Patents

Literature

233results about How to "Lower transition temperature" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

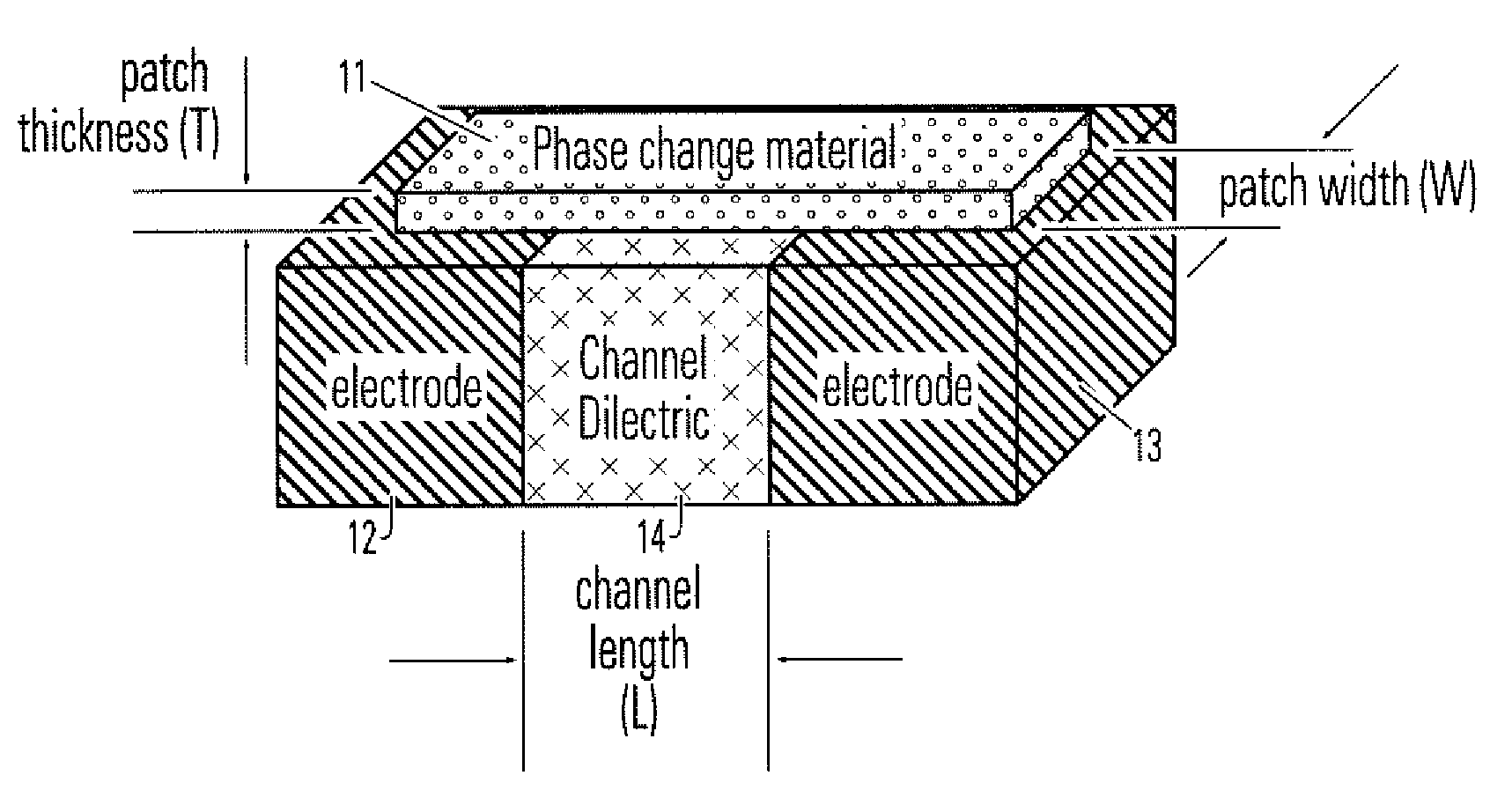

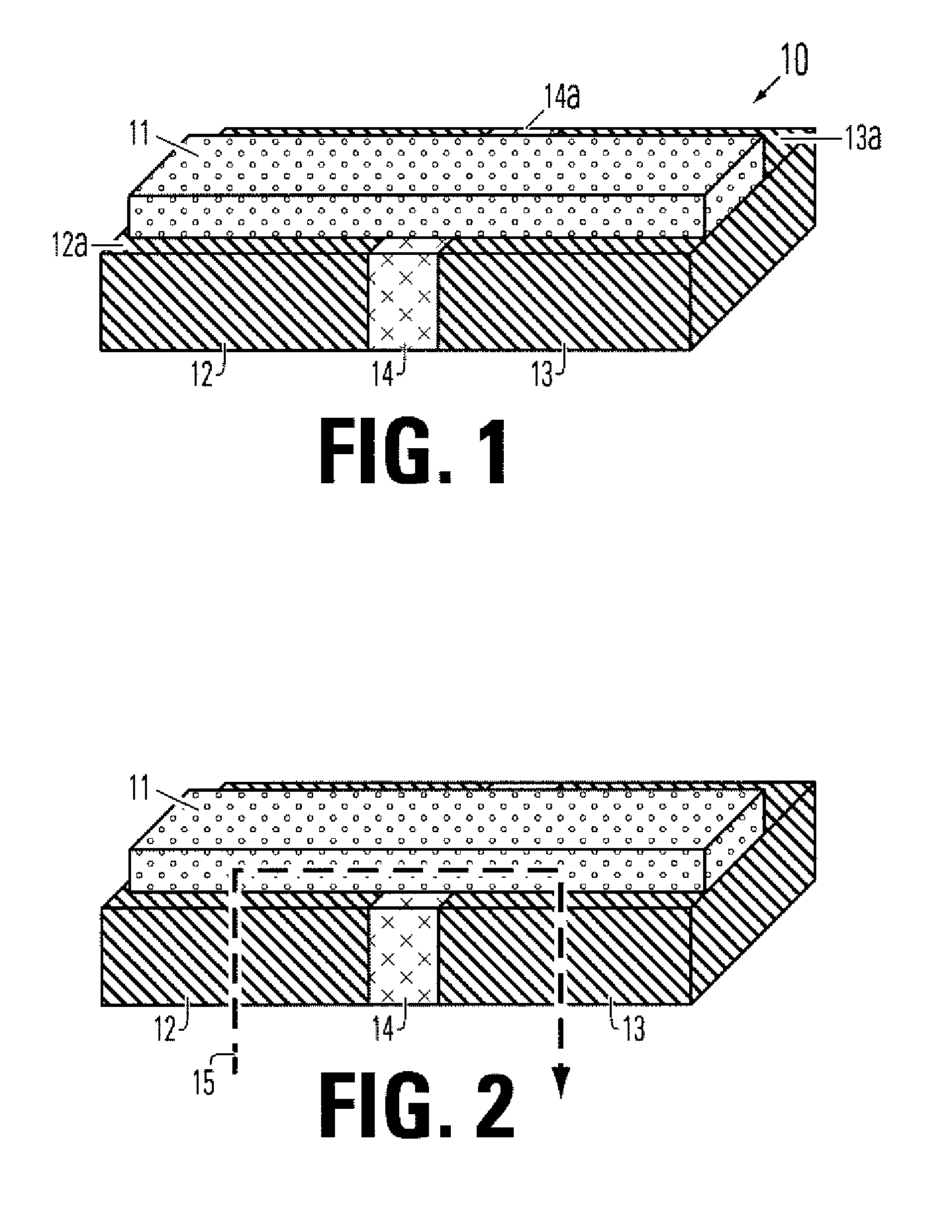

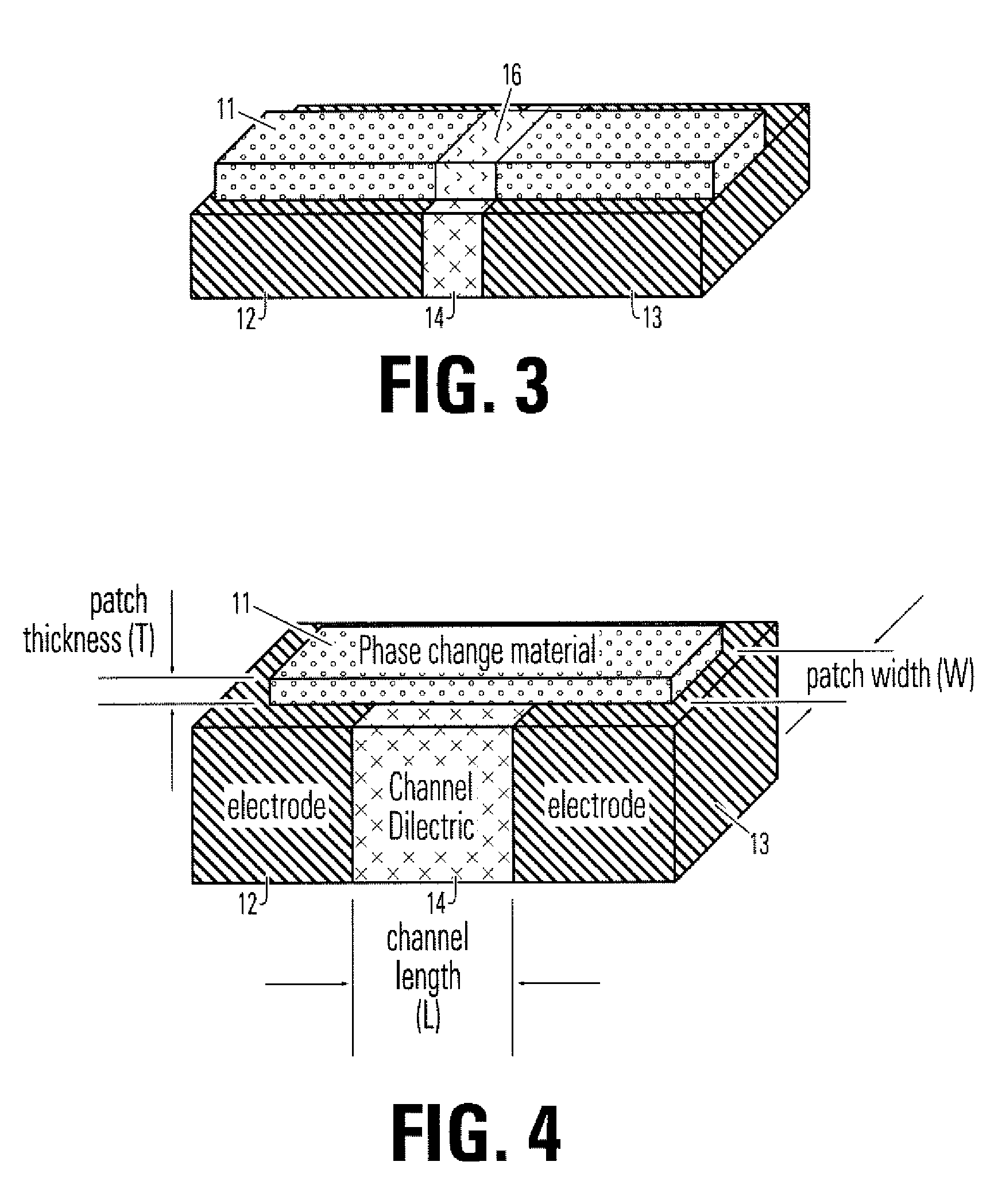

Phase Change Memory Cell and Manufacturing Method

ActiveUS20070121363A1Raise the transition temperatureLower transition temperatureSolid-state devicesDigital storageElectricityPhase-change memory

A phase change memory cell includes first and second electrodes having generally coplanar surfaces spaced apart by a gap and a phase change bridge electrically coupling the first and second electrodes. The phase change bridge may extend over the generally coplanar surfaces and across the gap. The phase change bridge has a higher transition temperature bridge portion and a lower transition temperature portion. The lower transition temperature portion comprises a phase change region which can be transitioned from generally crystalline to generally amorphous states at a lower temperature than the higher transition temperature portion. A method for making a phase change memory cell is also disclosed.

Owner:MACRONIX INT CO LTD

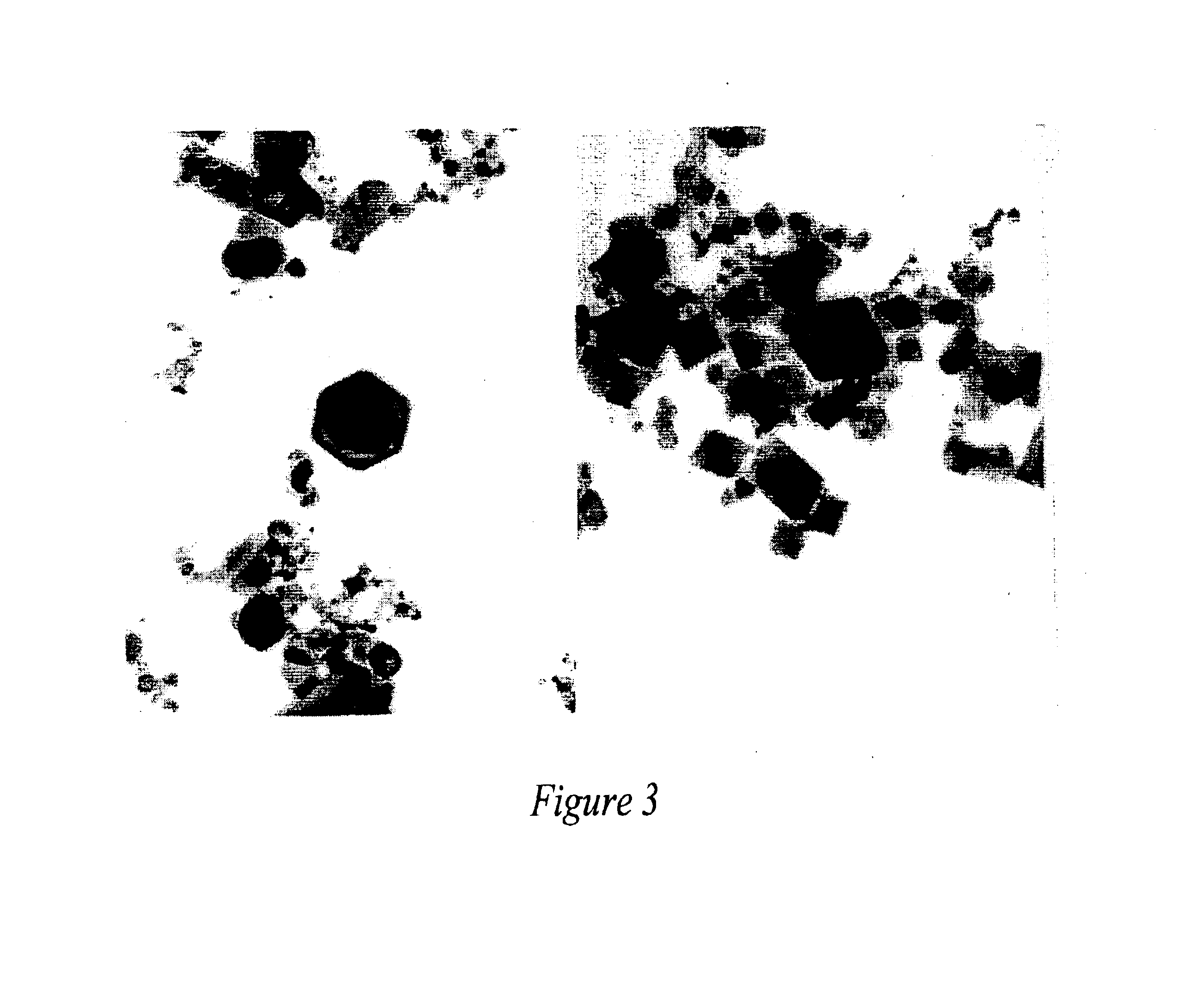

Inorganic dopants, inks and related nanotechnology

InactiveUS6849109B2Facilitated DiffusionLower transition temperatureSelenium/tellurium compundsCell electrodesIndiumCerium

Ink compositions with modified properties result from using a powder size below 100 nanometers. Colored inks are illustrated. Nanoscale coated, uncoated, whisker inorganic fillers are included. The pigment nanopowders taught comprise one or more elements from the group actinium, aluminum, antimony, arsenic, barium, beryllium, bismuth, cadmuim, calcium, cerium, cesium, chalcogenide, cobalt, copper, dysprosium, erbium, europium, gadolinium, gallium, gold, hafnium, hydrogen, indium, iridium, iron, lanthanum, lithium, magnesium, manganese, mendelevium, mercury, molybdenum, neodymium, neptunium, nickel, niobium, nitrogen, oxygen, osmium, palladium, platinum, potassium, praseodymium, promethium, protactinium, rhenium, rubidium, scandium, silver, sodium, strontium, tantalum, terbium, thallium, thorium, tin, titanium, tungsten, vanadium, ytterbium, yttrium, zinc, and zirconium.

Owner:PPG IND OHIO INC

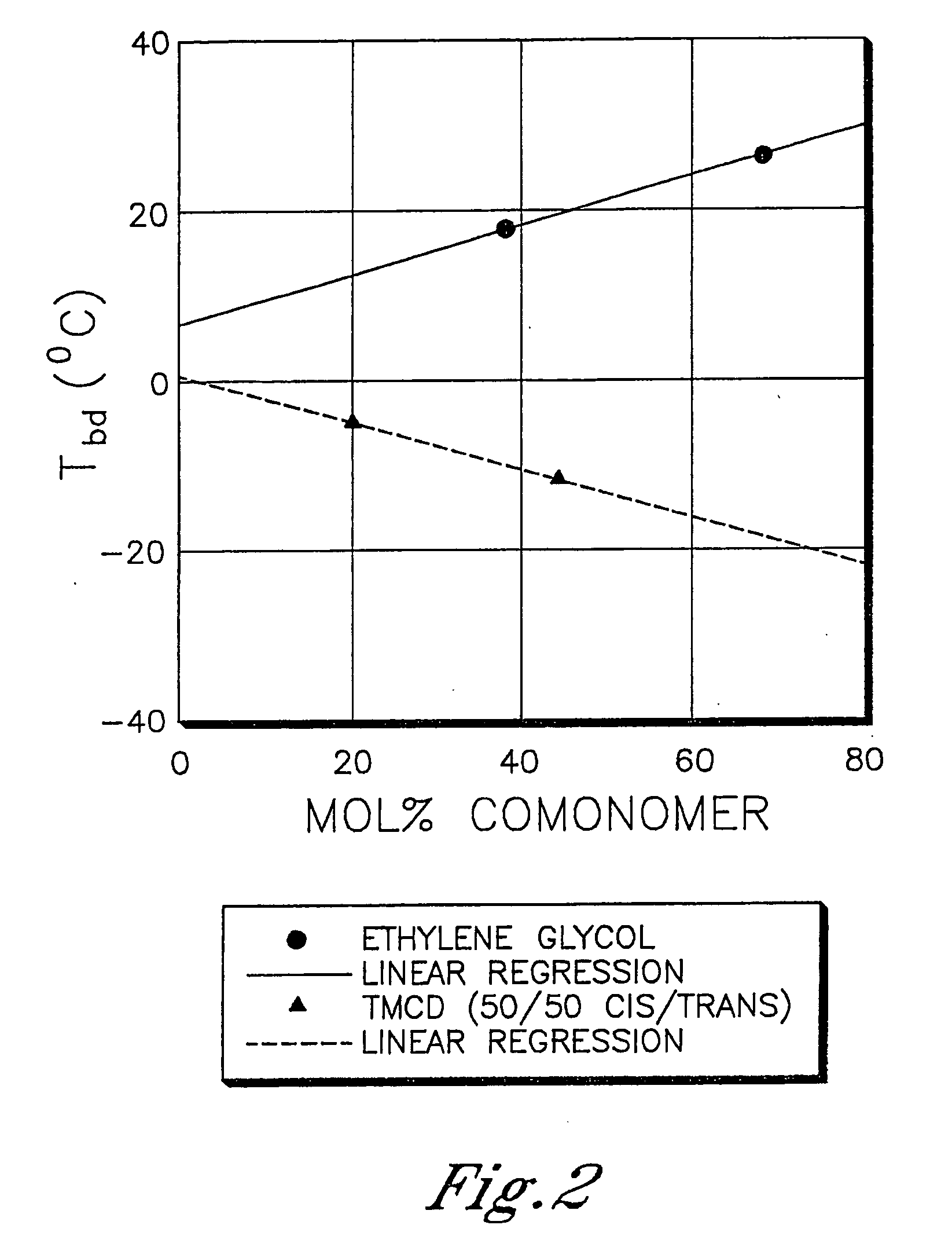

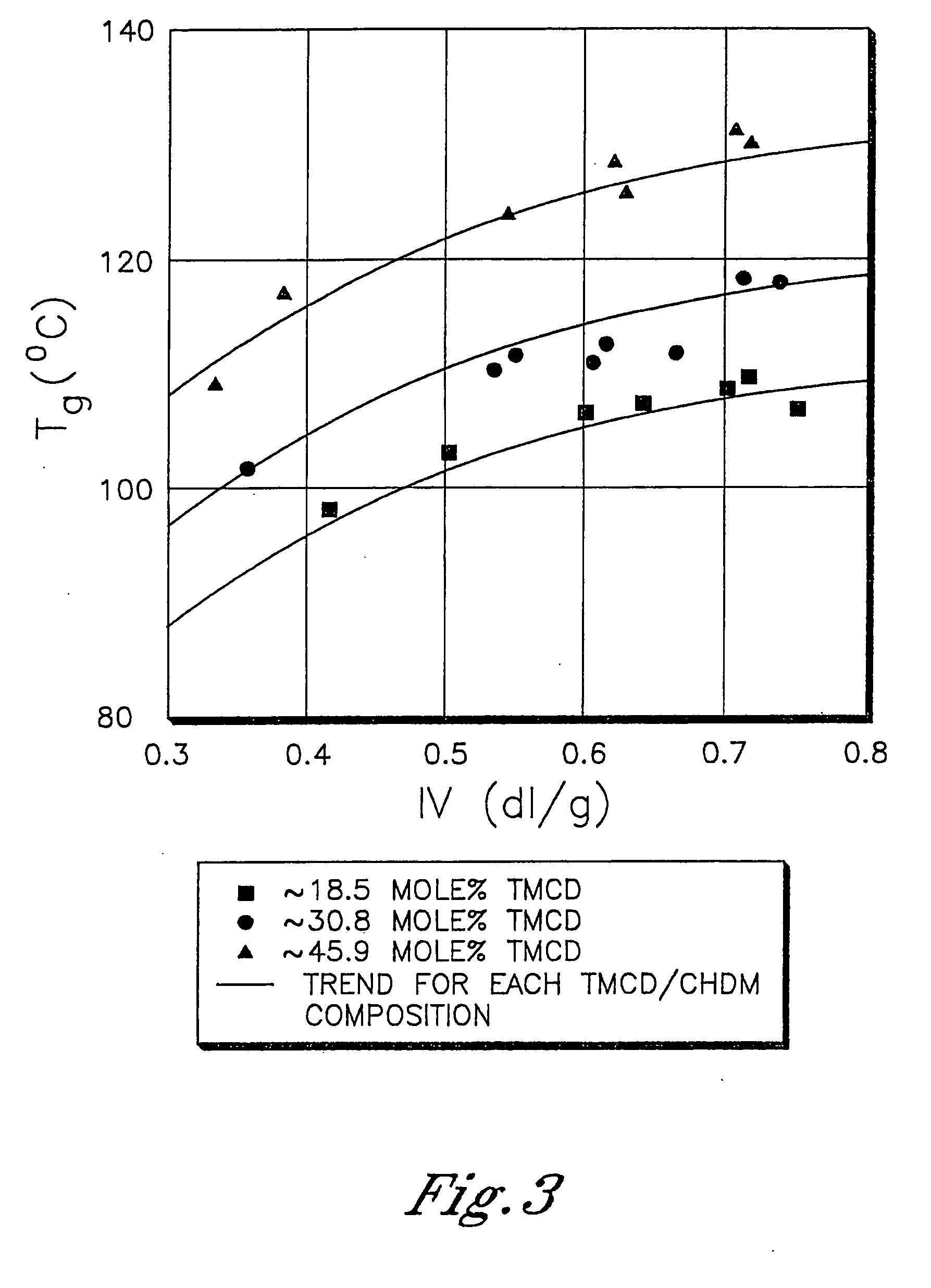

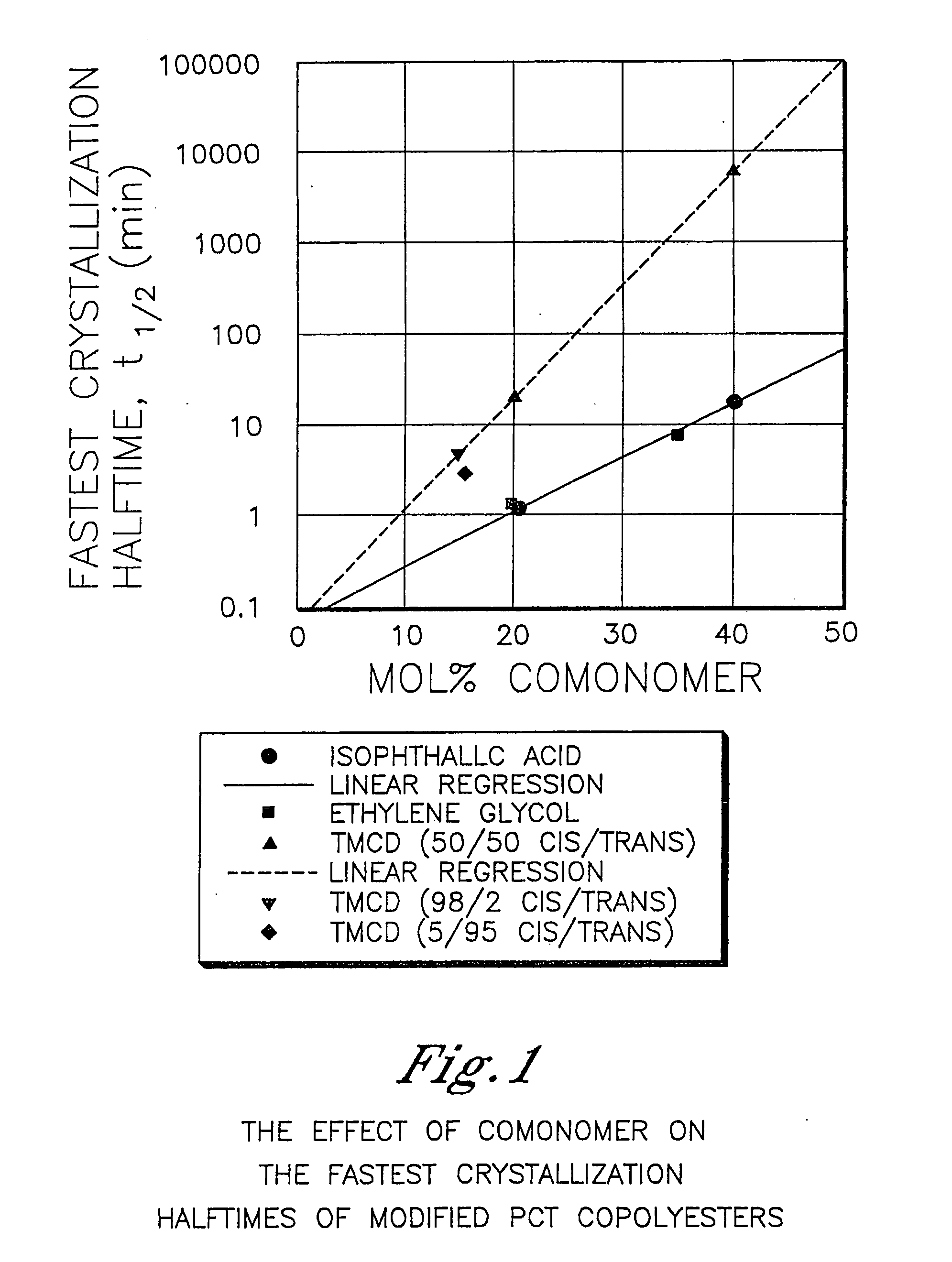

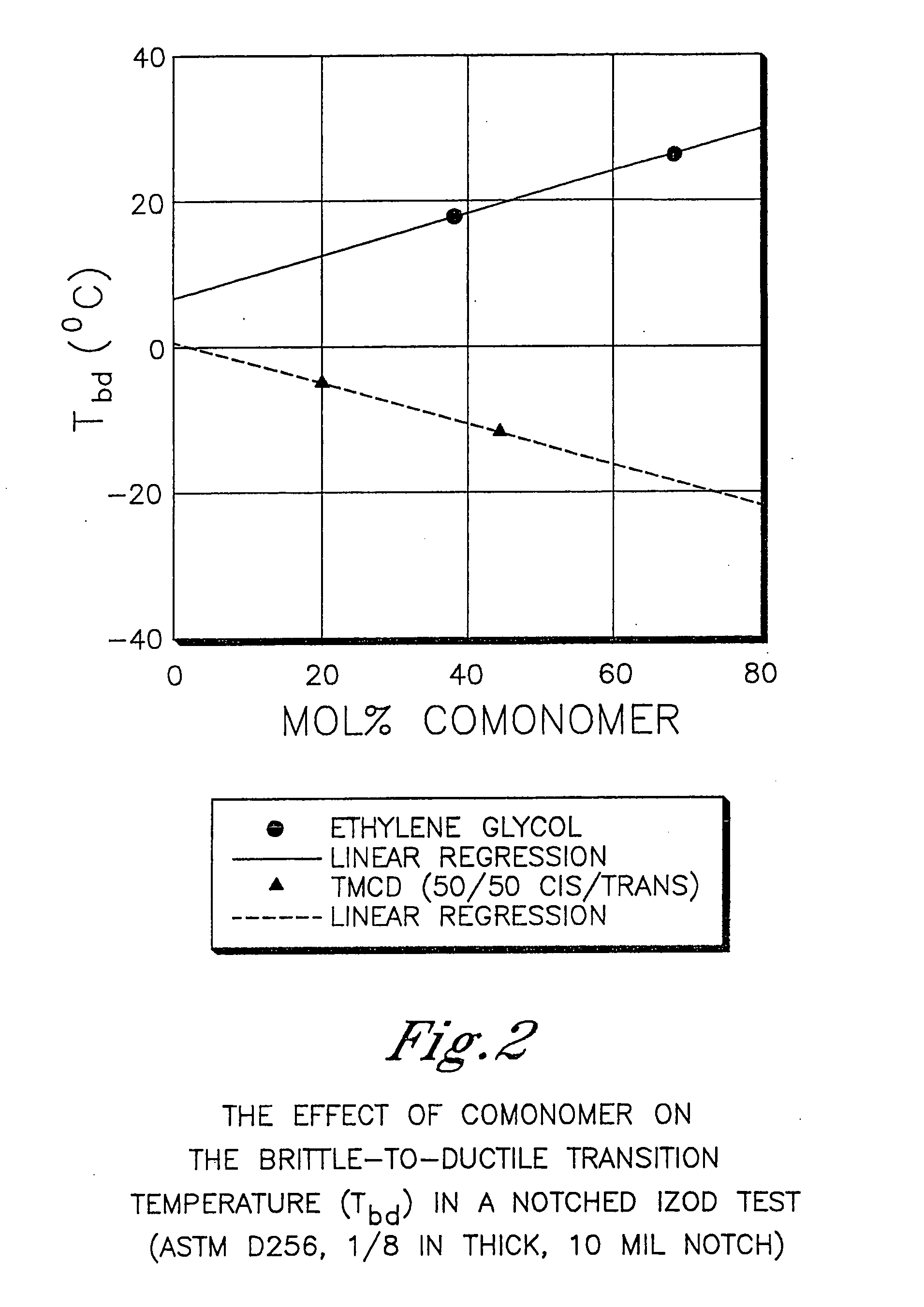

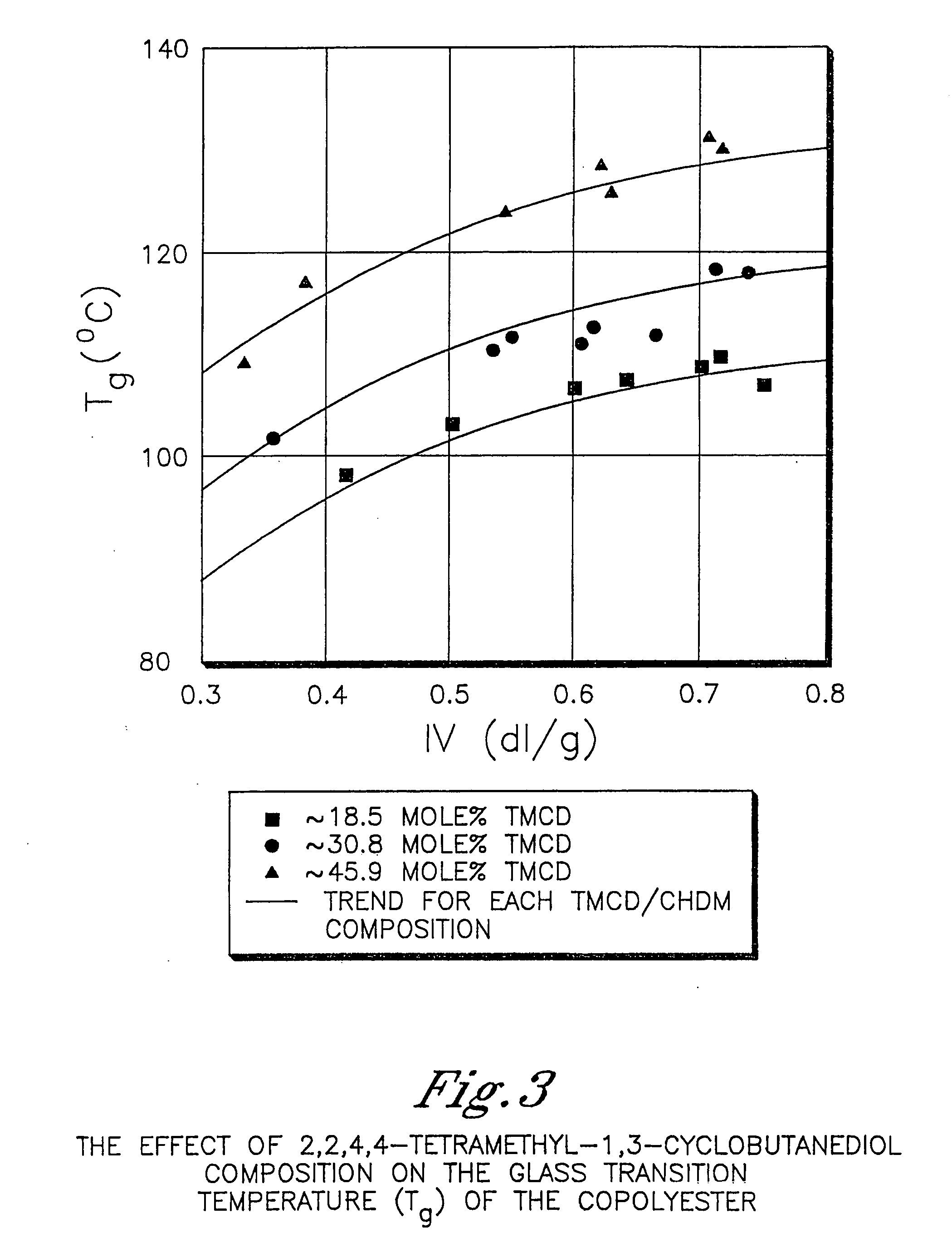

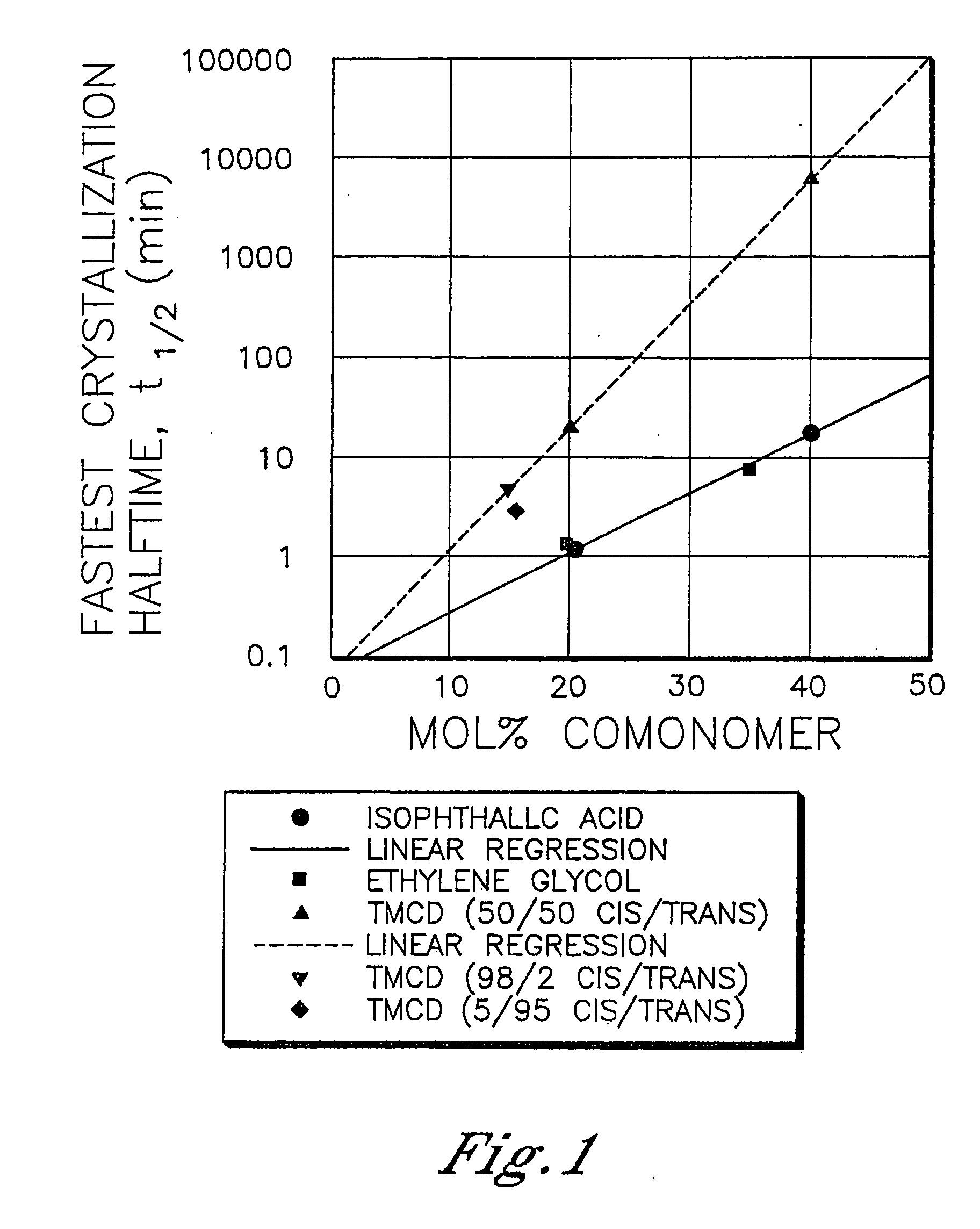

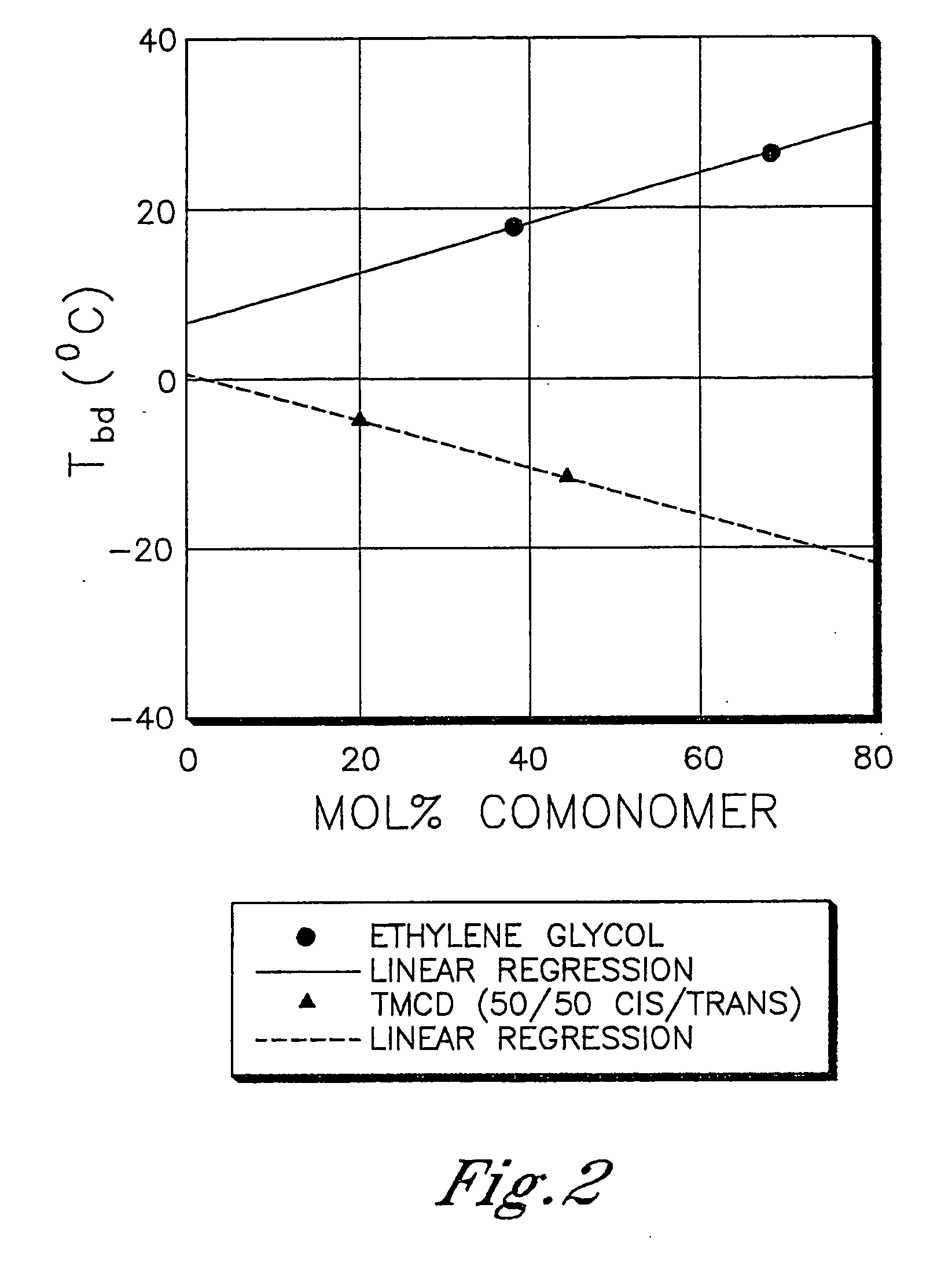

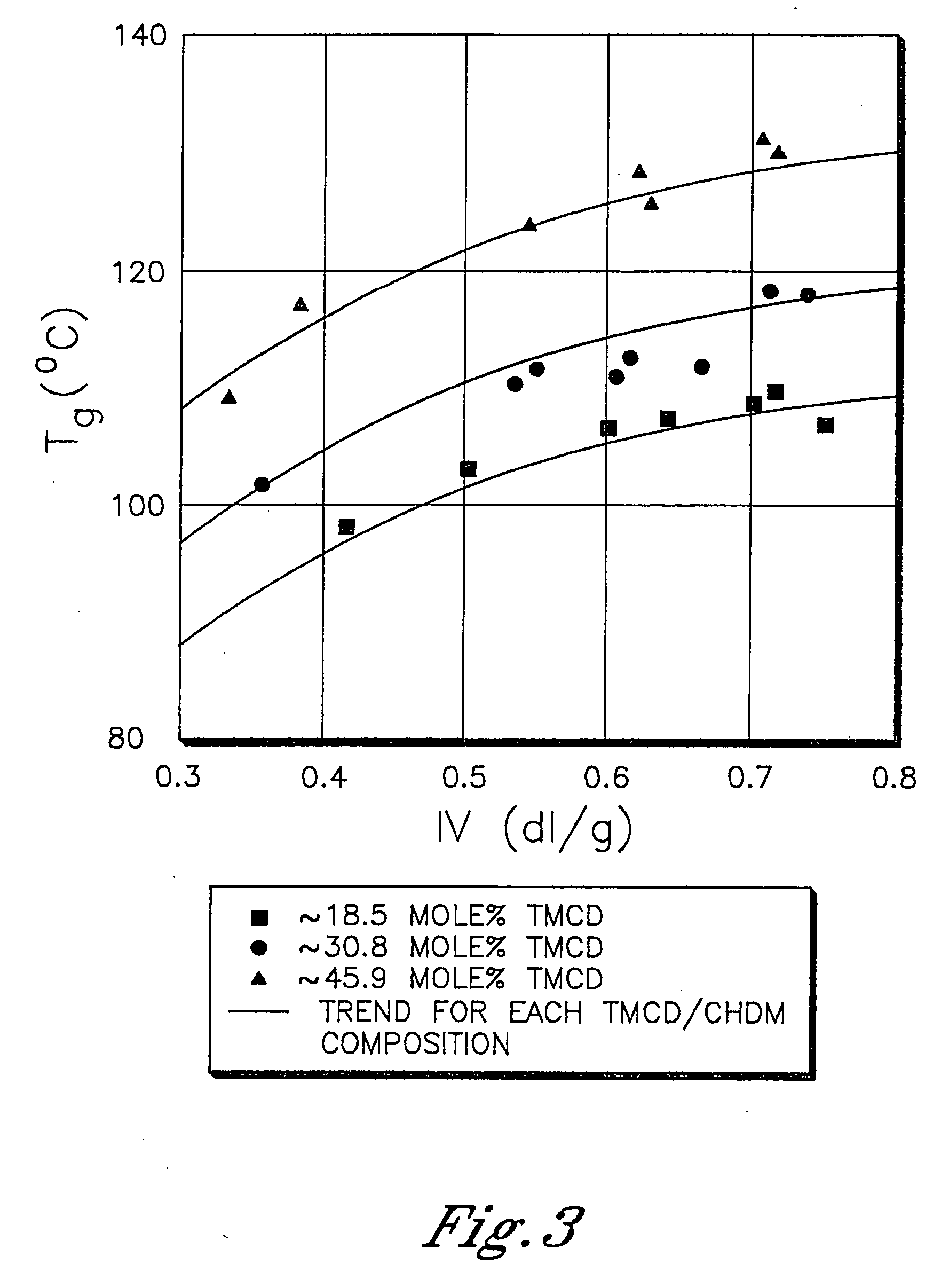

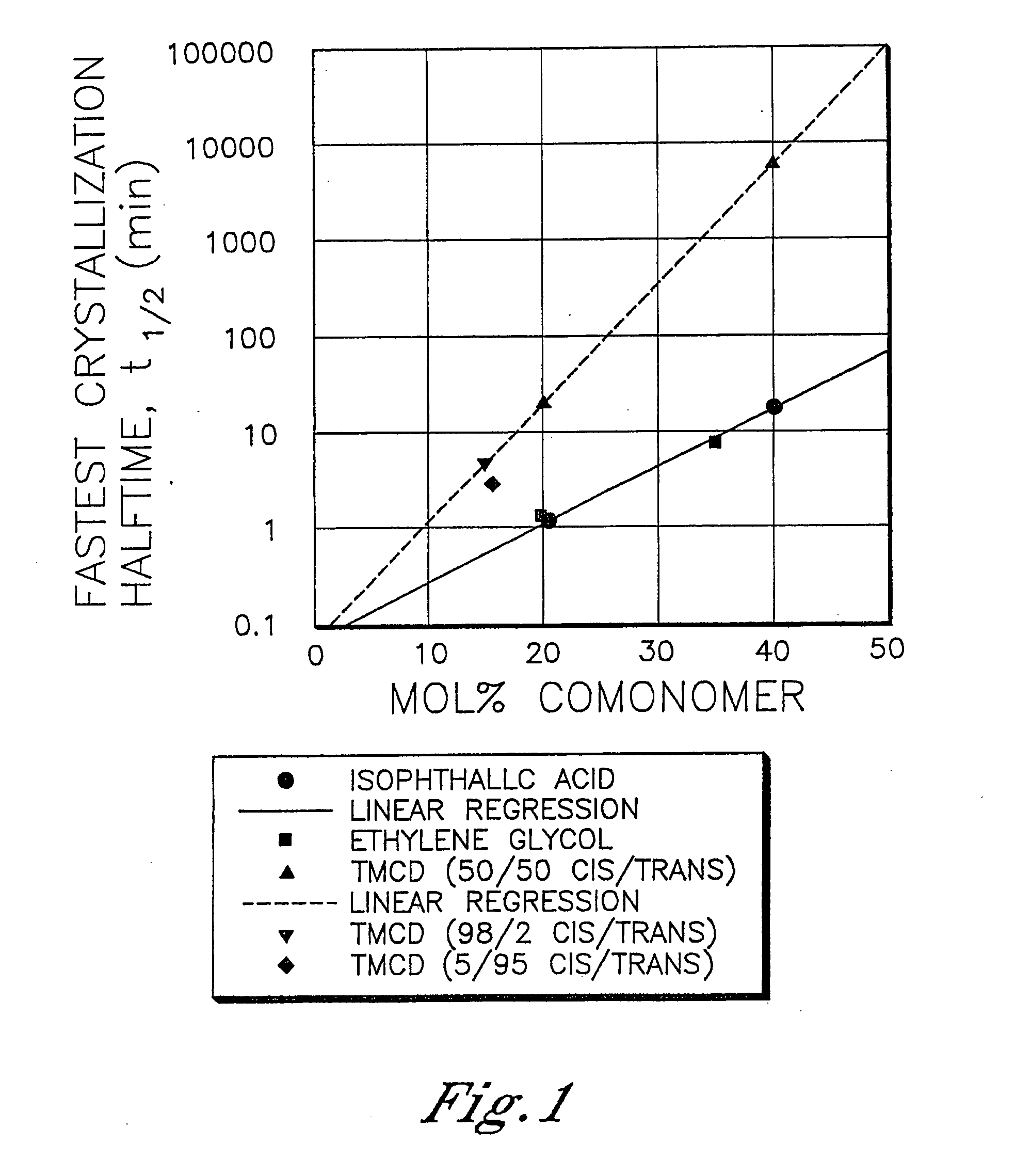

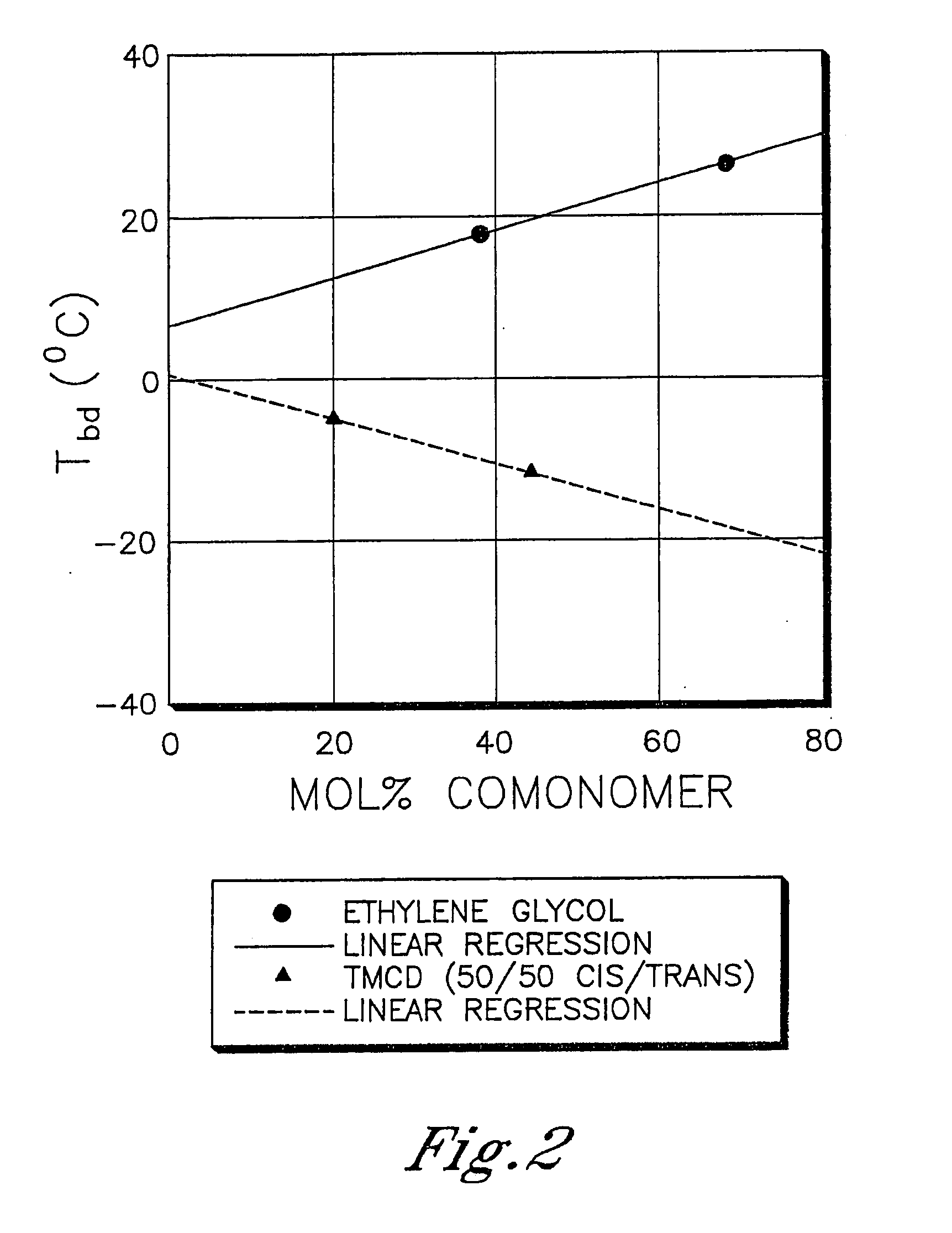

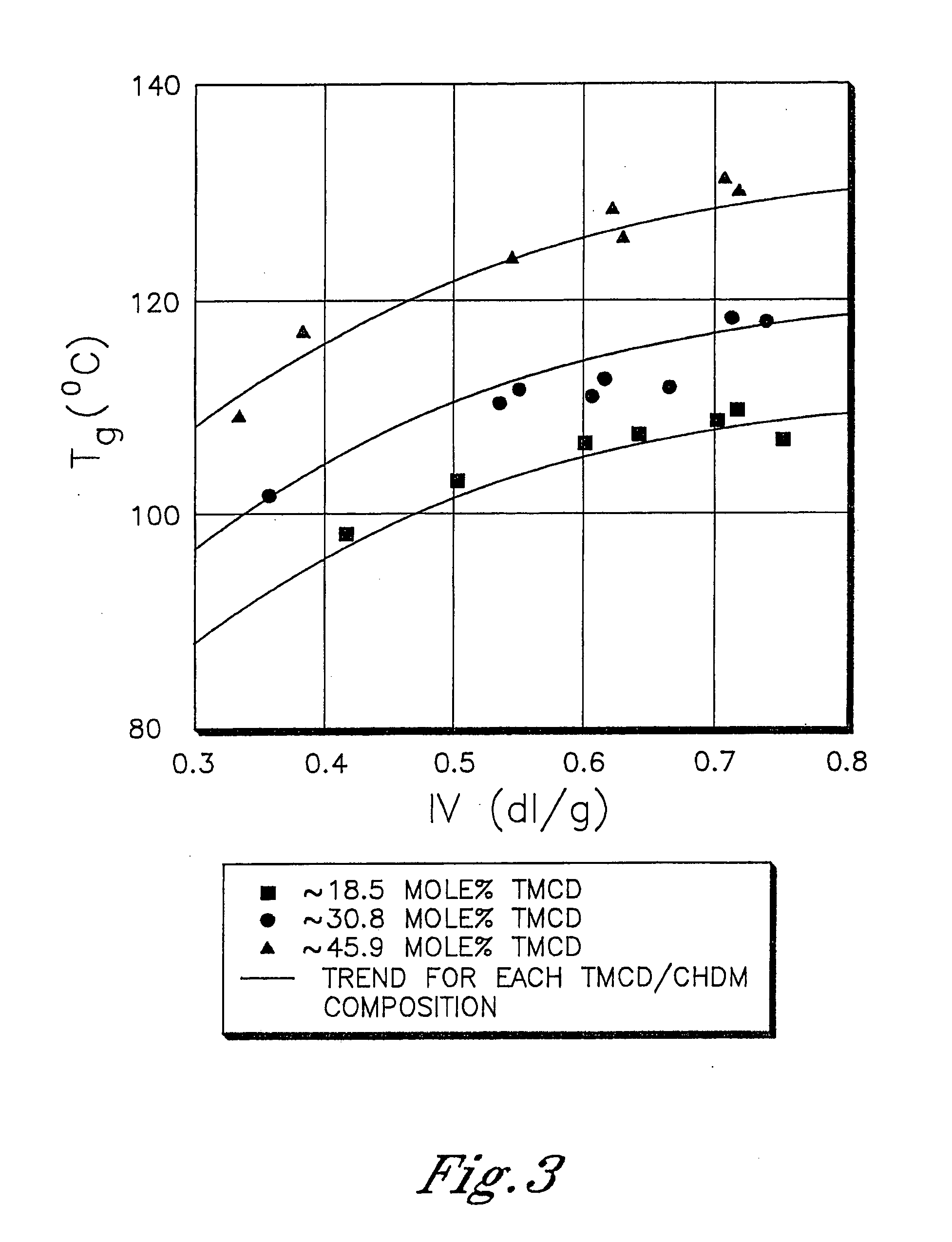

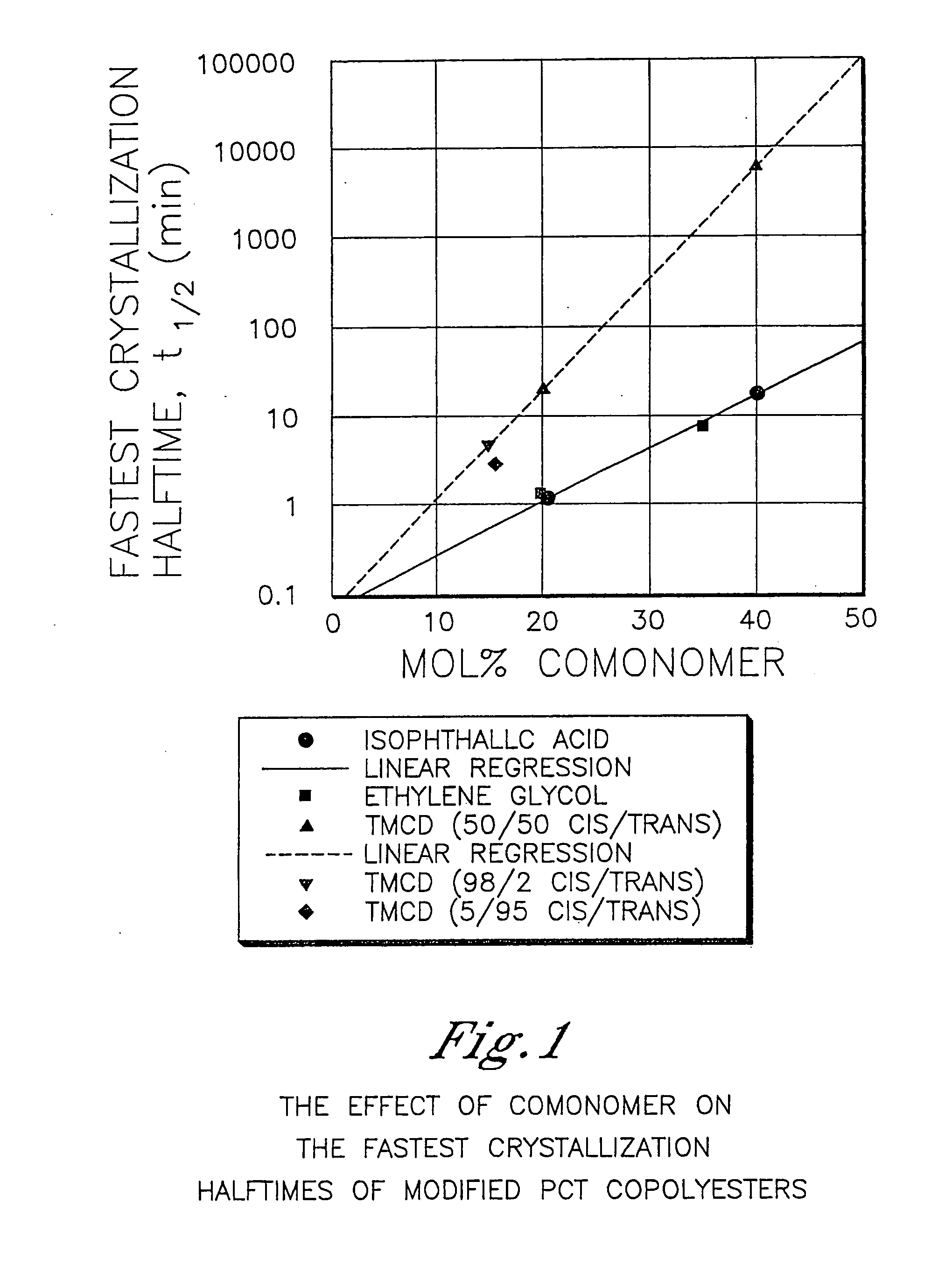

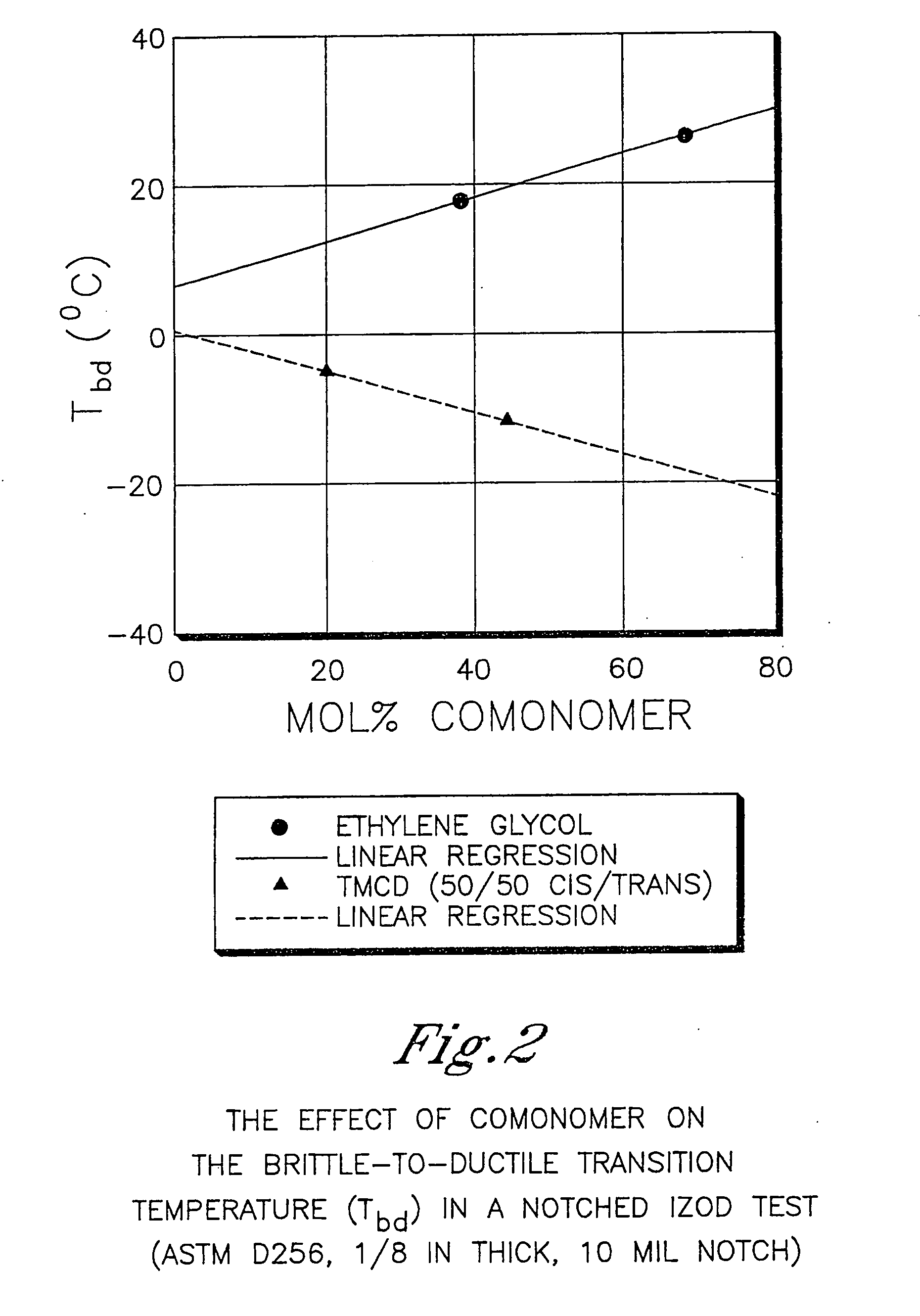

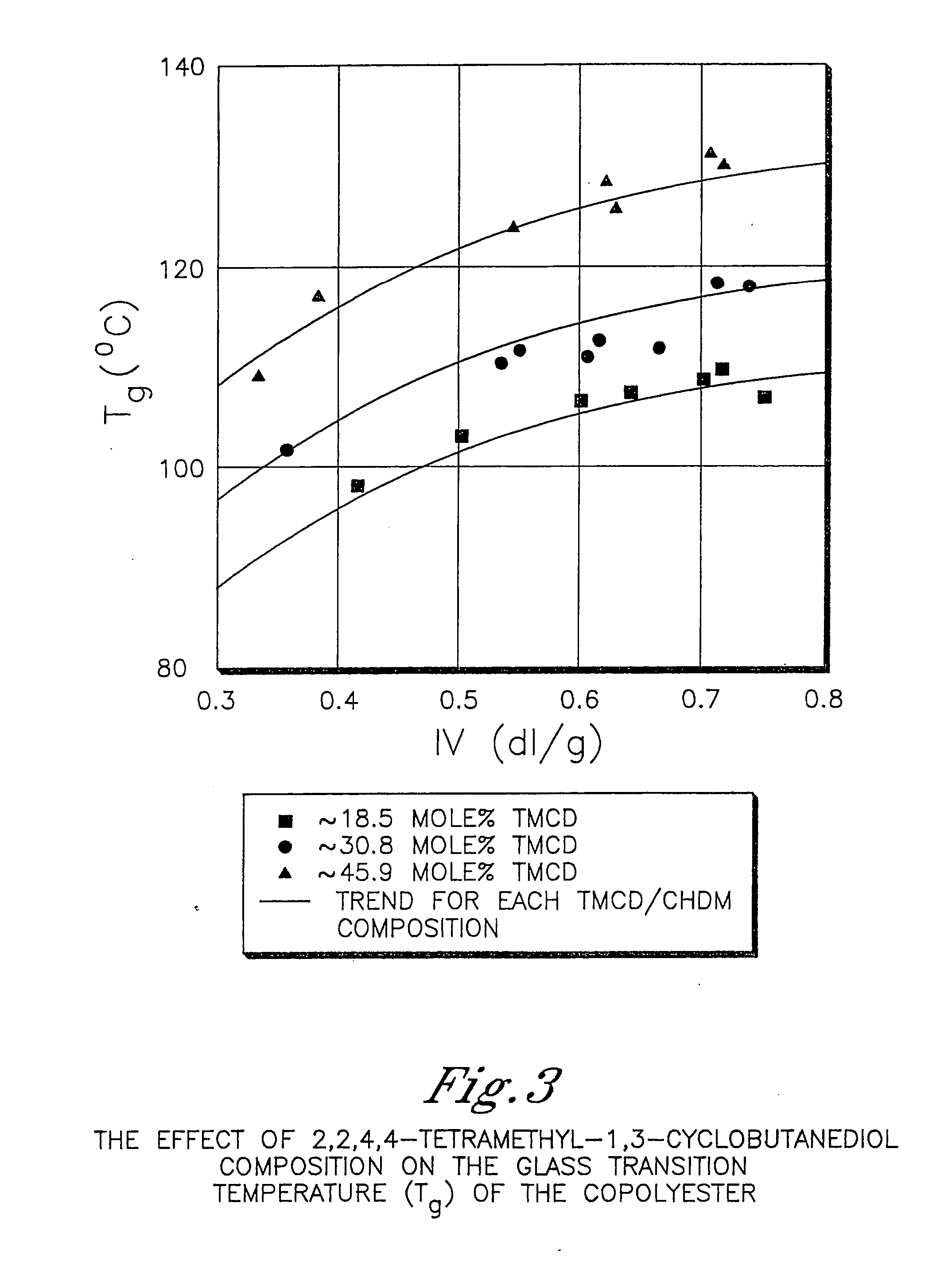

Polyester compositions containing cyclobutanediol having a certain combination of inherent viscosity and high glass transition temperature and articles made therefrom

Described are polyester compositions comprising at least one polyester which comprises terephthalic acid residues, 2,2,4,4-tetramethyl-1,3-cyclobutanediol, and cyclohexanedimethanol, wherein the inherent viscosity and the Tg of the polyester provides for certain polyester properties. The polyesters may be manufactured into articles such as fibers, films, bottles or sheets.

Owner:EASTMAN CHEM CO

Polyester compositions containing cyclobutanediol having a certain combination of inherent viscosity and high glass transition temperature and articles made therefrom

ActiveUS20060287482A1Good chemical resistanceHigh impact strengthDialysis systemsDialysisFiberPolymer science

Described are polyester compositions comprising at least one polyester which comprises terephthalic acid residues, 2,2,4,4-tetramethyl-1,3-cyclobutanediol, and 1,4-cyclohexanedimethanol, wherein the inherent viscosity and the Tg of the polyester provides for certain polyester properties. The polyesters may be manufactured into articles such as fibers, films, bottles or sheets.

Owner:EASTMAN CHEM CO

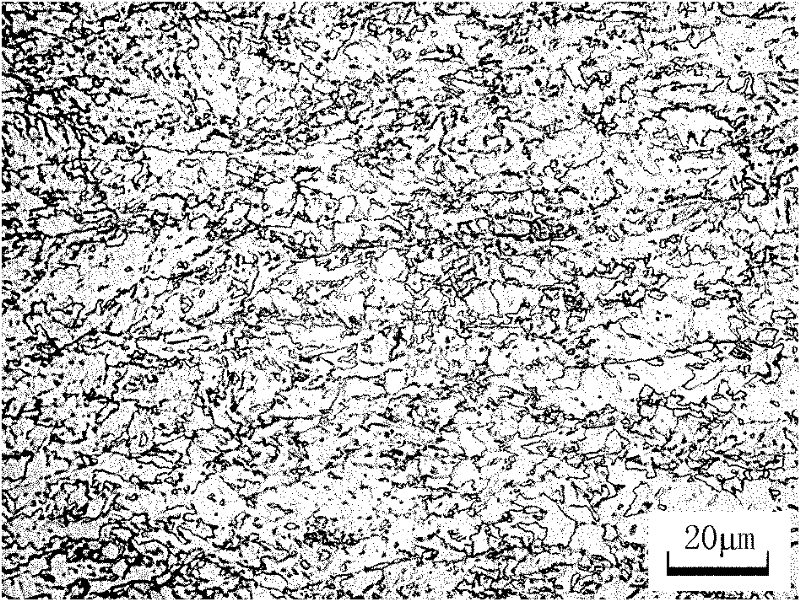

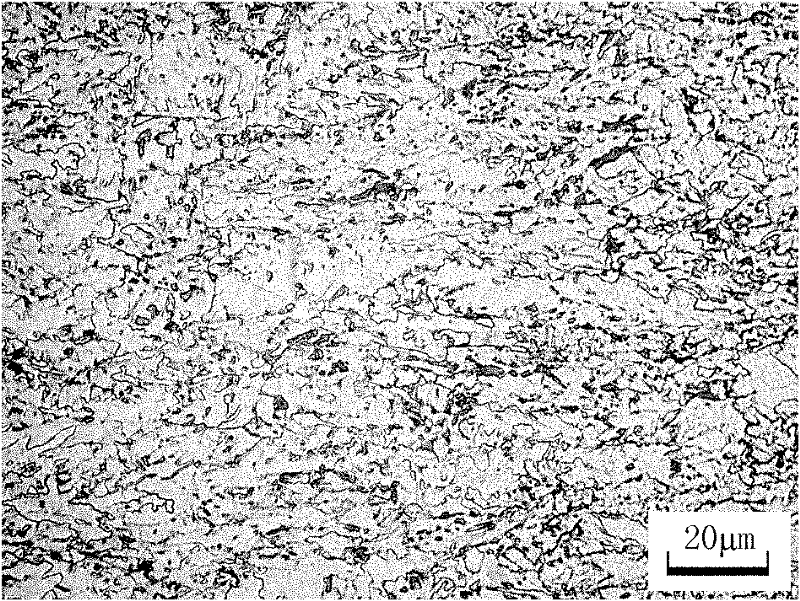

Automobile beam steel with tensile strength of 590MPa and manufacturing method thereof

ActiveCN101701316AHigh strengthImprove toughnessTemperature control deviceHeat treatment process controlChemical compositionLaminar cooling

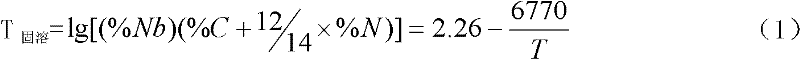

The invention discloses automobile beam steel with tensile strength of 590MPa and a manufacturing method thereof. The steel comprises the following components in percentage by weight: 0.07-0.13 C, 0.10-0.30 Si, 1.30-1.60 Mn, at most 0.025 P, at most 0.008 S, 0.015-0.070 Al, 0.025-0.050 Nb, 0.020-0.040 Ti, and the balance of Fe and unavoidable impurities. The manufacturing method comprises the technical steps of molten iron desulfuration, bessemerizing, alloying, vacuum treatment, continuous casting, hot tandem rolling, Laminar cooling, reeling and finishing. Proved by practices, the automobile beam steel has stable chemical compositions and mechanical property as well as good cold forming performance and surface quality and completely meets the requirement for manufacturing novel frame structures of heavy-duty trucks and large vans.

Owner:武汉钢铁有限公司

Polyester compositions containing cyclobutanediol and articles made therefrom

Described are polyesters containing (a) a dicarboxylic acid component having from 70 to 100 mole % of terephthalic acid residues, and up to 30 mole% of aromatic dicarboxylic acid residues or aliphatic dicarboxylic acid residues; and (b) a glycol component having from 40 to 65 mole % of 2,2,4,4-tetramethyl-1,3-cyclobutanediol residues, and from 35 to 60 mole % of cyclohexanedimethanol residues; wherein the total mole % of the dicarboxylic acid component is 100 mole %, and the total mole % of the glycol component is 100 mole %. The polyesters may be manufactured into articles such as fibers, films, containers, bottles or sheets.

Owner:EASTMAN CHEM CO

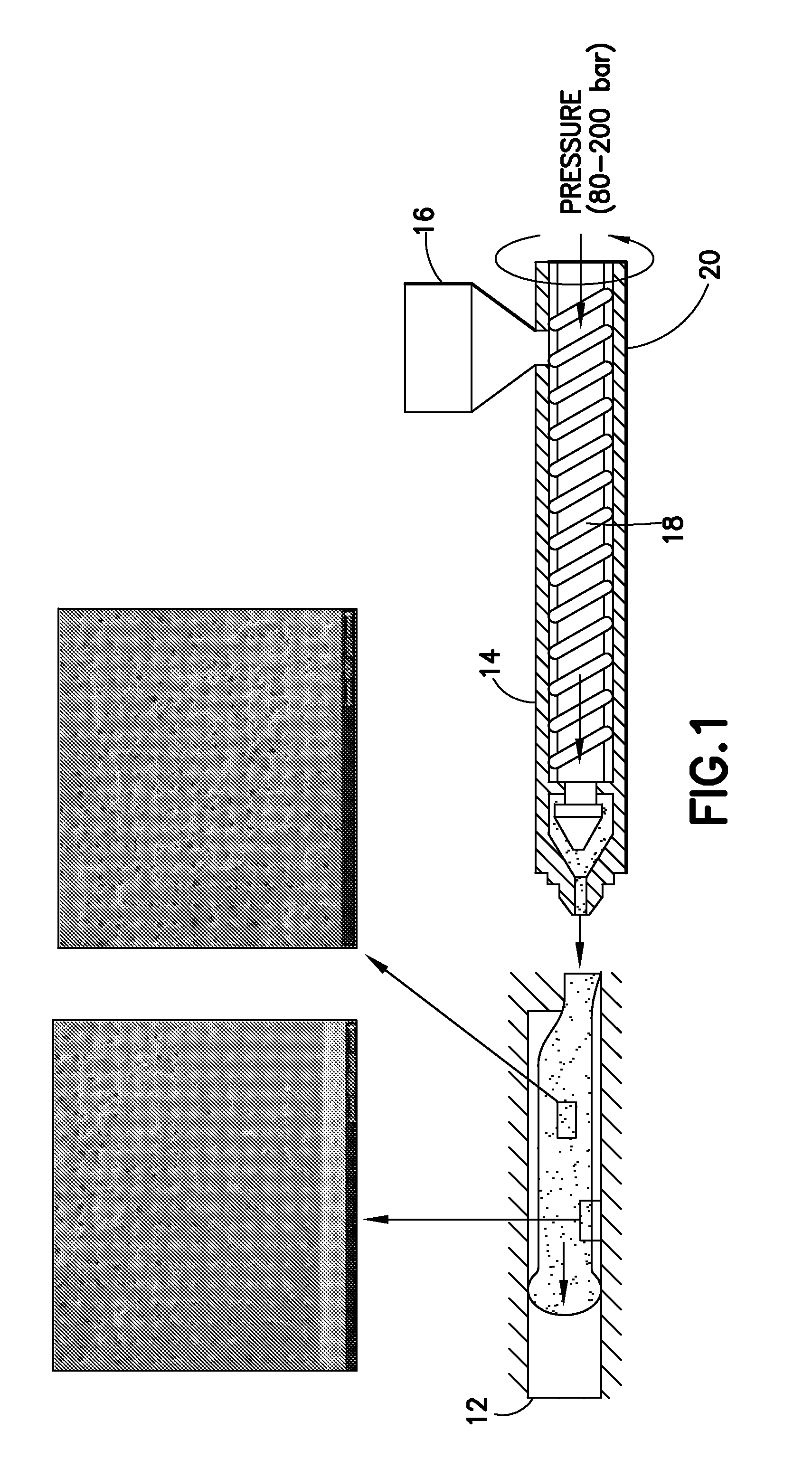

Microcellular injection molding processes for personal and consumer care products and packaging

InactiveUS20100198133A1Reduce viscosityTransition temperature be reduceSurgical adhesivesLayered productsSingle phaseMicro cell

A method of injection molding produces a microcellular material. In this method, a polymer is melted and blended with a supercritical fluid to produce a single-phase polymer-gas solution. This solution is injected through a nozzle and into a mold. When injected through the nozzle, gas in the solution (from the supercritical fluid) emerges from the polymer, which then solidifies. In emerging from the solution, the gas causes the nucleation of cells that result in a microcellular structure. A foam material comprises a polymer having a microcellular structure formed by the nucleation of micro-cells. The micro-cells are formed by the dispersing of a supercritical fluid in a liquid solution of the polymer when the polymer is subjected to a pressure drop. A feminine hygiene device is fabricated from a foamed polymer.

Owner:PLAYTEX PROD INC +1

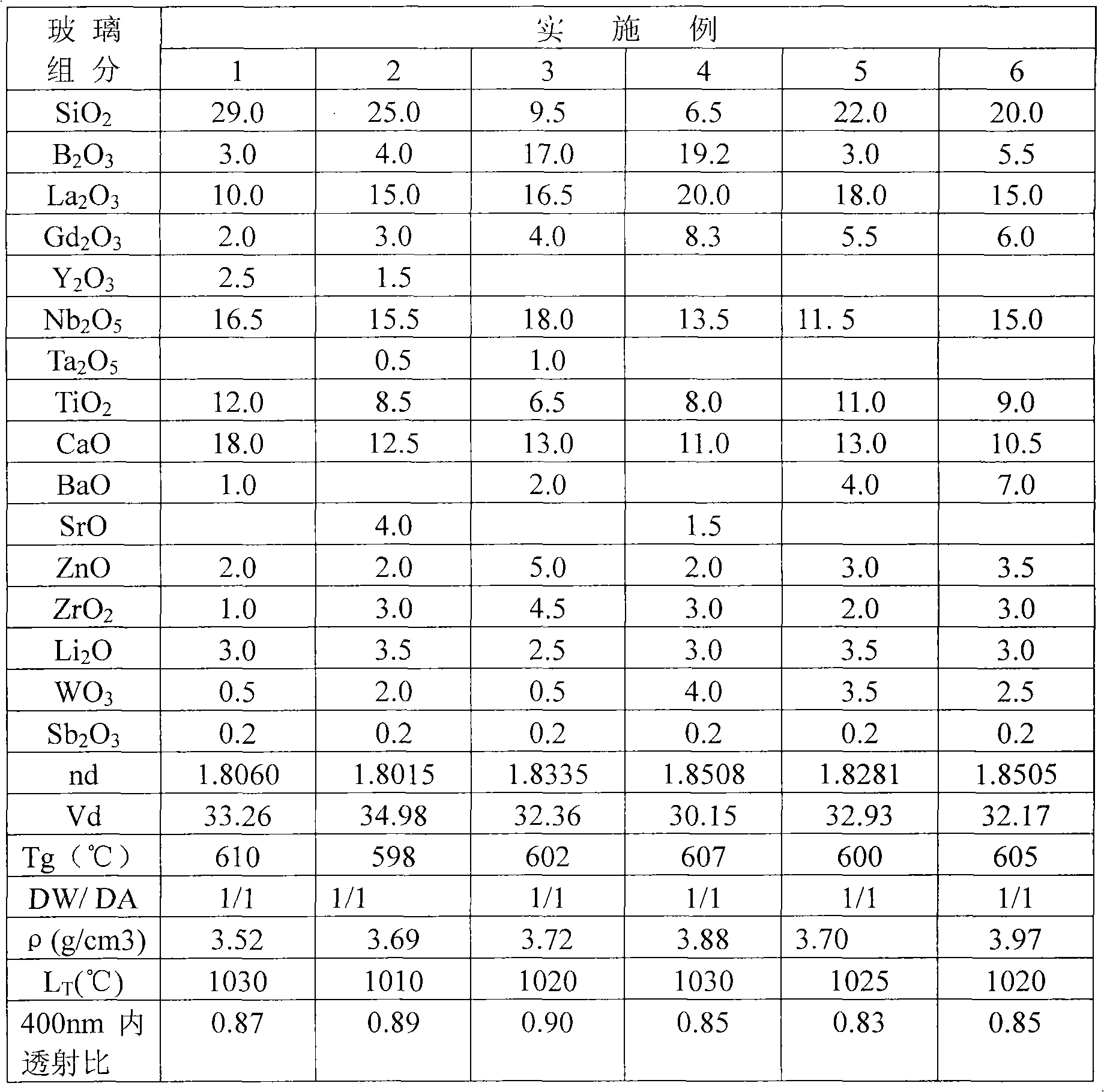

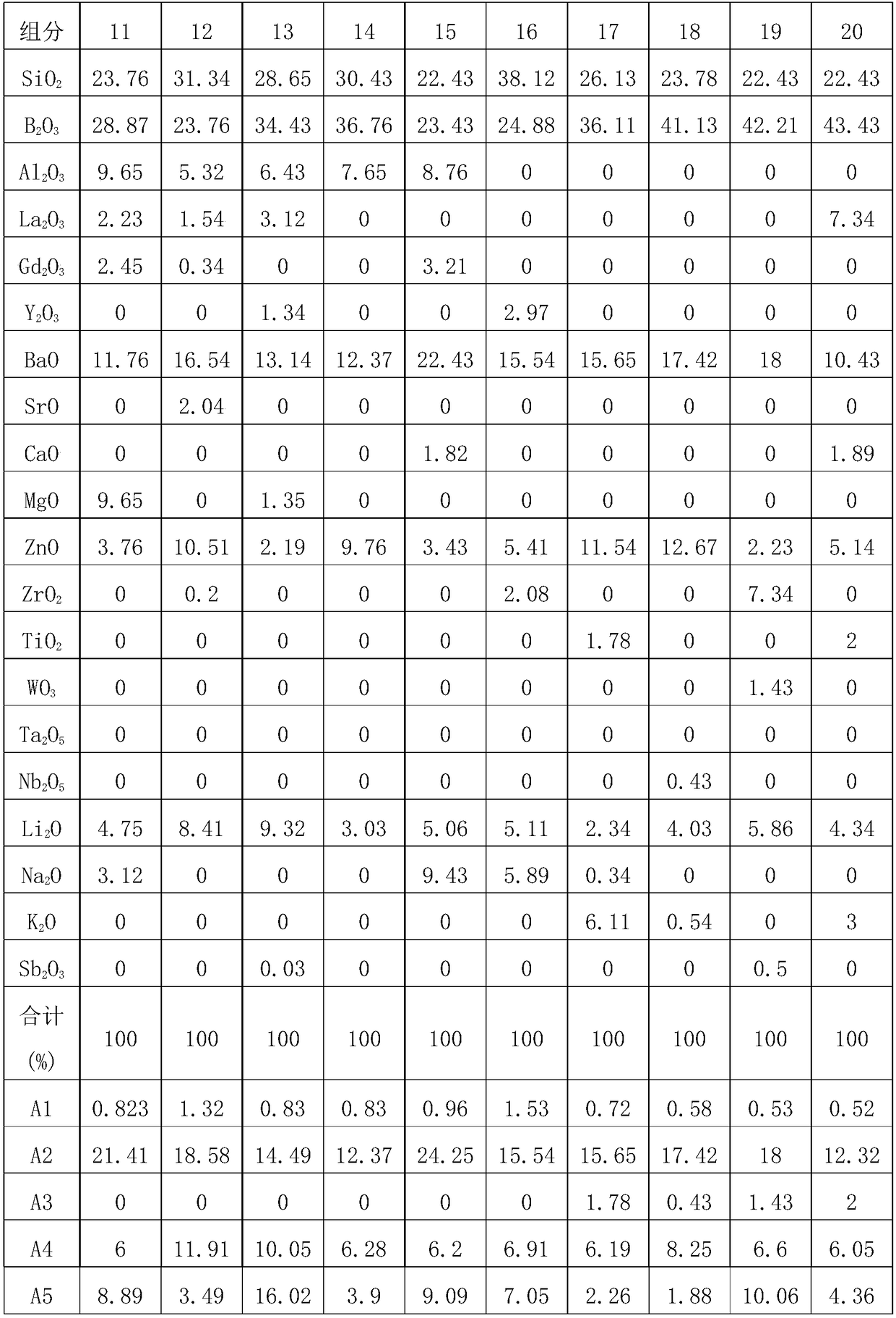

Optical glass, preform for press molding and optical part

InactiveUS6977232B2High-temperature viscosityLower transition temperatureGlass pressing apparatusGlass press-moulding apparatusRefractive indexOptical glass

Provided is an optical glass that has high-refractivity and high-dispersion properties and can give preforms for press-molding, which are excellent in shapability at high temperatures and suitable for precision press-molding.The optical contains, as essential components, 25 to 45 mol % of B2O3, 2 to 20 mol % of SiO2, 5 to 22 mol % of La2O3, 2 to 20 mol % of Gd2O3, 15 to 29 mol % of ZnO, 1 to 10 mol % of Li2O and 0.5 to 8 mol % of ZrO2, the optical glass having a B2O3 / SiO2 molar ratio of from 2 to 5.5 and having an La2O3 and Gd2O3 total content of 12 to 24 mol % and a ZnO and Li2O total content of 25 to 30 mol %, the optical glass having a refractive index (nd) of 1.75 to 1.85 and an Abbe's number (νd) of 40 to 55, or the optical glass contains, as essential components, B2O3, SiO2, La2O3, Gd2O3, ZnO, Li2O and ZrO2 and has a viscosity of at least 6 dPa·s at a liquidus temperature thereof, a glass transition temperature (Tg) of 600° C. or lower, a refractive index (nd) of 1.75 to 1.85 and Abbe's number (νd) of 40 to 55.

Owner:HOYA CORP

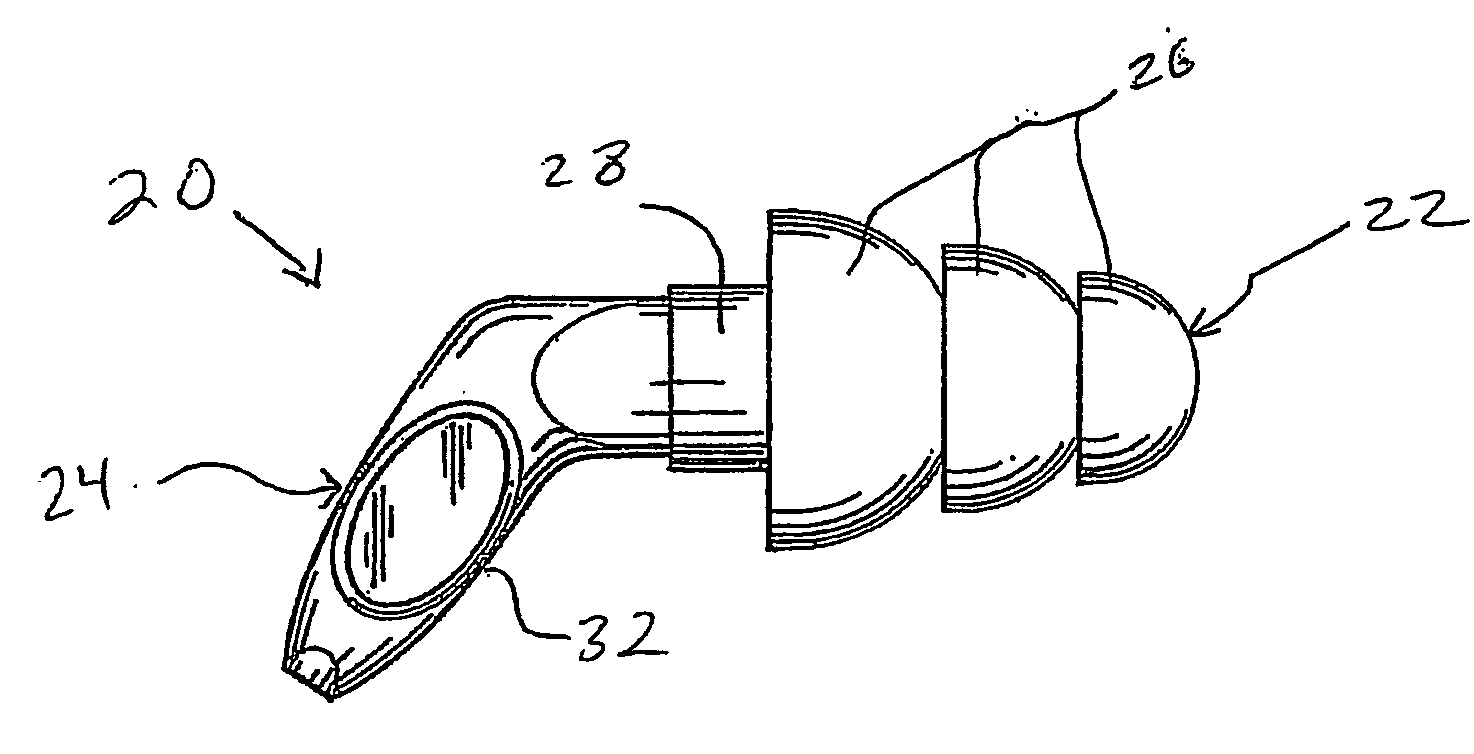

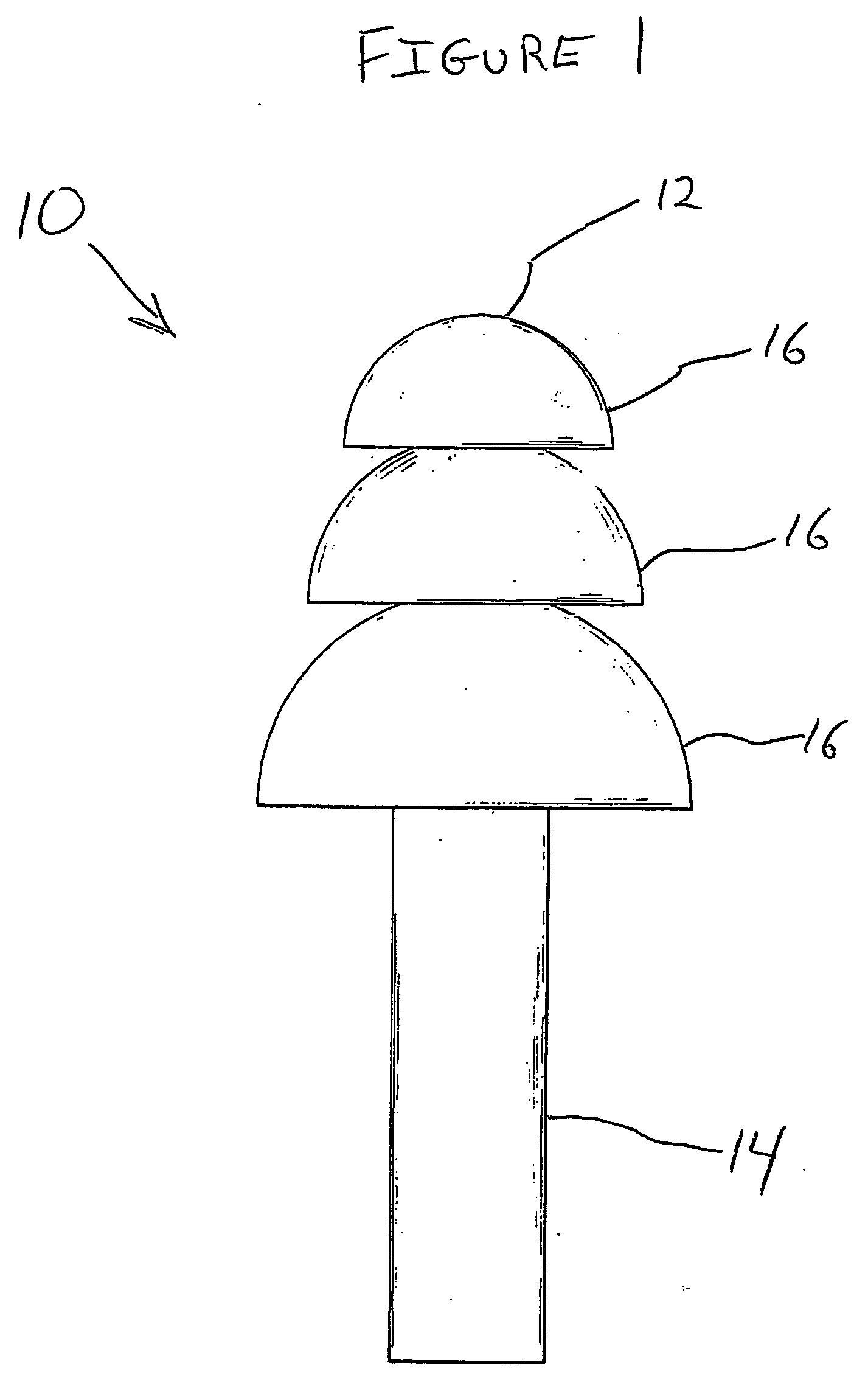

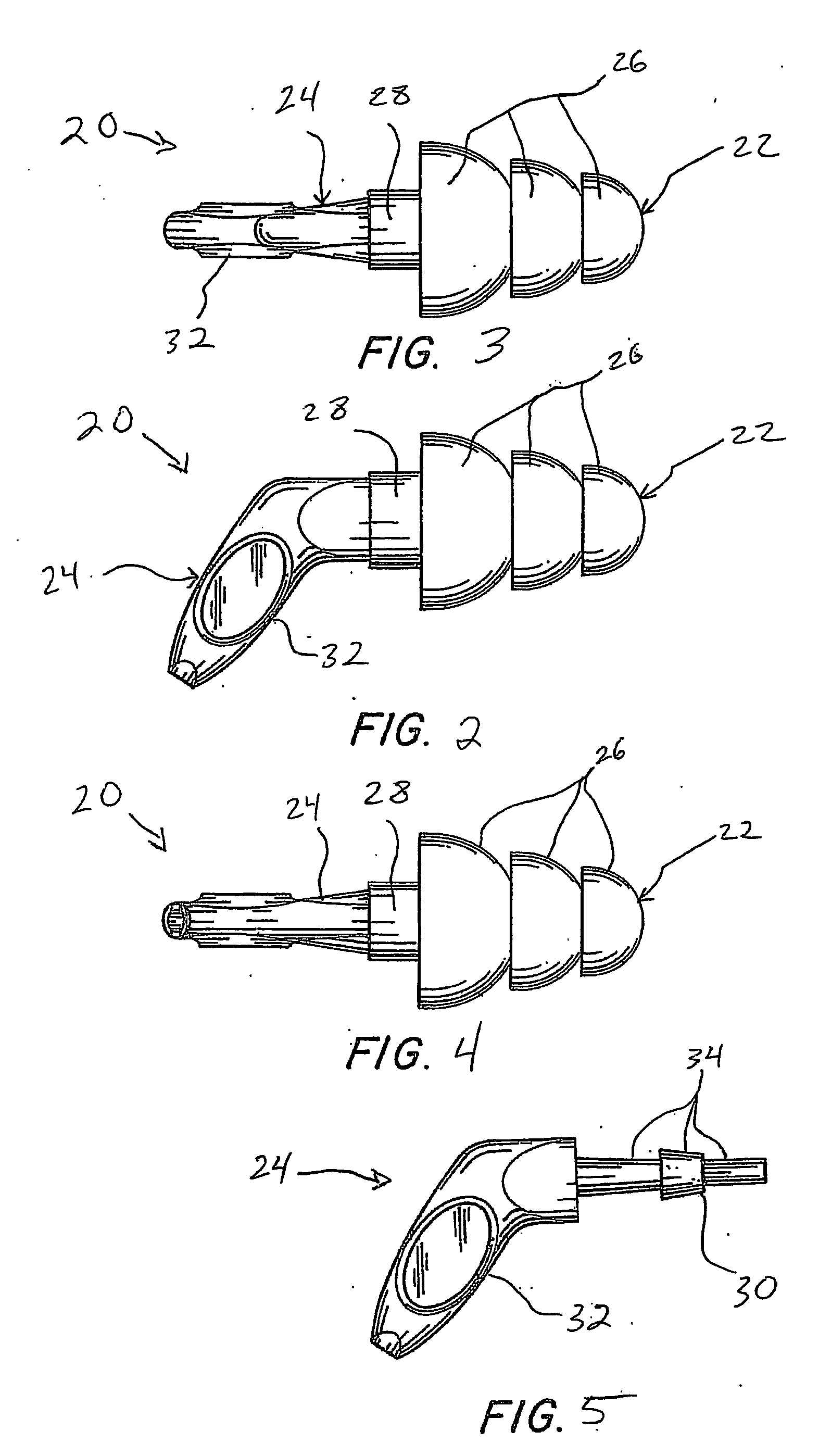

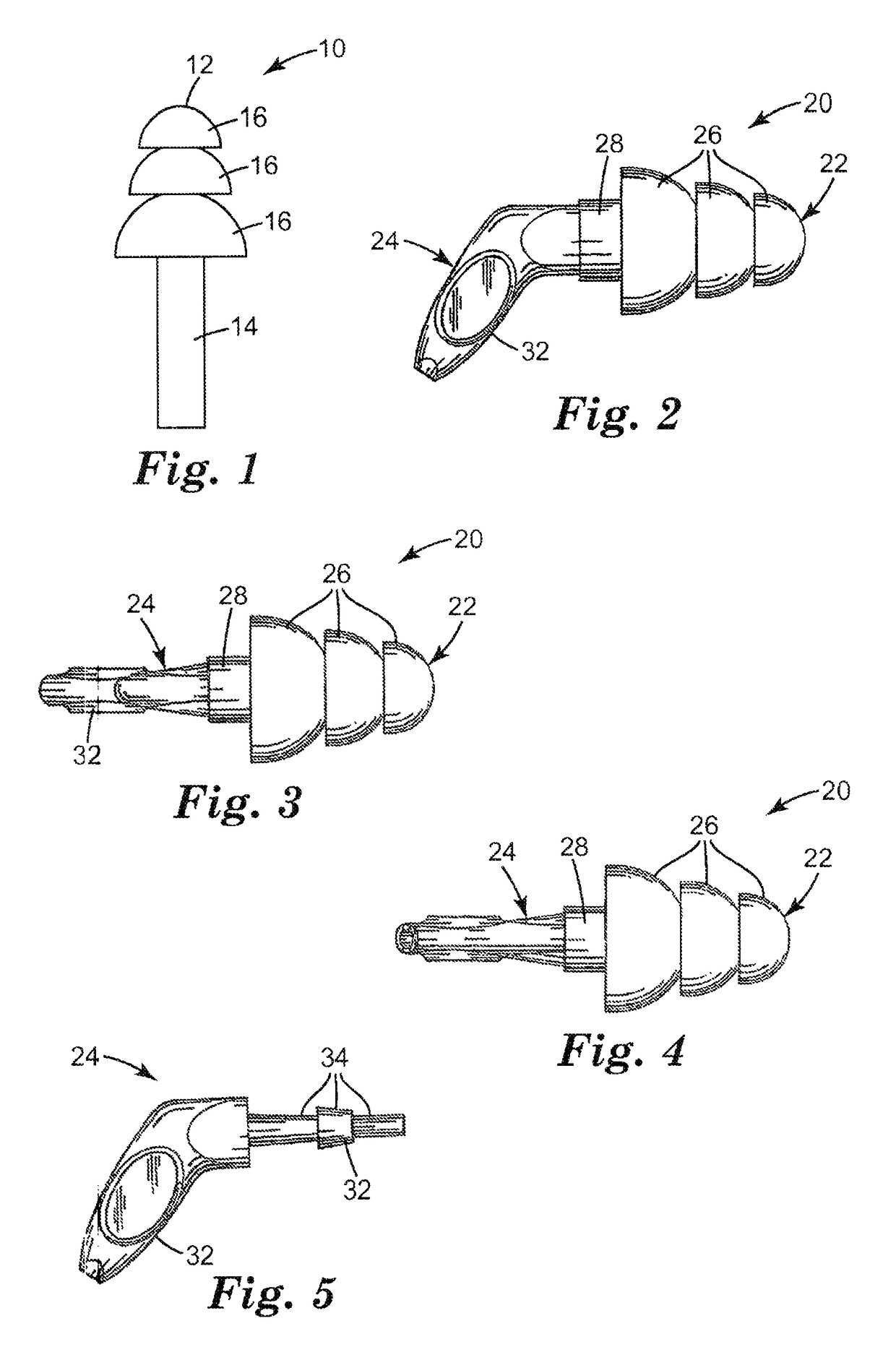

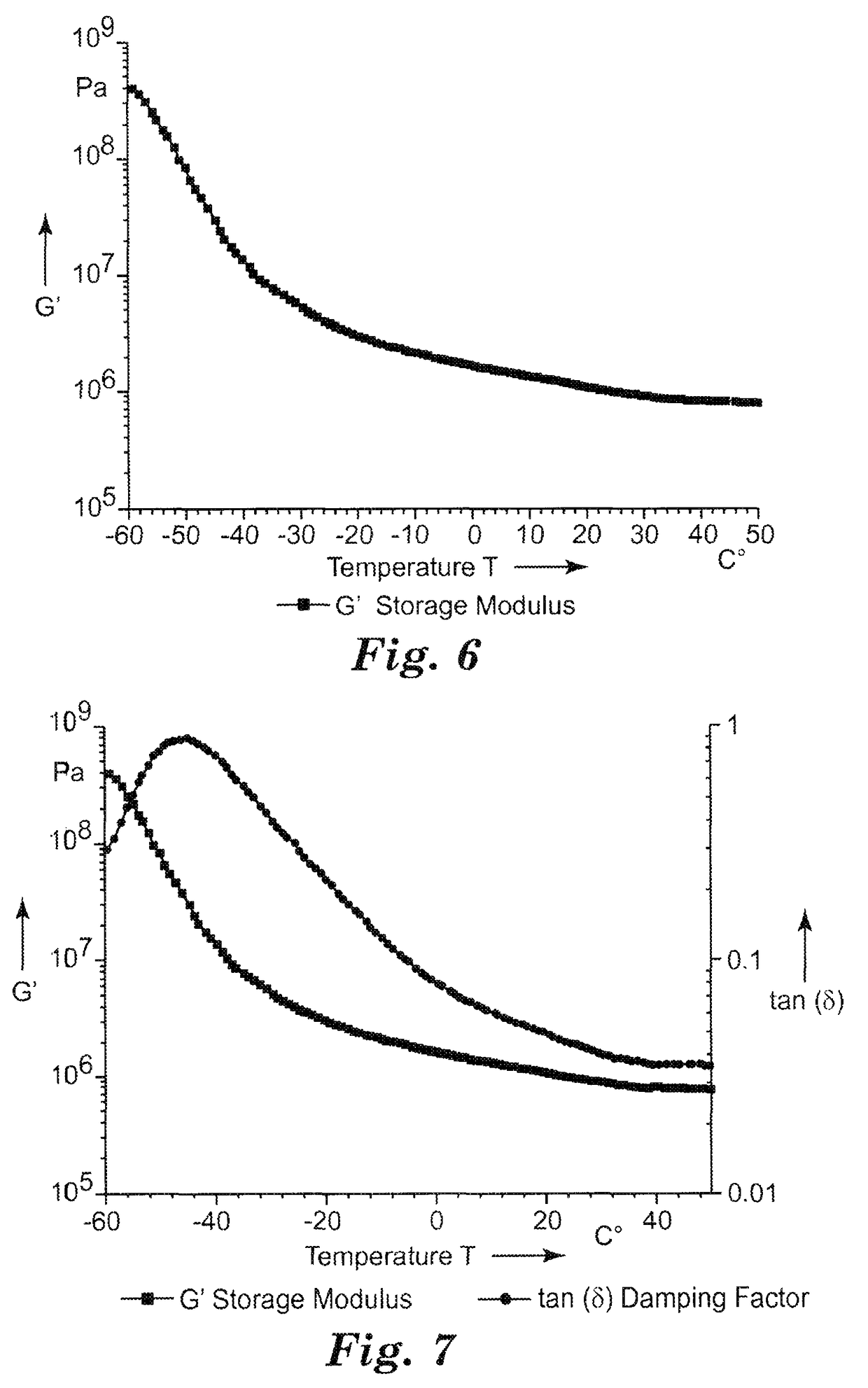

Hearing protection device with damped material

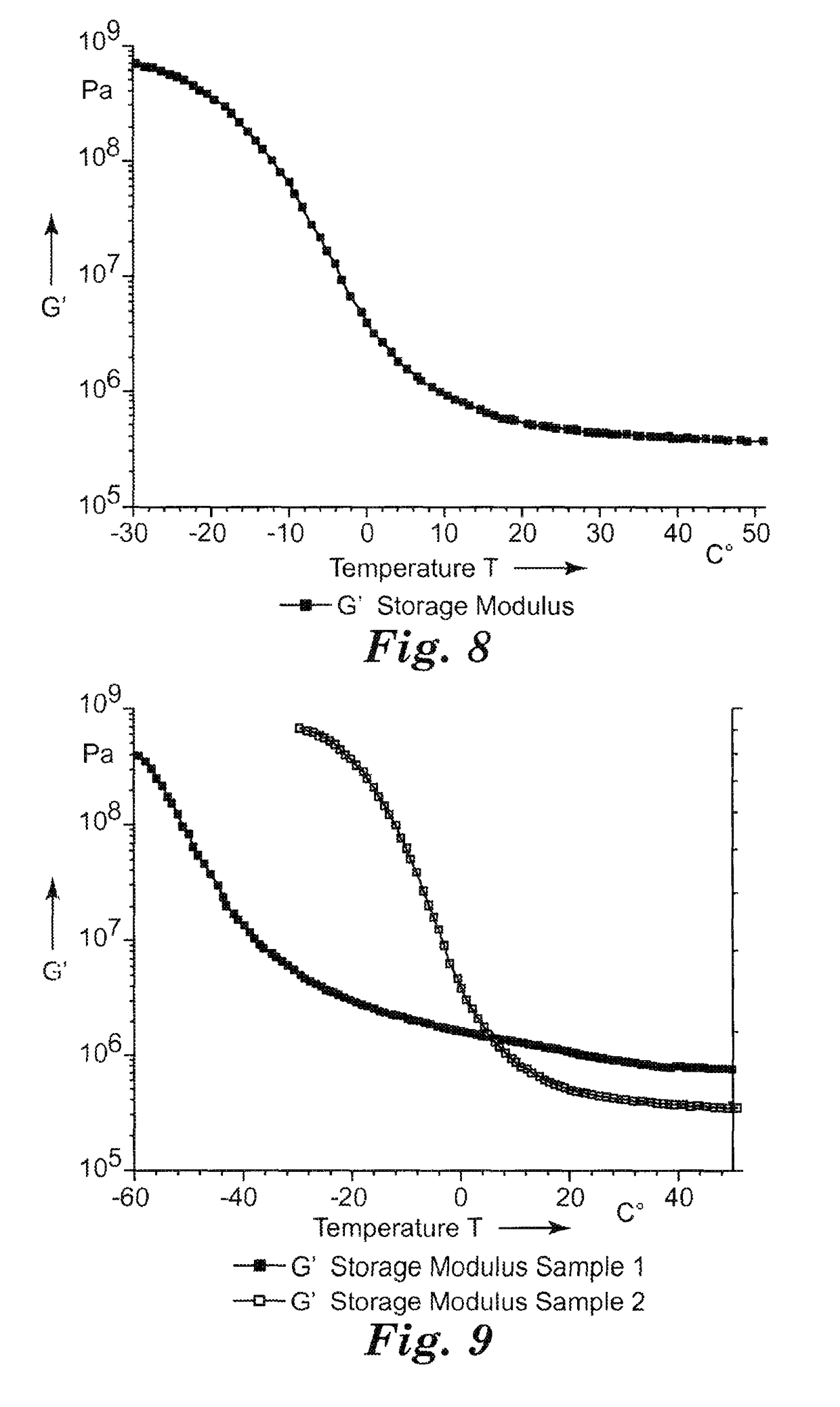

ActiveUS20060162992A1High glass transition temperatureLower transition temperatureStethoscopeEarplugsDamping factorElastomer

The invention provides a hearing protection device having an attenuating body composed of an elastomer with an increased glass transition temperature and a reduced glass-to-rubber transition temperature such that the damping factor of the material peaks at a higher temperature and, resultantly, the damping factor is increased over a range of temperatures and frequencies typically experienced by the device during usage. The increased damping results in higher sound attenuation provided by the hearing protection device.

Owner:3M INNOVATIVE PROPERTIES CO

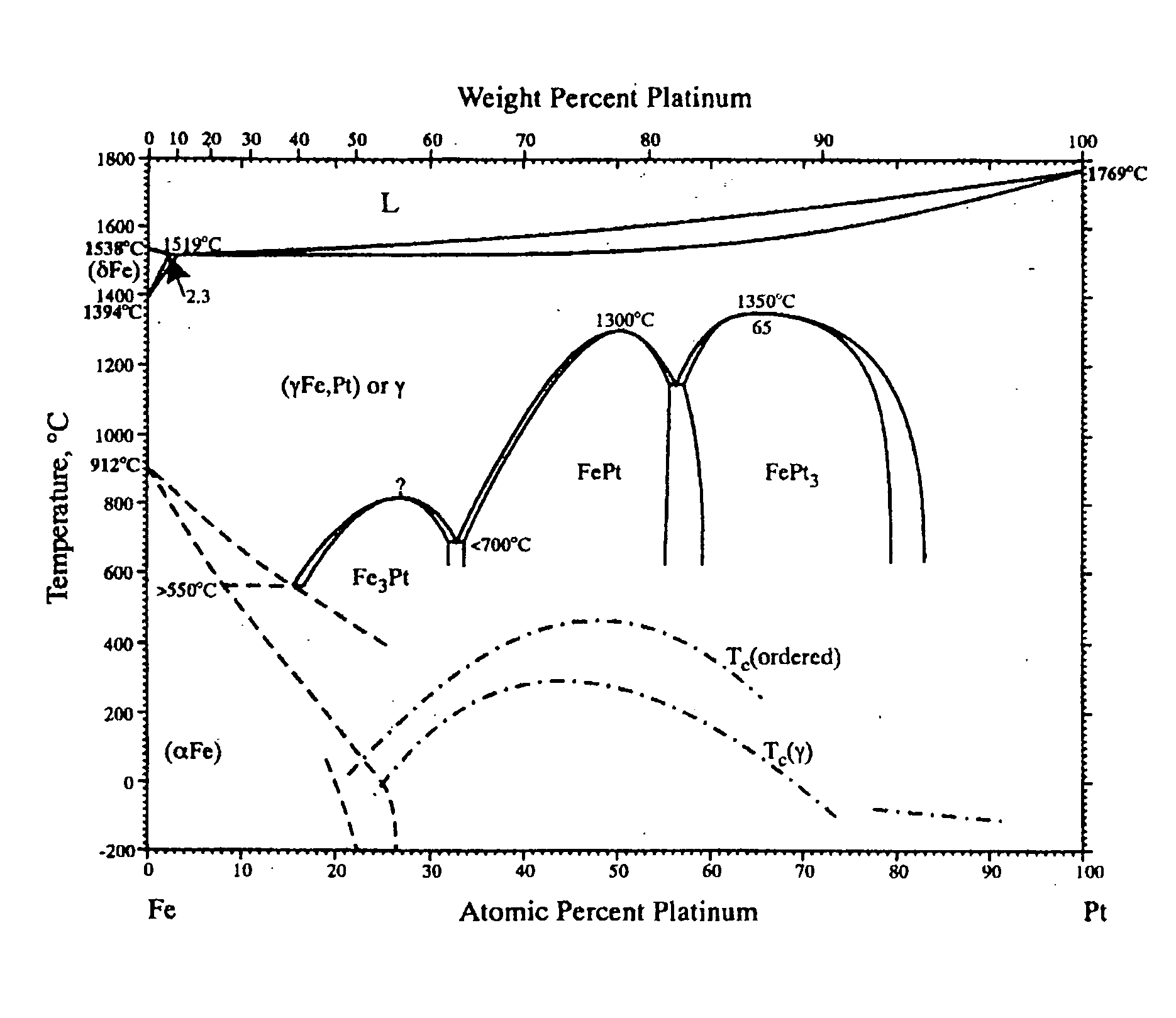

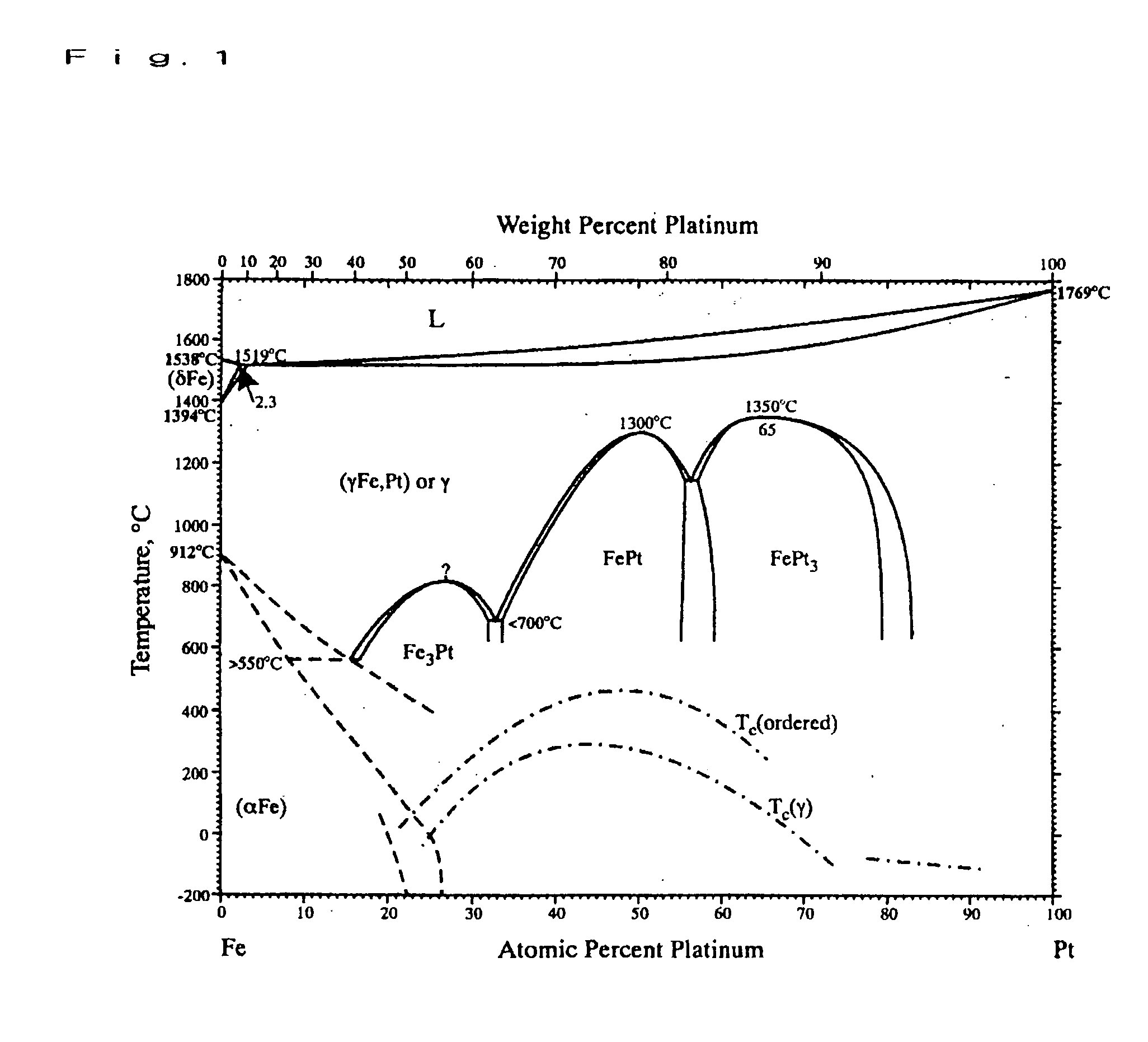

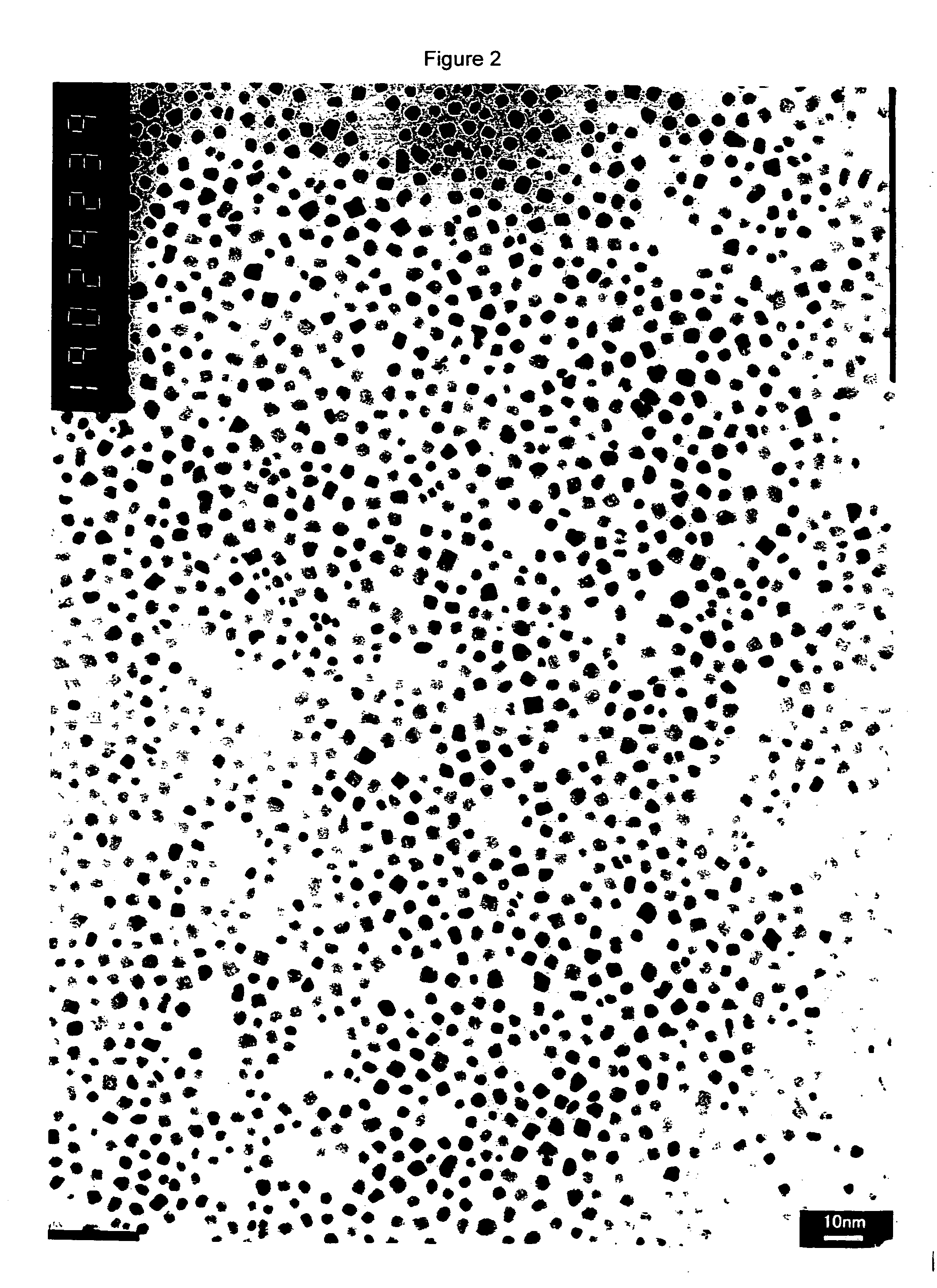

Face-centered cubic structure alloy particles and method of manufacturing same

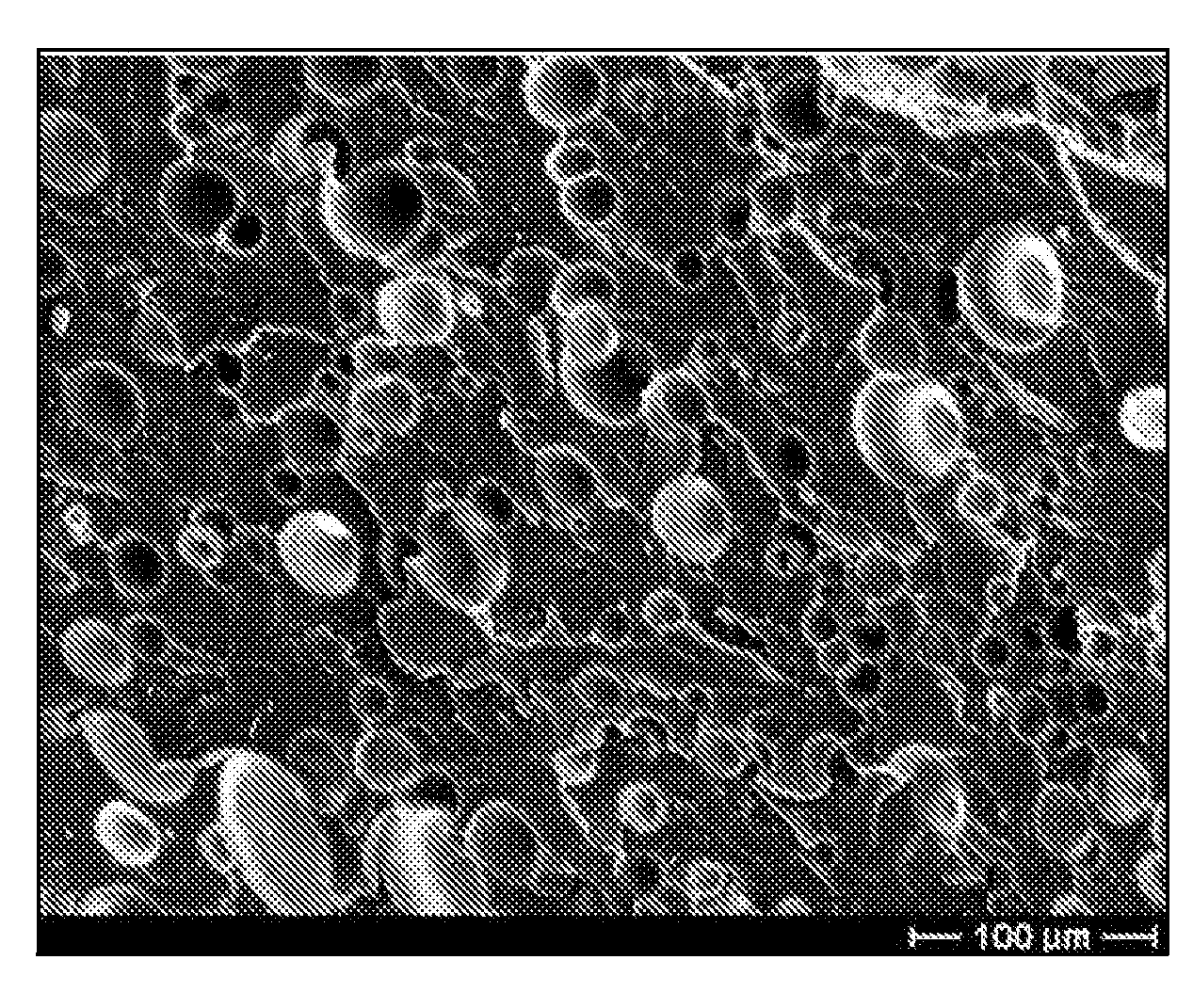

InactiveUS20060032330A1Improve distributionLower transition temperatureMaterial nanotechnologyMaterials with ironAlloyCrystallinity

Alloy particles of an alloy having a face-centered cubic structure comprise at least one selected from Fe and Co and at least one selected from Pt and Pd as principal components. The alloy particles have a TEM-measured average grain size (DTEM) of not more than 50 nm, and a single crystallinity (DTEM) / (DX) that is less than 1.50, where (DX) is X-ray crystallite size. These alloy particles can be advantageously manufactured by using the polyol process to synthesize the alloy particles in the presence of a complexing agent.

Owner:DOWA ELECTRONICS MATERIALS CO LTD

Hearing protection device with damped material

ActiveUS8118031B2High glass transition temperatureLower transition temperatureEarplugsDeaf-aid setsDamping factorUltrasound attenuation

Owner:3M INNOVATIVE PROPERTIES CO

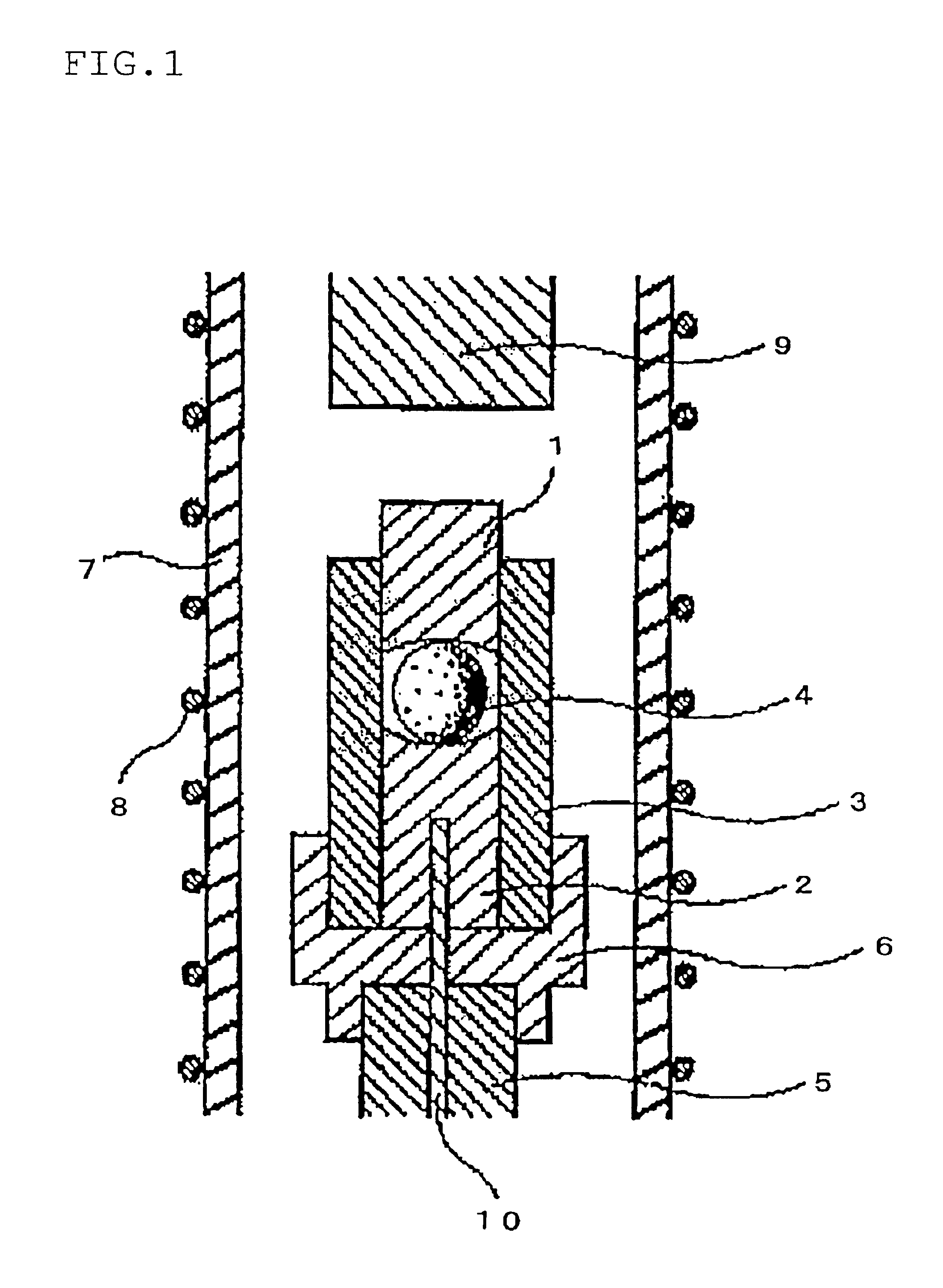

Nanoparticle, method of producing nanoparticle and magnetic recording medium

InactiveUS7066978B2Not easily coagulated with each otherImprove coatabilityNanostructure applicationMaterial nanotechnologySaline waterOrganic solvent

A method of producing a nanoparticle, the method comprising: a reducing step of adding an reverse micelle solution (II) obtained by mixing a water-insoluble organic solvent containing a surfactant with an aqueous metal salt solution to an reverse micelle solution (I) obtained by mixing a water-insoluble organic solvent containing a surfactant with an aqueous reducing agent solution, to carry out a reducing reaction; and a maturing step of raising the temperature of the reduced mixture to mature the reduced mixture is provided. A method of producing a plural type alloy nanoparticle, the method comprising producing a nanoparticle made of a plural type alloy through a reducing step of mixing one or more reverse micelle solutions (I) containing a metal salt with an reverse micelle solution (II) containing a reducing agent to carry out reducing treatment and a maturing step of carrying out maturing treatment is also provided.

Owner:FUJIFILM HLDG CORP +1

Lead-free niobium-bismuth-phosphate optical glass with a high index of refraction

InactiveUS7638448B2Excellent optical propertiesLower transition temperatureGlass furnace apparatusNiobiumRefractive index

The lead-free optical glass can be used in the fields of imaging, sensor technology, microscopy, medical technology, digital projection, photolithography, laser technology, wafer / chip technology, as well as of telecommunications, optical communication engineering and optics / lighting in the automotive sector. It has a refractive index nd of 1.82≦nd≦2.00 and / or an Abbe number vd of 18≦vd≦28 with good chemical stability, excellent crystallization stability and the following composition, in wt. based on oxide content, of:P2O512-35Nb2O530-50Bi2O3 2-13GeO20.1-7 Li2O≦6Na2O≦6K2O≦6Cs2O≦6MgO≦6CaO≦6SrO≦6BaO 7-<17ZnO≦6TiO2≦7ZrO2≦7WO3 2-14F ≦6.

Owner:SCHOTT AG

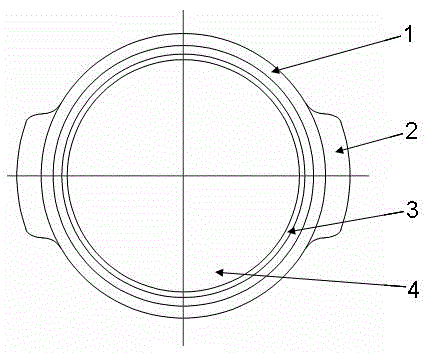

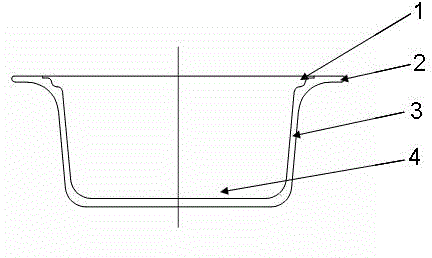

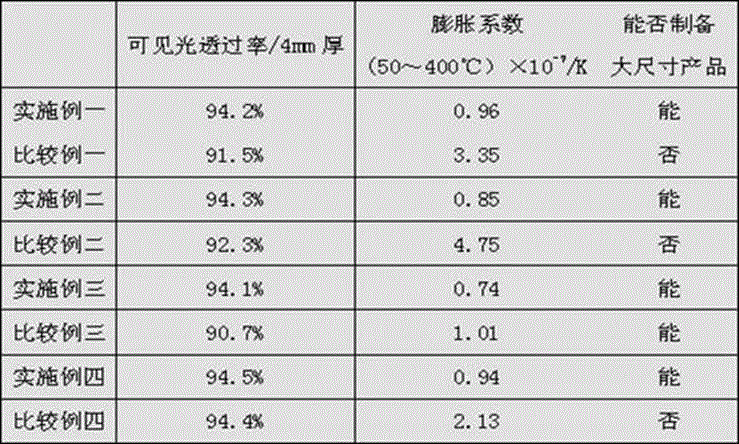

Ultralow-expansion-coefficient high-transparency microcrystalline glass and preparation method thereof

The invention discloses an ultralow-expansion-coefficient high-transparency microcrystalline glass which comprises the following components in percentage by weight: 65-69% of SiO2, 19-20% of Al2O3, 3.1-4.2% of Li2O, 3-4.5% of B2O3, 0.1-0.4% of Na2O, 0.1-0.4% of K2O, 0.3-0.5% of MgO, 0.6-1.4% of BaO, 0.6-1.4% of ZnO, 1.0-1.7% of TiO2, 1.0-1.3% of ZrO2, 0.4-0.8% of P2O5, 0.3-0.8% of F and 0.02-0.3% of CeO2. The preparation method comprises the following steps: melting glass raw materials, cooling, molding, annealing, crystallizing, and carrying out after treatment to obtain the microcrystalline glass finished product. The microcrystalline glass has the advantages of high transparency and ultralow expansion coefficient, and can be used for manufacturing large-size or complex-structure products.

Owner:虎石新材料(宜兴)有限公司

Polyester compositions containing low amounts of cyclobutanediol and articles made therefrom

InactiveUS20100096589A1Increase temperatureHigh viscosityLiquid crystal compositionsPlastic/resin/waxes insulatorsDicarboxylic acidCarboxylic acid

Described as one aspect of the invention are polyesters containing (a) a dicarboxylic acid component having from 70 to 100 mole % of terephthalic acid residues and up to 30 mole % of aromatic dicarboxylic acid residues or aliphatic dicarboxylic acid residues; and (b) a glycol component having from 11 to 25 mole % of 2,2,4,4-tetramethyl-1,3-cyclobutanediol residues, and 75 to 89 mole % of cyclohexanedimethanol residues; wherein the total mole % of the dicarboxylic acid component is 100 mole %, and the total mole % of the glycol component is 100 mole %. The polyesters may be manufactured into articles.

Owner:EASTMAN CHEM CO

Lead-free optical glasses with a hard flint position

Optical glasses are described, which are useful for imaging, sensors, microscopy, medical technology, digital protection, photolithography, laser technology, wafer / chip technology, as well as telecommunication, optical communications engineering and optics / lighting in the automotive sector, with a refractive index of 1.80≦nd≦1.95 and an Abbe value from 19≦νd≦28 with excellent chemical resistance and stability to crystallization. These optical glasses have a composition, in weight. % based on oxide content, of: P2O5, 14-35; Nb2O5, 45-50; Li2O, 0-4; Na2O, 0-4; K2O, 0.5-5; BaO, 17-23; ZnO, 0.1-5; TiO2, 1-<5; ZrO2, 0-6; and Sb2O3, 0.1-2.

Owner:SCHOTT AG

Optical glass suitable for mold forming at low temperature

InactiveUS20080032879A1High stability against devitrificationImprove mass productionDevitrificationMetallurgy

An optical glass suitable for mold forming at a low temperature including, in percent by weight, 9-25 percent of P2O5, 1-20 percent of GeO2, 12-28 percent of Nb2O5, 1-7 percent of TiO2, 0-55 percent of Bi2O3, 0-38 percent of WO3, 0-3 percent of SiO2, 0-5 percent of B2O3, 0-2 percent of Al2O3, 0-5 percent of Li2O, 0-11 percent of Na2O, 0-5 percent of K2O, 0-3 percent of Ta2O5, 0-1 percent of Sb2O3, at most 13 percent of at least one R2O selected from the group consisting of Li2O, Na2O and K2O, and at most 15 percent of at least one XO selected from the group consisting of CaO, SrO, BaO and ZnO. The optical glass essentially contains no environmental and human harmful components, facilitates mass production and is stable against devitrification near its softening temperature.

Owner:ASIA OPTICAL INT LTD

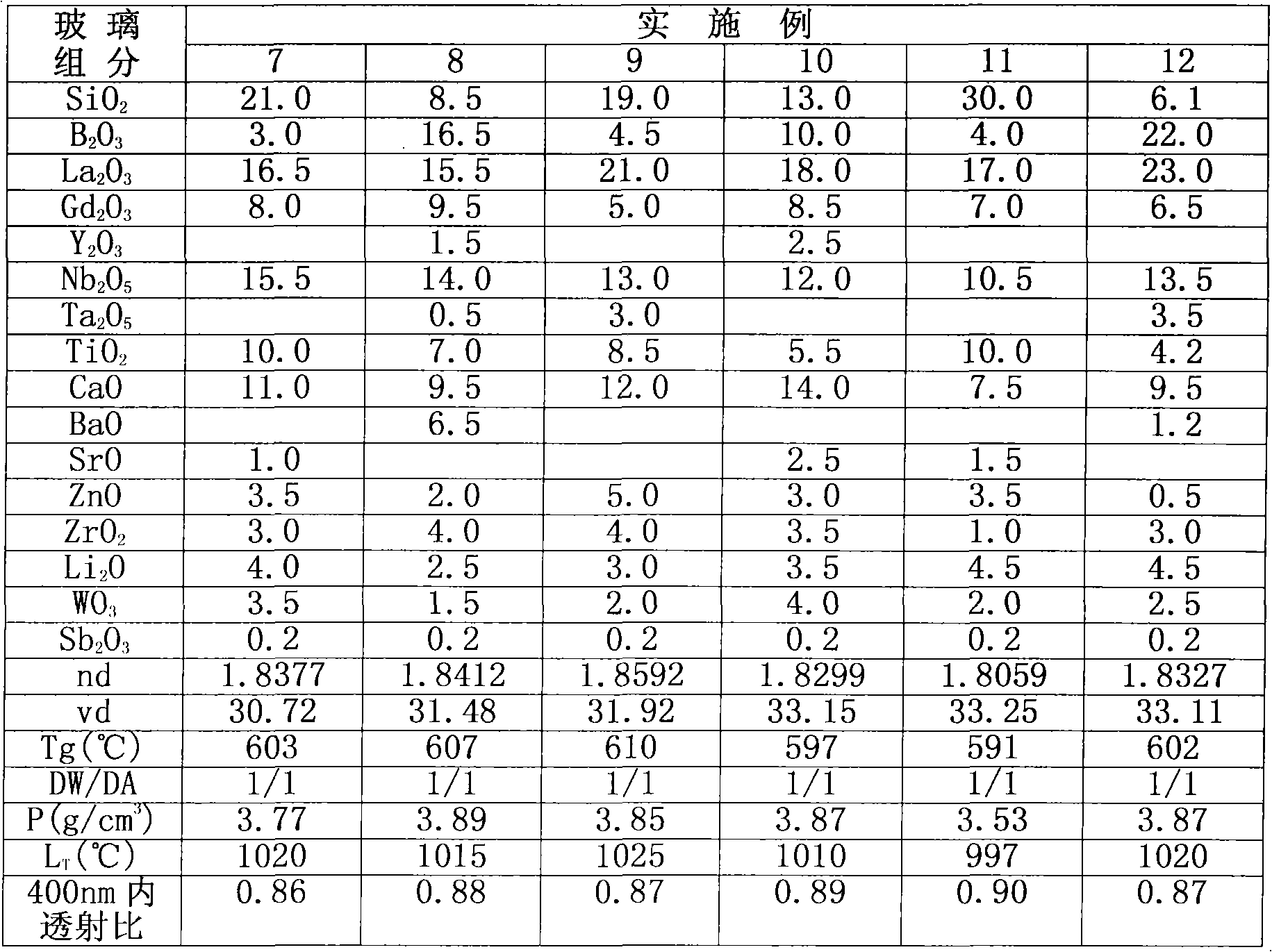

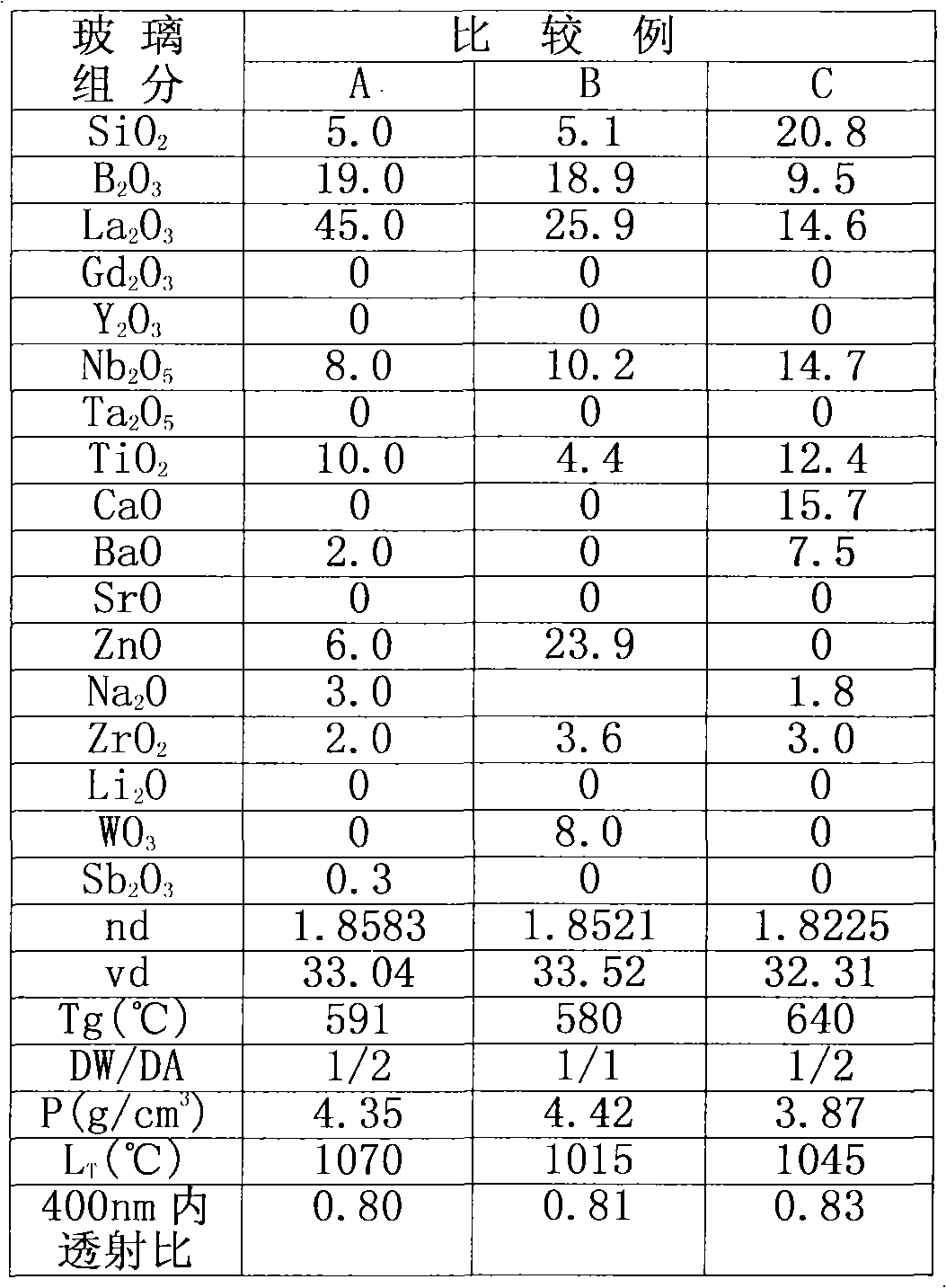

Optical glass with high refraction index and manufacturing method thereof

InactiveCN102167508ALight weightImprove transmittanceGlass pressing apparatusGlass productionRefractive indexGlass transition

The invention provides optical glass which has the optical characteristics that the refractive index nd is more than 1.80 and less than 1.86 and the Abbe coefficient vd is more than 30 and less than 35. The optical glass contains the following necessary components: SiO2, B2O3, La2O3, Gd2O3, Nb2O5, TiO2, CaO and Li2O. The glass transition temperature (Tg) is below 610 DEG C. The invention also provides a preparation method of the optical glass. The invention provides the optical glass which has small specific gravity and low liquidus temperature obtained during smelting and molding, high transmissivity and excellent chemical stability, and low transition temperature during molding and also provides a high-quality optical element formed by the optical glass.

Owner:CHENGDU UNITE OPTOELECTRONICS TECH CO LTD

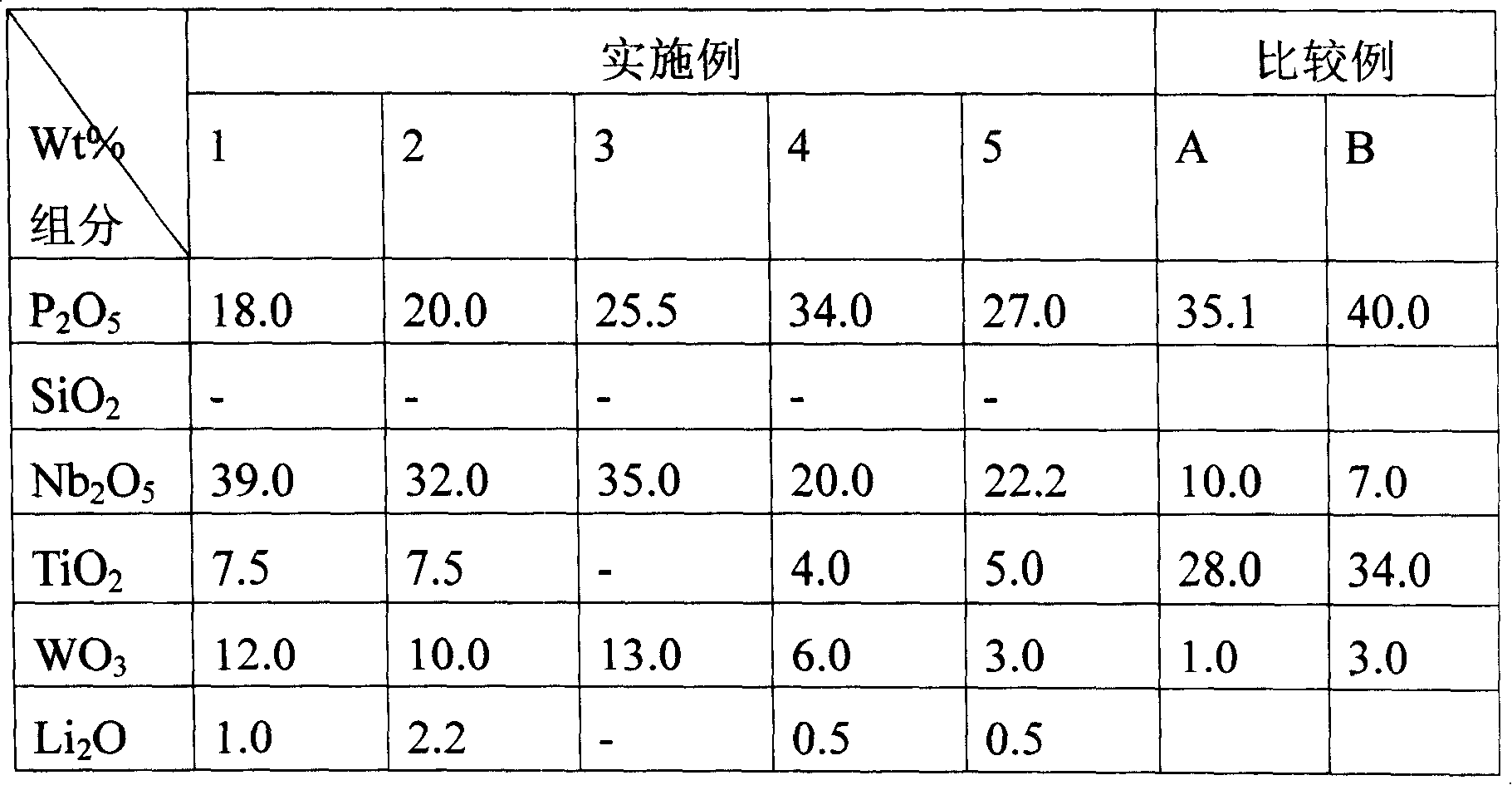

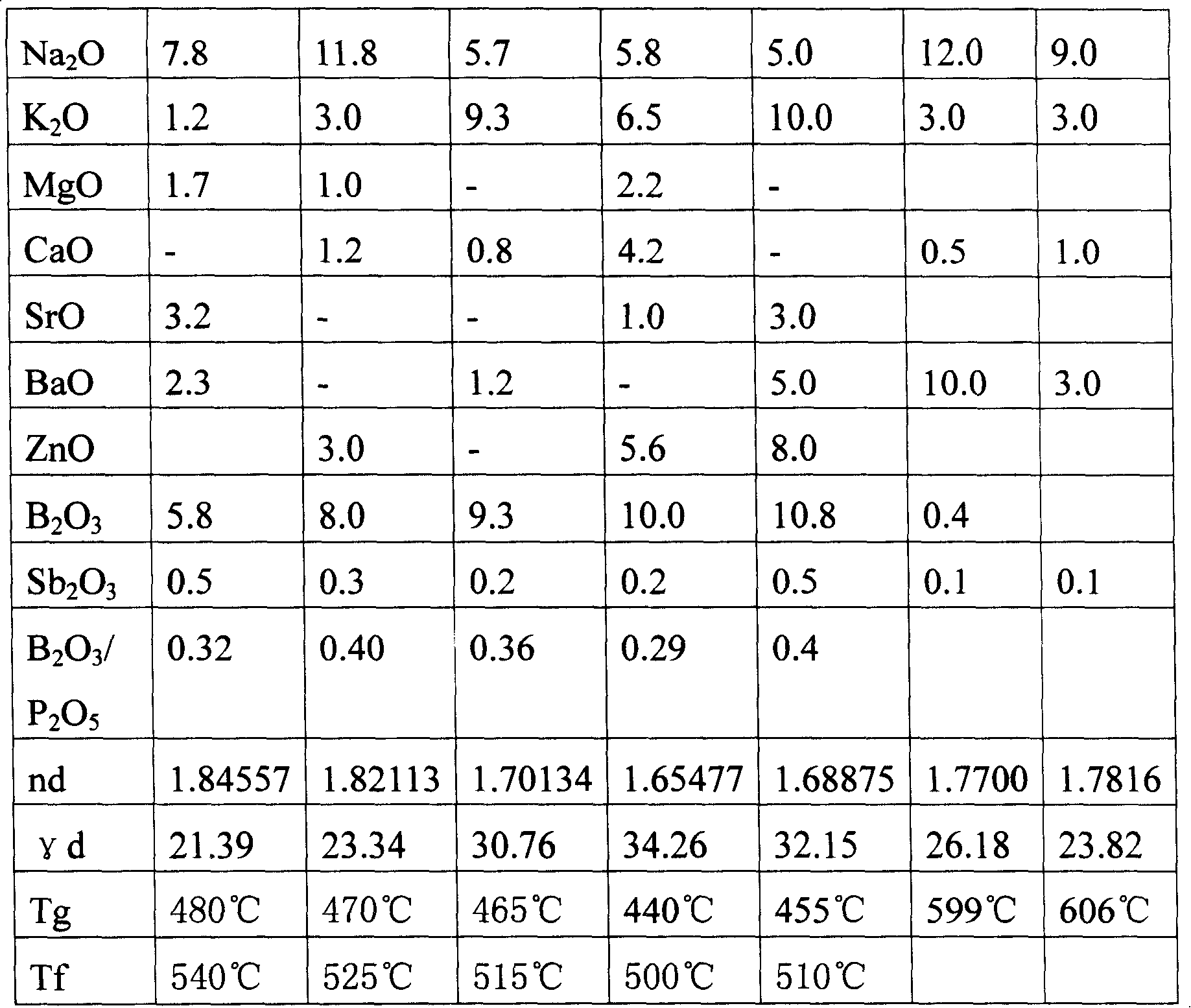

Low-melting point optical glass

InactiveCN101215086ALower transition temperatureImprove crystallization abilityRefractive indexOptical glass

The invention relates to low melting point optical glass, belonging to the low melting point optical glass without lead, arsenic, bismuth and fluorine, which resolves the problem that the existing optical glass has high transformation temperature, insufficient chemical stability, big glass specific weight and the like. the technical scheme of the invention is that the content of percentage by weight comprises: P2O5 holding 18-40%, Nb2O5 holding 20-40%, TiO2 holding 0-10%, WO3 holding 0-15%, B2O3 holding0-15%, R2O holding 10-45%, RO holding 0-20%, Sb2O3 holding 0-1% and total content holding 100%. The glass of the invention does not contain lead, arsenic, bismuth and fluorine, the transformation temperature of which is low (Tg < 500DEG C), the glass is adaptable to precise compression, the refractive index is 1.65-1.85, Abbe number is 20-35, chemical stability is good, bending and separation property is good, and the glass is easy in melting and processing, low in density and comparatively light in color.

Owner:HUBEI NEW HUAGUANG NEW INFORMATION MATERIALS CO LTD

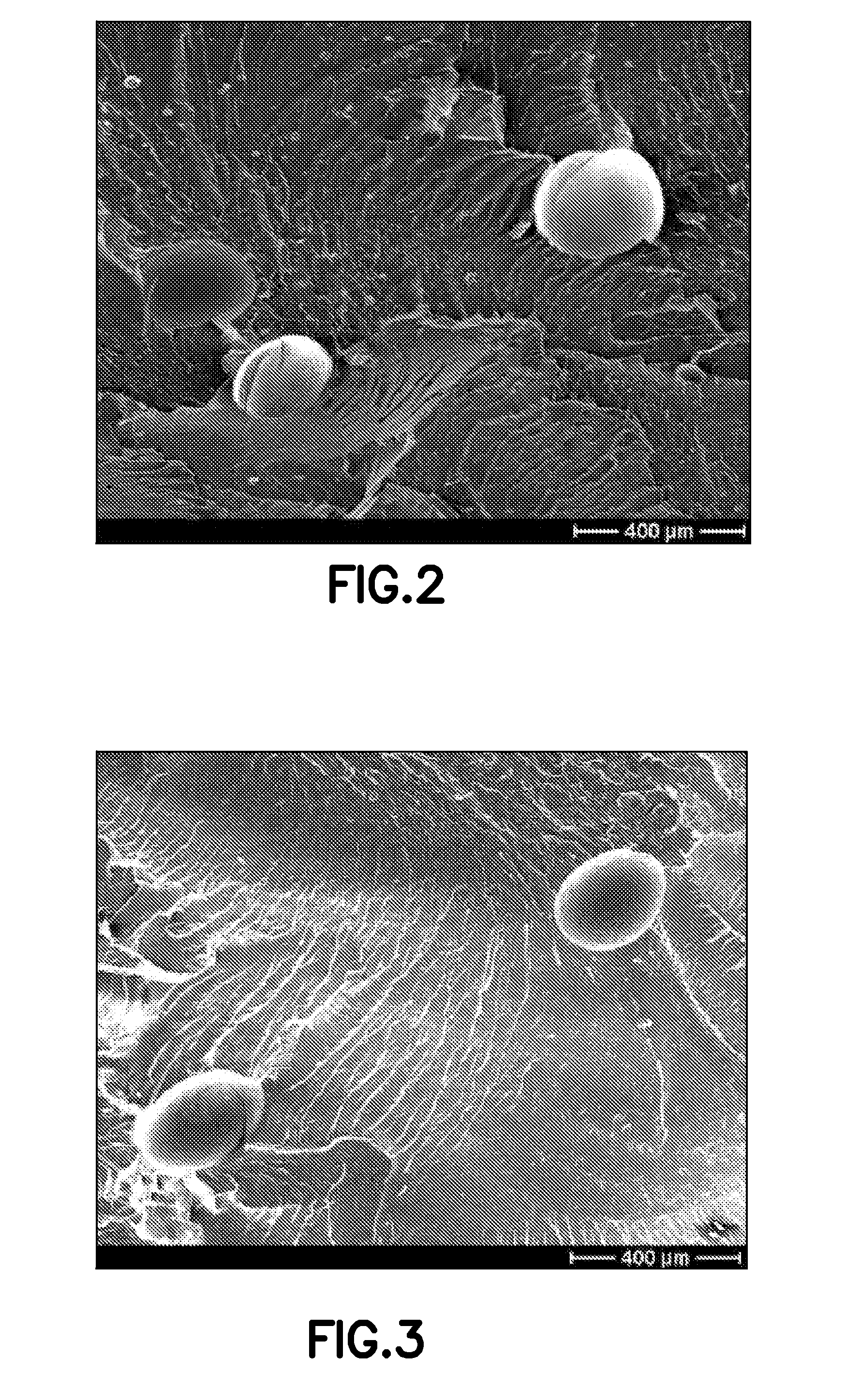

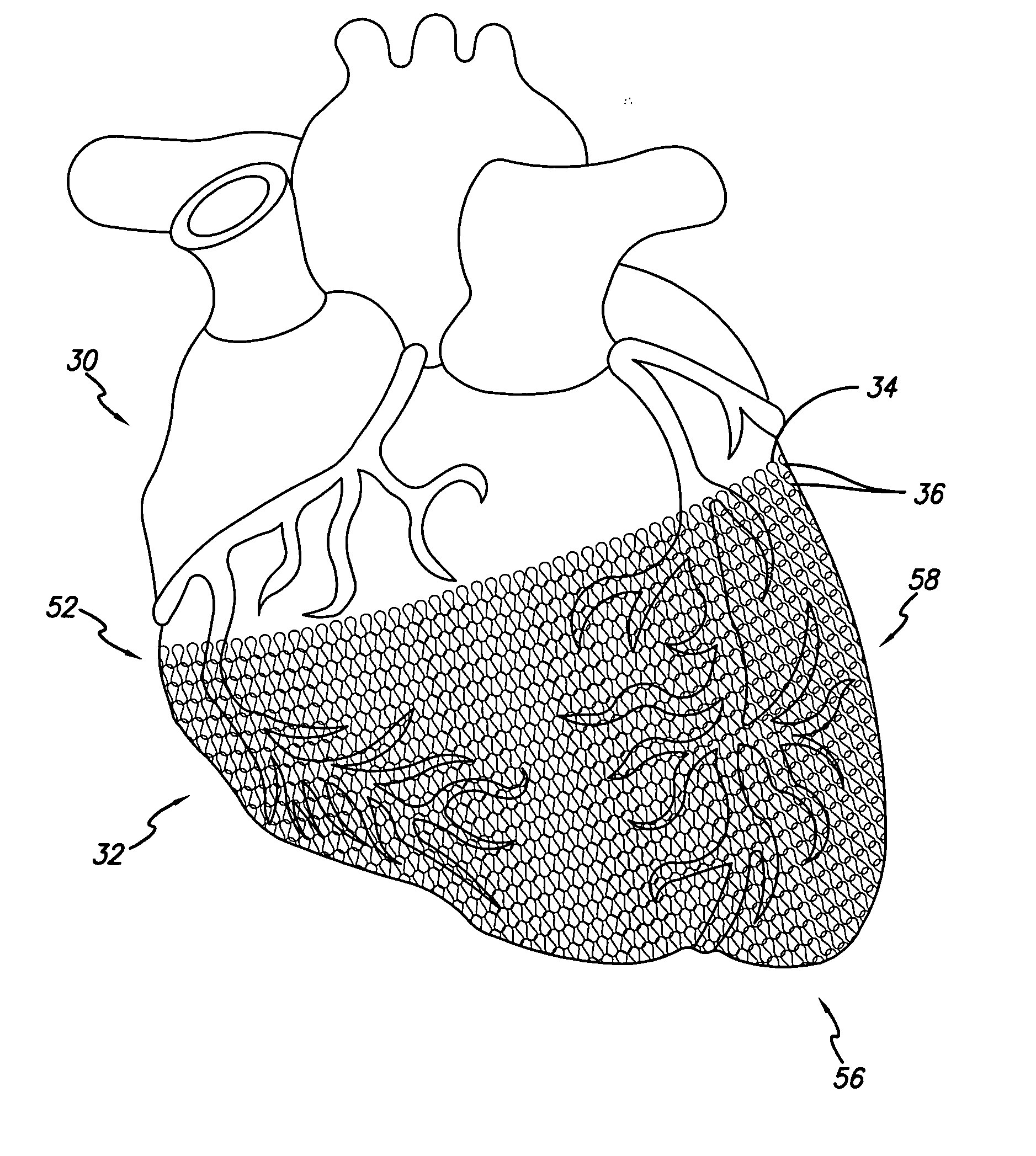

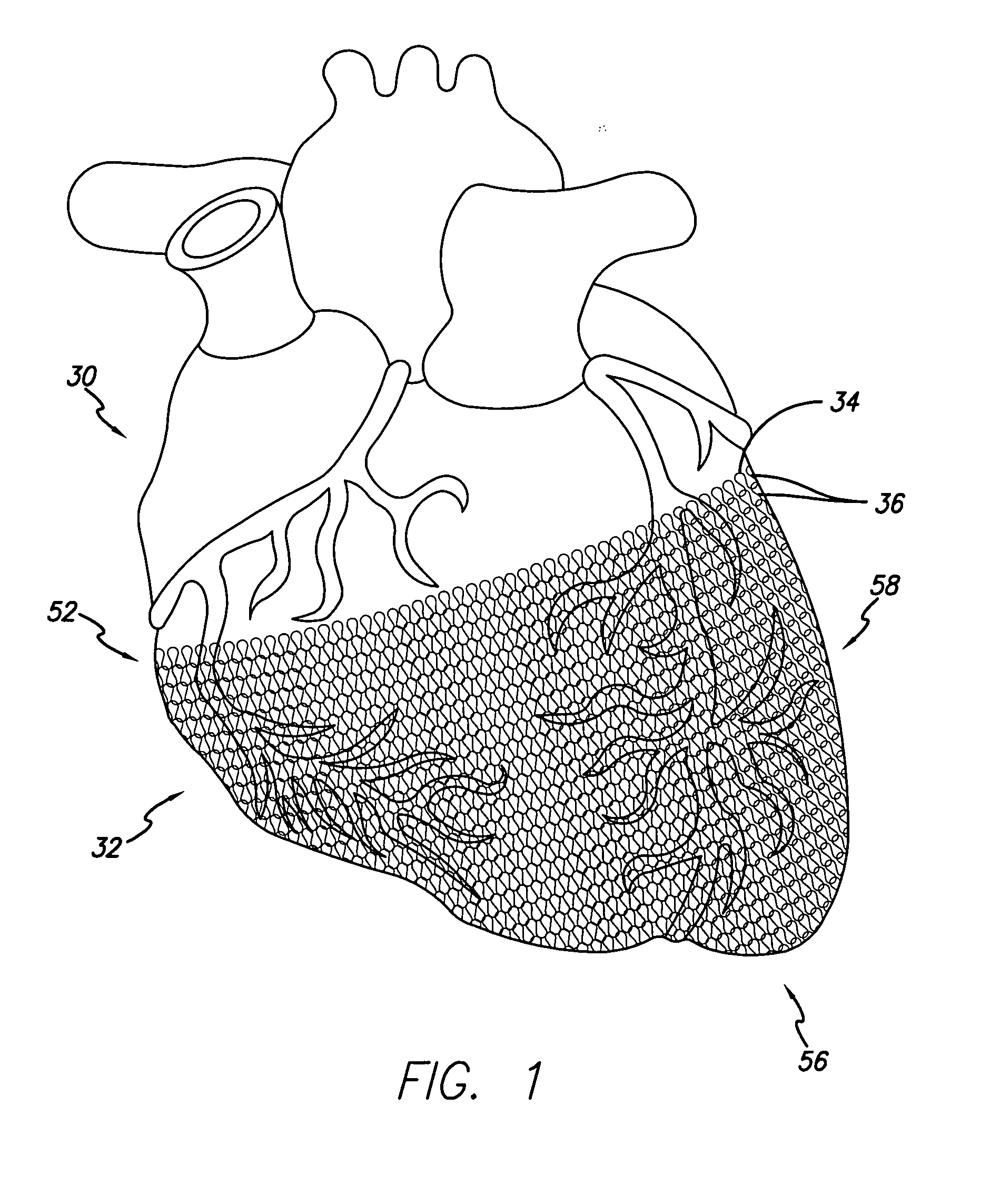

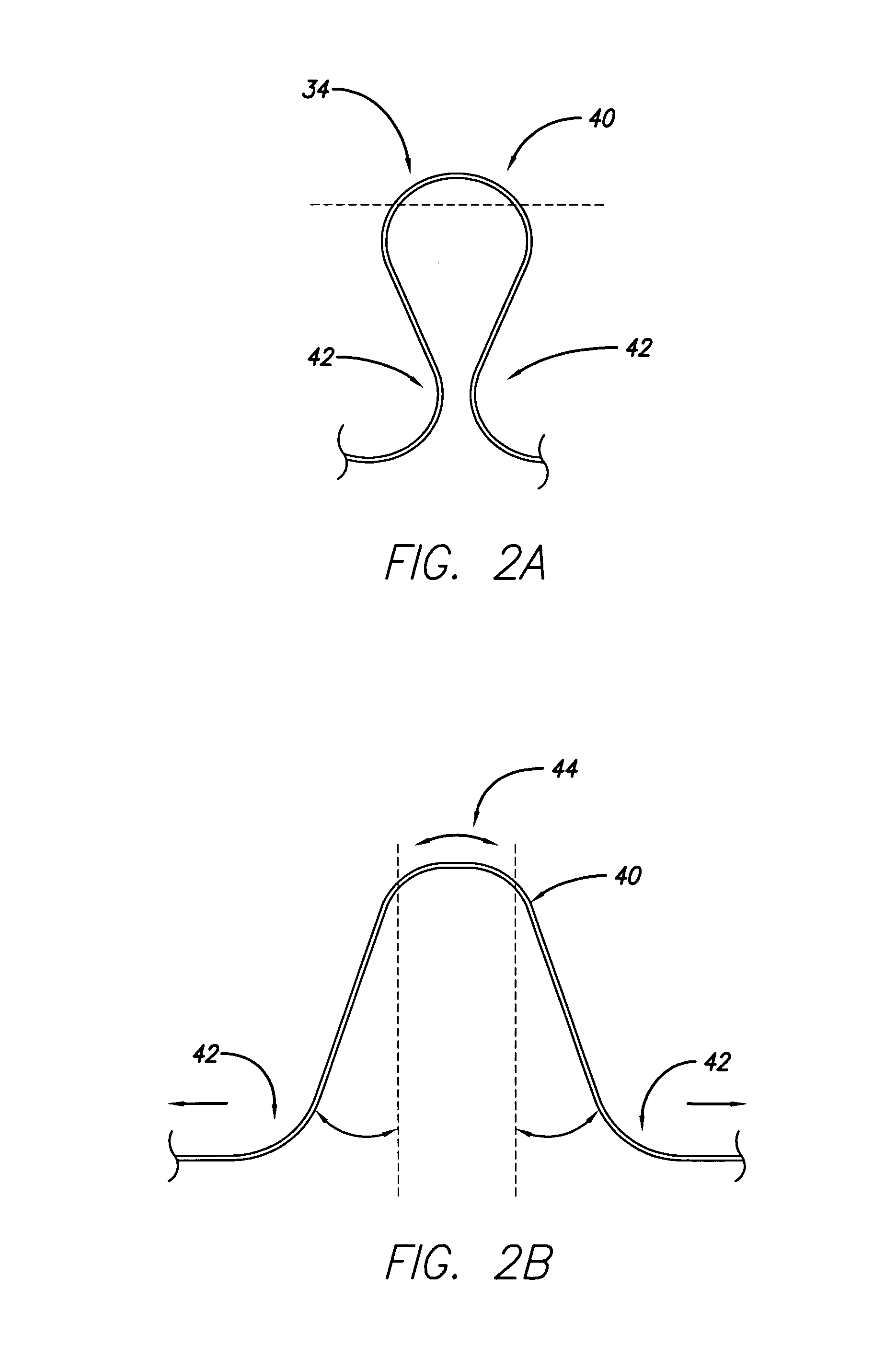

Apparatus and method of delivering biomaterial to the heart

InactiveUS20070100199A1Reduce apparent viscosityRelieve cardiac wall stressHeart valvesTissue regenerationCardiac cycleCardiac wall

A biomaterial for treating or preventing congestive heart failure is injected into the intrapericardial space of a patient's heart to apply a mild compressive force on the heart. A volume of biomaterial is placed in the intrapericardial space by an injection needle or catheter, adjacent at least the left ventricle, so that the biomaterial applies a compressive force on the myocardium to relieve cardiac wall tension during at least a portion of the cardiac cycle.

Owner:PARACOR MEDICAL

Polyester compositions containing low amounts of cyclobutanediol and articles made therefrom

ActiveUS20060287481A1High glass transition temperatureHigh viscosityDialysis systemsDialysisDicarboxylic acidCarboxylic acid

Described as one aspect of the invention are polyesters containing (a) a dicarboxylic acid component having from 70 to 100 mole % of terephthalic acid residues and up to 30 mole % of aromatic dicarboxylic acid residues or aliphatic dicarboxylic acid residues; and (b) a glycol component having from 11 to 25 mole % of 2,2,4,4-tetramethyl-1,3-cyclobutanediol residues, and 75 to 89 mole % of 1,4-cyclohexanedimethanol residues; wherein the total mole % of the dicarboxylic acid component is 100 mole %, and the total mole % of the glycol component is 100 mole %. The polyesters may be manufactured into articles.

Owner:EASTMAN CHEM CO

Hot rolling process capable of improving high-grade thick pipeline steel fracture toughness

InactiveCN102172619AIncrease the dislocation densityLower transition temperatureMetal rolling arrangementsDrop weightTemperature difference

The invention provides a hot rolling process capable of improving high-grade thick pipeline steel fracture toughness, sequentially comprising a plate blank reheating section process, a hot rolling section process, a plate reeling section process and a cooling section process, wherein the concrete processing parameters of each process are as follows: in the plate blank reheating section process, the plate blank heating temperature is equal to T solid solution plus 30-80 DEG C, the relation between in-furnace time and blank thickness is that the total in-furnace time is equal to 0.5t plus 30-50min, and the temperature difference of the upper surface and the lower surface after the plate blank is reheated is less than or equal to 30 DEG C; and in the hot rolling section process, the single track down rate in rough rolling is more than or equal to 15%, the accumulated down rate in fine rolling is more than or equal to 70%, and the finished rolling temperature is equal to Ar3 plus 0-60 DEG C, wherein Ar3 is a phase transformation point temperature. By utilizing the hot rolling process provided by the invention, the problem that DWTT (drop weight tear test) control is difficult to carry out on X70 and X80 steel more than 15mm can be effectively solved. The hot rolling process provided by the invention is practical and feasible and produces less loss on a rolling machine, a reeling machine and the like, and the qualifying rate of the DWTT properties of a product can reach up to more than 99%.

Owner:武钢集团有限公司

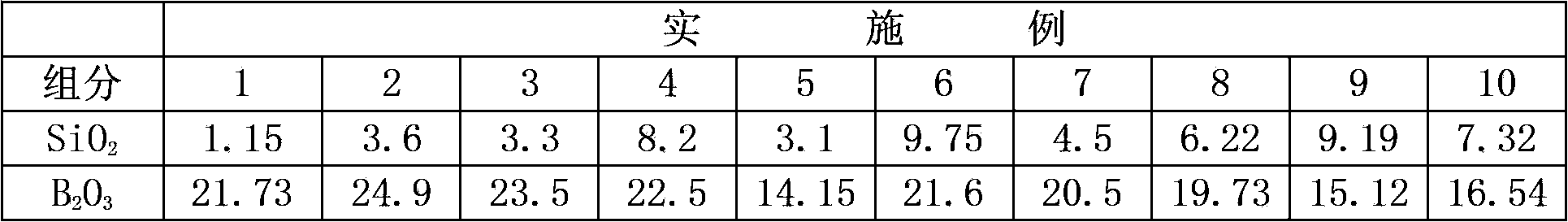

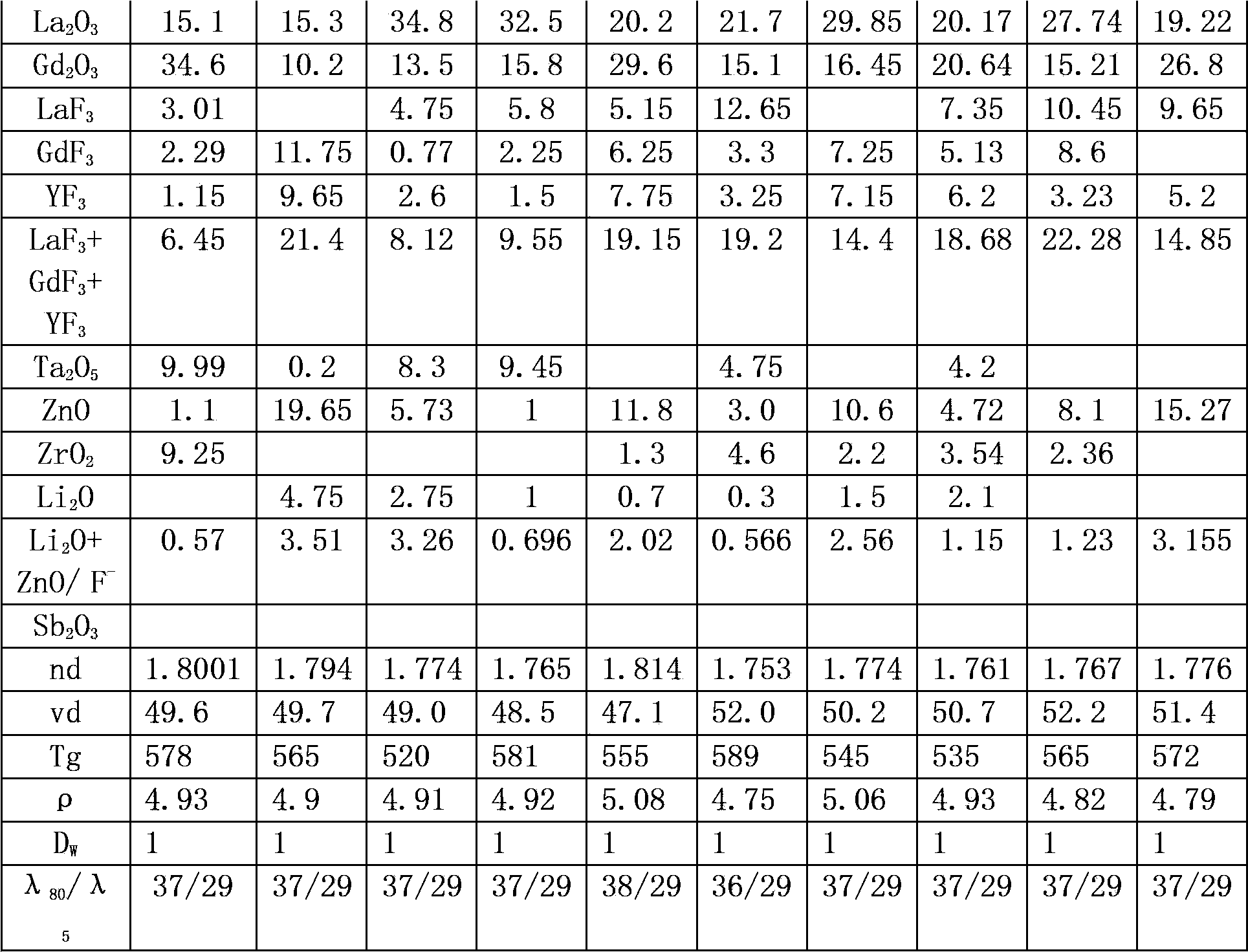

Optical glass used for precision mould pressing, glass prefab, optical element and optical instrument

ActiveCN103626394ALow dispersion performanceImprove uniformity and consistencyGlass pressing apparatusGlass productionRare-earth elementOptical instrument

The invention provides high-refraction low-dispersion optical glass used for precision mould pressing, a glass prefab formed by the optical glass, an optical element formed by the optical glass, and an optical instrument formed by the optical glass. The optical glass comprises following components by weight: 1-10% of SiO2, 10-25% of B2O3, 15-35% of La2O3, 10-35% of Gd2O3, 1-20% of ZnO, and at least one selected from LaF3, GdF3 and YF3. The refractive index of the optical glass is 1.75-1.82 and the Abbe number of the optical glass is 45-52. F<-> is introduced by utilization of a manner of combining with rare earth elements, and therefore the low dispersion performances required of the optical glass can be achieved and the uniformity and consistency of the glass can be increased. By a reasonable design of the combination ratio of the Li2O, the ZnO and the F, stability of the glass can be improved effectively, the quality level of the glass can be increased and the transistion temperature of the glass can be reduced, thus facilitating compression molding.

Owner:CDGM OPTICAL GLASS

Precisely pressed optical glass

ActiveCN1772671AExcellent devitrification resistanceImprove transmittanceDevitrificationRefractive index

The present invention provides one kind of precisely pressed optical glass. The optical glass consists of SiO2 8-30 wt%, B2O3 6-25 wt%, ZnO 8-30 wt%, Nb2O5 0.5-19 wt%, BaO 5-26 wt%, Li2O 0.5-7 wt% and ZrO2 1-6 wt% chemically. The optical glass of the present invention has refractivity of 1.65-1.74, Abbe number of 36-45, conversion temperature lower than 500 deg.c, high chemical stability, low liquid phase temperature, high devitrification resistance, high light permeability and low specific weight, and is especially suitable for precise mold pressing to form aspherical lens, spherical lens and other optical elements.

Owner:CDGM OPTICAL GLASS

Leadless low-melting point glasses with very high refractive index and method for making same

InactiveCN101323502ALower glass transition temperatureHigh refractive indexMetallurgyRefractive index

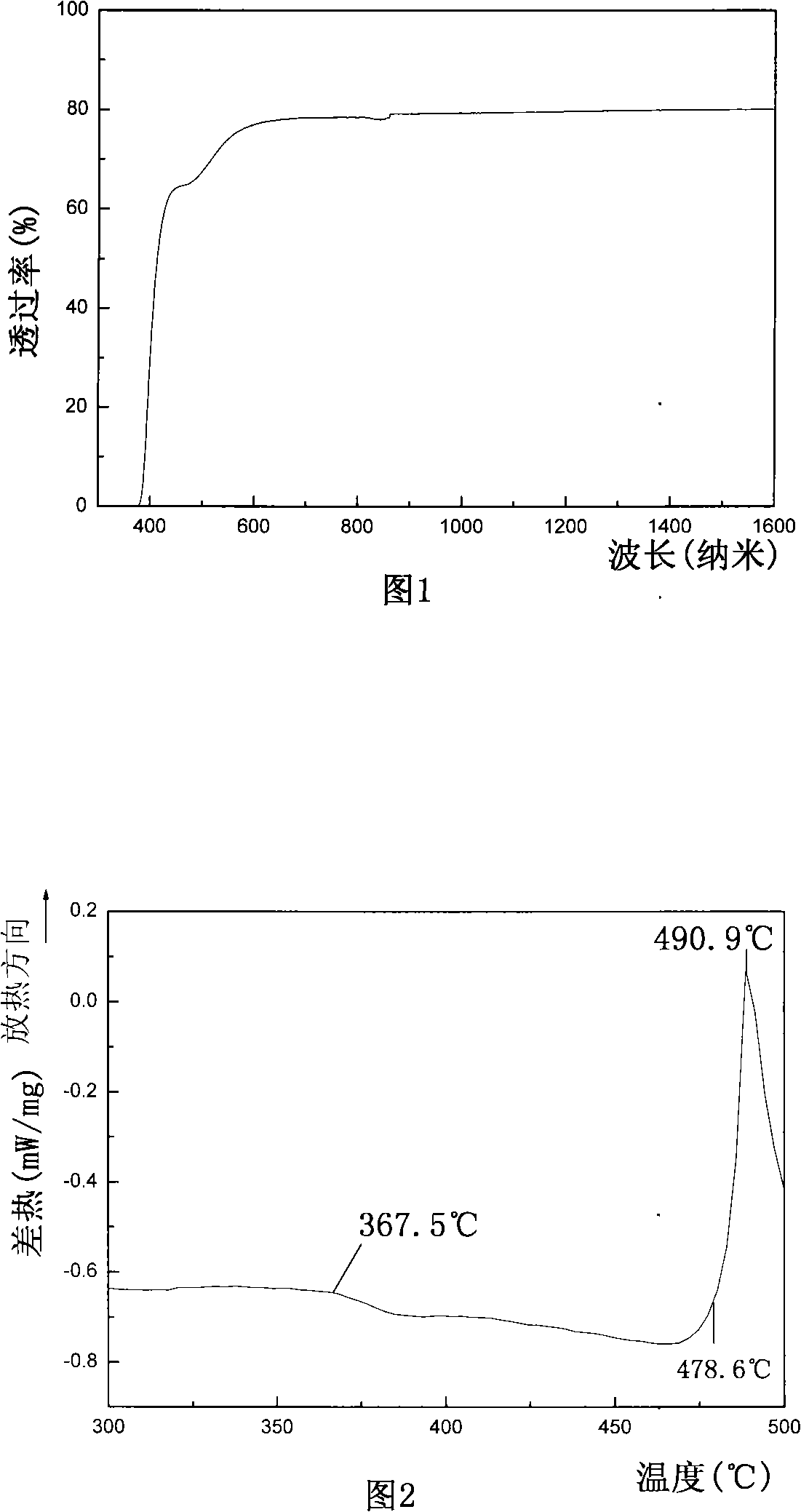

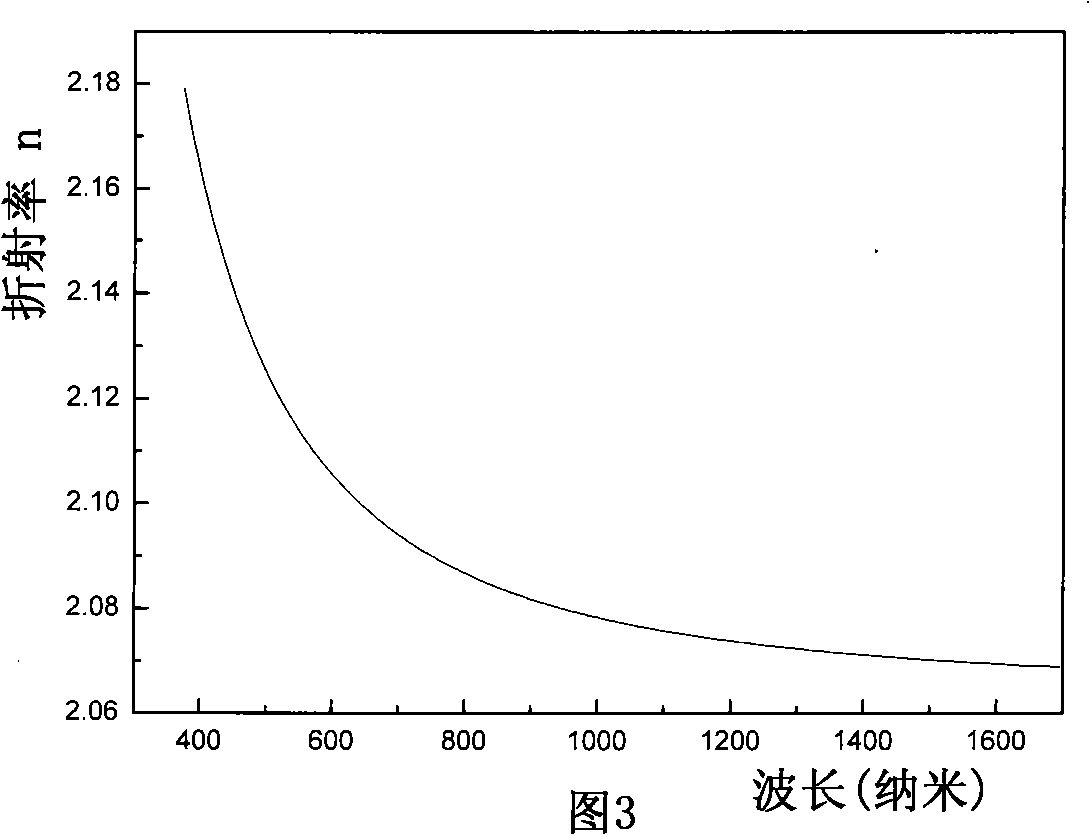

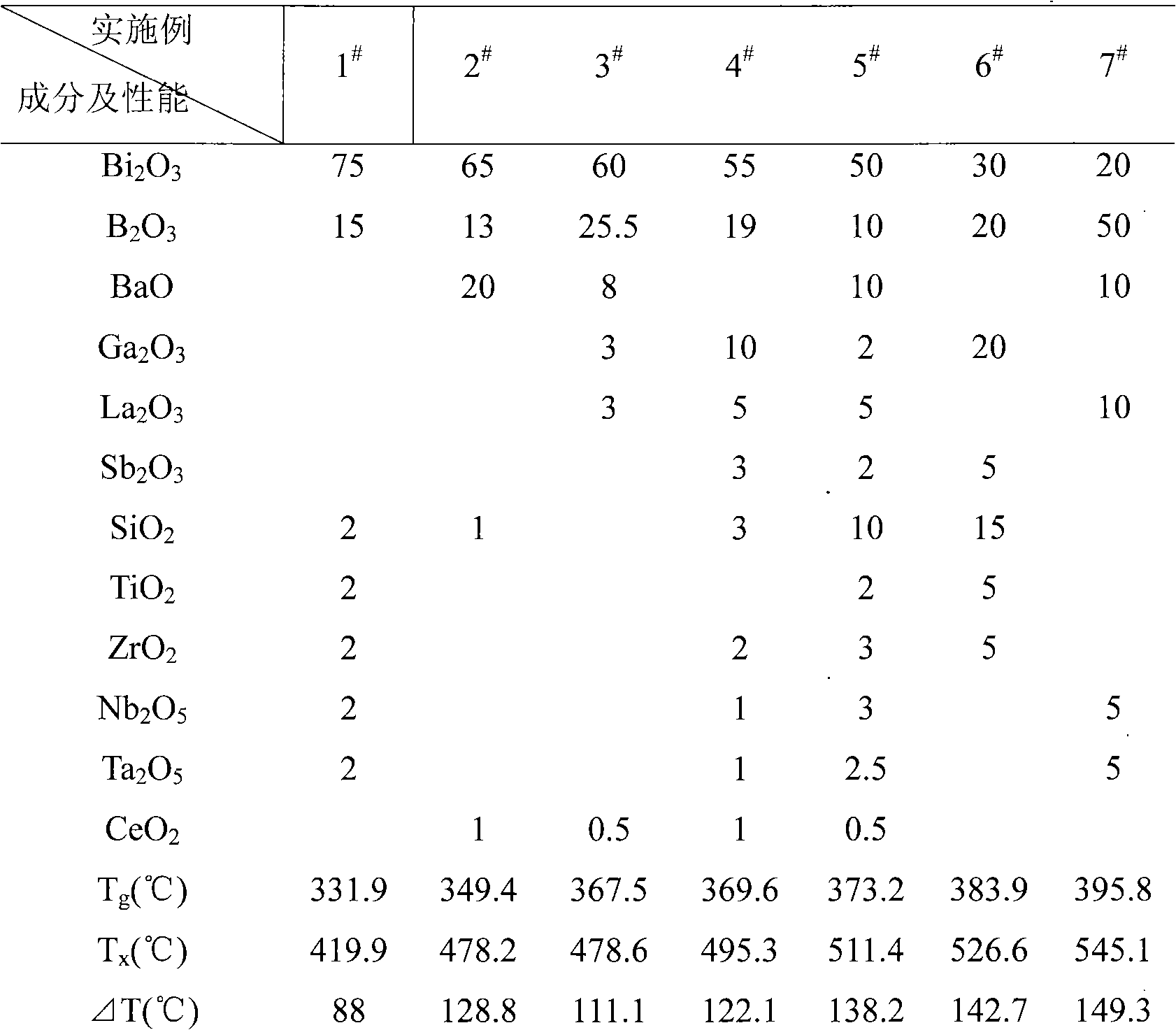

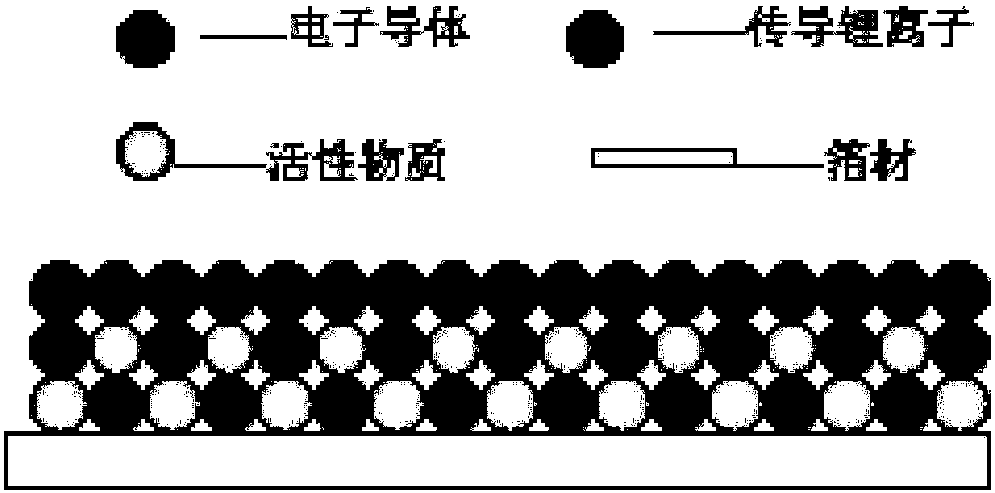

The invention relates to a leadless low-melting-point bismuthate glass and a corresponding preparation method. The glass consists of Bi2O3 (20 to 75), B2O3 (10 to 50), BaO (0 to 20), Ga2O3 (0 to 20), La2O3 (0 to 10), Sb2O3 (0 to 5), SiO2 (0 to 15), TiO2 (0 to 5), ZrO2 (0 to 5), Nb>O5 (0 to 5), Ta2O5 (0 to 5) and CeO2 (0 to 1). The glass of the invention is provided with glass transition temperature T<g> which is less than or equal to 395.8 DEG C, and a thermal stability parameter Delta T which is greater than or equal to 88 DEG C, and the refractive index n<d> which is up to 2.182; and the highest transmittance can reach 80 percent in a wave range between 400nm and 1600nm. The glass is suitable to be adopted as material with low fusion-point and high refractive index.

Owner:SHANGHAI INST OF OPTICS & FINE MECHANICS CHINESE ACAD OF SCI

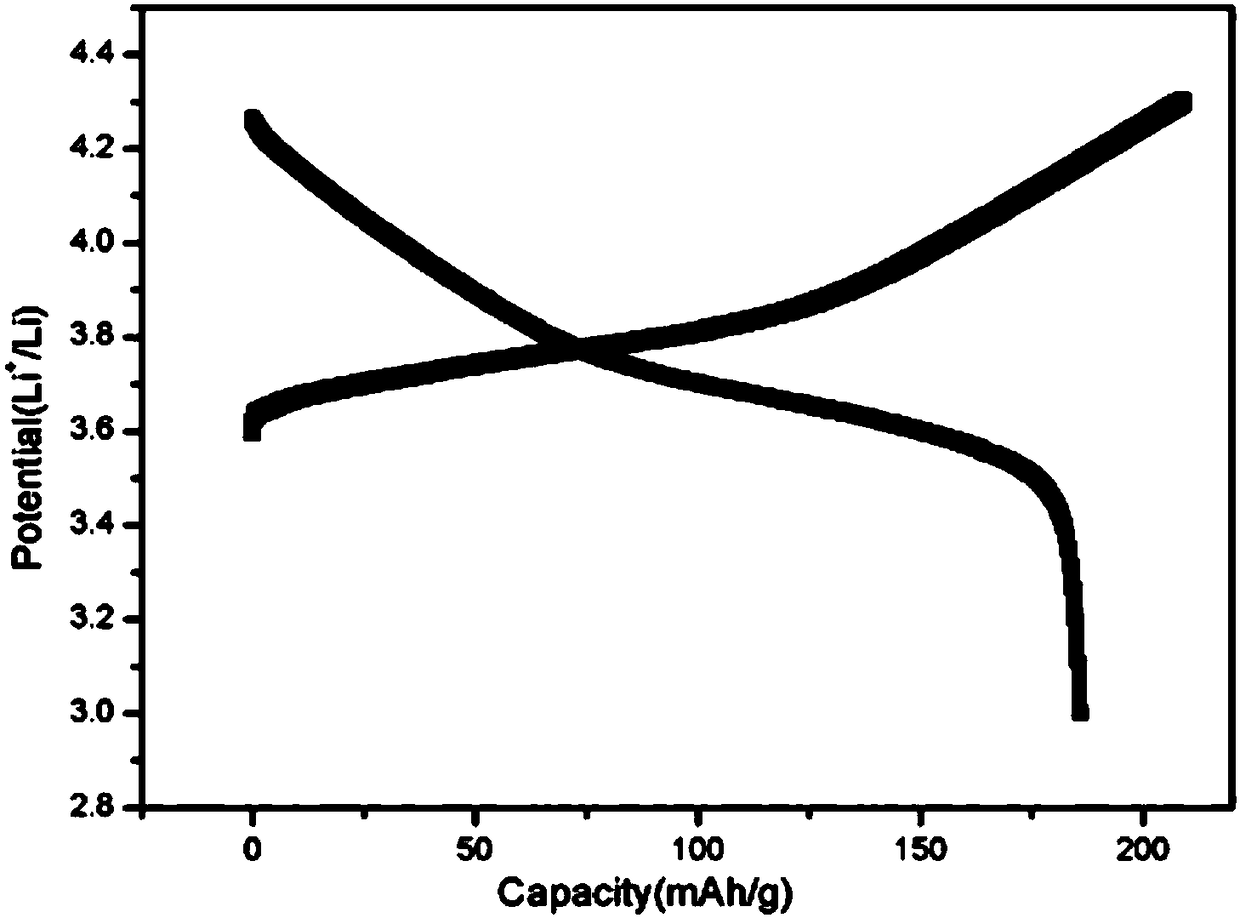

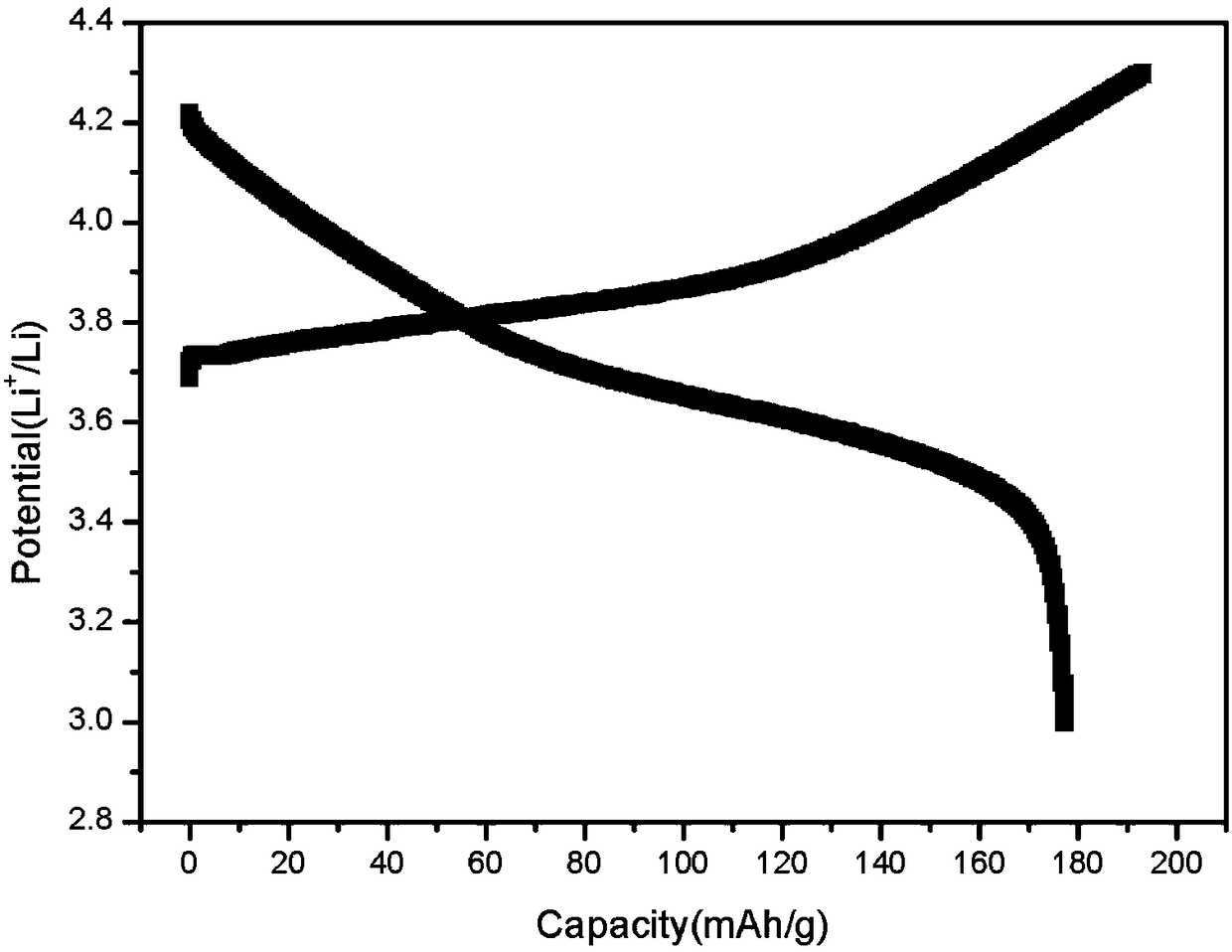

Preparation method of polymer-added composite cathode and application of composite cathode in solid-state battery

ActiveCN108232286ALower transition temperatureInhibits crystal formationSolid electrolytesFinal product manufactureSolid state electrolyteElectrical conductor

The invention discloses a preparation method of a polymer-added composite cathode and application of the composite cathode in a solid-state battery. The composite cathode is characterized by comprising a composite cathode pole piece and a solid-state electrolyte material, wherein the composite cathode pole piece is prepared from a cathode active material, an additive, a conductive agent and a binder; the solid-state electrolyte material is prepared from a high-molecular polymer with a long chain segment, lithium salt conducting a coordination reaction with the high-molecular polymer, and a fast ion conductor. The invention also discloses a preparation method of the polymer-added composite cathode applied to a solid-state lithium battery. The preparation method is characterized by comprising the following steps: preparing a cathode pole piece, preparing a solid-state electrolyte membrane. The preparation method disclosed by the invention has the following advantages: the arrangement regularity of polyoxyethylene molecular chains is damaged by the effect among the molecular chains of several polymers, the glass-transition temperature is lowered, the crystal formation is inhibited, and the ionic conductance is enhanced.

Owner:QINGTAO KUNSHAN ENERGY DEV CO LTD +1

Lead-free optical glasses with a hard flint position

Optical glasses are described, which are useful for imaging, sensors, microscopy, medical technology, digital protection, photolithography, laser technology, wafer / chip technology, as well as telecommunication, optical communications engineering and optics / lighting in the automotive sector, with a refractive index of 1.80≦nd≦1.95 and an Abbe value from 19≦νd≦28 with excellent chemical resistance and stability to crystallization. These optical glasses have a composition, in weight % based on oxide content, of: P2O5, 14-35; Nb2O5, 45-50; Li2O, 0-4; Na2O, 0-4; K2O, 0.5-5; BaO, 17-23; ZnO, 0.1-5; TiO2, 1-<5; ZrO2, 06; and Sb2O3, 0.1-2.

Owner:SCHOTT AG

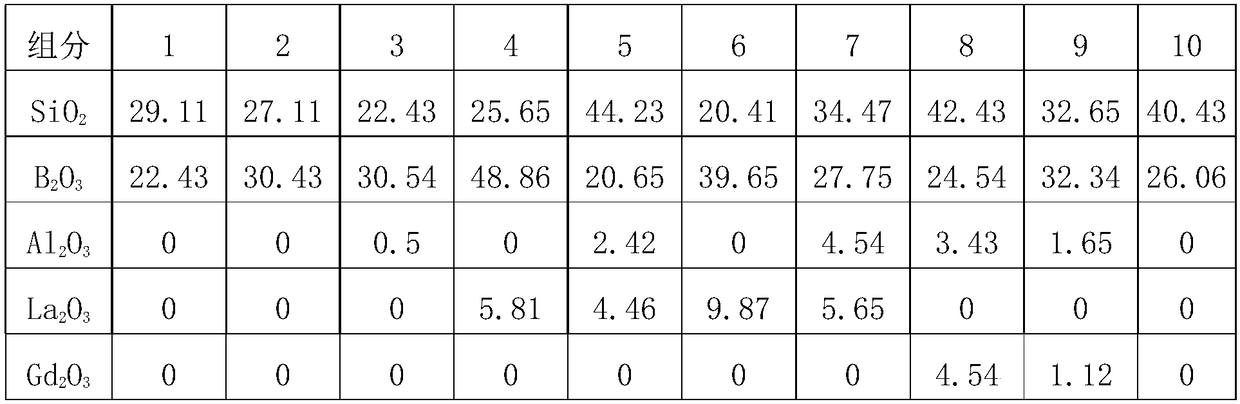

Optical glass, glass prefabticated member, optical element and optical instrument

PendingCN109250901ALower transition temperatureExcellent transition temperatureOptical elementsRefractive indexAlkaline earth oxides

The invention provides optical glass, wherein the range of the refractive index nd of the optical glass is 1.55 to 1.65; the range of the abbe number vd of the optical glass is 56 to 65; and the optical glass is prepared from the following components in percentage by weight: 20% to 45% of SiO2, 20% to 50% of B2O3, 0% to 10% of Al2O3, 0% to 10% of La2O3, 10% to 30% BaO, 2% to 15% of ZnO and 2% to 12% of Li2O. According to the optical glass, the glass transition temperature is lowered through optimizing the contents of alkaline earth metal oxides and a network former and regulating the contentsof the Li2O and the B2O3; the chemical stability of the glass is promoted by introducing the Al2O3 and the ZnO in a proper proportion; and precision mold pressing optical glass with excellent chemicalstability and the low transition temperature is obtained.

Owner:CDGM OPTICAL GLASS

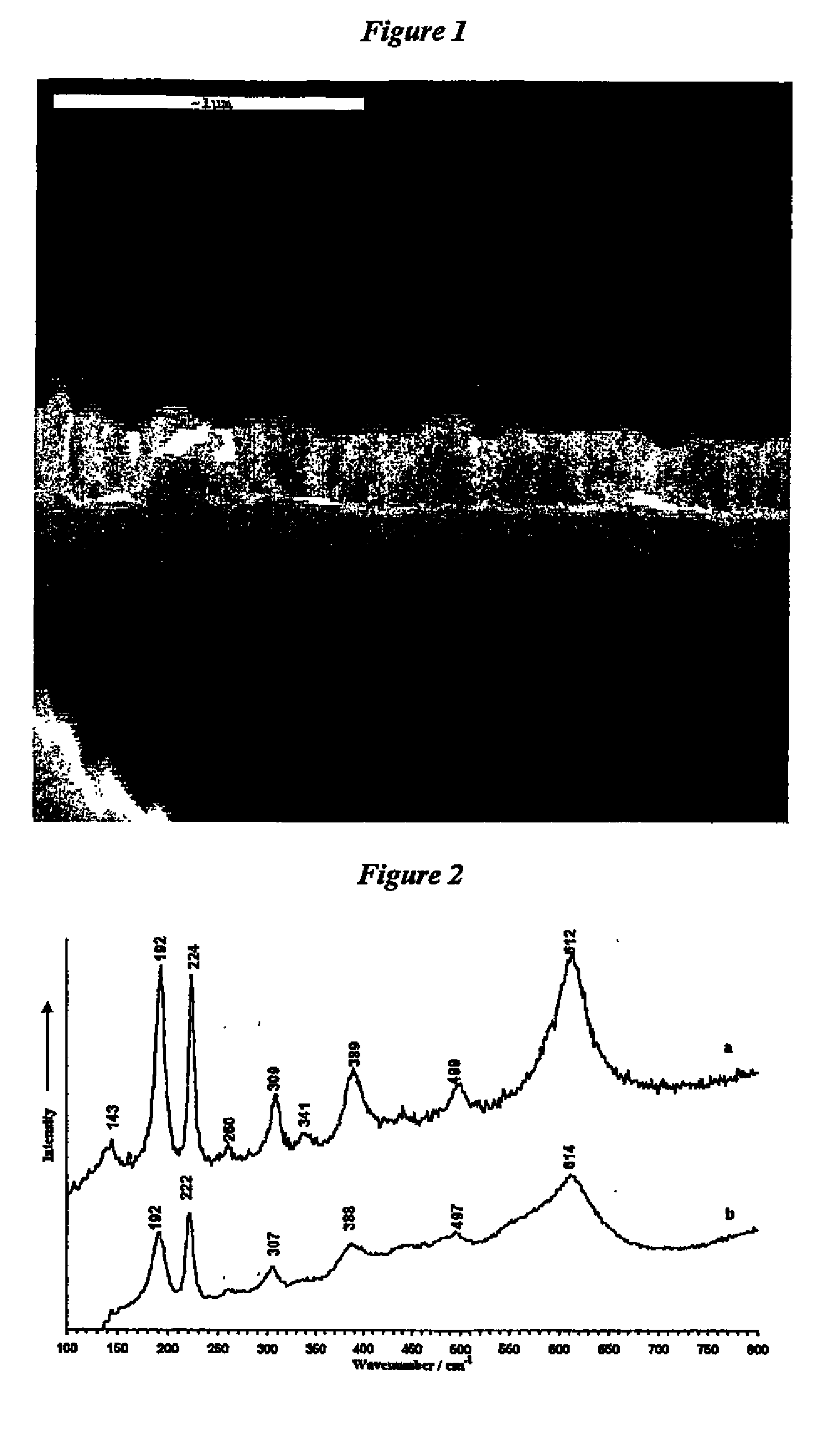

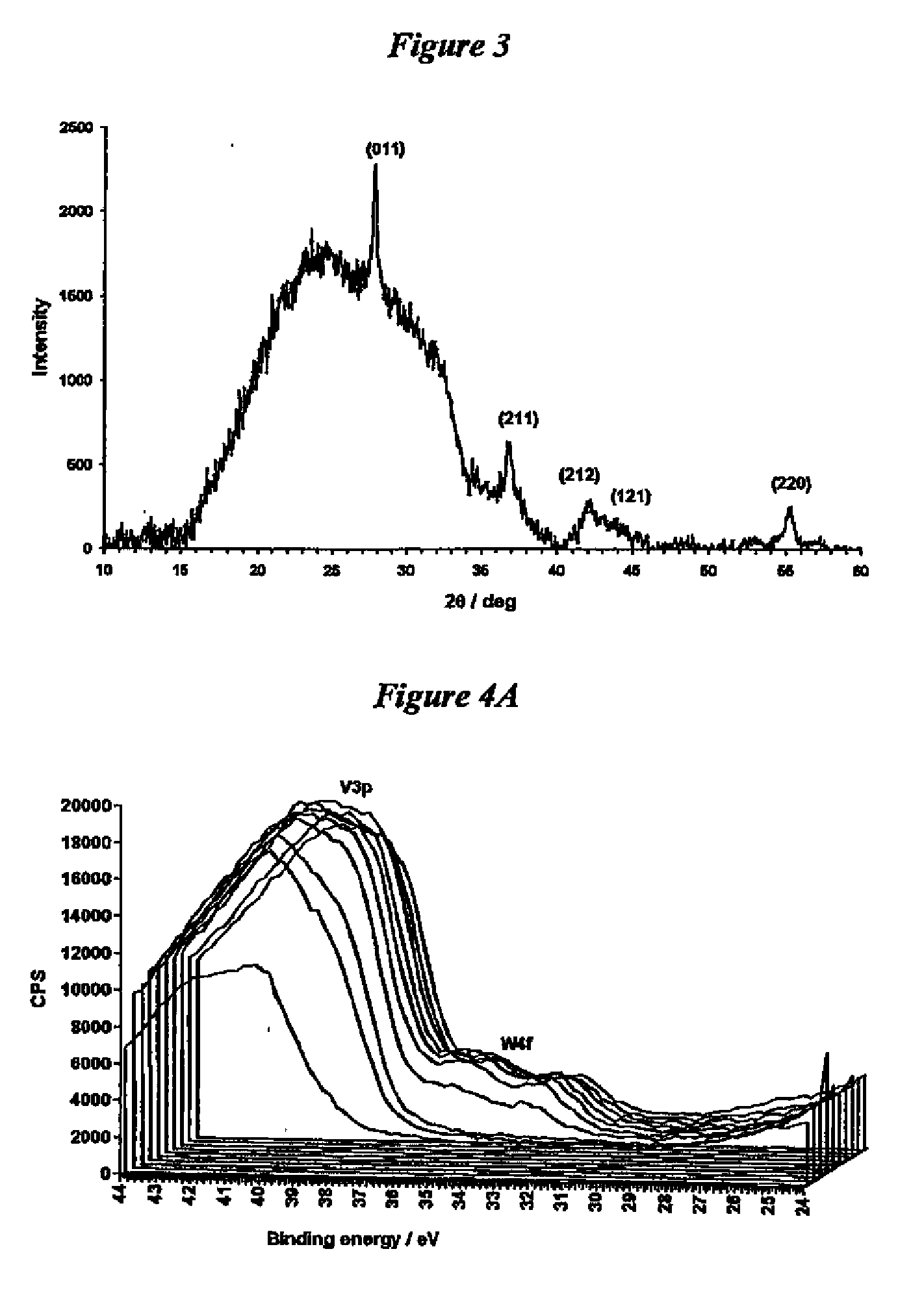

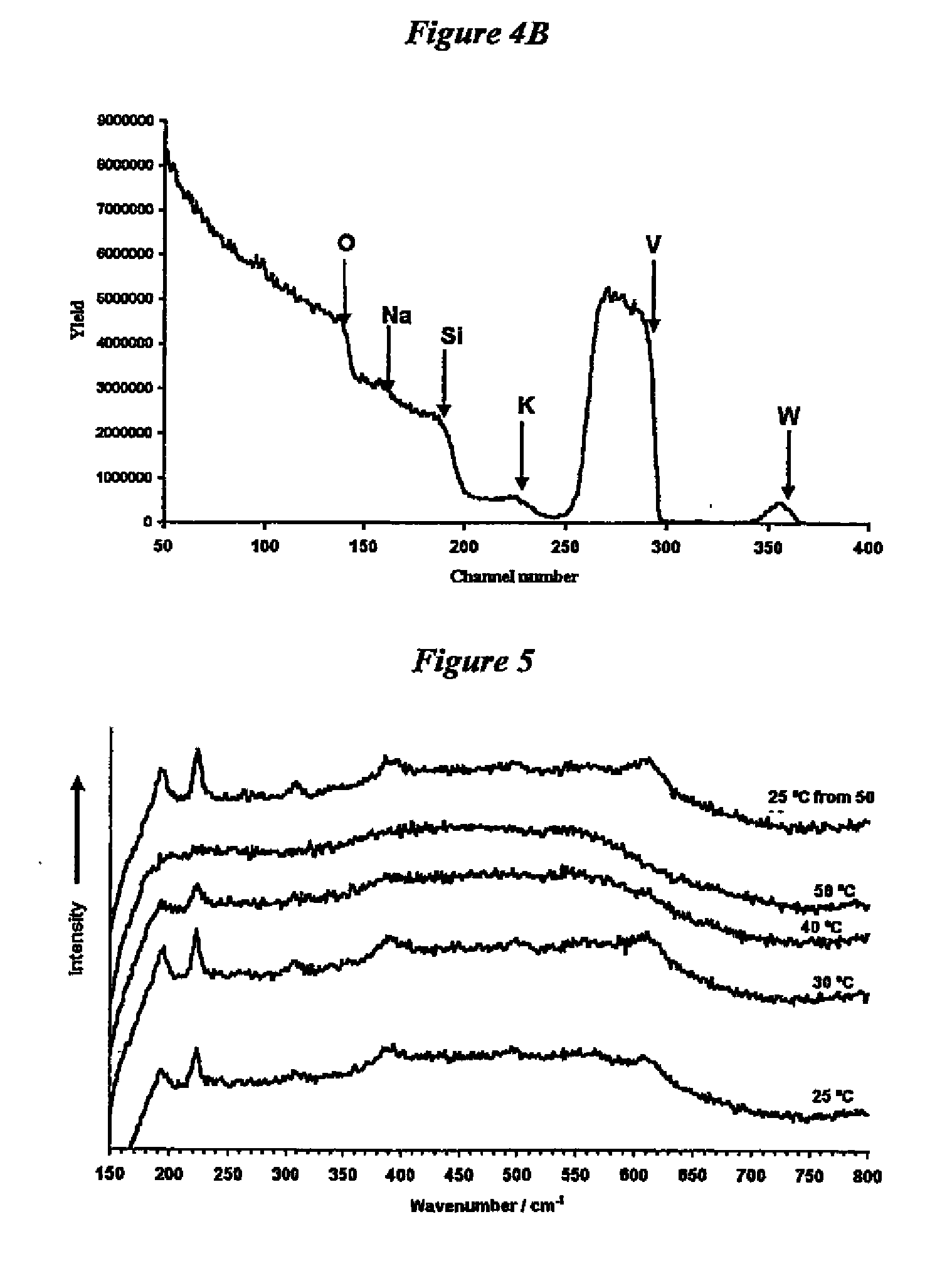

Thermochromic coatings

InactiveUS20070048438A1Improved mechanical propertyImprove adhesionVacuum evaporation coatingSputtering coatingCompound (substance)Oxide

The present invention provides the use of atmospheric pressure chemical vapour deposition (APCVD) for producing a film of thermochmmic transition metal-doped vanadium (iN) oxide on a substrate. Specifically, the invention prevides a method of producing a film of thermochromic transition metal-doped vanadium (IV) oxide on a substrate by atmospheric pressure chemical vapour deposition comprising the steps of: (i) reacting together (a) a vanadium precursor, (b) a transition metal dopant precursor, and (c) an oxygen precursor in an atmospheric pressure chemical vapour deposition reactor to form thermochromic transition metal-doped vanadium (IV) oxide, and (ii) depositing the thermochromic transition metal-doped vanadium (IV) oxide onto the substrate. A preferred transition metal dopant is tungsten. The invention also provides transition metal-doped vanadium (TV) oxide, films thereof and substrates (e.g., glass substrates) coated with a film of transition metal-doped vanadium (IV) oxide. Intelligent window systems, infrared modulators and data storage devices comprising such substrates are also provided.

Owner:UNIV COLLEGE OF LONDON

Low-melting glass containing nano zinc oxide and preparation thereof

The invention discloses a glass binder containing nanometer zinc oxide and a preparation method thereof. The glass binder is characterized in that the weight percentages of raw materials are as follows: Bi2O3 is 50-80 percent; B2O3 is 5-40 percent; ZnO is 5-30 percent; Al2O3 is 0.1-10 percent; SiO2 is 0.1-10 percent; MgO is 0.1-10 perent; CaO is 0.1-10 percent; and CuO is 0.1-10 percent. The preparation method comprises the following steps: the raw materials are fully mixed, wherein, the nanometer zinc oxide is finally added and mixed for producing a mixture; a crucible is put into an electric furnace at the temperature of 1100-1400 DEG C for preheating for 12-18 minutes; the mixture is added into a quartz crucible for melting at the melting temperature of 1100-1400 DEG C and heat-preserving for 5-40 minutes; the melted glass slurry is poured into water, or is milled into powder by a ball mill after tabletting, or is casted into powder, slurry, rods, powder pressed billets and the like, all of which are required when sealing is carried out; and then the detection and the package are carried out. The invention has the advantages that the application forms can be the powder, the slurry, the rods, the powder pressed billets, and the like; the cost performance is high; and the market development prospect is wide.

Owner:陈培

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com