Production process of large isotropic and isostatic high purity graphite with fine particles

An isotropic, production process technology, applied in inorganic chemistry, non-metallic elements, carbon compounds, etc., can solve the problems of low physical and chemical indicators of mechanical properties, low isostatic graphite specifications, uneven bulk density, etc. Good homogeneity performance, improving strength and reducing porosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

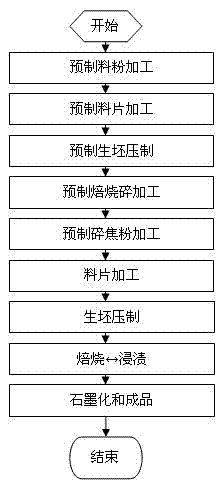

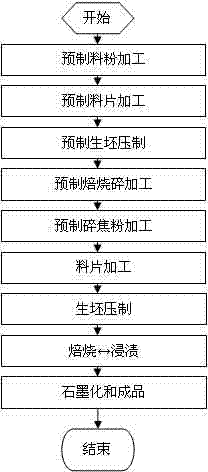

[0037] Further describe the technical scheme of the present invention below in conjunction with accompanying drawing and embodiment:

[0038] [Example 1] such as figure 1 Shown, the production process of large-scale fine particle isotropic isostatic graphite, it comprises the following steps, in the present embodiment, coke powder is used needle coke, additive is used boric acid:

[0039] (1) Prefabricated powder processing: the needle coke, recarburizer and graphite powder are respectively crushed by jaw type, and then ground into prefabricated powder with an average particle size of 4um by a mill or jet mill;

[0040] (2) Prefabricated flake processing: Weigh needle coke prefabricated powder, graphite powder prefabricated powder, carburant prefabricated powder, fine powder and modified asphalt according to the weight ratio of a formula and knead them at a high temperature of 140°C. The paste formed after the kneading is completed is put into a high-temperature rolling machi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com