Electrolysis machining process method and tool fixture of equal-thickness arc-shaped end face impeller

A processing method and arc-shaped end technology, applied in the field of CNC electrolytic machining, can solve the problems of secondary processing, undiscovered, and low processing efficiency, and achieve the effects of eliminating stress concentration, improving electrolytic processing efficiency, and improving processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0052] The following is a detailed description of the electrolytic machining process and fixture for an equal-thickness arc-shaped end face impeller proposed by the present invention in conjunction with the accompanying drawings.

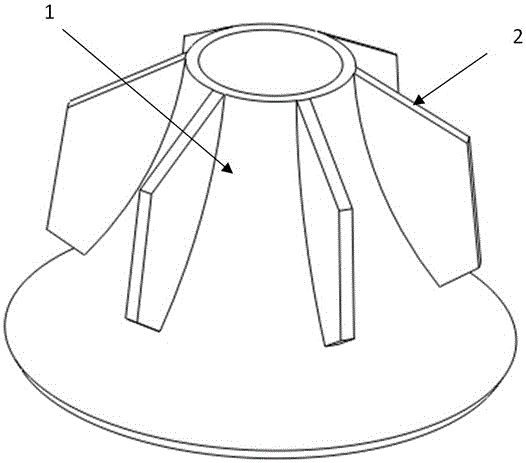

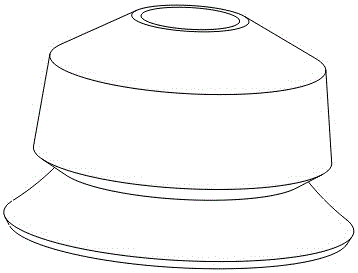

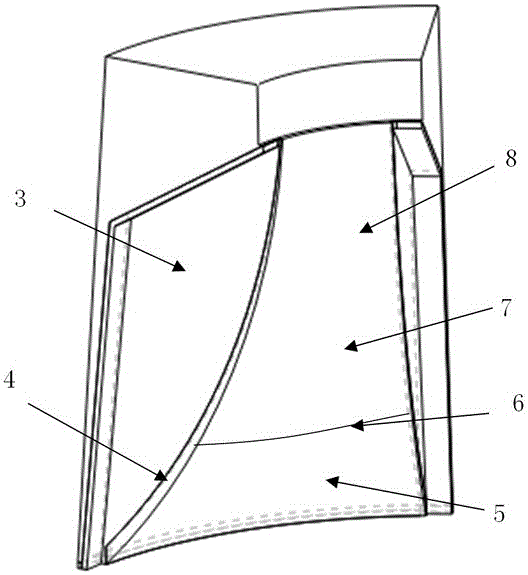

[0053] Such as figure 1 As shown, the electrolytic machining process of an equal-thickness arc-shaped end impeller of the present invention is mainly aimed at equal-thickness arc-end impellers with uniform blade thickness, no taper and curvature changes, small impeller size and thin blades , the base surface space between blades is small, which is suitable for electrolytic machining. On the basis of in-depth analysis of the local characteristics of the processed curved surface, the impeller is divided into two parts: the arc-shaped end surface matrix 1 and the thin-walled blade 2 between the blades. figure 2 For the impeller blank model used in the electrolytic machining method of the present invention, before the electrolytic machining, the numer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com