Patents

Literature

219 results about "Bake hardening" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Bake hardening (BH) is a phenomenon where the strain aging is exploited in a positive way to improve the strength of formed automotive components.

Dual-phase steel sheet excellent in stretch flange formability and production method thereof

Disclosed is a dual-phase steel sheet having low yield ratio, excellent in the balance for strength-elongation and for strength-stretch flange formability, and also excellent in bake hardening property containing (on the mass% basis). C: 0.01-0.20%, Si: 0.5% or less, Mn: 0.5-3%, sol. Al: 0.06% or less (inclusive 0%), P: 0.15% or less (exclusive 0%), and S: 0.02% or less (inclusive 0''), and in which the matrix phase contains tempered martensite; tempered martensite and ferrite; tempered bainite; or tempered bainite and ferrite, and the second phase comprises 1 to 30% of martensite at an area ratio based on the entire structure.

Owner:KOBE STEEL LTD

Car body aluminum alloy plate and manufacturing method thereof

InactiveCN103173661ALower yield strengthExcellent formabilityUltimate tensile strengthBake hardening

The invention provides a high-strength brake hardening car body aluminum alloy plate and a manufacturing method thereof, and belongs to the technical field of aluminum alloy. The aluminum alloy has the component characteristic that a Zn element is added on the basis of the conventional AL-Mg-Si-Cu quaternary alloy, so that the alloy has higher brake hardening performance; and interaction, strengthening-phase separation process and the like among solute elements are reasonably adjusted through reasonable pre-ageing process optimization control, and therefore, a novel car material Al-Mg-Si-Cu-Zn quinary aluminum alloy with excellent comprehensive performances is successfully developed. By adding the element Zn, the aluminum alloy material disclosed by the invention has the performance characteristic of being low in yield strength, good in plasticity and conductive to stamping and forming a car covering piece before baking finish; and after baking finish is finished, the yield strength is greatly improved, the tensile strength is high and the bake hardening performances are high.

Owner:UNIV OF SCI & TECH BEIJING +1

Alloyed hot galvanizing bake hardening steel and method for manufacturing same

ActiveCN101230437ANot easy to produceImprove PlatabilityHot-dipping/immersion processesTemperature control deviceCooking & bakingSheet steel

The invention relates to an alloyed hot-galvanized baking-hardened steel plate and the manufacturing method thereof, which solves the problems of the anti-pulverization of the galvanized layer, the surface quality and the baking-hardened value. The mass percentage for the chemical components of a baseplate is as follows: C 0.0015 to 0.0025 percent, Si less than or equal to 0.030 percent, Mn 0.50 to 0.60 percent, P 0.050 to 0.060 percent, S less than or equal to 0.015 percent, N less than or equal to 0.003 percent, sol.Al 0.030 to 0.055 percent, Nb 0.004 to 0.015 percent, O less than or equal to 0.0050 percent and the rest are Fe and unavoidable impurities. The weight of the galvanized layer (for a single side) is 30-60g / m2 and the mass percentage for the Fe component of the galvanized layer is 8 to 12 percent. The steel plate of the invention has excellent anti-pulverization performance of the galvanized layer, excellent surface quality and appropriate baking-hardened value.

Owner:BAOSHAN IRON & STEEL CO LTD

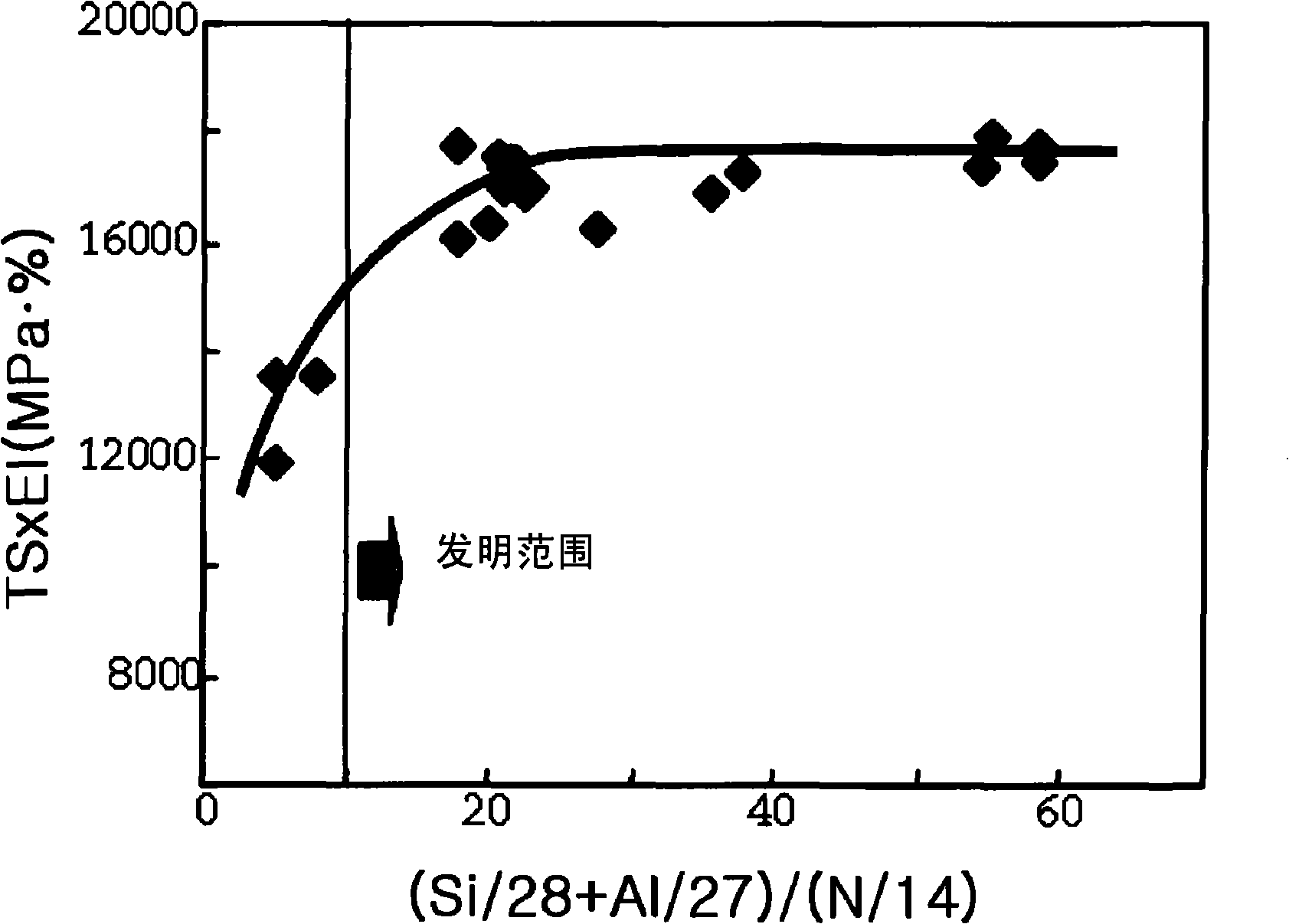

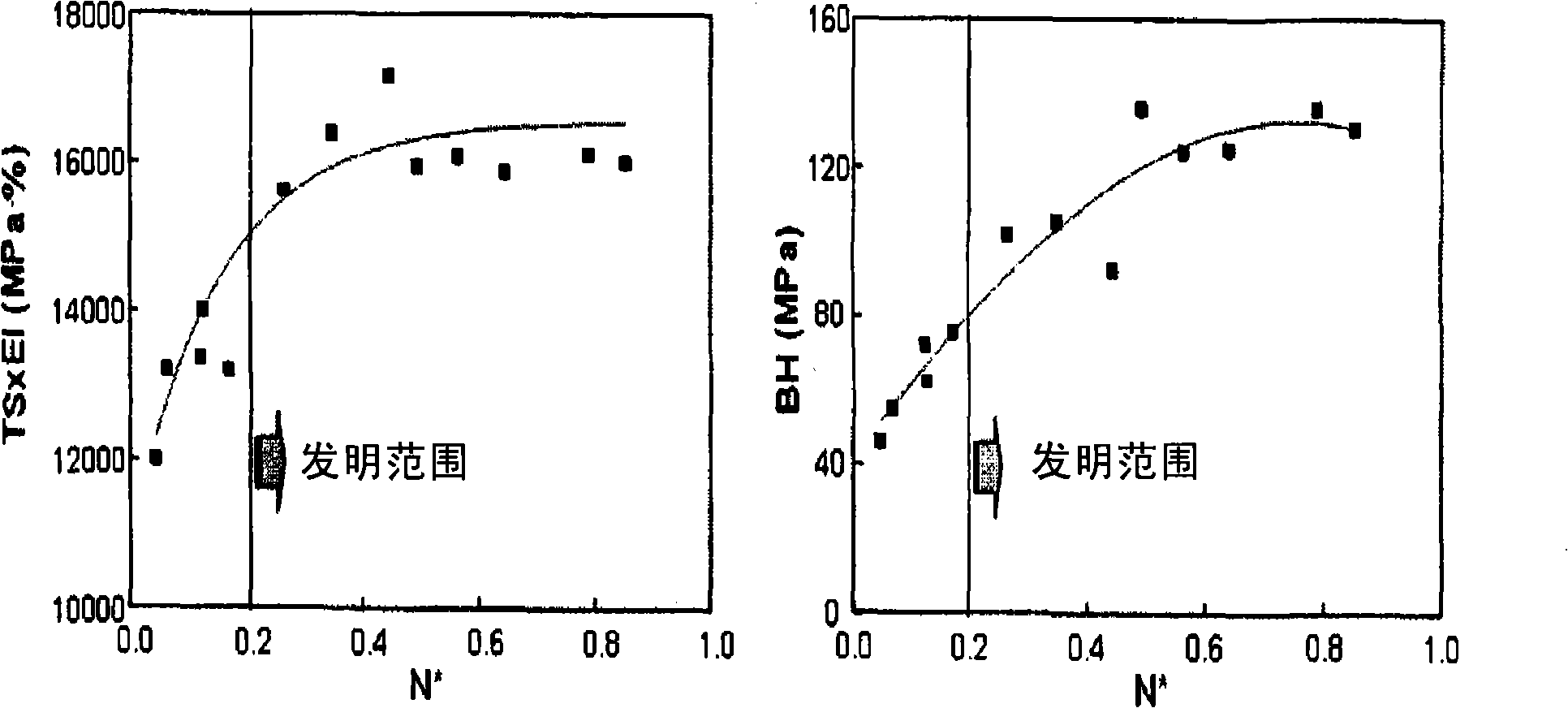

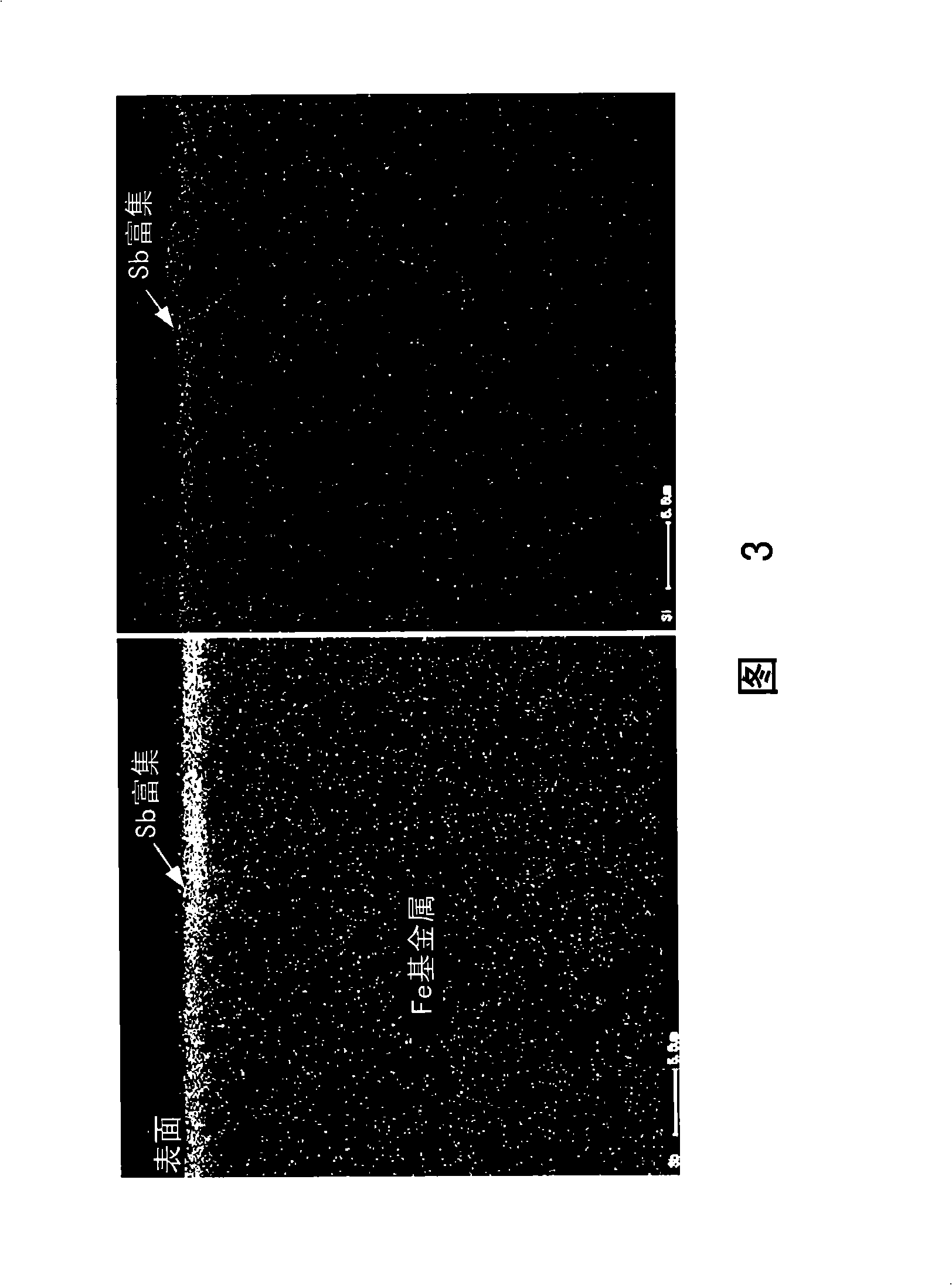

High strength cold rolled steel sheet and hot dip galvanized steel sheet having excellent formability and coating property, and the method for manufacturing thereof

The invention relates to high strength cold rolled steel sheet and high strength zinc-coated steel plate sheet mainly used as structural components and reinforcing members of a vehicle body, these steel sheets include remarkable formability and coating property and comprise: 0.01-0.2 weight percent of carbon (C), 0.01-2 weight percent of silicon (Si), 0.5-4.0 weight percent of manganese (Mn), less than 0.1 weight percent of phosphor (P), less than 0.03 weight percent of sulfur (S), less than 1.0 weight percent of soluble aluminum (Sol.Al), 0.001-0.1 weight percent of nitrogen (N), 0.005-1.0 weight percent of stibium (Sb), and remaining ferrum (FE) and inevitable impurities. The invention also relates to the zinc-coated steel plate sheet and a manufacturing method for these steel sheets. In accordance with the invention, remarkable coating property can be attained and tensile strength is more than 490 MPa. In the other hand, the formability thereof is ensured, TS*El balance thereof is more than 15,000. Furthermore, the outstanding bake hardenability of which BH value is more than 80 MPa can be attained.

Owner:POHANG IRON & STEEL CO LTD

High-strength hot-dip galvanized steel sheet, high-strength alloyed hot-dip galvanized steel sheet excellent in bake hardenability, and manufacturing method thereof

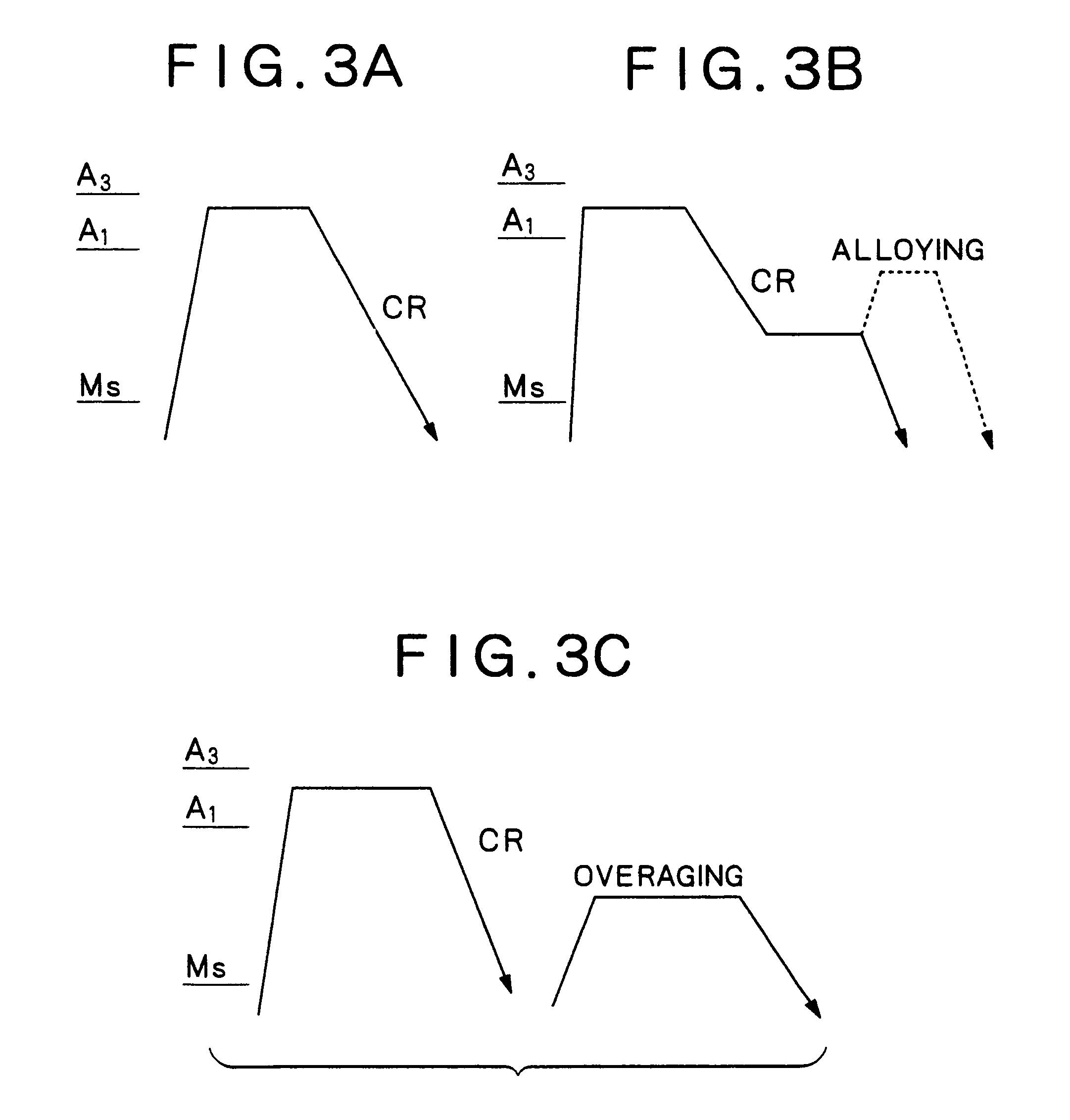

ActiveUS20140234660A1UnstableEnlarge bake hardening amountHot-dipping/immersion processesFurnace typesUltimate tensile strengthAustenite

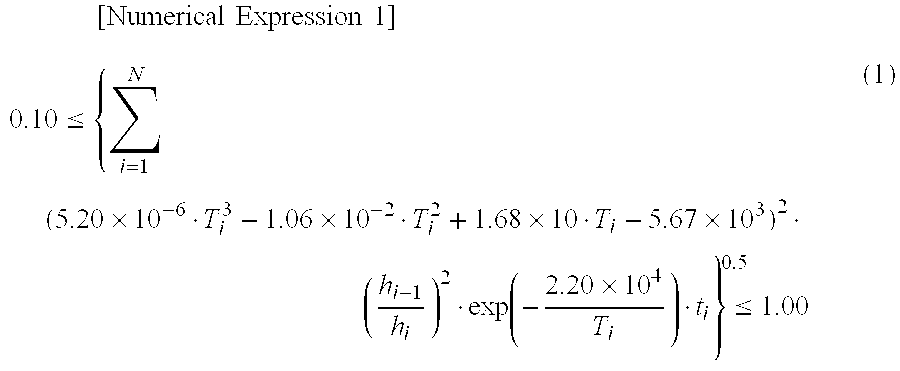

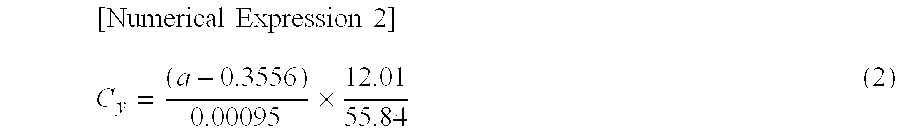

Steel contains each of C, Si, Mn, P, S, Al, N, O, at a range from ⅛ thickness centered around a ¼ sheet thickness from a surface to ⅜ thickness centered around the ¼ sheet thickness from the surface at a base steel sheet, a structure of the base steel sheet contains, in volume fraction, 3% or more of a retained austenite phase, 50% or less of a ferrite phase, and 40% or more of a hard phase, average dislocation density is 5×1013 / m2 or more, solid-solution C amount contained in the retained austenite phase is in mass % 0.70 to 1.00%, X-ray random intensity ratio of FCC iron in an texture of the retained austenite phase is 3.0 or less, ratio between a grain diameter relative to a rolling direction and a grain diameter relative to a sheet width direction of the retained austenite phase is 0.75 to 1.33.

Owner:NIPPON STEEL CORP

Hot-dip galvanized steel sheet and production method therefor

ActiveCN104093873AHigh strengthExcellent material uniformity with little variationHot-dipping/immersion processesFurnace typesMetallurgyYield ratio

Owner:JFE STEEL CORP

Dual phase steel sheet with good bake-hardening properties

ActiveUS20090242085A1Well-balanced strengthWell-balanced workabilityFurnace typesHeat treatment furnacesPre strainCooking & baking

A dual phase steel sheet with good bake-hardening properties is provided. The steel sheet is characterized in containing (in terms of percent by mass) C: no less than 0.06% and less than 0.25%; Si+Al: 0.5 to 3%; Mn: 0.5 to 3%; P: no more than 0.15%; and S: no more than 0.02%; and also meeting the following condition (in terms of space factor) that retained austenite is at least 3%, bainite is at least 30%, and ferrite is no more than 50%, and further characterized in differing in stress larger than 50 MPa before and after application of 2% pre-strain and ensuing heat treatment for paint baking at 170° C. for 20 minutes. The steel sheet has well-balanced strength and workability, exhibits good bake-hardening properties at the time of paint baking, and offers good resistance to natural aging.

Owner:KOBE STEEL LTD

Dual-phase steel sheet excellent in stretch flange formability and production method thereof

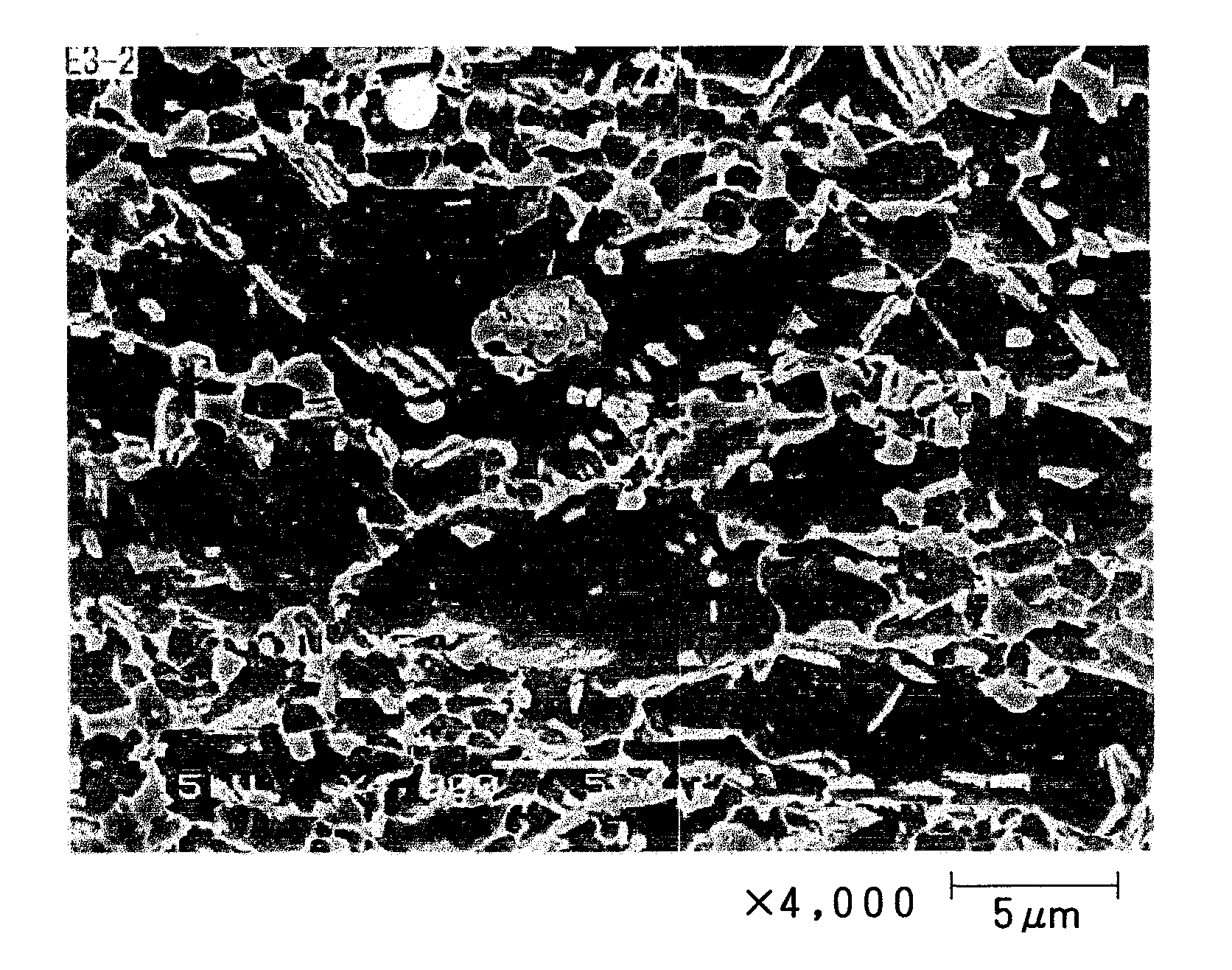

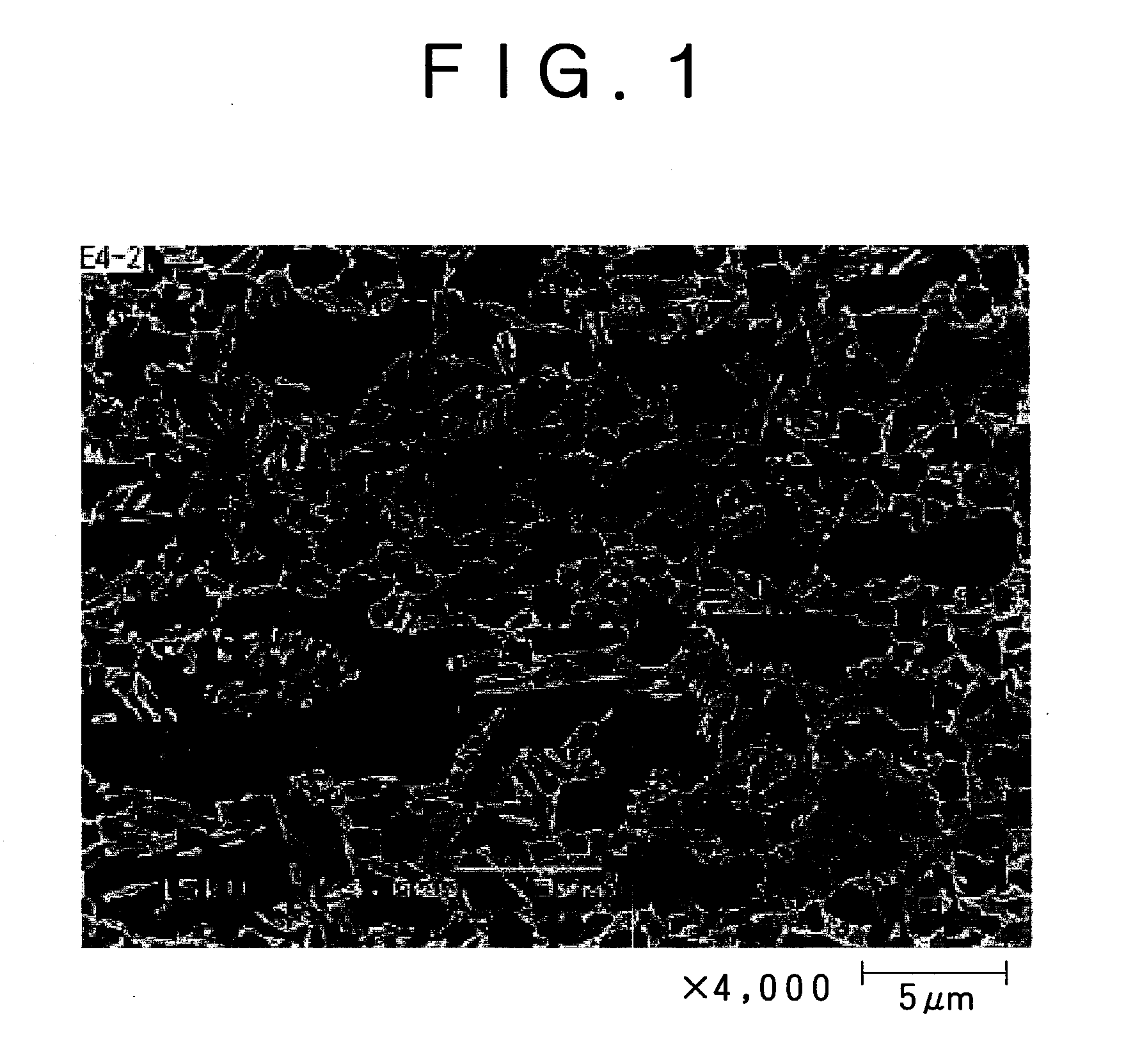

InactiveUS20070023113A1High strengthEfficiently provideHot-dipping/immersion processesFurnace typesArea ratioDual-phase steel

Disclosed is a dual-phase steel sheet having low yield ratio, excellent in the balance for strength-elongation and for strength-stretch flange formability, and also excellent in bake hardening property containing (on the mass % basis). C: 0.01-0.20%, Si: 0.5% or less, Mn: 0.5-3%, sol.Al: 0.06% or less (inclusive 0%), P: 0.15% or less (exclusive 0%), and S: 0.02% or less (inclusive 0″), and in which the matrix phase contains tempered martensite; tempered martensite and ferrite; tempered bainite; or tempered bainite and ferrite, and the second phase comprises 1 to 30% of martensite at an area ratio based on the entire structure.

Owner:KOBE STEEL LTD

Method for modifying baking and hardening performance of aluminum alloy automobile board with low content of Cu

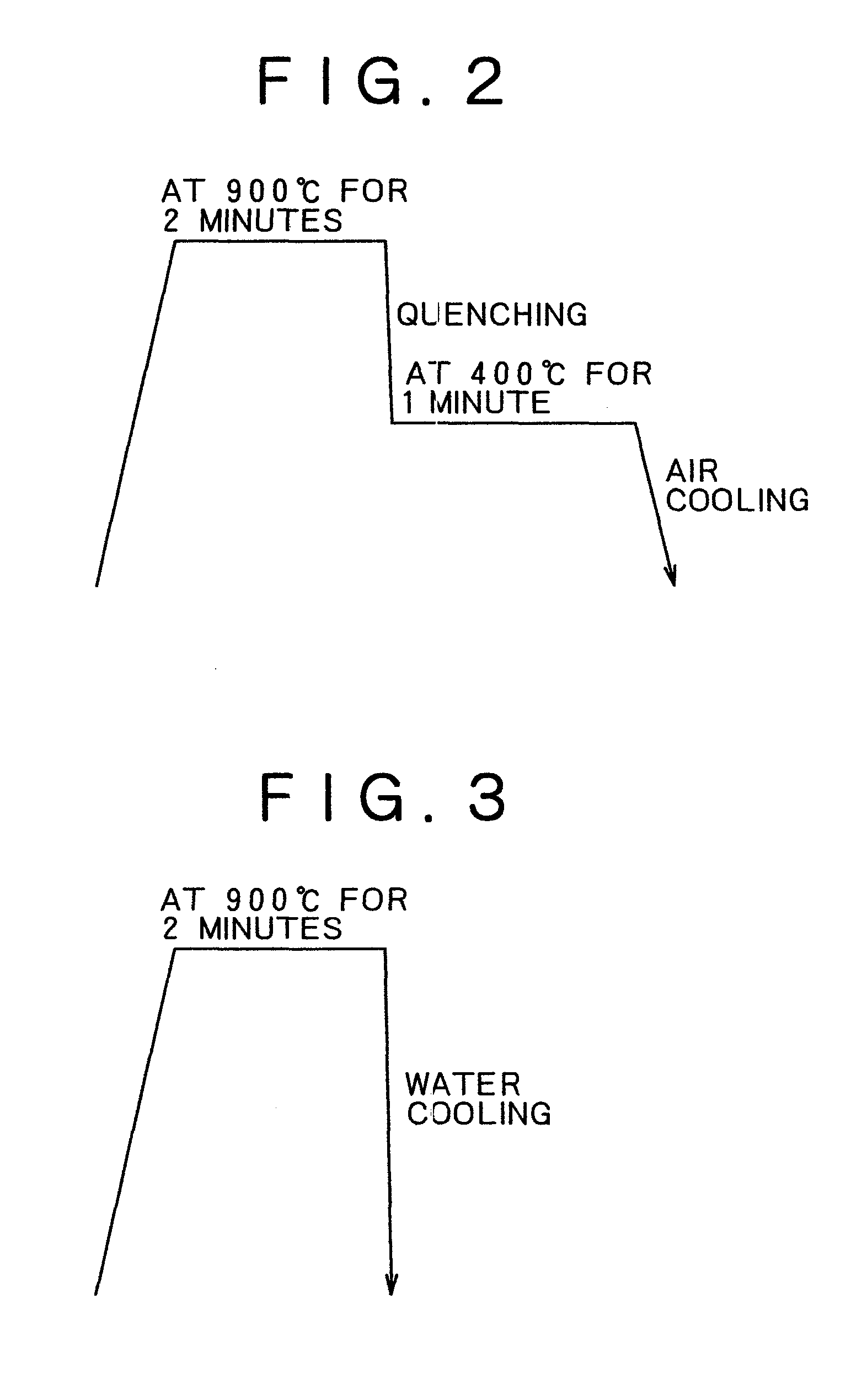

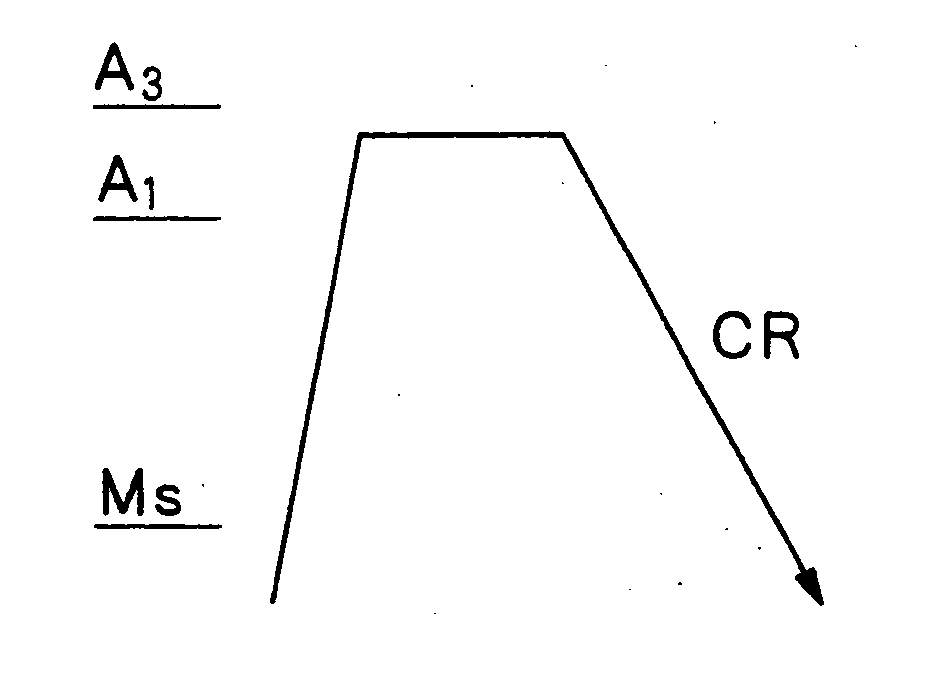

ActiveCN101168828AMeet the requirements of impact resistanceImproved bake hardenabilityPunchingQuenching

The invention provides a method for improving the baking and hardening performance of a low Cu content aluminum alloy vehicle plate material. After the 6022 aluminum alloy plate material is performed aluminum alloy and water quenching, the heat treatment is performed within one hour, the treatment temperature is 60 to 200 DEG C, and the treatment time is between 2 to 30 minutes. The baking and hardening performance is remarkably enhanced, the lower yielding strength and the higher plasticity before punching are advantageous to the punching and molding, the yielding strength after baking and hardening is larger than 200MPa, and the invention satisfies the request of impact resistance of a vehicle plate, and is suitable for the technology treatment of the aluminum alloy plate material used for a vehicle body.

Owner:CHINA ALUMINUM INT ENG CORP

Hot-dip galvanized ultra-low carbon bake-hardening steel and production method thereof

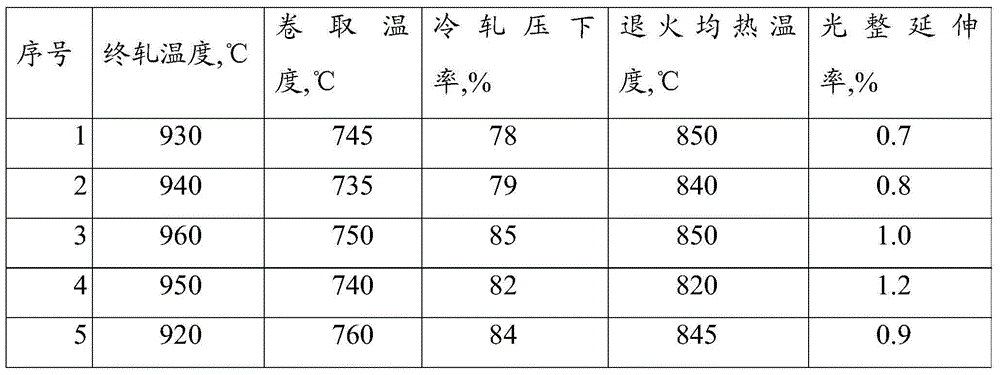

The invention discloses hot-dip galvanized ultra-low carbon bake-hardening steel. The hot-dip galvanized ultra-low carbon bake-hardening steel comprises the following chemical components in percentage by mass: 0.001-0.005% of C, 0-0.12% of Si, 0-1.0% of Mn, 0-0.50% of P, 0.01-0.30% of Al, 0.004-0.01% of Ti, 0.0003-0.0040% of B, less than or equal to 0.010% of S and less than or equal to 0.01% of S as limiting elements and the balance of Fe and unavoidable impurities. The invention also discloses a production method of the hot-dip galvanized ultra-low carbon bake-hardening steel. According to the hot-dip galvanized ultra-low carbon bake-hardening steel and the production method thereof which are disclosed by the invention, by adding the B element and reasonably controlling key alloying elements such as C, Mn, P and Ti and hot-rolling, cold-rolling and hot-dip galvanizing processes, the hot-dip galvanized ultra-low carbon bake-hardening steel which has the advantages of secondary processing embrittlement resistance and excellent comprehensive mechanical properties is produced, the requirements of high-end car users are met and considerable economic benefits are brought.

Owner:SHOUGANG CORPORATION

High-strength hot-rolled steel sheet having excellent baking hardenability and low temperature toughness with maximum tensile strength of 980 mpa or more

ActiveUS20150329950A1Excellent bake hardenabilityGuaranteed Low Temperature ToughnessHot-dipping/immersion processesFurnace typesCarbideHigh intensity

Provided is a high-strength hot-rolled steel sheet consisting of, in mass %, C: 0.01% to 0.2%, Si: 0% to 2.5%, Mn: 0% to 4.0%, Al: 0% to 2.0%, N: 0% to 0.01%, Cu: 0% to 2.0%, Ni: 0% to 2.0%, Mo: 0% to 1.0%, V: 0% to 0.3%, Cr: 0% to 2.0%, Mg: 0% to 0.01%, Ca: 0% to 0.01%, REM: 0% to 0.1%, B: 0% to 0.01%, P: less than or equal to 0.10%, S: less than or equal to 0.03%, O: less than or equal to 0.01%, one or both of Ti and Nb: 0.01% to 0.30% in total, and the balance being Fe and inevitable impurities. The steel sheet has a structure in which a total volume fraction of tempered martensite or lower bainite is 90% or more, a dislocation density thereof is greater than or equal to 5×1013 (1 / m2) and less than or equal to 1×1016 (1 / m2) and 1×106 (numbers / mm2) or more iron-based carbides are included therein.

Owner:NIPPON STEEL CORP

6000 series aluminum alloy material with high natural aging stability, aluminum alloy plate and preparing method of aluminum alloy plate

The invention discloses a 6000 series aluminum alloy material with high natural aging stability. The chemical elements of the material comprise, by mass, larger than or equal to 0.2% but smaller than or equal to 0.8% of Mg, larger than or equal to 0.8% but smaller than or equal to 1.5% of Si, larger than or equal to 0.07% but smaller than or equal to 0.25% of Sn, larger than 0 but smaller than or equal to 0.05% of Cu, larger than or equal to 0.02% but smaller than or equal to 0.2% of Mn, larger than 0 but smaller than or equal to 0.5% of Fe, larger than or equal to 0.05% but smaller than or equal to 0.15% of Ti, smaller than or equal to 0.2% of Zn, smaller than or equal to 0.1% of Cr and the balance Al and other inevitable impurities. Correspondingly, the invention further includes an aluminum alloy plate prepared through the 6000 series aluminum alloy material with high natural aging stability and a preparing method of the aluminum alloy plate. The aluminum alloy material and the aluminum alloy plate have good natural aging stability on the basis that the forming performance and the bake hardening performance are not reduced.

Owner:BAOSHAN IRON & STEEL CO LTD

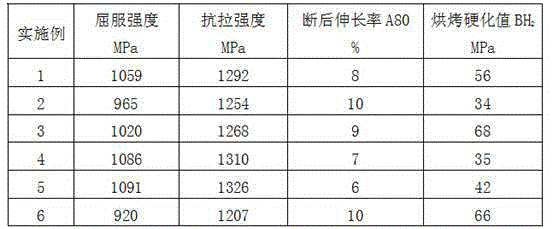

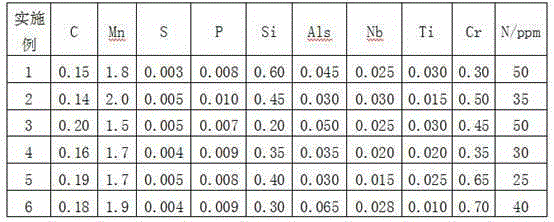

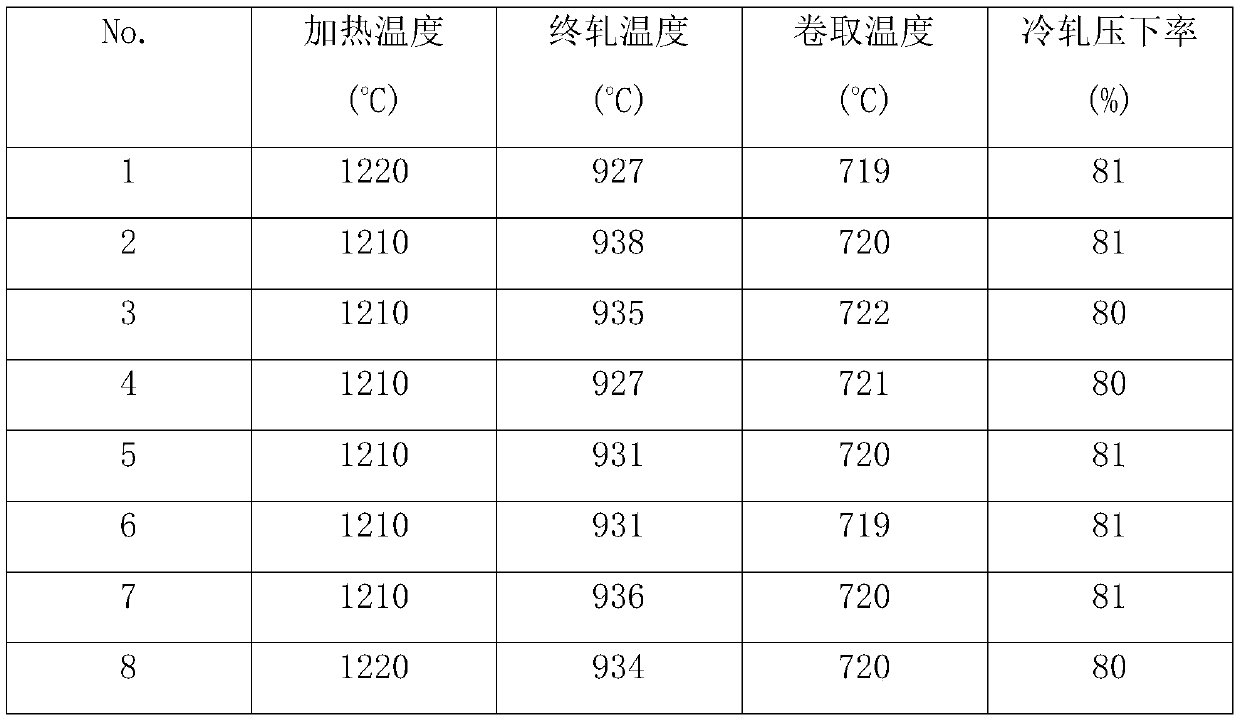

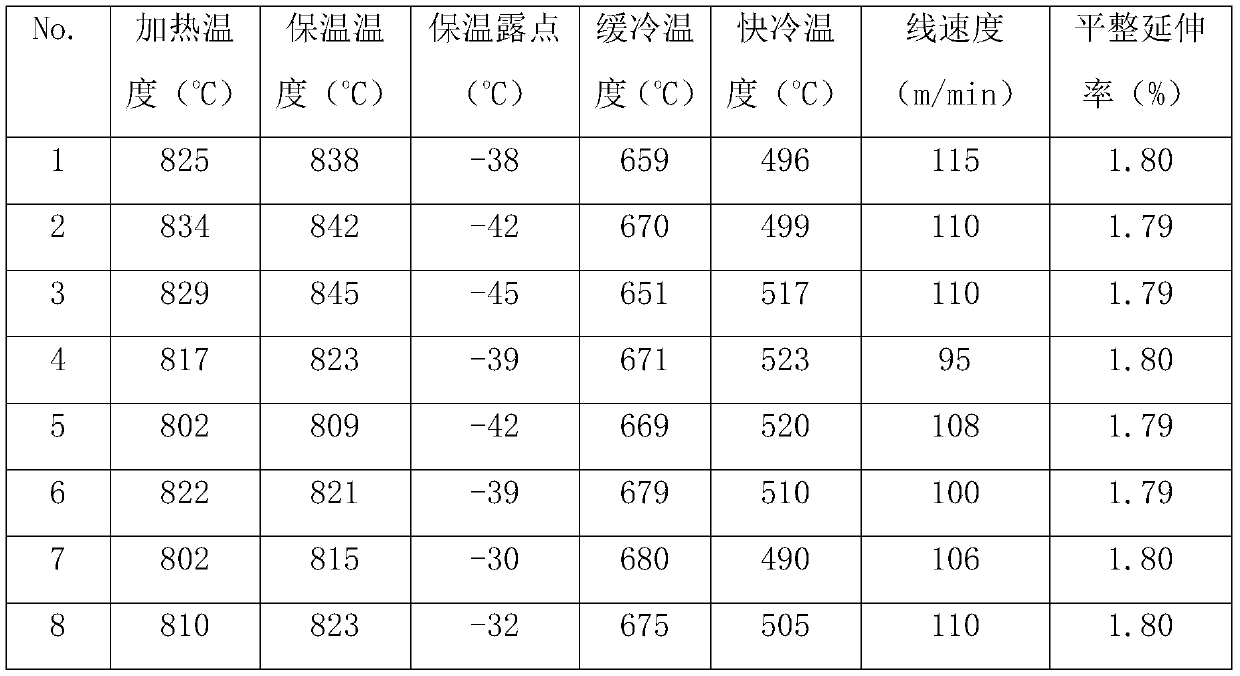

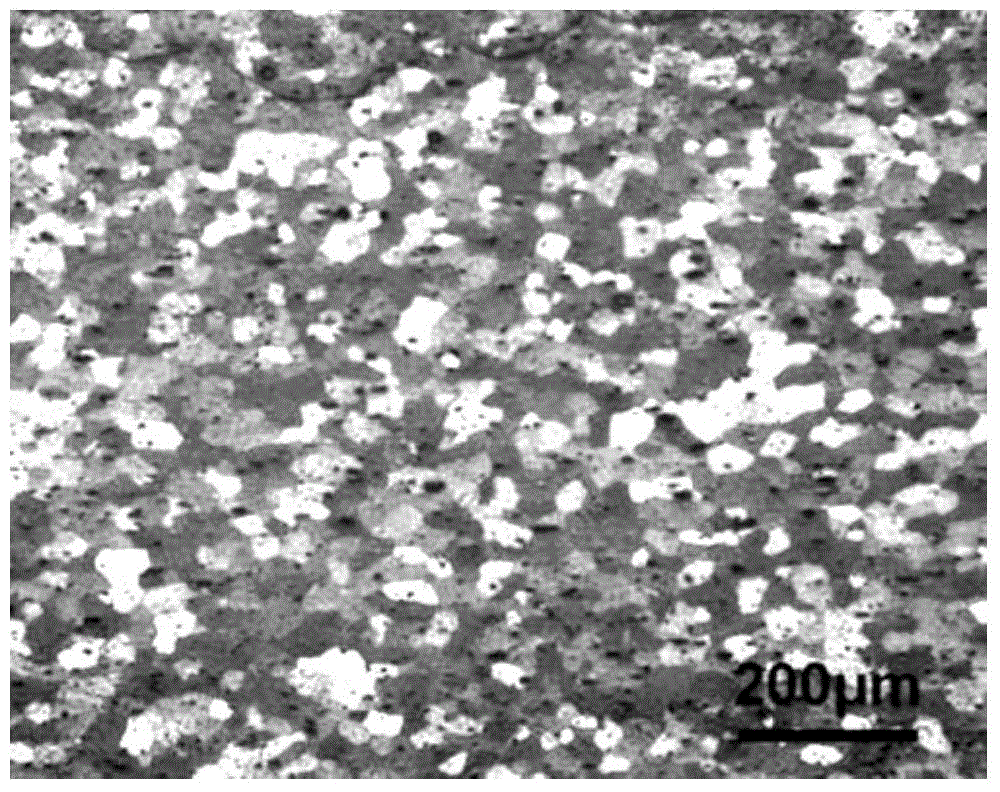

1200MPa-grade cold-rolled annealed dual-phase steel and production method thereof

InactiveCN105132817AContinuous Yield CharacteristicsExcellent bake hardenabilityChemical compositionImpurity

The invention discloses1200MPa-grade cold-rolled annealed dual-phase steel and a production method thereof. The production method of the 1200MPa-grade cold-rolled annealed dual-phase steel comprises the steps of hot rolling, cold rolling and annealing, and flattening. A continuous casted billet prepared from, by mass, 0.14%-0.20% of C, 1.5%-2.0% of Mn, 0%-0.005% of S, 0%-0.010% of P, 0.2%-0.6% of Si, 0.015%-0.030% of Nb, 0.010%-0.030% of Ti, 0.030% or more of Als, 0.30%-0.70% of Cr, 0%-0.000050% of N and the balance Fe and inevitable impurities is subjected to hot rolling. The tensile strength of the dual-phase steel is over 1200 MPa, the percentage elongation after fracture of the dual-phase steel is over 6%, and the dual-phase steel has the continuous yielding property and the good bake hardening performance; the dual-phase steel can be used for manufacturing mechanical anti-collision parts and reinforcing parts and particularly can be used for manufacturing anti-collision parts and reinforcing parts of automobiles and doorsill footboards of the automobiles.

Owner:TANGSHAN IRON & STEEL GROUP

Dual-phase steel sheet excellent in stretch flange formability and production method thereof

InactiveUS7553380B2High strengthHot-dipping/immersion processesFurnace typesManganeseUltimate tensile strength

Owner:KOBE STEEL LTD

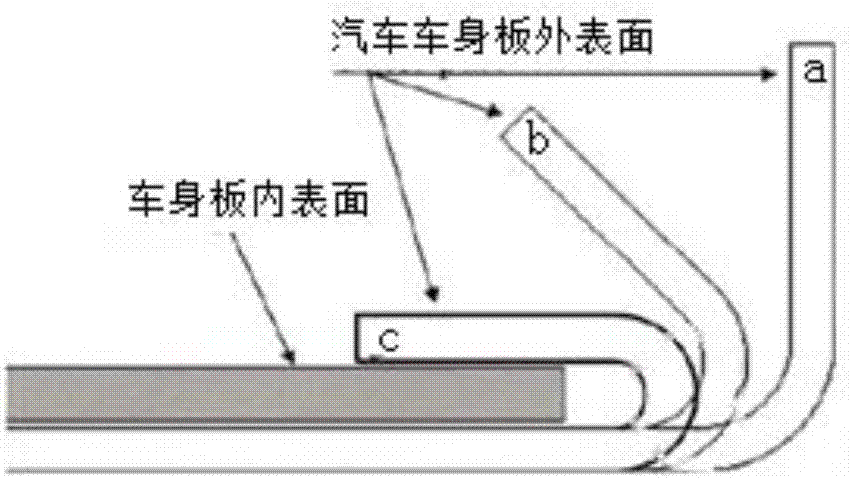

Production method for zinc electroplated baked hardened steel plate for automobile outer plate

ActiveCN105970094ANiobium is lowReduce carbon contentFurnace typesHeat treatment furnacesNatural agingCasting

The invention discloses a production method for a zinc electroplated baked hardened steel plate for an automobile outer plate and belongs to the field of cold-rolled deep-drawn zinc electroplating automobile steel. The production method comprises the following preparation steps that (1) constituent selection of the zinc electroplated baked hardened steel plate is conducted; (2) a plate blank is obtained through smelting and casting; (3) hot rolling is conducted after conventional heating; (4) conventional water cooling is conducted to the coiling temperature, and coiling is conducted; (5) cold rolling is conducted; (6) continuous annealing is conducted; (7) flattening is conducted; (8) conventional alkali washing, brushing, electrolytic degreasing and rinsing are conducted; and (9) zinc electroplating is conducted through a gravity method. According to the production method, the steel plate prepared through a conventional production technique is good in forming performance and baking and hardening performance, natural aging is avoided even if the steel plate is placed at the room temperature for months, and the performance is stable.

Owner:武汉钢铁有限公司

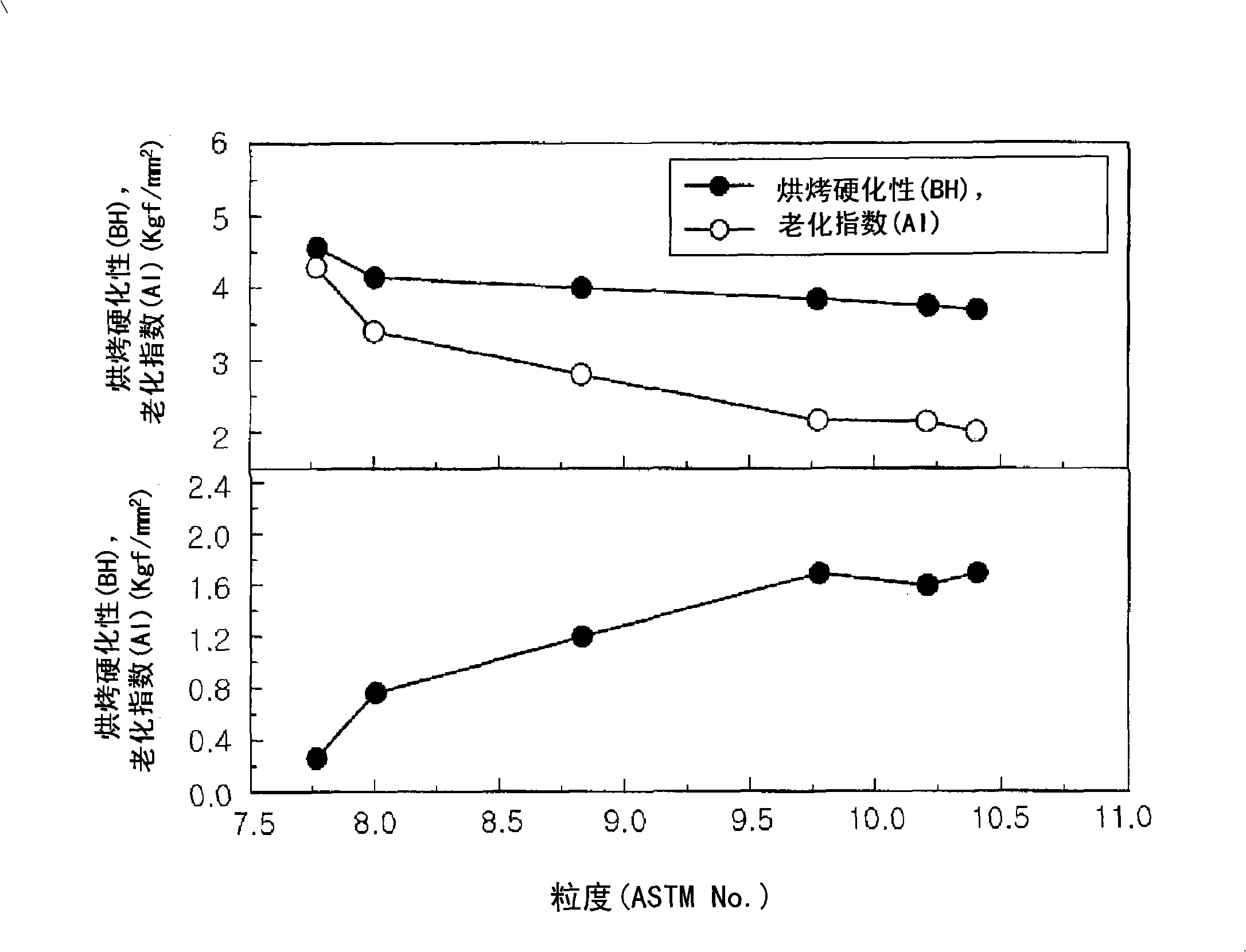

Aluminum alloy sheet with excellent baking paint hardenability

The aluminum alloy sheet of the present invention is a specific 6000-series aluminum alloy sheet in which the total sum (total amount) of Mg and Si existing in specific aggregates of atoms (clusters) is regulated and the total sum of Mg and Si existing in the aggregates of atoms is ensured so as to be balanced with the total amount of Mg and Si solid-solutionized in the matrix, and thus BH response (bake hardenability) after natural aging at room temperature and proof strength after BH treatment (bake hardening treatment) are further improved.

Owner:KOBE STEEL LTD

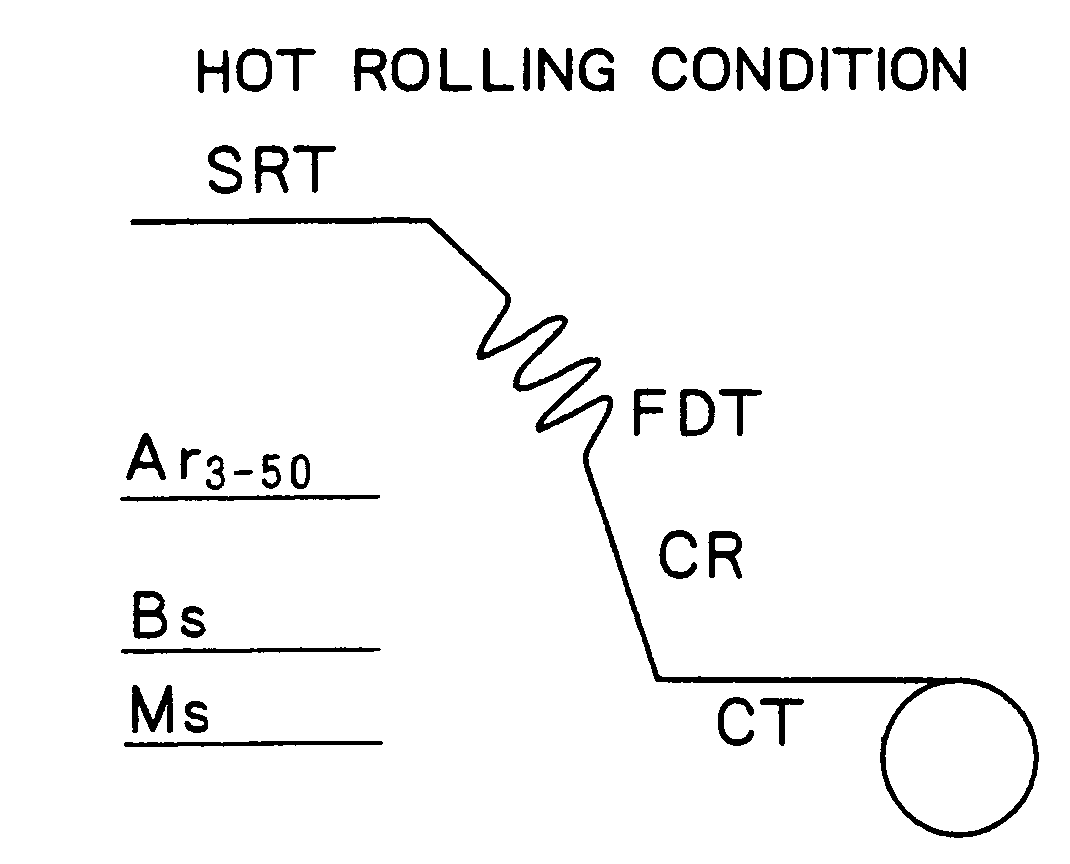

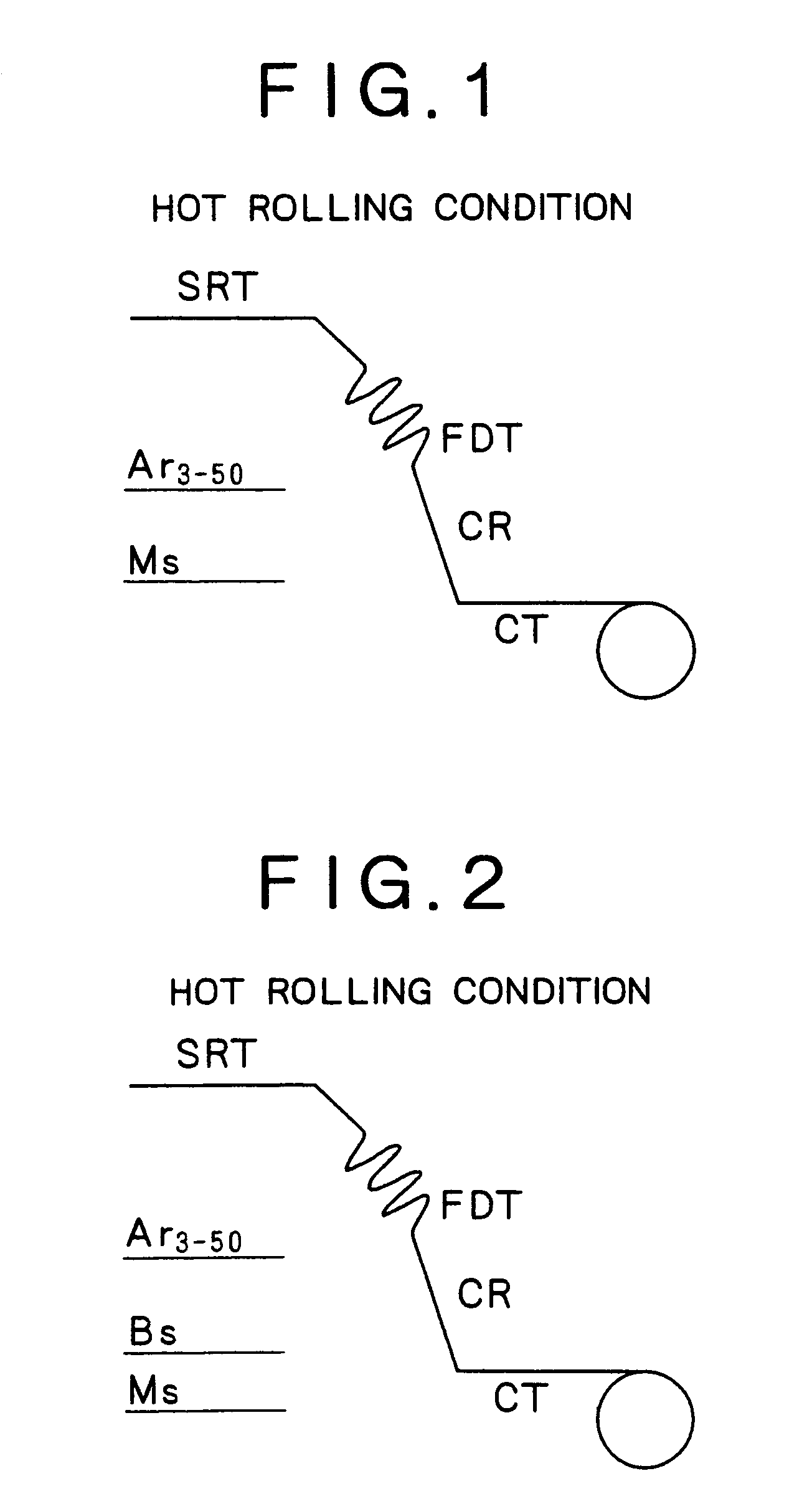

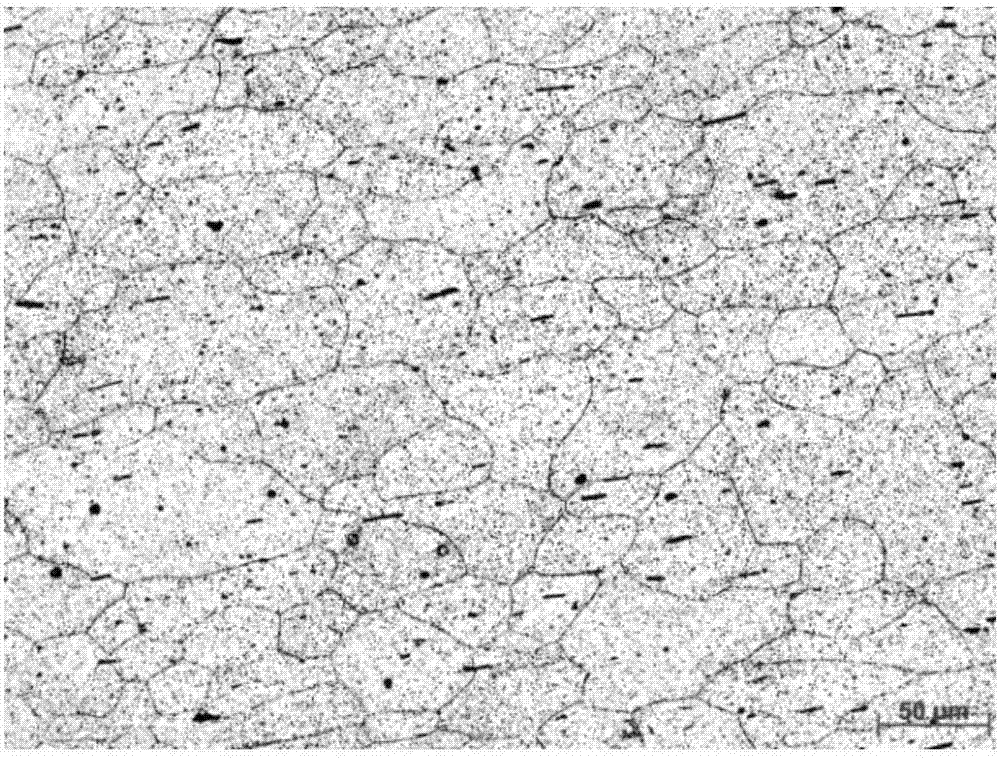

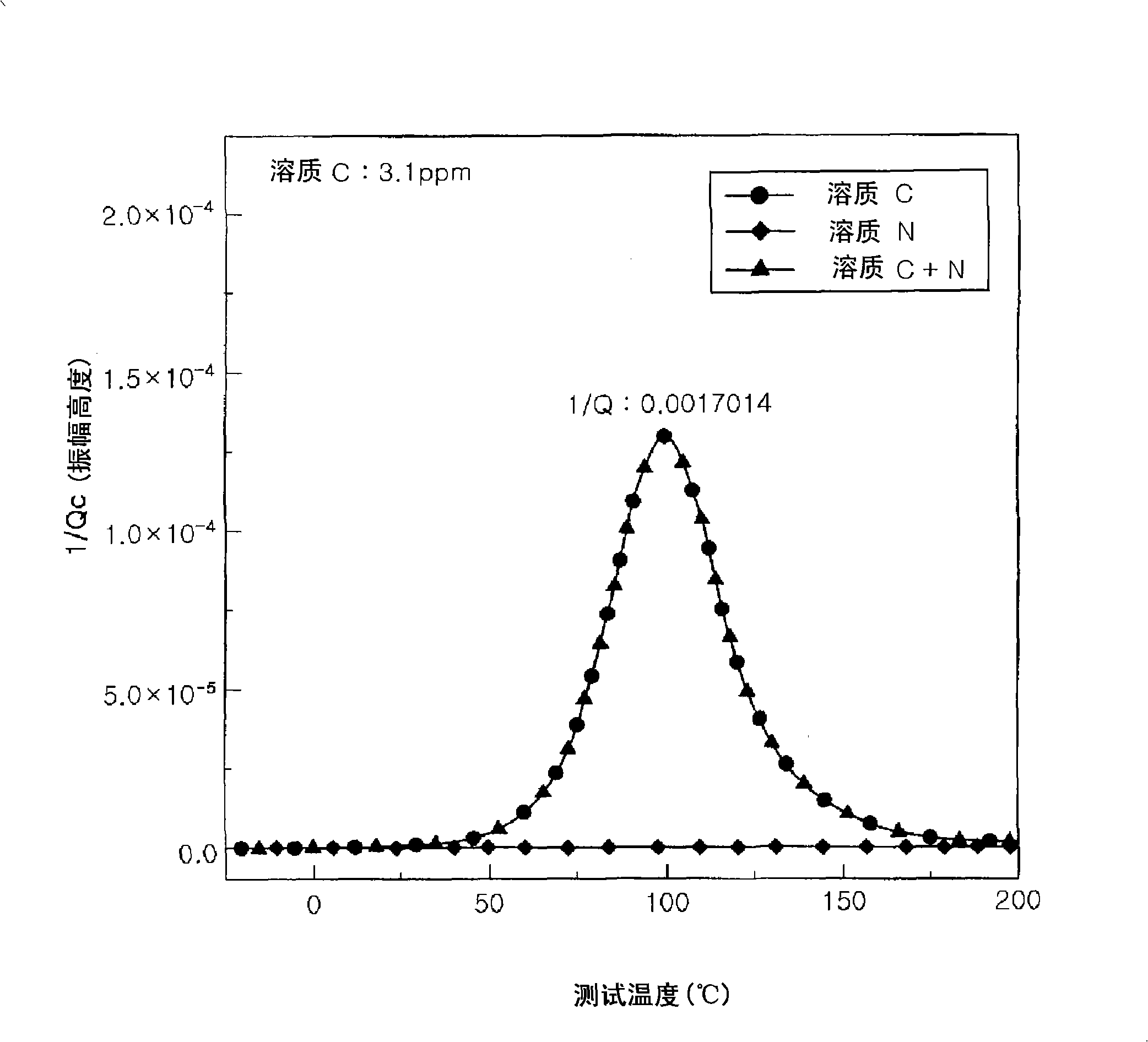

Bake-hardening hot-rolled steel sheet with excellent workability and method for manufacturing the same

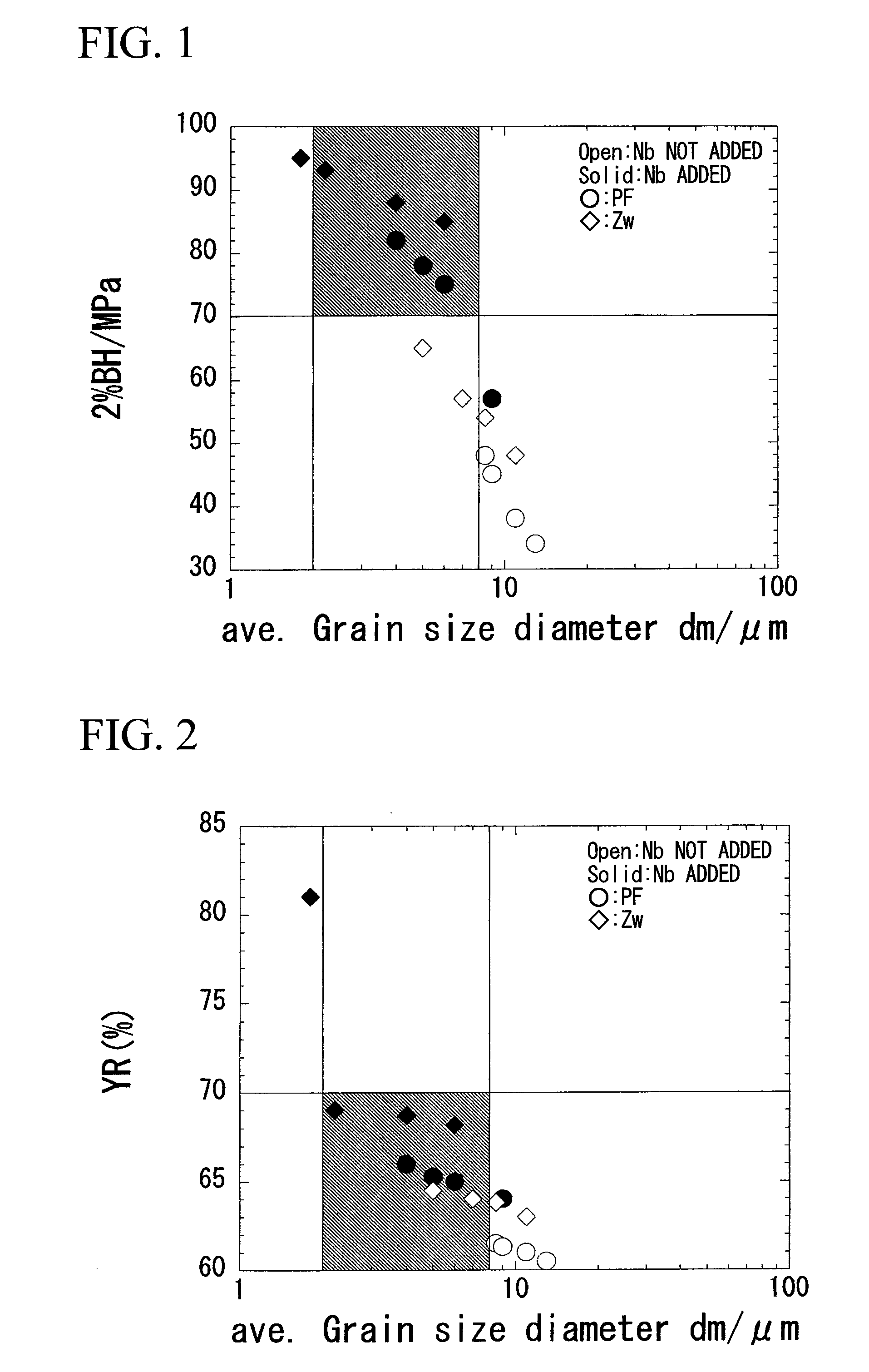

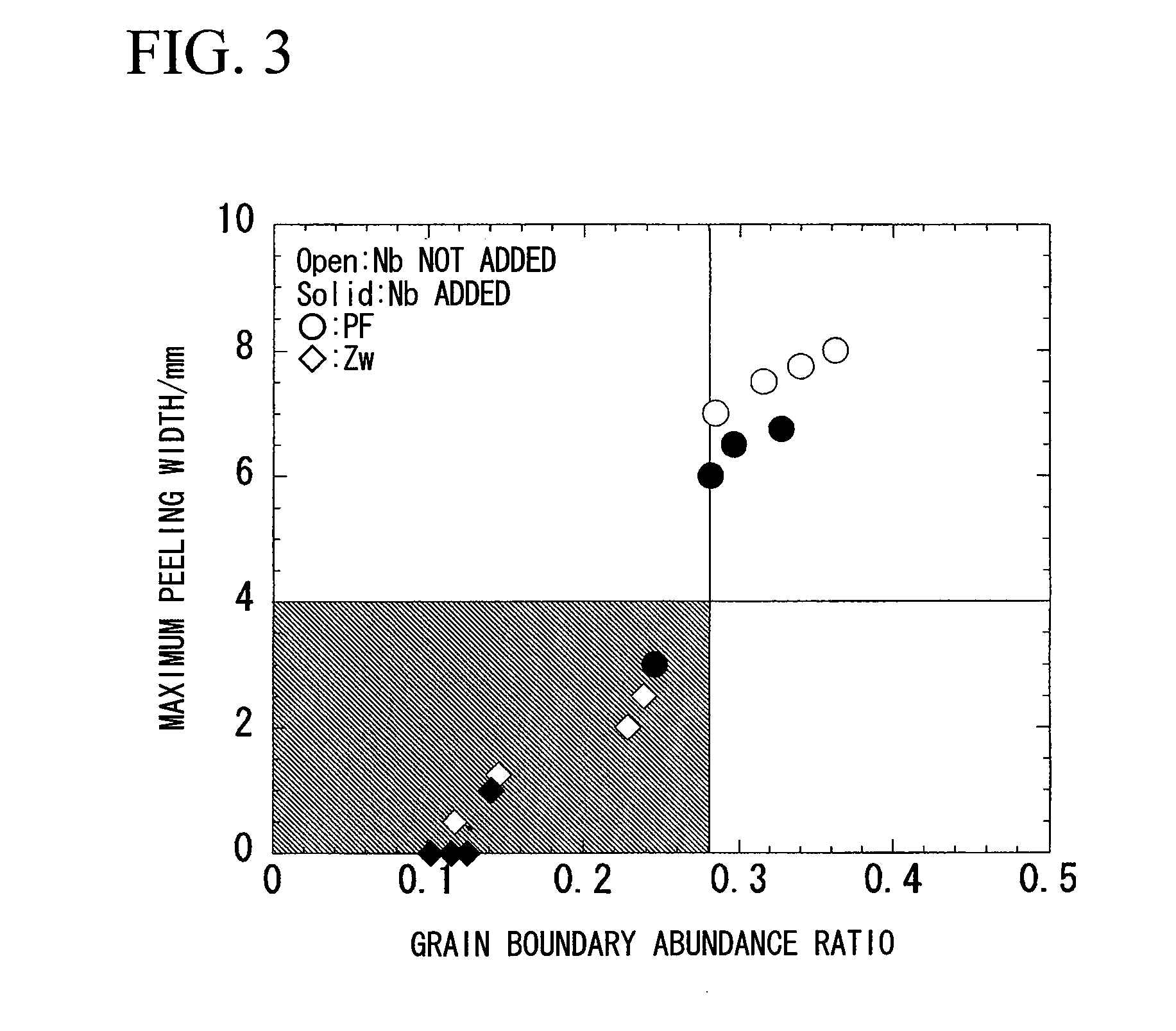

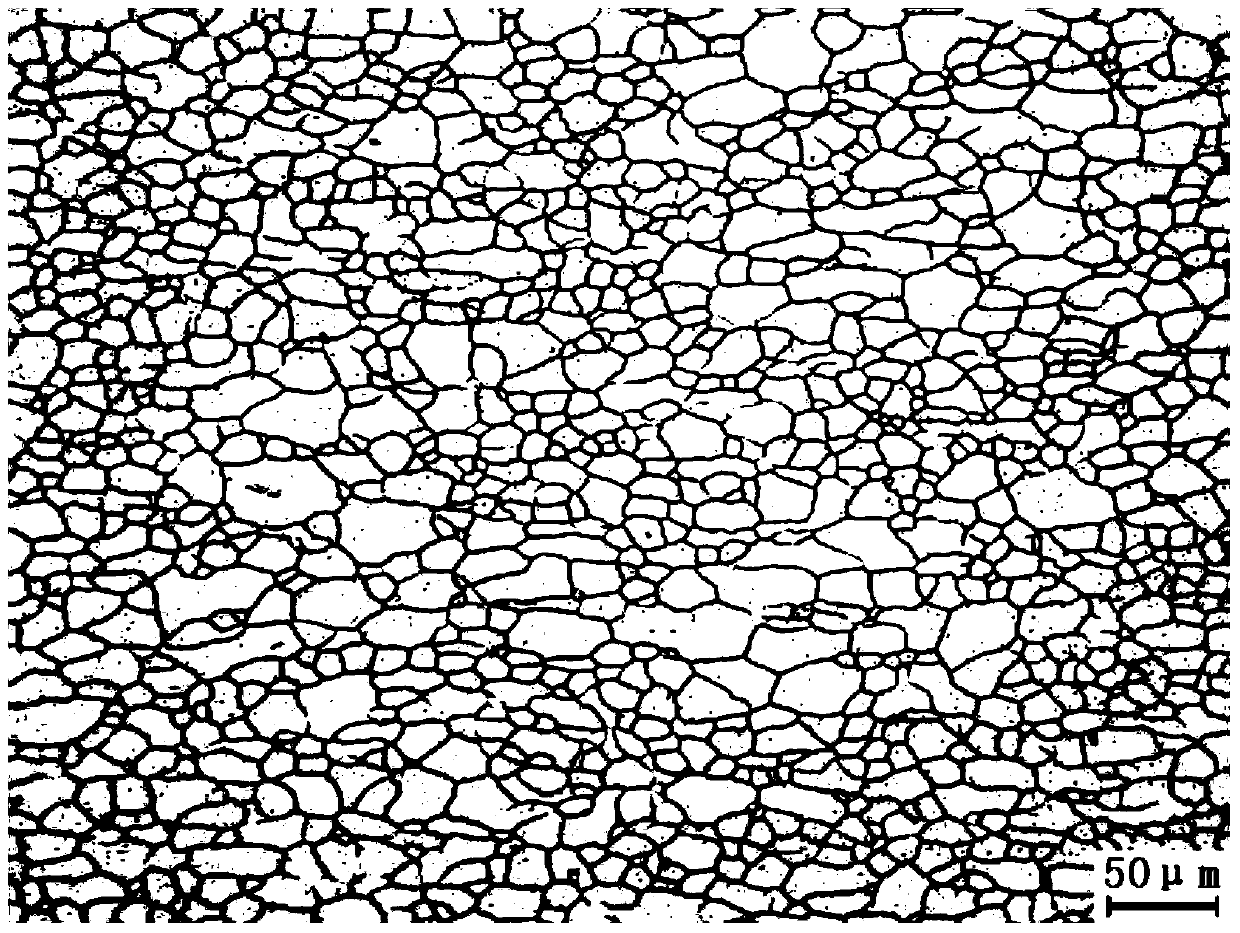

InactiveUS20100000633A1Well formedImprove machinabilityHot-dipping/immersion processesFurnace typesSheet steelGrain boundary

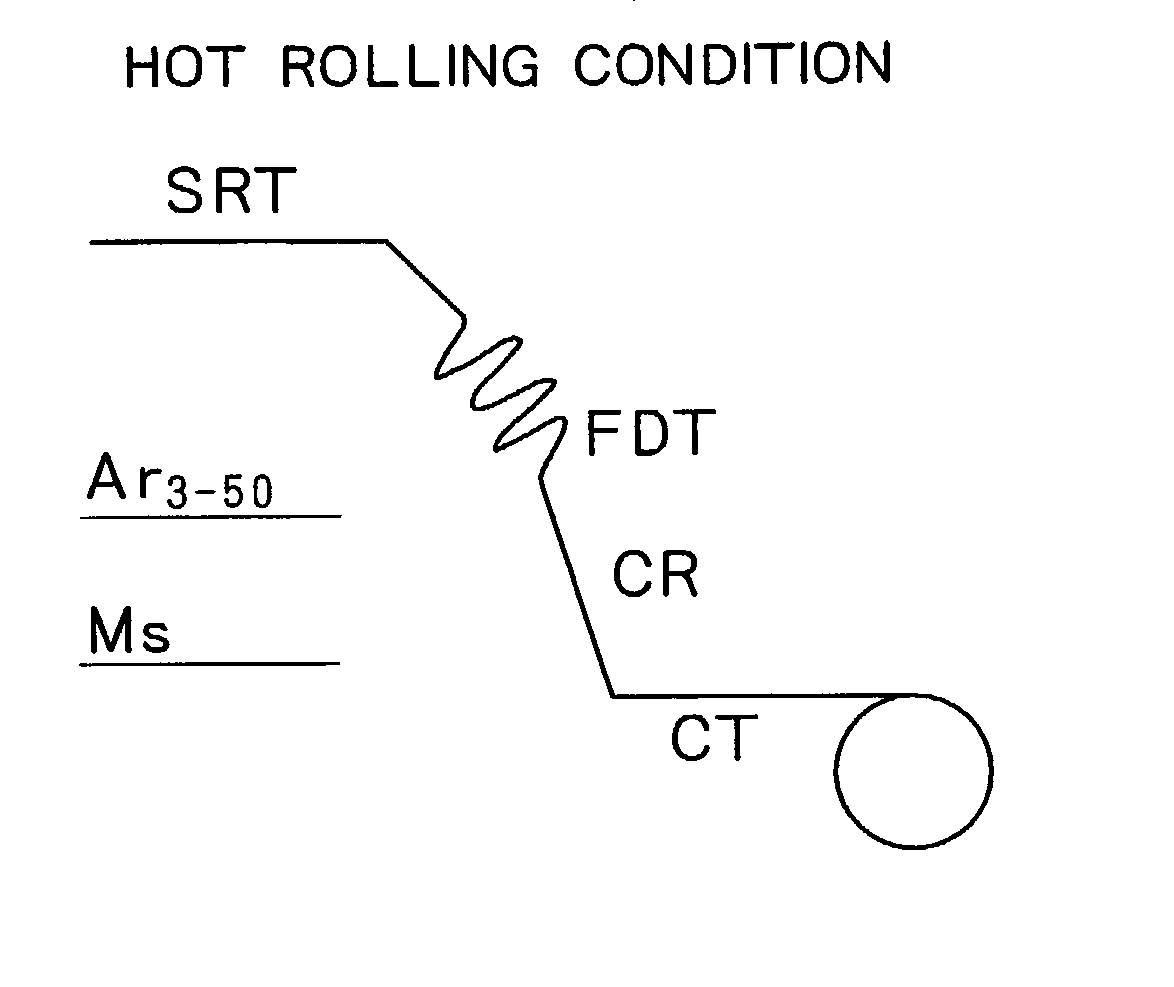

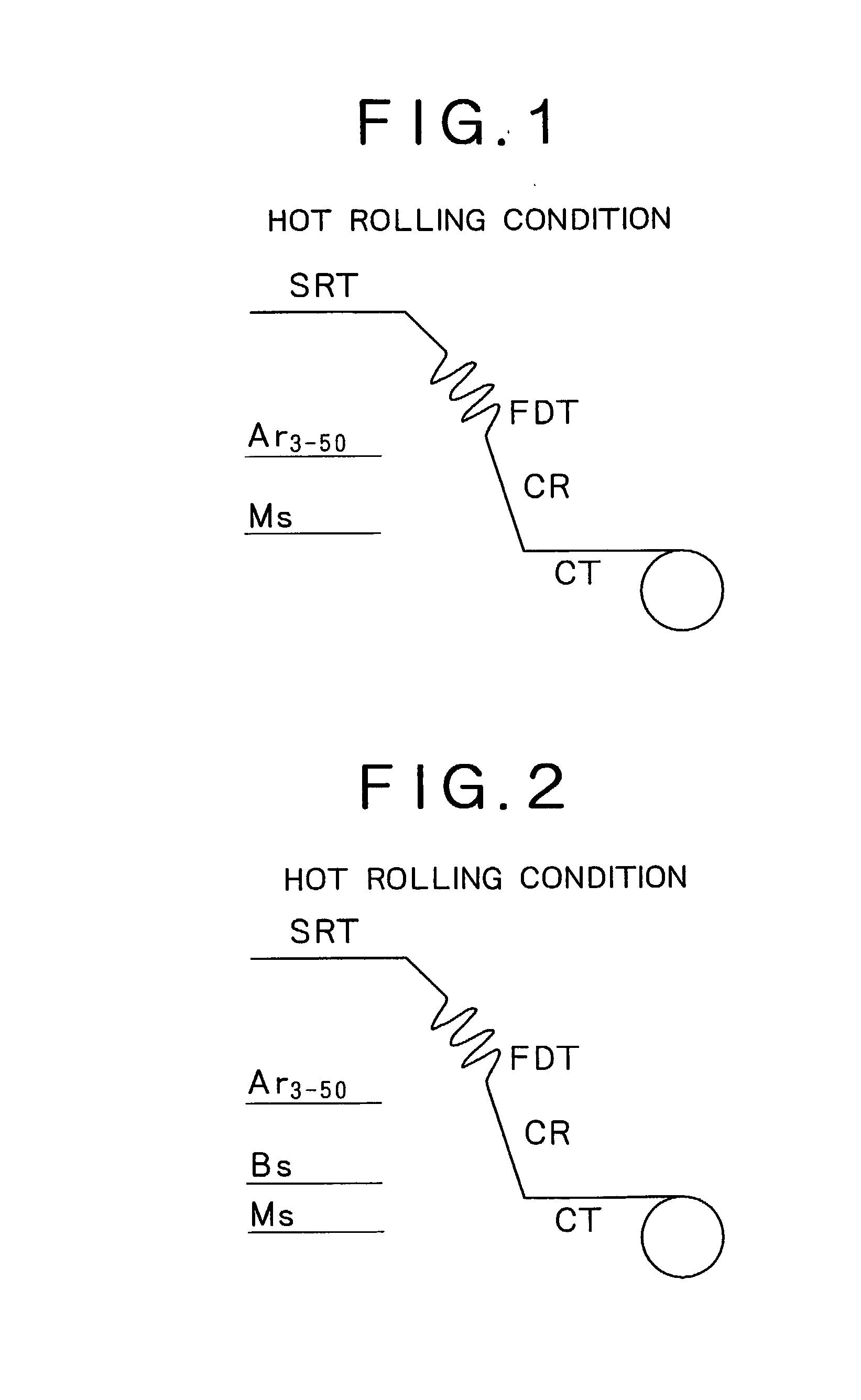

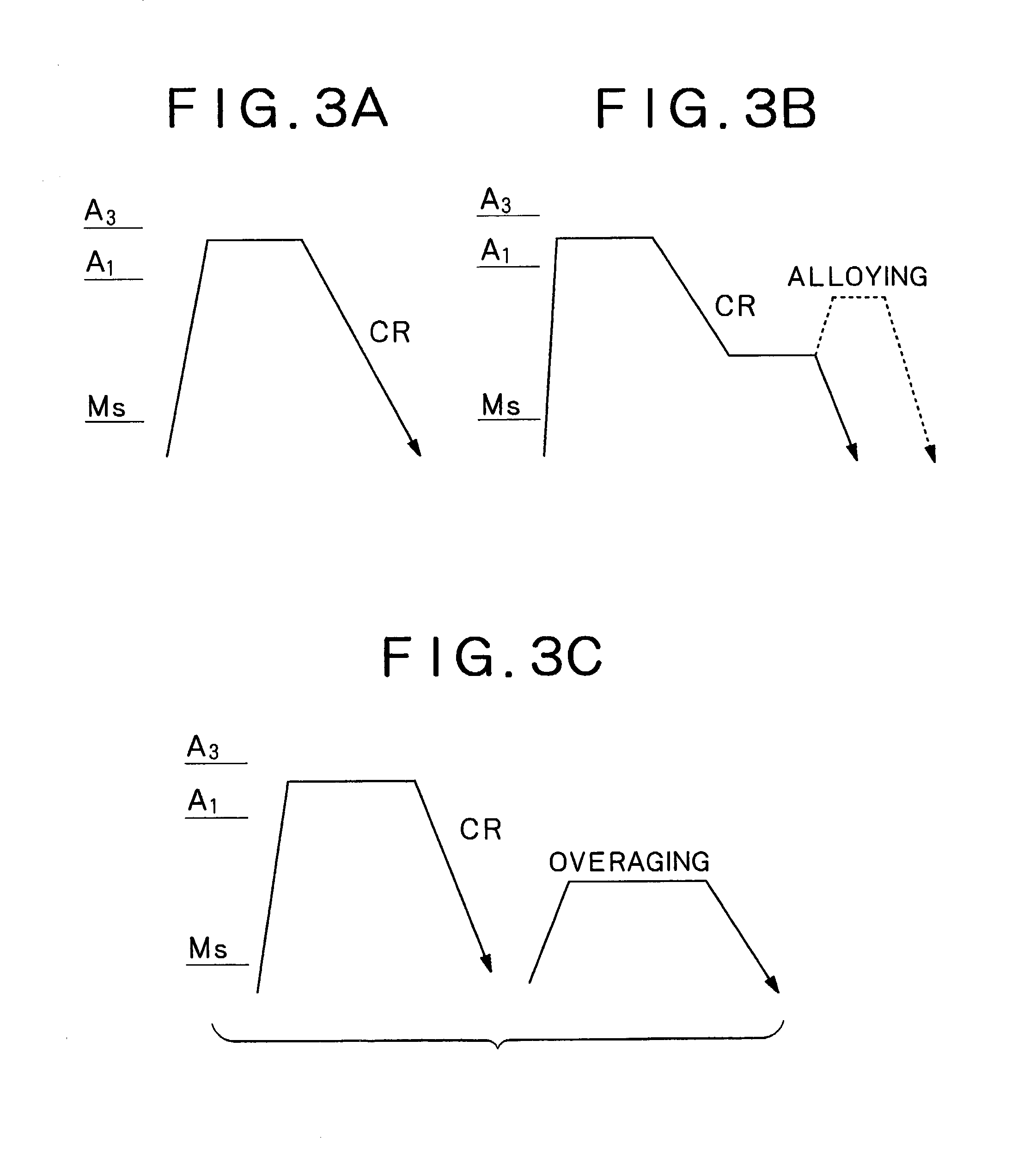

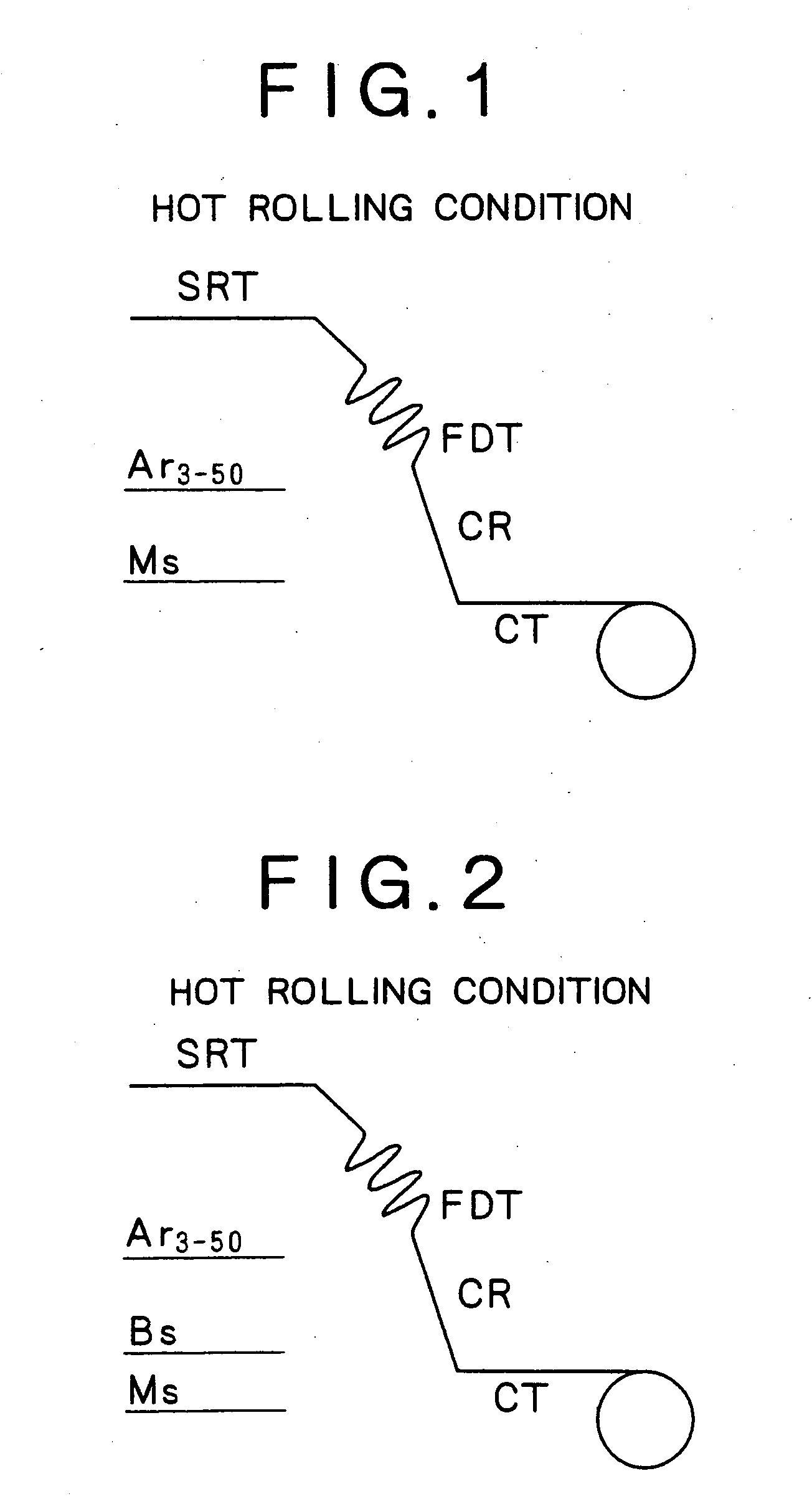

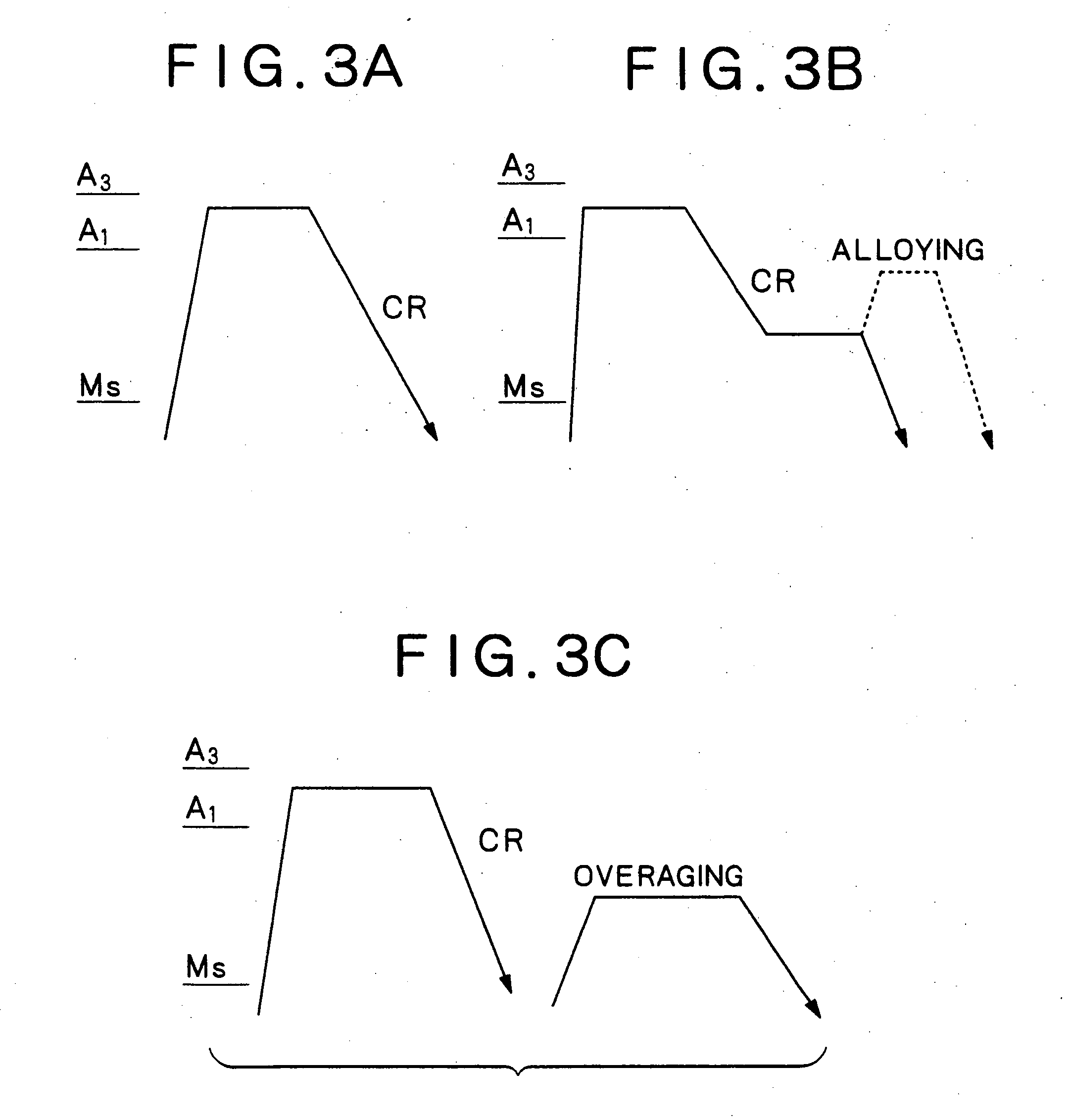

According to an exemplary embodiment of the present invention, a bake-hardening hot-rolled steel sheet with excellent workability can be provided. The exemplary steel sheet can contain, in terms of mass %, C of about 0.01 to 0.2%, Si of about 0.01 to 2%, Mn of about 0.1 to 2%, P of about 0.1% or less, S of about 0.03% or less, Al of about 0.001 to 0.1%, N of about 0.01% or less, Nb of about 0.005 to 0.05%, and as the remainder, Fe and unavoidable impurities. A microstructure of the steel sheet can be a polygonal ferrite and / or a continuous-cooled microstructure having an average particle diameter of about 2 μm to 8 μm, and the grain boundary abundance ratio of solute C and / or solute N may be about 0.28 or lower. An exemplary embodiment of the present invention can also be directed to a method for manufacturing a hot-rolled steel sheet. In this exemplary method, a slab containing aforementioned components can be heated to at least a temperature satisfying the equation of SRT (° C.)=6670 / {2.26−log(% Nb)(% C)}−273. The heated slab can be subjected to a rough rolling, a finish rolling under a condition where the final temperature can be in a range of the Ar3 transformation point temperature or higher and (Ar3 transformation point temperature+100° C.) or lower to obtain a rolled steel. The rolled steel can be cooled at a cooling rate of about 80° C. / sec or higher from cooling initiation down to a temperature range of about 500° C. or lower to obtain a hot rolled steel sheet; and such hot rolled steel sheet can be coiled.

Owner:NIPPON STEEL CORP

High-strength steel sheet having excellent processability and paint bake hardenability, and method for producing of high-strength steel sheet

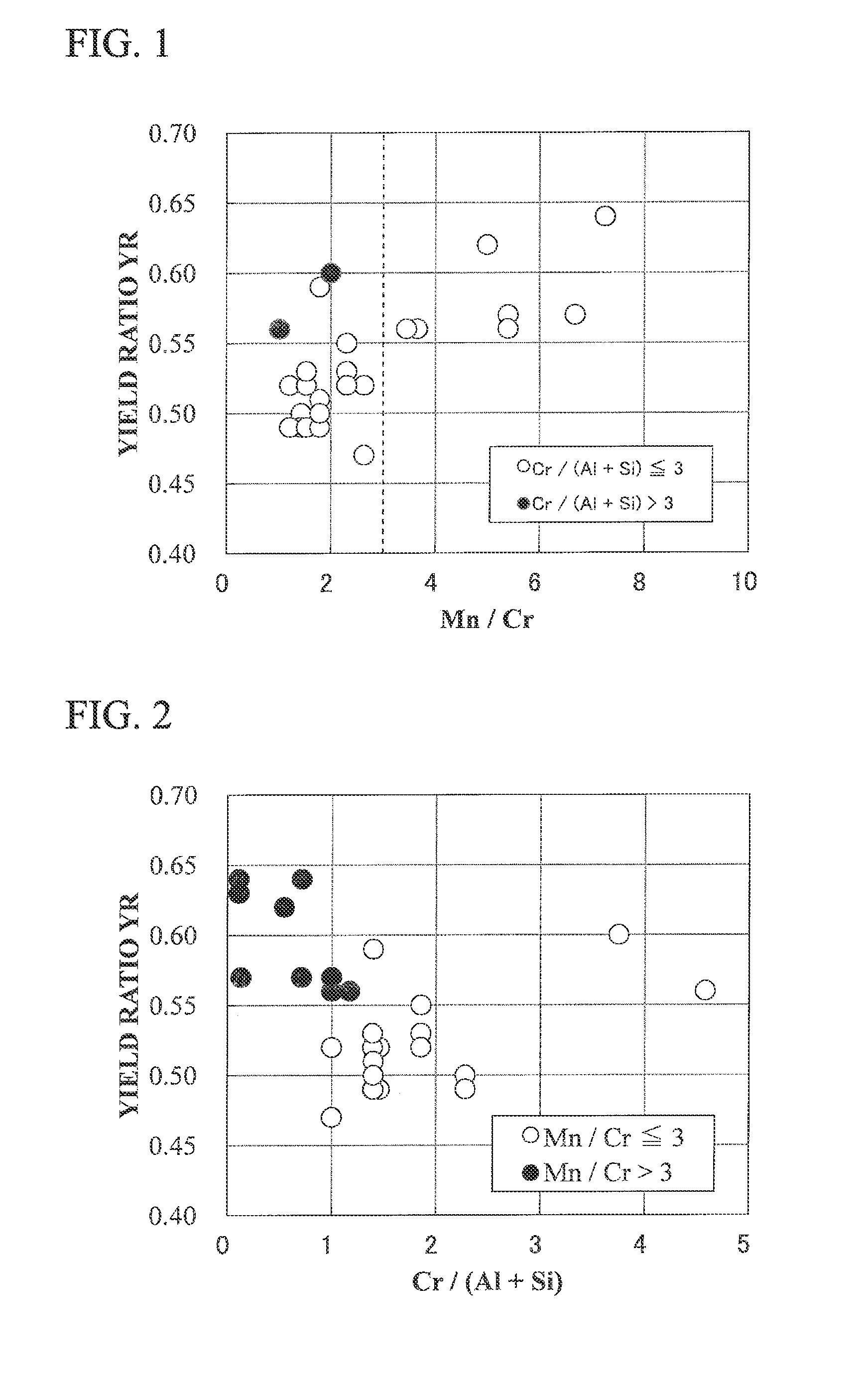

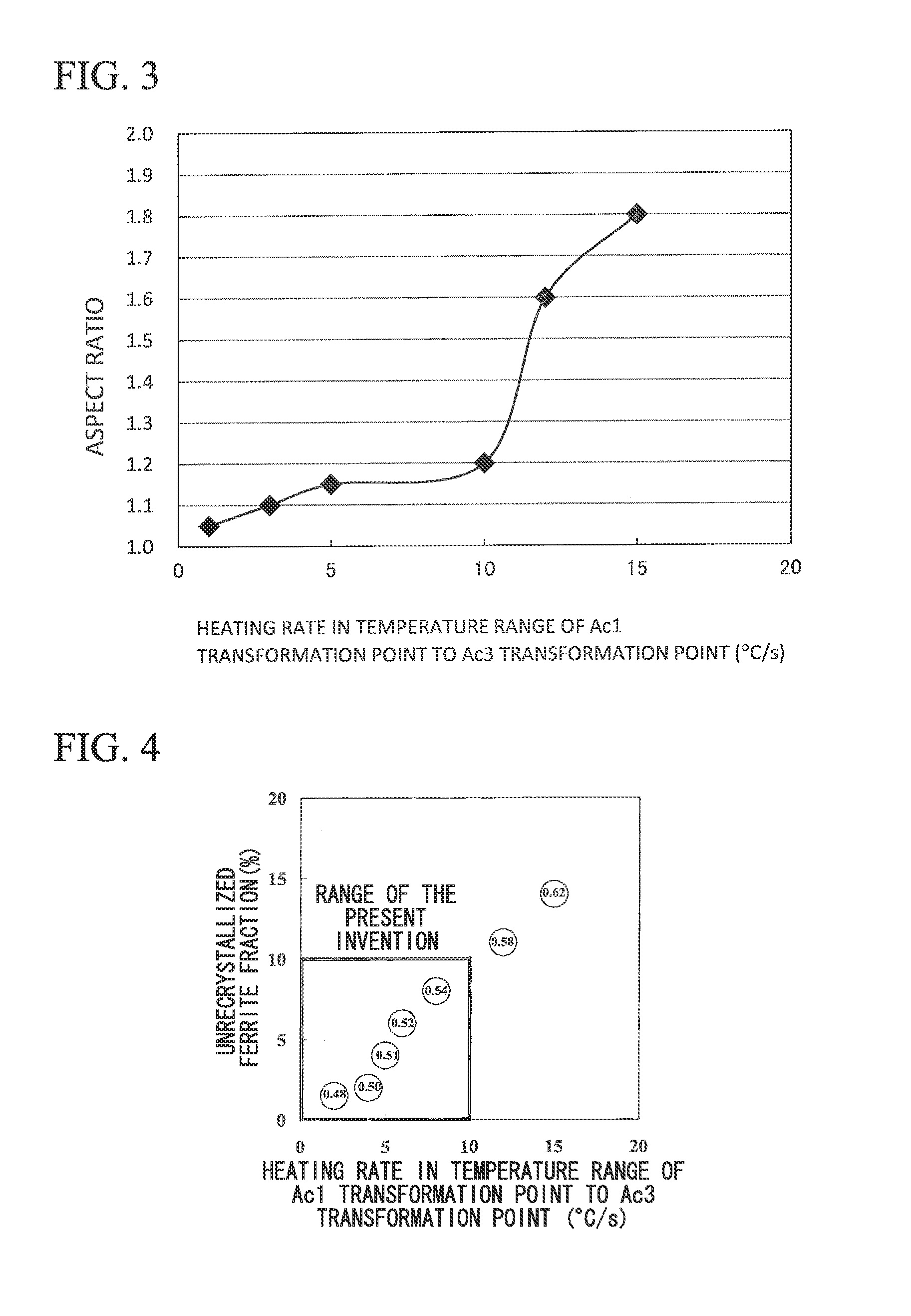

InactiveUS20120282487A1Lower ratioLow strengthHot-dipping/immersion processesFurnace typesManganeseMaterials science

The high-strength steel sheet includes, by mass %: C: 0.01% to 0.10%; Si: 0.15% or less; Mn: 0.80% to 1.80%; P: 0.10% or less; S: 0.015% or less; Al: 0.10% to 0.80%; Cr: 0.01% to 1.50%; N: 0.0100% or less; and a balance consisting of iron and inevitable impurities, in which a metallic structure is composed of ferrite and a hard second phase, the area fraction of the ferrite is 80% or more, the area fraction of the hard second phase is 1% to 20%, the fraction of unrecrystallized ferrite in the ferrite is less than 10%, the ferrite grain sizes are 5 μm to 20 μm, and the fraction of the ferrite crystal grains having an aspect ratio of 1.2 or less in the entire ferrite crystal grains is 60% or more.

Owner:NIPPON STEEL CORP

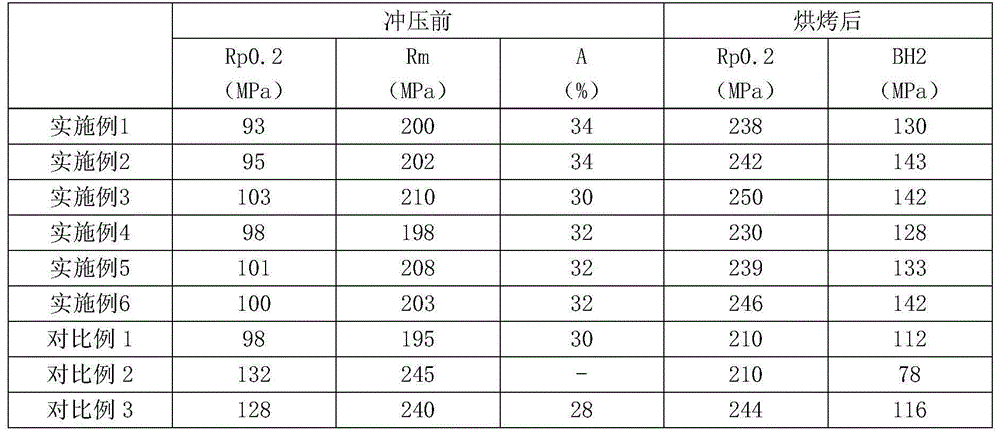

Cold rolling baking hardened steel with yield strength 220MPa and production method thereof

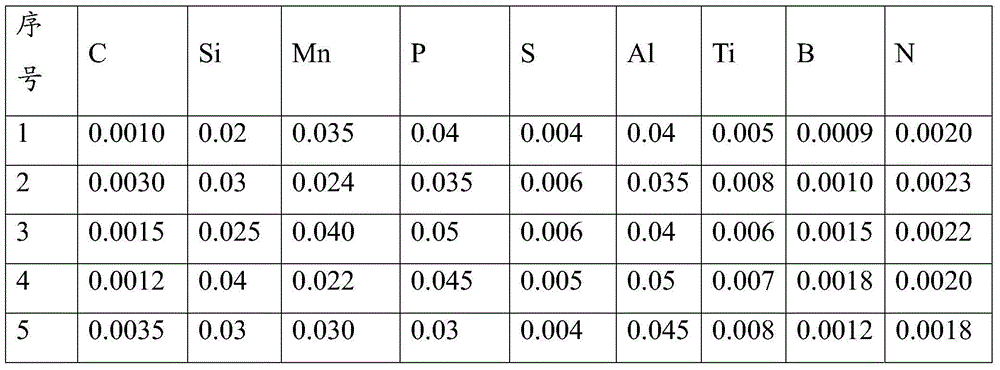

The invention relates to low alloyed steel and a production method thereof aiming at solving the defects of low yield strength, high production cost, and the like currently. The invention comprises the measures that the cold-rolling, baking and hardening steel with the yield strength of 220MPa contains components and percentages by weight of 0.05-0.10 percent of C, 0.20-0.70 percent of Mn, 0.01-0.06 percent of P, 0.01-0.06 percent of Als, 0.002-0.004 percent of B, less than or equal to 0.04 percent of Si, less than or equal to 0.015 percent of S, less than or equal to 0.005percent of N, and the rest of Fe and unavoidable impurities; and the production method comprises the following steps of heating a casting blank to 1180-1280 DEG C and finishing rolling under the temperature of 860-930 DEG C; adopting laminar cooling to 650-750 DEG C below and coiling; natural cooling to 10-70 DEG C and cold rolling with the total rolling reduction ratio of 66-85 percent; continuous annealing with the temperature of 780-830 DEG C; cooling in an annealing furnace with the temperature drop speed of 30-80 DEG C / second and the temperature of 390-420 DEG C after being cooled; overaging treatment under the temperature of 360-390 DEG C for 180-250 seconds; cooling and tapping with the temperature of 150-170 DEG C; and finally, leveling with the elongation ratio of 1.20-1.60 percent.

Owner:武汉钢铁有限公司

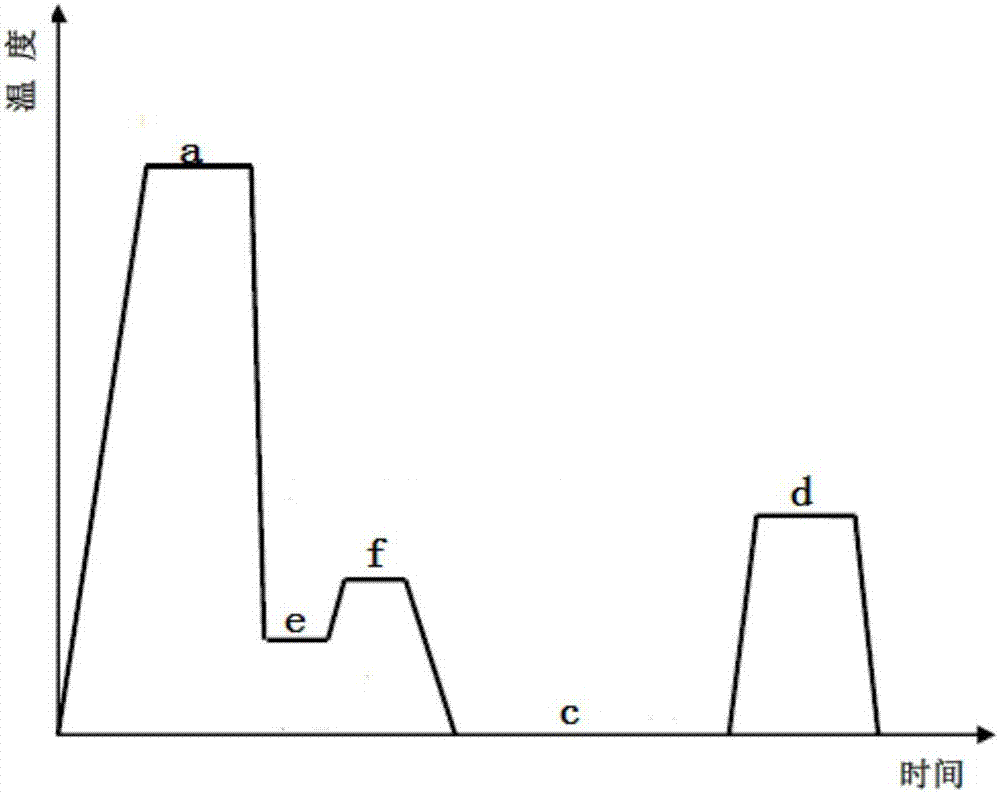

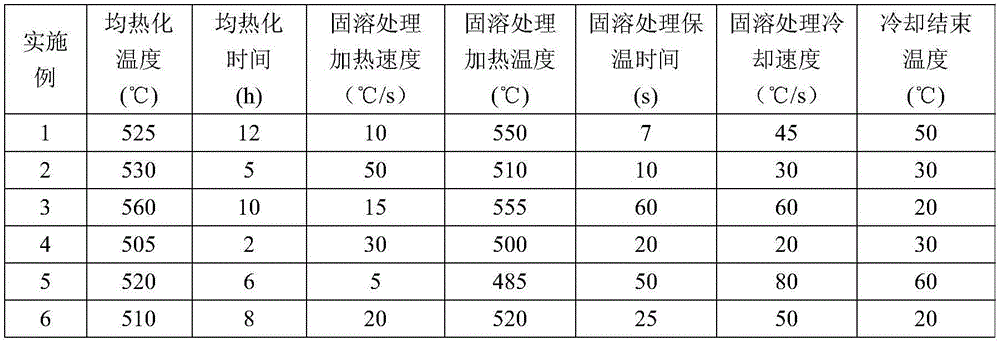

Heat treatment method capable of improving natural aging stability of 6000-series aluminum alloy and aluminum alloy plate

The invention discloses a heat treatment method capable of improving natural aging stability of 6000-series aluminum alloy and an aluminum alloy plate, and relates to the technical field of aluminum alloy heat treatment. The heat treatment method comprises the following steps that a 6000-series aluminum alloy plate is subjected to solid solution treatment and quenched to 40-60 DEG C, heat is preserved for 5-20 min, then the temperature is quickly increased to 100-120 DEG C, heat is preserved for 2-5 min, and then the plate is cooled to the room temperature. By means of the method, the problems that a traditional solid solution pre-aging treatment method is poor in natural aging stability and short in bake hardening performance maintaining time are relieved. By adoption of the heat treatment method, the stability in the room temperature stagnating process can be better regulated and controlled, and thus adverse influences of natural aging are restrained; and not only can the aluminum alloy keep a good forming property for a long time, but also the paint-bake hardenability of the aluminum alloy is obviously improved, after paint baking, the strength and hardness of the obtained aluminum alloy plate are obviously improved, the yield strength is greater than 200 MPa, and the hardness is greater than 95 HB.

Owner:SHANDONG NANSHAN ALUMINUM +1

High volume edge and high baking hardening performance aluminum alloy sheet material and preparation method thereof

The invention provides a high volume edge and high baking hardening performance aluminum alloy sheet material and a preparation method thereof. The alloy comprises, by mass, 0.4-0.8% of Si, 0.4-1% ofMg, no more than 0.3% of Fe, no more than 0.2% of Cu, no more than 0.2% of Mn, the balance Al, and less than 0.05wt% of other impurities. The high volume edge and high baking hardening performance aluminum alloy is good in the mechanical performance, and meanwhile, the high volume edge and high baking hardening performance aluminum alloy has a high volume edge performance and a high bake hardeningperformance, and is suitable for auto-body covering, especially for an auto-body covering piece shell plate.

Owner:CHINALCO MATERIALS APPL RES INST CO LTD

Ultra-low carbon cold-roll steel sheet and preparation method thereof

The invention provides an ultra-low carbon cold-roll steel sheet and a preparation method thereof. The preparation method comprises the steps of hot rolling, reeling, cold rolling, annealing, finishing, drawing and straightening a steel sheet blank sequentially, wherein the steel sheet blank comprises the following components by weight percent: 0.001-0.006% of C, 0.01-0.05% of Si, 0.1-0.5% of Mn, less than or equal to 0.015% of P, less than or equal to 0.015% of S, 0.005-0.03% of Nb, 0.01-0.08% of Al, and the balance of iron and inevitable impurities. The preparation method can provide the ultra-low carbon cold-roll steel sheet with good bake hardening performance.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

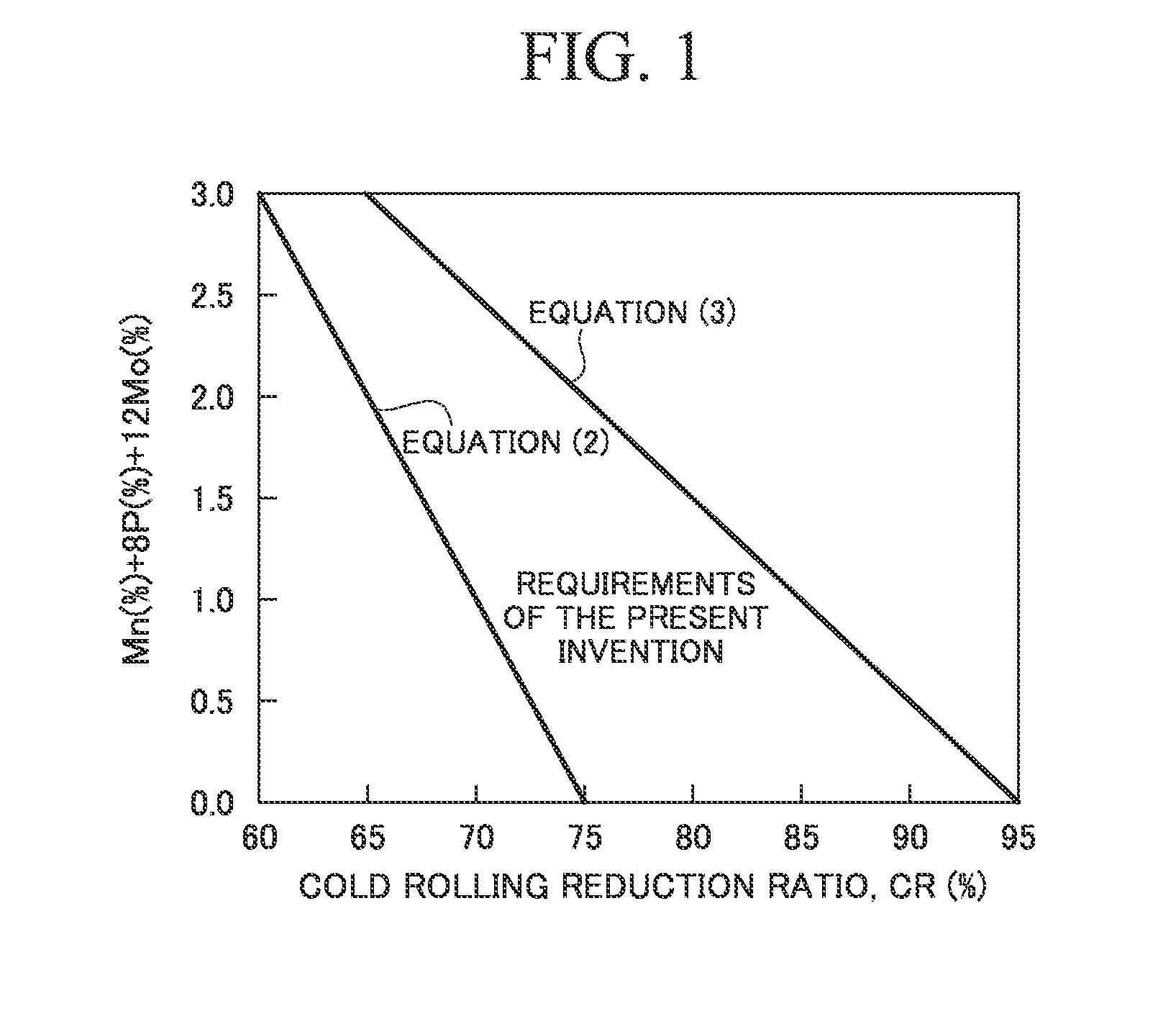

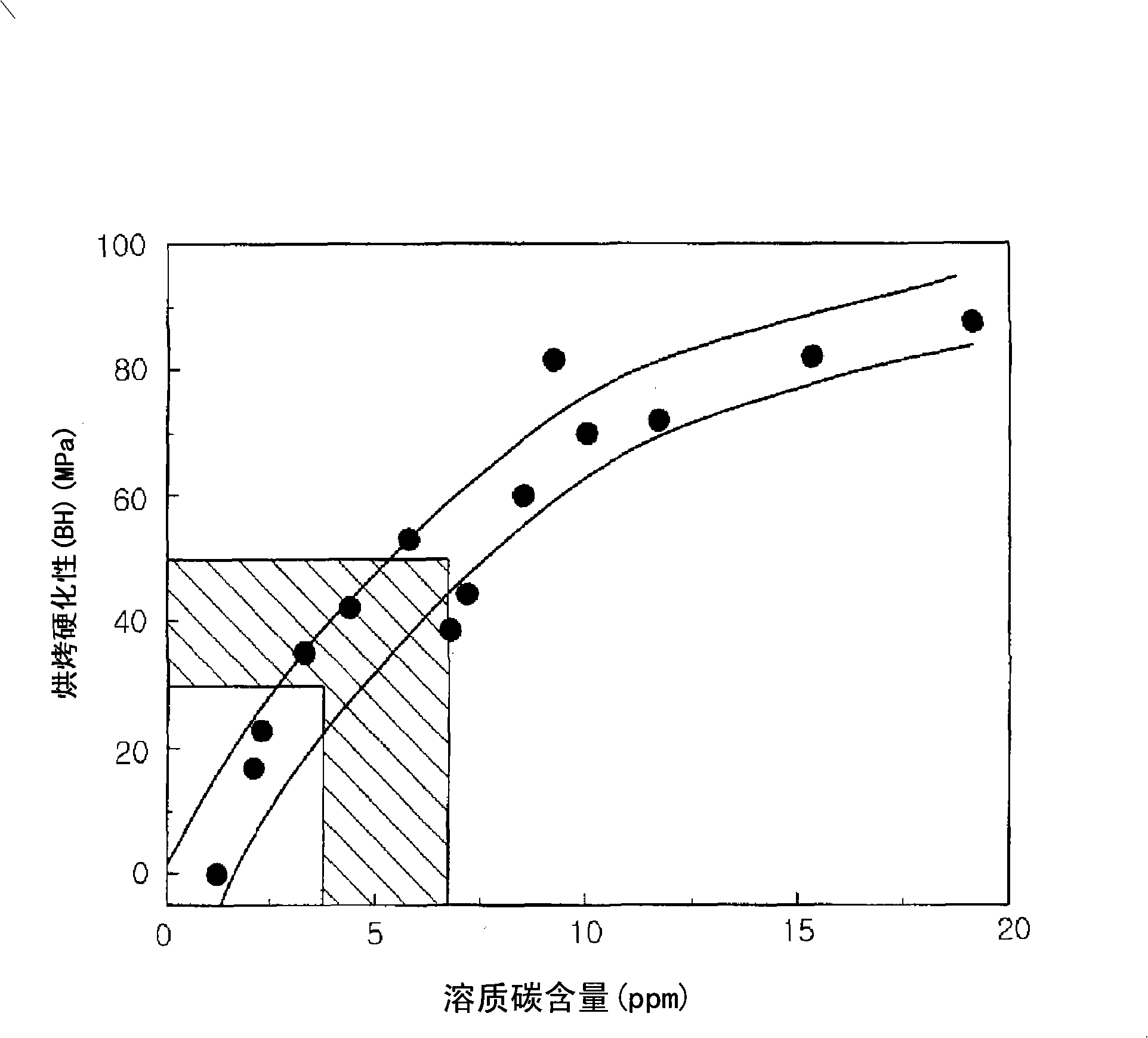

Bake-hardenable high-strength cold-rolled steel sheet and method of manufacturing the same

ActiveUS20130240094A1Excellent bake hardenabilityReduced planar anisotropyFurnace typesHeat treatment process controlHardenabilityAging resistance

The present invention provides a bake-hardenable high-strength cold-rolled steel sheet having excellent bake hardenability, cold aging resistance, and deep-drawability, and reduced planar anisotropy, containing chemical components in % by mass of: C: 0.0010% to 0.0040%, Si: 0.005% to 0.05%, Mn: 0.1% to 0.8%, P: 0.01% to 0.07%, S: 0.001% to 0.01%, Al: 0.01% to 0.08%, N: 0.0010% to 0.0050%, Nb: 0.002% to 0.020%, and Mo: 0.005% to 0.050%, a value of [Mn %] / [P %] being in the range of 1.6 to 45, where [Mn %] is an amount of Mn and [P %] is an amount of P, an amount of C in solid solution obtained from [C %]−(12 / 93)×[Nb %] being in the range of 0.0005% to 0.0025%, where [C %] is an amount of C and [Nb %] is an amount of Nb, with a balance including Fe and inevitable impurities, wherein the bake-hardenable high-strength cold-rolled steel sheet satisfies the following Equation (1), where X(222), X(110), and X(200) represent ratios of integrated intensity of X-ray diffraction of {222} plane, {110} plane, and {200} plane, respectively, being parallel to a plane located at a depth of ¼ plate thickness measured from the surface of the steel sheet, and the bake-hardenable high-strength cold-rolled steel sheet has tensile strength in the range of 300 MPa to 450 MPa.X(222) / {X(110)+X(200)}≧3.0 Equation (1)

Owner:NIPPON STEEL CORP

Clad automotive sheet product

InactiveCN102119078AImprove curling effectAbility to maintain age hardeningThin material handlingMetal layered productsImpurityBake hardening

The present invention relates to an automotive clad sheet product comprising a core Sayer and at least one clad layer wherein the core comprises an alloy of the following composition in weight %: Mg 0.45-0,8, Si 0.45-0.7, Cu 0.05-0.25, Mn 0.05-0.2, Fe up to 0,35, other elements (or impurities) <0,05 each and <0.15 in total, balance aluminium; and the at least one clad layer comprises an alloy of the following composition in weight %: Mg 0.3-0.7, Si 0,3-0.7, Mn up to 0,15, Fe up to 0.35, other elements (impurities) <0.05 each and <0.15 in total, balance aluminium. The clad automotive sheet product provides excellent hemmabtlity which does not substantially change over time and yet also provides a good age-hardening response after bake hardening.

Owner:NOVELIS INC

Bake-hardenable cold rolled steel sheet with superior strength and aging resistance, gal-vannealed steel sheet using the cold rolled steel sheet and method for manufacturing the cold rolled steel shee

ActiveCN101310031AHigh strengthImprove anti-agingFurnace typesHeat treatment furnacesSheet steelRoom temperature

A bake-hardenable cold rolled steel sheet with high strength and superior aging resistance used for outer panels of an automobile body, a galvannealed steel sheet using the cold-rolled steel sheet, and a method for manufacturing the cold-rolled steel sheet are disclosed. The steel sheet comprises, by weight%, C: 0.0016-0.0025%, Si: 0.02% or less, Mn: 0.2-1.2%, P: 0.05-0.11%, S: 0.01% or less, Sol. Al: 0.08-0.12%, N: 0.0025% or less, Ti: 0-0.003%, Nb: 0.003-0.011%, Mo: 0.01-0.1%, B: 0.0005-0.0015%, the balance of Fe and other unavoidable impurities. The steel sheet has superior bake hardenability, aging resistance at room temperature, and secondary work embrittlement resistance.

Owner:浦项股份有限公司

Pretreatment process for automobile deformed aluminum alloy plate

The invention relates to a technique of processing low-copper vehicle wrought aluminium alloy boards such as 6022, 6016 and the like, especially relates to a preprocessing technique for assuring baking hardenability and formability of vehicle wrought aluminium alloy boards.The preprocessing technique of vehicle wrought aluminium alloy boards is characterized by placing aluminum alloy boards into a furnace for solid solution treatment, 30 minutes after the solid solution heating and heat preserving under a temperature of 520 DEG C-550 DEG C, placing them into a polyether water-soluble medium of 5-10% for quenching, putting them in a room temperature for 2-3 days after being cooled, putting them into an aging treatment furnace for being treated for 10-15 minutes under a temperature of 140-170 DEG C. The invention which is a simple technique improves the yield strength, tensile strength and specific elongation of aluminum alloy boards, therefore, improving the formability, aging -resisting stability and baking hardenability of aluminum alloy boards, can achieve an satisfactory baking and overhardening effect on the existing oil paint line, improves rate of final products formed by pressing, reduces the pressing cost and promotes the application of aluminum boards in the lighteningof vehicles.

Owner:HENAN SUDA ELECTRIC AUTOMOBILE TECH

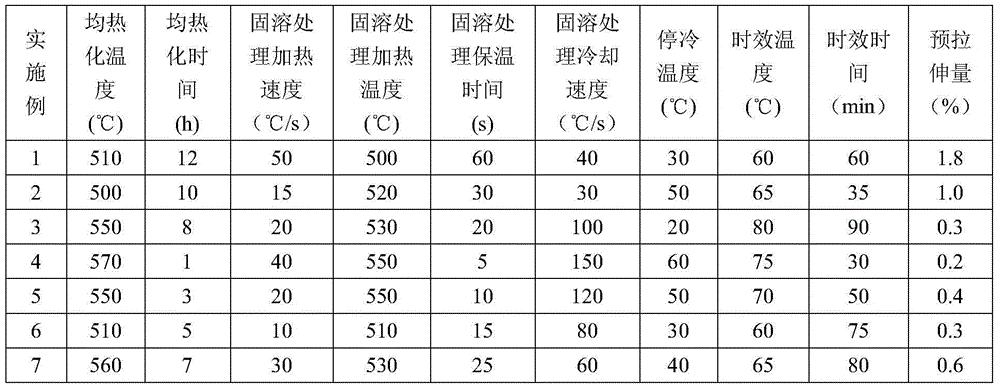

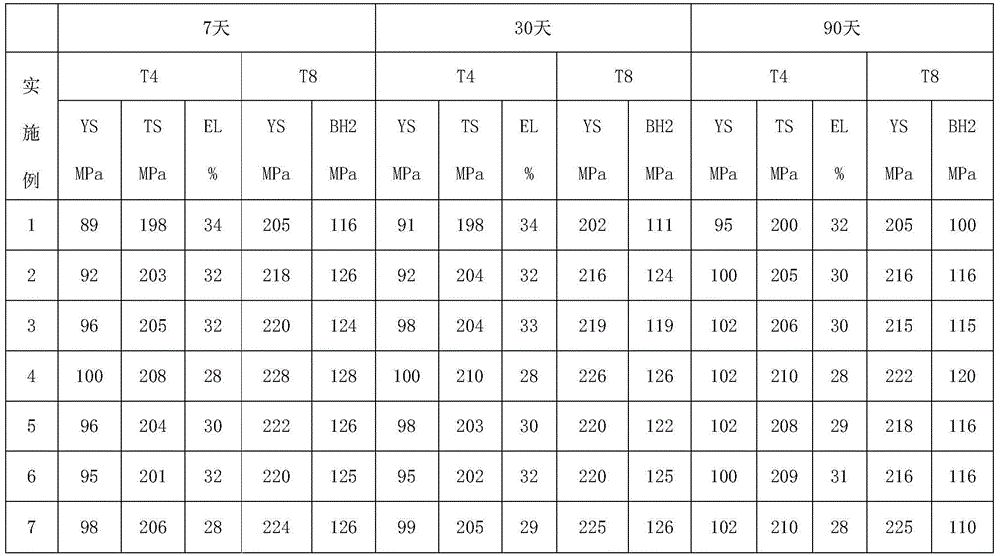

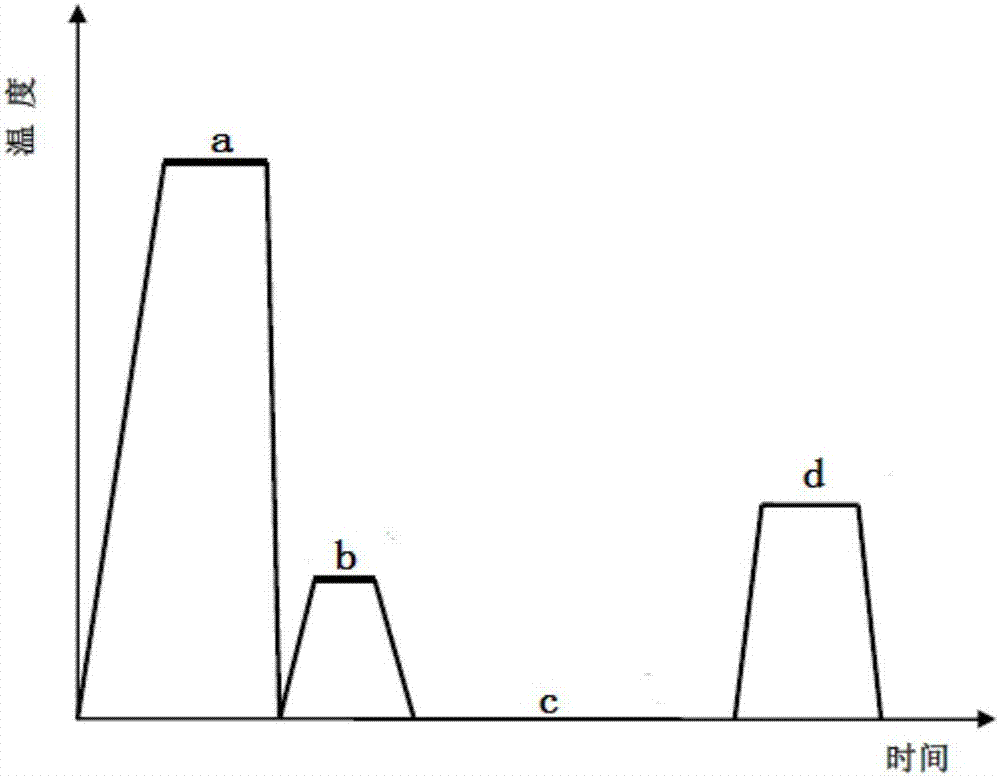

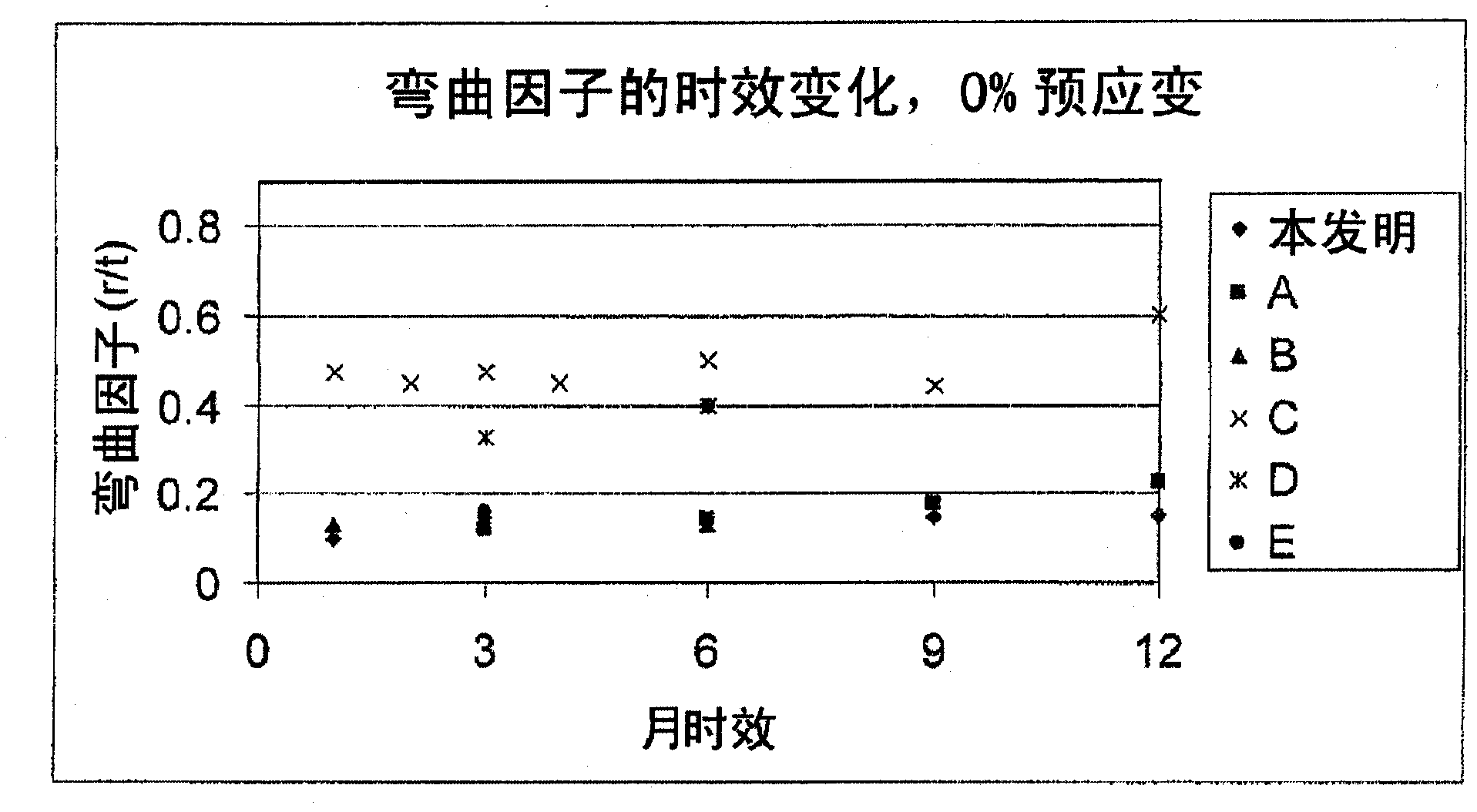

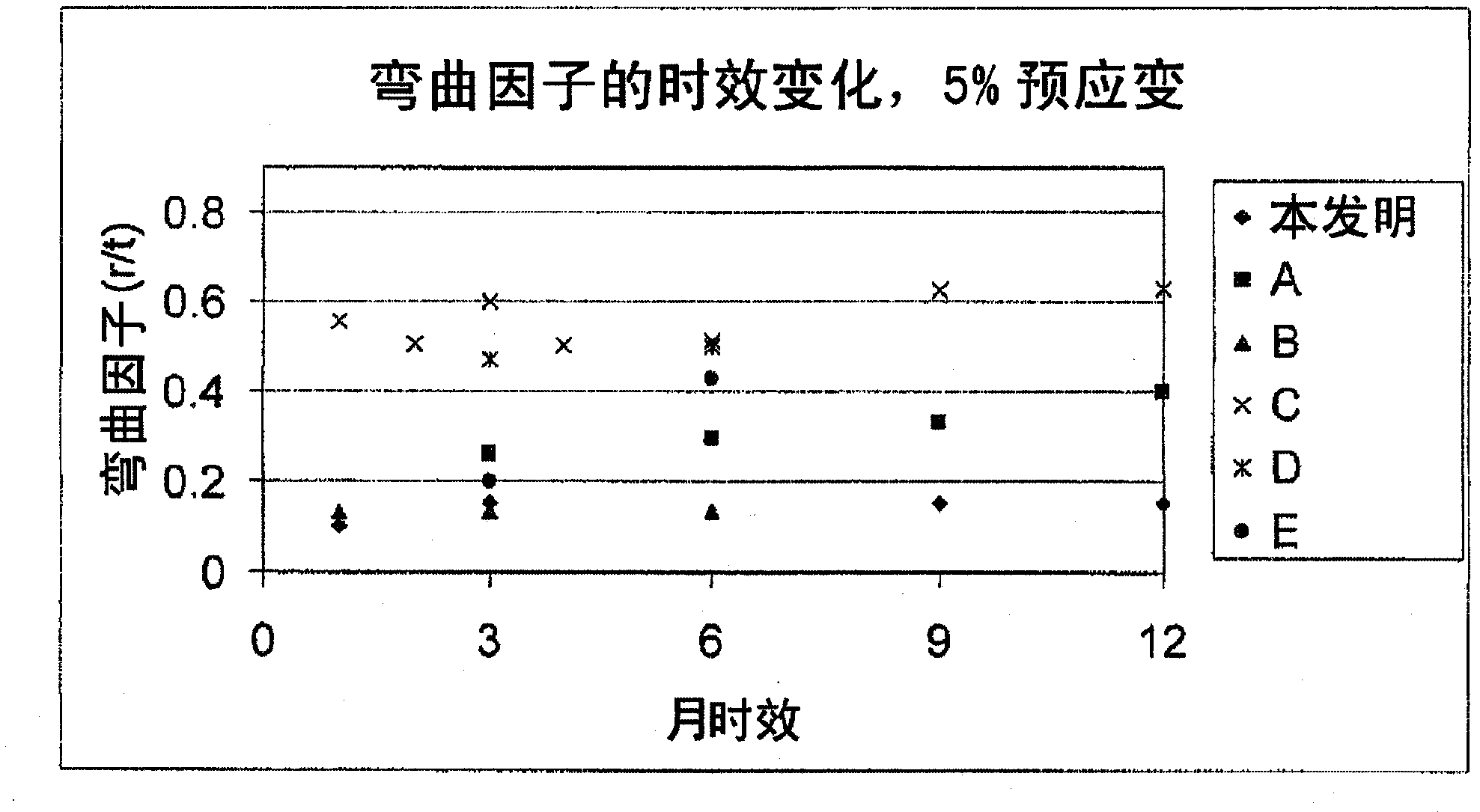

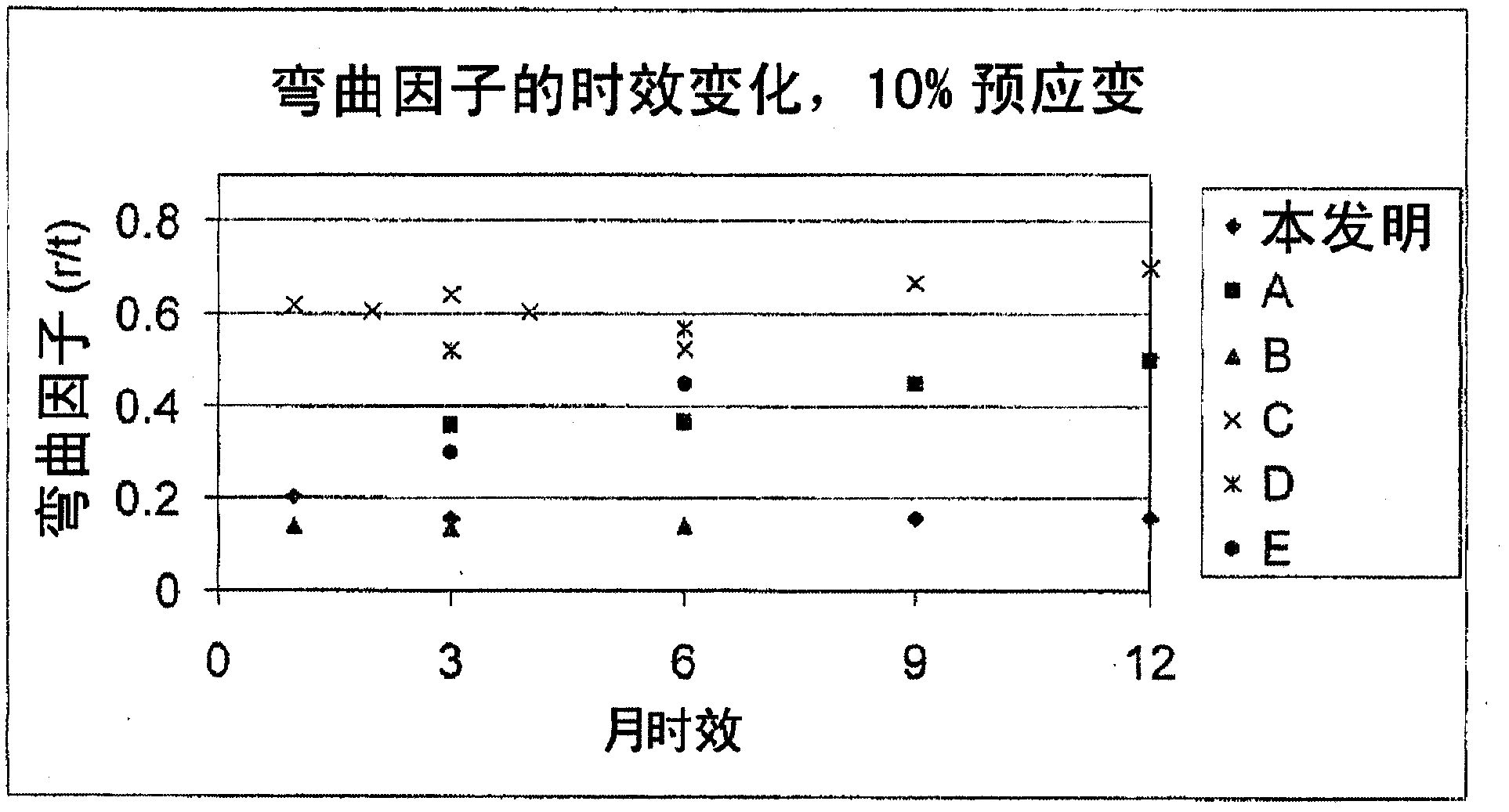

A heat treatment method that improves the formability and bake hardenability of 6XXX series aluminum alloy sheets

ActiveCN101545083AExtended retention of bake-hardening propertiesImprove machining accuracyEconomic benefitsEnergy conservation

The present invention provides a heat treatment method that may improve the formability and bake hardenability of 6XXX series aluminum alloy and remarkably lengthen the lasting time of bake hardenability. After solution hardening and before stamping, 6XXX series aluminum alloy sheets will undergo heat treatment for a certain period of time. The technical solution of the present invention facilitates automatic operation, can be easily realized and may save energy and equipment investment. After 6XXX series aluminum alloy sheets are treated by this method after solution hardening, its formability and bake hardenability are improved obviously. More importantly, after heat treatment by the method of the present invention, the lasting time of the bake hardenability of aluminum alloy sheets is greatly lengthened to 3-4 months, even 6 months. The above advantages will promote the substitution of aluminum alloy sheets for steel sheets to reduce car weight, thus saving energy and reducing emission while achieving desirable economic benefit.

Owner:HUNAN UNIV

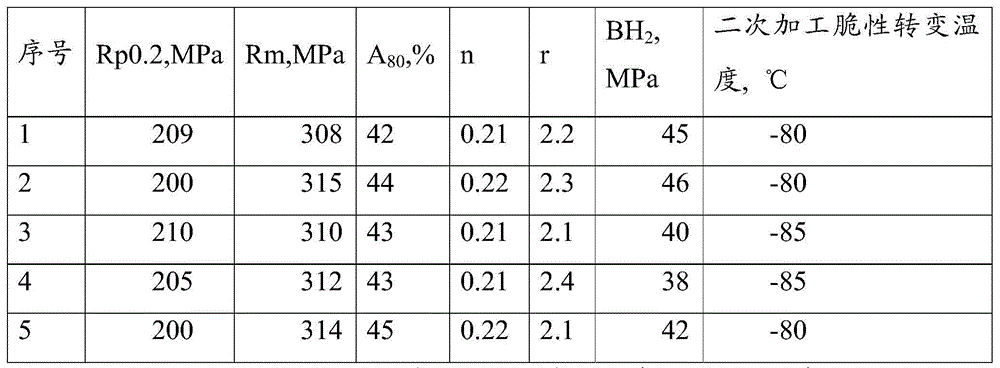

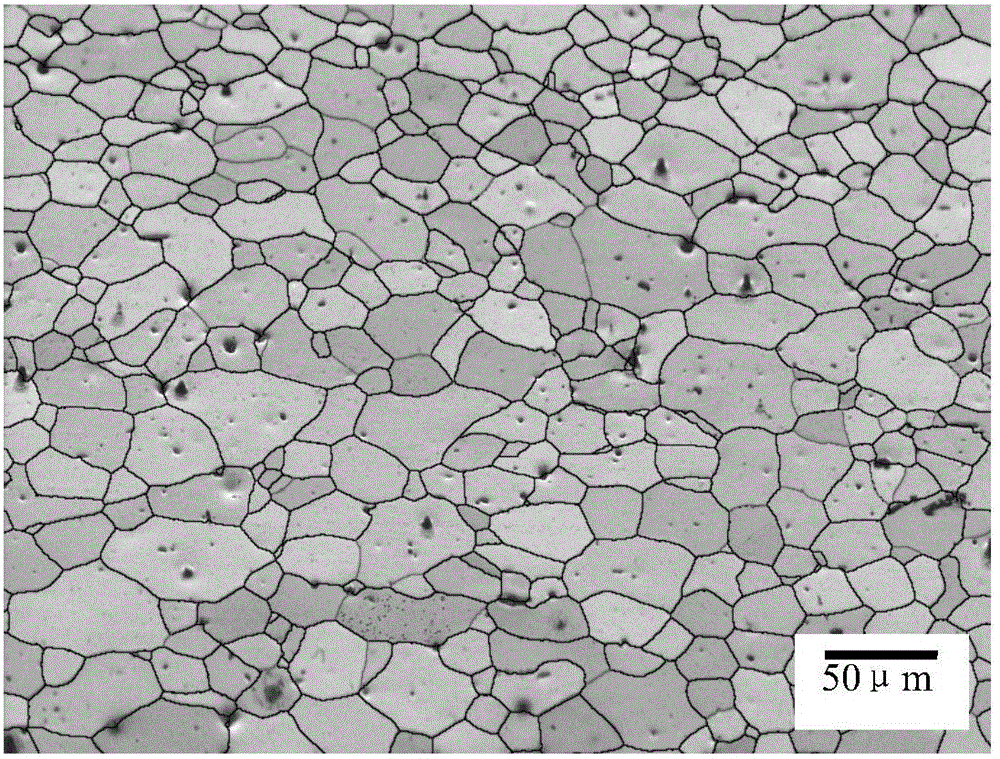

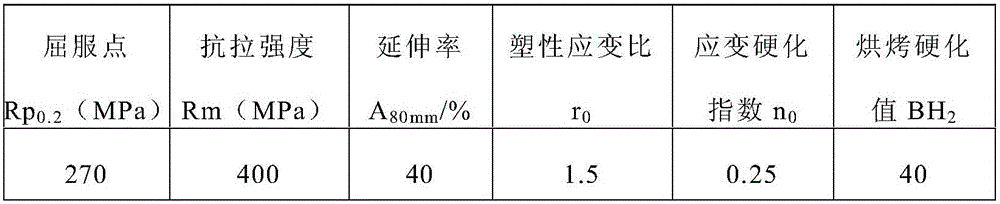

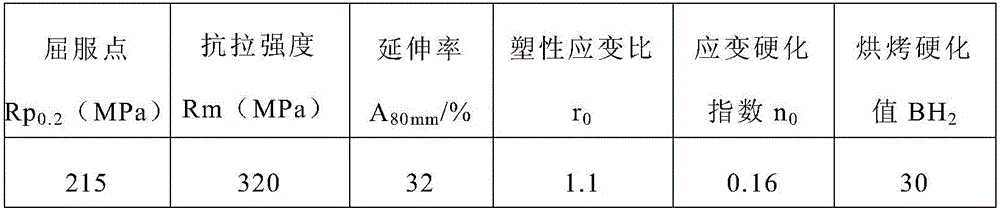

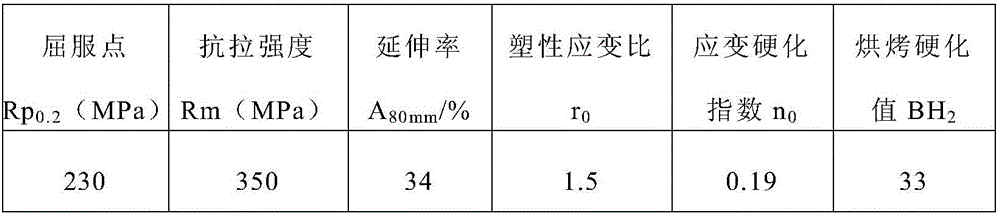

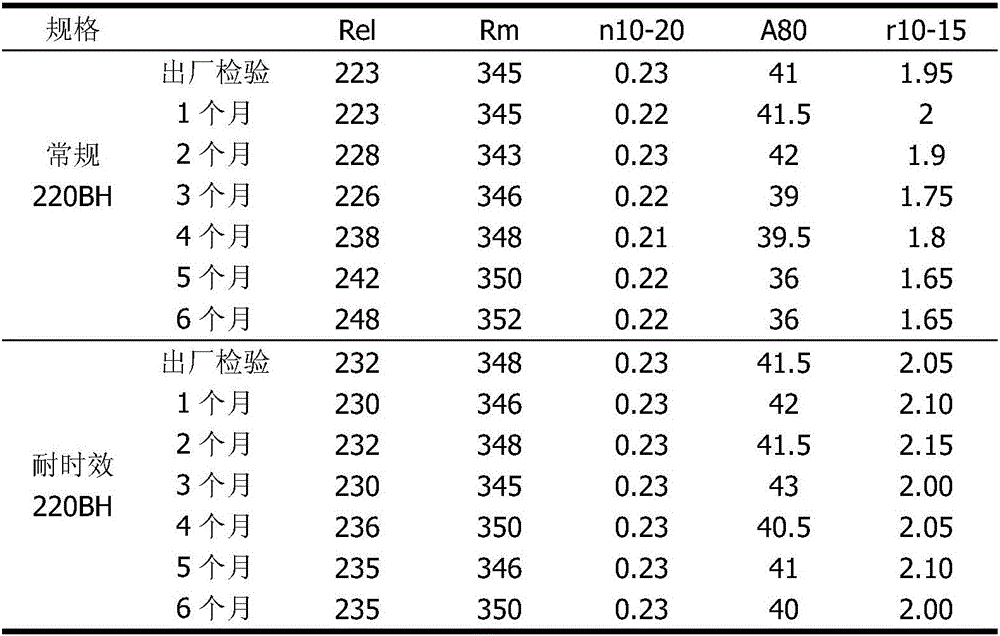

Hot-dip galvanized steel sheet with stable bake hardening performance and production method thereof

InactiveCN111101067AProduction control is less difficultGrain refinementSmelting processSolid solution

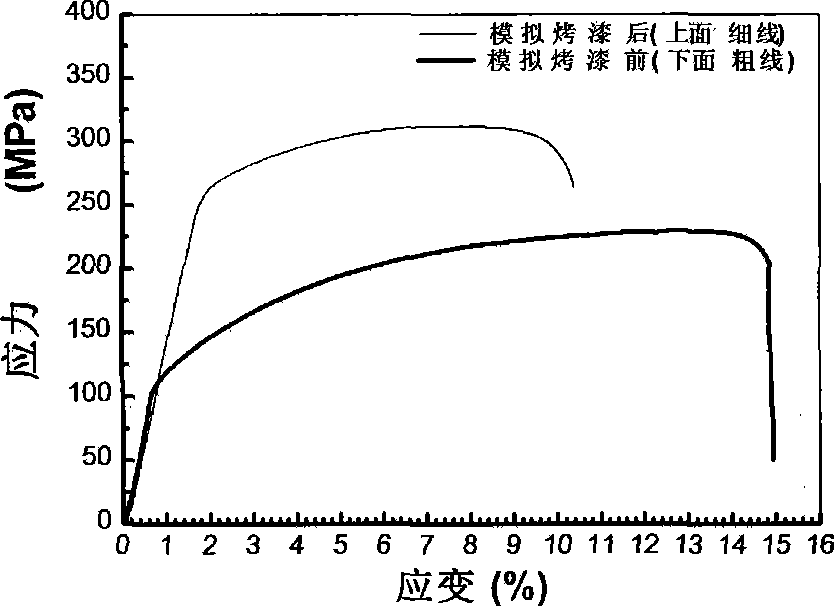

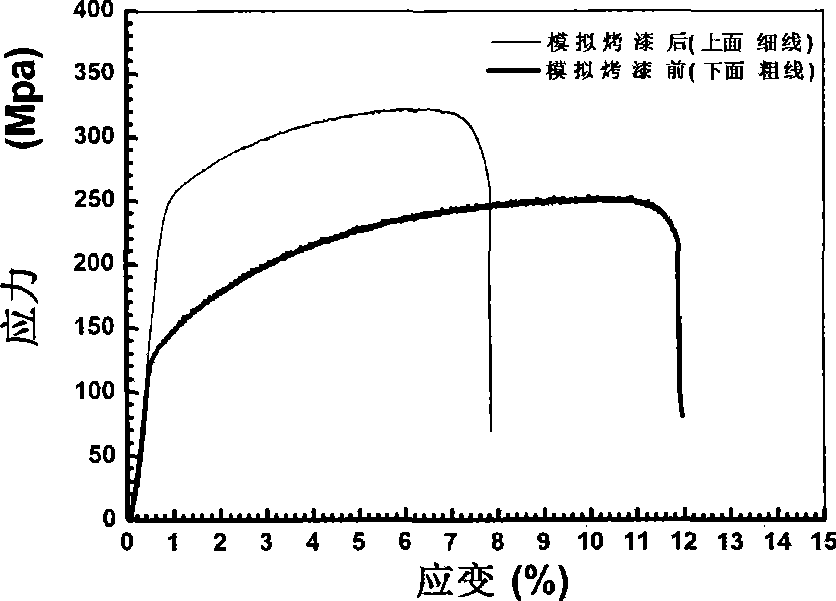

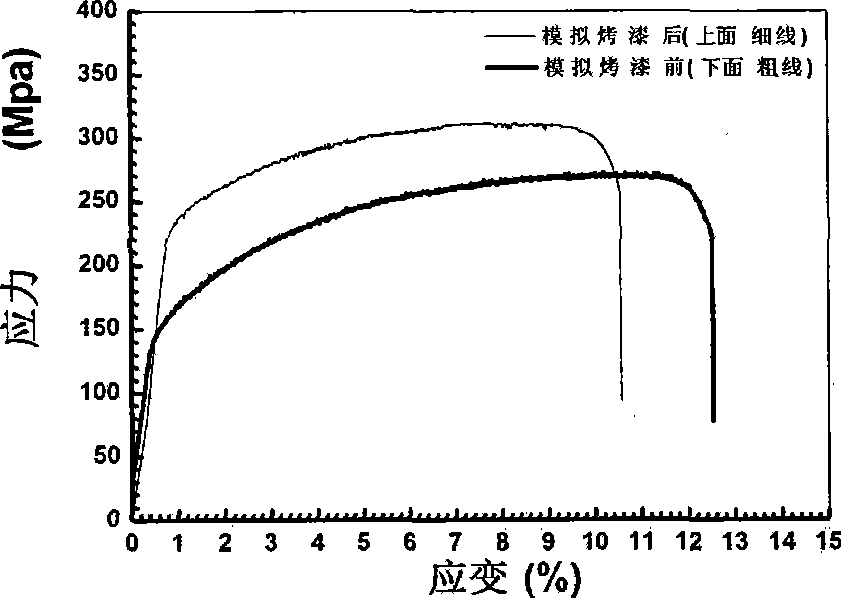

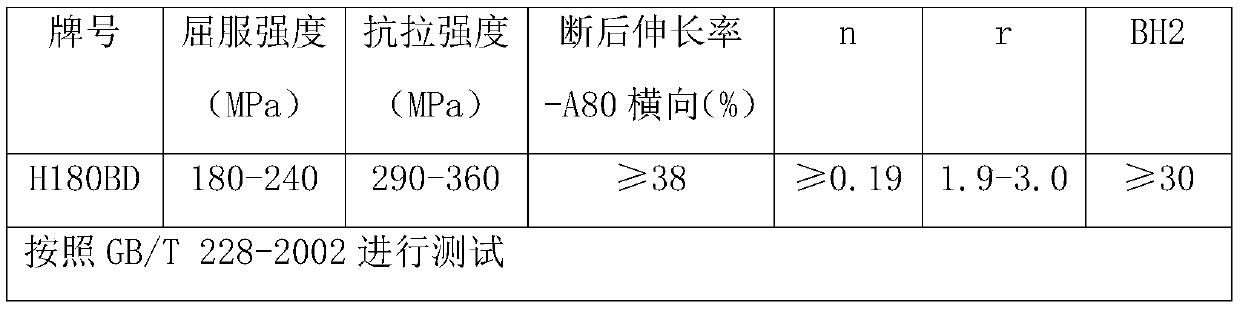

The invention relates to a hot-dip galvanized steel sheet with stable bake hardening performance. The sheet is characterized by comprising the following chemical components of, in percentage by mass,0.0018 %-0.0033 % of C, less than or equal to 0.02 % of Si, 0.22 %-0.30 % of Mn, 0.015 %-0.025 % of P, less than or equal to 0.01% of S, 0.002 %-0.01 % of Ti, 0.002 %-0.01 % of Nb, 0.04 %-0.06 % of Als, less than or equal to 0.003 % of N, 0.0005 %-0.0015 % of solid solution C, and the balance iron and other impurities in the smelting process. According to the hot-dip galvanized steel sheet, the thickness is 0.5-2.5 mm, the yield strength is 180-240 MPa, the tensile strength is 290-360 MPa, the elongation percentage A80 is larger than or equal to 38%, the n90 is larger than or equal to 0.19, the r90 is larger than or equal to 1.9 and smaller than or equal to 3.0, and the bake hardening value BH2 is larger than or equal to 30 MPa, and in six months after a product is manufactured, the bake hardening value is kept in an effective range of 30-50 MPa. According to the steel, the problems that according to an existing low-strength ultralow-carbon bake hardening steel sheet, the bake hardening performance is unstable, the timeliness is poor, and the performance fluctuation caused by the poor timeliness can be solved, so that the stamping performance and the concave resistance of the material are effectively improved.

Owner:ANSC TKS GALVANIZING

Al-Mg-Si aluminum alloy material, aluminum alloy plate, and preparation methods of Al-Mg-Si aluminum alloy material and aluminum alloy plate

The invention discloses an Al-Mg-Si aluminum alloy material. The Al-Mg-Si aluminum alloy material comprises the following chemical elements in mass percentage: Mg of which the mass percentage is equal to or larger than 0.5% and equal to or smaller than 1.0%, Si of which the mass percentage is equal to or larger than 0.6% and equal to or smaller than 1.5%, Sn of which the mass percentage is equal to or larger than 0.02% and equal to or smaller than 0.2%, Mn of which the mass percentage is equal to or larger than 0.1% and equal to or smaller than 0.45%, Fe of which the mass percentage is larger than 0 and equal to or smaller than 0.4%, Ti of which the mass percentage is equal to or larger than 0.02% and equal to or smaller than 0.1%, Zn of which the mass percentage is equal to or smaller than 0.15%, Cr of which the mass percentage is equal to or smaller than 0.1%, and the balance of Al and other inevitable impurities; in addition, the requirement that the total mass percentage of the Mg and the Si is equal to or smaller than 2.0% is met. In addition, the invention further discloses an aluminum alloy plate made from the Al-Mg-Si aluminum alloy material, and a preparation method of the aluminum alloy plate. The aluminum alloy material disclosed by the invention not only has an excellent forming property, but also has a preferable bake hardening effect.

Owner:BAOSHAN IRON & STEEL CO LTD

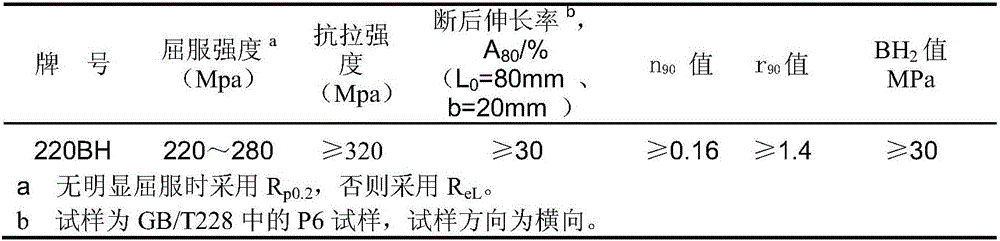

Ageing-resistant cold-rolled bake-hardening steel 220 BH and production method thereof

The invention belongs to the technical field of ageing-resistant cold-rolled bake-hardening steel and particularly relates to ageing-resistant cold-rolled bake-hardening steel 220 BH and a production method thereof. The ageing-resistant cold-rolled bake-hardening steel 220 BH comprises the following components: 0.001-0.003% of C, less than or equal to 0.05% of Si, 0.35-0.80% of Mn, 0.035-0.080% of P, less than or equal to 0.015% of S, 0.015-0.060% of Als, 0.005-0.030% of Nb, less than or equal to 0.0050% of N, 0.01-0.08% of Mo, and the balance of Fe and inevitable impurities. The problem of poor aging resistance of cold-rolled bake-hardening steel with the yield strength of 220 MPa in the prior art is solved, and application to the automobile industry is facilitated.

Owner:BENGANG STEEL PLATES

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com