Patents

Literature

357results about How to "Uniform flow field" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

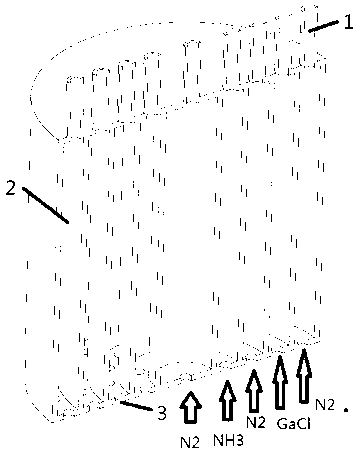

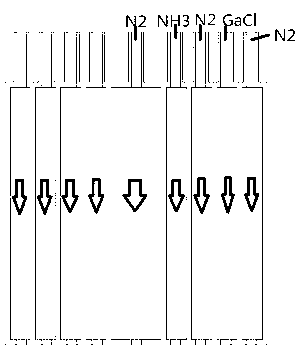

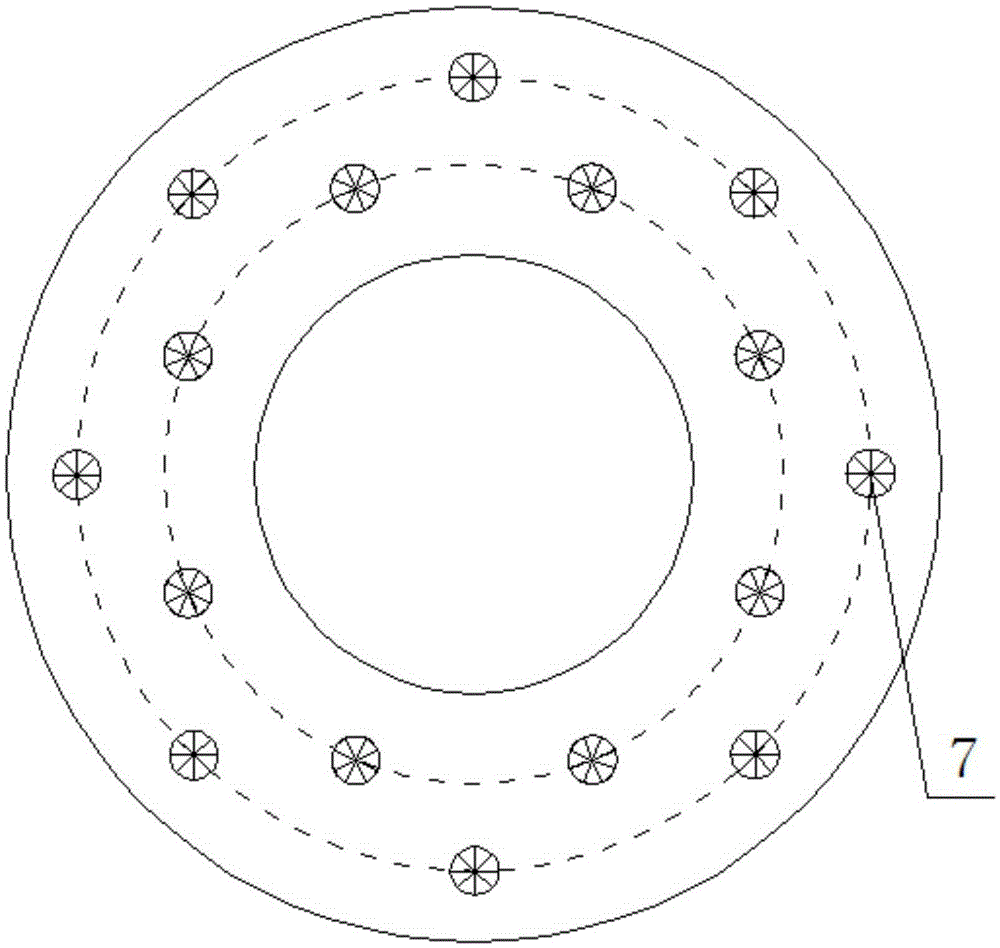

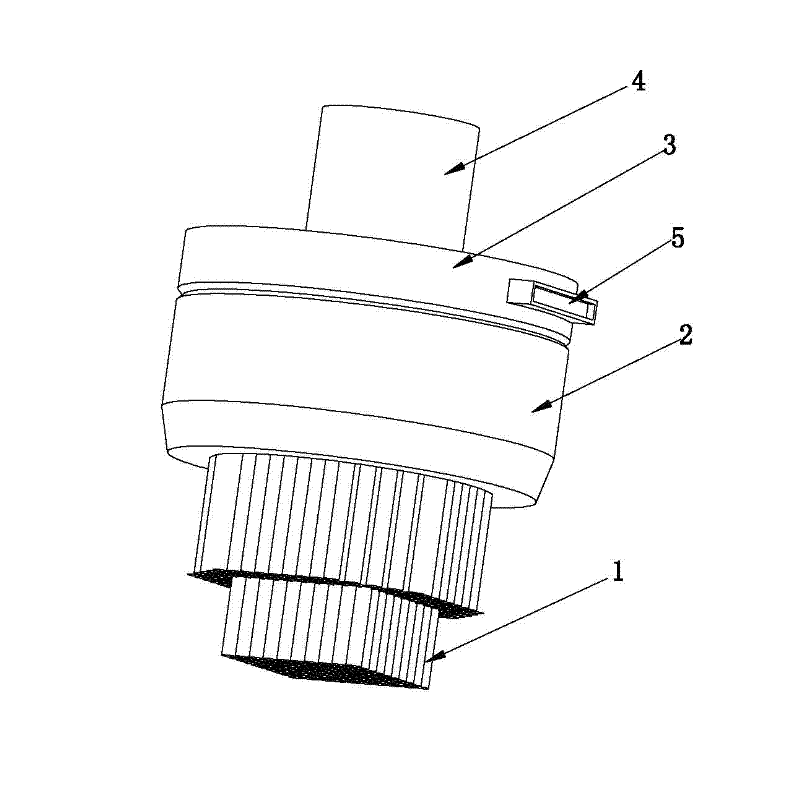

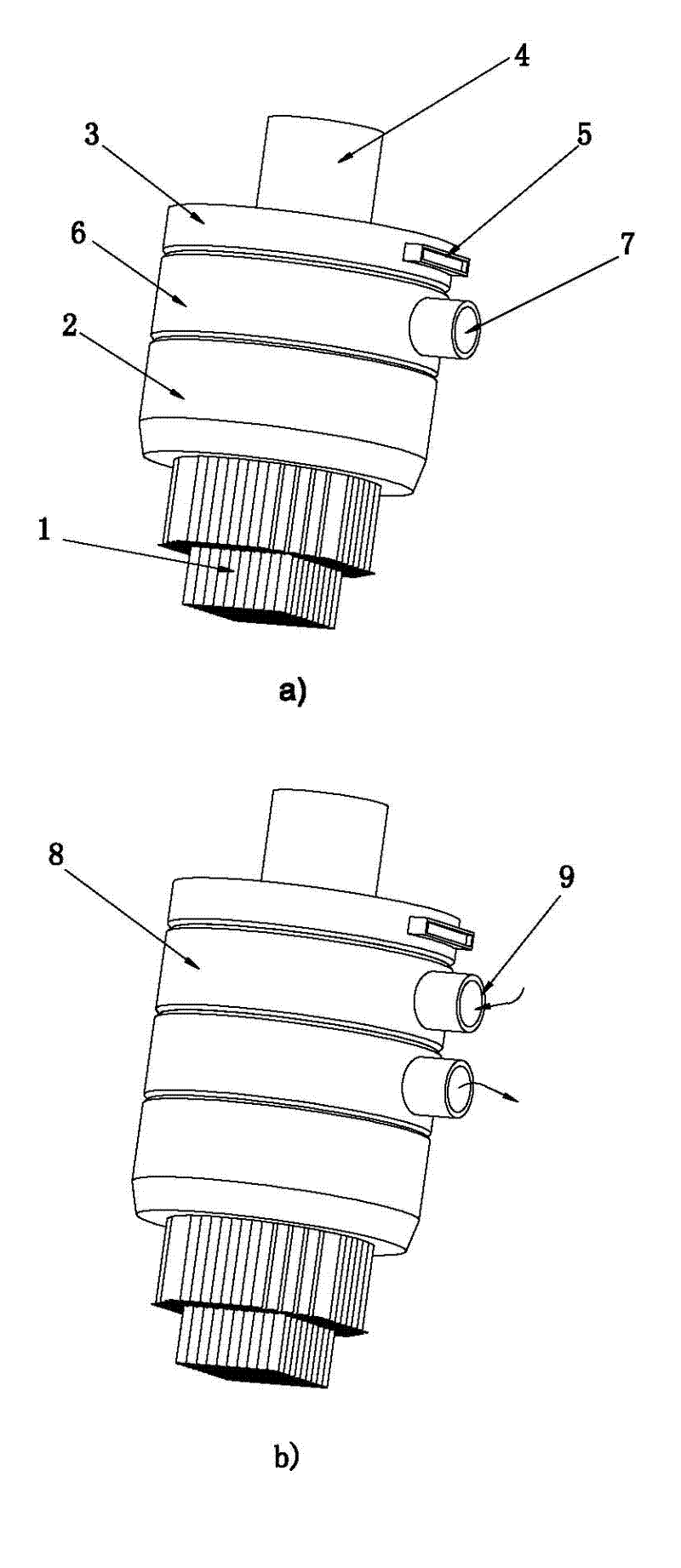

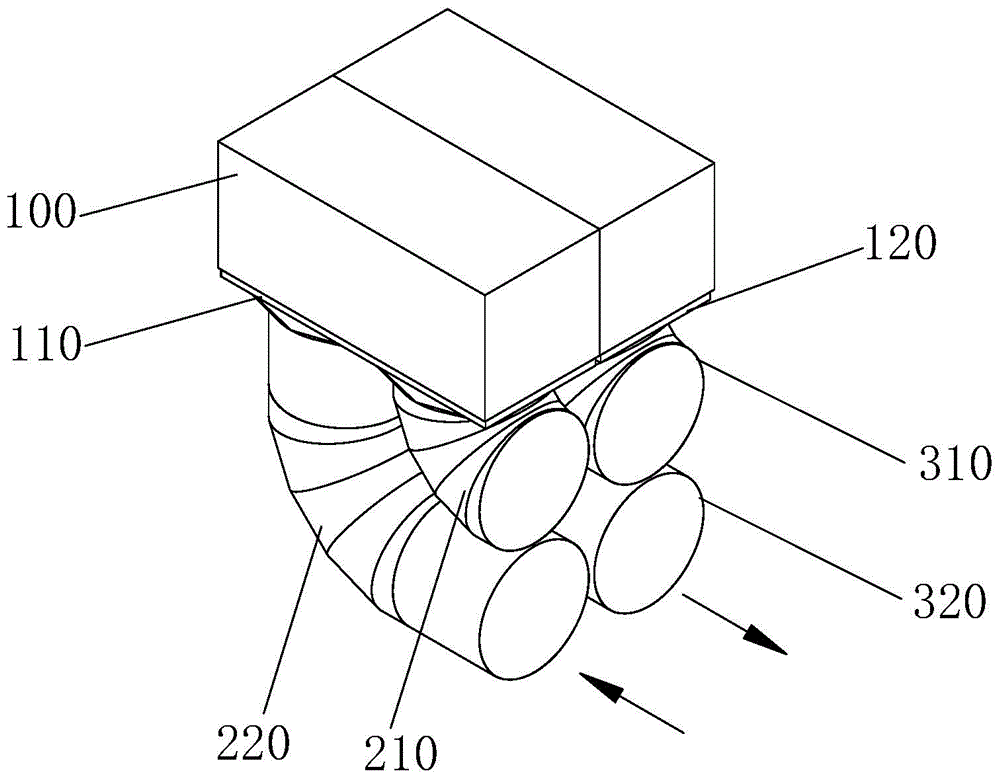

Concentric-ring sprayer structure for material vapor phase epitaxy

InactiveCN103014846ANo effect on growthGrowth impactFrom chemically reactive gasesVapour phase epitaxySprayer

The invention discloses a concentric-ring sprayer structure for material vapor phase epitaxy, which solves the problem that the large-area deposition region provides a uniform flow field of a precursor gas mixture in a large-substrate or multi-substrate crystal growth process. The sprayer structure comprises more than one independent air inlet pipeline, wherein each air inlet pipeline is provided with a controller for monitoring and regulating inlet gas flow speed and flow rate; the bottom of the sprayer is provided with an air outlet baffle; more than one concentric ring is arranged in the sprayer; independent cavities are formed among the concentric rings and are mutually separated; the top end of each concentric ring is connected with one independent air inlet pipeline; and the air outlet baffle at the bottom end of each concentric ring is provided with one or more air outlets. The air sources are mutually separated and independently controlled; and the multi-sprayer integrated use mode obviously improves the quality of the large-area deposited grown crystal, and greatly enhances the production efficiency.

Owner:SINO NITRIDE SEMICON +1

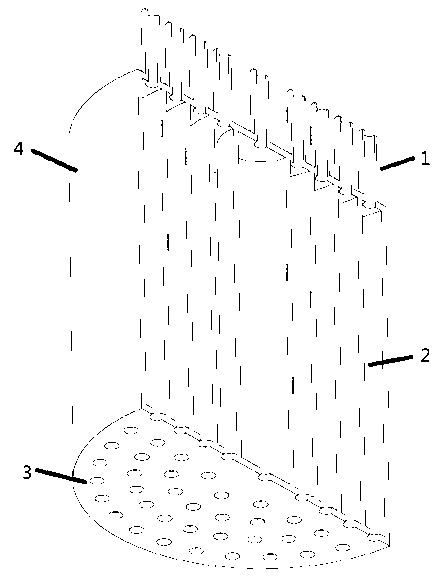

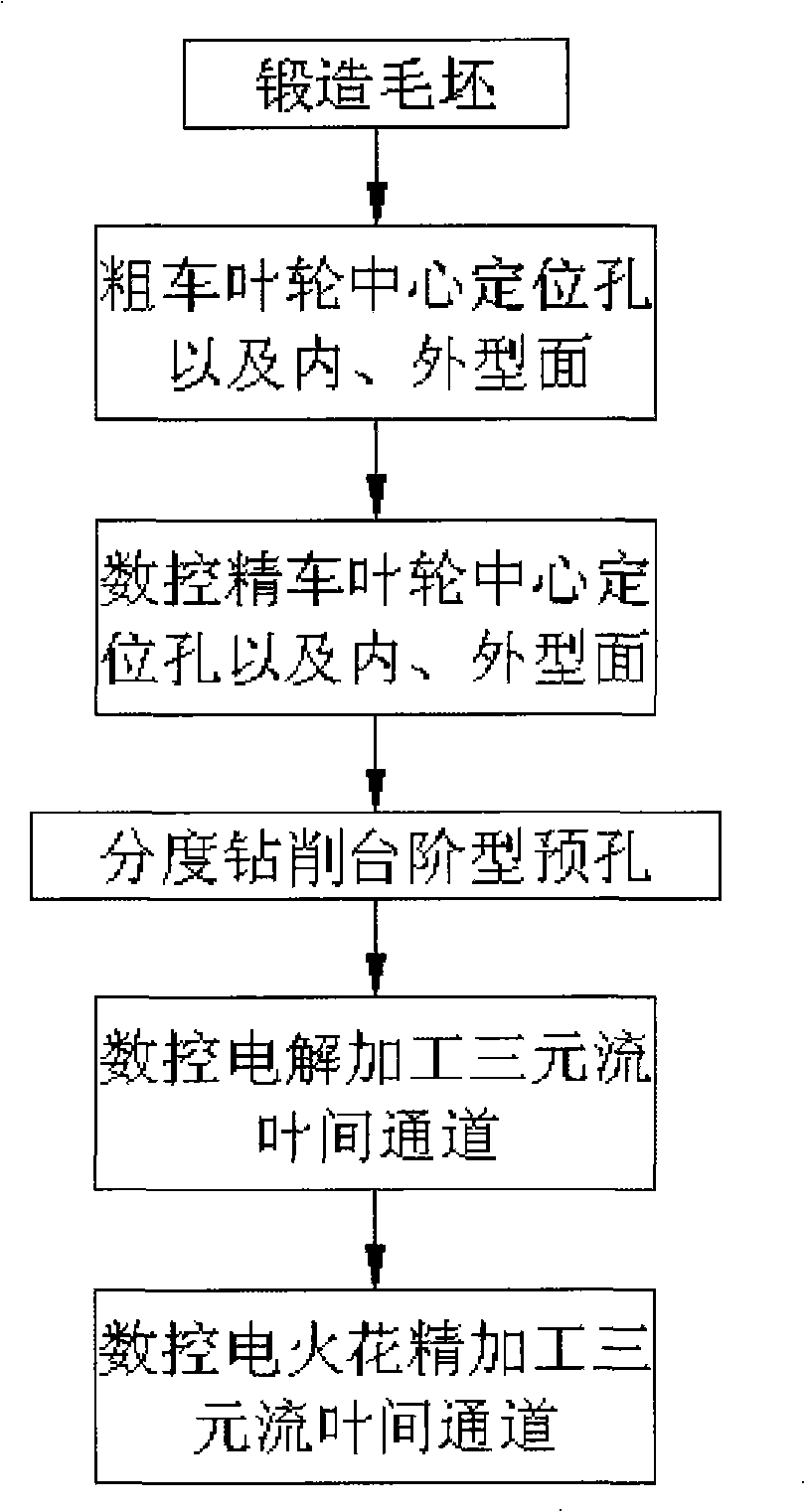

Method for manufacturing three-dimensional flow enclosed-type impeller inter-impeller passage and special clamp thereof

InactiveCN101524805AImprove efficiencyAvoid the phenomenon that is prone to blind spots in processingImpellerEngineering

The invention relates to a method for manufacturing a three-dimensional flow enclosed-type impeller inter-impeller passage and a special clamp thereof. A specially designed and manufactured molding or quasi-molding tool cathode is used for numerical control electrolytic processing to remove most remainder, then a specially designed and manufactured molding or quasi-molding tool electrode is used for numerical control electric spark precision processing to achieve the design requirement, thereby the three-dimensional flow enclosed-type impeller inter-impeller passage that can not be processed resulting from interference of numerical control milling cutter and undercutting can be manufactured, besides, the method has the technical and economical characteristics of high precision and efficiency, and low cost compared with the prior three manufacturing methods of integral casting, divided processing rewelding and numerical control milling.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

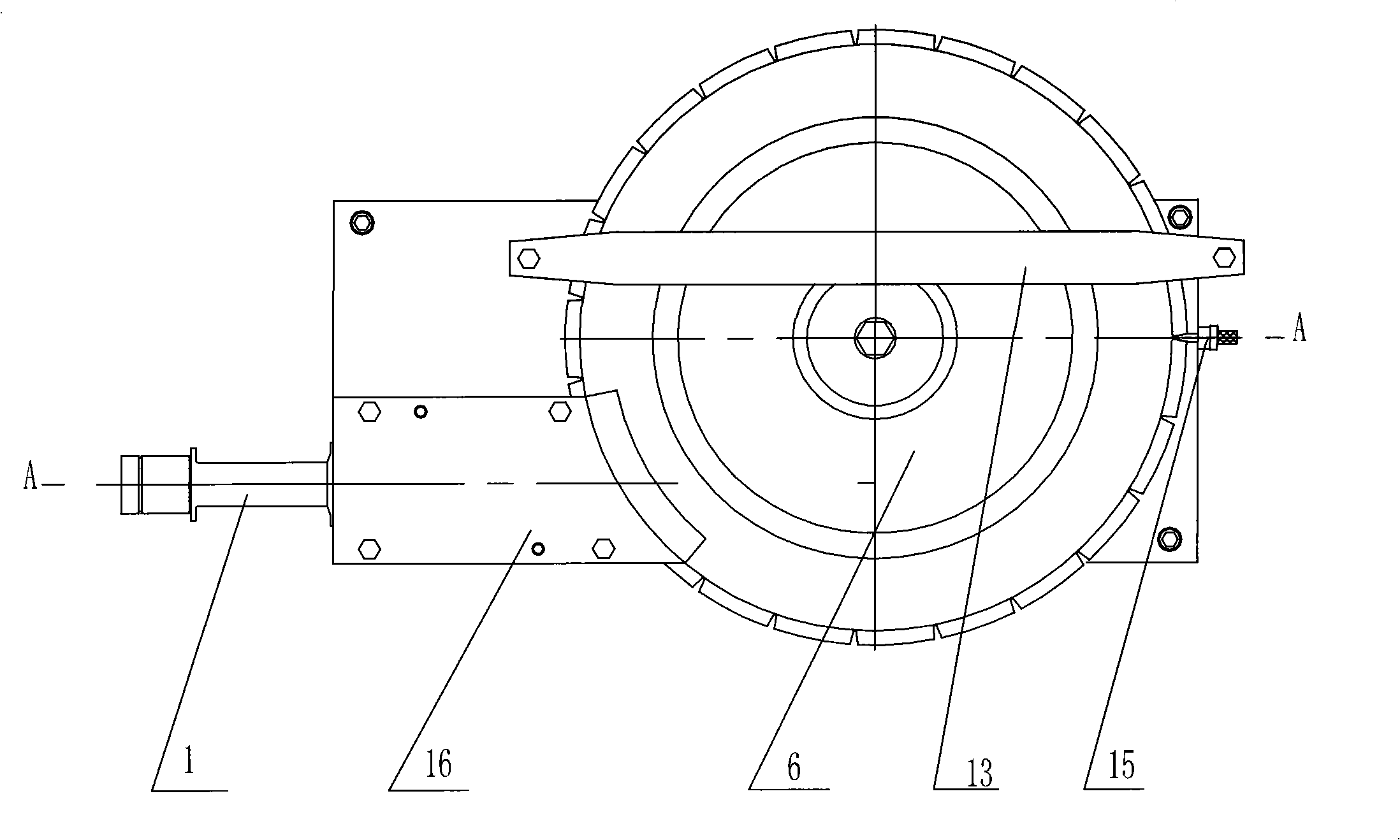

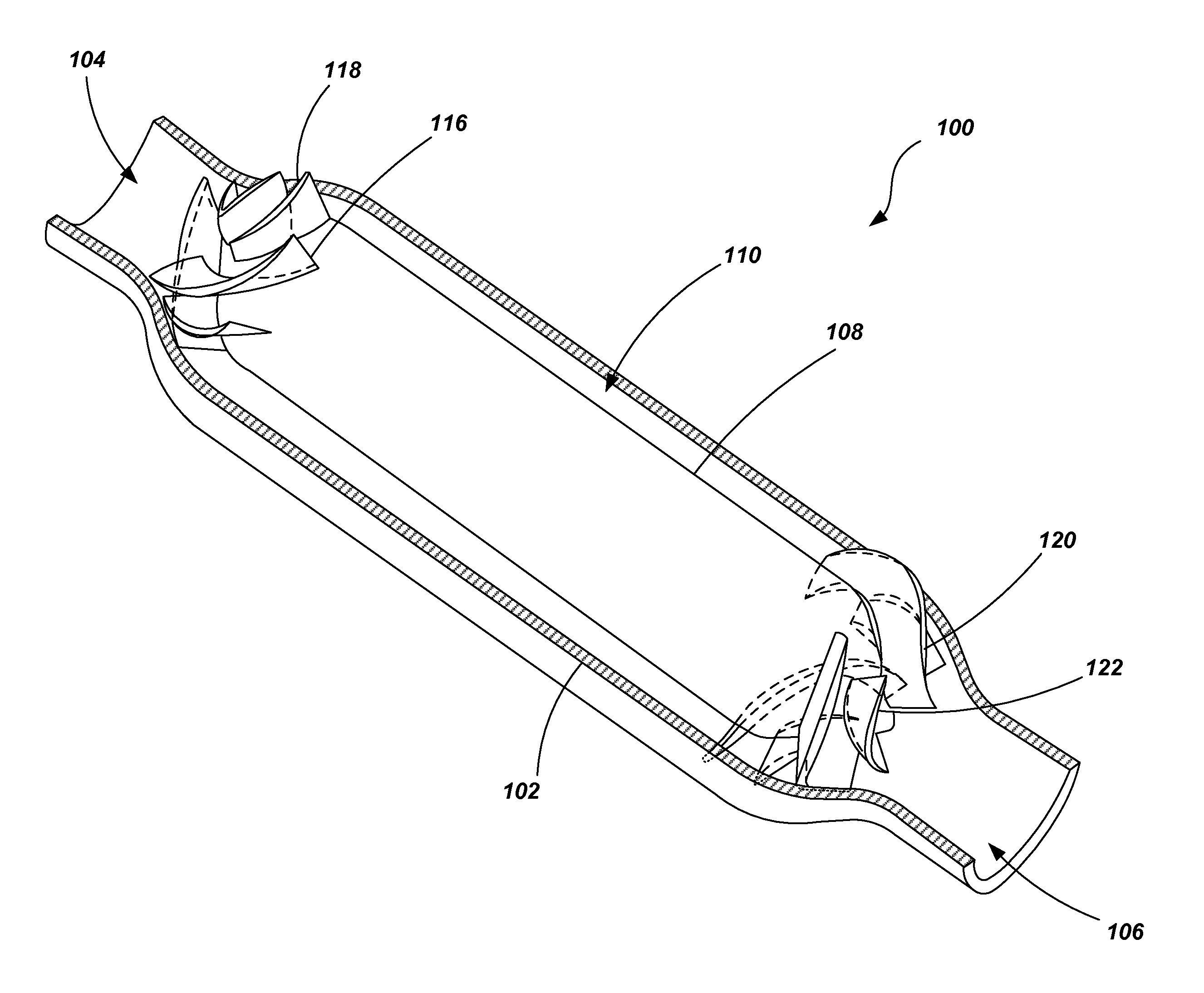

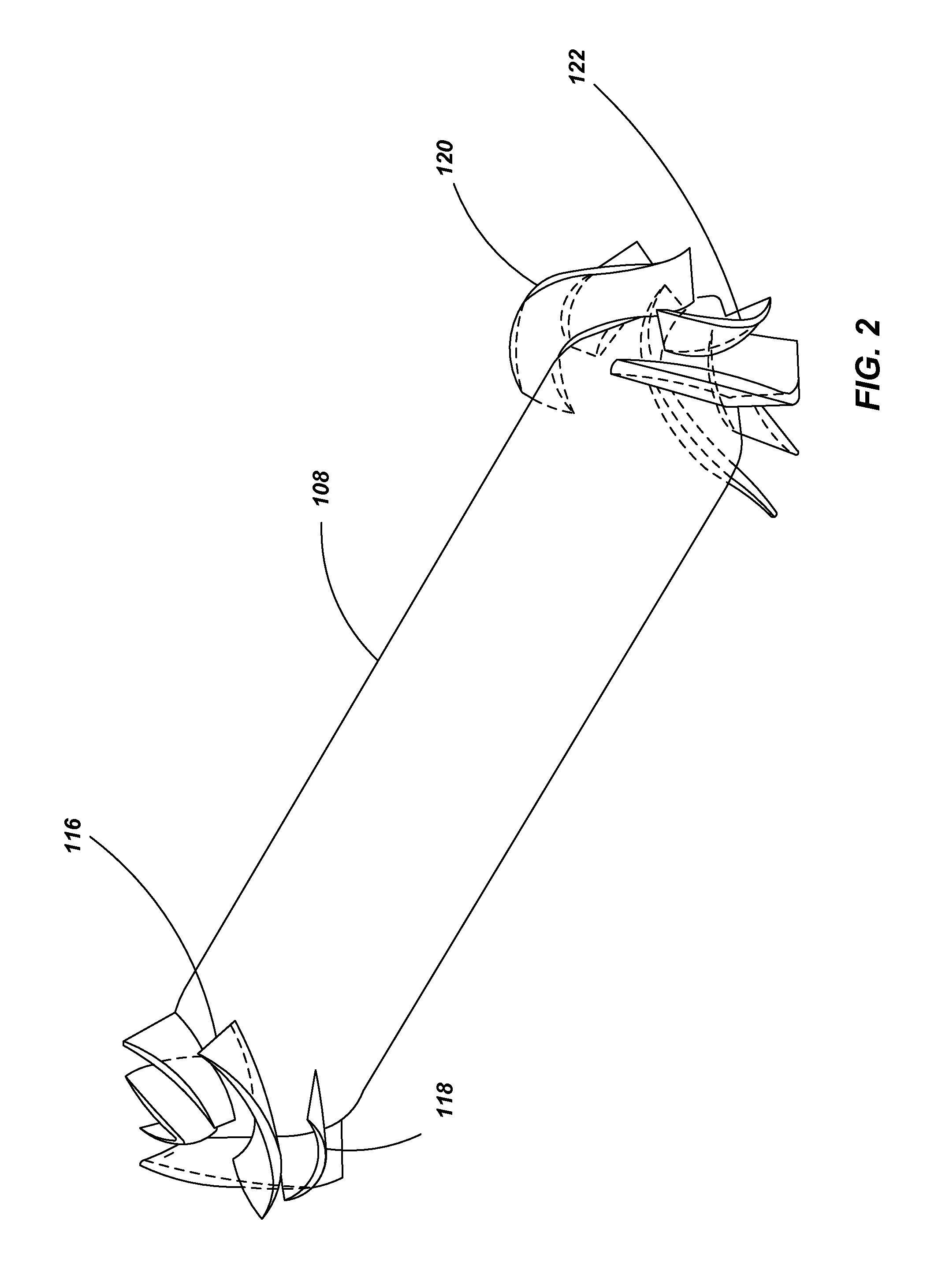

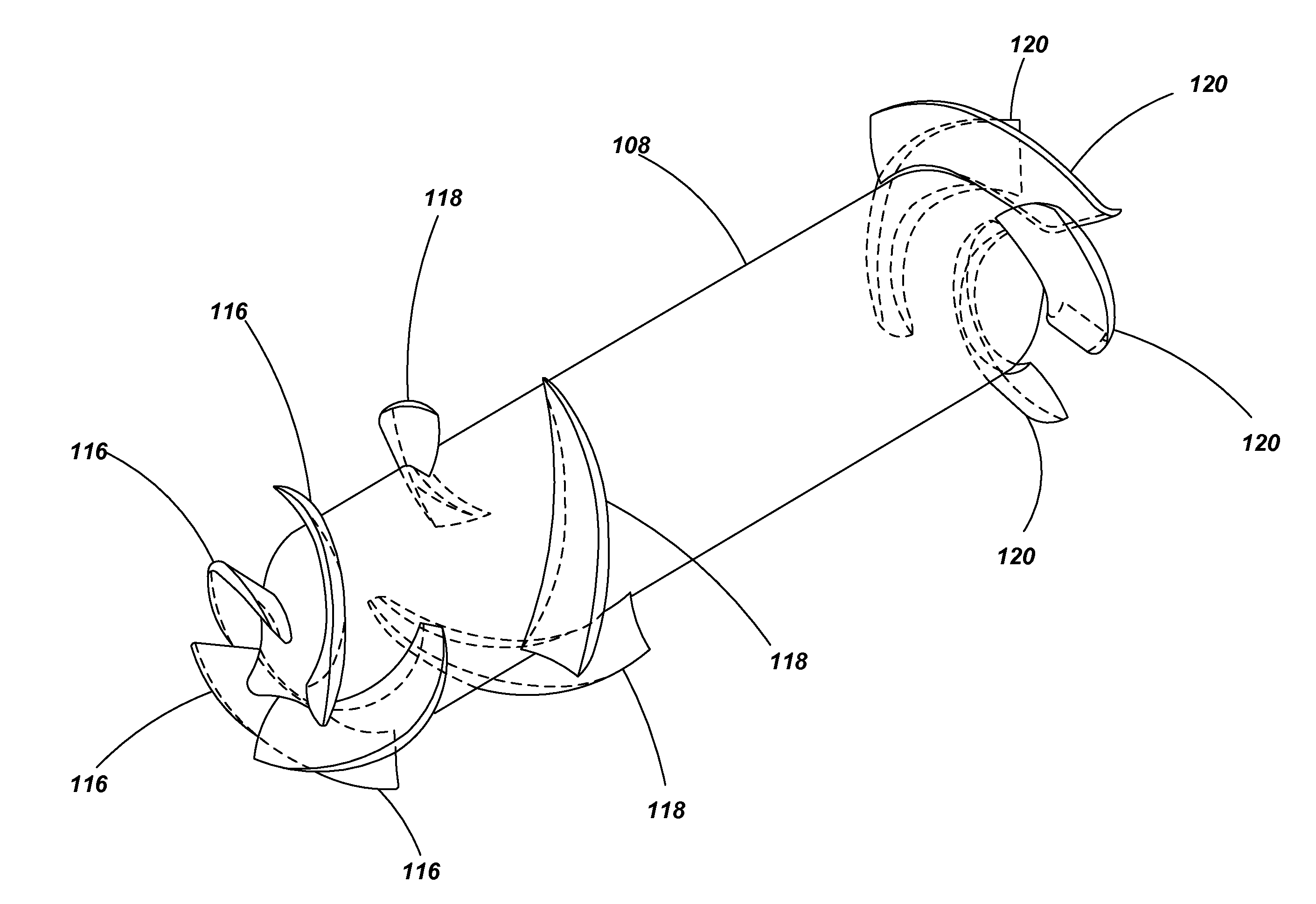

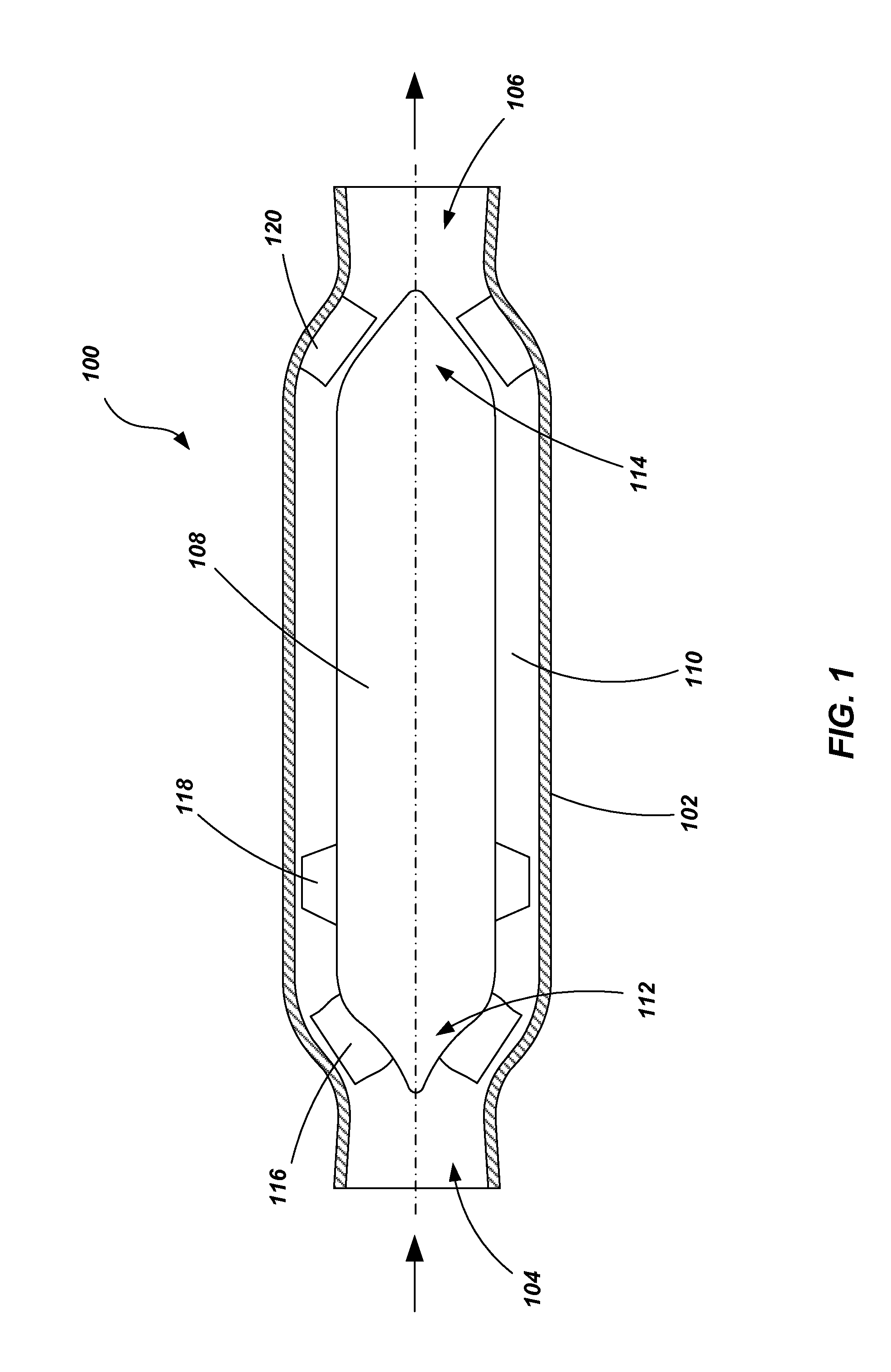

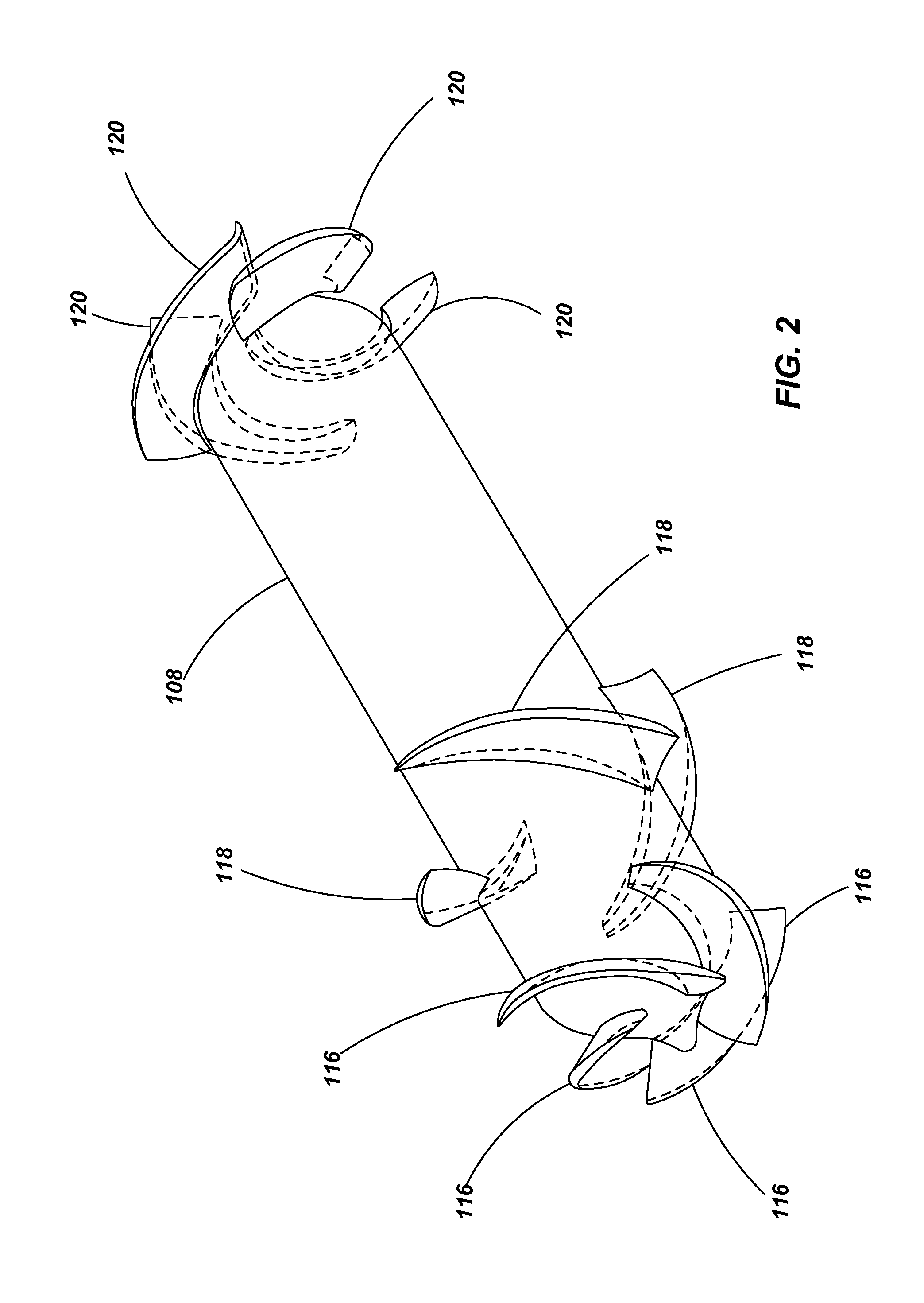

Blood pump with splitter impeller blades and splitter stator vanes and related methods

InactiveUS20120134832A1Low blood damageGuaranteed uptimePump componentsBlood pumpsImpellerMixed flow

A rotordynamic pump for delivering continuous flow of fluids, such as blood, is provided. In one embodiment, the pump includes a stator housing having an inlet and an outlet. A rotor hub is disposed within the stator housing having a mixed-stage or mixed-flow impeller. The mixed flow impeller includes both principle blades and splitter blades, the splitter blades exhibiting a shorter axial length than the principle blades. One or more stator vanes and extend radially inwardly from the stator housing. The splitter blades and principle blades are arranged in a circumferentially alternating pattern. The stator vanes include principle stator vanes and splitter stator vanes, the splitter stator vanes exhibiting a shorter axial length than the principle stator vanes. The splitter vanes and principle vanes are arranged in a circumferentially alternating pattern. The rotor hub may be magnetically suspended and rotated within the stator housing.

Owner:WORLD HEART

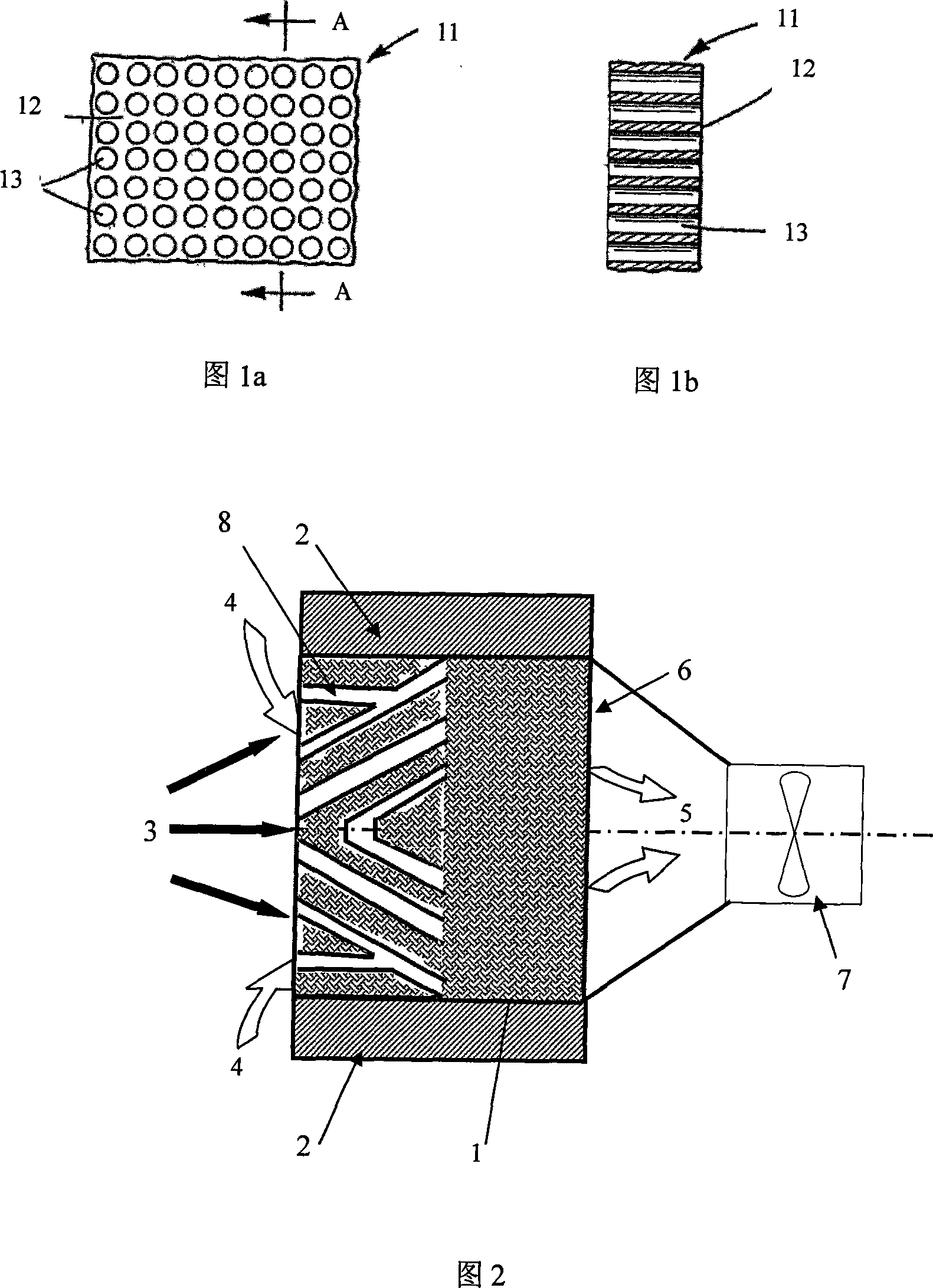

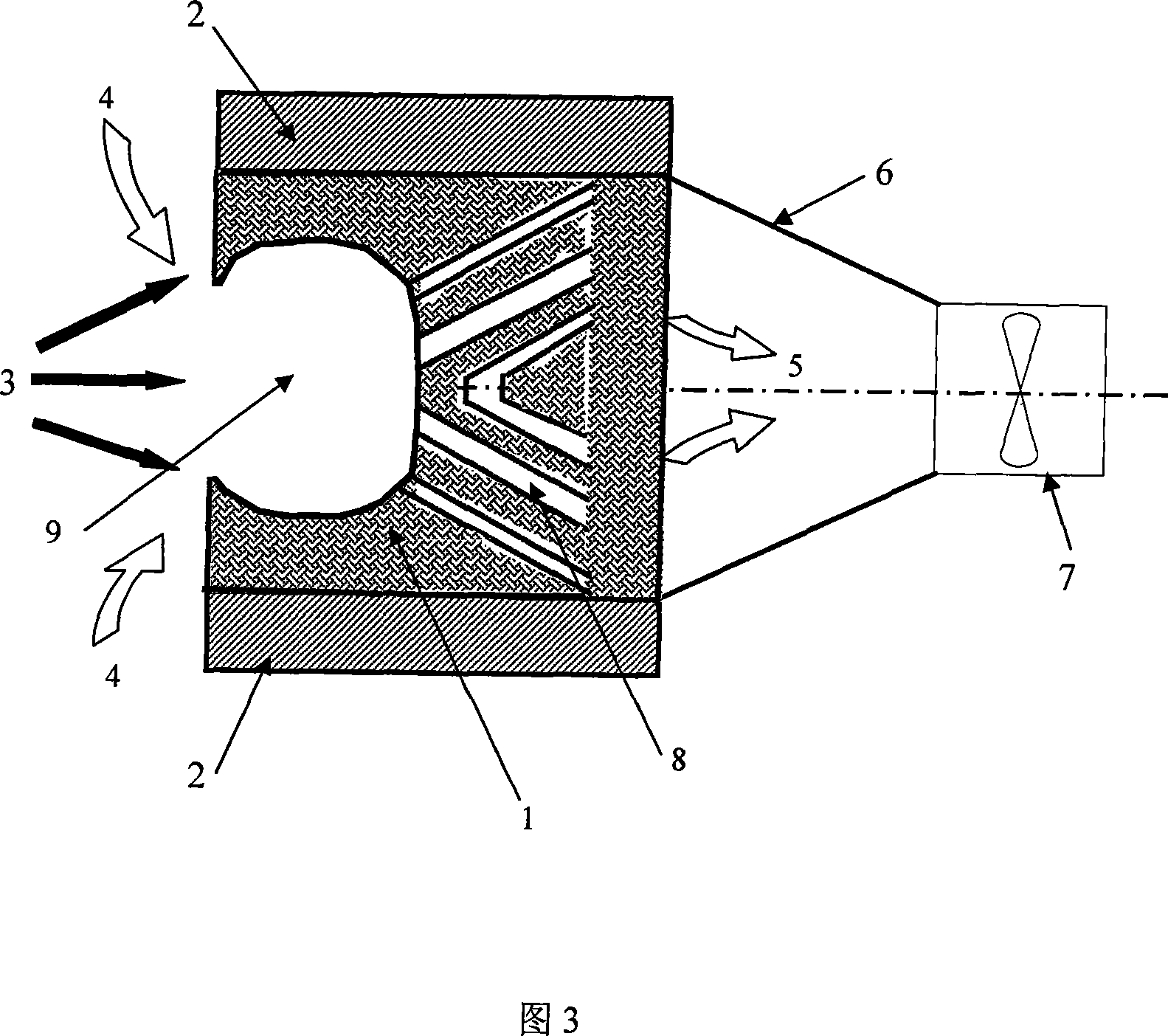

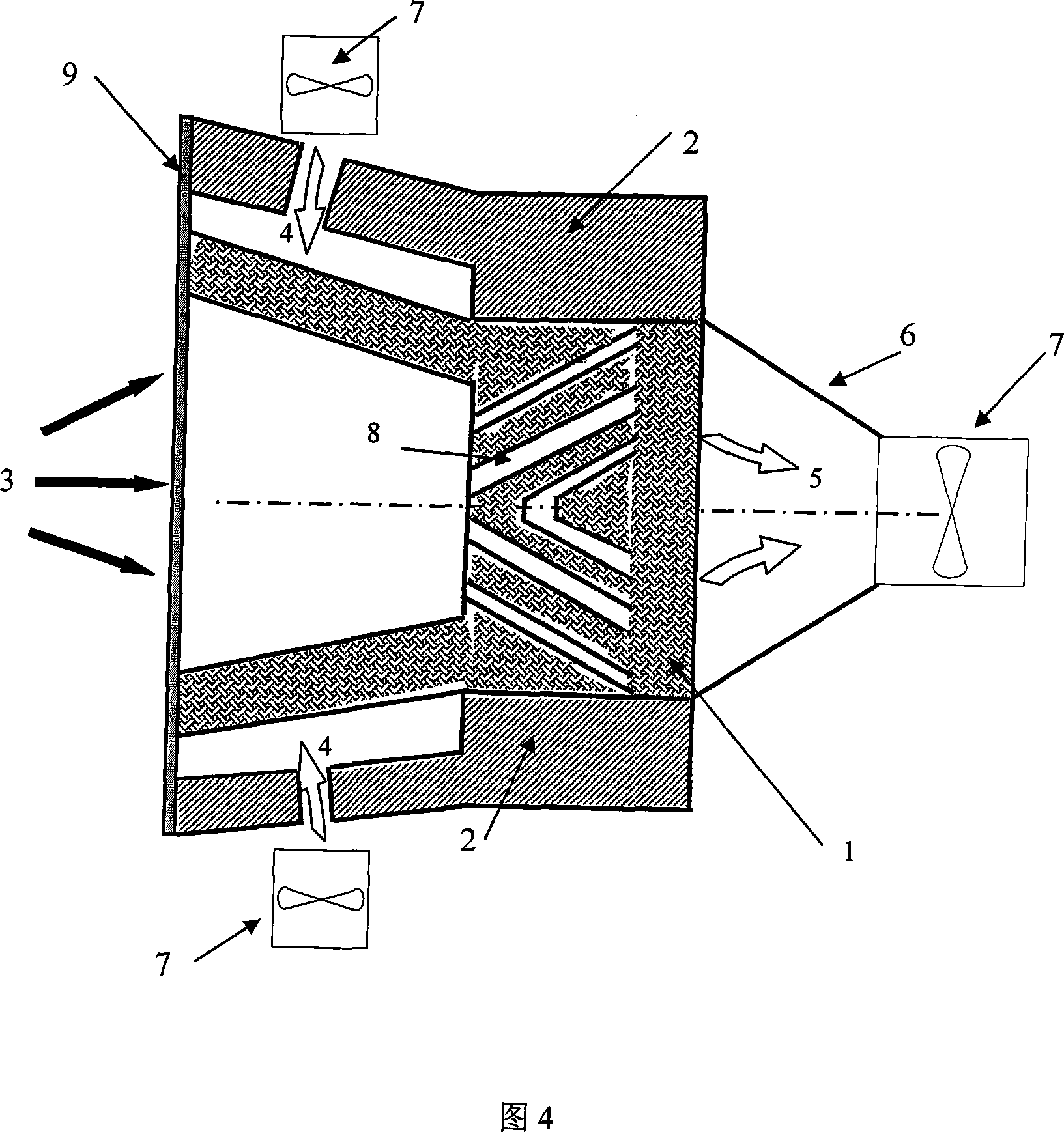

Silicon carbide foam ceramic solar energy air heat-absorbing device

InactiveCN101122425AImprove thermal conductivityFacilitate conductionSolar heating energySolar heat devicesCold airBlackbody cavity

A silicon carbide ceramic foam solar energy air heat absorber uses silicon carbide ceramic foam materials as solar energy absorber. The silicon carbide ceramic foam absorber is wrapped with an insulating layer (2). A radiant heat flux (3) projects onto the surface of the silicon carbide ceramic foam absorber (1) or into an artificial blackbody cavity (9) and is received by the silicon carbide ceramic foam absorber (1). Cold air (4) flows in from the side of the silicon carbide ceramic foam absorber (1) positive to the radiant heat flux (3). Hot air (5) is obtained through heat exchange of thecold air and the radiant heat flux. Or the cold air (4) flows in from the side of the silicon carbide ceramic foam absorber (1) positive to the radiant heat flux (3) or back to the radiant heat flux (3). The hot air (5) of 700 to 1300 DEG C is obtained through the heat exchange of the cold air and the radiant heat flux through a quartz window (10). The silicon carbide ceramic foam absorber (1) buries an air diversion channel (8) beforehand. The invention can effectively receive radiant heat and emit heat to the air and take advantage of self-sensible heat to store heat at the same time.

Owner:INST OF ELECTRICAL ENG CHINESE ACAD OF SCI

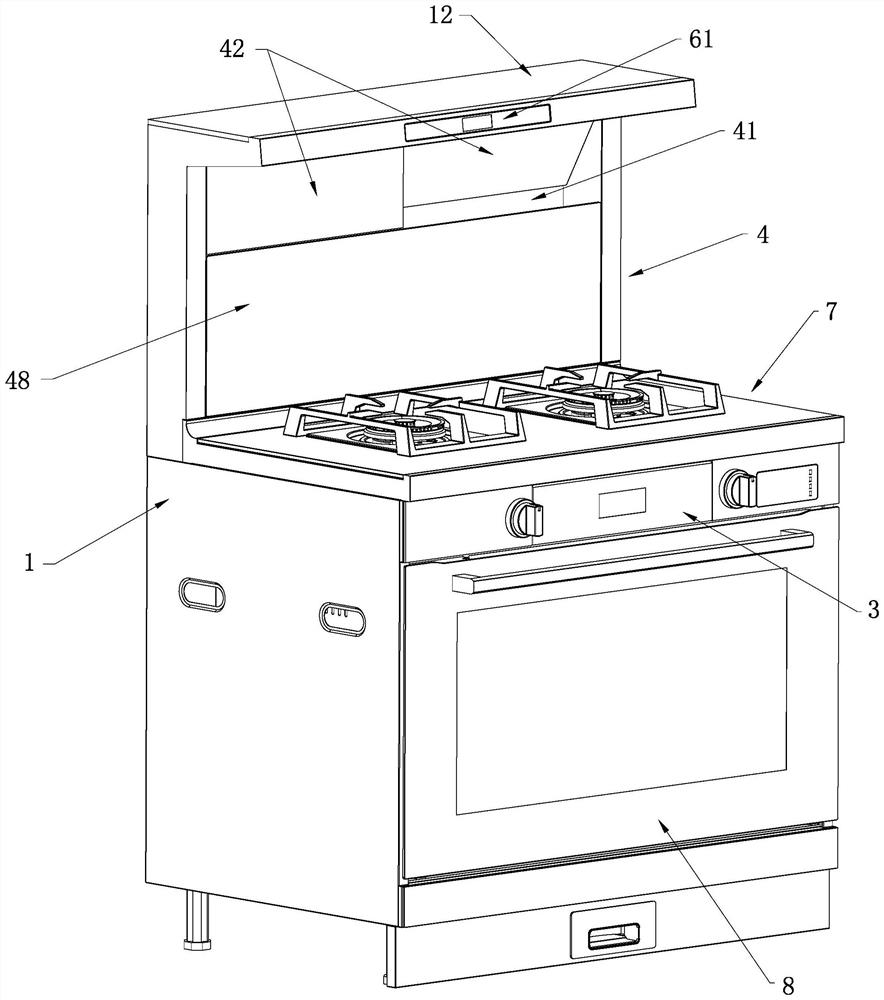

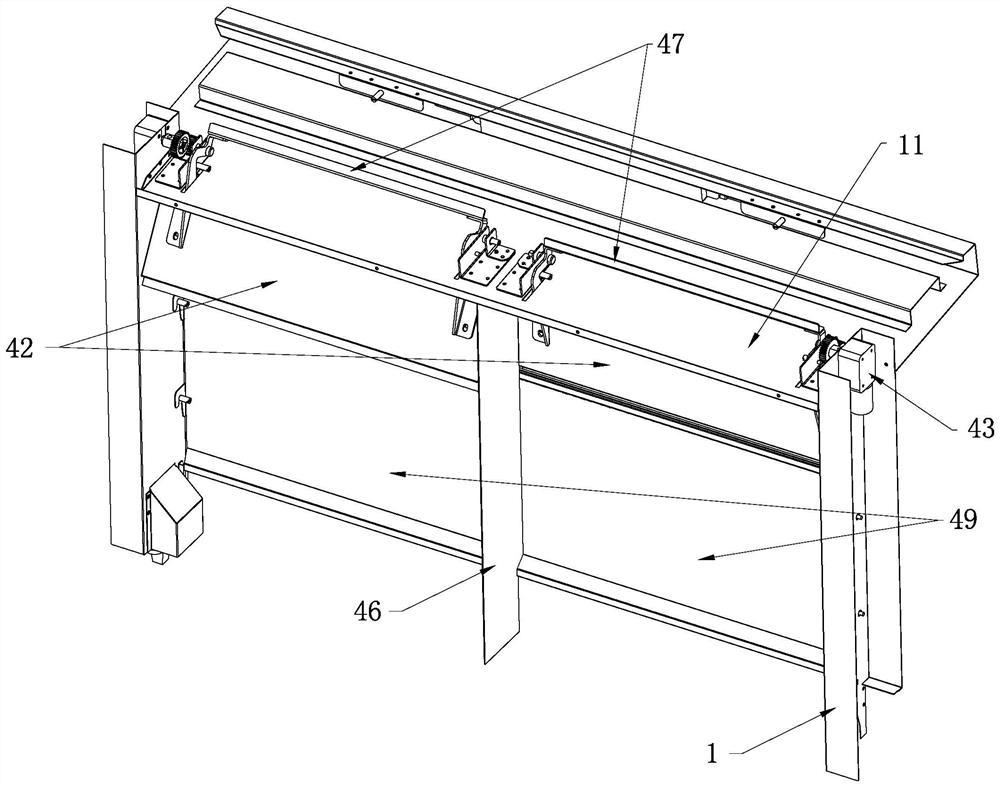

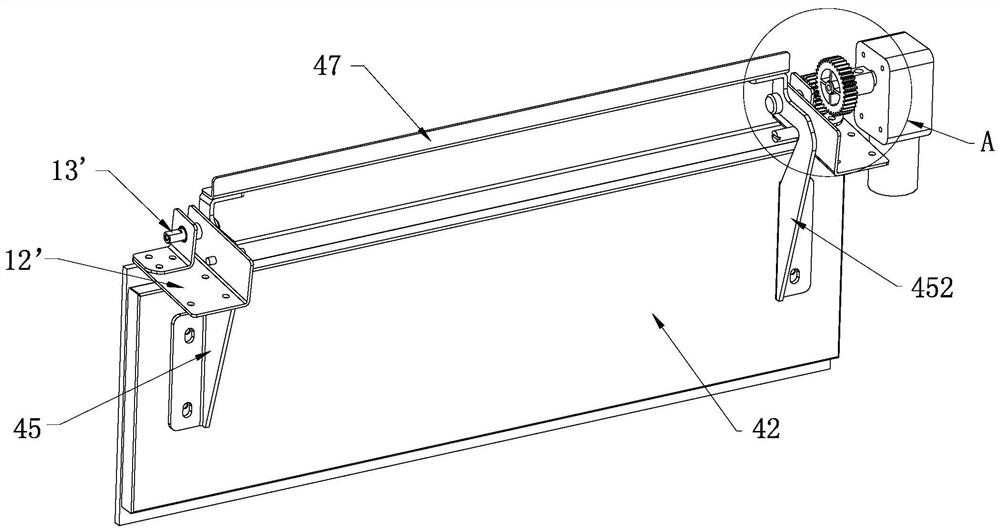

Integrated cooker

PendingCN112555906AOutstanding and Beneficial Technical EffectsGuaranteed tightnessDomestic stoves or rangesLighting and heating apparatusEngineeringCooker

The invention belongs to the technical field of kitchen appliances, and particularly relates to an integrated cooker. The integrated cooker comprises a machine body and a range hood body; the range hood body comprises an air inlet, an air collecting box and a fan assembly; the air collecting box communicates with the air inlet; the fan assembly is arranged in the air collecting box; a volute air duct of the fan assembly extends downwards to the wall face of the bottom of the air collecting box and extends out of the bottom of the air collecting box to be rotationally provided with an air outlet base; and an air outlet is formed in one side of the air outlet base. According to the integrated cooker, the volute air duct extends downwards to the wall face of the bottom of the air collecting box and extends out of the bottom of the air collecting box to be rotationally provided with the air outlet base; the air outlet base is directly located on the outer side of the air collecting box, and the situation that a channel is located inside and occupies too much space is avoided; a through hole does not need to be additionally formed in the side edge of the machine body, and leakproofnessof the side face of the machine body is guaranteed; and meanwhile, the air outlet base is rotatably arranged, so that a user can conveniently adjust the air outlet direction according to actual needs,and humanization is achieved.

Owner:浙江安德电器有限公司

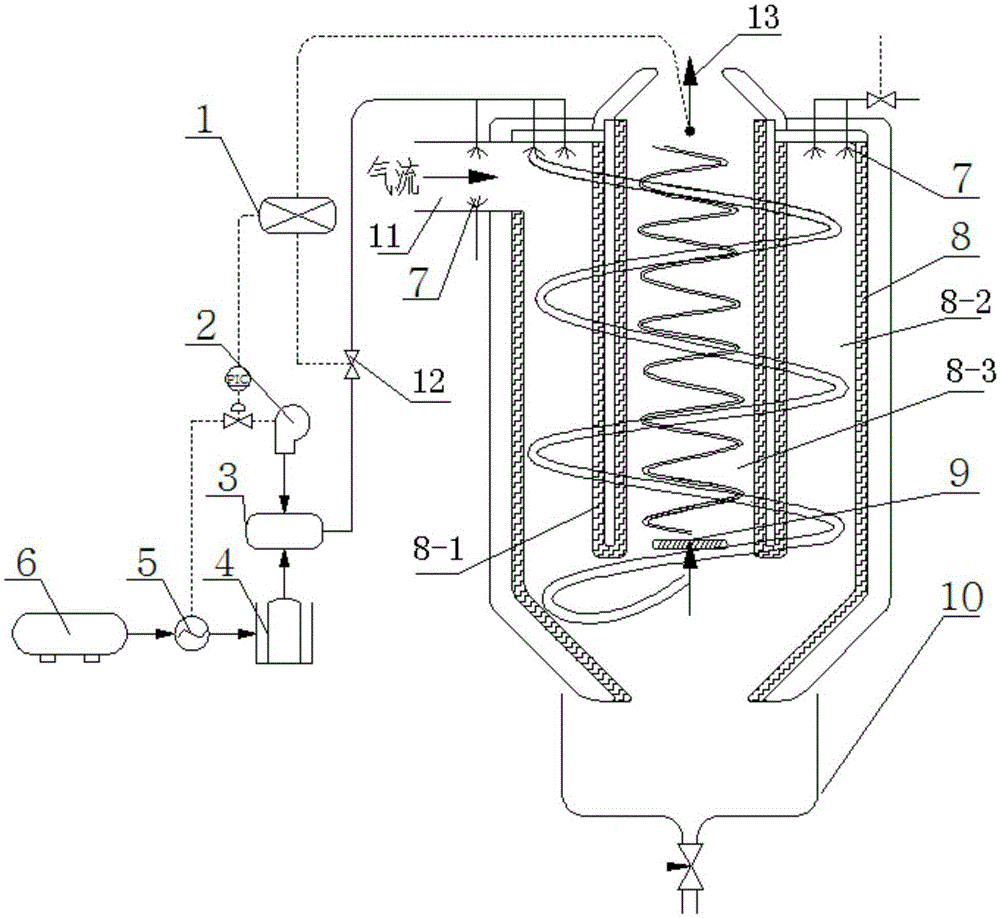

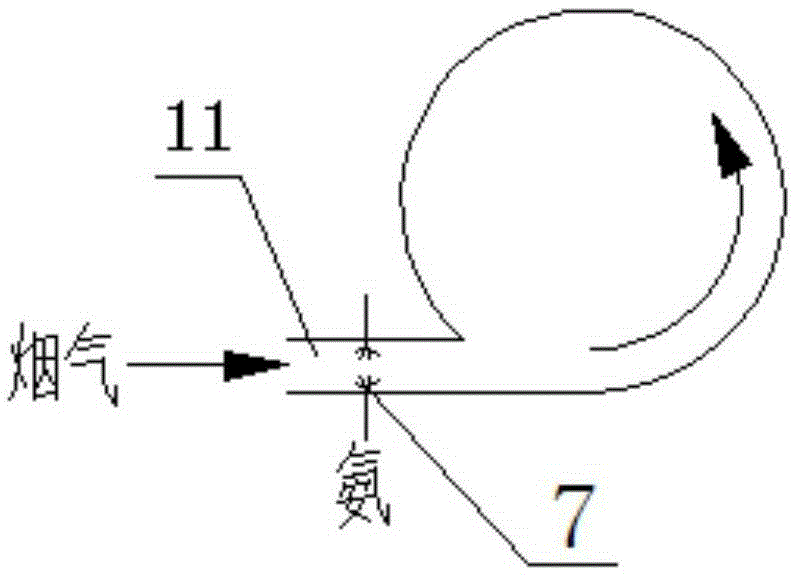

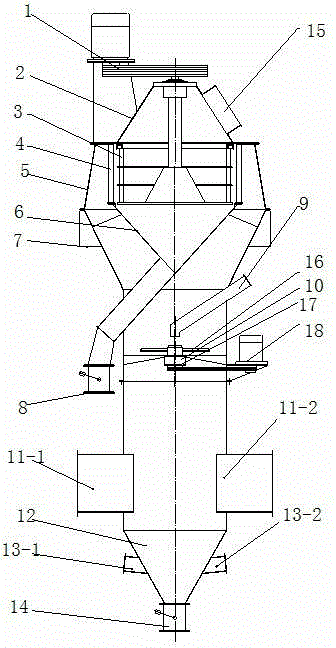

Double-rotation SCR denitration method and apparatus thereof

ActiveCN105289301AImprove denitrification efficiencyIncrease contact timeDispersed particle separationCycloneFlue gas

The invention discloses a double-rotation SCR denitration method and an apparatus thereof. According to the invention, a first eddy flow catalytic reaction chamber and a second eddy flow catalytic reaction chamber are arranged along a denitrating tower body; a flue gas introduction pipeline is arranged on a sidewall of the denitrating tower body; several eddy flow atomizing nozzles are respectively arranged on inner periphery of the flue gas introduction pipeline and the inner periphery at top of the first eddy flow catalytic reaction chamber; when flue gas is introduced into the flue gas introduction pipeline, the flue gas and ammonia gas injected by the eddy flow atomizing nozzle are mixed, and a mixture enables spiral sinking along circumference of the first eddy flow catalytic reaction chamber from up to down in a tangent circle mode, under effect of a cyclone, and then the mixture enable spiral rise along circumference of the second eddy flow catalytic reaction chamber from down to up in the tangent circle mode. Under prerequisite that high efficiency denitration is ensured, catalyst amount is less, operation of technical means is simple and easy, compared with the prior art, a denitrating tower structure is simple, cost of the apparatus is low, denitration efficiency is high, energy consumption is low, escapement ratio of ammonia is reduced, denitration cost is greatly reduced, and economic benefit is obviously increased.

Owner:SOUTH CHINA UNIV OF TECH

Blood pump with separate mixed-flow and axial-flow impeller stages, components therefor and related methods

ActiveUS20120134793A1Improve hydraulic efficiencyReduce power consumptionSpecific fluid pumpsPump componentsImpellerMixed flow

Owner:WORLD HEART

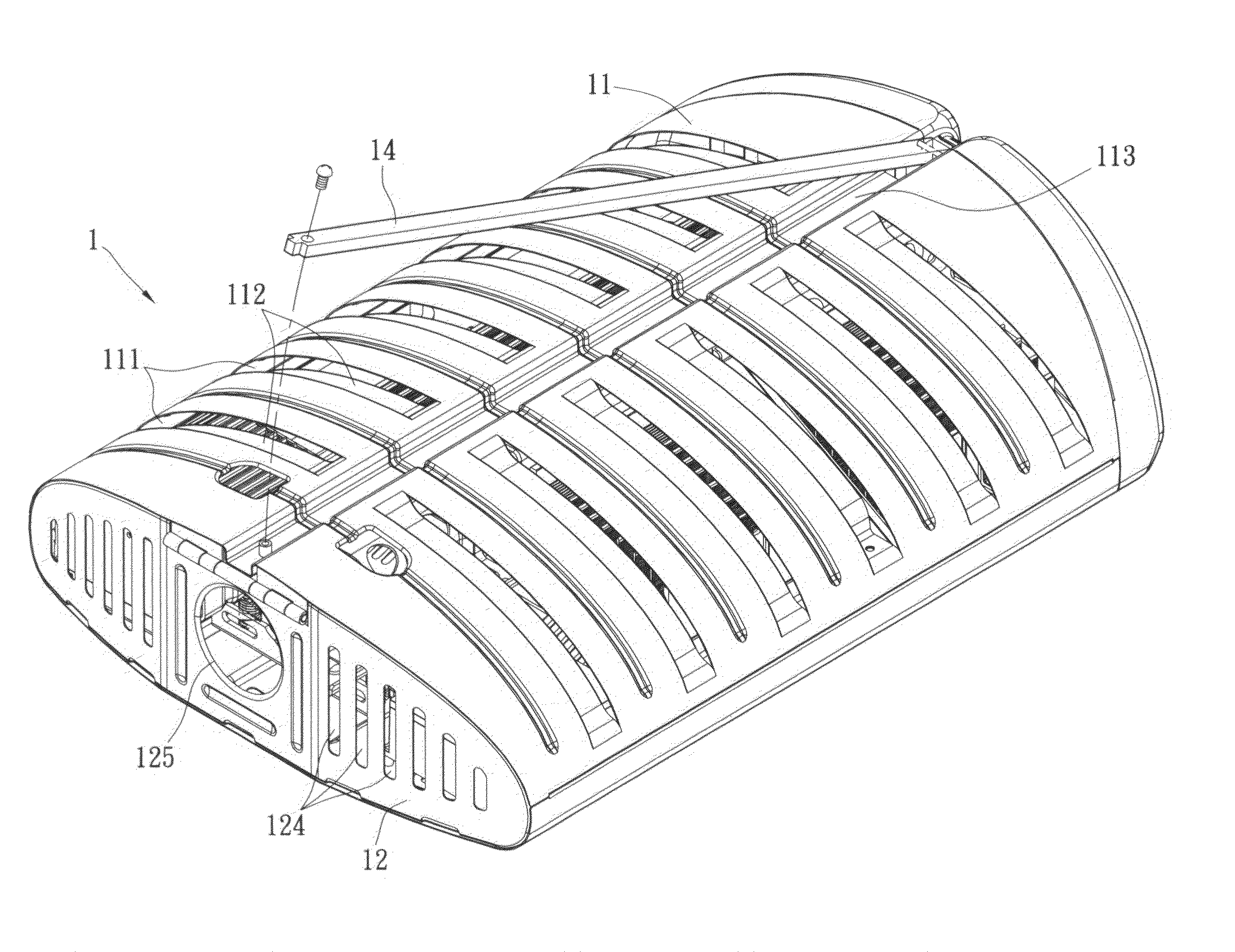

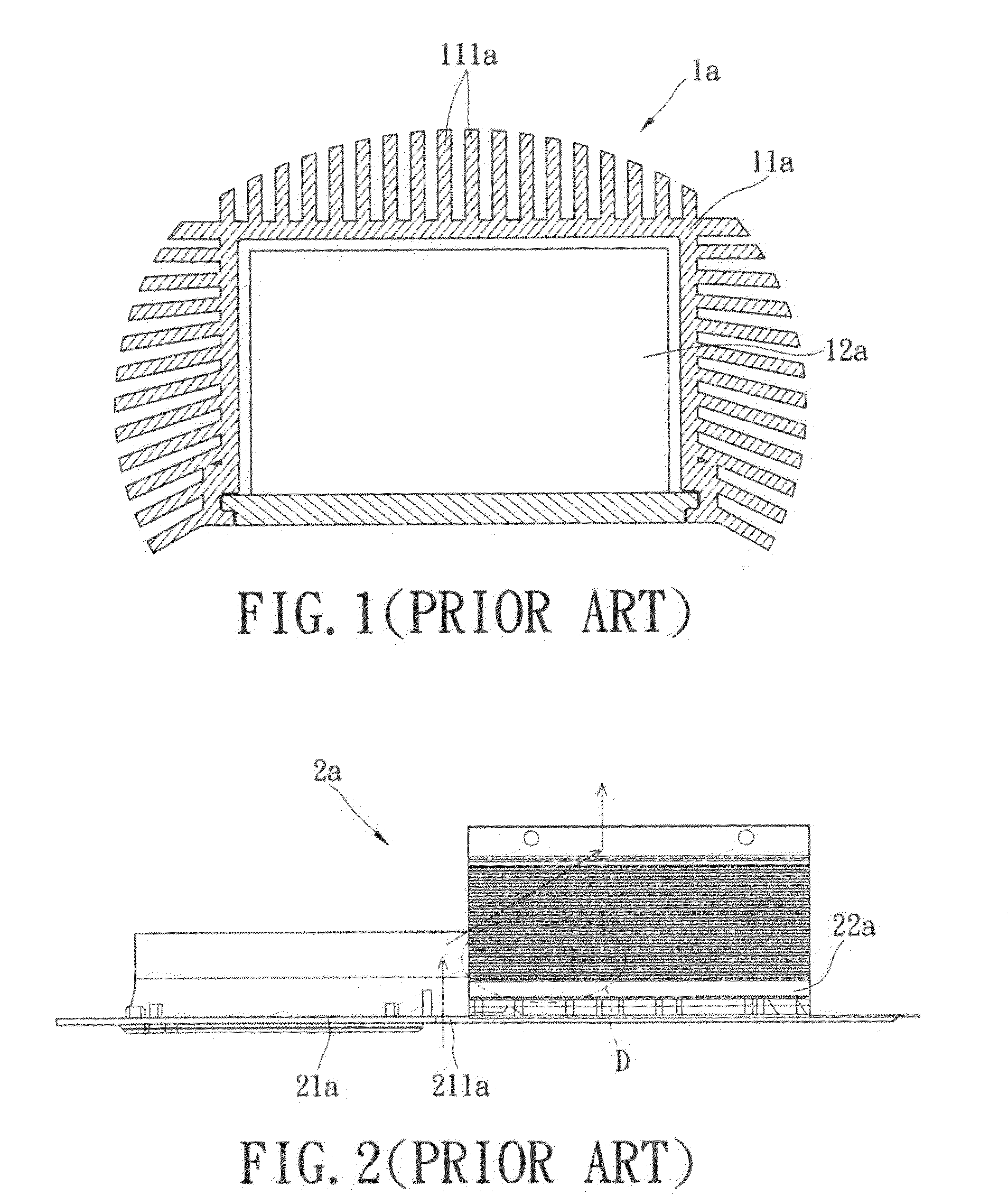

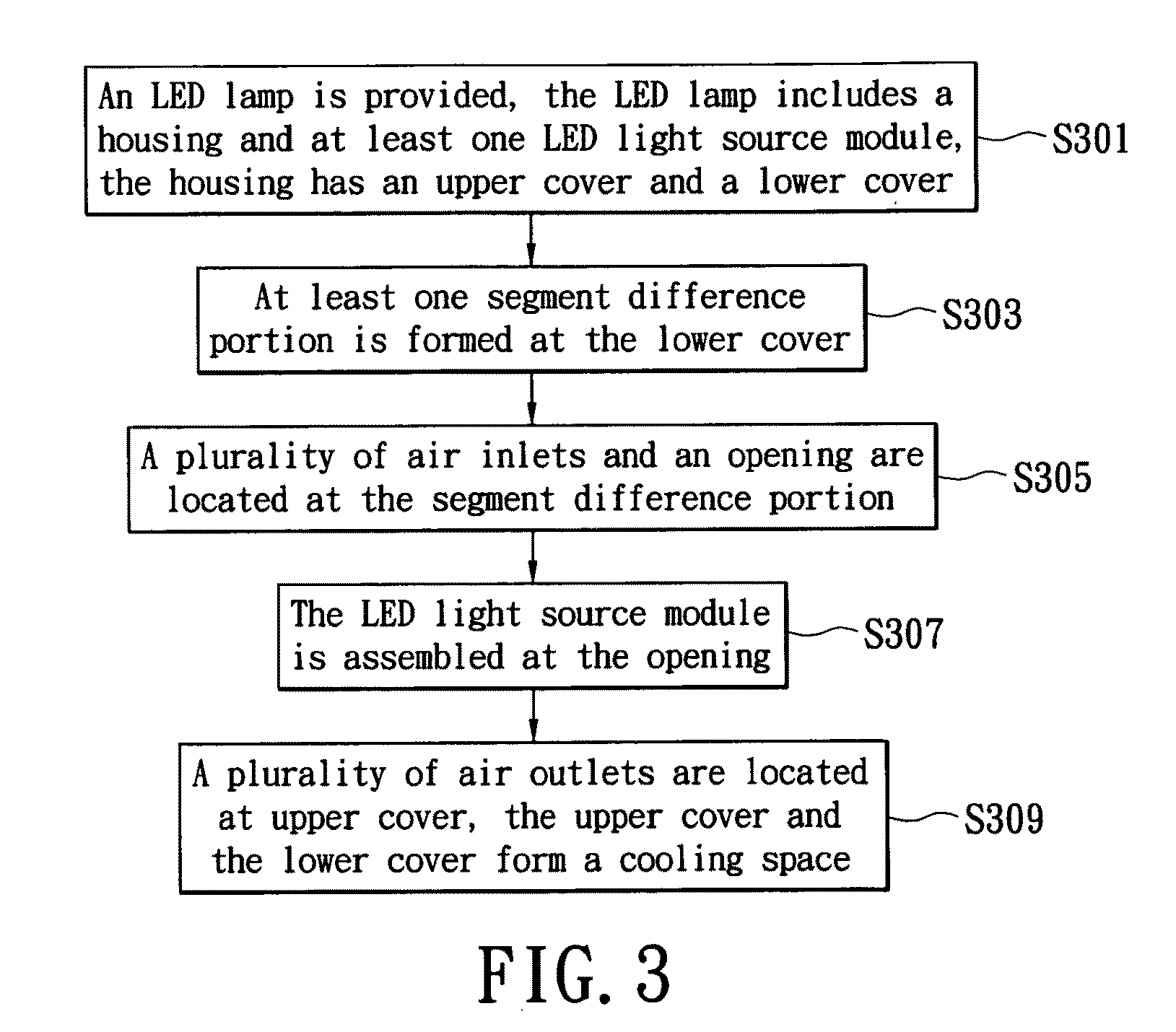

Led lamp and cooling method thereof

InactiveUS20110038153A1Easy to manufactureLow costMechanical apparatusPoint-like light sourceEngineeringLED lamp

A cooling method for an LED lamp is disclosed. An LED lamp is provided. The LED lamp includes a housing and at least one LED light source module. The housing has a cover body, a base and a plurality of air outlets. The base forms at least one segment difference portion. The slanted surface of the segment difference portion has a plurality of air inlets. The LED light source module is adjacent to the air inlets. The LED light source module has a cooling device and the cover body has a plurality of air outlets. Airflow is guided into the cooling space along the air inlet on the slanted surface of the segment difference portion. When the LED lamp generates heat, air entered into the cooling space is blown to the cooling device. The airflow with heat is exhausted from the air outlet of the cover body.

Owner:LEOTEK ELECTRONICS

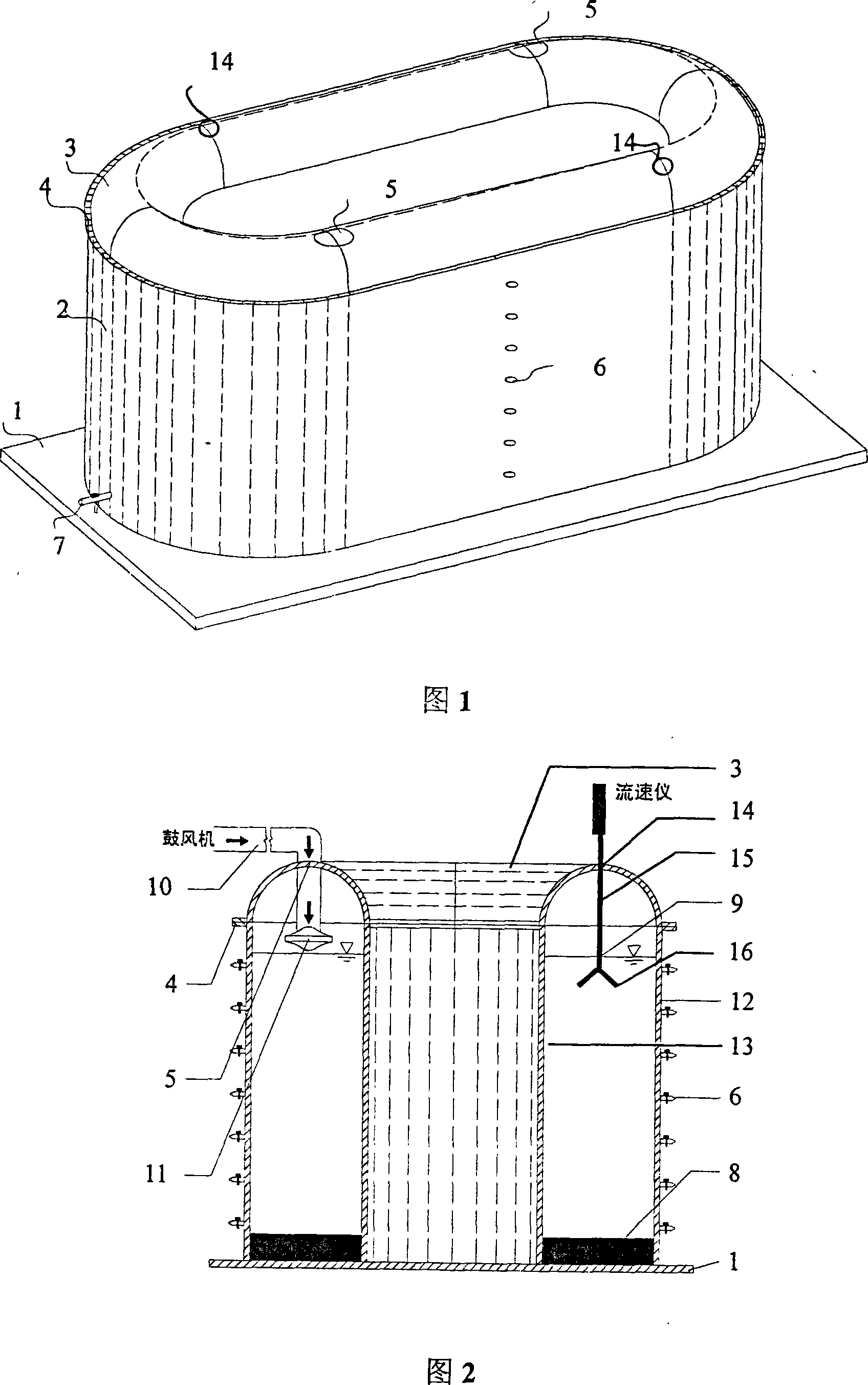

Method for re-suspending underwater deposit under simulated wave disturbance in annular water tank and device thereof

InactiveCN101110174AImprove sampling accuracyStable resuspension conditionsEducational modelsUnderwater explosionEngineering

The invention discloses a method for disturbing and resuspending underwater sediments with simulated wave in circular sink, which is characterized in that: place the sediments collected without disturbance at the bottom of the circular sink; plant submerged plant over the sediments and overlaying water; use a plurality of blowers to simulate different wind forces and apply it on the overlaying water, so as to generate water flow; adjust the position of the blower port and its included angle with the overlay water surface to make basically even flow field in the sink; the sediments at the bottom of the sink is resuspended under the action of hydrodynamic force, so as to realize the simulation for the resuspension of sediments under the disturbance of wave with different forces in the water body of lake and river where submerged plant grows. The invention has the flowing advantages: simulate the resuspension process of sediments due to the motion of flow field under the disturbance of wave with different forces in natural water body of lake and river where submerged plant grows; realize the collection of samples in water body of different depths under relative stable condition for the resuspension of sediments; meet the requirements for the study over the ration relations among wave disturbance-motion of flow field-resuspension of sediments; simple structure, low cost and convenient application of relevant device.

Owner:HOHAI UNIV

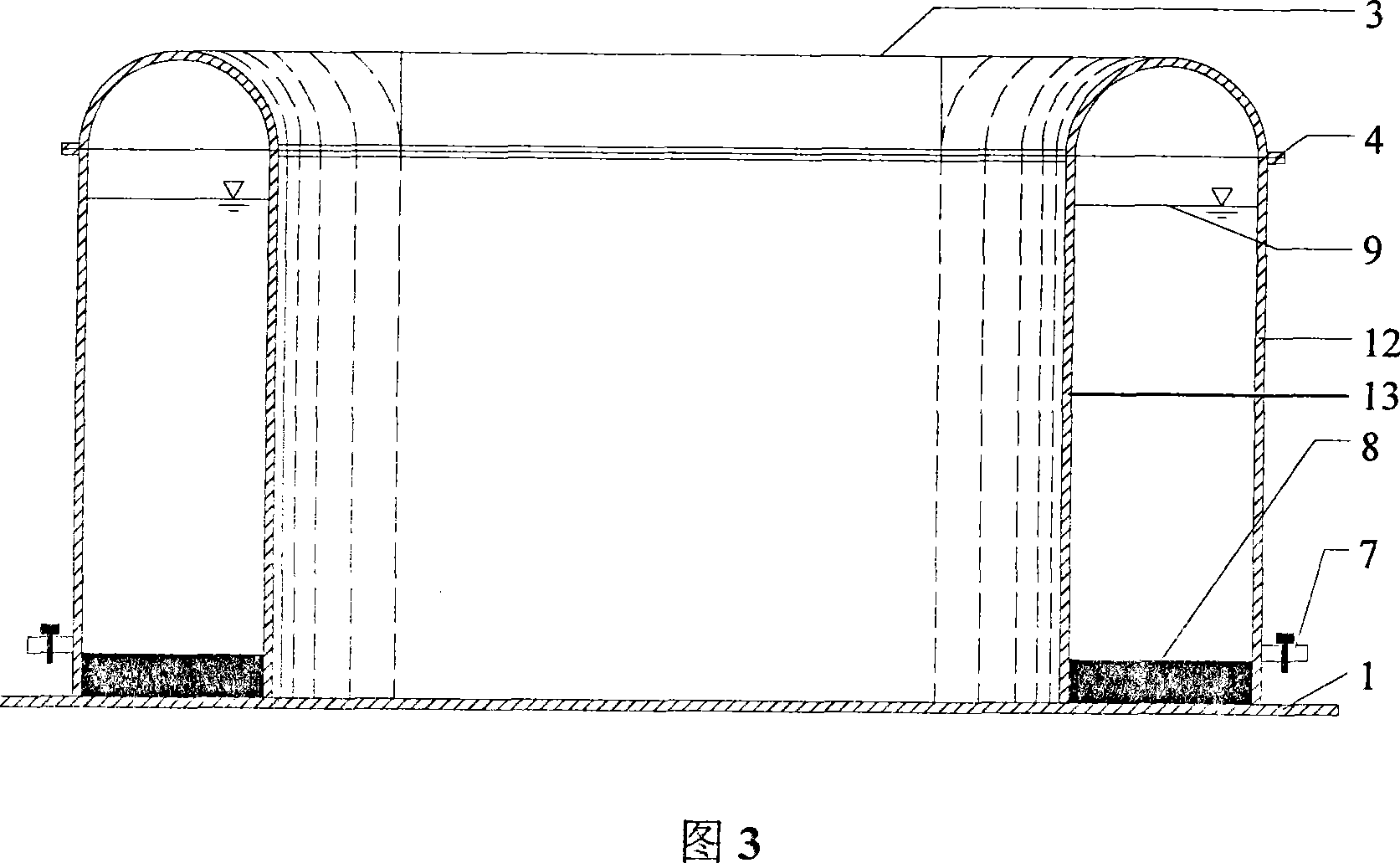

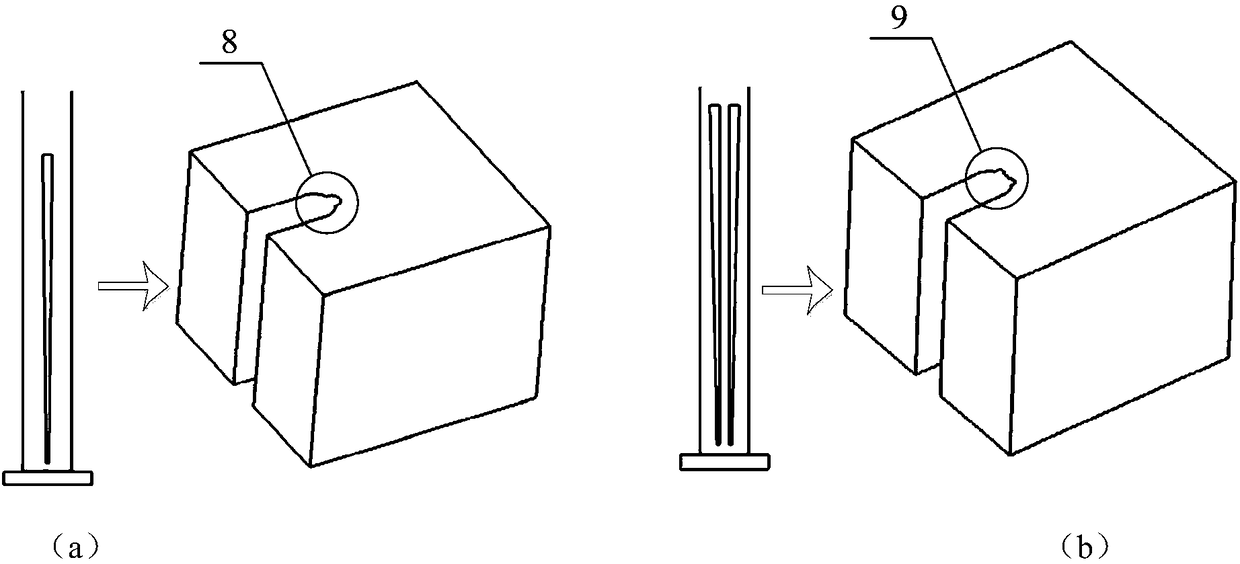

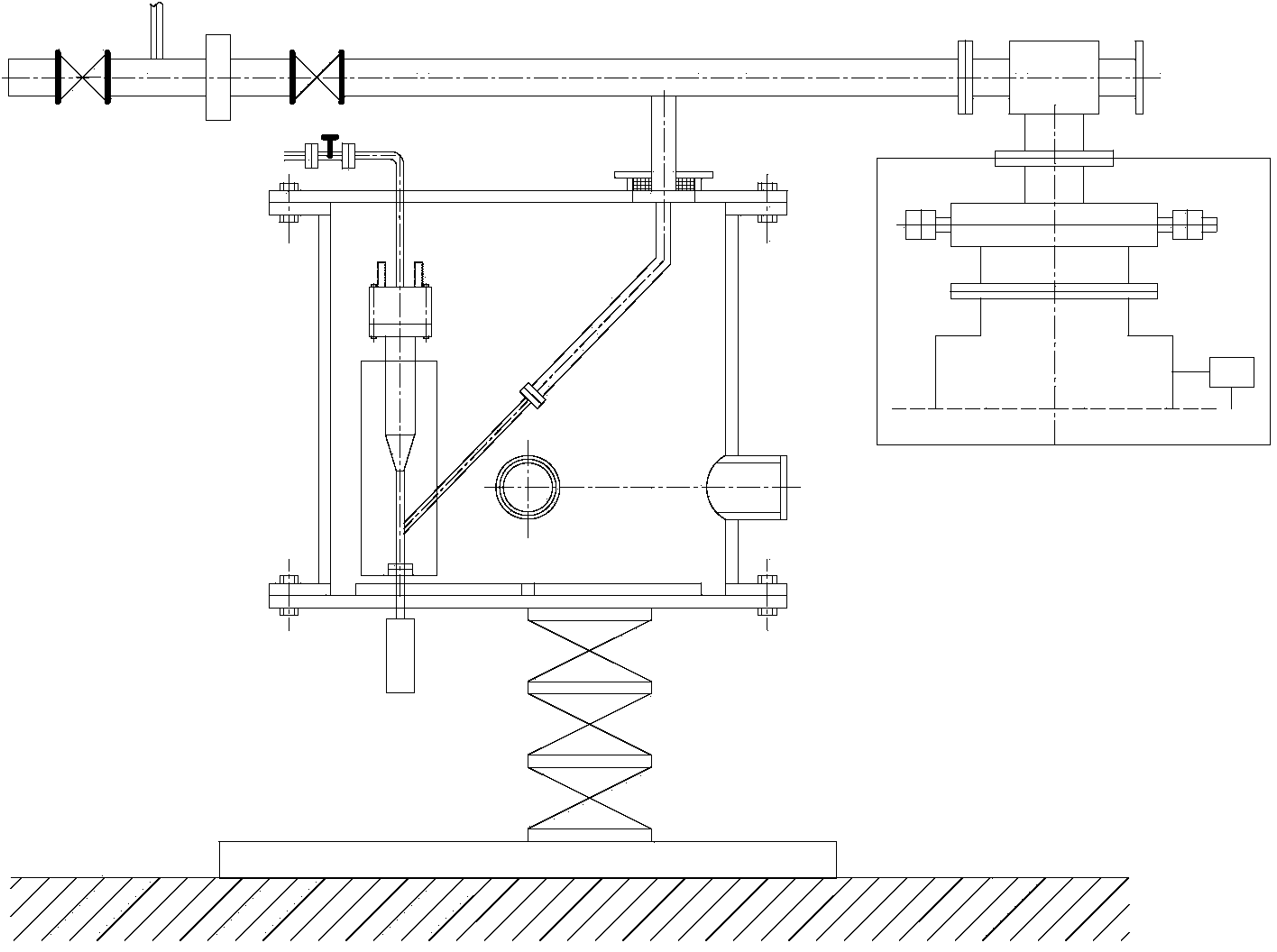

Suction liquid discharge assisted double-narrow-slit electrolytic cutting machining device and method

ActiveCN108161150AUniform flow fieldImproved processing effect and processing speedMachining working media supply/regenerationEngineeringMachine tool

The invention relates to a suction liquid discharge assisted double-narrow-slit electrolytic cutting machining device and belongs to the field of electrolytic machining. The suction liquid discharge assisted double-narrow-slit electrolytic cutting machining device is characterized in that axial and radial suction devices are additionally arranged on a tube electrode cutter, the flow speed of electrolyte in the machining area is increased, so that products are rapidly discharged, and the machining quality is improved; double narrow slits are formed in a tube electrode, so that the machining face, in the advancing direction, of the cutter is more smooth. The suction liquid discharge assisted double-narrow-slit electrolytic cutting machining device comprises a suction pump, an insulated suction pipe, a double-narrow-slit tube electrode, a power source, an electrolyte circulating system, an electrolysis machining machine tool and a work fixture. The suction liquid discharge assisted double-narrow-slit electrolytic cutting machining device has the important significance in improving the flow speed of the electrolyte, rapidly discharging the products and ensuring one-time electrolytic cutting super-thick workpieces (with the thickness larger than 100mm).

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

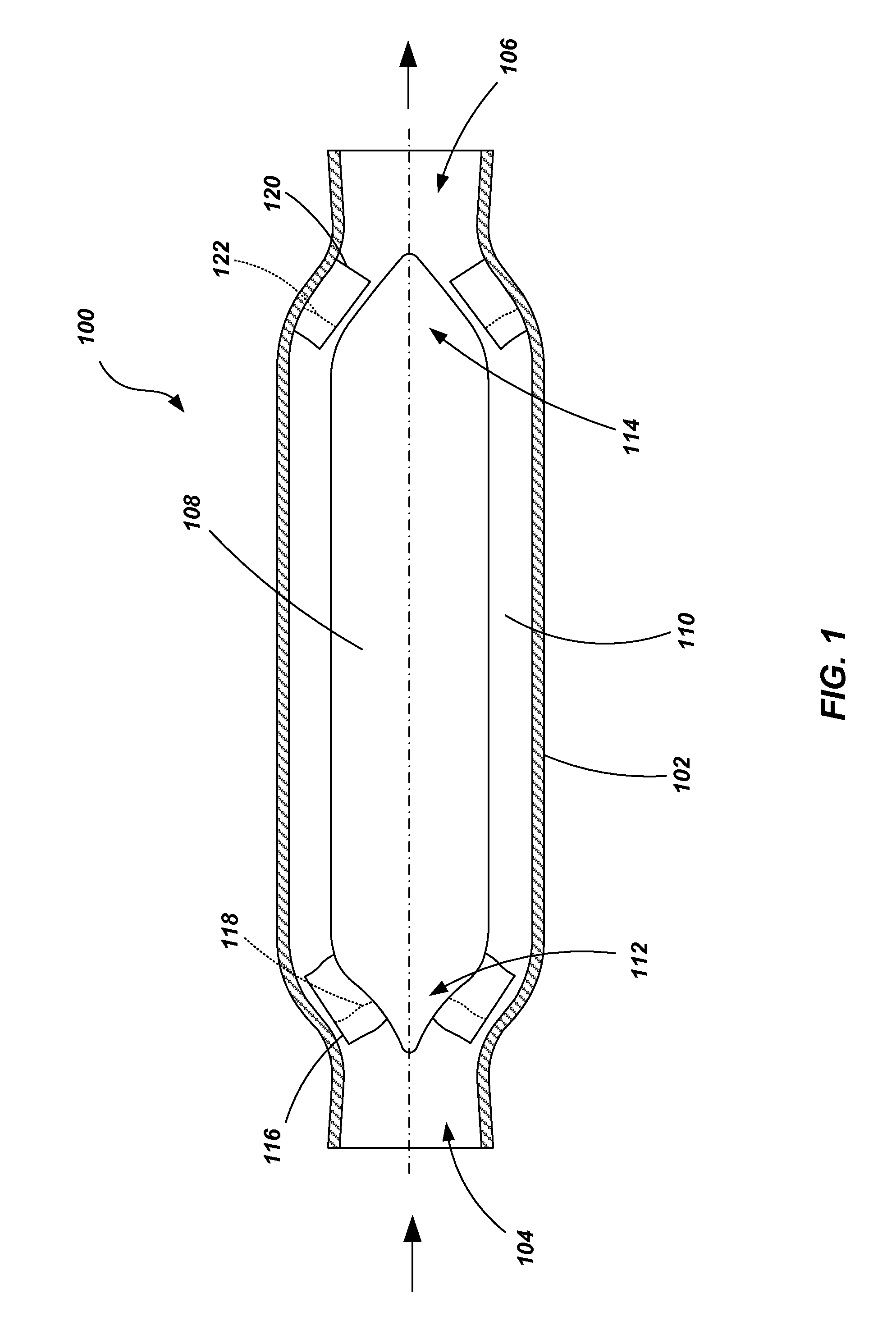

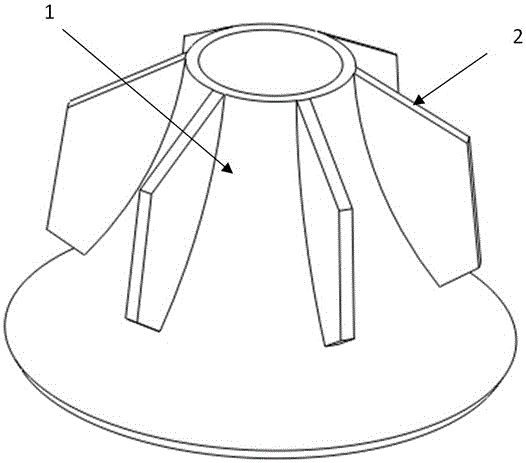

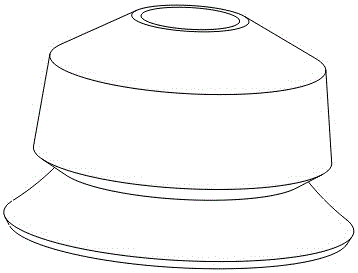

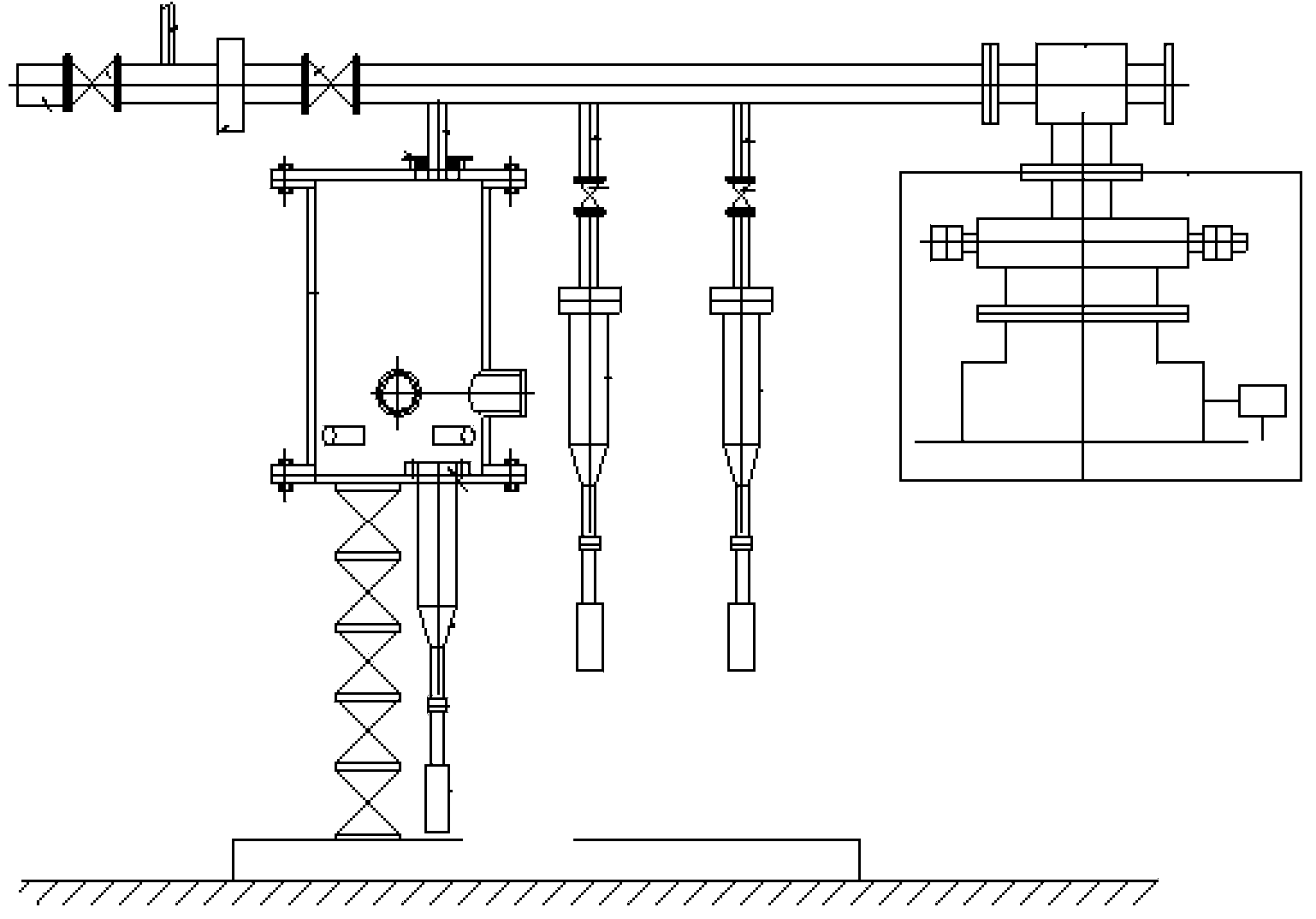

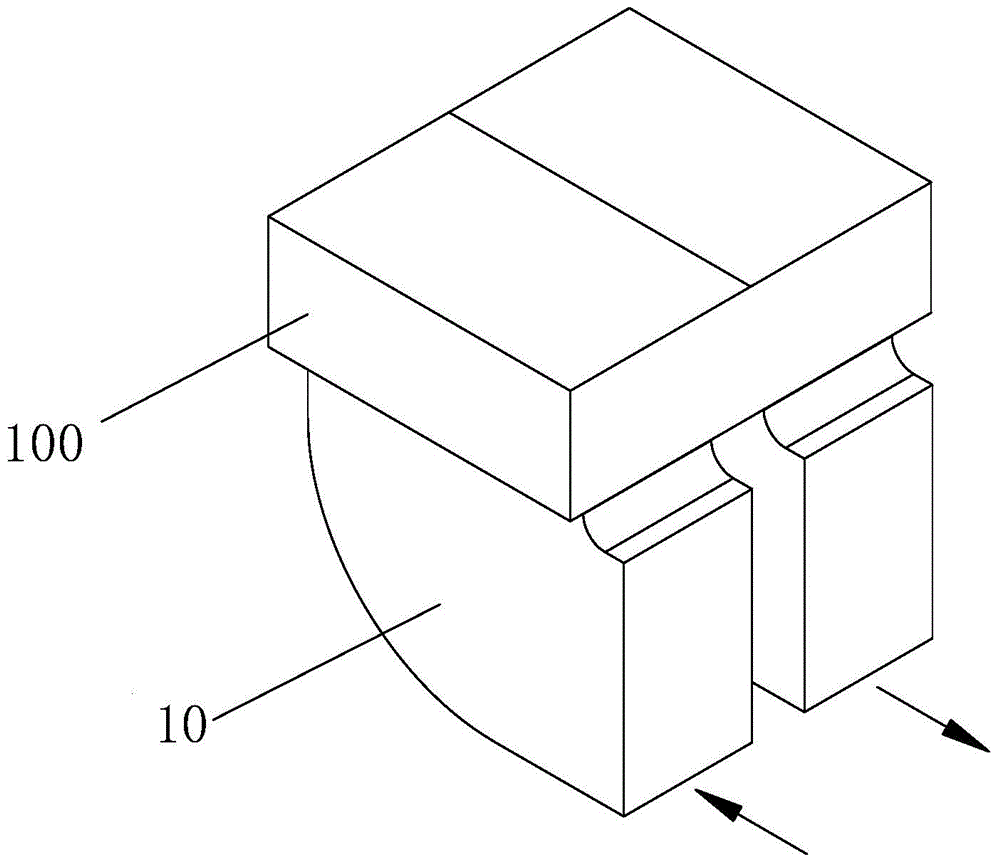

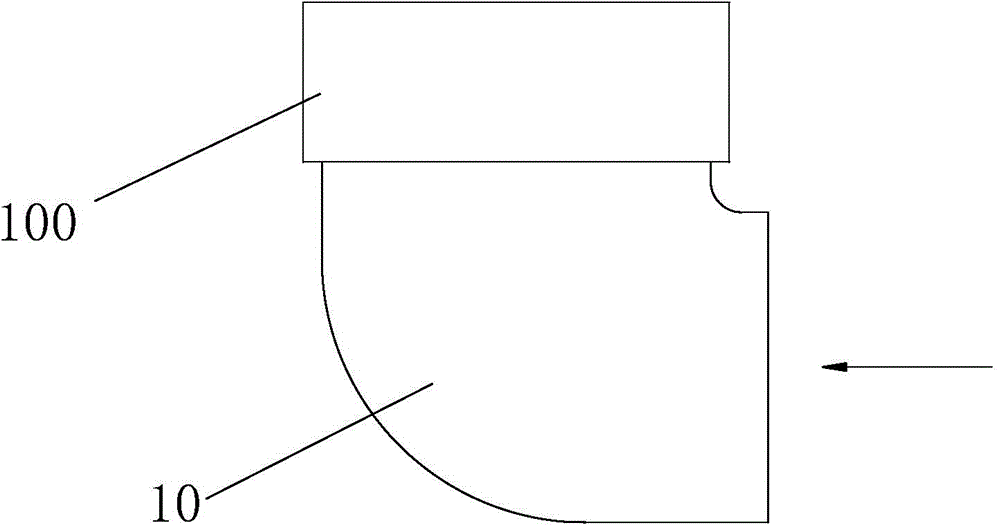

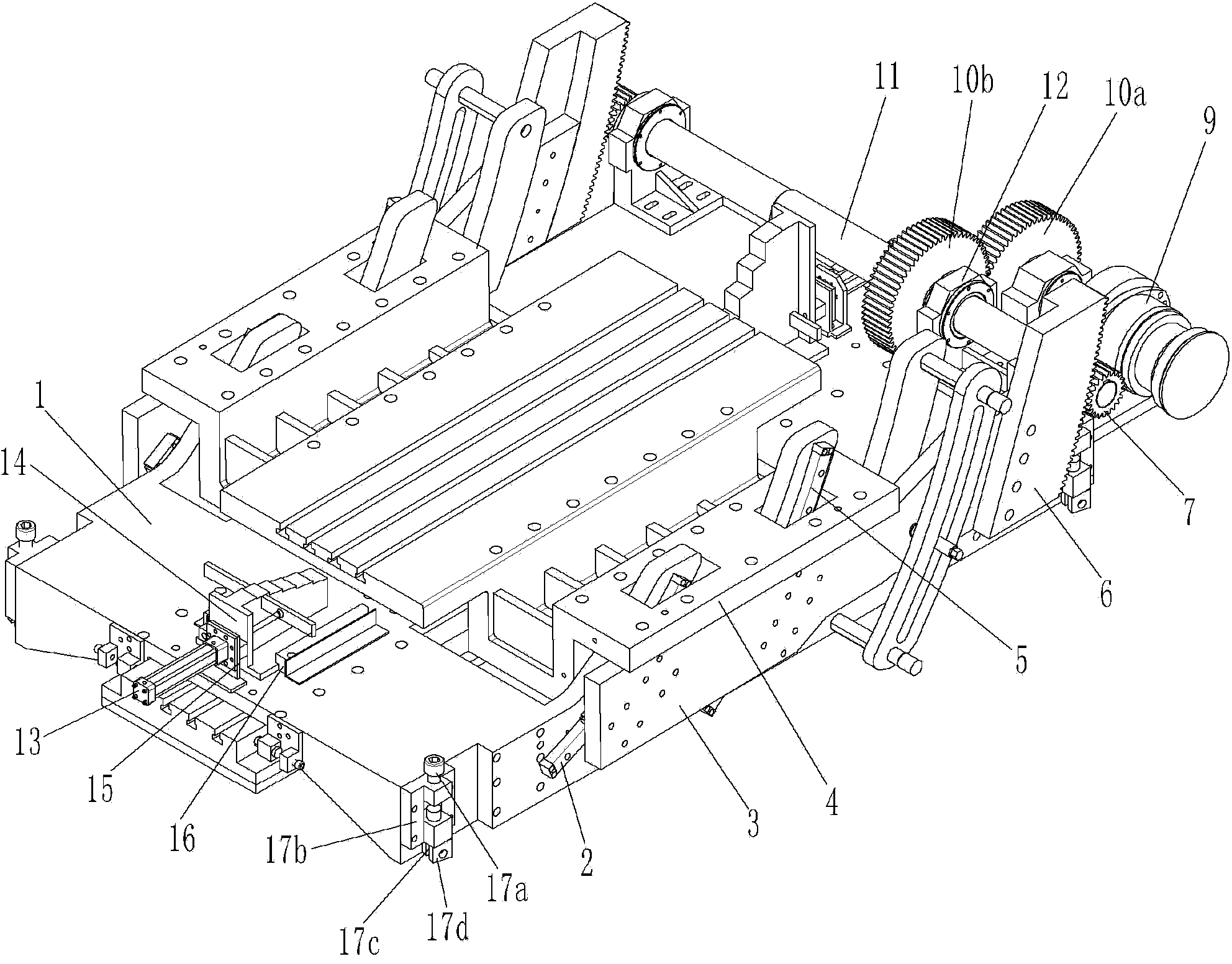

Electrolysis machining process method and tool fixture of equal-thickness arc-shaped end face impeller

ActiveCN106695032AImprove consistencyImprove ECM EfficiencyElectrochemical machining apparatusElectrical-based auxillary apparatusImpellerElectrolysis

The invention discloses an electrolysis machining process method and tool fixture of an equal-thickness arc-shaped end face impeller and belongs to the technical field of electrolysis machining. According to the electrolysis machining method, cathode blocks with the number being the same as that of blades are adopted and uniformly distributed along the center of the impeller, rapid feeding is performed in the axial direction of the impeller when machining is performed, and one-time machining and forming of the thin-wall blades and an arc-shaped end face base body of the overall impeller can be completed. Nearly-forming hook face radians at the bottom ends of the cathode blocks for machining are large, arc-shaped curved lines where the included angle theta i=30 degrees is located serve as boundaries to divide different areas, linear interpolation finishing is performed according to actual machining experience and machining results, and requirements for the normal direction and lateral balance can be met simultaneously. By means of the electrolysis machining method, one-time machining and forming of the overall impeller can be achieved, machining efficiency is improved, and high practical value is achieved.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

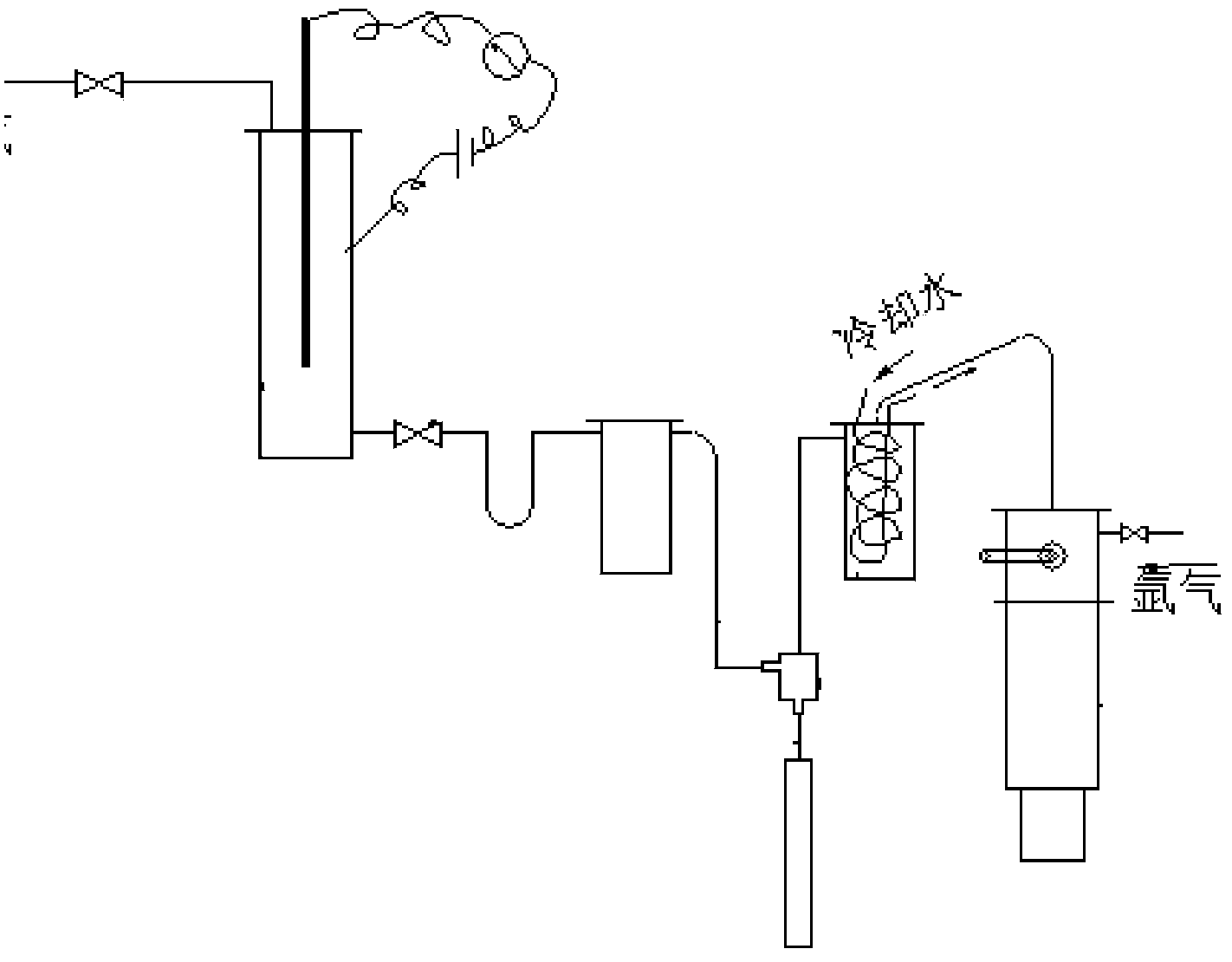

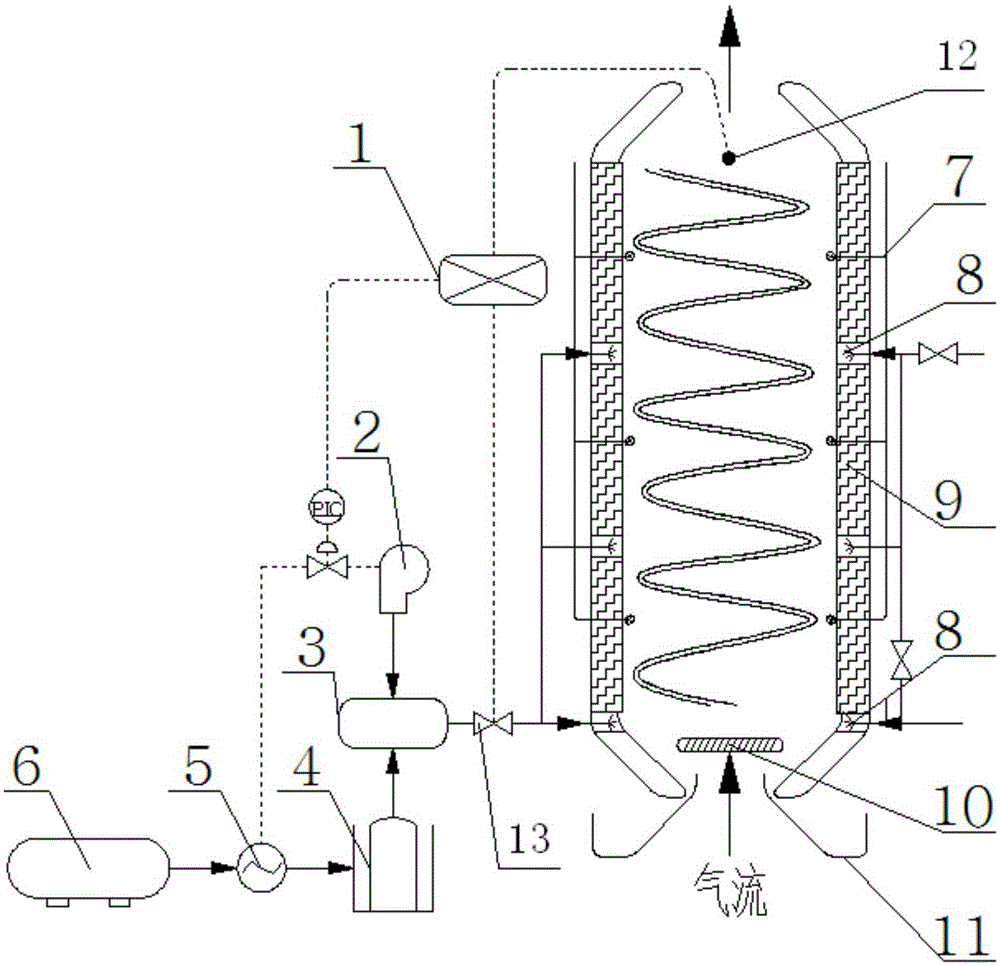

Automatic control SCR flue gas denitrification urea pyrolysis system

InactiveCN105498532AReduce plant power consumptionSolve the blockageGas treatmentCombustion processAutomatic controlUrea

The invention discloses an automatic control SCR flue gas denitrification urea pyrolysis system. The system is characterized in that a gas-gas heat exchanger is arranged in an inlet flue of an electric precipitator so as to form an air heating unit; a set of flue gas heating tube bundles are arranged in a boiler, so as to form an air reheating unit; after heated by the gas-gas heat exchanger and reheated by the flue gas heating tube bundles, air becomes high-temperature air at the temperature of heat resource required by urea pyrolysis; the high-temperature air is fed into a urea pyrolysis furnace and is mixed with a sprayed atomized urea solution, and then the pyrolysis is performed and an ammonia / air mixture is generated; the ammonia / air mixture is sprayed into an inlet flue of an SCR denitrification reactor through an AIG ammonia injection grating. The automatic control SCR flue gas denitrification urea pyrolysis system has the advantages that the technical structure is simple; the system can be widely applied to an SCR denitrification device of a coal-fired power plant; the urea atomizing pyrolysis efficiency can be effectively increased and the crystal plugging problem can be thoroughly solved; the waste-heat utilization of flue gas can be realized and the electrostatic precipitation efficiency can be increased; water used by a desulfurization system can be reduced.

Owner:ANHUI XINLT POWER TECH CONSULTING +1

Device and method for filling dual process interface heat pipe with solid working mediums

ActiveCN104075600AIncrease the exhaust channelSmooth vacuumingIndirect heat exchangersInterface designProcess engineering

The invention relates to a device for filling a dual process interface heat pipe with solid working mediums. The device comprises a glovebox, a working medium tank, an upper cover, an inert gas source, a vacuum molecular pump set, a heater and a cooler and the like. First dual process interface design is adopted, a main process interface is a vacuumizing interface and inert gas access interface and is also a working medium filling interface, an auxiliary process interface is a vacuumizing interface and is also an inert gas access interface, an exhaust passage of the heat pipe and a process tank is increased by one time, exhaust vacuumizing is smoother, the filling range can be expanded as required; an air pillow and a screen drum are added; novel design is performed on the cooler and the heater; the filling process is optimized, and the goals of heat pipe charging range expansion according to the requirements, no working medium residue on a pipeline during the filling, a more stable process, higher working medium purity, more convenient aftertreatment, more excellent heat pipe performance and longer service life are achieved.

Owner:CHINA ACAD OF AEROSPACE AERODYNAMICS

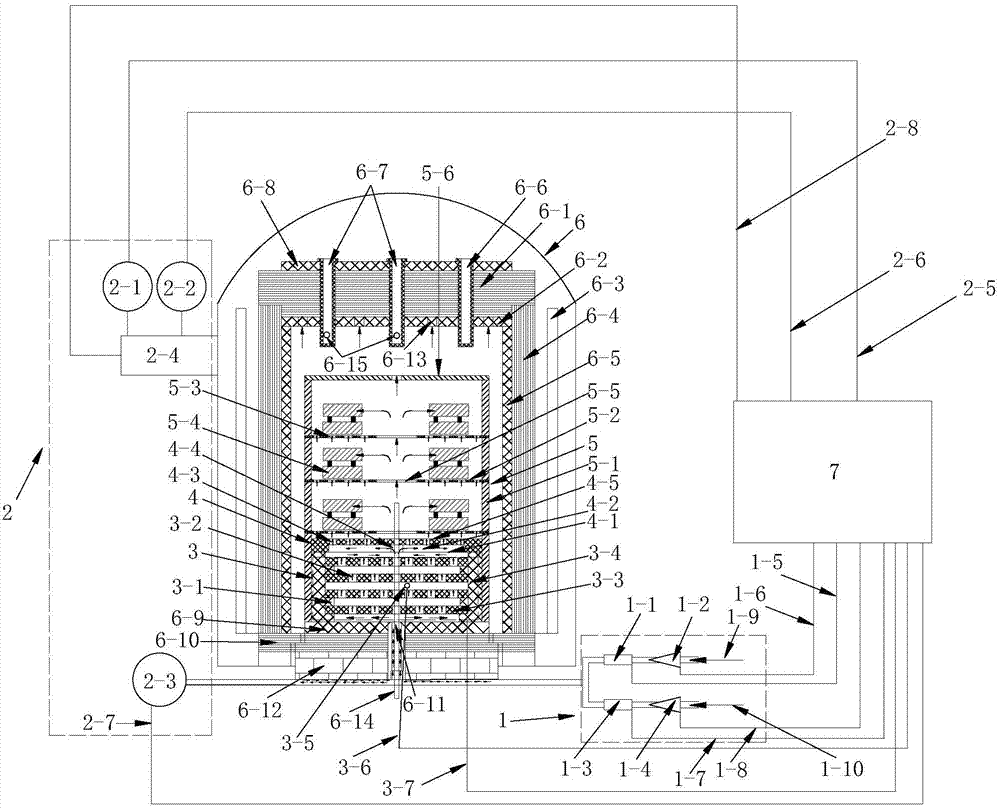

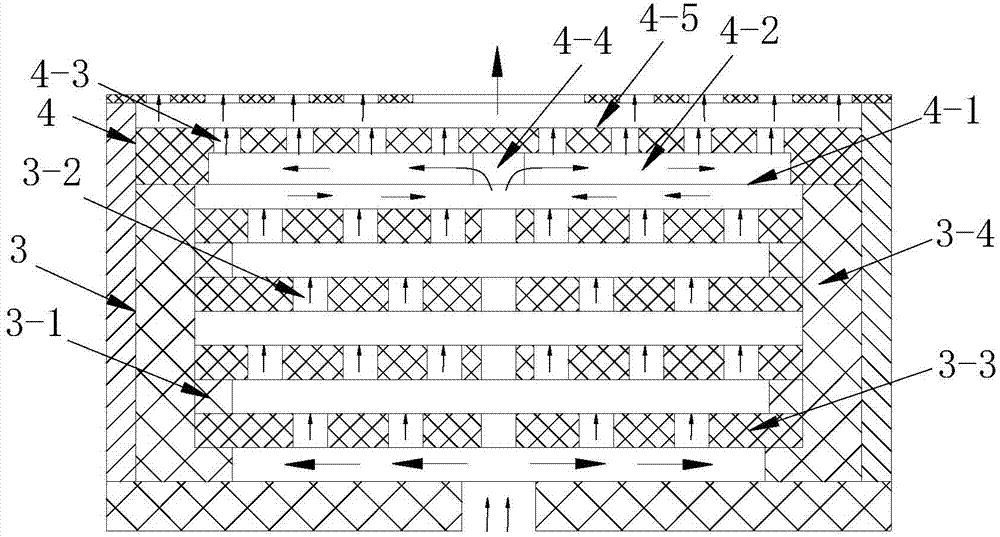

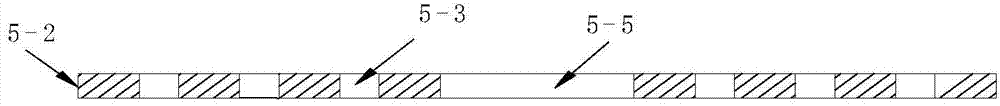

Carbon/carbon composite component chemical vapor infiltration device

ActiveCN104498891AWell mixedIncrease profitChemical vapor deposition coatingPressure controllerCarbon composites

The invention brings forward a carbon / carbon composite component chemical vapor infiltration device and aims to provide a device for solving problems of low reactant gas utilization rate and low infiltration efficiency existing by chemical vapor infiltration in the prior art. The invention is realized by the following technical scheme: a gas mixing and preheating device for primary control of reactant gas diversion direction and a temperature sensor for monitoring preheating temperature of reactant gas are arranged below a deep gas-mixing and outgassing device connected with a sealed infiltration chamber; the regulated and controlled reactant gas enters a gas mixing and preheating device from the bottom of a chemical vapor deposition furnace body through a gas supply device, and a controller automatically regulates electric power on a heater to obtain required preheating temperature; and the preheated reactant gas enters the sealed infiltration chamber and passes through a porous graphite liner plate to infiltrate through a composite preform placed inside the sealed infiltration chamber, and chemical vapor infiltration is performed under constant values by pressure control of a furnace pressure controller and temperature control of a temperature control sensor.

Owner:PLA NO 5719 FACTORY

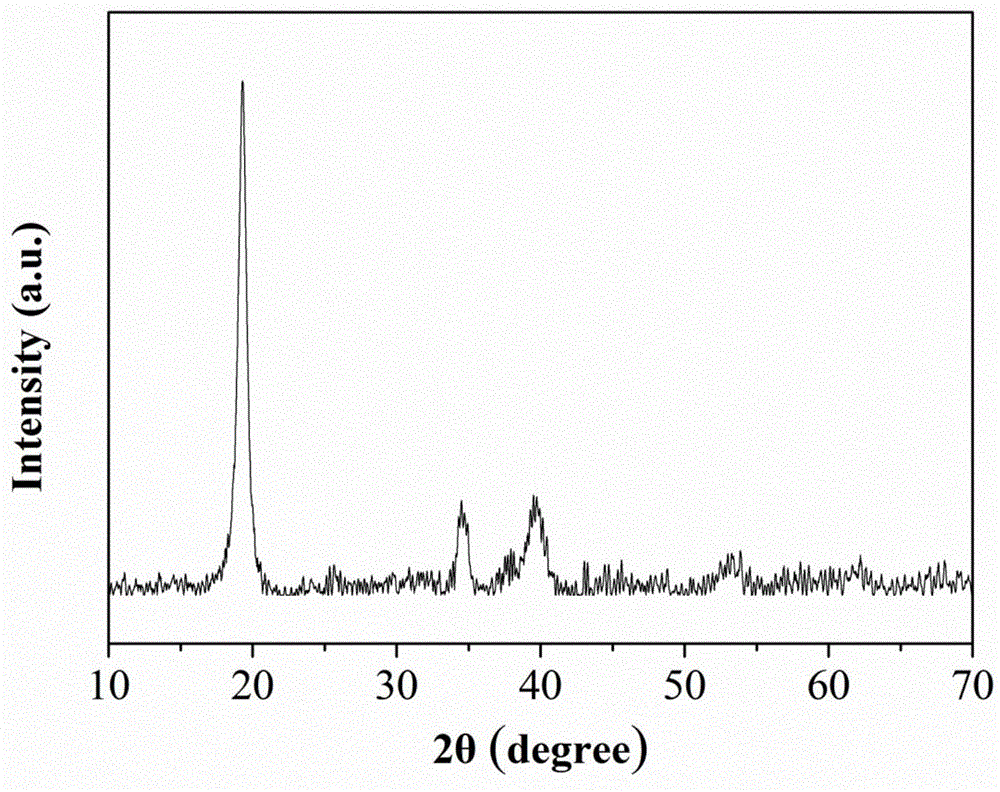

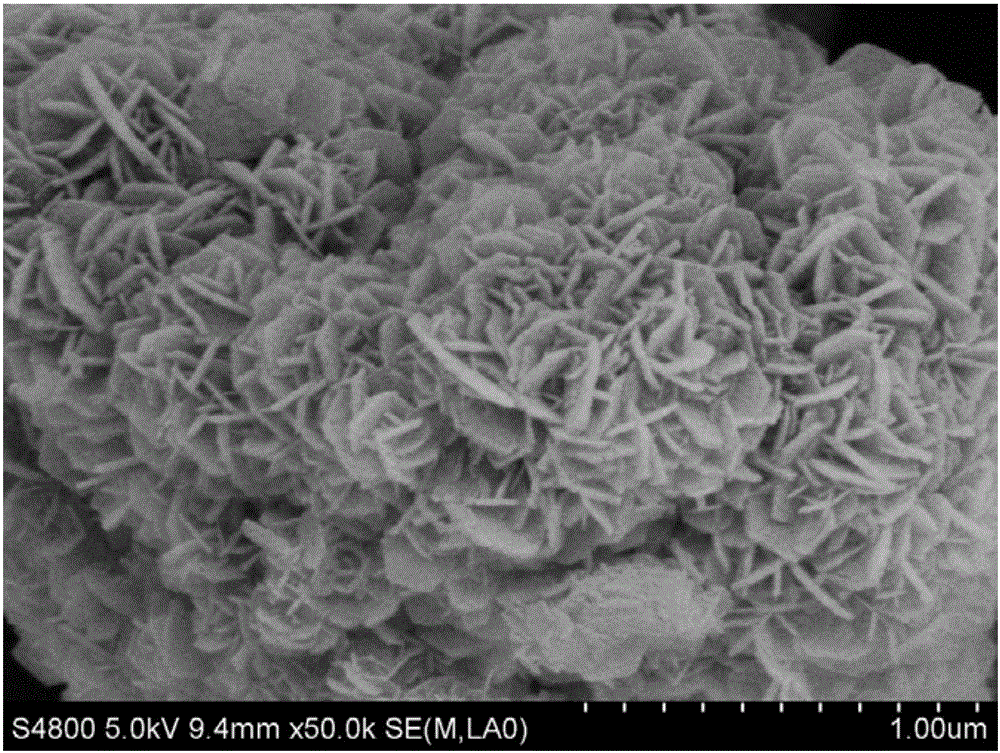

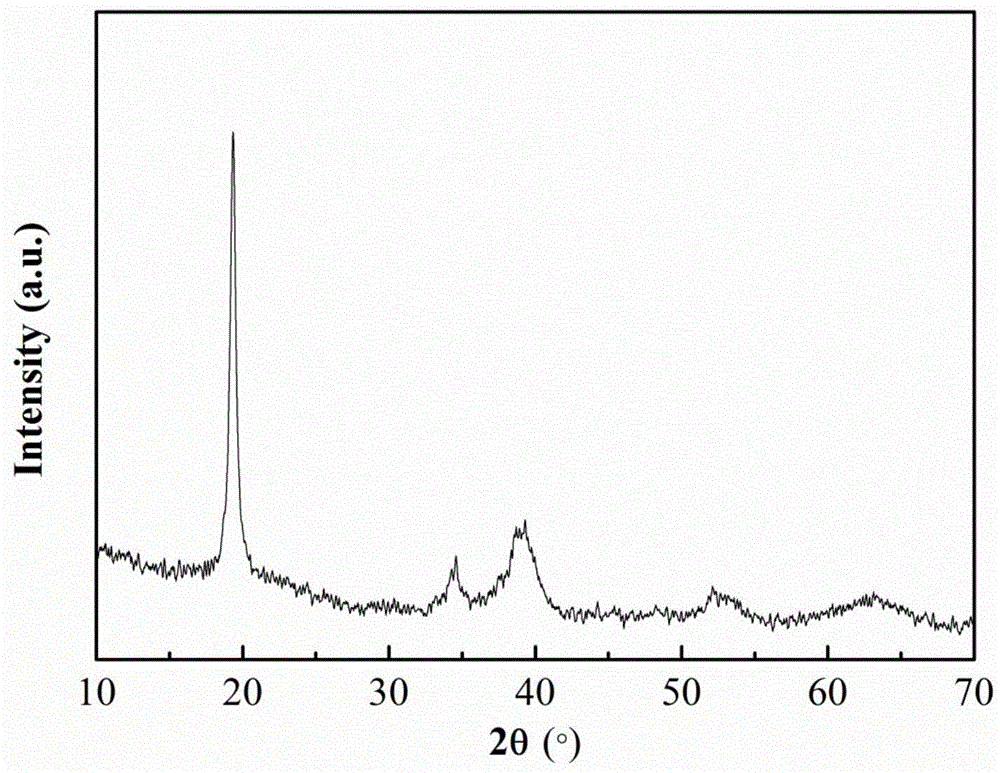

Method for continuously preparing nanoflower lithium ion battery layered anode material and reaction kettle thereof

InactiveCN106058237AWell mixedImprove the flow fieldMaterial nanotechnologyCell electrodesPrecipitationReagent

The invention provides a method for continuously preparing a nanoflower lithium ion battery layered anode material and a reaction kettle realizing the method. The method includes: (1), preparing a: preparing raw materials according to a chemical formula LiNixCoyMn1-x-yO2; (2), co-precipitating: using a co-precipitation method to obtain a reaction product, and subjecting the reaction product to aging, filtering, washing and drying to obtain precursor particles of a nanoflower structure; (3), calcining:calcining the precursor particles at high temperature to obtain the nanoflower lithium ion battery layered anode material. A template agent does not need to be added in the preparation process, and the particles are controllable in size, uniform in distribution and high in uniformity. Three layers of stirring paddles are arranged in the reaction kettle and stir at the same time, so that the materials are quick and uniform in reaction, and the particles are uniform and high in fluidity. By using the method, the lithium ion battery anode material in special nanoflower shape; the method is simple to operate, the reaction kettle is stable and reliable in structure, and industrial production is facilitated.

Owner:成都翔羽科技有限公司

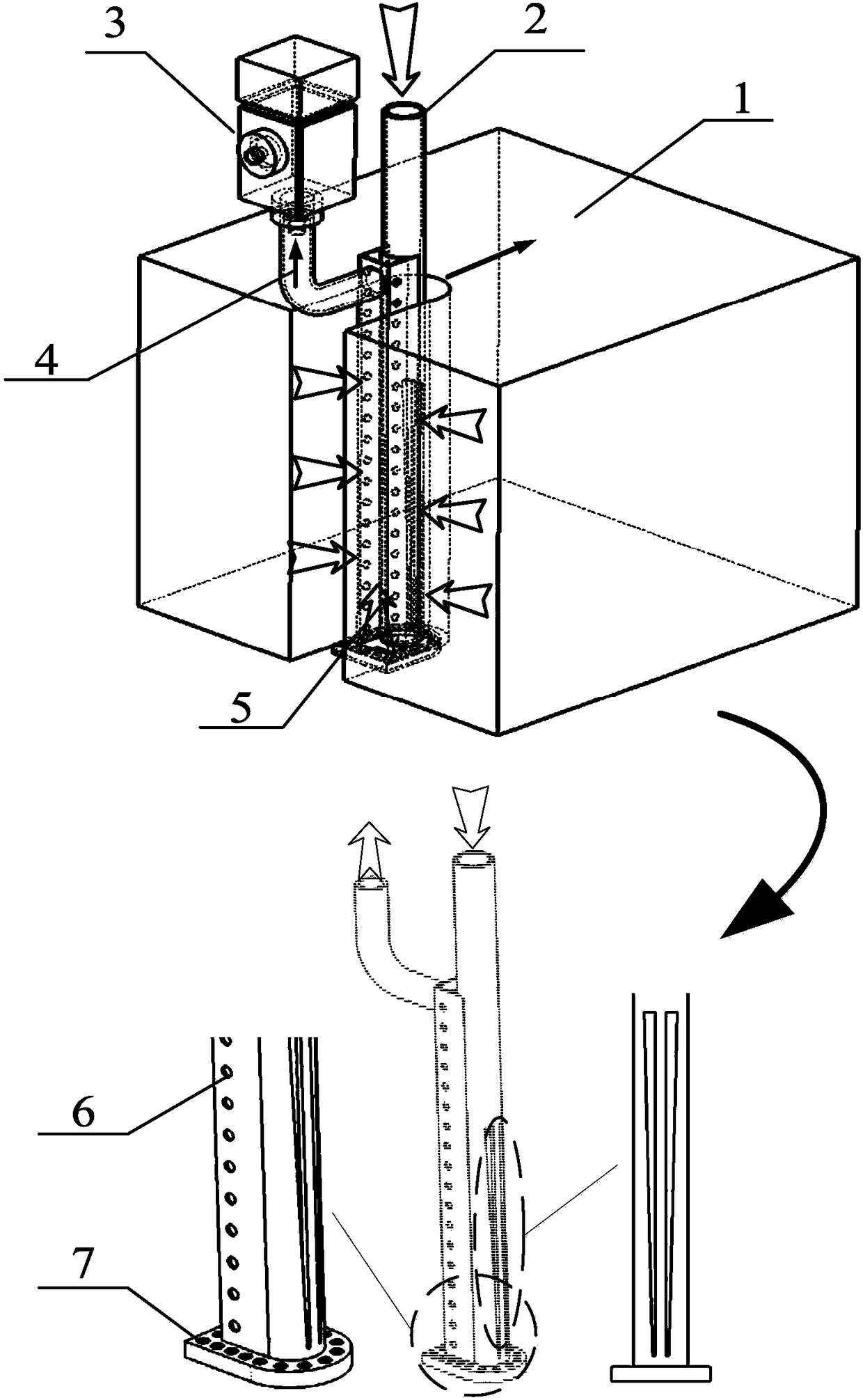

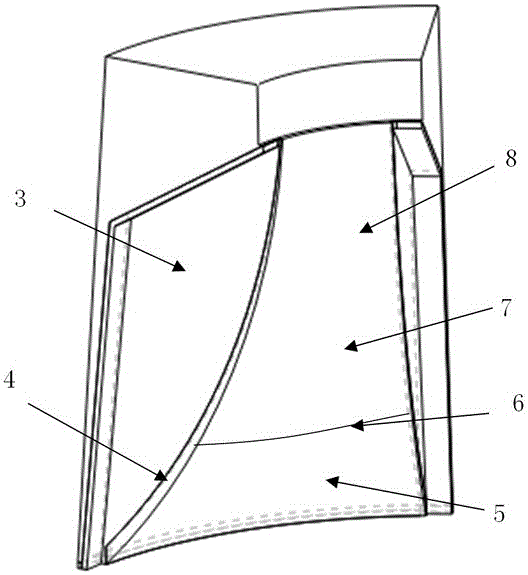

Electrochemical machining array electrode

InactiveCN102357689AEasy to processShort manufacturing cycleMachining electrodesElectrical-based machining electrodesElectrolysisEngineering

The invention discloses an electrochemical machining array electrode which is characterized by comprising electrode units, an array electrode clamp, a power module and an electrode clamp joint. The electrode unit is a strip-shaped solid, or a thin-wall hollow or grooved structure; the electrode units are clustered to form an array electrode unit cluster; the array electrode unit cluster is clamped by an electrode unit clamp; the bottom end of the array electrode unit cluster can form an end surface of any contour shape; and if the electrode unit is a thin-wall hollow structure or grooved structure, the electromechanical machining array electrode also comprises an electrolyte module so that the electrode units realize liquid flushing or absorption, or partial liquid flushing and partial liquid absorption. Through the invention, the electrode production time of electrolytic formation machining can be obviously shortened, the cost and difficulty in the electrode production are reduced, the utilization rate of the electrode material is improved, and the machining efficiency and speed are improved; and meanwhile, the electric field and flow field during the electromechanical machining are homogenized, selective machining can be realized at different positions of the electrode, and the machining accuracy and quality are improved.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

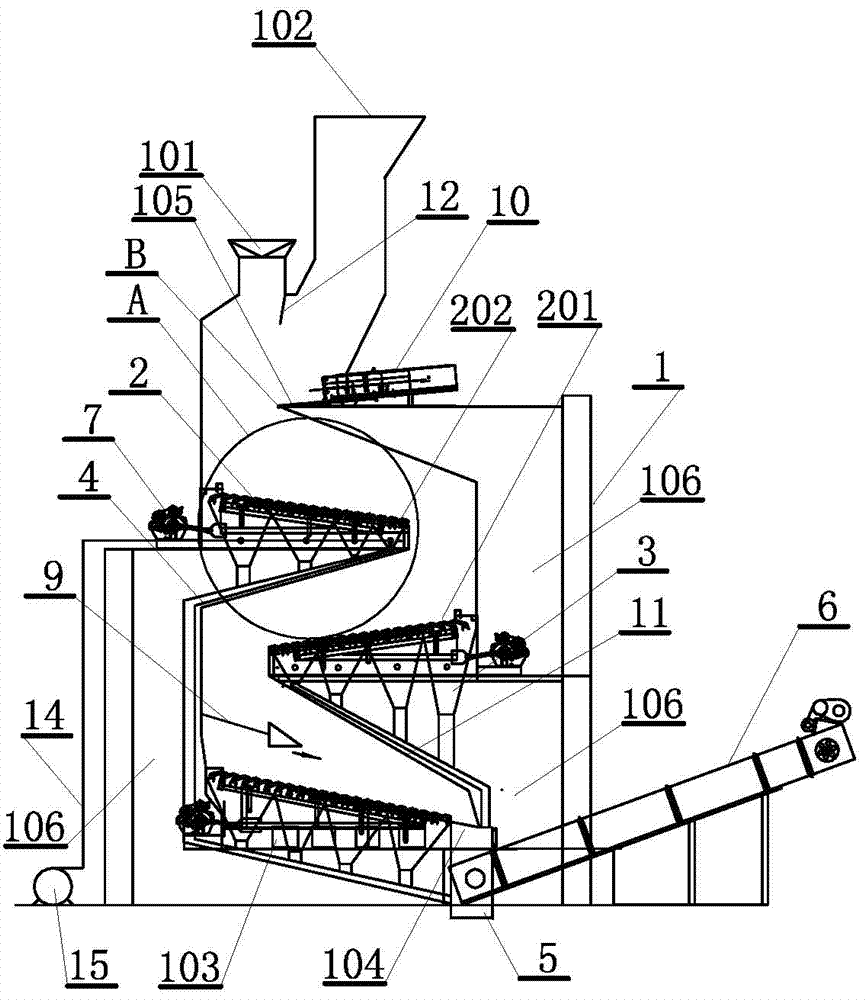

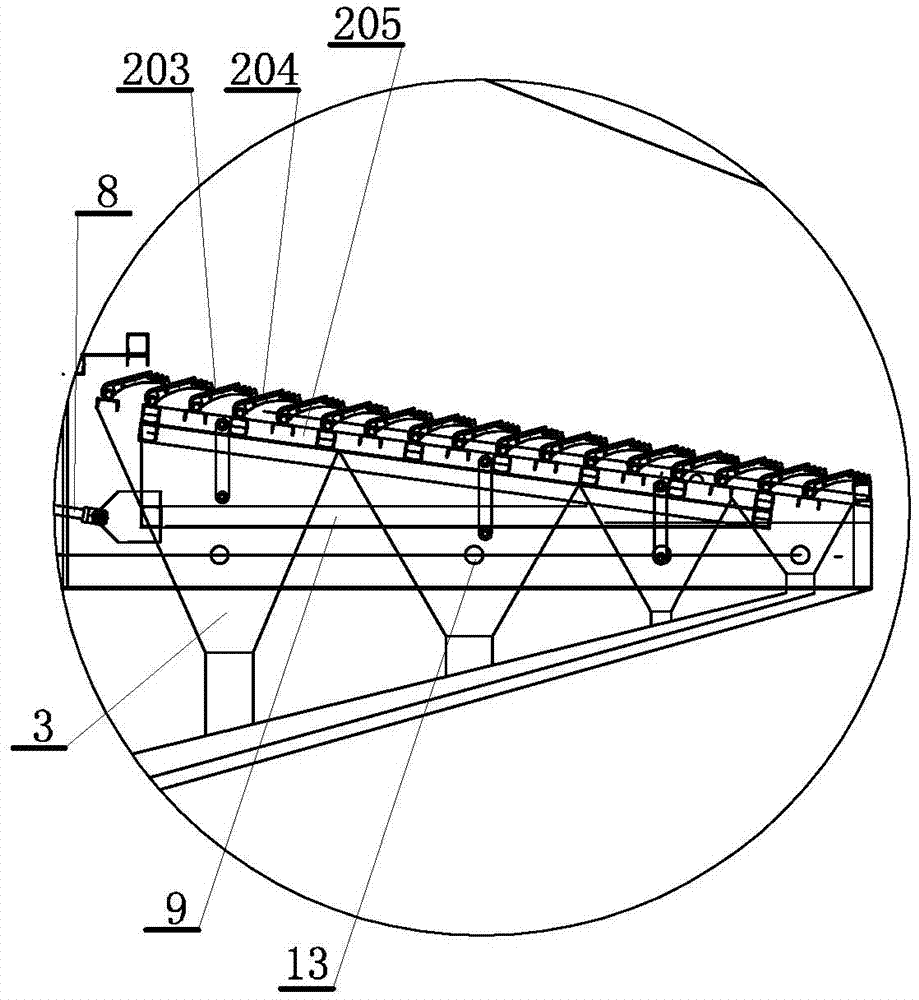

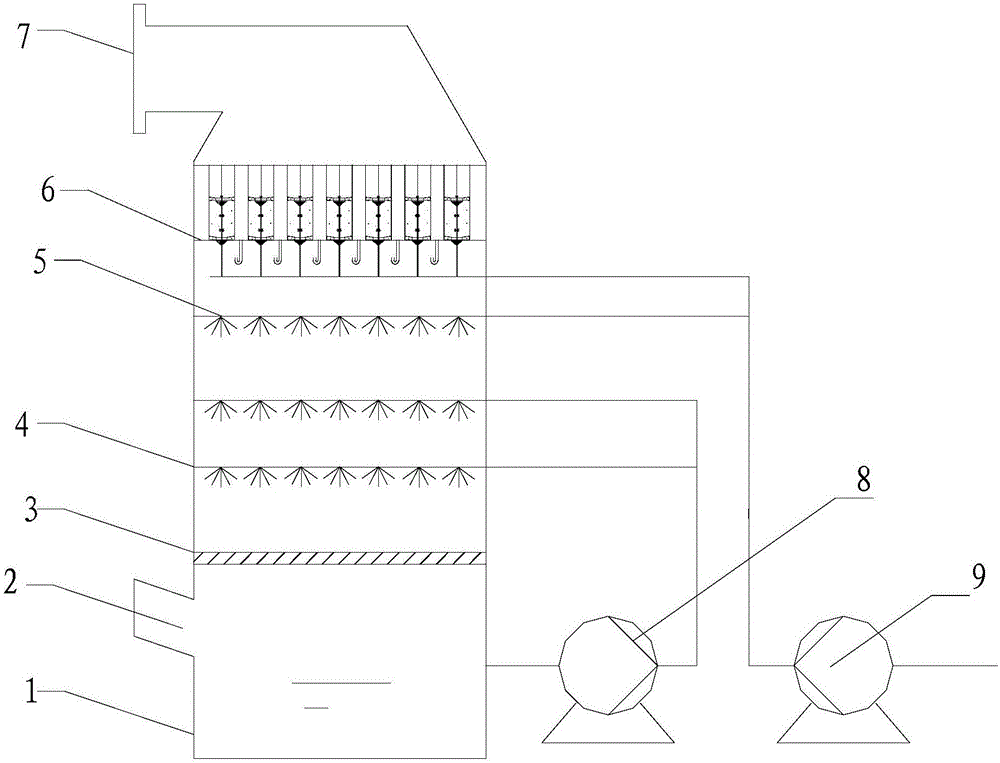

Multi-layer reciprocating type gasified combustion furnace

PendingCN107131503ASmall sizeLarge amount of disposalInclined grateIncinerator apparatusCombustionSlag

The invention discloses a multi-layer reciprocating type gasified combustion furnace comprising a combustion furnace body. A gasified fume discharging outlet and a gasified raw material garbage feeding inlet are formed in the upper end of the combustion furnace body, and a combustion gas inlet and a slag tapping outlet after combustion of gasified raw material garbage are formed in the lower end side of the combustion furnace body; a hearth in the furnace body is vertically provided with multiple layers of furnace rows from top to bottom; each layer of furnace row is arranged in a downward-inclining mode; the high end sides of the furnace rows at the lower layers stretch out of the low end sides of the furnace rows at the upper layers to enable the gasified raw material garbage on the furnace rows at the upper layers to fall into the high end sides of the furnace rows at the lower layers from the low end sides of the upper layers along the inclining gradient; and dust receiving funnels are arranged on the bottom face of the furnace row at each layer and connected with a dust discharging pipeline to output dust from the bottom side of the combustion furnace body. Because the garbage is fully dried and dehydrated through the multiple layers of furnace rows in the hearth, the heat value is increased, the combustion effect is more full, the structure is simple, the size of the combustion furnace is decreased greatly, investment is reduced, thermal decomposition gasified combustion of the furnace row at each layer can be achieved, and the application range of raw materials is wide.

Owner:BEIJING BUILDING MATERIALS ACADEMY OF SCI RES

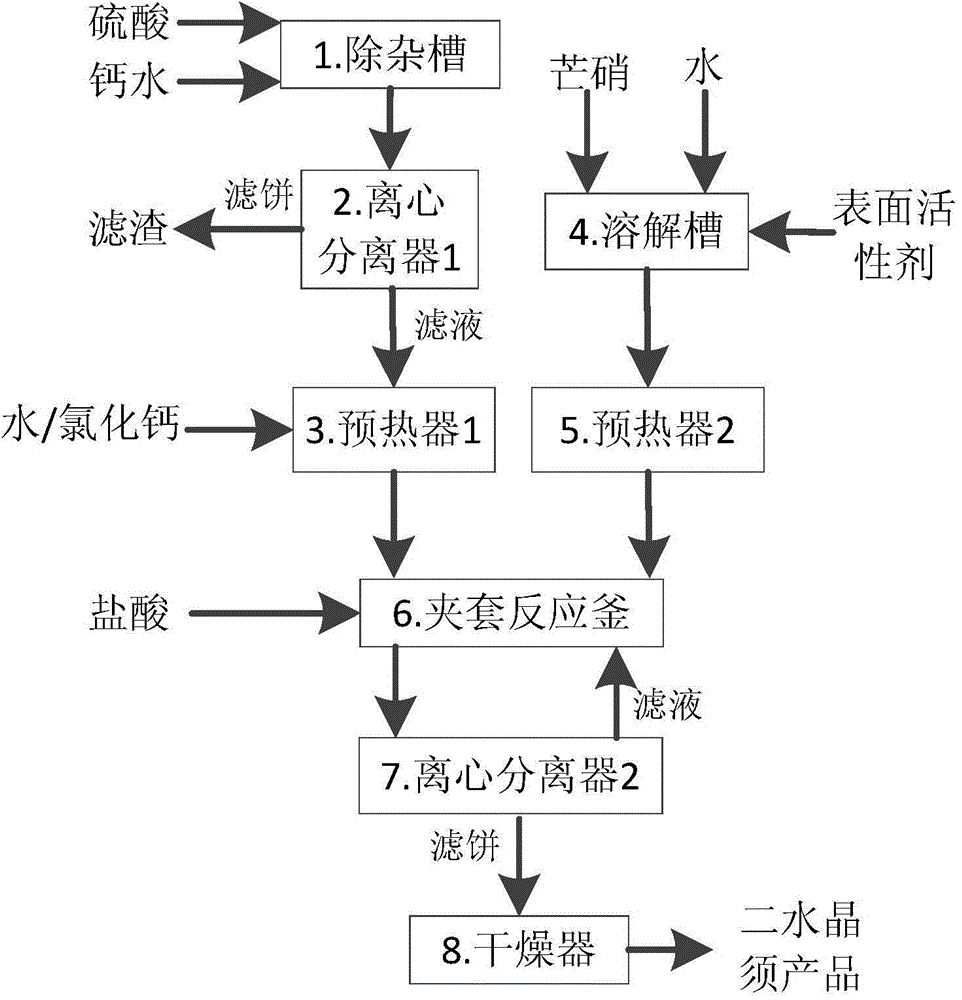

Method for preparing calcium sulfate dihydrate whisker from mirabilite and calcium water

ActiveCN104894650AUniform length and diameterUniform aspect ratioPolycrystalline material growthFrom normal temperature solutionsChemical industrySocial benefits

The invention discloses a method for preparing calcium sulfate dihydrate whisker from mirabilite and calcium water. The normal-pressure acidification process, which is utilized to produce the dihydrate gypsum whisker from industrial calcium water and mirabilite, can effectively utilize industrial wastewater (calcium water and mirabilite), solves the problem of discharge of the industrial wastewater, achieves the goal of green chemical industry, and completely conforms to the national industrial policy. The gypsum whisker belongs to a high-tech environment-friendly product, has the advantages of wide market demand prospects and obvious economic benefits, and has sufficient and cheap raw material resources in the local region after being put into production. The method is simple and easy to implement, and can easily implement industrialization. Therefore, the project can obtain huge economic benefit and social benefit if being researched and finally constructed in the local region. The finally obtained calcium sulfate dihydrate whisker has the advantages of uniform shape, proper length-diameter ratio (50 above), high yield (up to 84%) and high whiteness (at least 96%).

Owner:SICHUAN UNIVERSITY OF SCIENCE AND ENGINEERING

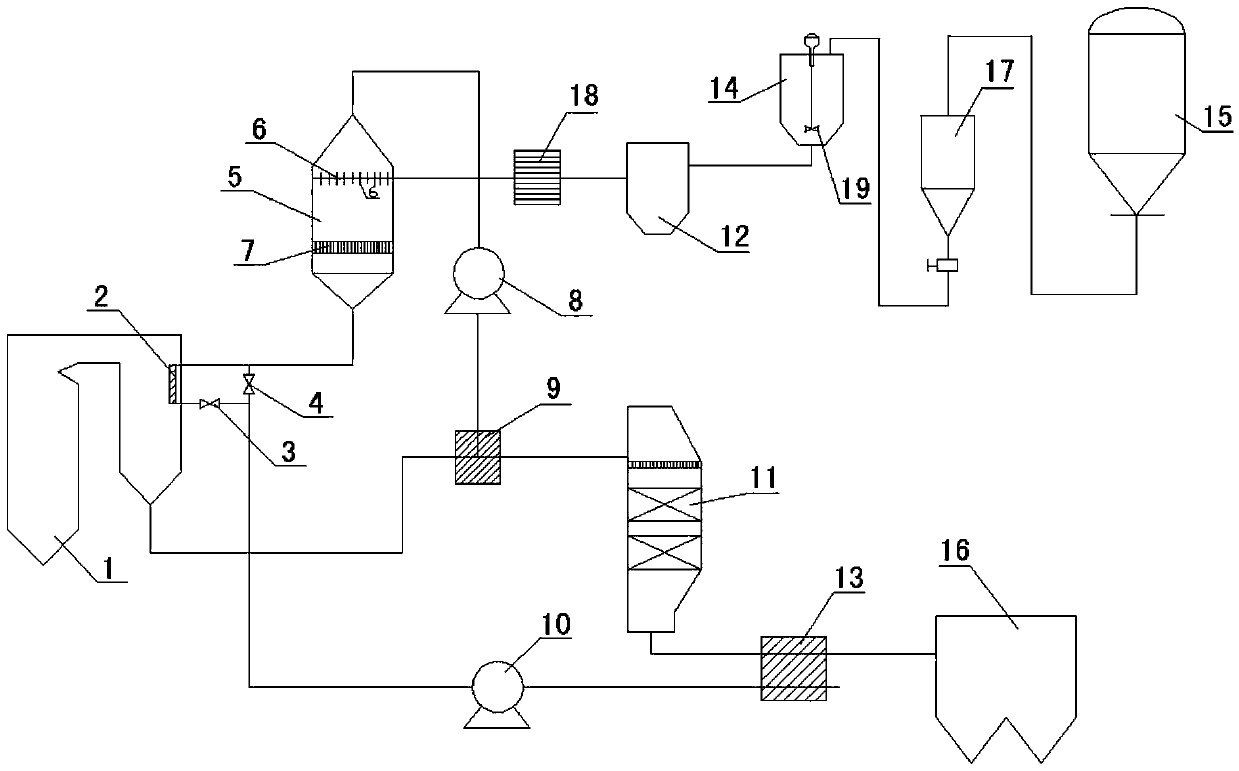

Flue gas wet desulphurization, dedusting integrated device and process

ActiveCN106582248AIncrease heightSmall particle sizeCombination devicesGas treatmentFlue gasProcess engineering

The invention discloses a flue gas wet desulphurization, dedusting integrated device and process. Original flue gas sequentially enters into an absorbing tower, then passes a pallet layer, a spraying layer, an ultra-fine atomizing and cooling zone and a swirling flow demisting layer to be discharged from an outlet of the absorbing tower. The pallet layer rectifies the flue gas entering into the absorbing tower, then the flue gas ascends in a uniform flow speed on the section of the absorbing tower. SO2 in the flue gas is absorbed and removed. The desulphurized saturated flue gas carrying tiny slurry droplets and dust undergoes atomizing and spraying to be cooled down. The tiny slurry droplets and dust in the flue gas is cooled down in temperature, then condenses and precipitates to a tower slurry pond. The over-saturated flue gas carrying tiny fog droplets continues to ascend to pass through the swirling, liquid knockout, enrichment and removal. The clean flue gas is emitted. The flue gas wet desulphurization, dedusting integrated device and process not only can enhance the removal efficiency of SO2, but also can obviously enhance the dedusting efficiency of the absorbing tower, and achieve the super low emission of the flue gas.

Owner:ZHEJIANG TIANLAN ENVIRONMENTAL PROTECTION TECH

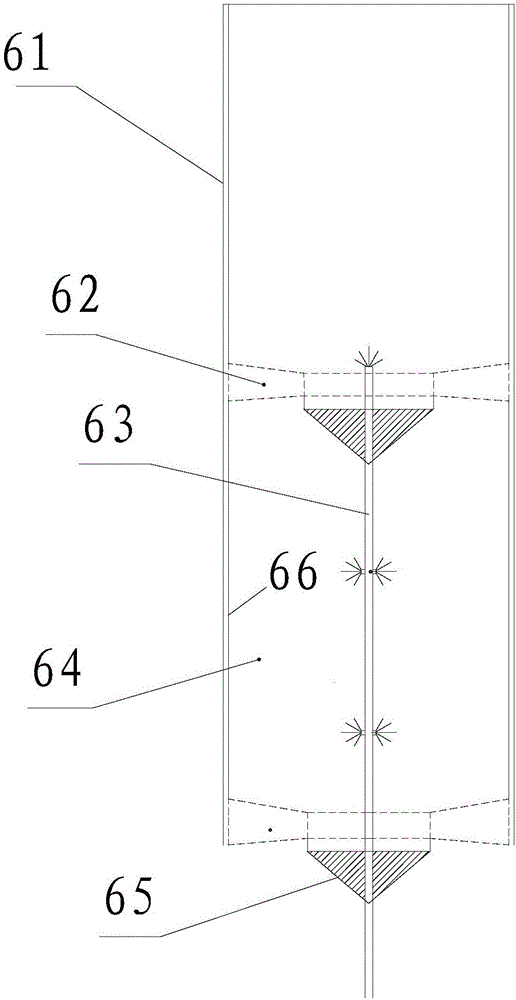

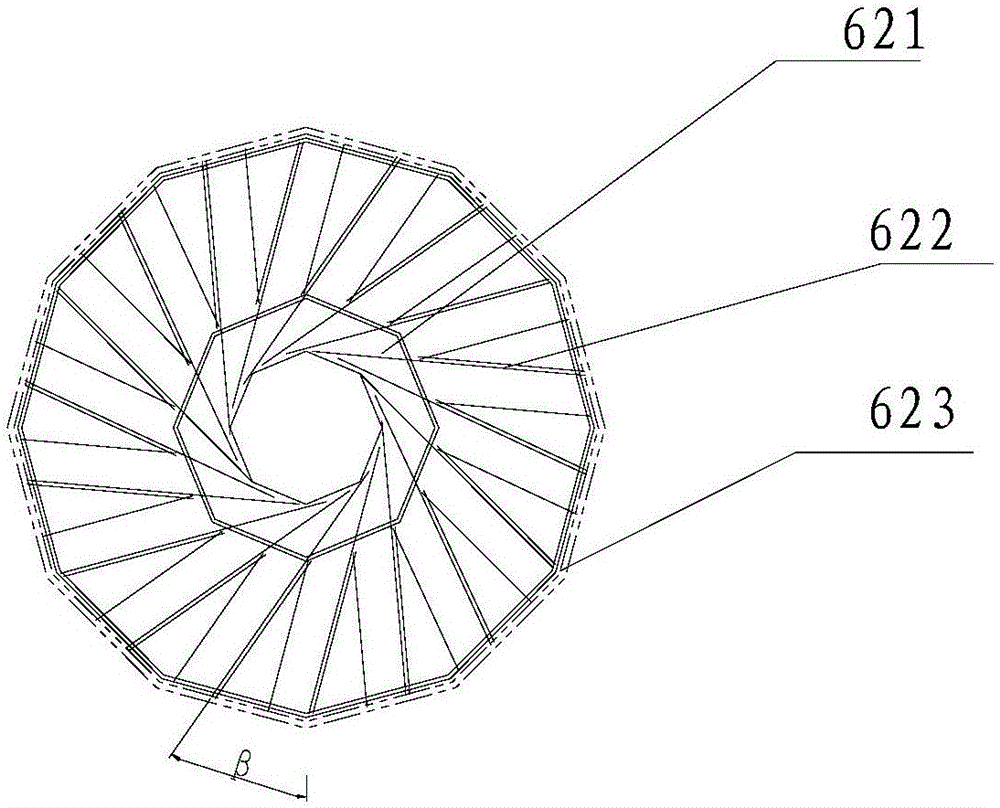

Rotational flow plate type SCR denitration tower and denitration method thereof

ActiveCN105289300AExtended stayThe catalytic reduction reaction is fullyDispersed particle separationFlue gasEscape rate

The invention discloses a rotational flow plate type SCR denitration tower and a denitration method thereof. The denitration tower comprises a denitration tower body and a corrugated plate type catalyst layer arranged along the inner circumference face of the denitration tower body, and the corrugated plate type catalyst layer forms a flue gas channel. A plurality of layers of rotational flow atomizing nozzles performing jetting in the contact circle direction are distributed on the circumference face of the corrugated plate type catalyst layer from bottom to top. When flue gas enters the flue gas channel from the bottom of the denitration tower body, and the flue gas encounters ammonia gas jetted by the whirlwind atomizing nozzles, the flue gas and the ammonia gas are mixed in an entrainment mode and spirally raises in the inner circumference direction of the flue gas channel in a contact circle mode because the ammonia gas is jetted in a rotational flow mode in the contact circle direction. On the premise that efficient denitration is guaranteed, the catalyst use amount of the denitration tower is small, the technical means is easy and convenient to use. Compared with the prior art, the denitration tower is simple in structure, low in manufacturing cost, high in denitration efficiency and low in energy consumption, reduces the ammonia escape rate, makes denitration cost greatly reduced, and remarkably improves economic benefits.

Owner:SOUTH CHINA UNIV OF TECH

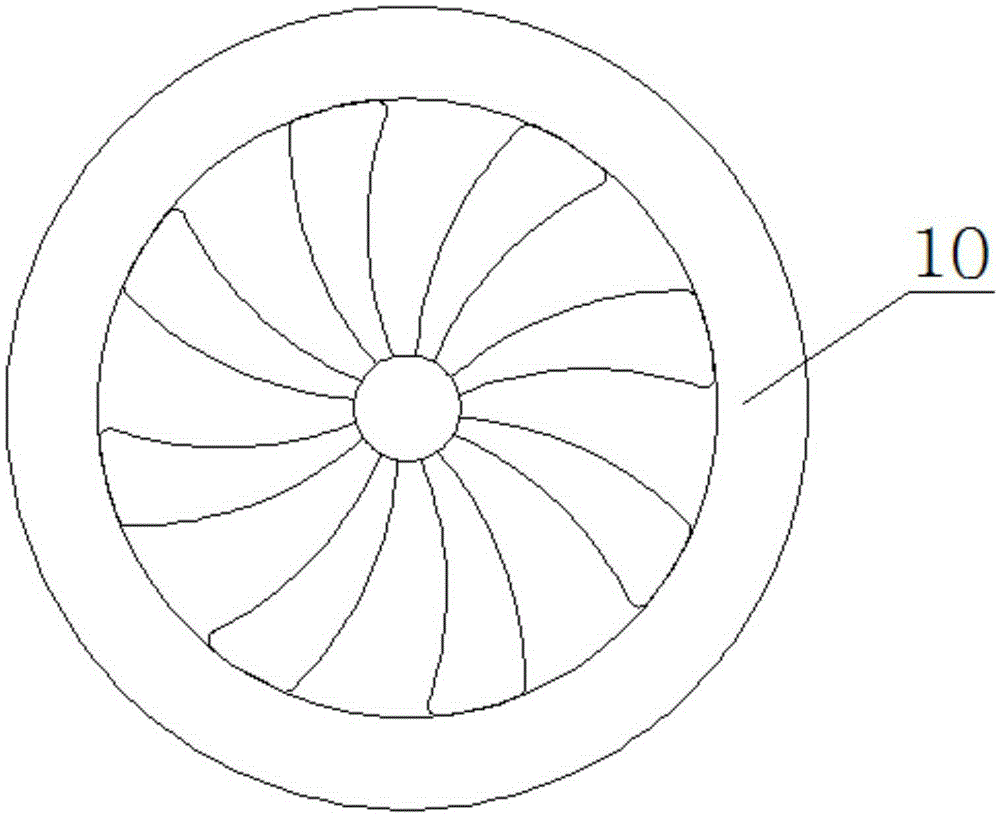

Efficient powder selecting machine with power material scattering device

InactiveCN104624499AFully dispersedFlow field stabilityGas current separationMaterial scatteringMechanical engineering

The invention provides an efficient powder selecting machine with a power material scattering device. A lower part power material scattering device (10) is arranged at the lower part of the powder selecting machine; the lower part power material scattering device (10) is composed of a material scattering disc (16), a supporting device (17) connected with the material scattering disc (16), and a second transmission device (18) connected with the supporting device (17). The efficient powder selecting machine has the following technical effects that the power material scattering device is arranged at the lower part so that powder materials to be selected are sufficiently dispersed, and a stable and uniform flow field is provided for rotor grading the next step; the powder selecting efficiency is improved by 10%-15%; feeding is carried out at a lower part: the power selecting concentration of a rotor of the powder selecting machine is greatly reduced and the power consumption of the rotor is reduced by 15%-20%; discharging is carried out at the lower part: large-particle materials and iron blocks are directly discharged from the lower part of a discharging opening, the upper part sealing is not blocked, and the abrasion of an upper guide blade is small.

Owner:JIANGSU XINYE HEAVY IND

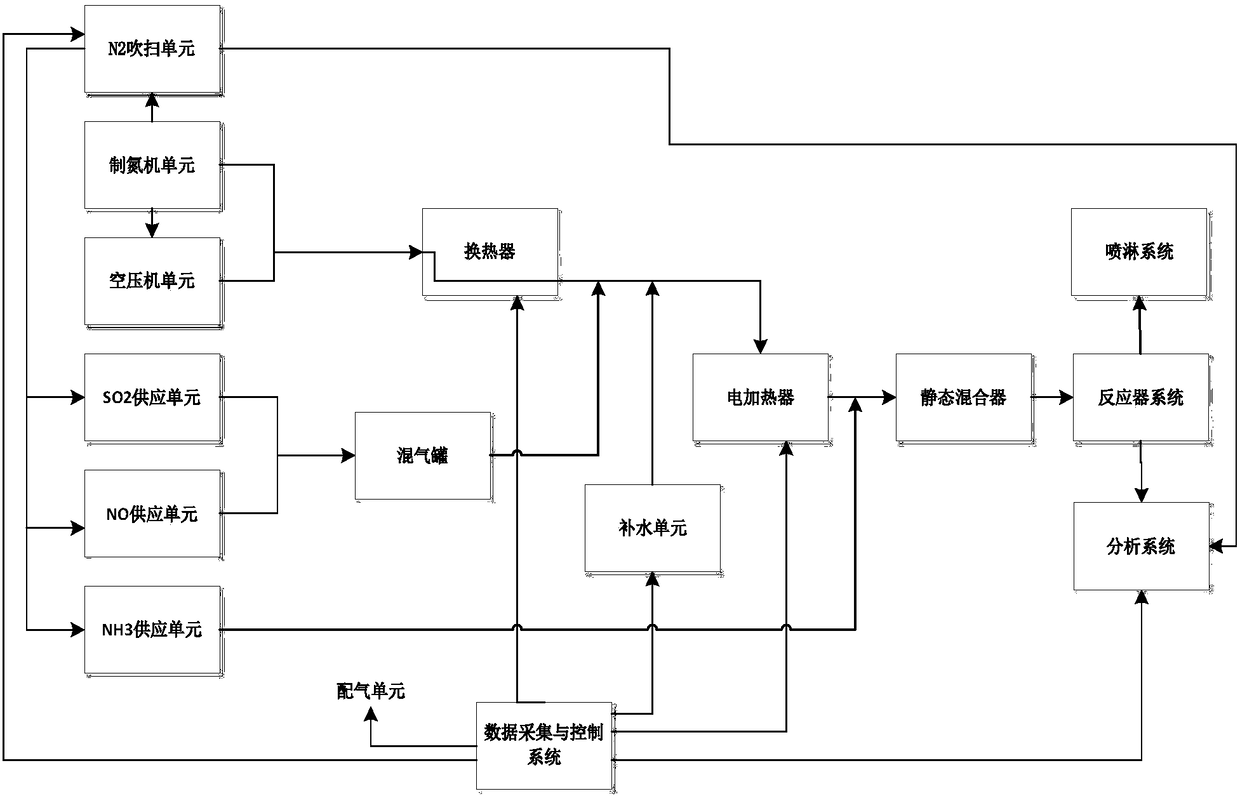

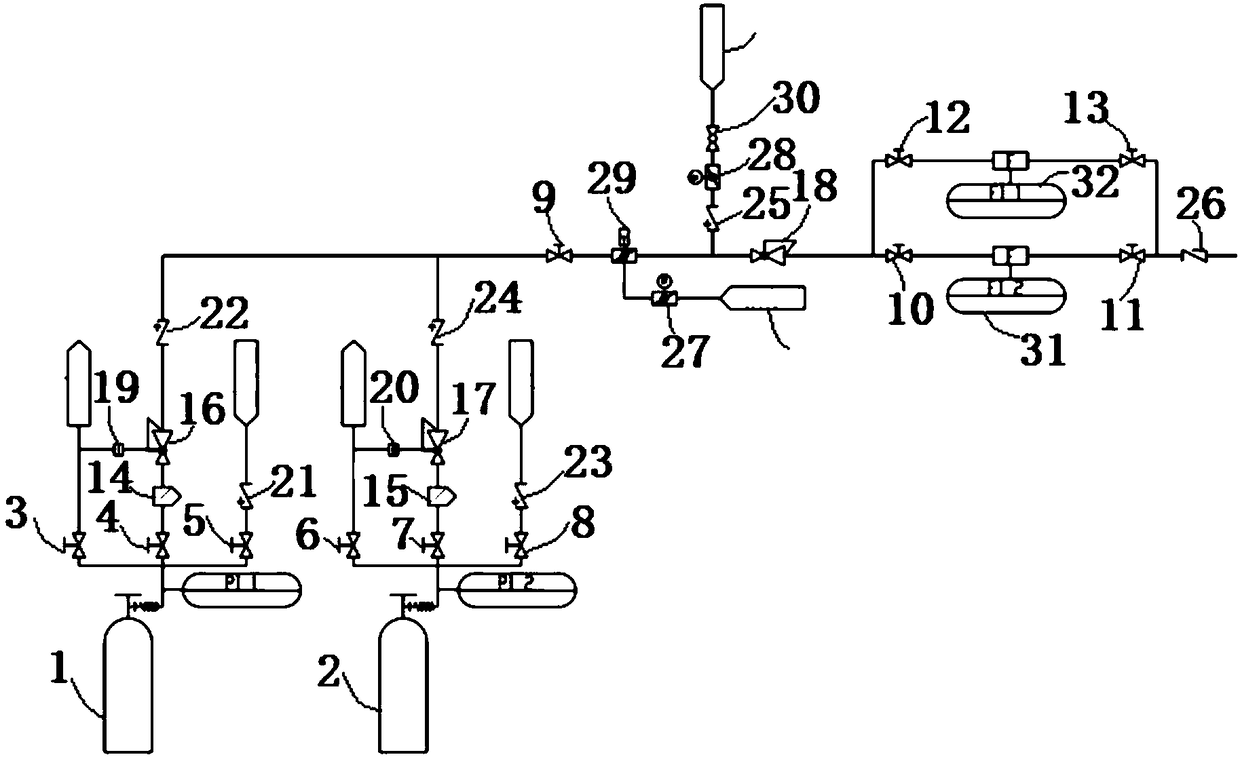

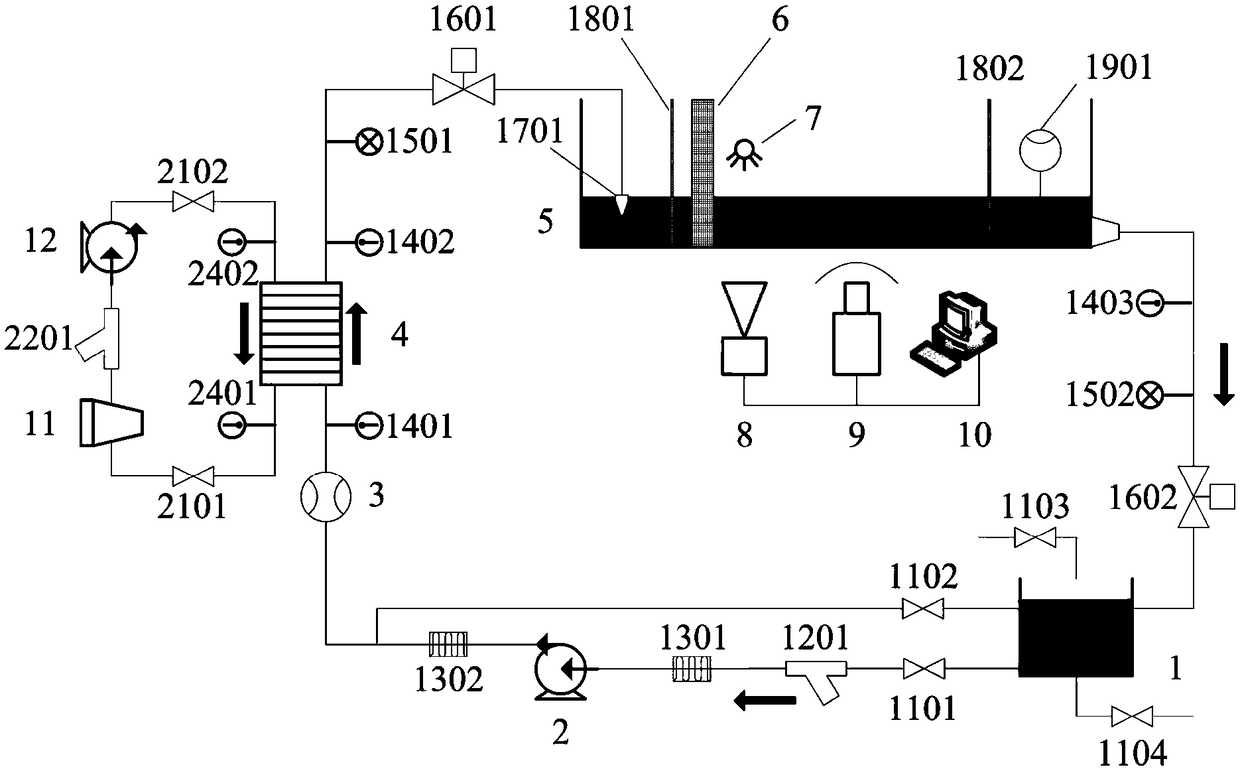

Full-scale performance detection and evaluation device of SCR (selective catalytic reduction) denitration catalyst and application method thereof

PendingCN108195993AEfficient measurementSave energyChemical analysis using combustionElectricityReactor system

The invention discloses a full-scale performance detection and evaluation device for a SCR denitration catalyst and an application method thereof, and belongs to the field of detection. The full-scaleperformance detection and evaluation device comprises an air distribution system, a main reaction system, an analyzing system, a spraying system and a data collecting and control system which is usedfor achieving parameter setting and automated operation of control elements, wherein the main reaction system comprises a heat exchanger, an electric heater and a reactor system which are sequentially connected. The reactor system comprises a plurality of reaction furnaces, and the reaction furnaces are connected mutually. In the situation of without stopping the furnaces, the full-scale performance detection and evaluation device can continuously measure the performance of the catalyst under four working situations, the energy is saved to the largest extent, the working efficiency is improved, and the parameters such as denitration efficiency, ammonia escape, SO2 / SO3 conversion rate and pressure drop can be effectively measured.

Owner:NANJING ASSEN ENVIRONMENT TECH

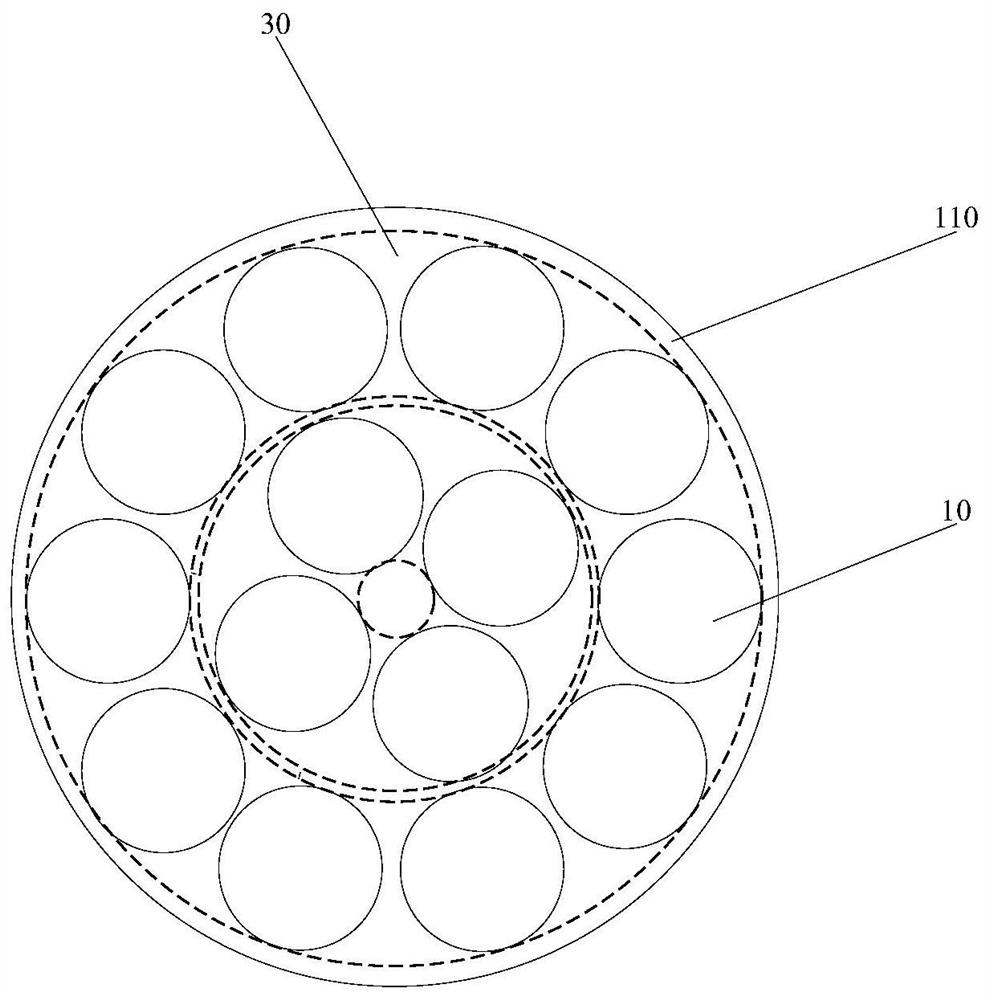

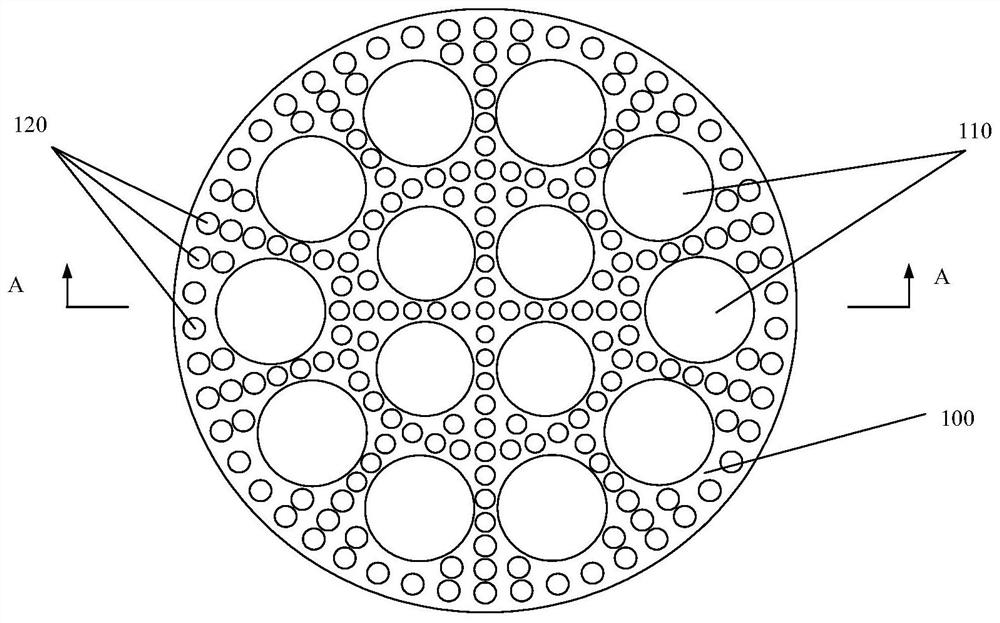

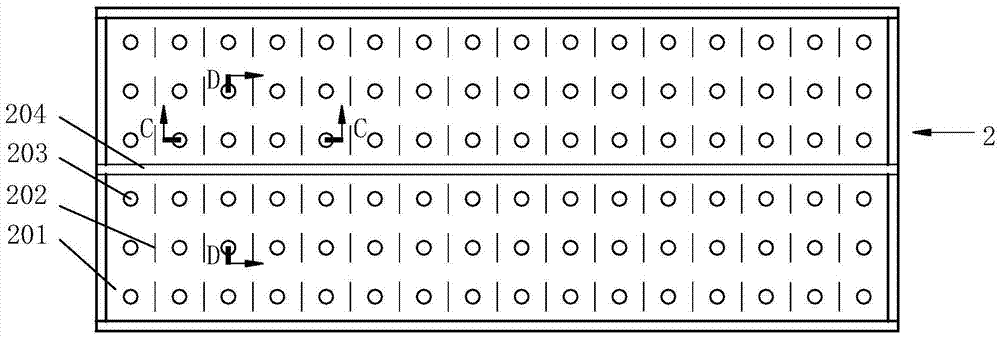

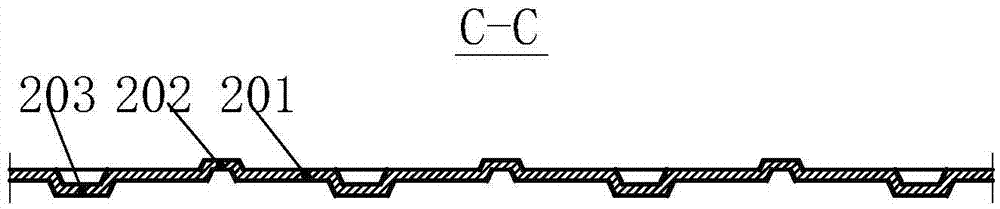

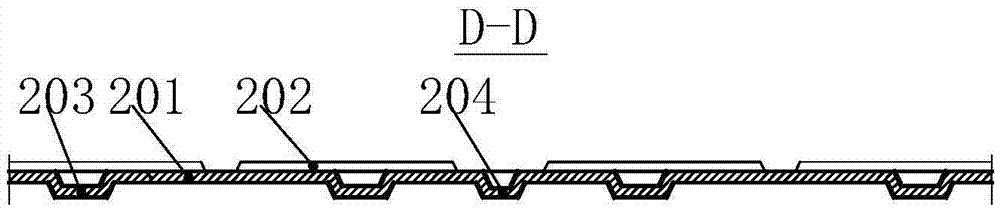

Graphite base and MOCVD equipment

InactiveCN112359414AImprove consistencyReduce viscous resistanceFrom chemically reactive gasesChemical vapor deposition coatingCircular discGraphite

The invention provides a graphite base and MOCVD equipment, and belongs to the technical field of semiconductors. The graphite base is of a disc-shaped structure, the first circular end face of the graphite base comprises a plurality of epitaxial wafer containing grooves and a plurality of cambered surface grooves, the epitaxial wafer containing grooves are arranged in a multi-layer circular ringmode in the radial direction of the first circular end face, and the circle center of the circular ring coincides with the circle center of the first circular end face. The cambered surface grooves are uniformly formed in the first circular end surface among the plurality of epitaxial wafer containing grooves at intervals, and the inner surfaces of the cambered surface grooves are spherical crown-shaped. The first circular end face of the graphite base comprises the plurality of epitaxial wafer containing grooves and the plurality of cambered surface grooves, and the cambered surface grooves are uniformly formed in the first circular end face between the epitaxial wafer containing grooves at intervals, so that the uniformity of the epitaxial layer at the edge position of the graphite baseis improved, and the consistency of epitaxial wafers is improved.

Owner:HC SEMITEK SUZHOU

Corrugated plate beam of single-side contact-free through flow way

ActiveCN107024124AEliminate cloggingEliminate scalingLaminated elementsStationary plate conduit assembliesPlate heat exchangerMechanical engineering

The invention relates to the technical field of plate type heat exchangers, in particular to a corrugated plate beam of a single-side contact-free through flow way. The corrugated plate beam comprises a plurality of plate pieces, and each plate piece comprises a main heat transfer face, turbulent flow ripples evenly distributed on the main heat transfer face, pressure bearing ripples and ranging ripples extending from one end to the other end in the direction of the length of the corresponding plate piece. According to the plate beam, the problems that in the prior art, a flow way of a plate type heat exchanger is blocked, fouling corrosion happens, and the cold and heat medium temperature is crossed are solved.

Owner:TIANJIN HUASAIER HEAT TRANSFER EQUIP

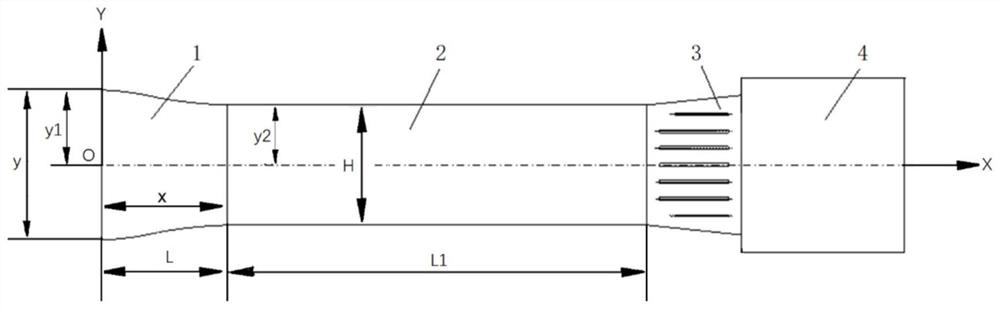

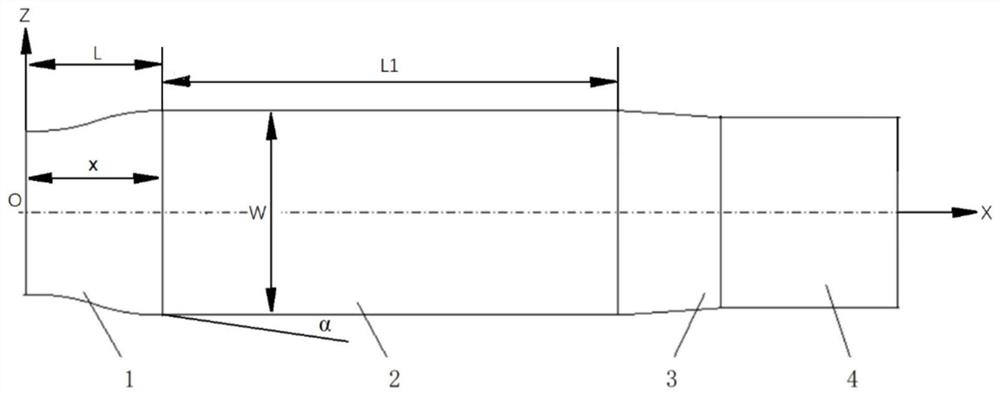

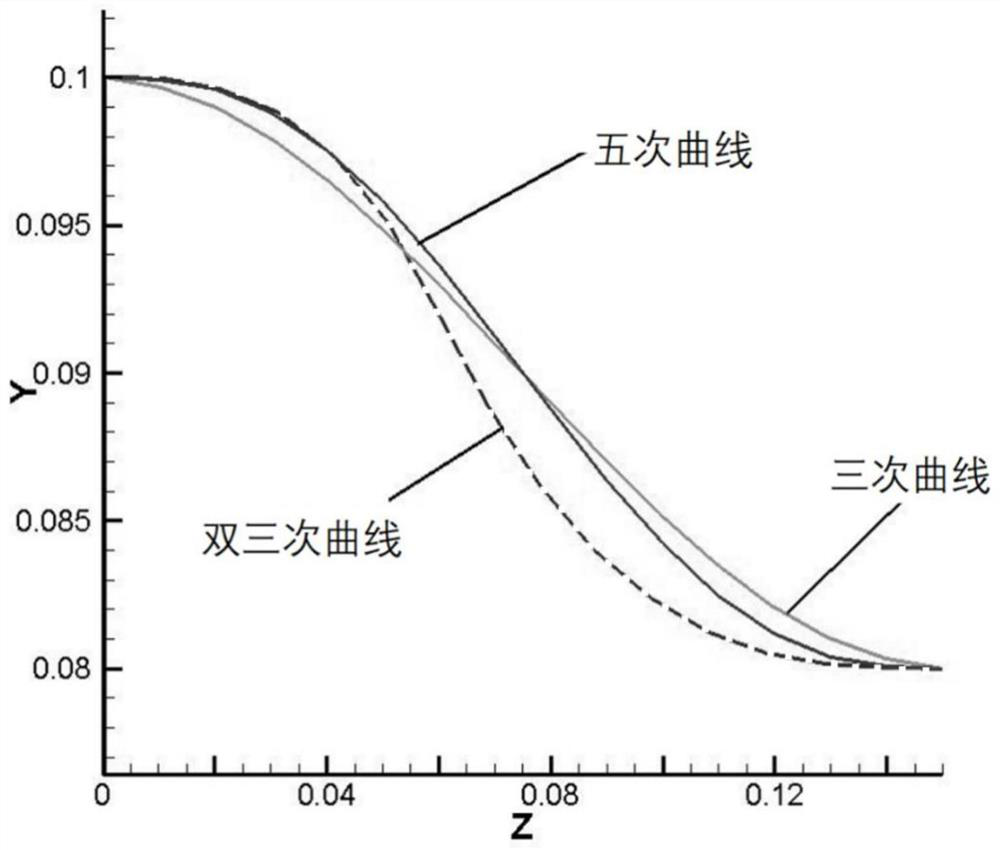

Transition profile calculation method for variable cross-section shape high-speed wind tunnel test section

ActiveCN112556970AExtended service lifeSimple design methodAerodynamic testingStructural engineeringMachining process

The invention discloses a transition profile calculation method for a variable cross-section shape high-speed wind tunnel test section. According to the transition profile calculation method, a cubiccurve, a bicubic curve and a quintic curve are adopted to design a transition profile; through computer numerical simulation, speed distribution cloud charts of rectangular section test section inletsof transition profiles of the cubic curve, the bicubic curve and the quintic curve are obtained respectively, whether a test section flow field meets high-speed wind tunnel test requirements or not is evaluated, curves which do not meet the requirements are excluded, and curves which meet the requirements are reserved; and machining process evaluation is carried out on the curves meeting the requirements, and the cubic curve is determined as the molded line of the transition profile. The transition profile calculation method is suitable for transforming an existing high-speed wind tunnel, expands the test field of the existing high-speed wind tunnel, and has high adaptability and high application value.

Owner:INST OF HIGH SPEED AERODYNAMICS OF CHINA AERODYNAMICS RES & DEV CENT

Wet desulphurization mechanism

ActiveCN103953939AImprove heat transfer efficiencyEliminate risks such as blockage downtimeChimneysPlate heat exchangerEngineering

The invention discloses a wet desulphurization mechanism. The wet desulphurization mechanism comprises an original smoke deflector and a smoke heat exchanger, wherein an original smoke opening is formed in the smoke heat exchanger, the cross section of the original smoke opening is rectangular, the original smoke deflector comprises a first elbow and a second elbow, the cross sections of the first elbow and the second elbow are round, and both the first elbow and the second elbow are mounted on the original smoke opening of the smoke heat exchanger. As the first elbow and the second elbow, of which the cross sections are round, are arranged at the original smoke opening of the smoke heat exchanger, smoke can be shunt by the first elbow and the second elbow before entering the smoke heat exchanger, and sufficient bending spaces are available at the first elbow and the second elbow. Besides, the first elbow and the second elbow have smaller round cross sections and great deflecting functions, the whole flow field becomes more uniform, the heat exchange efficiency of the smoke heat exchanger is effectively improved, and the risks that the easily torn deflector plate designed in the traditional rectangular runner causes corroded cracks, corroded flues, runner blocking shutdown and the like are eliminated.

Owner:CHINA ENERGY ENG GRP GUANGDONG ELECTRIC POWER DESIGN INST CO LTD

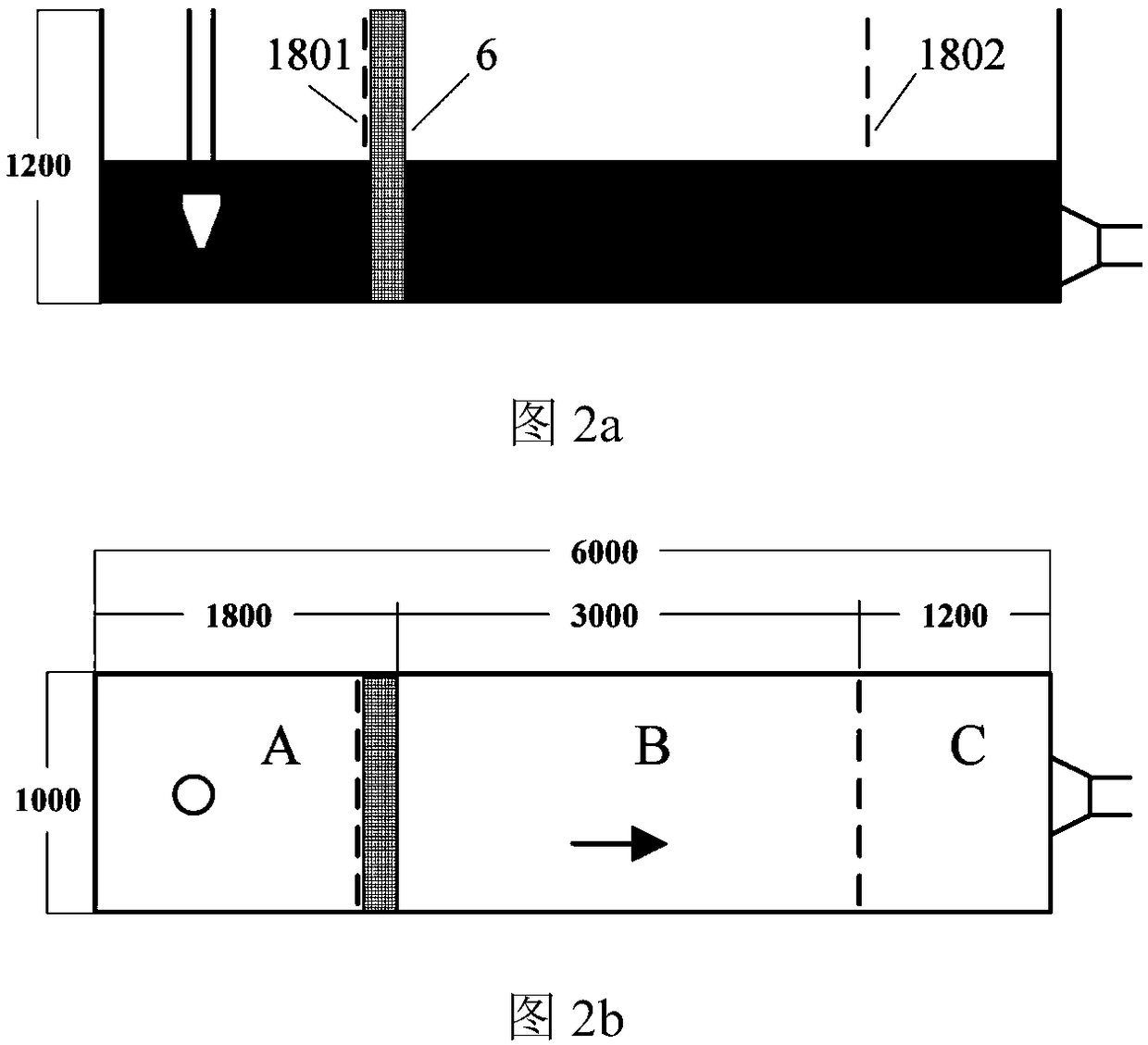

Migration transfer characteristic test system of fragments of reactor containment and test method thereof

ActiveCN109243638AGet sportyMeet the test strength requirementsNuclear energy generationNuclear monitoringCooling towerTest segment

The invention relates to a migration transfer characteristic test system of fragments of a reactor containment and a test method thereof. The system comprises a test segment module composed of a waterchannel, a rectifying grid, a filter screen and related equipment, a flow rate adjusting module composed of a water tank, a main water pump, an electric valve and related pipelines and instruments, acooling module composed of a cooling water pump, a heat exchanger, a cooling tower and related pipelines and instruments, a thermotechnical hydraulic parameter measuring module composed of a flowmeter, a temperature sensor, a pressure sensor and a liquidometer, an image collecting module composed of a high-speed camera, a local area network computer and related image processing software, a flow field information collection module composed of PIV equipment, a local area network computer and related flow field processing software and a remote control module composed of a programmable logic controller, a water pump, an electric valve and related equipment. The system simulates a ground water flow velocity field of the containment accurately after loss of coolant accident and acquires characteristic parameters of different fragments migrating in water.

Owner:XI AN JIAOTONG UNIV

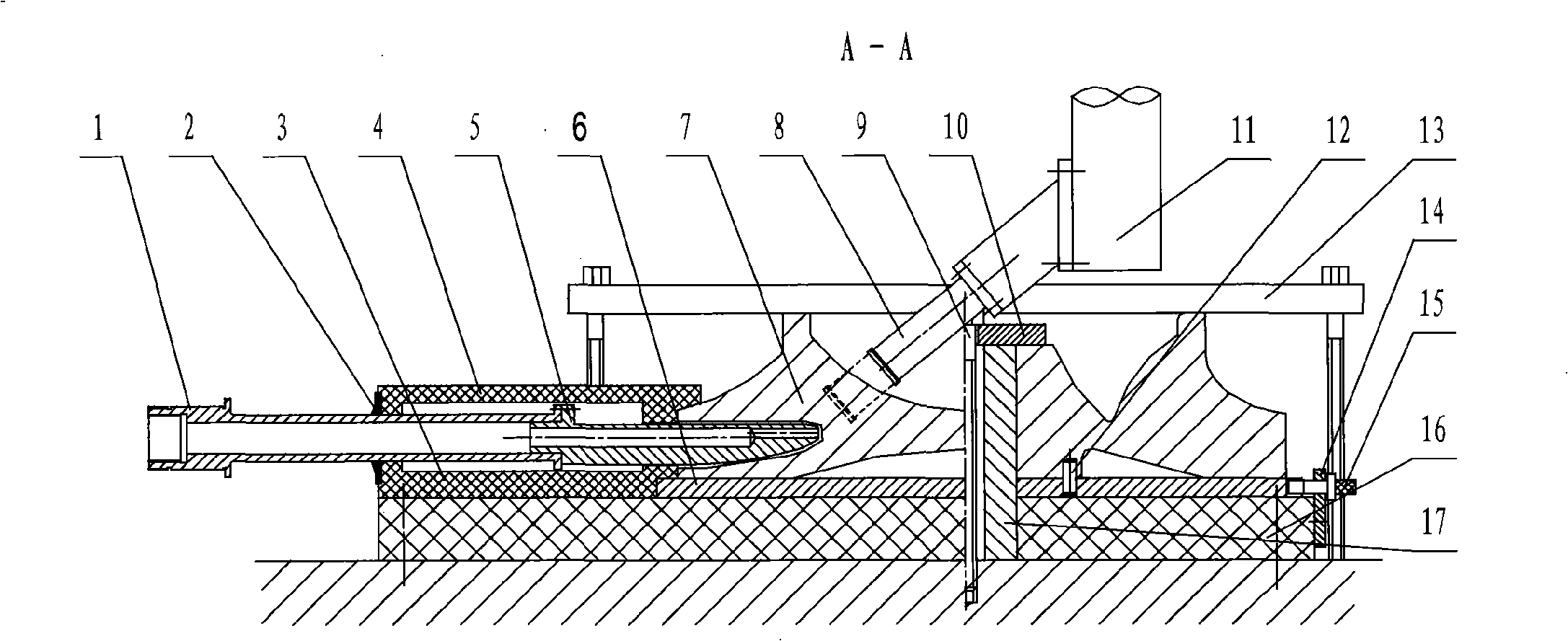

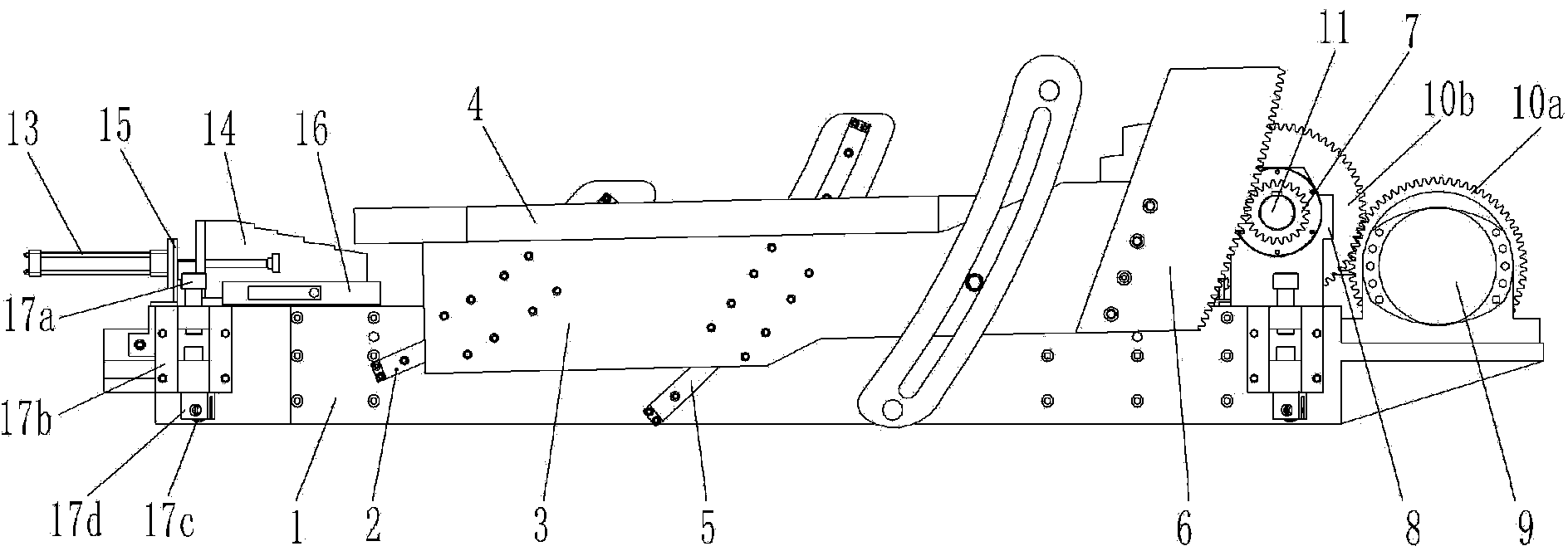

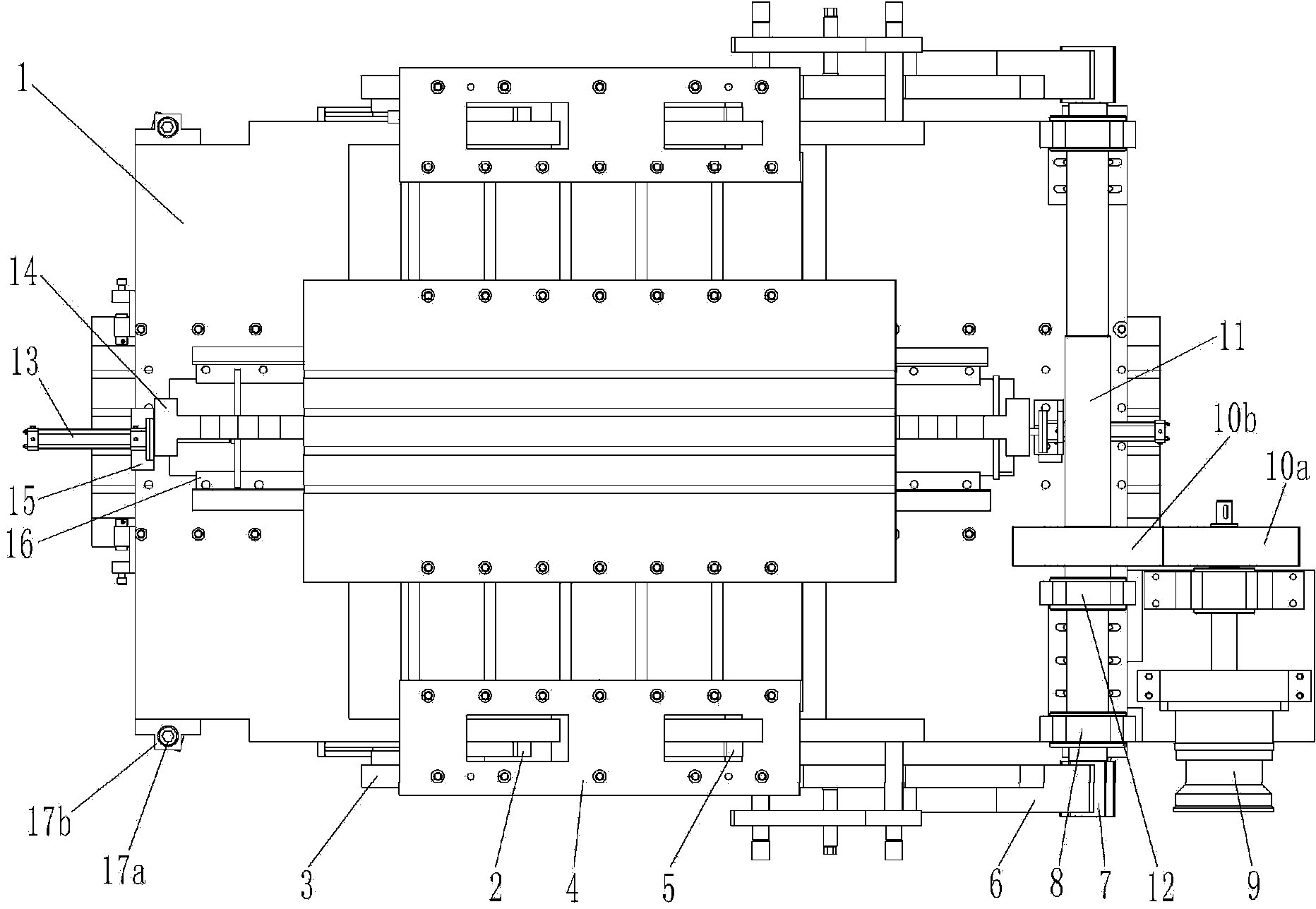

Variable attack angel apparatus for wind tunnel test of aircraft engine model

InactiveCN104019959AUniform flow fieldThe results of the wind tunnel test are accurateAerodynamic testingHydraulic motorInlet channel

Disclosed is a variable attack angel apparatus for a wind tunnel test of an aircraft engine model. A hydraulic motor is fixed to the right side of a frame, the rotation shaft of the hydraulic motor is connected with a first gear, the first gear is engaged with a second gear, the second gear and a third gear are fixed on a transmission shaft, the transmission shaft is fixed on the frame through a first bearing and a second bearing, the front side and the back side of the frame are connected with a mobile side plate respectively through a left arc guide pair and a right arc guide pair, the mobile side plate is fixedly connected with a workbench, a sector gear is fixed on the upper end surface of the right end of the mobile side plate, the third gear is engaged with the sector gear, the frame is provided with a self-lock mechanism, running mechanisms are installed at four corners of the frame, and the circle center of the left arc guide pair, the circle center of the right arc guide pair and the circle center of the sector gear are concentric and are disposed on a middle transverse line at the port surface of an inlet channel of the engine model. The variable attach angle apparatus can enable the attack angel of the engine model to be dynamically changed, and enables the result of the wind tunnel test of the aircraft engine model to be more accurate and reliable.

Owner:SOUTHWEST JIAOTONG UNIV

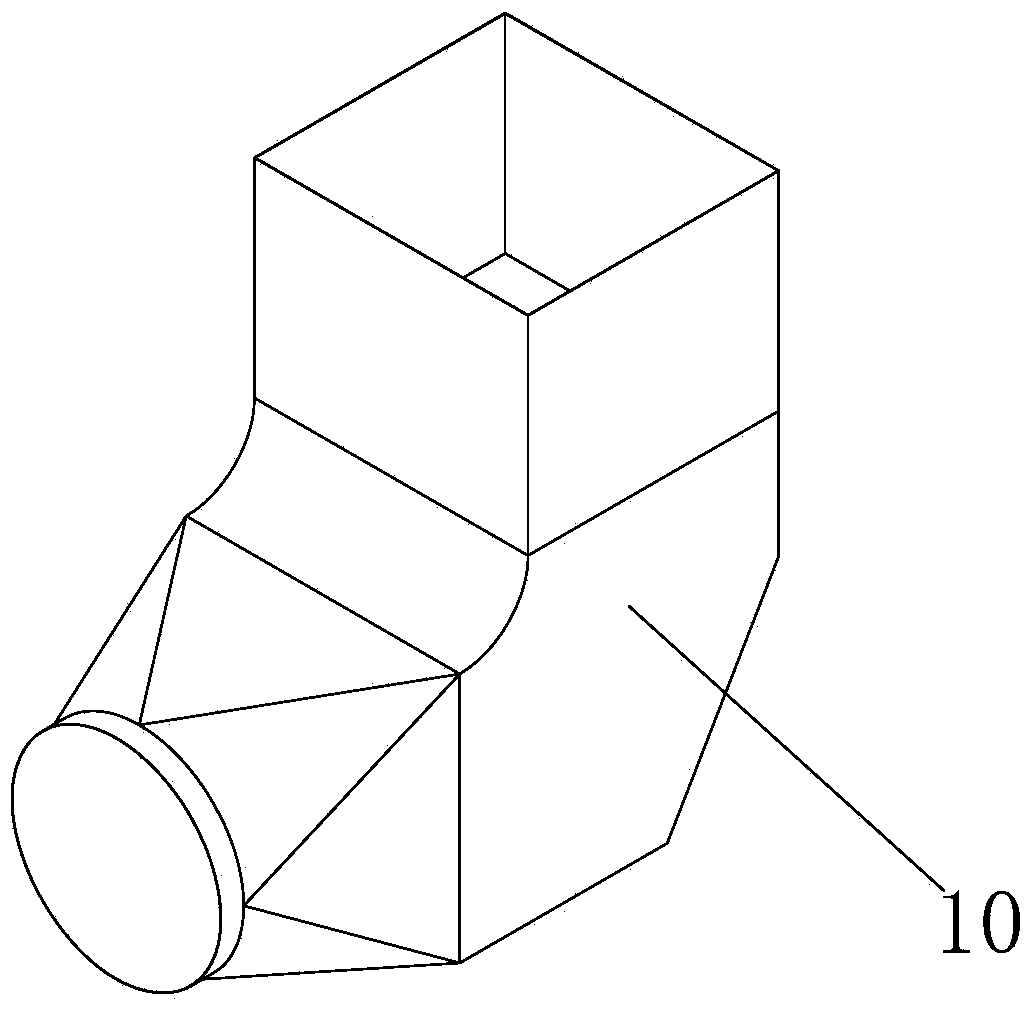

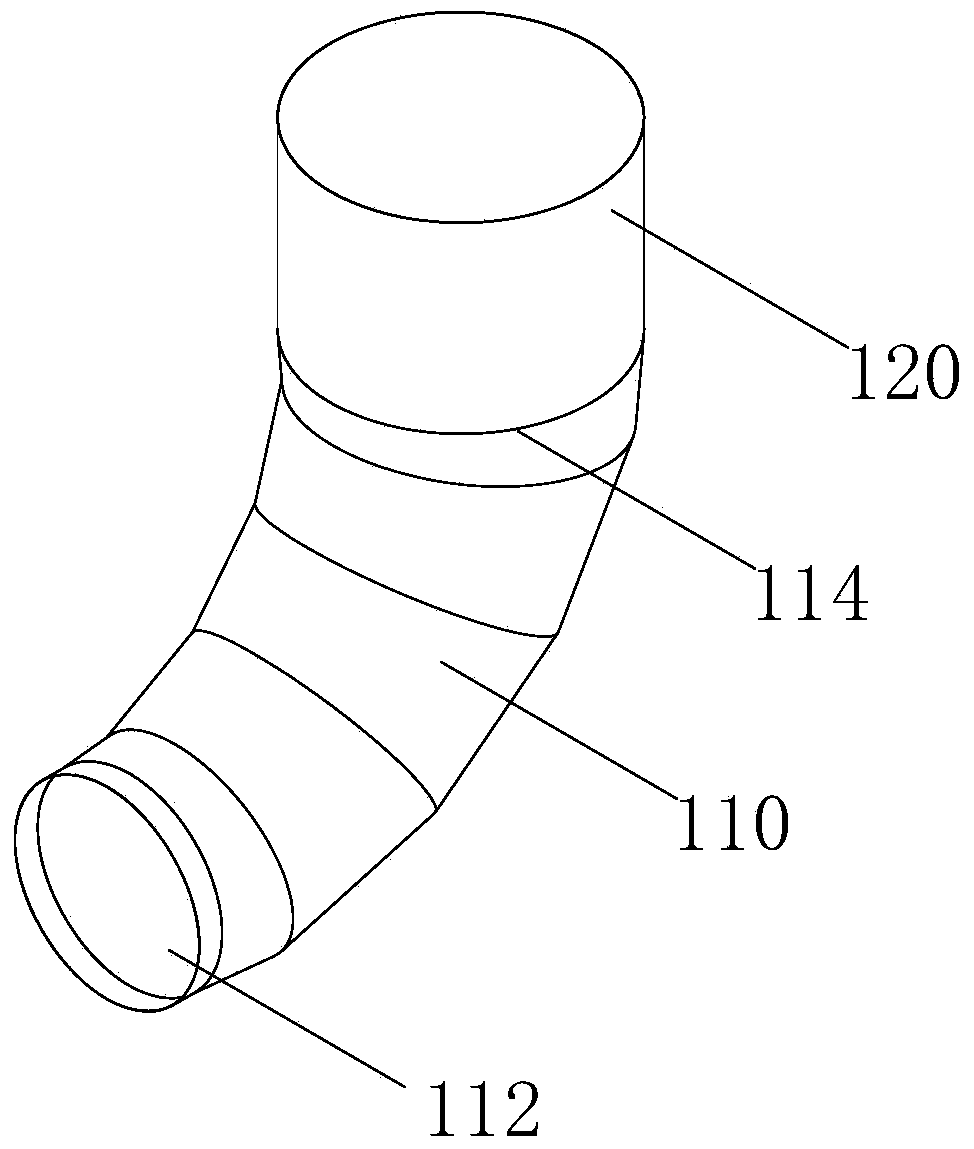

Smoke duct device and reducing elbow thereof

The invention discloses a reducing elbow which comprises a reducing section and a body section. The cross section of the reducing section and the cross section of the body section are circular, the reducing section comprises a large end and a small end, the diameter of the reducing section is gradually enlarged from the small end to the large end, the reducing section is curved, the large end of the reducing section is communicated with the body section, and the ratio of the curved radius of the reducing section to the diameter of the small end is 1.0-3.0. The cross section of the reducing section and the cross section of the body section are circular, the diameter of the reducing section is gradually enlarged from the small end to the large end, the reducing section is curved, the large end of the reducing section is communicated with the body section, and therefore reducing and turning are achieved synchronously, reducing has the enough diffusion section, turning has the enough turning radius, the reducing elbow is even in smoke flow field, and a smoke duct body is prevented from vibrating to generate noise. The conclusion that the resistance generated by the reducing elbow is far smaller than that generated by a traditional rectangular reducing elbow is obtained through FLUENT fluid simulation software analog computation. The invention further discloses a smoke duct device.

Owner:CHINA ENERGY ENG GRP GUANGDONG ELECTRIC POWER DESIGN INST CO LTD

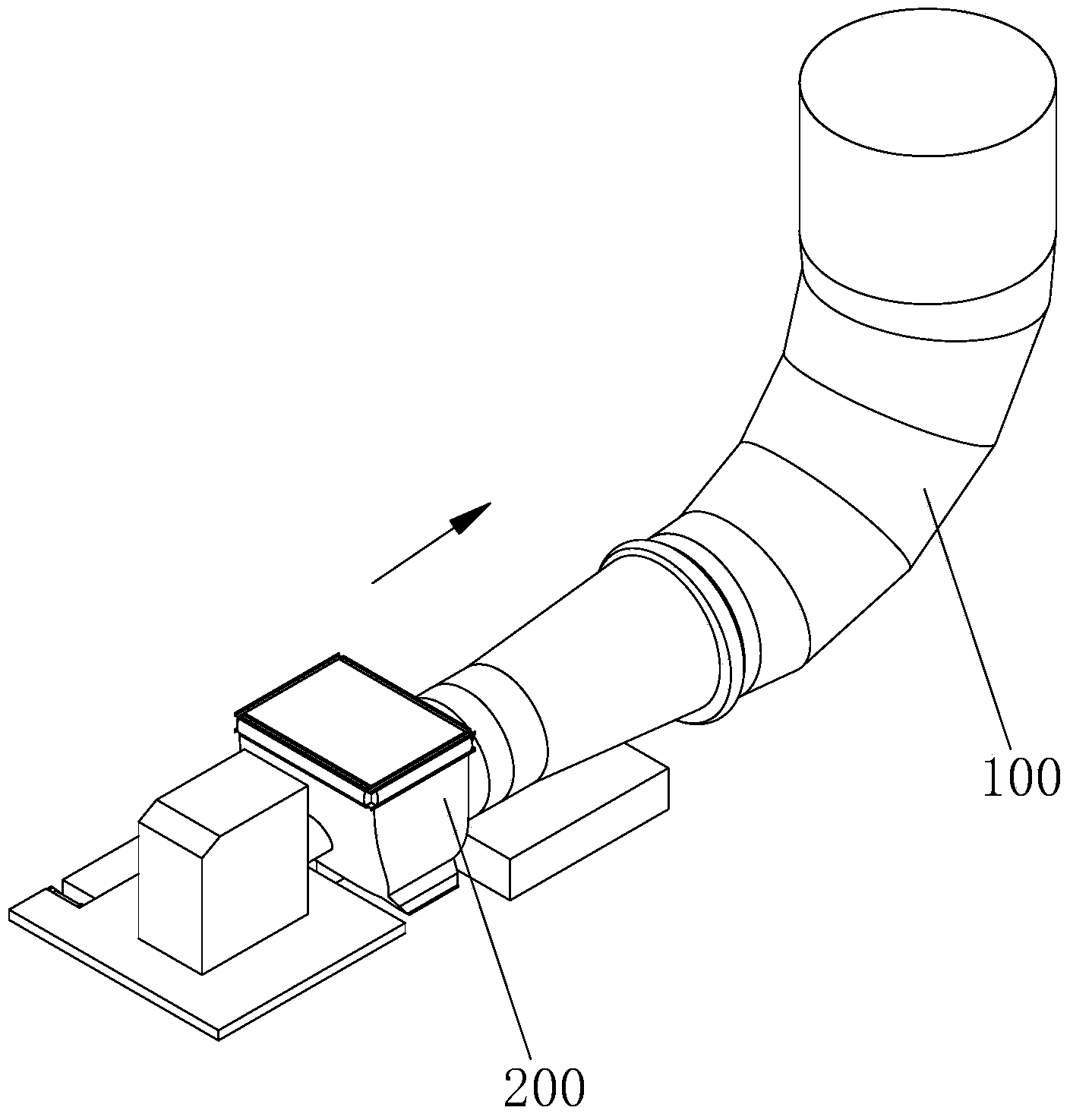

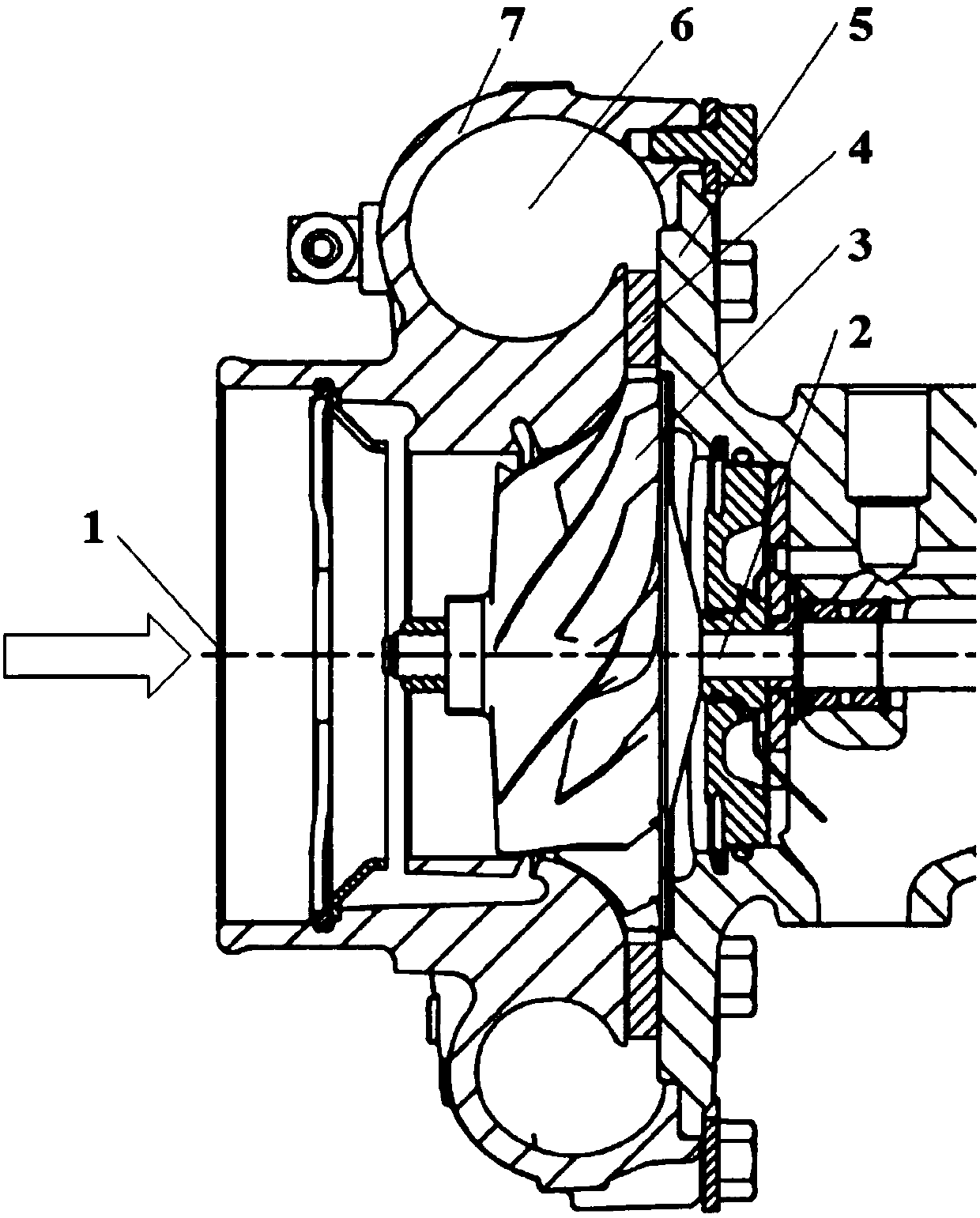

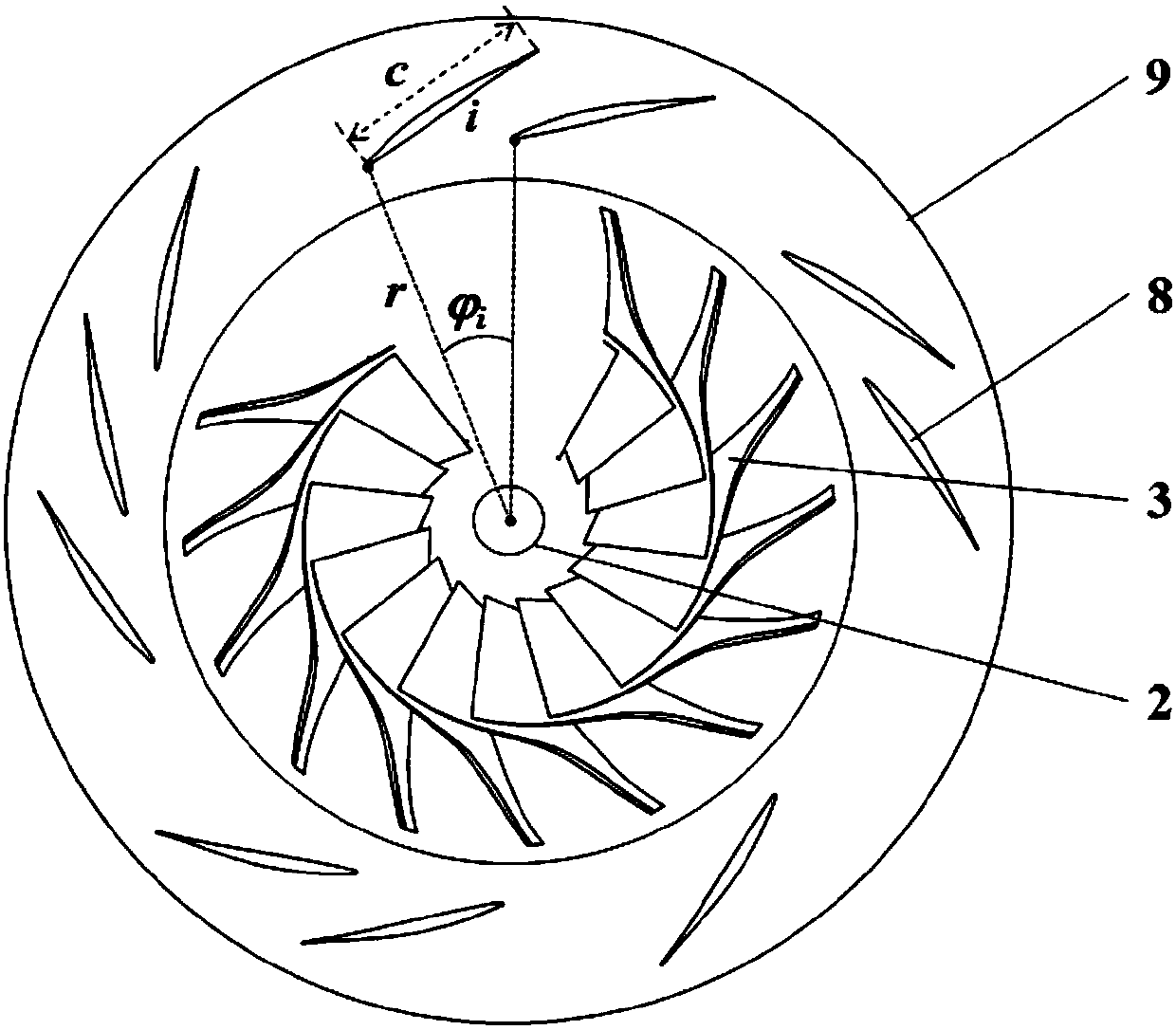

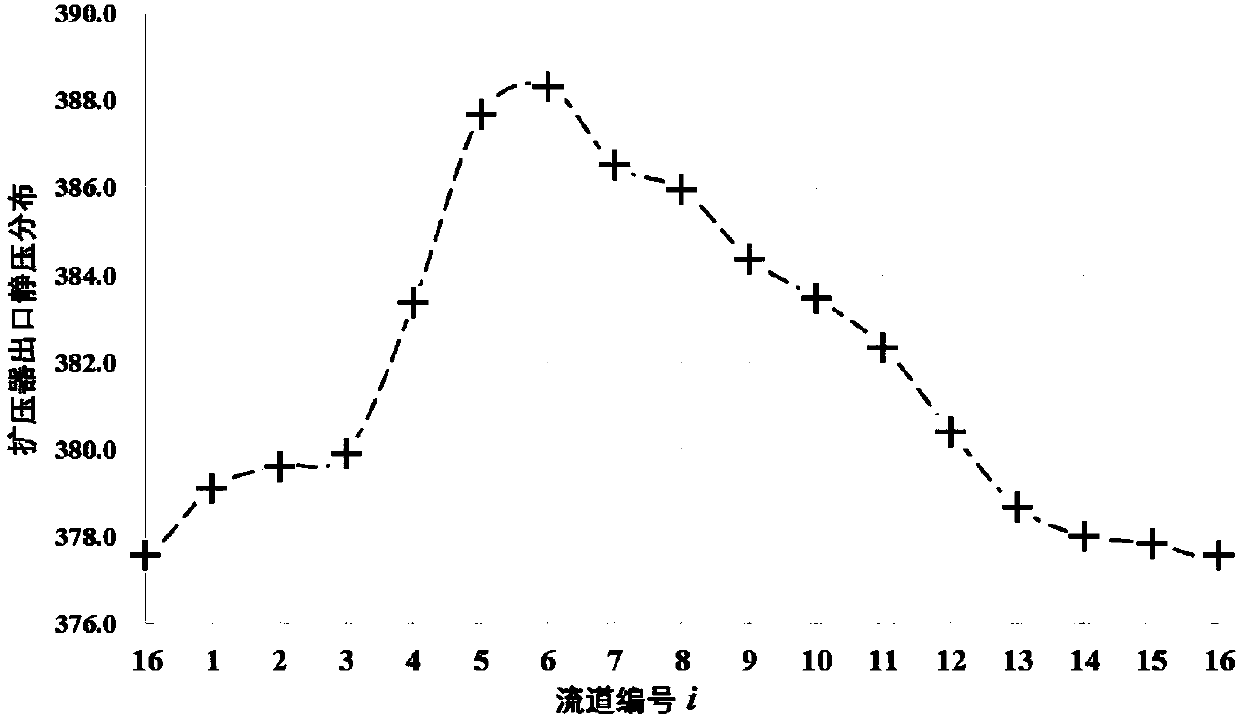

Centrifugal compressor using asymmetrical bladed diffuser with variable blade consistencies in circumferential direction

ActiveCN107061368AImprove flow field structureImprove performancePump componentsPumpsEngineeringFront edge

The invention relates to a centrifugal compressor using an asymmetrical bladed diffuser with variable blade consistencies in the circumferential direction, and belongs to the technical field of turbomachinery. The centrifugal compressor comprises a volute, a centrifugal impeller and the bladed diffuser. The inlet front edge positions and the bladed mounting angles are evenly distributed in the circumferential direction, the blade consistencies are asymmetrically distributed in the circumferential direction, and the consistencies are unequal in different circumferential positions. The blade consistencies are changed by changing the central angles (namely the front edge interval between every two adjacent blades) corresponding to flow channels. The compressor can effectively adapt to the downstream circumferential pressure distortion of the bladed diffuser, the nonuniformity of a flow field in the bladed diffuser is reduced, the flowing stability of the centrifugal compressor is effectively improved, and the stable working range of the centrifugal compressor is enlarged.

Owner:TSINGHUA UNIV +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com