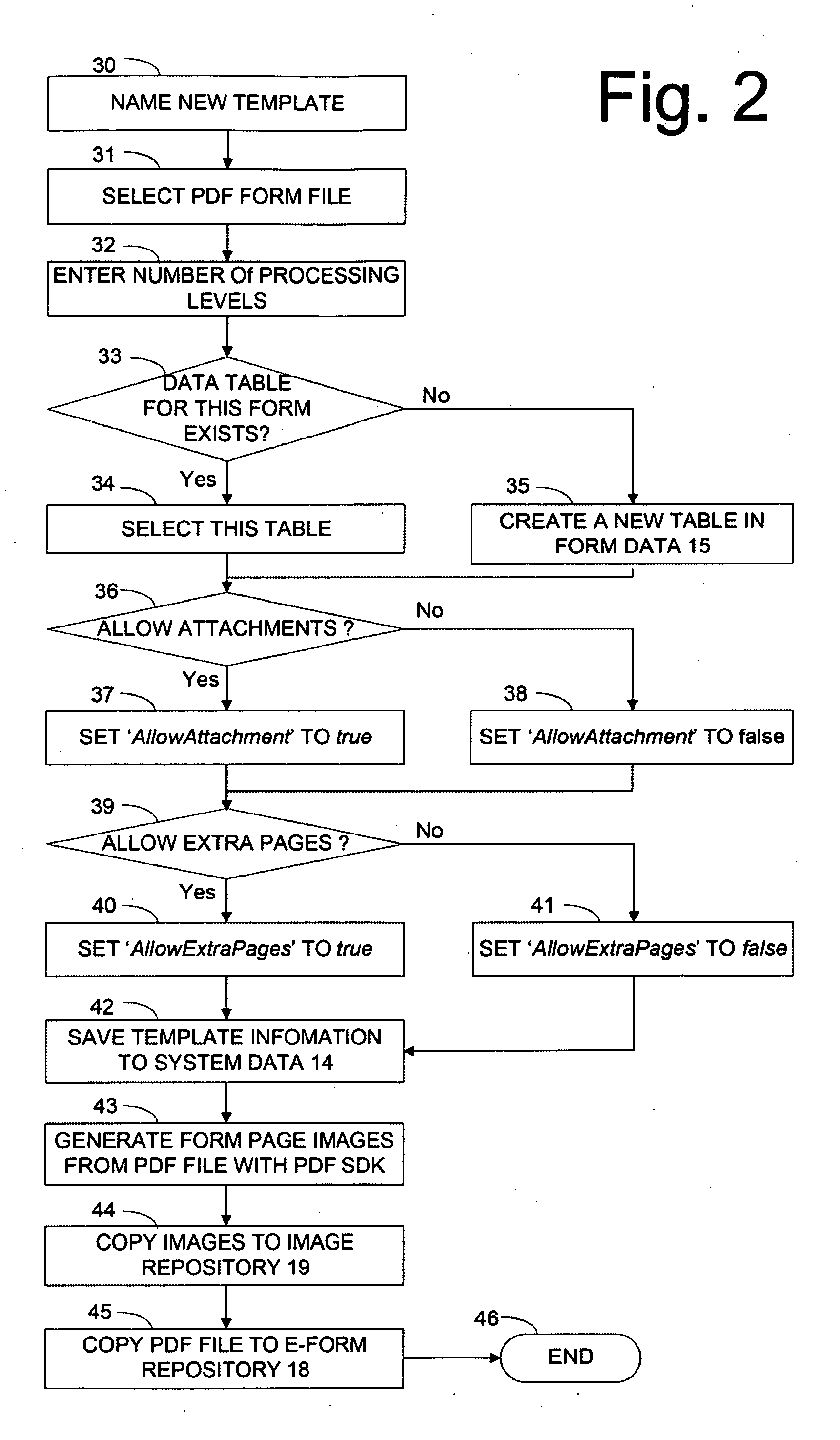

Method and System for Processing Fixed Format Forms Online

InactiveUS20100251092A1Simple processEasy to integrateNatural language data processingSpecial data processing applicationsElectronic formForm processing

A form processing system for processing electronic forms (e-form) forms while preserving the e-form fixed format is provided. The form processing system includes three functional modes or subsystems: the design mode, the edit mode and the view mode. The system, in design mode, designs form templates, manages permission and sets up dynamic workflow parameters. In the view mode, the form is read-only. The form looks like a regular PDF document. This mode is used for exporting data to e-form, printing form and sharing form by multiple users.

Owner:SUN JUN SHI

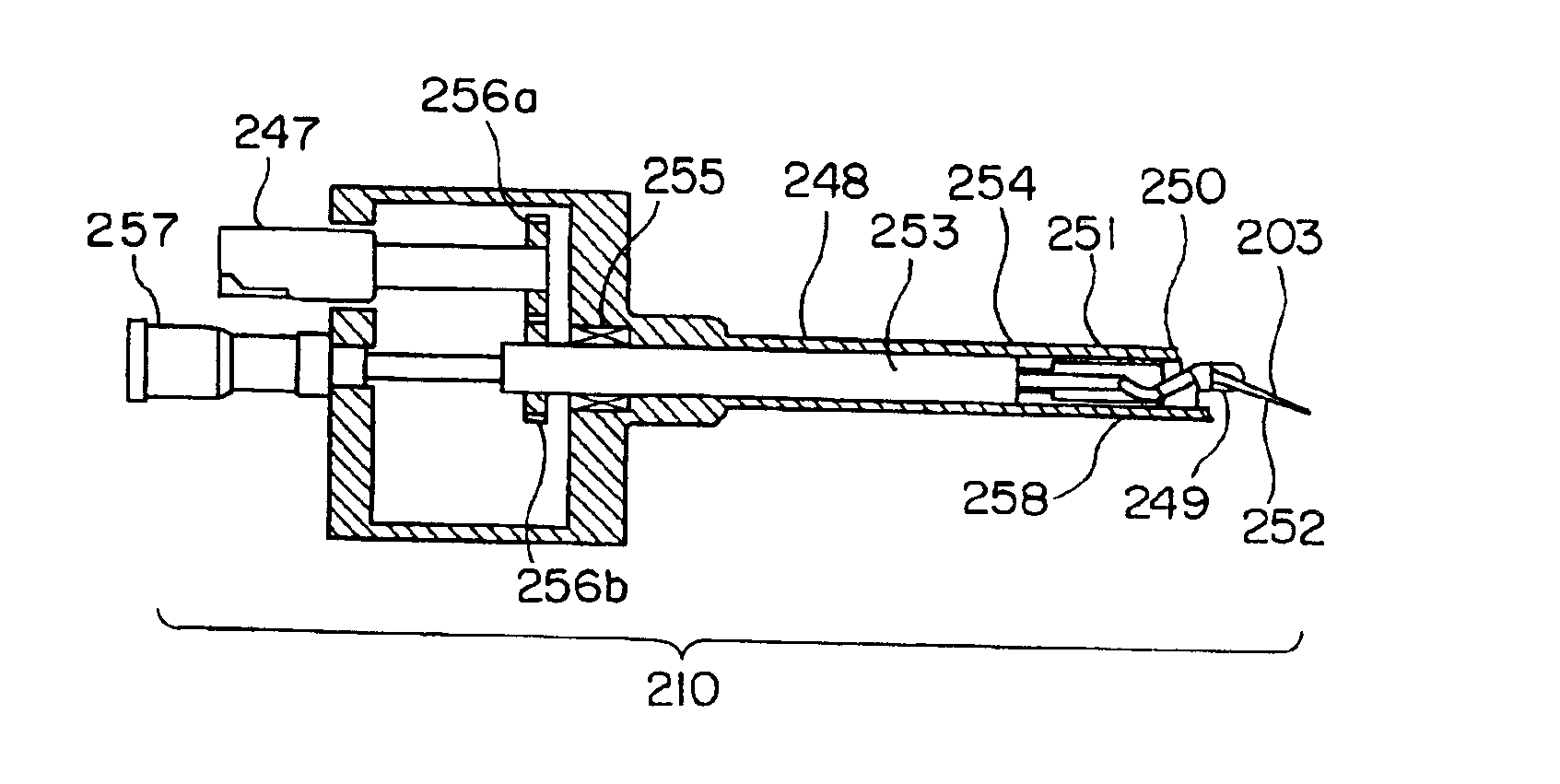

Method and apparatus for processing a micro sample

InactiveUS6927391B2Reduce resolutionGood for observationMaterial analysis using wave/particle radiationSemiconductor/solid-state device testing/measurementHigh fluxIon beam

Owner:HITACHI LTD

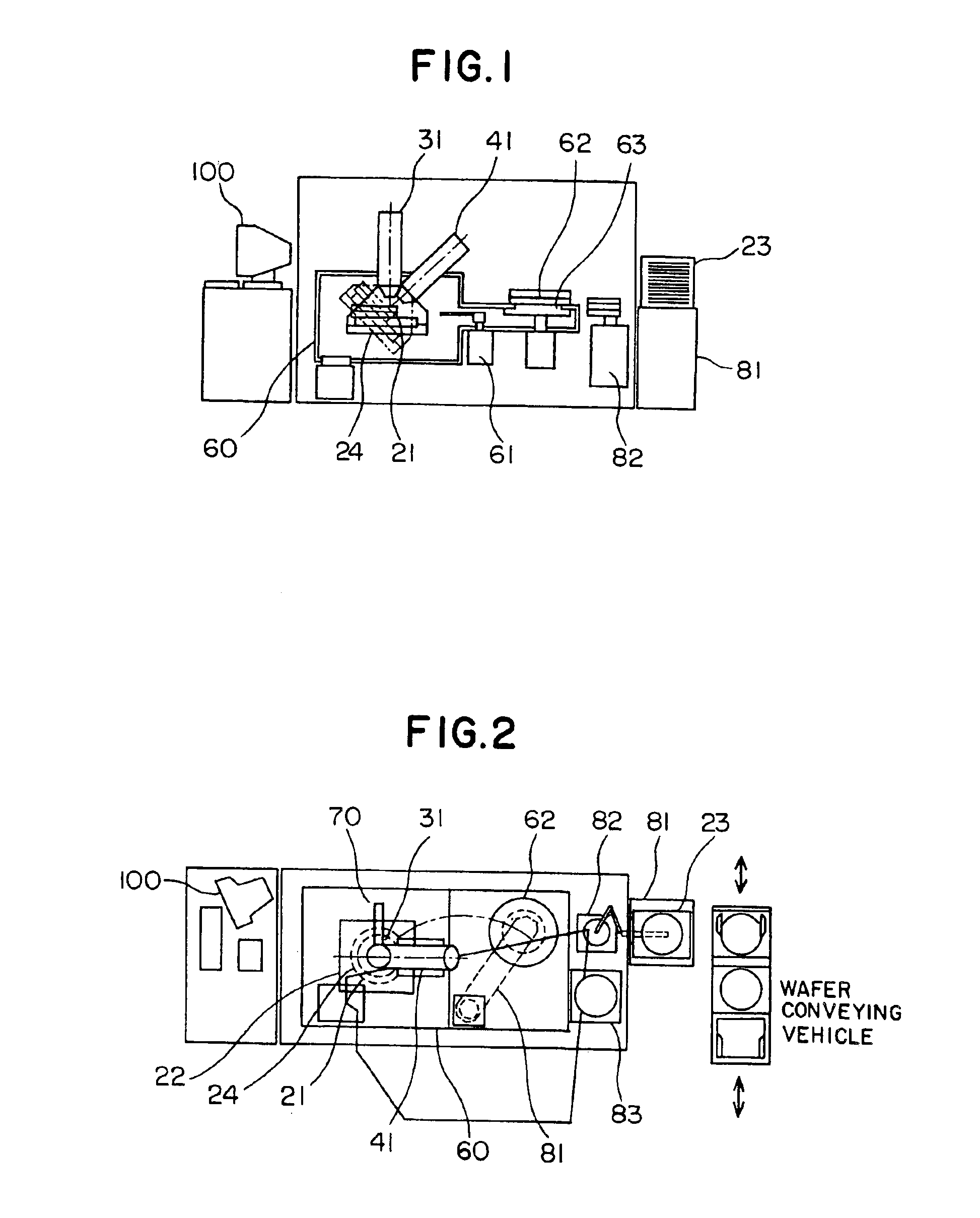

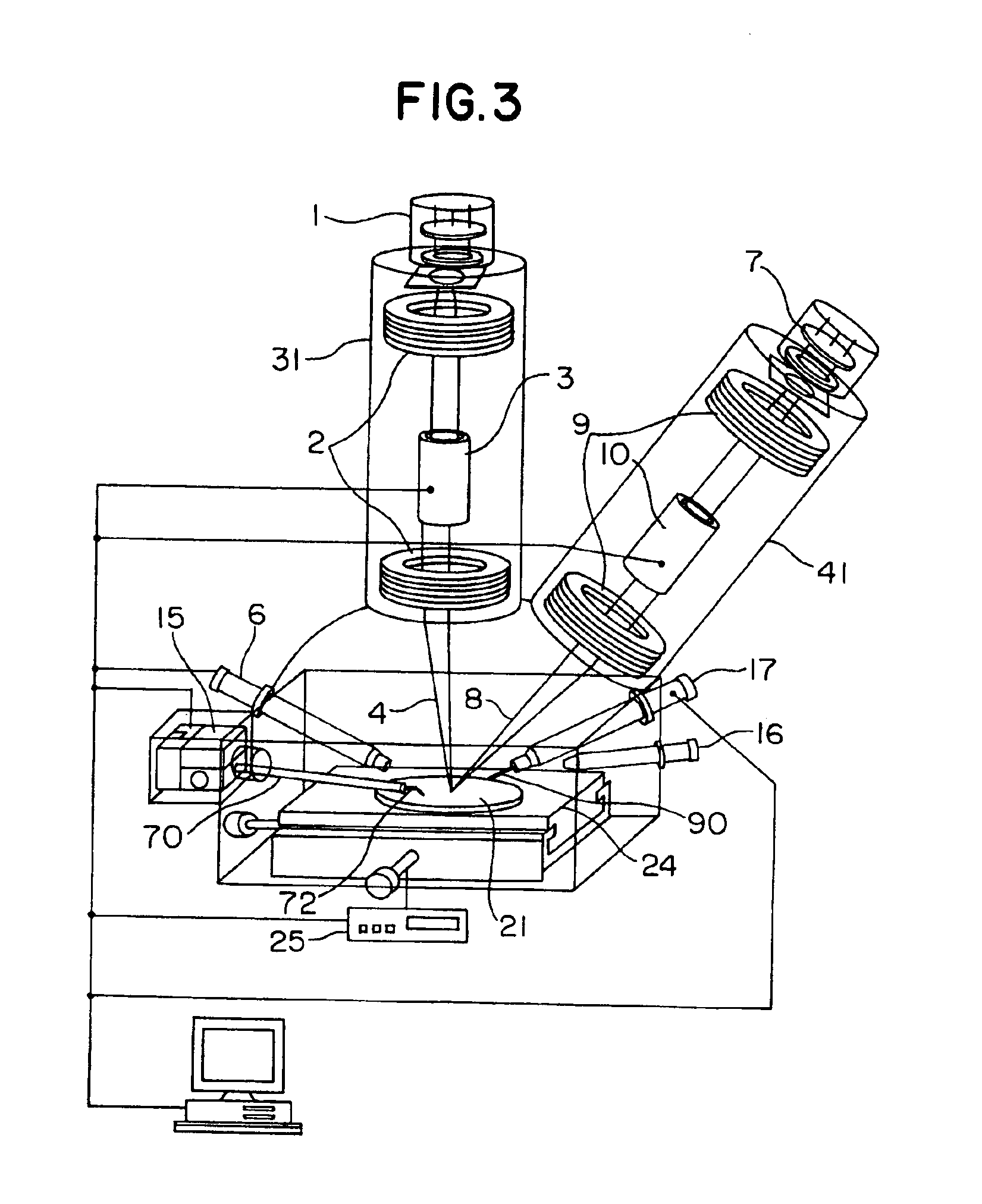

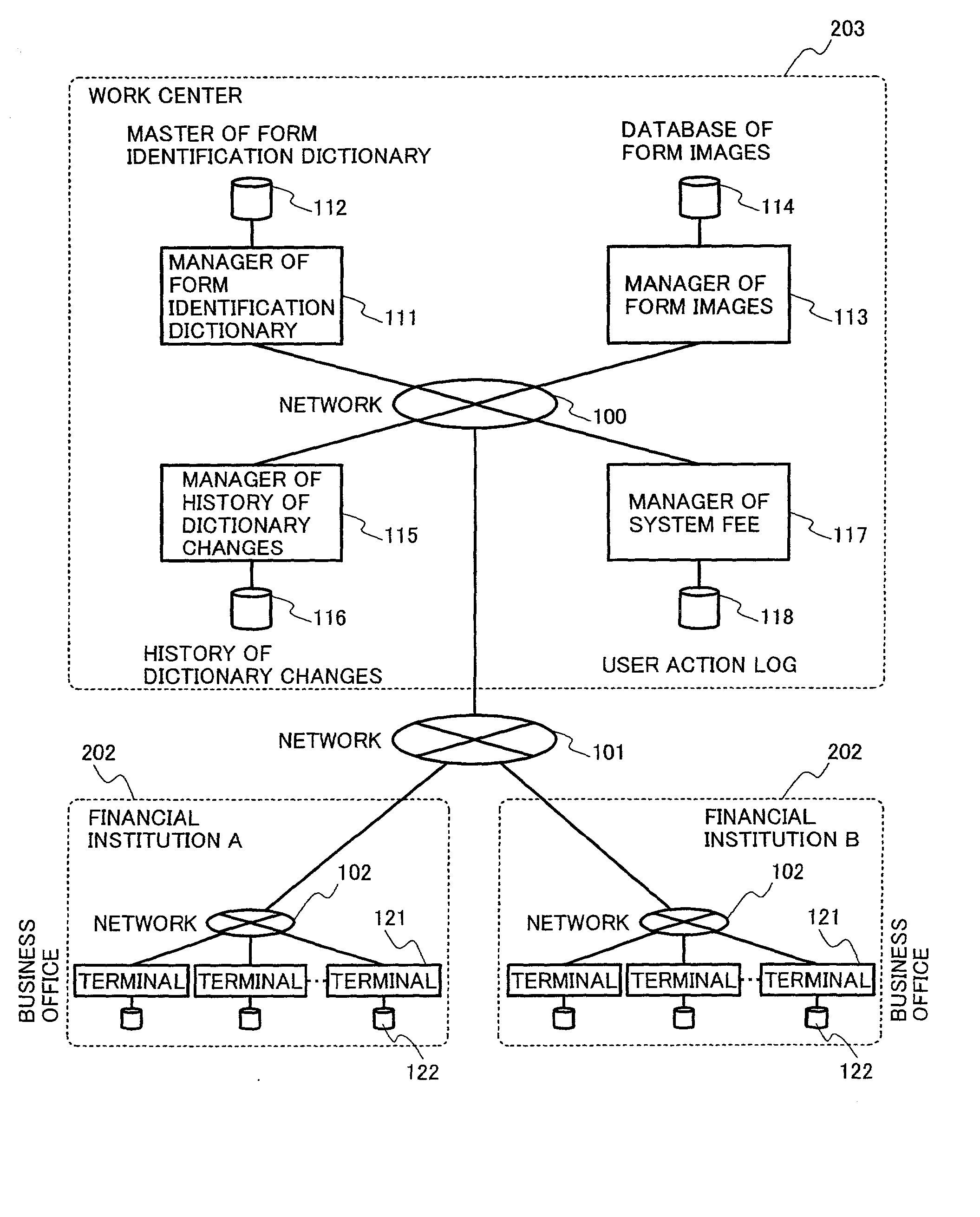

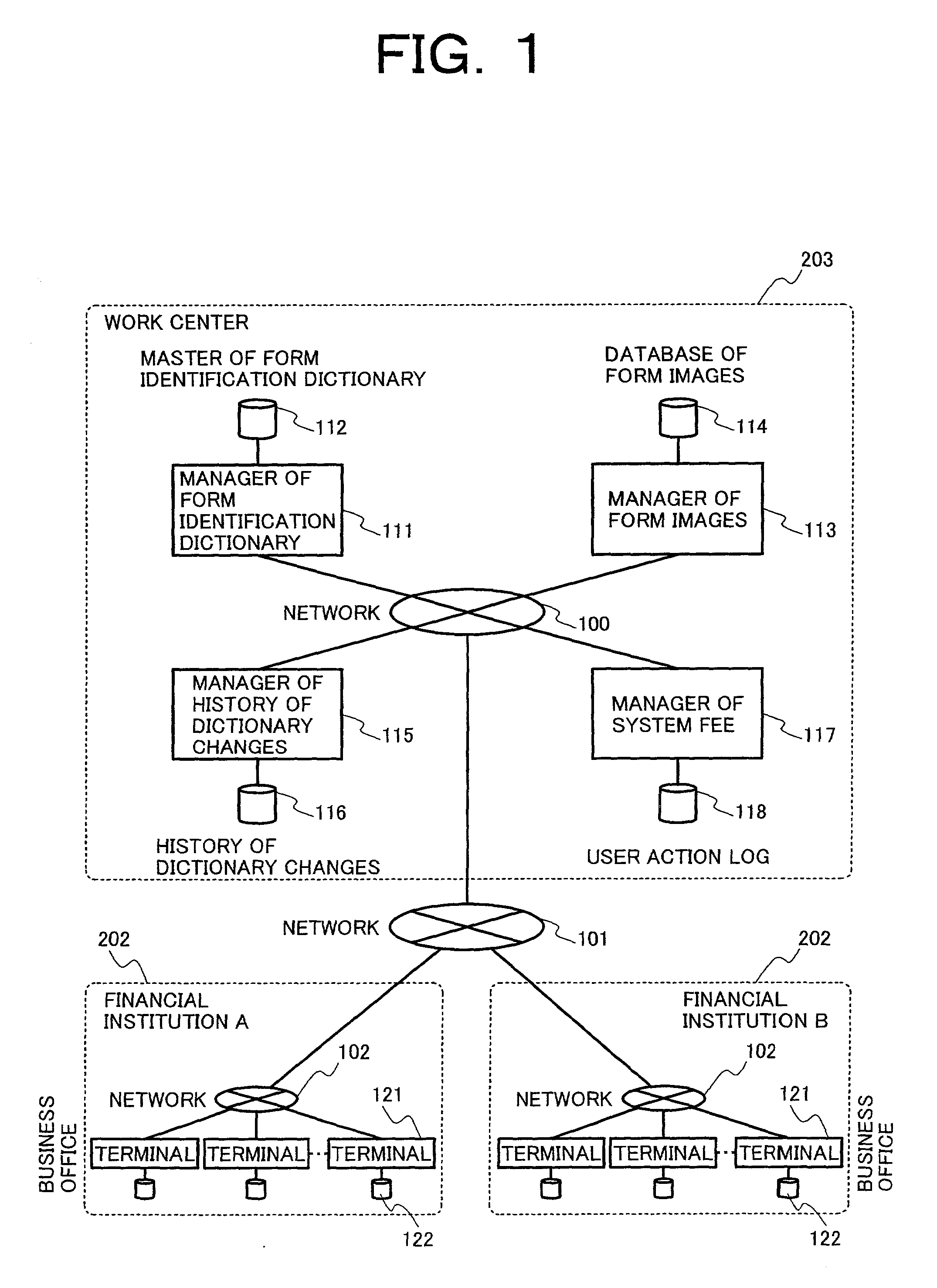

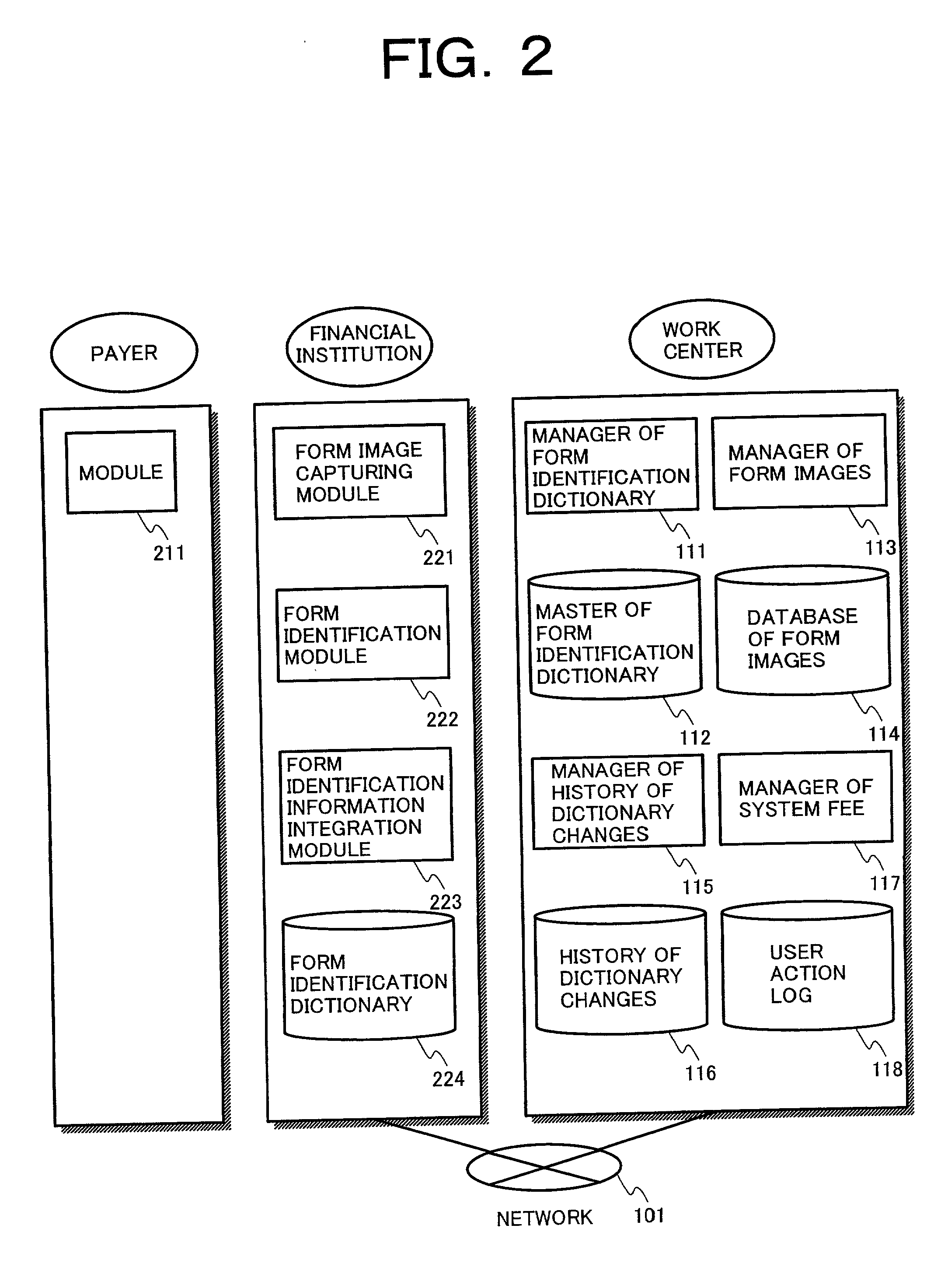

Form processing system, management system of form identification dictionary, form processing terminal and distribution mehtod of form identification dictionary

When a form processing terminal fails to identify a form, image information of the identification-failed form is transmitted to a work center. A manager of form identification dictionary of the work center analyzes the cause(s) of the identification failure, and updates the form identification dictionary while allowing the form processing system to operate. Update information is transmitted to the form processing terminal. The form processing terminal can also transmit to the work center information, which characterizes the form type, together with the image of the identification-failed form. The use of the updated information of the form by the form processing terminal is recorded in a user action log for fee charging purpose.

Owner:HITACHI OMRON TERMINAL SOLUTIONS CORP

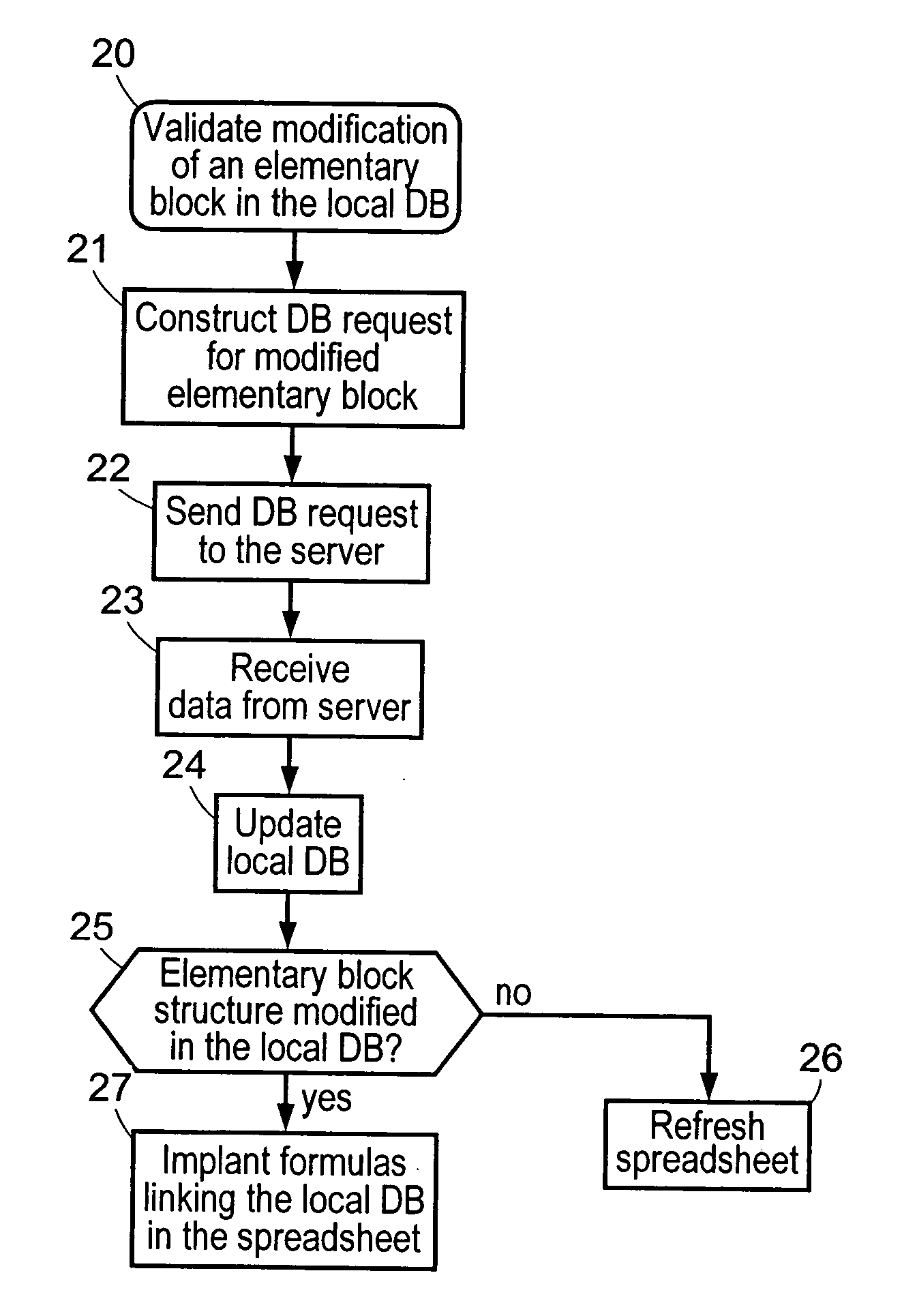

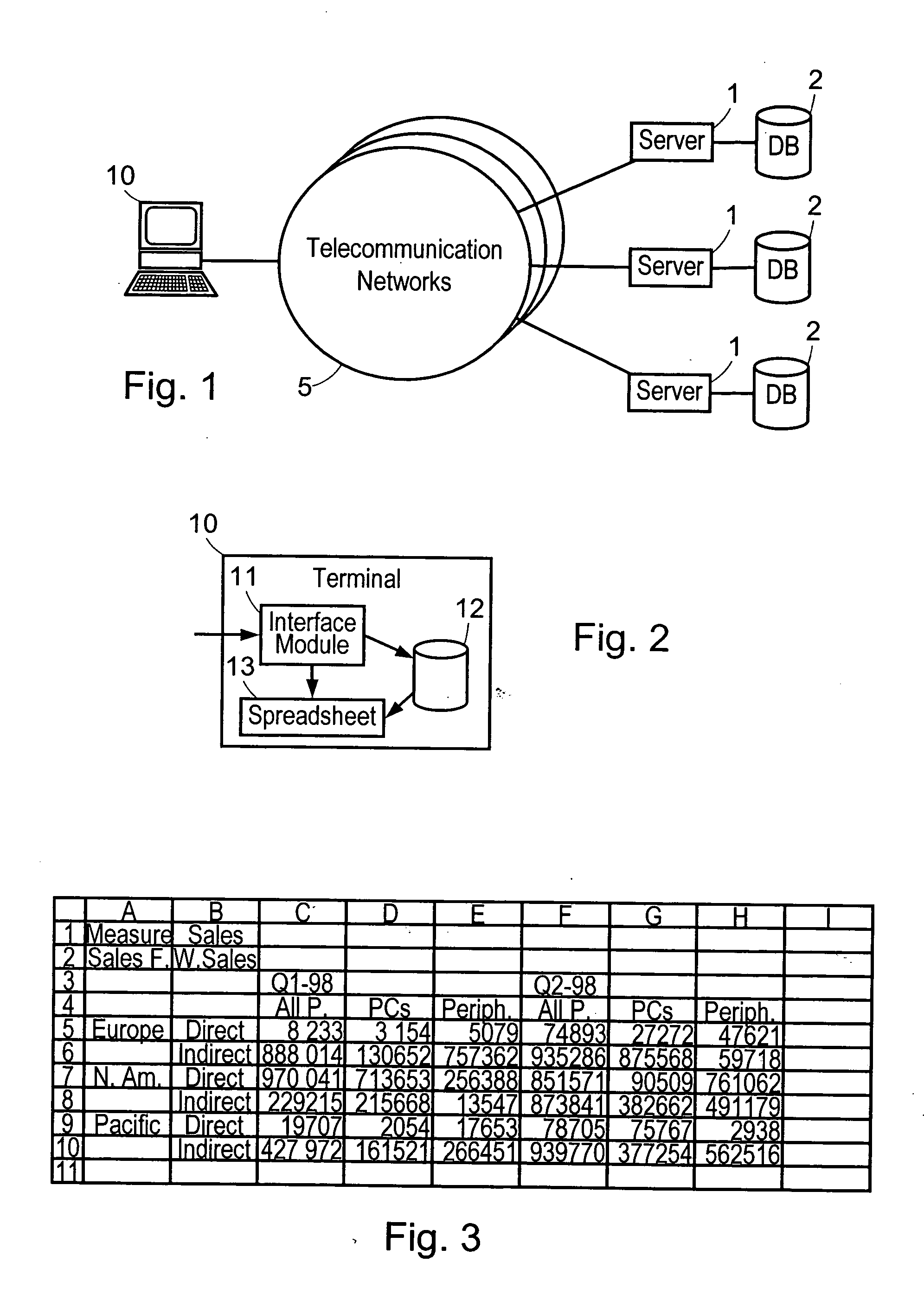

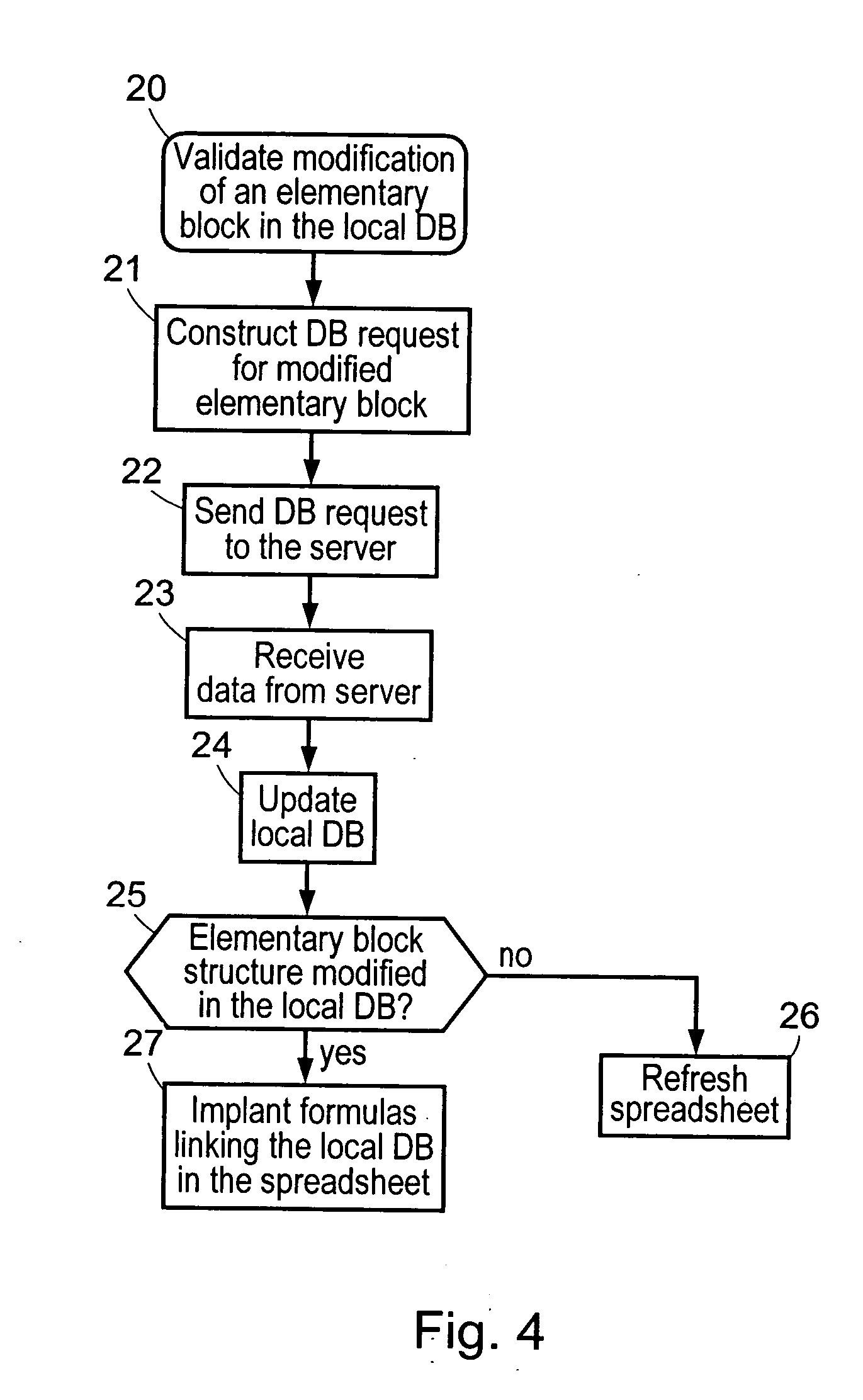

Method and system for handling data available in multidimensional databases using a spreadsheet

InactiveUS20050091206A1Suppression of shortcomingsDigital data processing detailsText processingElectronic formSelection criterion

To handle data stored in a multidimensional database in which the data is structured according to a number of dimensions, this process includes steps consisting in: generating a query to extract data from the multidimensional database based on selection criteria introduced by a user relating to at least part of the dimensions of the multidimensional database; executing the data extraction query on the multidimensional database so as to receive data extracted from the multidimensional database and corresponding to the selection criteria introduced by the user; storing the data received in the form of an elementary data block in a local database; and inserting into spreadsheet cells a formula for displaying a data item that points to a respective data item of the elementary data block stored in the local database.

Owner:GRANITE SOFTWARE

Biodegradable resin composition for modifying toughness and heat resistance and preparation method thereof

InactiveCN101143962AImprove toughnessImprove heat resistanceHeat deflection temperatureProcedure Agents

The invention provides a biodegradable resin component with toughness and heat resistance improved and a method for preparing the same, wherein the resin component contains 100 parts by mass of biodegradable resin, 1-40 parts by mass of thermoplastic elastomer, and 0.1-30 parts by mass of inorganic additive, and preferentially contains 3-25 parts by mass of flame retardant, 0.1-10 parts by mass of performance reinforcing agent and 0.1-10 parts by mass of processing aid; the resin component is granulated by a double screw extruder after melting mixing, the forming processing cycle of the resin component is short during injection forming, and after treatment for 10 min at 110DGE C, the lzod notched impact strength is higher than 30J / m, and the heat deformation temperature is higher than 90DGE C.

Owner:CHITEC TECH

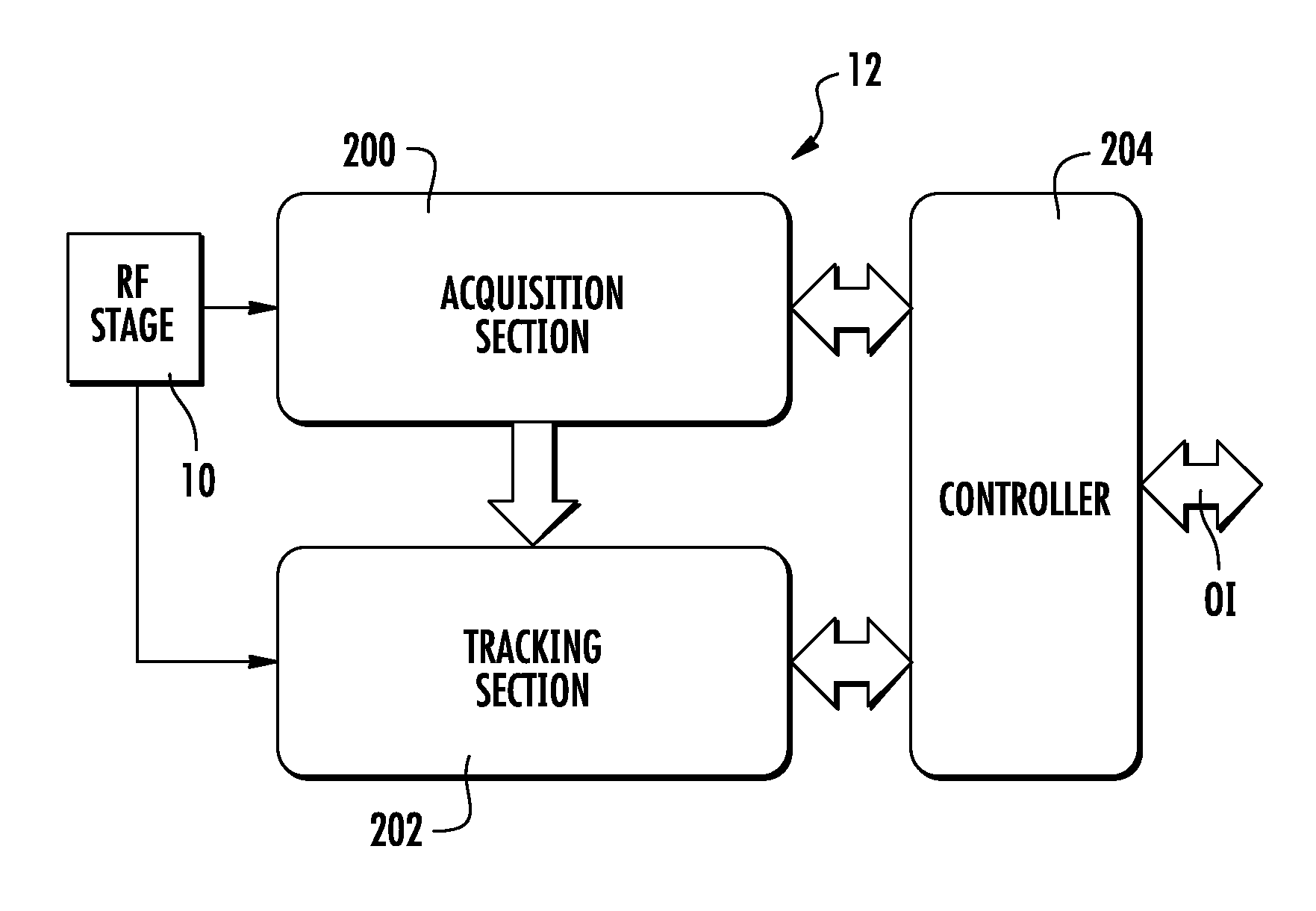

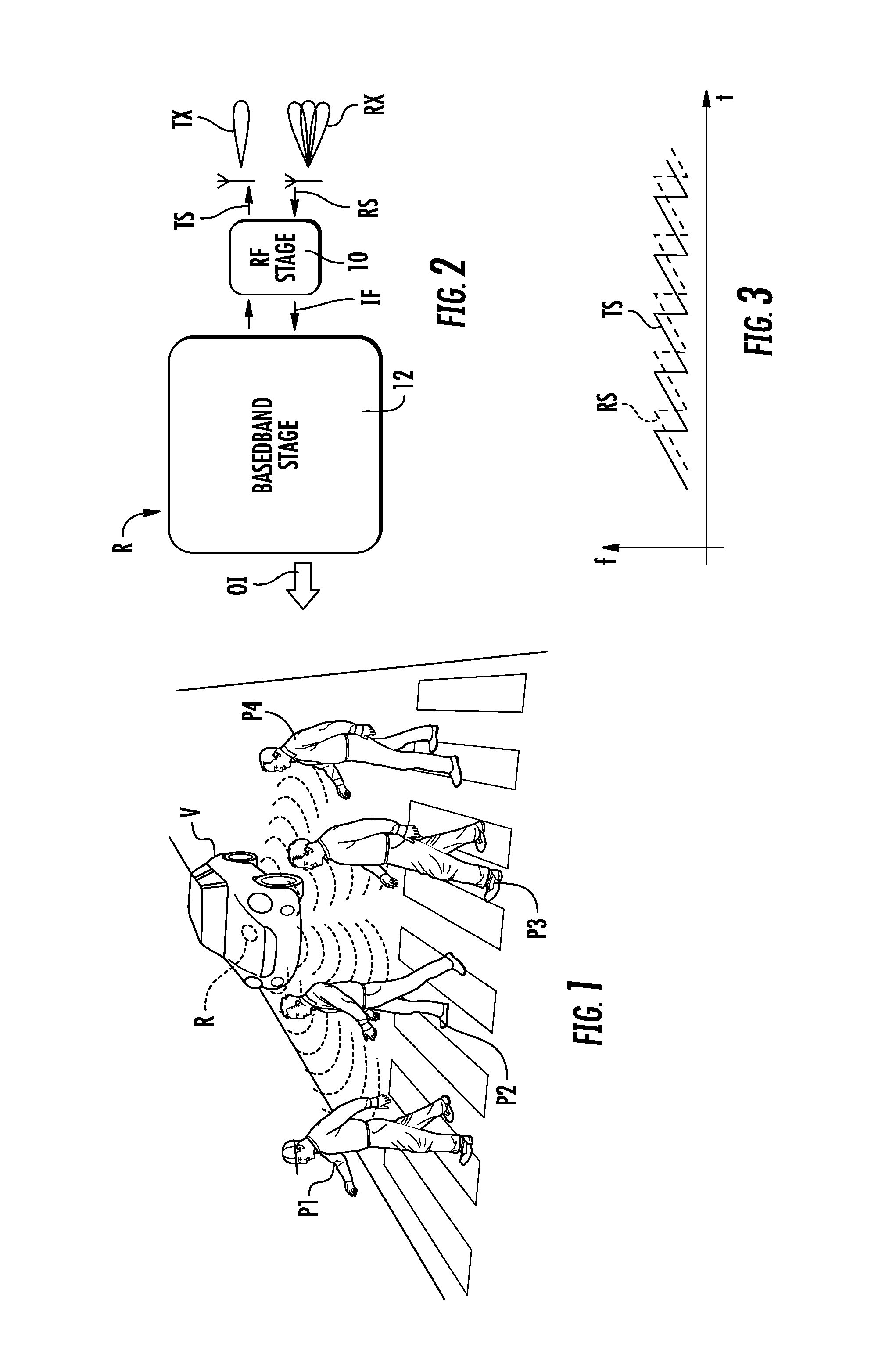

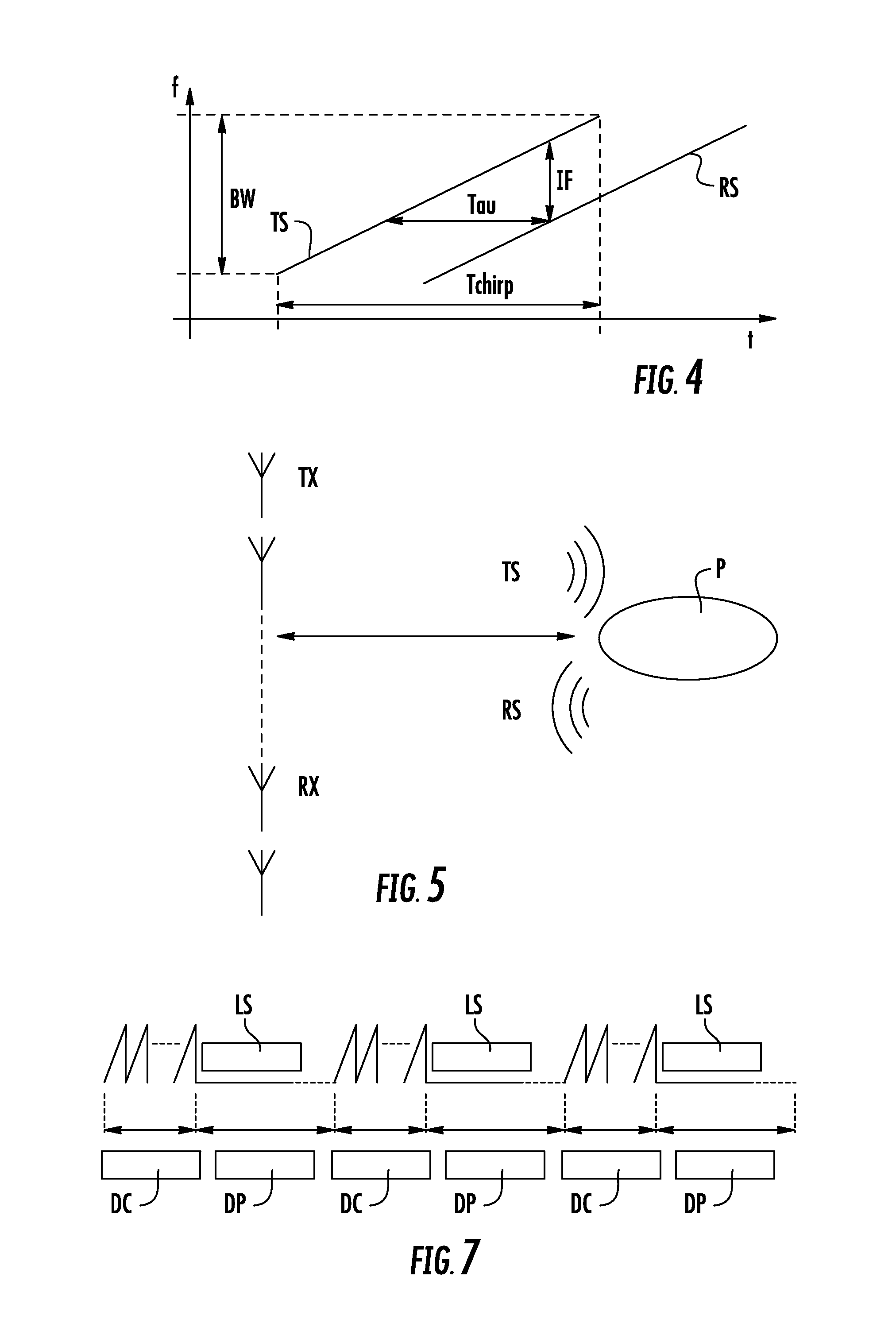

Method and devices for processing radar signals

A method for processing signals received by a plurality of receiving antennas in a radar system, for example for road safety, which emits sequences of chirp-modulated signals, wherein the received signals are mixed with local replicas of the transmitted signals so as to generate, for each receiving antenna, a sequence of detection signals. The detection signals are subjected to Fourier-transform processing and beam-forming processing for generating values of range, azimuth, and speed for at least one obstacle or “target” detected by the radar system. The method includes an acquisition process for yielding approximate values of range and azimuth of the obstacle, and a tracking process for yielding accurate range, azimuth and speed values of the obstacle itself.

Owner:STMICROELECTRONICS INT NV

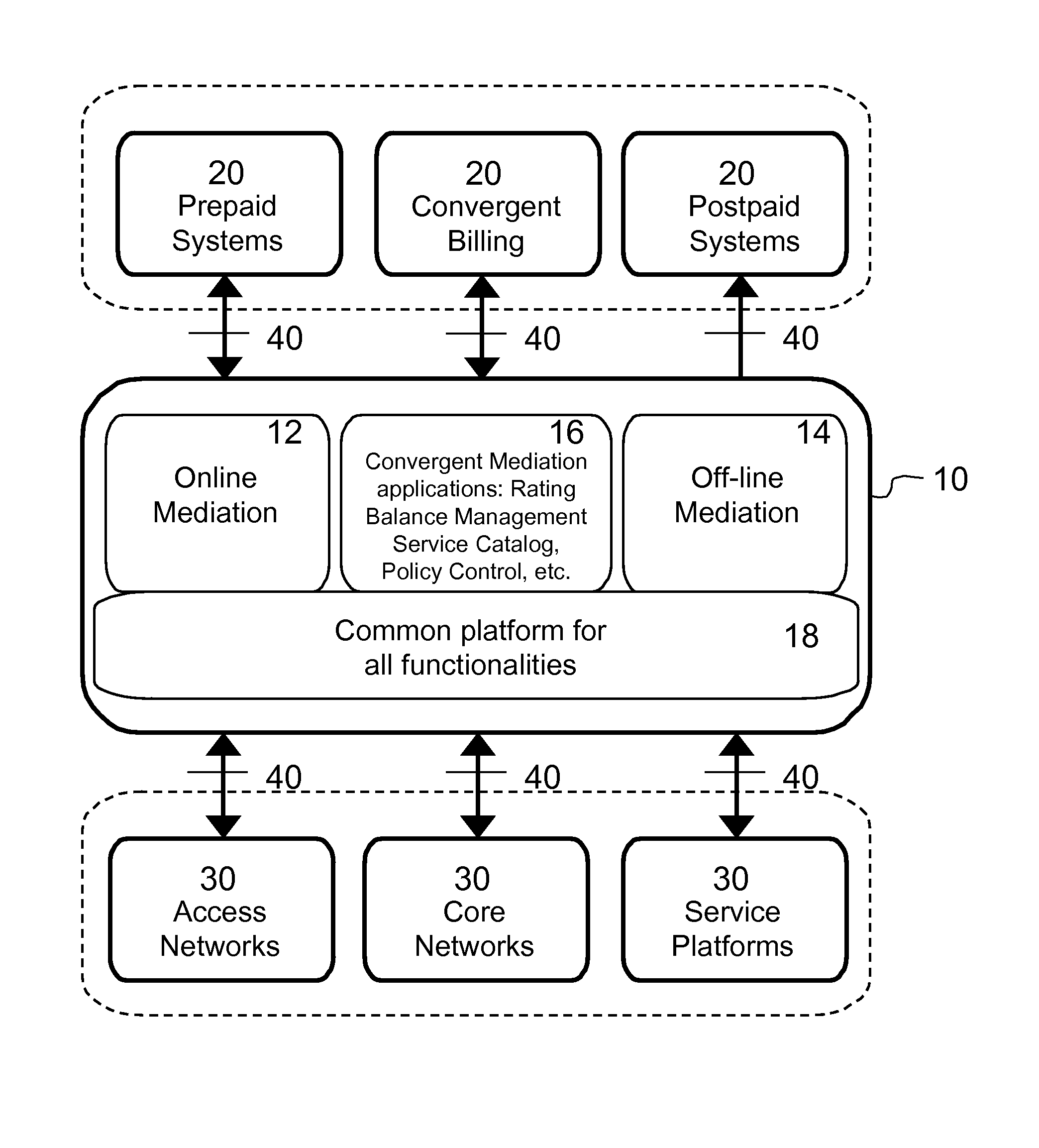

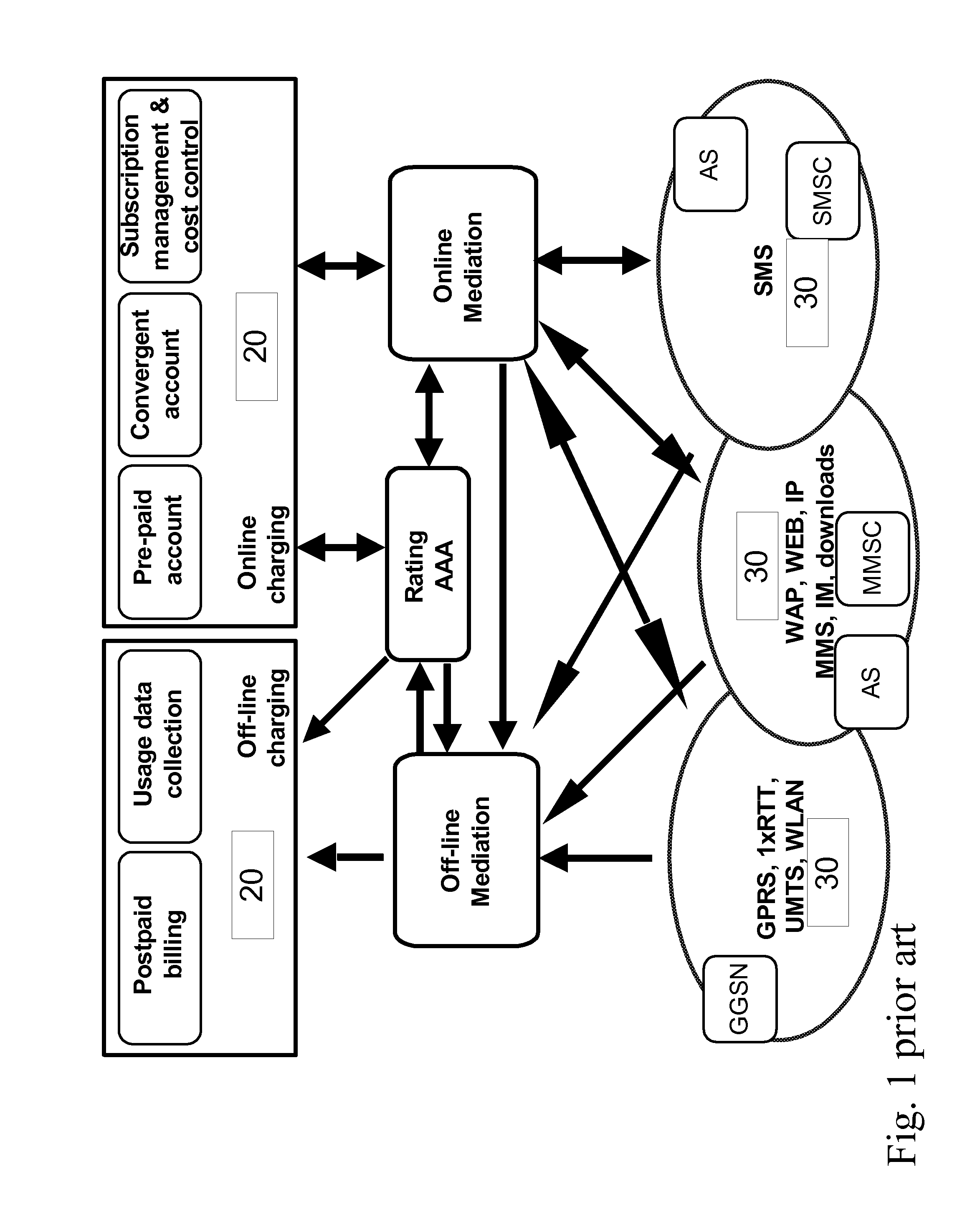

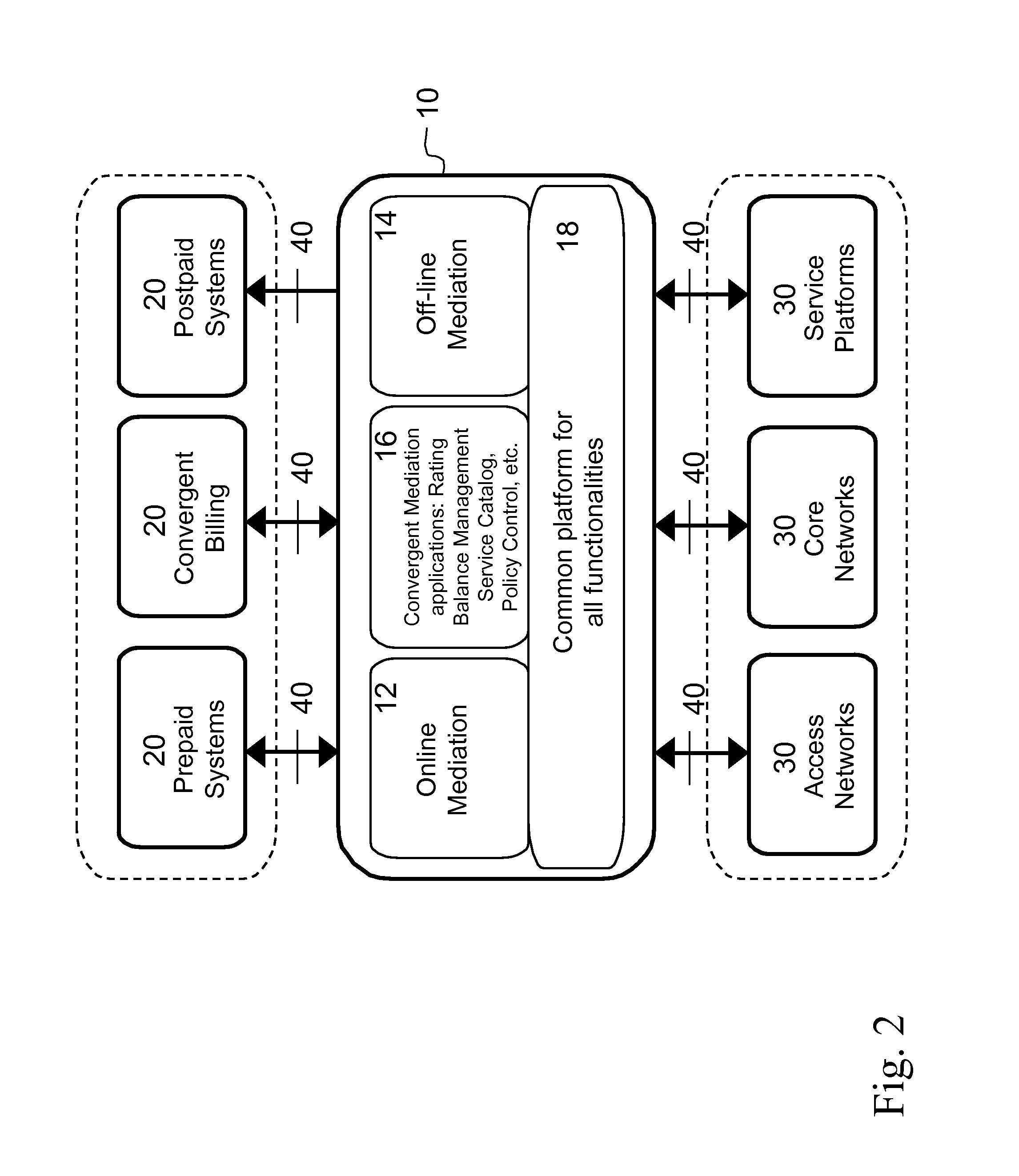

Convergent Mediation System With Improved Data Transfer

InactiveUS20110010461A1Reliability problemReduce latencyMetering/charging/biilling arrangementsMultiple digital computer combinationsStatic random-access memoryRandom access memory

An object is to create a convergent mediation system (10) and method that meet the technical requirements of low latency time and high reliability. According an aspect of the invention, these objects are achieved by providing a convergent mediation system (10) that comprises a plurality of independent processing nodes (120, 125) adapted to form processing streams (200) for the online processing (12) and off-line processing (14) of data. Each of the processing streams (200) comprises at least two independent nodes (120, 125) in sequence and buffers (145) between the nodes (120, 125). Furthermore, random access memory is utilized such that at least one of the buffers (145) in each of the online processing streams (212) is formed by a dedicated memory area in the random access memory.

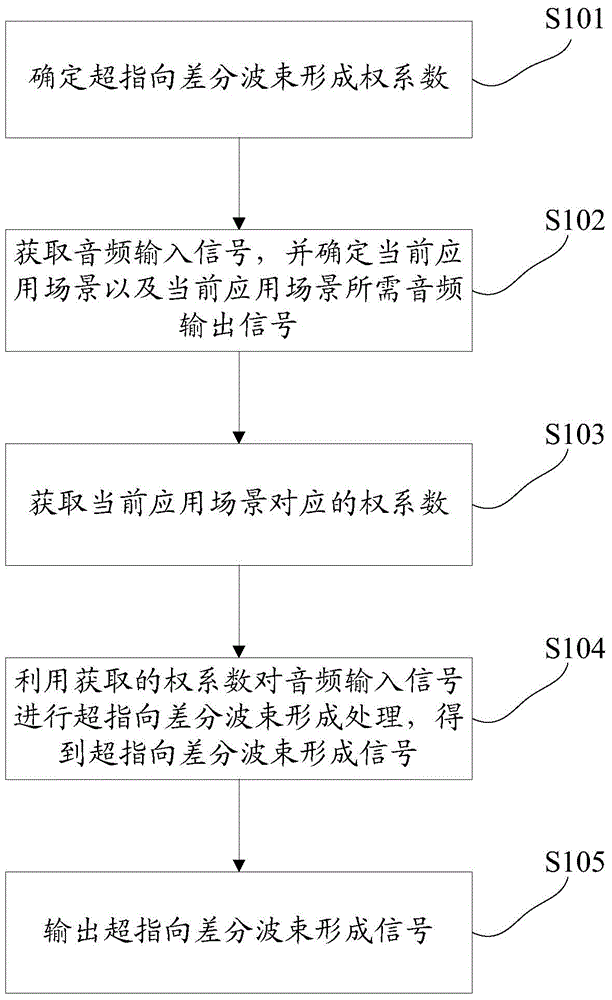

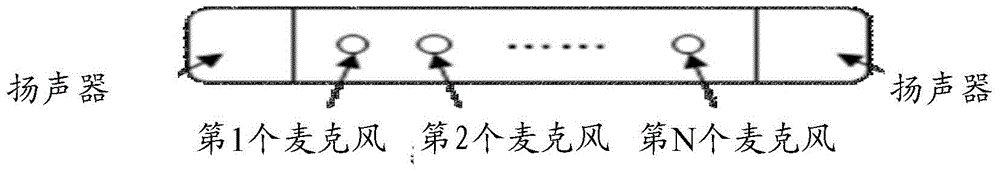

Audio signal processing method and device and difference beam forming method and device

ActiveCN104464739AMeet the needs of different audio signal processing methodsMicrophonesSignal processingDirectivityForm processing

The invention discloses an audio signal processing method and device and a difference beam forming method and device to solve the problem that an existing audio signal processing system can not be used for processing audio signals in different application scenes. The audio signal processing method comprises the steps of determining a super-directivity difference beam forming weight coefficient; acquiring the weight coefficient corresponding to the current application scene according to the output signal type required by the current application scene, and conducting super-directivity difference beam forming processing on an audio input signal by means of the acquired weight coefficient, so that a super-directivity difference beam forming signal in the current application scene is obtained; processing the forming signal to obtain a final audio signal required by the current application scene. By the adoption of the audio signal processing method and device and the difference beam forming method and device, the requirement for providing different audio signal processing methods for different application scenes can be met.

Owner:HUAWEI TECH CO LTD

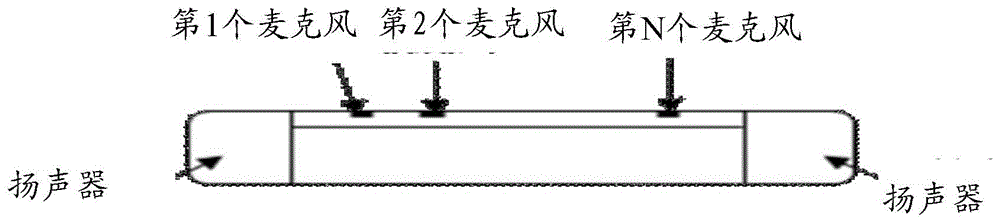

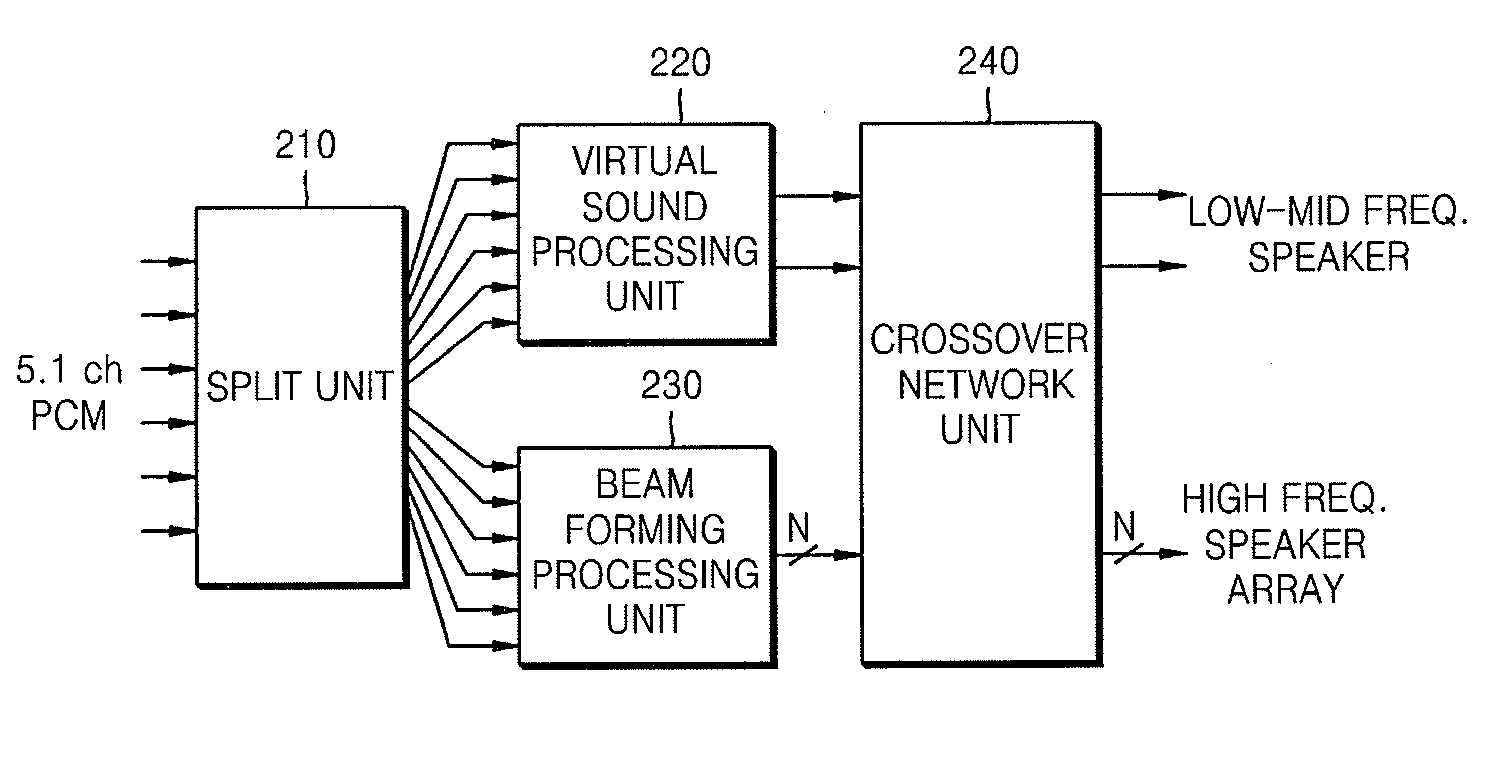

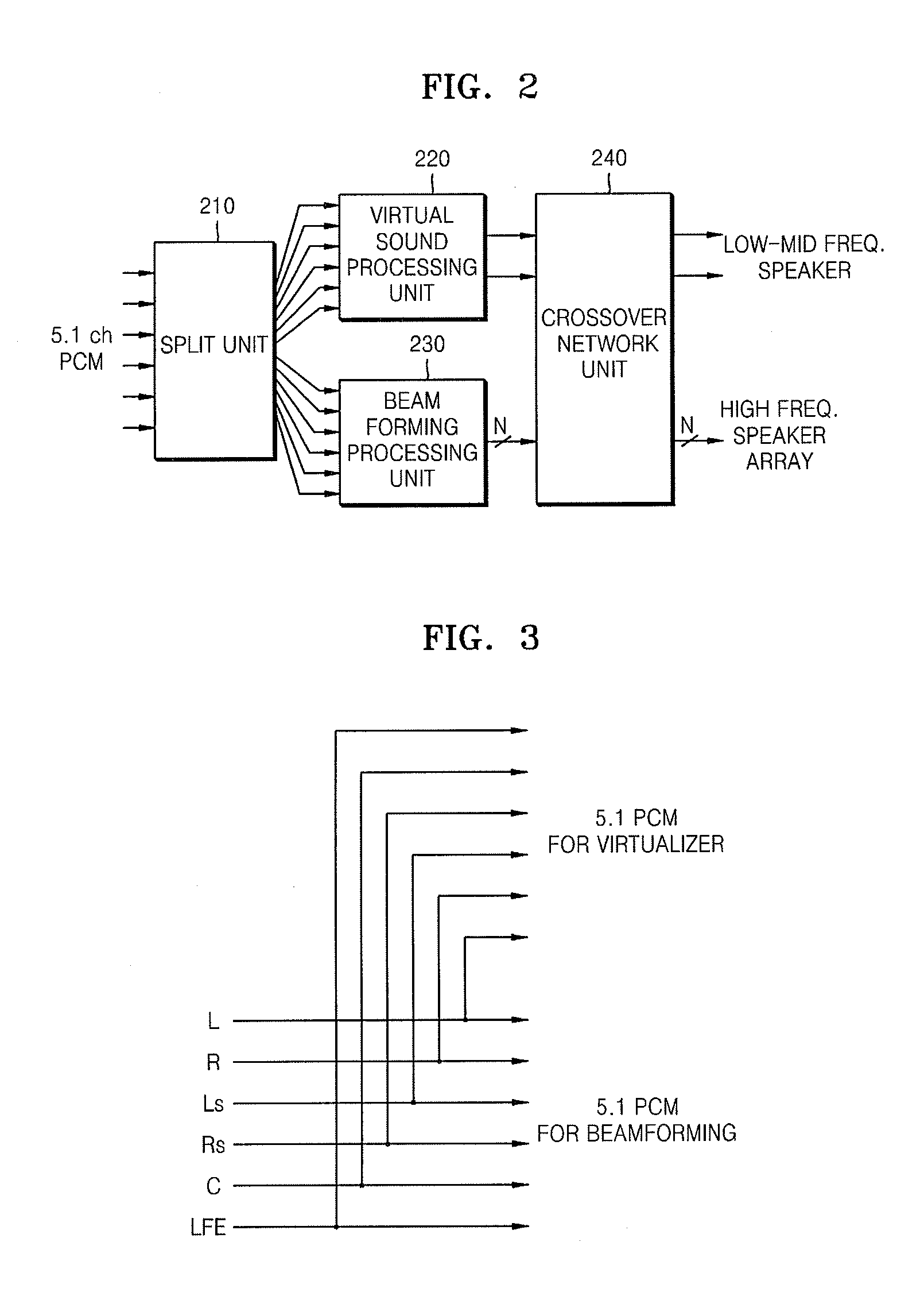

Front surround system and method of reproducing sound using psychoacoustic models

InactiveUS20070286427A1Enhanced Stereo EffectImprove system performanceMicrophonesLoudspeakersIntermediate frequencyLoudspeaker

A front surround reproduction system improving the stereo effect of mid and low frequency signals by using a psychoacoustic model, and a method thereof. An audio reproducing system to reproduce multi-channel audio signals by using a plurality of speakers includes a split unit to copy the input multi-channel signals and to split the signals into two groups of multi-channel signals, a virtual sound processing unit to generate a virtual sound signal based on a head related transfer function (HRTF) from the one group of the multi-channel signals split in the split unit, a beam forming processing unit to generate a sound beam signal by adjusting the delays and levels of the multi-channel signals belonging to the other group split in the split unit, and a crossover network unit to adjust the characteristics of the virtual sound signal and the sound beam signal generated in the virtual sound processing unit and the beam forming processing unit, respectively, and to provide the virtual sound signal and the sound beam signal to mid and low frequency speaker arrays and high frequency speaker arrays, respectively.

Owner:SAMSUNG ELECTRONICS CO LTD

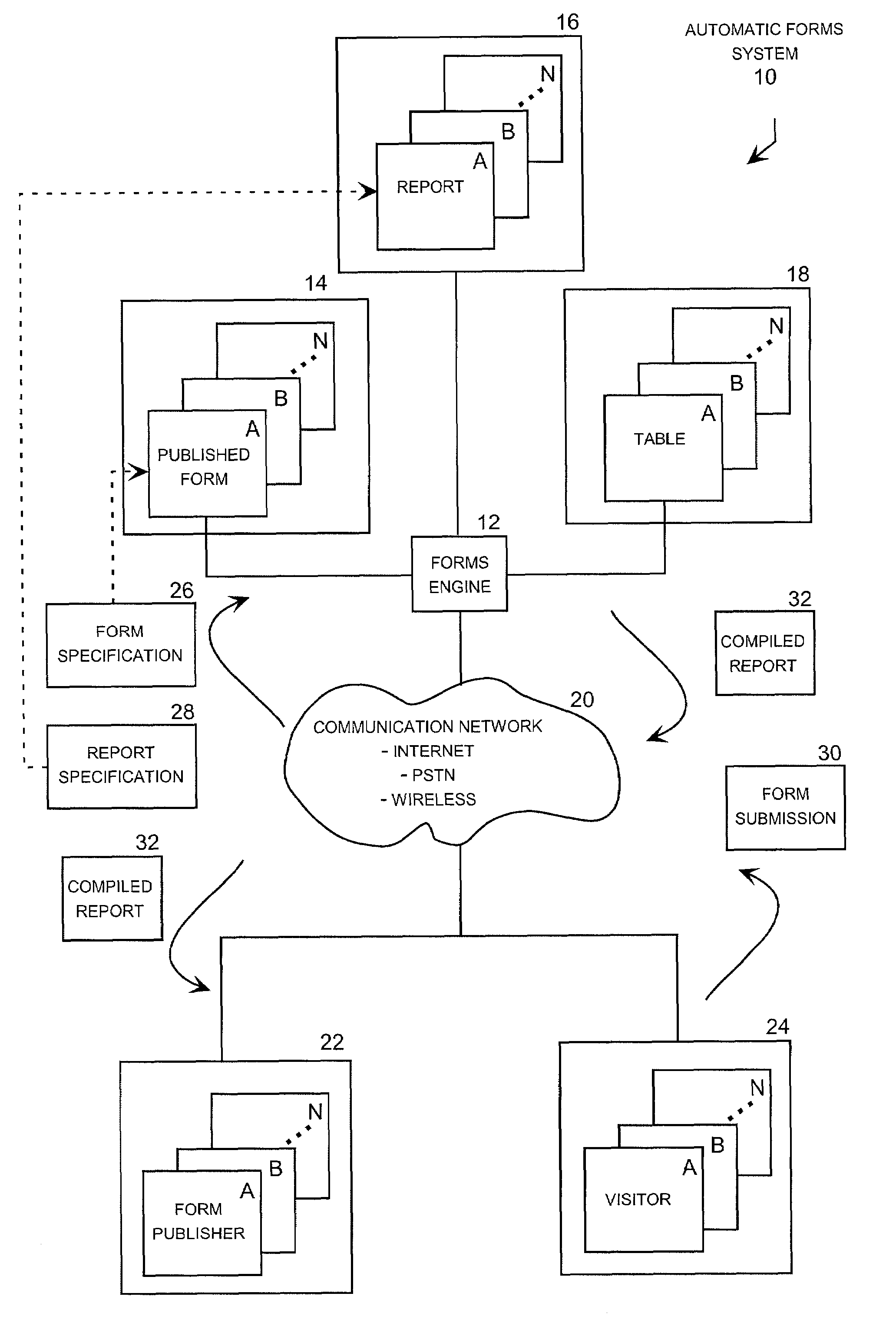

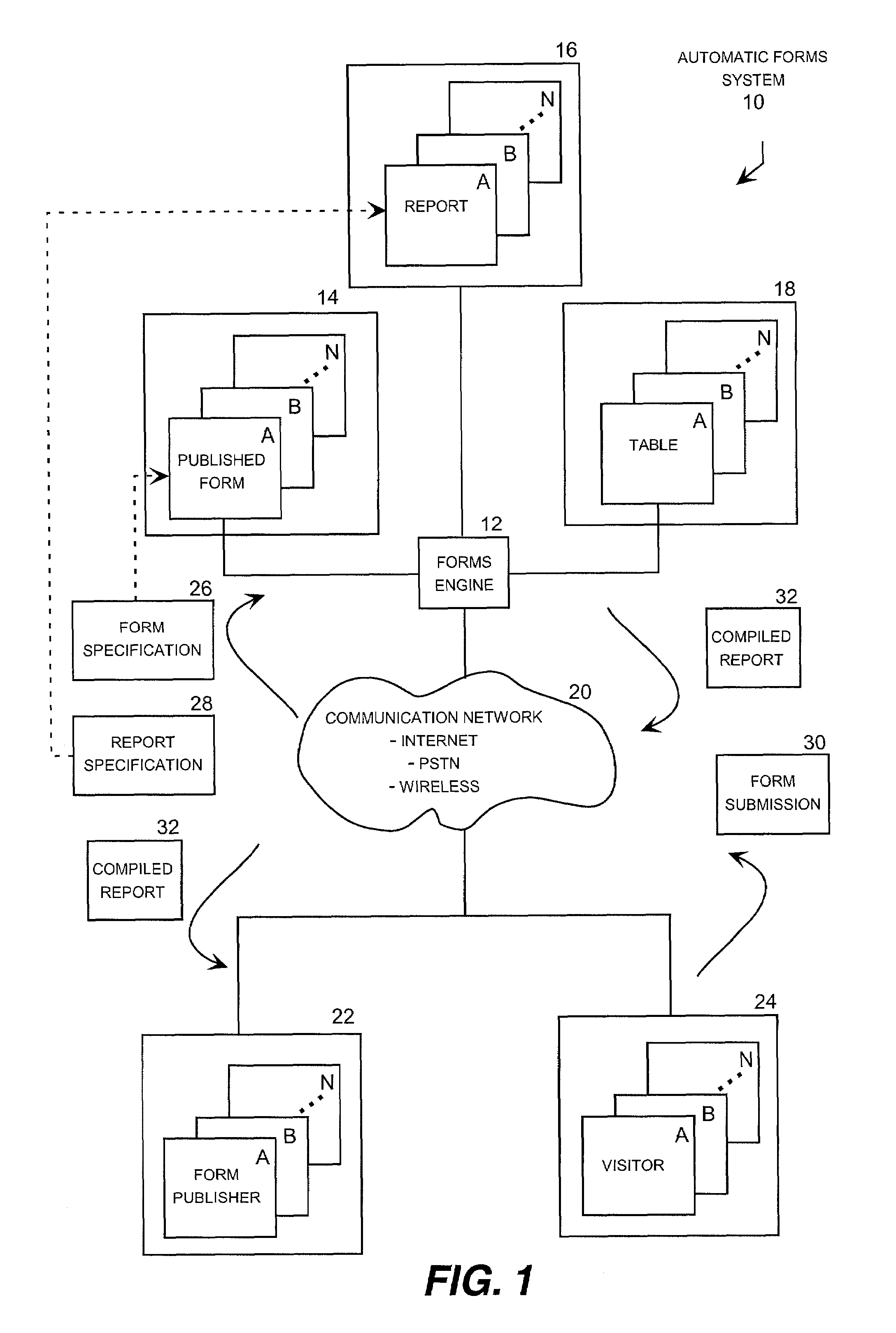

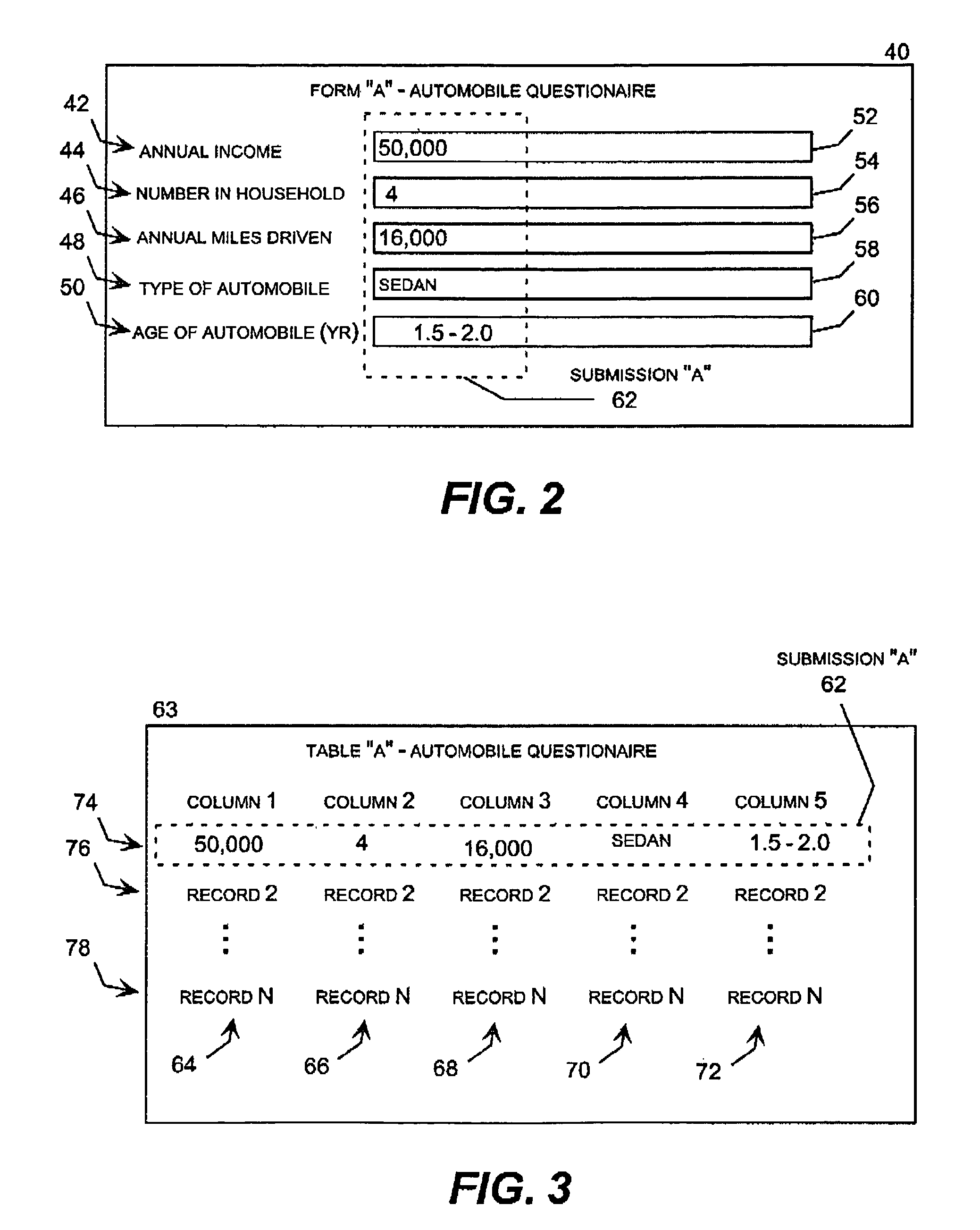

Automatic forms handling system

InactiveUS6968500B2Sufficient hardwareSufficient communication resourceData processing applicationsDigital data processing detailsThe InternetHandling system

An automatic forms handling application service provided on a global computer network, such as the Internet. A forms publisher submits a form and an associated report to the forms handling system. The form includes one or more data submission fields for accumulating data entries submitted into the form by visitors to the forms handling system. The report includes report elements for returning tabulated data entries accumulated using the form. The forms handling system automatically creates a database table corresponding to the form, and correlates each form submission field with a database storage element, such as a column in the database table, that accumulate data entries for its associated form submission field. The forms handling system also coordinates the database table with the associated report file, and periodically generates and delivers reports to the a specified location in accordance a service definition provided by the form publisher.

Owner:STRIPE INC

Data collection and processing system and methods

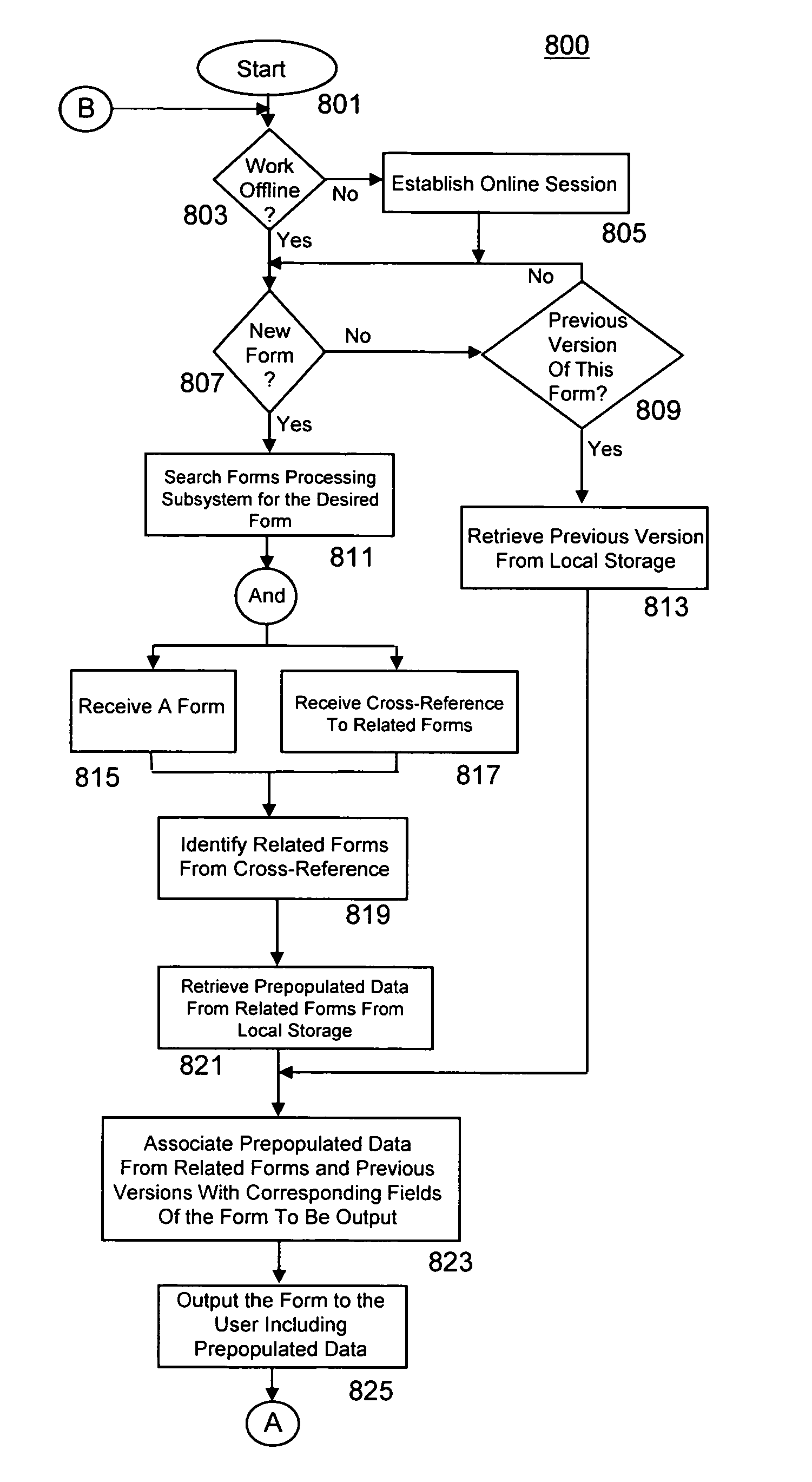

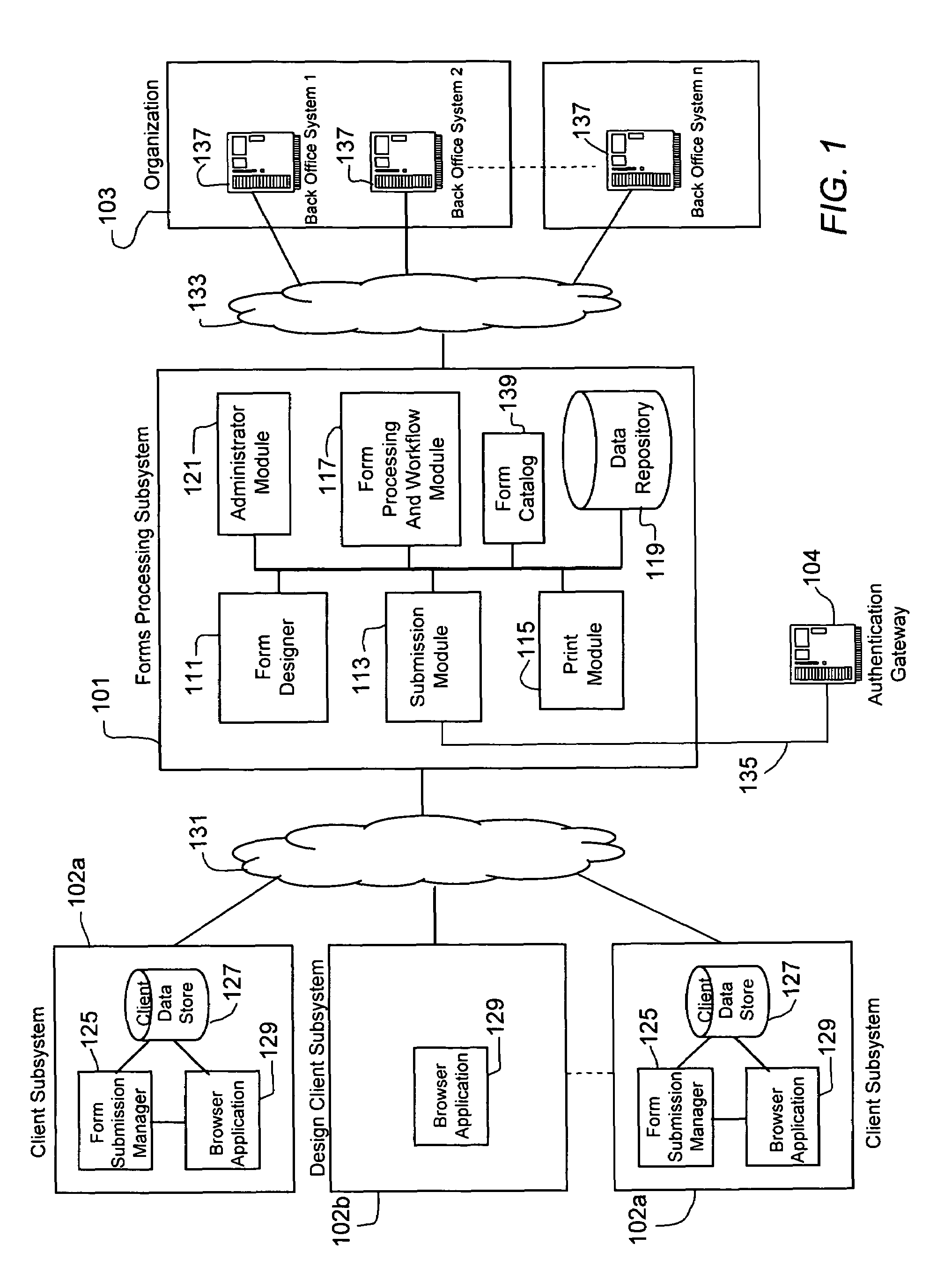

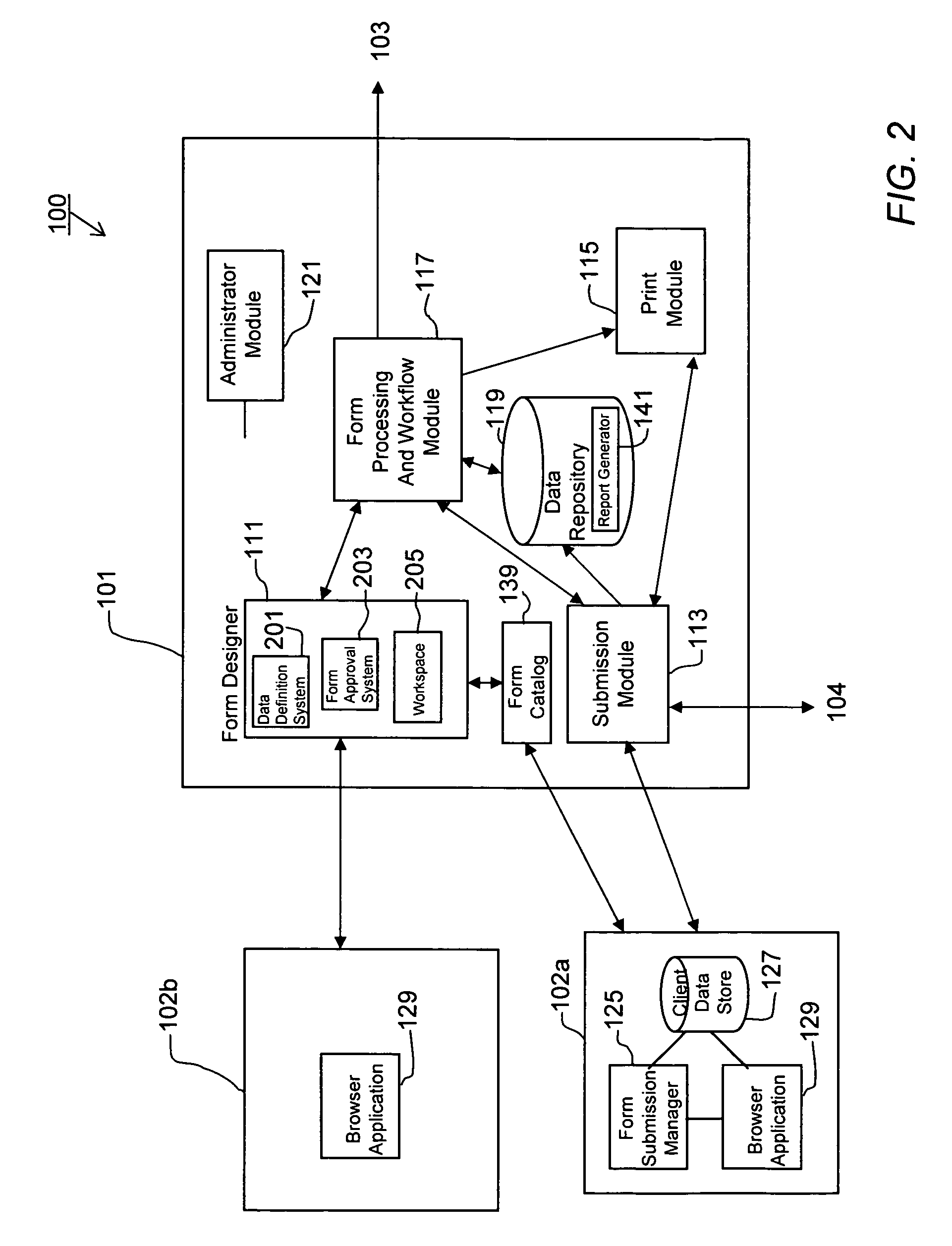

InactiveUS7644351B1Natural language data processingSpecial data processing applicationsClient dataClient-side

Systems and methods for data collection and processing. A system includes a forms processing subsystem including a form designer and a form processing and workflow module, and a client subsystem including a form submission manager and a client data store. User provided information is maintained locally in the client data store.

Owner:INFORMATION SCI CORP

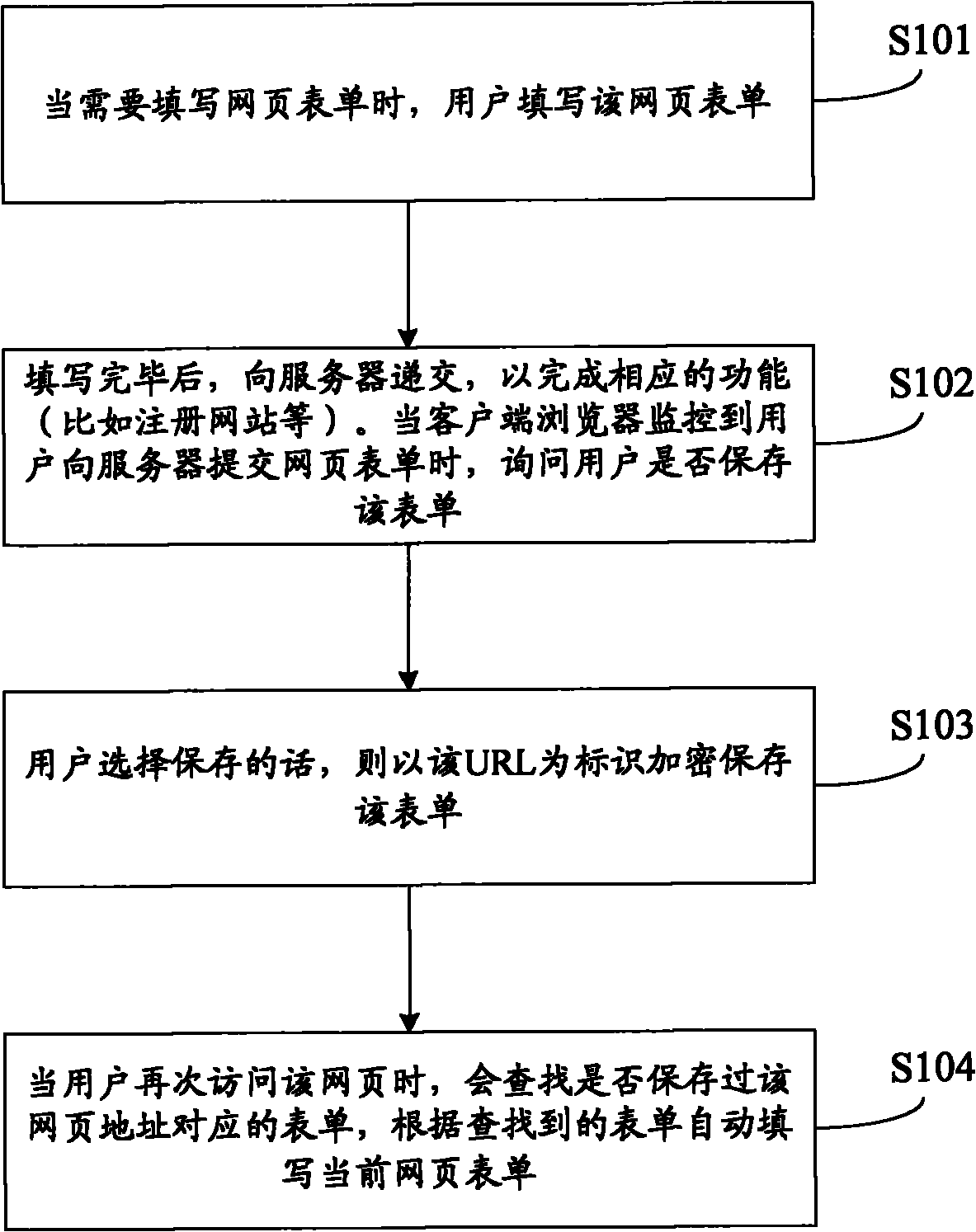

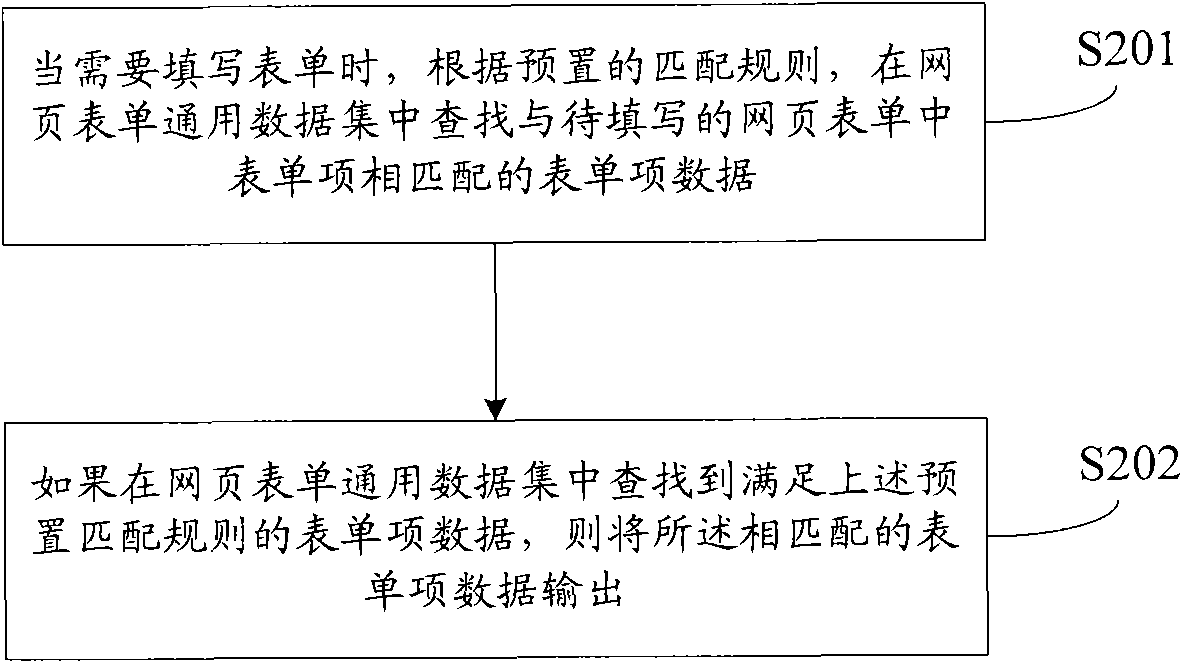

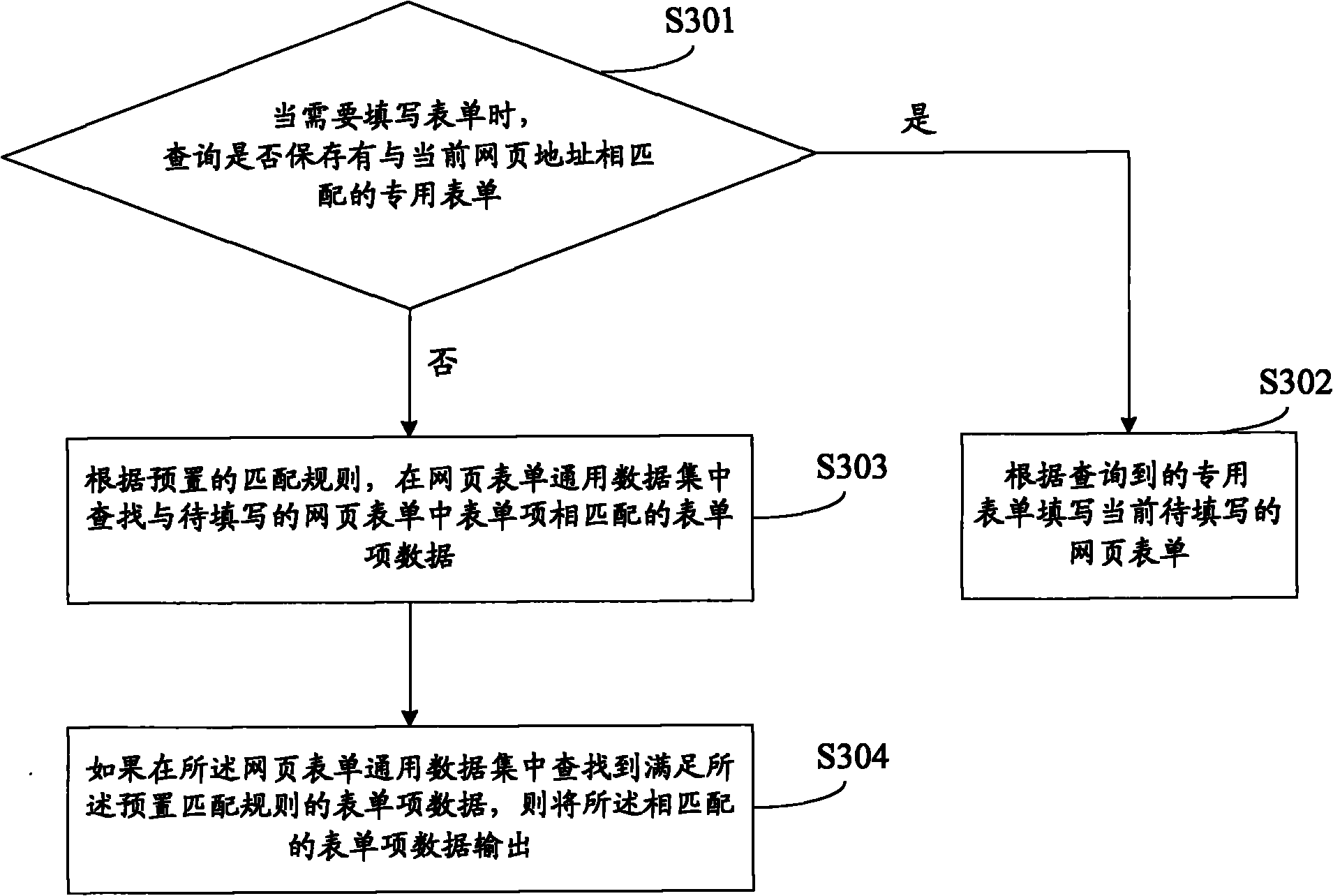

Web form data output method, device and form processing system

ActiveCN101782919AReduce workloadImprove filling efficiencyNatural language data processingSpecial data processing applicationsData setForm processing

The embodiment of the invention discloses a web form data output method, a device and a form processing system, relating to the technical field of a browser. The method comprises the steps: if trigger events output by a web form universal dataset is monitored, a form item data which is matched with the form item in the web form to be filled is found in the web form universal data set according to a preset matching rule; the web form universal data set is obtained by summarizing and analyzing the form items of at least two stored forms in advance; and if the form item data which meets the preset matching rule is found out in the web form universal data set, the matched form item data is output. The device comprises a form processing module, a matching finding module and a data output module. The system comprises a form finding module and an analyzing and summarizing module. The embodiment of the invention can increase the filling efficiency of the web form and is beneficial to improving the user experience.

Owner:BEIJING SOGOU TECHNOLOGY DEVELOPMENT CO LTD

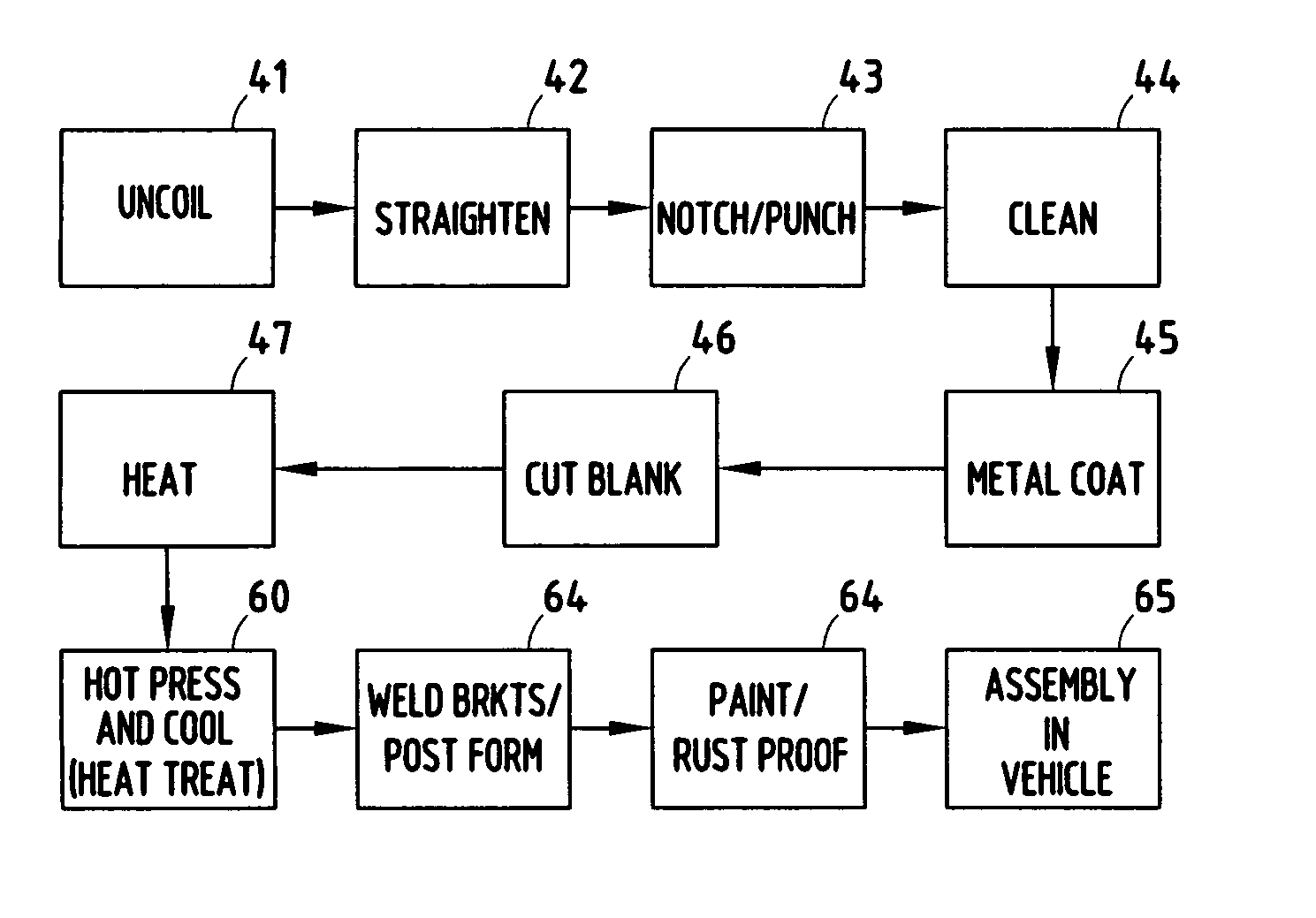

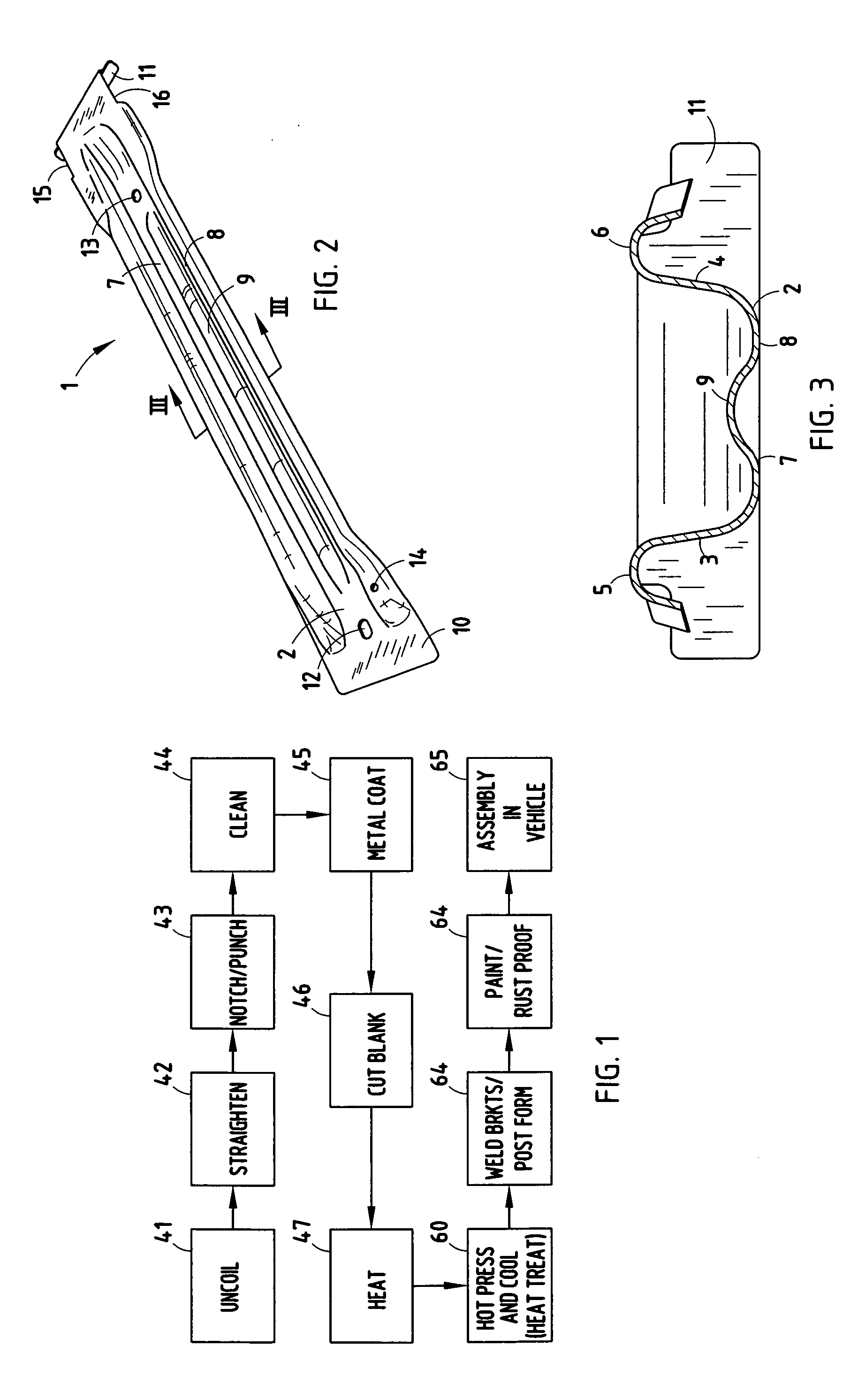

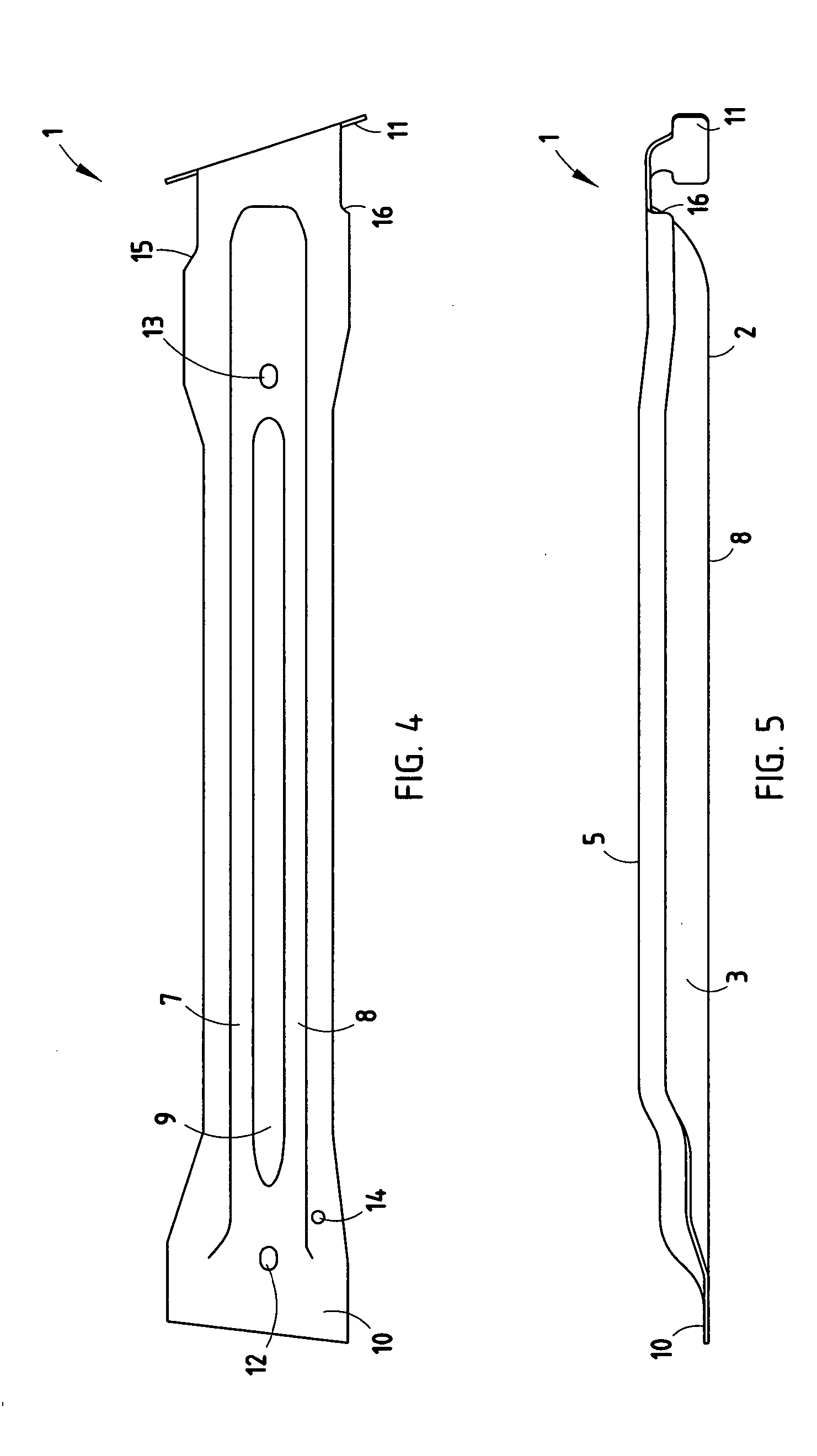

Method for making structural automotive components and the like

InactiveUS20060130940A1Reduce scaleReduced decarburizationVacuum evaporation coatingSurface reaction electrolytic coatingHigh intensityPhase change

A method for making structural automotive components and the like provides a strip of high strength steel having a selected thickness. A predetermined thickness of a metal coating, such as nickel, is applied to the opposite faces of the steel strip. The coated steel strip is cut to form a blank. The blank is heated in a generally open atmosphere to a temperature in the range of 800° C. to 1000° C. within less than ten minutes, thereby diffusing at least a portion of the metal coating a predetermined distance into the faces of the steel strip portion of the blank to alleviate scale formation, and simultaneously raise the temperature of the blank for hot forming the same. The heated blank is hot formed in a pressing tool, and cooled therein to heat treat the formed component through microstructure phase change, without substantial scale formation, such that the component need not be descaled prior to post-form processing and / or assembly in a vehicle.

Owner:BENTELER AUTOMOTIVE CORP

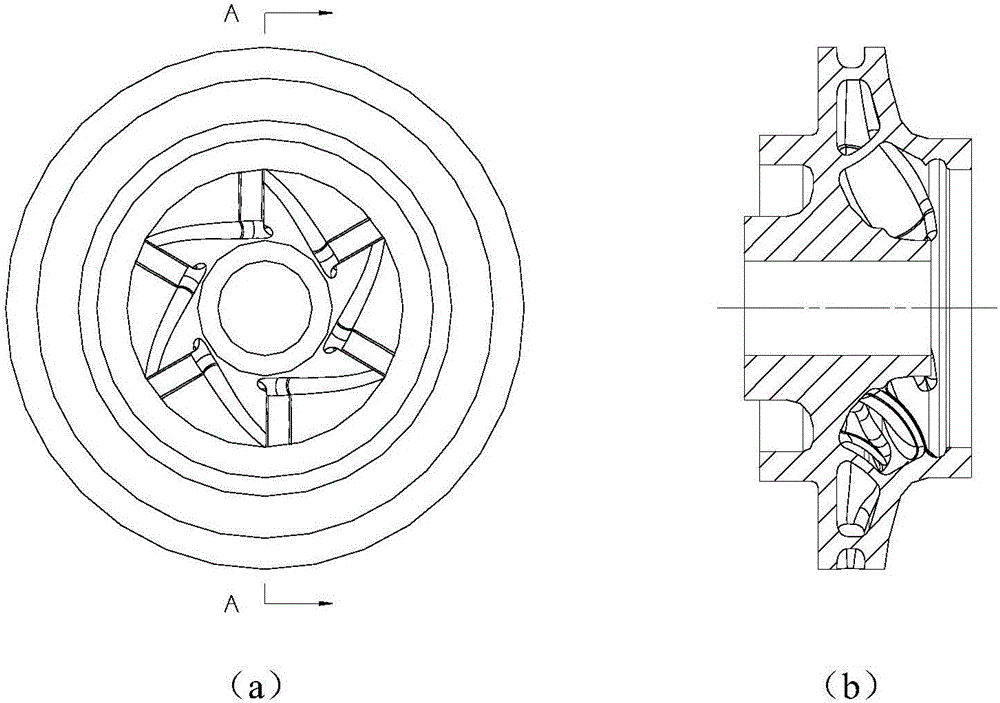

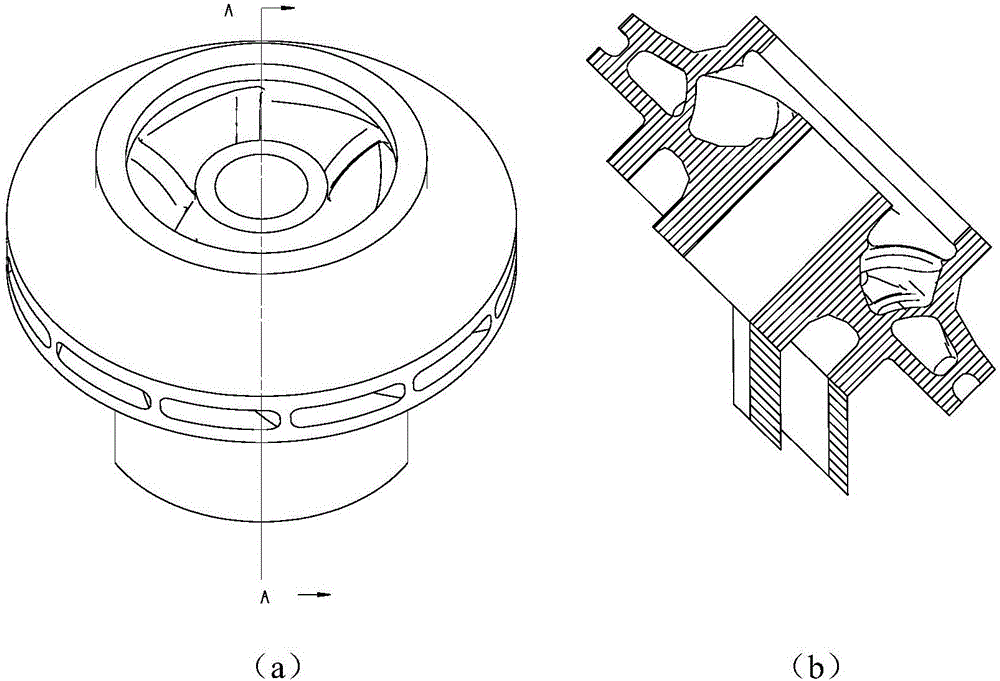

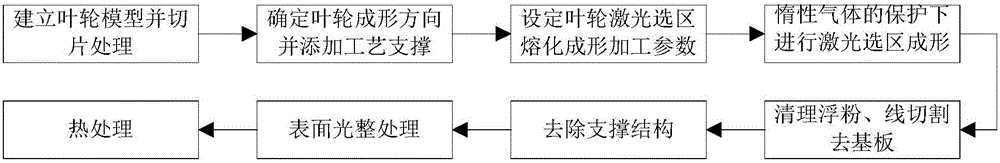

Integral manufacturing method of S-04/S-08 high-strength stainless steel three-dimensional flow shrouded impeller

ActiveCN106077643AShorten the manufacturing cycleCompact structureAdditive manufacturing apparatusEngine manufactureMaterials scienceAustenitic stainless steel

The invention provides an integral manufacturing method of an S-04 / S-08 high-strength stainless steel three-dimensional flow shrouded impeller. The integral manufacturing method comprises the steps of firstly, establishing an impeller three-dimensional model, and carrying out slicing treatment; determining the forming direction and support adding positions according to structural characteristics of the impeller; setting parameters of a laser selective melting forming processing technology according to characteristics of a high-strength stainless steel material; forming under protection of an inert gas; after forming, cleaning floating powder, removing a base plate through linear cutting, and removing supports; and finally, carrying out follow-up treatment such as surface treatment and thermal treatment on the impeller. According to the integral manufacturing method, complex cutters or fixtures do not need to be designed, materials can be directly added for part manufacturing only through the three-dimensional model of the impeller, the manufacturing cycle is greatly shortened, and the integral manufacturing method is applicable to trial manufacturing and middle and small-batch production in the development stage.

Owner:XIAN SPACE ENGINE CO LTD

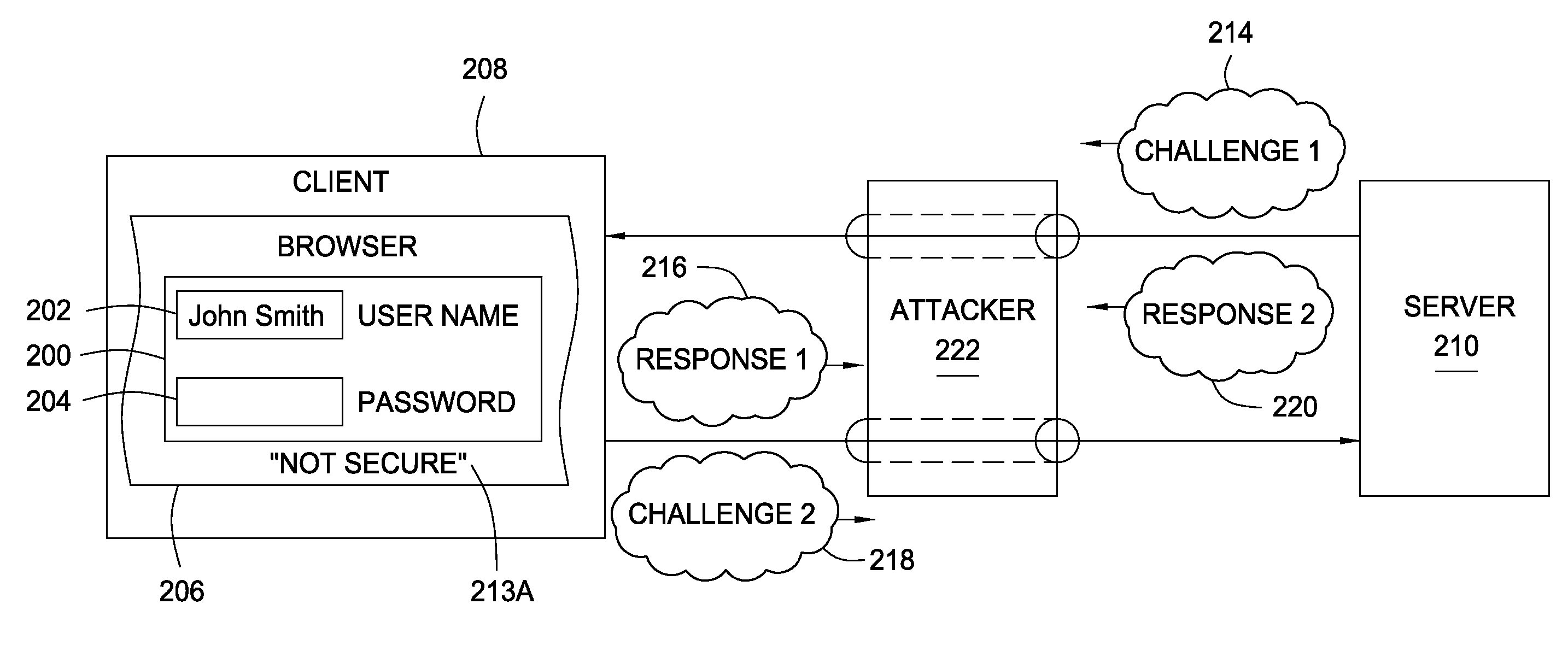

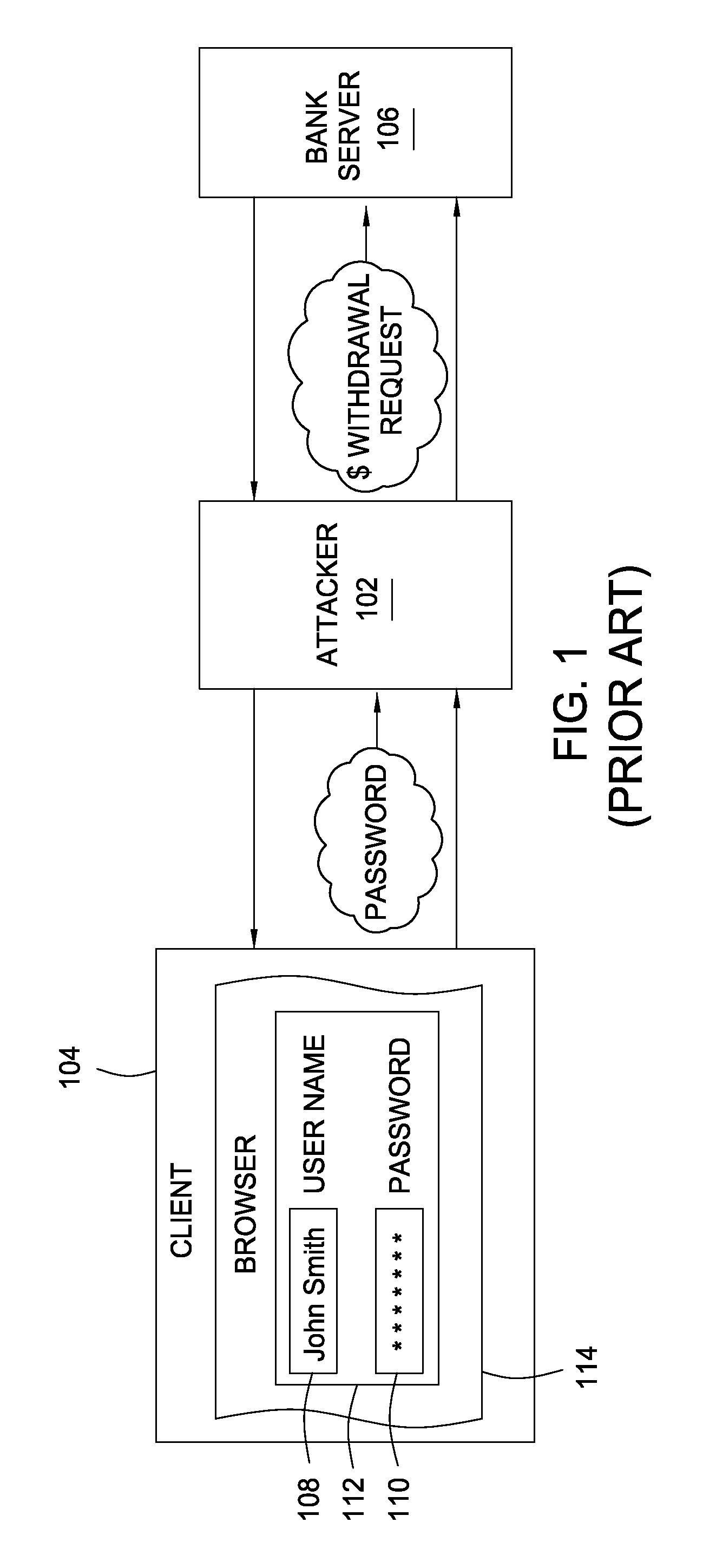

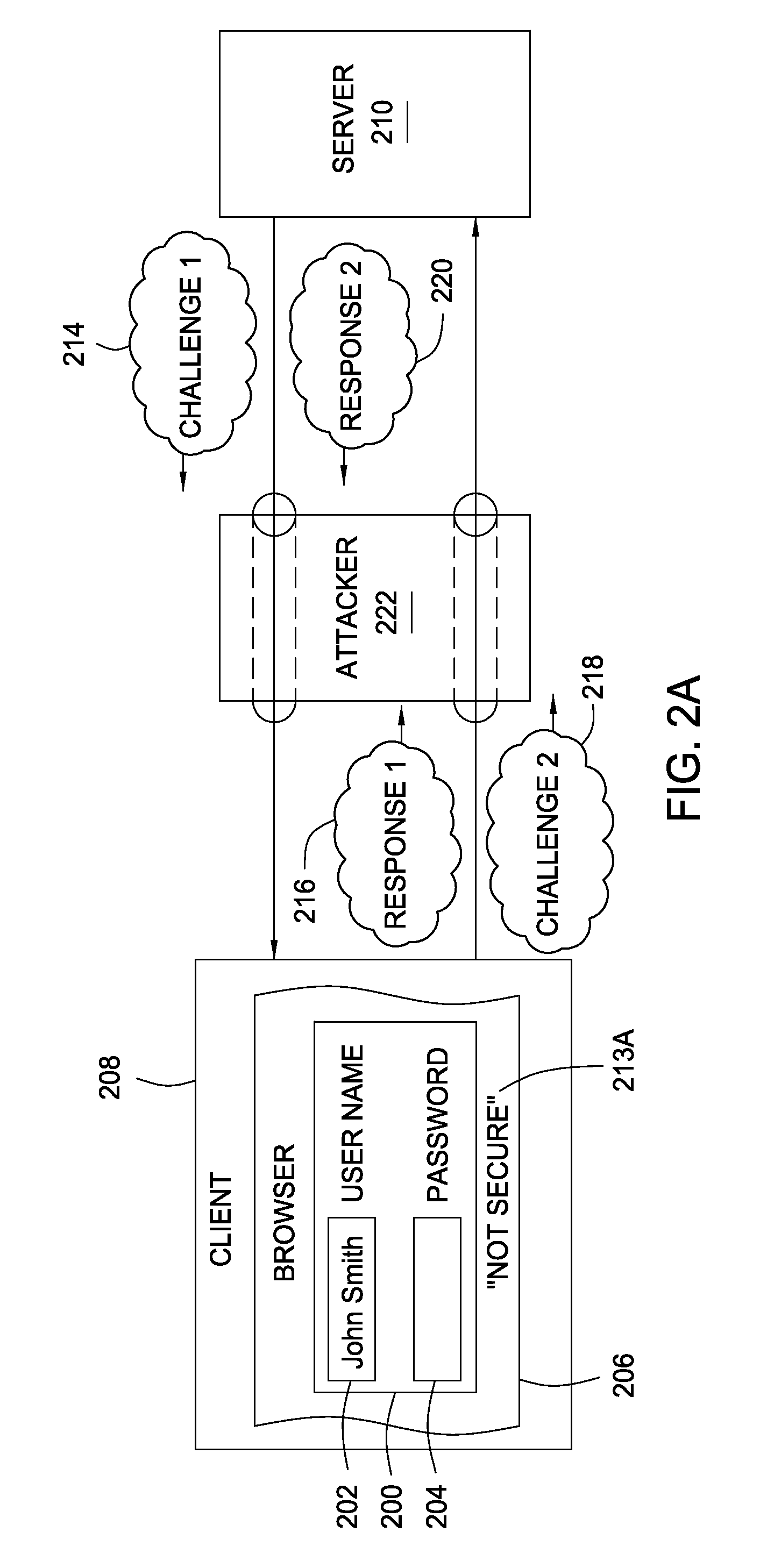

Bidirectional authentication for HTML form processing

ActiveUS20080082821A1Random number generatorsUser identity/authority verificationGraphicsInternet privacy

A method of posting HTML form data securely is provided. Some embodiments may use an existing security protocol to send the sensitive information as an encrypted challenge from a client to a server, while other embodiments may require a bidirectionally-authenticated tunnel to be created before sensitive data is transmitted. The browser displaying the HTML form may employ user interface elements, such as graphical images and / or display messages, that actively notify the user when the webpage form is not secure via bidirectional authentication.

Owner:CISCO TECH INC

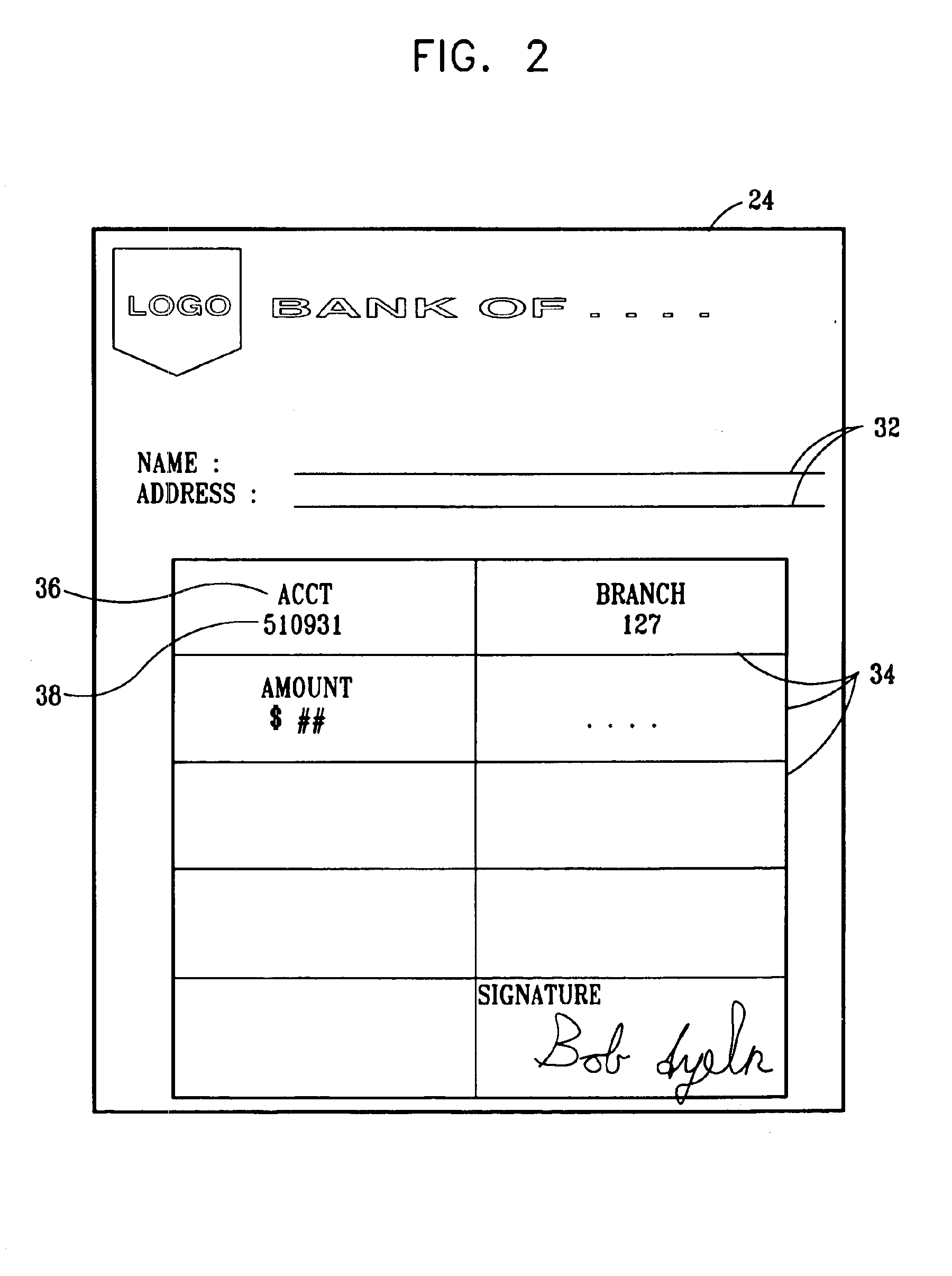

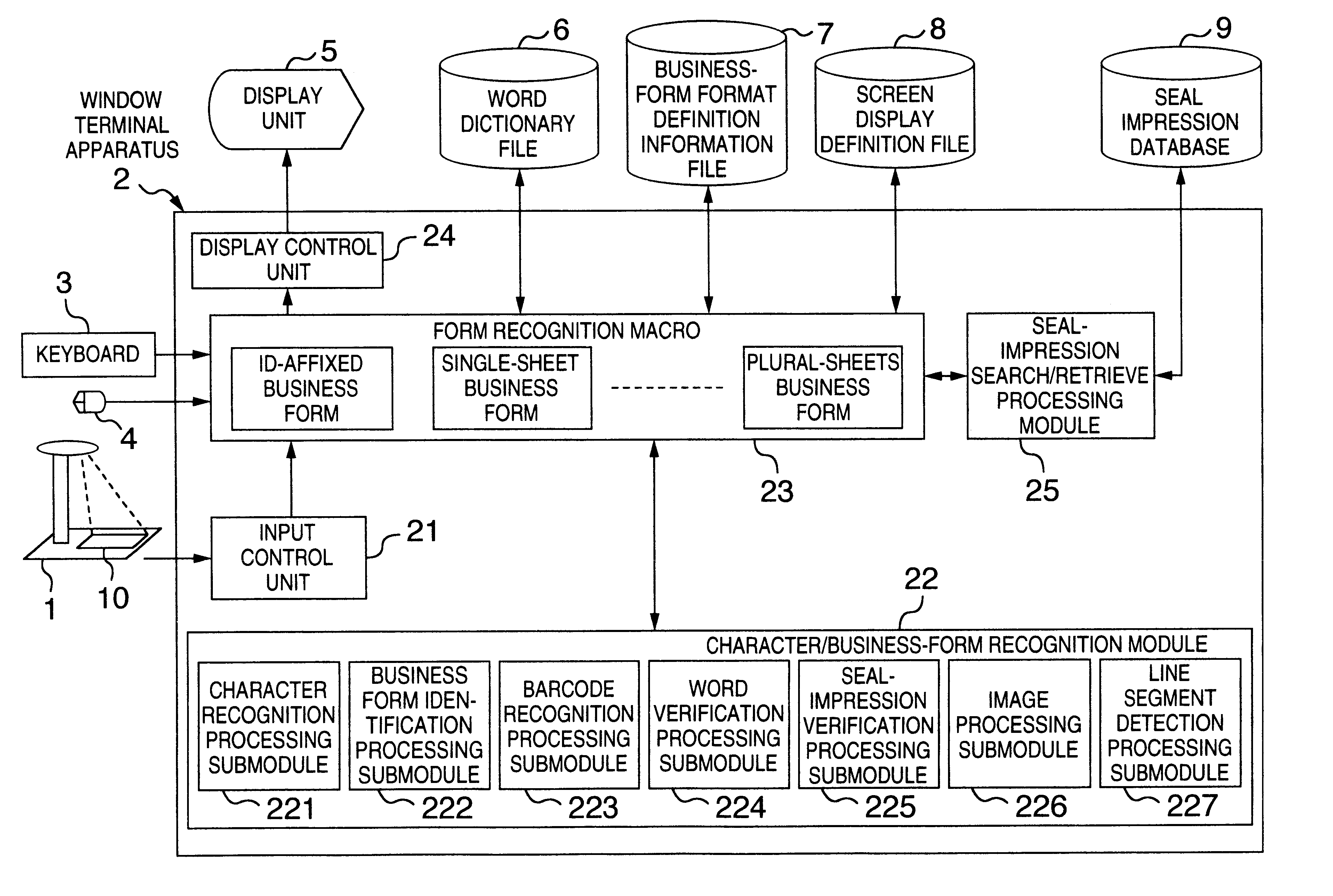

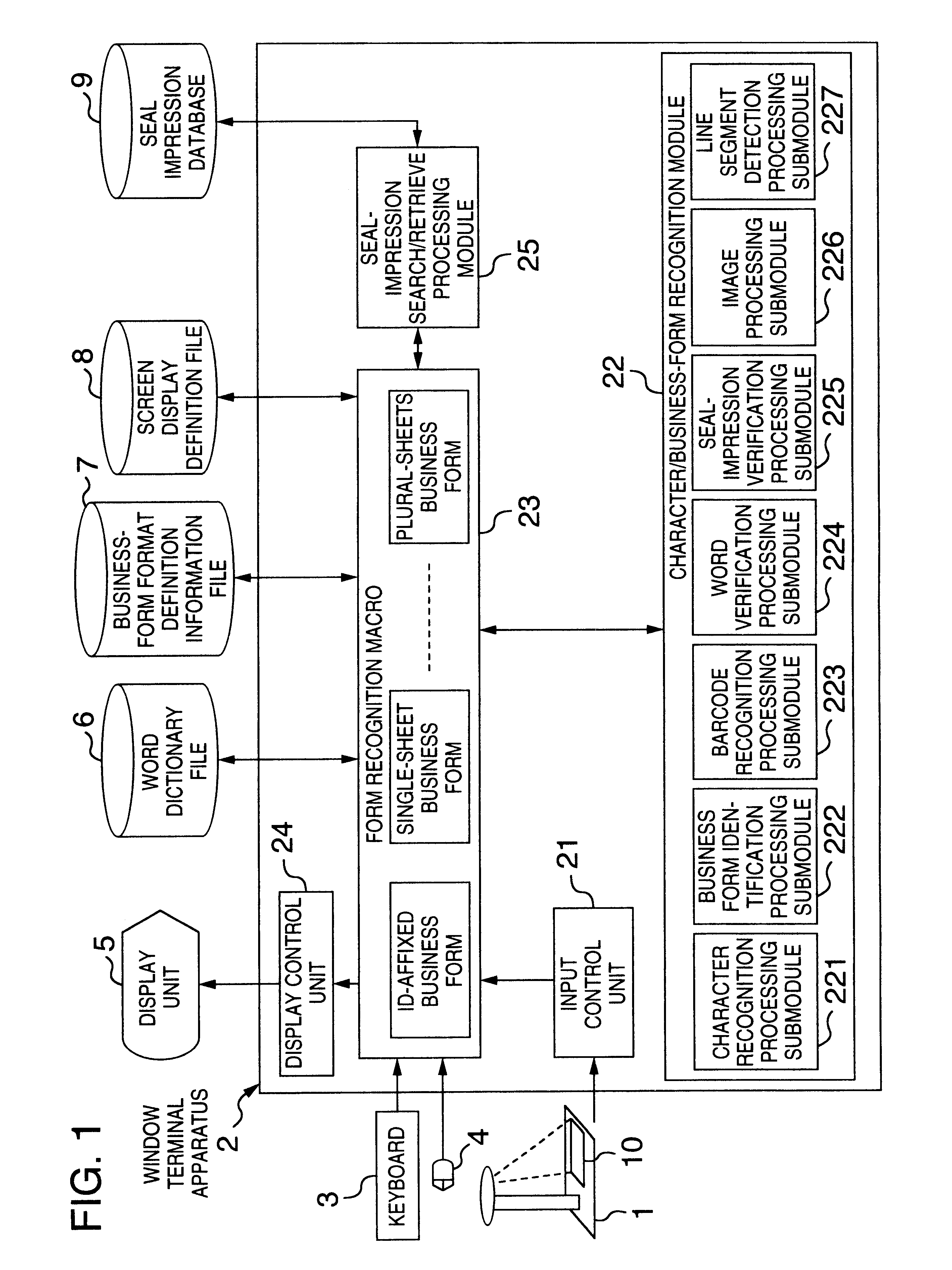

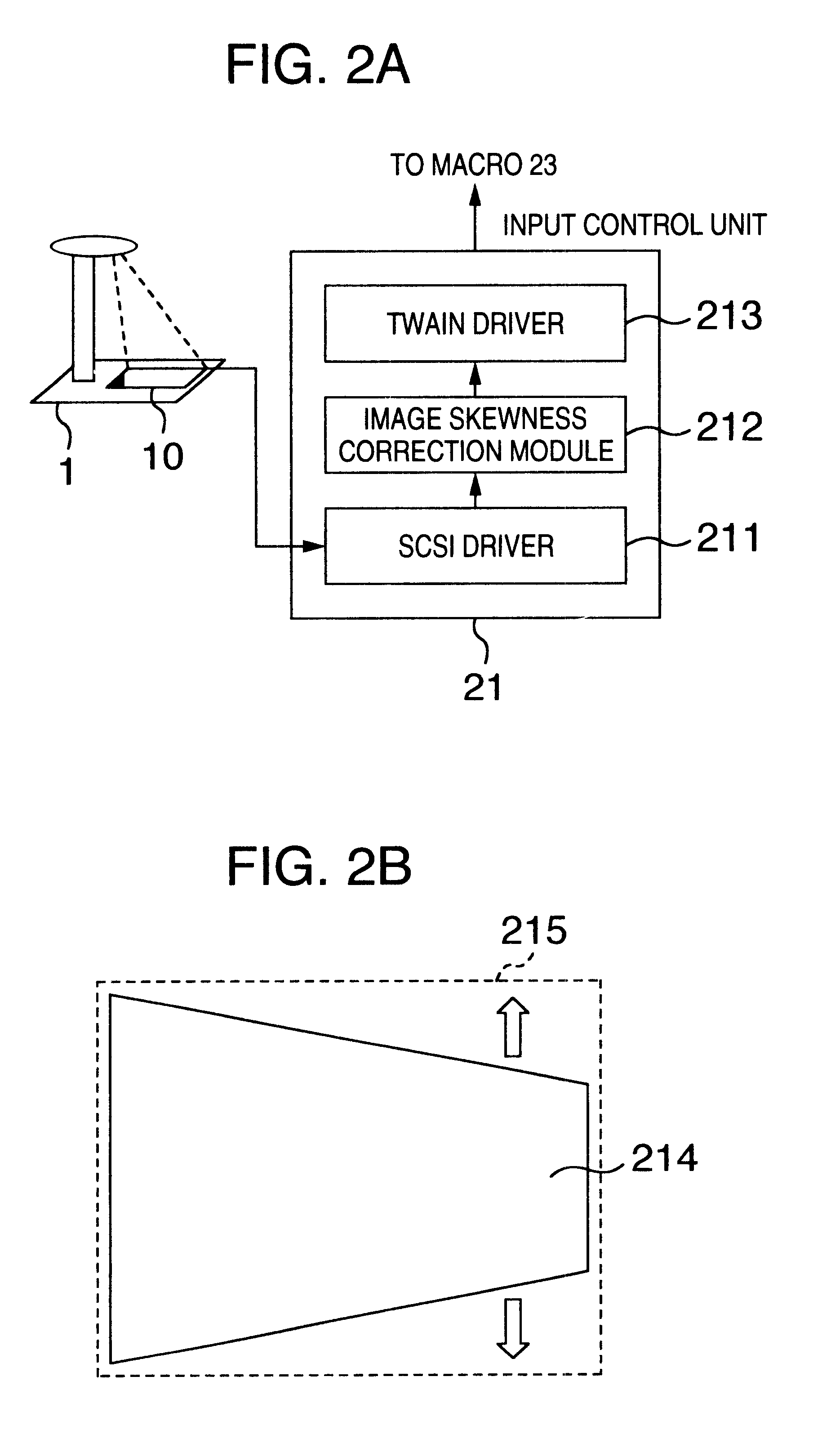

Business form handling method and system for carrying out the same

A business form handling system includes an image reading device for reading a business form and a terminal apparatus installed at the window for discriminatively deciding whether a read image corresponds to a first species of business form by referencing form species identifying definition information stored previously in a file. When the read image corresponds to the first species of business form, the terminal apparatus cuts an image from a field corresponding to a format inherent to the first species of business form to thereby recognize contents of statement from the cut image and executes processing in accordance with result of the recognition. Unless the read image corresponds to the first species of business form, the terminal apparatus decides discriminatively whether the read image corresponds to a second species of business form by referencing the form species identifying definition information. When the correspondence is found, the terminal apparatus cuts an image from a field corresponding to a format inherent to the second species of business form to thereby recognize contents of statement from the cut image.

Owner:HITACHI OMRON TERMINAL SOLUTIONS CORP

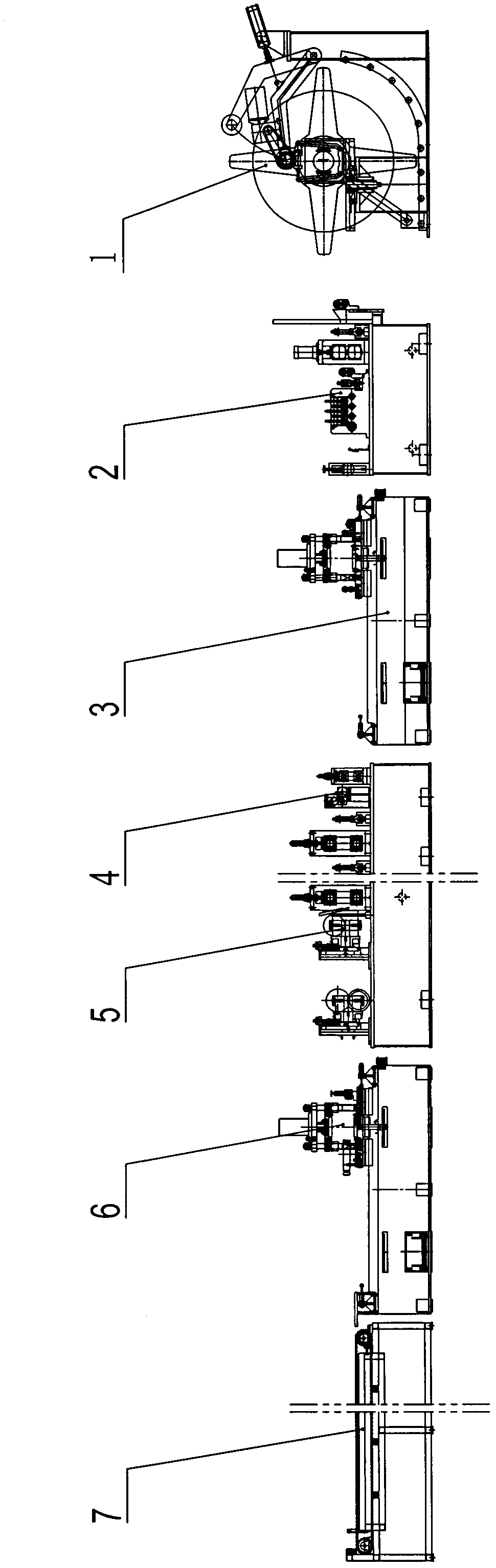

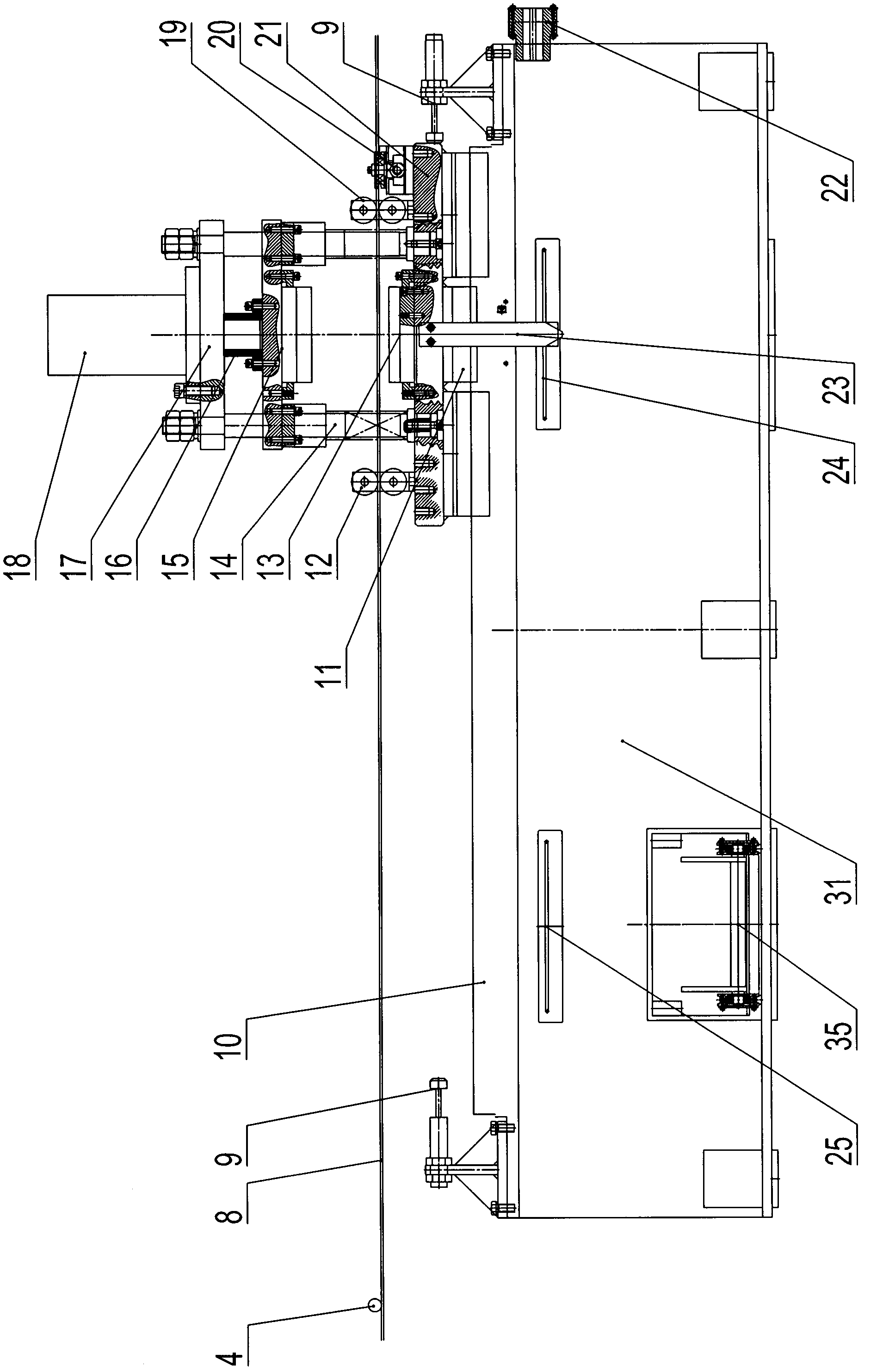

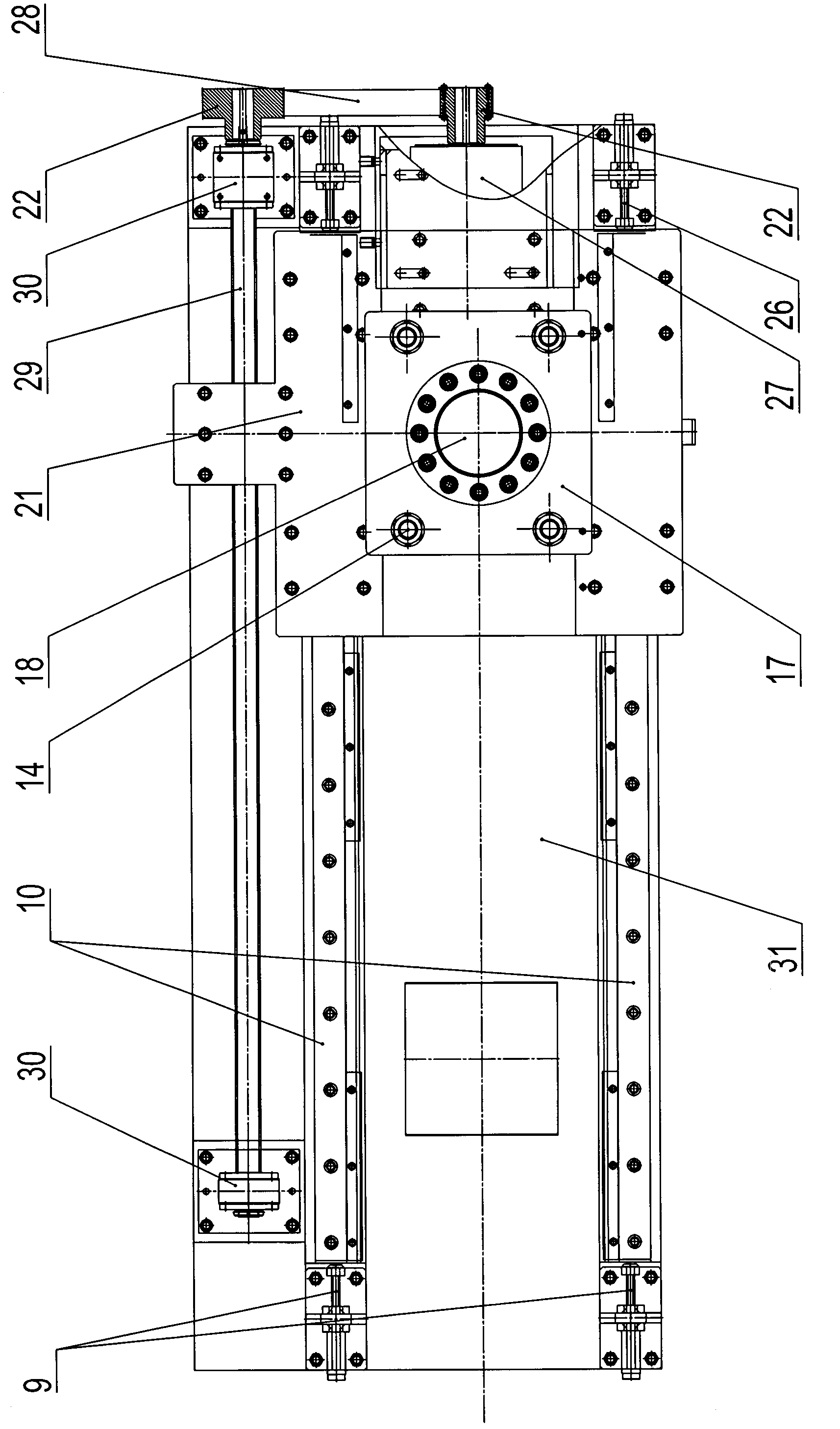

Roll forming processing method for online punching and production line

The invention relates to a roll forming processing method for online punching and a production line in the technical field of sheet roll forming. The method comprises the following steps of: emptying, leveling, punching, roll forming, cutting and blanking. The punching step comprises the following specific steps of: detecting a real-time displacement signal of the linear motion of a sheet; driving a punching mechanism to move at an accelerated speed according to the displacement signal and drive the sheet to a set punching position along the movement direction of the sheet; driving the punching mechanism to track the linear motion of a coiled sheet and keep moving synchronously with the sheet; in a process of keeping synchronous movement with the sheet, allowing the punching mechanism to punch a hole at the set position on the sheet; and returning the punching mechanism to an initial position. The invention also provides the production line for implementing the method. Punching is performed after a servo motor controlled by a programmable logic controller (PLC) drives a workbench to track the sheet. The processing method and the production line can improve sheet processing accuracy and increase sheet processing speed and can be used for molding, punching and processing sheets with fixedly shaped cross sections.

Owner:YANGZHOU NANYANG WELDING PIPE MOLD CO LTD

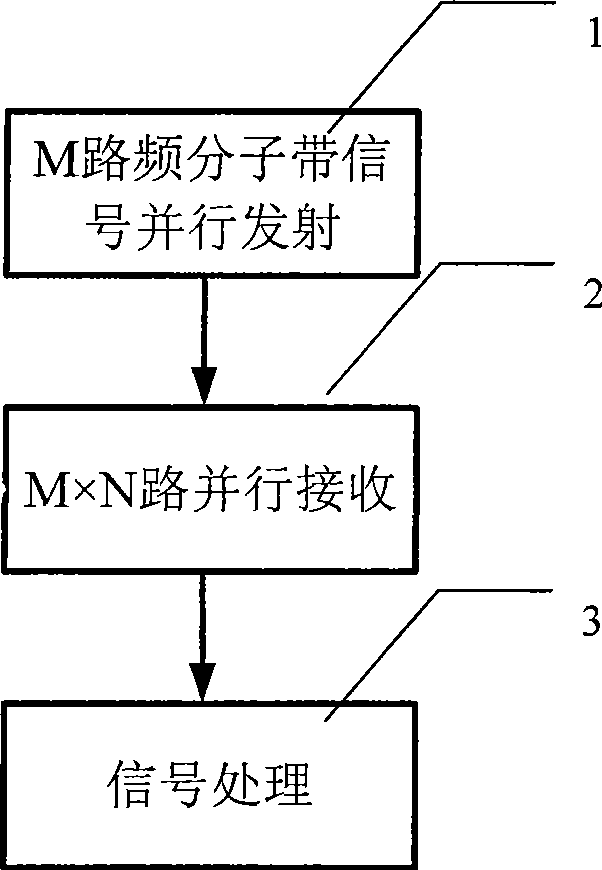

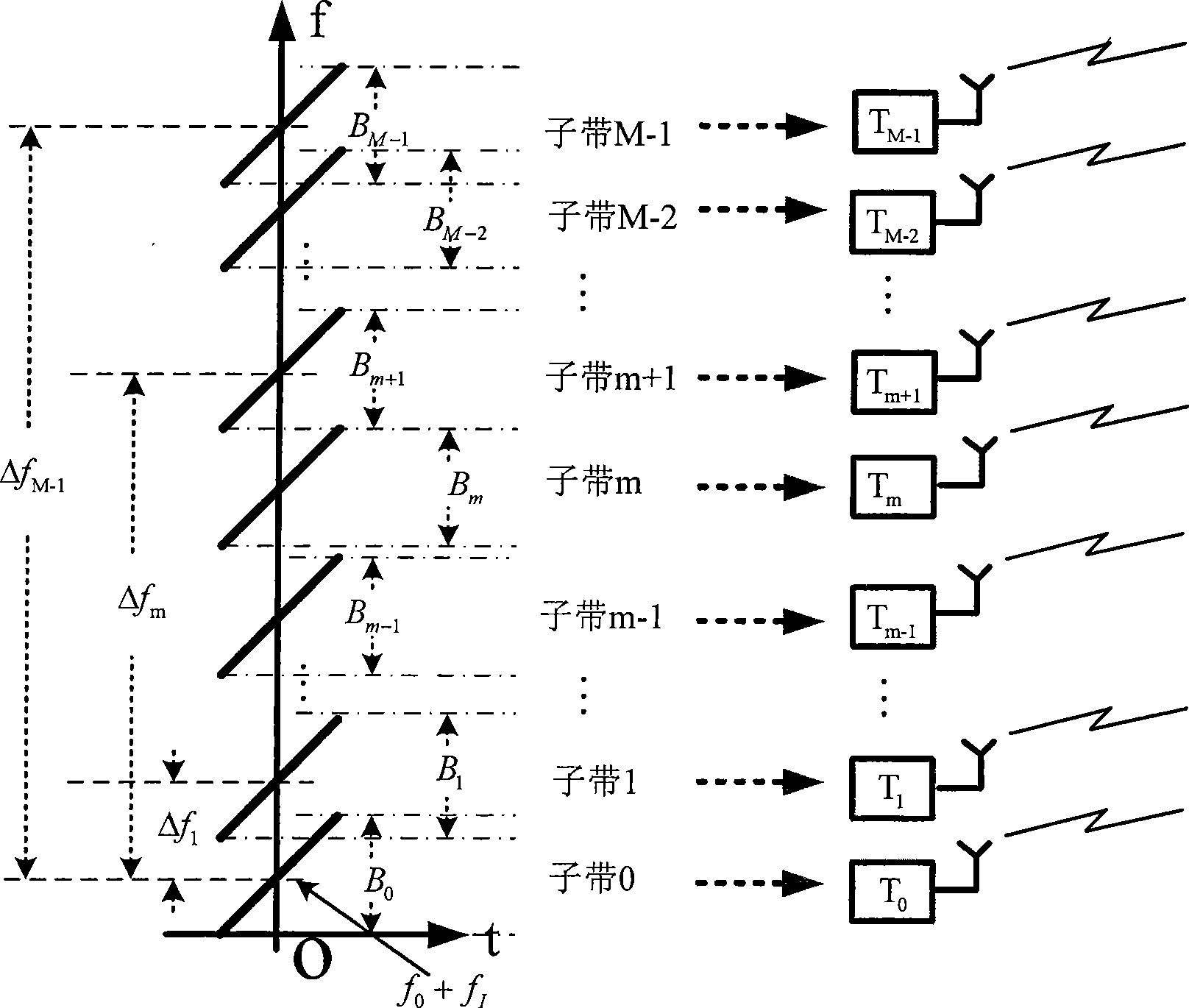

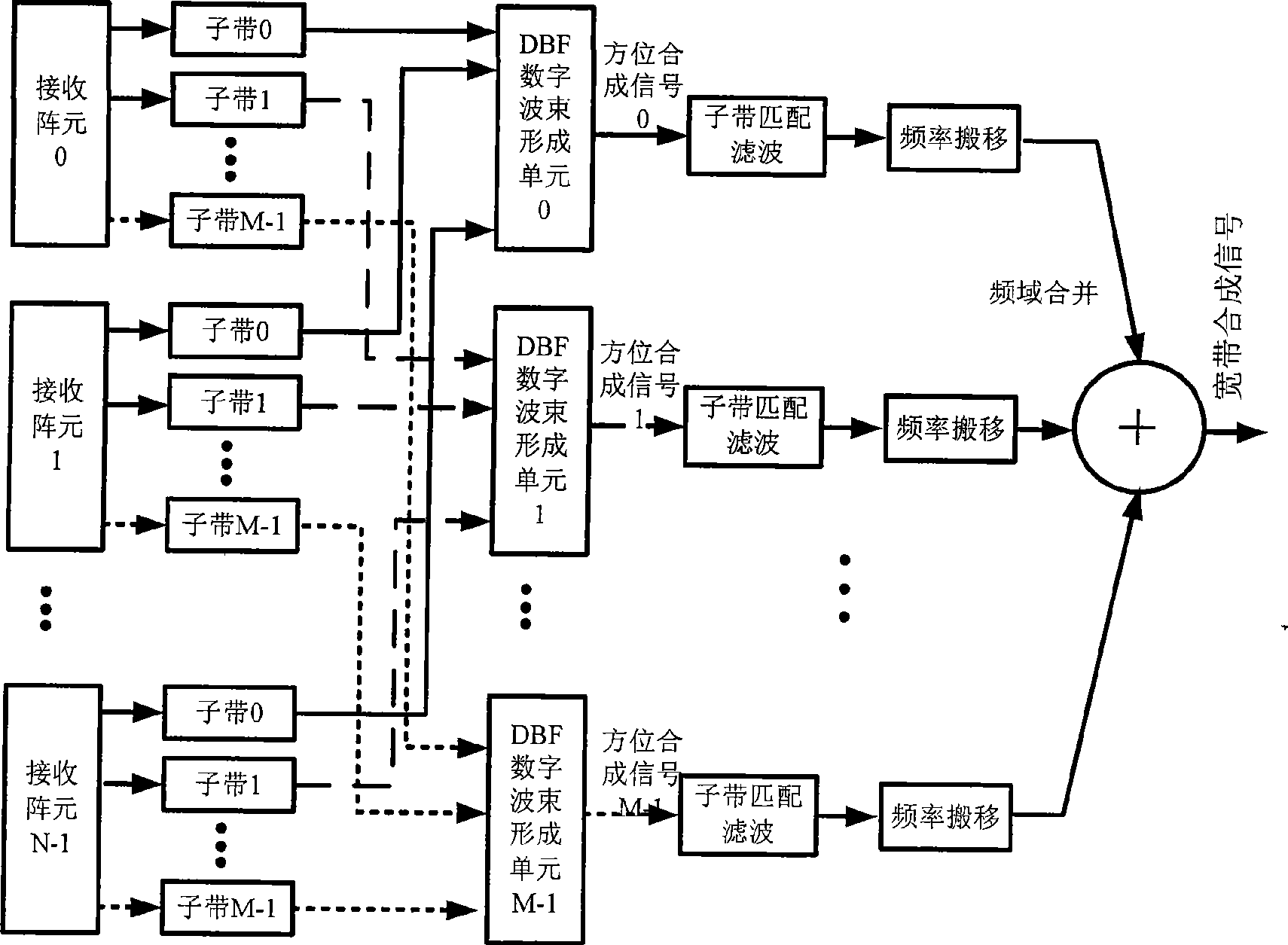

Broadband signal synthesizing method based on multi-sending and multi-receiving frequency division radar

InactiveCN101452073ASuppress interferenceLower performance requirementsRadio wave reradiation/reflectionFrequency spectrumArray element

Owner:TSINGHUA UNIV

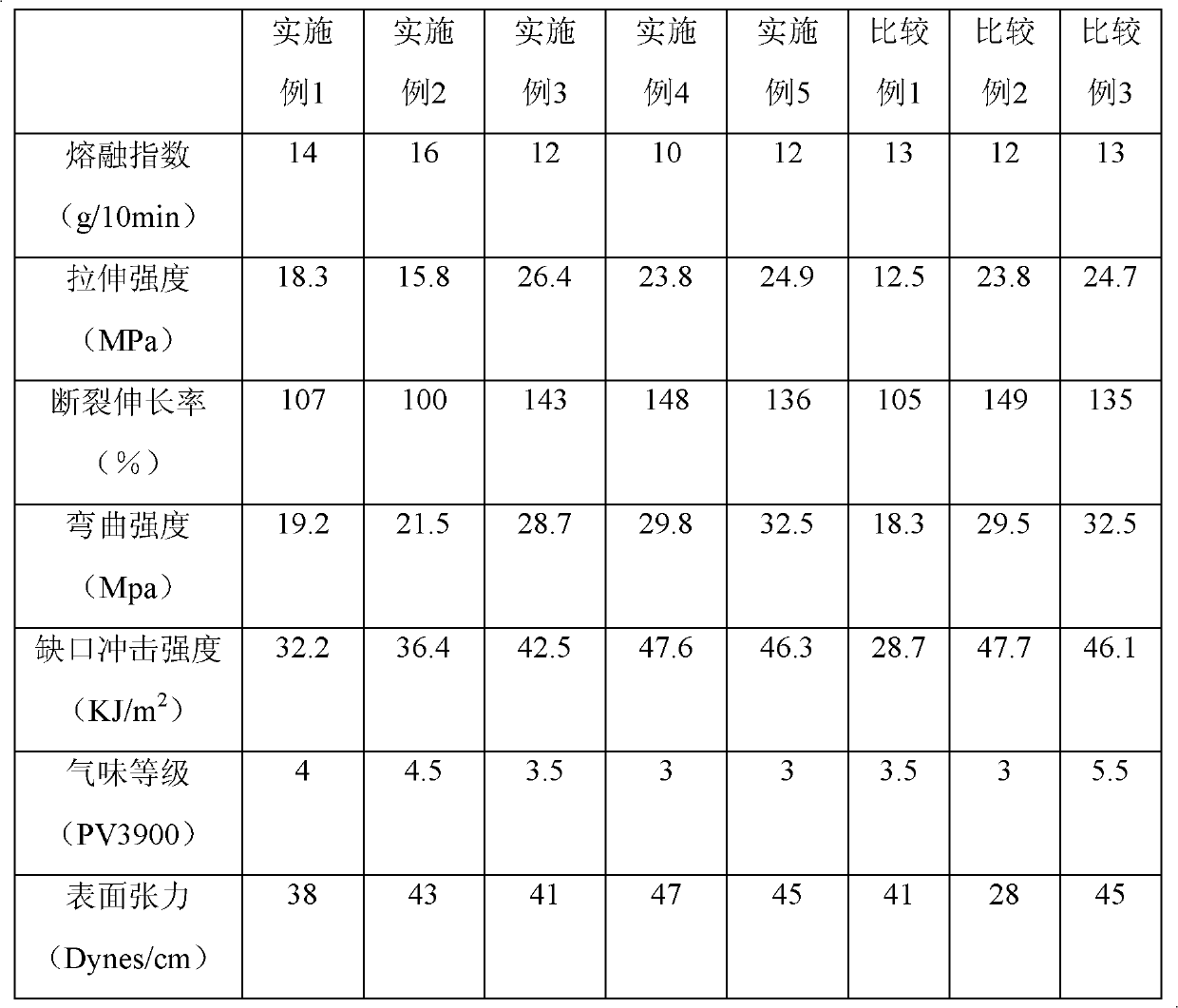

Polypropylene composite material and preparation method and application thereof

InactiveCN103374180AIncrease surface tensionGood compatibilityPolypropylene compositesHeat resistance

The invention belongs to the technical field of modification and processing of high-molecular materials, and relates to a polypropylene composite material and a preparation method and an application thereof. The polypropylene composite material is prepared from the following components in parts by weight: 100 parts of polypropylene, 20-60 parts of reinforced fibers, 8-20 parts of polar additives, 10-35 parts of toughening agents, 1.5-3.5 parts of antiaging agents, 1.2-4.4 parts of compatilizer, 5-12 parts of inorganic composite fire retardants, 1.5-6.6 parts of smell inhibitors and 0.3-0.8 part of processing auxiliary agents. Compared with the prior art, the prepared polypropylene composite material is high in surface tension, achieves good bonding property with other materials, has the advantages of good rigidity without being lacked of toughness, good heat resistance, ageing resistance and fire retardance, little smell and excellent forming processing property and can be widely used as a special material for inner and outer ornaments of various types of automobiles.

Owner:滁州格美特科技有限公司

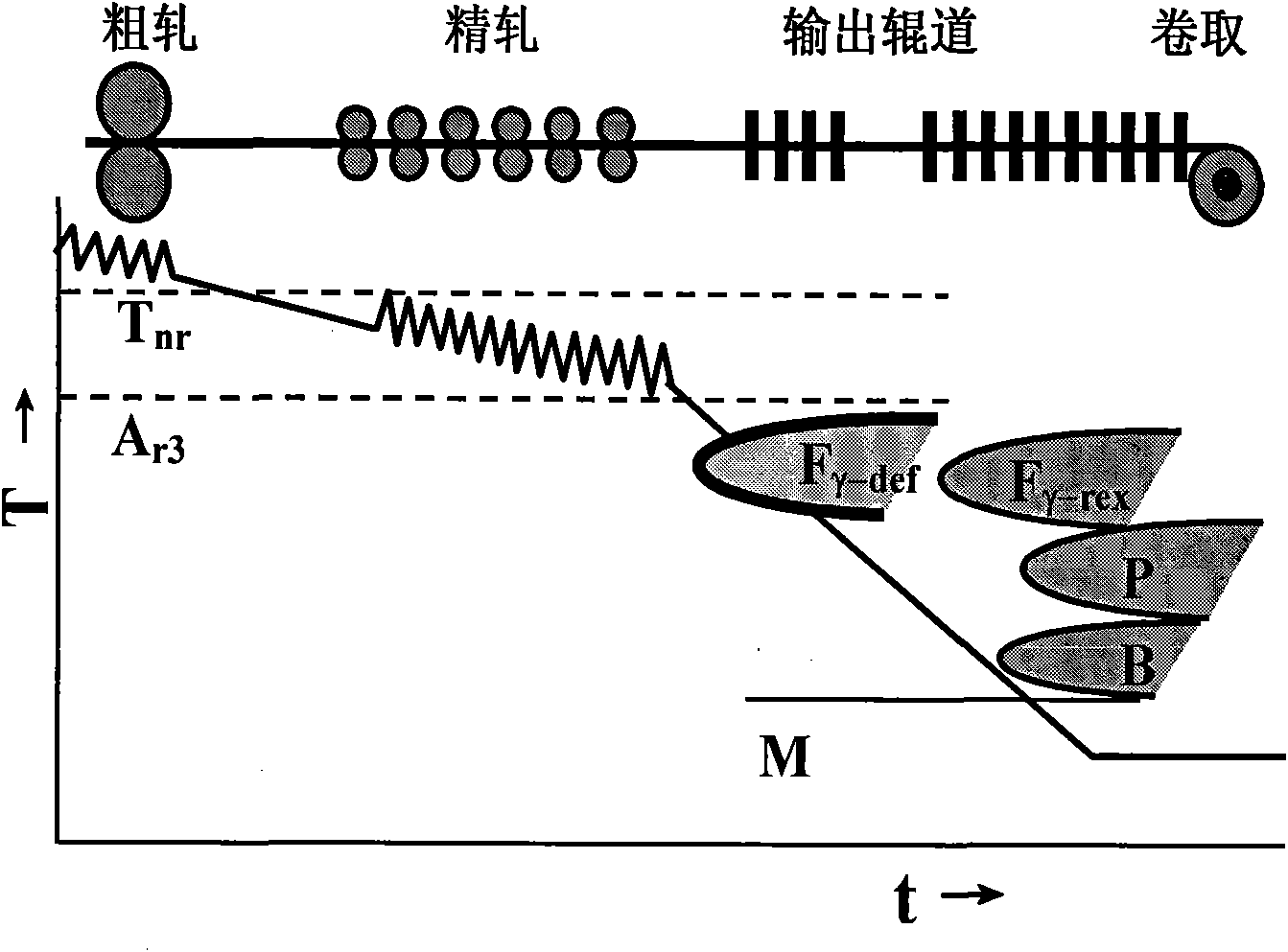

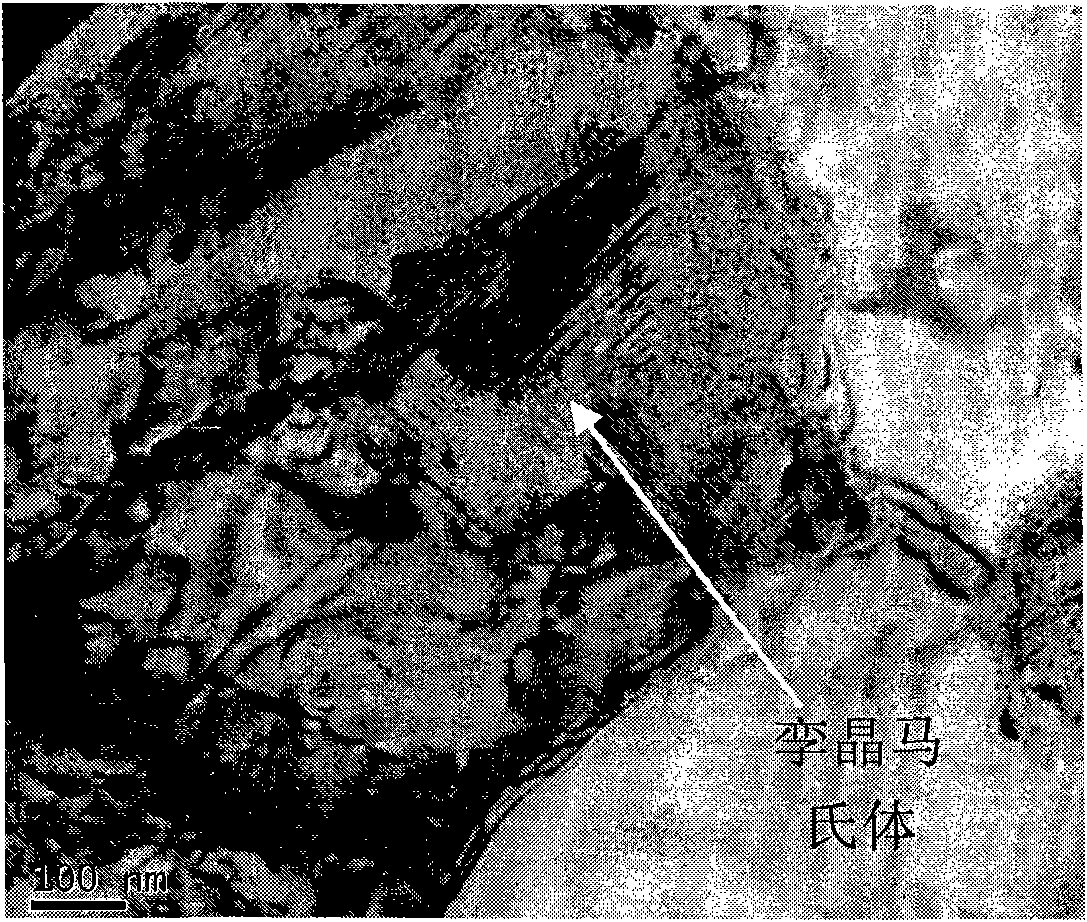

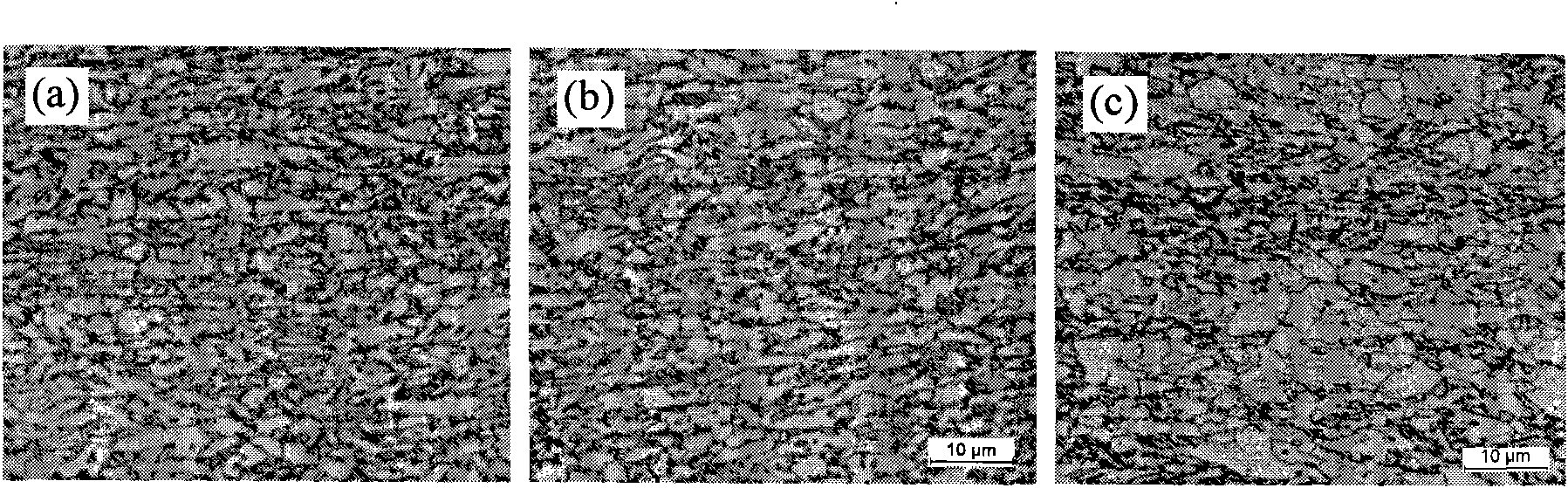

Ultrafine grained hot rolled dual-phase steel with tensile strength of above 750MPa and manufacturing method of plate thereof

The invention relates to ultrafine grained hot rolled dual-phase steel with tensile strength of above 750MPa and a manufacturing method of a plate thereof, belonging to the technical field of steel rolling, and the dual-phase steel comprises the following chemical components by weight percentage: 0.06-0.16% of C, 0.10-0.50% of Si, 1.00-2.00% of Mn, 0.02-0.06% of Al, 0.01-0.08% of Nb, 0-0.03% of Ti, not more than 0.1 of P, not more than 0.05 of S and the balance of Fe. The manufacturing method of the dual-phase steel comprises the following steps: 1) heating, heating a plate blank with the thickness of not less than 60mm to 1100-1250 DEG C, and keeping the temperature for 1-4h; 2) rolling and adopting the two-stage controlled rolling, wherein the reduction rate in a recrystallization zone is larger than 60%, the reduction rate in a non-recrystallization zone is larger than 70%, the initial rolling temperature of the recrystallization zone is 1100-1150 DEG C, the initial rolling temperature of the non-recrystallization zone is 880-940 DEG C, and the final rolling temperature is 770-860 DEG C; and 3) cooling, and adopting the continuous cooling after final rolling, wherein the cooling rate is 30-40 DEG C / s, the coiling temperature is lower than 350 DEG C, and the thickness of a finished product is 2-10mm. The manufacturing method can obtain the high-performance steel plate with high strength, low yield-strength ratio and good extension property, and the steel plate can be suitable for forming processing of high-strength automobiles, other industrial mechanical parts and the like.

Owner:NORTHEASTERN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com