Patents

Literature

34results about How to "Improve ECM Efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

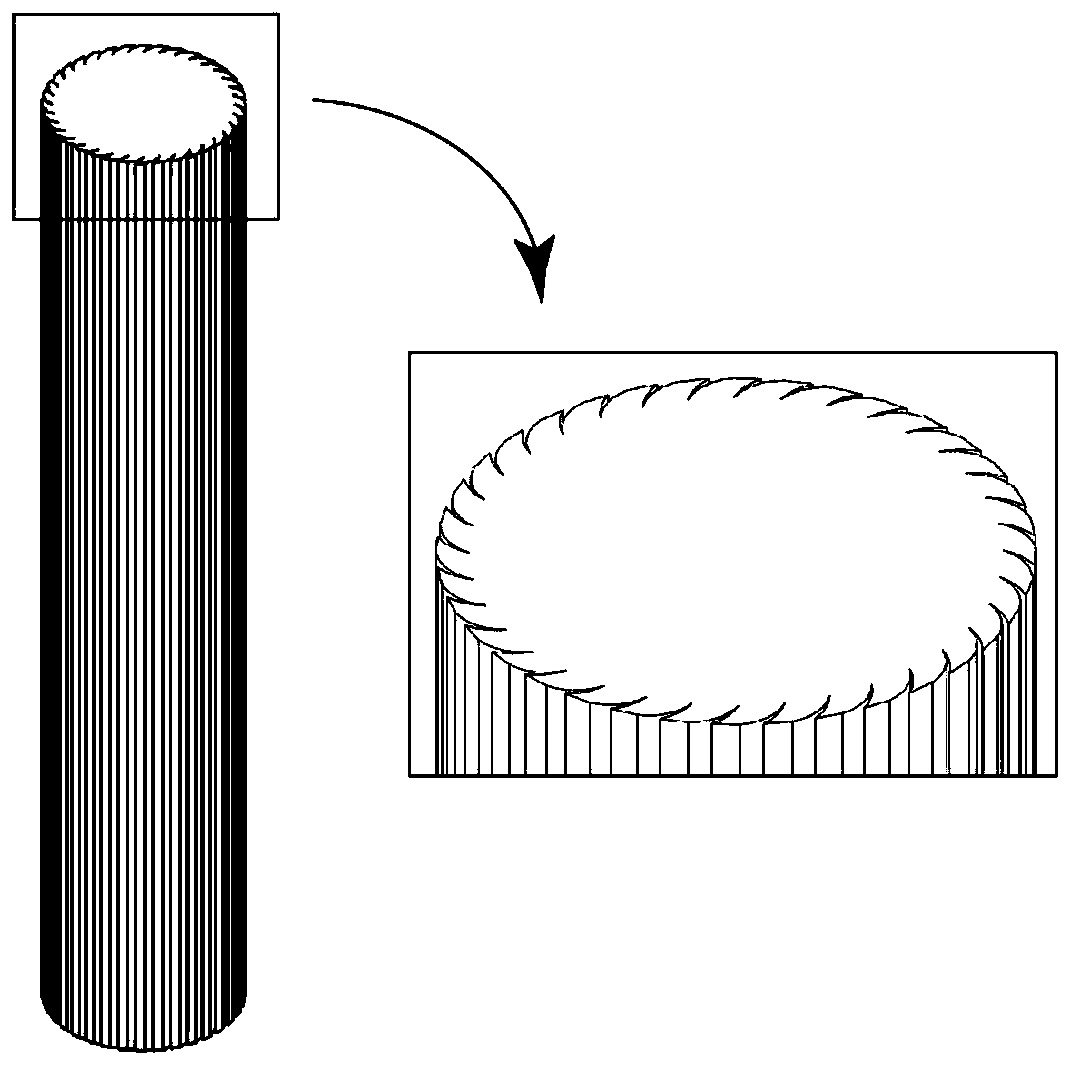

Electrolytic processing method for ribbed deep small holes and special tool cathode

InactiveCN1943951AImprove ECM EfficiencyEasy to prepareMachining electrodesElectrical-based machining electrodesMachining processSmall hole

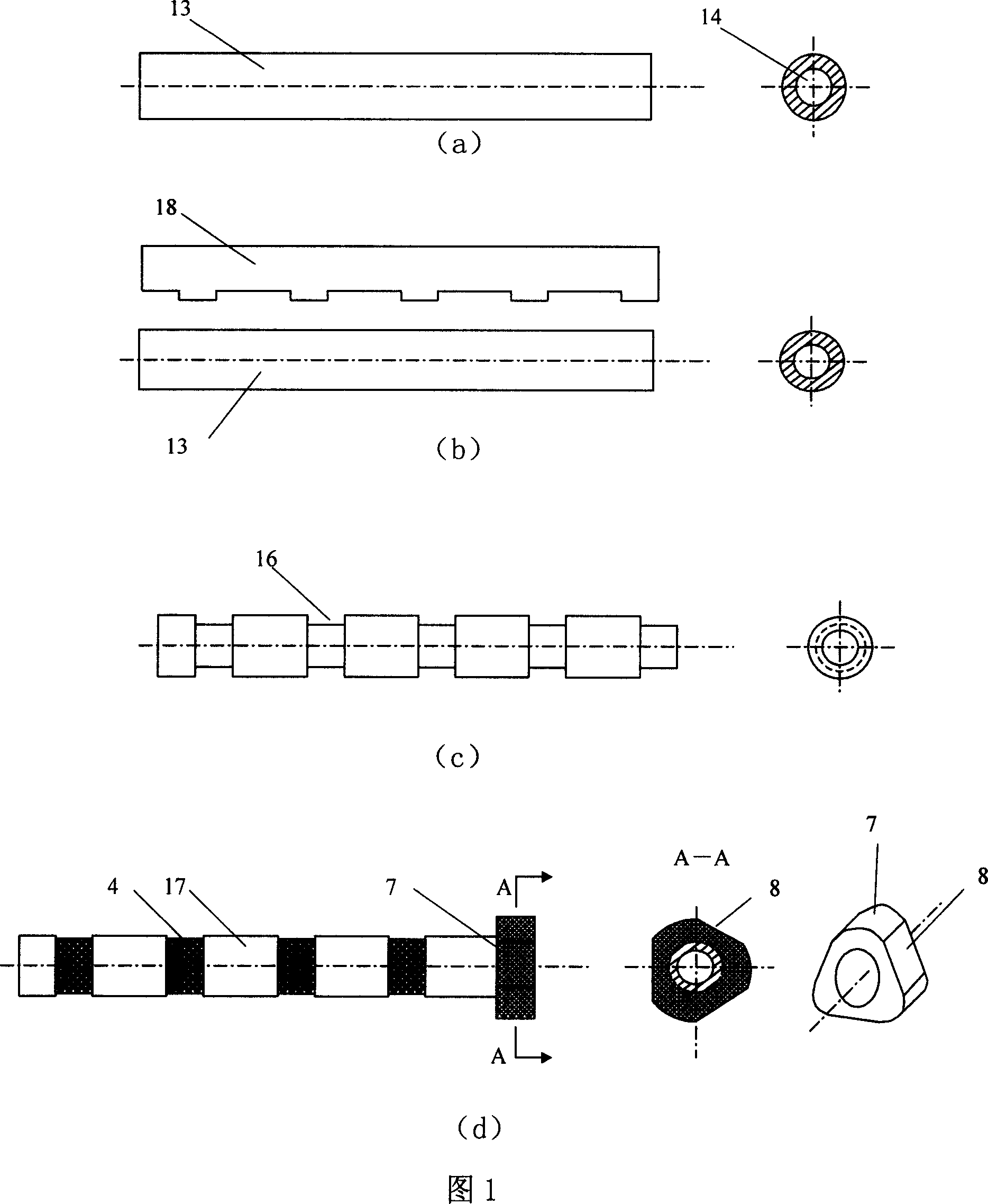

The present invention is electrolytic processing method for ribbed deep small hole and its special tool cathode, and belongs to the field of electrolytic machining technology. The method includes the following steps: electrolytic machining one metal pipe with one reversely copied cathode to form notches in the surface of the metal pipe; coating epoxy resin glue into the notches; installing positioning rack to the end of the tool electrode to make the forming tool electrode; machining smooth hole in the workpiece; stretching the forming tool electrode into the deep smooth hole to machine the ribbed deep small hole. The present invention has simple machining of the forming tool electrode, high ribbed hole machining precision, high machining stability and other advantages.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

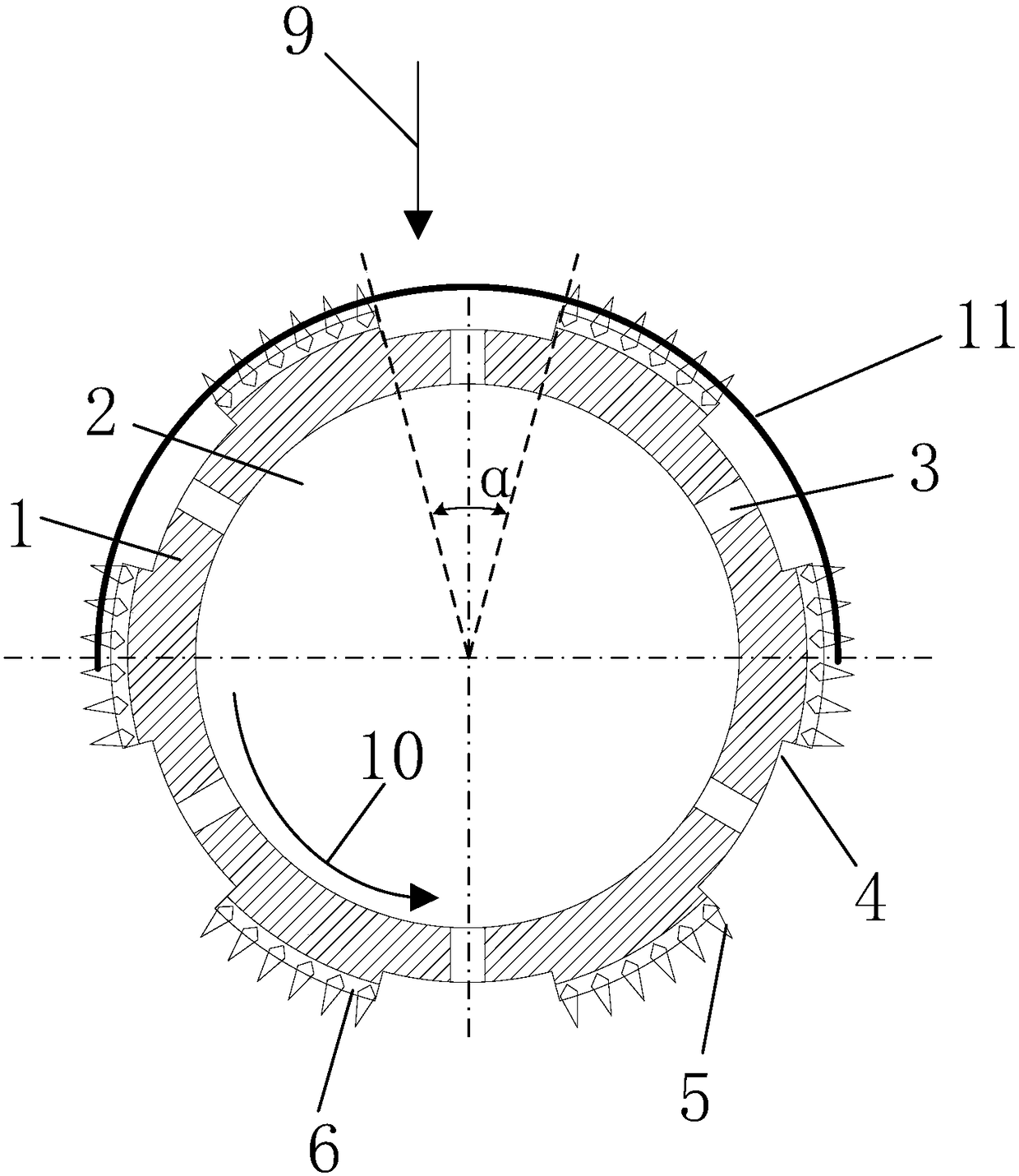

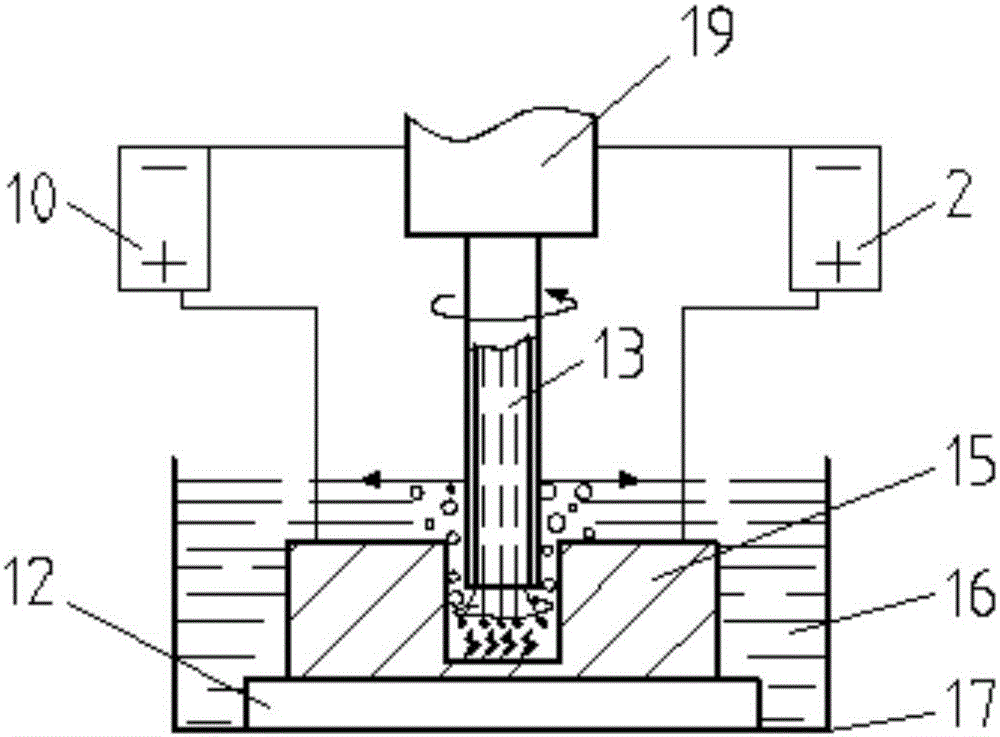

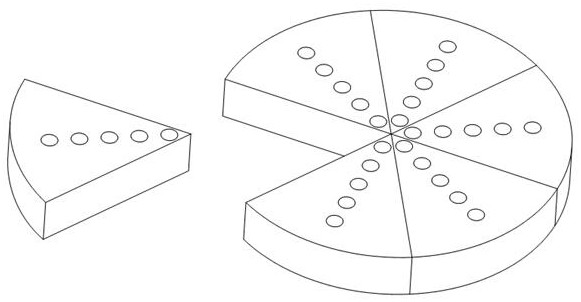

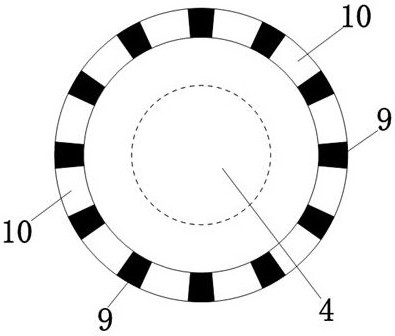

Electrolytic milling-grinding machining tool cathode with efficiency and precision and electrolytic milling-grinding method

The invention relates to an electrolytic milling-grinding machining tool cathode with efficiency and precision and an electrolytic milling-grinding method, and belongs to the field of electrolytic milling-grinding composite machining. According to the electrolytic milling-grinding machining tool cathode and the electrolytic milling-grinding method, a plurality of arc-shaped grooves at equal intervals are formed in the lower end of the side wall of the tool cathode, the side walls of the grooves are insulated, and diamond abrasive particles are inlaid in the wall surfaces of the portions, except for the grooves, of the side wall of a cathode base body through a resin binder, so that electrochemical anodic dissolution only exists in the surfaces of the portions, opposite to the grooves, of aworkpiece, at the moment, the depths of the grooves become a part of a machining gap, accordingly the contact depth between the diamond abrasive particles in the portions, except for the grooves, ofthe side wall of the cathode base body and the machining surface of the workpiece is increased, then the grinding effect of the diamond abrasive particles on the workpiece in the electrolytic milling-grinding process is enhanced, and the precision and the surface quality of the electrolytic milling-grinding machining can be improved; and moreover, compared with the electrolytic milling-grinding finish machining under the low current density in the past, the tool cathode can adopt higher current density, and the machining efficiency can be improved.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

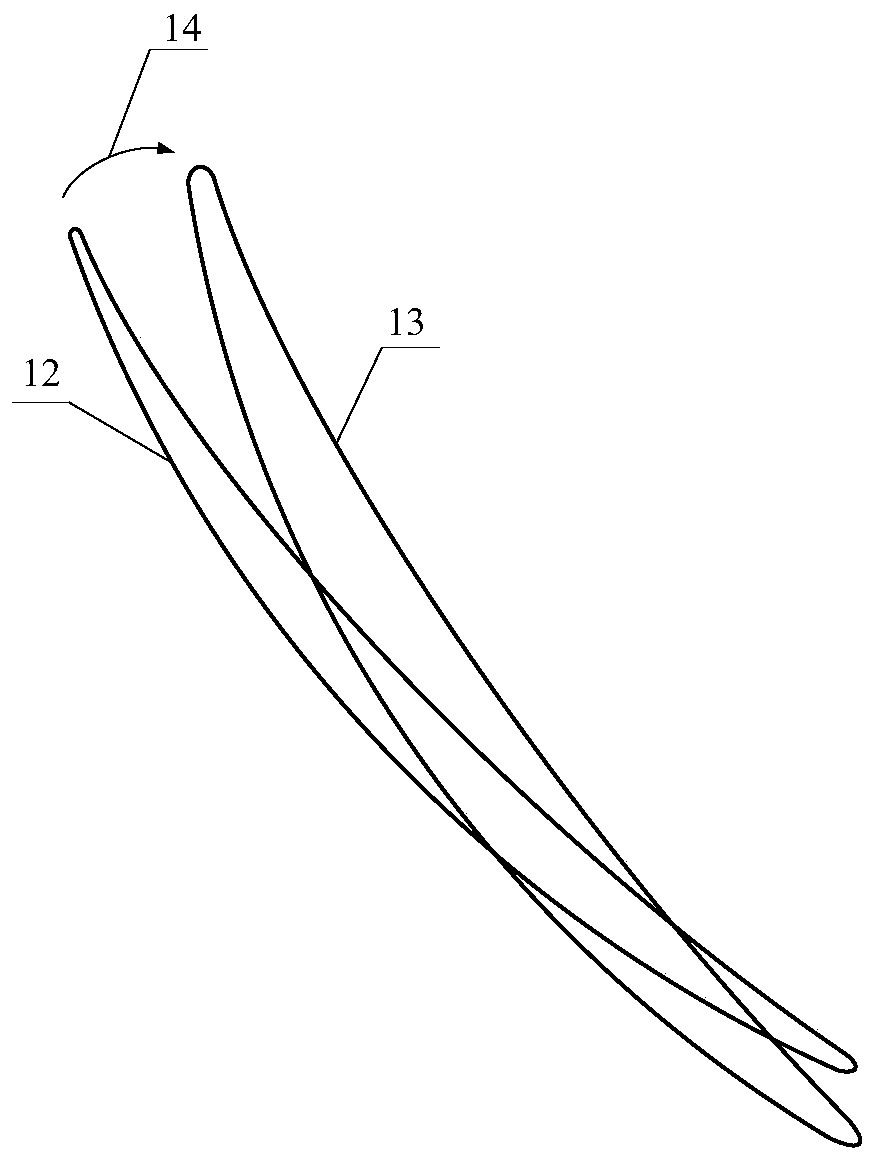

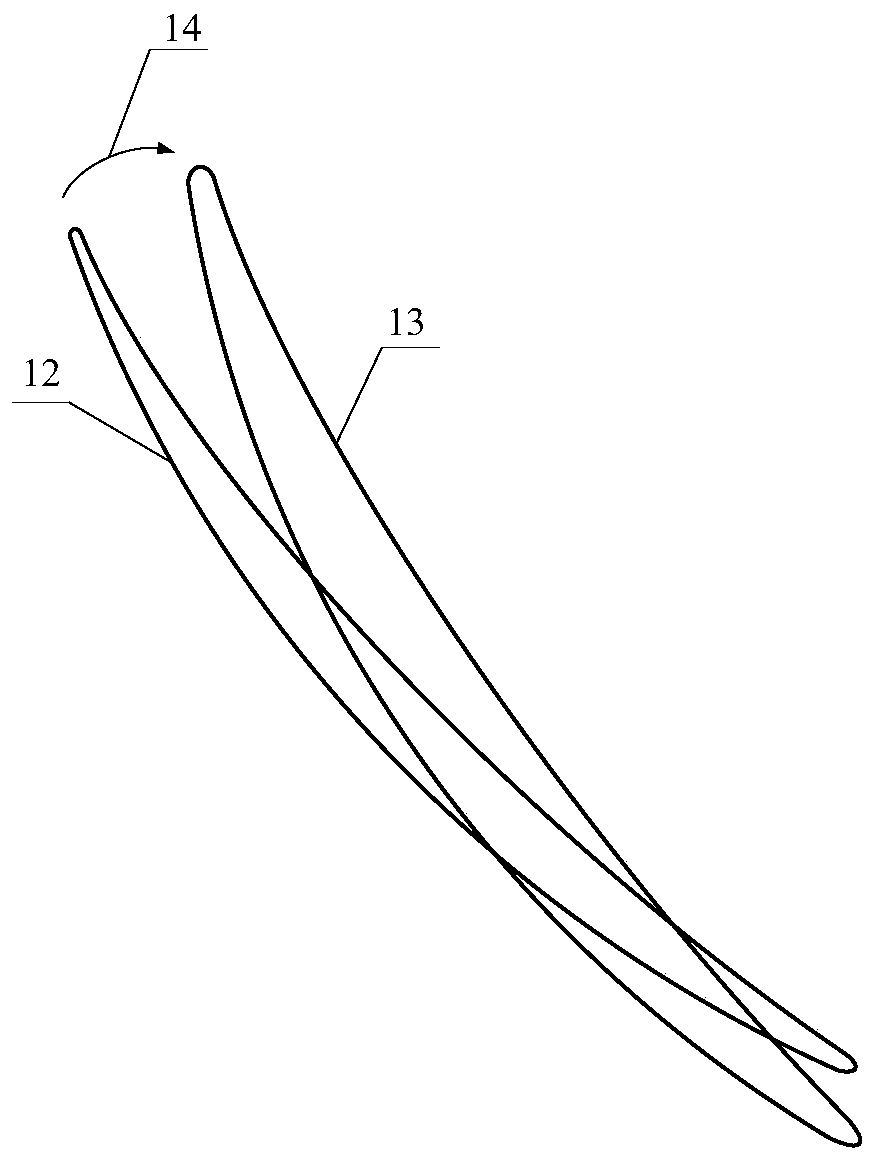

Non-uniform-speed double-rotation variable-machining-blade cathode blisk electrolytic machining method

ActiveCN110605445AImprove machining accuracyBalance evenly distributedElectrochemical machining apparatusDouble rotationRotation velocity

The invention discloses a non-uniform-speed double-rotation variable-machining-blade cathode blisk electrolytic machining method. The method comprises the following steps that a rotating feeding shaftof a tool cathode is determined through simulation solution; the rotation angles and the rotation speeds of the tool cathode at different positions are determined through simulation solution, and themotion track of the tool cathode simulation is obtained; the rotation direction, the rotation angle and the rotation speed of a blisk blank is determined through simulation solution; a machining blade of the tool cathode is designed to be a variable-width machining blade; the tool cathode is driven to perform one-way variable-speed rotating radial feeding from the tool setting position along therotating feeding shaft according to the motion track of the simulation by taking the twisting direction of a blisk design model blade profile as the rotation direction; and the blisk blank is driven to cooperate with the variable-direction variable-speed rotation of the tool cathode around the central axis according to the rotation direction, the rotation speed and the rotation angle of simulationoptimization, and a blade lattice channel is formed on the blisk blank. According to the method, the electrolytically-formed blade lattice channel is uniform in allowance distribution and high in surface machining quality, and precise electrolytic machining of the blade lattice channel of the blisk can be realized.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

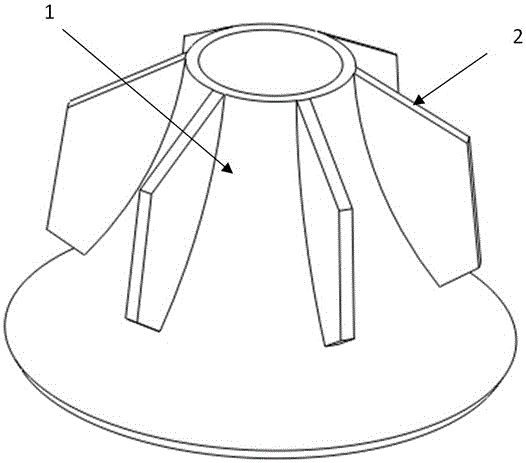

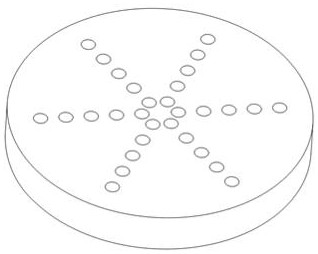

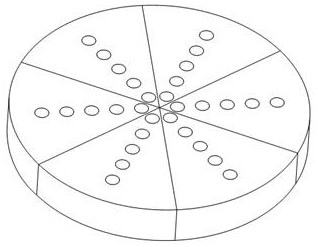

Electrolysis machining process method and tool fixture of equal-thickness arc-shaped end face impeller

ActiveCN106695032AImprove consistencyImprove ECM EfficiencyElectrochemical machining apparatusElectrical-based auxillary apparatusImpellerElectrolysis

The invention discloses an electrolysis machining process method and tool fixture of an equal-thickness arc-shaped end face impeller and belongs to the technical field of electrolysis machining. According to the electrolysis machining method, cathode blocks with the number being the same as that of blades are adopted and uniformly distributed along the center of the impeller, rapid feeding is performed in the axial direction of the impeller when machining is performed, and one-time machining and forming of the thin-wall blades and an arc-shaped end face base body of the overall impeller can be completed. Nearly-forming hook face radians at the bottom ends of the cathode blocks for machining are large, arc-shaped curved lines where the included angle theta i=30 degrees is located serve as boundaries to divide different areas, linear interpolation finishing is performed according to actual machining experience and machining results, and requirements for the normal direction and lateral balance can be met simultaneously. By means of the electrolysis machining method, one-time machining and forming of the overall impeller can be achieved, machining efficiency is improved, and high practical value is achieved.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

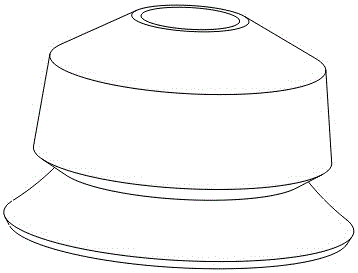

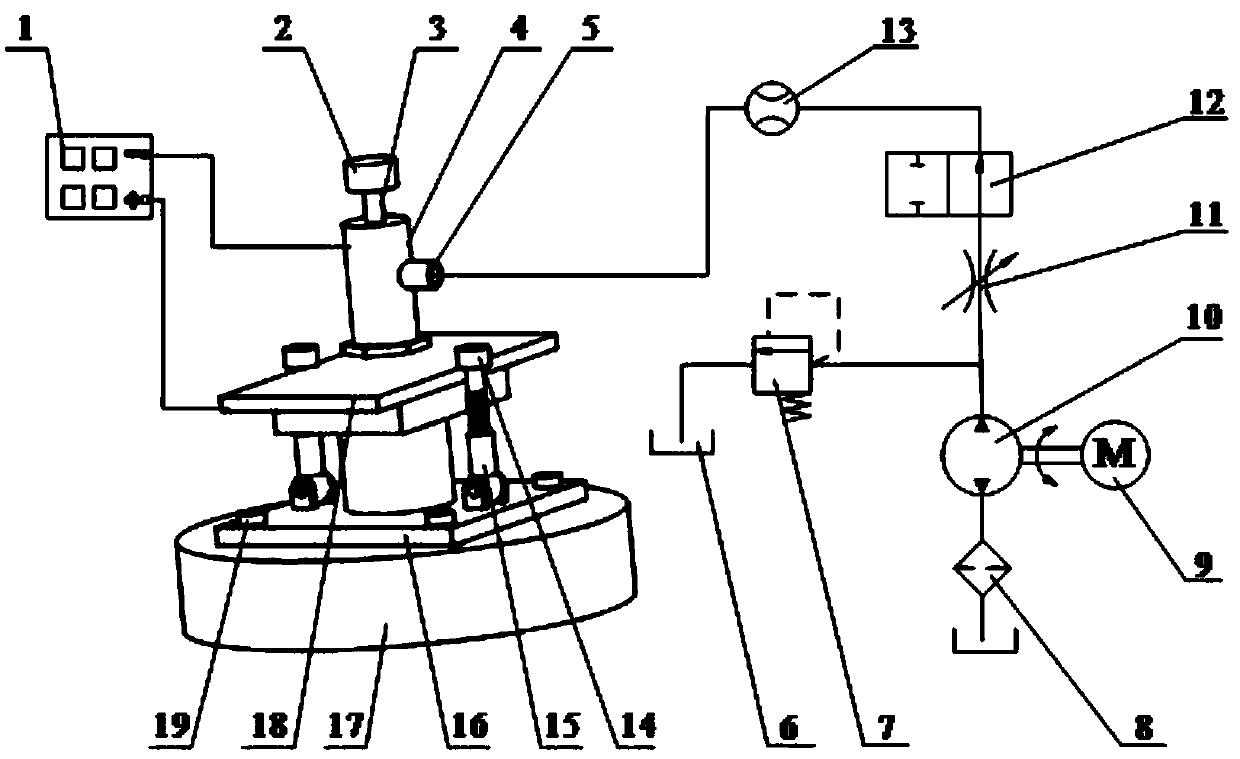

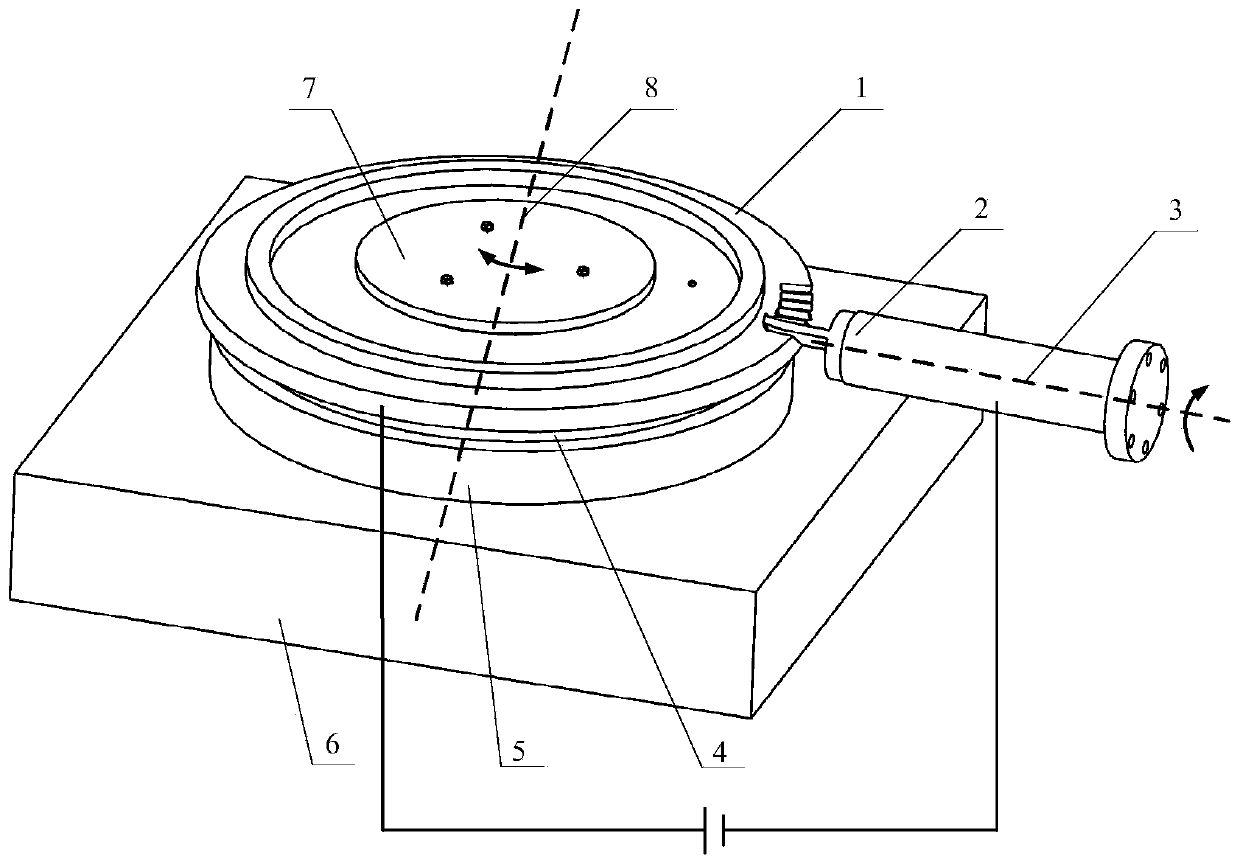

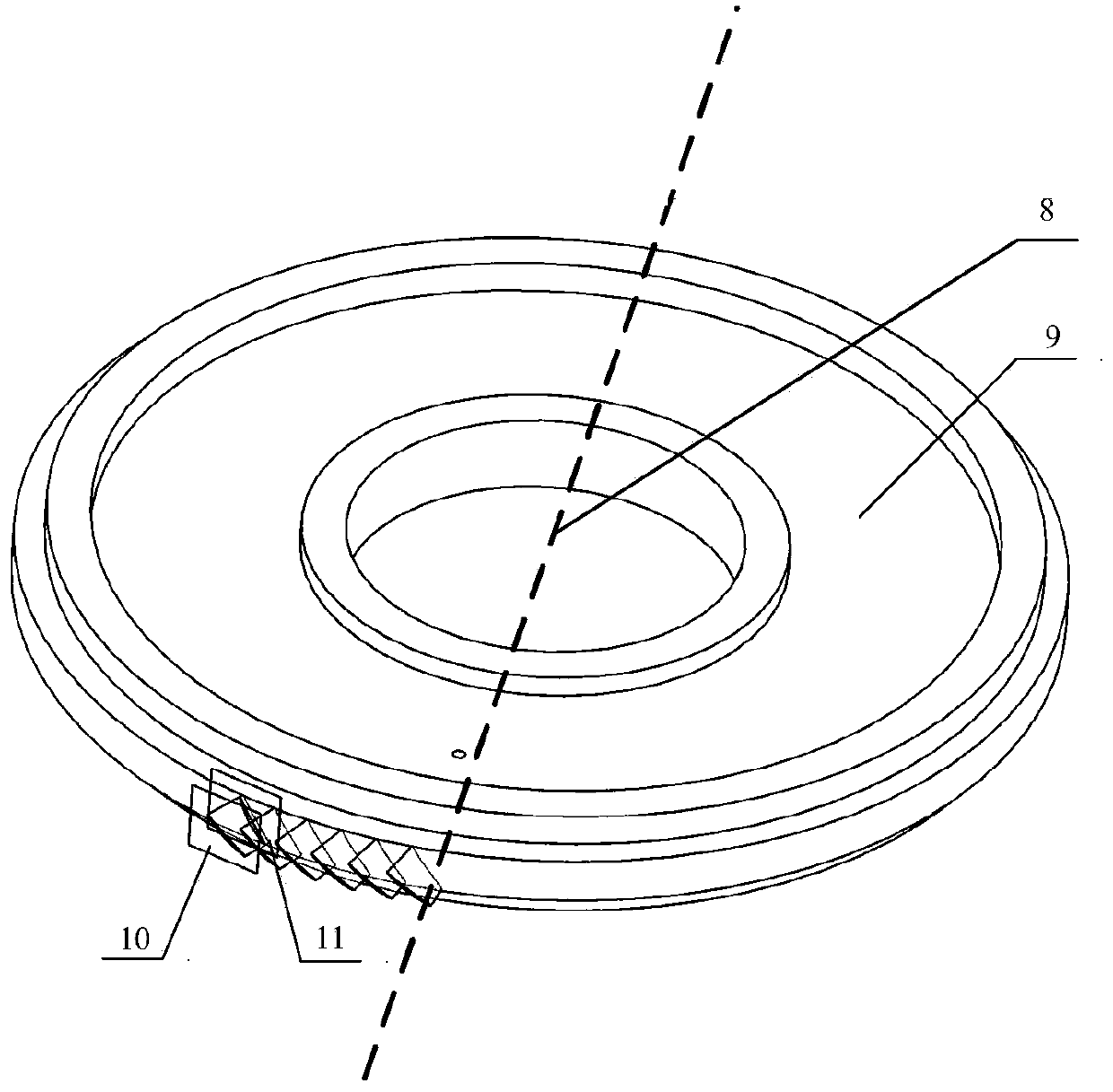

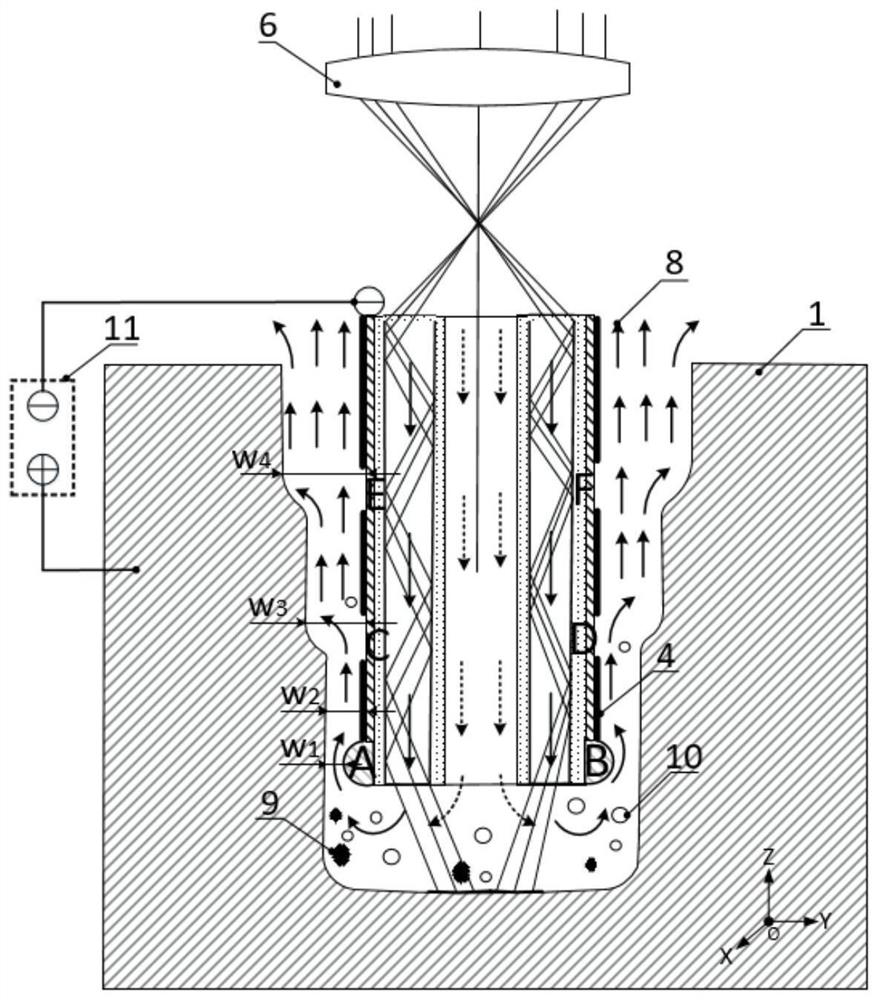

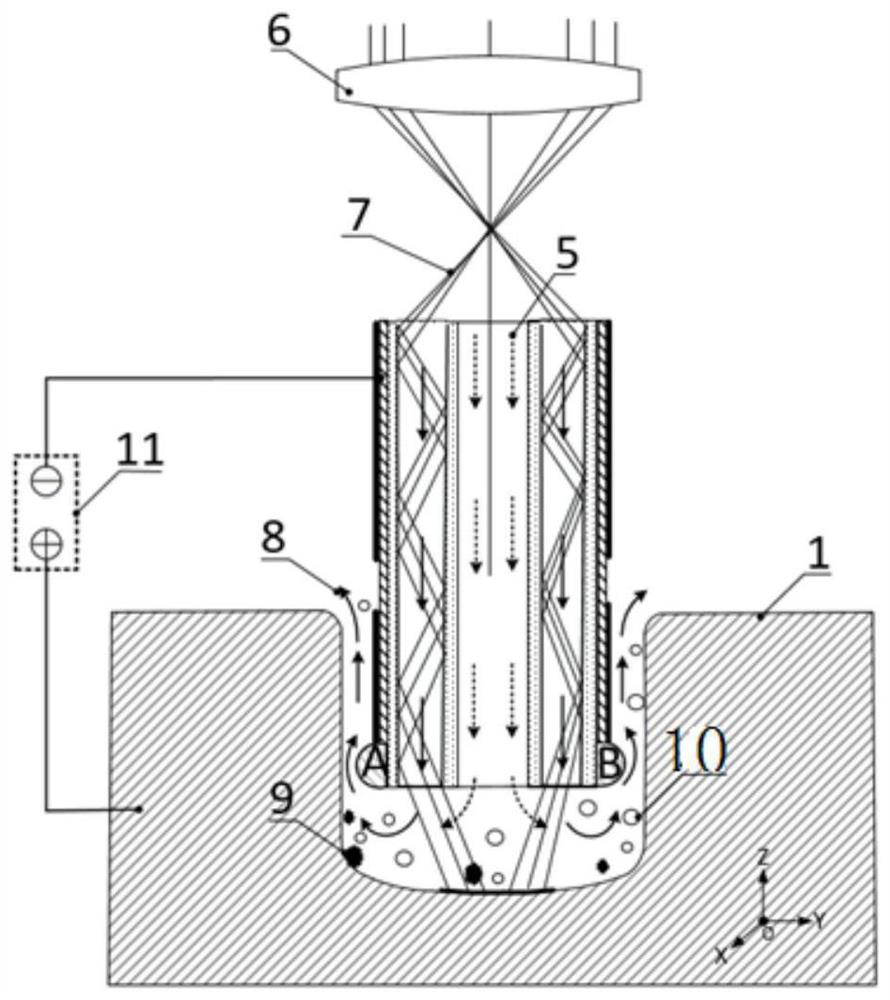

Specially-shaped blind hole rotating cathode electrolytic machining device

InactiveCN108672854AQuality improvementSimple structureMachining working media supply/regenerationElectrical-based auxillary apparatusElectrolysisEngineering

The invention discloses a specially-shaped blind hole rotating cathode electrolytic machining device. The specially-shaped blind hole rotating cathode electrolytic machining device comprises a tool cathode device, an electrolytic work fixture device, a workpiece and a machine tool system. The tool cathode device is controlled by a machine tool spindle to rotate, is provided with a rotatable rotarybody, and is used for stirring electrolyte. Electrolytic machining on a specially-shaped blind hole is completed through movement of the workpiece on the electrolytic work fixture device. The rotarytool cathode device comprises the rotary body, a cathode working head, a ceramic bearing and a carbon ring. The ceramic bearing is arranged outside the rotary body in a sleeving manner. The carbon ring is arranged between the rotary body and the ceramic bearing. According to the specially-shaped blind hole rotating cathode electrolytic machining device, a cathode is controlled by the machine toolspindle to rotate to stir the electrolyte so as to enable a fluid field to be uniform; a series of machining is achieved through movement of the workpiece on a tool, so that electrolytic machining onthe specially-shaped blind hole is completed; the device is simple in structure, uniform in fluid field, high in machining efficiency and capable of achieving blind hole machining, and has wide practical value.

Owner:CHANGZHOU INST OF TECH +1

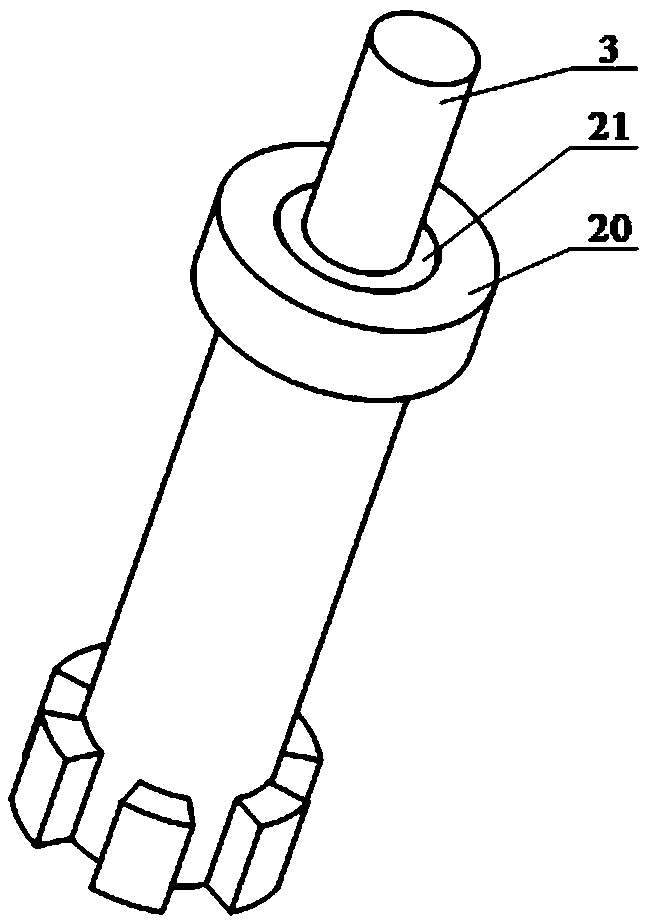

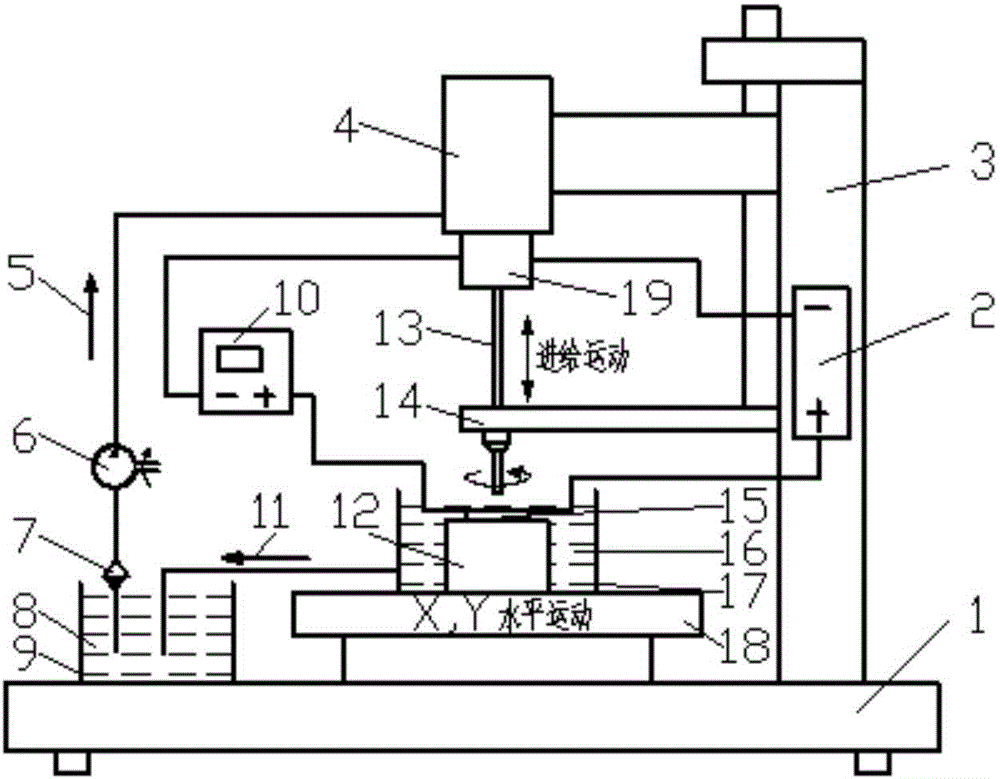

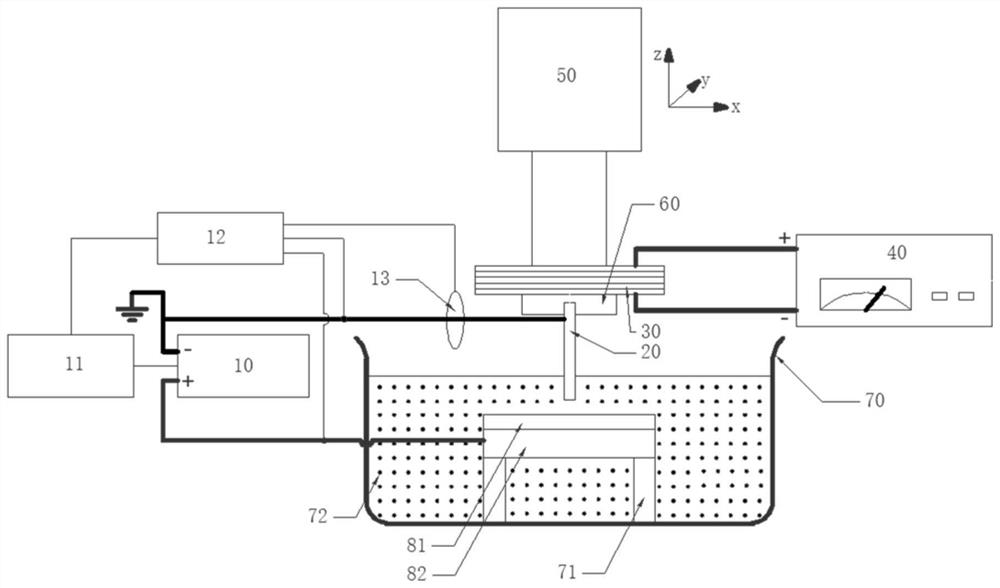

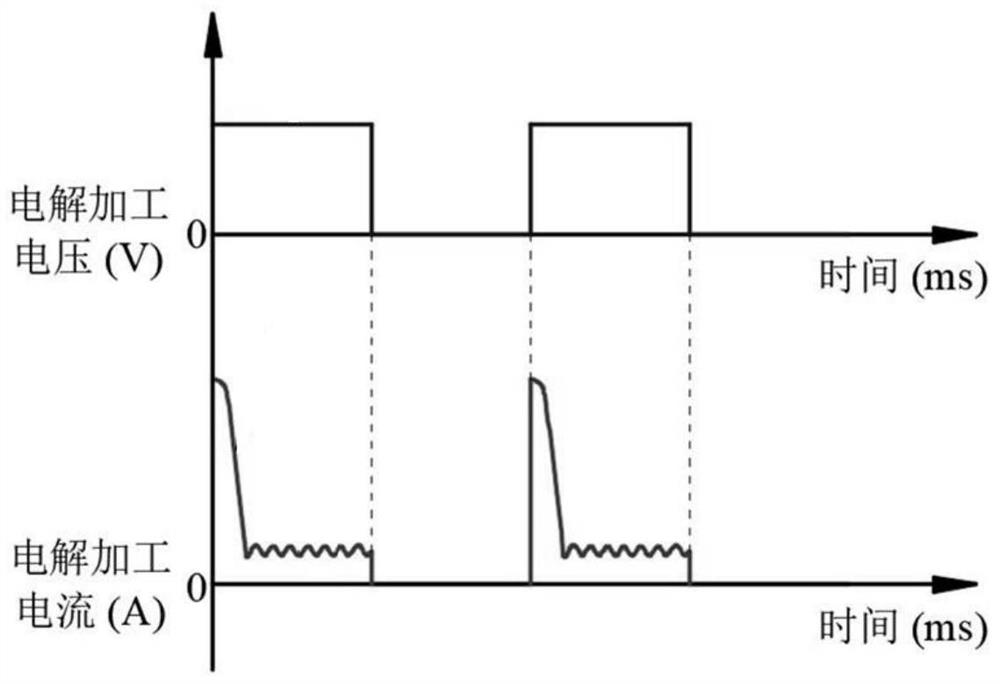

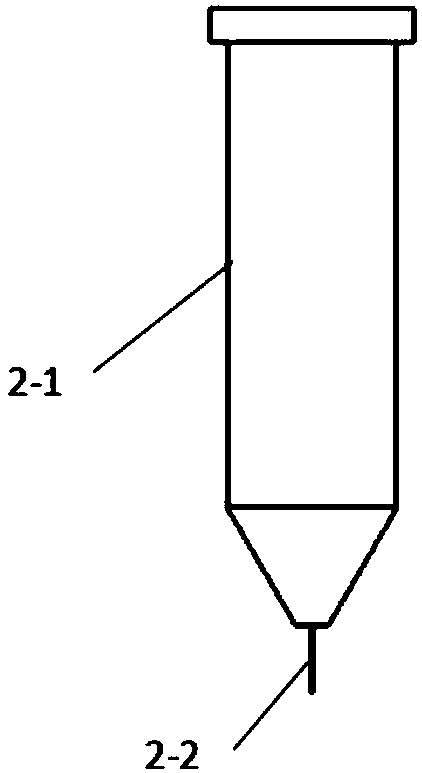

Micro hole machining method and equipment

The invention provides a micro hole machining method and equipment and belongs to the technical field of specially machining micro holes. The two ends of a tube electrode and the two ends of a machining workpiece are connected with double power supplies including an electrical discharge machining power supply and an electrochemical machining power supply respectively; and electrolysis and electrical discharge composite controllable machining is realized by controlling machining parameters of the electrical discharge machining power supply and the electrochemical machining power supply. According to the micro hole machining method and equipment, a recast layer and a burr generated by singly electrical discharge machining the micro hole can be removed, and the efficiency and the machining accuracy when the micro hole is singly electrical discharge machined are improved; and better quality of the machined surface of the micro hole as well as higher machining efficiency and machining accuracy can be obtained.

Owner:ANHUI UNIV OF SCI & TECH

Electrolytic machining process method of open type blisk

ActiveCN112191962AEnsure stabilityGuaranteed continuityFiling/rasping toolsElectrochemical machining apparatusPoly ether ether ketoneElectrolysis

The invention provides an electrolytic machining process method for an open type blisk. The electrolytic machining process method comprises the following steps of performing electrolytic machining bytaking the open type blisk as a workpiece anode, taking a machining tool as a tool cathode, connecting the workpiece anode with a power supply anode and connecting the tool cathode with a power supplycathode, wherein an insulating layer on the tool cathode is made of thermosetting polyether-ether-ketone. Stable and continuous electrolytic machining of the open type blisk is achieved, it is guaranteed that the machining precision and the machining quality of the blade profile meet the technological design requirements, and the defects that an existing open type blisk electrolytic machining process is frequently interrupted, short-circuit faults are prone to occurring, and the electrolytic machining efficiency is low are overcome.

Owner:AECC AVIATION POWER CO LTD

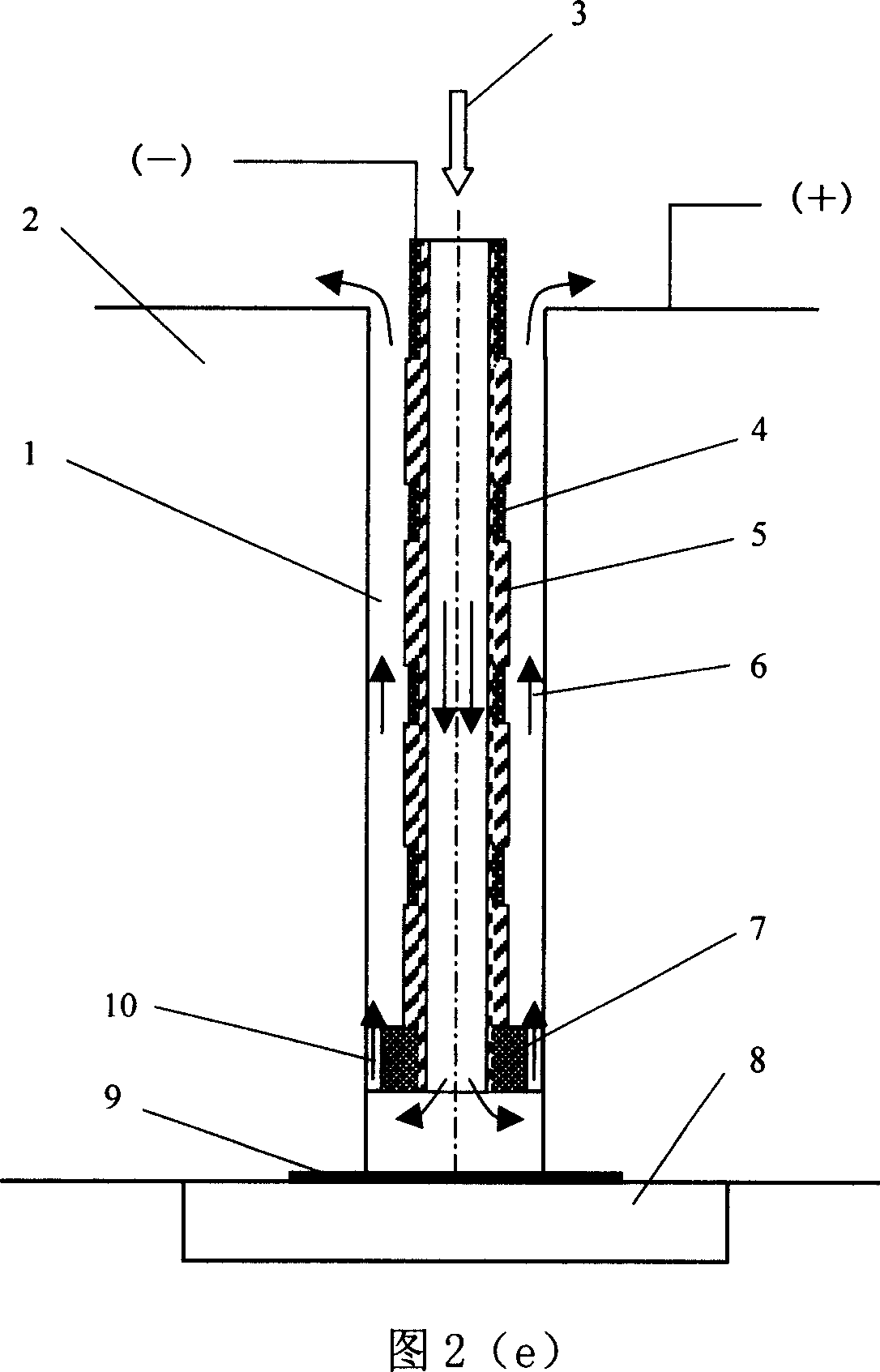

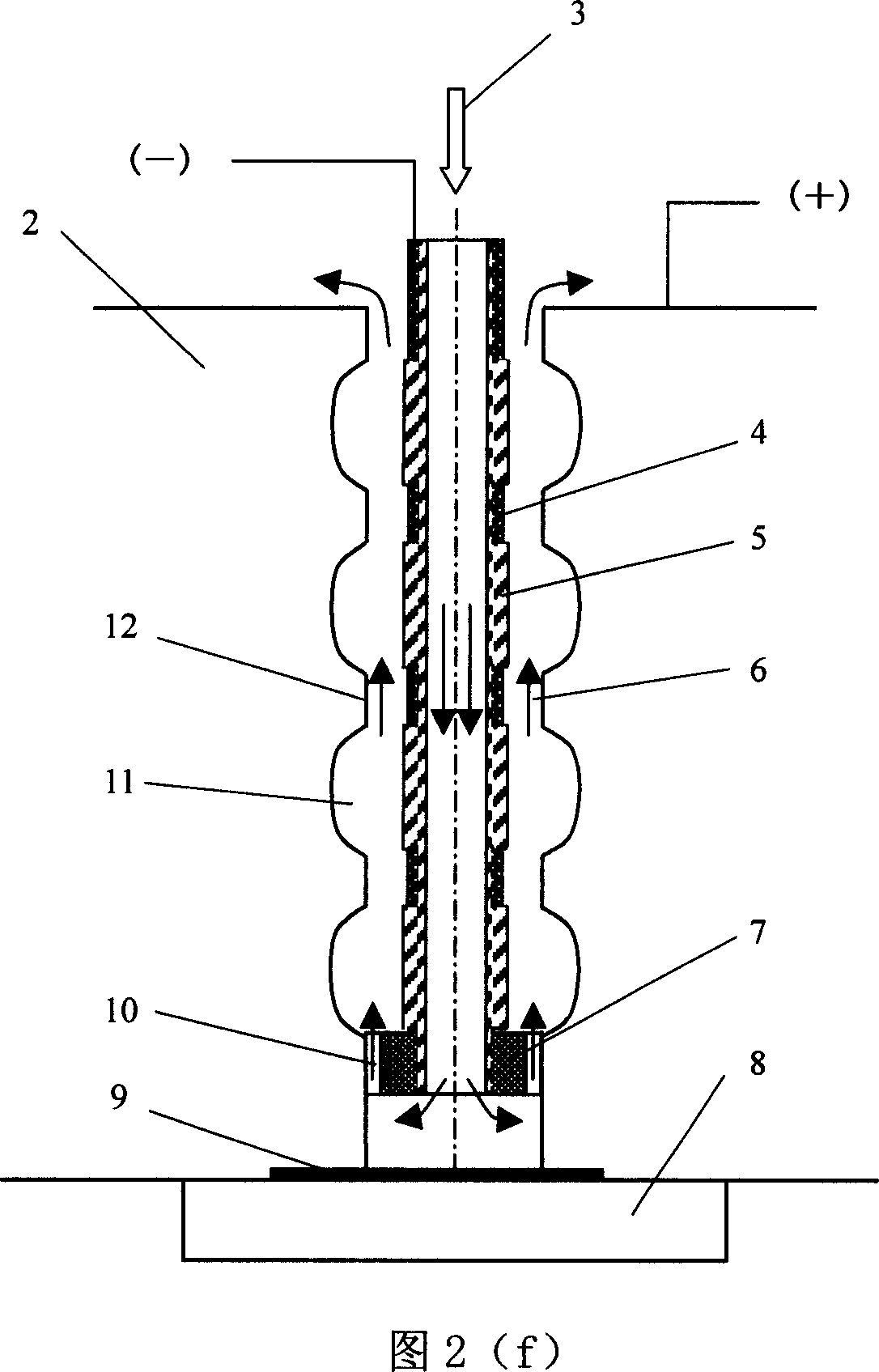

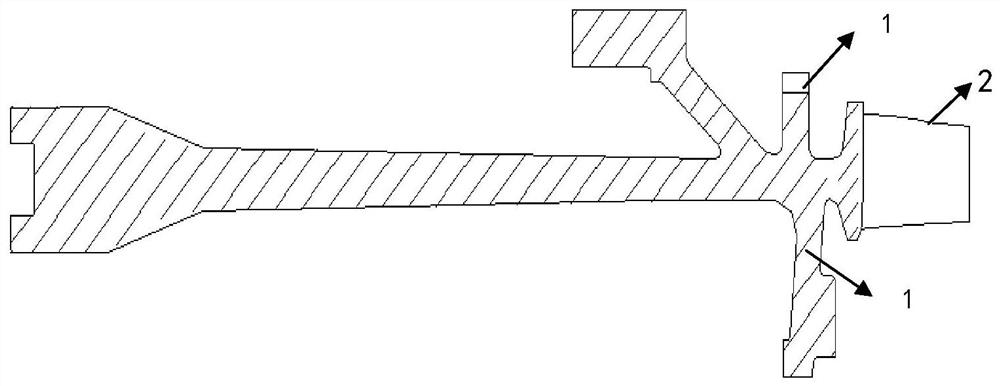

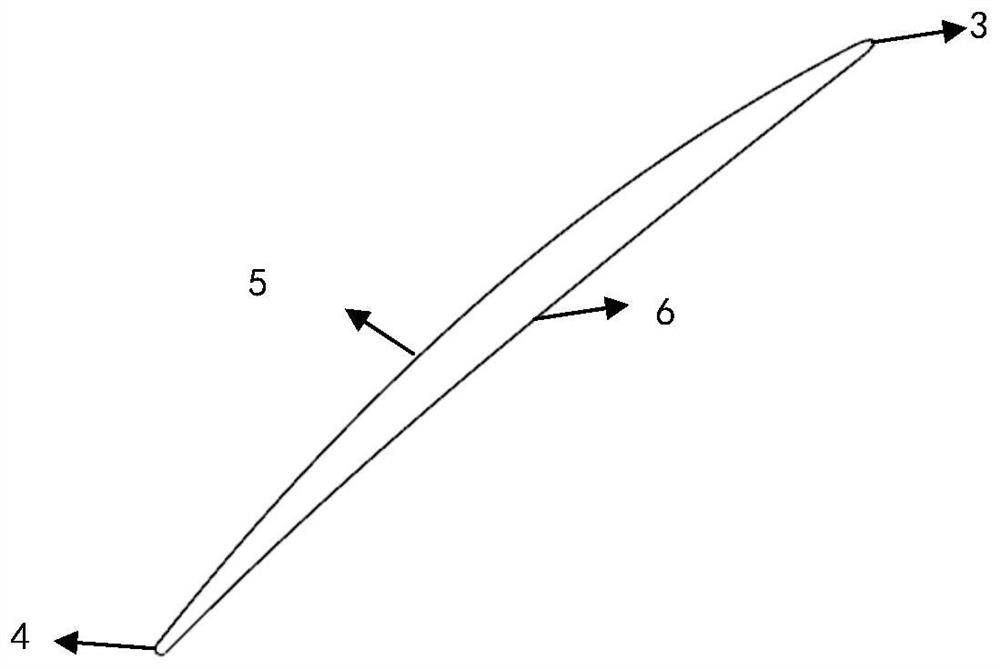

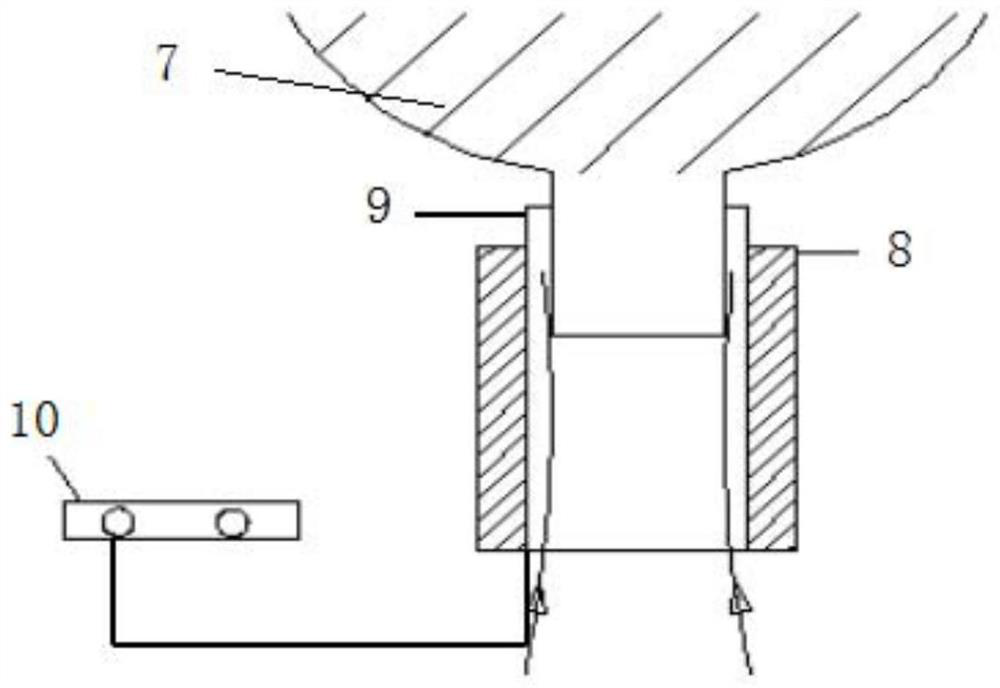

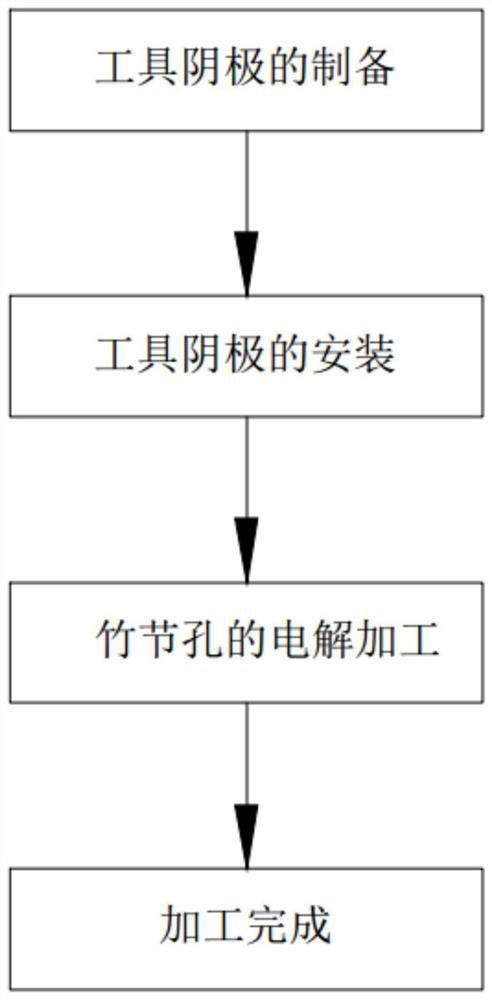

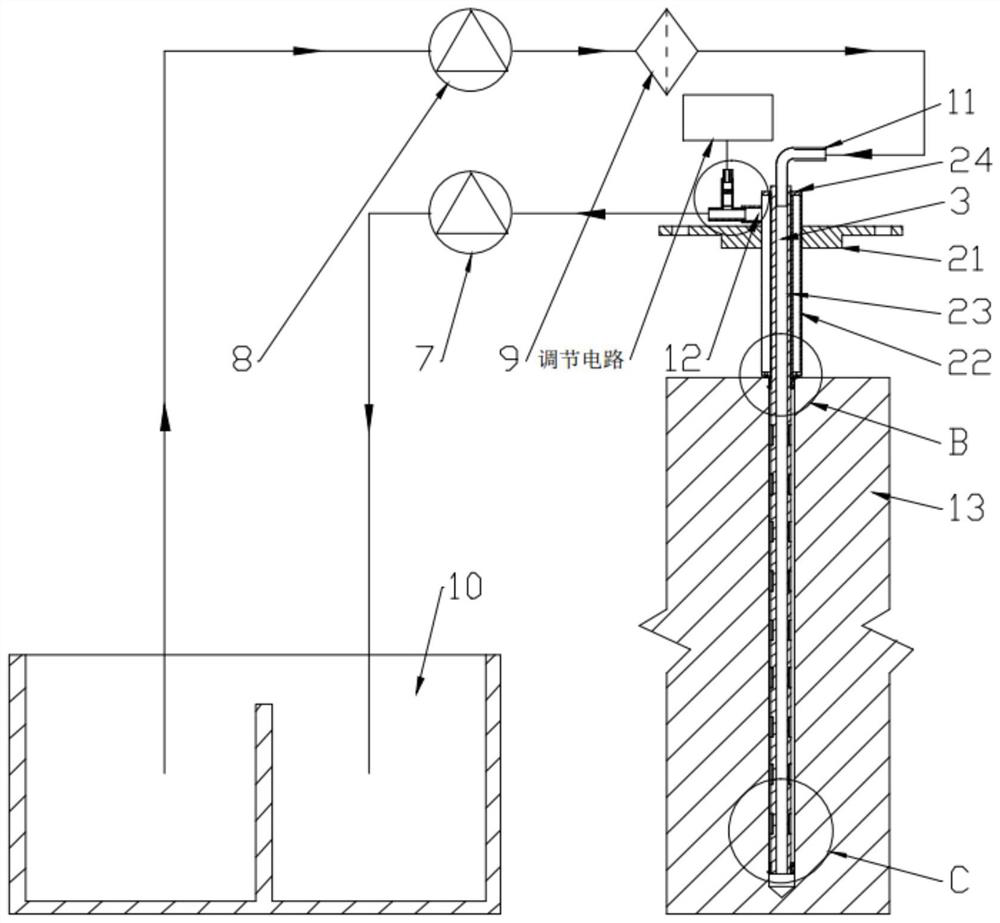

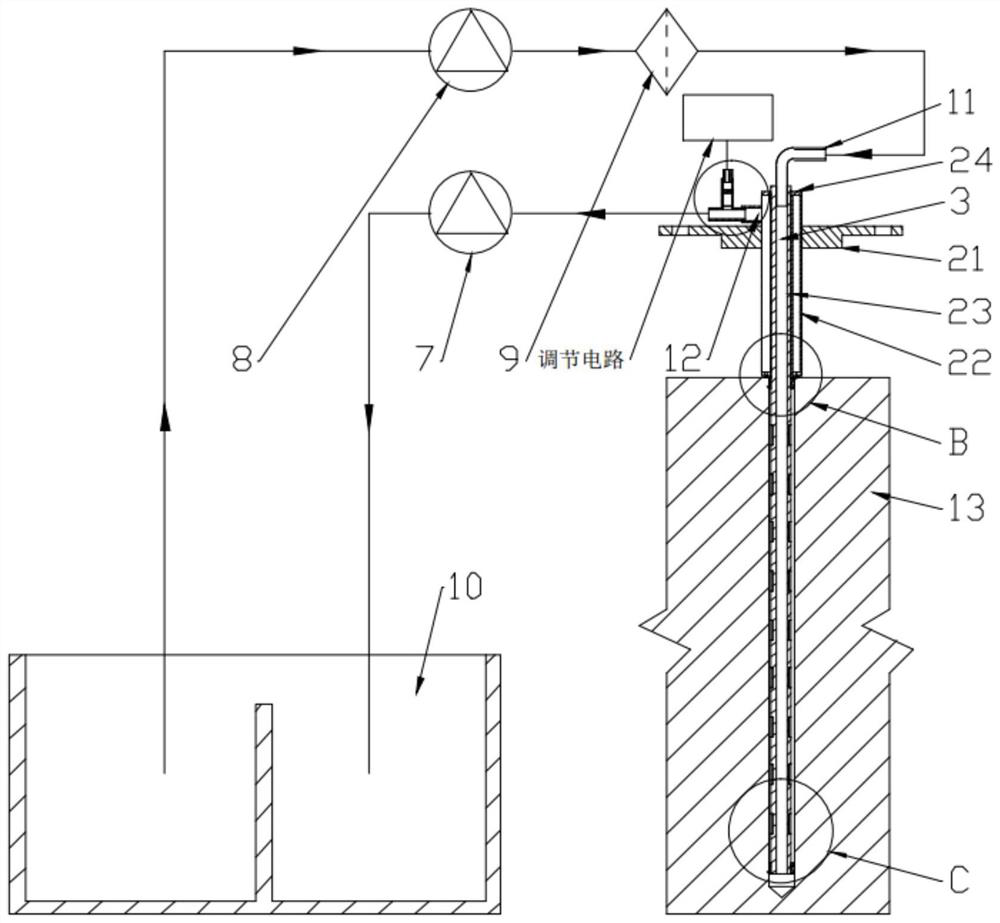

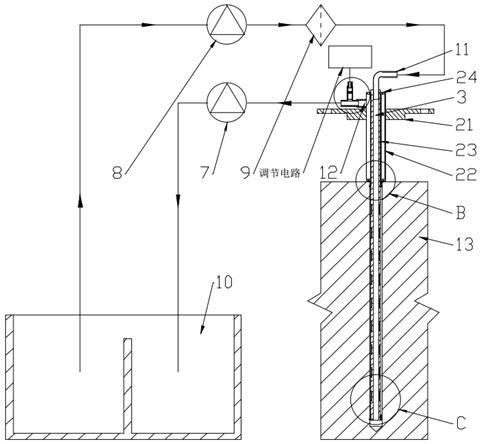

Precise electrolytic machining process for multi-tooth turbine blade

ActiveCN113182625AStable temperature controlAccelerate the lossMachining electrodesMachining working mediaElectrolytic agentTurbine blade

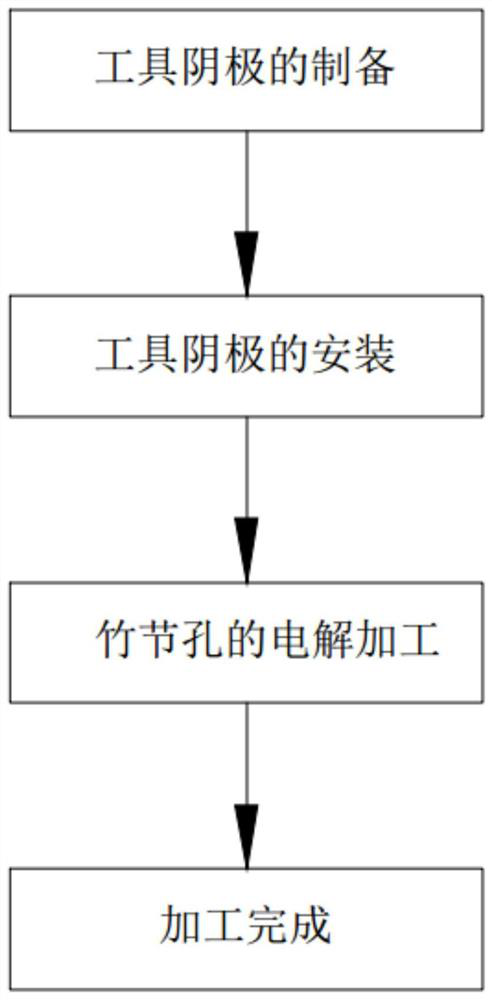

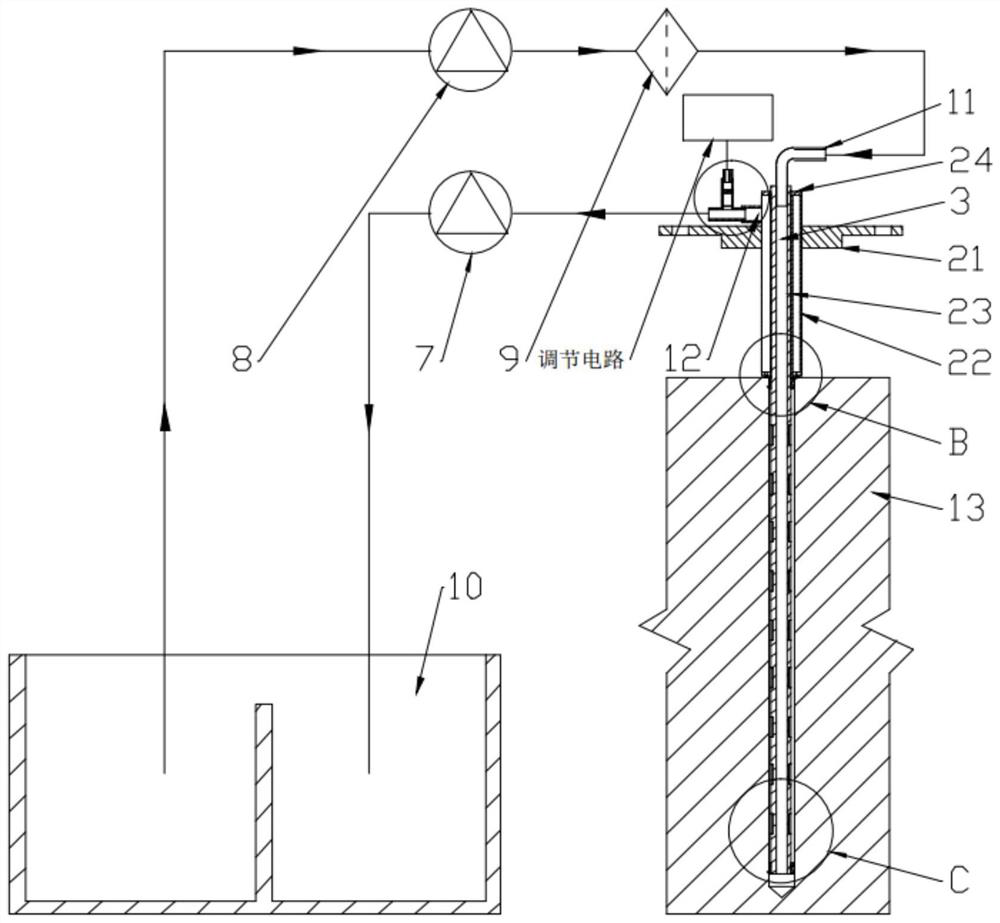

The invention discloses a precise electrolytic machining process for a multi-tooth turbine blade, and relates to the technical field of electrolytic machining for turbine blades. The precise electrolytic machining process for the multi-tooth turbine blade comprises the steps of preparation for a tool cathode, installation for the tool cathode, electrolytic machining for a bamboo joint hole and the like. According to the invention, the defects of a traditional method are overcome, and under the condition of high voltage, the stability of the machining process can still be guaranteed, so that the electrolytic machining efficiency is increased, and the machining time is shortened; and when the temperature of an electrolyte rises, the flow speed of the electrolyte can be adjusted through an adjusting module so as to accelerate heat dissipation of an electrolytic machining area, so that stable control over the temperature of the electrolyte is achieved.

Owner:JIANGSU JIANGHANGZHI AIRCRAFT ENGINE COMPONENTS RES INST CO LTD

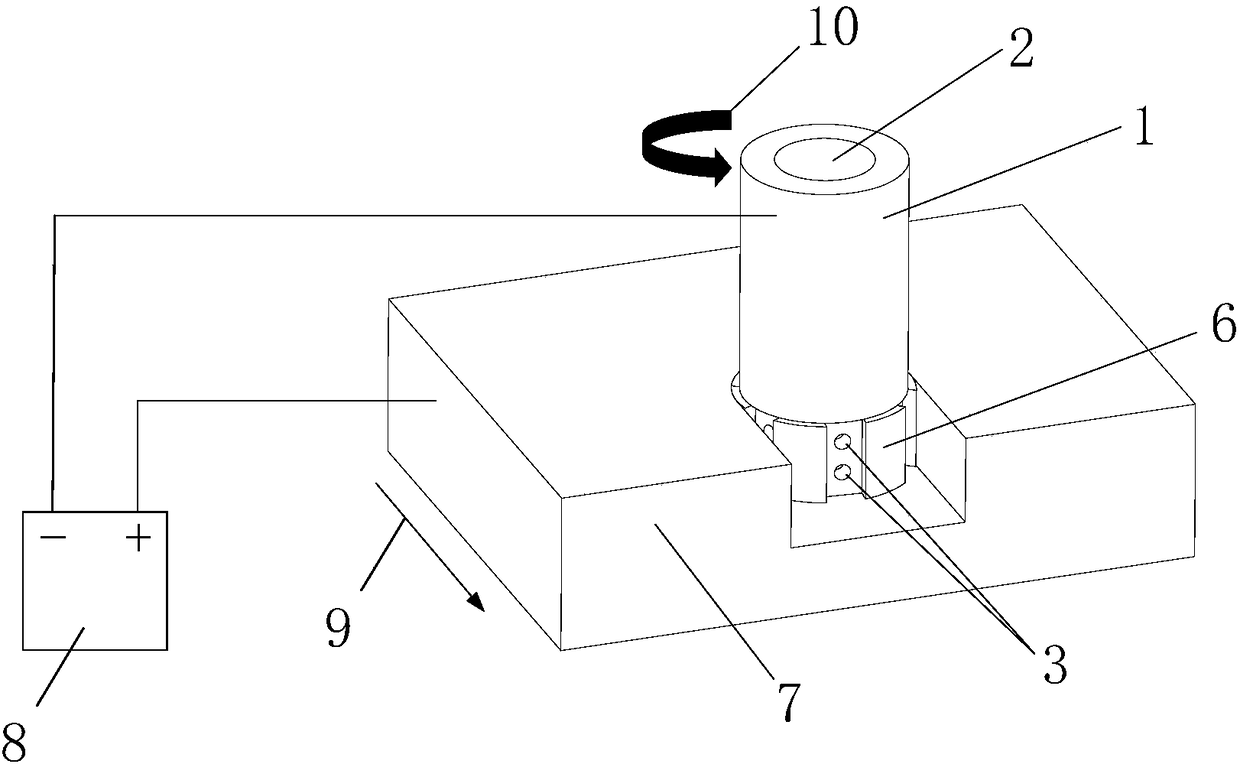

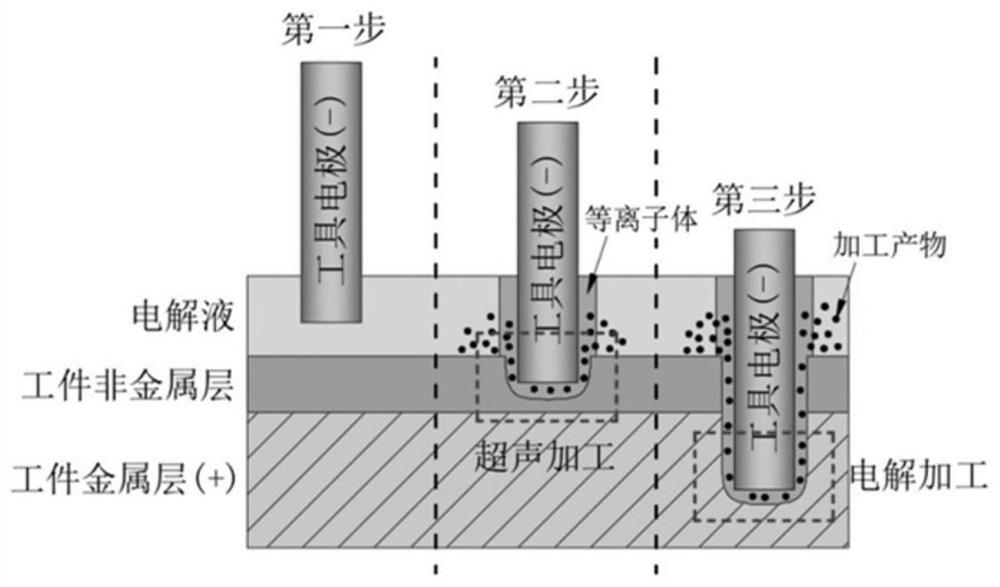

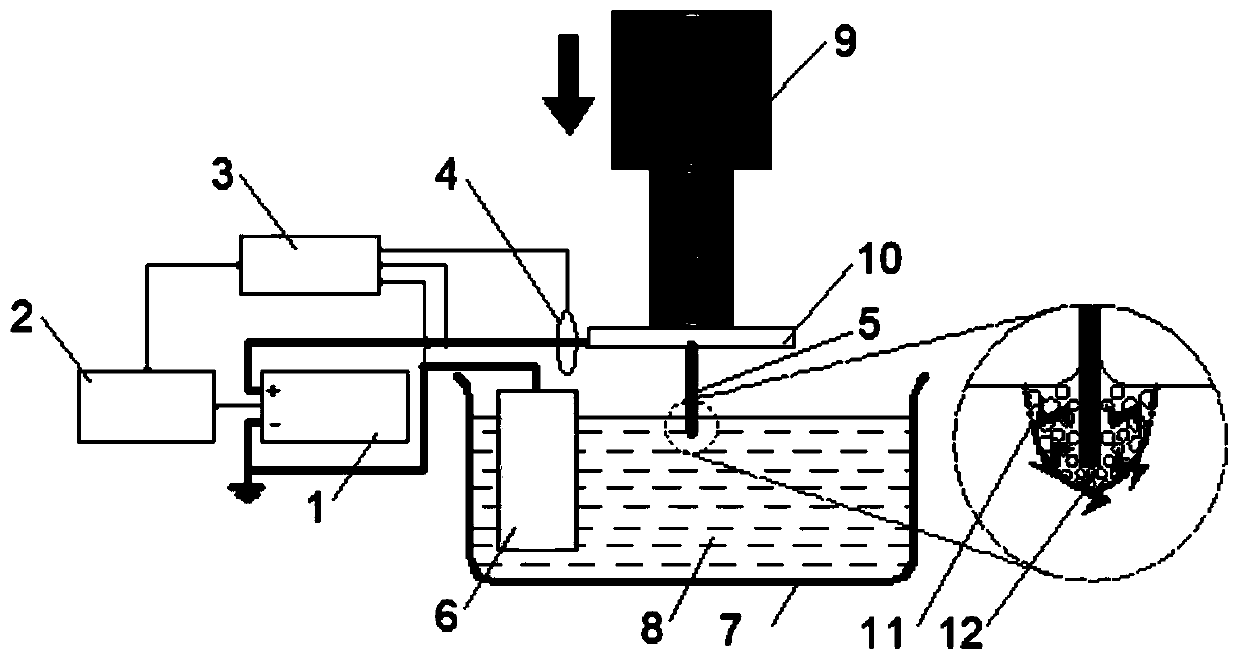

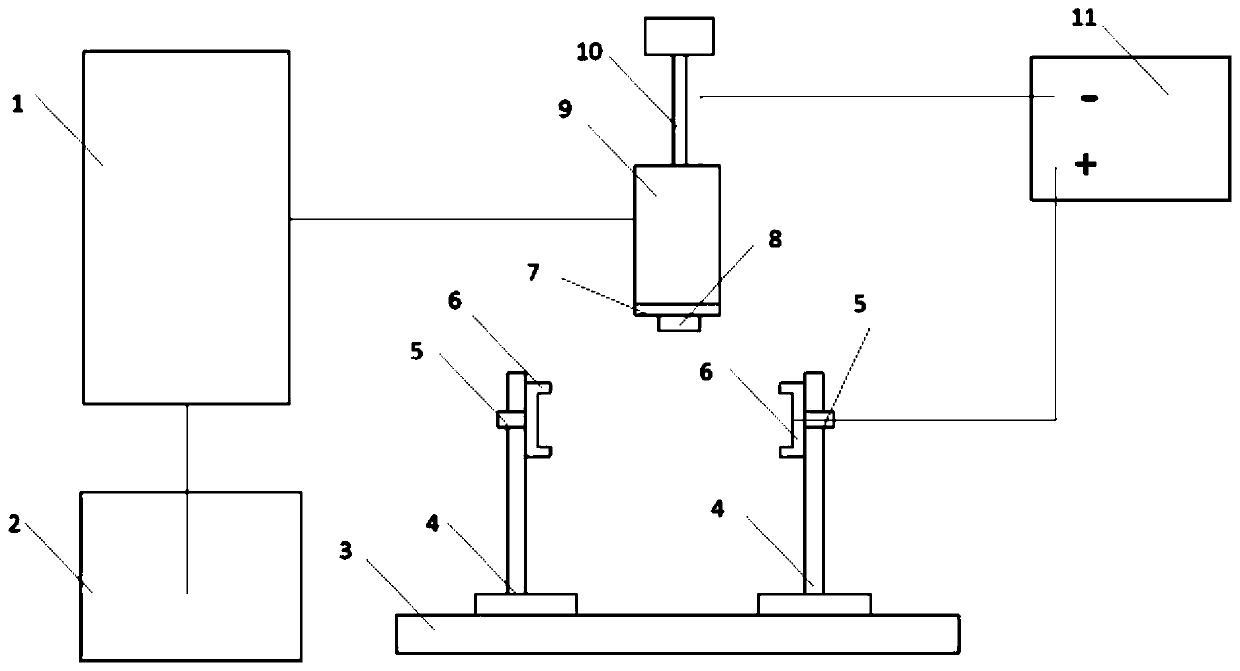

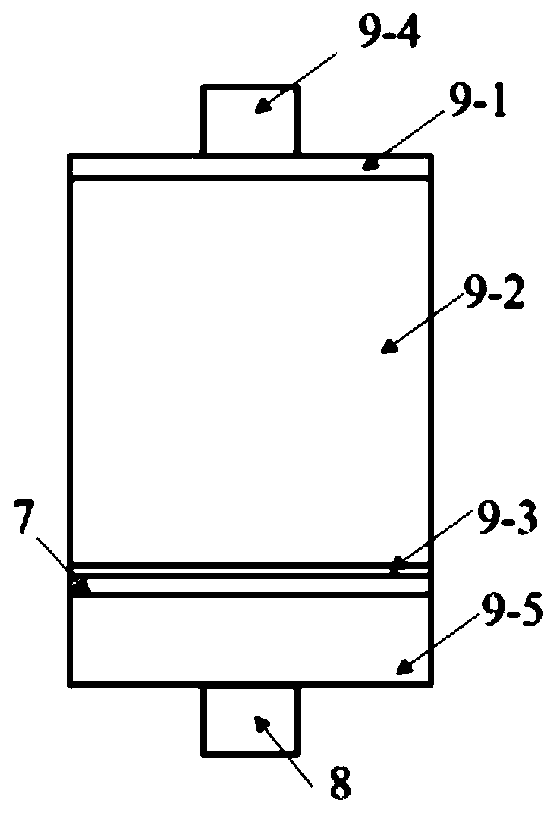

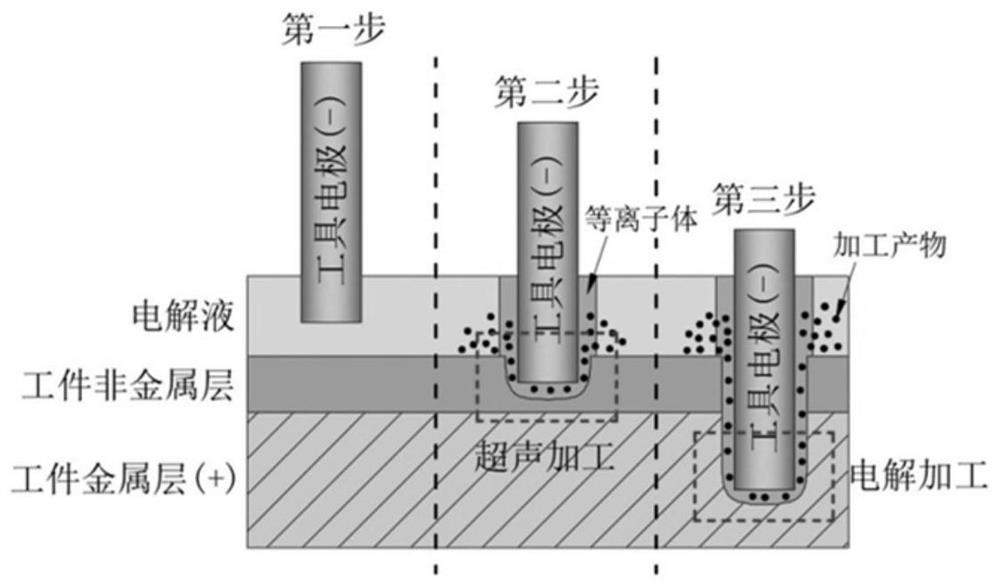

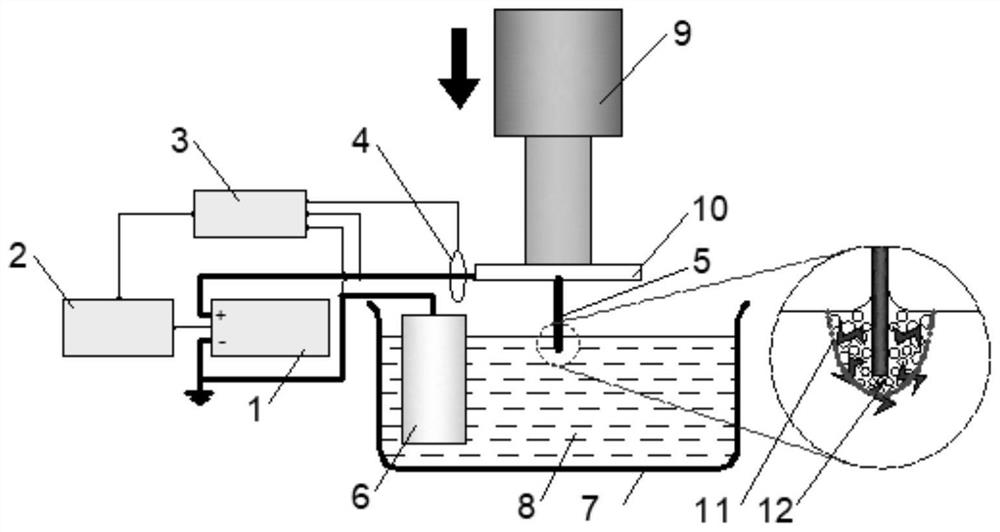

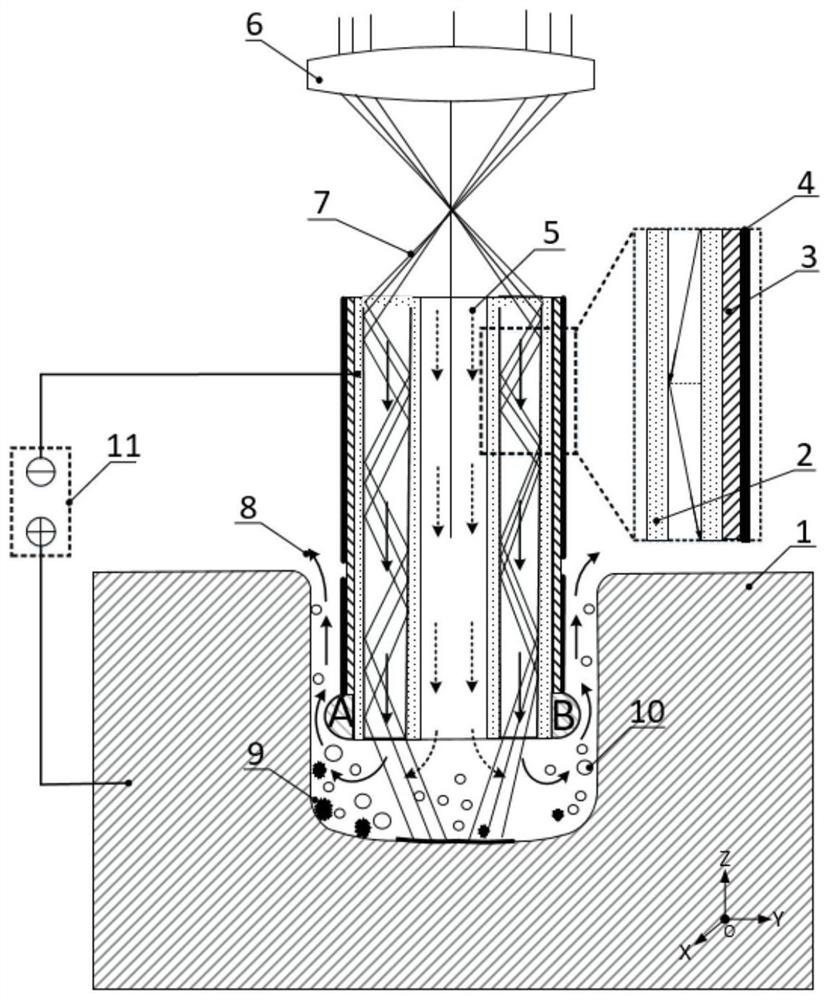

Workpiece ultrasonic-plasma electrolysis combined machining method and machining device

ActiveCN112809111AImprove ECM EfficiencyPromote circulationEfficient propulsion technologiesElectrolytic agentUltrasonic machining

The invention discloses a workpiece ultrasonic-plasma electrolysis combined machining method and a machining device. The machining method comprises the following steps that an electrolyte is provided between a non-metal layer and a tool electrode; a metal layer is connected with the anode of an electrolytic machining power supply, the tool electrode is connected with the cathode of the electrolytic machining power supply, and direct-current voltage is applied between the metal layer and the tool electrode; and the tool electrode moves relative to the non-metal layer from the side, far away from the metal layer, of the non-metal layer, and ultrasonic waves are guided to the non-metal layer. According to the method, firstly, the surface of the non-metal layer is machined through the ultrasonic waves guided to the non-metal layer, and in the ultrasonic machining process, plasma generated through induction can promote solution circulation of ultrasonic machining, so that products of ultrasonic machining are rapidly discharged out of a machining area. And after the non-metal layer is machined, the metal layer is exposed, so that ultrasonic electrolysis parallel processing is carried out on the metal layer.

Owner:SOUTH UNIVERSITY OF SCIENCE AND TECHNOLOGY OF CHINA

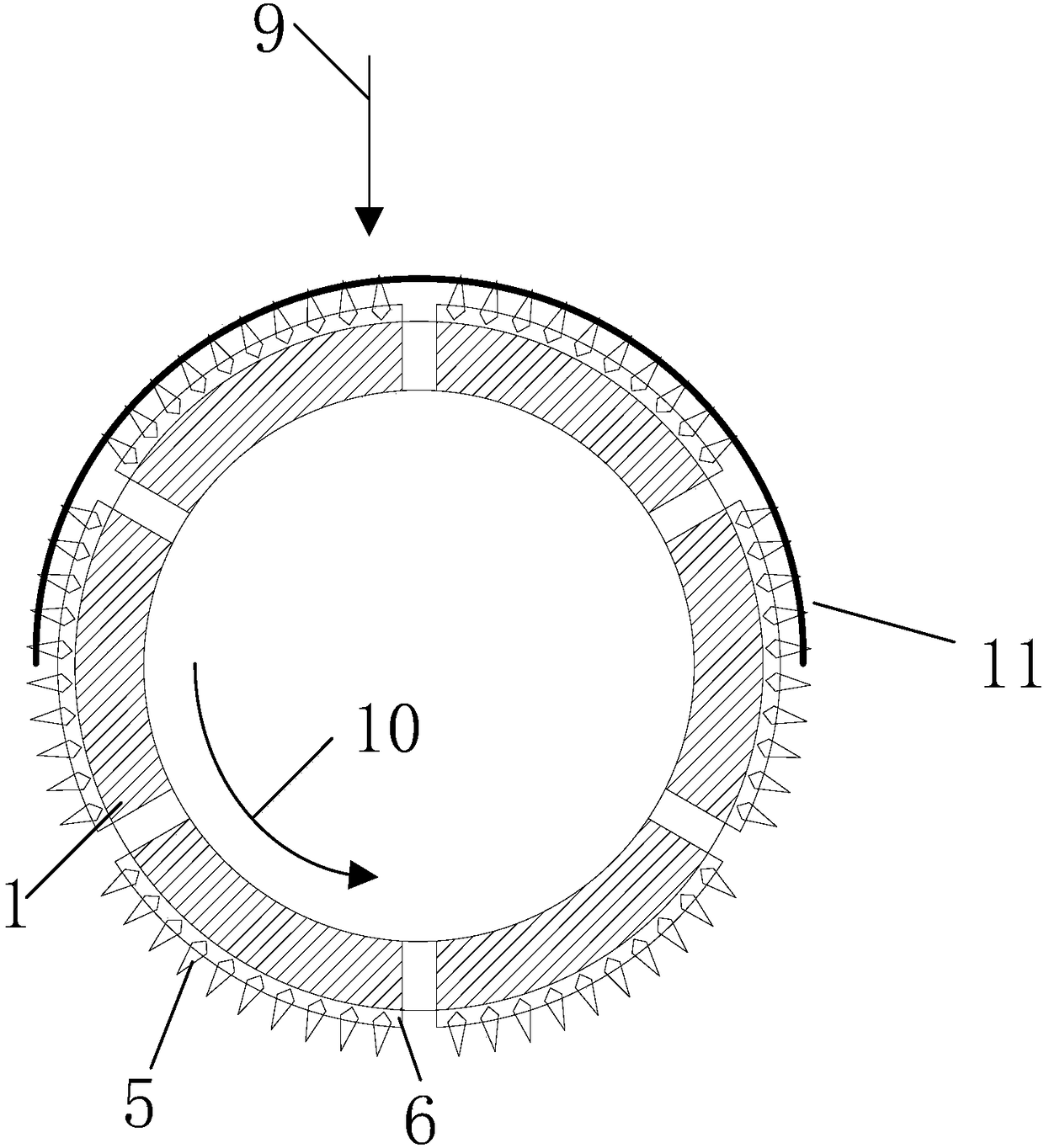

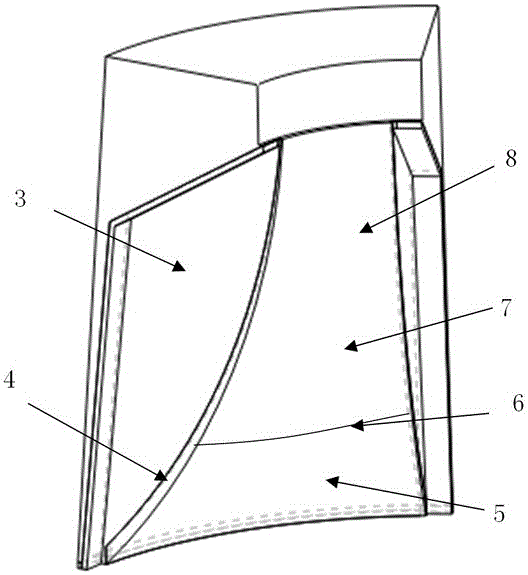

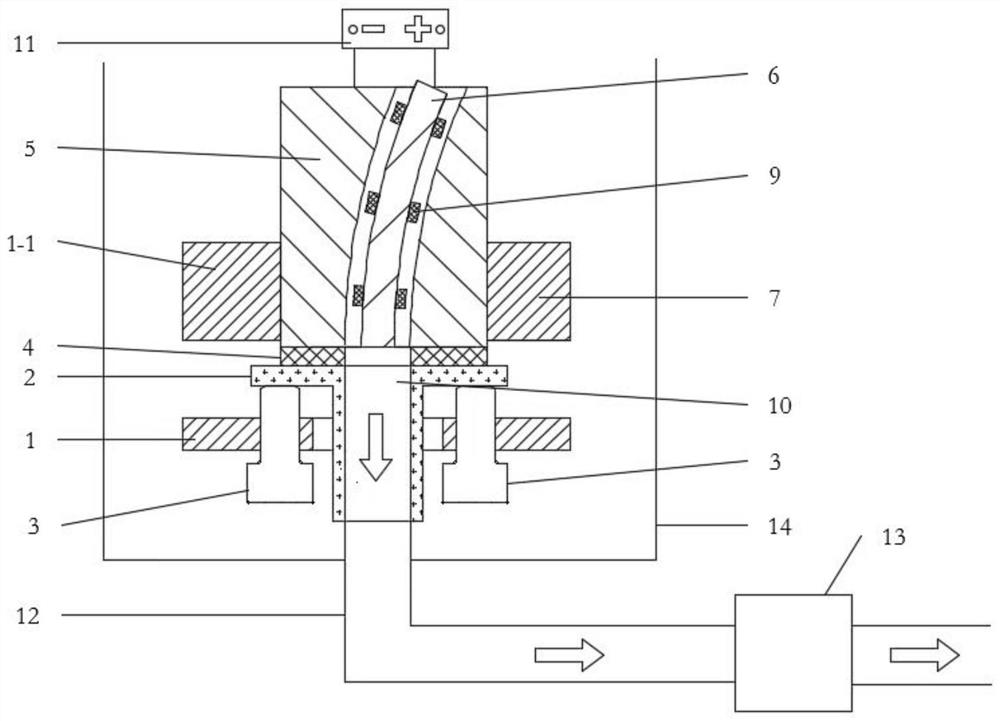

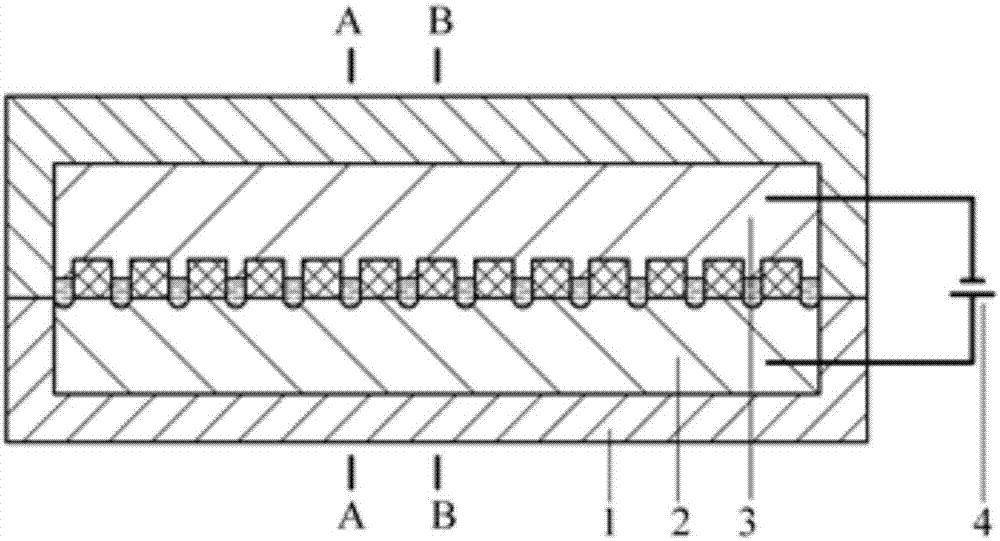

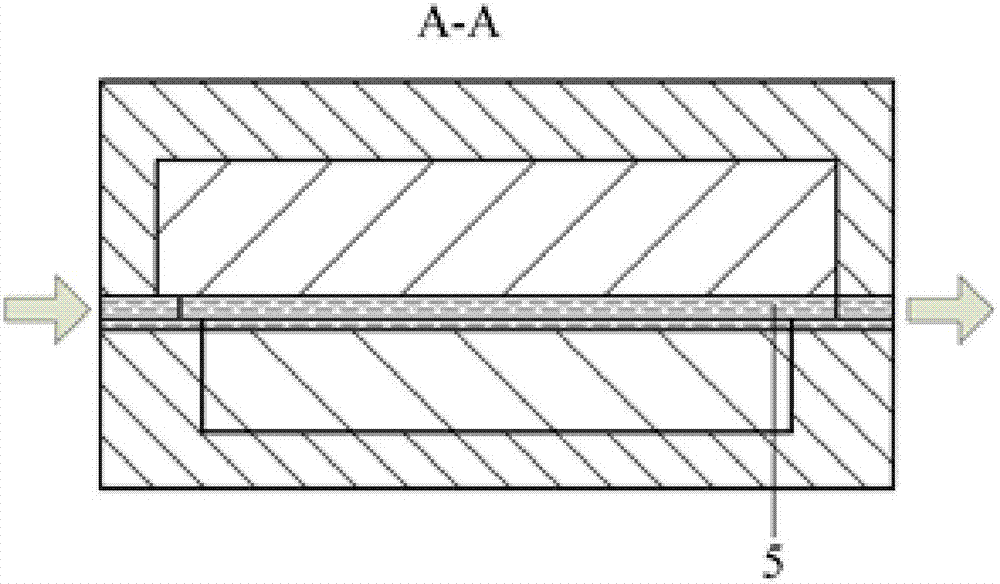

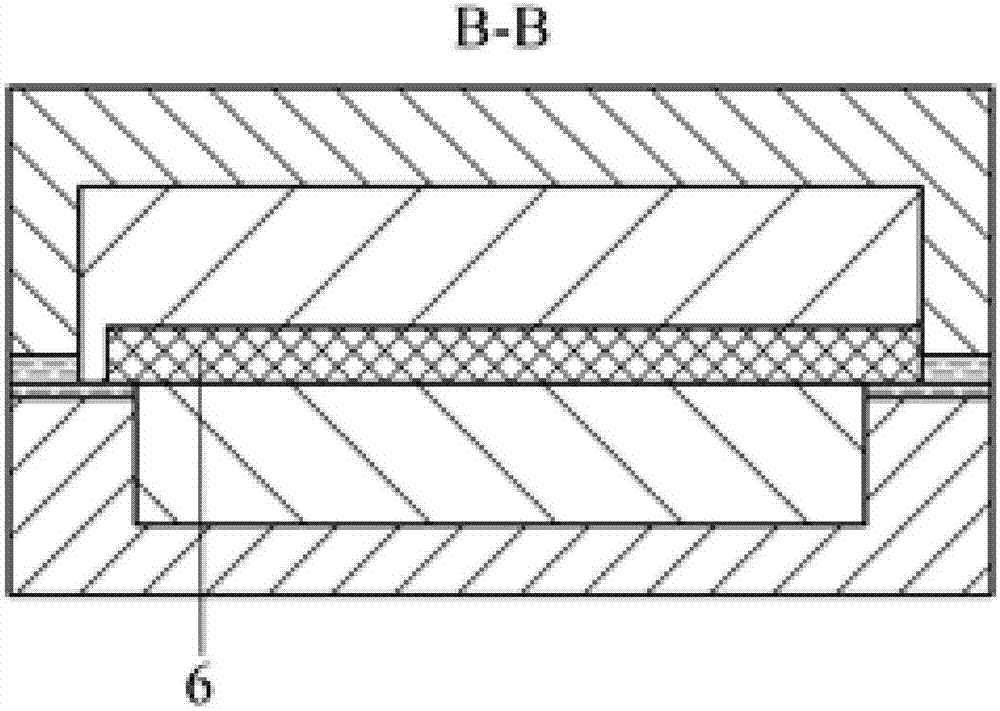

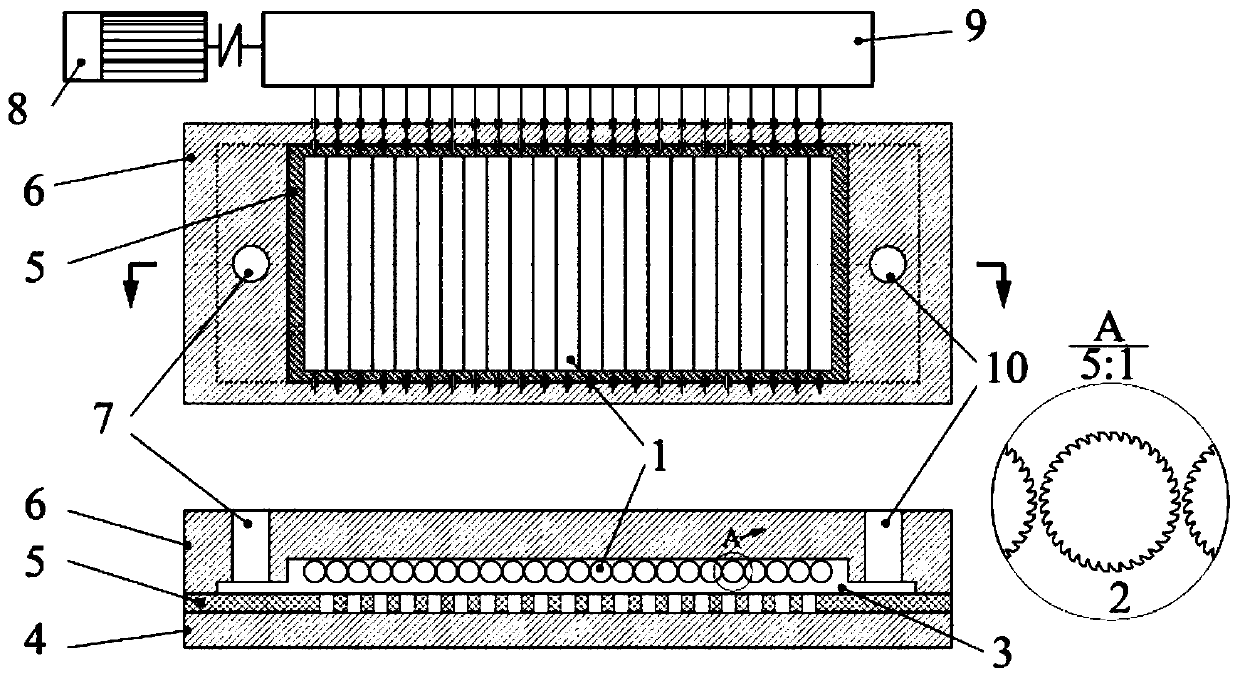

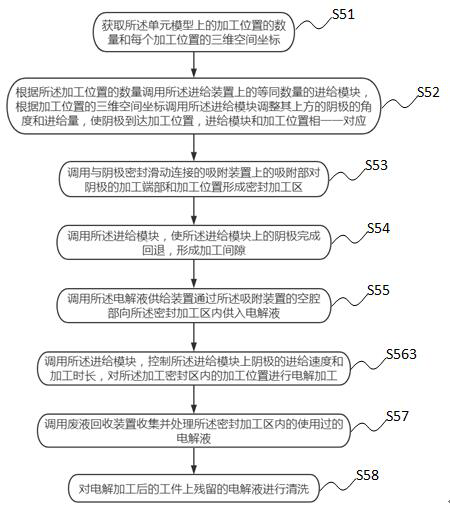

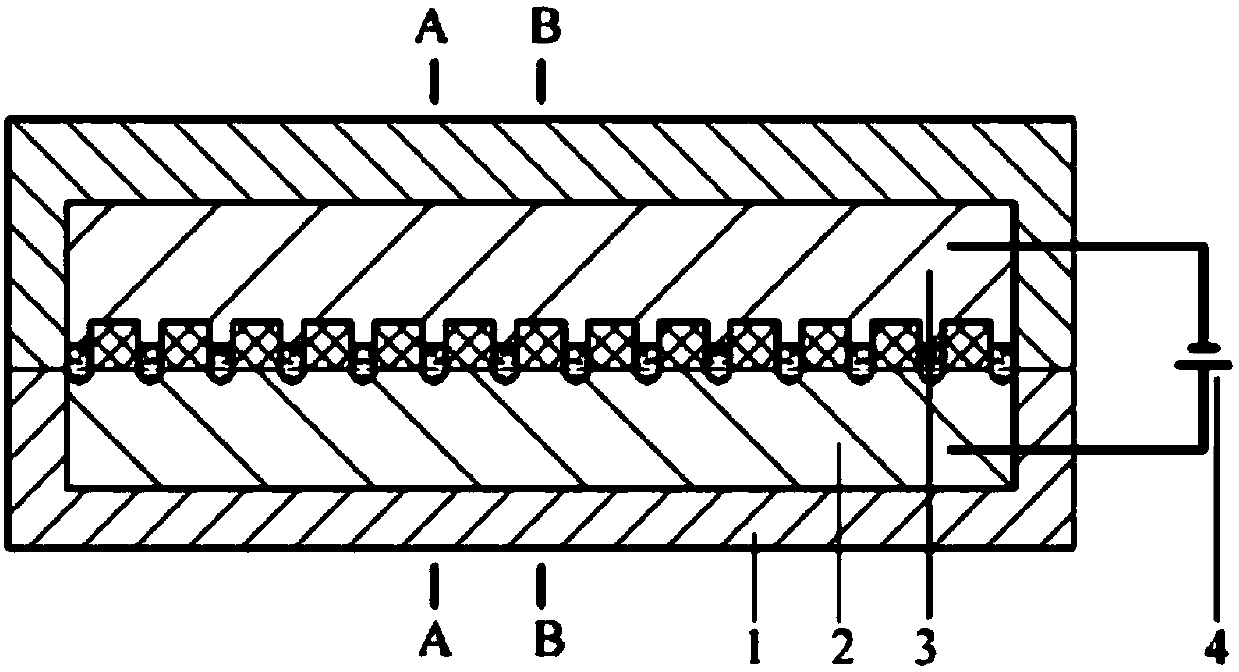

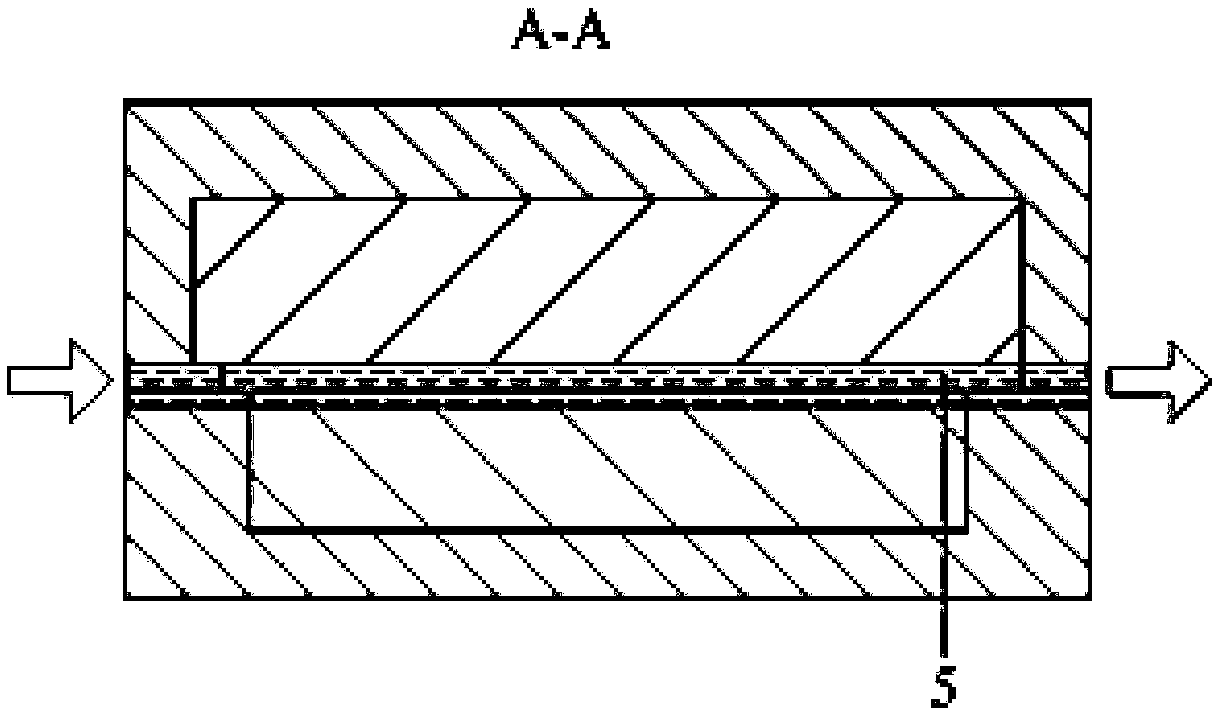

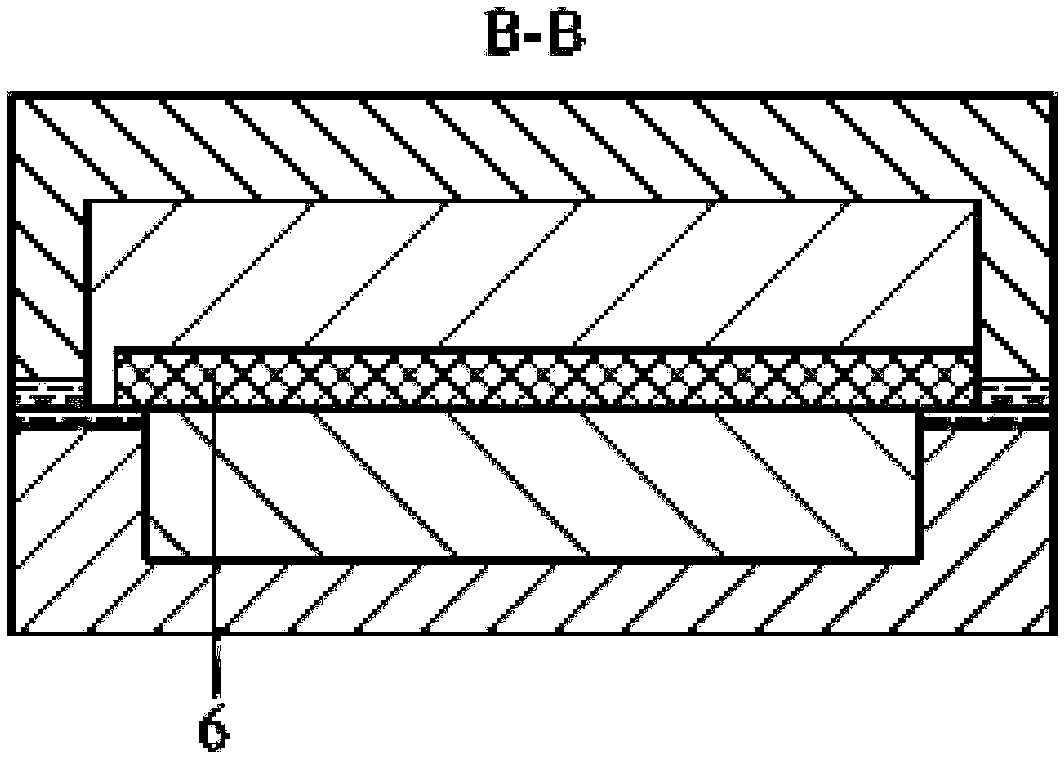

Suction type electrolytic machining device and method for finishing internal structure

ActiveCN112658415AImprove efficiencyImplement updateMachining working media supply/regenerationElectrical-based auxillary apparatusElectrochemical responseMachining process

The invention discloses a suction type electrolytic machining device and method for finishing an internal structure. The suction type electrolytic machining device comprises a workpiece anode, a tool cathode, insulating layers, a clamping frame, a sliding block, a bolt, a sealing gasket, a liquid extraction opening and a compression screw, and the problem that electrolysis products and bubbles are difficult to discharge during electrolytic machining of the internal structure is effectively solved; the insulating layers are fixedly distributed at equal intervals in the axis direction of a workpiece cathode to ensure insulation of the tool cathode and the workpiece anode in the machining process; the workpiece anode is clamped through the clamping frame, the sliding block and the bolt; the electrolyte in the internal structure of the workpiece anode is pumped out by connecting the liquid extraction opening and a suction pump through a connecting pipe, and the bubbles and the electrolysis products generated in the electrochemical reaction process are brought out; during machining, the tool cathode is moved for a certain distance at a certain time interval, so that the area of which the electric field is originally shielded by the insulating layers is processed, and the electrolytic finishing machining of the whole internal structure is realized; according to the device and the method, the electrolyte can be pumped out of the internal structure when the internal structure is subjected to electrolytic finishing machining, the bubbles and the electrolytic products generated in the electrolytic machining process are taken away, and electrolytic finishing machining of the surface of the whole internal structure is achieved.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

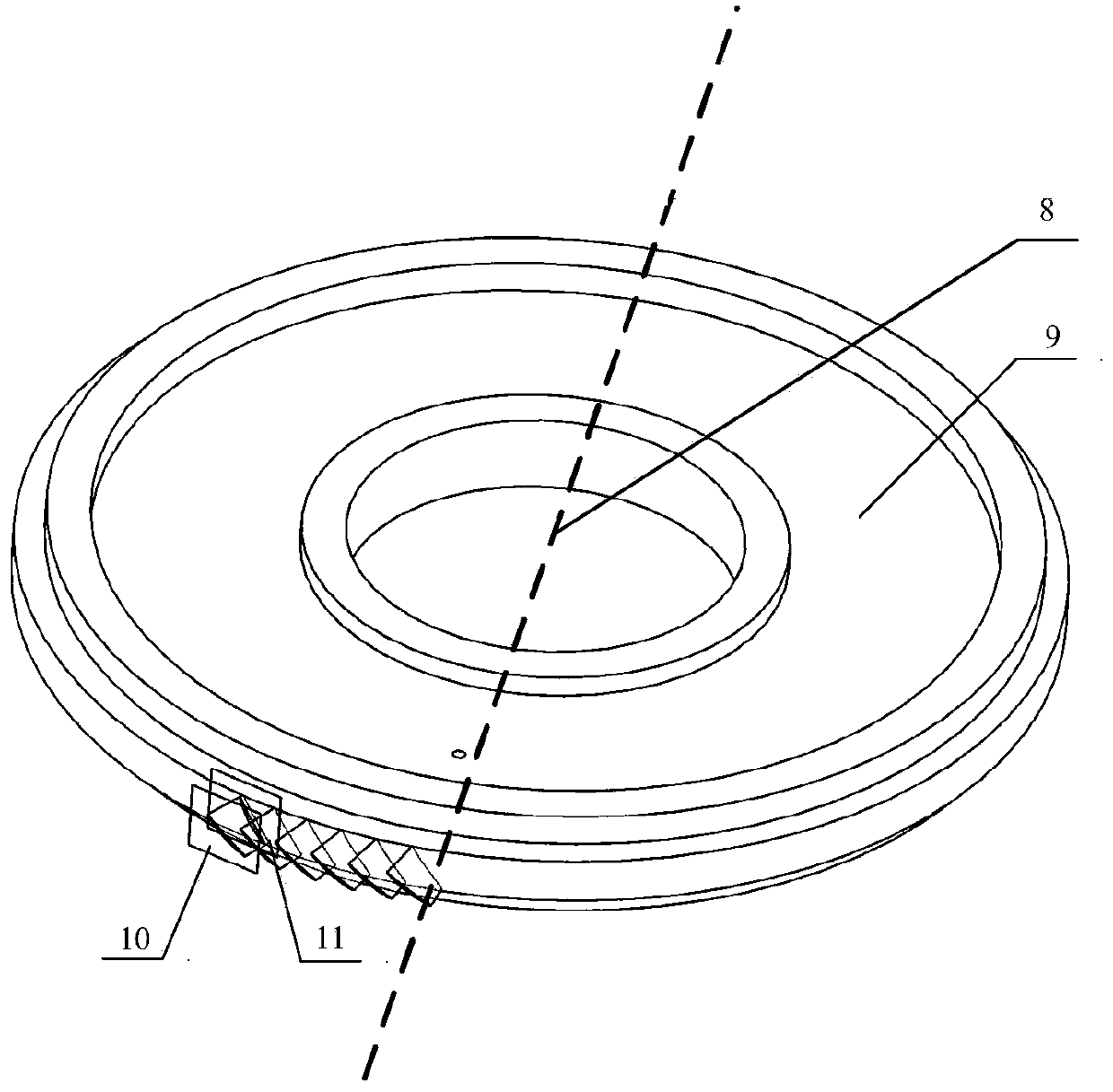

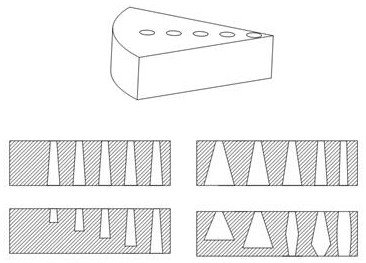

System and method for carrying out electrolytic machining on groove array on basis of PDMS template

ActiveCN107186298AGuaranteed spacingOvercome the defect of easy deformationMachining electrodesMachining working media supply/regenerationElectrolysisBiochemical engineering

The invention discloses a system and a method for carrying out electrolytic machining on a groove array on the basis of a PDMS template. The method comprises the following steps: a. producing a clamp; b. producing a cathode tool with a groove structure; c. producing the PDMS template; d. embedding the PDMS template in a groove of the cathode tool; e. clamping the PDMS template, the cathode tool and an anode workpiece; f. connecting the anode workpiece and the cathode tool to the positive pole and the negative pole of a power supply separately; g. charging an electrolyte into the clamp, wherein the pressure of the electrolyte is greater than 0.1MPa; and h. turning on the power supply, and carrying out electrolytic machining. The electrolytic machining is carried out through the method, the position of the PDMS template is fixed by the cathode tool, a uniform width of the machined grooves is ensured, and the PDMS template closely contacts with the anode workpiece, so that improvement for the electrolytic machining accuracy of the groove array is benefited; and because the PDMS template can be repeatedly used, the method increases the machining efficiency of the groove array.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

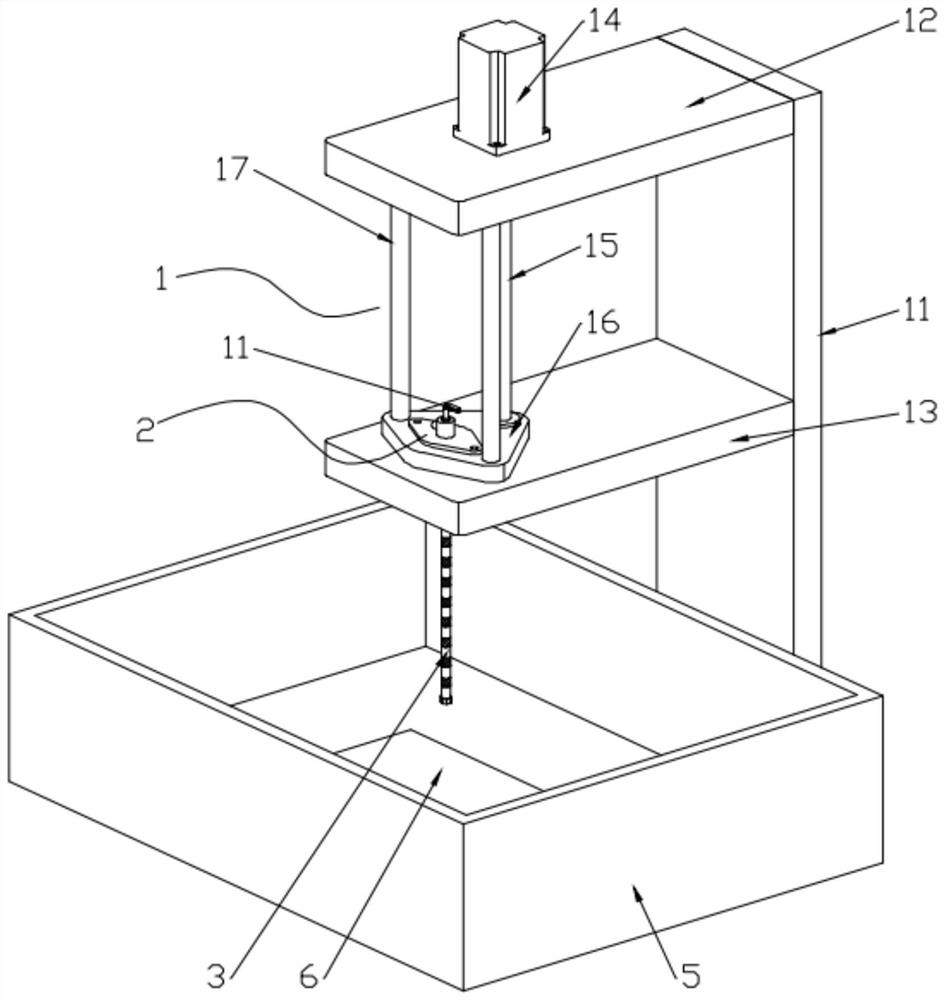

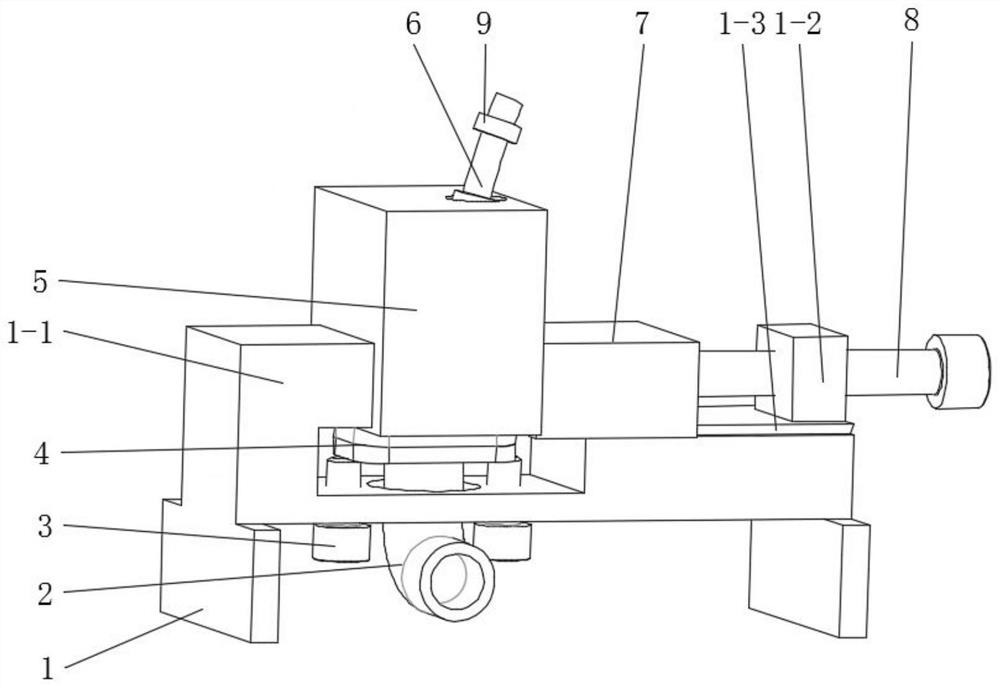

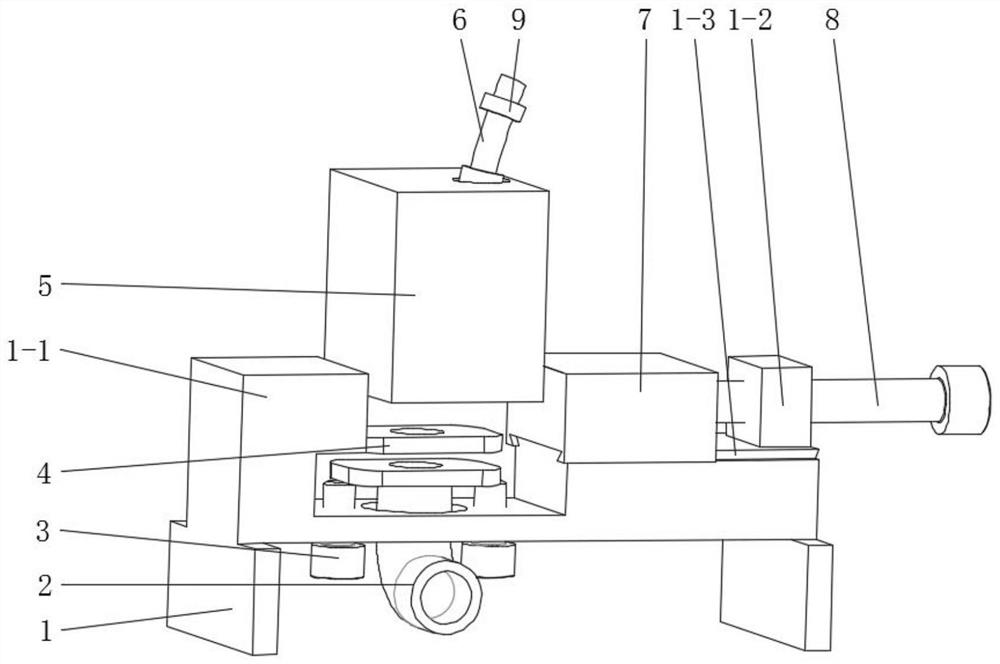

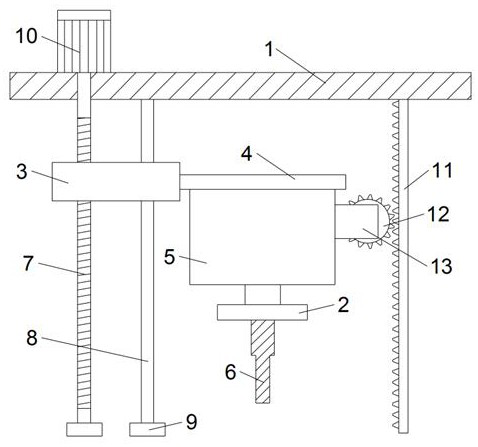

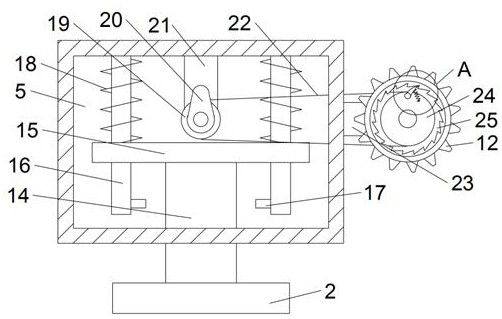

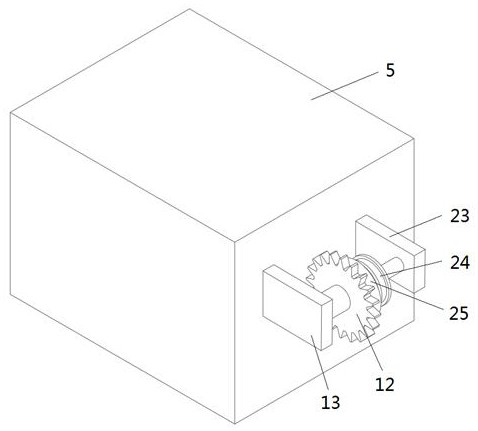

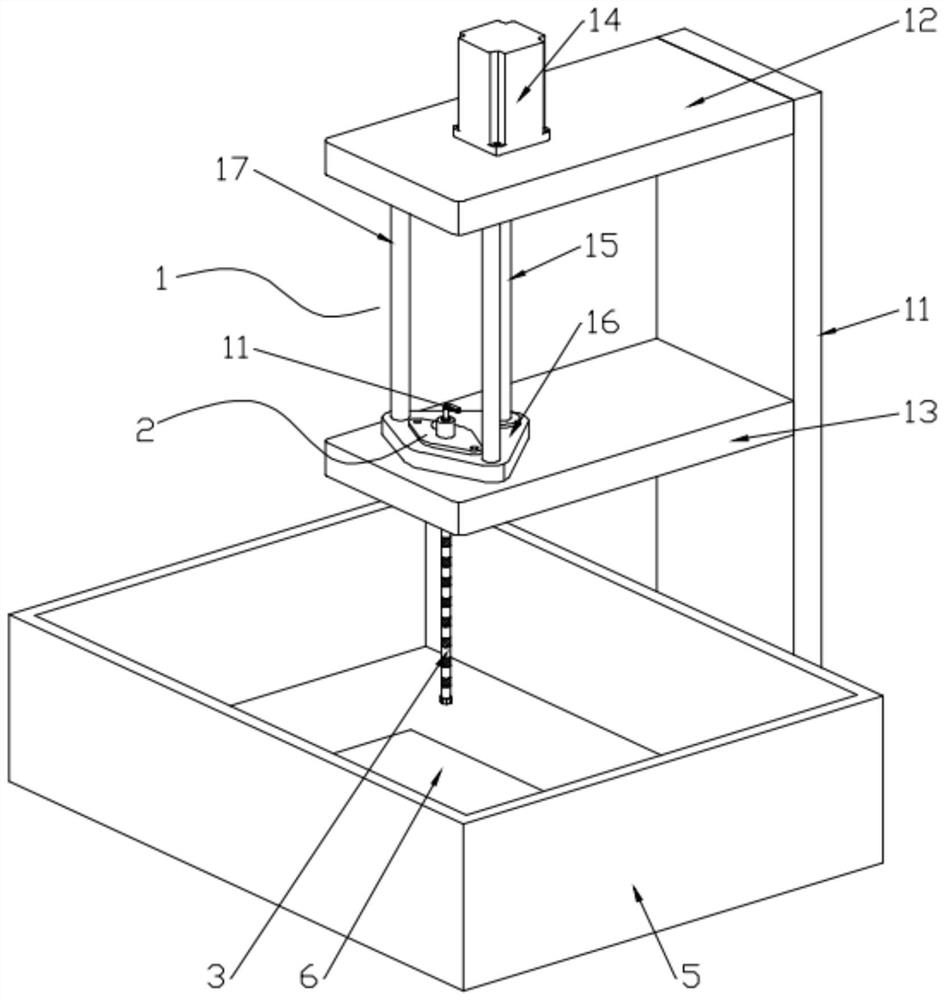

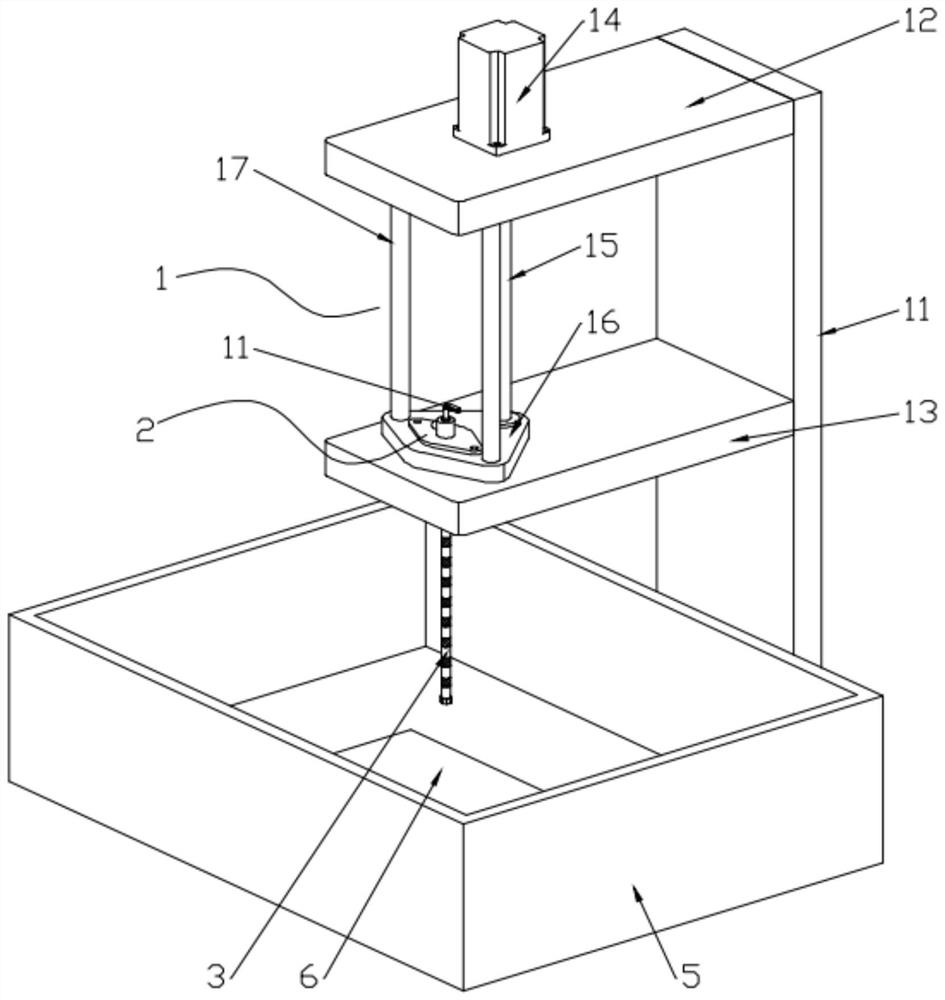

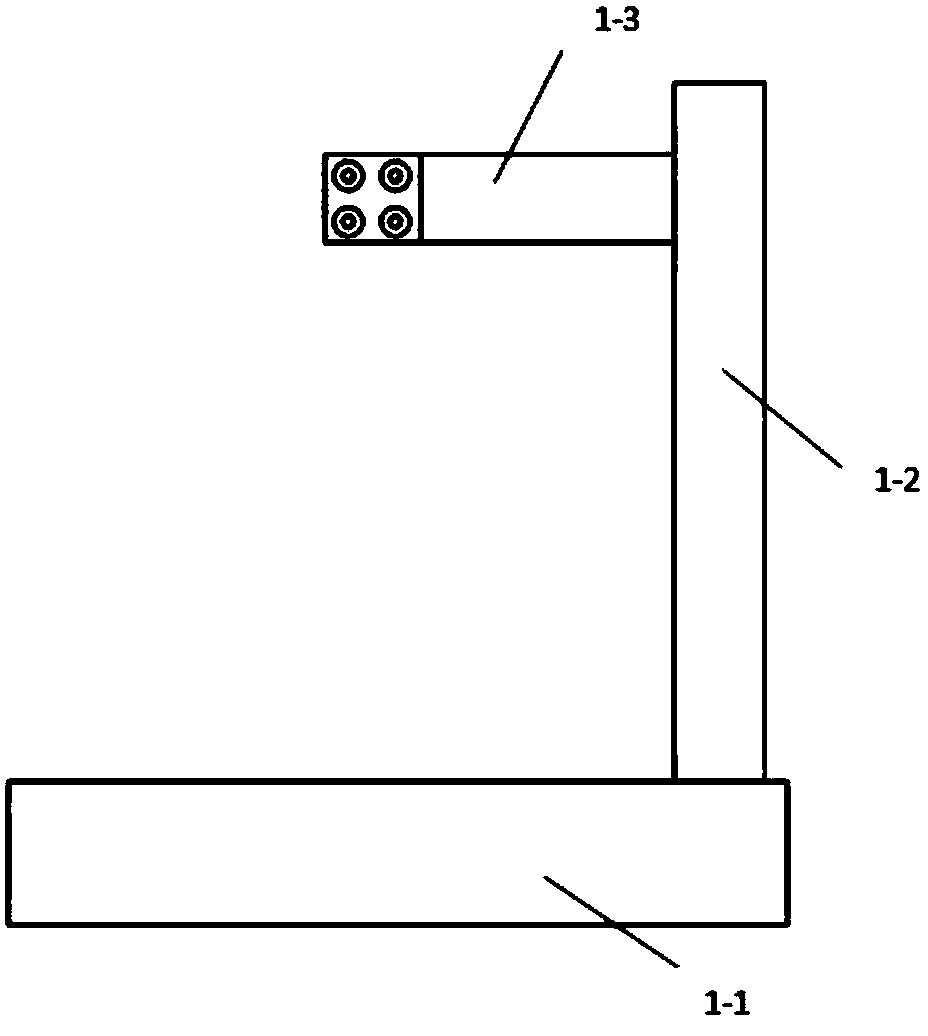

A Vibration Feed Movement Realization Device for Electrolytic Machining

InactiveCN110539043BImprove ECM EfficiencyElectrochemical machining apparatusElectrical-based auxillary apparatusMachining vibrationsReciprocating motion

The invention discloses a vibration feed motion realizing device for electrochemical machining and belongs to the technical field of electrochemical machining. The vibration feed motion realizing device comprises a fixed plate and a mounting block, wherein a sliding block is arranged below the fixed plate in a sling manner and is connected with a feed mechanism; a vibration chamber is arranged onthe sliding block; a moving plate is movably arranged in the vibration chamber; the mounting block is arranged at the bottom of the moving plate; the moving plate is connected with a vibration component; and a driving component is arranged between the vibration chamber and the fixed plate. According to the vibration feed motion realizing device, the mounting block is arranged at the bottom of themoving plate, the moving plate is arranged in the vibration chamber in a sliding manner and the vibration chamber is internally provided with the vibration component, so that the driving component candrive the moving plate to do up-down reciprocating motion while the vibration chamber descends, further a cathode tool does vibrating motion while doing feed motion, and eventually the efficiency ofelectrochemical machining can be improved.

Owner:HARBIN UNIV OF SCI & TECH

Electrolytic machining device for porous structure with gradually-changed aperture

ActiveCN113385761AImproving Efficiency of Electrochemical Machining of Deep Hole with Variable DiameterMeet processing needsElectrical-based machining electrodesElectrochemical machining apparatusElectrolytic agentEngineering

The invention discloses an electrolytic machining device for a porous structure with a gradually-changed aperture,which is provided with an obtaining module, a dividing module, a feeding module, a variable-diameter electrode, a moving electrode, an aperture adjusting module and a clamping module, the efficiency of machining multiple gradually-changed aperture deep holes at the same time can be improved, through cooperation of the moving electrode and the variable-diameter electrode, the discharge of electrolyte and electrolytic products is promoted while multiple gradually-changed aperture deep holes are machined, and the electrolytic machining efficiency is improved.

Owner:深圳市亚泽科技有限公司

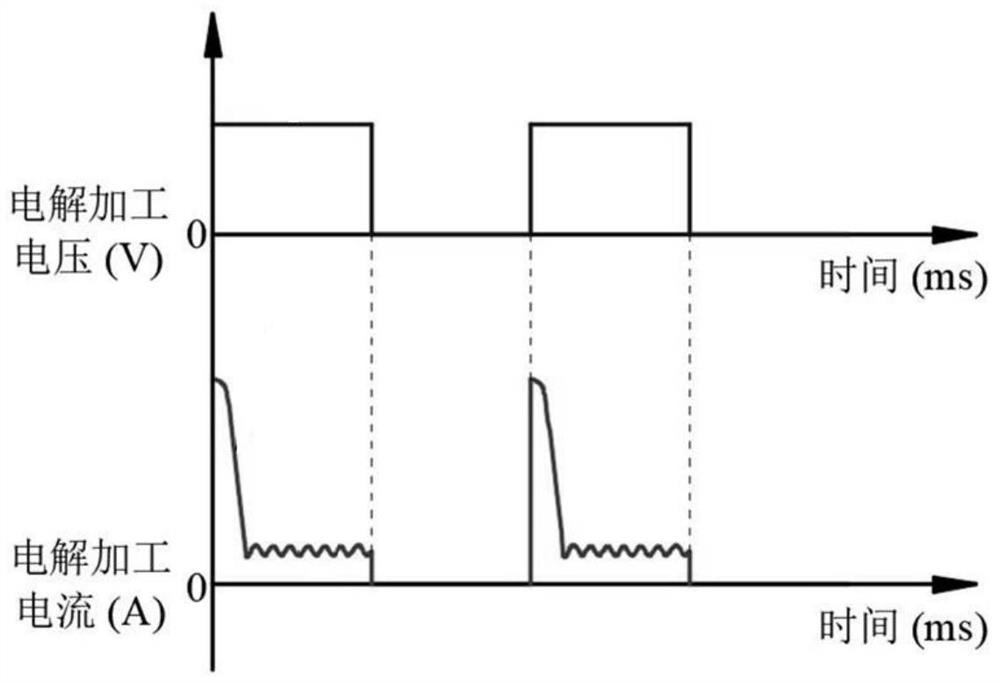

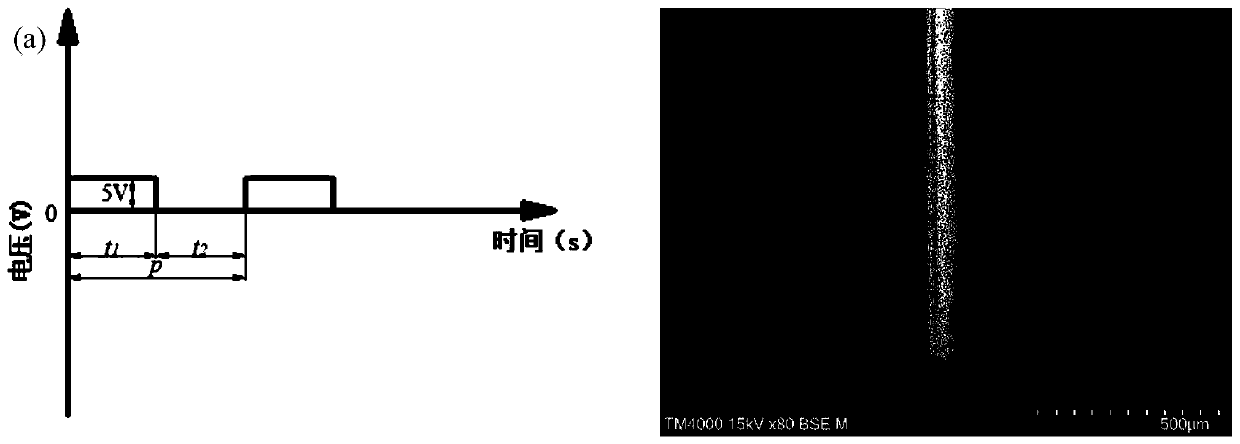

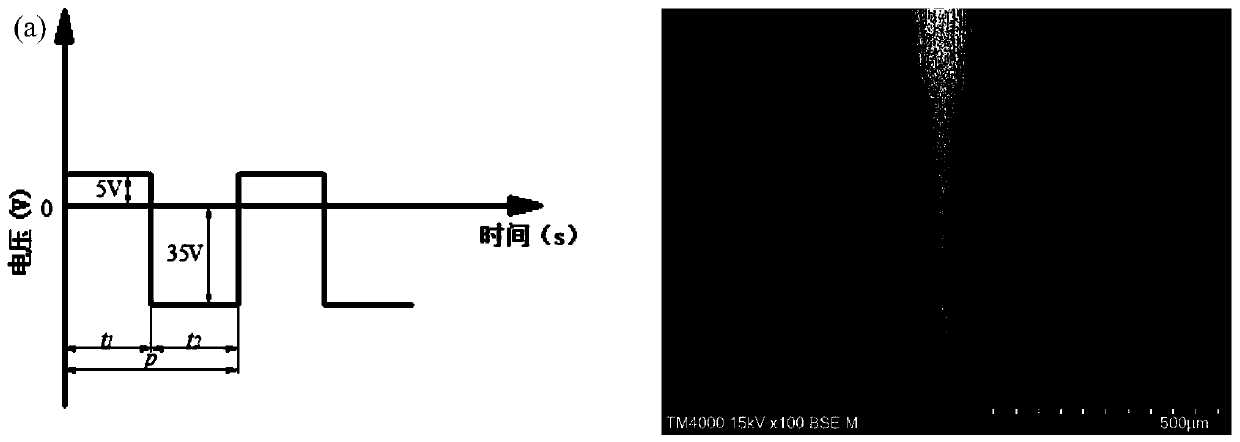

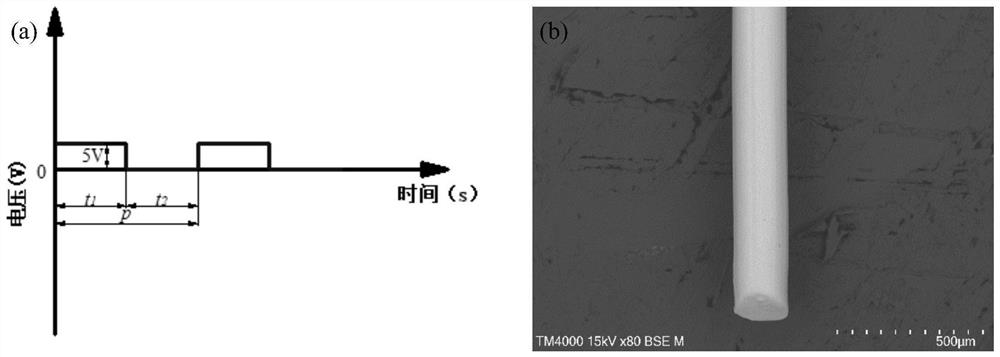

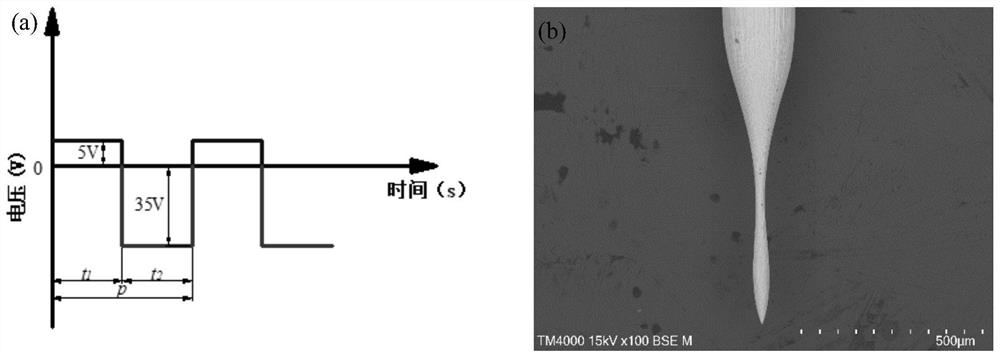

Method for bipolar electrolysis discharging machining of parts and implementing device

The invention discloses a method for bipolar electrolysis discharging machining of parts and an implementing device. The method for bipolar electrolysis discharging machining of parts comprises the following steps that a power source is supplied, wherein a positive electrode of the power source is connected with a conductive workpiece, and a negative electrode of the power source is connected witha conductive electrode; the conductive workpiece and the conductive electrode are soaked with an electrolyte; the power source is turned on to machine the conductive workpiece, the power source outputs bipolar pulse voltage, the bipolar pulse voltage includes positive polarity voltage and negative polarity voltage, and the voltage value of the negative polarity voltage is larger than 25 V. The positive polarity voltage is used for oxidizing and corroding the conductive workpiece, the negative polarity voltage is used for generating spark, the electrolysis discharging efficiency of an electrode in the positive polarity voltage pulse period is improved, and the high machining efficiency can still be achieved under the centimeter-scale machining interval.

Owner:SOUTH UNIVERSITY OF SCIENCE AND TECHNOLOGY OF CHINA

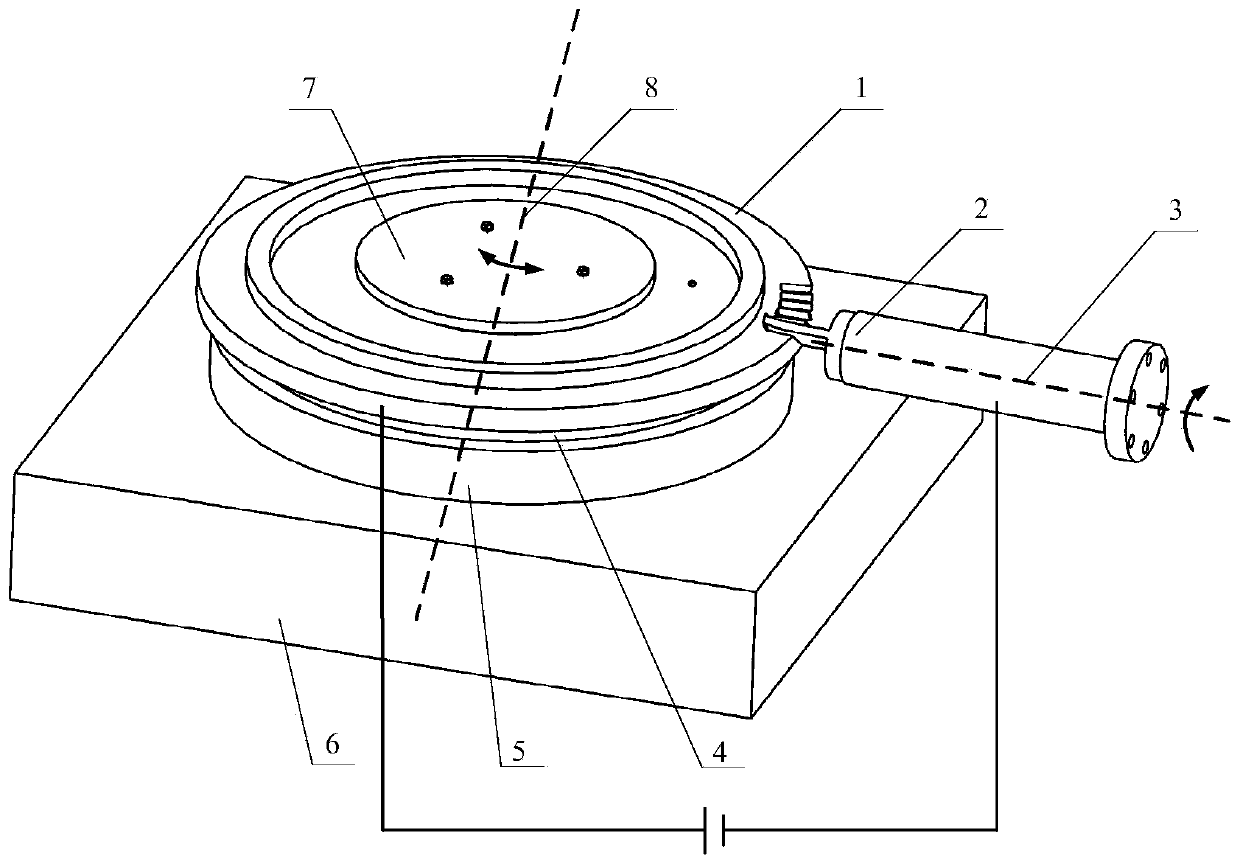

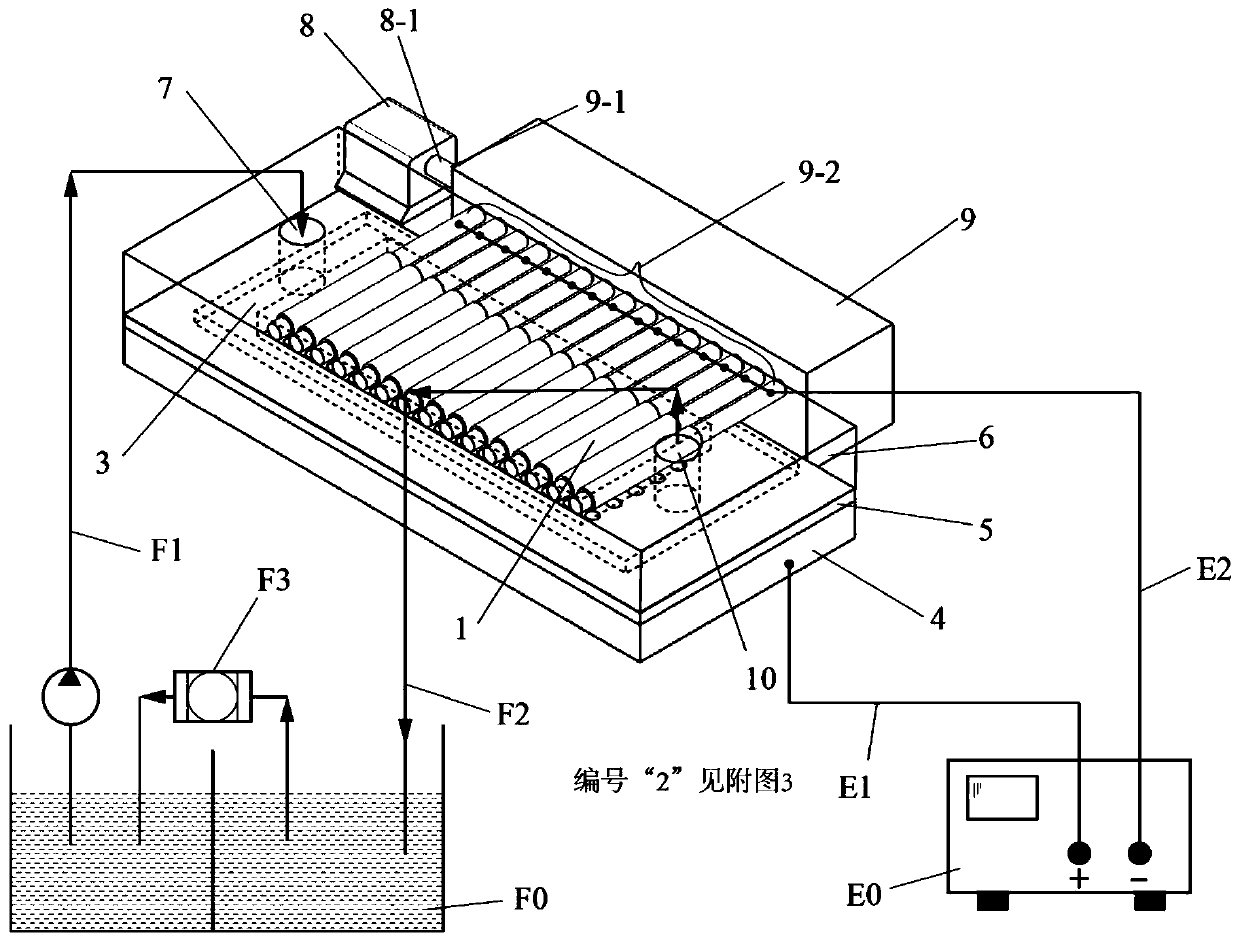

Device for electrochemical machining of template

ActiveCN110899876AIncrease flow rateImprove ECM EfficiencyMachining working media supply/regenerationElectrical-based auxillary apparatusElectrolytic agentMaterials science

The invention discloses a device for electrochemical machining of a template. The device comprises a fixture and the template, and an electrolyte flow chamber is formed between the fixture and the template; and the electrolyte flow chamber is internally provided with a group of metal columns connected with a negative electrode of a power supply, and the outer wall of each metal column is providedwith a circle of convex teeth. The convex teeth on the metal columns are inclined to the same direction. The electrolyte flow chamber is internally provided with a liquid inlet and a liquid outlet separately, and the rotation direction of the metal columns is consistent with the flow direction of electrolytes; and the inclination direction of the convex teeth is consistent with the rotation direction of the metal columns. According to the device, electrolytic products between the negative electrode and a positive electrode are directly stirred through mechanical motion, so that the mass transfer efficiency of the electrolytic products in an electrolyte flow field is improved.

Owner:NANJING UNIV OF TECH

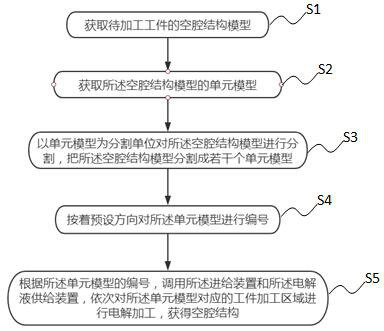

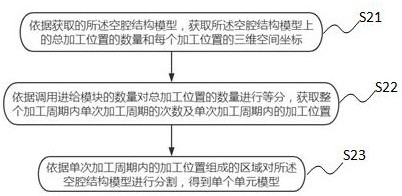

Electrolytic machining method for porous structure with gradually-changed aperture, terminal and storage medium

ActiveCN113385760AImproving Efficiency of Electrochemical Machining of Deep Hole with Variable DiameterMeet processing needsMachining working media supply/regenerationElectrical-based machining electrodesElectrolytic agentMachining

The invention discloses an electrolytic machining method for a porous structure with a gradually-changed aperture, a terminal and a storage medium. The method comprises the steps of acquiring a gradually-changed aperture porous structure model of a workpiece to be machined; acquiring a unit model of the gradually-changed aperture porous structure model; segmenting the gradually-changed aperture porous structure model by taking the unit model as a segmentation unit, and segmenting the gradually-changed aperture porous structure model into a plurality of unit models; numbering the unit models according to a preset direction; and according to the serial numbers of the unit models, calling a feeding device and an electrolyte supply device, using an aperture adjusting module to sequentially conduct electrolytic machining on gradually-changed aperture machining areas corresponding to the unit models, and acquiring the gradually-changed aperture porous structure. According to the electrolytic machining method for porous structure with the gradually-changed aperture provided by the invention, the efficiency of simultaneously machining multiple gradually-changed aperture deep holes can be improved, discharge of electrolyte and electrolytic products is promoted while the multiple gradually-changed aperture deep holes are machined through cooperation of a moving electrode and an variable-diameter electrode, and the electrolytic machining efficiency is improved.

Owner:深圳市亚泽科技有限公司

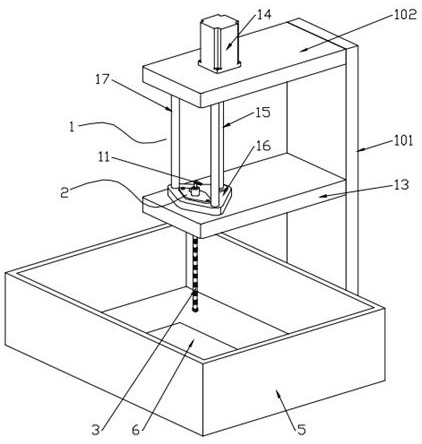

Subsequent electrolysis machining device and method for nickel-base superalloy member

InactiveCN111037011AHigh precisionConvenient post-electrolytic processingElectrochemical machining apparatusElectrical-based auxillary apparatusElectrolytic agentEngineering

The invention discloses a subsequent electrolysis machining device for a nickel-base superalloy member. The subsequent electrolysis machining device comprises an electrolyte tank and an electrolysis machining tool, wherein an electrolyte filtering system is connected to the electrolyte tank through a pipeline, the electrolysis machining tool comprises a base and a pulsed power source, a main shaftcapable of conducting feeding up and down is arranged above the base, a cathode assembly is connected to the lower end of the main shaft, the portion, located at the two sides of the main shaft, of the base is provided with supporting shafts, the two supporting shafts are symmetrically arranged along the main shaft, horizontal rotary shafts are rotatably arranged on the supporting shafts, clampsare fixed to the rotary shafts, and are correspondingly arranged to jointly clamp a workpiece, the positive electrode of the pulsed power source is electrically connected with the workpiece through acable, the negative electrode of the pulsed power source is electrically connected with the negative electrode assembly through a cable, and the cathode assembly is also connected with the electrolytefiltering system through a pipeline. By means of the subsequent electrolysis machining device, the problem in the prior art that the whole workpiece is filled with the electrolyte, resulting in low machining precision is solved. The invention furthermore discloses a subsequent electrolysis machining method for the nickel-base superalloy member.

Owner:XIAN BRIGHT ADDTIVE TECH CO LTD

A Method for Electrolytic Machining of Non-uniform Double-rotating Integral Blisk Cascade Channels

ActiveCN110605445BBalance evenly distributedImprove machining accuracyElectrochemical machining apparatusEngineeringMachining

The invention discloses a non-uniform-speed double-rotation variable-machining-blade cathode blisk electrolytic machining method. The method comprises the following steps that a rotating feeding shaftof a tool cathode is determined through simulation solution; the rotation angles and the rotation speeds of the tool cathode at different positions are determined through simulation solution, and themotion track of the tool cathode simulation is obtained; the rotation direction, the rotation angle and the rotation speed of a blisk blank is determined through simulation solution; a machining blade of the tool cathode is designed to be a variable-width machining blade; the tool cathode is driven to perform one-way variable-speed rotating radial feeding from the tool setting position along therotating feeding shaft according to the motion track of the simulation by taking the twisting direction of a blisk design model blade profile as the rotation direction; and the blisk blank is driven to cooperate with the variable-direction variable-speed rotation of the tool cathode around the central axis according to the rotation direction, the rotation speed and the rotation angle of simulationoptimization, and a blade lattice channel is formed on the blisk blank. According to the method, the electrolytically-formed blade lattice channel is uniform in allowance distribution and high in surface machining quality, and precise electrolytic machining of the blade lattice channel of the blisk can be realized.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

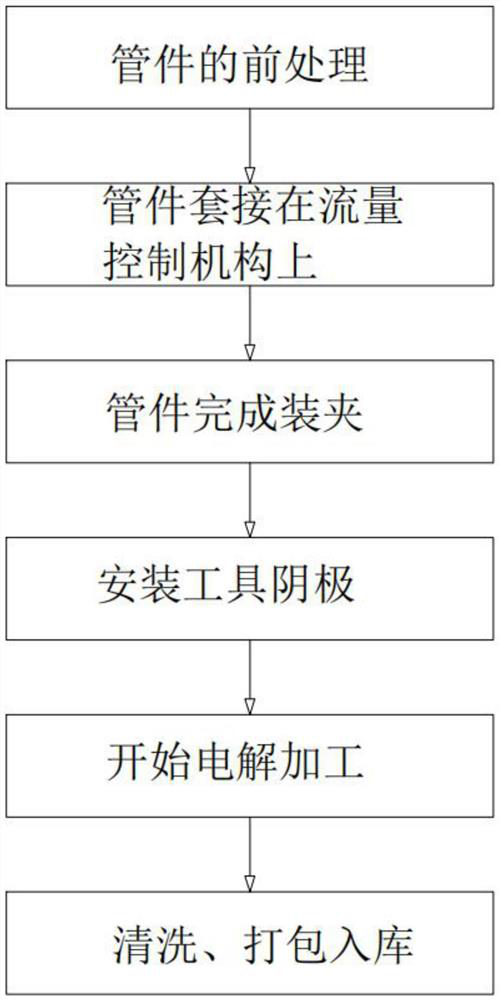

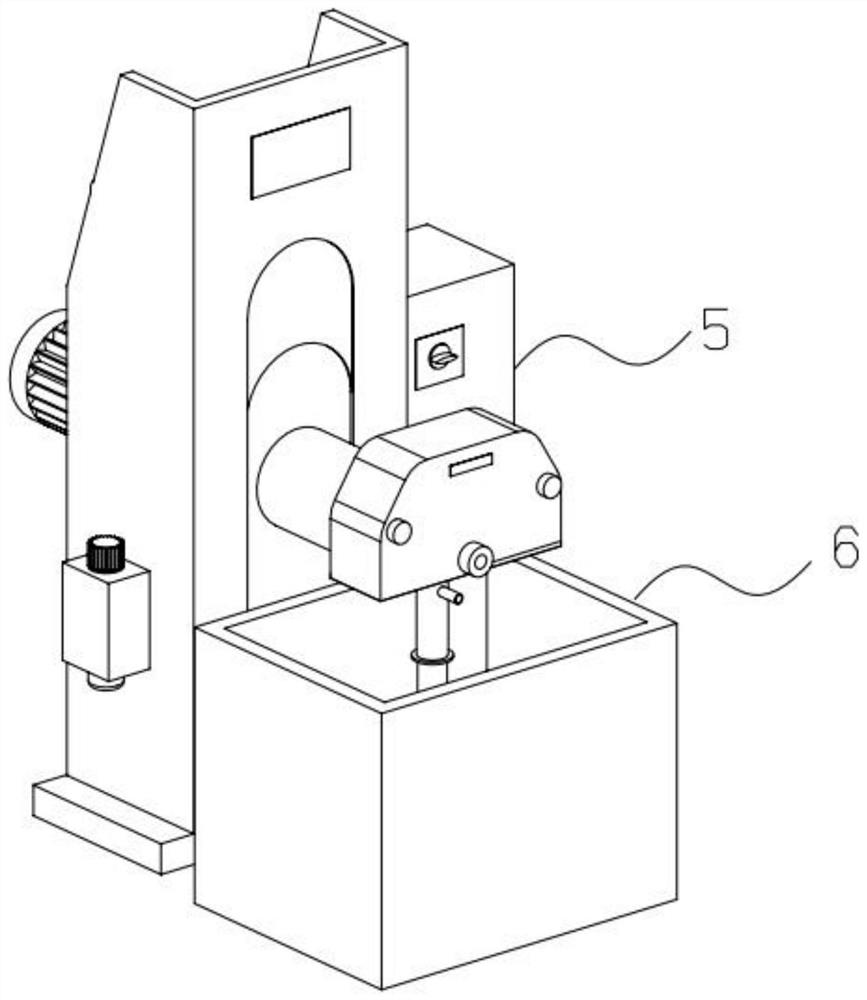

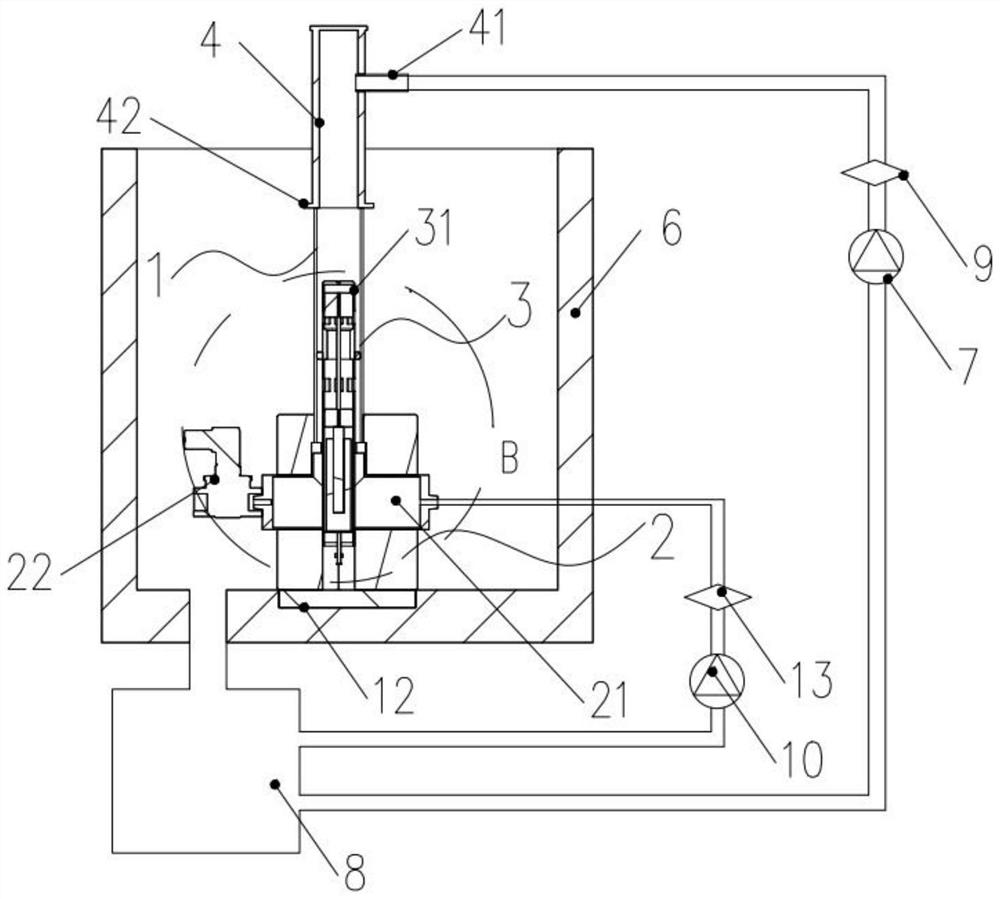

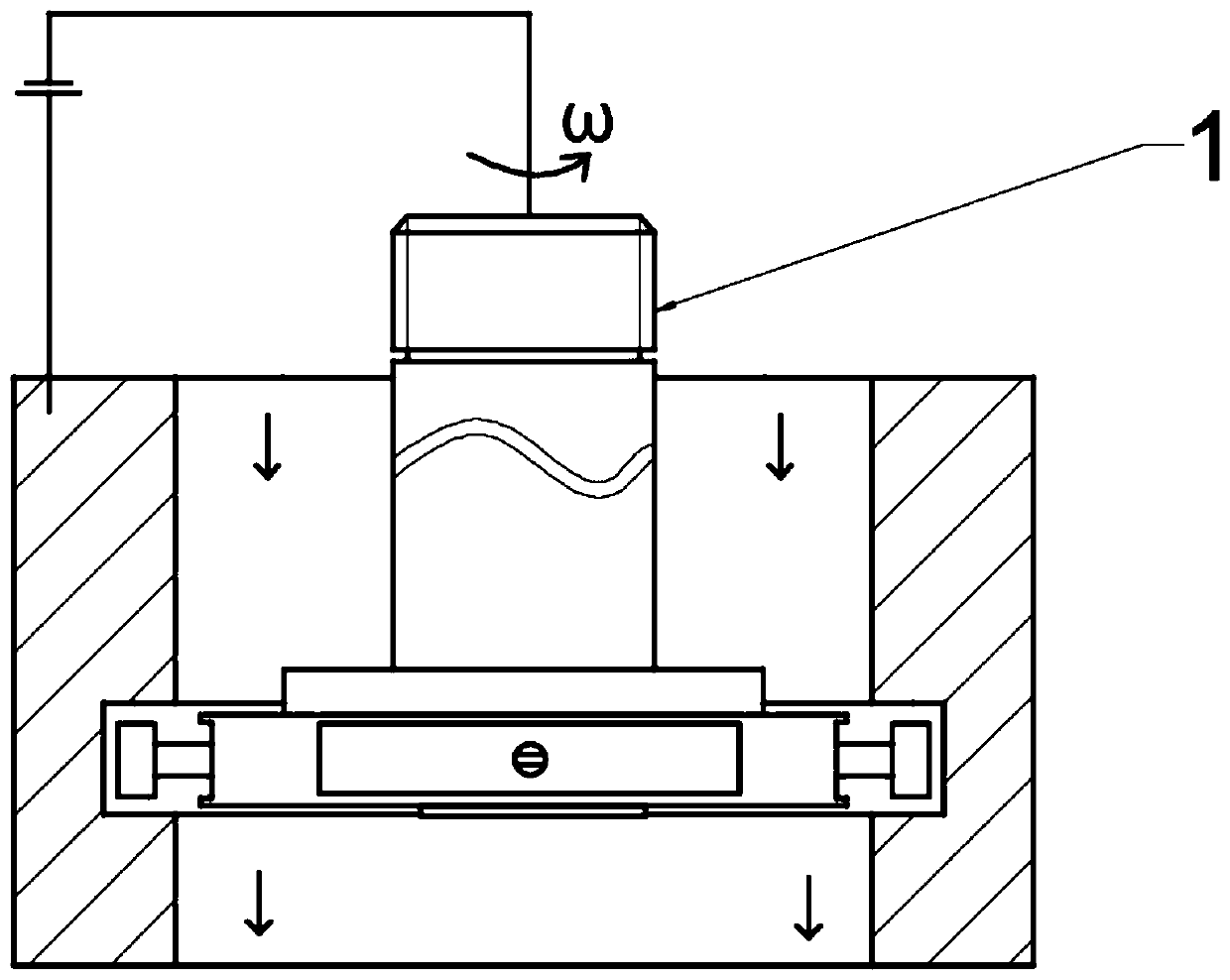

Precise electrolytic machining process for titanium alloy pipe fitting

ActiveCN114799757AGuaranteed liquidityImprove ECM EfficiencyMachining working media supply/regenerationElectrical-based auxillary apparatusElectrolytic agentPipe fitting

The invention discloses a precision electrolytic machining process for a titanium alloy pipe fitting, and belongs to the technical field of precision electrolysis. Comprising the steps of titanium alloy pipe fitting pretreatment, clamping, electrolytic machining, cleaning, packaging, warehousing and the like, the defects of a traditional method are overcome, the liquidity of electrolyte in the machining process can be guaranteed during electrolysis, and therefore the electrolytic machining efficiency is improved, and the machining time is shortened; the electrolyte flows into the tool cathode and the pipe fitting at the same time, the electrolyte can flow out through the machining gap between the tool cathode and the pipe fitting, impurities generated in electrolytic machining can be prevented from being deposited on the tool cathode or in the pipe fitting, and it can be guaranteed that the quality of the electrolyte flowing through the machining gap is stable.

Owner:JIANGSU JIANGHANGZHI AIRCRAFT ENGINE COMPONENTS RES INST CO LTD

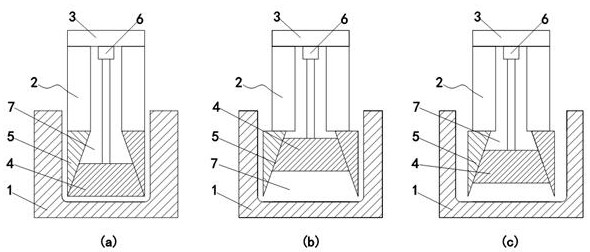

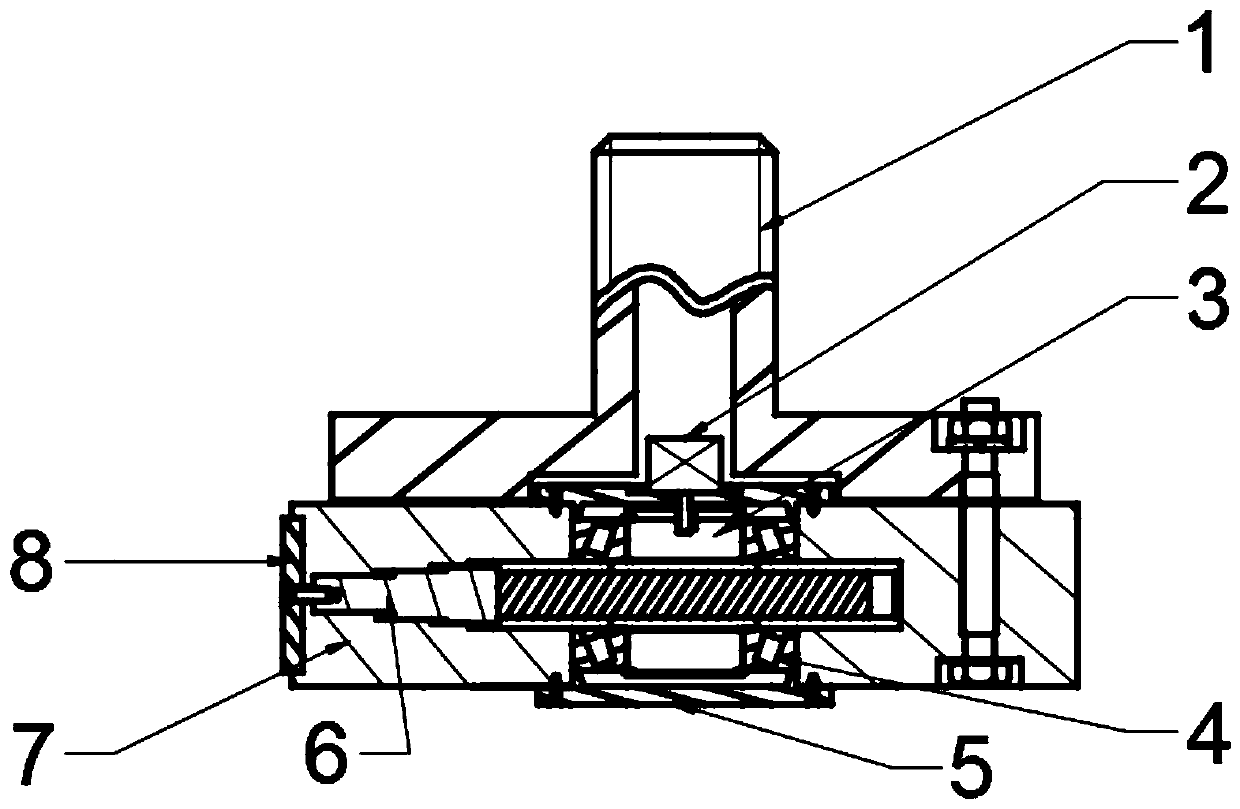

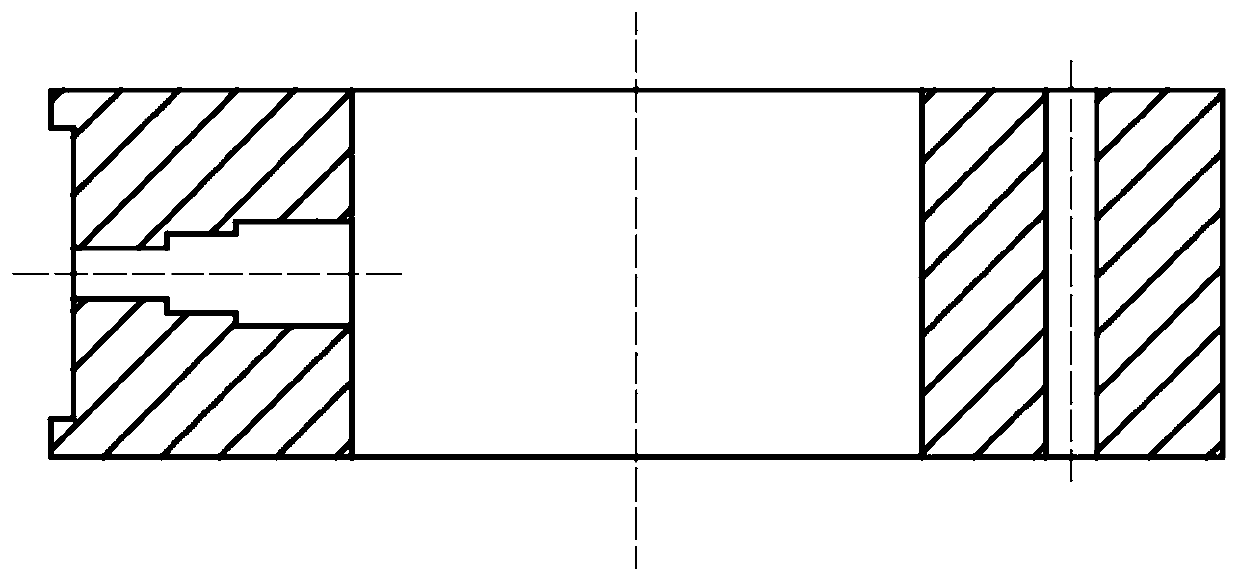

Cam expansion rotating tool cathode for electrolytic machining

PendingCN110202224AAvoid Positioning ErrorsLateral expansion of the working surfaceMachining electrodesElectrical-based machining electrodesManufacturing technologyElectrolysis

The invention relates to the technical field of electrolytic machining, in particular to a cam expansion rotating tool cathode for electrolytic machining, and solves the problems of difficult machining of inner wall structures with higher machining depth requirements, weak machining precision and low machining efficiency in the prior art. The cam expansion rotating tool cathode for electrolytic machining comprises a cathode mounting frame; the cathode mounting frame is arranged at the upper part of a base, and is connected with the base through a double-head screw rod; a camshaft is arranged in the center of the base, and is provided with three cams; conical roller bearings are arranged between the camshaft and the base, and are arranged on shaft necks on the two sides of the camshaft; anoutput shaft of a stepper motor is connected with the camshaft through a key; the horizontal rotation of the camshaft in the base is realized; the base is annular; transverse step through holes corresponding to arc working surfaces one to one are uniformly formed in the annular base; step-shaped push rods are arranged in the through holes; and the arc working surfaces are uniformly distributed onthe periphery of the base, and are fixedly connected with the push rods.

Owner:XIAN TECH UNIV

Ultrasonic-plasma electrolytic composite processing method and processing device for workpiece

ActiveCN112809111BImprove ECM EfficiencyPromote circulationEfficient propulsion technologiesElectrolytic agentDc voltage

The application discloses an ultrasonic-plasma electrolytic composite processing method and a processing device for workpieces. The processing method comprises the following steps: providing electrolyte solution between the non-metallic layer and the tool electrode; connecting the metal layer to the positive pole of the electrolytic machining power supply, connecting the tool electrode to the negative pole of the electrolytic machining power supply, and applying a DC voltage between the metal layer and the tool electrode; The tool electrode is moved relative to the non-metal layer from the side of the non-metal layer away from the metal layer, and the ultrasonic wave is guided to the non-metal layer. In the above method, the surface of the non-metallic layer is firstly processed by ultrasonic waves guided to the non-metallic layer. During the ultrasonic processing, the induced plasma can promote the circulation of the ultrasonic processing solution, so that the ultrasonic processing products can be quickly discharged from the processing area. After the non-metallic layer is processed, the metal layer is exposed, so that the metal layer is processed in parallel by ultrasonic electrolysis.

Owner:SOUTH UNIVERSITY OF SCIENCE AND TECHNOLOGY OF CHINA

Electrolytic machining method, terminal and storage medium

InactiveCN114769756AImprove ECM EfficiencyHigh degree of automationMachining working media supply/regenerationElectrolytic agentProcess engineering

The invention discloses an electrolytic machining method, a terminal and a storage medium, the method relates to calling a feeding device and an electrolyte supply device to machine a three-dimensional cavity, and the method comprises the steps that a cavity structure model of a workpiece to be machined is obtained; obtaining a unit model of the cavity structure model; segmenting the cavity structure model by taking a unit model as a segmentation unit, and segmenting the cavity structure model into a plurality of unit models; numbering the unit models according to a preset direction; according to the serial numbers of the unit models, the feeding device and the electrolyte supply device are called, electrolytic machining is conducted on workpiece machining areas corresponding to the unit models in sequence, and a cavity structure is obtained; a three-dimensional cavity structure is divided into unit model structures, a feeding device and an electrolyte device are called, a sealed machining area is formed at the machining end and the machining position of a cathode, electrolysis products and waste gas are recycled, and the environment is protected; and meanwhile, the machining efficiency is improved, and the protection effect on the cathode is improved.

Owner:刘宇

A precision electrolytic machining process for multi-tooth turbine blades

ActiveCN113182625BStable temperature controlAccelerate the lossMachining electrodesMachining working mediaElectrolytic agentTurbine blade

The invention discloses a multi-tooth turbine blade precision electrolytic machining process, which relates to the technical field of turbine blade electrolytic machining, including the preparation of tool cathodes, the installation of tool cathodes, and the electrolytic machining of slub holes. The invention overcomes the limitations of traditional methods. Defects, it can still ensure the stability of the processing process under the condition of high voltage, thereby improving the efficiency of electrolytic processing and shortening the processing time. When the temperature of the electrolyte rises, the flow rate of the electrolyte can be adjusted by the adjustment module to accelerate The loss of heat in the electrolytic processing area achieves stable control of the temperature of the electrolyte.

Owner:JIANGSU JIANGHANGZHI AIRCRAFT ENGINE COMPONENTS RES INST CO LTD

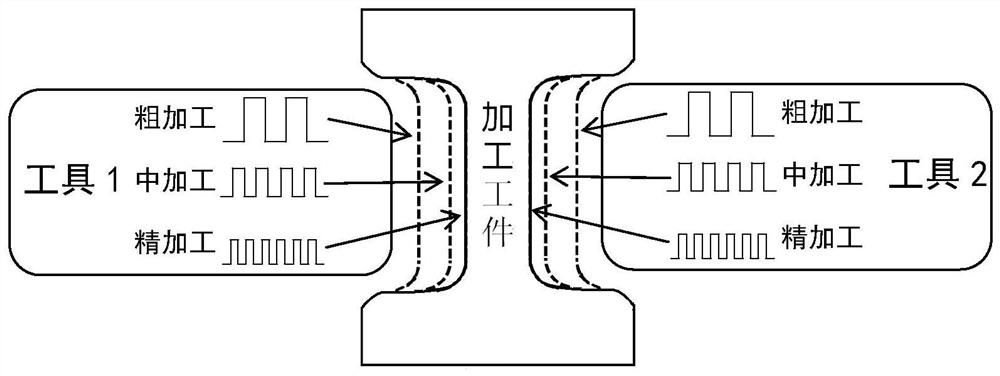

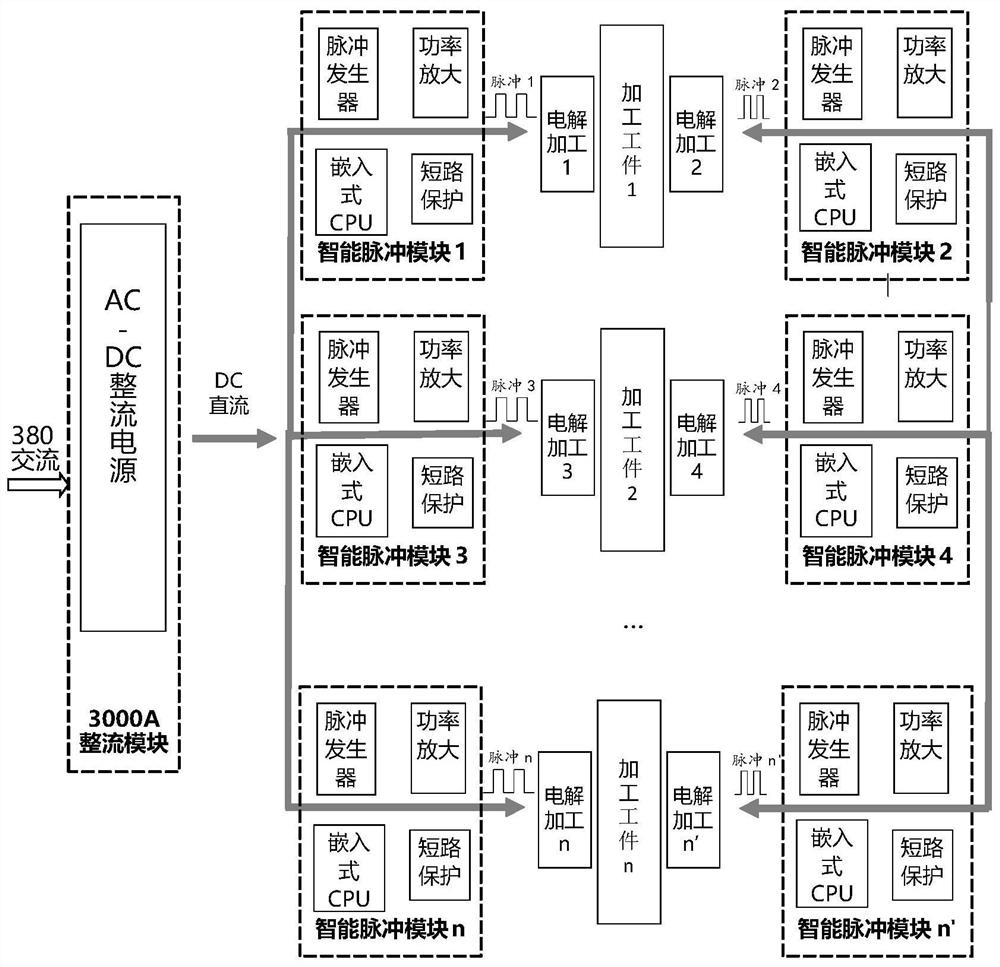

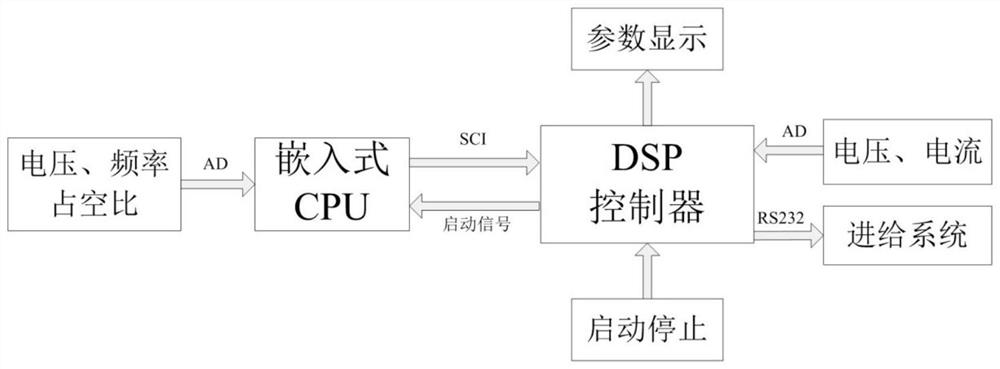

Intelligent control pulse power supply system and control method for multi-station blade electrolytic machining

ActiveCN109986154BSave spaceReduce output wiring lengthElectrochemical machining apparatusElectrical-based auxillary apparatusElectrolysisPulse power supply

The invention relates to an intelligent control pulse power supply system for multi-station blade electrolytic machining and a control method. The method rectifies a commercial direct-current power supply by adopting a high-current rectifying module; the intelligent pulse module is small in size, and can be even arranged in a multi-station machine tool body; therefore, the mutually independent andmatched intelligent pulse modules can generate and control processing pulse signals of a blade basin cathode and a blade back cathode; the wiring distance between a processing area and the intelligent pulse module is obviously reduced, so that the parasitic inductance of a loop is reduced to the minimum, the waveform distortion is reduced to the minimum, the anti-interference capability of the power supply is improved, and the method is an effective way for improving the blade processing precision and the production efficiency.

Owner:南京真笙机械科技有限公司

Method and implementation device for bipolar electrolytic electrolytic machining of workpieces

The invention discloses a method for bipolar electrolysis discharging machining of parts and an implementing device. The method for bipolar electrolysis discharging machining of parts comprises the following steps that a power source is supplied, wherein a positive electrode of the power source is connected with a conductive workpiece, and a negative electrode of the power source is connected witha conductive electrode; the conductive workpiece and the conductive electrode are soaked with an electrolyte; the power source is turned on to machine the conductive workpiece, the power source outputs bipolar pulse voltage, the bipolar pulse voltage includes positive polarity voltage and negative polarity voltage, and the voltage value of the negative polarity voltage is larger than 25 V. The positive polarity voltage is used for oxidizing and corroding the conductive workpiece, the negative polarity voltage is used for generating spark, the electrolysis discharging efficiency of an electrode in the positive polarity voltage pulse period is improved, and the high machining efficiency can still be achieved under the centimeter-scale machining interval.

Owner:SOUTH UNIVERSITY OF SCIENCE AND TECHNOLOGY OF CHINA

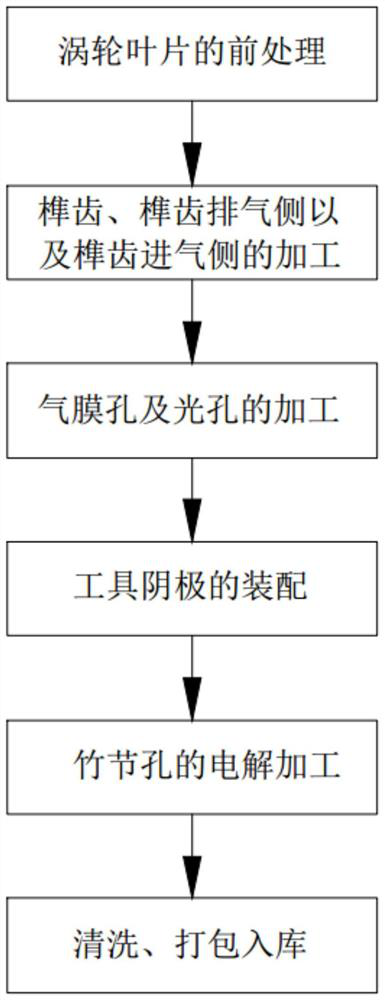

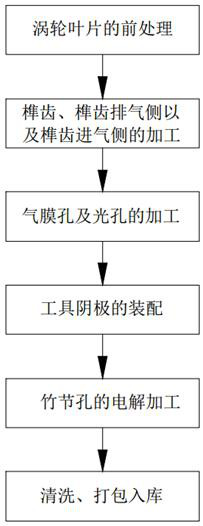

Precision machining method for multi-tooth turbine blade of aero-engine

ActiveCN113084465AStable temperature controlAccelerate the lossEfficient propulsion technologiesMachining working media supply/regenerationElectrolytic agentTurbine blade

The invention discloses a precision machining method for a multi-tooth turbine blade of an aero-engine, and relates to the technical field of turbine blade machining. The method comprises the steps of pretreatment of the turbine blade, machining of tenon teeth, the tenon tooth exhaust side and the tenon tooth air inlet side, machining of an air film hole and an unthreaded hole, assembling of a tool cathode, electrolytic machining of a bamboo joint hole, cleaning, packaging, warehousing and the like. According to the method, the defects of a traditional method are overcome, the stability of the machining process can still be guaranteed under the condition of high voltages, and therefore the electrolytic machining efficiency is improved, the machining time is shortened, and when the temperature of electrolyte rises, the flow speed of the electrolyte can be adjusted through an adjusting module so as to accelerate heat dissipation of an electrolytic machining area. And stable control of the temperature of the electrolyte is achieved.

Owner:JIANGSU JIANGHANGZHI AIRCRAFT ENGINE COMPONENTS RES INST CO LTD

A groove array electrolytic machining system and method based on pdms template

ActiveCN107186298BGuaranteed spacingOvercome the defect of easy deformationMachining electrodesMachining working media supply/regenerationElectrolysisBiochemical engineering

The invention discloses a system and a method for carrying out electrolytic machining on a groove array on the basis of a PDMS template. The method comprises the following steps: a. producing a clamp; b. producing a cathode tool with a groove structure; c. producing the PDMS template; d. embedding the PDMS template in a groove of the cathode tool; e. clamping the PDMS template, the cathode tool and an anode workpiece; f. connecting the anode workpiece and the cathode tool to the positive pole and the negative pole of a power supply separately; g. charging an electrolyte into the clamp, wherein the pressure of the electrolyte is greater than 0.1MPa; and h. turning on the power supply, and carrying out electrolytic machining. The electrolytic machining is carried out through the method, the position of the PDMS template is fixed by the cathode tool, a uniform width of the machined grooves is ensured, and the PDMS template closely contacts with the anode workpiece, so that improvement for the electrolytic machining accuracy of the groove array is benefited; and because the PDMS template can be repeatedly used, the method increases the machining efficiency of the groove array.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Tool and method for machining variable-section hole through total reflection laser and jet flow electrolysis assisted by dry ice impact

ActiveCN114309841ARealize one-time molding processingReduce unevennessMaintainance and safety accessoriesElectrical-based auxillary apparatusElectrolytic agentMachined surface

The invention discloses a tool and method for machining a variable cross-section hole through total reflection laser and jet flow electrolysis assisted by dry ice impact, and relates to the field of non-traditional machining, and the tool comprises a hollow annular glass tube, a metal layer and an insulating coating; a metal layer is electroformed on the outer side wall of the hollow annular glass tube, insulating coatings are coated on the outer side wall of the metal layer except a plurality of annular areas without insulating coatings in the axial direction, and secondary electrolysis is carried out on a hole processed at the end part of a tool electrode in the annular areas so as to realize reaming and polishing. According to the machining method, laser beams between the inner tube and the outer tube of the hollow annular glass tube form annular laser beams through total reflection conduction of electrolyte, so that machining efficiency is improved, and meanwhile the flatness of the machined surface is improved; the laser beams reach a machined area on a workpiece through multiple times of total reflection of the wall surfaces of the inner tube and the outer tube; dry ice microparticles are sprayed from the inner pipe of the hollow annular glass pipe to a processing area to promote disturbance and rapid cooling of the processing area. According to the invention, one-time forming processing of the variable cross-section hole can be realized.

Owner:JIANGSU UNIV

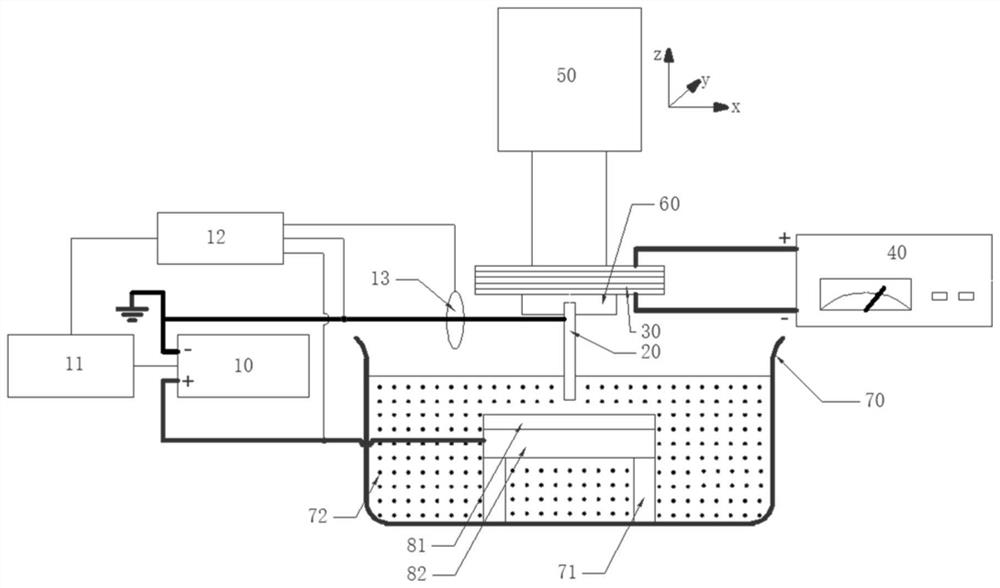

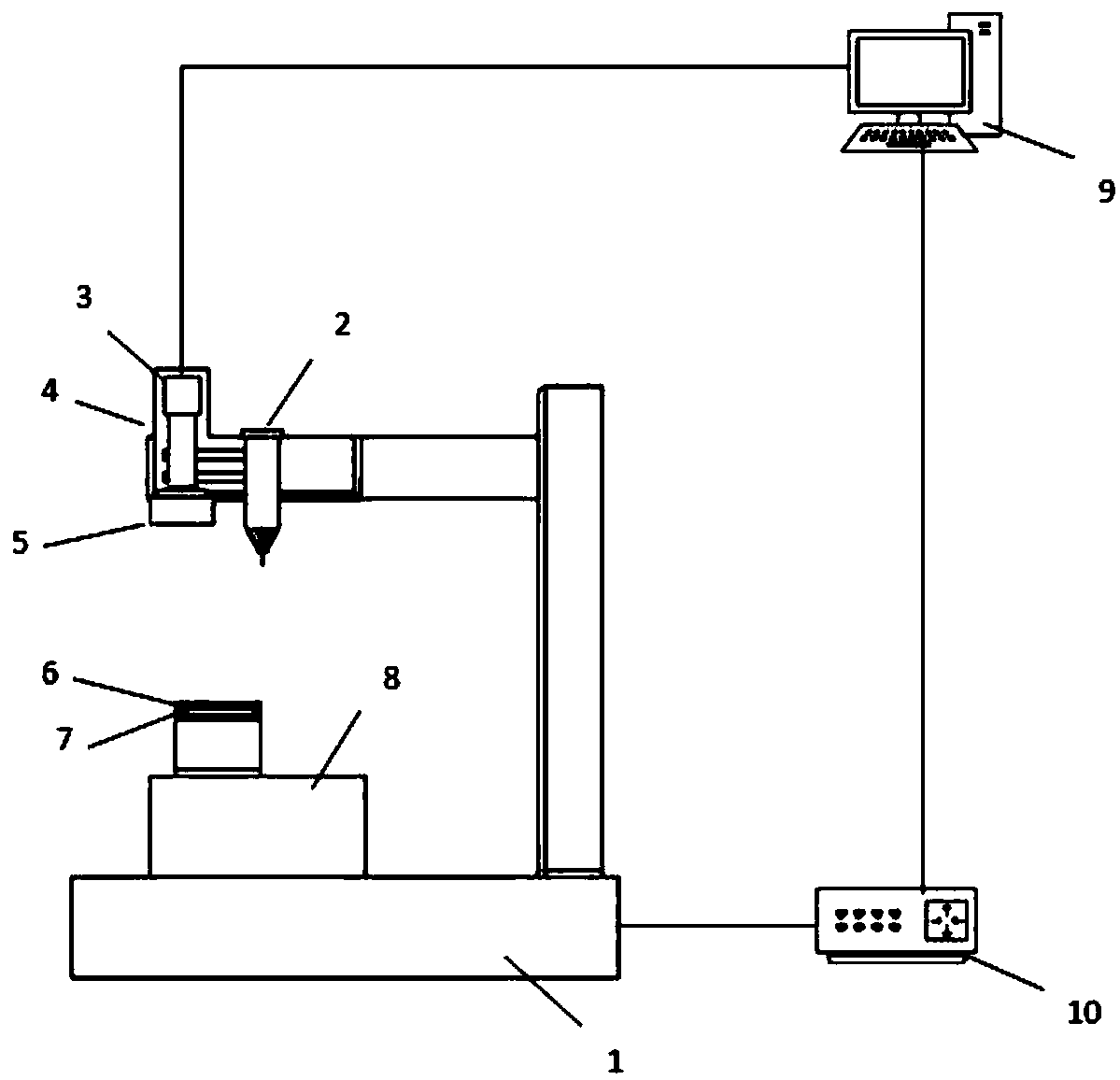

A kind of micro-hole electrolytic machining machine vision positioning and navigation method

InactiveCN106112152BReduce human errorImprove ECM EfficiencyElectrochemical machining apparatusElectrical-based auxillary apparatusMachine visionImaging processing

A microporous electrolytic machining machine vision positioning and navigation method. First, the vision device is used to install the target on the pad, and then the pixel equivalent of the vision device is calibrated, and then the electrode wire is used as the origin. The guide rail is the x and y axes of the coordinate system, establish the electrode wire coordinate system, calibrate the coordinate system of the vision device, and then calibrate the coordinate system offset of the vision device, and then place the workpiece to be processed on the fixture, and pass the vision device When the microhole to be processed is detected, the computer calculates the coordinates x and y of its center through the image processing program, and calculates the displacement information, and sends the displacement information to the control cabinet control workbench, so that the microhole to be processed and the electrode wire are aligned , electrolytically process the microhole, and then carry out the electrolytic machining of the next microhole. The present invention uses vision to detect the center of the microhole and completes the alignment of its electrode wire, which can greatly improve the accuracy and efficiency of electrolytic machining.

Owner:XI AN JIAOTONG UNIV

A precision machining method for multi-tooth turbine blades of an aero-engine

ActiveCN113084465BStable temperature controlAccelerate the lossEfficient propulsion technologiesMachining working media supply/regenerationElectrolytic agentTurbine blade

The invention discloses a precision machining method for multi-tooth turbine blades of an aero-engine, and relates to the technical field of turbine blade processing, including pretreatment of turbine blades, processing of tenon teeth, tenon tooth exhaust side and tenon tooth intake side, air film holes and light Hole processing, tool cathode assembly, bamboo hole electrolytic processing, cleaning, packaging and storage, etc., the present invention overcomes the defects of the traditional method, and can still ensure the stability of the processing process under the condition of high voltage. In this way, the efficiency of electrolytic machining is improved and the processing time is shortened. When the temperature of the electrolyte rises, the flow rate of the electrolyte can be adjusted through the adjustment module to accelerate the loss of heat in the electrolytic machining area and achieve stable control of the temperature of the electrolyte.

Owner:JIANGSU JIANGHANGZHI AIRCRAFT ENGINE COMPONENTS RES INST CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com