Ultrafine grained hot rolled dual-phase steel with tensile strength of above 750MPa and manufacturing method of plate thereof

A hot-rolled dual-phase steel, tensile strength technology, applied in the field of steel rolling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

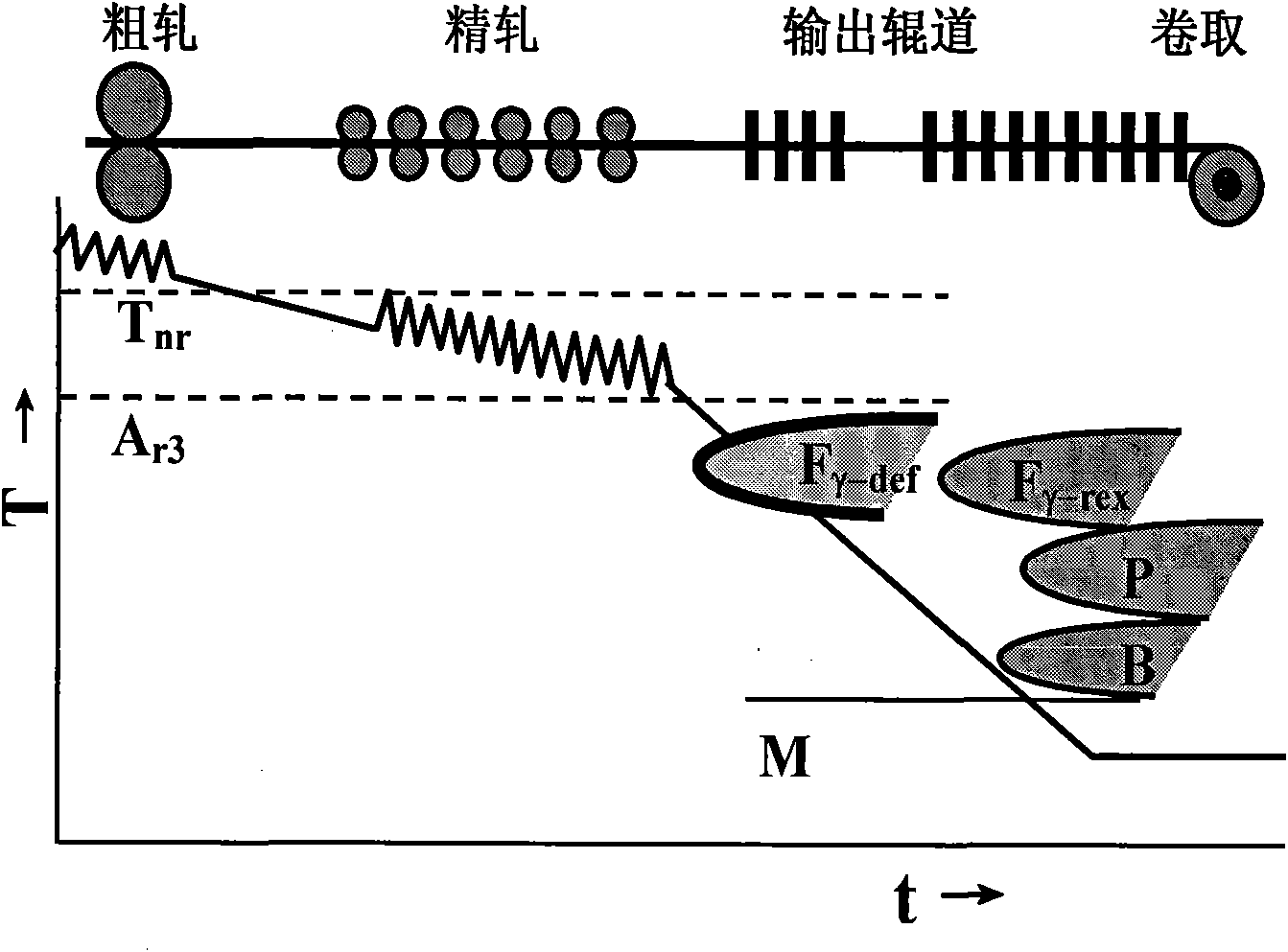

Method used

Image

Examples

Embodiment 1

[0060] The chemical composition of the experimental steel A is shown in Table 1. The initial thickness of the billet is 60 mm, and the thickness of the finished product is 3 mm. In order to completely dissolve the carbonitrides of Nb and Ti, the blank was heated to 1200°C in a box-type resistance furnace for 1 hour and then rolled and deformed 9 times. The deformation system is shown in Table 2. The rolling process is carried out on a Φ450×450 two-roll reversing hot rolling experimental unit. Continuous cooling is adopted after final rolling, and the coiling temperature is lower than 350°C. The cooling process parameters are shown in Table 3. The mechanical properties of the steel plates are listed in Table 4.

[0061] The chemical composition (%) of table 1 embodiment 1 experimental steel A

[0062]

[0063] The rolling schedule of table 2 embodiment 1

[0064]

[0065] The temperature and cooling system of table 3 embodiment 1

[0066]

[0067] The mechanical pr...

Embodiment 2

[0073] Example 2 The chemical composition of experimental steel B is shown in Table 5. The initial thickness of the billet is 60 mm, and the thickness of the finished product is 3 mm. The billet is heated to 1200° C. for 1 hour in a box-type resistance furnace, and then rolled and deformed for 9 passes. The deformation system is the same as in Example 1. The rolling process is carried out on a Φ450×450 two-roll reversing hot rolling experimental unit. Continuous cooling is adopted after final rolling, and the coiling temperature is lower than 350°C. The cooling process parameters are shown in Table 6. The mechanical properties of the steel plates are listed in Table 7.

[0074] The chemical composition (%) of table 5 embodiment 2 experimental steel B

[0075]

[0076] Temperature regime and cooling rate of table 6 embodiment 2

[0077]

[0078] The mechanical properties and tissue volume fraction of table 7 embodiment 2

[0079]

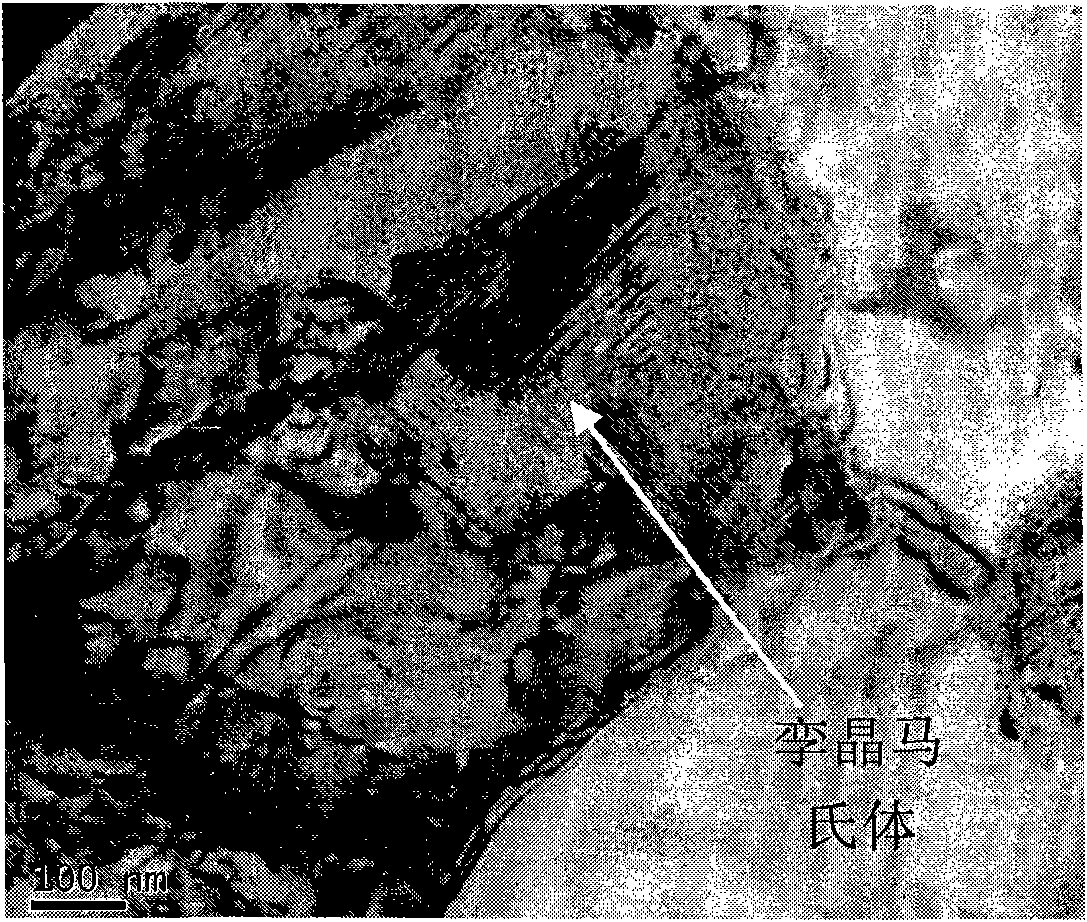

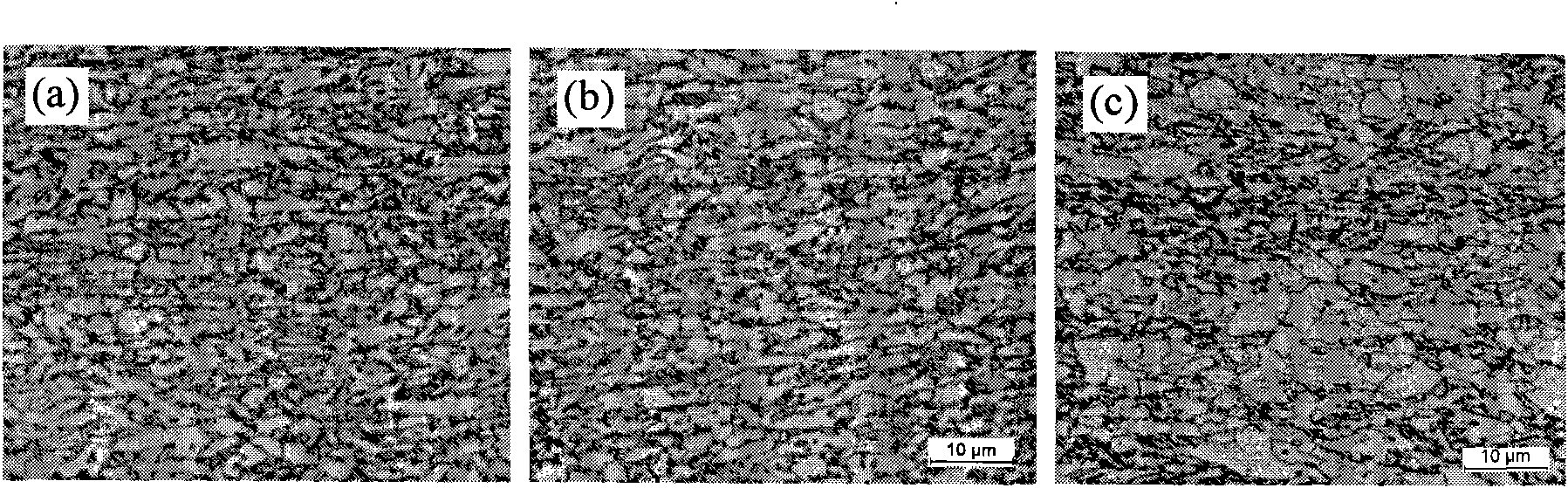

[0080] The final structure of exper...

Embodiment 3

[0082] Example 3 The chemical composition of experimental steel C is shown in Table 8. The initial thickness of the billet is 75 mm, and the thickness of the finished product is 4 mm. The billet was heated to 1200°C in a box-type resistance furnace for 1 hour and then rolled and deformed for 9 passes. The deformation system is shown in Table 9. The rolling process is carried out on a Φ450×450 two-roll reversing hot rolling experimental unit. Continuous cooling is adopted after final rolling, and the coiling temperature is lower than 350°C. The cooling process parameters are shown in Table 10. The mechanical properties of the steel plates are listed in Table 11.

[0083] The chemical composition (%) of table 8 embodiment 3 experimental steel C

[0084]

[0085] The rolling schedule of table 9 embodiment 3

[0086]

[0087] Temperature regime and cooling rate of table 10 embodiment 3

[0088]

[0089] The mechanical properties and tissue volume fraction of table 11 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com