Patents

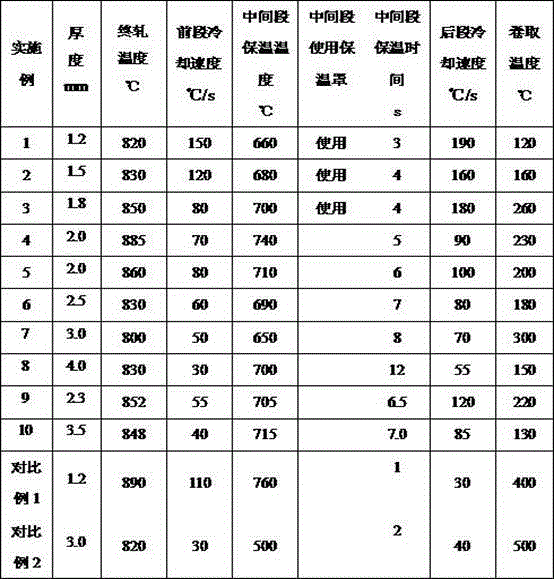

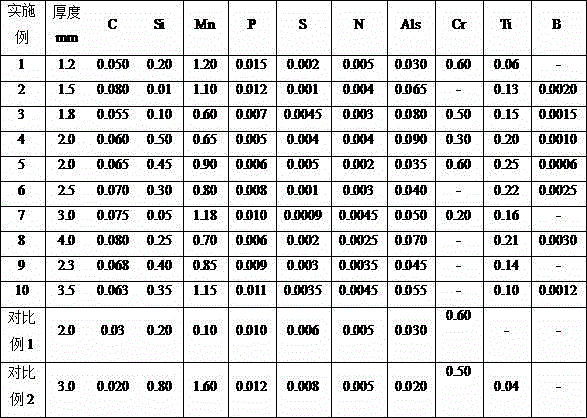

Literature

696 results about "Dual-phase steel" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

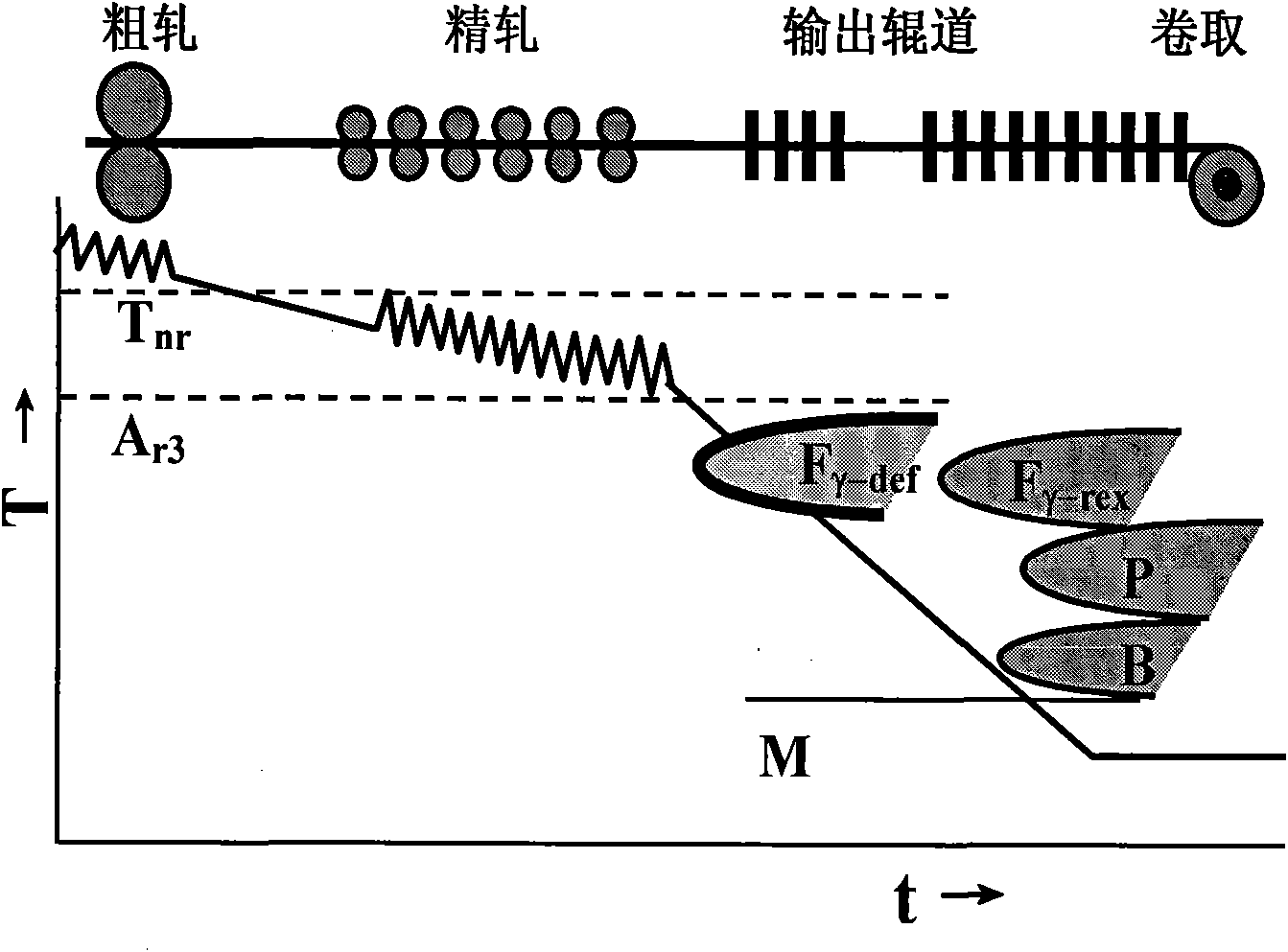

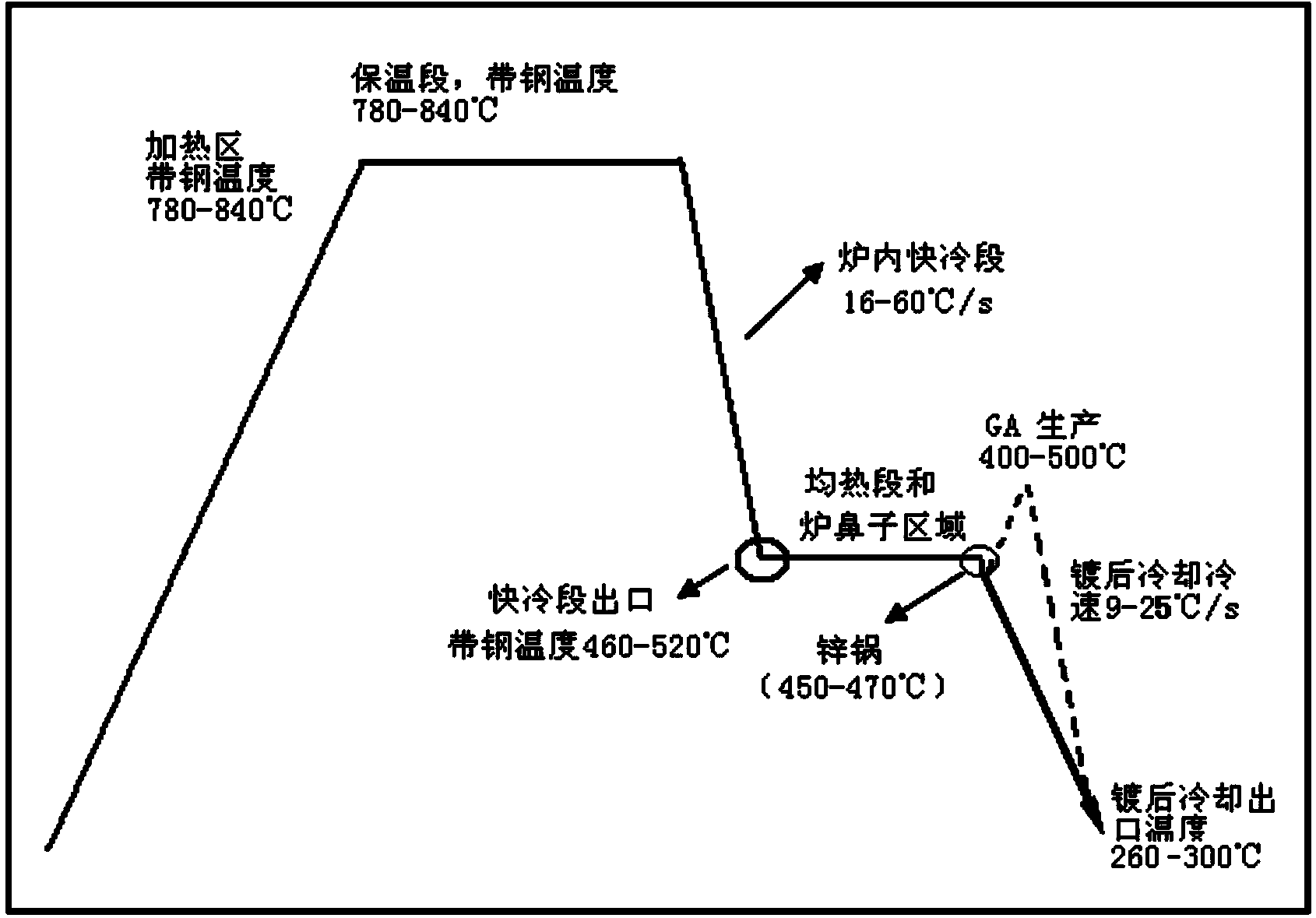

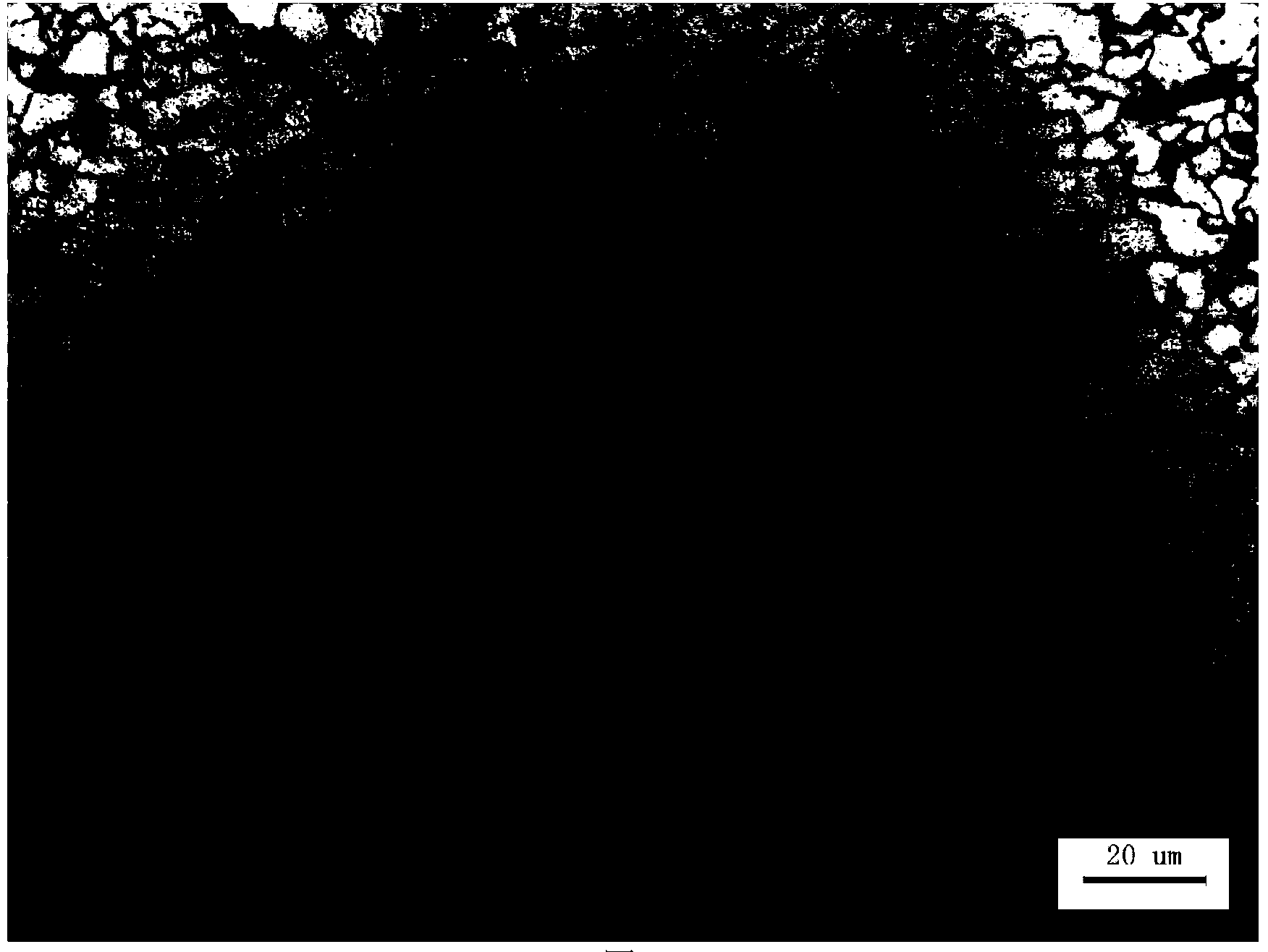

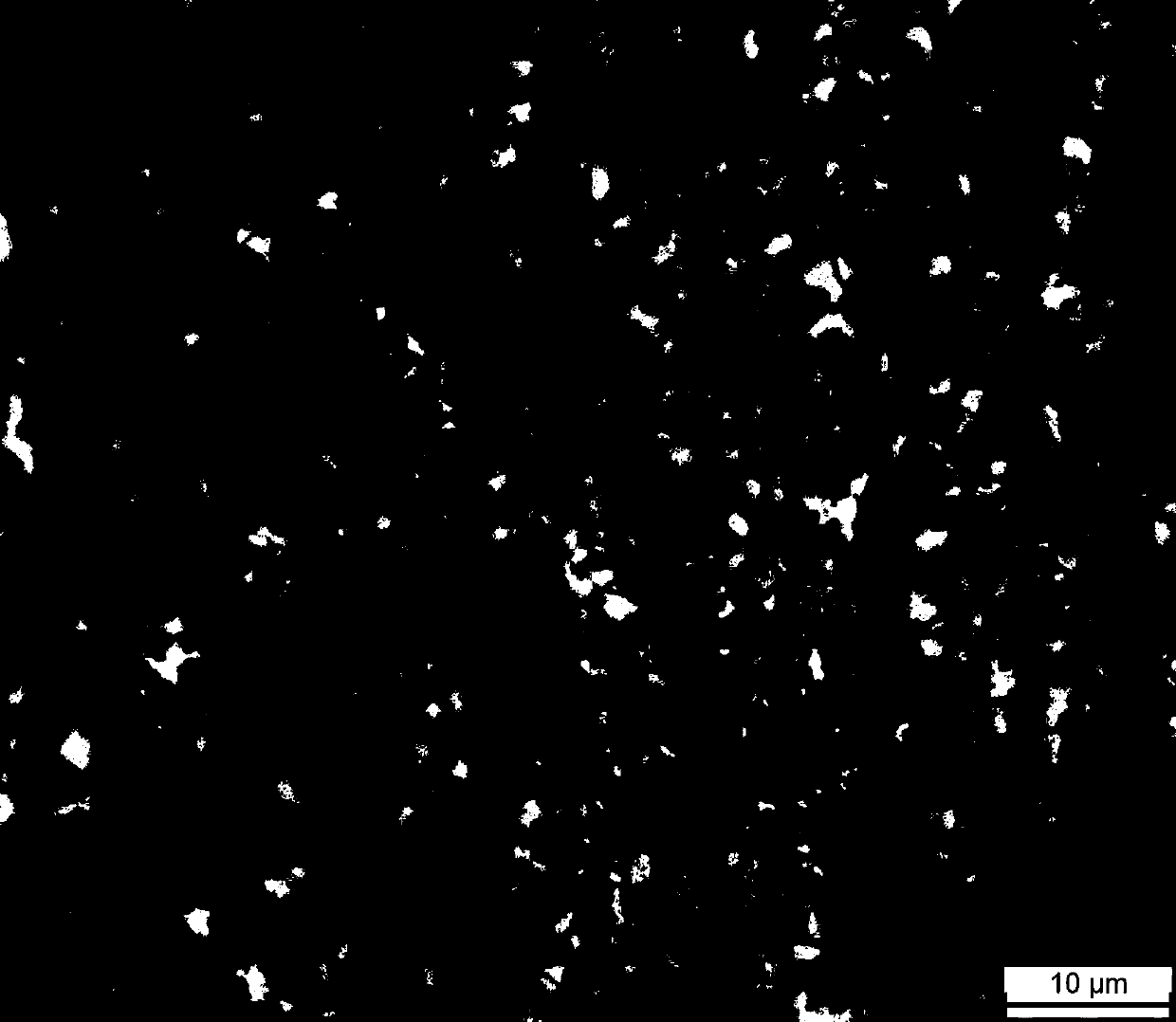

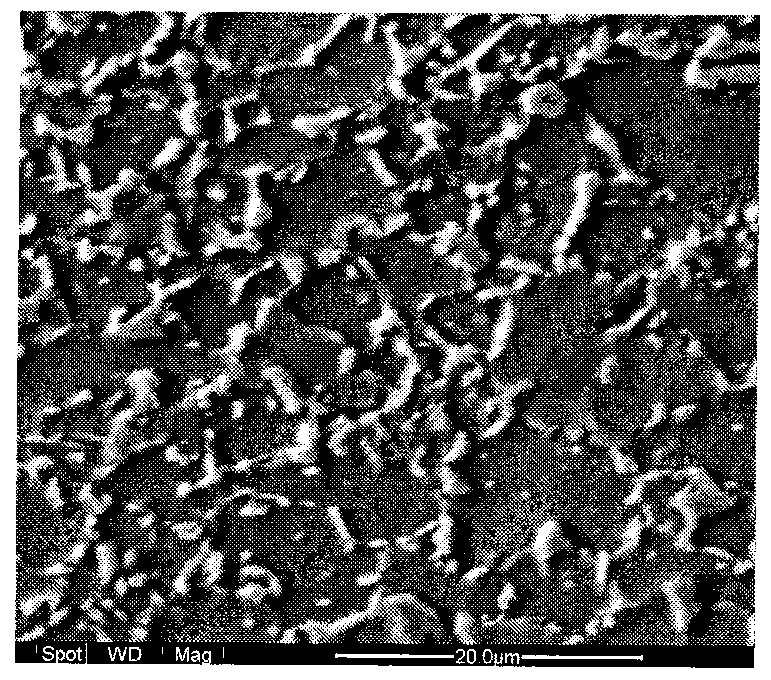

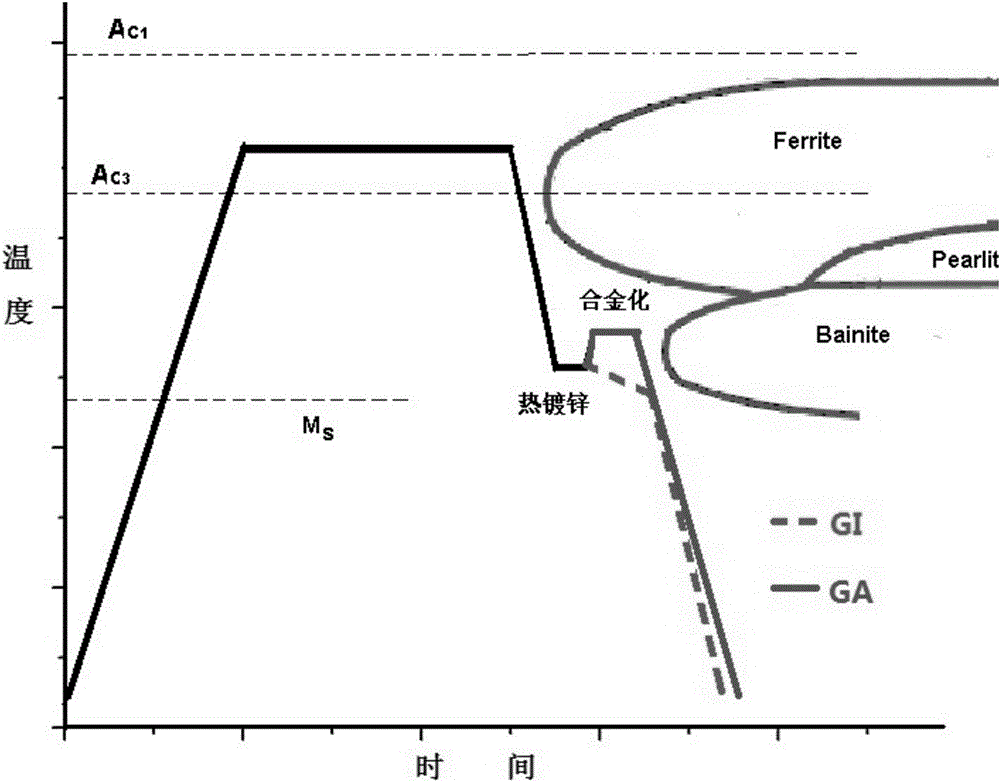

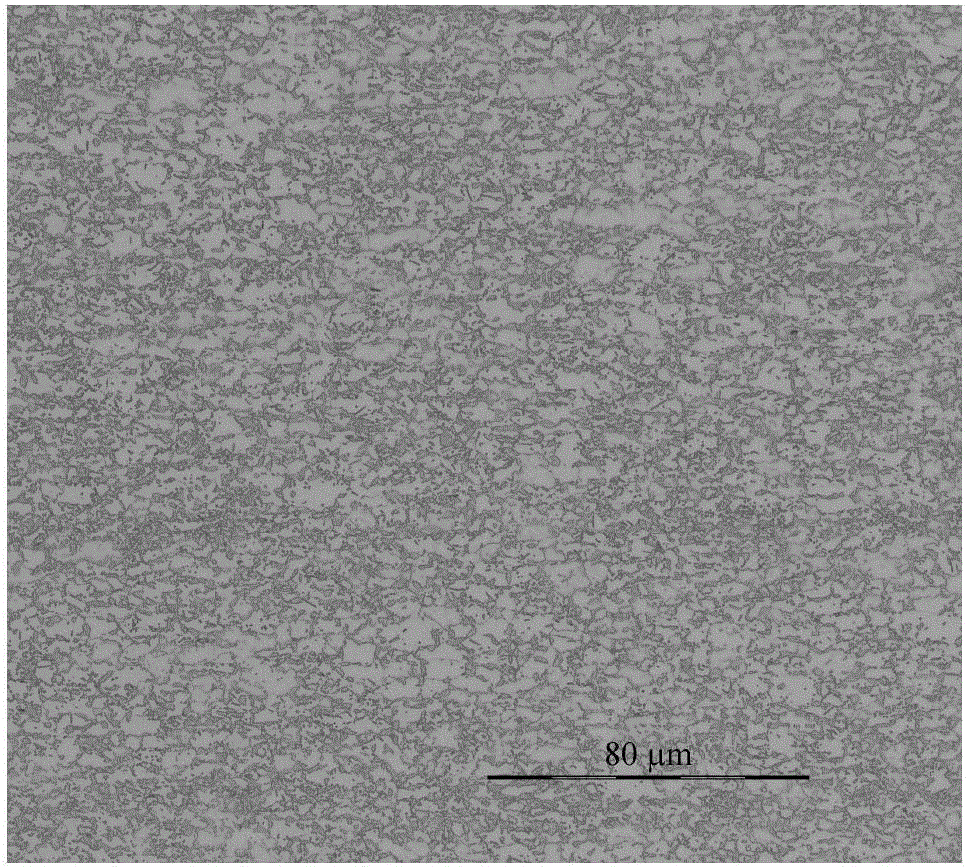

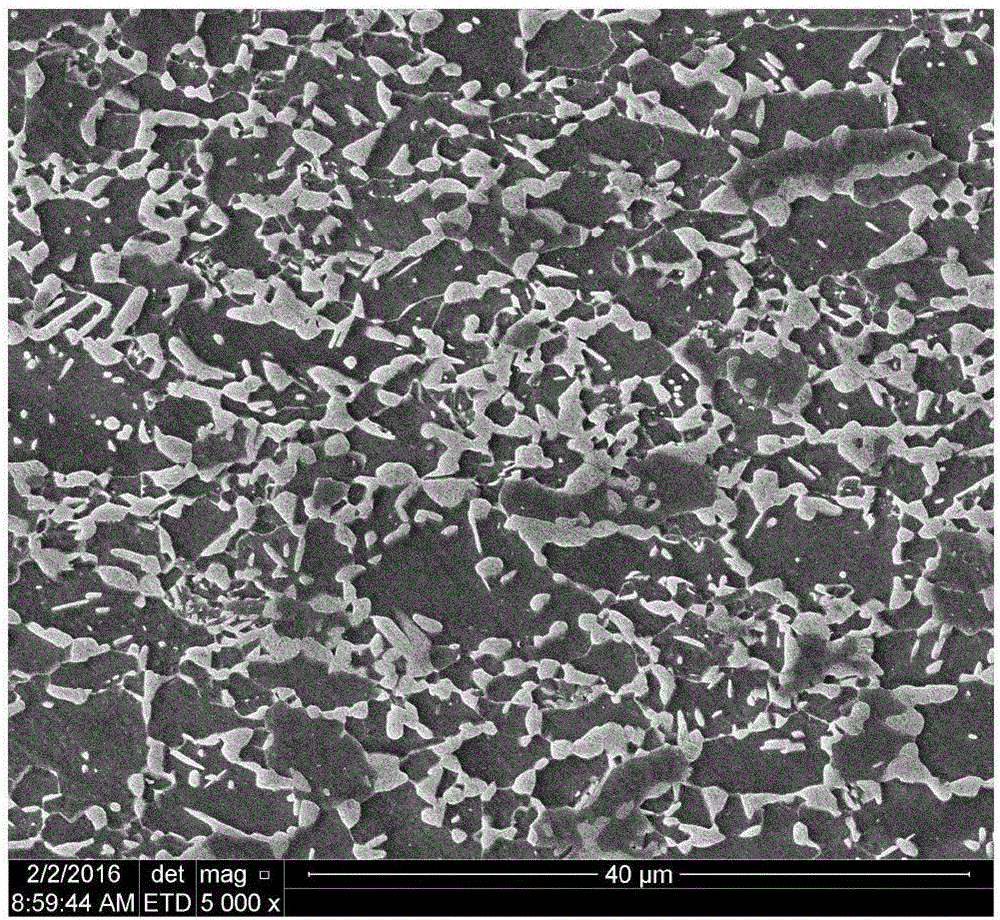

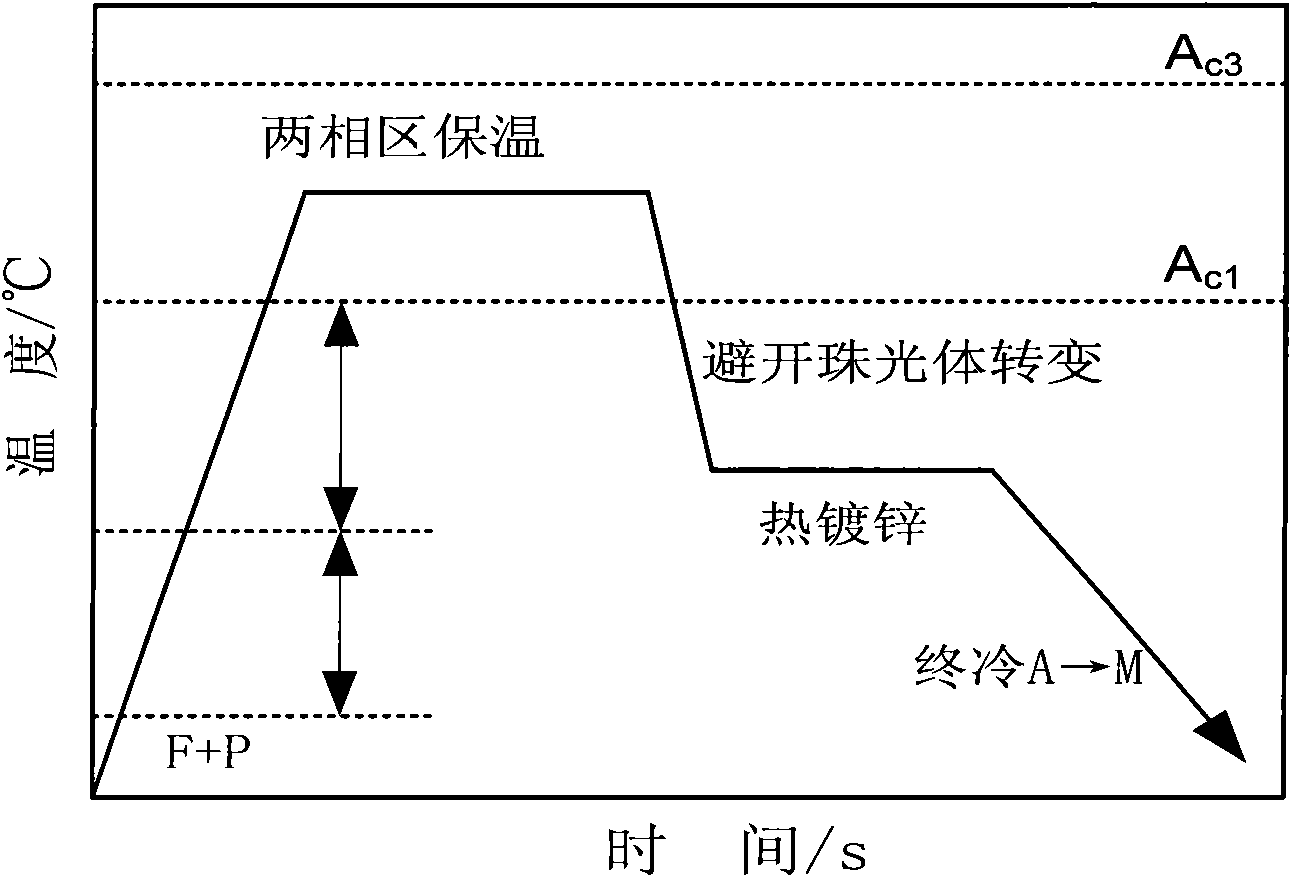

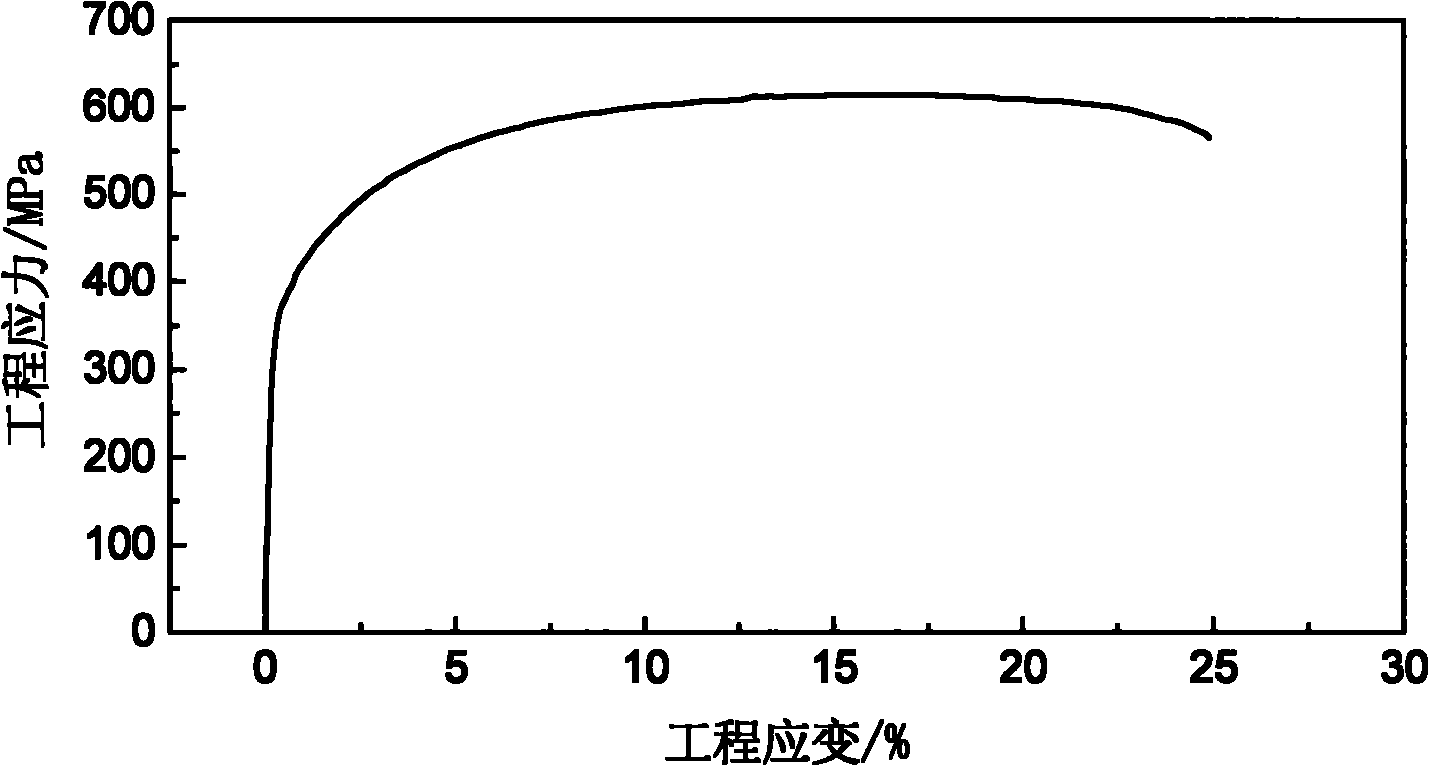

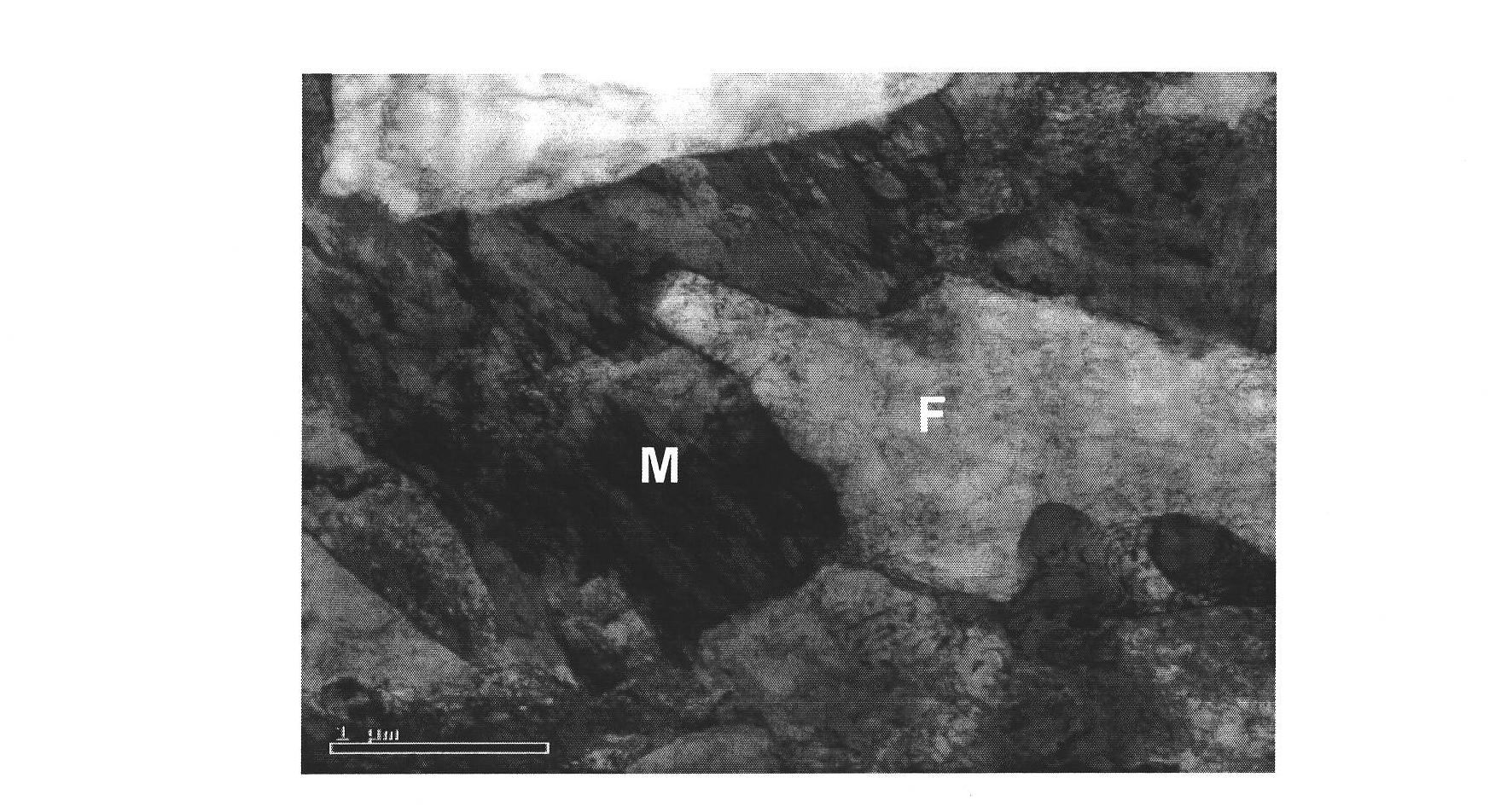

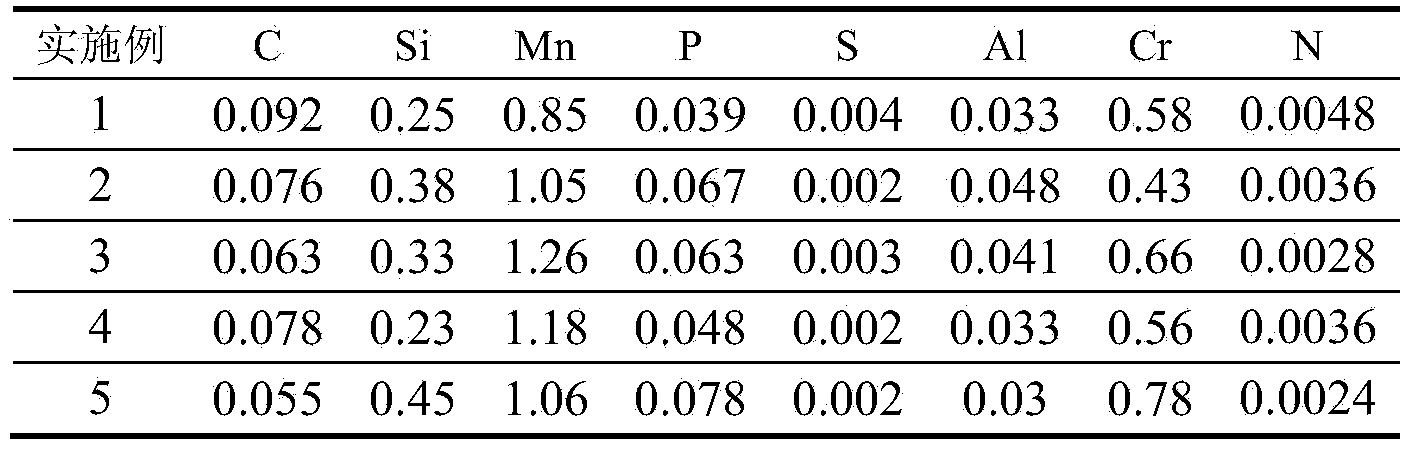

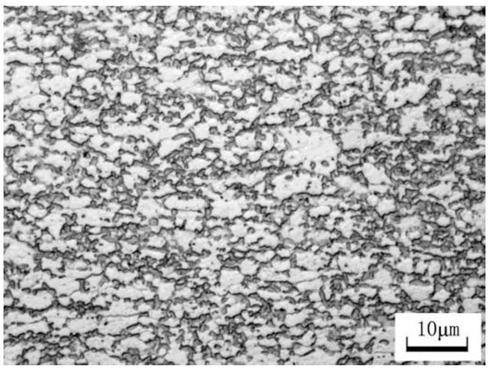

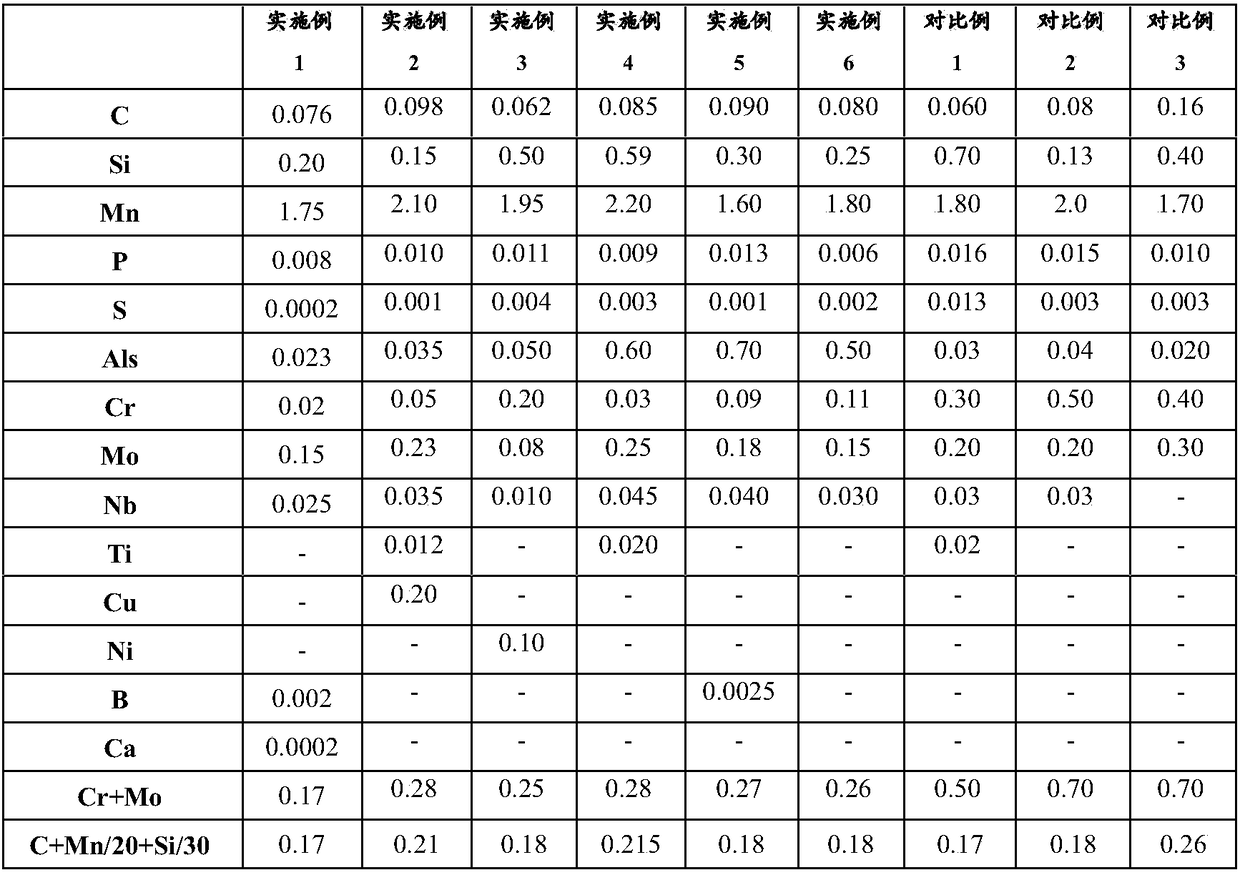

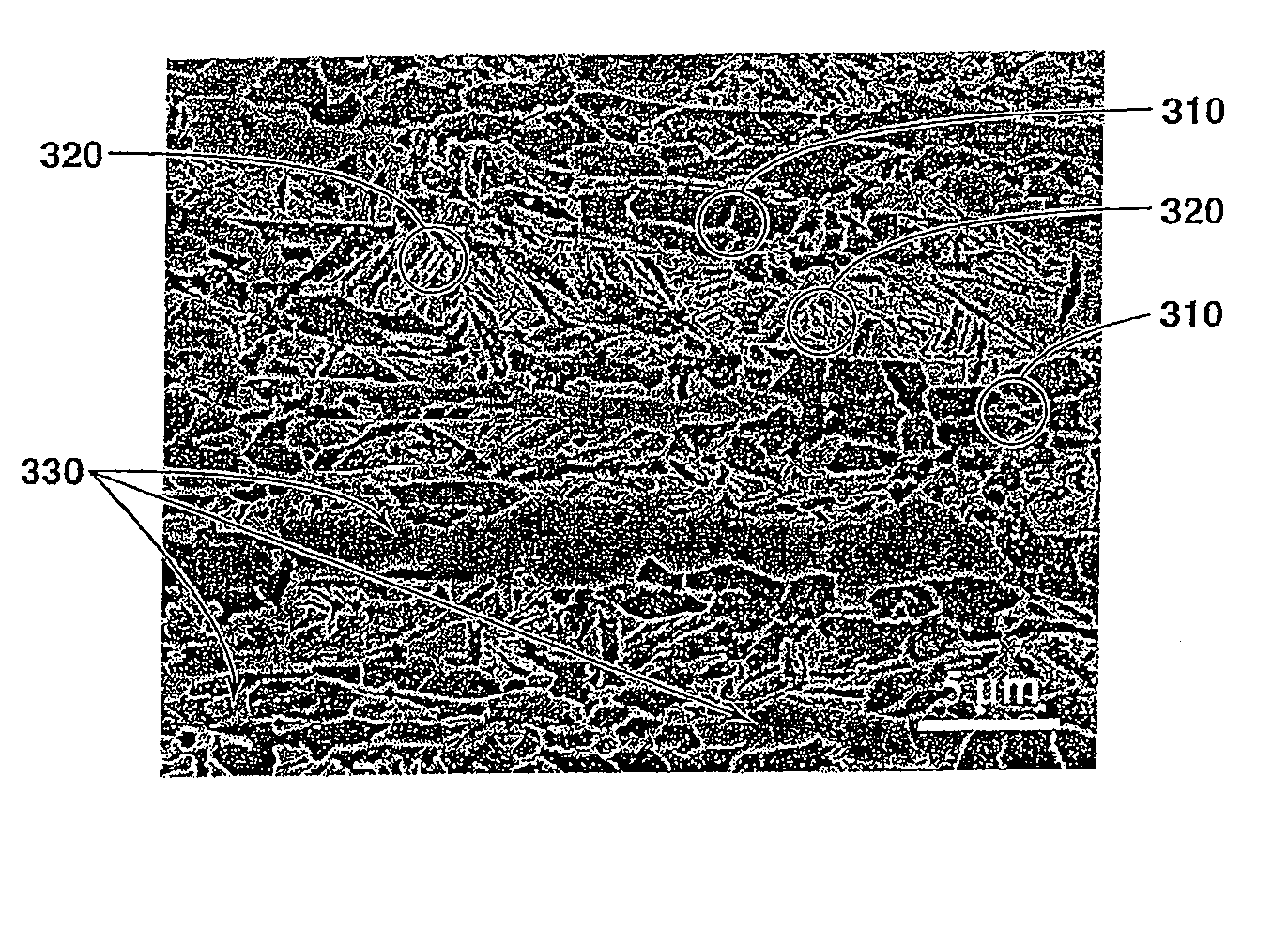

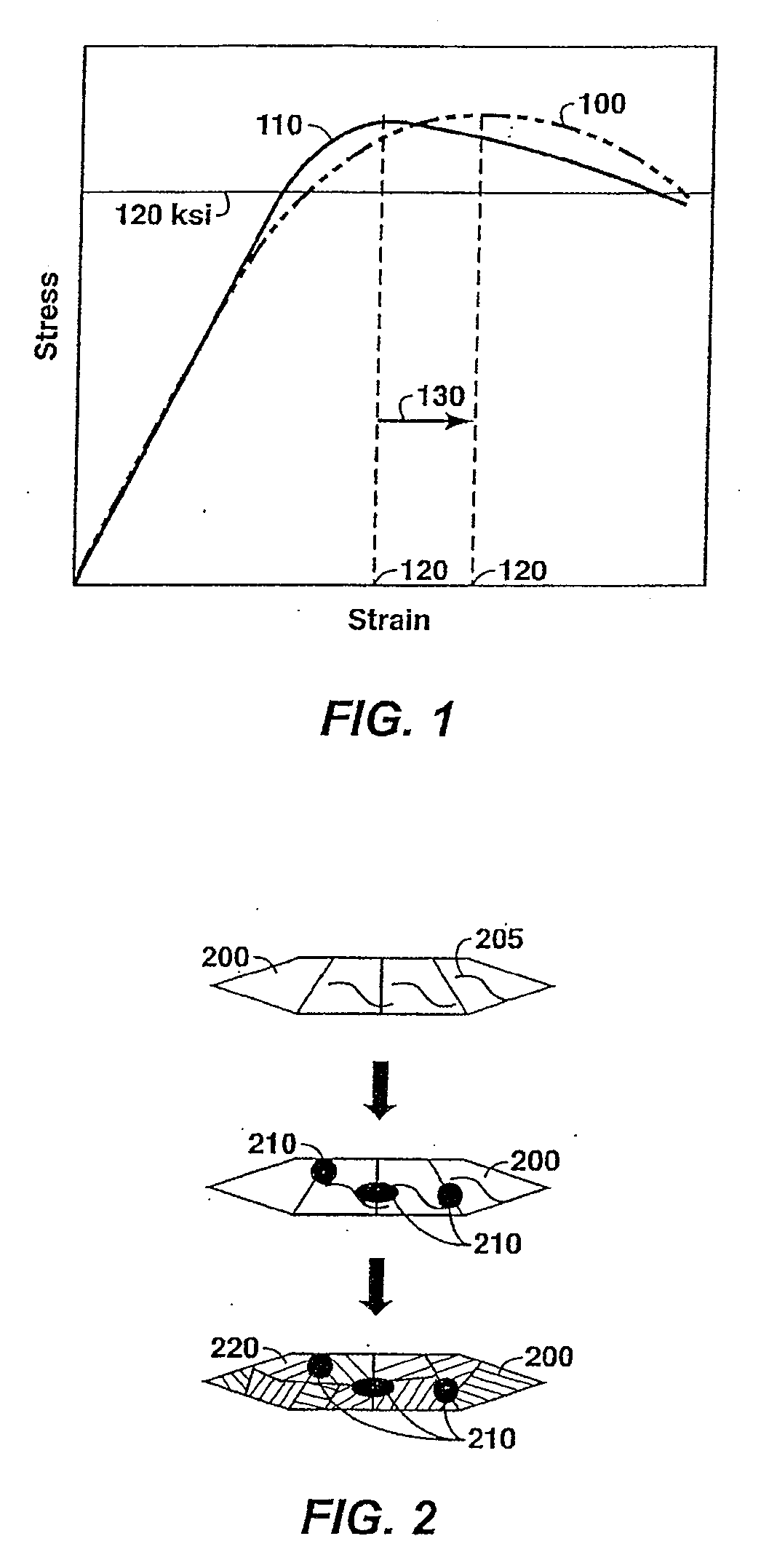

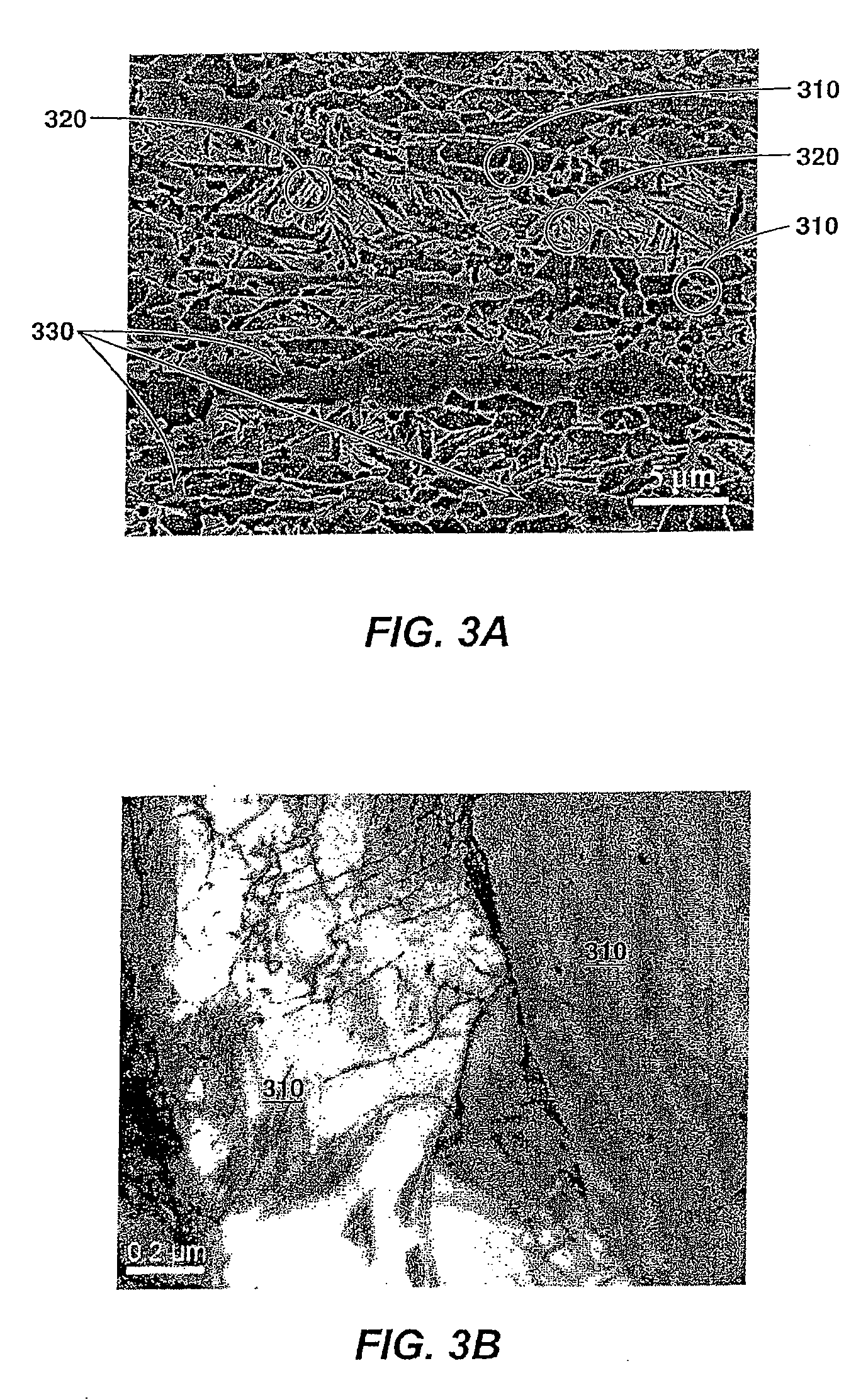

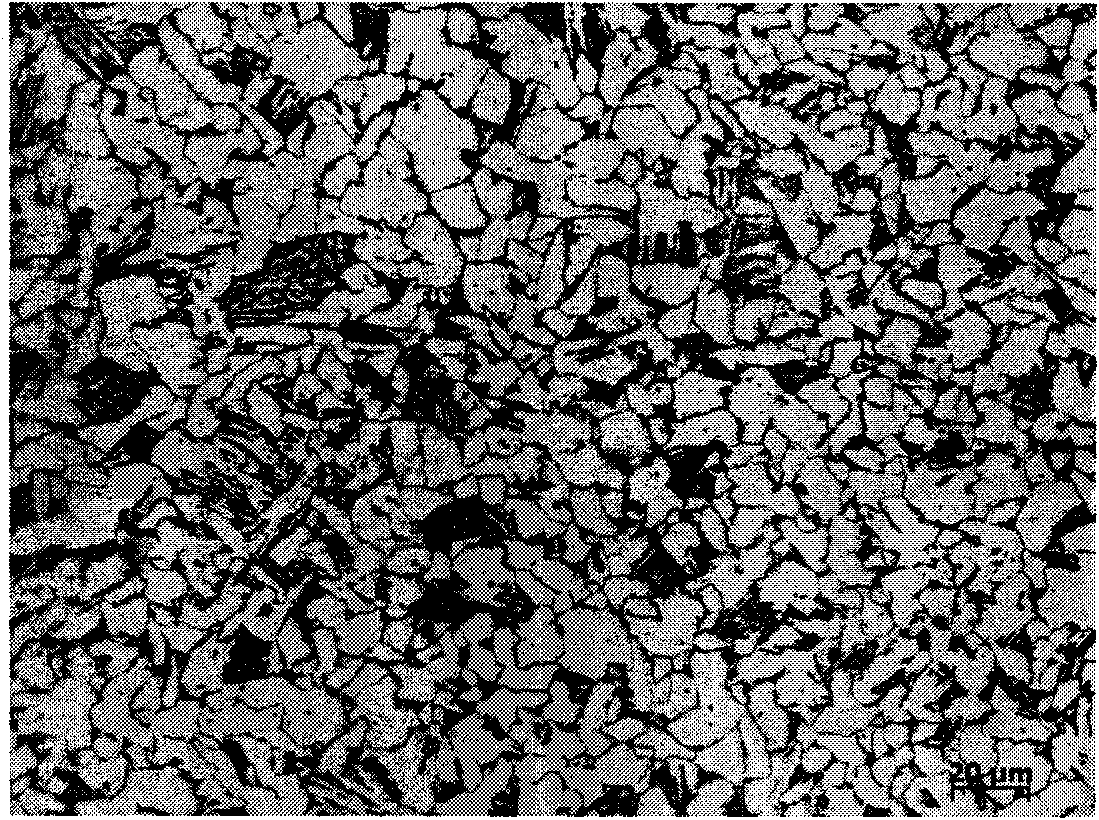

Dual-phase steel (DP steel) is a high-strength steel that has a ferritic–martensitic microstructure. DP steels are produced from low or medium carbon steels that are quenched from a temperature above A₁ but below A₃ determined from continuous cooling transformation diagram. This results in a microstructure consisting of a soft ferrite matrix containing islands of martensite as the secondary phase (martensite increases the tensile strength). Therefore, the overall behaviour of DP steels is governed by the volume fraction, morphology (size, aspect ratio, interconnectivity, etc.), the grain size and the carbon content. For achieving these microstructures, DP steels typically contain 0.06–0.15 wt.% C and 1.5-3% Mn (the former strengthens the martensite, and the latter causes solid solution strengthening in ferrite, while both stabilize the austenite), Cr & Mo (to retard pearlite or bainite formation), Si (to promote ferrite transformation), V and Nb (for precipitation strengthening and microstructure refinement). The desire to produce high strength steels with formability greater san than microalloyed steel led the development of DP steels in the 1970s.

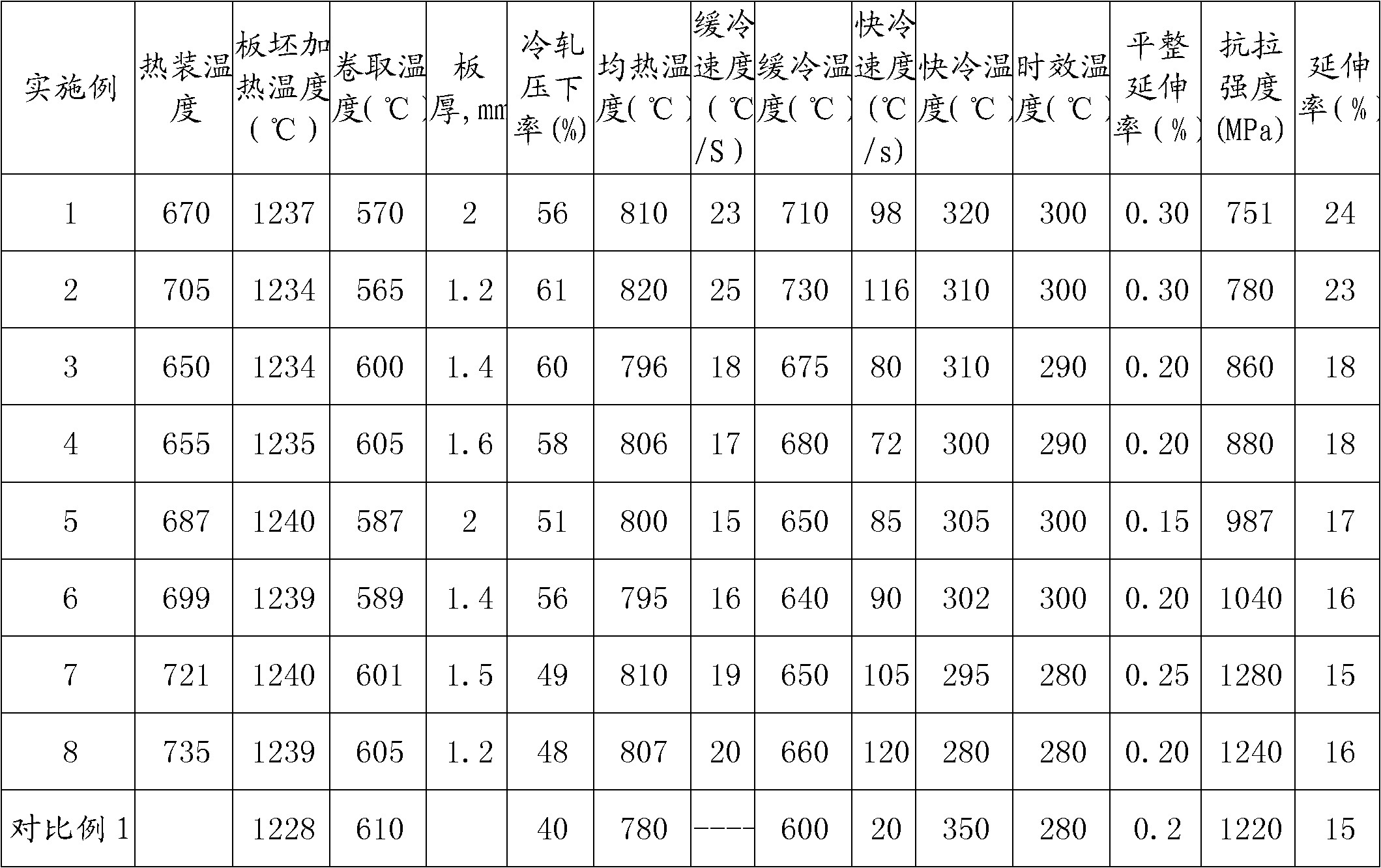

1000MPa grade cold rolling hot dip galvanizing two-phase steel and manufacturing method thereof

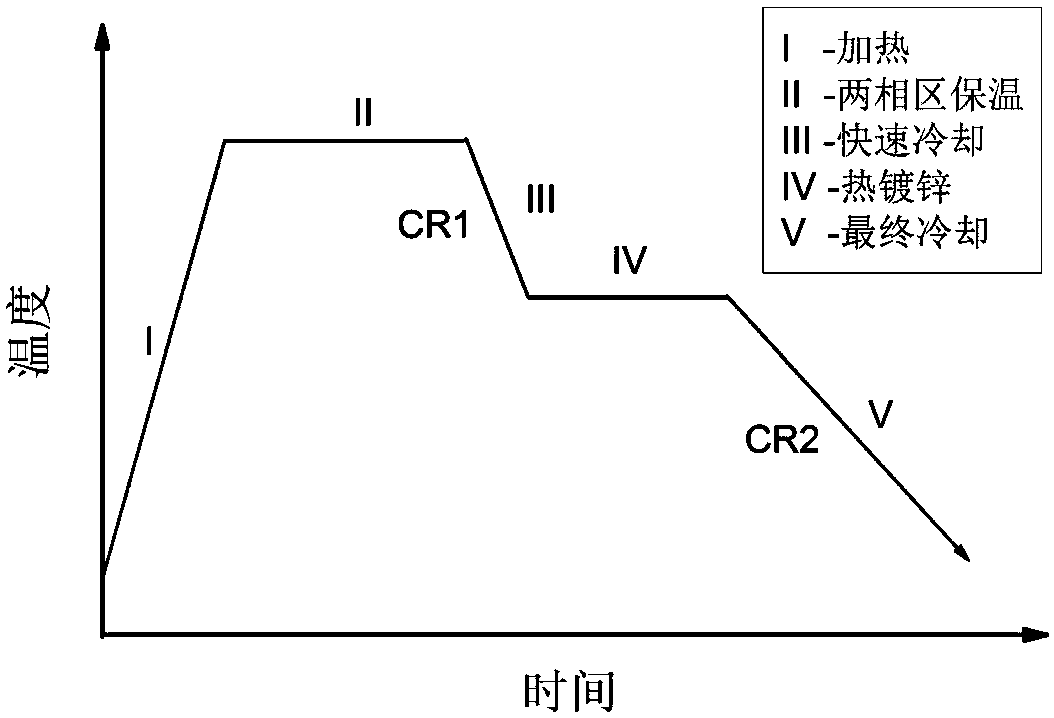

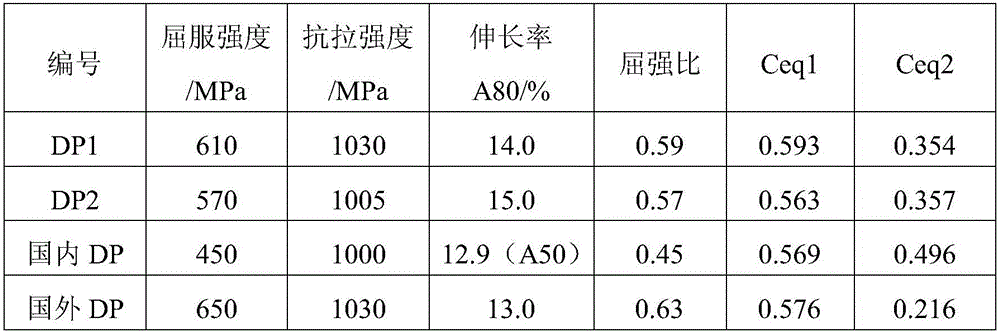

The invention provides 1,000 MPa cold-rolled hot-dip galvanized dual-phase steel and a manufacturing method thereof, belonging to the technical field of cold-rolled hot-dip galvanized high-strength steel plates. The chemical components in mass percentage of the cold-rolled hot-dip galvanized dual-phase steel are: 0.06 to 0.18 percent of C, less than or equal to 0.1 percent of Si, 1.2 to 2.5 percent of Mn,0.05 to 0.5 percent of Mo, 0.05 to 0.6 percent of Cr, 0.005 to 0.05 percent of Al, 0.01 to 0.06 percent of Nb, 0.01 to 0.05 percent of Ti, less than or equal to 0.02 percent of P, less than or equal to 0.01 percent of S, less than or equal to 0.005 percent of N, the balance being Fe and inevitable impurities. The manufacturing method adopts Cr or Mo to replace Si, so as to enlarge an austenitic and ferritic two-phase region and improve the hardenability of the dual-phase steel, and meanwhile, the manufacturing method improves the strength of toughness of the steel by adding Nb or Ti refined grains, so as to ensure that the steel has good weldability and usability, and the strength grade of the steel can reach over 1,000 Mpa.

Owner:UNIV OF SCI & TECH BEIJING +1

Dual-phase steel sheet excellent in stretch flange formability and production method thereof

Disclosed is a dual-phase steel sheet having low yield ratio, excellent in the balance for strength-elongation and for strength-stretch flange formability, and also excellent in bake hardening property containing (on the mass% basis). C: 0.01-0.20%, Si: 0.5% or less, Mn: 0.5-3%, sol. Al: 0.06% or less (inclusive 0%), P: 0.15% or less (exclusive 0%), and S: 0.02% or less (inclusive 0''), and in which the matrix phase contains tempered martensite; tempered martensite and ferrite; tempered bainite; or tempered bainite and ferrite, and the second phase comprises 1 to 30% of martensite at an area ratio based on the entire structure.

Owner:KOBE STEEL LTD

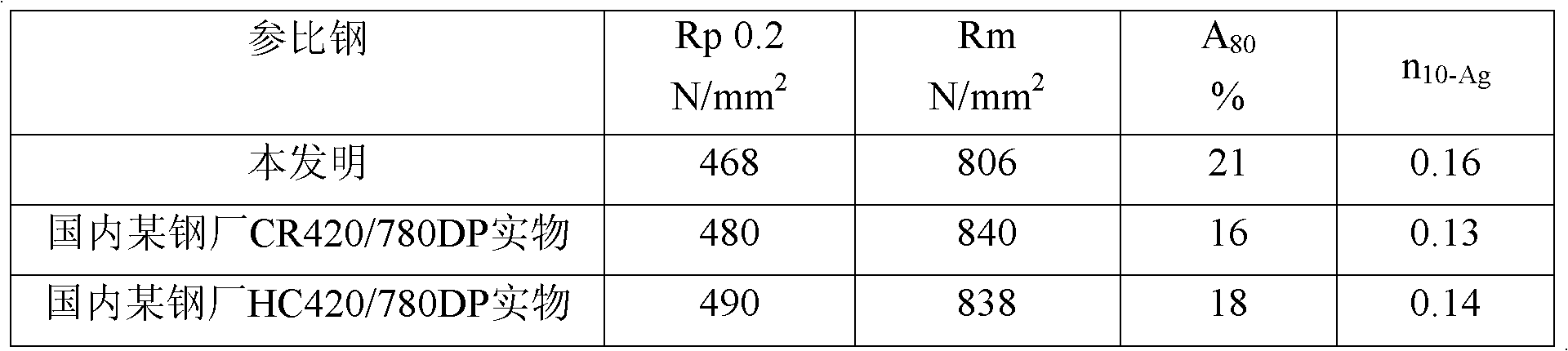

High-plasticity 780MPa-level cold rolled dual-phase steel and preparation method thereof

InactiveCN102212745ANominal C content decreasedGood welding performanceRoll mill control devicesHeat treatment process controlChemical compositionEconomic benefits

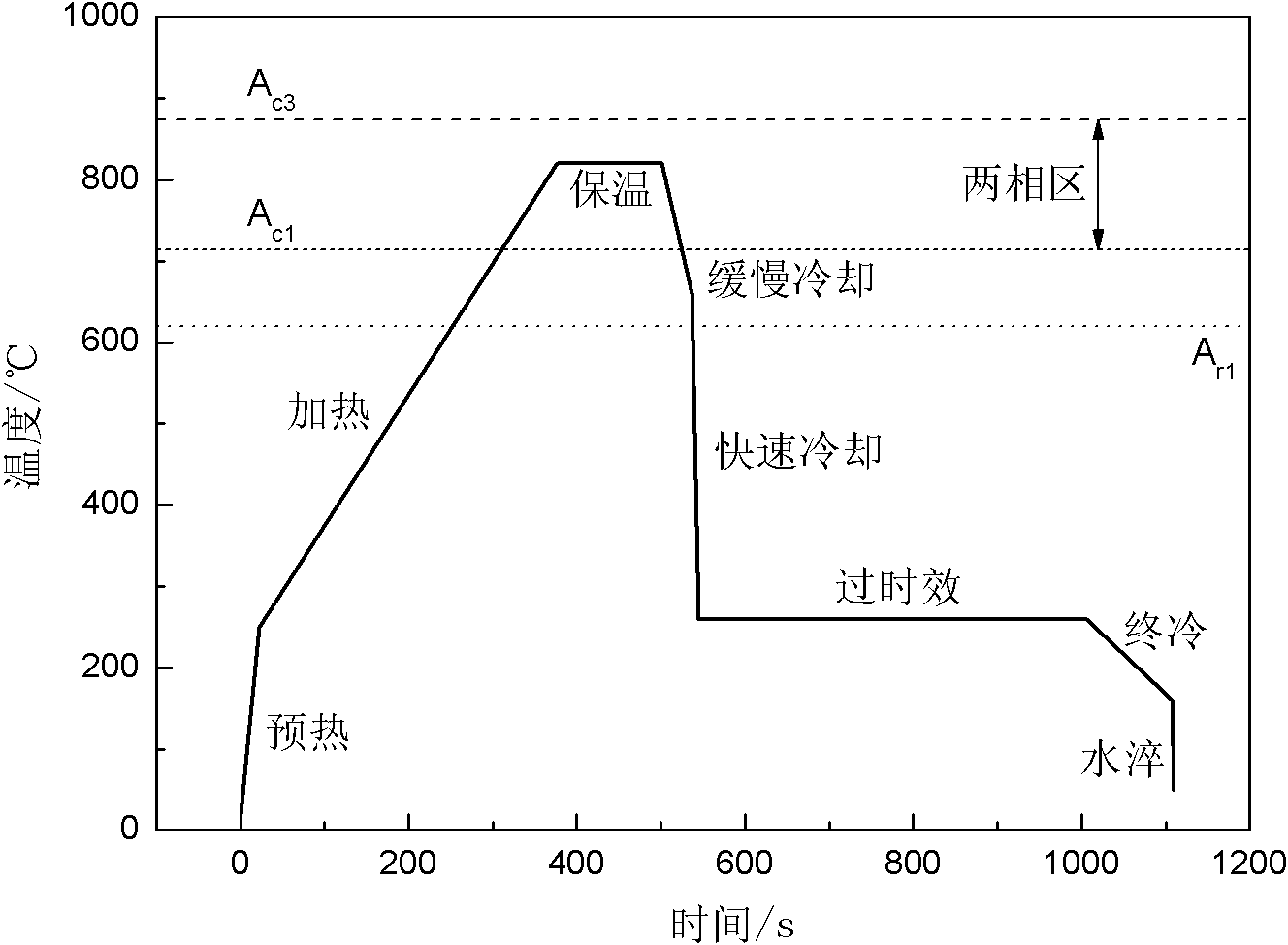

The invention discloses a high-plasticity 780MPa-level cold rolled dual-phase steel and a preparation method thereof. The steel comprises the following chemical components in percentage by weight: 0.06 to 0.08 percent of C, 1.0 to 1.3 percent of Si, 2.1 to 2.3 percent of Mn, less than or equal to 0.01 percent of P, less than or equal to 0.01 percent of S, 0.02 to 0.07 percent of Alt, less than or equal to 0.005 percent of N, and the balance of Fe and inevitable impurities. According to the hot rolling process parameters, the heating temperature of a continuously cast bloom is 1,250+ / -30 DEG C, the final rolling temperature is 890+ / -30 DEG C, the coiling temperature is 670+ / -30 DEG C, the cold rolling press-down rate is 50 to 70 percent, and the continuous annealing process is controlled. The invention has the advantages that: the C equivalent weight of the steel is effectively reduced by regulating the components of the alloy based on a conventional gas jet cooling and continuous annealing mode, the elongation of the steel is improved, and considerable economic benefit can be brought.

Owner:SHOUGANG CORPORATION

Two-phase automobile steel plate with low yield-strength ratio and high strength and production method of two-phase automobile steel plate

The invention discloses a two-phase automobile steel plate with low yield-strength ratio and high strength and a production method of the two-phase automobile steel plate, belonging to the technical field of steel for automobiles. The two-phase automobile steel plate comprises the following chemical components: 0.1-0.40wt% of C, 3.0-8.0wt% of Mn, less than or equal to 0.020wt% of P and less than or equal to 0.02wt% of S; on the basis, the two-phase automobile steel plate can be additionally provided with one or more of the following elements: 0.1-3.0wt% of Ni, 0.2-3.0wt% of Cr, 0.1-0.8wt% of Mo, 0.3-2.3wt% of Si, 0.5-2.0wt% of Cu, 0.0005-0.005wt% of B, 0.02-0.10wt% of Nb, 0.002-0.25wt% of [N], 0.05-0.25wt% of Ti, 0.02-0.25wt% of V, 0.015-0.060wt% of Al, 0.002-0.005wt% of RE (Rare Earth) and 0.005-0.03wt% of Ca. The two-phase automobile steel plate has the advantages that the two-phase automobile steel plate with low yield strength, high tension strength and favorable elongation can be produced through annealing within short time; the performance indexes of the two-phase automobile steel plate are as follows: two-phase steel with the tension strength of 980MPa has the yield-strength ratio of not larger than 0.55 and the elongation of larger than 22%, and two-phase steel with the tension strength of 1180MPa has the yield-strength ratio of not larger than 0.55 and the elongation of larger than 17%.

Owner:CENT IRON & STEEL RES INST

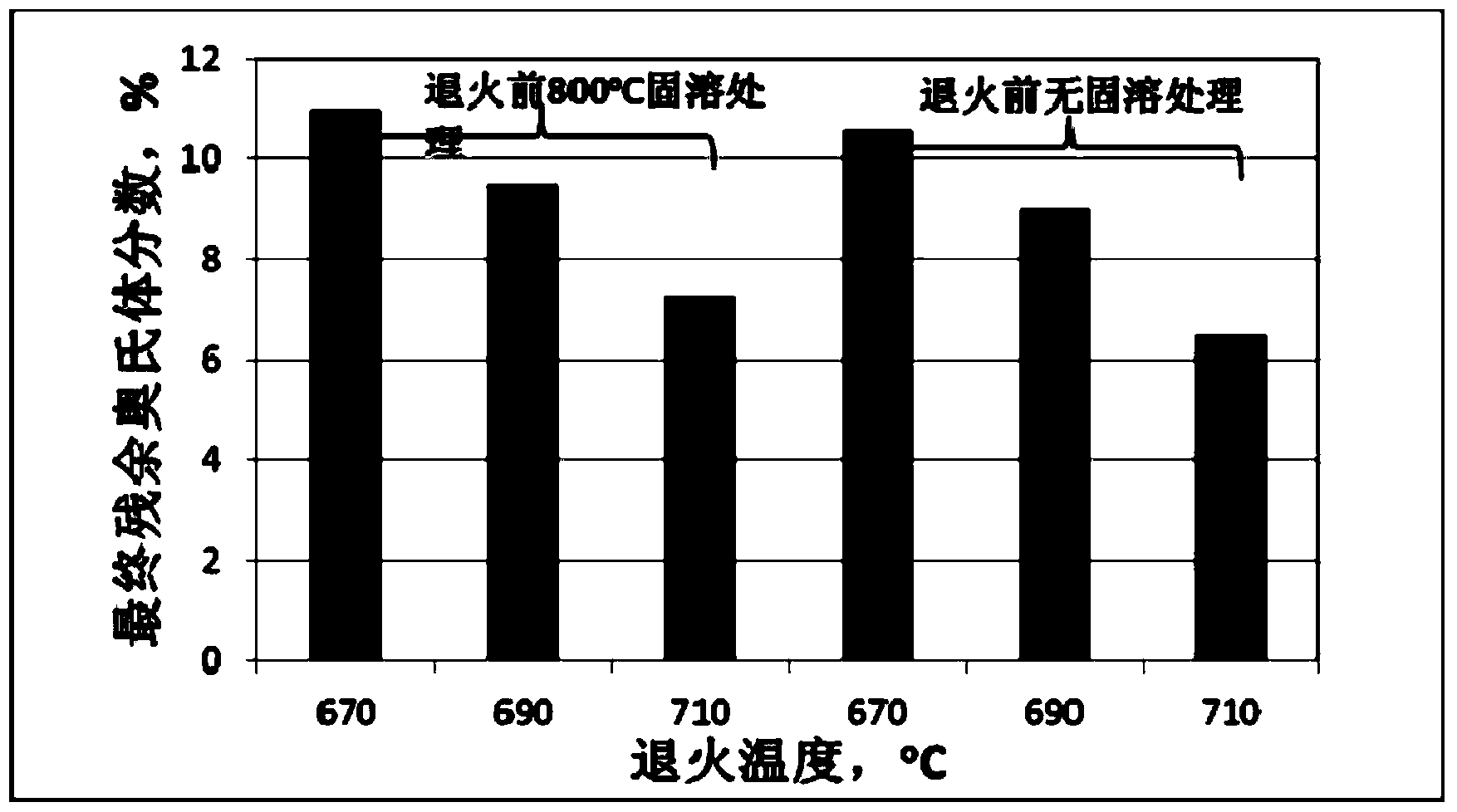

Ti microalloyed ultra-fine grained cold rolling dual-phase steel of 1,000MPa level and preparation method thereof

InactiveCN101768695ALow priceInhibit growthTemperature control deviceFurnace typesChemical compositionMicrometer

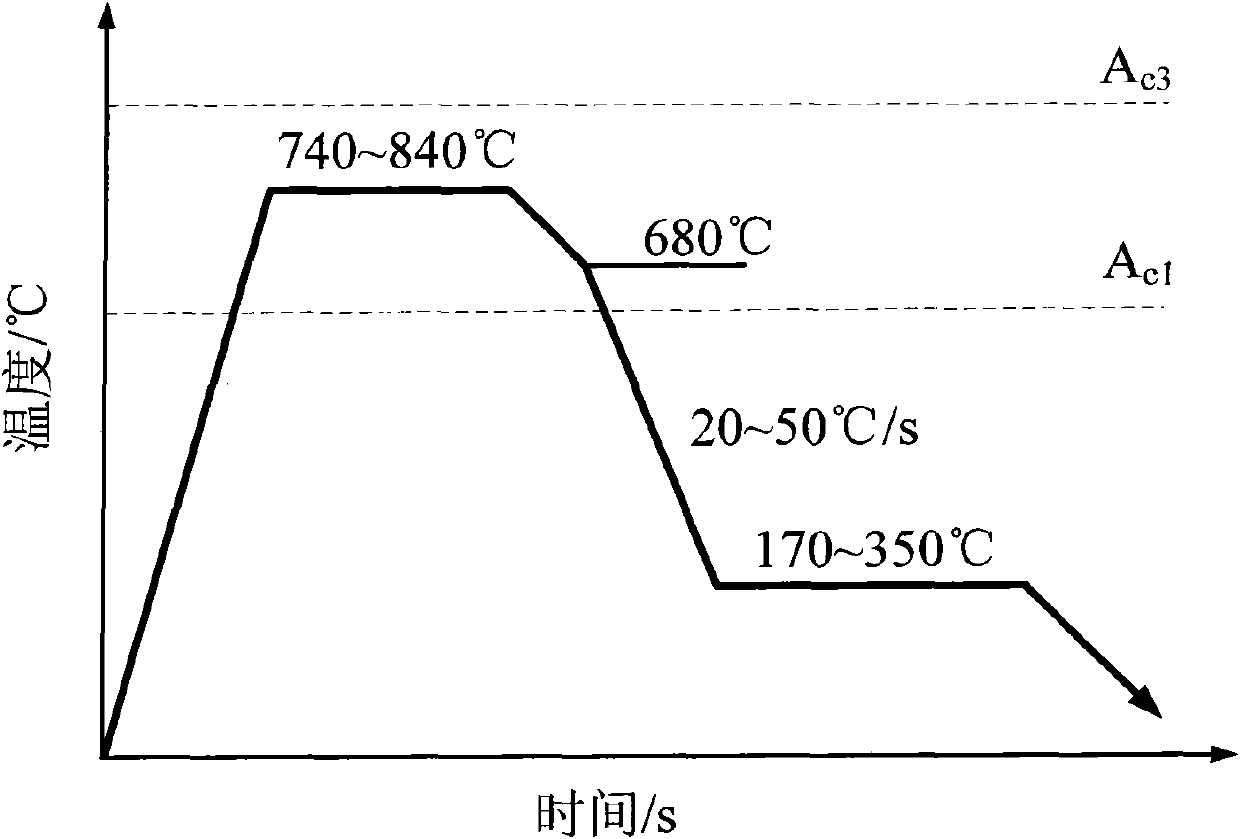

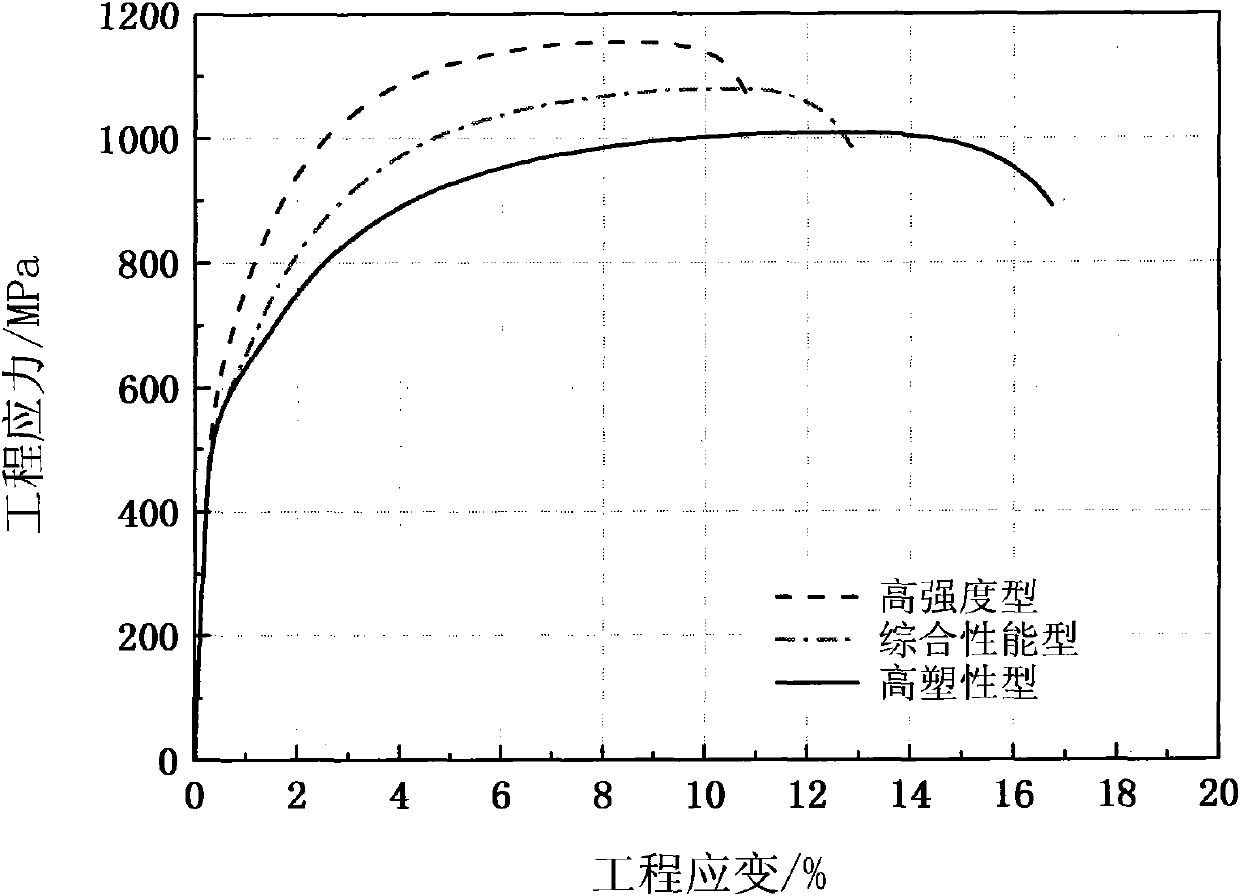

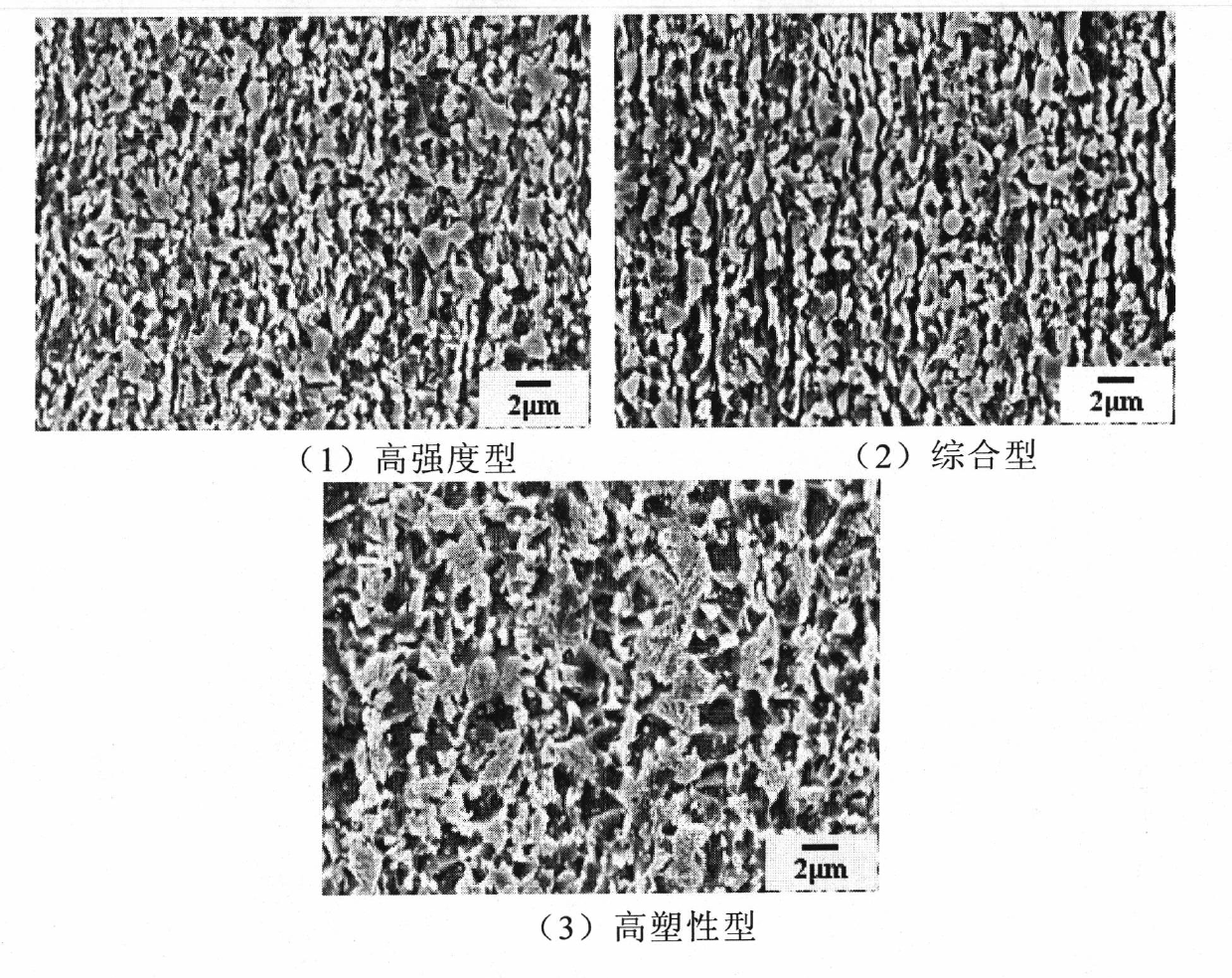

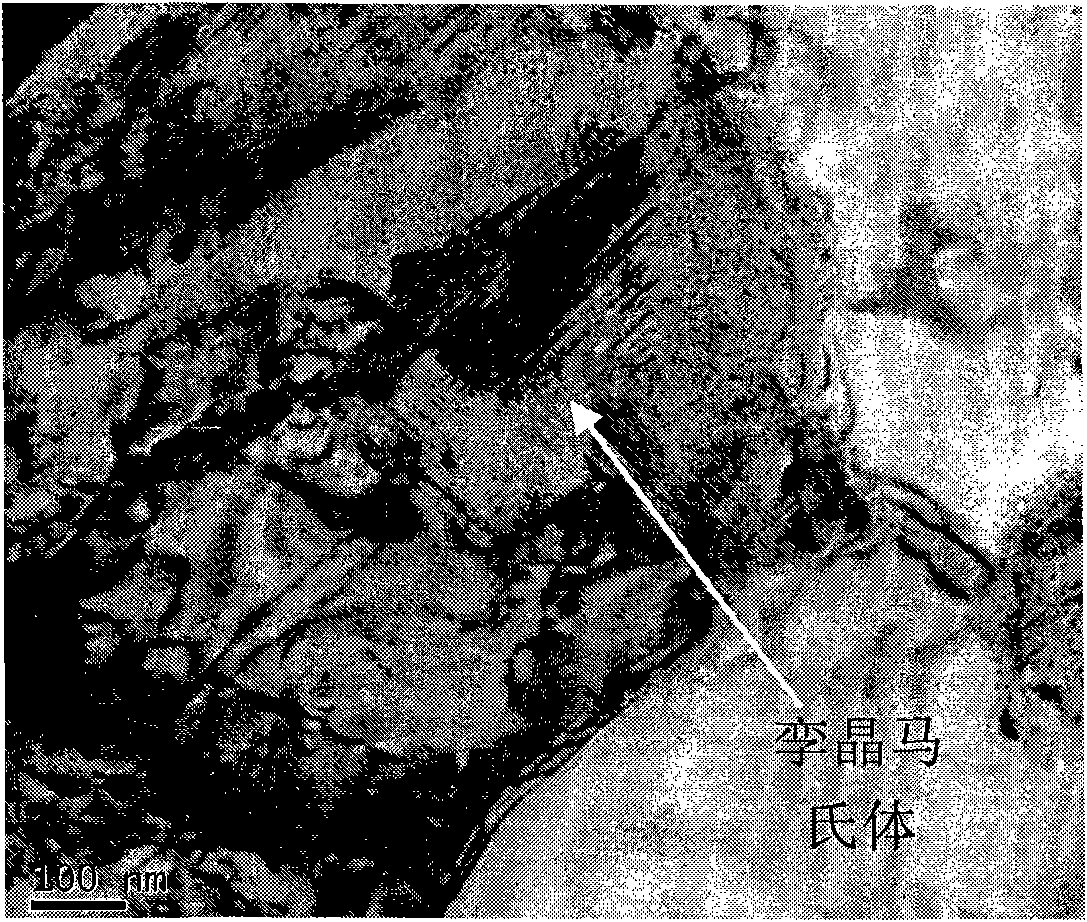

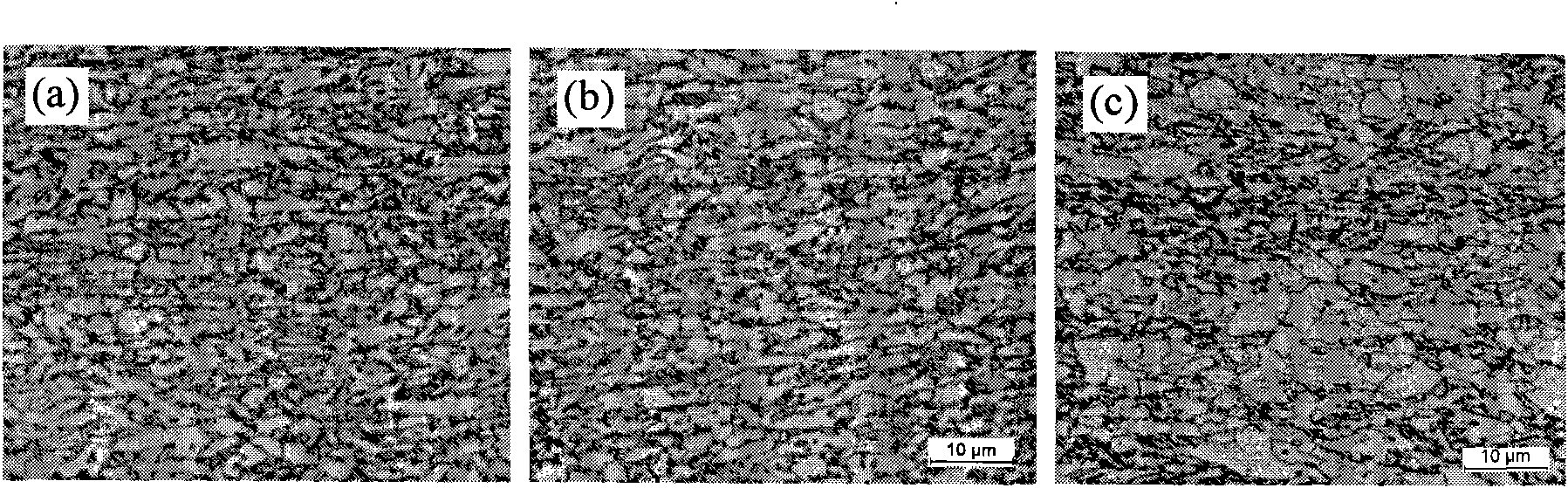

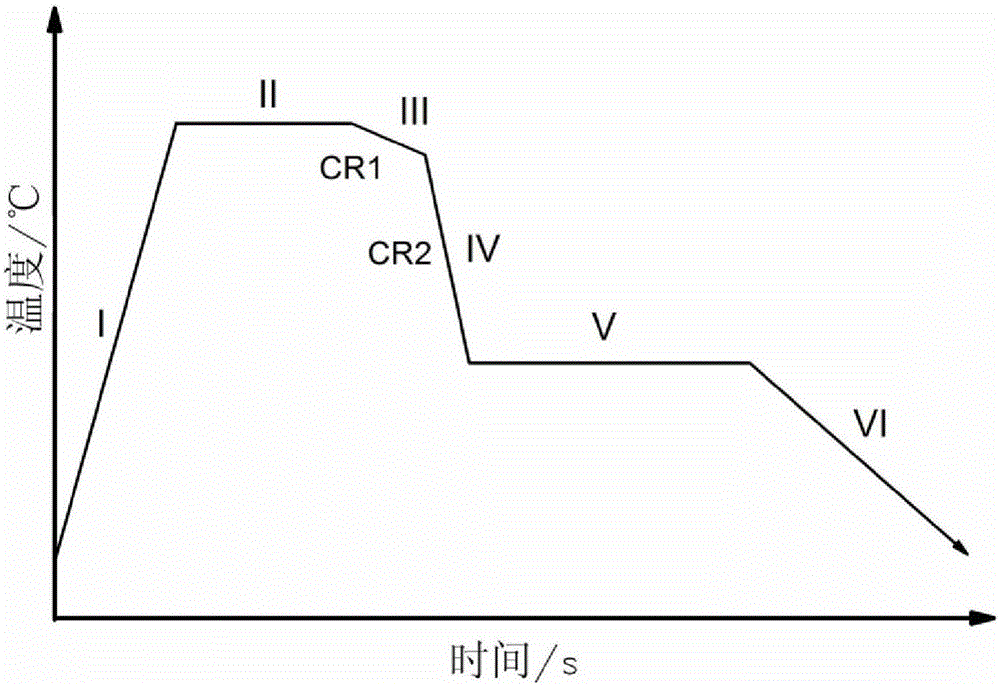

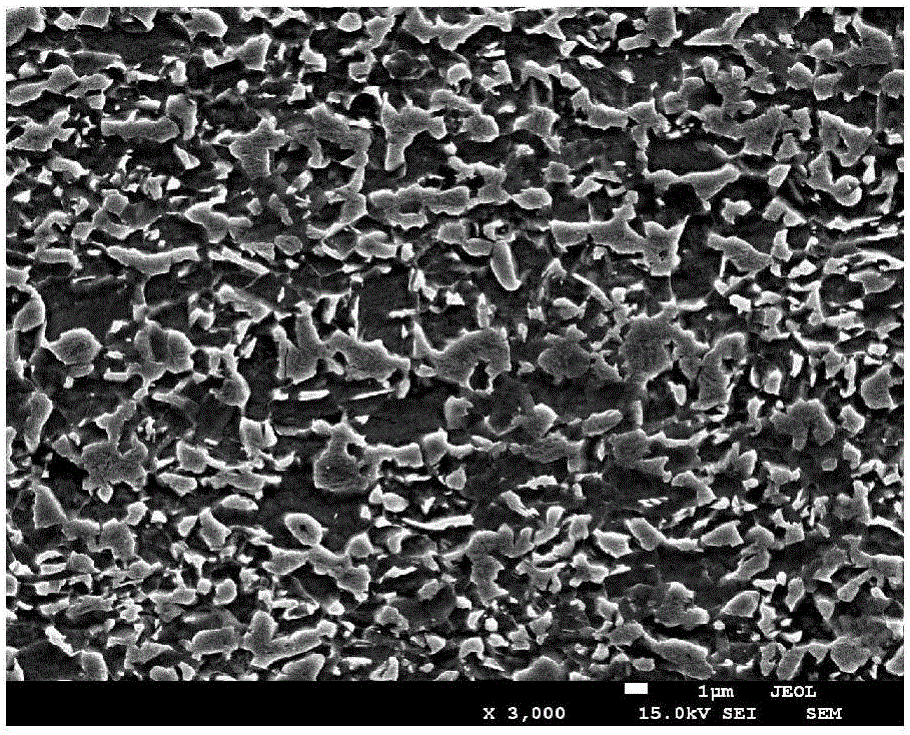

The invention relates to Ti microalloyed ultra-fine grained cold rolling dual-phase steel of a 1,000MPa level and a preparation method thereof, belonging to the technical field of cold rolling ultra-high strength steel for automobiles. The steel comprises the following chemical compositions in percentage by weight: 0.03-0.20 percent of C, 0.20-0.80 percent of Si, 1.2-2.0 percent of Mn, 0.03-0.15 percent of Ti, less than 0.15 percent of S, less than 0.020 percent of P, 0.02-0.15 percent of Als and the balance of Fe. In the invention, C-Si-Mn-Ti is used as a basic alloy system, low-price Ti is adopted, and alloy elements such as Cr, Mo, Nb, V, and the like are not added, thereby reducing the production cost; through a flexible continuous annealing process, the size of a martensite island can be controlled to be 1-2 micrometers or increased to about 5 micrometers under the condition that the quick cooling speed is lower than 50 DEG C / s in continuous annealing so as to obtain the following three different types of dual-phase steel: a high strength type (Rm is 980-1,200MPa, and A50 is 10-13 percent), a high plasticity type (Rm is 980-1,100MPa, and A50 is 14-18 percent) and a synthesizing type (Rm is 980-1,150MPa, and A50 is 12-15 percent); and the yield ratio is 0.47-0.65.

Owner:UNIV OF SCI & TECH BEIJING

Dual phase hot rolled steel sheet having excellent formability and stretch flangeability

InactiveUS20040118489A1Few facilitiesGood formabilityFurnace typesHeat treatment furnacesIngotUltimate tensile strength

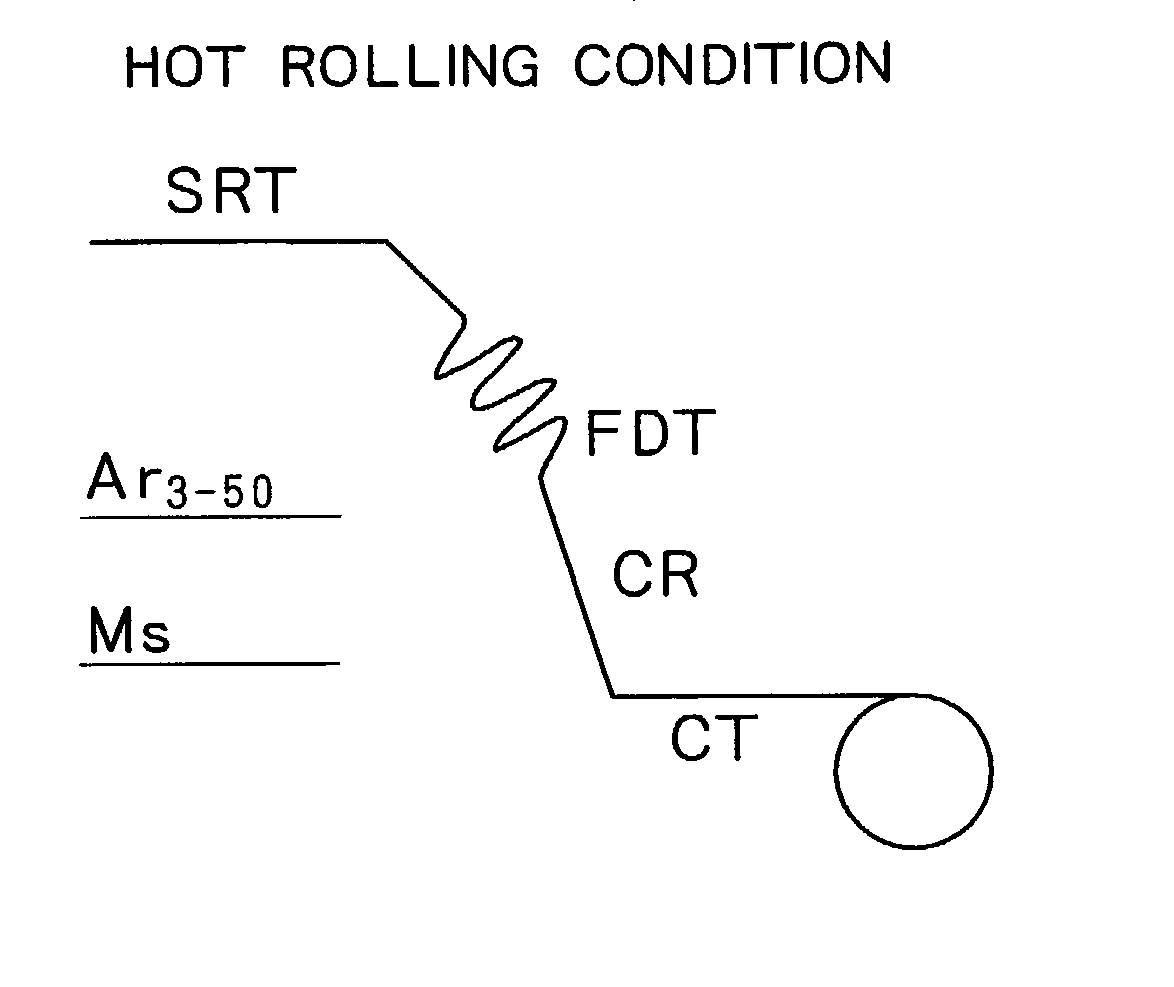

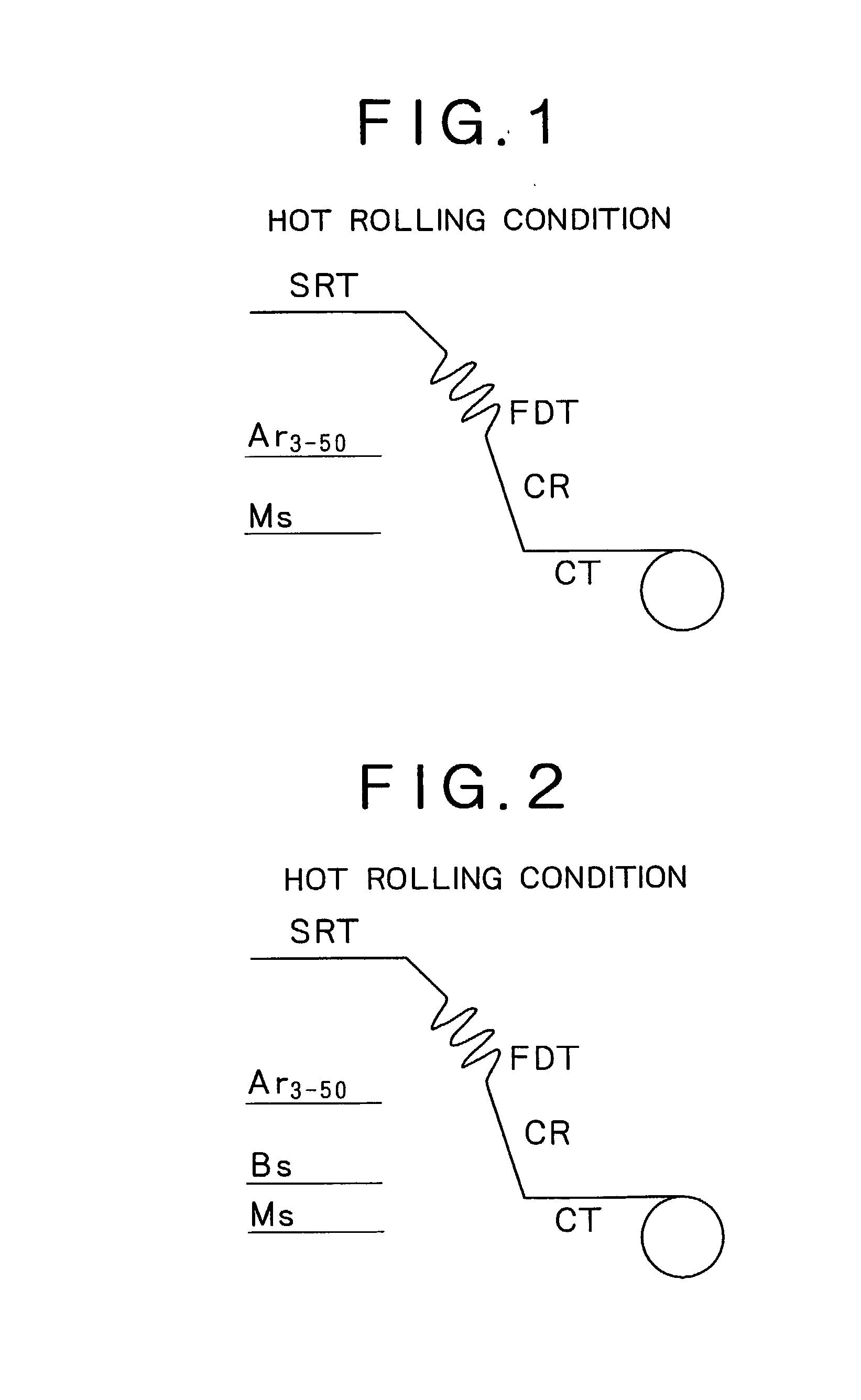

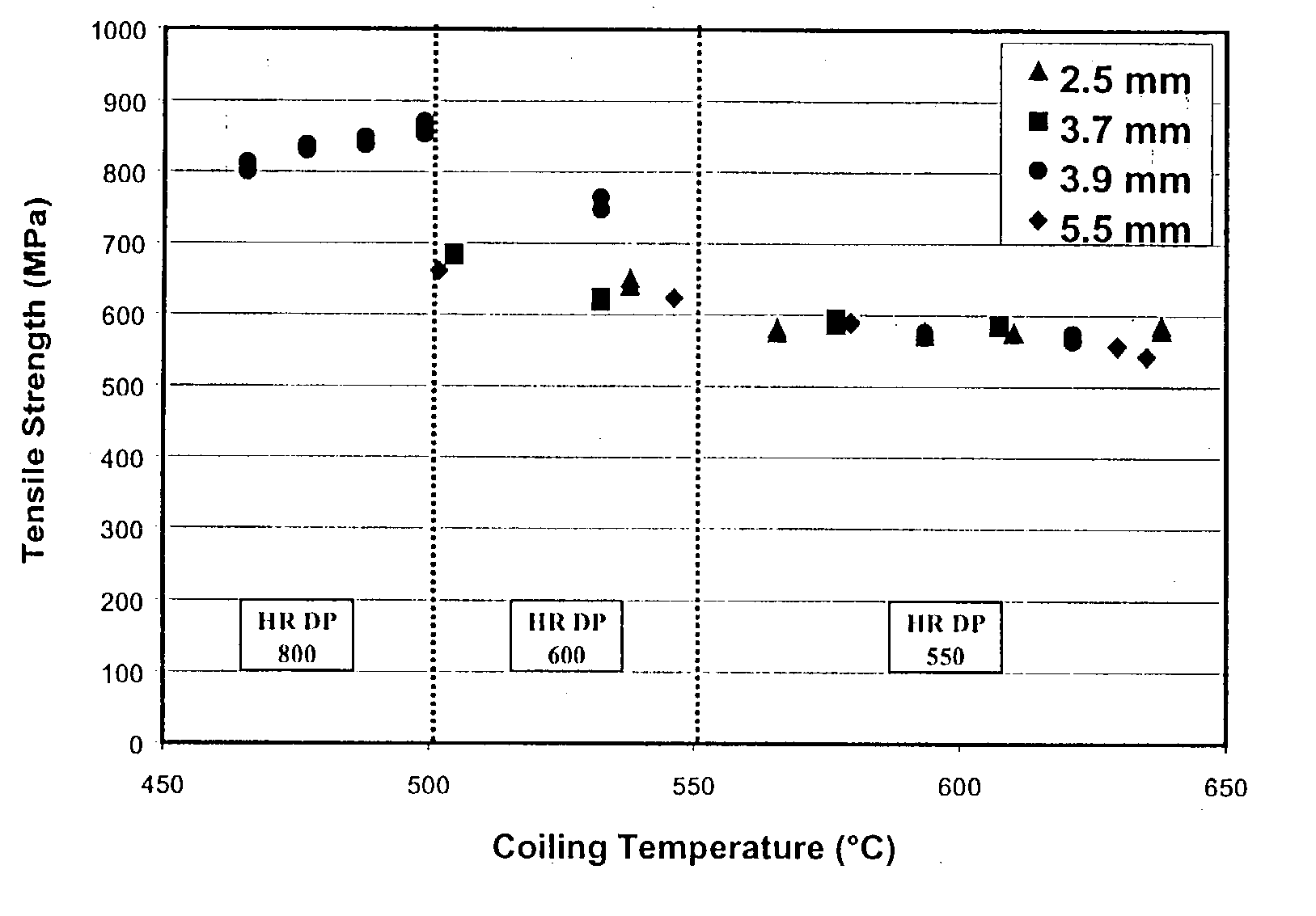

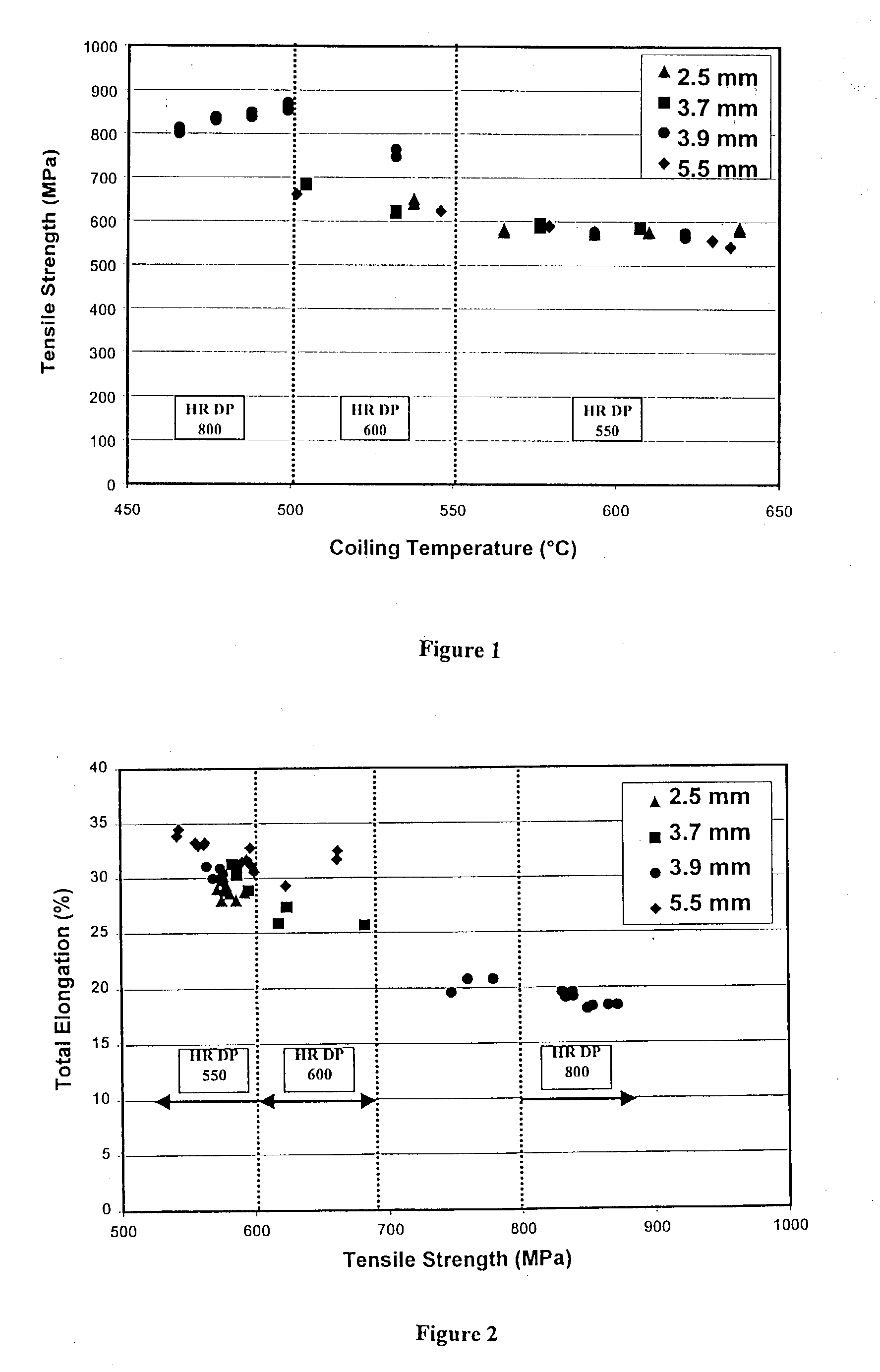

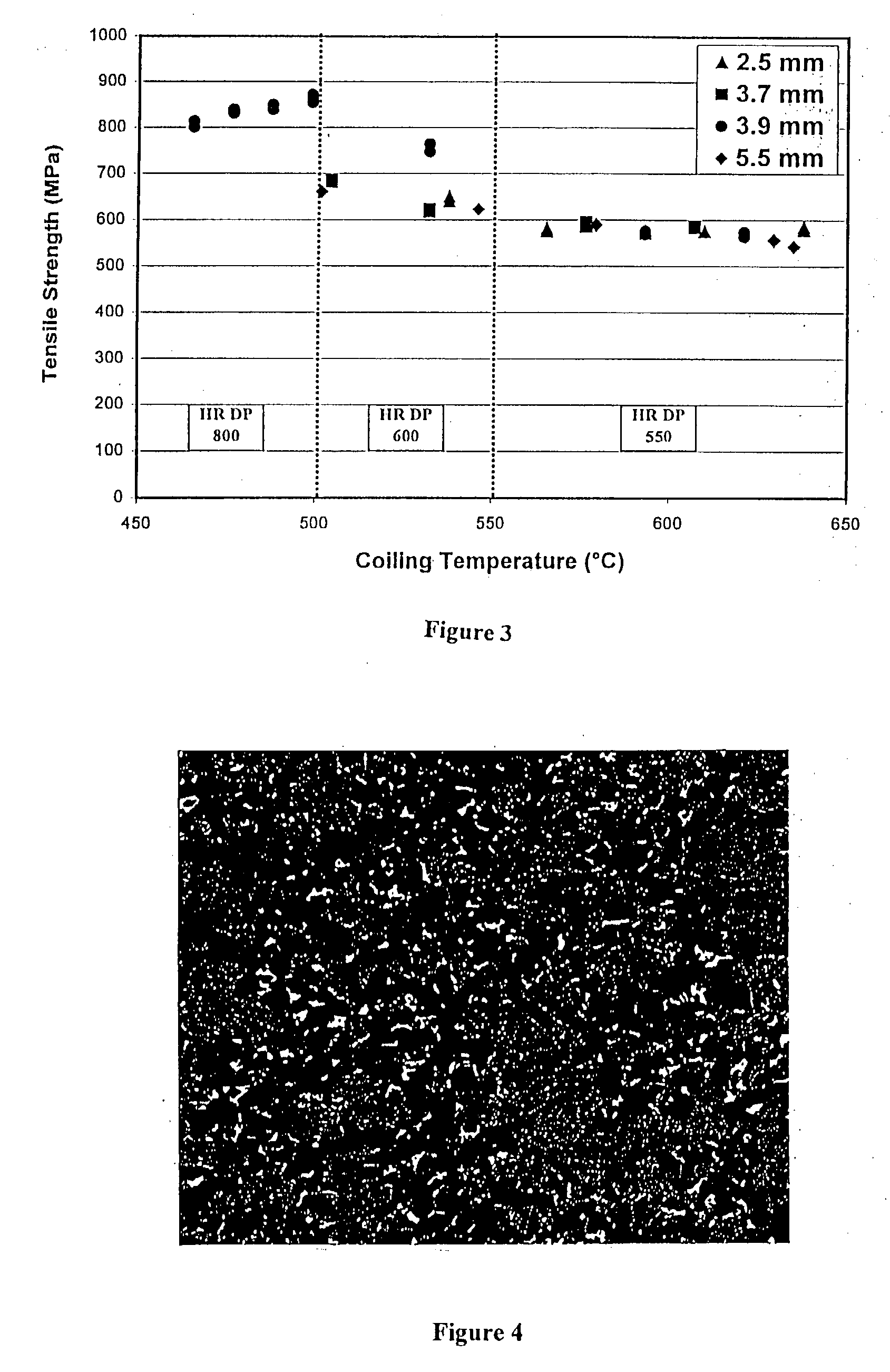

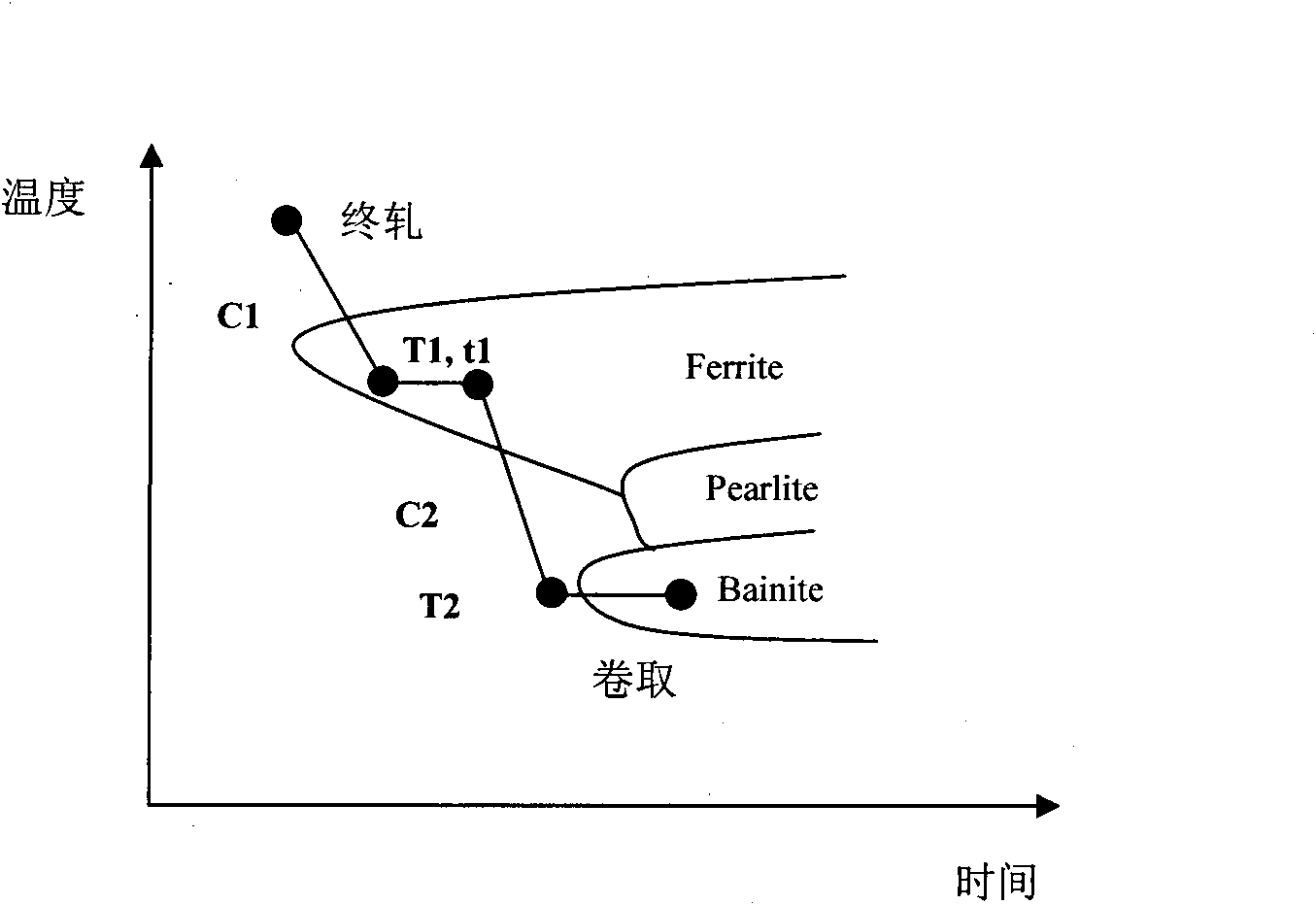

The present invention provides a process of producing a family of hot rolled dual phase steel sheets having excellent formability and stretch flangeability, with yield strengths of from about 500 MPa to about 900 MPa from a single steel chemistry consisting of, by weight percent, 0.02-0.15% of C, 0.3-2.5% of Mn, 0.1-2.0% of Cr, 0.01-0.2% Al, 0.001-0.01% Ca, not more than 0.1% P, not more than 0.03% S, not more than 0.2% Ti, not more than 0.2% V, not more than 0.2% Nb, not more than 0.5% Mo, not more than 0.5% Cu, not more than 0.5% Ni, the balance being Fe and unavoidable impurities. A slab or ingot of this composition is reheated to a temperature of between 1050° C. and 1350° C. and held at this temperature for at least 10 minutes, then hot rolled, completing the hot rolling at between 800° C. and 1000° C. The sheet is cooled, immediately after completion of hot rolling, at a rate of not lower than 10 C / sec., without requiring specific cooling patterns, and coiled at a temperature of not less than 450 C. The cooling temperature is controlled to produce the desired yield strength within the range of from about 500 MPa to about 900 MPa.

Owner:NATIONAL STEEL CORP +1

Ultrafine grained hot rolled dual-phase steel with tensile strength of above 750MPa and manufacturing method of plate thereof

The invention relates to ultrafine grained hot rolled dual-phase steel with tensile strength of above 750MPa and a manufacturing method of a plate thereof, belonging to the technical field of steel rolling, and the dual-phase steel comprises the following chemical components by weight percentage: 0.06-0.16% of C, 0.10-0.50% of Si, 1.00-2.00% of Mn, 0.02-0.06% of Al, 0.01-0.08% of Nb, 0-0.03% of Ti, not more than 0.1 of P, not more than 0.05 of S and the balance of Fe. The manufacturing method of the dual-phase steel comprises the following steps: 1) heating, heating a plate blank with the thickness of not less than 60mm to 1100-1250 DEG C, and keeping the temperature for 1-4h; 2) rolling and adopting the two-stage controlled rolling, wherein the reduction rate in a recrystallization zone is larger than 60%, the reduction rate in a non-recrystallization zone is larger than 70%, the initial rolling temperature of the recrystallization zone is 1100-1150 DEG C, the initial rolling temperature of the non-recrystallization zone is 880-940 DEG C, and the final rolling temperature is 770-860 DEG C; and 3) cooling, and adopting the continuous cooling after final rolling, wherein the cooling rate is 30-40 DEG C / s, the coiling temperature is lower than 350 DEG C, and the thickness of a finished product is 2-10mm. The manufacturing method can obtain the high-performance steel plate with high strength, low yield-strength ratio and good extension property, and the steel plate can be suitable for forming processing of high-strength automobiles, other industrial mechanical parts and the like.

Owner:NORTHEASTERN UNIV

1000 MPa low-carbon hot-galvanized dual-phase steel and preparation method thereof

ActiveCN105950998AGood mechanical propertiesGood formabilityHot-dipping/immersion processesMechanical propertyImpurity

The invention belongs to the technical field of steel for high-strength automobiles and particularly relates to 1000 MPa low-carbon hot-galvanized dual-phase steel and a preparation method thereof. The 1000 MPa low-carbon hot-galvanized dual-phase steel comprises, by weight, 0.05-0.10% of C, 0.20-0.60% of Si, 1.40-1.90% of Mn, 0.20-0.70% of Cr, 0.20-0.50% of Mo, 0.02-0.06% of Al, 0.020-0.050% of Ti, 0.010-0.040% of Nb, 0.0010-0.0030% of B, less than or equal to 0.015% of P, less than or equal to 0.005% of S, less than or equal to 0.006% of N, and the balance Fe and inevitable impurities. The 1000 MPa low-carbon hot-galvanized dual-phase steel has the high forming property and high welding property and the excellent galvanizing property and mechanical property. The 1000 MPa low-carbon hot-galvanized dual-phase steel is 630-700 MPa in yield strength, 1010-1050 MPa in tensile strength and 11-14% in elongation.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

980 MPa-level vanadium-contained ultrafine grain cold rolled dual-phase steel and preparing method thereof

The invention provides 980 MPa-level vanadium-contained ultrafine grain cold rolled dual-phase steel and a preparing method, and belongs to the technical field of cold rolling ultrahigh strength steel for an automobile. The 980 MPa-level vanadium-contained ultrafine grain cold rolled dual-phase steel is composed of, by weight percent, 0.10% to 0.20% of C, 0.30% to 1.00% of Si, 1.50% to 2.50% of Mn, 0.20% to 0.80% of Cr, 0.01% to 0.06% of Al, 0.05% to 0.15% of V, not larger than 0.020% of P, not larger than 0.015% of S, not larger than 0.006% of N and the balance Fe and inevitable impurities. Ferrite and martensite grains are refined through the micro amount of V; and meanwhile, VC dispersed precipitation plays a role in strengthening sedimentation, and the production cost is obviously reduced. The prepared cold rolled dual-phase steel is excellent in mechanical property, forming property and welding property, the cost advantages are obvious, and the obvious economic benefits and social benefits are achieved.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

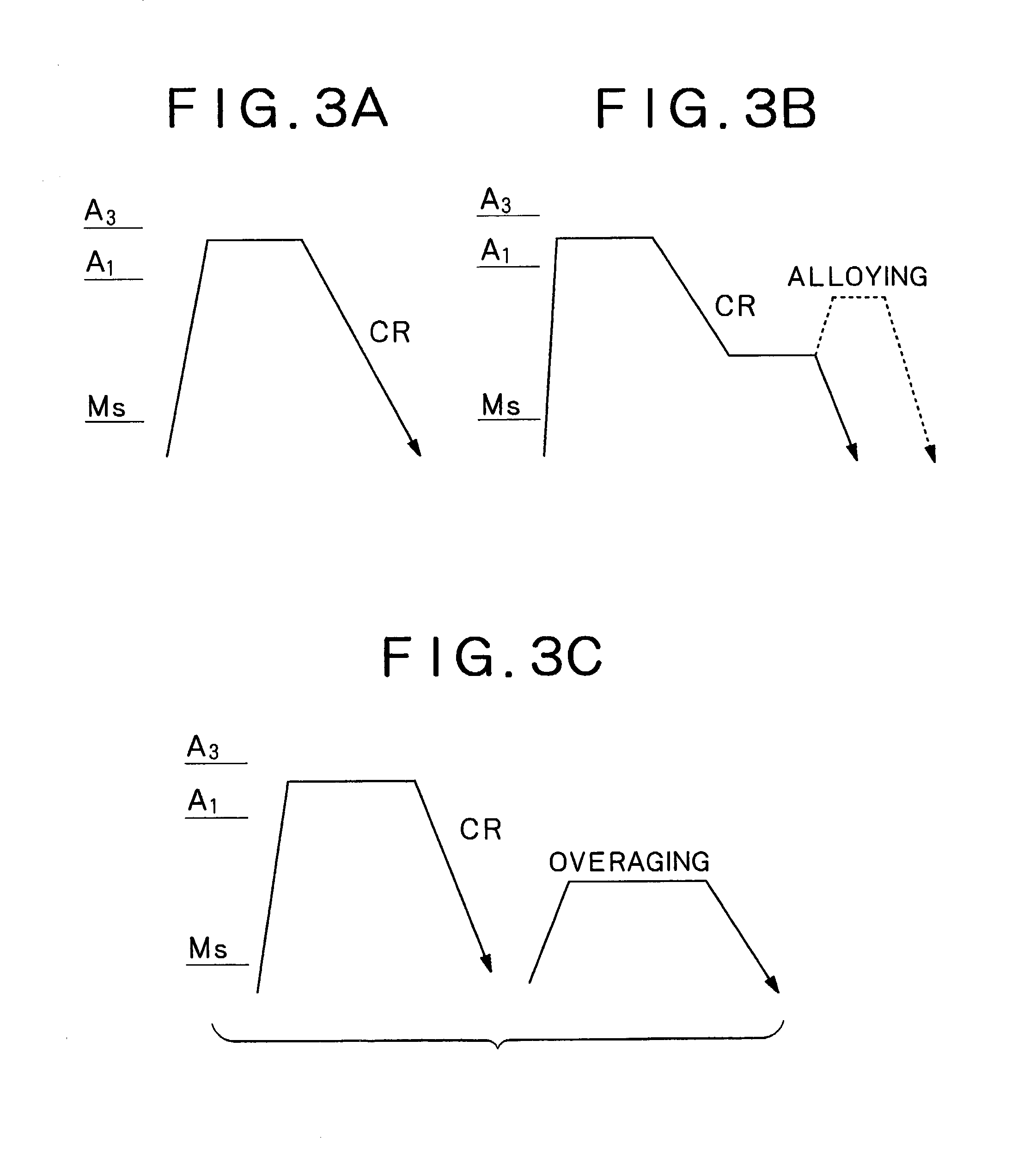

High-strength steel sheets and processes for production of the same

InactiveUS20090277547A1Improve stamping formabilityHigh strengthFurnace typesHeat treatment furnacesFlangingEquivalent weight

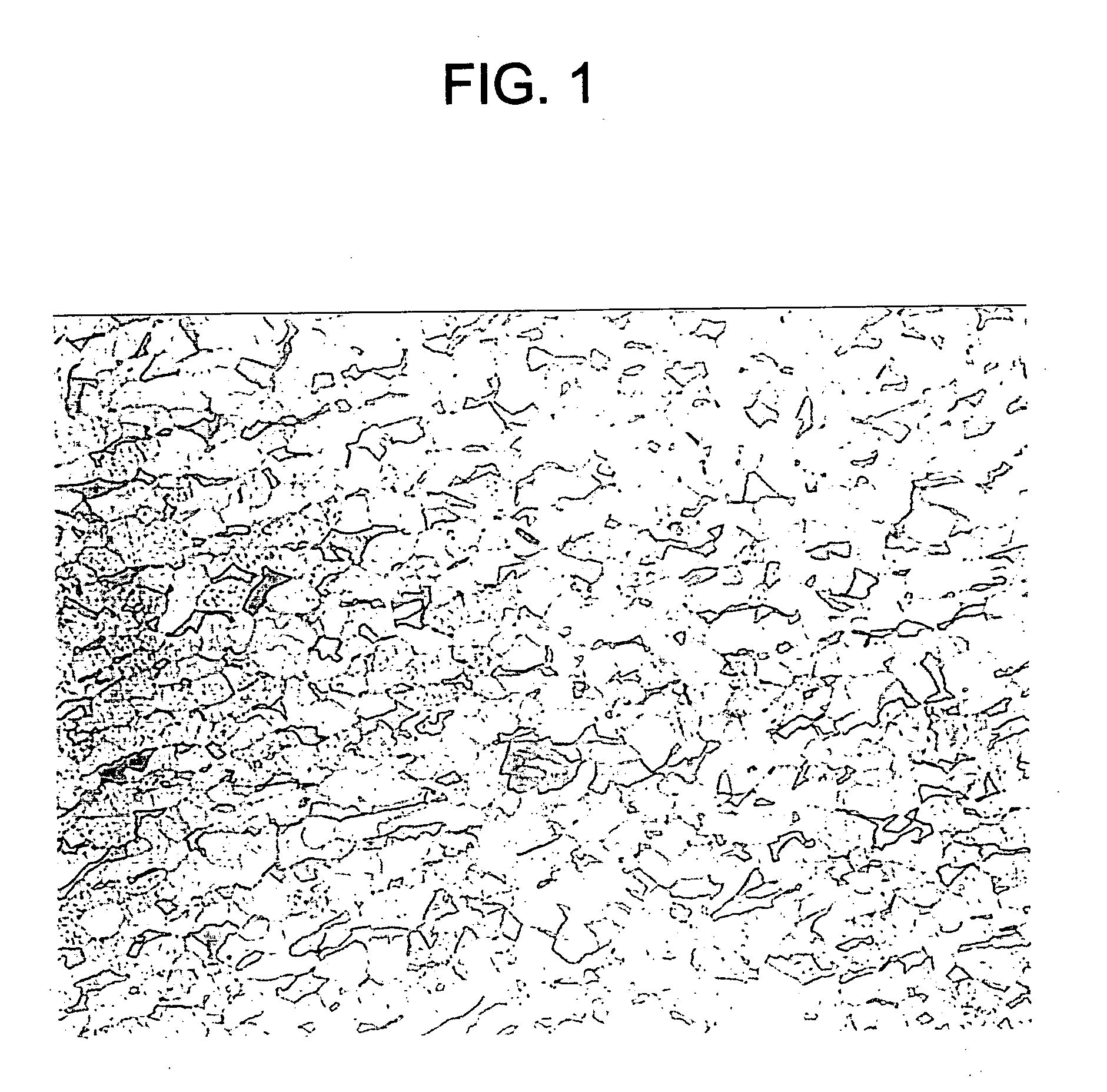

A high strength steel sheet with both excellent elongation and stretch-flanging performance is provided.The high strength steel sheet of the present invention comprises, in percent by mass, C: 0.05 to 0.3%, Si: 0.01 to 3.0%, Mn: 0.5 to 3.0%, Al: 0.01 to 0.1%, and Fe and inevitable impurities as the remainder, and has a structure mainly composed of tempered martensite and annealed bainite. The space factor of the tempered martensite is 50 to 95%, the space factor of the annealed bainite is 5 to 30%, and the mean grain size of the tempered martensite is 10 μm or smaller in terms of the equivalent of a circle diameter. The steel sheet has a tensile strength of 590 MPa or higher.The high strength steel sheet of the present invention has a space factor of the martensite phase which is a main component of the metal structure is 80% or higher; the mean grain size of the martensite phase is 10 μm or smaller in terms of the equivalent of a circle diameter; in the martensite phase, the space factor of the martensite phase having a grain size of 10 μm or larger in terms of the equivalent of a circle diameter is 15% or lower; and the space factor of the retained austenite phase in the metal structure is 3% or lower.The high strength steel sheet of the present invention is a dual phase steel sheet mainly composed of a ferrite phase and martensite, and the space factor of the ferrite phase is 5 to 30%, and the space factor of the martensite phase is 50 to 95%. Moreover, the ferrite phase is annealed martensite.

Owner:KOBE STEEL LTD

Diphasic steel plate by continuous casting and rolling middle bar strip and manufacturing method thereof

ActiveCN101130847ASimple chemical compositionHigh tensile strengthMetal rolling arrangementsChemical compositionSheet steel

The present invention provides a dual phase steel sheet made up by using medium-thin sheet billet through a certain continuous-casting and continuous-rolling process. The component composition of said steel sheet includes (by wt%) 0.04%-0.11% of C, 0.02%-1.5% of Si, 0.6%-2.50% of Mn, 0.02%-2.0% of Cr, also can contain Mo or Ti, the rest is Fe and unavoidable impurity. The microscopic structure of said steel sheet includes: matrix phase is ferrite and second phase mainly is martensite. Besides, said invention also provides the concrete operation steps of its production method.

Owner:ANGANG STEEL CO LTD

Cold-rolled hot-galvanized dual-phase steel plate with flanging property and manufacturing method thereof

The invention relates to a cold-rolled hot-galvanized dual-phase steel plate with a flanging property and a manufacturing method thereof. The steel plate comprises the following chemical components by weight percent: 0.06% to 0.095% of C, 0.3% to 0.6% of Si, 1.4% to 1.8% of Mn, greater than 0% and less than or equal to 0.02% of P, greater than 0% and less than or equal to 0.01% of S, 0.02% to 0.05% of Al, 0.35% to 0.55% of Cr, 0.02% to 0.04% of Nb, greater than 0% and less than or equal to 0.005% of N and the balance of Fe. According to the steel plate provided by the invention, the austenite is dispersedly distributed in a ferrite matrix via the refining of austenite grains by adding the Nb element and controlling temperatures during hot rolling and finish rolling and a rolling temperature; the amount of the austenite after annealing is increased by limiting the content of C and carrying out high-temperature annealing in a continuous hot-galvanized annealing furnace, so that tissues in low-C martensite are obtained after quenching. Thus, the hardness of the martensite is decreased. As a result, a hardness difference between the martensite phase and the ferrite phase is reduced.

Owner:ANSC TKS GALVANIZING

A method for manufacturing cold-rolled ultra-high-strength dual-phase steel with high partial formability

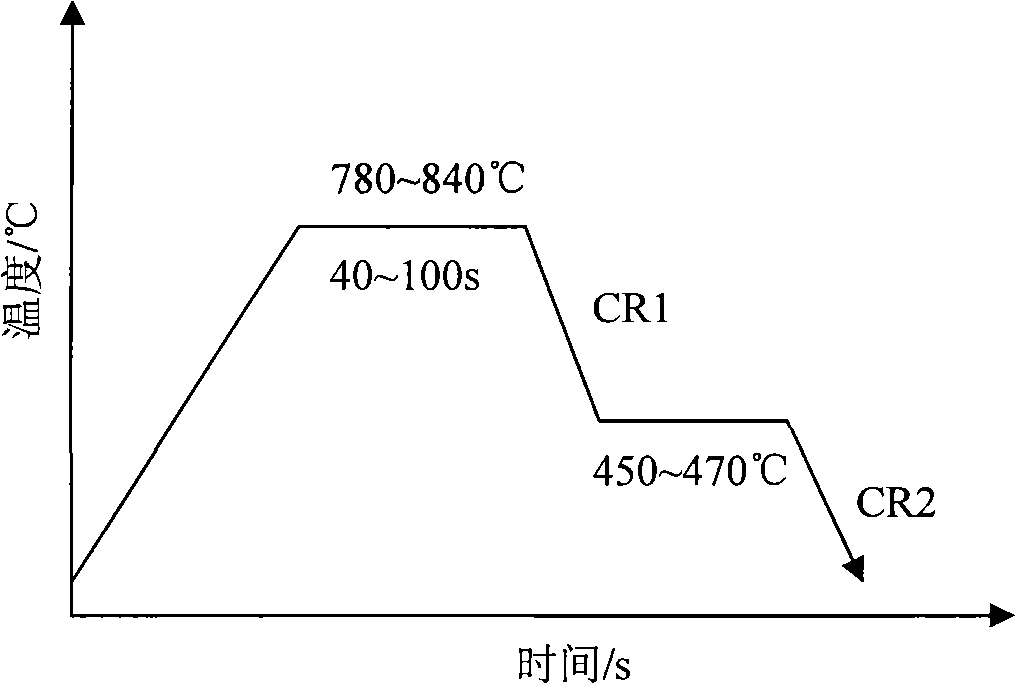

A method for manufacturing cold-rolled ultra-high-strength dual-phase steel with high local formability. The process steps are: (1) According to the weight percentage: C 0.08~0.12%, Si 0.1~0.5%, Mn 1.5~2.5%, Al 0.015‑ 0.05%, and the rest is the chemical composition of Fe and unavoidable impurity elements. Select the raw materials and smelt them into a cast slab; (2) Heat the cast slab at 1150~1250℃ for 1.5~2 hours and then hot-roll it. After rolling, it is heated at 50~200 Cool to 450~620℃ at a cooling rate of ℃ / s for coiling; (3) Cold roll the hot-rolled steel plate, then heat to 740~820℃ at a speed of 50~300℃ / s for annealing, and anneal at 2~6 Rapid cooling at ℃ / s to 620~680℃, and then rapid cooling at 30~100℃ / s to 250~350℃ and over-aging for 3~5 minutes to obtain ultra-high strength dual-phase steel.

Owner:NORTHEASTERN UNIV LIAONING

High-strength and high-plasticity dual-phase steel and manufacturing method thereof

Owner:SHOUGANG CORPORATION

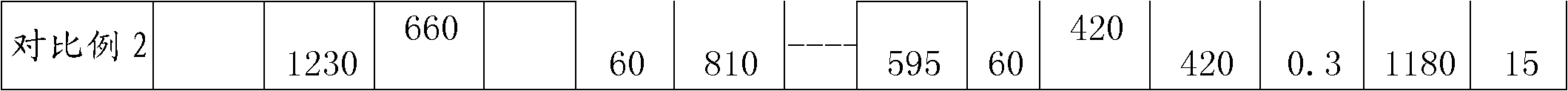

High-strength cold-rolled hot-galvanized dual-phase steel plate and manufacture method thereof

ActiveCN102719751AAdd lessReduce compositionTemperature control deviceContinuous annealingUltimate tensile strength

The invention discloses a high-strength cold-rolled hot-galvanized dual-phase steel plate, characterized in that components, in mass percentage, are: 0.03% to 0.15% of C, less than or equal to 0.15% of Si, 1.00% to 1.75% of Mn, less than or equal to 0.015% of P, less than or equal to 0.012% of S, 0.02% to 0.15% of Al, 0.35% to 0.75% of Cr, 0.02% to 0.15% of Cu, 0.010% to 0.035% of Ti, less than or equal to 0.005% of N, in addition meeting the requirement that the total percentage of Mn, 1.29Cr and 0.46Cu is not less than 1.5% and not more than 2.5%, and the balance being Fe and inevitable impurities. The manufacture method comprises converter smelting, secondary refining, continuous casting, hot continuous rolling, cold acid continuous rolling, annealing galvanizing and hot dipping, wherein a galvanized substrate with a reasonable organization and composition and an excellent plate shape is obtained through controlled rolling and controlled cooling while rolling; and through employing a micro-slowly cooling way for heating from an end segment to an isothermal segment and a secondary fast cooling way for a fast cooling segment during continuous annealing galvanizing, the cold-rolled hot-galvanized dual-phase steel plate is obtained, wherein the steel plate is advantageous by having a tensile strength between 490 to 700 MPa, well-matched strength and ductility, an excellent coating performance, and a thickness between 0.5 to 2.5 mm, and can be used as an automobile cover component, an inner plate, a structural component, etc.

Owner:ANGANG STEEL CO LTD

Production method for Si-contained cold-rolling hot galvanizing dual-phase steel with tensile strength reaching 800MPa level

ActiveCN106399857AStable productionLow costHot-dipping/immersion processesContinuous annealingImpurity

The invention relates to a production method for Si-contained cold-rolling hot galvanizing dual-phase steel with tensile strength reaching 800MPa level. The cold-rolling hot galvanizing dual-phase steel comprises, by mass, 0.08%-0.12% of C, 0.10%-0.18% of Si, 1.5%-2.5% of Mn, 0.2%-0.4% of Cr, 0.12%-0.20% of Mo, 0.03%-0.06% of Als, 0-0.015% of P, 0-0.04% of S, 0-0.005% of N, and the balance Fe and inevitable impurities. Due to the fact that chemical component design is combined with cold rolling, hot rolling, continuous annealing and hot galvanizing technical control, stable production of steel plates can be guaranteed. According to the steel produced through the method, yield strength is 426MPa-540MPa, tensile strength is larger than or equal to 800MPa, and the ductility is larger than or equal to 15%. The production method has the characteristics that cost is low, equipment is simple and product application performance is good.

Owner:马钢(合肥)钢铁有限责任公司

Tensile strength more than or equal to 780MPa grade hot-rolled dual phase steel and production method thereof

The invention provides tensile strength more than or equal to 780MPa grade hot-rolled dual phase steel. The dual-phase steel comprises the following components in percentage by weight: 0.05-0.08 percent of C, not more than 0.5 percent of S, 0.6-1.2 percent of Mn, less than or equal to 0.015 percent of P, less than or equal to 0.005 percent of S, less than or equal to 0.006 percent of N, 0.01-0.1 percent of Als, 0.05-0.25 percent of Ti, less than or equal to 0.6 percent of Cr or less than or equal to 0.003 percent of B or mixture of Cr and B. The production method by using CSP comprises the following steps: melting and continuously casting to form a slab; heating the continuous cast slab; rolling; carrying out laminar cooling; reeling; and naturally cooling to room temperature. The hot-rolled dual phase steel has the tensile strength of more than or equal to 780MPa, elongation of more than or equal to 15 percent and yield ratio of less than or equal to 0.70. An insulation cover additionally covers the intermediate insulation section, and the band steel cooling speed is reduced, so that generation of pearlite phase change can be effectively prevented. Production of hot-rolled dual phase steel with thickness of 1.2-4.0mm can be realized, the product has the advantages of uniform structure, small molding resilience and no cracking, existing equipment is utilized without adopting ultra fast cooling and other equipment, the production efficiency is high, and the investment is small.

Owner:武汉钢铁有限公司

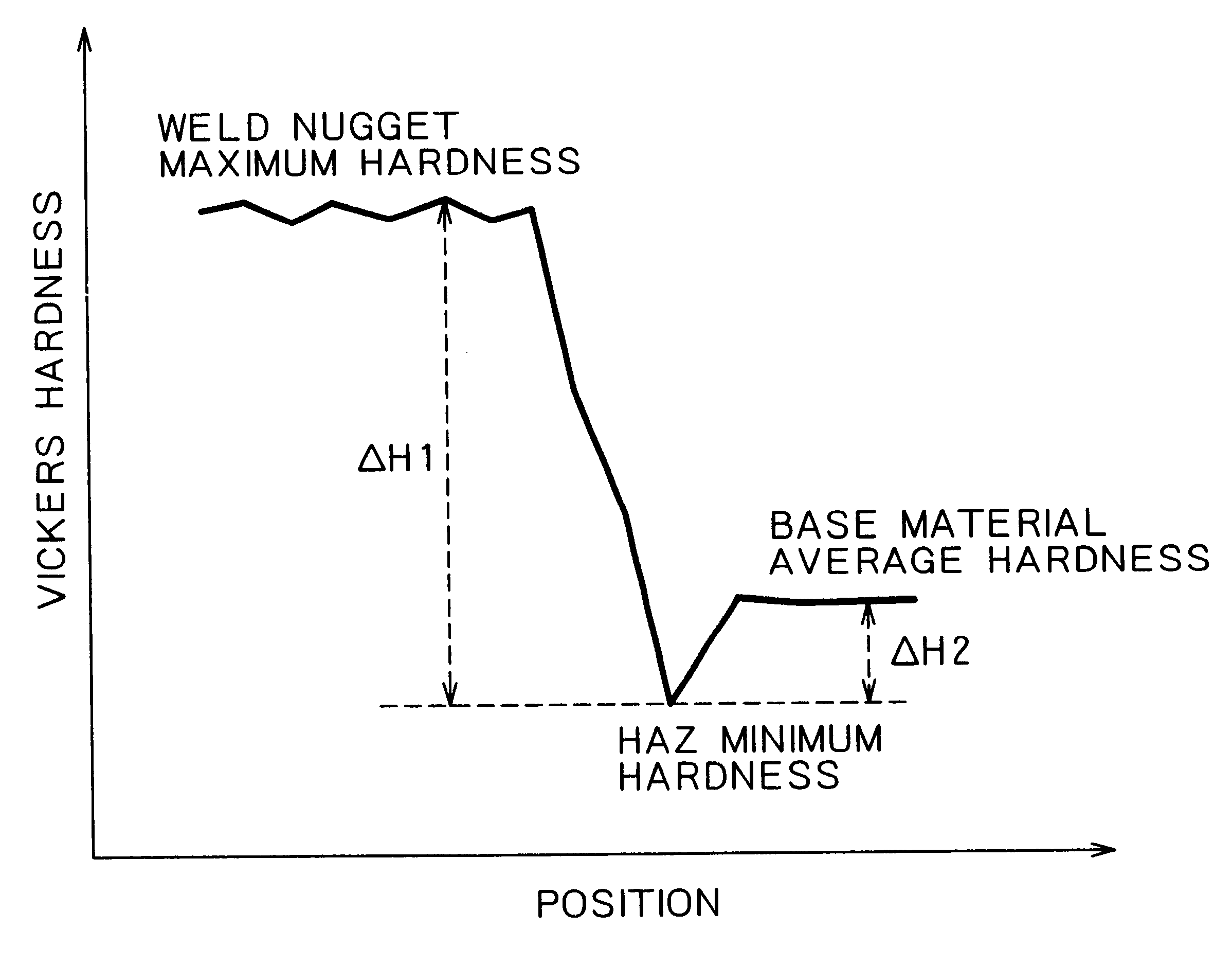

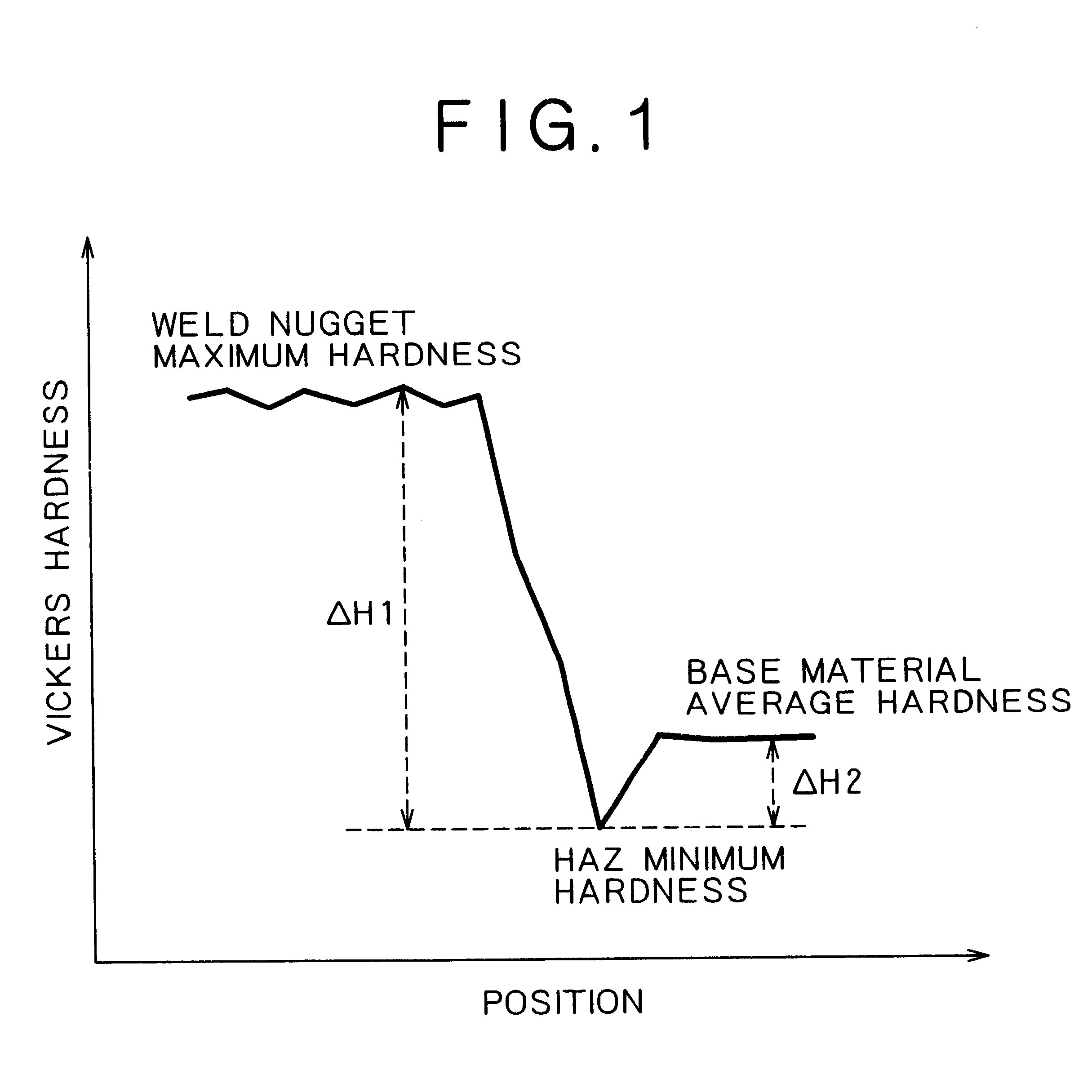

Superhigh-strength dual-phase steel sheet of excellent fatigue characteristic in a spot welded joint

InactiveUS6709535B2Hot-dipping/immersion processesThin material handlingHardnessUltimate tensile strength

A superhigh-strength dual-phase steel sheet containing ferritic microstructure and a martensitic microstructure-containing composite-phase steel sheet containing:C: 0.08-0.20% (mass% here and hereinafter),Si: 0.5% or less (inclusive of 0%)Mn: 3.0% or less (exclusive of 0%)P: 0.02% or less (inclusive of 0%)S: 0.02% or less (inclusive of 0%), andAl: 0.001-0.15%, and further containingMo: 0.05-1.5%, andCr: 0.05-1.5%, and which satisfying that:the average Vickers hardness of the ferritic microstructure is 150 Hv or more and the average Vickers hardness of the martensitic microstructure is 500 Hv or more, the superhigh-strength dual-phase steel sheets being of excellent fatigue characteristic in a spot welded joint.

Owner:KOBE STEEL LTD

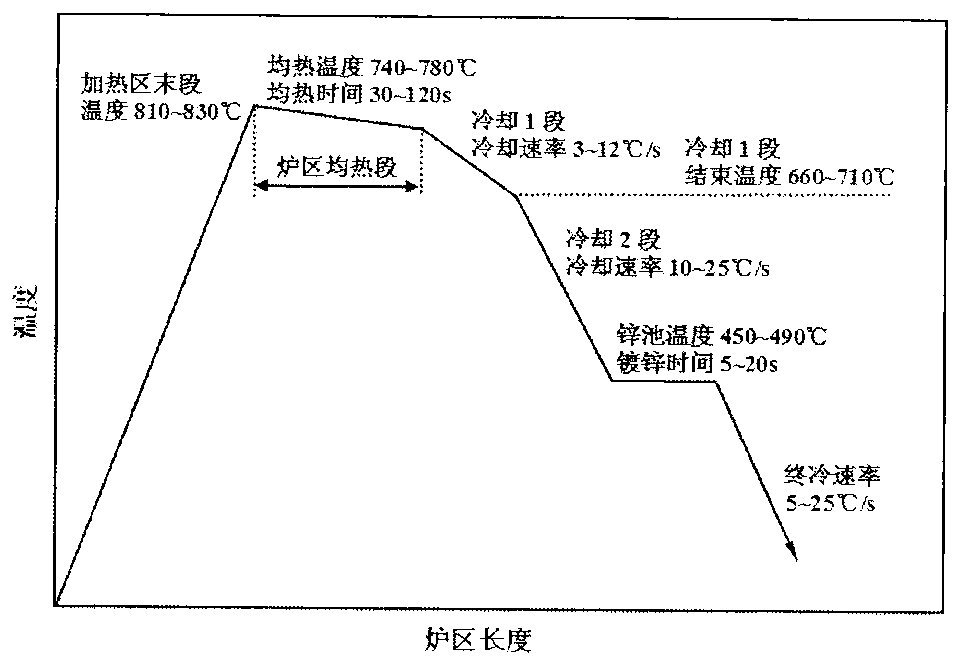

Cold rolled dual-phase sheet steel with 1000MPa grade tensile strength and preparation method thereof

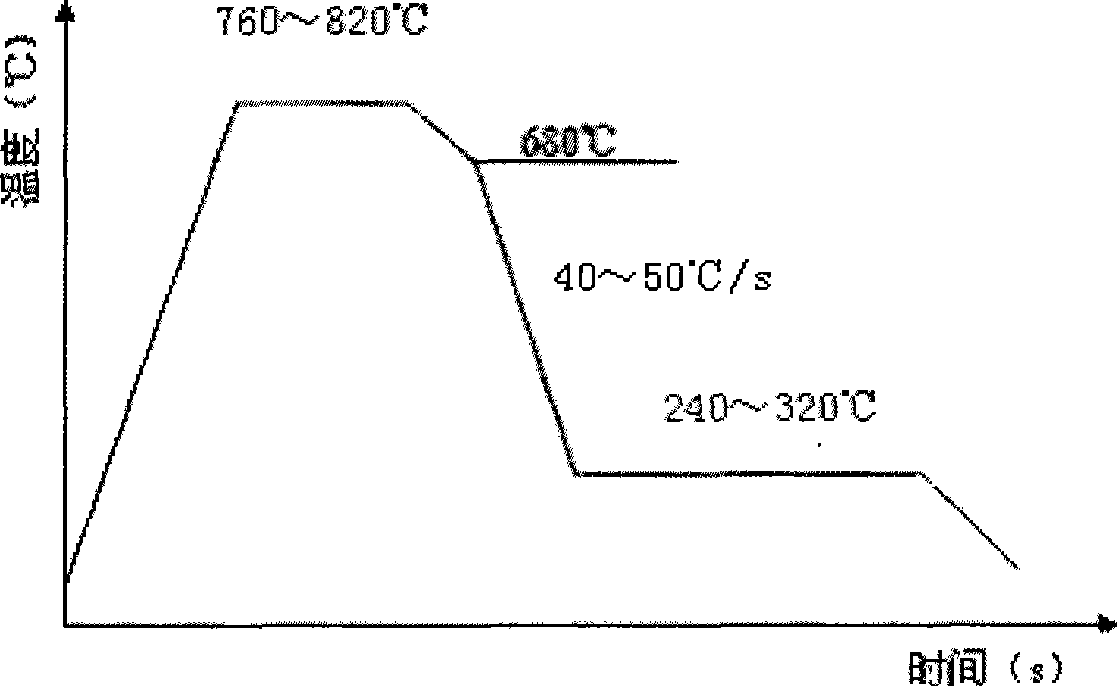

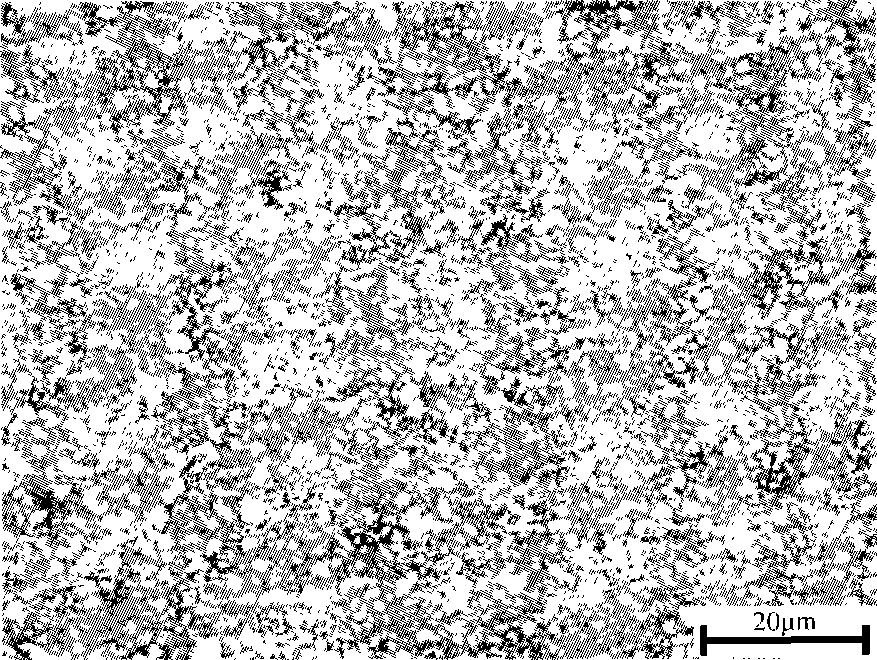

A cold-rolled biphase steel plate with 1000 MPa of tensile strength and a production method thereof belong to the technical field of high-intensity cold-rolled biphase steel. The steel plate comprises the following chemical components by mass percentages: 0.14%-0.21% of C, 0.40%-0.90% of Si, 1.5%-2.1% of Mn, 0.01%-0.05% of Nb, less than 0.02% of P, less than 0.01% of S, and Fe and inevitable impurities. The production method is as follows: a billet is treated by the conventional hot rolling, pickling, cold rolling and continuous annealing, the annealing temperature is 760-820 DEG C and is kept for 70-120s, the fast cooling speed is 40-50 DEG C per second, the aging temperature is 240-320 DEG C and the aging time is 180-300s. The cold-rolled biphase steel plate has the advantages of high tensile strength, low tensile ratio, high initial work hardening rate, no yield elongation which avoids wrinkles on the formed parts. The cold-rolled biphase steel plate has a biphase organization with fine grain ferrite and martensite, wherein, the volume fraction of the martensite is 30%-40% and the average grain size of the ferrite is 2mum.

Owner:UNIV OF SCI & TECH BEIJING +1

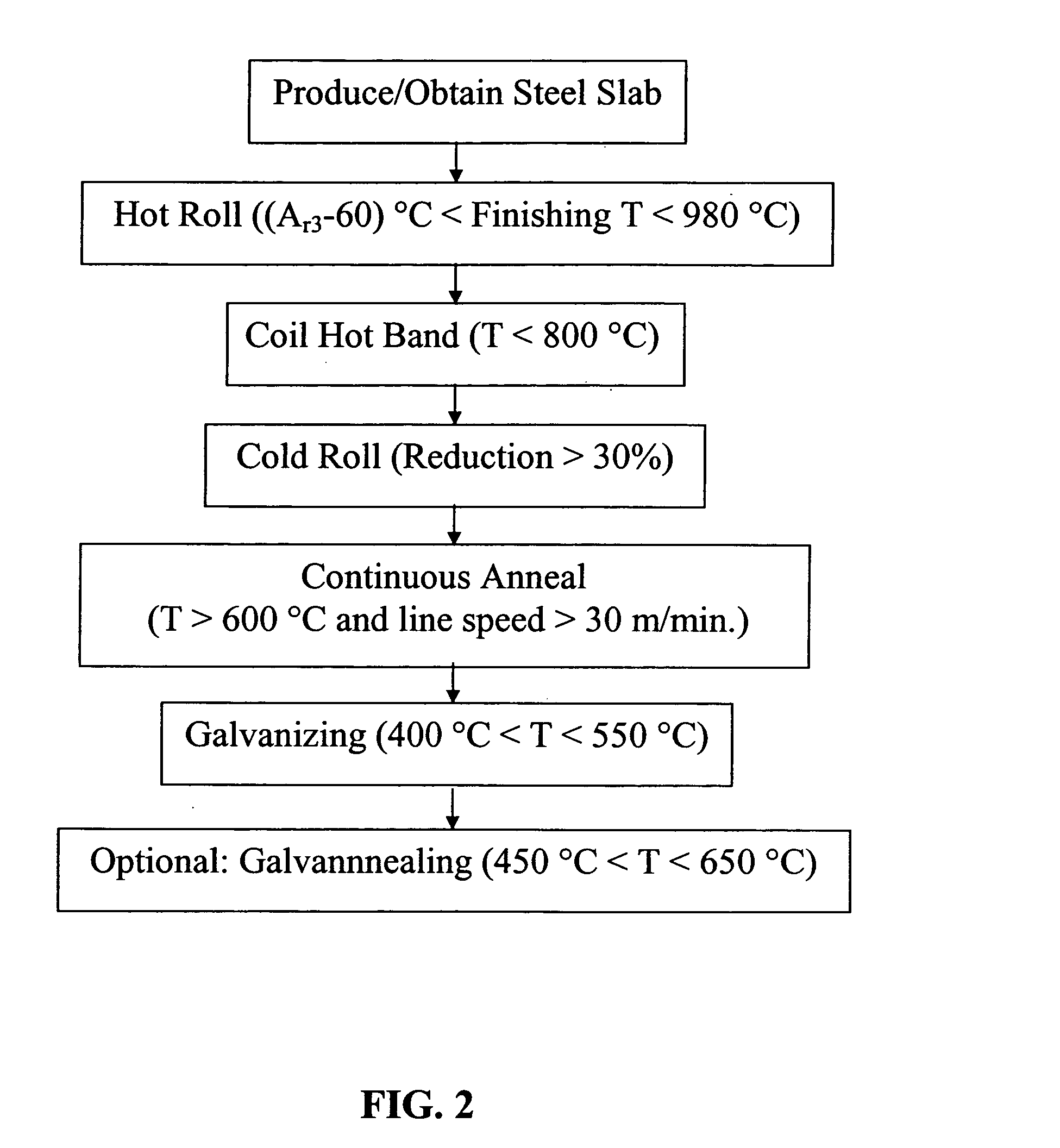

High strength, hot dip coated, dual phase, steel sheet and method of manufacturing same

ActiveUS20080075971A1Good energyGood formabilityHot-dipping/immersion processesFurnace typesNiobiumManganese

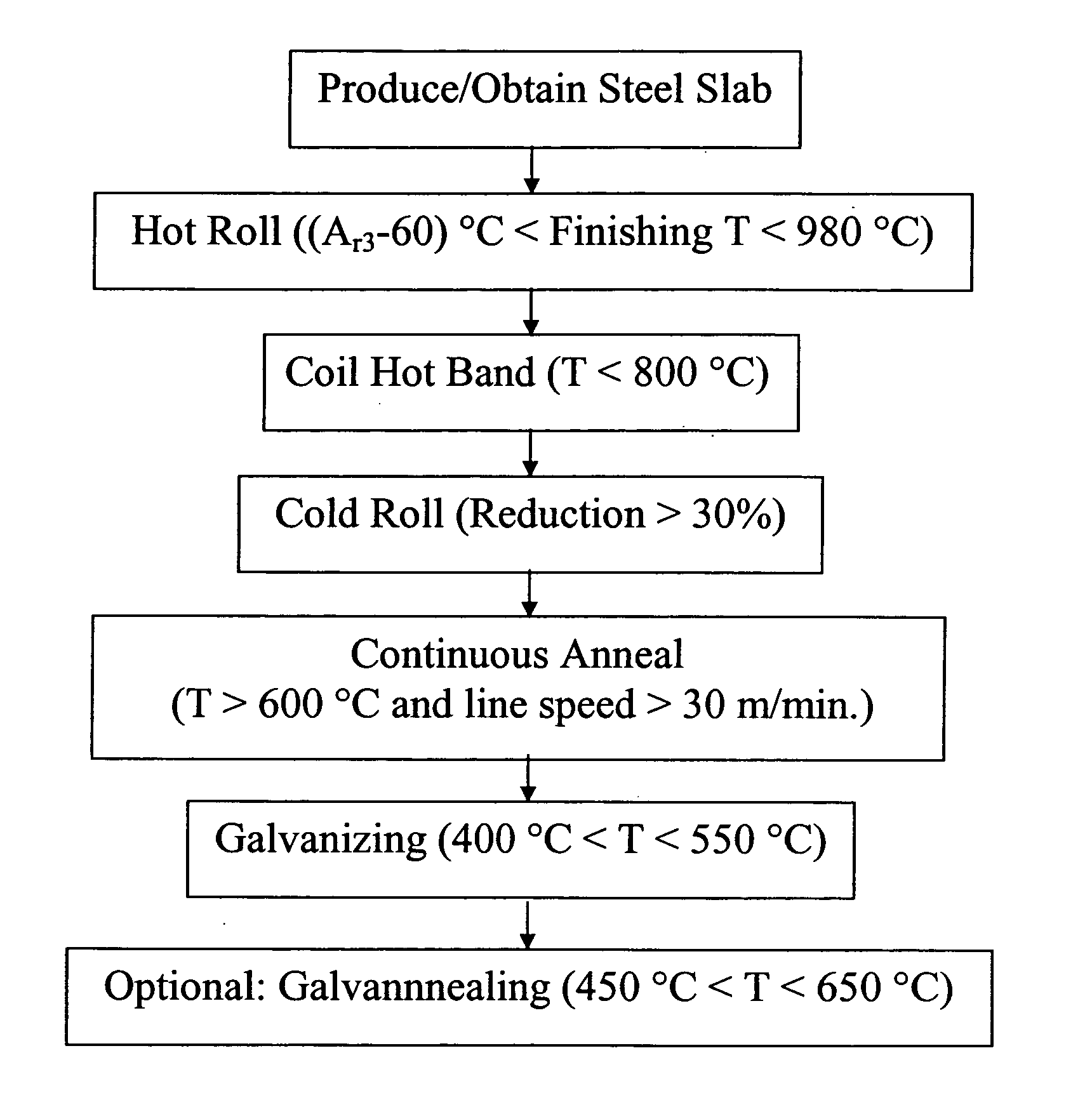

A galvanized steel sheet having (a) a dual phase microstructure with a martensite phase and a ferrite phase and (b) a composition containing by percent weight: carbon in a range from about 0.01% to about 0.18%; manganese in a range from about 0.2% to about 3%; silicon ≦ about 1.2%; aluminum in a range from about 0.01% to about 0.1%; one or both of chromium and nickel in a range from about 0.1% to about 3.5%; calcium in a range from about 0.0003% to about 0.01%; phosphorus ≦ about 0.01%; sulfur ≦ about 0.03%; nitrogen ≦ about 0.02%; molybdenum ≦ about 1%; copper ≦ about 0.8%; one or more of niobium, titanium, and vanadium ≦ about 1%; and boron ≦ about 0.006% by weight; and with the balance of the composition being iron and incidental ingredients. In one embodiment, the steel sheet is both galvanized and galvannealed.

Owner:NUCOR CORP

Plasticity-enhanced cold-rolled hot-dip galvanized dual-phase steel and production method thereof

The invention discloses plasticity-enhanced cold-rolled hot-dip galvanized dual-phase steel and a production method thereof. The dual-phase steel comprises the chemical components of, by weight, 0.12-0.18% of C, 0.3-0.6% of Si, 1.3-2.3% of Mn, 0-0.01% of P, 0-0.01% of S, 0.4-0.9% of Al, and the balance Fe and inevitable impurities. The technical problems of how to reduce the alloy or process cost and improve the galvanized surface quality on the basis of meeting the intensity requirement are solved, and the technical effects of reducing the alloy cost and improving the galvanized surface quality are achieved.

Owner:SHOUGANG CORPORATION

600MPa-level ultra-low silicon cold rolling hot galvanizing dual-phase steel and preparation process thereof

The invention discloses 600MPa-level ultra-low silicon cold rolling hot galvanizing dual-phase steel and a preparation process. The dual-phase steel contains the following chemical components in the weight percentage (wt.%): 0.03-0.16 percent of C, less than 0.02 percent of Si, 1.2-2.2 percent of Mn, 0.2-0.6 percent of Cr, less than 0.015 percent of S, less than 0.020 percent of P, 0.01-0.08 percent of Als and the balance of Fe. The preparation process comprises the following steps of: (1) smelting the chemical compositions in a claim 1 to obtain a cast slab; (2) carrying out heating and hot rolling on the cast slab to obtain a hot-rolled plate; (3) carrying out acid washing and then cold rolling on the hot-rolled plate to manufacture a cold-rolled sheet, wherein the cold rolling down rate is 45-80 percent; and (4) carrying out hot galvanizing annealing on the cold-rolled sheet to prepare a finished steel plate. The dual-phase steel has the characteristics of high strength, low cost, low carbon equivalent, ultra-low silicon and good surface quality and is suitable for automobile steel.

Owner:UNIV OF SCI & TECH BEIJING +1

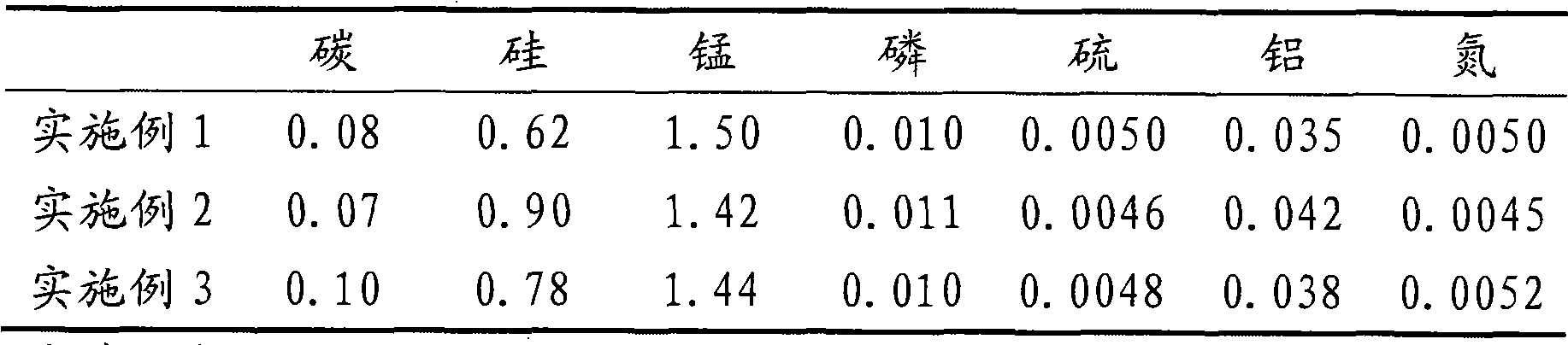

Hot rolling ferrite/bainite high strength steel plate and manufacturing method thereof

The invention relates to hot rolling ferrite / bainite high strength steel and a manufacturing method thereof. The hot rolling ferrite / bainite high strength steel comprises the following main chemical components by mass percentage: 0.05-0.10% of C, 0.20-0.50% of Si, 0.80-1.30% of Mn, 0.02-0.06% of Alt, 0.40-0.8% of Cr, less than or equal to 0.09% of P, less than or equal to 0.010% of S, less than or equal to 0.006% of N, and the balance of Fe and unavoidable impurities. The manufacturing method of the hot rolling ferrite / bainite high strength steel comprises the steps of molten iron pretreatment, converter smelting, alloy fine adjustment and argon blowing, LF (ladle furnace) refining, a continuous casting heating technology, a rolling technology, a cooling technology and a rolling technology. According to the steel and the method, C and Mn contents are strictly controlled based on the composition of C-Mn steel, an Si content is reduced, Cr and P are added appropriately, Nb, V and Ti microalloy elements are not added, noble alloys such as Mo and Ni are not added, the cost is lowered greatly, the hot rolling ferrite / bainite dual phase steel with the tensile strength reaching 550-650MPa is obtained by adopting an appropriate rolling and cooling control technology, a hole expansion rate is high, and the forming property is excellent.

Owner:JIGANG GRP

600 Mpa grade hot-rolling dual-phase steel and preparation method thereof

The invention relates to the technical field of metallurgy, in particular to 600 Mpa grade hot-rolling dual-phase steel and a preparation method thereof. The 600 Mpa grade hot-rolling dual-phase steel is characterized in that a steel plate comprises the following chemical compositions in mass percent: 0.05-0.07% of C, 0.1-0.4% of Si, 1.10-1.50% of Mn, 0.5-0.7% of Cr and the rest of Fe; the structure of the 600 Mpa grade hot-rolling dual-phase steel is soft-phase ferrite and hard-phase martensite, the volume percentage of the ferrite is 70-90%, the volume percentage of the martensite is 10-30%, and the 600 Mpa grade hot-rolling dual-phase steel has the yield strength Rp0.2 of 355-375Mpa, the tensile strength Rm of 590-650Mpa, the yield ratio of 0.56-0.60 and the percentage of total elongation after fracture of 24-30%. On the basis of C-Mn-Cr system chemical compositions, the 600 Mpa grade hot-rolling dual-phase steel is produced on a continuous casting and rolling production line for sheet billets by adopting a three-stage type cooling technology by applying a semi endless rolling technology.

Owner:NORTHEASTERN UNIV +2

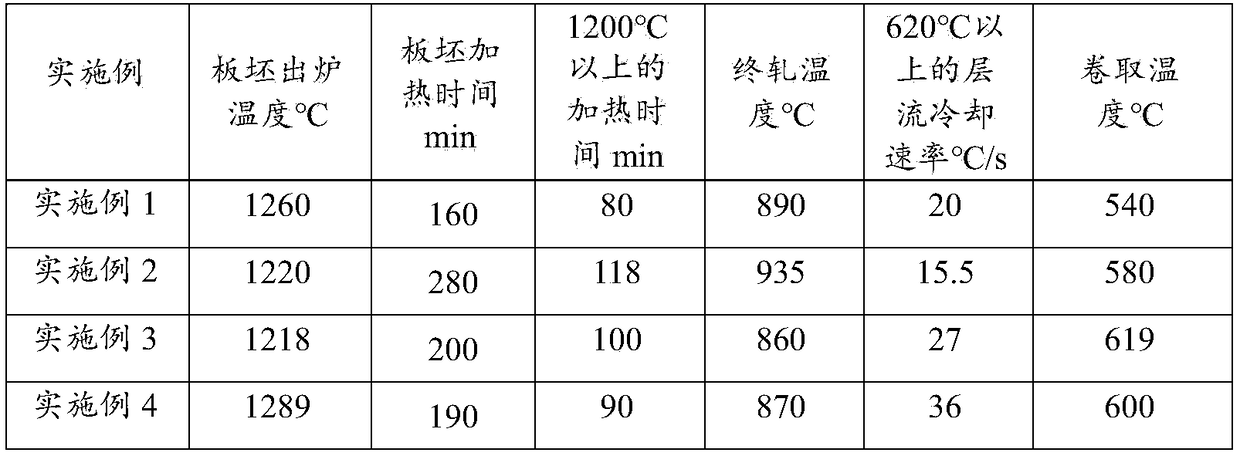

800MPa-grade cold-rolled hot-galvanizing dual-phase steel and production method thereof

The invention discloses 800MPa-grade cold-rolled hot-galvanizing dual-phase steel. The 800MPa-grade cold-rolled hot-galvanizing dual-phase steel comprises the following raw materials taken as chemicalcomponents in percentage by mass (%): 0.05% to 0.10% of C, 1.60% to 2.30% of Mn, 0.010 to 1.0% of Als, 0.10% to 0.60% of Si, 0.010 to 0.050% of Nb, 0.05 to 0.30% of Cr, 0.05 to 0.30% of Mo, P not smaller than 0.015%, S not greater than 0.010%, N not greater than 0.008%, and the balance of Fe and inevitable impurities, and noble metal elements Cr and Mo satisfy the relation that Cr+Mo is not smaller than 0.05 and not greater than 0.30, and C+Si / 30+Mn / 20 is not greater than 0.22. The production method for the hot-galvanizing steel for an automobile wheel cover comprises the steps of smelting, continuous casting, heating, hot rolling, cooling, coiling, pickling, cold rolling, annealing and coat-plating. According to the invention, the obtained cold-rolled hot-galvanizing dual-phase steel hasless precious alloying elements, so that the product has good mechanical properties, surface quality, formability and welding performances. Furthermore, the 800MPa-grade cold-rolled hot-galvanizing dual-phase steel disclosed by the invention can be produced on the existing conventional production line without additional equipments.

Owner:武汉钢铁有限公司

High Strength Dual Phase Steel With Low Yield Ratio, High Toughness and Superior Weldability

A dual phase, high strength steel having a composite microstructure of soft and hard phases providing a low yield ratio, high strain capacity, superior weldability, and high toughness is provided. The dual phase steel includes from about 10% by volume to about 60% by volume of a first phase or constituent consisting essentially of fine-grained ferrite. The first phase has a ferrite mean grain size of about 5 microns or less. The dual phase steel further includes from about 40% by volume to about 90% by volume of a second phase or constituent comprising fine-grained martensite, fine-grained lower bainite, fine-grained granular bainite, fine-grained degenerate upper bainite, or any mixture thereof. Methods for making the same are also provided.

Owner:NIPPON STEEL CORP

Narrow lap joint welding process for cold-rolled dual-phase steel strips

InactiveCN104842056AImprove welding strengthImprove plasticityResistance welding apparatusProduction linePower flow

The invention discloses a narrow lap joint welding process for cold-rolled dual-phase steel strips and belongs to the technical field of steel strip welding processes. A narrow lap joint resistance welding machine is utilized to weld the cold-rolled dual-phase steel strips. According to the technical scheme, the welding process conditions include that welding current is 9-26 KA, welding speed is 6-13m / min, the welding wheel pressure of the welding machine is 6.5-13KN, the lap joint amount of the tail portion of a previous steel strip roll and the heat portion of a later steel strip roll is 0.4-2.0 mm, and compensation amount is 0.25-0.7 mm. The narrow lap joint welding process is a bold trial, the design limits on the strength, component and the like of the narrow lap joint resistance welding machine are broken through, and narrow lap joint welding operation of the cold-rolled dual-phase steel strips is achieved through innovative operation. The narrow lap joint resistance welding machine on an existing processing line of an enterprise can be used for welding the cold-rolled dual-phase steel strips, the functions of the existing production line are greatly widened, the fund cost, production cost and device cost of the cold-rolled dual-phase steel strips are effectively reduced, and huge economic benefit is brought to the enterprise.

Owner:TANGSHAN IRON & STEEL GROUP

High tensile strength hot rolled ferrite bainite dual phase steel and preparation method thereof

ActiveCN101643880AExcellent hole expandabilityGood molding effectTemperature control deviceManganeseImpurity

The invention relates to a hot rolled ferrite bainite dual phase steel of which tensile strength is not less than 490MPa and a preparation method thereof. The dual phase steel comprises the followingcomponents by weight percent: 0.05-0.15% of carbon, 0.5-1.0% of silicon, 1.0-1.5% of manganese, 0.02% or less of phosphorus, 0.010% or less of sulfur, 0.03-0.05% of aluminum, 0.0060% or less of nitrogen and the balance Fe and impurities. The preparation method of the dual phase steel comprises the following steps: performing hot rolling treatment to steel ingot, treating by subsection cooling technology and finally reeling the obtained steel. The dual phase steel of the invention has high tensile strength, good chambering performance and formability and cheap cost; in addition, the productionprocess is simple, no precious alloy element is needed to add and different strength levels can be obtained by controlling the process. The hot rolled ferrite bainite dual phase steel of the inventioncan widely and mainly used for the forming of complex shape parts such as automobile wheels, suspension parts and the like.

Owner:INST OF RES OF IRON & STEEL JIANGSU PROVINCE

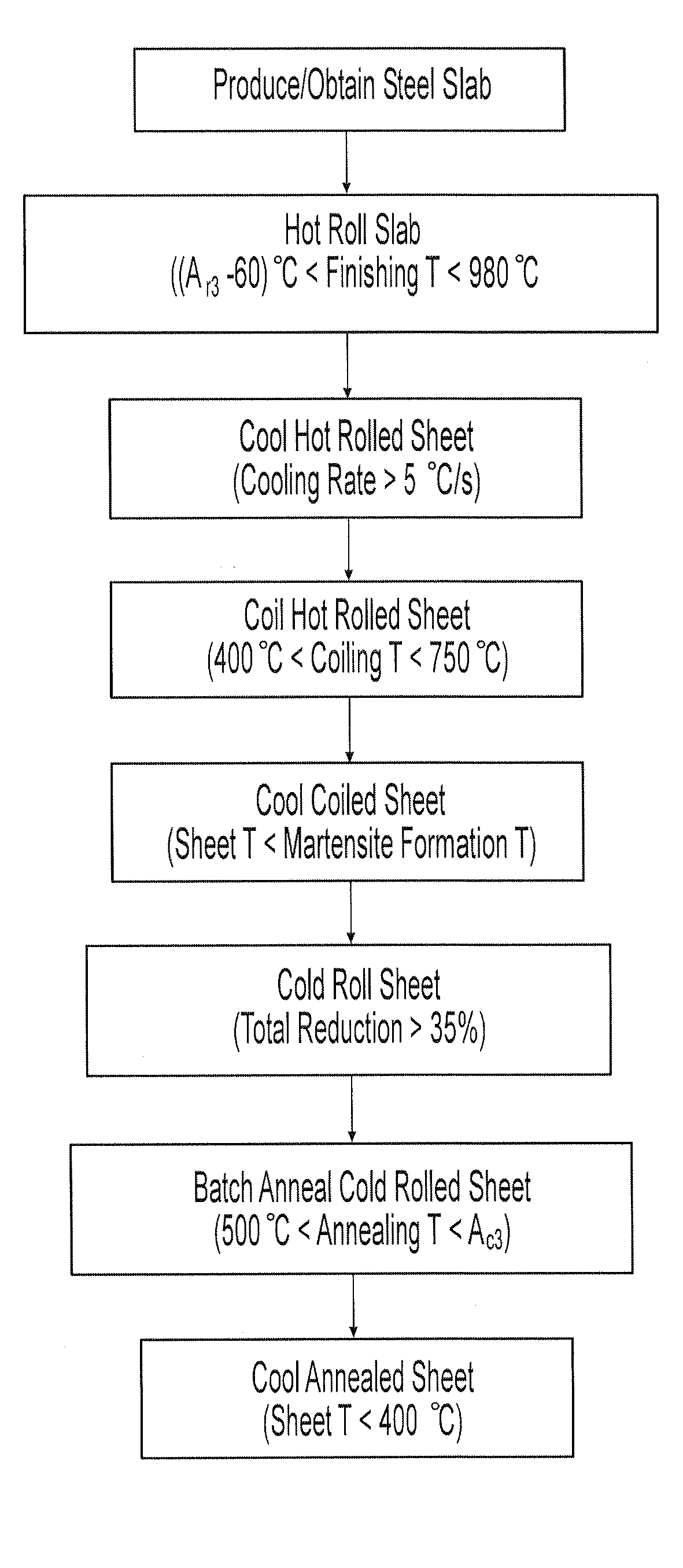

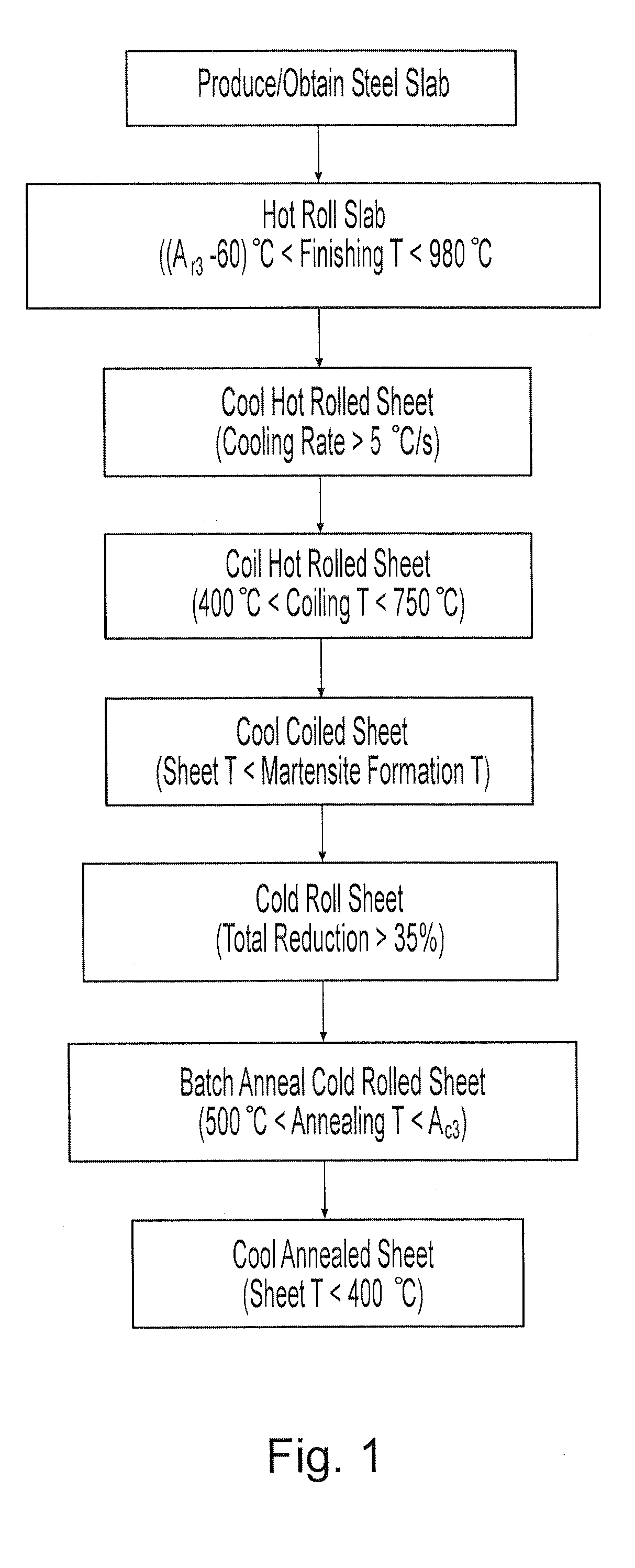

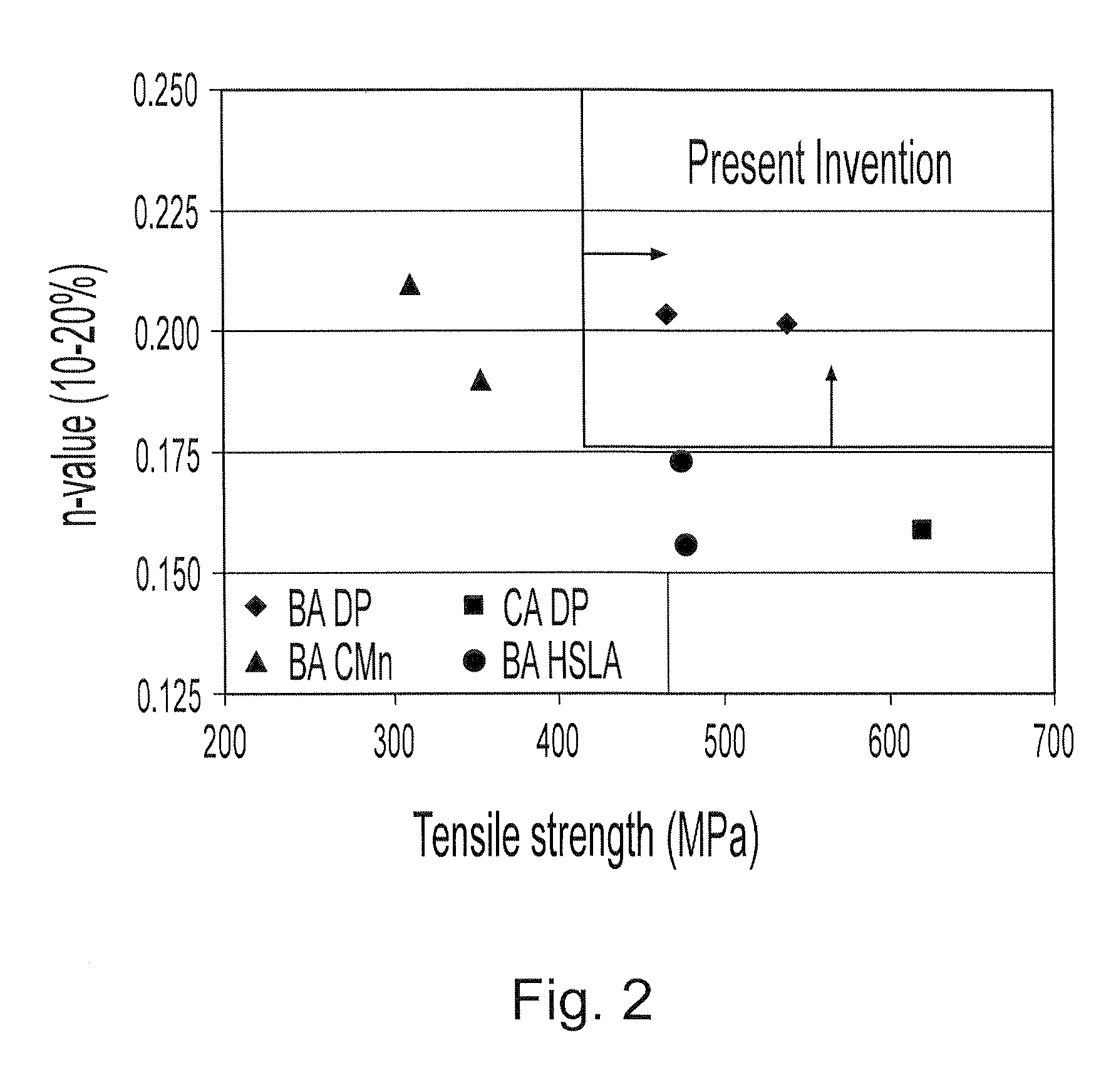

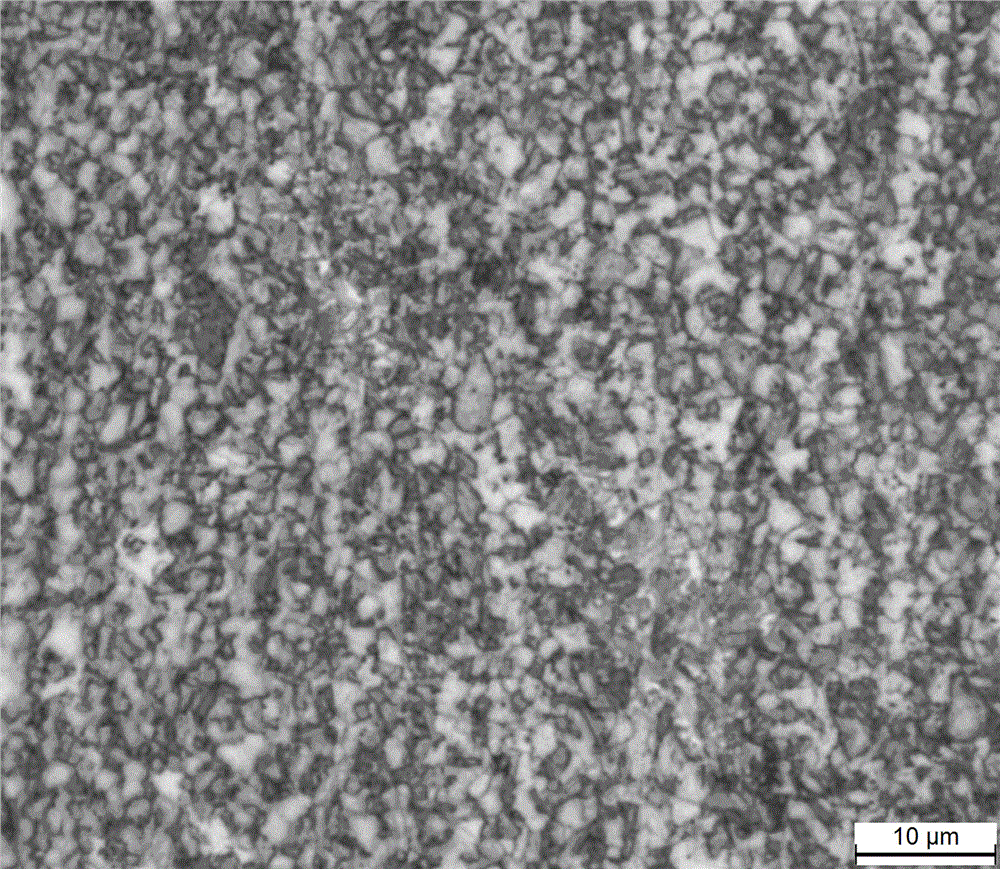

Cold rolled dual phase steel sheet having high formability and method of making the same

ActiveUS20090071574A1Increase production capacityLess demanding processing requirementHot-dipping/immersion processesFurnace typesSheet steelManganese

A steel sheet having (a) a dual phase microstructure with a martensite phase and a ferrite phase and (b) a composition containing by percent weight: 0.01≦C≦0.2; 0.3≦Mn≦3; 0.05≦Si≦2; 0.2≦Cr+Ni≦2; 0.01≦Al≦0.10; 0.0005≦Ca≦0.01, with the balance of the composition being iron and incidental ingredients. Also, the steel sheet is made by a batch annealing method, and has a tensile strength of at least approximately 400 megapascals and an n-value of at least approximately 0.175.

Owner:NUCOR CORP

Method for manufacturing cold-rolled ultrahigh-strength dual-phase steel with high local forming performance

The invention relates to a method for manufacturing cold-rolled ultrahigh-strength dual-phase steel with high local forming performance. The method comprises the process steps that 1, chemical components which comprise, by weight percent, 0.08%-0.12% of C, 0.1%-0.5% of Si, 1.5%-2.5% of Mn, 0.015%-0.05% of Al and the balance Fe and inevitable impurities are selected as raw materials, and the raw materials are smelted into a casting blank; 2, the casting blank is subjected to hot rolling after being heated at the temperature ranging from 1,150 DEG C to 1,250 DEG C for 1.5-2 hours, and after rolling, the casting blank is cooled to 450-620 DEG C at the cooling speed being 50-200 DEG C / s to be coiled; and 3, a hot-rolled steel plate is subjected to cold rolling, then the hot-rolled steel plate is heated to 740-820 DEG C at the speed of 50-300 DEG C / s for annealing, the hot-rolled steel plate is cooled to 620-680 DEG C at the cooling speed being 2-6 DEG C / s, then the hot-rolled steel plate is cooled to 250-350 DEG C at the cooling speed being 30-100 DEG C / s, and the ultrahigh-strength dual-phase steel is obtained.

Owner:NORTHEASTERN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com