Method for preparing precursor for chemical vapor deposition of metallic rhenium

A chemical vapor deposition and precursor technology, used in chemical instruments and methods, inorganic chemistry, rhenium compounds, etc., can solve problems such as reducing yield, and achieve the effects of improving purity, simple control of process parameters, and improving yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

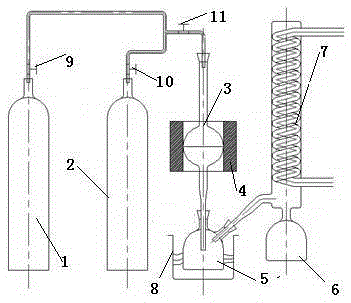

[0026] The preparation method of the precursor for chemical vapor deposition metal rhenium described in this embodiment specifically includes the following steps:

[0027] (1) Weigh 100 powdered ReCl 5 (purity ≥ 99%) placed in the sand core filter ball, spread evenly.

[0028] (2) Put the sand core filter ball in the tube furnace, connect the whole system pipeline tightly, and fix the ground joints with stainless steel chucks to check the air tightness; start the valve to feed nitrogen (≥99.9%), and carry out Cleaning process, nitrogen pressure: 0.1MPa, flow rate: 0.1L / min, clean the entire pipeline for 50 minutes; start the valve to feed high-purity oxygen (≥99.9%), oxygen pressure: 0.1MPa, flow rate: 0.05L / min, inert The flow ratio of gas to oxygen is controlled at 2:1, and the gas is supplied stably for 2 minutes; the tube furnace is started, and the temperature is raised from room temperature to 120°C at a temperature increase rate of 1°C / min.

[0029] (3) The temperature ...

Embodiment 2

[0031] The preparation method of the precursor for chemical vapor deposition metal rhenium described in this embodiment specifically includes the following steps:

[0032] (1) Weigh 200 powdered ReCl 5 (purity ≥ 99%) placed in the sand core filter ball, spread evenly.

[0033] (2) Put the sand core filter ball in the tube furnace, connect the entire system pipeline tightly, and fix the ground joints with stainless steel chucks to check the air tightness; start the valve to feed argon (≥99.9%), Carry out the cleaning process, argon pressure: 0.6MPa, flow rate: 0.5L / min, clean the entire pipeline for 20 minutes; start the valve to feed high-purity oxygen (≥99.9%), oxygen pressure: 0.6MPa, flow rate: 0.1L / min , the flow ratio of inert gas to oxygen is controlled at 5:1, and the gas is supplied stably for 10 minutes; start the tube furnace, and heat up from room temperature to 220°C at a heating rate of 5°C / min.

[0034] (3) The temperature of the oil bath is controlled at 100°C...

Embodiment 3

[0036] The preparation method of the precursor for chemical vapor deposition metal rhenium described in this embodiment specifically includes the following steps:

[0037] (1) Weigh 100 powdered ReCl 5 (purity ≥ 99%) placed in the sand core filter ball, spread evenly.

[0038] (2) Put the sand core filter ball in the tube furnace, connect the entire system pipeline tightly, and fix the ground joints with stainless steel chucks to check the air tightness; start the valve to feed helium (≥99.9%), Carry out the cleaning process, helium pressure: 0.3MPa, flow rate: 2L / min, clean the entire pipeline for 20 minutes; start the valve to feed high-purity oxygen (≥99.9%), oxygen pressure: 0.3MPa, flow rate: 0.5L / min, The flow ratio of inert gas to oxygen is controlled at 4:1, and the gas is supplied stably for 10 minutes; the tube furnace is started, and the temperature is raised from room temperature to 180°C at a heating rate of 3°C / min.

[0039] (3) The temperature of the oil bath ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com