Rock mechanics experiment loading unit for bittern flow field corrosion condition

A technology of rock mechanics and loading device, which is applied to measuring devices, scientific instruments, soil material testing, etc., can solve the problems of inability to automatically adjust, not considering the mechanical properties of rocks, and the cumbersome process of installing samples, so as to reduce adverse effects, Good observability, simple structure effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

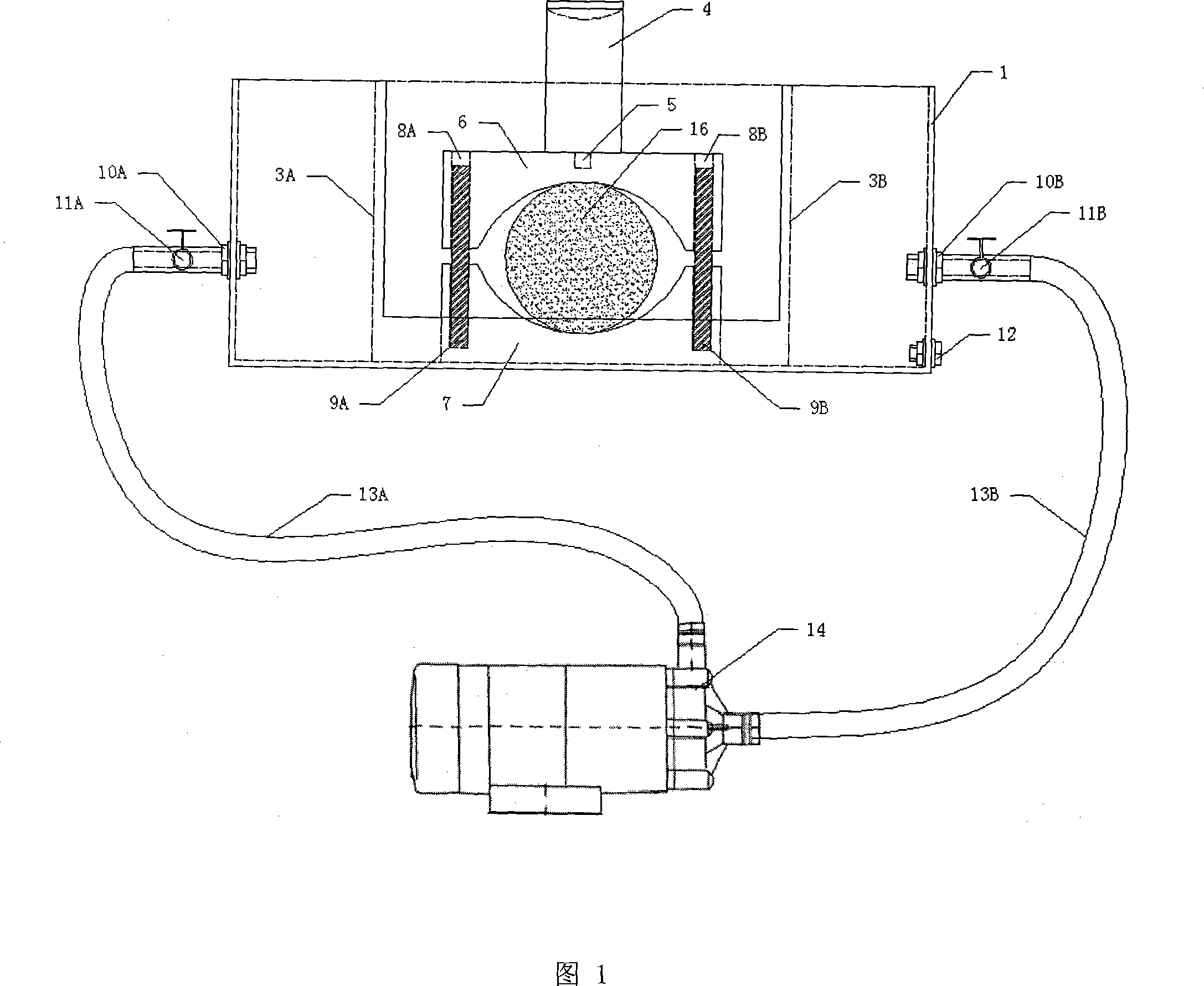

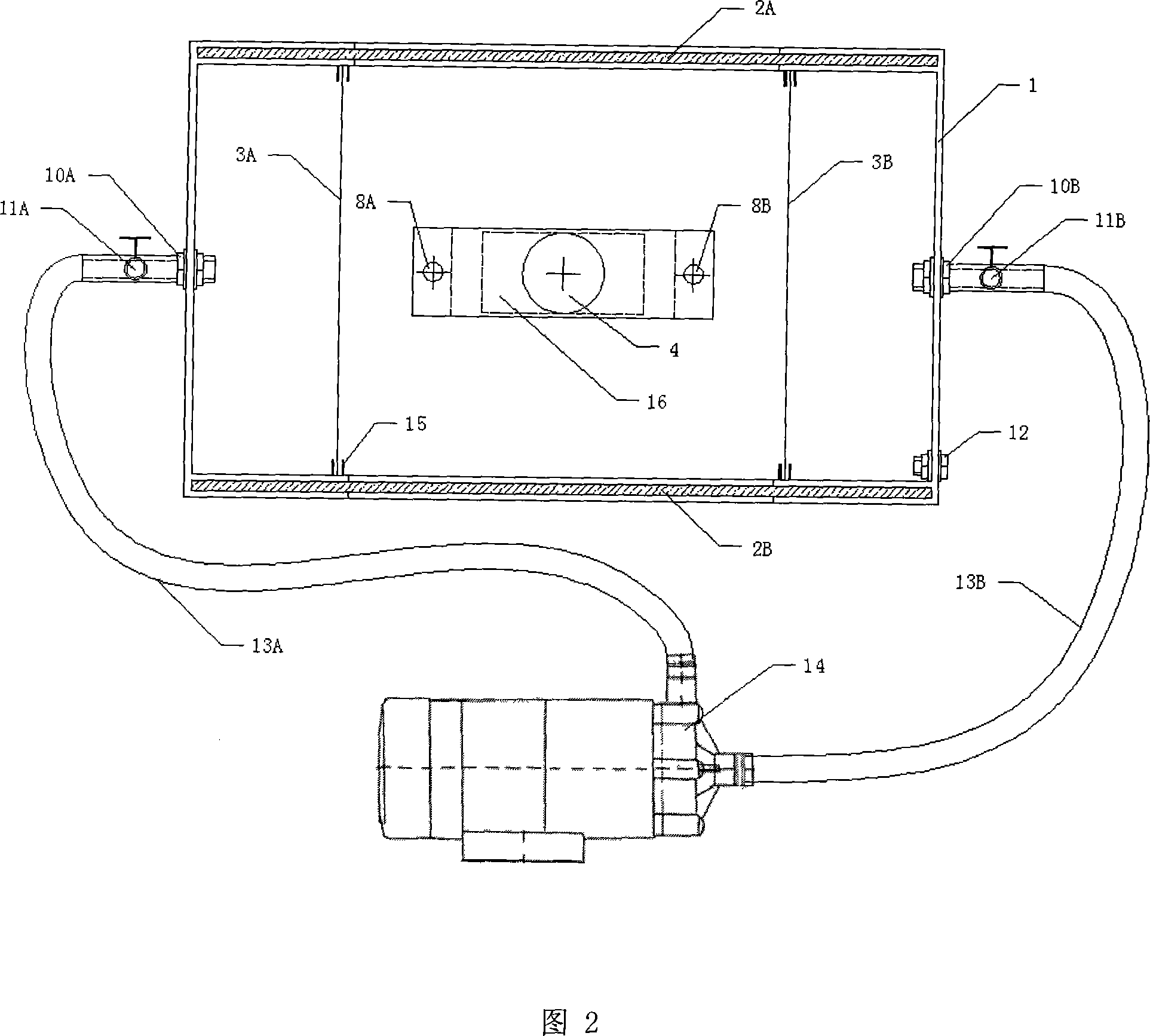

[0030] Specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

[0031] The invention is composed of a container (1), a ball head cylindrical indenter (4), a jig upper jaw (6), a jig lower jaw (7), a circulating pump (14) and a rock sample (16). Below in conjunction with accompanying drawing, connection mode and effect thereof of each part of the present invention are set forth as follows:

[0032] The container (1) consists of a stainless steel frame and plexiglass plates (2A, 2B), and is used to hold brine. The stainless steel frame is welded by stainless steel plates. After the stainless steel frame of the container (1) is processed, glass glue is applied to the two gaps reserved for the stainless steel frame, and then the plexiglass plates (2A, 2B) are inserted into the gaps where the glass glue is applied. ) to ensure a good seal between the plexiglass plates (2A, 2B) and the stainless steel plate to pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com