Large-deformation-preventing pipeline steel with excellent aging resistance and production method thereof

A technology of anti-large deformation and production method, which is applied in the direction of manufacturing tools, furnace types, furnaces, etc., can solve the problems of no investigation of aging performance and complicated production process, and achieve the effect of decreasing yield ratio, benefiting the strength of the plate, and deteriorating performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

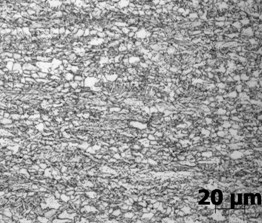

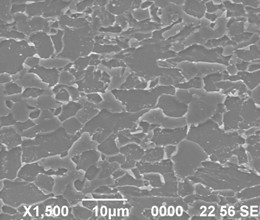

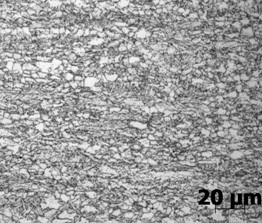

[0021] A large-deformation-resistant pipeline steel with excellent aging resistance, the chemical composition of the pipeline steel is shown in Table 1 by weight percentage.

[0022] The specific requirements for the production method of the above-mentioned large-deformation-resistant pipeline steel with excellent aging resistance are as follows:

[0023] Rolling process: controlled rolling and controlled cooling process (TMCP) two-stage rolling; the heating temperature of the continuous casting slab before rolling is 1150 ℃ ~ 1250 ℃, the rough rolling temperature is 950 ~ 1050 ℃, and the finishing rolling temperature is 880 ~ 900 ℃; laminar flow cooling is adopted after rolling, the final cooling temperature is 600-650 ℃, and the cooling rate is 5-15 ℃ / s; then air cooling;

[0024] Heat treatment process: In order to obtain a low yield ratio for the finished product, select X70 grade steel plate with a yield strength higher than 515MPa, then the pipeline steel is quenched in ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com