Patents

Literature

78results about How to "Chemical resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Plasma curing process for porous silica thin film

InactiveUS6558755B2Low dielectric constantHigh elastic modulusSilicaSemiconductor/solid-state device manufacturingSilicon dioxideHeat treated

Low dielectric constant films with improved elastic modulus. The method of making such coatings involves providing a porous network coating produced from a resin containing at least 2 Si-H groups and plasma curing the coating to convert the coating into porous silica. Plasma curing of the network coating yields a coating with improved modulus, but with a higher dielectric constant. The costing is plasma cured for between about 15 and about 120 seconds at a temperature less than or about 350° C. The plasma cured coating can optionally be annealed. Rapid thermal processing (RTP) of the plasma cured coating reduces the dielectric constant of the coating while maintaining an improved elastic modulus as compared to the plasma cured porous network coating. The annealing temperature is typically loss than or about 475° C., and the annealing time is typically no more than or about 180 seconds. The annealed, plasma cured coating has a dielectric constant in the range of from about 1.1 to about 2.4 and an improved elastic modulus.

Owner:AXCELIS TECHNOLOGIES +1

Plasma curing process for porous silica thin film

InactiveUS20010038919A1High elastic modulusLow dielectric constantSilicaPretreated surfacesSilicon dioxideMaterials science

Low dielectric constant films with improved elastic modulus. The method of making such coatings involves providing a porous network coating produced from a resin containing at least 2 Si-H groups and plasma curing the coating to convert the coating into porous silica. Plasma curing of the network coating yields a coating with improved modulus, but with a higher dielectric constant. The coating is plasma cured for between about 15 and about 120 seconds at a temperature less than about 350° C. The plasma cured coating can optionally be annealed. Rapid thermal processing (RTP) of the plasma cured coating reduces the dielectric constant of the coating while maintaining an improved elastic modulus as compared to the plasma cured porous network coating. The annealing temperature is typically less than about 475° C., and the annealing time is typically no more than about 180 seconds. The annealed, plasma cured coating has a dielectric constant in the range of from about 1.1 to about 2.4 and an improved elastic modulus.

Owner:AXCELIS TECHNOLOGIES +1

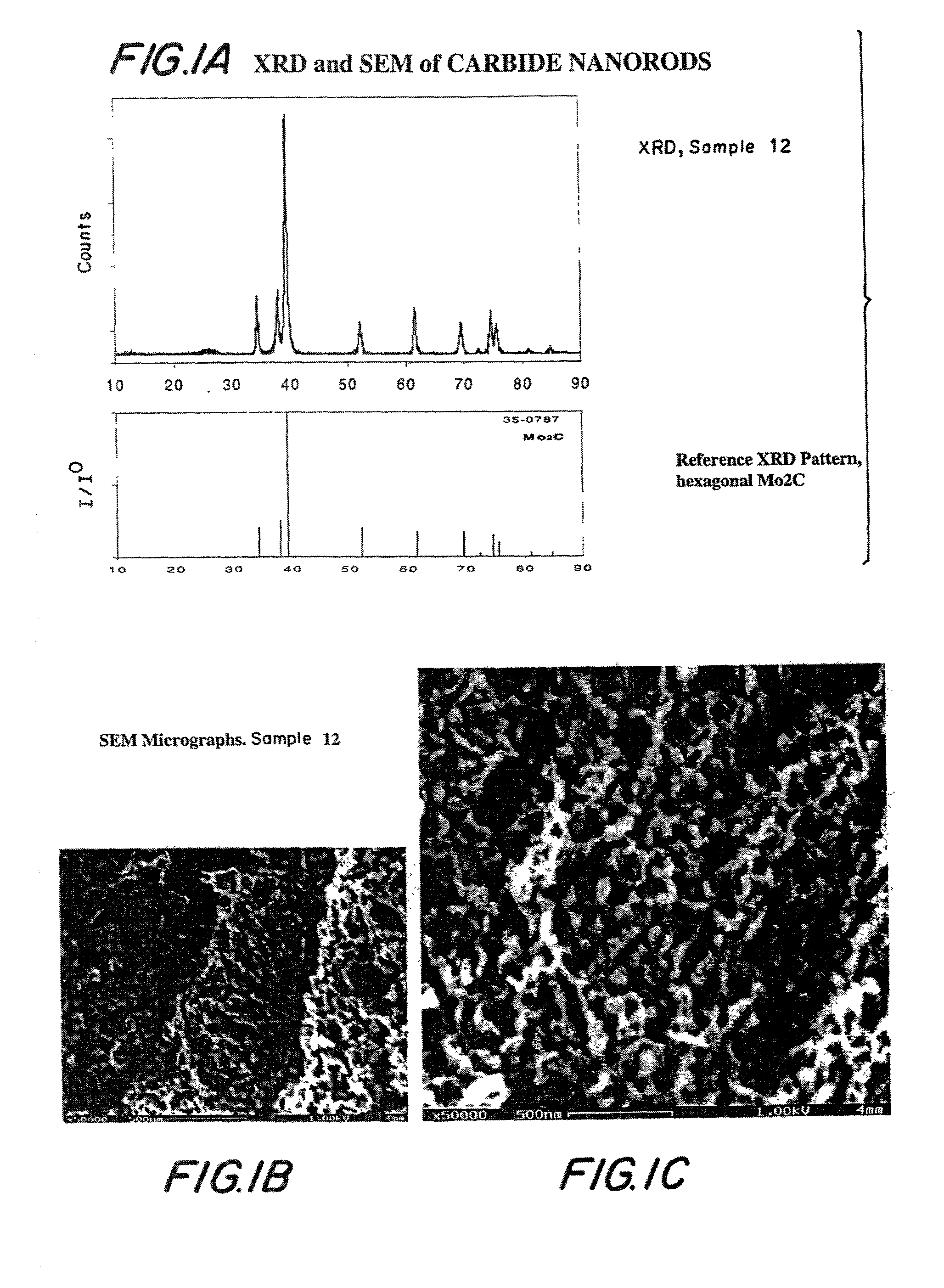

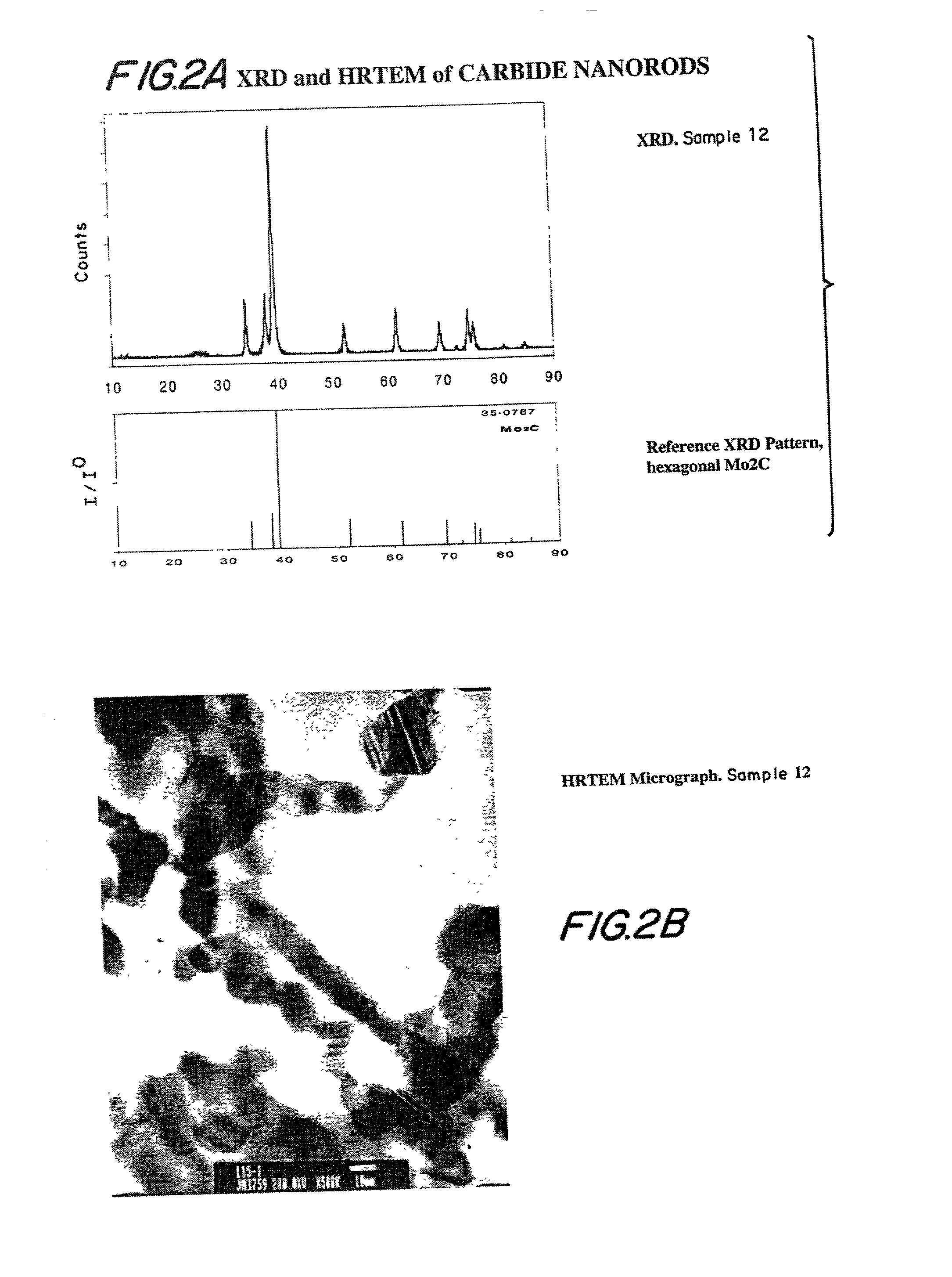

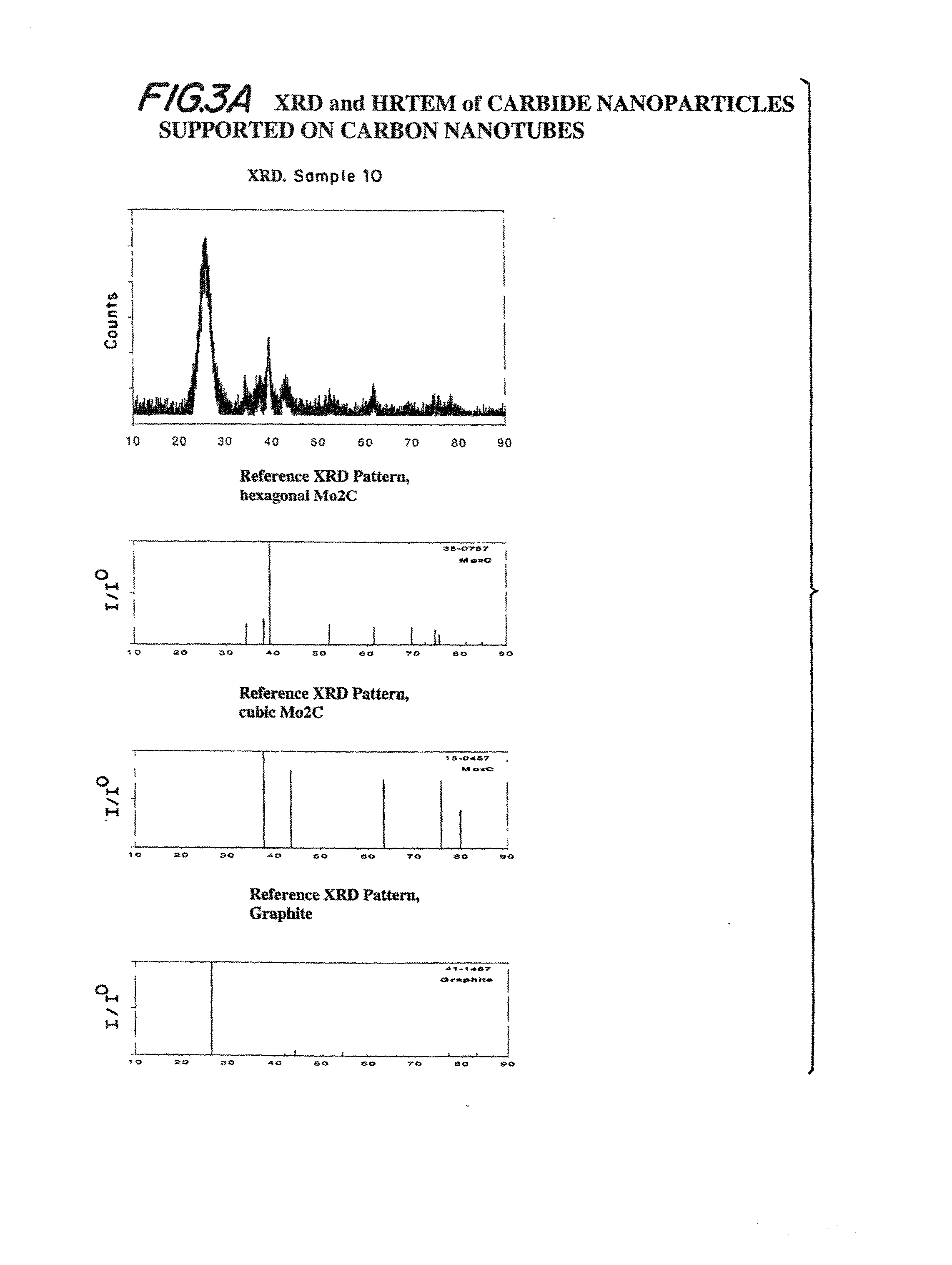

Method of using carbide and/or oxycarbide containing compositions

InactiveUS20020121460A1Facilitated DiffusionHigh porosityMaterial nanotechnologyHydrocarbon by isomerisationFluid phaseChemical reaction

Compositions including carbide-containing nanorods and / or oxycarbide-containing nanorods and / or carbon nanotubes bearing carbides and oxycarbides and methods of making the same are provided. Rigid porous structures including oxycarbide-containing nanorods and / or carbide containing nanorods and / or carbon nanotubes bearing carbides and oxycarbides and methods of making the same are also provided. The compositions and rigid porous structures of the invention can be used either as catalyst and / or catalyst supports in fluid phase catalytic chemical reactions. Processes for making supported catalyst for selected fluid phase catalytic reactions are also provided.

Owner:HYPERION CATALYSIS INT

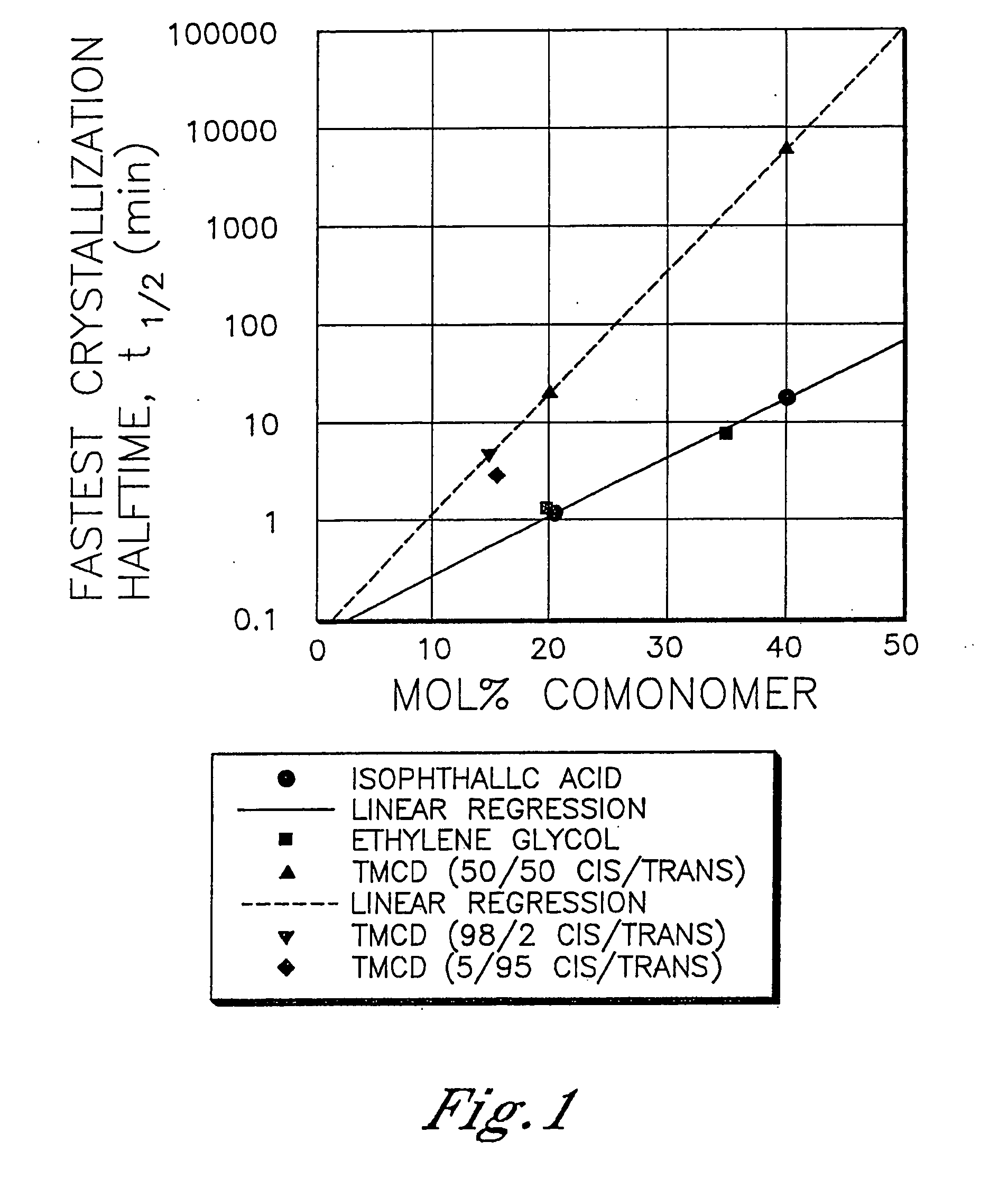

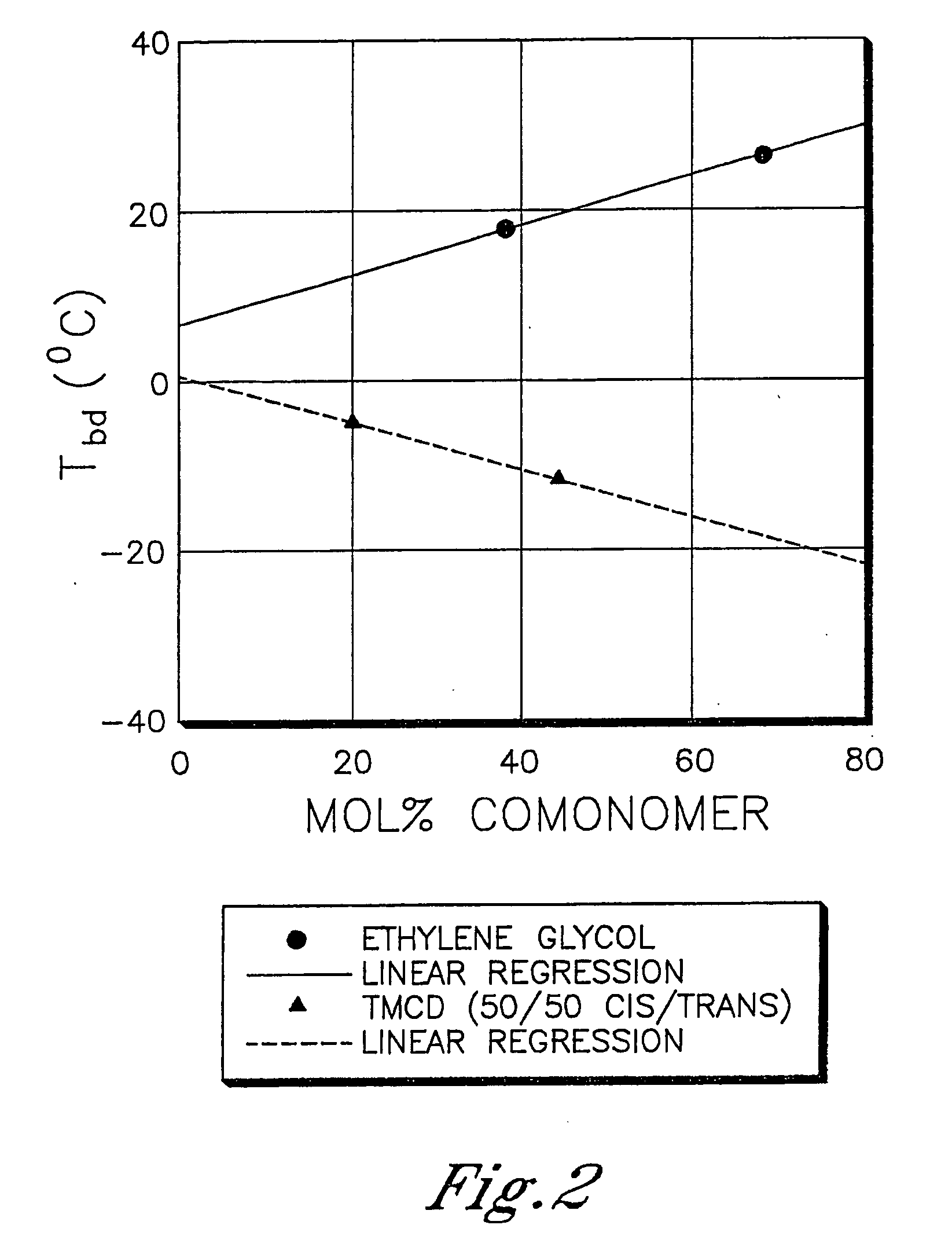

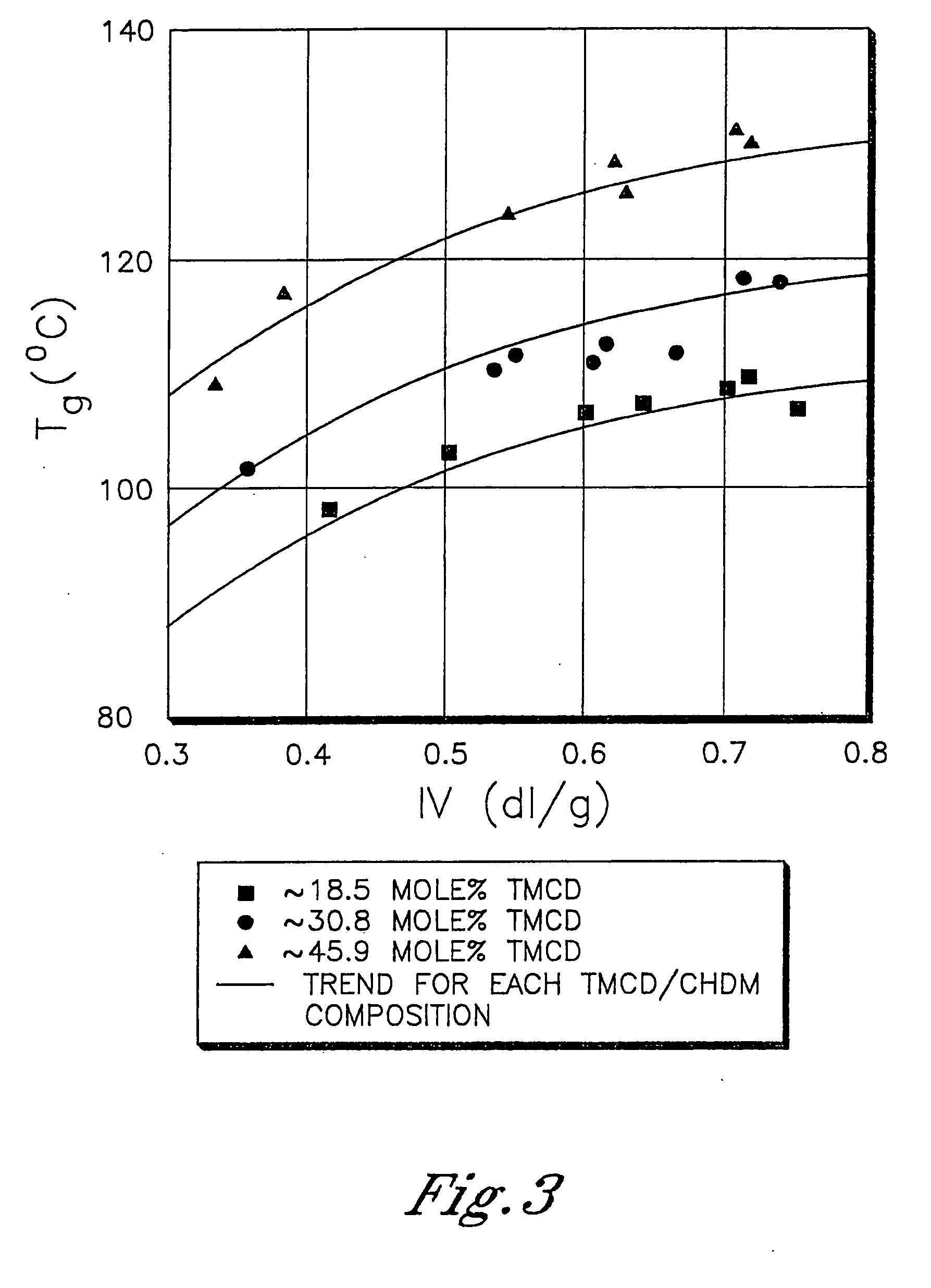

Polyester compositions containing cyclobutanediol having a certain combination of inherent viscosity and high glass transition temperature and articles made therefrom

Described are polyester compositions comprising at least one polyester which comprises terephthalic acid residues, 2,2,4,4-tetramethyl-1,3-cyclobutanediol, and cyclohexanedimethanol, wherein the inherent viscosity and the Tg of the polyester provides for certain polyester properties. The polyesters may be manufactured into articles such as fibers, films, bottles or sheets.

Owner:EASTMAN CHEM CO

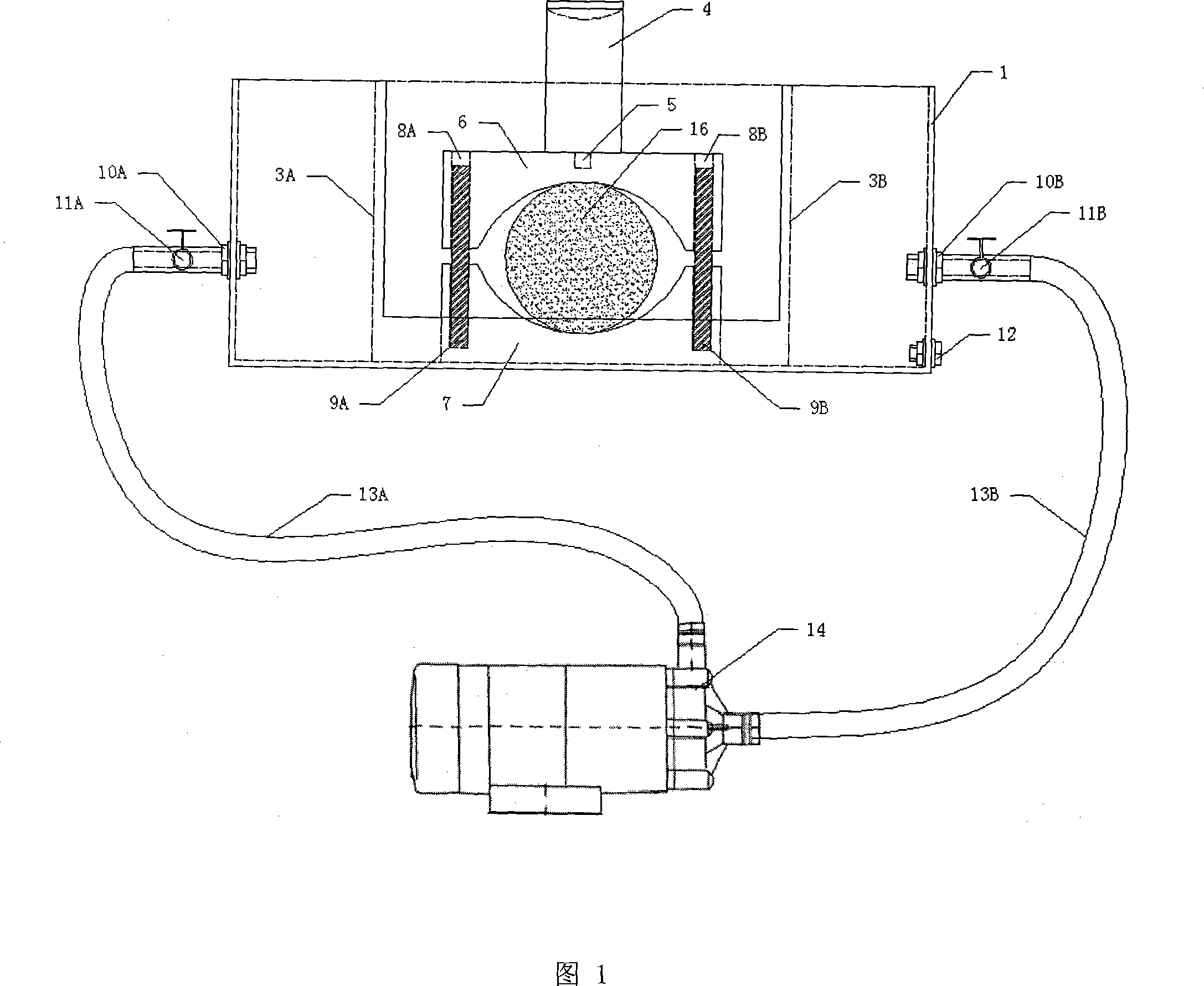

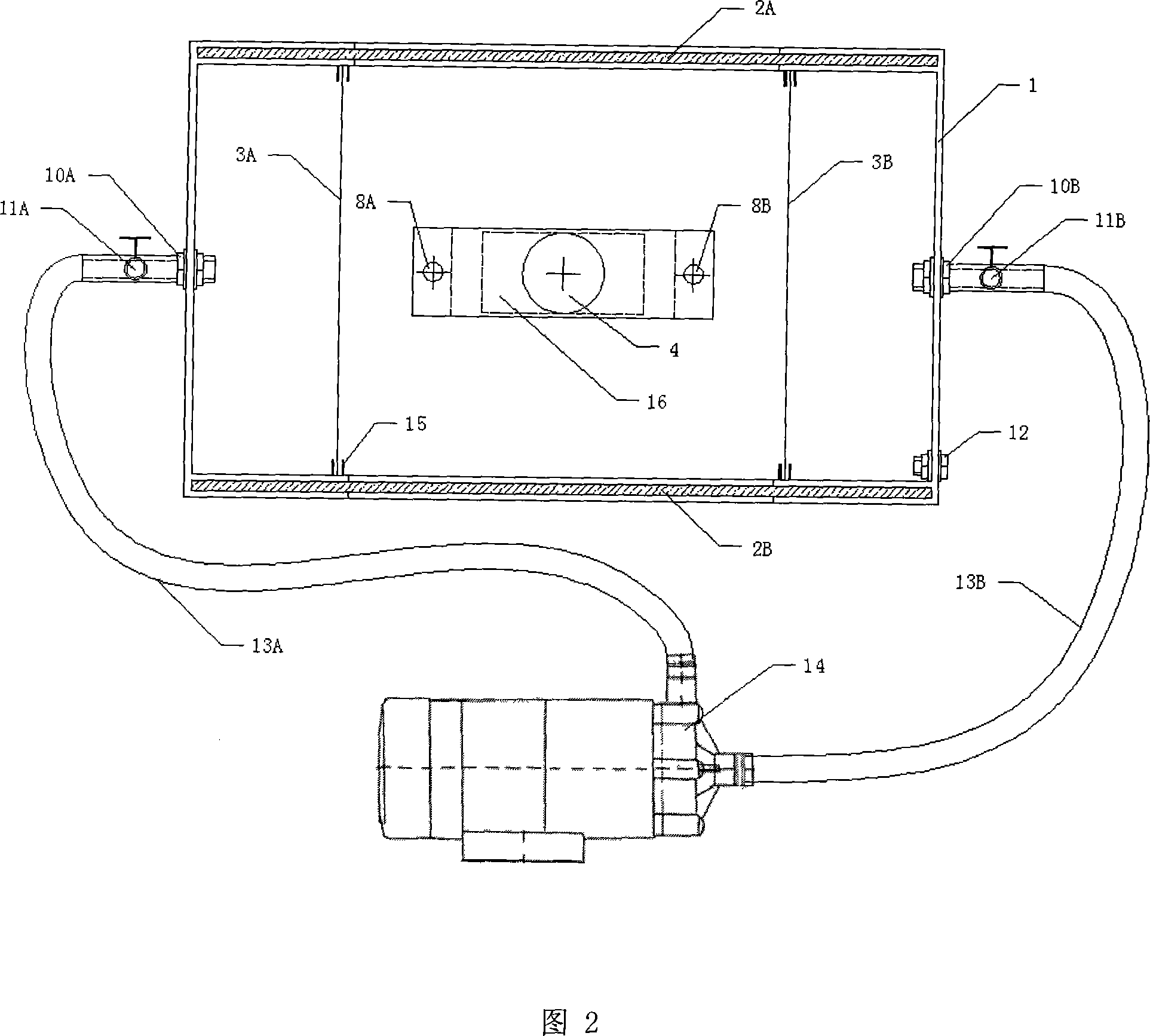

Rock mechanics experiment loading unit for bittern flow field corrosion condition

InactiveCN101216391ASimple structureLow costWeather/light/corrosion resistanceEarth material testingSteel frameRock sample

The invention discloses a rock mechanical test loading device under brine corrosion conditions, comprising a container, a ball-end cylindrical indenter, the upper jaw of a fixture, the lower jaw of the fixture and a circulation pump. Glass cement is applied in two pre-reserved slits on a stainless steel frame, an organic glass plate is inserted into the slits, symmetrical screen sandwich grooves are welded on the container, screens are inserted into the symmetrical screen sandwich grooves, a drain hole on the bottom of the container is sealed by a screw plug and a rubber gasket, a ball valve is connected with the container, and the ball valve on the container is connected with a circulating pump through a transparent plastic hose. A rock sample splitting fixture is disposed in the container and consists of the arc-shaped upper jaw and the arc-shaped lower jaw of the fixture, and the upper jaw of the fixture is connected with the ball-end cylindrical indenter. The invention has simple structure and convenient operation, and can simulate the actual operating condition that brine and a flow field cooperatively act on a dissolution cavity in the cavity creating process of gas (oil) storage, thus obtaining more actual and reliable parameters detected by indoor test.

Owner:INST OF ROCK AND SOIL MECHANICS - CHINESE ACAD OF SCI

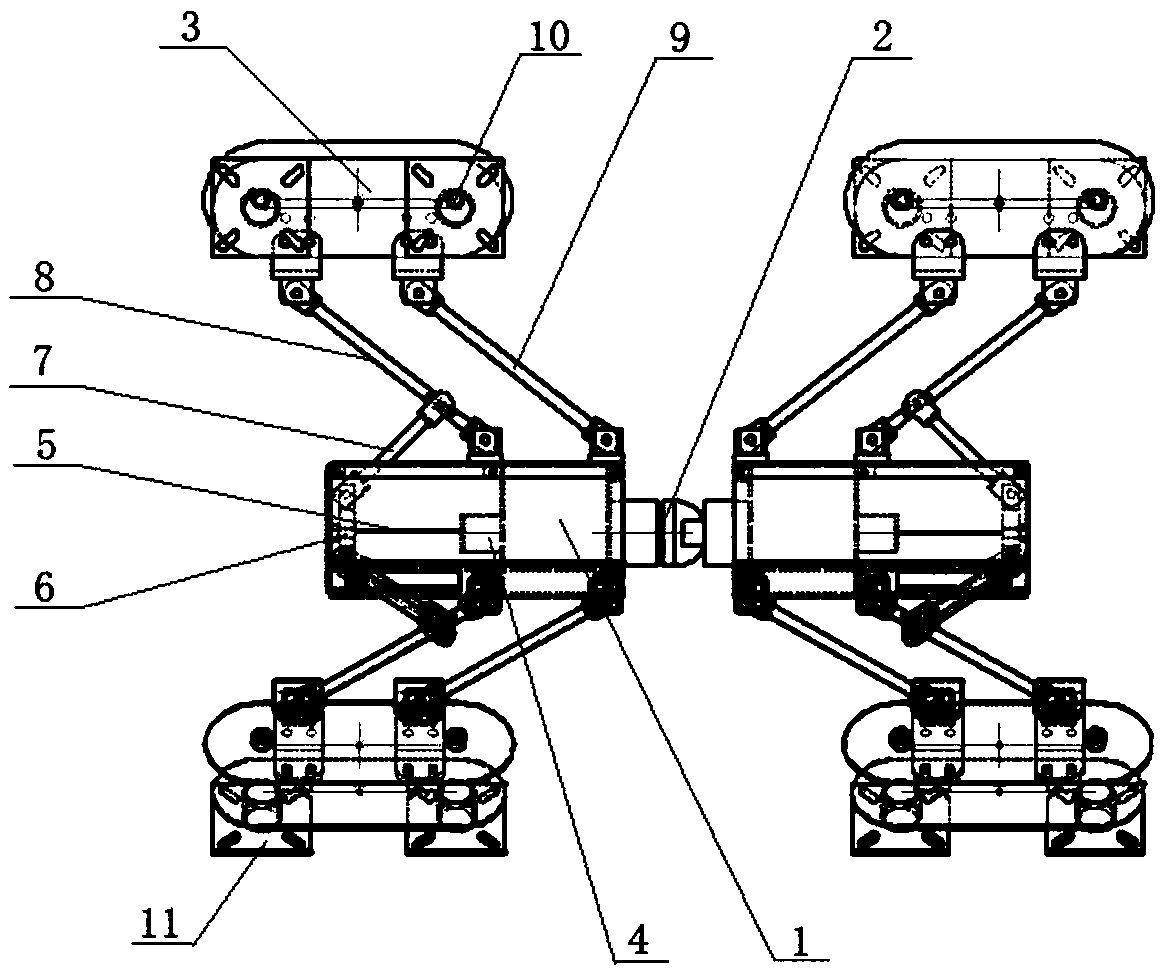

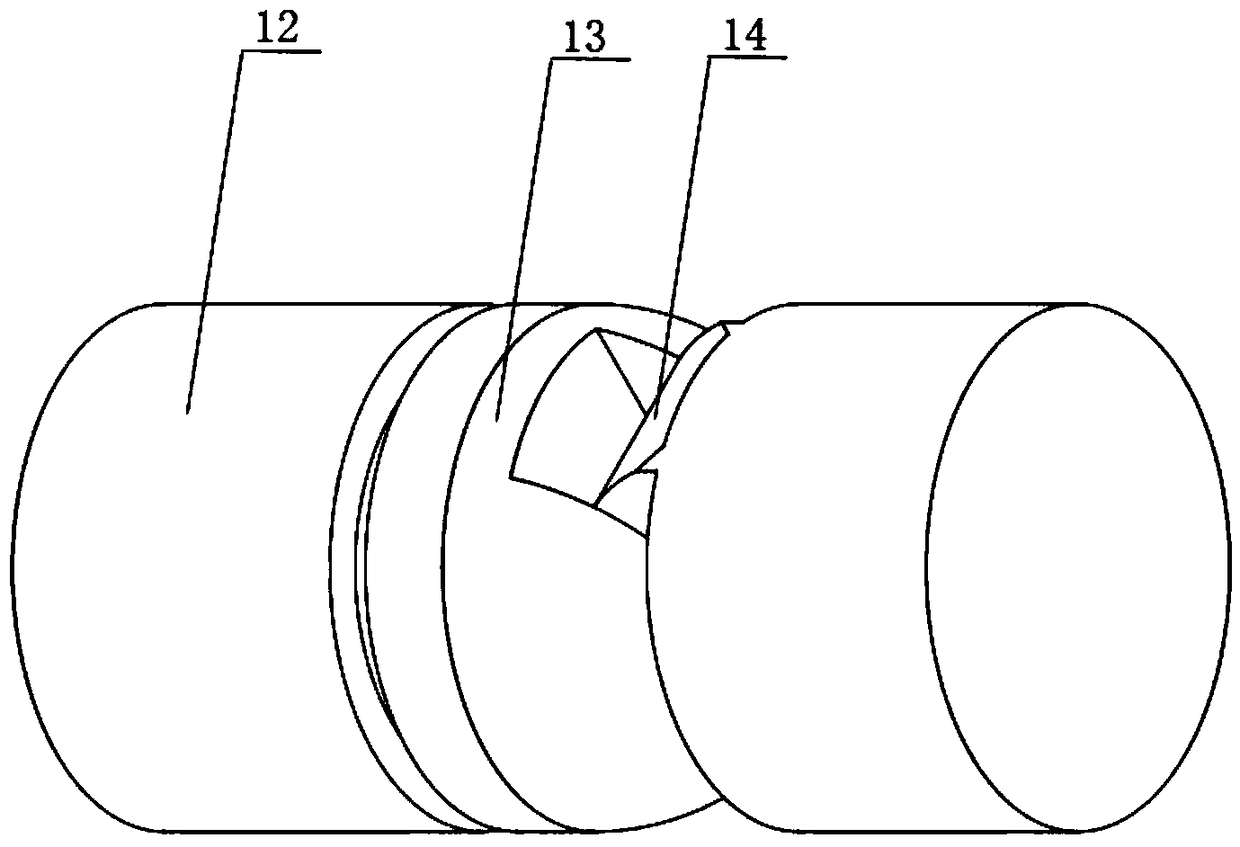

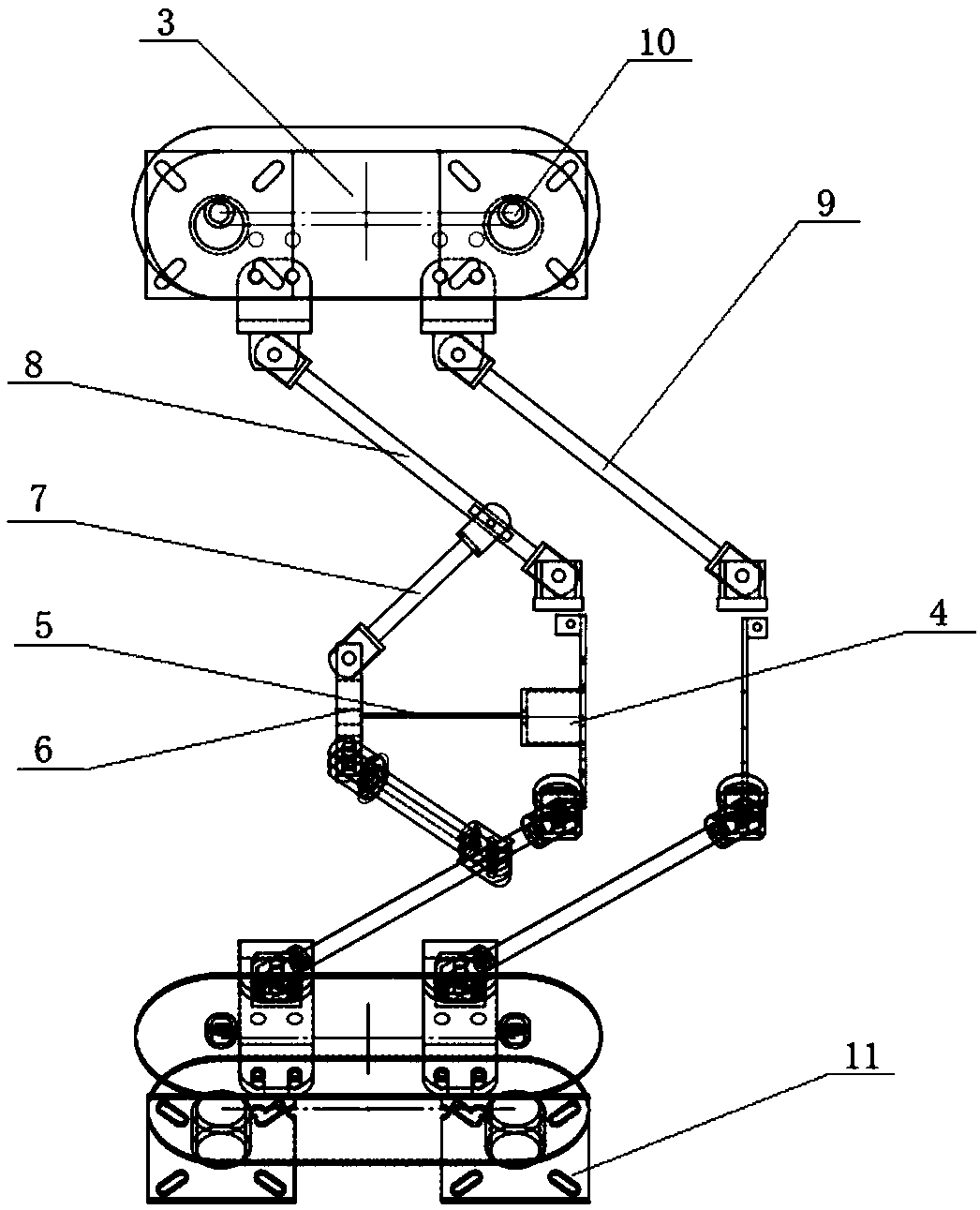

Novel pipeline robot

The invention discloses a novel pipeline robot. The robot is composed of two robot bodies which are the same in structure and are in mirror symmetry connection through a universal rotating module connector. Each robot body comprises a robot main body of a prismoid, three crawler-type walking mechanisms evenly arranged in the circumferential direction of the robot main body, and a connecting mechanism connected with the robot main body and the walking mechanisms. Each connecting mechanism is further connected with a stepping motor through a lead screw nut and a lead screw, and the stepping motors rotate to control the expanding degree of crawler belt feet. The novel pipeline robot has the beneficial effects that the pipeline robot can go straight and turn in a pipeline and can also move ina horizontal-to-vertical pipeline. The expanding angles of the crawler belt feet can be adjusted at any time by adjusting the connecting mechanisms to meet the walking needs of different pipe diameters. The crawler-type walking mechanisms are high in road holding force, the multiple motors carry out independent driving, the robot can adapt to various pipeline environments, and the whole equipmenthas the function of preventing water and corrosion.

Owner:DATANG ENVIRONMENT IND GRP

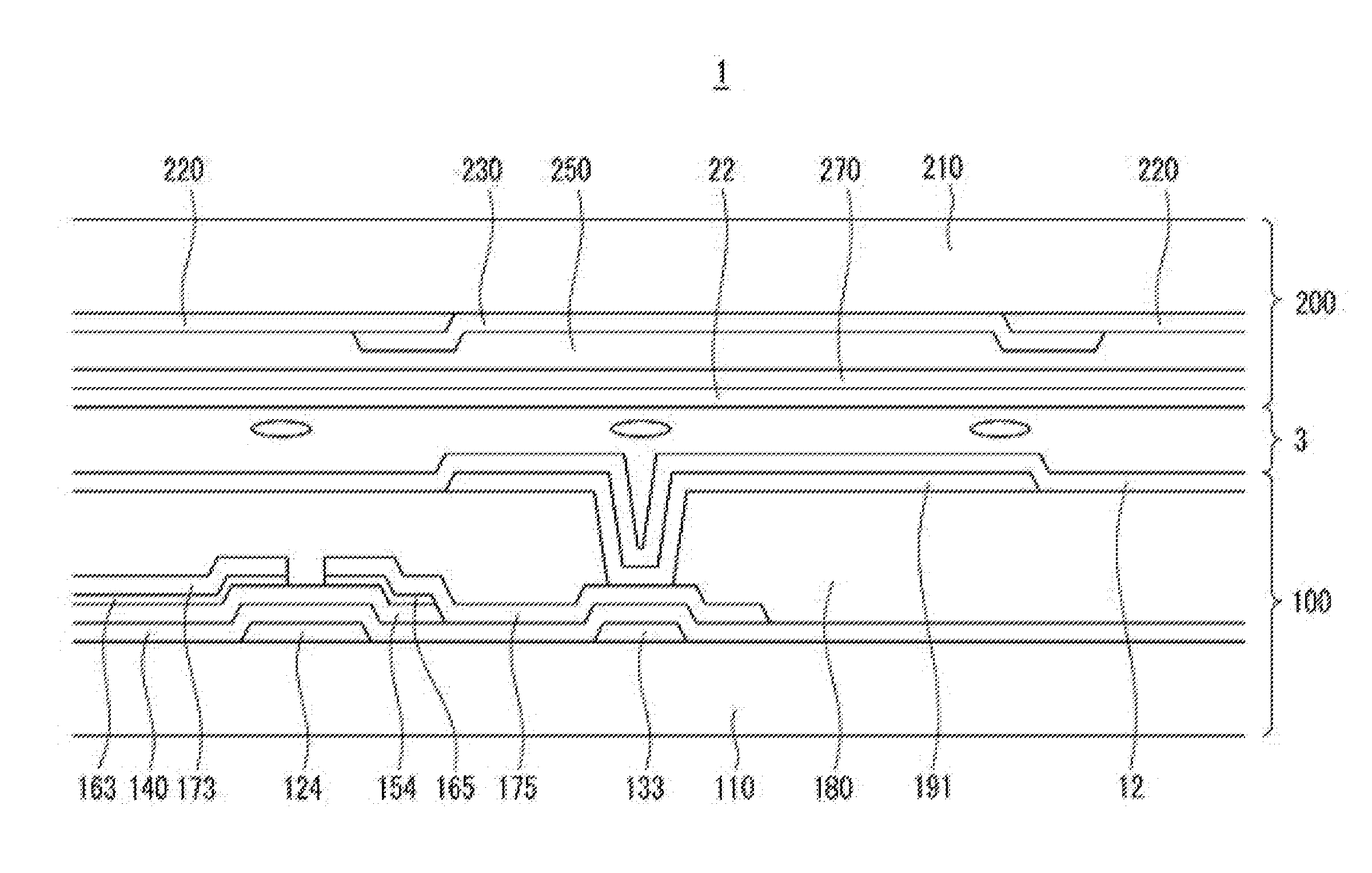

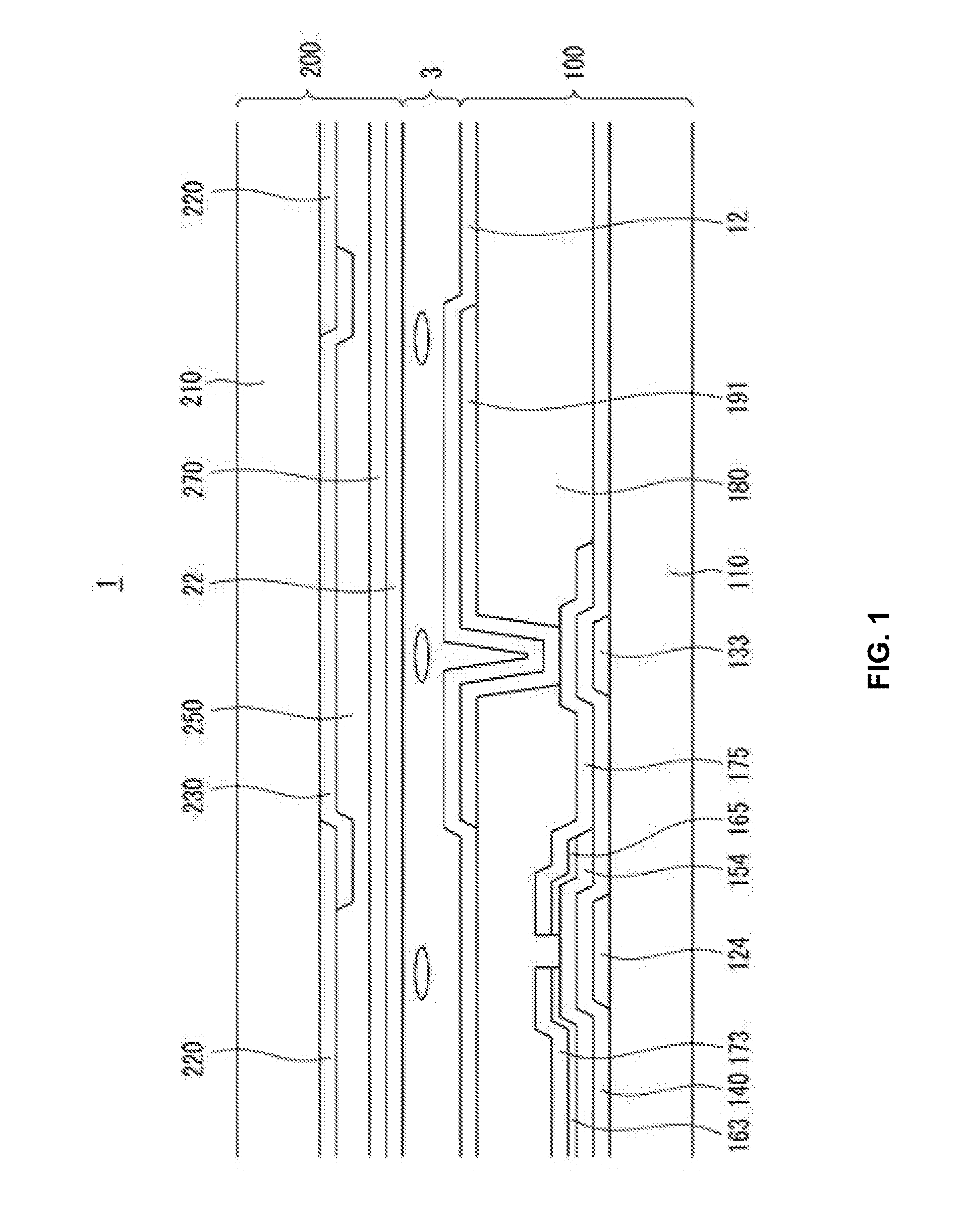

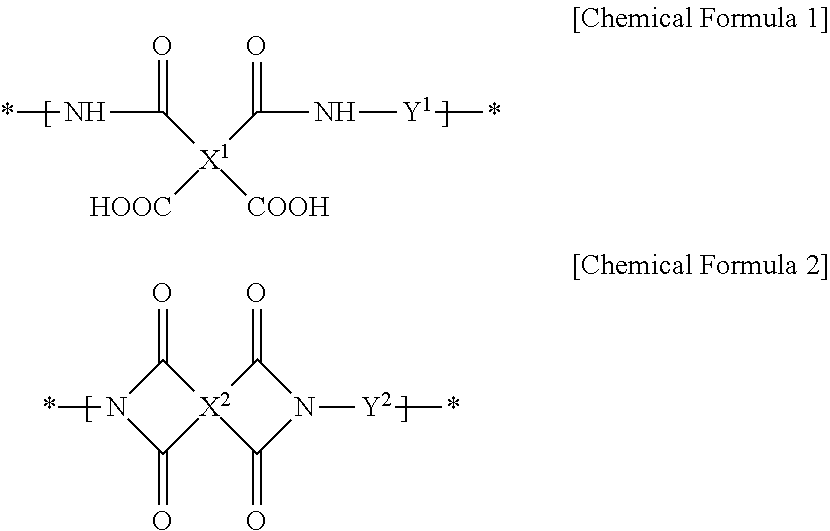

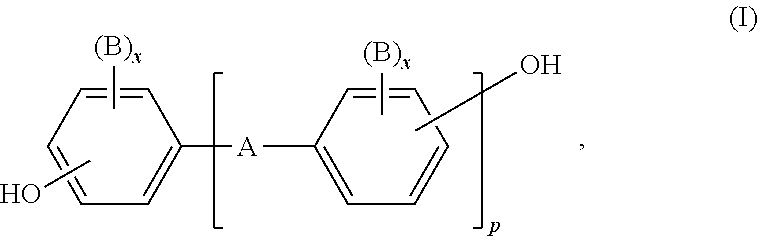

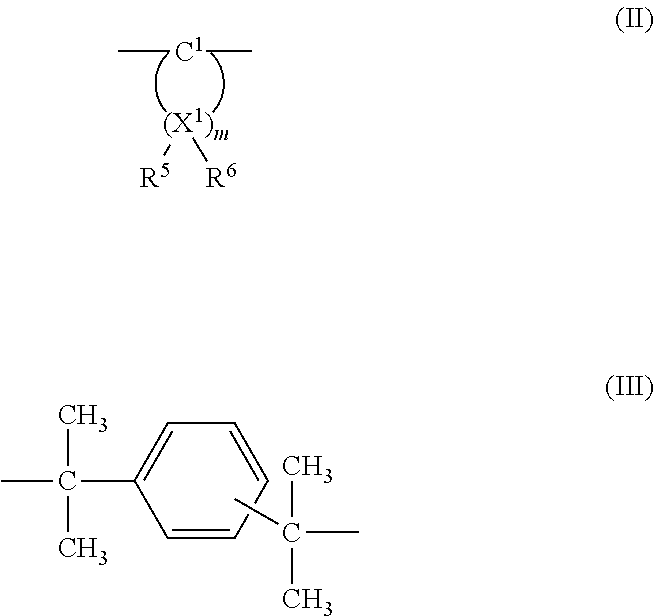

Liquid Crystal Alignment Agent, Liquid Crystal Alignment Film Manufactured Using the Same, and Liquid Crystal Display Device Including the Liquid Crystal Alignment Film

InactiveUS20120172522A1Improve textureMaintain good propertiesLiquid crystal compositionsNon-fibrous pulp additionCrystallographyLiquid-crystal display

Disclosed is a liquid crystal alignment agent that includes a polymer comprising polyamic acid including a repeating unit represented by the following Chemical Formula 1, polyimide including a repeating unit represented by the following Chemical Formula 2, or a combination thereof.In Chemical Formulae 1 and 2, X1, X2, Y1 and Y2 are the same in the detailed description.

Owner:CHEIL IND INC

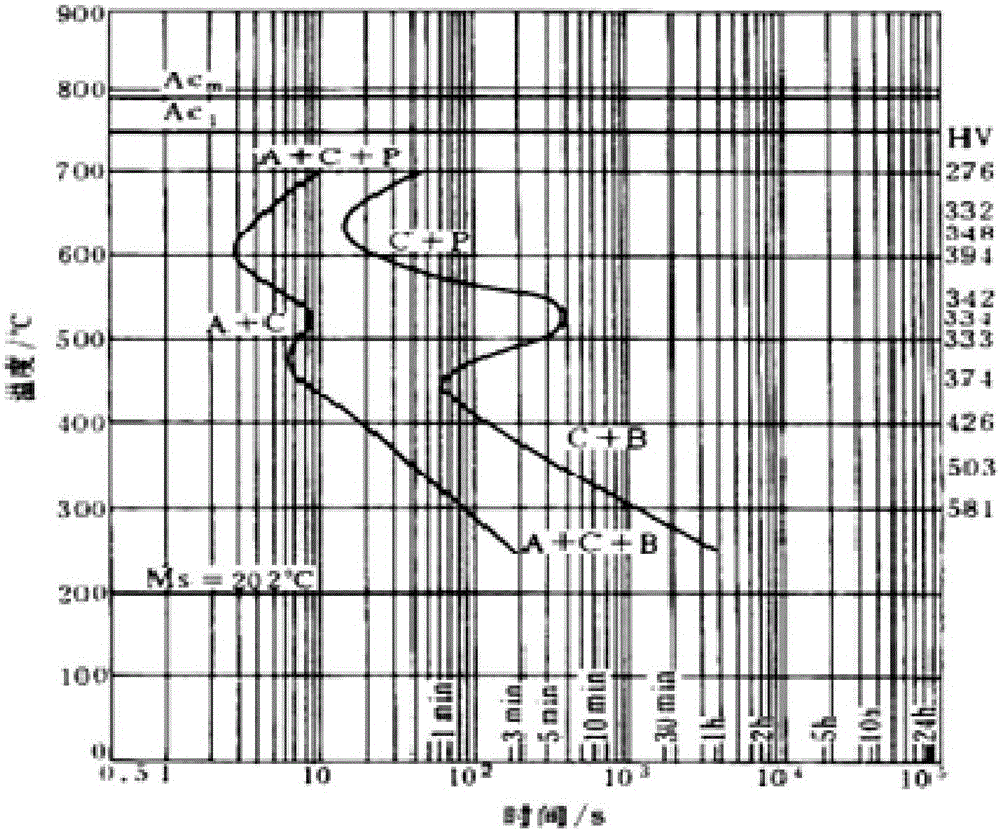

Bearing steel material with long service life and machining method thereof

The invention discloses bearing steel material with long service life and a machining method thereof. The bearing steel material with the long service life comprises, by weight percentage, 0.95-1.05% of C, 0.15-0.35% of si, 0.25-0.45% of Mn, 1.40-1.60% of Cr, 0.05-0.09% of Ni, 0.02-0.05% of M0, smaller than or equal to 0.05% of Al, 0.05-0.08% of Cu, smaller than or equal to 0.01% of P, smaller than or equal to 0.008% of S, smaller than or equal to 0.0025% of Ti, smaller than or equal to 0.002% of O, smaller than or equal to 0.04% of As, smaller than or equal to 0.03% of Sn, smaller than or equal to 0.005% of Sb, smaller than or equal to 0.002% of Pb, smaller than or equal to 0.001% of Ca and the balance Fe. The bearing steel material with the long service life has high elastic limit, tensile strength and contact fatigue strength, has high hardening capacity and necessary hardenability so that the high wear resistance can be guaranteed, has certain impact toughness, has good dimensional stability or structure stability, can resist chemical corrosion and can effectively reduce the phenomena of fatigue flaking, jamming, ferrule breakage, wear and corrosion.

Owner:建龙北满特殊钢有限责任公司

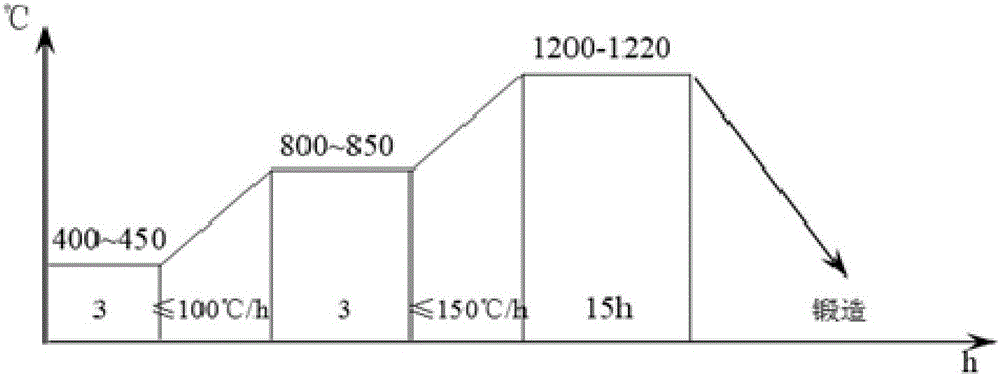

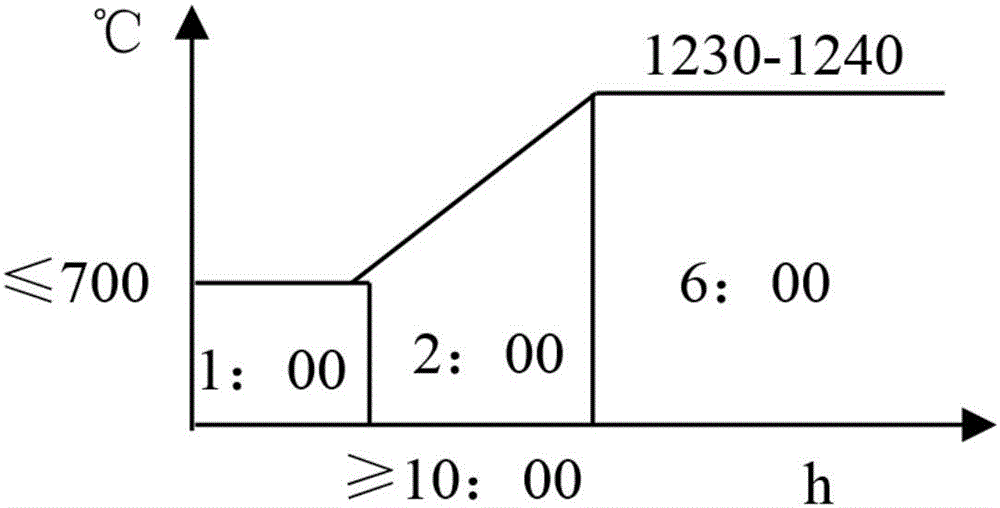

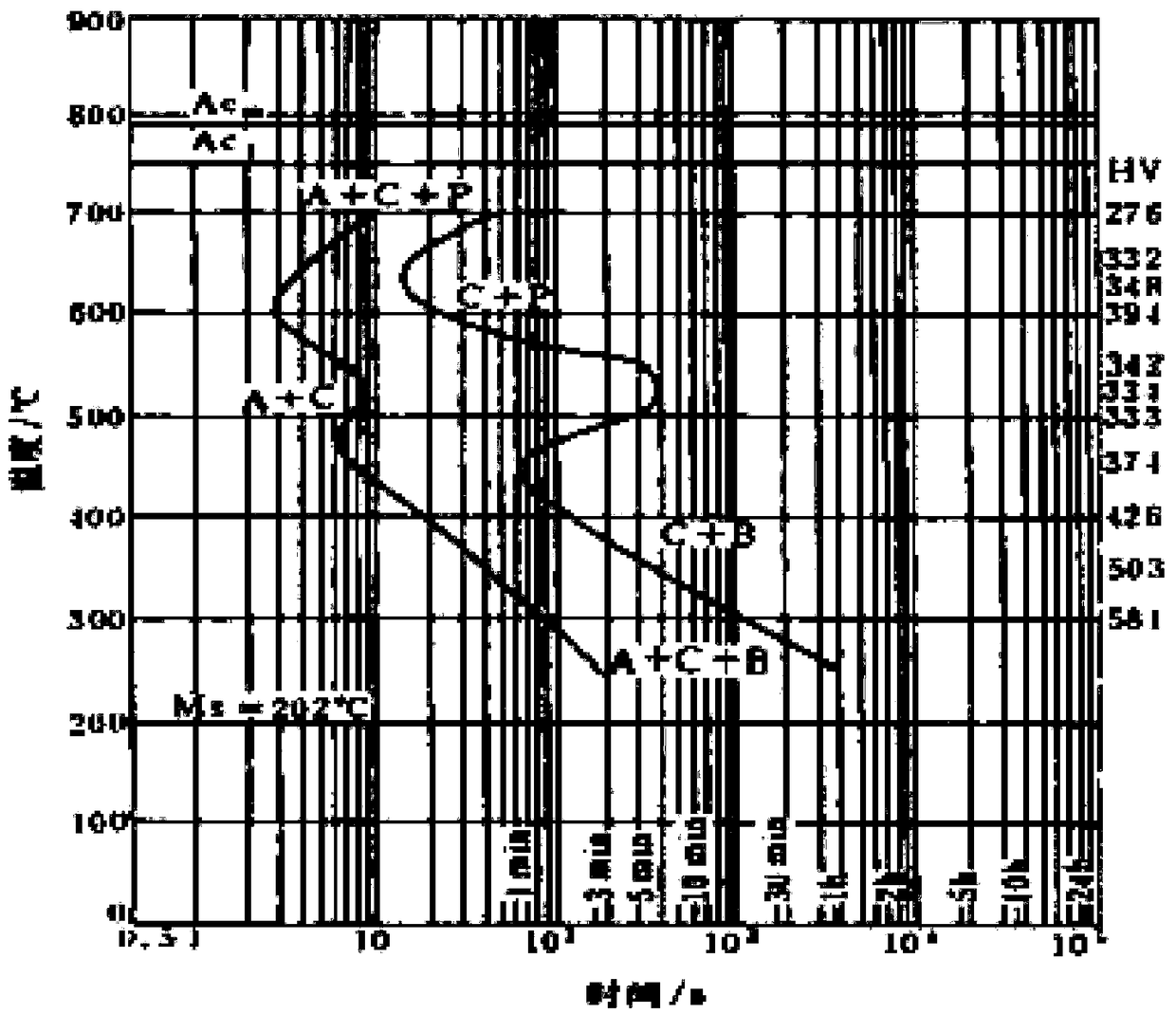

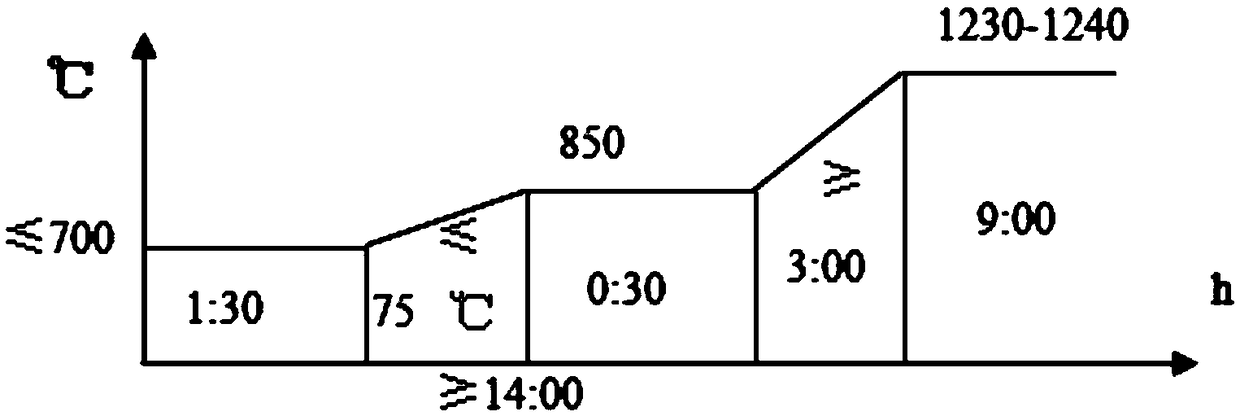

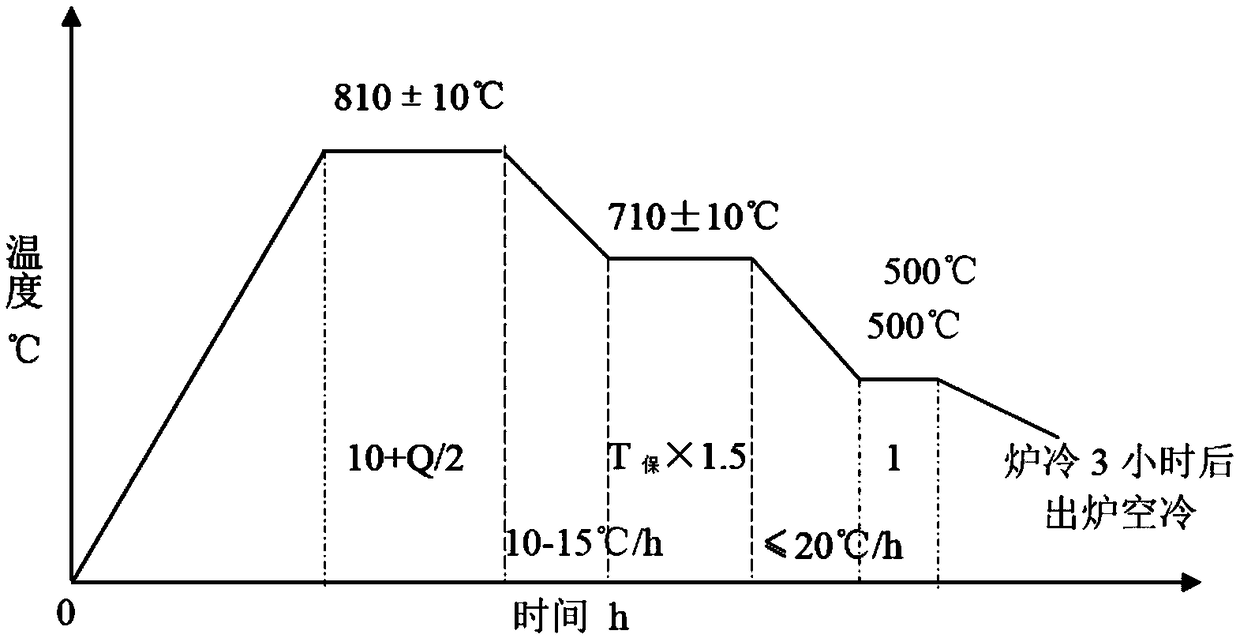

Rare earth microalloying bearing steel and preparation method thereof

ActiveCN109457081AHigh elastic limitImprove hardenabilityFurnace typesHeat treatment furnacesSlow coolingMaterials science

The invention discloses rare earth microalloying bearing steel and a preparation method thereof and belongs to the technical field of bearing steel manufacturing. According to the technical aim, the performance of the bearing steel is improved. According to the rare earth microalloying bearing steel, converter, LF-RH refining and square billet continuous casting are carried out, electroslag remelting is carried out after scaling of a prepared continuous casting billet, then cover cooling and pit cooling are carried out, and then primary heating rolling cogging is carried out; after annealing or slow cooling is carried out, checking and cleaning are carried out, and a primary rolled steel billet is prepared and subjected to secondary heating rolling; and after stack cooling or slow coolingis carried out, a secondary rolled steel billet is prepared and subjected to spheroidizing annealing, straightening, polishing or scaling, flaw detection, cleaning and checking are carried out, and then the rare earth microalloying bearing steel is prepared. The content design ingredient of Nb ranges from 0.010% to 0.45%, and the rare earth microalloying bearing steel is suitable for being used for manufacturing various bearing rings and rolling elements and roller pins within a wide size range.

Owner:建龙北满特殊钢有限责任公司

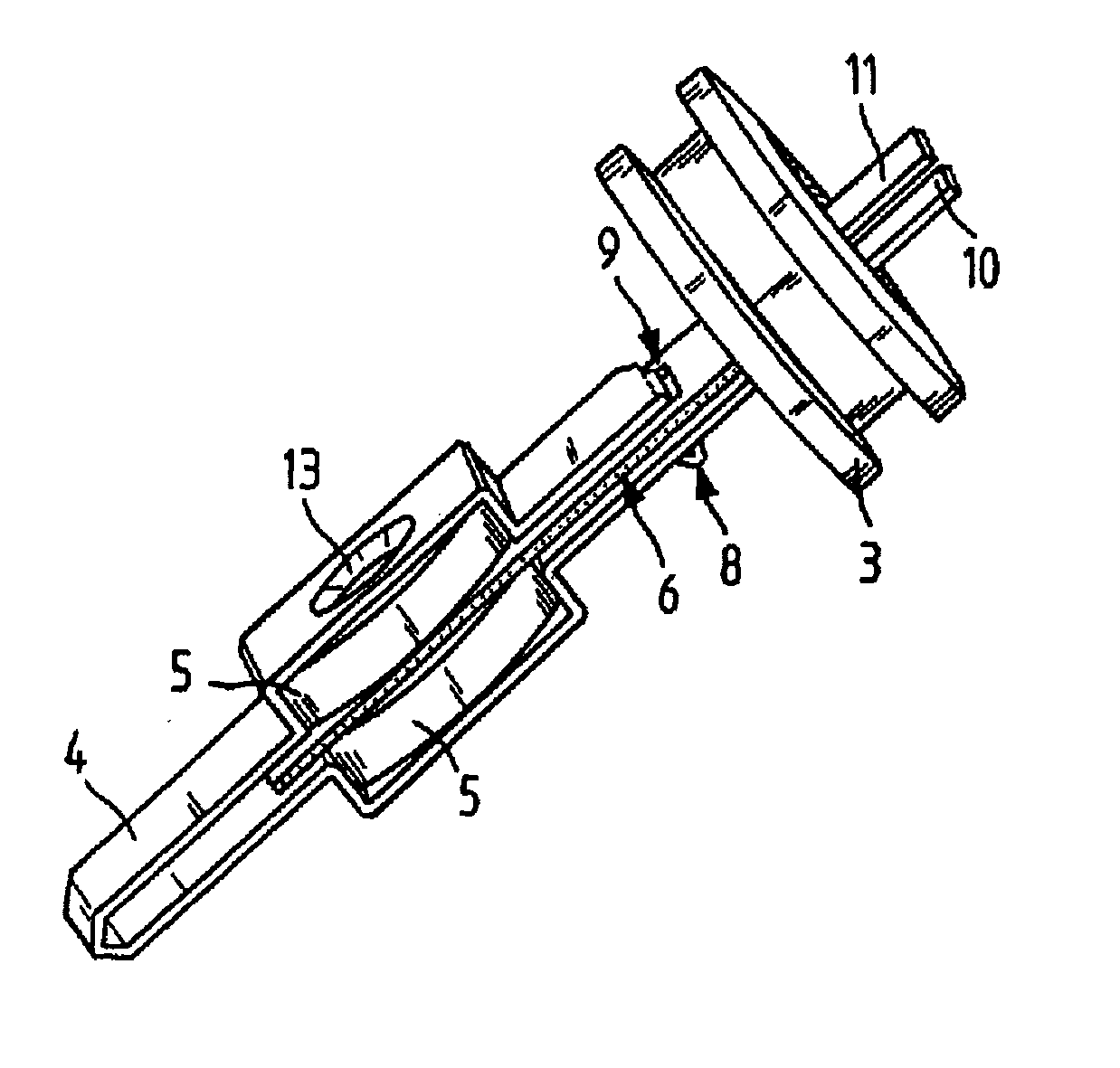

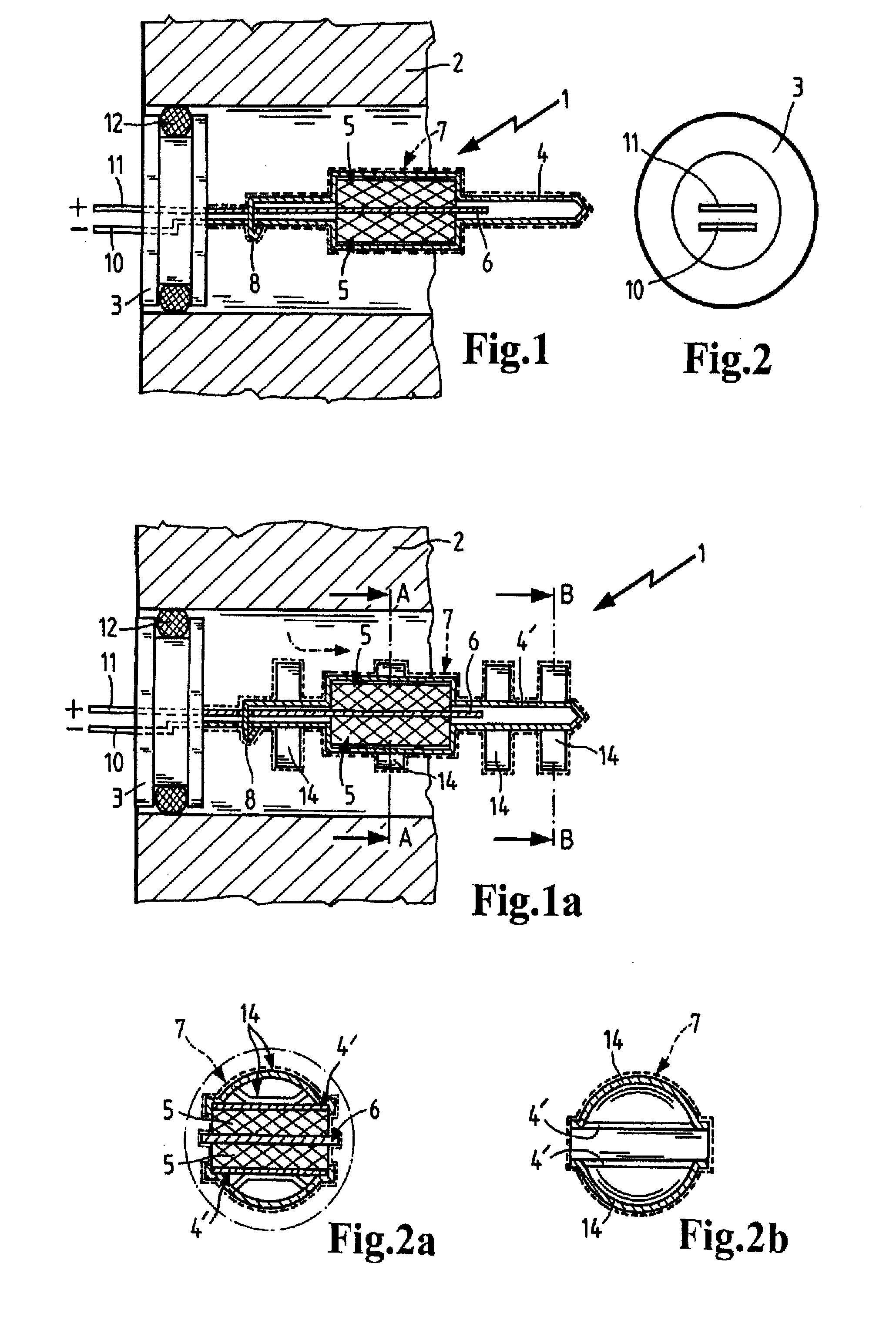

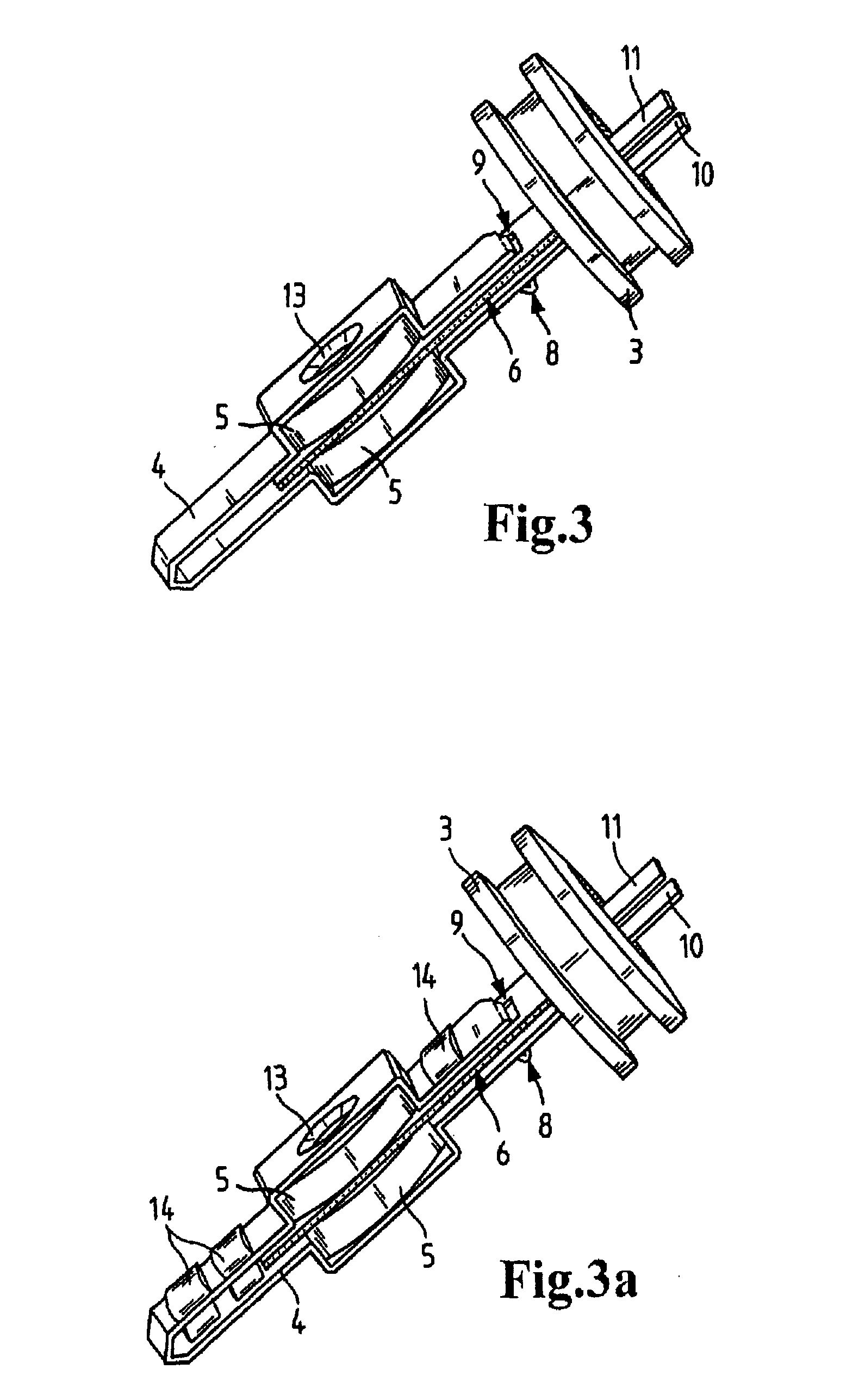

Heating Device for Fuel

InactiveUS20080037967A1Prevent short-circuitingSimple and cost-effective constructionInternal combustion piston enginesImmersion heating arrangementsEngineeringCoating

A heating device for fuel comprising an electric heating element (5), which is mounted on a carrier body (4). The carrier body (4) surrounds the heating element (5), and an insulating protective layer coating (7) is applied to the carrier body.

Owner:MANN HUMMEL GMBH

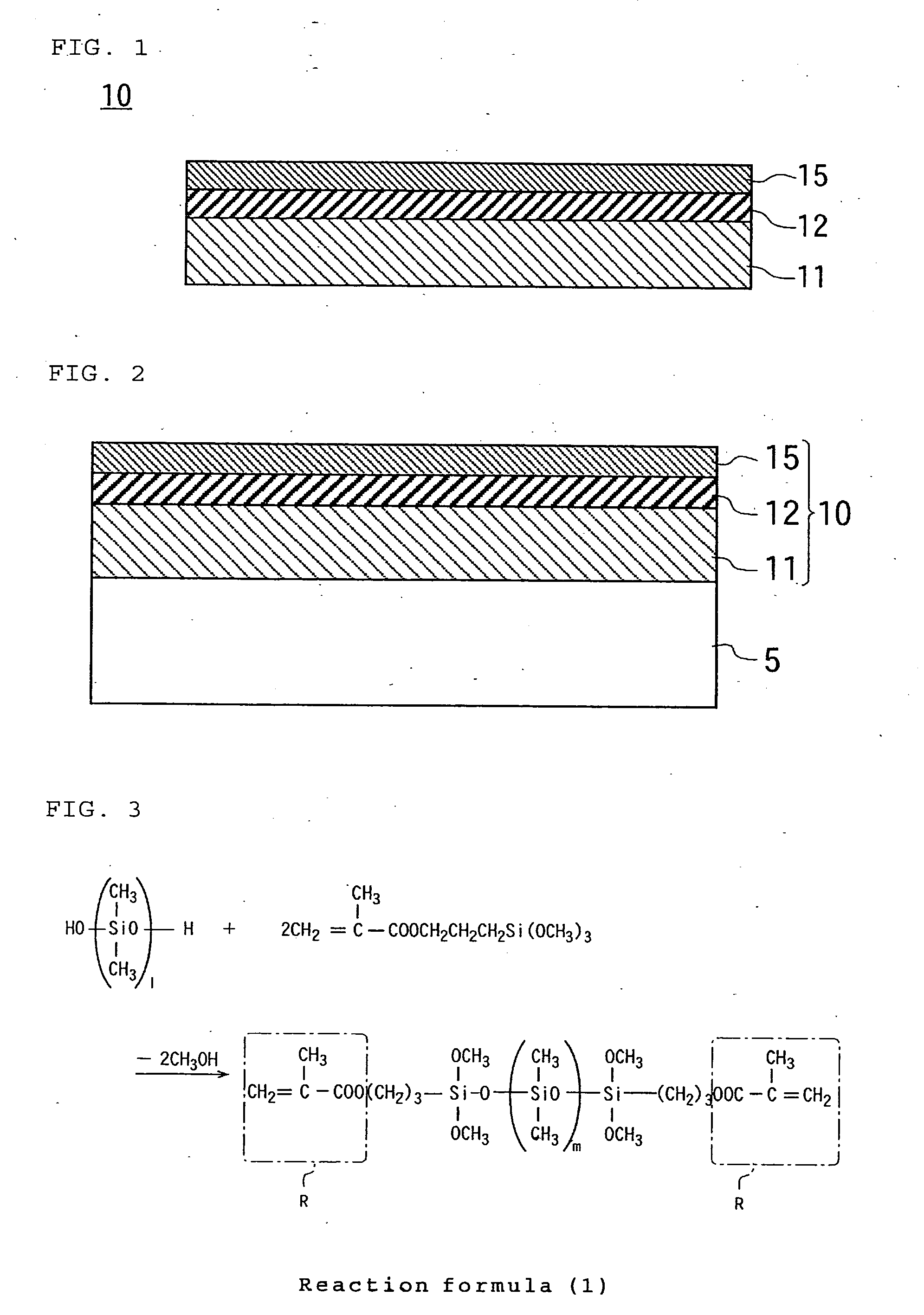

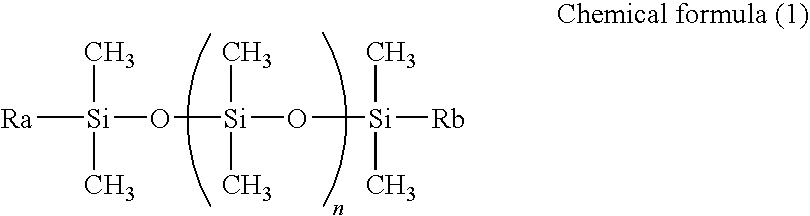

Antireflection Film

InactiveUS20100118406A1Scratch resistantEasily wiped offSynthetic resin layered productsAnti-reflective coatingsSilica particleMeth-

Disclosed is an antireflection film having high antifouling property. Specifically disclosed is an antireflection film comprising a transparent base, a high refractive index layer and a low refractive index layer. The low refractive index layer is made of a cured product of a polymerizable composition which contains hollow fine particles such as hollow silica particles, a modified silicone compound, and a second resin component such as a polyfunctional (meth)acrylate.

Owner:DEXERIALS CORP

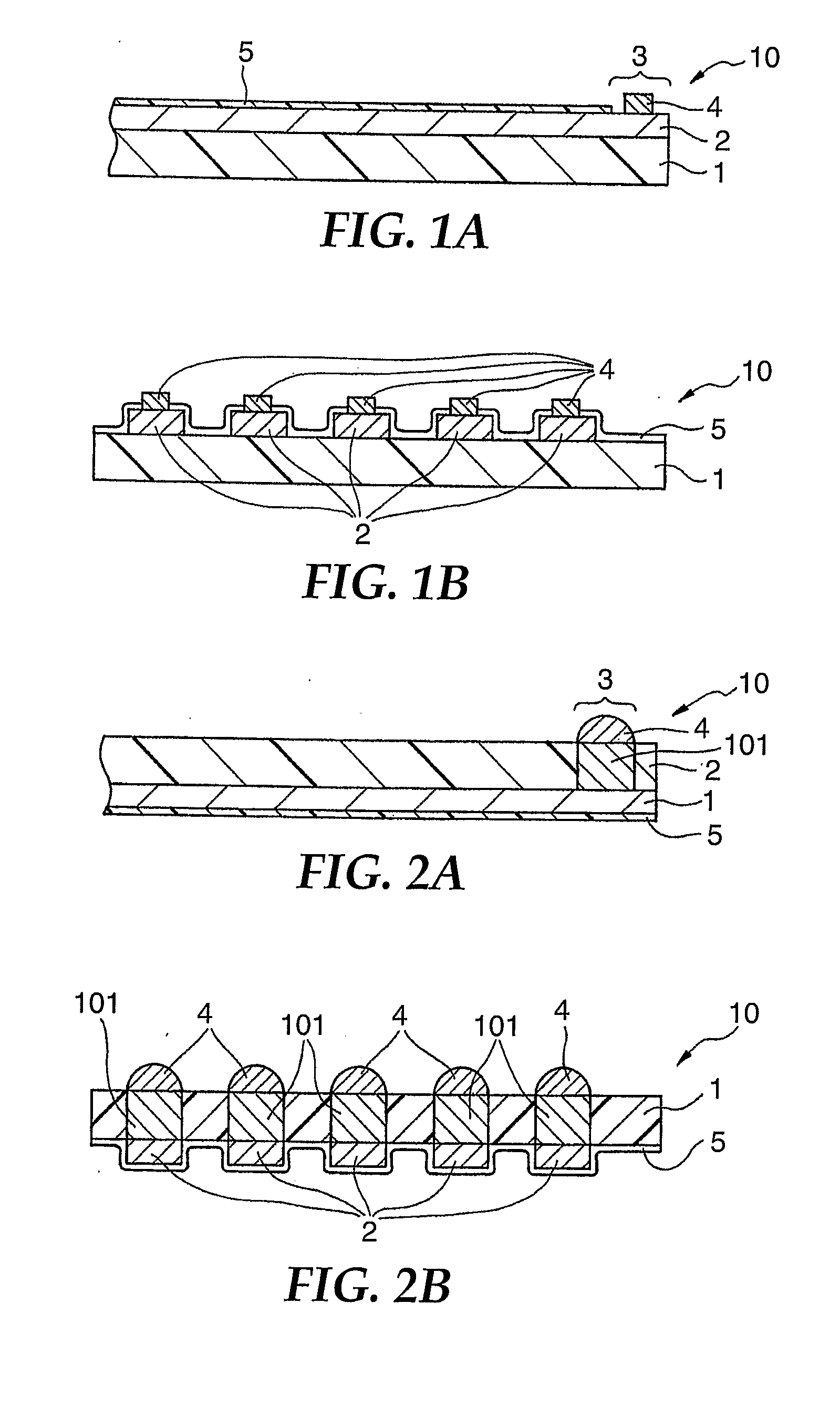

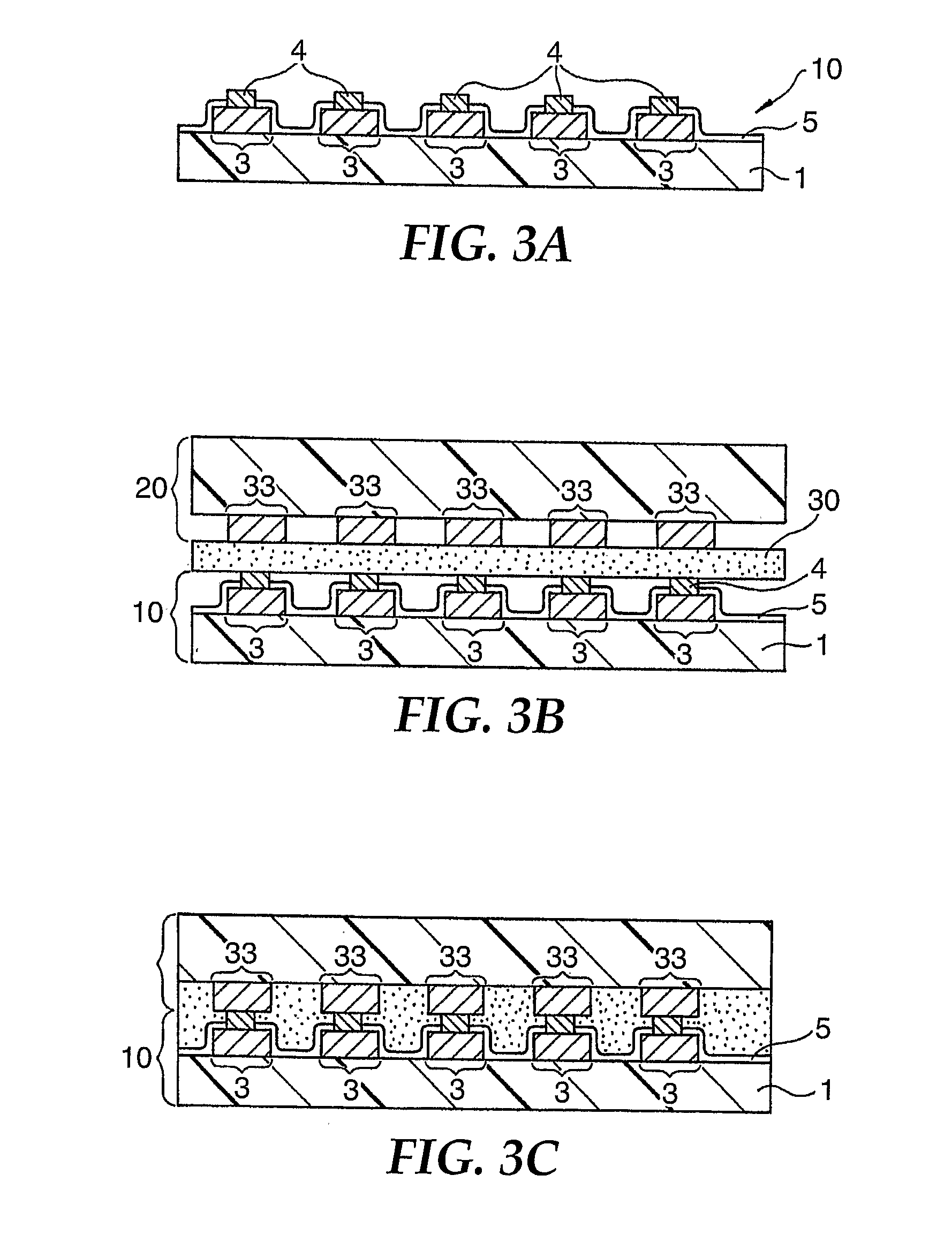

Method for Connecting Printed Circuit Board

InactiveUS20080110665A1Improve high-temperature characteristicChemical resistancePrinted circuit assemblingPrinted circuit aspectsAdhesivePrinted circuit board

To provide a PCB that does not generate a short-circuit problem even at a very small pitch and has high connection reliability a method is provided for connecting a printed circuit board (PCB) to a second circuit board comprising: providing a printed circuit board (PCB) having a connection portion; providing a second circuit board having a connection portion, the second circuit board to be connected to the PCB, wherein the connection portion of one or both of the PCB and second circuit board has at least one conductive bump, positioning the connection portion of the PCB opposite the connection portion of the second circuit board with a thermosetting adhesive film between the connection portions of the PCB and second circuit board, and applying heat and pressure to the connection portions and the thermosetting adhesive film such that the adhesive film is displaced sufficiently to allow electrical contact between the at least one bump and the connection portion of the opposing circuit board and such that the heat is sufficient to cause the adhesive to set. Also provided is an article comprising a PCB having a connection portion with at least one conductive bump, and a thermosetting adhesive film on the surface of the connection portion.

Owner:3M INNOVATIVE PROPERTIES CO

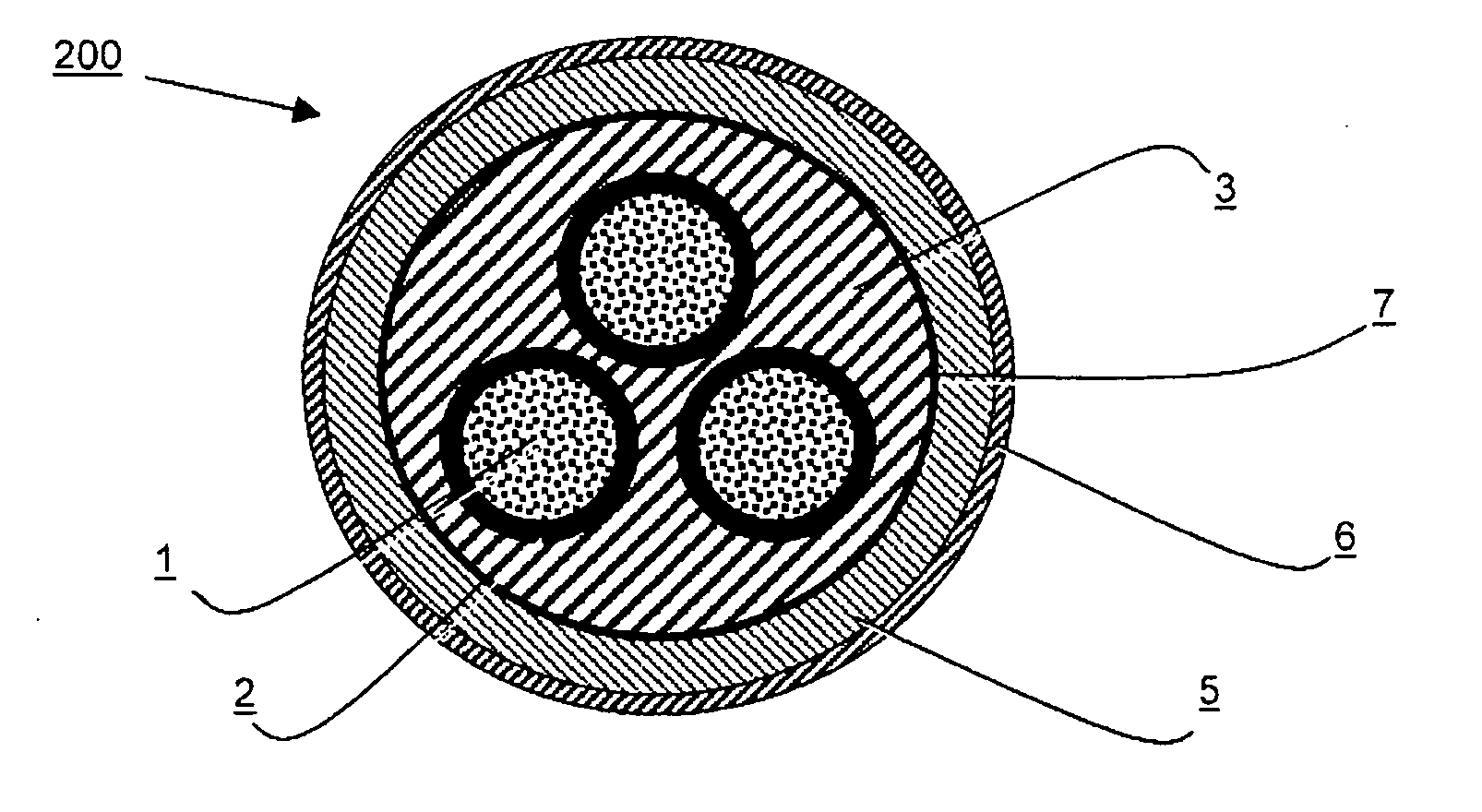

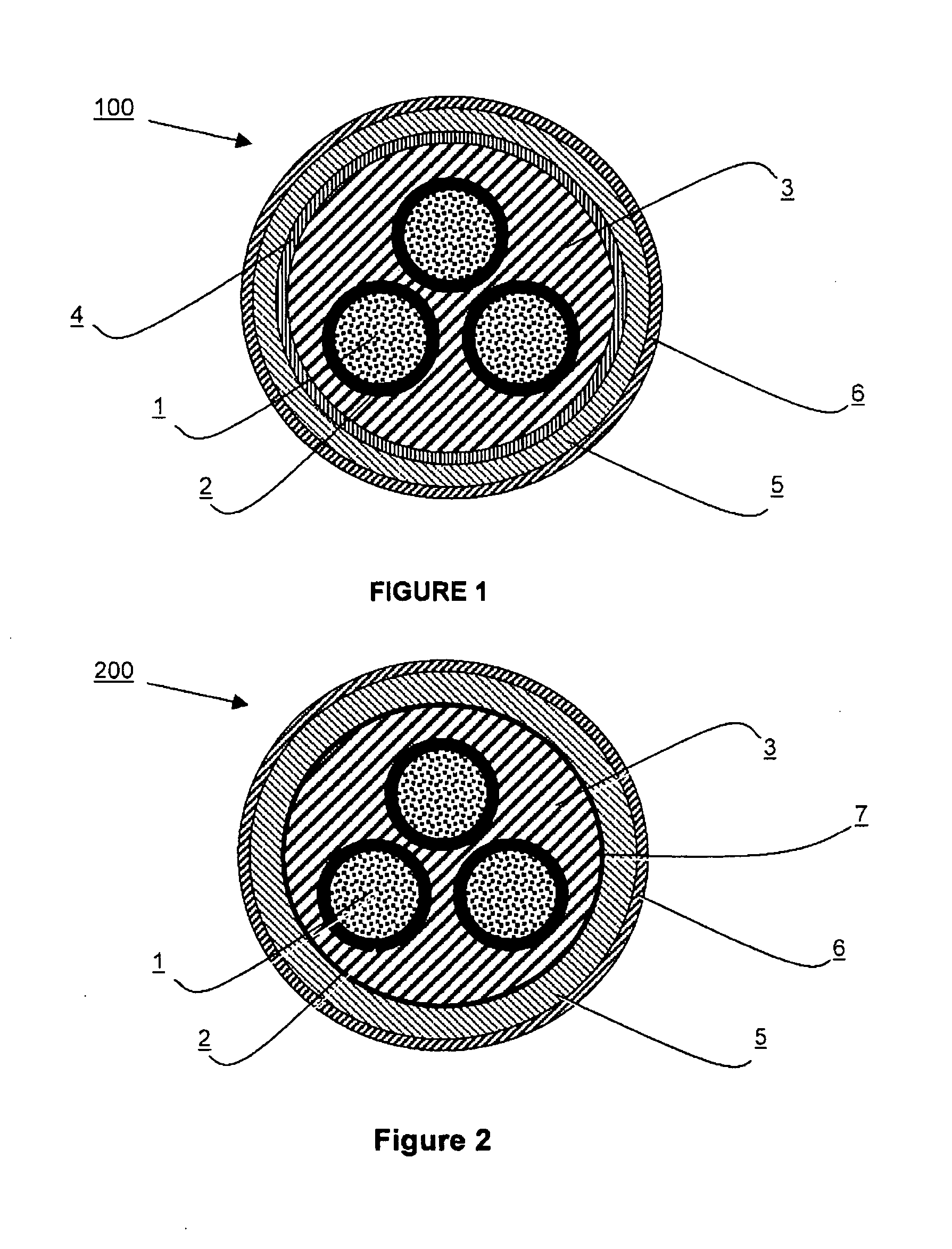

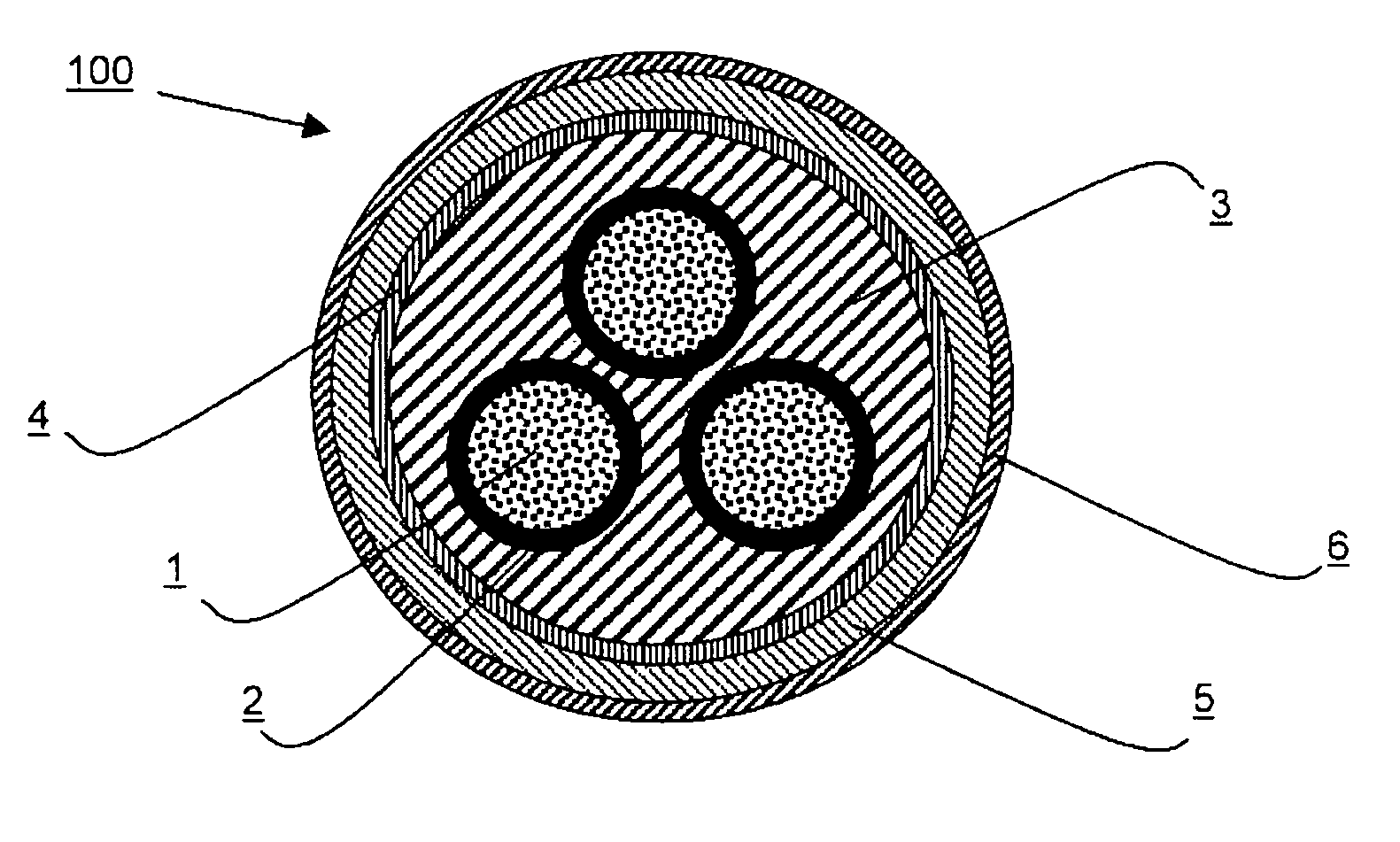

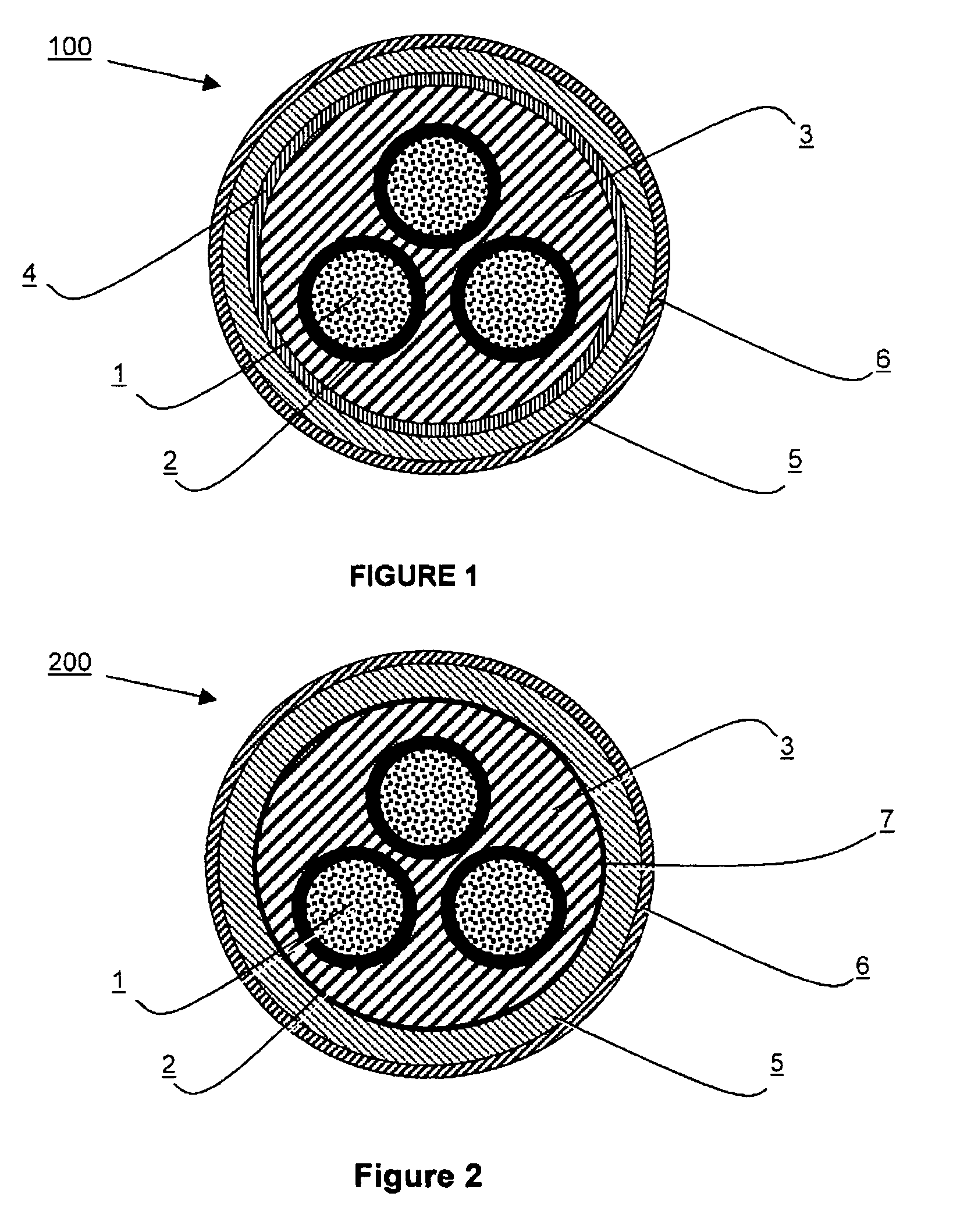

Power transmission cable

ActiveUS20100051315A1Chemical resistancePlastic/resin/waxes insulatorsInsulated cablesElectric power transmissionVitrification

A power transmission cable comprising at least one power conductor, an insulating layer surrounding said conductor to form at least one insulated conductor, a flame-retardant halogen free protective sheath provided in a radially external position with respect to said insulated conductor, wherein said sheath has an inner and an outer layer in contact one another, said inner layer has a thickness at least equal to a thickness of said outer layer, the inner layer comprises a polymer material having a glass transition temperature equal to or lower than −30° C., and the outer layer comprises a mud resistant polymer material.

Owner:PRYSMIAN SPA

PVC (Polyvinyl Chloride)-M (Modified) shock-resistant tubular product

InactiveCN102827439AGood toughness and impact resistanceChemical resistanceRigid pipesWaxStearic acid

The invention relates to a PVC (Polyvinyl Chloride) tubular product, and in particular relates to a PVC (Polyvinyl Chloride)-M (Modified) shock-resistant tubular product. The tubular product is made of the following raw materials in parts by weight: 100 parts of a PVC resin, 6 parts of calcium powder, 3 parts of titanium dioxide powder, 6 parts of a stabilizer, 2 parts of stearic acid, 13 parts of a shock-resistant modifier, 1 part of PE (Polyethylene) wax, 0.5 part of an MBS (Methyl-methacrylate-Butadiene-Styrene) resin, and 4 parts of ACR (Acrylic Resin)-530. The PVC (Polyvinyl Chloride)-M (Modified) shock-resistant tubular product by the invention has good toughness and good shock resistance, can resist chemical corrosion, is improved in tension strength and elongation at break, and has difficulty in leaking or penetrating water, and cracking; and the MBS resin is added into the PVC tubular product for improving plasticization, so that the dispersion of inorganic matters and the processing fluidity of PVC melts are enhanced, and the low-temperature shock strength of the tubular product is improved.

Owner:ANHUI KANGJIA PLASTIC BUILDING MATERIAL

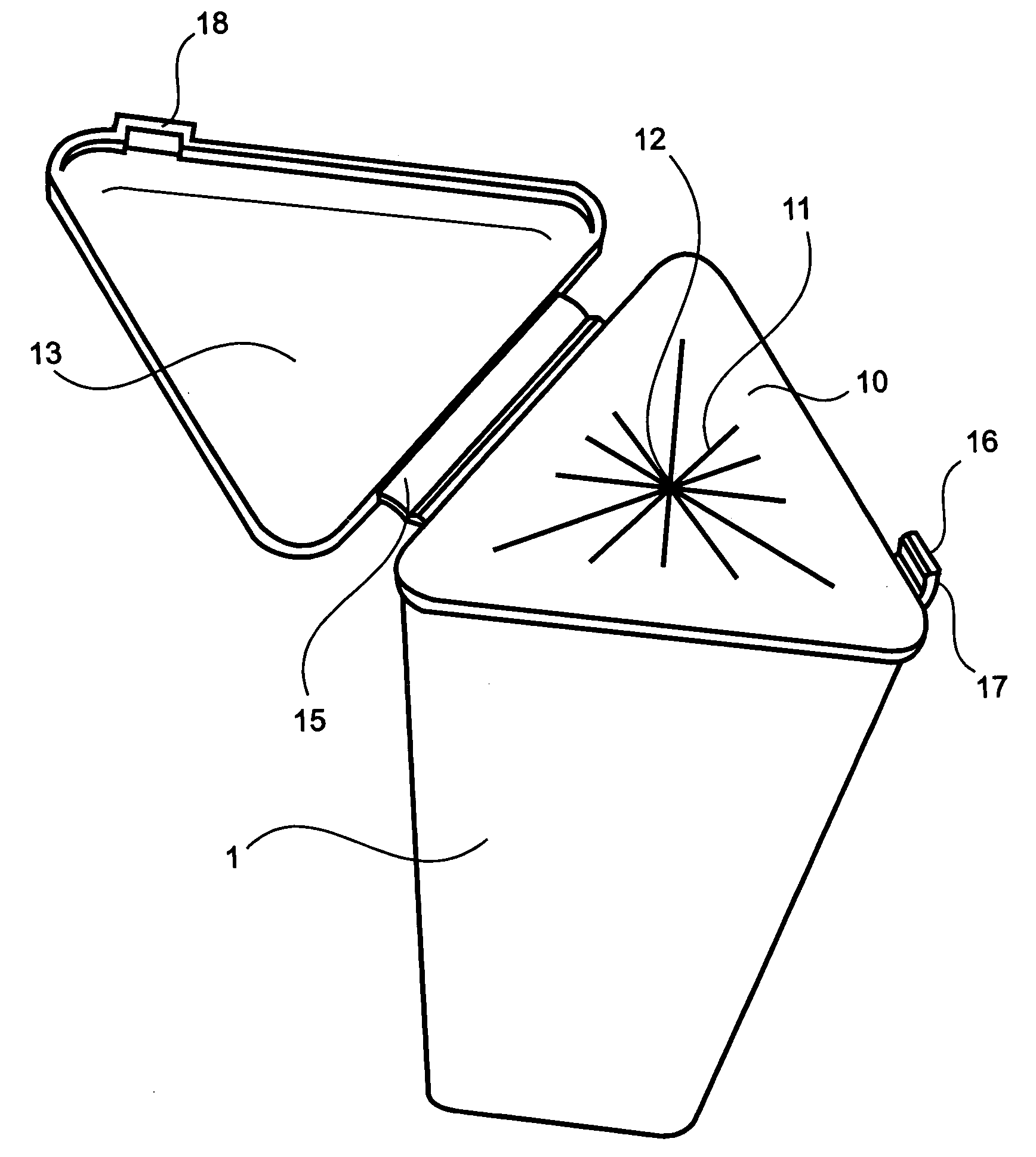

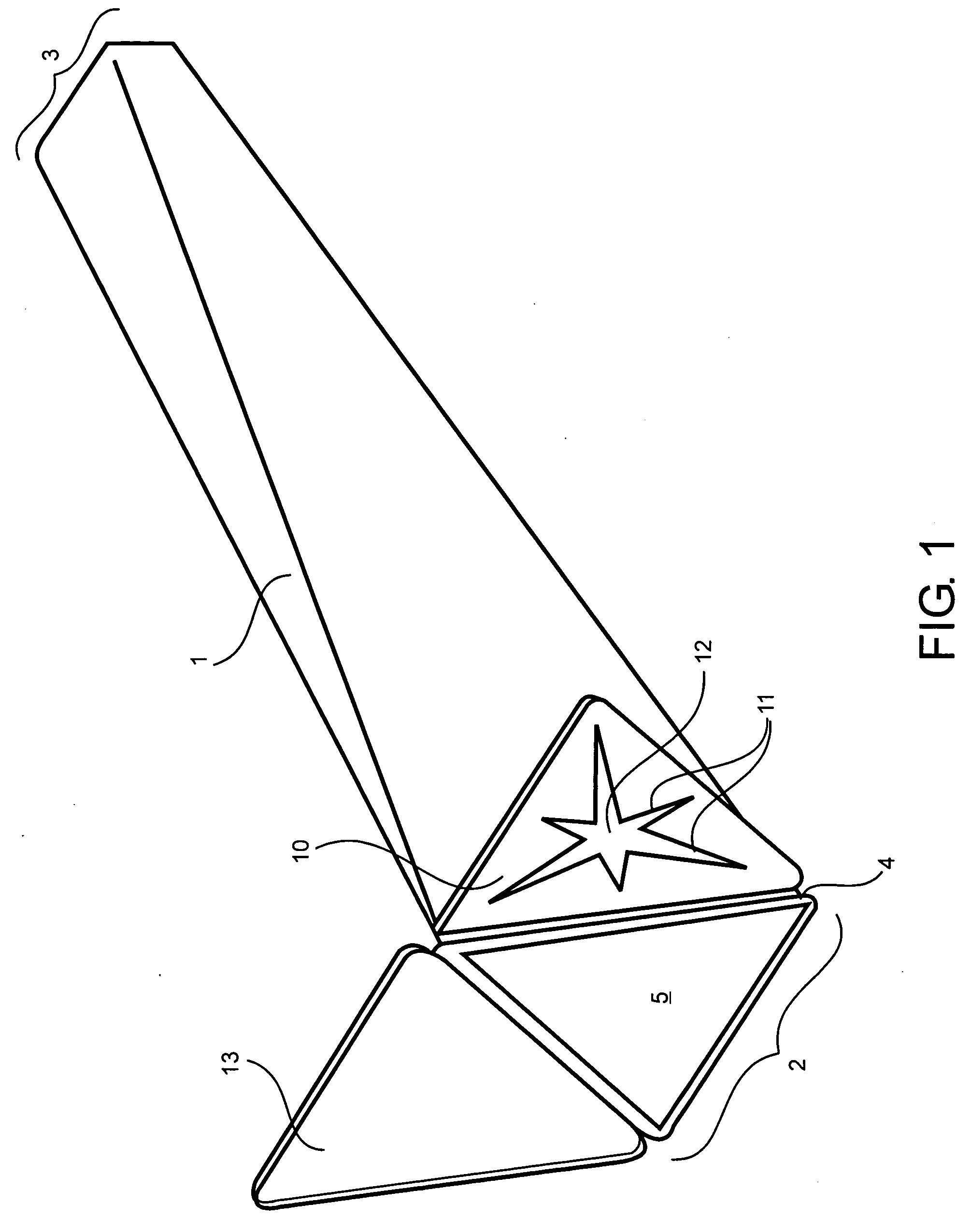

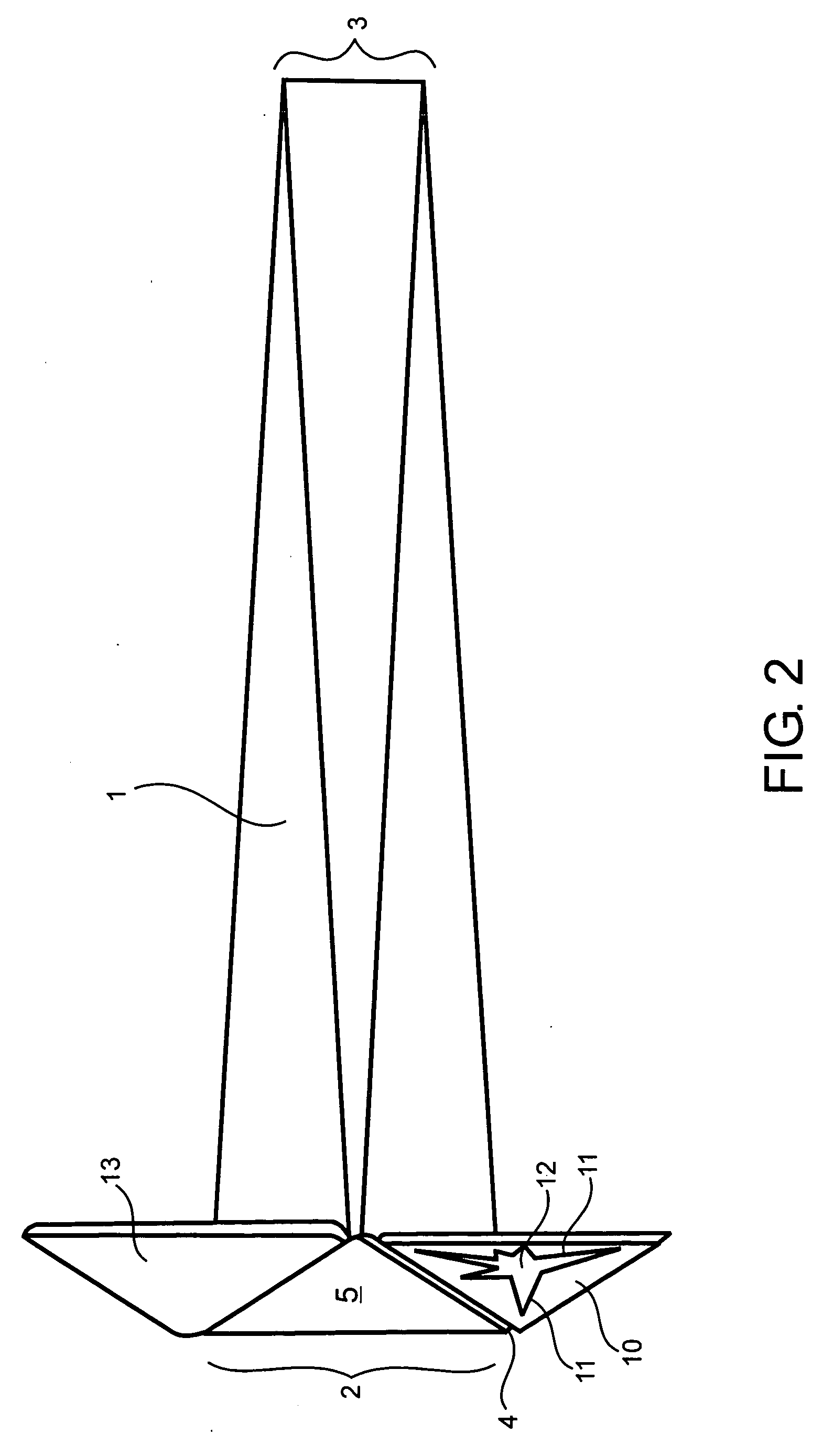

Bedside disposal of contaminated sharps

InactiveUS20050103663A1Improve stabilityReduce sizeSurgical furnitureDispensing apparatusHypodermic needleEngineering

Owner:SAFE SOLUTIONS

Preparation method for synthesizing artificial leather by nano bamboo charcoal UV

ActiveCN104499300ASimple processFunctionalLamination ancillary operationsLaminationAntibiosisNanometre

The invention relates to the artificial leather field, and concretely relates to a preparation method for synthesizing artificial leather by nano bamboo charcoal UV. The artificial leather is prepared by polyurethane and nano bamboo powder or nano bamboo charcoal powder. The artificial leather has the advantages of simple process, emission reduction and energy saving environmental protection, excellent function, chemical resistance, antibiosis and disinfection.

Owner:杭州苏威家居科技有限公司

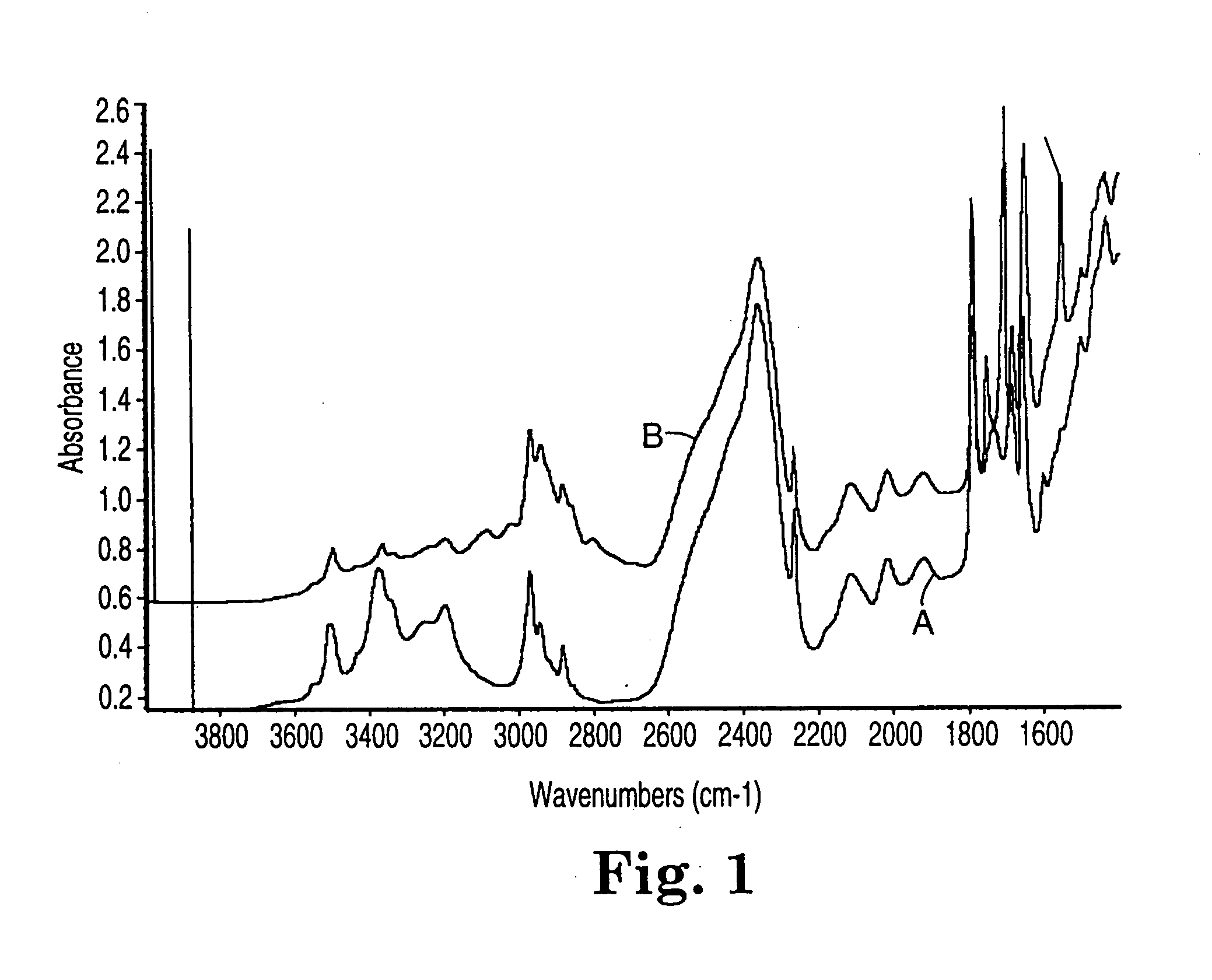

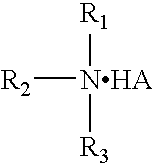

Fluoropolymer curing system

InactiveUS20050054783A1High-temperature performance property and chemical resistanceImproved compression set valueEngine sealsOther chemical processesArylNitrogen

A composition of a fluoropolymer comprising interpolymerized units of nitrogen-containing cure site monomer and a catalyst comprising a compound having the formula: wherein HA is an acid, each R1, R2, and R3 is independently a C1-C20 alkyl group, which may be cyclic or heterocyclic, or Rf(CH2)n— wherein Rf is a C1-C8 linear or branched and at least partially fluorinated, and x is 1 to 4, and one R group may be a bond to another R group such that the nitrogen is bonded to or part of an alkenyl, cycloalkenyl, or aromatic group. This may further comprise a catalyst composition comprising a compound of the formula R1C(OR2)═NH, and salts thereof, where each R1 and R2 is, independently, a substituted or unsubstituted alkyl, aryl, aralkyl, alkenyl, cycloalkyl, or cycloalkenyl. Also provided are a method of making a fluoropolymer composition and articles prepared from the compositions.

Owner:3M INNOVATIVE PROPERTIES CO

Aqueous hybrid dispersions

ActiveUS20120088878A1Latent crosslinkabilityImprove mechanical propertiesInksEster polymer adhesivesPolymer scienceAddition polymer

The invention relates to a process for the preparation of an aqueous hybrid polymer dispersion comprising an auto-oxidatively crosslinkable polymer and an addition polymer. The invention further relates to the aqueous hybrid polymer dispersion obtainable by said process, the use thereof for the manufacture of coating compositions, ink compositions or adhesives and to coating compositions includes the hybrid polymer dispersion as a binder. The process includes a first polymerization step wherein a first hybrid polymer dispersion is formed by addition polymerization of vinyl monomers in the presence of dispersed auto-oxidatively crosslinkable polymer and a second polymerization step wherein secondary polymerization loci are provided in the first hybrid polymer dispersion to polymerise residual vinyl monomer of the first polymerisation step. The aqueous hybrid polymer dispersions have very low residual vinyl monomer content by achieving a high if not full conversion of the vinyl monomers at the end of the polymerization.

Owner:ALLNEX NETHERLANDS BV

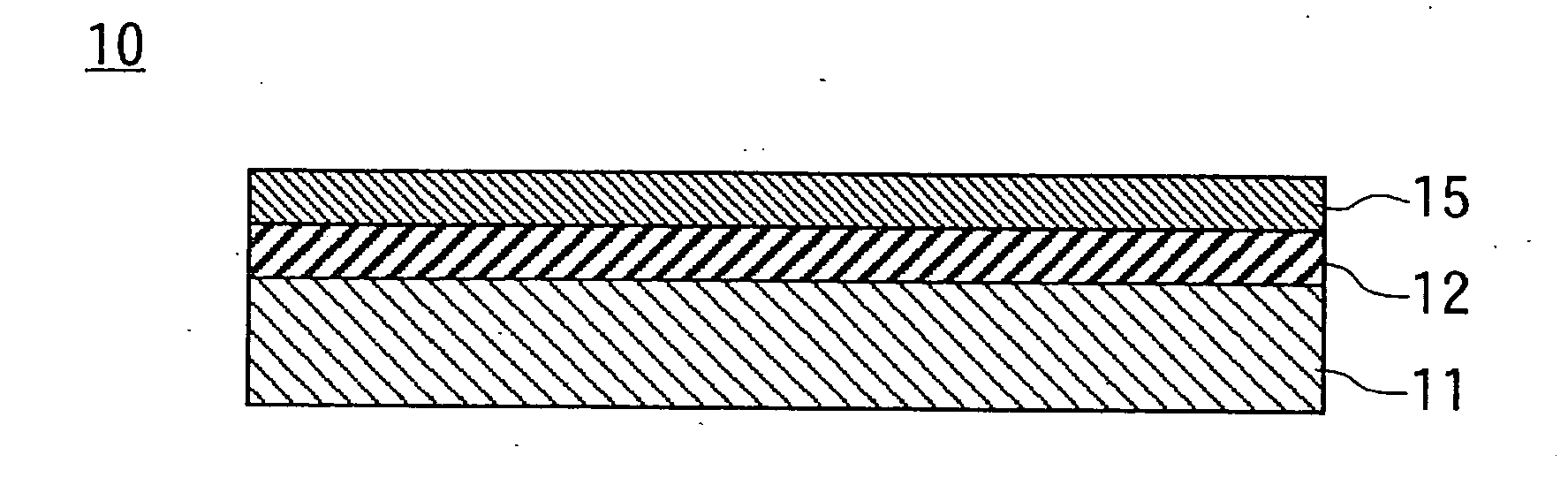

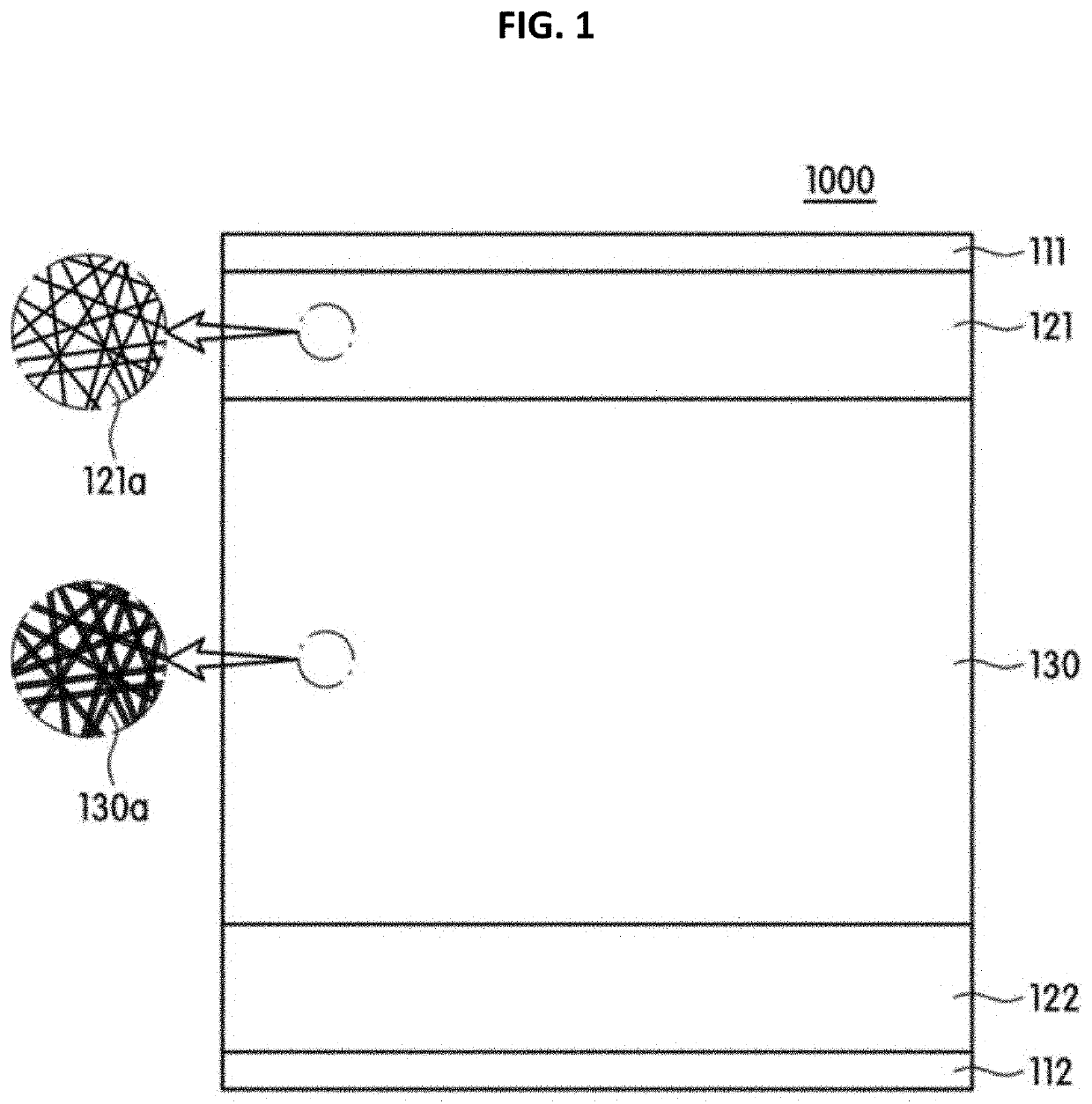

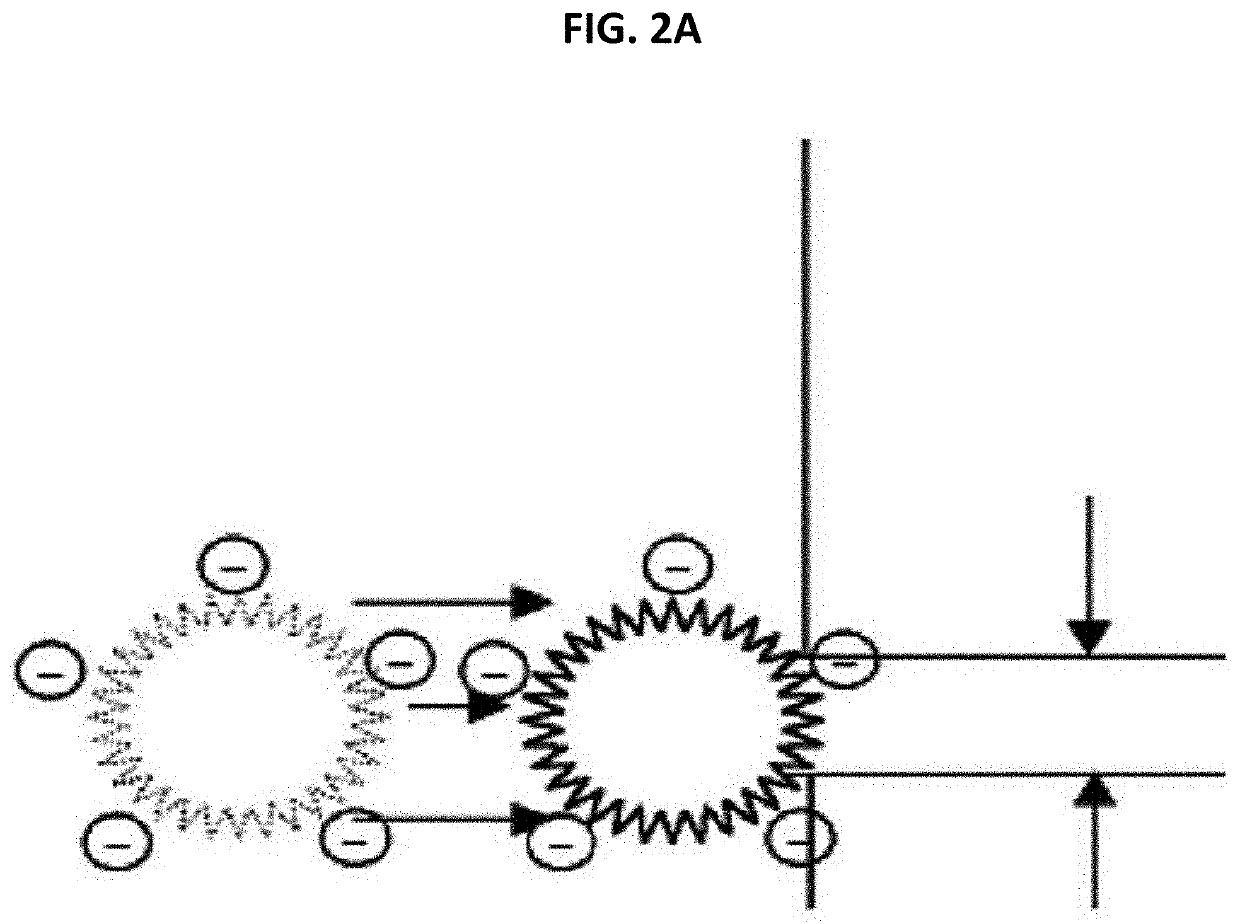

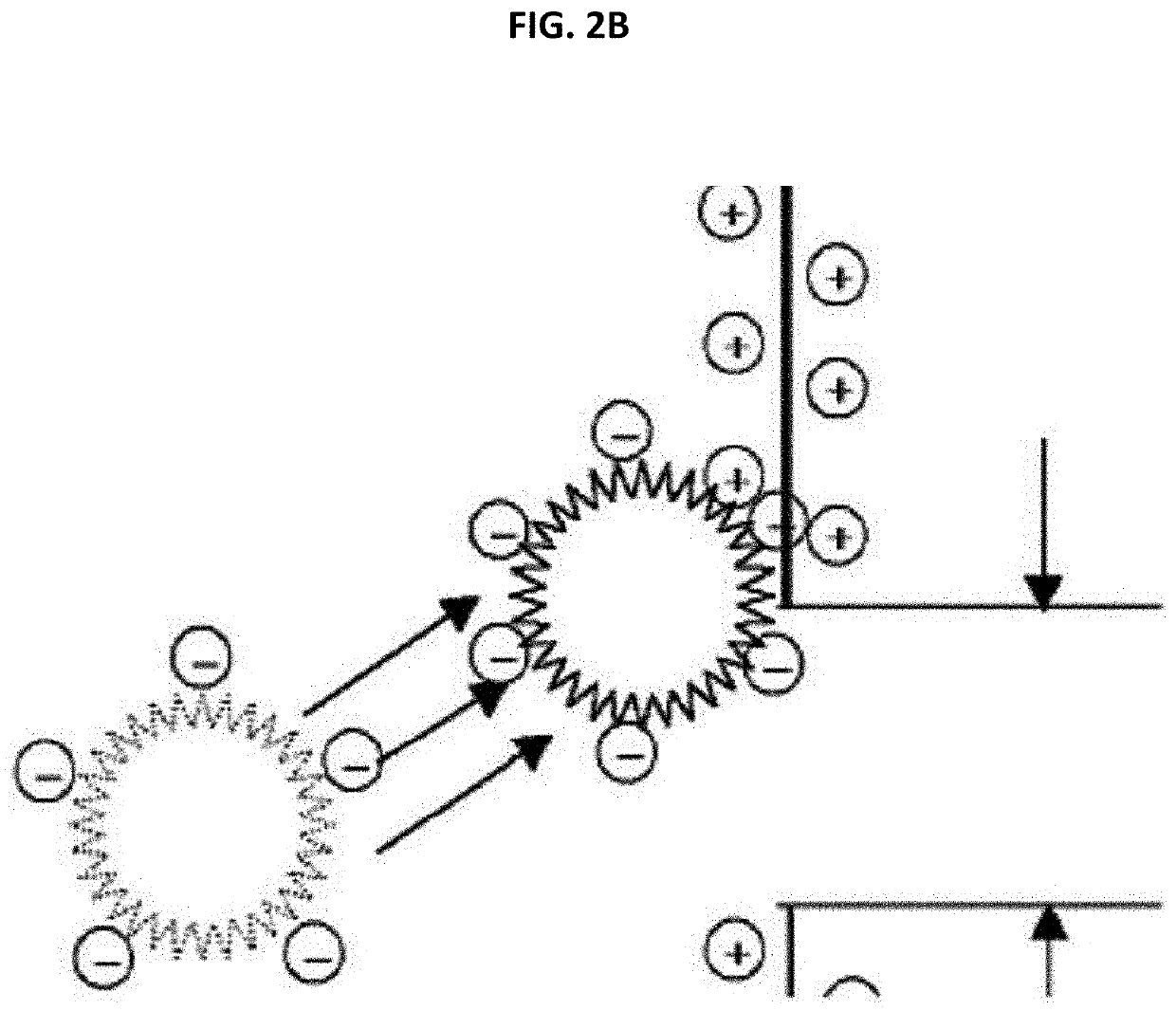

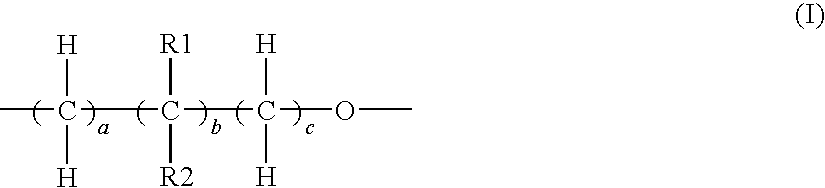

Filter medium, method for manufacturing same, and filter unit comprising same

ActiveUS20200016545A1Increase flow rateIncreased durabilitySemi-permeable membranesMembranesHydrophilic coatingPolymer science

A filter medium according to one embodiment of the present invention comprises: a first support having a plurality of pores; a nanofiber web comprising nanofibers disposed on upper and lower portions of the first support and forming a three-dimensional network structure, and a hydrophilic coating layer formed on at least a part of an outer surface of the nanofibers, wherein the hydrophilic coating layer is formed of a hydrophilic coating composition comprising a hydrophilic polymer compound having at least one functional group selected from a hydroxyl group and a carboxyl group and a crosslinking agent comprising at least one sulfone group; and a second support having a plurality of pores interposed between the first support and the nanofiber web.

Owner:AMOGREENTECH CO LTD

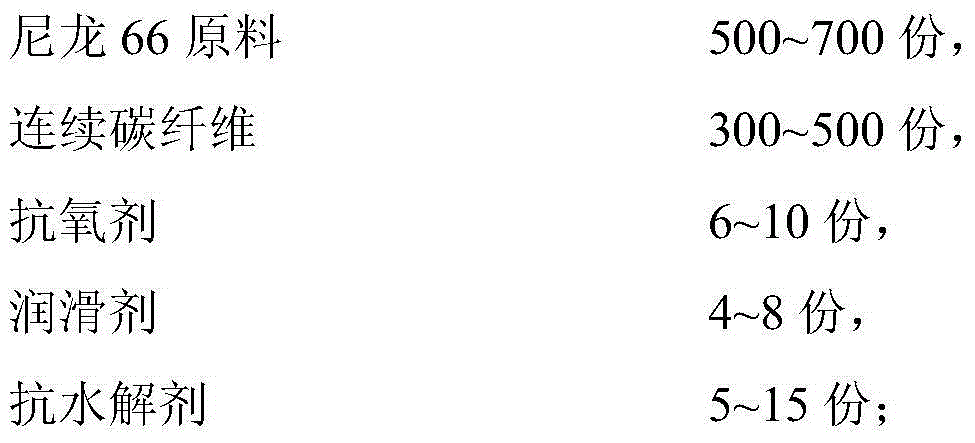

Nylon 66 material and preparation method thereof

The invention falls into the technical field of polymer material, and discloses Nylon 66 material and a preparation method thereof. The material comprises (by weight parts) Nylon 66 raw material 500-700, continuous carbon fibers 300-500, an antioxidant 6-10, a lubricant 4-8 and an anti-hydrolysis agent 5-15. Compared with prior art, the invention has reasonable design, simple operation and strong practicability; the adoption of continuous carbon fibers for reinforcing the Nylon 66 material results in that the length of carbon fibers in products can be kept at 3-6 mm, and as a result, the rigidity and the strength of the material are improved greatly, the impact resistance and the heat resistance of the material are improved remarkably, and the material possesses a long-term hydrolytic stability and a resistance to chemical corrosion.

Owner:上海事升新材料有限公司

Carbon-fiber-reinforced wear-resistant polyformaldehyde gear and preparation method thereof

The invention relates to a carbon-fiber-reinforced polyformaldehyde gear which is prepared from polyformaldehyde resin, chopped carbon fiber, molybdenum disulfide, calcium stearate, coupling agent and phenolic resin. The invention also relates to a preparation method of the carbon-fiber-reinforced polyformaldehyde gear, which comprises the following steps: carrying out composite surface treatmenton the carbon fiber; and putting the raw materials into a high-speed mixer according to the percentage in the formula, sufficiently mixing, granulating, and carrying out injection molding in an injection molding machine. The composite surface treatment, which is carried out on the chopped carbon fiber, greatly improves the wettability of the carbon fiber surface, and maximally enhances the interfacial adhesiveness between the carbon fiber and the polyformaldehyde matrix, thereby greatly enhancing the mechanical properties of the composite material. The gear prepared from the carbon-fiber-reinforced wear-resistant polyformaldehyde has the advantages of low specific gravity, low noise, favorable wear resistance, favorable self-lubrication effect, chemical corrosion resistance, high specificstrength, large specific modulus, small thermal expansion coefficient, static resistance and the like, and does not produce sparks, thereby being capable of replacing the original steel part. In addition, the invention reduces the labor intensity of workers, and lowers the energy consumption.

Owner:常州神鹰碳塑复合材料有限公司

A kind of anti-hydrolysis continuous carbon fiber reinforced nylon 6 material and preparation method thereof

The invention belongs to the technical field of a high polymer material and discloses a hydrolysis resistant continuous carbon fiber reinforced nylon 6 material and a preparation method thereof. The material disclosed by the invention comprises the following components in percentage by weight: 500-700 parts of nylon 6, 300-500 parts of continuous carbon fiber, 6-10 parts of oxidation inhibitor, 4-8 parts of lubricating agent and 5-15 parts of hydrolysis resistant agent. The invention also discloses the preparation method of the hydrolysis resistant continuous carbon fiber reinforced nylon 6 material. Compared with the prior art, the preparation method is reasonable in design, simple in operation and strong in practicability and adopts the continuous carbon fiber reinforced nylon 6 material so that the length of carbon fibers in a workpiece can be remained at 3-6mm, thereby the rigidity and the strength of the material are increased, the shock resistance and heat resistance of the material are obviously improved, and the material has long-term hydrolysis resistant stability and anti-chemical corrosion performance.

Owner:HEFEI GENIUS NEW MATERIALS

Dacron aculeus filtering felt surface coating process

The invention provides a surface coating technique for a polyester fiber needling filter felt, comprising: step 1, formulating a surface coating liquid; step 2, penetrating a semi-finished product of the polyester fiber needling felt, which is subjected to singeing in impregnation technology, into a coating apparatus to then enter into a stenter shaping box at the temperature of 150 DEG C; pouring the well-formulated coating liquid into a coating rubber groove to the half height thereof; step 3, placing a Phi300 coating roller downwards inside the rubber groove with the area occupied being about one third of that of the rubber groove; step 4, regulating the spacing between a scraper and an rubber roller to 5mm; step 5, launching the coating apparatus while synchronously launching an oven at a speed of 3.5m / min; step 6, maintaining the coating liquid in the rubber groove at the same height in the whole coating process; step 7, subjecting the coating liquid to hot pressing technique after drying and curing in order to be cut into products. The invention has the advantages of resisting chemical erosion, high mechanical strength, resisting higher filtration load, smooth surface of the filter felt, easiness for dust removal, low resistance in operating dust removal apparatuses and high filter precision.

Owner:上海华成针刺材料有限公司

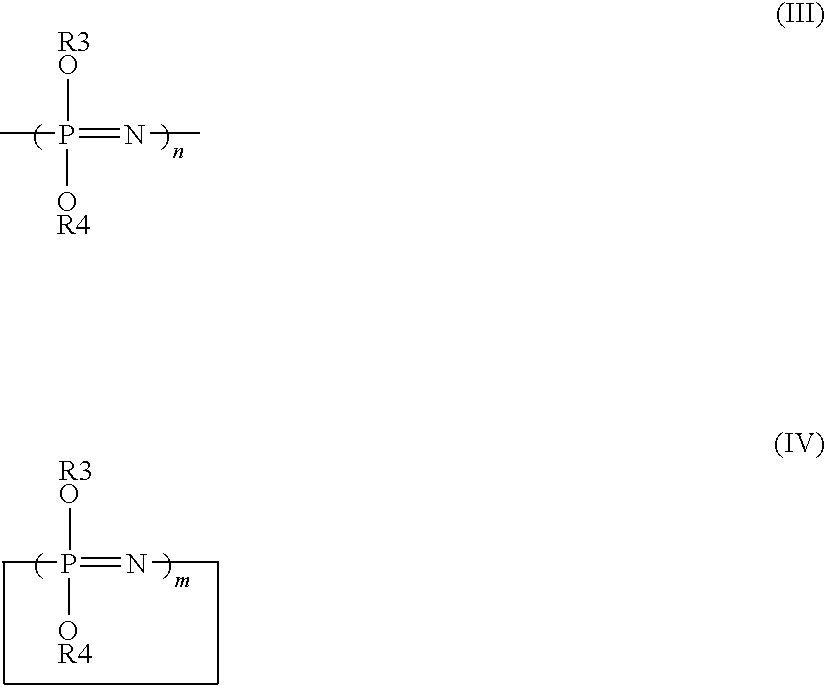

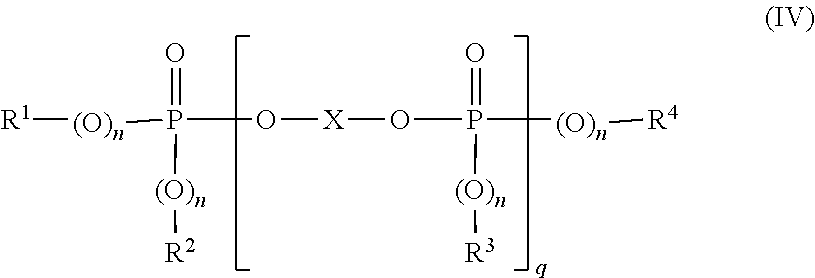

Elastic polyurethane yarn and method of manufacturing the same

InactiveUS8277941B2Chemical resistanceImprove recoverabilityMonocomponent polyurethanes artificial filamentFlame-proof filament manufactureYarnHeat resistance

The present invention provides elastic polyurethane yarns which possess excellent elongation, recoverability, heat resistance and chemical resistance, as well as a method of manufacturing the same. The elastic polyurethane yarns comprise a polyurethane being composed mainly of a polymeric diol and a diisocyanate, and contains through incorporation a compound having within the molecule a phosphorus-nitrogen interatomic bond(s). The process can produce the elastic polyurethane yarns by adding to a solution of the polyurethane a compound having within the molecule a phosphorus-nitrogen interatomic bond(s), followed by spinning.

Owner:TORAY OPELONTEX

Nylon 66 material and preparation method thereof

The invention falls into the technical field of polymer material, and discloses Nylon 66 material and a preparation method thereof. The material comprises (by weight parts) Nylon 66 raw material 500-700, continuous carbon fibers 300-500, an antioxidant 6-10, a lubricant 4-8 and an anti-hydrolysis agent 5-15. Compared with prior art, the invention has reasonable design, simple operation and strong practicability; the adoption of continuous carbon fibers for reinforcing the Nylon 66 material results in that the length of carbon fibers in products can be kept at 3-6 mm, and as a result, the rigidity and the strength of the material are improved greatly, the impact resistance and the heat resistance of the material are improved remarkably, and the material possesses a long-term hydrolytic stability and a resistance to chemical corrosion.

Owner:上海事升新材料有限公司

Power transmission cable

ActiveUS8878066B2Chemical resistancePlastic/resin/waxes insulatorsInsulated cablesElectric power transmissionElectrical conductor

A power transmission cable includes at least one power conductor, an insulating layer surrounding the conductor to form at least one insulated conductor, a flame-retardant halogen free protective sheath provided in a radially external position with respect to the insulated conductor, wherein the sheath has an inner and an outer layer in contact with each other, the inner layer having a thickness at least equal to a thickness of the outer layer, the inner layer including a polymer material having a glass transition temperature equal to or lower than −30° C., and the outer layer including a mud resistant polymer material.

Owner:PRYSMIAN SPA

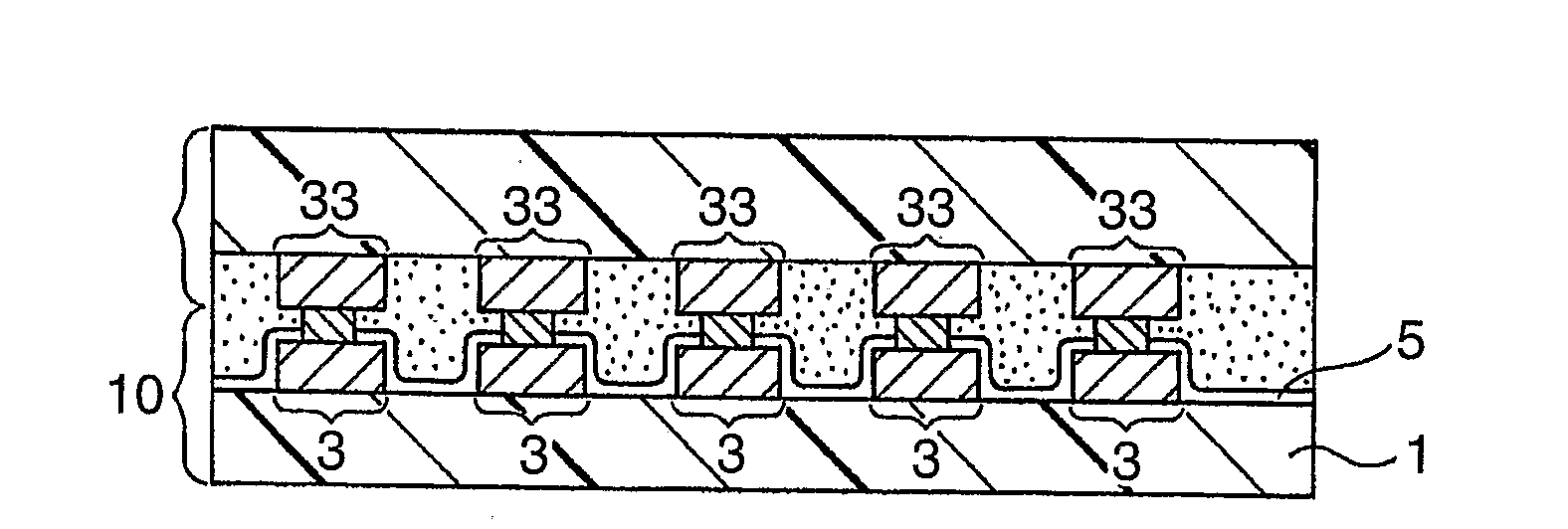

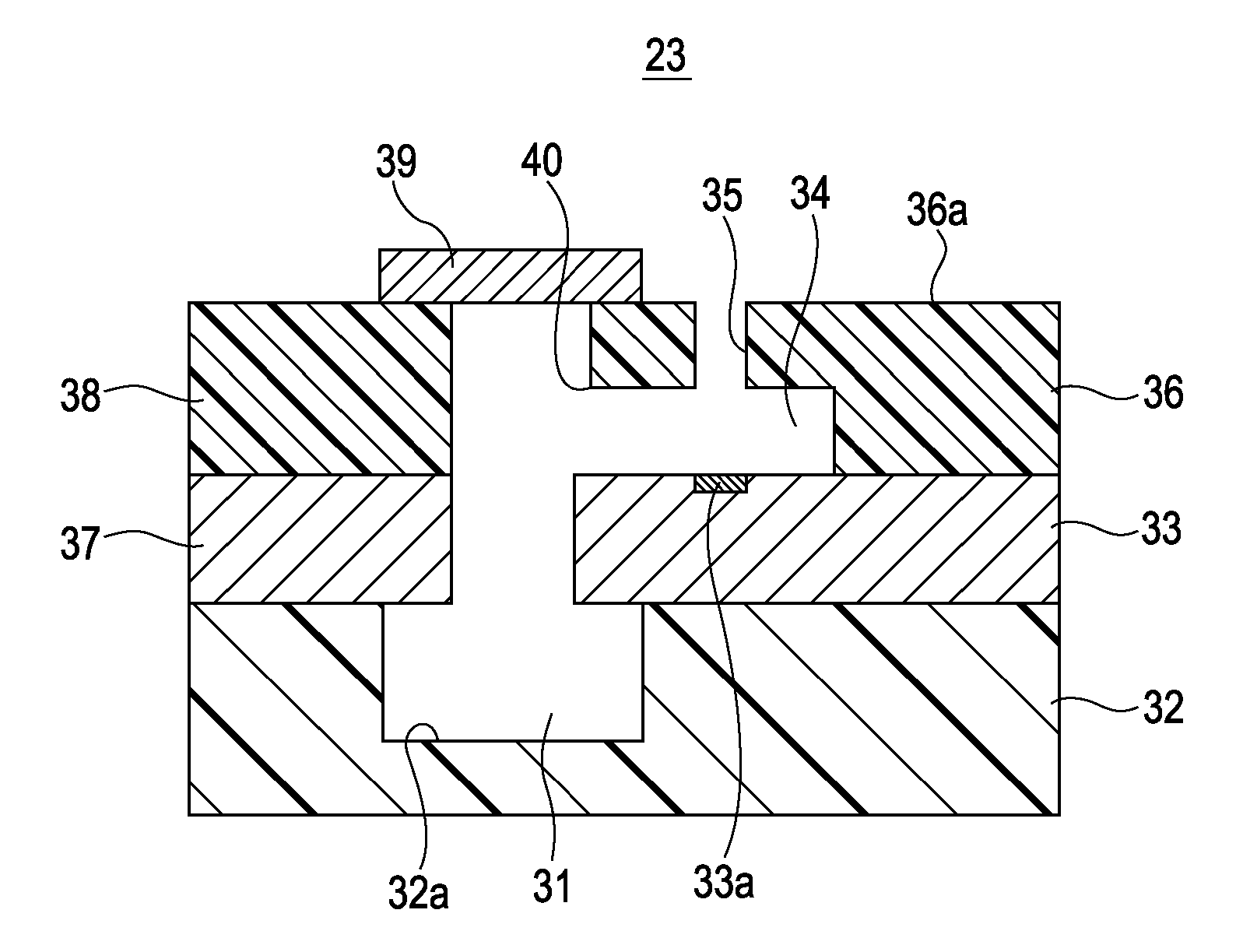

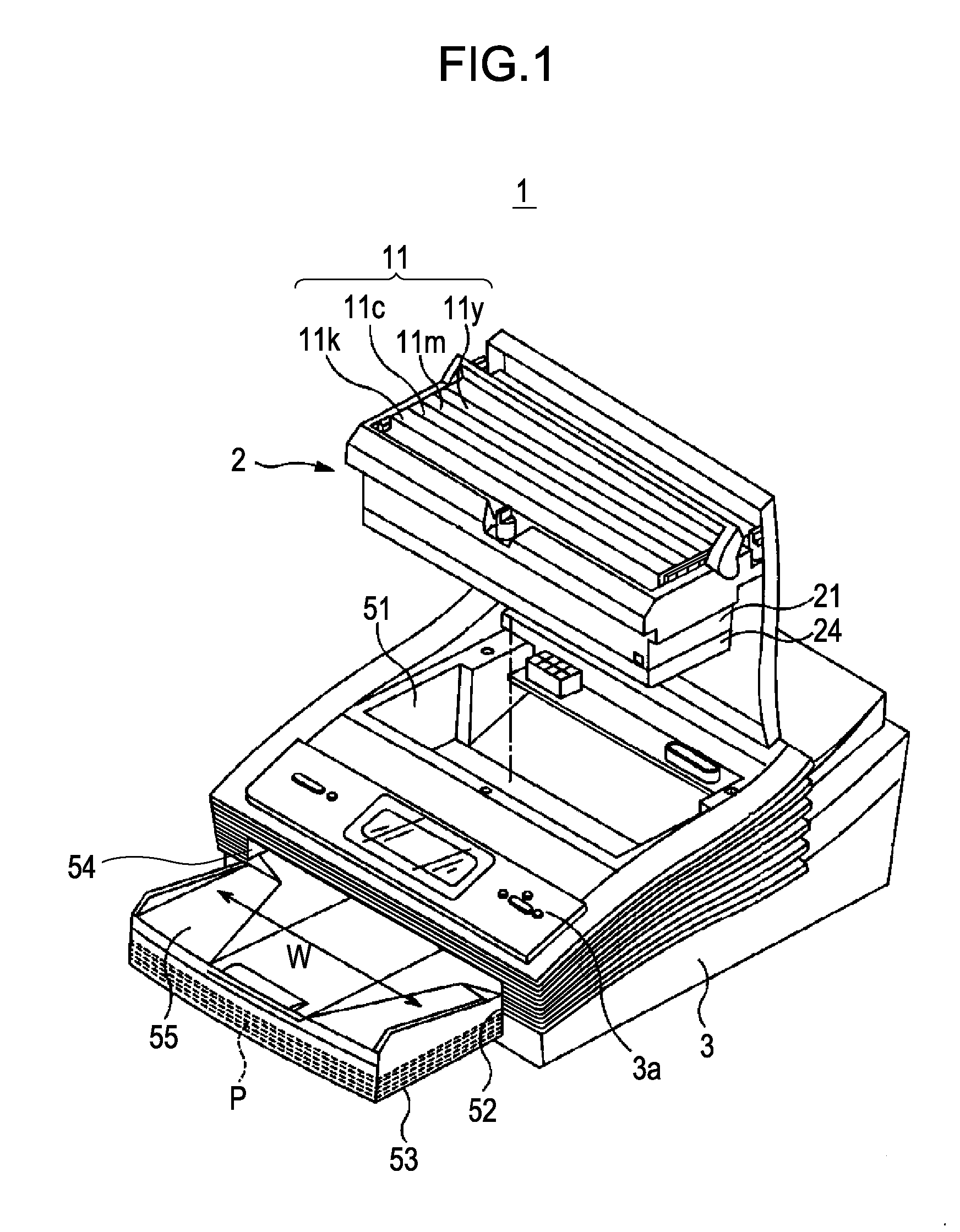

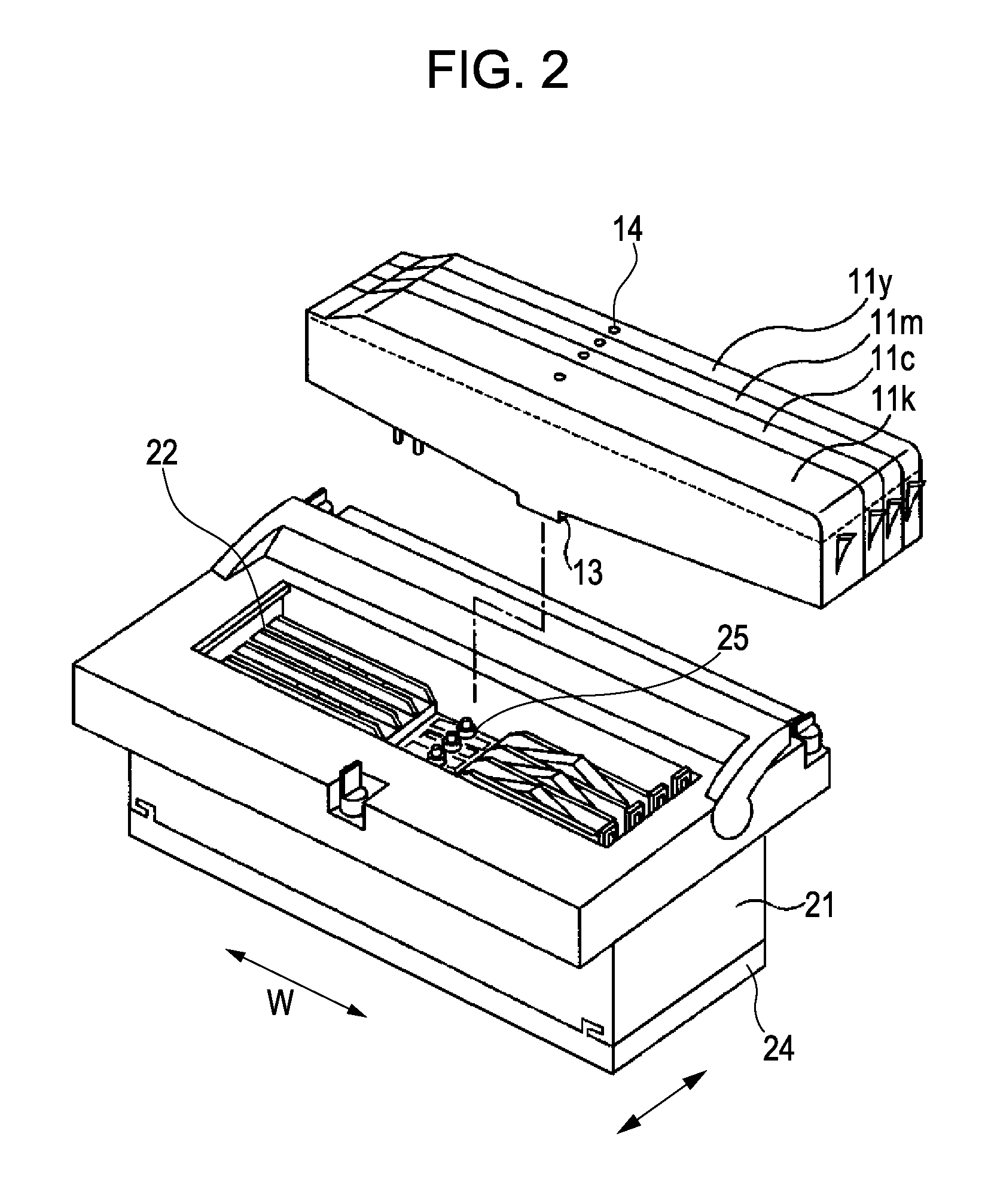

Liquid discharge recording head and liquid discharge apparatus

A liquid discharge recording head which discharges a liquid includes a substrate on which liquid-discharge-energy-generating elements are provided and which constitutes a part of a flow path for supplying the liquid; and a covering resin layer which is provided on the substrate, which constitutes a part of the flow path, and which includes orifices for discharging the liquid, wherein the covering resin layer is composed of an oxetane resin composition containing an oxetane compound having at least one oxetanyl group in its molecule and a photocationic polymerization initiator as essential components.

Owner:SONY CORP

Multilayer composite fiber

ActiveUS20110171868A1Chemical resistanceEasily biodegradableFilament/thread formingWoven fabricsNonwoven fabricPetroleum

The present invention has an object of providing a novel multilayer composite fiber using polyacetal mainly derived from methanol, which is a petroleum-independent raw material, and having a low environmental load, and also providing a nonwoven fabric obtained by thermally bonding such fibers. According to the present invention, a multilayer composite fiber comprising a resin containing polylactic acid as a main component and a resin containing polyacetal as a main component, in which the components both form continuous layers in an axial direction of the fiber, and also a nonwoven fabric obtained by thermally bonding such fibers, can be provided.

Owner:MITSUBISHI GAS CHEM CO INC

Polycarbonate molding compositions with improved melt flow and chemical resistance

ActiveUS7674855B2Speed up the flowChemical resistanceCosmetic preparationsToilet preparationsPolyesterPolymer science

A thermoplastic molding composition having improved melt flow and chemical resistance is disclosed. The composition contains A) at least one member selected from the group consisting of aromatic polycarbonate and polyester carbonate, B) a graft polymer of at least one vinyl monomer on at least one rubber having a glass transition temperature of <10° C. as graft base and C) vinyl (co)polymer having weight-average molecular weight of 1500 to 5000 g / mol and glass transition temperature of >40° C. The composition may optionally further contain D) a phosphorus-based flame retardant and E) an anti-dripping agent.

Owner:COVESTRO DEUTSCHLAND AG

High-molecular-weight polyethylene fiber eight-strand rope

The invention relates to a high-molecular-weight polyethylene fiber eight-strand rope. Eight strands herein include four Z-twist and four S-twist ones subjected to alternate hollow braiding by twisting; in terms of the selection and design of strand material and structure, the strands are composed of a core, a strand body and a surface treatment layer, the core is made by twisting high-molecular-weight polyethylene fibers, an outer layer is made by braiding twisted yarns of the high-molecular-weight polyethylene fibers, and the outer layer of the high-molecular-weight polyethylene is infiltrated with the surface treatment layer with an ethanol or propylene glycol solvent. The high-molecular-weight polyethylene fibers have high specific strength and high specific modulus, so that the rope herein can float on water and is nearly twice as high as aromatic amide fibers in elongation, chemical corrosion resistance and impact absorbing capacity; the cores made with twisted fibers have excellent impact resistance and cutting resistance; the outer layer is made with braided twisted yarns, so that the rope herein is convenient for human hands to hold with rarity of loosening; the high-molecular-weight polyethylene fibers selected herein help reduce the high labor intensity in marine project construction due to high water absorption, and provide improved construction efficiency; the surface treatment layers can soften the rope herein and prevent mildews, so that the life of the rope is extended.

Owner:涂巨丹

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com