Patents

Literature

251results about How to "High yield ratio" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

High yield ratio and high-strength hot-dip galvanized steel sheet excellent in workability and production method thereof

InactiveCN101724776AHigh yield ratioHigh elongationHot-dipping/immersion processesFurnace typesSheet steelCrystal orientation

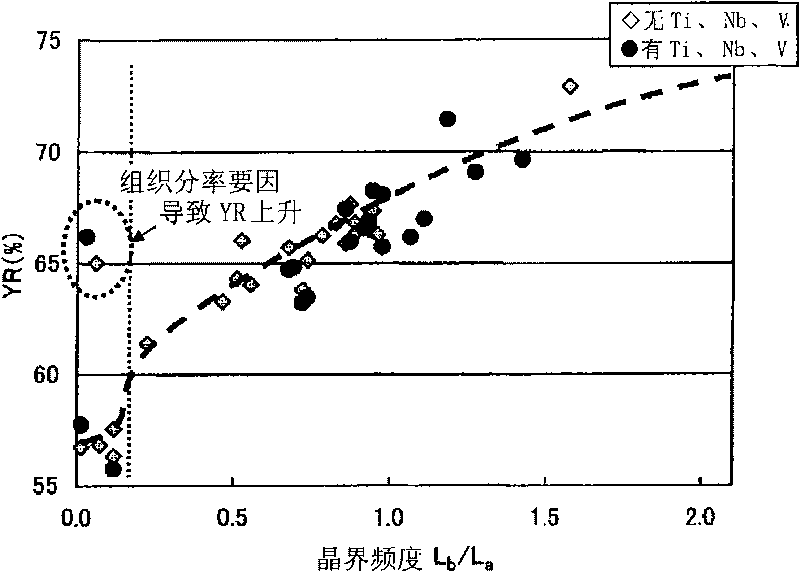

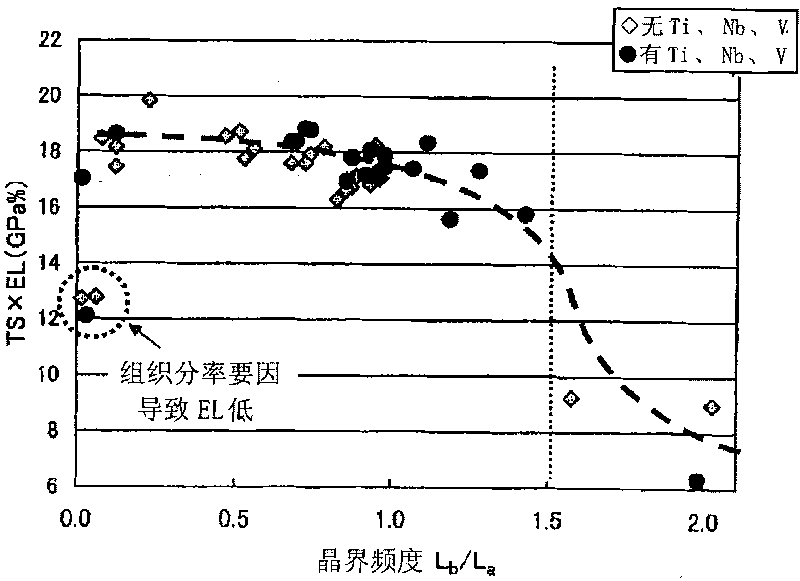

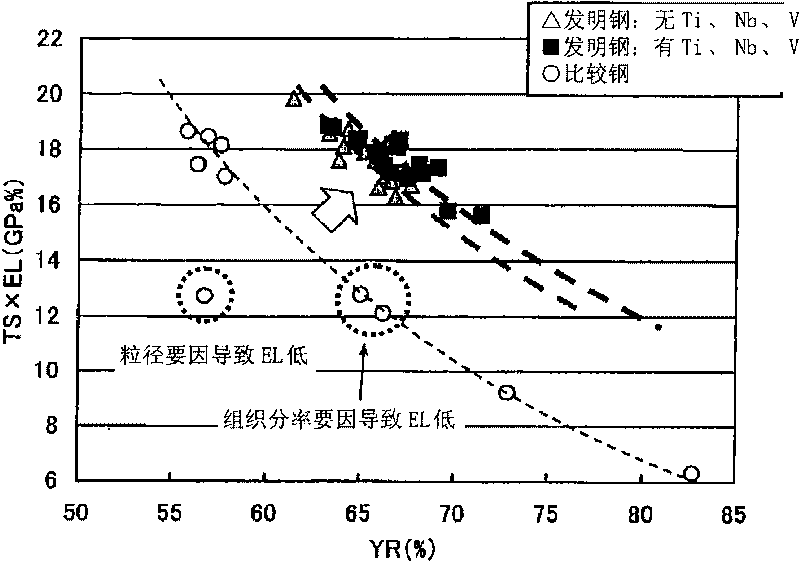

A high-strength hot-dip galvanized steel sheet excellent in workability according to the present invention: contains C, Si, Mn and other elements; has a dual phase structure containing ferrite and martensite as the metallographic structure; and, in the ferrite structure, satisfies the expression 0.2<=(Lb / La)<=1.5 when the length per unit area of the grain boundaries of crystal grains the crystal orientation differences of which are 10 degrees or more is defined as La and the length per unit area of the grain boundaries of crystal grains the crystal orientation differences of which are less than 10 degrees is defined as Lb and further satisfies the requirements that the average value of D is 25 [mu]m or less and the area ratio of crystal grains satisfying the expression D<=30 [mu]m in the ferrite grains surrounded by the grain boundaries of crystal grains the crystal orientation differences of which are 10 degrees or more is 50% or more when the circle equivalent diameter of each of ferrite grains surrounded by the grain boundaries of crystal grains the crystal orientation differences of which are 10 degrees or more is defined as D; and has a tensile strength of 980 MPa or more.

Owner:KOBE STEEL LTD

Austenitic, lightweight, high-strength steel sheet of which the yield ratio and flexibility are outstanding and a production method therefor

ActiveCN103370434AHigh yield ratioImprove ductilityHot-dipping/immersion processesThin material handlingPliabilityManganese

The present invention relates to an austenitic, lightweight, high-strength steel sheet having a high yield ratio and ductility and a method for producing the same, and more particularly, to a high-strength steel sheet for automotive interior panels, exterior panels, and structural parts, and a method for producing the steel sheet. An aspect of the present invention provides austenitic, lightweight, high-strength hot rolled steel sheet , cold rolled steel sheet and coated steel sheet having a high yield ratio and ductility and a method for producing thereof including appropriate concentrations of alloying elements such as Mn, Si, and Al to obtain a tensile strength of 800 MPa or greater, an elongation of 30% or greater, and a yield ratio of 60% or greater that are difficult to obtain from high-carbon, high-manganese steel sheets or high-manganese, lightweight steel sheets of the related art. The present invention provides a steel sheet having a low specific gravity, a high yield ratio, and high ductility as compared to high-strength steel sheets of the related art such as advanced high strength steels (AHSS). The steel sheet of the present invention is effective in maintaining the rigidity of a structural member and have good press processing characteristics so that the steel sheet can be used for manufacturing automotive parts to reduce the weight of automobiles and combining a plurality of parts into a single module or as one part to simplify machining or assembly processes.

Owner:POSCO CO LTD

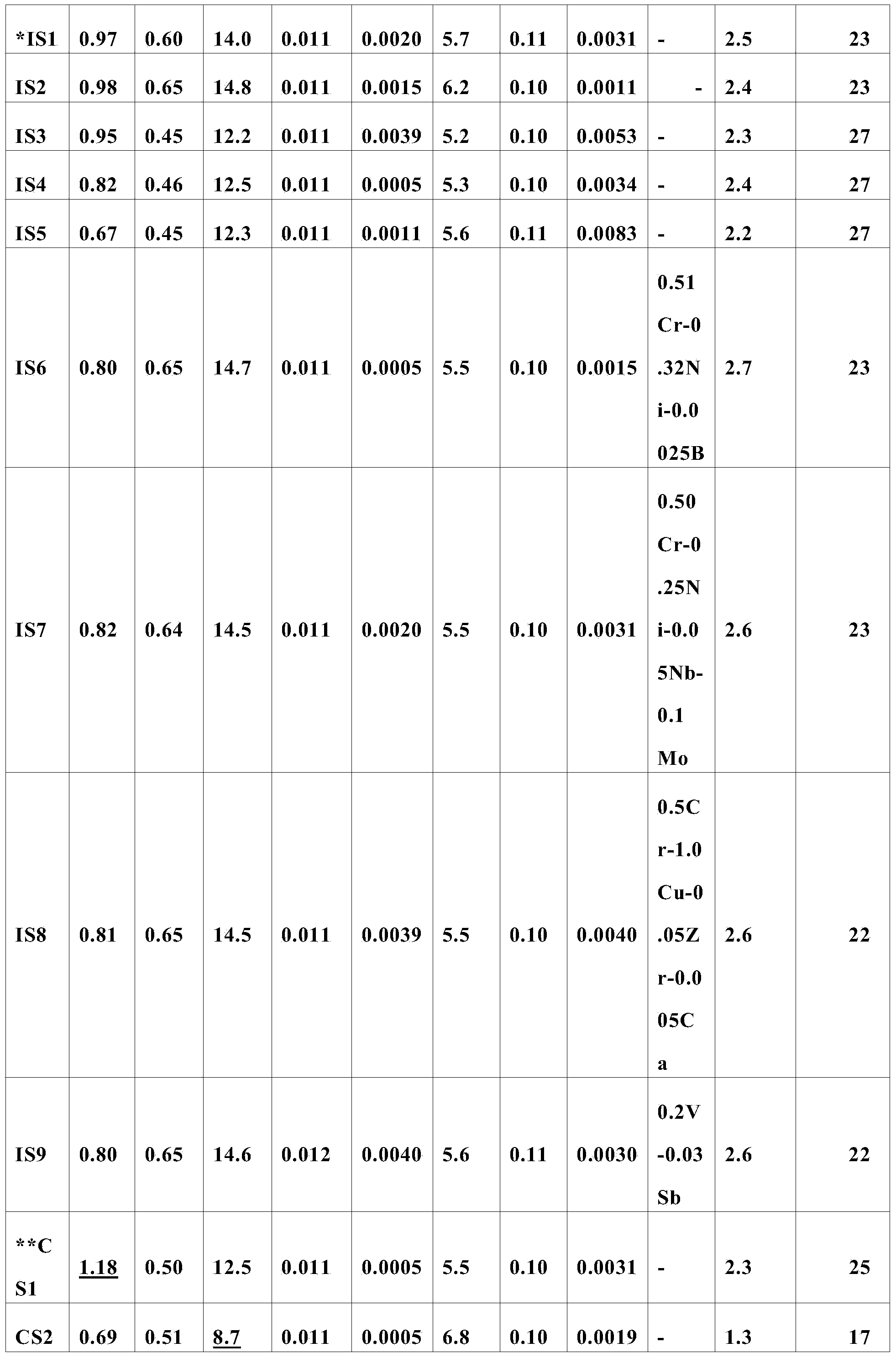

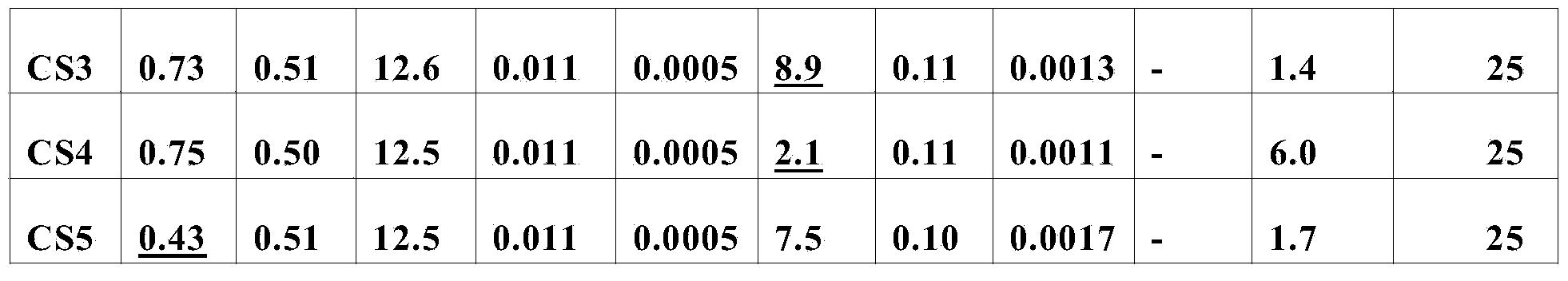

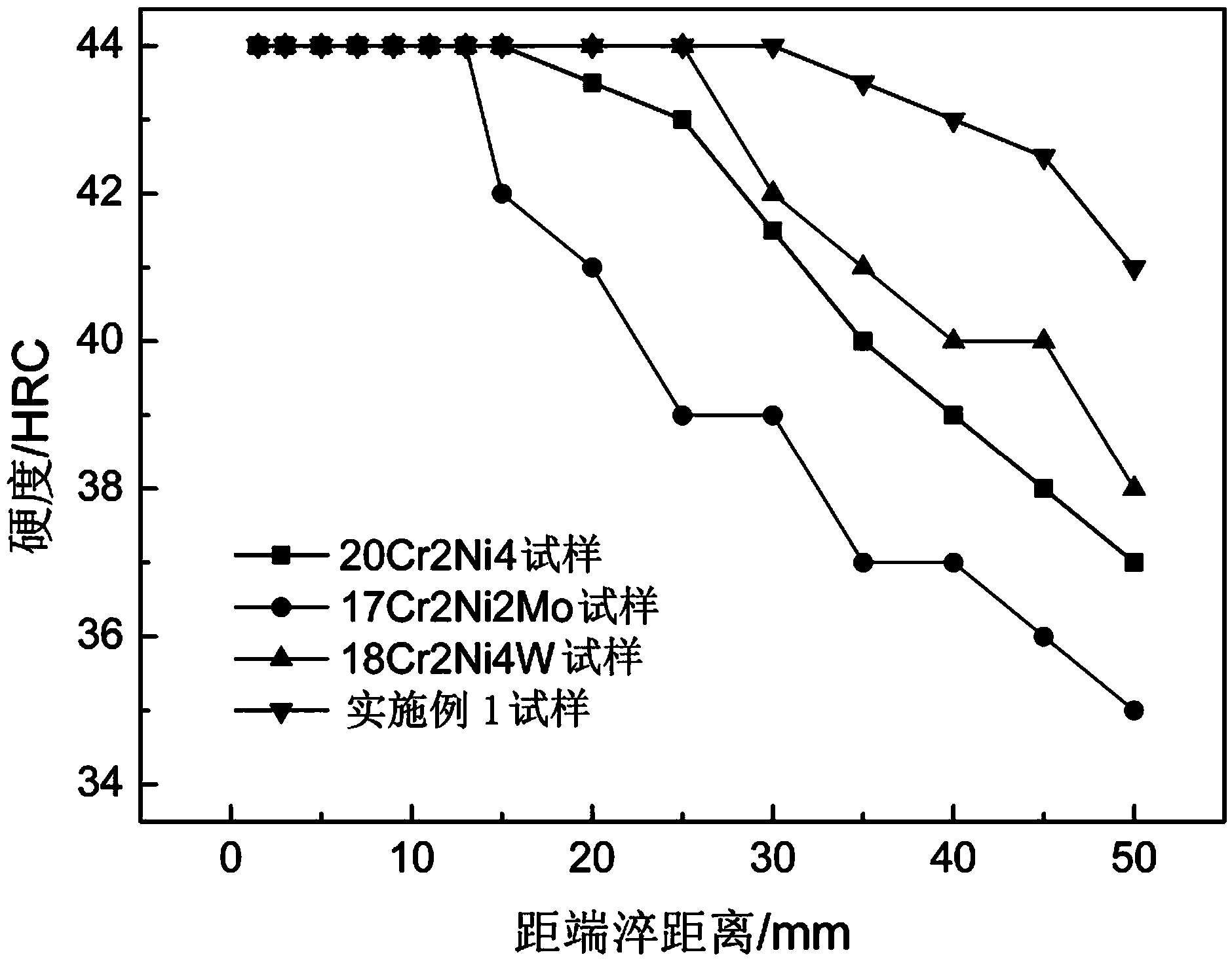

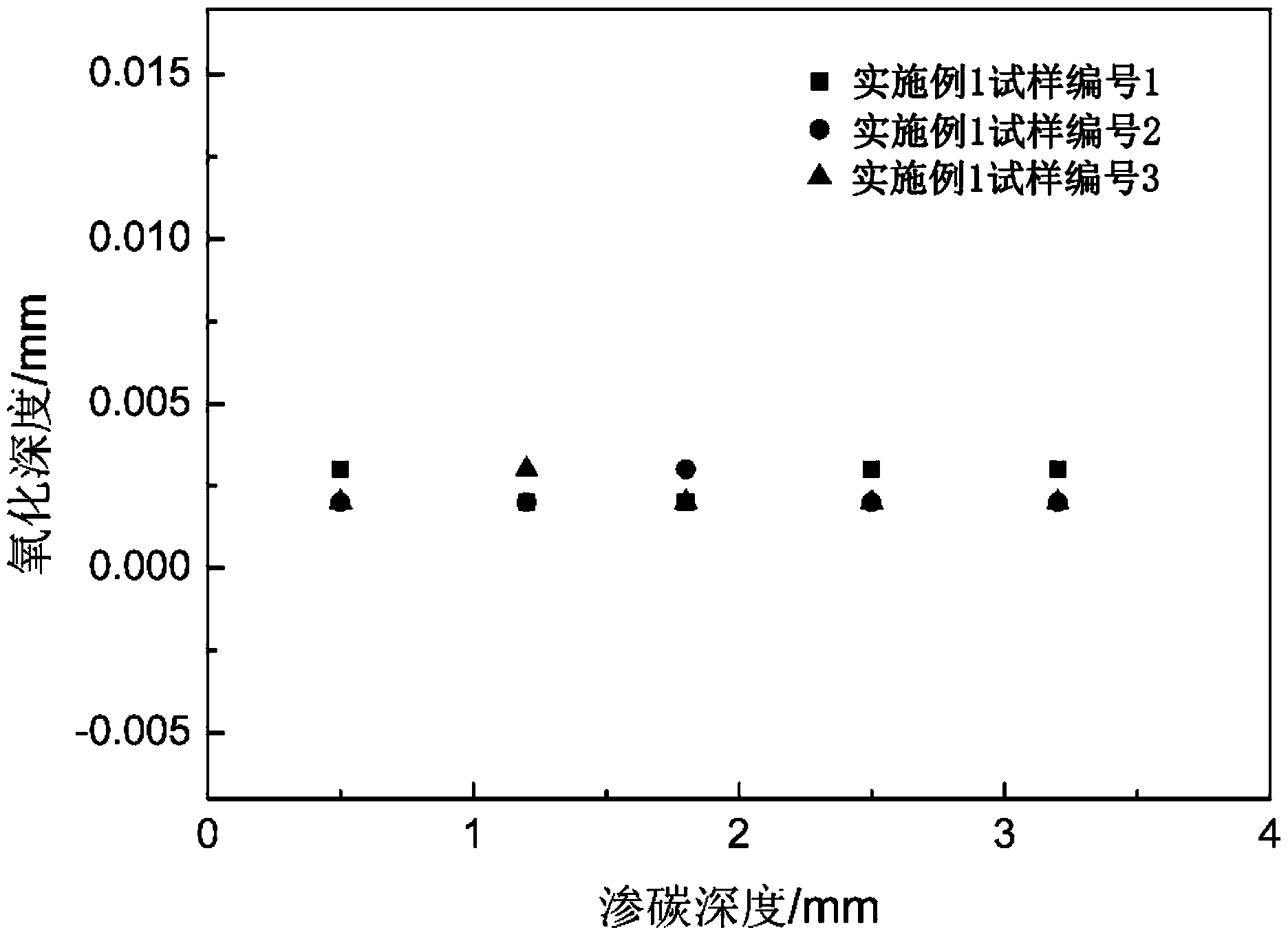

Carburizing alloy steel, and preparation method and application thereof

The invention relates to carburizing alloy steel, and a preparation method thereof. The alloy of the carburizing alloy steel comprises, by mass, 0.15%-0.25% of C, less than or equal to 0.30% of Si, 0.30%-1.20% of Mn, less than or equal to 0.015% of P, less than or equal to 0.010% of S, 0.30%-1.50% of Cr, 2.80%-3.80% of Ni, 0.30%-1.00% of Mo, 0.01%-0.08% of Al, at least one selected from 0.05%-0.15% of V and 0.025-0.10% of Nb, and the balance being Fe and inevitable impurities. A mass percentage of V, Nb and Al meets an equation of V+Nb+Al <= 0.30%. The carburizing alloy steel provided by the invention has good anti-fatigue performance, excellent comprehensive properties, good hardenability, high yield ratio, extremely small internal oxidation and the characteristic of resisting grain growth at a high temperature, and is suitable for manufacturing heavy-duty gears.

Owner:CRRC QISHUYAN INSTITUTE CO LTD

Fine crystal strengthen carbon constructional steel and manufacture process for hot-rolling thin slab thereof

InactiveCN101153367AHigh strengthHigh elongationShaping toolsHeat treatment process controlChemical compositionThin slab

The invention relates to a manufacture process of carbon steel and carbon steel hot rolling plate, in particular to a manufacture process of fine grain reinforcement carbon structural steel and hot rolling sheet plate of the steel. The invention mainly solves the technical problem that hot rolling plate of higher strength can not be produced on common completely continuous hot continuous rolling mill by use of common carbon structural steel at present. The fine grain reinforcement carbon structural steel adopts the following chemical composition (weight percent): 0.14 percent to 0.20 percent of C, 0.10 percent to 0.40 percent of Si, 0.65 percent to 0.90 percent of Mn, less than or equal to 0.025 percent of P, less than or equal to 0.015 percent of S and the rest, Fe. The manufacture process of the hot rolling sheet plate is as follows: a continuous casting slab which meets the requirements of compositions is heated to 1,210 DEG C to 1,250 DEG C; a rough rolling stage comprises five-pass tandem rolling and the end temperature of the rough rolling stage is between 1,050 DEG C and 1,060 DEG C; in addition, the thickness of an intermediate slab ranges from 35 mm to 45 mm. When rough rolling is finished, the intermediate slab is curled through a hot coil box and then is unfolded for finish rolling; a finish rolling stage comprises six-pass tandem rolling with the start rolling temperature ranging between 920 DEG C and 940 DEG C and the end temperature ranging between 820 DEG C and 860 DEG C; after finish rolling, the thickness of a steel plate is between 2 mm to 8 mm; in addition, a laminar flow cooling stage adopts forepart intensive cooling with the coiling temperature ranging from 520 DEG C to 620 DEG C.

Owner:SHANGHAI MEISHAN IRON & STEEL CO LTD

Steering knuckle non-quenched and tempered steel substituting 40Cr quenched and tempered steel and production method thereof

ActiveCN106521336AAvoid quenching and tempering heat treatmentOmit straighteningChemical compositionSmelting process

The invention discloses a steering knuckle non-quenched and tempered steel substituting 40Cr quenched and tempered steel and a production method thereof. The steering knuckle non-quenched and tempered steel substituting 40Cr quenched and tempered steel comprises the following components by weight percentage (%):0.35-0.42 of C, 0.50-0.80 of Si, 1.20-1.40 of Mn, less than or equal to 0.013 of P, 0.030-0.050 of S, less than or equal to 0.20 of Cu, 0.20-0.35 of Cr, less than or equal to 0.05 of Mo, 0.010-0.035 of Al, 0.12-0.20 of V, less than or equal to 0.035 of Nb, 0.007-0.020 of Ti, 0.014-0.02 of N, and the balance Fe. According to the component ratio and production method provided by the invention, through perfect combination of the chemical composition optimal design and controlled rolling and controlled cooling technology (rolling parameters), the smelting process, the start rolling temperature and finishing rolling temperature, and the cooling way of the formula are strictly controlled, thus realizing production of the steering knuckle non-quenched and tempered steel with the characteristics of easy turning and high strength and toughness.

Owner:JIANGSU LIHUAI IRON AND STEEL CO LTD +1

Hot-dip galvanized steel sheet and production method therefor

ActiveCN104093873AHigh strengthExcellent material uniformity with little variationHot-dipping/immersion processesFurnace typesMetallurgyYield ratio

Owner:JFE STEEL CORP

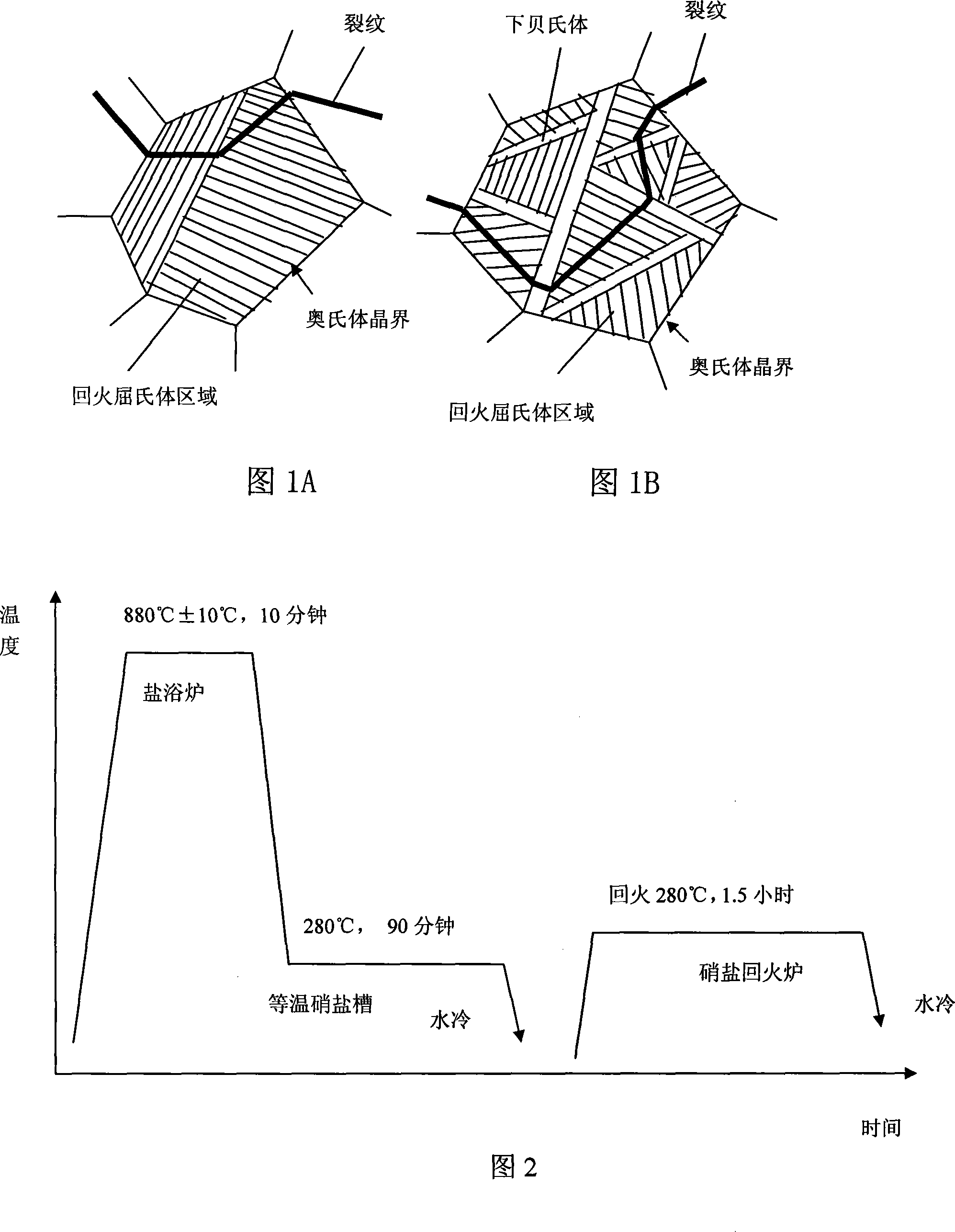

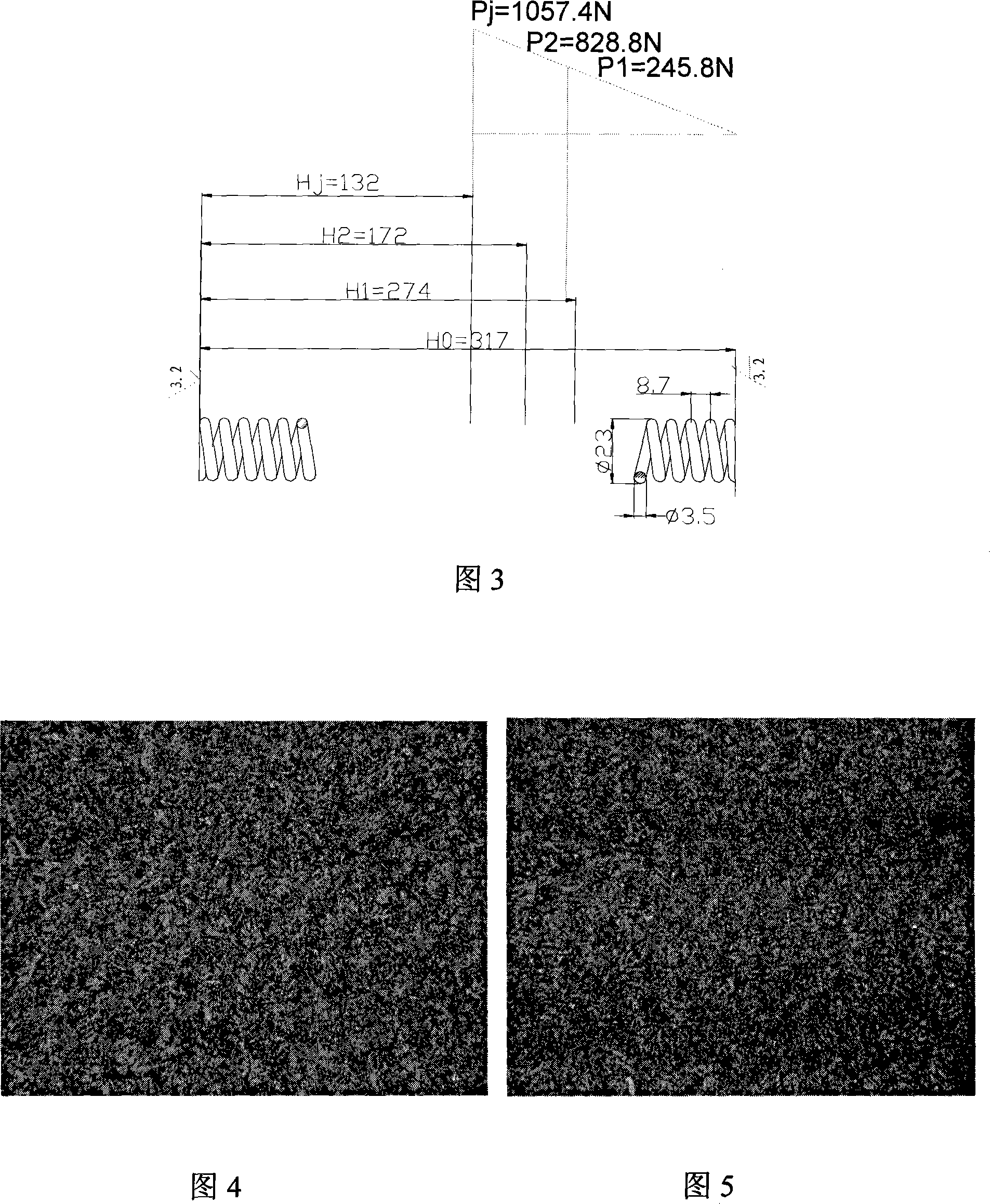

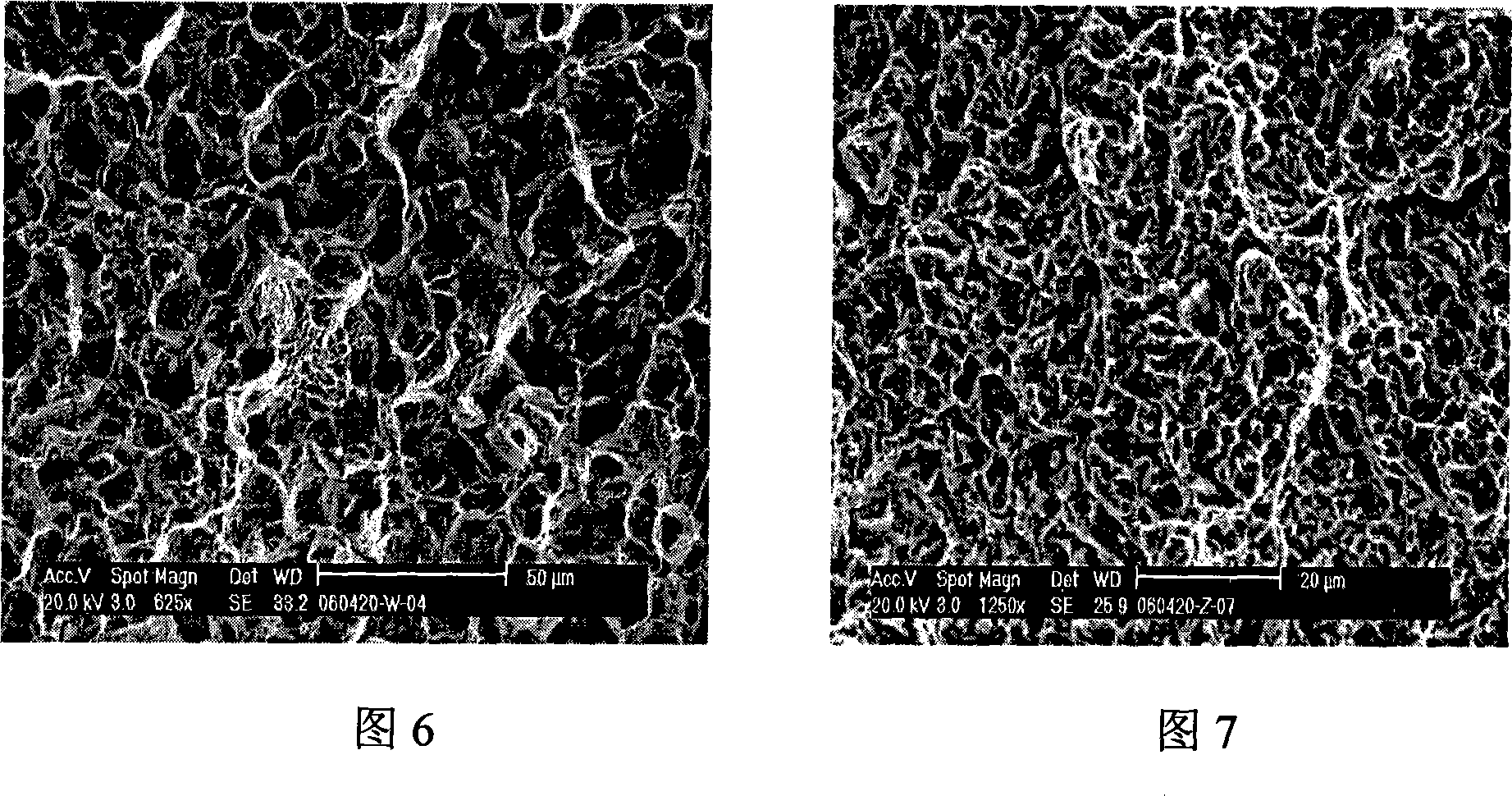

Alloy spring steel ultra-fine martensite heat treatment quenching strengthening process

InactiveCN101134995AHigh tensile strengthYield ratio highFurnace typesHeat treatment furnacesAlloyUltra fine

The present invention is heat treatment process of quenching to enhance alloy spring steel of super strong fined martensite. The heat treatment process includes the steps of treating spring material at 880 deg.c to form for austenizing, quenching at 280+ / -10 deg.c in an isothermal nitrate furnace for 60-90 min, cooling in water, tempering at 280-300 deg.c in a tempering nitrate furnace or a well-type electric furnace for 90-120 min, and final water cooling. The technological process can raise the yield strength, reduction of area, impact toughness and elasticity of spring material.

Owner:CHANGAN AUTOMOBILE (GRP) CO LTD

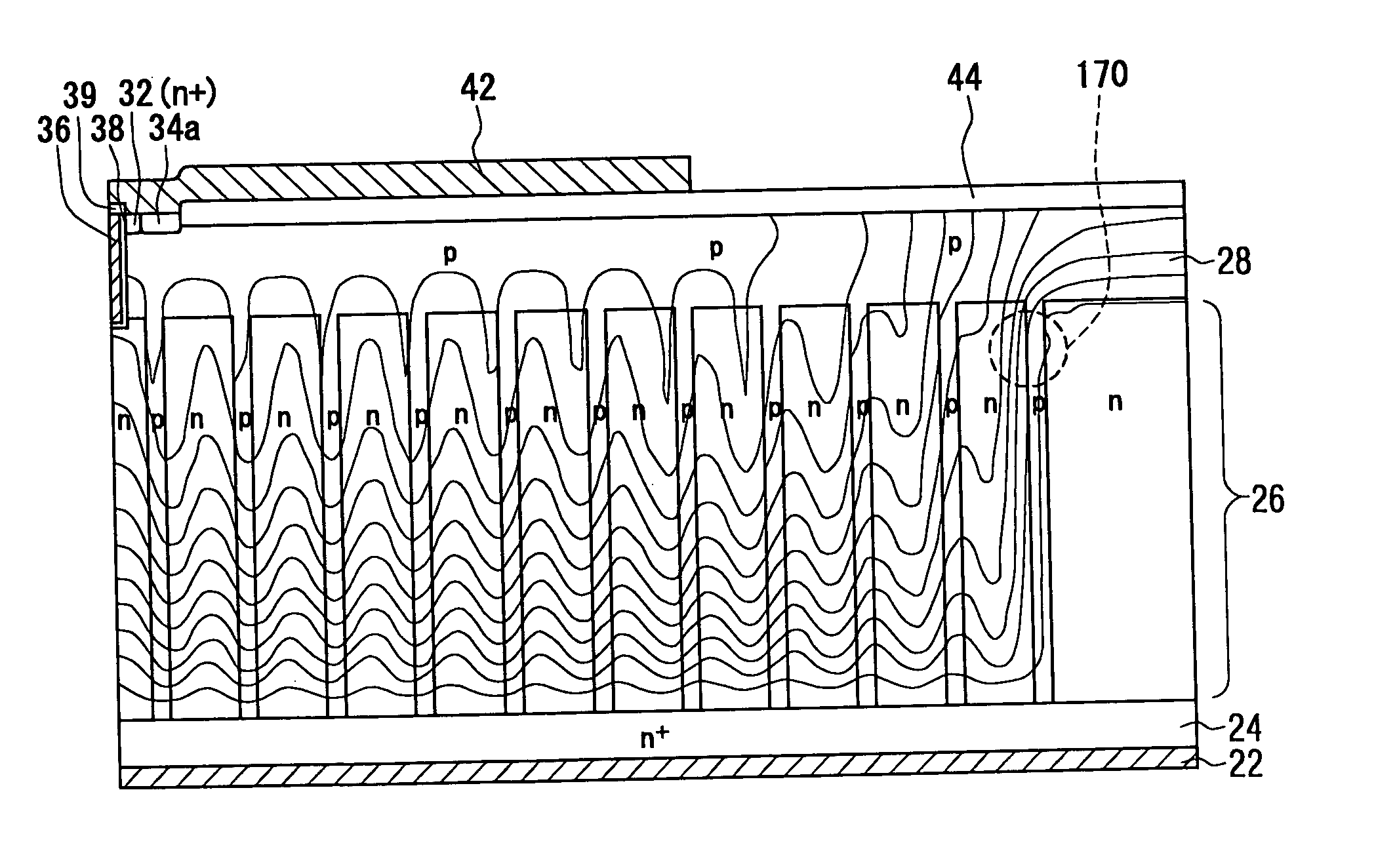

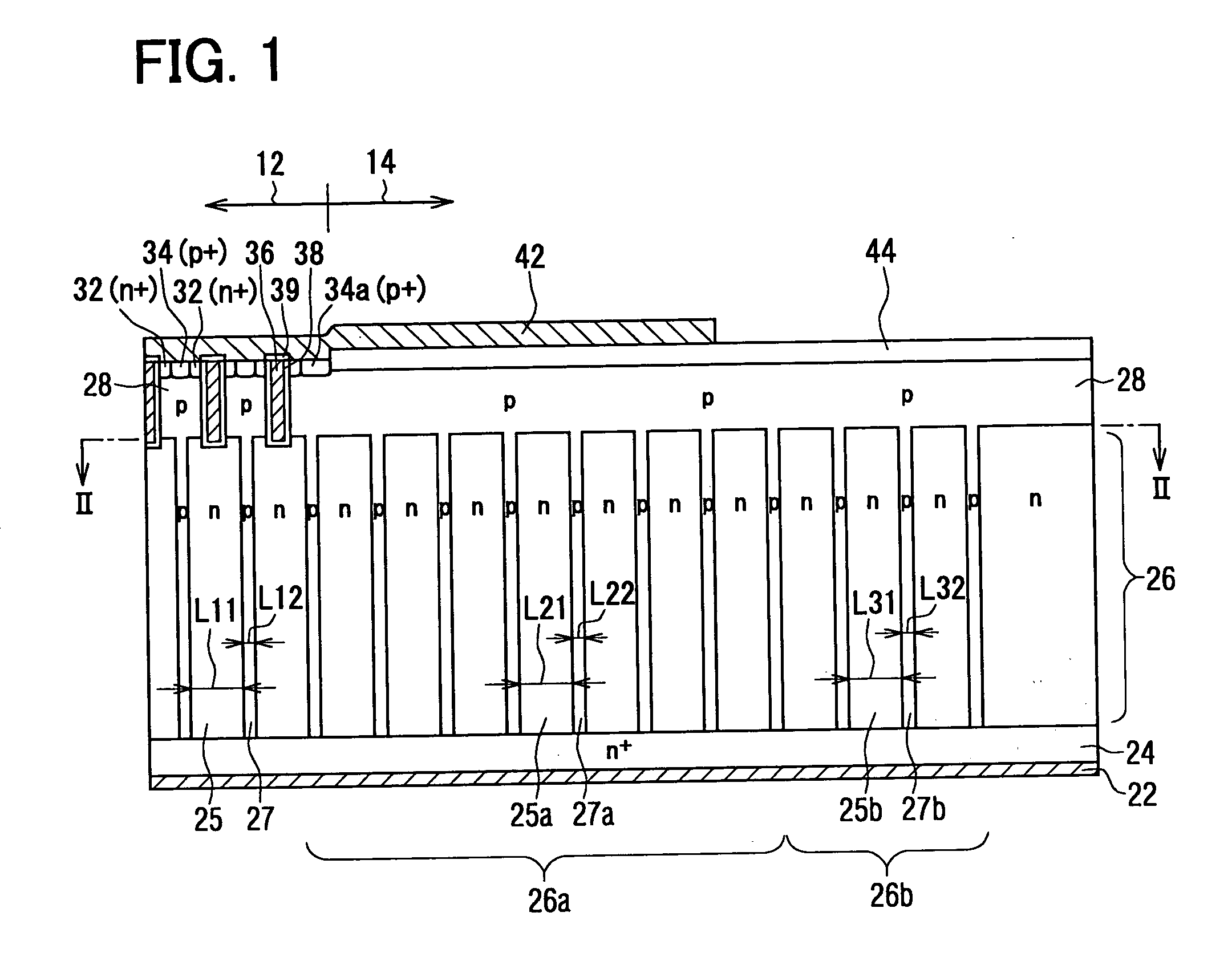

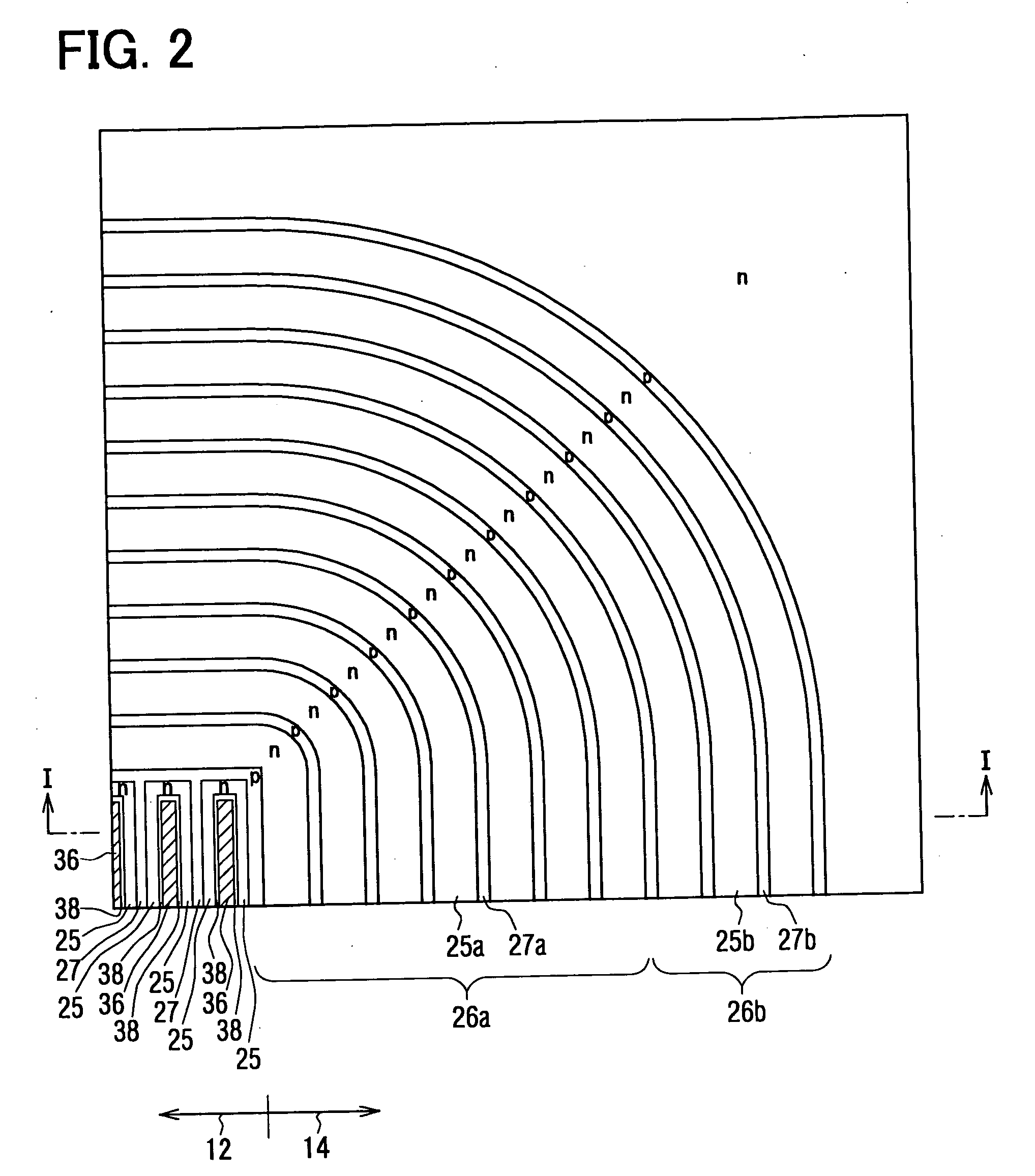

Semiconductor device having super junction structure and method for manufacturing the same

ActiveUS20060043478A1Easy to implementIncreasing voltage of overall deviceSemiconductor devicesDevice materialEngineering

A semiconductor device includes: a center region; a periphery region; and a semiconductor layer including pairs of a first region having a first impurity amount and a second region having a second impurity amount. The first and the second regions are alternately aligned in a plane. The periphery region includes an utmost outer and an utmost inner periphery pairs. The utmost outer periphery pair has a difference between the second and the first impurity amounts, which is smaller than a maximum difference in the periphery region. The utmost inner periphery pair has a difference between the second and the first impurity amounts, which is larger than a difference in the center region.

Owner:DENSO CORP

Hot-rolling double-phase weather-resistant steel plate and mfg. method thereof

InactiveCN1752260ALower yield strengthHigh tensile strengthTemperature control deviceDouble phaseDual-phase steel

A hot-rolled dual-phase steel plate with high mechanical performance, cold processibility, weldability and weatherability contains proportionally Fe, C, P and Cu, and is prepared through heating raw plate to 1100-1250 deg.C, hot rolling, cooling to 400-650 deg.C, and winding or fast cooling. Its structure is composed of ferrite and martensite.

Owner:YANSHAN UNIV

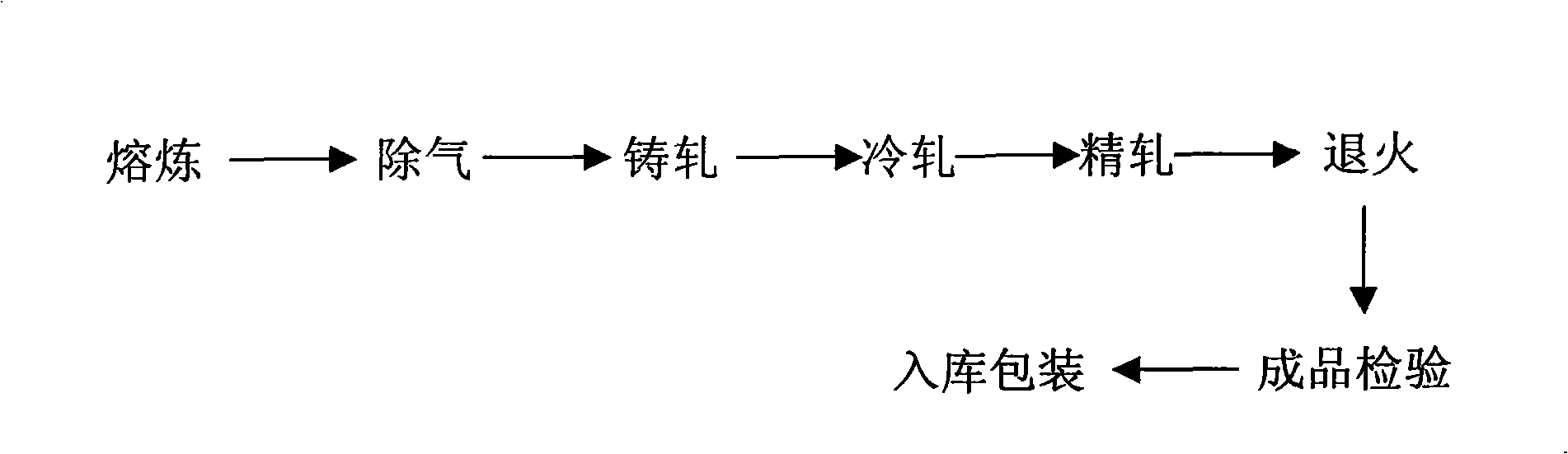

High performance air conditioning aluminum foil and method for preparing same

InactiveCN101307404AHigh strengthImprove plasticityRoll mill control devicesMetal rolling arrangementsFlangingAlloy

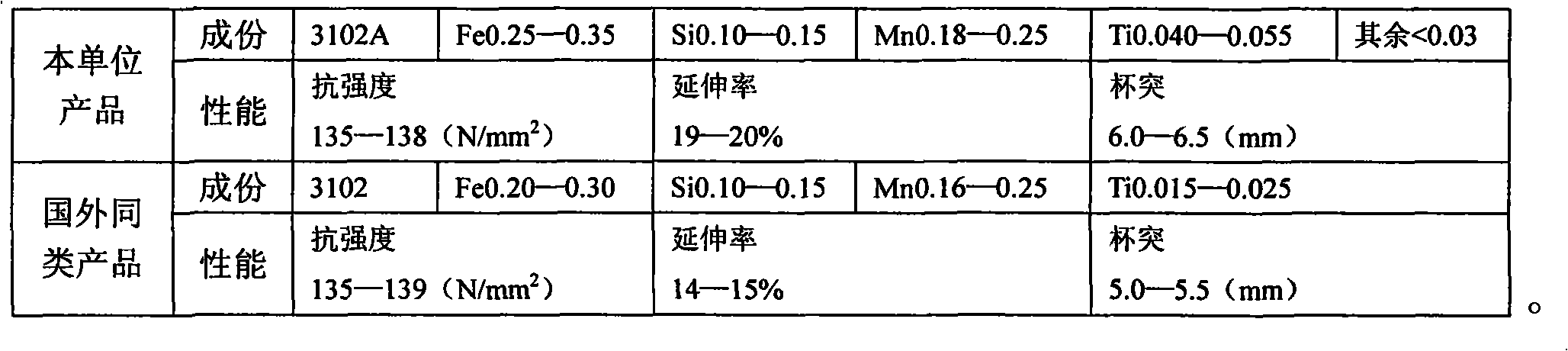

The invention relates to a high-performance air conditioner aluminum foil and a method for preparing the same. The aluminum foil mainly consists of the following alloying elements in percentage by weight: 0.28 to 0.33 percent of FeO, 0.1 to 0.15 percent of Si, 0.20 to 0.25 percent of Mn, 0.01 percent of Cu, 0.05 percent of Zn, 0.04 to 0.055 percent of Ti and the balance being Al and inevitable impurities. The preparation method mainly comprises the following: step one, melting, refining and heat preservation; step two, casting and rolling; step three, cold rolling and trimming cut; step four, precision rolling; step five, annealing at an annealing temperature of between 260 and 310 DEG C and heat preservation for 2 to 3 hours; step six, checkup and packaging. The high-performance air conditioner aluminum foil and the method can lessen the thickness of the air conditioner aluminum foil and ensure plasticity, height of the air conditioner aluminum foil and no flanging of longthrust.

Owner:江阴博威合金材料有限公司

High-strength cold-rolled steel sheet and method for manufacturing same

ActiveCN105492643AHigh strengthHigh yield ratioFurnace typesHeat treatment furnacesYield ratioBainite

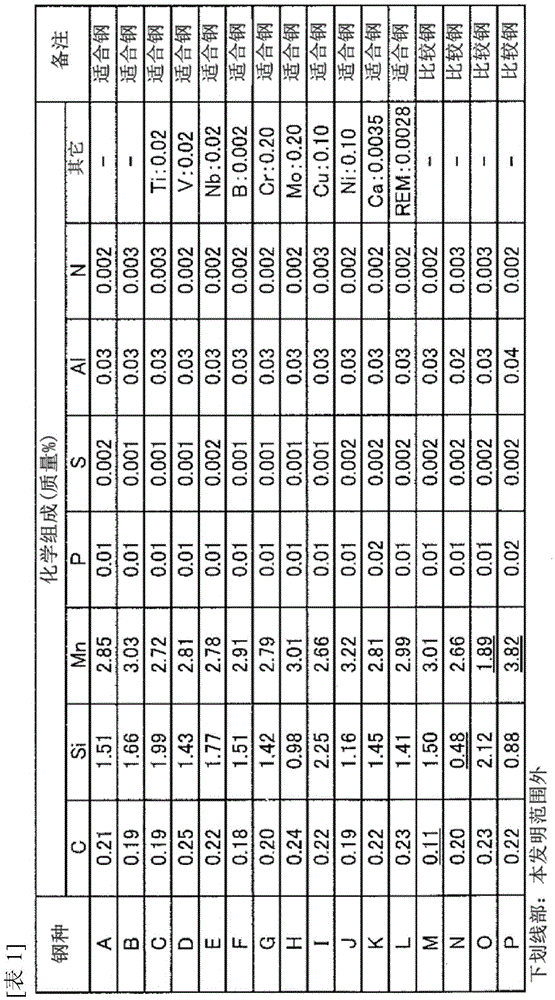

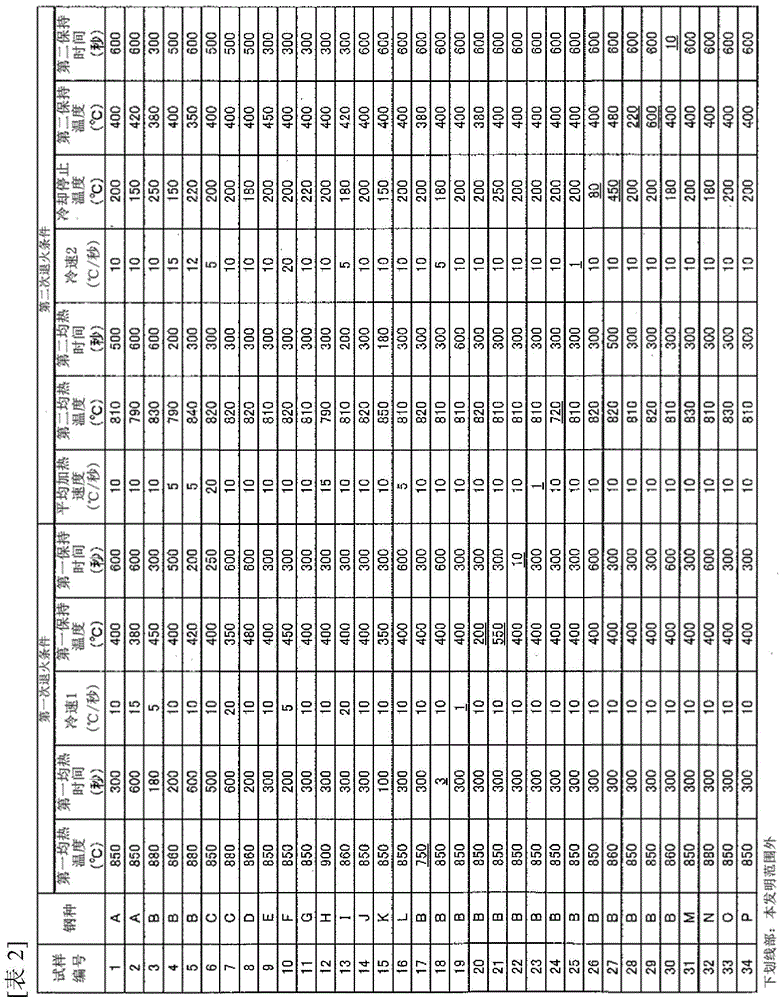

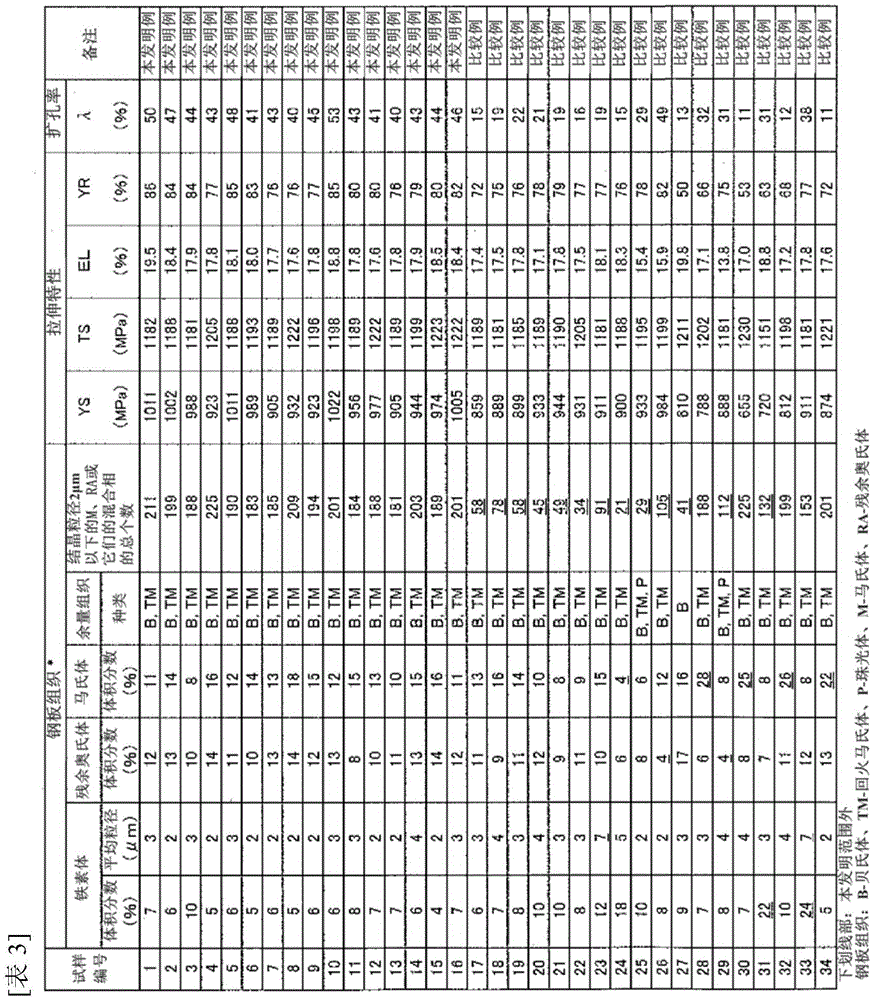

Provided is a high-strength cold-rolled steel sheet having excellent elongation and stretch flangeability, and a high yield ratio, as well as a method for manufacturing same. A high-strength cold-rolled steel plate comprising 0.10-0.27% of C, 0.8-2.4% of Si, 2.3-3.5% of Mn, 0.08% or less of P, 0.005% or less of S, 0.01-0.08% of Al, and 0.010% or less of N (percentages given with respect to mass), the balance comprising Fe and inevitable impurities. The average ferrite crystal grain size is 5 [mu]m or less. Ferrite is present in a volumetric ratio of 3-20%, residual austenite is present in a volumetric ratio of 5-20%, and martensite is present in a volumetric ratio of 5-20%. Bainite and / or annealed martensite are included in the remainder. Said steel plate has a microstructure in which the total quantity of residual austenite, martensite, or a phase combined therefrom, in which the crystal grain size is 2 [mu]m or less, is 150 or more per 2000 [mu]m2 within a plate-thickness cross section parallel to the rolling direction of the steel plate.

Owner:JFE STEEL CORP

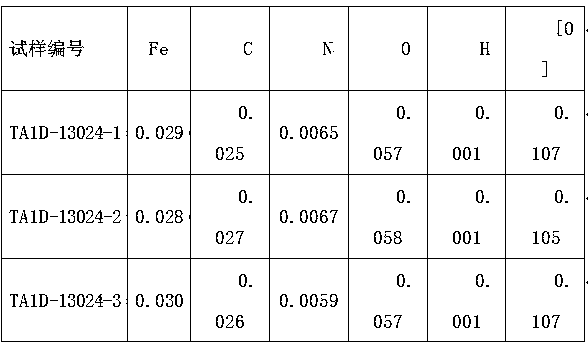

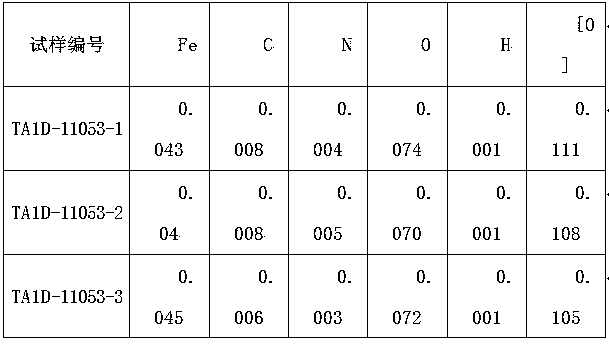

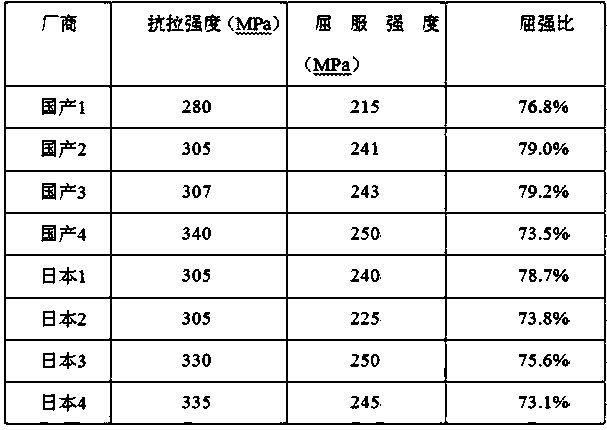

Processing method of low yield ratio high strength titanium coiled plate for heat exchanger

The invention provides a processing method of a low yield ratio high strength titanium coiled plate for a heat exchanger. The processing method of the titanium coiled plate comprises the following steps of: preparing a plate blank; rolling a hot coil; annealing the hot coil; performing surface treatment on the hot coil; cold rolling; degreasing; and annealing to obtain the low yield-ratio high titanium coiled plate for the heat exchanger. According to the processing method, the content of a titanium cast ingot is controlled, and the processing technology of a titanium tape is utilized, so that the tensile strength of a titanium plate is about 385+ / -15MPa, and the yield ratio is not greater than 70%; and with the improvement of the tensile strength of the titanium plate for the heat exchanger, the design thickness of the titanium plate can be reduced by more than 10%, and therefore, the titanium plate being 0.5 to 1.2mm in thickness can be prepared for the heat exchanger. Compared with the titanium coiled plate in the prior art, the titanium coiled plate processed by the method provided by the invention has high strength, low yield ratio and high deep drawing performance, and the production cost is also greatly decreased.

Owner:LUOYANG SUNRUI TI PRECISION CASTING

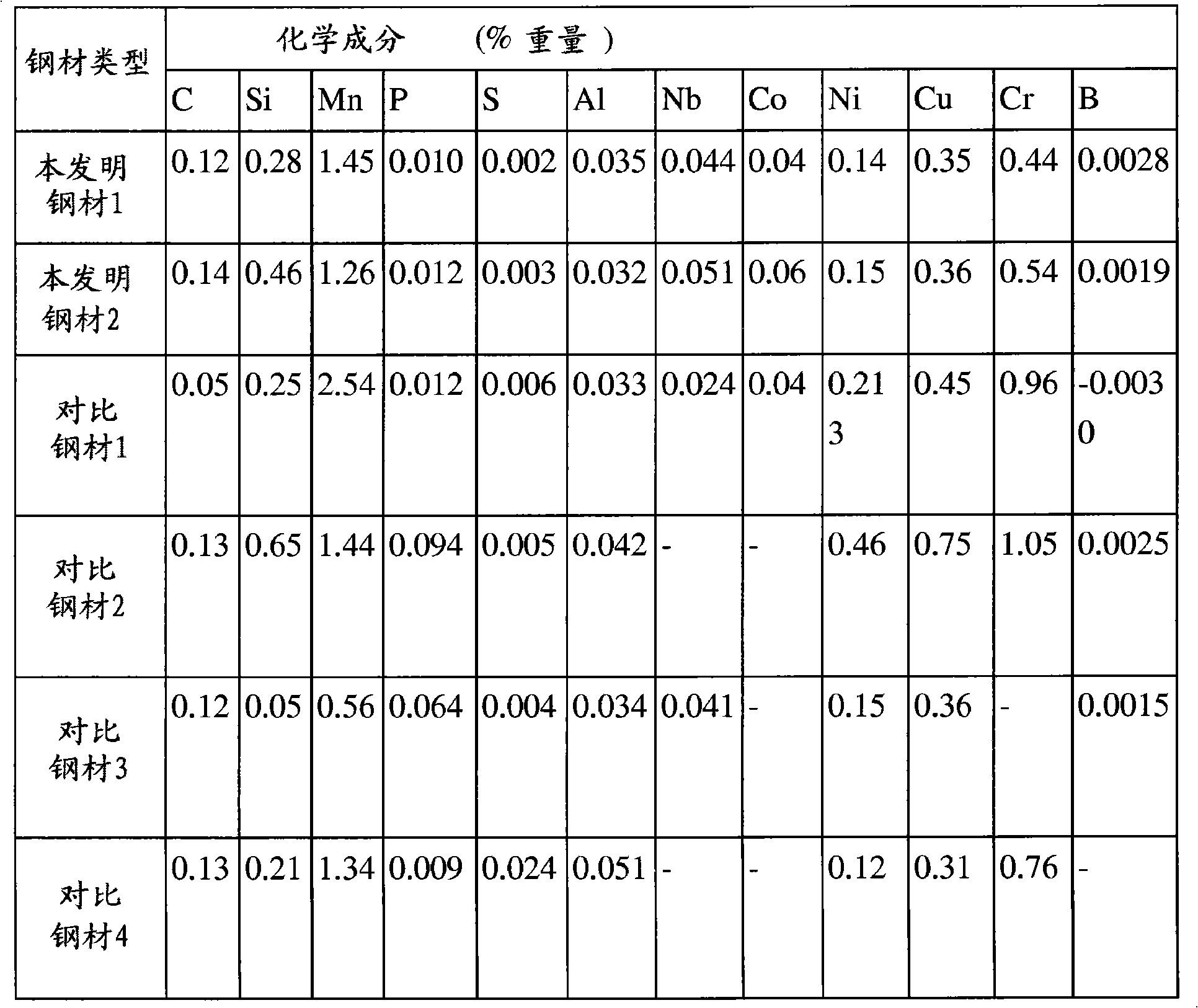

Cold-rolled steel sheet with high yield ratio and excellent weather resistance

There is provided a cold-rolled steel sheet with a high yield ratio, and excellent weather resistance and workability. The cold-rolled steel sheet including, by weight: 0.08 to 0.20% C, 0.1 to 0.5% Si, 0.9 to 2.0% Mn, <0.02% P, <0.01% S, 0.02 to 0.07% Al, 0.03 to 0.06% Nb, 0.05 to 0.30% Ni, 0.2 to 0.5% Cu, 0.3 to 0.6% Cr, 0.001 to 0.004% B, 0.02 to 0.08% Co, the balance being Fe and unavoidable impurities. Also, there is provided a method of manufacturing the same.

Owner:POSCO

Cold-rolled steel sheet with yield strength of 980 MPa grade and manufacturing method thereof

ActiveCN102925817AHigh yield ratioLow annealing temperatureBell type furnacesRolling millHigh strength steel

The invention discloses a cold-rolled steel sheet with yield strength of 980 MPa grade, and belongs to the technical field of cold-rolled high strength steel. The steel sheet comprises the following chemical components in percentage by weight: 0.08-0.13% of C, 0.05-0.5% of Si, 1.2-2.0% of Mn, less than or equal to 0.010% of P, less than or equal to 0.005% of S, 0.6-1.5% of Cr, 0.08-0.20% of Ti, 0.02-0.08% of Nb, 0.04-0.2% of V, one or more of Nb, V and Ti, 0.02-0.1% of Alt, less than or equal to 0.006% of N, less than or equal to 0.004% of O, and the balance of Fe and unavoidable impurities. The tensile strength of the steel sheet is more than 980 MPa, therefore, the steel sheet is excellent in plasticity and forming performance. The manufacturing method of the steel sheet is a low-cost cold-rolled annealed steel sheet manufacturing method, and can be implemented on common reversing cold rolling mills and cover annealing devices.

Owner:LAIWU IRON & STEEL GRP

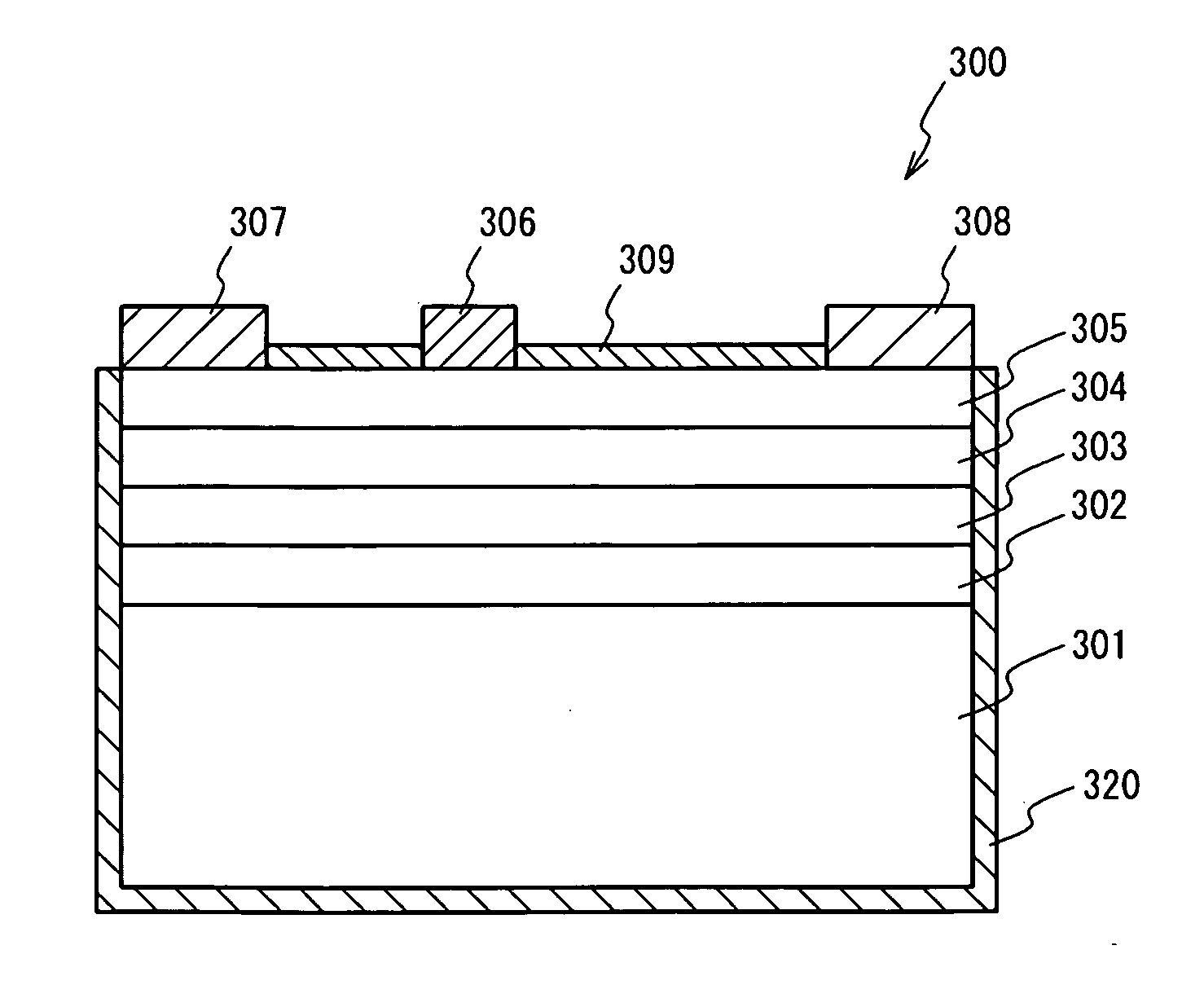

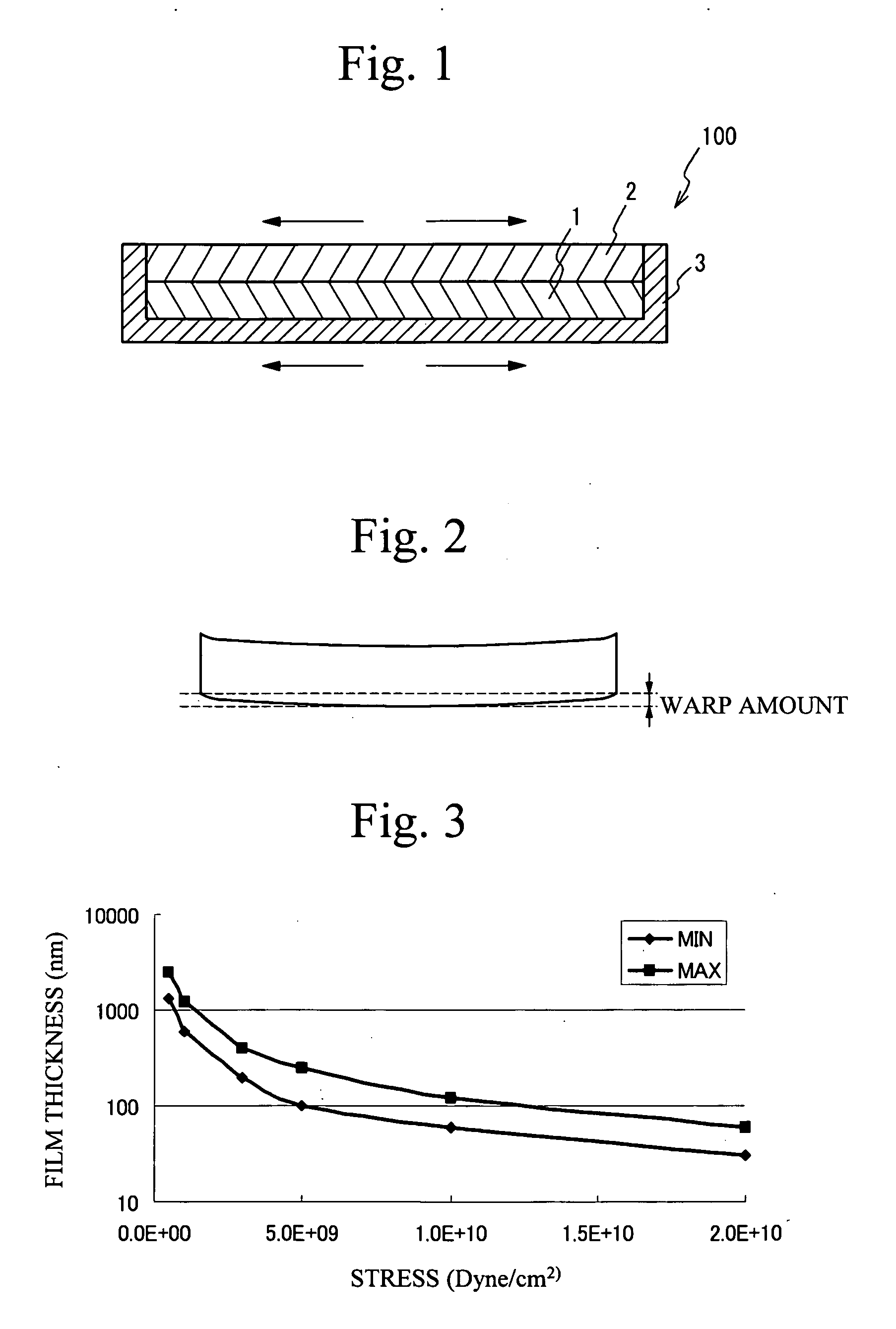

Semiconductor substrate, substrate for semiconductor crystal growth, semiconductor device, optical semiconductor device, and manufacturing method thereof

ActiveUS20060220192A1Enhance detailsHigh yield ratioPolycrystalline material growthLaser detailsStress relaxationCrystal growth

A semiconductor substrate includes: a semiconductor crystal layer grown on one face of a substrate; and a stress relaxation layer, which is formed on the other face opposite to the one face and the side face of the substrate and applies stress to the substrate in the same direction as the direction of stress which the semiconductor crystal layer applies to the substrate. In this case, stress of the semiconductor crystal layer to the substrate is offset. Therefore, warp of the semiconductor substrate and generation of cracks are inhibited.

Owner:SUMITOMO ELECTRIC DEVICE INNOVATIONS

Manufacturing method for nodular cast iron

A technology for producing nodular graphite cast iron QT800-6 features that it contains Ca (0.001-0.05 wt.%) and Ba (0.006-0.1) beside conventional components, and its heat treatment includes normalizing at 860+ / -40 deg.C for 1.5+ / -1.0 hr and tempering at 600+ / -50 deg.C for 2.0+ / -1.0 hr. Its casting features high tension strength, elongation, impact toughness and hardness, and low cost.

Owner:GUANGXI YUCHAI MACHINE PARTS MFG CO LTD

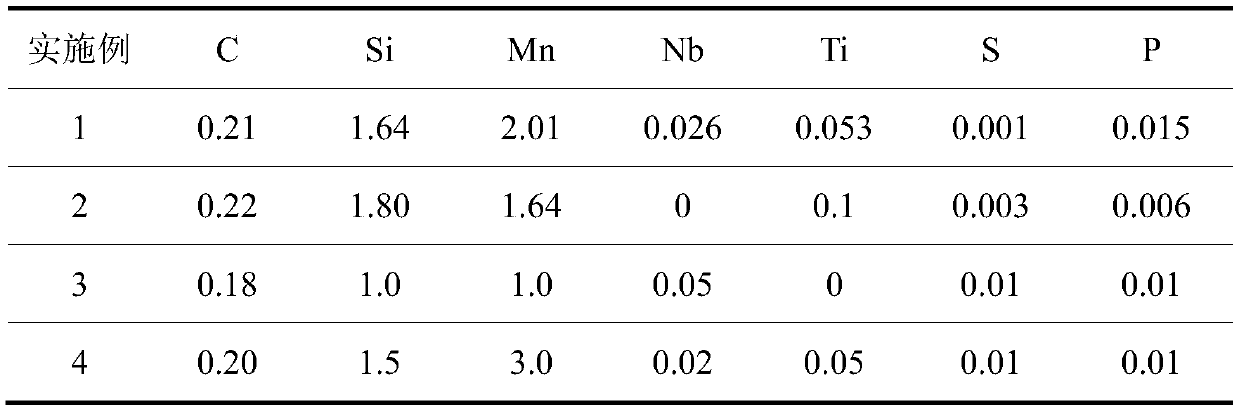

1180 MPa-grade ultrahigh-strength low-cost cold-rolled quenched partition steel and manufacturing method thereof

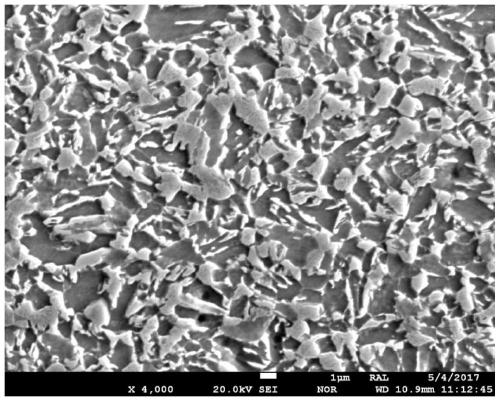

InactiveCN110093564AIncrease contentOrganizational stabilityUltimate tensile strengthMechanical property

The invention relates to the field of third-generation advanced high-strength steel used for automobiles and discloses 1180 MPa-grade ultrahigh-strength low-cost cold-rolled quenched partition steel and a manufacturing method thereof. A steel plate comprises the chemical components including, by mass percent, 0.18-0.22% of C, 1.0-3.0% of Mn, 1.0-2.0% of Si, not greater than 0.05% of P, not greaterthan 0.02% of S, 0-0.05% of Nb, 0-0.2% of Ti and the balance iron and inevitable impurities. The steel plate manufacturing method relates to the process of steel smelting, hot rolling, cold rolling,pre-quenching and heat treatment, and finally, a ferrite-bainite-martensite-retained austenite mixed structure is obtained. According to the 1180 MPa-grade ultrahigh-strength low-cost cold-rolled quenched partition steel and the manufacturing method thereof, on the basis of traditional C-Mn-Si series quenched partition steel, Nb and Ti elements are added for refining the structure, pre-quenching treatment and a one-step partition process are adopted, finally the ultrahigh-strength quenched partition steel with the yield strength being 500-800 MPa, the tensile strength not smaller than 1180 MPa, the elongation after fracture not smaller than 20% and the product of strength and elongation not smaller than 24GPa.% is obtained, and the mechanical property is quite excellent.

Owner:NORTHEASTERN UNIV

Corrosion resistant multi-aluminum bronze material for pipe

The invention provides a pipe corrosion-resistant multielement aluminium bronze alloy material and the ingredients are as follows: 4.0 to 10.0wt percent of Al, 1.0 to 4.5wt percent of Fe, 1.0 to 4.5wt percent of Mn, 0.8 to 4.0wt percent of Ni, 0.05 to 0.5wt percent of Cr and the balance of Cu and unavoidable impurities; in casting state, the tensile strength is more than 385MPa, the yield strength is more than 180MPa, the yield ratio is more than 0.48, and the specific elongation is more than 27 percent; in annealing state, the tensile strength is more than 525MPa, the yield strength is more than 285MPa, the yield ratio is more than 0.55, the specific elongation is more than 42 percent and the complete immersion uniform corrosion rate is 0.01 to 0.035mm / a; the copper alloy has excellent performance, is particularly suitable for the environment with high flow rate of seawater and is an ideal material for manufacturing sea water desalinating condenser equipment, shipping sea water condenser equipment and seashore power plant condensers.

Owner:CHINALCO MATERIALS APPL RES INST CO LTD

Alloy vermicular graphite cast iron for railway vehicle brake disc and smelting method of alloy vermicular graphite cast iron

The invention relates to alloy vermicular graphite cast iron for a railway vehicle brake disc and a smelting method of the alloy vermicular graphite cast iron. The vermicular graphite cast iron is composed of, by mass, 3.3%-3.5% of C, 2.3%-2.5% of Si, 0.4%-0.7% of Mn, 0.6%-1.0% of Cu, 0.2%-0.6% of Mo, 0.6%-1.0% of Ni, 0-0.07% of P, 0-0.02% of S and the balance Fe. The vermicular graphite rate of the vermicular graphite cast iron brake disc is higher than or equal to 75% and the pearlite content is 50% to 60%. According to the alloy vermicular graphite cast iron for the railway vehicle brake disc and the smelting method of the alloy vermicular graphite cast iron, the stress threshold value when a disc body is cracked and extended due to thermal stress concentration can be increased, and the mechanical property of the railway vehicle brake disc is improved.

Owner:CHANGZHOU LANGRUI CASTING +1

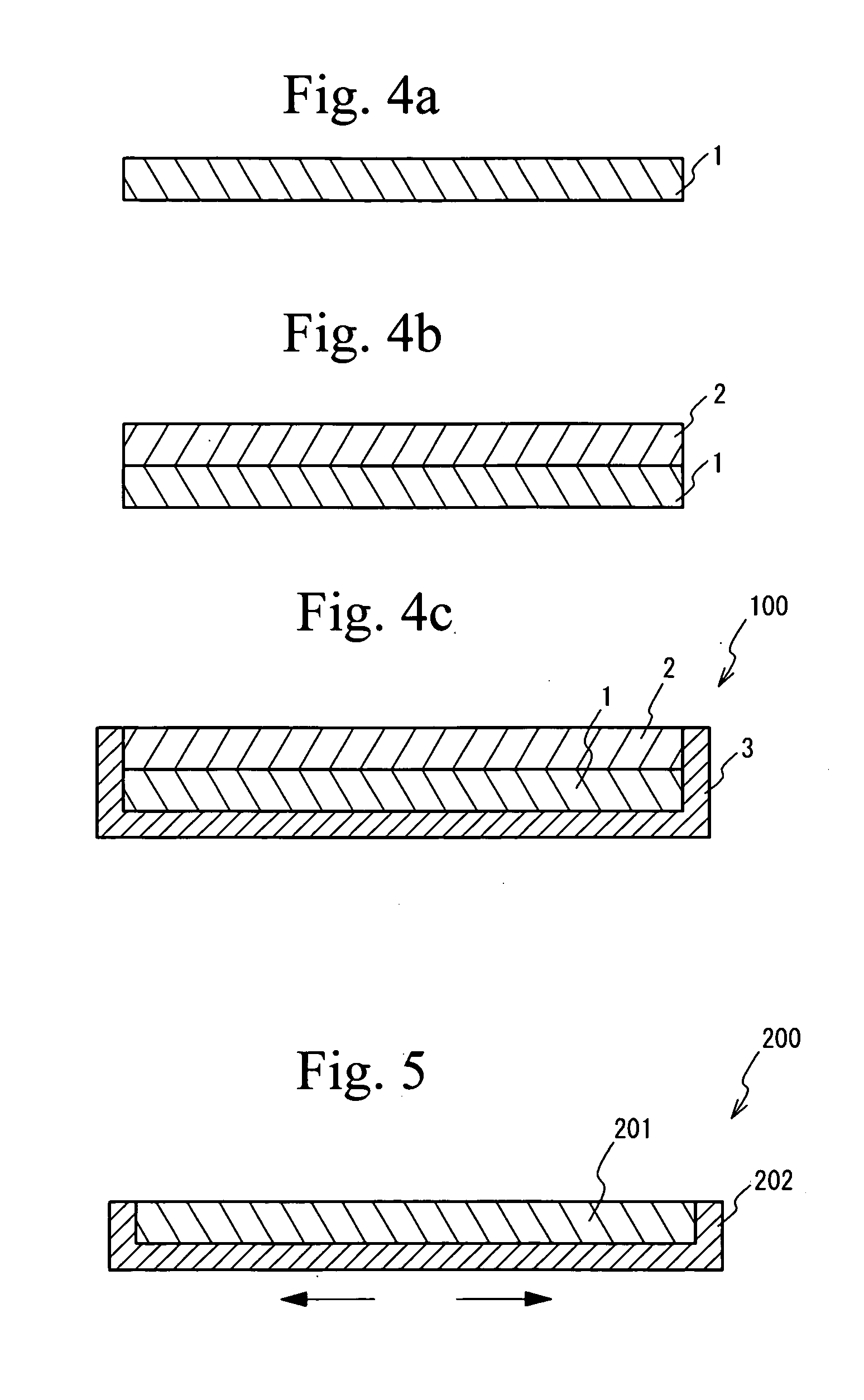

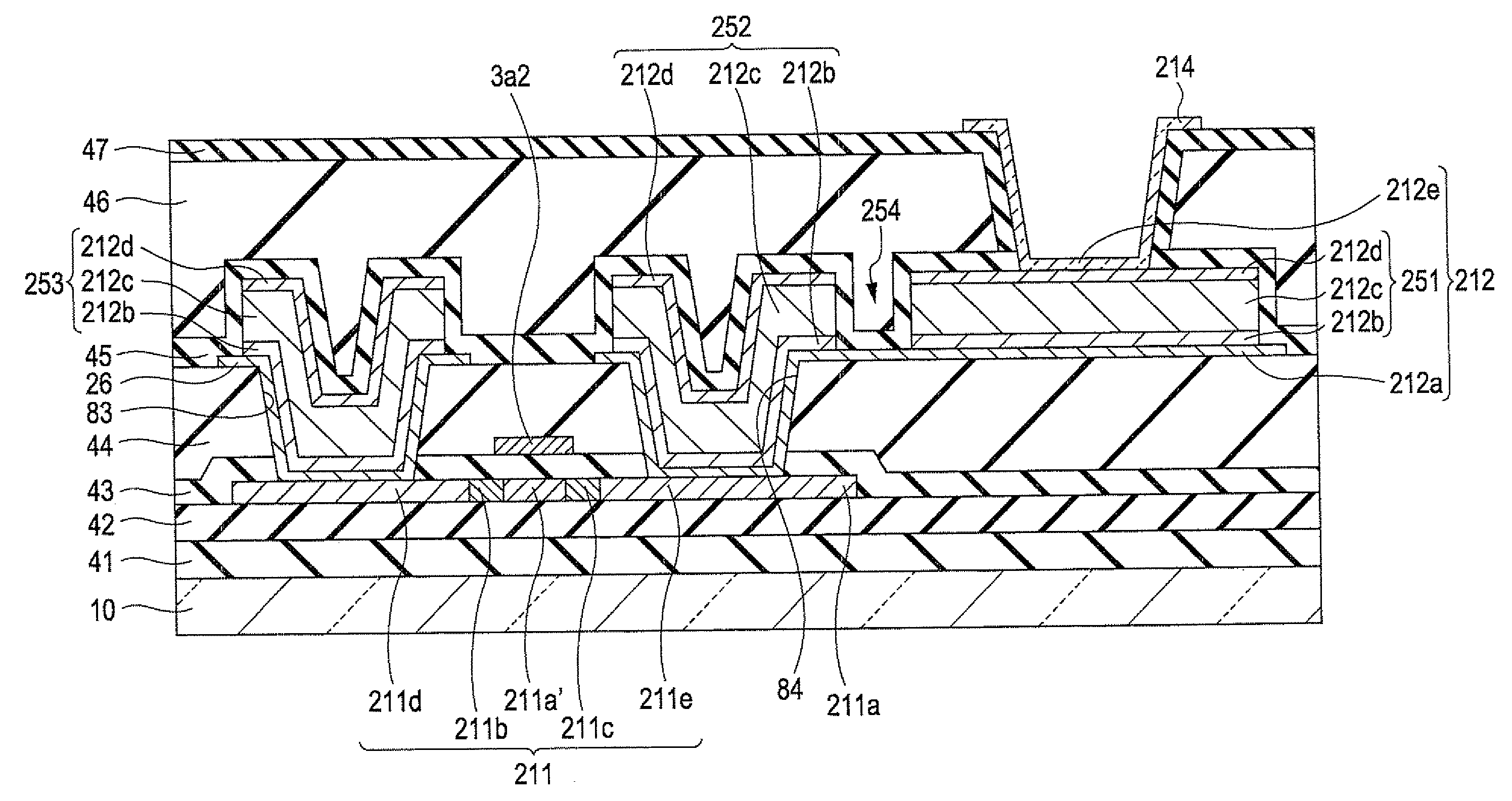

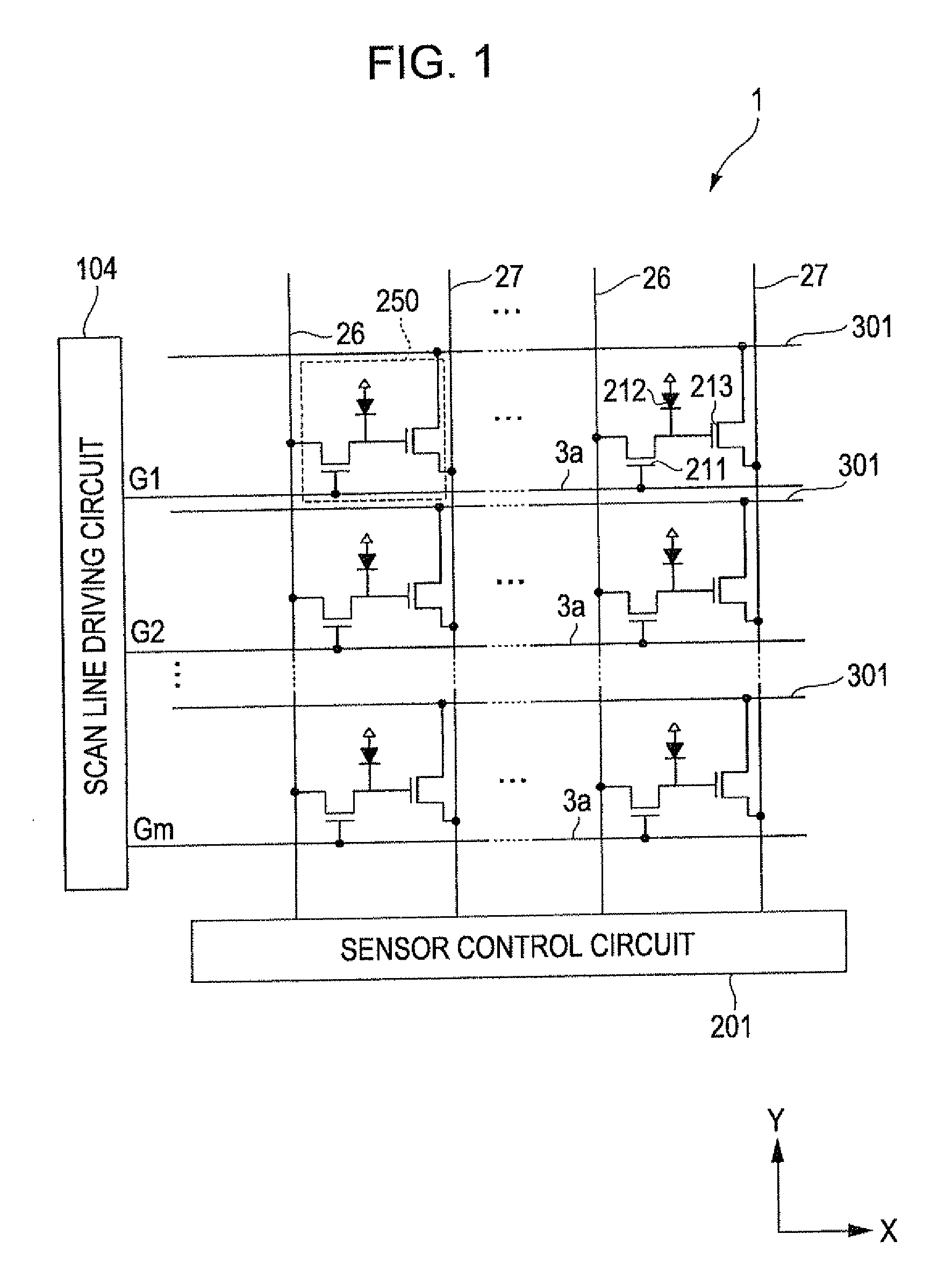

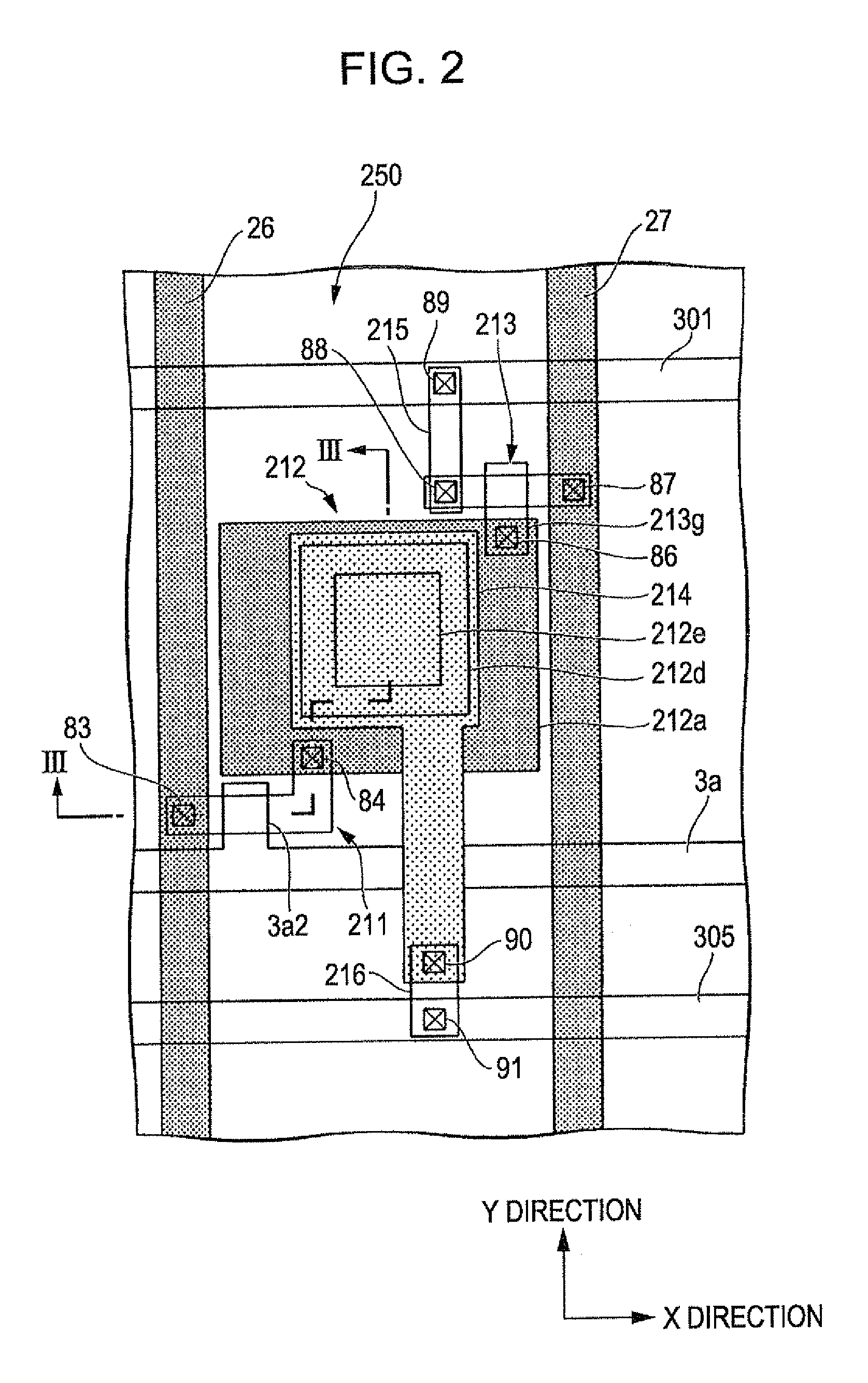

Photoelectric conversion device, electro-optic device, and electronic device

ActiveUS20100171122A1High sensitivityHigh yield ratioSolid-state devicesRadiation controlled devicesEngineeringElectro-optics

The photoelectric conversion device includes: a photoelectric conversion element in which a first electrode, a photoelectric conversion layer, and a second electrode are stacked in this order; and a thin film transistor (TFT) connected to the first electrode of the photoelectric conversion element via a contact hole, wherein the photoelectric conversion layer including a first photoelectric conversion layer disposed at a location which does not overlap with the contact hole and a second photoelectric conversion layer disposed at a location which overlaps with the contact hole, the first photoelectric conversion layer and the second photoelectric conversion layer are separated from each other by a separation groove, and the second electrode is selectively formed on the first photoelectric conversion layer, and the photoelectric conversion element is formed by the first electrode, the first photoelectric conversion layer, and the second electrode.

Owner:SEIKO EPSON CORP

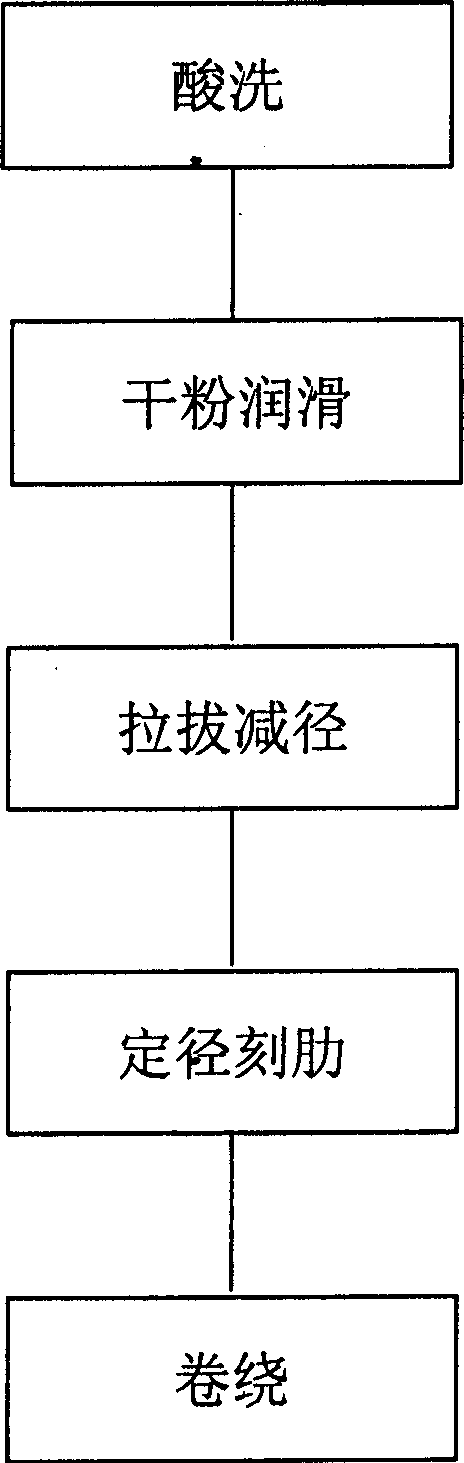

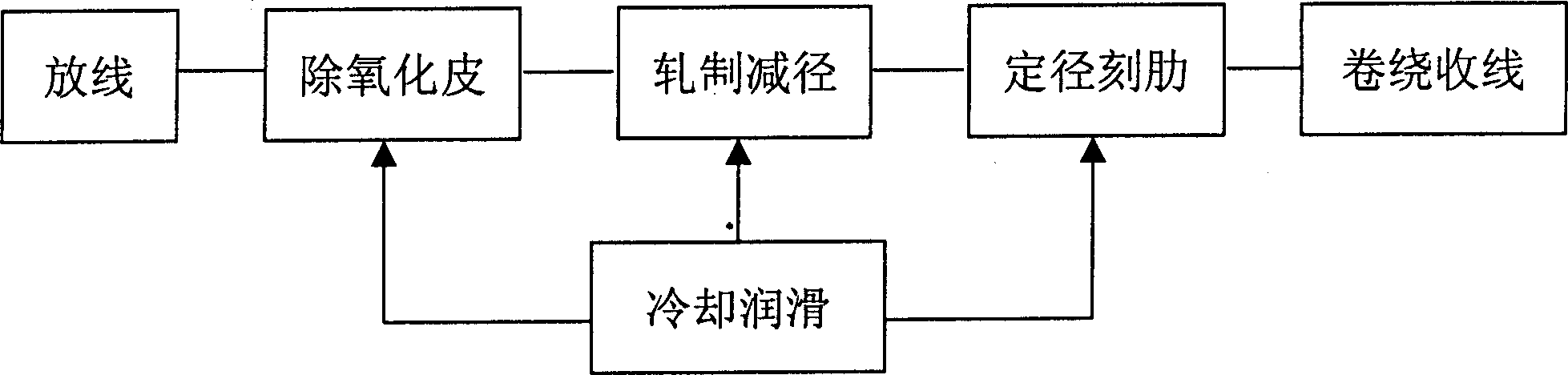

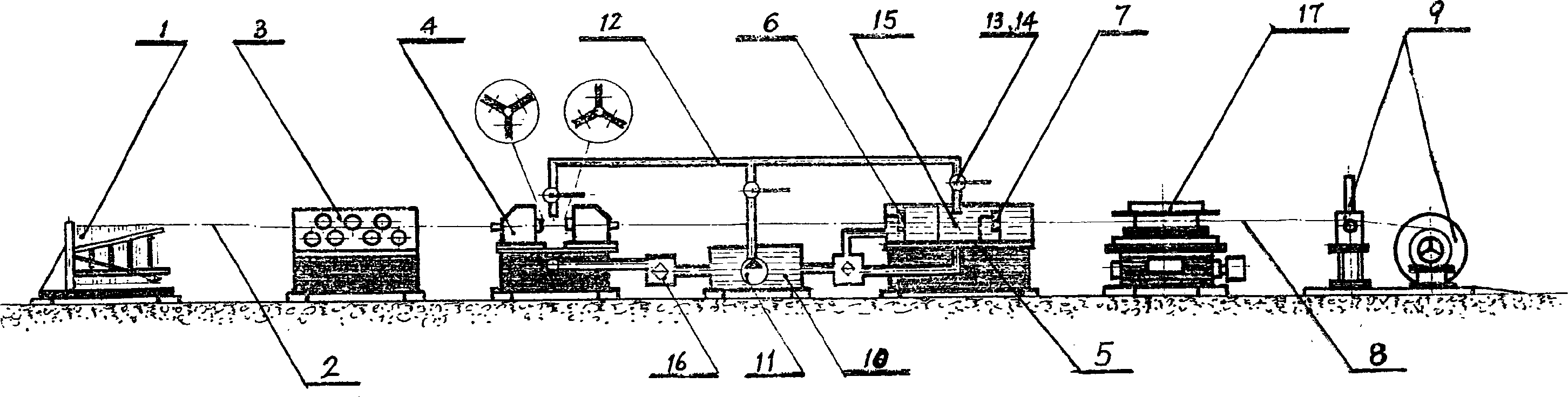

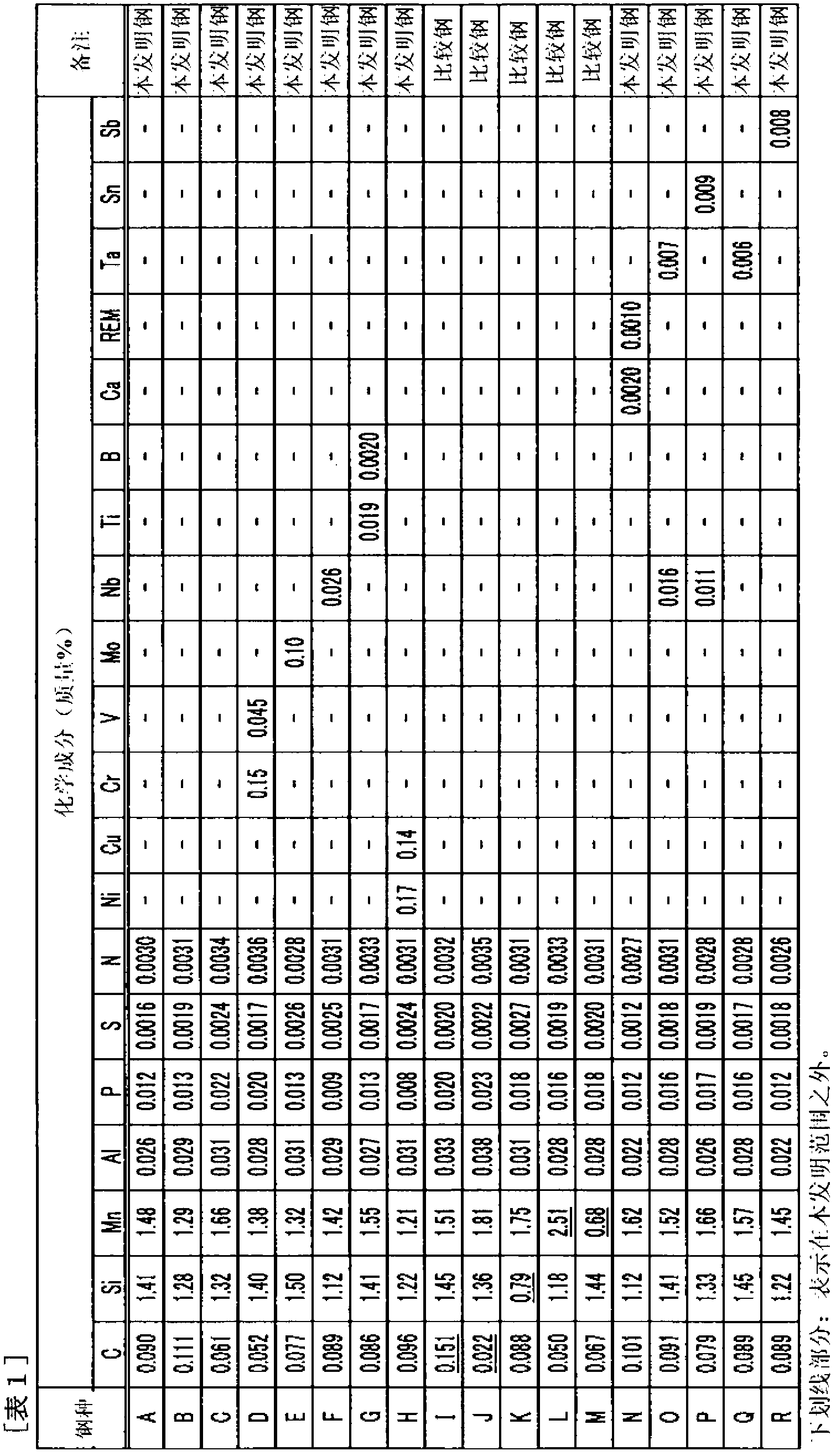

Process for producing screw-thread steel by draw-milling

A technology for manufacturing the reinforcing bar with spiral ribs by rolling-drawing method includes such steps as paying-off removing oxidized surface by multiple rolling rollers, reducing diameter by Y-type three-roller rolling-drawing unit, forming ribs by dual-die spiral rib forming unit, and taking-up. It features use of a cooling-lubricating system.

Owner:吴英剑

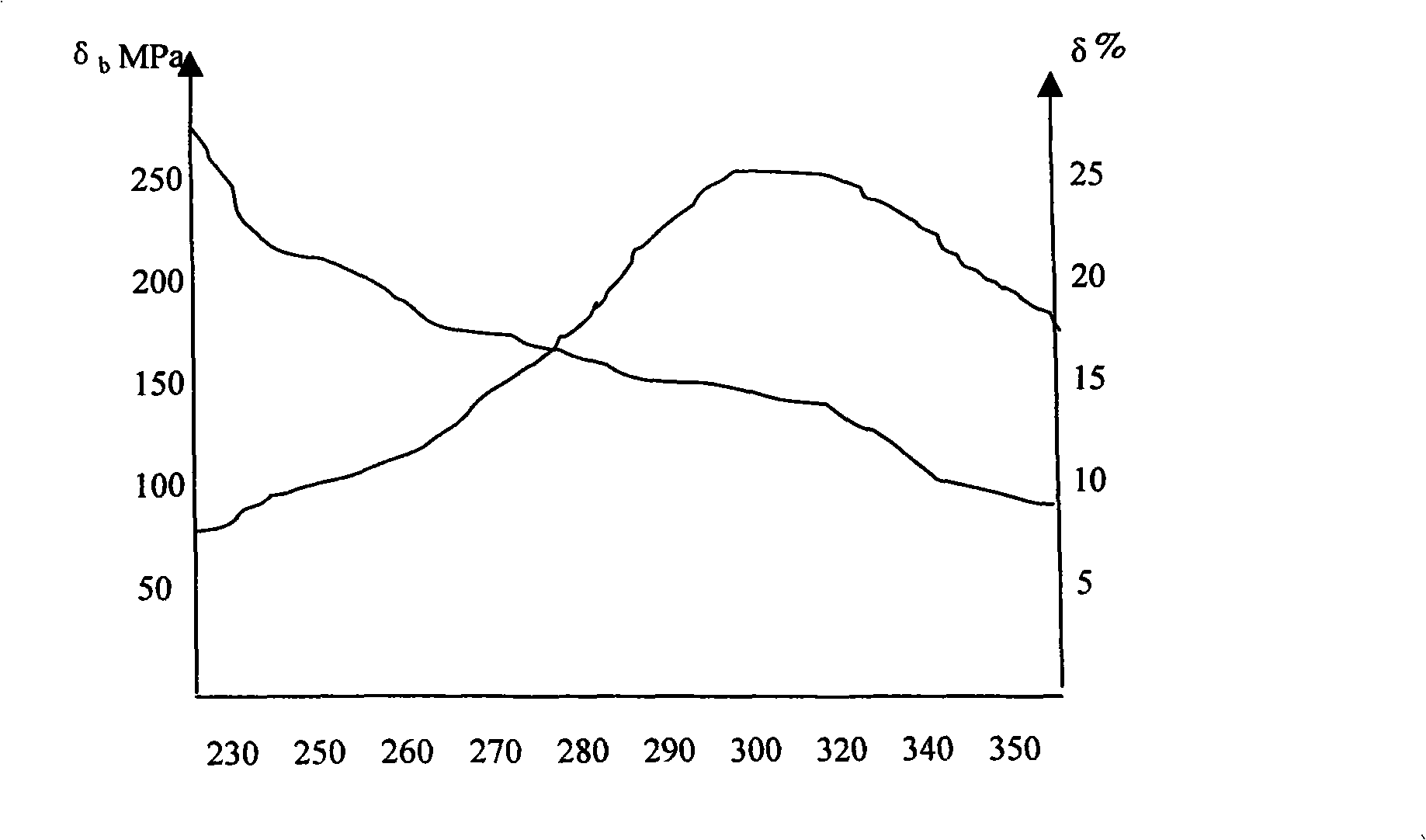

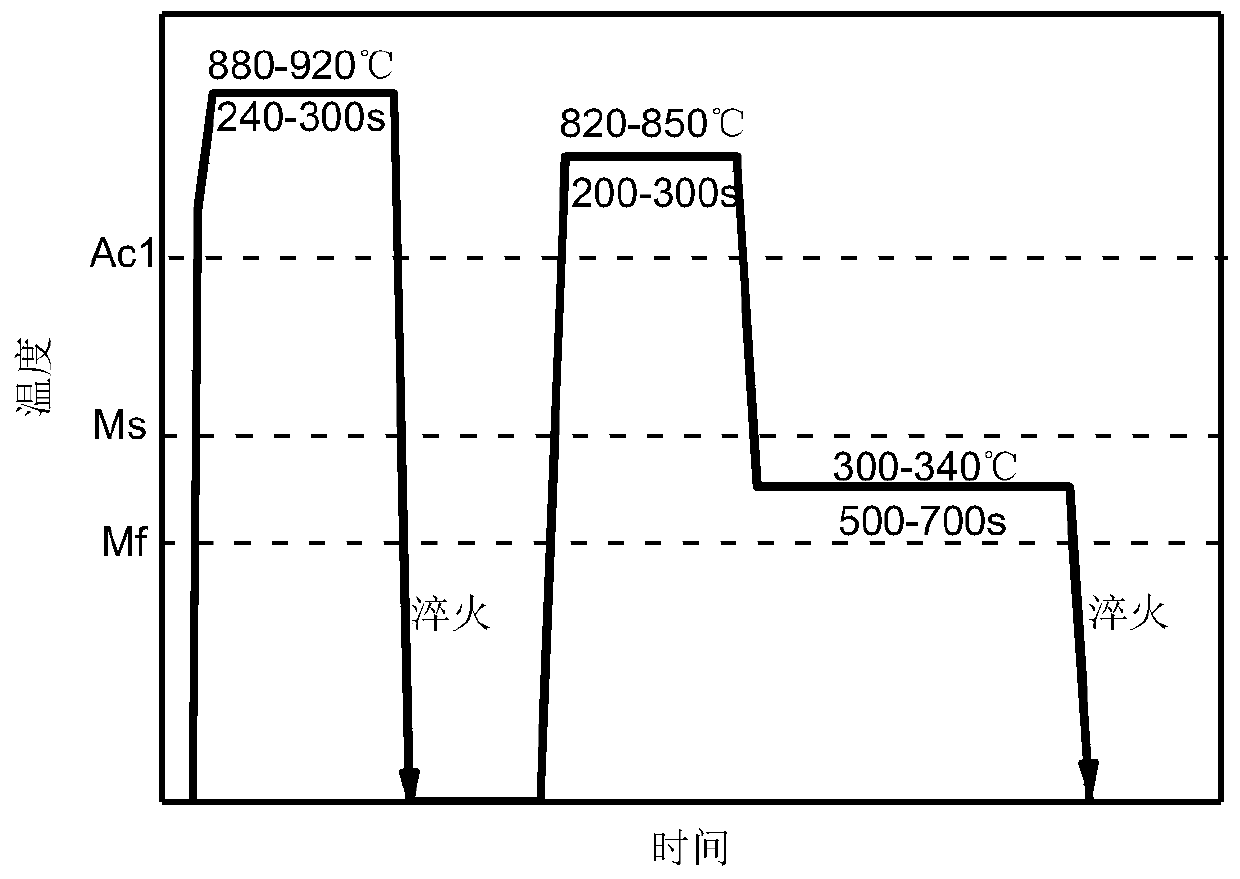

Process for quenching-distribution heat treatment on 60Si2CrVA steel spring for trains

InactiveCN101597680AHigh yield limitImprove fatigue strengthIncreasing energy efficiencyFurnace typesYield ratioRound bar

The invention discloses a process for quenching-distribution heat treatment on 60Si2CrVA steel spring for trains. The process comprises the following steps: polishing a 60Si2CrVA steel round bar with diameter less than or equal to 50mm, and heating the steel round bar to a temperature of between 960 and 1,060 DEG C through an inductive heating mode; then, wrapping the 60Si2CrVA steel round bar into a spring in the temperature state; cooling the wrapped spring to a temperature of between 810 and 900 DEG C, quenching the spring at a temperature of between 130 and 210 DEG C, and keeping constant temperature for 10 to 60 seconds; quickly placing the spring in a medium at a temperature of between 280 and 350 DEG C, maintaining for 50 to 800 seconds, and placing the spring into water or oil for cooling; and tempering the spring at a temperature of between 250 and 470 DEG C for 60 to 120 minutes. The 60Si2CrVA steel spring product has the advantages of high yield limit and fatigue strength, good quenching harden ability, high tensile strength and yield ratio, high toughness and the like.

Owner:GUIZHOU UNIV

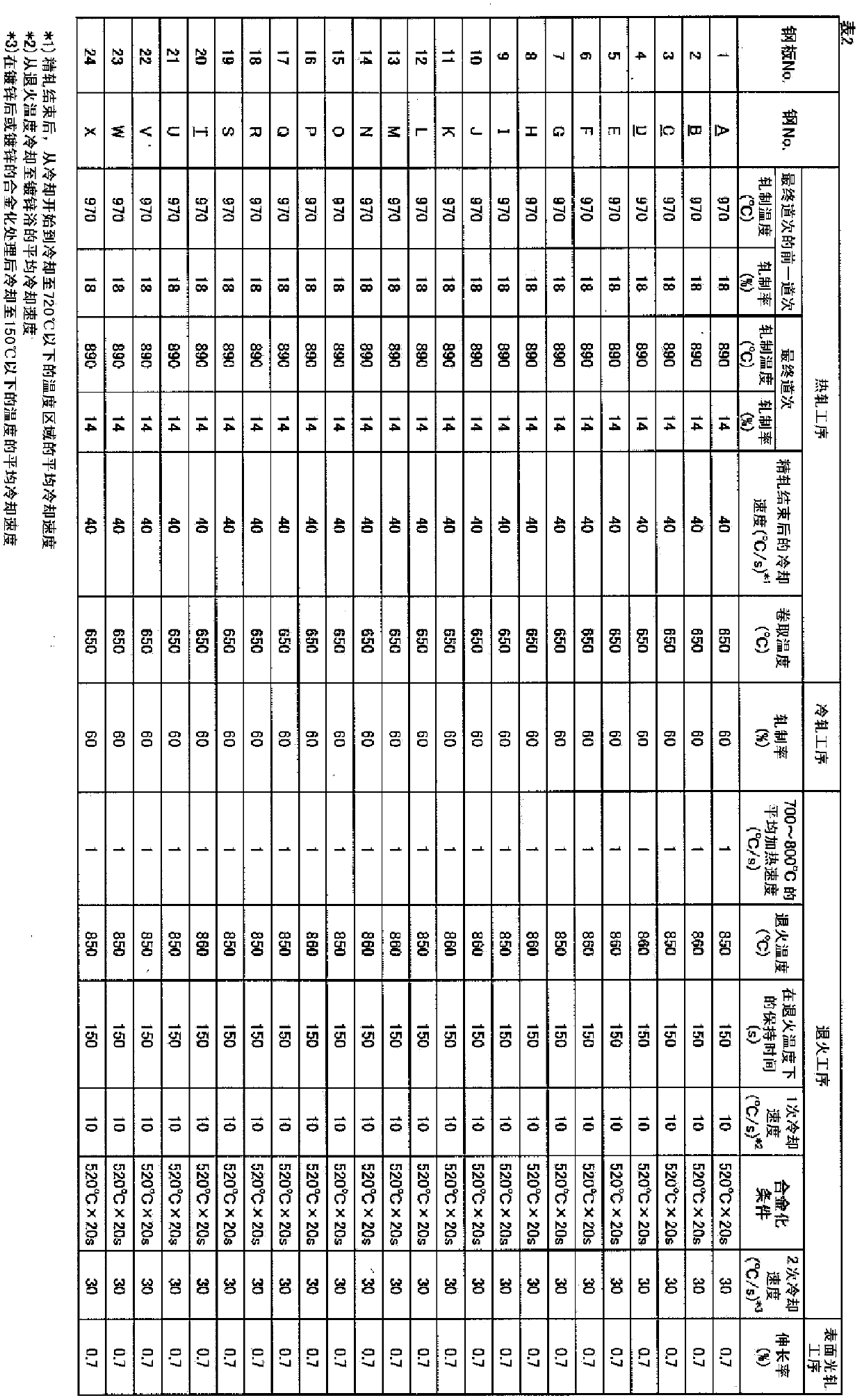

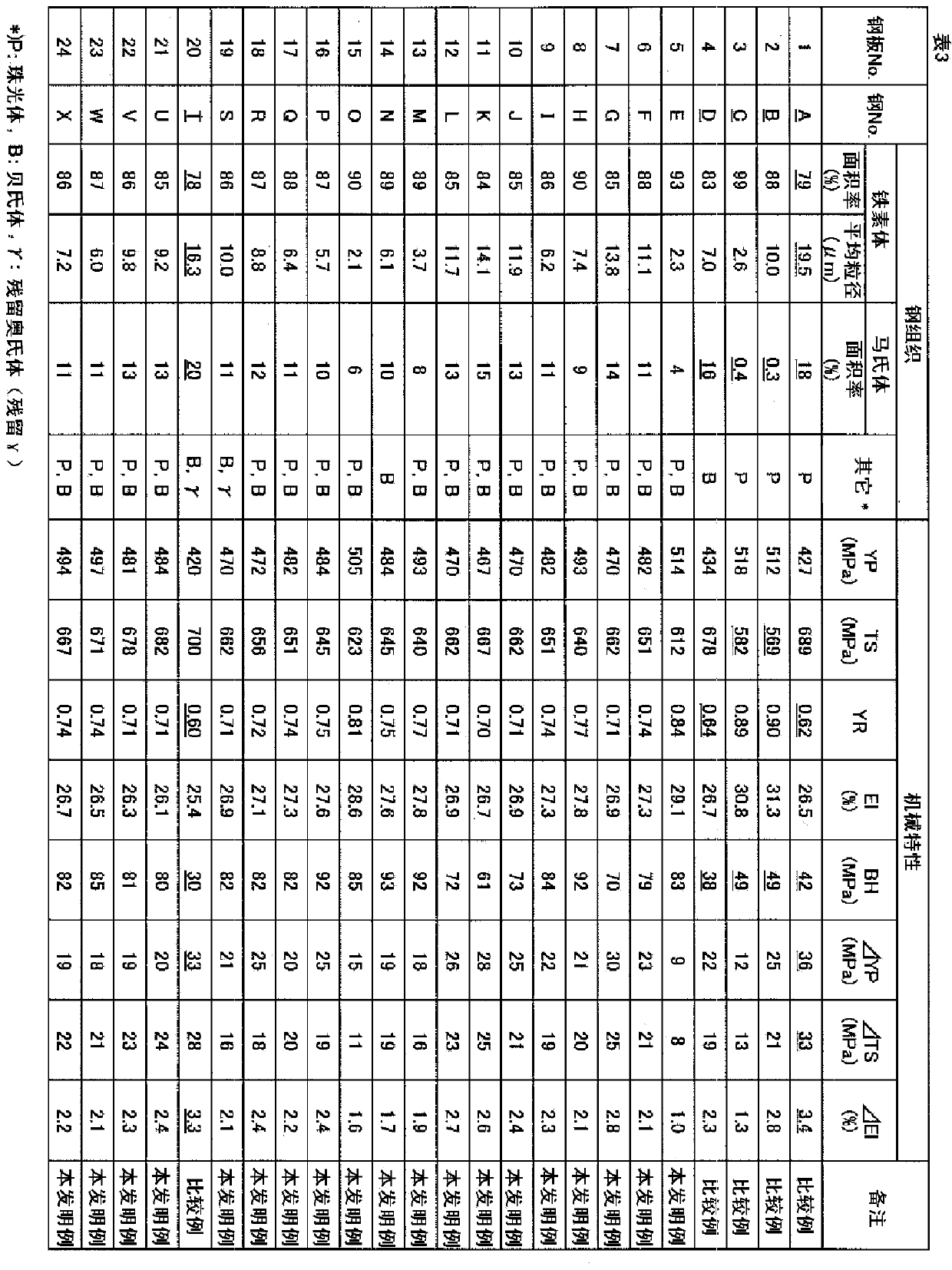

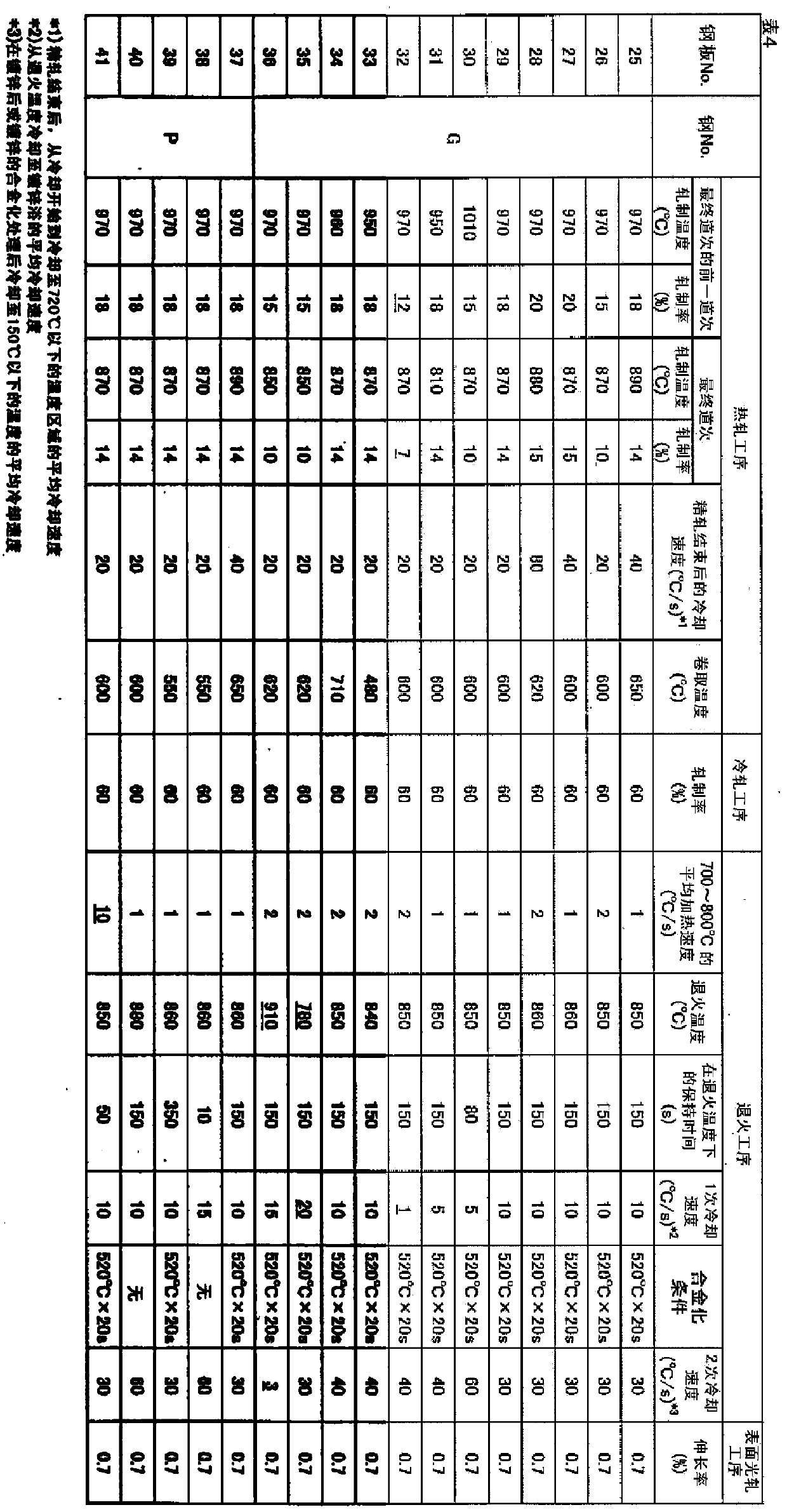

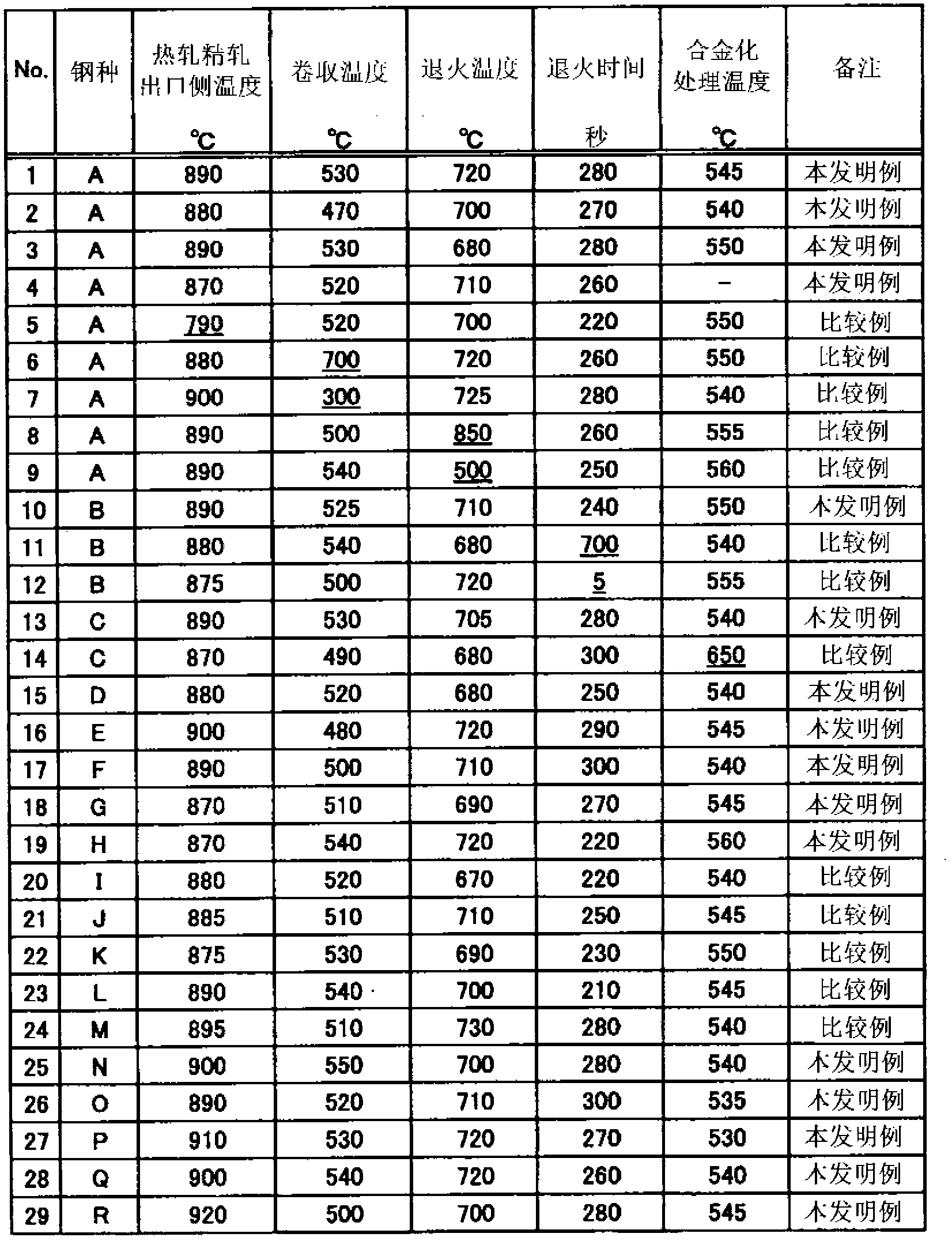

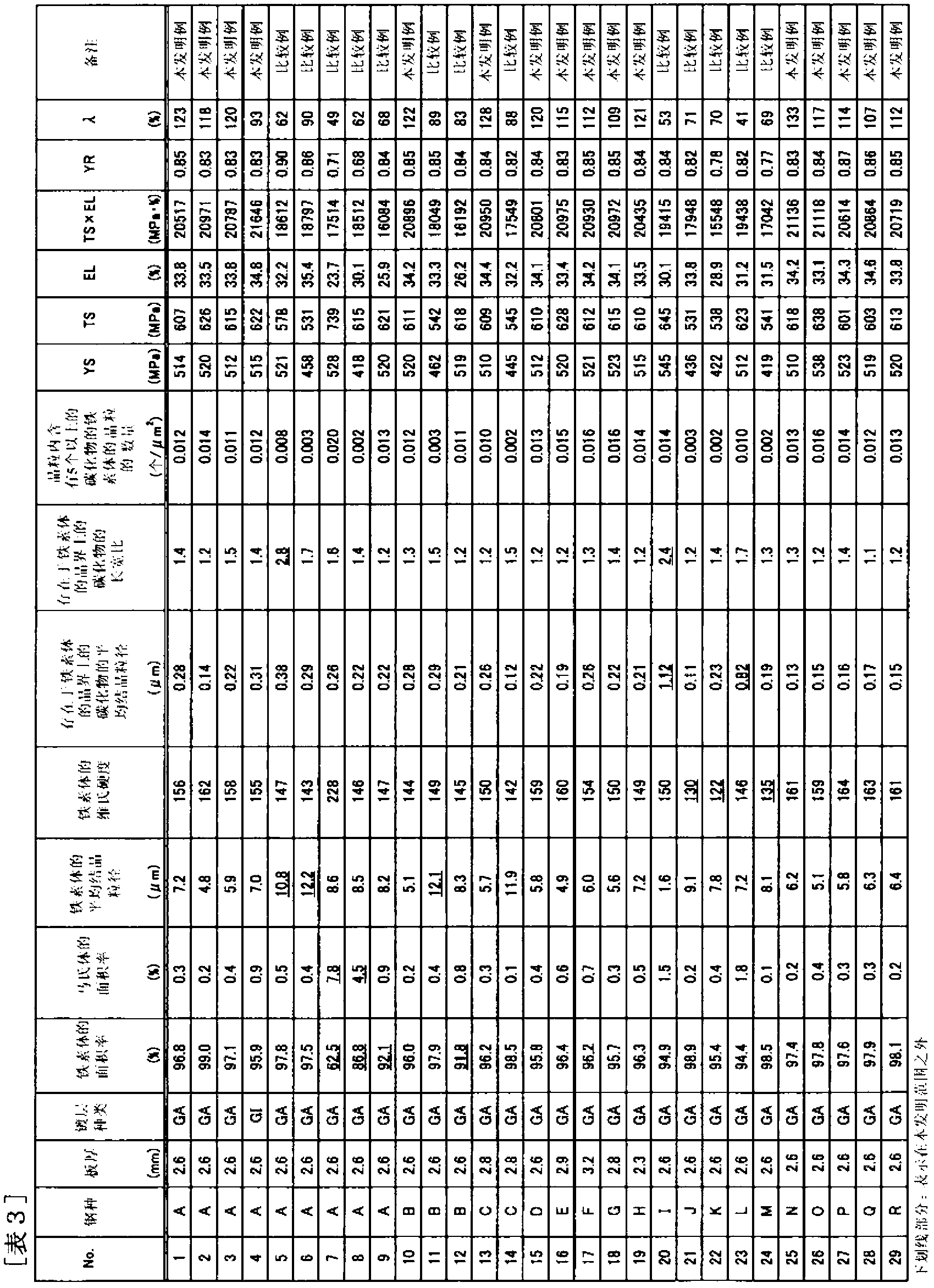

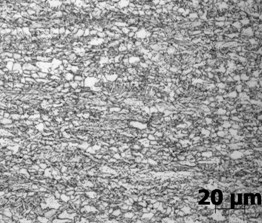

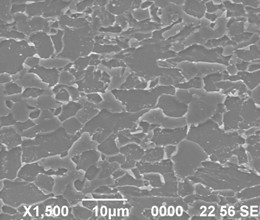

High yield ratio high-strength hot-dip galvanized steel sheet with excellent ductility and hole expansion properties, and manufacturing method thereof

ActiveCN103003460AHigh strengthHigh yield ratioHot-dipping/immersion processesPretreated surfacesSheet steelCarbide

Disclosed is a high yield ratio hot-dip galvanized steel sheet with excellent ductility and hole expansion properties and having a tensile strength: TS) of 590 MPa or greater; also disclosed is a manufacturing method thereof. The disclosed high yield ratio high-strength hot-dip galvanized steel sheet with excellent ductility and hole expansion properties contains, by mass%, C: between 0.04% and 0.13%, Si: between 0.9% and 2.3%, Mn: between 0.8% and 2.4%, P: less than 0.1%, S: .01% or less, Al: between 0.01% and 0.1%, N: 0.008% or less, with the remainder consisting of iron and inevitable impurities. The composition is 94% or more ferrite and 2% or less martensite by area ratio, the average grain size of the ferrite is 10[mu]m or less, the Vickers hardness of the ferrite is 140 or greater, the average grain size of the carbides present on the ferrite grain boundaries is 0.5[mu]m or less, and the aspect ratio of the carbides present on the ferrite grain boundaries is 2.0 or less.

Owner:JFE STEEL CORP

Large-deformation-preventing pipeline steel with excellent aging resistance and production method thereof

ActiveCN102080194AHigh yield strengthThe yield strength is slightly lower than the yield strength before aging, and the tensile strength is increasedTemperature control deviceFurnace typesChemical compositionLarge deformation

The invention discloses large-deformation-preventing pipeline steel with excellent aging resistance and a production method thereof. The pipeline steel comprises the following chemical components by weight percentage: 0.03 to 0.12 percent of C, 0.10 to 0.30 percent of Si, 1.20 to 1.80 percent of Mn, 0.010 percent of P or less, 0.005 percent of S or less, 0.030 to 0.060 percent of Nb, 0.006 to 0.020 percent of Ti, 0.10 to 0.40 percent of Cr, 0.10 to 0.30 percent of Ni, 0.01 to 0.03 percent of Cu, 0.010 to 0.050 percent of Al, and the balance of Fe and unavoidable impurity. The pipeline steel is fabricated by the controlled rolling and cooling technique, the heating temperature before rolling is 1150 to 1250 DEG C, the rough rolling temperature is 950 to 1050 DEG C, and the initial finish rolling temperature is 880 to 900 DEG C; the steel is subjected to laminar flow cooling after being rolled, the final cooling temperature is 600 to 650 DEG C, and the cooling rate is 5 to 15 DEG C per second; and finally, the steel is subjected to two-phase region quenching at the temperature between Ac1 and Ac3. The produced large-deformation-preventing pipeline steel is characterized by low yield ratio, high strength, high plasticity, high aging resistance and the like.

Owner:NANJING IRON & STEEL CO LTD

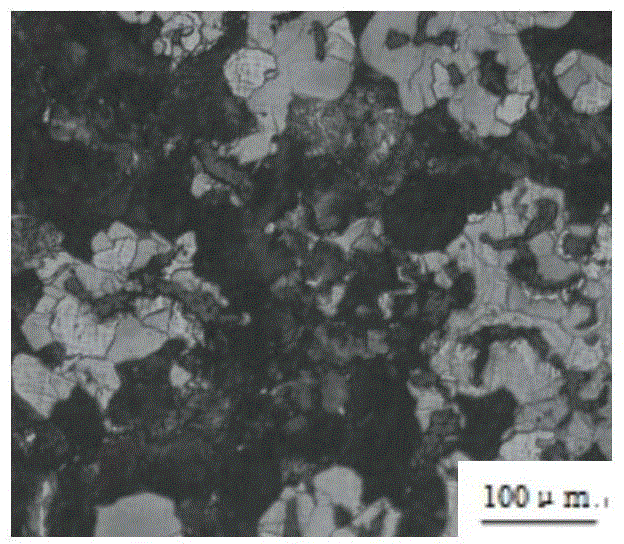

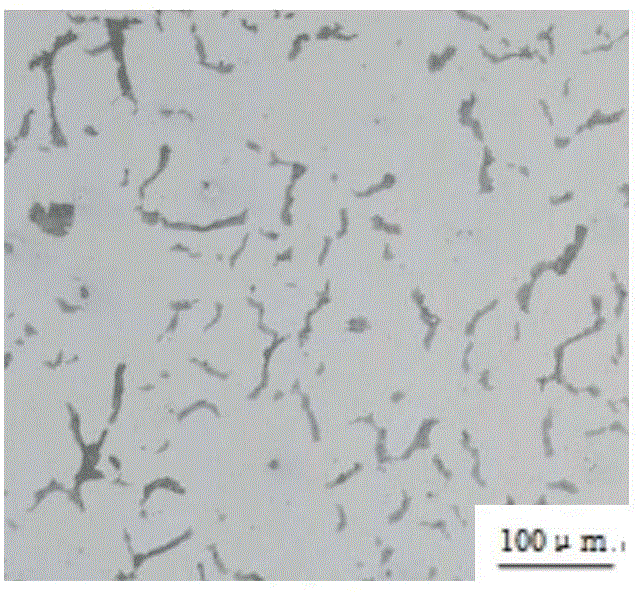

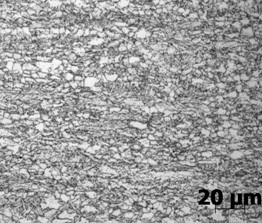

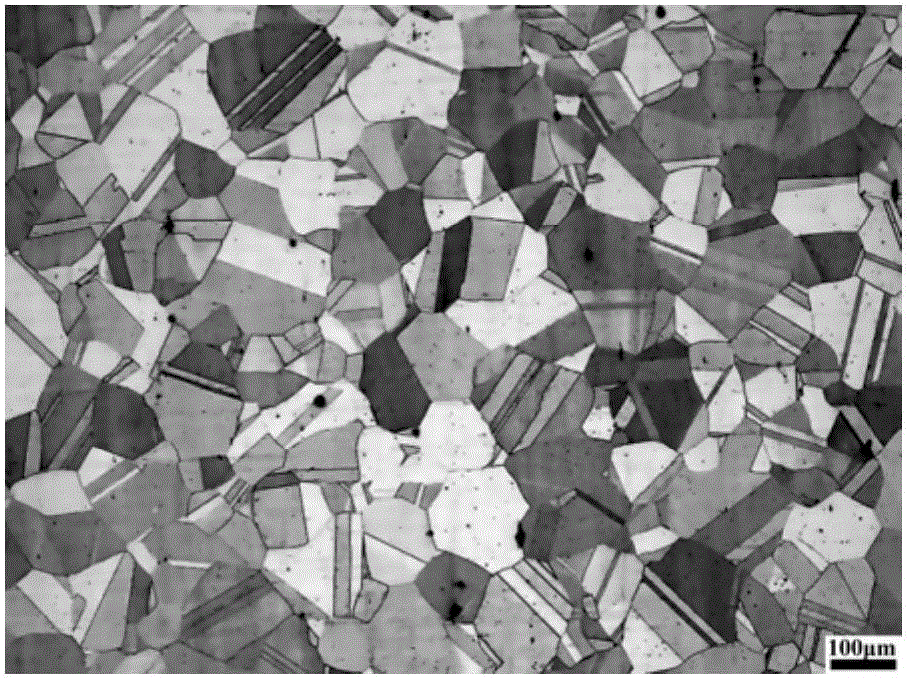

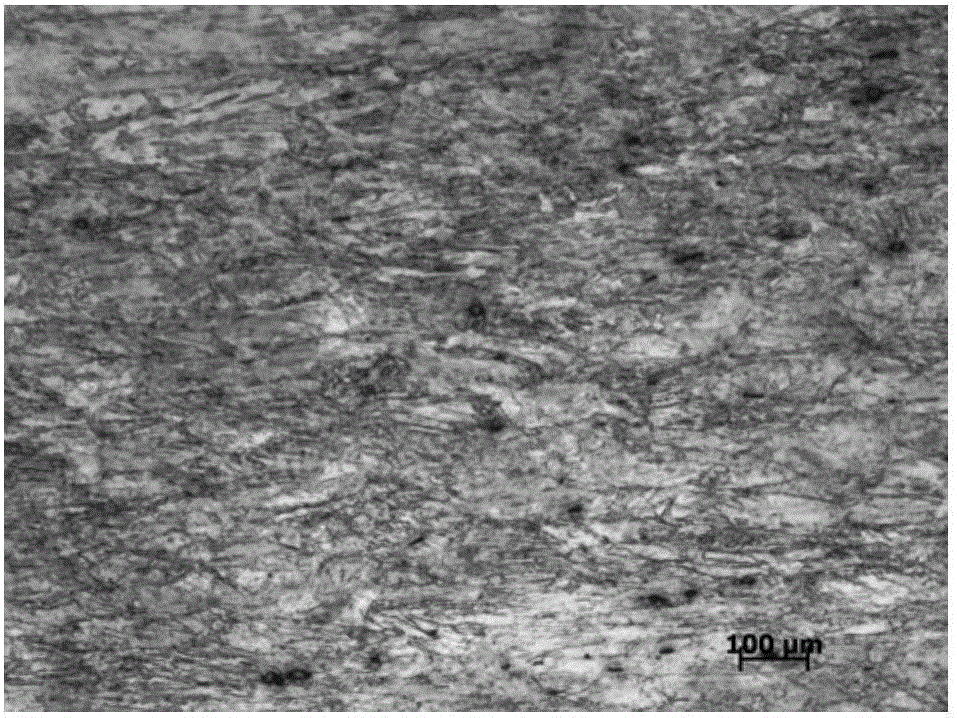

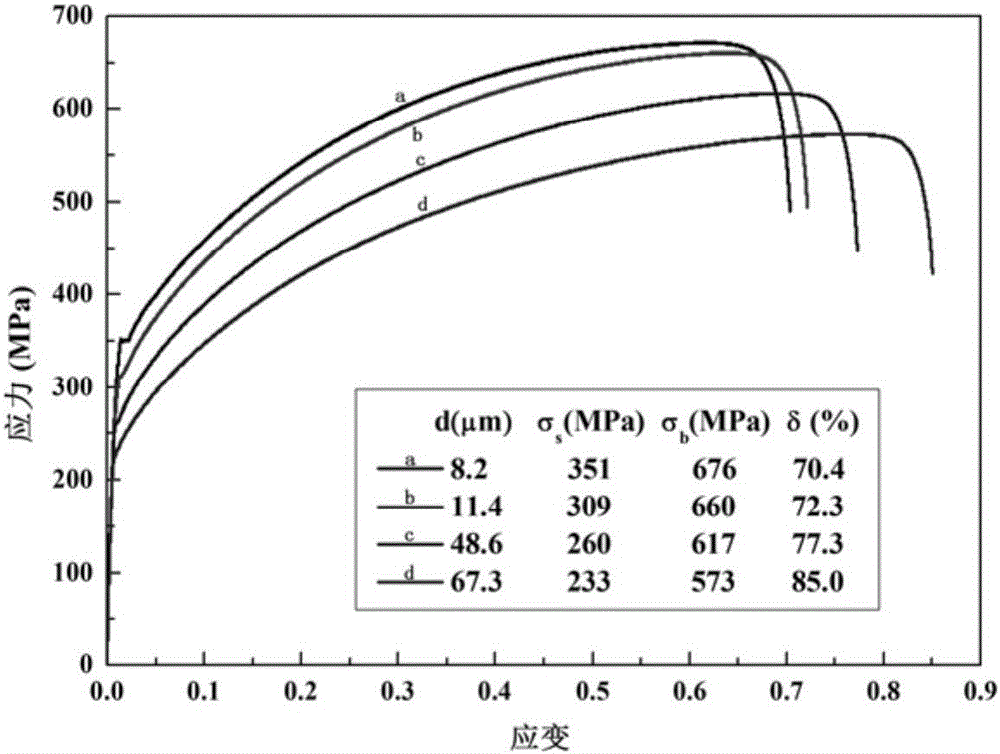

Production method for twinning induced plasticity steel of deformed grain/partial re-crystallization structures

The invention discloses a production method for twinning induced plasticity steel of deformed grain / partial re-crystallization structures. Deformed grains are formed through medium-temperature plastic processing, and then partial isometric crystals grow in the deformed structure through medium-temperature short-time annealing or quenching. External force needed by dislocation glide in the stretching process is increased through high-density dislocation and complicated dislocation configurations in the deformed grains, so that the yield strength of a material is improved, the isometric crystals formed in the re-crystallization process promote twinning deformation, and therefore the high plasticity of the material can be guaranteed. The energy absorption ability, the energy absorption efficiency and the bearing capacity of the material are improved simultaneously through the combined effect of the two structures, the relative proportion of the two structures can be adjusted by changing plastic processing and thermal treating technologies, and therefore different energy absorption characteristics can be obtained. Compared with common twinning induced plasticity steel, the twinning induced plasticity steel produced through the method has the advantages that the energy absorption ability, the energy absorption efficiency and the bearing capacity of the material are high.

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI

Steel sheet, plated steel sheet, and method for producing the same

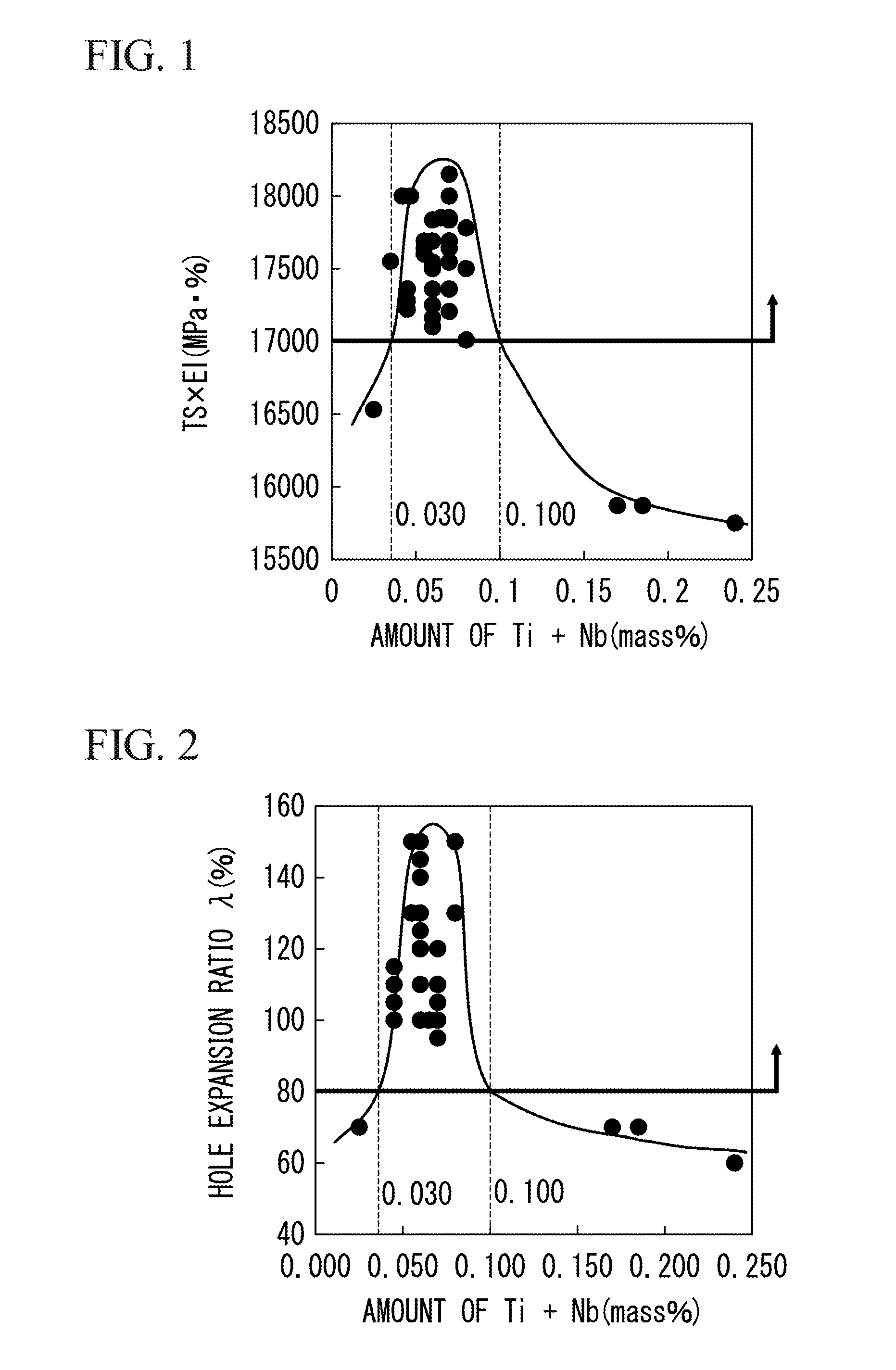

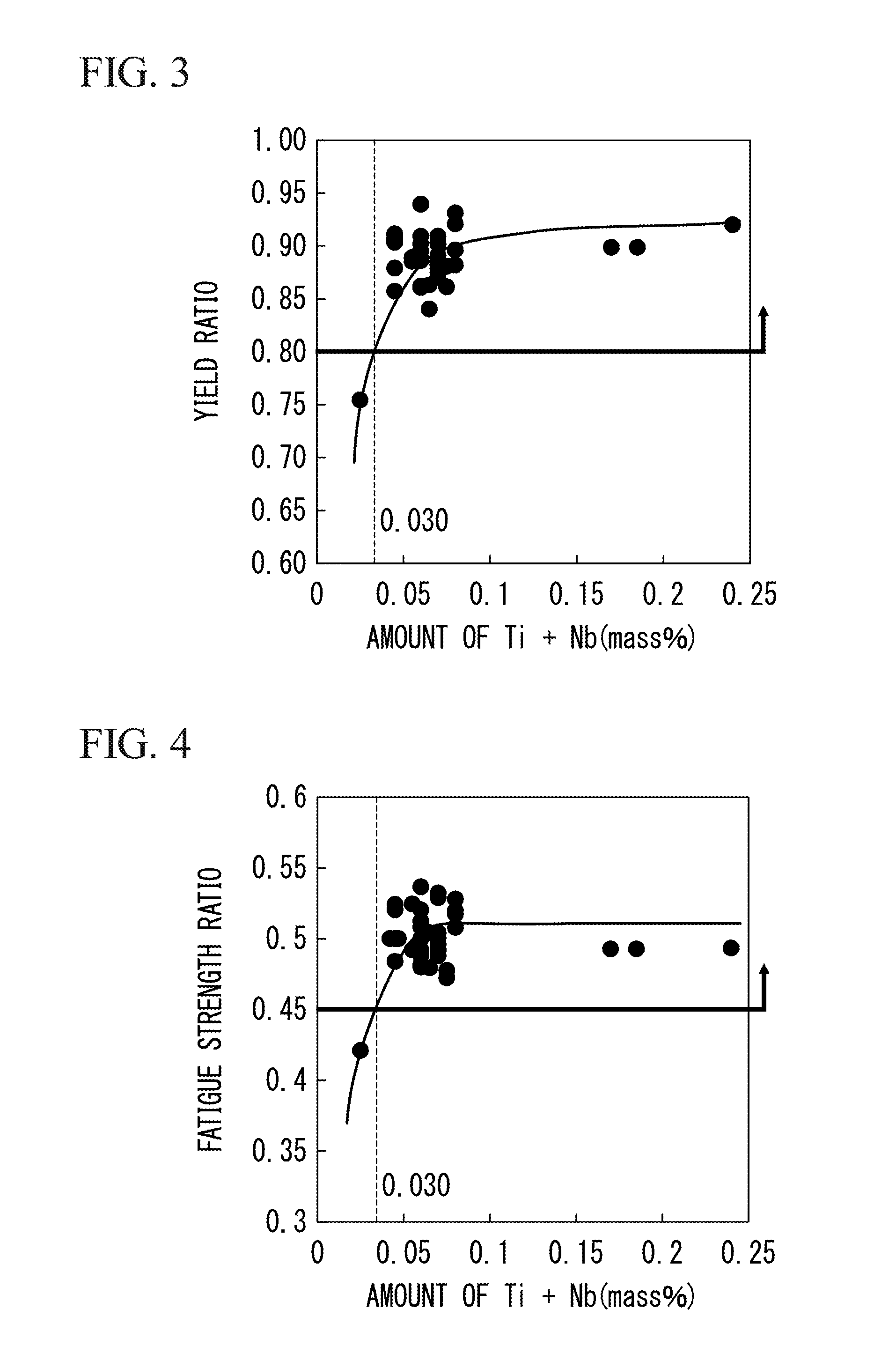

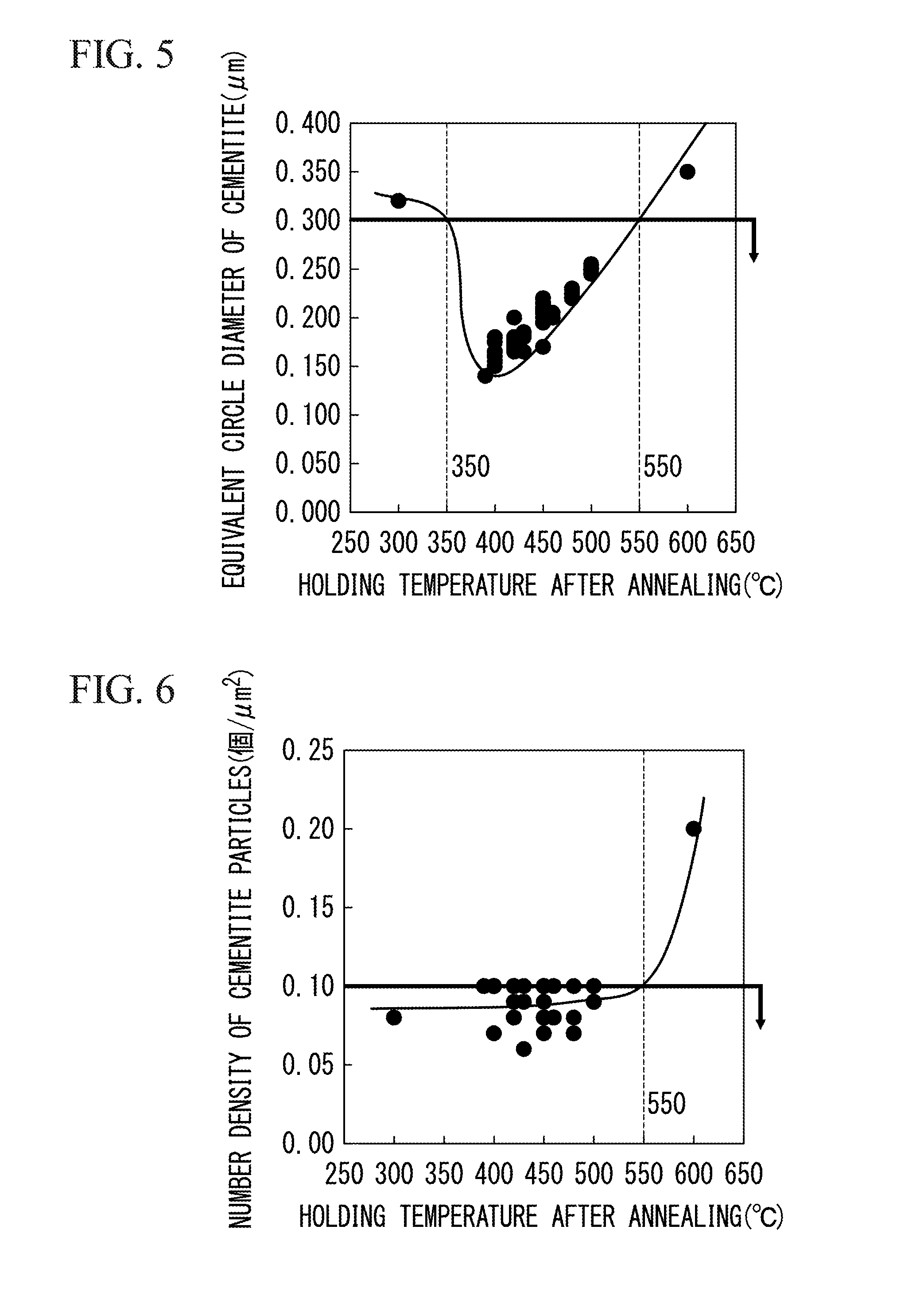

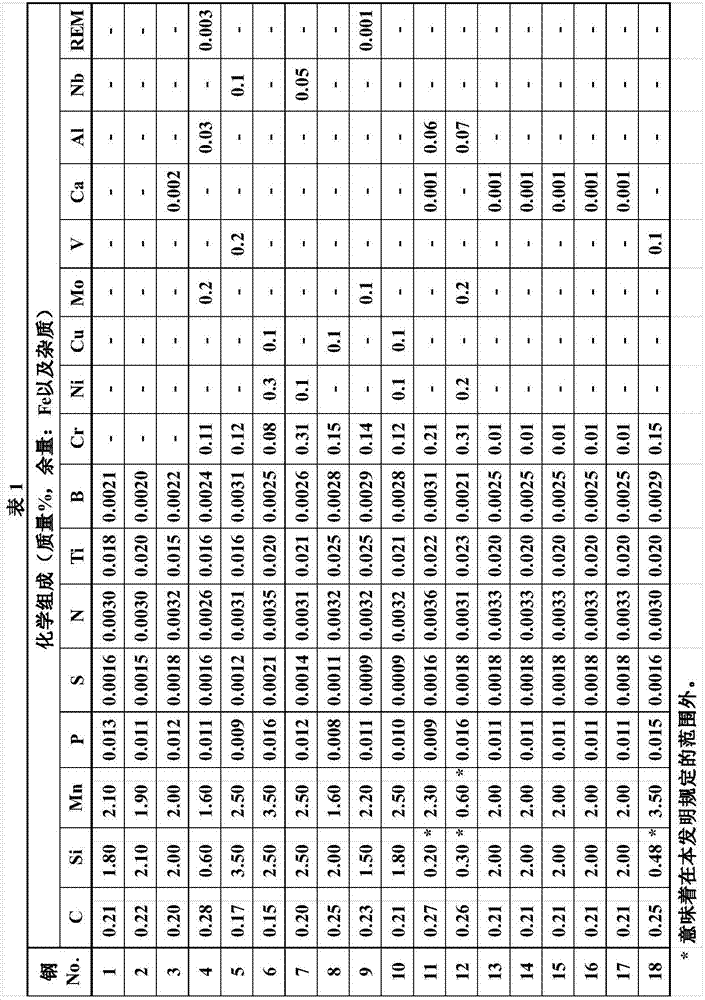

ActiveUS20150004433A1Reduce sheet thicknessReduce vehicle weightHot-dipping/immersion processesFurnace typesMetallurgyBainite

A steel sheet includes, by mass %: C: 0.020% to 0.080%; Si: 0.01% to 0.10%; Mn: 0.80% to 1.80%; and Al: more than 0.10% and less than 0.40%; and further includes: Nb: 0.005% to 0.095%; and Ti: 0.005% to 0.095%, in which a total amount of Nb and Ti is 0.030% to 0.100%, and the steel sheet includes, as a metallographic structure, ferrite, bainite, and other phases, an area fraction of the ferrite is 80% to 95%, an area fraction of the bainite is 5% to 20%, a total fraction of the other phases is less than 3%, a tensile strength is 590 MPa or more, and a fatigue strength ratio as a fatigue strength to the tensile strength is 0.45 or more.

Owner:NIPPON STEEL CORP

Heat-treated steel sheet member, and production method therefor

ActiveCN107532255ASufficient tensile strengthHigh yield ratioFurnace typesHeat treatment furnacesChemical compositionSheet steel

Owner:NIPPON STEEL CORP

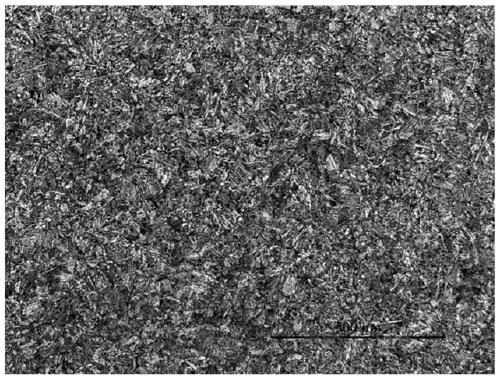

V microalloying high-toughness bainite non-quenched and tempered steel and controlled forging and controlled cooling technology and production technology thereof

The invention discloses V microalloying high-toughness bainite non-quenched and tempered steel and a controlled forging and controlled cooling technology and a production technology thereof. The V microalloying high-toughness bainite non-quenched and tempered steel comprises the following chemical components including, by weight, 0.20%-0.30% of C, 0.20%-0.40% of Si, 1.90%-2.10% of Mn, smaller thanor equal to 0.010% of P, 0.030-0.050% of S, 0.40%-0.60% of Cr, 0.10%-0.20% of V, 0.015%-0.025% of Ti, smaller than or equal to 0.20% of Ni, smaller than or equal to 0.20% of Mo, 0.020%-0.045% of Al,60 ppm-120 ppm of N and the balance Fe and inevitable impurity elements, and Ti*N is smaller than or equal to 0.00016. Compared with 42CrMo quenched and tempered steel, the fatigue performance of thesteel ball is equivalent to that of the 42CrMo quenched and tempered steel on the premise that the raw material cost is equivalent, a heat treatment tempering process is omitted for a forging enterprise, the part manufacturing cost is reduced, energy consumption is reduced, and the 42CrMo quenched and tempered steel can be replaced for manufacturing parts with the high requirement for high toughness.

Owner:MAANSHAN IRON & STEEL CO LTD

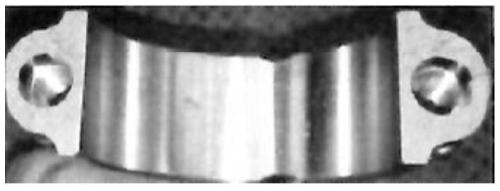

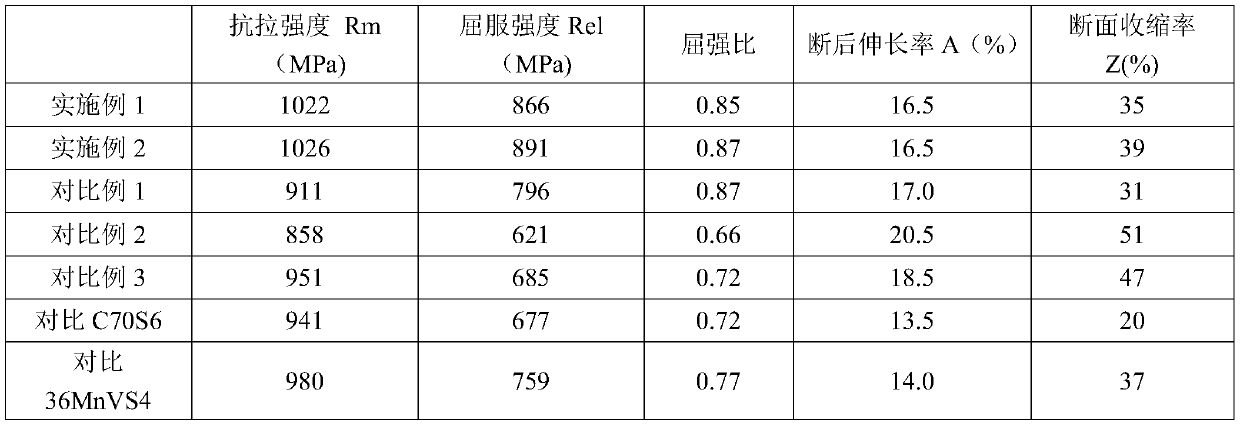

High-strength and high-yield-ratio non-quenched and tempered steel for automobile engine stretch-broken connecting rod and production method thereof

The invention discloses high-strength and high-yield-ratio non-quenched and tempered steel for an automobile engine stretch-broken connecting rod and a production method thereof. The steel comprises the following chemical components in percentage by weight, 0.40-0.50% of C, 0.40-0.60% of Si, 1.00-1.30% of Mn, 0.040-0.060% of S, 0.10-0.20% of V, 0.020-0.035% of Nb, 0.10-0.30% of Cr, 0.10-0.30% of Ni, 0.010-0.020% of N, and the balance Fe and impurity elements. Through the combination of the group distribution ratio and a controlled rolling and controlled cooling process, the mechanical propertyRel of the connecting rod material is greater than or equal to 850 MPa, the Rm is greater than or equal to 1000 MPa, and the yield ratio can reach more than 0.84, so that the light weight of an automobile engine is facilitated.

Owner:ZENITH STEEL GROUP CORP +1

Alloy for producing cold rolled working roll and method for producing same

The invention relates to an alloy for cold-rolling worker rollers and its preparing process, wherein the alloy comprises the main chemical constituents of: C 0.9-1.2%, Si 0.85-1.25%, Mn 0.40-0.60%, Cr 2.50-5.50%, Ni 0.25-0.45%, Mo 0.25-0.45%, V 0.05-0.155 and balancing Fe.

Owner:BAOSTEEL ROLL SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com