Hot-dip galvanized steel sheet and production method therefor

一种热镀锌钢板、制造方法的技术,应用在制造工具、热浸镀工艺、化学仪器和方法等方向,能够解决未提及拉伸强度高强度钢板等问题,达到材质均匀性优良、材质均匀性良好、优良耐碰撞性能的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

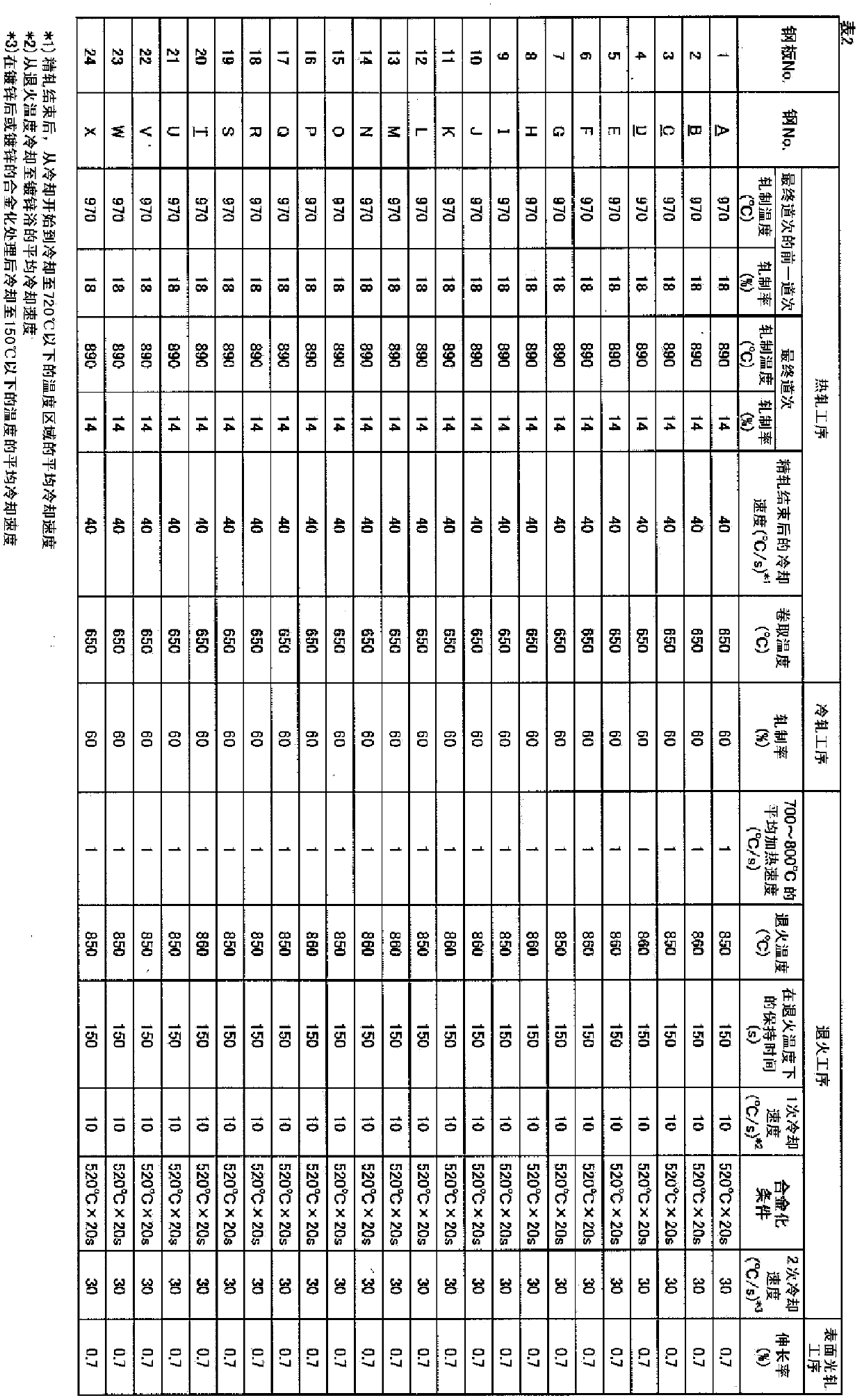

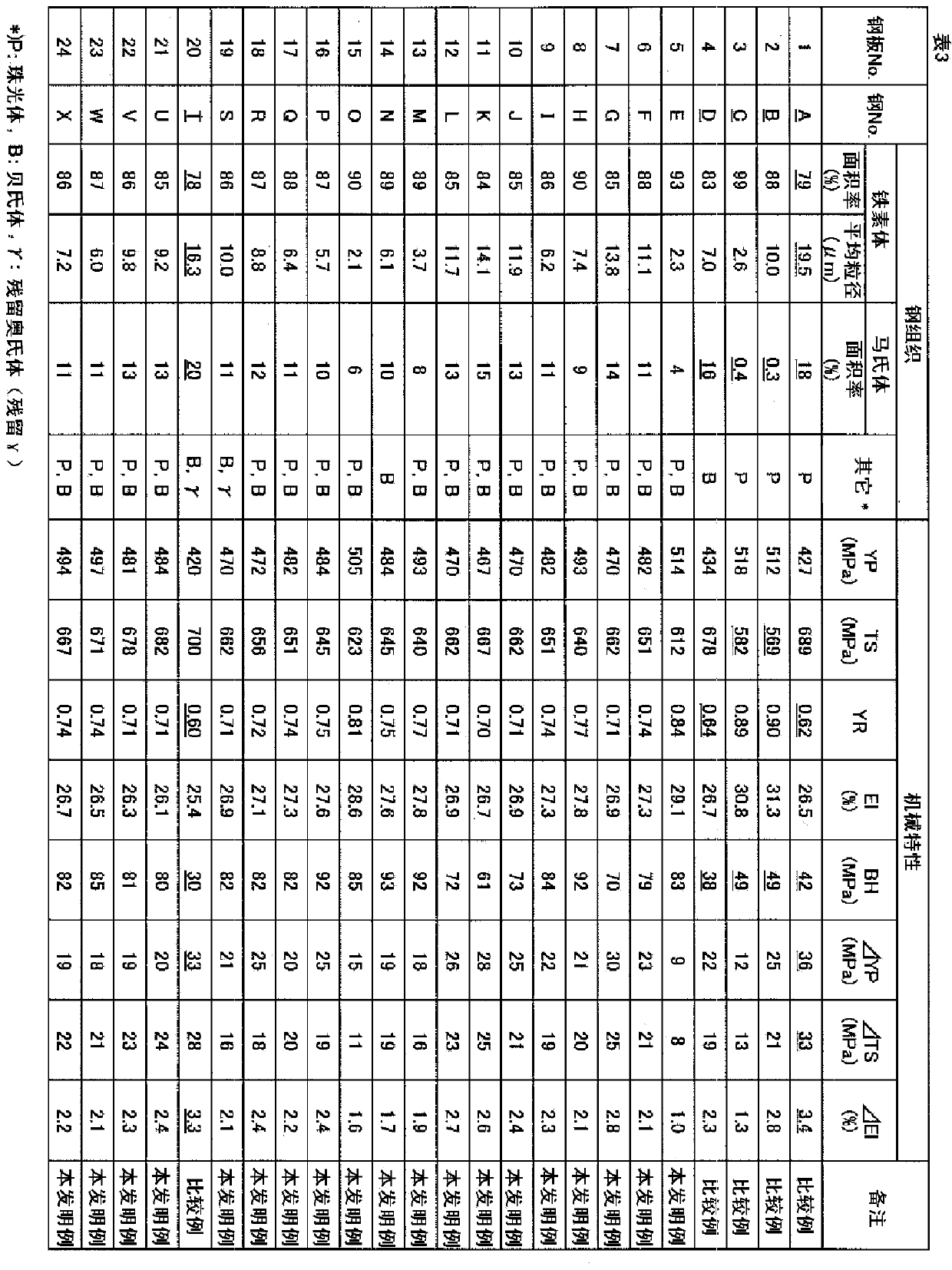

[0133] The molten steel containing the components shown in Table 1 was smelted in a converter, and a slab having a thickness of 230 mm was produced by a continuous casting method. After heating these billets to 1220°C, they were hot-rolled and coiled to obtain a hot-rolled sheet having a thickness of 3.5 mm. In addition, in the finish rolling of the above-mentioned hot rolling, the rolling temperature and rolling ratio of the final pass and the pass preceding the final pass, and the average cooling rate from the start of cooling after the finish rolling to a temperature range of 720° C. or lower , the coiling temperature is shown in Table 2. In addition, the time from the end of finish rolling to the start of cooling was set within 3 seconds.

[0134] Next, the hot-rolled sheet obtained above was pickled, and then cold-rolled under the conditions shown in Table 2 to prepare a cold-rolled steel sheet having a thickness of 1.4 mm. It was annealed and subjected to temper rollin...

Embodiment 2

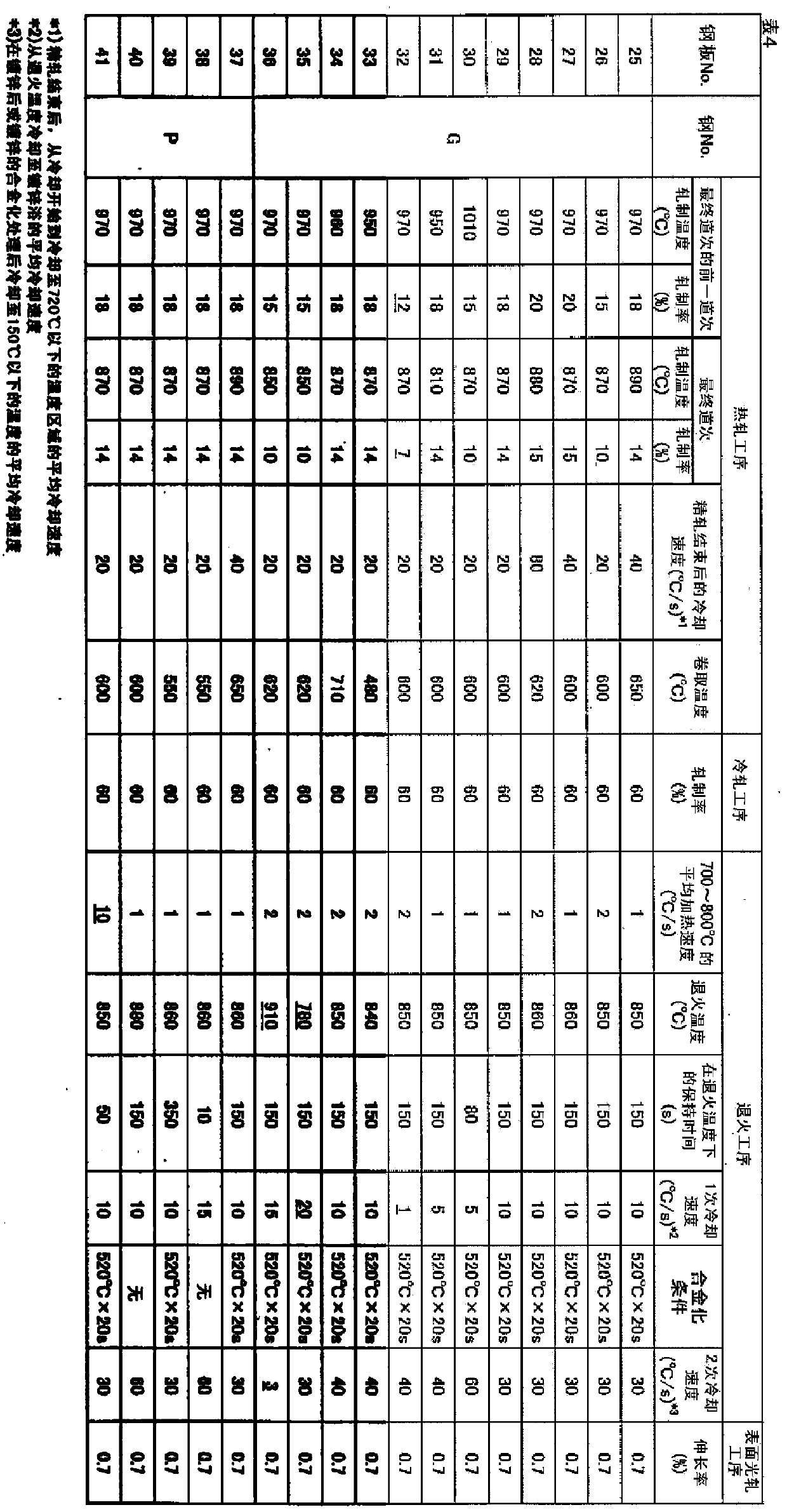

[0149]The molten steel having the chemical compositions of steels G and P shown in Table 1 was smelted in a converter, and a slab having a thickness of 230 mm was produced by a continuous casting method. After heating these billets to 1220°C, they were hot-rolled and coiled to obtain a hot-rolled sheet having a thickness of 3.5 mm. In addition, in the finish rolling of the above-mentioned hot rolling, the rolling temperature and rolling ratio of the final pass and the pass preceding the final pass, and the average cooling rate from the start of cooling after the finish rolling to a temperature range of 720° C. or lower , the coiling temperature is shown in Table 4. In addition, the time from the end of finish rolling to the start of cooling was set within 3 seconds.

[0150] Next, the hot-rolled sheet obtained above was pickled, and then cold-rolled under the conditions shown in Table 4 to obtain a cold-rolled steel sheet having a thickness of 1.4 mm. It was annealed and sub...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| area ratio | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com