Patents

Literature

1201 results about "Gas analysis" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

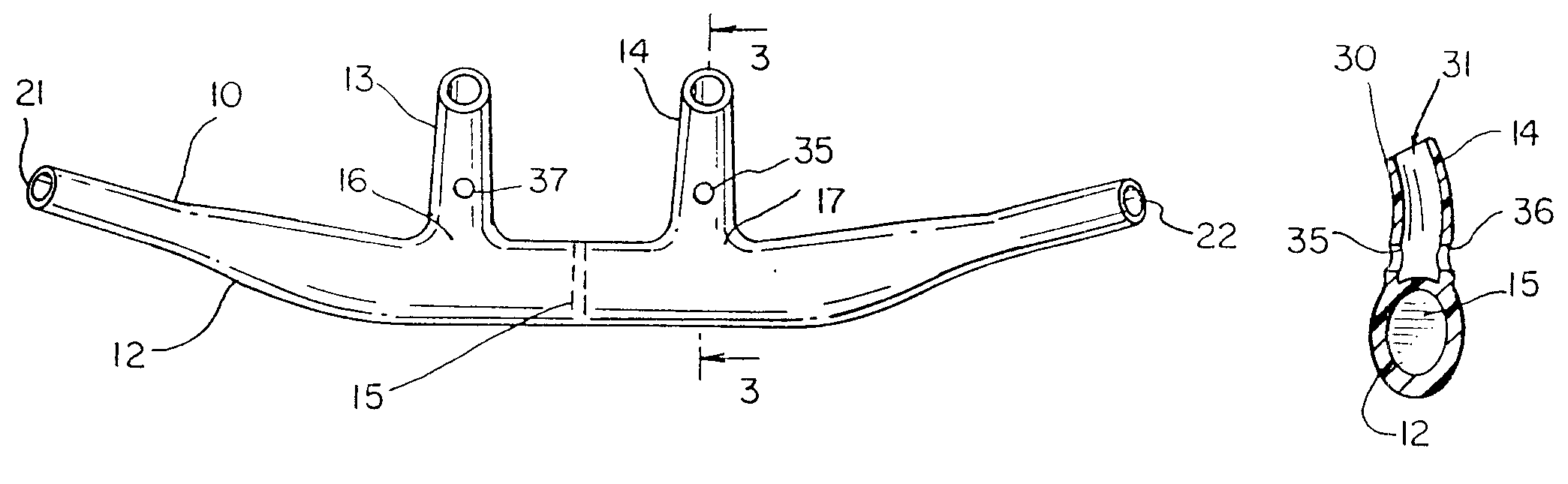

Nasal cannula

InactiveUS6439234B1Reduces and eliminates incidenceAccurate monitoringOperating means/releasing devices for valvesRespiratory masksGas analysisNose

Owner:SALTER LABS

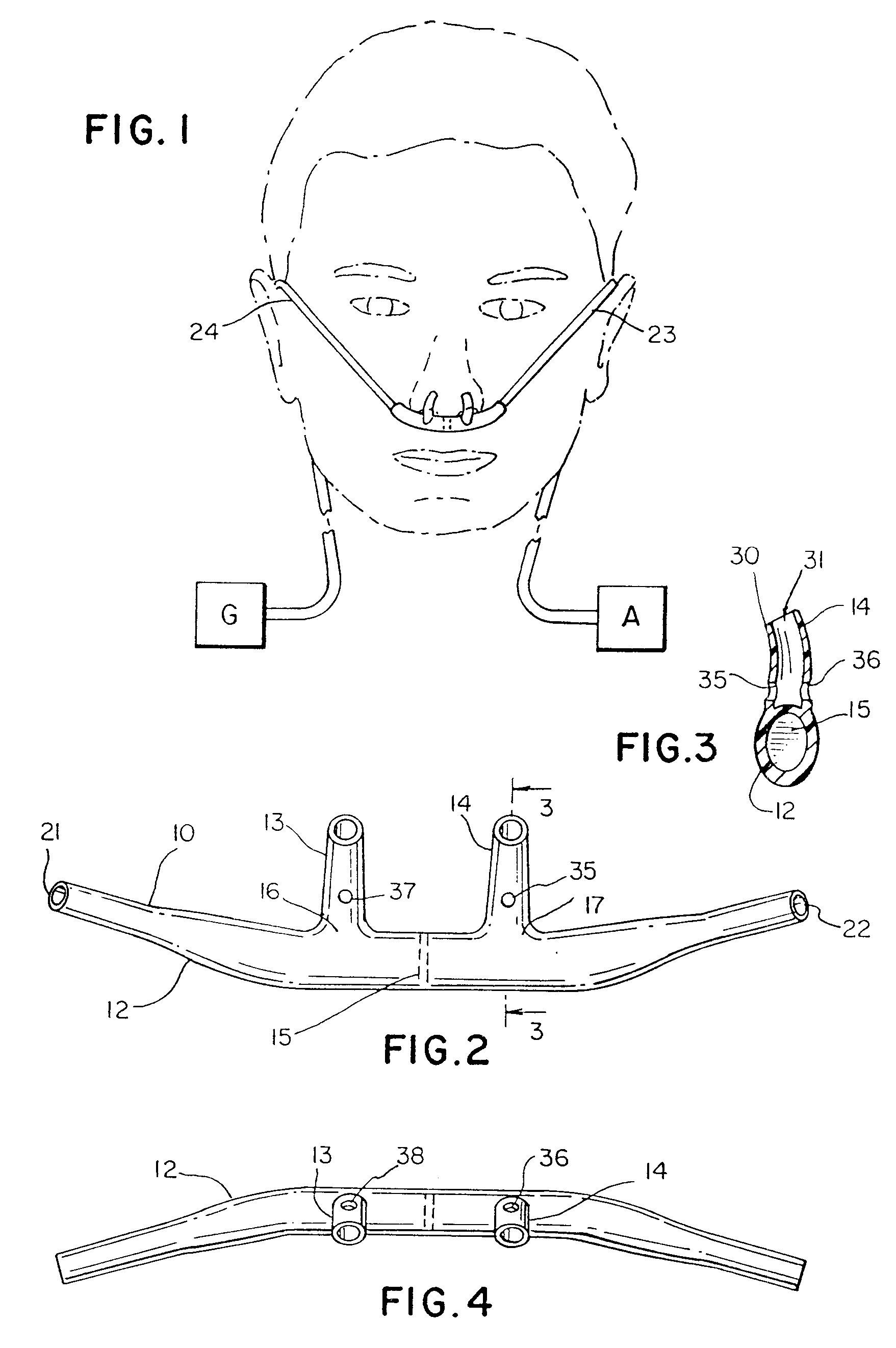

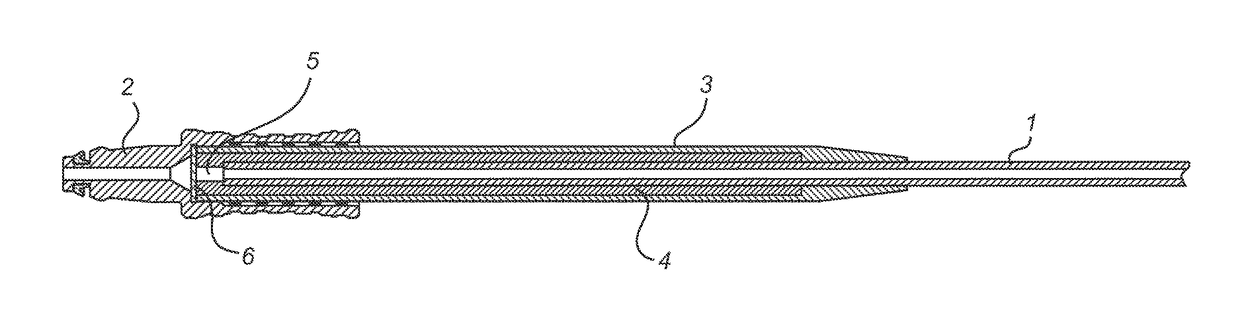

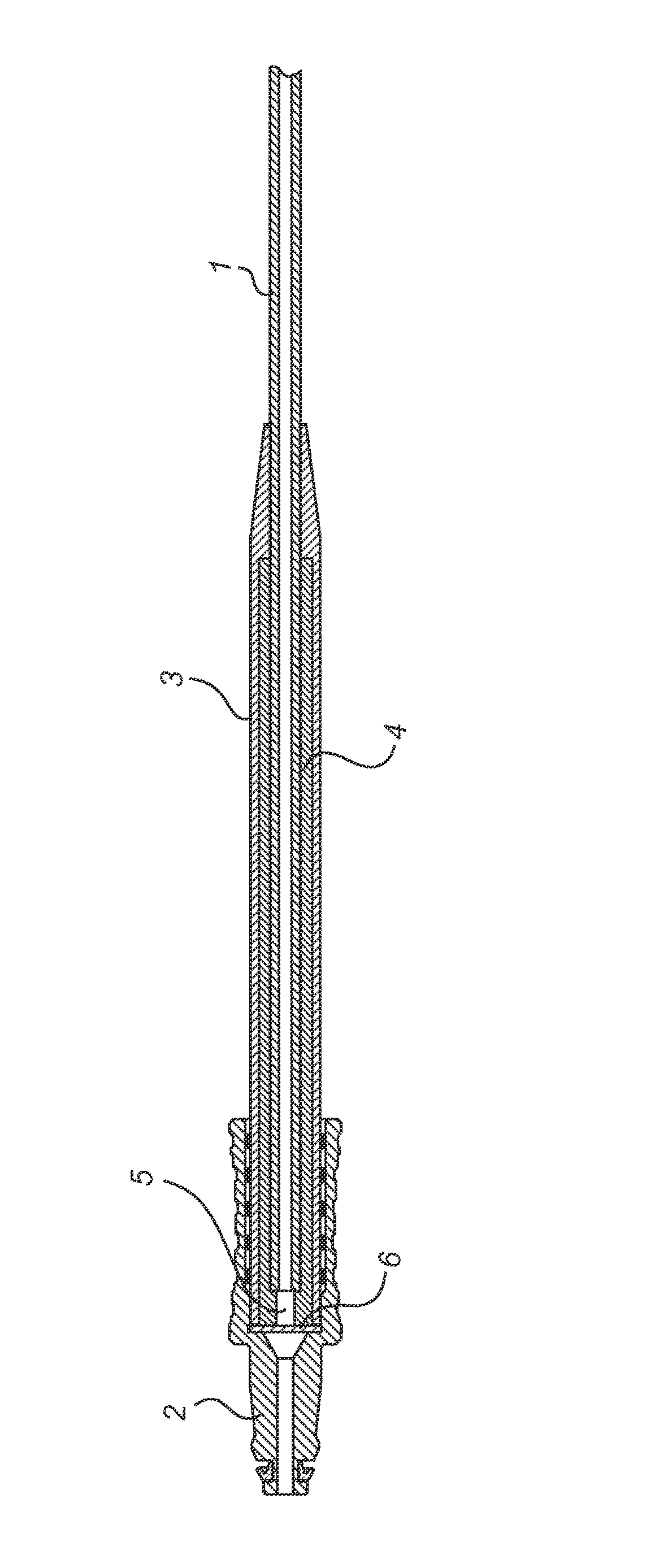

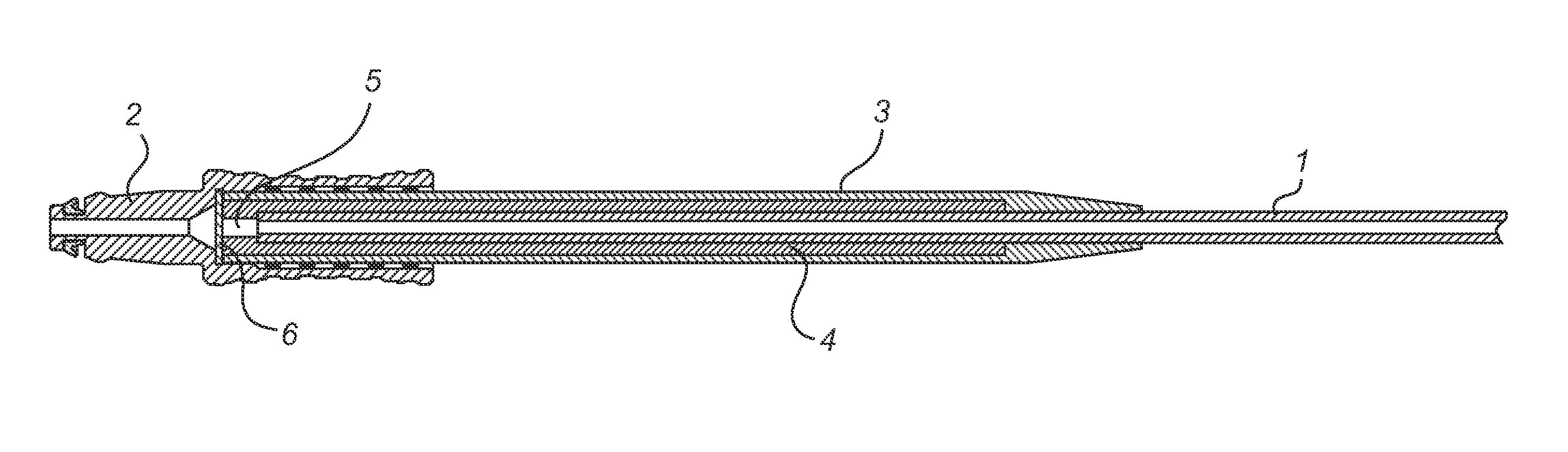

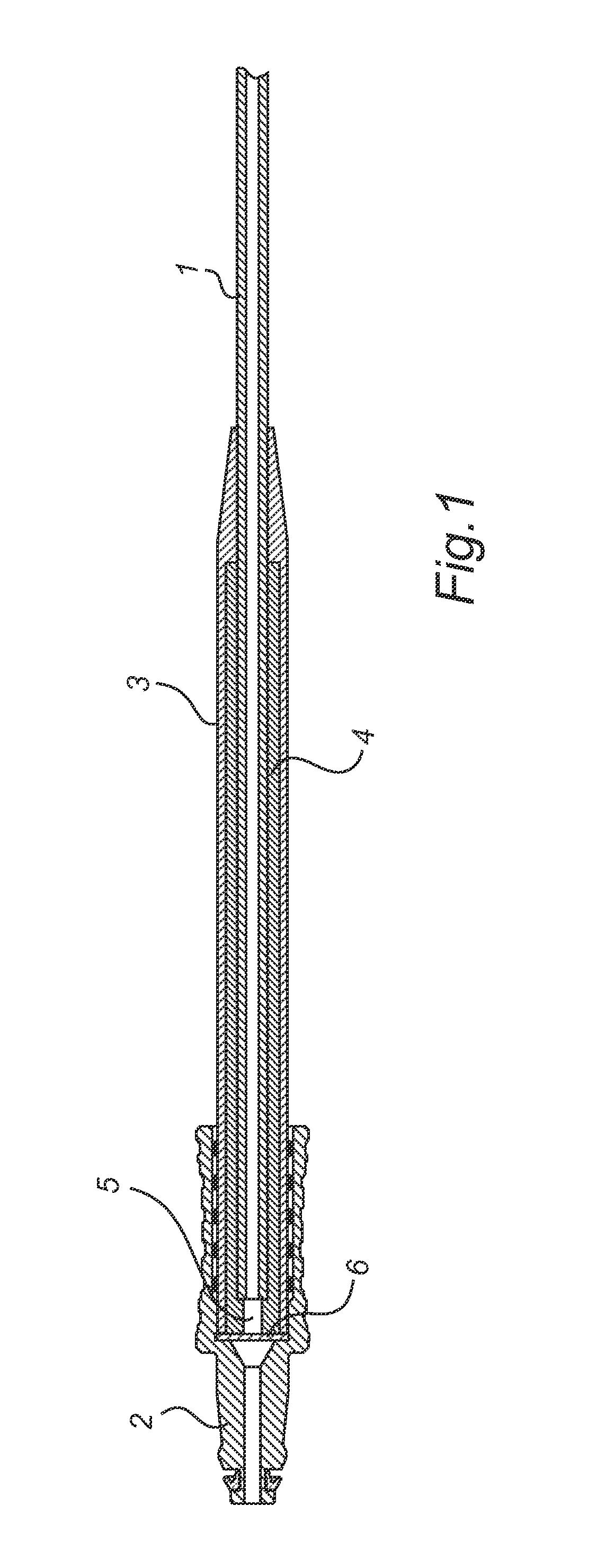

Gas sampling line

ActiveUS9861298B2Improve accuracyReduce distortion problemsDispersed particle separationRespiratory organ evaluationGas analysisLine tubing

A gas sampling line having a channel for conducting respiratory gases from a patient respiratory interface to a gas monitor, the gas sampling line comprising, i.a., a gas sampling tube comprised of a polyether block amide material, the polyether segments of which comprise polyethyleneoxide. Use of a tube comprised of a polyether block amide material, the polyether segments of which comprise polyethyleneoxide, for sampling of respiratory gases; and a method for sampling of respiratory gases, the method comprising conducting respiratory gases through such a tube. A gas analysis system for analyzing respiratory gases, comprising a gas sampling line as defined above and a gas monitor connectable to the gas sampling line.

Owner:JPMORGAN CHASE BANK NA

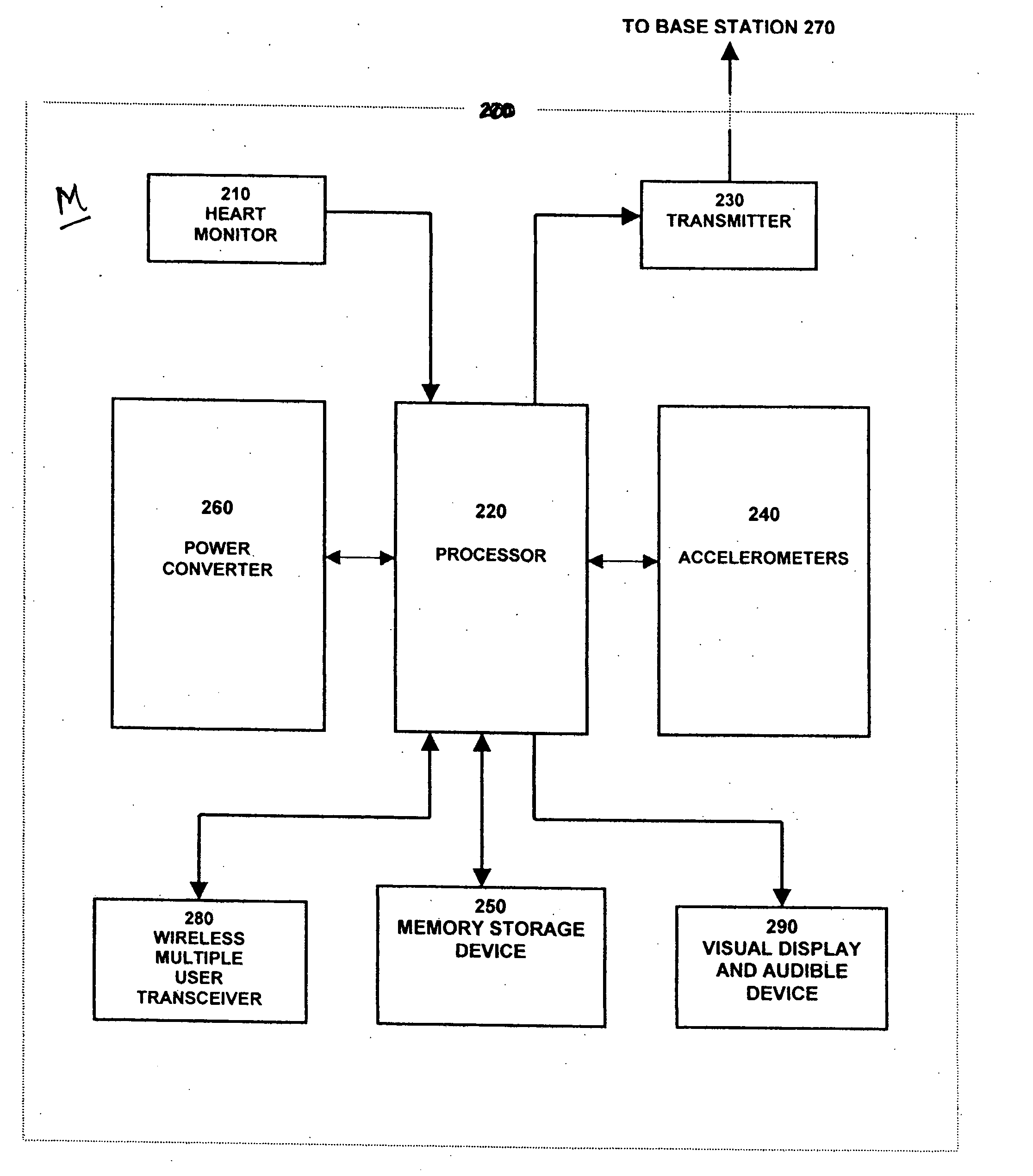

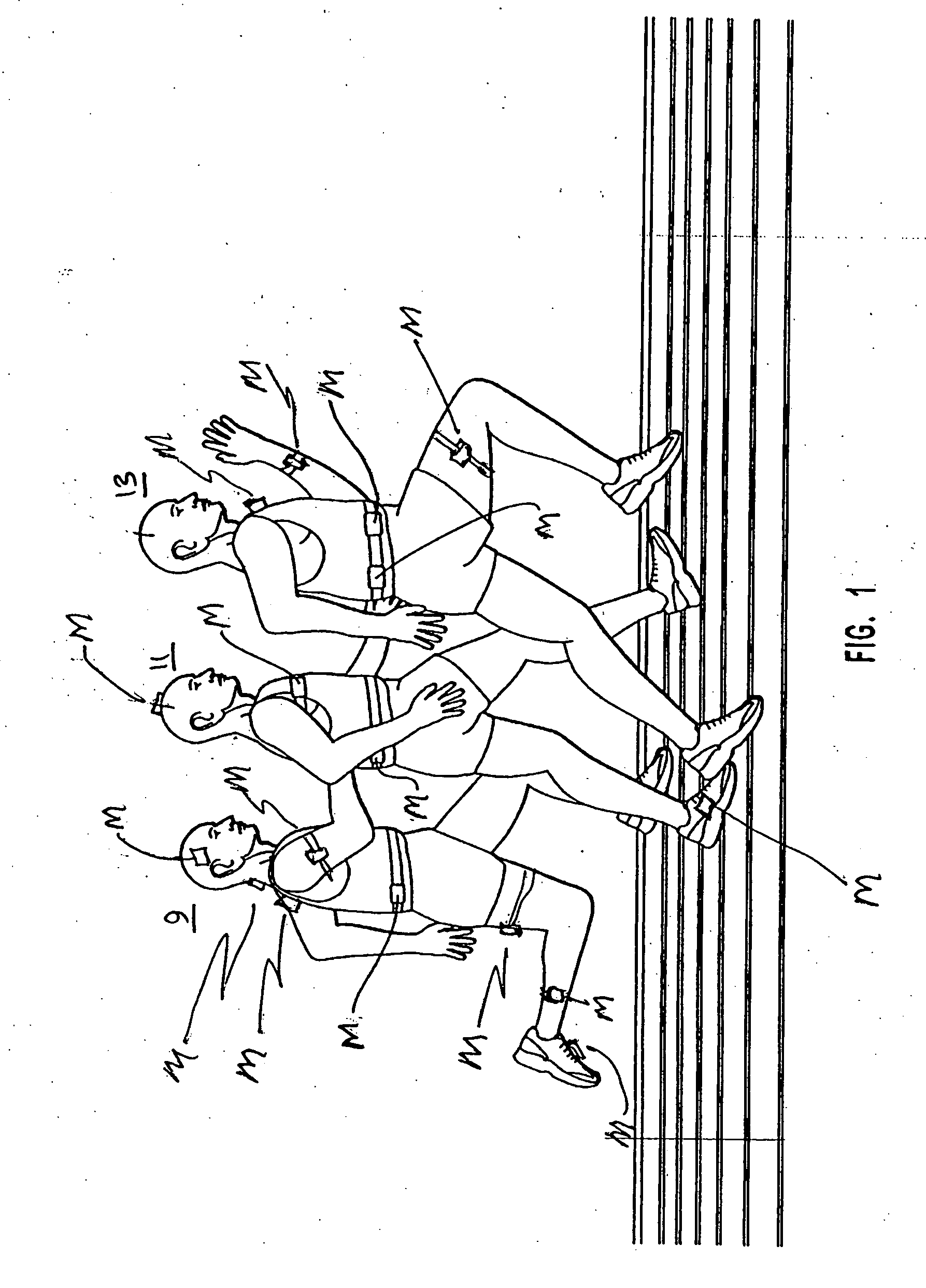

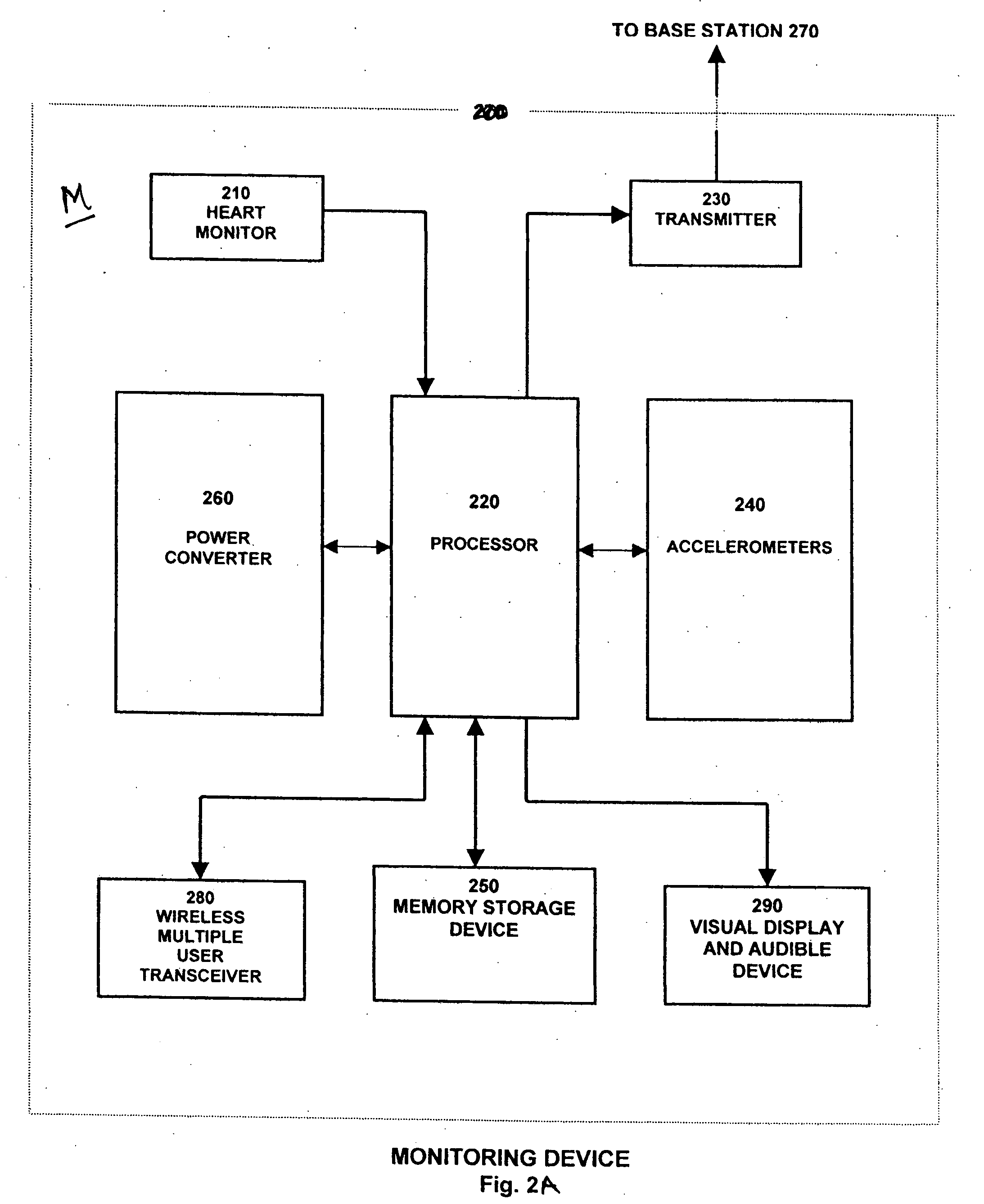

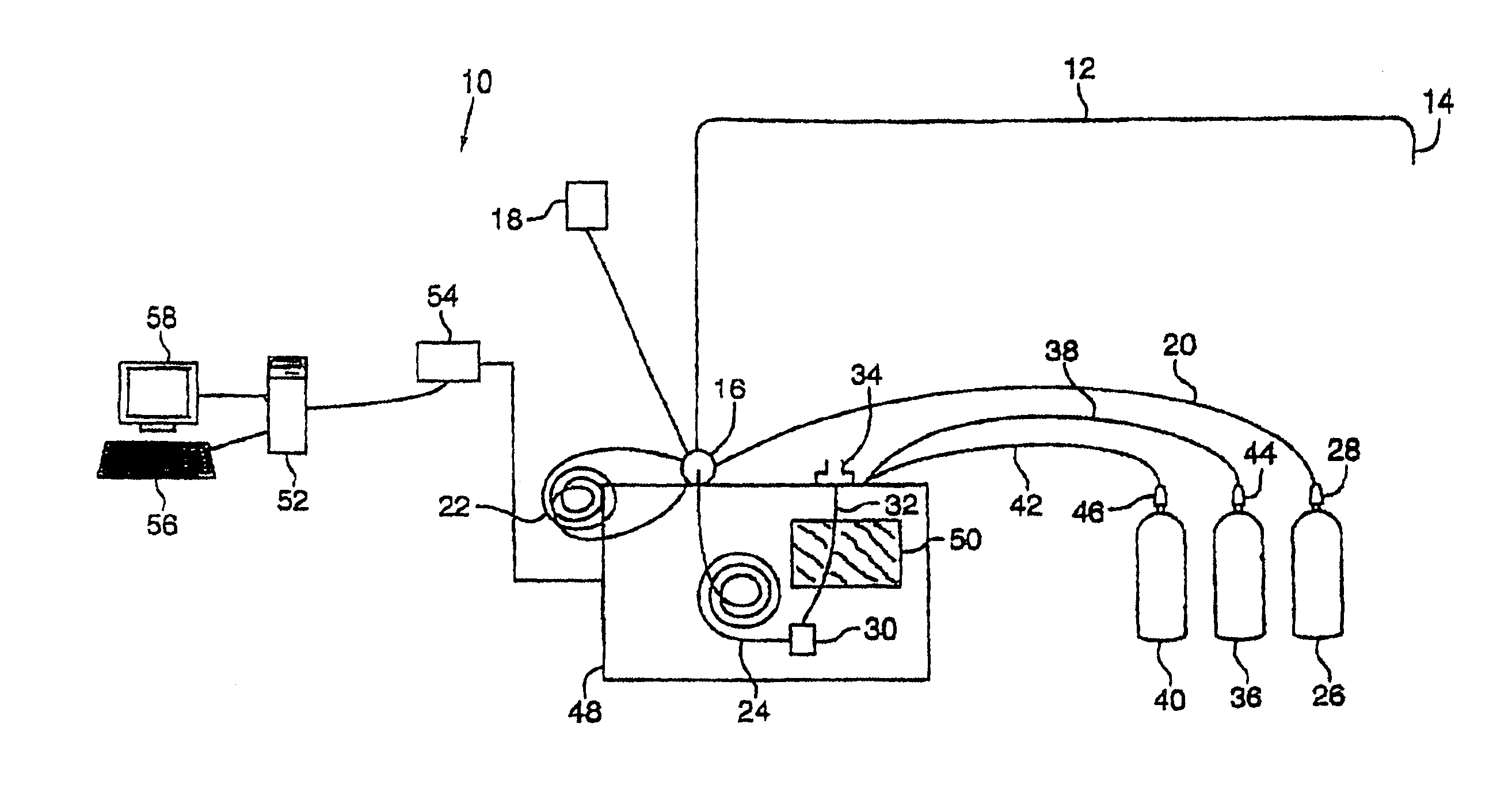

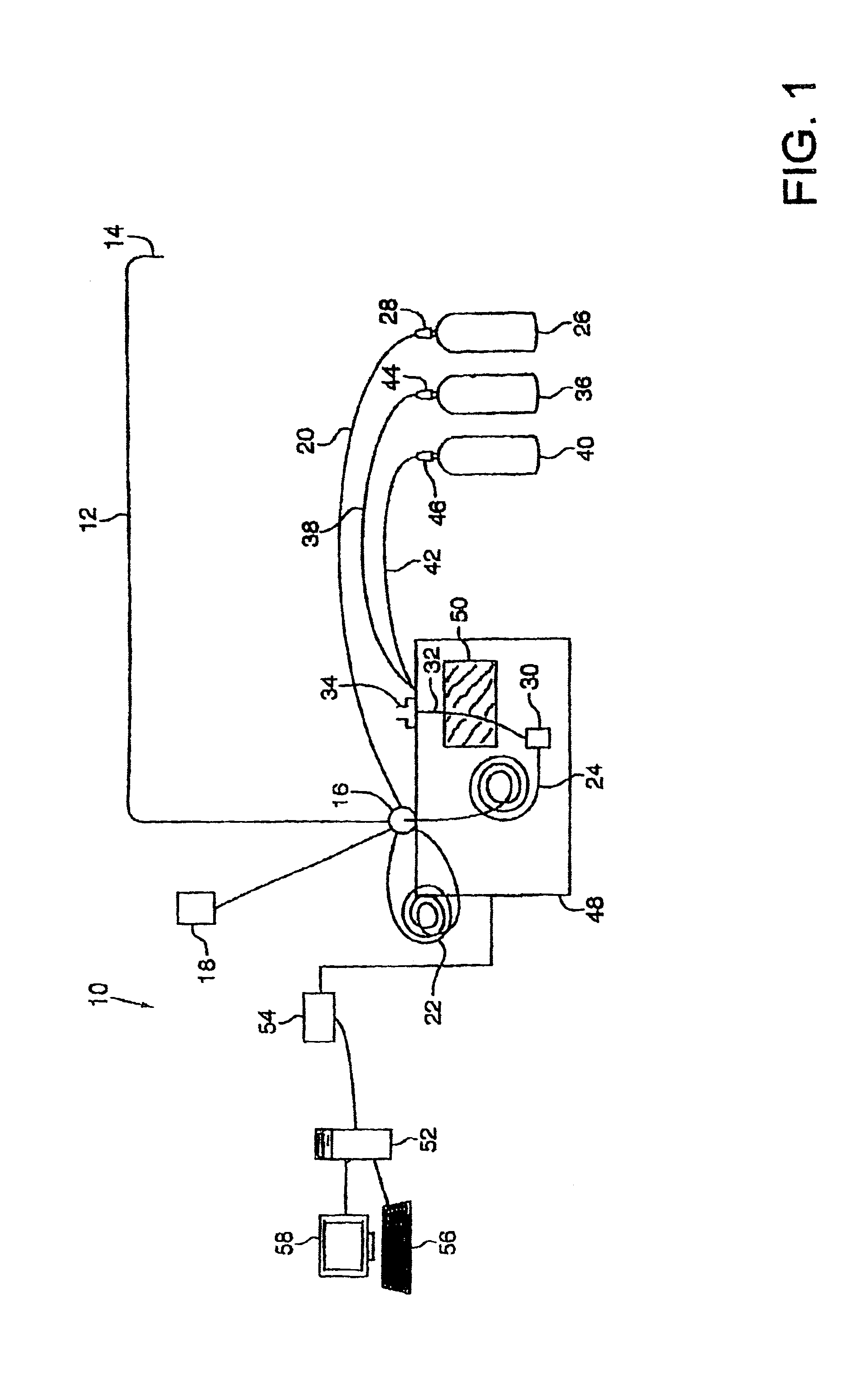

Methods and apparatus for determining work performed by an individual from measured physiological parameters

InactiveUS20050107723A1Promote productionPhysical therapies and activitiesPerson identificationAccelerometer dataGas analysis

Methods and apparatus for gathering and processing data sensed on an individual from portable heart monitors and accelerometers aligned along three orthogonal axes determine substantially equivalent oxygen consumption information during an individual's physical activities without requiring gas-flow or gas-analysis equipment. Such information promotes calculations of physiological energy expenditures, and analyses of the accelerometer data associated with a specific sensing location on an individual's body provide indication of the particular physical activity for selecting appropriate scaling factors and filtering requirements in analyzing the data to determine various parameters indicative of the individual's expenditure of physiological energy, and other health-oriented factors.

Owner:TELECOM MEDICAL

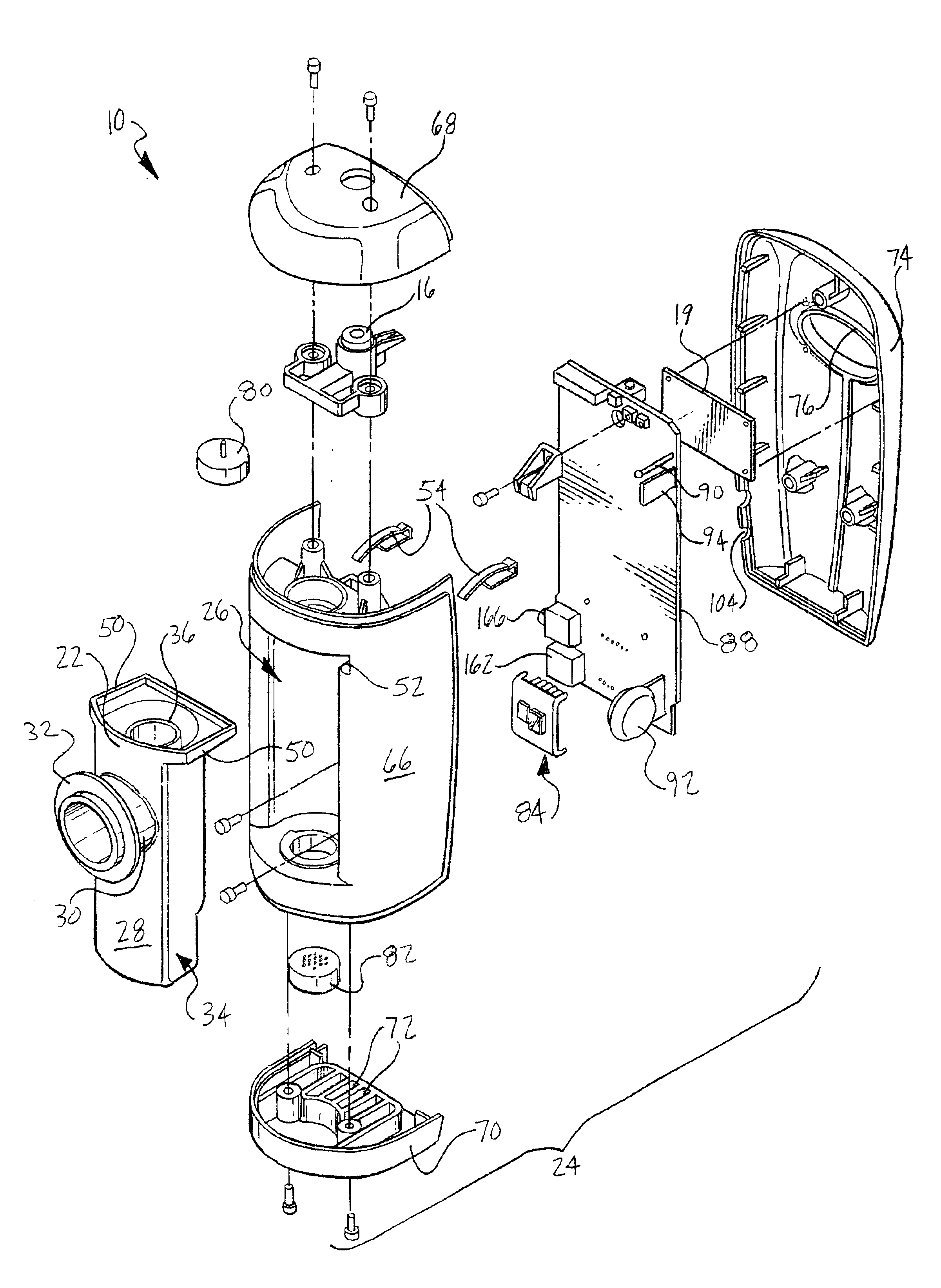

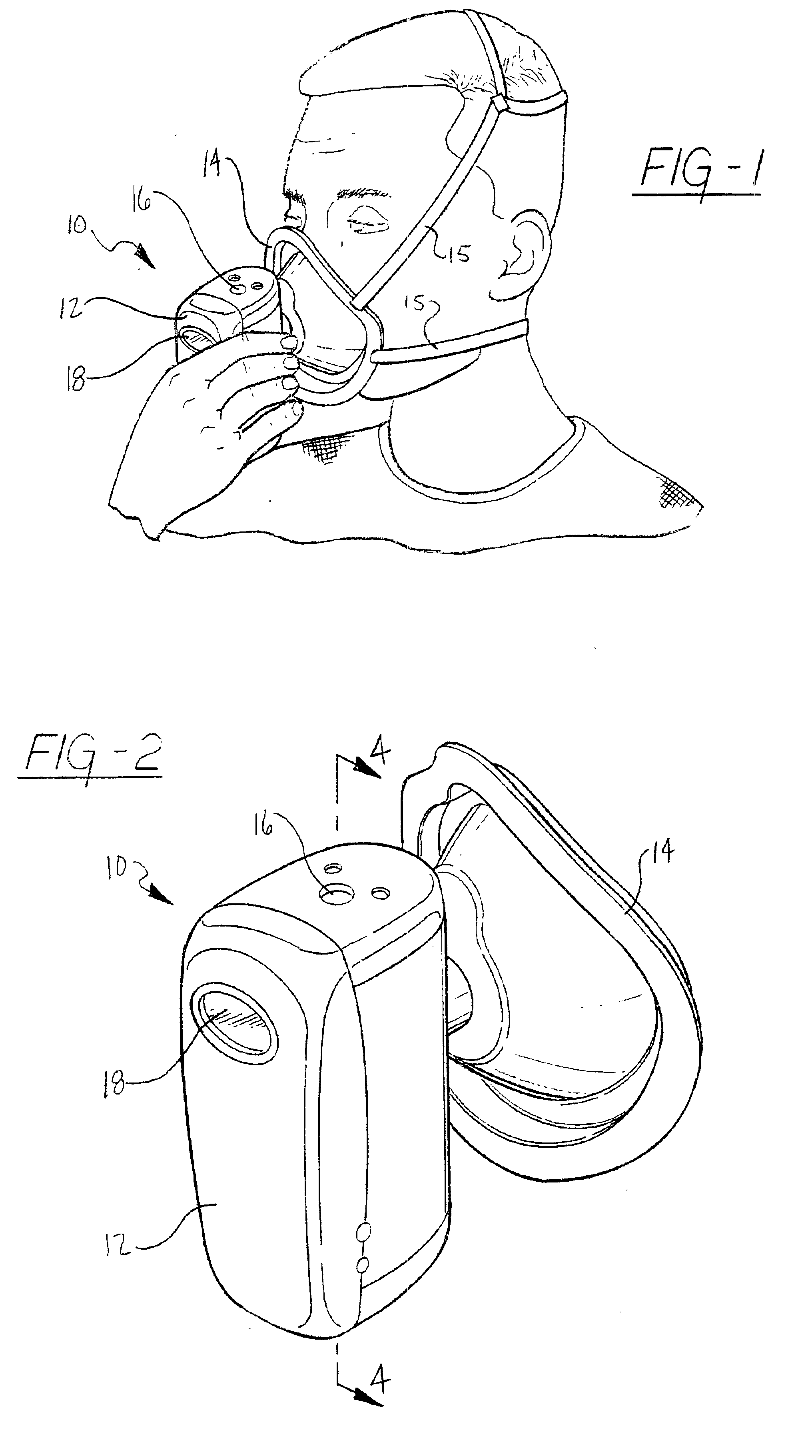

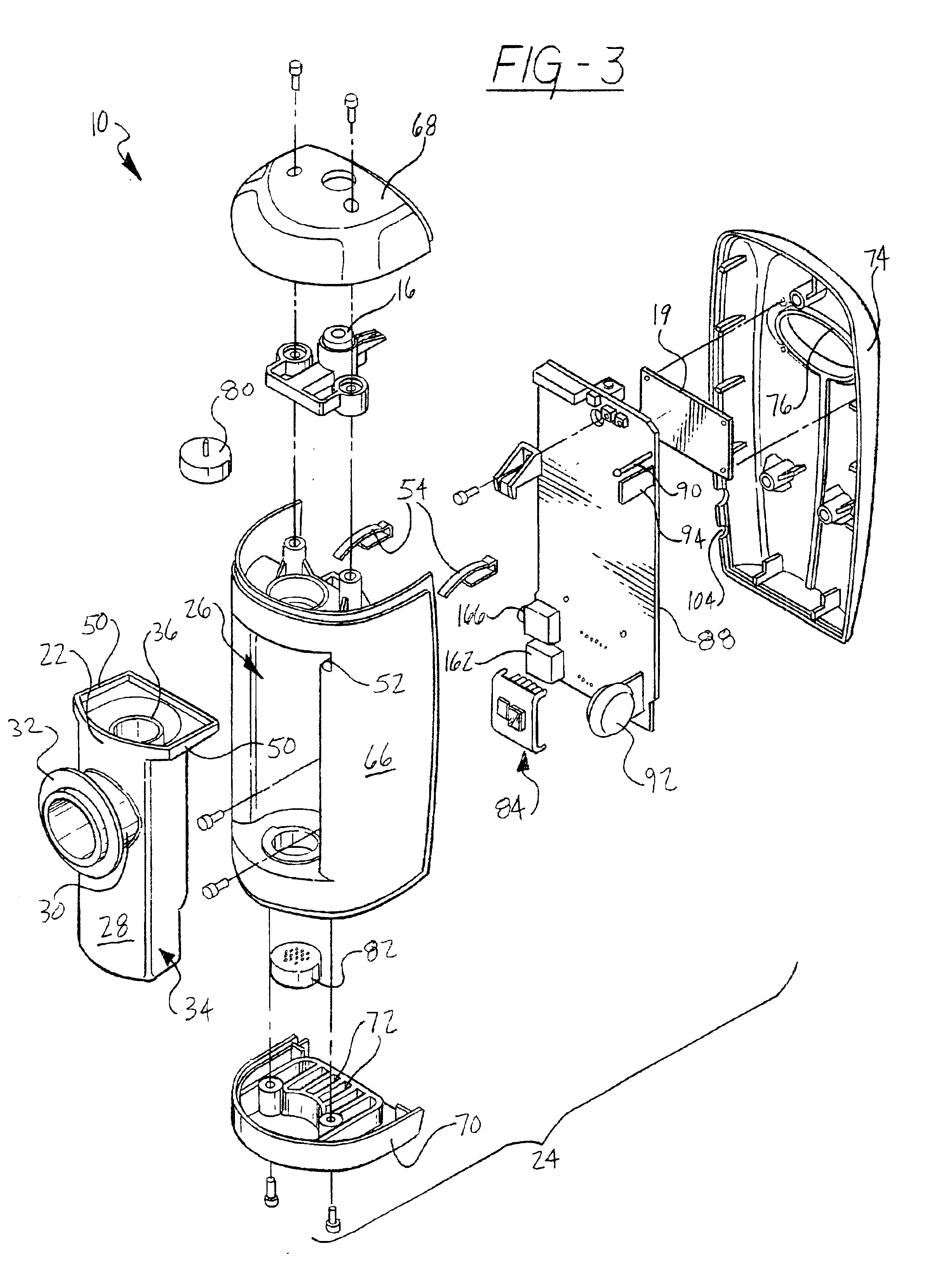

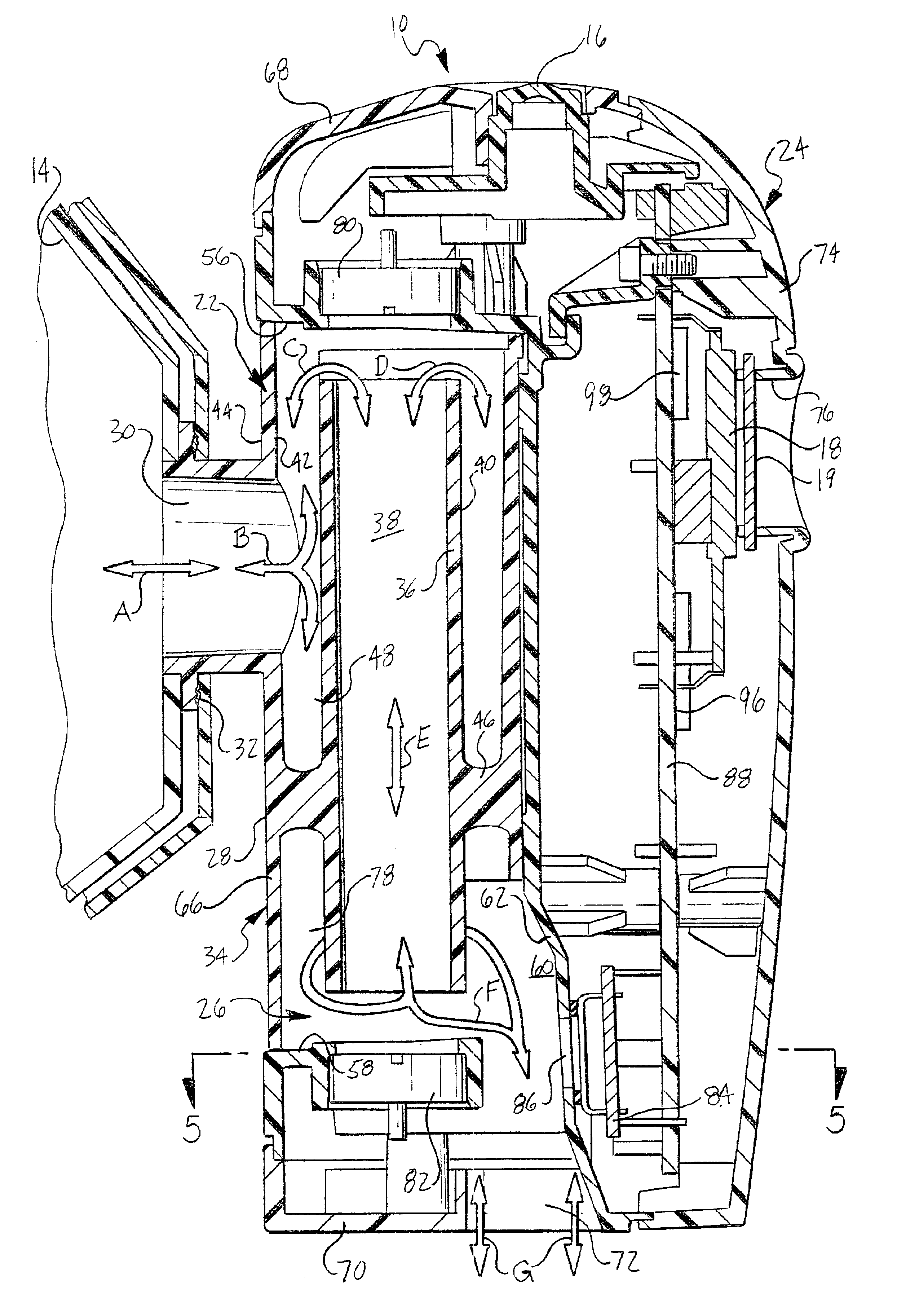

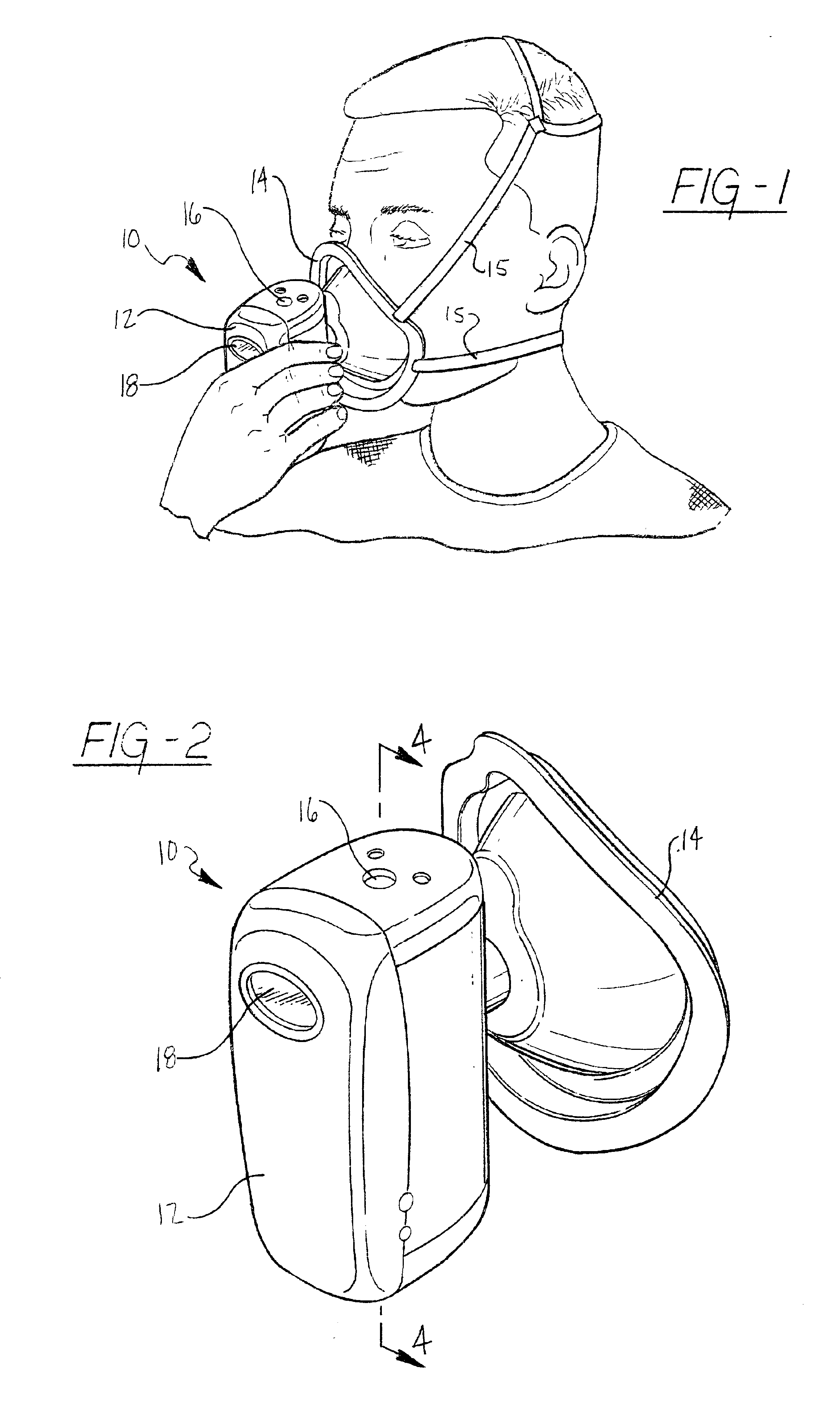

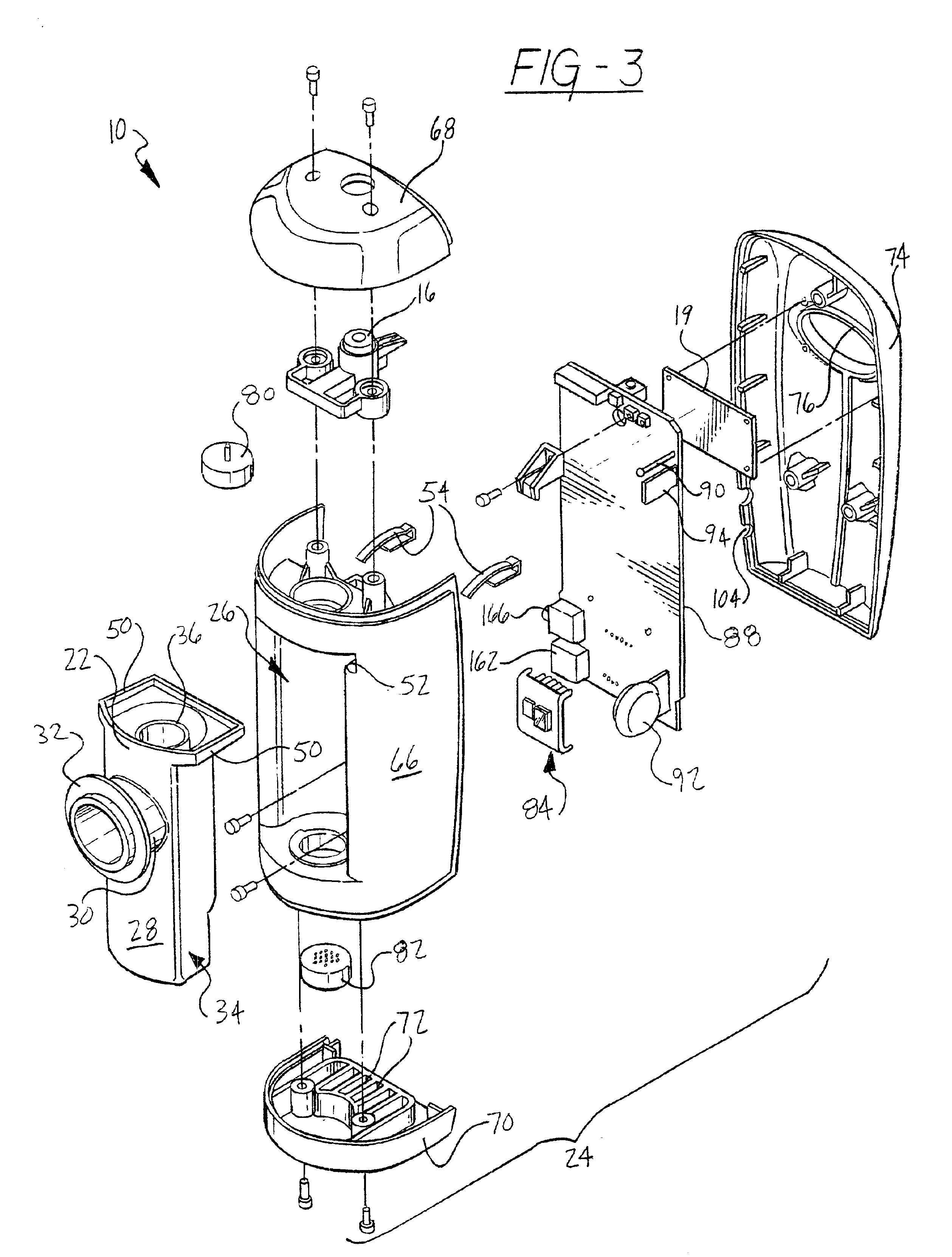

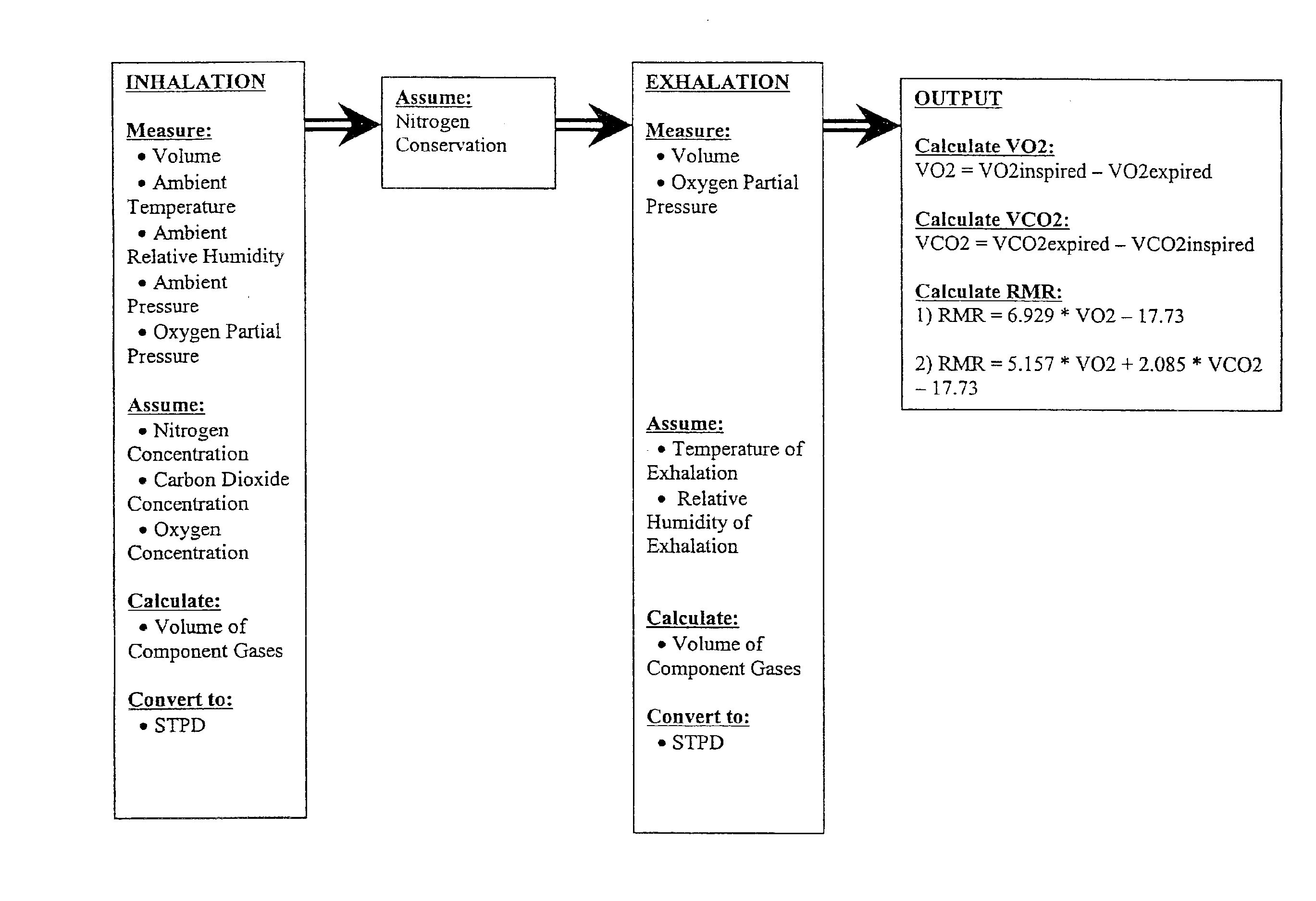

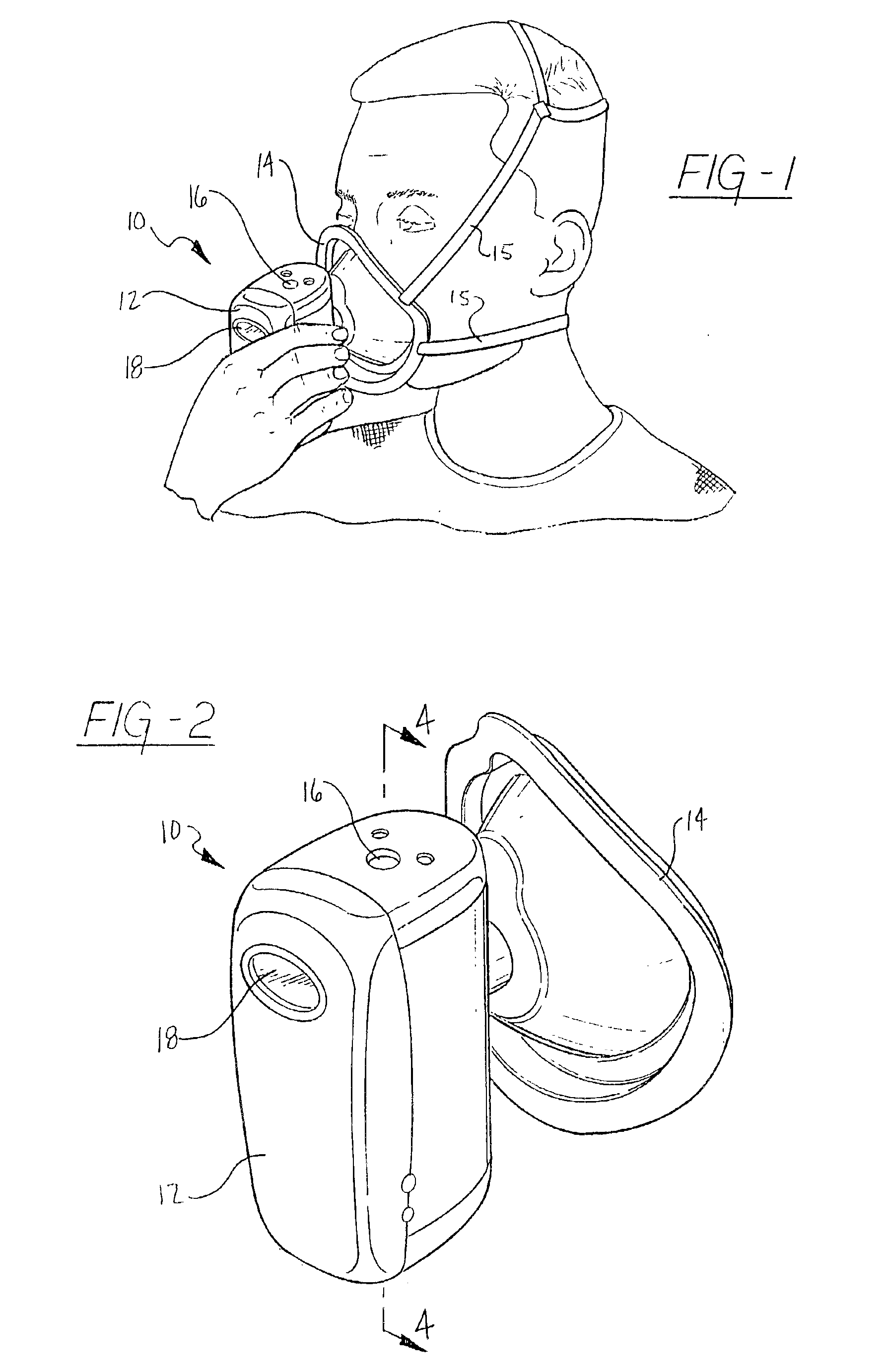

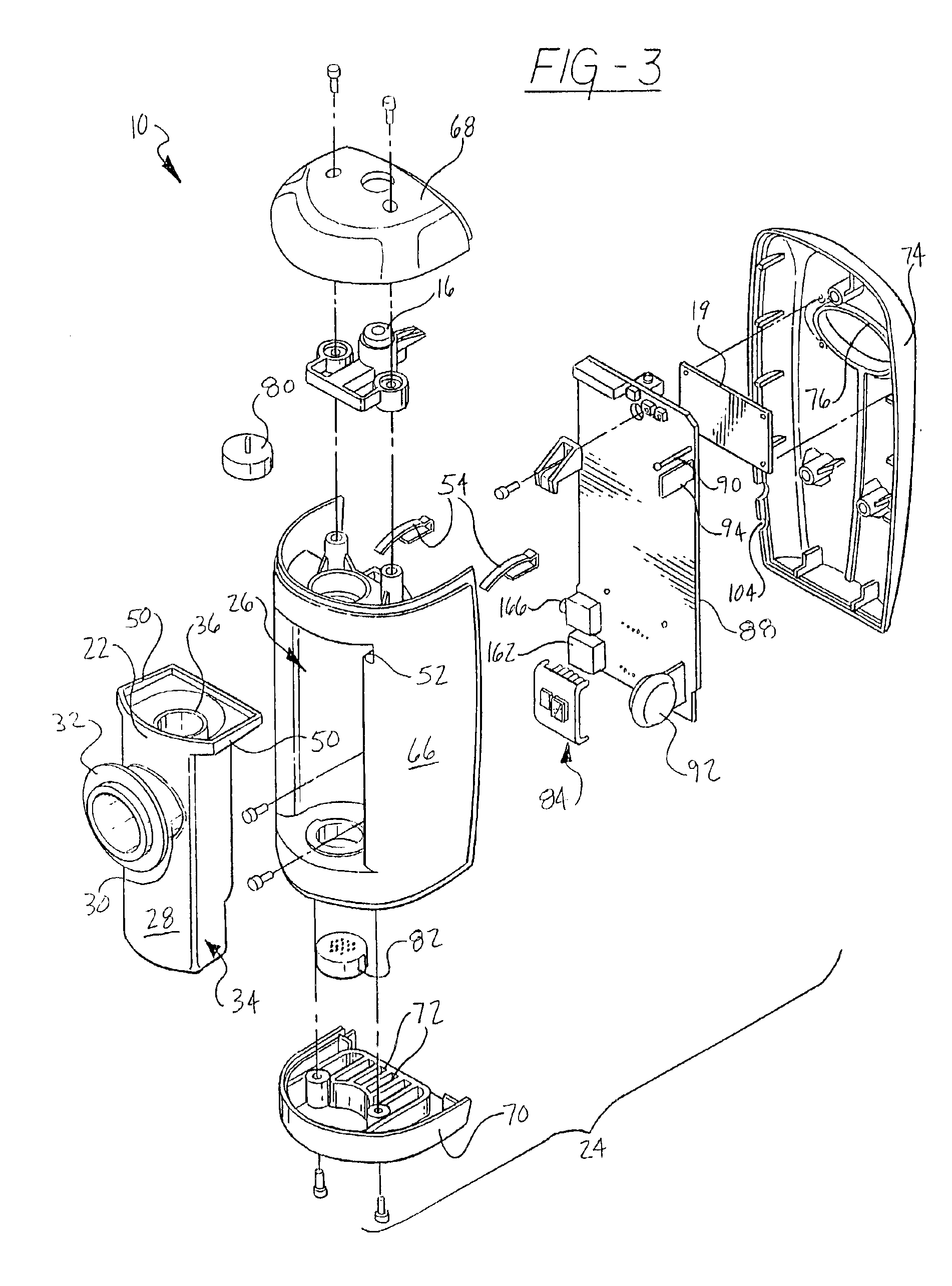

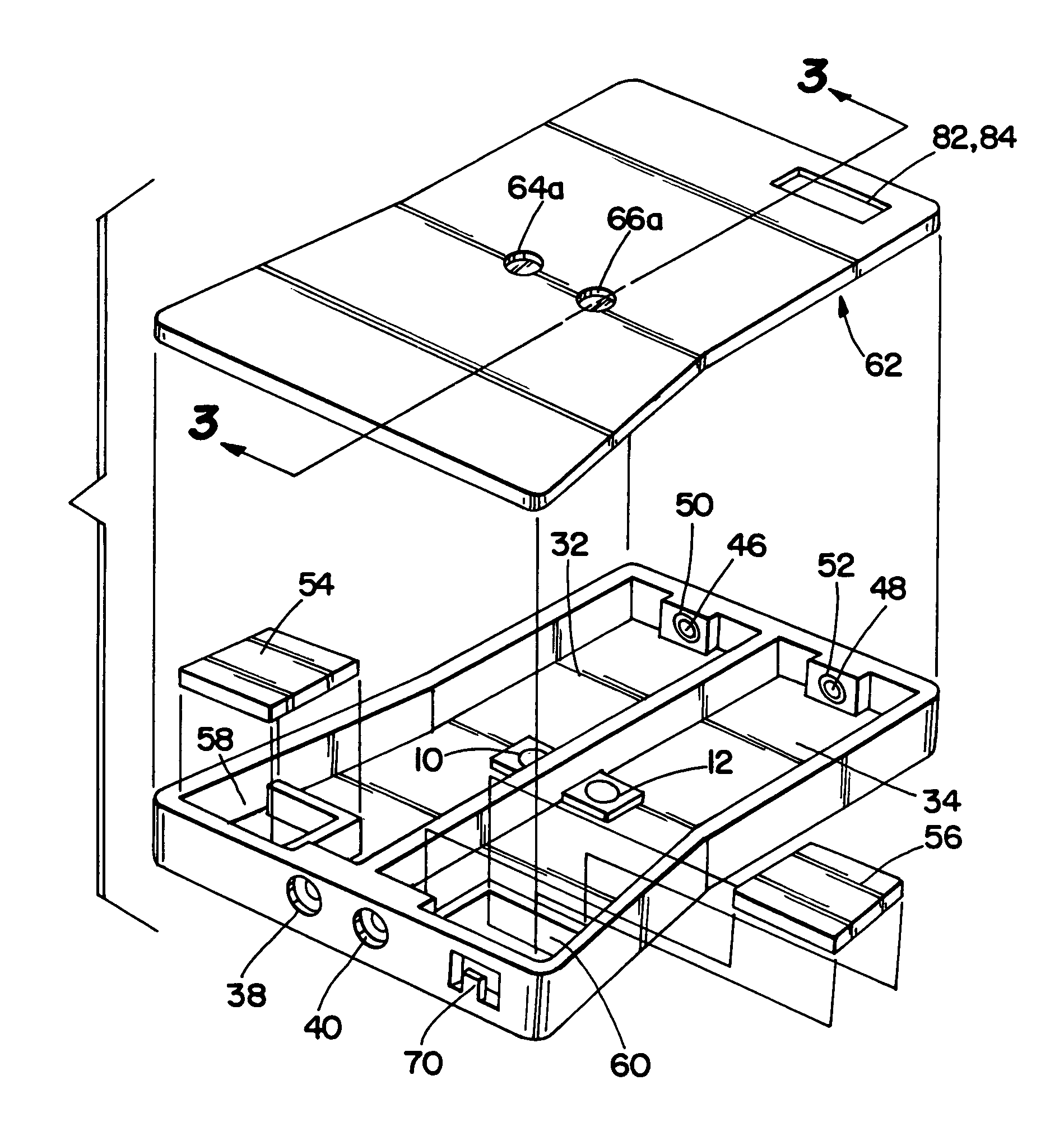

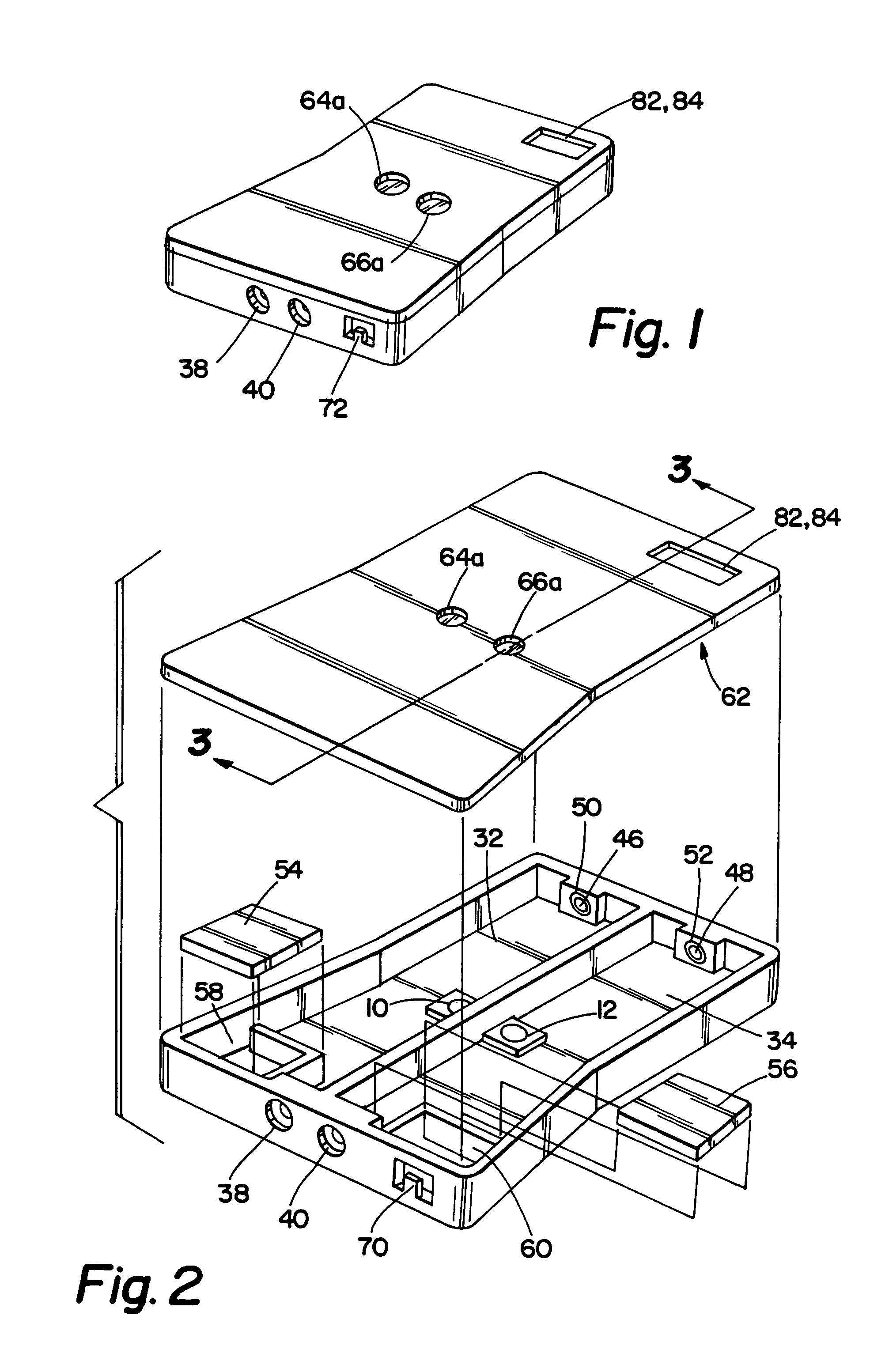

Metabolic calorimeter employing respiratory gas analysis

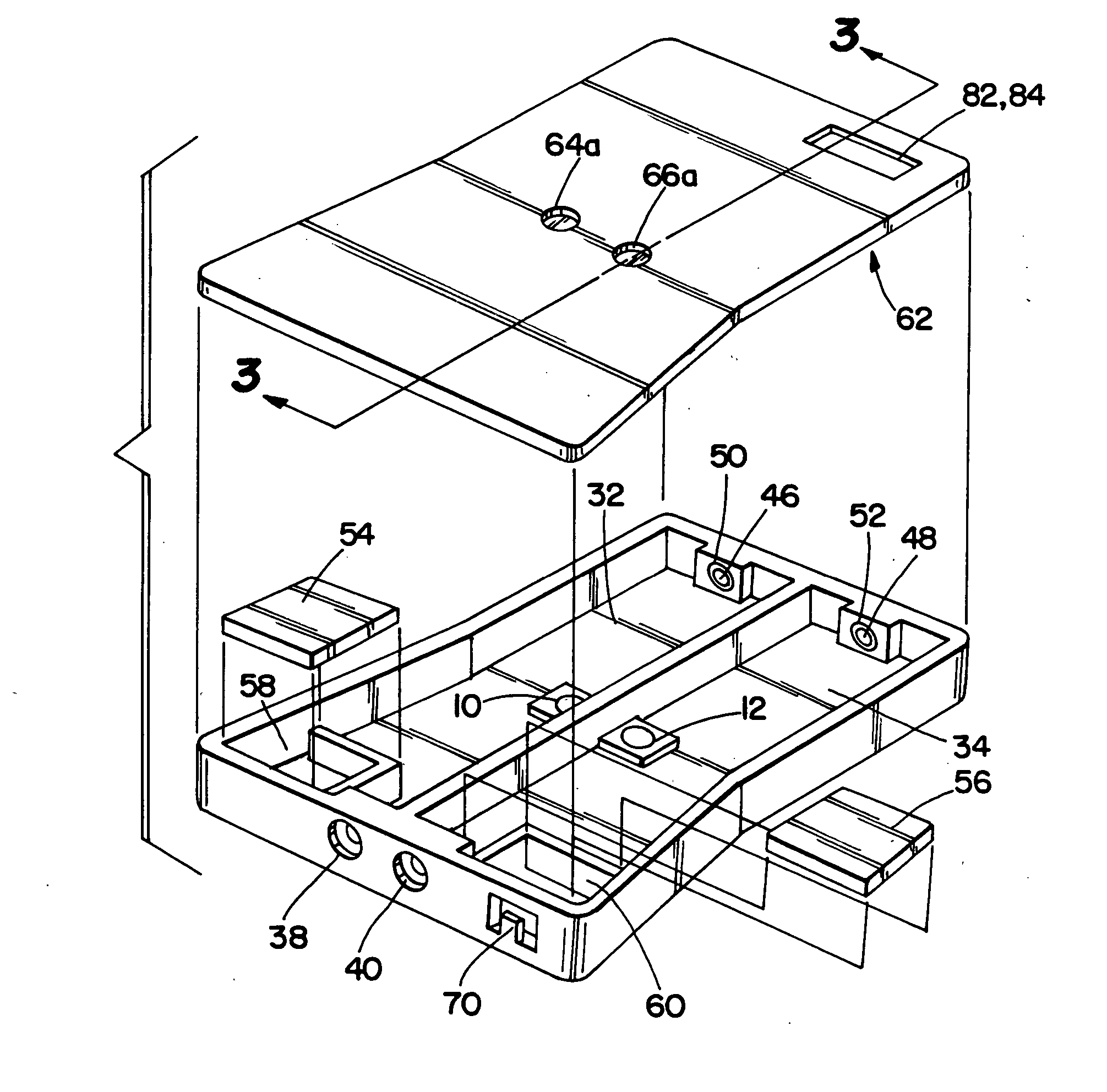

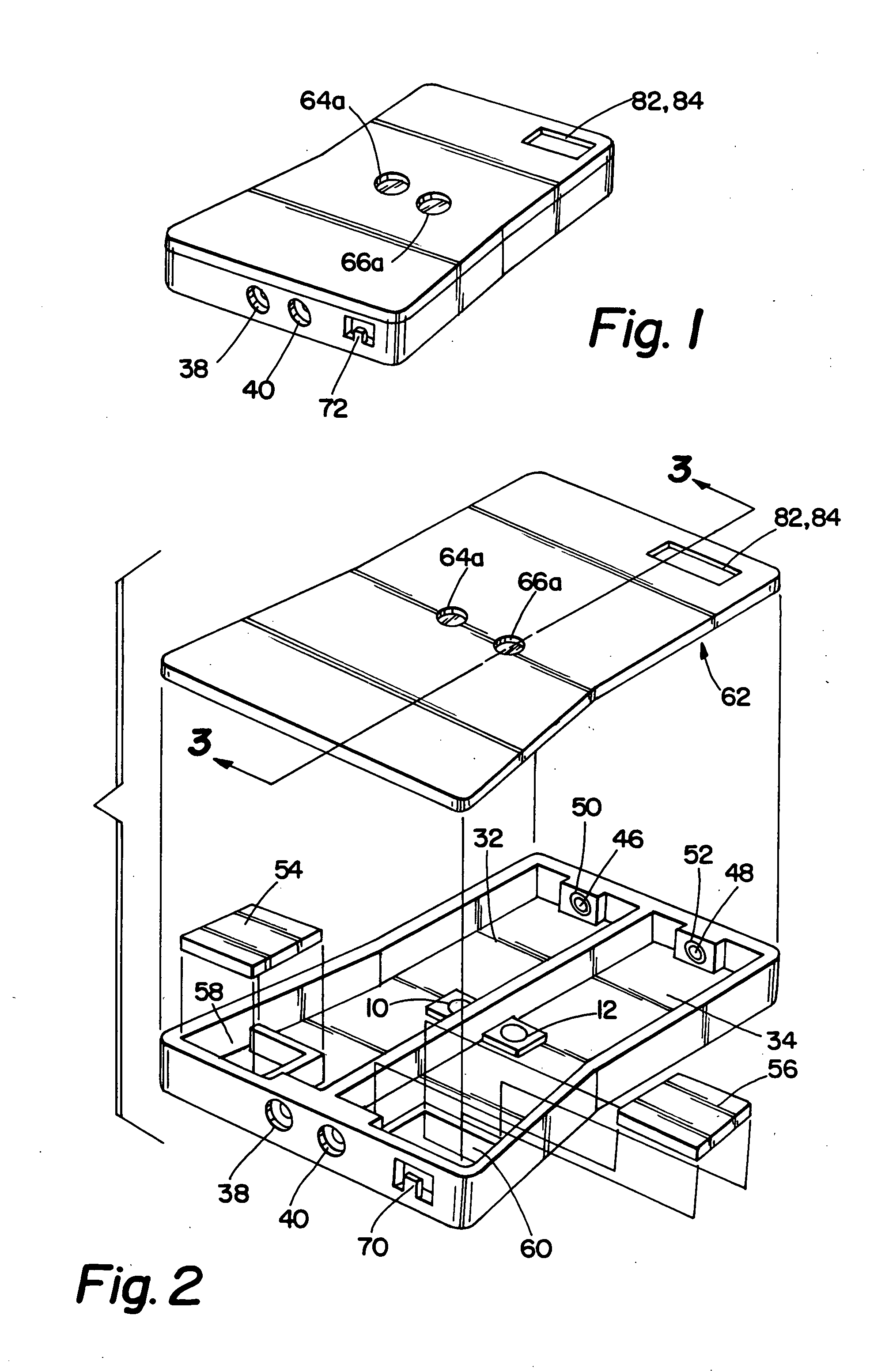

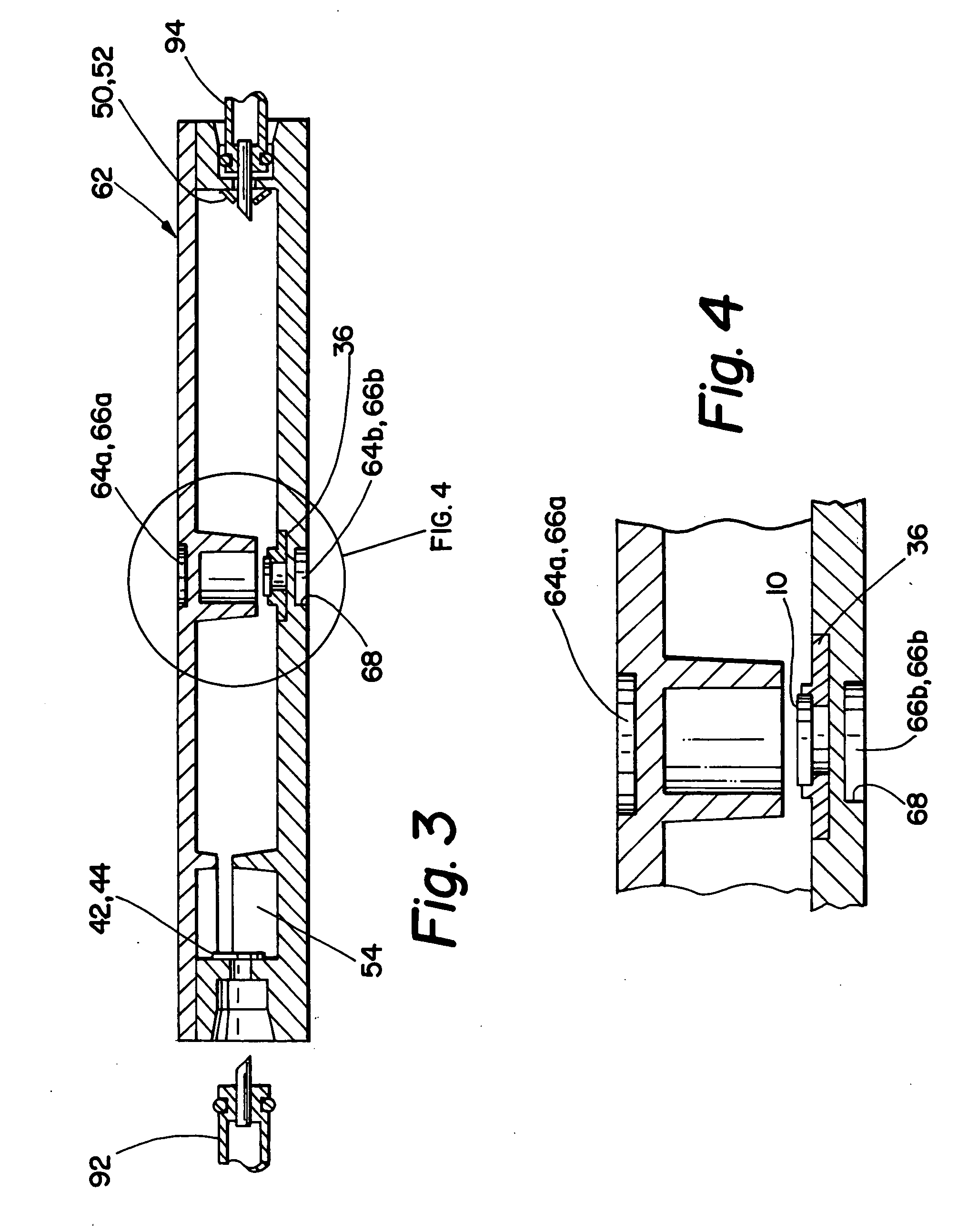

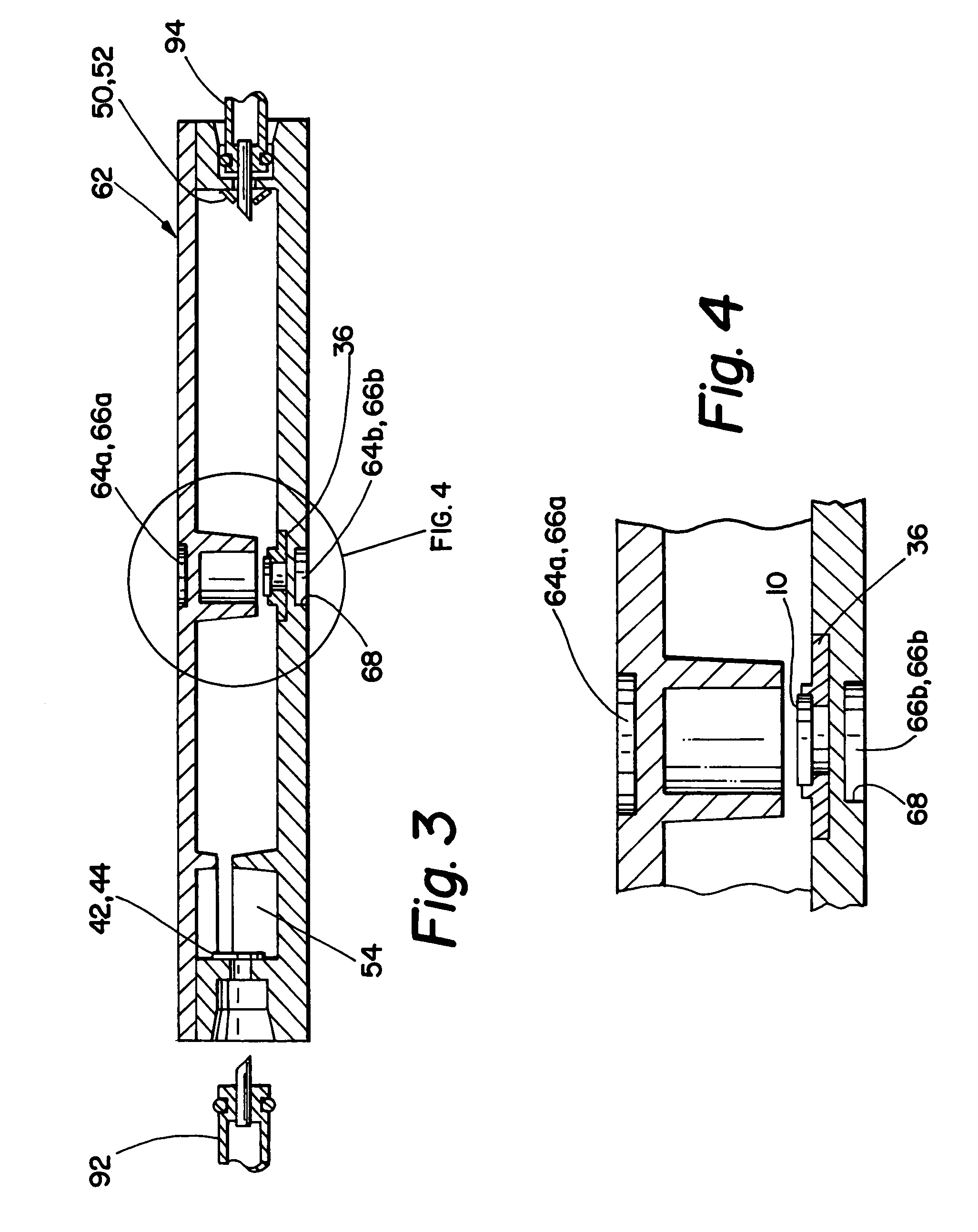

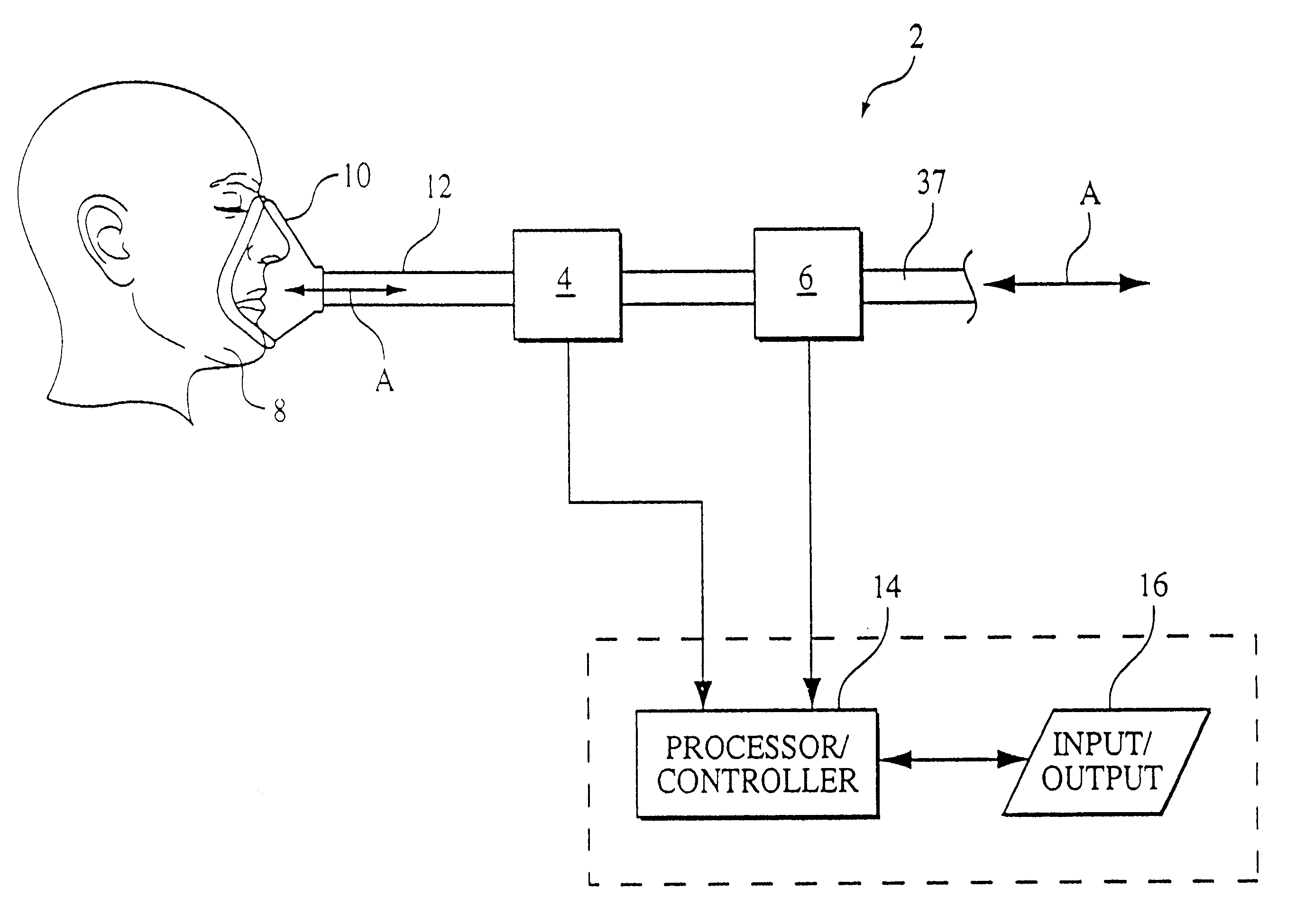

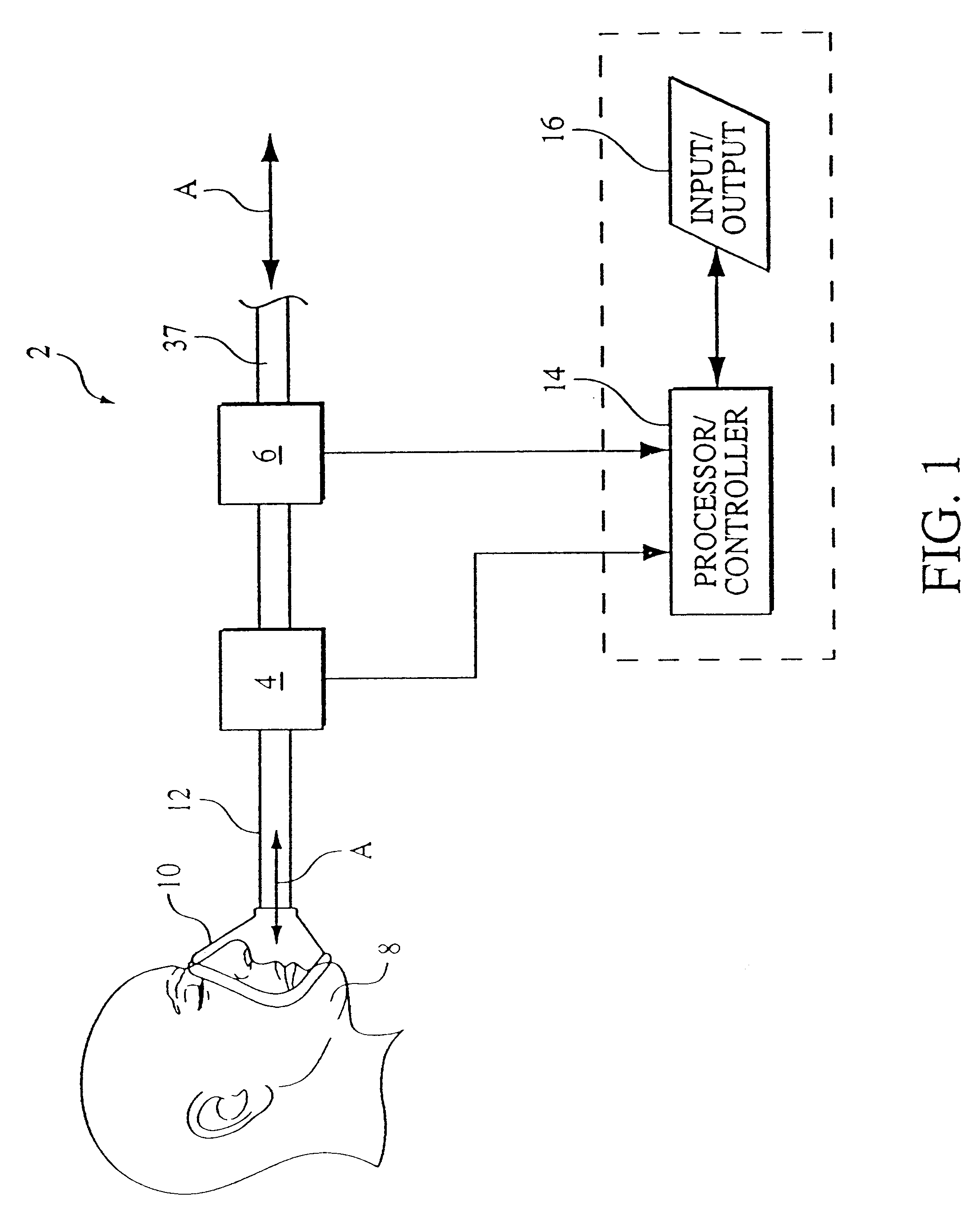

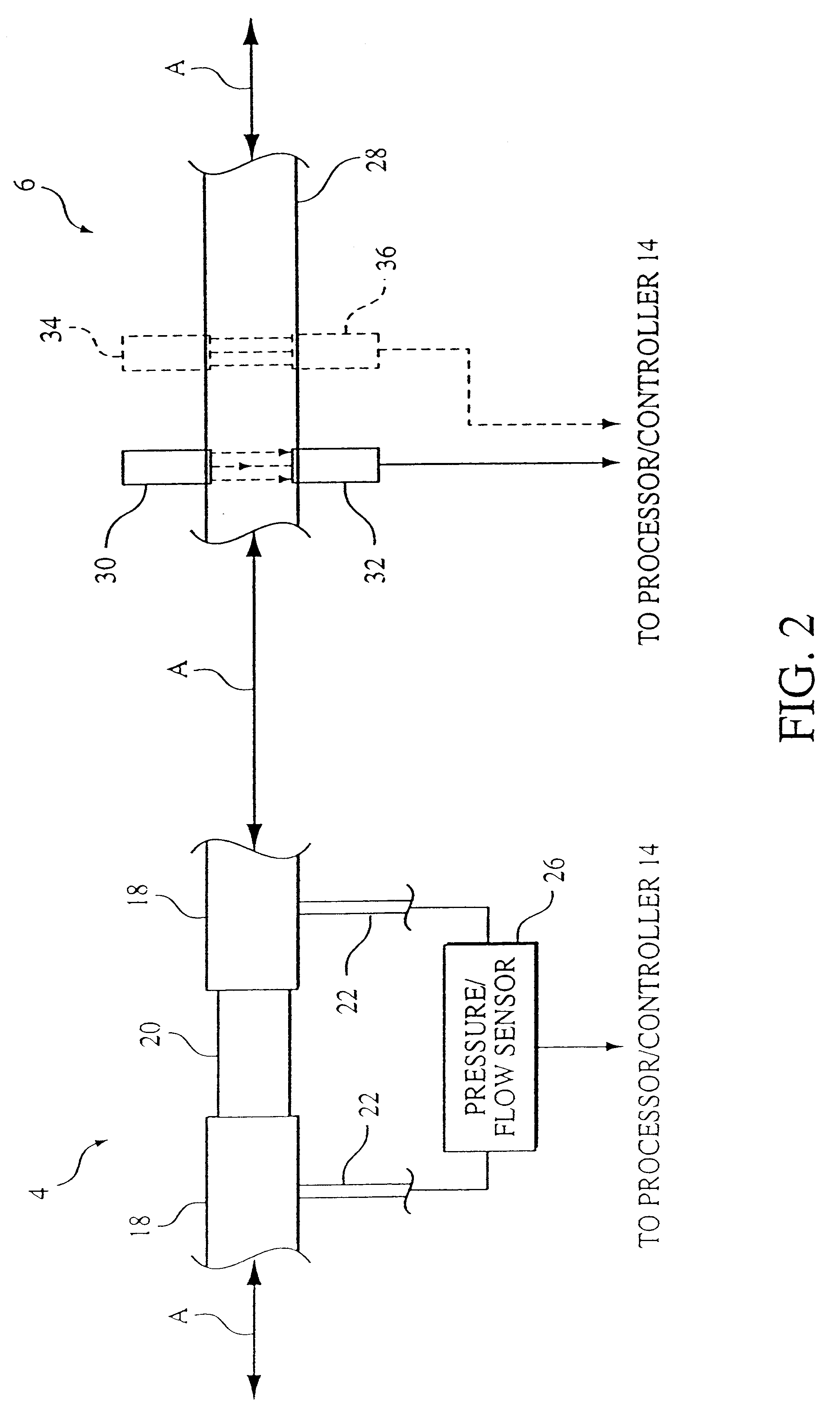

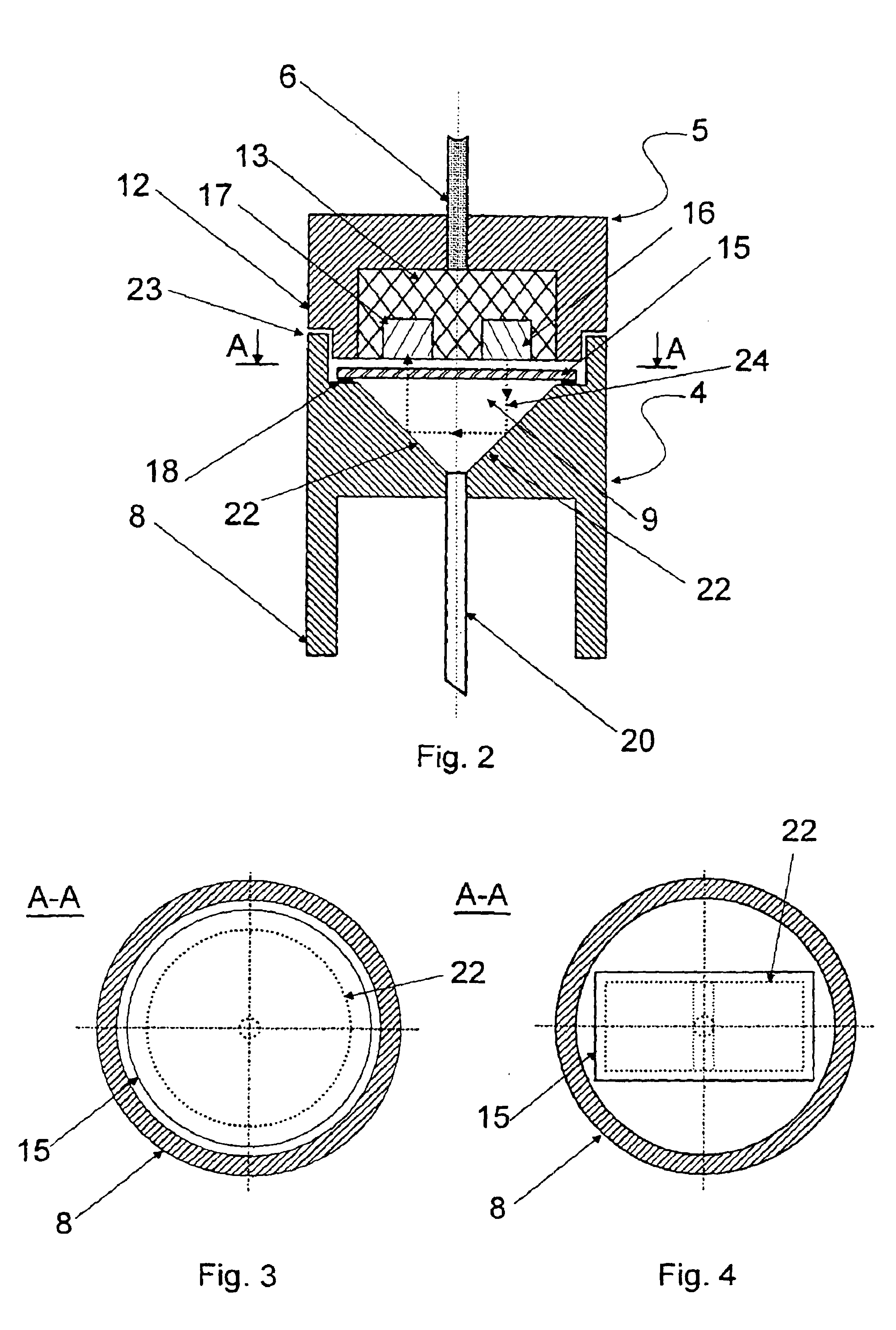

An indirect calorimeter for measuring the metabolic rate of a subject includes a disposable portion and a reusable portion. The disposable portion includes a respiratory connector configured to be supported in contact with the subject so as to pass inhaled and exhaled gases as the subject breathes. The disposable portion also includes a flow pathway operable to receive and pass inhaled and exhaled gases, having a first end in fluid communication with the respiratory connector and a second end in fluid communication with a source and sink for respiratory gases. The disposable portion is disposed within the reusable portion, which includes a flow meter, a component gas concentration sensor, and a computation unit. The flow meter generates a signal as a function of the instantaneous flow volume of respiratory gases passing through the flow pathway and the component gas concentration sensor generates a signal as a function of the instantaneous fraction of a predetermined component gas in the exhaled gases. The computation unit receives the electrical signals from the flow meter and the concentration sensor and calculates at least one respiratory parameter for the subject as the subject breathes through the calorimeter.

Owner:MICROLIFE MEDICAL HOME SOLUTIONS

Metabolic calorimeter employing respiratory gas analysis

An indirect calorimeter for measuring the metabolic rate of a subject includes a respiratory connector configured to be supported in contact with the subject so as to pass inhaled and exhaled gases as the subject breathes, a flow pathway, and a hygiene barrier positioned to block a predetermined pathogen from the exhaled gases. The indirect calorimeter also includes a flow pathway having a first end in fluid communication with the respiratory connector and a second end in fluid communication with a source and sink for respiratory gases. The flow pathway includes a flow tube through which the inhaled and exhaled gases pass, an outer housing surrounding the flow tube, and a chamber disposed between the flow tube and the first end. The indirect calorimeter also includes a flow meter configured to generate electrical signals as a function of the instantaneous flow volume of inhaled and exhaled gases passing through the flow pathway, and a component gas concentration sensor operable to generate electrical signals as a function of the instantaneous fraction of a predetermined component gas in the exhaled gases as the gases pass through the flow pathway. The indirect calorimeter further includes a computation unit operable to receive the electrical signals from the flow meter and the concentration sensor and operative to calculate at least one respiratory parameter for the subject as the subject breathes through the calorimeter.

Owner:MICROLIFE MEDICAL HOME SOLUTIONS

Method of respiratory gas analysis using a metabolic calorimeter

A method of determining a respiratory parameter for a subject using an indirect calorimeter is provided. The indirect calorimeter includes a respiratory connector for passing inhaled and exhaled gases, a flow pathway operable to receive and pass inhaled and exhaled gases having a flow tube within the flow pathway through which the inhaled and exhaled gases pass, a flow meter for determining an instantaneous flow volume of the inhaled and exhaled gases, a component gas concentration sensor for determining an instantaneous fraction of a predetermined component gas and a computation unit having a processor and a memory. The method includes the steps of initializing the indirect calorimeter and the subject breathing into the respiratory connector if the indirect calorimeter is initialized, sensing the flow volume of the inhaled and exhaled gases passing through the flow pathway using the flow meter and transmitting a signal representing the sensed flow volume to the computation unit. The method also includes the steps of sensing a concentration of a predetermined component gas as the inhaled and exhaled gases pass through the flow pathway using the component gas sensor, and transmitting a signal representing the sensed concentration of the predetermined component gas to the computation unit. The method further includes the steps of calculating at least one respiratory parameter for the subject as the subject breathes through the calorimeter using the sensed flow volume and the sensed concentration of the predetermined component gas, and providing the subject with the at least one respiratory parameter.

Owner:MICROLIFE MEDICAL HOME SOLUTIONS

Gas sampling line

ActiveUS20110237969A1Improve accuracyReduce distortion problemsDispersed particle separationRespiratory organ evaluationGas analysisPolyethylene oxide

Owner:JPMORGAN CHASE BANK NA

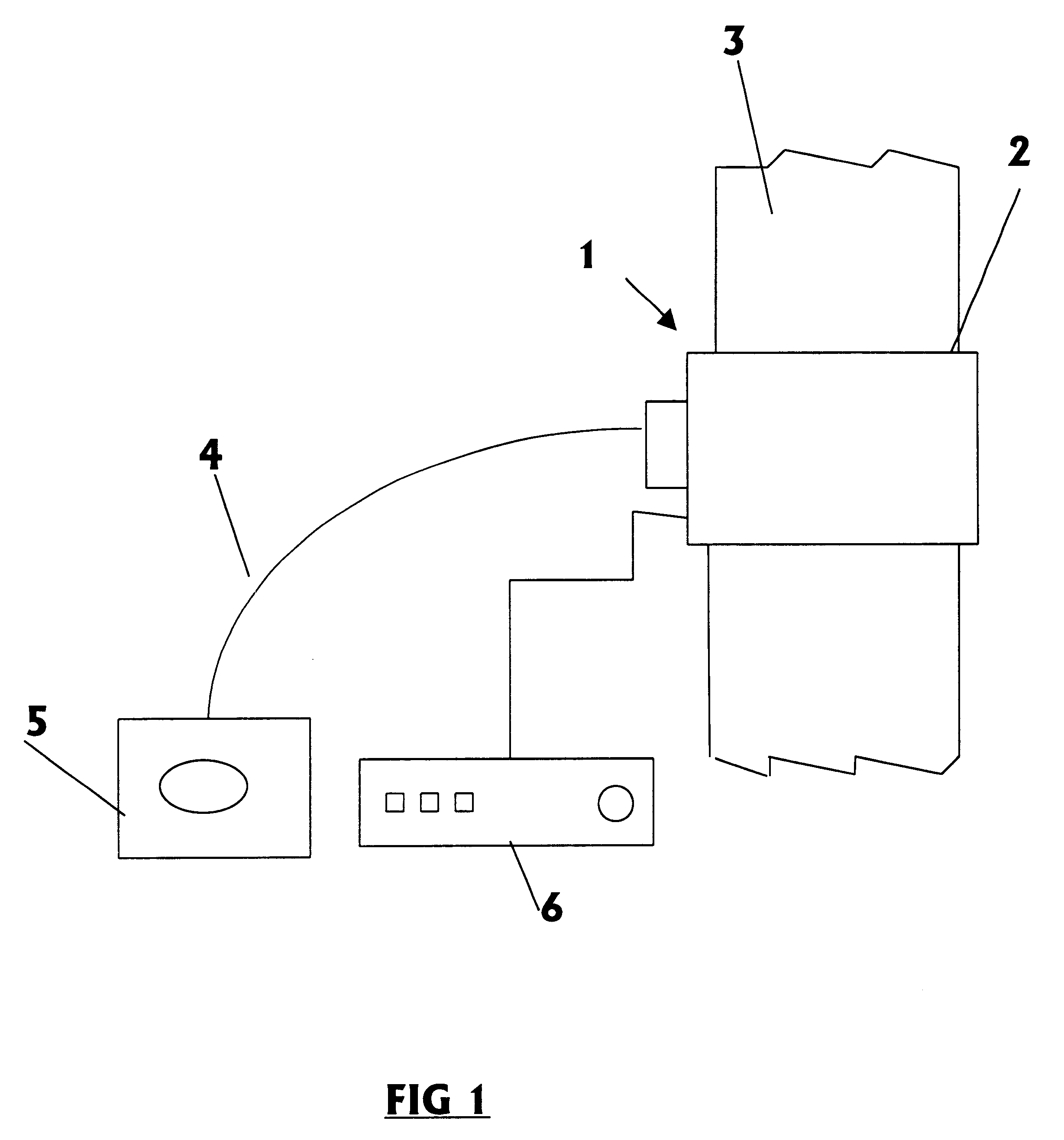

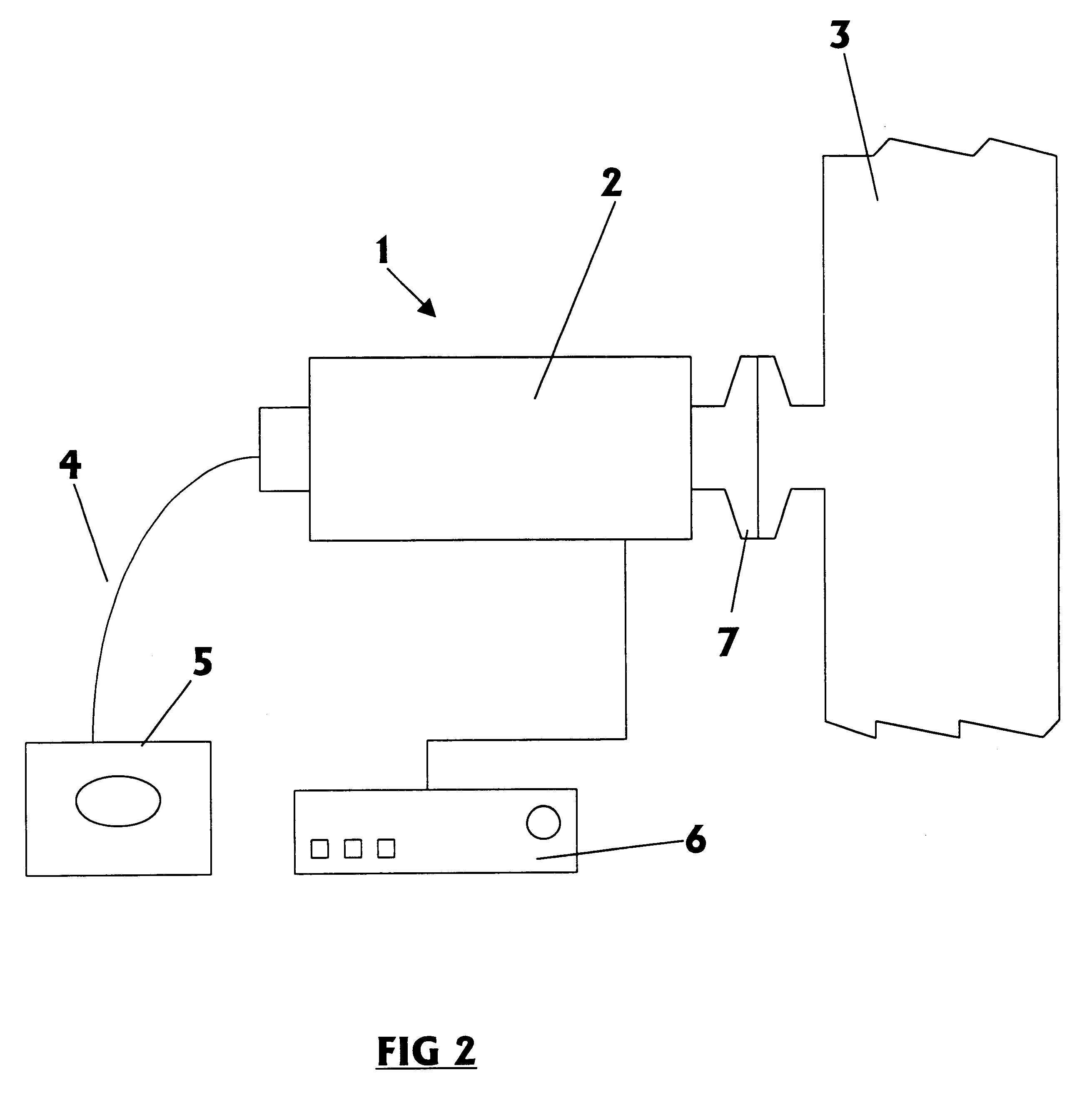

Method and apparatus for sample analysis

InactiveUS6865926B2Easy to operateAnalysing fluids using sonic/ultrasonic/infrasonic wavesComponent separationParticulatesGas analysis

Methods and systems for analyzing samples, such as gas samples, are described. One method comprises providing a gas sample, increasing pressure applied to the gas sample to compress the sample to a smaller volume and provide a pneumatically focused gas sample, and analyzing the pneumatically focused gas sample using any of a variety of analytical techniques. Also disclosed are systems for gas analysis, including systems for analysis of pneumatically focused, and thereby concentrated, gas samples and for analysis of particulate matter in gas samples. Analytical systems constructed within personal computer cases also are disclosed.

Owner:PORTLAND STATE UNIV

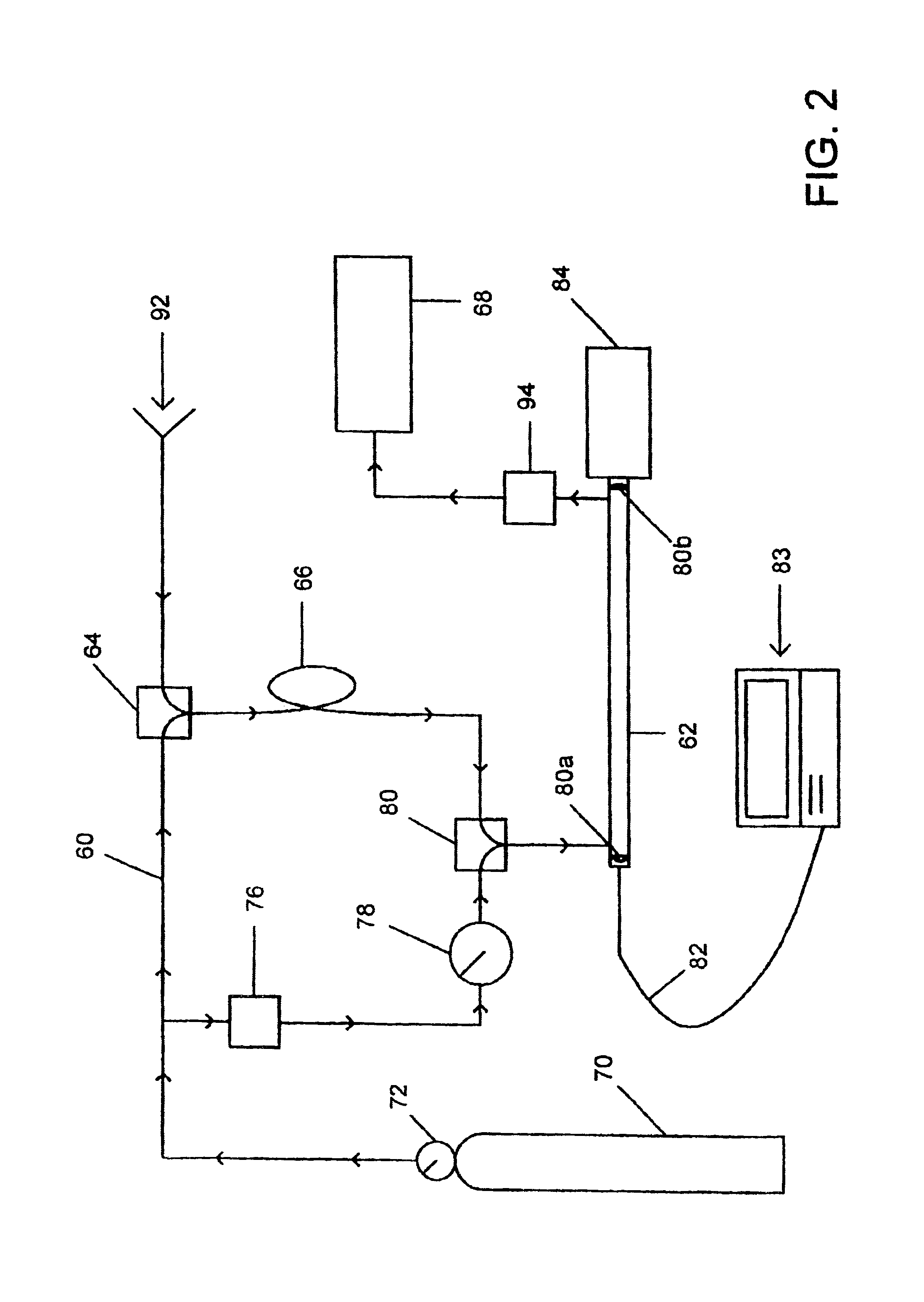

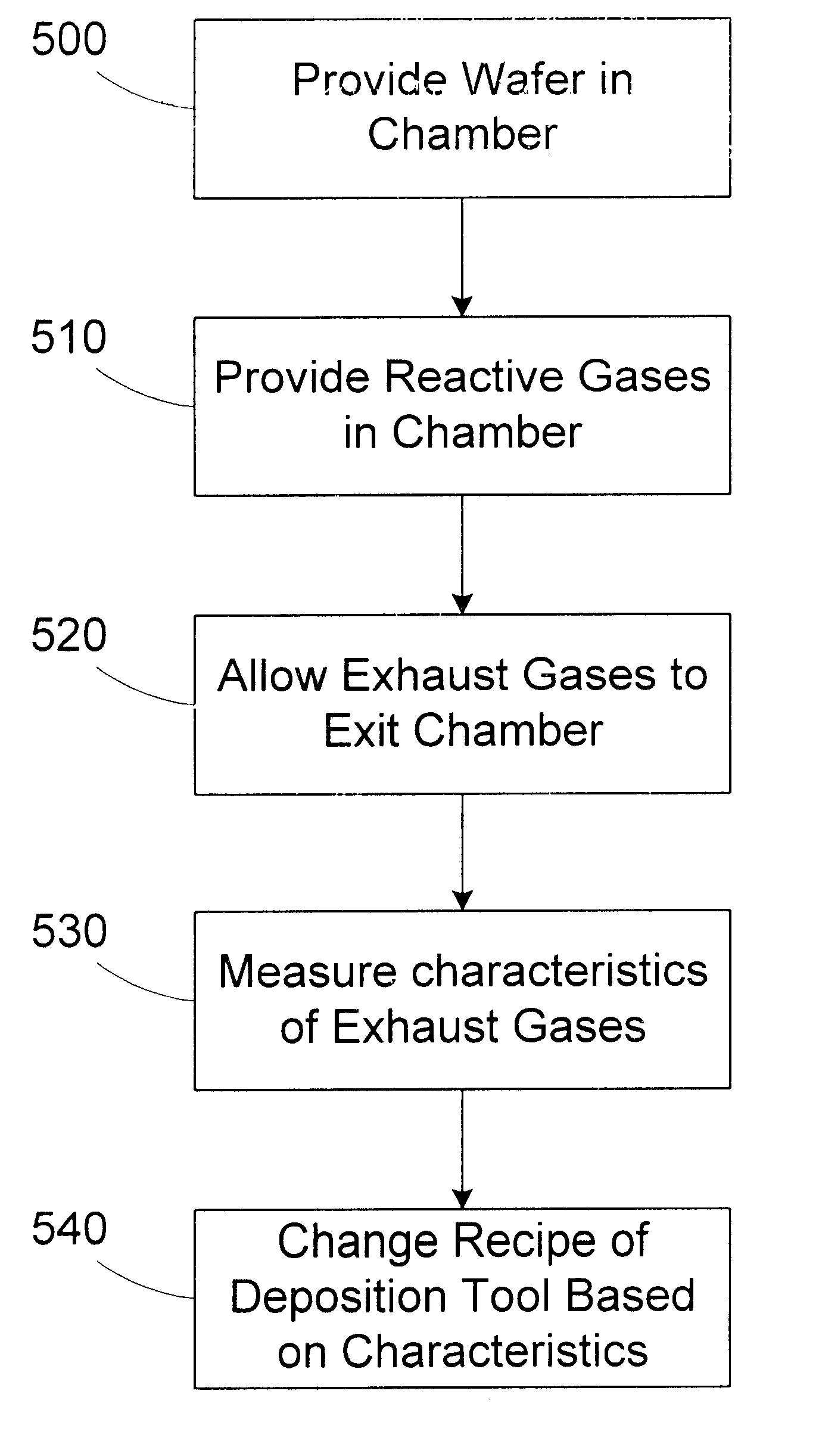

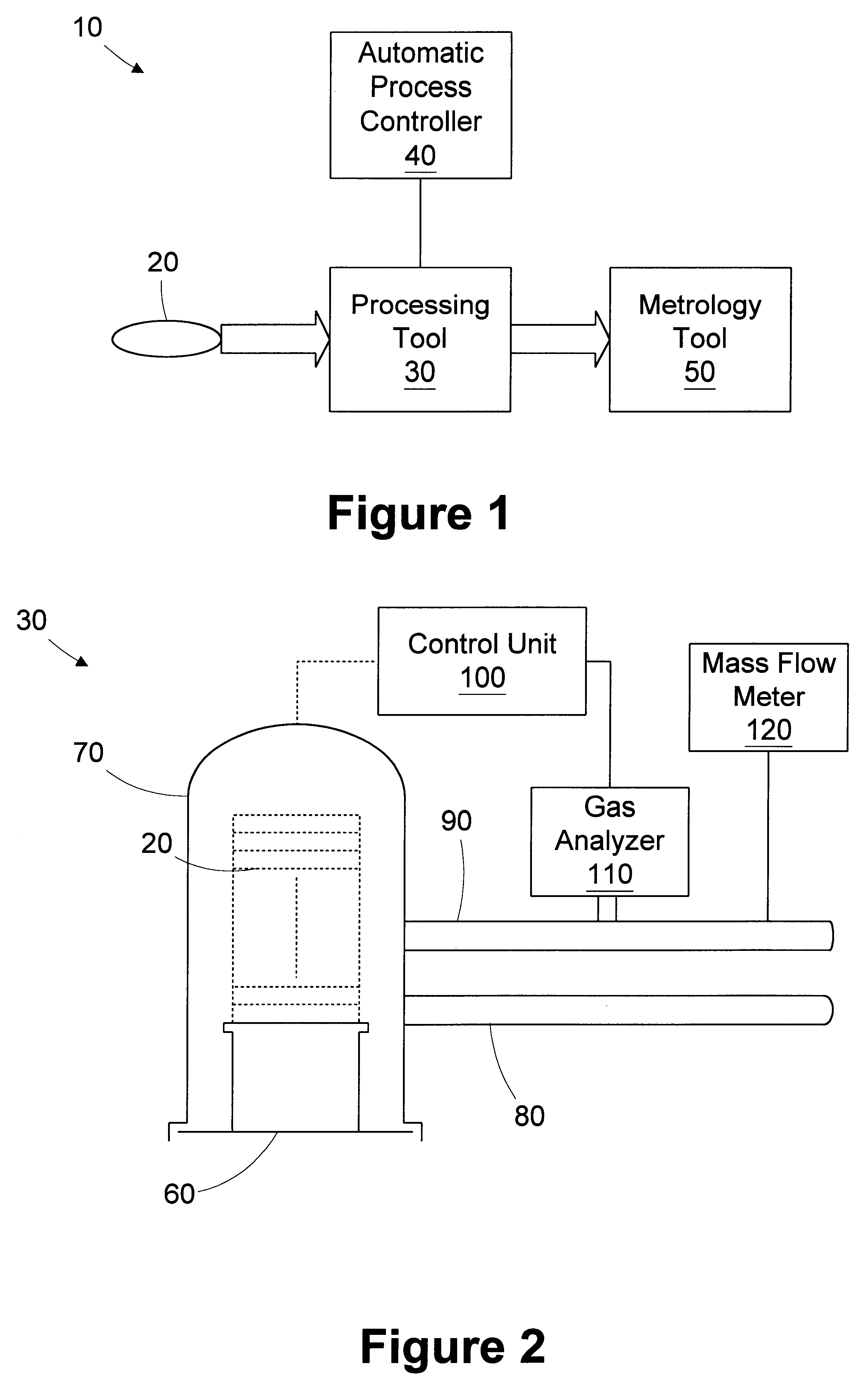

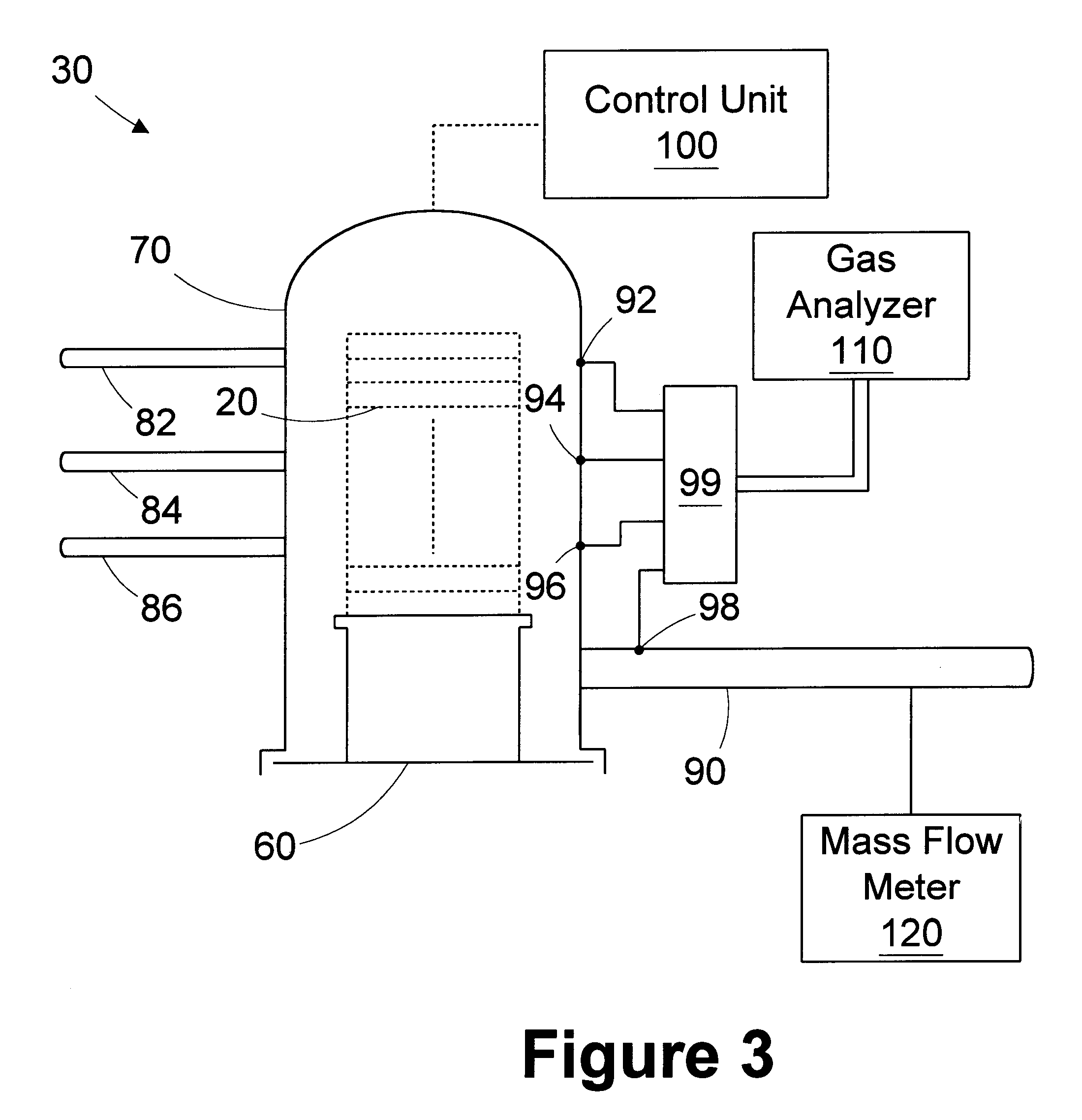

Method and apparatus for controlling deposition process using residual gas analysis

InactiveUS6387823B1Vacuum evaporation coatingSemiconductor/solid-state device manufacturingGas analysisReactive gas

A method for controlling a deposition process, includes providing a wafer in a chamber of a deposition tool, the deposition tool being adapted to operate in accordance with a recipe; providing reactant gases to the chamber, the reactant gases reacting to form a layer on the wafer; allowing exhaust gases to exit the chamber; measuring characteristics of exhaust gases; and changing the recipe based on the characteristics of the exhaust gases. A deposition tool includes a chamber, a gas supply line, a gas exhaust line, a gas analyzer, and a controller. The chamber is adapted to receive a wafer. The gas supply line is coupled to the chamber for providing reactive gases. The gas exhaust line is coupled to the chamber for receiving exhaust gases. The gas analyzer is coupled to the gas exhaust line and adapted to determine characteristics of the exhaust gases. The controller is adapted to control the processing of the wafer in the chamber based on the characteristics of the exhaust gases.

Owner:GLOBALFOUNDRIES INC

Disposable sensor for use in measuring an analyte in a gaseous sample

ActiveUS20050083527A1Material analysis by observing effect on chemical indicatorWithdrawing sample devicesGas analysisAnalyte

The present invention is a disposable sensor for use with a device that quantifies analytes in a gaseous sample. It comprises (i) a sensing element, (ii) a means for interfacing the disposable sensor with a gas analysis device, and (iii) a housing. When used with a device that can quantify the concentration of an analyte in a gas sample, the present invention facilitates the use of exhaled breath analysis as a clinical tool.

Owner:CIRCASSIA AB

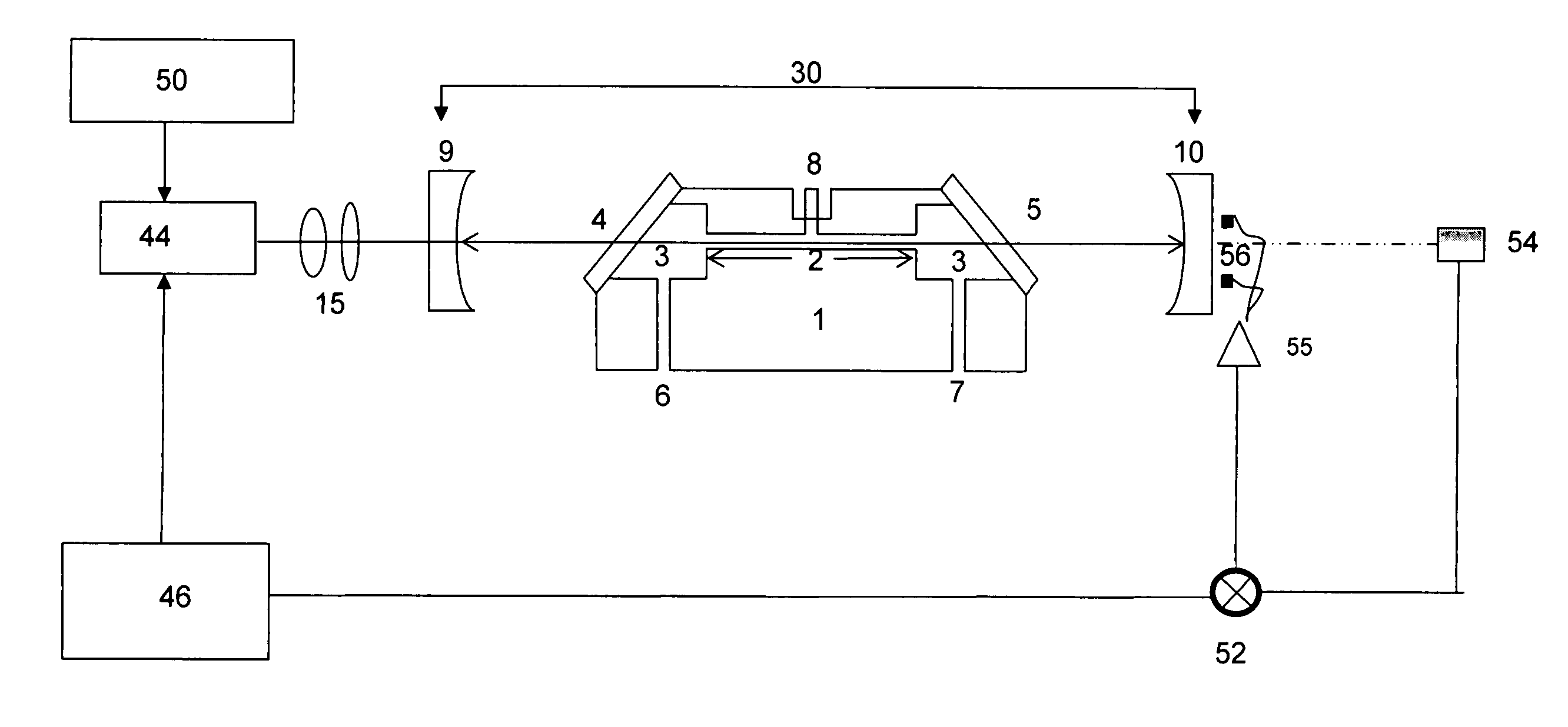

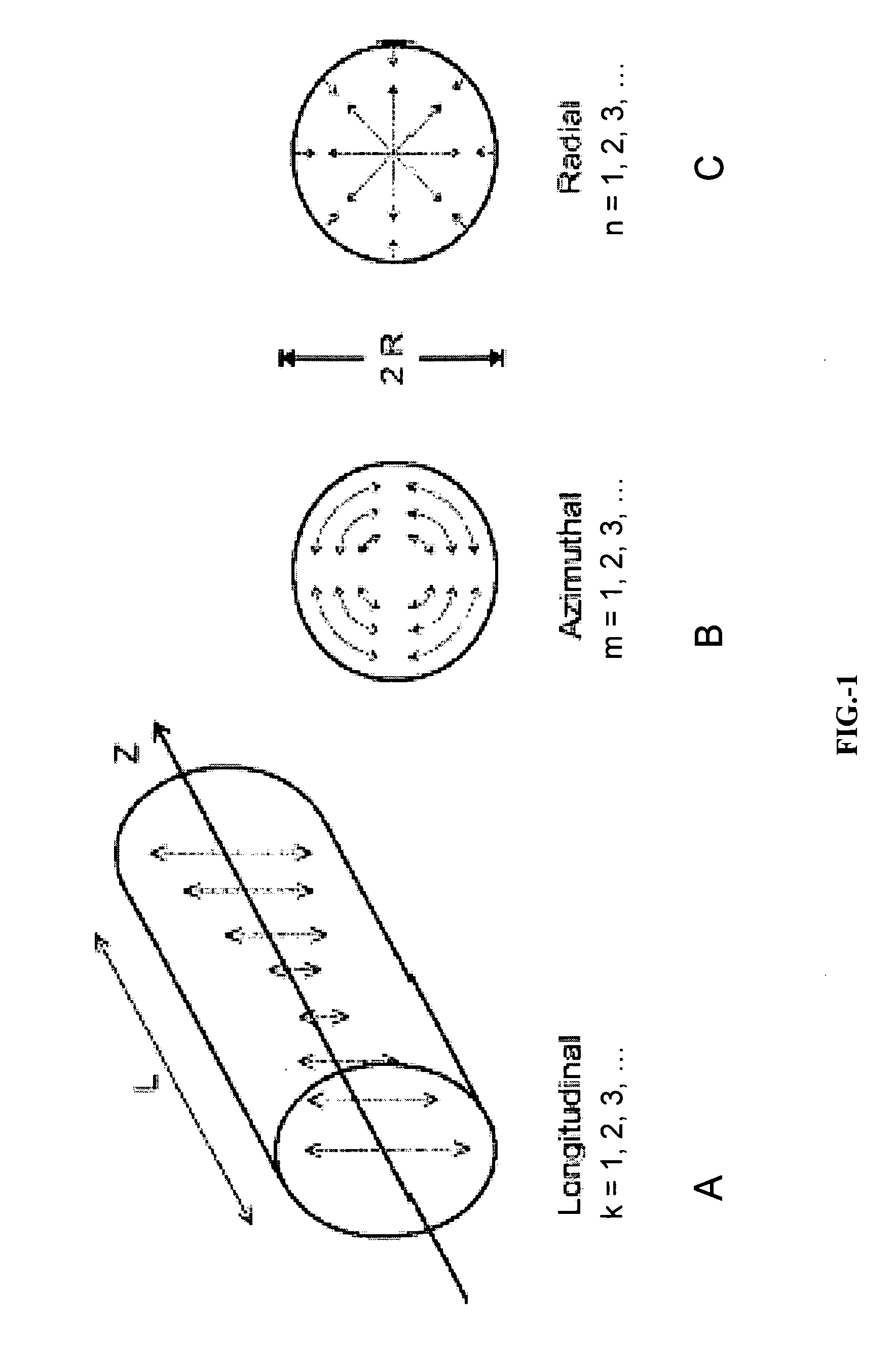

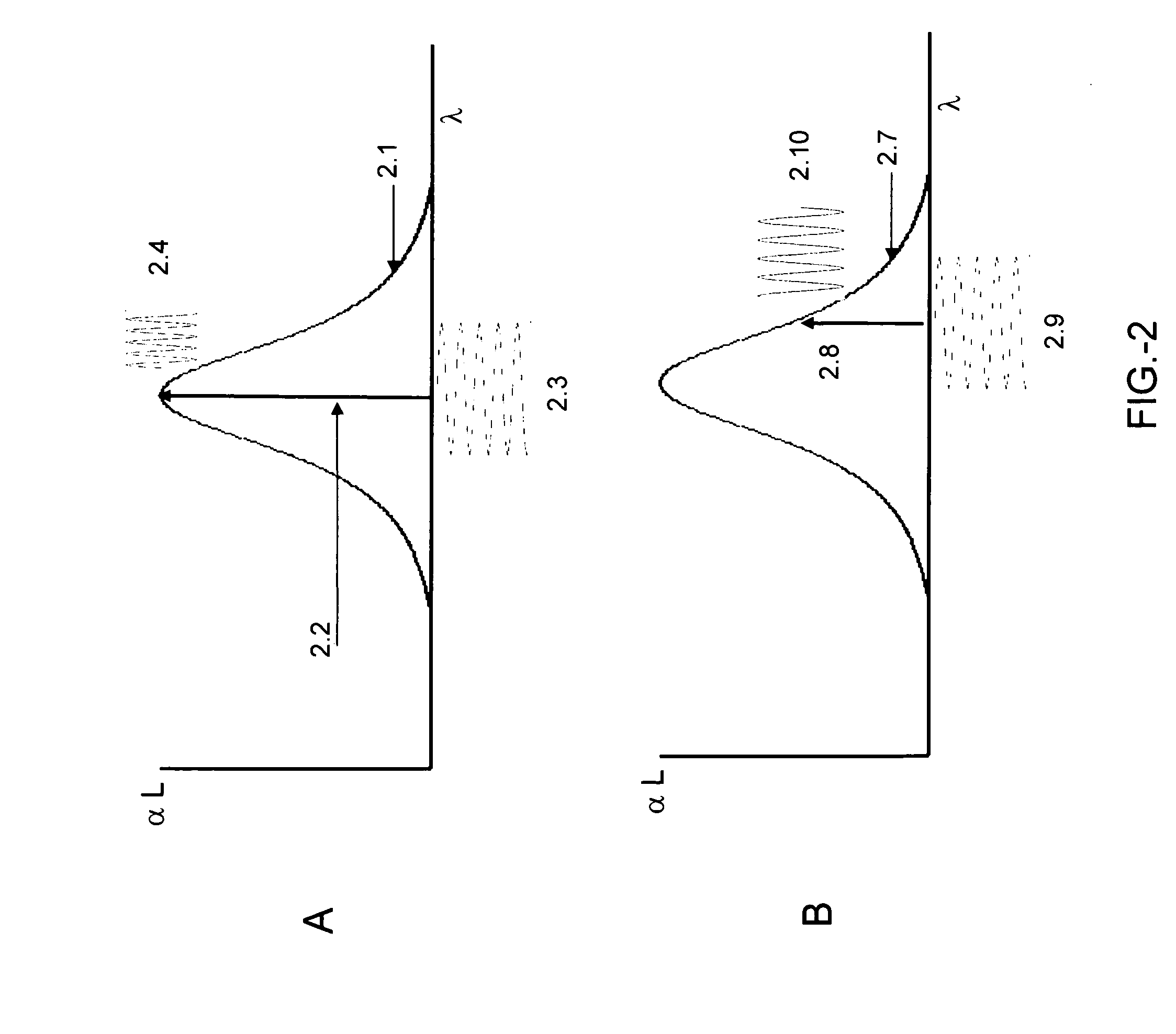

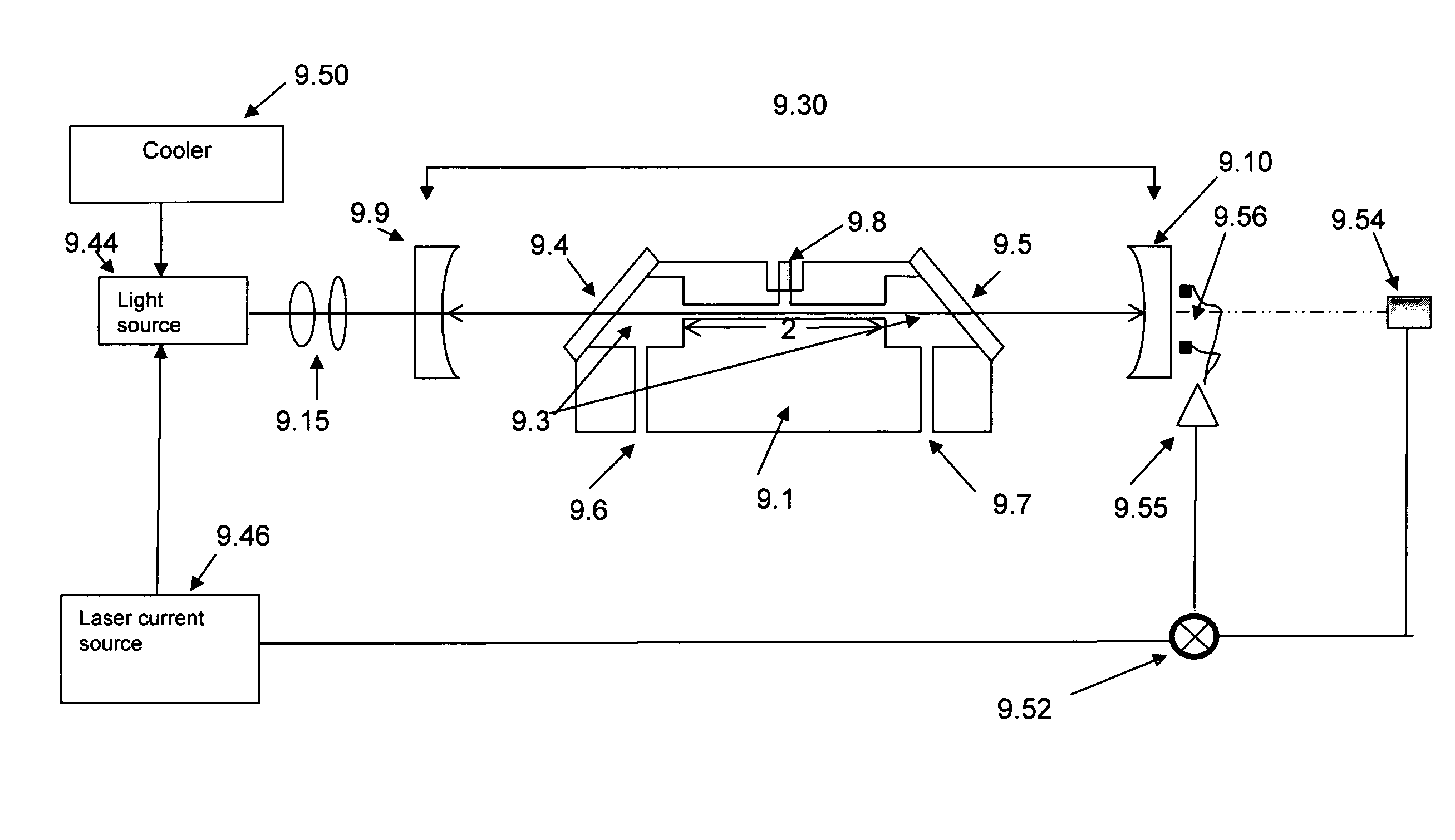

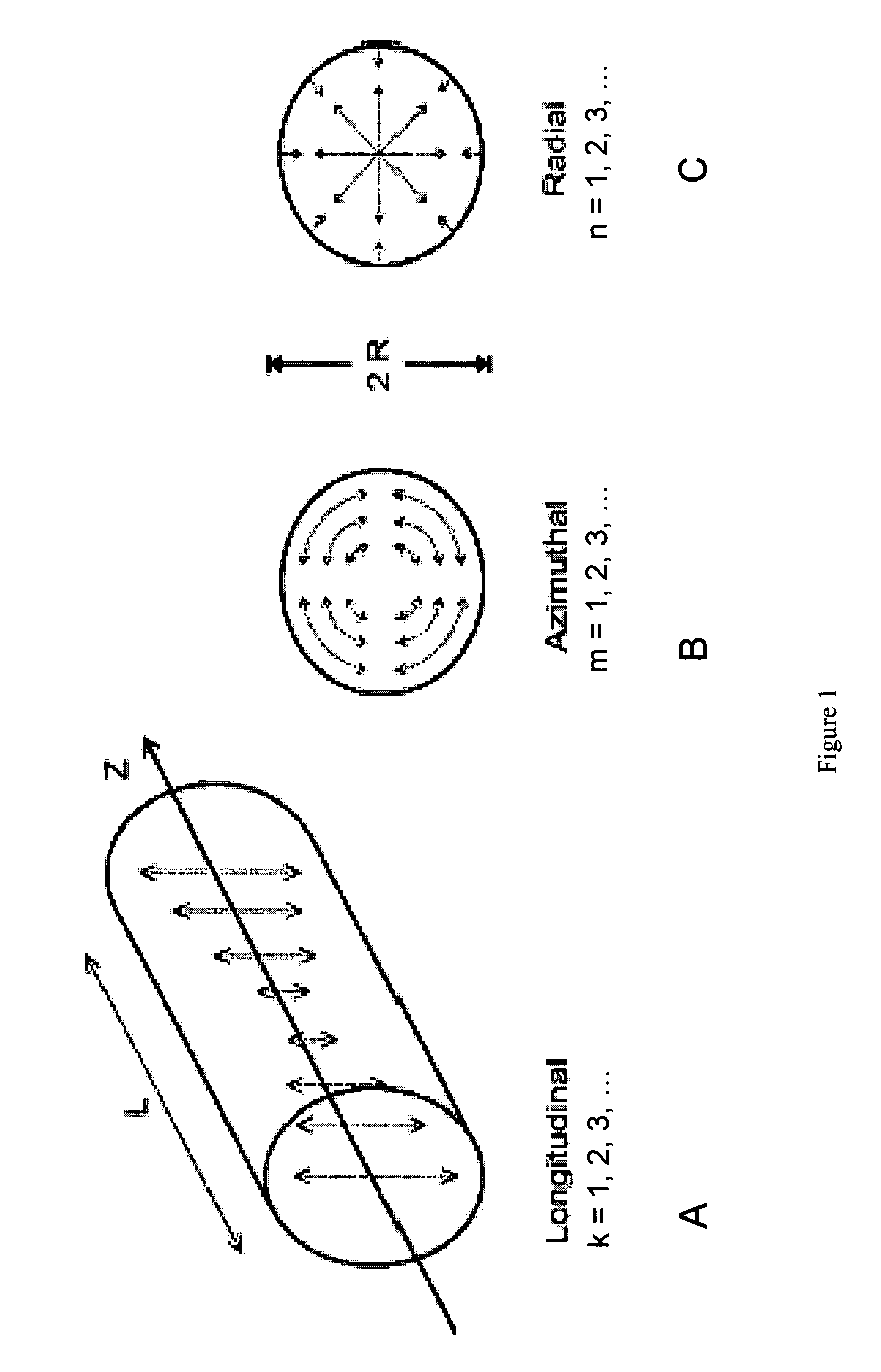

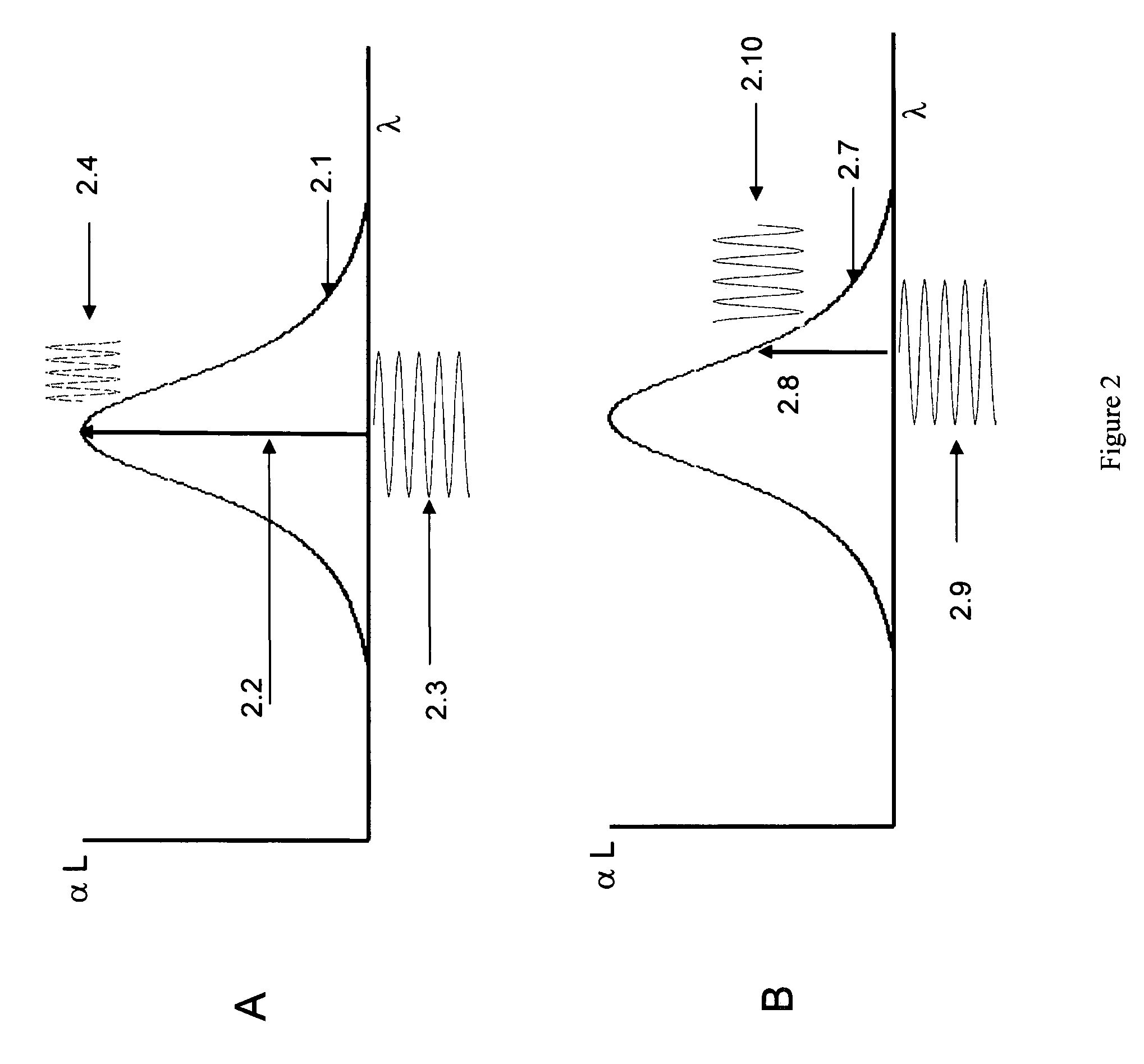

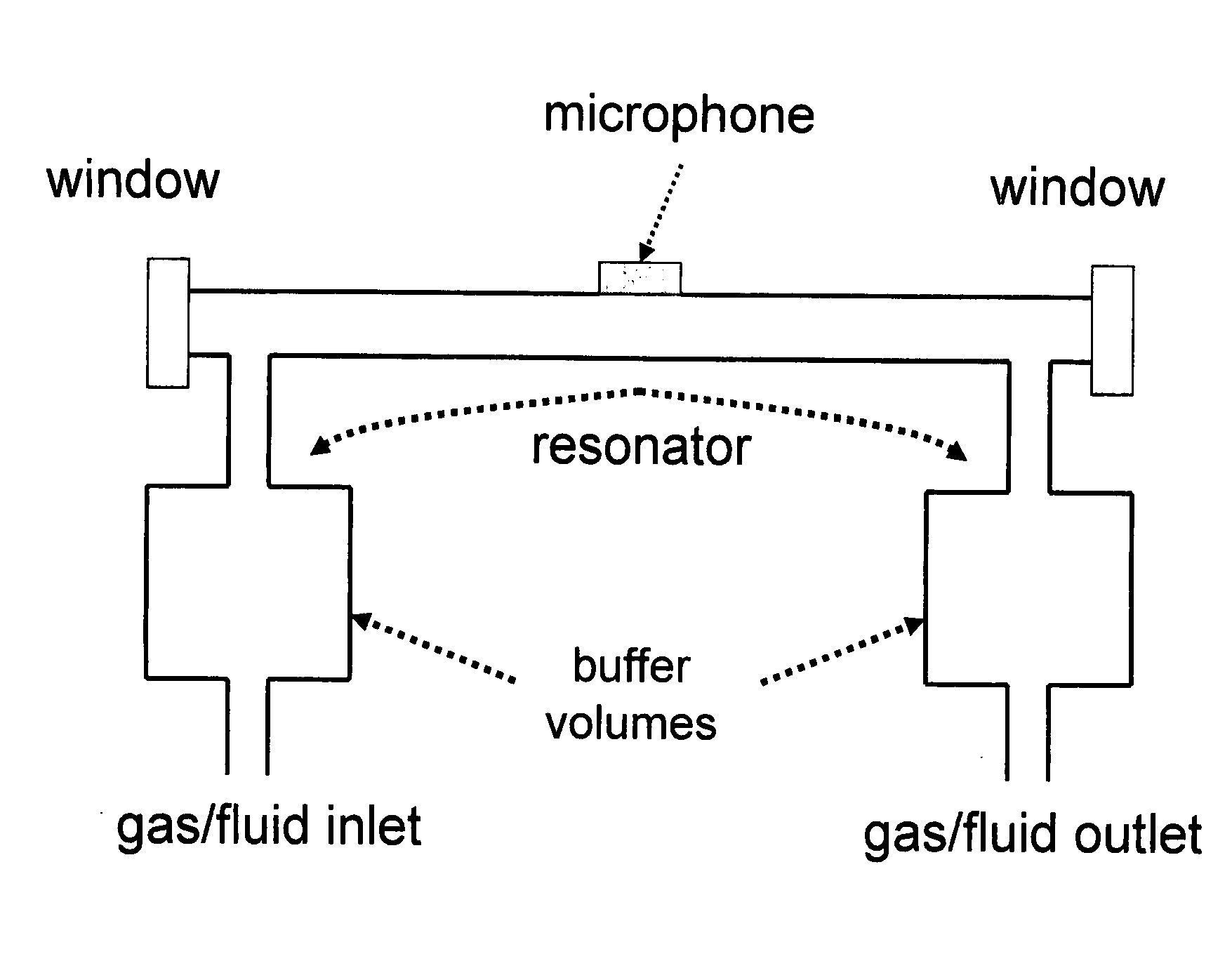

System and method for gas analysis using doubly resonant photoacoustic spectroscopy

ActiveUS20060123884A1Increase productionReduce equipment downtimeMaterial analysis using wave/particle radiationMaterial analysis using microwave meansGas analysisGas detector

A method for analyzing gas concentration using doubly resonant photoacoustic spectroscopy, and a doubly resonant photaoacoustic gas detector comprising: i) a continuous wave light beam whose wavelength coincides with an absorption wavelength of a gaseous analyte; ii) a closed path optical cavity having at least two reflective surfaces; iii) an acoustic resonator chamber contained within said optical cavity, and comprising an acoustic sensor for detecting sound waves generated by a gaseous analyte present within said chamber, the light beam passing sequentially into, through and out of said chamber, and being repeatedly reflected back and forth through said chamber, and being modulated at a frequency which is equal to or equal to one-half of an acoustic resonance frequency of said acoustic resonator chamber.

Owner:LI COR

Disposable sensor for use in measuring an analyte in a gaseous sample

InactiveUS7220387B2Material analysis by observing effect on chemical indicatorWithdrawing sample devicesGas analysisAnalyte

The present invention is a disposable sensor for use with a device that quantifies analytes in a gaseous sample. It comprises (i) a sensing element, (ii) a means for interfacing the disposable sensor with a gas analysis device, and (iii) a housing. When used with a device that can quantify the concentration of an analyte in a gas sample, the present invention facilitates the use of exhaled breath analysis as a clinical tool.

Owner:CIRCASSIA AB

System and method for gas analysis using doubly resonant photoacoustic spectroscopy

ActiveUS7263871B2High frequencyLow costAnalysing fluids using sonic/ultrasonic/infrasonic wavesMaterial analysis using wave/particle radiationGas analysisGas detector

A method for analyzing gas concentration using doubly resonant photoacoustic spectroscopy, and a doubly resonant photaoacoustic gas detector comprising:i) a continuous wave light beam whose wavelength coincides with an absorption wavelength of a gaseous analyte;ii) a closed path optical cavity having at least two reflective surfaces;iii) an acoustic resonator chamber contained within said optical cavity, and comprising an acoustic sensor for detecting sound waves generated by a gaseous analyte present within said chamber, the light beam passing sequentially into, through and out of said chamber, and being repeatedly reflected back and forth through said chamber, and being modulated at a frequency which is equal to or equal to one-half of an acoustic resonance frequency of said acoustic resonator chamber.

Owner:LI COR

Method and apparatus for controlling a gas cluster ion beam formed from a gas mixture

ActiveUS20090140165A1Scattering properties measurementsSemiconductor/solid-state device manufacturingGas analysisGas cluster ion beam

Methods and apparatus for controlling a gas cluster ion beam formed from a plurality of process gases in a gas mixture. The methods and apparatus involve measuring gas analysis data relating to the composition of the gas mixture and modifying the irradiation of the workpiece in response to the detected parameter. The gas analysis data can be derived from samples of the composition of the gas mixture flowing from a gas source to the gas cluster ion beam apparatus or samples of the residual gases inside the vacuum vessel of the gas cluster ion beam apparatus.

Owner:TEL EPION

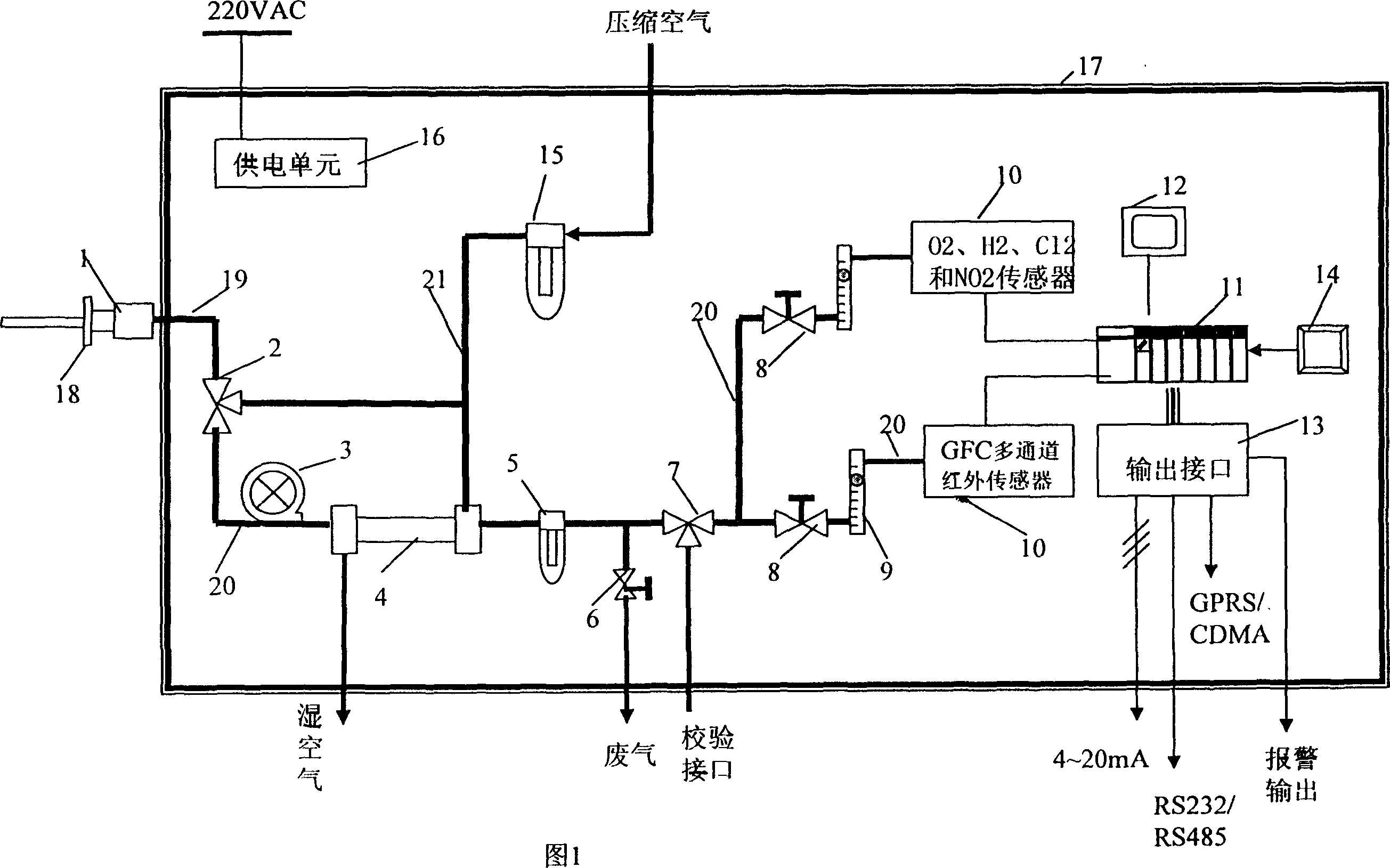

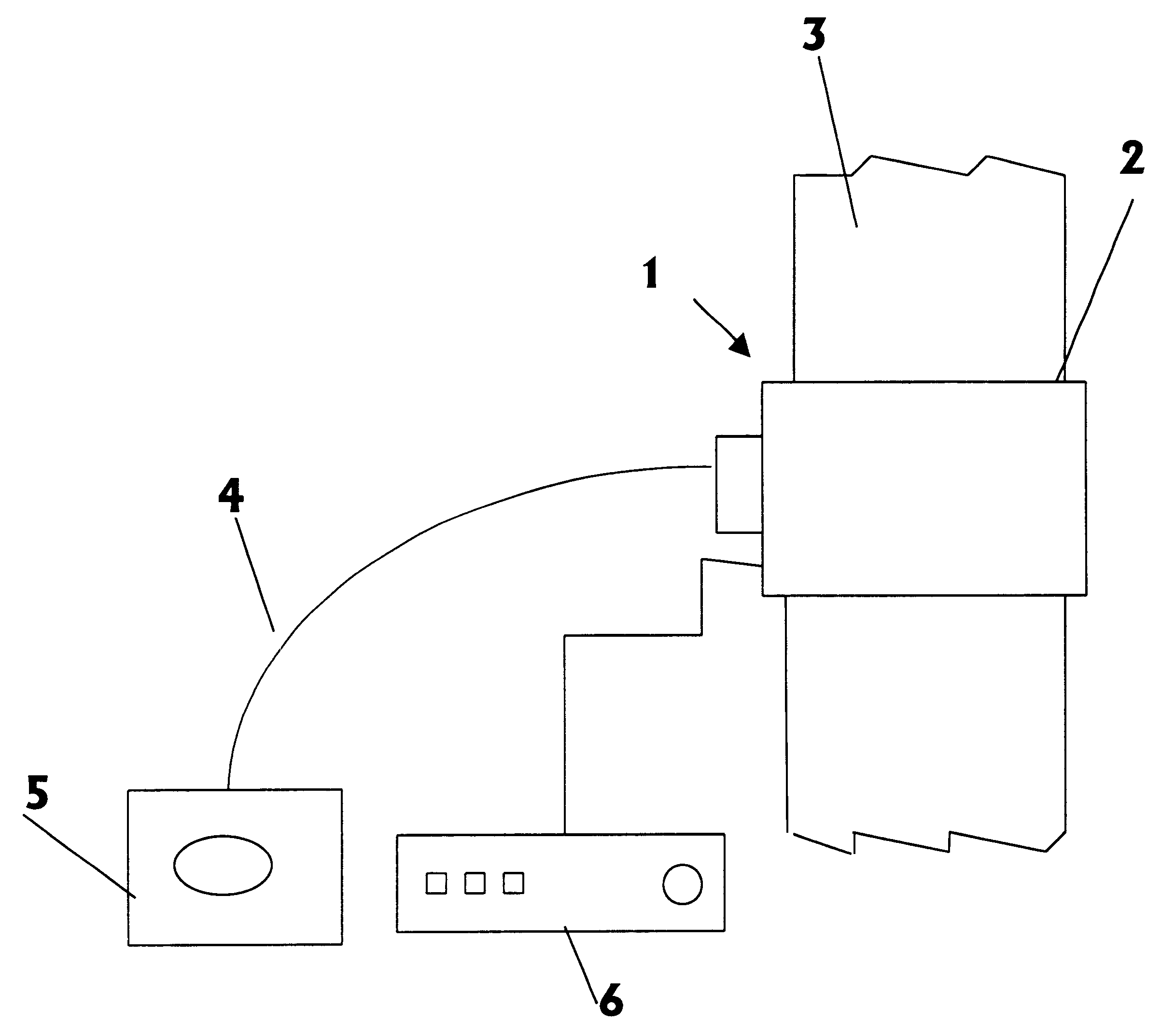

Integrated gas online detector

InactiveCN1866027ARealize simultaneous measurementAvoid long distance transportPreparing sample for investigationMaterial analysis by electric/magnetic meansGas analysisGas composition

The related integrated on-line gas detector can continual detect the content of CO, CO2, SO2, NO, NO2, N2O, CH4, HCl, H2S, HF, O2, H2 and Cl2 in smoke gas, kiln gas and furnace gas, which comprises: a sampling probe, a back-blow valve, a pump, a dehydrator, a fine filter, a bypass valve, a check valve, a stable valve, a flowmeter, a gas analysis sensor, a controller, a signal display, a signal output interface, an operation button, a drier, a power, an outdoor case, a sampling pipe, a sample-gas pipe, and a back-blow pipe. This invention has wide application.

Owner:南京卓成自动化设备有限公司

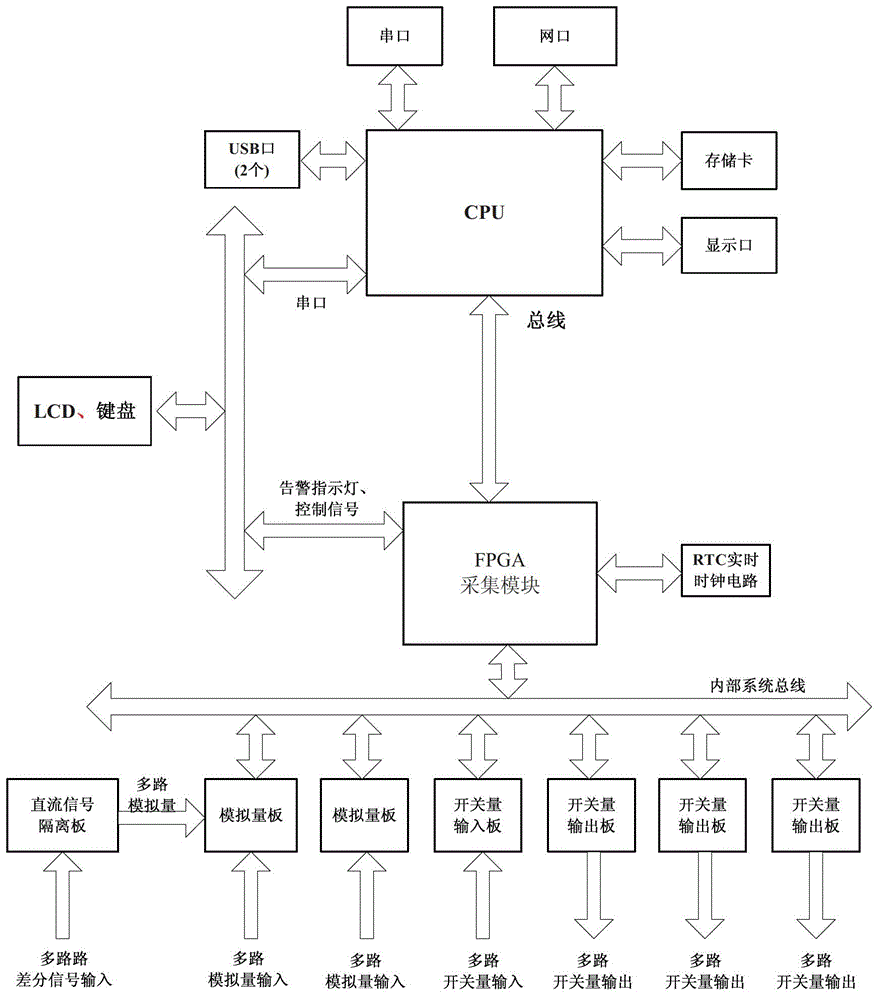

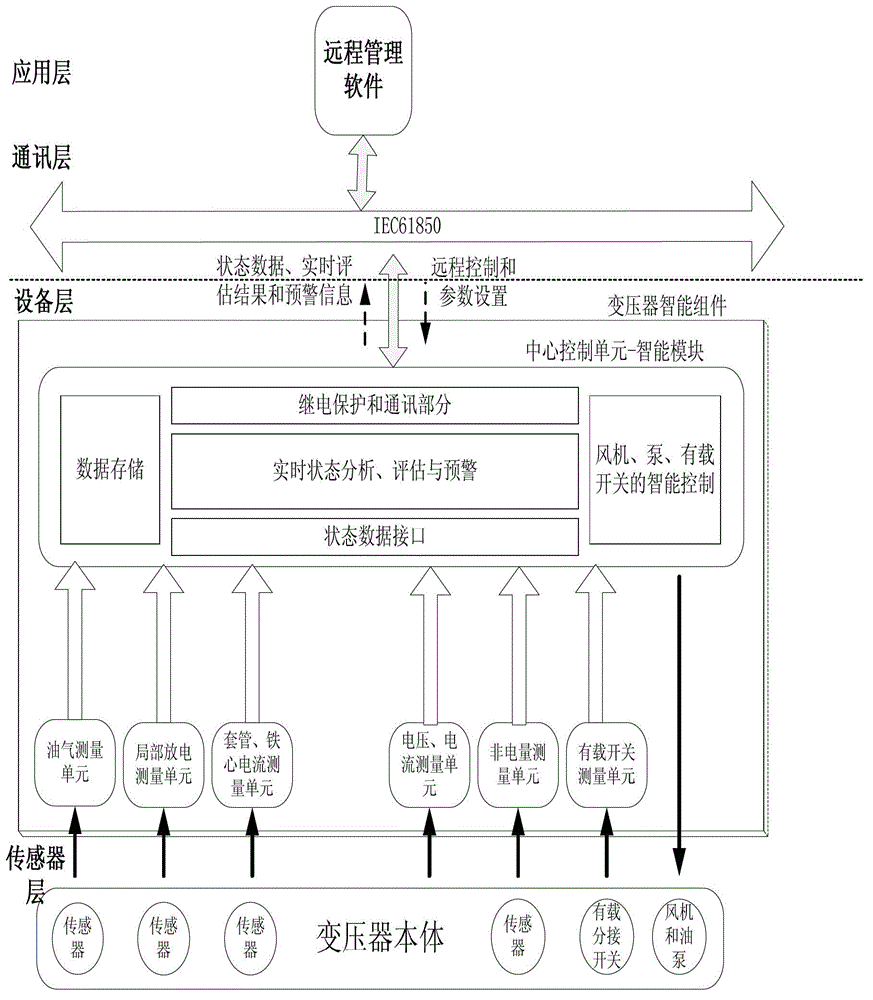

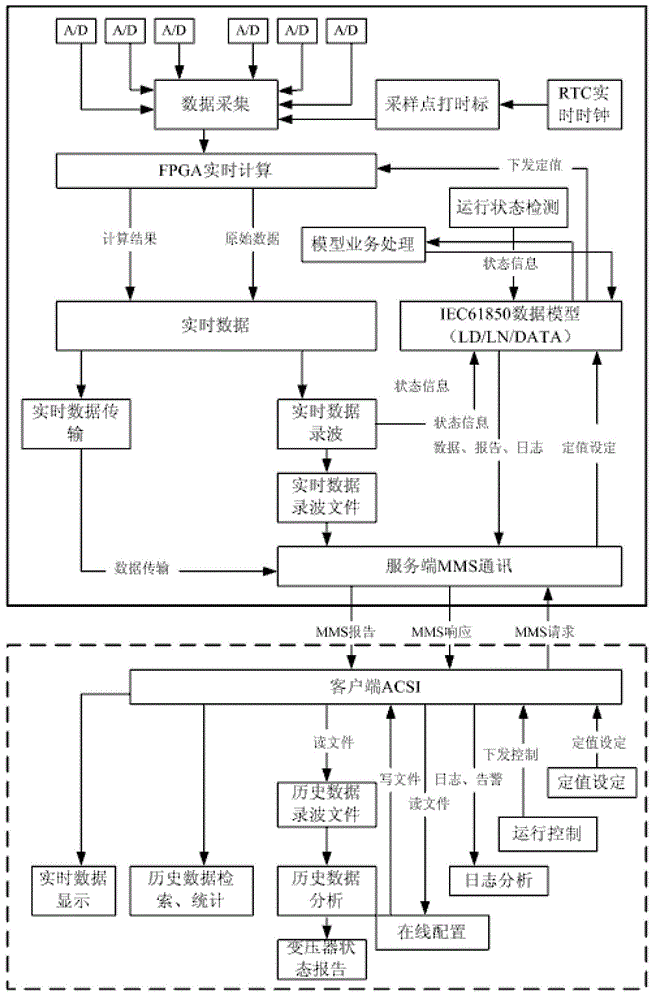

Comprehensive monitoring system for electric power system transformers

ActiveCN102981084AExtended service lifeImprove accuracyTesting dielectric strengthGas analysisMathematical model

A comprehensive monitoring system for electric power system transformers comprises an IEC61850-based unified modularized CPU (central processing unit) hardware platform, a sensor, a system terminal, at least one of nine monitoring logical devices, and further comprises an expert analysis system, including a thermal management mathematical model and an oil and gas analysis mathematical model, wherein by configuring and starting software, a function for monitoring corresponding LDs (logical device) which are independent of one another is achieved; and by performing independent effective data acquisition on the transformers respectively, and integrating and processing the data by the CPU, the electric power system transformers are comprehensively monitored in a configurable way. The comprehensive monitoring system for the electric power system transformers is convenient and flexible in application; current situations of repeated data acquisition, and shortage of data integration, data processing, information exchange and information sharing are changed; conversion from the conventional mechanism-based timed maintenance to the state-based preventative maintenance is facilitated; the maintenance cost is obviously saved; service lives of the transformers are prolonged; and a customer can obviously reduce the purchase cost and the management cost.

Owner:SHENZHEN SHUANGHE ELECTRIC CO LTD

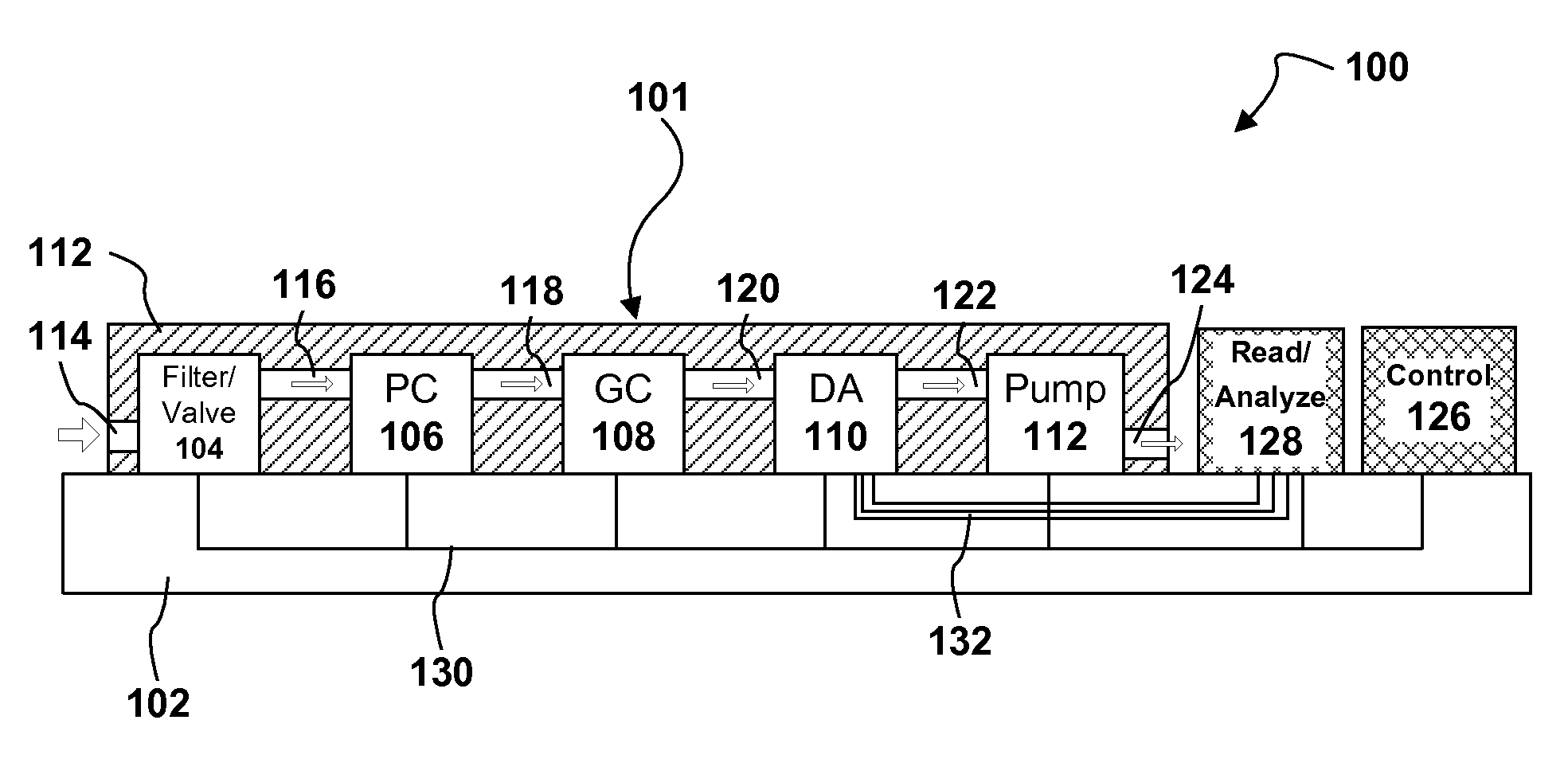

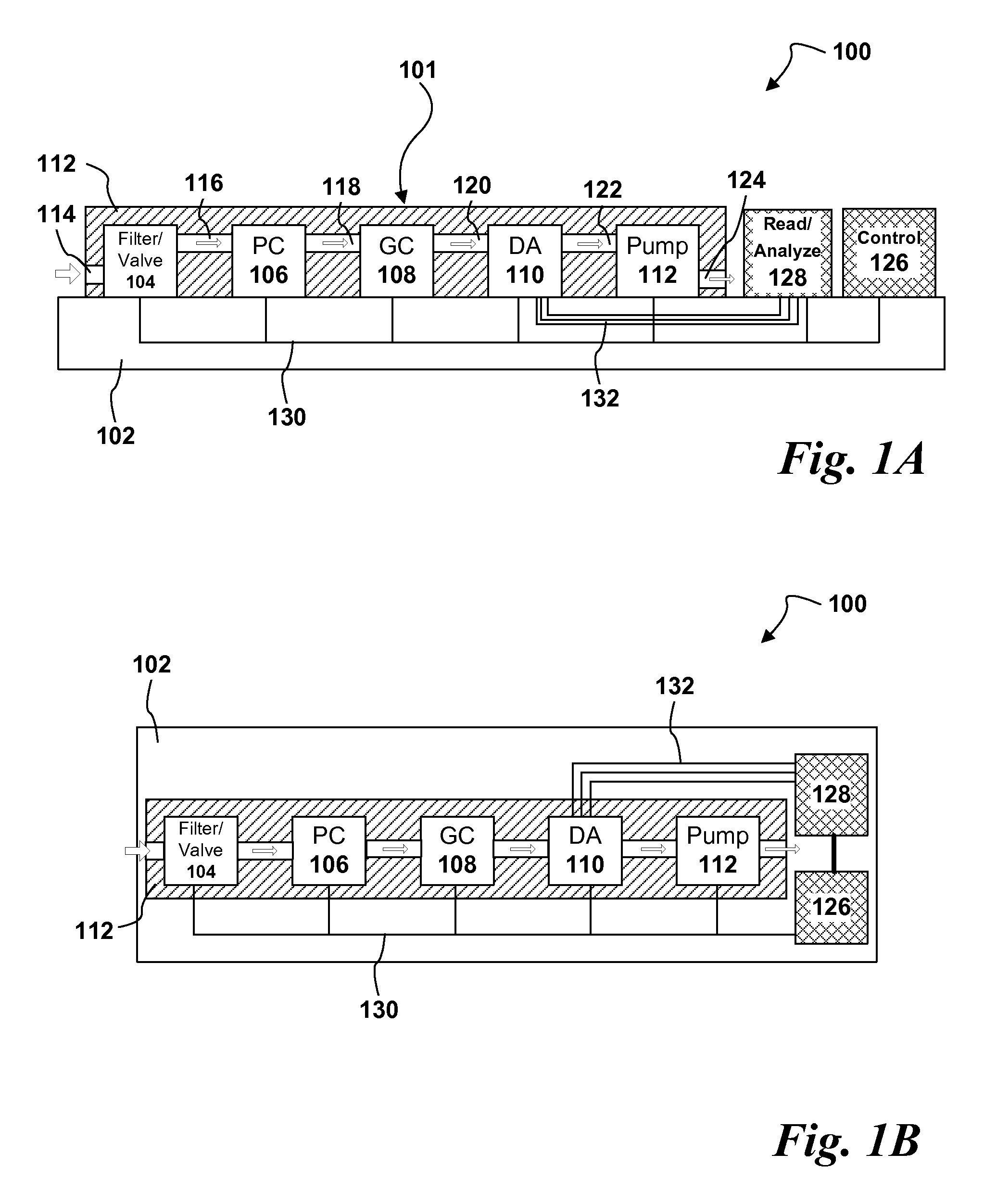

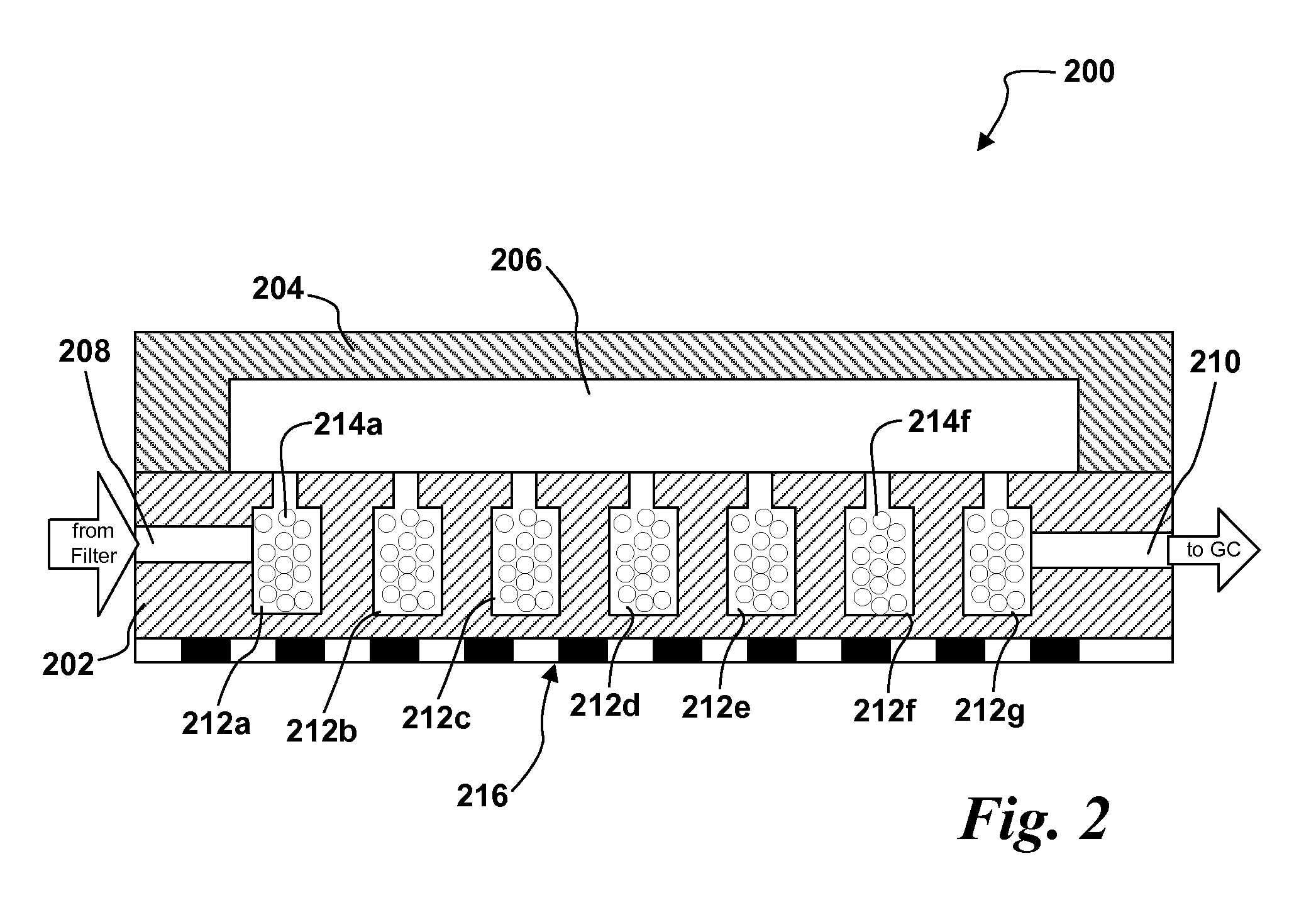

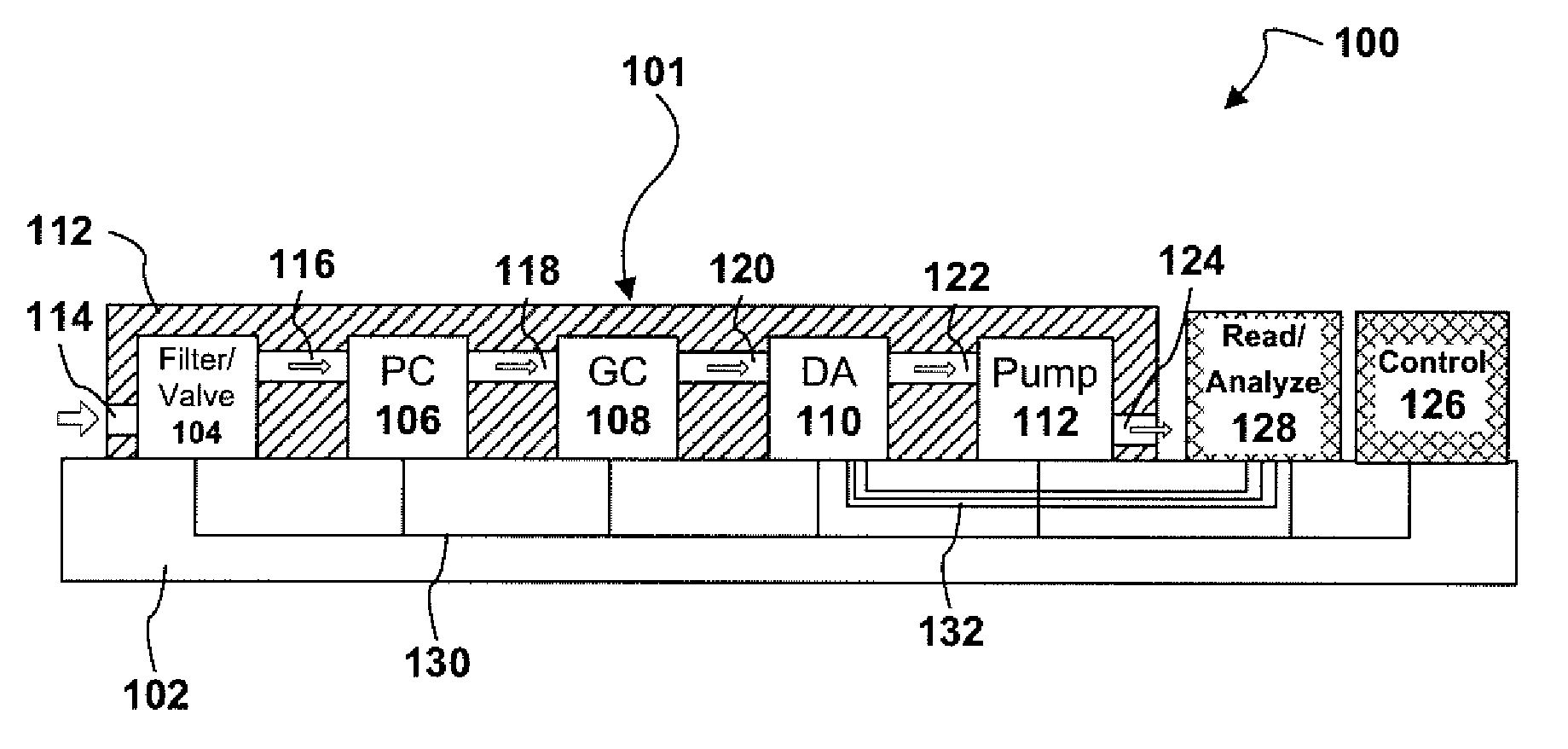

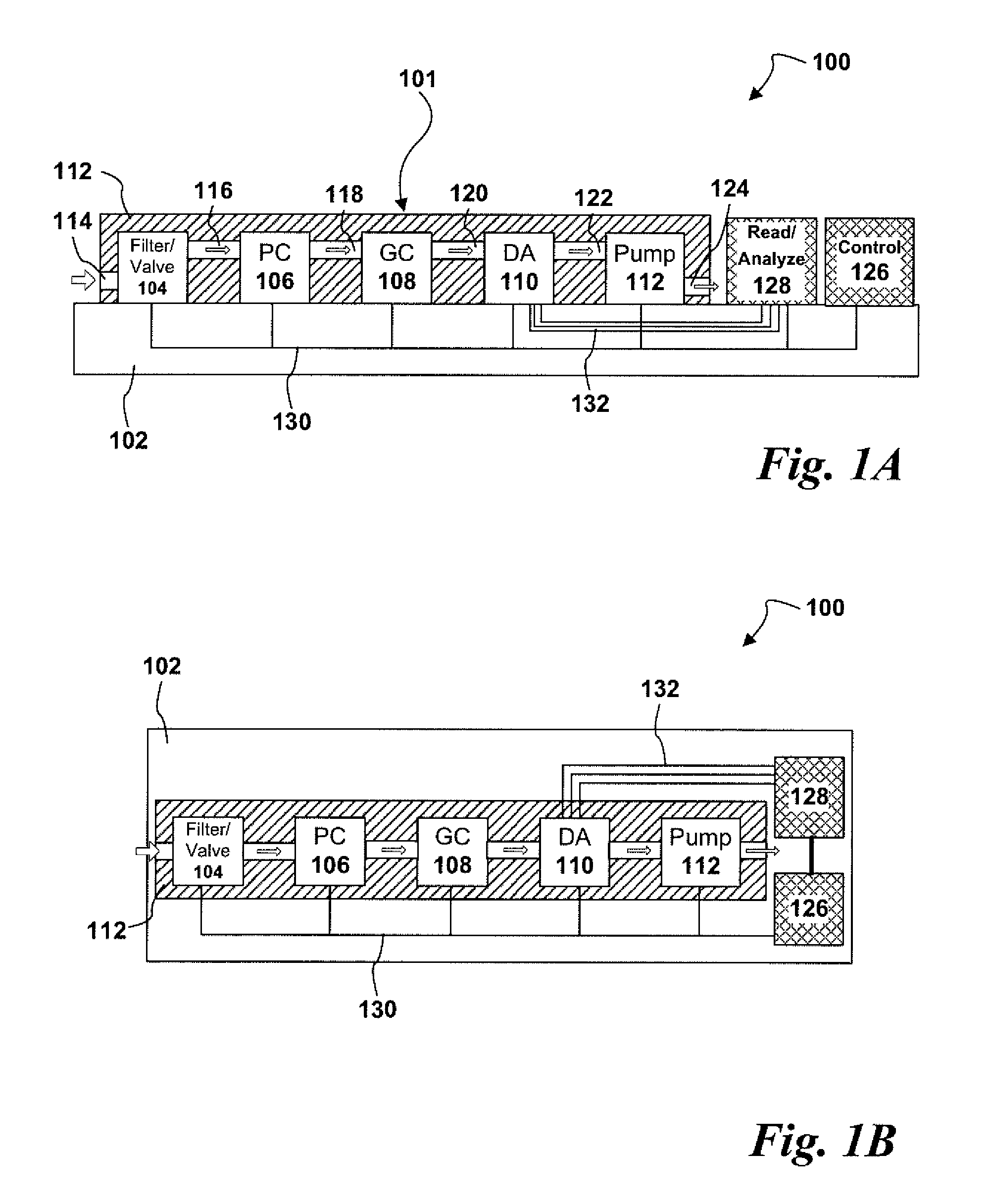

Handheld gas analysis systems for point-of-care medical applications

The disclosure describes an apparatus including a substrate and a gas chromatograph having a fluid inlet and a fluid outlet and being mounted to the substrate. A detector array having a fluid inlet and a fluid outlet and is mounted to the substrate, and the fluid inlet of the detector array is fluidly coupled to the fluid outlet of the gas chromatograph. A control is circuit coupled to the gas chromatograph and to the detector array such that the control circuit can communicate with the gas chromatograph and to the detector array, and a readout circuit is coupled to the detector array and to the control circuit such that the readout circuit can communicate with the control circuit and the detector array. Other embodiments are disclosed and claimed.

Owner:TRICORNTECH TAIWAN

Method and apparatus for anatomical deadspace measurement

An apparatus and method for determining an anatomical deadspace volume VDANA of a patient. The apparatus includes a sensor that measures a parameter indicative of the volume of gas exhaled by the patient and a gas analyzer that measures a concentration of a gas constituent in the patient's expiratory flow. A controller determines the patient's anatomical deadspace volume based on signals provided by the sensor and the gas analyzer.

Owner:RIC INVESTMENTS LLC

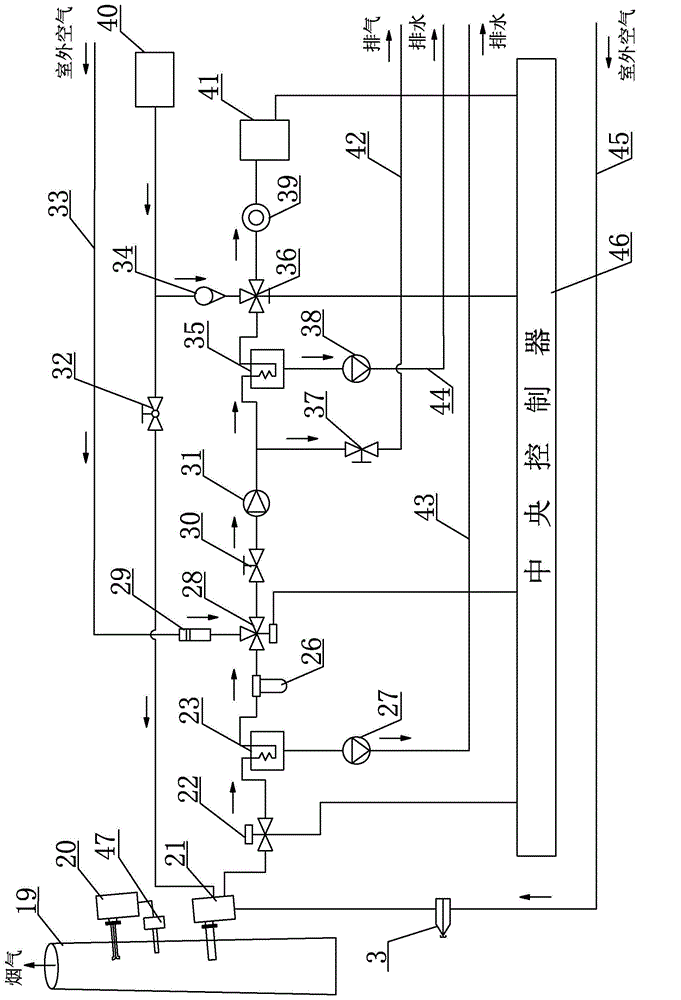

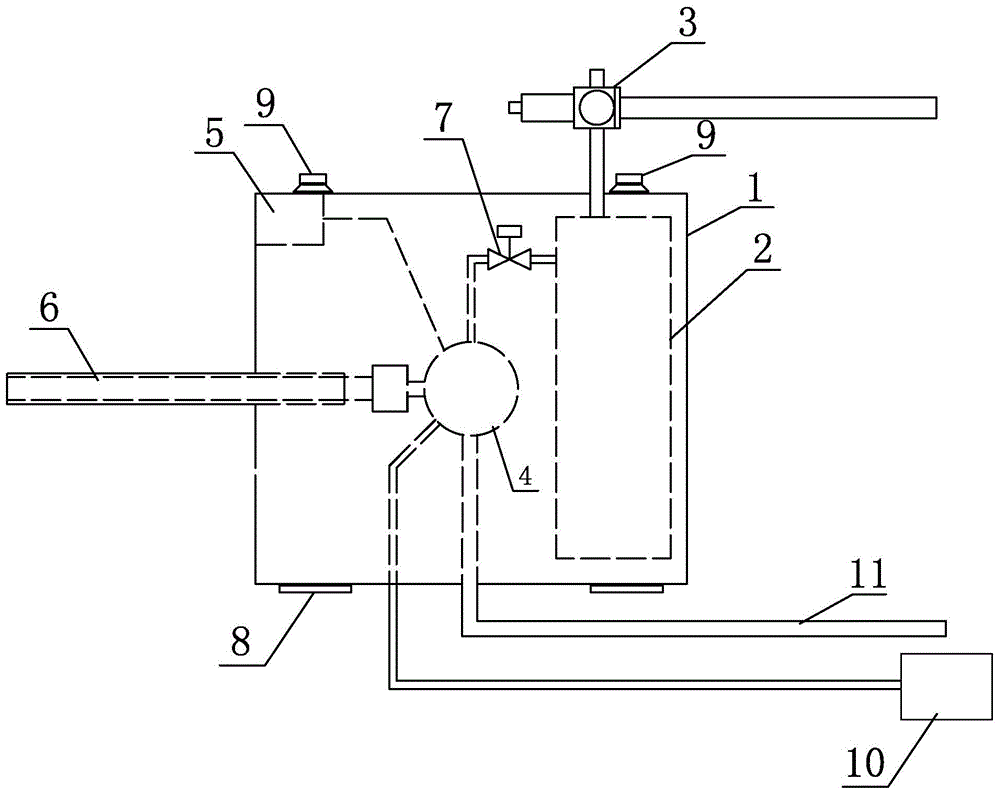

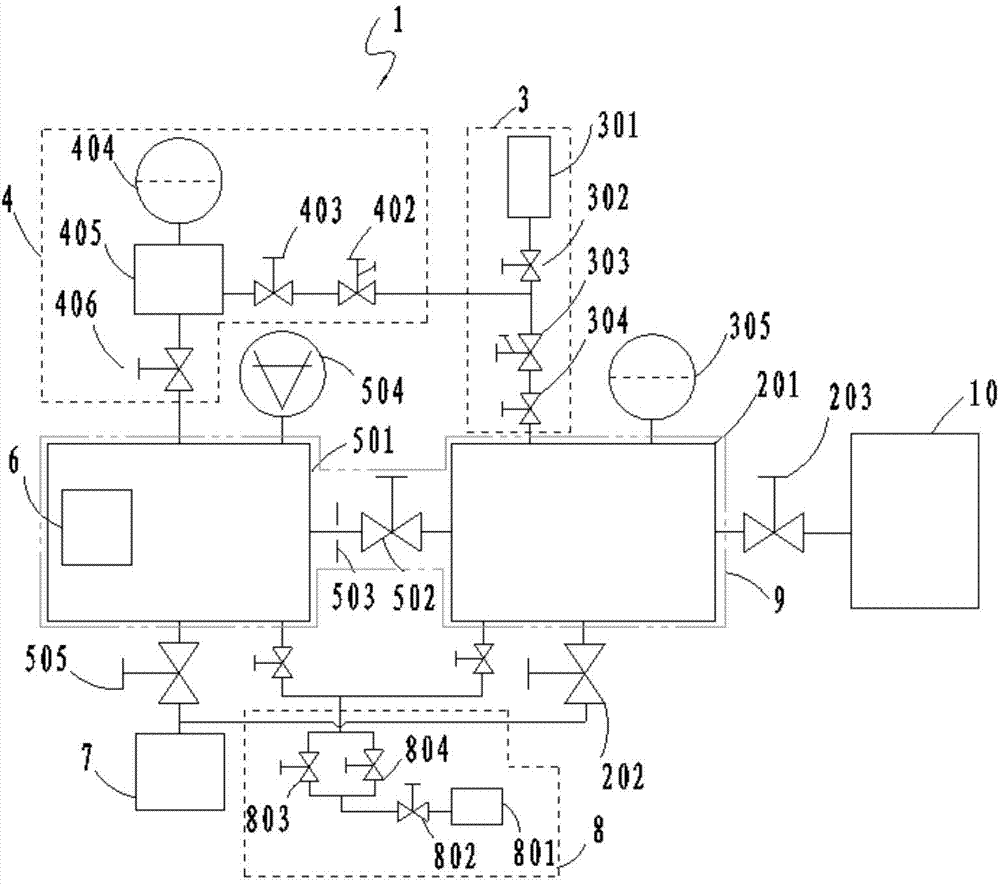

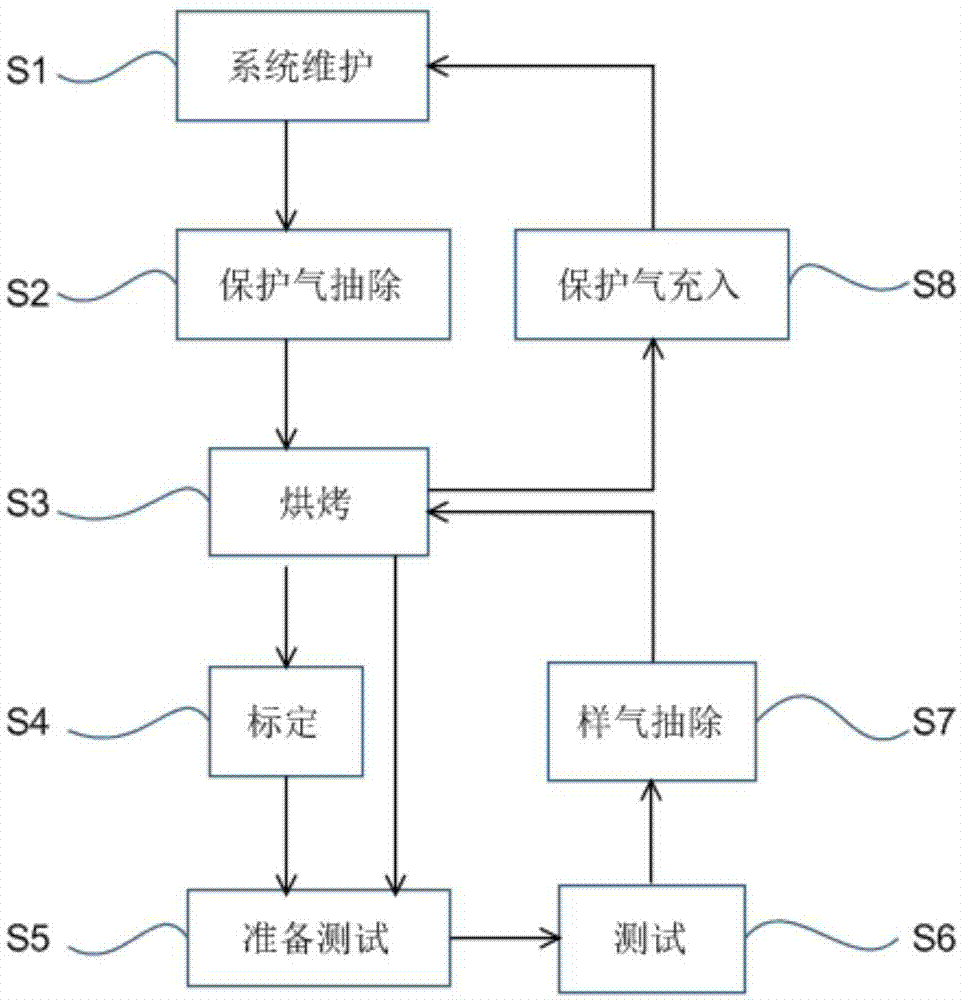

Smoke gas on-line monitoring system and smoke gas on-line monitoring method

ActiveCN104407161AAnalysis and detection are accurateStable flow rateMaterial analysisGas analysisParticulates

The invention relates to a smoke gas on-line monitoring system and a smoke gas on-line monitoring method, and aims at providing the smoke gas monitoring system and the monitoring method which have the advantages of being simple in structure, high in automation degree and accurate in monitoring. The system comprises a pitot pitometer, a smoke gas sampler, a particulate matter monitor, sampling pipelines and demarcating pipelines, wherein the pitot pitometer, the smoke gas sampler and the particulate matter monitor are all provided with anti-purging devices, signal receiving terminals of all the anti-purging devices are respectively connected with a central controller, and all the anti-purging devices are controlled by the central controller to regularly purge. Smoke gas collected by the smoke gas sampler successively passes through a first refrigerator, a gas filter, a second refrigerator and a membrane type filter, the collected smoke gas is cooled and filtered by the first refrigerator, the gas filter, the second refrigerator and the membrane type filter, and the rest smoke gas finally obtained is fed into a multicomponent gas analysis instrument to be analyzed and detected. For the system, whole calibrated pipelines and partial calibrated pipelines are also arranged, so that the analysis instrument in a line can be wholly calibrated and partially calibrated.

Owner:汇众翔环保科技股份有限公司

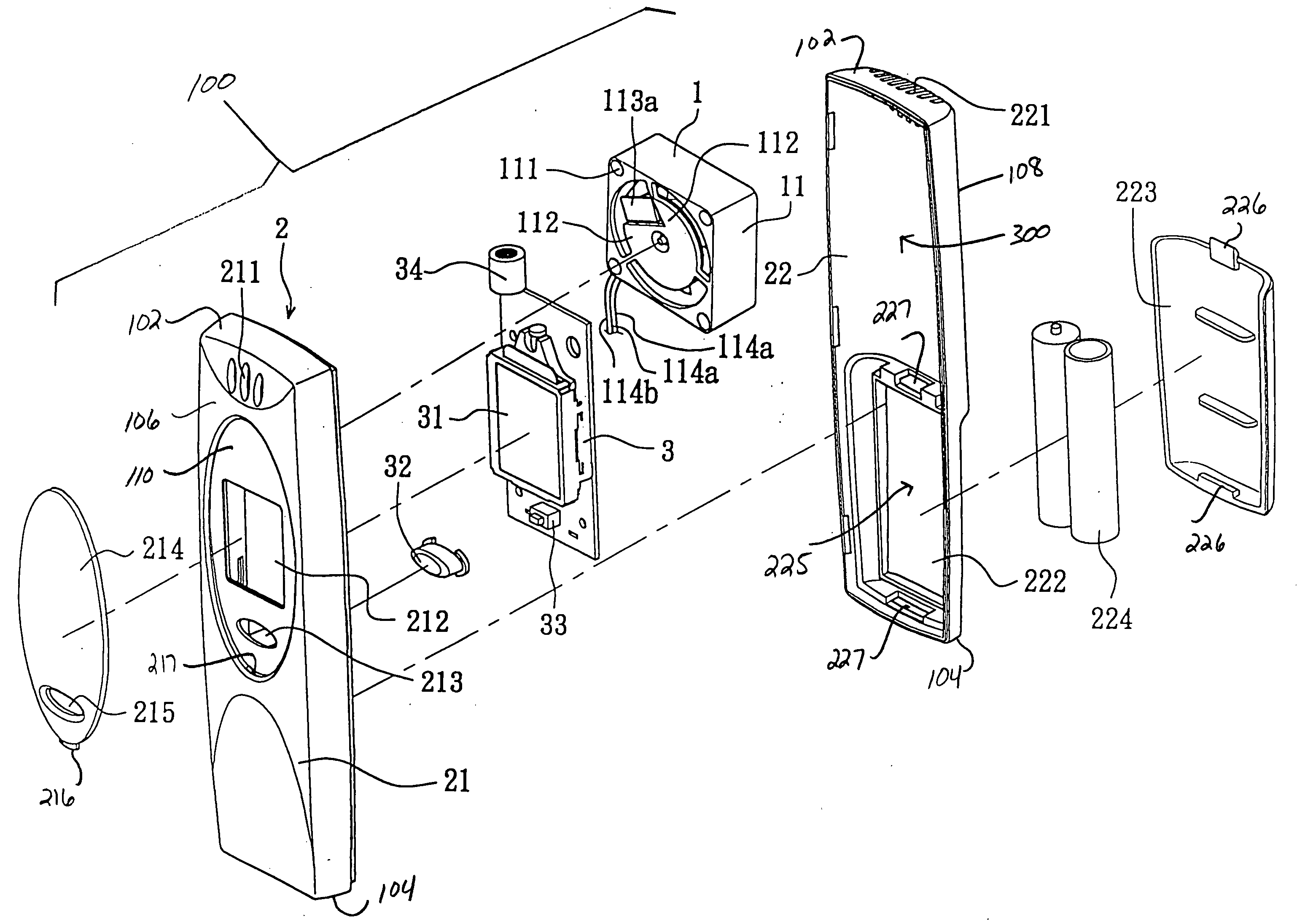

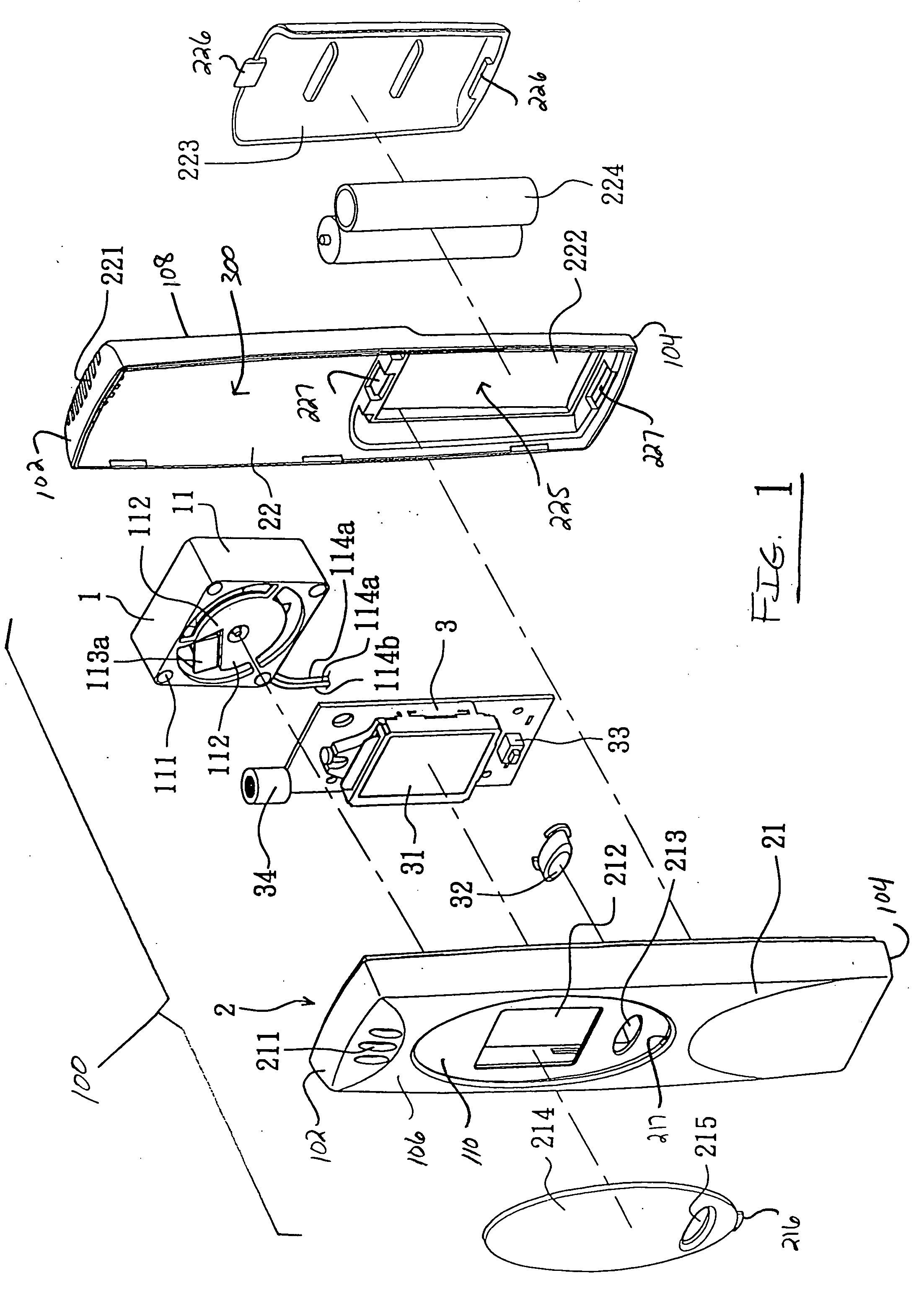

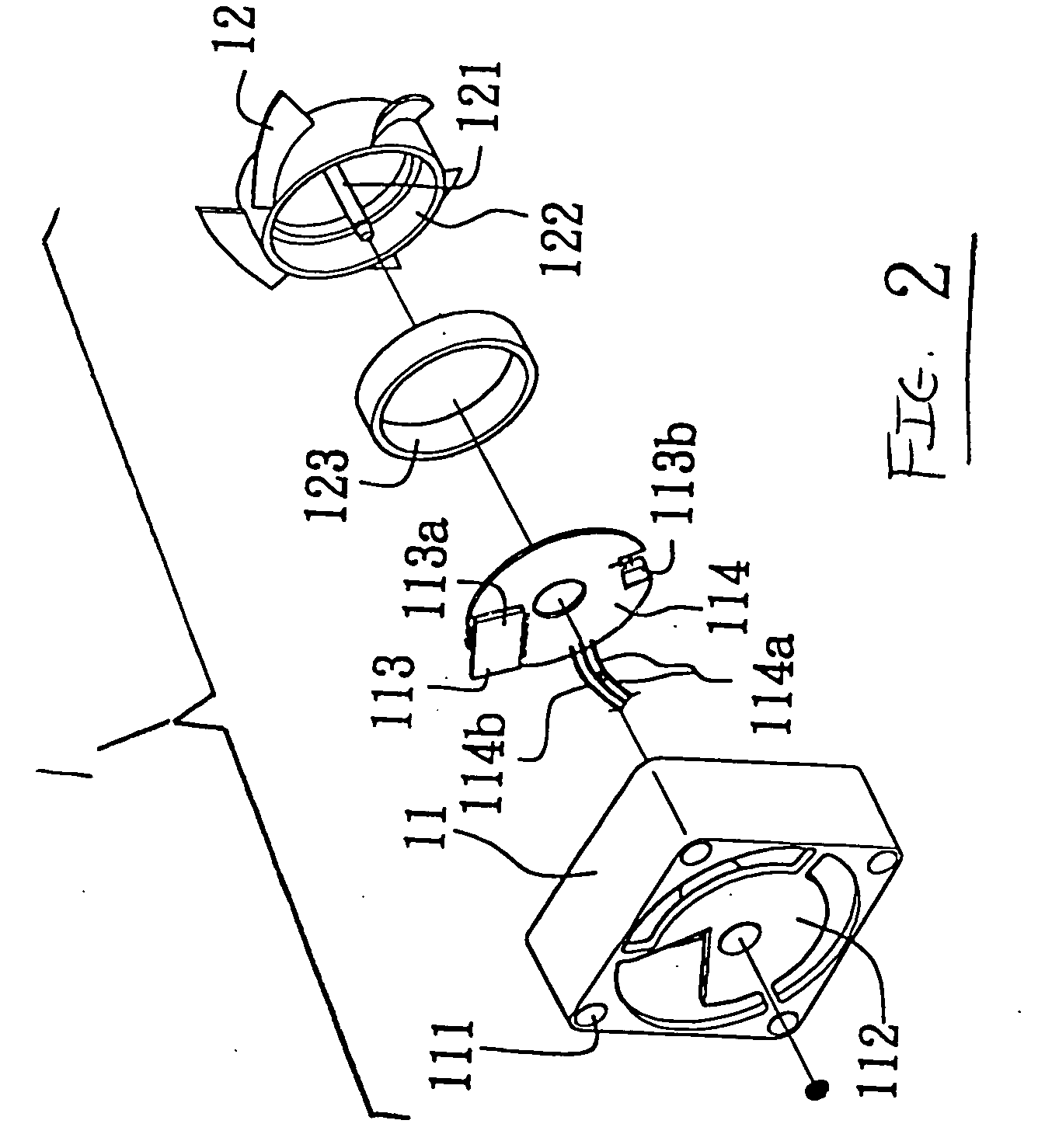

Device for analyzing the alcohol content of respiratory gas

InactiveUS20050009195A1Material analysis by electric/magnetic meansBiological testingGas analysisAlcohol content

Disclosed is a hand-held device for analyzing the alcohol content found in expelled respiratory gas, the device comprising an outer analyzer housing, a gas analysis and readout assembly, and a control circuit. The expulsion of respiratory gas into the device rotates a fan member. The number of revolutions of the fan member generates a revolution signal that is compared to a predetermined revolution value programmed into the control circuit. When the comparison generates a positive result, alcohol detecting means sample and test the respiratory gas passing through the device. The device thus forces the user to expel so-called low-lung, residual respiratory gas, which gas typically comprises more accurate levels of alcohol as compared to the consumer's blood alcohol content. If the comparison results in a negative signal, the user is prompted to repeat the procedure until a reading of low-lung respiratory gas has been acquired.

Owner:WANG CHI HSIANG

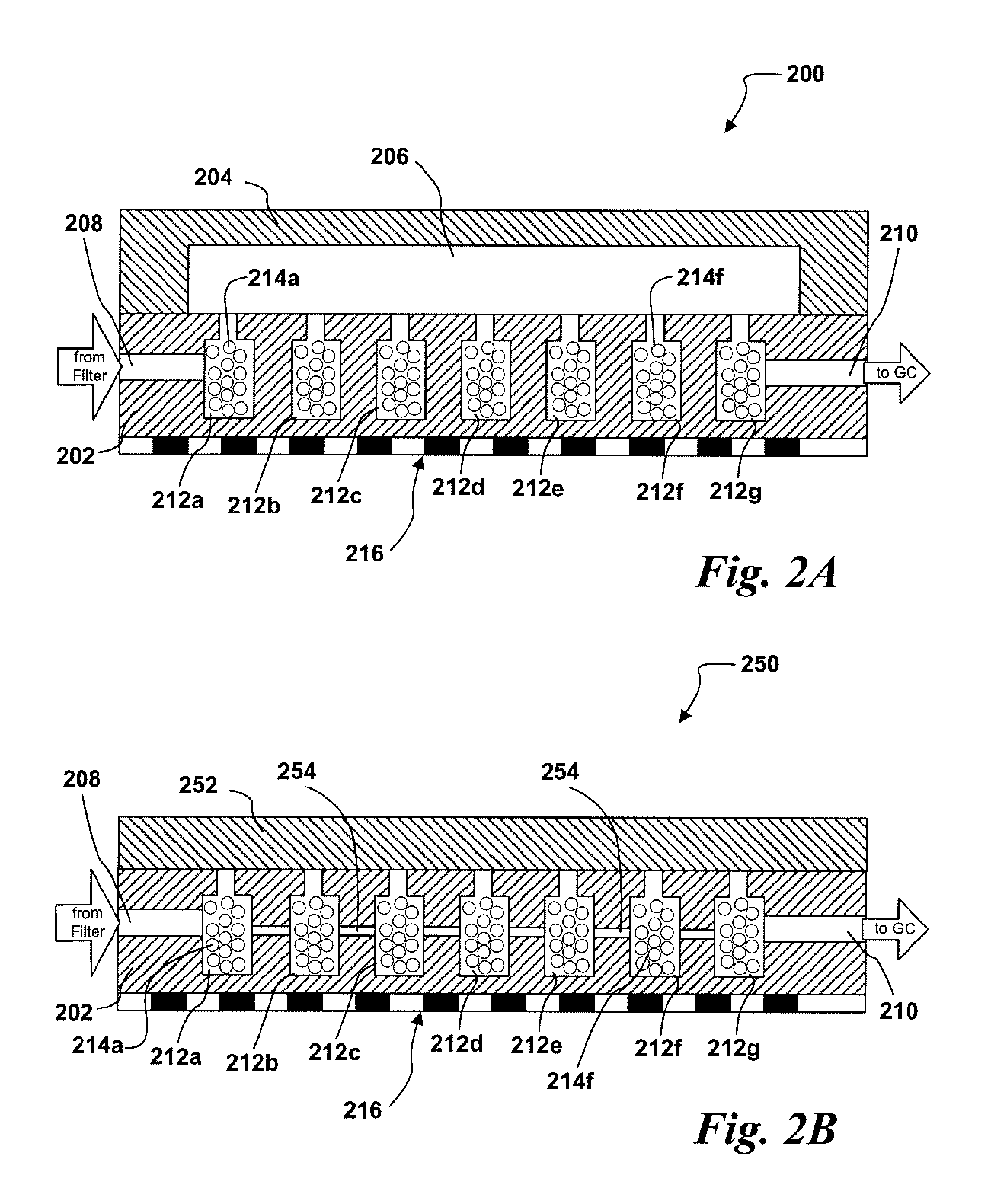

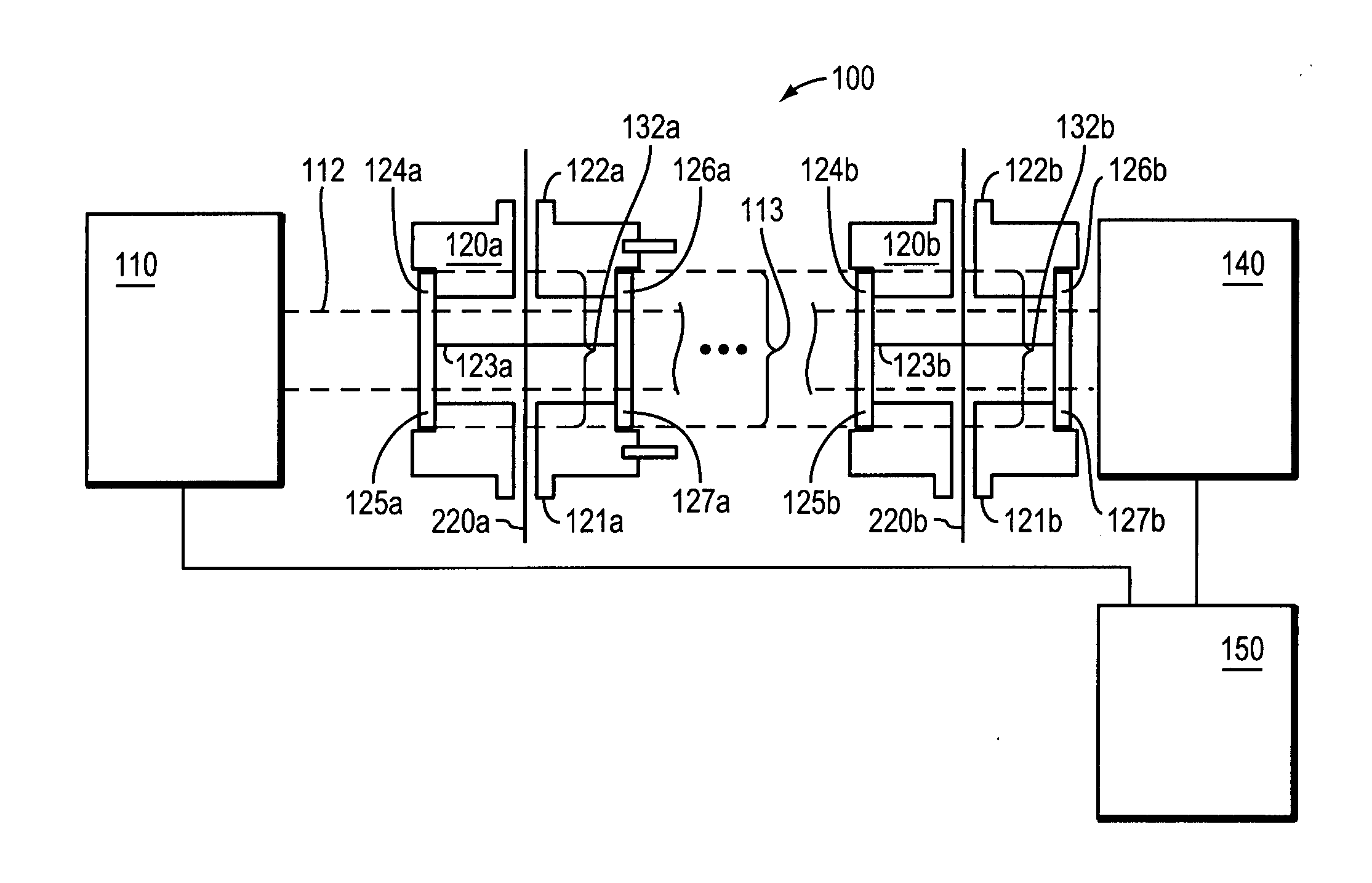

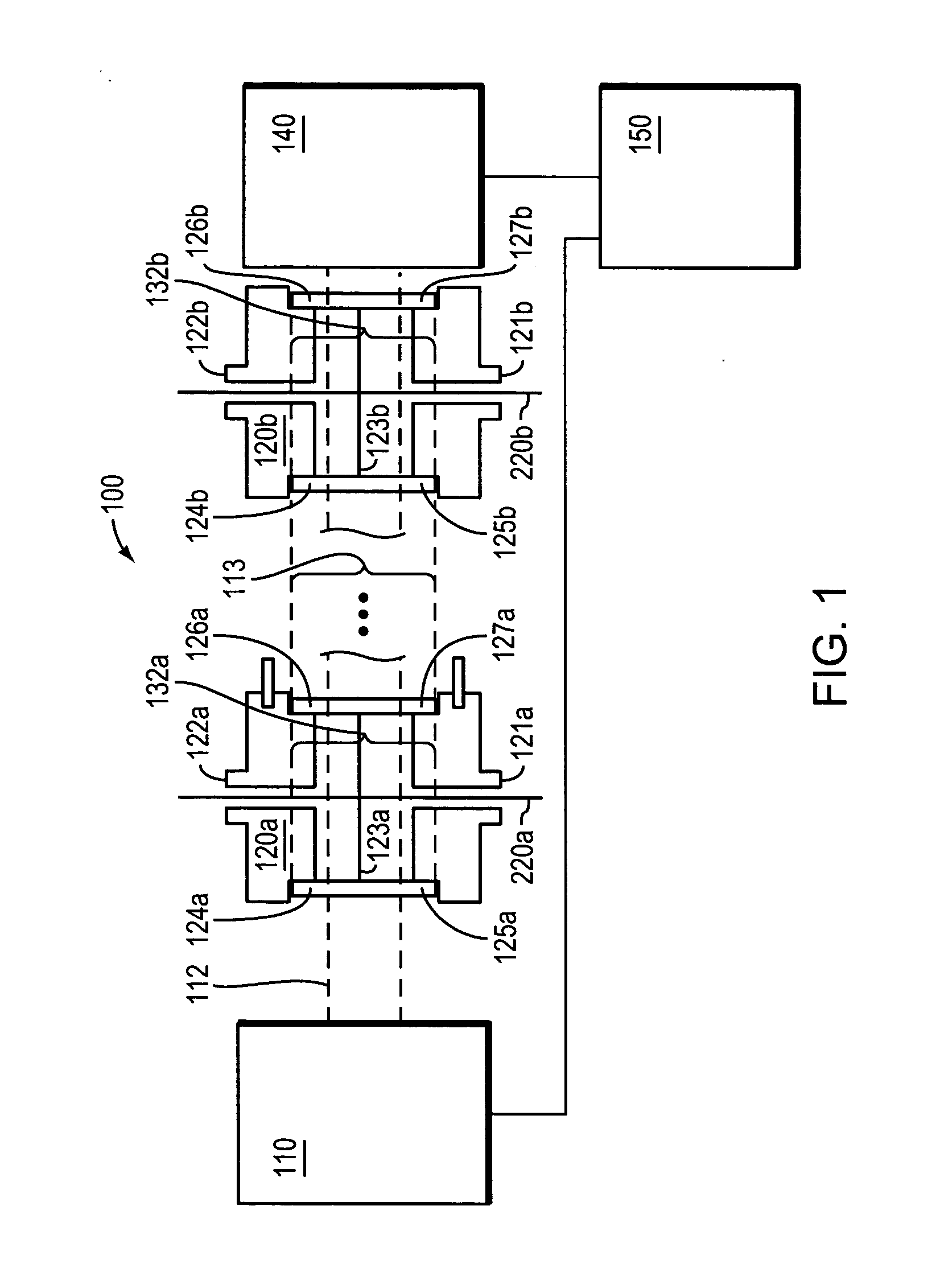

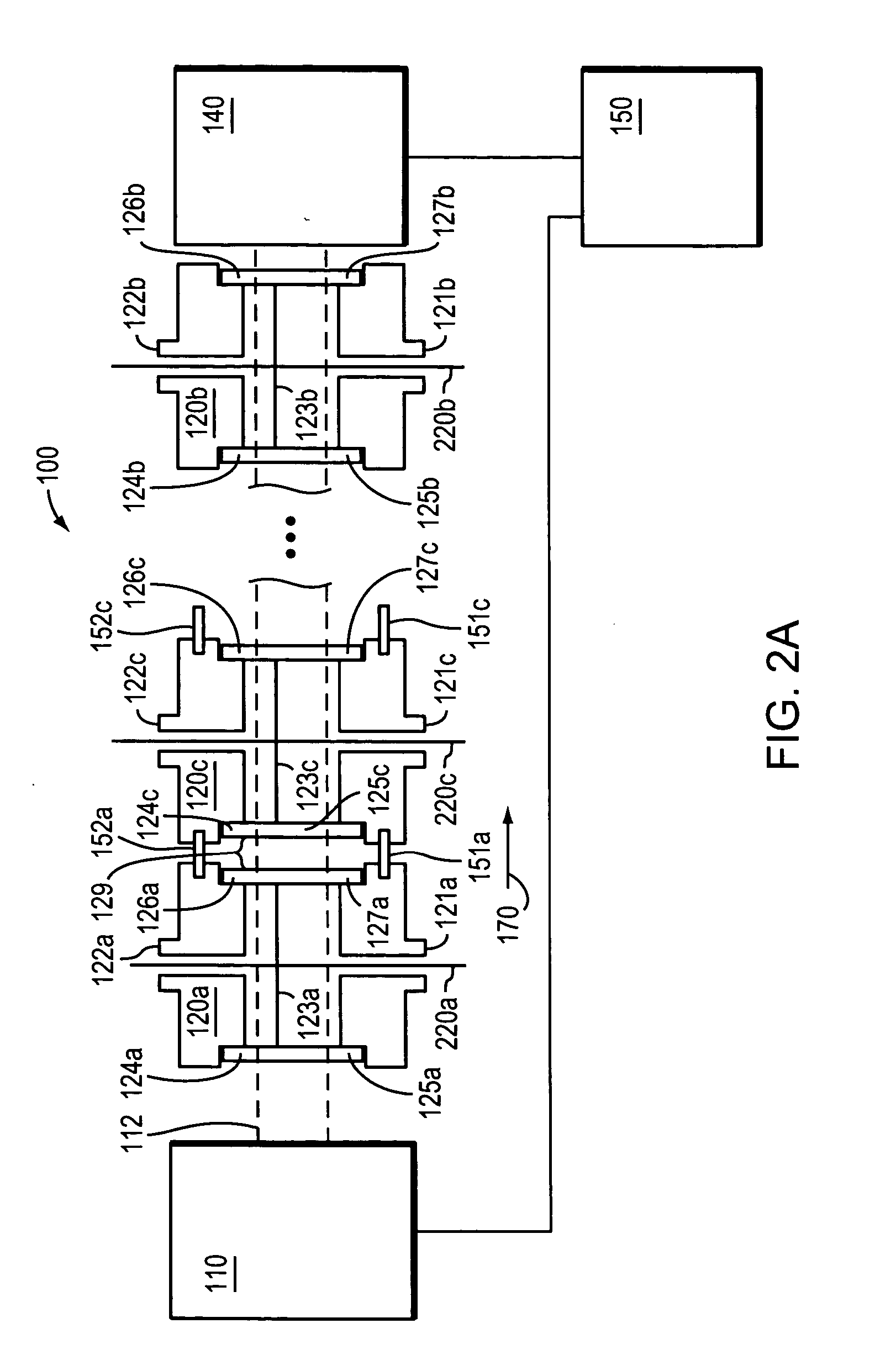

CASCADED GAS CHROMATOGRAPHS (CGCs) WITH INDIVIDUAL TEMPERATURE CONTROL AND GAS ANALYSIS SYSTEMS USING SAME

The disclosure describes a cascaded gas chromatograph including a first gas chromatograph having a first temperature control and a second gas chromatograph coupled to the first gas chromatograph. The first and second chromatographs have individual temperature controls that can be controlled independently of each other. Other embodiments are disclosed and claimed.

Owner:TRICORNTECH TAIWAN

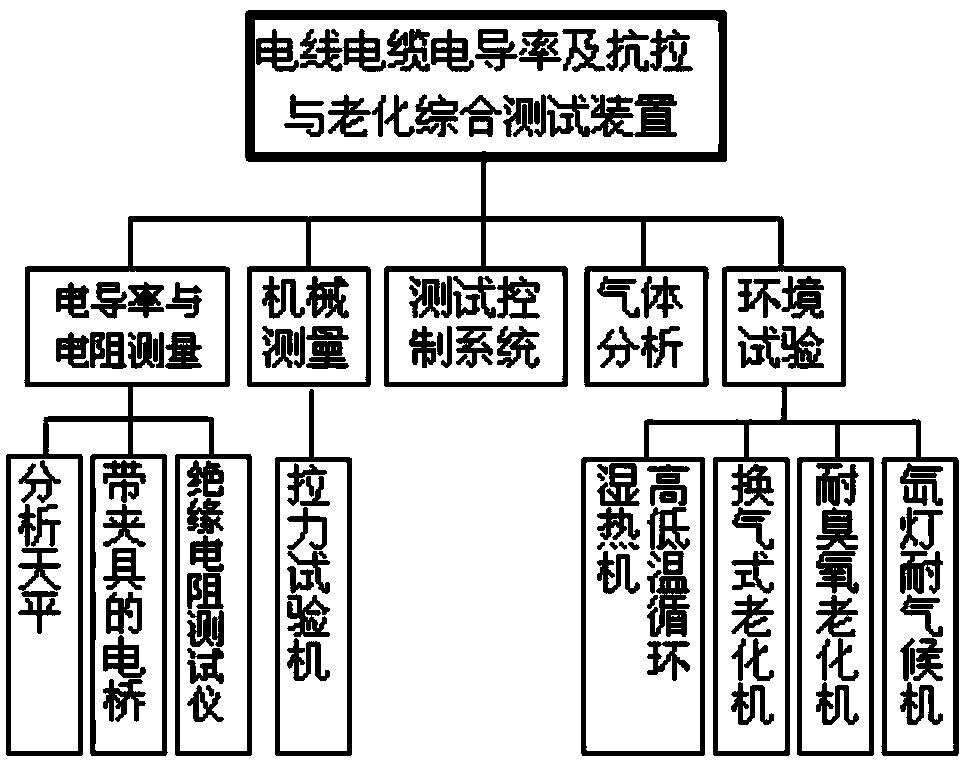

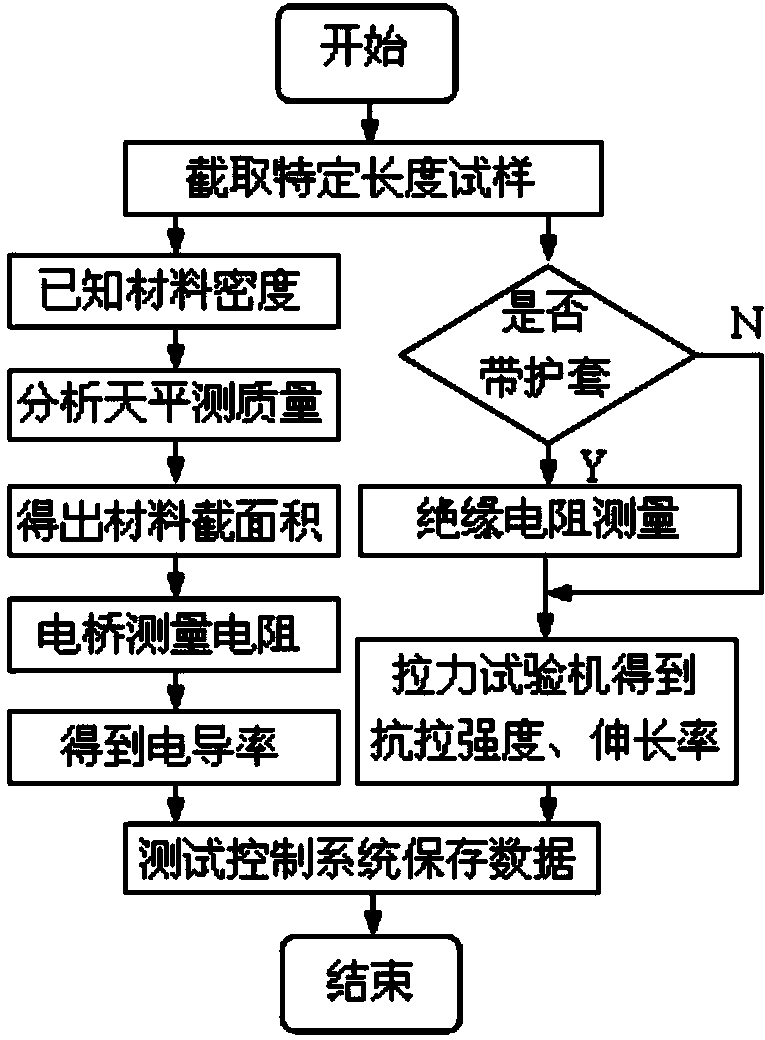

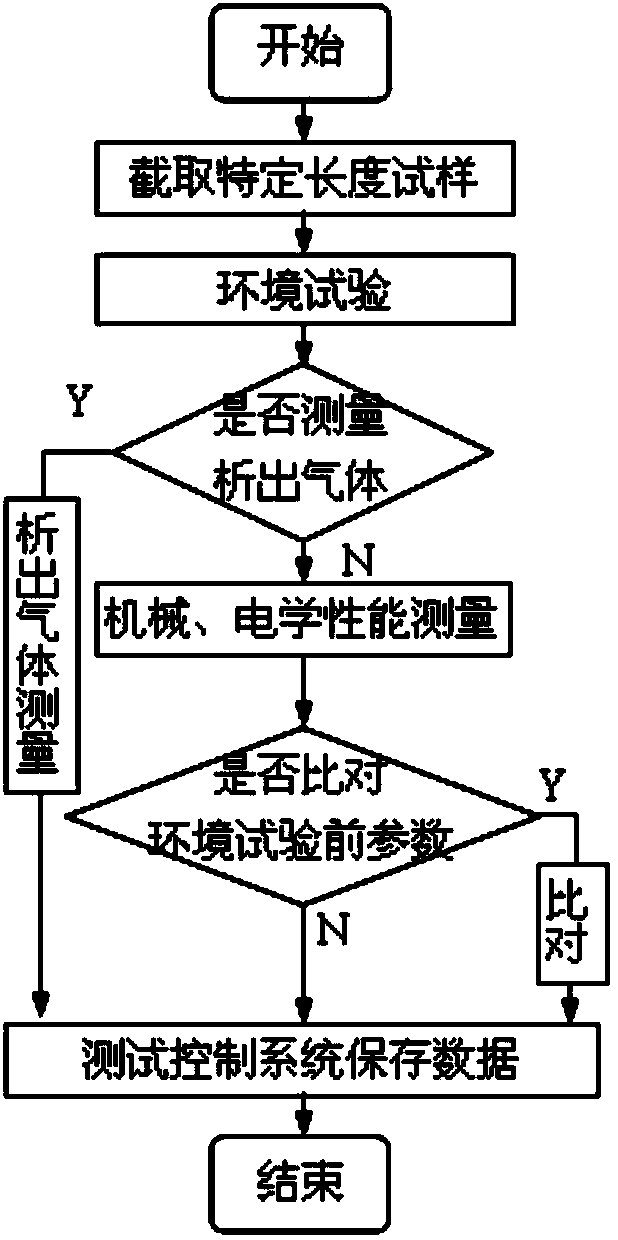

Electric wire and cable conductivity, tensile strength and aging comprehensive testing device

ActiveCN103439611AReduced measurement workloadMechanical concentrationElectrical testingGas analysisProof test

An electric wire and cable conductivity, tensile strength and aging comprehensive testing device comprises a testing control system, an analytical balance, an electrical bridge with a clamp, an insulation resistance tester, a tension testing machine, a high-temperature low-temperature humidity thermal cycling testing machine, an air-exchange aging testing machine, an ozone-proof aging testing machine, an xenon lamp weather-proof testing machine, a gas analysis device and a test control system. The device can test mechanical performance of an electric wire and cable, electric performance of the electric wire and cable and performance of the electric wire and cable under the influence of environment at a time, can effectively reduce work load of a test of the electric wire and cable, enables the test of the mechanical performance, the electricity performance, and the performance of the electric wire and cable under the influence of the environment to be concentrated and effective, and can synchronously test components of released gases of a cable with a sheath in the aging process.

Owner:ELECTRIC POWER RES INST OF STATE GRID ANHUI ELECTRIC POWER

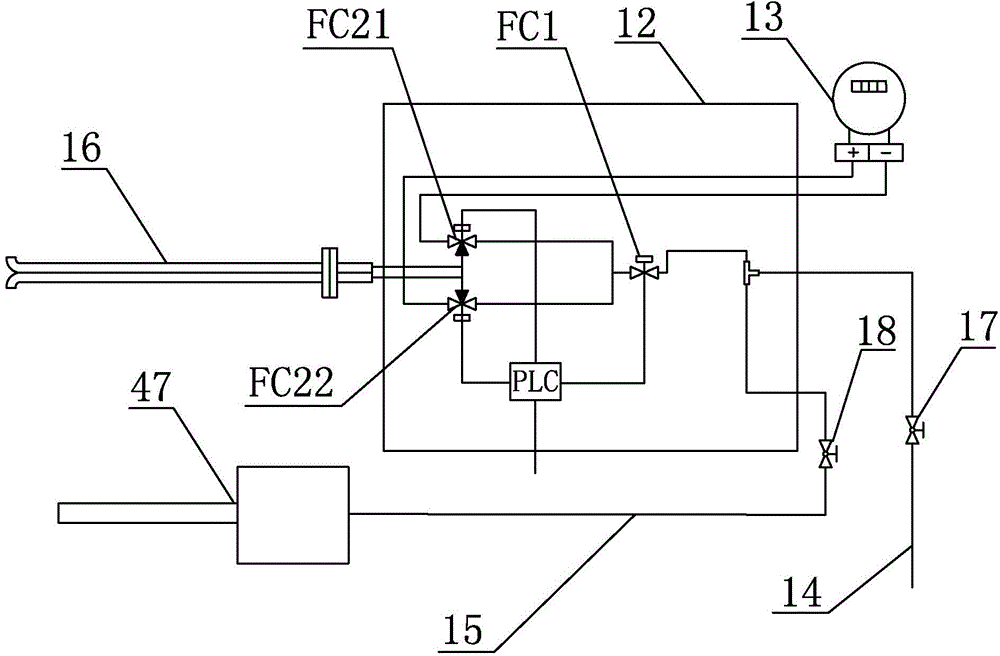

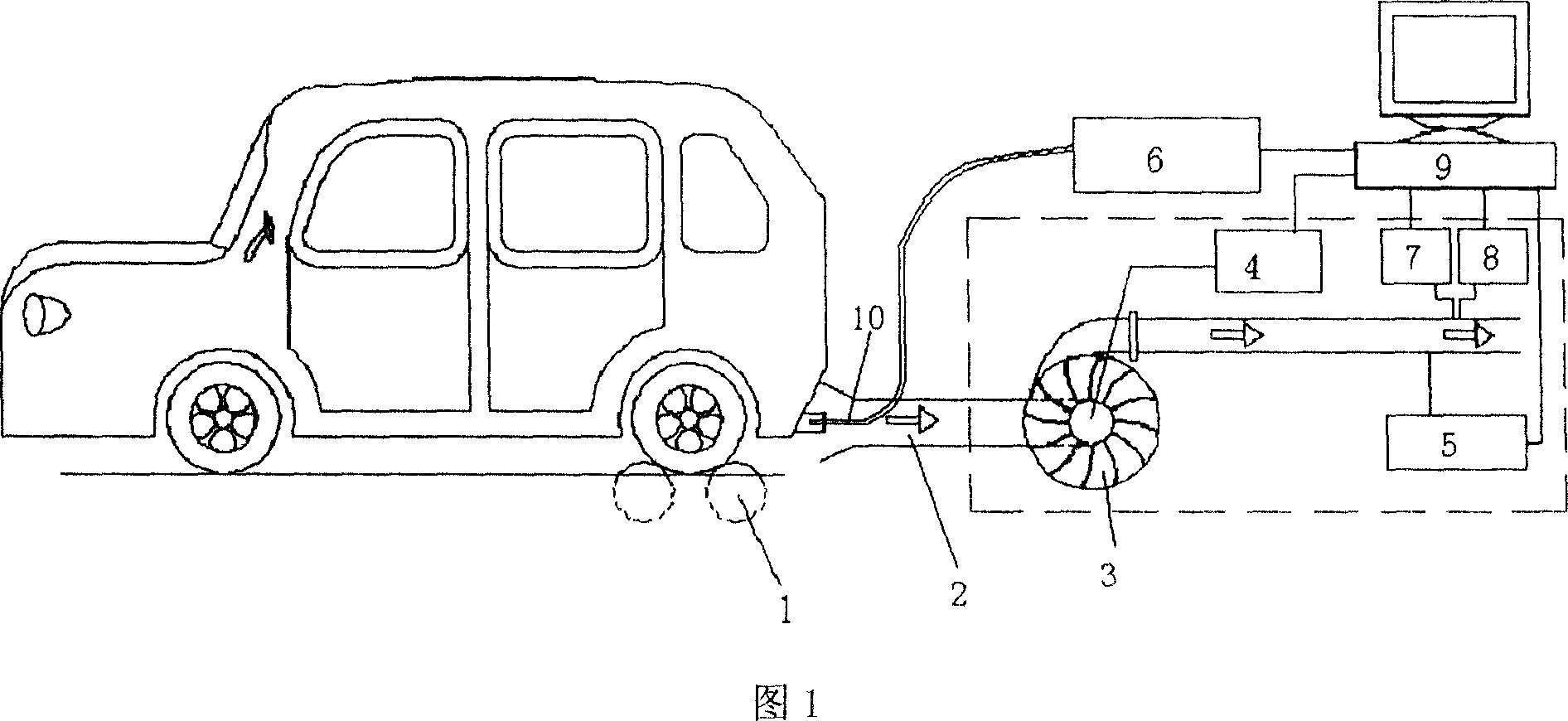

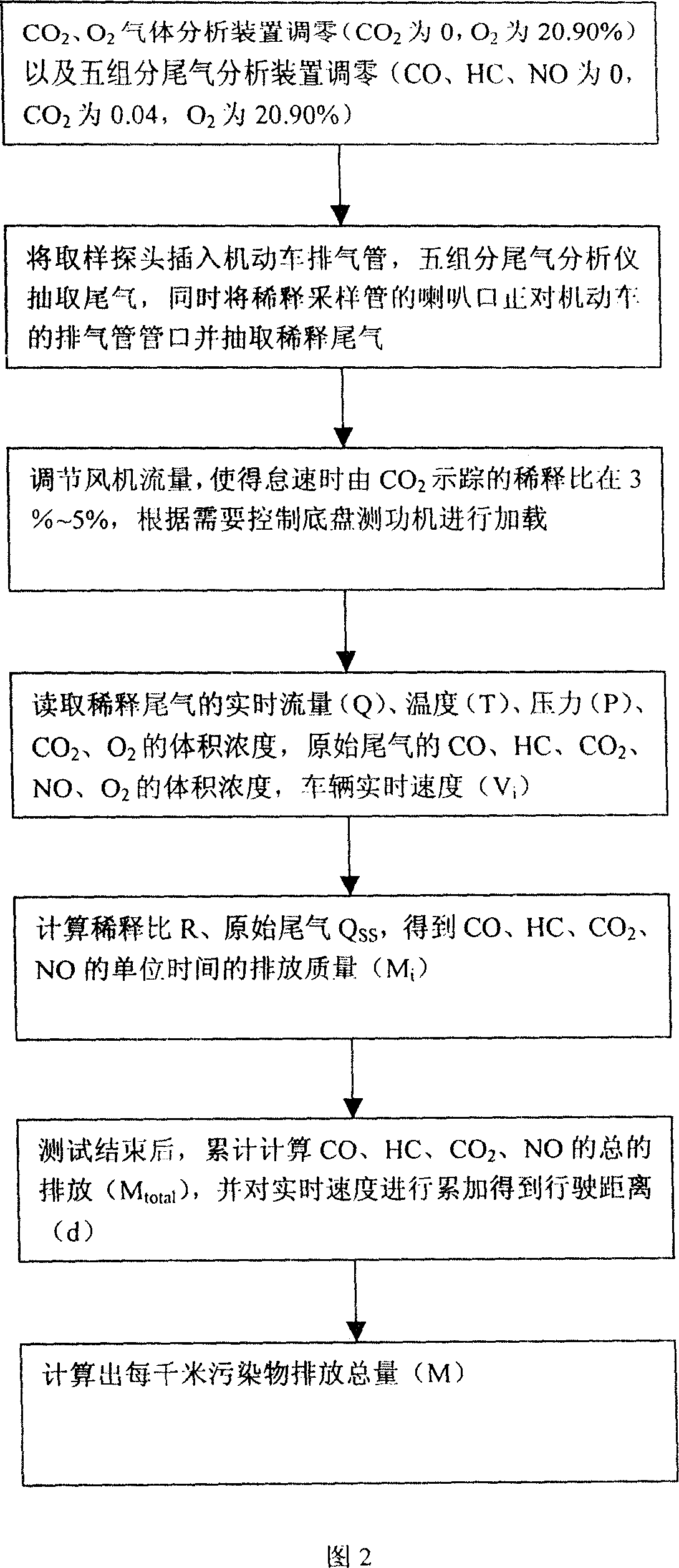

Method and device for measuring pollutant discharging total of motor vehicle

InactiveCN101000278AImprove detection accuracyOvercome the shortcomings of low measurement accuracyVehicle testingInternal-combustion engine testingGas analysisAir volume

The invention relates to vehicle pollutant discharging total measuring device and method. The device is made up of diluting sampling tube, fan, computer measure-control system, chassis power measuring machine, fan flow rate adjusting device, flow rate, temperature, and pressure measuring devices, five components tail gas, O2, CO2 gas analysis devices. The measuring method includes the following steps: using fan flow rate adjusting device to control pumping drainage fan, measure diluted tail gas flow rate, temperature, pressure, O2, CO2 volume density; using five components gas analysis device to measure undiluted tail gas for each gas volume density; calculating out the undiluted tail gas flow rate by the volume density ratio to gain vehicle pollutants discharging gross. The invention has high detecting precision for tail gas, can be used in pollutants discharging gross detecting for vehicle operating condition method tail gas detecting line or repair shop.

Owner:WUHAN CUBIC OPTOELECTRONICS

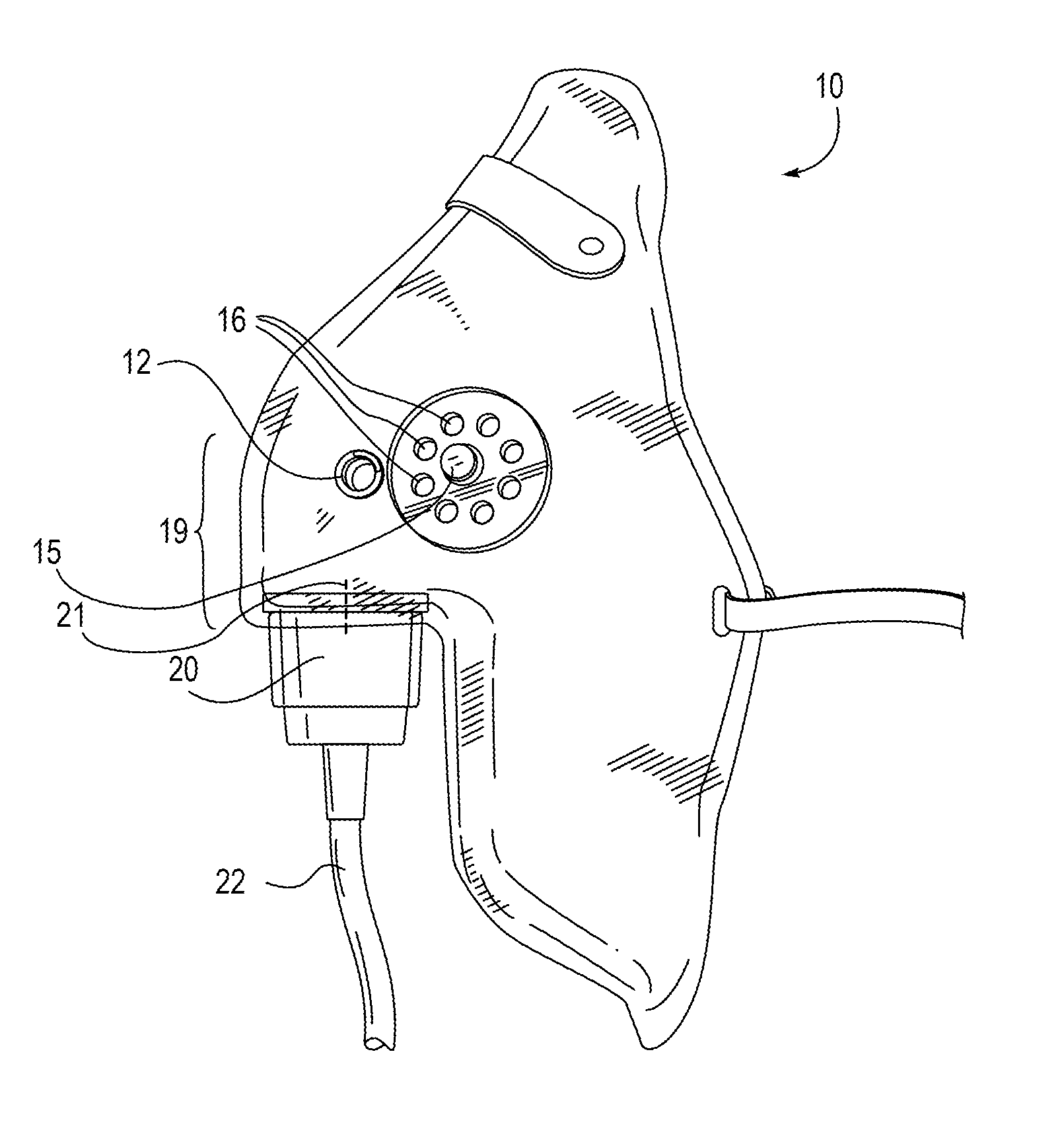

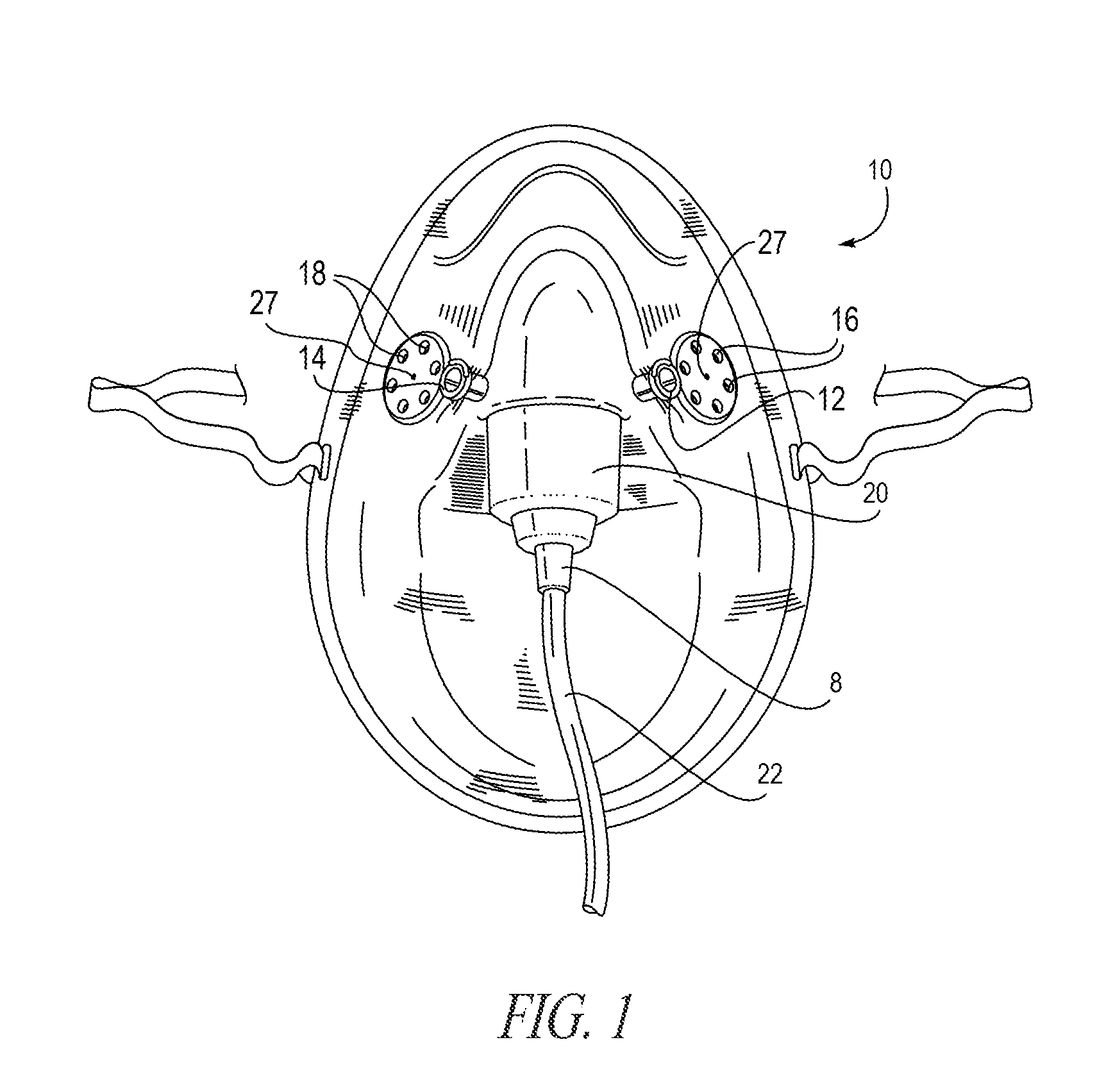

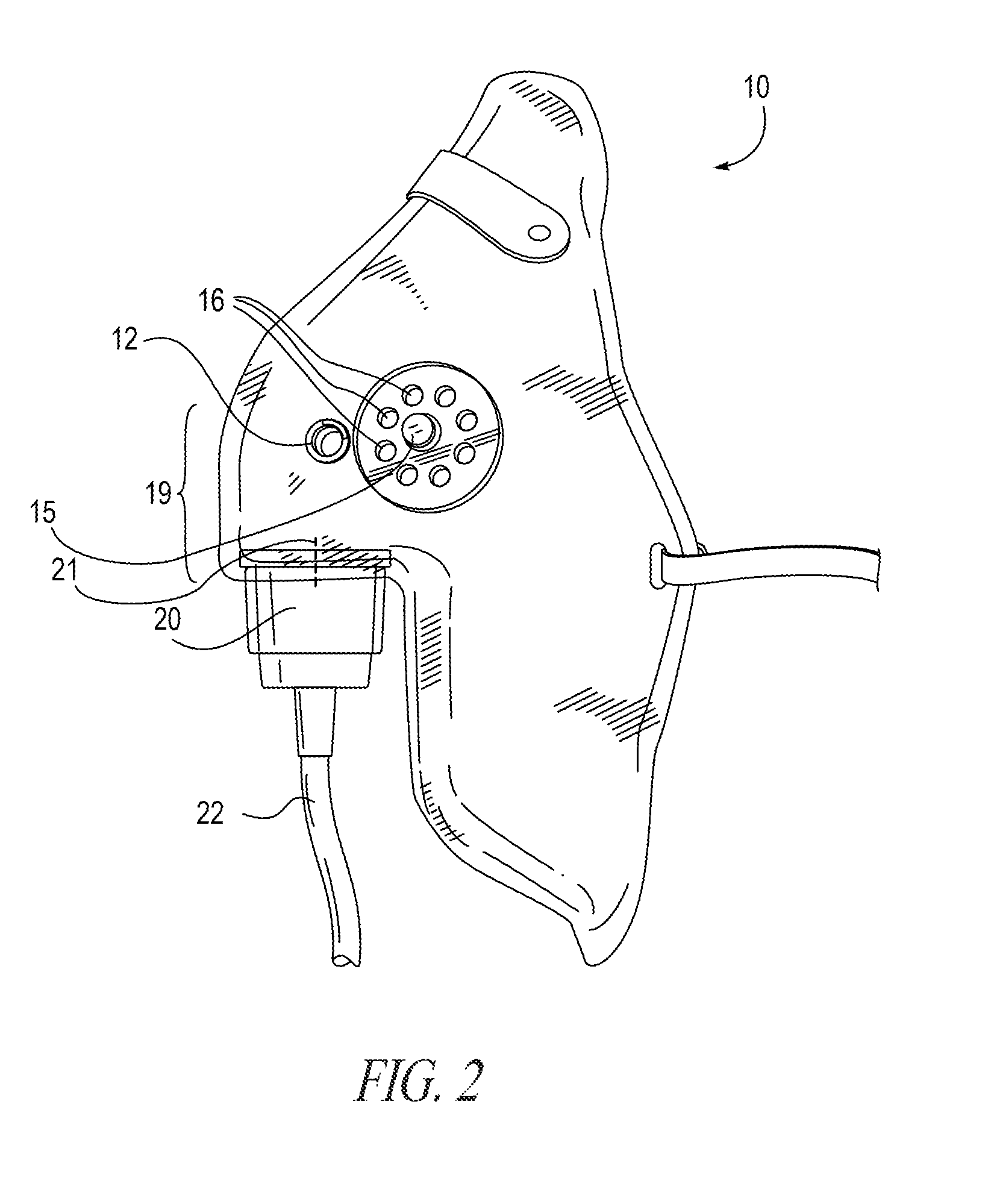

Oxygen face mask and component system

An oxygen face mask and component system is provided, the mask is designed to cover a user's nose and at least partially cover a user's mouth, the mask having lateral ports. Systems and assemblies including such a face mask and additional components are further provided, including a colorimetric CO2 detector, a sealing cap with or without a resilient sealing flap, a capnography gas analysis unit, a non-rebreather valve, a pulmonary function module, nebulizer, a gas scavenging system, a gas reservoir system, a gas filter, sample lines that are either straight or at an angle, and an aerosol mask platform; and methods of making and using such a face mask are also provided.

Owner:MONITOR MASK

Gas analysis device and method

ActiveCN103487593AGood test backgroundGuaranteed test accuracySemiconductor/solid-state device testing/measurementWithdrawing sample devicesGas analysisComputer module

Owner:RAINBOW SOURCE LASER RSLASER

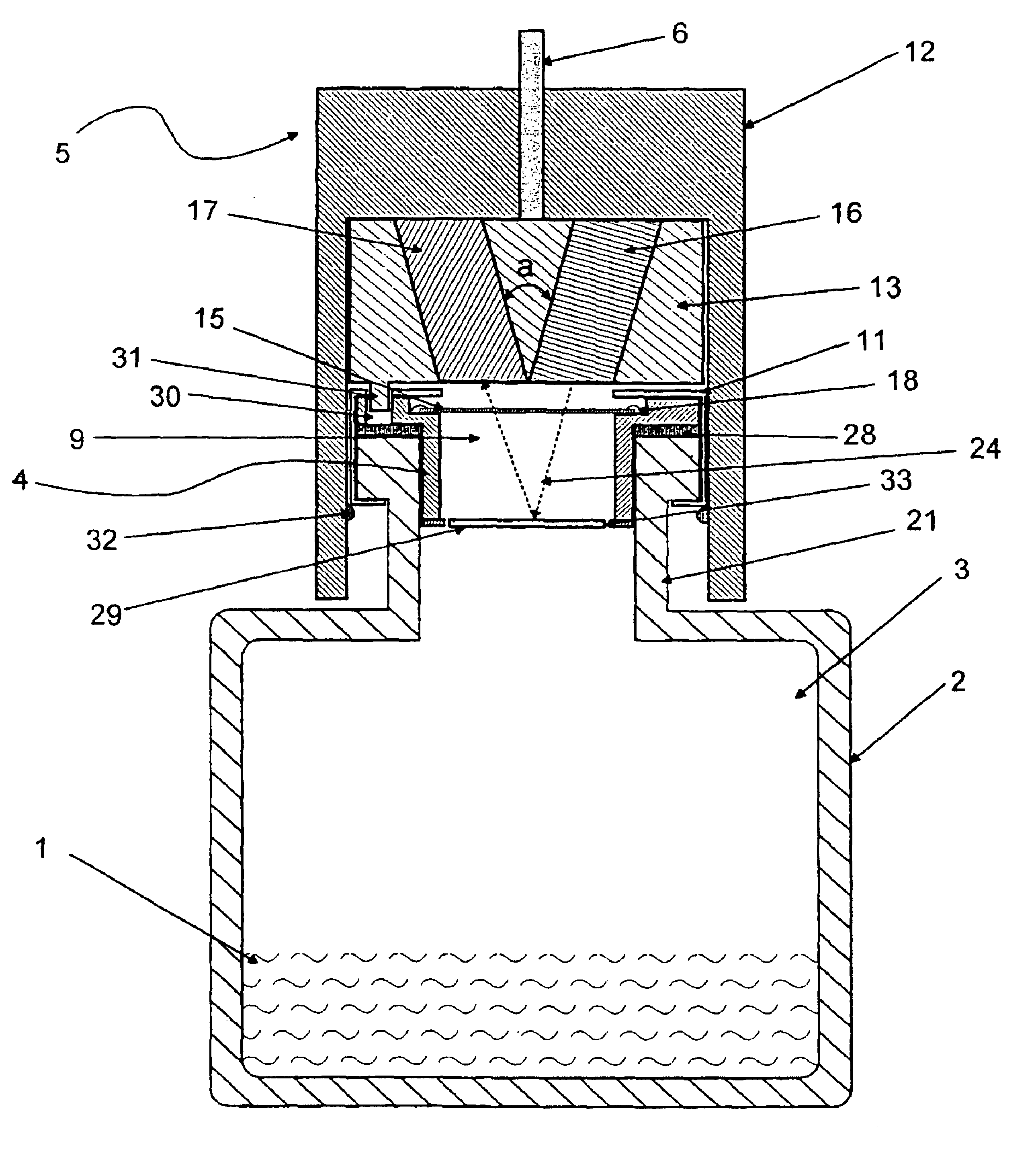

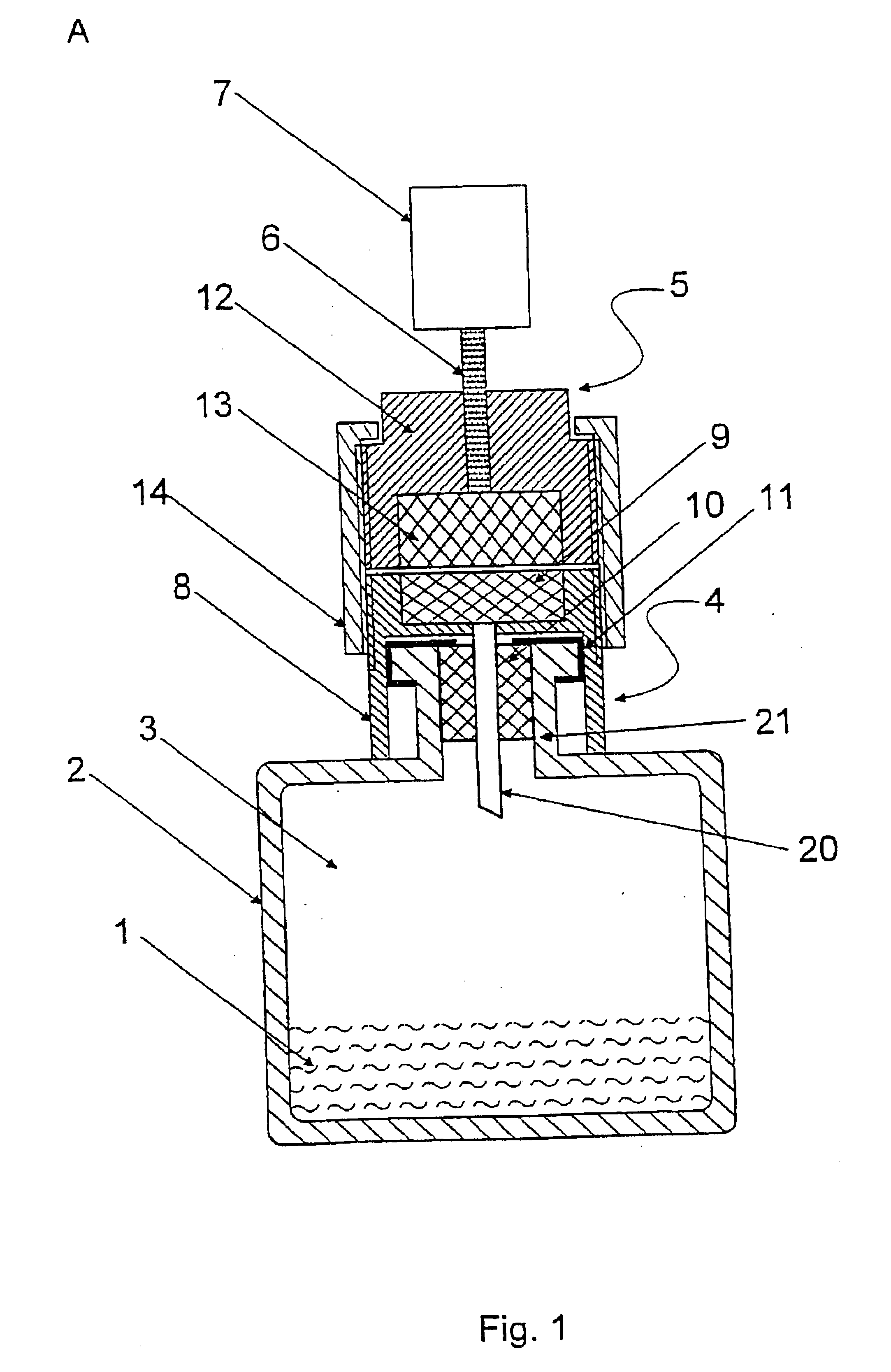

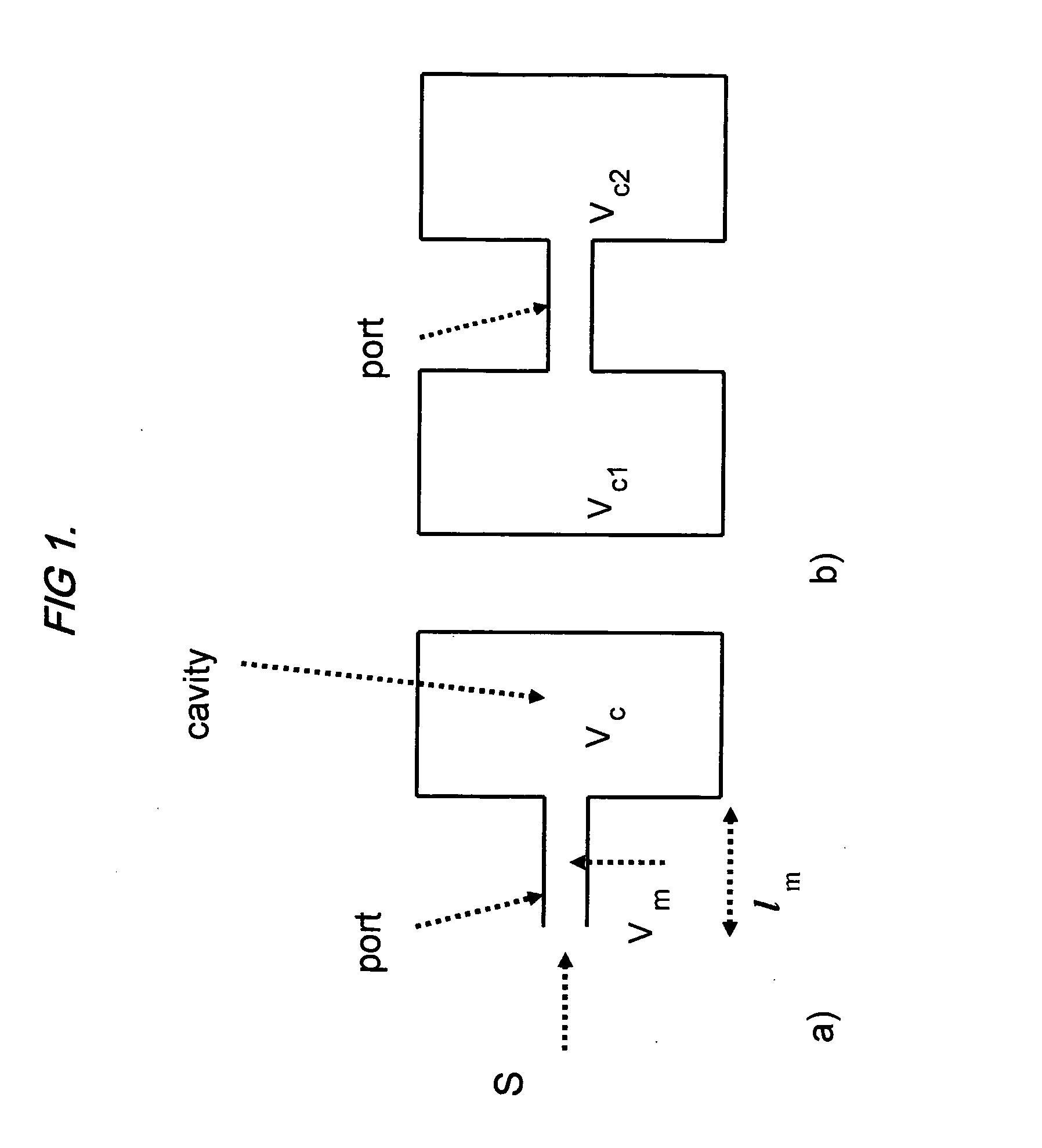

Method and device for the quantitative gas analysis

InactiveUS6903823B1Economical and simpleLarge lengthBioreactor/fermenter combinationsBiological substance pretreatmentsGas analysisDiffusion

The invention relates to a device and a method for the quantitative gas analysis in which the gas analysis of a sample atmosphere is implemented by means of a sensor device, a diffusion seal being produced between the sample atmosphere contained in a sample system and a measuring chamber and the gas analysis of the sample atmosphere which is diffused into the measuring chamber being implemented with the sensor device, the sensor head (5) being able to be coupled to the measuring adapter (4) and the radiation source (16) and the detector device (17) being fixed to the measuring chamber (9) in a defined orientation and the measuring radiation (24) emitted from the radiation source (16) traversing at least once through the measuring chamber (9) and being detected by the detector device (17) after leaving the measuring chamber (9).

Owner:MULLER HOLGER +1

Linked extendable gas observation system for infrared absorption spectroscopy

InactiveUS20070182965A1Facilitate analysis sensitivityEasy to adjustTransmissivity measurementsColor/spectral properties measurementsGas analysisGas detector

A modular system for gas analysis has a first gas cell that receives and passes at least a portion of an infrared light beam through at least a portion of the first gas cell. A second gas cell disposed proximal to the first gas cell receives and passes at least a portion of the infrared light beam from the first gas cell through at least a portion of the second gas cell. At least a portion of the first gas cell and at least a portion of the second gas cell define a light path having an effective length. The system includes a means for adjusting the effective length of the light path to vary a property of the infrared light beam. Methods of making a variable effective length light path and methods of making a gas detector are also disclosed.

Owner:MKS INSTR INC

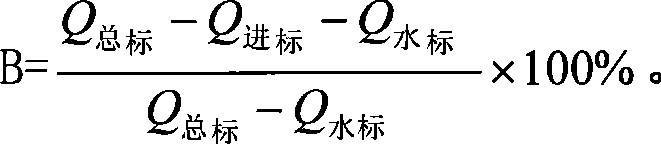

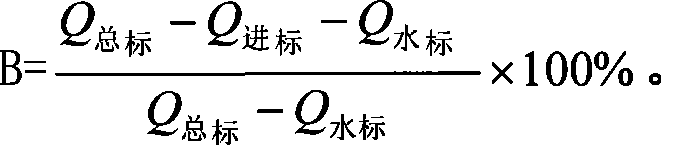

Air leakage rate measuring method of sintering machine system

InactiveCN101435711ASolve the large measurement errorReduce contentFurnace typesIndirect mass flowmetersObservational errorGas analysis

The invention relates to a method for measuring system air leakage rate of a sintering machine in metallurgy. The invention discloses a method for measuring the system air leakage rate of the sintering machine. The method comprises the following steps: firstly, by measuring charge level air speeds at different parts of a machine pallet of the sintering machine, the effective air quantity(Q[inlet]) entering a sinter layer is worked out, by measuring the air speed in a main duct in front of an electrostatic dust collector, the total air quality(Q[total]) pumped in the main duct by an air exhauster is worked out, and by the water content in mixing material, the content of the air converted into vapor is worked out; secondly, the air qualities(Q[total standard], Q[inlet standard] and Q[water standard]) at the standard state are converted all together; and finally, the air leakage rate(B) is worked out according to the formula. The measuring method has strong operability and can overcome the defects of inconvenient measurement, big measurement error and complex air analysis existing in daily production and the defect existing in prior art that the local air leakage rate can only be measured by the air leakage point air speed measuring method. In a word, the method has the advantages of easy operation, accurate measurement and good use effect.

Owner:武钢集团有限公司

Method and a system for identifying gaseous effluents, and a facility provided with such a system

InactiveUS6643014B2High measurement accuracyLower the volumeRadiation pyrometrySpectrum investigationElectricityGas analysis

The invention relates to a gas analysis system for analyzing gases in an enclosure under controlled pressure, which system comprises apparatus for ionizing the gases to be analyzed, and apparatus for analyzing the ionized gases. According to the invention the apparatus for ionizing the gases to be analyzed comprises a dedicated plasma source in contact with the gases contained in the enclosure and combined with a generator for generating a plasma from the gases to be analyzed; and the apparatus for analyzing the ionized gases comprises a radiation sensor situated in the vicinity of the zone in which the plasma is generated, and connected to an optical spectrometer for analyzing the variation of the radiation spectrum emitted by the generated plasma.

Owner:ALCATEL LUCENT SAS

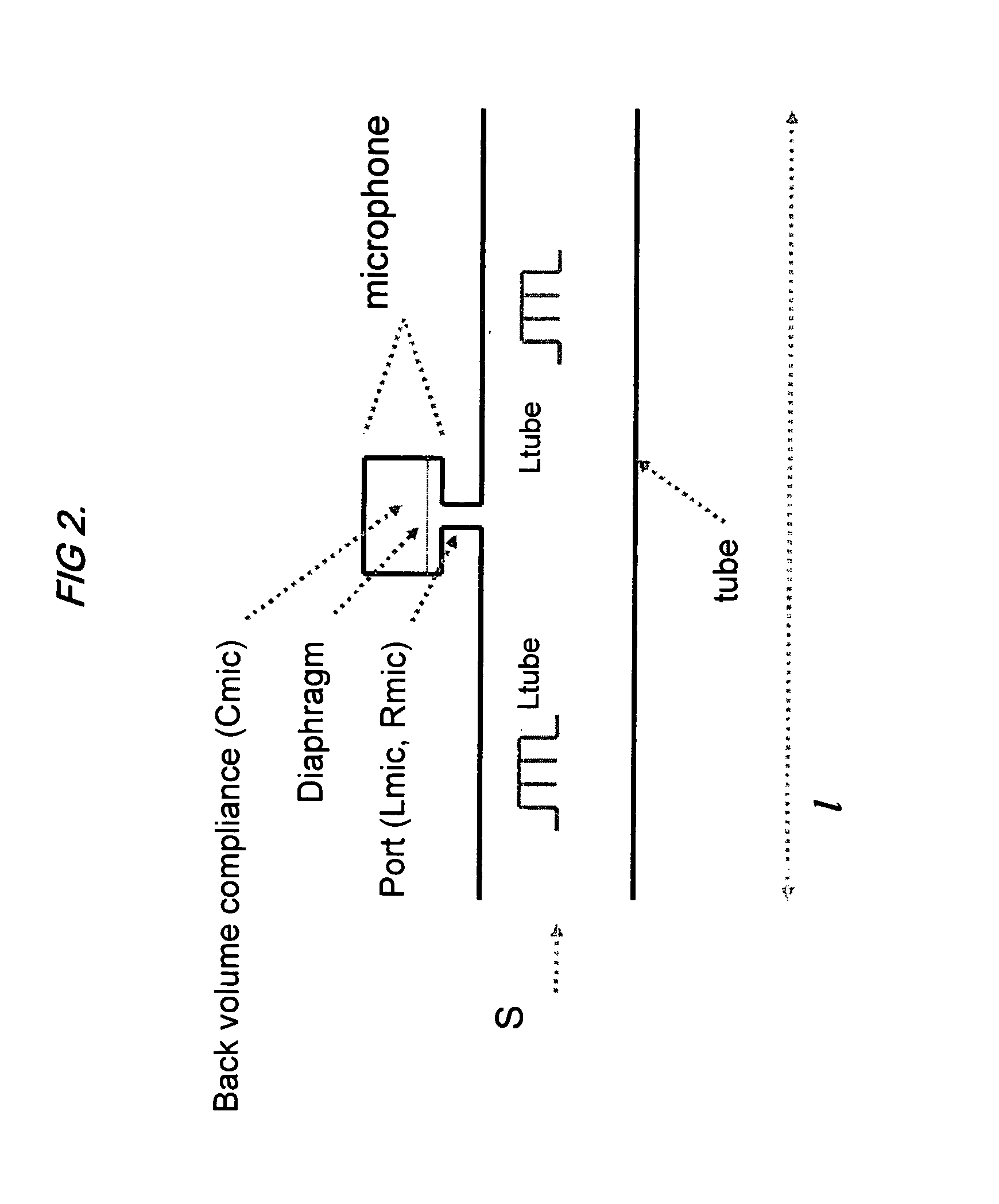

System and method for gas analysis using photoacoustic spectroscopy

ActiveUS20080134756A1Vibration measurement in solidsMaterial analysis using wave/particle radiationGas analysisPhotoacoustic microscopy

A system and method for analyzing a target analyte gas concentration using a photoacoustic spectroscopy cell comprising:i) a modulatable light source which provides optical radiation at an absorption wavelength of a target analyte;ii) a resonant acoustic chamber for containing said analyte;iii) a microphone positioned within said chamber whereby the acoustic reactance of the microphone is a substantial factor in determining the acoustic resonant frequency of the acoustic chamber and where the magnitude of the acoustic reactance of the microphone is at least two times the acoustic resistance of the microphone.

Owner:LI COR

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com