Precision machining method for multi-tooth turbine blade of aero-engine

An aero-engine and turbine blade technology, applied in electric processing equipment, air transportation, metal processing equipment, etc., can solve problems such as restricting the processing efficiency of turbine blades and reducing processing stability, shortening processing time, increasing flow rate, and preventing short circuits. effect of the phenomenon

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

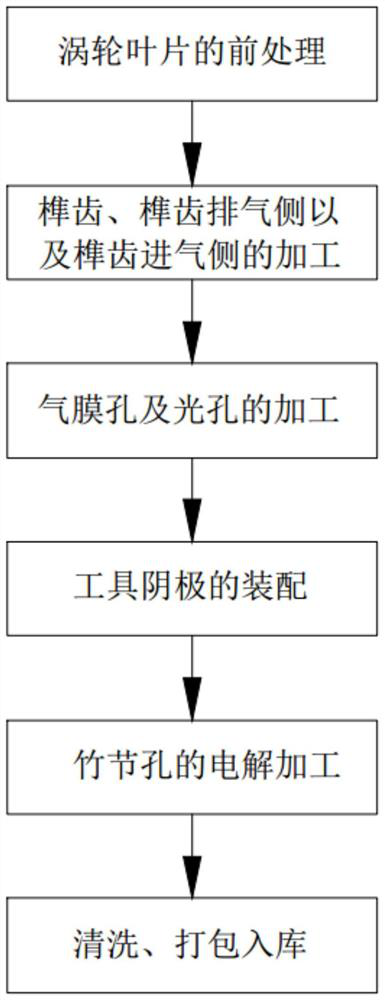

[0040] Such as Figure 1 to Figure 11 As shown, the present invention discloses a precision machining method for multi-tooth turbine blades of an aero-engine, which specifically includes the following steps:

[0041] Step 1. Take the rough blank of the turbine blade and clean the surface. After cleaning, use the positioning mechanism to perform multi-point positioning of the turbine blade;

[0042] Step 2. Machining the mortise teeth, the mortise teeth exhaust side and the mortise teeth intake side by using the CNC machining center;

[0043] Step 3, using the electric discharge process to process air film holes and light holes radially distributed along the blade body on the blade body;

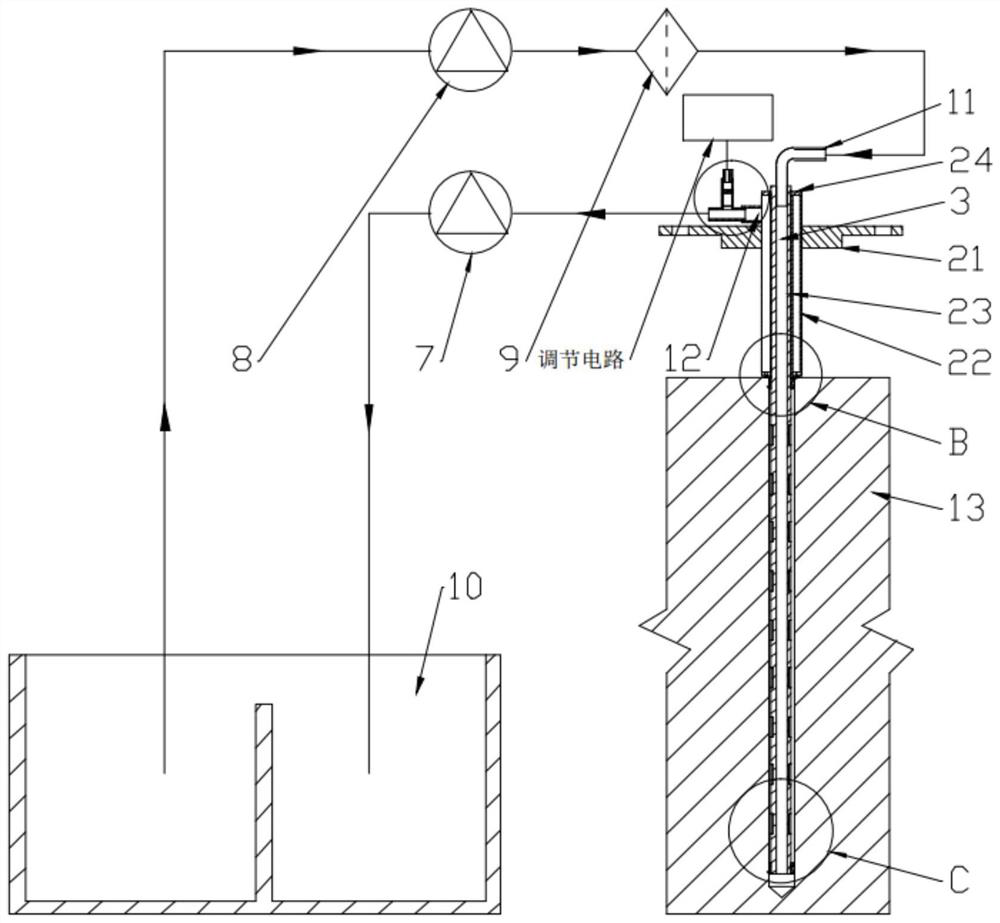

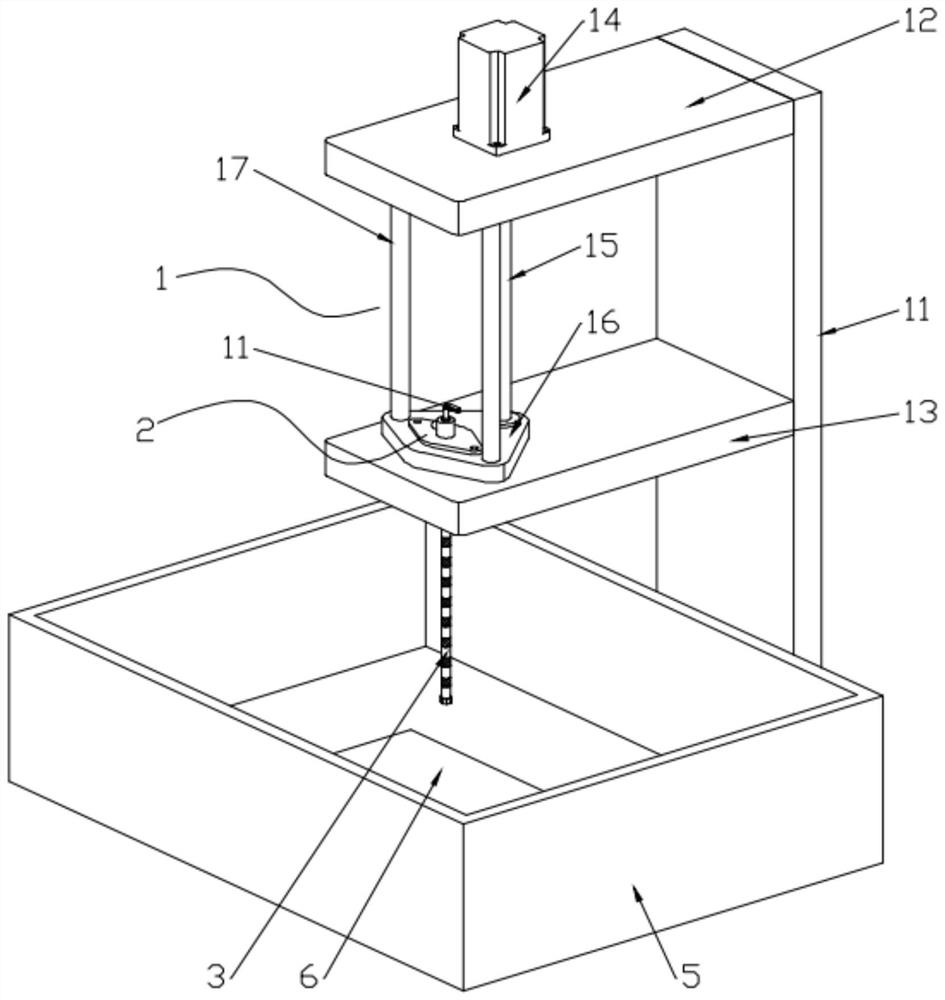

[0044] Step 4: Take the tool cathode 3 and install the supp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com