Digital signal processing and controlling system of nondispersive infrared gas analyzer

A technology of digital signal processing and gas analyzers, which is applied in the direction of material analysis, analysis materials, instruments, etc. through optical means, and can solve the problems of not disclosing technical details

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

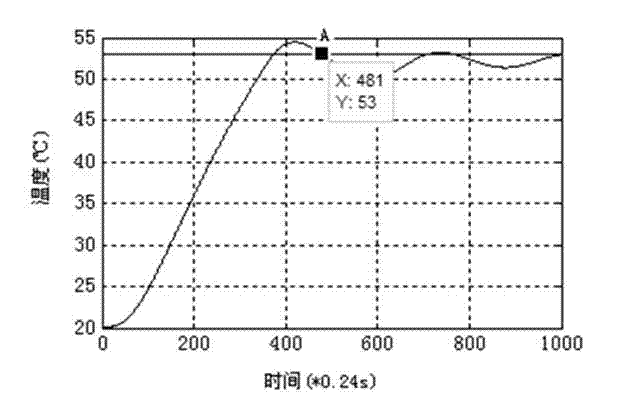

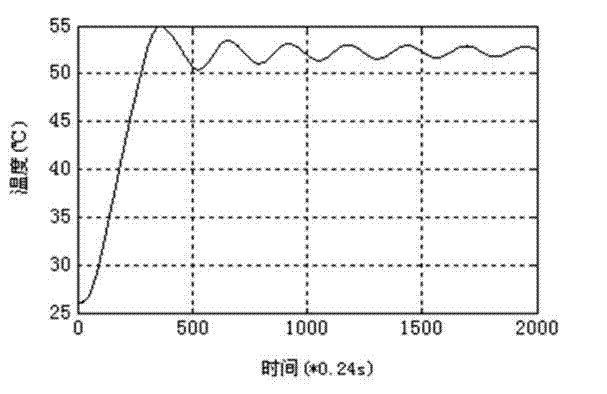

[0044] The present invention will be further described below in conjunction with the accompanying drawings.

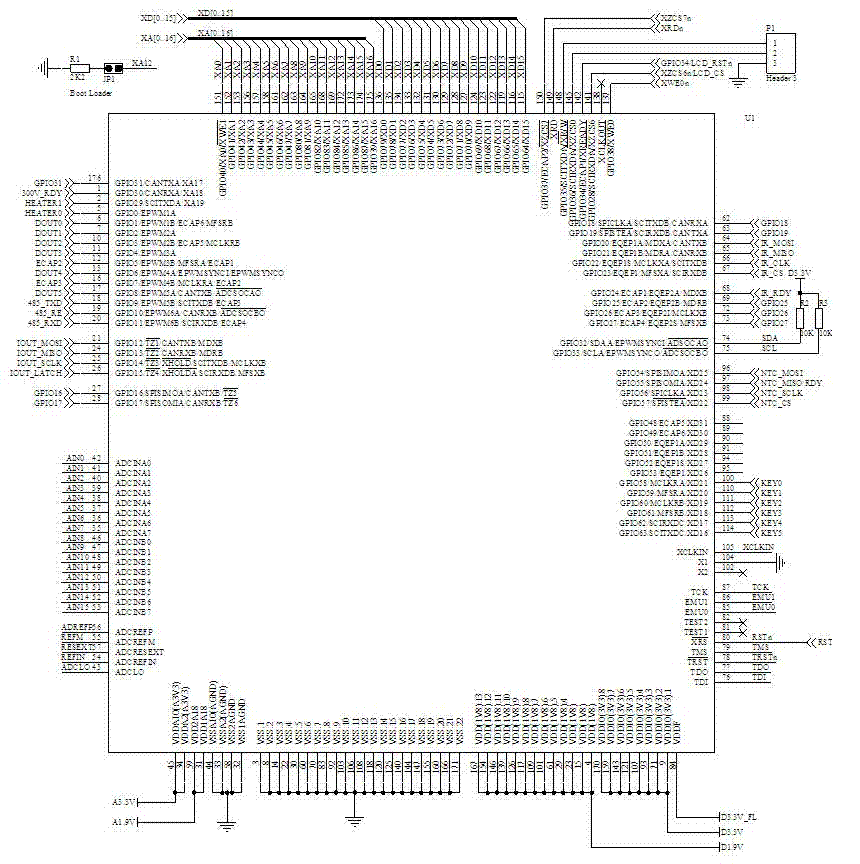

[0045] 1) System hardware solution

[0046] According to the characteristics of the non-spectral infrared gas analyzer and the needs of digital signal processing and control algorithms, the hardware scheme of the digital signal processing and control system shown in Figure 1 is determined. The whole system hardware circuit includes TMS320F28335DSP chip, infrared signal conditioning circuit, voltage reference buffer circuit, 24-bit ADC, temperature acquisition circuit, air pressure acquisition circuit, 16-bit ADC, external expansion SRAM circuit, ferroelectric memory (FRAM) circuit, real-time clock ( RTC) circuit, reset circuit with watchdog and power monitoring, thermal resistance drive circuit, button circuit, digital output circuit, RS-232 / 485 interface circuit, liquid crystal display circuit, 4~20mA / 0~20mA output circuit. The infrared signal conditioning circuit re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com