Patents

Literature

2126 results about "Rhenium" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Rhenium is a chemical element with the symbol Re and atomic number 75. It is a silvery-gray, heavy, third-row transition metal in group 7 of the periodic table. With an estimated average concentration of 1 part per billion (ppb), rhenium is one of the rarest elements in the Earth's crust. Rhenium has the third-highest melting point and highest boiling point of any stable element at 5903 K. Rhenium resembles manganese and technetium chemically and is mainly obtained as a by-product of the extraction and refinement of molybdenum and copper ores. Rhenium shows in its compounds a wide variety of oxidation states ranging from −1 to +7.

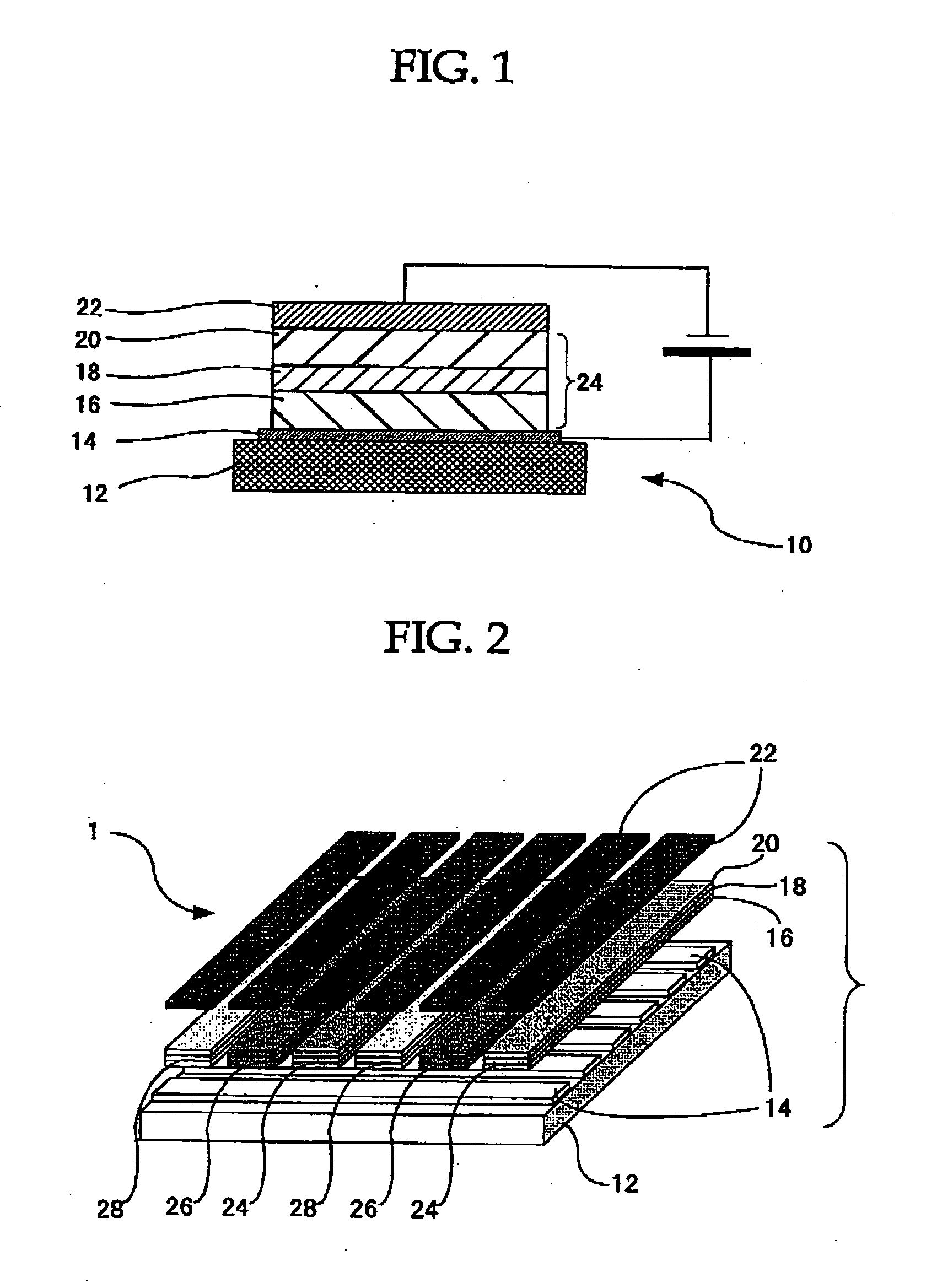

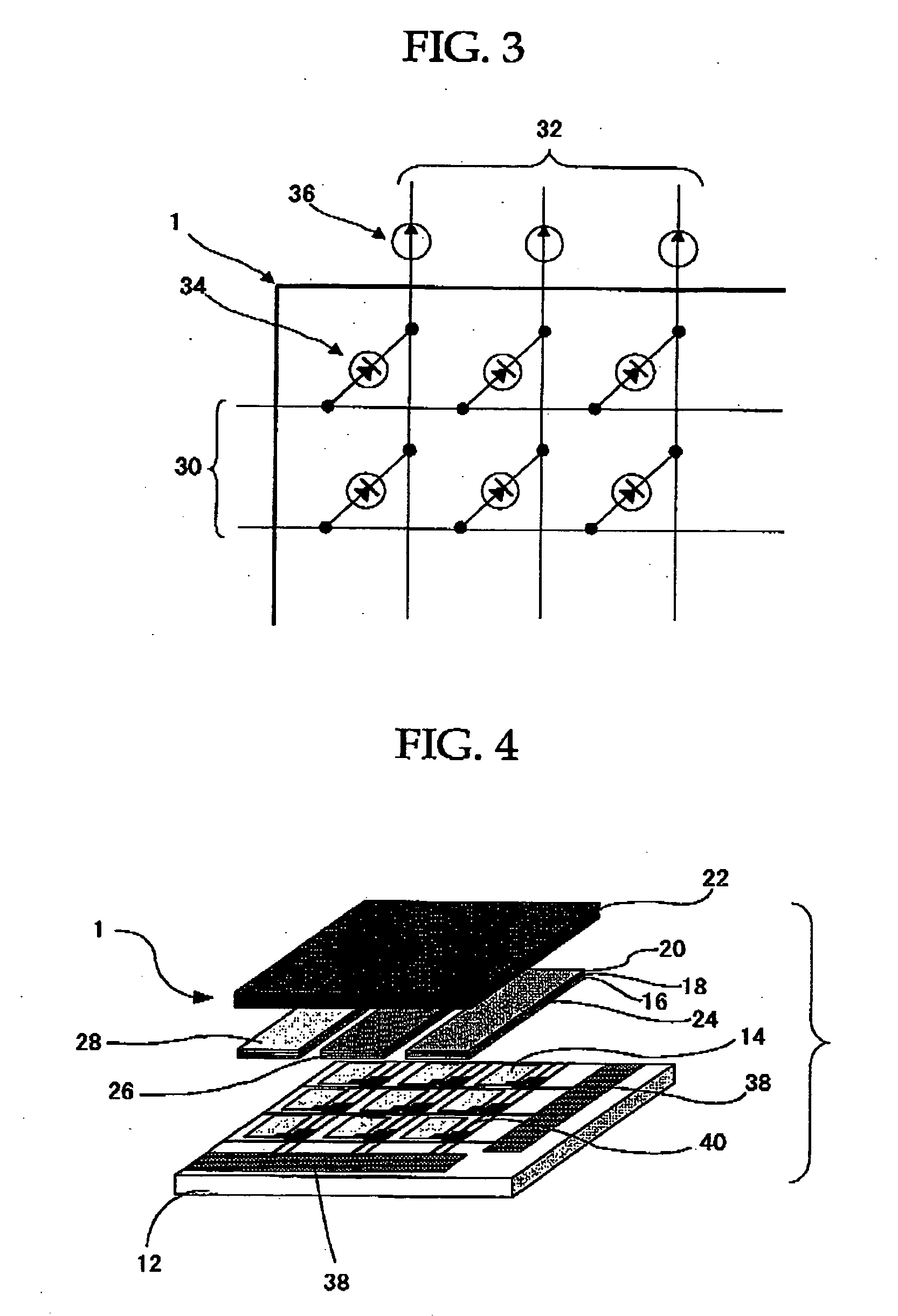

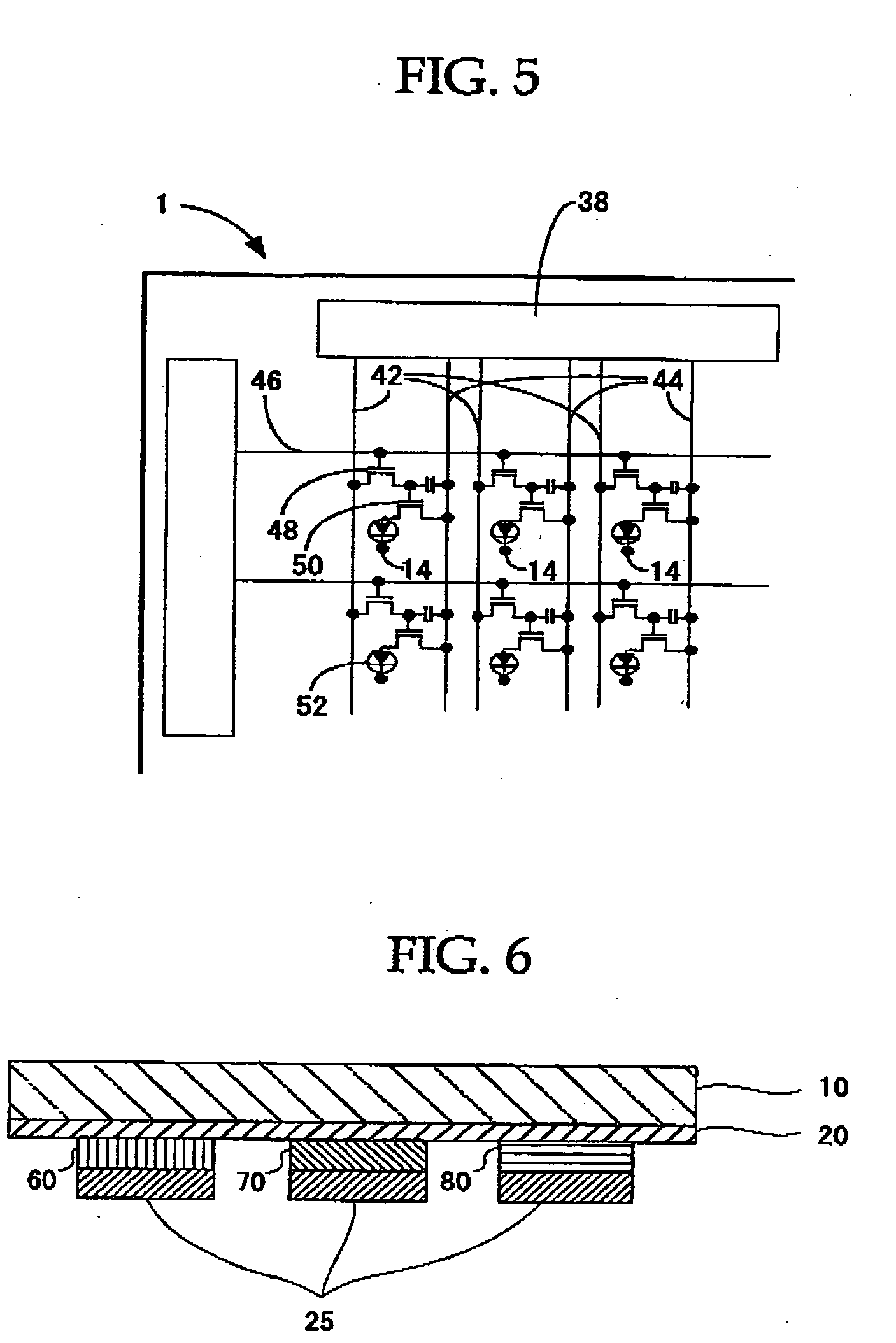

Organometallic complex, organic EL element and organic EL display

InactiveUS20050244673A1Improve efficiencyExcellent lifetimeGroup 8/9/10/18 element organic compoundsSolid-state devicesRheniumNitrogen

An organic EL element includes an organometallic complex including a rhenium atom; one ligand which has a coordinated nitrogen atom and a coordinated oxygen atom, each coordinated with the rhenium atom, and has at least one π conjugation part; and the other ligand coordinated with the rhenium atom in such a way that the ligand saturates the coordination number of the rhenium atom and the charge of the whole organometallic complex is neutral.

Owner:FUJIFILM HLDG CORP +1

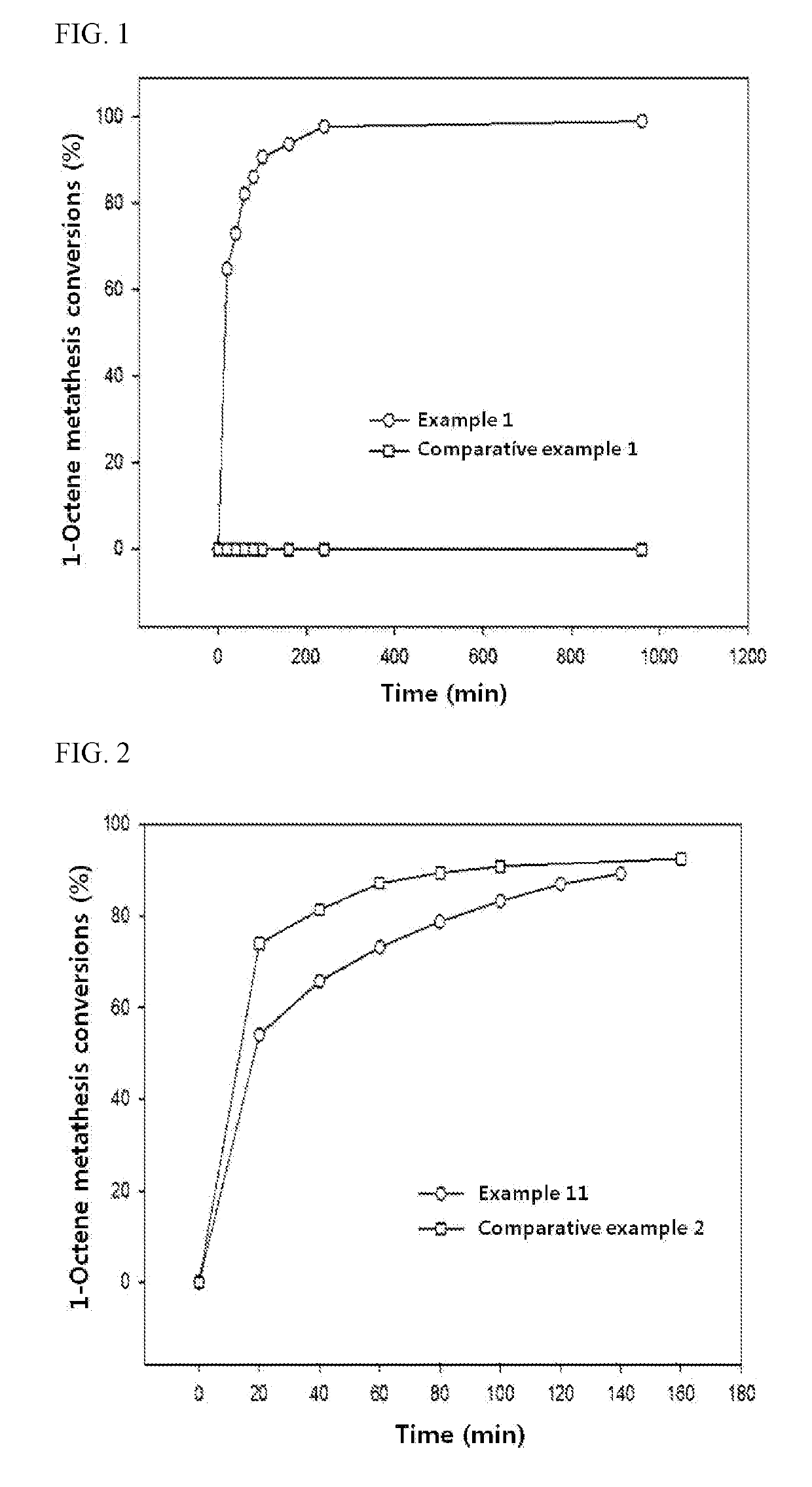

Olefin metathesis reaction catalyst and preparation method therefor

ActiveUS20190217277A1Separated/recovered readilyEasy to useMolecular sieve catalystsOrganic-compounds/hydrides/coordination-complexes catalystsRheniumUnsaturated hydrocarbon

The present invention relates to an olefin metathesis reaction catalyst where rhenium (Re) oxide or molybdenum (Mo) oxide is supported, as a catalyst main component, on a surface-modified mesoporous silica or mesoporous alumina support, and a preparation method therefor. The olefin metathesis reaction catalyst of the present invention allows highly efficient metathesis of long-chain unsaturated hydrocarbons having at least eight carbons at a low temperature of 150° C. or lower. The catalyst can be separated readily from reaction solution, regenerated at a low temperature of 400° C. or lower by removing toxins accumulated on it during the metathesis reaction, and used repeatedly in metathesis reaction many times, thereby being made good use in commercial olefin metathesis processes.

Owner:KOREA RES INST OF CHEM TECH

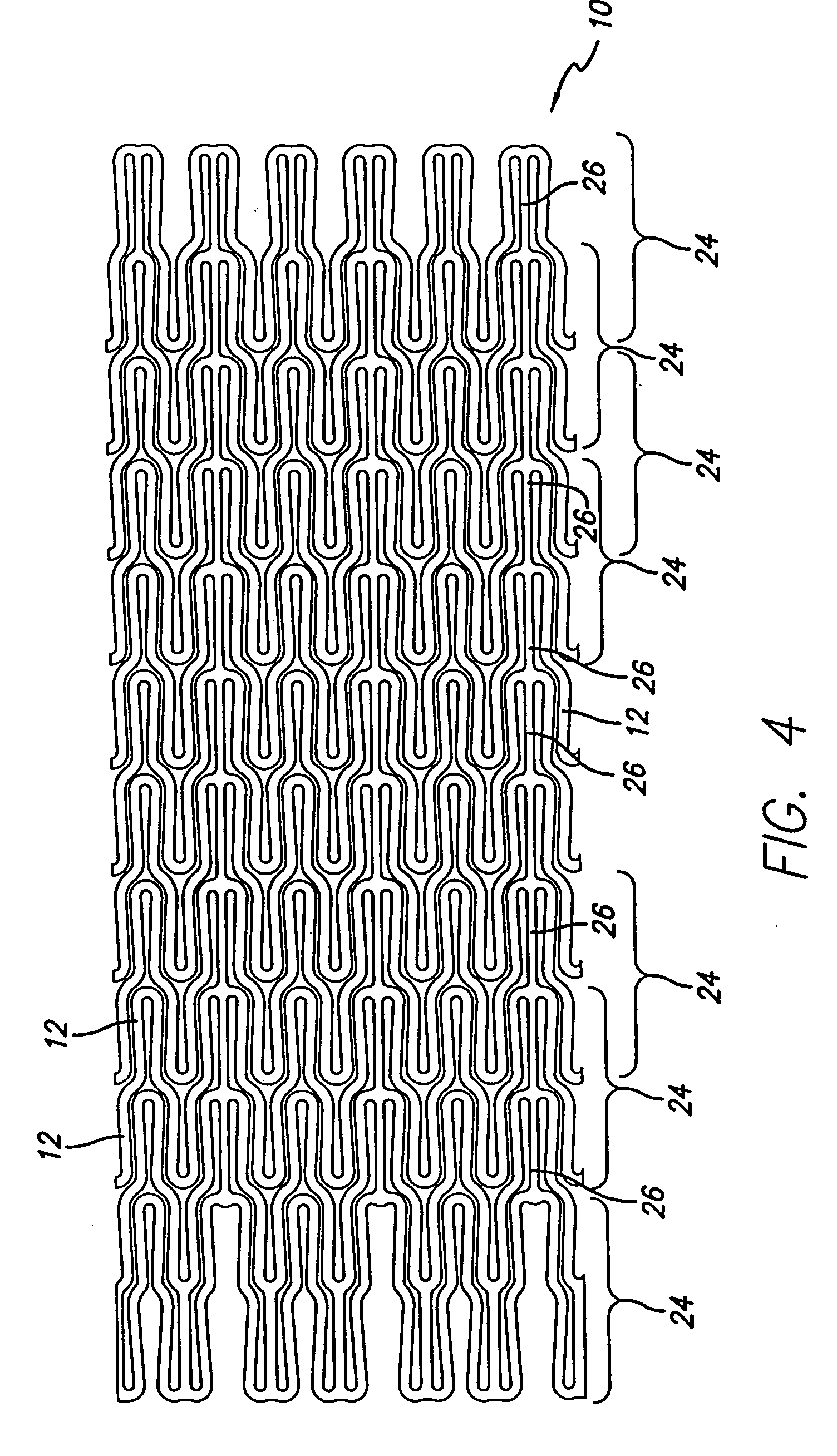

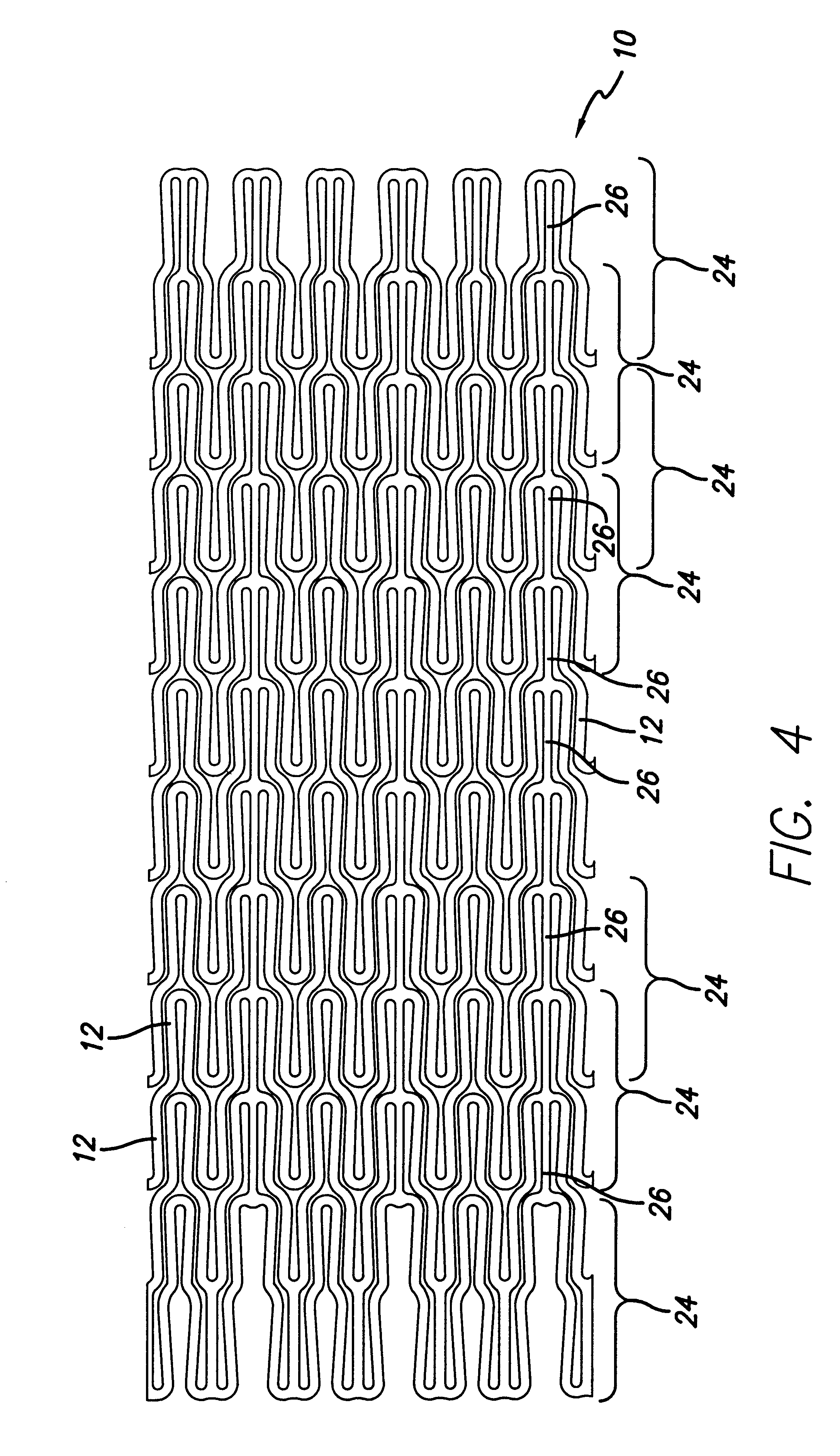

Radiopaque nitinol alloys for medical devices

Owner:ABBOTT CARDIOVASCULAR

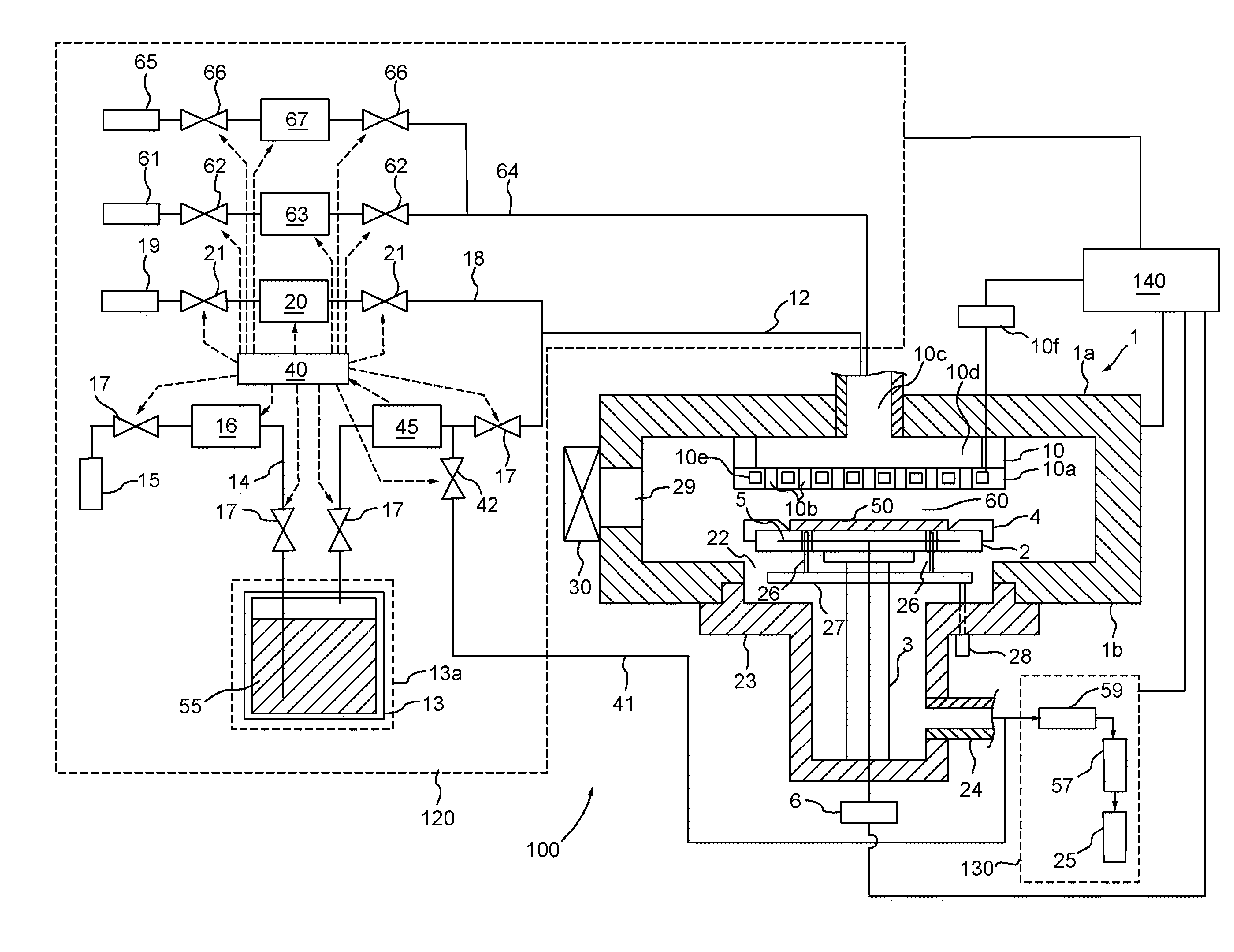

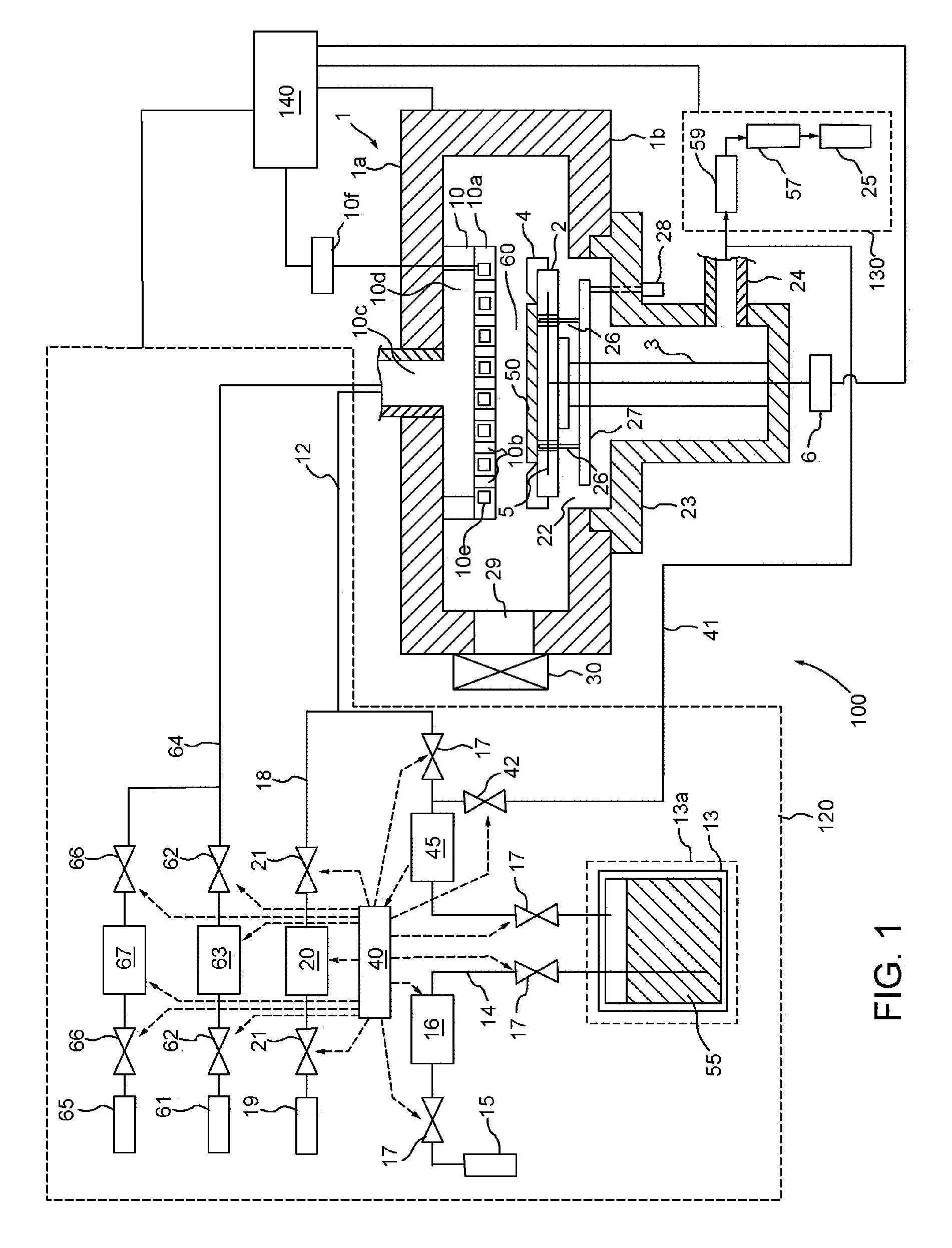

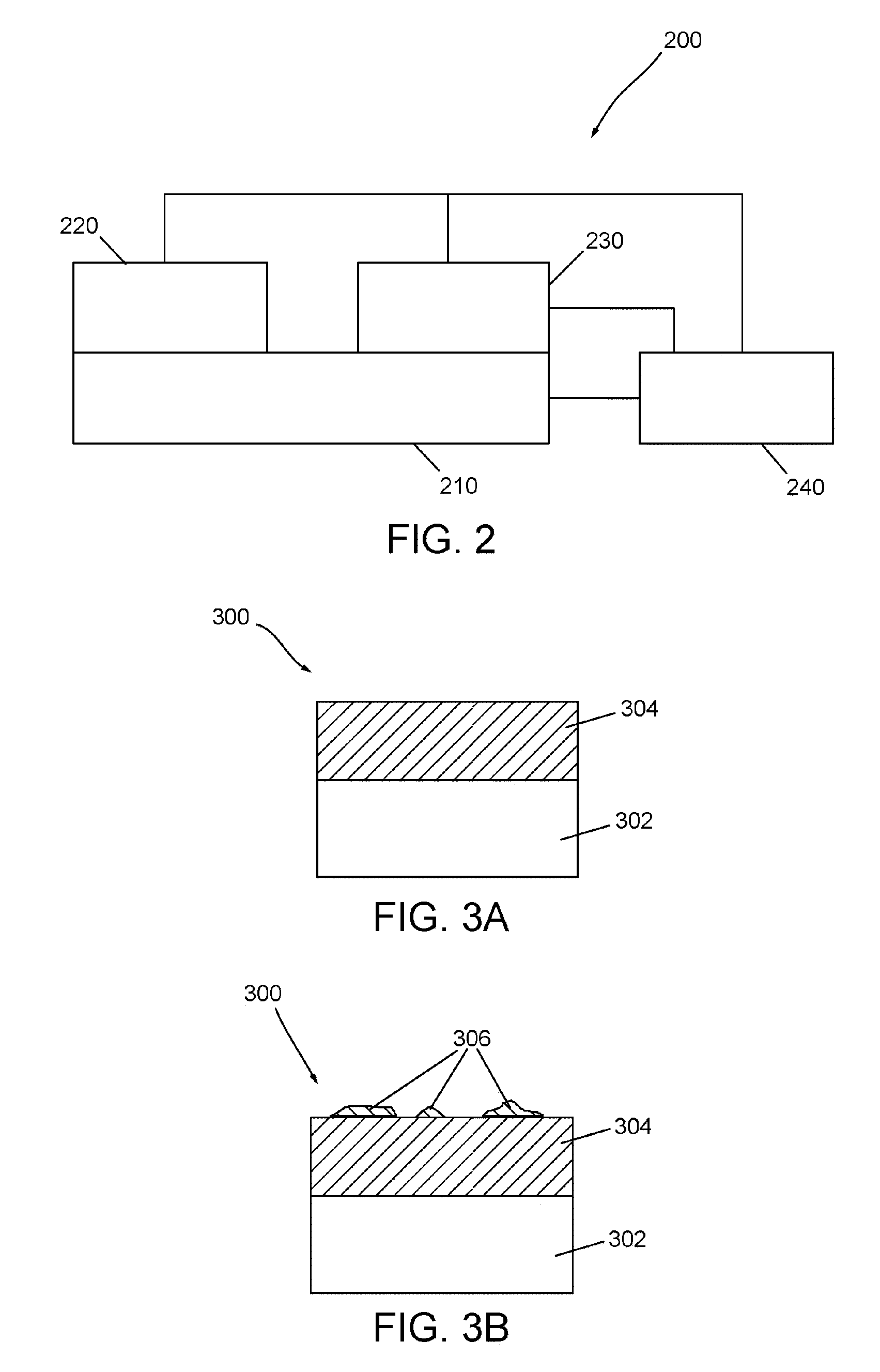

Method for forming a passivated metal layer

InactiveUS20060068097A1Growth inhibitionInhibiting oxygen-induced growth of Re-containingPretreated surfacesSemiconductor/solid-state device manufacturingRheniumGas phase

A method for forming a passivated metal layer that preserves the properties and morphology of an underlying metal layer during subsequent exposure to oxygen-containing ambients. The method includes providing a substrate in a process chamber, exposing the substrate to a process gas containing a rhenium-carbonyl precursor to deposit a rhenium metal layer on the substrate in a chemical vapor deposition process, and forming a passivation layer on the rhenium metal layer to thereby inhibit oxygen-induced growth of rhenium-containing nodules on the rhenium metal surface.

Owner:TOKYO ELECTRON LTD +1

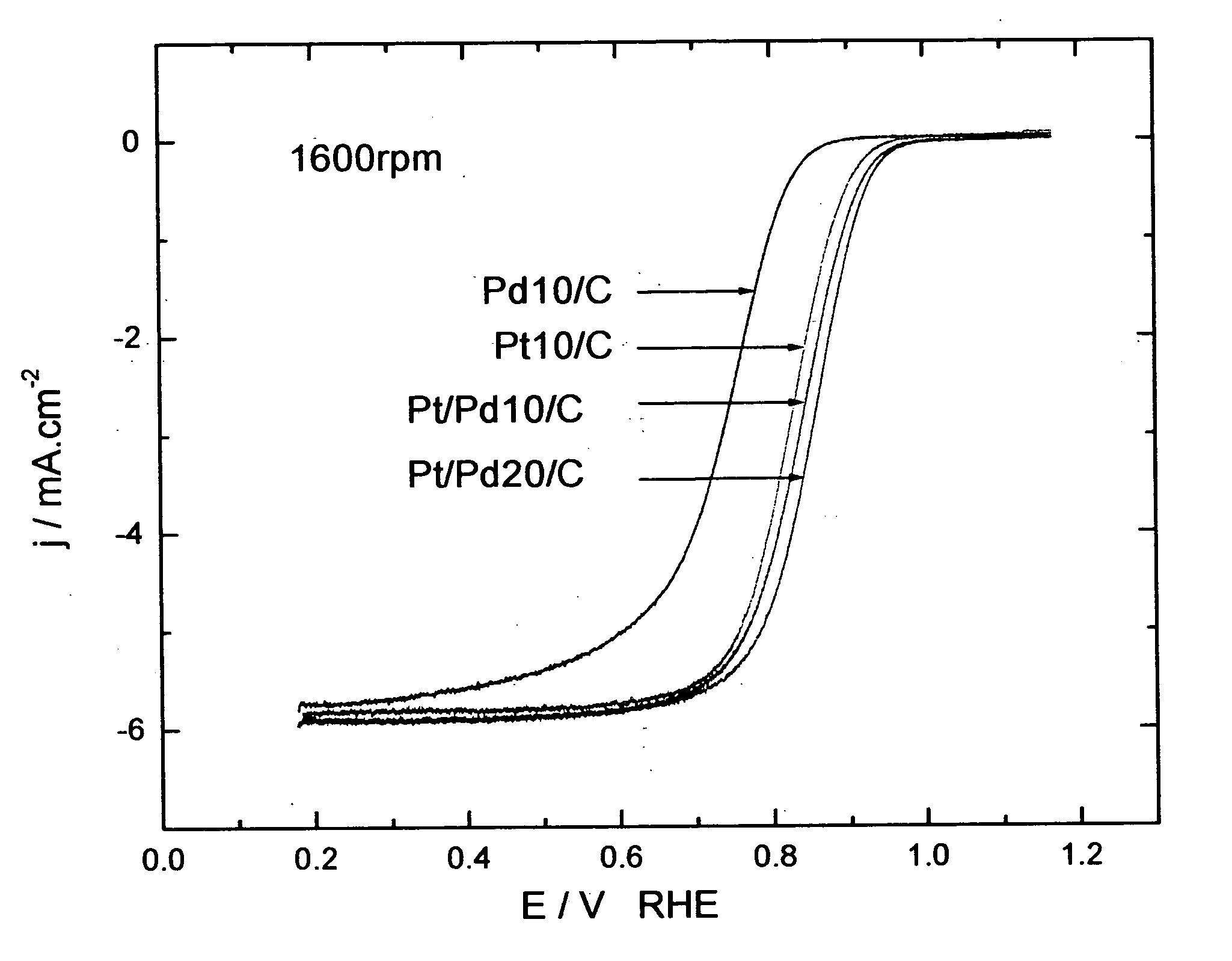

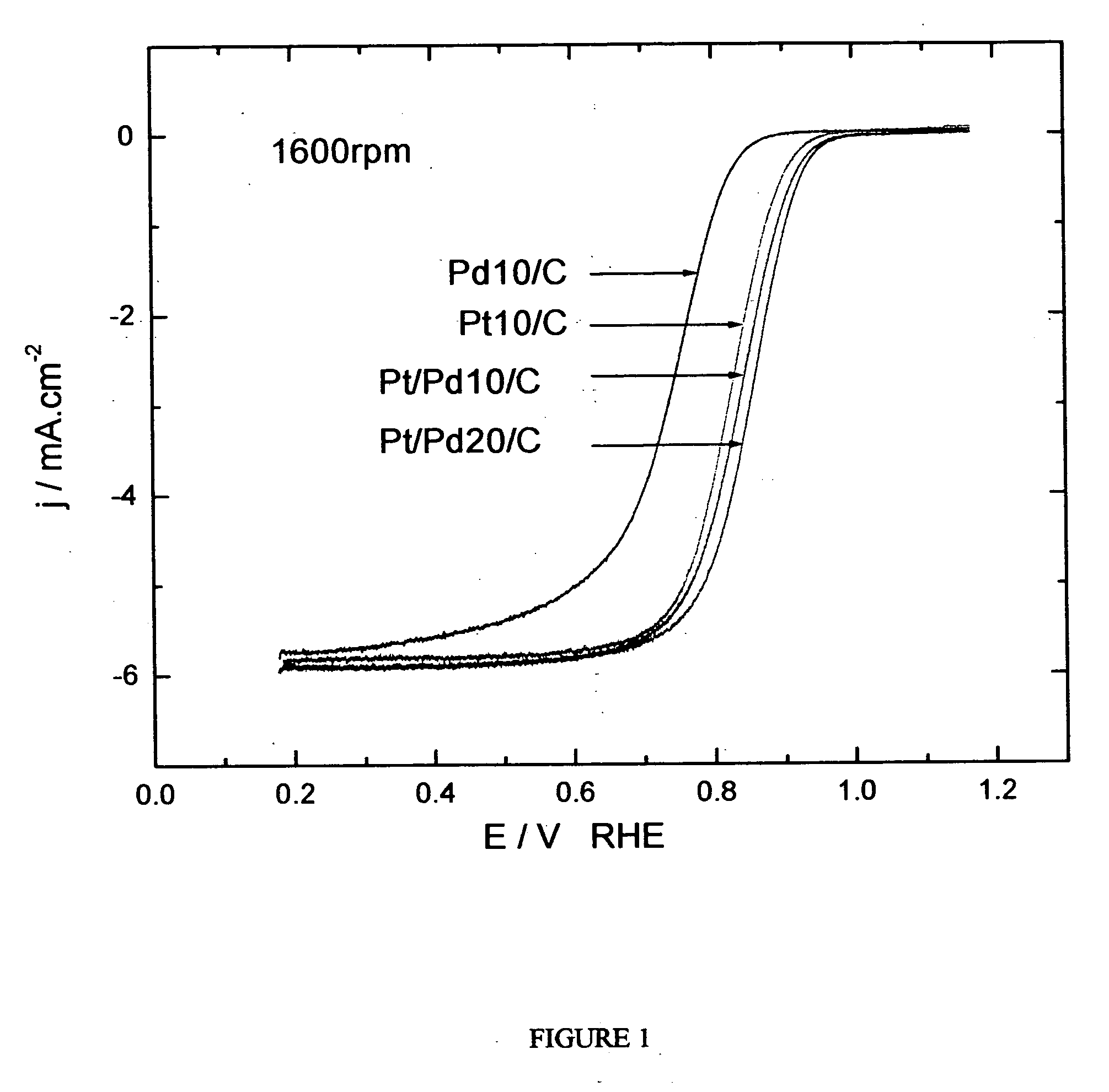

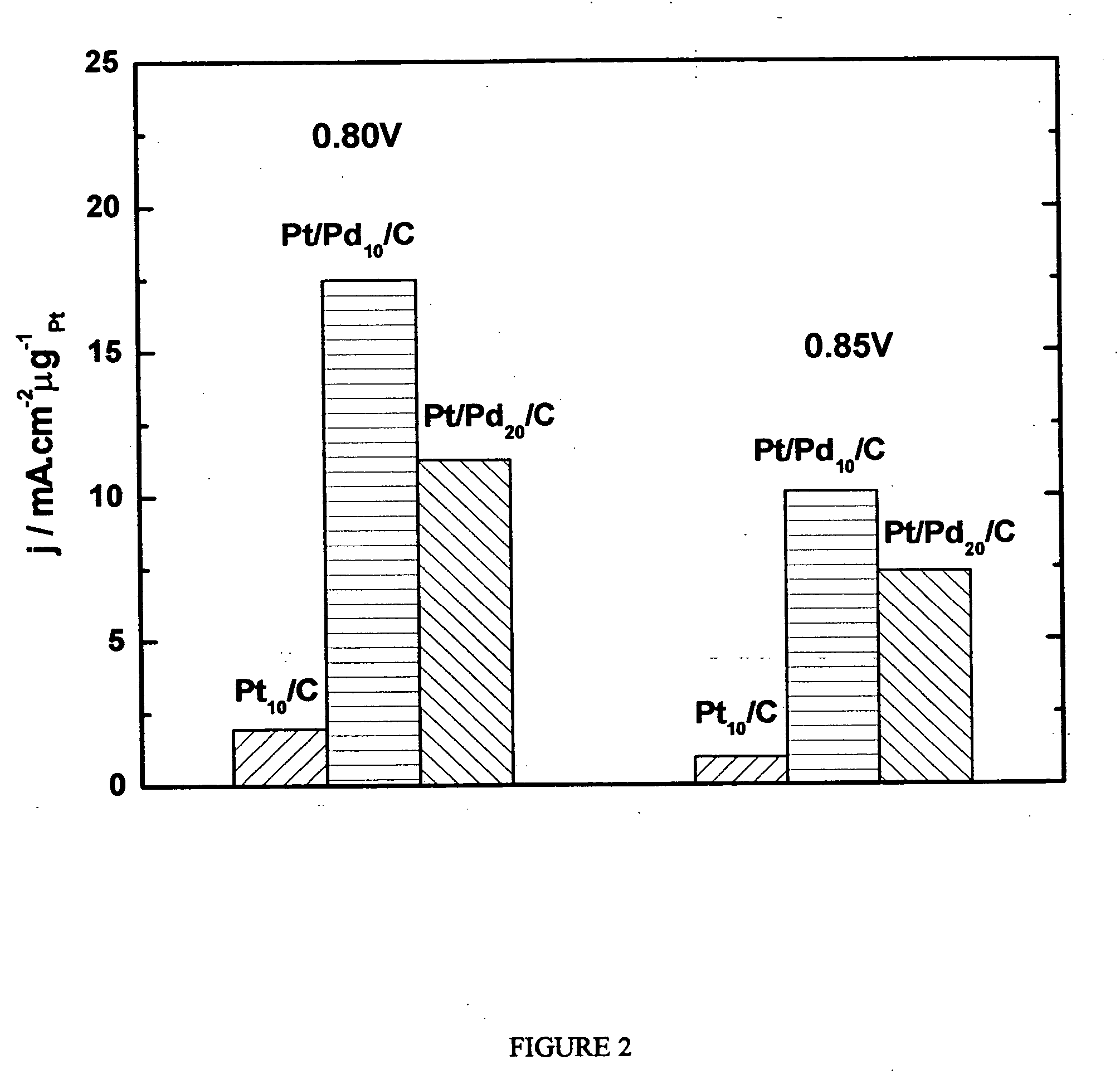

Electrocatalysts having platinum monolayers on palladium, palladium alloy, and gold alloy nanoparticle cores, and uses thereof

ActiveUS20070031722A1Improved oxygen-reducing catalytic activityLow platinum loadingMetal-working apparatusActive material electrodesRheniumGold alloys

The invention relates to platinum-coated particles useful as fuel cell electrocatalysts. The particles are composed of a noble metal or metal alloy core at least partially encapsulated by an atomically thin surface layer of platinum atoms. The invention particularly relates to such particles having a palladium, palladium alloy, gold alloy, or rhenium alloy core encapsulated by an atomic monolayer of platinum. In other embodiments, the invention relates to fuel cells containing these electrocatalysts and methods for generating electrical energy therefrom.

Owner:BROOKHAVEN SCI ASSOCS

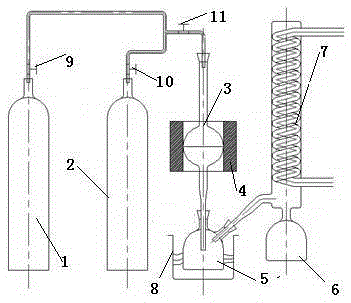

Method for preparing precursor for chemical vapor deposition of metallic rhenium

The invention discloses a method for preparing a precursor for chemical vapor deposition of metallic rhenium and belongs to the technical field of material preparation. According to the method, ReCl5 is made to react in an oxidizing atmosphere, efficient solid-liquid-gas separation is conducted on reactants and products with a sand core filter bulb so that reactants, reaction products and waste gas can be effectively separated, the reaction products ReOCl4 and ReO3Cl are gathered in a collection vessel heated by an oil bath pan at the same time, oxygen introduction is stopped after reaction ends, circulation of inert gases is maintained, a tube furnace is cooled, the oil bath pan is heated at the same time to enable ReO3Cl to volatilize to enter a rectification unit to be collected, ReOCl4 is purified, and then the high-purity precursor ReOCl4 for chemical vapor deposition of metallic rhenium is obtained. By the adoption of the method, reaction efficiency is high, ReOCl4 and ReO3Cl are separated through rectification, and the purity of the product ReOCl4 is improved.

Owner:海朴精密材料(苏州)有限责任公司

Radiopaque markers for medical devices

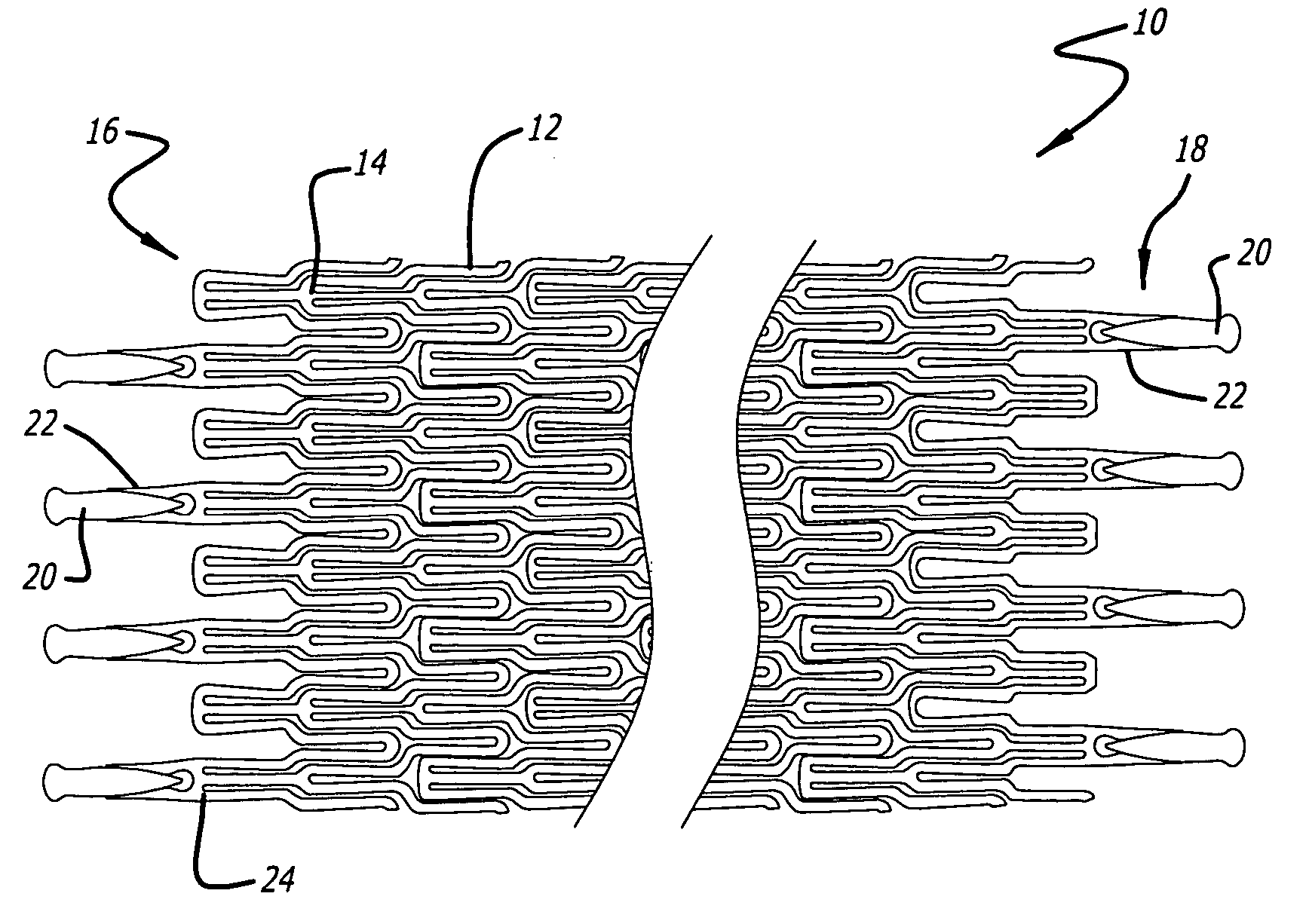

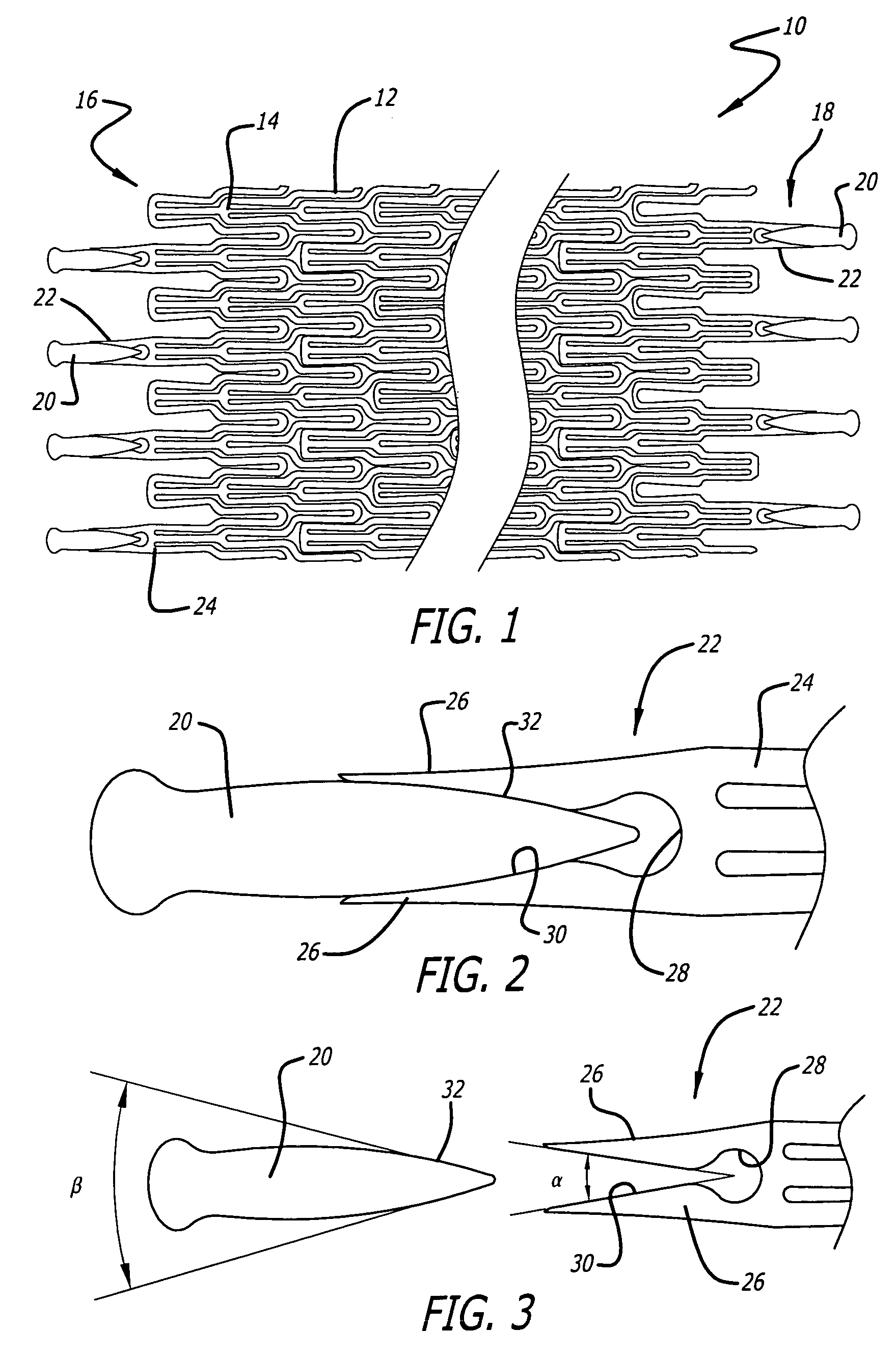

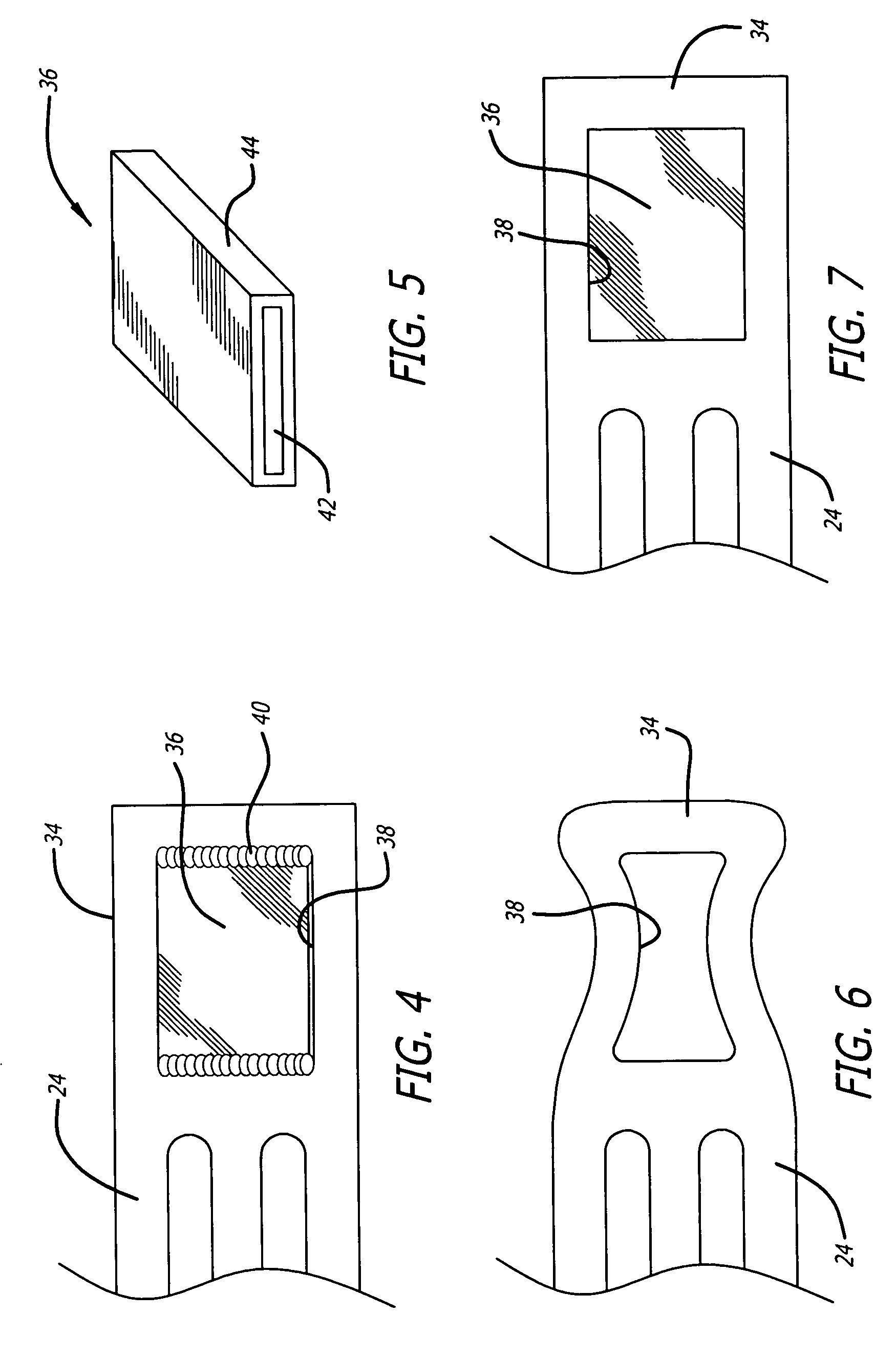

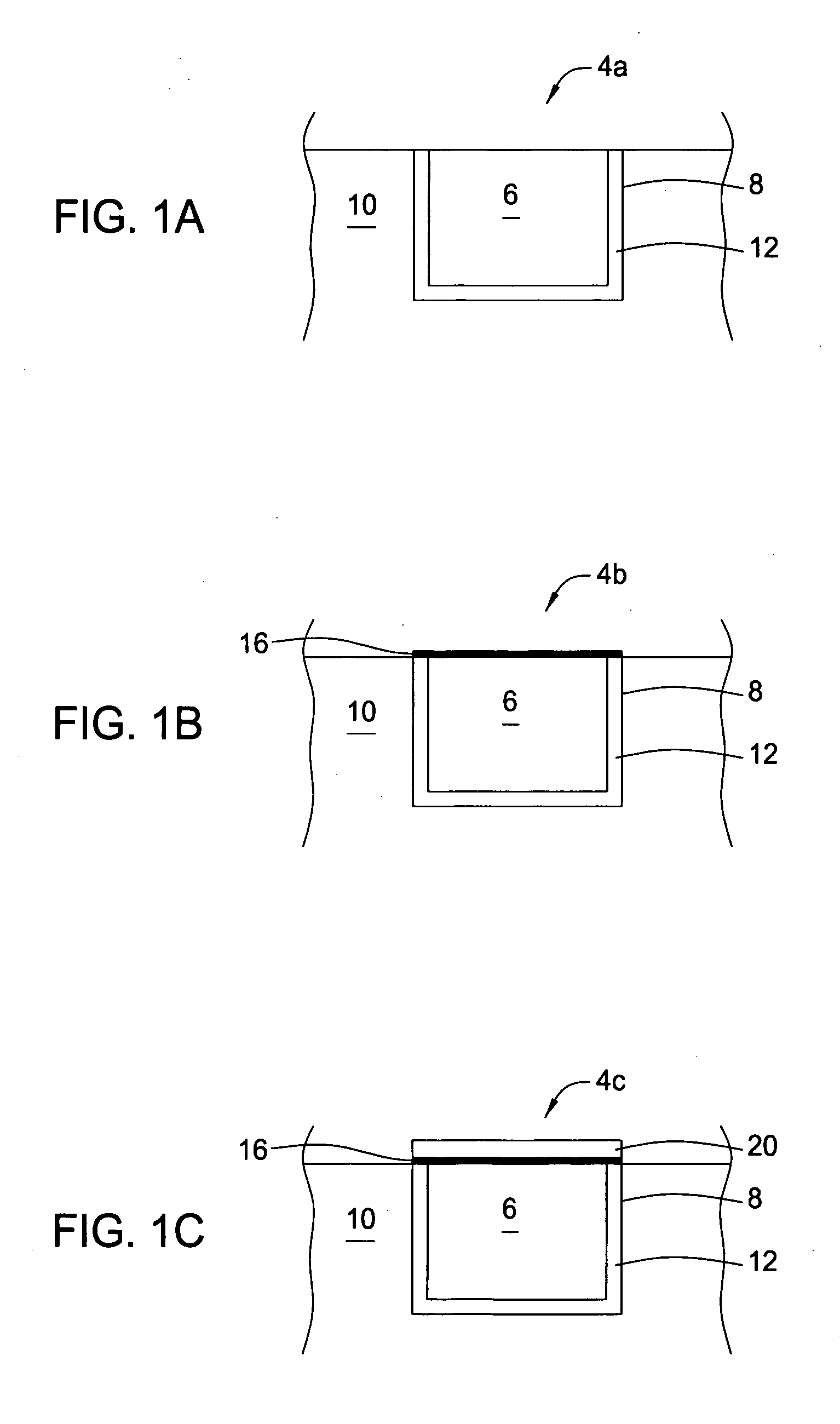

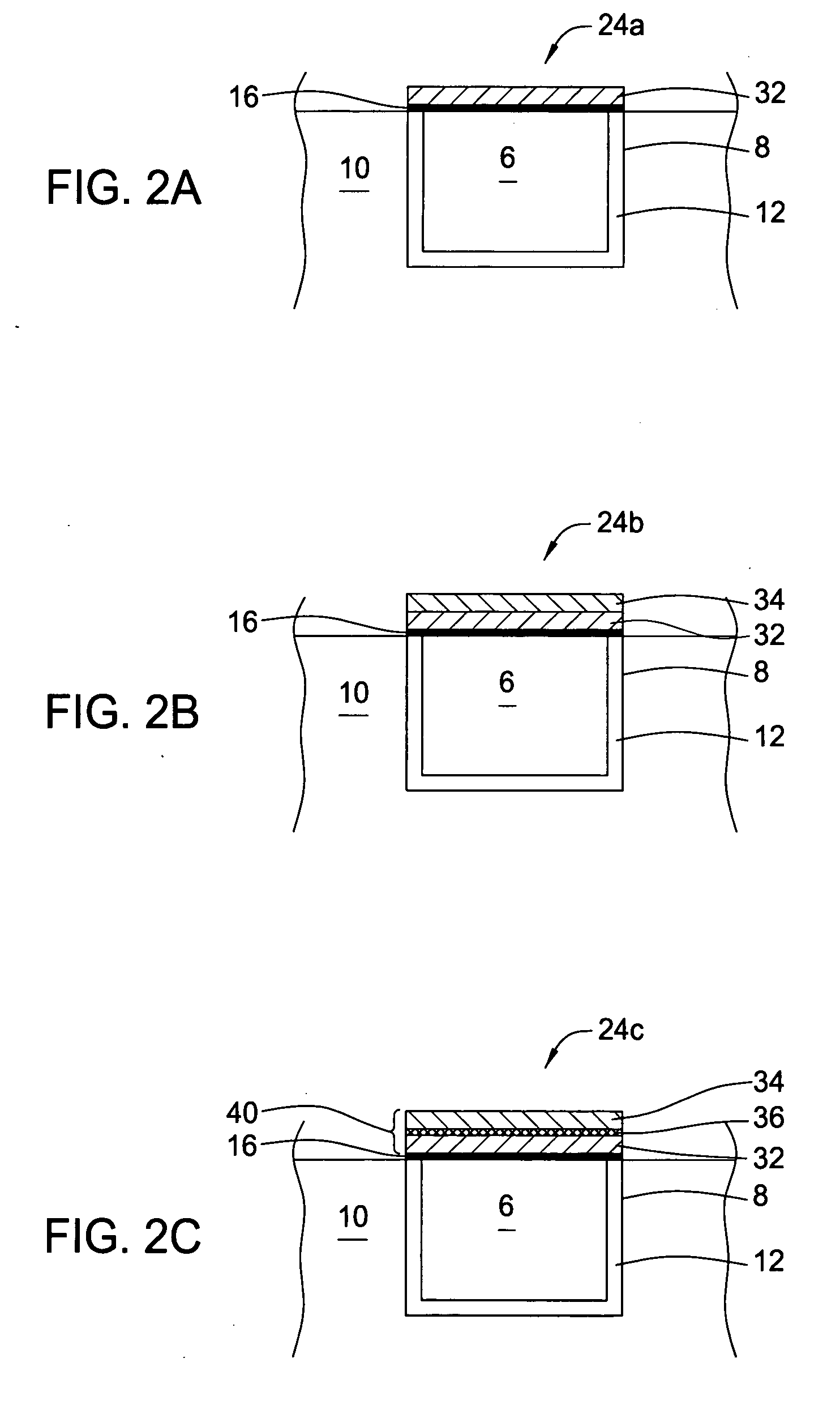

InactiveUS20050060025A1High level of radiopacitySufficient radiopacityStentsBlood vesselsIridiumRhenium

An implantable medical device includes a structural body made from a superelastic material and includes one or more marker holders integrally formed on the structural body. Each marker holder is designed to hold a radiopaque marker which has a level of radiopacity greater than the superelastic material. The radiopaque marker can be made from a nickel-titanium alloy which includes a ternary element. The ternary element can be selected from the group of elements consisting of iridium, platinum, gold, rhenium, tungsten, palladium, rhodium, tantalum, silver, ruthenium, and hafnium. In one form, the marker holder includes a pair of projecting fingers connected together at a notched region to cooperatively create a particular-shaped opening. This opening, in turn, is adapted to receive a similarly shaped portion formed on the radiopaque marker. In one form, the radiopaque marker includes an inner core which is partially, or completely, encased by an outer layer. This inner core can be made from a highly radiopaque material while the outer layer is formed from a material that is easier to weld to the marker.

Owner:ABBOTT VASCULAR SOLUTIONS

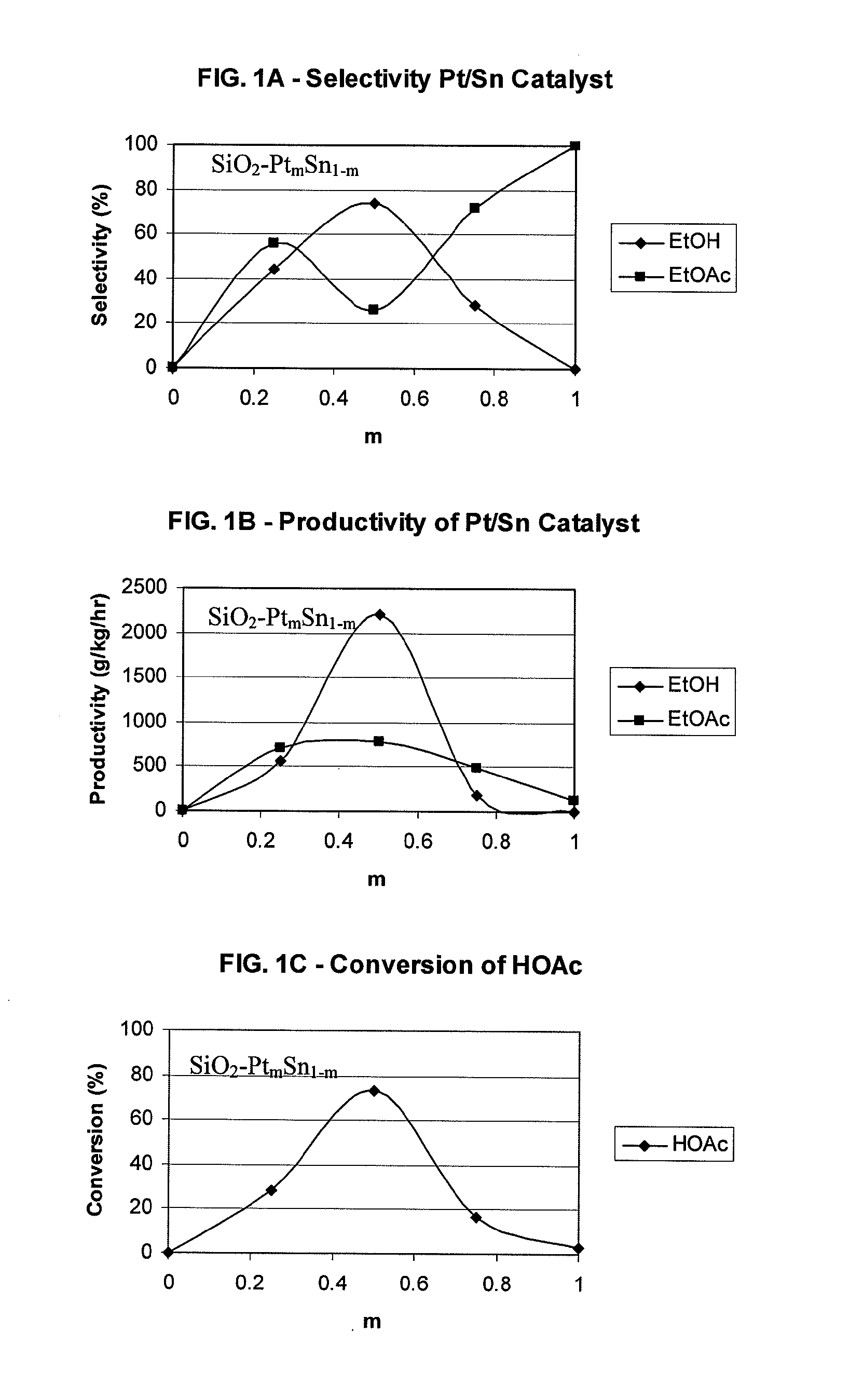

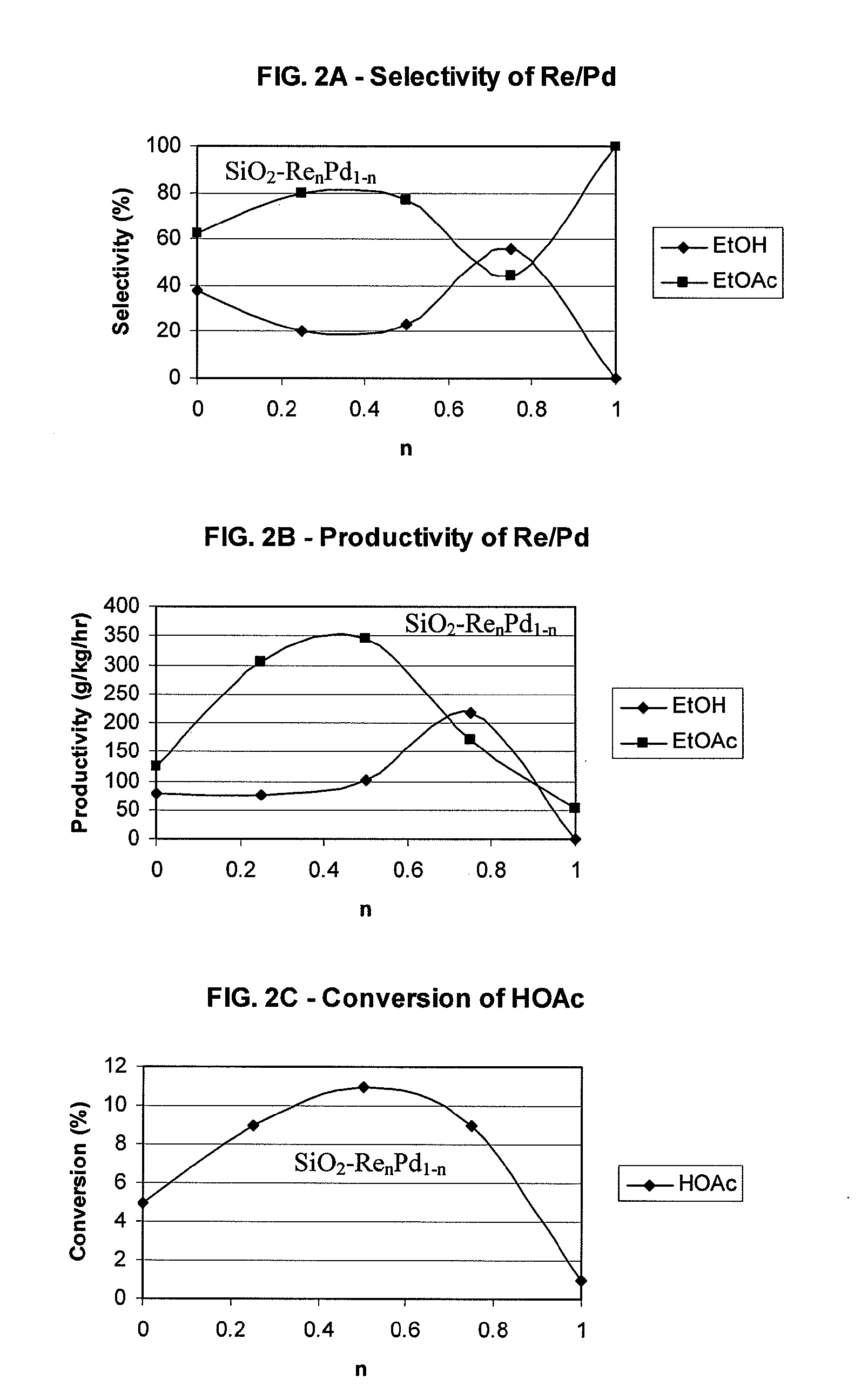

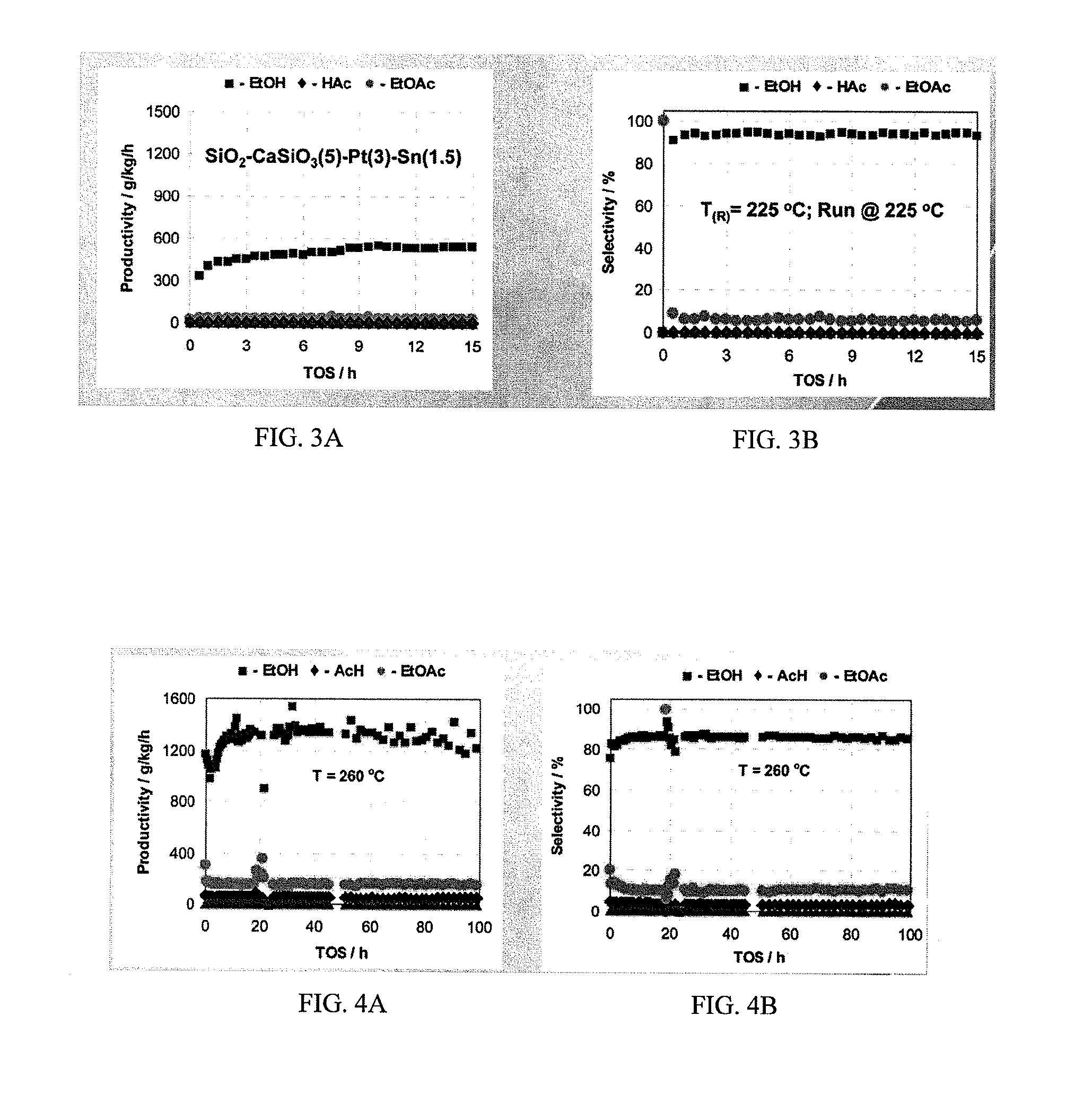

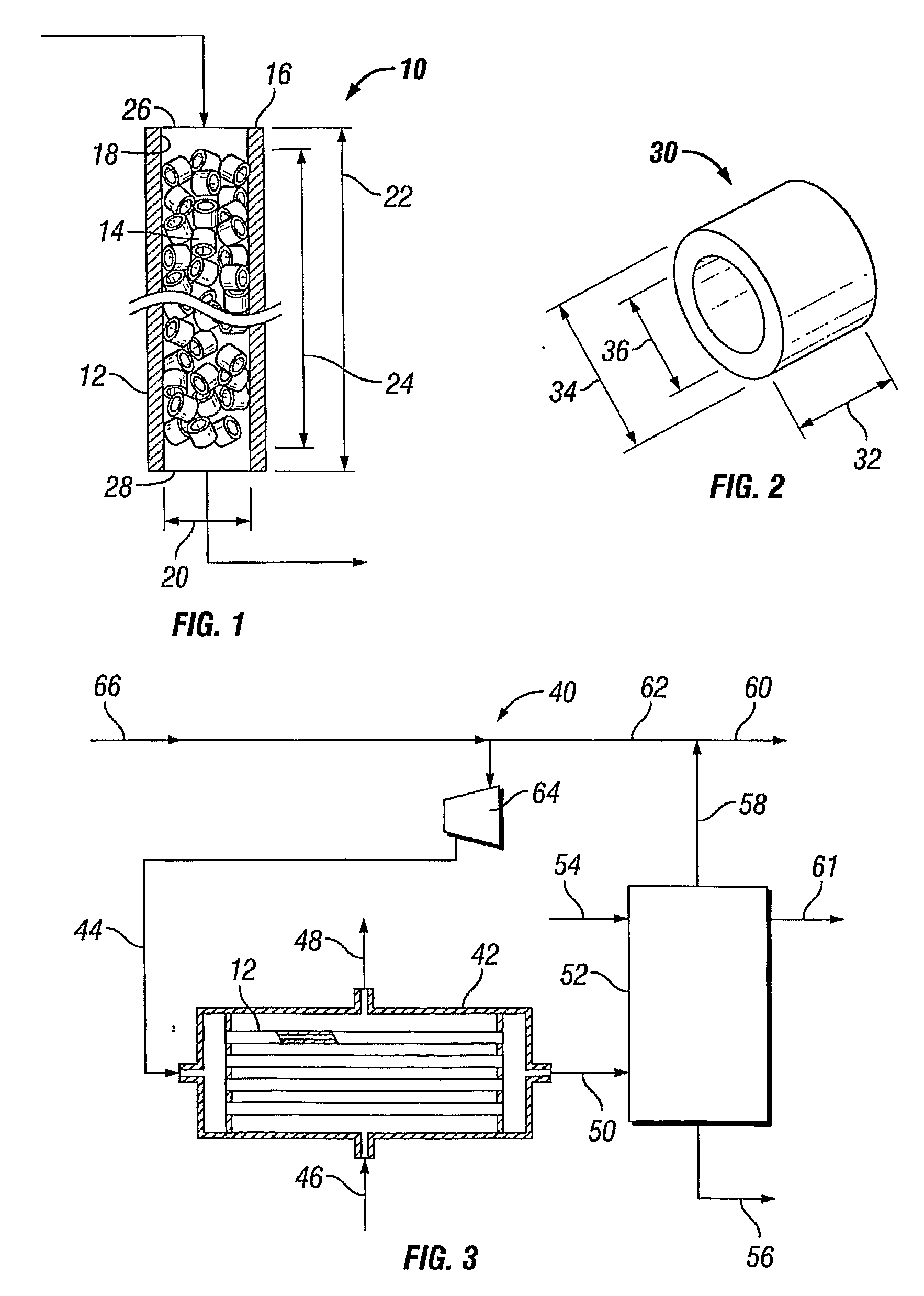

Processes for making ethanol from acetic acid

InactiveUS20100197985A1High selectivityPreparation by oxo-reaction and reductionEthylene productionCeriumCobalt

A process for selective formation of ethanol from acetic acid by hydrogenating acetic acid in the presence of first metal, a silicaceous support, and at least one support modifier. Preferably, the first metal is selected from the group consisting of copper, iron, cobalt, nickel, ruthenium, rhodium, palladium, osmium, iridium, platinum, titanium, zinc, chromium, rhenium, molybdenum, and tungsten. In addition the catalyst may comprise a second metal preferably selected from the group consisting of copper, molybdenum, tin, chromium, iron, cobalt, vanadium, tungsten, palladium, platinum, lanthanum, cerium, manganese, ruthenium, rhenium, gold, and nickel.

Owner:CELANESE INT CORP

High surface area sol-gel route prepared hydrogenation catalysts

InactiveUS6686310B1Good dispersionImprove uniformityCatalyst activation/preparationMetal/metal-oxides/metal-hydroxide catalystsRheniumSilicon oxide

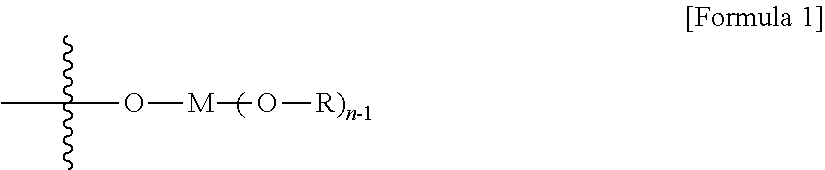

This invention concerns novel compositions, useful as hydrogenation catalyst, said compositions comprising metals and metal ions such as ruthenium (Ru) or palladium (Pd) dispersed in and distributed throughout a matrix comprising an inorganic or silicon oxide network. The catalyst may be prepared by the sol-gel method; a solution of at least one catalytic metal compound is added to a solution of at least one metal alkoxide selected from Al, Ti, Nb, Zr, Ta, Si and other inorganic alkoxides, and then gelling the mixture. Promotors such as rhenium (Re), molybdenum (Mo) and tin (Sn) may be added. The catalyst may be used in the reduction of metallic acid or gamma-butyrolactone to tetrahydrofuran (THF) and 1,4-butanediol (BDO).

Owner:EI DU PONT DE NEMOURS & CO

Inorganic dopants, inks and related nanotechnology

InactiveUS6849109B2Facilitated DiffusionLower transition temperatureSelenium/tellurium compundsCell electrodesIndiumCerium

Ink compositions with modified properties result from using a powder size below 100 nanometers. Colored inks are illustrated. Nanoscale coated, uncoated, whisker inorganic fillers are included. The pigment nanopowders taught comprise one or more elements from the group actinium, aluminum, antimony, arsenic, barium, beryllium, bismuth, cadmuim, calcium, cerium, cesium, chalcogenide, cobalt, copper, dysprosium, erbium, europium, gadolinium, gallium, gold, hafnium, hydrogen, indium, iridium, iron, lanthanum, lithium, magnesium, manganese, mendelevium, mercury, molybdenum, neodymium, neptunium, nickel, niobium, nitrogen, oxygen, osmium, palladium, platinum, potassium, praseodymium, promethium, protactinium, rhenium, rubidium, scandium, silver, sodium, strontium, tantalum, terbium, thallium, thorium, tin, titanium, tungsten, vanadium, ytterbium, yttrium, zinc, and zirconium.

Owner:PPG IND OHIO INC

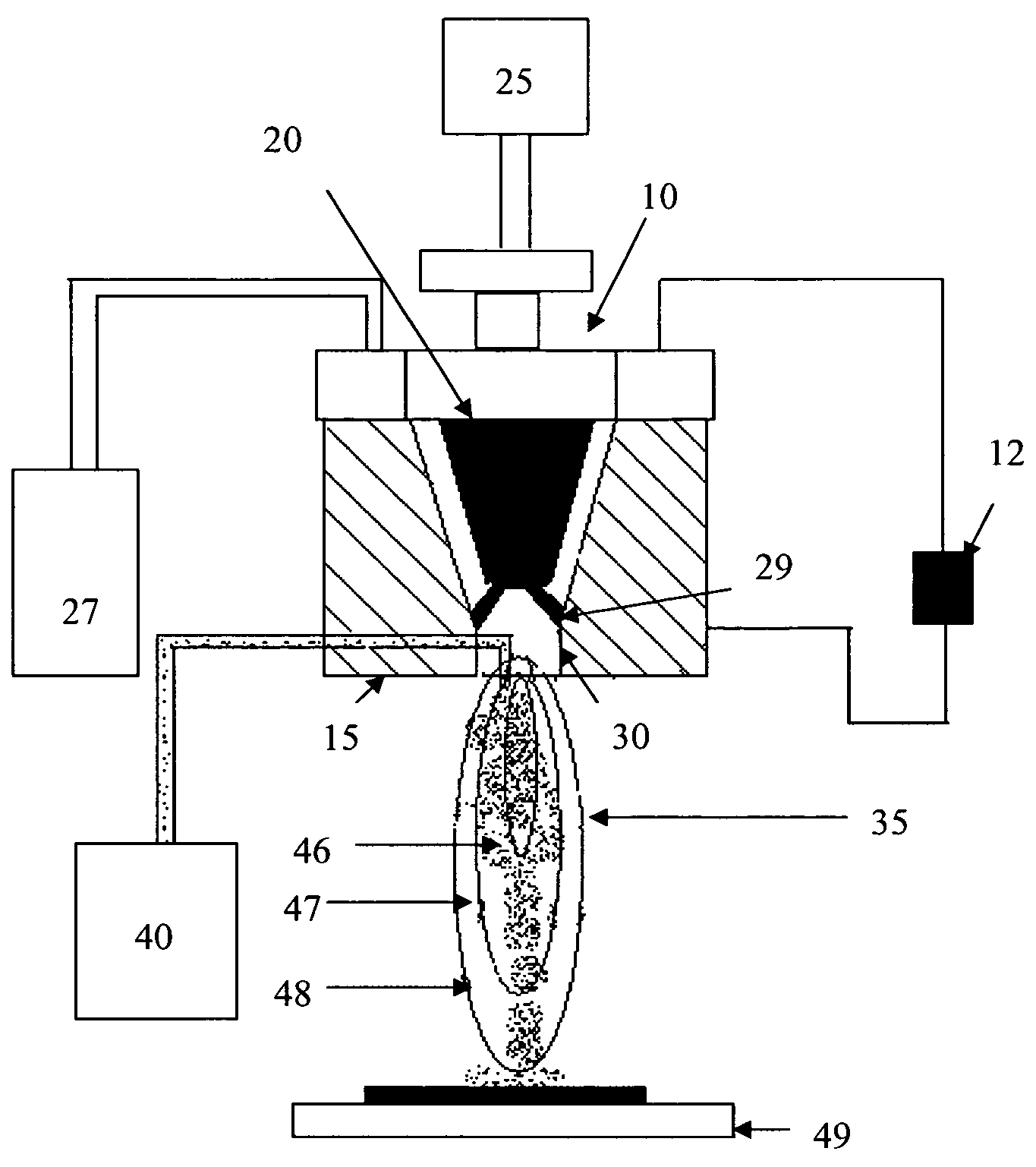

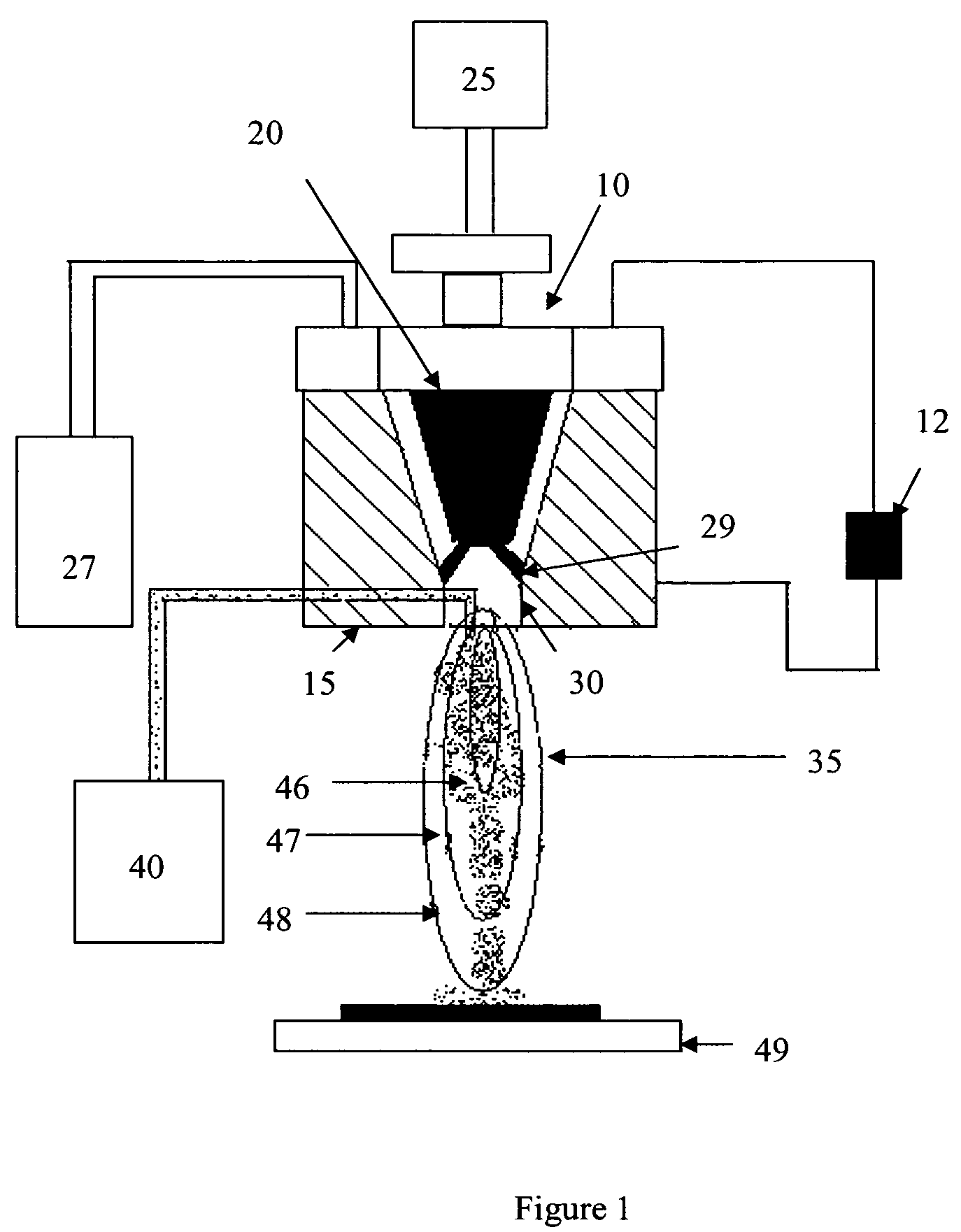

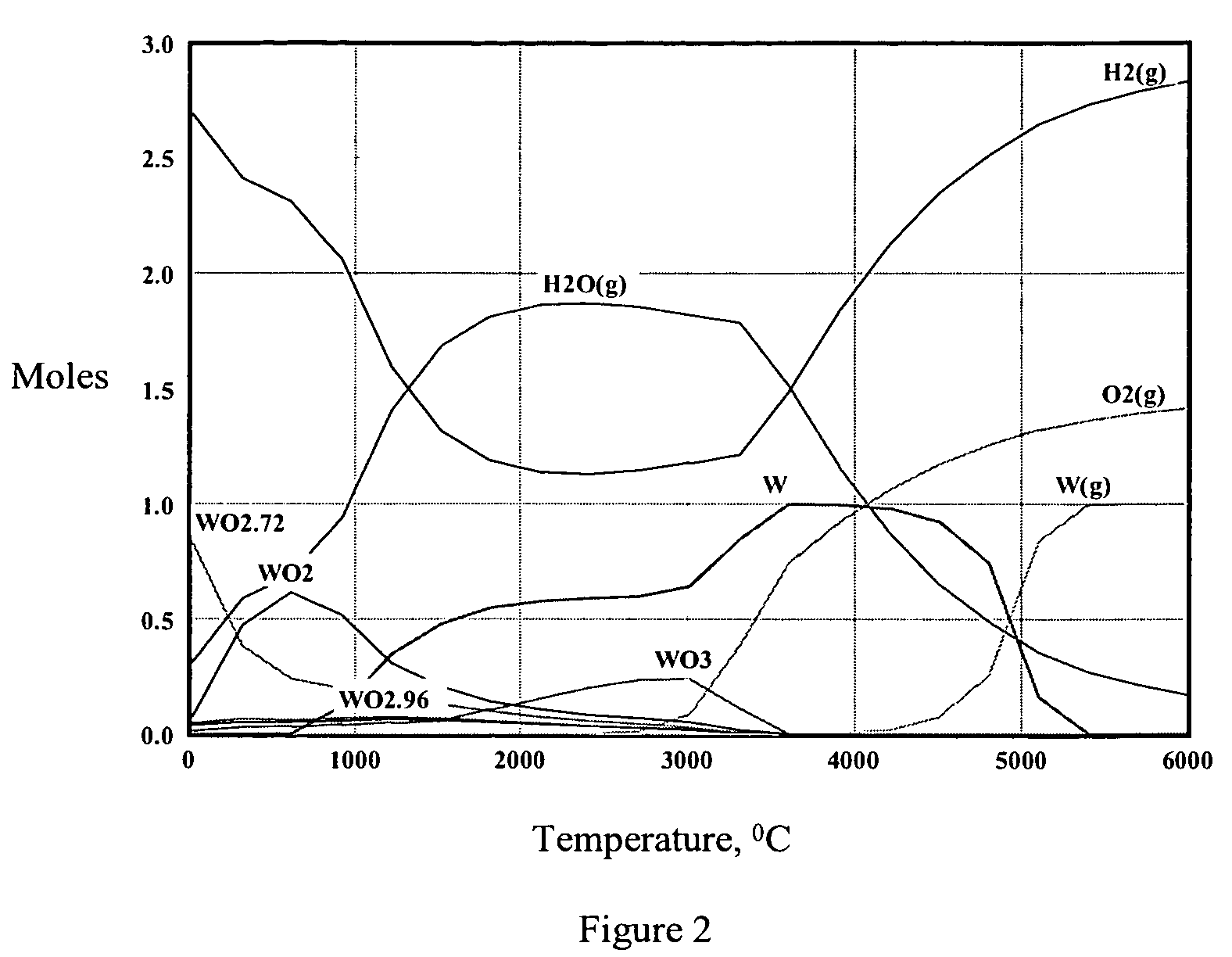

Nano powders, components and coatings by plasma technique

ActiveUS7615097B2Rapid quenching and generationHigh materialLiquid surface applicatorsMolten spray coatingRheniumChemical reaction

Ultra fine and nanometer powders and a method of producing same are provided, preferably refractory metal and ceramic nanopowders. When certain precursors are injected into the plasma flame in a reactor chamber, the materials are heated, melted and vaporized and the chemical reaction is induced in the vapor phase. The vapor phase is quenched rapidly to solid phase to yield the ultra pure, ultra fine and nano product. With this technique, powders have been made 20 nanometers in size in a system capable of a bulk production rate of more than 10 lbs / hr. The process is particularly applicable to tungsten, molybdenum, rhenium, tungsten carbide, molybdenum carbide and other related materials.

Owner:PLASMA PROCESSES

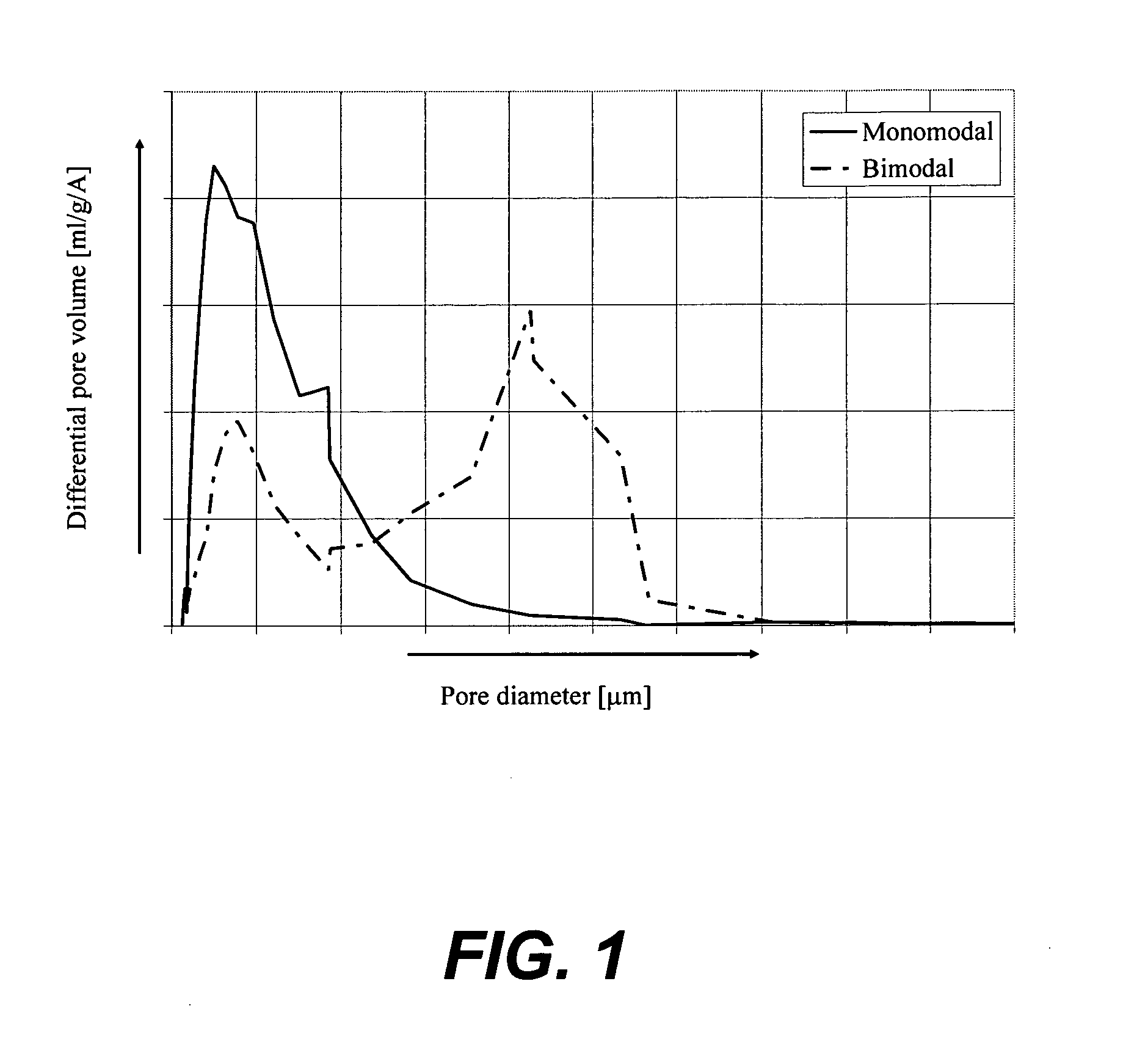

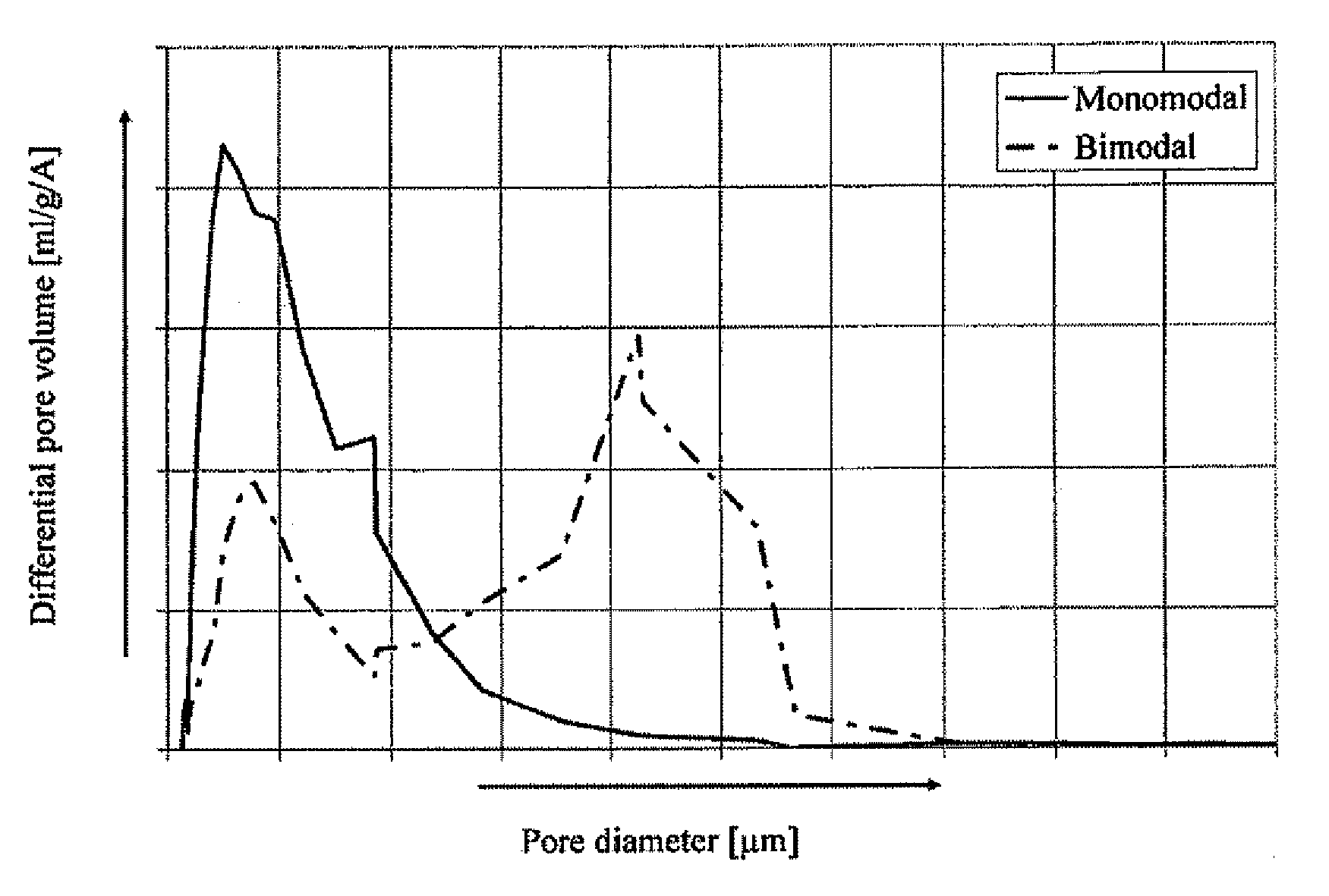

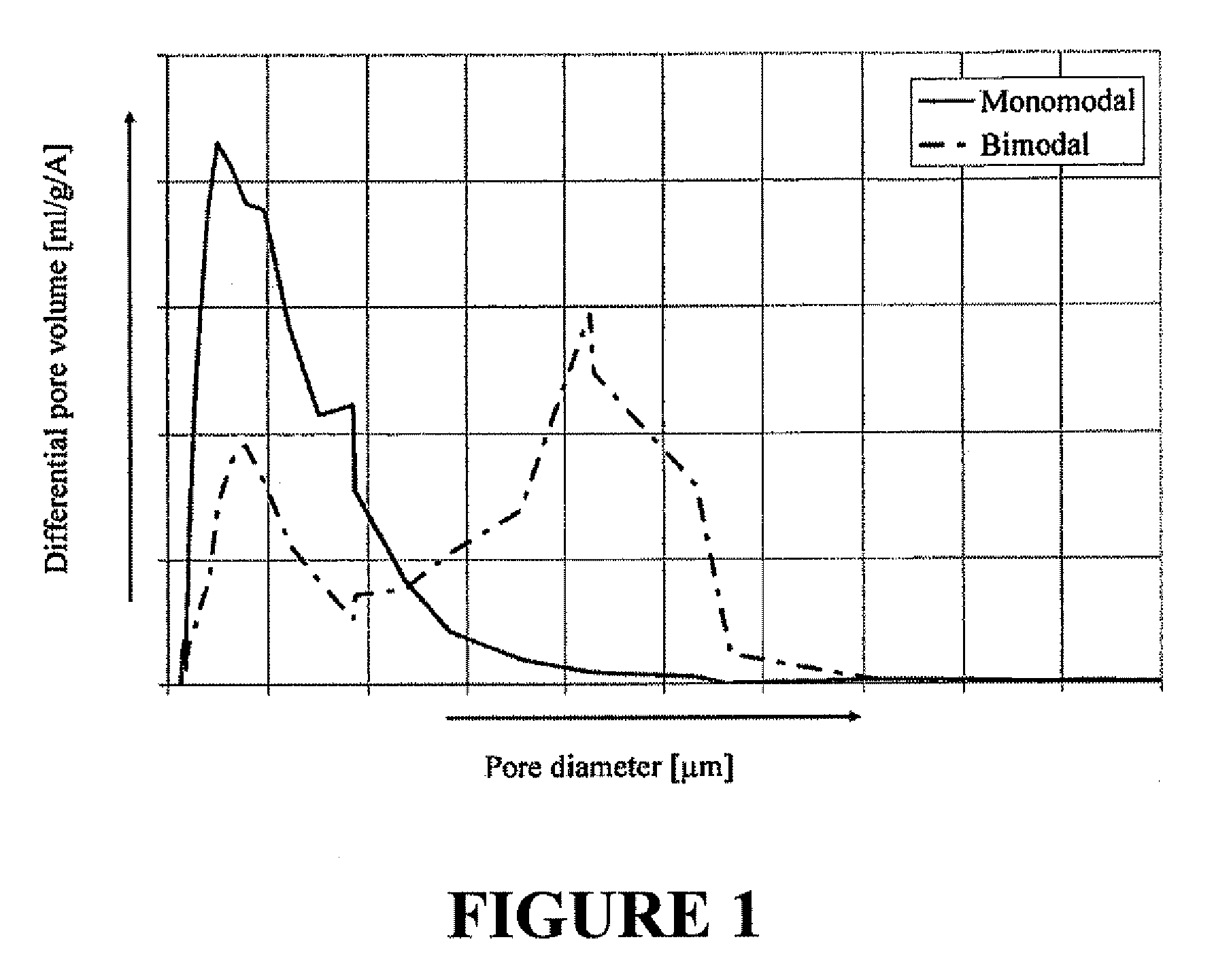

Catalyst with bimodal pore size distribution and the use thereof

The invention pertains to a catalyst useful for the epoxidation of an olefin. More particularly, the invention pertains to an improved catalyst useful for the epoxidation of ethylene to ethylene oxide. The catalyst has improved selectivity in the epoxidation process. The catalyst comprises a solid support having a surface, which has a first mode of pores which have a diameter ranging from about 0.01 μm to about 5 μm and having a differential pore volume peak in the range of from about 0.01 μm to about 5 μm. The surface then has a second mode of pores, different from the first mode of pores, which second mode of pores have a diameter ranging from about 1 μm to about 20 μm and have a differential pore volume peak in the range of from about 1 μm to about 20 μm. On the bimodal pore surface is a catalytically effective amount of silver or a silver-containing compound, a promoting amount of rhenium or a rhenium-containing compound, and a promoting amount of one or more alkali metals or alkali-metal-containing compounds.

Owner:SD LIZENZVERWGMBH

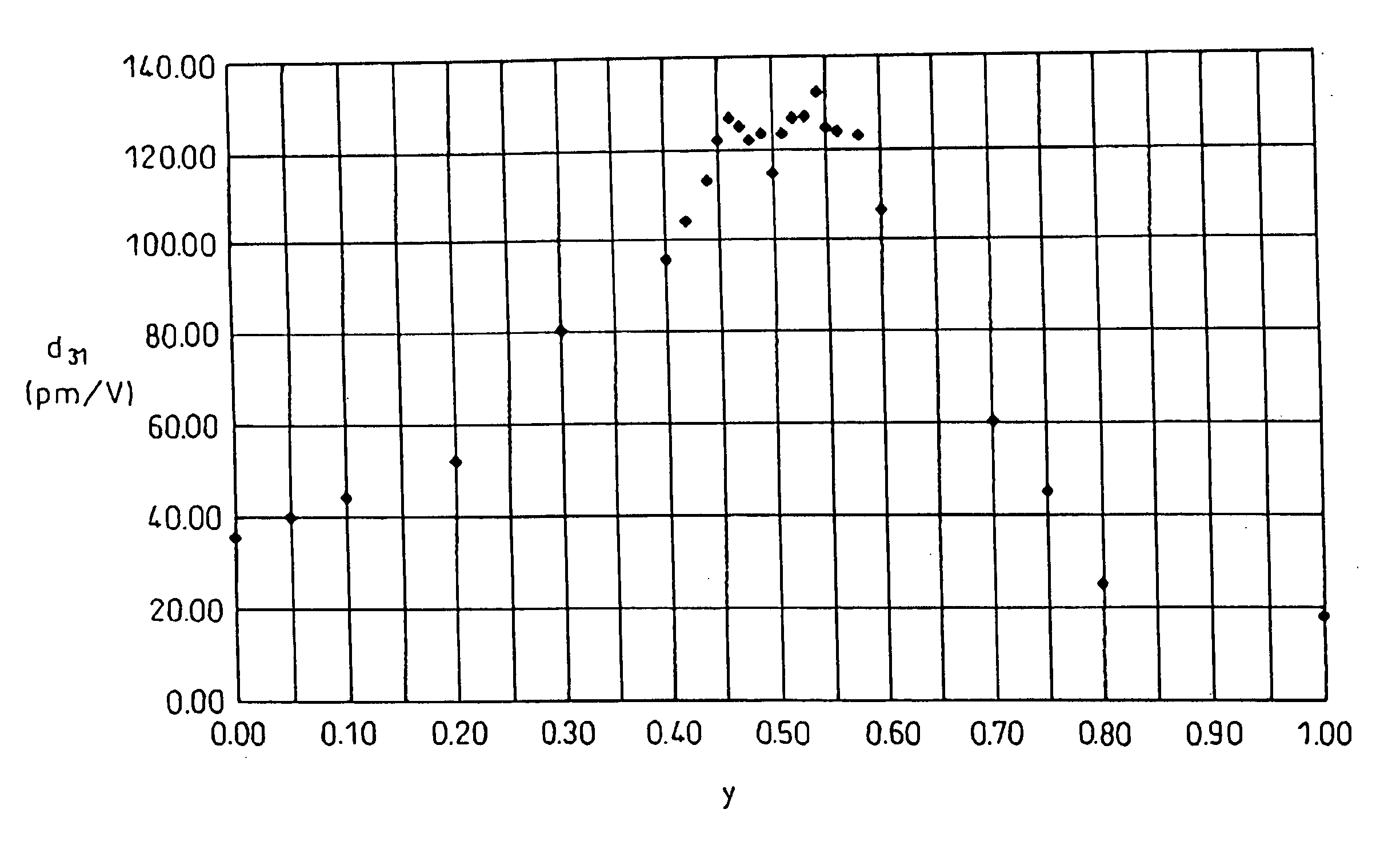

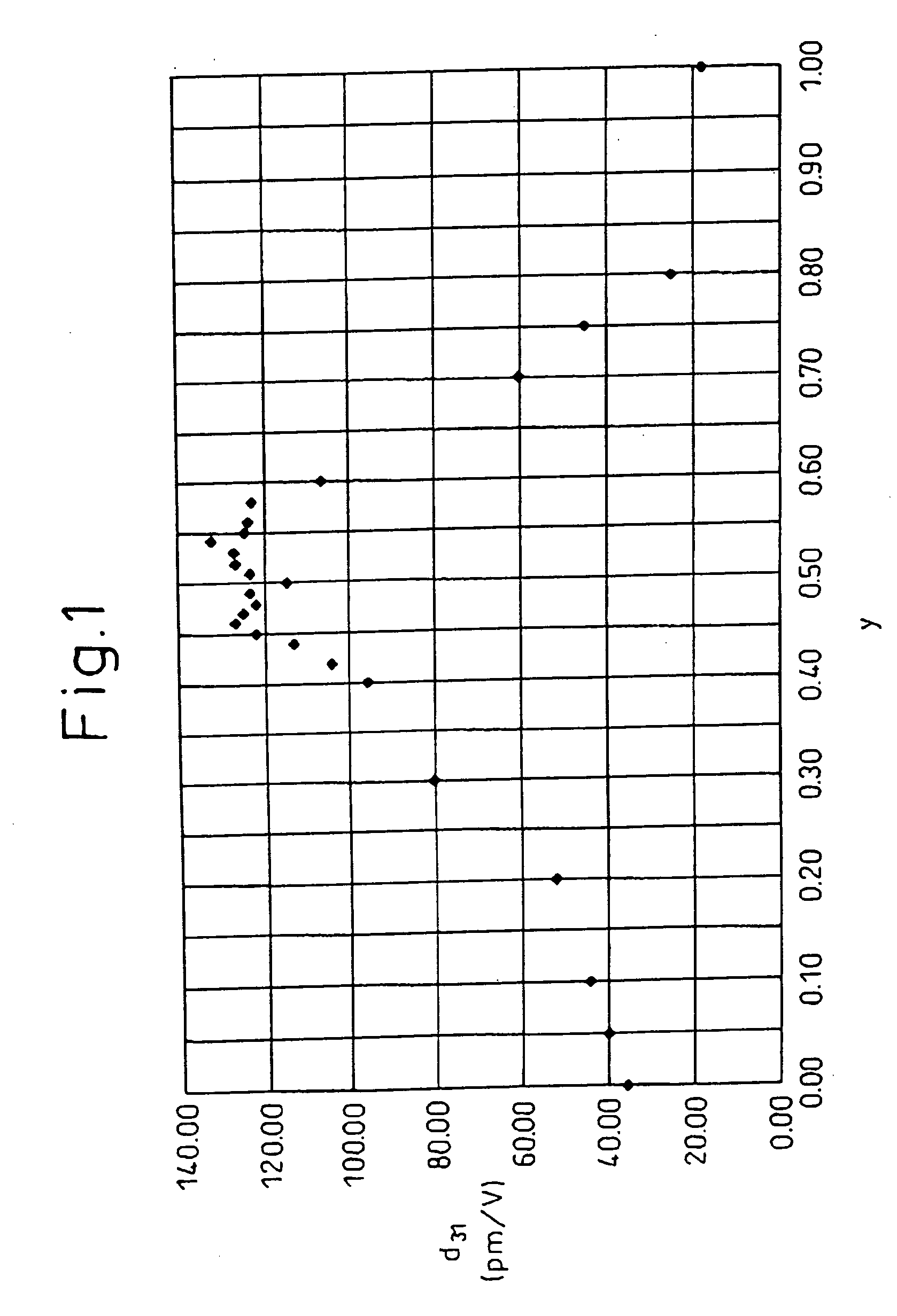

Piezoelectric ceramic composition and method of production of same, piezoelectric element, and dielectric element

InactiveUS20040058797A1Excellent piezoelectric propertiesIncrease temperaturePiezoelectric/electrostrictive device manufacture/assemblyPiezoelectric/electrostrictive device material selectionRheniumIridium

A piezoelectric ceramic composition not containing lead, able to be sintered at ordinary pressure, and superior to the past in at least one of the properties unique to piezoelectric ceramic compositions such as the piezoelectric d31 constant, that is, a piezoelectric ceramic composition having a compound of a general formula {Lix(K1-yNay)1-x}(Nb1-z-wTazSbw)O3 where x, y, z, and w are in the ranges of 0<=x<=0.2, 0<=y<=1, 0<z<=0.4, and 0<w<=0.2 as a main ingredient, where the piezoelectric ceramic composition contains at least one metal element selected from (1) palladium, silver, gold, ruthenium, rhodium, rhenium, osmium, iridium, and platinum, (2) nickel, iron, manganese, copper, and zinc, or (3) magnesium, calcium, strontium, and barium as an added element, and a method of production of the same and a piezoelectric element and dielectric element utilizing that piezoelectric ceramic composition.

Owner:DENSO CORP +1

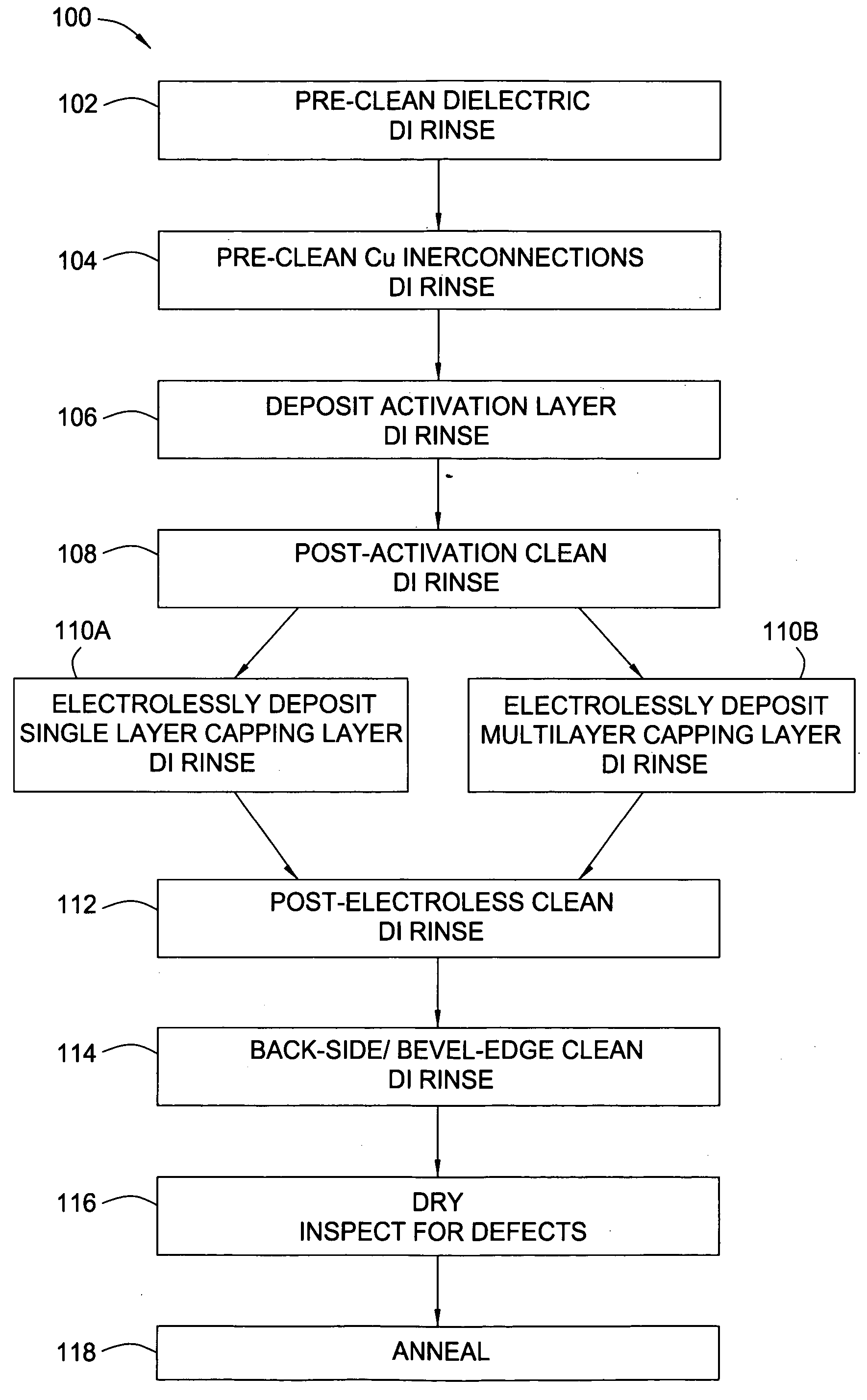

Method and tool of chemical doping CoW alloys with Re for increasing barrier properties of electroless capping layers for IC Cu interconnects

InactiveUS20050101130A1Semiconductor/solid-state device manufacturingLiquid/solution decomposition chemical coatingRheniumAlloy

A method for fabricating a capping layer with enhanced barrier resistance to both copper and oxygen diffusion, comprises forming a capping layer on a conductive surface of an interconnect, wherein the capping layer comprises cobalt (Co), tungsten (W), rhenium (Re), and at least one of phosphorus (P) and boron (B). In an embodiment of the invention, forming the capping layer comprises exposing the conductive surface to an electroless capping solution comprising a cobalt source, a tungsten source, a rhenium source, and at least one of a phosphorus source and a boron source, and annealing the capping layer.

Owner:APPLIED MATERIALS INC

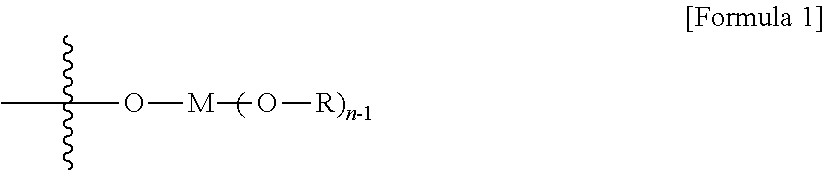

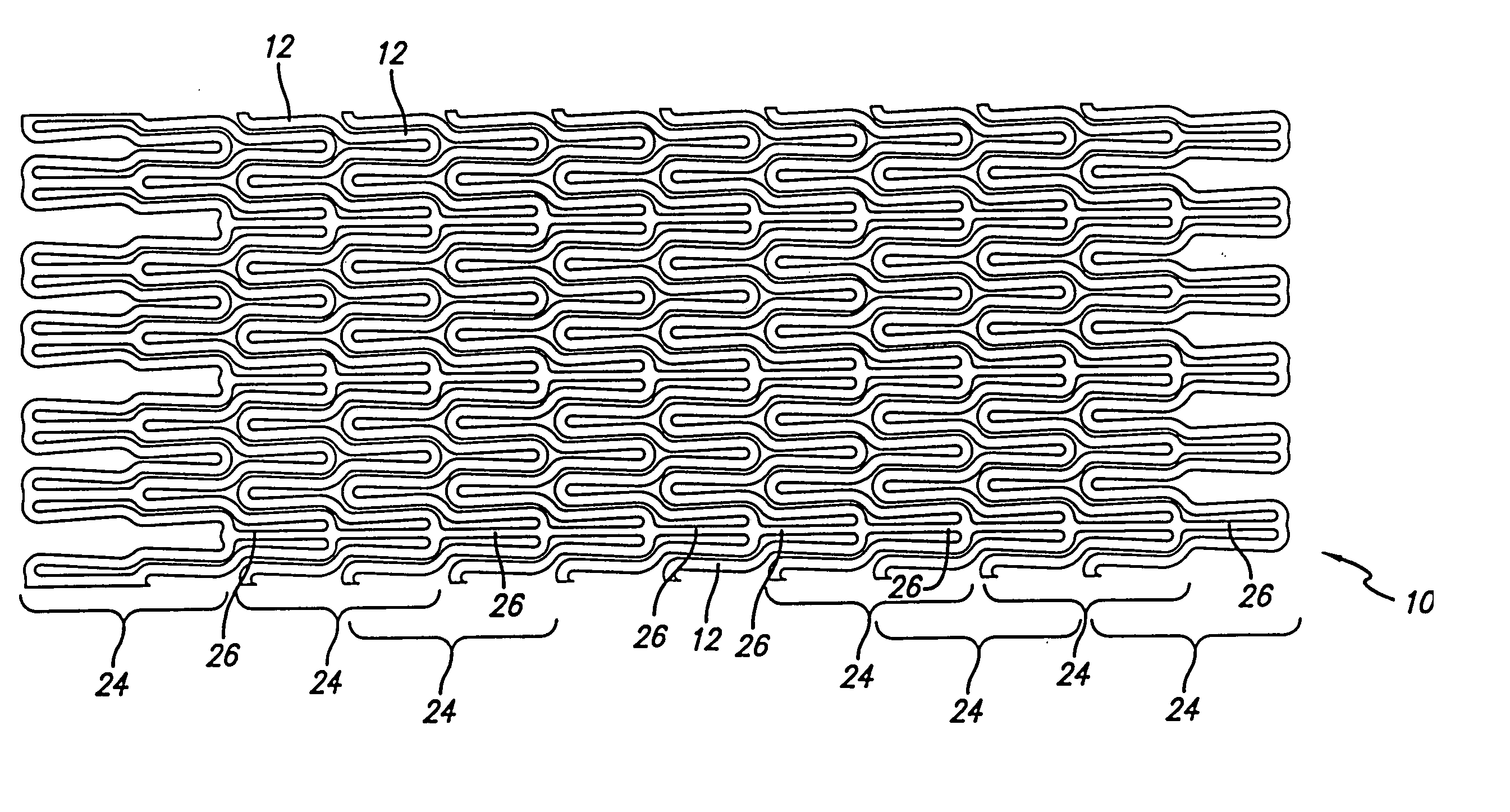

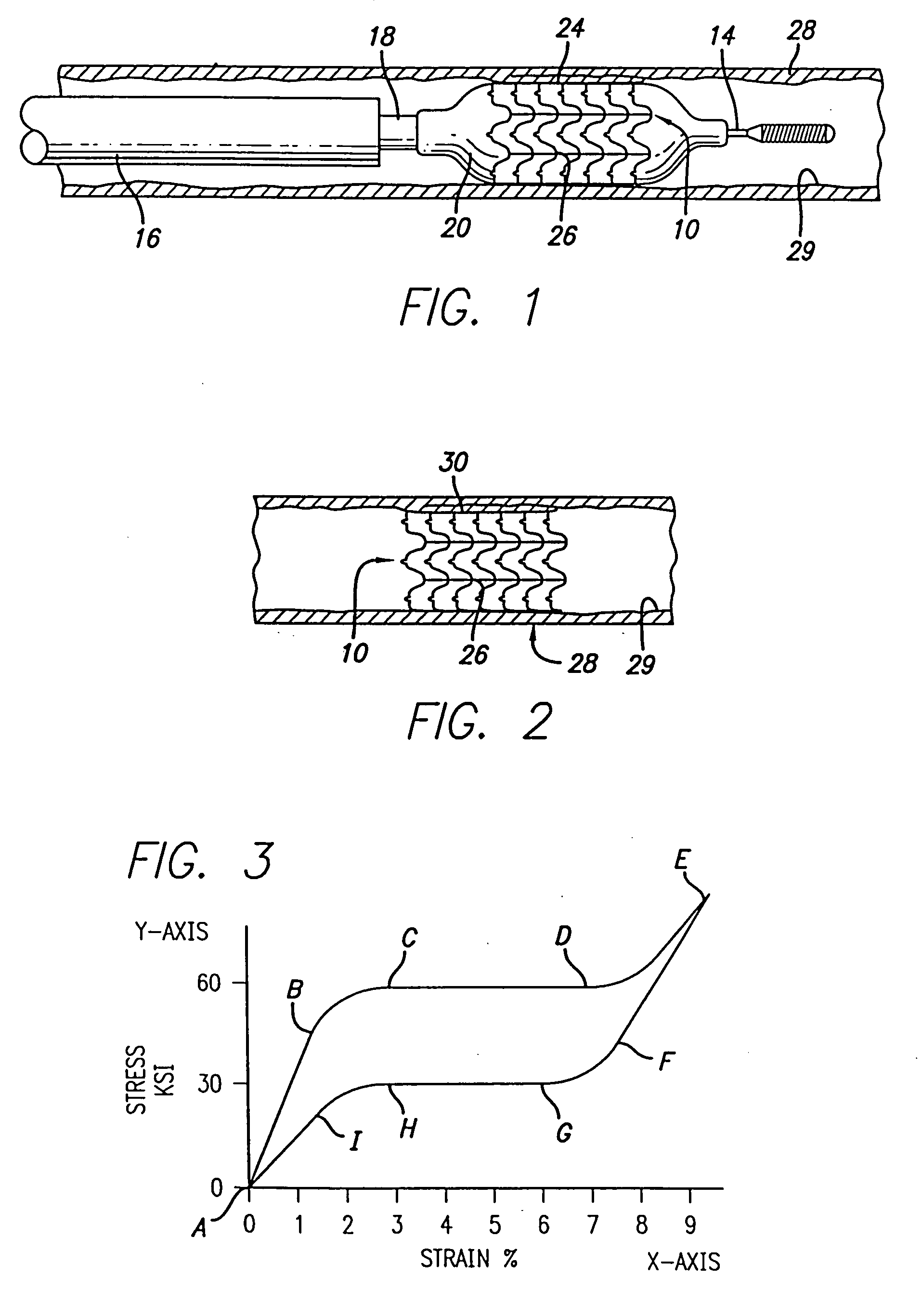

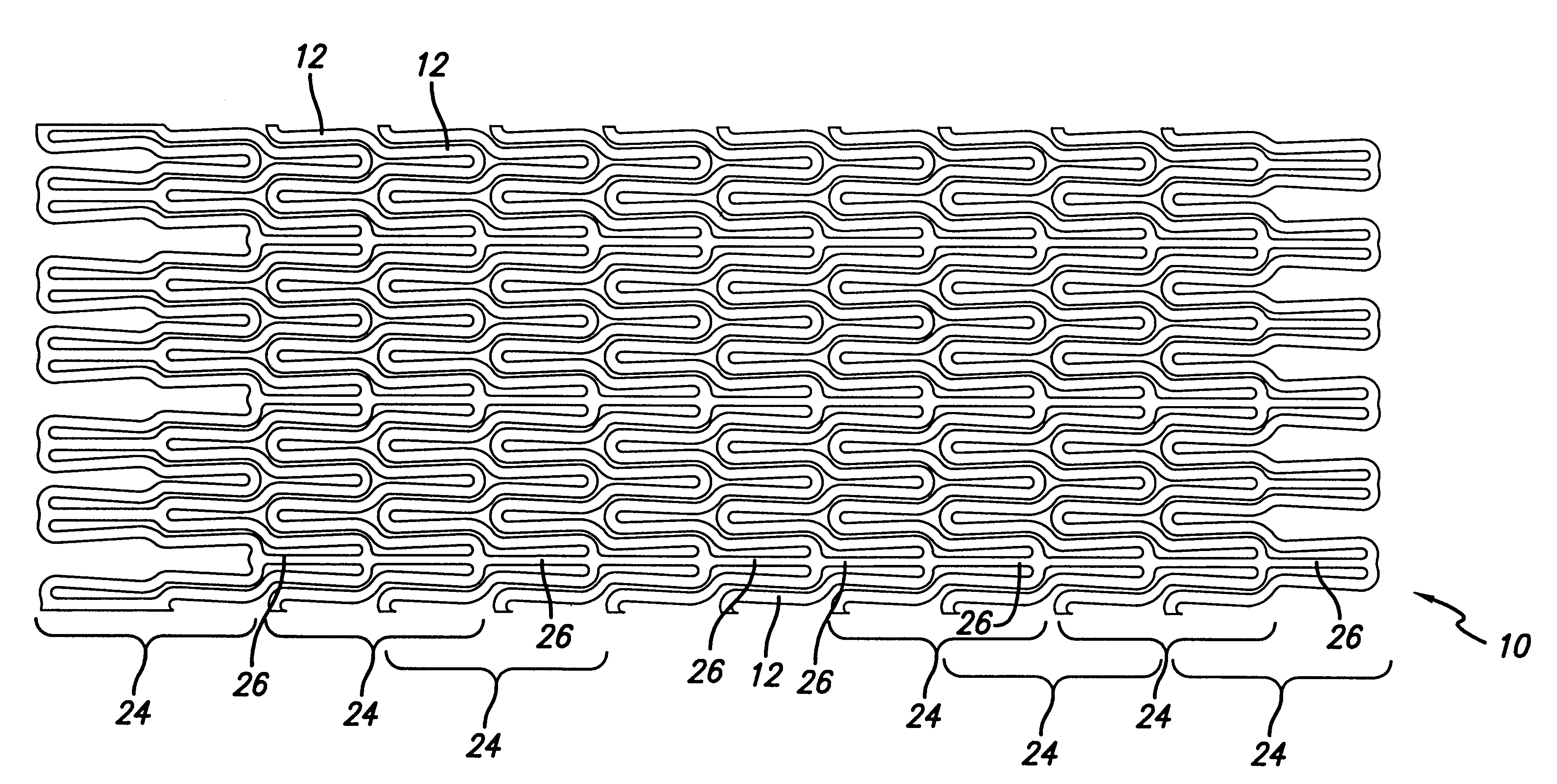

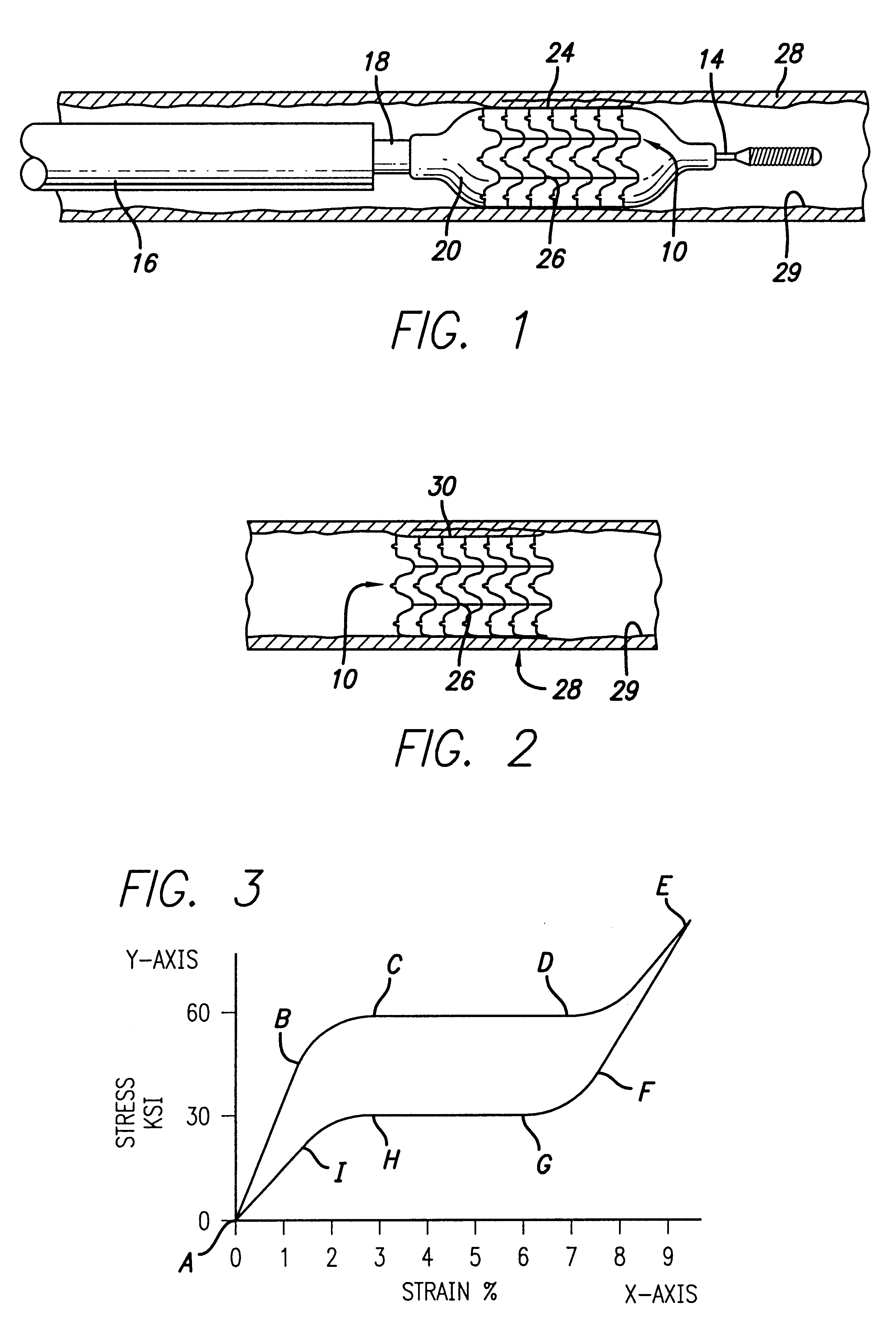

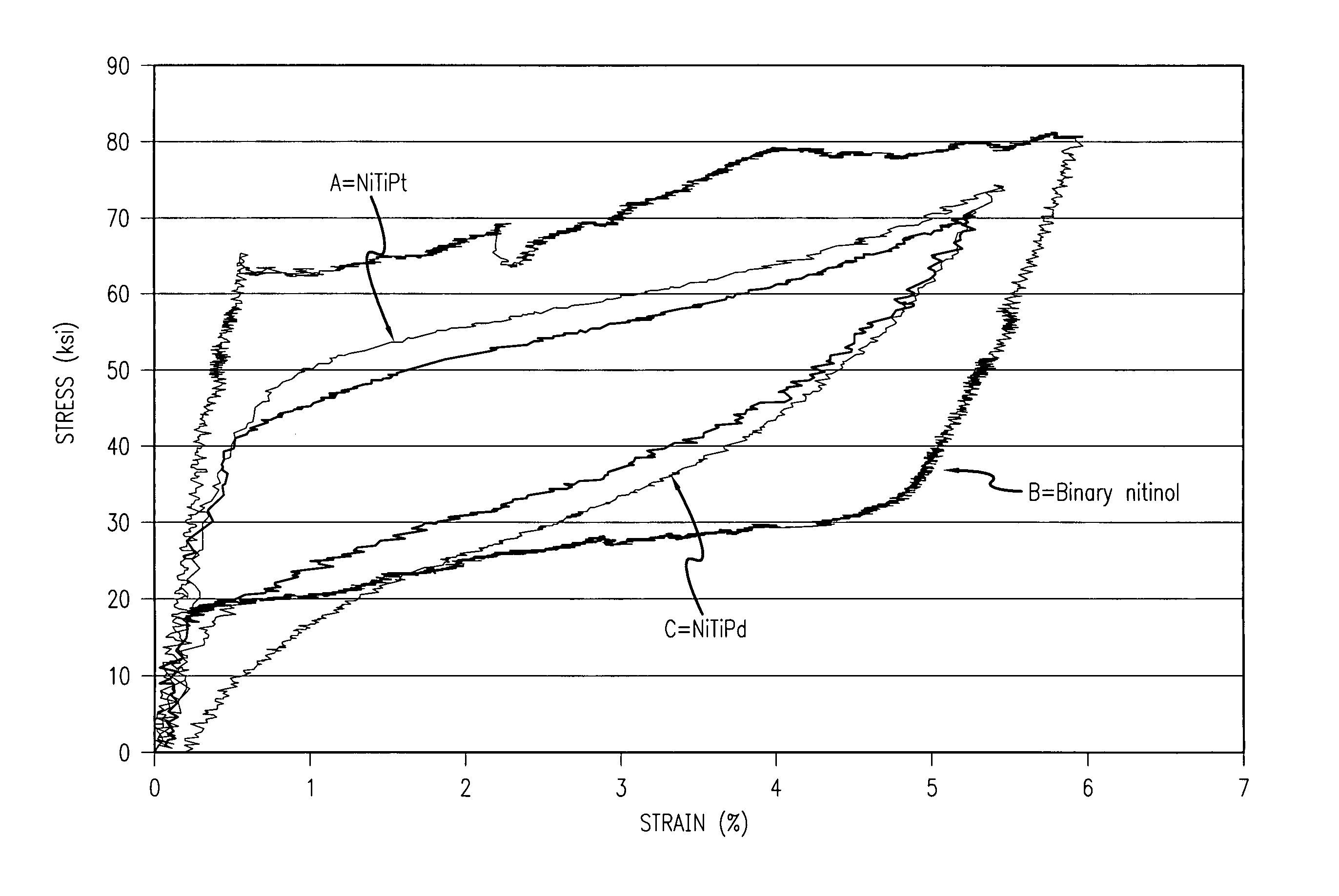

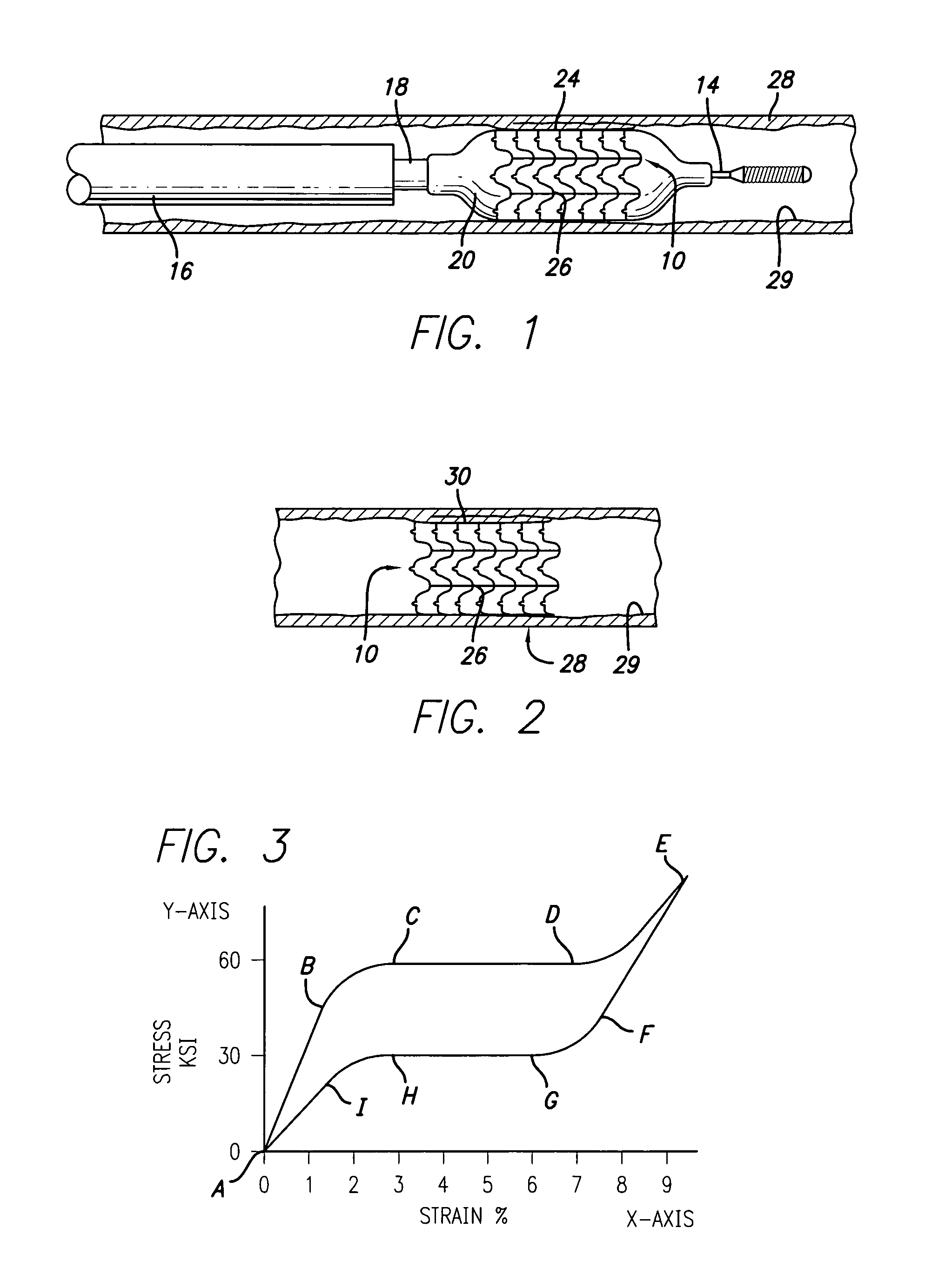

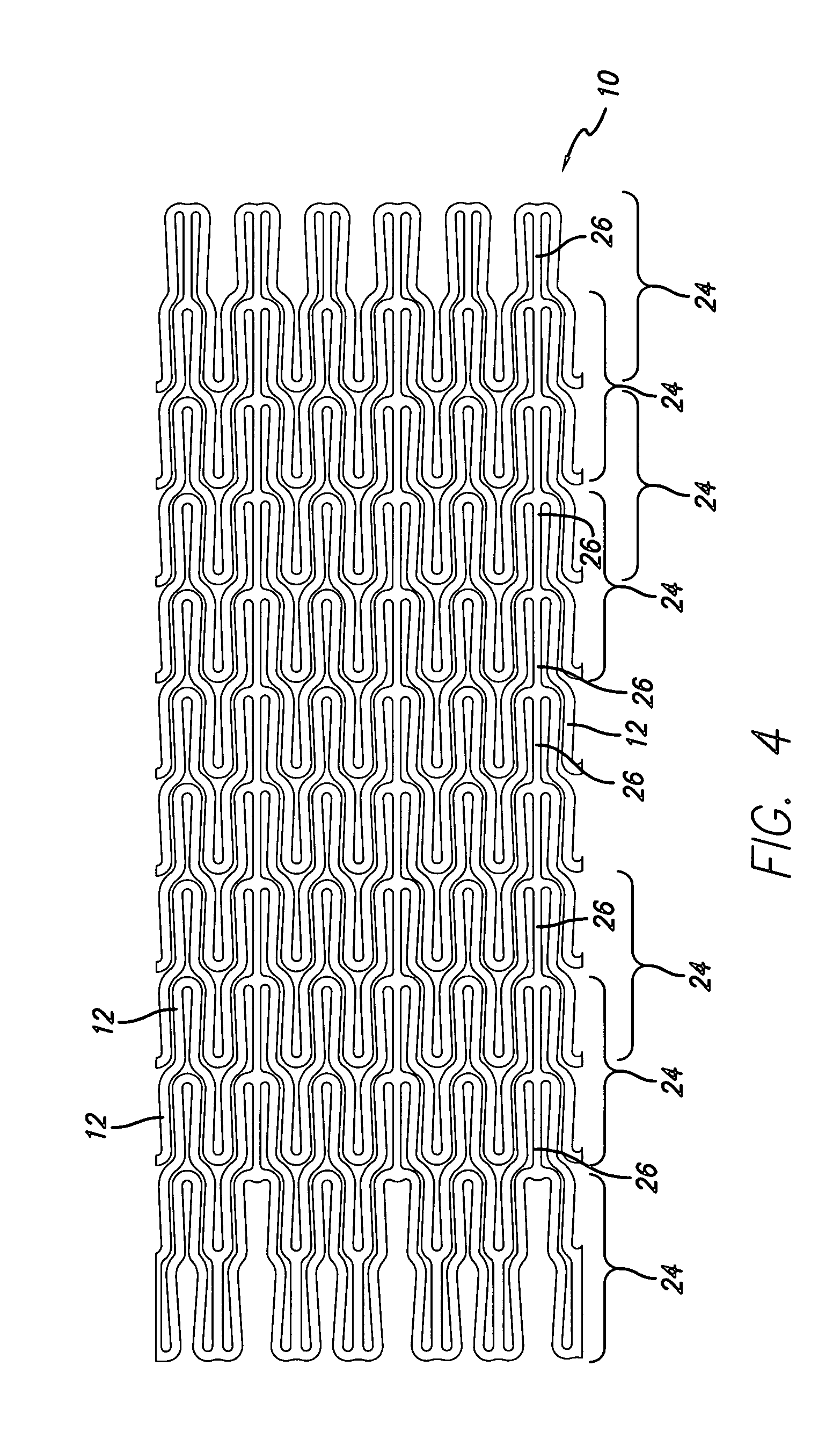

Radiopaque nitinol alloys for medical devices

InactiveUS6855161B2Enhance alloy 's formabilityEnhance thermomechanical propertyStentsSurgeryIridiumRhenium

A radiopaque nitinol medical device such as a stent for use with or implantation in a body lumen is disclosed. The stent is made from a superelastic alloy such as nickel-titanium or nitinol, and includes a ternary element selected from the group of chemical elements consisting of iridium, platinum, gold, rhenium, tungsten, palladium, rhodium, tantalum, silver, ruthenium, or hafnium. The added ternary element improves the radiopacity of the nitinol stent comparable to that of a stainless steel stent of the same size and strut pattern coated with a thin layer of gold. The nitinol stent has improved radiopacity yet retains its superelastic and shape memory behavior and further maintains a thin strut / wall thickness for high flexibility.

Owner:ABBOTT CARDIOVASCULAR

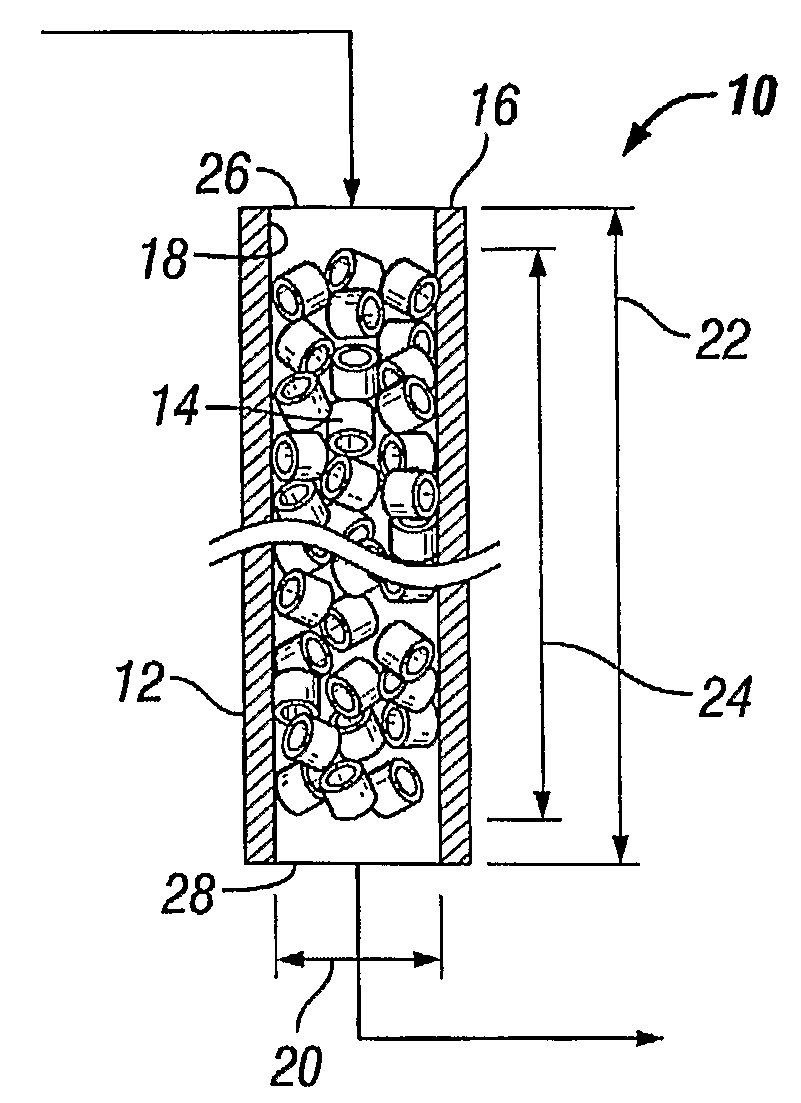

Fixed bed catalysts

InactiveUS6284703B1Promote hydrogenationHigh activityOrganic compound preparationPreparation by hydrogenationRheniumPowder mixture

A shaped, activated, fixed-bed Raney metal catalyst prepared by a method comprising preparing a mixture of powders comprising at least one catalyst alloy of (1) at least one catalytically active Raney process metal, a leachable alloy component and optionally a promoter, (2) at least one binder containing at least one pure Raney metal and (3) a moistening agent. Shaping, calcining and activating said catalyst and doping said catalyst with rhenium.

Owner:DEGUSSA AG

Reactor System and Process for the Manufacture of Ethylene Oxide

A reactor system for the epoxidation of ethylene, which reactor system comprises an elongated tube having an internal tube diameter of more than 40 mm, wherein contained is a catalyst bed of catalyst particles comprising silver and a promoter component deposited on a carrier, which promoter component comprises an element selected from rhenium, tungsten, molybdenum and chromium; a process for the epoxidation of ethylene comprising reacting ethylene with oxygen in the presence of the catalyst bed contained in the reactor system; and a method of preparing ethylene glycol, an ethylene glycol ether or an ethanol amine comprising obtaining ethylene oxide by the process for the epoxidation of ethylene, and converting the ethylene oxide into ethylene glycol, the ethylene glycol ether, or the ethanol amine. Preferably, the internal tube diameter is at least 45 mm.

Owner:SHELL OIL CO

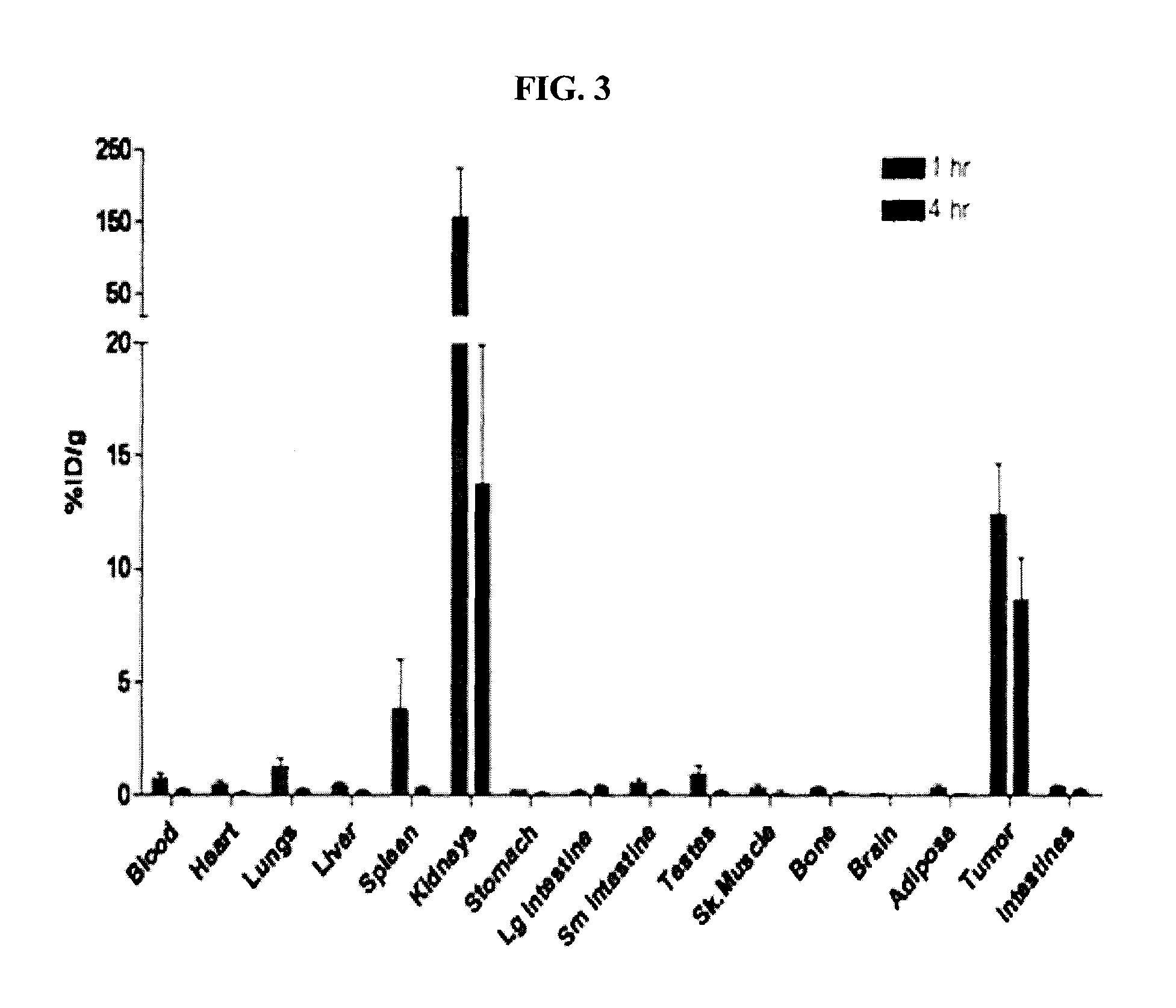

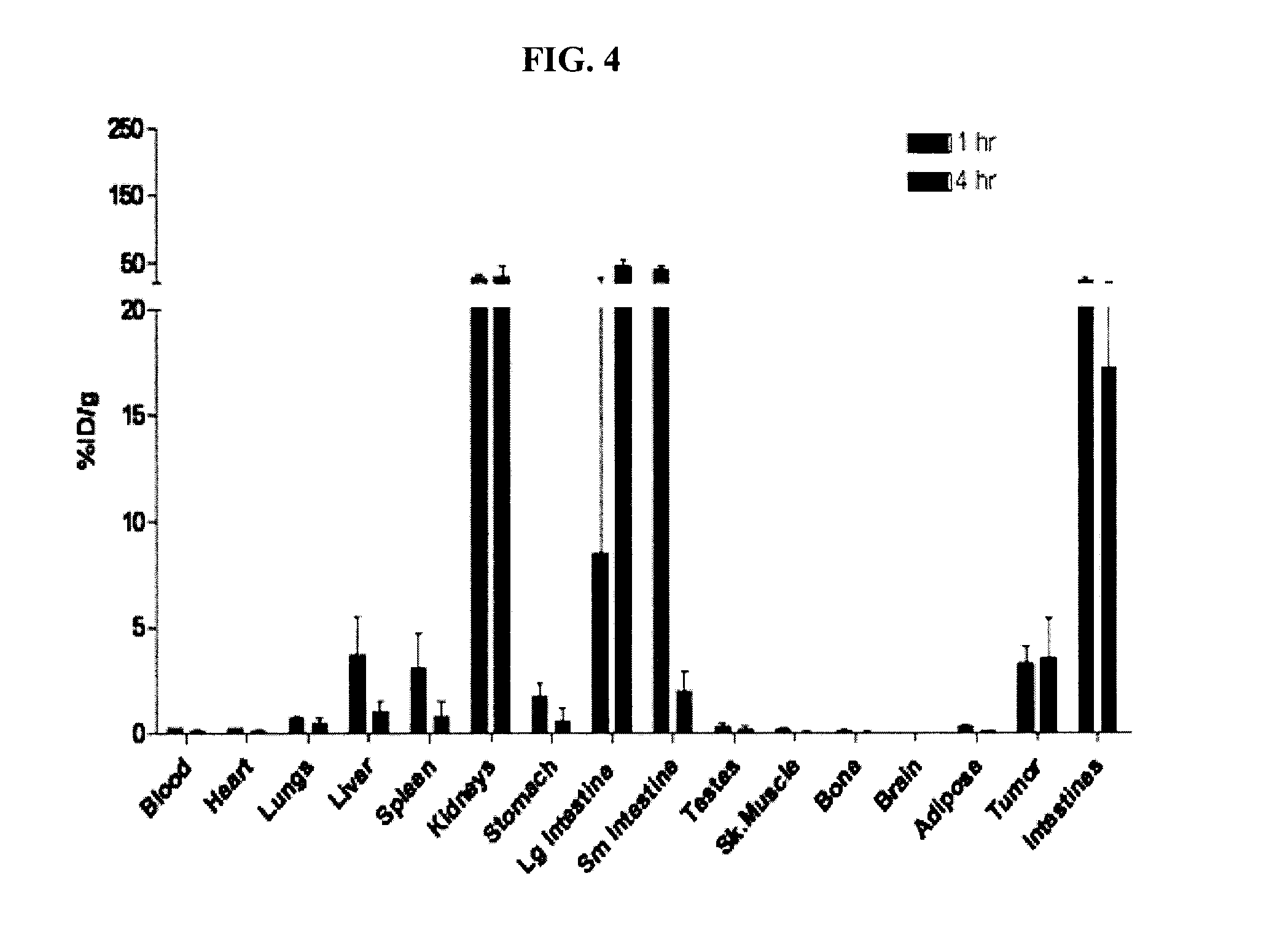

Technetium- and rhenium-bis(heteroaryl) complexes and methods of use thereof for inhibiting PSMA

Owner:MOLECULAR INSIGHT PHARMA

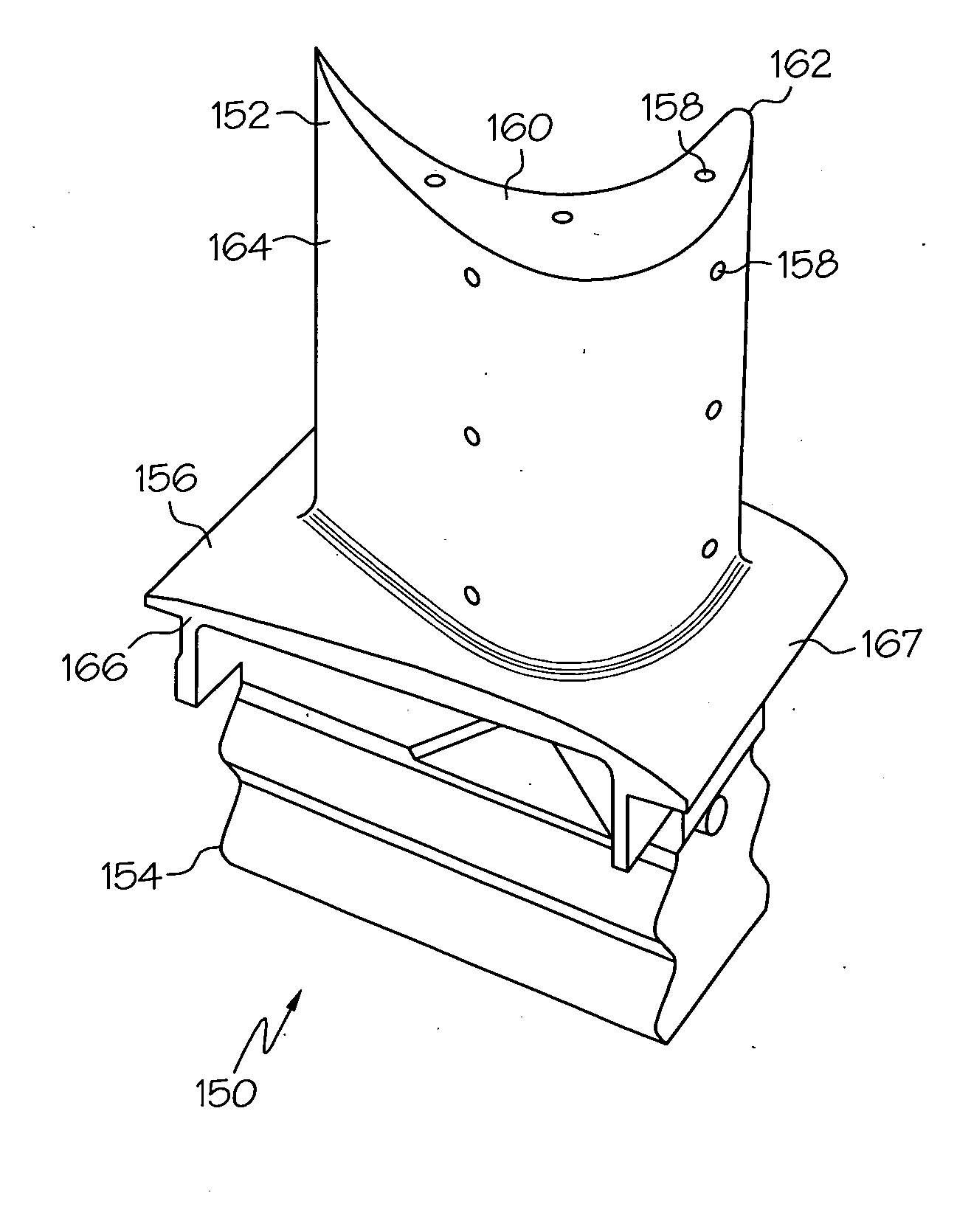

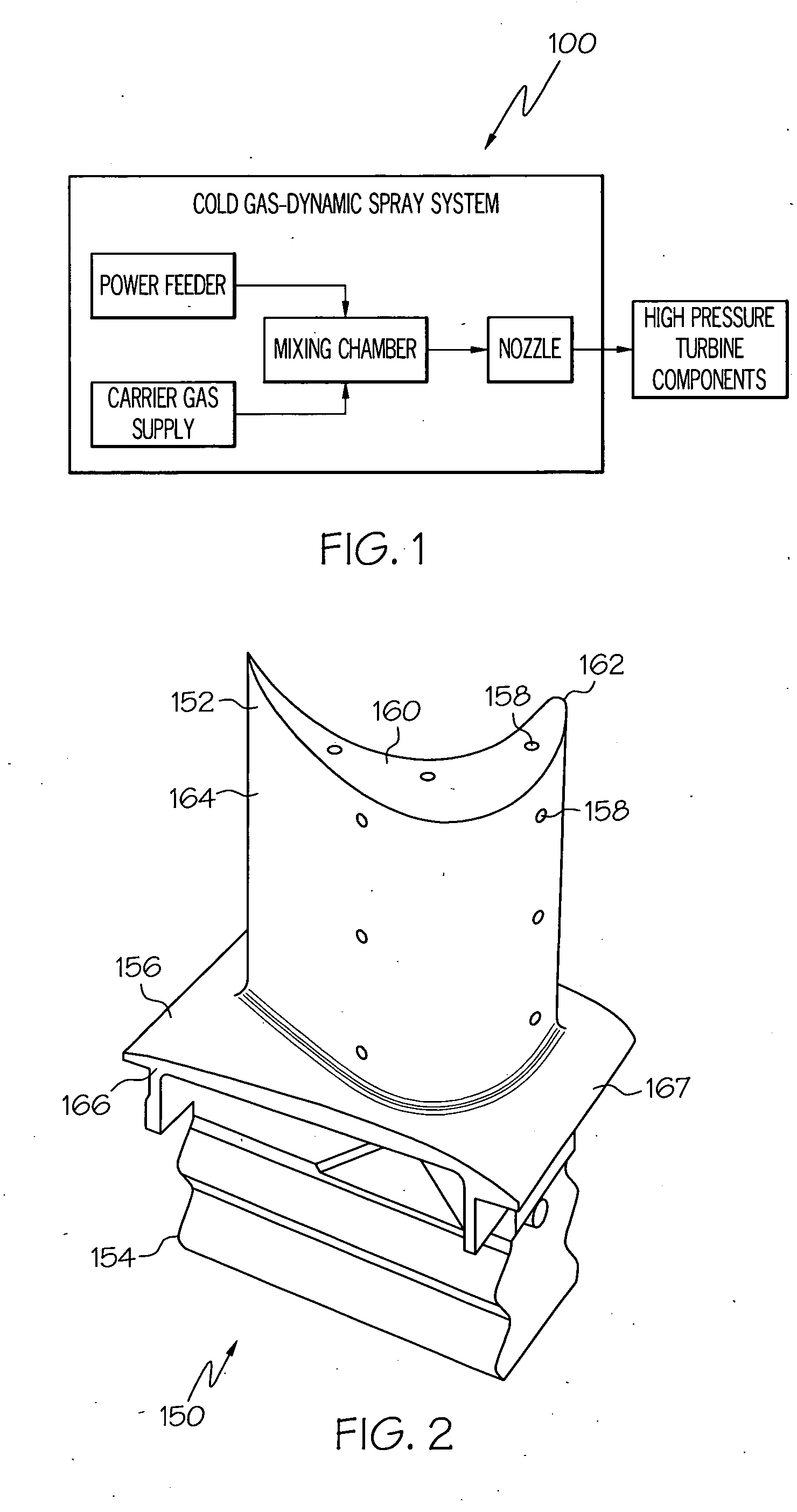

Environment-resistant platinum aluminide coatings, and methods of applying the same onto turbine components

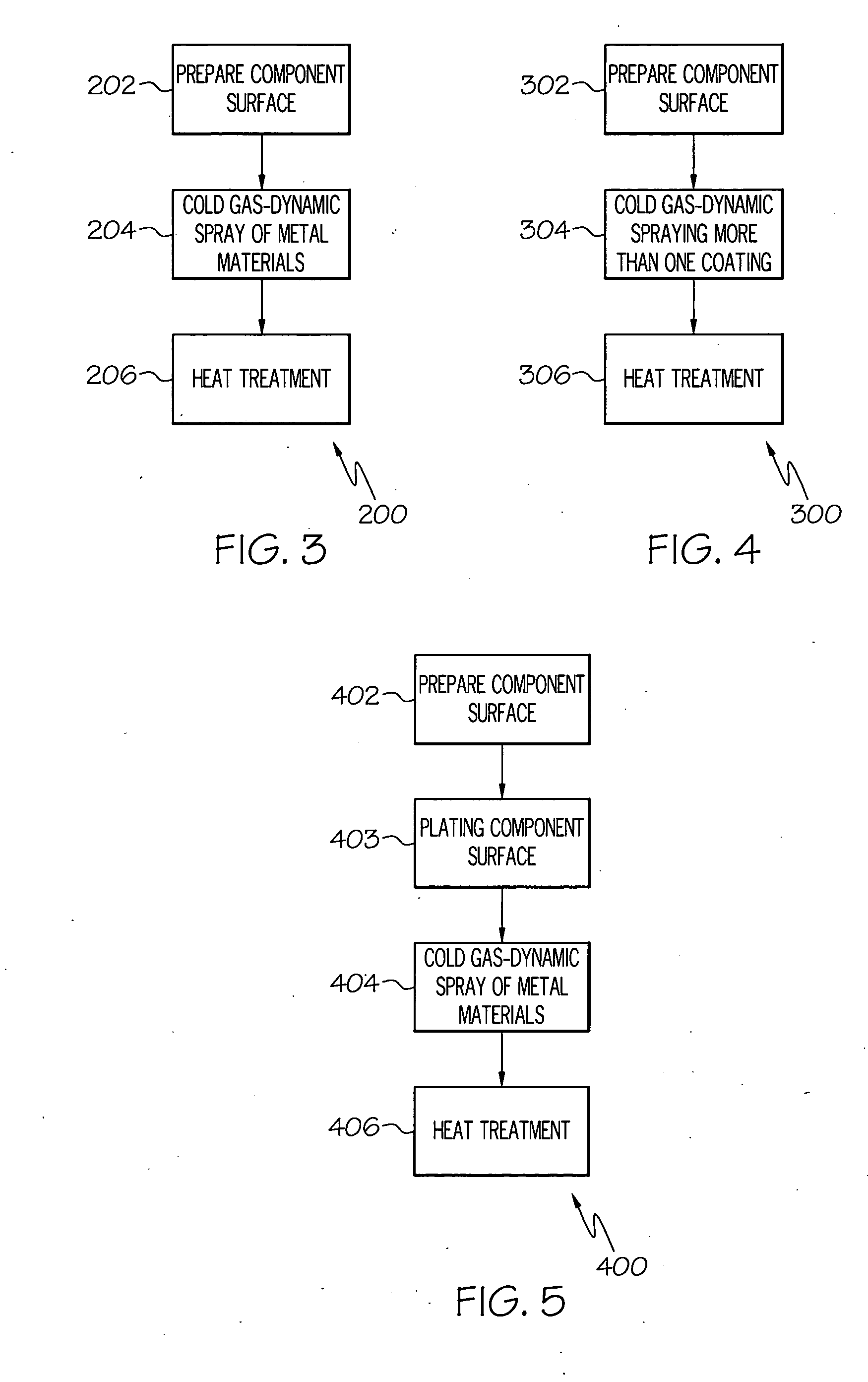

In a method for coating a surface of a turbine component with an environment-resistant aluminide, a coating is formed by cold gas-dynamic spraying a powder material on the turbine component surface, the powder material comprising aluminum, platinum, and at least one additional metal selected from the group consisting of nickel, chromium, hafnium, silicon, yttrium, rhenium, zirconium, cobalt, and tantalum. After forming the coating, at least one thermal diffusion treatment is performed on the turbine component to metallurgically homogenize the coating and thereby form an aluminide coating that includes by weight about 12 to about 30% aluminum, up to about 50% platinum, about 2 to about 25% chromium, about 1 to about 5% hafnium, about 1 to about 5% silicon, about 0.1 to about 1% yttrium, and about 1 to about 3% Zr, and nickel.

Owner:HONEYWELL INT INC

Catalyst with bimodal pore size distribution and the use thereof

ActiveUS20090198076A1Promoting amountExcessive amountMolecular sieve catalystsOther chemical processesRheniumPore diameter

The invention is directed to a catalyst for the epoxidation of an olefin to an olefin oxide, the catalyst comprising a support having at least two pore size distributions, each pore size distribution possessing a different mean pore size and a different pore size of maximum concentration, the catalyst further comprising a catalytically effective amount of silver, a promoting amount of rhenium, and a promoting amount of one or more alkali metals, wherein the at least two pore size distributions are within a pore size range of about 0.01 μm to about 50 μm. The invention is also directed to a process for the oxidation of an olefin to an olefin oxide using the above-described catalyst.

Owner:SCI DESIGN

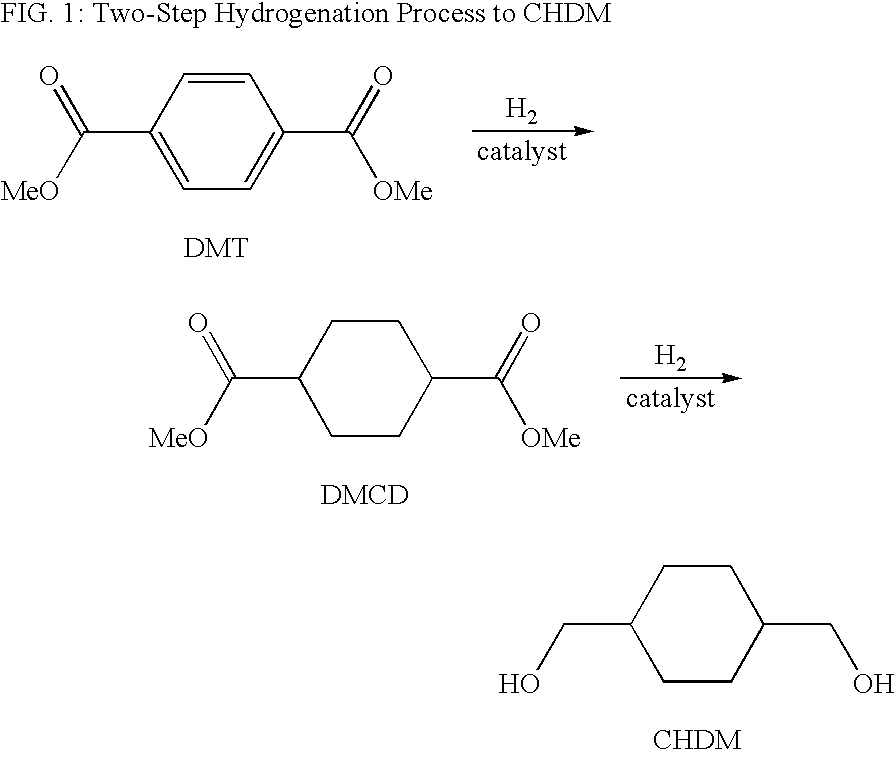

Process for a cyclohexanedimethanol using raney metal catalysts

InactiveUS6919489B1High trans contentOrganic compound preparationOxygen compounds preparation by reductionRheniumCyclohexanedimethanol

Disclosed is a process for a cyclohexanedimethanol by hydrogenation of a cyclohexane-dicarboxylate ester in the presence of a Raney metal catalyst doped with rhenium. The process is useful for the reparation of 1,4-cyclohexanedimethanol from dialkyl esters of 1,4-cyclohexanedicarboxylate or dialkyl terephthalates. When Raney nickel is used as the catalyst, the process produces CHDM having a high trans content.

Owner:EASTMAN CHEM CO

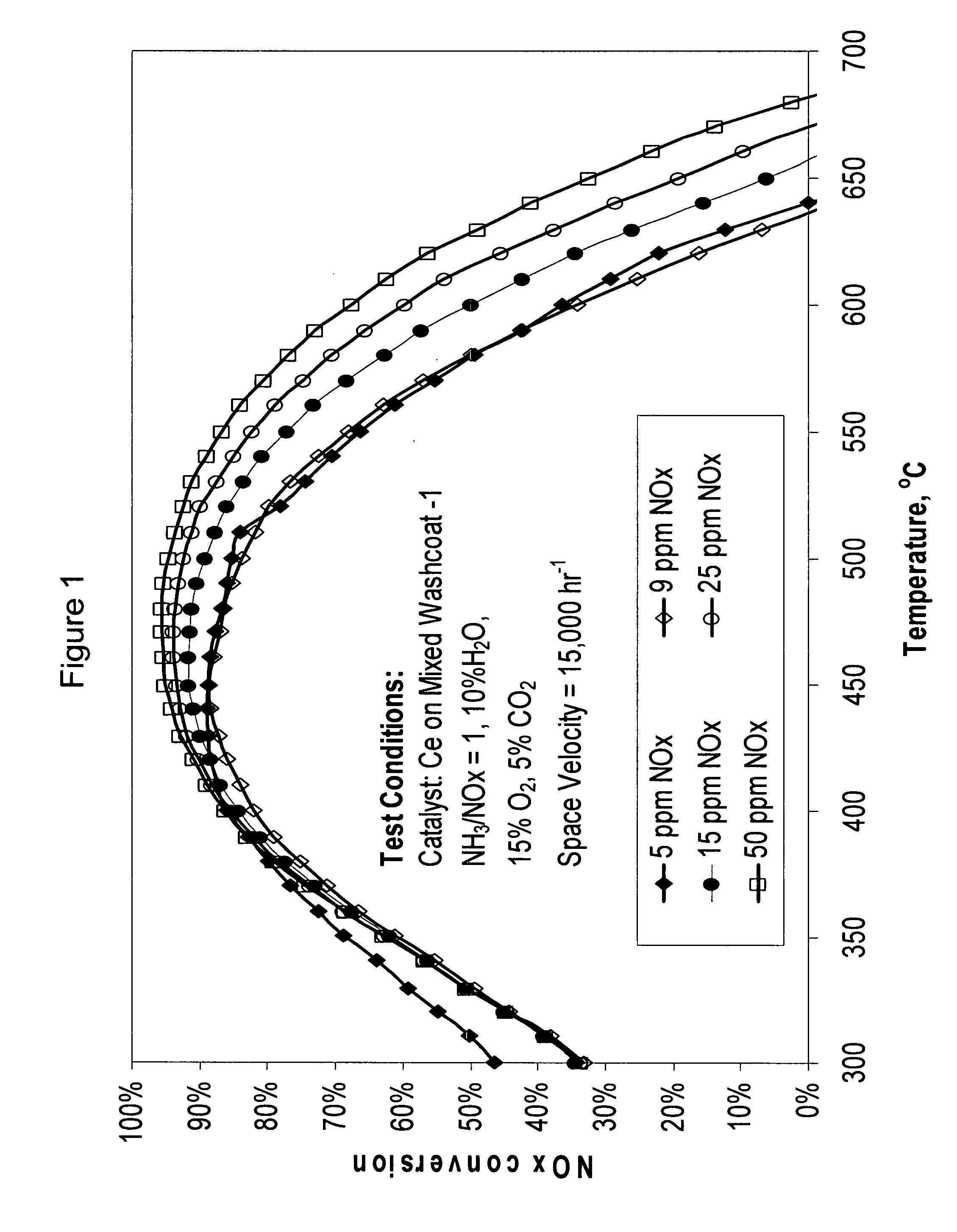

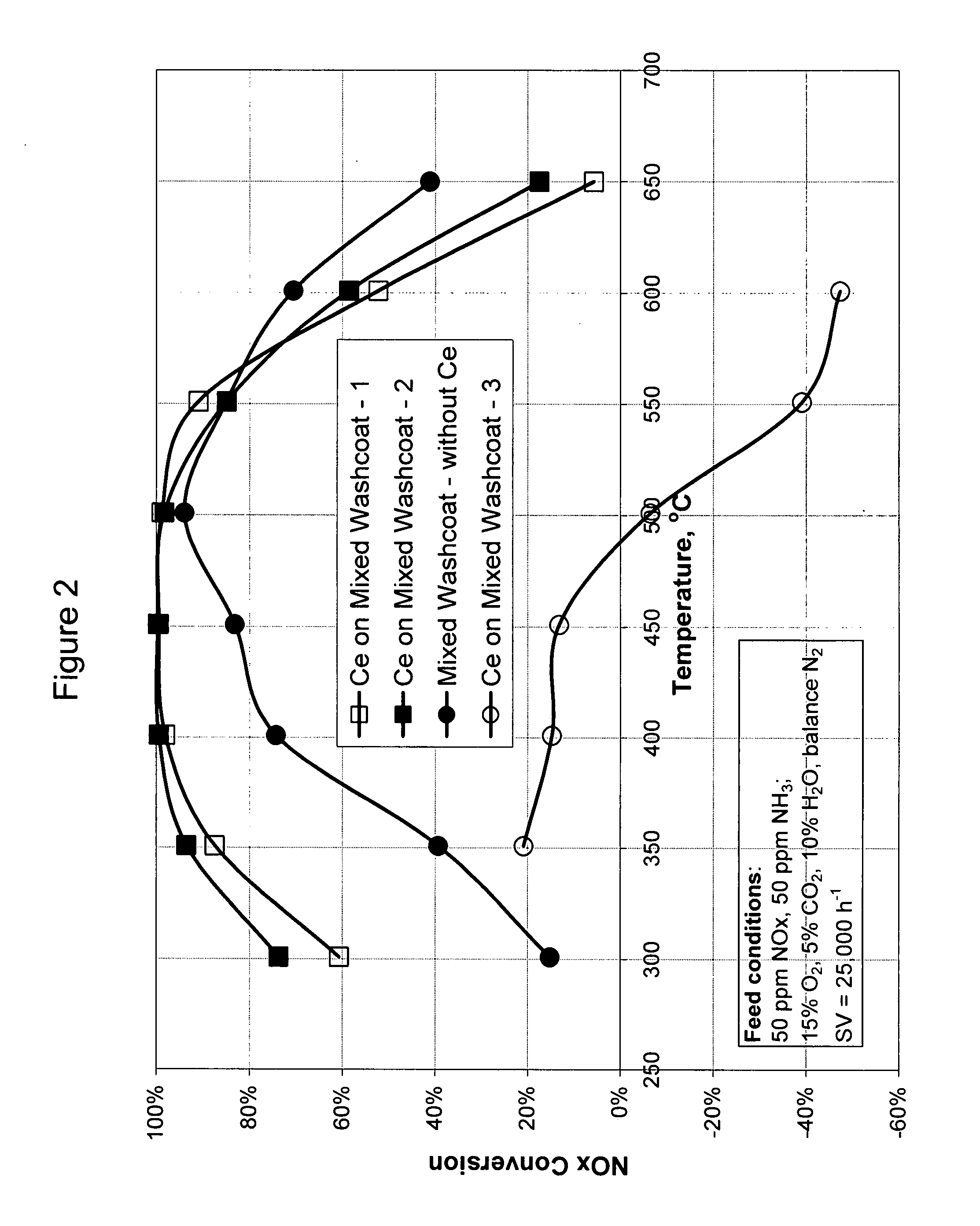

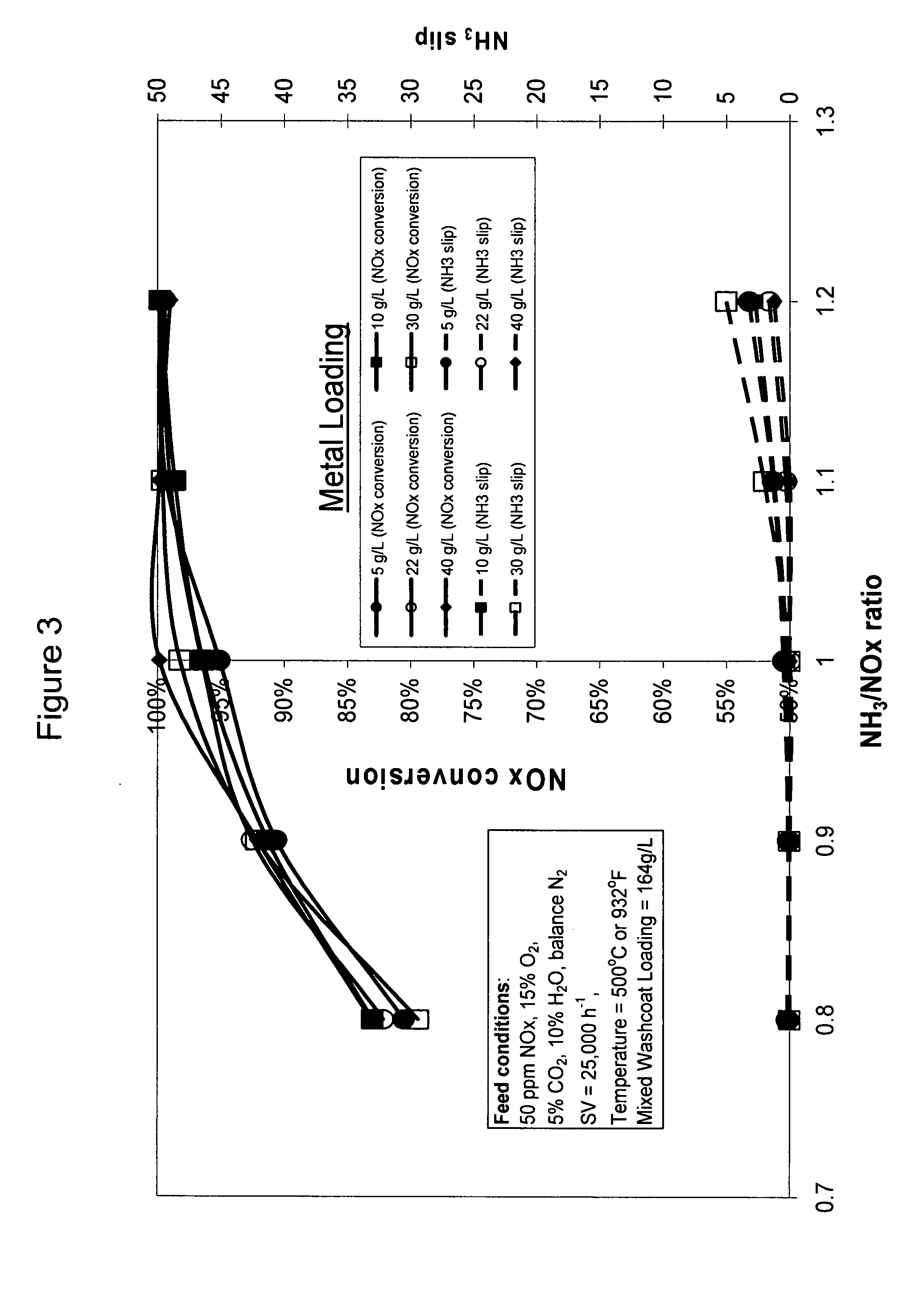

High temperature ammonia SCR catalyst and method of using the catalyst

ActiveUS20080167178A1Reduce selection requirementsMolecular sieve catalystsInternal combustion piston enginesCeriumMordenite

A catalyst and a method for selectively reducing nitrogen oxides (“NOx”) with ammonia are provided. The catalyst includes a first component comprising a zeolite or mixture of zeolites selected from the group consisting of ZSM-5, ZSM-11, ZSM-12, ZSM-18, ZSM-23, MCM-zeolites, mordenite, faujasite, ferrierite, zeolite beta, and mixtures thereof; a second component comprising at least one member selected from the group consisting of cerium, iron, copper, gallium, manganese, chromium, cobalt, molybdenum, tin, rhenium, tantalum, osmium, barium, boron, calcium, strontium, potassium, vanadium, nickel, tungsten, an actinide, mixtures of actinides, a lanthanide, mixtures of lanthanides, and mixtures thereof; optionally an oxygen storage material and optionally an inorganic oxide. The catalyst selectively reduces nitrogen oxides to nitrogen with ammonia at high temperatures. The catalyst has high hydrothermal stability. The catalyst has high activity for conversion of low levels of nitrogen oxides in exhaust streams. The catalyst and the method may have special application to selective reduction of nitrogen oxides in exhaust gas from gas turbines and gas engines, although the catalyst and the method have broad application to a wide range of gas streams that have excess oxygen and high temperatures. The temperature of exhaust gas from gas turbines and gas engines is high. Both the high temperature and the low levels of inlet NOx are challenging for selective catalytic reduction (SCR) catalysts.

Owner:CATALYTIC SOLUTIONS INC

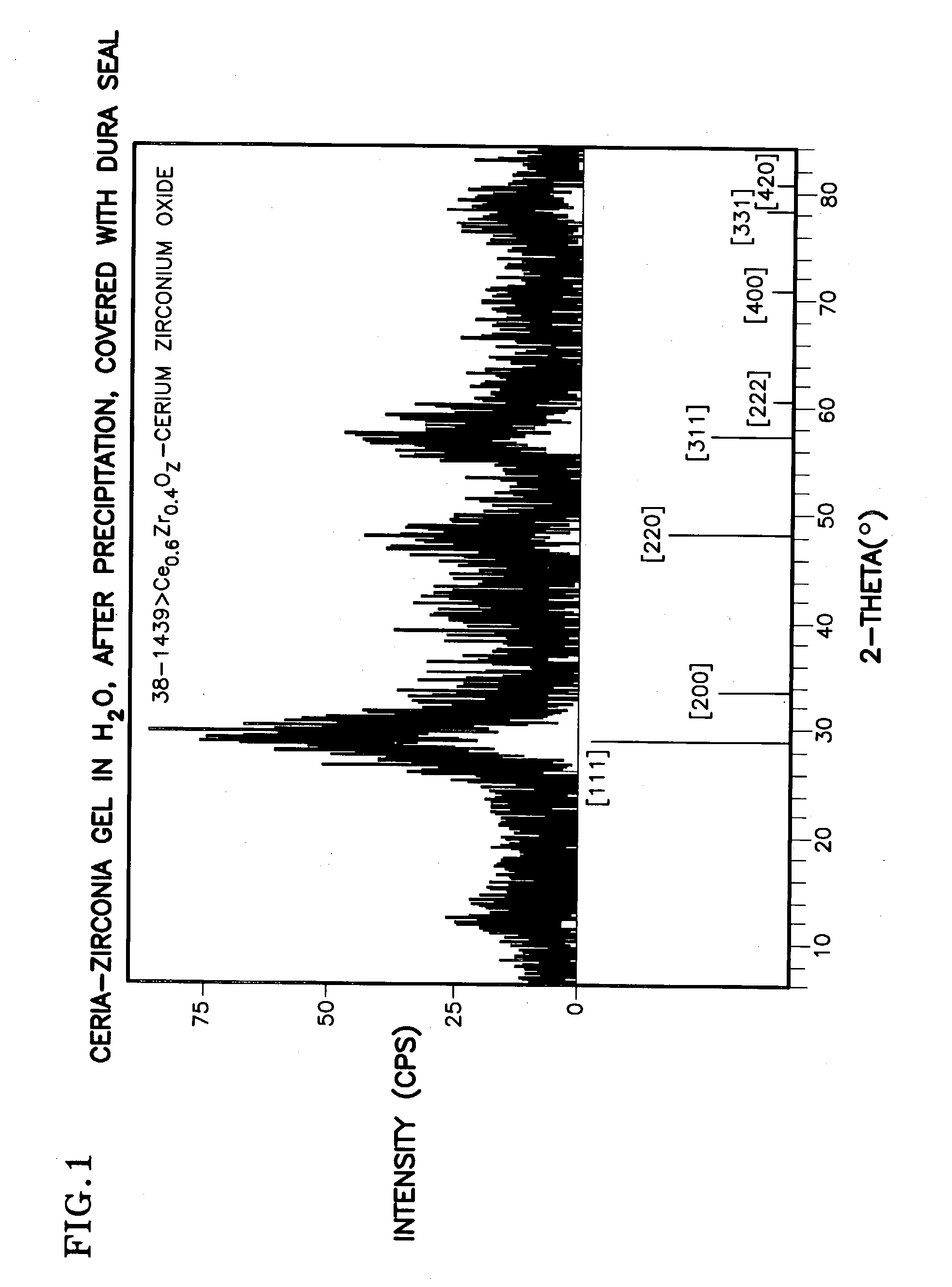

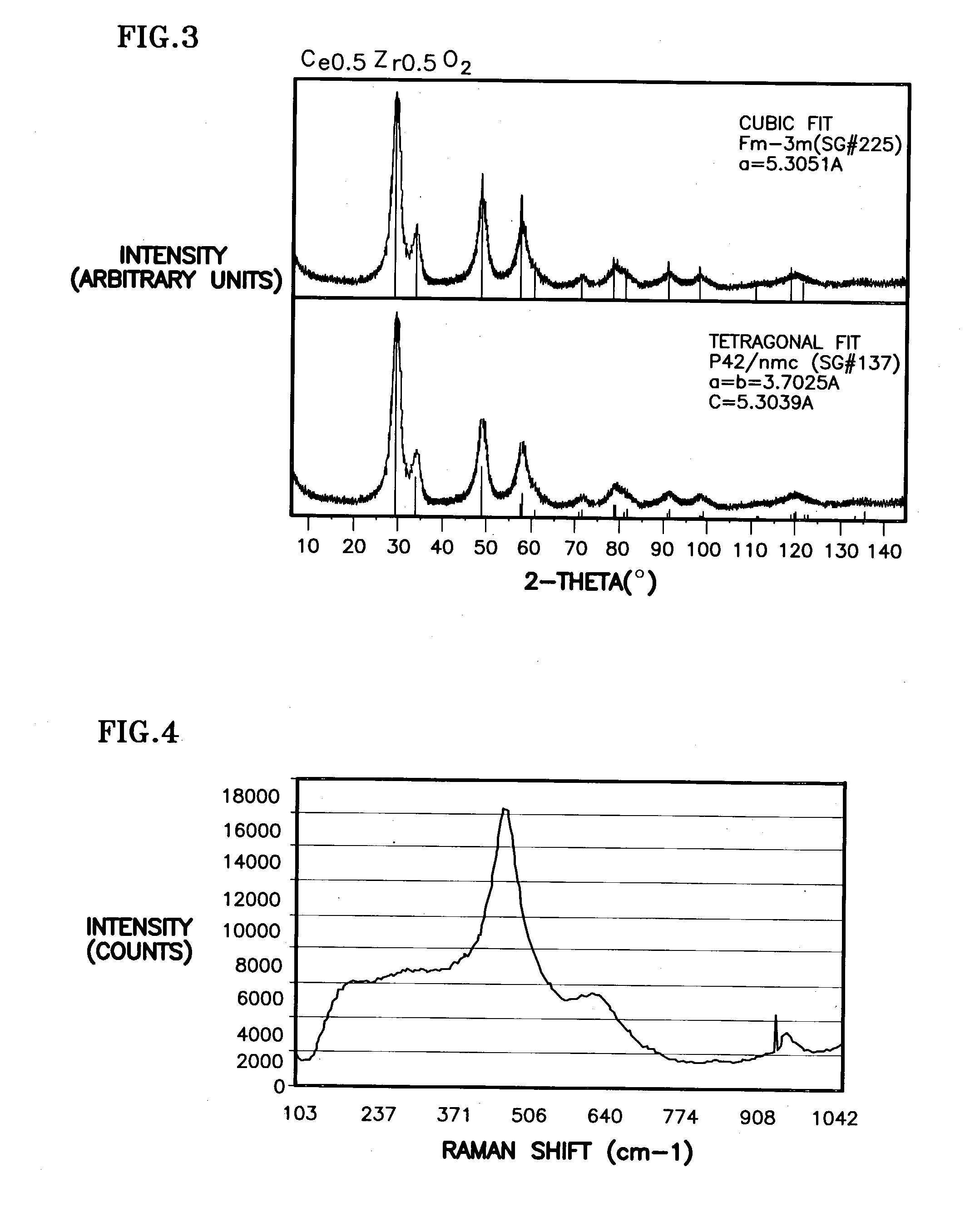

Ceria-based mixed-metal oxide structure, including method of making and use

InactiveUS20030235526A1Increased internal surface areaHigh catalytic activityRare earth metal oxides/hydroxidesMaterial nanotechnologyRheniumFuel cells

A homogeneous ceria-based mixed-metal oxide, useful as a catalyst support, a co-catalyst and / or a getter has a relatively large surface area per weight, typically exceeding 150 m<2> / g, a structure of nanocrystallites having diameters of less than 4 nm, and including pores larger than the nanocrystallites and having diameters in the range of 4 to about 9 nm. The ratio of pore volumes, VP, to skeletal structure volumes, VS, is typically less than about 2.5, and the surface area per unit volume of the oxide material is greater than 320 m<2> / cm<3>, for low internal mass transfer resistance and large effective surface area for reaction activity. The mixed metal oxide is ceria-based, includes Zr and or Hf, and is made by a novel co-precipitation process. A highly dispersed catalyst metal, typically a noble metal such as Pt, may be loaded on to the mixed metal oxide support from a catalyst metal-containing solution following a selected acid surface treatment of the oxide support. Appropriate ratioing of the Ce and other metal constituents of the oxide support contribute to it retaining in a cubic phase and enhancing catalytic performance. Rhenium is preferably further loaded on to the mixed-metal oxide support and passivated, to increase the activity of the catalyst. The metal-loaded mixed-metal oxide catalyst is applied particularly in water gas shift reactions as associated with fuel processing systems, as for fuel cells.

Owner:AUDI AG

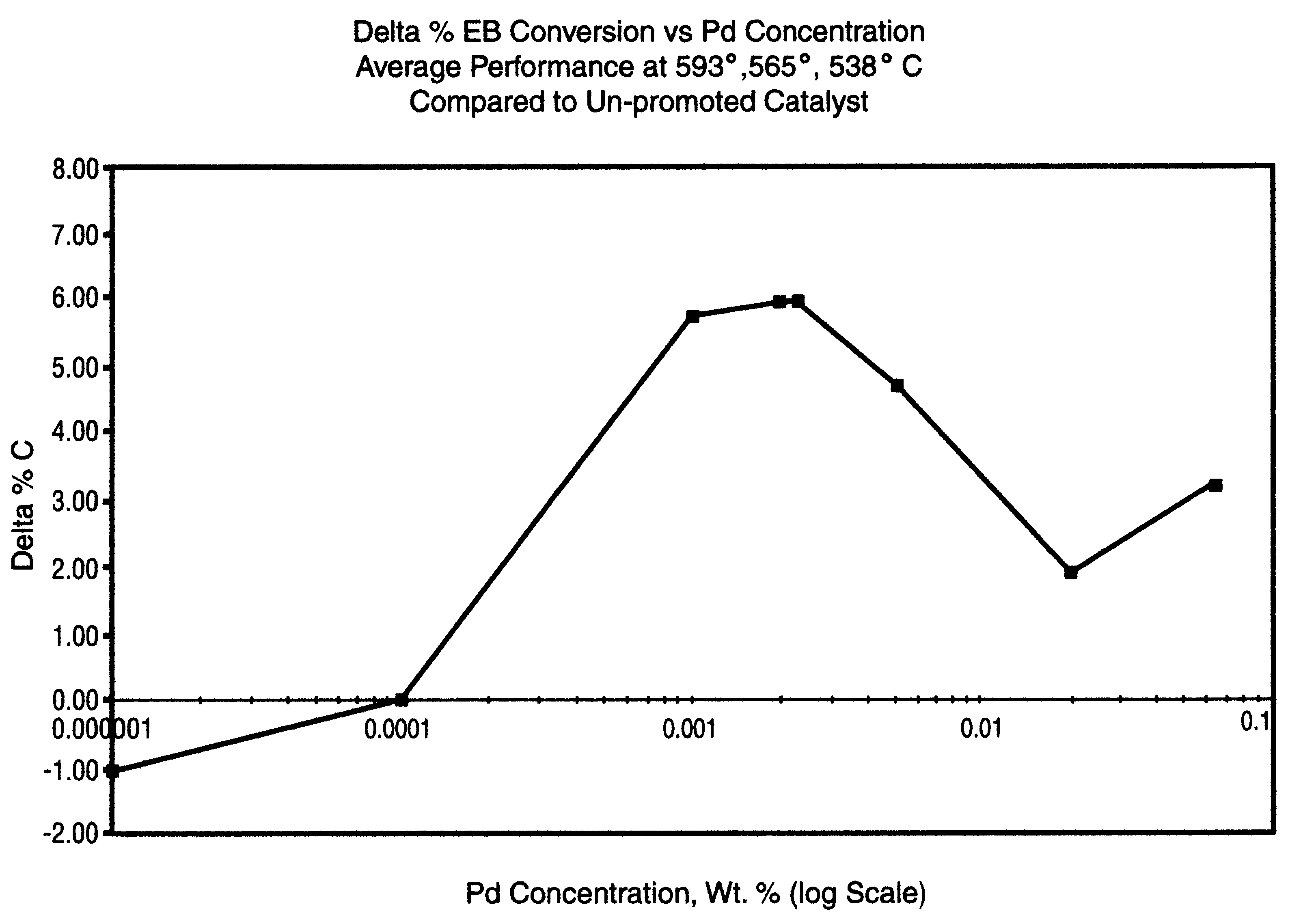

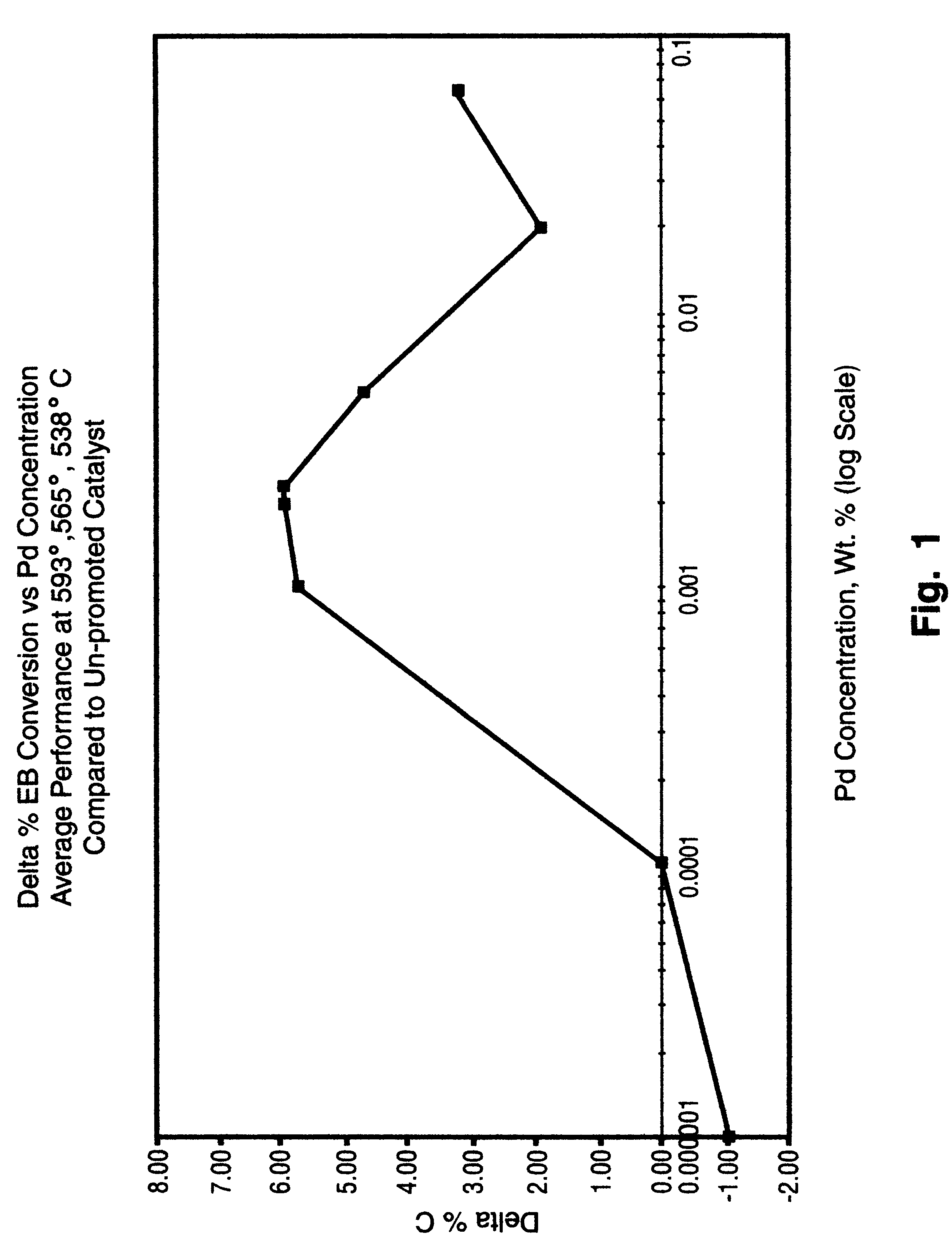

Dehydrogenation catalysts

InactiveUS6191065B1High activityHigh selectivityHydrocarbon by dehydrogenationCatalystsIridiumRhenium

A catalyst for the production of alkenylaromatics from alkylaromatics, wherein the catalyst is predominantly iron oxide, an alkali metal compound and less than about 100 ppm of a source for a noble metal, such as palladium, platinum, ruthenium, rhenium, osmium, rhodium or iridium. Additional components of the catalyst may include compounds based on cerium, molybdenum, tungsten and other such promoters. Also a process for the production of alkenylaromatics from alkylaromatics using this catalyst.

Owner:SUD CHEM INC

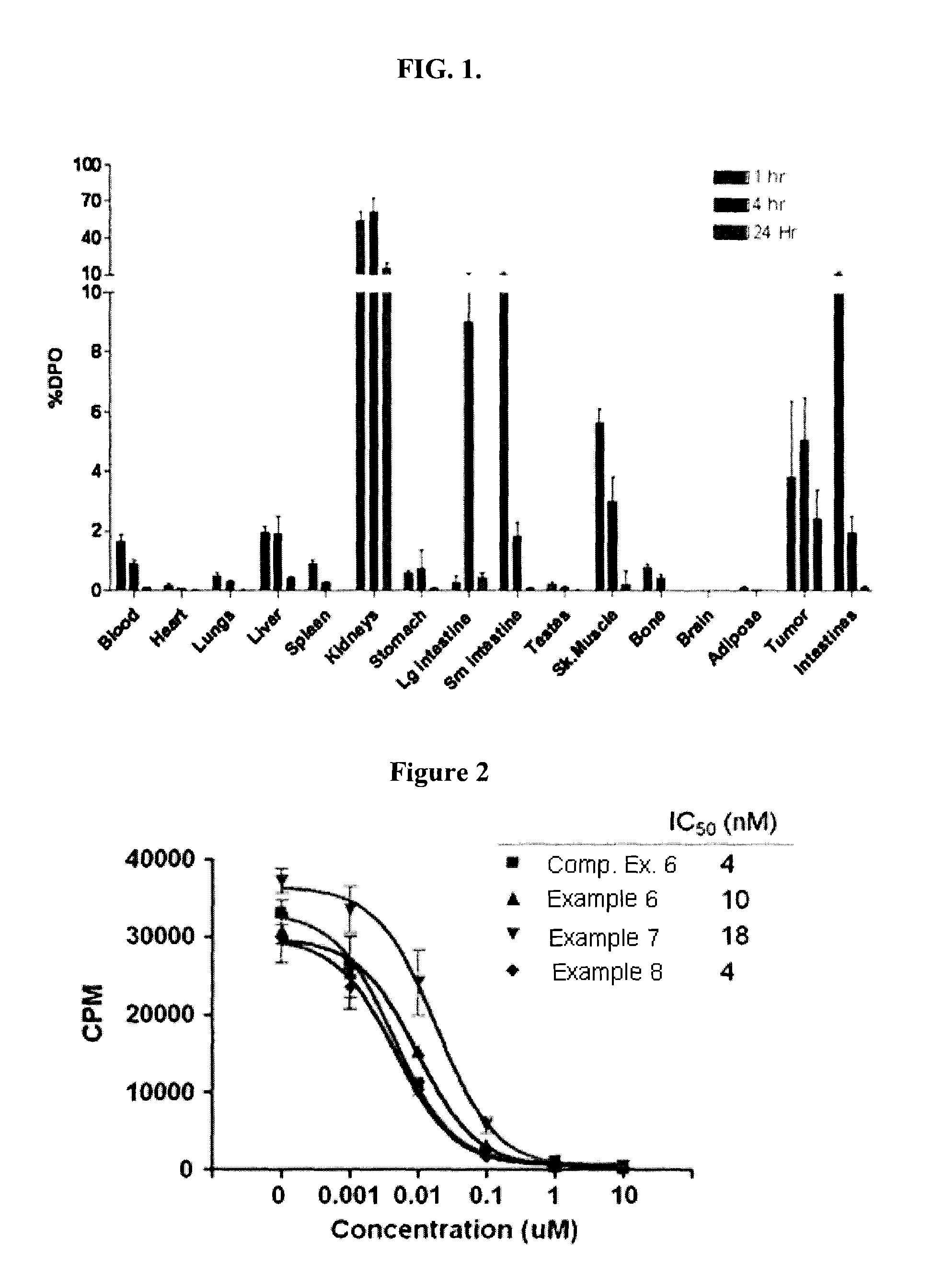

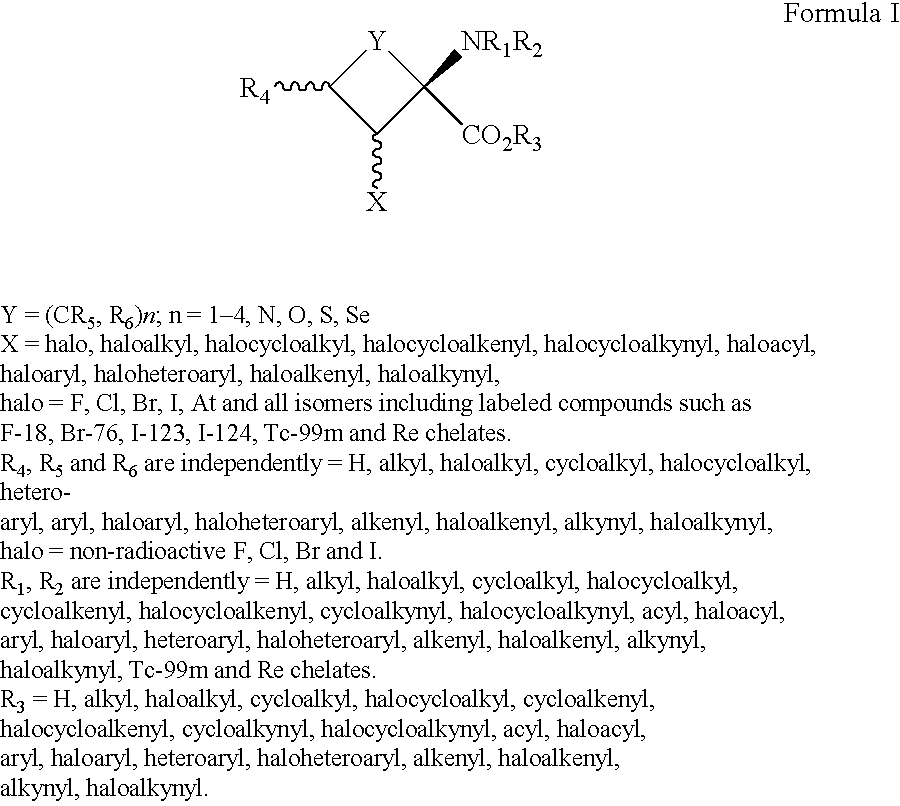

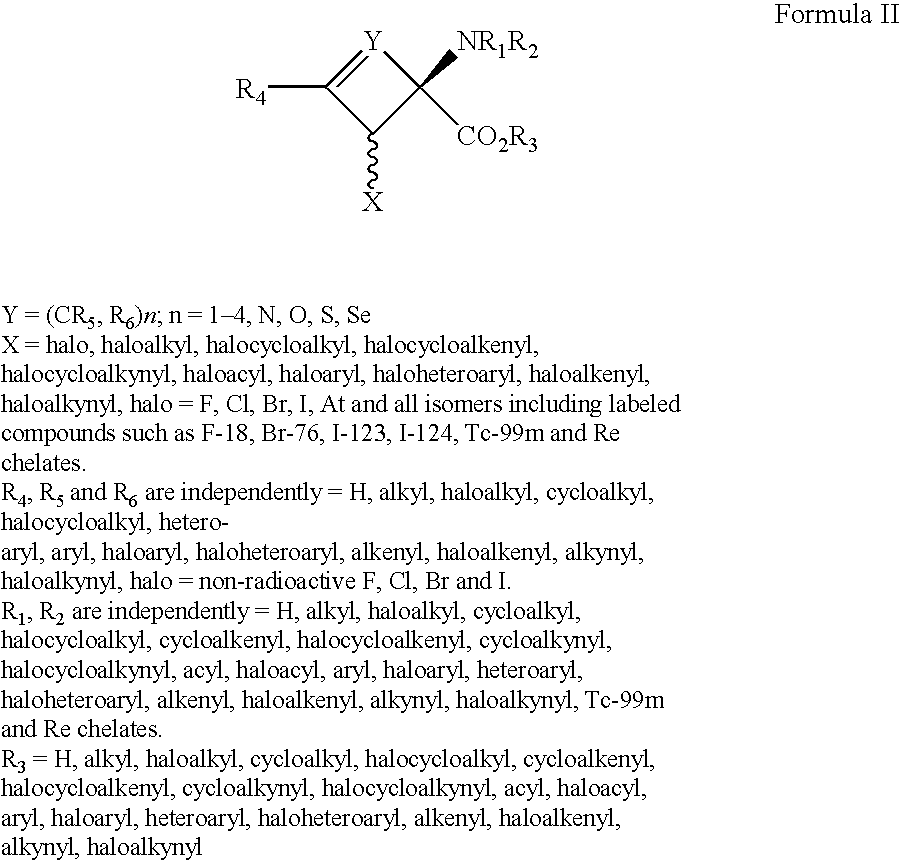

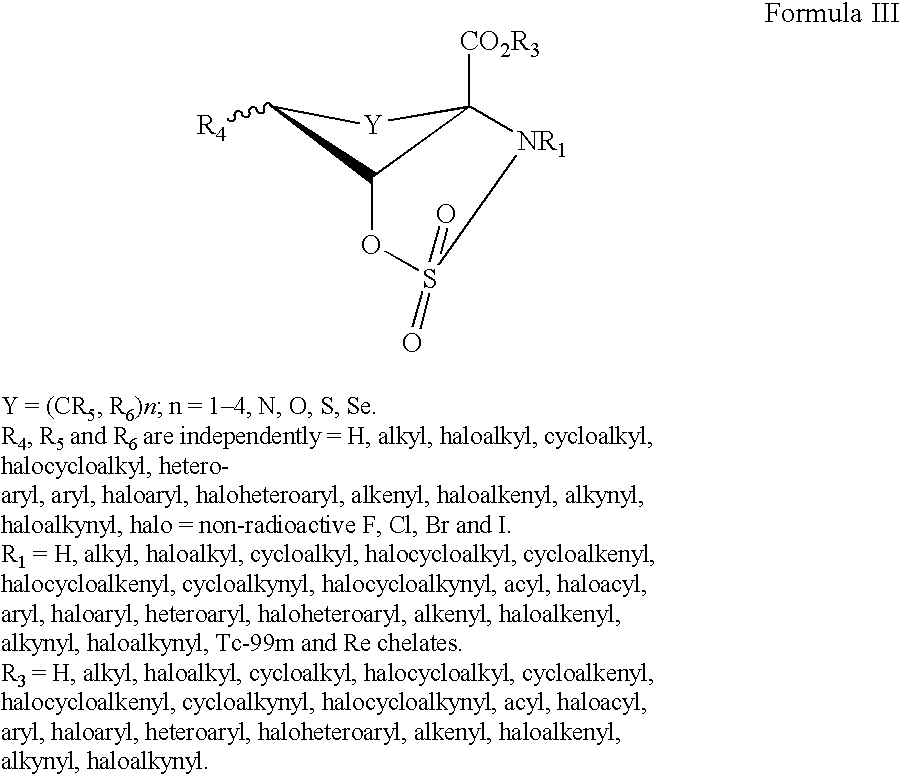

Imaging Agents

InactiveUS20070082879A1High yieldExcessive reactionBiocideIn-vivo radioactive preparationsRheniumAbnormal tissue growth

The present invention provides novel amino acid compounds useful in detecting and evaluating brain and body tumors. These compounds have the advantageous properties of rapid uptake and prolonged retention in tumors and can be labeled with halogen isotopes such as fluorine-18, iodine-123, iodine-124, iodine-125, iodine-131, bromine-75, bromine-76, bromine-77, bromine-82, astatine-210, astatine-211, and other astatine isotopes. These compounds can also be labeled with technetium and rhenium isotopes using known chelation complexes. The compounds disclosed herein bind tumor tissues in vivo with high specificity and selectivity when administered to a subject. Preferred compounds show a target to non-target ratio of at least 2:1, are stable in vivo and substantially localized to target within 1 hour after administration. Preferred compounds include 1-amino-2-[18F]fluorocyclobutyl-1-carboxylic acid (2-[18F]FACBC) and 1-amino-2-[18F]fluoromethylcyclobutyl-1-carboxylic acid (2-[18F]FMACBC). The labeled amino acid compounds of the invention are useful as imaging agents in detecting and / or monitoring tumors in a subject by PET or SPECT.

Owner:EMORY UNIVERSITY

Method for the Decomposition of N2O, Catalyst Therefor and Preparation of This Catalyst

ActiveUS20080044334A1Promote conversionImprove stabilityNitrous oxide captureNitrogen compoundsRheniumIridium

The invention relates to a method for the catalytic decomposition of N2O in a gas containing N2O in the presence of a catalyst, wherein the catalyst comprises a zeolite that has been loaded with a first metal selected from the group of noble metals consisting of ruthenium, rhodium, silver, rhenium, osmium, iridium, platinum and gold, and with a second metal selected from the group of transition metals consisting of chromium, manganese, iron cobalt, nickel and copper, and wherein the loading of the zeolite with metals has been obtained by first loading the zeolite with the noble metal and then with the transition metal, as well as a catalyst for this method and a method for the preparation of this catalyst.

Owner:NEDERLANDSE ORG VOOR TOEGEPAST-NATUURWETENSCHAPPELIJK ONDERZOEK (TNO)

Process for preparing metal powders having low oxygen content, powders so-produced and uses thereof

The present invention is directed to a process for the preparation of a metal powder having a purity at least as high as the starting powder and having an oxygen content of 10 ppm or less comprising heating said metal powder containing oxygen in the form of an oxide, with the total oxygen content being from 50 to 3000 ppm, in an inert atmosphere at a pressure of from 1 bar to 10−7 to a temperature at which the oxide of the metal powder becomes thermodynamically unstable and removing the resulting oxygen via volatilization. The metal powder is preferably selected from the group consisting of tantalum, niobium, molybdenum, hafnium, zirconium, titanium, vanadium, rhenium and tungsten. The invention also relates to the powders produced by the process and the use of such powders in a cold spray process.

Owner:GLAS TRUST +1

Radiopaque and MRI compatible nitinol alloys for medical devices

A radiopaque nitinol medical device such as a stent for use with or implantation in a body lumen is disclosed. The stent is made from a superelastic alloy such as nickel-titanium or nitinol, and includes a ternary element selected from the group of chemical elements consisting of iridium, platinum, gold, rhenium, tungsten, palladium, rhodium, tantalum, silver, ruthenium, or hafnium. The nitinol stent has improved radiopacity yet retains its superelastic and shape memory behavior and further maintains a thin strut / wall thickness for high flexibility. Another embodiment includes a balloon expandable stent made from a radiopaque and MRI compatible alloy such as nitinol and includes a ternary element selected from the group of chemical elements consisting of iridium, platinum, gold, rhenium, tungsten, palladium, rhodium, tantalum, silver, ruthenium, hafnium, osmium, zirconium, niobium, or molybdenum.

Owner:ABBOTT CARDIOVASCULAR

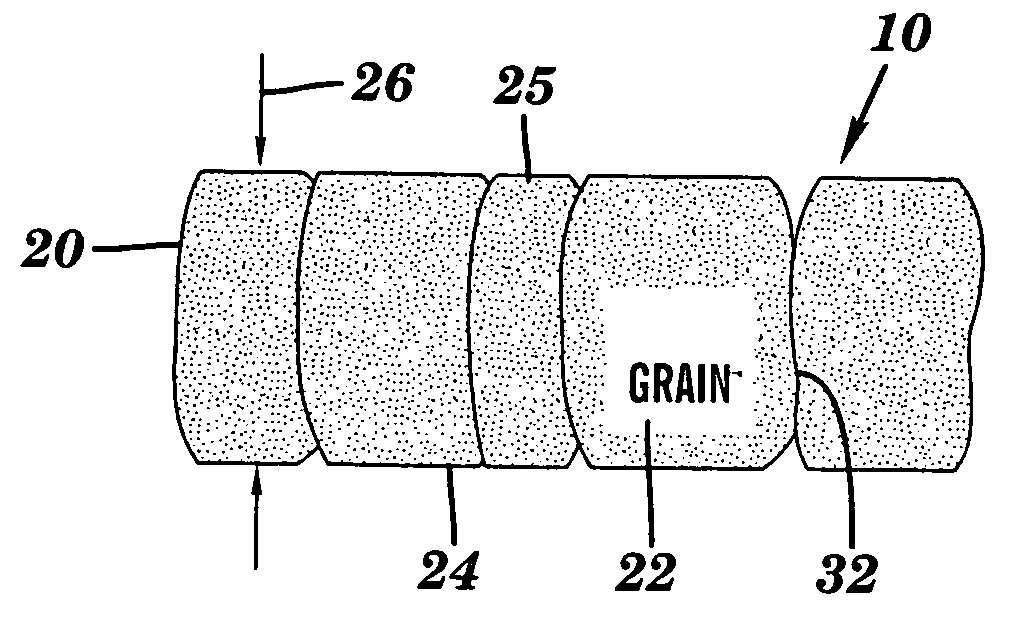

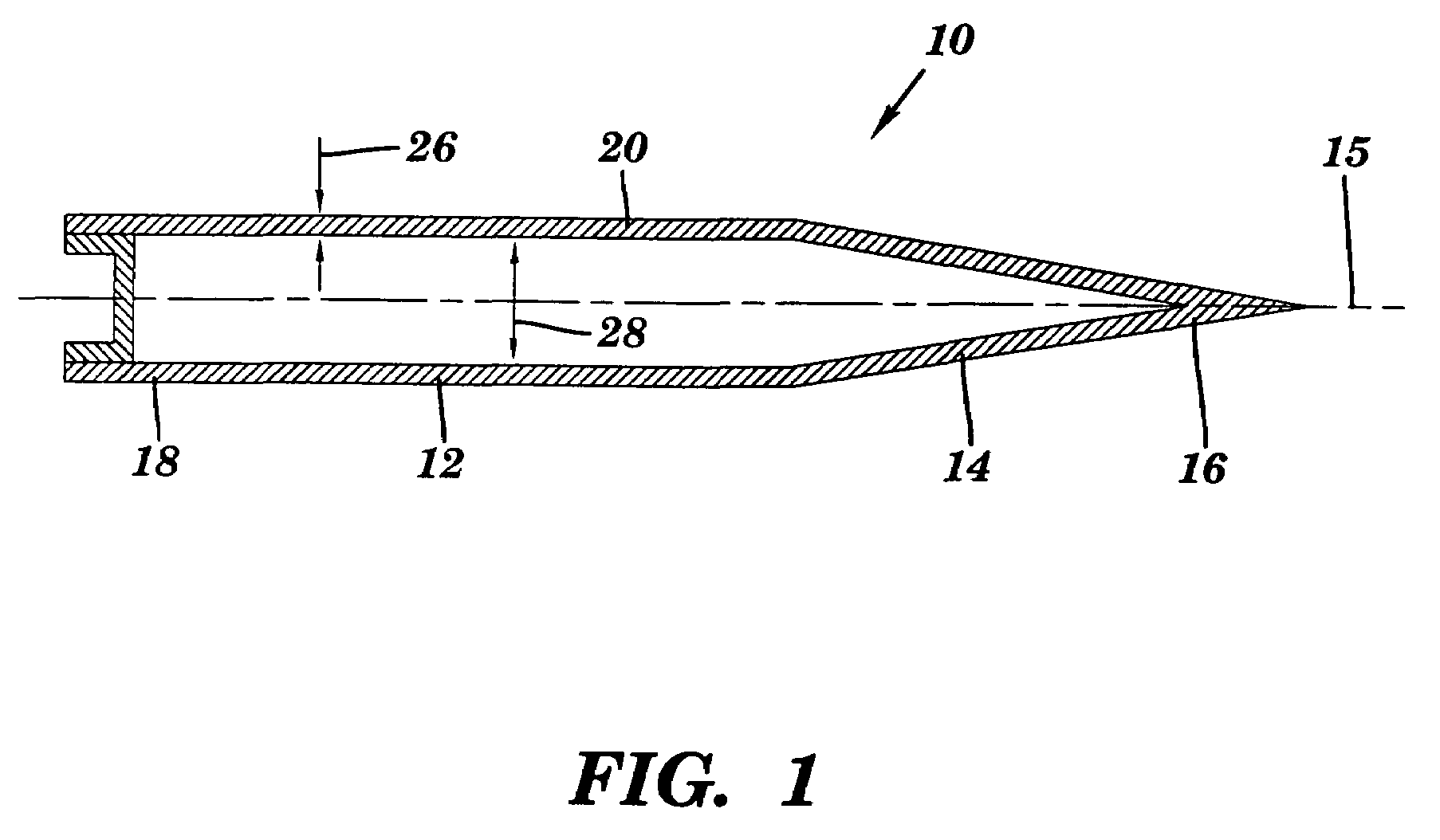

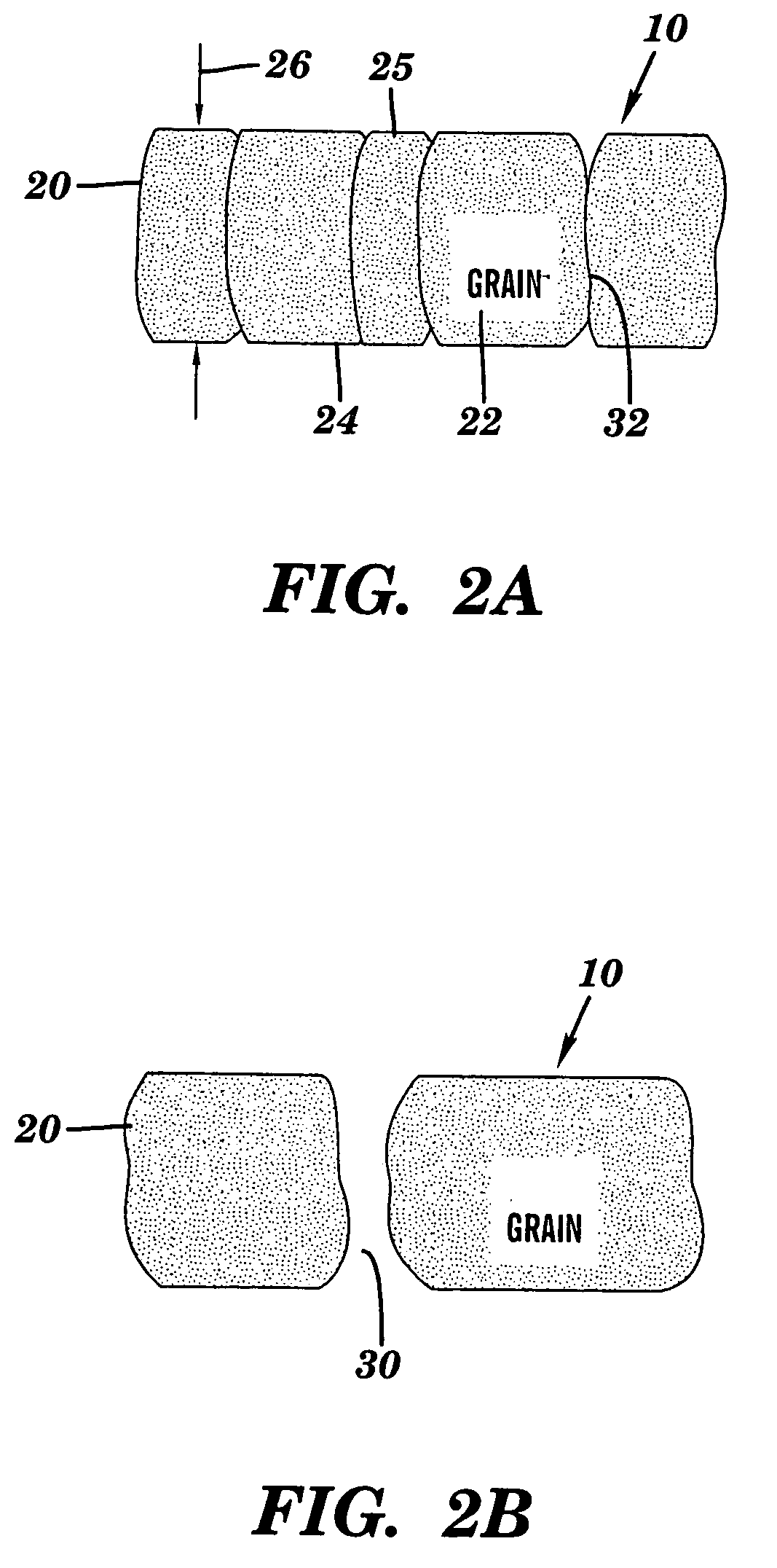

Powder metallurgy crucible for aluminum nitride crystal growth

A crucible for growing III-nitride (e.g., aluminum nitride) single crystals is provided. The crucible includes an elongated wall structure defining an interior crystal growth cavity. Embodiments include a plurality of grains and a wall thickness of at least about 1.5 times the average grain size. In particular embodiments, the crucible includes first and second layers of grains the first layer including grains forming an inside surface thereof and the second layer being superposed with the first layer. The crucible may be fabricated from tungsten-rhenium (W—Re) alloys; rhenium (Re); tantalum monocarbide (TaC); tantalum nitride (Ta2N); hafnium nitride (HfN); a mixture of tungsten and tantalum (W—Ta); tungsten (W); and combinations thereof.

Owner:CRYSTAL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com