Patents

Literature

1375 results about "Volume density" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Density is a measure of mass per unit of volume. Density is a measure of mass per volume. The average density of an object equals its total mass divided by its total volume.

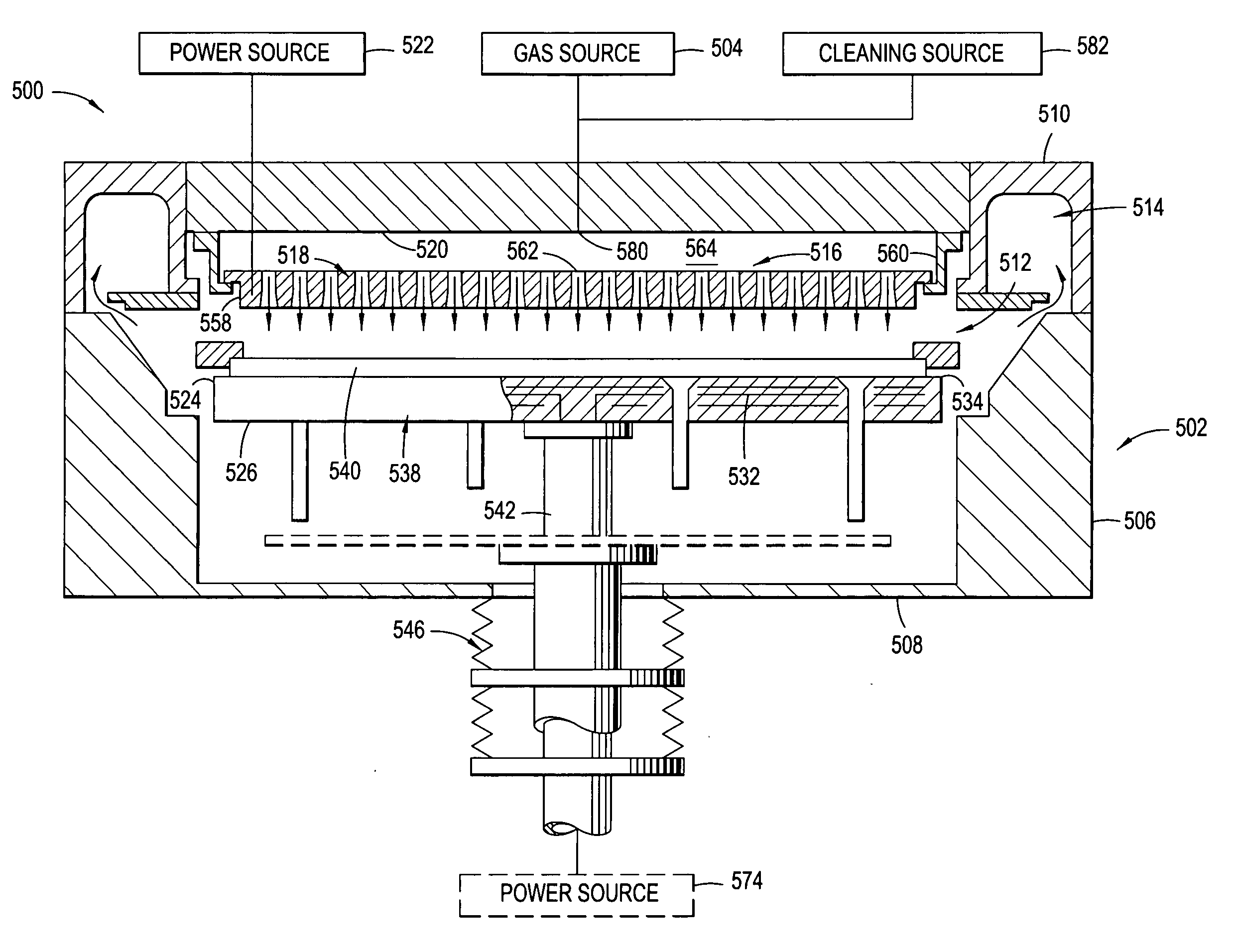

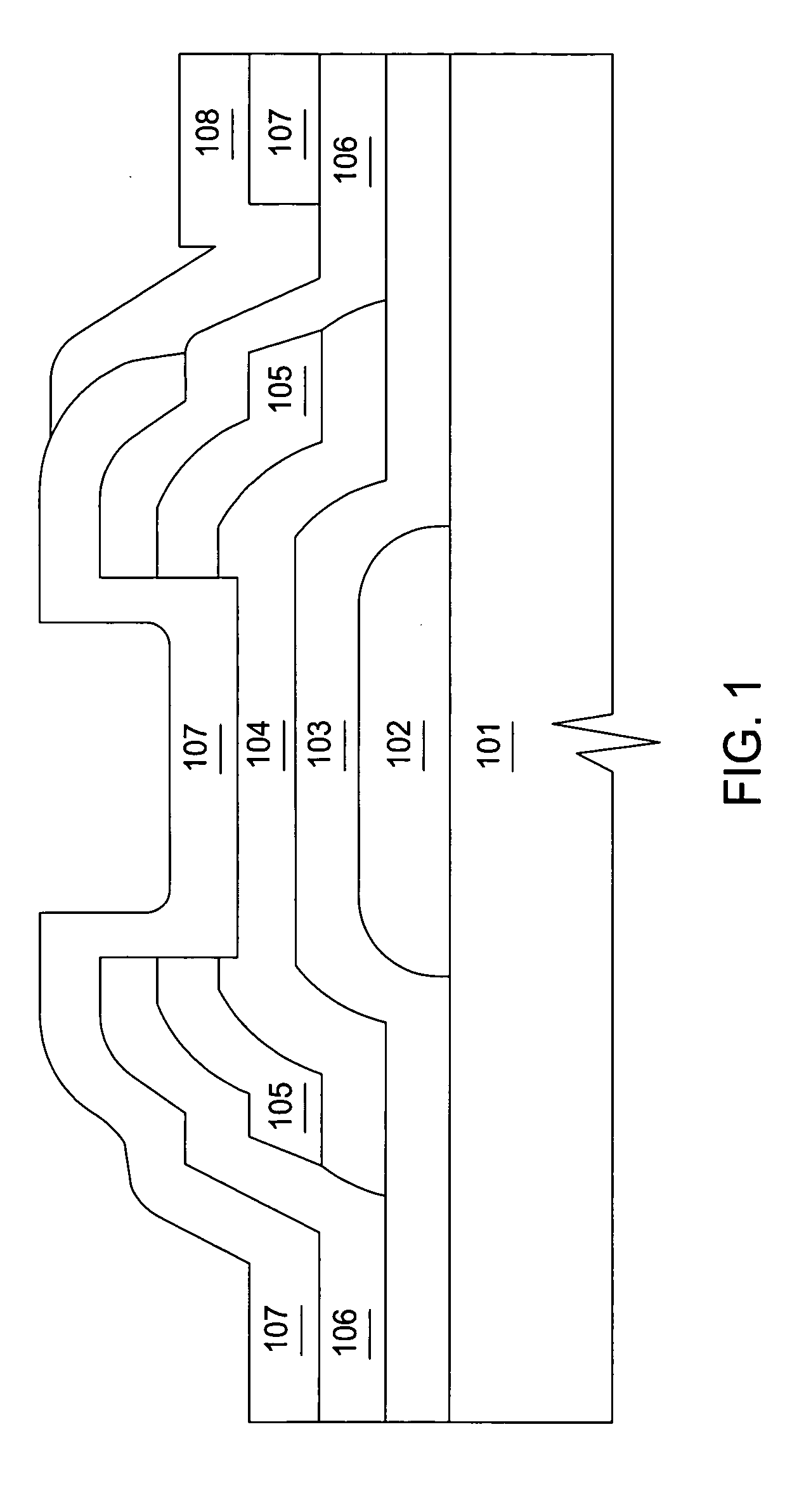

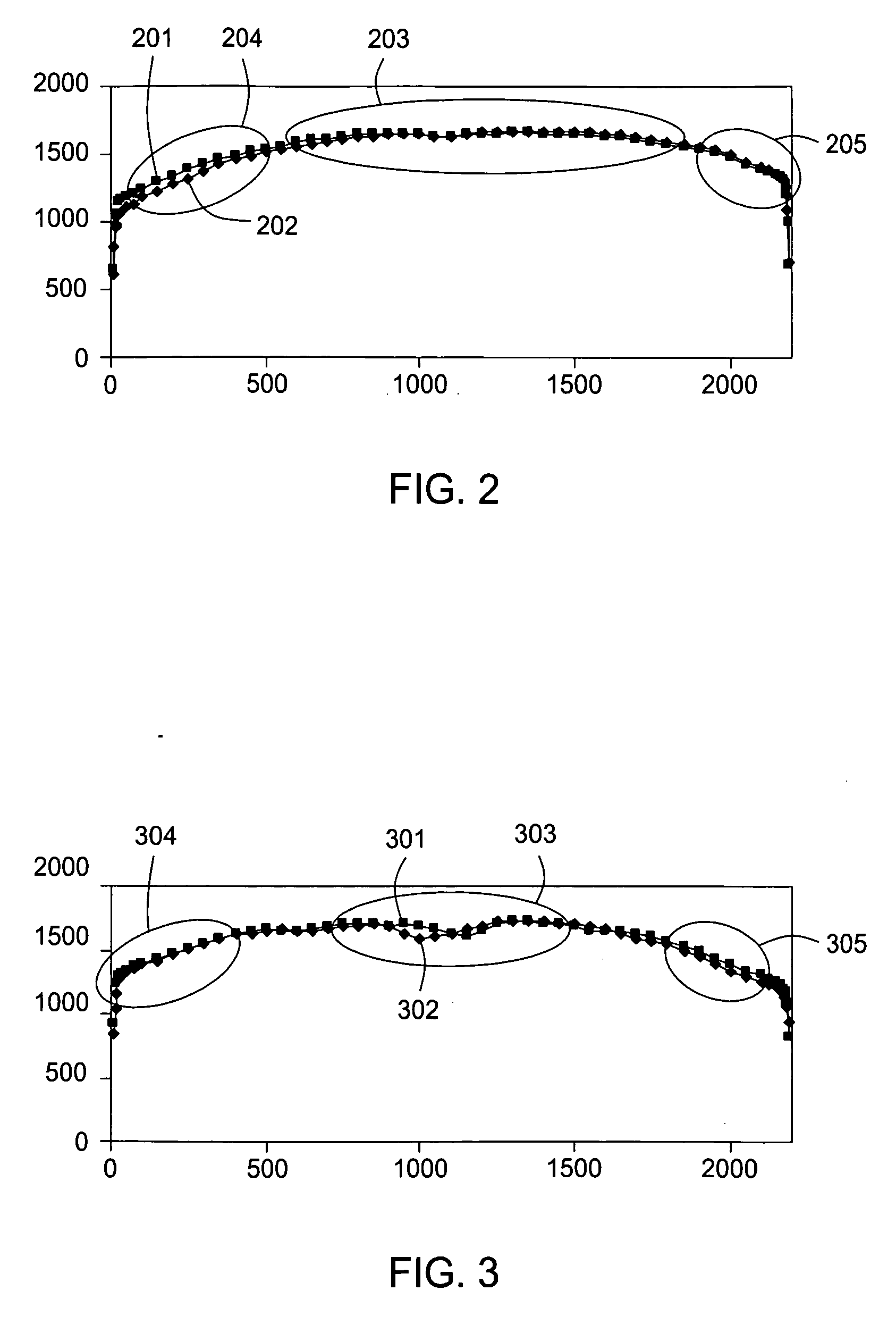

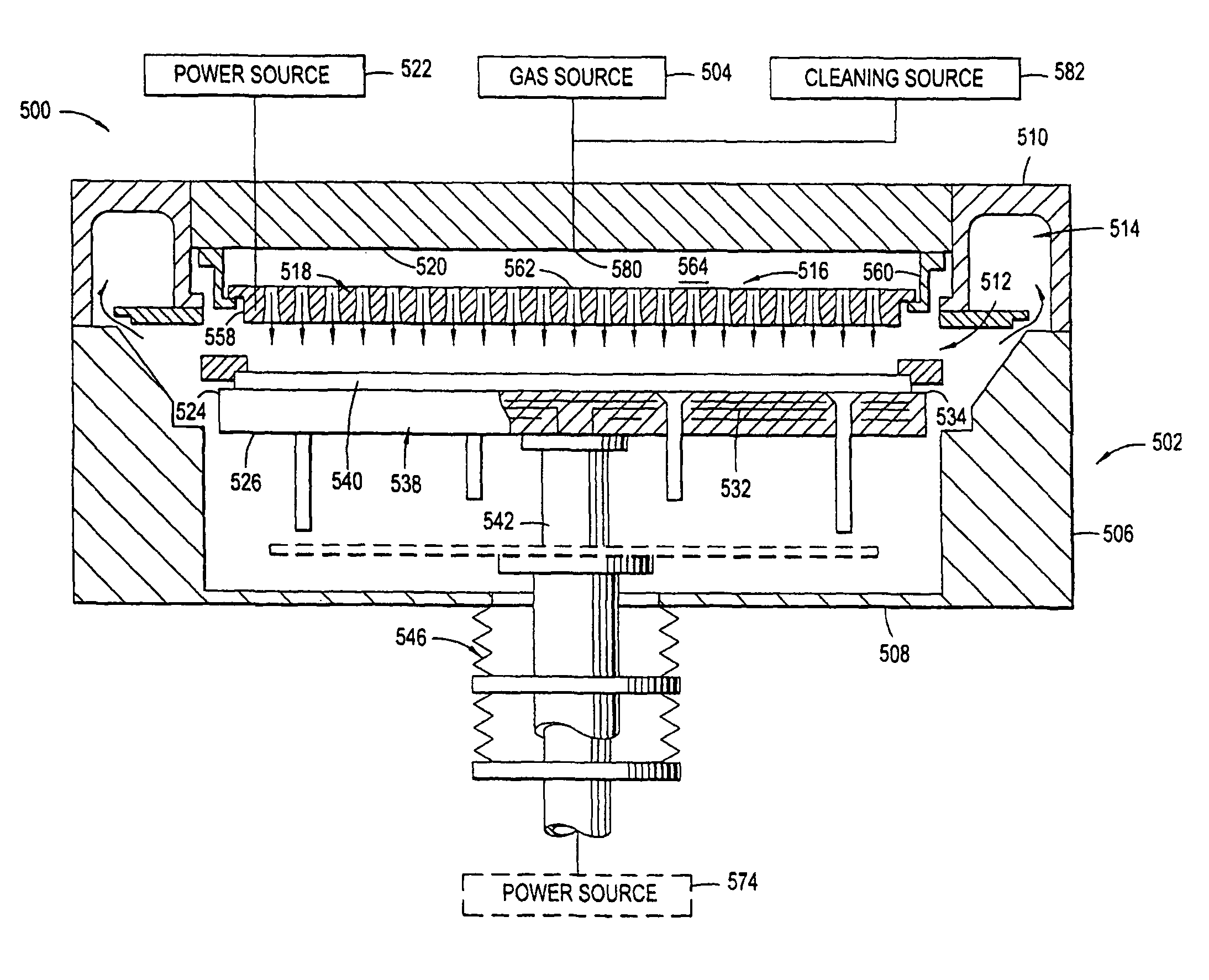

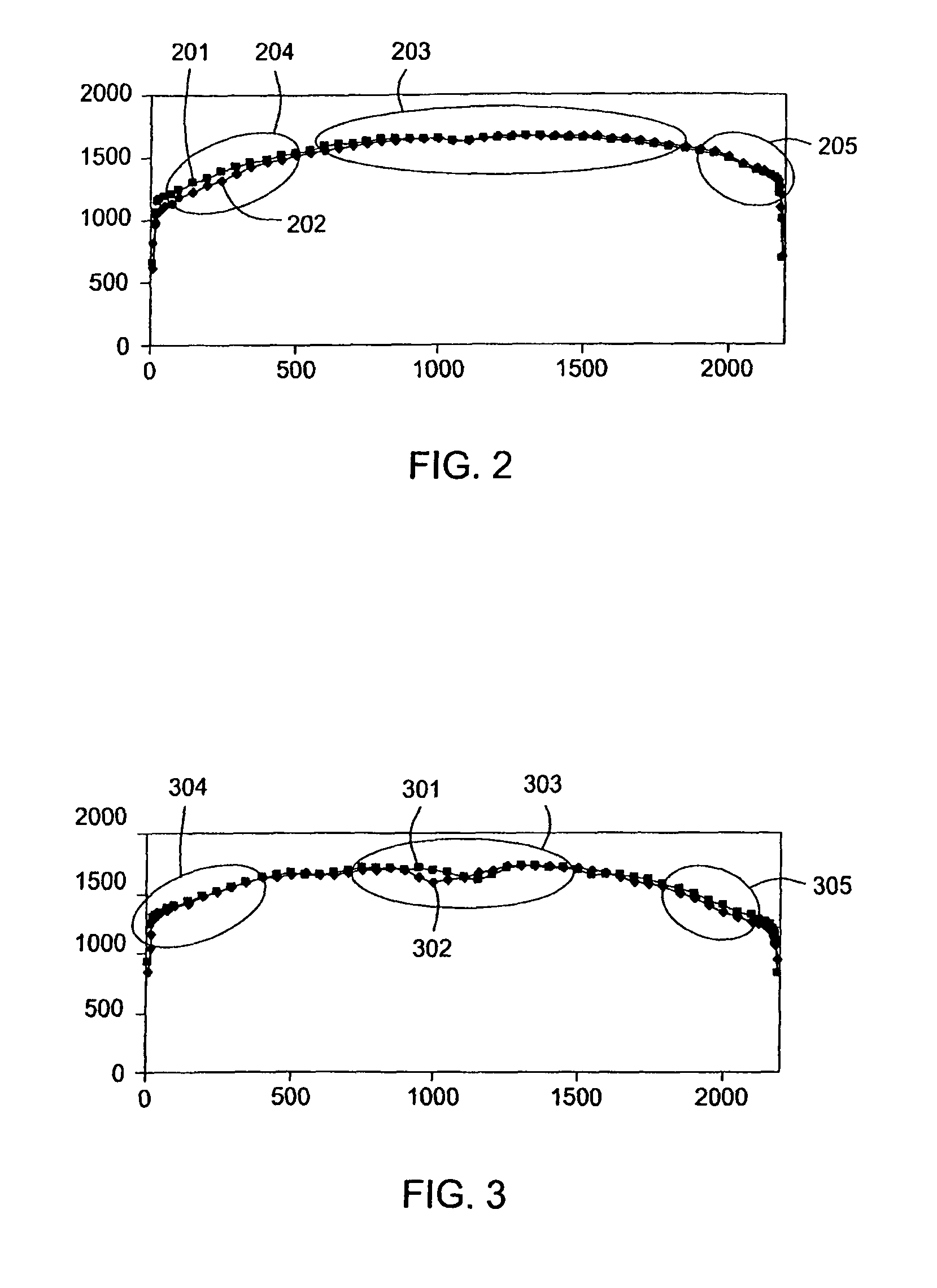

Plasma uniformity control by gas diffuser curvature

ActiveUS20060228496A1Improve thickness uniformityImprove filmElectric discharge tubesSemiconductor/solid-state device manufacturingGaseous diffusionAmorphous silicon

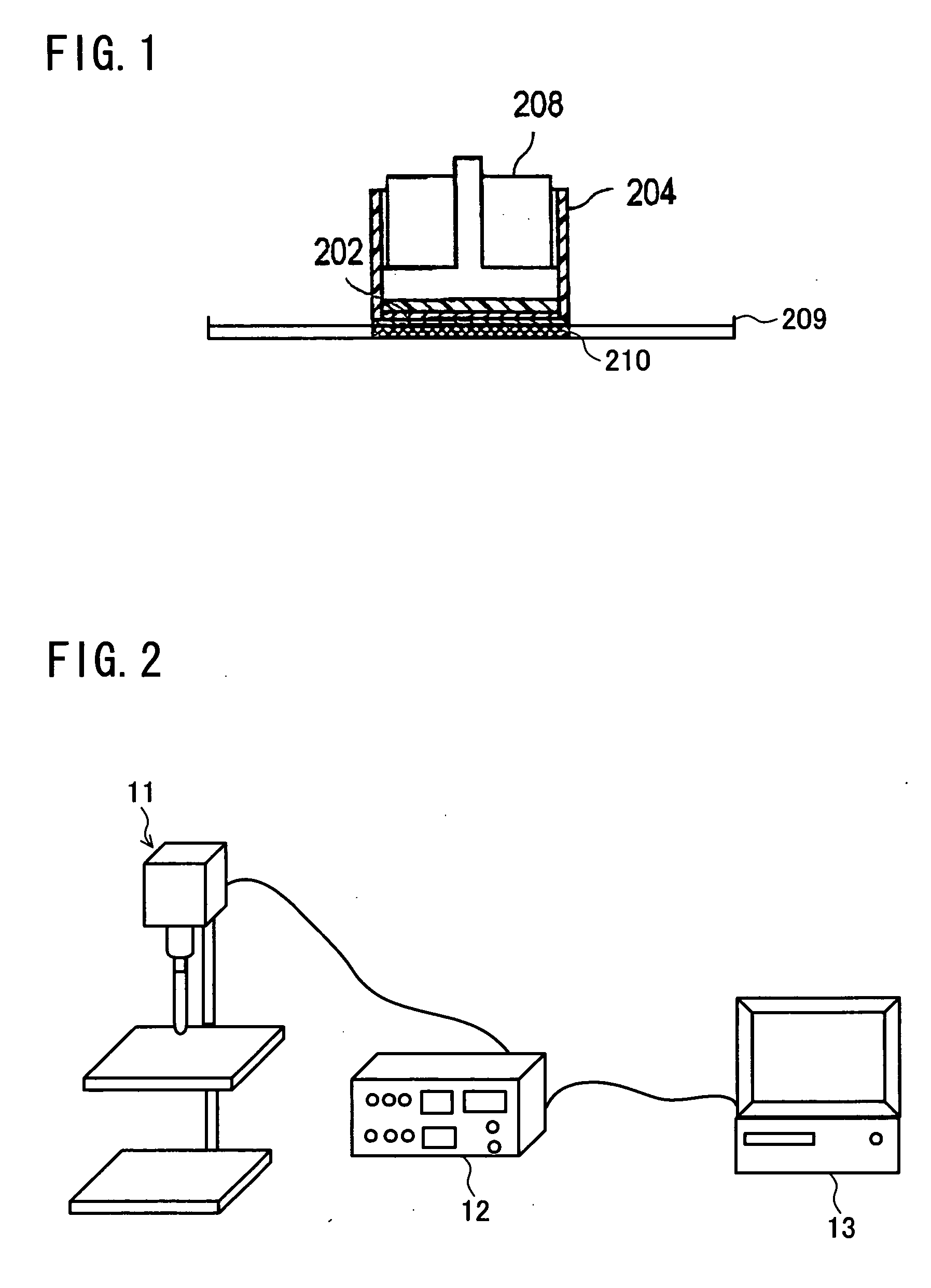

Embodiments of a gas distribution plate for distributing gas in a processing chamber are provided. In one embodiment, a gas distribution assembly for a plasma processing chamber comprises a diffuser plate with gas passages passing between its upstream and downstream sides and hollow cathode cavities at the downstream side of the gas passages. The downstream side of the diffuser plate has a curvature to improve the thickness uniformity and film property uniformity of thin films deposited by PECVD, particularly SiN and amorphous silicon films. The curvature is preferably described by an arc of a circle or ellipse, the apex thereof located at the center point of the diffuser plate. In one aspect, the hollow cathode cavity volume density, surface area density, or the cavity density of the diffuser increases from the center of the diffuser to the outer edge. Methods for manufacturing such a diffuser plate are also provided.

Owner:APPLIED MATERIALS INC

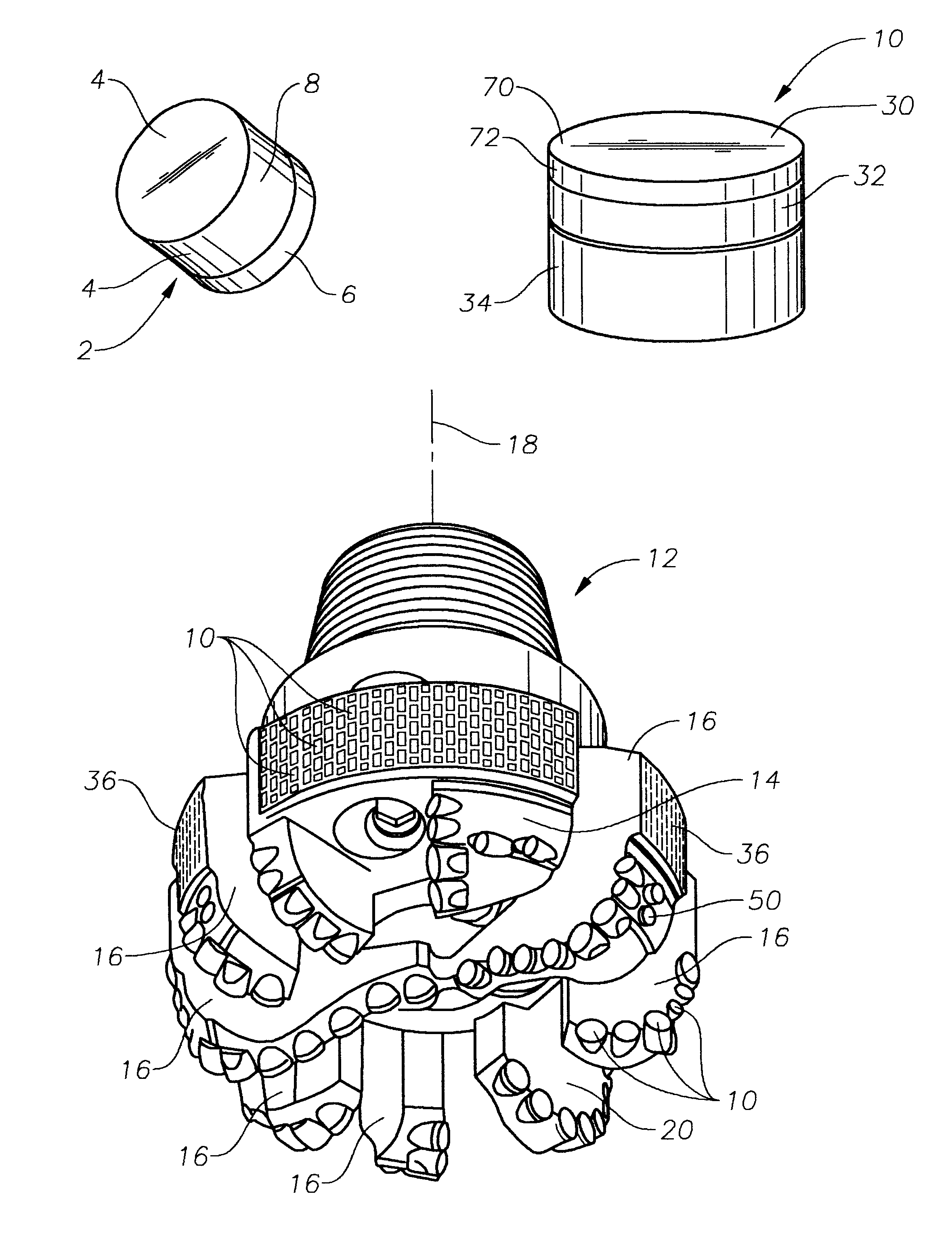

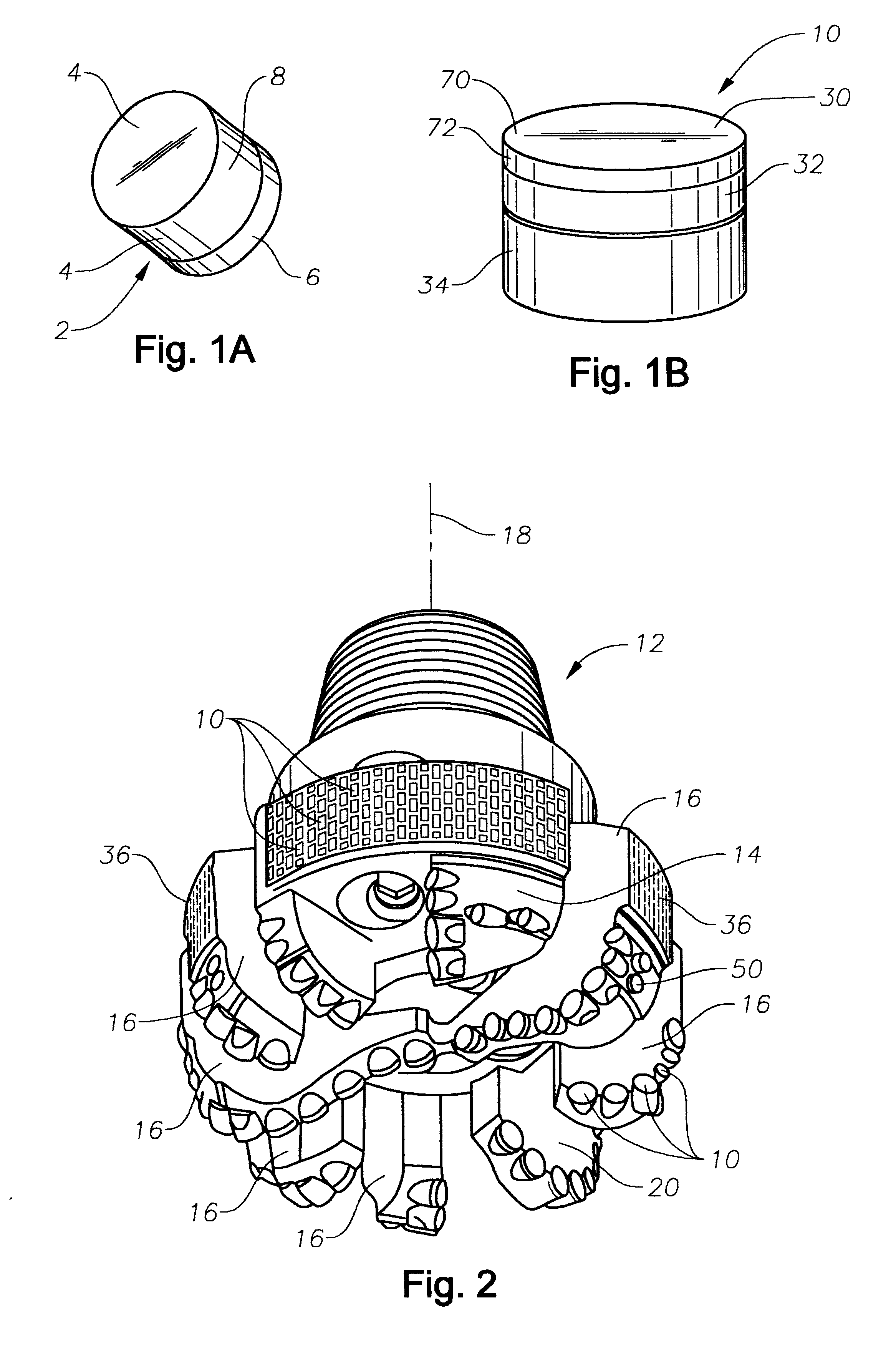

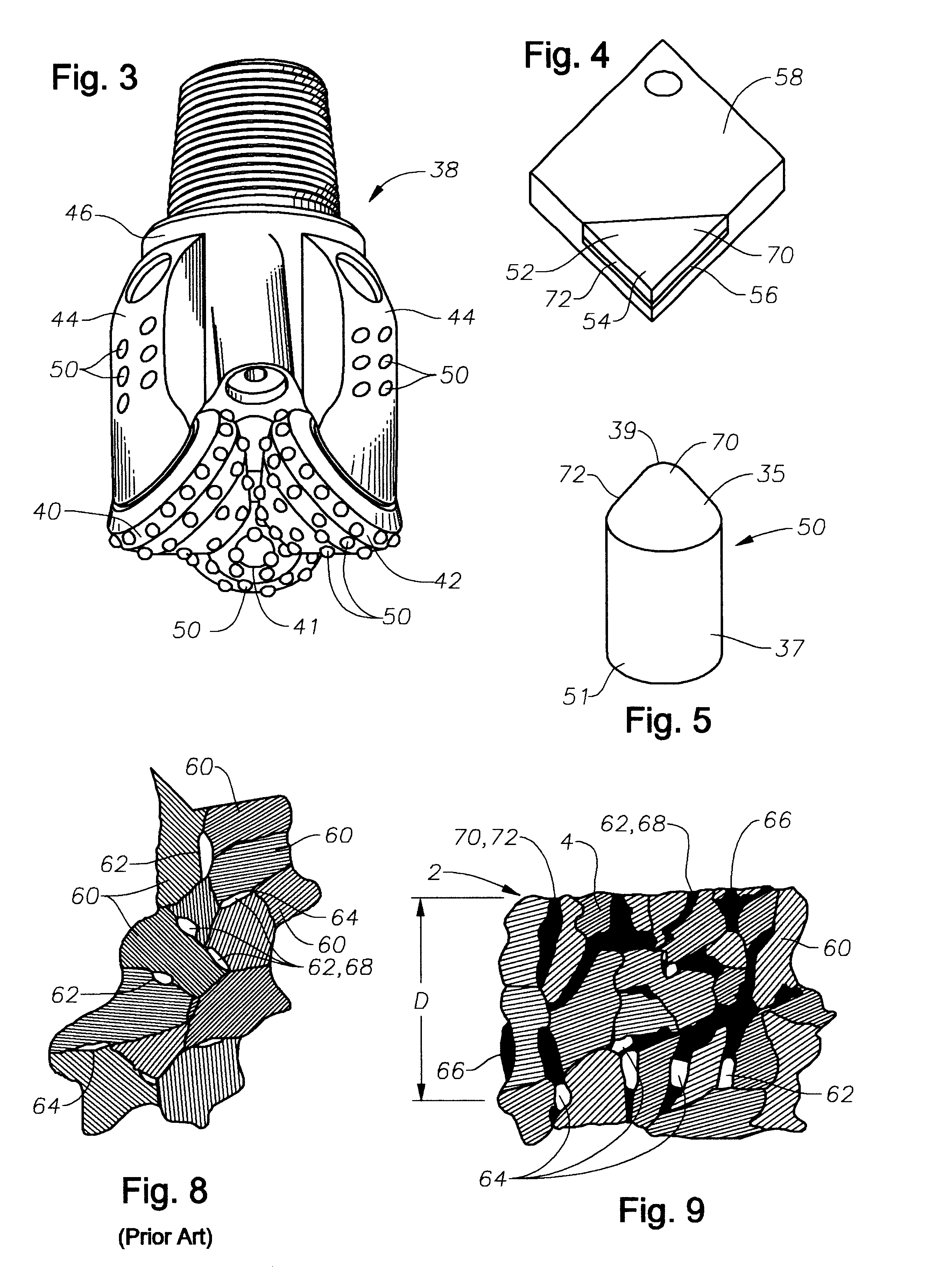

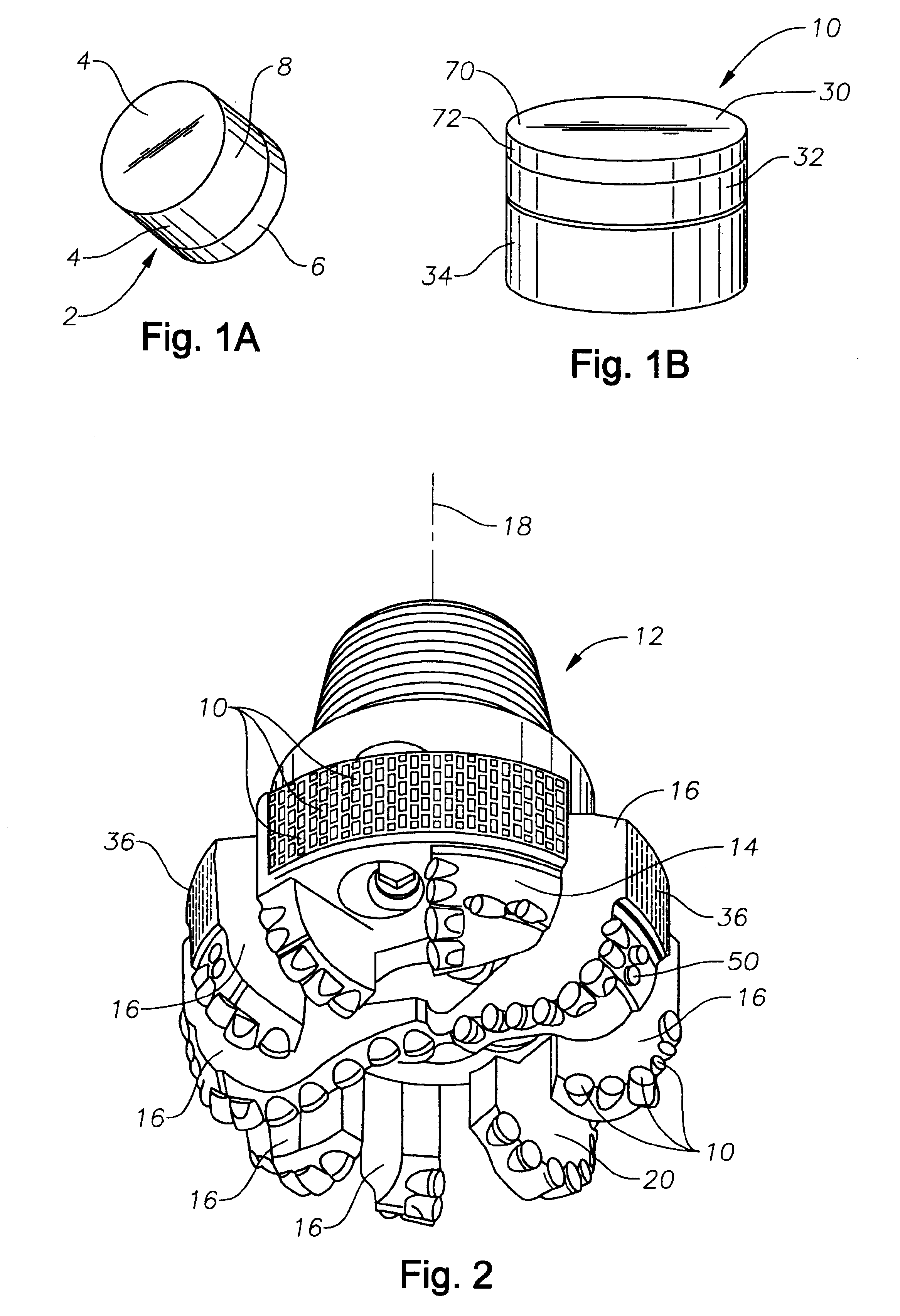

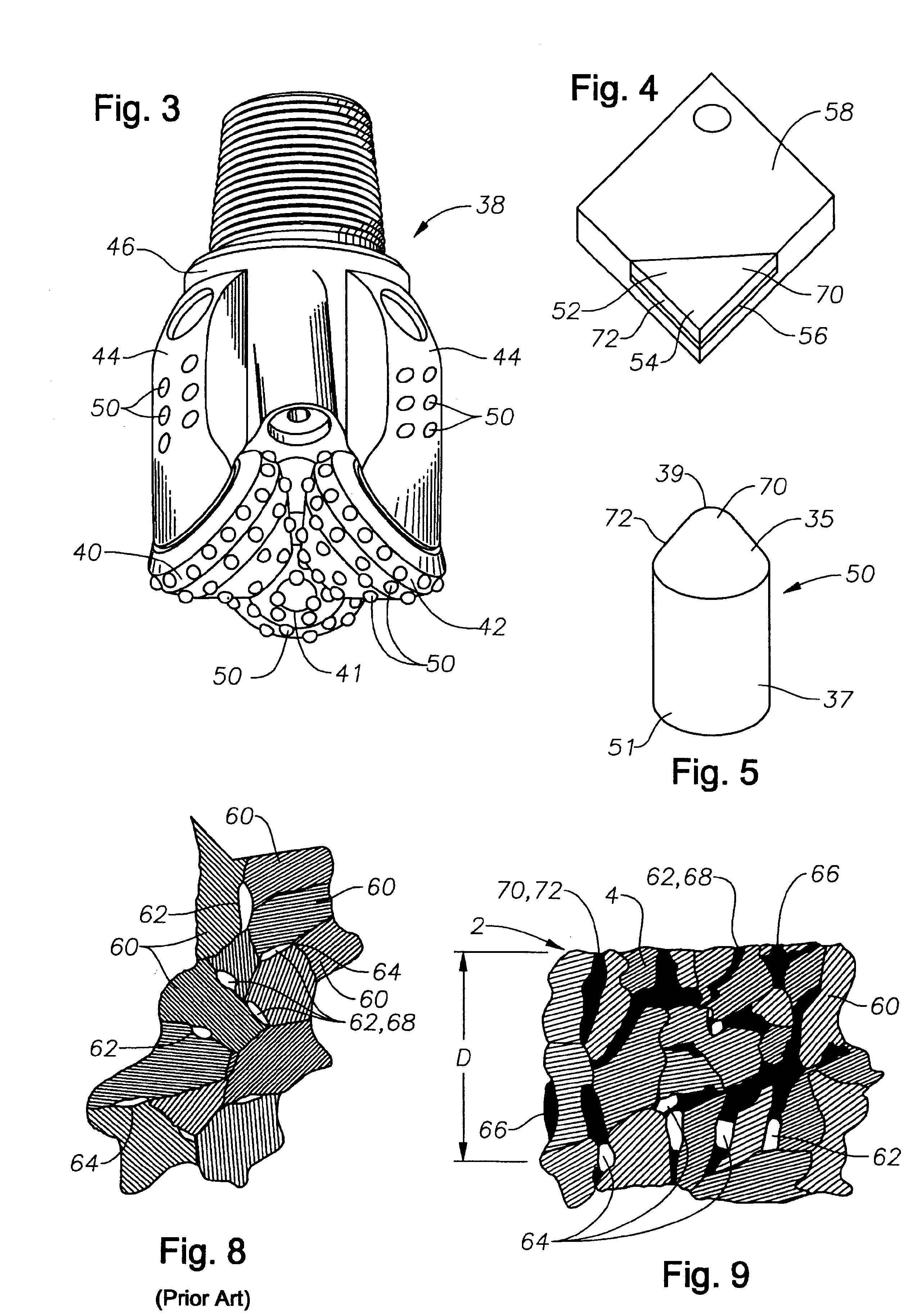

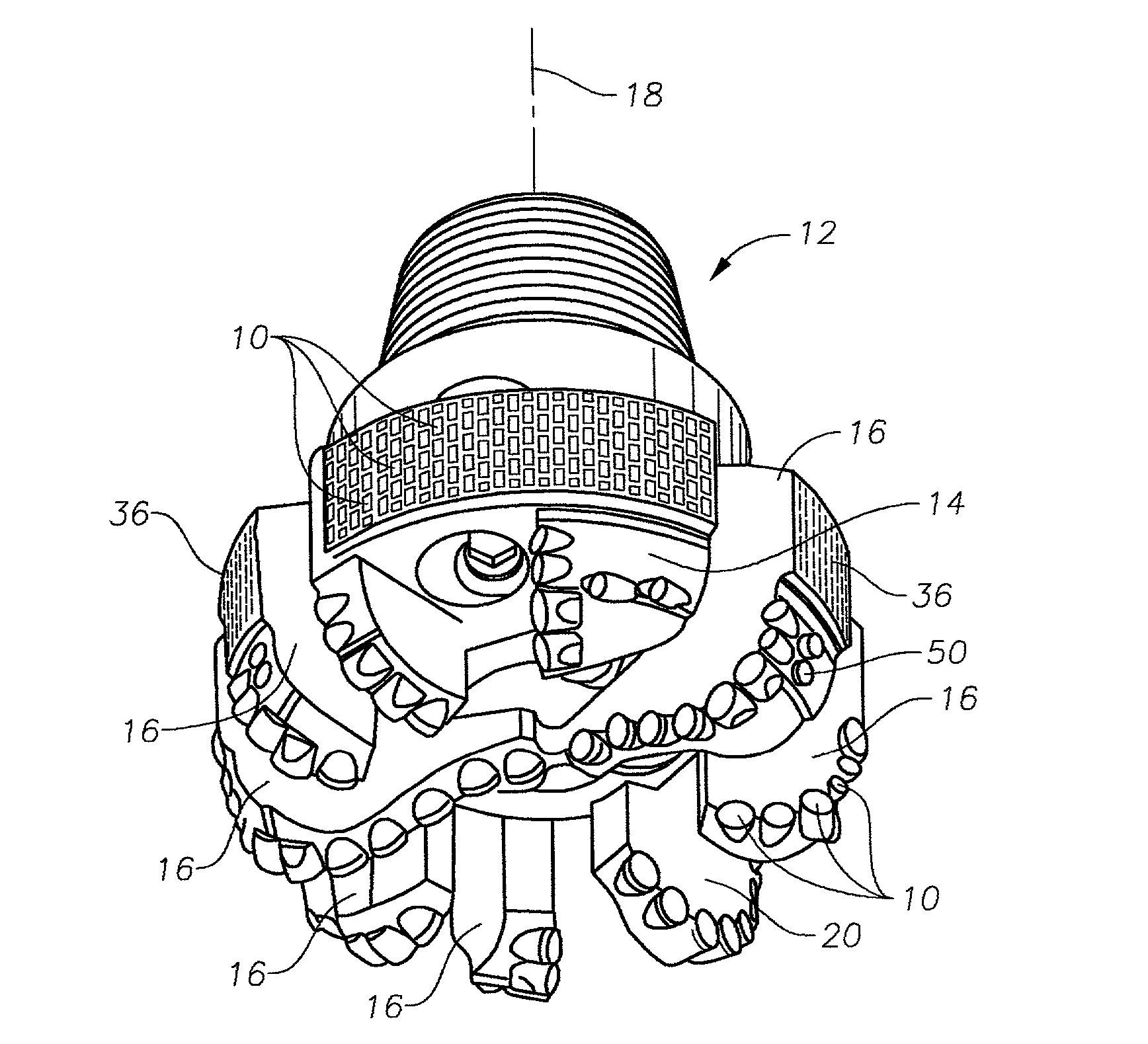

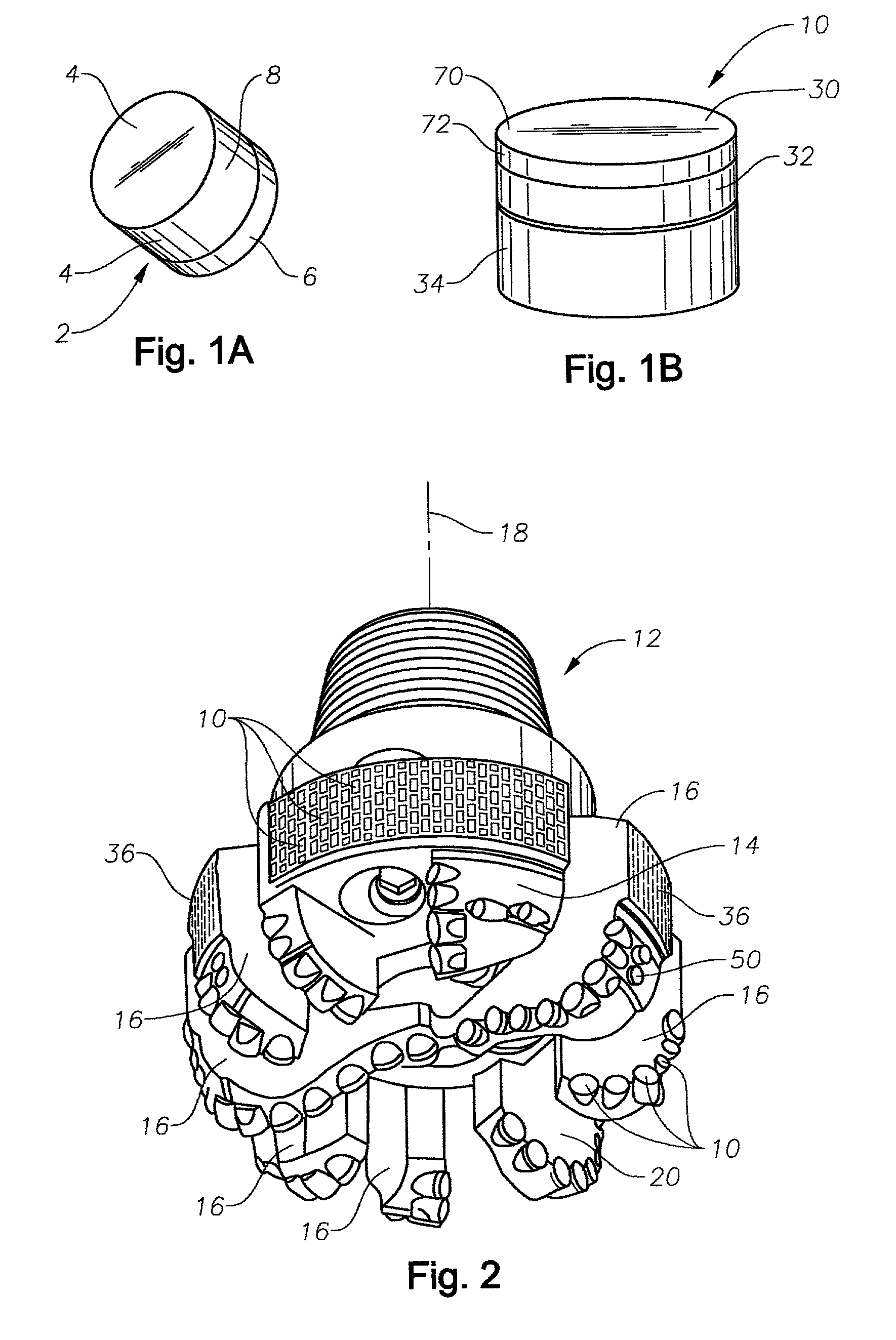

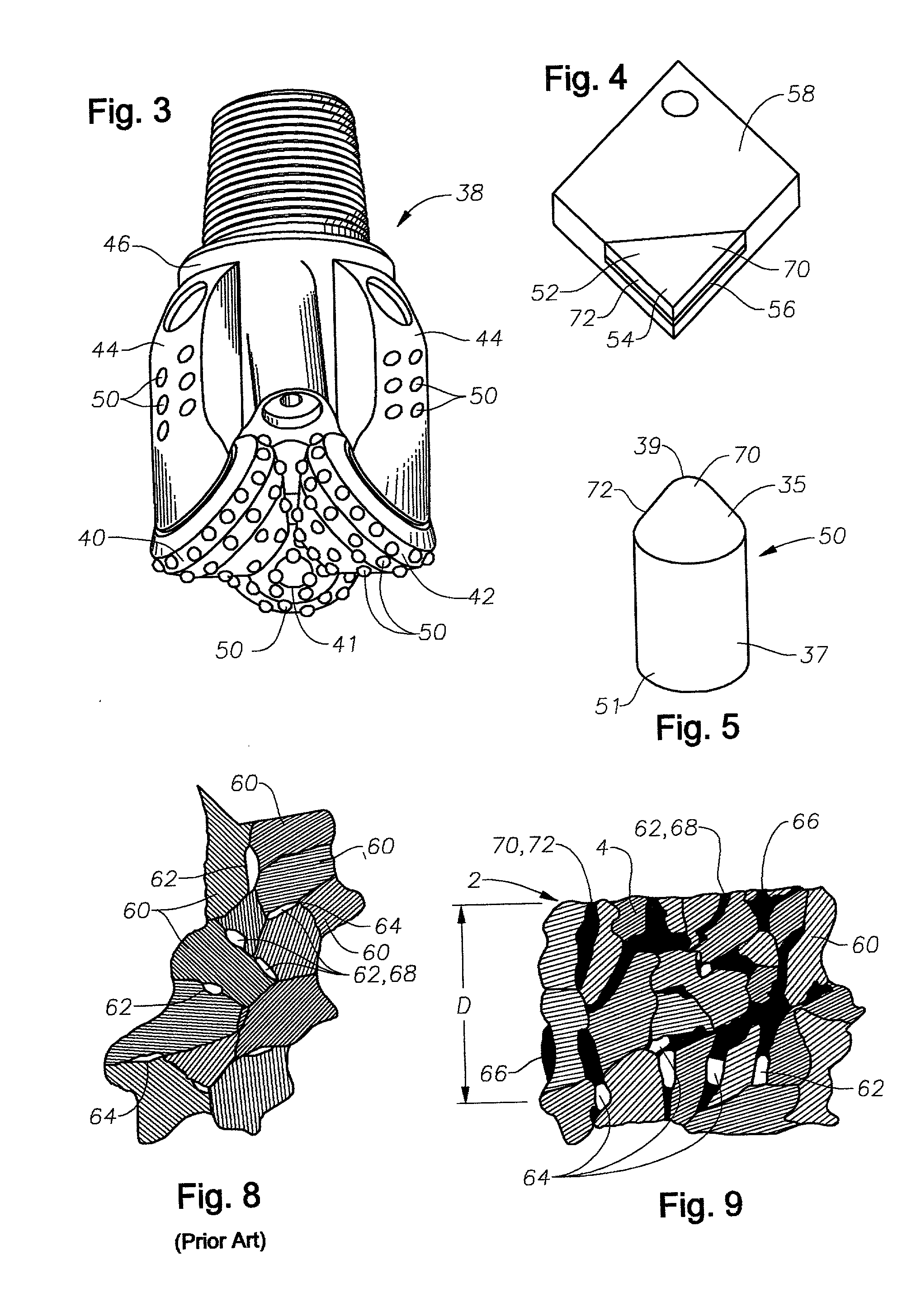

Polycrystalline diamond cutters with working surfaces having varied wear resistance while maintaining impact strength

InactiveUS6601662B2Improve wear resistanceMaintain strengthDrill bitsConstructionsDiamond crystalPolycrystalline diamond

Disclosed is a polycrystalline diamond or diamond-like element with greatly improved wear resistance without loss of impact strength. These elements are formed with a binder-catalyzing material in a high-temperature, high-pressure (HTHP) process. The PCD element has a body with a plurality of bonded diamond or diamond-like crystals forming a continuous diamond matrix that has a diamond volume density greater than 85%. Interstices among the diamond crystals form a continuous interstitial matrix containing a catalyzing material. The diamond matrix table is formed and integrally bonded with a metallic substrate containing the catalyzing material during the HTHP process. The diamond matrix body has a working surface, where a first portion of the interstitial matrix in the body adjacent to the working surface is substantially free of the catalyzing material, and a second portion of the interstitial matrix in the body adjacent to the working surface contains the catalyzing material. The first portion of the interstitial matrix and the second portion of the interstitial matrix have substantially the same impact strength.

Owner:REEDHYCALOG UK

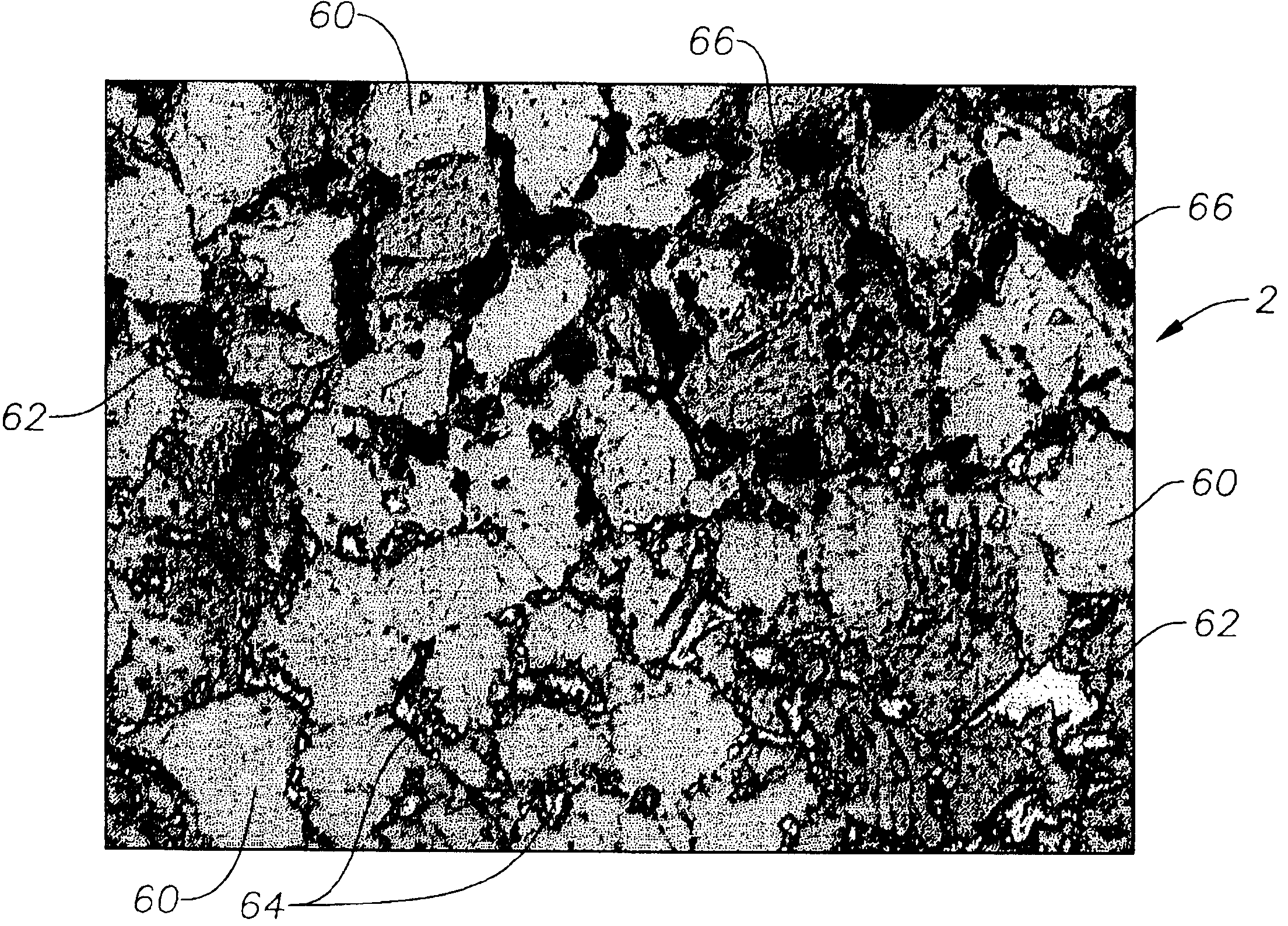

High volume density polycrystalline diamond with working surfaces depleted of catalyzing material

InactiveUS6861137B2Improve wear resistancePigmenting treatmentDrill bitsDiamond crystalPolycrystalline diamond

Disclosed is a method for manufacturing a polycrystalline diamond or diamond-like element with greatly improved wear resistance without loss of impact strength. These elements are formed with a binder-catalyzing material in a high-temperature, high-pressure (HTHP) process. The PCD element has a body with a plurality of bonded diamond or diamond-like crystals forming a continuous diamond matrix that has a diamond volume density greater than 85%. Interstices among the diamond crystals form a continuous interstitial matrix containing a catalyzing material. The diamond matrix table is formed and integrally bonded with a metallic substrate containing the catalyzing material during the HTHP process. The diamond matrix body has a working surface, where a portion of the interstitial matrix in the body adjacent to the working surface is substantially free of the catalyzing material, and the remaining interstitial matrix contains the catalyzing material. Typically, less than about 70% of the body of the diamond matrix table is free of the catalyzing material.

Owner:REEDHYCALOG UK

Plasma uniformity control by gas diffuser curvature

ActiveUS8074599B2Improve thickness uniformity and film property uniformityElectric discharge tubesSemiconductor/solid-state device manufacturingEllipseAmorphous silicon

Embodiments of a gas distribution plate for distributing gas in a processing chamber are provided. In one embodiment, a gas distribution assembly for a plasma processing chamber comprises a diffuser plate with gas passages passing between its upstream and downstream sides and hollow cathode cavities at the downstream side of the gas passages. The downstream side of the diffuser plate has a curvature to improve the thickness uniformity and film property uniformity of thin films deposited by PECVD, particularly SiN and amorphous silicon films. The curvature is preferably described by an arc of a circle or ellipse, the apex thereof located at the center point of the diffuser plate. In one aspect, the hollow cathode cavity volume density, surface area density, or the cavity density of the diffuser increases from the center of the diffuser to the outer edge. Methods for manufacturing such a diffuser plate are also provided.

Owner:APPLIED MATERIALS INC

Cathode active material, method of preparing the same, and cathode and lithium battery containing the material

ActiveUS20060257745A1Improve high voltage stabilityImprove thermal stabilityWalking sticksElectrode rolling/calenderingComposite cathodeHigh rate

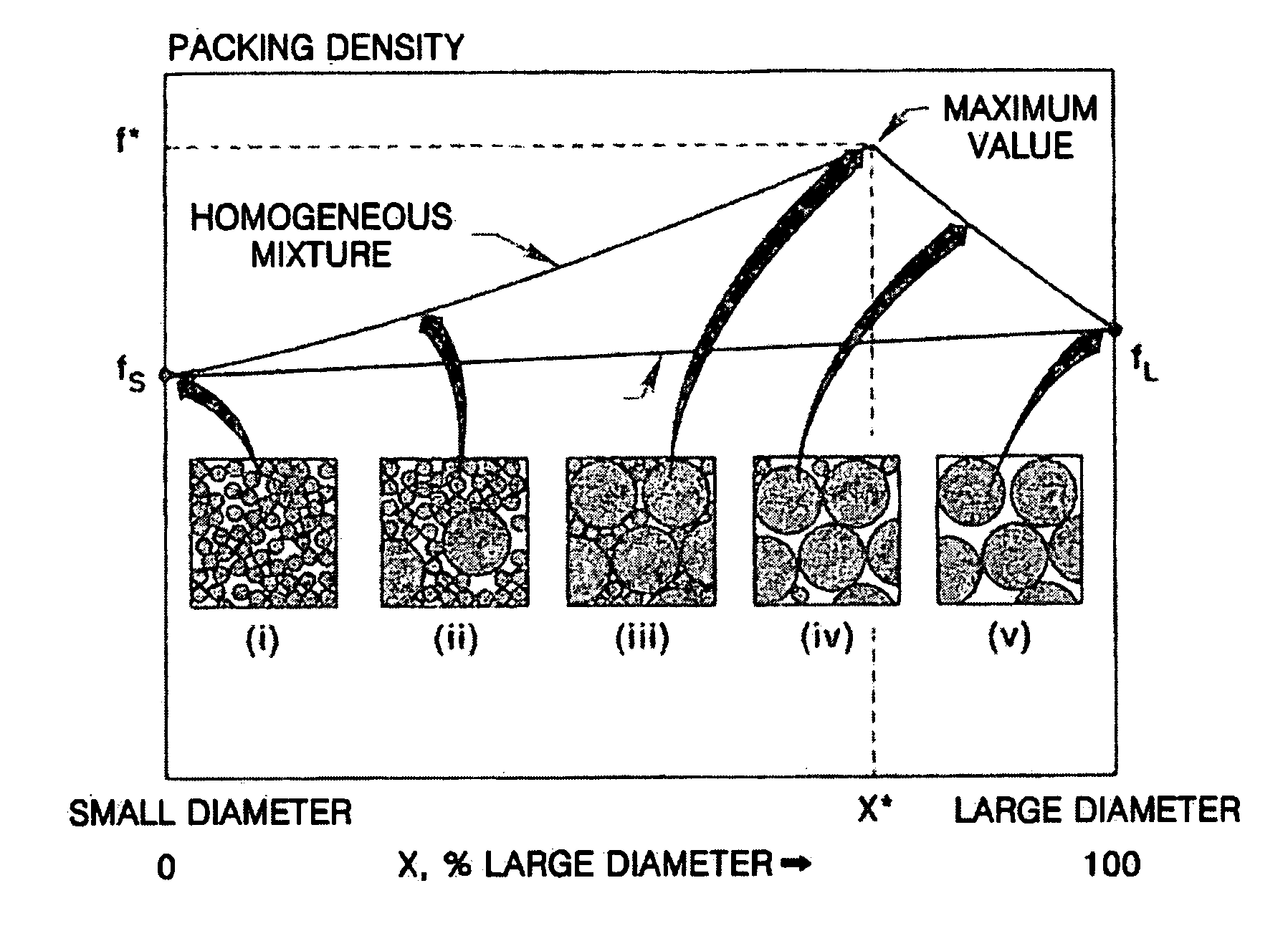

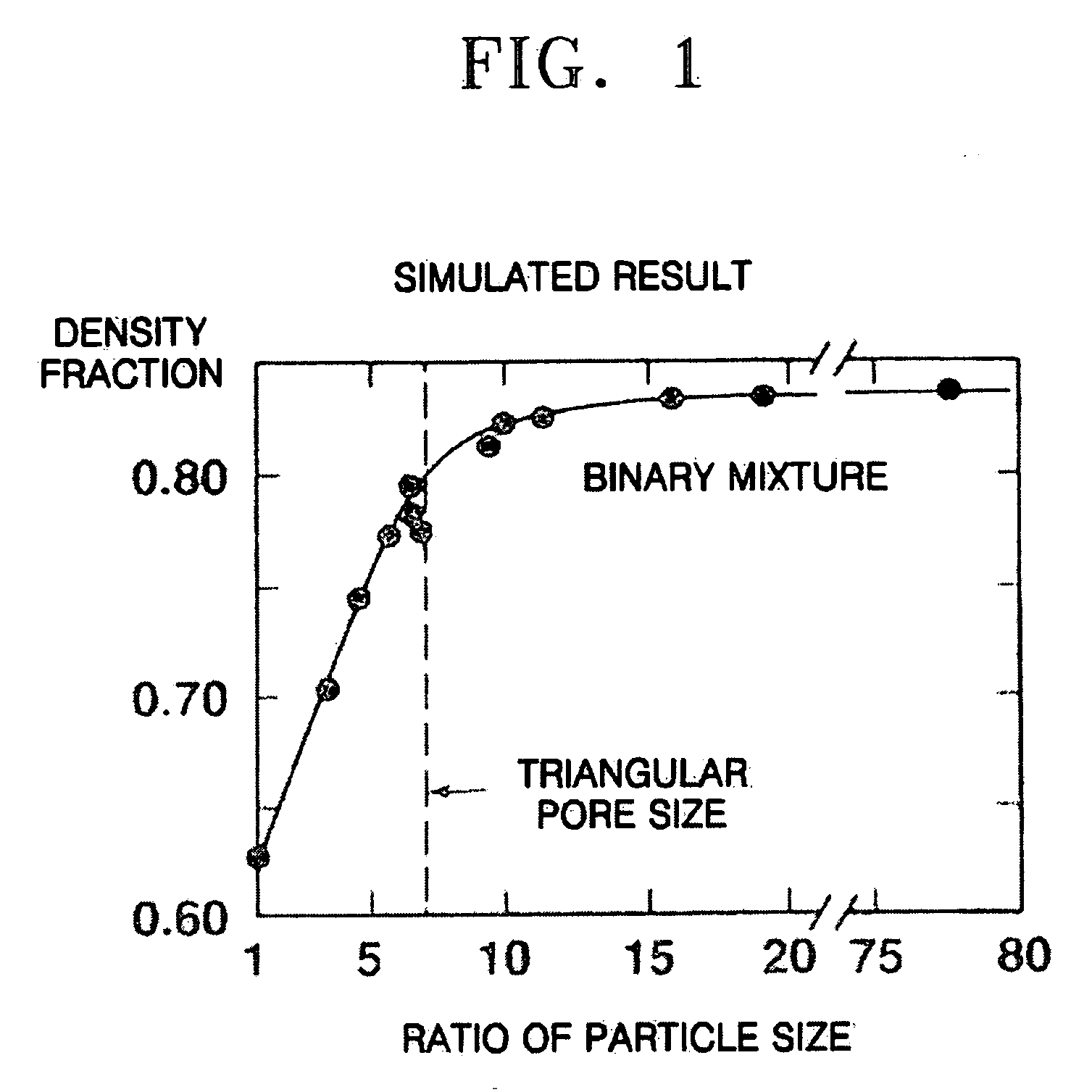

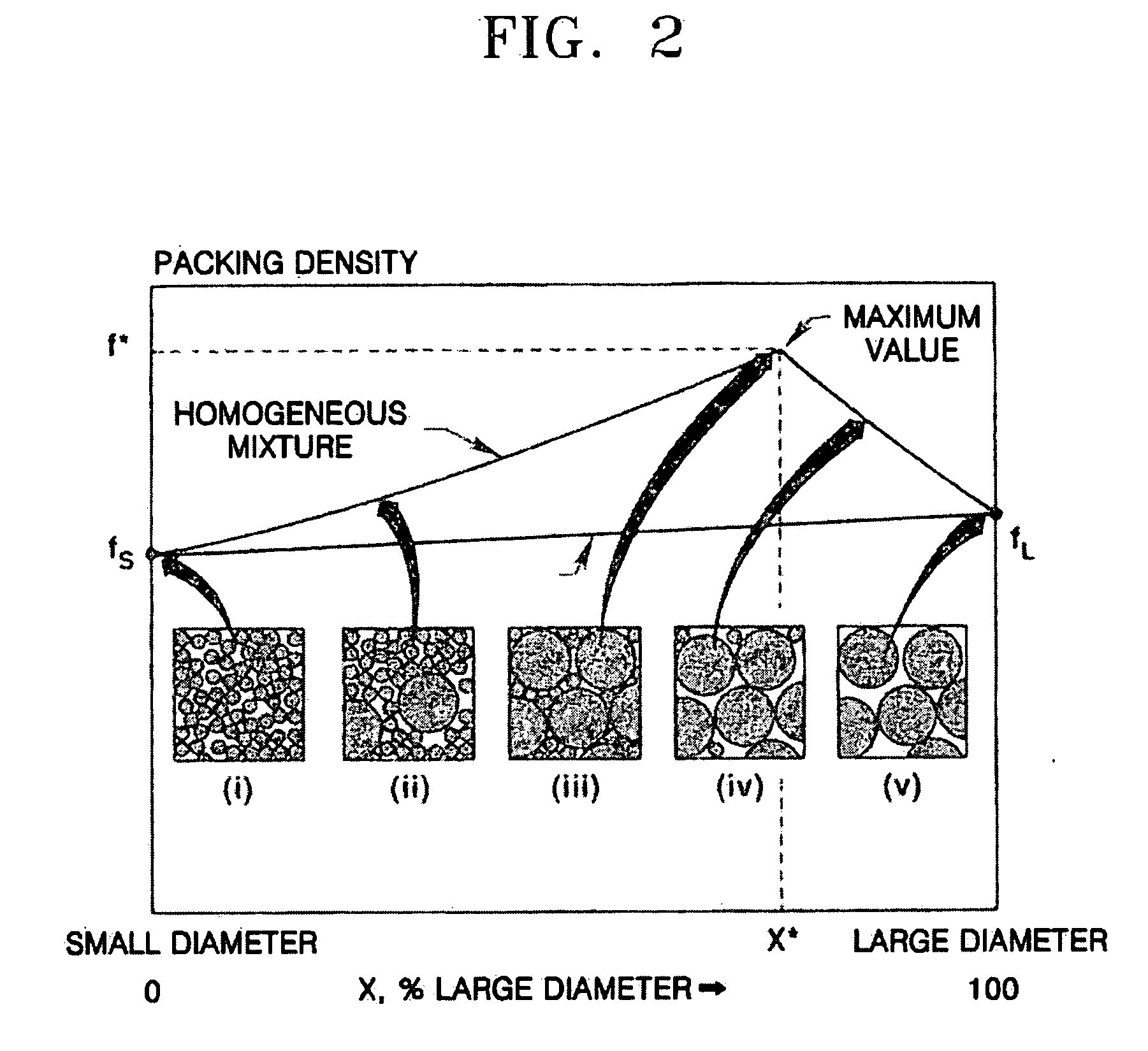

Composite cathode active materials having a large diameter active material and a small diameter active material are provided. The ratio of the average particle diameter of the large diameter active material to the average particle diameter of the small diameter active material ranges from about 6:1 to about 100:1. Mixing the large and small diameter active materials in a proper weight ratio improves packing density Additionally, including highly stable materials and highly conductive materials in the composite cathode active materials improves volume density, discharge capacity and high rate discharge capacity.

Owner:SAMSUNG SDI CO LTD

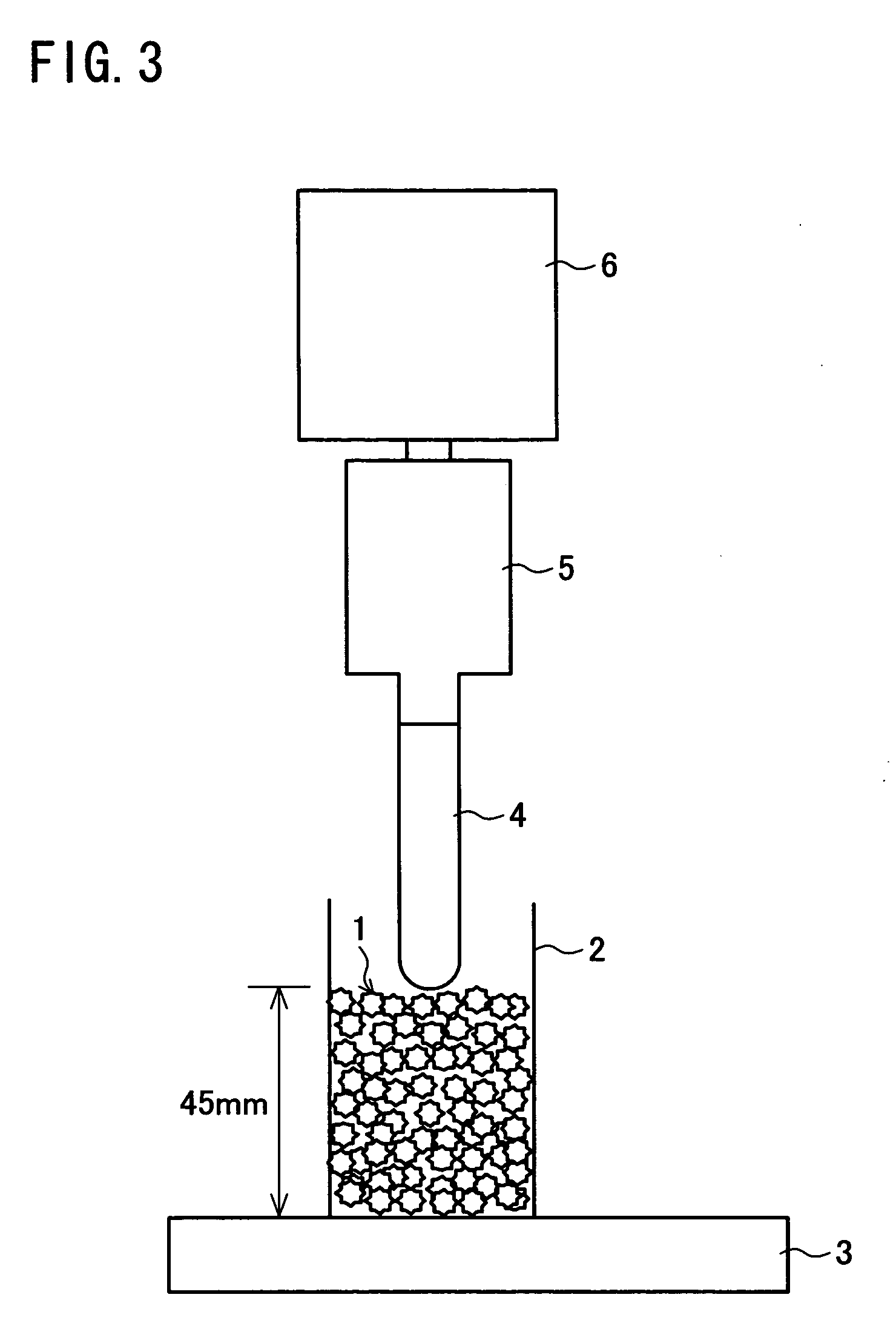

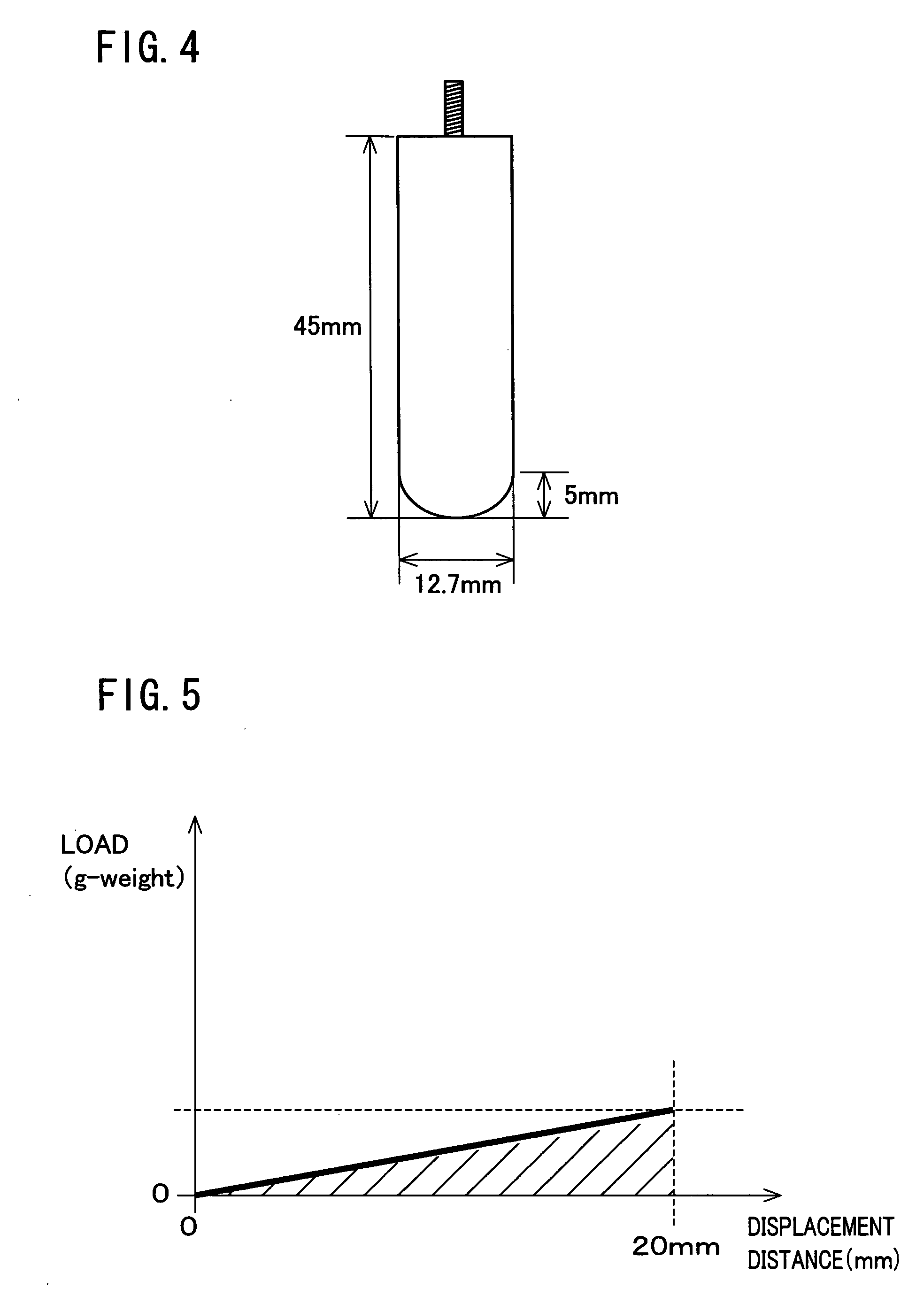

Particulate water absorbent agent and production method thereof, and water absorbent article

ActiveUS20050209352A1Improve liquidityImprove water absorptionOther chemical processesAbsorbent padsParticulatesSaline water

A particulate water absorbing agent of the present invention includes a water absorbent resin, having a cross-linking structure, whose surface has been cross-linked by adding a surface treatment agent, wherein: (i) a mass average particle diameter (D50) ranges from 200 to 600 μm and 95 to 100 wt % of a particulate water absorbing agent whose particle diameter ranges from less than 850 μm to not less than 150 μm is contained with respect to 100 wt % of whole the particulate water absorbing agent, and (ii) a logarithmic standard deviation (σζ) of particle size distribution ranges from 0.25 to 0.45, and (iii) a compressibility rate defined by a following equation ranges from 0 to 18%, and (iv) a surface tension of a supernatant liquid obtained in 4 minutes after dispersing 0.5 g of the particulate water absorbing agent in 50 ml of physiological saline whose temperature is 20° C. is 55 mN / m or more, the compressibility rate (%)=(P−A) / P×100 where P represents a tapped bulk density of the particulate water absorbing agent and A represents a loose bulk density of the particulate water absorbing agent.

Owner:NIPPON SHOKUBAI CO LTD

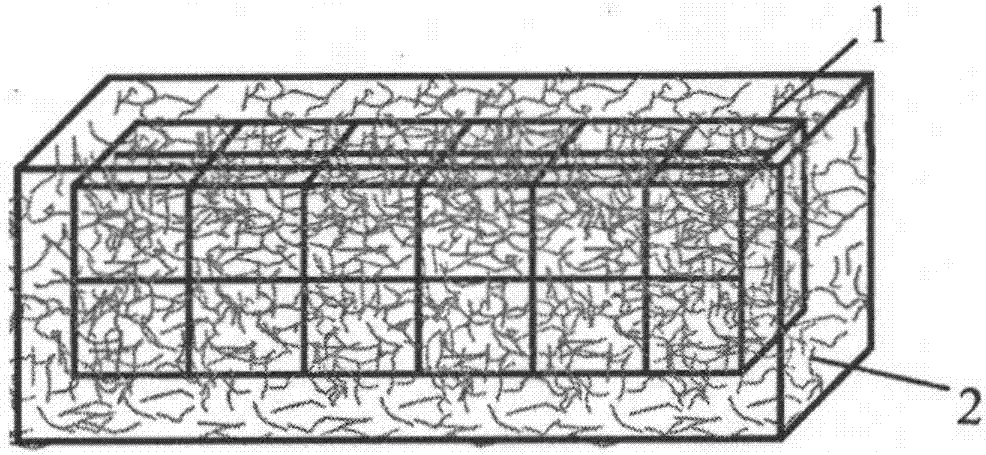

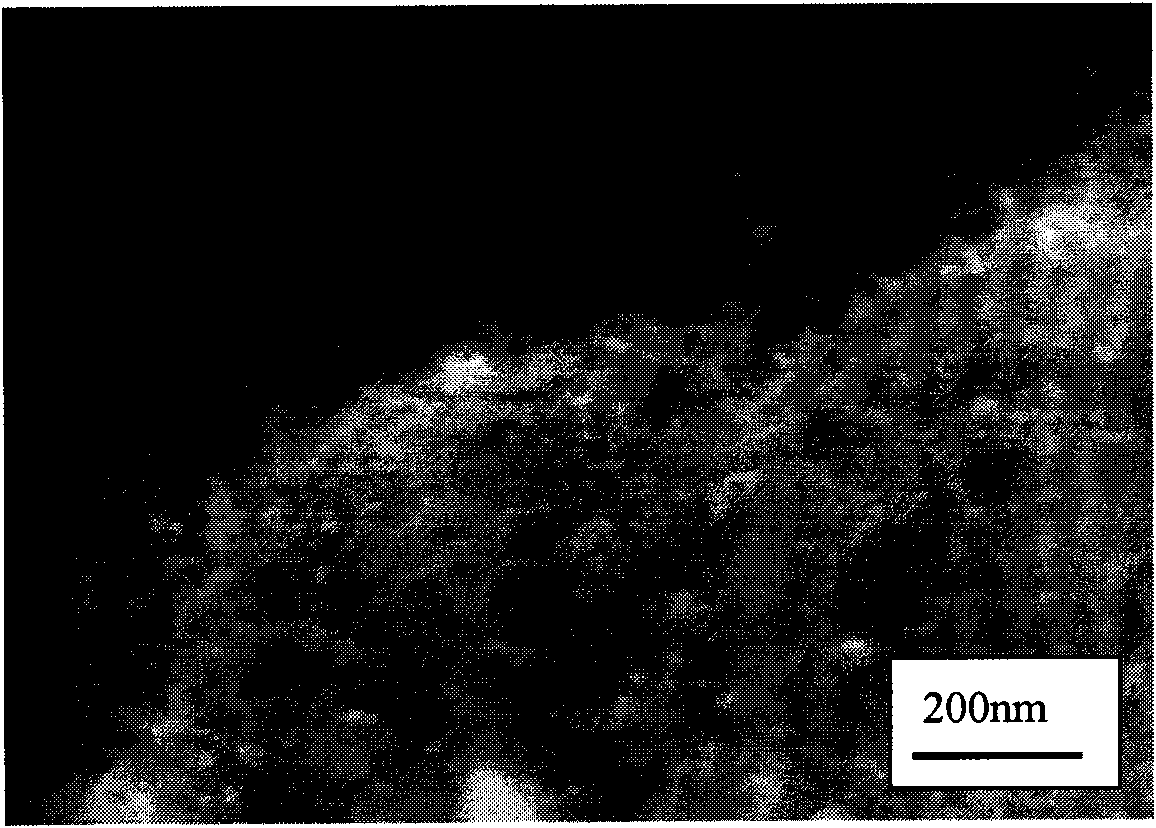

Preparation method of three-dimensional fiber-based aerogel material and product thereof

ActiveCN103285789AImprove pore structureWide pore structure adjustable rangeColloidal chemistry detailsSolubilityFiber

The invention relates to a preparation method of a three-dimensional fiber-based aerogel material and a product thereof. The preparation method comprises the following steps of: firstly dispersing fibers in solvents which do not have fiber solubility to form turbid liquid; secondly curing the turbid liquid to form cured pieces; thirdly removing cured solvents in the cured pieces to form non-crosslinked fiber-based aerogel; and finally carrying out crosslinking stabilization treatment on the non-crosslinked fiber-based aerogel to obtain the fiber crossing point bonded and fixed three-dimensional fiber-based aerogel material. The product is a three-dimensional network-shaped material formed through mutual penetration and stagger of fibers. The fiber crossing points are effectively interconnected through non-hydrogen-bond bonding. The three-dimensional fiber-based aerogel material has volume density of 0.1-500mg / cm<3>, average pore size of 0.01-2000mu m and specific surface area of 0.2-2000m<2> / g. The preparation method and the product have the advantages that the preparation process is simple; the raw material limitations are less; and the aerogel product has good flexibility and connectivity and has broad application prospects in numerous fields.

Owner:DONGHUA UNIV

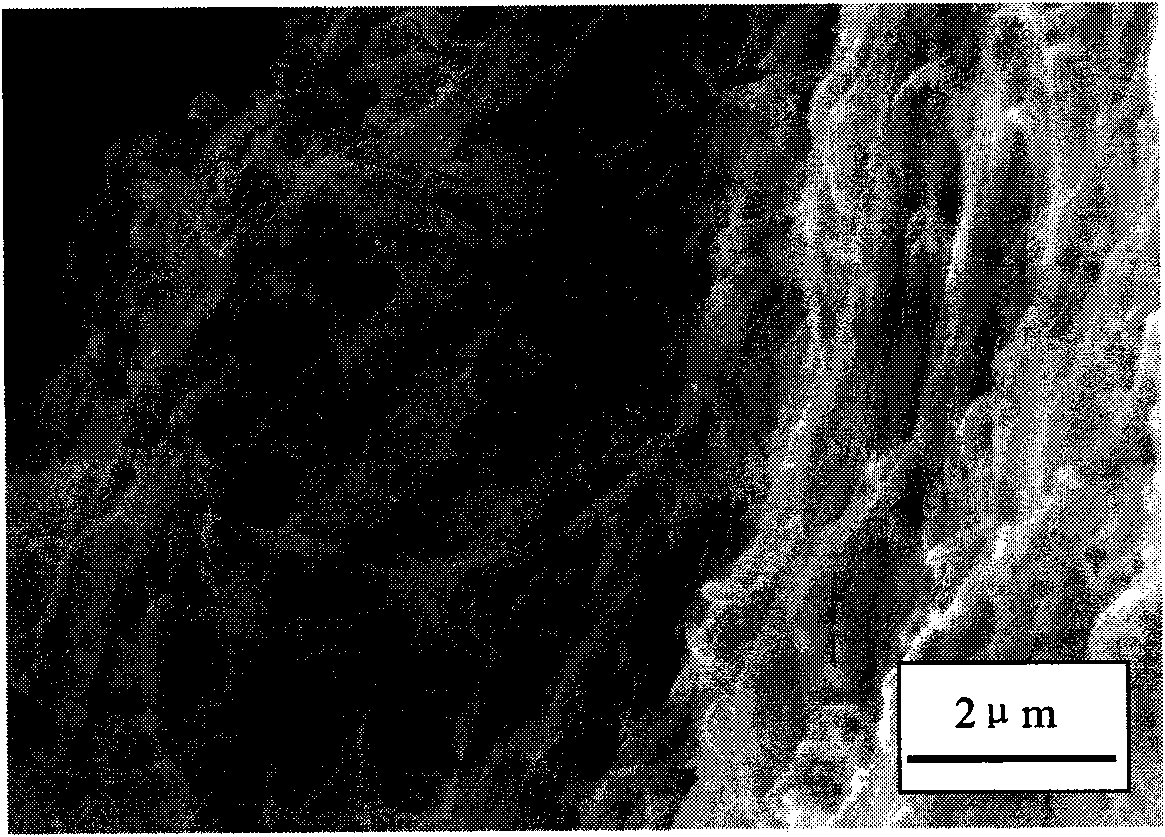

Three-dimensional carbon fiber based aerogel material and preparation method thereof

ActiveCN103265010AImprove conductivityStrong modifiabilityCarbon preparation/purificationFiberCarbon fibers

The invention relates to a three-dimensional carbon fiber based aerogel material and a preparation method thereof. The preparation method comprises the following steps of: first, dispersing fiber in a solvent to form a turbid liquid; then, curing the turbid liquid to form a cured block; then, removing the cured solvent in the cured block to form an uncrosslinked fiber based aerogel; and crosslinking and stabilizing the uncrosslinked fiber based aerogel and pre-oxidizing and carbonizing to obtain the three-dimensional carbon fiber based aerogel material. The product is a three-dimensional network-shaped material formed by carbon fibers in a penetrated and staggered mode. The fiber crosslinking points show effective bonding and interconnection of bonding effect of non-hydrogen bond. The volume density is 0.1-500mg / cm<3>, the average aperture is 0.01-200mu m, and the specific surface area is 0.2-2000m<2> / g. The preparation process is simple and the raw material limit is less. The three-dimensional carbon fiber based aerogel product has good flexibility, connectivity and conductivity, and has a wide application prospect in many fields.

Owner:DONGHUA UNIV

Three-dimensional fiber-based aerogel tissue engineering scaffold and preparation method thereof

The invention relates to a preparation method of a three-dimensional fiber-based aerogel tissue engineering scaffold and a product thereof. The preparation method comprises the following steps of: firstly dispersing fibers in solvents to form turbid liquid; secondly curing the turbid liquid to form cured pieces; thirdly removing cured solvents to form non-crosslinked fiber-based aerogel; finally carrying out crosslinking stabilization treatment and then carrying out sterilization treatment, thus obtaining the three-dimensional fiber-based aerogel tissue engineering scaffold. The product is a three-dimensional network-shaped material formed through mutual penetration and stagger of fibers. The fiber crossing points are effectively interconnected through non-hydrogen-bond bonding. The three-dimensional fiber-based aerogel tissue engineering scaffold has volume density of 0.1-500mg / cm<3>, average pore size of 0.01-2000mu m and specific surface area of 0.2-2000m<2> / g. The preparation method and the product have the advantages that the preparation process is simple; the raw material limitations are less; the aerogel tissue engineering scaffold product has good flexibility, connectivity and tissue growing environment and has broad application prospects in the tissue engineering field.

Owner:DONGHUA UNIV

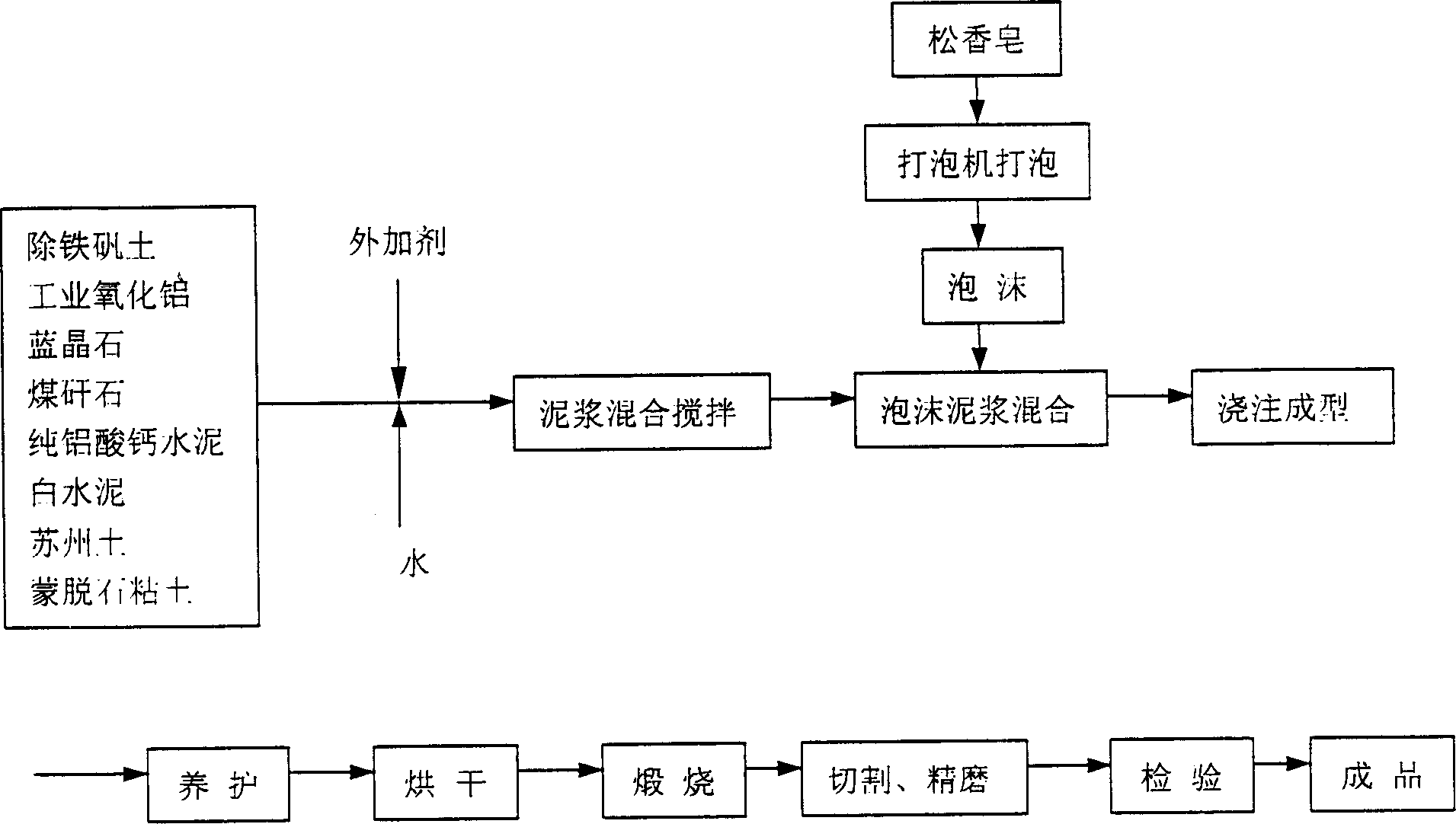

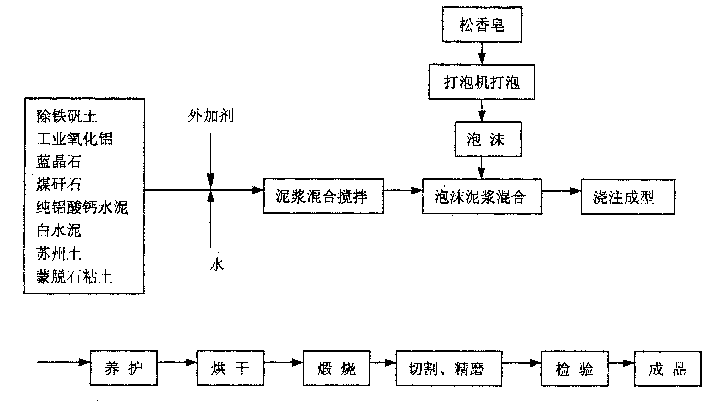

Water-proof acid resistant heat resistant light heat insulating casting material and its manufacturing method

InactiveCN1537821AReduce intensityGood impermeability and antifreeze performanceSolid waste managementCeramic shaping apparatusHigh resistancePolymer science

A water-proof light-weight insulating casting material resisting acid and high temp for the liner of chimney is prepared from the inorganic light aggregate particles resisting acid and high temp, the acid and high temp resistant powder, the acid and high temp resistant adhesive and additive through proportional mixing, stirring, casting in mould for 1-5 days, demoulding, and natural drying and curing. Its advantages are high volume density and strength, light weight and high resistance to water, acid and high temp.

Owner:张东辉 +1

Polycrystalline diamond cutters with working surfaces having varied wear resistance while maintaining impact strength

InactiveUS20020074168A1Improve wear resistanceMaintain strengthDrill bitsConstructionsPolycrystalline diamondHigh pressure

Disclosed is a polycrystalline diamond or diamond-like element with greatly improved wear resistance without loss of impact strength. These elements are formed with a binder-catalyzing material in a high-temperature, high-pressure (HTHP) process. The PCD element has a body with a plurality of bonded diamond or diamond-like crystals forming a continuous diamond matrix that has a diamond volume density greater than 85%. Interstices among the diamond crystals form a continuous interstitial matrix containing a catalyzing material. The diamond matrix table is formed and integrally bonded with a metallic substrate containing the catalyzing material during the HTHP process. The diamond matrix body has a working surface, where a first portion of the interstitial matrix in the body adjacent to the working surface is substantially free of the catalyzing material, and a second portion of the interstitial matrix in the body adjacent to the working surface contains the catalyzing material. The first portion of the interstitial matrix and the second portion of the interstitial matrix have substantially the same impact strength

Owner:REEDHYCALOG UK

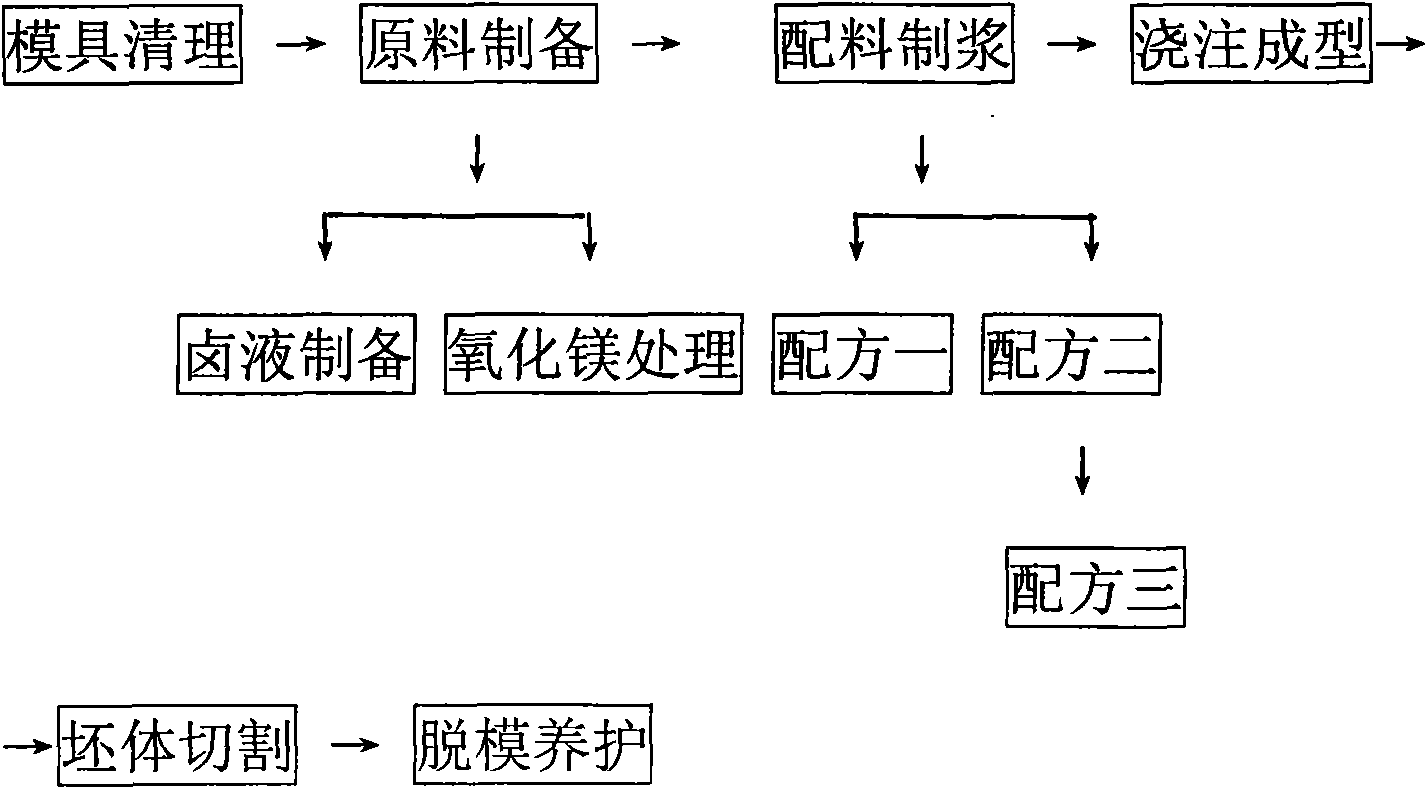

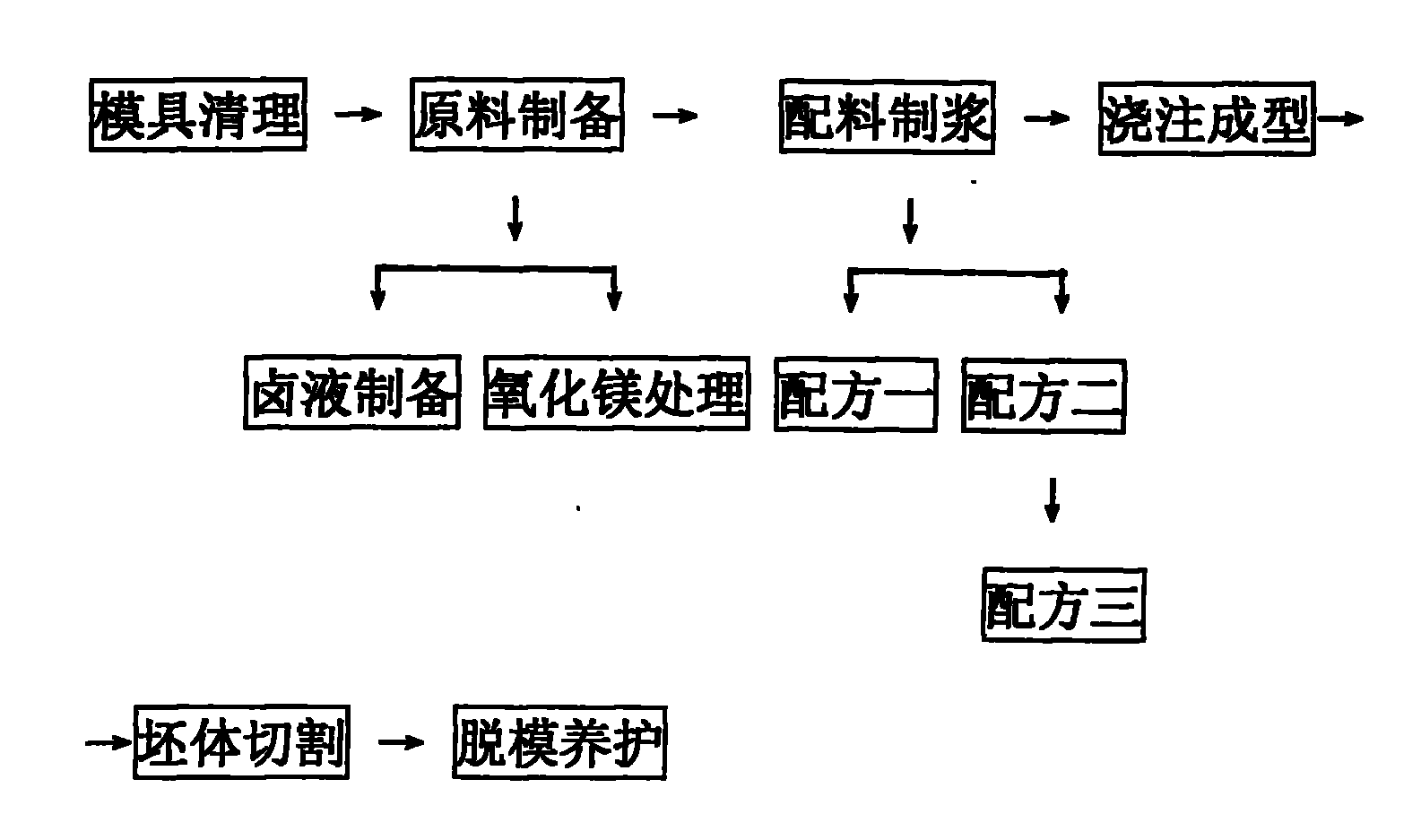

Composite light building block and preparation method thereof

The invention relates to composite light building block and preparation method thereof. The slurry comprises brine, light burnt powder, filler, air producing agent, foam stabilizer, adjusting agent, cement, water and aggregate. Taking a 60*15*25cm building block with the volume weight of 18kg as an example, the slurry is prepared from the following raw material in percentage by weight: 30-50% of brine, 0.008-0.01% of air producing agent, 25-35% of light burnt powder, 0.0005-0.001% of foam stabilizer, 20-30% of filler, and the balance of adjusting agent. The invention can improve the processing property, increases the slurry flowability, is easy to cast in forming, has short production period and low manufacturing cost, increases the activity, enhances the impermeability and post strength, reduces dry shrinkage, and prevents cracking. The composite light building block has the advantages of light weight, high strength, small volume density, low heat conduction coefficient, heat insulation, sound insulation, fire prevention, heat isolation, freezing and melting resistance, little dry shrinkage, and the like. By using the gas-added building block to replace the traditional bearing building block as the building wall filling material, the self weight of the building structure is decreased, the foundation burden is reduced, and the energy and material are saved.

Owner:黄丹平

Method and apparatus for determining multi-dimensional structure

InactiveUS6345235B1Chemical property predictionDigital computer detailsFeature vectorMulti dimensional

This invention relates to methods and apparatus for determining the multi-dimensional topology of a substance (system) within a volume (space). A method according to a preferred embodiment of the invention comprises the steps of: acquiring a set of relative values for the density (scalar properties) of the volume, each value for a given location (point) within the volume; interpolating a set of functions to generate a continuous relative density for the volume; identifying critical points of the continuous relative density by using an eigenvector following method; and associating critical points with one another by following a gradient path of the continuous relative density between the critical points, The method is applicable to a wide range of data relating to fields such as crystallography, fluid dynamics, edge detection, and financial markets, to determine the topology of structures contained therein.

Owner:EDGECOMBE KENNETH E

Three-dimensional fiber-based aerogel catalyst carrier and preparation method thereof

ActiveCN103285920AGood flexibilitySufficient reactive sitesCatalyst carriersOrganic-compounds/hydrides/coordination-complexes catalystsFiberPliability

The invention relates to a preparation method of a three-dimensional fiber-based aerogel catalyst carrier and a product thereof. The preparation method comprises the following steps of: firstly dispersing fibers in solvents to form turbid liquid; secondly curing the turbid liquid to form cured pieces; thirdly removing cured solvents to form non-crosslinked fiber-based aerogel; finally carrying out crosslinking stabilization treatment and then carrying out activation treatment, thus obtaining the three-dimensional fiber-based aerogel catalyst carrier. The product is a three-dimensional network-shaped material formed through mutual penetration and stagger of fibers. The fiber crossing points are effectively interconnected through non-hydrogen-bond bonding. The three-dimensional fiber-based aerogel catalyst carrier has volume density of 0.1-500mg / cm<3>, average pore size of 0.01-2000mu m and specific surface area of 0.2-2000m<2> / g. The preparation method and the product have the advantages that the preparation process is simple; the raw material limitations are less; and the aerogel catalyst carrier product has good flexibility, connectivity and catalyst supporting capacity and has broad application prospects in the catalytic application field.

Owner:DONGHUA UNIV

Three-dimensional porous frame-reinforced fiber aerogel material and preparation method thereof

InactiveCN106955650AGood flexibilityImprove connectivityAerogel preparationColloidal chemistry detailsFiberPorosity

The invention provides a three-dimensional porous frame-reinforced fiber aerogel material and a preparation method thereof. The three-dimensional porous frame-reinforced fiber aerogel material is characterized by comprising a three-dimensional porous frame as a main body support-reinforced structure; and the three-dimensional porous frame-reinforced fiber aerogel material is obtained through putting the three-dimensional porous frame into fiber dispersing slurry and carrying out slurry molding, solvent drying and solidification treatment. The volume density of the obtained three-dimensional porous frame-reinforced fiber aerogel material is 10-1000mg / cm<3>, the mean pore size is 0.05-1000 microns and the tensile strength is 20-50kPa. The internal structure of the obtained aerogel material is that fibers are uniformly dispersed into meshes of the three-dimensional frame and the fibers are interlaced with each other and run through to form holes, so that the three-dimensional porous frame-reinforced fiber aerogel material is endowed with a high porosity and small-pore size structure while the mechanical strength of the aerogel material is improved, and the three-dimensional porous frame-reinforced fiber aerogel material has wide application prospects in the fields such as thermal insulation, heat preservation, sound absorption and noise reduction.

Owner:DONGHUA UNIV

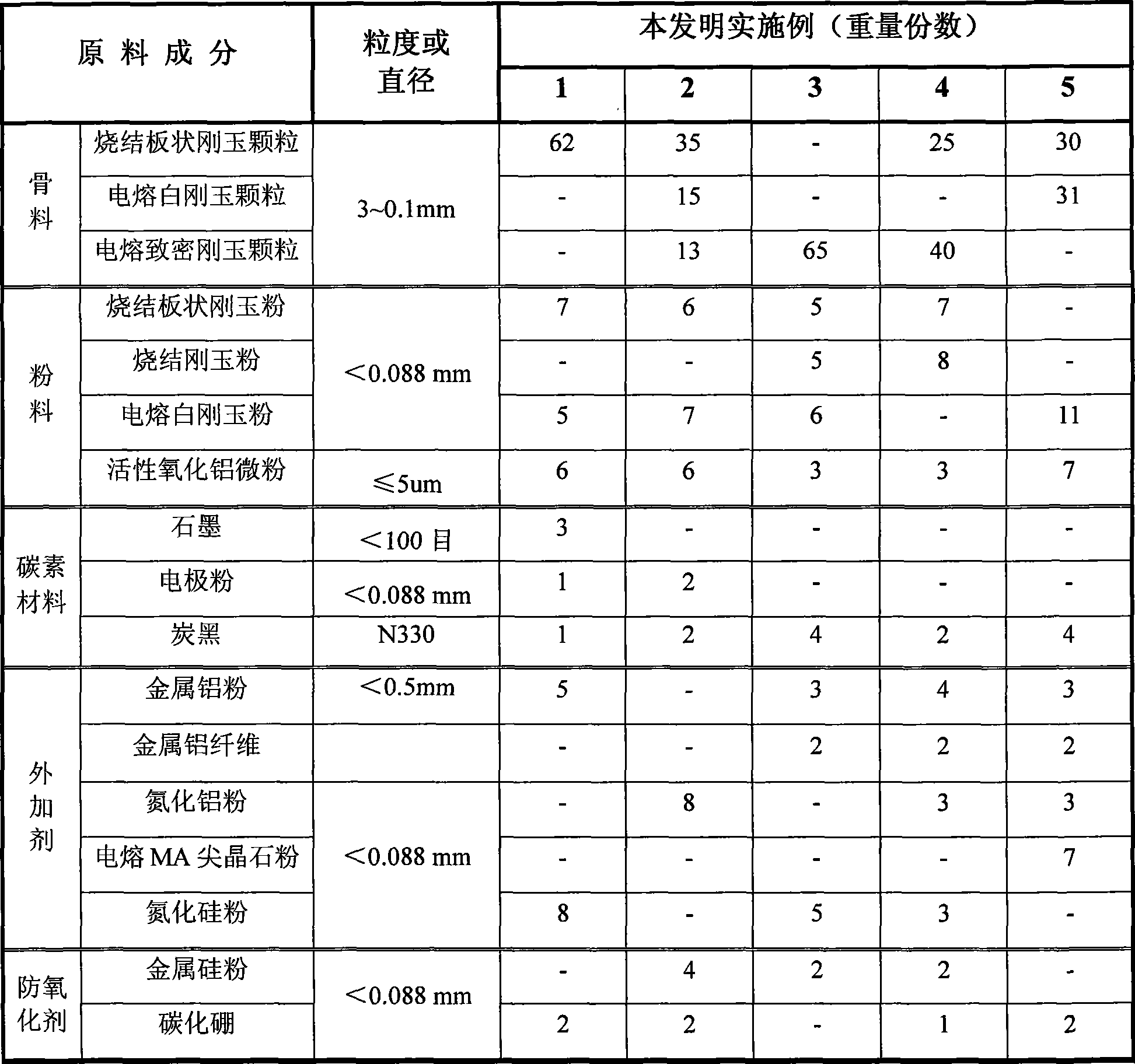

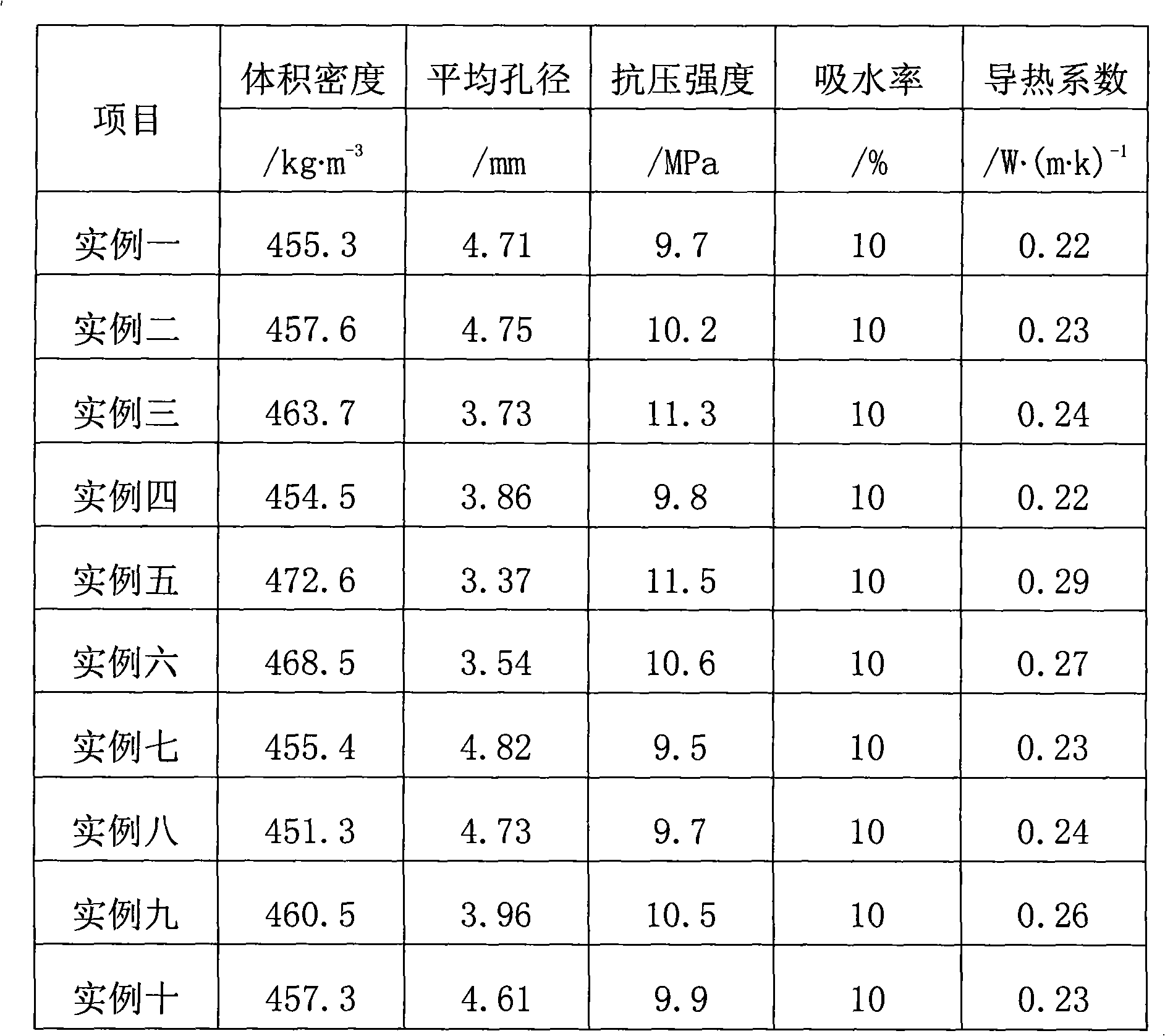

Aluminum-carbon sliding tile and method of producing the same

The invention provides an aluminum-carbon sliding brick, which comprises the following compositions: 60 to 75 percent of aggregate, 15 to 30 percent of powder, 1 to 6 percent of carbon element materials, 2 to 7 percent of antioxidant and 3 to 20 percent of additive. The production method for the aluminum-carbon sliding brick comprises the following steps: firstly, the powder in the raw materials is premixed and prepared into mixed powder for standby; secondly, mixing is performed according to the feeding order of granular materials, a binder and the mixed powder; thirdly, the mixture is discharged and subjected to mechanical pressing; and fourthly, a green brick is dried and prepared into the aluminum-carbon sliding plate brick by an unfired technology or a light burning technology. The method adds nitride and spinel materials in the sliding brick to substantially improve the thermal shock stability of the sliding brick, so as to achieve the level of the aluminum-zirconium-carbon sliding brick; and because the addition of Al metals is adequately increased, air holes can be filled, and the method reduces the brittleness of materials, is favorable for green brick formation, and improves the volume density, the normal temperature strength and the high temperature strength, so as to improve the oxidation resistance of the sliding brick. The aluminum-carbon sliding brick produced by the method not only has good product quality and high strength but also has simple procedure and saves the sintering cost.

Owner:鞍山钢铁集团耐火材料有限公司

Method for preparing microcrystalline foamed glass by titanium-containing blast furnace slag

ActiveCN101323503ASolve the problem of difficult utilization of titanium-containing blast furnace slagReduce manufacturing costSlagFoam glass

The invention provides a method adopting the blast-furnace slag containing titanium to prepare foam glass, belonging to the metallurgy source comprehensive utilization and material preparation filed. The invention mainly adopts the blast-furnace slag containing 14 to 29 percent of TiO2 as the basic material, and properly adopts silicon materials to generate glass substances, and then adds foaming agent, foam stabilizer and fusing assistant to prepare foam glass-ceramic according to a special heat disposal system. The invention has the advantages that the manufacturing cost is low; the product quality is better; the manufacturing operation is simple; the second-time contamination can be avoided and the product volume density is low, etc.

Owner:NORTHEASTERN UNIV

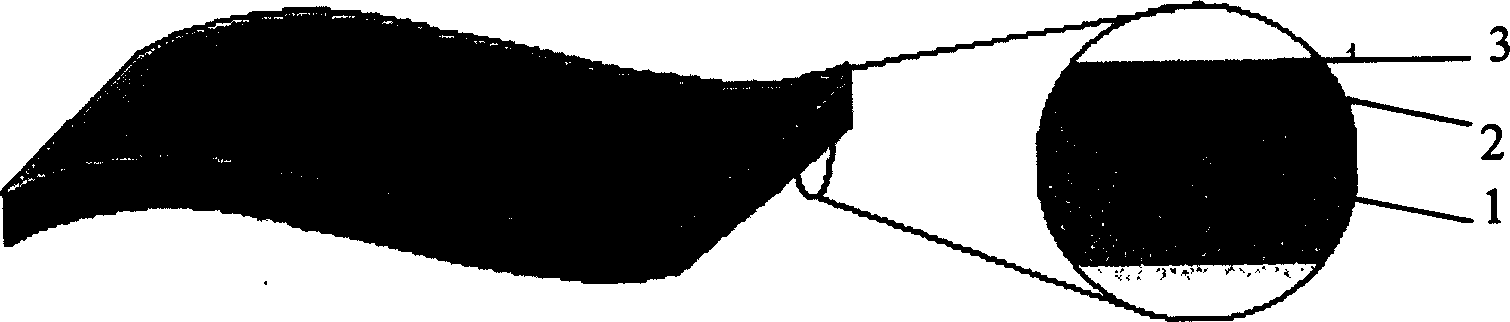

Low-density oil fracturing propping agent and preparation method thereof

InactiveCN102786921AIncrease productionQuality improvementFluid removalVolumetric Mass DensityOil and natural gas

The invention discloses a low-density oil fracturing propping agent. The low-density oil fracturing propping agent comprises the following components in parts by weight: 40 to 90 parts of bauxite, 5 to 30 parts of clay and 1 to 30 parts of auxiliary additive, wherein the mass percentage of Al2O3 in the bauxite is 30 to 75 percent. The oil fracturing propping agent is prepared by blending the bauxite, the clay and the auxiliary additive in special proportion, and performing a pulverizing process, a pelletizing process and a sintering process on the mixture. Detection on the propping agent shows that the propping agent has the characteristics of wide raw material resource, low production cost and the like; the yield and mass of powder are improved, and the production cost is reduced; and the problems of large fracturing and propping volume density and visual density, large abrasion of fracturing to equipment, high construction cost and the like in exploitation of shale oil and shale gas, and shallow shaft fracturing construction of an oil well and a natural gas well in the prior art are solved. A preparation method of the low-density oil fracturing propping agent is simple in process, easy to operate and very suitable for industrial production.

Owner:贵州林海陶粒制造有限公司

Aerogel recombination flexible thermal insulation heat-proof thin film and process for preparing same

InactiveCN1546312AHigh porositySmall apertureWater-setting substance layered productThermal insulationVacuum coating

The invention is a kind of aerogel compound soft thermal retardation and insulation film and the manufacturing method. It uses orthosilicate ethyl ester and distilled water as material; the invention can produce transparent SiO2 multi-aperture aerogel with colloidal sols and jell. The aperture rate of the aerogel is bigger than 90%, the aperture radius size is about 20nm, the volume density is 0.03g / cm3, the specific surface is 1120m2 / g, the aerogel is blended with organic silicon resin after being crushed, and they are distributed onto polymide film. The other surface of the polymide uses vacuum plating deposited metal aluminum film forms the compound soft thermal retardation film which uses SiO2 multi-aperture aerogel / polymide film / metal aluminum as structure, the heat conductivity of aerogel compound soft thermal insulation film is 0.035w / mk under temperature of 500oC; it is a kind of excellent thermal insulation materials.

Owner:TONGJI UNIV

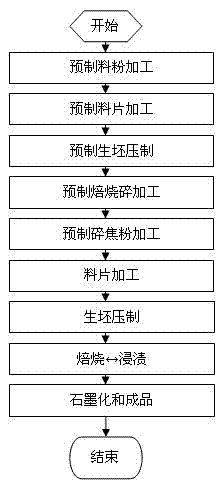

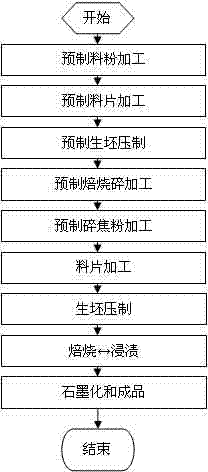

Production process of large isotropic and isostatic high purity graphite with fine particles

The invention discloses a production process of large isotropic and isostatic high purity graphite with fine particles, which comprises the following steps: processing prefabricated powder; processing prefabricated tablets; pressing prefabricated green bodies; processing prefabricated roasting scraps; processing prefabricated smashed coke powder; processing tablets; pressing green bodies; roasting and soaking; and graphitizing and finishing. A graphite product produced by the production process provided by the invention has a large size and has the diameter being more than phi 900; the strength, the density and the elasticity of the product are improved, and the mechanical behavior physical and chemical indicators of a final product is improved; and simultaneously, the produced graphite product has the characteristics of favorable isotropic performance, uniform and delicate structure, high volume density and the like.

Owner:雅安恒圣高纯石墨科技有限责任公司

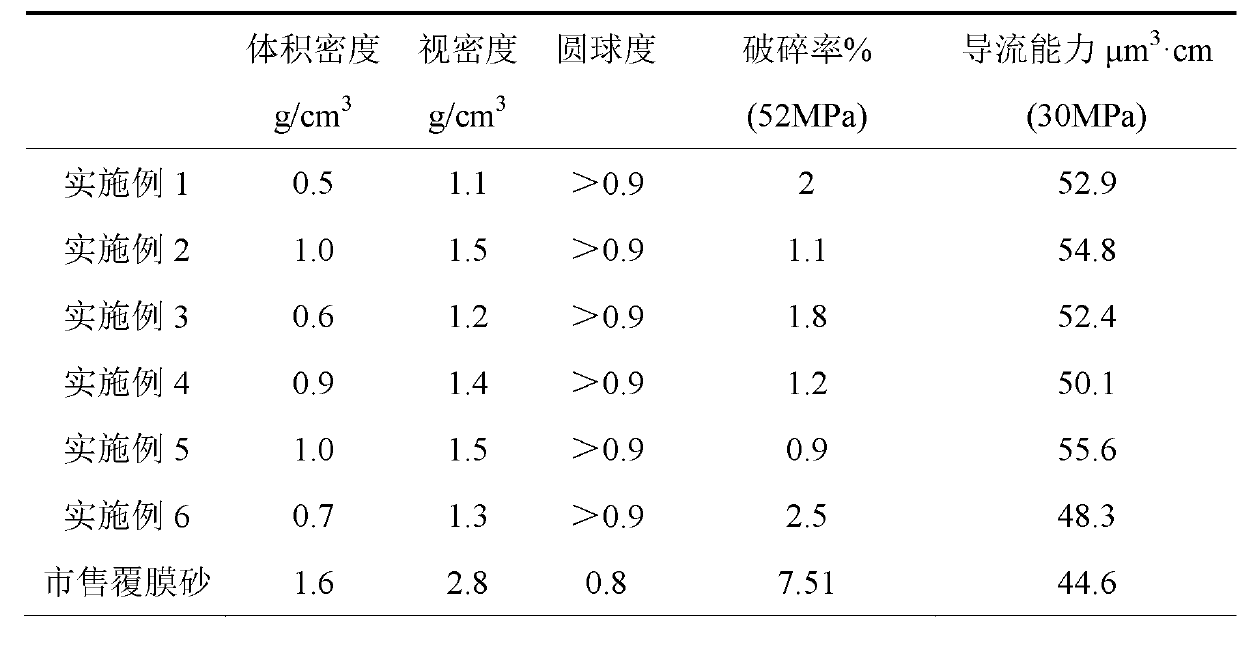

Clean-water-carrying petroleum proppant for petroleum production of low-permeability petroleum reservoir and preparation method thereof

The invention provides a clean-water-carrying petroleum proppant for petroleum production of a low-permeability petroleum reservoir. The proppant is prepared through coating macromolecular polymer particles with the particle sizes of 3-100 meshes by using macromolecular resin, wherein the macromolecular polymer particles are white polymer balls formed through polymerizing olefin monomers or polymer microspheres formed through compounding after a silane coupling agent modified mineral material is added; and the proppant has the volume density of 0.5-1.0 g / cm<3> and the apparent density of 1.1-1.5 g / cm<3>. The invention simultaneously provides a preparation method of the petroleum proppant. The clean-water-carrying petroleum proppant prepared by adopting the preparation method can greatly reduce the viscosity of sand carrying liquid, reduce the damage to strata and pumps and even realize clean fracturing. Through the low-density proppant, the entire construction cost can be reduced, and the phenomenon of proppant discharging or crack emptying is difficult to occur.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

Air brick for magnesia carbon ladle and method for producing the same

The invention discloses an air brick used for a magnesium and carbon ladle, and a producing method thereof, aiming at producing high-quality air bricks used for the ladles. The mass percentage of the chemical compositions of the air brick is: 55 to 99 percent of MgO, 0 to 20 percent of C, 0 to 20 percent of AI2O3, 0 to 5 percent of ZrO2, 0 to 5 percent of AI, 0 to 5 percent of AI-Mg alloy, 0 to 5 percent of CaB6, and 0 to 2 percent of B4; the physical property indexes are: volume density (g / cm<3>): 3.00 to 3.15, apparent porosity (%): 1.5 to 5.0, cold compressive strength (MPa): 40 to 65, and distortion resistance at high temperature (MPa): 14.0 to 25.0. Raw materials adopted by the invention comprise fused magnesite, magnesite clinker, crystalline flake graphite, corundum, zirconia and oxidation inhibitor. The raw materials are added into a pug mill and externally added with a bonding agent for mulling. Mulled pug is added into a mould, and molded by utilizing isopressing equipment or a friction brick press or a hydraulic press. The invention obviously reduces the apparent porosity of the air brick, not only can improve the basic slag corrosion resistant capability of the air brick, but also can reduce the cost of the raw materials by more than two thirds.

Owner:UNIV OF SCI & TECH LIAONING

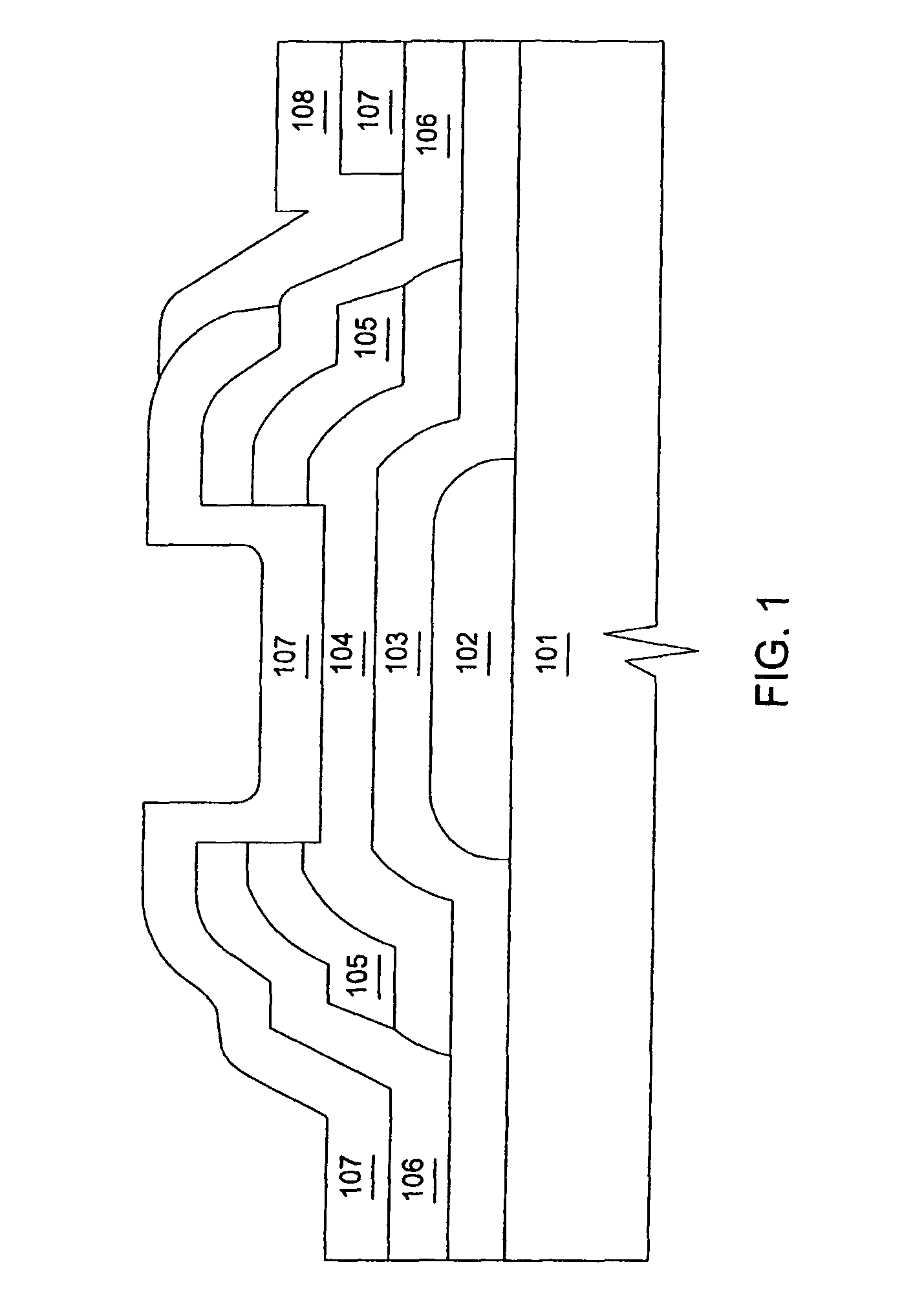

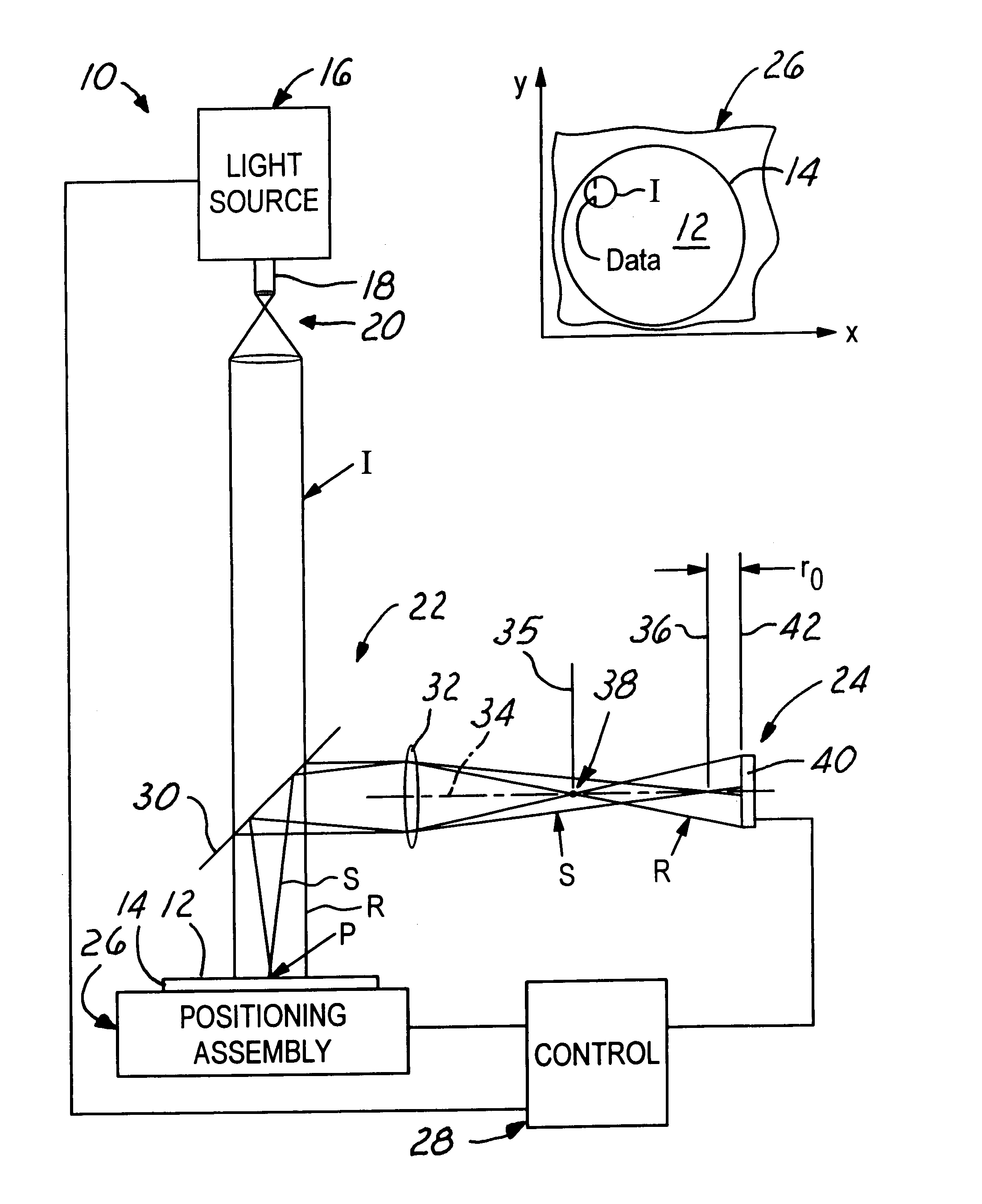

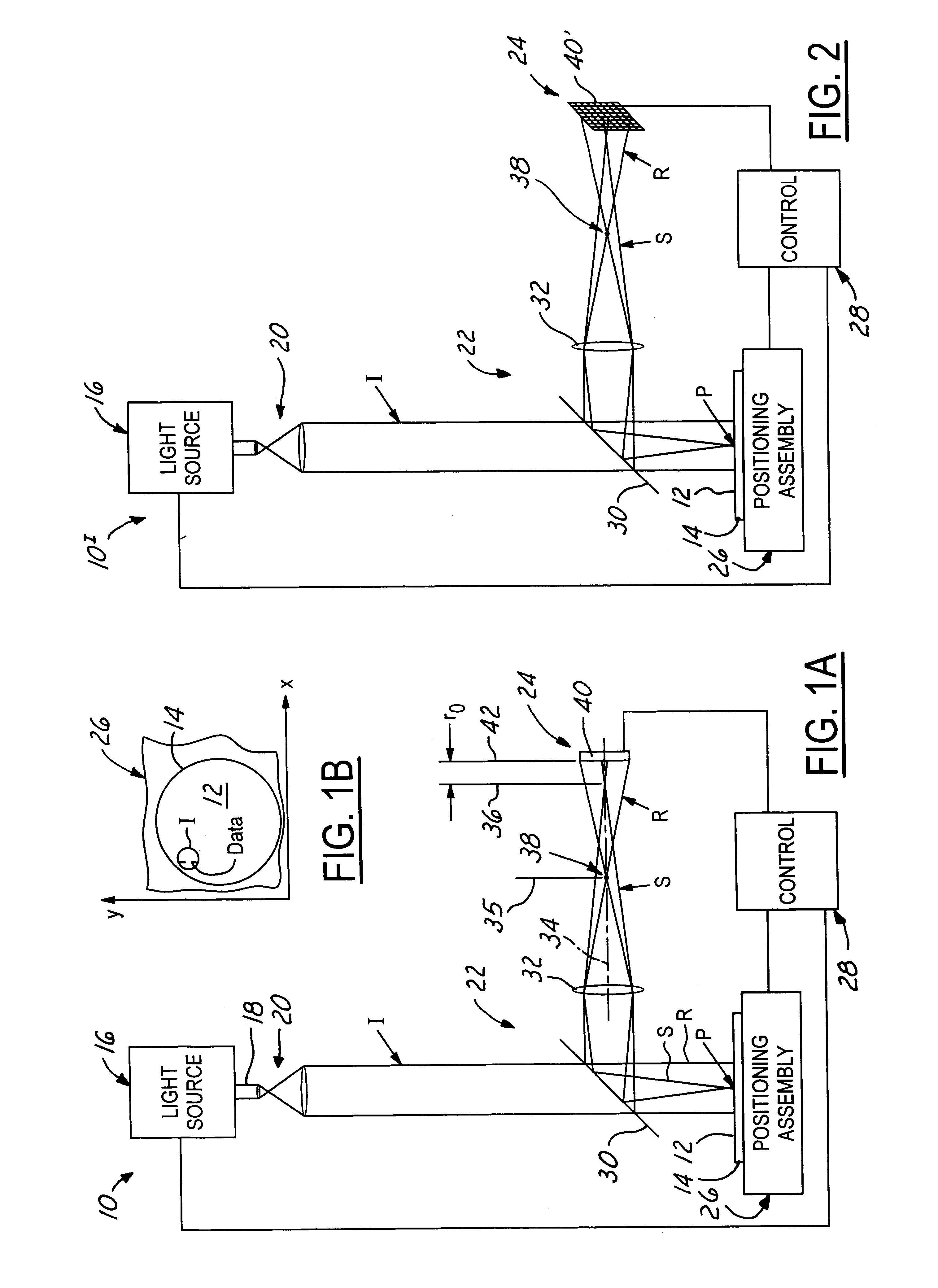

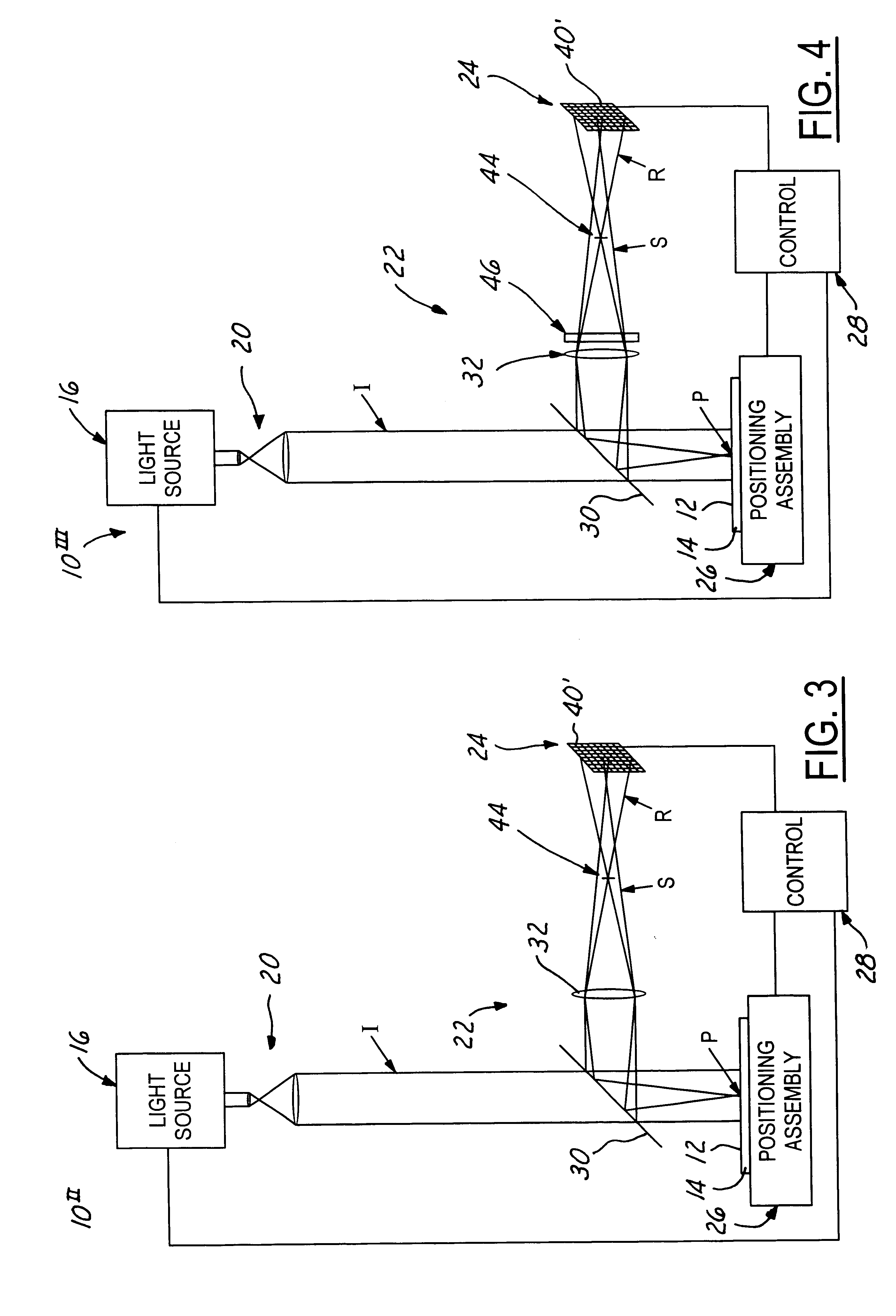

Holographic scatterometer for detection and analysis of wafer surface deposits

InactiveUS6597446B2Prevent false detectionErroneous detectionInvestigating moving sheetsOptically investigating flaws/contaminationChemical compositionScatterometer

A holographic scatterometer with continuous readout can rapidly identify the presence of deposits (particles or other defects) on an unpatterned wafer surface and determine the volume density (size) and location. The scatterometer can also determine chemical composition of the detected deposits. The range of the deposit (particle) size to be measured is below 80 nm, which currently existing scatterometer type instruments cannot readily detect. The inspection can be achieved as an in-line stage during the processing of wafers or in situ in combination with another processing tool or as a separate off-line analysis device.

Owner:SENTEC CORP

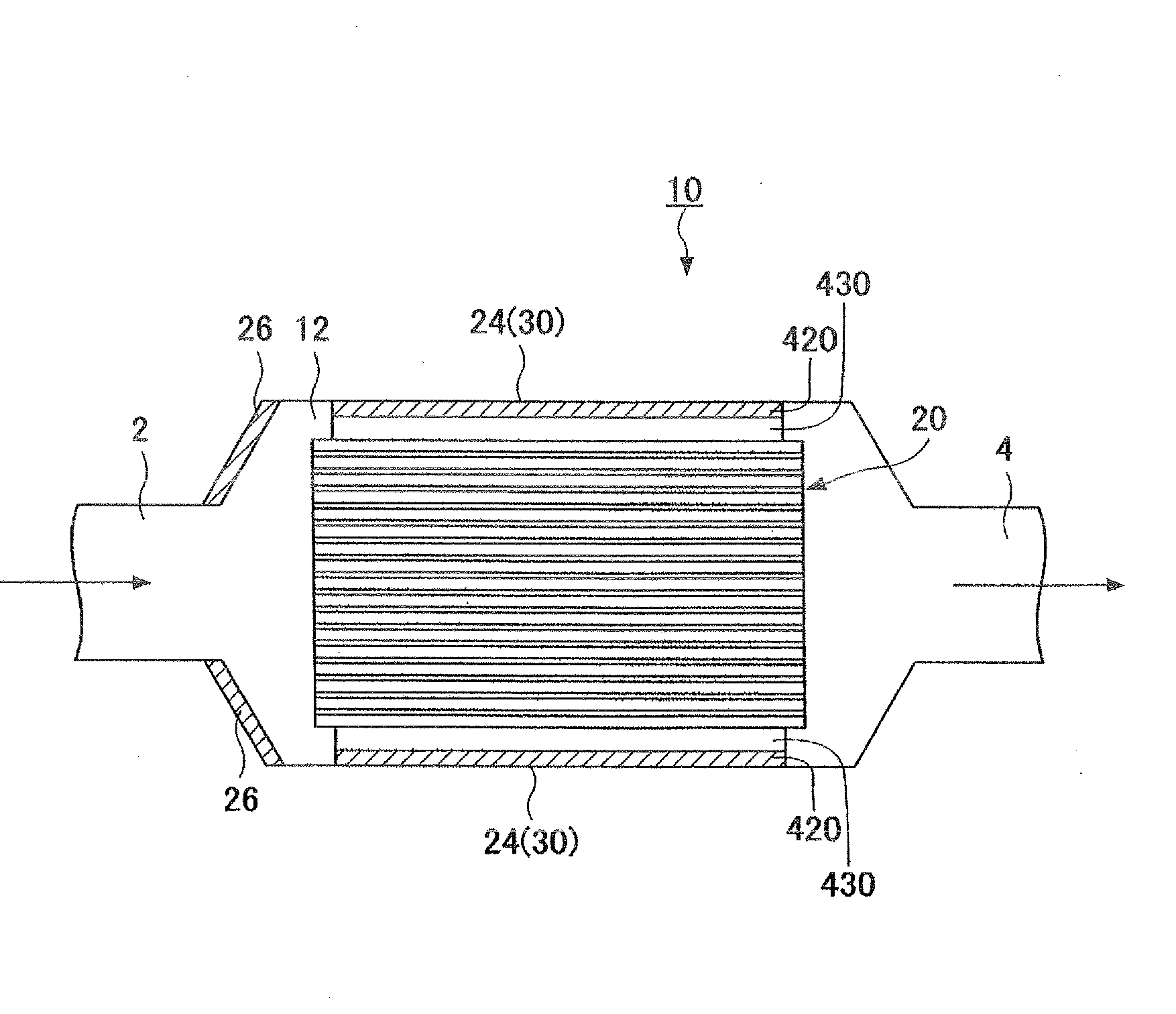

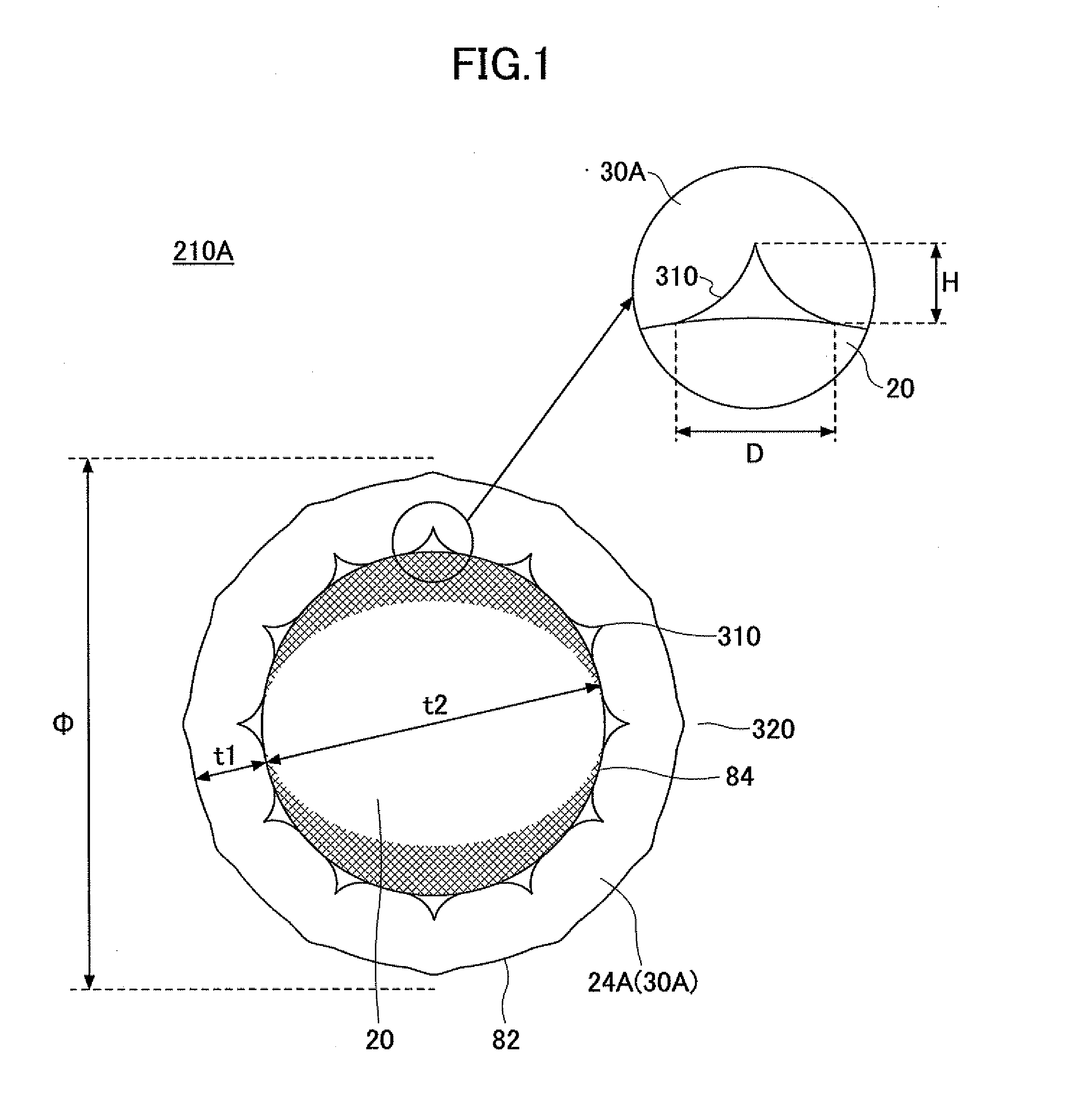

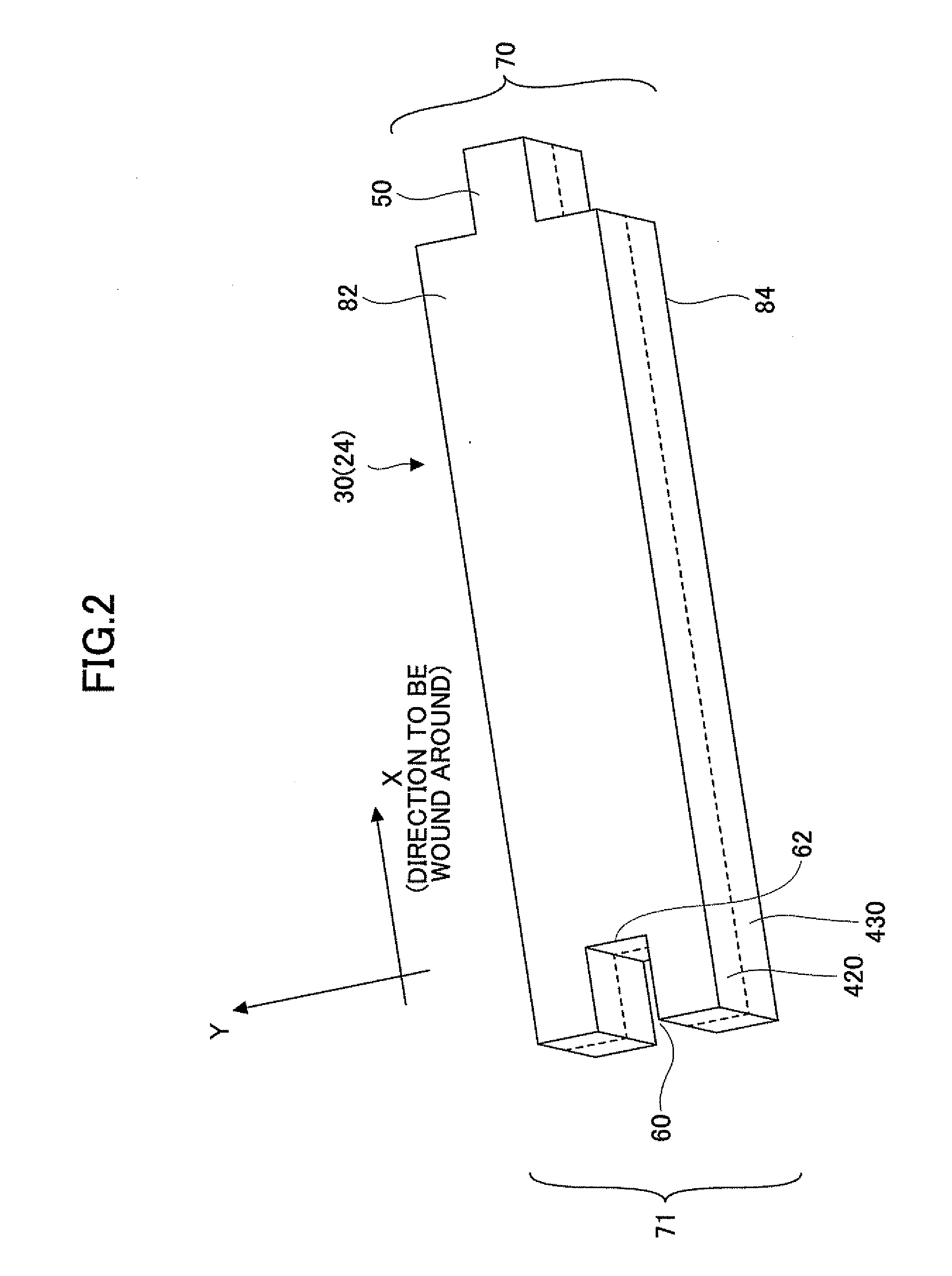

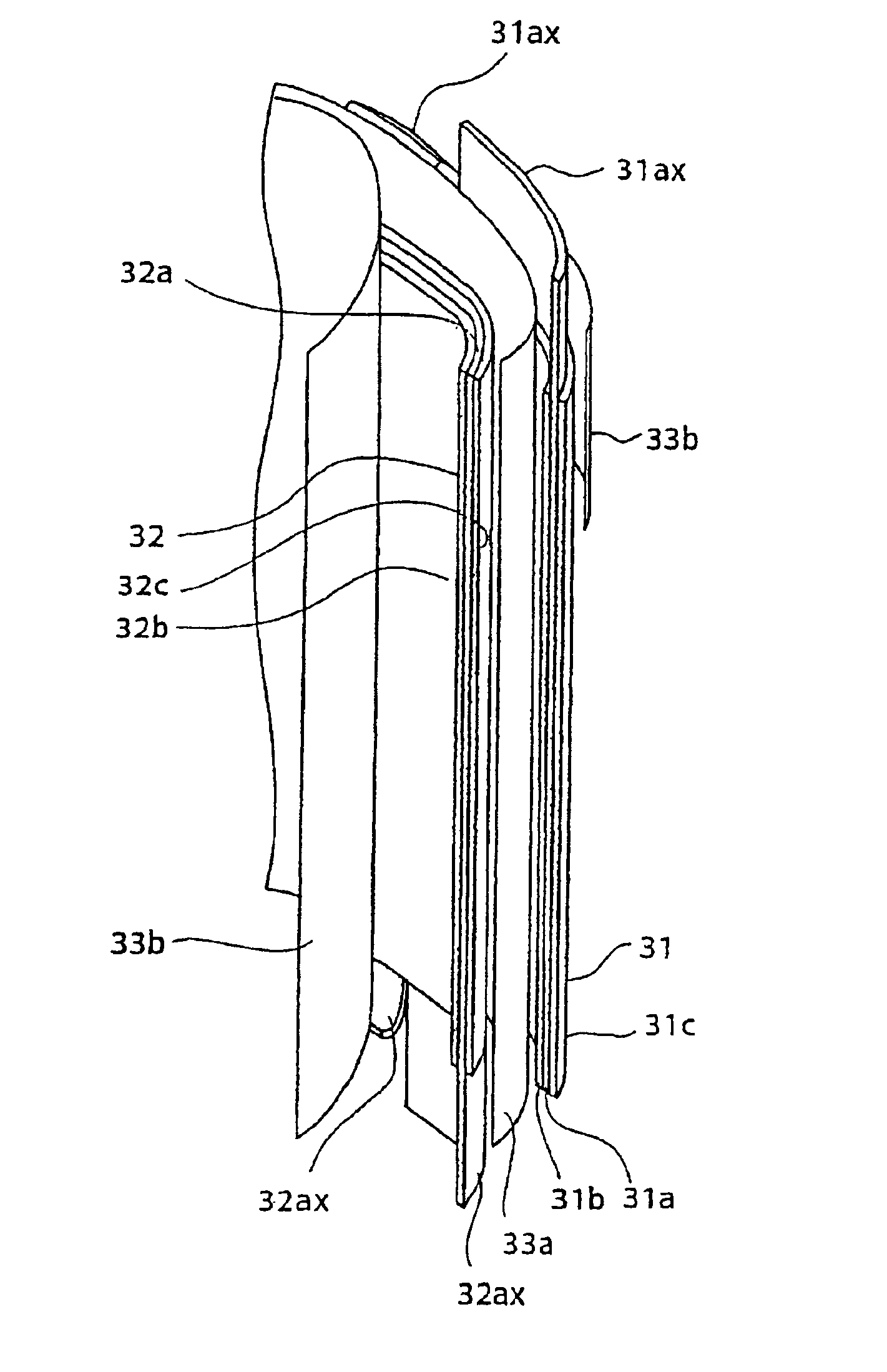

Sheet member and manufacturing method thereof, exhaust gas treating apparatus and manufacturing method thereof, and silencing device

A sheet member includes inorganic fiber; and a first surface and a second surface that are substantially perpendicular with respect to a thickness direction of the sheet member. The first surface includes a first sheet portion having a first volume density. The second surface includes a second sheet portion having a second volume density that is higher than the first volume density.

Owner:IBIDEN CO LTD

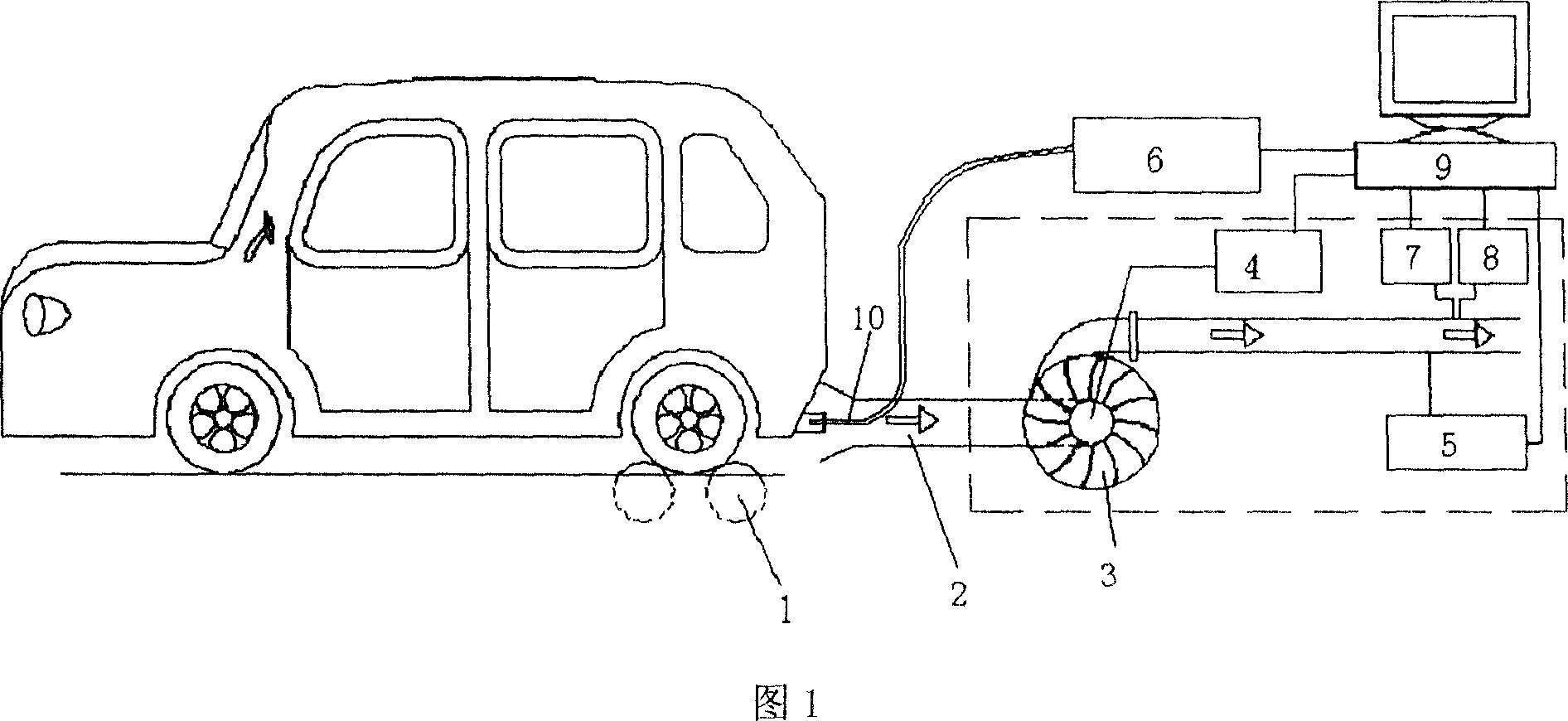

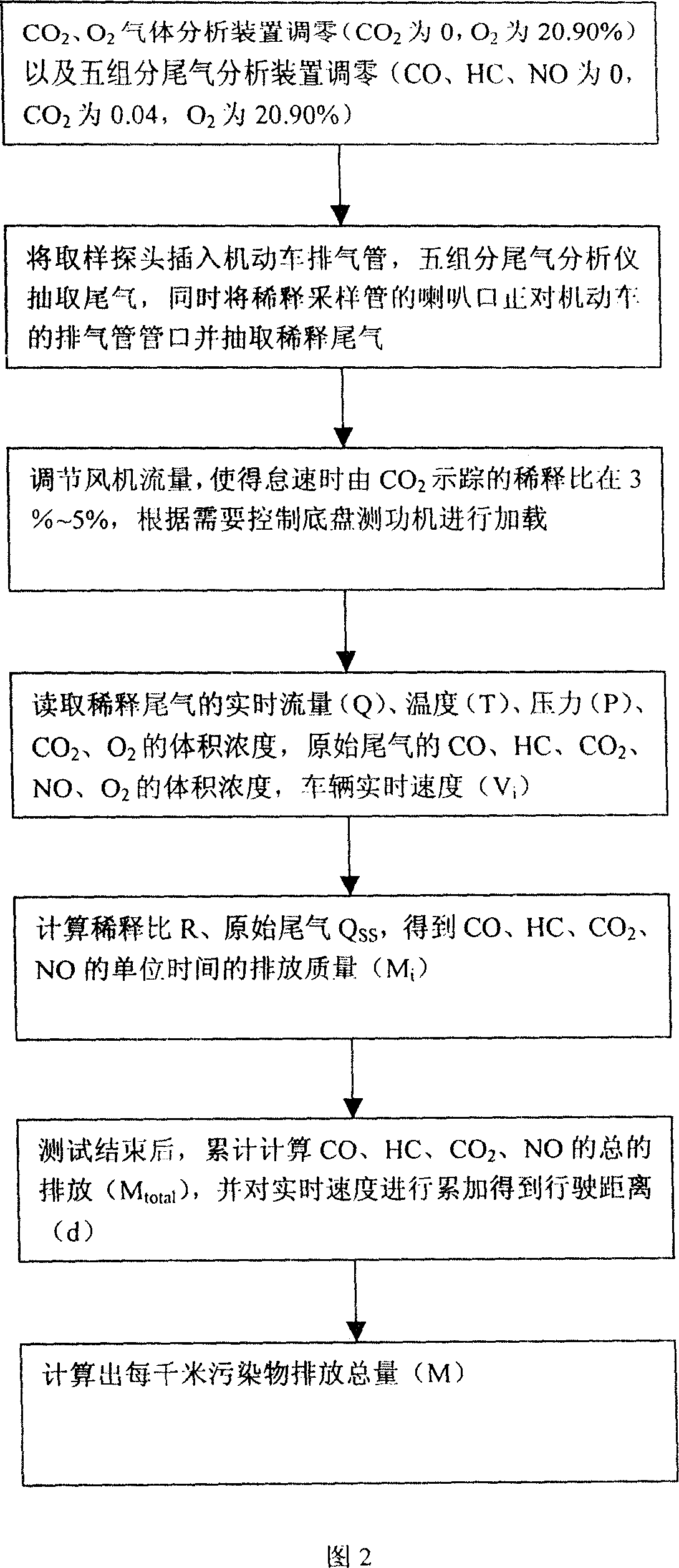

Method and device for measuring pollutant discharging total of motor vehicle

InactiveCN101000278AImprove detection accuracyOvercome the shortcomings of low measurement accuracyVehicle testingInternal-combustion engine testingGas analysisAir volume

The invention relates to vehicle pollutant discharging total measuring device and method. The device is made up of diluting sampling tube, fan, computer measure-control system, chassis power measuring machine, fan flow rate adjusting device, flow rate, temperature, and pressure measuring devices, five components tail gas, O2, CO2 gas analysis devices. The measuring method includes the following steps: using fan flow rate adjusting device to control pumping drainage fan, measure diluted tail gas flow rate, temperature, pressure, O2, CO2 volume density; using five components gas analysis device to measure undiluted tail gas for each gas volume density; calculating out the undiluted tail gas flow rate by the volume density ratio to gain vehicle pollutants discharging gross. The invention has high detecting precision for tail gas, can be used in pollutants discharging gross detecting for vehicle operating condition method tail gas detecting line or repair shop.

Owner:WUHAN CUBIC OPTOELECTRONICS

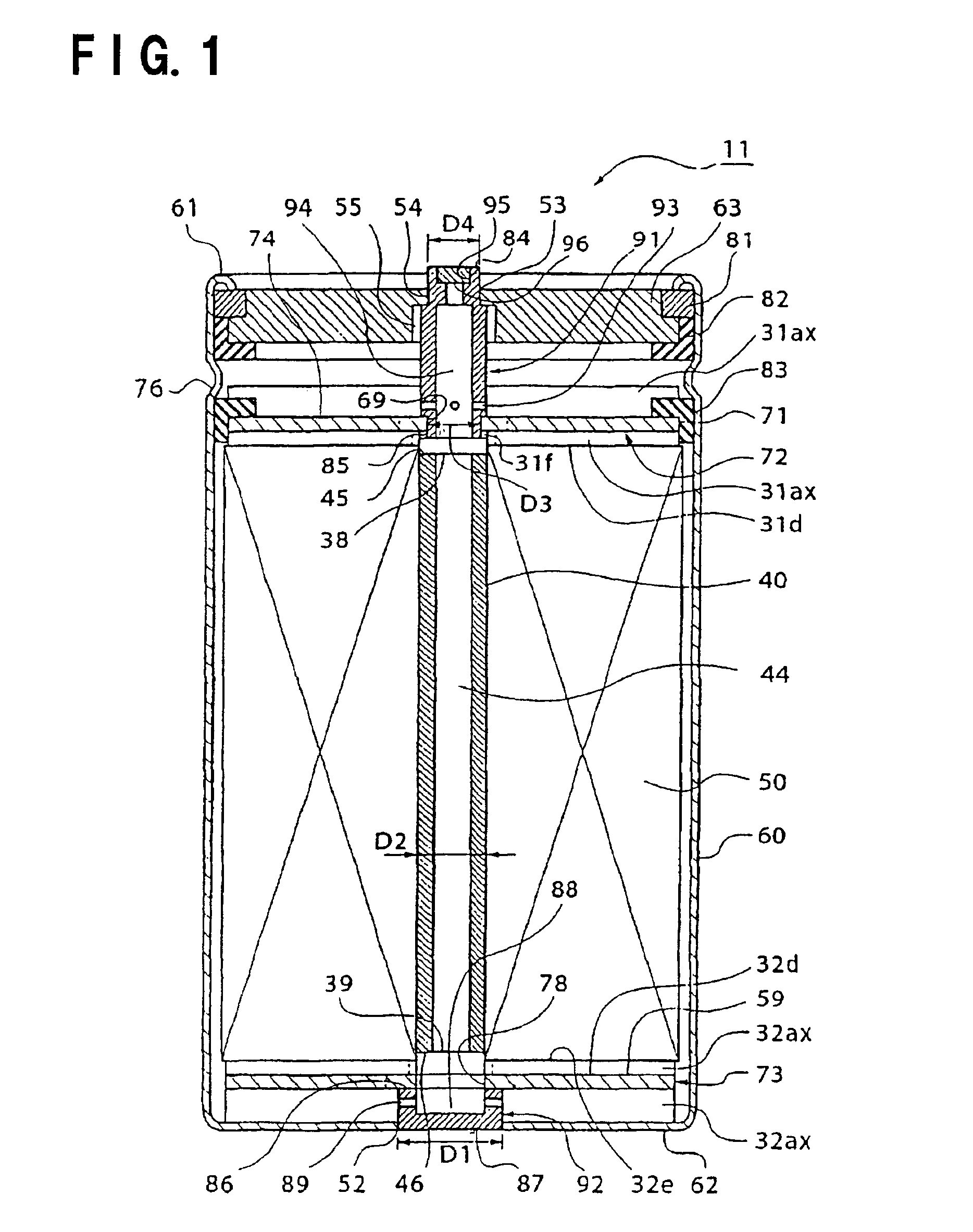

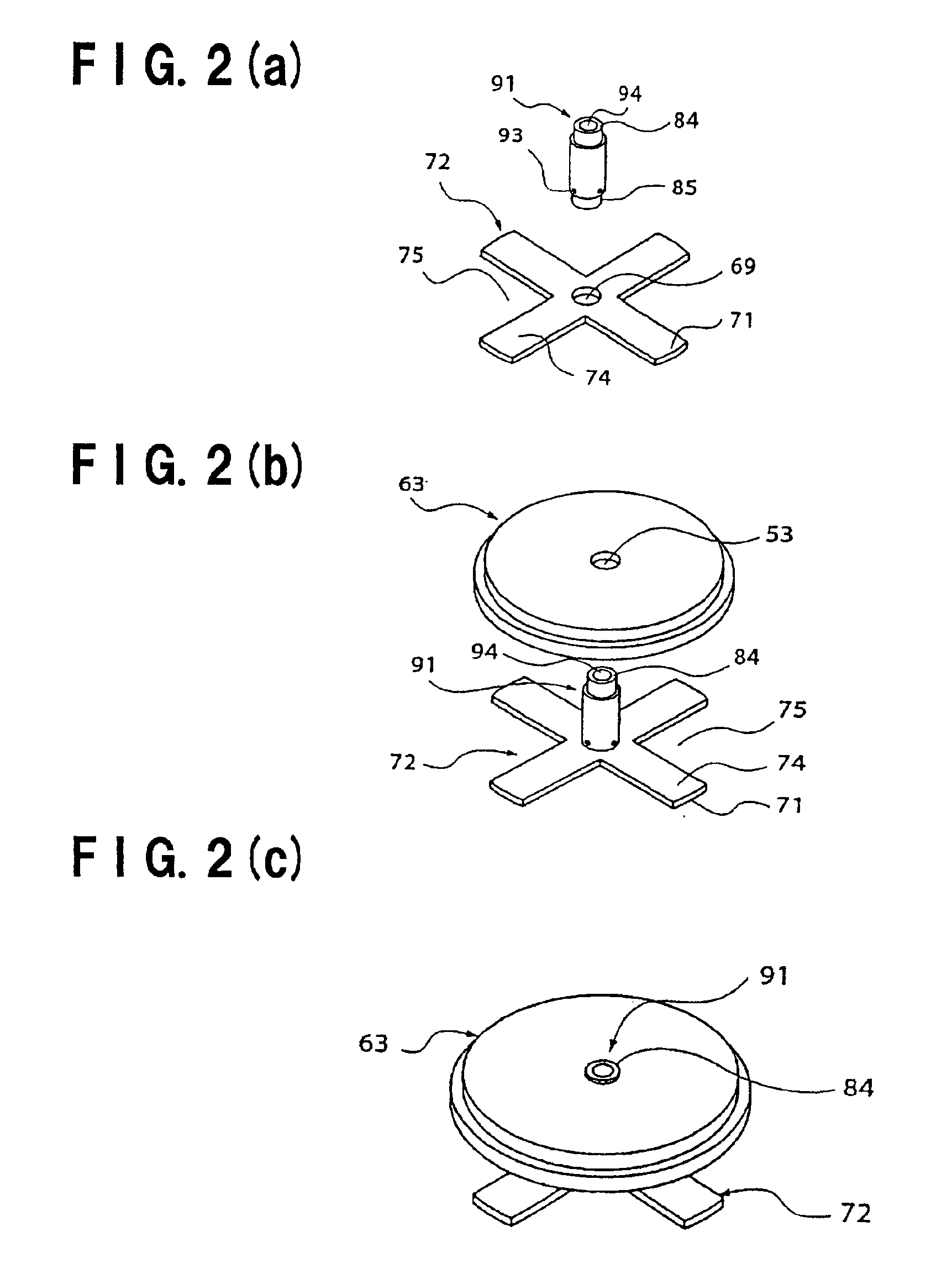

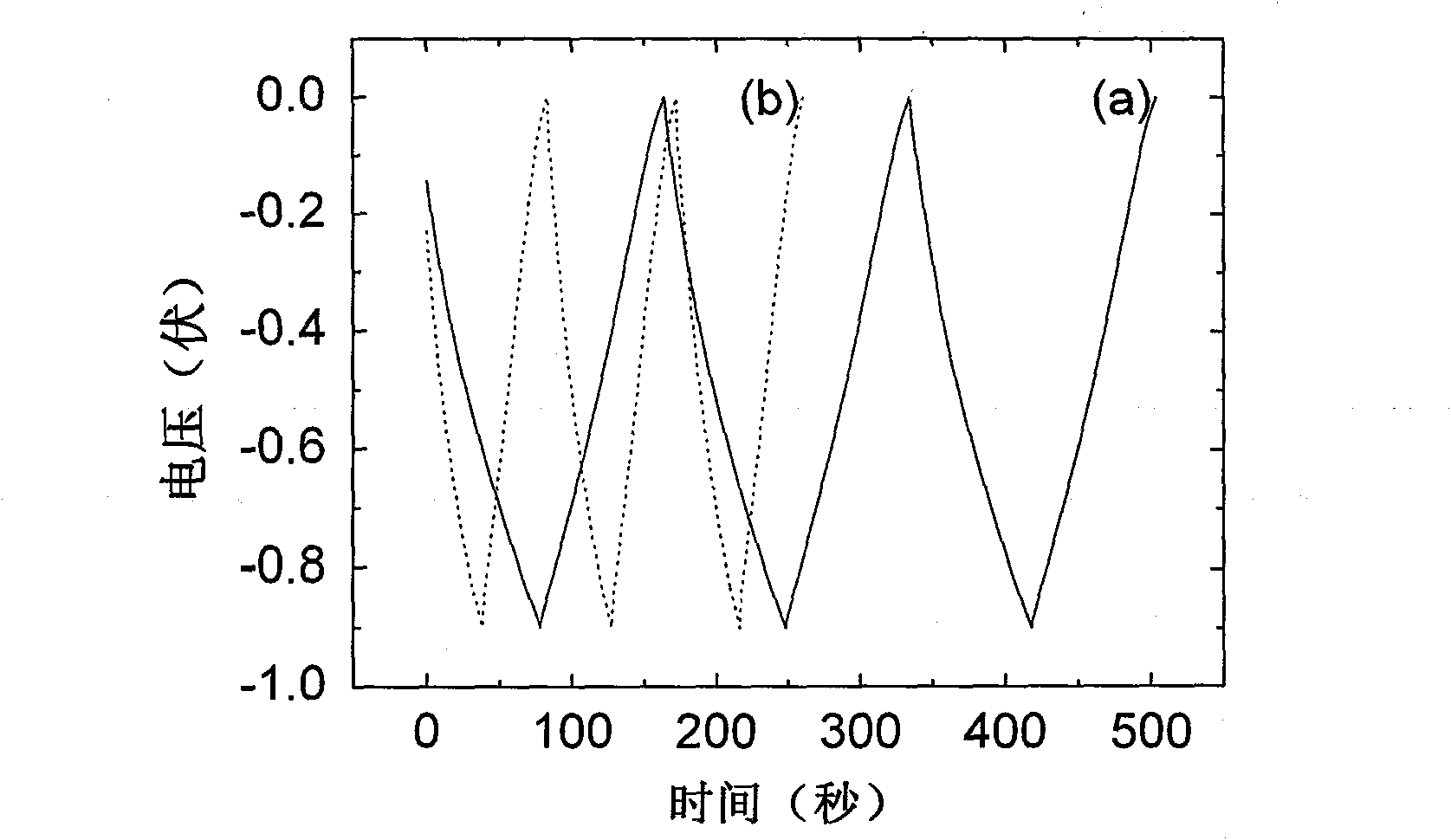

Electrochemical device comprising a pair of electrodes and an electrolyte

InactiveUS6896993B2Short timeEasy to processFinal product manufactureDouble layer capacitorsInternal resistanceBand shape

An electrochemical device comprises a pair of electrodes having electrode layers formed on strip-like collectors except on their strip-like portions along a longitudinal side of the strip-like collectors; strip-like separators insulating these; two collector plates connected to the strip-like portions; a case accommodating these; a lid for sealing the case; a pair of terminals connected to the collector plates and being connectable to an outside of the case. The pair of terminals is respectively connected to the lid and the case, and the pair of electrodes are wound interposing the separators therebetween, and the strip-like portions are located on both end surfaces. The electrochemical device has high volume density and low internal resistance and it can be manufactured in short time.

Owner:HONDA MOTOR CO LTD

Light refractory bricks

InactiveCN1424280AIncrease optionalityReduce manufacturing costFurnace componentsCeramicwareMulliteAluminum silicate

A light-weight refractory brick used for liner of high-temp furnace is prepared from mullite as primary crystal phase, huronite as binding phase, disthene and coal gangue. Its main chemical components are Al2O3 (54-57 wt.%), SiO2 (40-43), CaO (1-2), Fe2O3 (0.1-1) and impurities (0.1-0.7). Its advantages are light weight, low heat conductivity and volume density, and high strength.

Owner:UNIV OF SCI & TECH BEIJING

Method for preparing microcrystalline foam glass by using high titanium blast furnace slag and waste glass powder

The invention discloses a method for preparing microcrystalline foam glass by using high titanium blast furnace slag and waste glass powder. The method comprises the following steps: grinding the high titanium blast furnace slag and waste glass powder, uniformly and fully mixing the high titanium blast furnace slag, the waste glass powder, a fluxing agent, a foaming agent and a foam stabilizer, pressing into a block, adding the mixture block into a heating device and preparing the microcrystalline foam glass at a low temperature according to a specific heat treatment process by using a one-step sintering method. According to the characteristic that the high titanium blast furnace slag which is rich in TiO2 can serve as a nucleation agent, the low-melting-point waste glass powder serves as a silicious raw material, a proper amount of corresponding fluxing agent and sintering process are matched, the preparation temperature is greatly reduced, and the preparation can be finished through one-step sintering; and therefore, the energy consumption can be reduced, the process is simplified, the cycle is shortened, the cost is saved, the product which is uniform in cells, moderate in cell diameter, low in volume density, low in water absorption rate, good in thermal insulation effect and high in mechanical strength can be obtained, and the additional value of high titanium blast furnace slag utilization is improved.

Owner:SICHUAN UNIV

Preparation method of super capacitor

InactiveCN101661840AEasy to manufactureLower internal resistanceElectrolytic capacitorsHybrid/EDL manufactureGas phaseArgon atmosphere

The invention relates to a preparation method for a super capacitor, comprising the following steps: (1) placing a foam nickel substrate in a chemical gas phase deposition reacting furnace, introducing argon for 10-60 minutes, exhausting air in the furnace, then heating the furnace to 450-750 DEG C, introducing hydrocarbon gases in an argon atmosphere at a flow rate between 25ml / min and 40ml / min,reacting the mixture for 30 seconds to 50 minutes at a temperature of 450-750 DEG C, and obtaining foam nickel on which carbon nano tubes grow after finishing the reaction; (2) removing surface loosing layer products, directly using the foam nickel substrate on which the carbon nano tubes grow as electrodes of the super capacitor; and (3) drying the electrodes with same thickness and size, which are obtained from the step (2), fully soaking the electrode with electrolyte for 1-36 hours, separating a diaphragm soaked with the electrolyte and assembling the components to obtain the super capacitor; and the hydrocarbon gases are acetylene, methane, ethylene or propylene. The carbon nano tubes directly grow on the foam substrate without a binding agent; and the foam nickel is used as the substrate, the volume density of electrode substances is higher and holes are reasonably distributed.

Owner:JIANGSU CHUANGLAN SOLAR AIR CONDITIONER

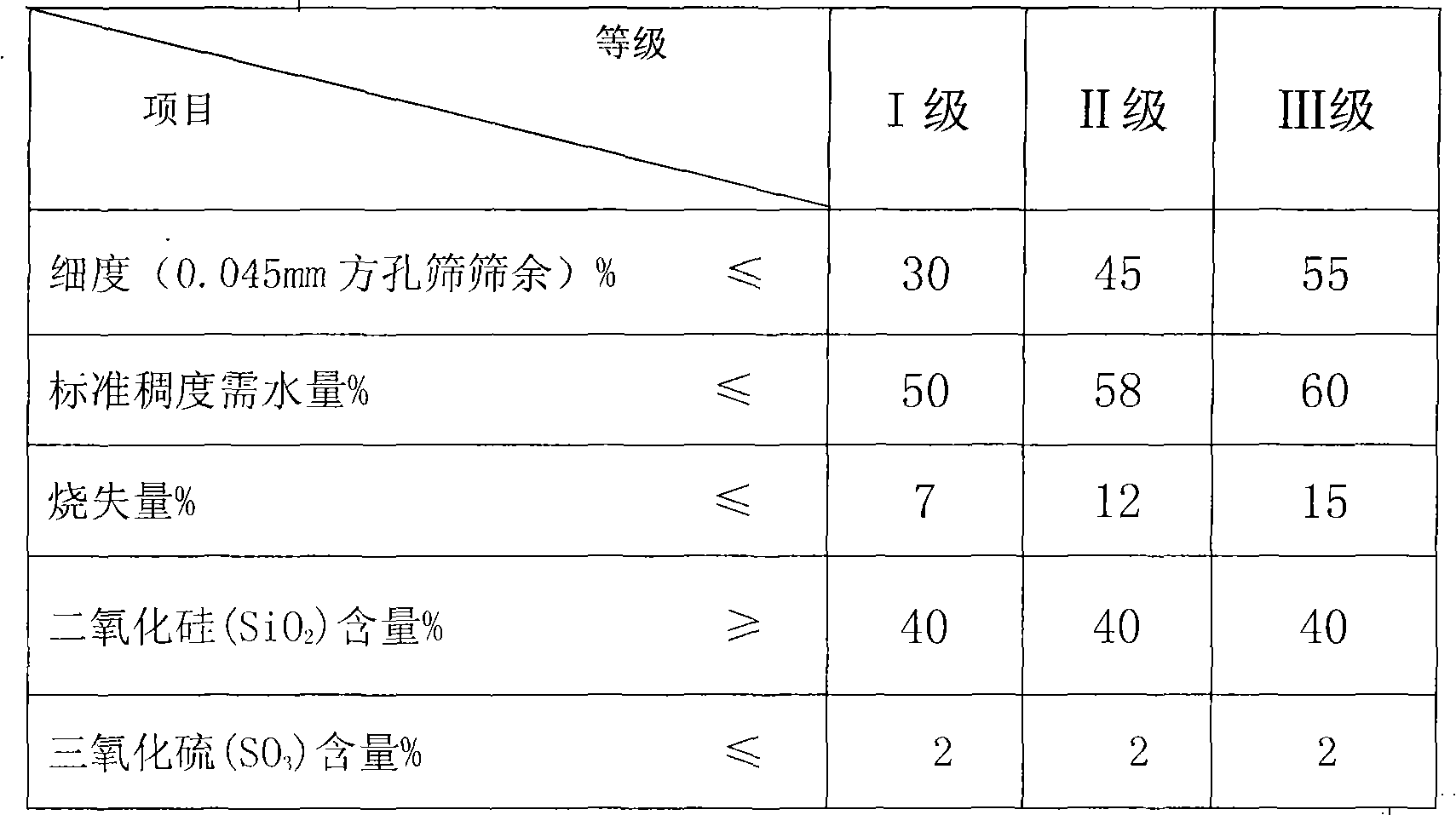

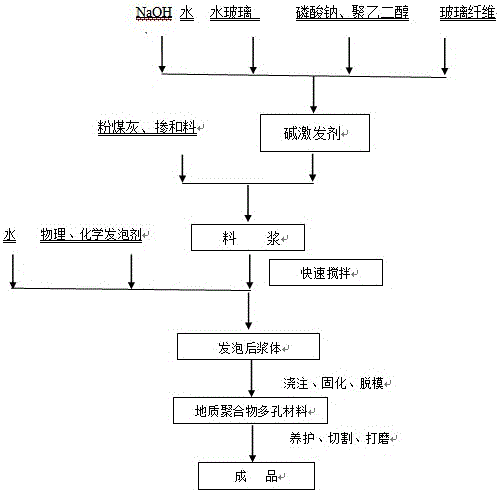

Flyash geopolymer based porous material and preparation process thereof

InactiveCN105800972APracticalSimple production processCement productionSodium phosphatesPolyethylene glycol

The invention provides a flyash geopolymer based porous material and a preparation process thereof. The porous material comprises the following components in parts by weight: 60-100 parts of flyash, 40-70 parts of alkali activator, 0-40 parts of admixtures, 0-5 parts of glass fibers, 2-8 parts of physical foaming agents and 0-0.8 part of chemical activators, wherein the alkali activator is alkaline mixed liquor containing various ions and comprises industrial water glass, sodium hydroxide, water, polyethylene glycol and sodium phosphate; the admixtures refer to levigated metakaolin, silicon micropowder and calcined coal gangue; the physical foaming agents include expired shampoo, an anionic surfactant sodium dodecyl sulfate (SDS), fatty alcohol polyoxyethylene ether sodium sulfate (AES) and disodium fatty alcohol polyoxyethylene ether monosulfosuccinate (AESS); the chemical foaming agents include aluminium powder, hydrogen peroxide, and the like. The porous material has adjustable volume density, fine and uniform pore diameter, low heat conductivity, high strength, the same life as buildings and good fireproof performance.

Owner:QINGHAI UNIVERSITY +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com